Micro-nano structure interface induced growth method for perovskite film of solar cell

A technology of solar cells and micro-nano structures, applied in nanotechnology, circuits, nanotechnology, etc. for materials and surface science, can solve the problem that metal halides cannot be quickly and completely transformed, and avoid self-organized growth, The effect of shortening the conversion time and increasing the rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Embodiment 1 Utilizes the micro-nano structure interface induced growth method of the perovskite thin film for solar cells of the present invention to prepare an upright planar structure perovskite solar cell:

[0033] 1) Substrate cleaning and preparation of dense electron transport layer: Ultrasonic cleaning of indium tin oxide (FTO) conductive glass with decontamination solution, deionized water, acetone and ethanol for 20 minutes, drying with nitrogen gun, and then UV ozone treatment for 15 minutes to obtain Clean FTO substrate. Then spin-coat 0.15M and 0.3M n-butanol solutions of bis(acetylacetonato)diisopropyl titanate (TiAcAc) on the substrate respectively. After each layer is spin-coated, the substrate is annealed at 125°C for 10min to make the thickness A dense layer of titanium dioxide of about 50 nm;

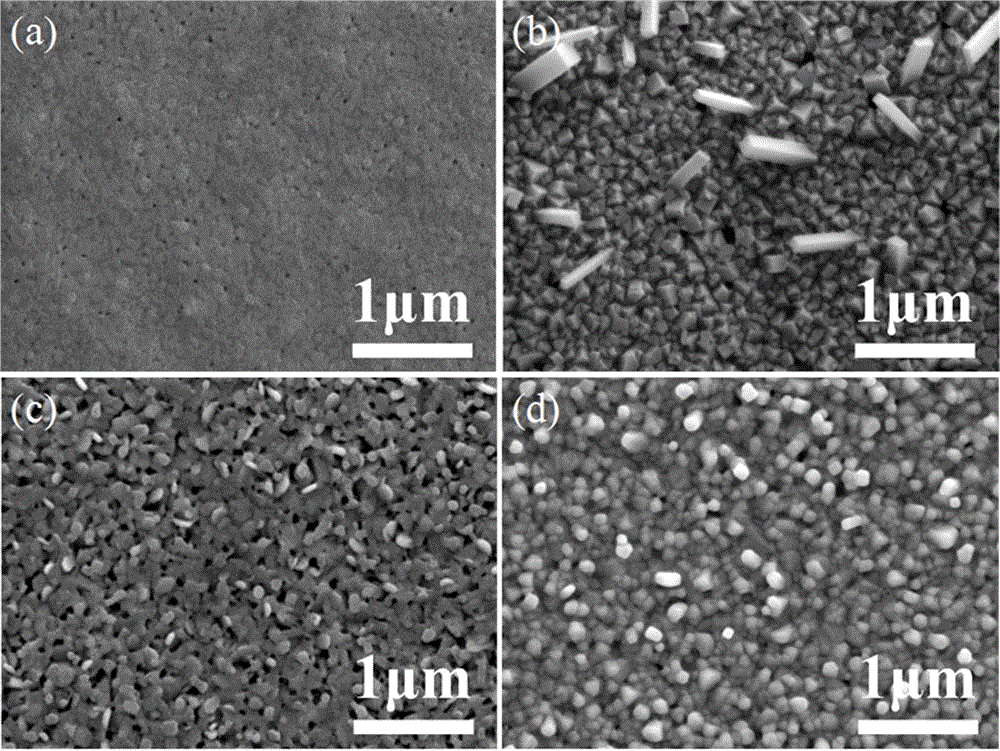

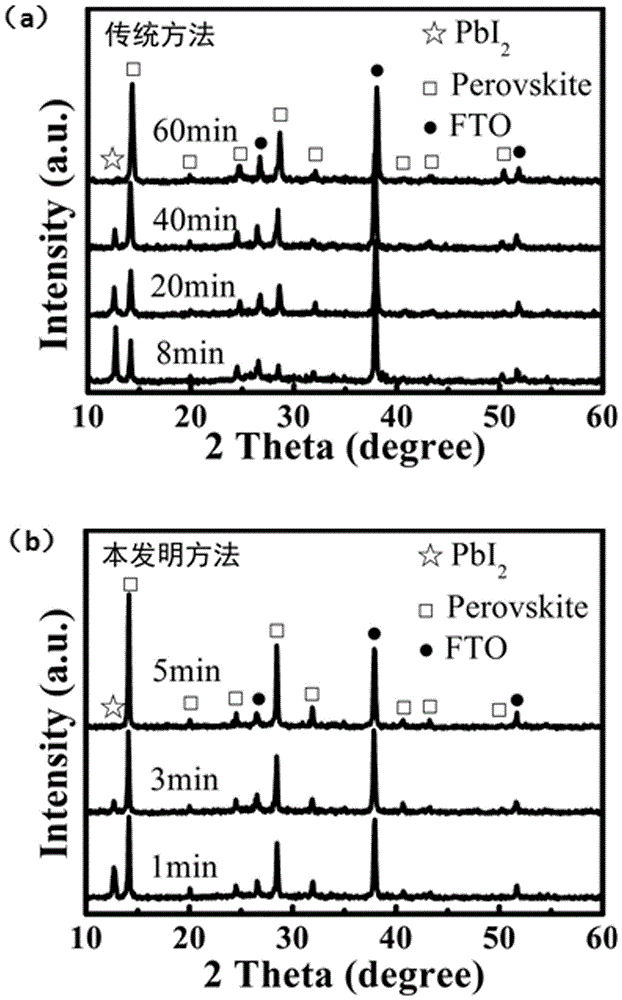

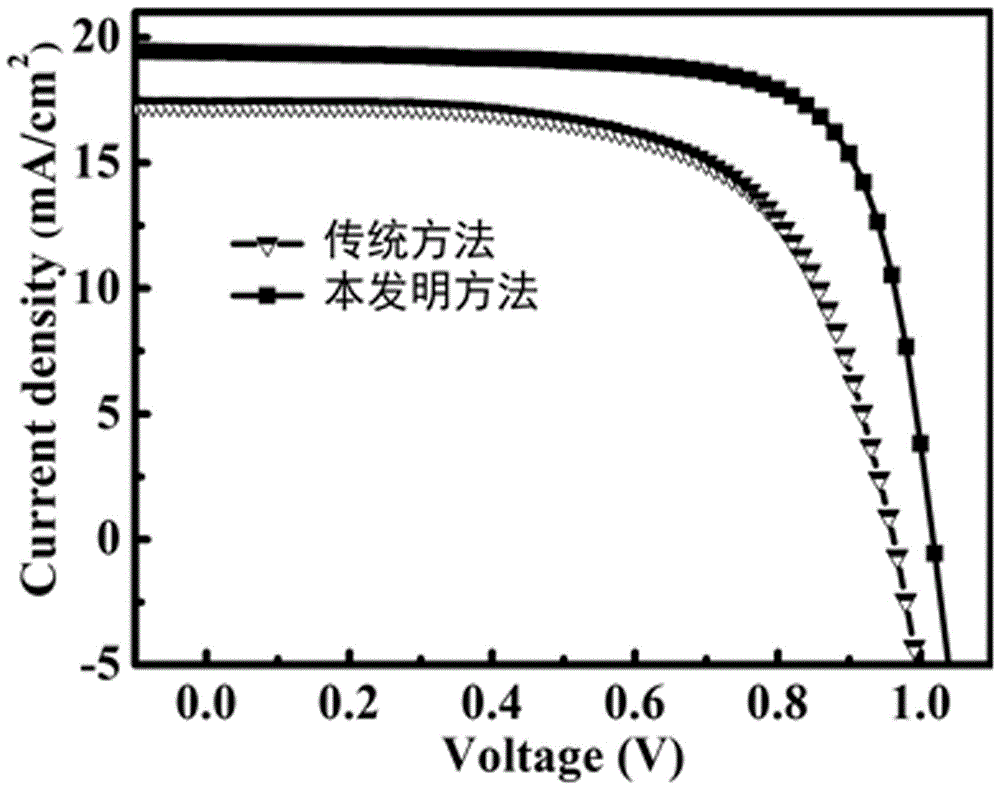

[0034] 2) Preparation of perovskite thin film: 507mg PbI 2 Dissolve in 1mL dimethylformamide, add 78mg dimethyl sulfoxide, and stir at 60°C for 12 hours to o...

Embodiment 2

[0036] Embodiment 2, using the micro-nano structure interface induced growth method of the perovskite film for solar cells of the present invention to prepare upright mesoporous structure perovskite solar cells:

[0037] 1) Substrate cleaning and preparation of dense electron transport layer: Ultrasonic cleaning of indium tin oxide (FTO) conductive glass with decontamination solution, deionized water, acetone and ethanol for 20 minutes, drying with nitrogen gun, and then UV ozone treatment for 15 minutes to obtain Clean FTO substrate. Then spin-coat 0.15M and 0.3M n-butanol solutions of bis(acetylacetonato)diisopropyl titanate (TiAcAc) on the substrate respectively. After each layer is spin-coated, the substrate is annealed at 125°C for 10min to make the thickness A dense layer of titanium dioxide of about 50 nm;

[0038] 2) Preparation of the mesoporous structure electron transport layer: configure the ethanol solution of titanium dioxide nanoparticles (18NRT) with a mass ra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com