Method for preparing light-blue cobalt blue hybrid pigment from aluminum-rich non-metallic minerals

A non-metallic mineral, bright blue technology, applied in chemical instruments and methods, inorganic pigment treatment, inorganic chemistry, etc., can solve problems such as poor chromaticity of cobalt blue hybrid pigments, and achieve excellent dispersion performance and suspension stability , to achieve high-value utilization, bright color effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

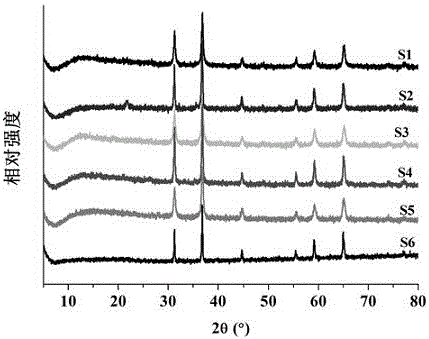

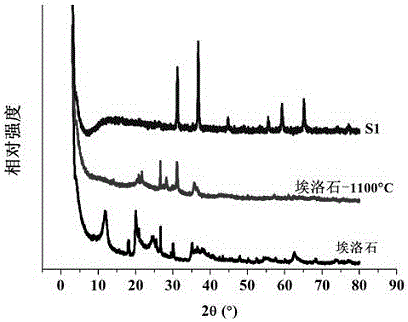

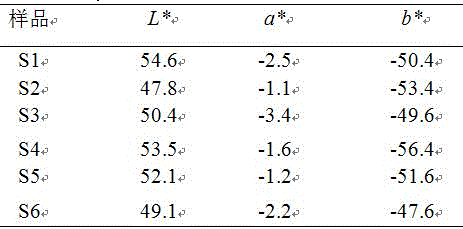

[0024] Stir and disperse 0.354 g of halloysite in 50 mL of water, add 2.91 g of cobalt nitrate and 7.50 g of aluminum nitrate and stir to dissolve, then slowly drop 8 M NaOH until the pH of the system is 9, and react for 1 h. Directly placed in a tube furnace, crystallized at a high temperature of 1100°C for 1 h to obtain a bright blue cobalt blue hybrid pigment, sample number S1.

Embodiment 2

[0026] Stir and disperse 1.074g bauxite in 50 mL water, add 2.38 g cobalt chloride and 7.50 g aluminum nitrate and stir to dissolve, then slowly drop 8 M NaOH until the pH of the system is 10, and the solid product obtained after reaction for 1 h is washed by centrifugation Afterwards, it was directly placed in a tube furnace, and crystallized at a high temperature of 1200°C for 1.5 h to obtain a bright blue cobalt blue hybrid pigment, the sample number of which was S2.

Embodiment 3

[0028] Stir and disperse 1.416g andalusite in 50 mL water, add 2.38 g cobalt chloride, 1.33 g aluminum chloride and 3.75 g aluminum nitrate and stir to dissolve, then slowly add 8 M NaOH dropwise until the pH of the system is 9, and react for 1 h to obtain After the solid product was washed by centrifugation, it was directly placed in a tube furnace and crystallized at 1100 °C for 1 h to obtain a bright blue cobalt blue hybrid pigment. The sample number is S3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com