Method for microwave and hydrothermal-assisted preparation of high-chroma cobalt blue/clay mineral hybrid pigment

A clay mineral, microwave hydrothermal technology, applied in chemical instruments and methods, inorganic pigment processing, dyeing physical processing, etc., can solve problems such as non-ideal and non-equilibrium conditions, and achieve improved sample blue value and high tinting strength. , the effect of reducing production energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

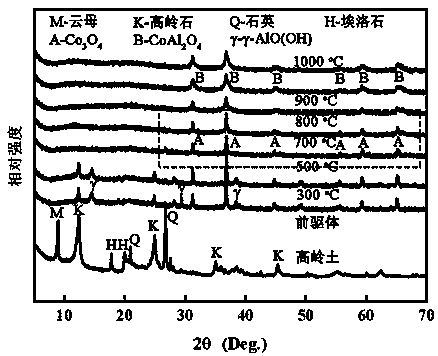

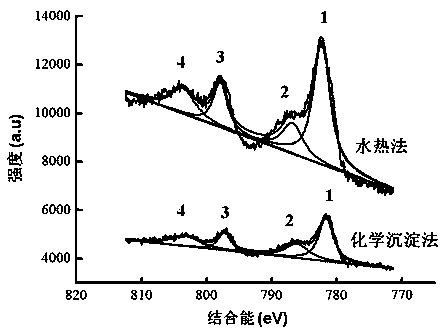

[0029] First, 1.09 g of kaolinite, 2.91 g of cobalt nitrate and 7.52 g of aluminum nitrate were added to 50 mL of water. After stirring and dissolving, the pH value of the system was adjusted to 8 with NaOH; the reaction solution was transferred to a microwave hydrothermal reactor (microwave reactor The power is 700W), reacted at 240°C for 1 h and cooled to room temperature to obtain the precursor; the precursor was centrifuged and washed at 900°C for 1 h to obtain a high-chroma cobalt blue / kaolinite hybrid pigment, corresponding to The sample number is S1. See Table 1 for the L*, a*, and b* color values of S1.

Embodiment 2

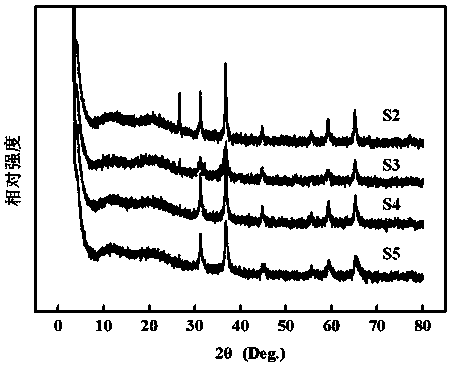

[0031] First, 1.09 g of halloysite, 2.91 g of cobalt nitrate and 15.04 g of aluminum nitrate were added to 50 mL of water. After stirring and dissolving, the pH value of the system was adjusted to 12 with NaOH, and the reaction solution was transferred to a microwave hydrothermal reactor (microwave reactor The power is 800W), reacted at 240°C for 0.5 h and then cooled to room temperature to obtain the precursor; the precursor was centrifuged and washed at 900°C for 2 h to obtain a high-chroma cobalt blue / halloysite hybrid pigment. The corresponding sample number is S2. See Table 2 for the L*, a*, and b* color values of S2.

Embodiment 3

[0033] Add 2.18 g of dickite, 2.91 g of cobalt acetate and 6.84 g of aluminum sulfate into 50 mL of water, stir and dissolve, adjust the pH value of the system to 10 with NaOH, and transfer the reaction solution to a microwave hydrothermal reactor (microwave reactor’s The power is 600W), reacted at 200°C for 2 h and then cooled to room temperature to obtain the precursor; the precursor was centrifuged and washed at 800°C for 0.5 h to obtain a high-chroma cobalt blue / dickite hybrid pigment, corresponding to The sample number is S3. See Table 2 for the L*, a*, and b* color values of S3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com