Patents

Literature

121results about How to "Soft and delicate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Production technology of flexible silk azelon laschel blanket

ActiveCN102912552ABright colorSoft and delicateWarp knittingHeating/cooling textile fabricsTextile printerEngineering

The invention relates to a production technology of a flexible silk azelon laschel blanket. The production technology comprises the following steps of: chaining, beaming, knitting, bleaching, sizing, dyeing, soaping, mellowing, drying and postprocessing and the like. The production technology of the flexible silk azelon laschel blanket provided by the invention optimizes a spinning technology, and techniques of weaving, front finishing, textile printing (dyeing) and after finishing according to characteristics of flexible silk azelon and acrylic fibers, so that a functional blanket meeting new requirements that consumers pursue comfort and heath and the like is produced. The flexible silk azelon laschel blanket provided by the invention is bright in color, soft, fine and smooth in hand feeling, and mothproof and mildewproof, and simultaneously has health-care functions of far infrared emission and anions and the like.

Owner:ZHEJIANG TRUELOVE CARPET IND SCI & TECH

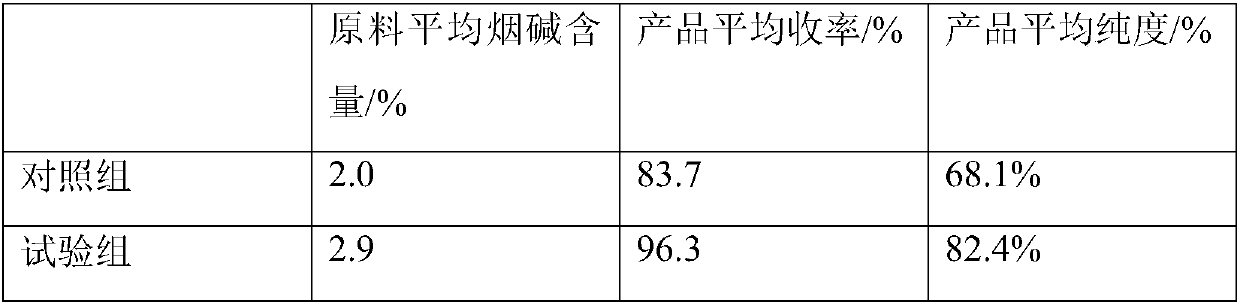

A method of extracting nicotine from tobacco

The invention provides a method for extracting nicotine from tobacco. The method comprises the following steps: mixing a tobacco raw material with carbonate or bicarbonate and an alkaline solution ina certain proportion at 70-90 DEG C and enabling reflux for 1-2 hours, carrying out filtering to obtain a filtrate, conducting extraction twice to three times by an organic solvent, separating an extracting solution from a raffinate, combining the extracting solution, concentrating an organic phase extract at 25-50 DEG C to obtain a yellow oily liquid, and thus obtaining nicotine in tobacco. According to the method for extracting nicotine from tobacco, the nicotine yield is 96.3%, the purity is 82.4%, the aroma of cigarettes is reserved while stimulation to the throat is reduced and the comfort is improved, the nicotine has the original aroma of tobaccos and provides good satisfaction, the requirement of consumers for smoking electronic cigarettes is further met, the sensory evaluation comprehensive index is excellent, and the economic value of the tobacco industry can be improved. The method has great popularization prospects.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Production process for Raschel blanket

InactiveCN105002647ABright colorSoft and delicateSucessive textile treatmentsFibre treatmentTextile printerMildew

The invention relates to a production process for a Raschel blanket. The production process comprises steps of chaining, beaming, knitting, bleaching, sizing, dyeing, soaping, mellowing, drying, post-processing and the like. The production process optimizes the spinning technology and techniques of weaving, pre-treatment, textile printing (dyeing) and post-treatment according to characteristics of bamboo charcoal fibers and acrylic fibers, so that a functional blanket meeting new requirements that consumers pursue comfort and heath and the like is produced. The Raschel blanket is bright in color, is soft and fine in hand feeling, is mothproof and mildew-proof, and simultaneously has health-care functions of far-infrared emission and anion generation.

Owner:CHANGXING HONGBO TEXTILE

Super-fine-denier polyester fiber and manufacturing method thereof

ActiveCN105002603ASoft and delicateConvenient careArtificial thread manufacturing machinesFibre typesPolyesterEthylene oxide

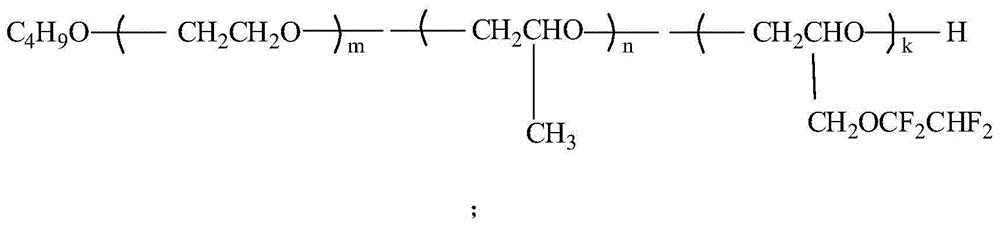

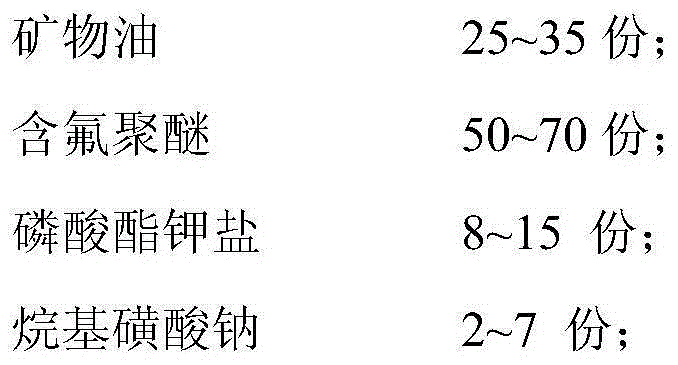

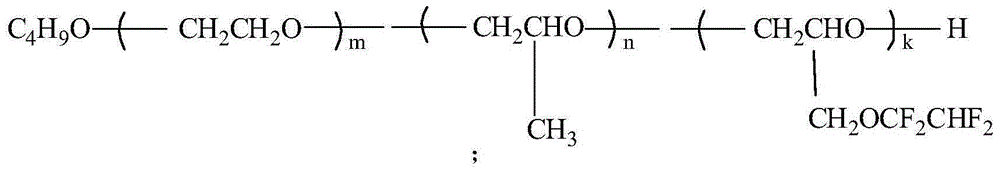

The invention relates to a super-fine-denier polyester fiber and a manufacturing method thereof. The super-fine-denier polyester fiber is mainly made of polyester through spinneret orifice melt spinning and high-speed coiling by the adoption of a grazing agent. The grazing agent at least comprises fluorine-containing polyether, and the mass of the fluorine-containing polyether is larger than or equal to 45% of the mass of the grazing agent. The fluorine-containing polyether is a random copolymer of ethylene oxide, oxirane,2-[(1,1,2,2-tetrafluoroethoxy)methyl] and epoxypropane. The structural formula of the fluorine-containing polyether is as shown in the specification. The manufacturing method of the super-fine-denier polyester fiber comprises the steps of conducting measuring, extrusion, cooling, grazing, stretching and thermal shaping on the polyester and then conducting high-speed winding, and then the super-fine-denier polyester fiber is manufactured. The super-fine-denier polyester fiber has the advantages of being soft in hand feel, high in flexibility, gentle in gloss, high in water absorbing and oil absorbing performance, density, specific surface area and heat preservation performance and the like. The development of the weaving technology and the printing and dyeing technology enables more potential features of the super-fine-denier polyester fiber to be explored gradually.

Owner:JIANGSU HENGKE ADVANCED MATERIALS CO LTD

Process for production of superbright glossy wool worsted face fabric

InactiveCN101012614ASoft and delicateUnique textureSingeingHeating/cooling textile fabricsWorstedCombing

The invention relates to a manufacturing method for the worsted fabric with super-bright gloss, which selects wool and terylene to product the worsted fabric with super-bright gloss by double combing, spinning, weaving, dyeing and finishing. In the manufacturing method of invention, by setting dyeing and finishing process, selecting and proportioning assistant, and selecting calendering equipment, the effect of increasing brightness is achieved for production and the hand feeling of fabric is guaranteed at the same time. Merits of invention are that the produced fabric is provided with soft and fine hand feeling, unique texture, and gloss as silk; it breaks through the style of conventional fabric; and the fabric can maintain high gloss after ironing in high temperature and dry-cleaning.

Owner:杨毅方

Super-soft cotton wool and preparation method thereof

InactiveCN102534933ASoft and delicateWith smooth finishFibre treatmentSingeingAgricultural engineeringCOTTON WOOL

The invention relates to a super-soft cotton wool and a preparation method thereof. In organization circulation of cotton wool tissues, two warps and two wefts are arranged, and two warp interlacing points and two weft interlacing points are arranged. The preparation method comprises (1) adopting 100% long stapled cotton to serve as a raw material, and carrying out napping processing to a lining of the long stapled cotton; (2) adopting singeing and multicomponent biological complex enzyme to carry out polishing, biological deoxidation and dyeing to the long stapled cotton; and (3) finally performing afterfinish to the long stapled cotton, and obtaining the super-soft cotton wool. The super-soft cotton wool is super bright and clean in fabric, soft and environment-friendly. The preparation method is simple in process and low in cost, and has good application prospect.

Owner:NINGBO DAQIAN TEXTILE

Hodo fleece fabric and production method thereof

ActiveCN103966745AThe process steps are simpleSoft and delicateWeft knittingHeating/cooling textile fabricsYarnPolymer science

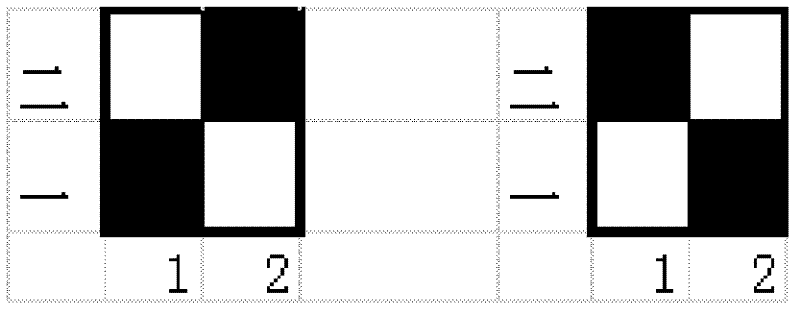

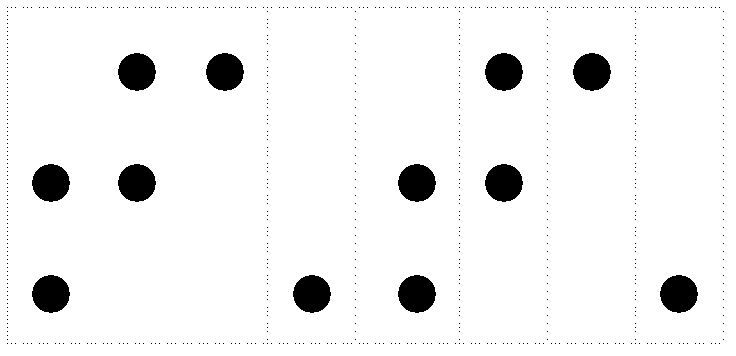

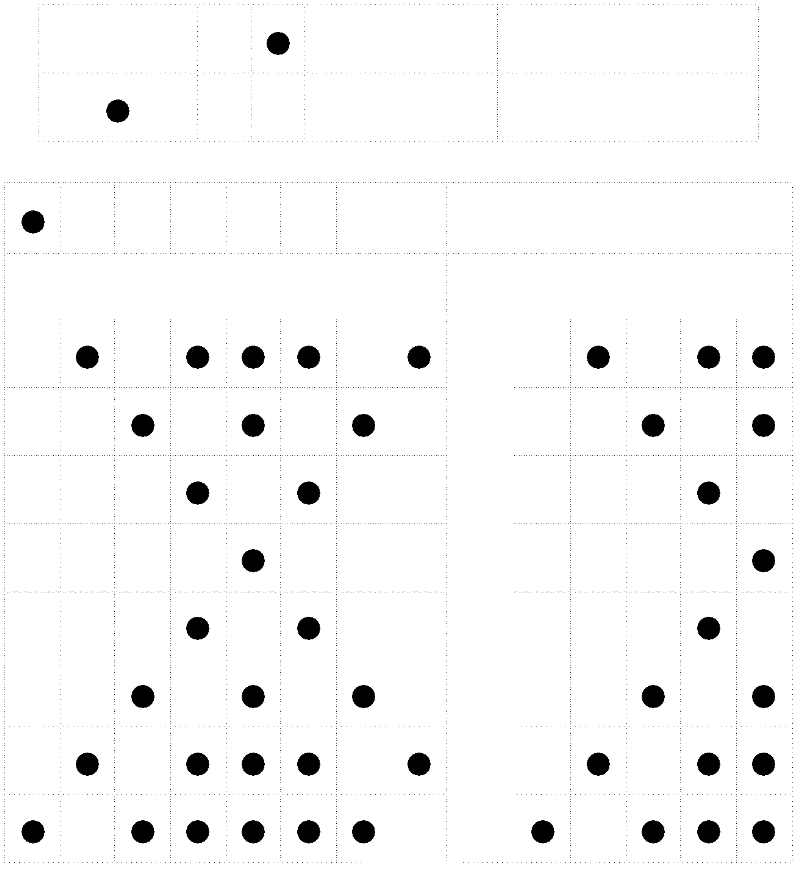

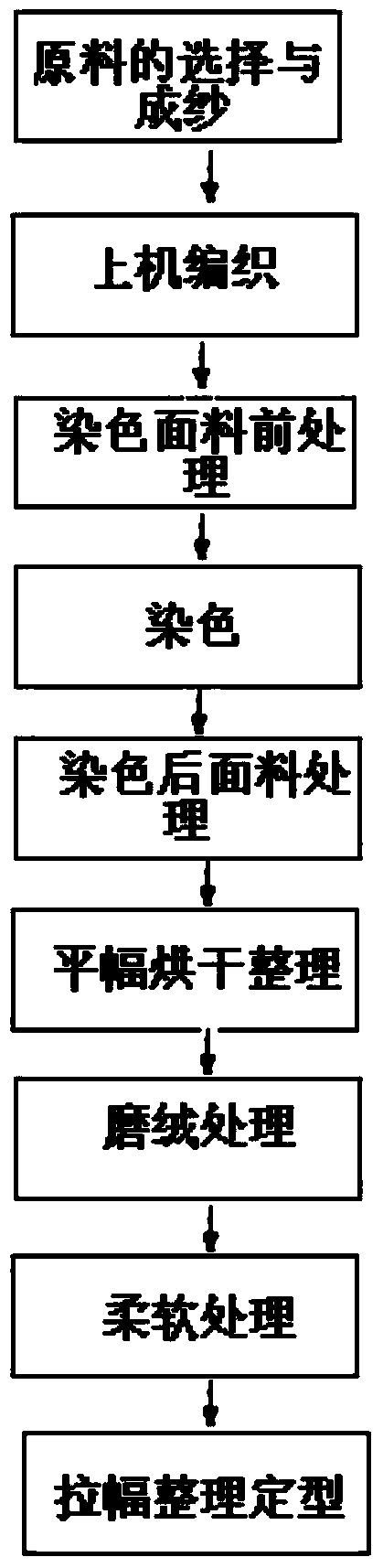

The invention relates to a Hodo fleece fabric and a production method of the Hodo fleece fabric. The production method includes the steps that selection and yarn forming of raw materials, placement of yarns on a machine for knitting, dyeing, fabric treatment after dyeing, full width drying trimming, napping treatment, softening treatment and tentering trimming setting. According to the Hodo fleece fabric produced through the process method, the length of 90% of naps ranges from 0.3 mm to 0.6 mm, and the average density of the suede is 100 stalks per square centimeter. The process steps are simple, the produced fabric naps are short and large in density, and the Hodo fleece fabric is fine, smooth and comfortable in hand feeling and is suitable for underwear fabric.

Owner:WUXI HODOHOME GARMENT

Production method of double-layer Raschel super soft blanket

InactiveCN107587253ASmooth and reverse hair with good glossSoft and delicateDouble pile fabrics splittingWarp knittingYarnAfter treatment

The invention provides a production method of a double-layer Raschel super soft blanket. The production method comprises the following steps of 1, spinning, wherein velvet yarn and bottom yarn are warped through a warping machine and then spun on a braider, and after slitting and cloth inspecting, grey cloth is obtained; 2, before-finishing, wherein the obtained grey cloth is subjected to grey cloth shaping, grey fabric hot lighting and grey cloth brushing; 3, dyeing and finishing, wherein the grey cloth subjected to before-finishing is subjected to printing or ironing, primary drying, steaming color curing, water curing and secondary drying; 4, after-treatment, wherein cotton print after being dyed and finished is subjected to brushing, hot light ironing and shearing, embossing and cutting, and two blankets are oppositely sewed together to obtain the double-layer Raschel super soft blanket; 5, package warehousing, the obtained double-layer Raschel super soft blanket is packaged and warehoused. The produced blanket product is good in luster whether in smooth and straight hair or in retrorse hair, thick, plump, soft and fine in hand feeling and high in product stability.

Owner:无锡中天丝路云联纺织股份有限公司

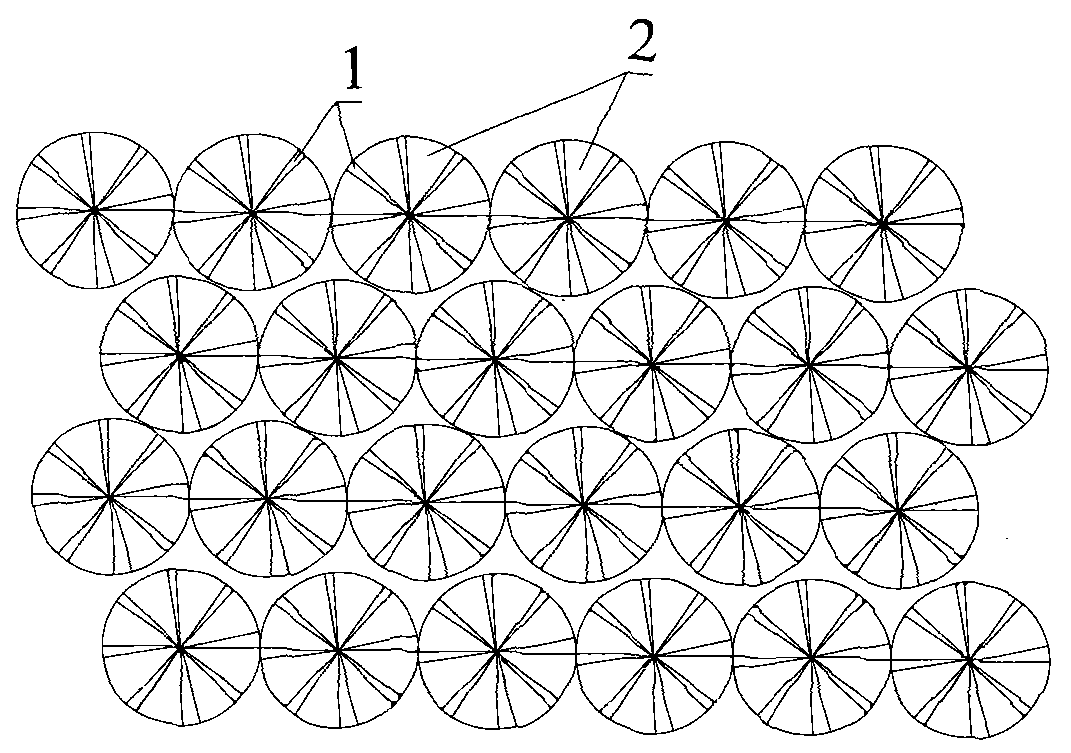

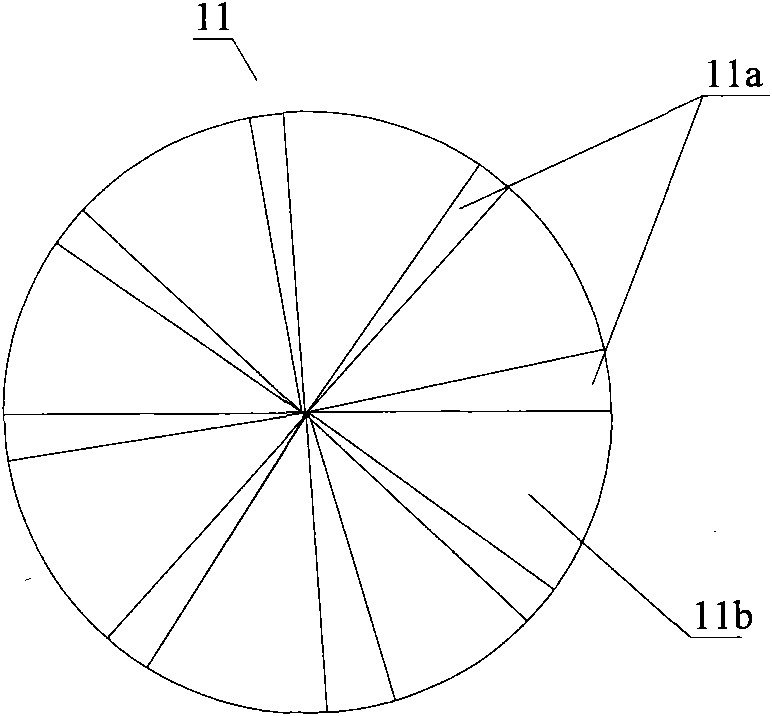

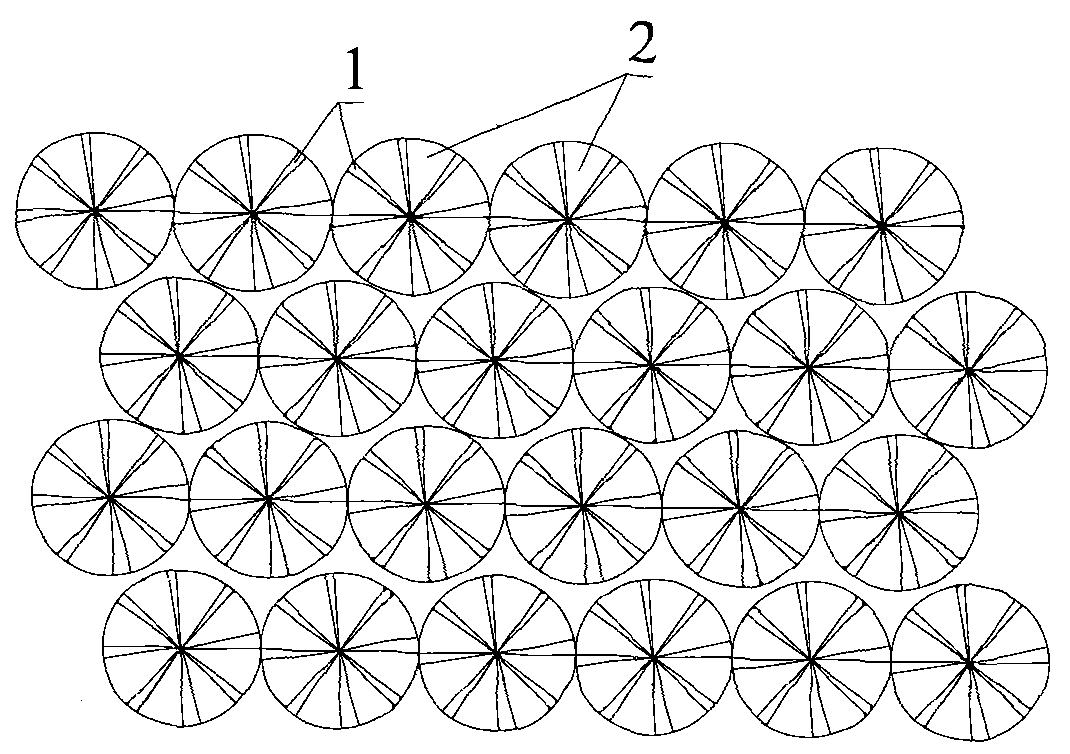

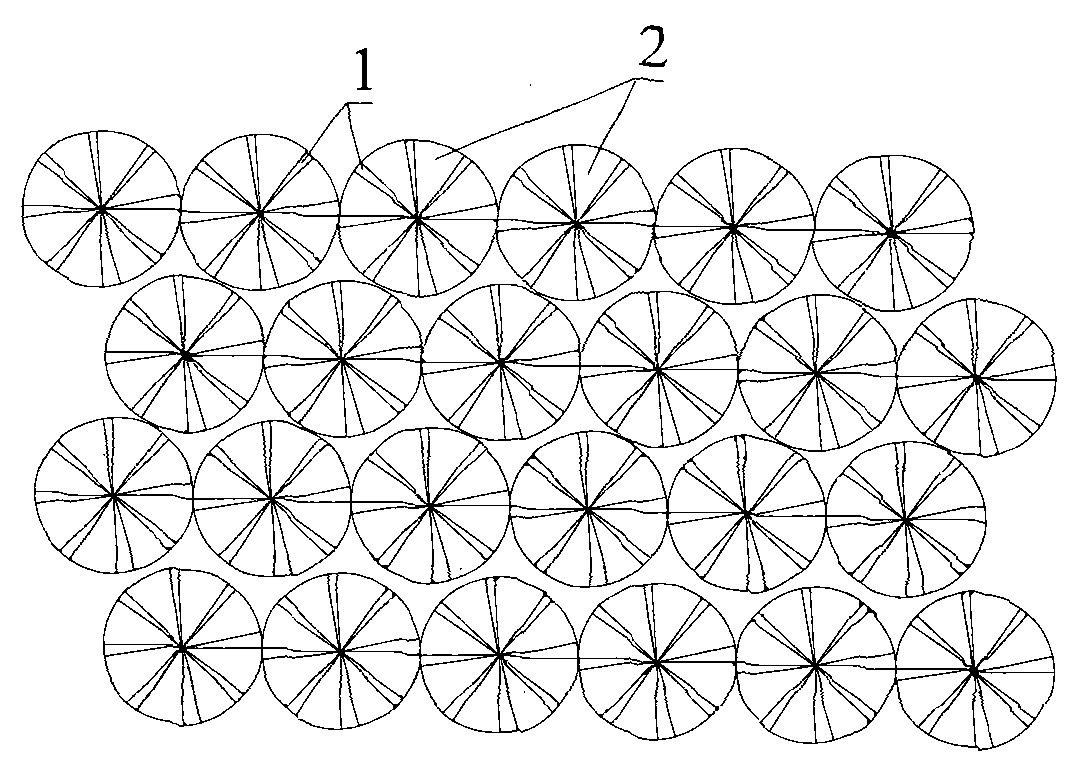

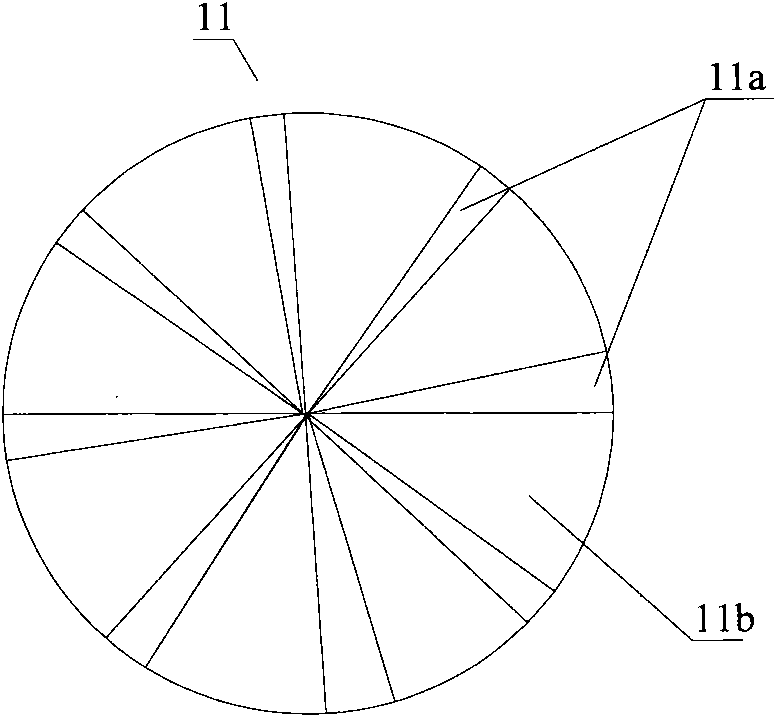

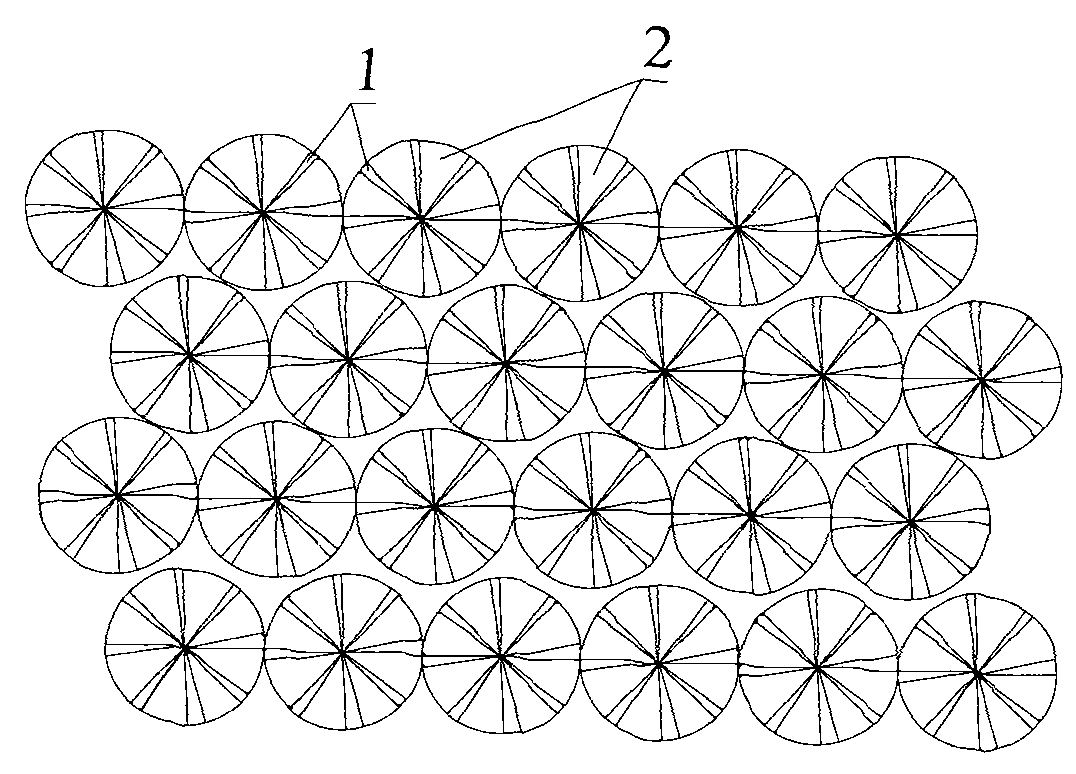

Spinneret plate, profiled nylon 6 fiber and making method thereof

InactiveCN106120003ALarge specific surface areaHigh glossFilament/thread formingMonocomponent polyamides artificial filamentFiberNylon 6

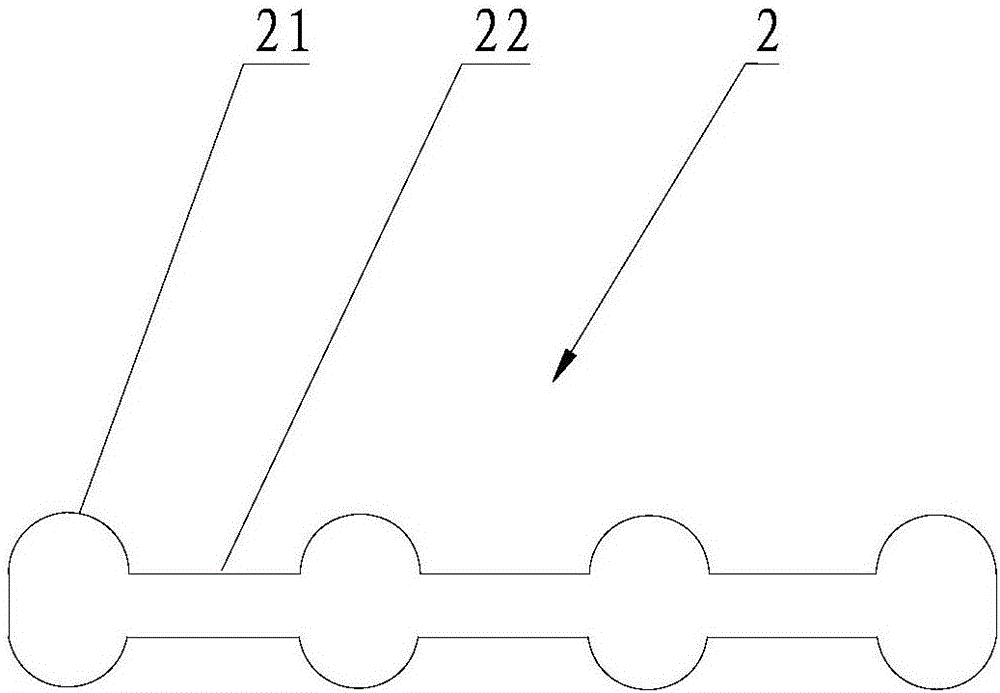

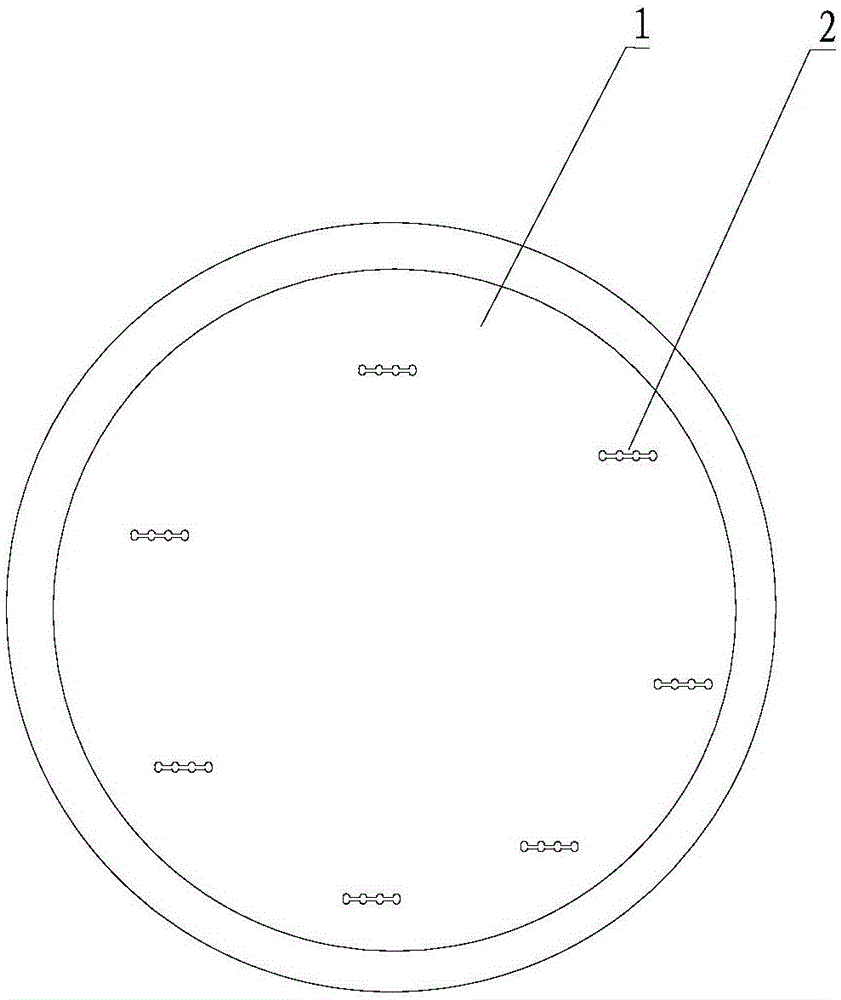

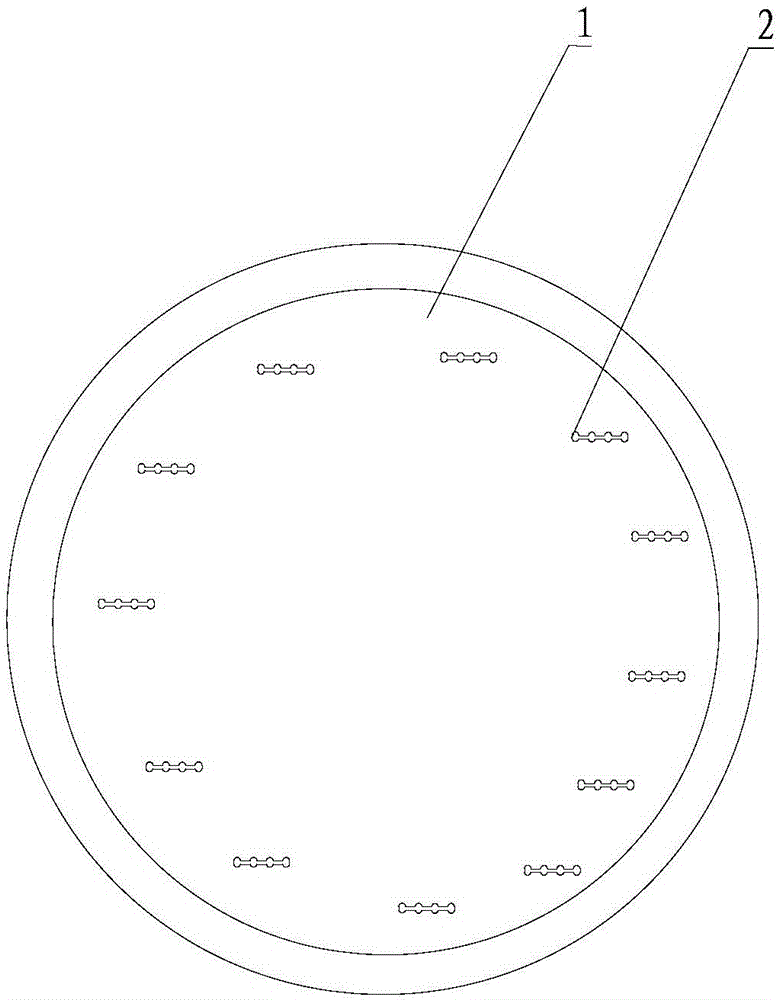

The invention relates to a spinneret plate which comprises a base plate and at least one spinneret micro-hole. The spinneret micro-hole is formed in the base plate, a cross section of the spinneret micro-hole is of a sawtooth structure, the sawtooth structure comprises two sawtooth portions, each sawtooth portion comprises four semi-circular arcs identical in radius, the four semi-circular arcs are sequentially arranged, the adjacent two semi-circular arcs are connected linearly, the two sawtooth portions are mutually connected to form a symmetrical closed structure, and the four semi-circular arcs at one sawtooth portion correspond to the four semi-circular arcs at the other sawtooth portion in a one-to-one mode. The invention further relates to a profiled nylon 6 fiber and a making method thereof. The profiled nylon 6 fiber has good luster and moisture absorption and sweat releasing functions, and a fabric made from the fiber has the soft and exquisite hand feeling of cashmere and also has good dyeing properties, rapid moisture absorption and guidance properties and other excellent characteristics.

Owner:FUJIAN JINJIANG TECH

Regressive reflecting fabric and its prepn

InactiveCN1548293AHigh densityUniform appearanceGlass/slag layered productsSurface layerPolymer adhesive

The present invention relates to product with special surface layer and its making process. The product includes successively basic fabric layer, opaque mirror reflecting layer, polymer adhesive layer, and optical lens element layer containing glass bead in the amount of 90-130 g / sq m. The making process includes first forming opaque mirror reflecting layer on the basic fabric layer, and then then forming the optical lens element layer. The present invention may be used in makes suits for night worker to reduce accident.

Owner:CHINESE TEXTILE ACAD

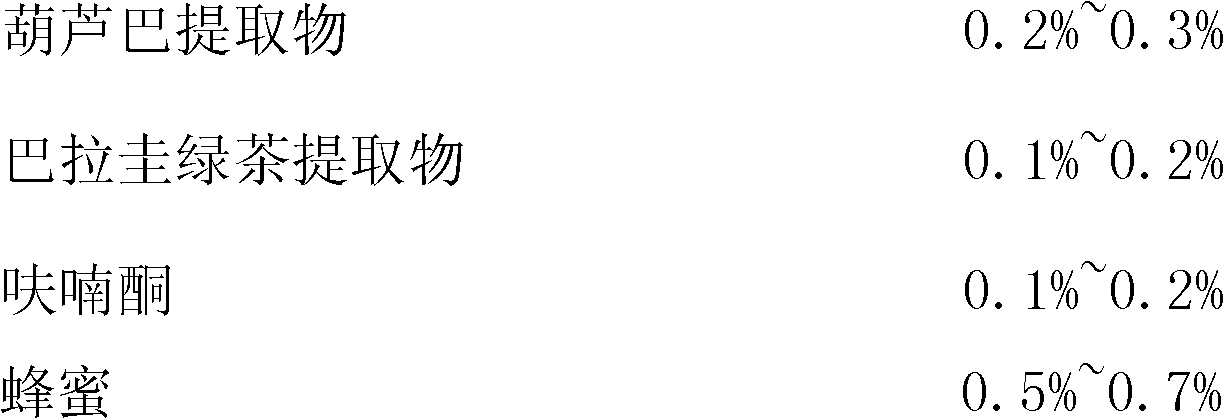

Reinforced essence for baking aromatic tobacco and preparation method for reinforced essence

ActiveCN103300468ARich aromaElegant and tastyTobacco preparationTobacco treatmentCooking & bakingGreen tea extract

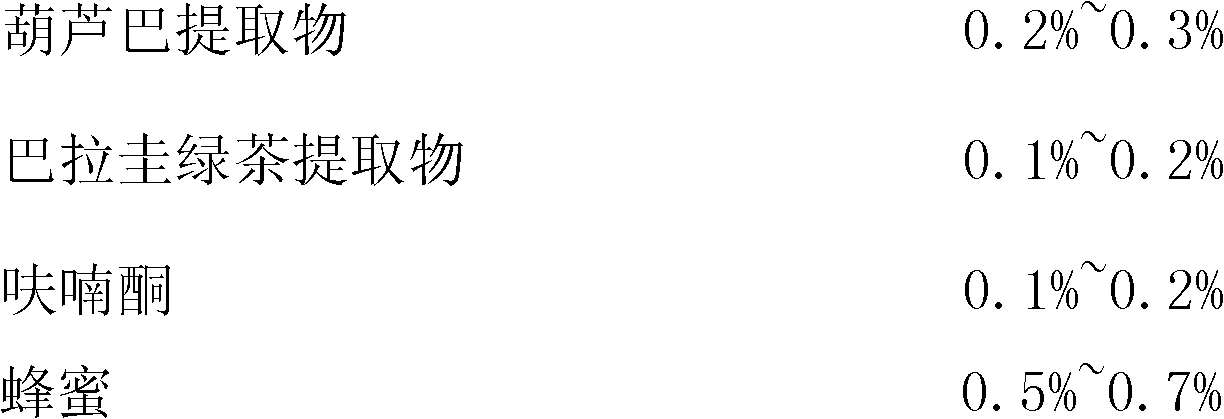

The invention discloses a reinforced essence for baking aromatic tobacco and a preparation method for the reinforced essence. The reinforced essence comprises two parts, namely an interior essence and a surface essence, wherein the interior essence comprises the following components in weight percentage based on cut tobacco: 0.5 percent of propylene glycol and 0.3 percent of sorbitol; and the surface essence comprises the following components in weight percentage based on the cut tobacco: 0.2-0.3 percent of fenugreek extract, 0.1-0.2 percent of Paraguayan green tea extract, 0.1-0.2 percent of furanone and 0.5-0.7 percent of honey. 15 weight percent of interior essence is applied to the cut tobacco when sheets of the aromatic tobacco are prepared; and 5 weight percent of surface essence is applied to shreds when the shreds of the aromatic tobacco are prepared. By the reinforced essence, according to the characteristic aroma of the aromatic tobacco, several aromatic matters are added for blending on the design of a feed liquid, the reinforced essence is added in the aromatic tobacco baking process, the characteristic aroma of the baked aromatic tobacco is weakened, and the reinforced essence has elegant aroma and taste and can be well coordinated with flue-cured tobacco to form a unique cigarette style.

Owner:CHINA TOBACCO FUJIAN IND

Blended yarn of terylene, rabbit hair and silkworm pupa protein fiber

The invention provides blended yarn of terylene, rabbit hair and silkworm pupa protein fiber. The blended yarn comprises the following components: 65-75 weight parts of terylene, 25-35 weight parts of rabbit hair and 10-20 weight parts of silkworm pupa protein fiber. The blended yarn provided by the invention enables the characteristics of terylene, rabbit hair and silkworm pupa protein fiber to be complementary and brings the advantages thereof into play.

Owner:HAIAN COUNTY BROS SYNTHETIC FIBER

Blending shell fabric containing tea fiber and production technology thereof

The invention relates to a blending shell fabric containing tea fiber which comprises the following compositions by weight percent: 25-35% of tea fiber, 10-20% of borlar fiber, 25-35% of counterstat and 20-30% of cotton fiber. A production technology of the blending shell fabric containing tea fiber comprises the following steps of: during a blowing process, setting a beater speed of a cotton slitter as 480 revolutions per minute and a beater speed of a single beater scutcher as 950 revolutions per minute; during a cotton carding process, setting a cylinder speed as 330 revolutions per minute, a doffer speed as 18 revolutions per minute and a licker-in speed as 750 revolutions per minute; during a roving process, setting a roving twisting coefficient as 80 and drafting times of a back zone as 1.30; during a spinning process, setting a spinning twisting coefficient as 380 and drafting times of the back zone as 1.25; during a warping process, setting a running speed as 500m / min; and during a weaving process, setting a let-off tension as 370kg. The blending shell fabric containing tea fiber is excellent in visual effect, has a remarkable feature in the aspect of wearing comfort and has environmental friendliness and anti-bacteria mildew-proof function.

Owner:山东万泰创业投资有限公司

Skin-moistening bread by utilizing grapefruit and chayote and preparation method thereof

InactiveCN105341091AMoisturizerGood moisturizing effectDough treatmentModified nutritive productsRHODIOLA ROSEA ROOTWhole milk

The invention discloses skin-moistening bread by utilizing grapefruit and chayote and a preparation method thereof. The skin-moistening bread comprises following raw materials: 3-4 parts by weight of grapefruit, 2-3 parts by weight of dried vegetables, 3-4 parts by weight of salak, 0.5-1 part by weight of rhodiola rosea, 0.5-1 part by weight of schisandra chinensis, 0.5-1 part by weight of lilies, 100-110 parts by weight of flour, 20-25 parts by weight of chayote, 0.05-0.06 part by weight of xanthan gum, 1-1.1 parts by weight of arabic gum, 6-7 parts by weight of white granulated sugar, 0.8-0.9 part by weight of salt, 1.5-1.7 parts by weight of dried yeast, 2-3 parts by weight of waxy corn starch, 2-3 parts by weight of soy proteins, 5-6 parts by weight of shortening oil, 6-7 parts by weight of eggs, 4-5 parts by weight of whole milk powder and a proper amount of ascorbic acid solutions, raisin broths, filtered juice in fermented glutinous rice fermented for 36 hours, salad oil and water.The skin-moistening bread by utilizing grapefruit and chayote and the preparation method thereof have following beneficial effects: due to the fact that grapefruit and chayote are mixed to squeeze in order to obtain juice and dried vegetables are dried and subjected to superfine grinding operation; superfine grinding stuff heighten a sense of soft and smooth feelings; and chayote has better effect for moistening skin and tastes smooth.

Owner:李桦

Elastic polyester drawing yarn

InactiveCN103014886AIncrease elasticityIncrease chanceMelt spinning methodsMonocomponent polyesters artificial filamentFiberWrinkle skin

The invention discloses an elastic polyester drawing yarn, which is characterized in that polyethylene terephthalate (PET) and polybutylene terephthalate (PBT) are compositely spun. The elastic polyester drawing yarn adopts different components with different viscosities to be compositely spun, by utilizing the difference of retraction rate of boiled water, the yarns are automatically coiled, so that the fiber has high elasticity; when the elastic polyester drawing yarn is used on a home textile fabric, the elastic polyester drawing yarn has advantages of high feeding rate, fineness, softness, good drapability, good ventilation, strong water absorption property and good wrinkle resistance; and the production process is simple, no burr and no flying filament are produced, and the production cost is greatly reduced.

Owner:ZHONGRUN SCI & TECH

Production method of warp-knitted nap type fabric

InactiveCN105780285AClear suedeSoft and delicateOrnamental textile articlesFibre typesPulp and paper industryPhysical property

The invention relates to a production method of warp-knitted nap type fabric. The method comprises steps of weaving, setting, drawing, presetting, dyeing, padding, drying and finished product setting. The method is characterized in that a warp knitting machine knits at least three guide bars into gray fabric in the weaving step, the length of extension lines of front combs of the gray fabric does not exceed 5 stitches, the extension lines of the front combs are drawn off to form nap in the drawing step, and the height of the nap is smaller than 0.5 mm. The height of the nap of the warp-knitted nap type fabric produced with the production method is smaller than 0.5 mm, and the warp-knitted nap type fabric has a clear nap surface, touches fine and soft and is excellent in mechanical and physical property. The process of the production method of the warp-knitted nap type fabric is short, the yarn utilization rate is high, and the production cost is low.

Owner:HAIAN QI HONG TEXTILE TECH CO LTD

Technology for producing deodorant socks

InactiveCN106498602ASoft and delicateImprove comfortLinking machinesHeating/cooling textile fabricsYarnDeodorant

The invention relates to the technical field of production technology of socks and particularly relates to a production technology of deodorant socks. The production technology of the deodorant socks comprises the following steps: (1) preparing yarns, (2) dyeing and deodorizing, (3) softening, (4) weaving socks, (5) jointing, (6) setting, (7) pairing and packaging. The yarn of the technology for producing deodorant socks adopts the proportion of cotton yarn 70%, nylon 25% and spandex 5% to be matched. The technology for producing deodorant socks has the advantages of being reasonable in design, delicate, soft, comfortable and good in handfeel, more deodorant, more wear-resisting, capable of reducing friction, thin in air permeability, capable of being better in elasticity, better in sweat moisture conductivity, not stuffy in feet, easy in washing and quick drying, durable in wearing, and not easy to deformed.

Owner:浙江欧美特袜业有限公司

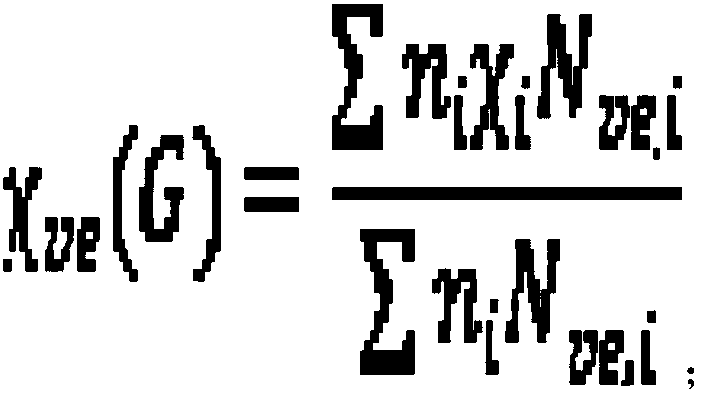

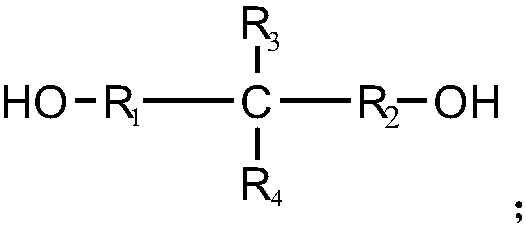

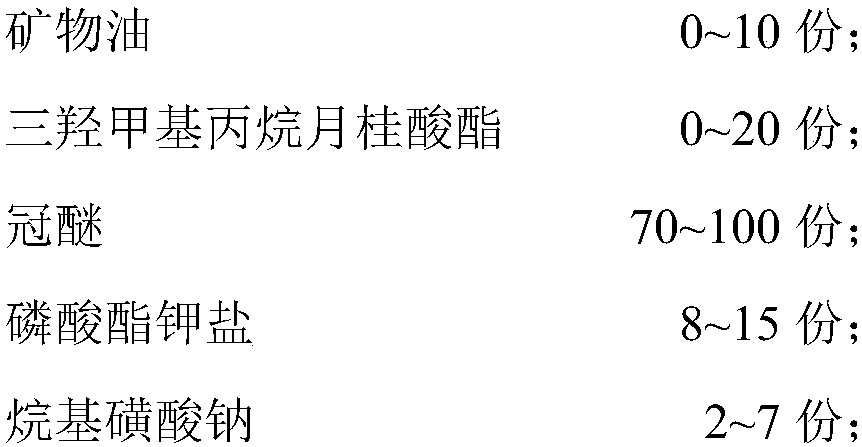

Ultra-fine denier polyester drawn yarn and preparation method thereof

ActiveCN108035007ASimple preparation processSoft and delicateFibre typesMonocomponent copolyesters artificial filamentUltra fineFineness

The invention relates to an ultra-fine denier polyester drawn yarn and a preparation method thereof. A modified polyester is subjected to metering, extruding, cooling, oiling, stretching, heat settingand winding to obtain the ultra-fine denier polyester drawn yarn. An oiling agent used for oiling contains crown ether, and content of the crown ether is 67.30 to 85.58wt%. A modified polyester molecular chain includes a terephthalic acid chain segment, an ethylene glycol chain segment and a dihydric alcohol chain segment with a branched chain. A structural formula of the ethylene glycol with thebranched chain is as follows: the structural formula is shown in the description. R1 and R2 are each independently selected from straight-chain alkylene groups with 1 to 3 carbon atoms, R3 is selected from alkyl groups with 1 to 5 carbon atoms, and R4 is selected from alkyl groups with 2 to 5 carbon atoms, and the resulting ultra-fine denier polyester drawn yarn is obtained. The single-filament fineness of the ultra-fine denier polyester drawn yarn is 0.2 to 0.3 dtex. The method is simple and reasonable, and the prepared ultra-fine denier polyester drawn yarn is soft and delicate, and has high quality.

Owner:JIANGSU HENGLI CHEM FIBER

Blended yarn of acrylic fiber, jute fiber and silkworm pupa protein fiber

The invention provides a blended yarn of acrylic fiber, jute fiber and silkworm pupa protein fiber. The blended yarn is characterized by comprising the following components: 60-70 weight parts of acrylic fiber, 15-25 weight parts of jute fiber and 15-25 weight parts of silkworm pupa protein fiber. The blended yarn provided by the invention enables the characteristics of acrylic fiber, jute fiber and silkworm pupa protein fiber to be complementary and brings the advantages thereof into play.

Owner:JIANGSU TONGHAI THREAD

Manufacturing method of powder-wax synthetic leather

ActiveCN102899921APowder wax feeling is strongFull patternLamination ancillary operationsSynthetic resin layered productsFiberWax

The invention discloses a manufacturing method of powder-wax synthetic leather. The method comprises the steps of mixing 5-10 parts of dimethyl formamide and 0.5-2 parts color paste uniformly; filtering the mixture; adding 100-120 parts of dimethyl formamide and 20-30 parts of wood powder to the above mixture, stirring uniformly and swelling; adding 100 parts of a polyurethane wet resin, stirring uniformly, defoaming and coating the obtained mixture on the textile fabric fiber; immersing in a solution of 18-22% dimethyl formamide to make the mixture solidified, squeezing water, washing with water and drying to obtain a wet base; mixing 100 parts of polyurethane dry resin, 15-20 parts of dimethyl formamide, 15-20 parts of butanone, 15-20 parts of toluene, 0.5-1.0 part of an auxiliary agent and 3-5 parts of a toner uniformly and coating the obtained mixture on release paper to obtain a dry veneer; adhering the wet base to the dry veneer, drying, separating from the release paper, heat-embossing, cool-shaping, coating a surface-treatment agent with relatively strong powder-wax feeling on the embossed surface; drying and cooling. The obtained product has strong powder-wax feeling; full patterns, soft and delicate hand feel.

Owner:KUNSHAN XIEFU NEW MATERIALS LTD BY SHARE LTD

Nylon-acrylon-pupa azelon blended yarn

The invention provides a nylon-acrylon-pupa azelon blended yarn which comprises the following components in parts by weight: 40-50 parts of nylon, 40-50 parts of acrylon and 15-25 parts of pupa azelon. The invention complements the mutual characteristics of the nylon, acrylon and pupa azelon, and displays the advantages of the nylon, acrylon and pupa azelon.

Owner:HAIAN ZHONGSHAN SYNTHETIC FIBER

Two-component split type composite FDY fiber and preparation method thereof

InactiveCN101845685ALoose molecular structureEasy accessMelt spinning methodsConjugated synthetic polymer artificial filamentsPolyamideMicrofiber

The invention provides a two-component split type composite FDY fiber which is characterized in that he two components in the two-component composite DTY fiber are a polyester component and a polyamide component, wherein the polyester component is selected from one or more of polytrimethylene terephthalate, polybutylene terephthalate and cation normal-pressure dyeable polyester. The invention also provides a preparation method for preparing the split type composite FDY fiber, which comprises the following steps: respectively melting the polyester component and the polyamide component, then carrying out extrusion molding through a spinneret plate, cooling, applying oil, drafting and winding to obtain the two-component split type composite FDY fiber. The composite FDY fiber and the two-component superfine fiber fabric which are prepared by the method have the characteristics of good dyeing property and soft texture.

Owner:XIAMEN HONGXIN SPECIAL FIBER CO LTD

Multifunctional comfortable fabric

InactiveCN103526428AGood moisture absorption and air permeabilitySoft and delicateWoven fabricsUndergarmentsMoisture absorptionPulp and paper industry

The invention discloses multifunctional comfortable fabric which comprises soybean fibers, silk fibers, cotton fibers and vinylon fibers. The multifunctional comfortable fabric is formed by interweaving warp yarn and weft yarn, the warp yarn is formed by blending the soybean fibers and the cotton fibers, the weft yarn is formed by blending the silk fibers and the vinylon fibers, the warp yarn accounts for, by weight, 56% of the multifunctional comfortable fabric, and the weft yarn accounts for, by weight, 44% of the multifunctional comfortable fabric. By means of the mode, the multifunctional comfortable fabric contains various high-quality fiber components, has good moisture absorption and air permeability and is soft, fine and smooth in hand touch, and manufactured closed-fit clothes can maintain the skin to be moist and glossy, and have the functions of bacterium resistance and healthcare.

Owner:WUJIANG SENHAO TEXTILE

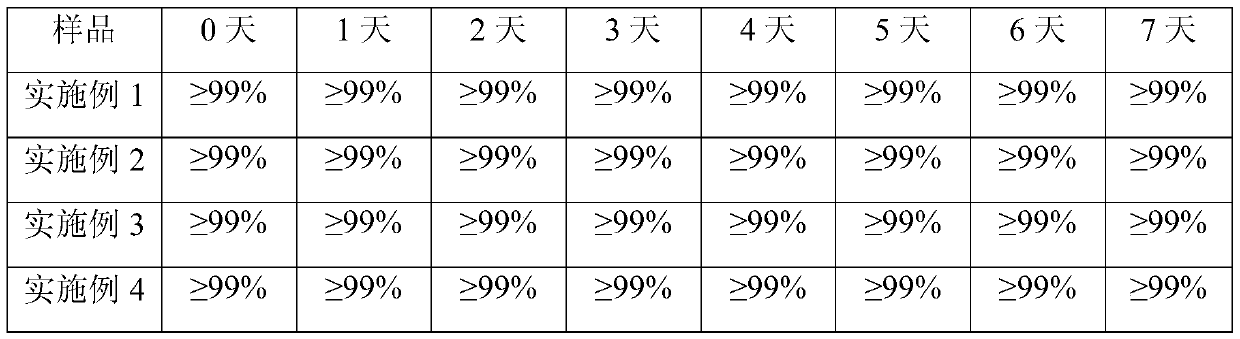

Silk woven medical suture with color discrimination and anti-bacterial functions and preparing method thereof

ActiveCN105497974AImprove antibacterial propertiesLess hairySuture equipmentsYarnEscherichia coliStaphylococcus aureus

The invention discloses a silk woven medical suture with color discrimination and anti-bacterial functions and a preparing method thereof. One-ply silk threads are used as a raw material and are dyed through a natural dyestuff post-mordant method; waxing and rewinding are simultaneously conducted on the dyed silk threads with food-grade beeswax, and center threads and shell threads are arranged by the ratio of center threads: shell threads=0.083-0.25 and woven on an automatic weaving machine to obtain silk woven threads; high-temperature fast heat setting is carried out on the silk woven threads, Co60 irradiation sterilization is carried out, and the silk woven medical suture with the diameter range of 0.04-0.5 mm is obtained, wherein the tensile strength is 1.5-50 N, the appearance color is black, the silk woven medical suture does not fade when washed with water, the rate of inhibiting staphylococcus aureus and escherichia coli is 99% or more, and the bacterium inhibiting duration time is 7 days or longer. The physical properties and antibacterial performance of the silk woven medical suture meets related standards, and the silk woven medical suture is easy to recognize in the operation process and has excellent antibacterial performance.

Owner:HUBEI SAILUO BIOLOGICAL MATERIAL CO LTD

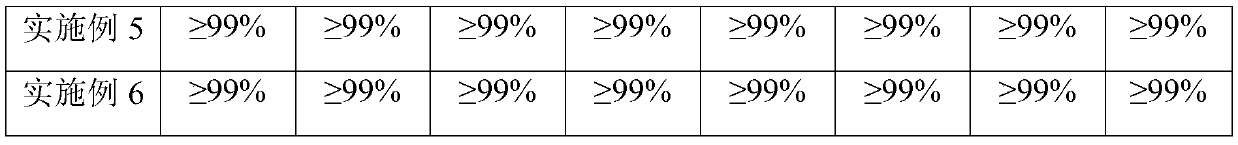

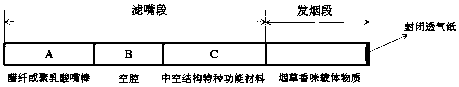

Novel heat-not-burn cigarette and preparation method thereof

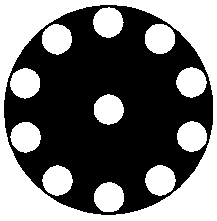

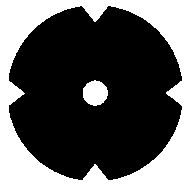

The invention discloses a novel heat-not-burn cigarette and a preparation method thereof. The cigarette comprises a filter tip section and a smoke generation section, the filter tip section comprisesa part A, a part B and a part C; wherein the part A is an acetate fiber or polylactic acid filter tip with the length of 7-10mm; the part B is a section of cavity with the length of 10-15 mm, and thecigarette is characterized in that the part C is a functional material body with a hollow structure, the length of the part C is 5-10 mm, the length of the smoke generation section is 15-20 mm, a tobacco aroma carrier substance is arranged in the fuming section, and the exterior of the fuming section is sealed by a layer of breathable paper. The material has the advantage of remarkably reducing the smoke temperature, is environmentally friendly, and is non-toxic and harmless; the product is sufficient in sensory smoking fog amount, high in tobacco aroma quality, fine and soft in sense and freeof scorch flavor.

Owner:CHINA TOBACCO JIANGXI IND CO LTD

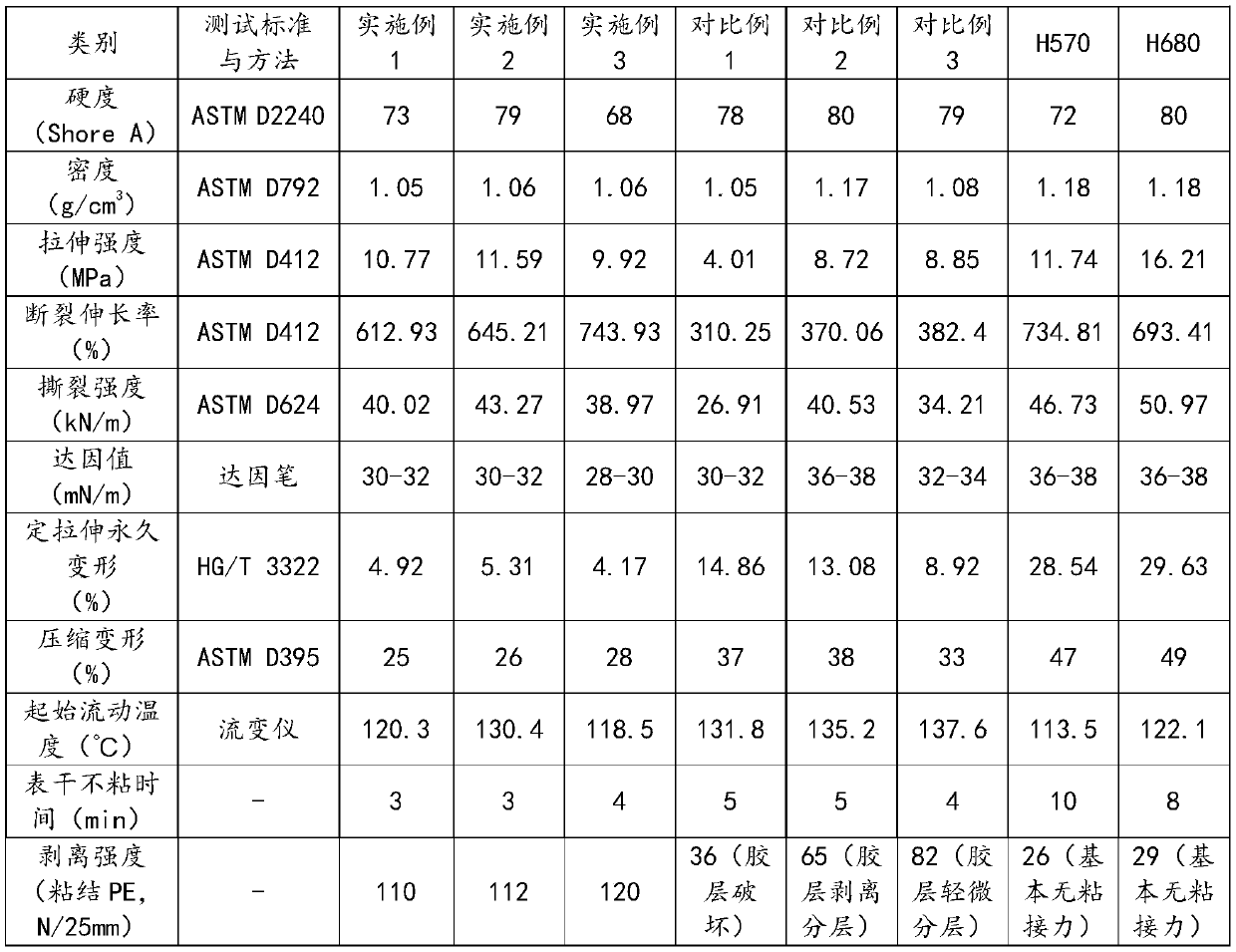

Low-polarity and high-resilience polyurethane hot melt adhesive as well as preparation method and application thereof

ActiveCN110903805AIncrease polarityReduce polarityPolyureas/polyurethane adhesivesPolymer scienceHot melt

The invention belongs to the technical field of polyurethane materials, and particularly relates to a low-polarity and high-resilience polyurethane hot melt adhesive as well as a preparation method and application thereof. The polyurethane hot melt adhesive disclosed by the invention has the advantages of low polarity, high resilience, low thermal activation temperature, low pressure change, low density, low dielectric constant and the like. Specifically, the dyne value is less than or equal to 32mN / m, the hardness is 60-80A, the initial flow temperature Tfb is less than or equal to 135 DEG C,the 200% fixed elongation permanent deformation rate is less than or equal to 10%, and the 24-hour compression deformation at 100 DEG C is less than or equal to 30%. The problem that the conventionalTPU cannot be adhered to a low-polarity or non-polar material due to high polarity and is poor in resilience can be solved. The surface drying non-sticking time is obviously shorter than that of a conventional TPU hot melt adhesive product, and positioning and sticking in use are better facilitated.

Owner:MIRACLL CHEM

Production process of sweat-absorbent breathable sports socks

The invention relates to the technical field of sock production processes, in particular to a production process of sweat-absorbent breathable sports socks. The production process of the sweat-absorbent breathable sports socks comprises the following steps that 1, yarn is prepared; 2, the yarn is softened; 3, the socks are prepared; 4, the socks are disinfected; 5, afterfinishing is carried out on the socks; 6, the socks are checked and packaged. The sports socks are reasonable in design, fine, smooth and soft in hand feeling and good in comfort, deodorization and wear resisting are achieved better, and friction force is reduced; the socks are ultrathin and breathable, super-good elasticity is achieved, sweat absorption and wet permeability are better, the feet are not covered tightly, and the socks are easy to wash and fast to dry, solid and durable, and not likely to deform.

Owner:沈汇明

Antistatic surface tensile-shear thick needle single faced flannelette and production method thereof

InactiveCN102965805ASoft and comfortableRich in colorWeft knittingHeating/cooling textile fabricsYarnPulp and paper industry

The invention discloses antistatic surface tensile-shear thick needle single faced flannelette and a production method thereof. The thick needle single faced flannelette comprises surface yarns and bottom yarns, wherein the surface yarns are knitted by 900D / 768F terylene, the 900D / 768F terylene is twisted by 30% of common terylene and 70% of cation modified terylene in the draw texturing process, the bottom yarns are knitted by 150D / 48F terylene, the surface yarns and the bottom yarns are inter-looped, grey fabric knitted by the surface yarns and the bottom yarns is subjected to dyeing and drying, and the surface of the fabric is subjected to tensile and shearing treatment and the antistatic treatment, so that the thick needle single faced flannelette with rough style and soft and comfortable handfeel is formed.

Owner:JIANGSU SHENGLI ENTERPRISE

Two-component split type composite DTY fiber and preparation method thereof

ActiveCN101845687ALoose molecular structureEasy accessConjugated synthetic polymer artificial filamentsStretch-spinning methodsPolytrimethylene terephthalatePolyamide

The invention provides a two-component split type composite DTY fiber which is characterized in that the two components in the two-component composite DTY fiber are a polyester component and a polyamide component, wherein the polyester component is selected from one or more of polytrimethylene terephthalate, polybutylene terephthalate and cation normal- pressure dyeable polyester. The invention also provides a preparation method for preparing the composite DTY fiber, which comprises the following steps: respectively melting the polyester component and the polyamide component, then carrying out extrusion molding through a spinneret plate, cooling, applying oil, drafting, relieving stress and deforming by false twisting to obtain the two-component split type composite DTY fiber. The composite DTY fiber and the two-component superfine fiber fabric which are prepared by the method have the characteristics of good dyeing property and soft texture.

Owner:厦门象屿兴泓特种材料有限公司

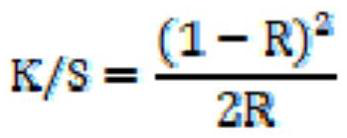

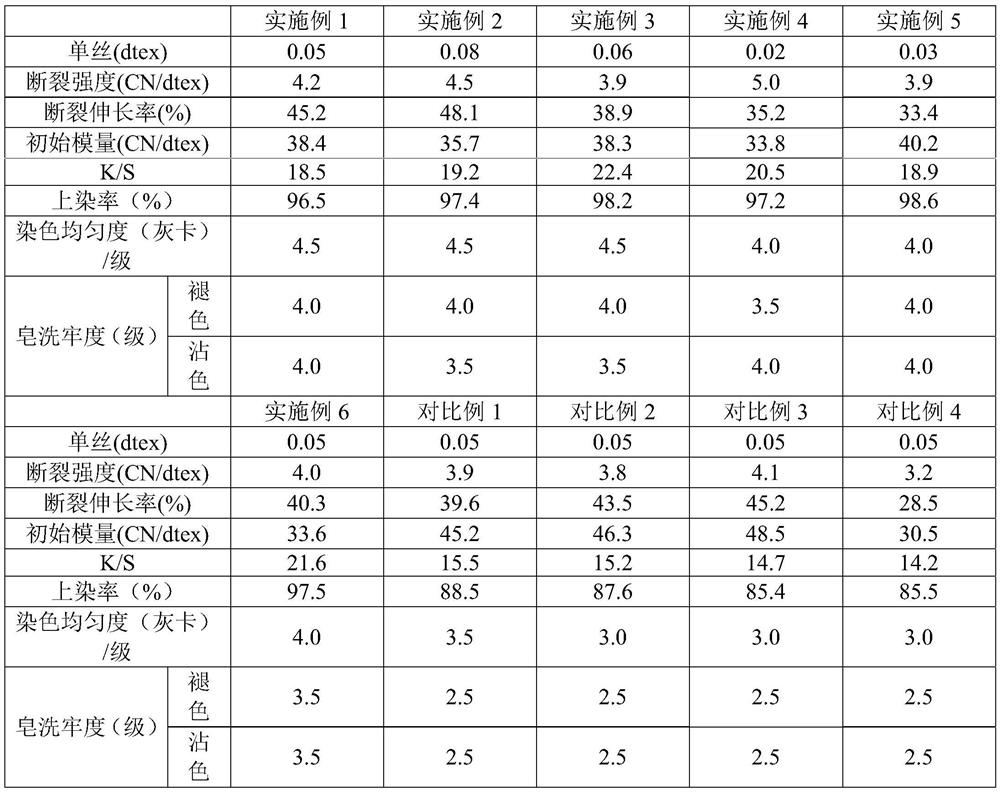

Polyamide sea-island fiber and preparation method and application thereof

PendingCN112680826AEmission reductionReduce the greenhouse effectArtificial filament heat treatmentMelt spinning methodsPolyesterFiber

The invention relates to the technical field of polyamide materials, and in particular relates to a polyamide sea-island fiber and a preparation method and application thereof. In the polyamide sea-island fiber, an island component is polyamide resin and is selected from one of polyamide 56, polyamide 510, polyamide 511, polyamide 512, polyamide 513, polyamide 514, polyamide 515 and polyamide 516, and preferably, the polyamide 56 or the polyamide 510; and a sea component is selected from one of polyethylene, low-density polyethylene, polystyrene, water-soluble polyester, polyester and polyurethane, preferably the polyethylene, the low-density polyethylene or the water-soluble polyester. The polyamide sea-island fiber disclosed by the invention has the advantages of better mechanical property, better softness, good dyeing property, high dyeing grey card grade, high dye uptake, deep dyeing and high color fastness.

Owner:CATHAY R&D CENT CO LTD +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com