Patents

Literature

154 results about "Phase purity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

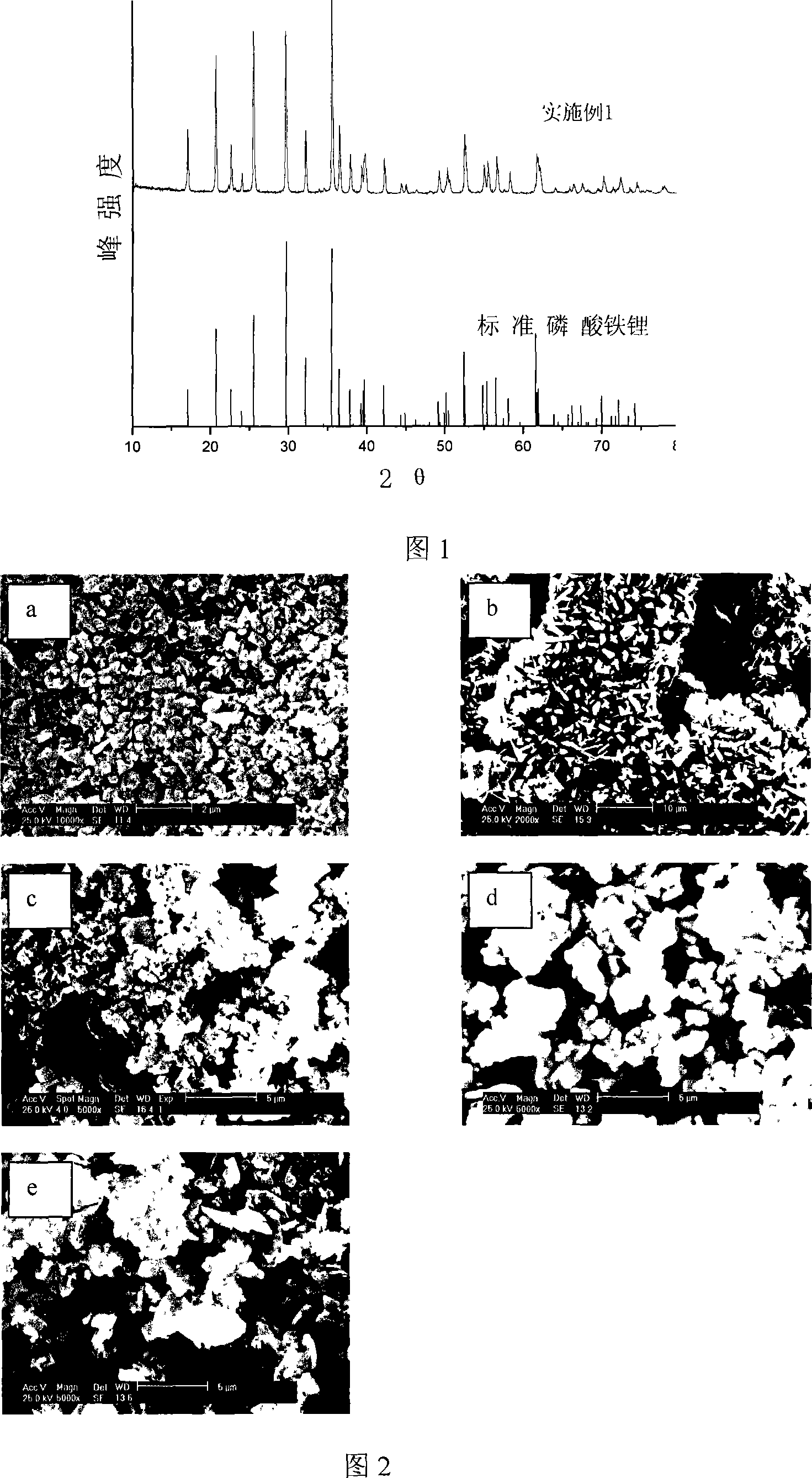

Hydrothermal synthesis method for lithium ion-cell anode material of ferric phosphate lithium

InactiveCN101117216AImprove electrochemical performanceShorten the diffusion pathCell electrodesPhosphorus compoundsExhaust valveDead volume

The invention discloses a hydrothermal synthesis method of lithium-ion battery anode material of lithium iron phosphate, relating two kinds of metal phosphate. The steps are as follows: lithium source and phosphorus source are dissolved in water or mixed with water, and added into the reaction autoclave, the quaternary cationic surfactants and the alkylphenols polyoxyethylene ethers nonionic surfactant is also added into the reaction autoclave, the air in the dead volume of the autoclave inside is purged by the inert gas, the autoclave is sealed and heated to 40-50 DEG C with stirring, a feed valve and an exhaust valve are opened, pure ferrous salting liquid is added into the autoclave, and then the autoclave is sealed for the reaction of the material at 140 to 180 DEG C for 30 to 480 minutes; the mixture ratio of the invention is set as follows: the molar ratio of Li, Fe and P is 3.0-3.15:1:1.0-1.15, and then the resultant is filtered, washed, dried and carbon-coated, thus the lithium iron phosphate is obtained. The lithium iron phosphate which is produced by the invention has the advantages that: the electrochemical performance is excellent, the particle size distribution of which the D50 is between 1.5 um to 2 um is even, the phase purity is above 99 percent and the electronic conductivity of the material is improved.

Owner:HEBEI LITAO BATTERY MATERIAL

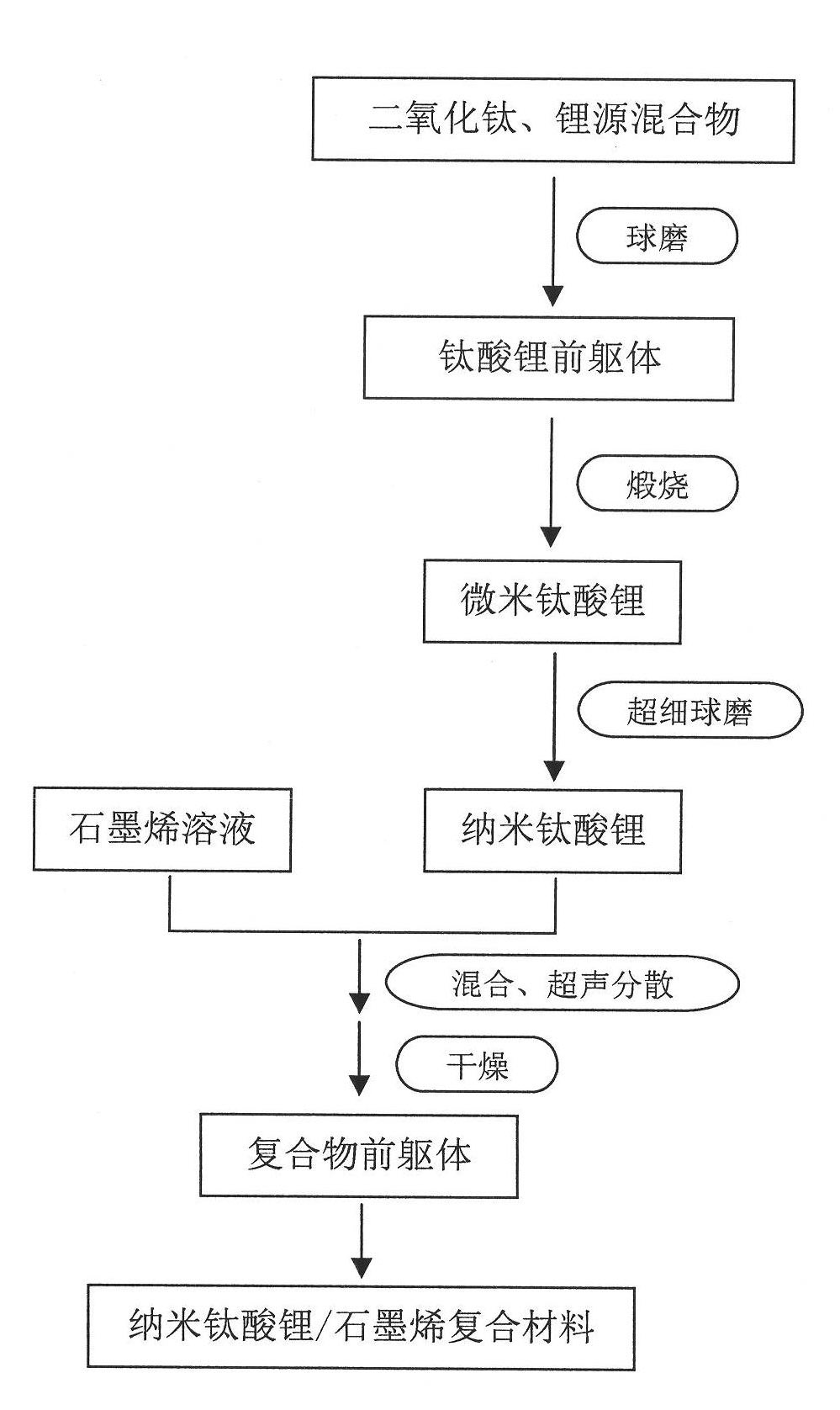

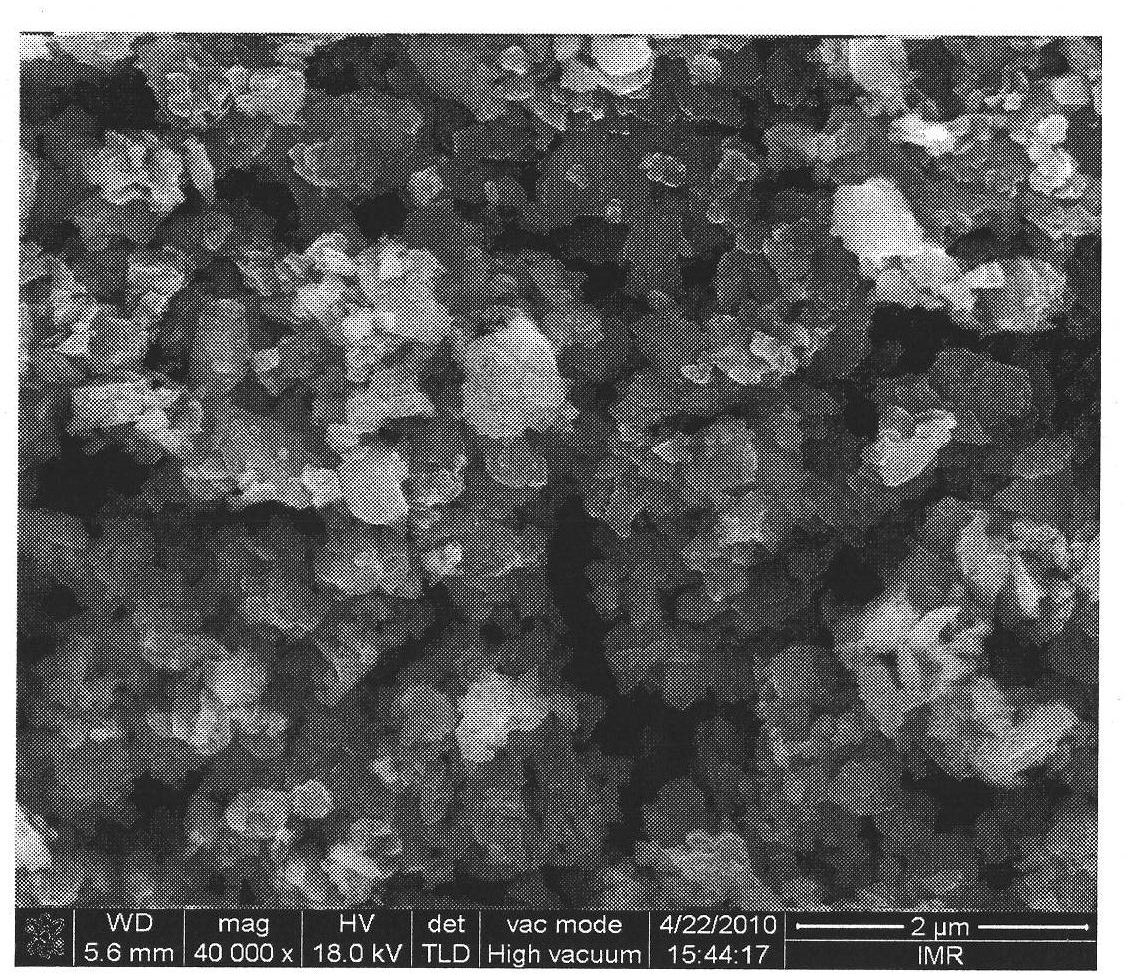

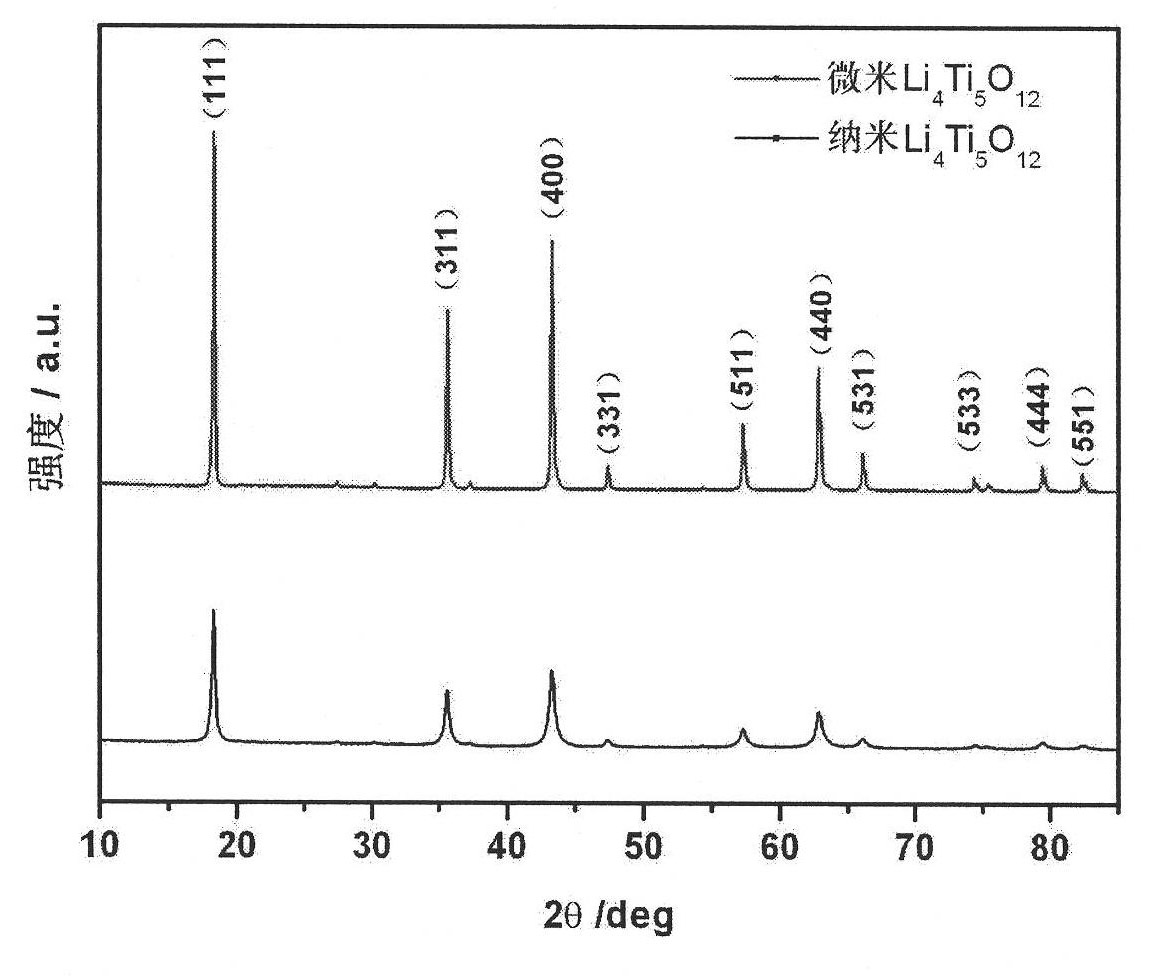

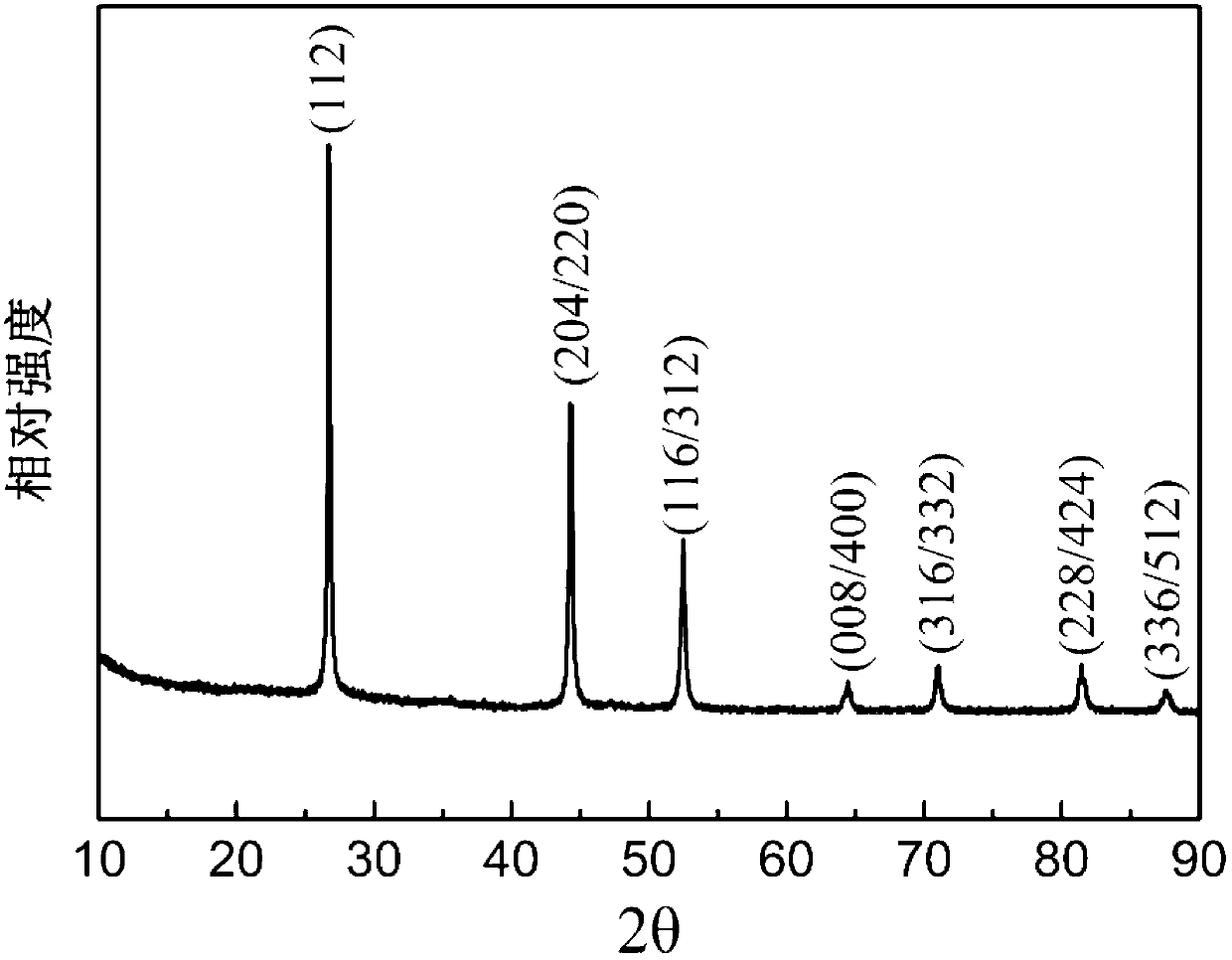

Nanometer lithium titanate/graphene composite negative electrode material and preparation process thereof

InactiveCN102376937AImprove electrochemical performanceAvoid defectsNon-aqueous electrolyte accumulator electrodesGrain treatmentsSodium-ion batteryCvd graphene

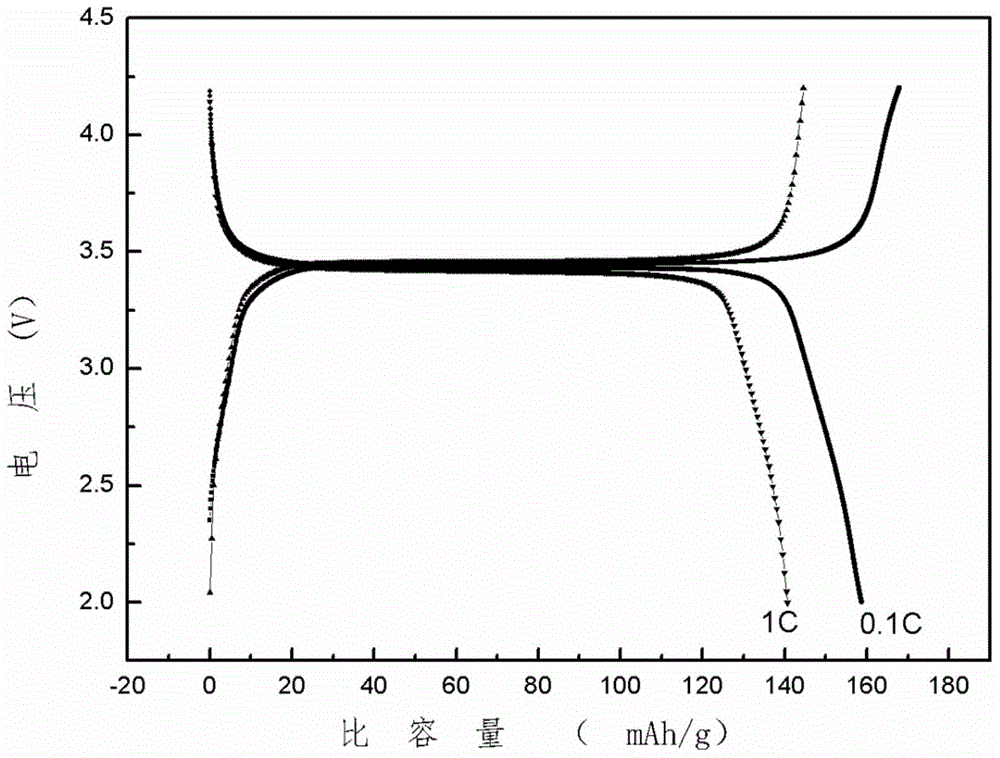

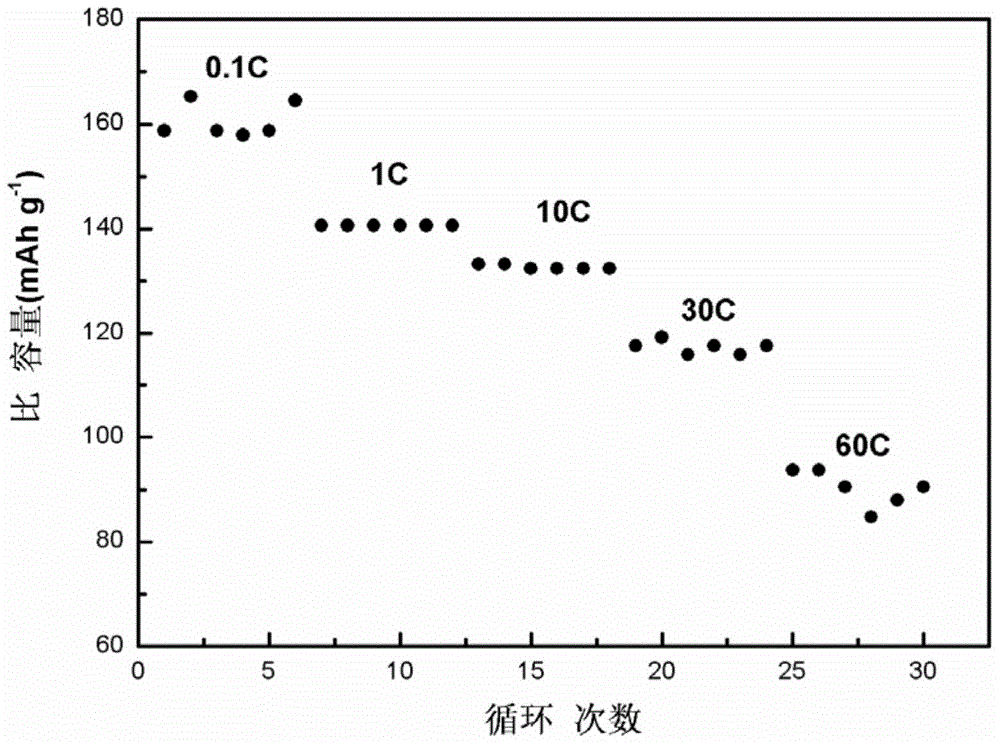

The invention relates to the field of negative electrode materials of lithium ion batteries, and specifically to a nanometer lithium titanate / graphene composite negative electrode material and a preparation process thereof. According to the invention, micron-sized lithium titanate prepared by the solid phase method is subjected to ultrafine ball milling to obtain nanometer powder, and the nanometer lithium titanate powder and graphene are uniformly compounded and subjected to heat treatment so as to obtain a high performance lithium ion battery negative electrode material; the invention is characterized in that uniform distribution of graphene in the nanometer lithium titanate powder is realized through in situ compounding; the weight of graphene in the composite negative electrode material accounts for 0.5 to 20%, and the weight of lithium titanate accounts for 80 to 99.5%. The lithium ion battery negative electrode material has good electrochemical performance, 1C capacity greater than 165 mAh / g, 30C capacity greater than 120 mAh / g and 50C capacity greater than 90 mAh / g. Nanometer lithium titanate in the lithium ion battery negative electrode material prepared in the invention has high phase purity; the preparation process of the material is simple and is easy for industrial production.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

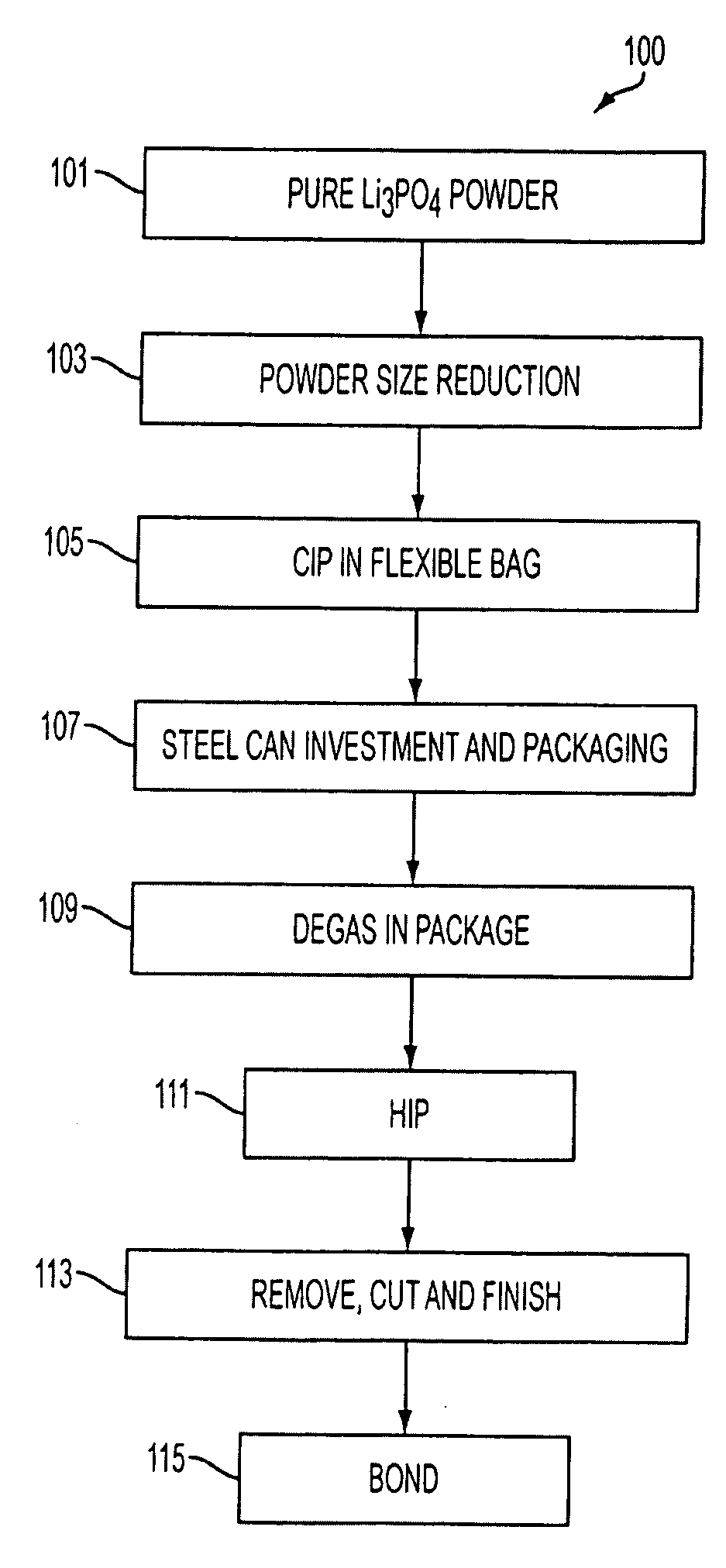

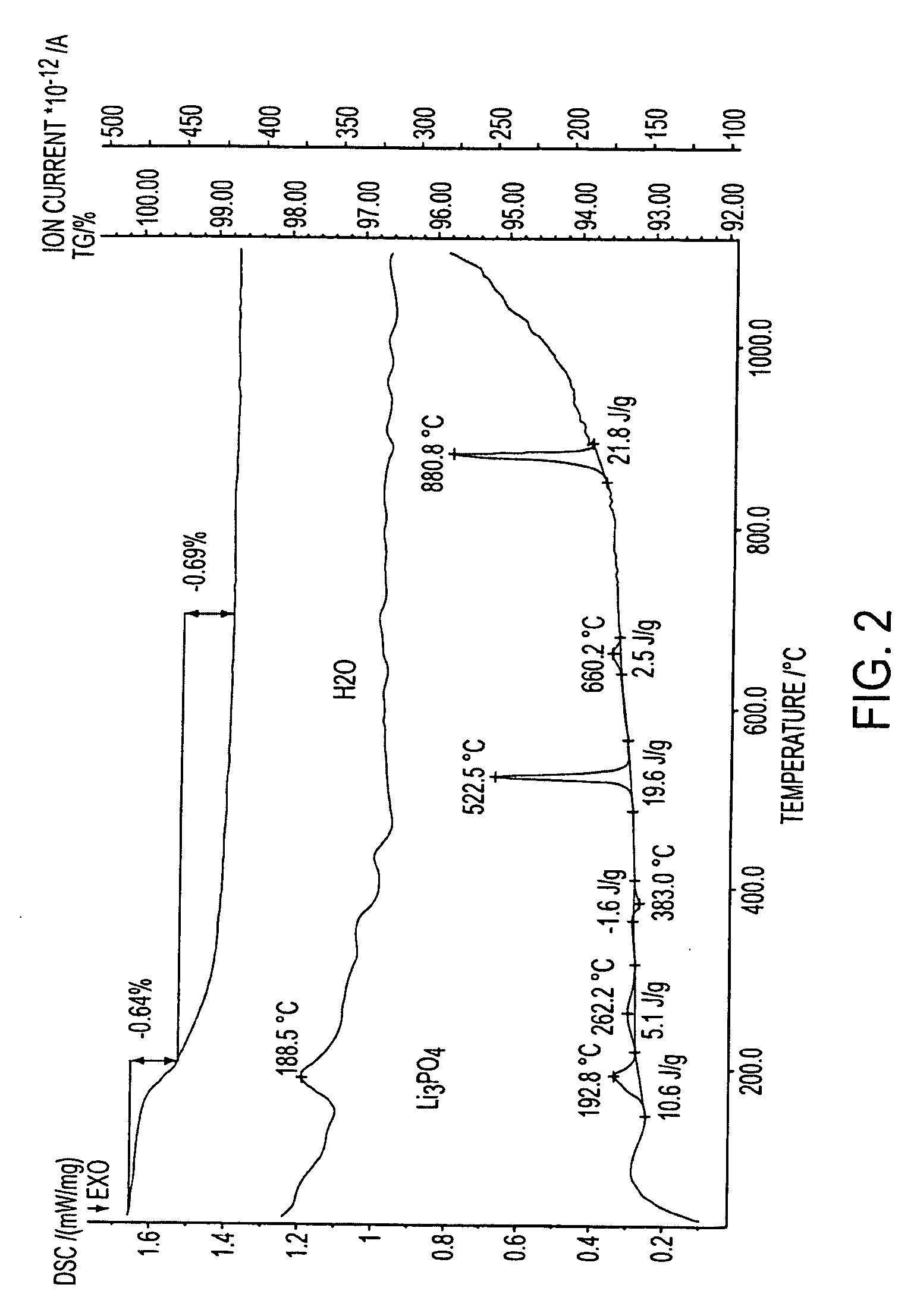

SPUTTERING TARGET OF Li3PO4 AND METHOD FOR PRODUCING SAME

A method of forming a lithium orthophosphate sputter target or tile and resulting target material is presented. The target is fabricated from a pure lithium orthophosphate powder refined to a fine powder grain size. After steps of consolidation into a ceramic body, packaging and degassing, the ceramic body is densified to high density, and transformed into a stable single phase of pure lithium orthophosphate under sealed atmosphere. The lithium orthophosphate target is comprised of a single phase, and can preferably have a phase purity greater than 95% and a density of greater than 95%.

Owner:SAPURAST RES

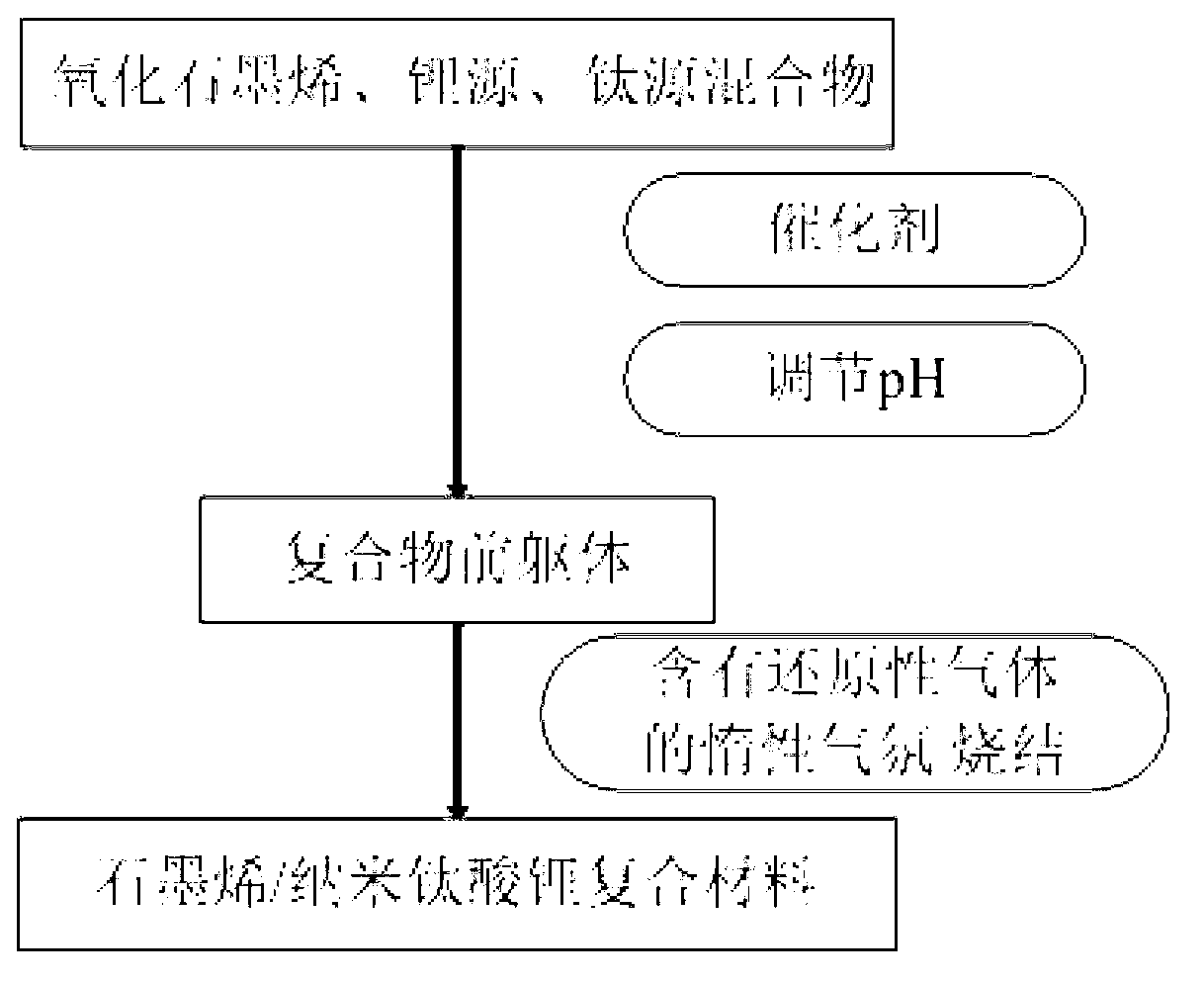

Preparation method of graphene/lithium titanate composite anode material

ActiveCN103022459AImprove electrochemical performanceGood magnificationCell electrodesHybrid/EDL manufactureActivated carbonSupercapacitor

The invention discloses a preparation method of a graphene / lithium titanate composite anode material, which comprises the following steps: compounding compounds serving as a lithium source and a titanium source and graphene oxide through a liquid-phase method and reducing graphene oxide of the compound in inert gas mixed with reducing gas into graphene so as to obtain the graphene / lithium titanate composite anode material. The method has the characteristic of realizing uniform distribution of graphene in lithium titanate through an in-situ compounding technique. Under the same conditions, the discharge time of a hybrid capacitor which respectively takes the graphene / lithium titanate composite anode material and activated carbon as the anode and cathode is obviously greater than that of an electric double-layer capacitor which takes activated carbon as an electrode and that of a hybrid capacitor which respectively takes lithium titanate and activated carbon as the anode and cathode. The lithium titanate phase purity of a hybrid supercapacitor and lithium ion battery composite anode materials prepared by the method disclosed by the invention is higher. Furthermore, the preparation method further has the characteristic of easily realizing the large-scale industrial production.

Owner:ZHANGJIAGANG IND TECH RES INST CO LTD DALIAN INST OF CHEM PHYSICS CHINESE ACADEMY OF SCI +1

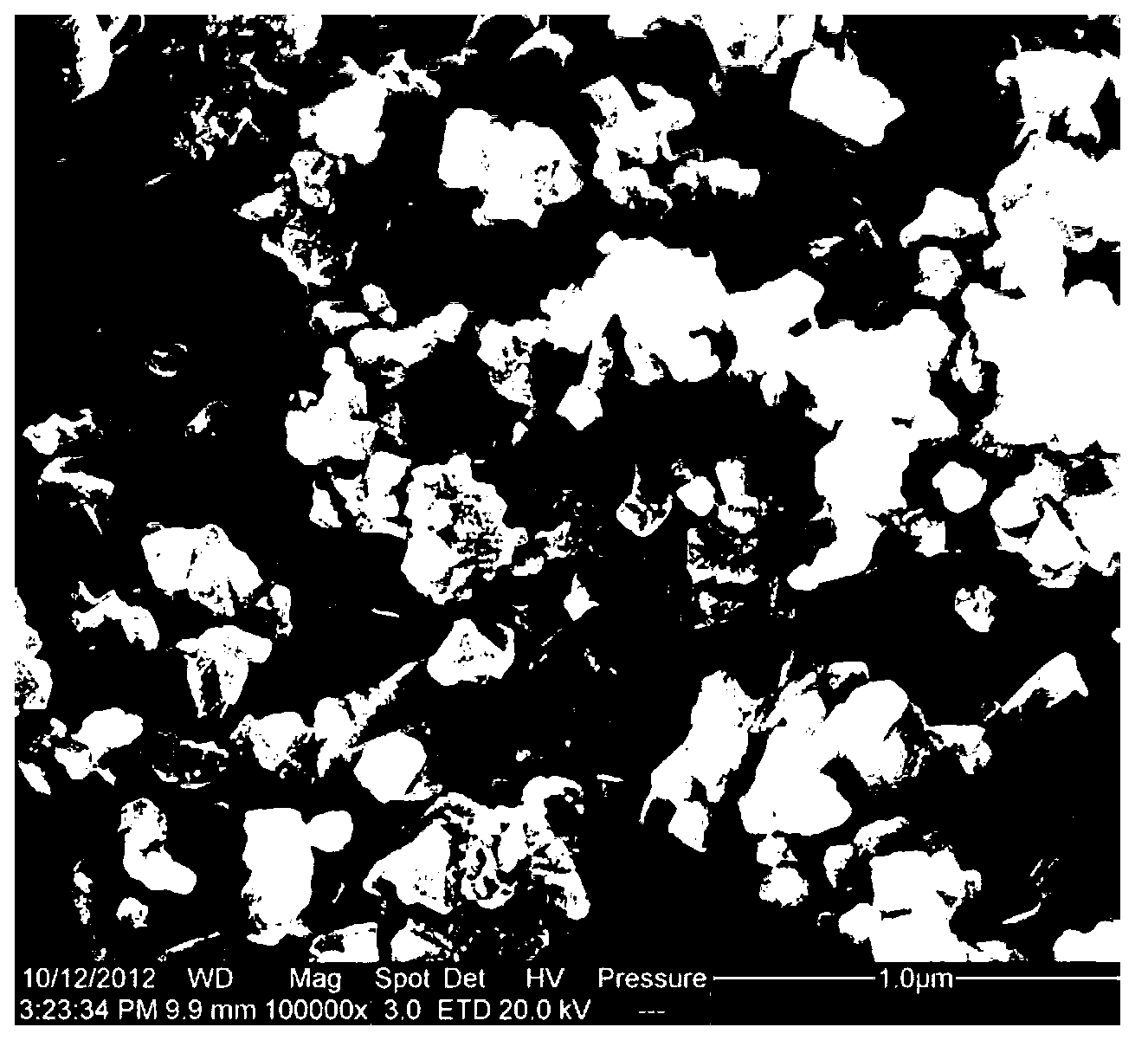

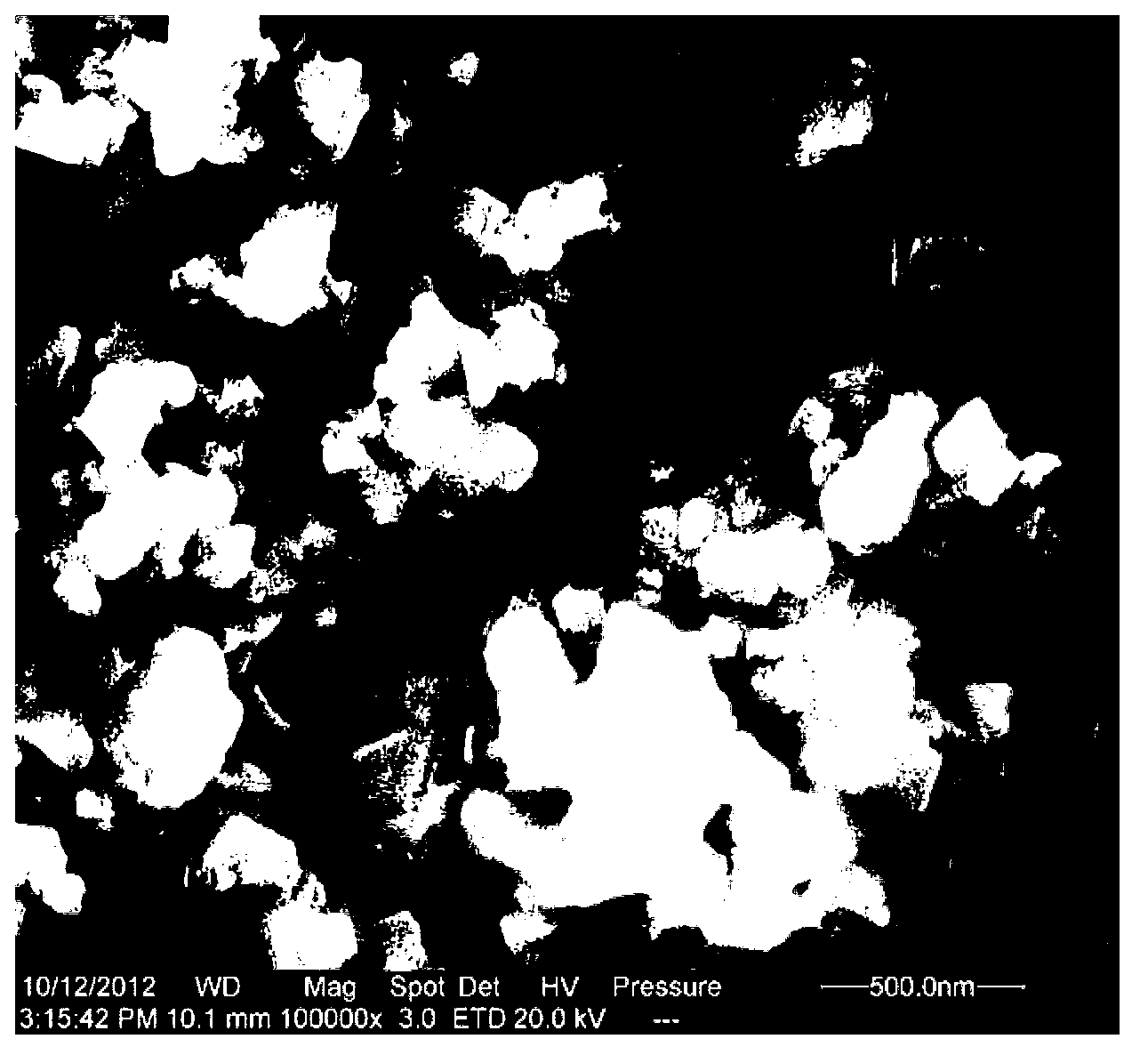

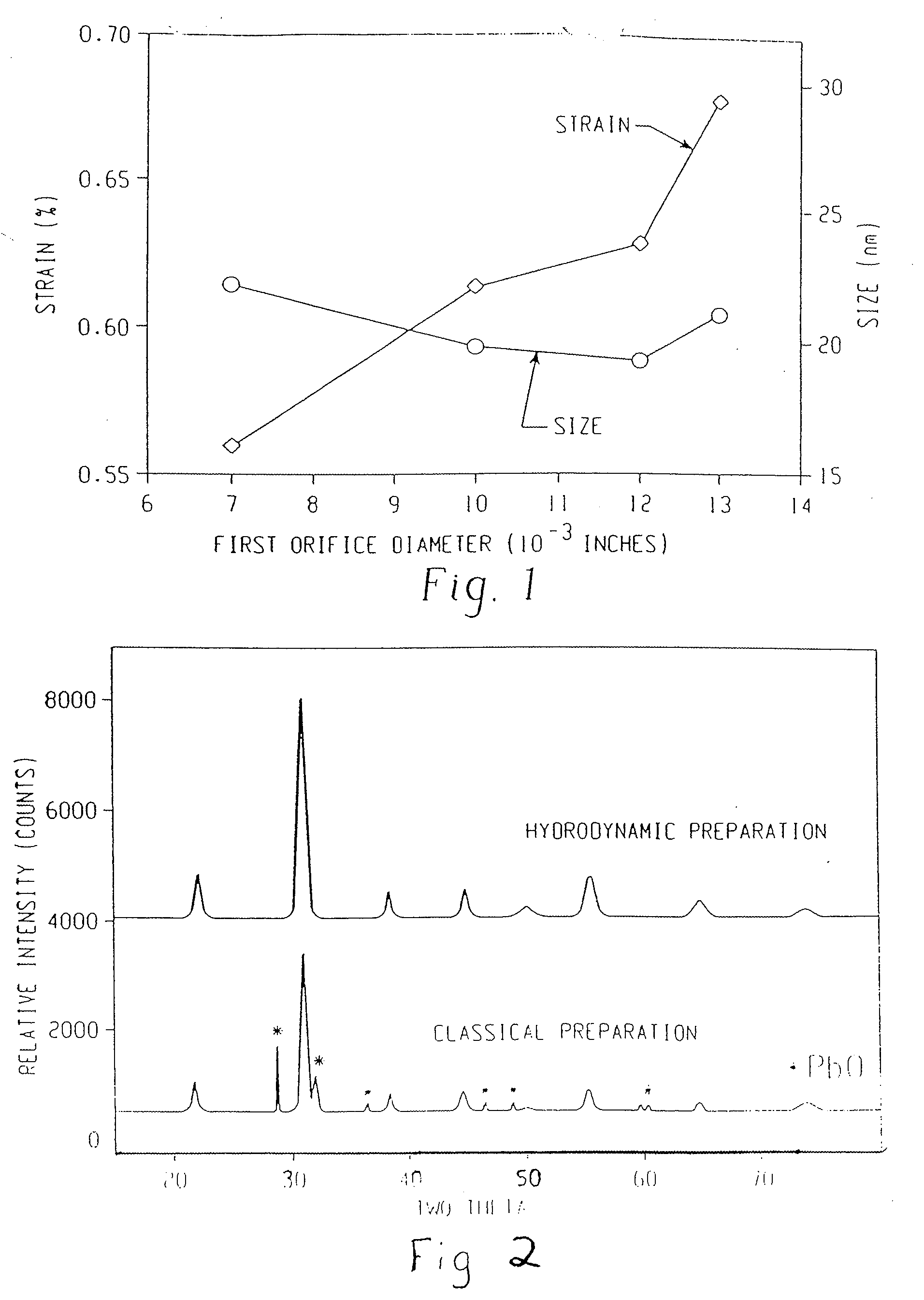

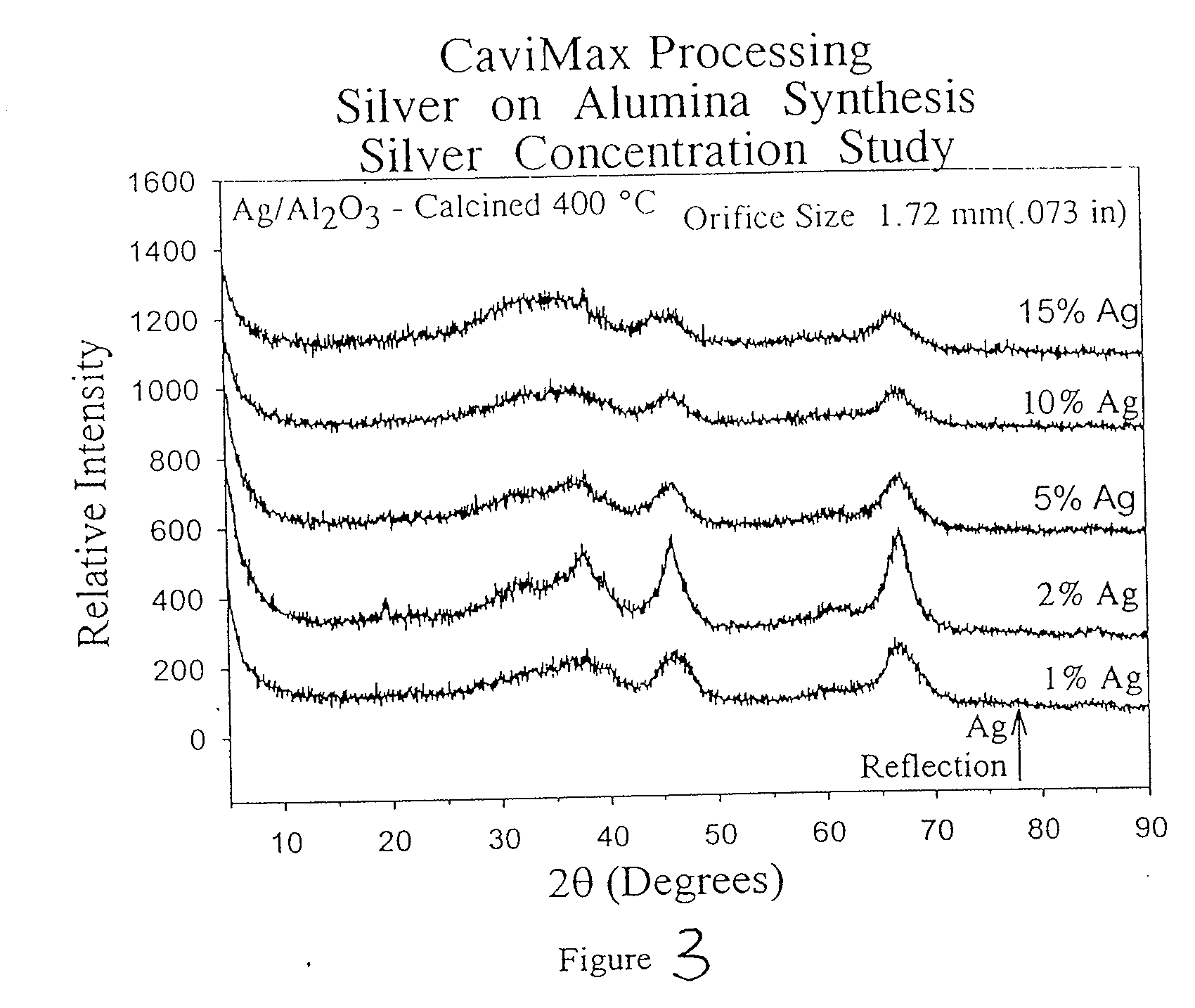

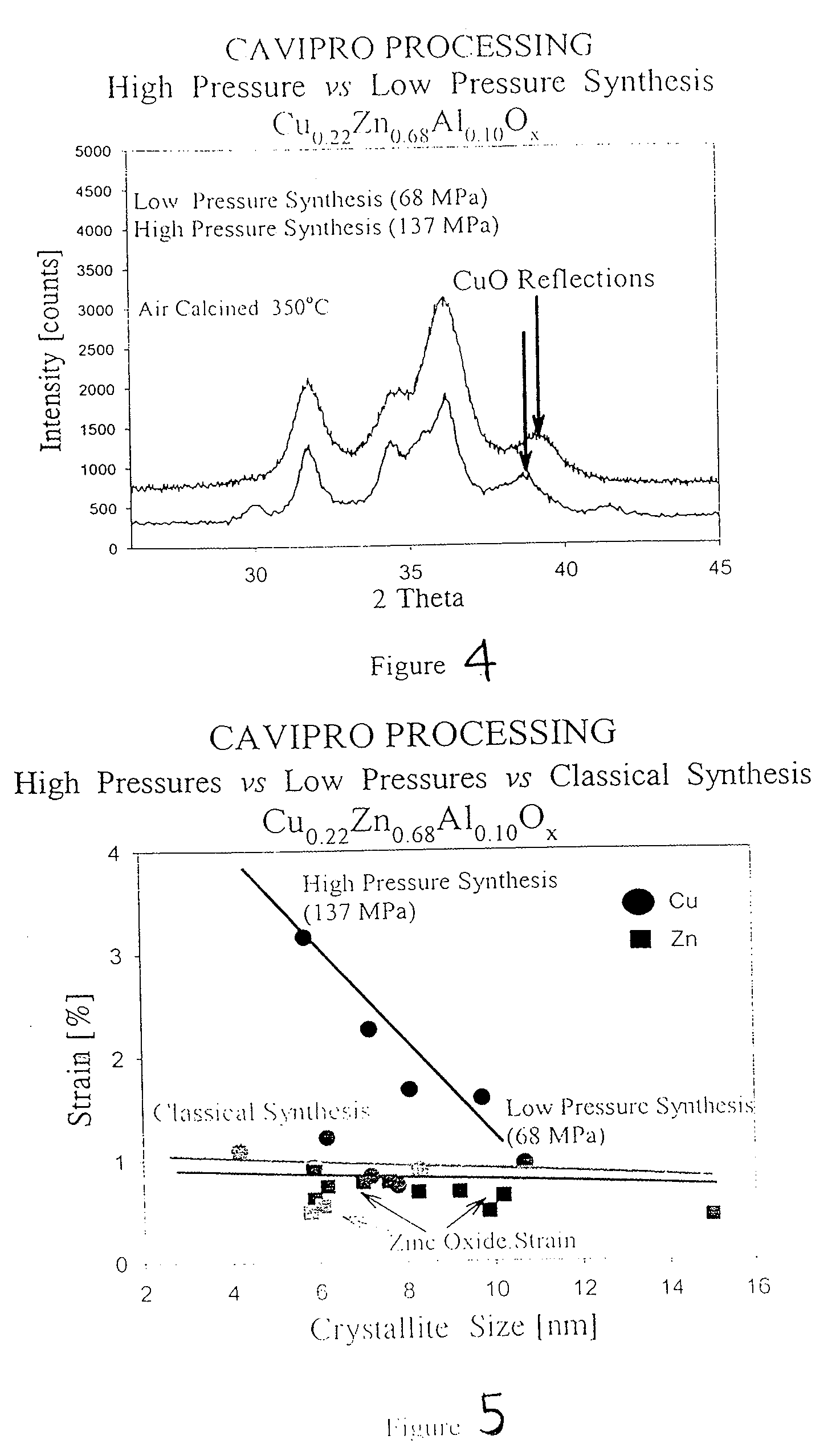

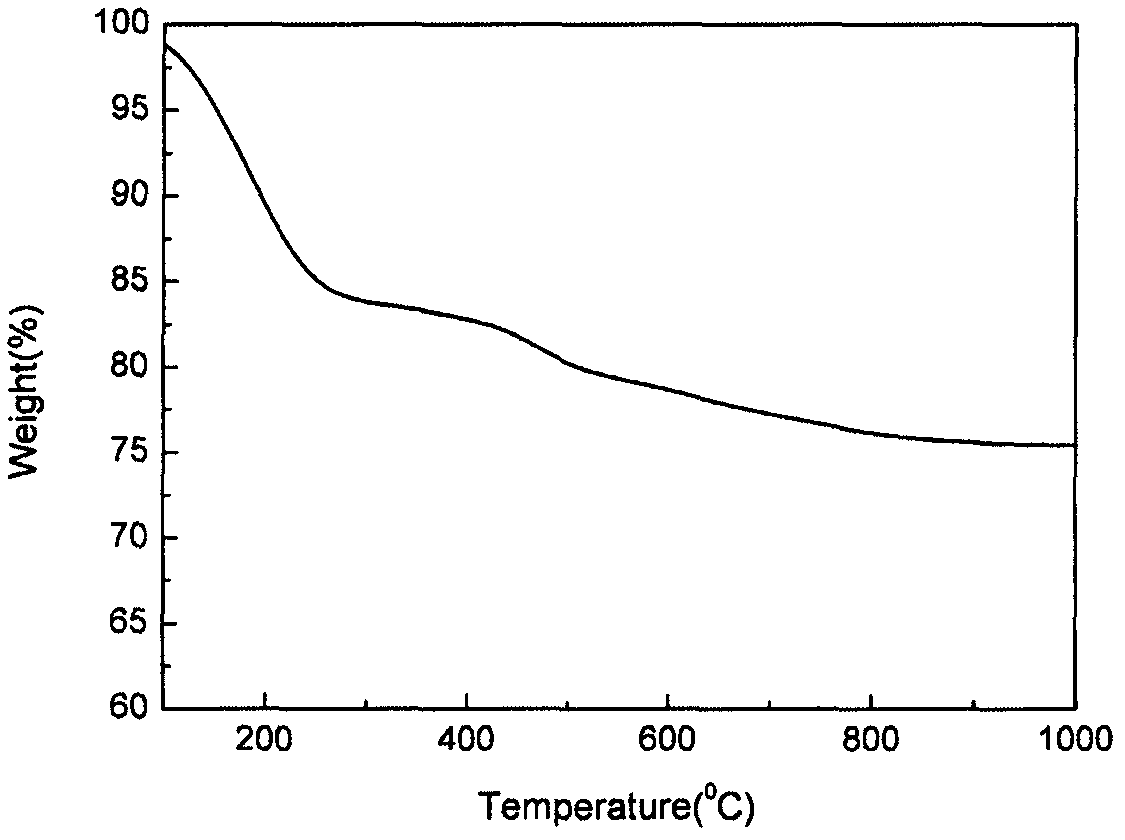

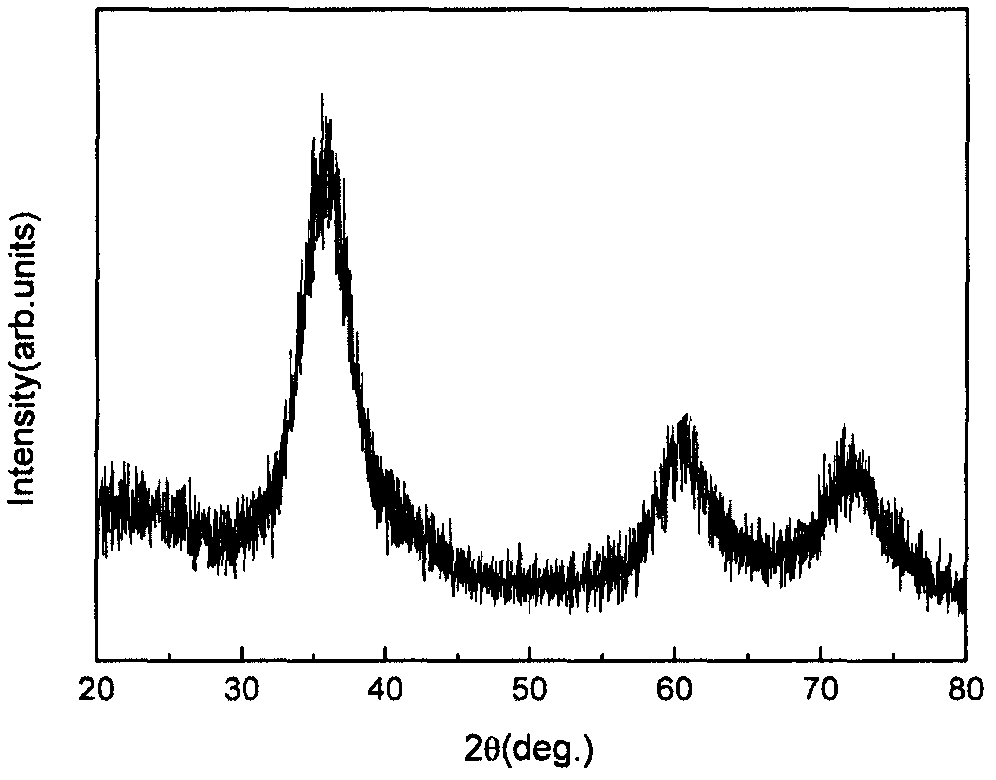

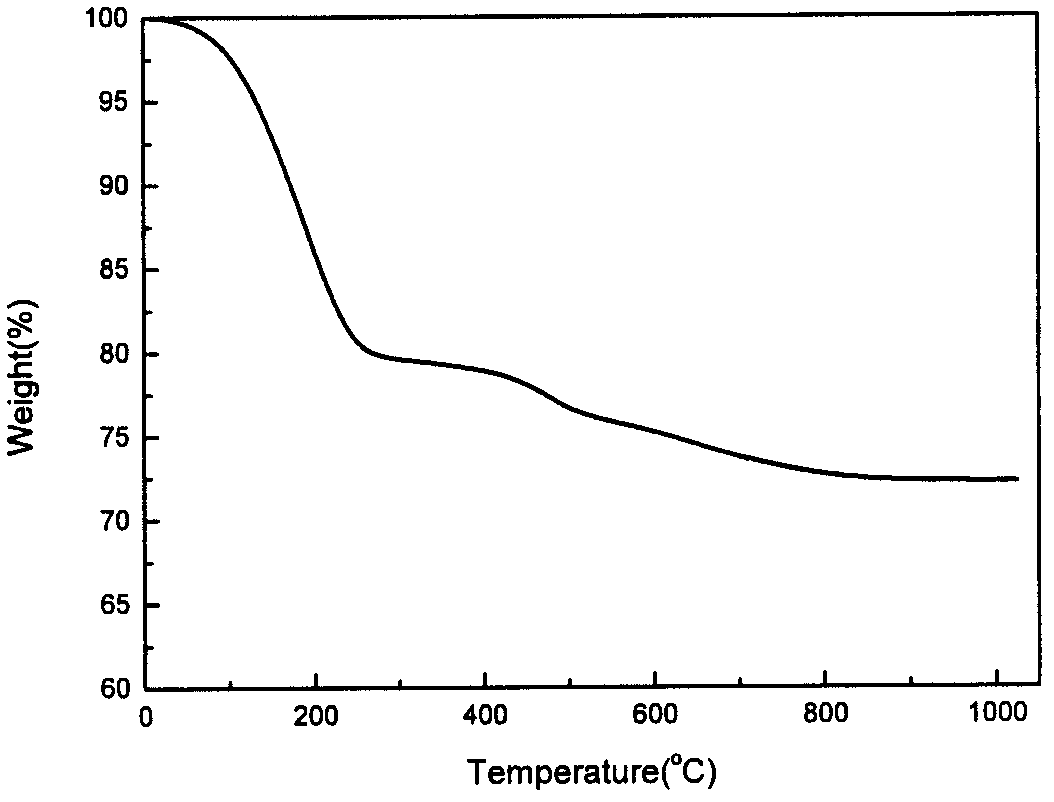

Method of preparing compounds using cavitation and compounds formed therefrom

InactiveUS20070066480A1Efficient modificationEasy to adjustMaterial nanotechnologyTransportation and packagingCompound (substance)Nanostructured materials

Nanostructured materials and processes for the preparation of these nanostructured materials in high phase purities using cavitation is disclosed. The method preferably comprises mixing a metal containing solution with a precipitating agent and passing the mixture into a cavitation chamber. The chamber consists of a first element to produce cavitation bubbles, and a second element that creates a pressure zone sufficient to collapse the bubbles. The process is useful for the preparation of catalysts and materials for piezoelectrics and superconductors.

Owner:WORCESTER POLYTECHNIC INSTITUTE +1

Novel polycarbosilane and preparation method thereof

The invention relates to novel polycarbosilane and a preparation method thereof. A polycarbosilane ceramic precursor is prepared by adopting a Grignard reagent coupling method; a molecular structure contains unsaturated groups such as a Si-H bond, C=C and the like; the precursor can be crosslinked and cured at a certain temperature, and has low curing weight loss and high manufacturability; the Si / C ratio in the precursor and the process performance of a precursor product can be adjusted effectively by adjusting the functionality and feed ratio of a chlorosilane monomer serving as a reactant and optimizing reaction conditions; and the obtained product has excellent heat resistance, high ceramic yield, low free carbon content in ceramic and high SiC ceramic phase purity, is suitable for serving as a high-performance SiC ceramic precursor, and can be used for preparing an ultrahigh-temperature ceramic-based composite material submerged substrate as well as high-performance materials such as SiC ceramic coatings, fibers and the like.

Owner:AEROSPACE RES INST OF MATERIAL & PROCESSING TECH +1

Medical fluorinated calcium phosphate coating material and its prepn process

InactiveCN1486751AHigh phase purityIncrease profitMetallic material coating processesCalcium phosphate coatingPhosphoric acid

The present invention relates to one kind of medical material used for hard tissue. It consists of medical base body and surface fluorinated calcium phosphate coating, which is fluorinated hydroxyapatite, fluorinated calciprivic hydroxyapatite, fluorinated tricalcium phosphate or carbonate radical substituted hydroxyapatite. During the preparation, alcohol solution of the mixture of alcohol soluble calcium salt and phosphate or partially esterified phosphoric acid is used as precursor and surface coating is formed on alumina ceramic or medical metal base body via conventional sol-gel soaking pulling process, rotary painting process, combined soaking pulling and centrifuging process or hot solution spraying process. The coating has high crystalline phase content, no impurity phase and high phase purity. The preparation process of th present invention can obtain coating with thickness adjustable from several hundred nanometers to several decade microns.

Owner:ZHEJIANG UNIV

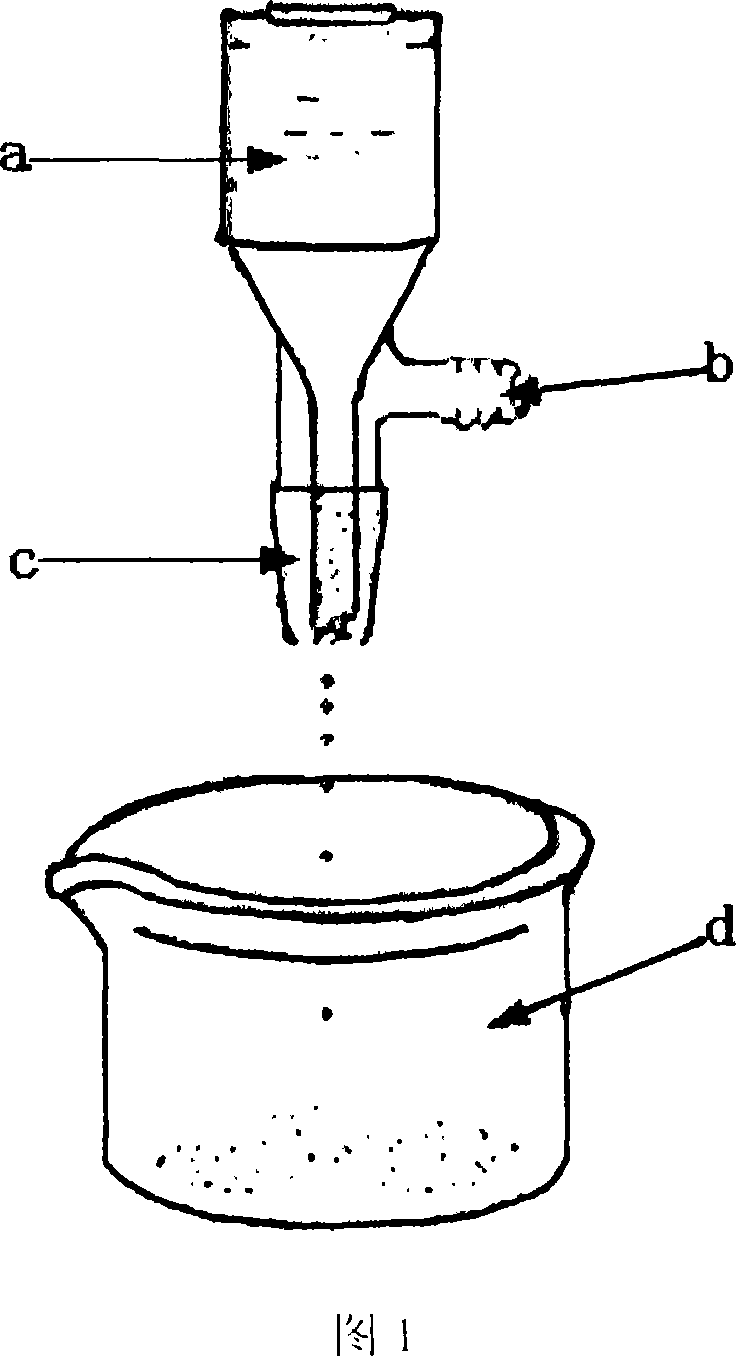

Freeze forming prepn process of ternary lithium ceramic microphere

The freeze forming preparation process of ternary lithium ceramic microsphere includes the following steps: mixing the material for ternary lithium ceramic microsphere, high molecular adhesive and solvent, mixing in a ball mill to form suspension slurry and defoaming; dropping the slurry into cooling medium to form microsphere in a microsphere forming unit, and low temperature vacuum drying in a freezing drier to form ceramic microsphere precursor; roasting, calcining and sintering; and programmed heat treatment to obtain ternary lithium ceramic microsphere. The ternary lithium ceramic microsphere has high sphericity, controllable size, high size dispersivity, high apparent density, high phase purity, high strength and other features.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

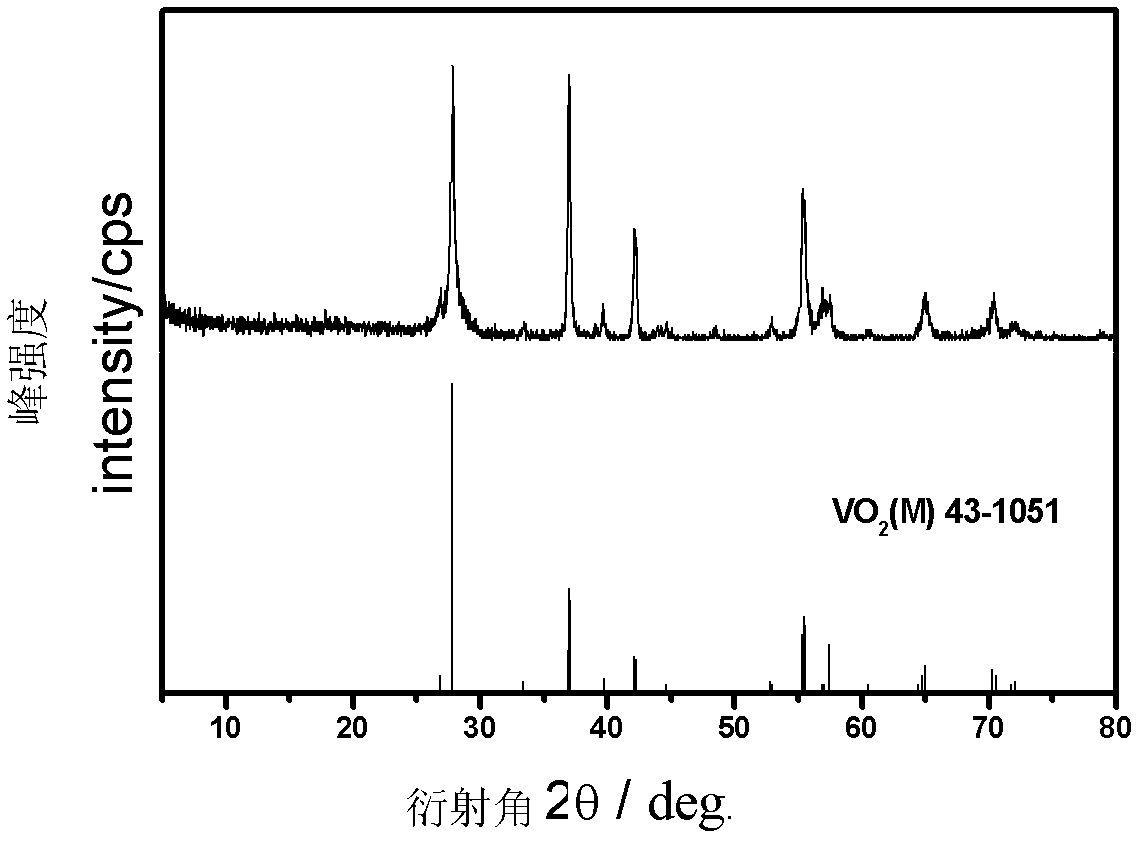

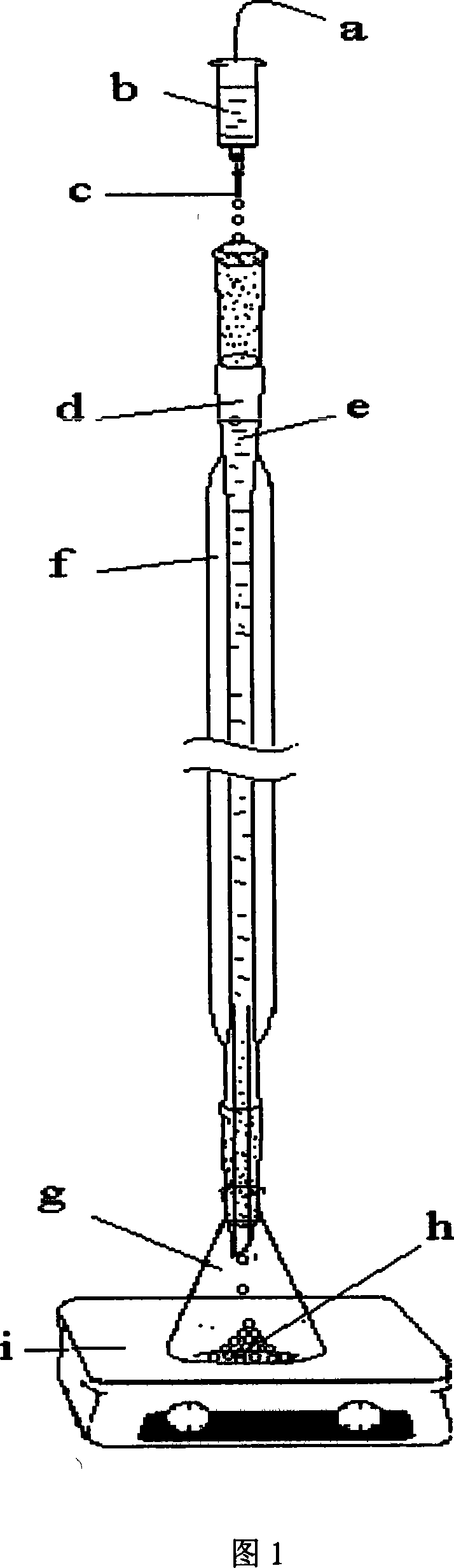

Method for directly synthesizing M-phase vanadium dioxide nano particles by liquid phase method

ActiveCN102616849AGentle conditionsEasy to controlNanotechnologyVanadium oxidesVanadium dioxideFilling rate

The invention provides a method for directly synthesizing M-phase vanadium dioxide nano particles by a liquid phase method. The method comprises the following steps of: dissolving one or a mixture of vanadium pentoxide and metavanadate, which is taken as a raw material in water, heating under normal pressure with stirring, slowly dripping a reducing agent, and reacting at constant temperature to obtain precursor substance; and centrifuging and precipitating the precursor substance, mixing with distilled water, transferring into a reaction steel kettle with a teflon lining, and controlling phase purity and the particle size of a product by controlling reaction temperature, reaction time, reaction kettle filling rate, substance concentration and the like to obtain black blue M-phase vanadium dioxide nano particles. The preparation process is performed under the condition of liquid phase, a solid-phase high-temperature heating step is eliminated, and the method belongs to a low-carbon technology; and moreover, the generation condition of M-phase vanadium dioxide is mild and easy to control, and the particle size of the product is in a nano level. The method has obvious competition advantages and profit margins in the aspects of manufacturing cost, product performance, environment-friendliness and the like.

Owner:DALIAN NATIONALITIES UNIVERSITY

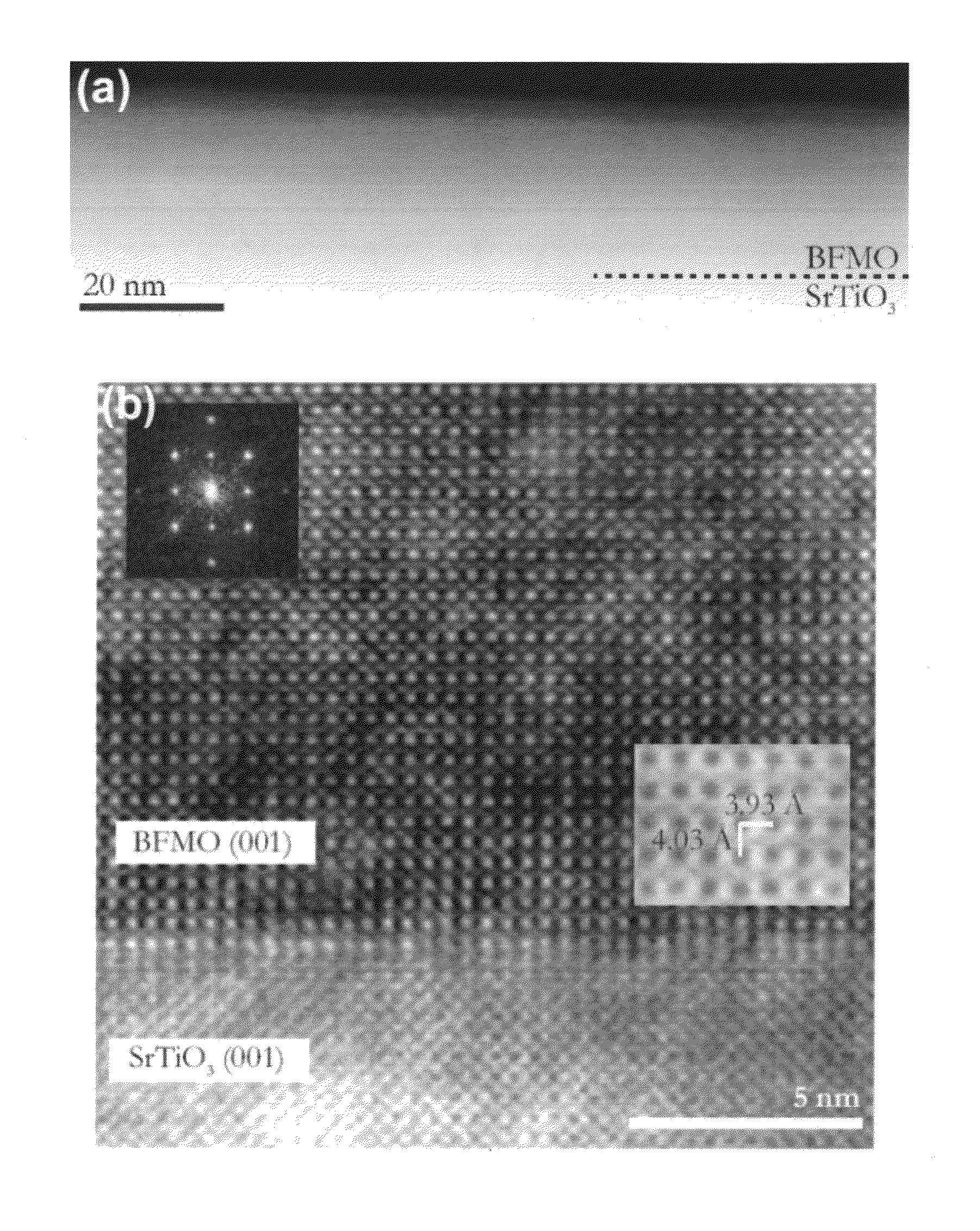

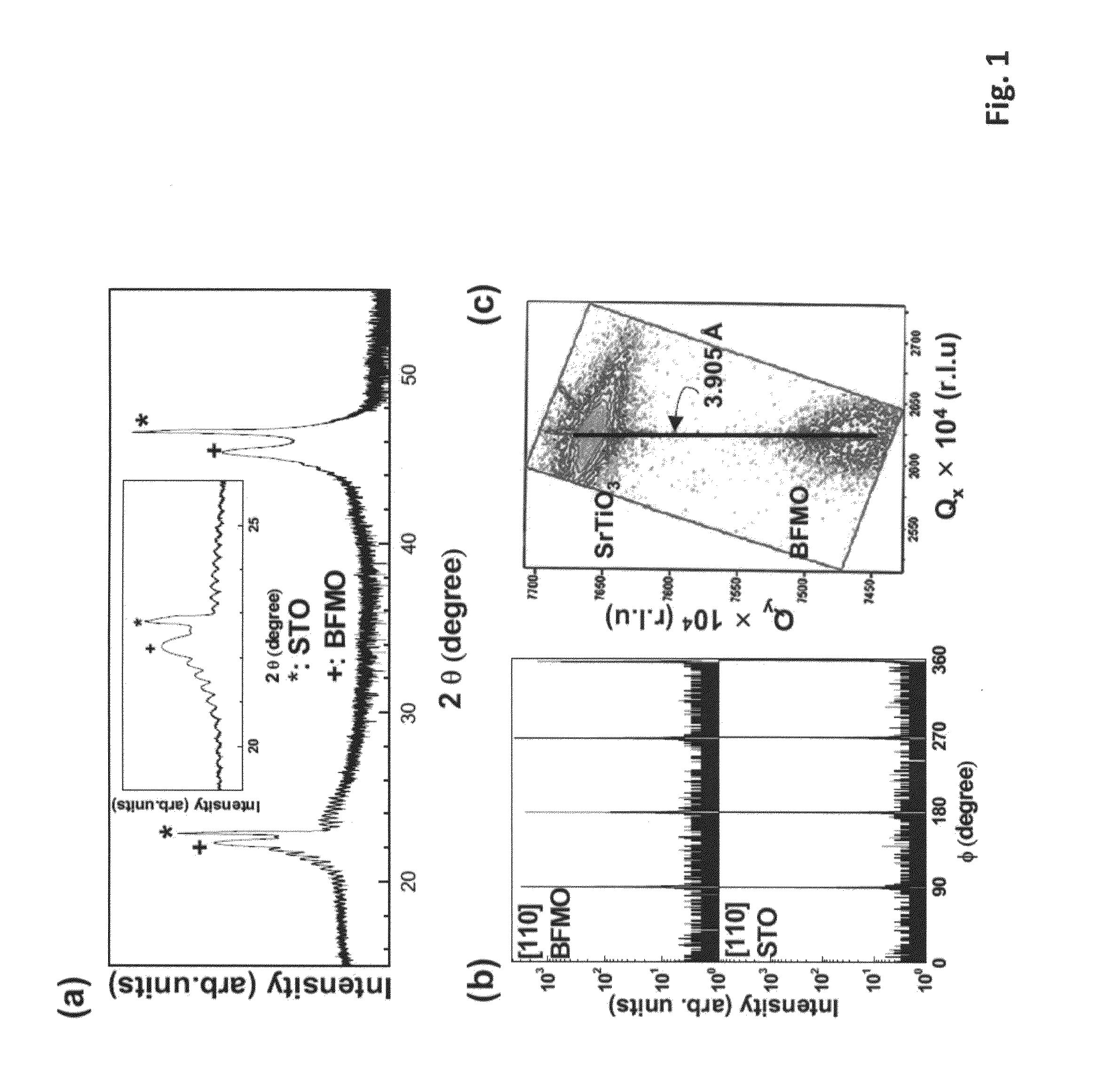

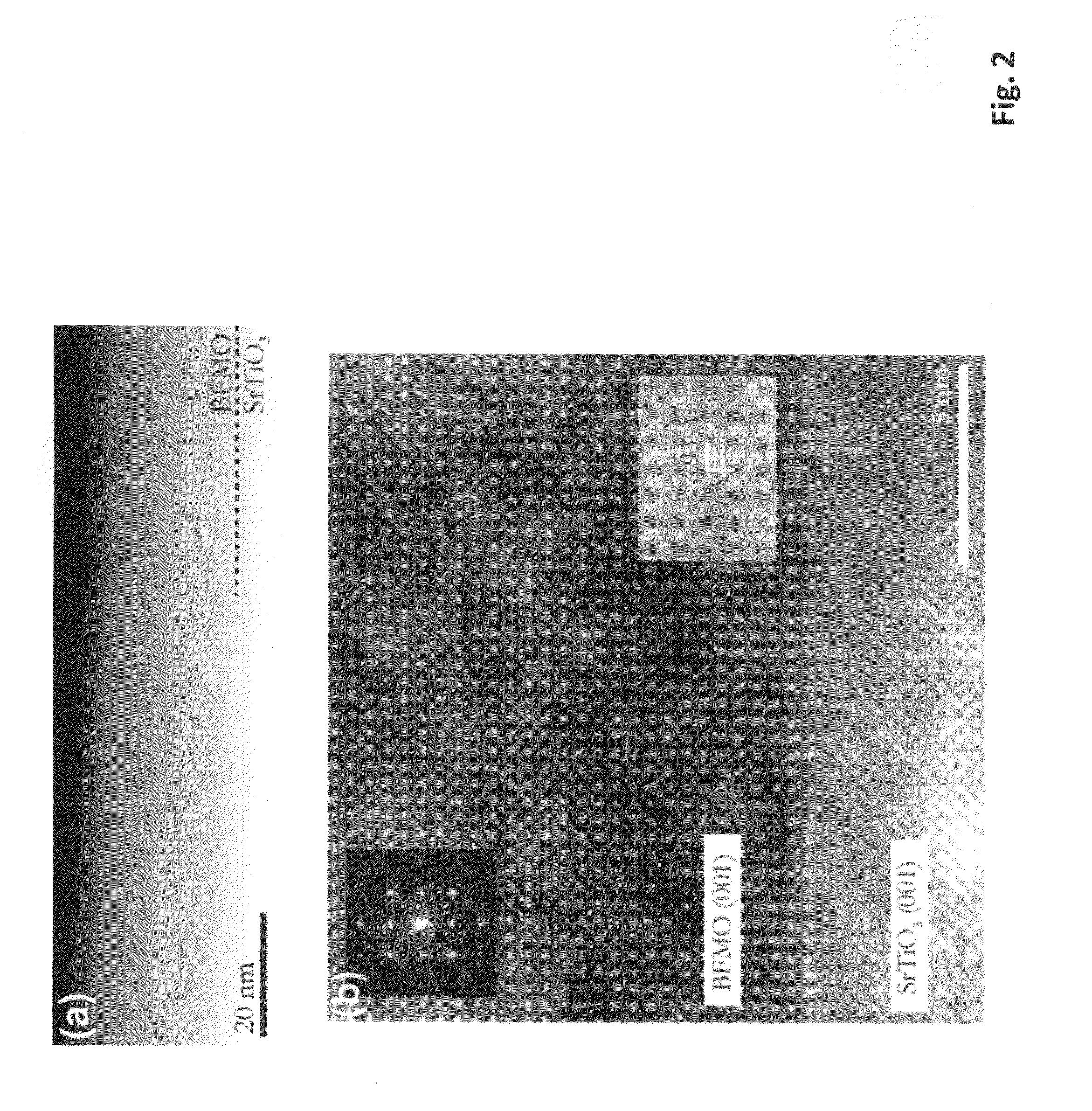

Multiferroics that are both ferroelectric and ferromagnetic at room temperature

InactiveUS20120177902A1Polycrystalline material growthIron oxides/hydroxidesNb dopedStrontium titanate

Multiferroic articles including highly resistive, strongly ferromagnetic strained thin films of BiFe0.5Mn0.5O3 (“BFMO”) on (001) strontium titanate and Nb-doped strontium titanate substrates were prepared. The films were tetragonal with high epitaxial quality and phase purity. The magnetic moment and coercivity values at room temperature were 90 emu / cc (H=3 kOe) and 274 Oe, respectively. The magnetic transition temperature was strongly enhanced up to approximately 600 K, which is approximately 500 K higher than for pure bulk BiMnO3.

Owner:LOS ALAMOS NATIONAL SECURITY

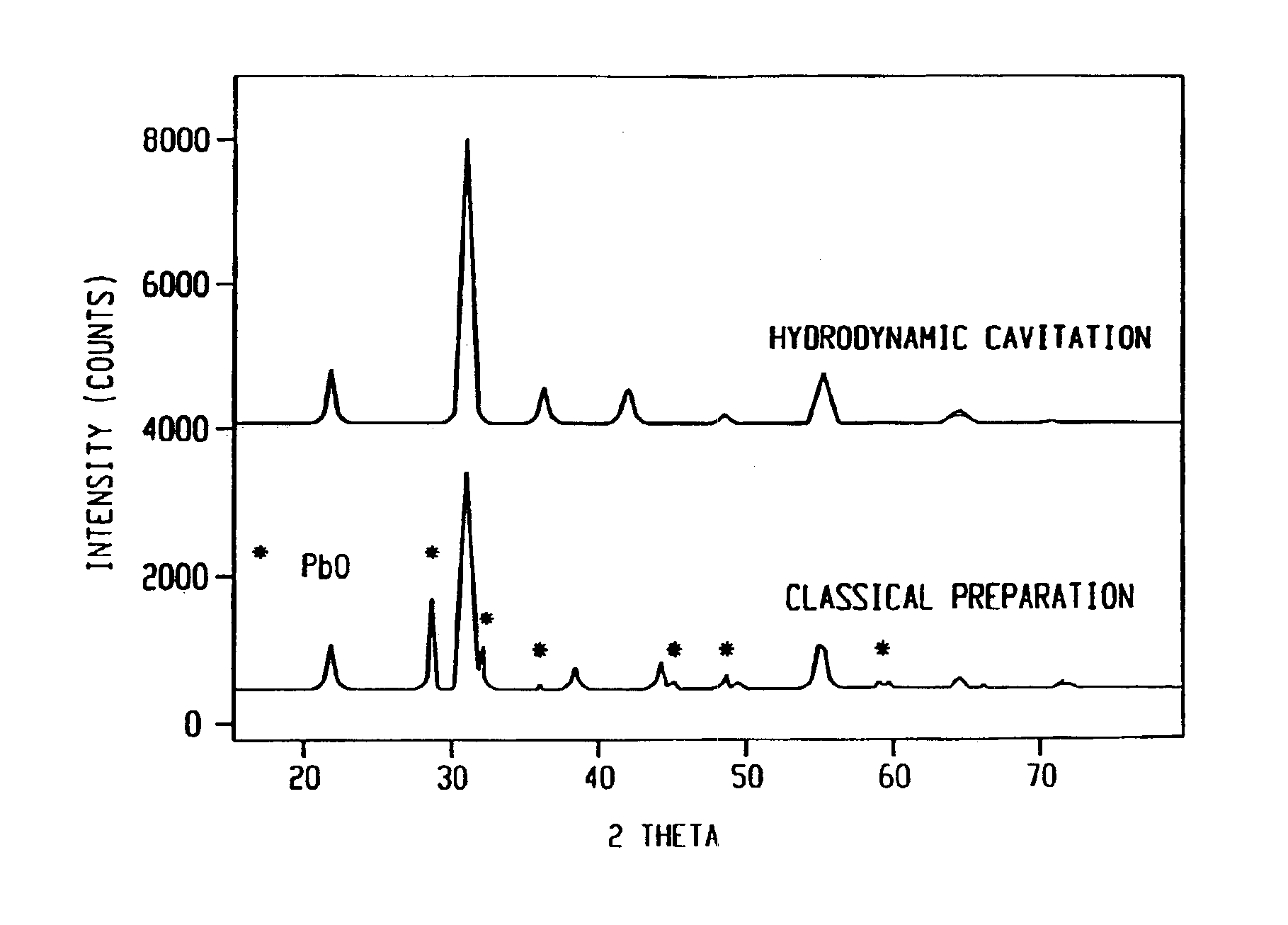

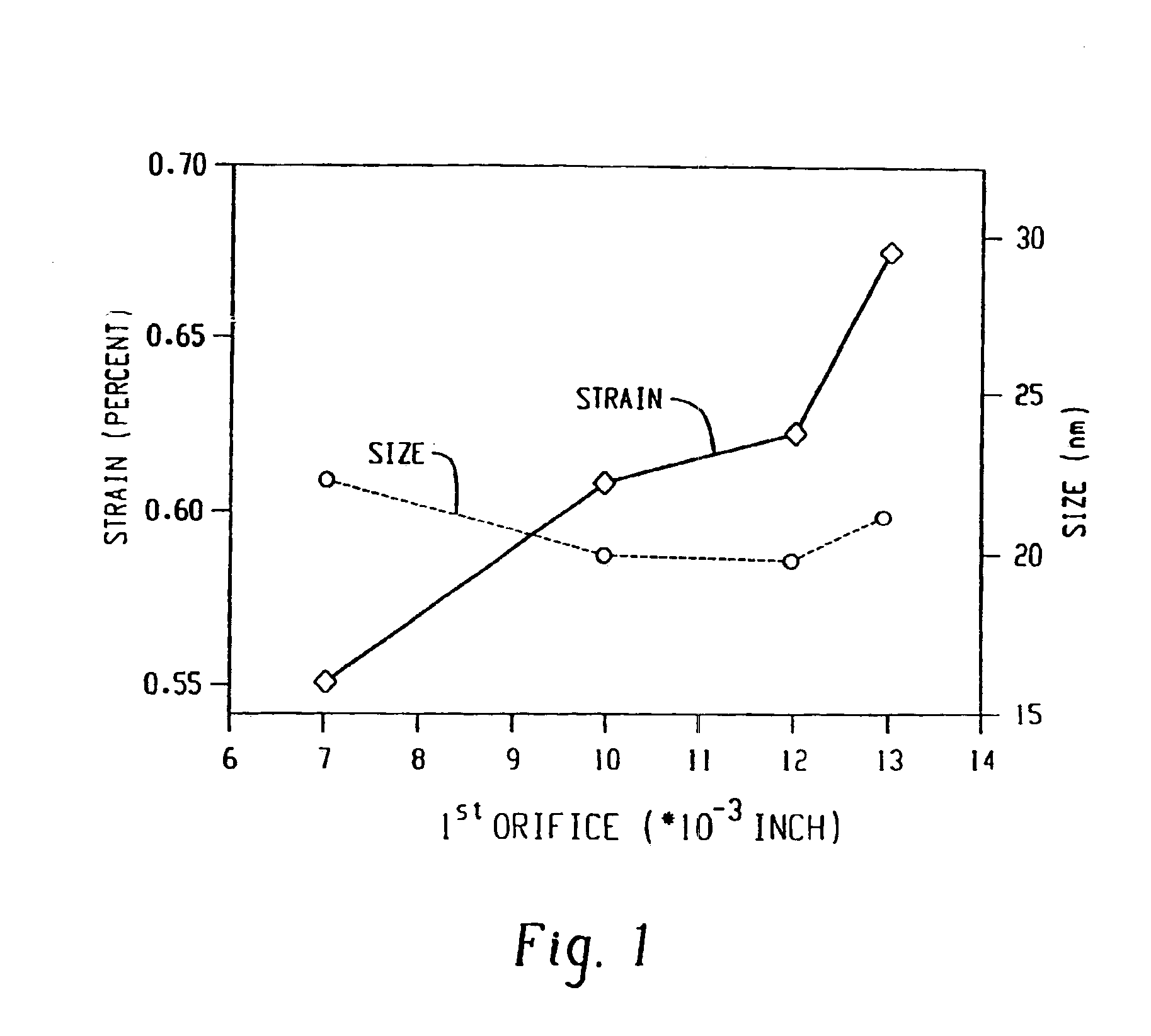

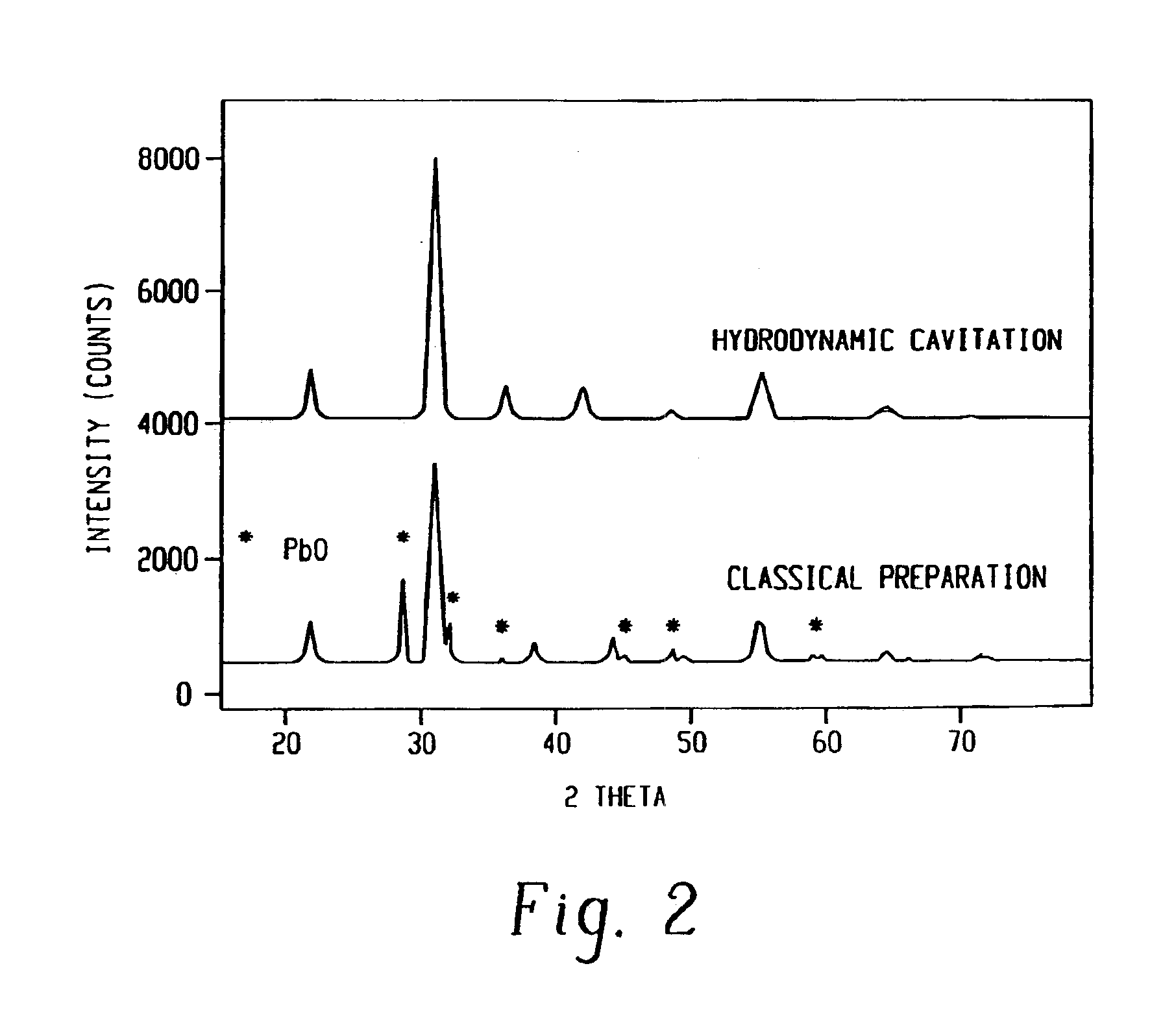

Method of preparing metal containing compounds using hydrodynamic cavitation

InactiveUS6869586B1Increase shearSuitably producedMaterial nanotechnologyTransportation and packagingNanostructured materialsCavitation bubble

A process for the preparation of nanostructured materials in high phase purities using cavitation is disclosed. The method comprises mixing a metal containing solution with a precipitating agent and passing the mixture into a cavitation chamber. The chamber consists of a first element to produce cavitation bubbles, and a second element that creates a pressure zone sufficient to collapse the bubbles. The process is useful for the preparation of mixed metal oxide catalysts and materials for piezoelectrics and superconductors.

Owner:WORCESTER POLYTECHNIC INSTITUTE +1

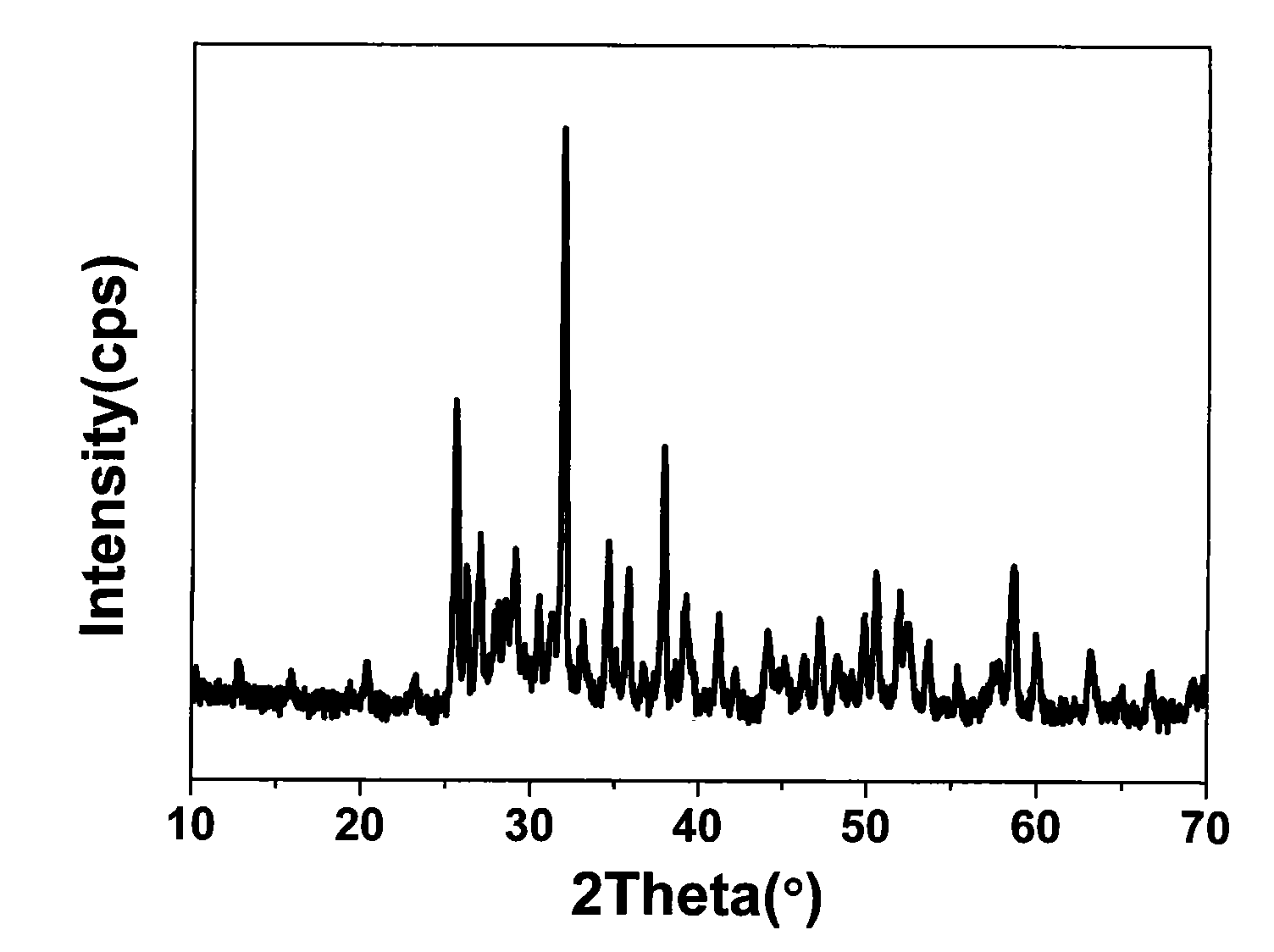

Method for preparing silicon-based oxynitride fluorescent powder

InactiveCN101818063ALow costSynthesis temperature is lowLuminescent compositionsLuminous intensityFluorescence

The invention discloses a method for preparing silicon-based oxynitride fluorescent powder, which comprises the following steps of: weighing corresponding raw materials and silica powder based on stoichiometric proportion of each element in the chemical formula of the silicon-based oxynitride fluorescent powder, after uniformly mixing the raw materials and the silica powder, raising the temperature to 800 to 1,000 DEG C under any one of the conditions of condition a to condition c, performing reduction reaction under the condition c or the condition d, and cooling the reaction product to roomtemperature to obtain the silicon-based oxynitride fluorescent powder, wherein the condition a is vacuum; the condition b is the atmosphere of inert gases; the condition c is the atmosphere of nitrogen-containing gases; and the condition d is the atmosphere of reductive gas. The silicon-based oxynitride fluorescent powder doped with various luminescent ions and prepared by the method has bright fluorescence under the excitation of ultraviolet ray, near ultraviolet or visible light. The method has the advantages of low preparation temperature of the product, high phase purity of the product, controllable particle size of the product, good luminous intensity of the product, low cost, simple process and the like, and is easy to enlarge industrialization.

Owner:UNIV OF SCI & TECH OF CHINA

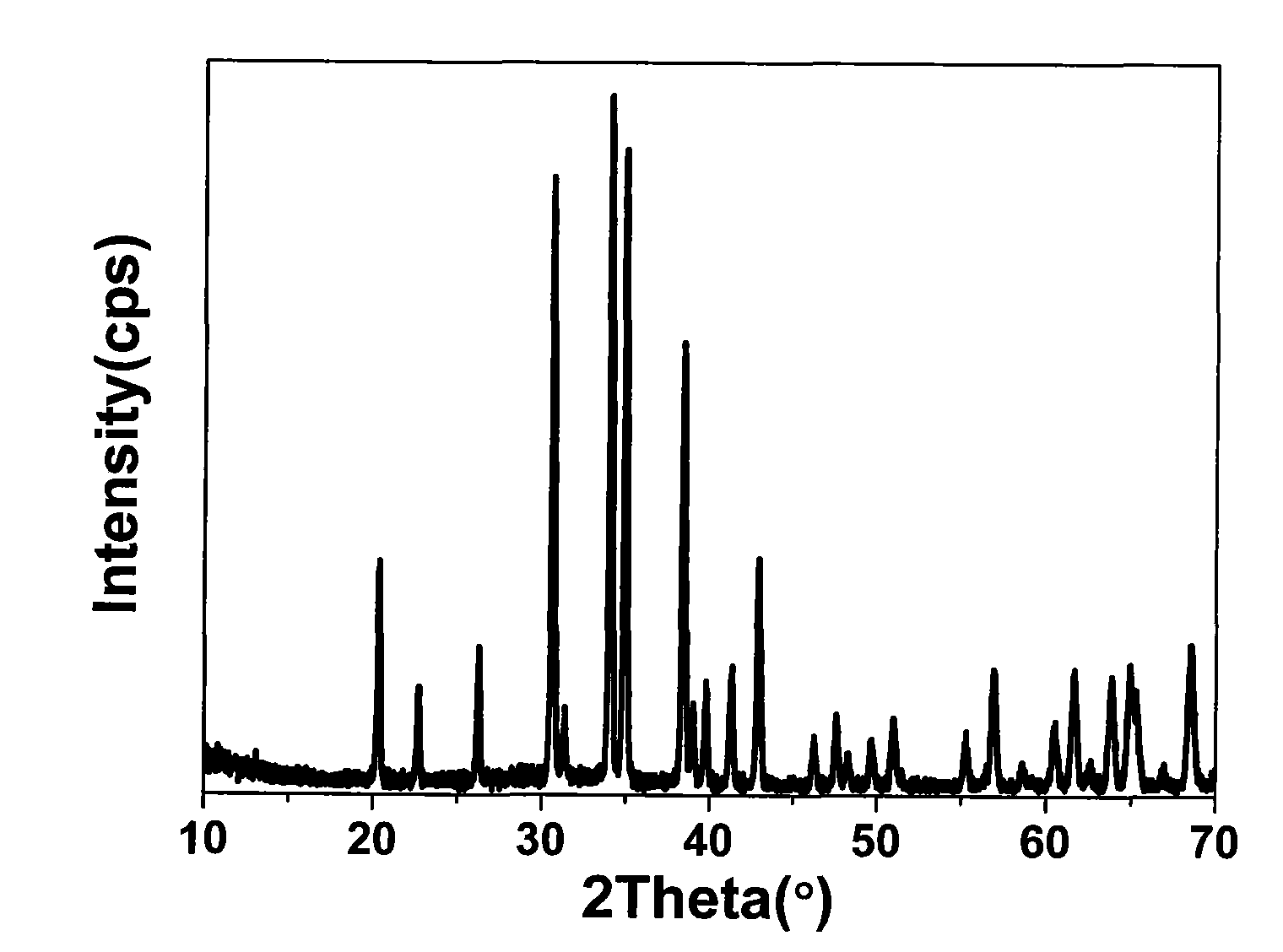

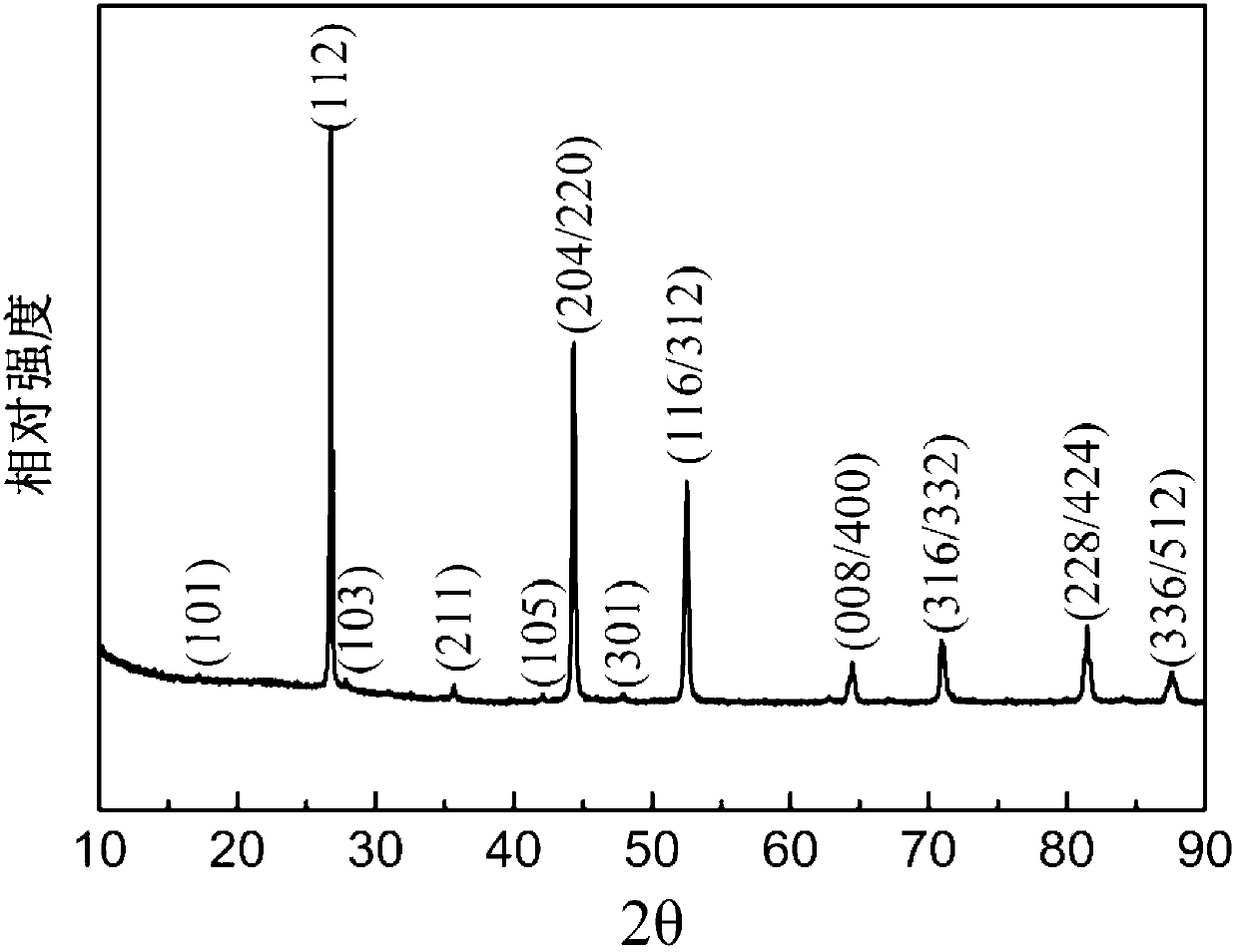

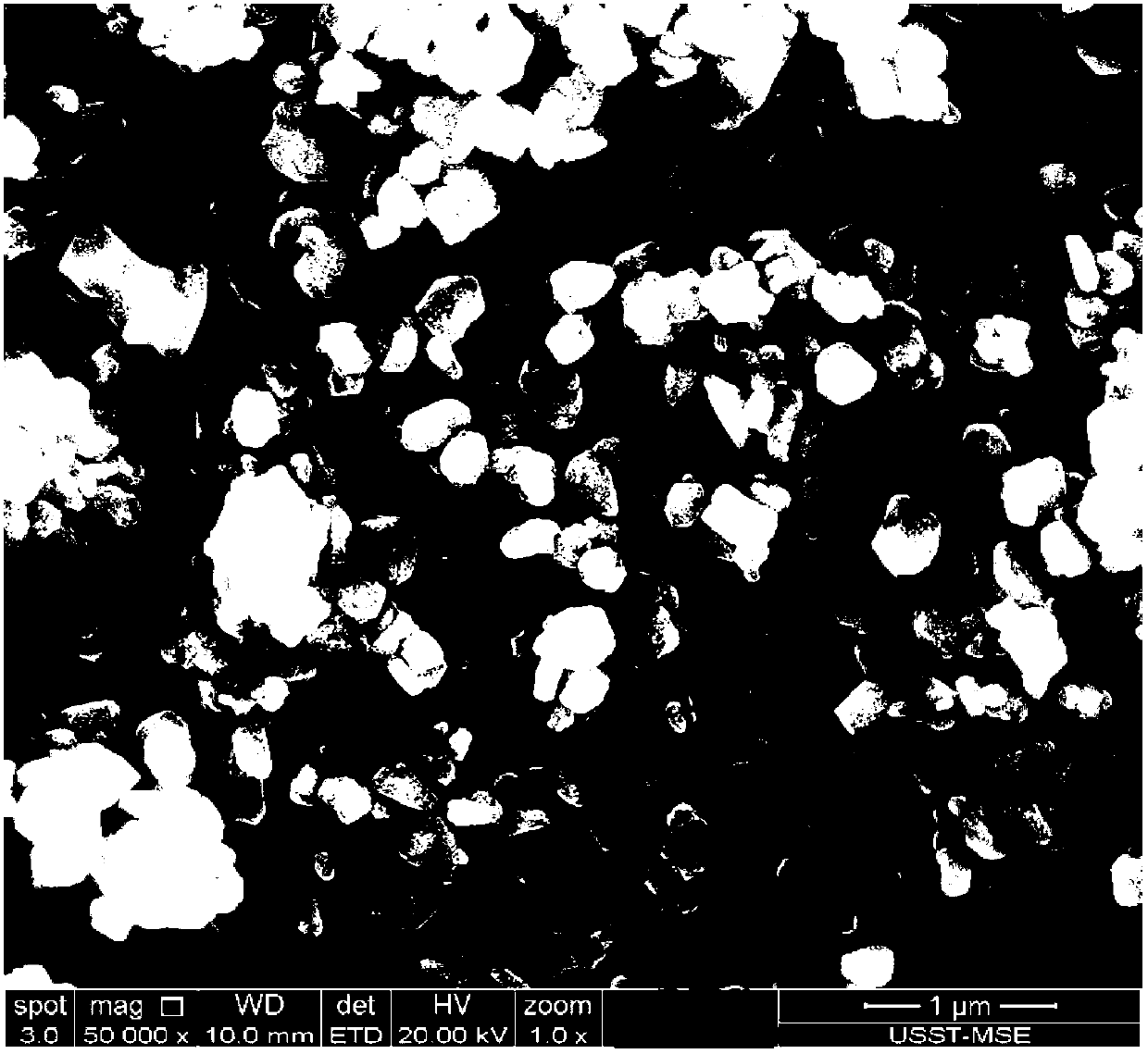

Preparation method of CuInSe2 with a chalcopyrite structure and CuIn1-xGazSe2 nano particles

InactiveCN103213956AGood dispersionHigh phase purityMaterial nanotechnologySelenium/tellurium compundsChalcopyriteCentrifugation

The invention relates to a preparation method of CuInSe2 with a chalcopyrite structure and CuIn1-xGazSe2 nano particles. Firstly, a metal precursor solution containing Cu+ or Cu2+, In3 or Ga3+ cation and a Se powder precursor solution are respectively prepared, and then the metal precursor solution and the Se powder precursor solution are mixed and uniformly stirred, and the solution is heated to 200-285 DEG C. with high purity nitrogen protection and reacted for 0.5-2 hours, and then the CuInSe2 or CuIn1-xGazSe2 nano particle solution is obtained, after high speed centrifugation, cleaning and drying steps, the CuInSe2 or CuIn1-xGazSe2 nano particles are obtained. The CuInSe2 or CuIn1-xGazSe2 nano particle has the advantages of chalcopyrite crystal structure, good dispersibility and high phase purity, and the element ingredient approaches to the stoichiometric ratio, thereby laying a foundation for preparing a high conversion efficiency film solar energy battery. The invention employs cheap metal salt and selenium powder as precursors, and employs a simple one-pot synthetic method, and has the advantages of simple operation, short synthesis period, strong repeatability without injection, and is suitable for mass production.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Polymerization forming prepn process of ternary lithium ceramic microsphere

InactiveCN101066884ASolve the problem that hardening is not conducive to the release of tritium in the next stepOvercome the problem of not getting higher phase purityCeramicwareCross-linkApparent density

The polymerization forming preparation process of ternary lithium ceramic microsphere includes the following steps: polymerizing polymer monomer, cross-linking agent, initiator, catalyst, etc to form cross-linked networked macromolecular supporting skeleton and adhering the solid reactant to form ceramic microsphere precursor; roasting at certain temperature for certain time to produce solid phase reaction generating ceramic microsphere biscuit of ternary lithium compound; and high temperature sintering to obtain ternary lithium ceramic microsphere. The ternary lithium ceramic microsphere has simple preparation process, low cost, high sphericity, controllable size, high size dispersivity, high apparent density, high phase purity and other features.

Owner:INST OF NUCLEAR PHYSICS & CHEM CHINA ACADEMY OF

Method for preparing lithium iron phosphate cathode material of lithium ion battery by supercritical hydrothermal process

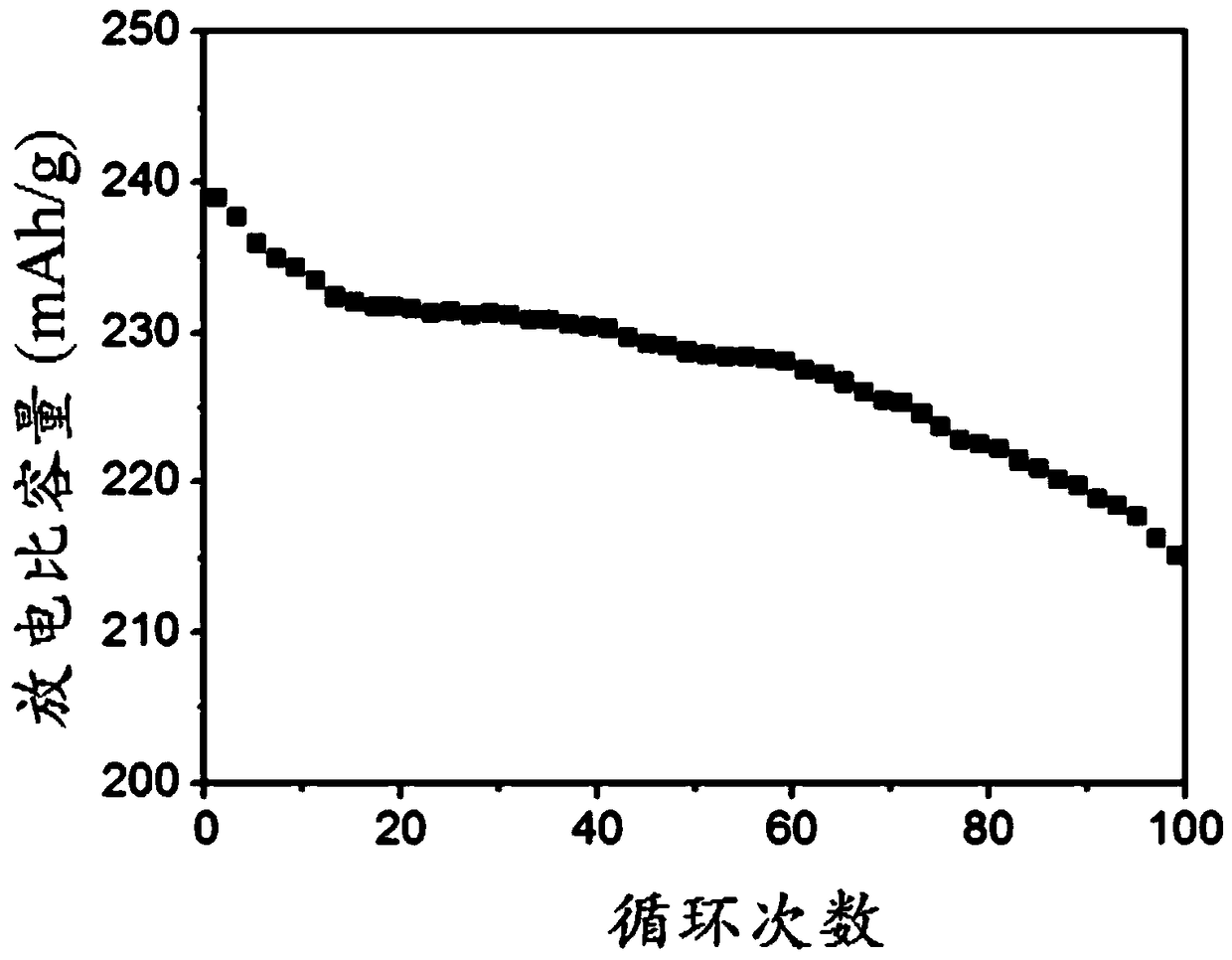

InactiveCN102569800AImprove discharge capacityImprove cycle lifeCell electrodesCarbon coatingFiltration

The invention relates to a method for preparing a lithium iron phosphate cathode material of a lithium ion battery by a supercritical hydrothermal process and belongs to the technical field of a novel material. The method comprises the following steps: (1) hydrothermal synthesis reaction, i.e. dissolving an iron source, a phosphorus source, a lithium source and a template agent in water, placing mixes solution into a reaction kettle, pumping out the air in the kettle by adopting a vacuum pump, heating the reaction kettle to the temperature of 380 DEG C to 500 DEG C, regulating the pressure in the kettle into 23MPa to 40MPa by a water injection pump, performing a reaction for 10s to 100min, and controlling the proportion of the added materials into a molar ratio of Li to Fe to P of (3.0 to 3.15):1:(1.0 to 1.15); (2) filtration, washing and drying of a product, i.e. after the reaction is completed, carrying out water-cooling temperature reduction on the reaction kettle and finally, filtering, washing and drying the generated product to obtain gray white LiFePO4 powder; (3) calcining and carbon coating treatment, i.e. calcining the obtained product for 1 to 8 hours at the temperature of 500 DEG C to 800 DEG C in the protective atmosphere to obtain carbon-coated lithium iron phosphate. The product obtained by the method of the invention has excellent electrochemical performance and uniform particle size distribution. The sizes of the particles of the product are in the range of 300nm to 800nm. The phase purity of the product can reach over 99%. The electron conductivity of the material and the diffusion performance of lithium ions are improved.

Owner:DALIAN UNIV OF TECH

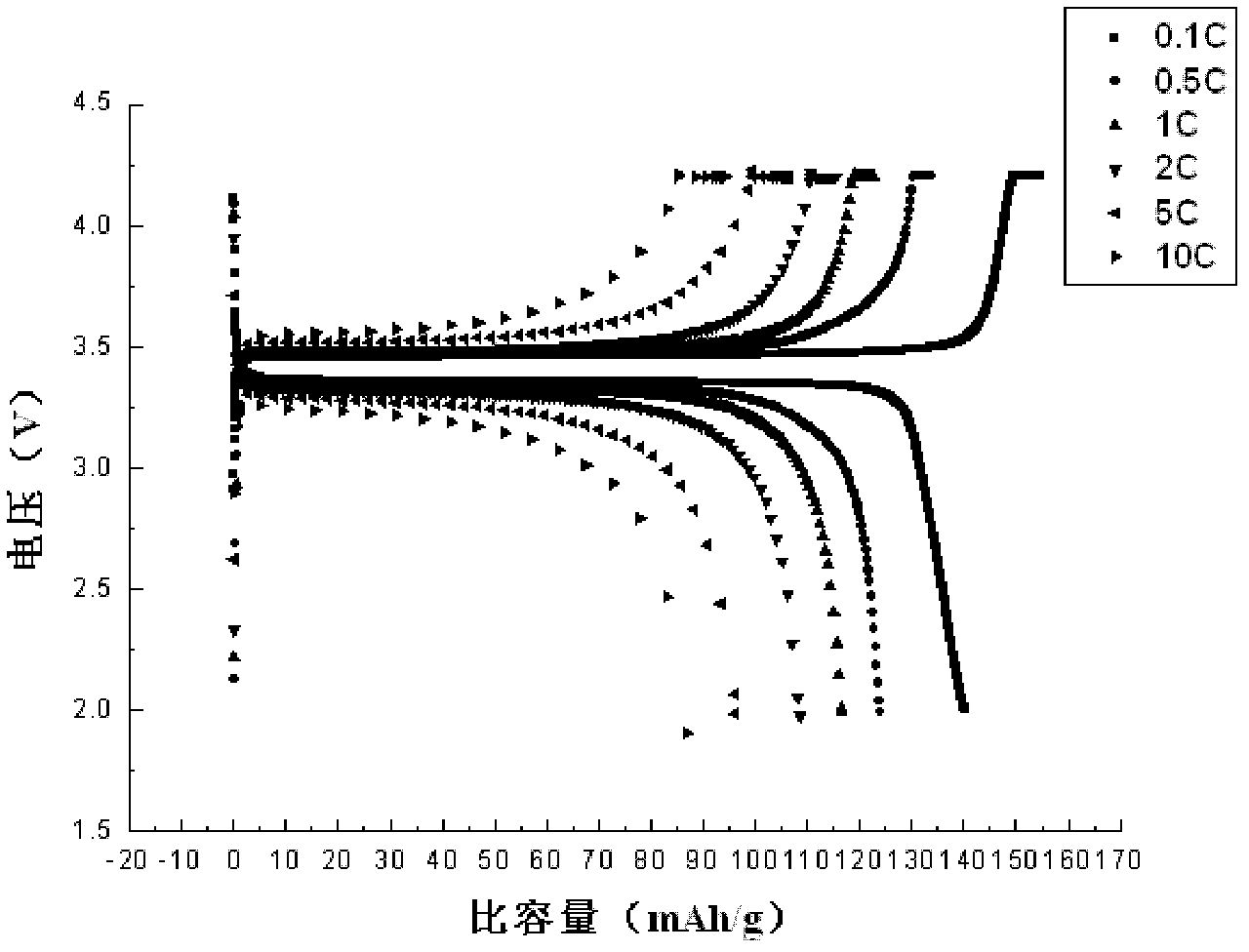

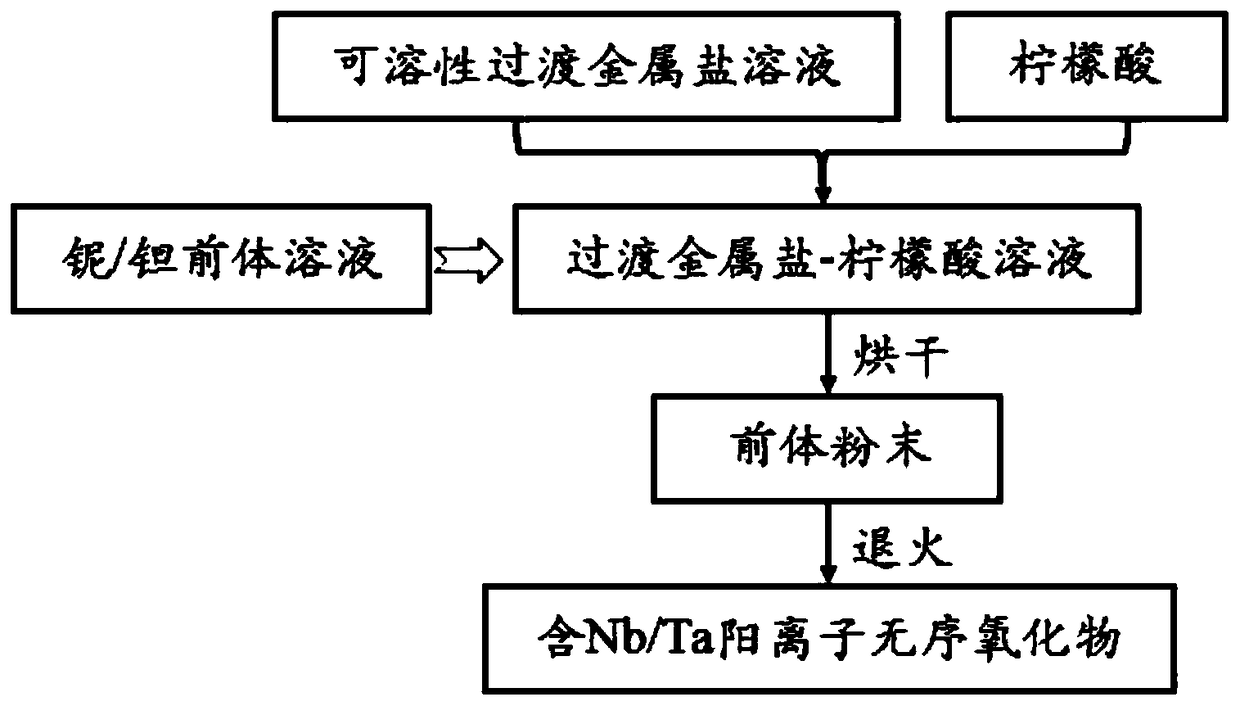

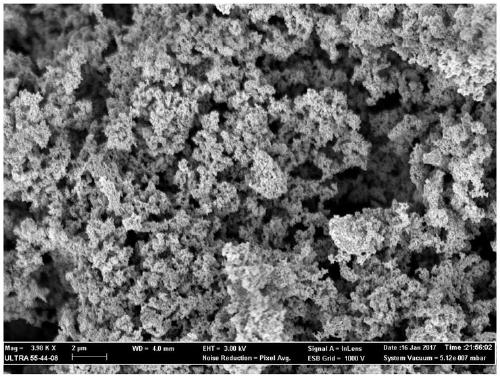

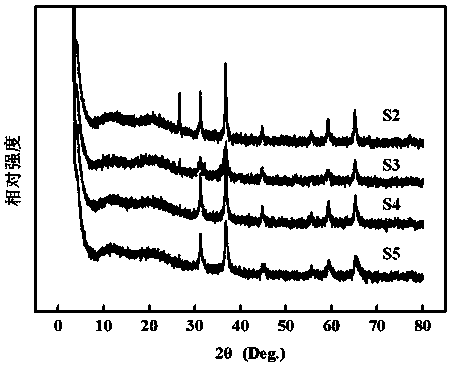

Preparation method for niobium/tantalum cation disordered rock salt structure anode material

ActiveCN109305700AHigh phase purityPhase Purity OptimizationCell electrodesSecondary cellsNew energyNiobium

The invention discloses a preparation method for a niobium / tantalum cation disordered rock salt structure anode material, and belongs to the field of new energy materials. According to the method, a stable water-soluble citric acid Nb / Ta precursor is adopted, the Nb / Ta cation disordered rock salt structural oxide anode material is synthesized through a wet chemistry method, a synthesis process issimple, the reaction is easy to control, the production efficiency is high, and special equipment or protection is not needed; and the phase purity of oxide can be improved, the grain size and the like can be optimized, and meanwhile, the electrochemical performance of the oxide anode material can be improved.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

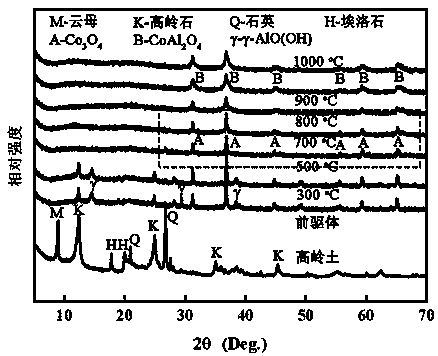

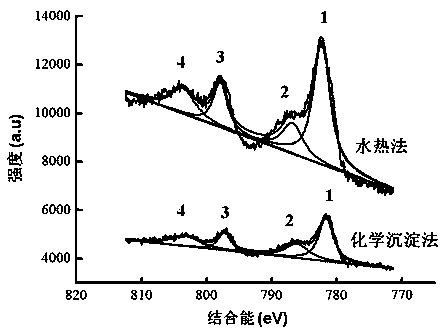

Method for microwave and hydrothermal-assisted preparation of high-chroma cobalt blue/clay mineral hybrid pigment

ActiveCN109181369AHigh chroma valueImprove Co

<sup>2+</sup>

contentPigment physical treatmentClay mineralsMicrowave

The invention discloses a method for microwave and hydrothermal-assisted preparation of a high-chroma cobalt blue / clay mineral hybrid pigment. The method comprises the following steps: uniformly dispersing natural clay mineral in water, adding soluble a Co<2+> salt and an Al<3+> salt, performing stirring to achieve dissolving, and adjusting the pH value of the obtained solution to 8-12 by a NaOH solution; transferring the obtained reactant material into a microwave reactor, and carrying out a hydrothermal reaction to obtain a precursor; and centrifuging and washing the precursor, and carryingout high-temperature calcination to obtain the high-chroma cobalt blue / clay mineral hybrid pigment. The method combines the technological advantages of a microwave heating technology and a traditionalhydrothermal technology, so the method has the advantages of short reaction period, and low temperature of calcination for forming spinel cobalt blue, and the obtained pigment product has the advantages of high crystal phase purity, excellent weather resistance and bright color, has a blue value b<*> being higher than -70, and can be comparable to blue organic pigments.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

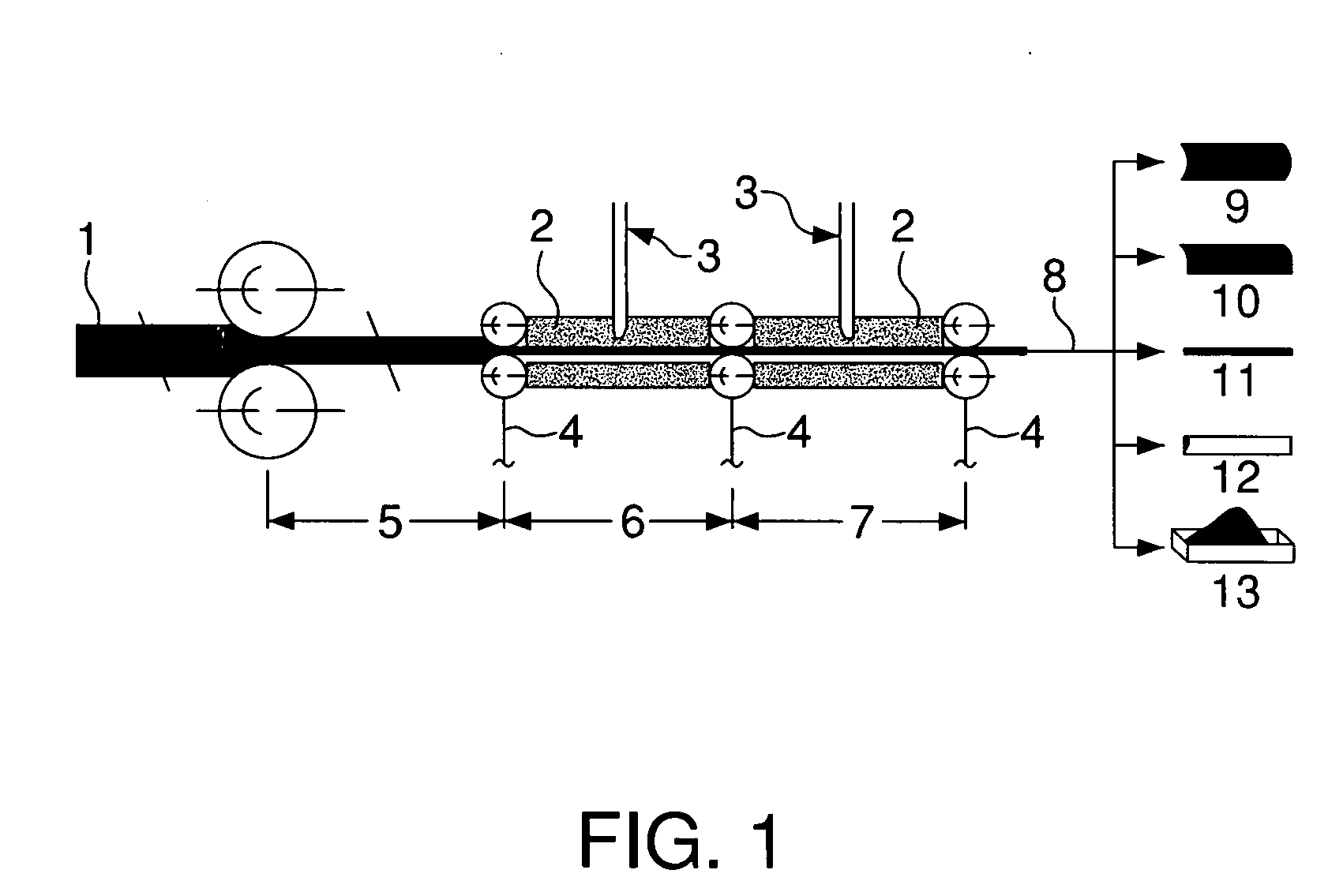

Process for the continuous production of magnesium diboride based superconductors

InactiveUS20070123427A1Energy efficient and simplifiedQuality improvementSuperconductors/hyperconductorsSuperconductor device manufacture/treatmentState of artMagnesium diboride

The present invention provides a simple, energy efficient and cost effective process for continuous production of high quality MgB2 based superconducting wires, tapes, bulk bodies and powders with better phase purity, microstructure and superconducting properties by introducing some innovative steps namely processing the reactants in evacuated and sealed metal tubes by electrical self-heating cum hot rolling followed by annealing under electrical self-heating, thereby overcoming various deficiencies and shortcomings associated with the prior art.

Owner:COUNCIL OF SCI & IND RES

High rate LiFePO4/C positive electrode material and preparation method thereof

InactiveCN104638261AWide variety of sourcesLow process temperatureCell electrodesHigh rateLithium iron phosphate

The invention provides a high rate LiFePO4 / C positive electrode material and a preparation method thereof. The method comprises the following steps: uniformly mixing an aqueous solution of a phosphorus source, an aqueous solution of a lithium source and an aqueous solution of a divalent iron source with a dispersant and / or a surfactant; carrying out a hydrothermal reaction on the above obtained uniformly mixed solution at 120-250DEG C; separating out a precipitate from a material obtained after the hydrothermal reaction, washing the precipitate, and carrying out first stage drying on the precipitate; and uniformly mixing the obtained first stage dried solid with a carbon source, carrying out second stage drying, sintering the obtained solid, and cooling the sintered solid. The particle size of lithium iron phosphate (LiFePO4) synthesized through the method along b direction (the lithium ion diffusion direction) is 20-200nm, and the LiFePO4 / C positive electrode material has the advantages of small particle size and uniform distribution of particles, high phase purity, improvement of the diffusion performance and the electrochemical performances of lithium ions in the lithium iron phosphate material, high conductivity, large specific capacity and good cycle life.

Owner:THE NAT CENT FOR NANOSCI & TECH NCNST OF CHINA

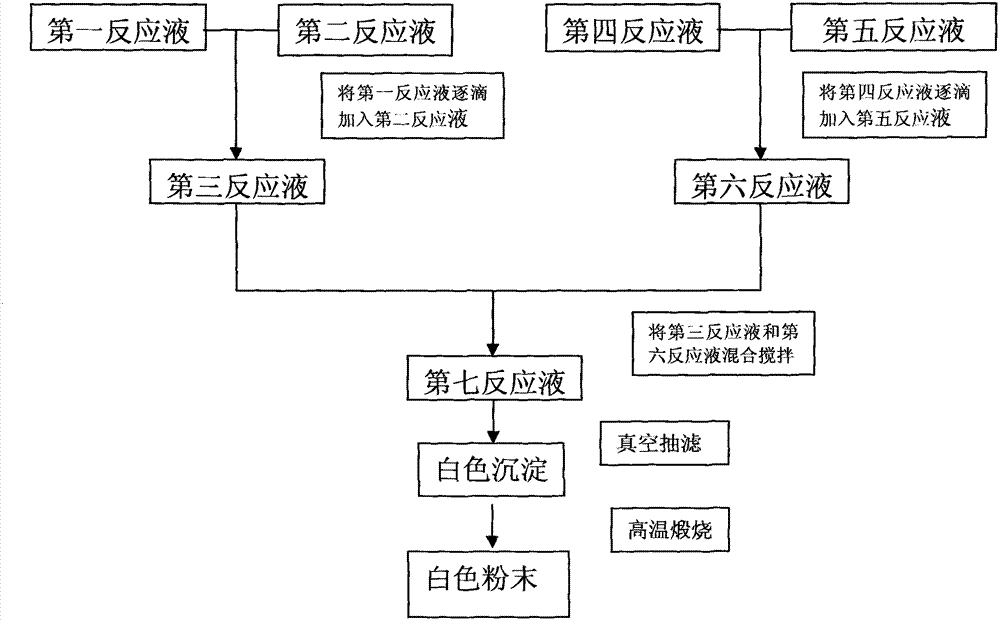

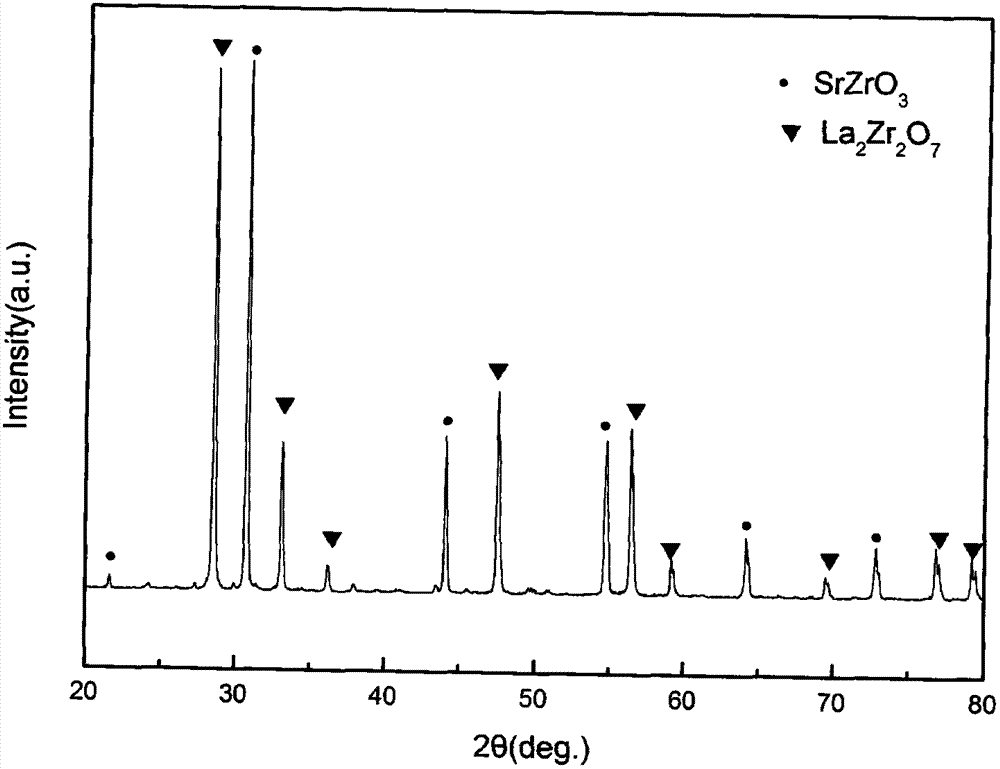

Ceramic nanometer composite material for heat barrier coating and preparation method of ceramic nanometer composite material

The invention belongs to the technical field of a ceramic nanometer composite material, and provides a ceramic nanometer composite material for a heat barrier coating and a preparation method of the ceramic nanometer composite material. Cheap Ln(NO3)3.6H2O, Sr(NO3)2 and Zr(NO3)4.5H2O are used as raw materials and are subjected to solution preparation, sedimentation, suction filtration, drying and calcination to obtain the required ceramic nanometer composite material. The size of crystal grains of each phase in the prepared ceramic nanometer composite material is less than 70 nm; each phase is uniform in distribution; the ceramic nanometer composite material has good high-temperature chemical stability, scouring resistance and heat insulation; growth of the crystal grains under a high temperature condition is favorably suppressed; the mechanical property, particularly toughness, of the ceramic nanometer composite material is improved; and the ceramic nanometer composite material is used as a superior candidate material for the heat barrier coating. The ceramic nanometer composite material has the advantages of simple preparation method, relatively low synthesis temperature, short time, high phase purity, energy saving, suitability for large-scale synthesis and high promotion and application values.

Owner:INNER MONGOLIA UNIV OF TECH

Synthesis method of fine-grained alpha-AlH3

ActiveCN106335877ASmall particle sizeNarrow distributionMetal hydridesSynthesis methodsUltrasonic oscillation

A synthesis method of fine-grained alpha-AlH3 is characterized in that ultrasonic catalytic crystallization is introduced in the crystallization stage on the basis of an ether process synthesis technology, and the energy, the strength, the frequency and other parameters of ultrasonic oscillation are controlled on the basis of guaranteeing the crystal phase purity of alpha-AlH3 to control the crystallization granularity of the alpha-AlH3 to be 10-80 [mu]m and realize controllable granularity. Ultrasonic assisted alpha-AlH3 crystallization is carried out to synthesize the fine-grained alpha-AlH3 with the purity being greater than 99%, and the frequency, the amplitude and the working mode of ultrasonic waves are adjusted to adjust the granularity in a range of 10-80 [mu]m. The method has the advantages of simple required device, easiness in realization of amplification, and realization of repeated and stable generation of granularity-controllable fine-grained high quality alpha-AlH3, and allows the total yield to be greater than 70%, the purity to be greater than 99% and the chlorine content to be lower than 0.2%.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

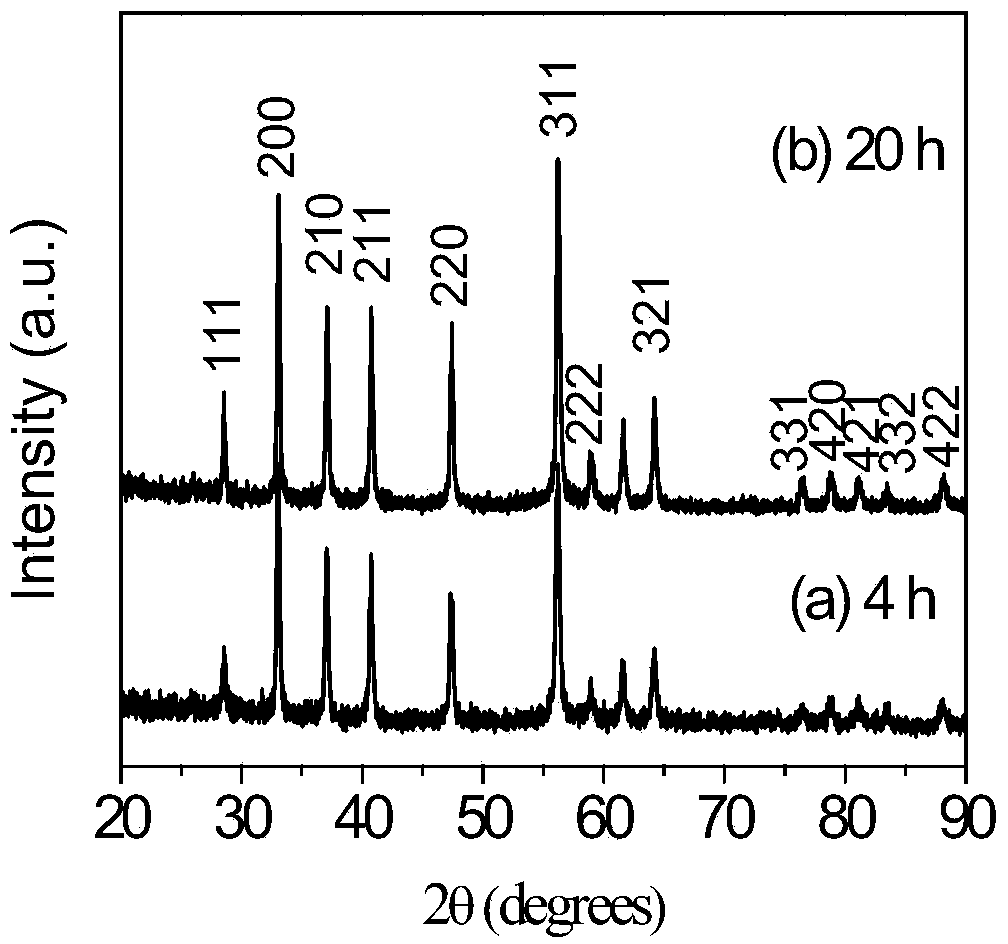

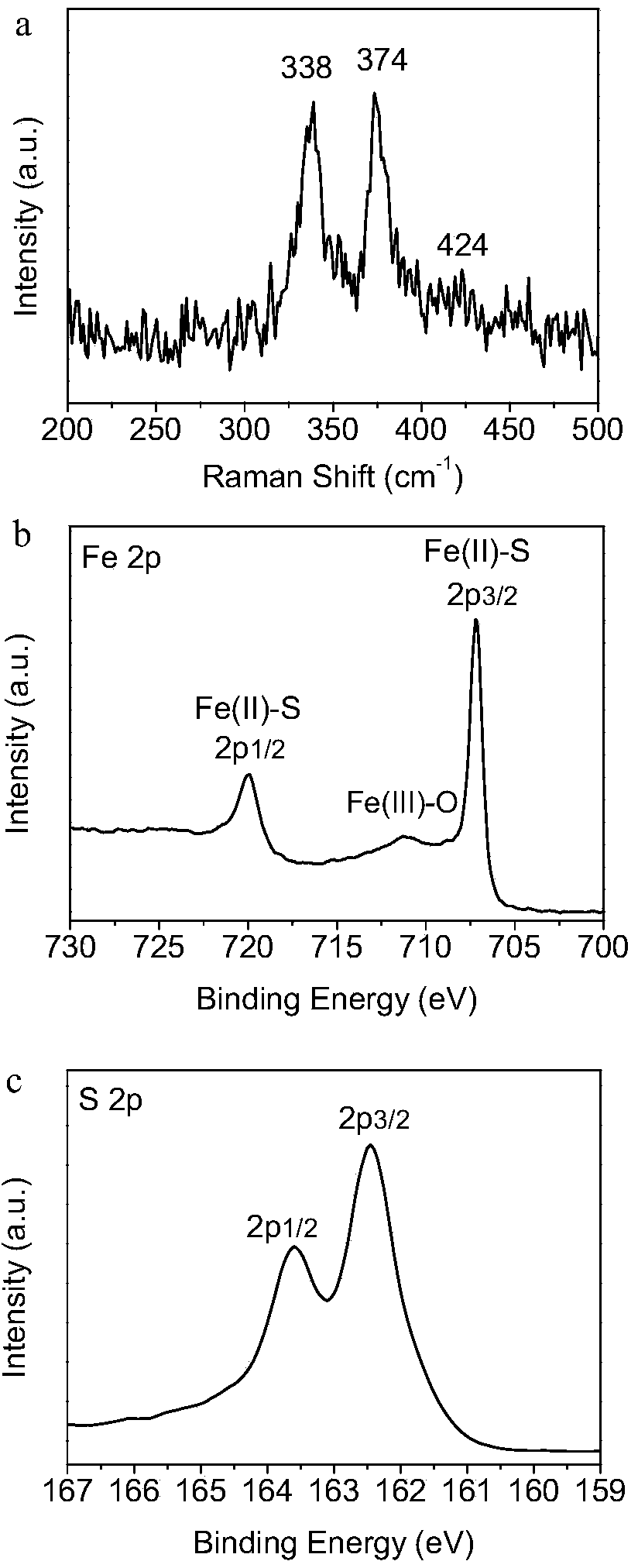

Preparation method for FeS2 pyrite microballoon sphere and application thereof

InactiveCN103950890ASimple processMild reaction conditionsNanostructure manufactureElectrolytic capacitorsMicrosphereCrystallinity

The invention discloses a preparation method for an FeS2 pyrite microballoon sphere and the application thereof. The preparation method for the FeS2 pyrite microballoon sphere is characterized in that an iron source is dissolved in triethylene glycol, and then powdered sulfur is added and stirred to be dissolved to obtain mixed solution; the mixed solution is reacted for 4-20h at the temperature of 170-220DEG C to obtain product solution; the product solution is centrifuged, cleaned and dried to obtain the target product FeS2 pyrite microballoon sphere. The preparation method disclosed by the invention has the advantages of simple technology and convenience in operation, and the product has stable performance, good uniformity, high phase purity and the like. The iron source and the reaction time are changed to improve the degree of crystallinity of the FeS2 pyrite microballoon sphere, and the size and the morphology of the FeS2 pyrite microballoon sphere are regulated and controlled. The FeS2 pyrite shows extremely outstanding electrocatalytic activity for the catalytic regeneration of electrolyte in a semiconductor sensitized solar cell and can be used as the counter electrode material of the sensitized solar cell by replacing noble metal Pt, and therefore the cell is caused to have higher photoelectric conversion efficiency.

Owner:HEFEI UNIV OF TECH

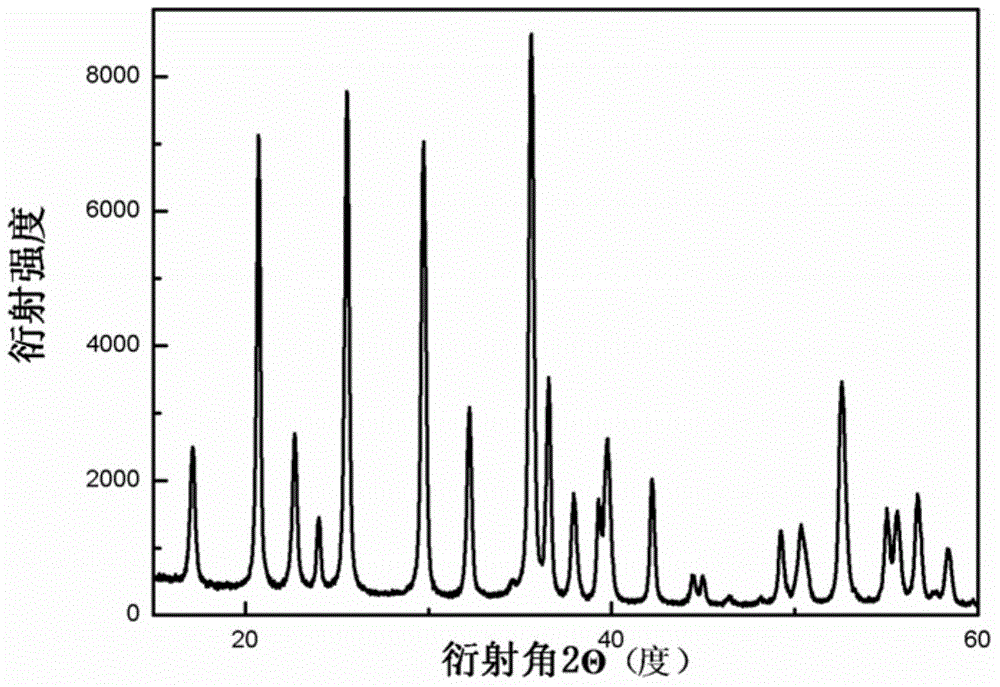

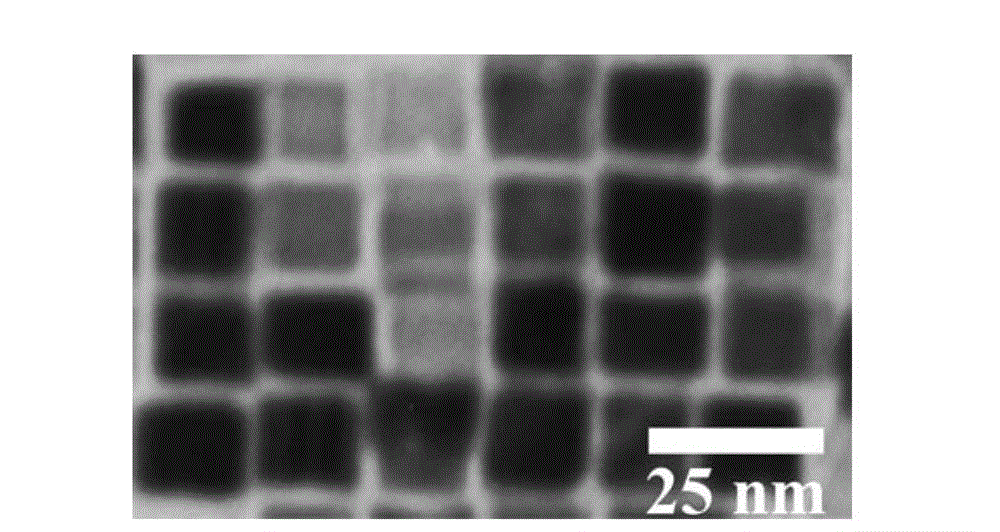

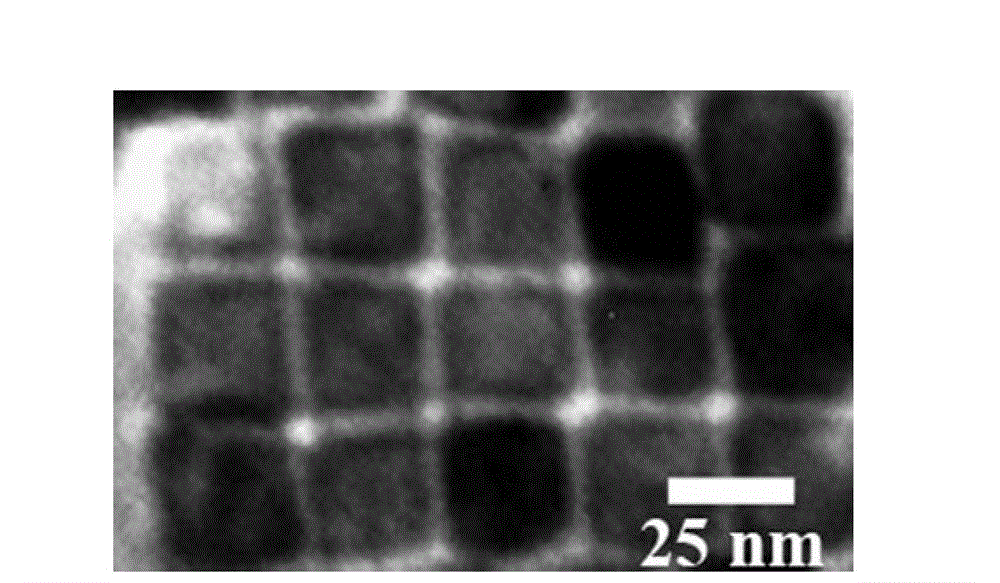

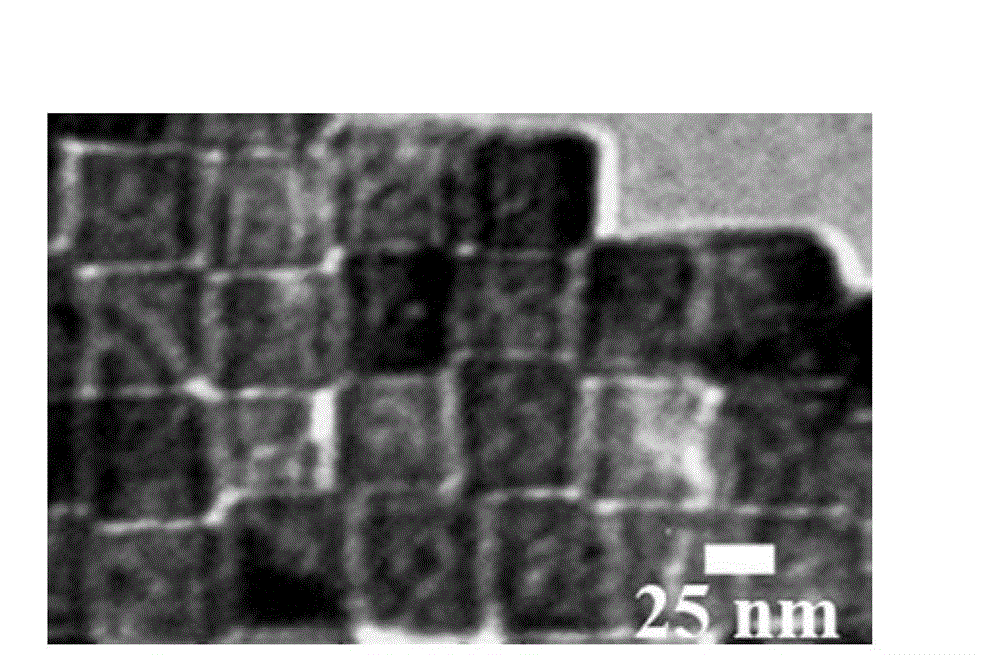

Synthesis method for rock salt mine MnS nano-cuboid superlattice

InactiveCN102942224AStabilized Rock Salt Mine StructureStable structureMaterial nanotechnologyManganese compoundsSynthesis methodsCrystallinity

A synthesis method for a rock salt mine MnS nano-cuboid superlattice, which is disclosed by the invention, belongs to the technical field of nano-material preparation. Anhydrous manganese chloride and thioacetamide as materials and oleylamine and oleic acid as ligands are mixed, agitated and heated until uniform orange solution is obtained; the solution is then heated to 240 DEG C to 260 DEG C, and reacts for 0.5 to 2 hours, so that rock salt mine MnS nano-crystals are formed; and finally, the solution is naturally cooled to room temperature, so that the rock salt mine MnS nano-cuboid superlattice is obtained. The synthesis method has the advantages of common used materials, simple process, short synthesis time, high repeatability, safety and the like, and the nano-crystal size of the product is controllable; and the prepared rock salt mine MnS nano-cuboid superlattice has the advantages of stable structure, high phase purity, good crystallinity, uniform grain size distribution and good optical and magnetic properties.

Owner:JILIN UNIV

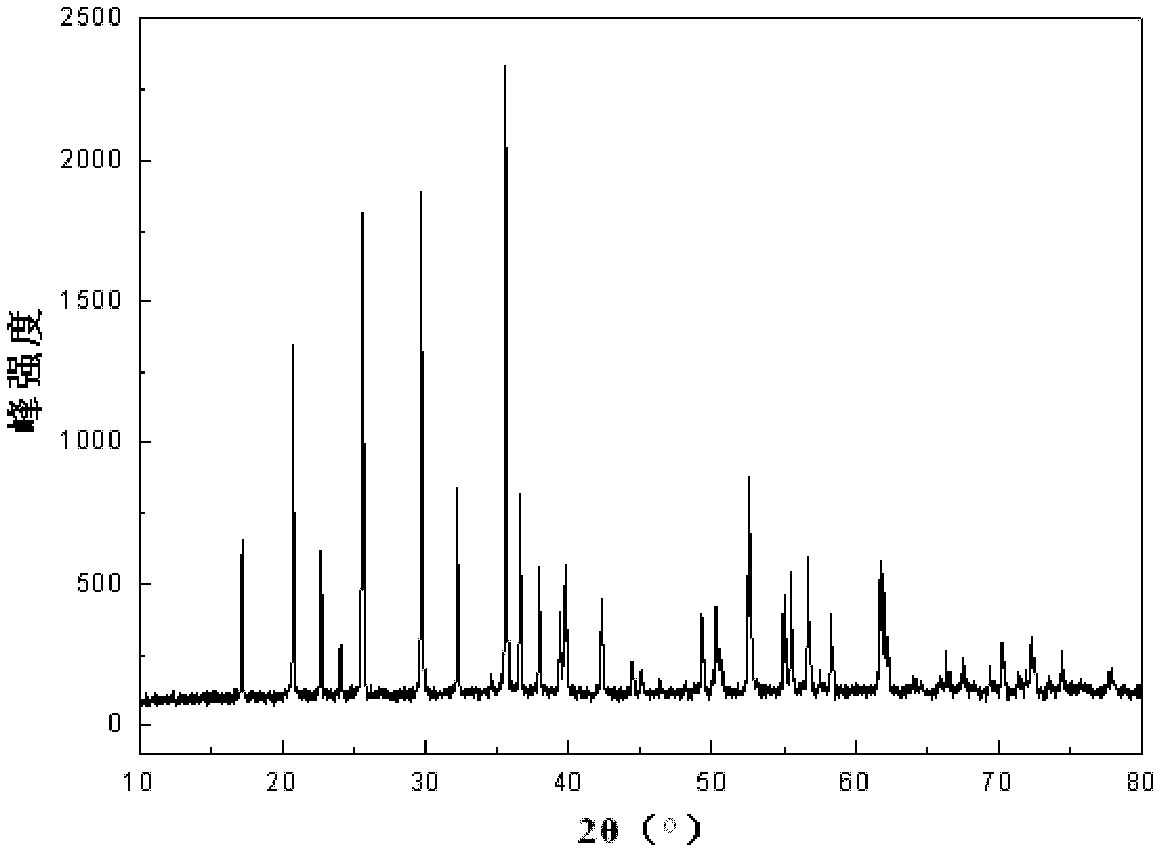

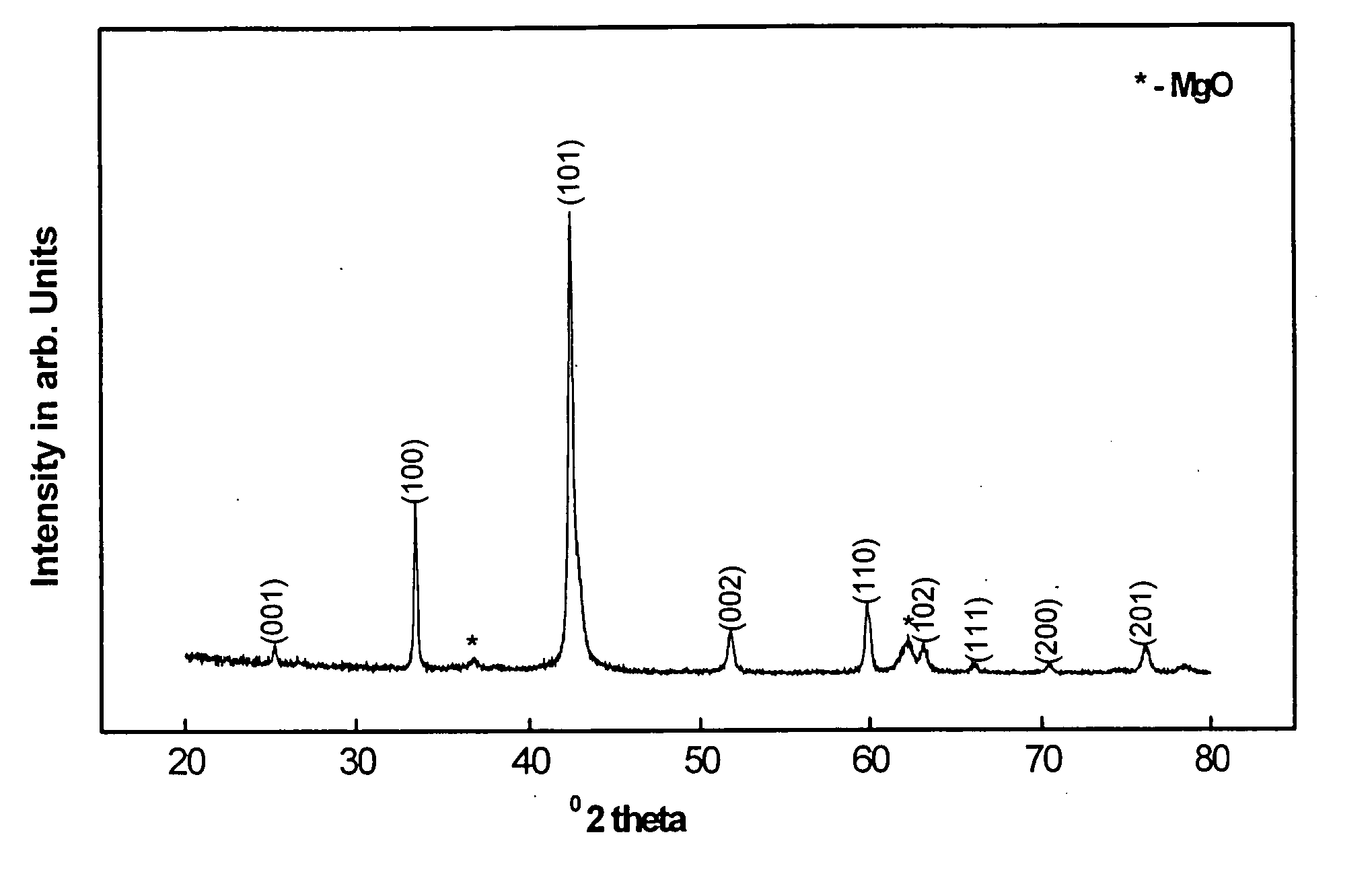

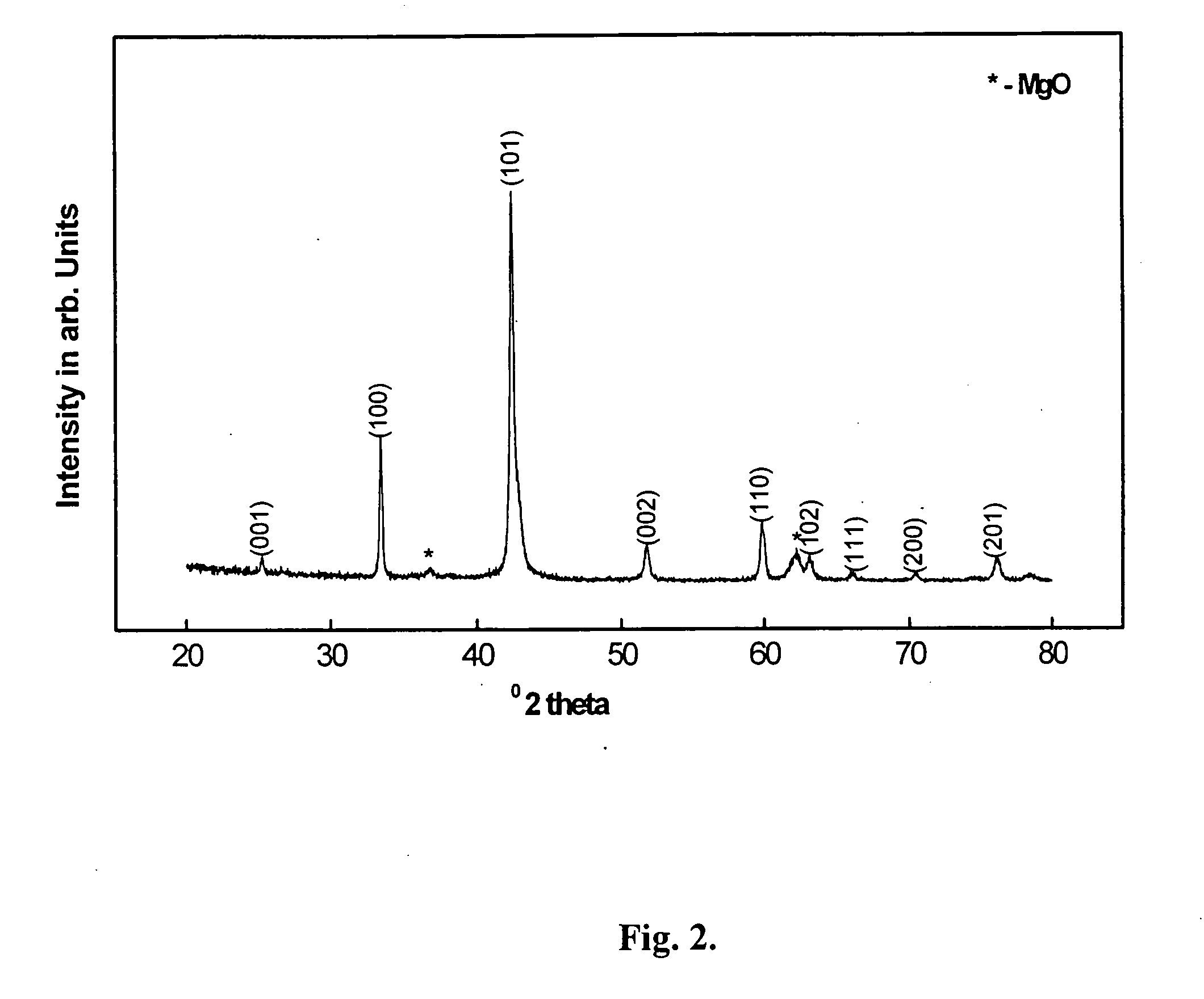

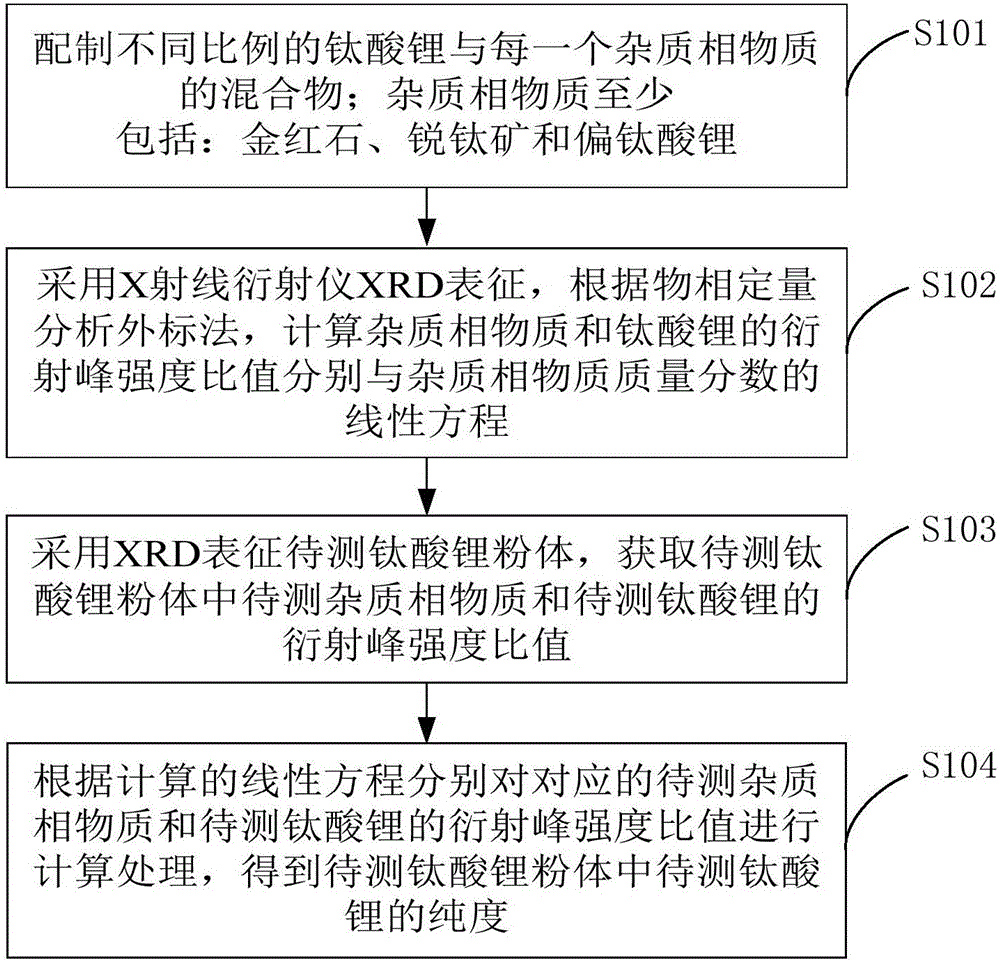

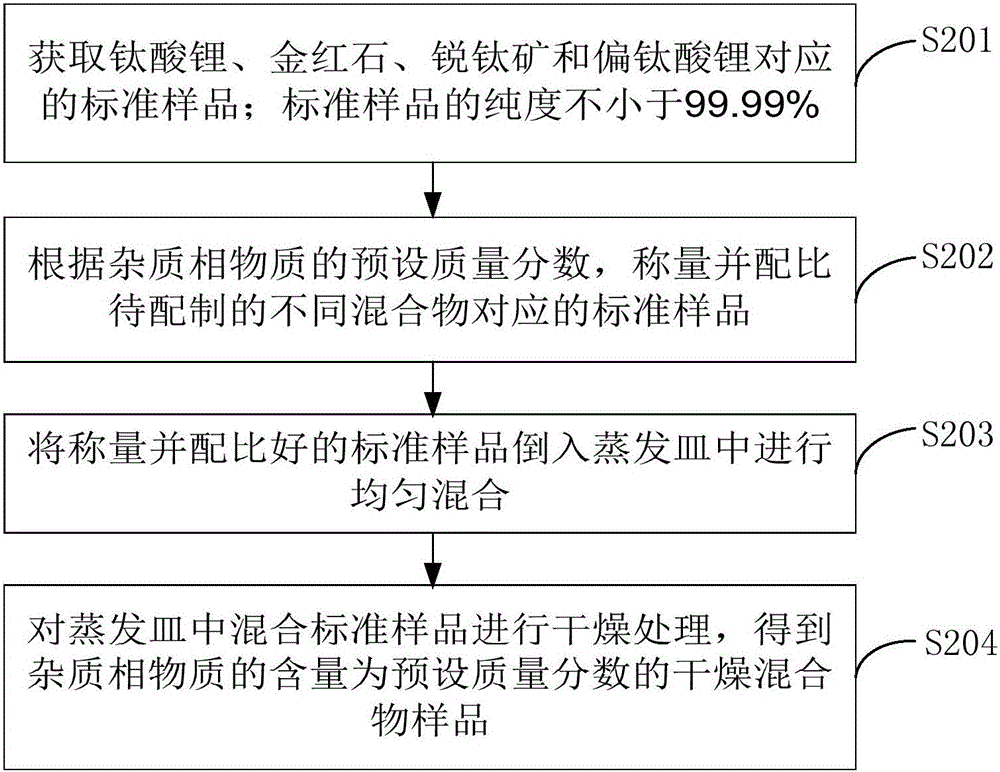

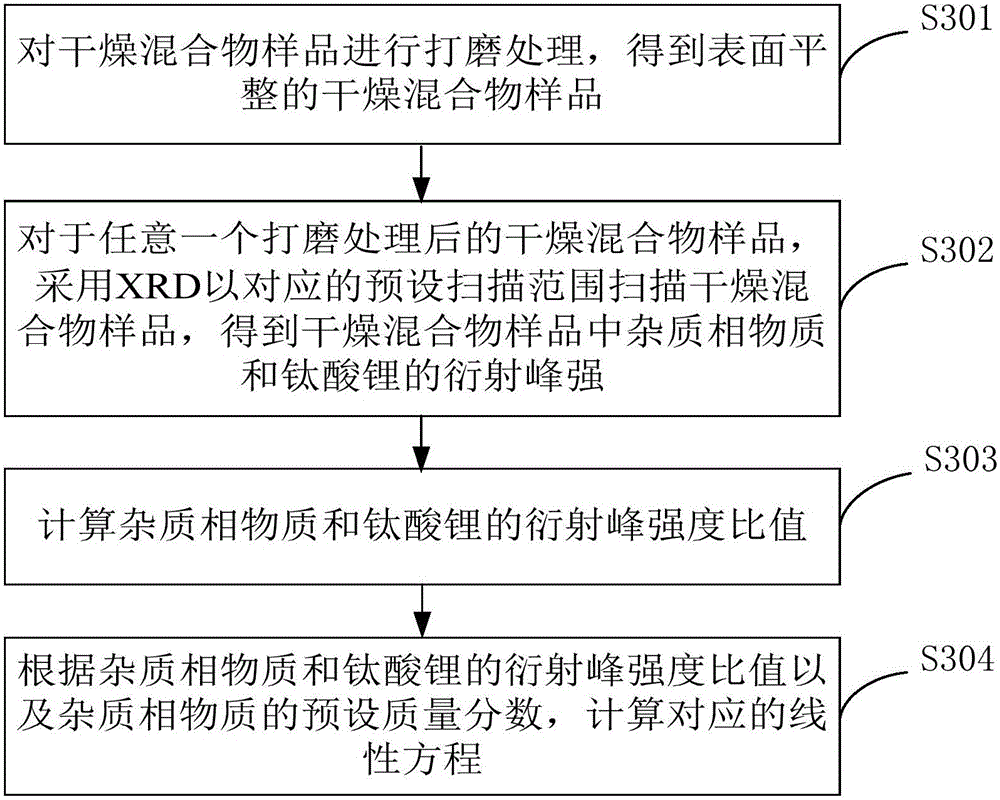

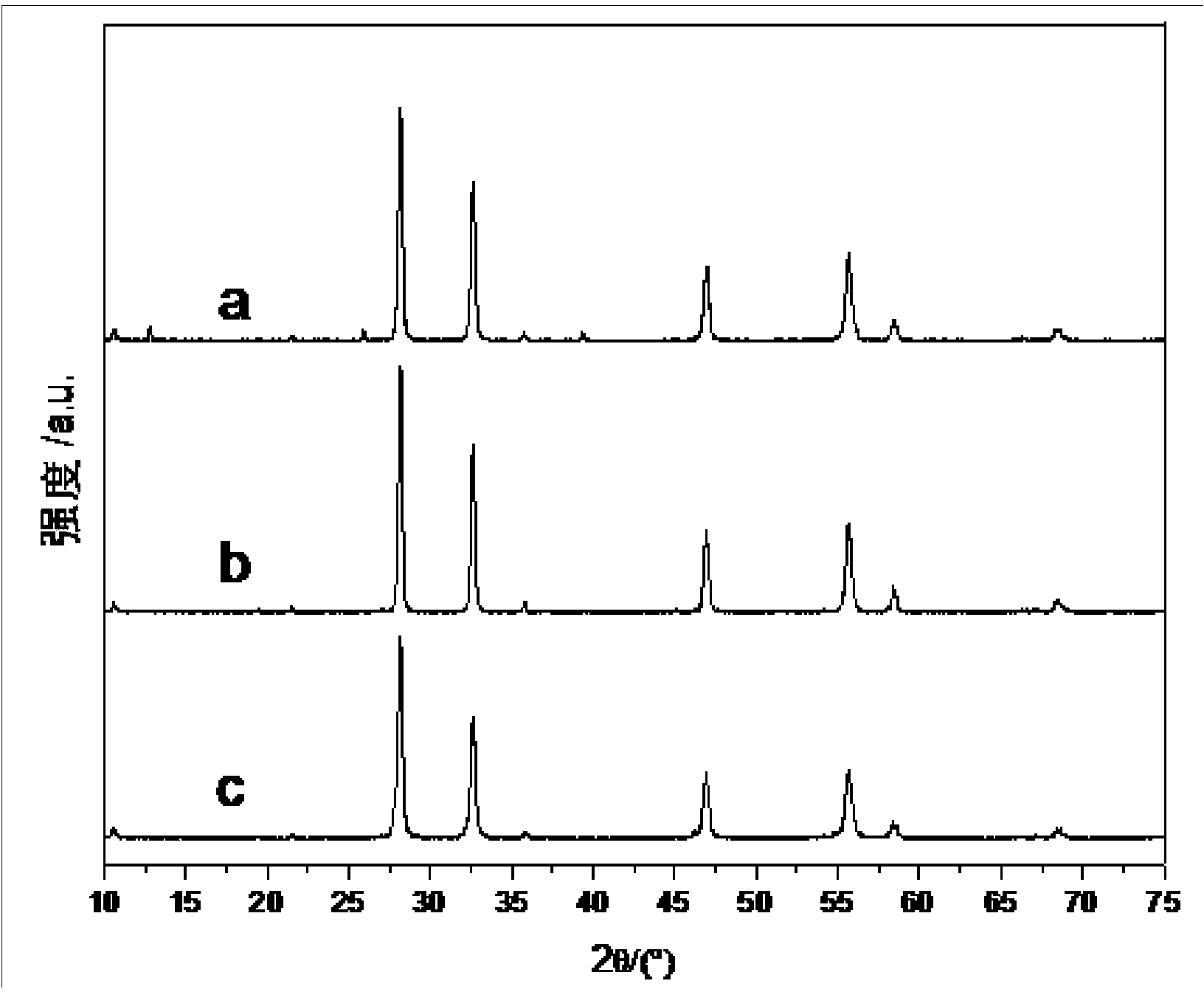

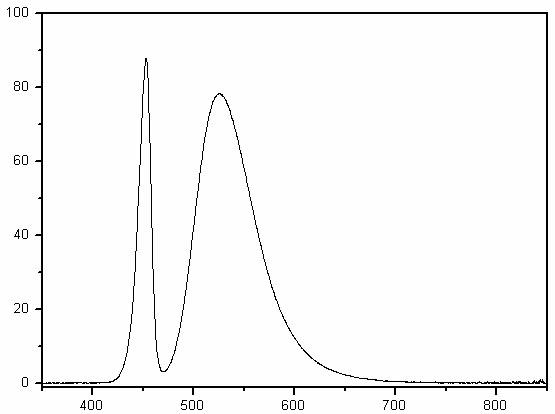

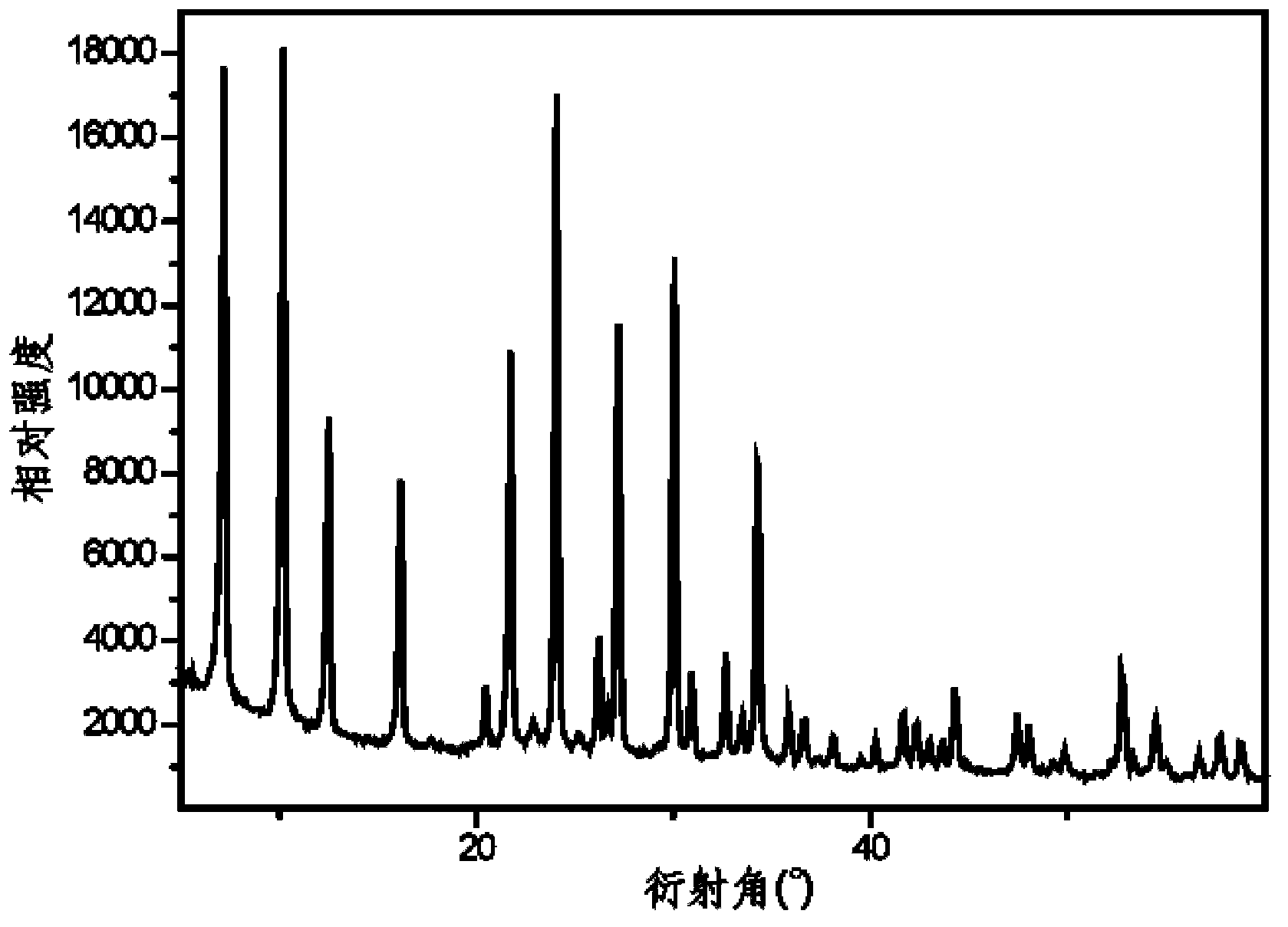

Method for detecting phase purity of lithium titanate composition

InactiveCN106053500AFast and accurate calculationThe assessment results are accuratePreparing sample for investigationMaterial analysis using radiation diffractionPhysical chemistryElectrochemistry

The invention provides a method for detecting the phase purity of a lithium titanate composition. The method comprises the following steps: preparing mixtures with different ratios of lithium titanate to each impurity phase substance; adopting XRD characterization, according to a phase quantitative analysis external standard method, calculating the linear equation of diffraction peak strength ratio of the impurity phase substance and lithium titanate to mass percentage of the impurity phase substance; adopting XRD to characterize lithium titanium powder to be detected so as to obtain the diffraction peak strength ratio of the impurity phase substance to be detected in lithium titanium powder and lithium titanium to be detected; according to the calculated linear equation, and individually subjecting the diffraction peak strength ratios of corresponding impurity phase substance and lithium titanium to a calculation treatment to obtain the purity of lithium titanium in the lithium titanium powder. The provided method can rapidly and accurately calculate the purity of lithium titanate in a lithium titanium composition sample. The detection precision and detection efficiency are both improve. Moreover, the precise detection results can be used to evaluate the electrochemical performance of a lithium ion battery, and the evaluation results become more accurate.

Owner:NORTHERN ALTAIR NANOTECH CO LTD

Nanometer bismuth tungstate with hollow square ball structure and preparation method thereof

InactiveCN103950985ANoveltySimple preparation processMaterial nanotechnologyTungsten compoundsTungstatePollution

The invention discloses nanometer bismuth tungstate with a hollow square ball structure and a preparation method thereof. The preparation method is characterized in that a hollow square ball formed by stacked bismuth tungstate nanosheets is prepared by using bismuth nitrate pentahydrate as a bismuth source, sodium tungstate dihydrate as a tungsten source and an STAB (Sodium triacetoxyborohydride)-containing alcohol-water solution as a dispersing agent and utilizing ammonia water and sodium hydroxide under a hydrothermal condition, and the thicknesses of the nanosheets are about 30nm; and the inner diameter of the square ball is about 1.5 micrometers, and the outer diameter of the square ball is about 2 micrometers. The preparation method has the advantages of simplicity, easiness in operation, strong repeatability, environment protection, no toxicity and harmlessness in a preparation process, novel product morphology, high phase purity and the like and has a high application value in terms of pollution treatment, ray absorption and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

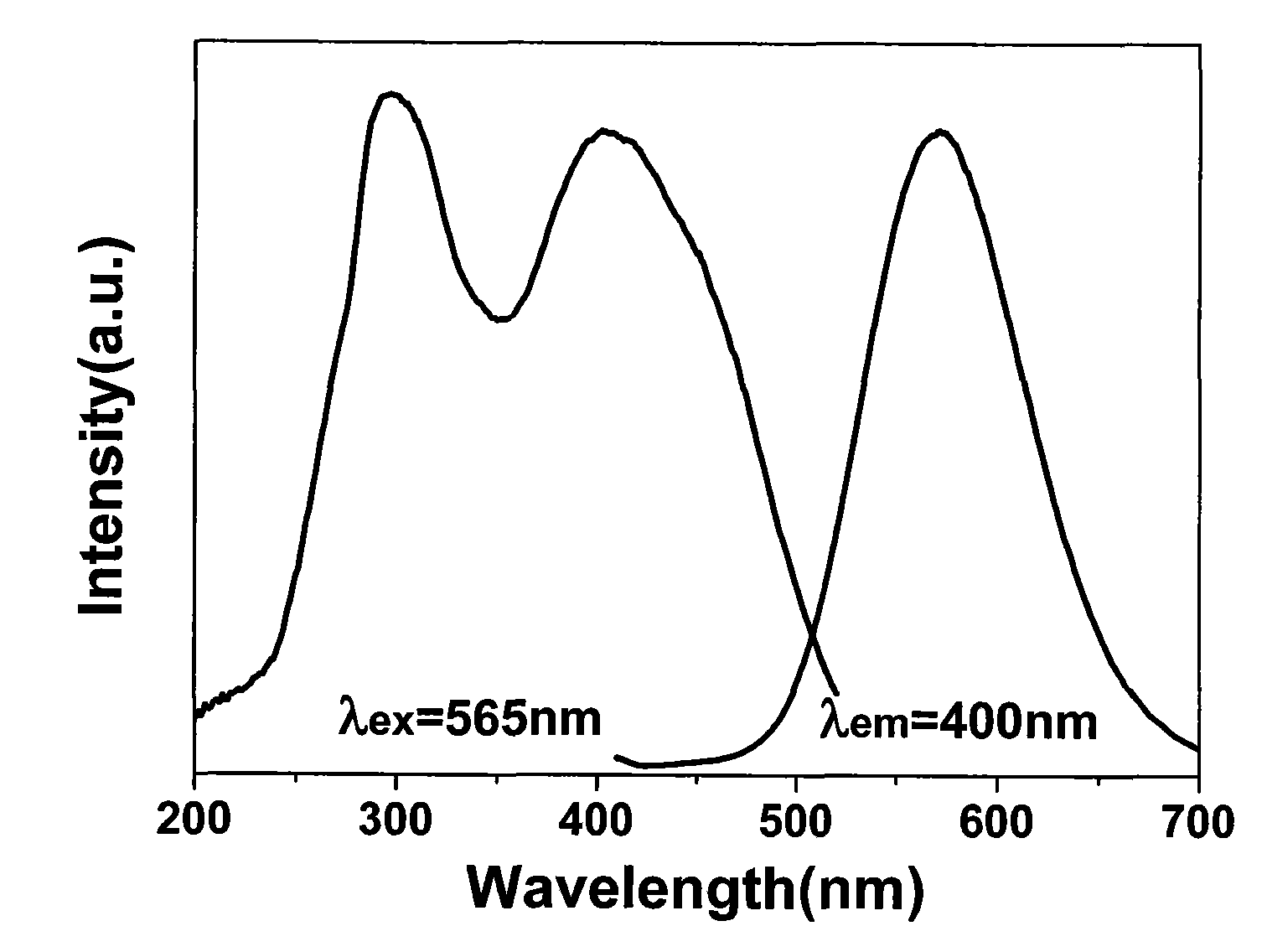

Fluorescent powder for white light-emitting diodes (LEDs) and backlight LEDs

InactiveCN102352248AUniform distribution of luminescent ionsIncrease brightnessEnergy efficient lightingLuminescent compositionsRare-earth elementAlkaline earth metal

The invention belongs to the technical field of light-emitting diode (LED) light source and in particular relates to fluorescent powder for white LEDs and backlight LEDs. The chemical structural formula of the fluorescent powder is RE1xCexM2AlO5, wherein M is one or more of alkaline-earth metals; RE is one or more of La, Ce, Pr, Nd, Sm, Gd, Tb, Dy, Ho, Er, Tm and Lu in rare-earth elements; and x is more than or equal to 0.001 and less than 1. During preparation, nitrates of various elements serve as original reactants; NH4X, BaX2, SrX2, boric acid or borate serves as a cosolvent; a liquid phase method is adopted; the materials are burned at high temperature in air and then are reduced in reducing atmosphere; the prepared fluorescent powder has higher brightness and stability and a more complete crystal form. During preparation, oxalate and ammonia water serve as precipitating agents, so that the elements RE, Ce, Al and M in the structural formula are precipitated completely, and the phase purity of the fluorescent powder can be improved. The fluorescent powder can be used for preparing the white LEDs and the backlight LEDs.

Owner:上海穗杉实业股份有限公司

Preparation method of doping-modified spinel-type lithium manganate

InactiveCN104393276AHigh phase purityHigh crystallinityCell electrodesManganates/permanganatesWater bathsMANGANESE ACETATE

The invention relates to preparation of lithium ion positive pole materials and especially relates to a preparation method of doping-modified spinel-type lithium manganate. The preparation method comprises the following steps of preparing a mixed solution of lithium acetate, chromium acetate, nickel acetate and manganese acetate, adding resorcinol into the mixed solution, carrying out stirring until resorcinol is completely dissolved, adding a formaldehyde solution into the obtained mixed solution, putting the mixed solution into a constant-temperature water bath, carrying out a reaction process to obtain gel, drying the gel by an oven, carrying out pre-sintering, grinding the pre-sintered product, carrying out secondary sintering, and grinding the re-sintered product to obtain the modified spinel-type lithium manganate. The preparation method utilizes lithium acetate, manganese acetate, chromium acetate, nickel acetate, resorcinol and formaldehyde as raw materials to prepare the doping-modified spinel-type lithium manganate, utilizes pre-sintering to improve product phase purity, utilizes secondary sintering to improve material crystallization performances, specific discharge capacity and energy density, and utilizes a reasonable raw material ratio to improve material electrochemical performances.

Owner:LIUZHOU HAOXIANGTE SCI & TECH

New CuI Crystal and growing method thereof

InactiveCN1609285AHigh purityReduce stressFrom gel statePolycrystalline material growthX-rayGamma ray

The present invention discloses one kind of CuI crystal and its growth method, and the CuI crystal is in regular gamma phase tetrahedron structure of size greater than 2 mm. The crystal growth process adopts concentration controlling technology, combines complexing and de-complexing, and has the advantages of simple equipment, low cost, low growth temperature, easy-to-control growth process, etc. The grown CuI crystal has high gamma phase purity, less stress, less faults, good appearance and relatively large size. As one new generation of very fast scintillator, the present invention may find its important application in high speed X-ray counting, gamma ray, electronic beam measurement, etc. and may be also used as fast ion conductor.

Owner:TONGJI UNIV

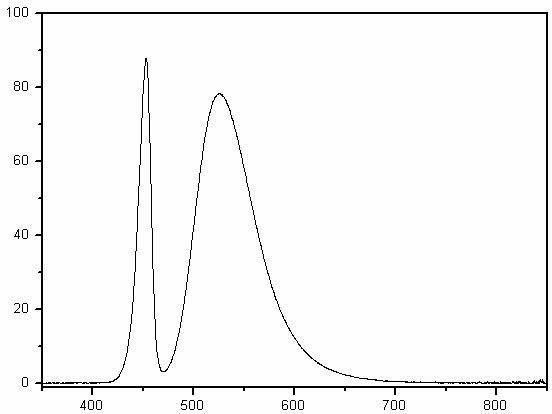

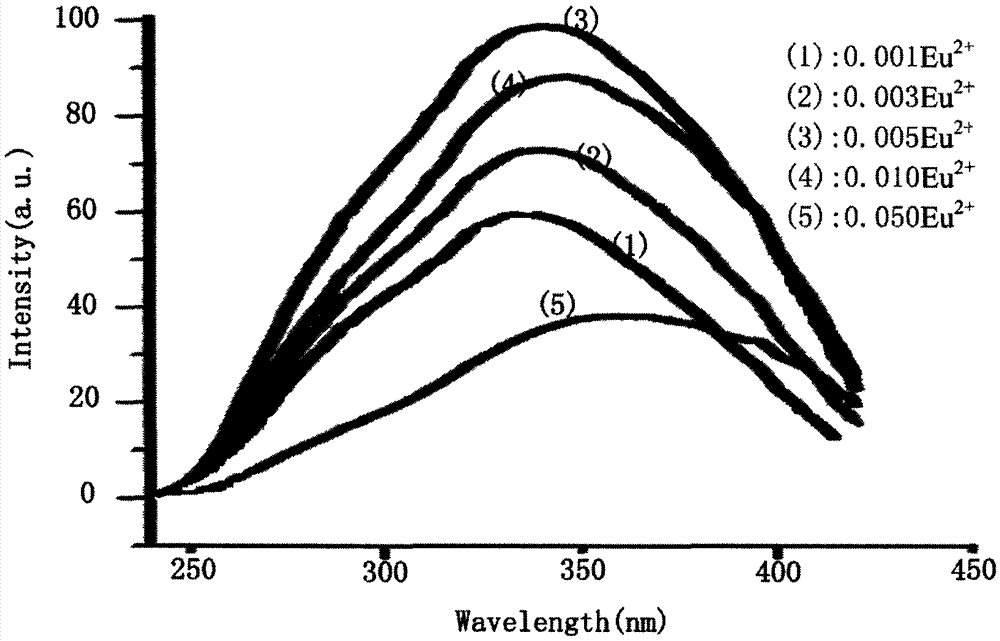

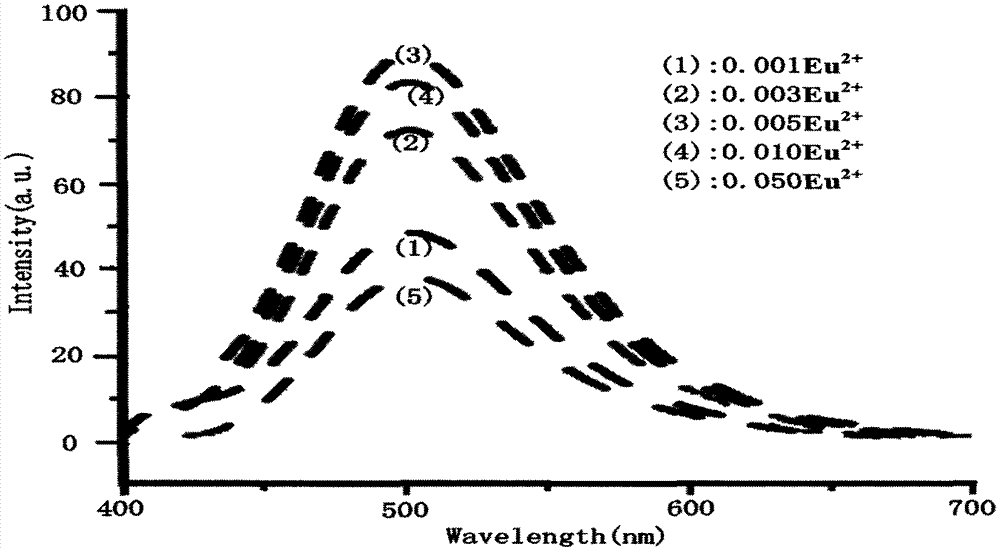

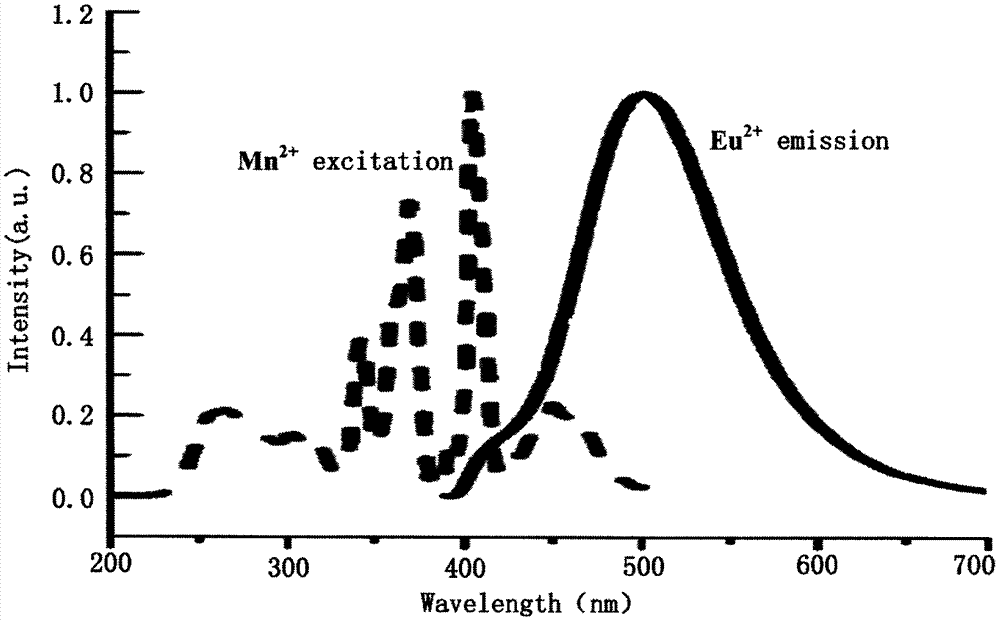

Emission peak-adjustable phosphate fluorescent powder for white-light LED (Light-Emitting Diode) and preparation method thereof

InactiveCN103773372AImprove luminosityHigh color rendering indexLuminescent compositionsPhosphateRare earth

The invention belongs to the technical field of rare-earth light-emitting materials, relates to emission peak-adjustable phosphate fluorescent powder for a white-light LED (Light-Emitting Diode) and a preparation method thereof. Fluorescent powder for the white-light LED, which is stable in chemical property, high in light-emitting performance, high in physical phase purity and adjustable in the emission peak from green light to red light when being excited by near ultraviolet light, purple light and blue light and can be applied to the white-light LED excited by using a blue-light LED chip. The chemical components of the fluorescent powder can be shown as a chemical formula, namely, Ca9(1-x-y)-La(PO4)7:xEu<2+>,yMn<2+>, wherein x is more than or equal to 0.002 and less than or equal to 0.2, and y is more than or equal 0.002 and less than or equal to 0.2. The fluorescent powder can be used for exciting white light together with blue fluorescent powder BaMgAl10O17:xEu<2+>. An encapsulated device can reach a white-light area with low color temperature, warm tone (CCT is less than or equal 5,000K), high color rendering index (CRI, RA is more than or equal to 90) and a color coordinate being up to CIE1931. The preparation method is simple and easy to operate, contributes to saving energy and time, and has extremely good application prospect in the field of solid illumination.

Owner:CHINA JILIANG UNIV

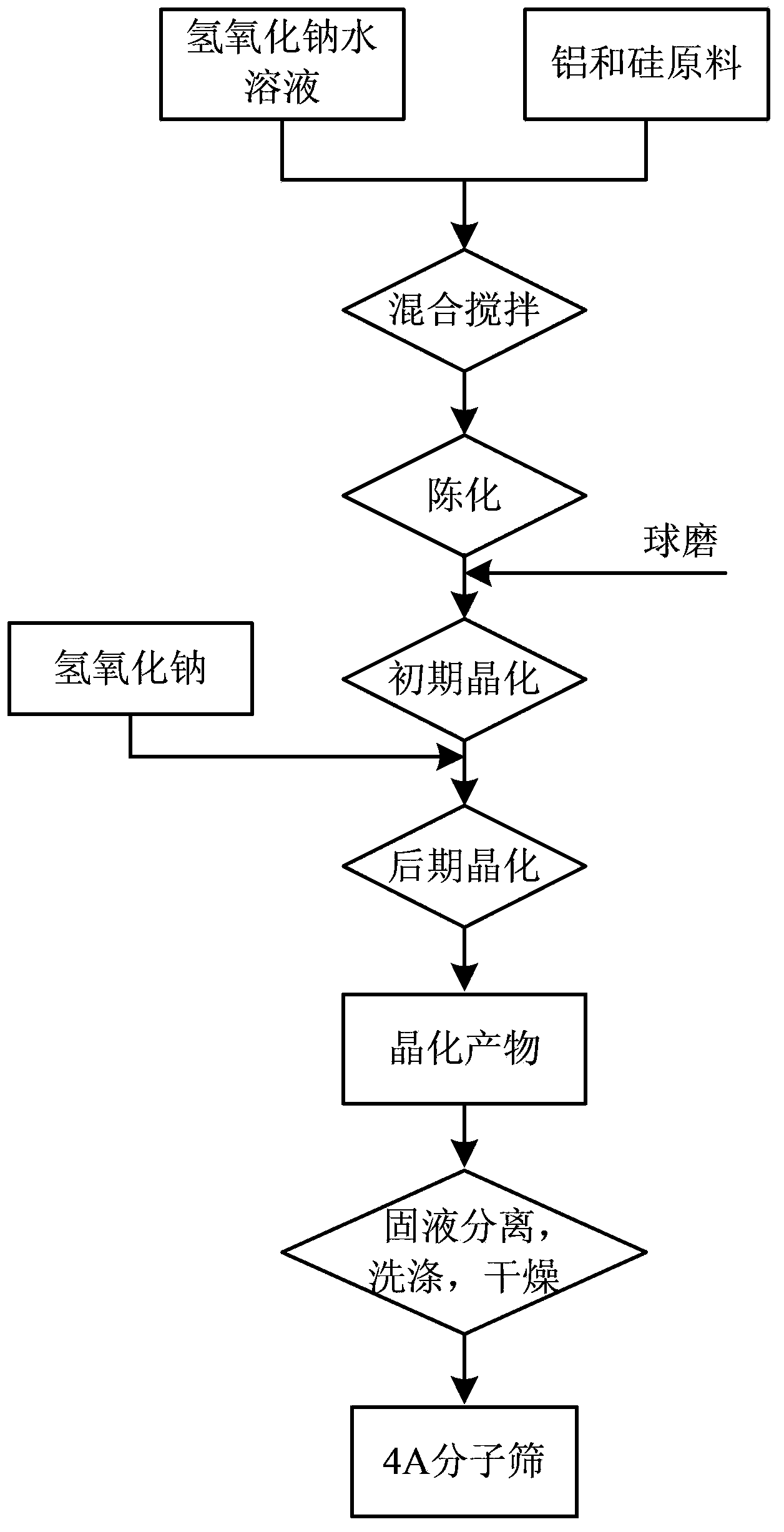

Hydrothermal synthesis method of 4A molecular sieve

ActiveCN104340989AHigh solid phase yieldHigh solid contentAluminosilicate zeolite type-AMolecular sieveWastewater

The invention relates to a hydrothermal synthesis method of a 4A molecular sieve. The hydrothermal synthesis method is characterized in that a ratio of water to sodium is not more than 25, and mechanochemical treatment is carried out. The preparation method of the 4A molecular sieve improves the solid phase yield of the hydrothermal synthesized 4A molecular sieve, guarantees the phase purity of the 4A molecular sieve, reduces the amount of water and the emission of wastewater, and also reduces the device and personnel investment.

Owner:INST OF PROCESS ENG CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com