Patents

Literature

198 results about "Cobalt blue" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

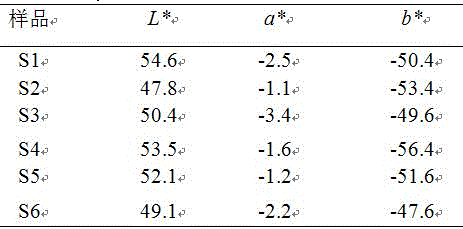

Cobalt blue is a blue pigment made by sintering cobalt(II) oxide with alumina at 1200 °C. Chemically, cobalt blue pigment is cobalt(II) oxide-aluminium oxide, or cobalt(II) aluminate, CoAl₂O₄. Cobalt blue is lighter and less intense than the (iron-cyanide based) pigment Prussian blue. It is extremely stable and has historically been used as a coloring agent in ceramics (especially Chinese porcelain), jewelry, and paint. Transparent glasses are tinted with the silica-based cobalt pigment smalt.

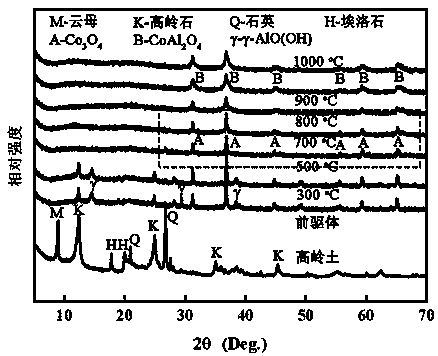

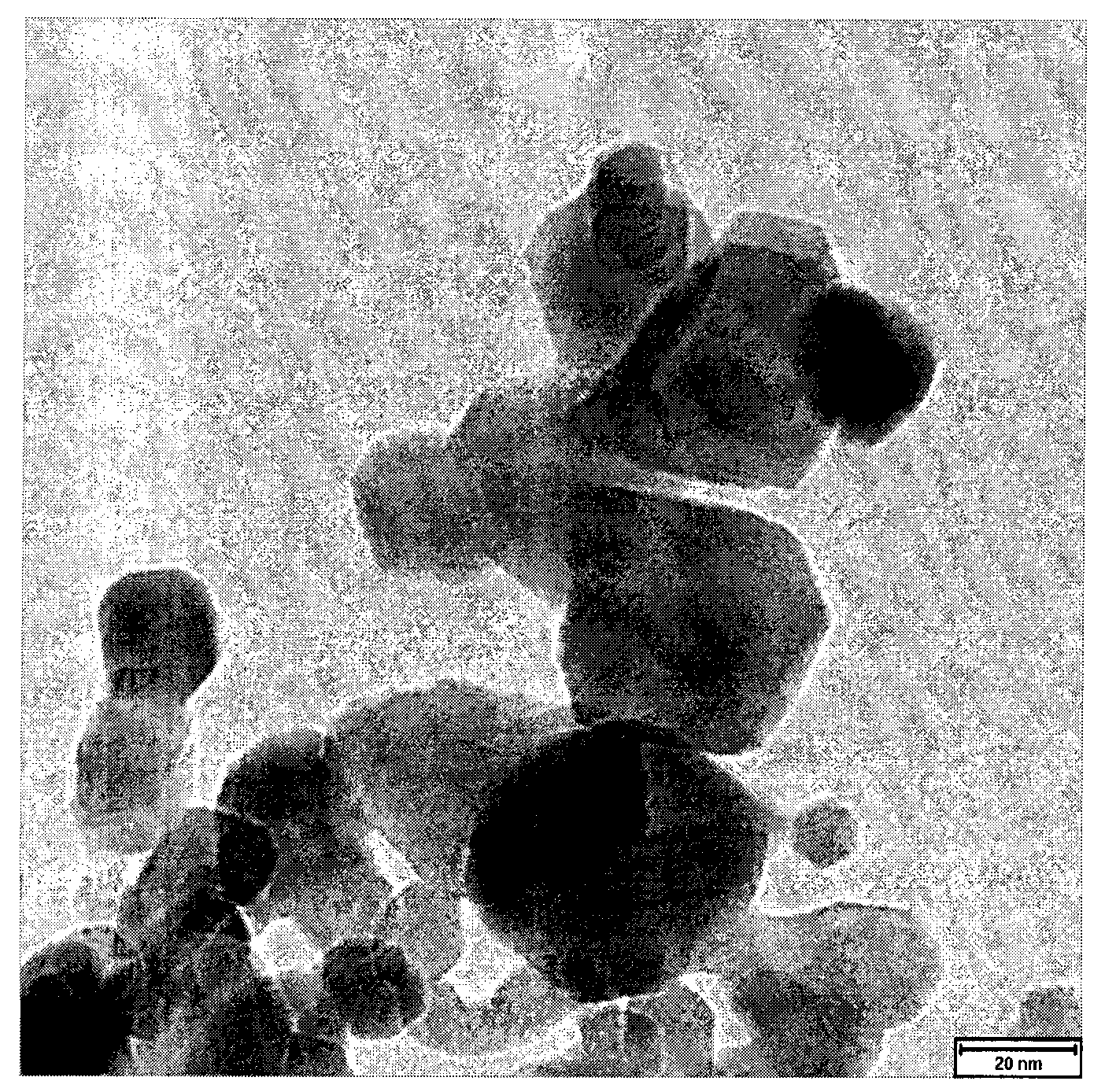

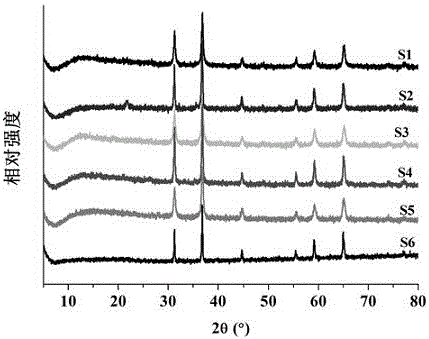

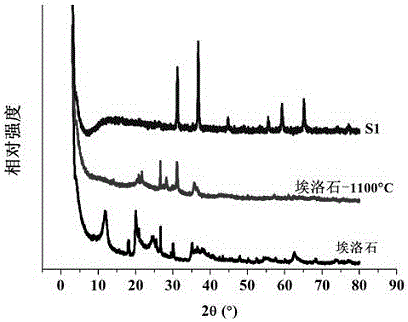

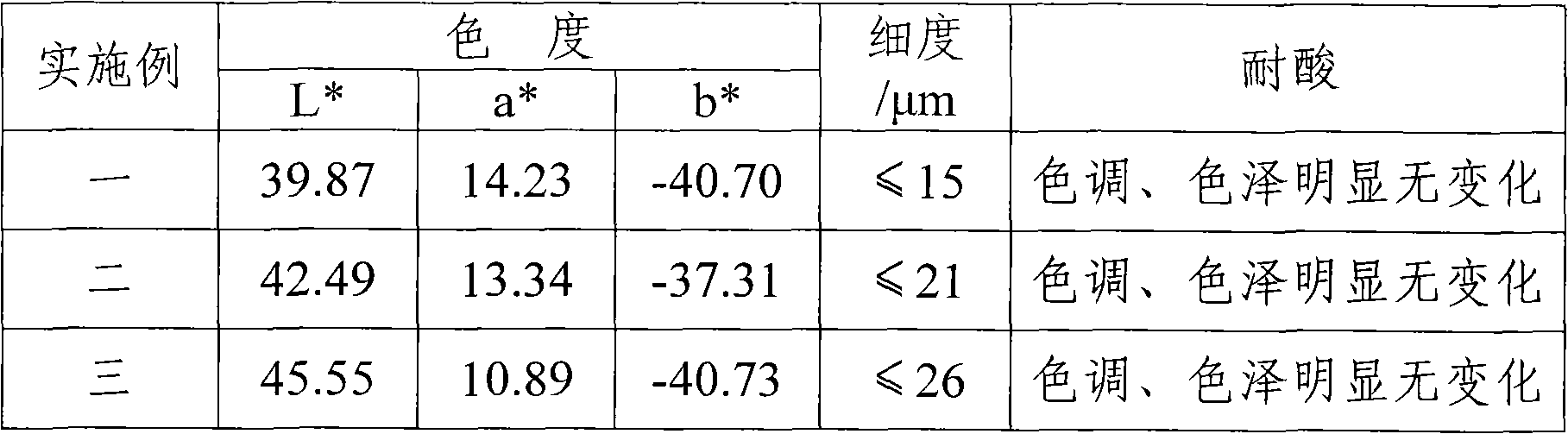

Preparation method of cobalt blue and clay mineral hybrid pigment

ActiveCN105199435ALow costReduce manufacturing costPigment physical treatmentClay mineralsCobalt blue

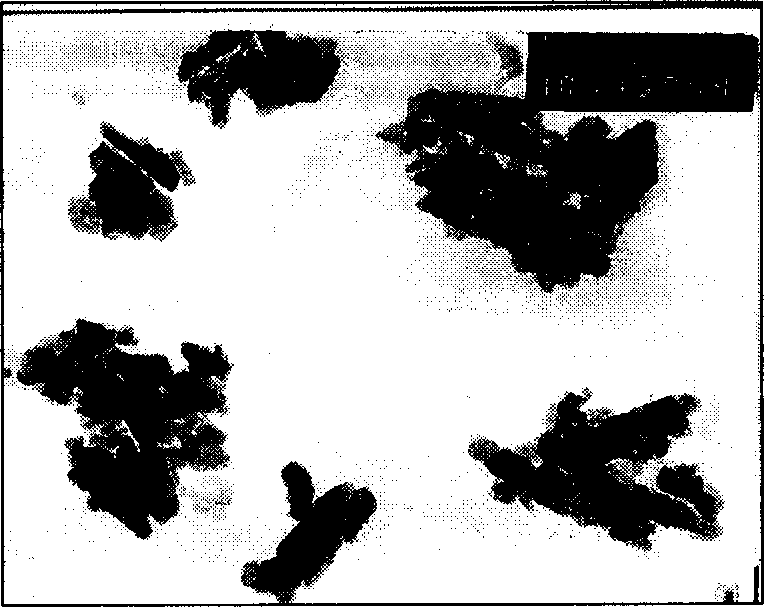

The invention relates to a preparation method of a cobalt blue and clay mineral hybrid pigment and belongs to the technical field of preparation of nano-spinel hybrid pigments. A hybridization precursor is prepared with a co-precipitation technique with Co(III) salt and Al(III) salt as raw materials and inorganic clay minerals as filler, and the cobalt blue and clay mineral hybrid pigment is prepared through high-temperature crystallization. With the adoption of the clay minerals, the preparation cost of the cobalt blue pigment can be reduced, cobalt blue nanoparticles can be effectively prevented from aggregating and enlarging in the following high-temperature crystallization process, the particle diameter of the nanoparticles ranges from 10 nm to 20 nm, and the prepared cobalt and clay mineral hybrid pigment has a bright color and can meet requirements of durable coatings, neutral ink, CRT (cathode ray tube) fluorescent powder coating pigment products and the like in the cobalt blue market. Besides, the preparation process is simple, the cost of the raw materials is low, and large-scale production is facilitated.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

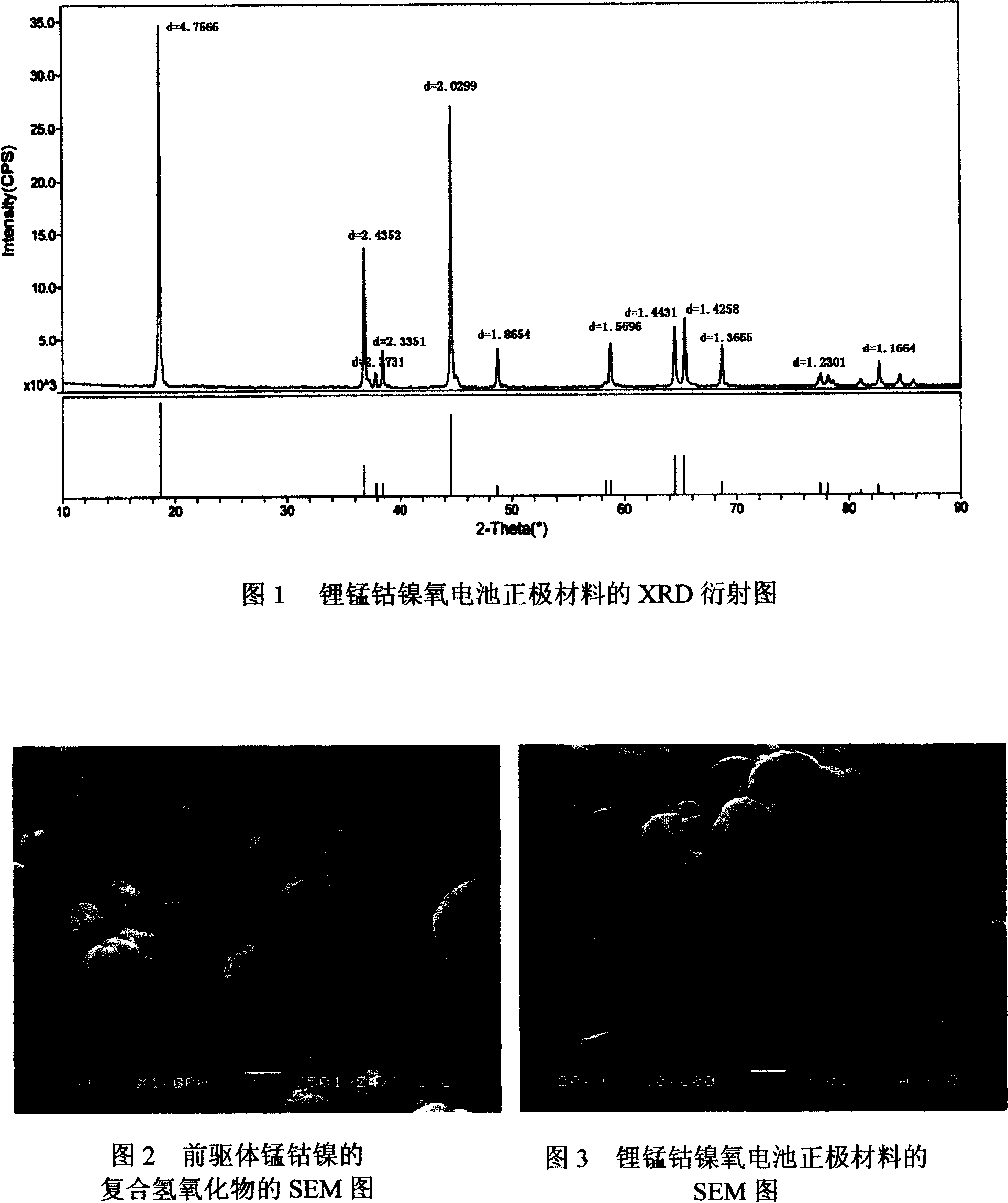

Lithium manganese cobalt nickle oxygen of manganese cobalt nickle triple lithium ionic cell positive material and its synthesizing method

InactiveCN101083321APrevent oxidationCrystal denseElectrode manufacturing processesLithium compoundsNickel saltManganese

The invention belongs to a manganese cobalt nickel three Yuan lithium ionization cell anode material, specifically relates to the lithium manganese cobalt nickel oxygen and its synthetic method. The high-capacity, the high safety performance of other battery positive electrode material is unable to compare with lithium manganese cobalt nickel oxygen, moreover low in price, the good compatibility with the electrolyte, the outstanding circulation performance, will certainly to thrust the market in the recent several years. The chemical formula of lithium manganese cobalt nickel oxygen is: The LiMn1 / 2Co1 / 4Ni1 / 4O2 crystal structure is a hexagonal system. The synthetic method of lithium manganese cobalt nickel oxygen is: (1) preparing the mix solution which is composed by the manganese salt, the cobalt blue, the nickel salt, under the agitation situation, joining the alloy salt brine, the complexing agent simultaneously in the reacting system according to the certain proportion distinction, simultaneously adjusts the join speed of alkali to maintain pH to be constant; After continuous feed certain times, filtrate and wash the precipitate to obtain the forerunner body. (2) Grinding and mixing lithium source element and forerunner body ball, after mixed evenly, compacting, roasting, and decomposing to obtain the lithium manganese cobalt nickel oxygen. Then cooling, grading, mixing to obtain the product.

Owner:湖南美特新材料科技有限公司

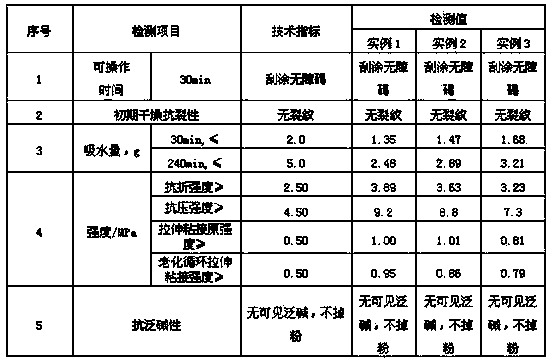

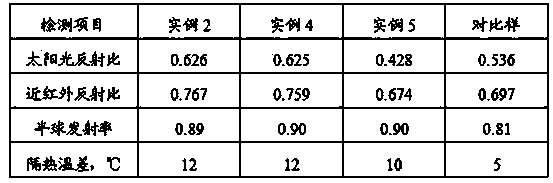

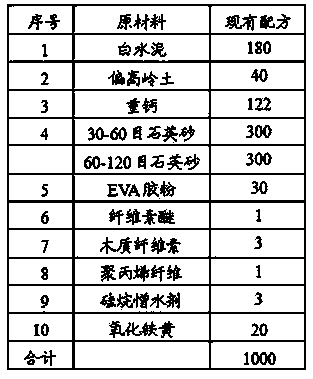

Color thermal insulation mortar with heat reflection function for exterior wall

The invention provides a color thermal insulation mortar with a heat reflection function for an exterior wall. The color thermal insulation mortar comprises the following components by weight percent: 20-25% of white cement, 4-6% of early strength agent, 2-4% of active admixture, 10-20% of finer filler, 20-40% of light filling, 10-30% of fine sand, 1-3% of pigment and 4-6% of additive, wherein the early strength agent is white amorphous calcium aluminate of which the specific surface area is greater than or equal to 5,000m<2>kg; the light filling is a glass bead, which has a honeycomb mesh structure and of which the particle size is 0.09-0.60mm, the bulk density is 270-400Kg / m<3>, the cylinder compressive strength is greater than 2.0MPa, and the pigment is chromium titanium yellow, nickel titanate yellow, chromite-cobalt blue or ferrochromium black. The color thermal insulation mortar disclosed by the invention not only has the characteristics of being light in weight, strong in strength and low in water absorption rate by adding an inorganic composite pigment burnt at high temperature and the glass bead with a special structure, but also has high near infrared solar reflectance and low coefficient of thermal conductivity. Compared with the common mortar, the color thermal insulation mortar has better insulating and cooling effects, and is especially applicable to decoration of the exterior wall.

Owner:广东龙湖科技股份有限公司

Firing technique of blue and white porcelain

The invention discloses a firing technique of blue and white porcelain, which comprises the following steps: 1) a blank is composed of Nixing argil, potash feldspar, quartz, calcined talcum and zirconium silicate; a glaze is composed of lead-free cadmium fusion cake, potash feldspar, calcined talcum, wollastonite and Nixing argil; and a blue material is composed of 10-20 parts of blank, glaze and a cobalt blue material; and 2) making the blank into a billet, trimming, drawing patterns or writing characters on the billet surface by sing the blue material, carrying out glazing treatment, airing, firing in a kiln at 1060-1160 DEG C for 10-15 hours, cooling, and discharging to obtain the finished product. The technique has the advantage of lower firing temperature. The finished blue and white porcelain product has the advantages of high glaze whiteness, bright blue-and-white coloration and clear lines without blooming, and is very delicate.

Owner:潮州市华利达陶瓷制作有限公司

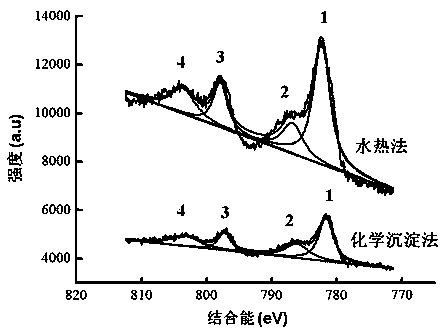

Method for preparing nanometer cobalt blue dye

InactiveCN1831047ASmall particle sizeSimple production processPigmenting treatmentTitanium tetrachlorideSodium hydroxide

This invention discloses a preparation method of nm cobalt blue, and it belongs to synthetic technique of nm spinel style colorant. This method includes following procedures cobaltous sulfate and aluminium sulphate, chromic chloride and titanium tetrachloride are mixed with water and agitated to solve, there mol ratio is that 1:(0.5-2): (0-3): (0-3), then they are heated and sodium hydrate solution is added to adjust pH value to 8-10. They are agitated, aging and water flushed, the precipitate stuff is hydrothermal cultivated at 160-260 degrees centigrade, then the hydrothermal cultivated stuff is filtrated, dried and crashed, finally it is solid phase high temperature crystallized at 900-1200 deg.C to get nm cobalt blue product. The advantage of this invention is that two step ways synthetic technique are used, so the particles can reach nm grade after high temperature crystallization, the particle diameter of cobalt blue particles made is small, the average particle diameter is 30-80nm, and its production technique is simple, energy consumption is relatively low.

Owner:TIANJIN UNIV

Medium-temperature cobalt blue disperse dye

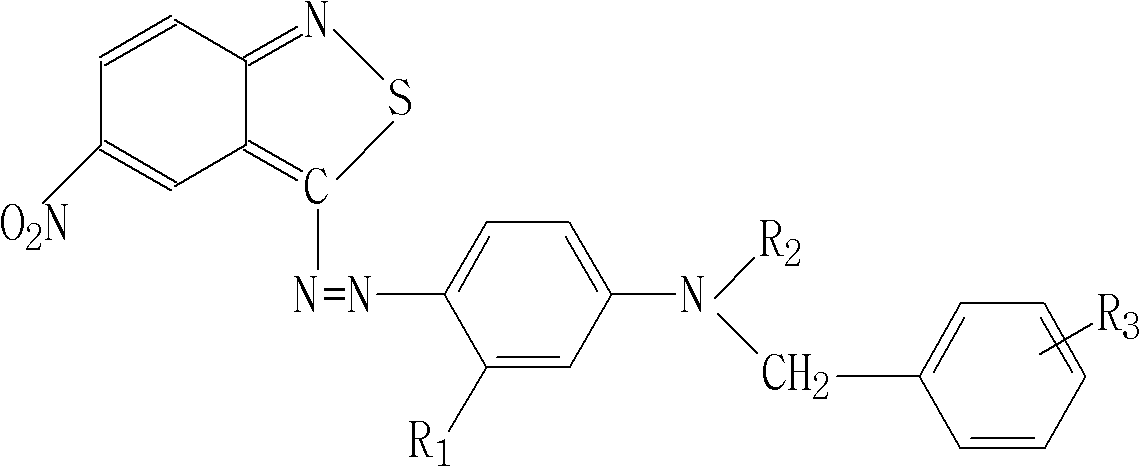

ActiveCN102250486AHigh sublimation fastnessGood light fastnessMonoazo dyesDyeing processDisperse dyeHydrogen

The invention relates to a medium-temperature cobalt blue disperse dye, of which the general formula is shown in the specification, wherein R1 is H or methyl; R2 is C1-C4 alkyl; and R3 is Cl or methyl. The medium-temperature cobalt blue disperse dye provided by the invention can be used for dyeing and printing of polyester fibers and blended fabrics, is suitable for high-temperature high-pressuredyeing, is especially suitable for an energy-saving, discharge-reducing and medium-temperature thermosol dyeing process, and has good solarization performance and water washing fastness.

Owner:PENGLAI JIAXIN DYES & CHEM

Cobalt blue pigment for ceramic ink and preparation method of cobalt blue pigment

The invention discloses a preparation method of cobalt blue pigment for ceramic ink. The preparation method comprises steps as follows: S1, weighing: a cobalt source, an aluminum source and a siliconsource are weighed; S2, primary mixing: the weighed raw materials are fed into a conical mixing machine for primary mixing; S3, pulverizing: the primarily mixed raw materials are fed into a claw typepulverizer and further mixed uniformly; S4, calcination: the pulverized raw materials are calcined at 1130-1200 DEG C for 2-3 h; S5, smashing and refining: a crude product obtained after calcination is subjected to ultrafine grinding treatment, and a submicron finished product is obtained. According to the preparation method, after the raw materials including the cobalt source, the aluminum sourceand the silicon source are mixed, a mixed crystal with CoO.Al2O3 spinel and 2 CoO.SiO2 olivine as main crystals is synthesized with a solid reaction process, and an eutectic point of Al2O3 and SiO2 can be formed in glaze, so that negative effects of the pigment on the glazed surface can be prevented; meanwhile, unexpected discovery shows that compared with pigment independently prepared from theCoO.Al2O3 spinel and the 2 CoO.SiO2 olivine, the prepared pigment has the advantage that color generation capacity in glaze is remarkably improved.

Owner:广东丰霖新材料科技有限公司

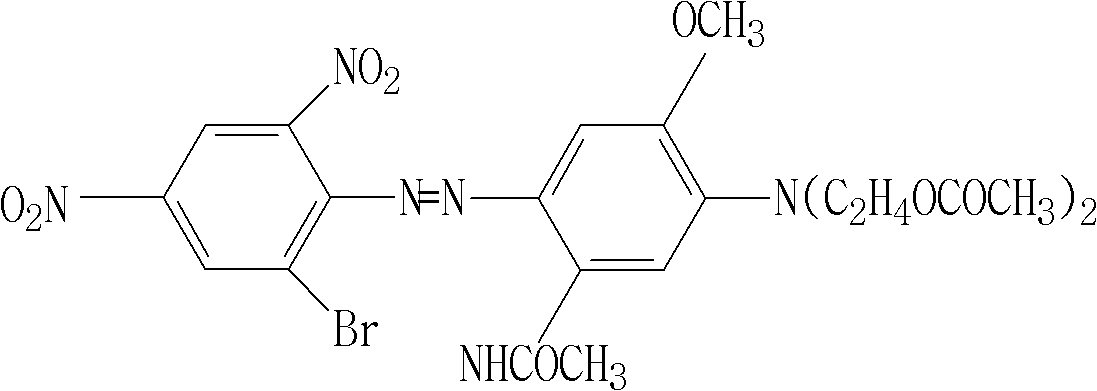

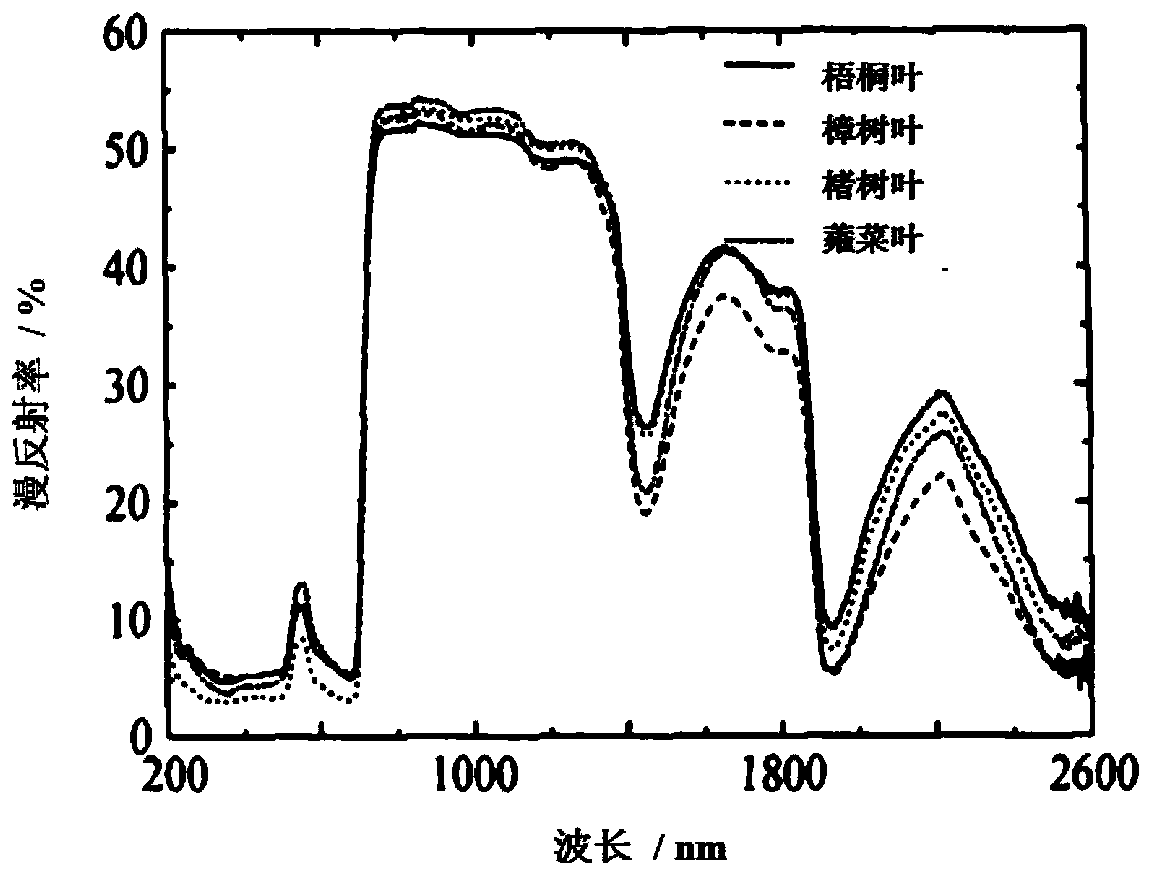

Environment-friendly paint simulating hyperspectrum of green vegetation and preparation method of environment-friendly paint

ActiveCN103436151AHigh near-infrared diffuse reflectanceHyperspectral bionic effectPolyurea/polyurethane coatingsKetoneSolvent

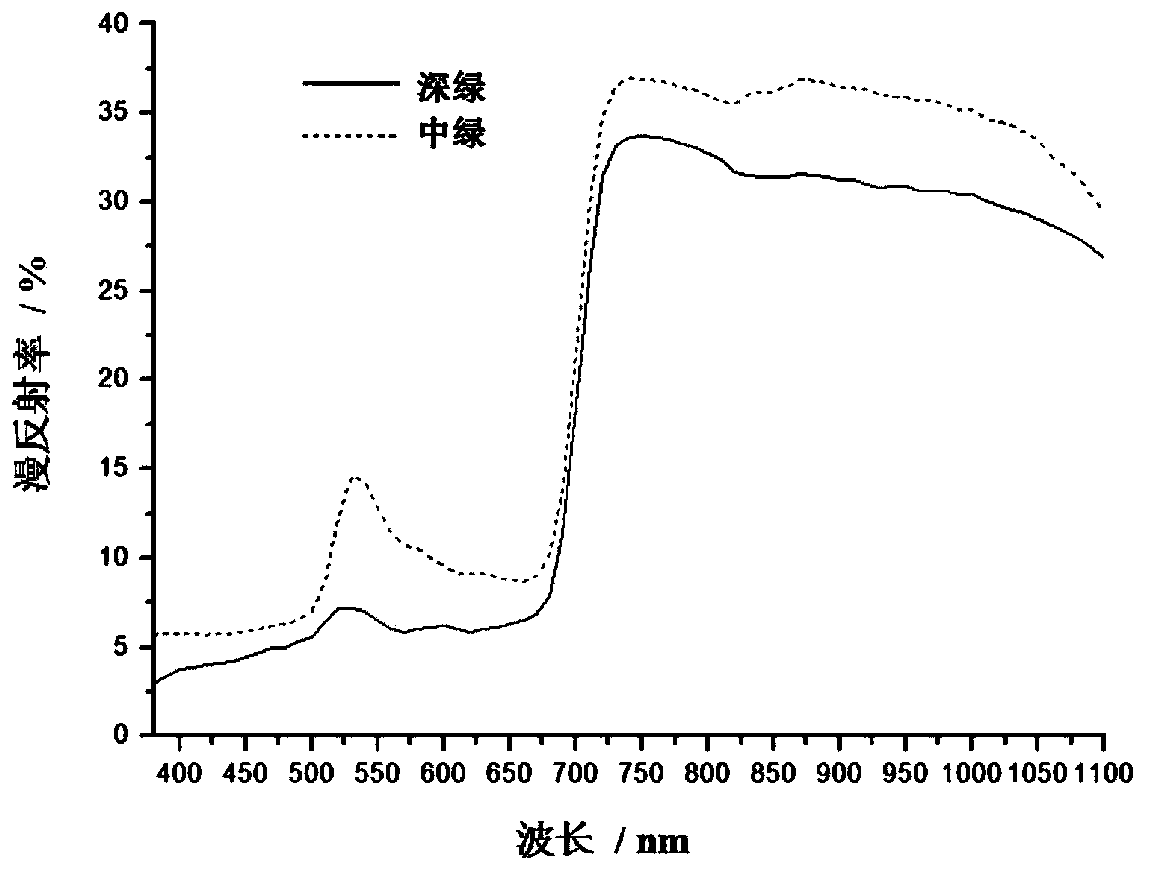

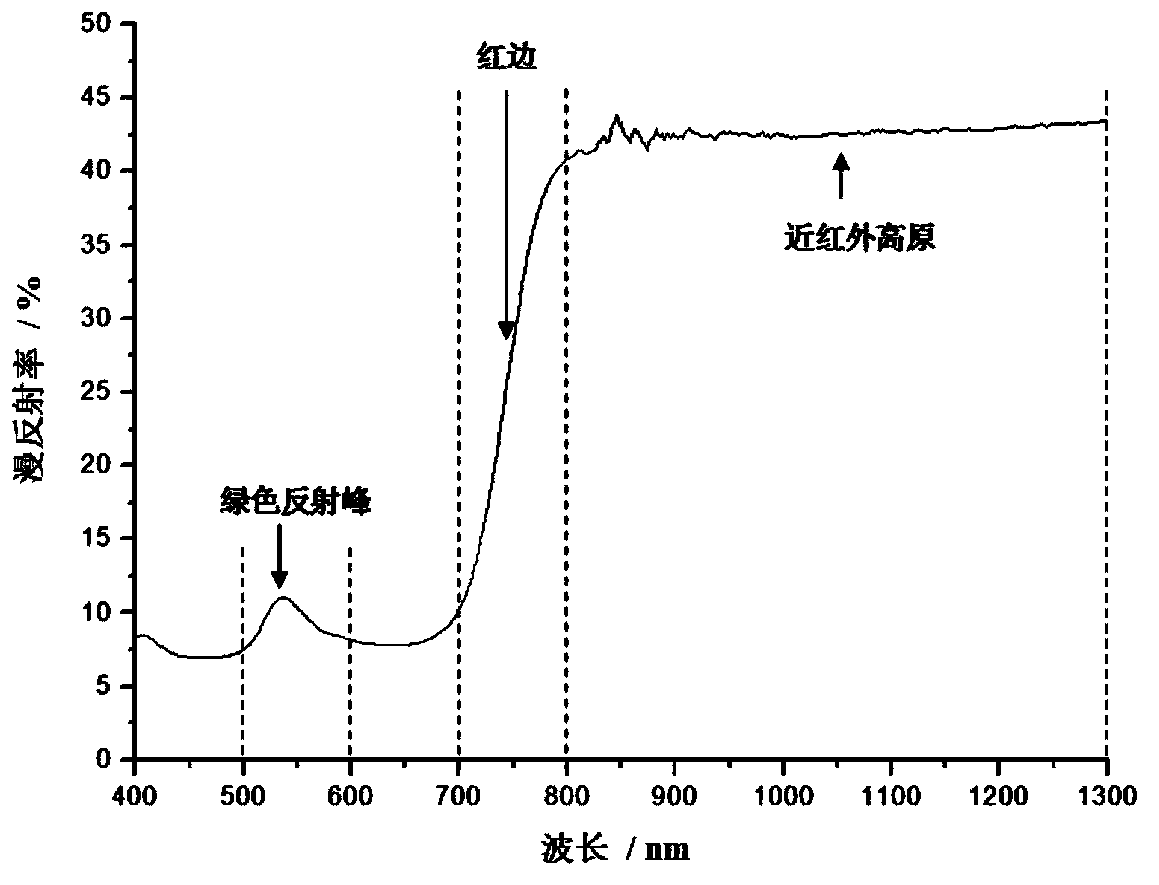

The invention relates to environment-friendly paint simulating a hyperspectrum of green vegetation and a preparation method of the environment-friendly paint. A component B of the paint comprises the following ingredients in percentage by mass: 30-45% of fluorocarbon resin, 10-30% of special pigment, 10-25% of filling, 1-8% of dispersing agent, 0.1-1% of flatting agent, 1-5% of matting agent, 0.01-0.3% of drier and 15-25% of mixed solvent; the special pigment comprises the following ingredients in percentage by mass: 1-13% of rutile titania, 1-8% of 1,4 diketopyrrolopyrrole organic red pigment, 0-4% of inorganic cobalt blue, 2-20% of benzimidazolone organic yellow pigment, 17-60% of green pigment and 10-75% of black pigment; a component A is aliphatic polyisocyanate; and a mass ratio of the component A to the component B is 1:14. The paint has good film coating luster, corrosion resistance and weather resistance, is free from hexavalent chromium, and an effective hyperspectrum (400-1300nm) scope has a specific reflection spectrum characteristic of the green vegetation.

Owner:CHINA NAT OFFSHORE OIL CORP +3

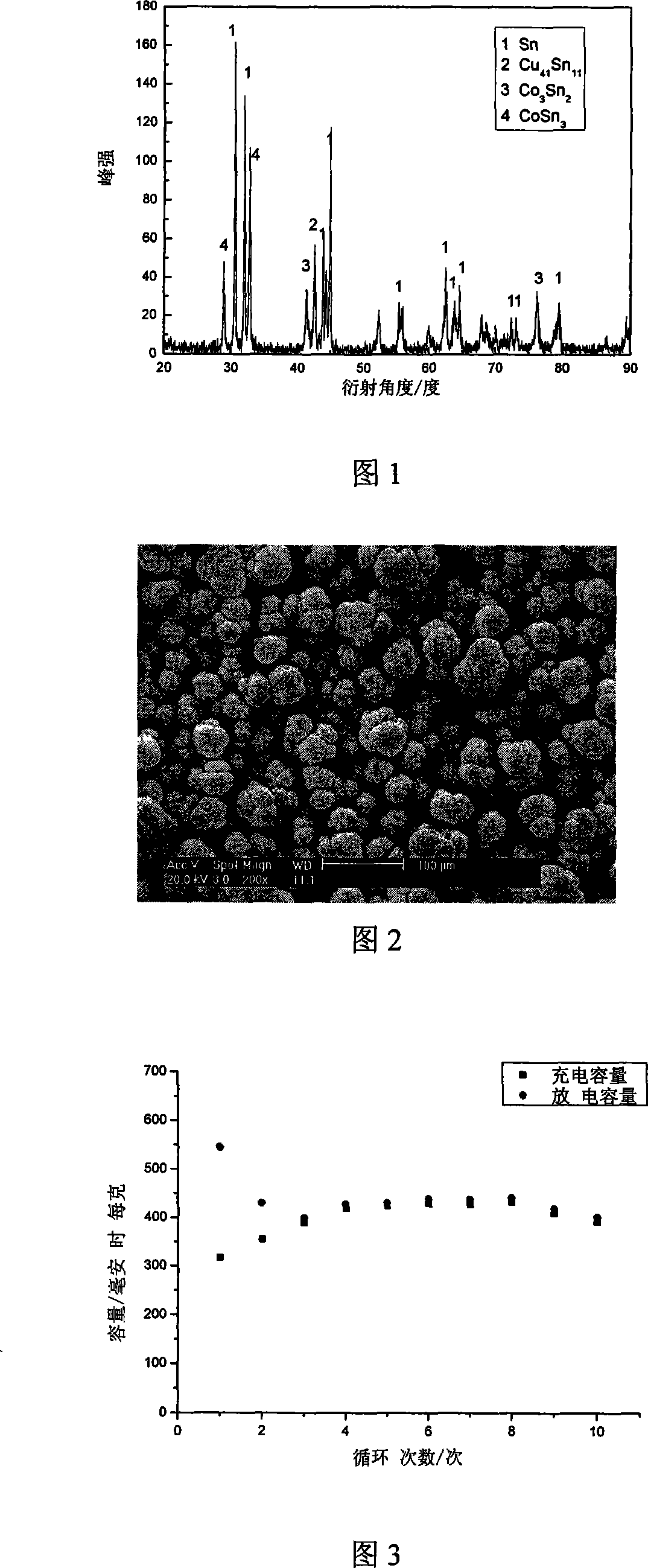

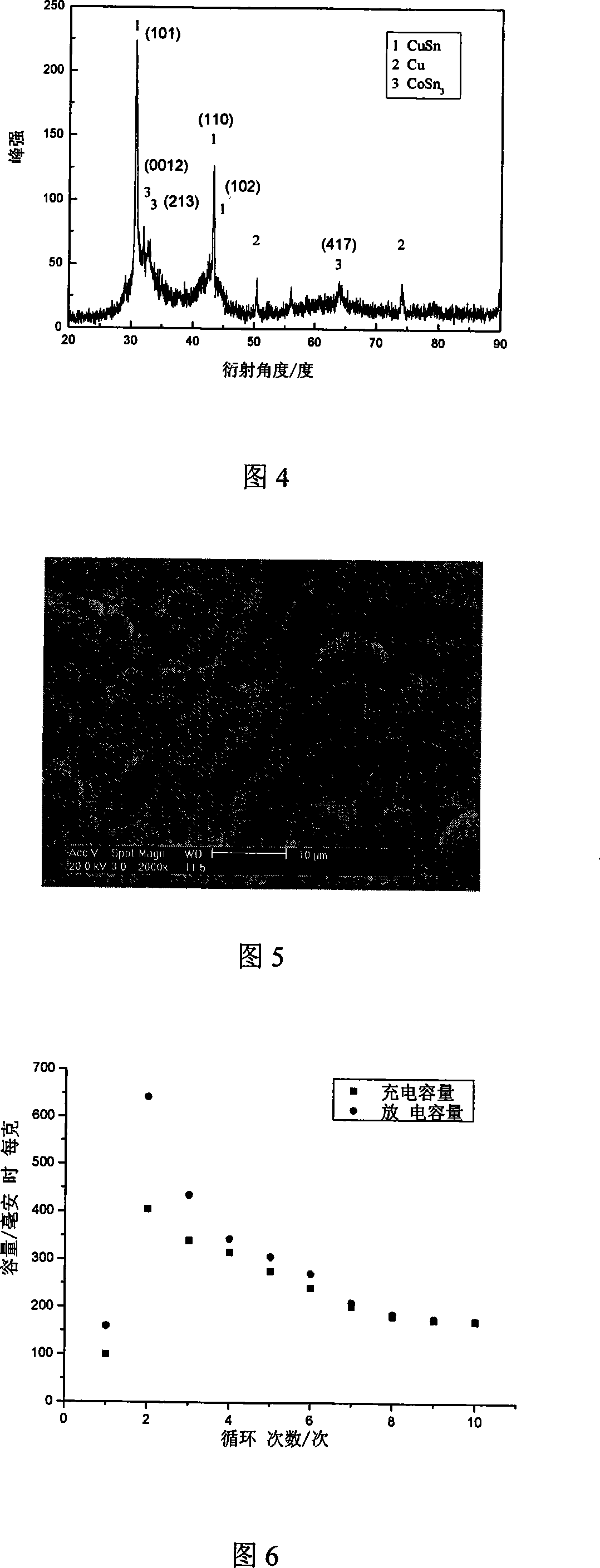

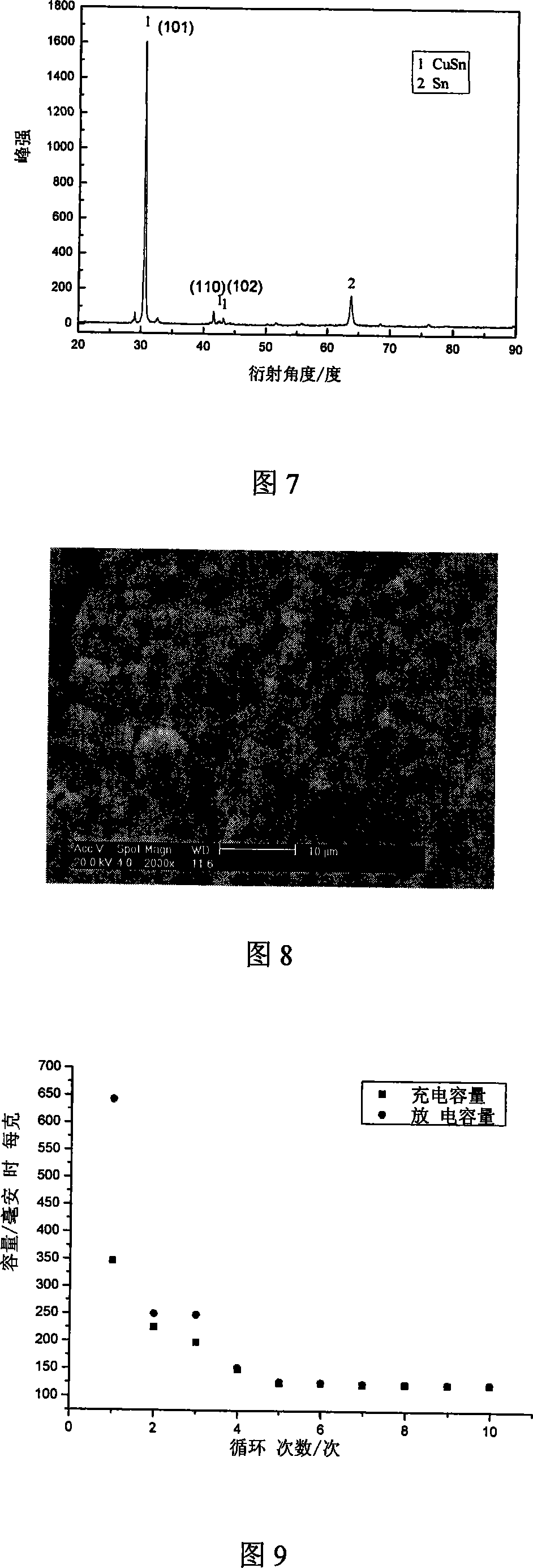

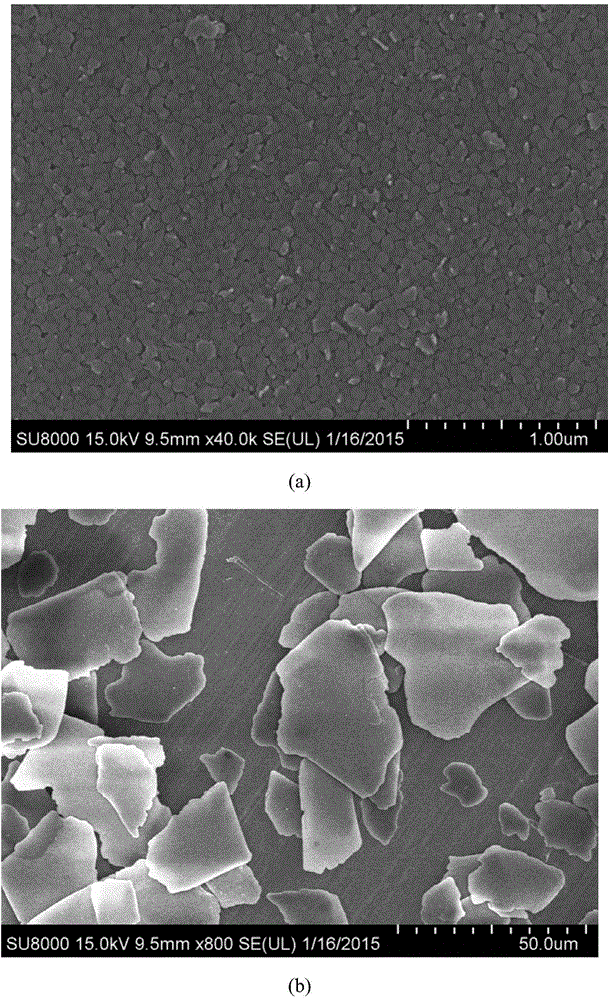

Tin-cobalt alloy negative electrode material for lithium ion cell and its preparing method

InactiveCN101071851AHigh crystallinityReduce irreversible capacityElectrode manufacturing processesActive material electrodesCrystallinityLithium-ion battery

This invention involves the lithium ion battery tin cobalt alloy cathode material and the preparation method. The tin cobalt alloy cathode material at least includes Sn, Co3Sn2, CuSn or the CoSn3 two kind of materials, the surface has bud shape and the spherical two kind of shapes, the size is 5-50mum. Preparetion is that: 1) firstly attach a layer of tin on copper substrate; 2) prepare plating liquid: tin salt 10-50g / L, cobalt blue 5-20g / L, K4P2O73H2O100-400g / L, citric acid 10-30g / L, glycine 10-30g / L, methionine 2-10g / L; 3) use electric deposition method to control temperature at 15-35 degree C, pH = 8-9, the current density is 5-20mA / cm2, power on time is 0.5-2.5h, obtain the tin cobalt alloy material. This tin cobalt alloy is high in crystallization degree, not easy to have the serious reunion and the superficial oxidation, reduced the cathode material irreversible capacity.

Owner:TIANJIN UNIV

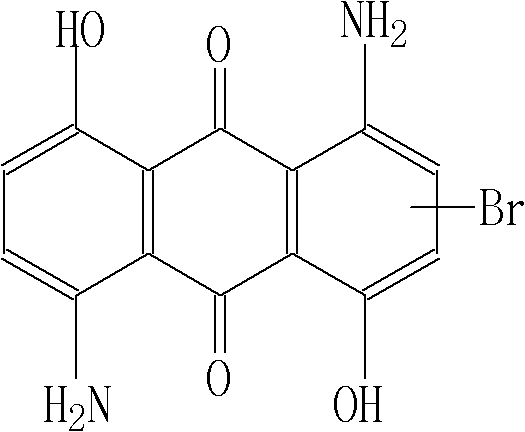

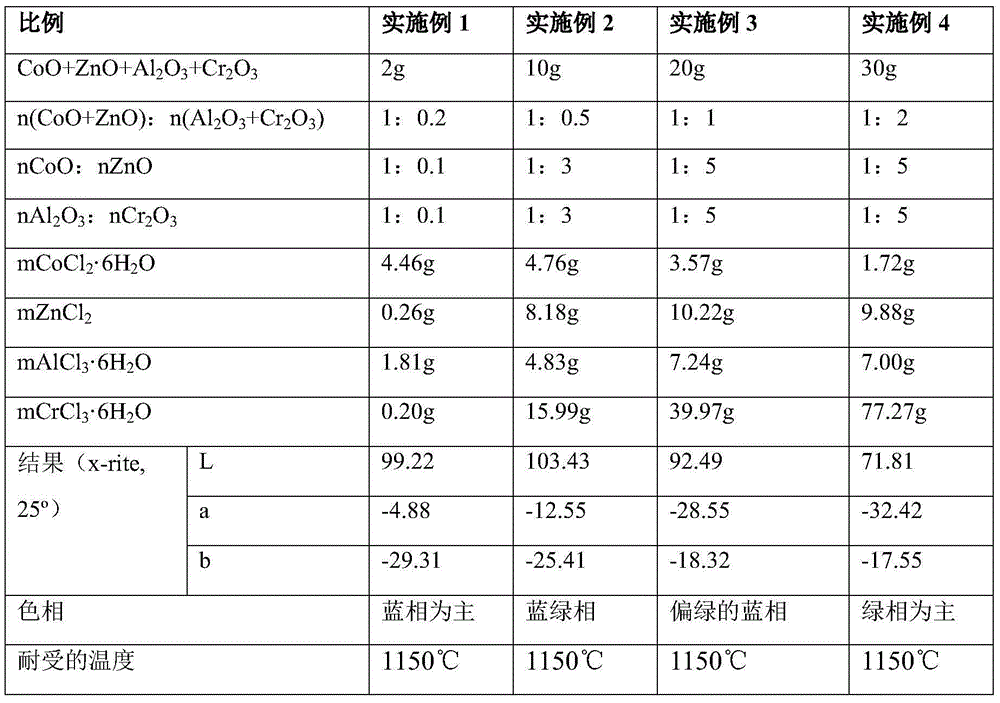

Blue-green series pigment with pearlescent effect and preparation method of pigment

ActiveCN104804475AStrong Optical Interference EffectAdd colorful effectInorganic pigment treatmentCoatingsCobalt blueTio2 coating

Blue-green series pearlescent pigment comprises the following components: 1), a substrate; 2), a SnO2 and TiO2 coating layer deposited on the substrate; and 3) a chromium, zinc and cobalt blue pigment coating layer deposited on the SnO2 and TiO2 coating layer, wherein the chromium, zinc and cobalt blue pigment coating layer comprises chromium oxide, zinc oxide, cobalt oxide and aluminum oxide or mainly comprises chromium oxide, zinc oxide, cobalt oxide and aluminum oxide. The invention further provides a method for preparing the blue-green series pearlescent pigment and an application of the blue-green series pearlescent pigment.

Owner:GUANGXI CHESIR PEARL MATERIAL CO LTD

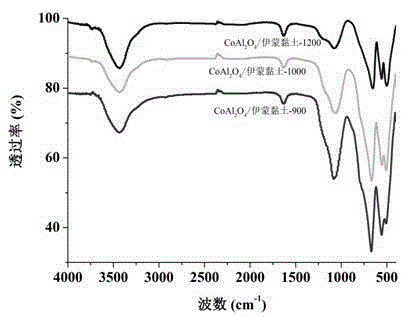

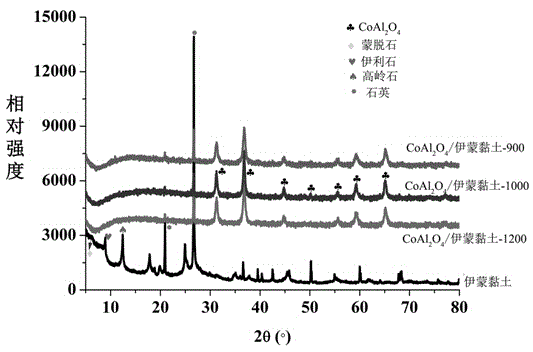

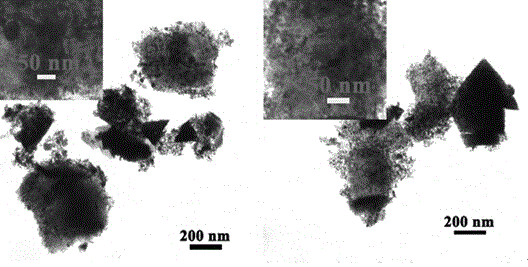

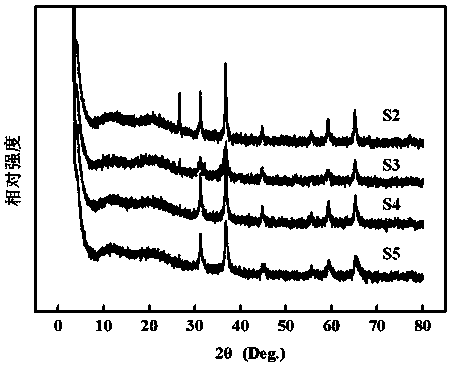

Method for microwave and hydrothermal-assisted preparation of high-chroma cobalt blue/clay mineral hybrid pigment

ActiveCN109181369AHigh chroma valueImprove Co

<sup>2+</sup>

contentPigment physical treatmentClay mineralsMicrowave

The invention discloses a method for microwave and hydrothermal-assisted preparation of a high-chroma cobalt blue / clay mineral hybrid pigment. The method comprises the following steps: uniformly dispersing natural clay mineral in water, adding soluble a Co<2+> salt and an Al<3+> salt, performing stirring to achieve dissolving, and adjusting the pH value of the obtained solution to 8-12 by a NaOH solution; transferring the obtained reactant material into a microwave reactor, and carrying out a hydrothermal reaction to obtain a precursor; and centrifuging and washing the precursor, and carryingout high-temperature calcination to obtain the high-chroma cobalt blue / clay mineral hybrid pigment. The method combines the technological advantages of a microwave heating technology and a traditionalhydrothermal technology, so the method has the advantages of short reaction period, and low temperature of calcination for forming spinel cobalt blue, and the obtained pigment product has the advantages of high crystal phase purity, excellent weather resistance and bright color, has a blue value b<*> being higher than -70, and can be comparable to blue organic pigments.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI

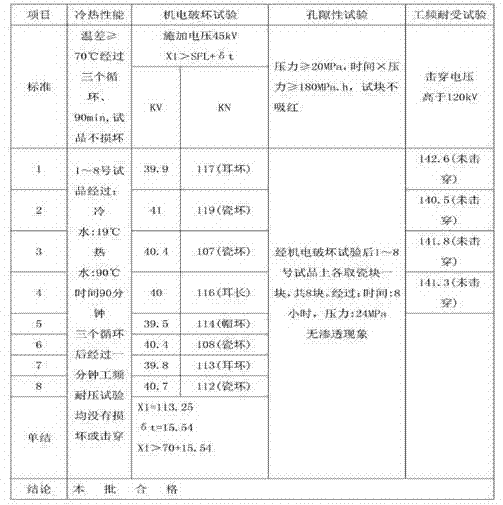

High-voltage ceramic insulated dark blue glaze

The invention discloses a high-voltage ceramic insulated dark blue glaze which comprises the following components in parts by weight: 10-50 parts of high-potassium low-iron feldspar, 5-25 parts of Yichun quartz powder, 3-20 parts of Yunnan kaolin, 2-15 parts of Guangdong Xinhui soil, 2-10 parts of limestone, 2-10 parts of calcined talcum, 3-15 parts of spodumene, 1-3 parts of barium carbonate, 2-10 parts of albite and 1-8 cobalt blue agent. The glaze formula can enhance the mechanical, electric and thermal properties of the electric ceramic, and the properties exceed the GB8411 standard.

Owner:CHONGQING PIGEON ELECTRIC PORCELAIN CO LTD

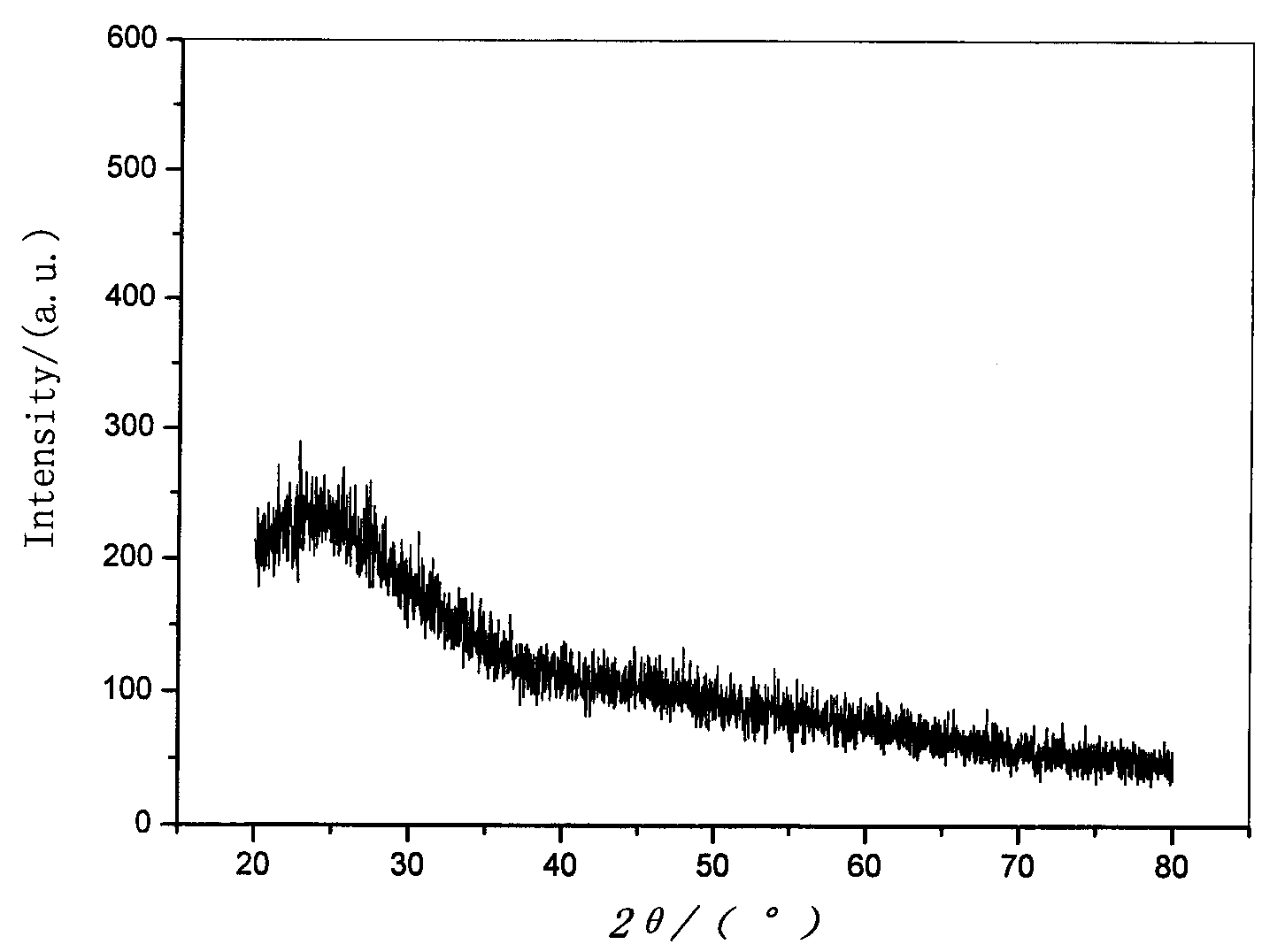

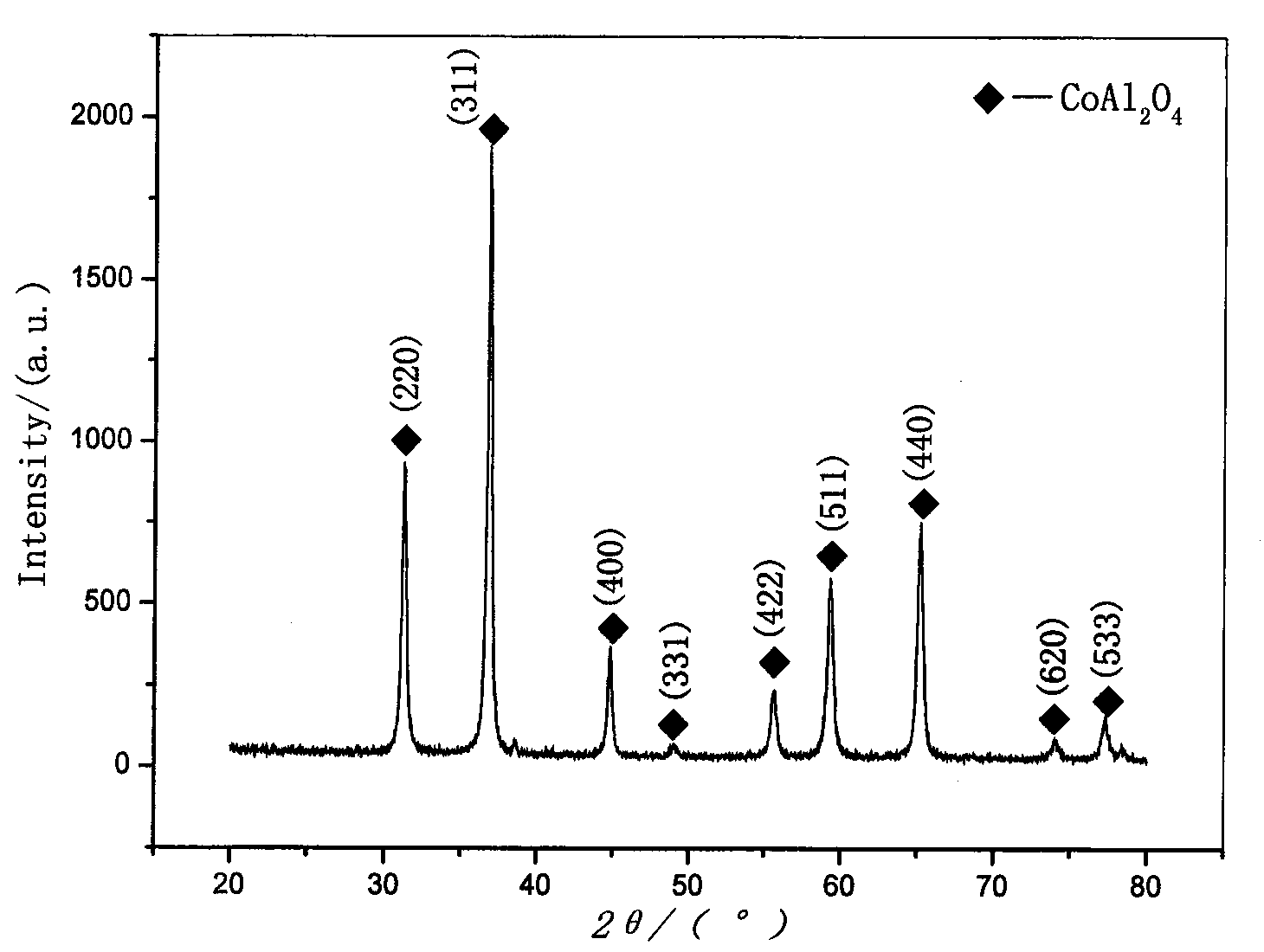

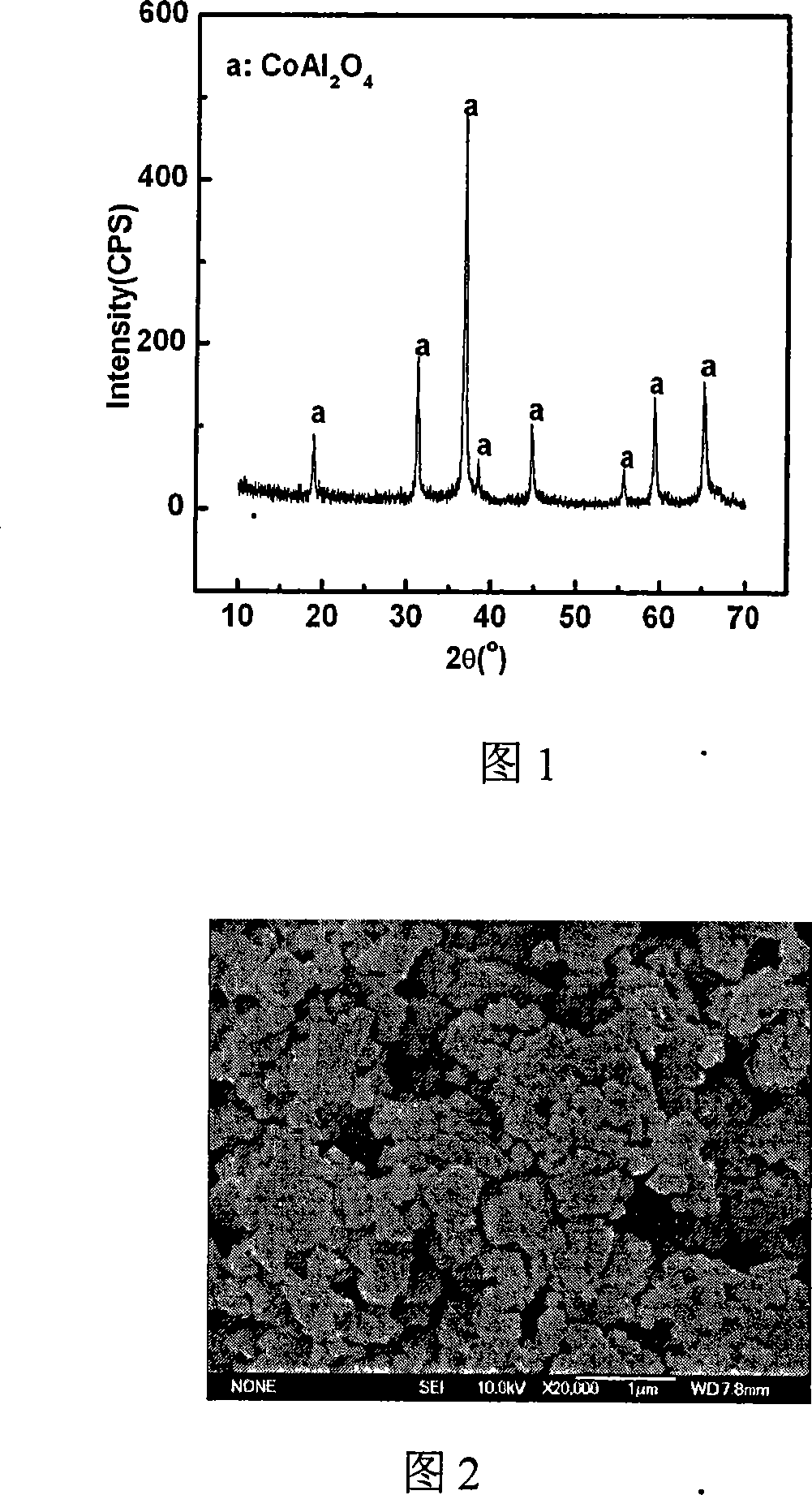

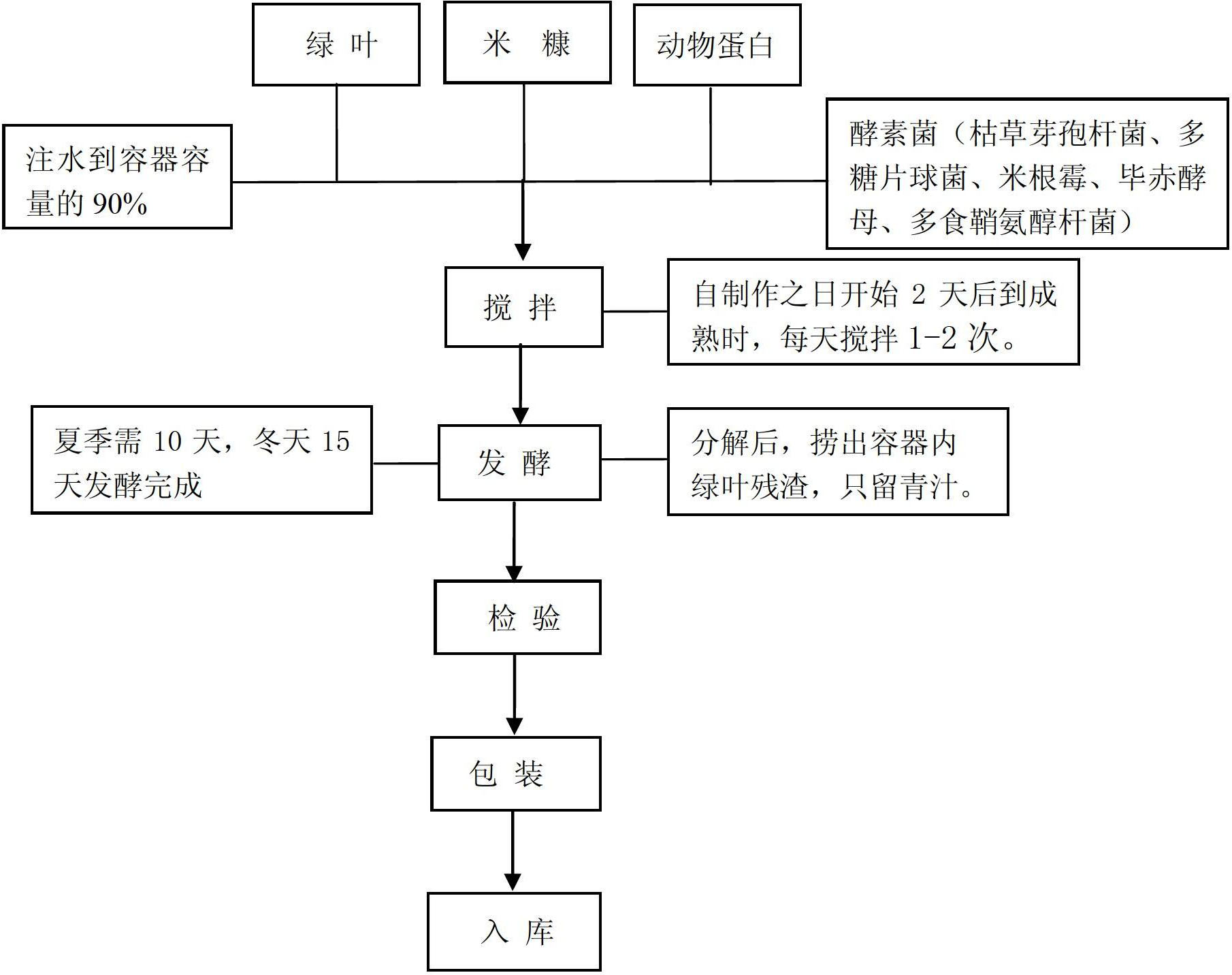

Method for preparing nano-cobalt blue pigment CoAl2O4

InactiveCN101575465AInhibition of segregationAvoid reunionPigmenting treatmentAir atmosphereFreeze-drying

A method for preparing a nano-cobalt blue pigment CoAl2O4 belongs to the field of powder metallurgy preparation. The problems existing in the current cobalt blue pigment preparation are as follows: large pigment particle size, wide distribution, dark color, conglobation, and the like. The cobalt blue pigment CoAl2O4 powder material is characterized by 1:2 of Co-Al molar ratio, thereby forming pure-phase cobalt aluminum. The method for preparing the nano-cobalt blue pigment comprises the steps of: respectively dissolving acetic acid cobalt powder and aluminum sulfate powder in distilled water and then obtaining even clarified mixed solution by mixing, using a nitrogen spray gun to disperse the solution in liquid nitrogen for pre-freezing, later placing the liquid nitrogen in a freezedrier for conducting vacuum drying to obtain freeze-dried powder; and finally calcining the freeze-dried powder in air atmosphere for obtaining bright blue powder, namely the nano-cobalt blue powder. The method leads the cobalt and the aluminum to be mixed at the molecular order of magnitude and can decrease the firing temperature in the calcining process; moreover, as the powder crystal grain size is obviously refined without conglobation, the properties such as the reflectivity of the cobalt blue pigment and the like are improved.

Owner:BEIJING UNIV OF TECH

Epithermal energy-increasing heat-transfer medium and its heat-trarsfer element

InactiveCN1422931AHas heat transfer and energy enhancing propertiesImprove heat transfer performanceHeat-exchange elementsBoron carbideLithium aluminate

The invention discloses an ultra-heat energy-adding heat transmission working medium and the heat transmission component. It is a mixture composed of at least two matters respectively selected from A-matters as basic heat transmission ones and B-matters as energy-adding ones. A matters mainly include: Na, Nai, K, Cs, heat transmission oil, water Hg, acetone, methyl alcohol, ethanol, F-22, ethane and nitrogen; B-matters: manganese tetroxide, powder blue, aquamarine, cobalt blue, tungsten cadmium borate, titanic acid kalium, boron carbide, tantalum oxide, ferric tetroxide and so on. It evacuates the sealed container into vacuum, places the container in the above working medium and then packs to make the heat transmission component. The heat transmission efficiency is greater than 1.

Owner:AONENGZHI SCI & TECH CHENGDU

Method for preparing light-blue cobalt blue hybrid pigment from aluminum-rich non-metallic minerals

ActiveCN106629867ABright colorFull colorCobalt compoundsPigment physical treatmentNanoparticleTube furnace

The invention provides a method for preparing a light-blue cobalt blue hybrid pigment from aluminum-rich non-metallic minerals. The method comprises the following steps: stirring and dispersing aluminum-rich non-metallic minerals in water, adding a Co (II) salt and an Al (III) salt, dissolving by stirring, regulating the pH value of the system to 9-10 with NaOH, carrying out centrifuge washing on the obtained solid product, directly putting the solid product in a tube furnace, and carrying out high-temperature crystallization at 1000-1200 DEG C for 1-2 hours to obtain the product. The introduced aluminum-rich non-metallic minerals are used as the carrier material of cobalt blue nanoparticles to prevent aggregation, and more importantly, participate in the high-temperature crystallization process of cobalt blue, thereby greatly enhancing the chroma of the cobalt blue pigment. The b* value of the obtained hybrid pigment can reach -56; and thus, the hybrid pigment is hopeful to be a high-grade cobalt blue pigment for the fields of high-temperature-resistant paints, ceramics, painting pigments and the like.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

Method for preparing ultra-fine cobalt blue pigment under low-temperature

InactiveCN101117452AGood grain developmentImprove hair colorPigmenting treatmentAluminium oxides/hydroxidesFiltrationAluminium hydroxide

A method for preparing superfine cobalt blue colorant at low temperature comprises the following steps: firstly, cobaltosic oxide, aluminium hydroxide, zinc oxide and chromic oxide are mixed according to the general chemical formula of Co1-xZnxAl2-yCryO4 to obtain reactants, wherein x is more than or equal to 0 and is less than 1, while y is more than or equal to 0 and is less than or equal to 2; secondly, one sort or more sorts of KOH, NaOH, KCl, NaCl, Li2SO4 and Na2SO4 are added into the reactants to obtain mixture after being mixed uniformly; finally, the mixture is calcined 1 to 2 hours at the temperature ranging from 800 DEG C to 1,000 DEG C and then the calcined products is under the treatments of grinding, cleaning and filtration. The invention possesses simple technical process and equipment, convenient operation, cheap and easily obtained raw material and low cost for preparing colorant; moreover, the colorant obtained through adopting the preparing method is characterized in high development degree of crystal grain, ideal chromophoric effect of colorant, fine granularity, less agglomeration and good homogeneity etc.; meanwhile, the introduction of salt can lower synthesis temperature.

Owner:SHAANXI UNIV OF SCI & TECH

Cobaltless blue color-changing indicator and production method thereof

InactiveCN103091321AHigh sensitivityGood discoloration effectMaterial analysis by observing effect on chemical indicatorCobalt blueSilica gel

The invention discloses a cobaltless blue color-changing indicator, which comprises 0.01-0.1wt% of color indicator and a granular compound or mixture with a nano-sized microporous structure or adsorptive property, and is free of cobalt. The production method of the cobaltless blue color-changing indicator comprises the following steps of: (a) preparing the solution of a soaking carrier according to claim 3, and (b) enabling the carrier to contact the solution, and drying the carrier. The cobaltless blue color-changing indicator and the production method of the cobaltless blue color-changing indicator have the advantages that the cobaltless blue color-changing indicator can indicate humidity at a relative humidity of 5-90%, is high in sensitivity, and does not contain cobalt, copper, iron and other metal salts, so that the pollution to environment and the harm to human bodies can be eliminated from source; furthermore, the cobaltless blue color-changing indicator is accordant with conventional blue silica gel in appearance and color display and high in commercial value; and the humidity indicator provided by the invention is obvious in color changing effect, simple to use, capable of being repeatedly used for many times, and good in applicability, and has a very wide application range.

Owner:山东辛化硅胶有限公司

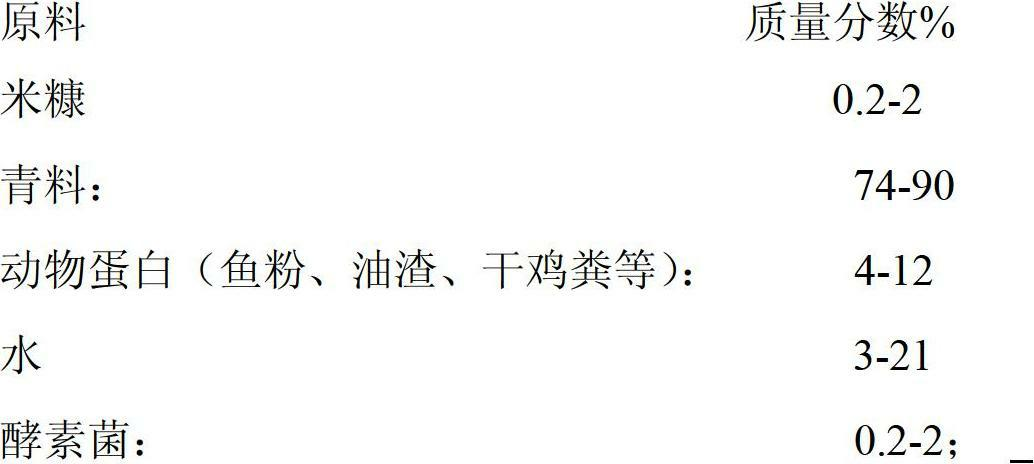

Organic fluid fertilizer and preparation method

InactiveCN102674913ASimple structureImprove the ecological environmentOrganic fertilisersBiotechnologyOrganic fluid

The invention discloses an organic fluid fertilizer and a preparation method. The organic fluid fertilizer is prepared by comprising rice bran, animal protein, cobalt blue pigment, ferment bacteria and the like according to certain proportion. The preparation method comprises the steps of: container and raw materials preparation: preparing a cement barrel type trough; preparing the cobalt blue pigment, animal protein, ferment bacteria and rice bran, and chopping the cobalt blue pigment into sections; mixing: placing the cobalt blue pigment in the trough for pressing; sequentially adding the animal protein, the ferment bacteria and rice bran for mixing and agitating evenly; injecting water into the container with 90 percent capacity, and tightly binding a jar opening with cloth; agitation: agitating every day after two days starting from the manufacturing day; fermentation: completing fermentation within 10-15 days; filtering residues, and only leaving green water; and verification and packaging. The method is easy, simple and convenient to operate, and capable of killing harmful and toxic substances in the cobalt blue pigment, provides beneficial microorganisms for plants, improves soil structure, and optimizes physicochemical properties of soil.

Owner:湖北嘉益田生物肥业有限公司

Poor petrol catalytic hydrofinishing method

ActiveCN1935949AImprove anti-coking performanceExtended service lifeRefining to eliminate hetero atomsCobalt blueGasoline

The invention relates to hydro-fining method for ungraded gasoline, especially for delayed coking gasoline and pressure gasoline. Its feature is that processing hydro-fining for olefin and sulfur containing delayed coking gasoline and pressure gasoline under the action of catalyst and in condition that reacting hydrogen partial pressure 2.0MPa-6.0MPa, reacting temperature 200-300 degree centigrade, liquid hour volume airspeed 1.0h-1-5.0h-1, hydrogen gasoline volumetric ratio 200-500:1; the catalyst components weight percentages are as follows: alumina 30.0-80.0%, titanium dioxide 1.0-20.0%, molybdenum oxide 10.0-25.0%, cobalt blue 2.0-10.0%, tungsten trioxide 1.0-7.0%, boron trioxide 0.5-5.0%, and strontium oxide 0.1-5.0%. The catalyst of the invention can process the olefin and sulfur containing ungraded gasoline at the hydrogenation condition after precuring, has higher olefin saturation and desulfurizing denitriding performance, has less than 2.0v% olefin content for hydrogenated products, not less than 99.0wt% for gasoline yield.

Owner:PETROCHINA CO LTD

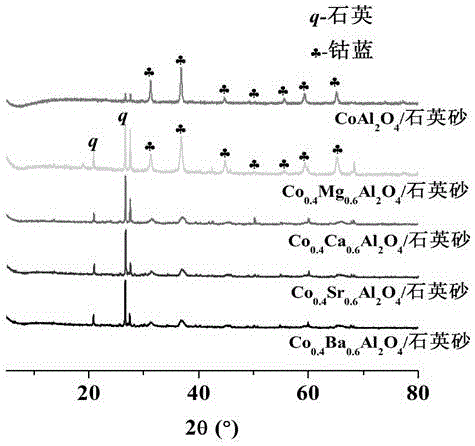

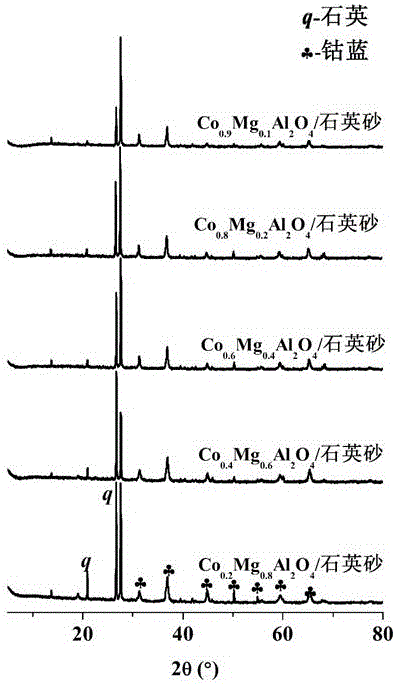

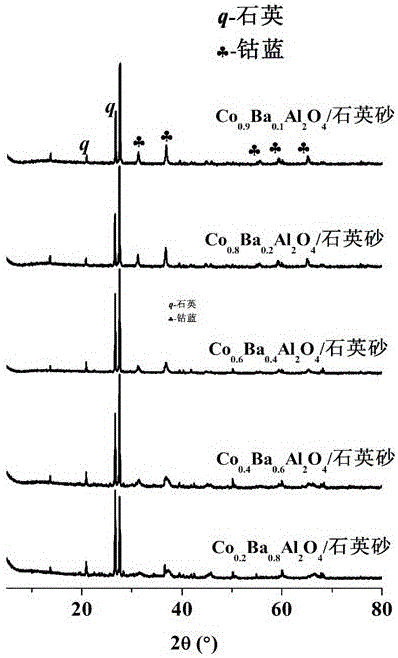

Bright blue metal ion doping cobalt blue/quartz sand hybrid pigment and preparation method thereof

ActiveCN107177217ABright colorImprove stabilityInorganic pigment treatmentUltraviolet lightsSodium hydroxide

The invention discloses a preparation method of a bright blue metal ion doping cobalt blue / quartz sand hybrid pigment. According to the method, quartz sand is crushed and is then stirred at a high speed to be dispersed into a water solution containing cobaltous salt, trivalent aluminum salts and doped metal ion salts; then, under the stirring condition, the system pH is regulated to 8 to 10 by a sodium hydroxide solution; the stirring is continuously performed for reaction for 0.5 to 2h; obtained solid products are subjected to centrifugation; after the washing, the materials are put into a tubular furnace; high-temperature crystallization is performed for 0.5 to 2h at 1000 to 1200 DEG C; the bright blue metal ion doping cobalt blue / quartz sand hybrid pigment is prepared. The metal ion doping is utilized; the color performance of the cobalt blue / quartz sand hybrid pigment can be obviously improved; the obtained hybrid pigment has bright and beautiful color and luster; excellent acid and alkali resistant and ultraviolet light resistant performance is realized; the application of the cobalt blue pigment is expanded. In addition, through the introduction of low-grade quartz sand and metal ions, the consumption of cobalt compounds and the production cost of the cobalt blue pigments can be reduced.

Owner:LANZHOU INST OF CHEM PHYSICS CHINESE ACAD OF SCI +1

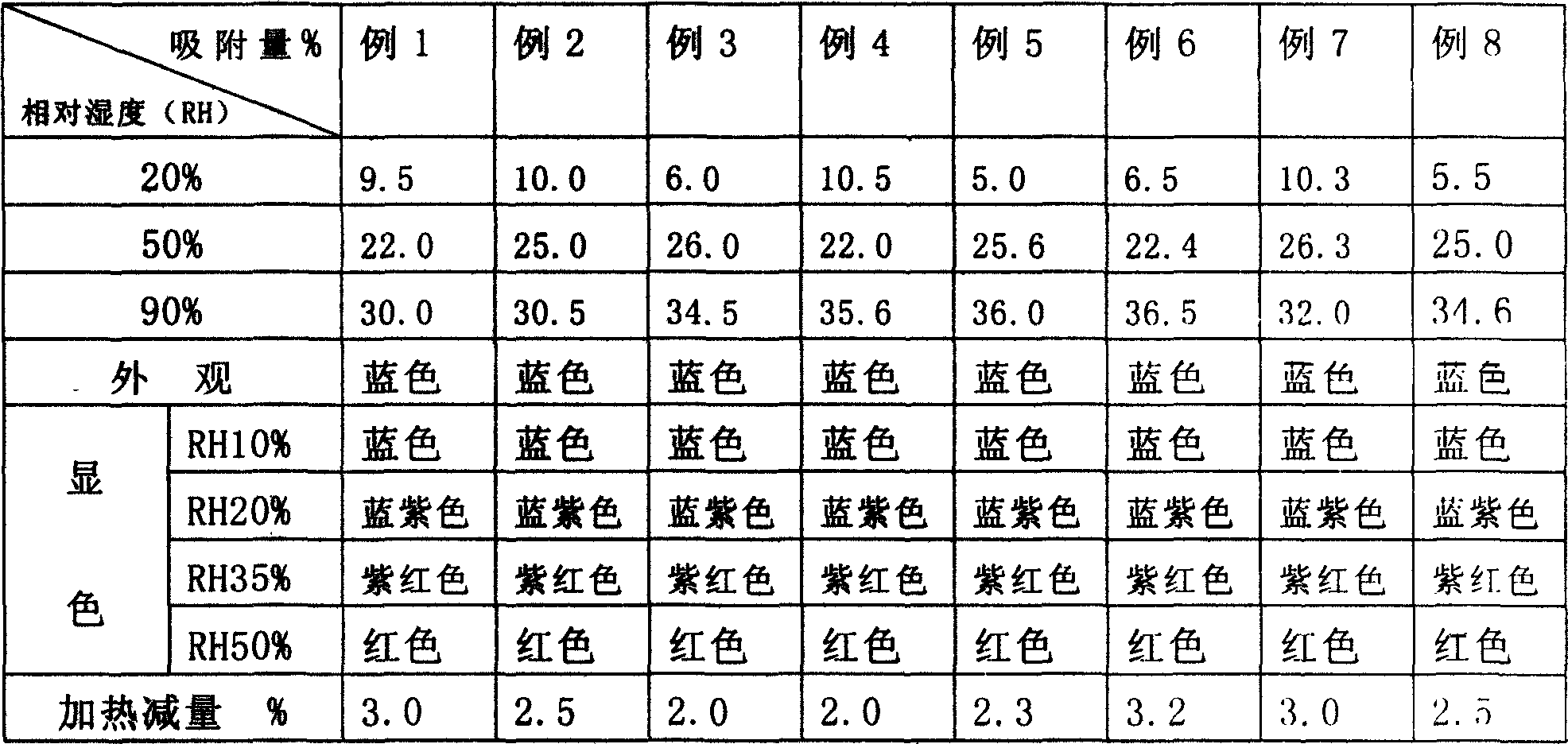

Novel blue variable colour indicator agent and producing process thereof

InactiveCN1740781AKeep healthyMeet the habit of changing colorMaterial analysis by observing effect on chemical indicatorSolution treatmentSorbent

The present invention discloses a blue discoloration indicator. It is made up by utilizing tangible granular adsorbent of silica gel and alumino silica gel and making it undergo the process of cobaltless dyeing solution treatment. It has the following physical and chemical indexes: adsorptive capacity below RH20% is 3.0-12.0%, adsorptive capacity below RH5-% is 10.0-30.0% and heating loss is less than or equal to 5.0%, and the reversible discoloration range is that under the condition of RH10%,20%,35% and 50% it can display blue, blue-purple, mauve and red. Said indicator can be used for absorbing water content in neutral gas.

Owner:青岛海洋化工有限公司

Oxidized white china clay and preparation method thereof

InactiveCN104446360AUniform compositionOptimizing componentsCeramic materials productionClaywaresCobalt blueEconomic benefits

The invention discloses an oxidized white china clay which comprises the following components by weight ratio: 20-25 parts of feldspar, 15-20 parts of quartz, 5-10 parts of raw ores, 40-45 parts of kaolin, 5-10 parts of white china powder and 0.005-0.008% of cobalt blue pigment. The invention also discloses a preparation method of the oxidized white china clay. According to the oxidized white china clay and the preparation method, the waste white china is processed into another man-made high-quality barren material, so that the source of the high-quality barren material can be partially increased and large economic benefit can be produced at the same time; a trace amount of cobalt blue pigment is added in the clay according to weight proportion, so that the china clay is bluish white under oxidation burning atmosphere, the chinaware whiteness is increased by 4-8% and the shrinking percentage is reduced by 2-3%.

Owner:FUJIAN JIAMEI GRP

Water-soluble metal fluorocarbon coatings with acid rain resistant function for external wall

The invention relates to an acid rain resistant aqueous fluorocarbon coating used for external walls. The coating consists of the following raw materials in the following percents by weight: 55-75 percent of fluorocarbon emulsion, 5-35 percent of pigment, 0.2-2.2 percent of wetting and dispersing agent, 0-0.5 percent of neutralizing agent, 0.1-0.5 percent of antifoam agent, 0-0.5 percent of preservative, 0.1-5.0 percent of thickening agent, 0-5.0 percent of orienting agent, 0-10.0 percent of solvent, 1-6 percent of film forming agent, 1-3 percent of anti-freezing agent, and deionized water as the rest, wherein, the pigment is aluminum paste, pearl pigment, ceramic pigment, rutile titanium dioxide powder, chrome oxide green, cobalt blue, high quality carbon black or phthalocyanine blue. The acid rain resistant aqueous fluorocarbon coating for external walls can permanently protect the decorated buildings against corrosion of acid rain.

Owner:上海三银制漆有限公司

Method for preparing cobalt blue material for decorating ceramic

The invention relates to a method for preparing a cobalt blue material for decorating ceramic. In the method, industrial pure chemical raw materials are adopted; and the method comprises the following steps of: mixing 22 to 45 weight percent of cobalt sesquioxide, 48 to 70 weight percent of aluminum sesquioxide, 0 to 10 weight percent of zinc oxide, 0 to 10 weight percent of magnesium carbonate and 0 to 4 weight percent of chromium sesquioxide; adding 2 to 4 weight percent of boric acid and 6 to 10 weight percent of nucleating agent and uniformly mixing to obtain a reactant; adding acetone in an amount which is 80 percent based on the weight of the reactant; and performing quick ball-milling, drying, baking at the temperature of between 1,100 and 1,200 DEG C, preserving heat, naturally cooling, grinding, cleaning and sieving to obtain the color material. In the method, a large amount of nucleating agent with a small grain size is added into the solid-phase reactant in advance to ensure that crystal simultaneously grows in and on the surface of the reactant, so the grain size of the color material is controlled well, the crystallization completeness is improved, the solid-phase firing temperature is reduced, the firing time is shortened, the acid resistance of the color material is enhanced, and the defects of the conventional solid-phase method for preparing the ceramic color material are overcome.

Owner:JINGDEZHEN CERAMIC INSTITUTE

Feed special for geese in middle stage of growth

InactiveCN105104809APromote digestion and absorptionPromote digestionAnimal feeding stuffBiotechnologyDisease

The invention discloses feed special for geese in the middle stage of growth. The feed is characterized by comprising, by weight, 5-15 parts of corn, 15-30 parts of wheat, 20-30 parts of rice bran, 1-3 parts of pumpkin, 1-5 parts of cobalt blue pigment, 1-3 parts of soya bean meal, 12-15 parts of rapeseed cake, 5-8 parts of soybean pods, 10-20 parts of chrysanthemum meal, 5-15 parts of corn bran, 2-6 parts of fermented bioprotein, 0.5-2 parts of feather meal, 1-5 parts of cottonseed meal, 2-6 parts of Chinese herbal medicine additives, 8-13 parts of corn germ meal, 0.2-1.5 parts of mountain flour, 0.2-0.6 part of calcium hydrophosphate, 2-4 parts of natural pigment, 1-4 parts of selenium malt, 2-5 parts of spirulina powder, 1-2 parts of red chili powder, 1-5 parts of soya bean lecithin, 0.5-2 parts of vitamins and 2-6 parts of phagostimulant. By the adoption of the feed, a good preparation can be made for fattening in the later period, nutrients are balanced, feeding can be effectively promoted, and disease resistance is enhanced.

Owner:ANHUI BAIXIN FEED CO LTD

Preparation method of blue-and-white Nixing ceramic

The invention discloses a preparation method of blue-and-white Nixing ceramic. The preparation method comprises the following step: (1) preparing a blank: preparing the blank from the following raw materials in parts by weight: 45 to 55 parts of east mud, 40 to 50 parts of west mud, 7 to 9 parts of kaolin, 1 to 3 parts of bentonite, 1 to 3 parts of feldspar, 4 to 6 parts of quartz and 2 to 4 parts of talcum; (2) forming the blank; (3) trimming the blank; (4) drying the blank; (5) decorating the blank: drawing a pattern and writing characters on the blank by using cobalt blue material; (6) firing. According to the preparation method, by adjusting the formula of the blue-and-white paint, a color development temprature range of the blue-and-white paint is consistent with a firing temperature range of the Nixing ceramic blank; a stepped continuous temperature rising and reducing method is used for firing, so that the blue-and-white decorative Nixing ceramic is realized and a practical value of the Nixing ceramic is increased; the formula is reasonable, the production cost is low and the firing rate is high.

Owner:QINZHOU CITY HUAXIA TAIJIQUAN NINGXING POTTERY

One-time sintered cobalt blue frit dry particles and preparation method thereof

The invention discloses one-time sintered cobalt blue frit dry particles and a preparation method thereof. The frit dry particle preparation raw materials comprise boric acid, borax, feldspar, quartz, dolomite, barium carbonate, non-calcined alumina, zirconium silicate, fluorspar, and cobalt oxide. The frit dry particles have an intrinsic cobalt blue color and good gloss, and are semitransparent. The particles are shiny under light. The frit dry particles has high initial melting temperature, low high-temperature viscosity, appropriate expansion coefficient, wide sintering range, and good combination with a ceramic blank. The particles can be sintered in one time, such that energy consumption is reduced by approximately 15% than that of twice sintering.

Owner:广东道氏陶瓷材料有限公司

Preparation of acetylacetone cobalt

InactiveCN1746180ASimple preparation processEasy to operateGroup 8/9/10/18 element organic compoundsCobalt blueMaterials science

Production of cobalt acetylacetone is carried out by reacting soluble ceramic cobalt blue solution with NAOH solution to generate cobaltous hydroxide deposit, and adding into acetylacetone to generate cobaltous acetylacetone crystal at 130 Deg C.. It achieves simple process, higher production efficiency and recovery rate.

Owner:BEIJING UNIV OF CHEM TECH

Preparation method of anti-counterfeiting cobalt blue pigment with infrared reflectance function and fluorescence emission function

The invention relates to a preparation method of an anti-counterfeiting cobalt blue pigment with an infrared reflectance function and a fluorescence emission function. A molecular formula of a blue material is CoAl2O4; and the structural composition is CoO.Al2O3. According to the method, a soluble raw material firstly reacts in a solution, is mixed evenly at a molecular level, and is burnt to obtain a product; meanwhile, a redox assistant is added to reduce the burning temperature and reduce energy consumption; and finally, the cobalt blue pigment with non-infrared absorption characteristic and fluorescence emission is finally synthesized. Compared with the prior art, the anti-counterfeiting cobalt blue pigment has the advantages that the anti-counterfeiting cobalt blue pigment is simple in preparation technology and low in burning temperature; and the pigment has no absorption in a near infrared region, has fluorescence emission in an ultraviolet region, and also has application value as an anti-counterfeiting pigment.

Owner:SHANGHAI UNIV

Preparation method for cobalt blue material decorative Nixing pottery

The invention discloses a preparation method for cobalt blue material decorative Nixing pottery. The preparation method comprises the following steps: (1) preparing a preform body, wherein the preform body is prepared from the following raw materials in parts by weight: 50 to 60 parts of east clay, 30 to 40 parts of west clay, 5 to 8 parts of kaolin, 1 to 3 parts of bentonite, 4 to 6 parts of feldspar and 2 to 4 parts of quartz; (2) shaping the preform body; (3) finishing the preform body; (4) drying the preform body; (5) decorating the preform body: painting patterns or writing characters on the preform body with a cobalt blue material; (6) firing. According to the preparation method disclosed by the invention, by adjusting the formula of the cobalt blue material, the developing temperature range of the cobalt blue material is consistent with the firing temperature range of the Nixing pottery preform body, and firing is performed by combining with a stepped continuous heating and cooling method, not only is the cobalt blue material decorative Nixing pottery realized and the practical value of the Nixing pottery increased but also the formula is reasonable, the production cost is low, and the firing rate is high.

Owner:QINZHOU CITY HUAXIA TAIJIQUAN NINGXING POTTERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com