Process for anode oxidation coloration of titanium and titanium alloy surface

An anodizing and titanium alloy technology, applied in the field of titanium and titanium alloys, can solve the problems of uneven color, single coloring effect, chemical instability, etc., and achieve good bonding force and corrosion resistance, good decorative effect, and fewer process steps. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] 1) Alkali washing, at room temperature, add sodium carbonate (20g), sodium phosphate (20g), sodium silicate (10g) in turn to deionized aqueous solution (1L), heat up to 70°C after the dissolution is complete, and process it into 10mm Put the commercially pure titanium sample of size ×10mm×2mm into the alkaline cleaning solution and continue to stir it ultrasonically, and take it out after 15 minutes of treatment. At room temperature, put the alkali-washed titanium into flowing deionized water for 2 minutes and take it out.

[0025] 2) Pickling, at room temperature, add hydrofluoric acid (50mL) and nitric acid (200mL) with a concentration of 40% in sequence in deionized aqueous solution (750mL), and put the titanium after alkali washing into the pickling solution Take out after processing for 60s. At room temperature, put the acid-washed titanium into flowing deionized water and wash it for 2 minutes before taking it out.

[0026] 3) Anodizing coloring, at 15°C, add ph...

Embodiment 2

[0037] 1) Alkali washing, at room temperature, add sodium carbonate (20g), sodium phosphate (20g), sodium silicate (15g) in turn to deionized aqueous solution (1L), and heat to 70°C after the dissolution is complete, and TC4 titanium alloy Put the sample into the alkaline cleaning solution and continue ultrasonic stirring, and take it out after 15 minutes of treatment. At room temperature, put the alkali-washed titanium alloy into flowing deionized water for 2 minutes and take it out.

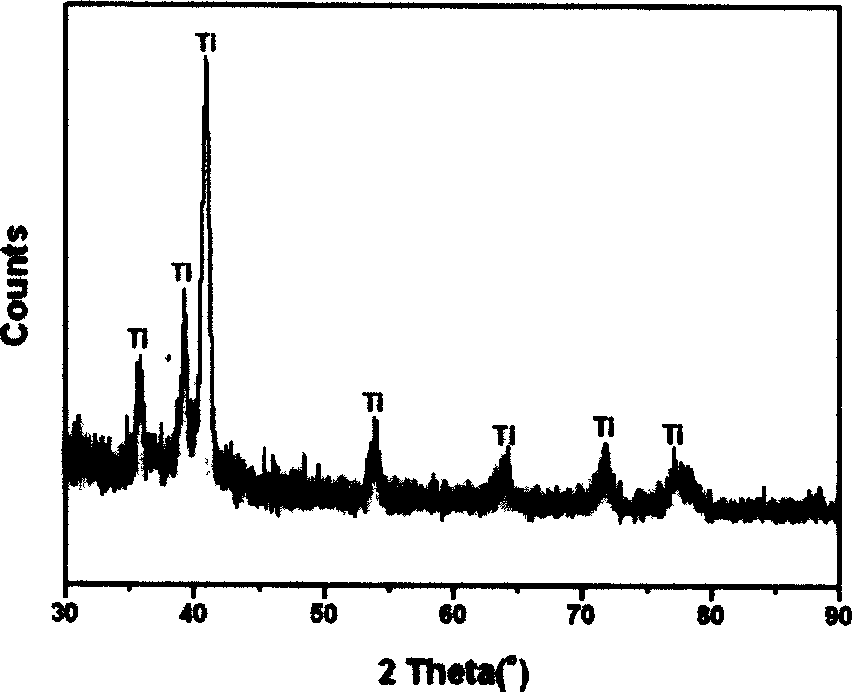

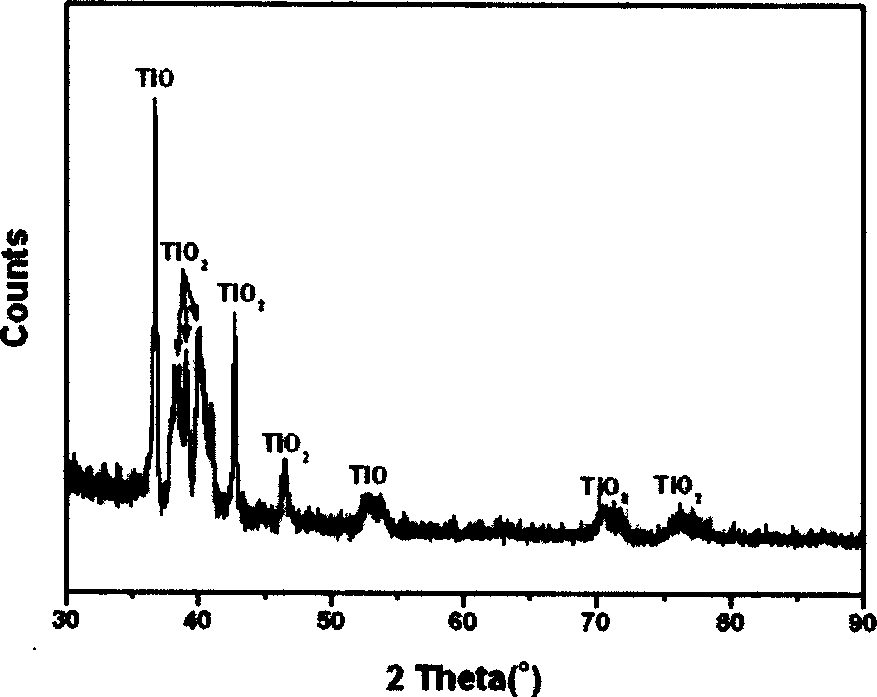

[0038] 2) Pickling, at room temperature, add hydrofluoric acid (50mL) and nitric acid (200mL) with a concentration of 40% in sequence in a deionized aqueous solution (750mL), and put the titanium alloy after alkali cleaning into the pickling solution Take it out after 60 seconds of medium treatment. At room temperature, put the pickled titanium alloy in flowing deionized water for 2 minutes and take it out. The surface structure analysis of the treated titanium alloy is shown in figure 1 , t...

Embodiment 3

[0048] 1) alkali washing, with embodiment 2.

[0049] 2) pickling, with embodiment 2.

[0050] 3) Anodic oxidation coloring, at 25°C, add phosphoric acid (80mL), oxalic acid (12g), manganese sulfate (3g) in sequence in deionized water solution (700mL) under stirring, after the dissolution is complete, add the composite additives under stirring, in turn For: sodium p-benzenesulfonate (3g), sulfosalicylic acid (3g). Finally, deionized water was added to make up to 1 L. Put the titanium alloy after the above treatment into the solution, use stainless steel as the cathode and titanium alloy as the anode, apply 7A·dm -2 The constant current is boosted to 45V and then the constant voltage is taken out after 25 minutes of treatment. At room temperature, put the anodized titanium alloy into flowing deionized water and wash it for 2 minutes before taking it out.

[0051] 4) Sealing, put the anodized and colored titanium alloy into boiling deionized water, and seal for 30 minutes. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com