Super-soft cotton wool and preparation method thereof

A cotton wool, super-soft technology, applied in singeing, textile, fabric elongation and other directions, can solve the problems of fabric environmental protection performance to be improved, insufficient softness, etc., and achieve good application prospects, delicate and soft feel, and low cost. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

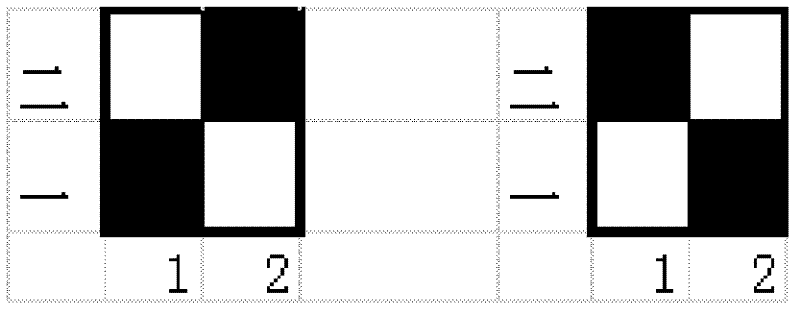

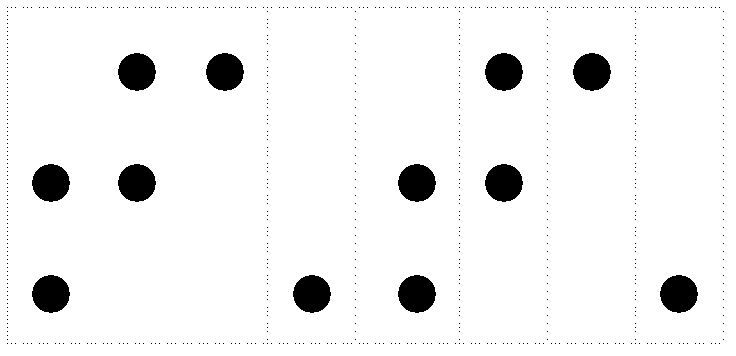

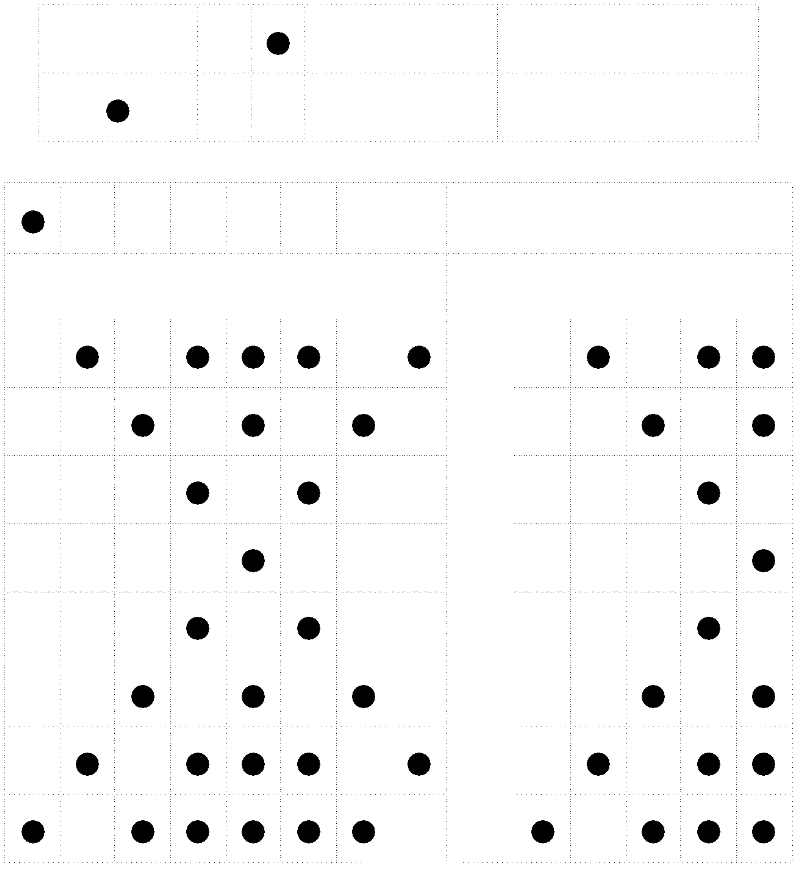

Image

Examples

Embodiment 1

[0029] (1) 100% long-staple cotton is used as raw material, and the long-staple cotton rough is sanded. The process is to use an imported carbon sanding machine to sand the inner layer of the fabric. The sanding process is sanding twice. , the vehicle speed is 8m / min, the tension is 30kg, and the rotation speed of the bristle stick is 70%;

[0030] (2) Carrying out gas open-width singeing to the rough blank after above-mentioned finishing, polishing, biological deoxygenation and dyeing with multi-component biological enzyme;

[0031] (3) Finishing, process:

[0032] SANTEX stenter drying: temperature 140°C, mesh belt overfeed -20%, vehicle speed 20m / min, air volume 2, vibrating net 800.

[0033] Open width setting: temperature 150℃, overfeed 40%, air volume 80%, vehicle speed 30m / min

[0034] Add soft and anti-wrinkle additives to the rolling groove: F-AP 65g / l F-M 20g / l SIE 30g / l PEP 30g / l

[0035] (4) performance testing is carried out to gained cotton wool cloth:

[003...

Embodiment 2

[0042] (1) Using 100% long-staple cotton as the raw material, the long-staple cotton rough is sanded. The process is to use an imported carbon sanding machine to sand the inner layer of the fabric. The sanding process is sanding 3 times , the vehicle speed is 15m / min, the tension is 50kg, and the rotation speed of the bristle stick is 85%;

[0043] (2) Carrying out gas open-width singeing to the rough blank after above-mentioned finishing, polishing, biological deoxygenation and dyeing with multi-component biological enzyme;

[0044] (3) Finishing, process:

[0045] SANTEX tenter drying: temperature 180°C, mesh belt overfeed 40%, vehicle speed 30m / min, air volume 2, vibration net 800.

[0046] Open width shaping: temperature 170°C, overfeed 60%, air volume 60%, vehicle speed 50m / min

[0047] Add soft and anti-wrinkle additives to the rolling groove: F-AP 50g / l F-M 10g / l SIE 10g / l PEP 10g / l

[0048] (4) performance testing is carried out to gained cotton wool cloth:

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com