Patents

Literature

223results about How to "Slow crystallization rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

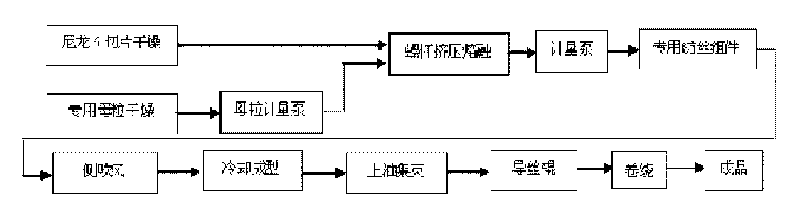

Denier/superfine denier nylon master granule, preoriented yarn (POY) and draw textured yarn (DTY) stretch yarn and preparation method thereof

ActiveCN101724265AHigh tensile strengthImprove mixing performanceMelt spinning methodsMonocomponent polyamides artificial filamentYarnEngineering

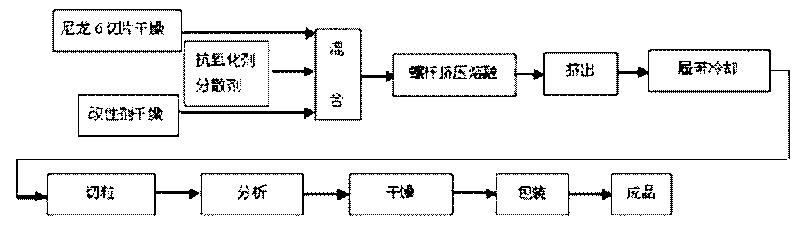

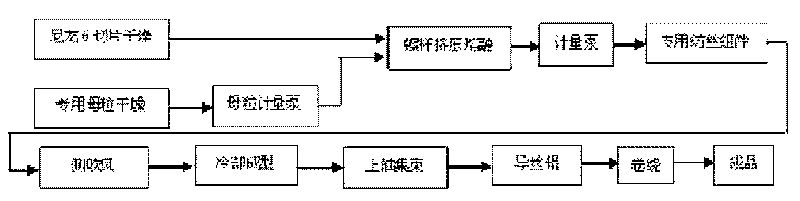

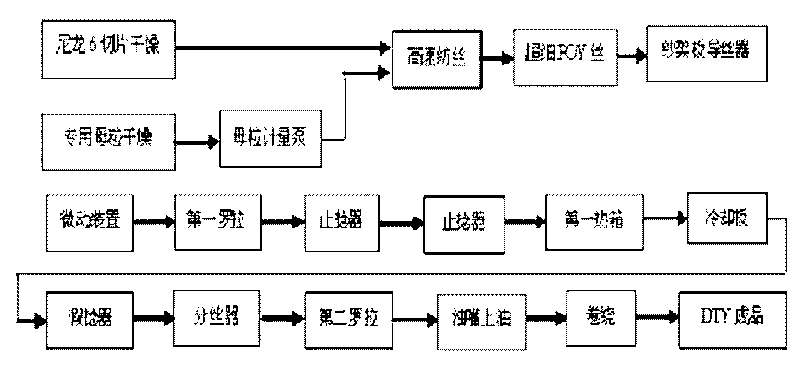

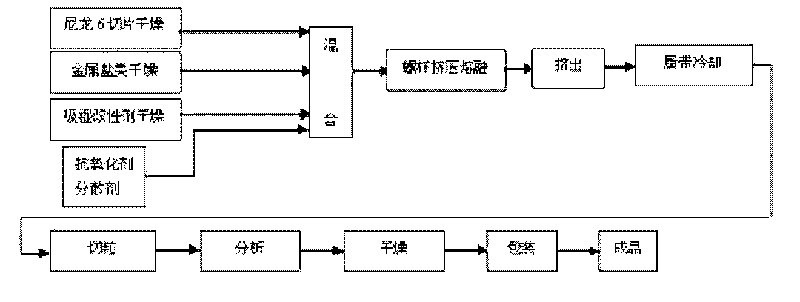

The invention belongs to the field of spinning materials. Firstly, the invention provides a fine denier / superfine denier nylon master granule prepared by proportionally adding a modifying agent, an antioxidant and a dispersant to nylon 6 sliced sheets according to the proportion, melting, mixing and extruding, and the modifying agent is a metallic salt which can take effect on nylon base; The fine denier / superfine denier nylon master granule and the nylon 6 sliced sheets are proportionally mixed, melted and spun, and the fine denier / superfine denier nylon POY is prepared by cooling, oiling, bundling and coiling; and the POY is textured to obtain the DTY. The invention provides the fine denier / superfine denier nylon POY of which the filament size is 0.3-0.8dtex, the filament size of the DTY is 0.25-0.70dtex, which fills the vacancy that the fine denier / superfine denier nylon POY and the DTY are produced by the conventional yarn-spinning process at home and abroad.

Owner:HANGZHOU NORMAL UNIVERSITY

Films comprising biodegradable PHA copolymers

InactiveUS6174990B1High ratioSmall cross sectionFlexible coversWrappersBiodegradable copolymersMonomer

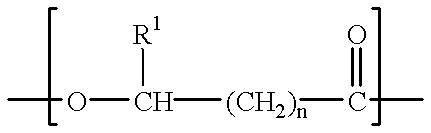

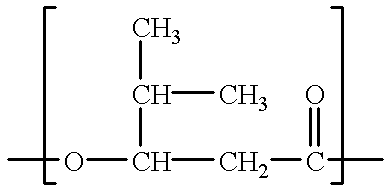

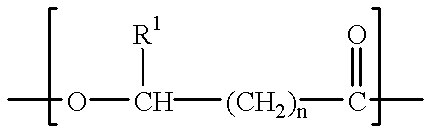

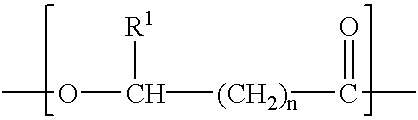

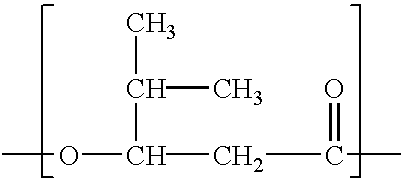

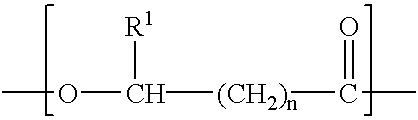

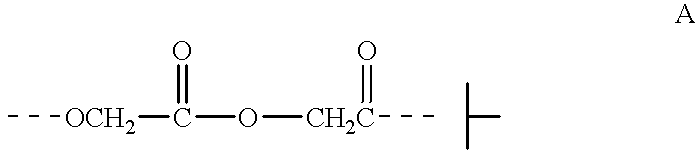

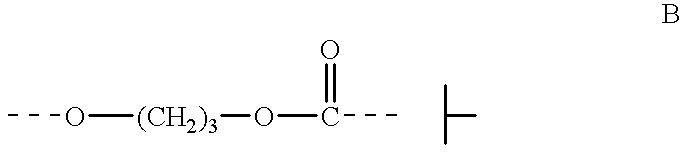

The present invention relates to biodegradable PHA copolymers comprising at least two randomly repeating monomer units. The present invention further relates to a plastic article comprising a biodegradable copolymer, wherein the biodegradable copolymer comprises at least two randomly repeating monomer units (RRMU) wherein the first RRMU has the structurewherein R1 is H, or C1 or C2 alkyl, and n is 1 or 2; the second RRMU has the structureand wherein at least 50% of the RRMUs have the structure of the first RRMU. The present invention further relates to an absorbent article comprising a liquid pervious topsheet, a liquid impervious backsheet comprising a film comprising a PHA of the present invention and an absorbent core positioned between the topsheet and the backsheet.

Owner:DANIMER IPCO LLC

Absorbent articles comprising biodegradable PHA copolymers

InactiveUS6160199AProtect and promote and control plant growthRaise the ratioSynthetic resin layered productsBaby linensBiodegradable copolymersPolymer chemistry

The present invention relates to biodegradable PHA copolymers comprising at least two randomly repeating monomer units. The present invention further relates to a plastic article comprising a biodegradable copolymer, wherein the biodegradable copolymer comprises at least two randomly repeating monomer units (RRMU) wherein the first RRMU has the structure wherein R1 is H, or C1 or C2 alkyl, and n is 1 or 2; the second RRMU has the structure and wherein at least 50% of the RRMUs have the structure of the first RRMU. The present invention further relates to an absorbent article comprising a liquid pervious topsheet, a liquid impervious backsheet comprising a film comprising a PHA of the present invention and an absorbent core positioned between the topsheet and the backsheet.

Owner:DANIMER IPCO LLC

Biodegradable PHA copolymers

The present invention relates to biodegradable PHA copolymers comprising at least two randomly repeating monomer units. The present invention further relates to a plastic article comprising a biodegradable copolymer, wherein the biodegradable copolymer comprises at least two randomly repeating monomer units (RRMU) wherein the first RRMU has the structure wherein R1 is H, or C1 or C2 alkyl, and n is 1 or 2; the second RRMU has the structure and wherein at least 50% of the RRMUs have the structure of the first RRMU. The present invention further relates to an absorbent article comprising a liquid pervious topsheet, a liquid impervious backsheet comprising a film comprising a PHA of the present invention and an absorbent core positioned between the topsheet and the backsheet.

Owner:MEREDIAN

Anti-electrostatic nano compound polyester fibre and making method thereof

InactiveCN1372020ASlow crystallization rateReduce crystallinityElectroconductive/antistatic filament manufactureConjugated synthetic polymer artificial filamentsPolyethylene glycolCopolyester

The antistatic nano composite polyester fibre is made of polyester or modified polyester, promotor and nano powder body through the processes of mixing and melt-spinning, in which the promotor is a condensation product of copolyester containing metaphenylene and polyethylene glycol, and can effectively improve dispersion property of nano powder body in the polyester or modified polyester, and possesses antistatic synergistic effect, and said nano powder body is a metal oxide with good conductivity.

Owner:DONGHUA UNIV

Plastic articles comprising biodegradable PHA copolymers

InactiveUS6569990B1Easy to processDifficult to processFlexible coversWrappersBiodegradable copolymersBiodegradable polymer

The present invention relates to biodegradable PHA copolymers comprising at least two randomly repeating monomer units. The present invention further relates to a plastic article comprising a biodegradable copolymer, wherein the biodegradable copolymer comprises at least two randomly repeating monomer units (RRMU) wherein the first RRMU has the structurewherein R1 is H, or C1 or C2 alkyl, and n is 1 or 2; the second RRMU has the structureand wherein at least 50% of the RRMUs have the structure of the first RRMU. The present invention further relates to an absorbent article comprising a liquid pervious topsheet, a liquid impervious backsheet comprising a film comprising a PHA of the present invention and an absorbent core positioned between the topsheet and the backsheet.

Owner:DANIMER IPCO LLC

Modified butanediol ester poly succinic acid and synthetic method

InactiveCN1796435AImproved crystallization behaviorSlow crystallization ratePolymer scienceSynthesis methods

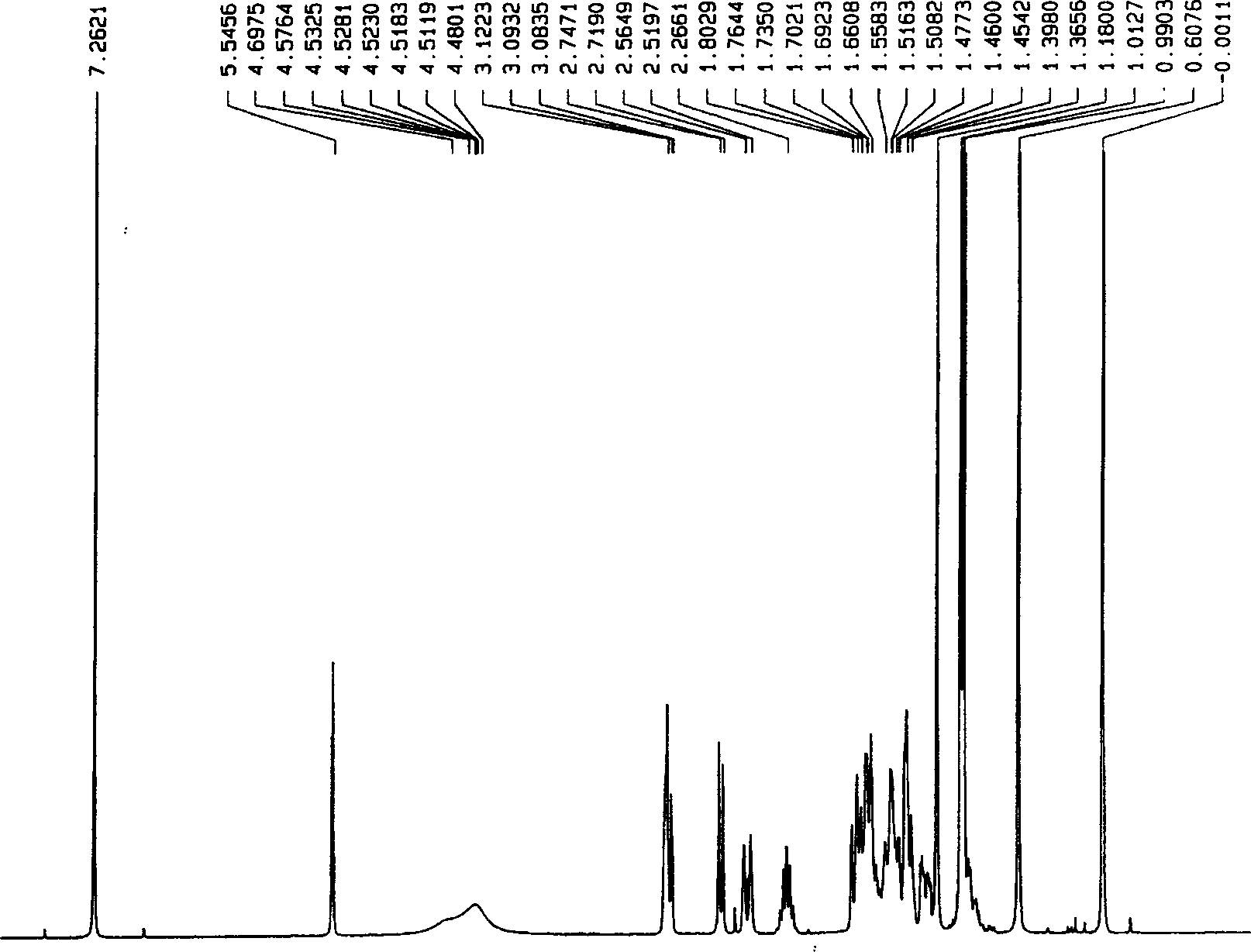

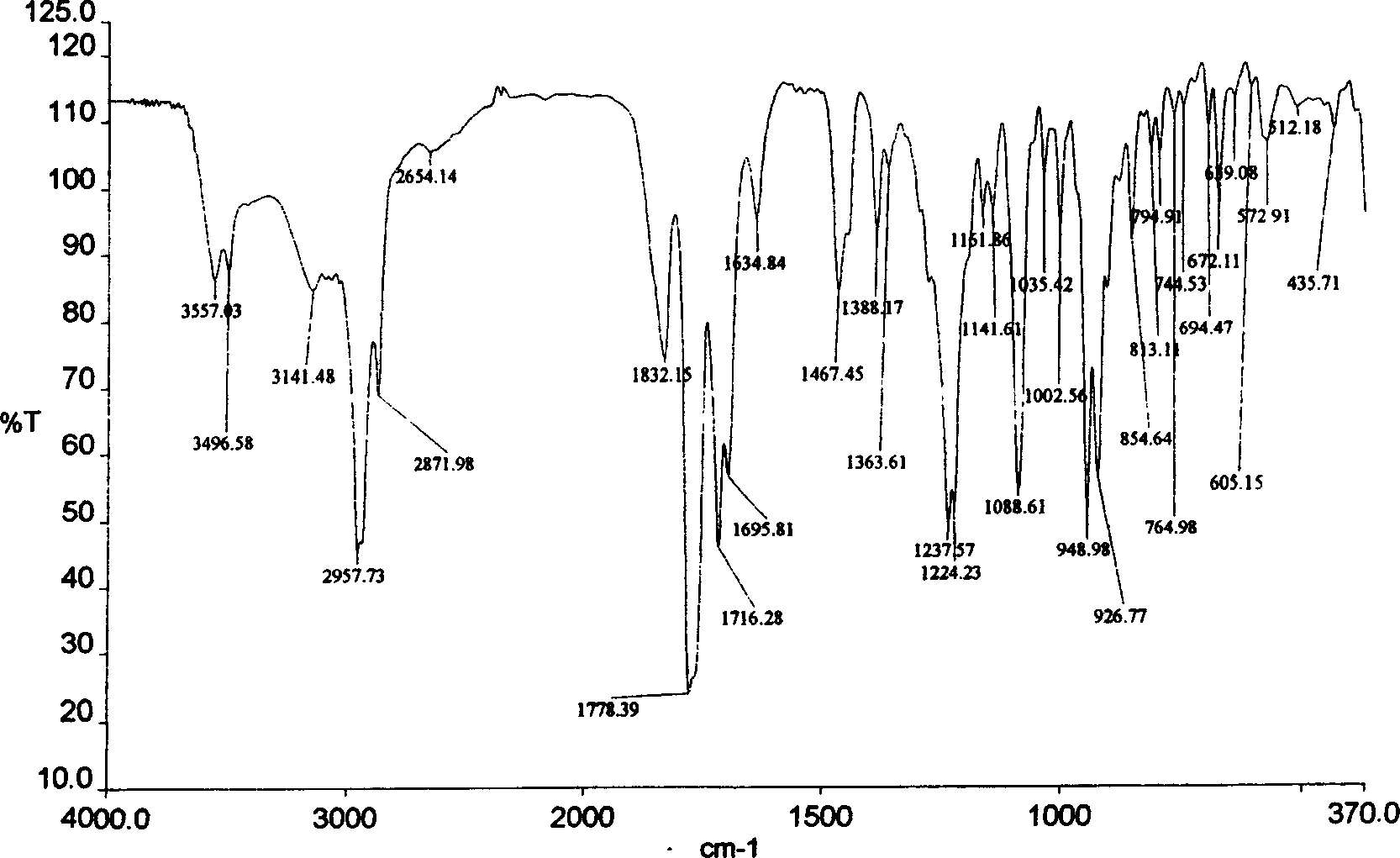

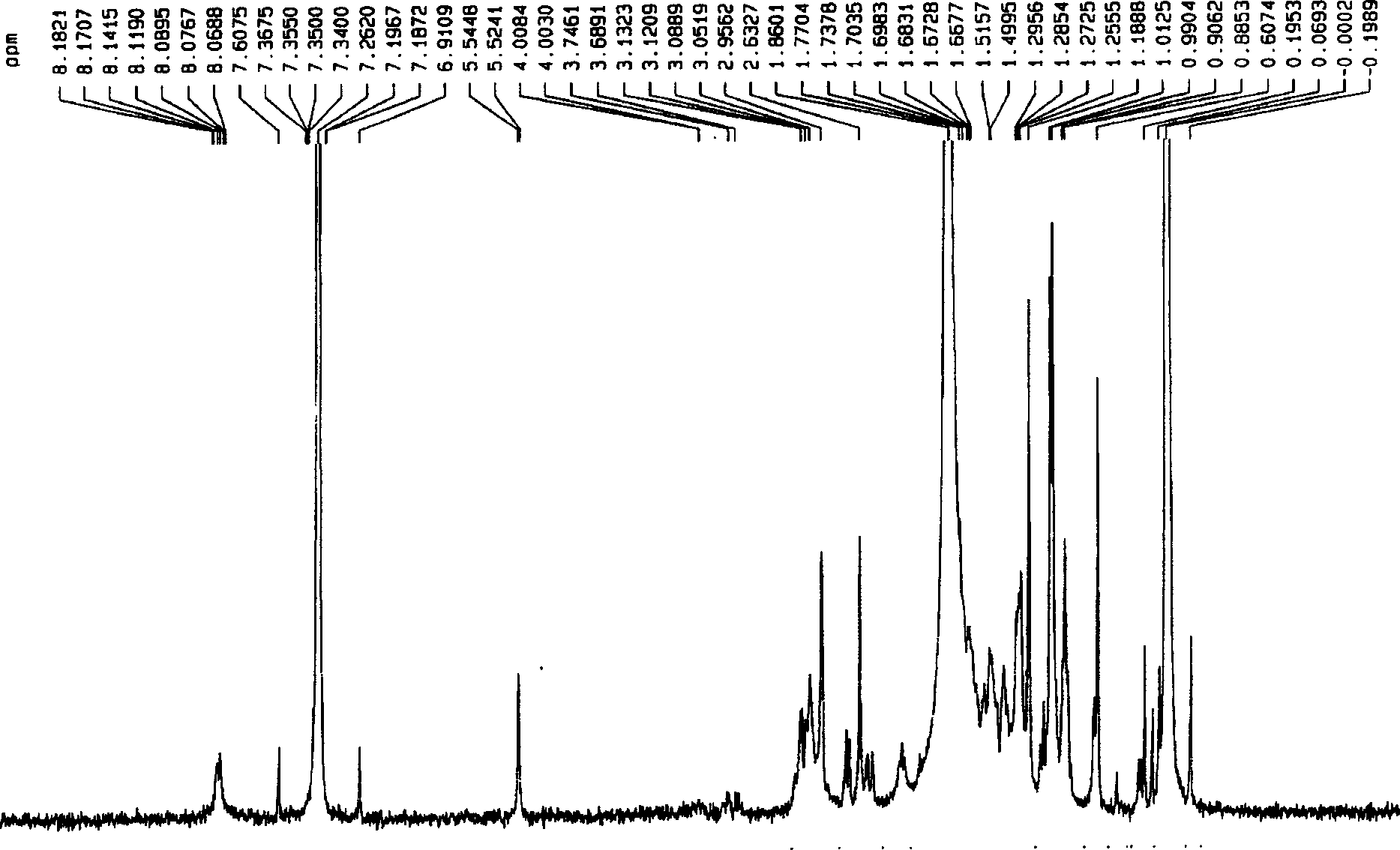

This invention relates to a cyclic compound, especially poly (butylenes succinate) modified by copolymerization with maleopimaric anhydride and its synthesis method. Succinic acid, 1,4-butanediol are mixed at a mole ratio of 1:1~4, and 4~20g maleopimaric imine dicarboxylic ester oligomers are added per 163g succinic acid / 1,4-butanediol mixture. The system is stirred at a temperature of 160~200 deg.C in the presence of inert gas, and cadmium acetate, zincum acetate, stibium oxide, butyl titanate or their optional combinations are added as catalysts at a mass fraction of 0.1~3% for a polymerization at a temperature of 230~280 deg.C and a pressure of 5~10Pa to produce modified poly(butylenes succinate) with a following structure. Such an environmentally friendly polymer performs a good elongation rate at break, impact-resistance strength and bending strength.

Owner:INST OF CHEM CHINESE ACAD OF SCI

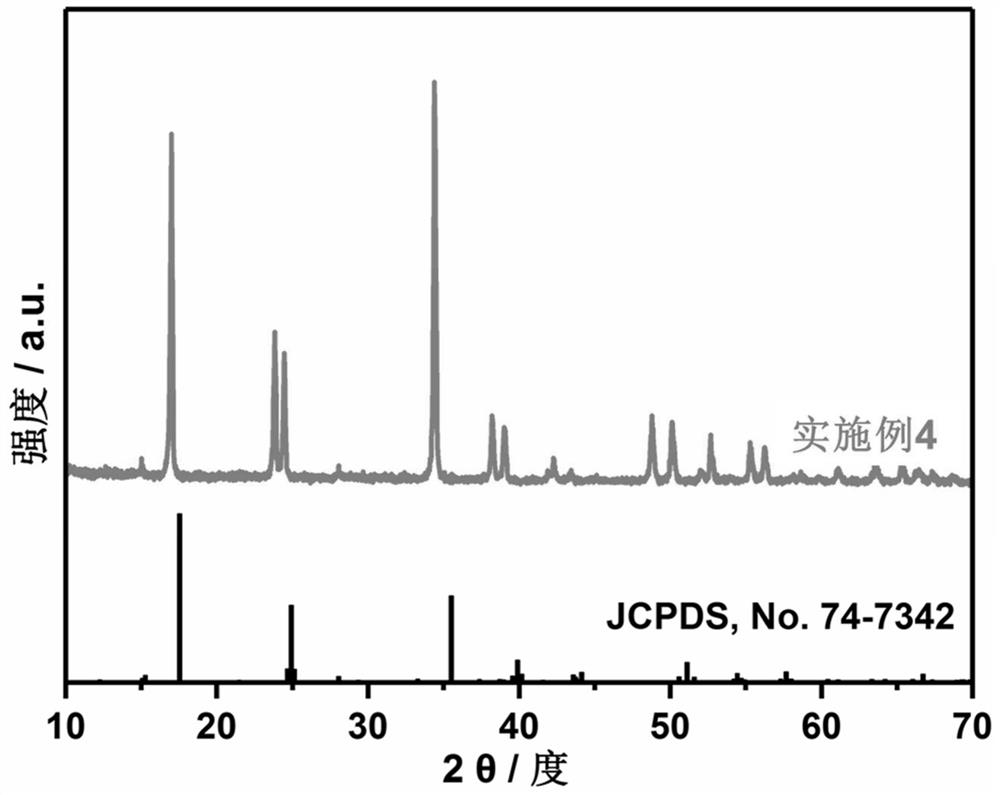

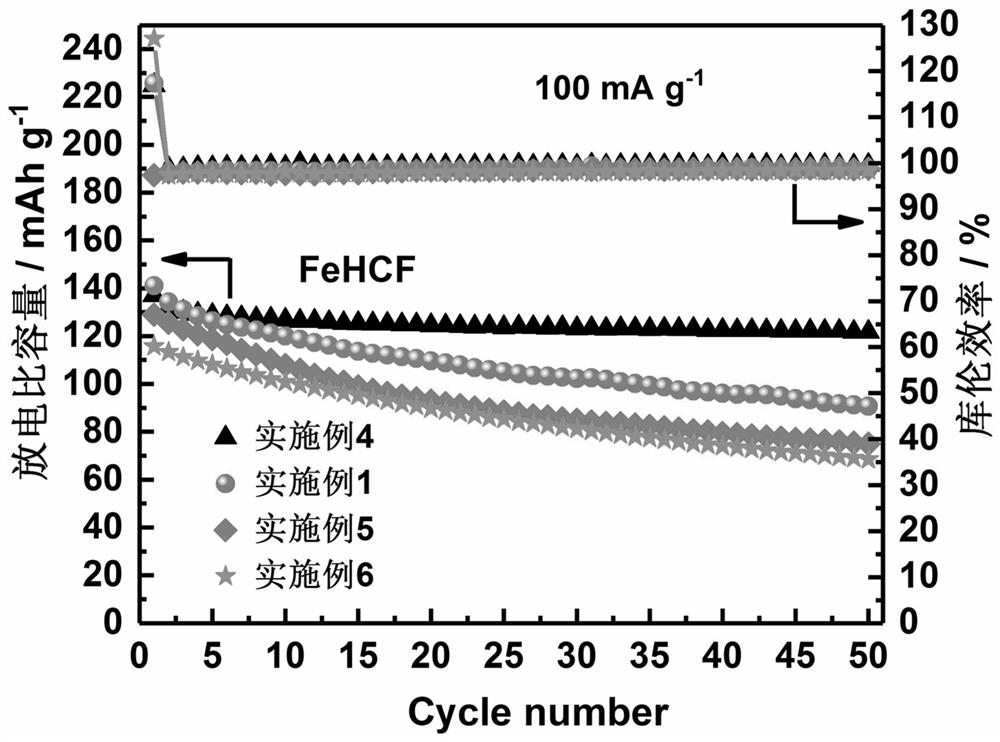

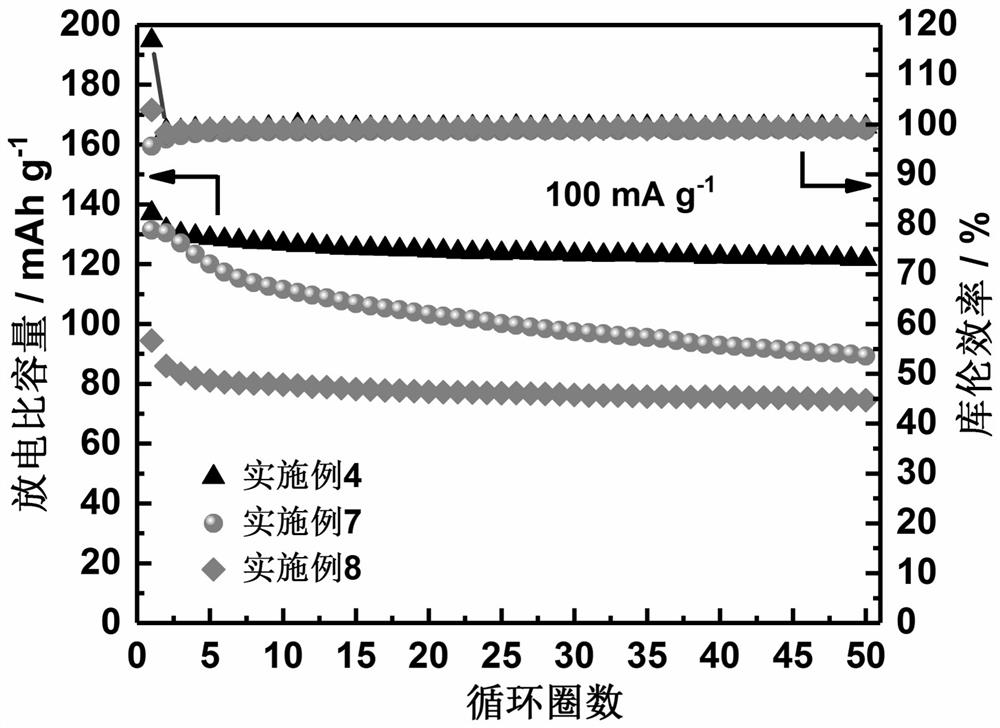

Prussian white analog cathode material and preparation method and application thereof

ActiveCN110002465AImprove crystal structureReduce defectsIron cyanidesSecondary cellsNew energyAqueous solution

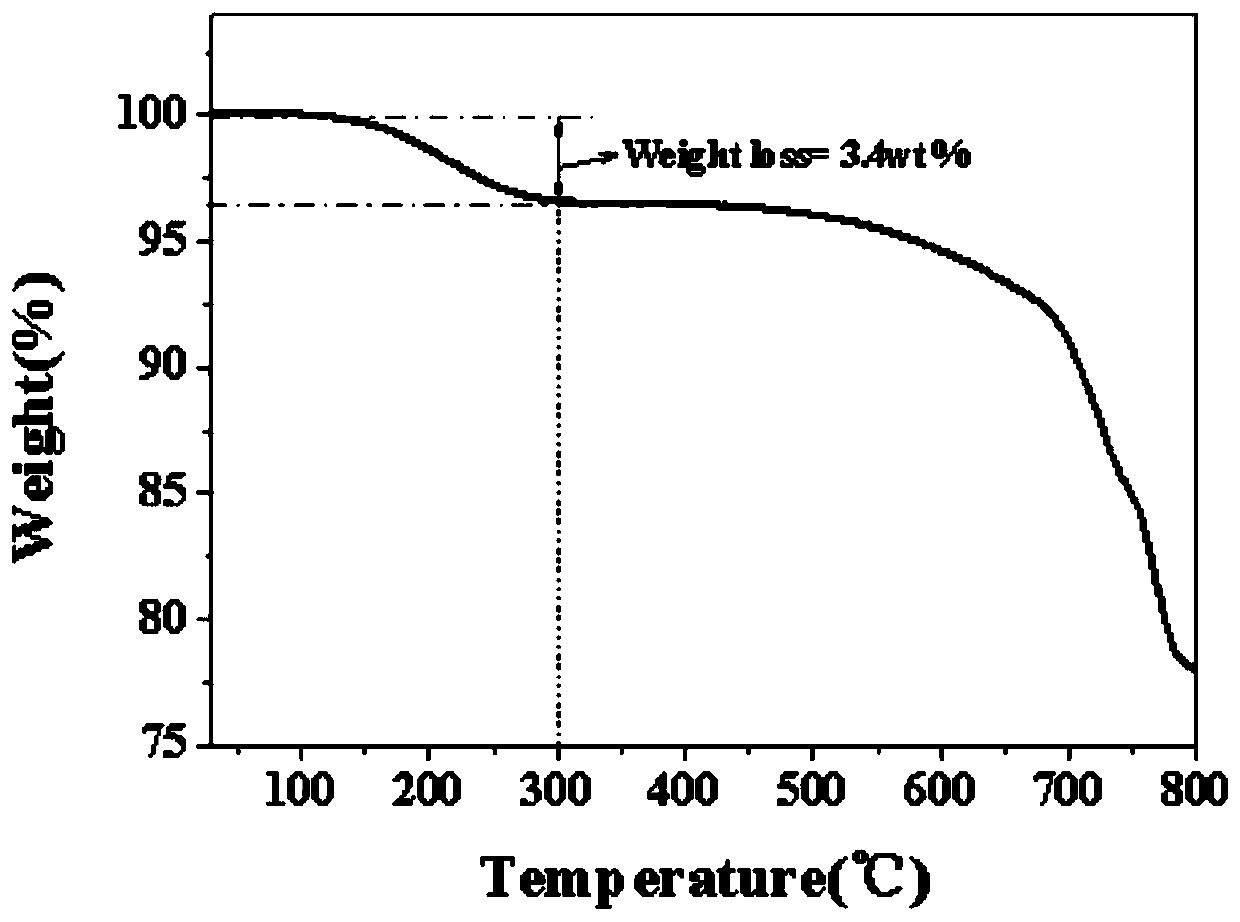

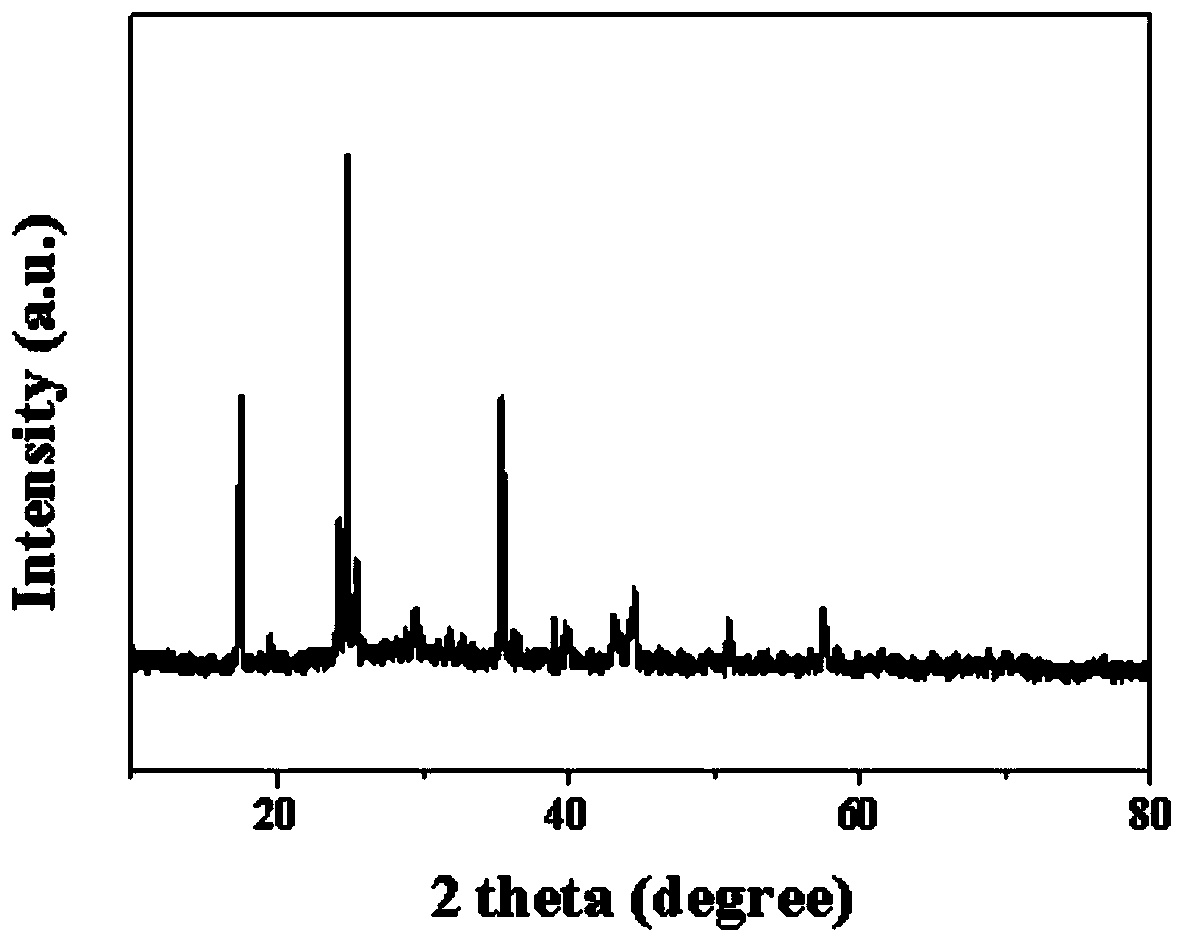

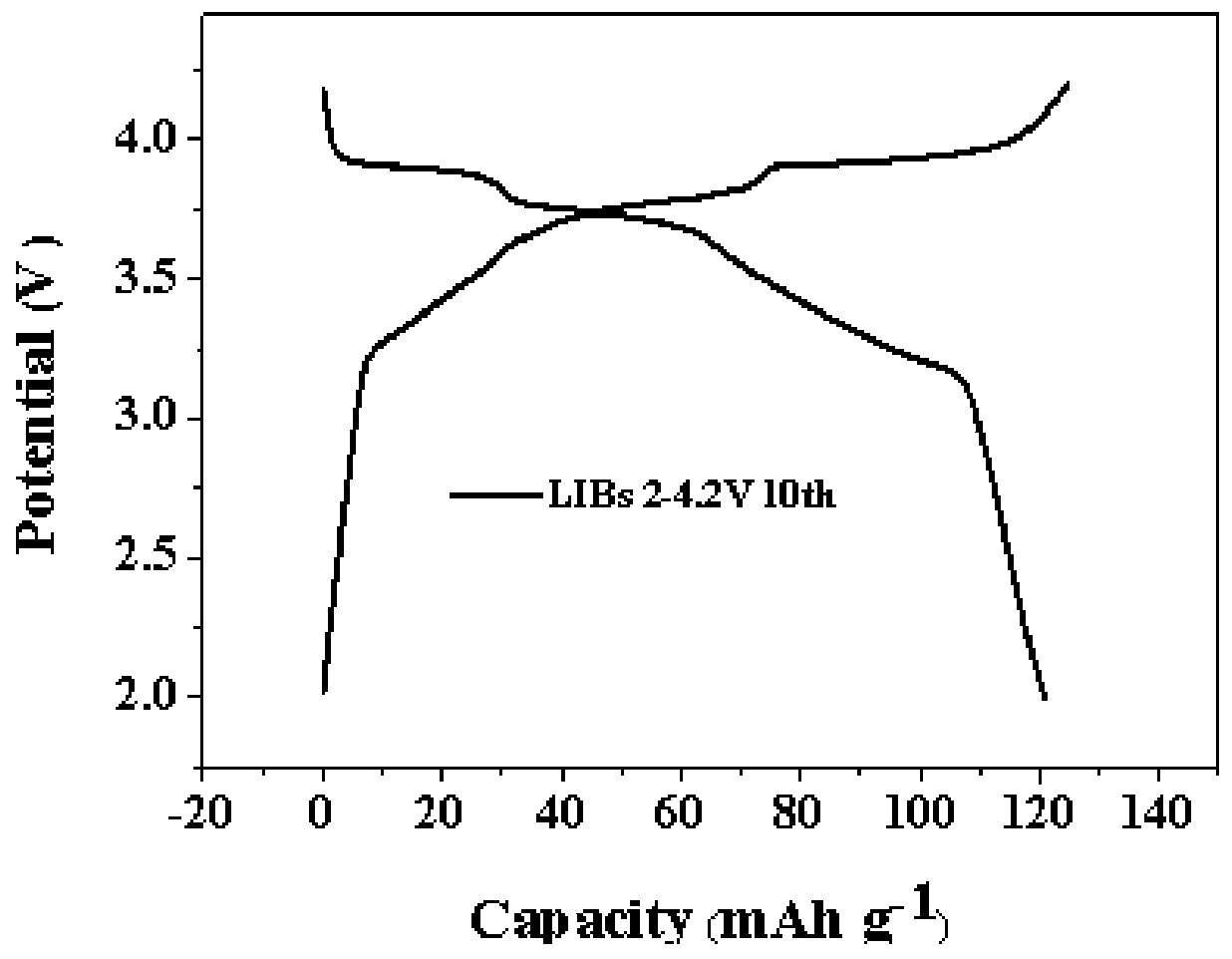

The invention belongs to the field of new-energy batteries, and particularly relates to a Prussian white analog cathode material and a preparation method and application thereof. The preparation method of the Prussian white analog cathode material comprises the following steps: (1), acquiring an aqueous solution of K4Fe (CN)6, which is recorded as a solution A; (2), acquiring a mixed aqueous solution of a transition metal salt of Mn and potassium citrate, which is recorded as a solution B; and (3), dropwise adding the solution A into the solution B, continuing heating and stirring after completion of dropwise addition, aging for several hours, performing solid-liquid separation, collecting and washing a precipitate, and drying to obtain the Prussian white analog cathode material. The Prussian white analog cathode material adopts an open three-dimensional network frame structure, has a large gap position, and can guarantee free deintercalation of various ions such as Li<+>, Na<+> and K<+>.

Owner:HUAZHONG UNIV OF SCI & TECH

Micro-nano structure interface induced growth method for perovskite film of solar cell

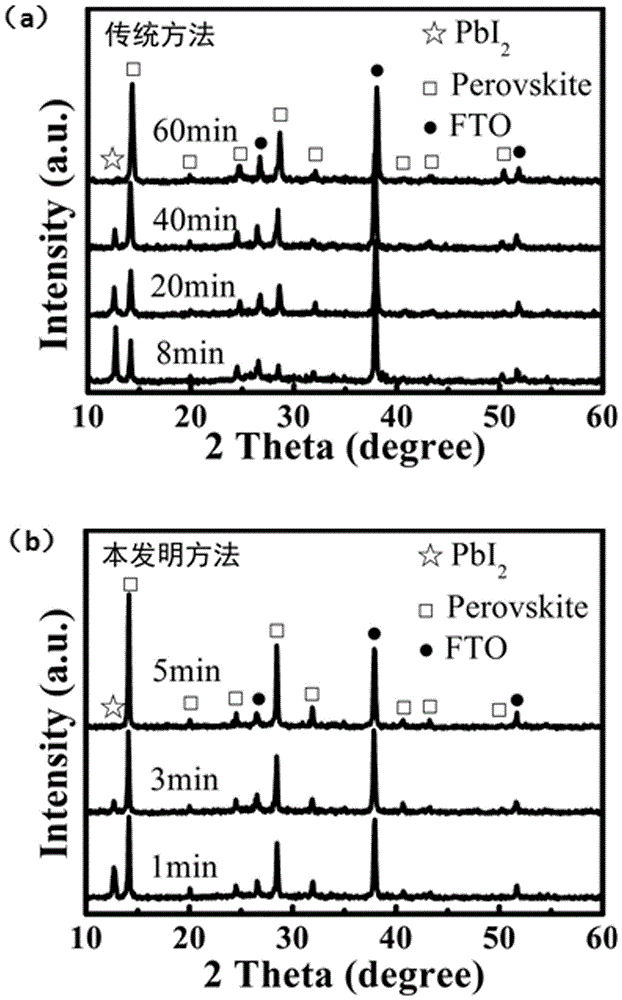

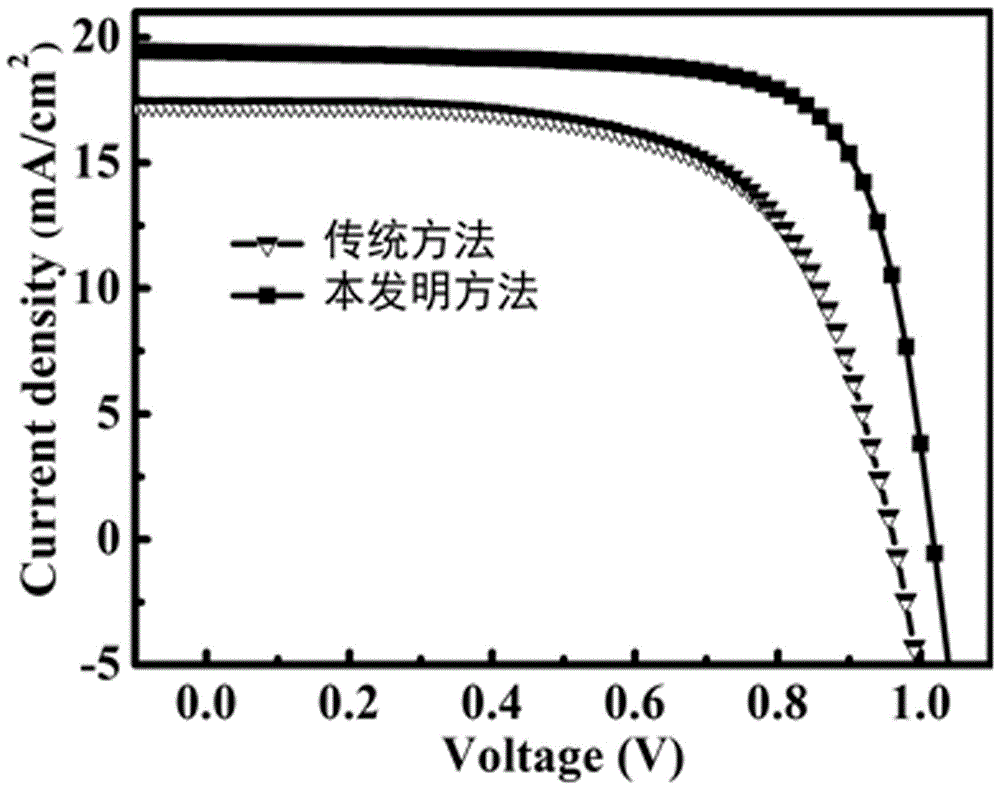

InactiveCN106611819AShort conversion timeSlow crystallization rateMaterial nanotechnologySolid-state devicesManufacturing cost reductionMicro nano

The invention discloses a micro-nano structure interface induced growth method for an organic metal halide perovskite film of a solar cell, and the method is characterized in that the a solvent coordination-anti-solvent extraction method is employed for preparing a metal halide film with a micro-nano structure interface, and then the micro-nano structure interface is used for inducing the quick conversion and growth of perovskite crystal particles, so as to prepare a high-quality perovskite film and a high-performance solar cell. According to the invention, the coordination solvent in the solvent coordination-anti-solvent extraction method has the strong coordination capability for metal halide, so the crystallization velocity can be reduced. The anti-solvent extraction can avoid the self-organization growth, and achieves the quick deposition to form the film with the micro-nano structure interface, thereby greatly improving the reaction rate of diffusion of organic halide molecules to the interior, and achieving the quick and complete conversion of perovskite. The method does not need to carry out the high-temperature annealing and the vacuum technology, and facilitates the reduction of manufacturing cost.

Owner:TAIYUAN UNIV OF TECH

Flame retardant PTT polyester fiber and production method thereof

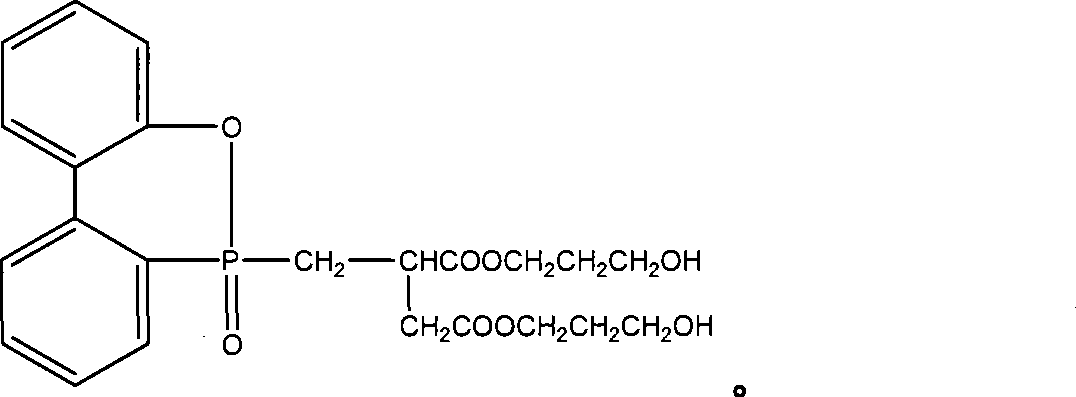

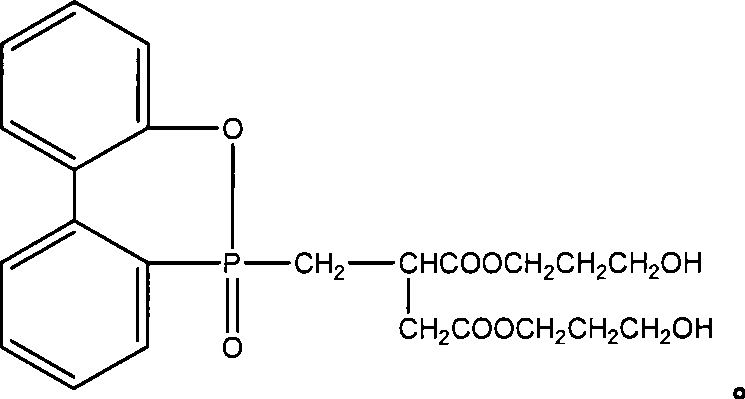

ActiveCN101532189AImprove flame retardant performanceHigh breaking strengthFlame-proof filament manufactureMonocomponent polyesters artificial filamentBreakdown strengthFiber

The invention relates to a flame retardant PTT polyester fiber and production method thereof, wherein the polyester comprises a phosphor based copolymerization flame retardant accounting for 1.2-8.5% of the total weight of the polyester and the phosphor based copolymerization flame retardant comprises a double-reaction functional group and the phosphor element quality content in polyester is 1400-12000ppm and the PTT polyester also comprises an inorganic nano-material accounting for 0.1%-5.0% of the total weight of the polyester and the inorganic nano-material is selected from one kind or several kinds of silicon dioxide, calcium carbonate, magnesium carbonate and barium sulphate. The production method is the improvement of the conventional method, specifically before drying polyester chip, the polyester chip is precrystallized at 110-125 DEG C for 1.5-3 hour and the drying temperature is 130-145 DEG C and the drying time is 3.5-5 hours. The polyester fiber has features of good and permanent flare retardant resistance, high breakdown strength, good fiber forming property, good thermal stability and good thermal oxidation stability performance.

Owner:JIANGSU ZHONGLU TECH DEV

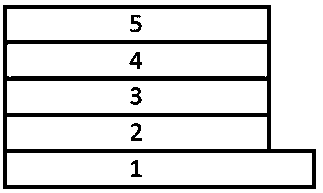

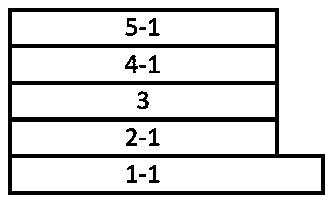

Bend-resistant perovskite solar cell and preparation method thereof

InactiveCN107611190ASlow crystallization rateRefine the grain sizeFinal product manufactureSemiconductor devicesPerovskite solar cellHole transport layer

The invention discloses a bend-resistant perovskite solar cell, comprising a transparent substrate, an anode, an electron transport layer, a perovskite active layer, a hole transport layer and a cathode. The perovskite active layer is composed of a perovskite material and an additive. The additive is polyurethane. The perovskite material is CH<3>NH<3>PbI<3>, CH<3>NH<3>PbI<3>-xClx or (FAPbI<3>)l-x(MAPbBr<3>)x. The additive polyurethane is added to perovskite precursor solution according to mass concentration of 0.01wt%-5wt%. According to the bend-resistant perovskite solar cell, the polyurethane is introduced into perovskite precursor solution, perovskite crystals are controlled to nucleate, a crystallization rate is reduced, the bend-resistance of perovskite film is improved, a new thoughtfor preparing high performance flexible perovskite solar cell is provided, and the flexible roll-to-roll commercialized production of the perovskite solar cell is realized.

Owner:NANCHANG UNIV

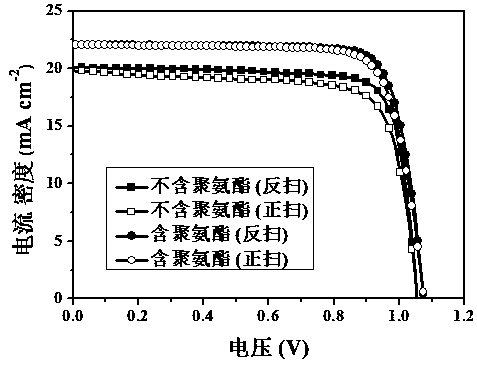

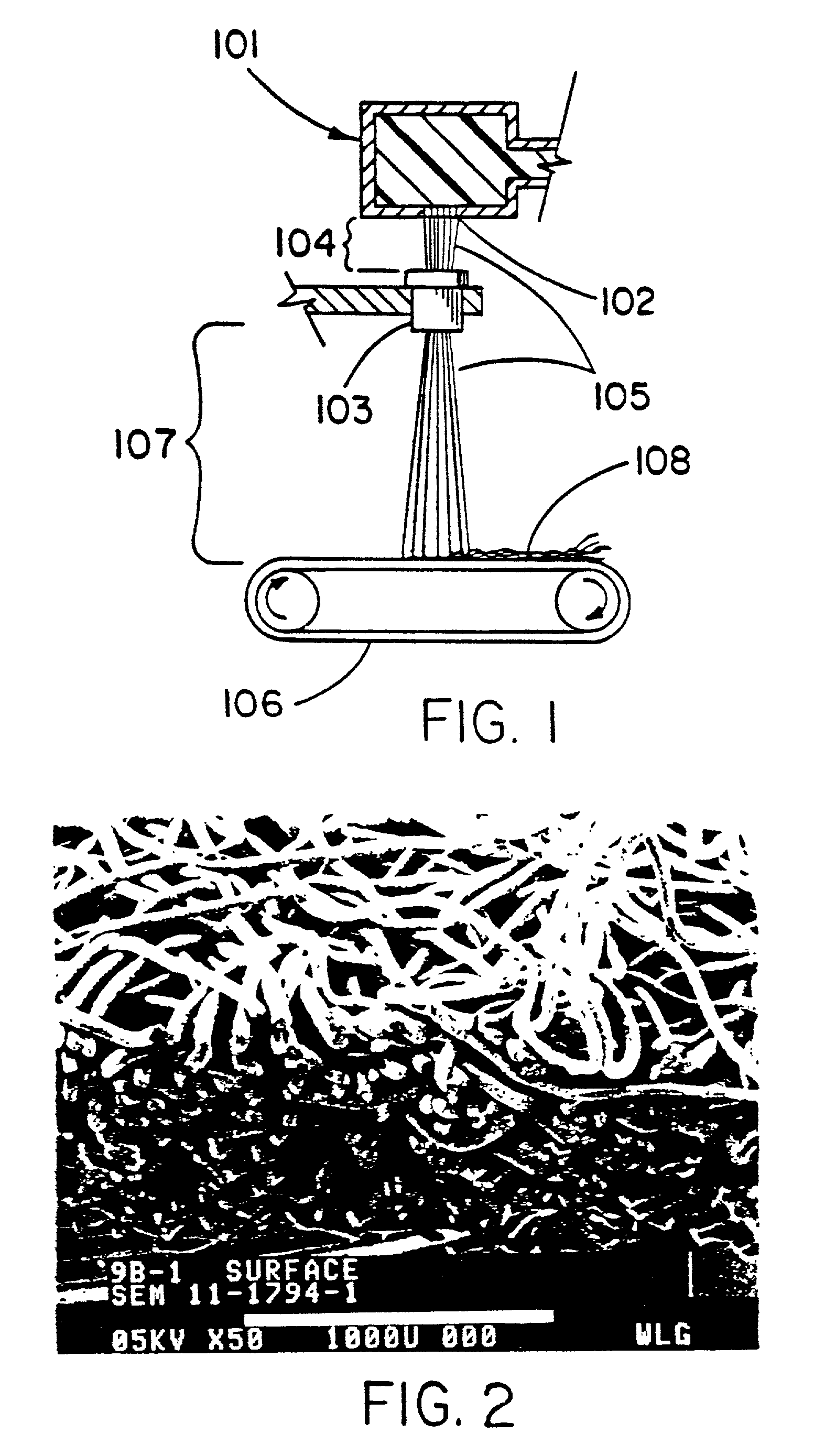

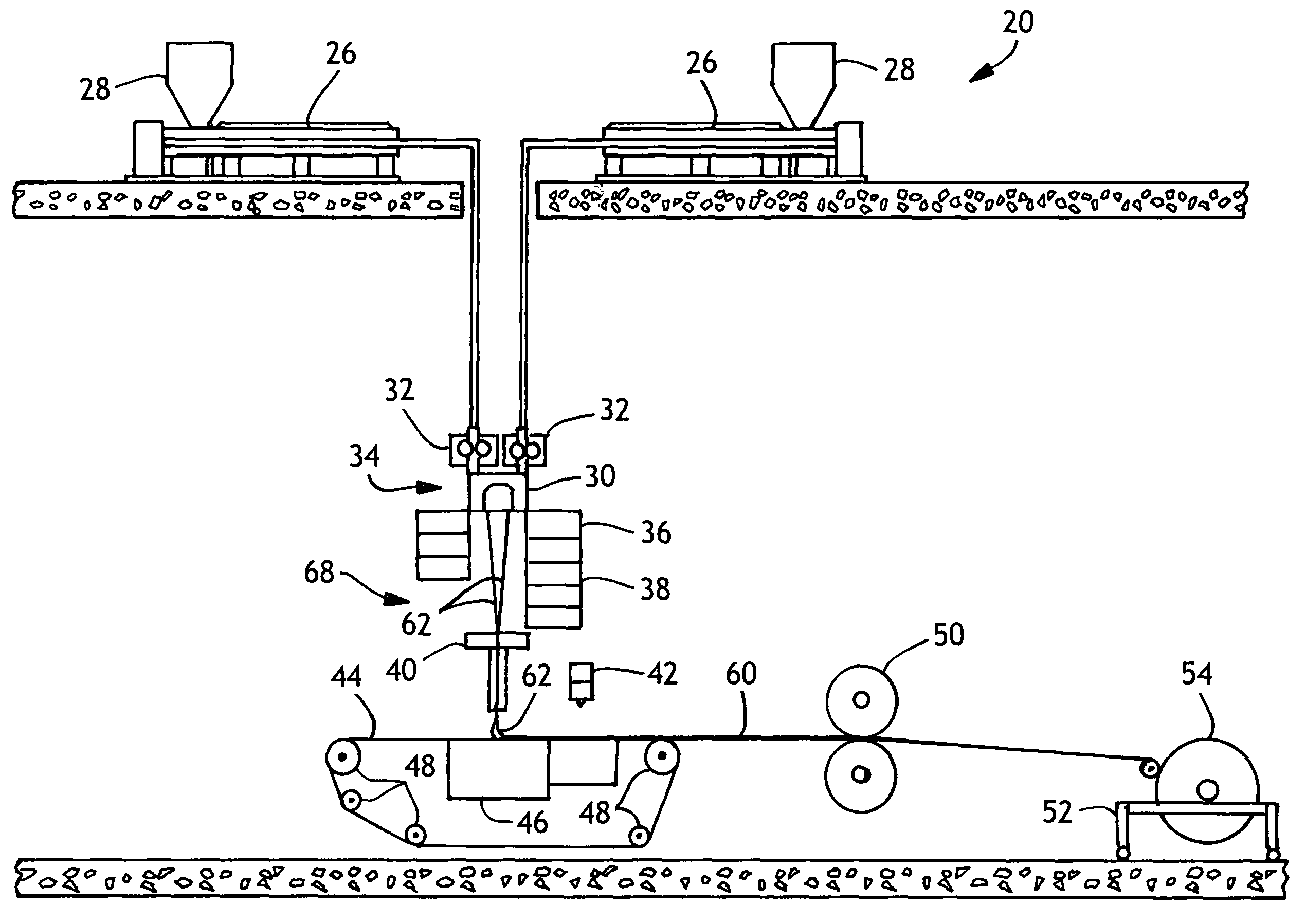

Fibers and nonwovens with improved properties

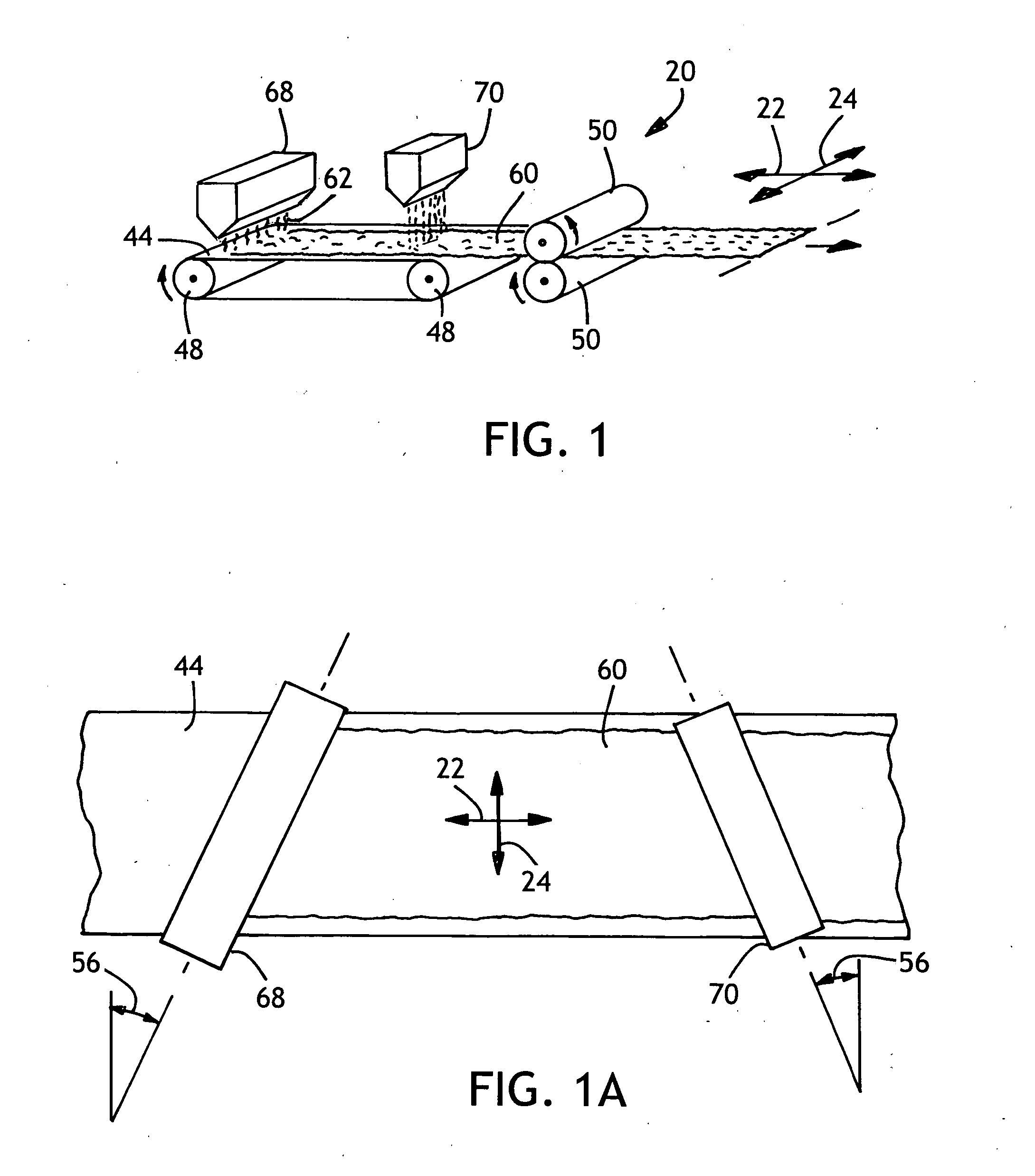

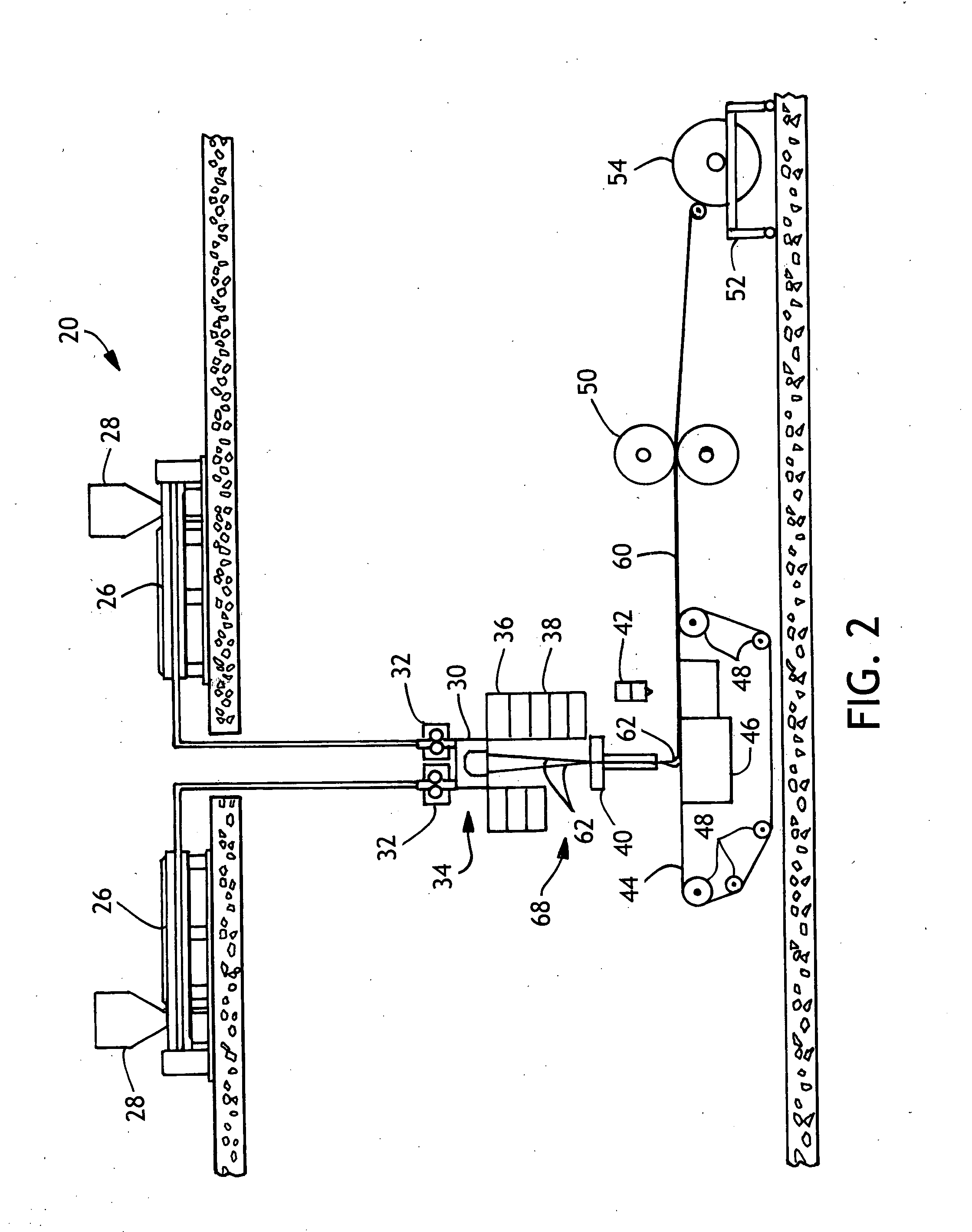

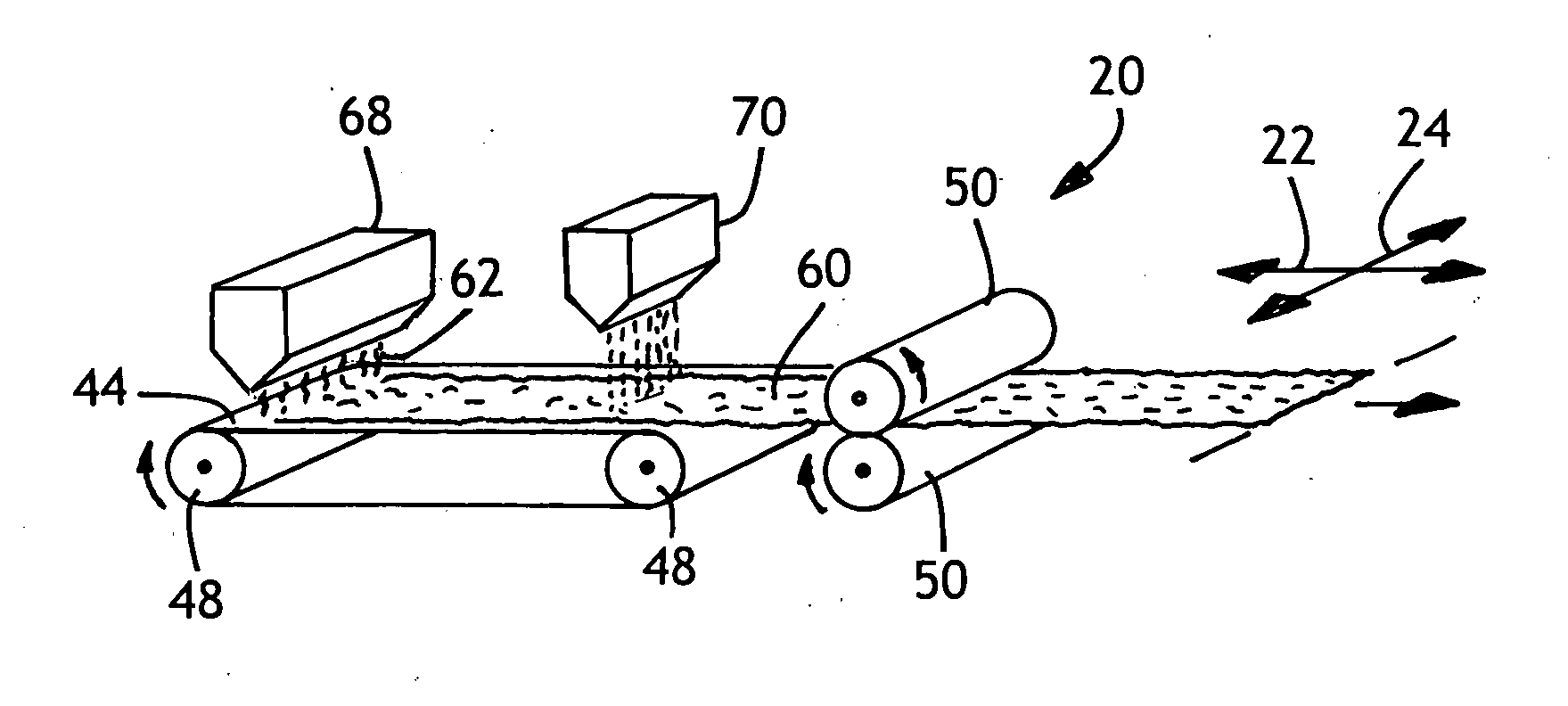

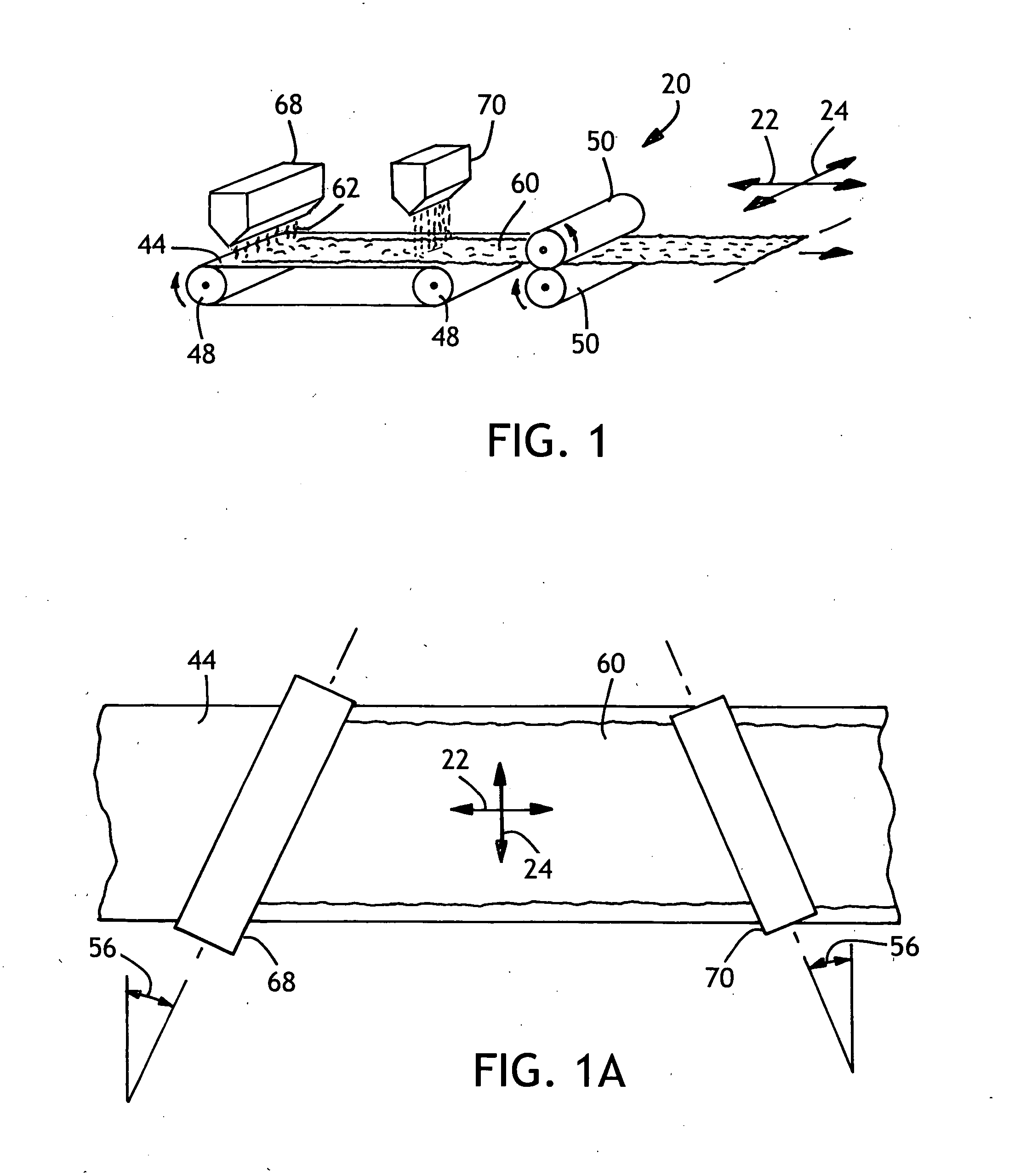

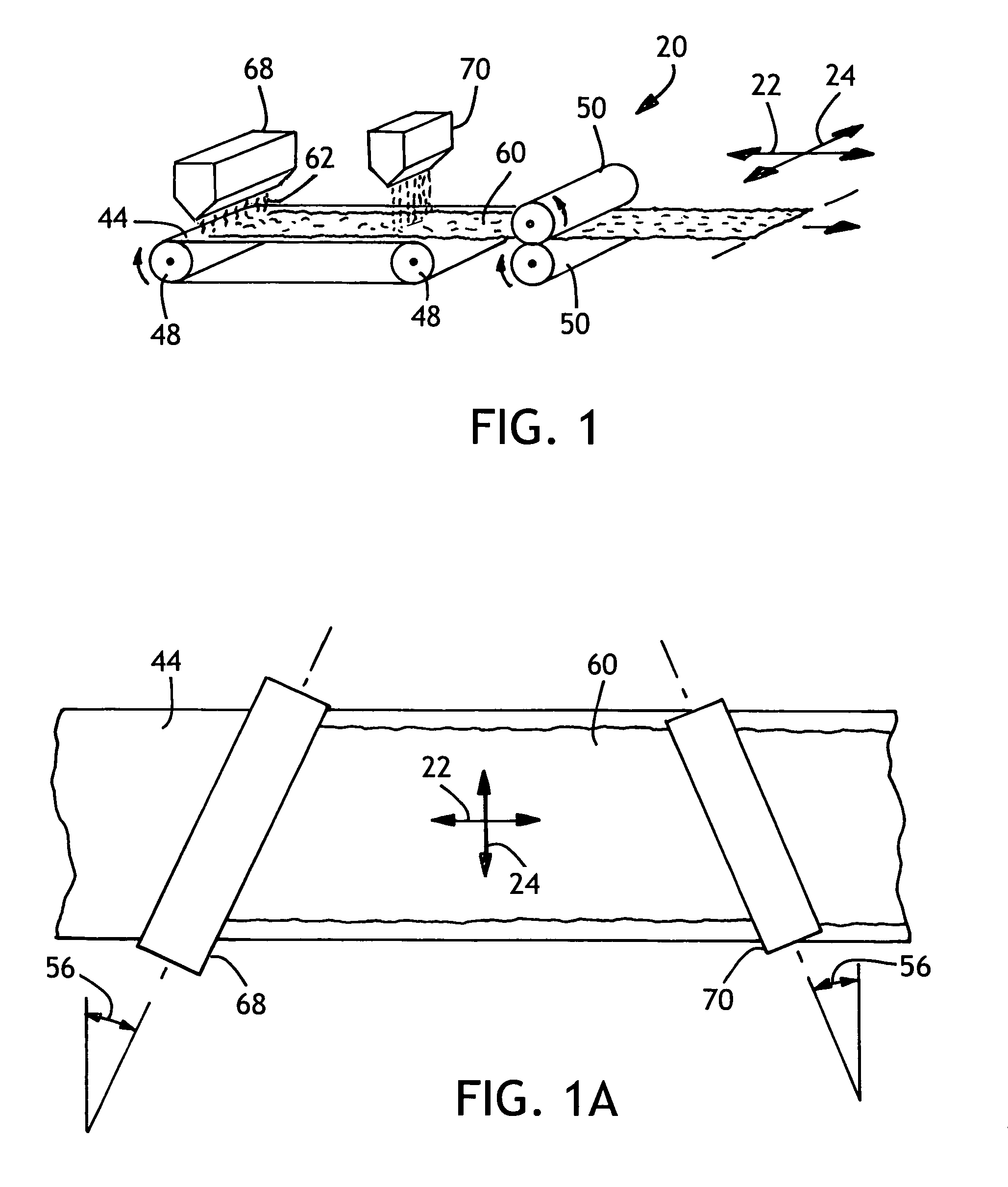

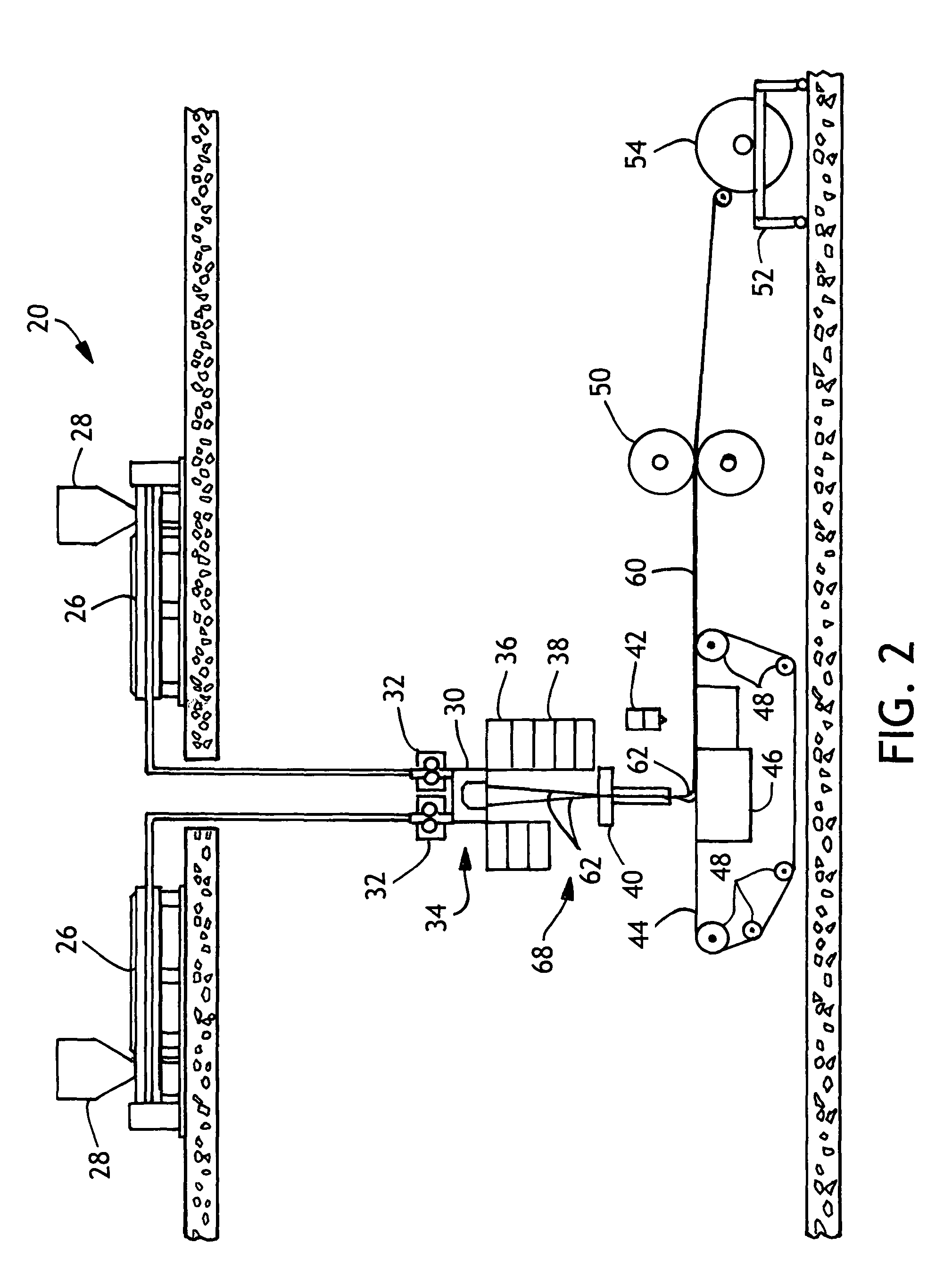

InactiveUS20060276092A1Slow crystallization rateHigh crystallinitySynthetic resin layered productsFilament/thread formingPolymer scienceCrystallinity

The present invention can provide a distinctive article which includes a plurality of fibers (62), wherein the fibers include a selected polymer, fiber material. In a particular aspect, the fiber material can exhibit a “low” crystallization rate. In other aspects, the fiber material has been subjected to a low fiber-draw percentage, and the polymer in the fibers can have a high crystallinity. Further aspects can include a fiber material which has been subjected to a low fiber-draw speed, and can include fibers which have a high tenacity. In still other aspects, the fibers can be configured to provide a fibrous web (60), and the fibrous web (60) can have a distinctive tensile strength quotient, with respect to tensile strengths along its machine-direction (22) and cross-direction (24).

Owner:KIMBERLY-CLARK WORLDWIDE INC

Hydroscopic fine denier/superfine denier chinlon master batch, chinlon POY filaments and preparation method thereof

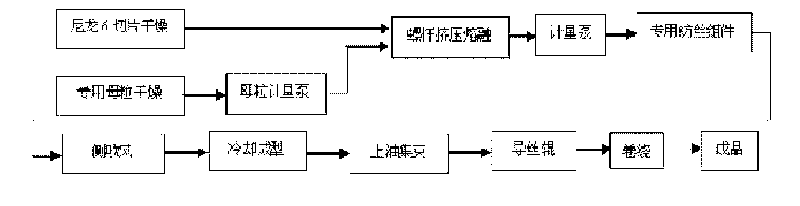

InactiveCN101735608AChange the melt structureGood moisture absorption and permeabilityMelt spinning methodsMonocomponent polyamides artificial filamentBreaking strengthPolymer science

The invention belongs to the field of spinning materials, and firstly provides a hydroscopic fine denier / superfine denier chinlon master batch which is prepared by adding a hydroscopic modifier, a metallic salt, an antioxidant and other auxiliary agents into nylon 6 chips in proportion to perform melt blending and extrusion, wherein the hydroscopic modifier is PVP; the hydroscopic fine denier / superfine denier chinlon master batch is mixed with the nylon 6 chips to perform melt spinning in proportion, and hydroscopic fine denier / superfine denier chinlon POY filaments are prepared by further performing cooling, oiling bunching and winding on the hydroscopic fine denier / superfine denier chinlon master batch and the nylon 6 chips. The hydroscopic fine denier / superfine denier chinlon POY filaments have the filament number of 0.4 to 0.88 dtex, the breaking strength of 3.3 to 3.8 cN / dtex, the elongation at break of 60 to 120 percent and the fiber hydroscopicity of 4 to 10 percent, so the blank of producing the hydroscopic fine denier / superfine denier chinlon POY filaments by adopting a conventional spinning method at home and abroad is filled up, and simultaneously the improvement on the hydroscopicity of the chinlon POY filaments provides a wider application space for the chinlon POY filaments.

Owner:HANGZHOU NORMAL UNIVERSITY

Self-cohering, continuous filament non-woven webs

InactiveUS20010000352A1Increase temperatureSlow crystallization rateSurgeryFilament/thread formingEngineeringUltimate tensile strength

A web of continuous filaments which are made of at least one semi-crystalline polymeric component covalently bonded as a linear block copolymer with or blended with one or more semi-crystalline or amorphous polymeric components. The filaments are intermingled together to form a porous web of filaments, the filaments having multiple contact points with each other within the web. The filaments are bonded at the contact points without requisite for added adhesive binders, adjuncts or post extrusion melt processing. The web may be bioresorbable. The web may also be provided in forms with relatively high cohesive shear strength. The polymeric components of the filaments exist, at least temporarily, in a homogenous substantially phase miscible uncrystallized state. If preserved in the homogenous substantially phase miscible uncrystallized state, the object can then be manipulated into a distinct desirable molded shape and then subsequently set or crystallized to retain the desired form particularly suitable for a specific use or application.

Owner:WL GORE & ASSOC INC

Method of making fibers and nonwovens with improved properties

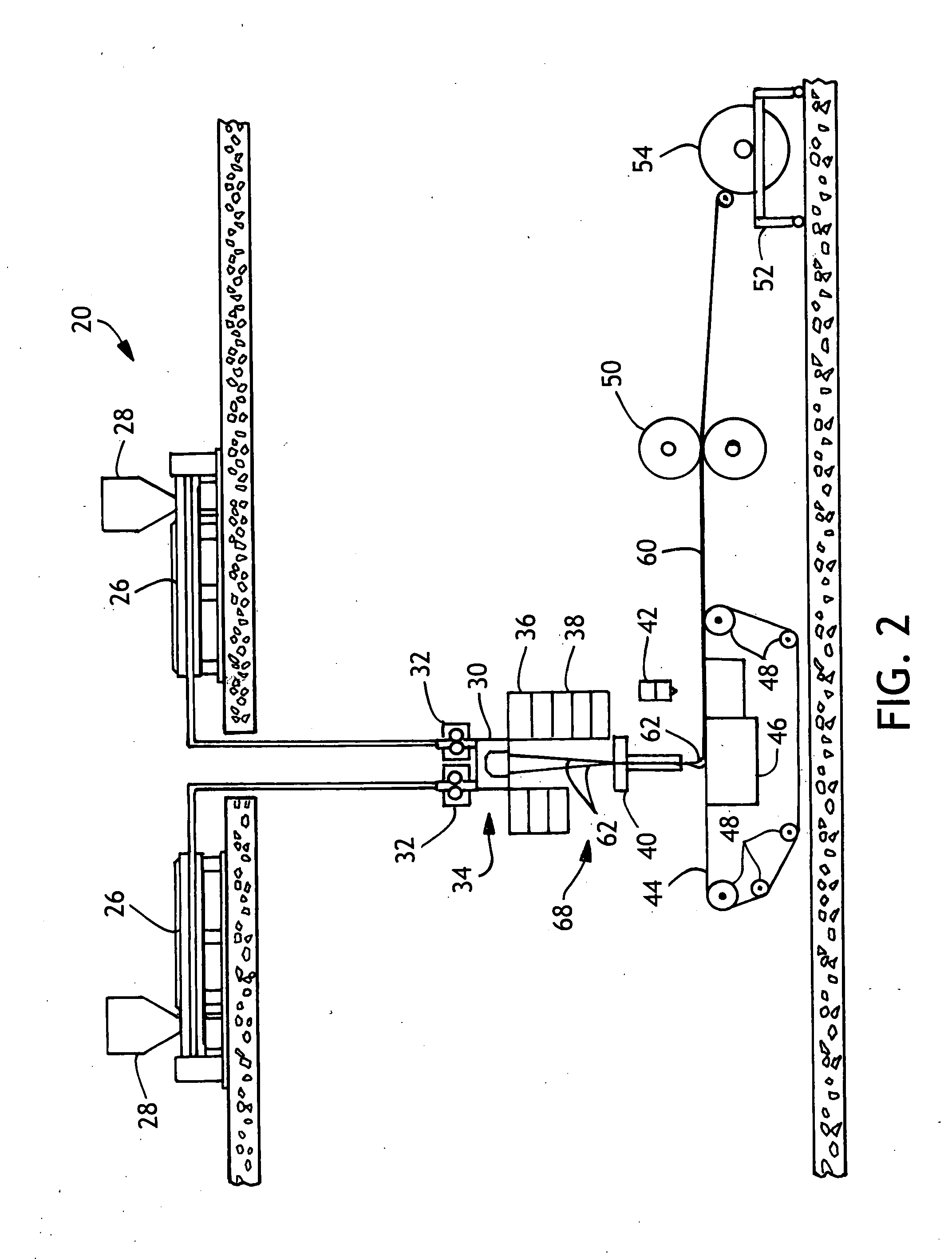

ActiveUS20060273495A1Slow crystallization rateReduce speedWoven fabricsNon-woven fabricsPolymer scienceNonwoven fabric

The present invention can provide a distinctive method and process for making polymer fibers (62) and nonwoven fabric webs (60). The method can include providing a fiber material that exhibits a low crystallization rate. In a particular aspect, the fiber material can be subjected to an anneal-quench at an anneal-quench temperature that approximates a prime-temperature at which the polymer material most rapidly crystallizes. In another aspect, the fiber material can be subjected to a fiber-draw at a selected fiber-draw temperature, and in a further aspect, the fiber-draw temperature can be configured to approximate the prime-temperature of the polymer material. In still other aspects, the fiber material can be subjected to a relatively small amount of fiber-draw, and the fiber-draw can be provided at a relatively low fiber-draw speed.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Process and apparatus for recovering lactide from polylactide or glycolide from polyglycolide

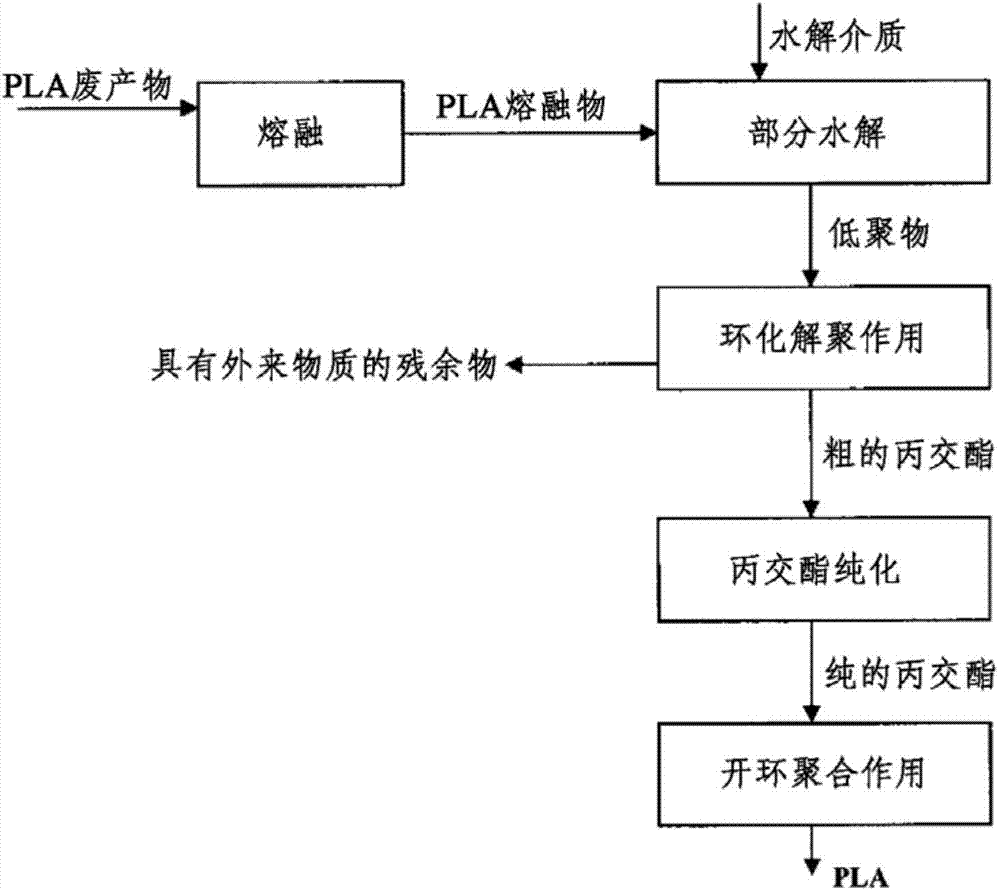

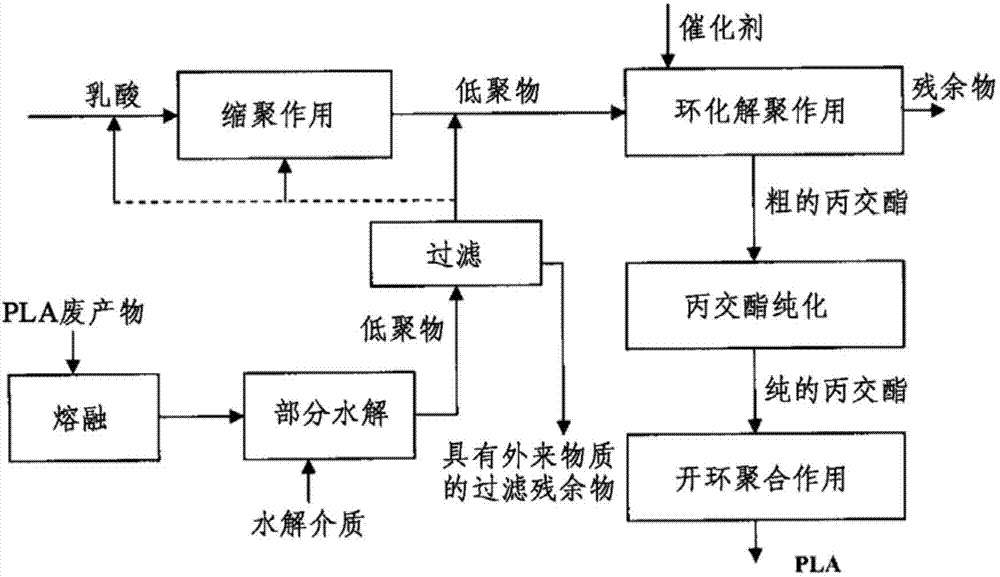

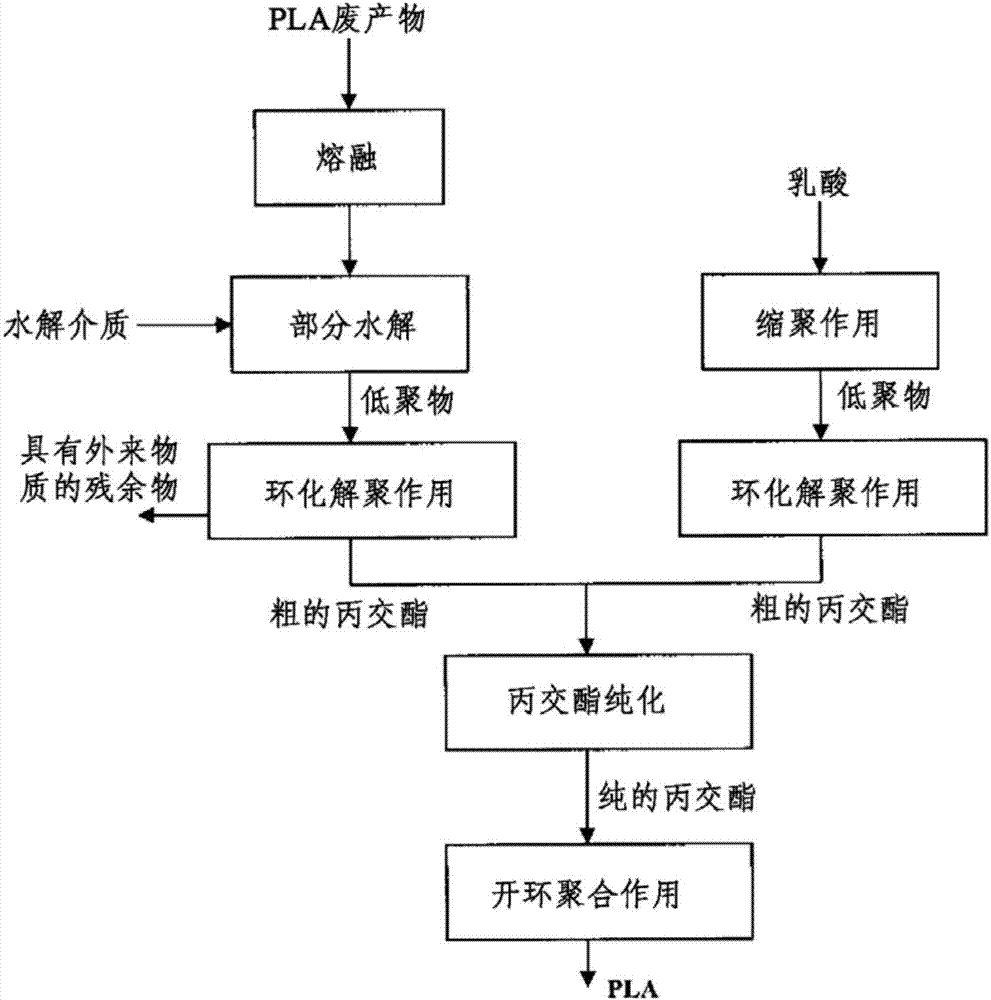

ActiveCN103781833ASave energySaverPlastic recyclingPreparation from carboxylic acid esters/lactonesPartial hydrolysisOligomer

The present invention relates to a process for recovering lactide from polylactide (PLA) or glycolide from polyglycolide (PGA), in which, in a first step, PLA or PGA is contacted with a hydrolysing medium and hydrolytically degraded to oligomers. In a further step, a cyclising depolymerisation of the oligomers obtained in the first step is effected to give lactide or glycolide. In addition, the present invention relates to an apparatus based on the combination of a hydrolysis apparatus with a depolymerisation reactor, with which the above-described process can be performed. The core of the process according to the invention is a partial hydrolysis of the polymeric materials originally used in combination with a cyclising depolymerisation.

Owner:UHDE INVENTA FISCHER

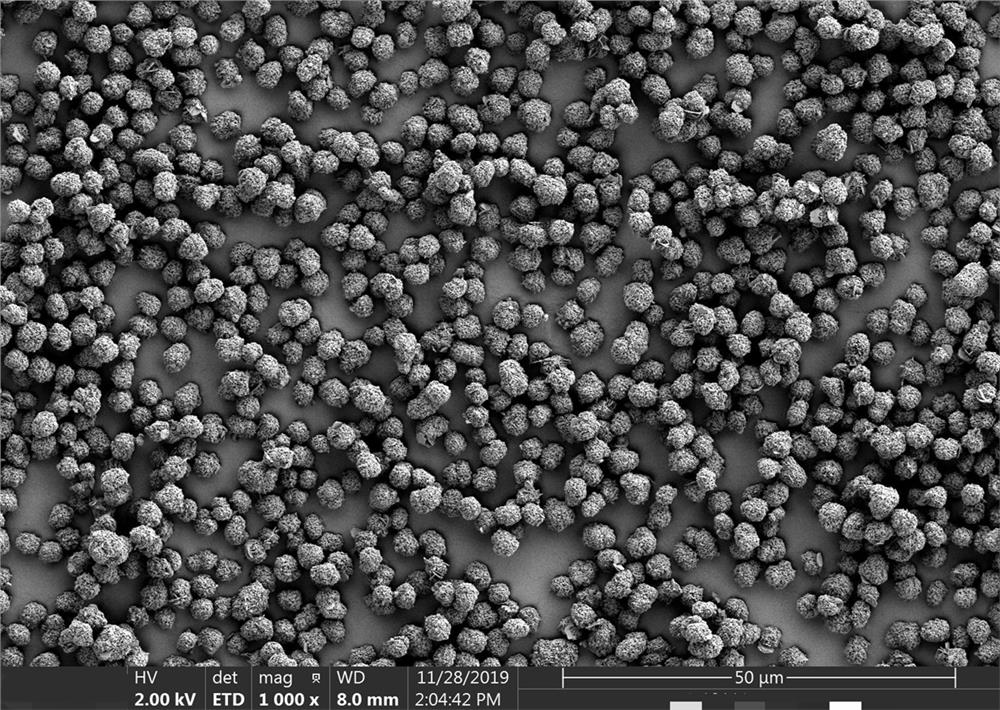

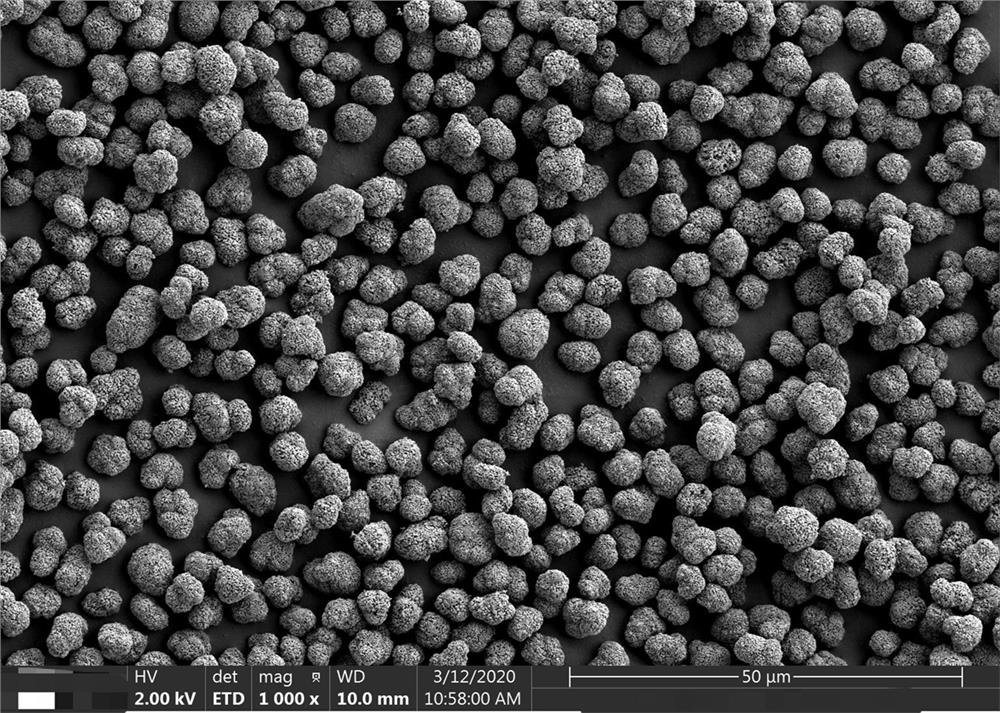

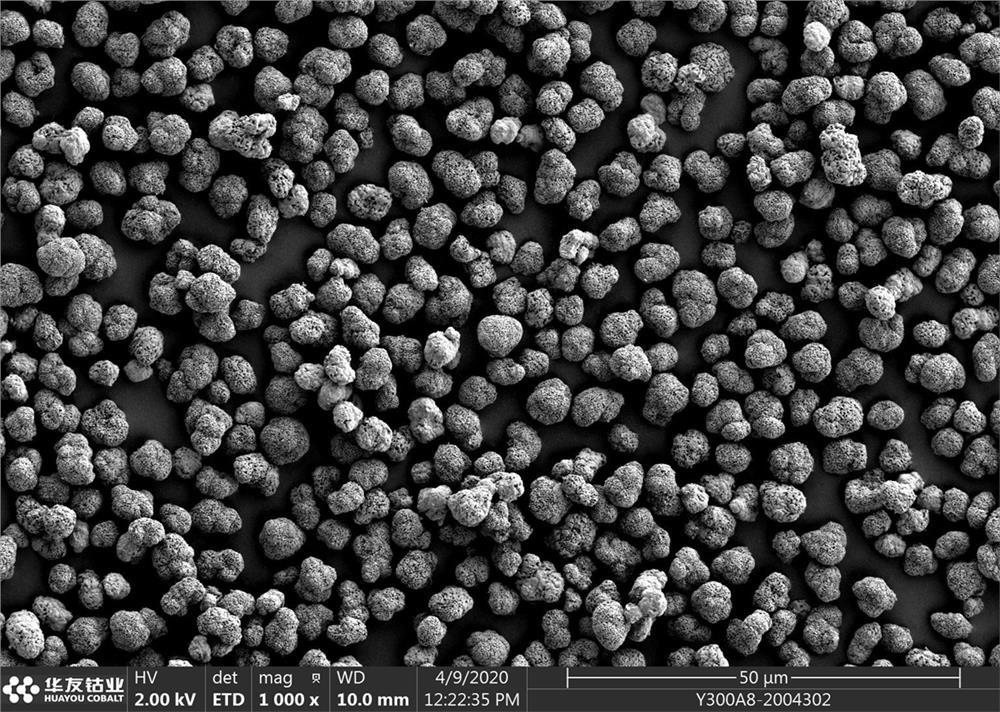

Preparation method of aluminum-doped cobaltosic oxide

PendingCN111646519AUniform particlesSlow crystallization rateCobalt oxides/hydroxidesPhysical chemistrySeed crystal

The invention relates to the technical field of battery material preparation, in particular to a preparation method of aluminum-doped cobaltosic oxide. The preparation method specifically comprises the following steps of: step 1, solution preparation: preparing an aluminum-doped cobalt solution and an ammonium bicarbonate solution; step 2, seed crystal synthesis; step 3, growing of cobalt carbonate; step 4, washing and drying; step 5, calcining; and step 6, mixing and packaging. According to the preparation method of the aluminum-doped cobaltosic oxide, the prepared aluminum-doped cobaltosic oxide is uniform in particle and free of compact blocky particles and particle aggregates.

Owner:취저우화여우코발트뉴머터리얼컴퍼니리미티드 +1

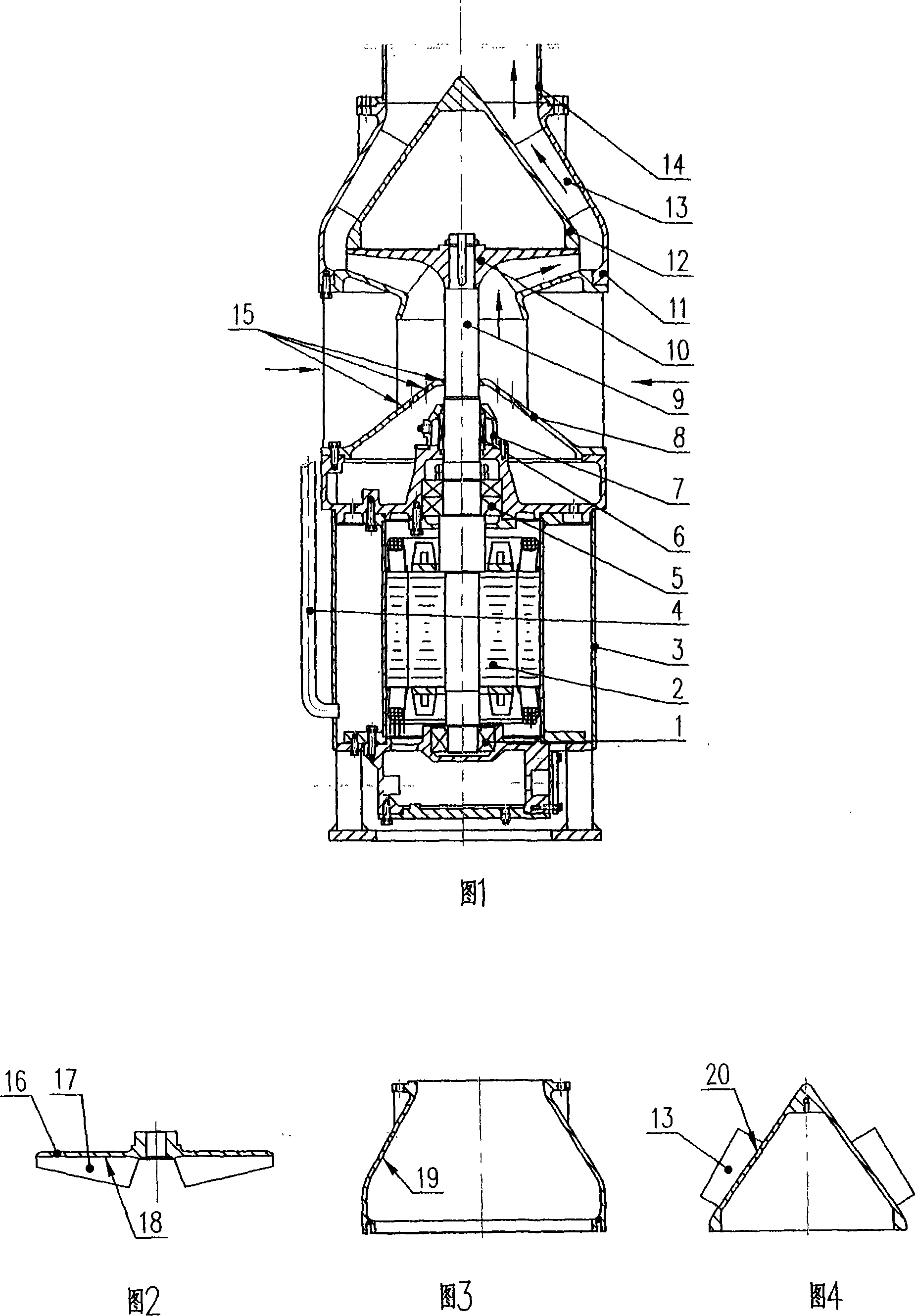

Underground brine collection and transport dedicated pump and its production method

InactiveCN101187378ASlow crystallization rateImprove operating conditionsSpecific fluid pumpsPump componentsImpellerSemi open

The invention provides a special pump for collecting and transporting underground bittern and a process for preparation. The pump comprises an impeller, a water inlet part, and a submersible motor from top to bottom, and is penetrated by a pump shaft. The pump is characterized in that the impeller is designed into a semi-open impeller structure, a diversion core is arranged on the upper portion of the impeller, a guide blade is mounted on a conical face of the diversion core, a diversion casing is arranged on the peripheries of the diversion core and the guide blade, a water jacket is arranged on the periphery of the submersible motor, a fresh water intake pipe is arranged on the lower end of the water jacket, a fresh water spray hole is arranged on the conical bottom of the water inlet part, and motor metal bearings are respectively arranged on the upper portion and the lower portion of the submersible motor. The invention polishes each over-current surface, reduces the rotary speed of the motor, and arranges the water jacket on the periphery of the submersible motor, and fresh water are transferred into the water jacket to positively cool up the motor. The invention has high working efficiency, low operation costs, and saves fresh water resource, retards the crystallization velocity of bittern on the over-current surface, and increases five times of operation life.

Owner:ZHENJIANG ZHENGHAN PUMP

Polypropylene wire material for 3D printing and preparation method thereof

ActiveCN108641197ANo significant change in melting pointWon't breakAdditive manufacturing apparatusWire rodPolymer science

The invention discloses a polypropylene wire material for 3D printing and a preparation method thereof. The polypropylene wire material is composed of co-polypropylene, low-melting-point homo-polypropylene, inorganic filler, thermoplastic elastomers, a plasticizer and a stabilizer. The polypropylene wire material is low in material crystallinity degree, shrinkage distortion and warping, has good 3D printing effects and printing accuracy, and can reduce cost to a large extent. The preparation method for the polypropylene wire material for 3D printing is simple in technology and lower in production equipment requirement, can achieve large-scale production and popularization, and has a wide market prospect.

Owner:WANHUA CHEM GRP CO LTD

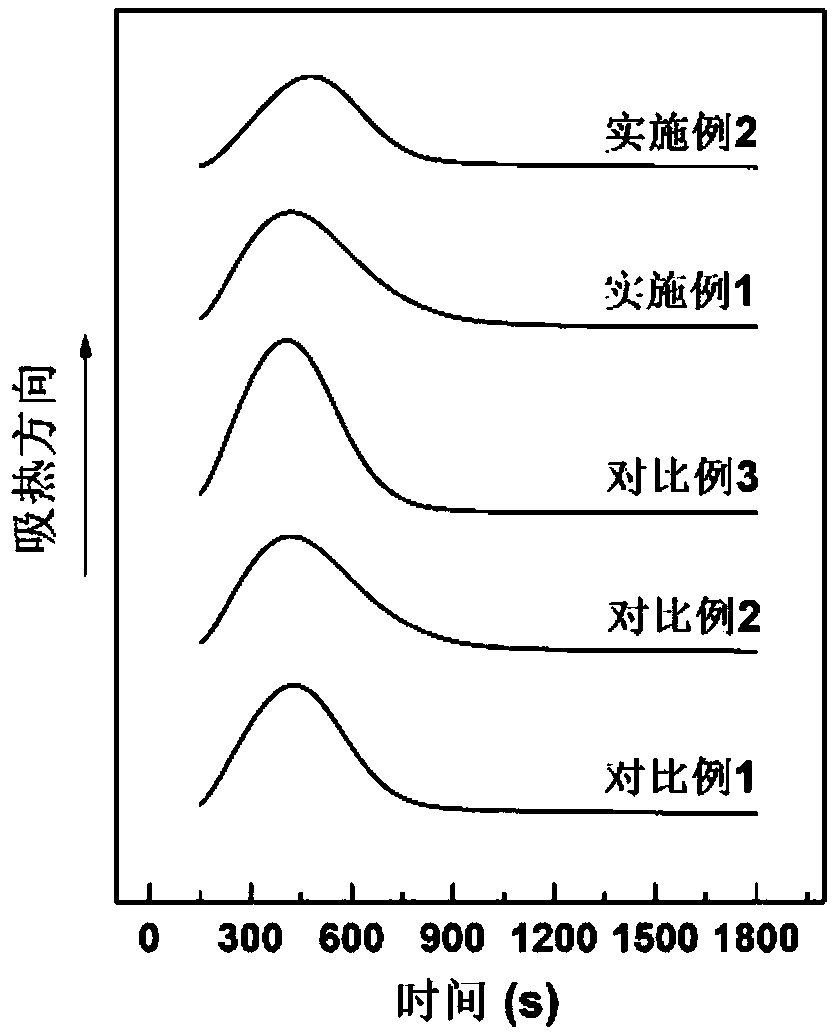

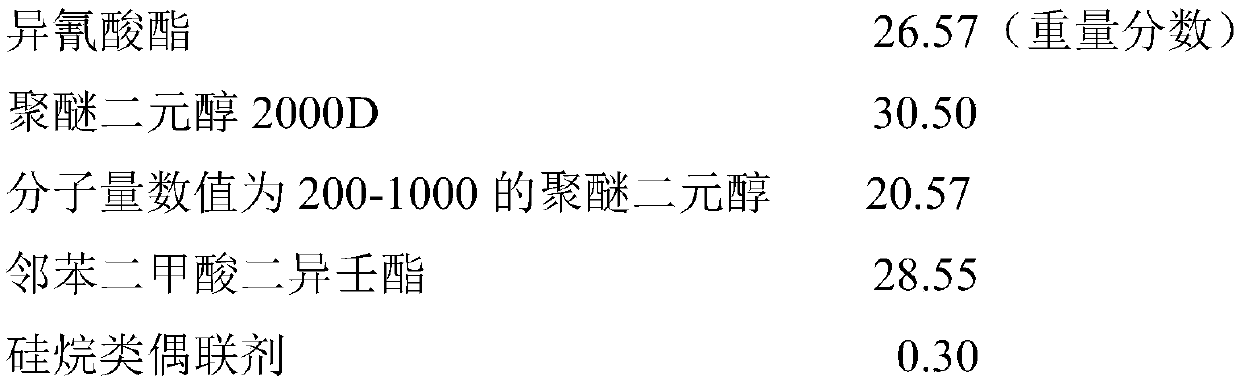

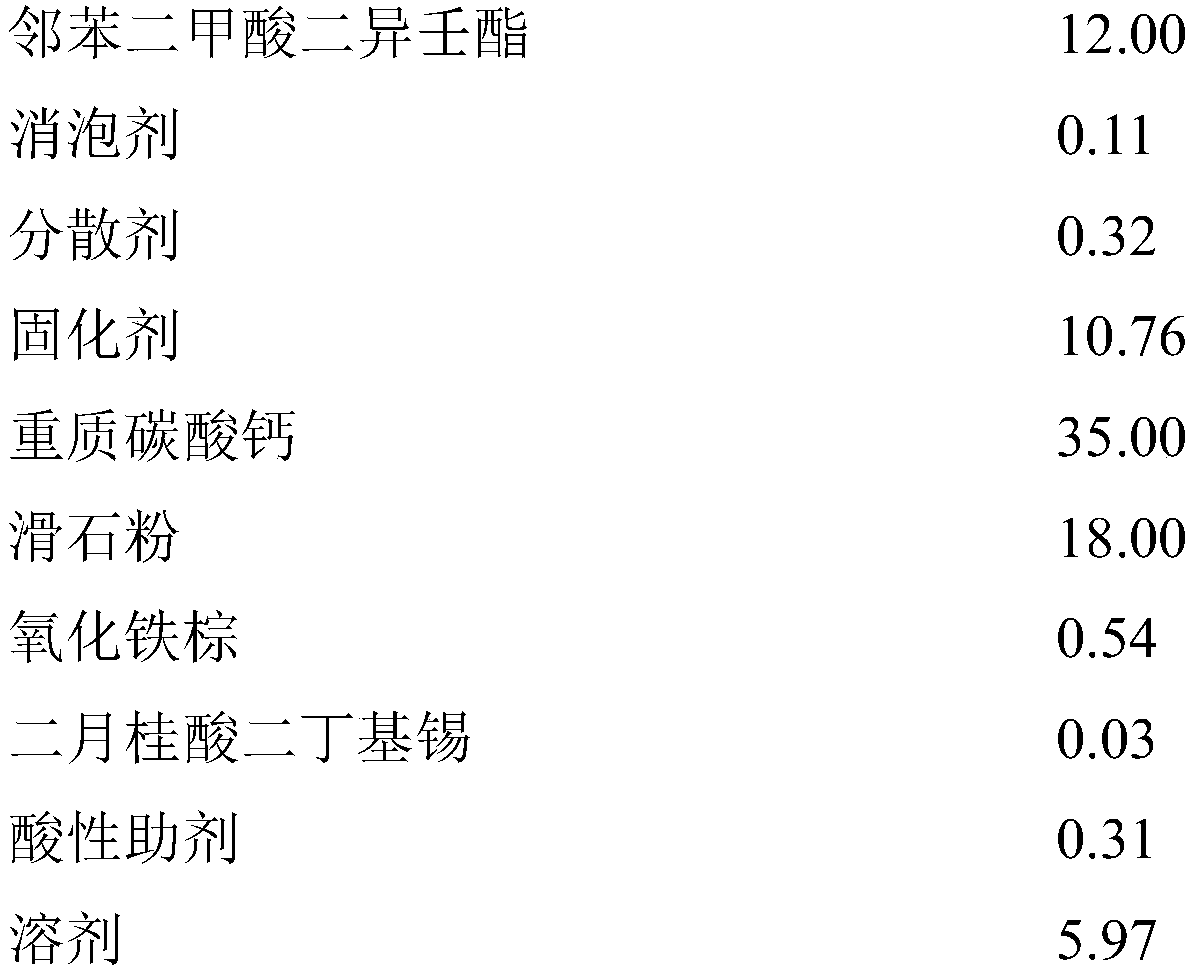

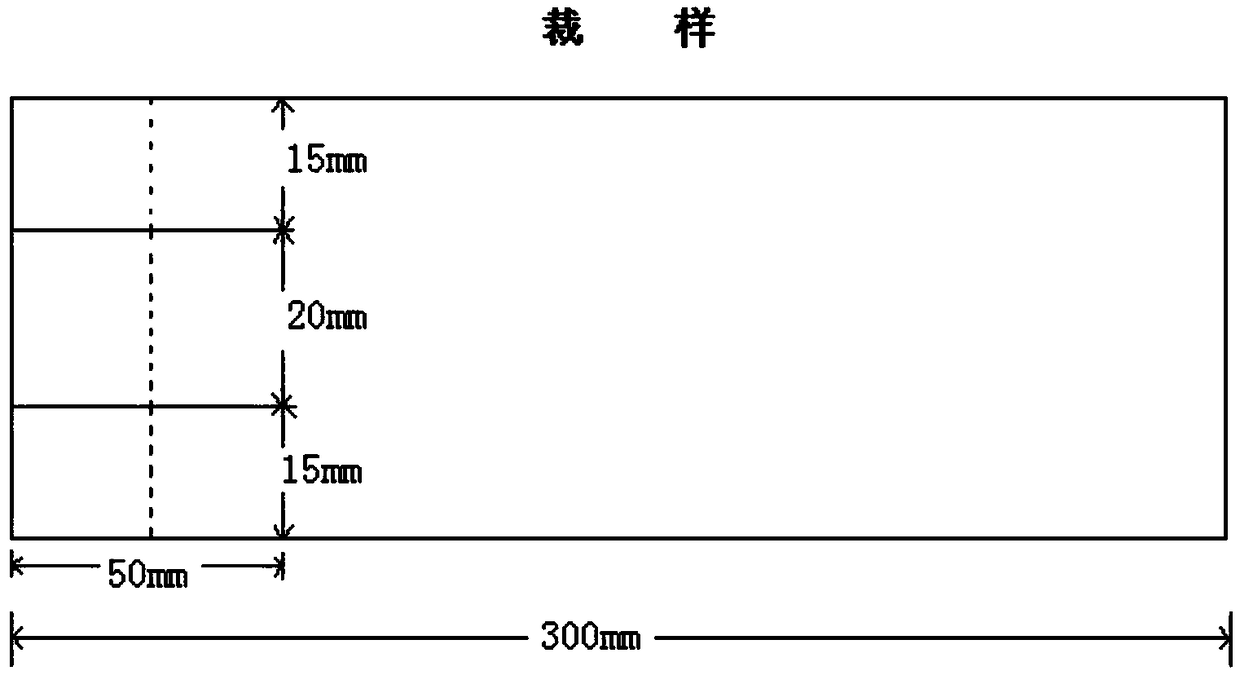

Polyurethane waterproof coating material

The invention discloses a polyurethane waterproof coating material, which comprises a component A and a component B, wherein the component A comprises: isocyanate, hydroxyl-terminated polyether diol having a molecular weight of 2000-5000, hydroxyl-terminated polyether diol having a molecular weight of 200-1000, a plasticizer and a silane coupling agent, and the component B comprises: hydroxyl-terminated polyether polyol, a plasticizer, an organic solvent, a pigment filler, a catalyst, a curing agent, a high performance auxiliary agent and an acidic aid. According to the present invention, thepolyurethane waterproof material has advantages of high tensile strength, high elongation at break, high right angle tear strength, high bond strength, moisture heat resistance, aging resistance, chemical corrosion resistance, low cost, dense film sheet, high brightness, reliable construction and the like, has all the performances higher than the standards of TB / T 2965-2011 Technical specificationfor waterproof layer of railway concrete bridge, and is especially suitable for railway bridges.

Owner:TANGSHAN DONGFANG YUHONG WATERPROOF TECH CO LTD

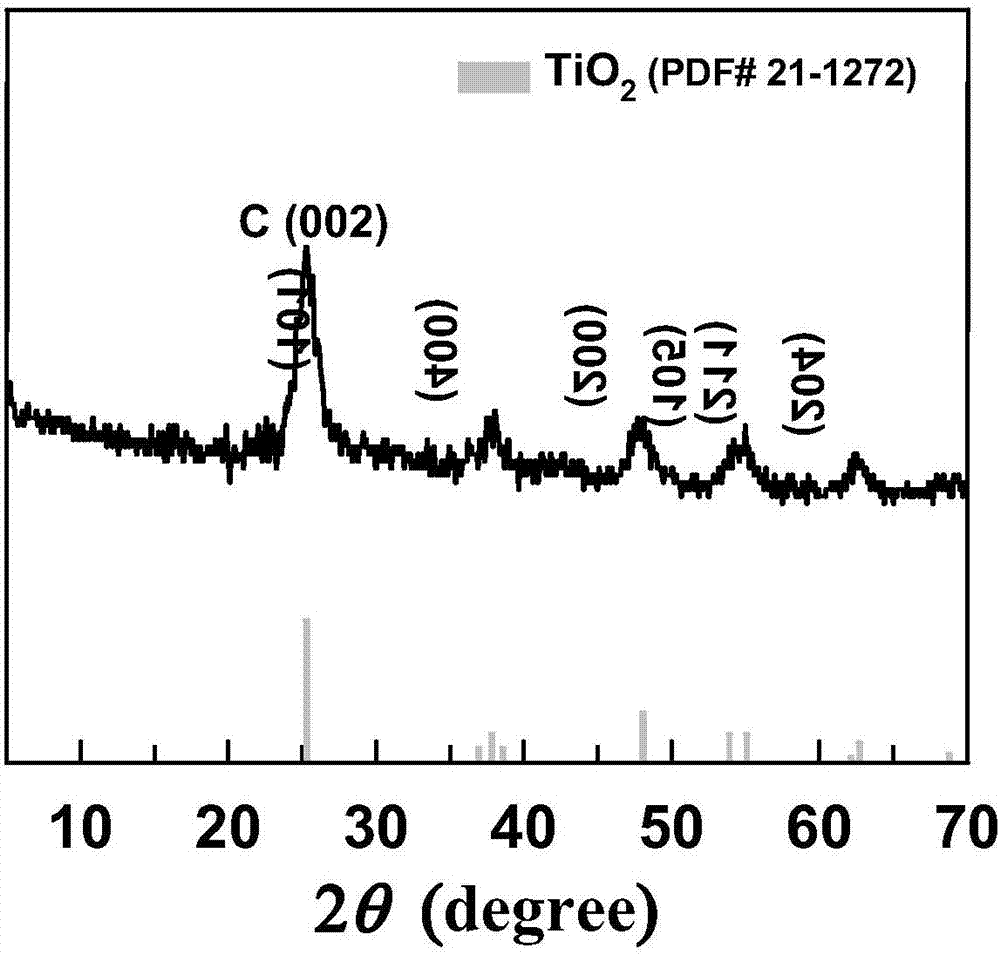

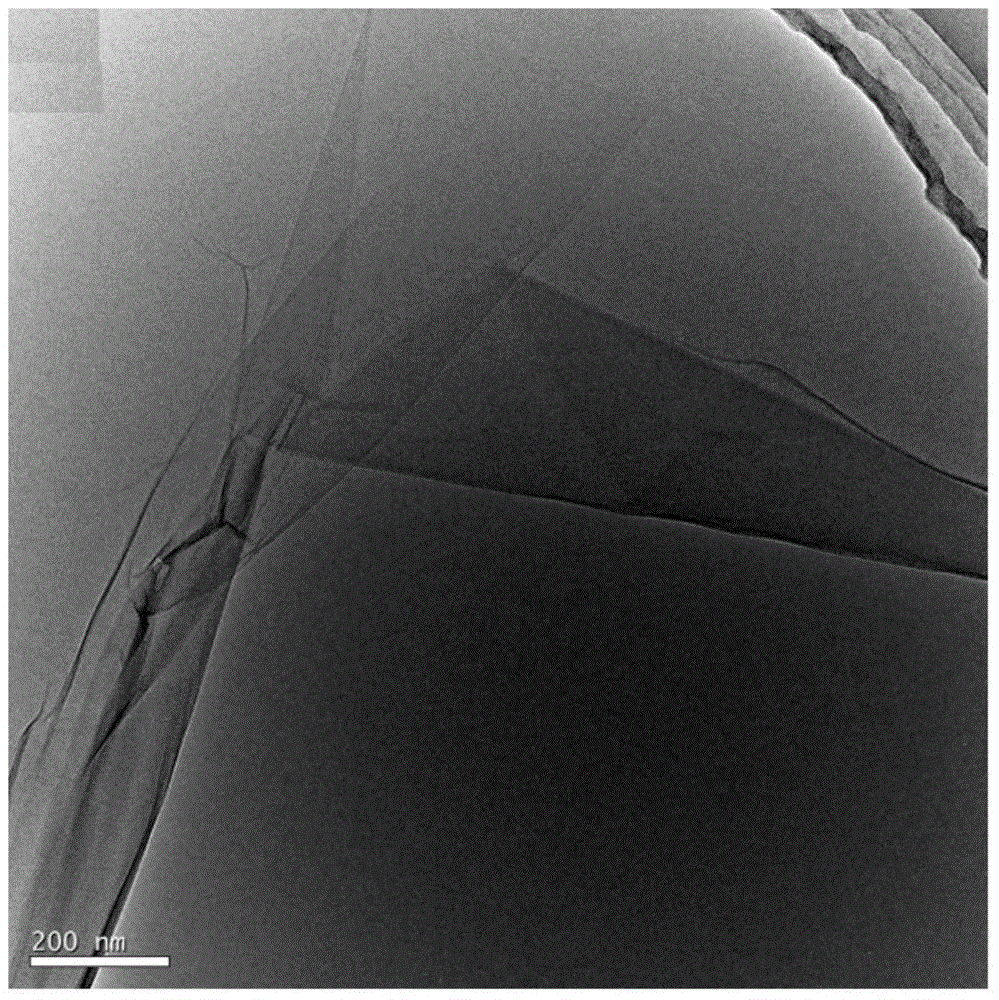

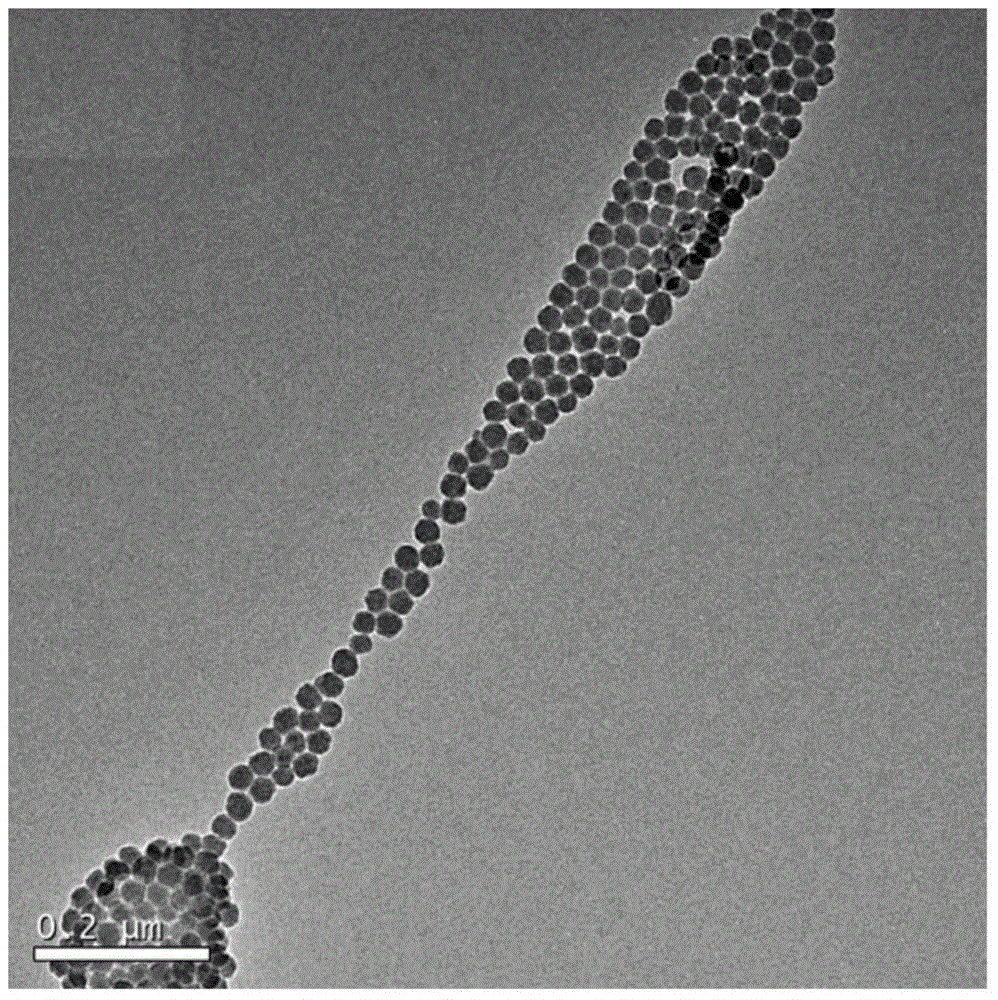

Flexible self-supporting metal oxide / graphene nano-composite membrane and preparing method and application thereof

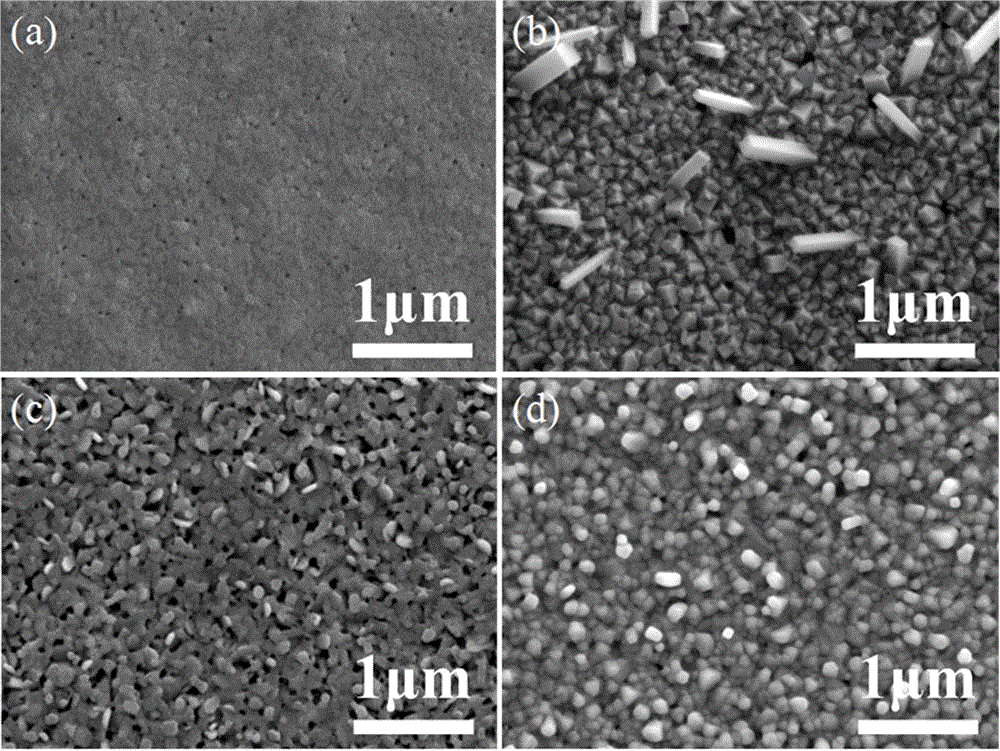

InactiveCN106876670AAccelerated nucleationIncrease the rate of crystallizationMaterial nanotechnologyHybrid capacitor electrodesHigh rateFiltration

The invention discloses a method for preparing a flexible self-supporting metal oxide / graphene nano-composite membrane. The method for preparing the flexible self-supporting metal oxide / graphene nano-composite membrane comprises the following steps: adding the graphene oxide to an organic solvent dissolved in metal salts, and transferring to a hydrothermal reactor after being dispersed evenly to perform hydrothermal reaction at 100 to 140 degrees centigrade for 0.5 to 12 hours; preparing the metal oxide / graphene nano-composite filter membrane through vacuum filtration to form a membrane, washing, evaporating and drying. The method disclosed by the invention has the advantages of simple method, low cost and easy to scale. According to the invention, the metal oxide in the resultant composite membrane is grown uniformly in situ on the surface of the graphene; the average particle size is 1 to 5nm; and the flexible self-supporting metal oxide / graphene nano-composite membrane has a flexible and self-supporting structure, can be bent freely, and is suitable for flexible electronic devices; and if the flexible self-supporting metal oxide / graphene nano-composite membrane is used in electrochemical storage fields such as lithium ion batteries and supercapacitors, the high electrochemical performances such as high specific capacity, ultra-high rate performance and high cycle stability can be realized.

Owner:GUANGDONG UNIV OF TECH

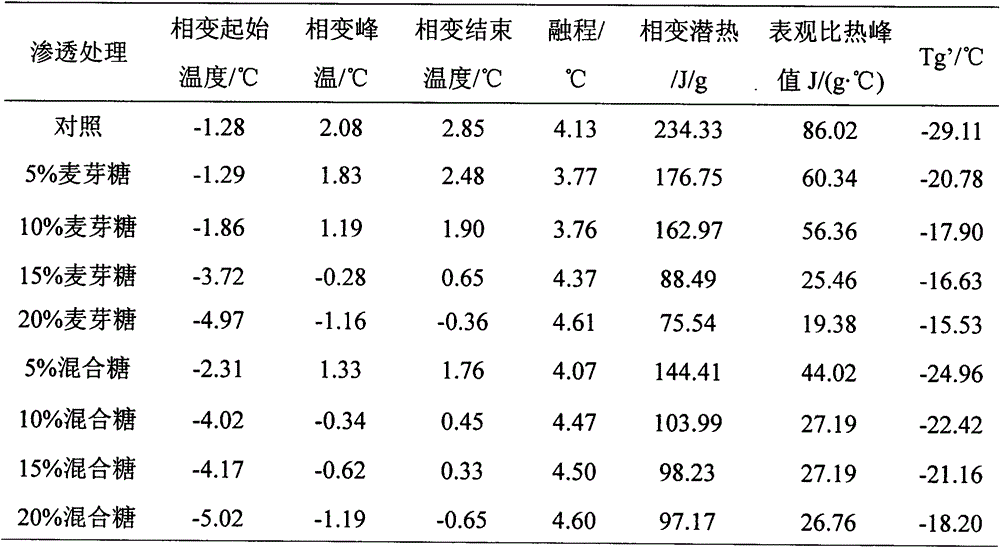

Processing method of high-quality frozen lotus root slices

ActiveCN103947744AIncrease moisture contentAvoid damageFruits/vegetable preservation by irradiation/electric treatmentClimate change adaptationChemistryLotus root

The invention relates to the vegetable and fruit freezing processing field and specifically relates to a processing method of high-quality frozen lotus root slices. The processing method comprises the following steps: performing color-protecting and microwave blanching treatment on lotus roots which are cleaned, peeled and sliced previously, putting the lotus root slices under a vacuum condition and performing permeation treatment on the lotus root slices in a conditioning solution at a temperature ranging from 15 to 25 DEG C for 20-50 minutes, wherein the weight ratio of the lotus root slices to the conditioning solution is 1:1.5 to 1:2.5; draining, and then quickly freezing at a temperature ranging from -40 DEG C to -30 DEG C until the core temperature of the lotus root slices is below -18 DEG C; and putting the frozen lotus root slices in cold storage at a temperature ranging from -22 DEG C to -25 DEG C. The method has the advantages that the storage quality of the frozen lotus root slices is improved, and the obtained high-quality frozen lotus root slices are kept to be good in nutrition, color and luster, and brittleness.

Owner:JIANGSU ACADEMY OF AGRICULTURAL SCIENCES +1

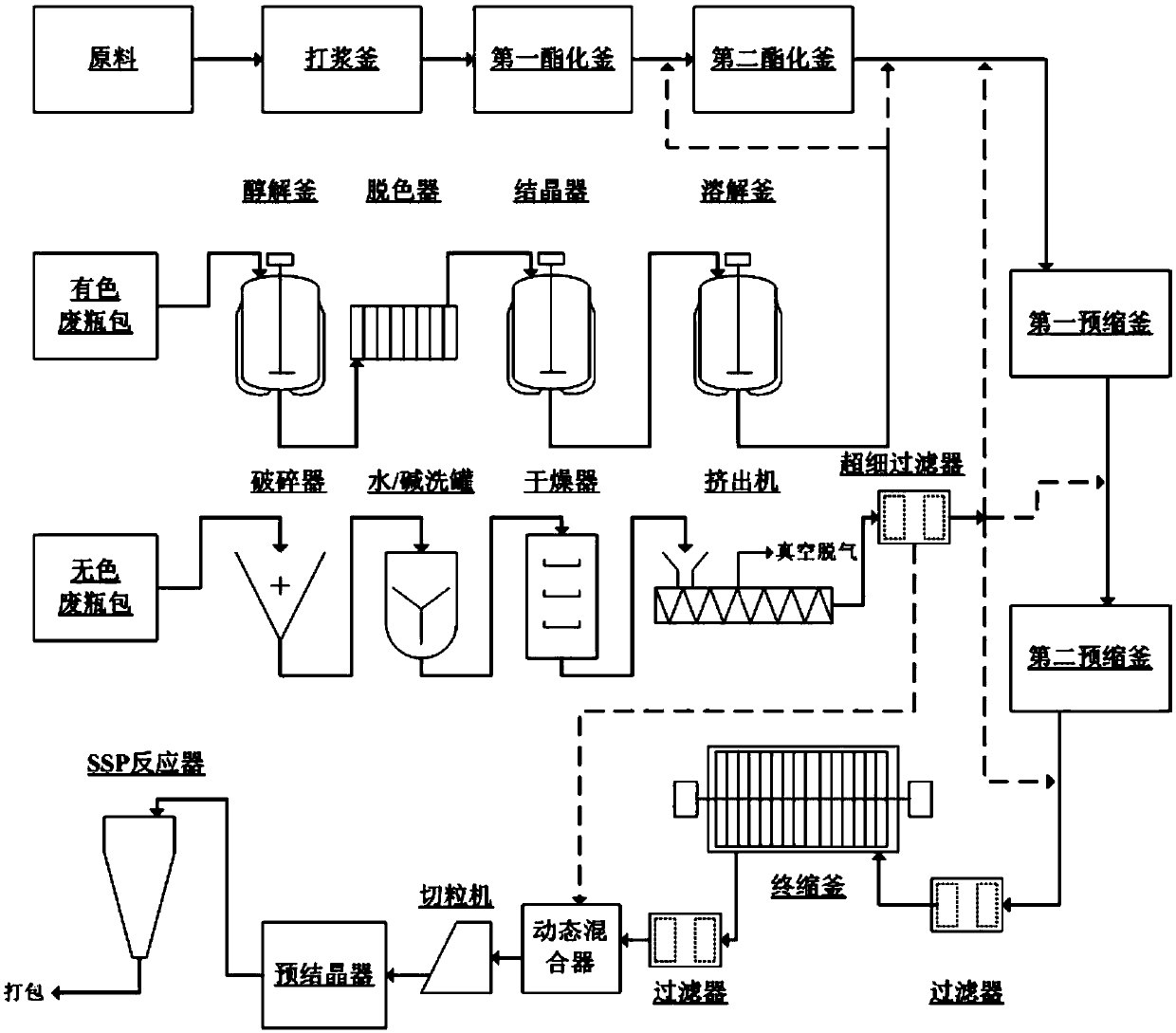

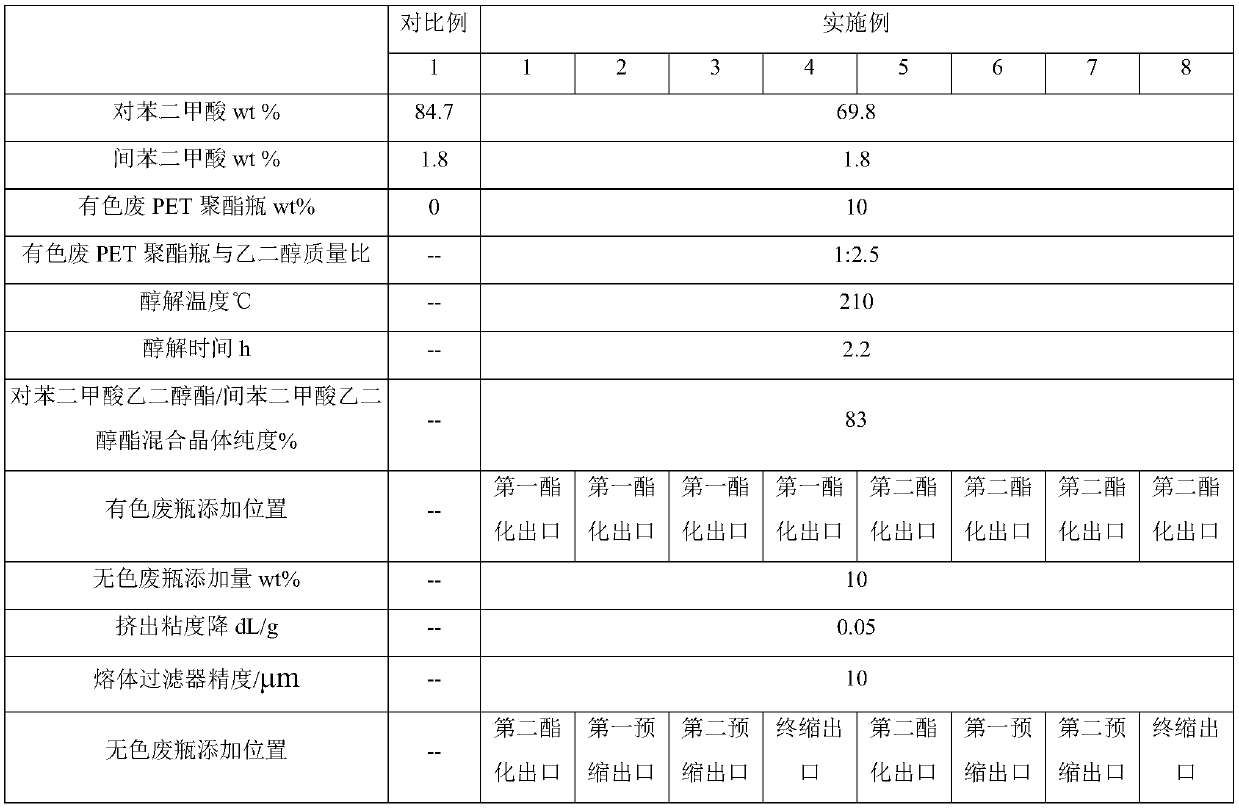

Method for preparing bottle-grade slices by recycling waste polyester bottles

ActiveCN111138641AImprove cleanlinessLow color requirementPlastic recyclingPolyesterTransesterification reaction

The invention discloses a method for preparing bottle-grade slices by recycling waste polyester bottles. According to the method, colored bottles are subjected to alcoholysis, decoloration, crystallization, dissolution and other methods to obtain high-purity BHET, and then the high-purity BHET enters a reaction system; the melt of colorless bottles is injected into a condensation polymerization reaction system through melt extrusion to participate in a transesterification reaction of primary melt, and harmful gas is further removed in the reaction process to improve the cleanliness of the melt; and the crystallization rate is reduced by optimizing the addition amount of a raw material IPA, the intrinsic viscosity of the melt can be flexibly adjusted after the alcoholysis product, the recovered melt and the primary melt pass through a reactor, and volatile substances generated by degradation in the alcoholysis and melting processes of the recovered bottles can be effectively removed byvirtue of disc vacuum film formation. The method has the advantages that the amount of recycled waste polyester bottles can be adjusted, the color requirement of the waste polyester bottles is low, the intrinsic viscosity of the product is stable, the acetaldehyde content is low, and the crystallization rate is consistent with the crystallization rate of raw materials. Compared with the existing bottle-to-bottle technology, the method of the invention can be applied to the fields of food-grade bottle slices such as water bottles, carbonic acid bottles, oil bottles and the like.

Owner:CHINA PETROLEUM & CHEM CORP +1

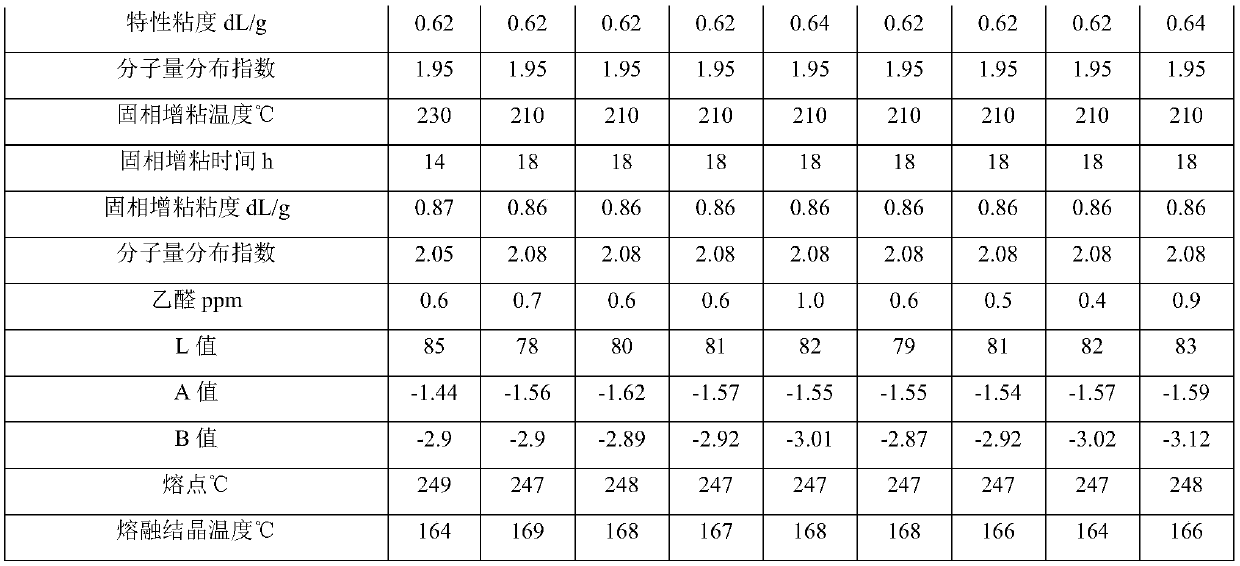

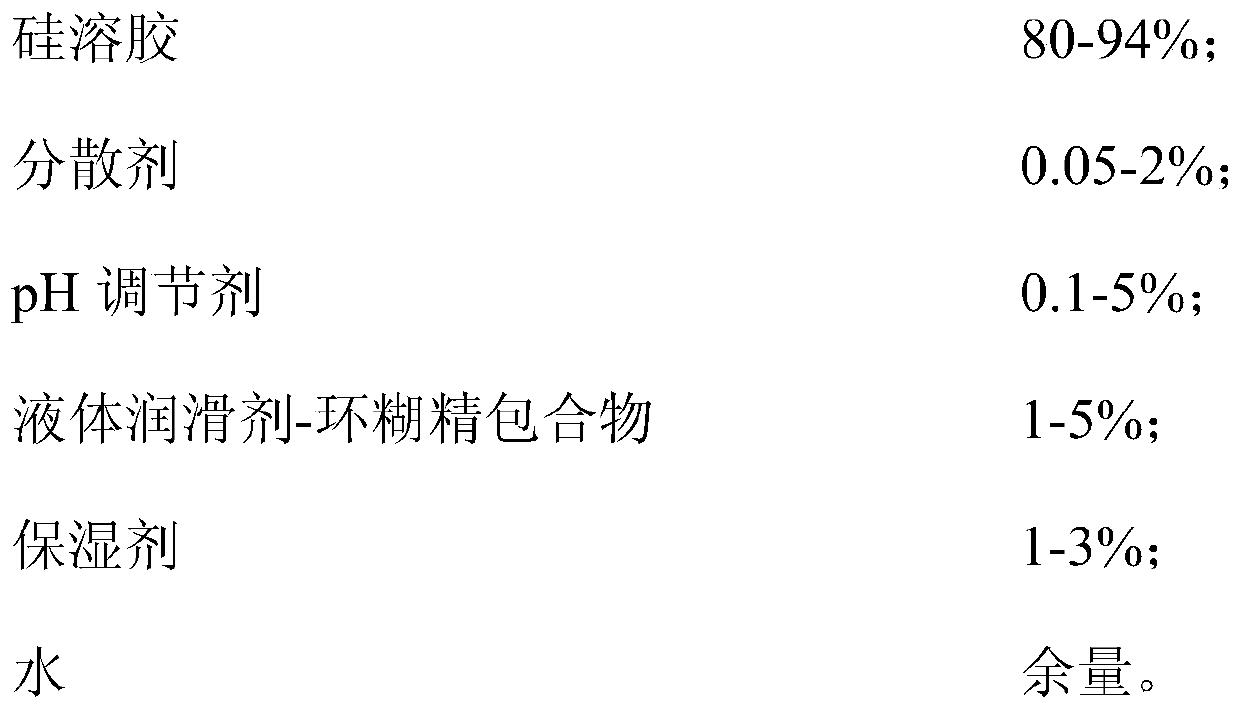

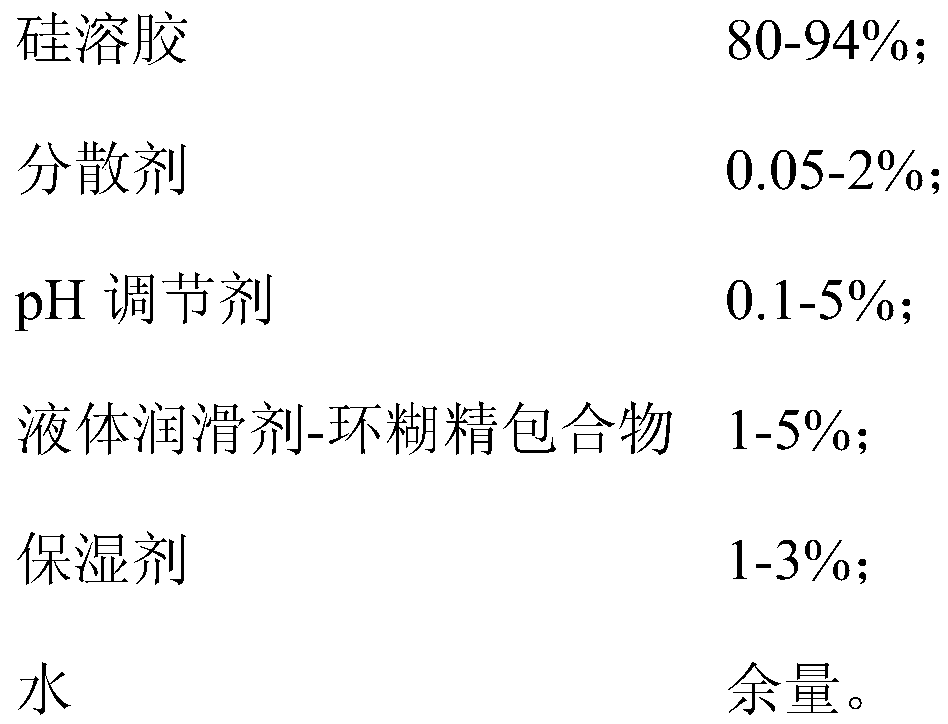

Polishing liquid, preparation method and application thereof

ActiveCN110003798AReduce scratchesScratch reliefPolishing machinesPolishing compositions with abrasivesCyclodextrinSapphire wafer

The invention provides a polishing liquid, a preparation method and an application thereof, wherein the polishing liquid comprises the following components by weight percent: 80-94% of silicon sol; 0.05-2% of dispersant; 0.1-5% of PH regulator;1-5% of liquid lubricant-cyclodextrin inclusion complex; 1-3% of moisturizer; the balance of water. When the polishing liquid is used in the process of sapphire wafer polishing, the average polishing rate can be ensured, the precipitation of silicon dioxide crystal can be reduced, and the scratch of silicon dioxide crystal on sapphire wafer can be reduced, on the other hand, the crystallization of polishing liquid on the machine table can be reduced, and the time of cleaning the machine table can be reduced, so that the production efficiency can be improved.

Owner:广东惠尔特纳米科技有限公司

Manufacture method for biaxially oriented PVDF thin film

The invention discloses a manufacture method for a biaxially oriented PVDF thin film, and relates to the manufacture field of plastic film. The method comprises the steps of adding a proper amount of polymer which is compatible with PVDF, into a PVDF resin to form a blend; blowing and stretching the blend twice by a double-bubble tube twice blowing-stretching film manufacture process, to obtain the PDVF thin film having high orientation degrees in both horizontal direction and vertical direction. Compared with the method of the prior art, the method of the invention can manufacture the biaxially oriented PVDF thin film with better performance, is relatively simple in both manufacture process and equipment, and has low investment for production line.

Owner:CHENGDU WISEDONE TECH

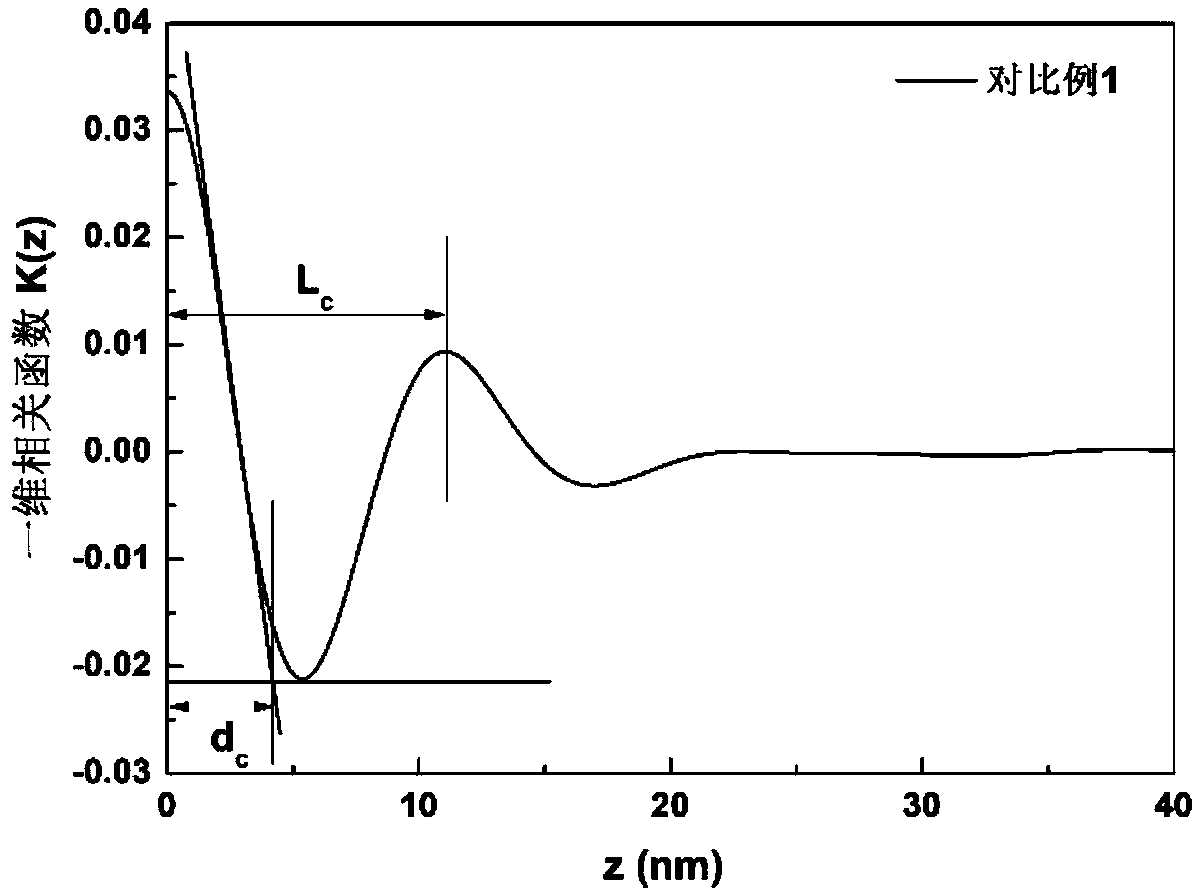

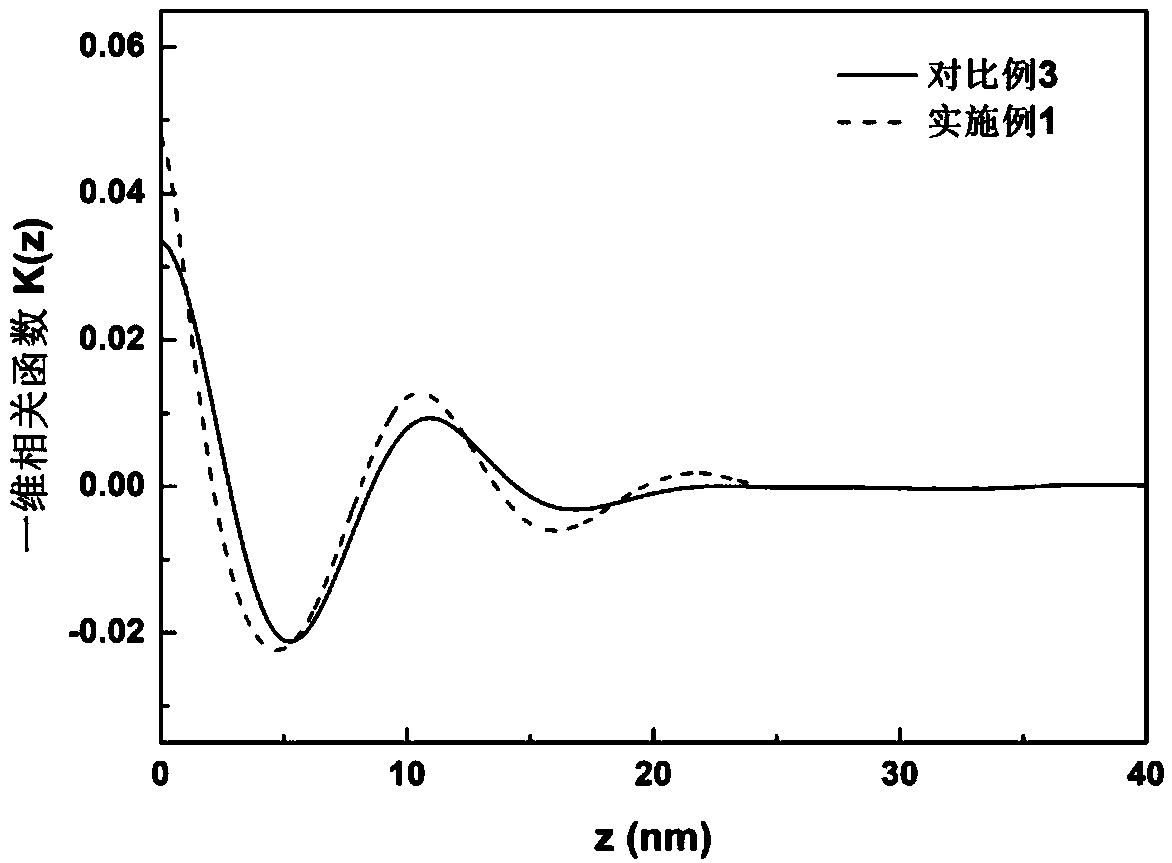

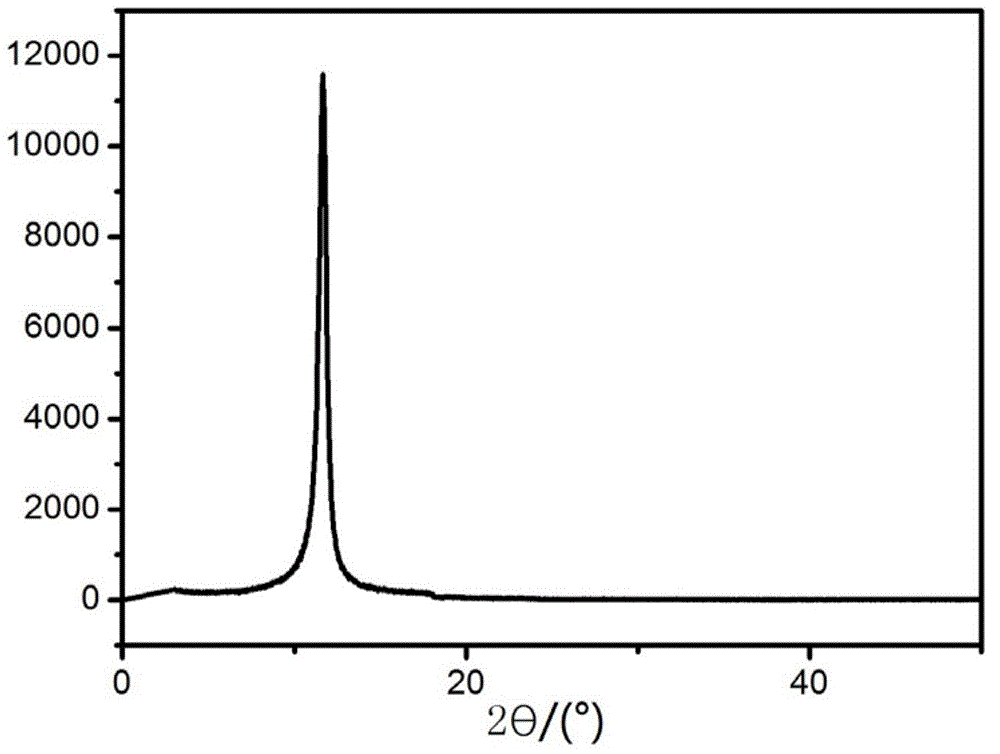

Prussian blue sodium ion battery positive electrode material and preparation method thereof

InactiveCN113488646ASlow crystallization rateHigh crystallinityIron cyanidesComplex cyanidesElectrical batteryPyrrolidinones

The invention relates to a Prussian blue sodium ion battery positive electrode material and a preparation method thereof. The method comprises the following steps: dissolving transition metal salt and tartaric acid in deionized water to form a solution A, dissolving sodium ferrocyanide decahydrate and ascorbic acid in deionized water to form a solution B, and dissolving polyvinylpyrrolidone and sodium chloride in deionized water to form a solution C; simultaneously adding the solution A and the solution B into the solution C through a peristaltic pump, and performing stirring while heating in an N2 atmosphere until the solution becomes a suspension liquid after dropwise adding is completed; keeping heating and stirring the suspension for 12 hours, finally aging at room temperature for 24 hours, then centrifugally washing with deionized water and absolute ethyl alcohol for three times respectively, and finally drying in vacuum at 120 DEG C for 24 hours to obtain the Prussian blue positive electrode material.

Owner:CHINA THREE GORGES UNIV

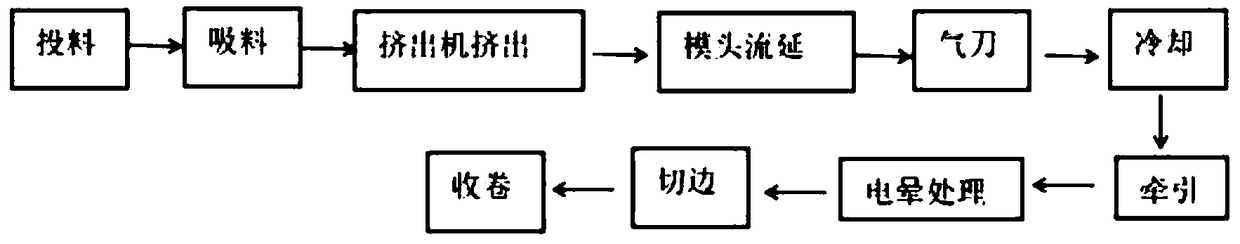

Two-way linear easy-to-tear polyethylene film and production process thereof

ActiveCN109263200ALow hazeHigh light transmittanceSynthetic resin layered productsFlat articlesLow-density polyethyleneLinear low-density polyethylene

The invention relates to a two-way linear easy-to-tear polyethylene film and a production process thereof. The polyethylene film is obtained through the processing by a tape casting process; the polyethylene film comprises a hot sealing layer, a middle layer and a corona layer; the hot sealing layer is prepared from the following ingredients by weight: 80 to 84 percent of low density polyethylene,15 to 18 percent of polybutylene, 0.5 to 1.0 percent of smoothening agent and 0.5 to 1.0 percent of opening master batch; the middle layer is prepared from the following ingredients by weight: 65 to70 percent of low density polyethylene, 20 to 25 percent of high density polyethylene, 0.1 to 0.5 percent of processing auxiliary agent and 8 to 12 percent of polybutylene; the corona layer is prepared from the following ingredients by weight: 99.5 to 99.9 percent of low density polyethylene and 0.1 to 0.5 percent of processing auxiliary agent. The polyethylene film has the advantages that the mist degree is low; the light transmission rate is high; the mechanical performance is good; the linear easy-to-tear performance is excellent; the processing cost is low.

Owner:HUANGSHAN NOVEL

Method of making fibers and nonwovens with improved properties

ActiveUS7780903B2Slow crystallization rateReduce speedMelt spinning methodsWoven fabricsPolymer scienceNonwoven fabric

The present invention can provide a distinctive method and process for making polymer fibers (62) and nonwoven fabric webs (60). The method can include providing a fiber material that exhibits a low crystallization rate. In a particular aspect, the fiber material can be subjected to an anneal-quench at an anneal-quench temperature that approximates a prime-temperature at which the polymer material most rapidly crystallizes. In another aspect, the fiber material can be subjected to a fiber-draw at a selected fiber-draw temperature, and in a further aspect, the fiber-draw temperature can be configured to approximate the prime-temperature of the polymer material. In still other aspects, the fiber material can be subjected to a relatively small amount of fiber-draw, and the fiber-draw can be provided at a relatively low fiber-draw speed.

Owner:KIMBERLY-CLARK WORLDWIDE INC

Polyethylene catalyst carrier material with ultrahigh molecular weight and preparation method thereof

The invention provides a polyethylene catalyst carrier material with an ultrahigh molecular weight and a preparation method thereof. The preparation method comprises the following steps: mixing a graphene oxide aqueous solution with a silica sol to obtain a mixed dispersion solution; spraying the mixed dispersion solution into liquid nitrogen, performing atomization, then curing instantly, volatizing to remove the liquid nitrogen, and performing vacuum drying to remove water so as to obtain a sample; heating the sample to perform activation reaction, thereby obtaining a graphene oxide / silicon dioxide spherical catalyst carrier material; mixing the graphene oxide / silicon dioxide spherical catalyst carrier material with butyl magnesium chloride in a tetrahydrofuran solution, and stirring for reaction to obtain a reaction product; and cleaning the reaction product, and heating at 600 DEG C for 2 hours to obtain the polyethylene catalyst carrier material with the ultrahigh molecular weight. The catalyst carrier provided by the invention can effectively reduce entanglement of polymer molecular chains, so that a graphene / ultrahigh-molecular-weight polyethylene composite material can be prepared.

Owner:PETROCHINA CO LTD +1

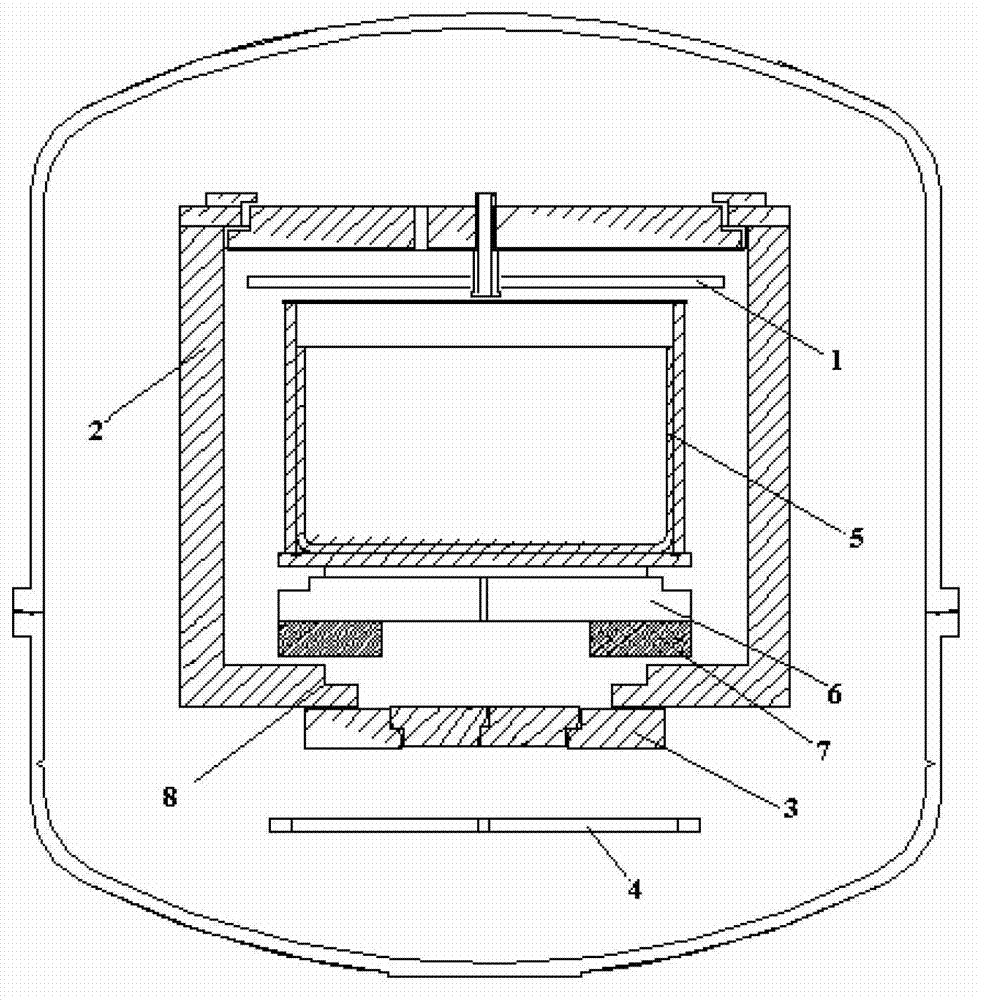

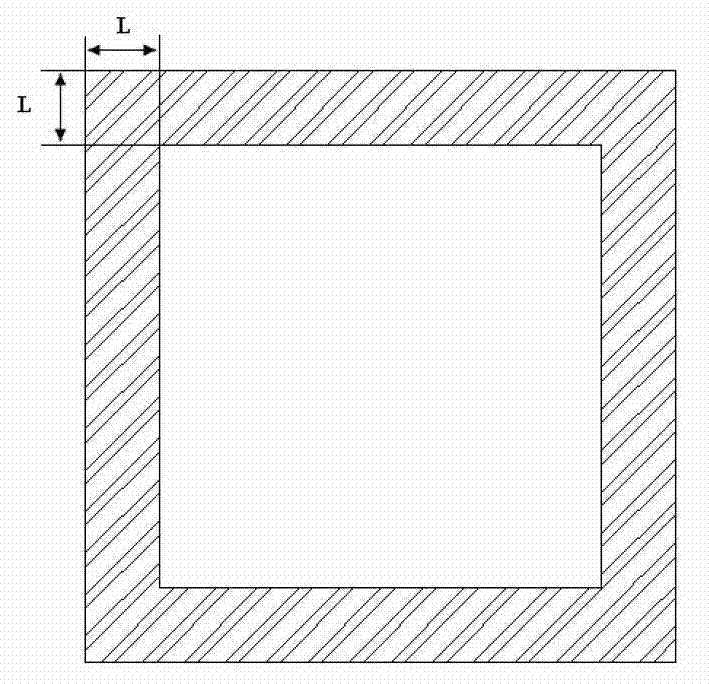

Polycrystalline silicon ingot and casting method thereof

ActiveCN102965727AImprove performanceQuality improvementPolycrystalline material growthSingle crystal growth detailsMolten stateThermal insulation

The invention discloses a polycrystalline silicon ingot and a casting method thereof, and applies to an ingot furnace which is provided with a top heater, and a thermal insulation bottom plate is arranged at the bottom periphery of a heat radiation platform. The casting method comprises the following steps of: loading a silicon material in a crucible, and heating the silicon material to a molten state; reducing the power of the top heater on the polysilicon ingot furnace, simultaneously opening a shutter to the angle of 25 degrees to 35 degrees gradually, and reducing the surface temperature of a silicone fluid in the molten state to 1400 DEG C-1450 DEG C so that the silicone fluid at the bottom starts crystallizing; continuing gradually opening the shutter to the maximum opening vertical angle, and keeping a stable silicone fluid crystallization rate, wherein the opening speed rate of the shutter is less than the opening speed rate of the shutter in the second step, and the opening speed rate of the shutter is gradually reduced; and maintaining the maximum opening of the shutter until crystallization is finished. The polycrystalline silicon ingot and the casting method thereof provided by the invention solve the problem that the peripheral impurities of the silicon ingot are distributed in a scattering manner through changing a oriented polycrystalline silicon crystallizing process, the property of the polycrystalline silicon ingot is improved, the polycrystalline silicon ingot with good quality and high compound output rate is prepared, the utilization ratio of the silicon material is improved, and the manufacturing cost of the silicon ingot is reduced.

Owner:YINGLI ENERGY CHINA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com