Patents

Literature

659results about How to "Reduce the greenhouse effect" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Process for supercritical preparation of biologic diesel oil

InactiveCN1594504AReduce pollutionRaw materials are easy to getBiofuelsLiquid hydrocarbon mixture productionBiodieselPhase splitting

The invention discloses a process for supercritical preparation of biologic diesel oil by using animal or plant oil, waste edible oil, oiling crop seeds as raw material through the steps of filtering, dewatering, esterification, ester interchange, filtering, steaming methanol and phase-splitting.

Owner:WUHAN CHEM COLLEGE

Method for producing biological diesel oil by using high-acidity waste animal and vegetable oil

InactiveCN1412278ASolve pollutionReduce pollutionLiquid hydrocarbon mixture productionBio-feedstockVegetable oilPtru catalyst

The present invention relates to a method for producing biological diesel oil-fatty acid methyl ester by using waste animal and vegetable oil with high acid value. It is characterized by that it adopts acidic catalysis method, under the action of acidic catalyst is makes the waste animal and vegetable oil react with low carbon alcohol, and adopts the following four steps: (1) dewatering; (2) esterification and ester exchange; (3) phase separation; and (4) decolouring so as to produce the invented biological diesel fatty acid methyl ester.

Owner:宋庭礼 +1

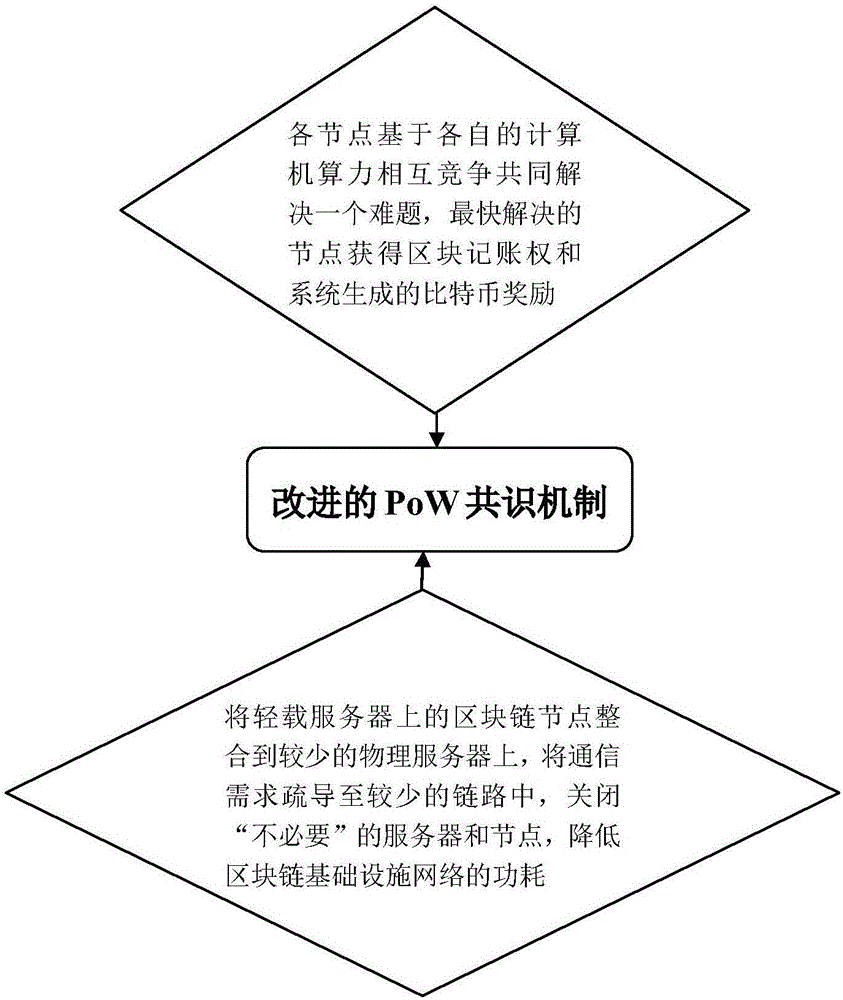

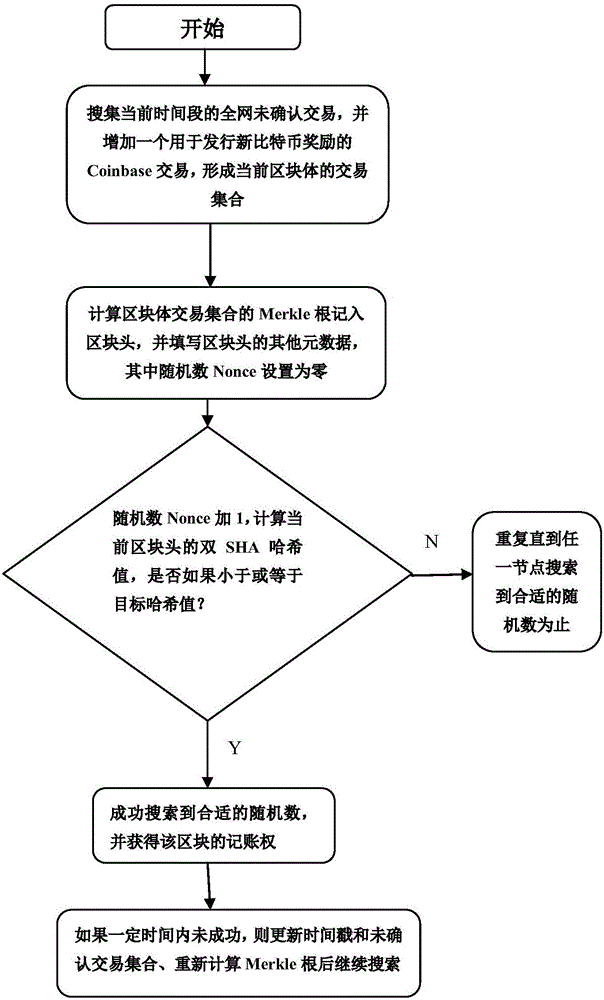

Block chain power consumption perception PoW consensus mechanism

InactiveCN106296191AImprove performanceEmission reductionResource allocationPayment protocolsGeolocationWdm mesh networks

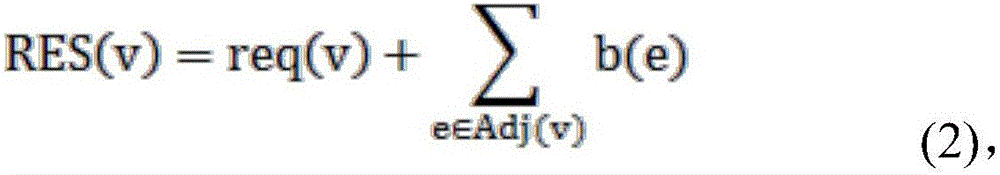

The present invention provides a block chain power consumption perception PoW consensus mechanism. The mechanism comprises the following steps: (1) in a Bitcoin system, each node is subjected to mutual competition based on each computer power to commonly solve an SHA math problem with complex solution and easy verification, and the node which solves the problem at the fastest speed obtains a block account right and Bitcoin award automatically generated by the system; and (2) employing a WDM mesh network to interconnect physics servers located at different geographic positions to form a block chain basic facility network, respond to the block chain request generation power consumption and allow the block chain node on a light load server to integrate on few physics servers, and the communication requirement is dredged to few chains to close unnecessary servers and nodes. The power consumption perception PoW consensus mechanism is employed to further execute the resources potential of the basic facility network while improving the block chain performance, perform power consumption perception and reduce the carbon emission and the greenhouse effect.

Owner:SHENZHEN FANXI ELECTRONICS CO LTD

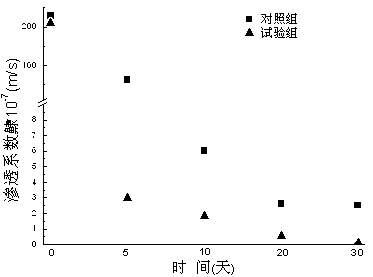

Method for repairing crack of cement-based material

ActiveCN103342484APassive repair implementationGuaranteed durabilityBacteriaBiotechnologyMicroorganism

The invention discloses a method for repairing a crack of a cement-based material. According to the method, carbonic anhydrase microorganisms are adopted for generating carbonic anhydrase used for catching CO2, CO2 is promoted to be converted into CO3<2->, and the deposition of calcium carbonate within a surface area of the crack is accelerated; the method has the advantage that the repair speed is faster than that of other methods for repairing the crack through the microorganisms. The method comprises the following steps of: inoculating bacillus mucilaginosus to a culture medium; culturing; preparing bacillus mucilaginosus concentrated bacteria liquid; immobilizing bacteria on carriers; uniformly burying calcium sources into the cement-based material during forming the cement-based material; concentrating the carriers with the bacteria immobilized into a range of 5mm under a surface area of a test part; manufacturing the crack after a part to be tested is cured; transferring into a thermostatic waterbath; continuously charging air for maintaining and repairing. The repair test result shows that the osmotic coefficient is greatly reduced after repairing for 5 days, and the crack is repaired completely after continuously repairing for 30 days.

Owner:SOUTHEAST UNIV

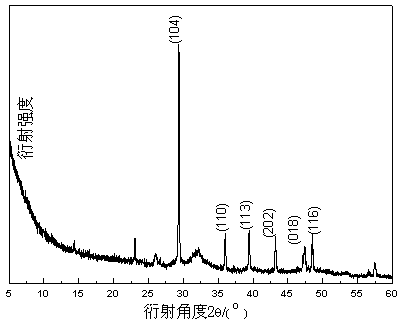

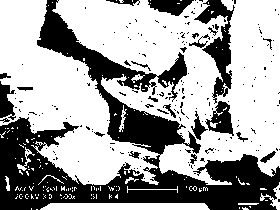

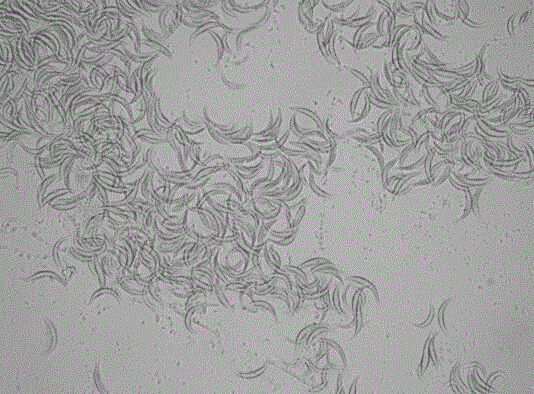

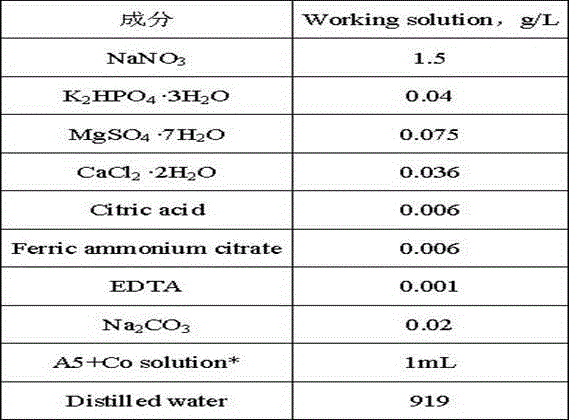

Ankistrodesmus sp containing lipid as well as culture and applications of ankistrodesmus sp

ActiveCN105713836AReduce the greenhouse effectAvoid photosynthesisUnicellular algaeDispersed particle separationMicroorganismBiodiesel

The invention discloses ankistrodesmus sp containing lipid as well as culture and applications of ankistrodesmus sp, wherein the ankistrodesmus strain is SS-B7, the classification name of SS-B7 is Ankistrodesmus sp, and the ankistrodesmus sp SS-B7 is preserved in the China General Microbiological Culture Collection Center (CGMCC) on April 15, 2013, and has the preservation number CGMCC No.7478. The ankistrodesmus sp SS-B7 has tolerance to CO2 and NOx with high concentrations, and has high carbon sequestration efficiency, the content of total lipids in the cells of the obtained biomass accounts for 40% or above of the dry cell weight, and the ankistrodesmus sp SS-B7 can be used for producing biodiesel.

Owner:CHINA PETROLEUM & CHEM CORP +1

Carbon-based fertilizer potentiating agent and application thereof

InactiveCN102675001ASimple production processRaw materials are easy to getClimate change adaptationFertilising methodsNitrification inhibitorsPollution

Owner:SHENYANG AGRI UNIV

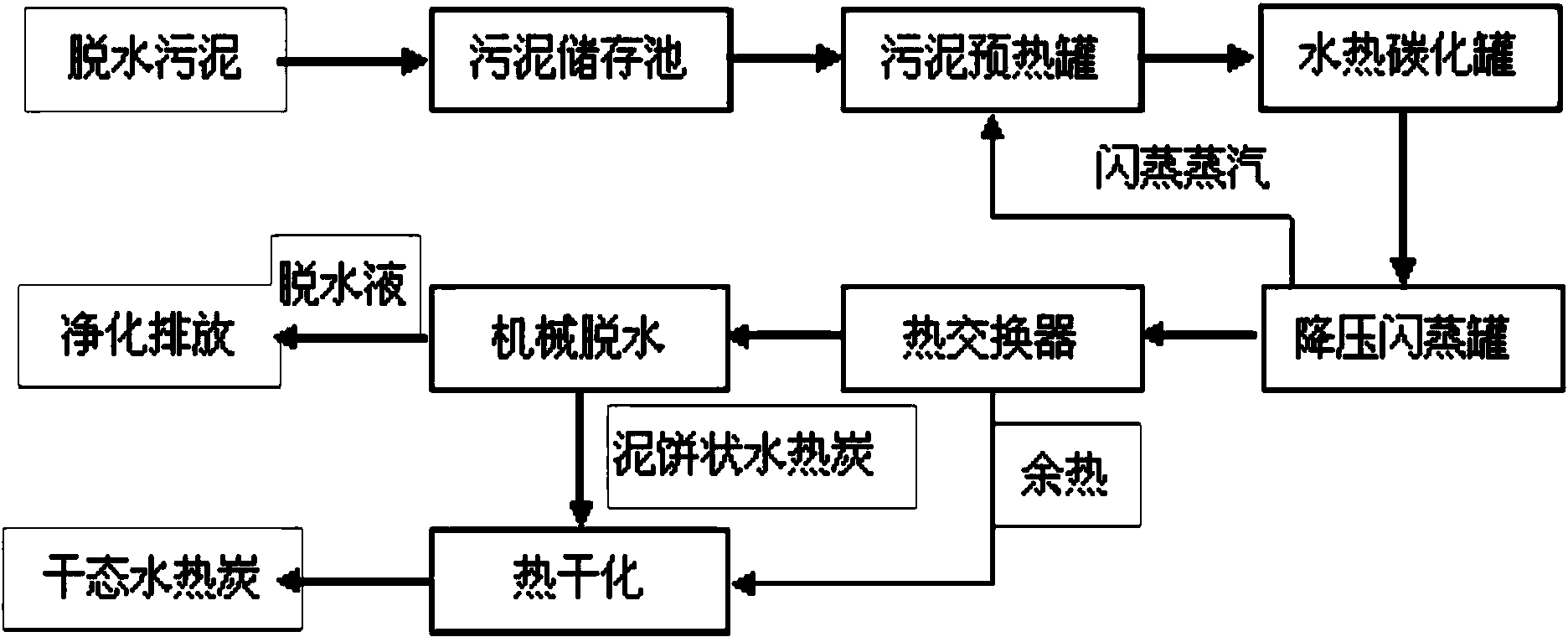

Sludge treatment method based on hydrothermal carbonization

InactiveCN103755124AEmission reductionIncrease organic carbon contentSludge treatment by de-watering/drying/thickeningSludge treatment by thermal conditioningSludgeToxic material

The invention relates to a treatment method of sludge generated by urban sewage treatment plant and industrial sludge and discloses a sludge treatment method based on hydrothermal carbonization. The sludge treatment method comprises four steps: sludge preheating treatment, hydrothermal carbonization, waste heat recovery and dehydration desiccation. By adopting the sludge treatment method, as the sludge is converted to hydrothermal carbon by adopting a hydrothermal carbonization technology, pathogenic microorganisms in the sludge are completely killed, most heavy metal pollutants in the sludge are dissolved out, and organic toxic substances in the sludge are effectively decomposed, so that the energy recovery utilization rate is high, and the sludge treatment method is clean, environment-friendly, rapid and effective and has high product additional values.

Owner:HANGZHOU HUHUI ENVIRONMENTAL PROTECTION TECH

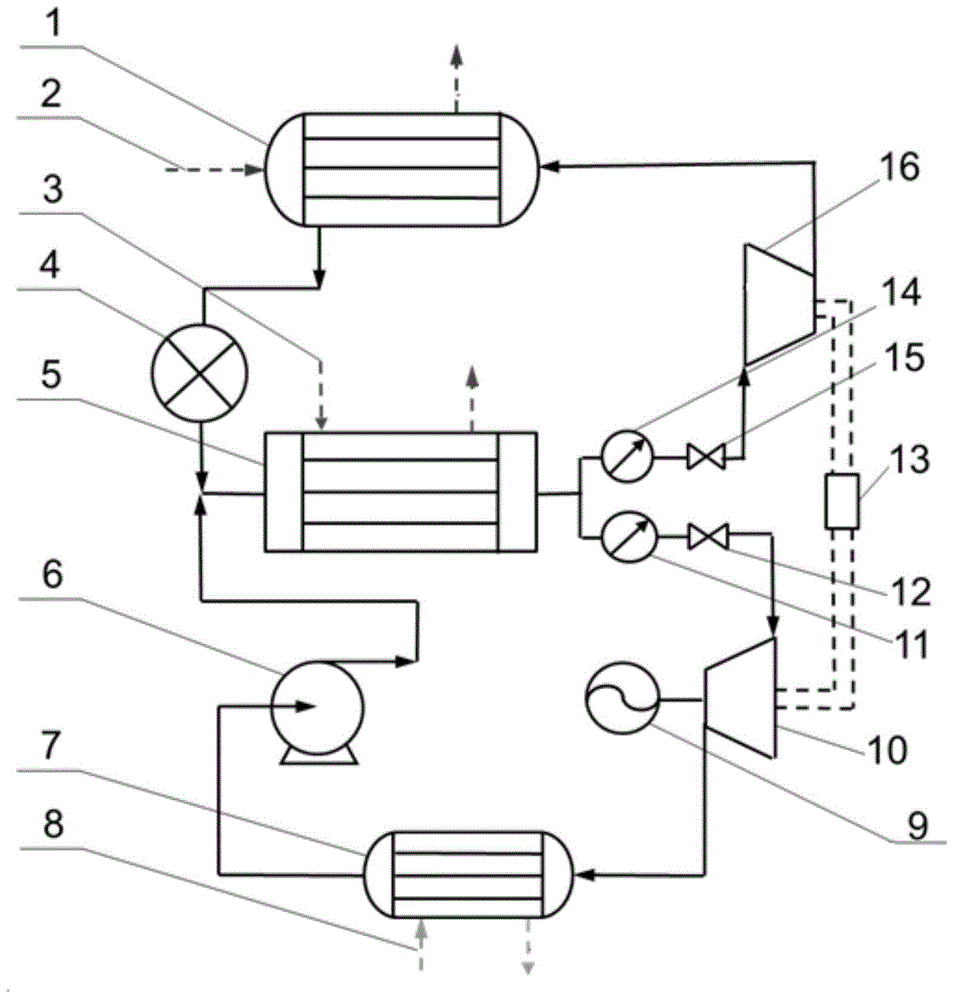

Organic Rankin cycle and heat pump cycle coupling system

InactiveCN104879177AMeet power needsMeet the needs of different heat-to-electricity ratiosClimate change adaptationEnergy industryOrganic Rankine cycleHeat energy

The invention relates to an organic Rankin cycle and heat pump cycle coupling system. The organic Rankin cycle and heat pump cycle coupling system comprises an organic Rankin cycle unit and a heat pump cycle unit, which are coupled. The organic Rankin cycle unit and the heat pump cycle unit share the same evaporator and are coupled by the same. During operation, cycle working medium and recovered low-temperature waste heat exchanges heat in the evaporator and are divided into two parts of gaseous working medium, one part enters an expansion machine to be involved in organic Rankin cycle, and the other part enters a compressor to be involved in heat pump cycle. The power of the expansion machine superiorly drives the compressor coaxially connected with the expansion machine, output of high-temperature heat energy of the heat pump cycle is realized, the rest power drives a generator to generate power and heat and power are supplied at the same time. Compared with the prior art, the organic Rankin cycle and heat pump cycle coupling system is energy saving and environment friendly, low-grade waste heat can be effectively recycled and utilized at high temperature, consumption of electric energy or fossil energy is reduced, heat and power can be supplied together, and greenhouse effect and air pollution are reduced.

Owner:TONGJI UNIV

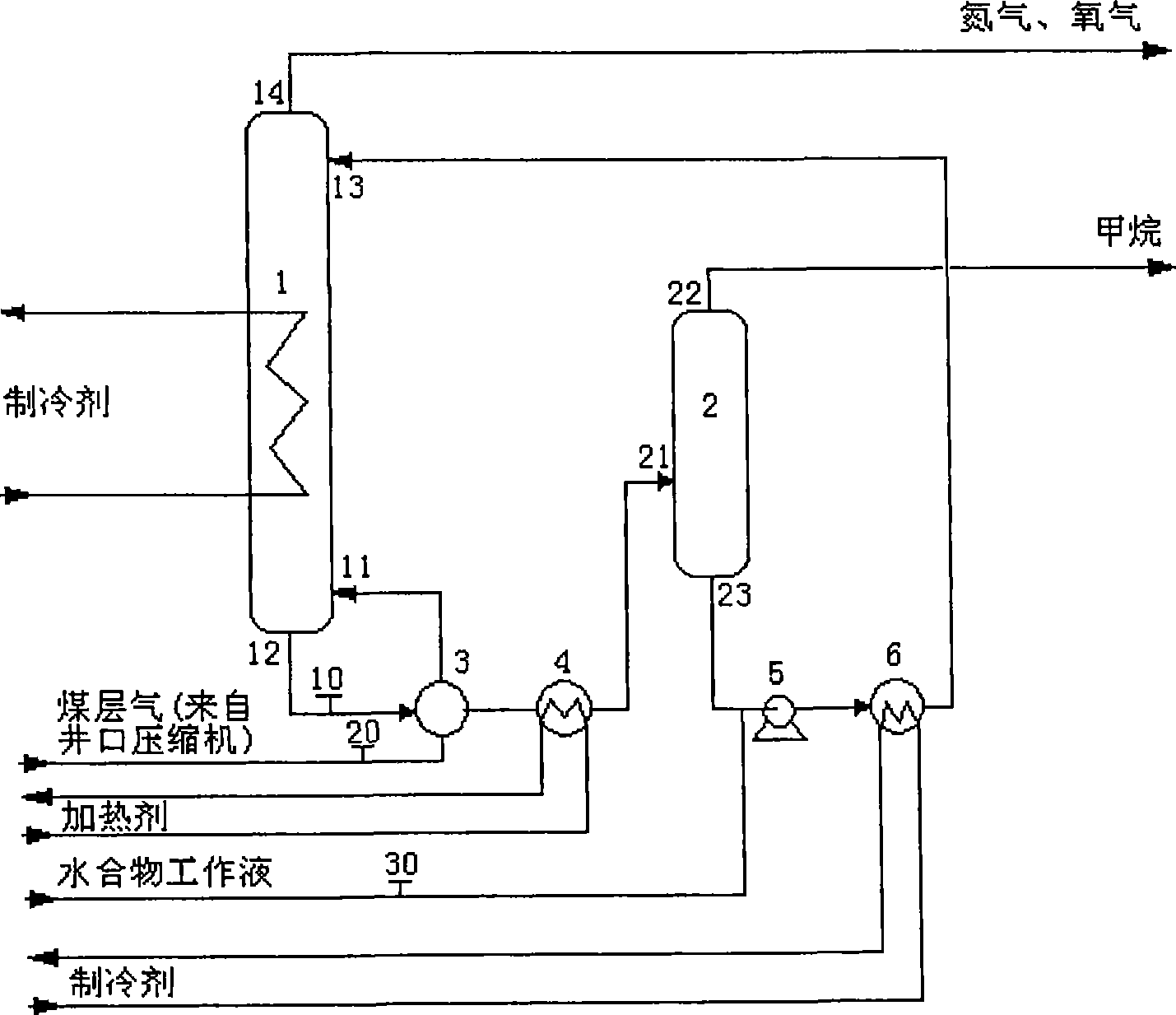

Method and device for low-pressure processing of coal bed gas

InactiveCN101530719AReduce concentrationEmission reductionDispersed particle separationAbsorption purification/separationHydration reactionHigh concentration

The invention relates to a method for low-pressure processing of coal bed gas, comprising the steps of: introducing the coal bed gas into a hydration reactor from the bottom part of a hydration reactor so as to be contacted with hydrate working liquid in the hydration reactor, leading methane contained in the coal bed gas and water in the hydrate working liquid to generate hydration reaction to form a hydrate which is removed from the coal bed gas; meanwhile, the purified gas is obtained after the methane in the coal bed gas is removed; wherein the operation pressure of the hydration reactor is 0.11-0.85MPa, and the temperature is 3-18 DEG C. The formed hydrate can be further introduced into a hydrate decomposition device for decomposition, thereby obtaining the methane with high concentration. The invention simultaneously relates to a device for realizing the method for low-pressure processing of the coal bed gas. The invention can safely purify the oxygen-containing coal bed gas under lower pressure and remove the contained methane to be lower than 0.05 molar fraction, thereby reducing the emission of the methane, reducing the greenhouse effect and simultaneously avoiding the risk of explosion.

Owner:CHINA UNIV OF PETROLEUM (BEIJING)

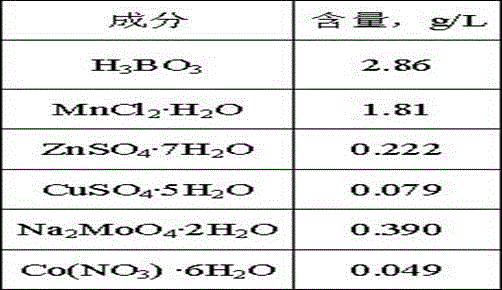

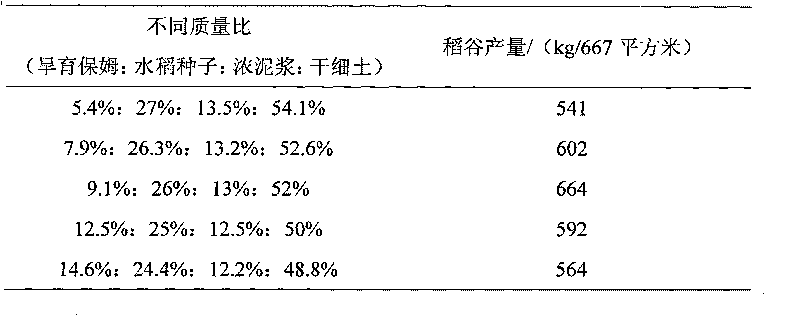

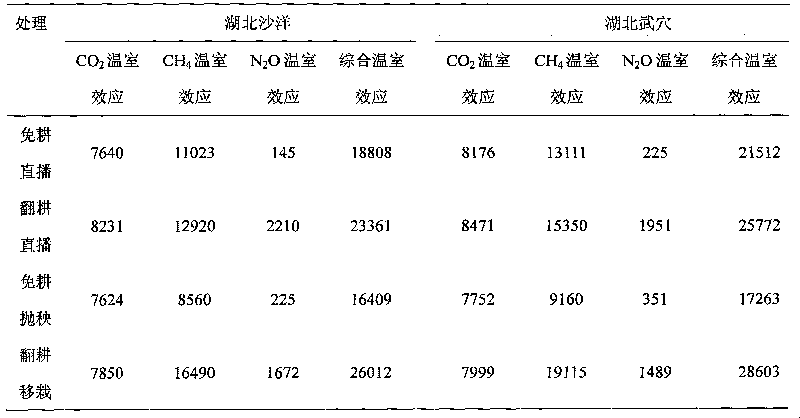

No-tillage seedling-throwing overall aerobic cultivation method for oil crop-medium rice fixed compartment ditch

The invention belongs to the field of rice cultivation, and particularly relates to a cultivation method suitable for no-tillage rice in a fixed compartment of an oil crop-medium rice field. The cultivation method comprises the following steps that: (1) rice seeds are coated by using dry-raised nurse, thick mud and dry fine soil serving as coating agents, wherein the components comprise 7.9 to 12.5 percent of dry-raised nurse, 25 to 26.3 percent of rice seeds, 12.5 to 13.2 percent of thick mud with 37 percent of water content and 50 to 52.6 percent of dry fine soil with 3 percent of water content in percentage by mass; the rice field is finished as required and the soil moisture is kept; and keeping the seedling age at 15 to 18 days; (2) the compartment width of the oil crop field is 1.2 meters, the width of the ditch is 0.3 meter, and the depth of the ditch is 0.25 meter; the rape seedlings are applied to the field; a ternary compound fertilizer of which pure nutrients comprise 15 percent of N, 15 percent of P2O5 and 15 percent of K2O is applied, and 30 kilograms of pure nitrogen is applied in each mu; 5.80 kilograms of zinc is applied in each mu; and 4.8 kilograms of boron fertilizer is applied in each mu, and the ditch is kept full of water; (3) rice seedlings with 50 to 100 grams of soil in each seedling in 15 to 18 days are directionally thrown according to a row space of 20 centimeters; and (4) the ditch is kept with water and the compartment surface has no water after throwing the seedlings till the heading stage, and dry and wet alternated cultivation is adopted from the grain filling stage to the maturation stage. Compared with the conventional method, the yield is averagely increased by 8.7 percent.

Owner:HUAZHONG AGRI UNIV

Filling and mining method of coal gases

InactiveCN102155225ALow costWide variety of sourcesUnderground miningSurface miningMining engineeringHigh pressure

The invention relates to a filling and mining method of coal gases, comprising the following steps: arranging a gas pressurization room on the ground and then arranging an underground gas booster pump connected with a ground high-pressure gas storage tank pipeline in a mining region haulage way in front of an underground coal mining working face; distributing a row of cylindrical rubber airbags in a gob behind the coal mining working face when the coal mining working face is advanced for 5-8 m from the open-off cut; filling gas into the cylindrical rubber airbags till the top is tight; sealing the openings of the cylindrical rubber airbags to finish filling gas into one cylindrical rubber airbag; continuously distributing a row of cylindrical rubber airbags behind the row of gas-filling cylindrical rubber airbags when the coal mining working face is advanced for each step along with the continuous advance of the coal mining working face and charging gas in rows till finishing the gas filling and supporting in the whole gob. In the invention, the filling method is simple, the gas filling speed is high, the cost is low and the filling capacity is great, and the method is convenient for onsite underground operation.

Owner:CHINA UNIV OF MINING & TECH

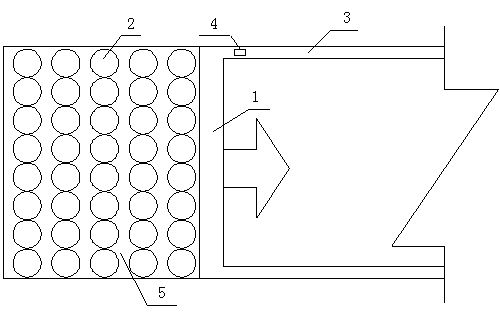

Method for producing acid soil modifier by using agricultural waste

InactiveCN103396809AImprove soil condition and microfloraAddress soil acidificationAgriculture tools and machinesOther chemical processesToxicityAgriculture

The invention relates to a method for producing an acid soil modifier by using agricultural waste. The method comprises: crushing agricultural waste, and heating one part of the crushed agricultural waste in the absence of air to obtain biomass carbon powder; and mixing the biomass carbon powder, the other part of the crushed material, and limestone powder, and uniformly stirring to obtain the finished product. With application of 50-500 kg of the soil modifier on per mu of soil, soil acidity can be effectively reduced, physical and chemical properties of soil can be improved, and economic values of crops can be increased. In addition, the acid soil modifier has characteristics of wide raw material source, low product cost, simple production process, no toxicity and no harm, is a green soil modifier, and has good ecological and social benefits.

Owner:QIONGZHOU UNIVERSITY

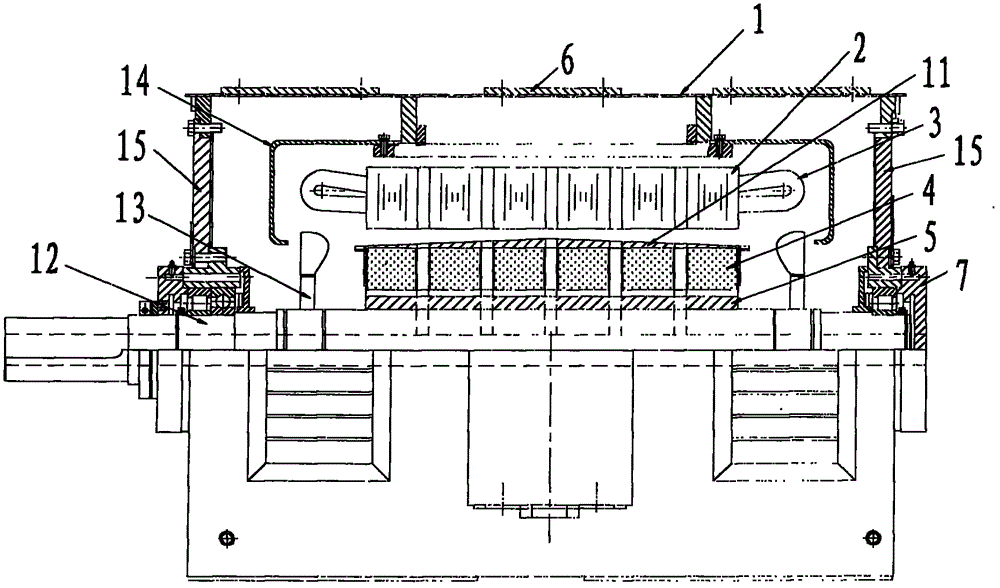

Permanent magnet synchronous motor

InactiveCN102723834AEliminate axial tensionAvoid harmMagnetic circuit rotating partsMagnetic circuit stationary partsPermanent magnet synchronous motorPermanent magnet synchronous generator

The present invention provides a permanent magnet synchronous motor, belonging to the technical field of motors. The permanent magnet synchronous motor is characterized by: adoption of a solid shuttle-shaped rotor structure; a large radial air gap and an axial non-constant air gap; a permanent magnet adopting a radial buried structure; a starting squirrel cage embedded on the rotor; and the rotor and a stator both provided with corresponding ventilation ducts that facilitate cooling air which passes through the large radial air gap to take away heat of the surface of the solid rotor and heat of the stator itself. The permanent magnet synchronous motor in the invention not only solves a problem of starting difficulty in a permanent magnet motor having a conventional laminated rotor, but also solves a problem of heat dissipation difficulty in a permanent magnet motor having a conventional solid rotor. The permanent magnet synchronous motor in the invention with a starting torque from 2.0 to 3.0 further overcomes a problem of easy demagnetization of the permanent magnet caused by a too high temperature of the rotor.

Owner:SHANXI NORTH MACHINE BUILDING

Production method of biodiesel

InactiveCN101649332ANo pollutionReduce pollutionFatty acid esterificationBiofuelsSocial benefitsBiodiesel

The invention relates to a production method of biodiesel, which comprises the following steps: using algae capable of generating fat in the algae comprising chlorella, haematococcus pluvialis and halophila, and using the algae as raw materials; performing algae culture first, and then extracting the fat from the algae; and performing ester exchange reaction, standing, demixing and redistillationon the fat to obtain the biodiesel. The production method has the advantages of simple process, short reaction time, high efficiency and no pollution to the biodiesel, can reduce the environmental pollution and the greenhouse effect, has wide resources of the raw materials, is suitable for mass production, and can produce huge economic benefits and social benefits.

Owner:上海高技企业发展公司

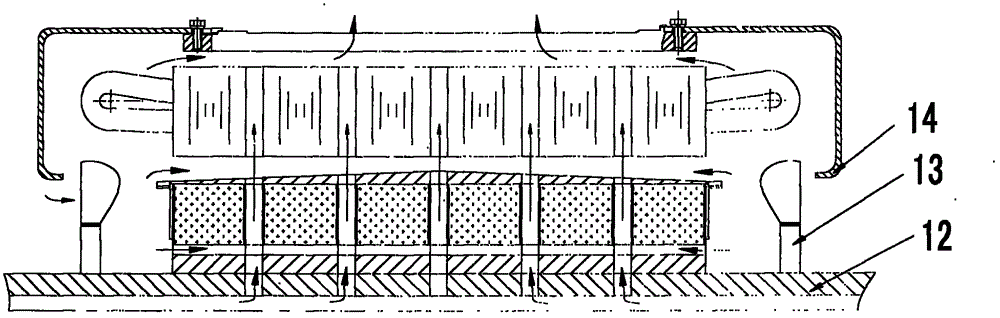

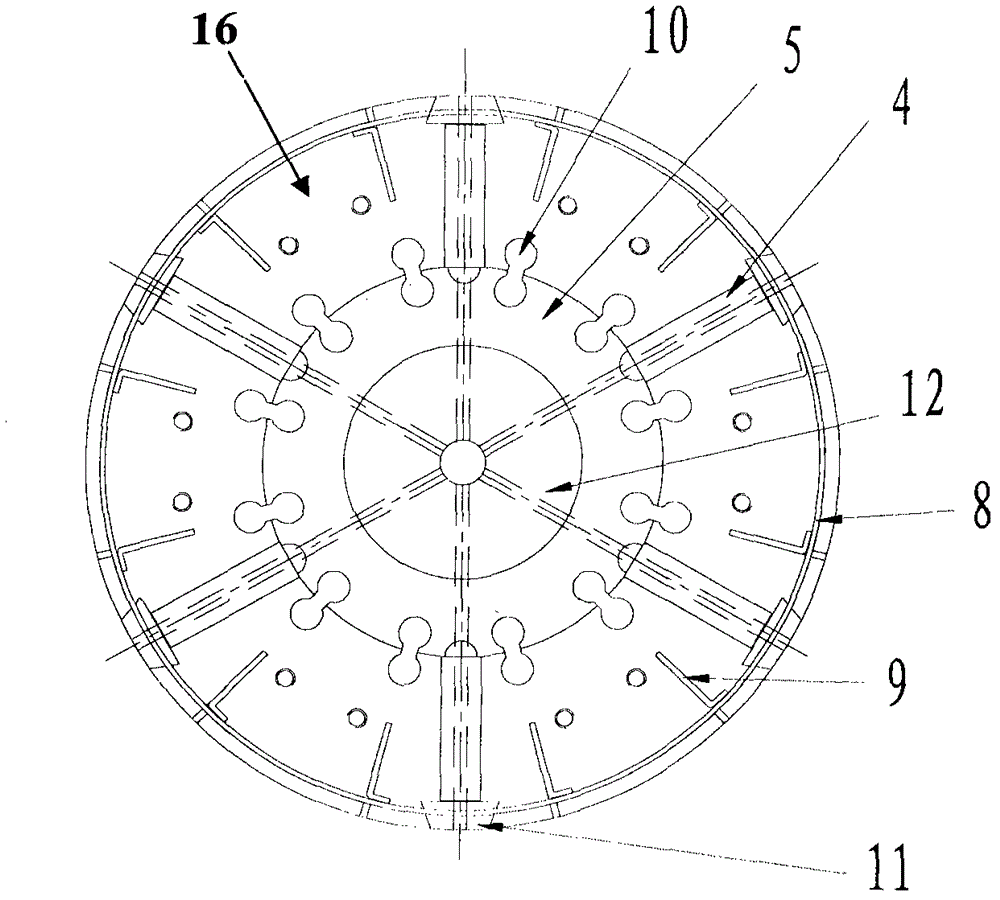

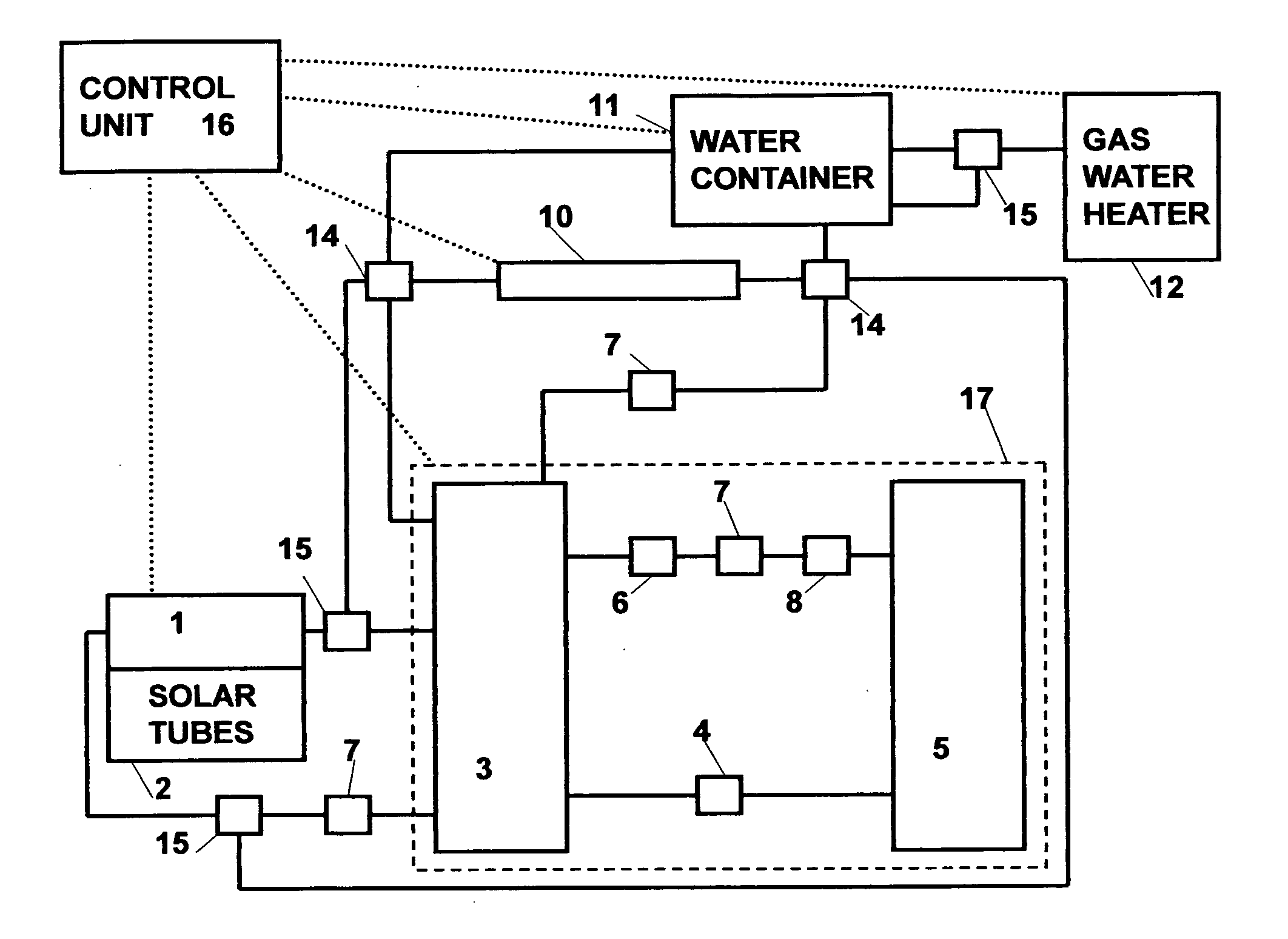

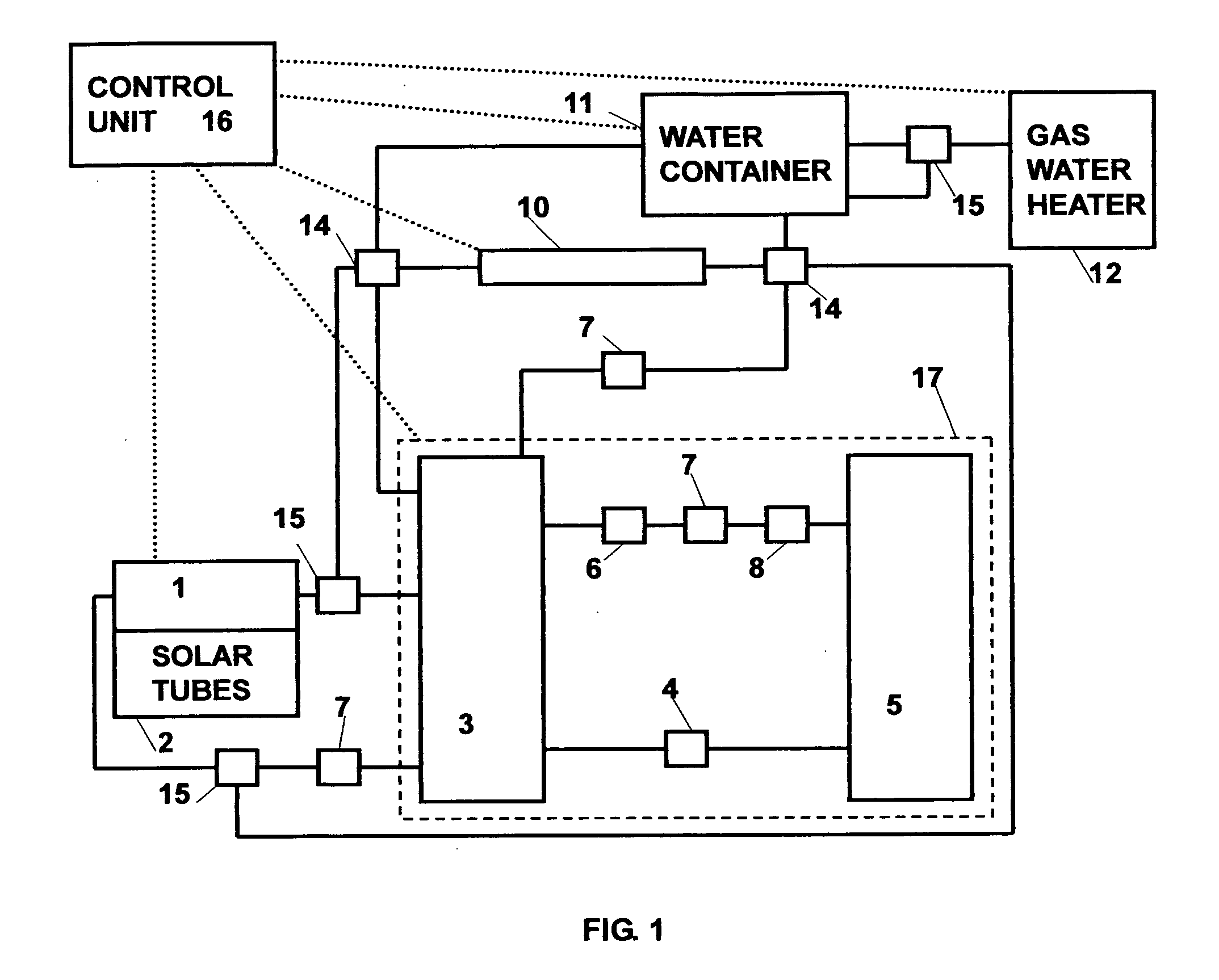

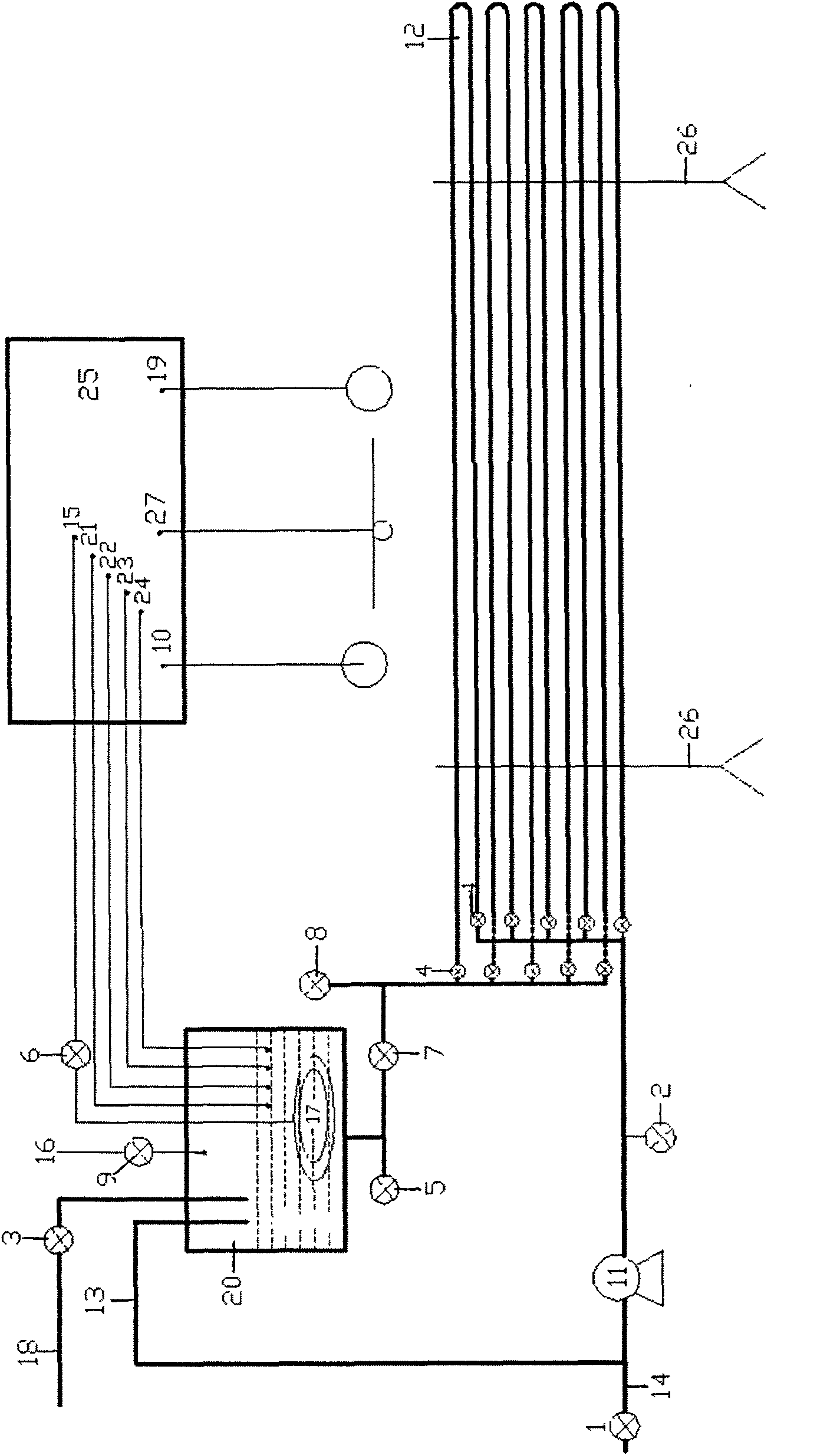

Solar energy saving system using gas and electricity as compensation

InactiveUS20090159076A1Save energyEmission reductionSolar heating energyCentral heating with accumulated heatComputer control systemElectricity

A solar energy saving system composed of solar collectors, a custom built heat pump and a conventional gas heater, a centralized computer control system, a group of sensors, pumps and valves, and the mechanical and electrical connections, is disclosed herein along with the processes and methods for applying the system.

Owner:ZHENG KE TING

Method for sequestering carbon dioxide

InactiveCN102942006AEmission reductionSimple and fast operationCarbon-dioxide storageStorage devicesCoalGreenhouse effect

The invention discloses a method for sequestering carbon dioxide. The method includes the following steps: (1) selecting the injection layer which includes an unworkable seam and / or a coal seam gob; (2) drilling a well according to the position where the injection layer is located; (3) performing perforating for a fissure zone of a top plate of the unworkable seam and / or the coal seam gob; (4) sequentially injecting carbon dioxide from bottom to top layer by layer when the number of the needed injection layer is larger than one, and performing injecting and sealing storage for the next injection layer after completing injecting and sealing storage for the former injection layer; and (5) burying the drilled well and sealing a cover on the drilled well. The method for sequestering carbon dioxide aims at solving the problems of large carbon dioxide emission, obvious greenhouse effect, complex processing procedures, high expanse and the like of the existing coal power generation mode, and achieves the purposes of permanently sequestering carbon dioxide and reducing carbon dioxide treatment expanse by adopting the carbon dioxide sequestering method of injecting carbon dioxide gases into the unworkable seam or the coal seam gob to sequester carbon dioxide.

Owner:HENAN POLYTECHNIC UNIV

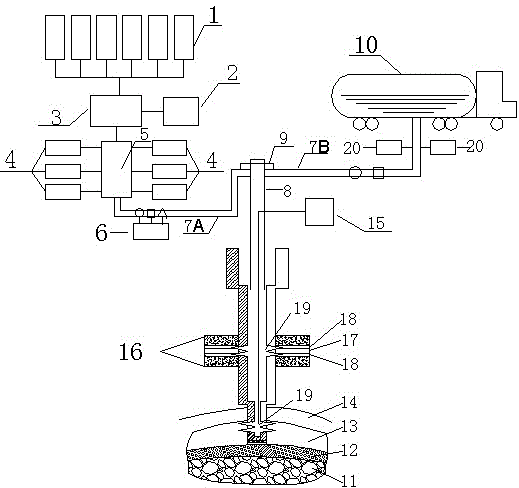

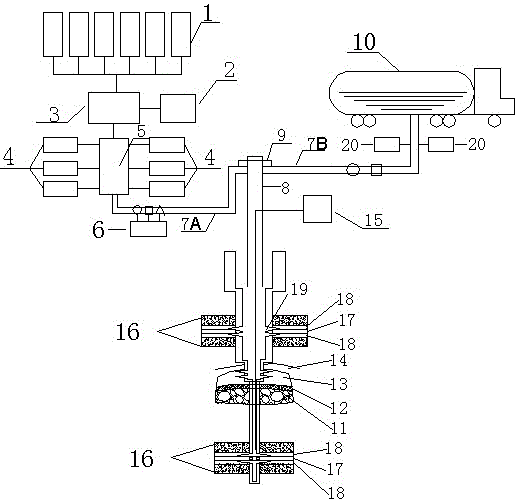

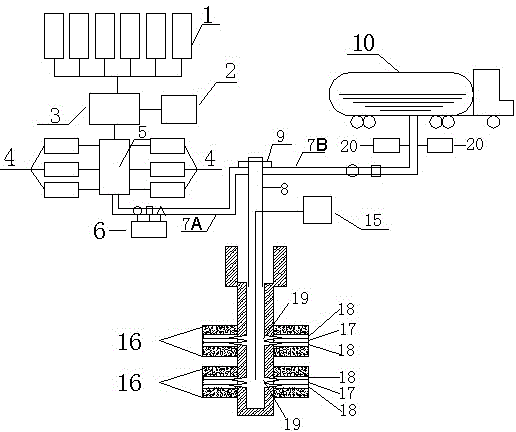

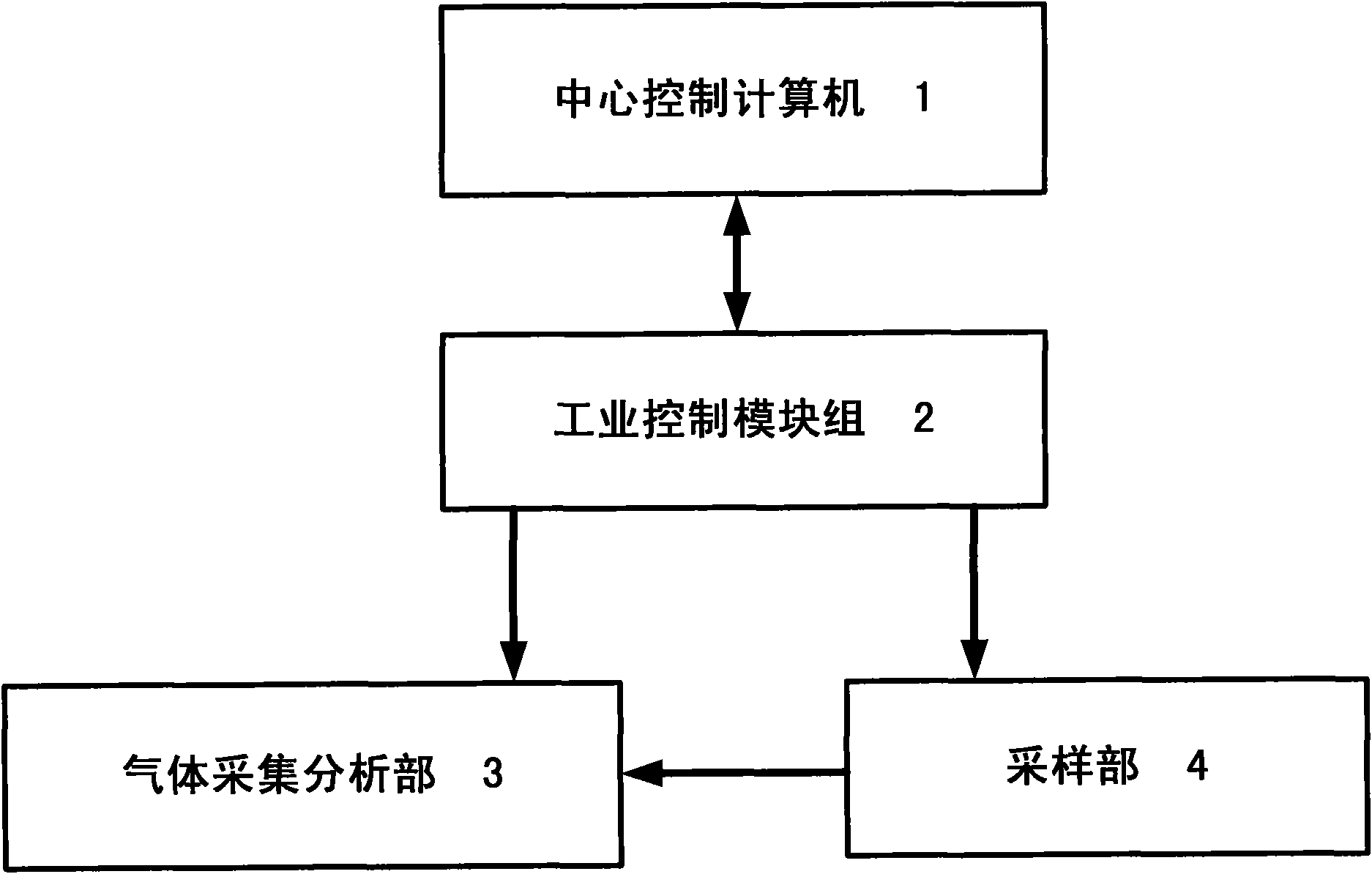

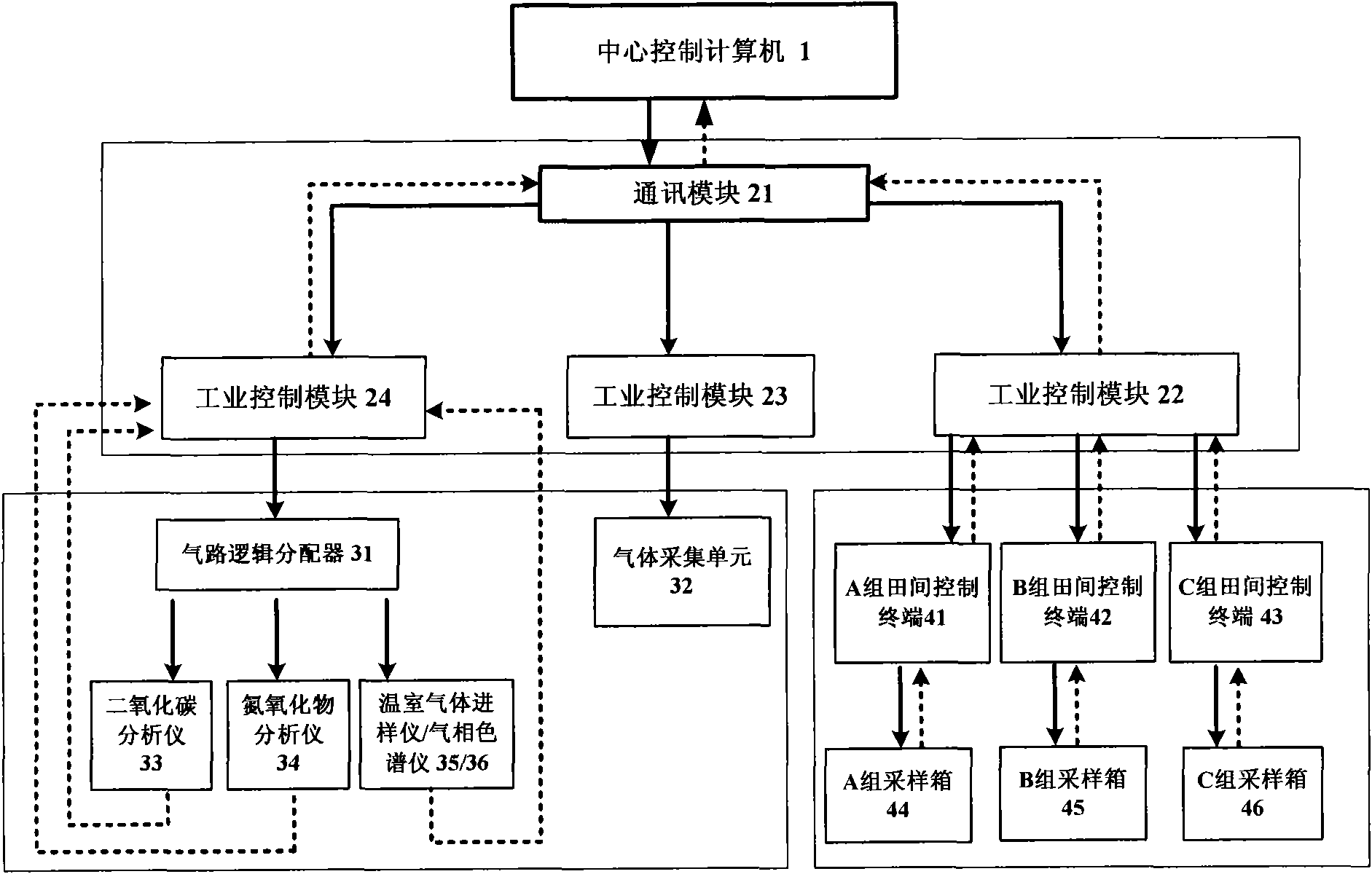

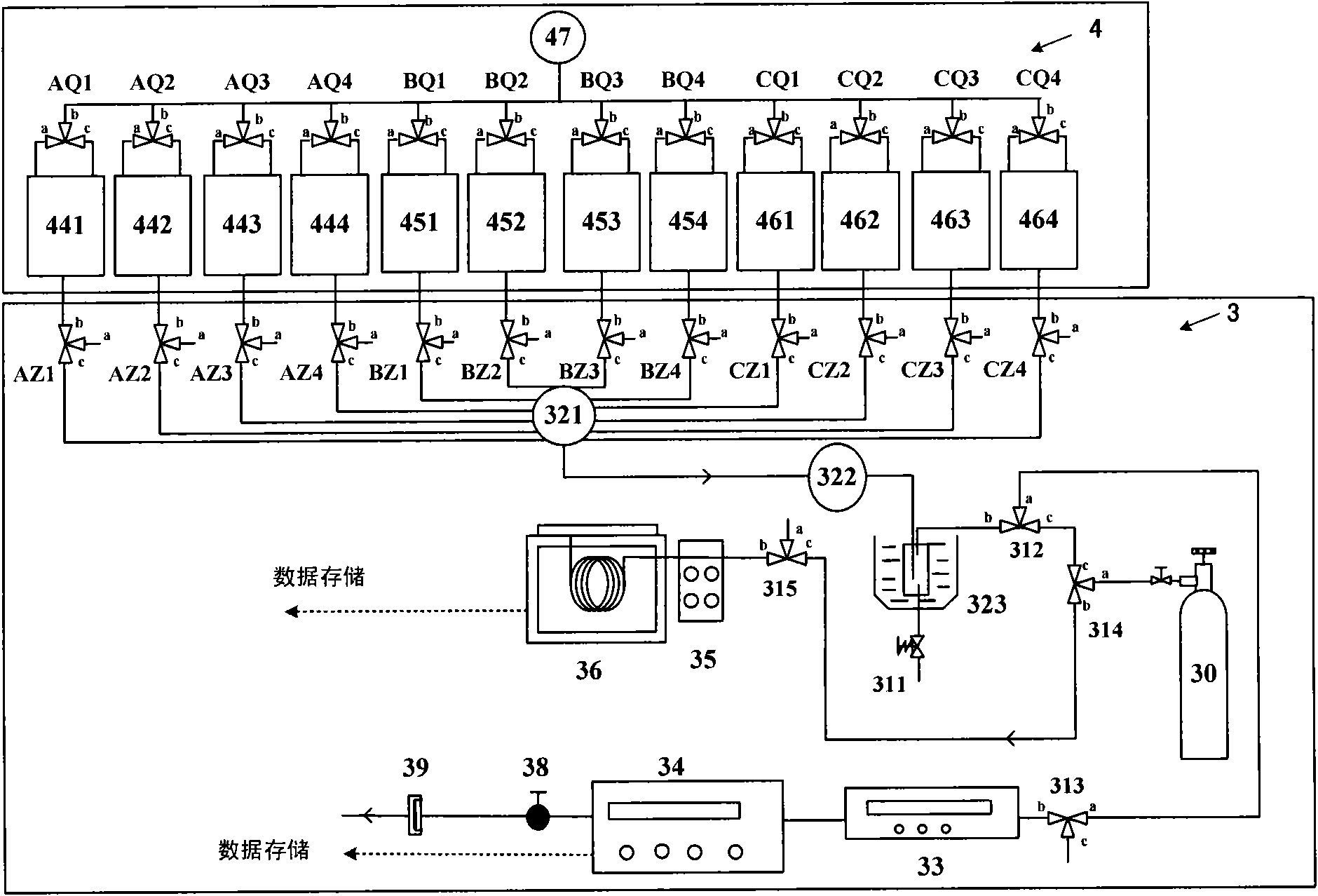

System and method for automatically acquiring and analyzing trace gas

InactiveCN102053164AImprove ventilationReduce the greenhouse effectComponent separationWithdrawing sample devicesMultiway switchingTrace gas

The invention relates to a system for automatically acquiring and analyzing a trace gas, which comprises a central control computer, an industrial control module group, a sampling part and a gas acquisition and analysis part, wherein the central control computer is used for writing programs by means of industrial control configuration software, generating and transmitting tank cover, gas passage and gas analysis commands, and receiving and storing analog signals which contain environmental meteorologic parameters and trace gas concentration data and are transmitted by the industrial control module group; the industrial control module group is respectively connected with the central control computer, the sampling part and the gas acquisition and analysis part; the gas acquisition and analysis part is connected with a pipeline of the sampling part; the industrial control module group is used for receiving industrial control commands, outputting multiple switching signals, and controlling the sampling part and the gas acquisition and analysis part to automatically carry out tank cover switching, gas acquisition and trace gas concentration analysis according to the programs; and the industrial control module group is used for processing current signals output by the sampling part and voltage signals output by the gas acquisition and analysis part and outputting the analog signals containing the environmental meteorologic parameters and the gas concentration data.

Owner:INST OF ATMOSPHERIC PHYSICS CHINESE ACADEMY SCI

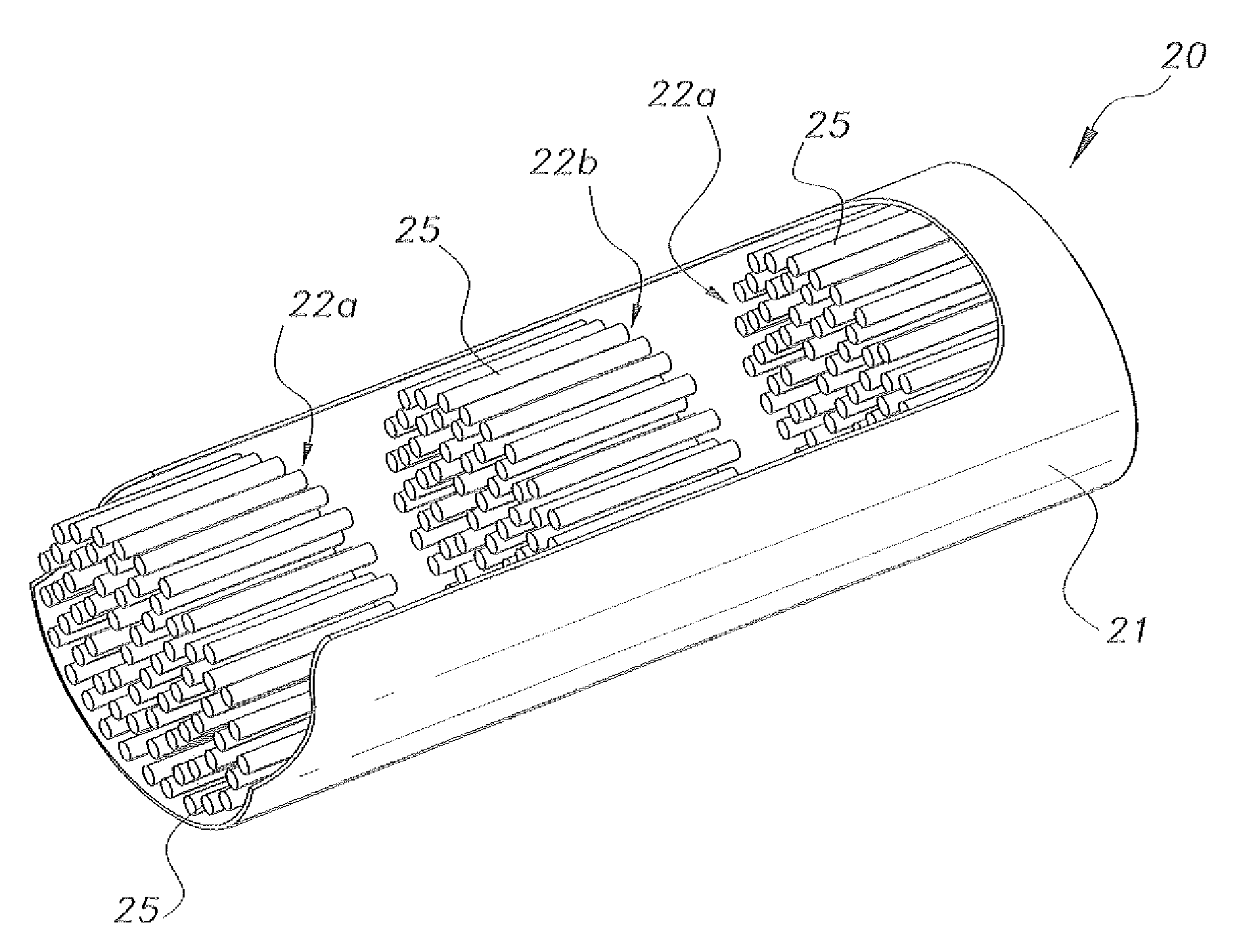

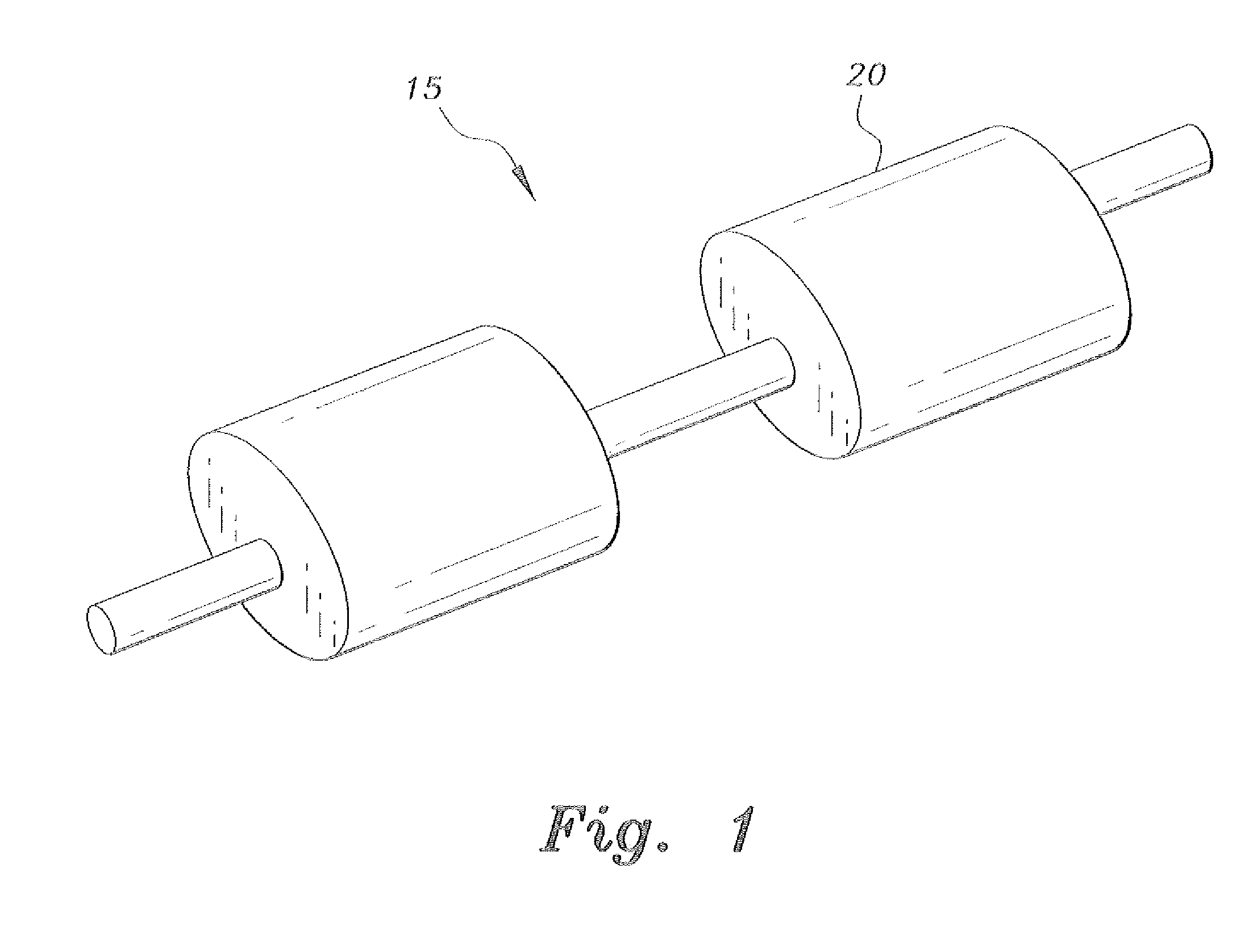

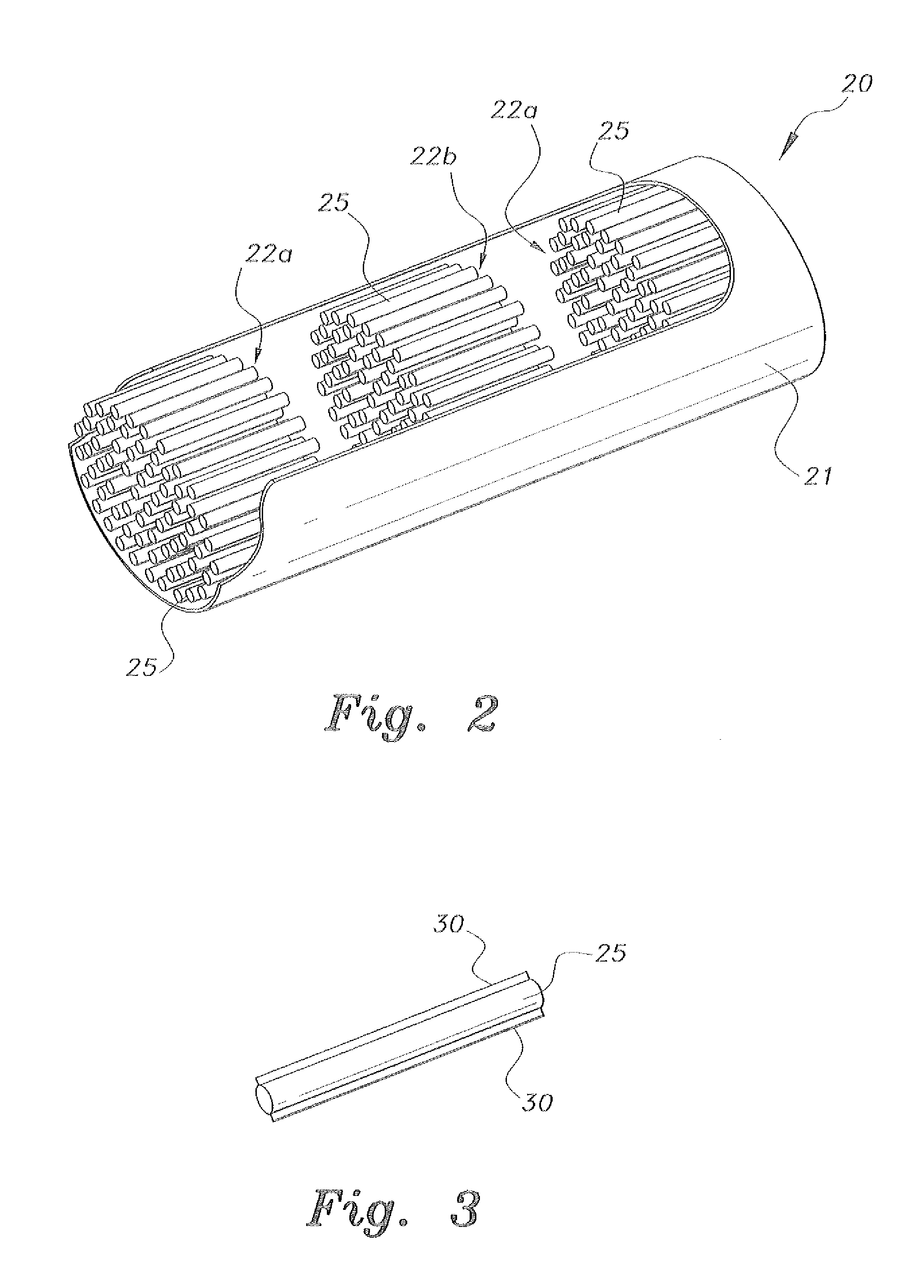

Vehicle electrocatalyzer for recycling carbon dioxide to fuel hydrocarbons

InactiveUS20120137664A1Reduce fuel consumptionReduce the greenhouse effectElectrolysis componentsNon-fuel substance addition to fuelElectrolysis of waterChemistry

The vehicle electrocatalyzer for recycling carbon dioxide to fuel hydrocarbons includes a main tubular member having a plurality of tubular catalytic cells, electrically connected in series disposed inside and separated from one another by semipermeable membranes allowing the passage of fluids, but not solids. The electrocatalyzer can be attached in the exhaust system where hydrogen could be generated by the electrolysis of water. Metallic copper, iron, carbonaceous materials (such as activated carbon, carbon nanomaterials, or graphite), metal oxides, or metal-supported catalysts may be used in each catalytic cell. A DC current connected across the cells is used to initiate reaction of the carbon dioxide with hydrogen gas. The resulting hydrocarbons are recycled back to the vehicle engine and used as a makeup fuel.

Owner:KING FAHD UNIVERSITY OF PETROLEUM AND MINERALS +1

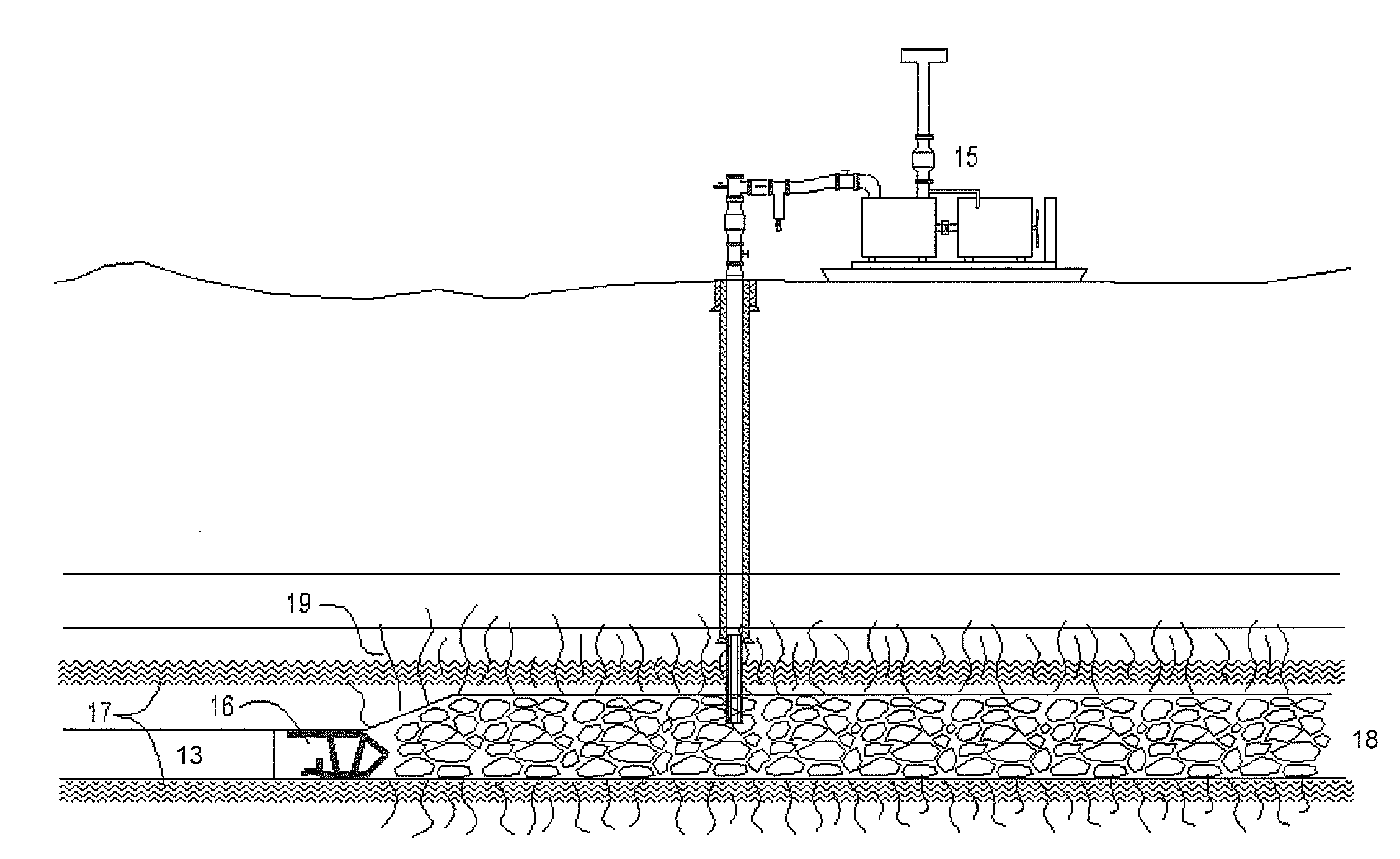

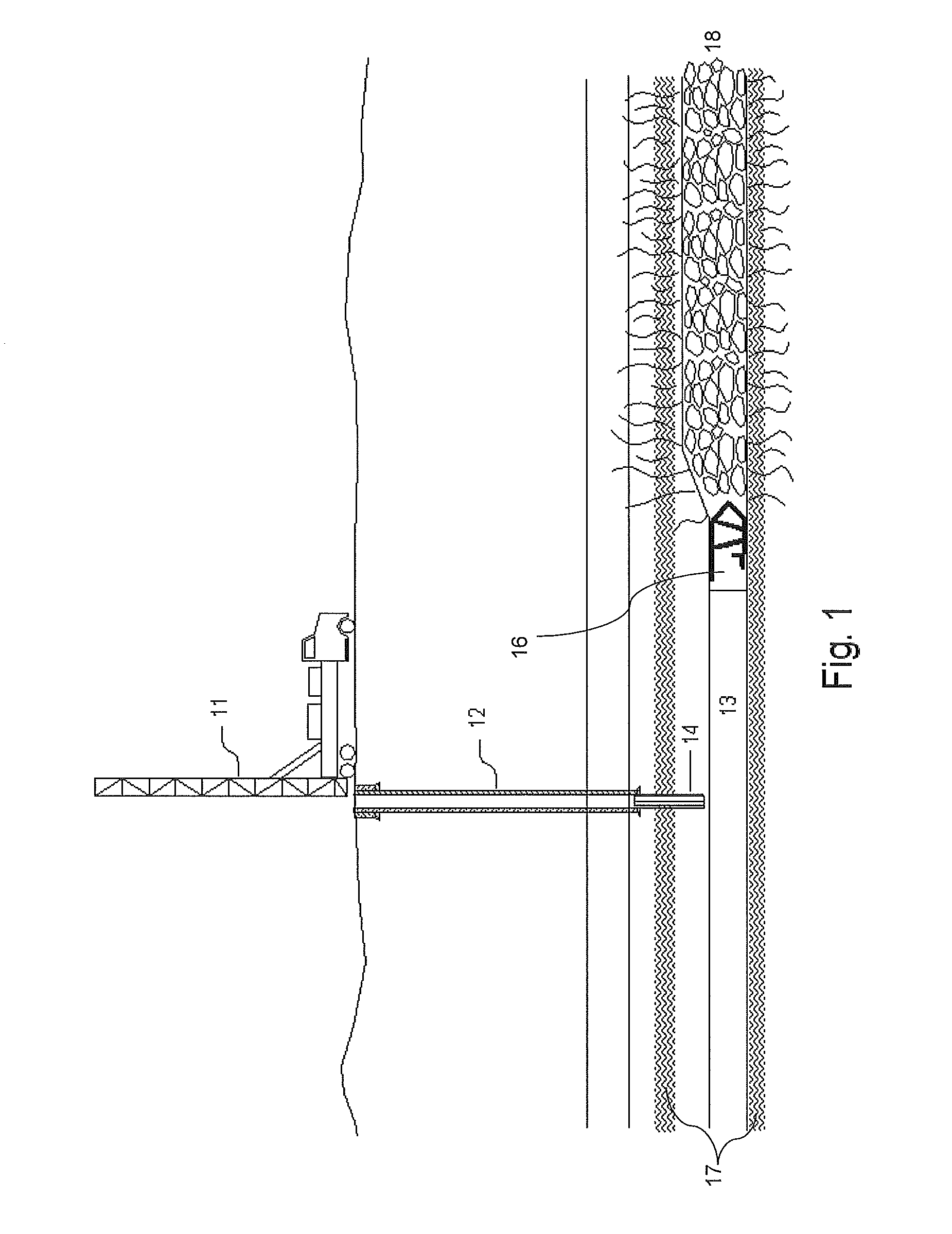

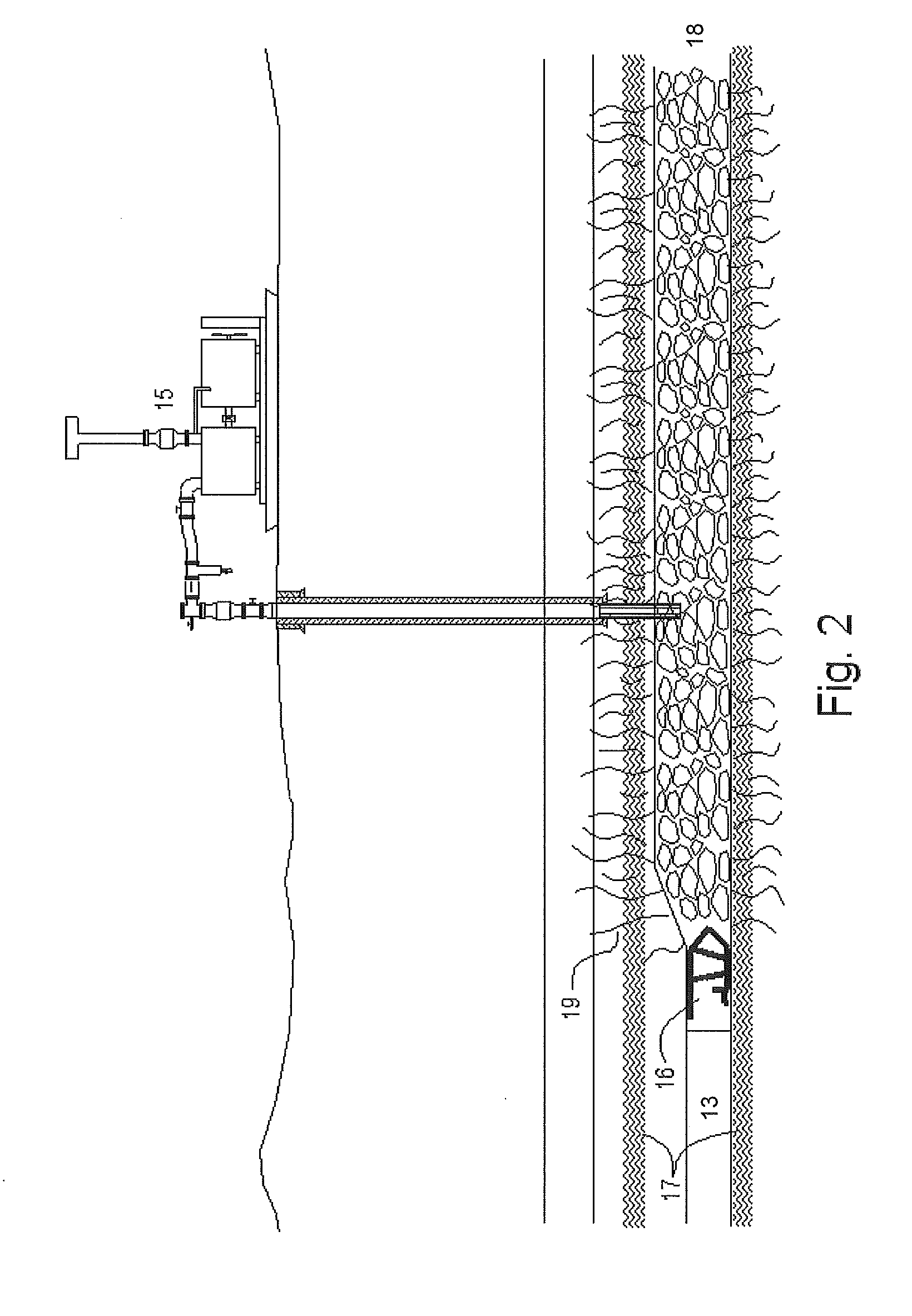

Mining method for co-extraction of non-combustible ore and mine methane

ActiveUS20090315388A1Safer working environment undergroundAvoid excessive dilutionDisloding machinesUnderground miningMineralogyMethane

Mining method for co-extraction of non-combustible ore and mine methane A method for co-extracting non-combustible ore (e.g., trona) and methane from an underground formation comprising at least one methane-bearing layer and a non-combustible ore bed having a rock roof, comprising:providing a well having a downhole end positioned above the ore bed roof;mining an ore region from an initial cavity and removing the mined ore, thereby creating a subsequent cavity;advancing the mining step to another ore region from the subsequent cavity;allowing the roof of the initial cavity to cave so as to create a gob;repeating the mining, advancing and caving steps, the caving being effective in generating fluid communication between the gob and the well downhole end and in fracturing the methane-bearing layer so as to release methane into the gob; andrecovering a gob gas comprising released methane through the well to the surface.

Owner:SOLVAY CHEM INC

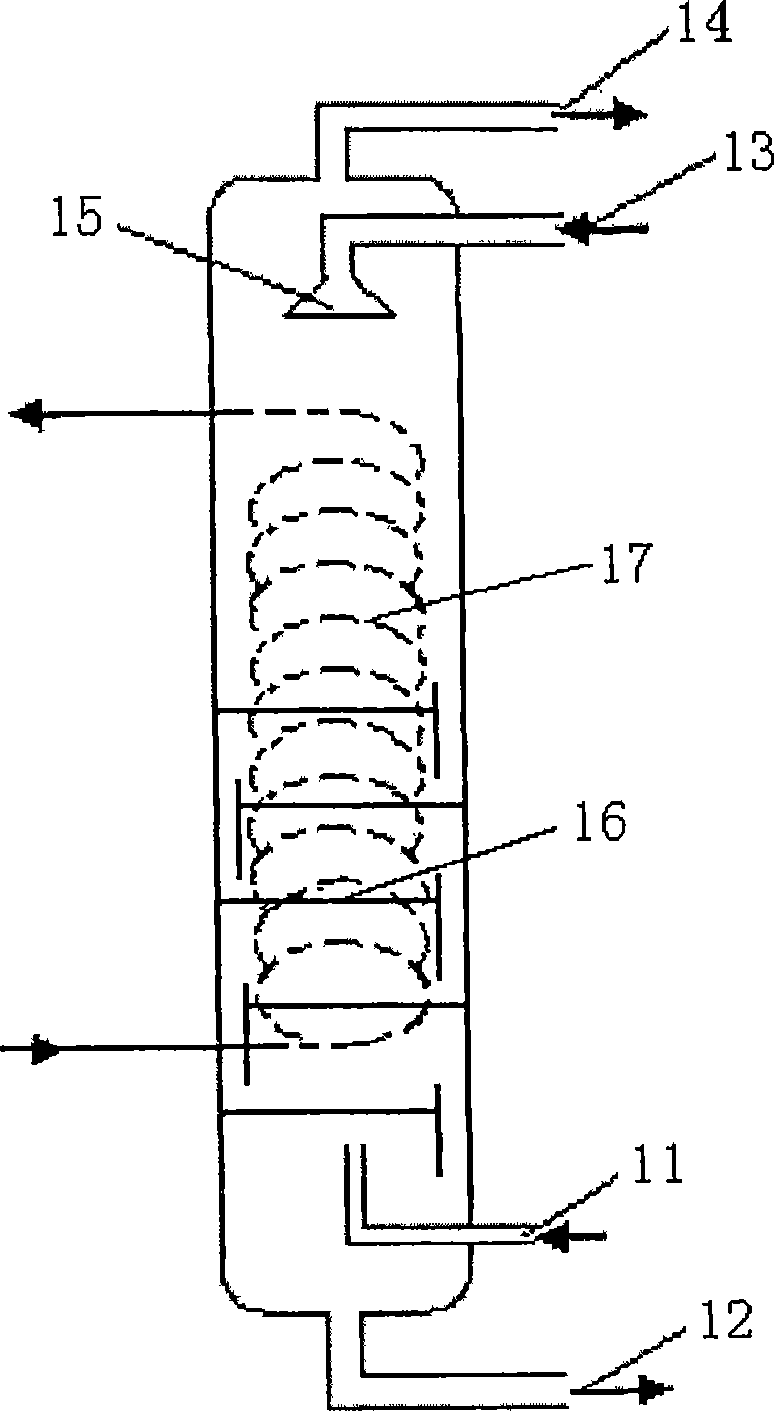

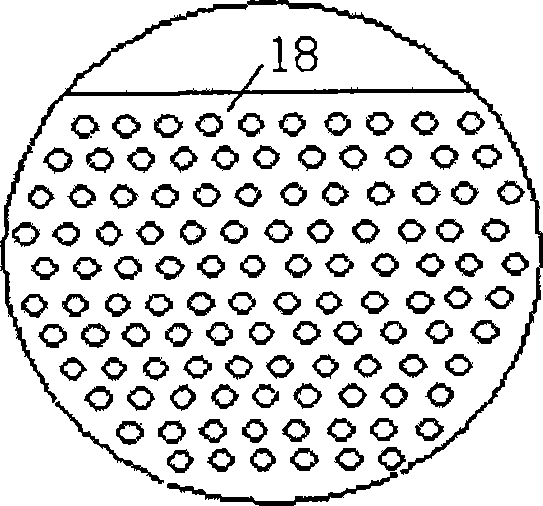

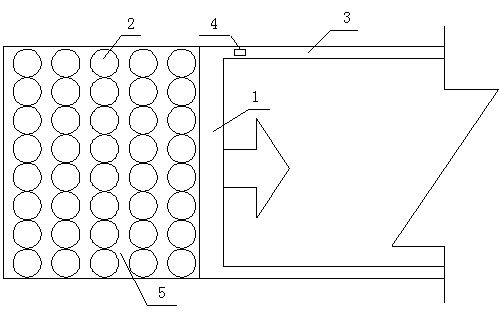

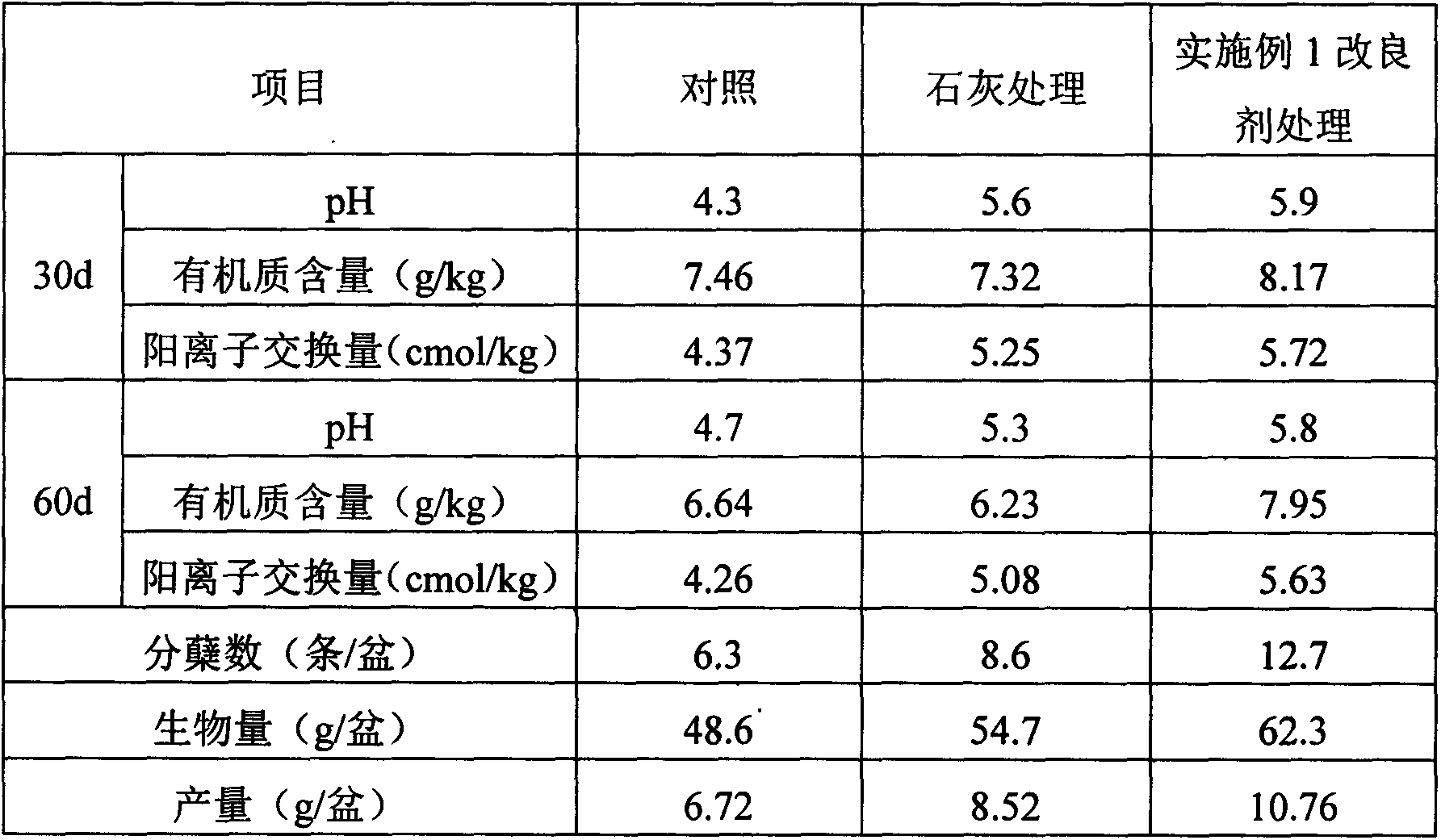

Light bioreactor for culturing microalgae systematically

ActiveCN101654653ARelieve pressureAvoid breakingBioreactor/fermenter combinationsBiological substance pretreatmentsBiodieselSprayer

The invention relates to a light bioreactor for culturing microalgae systematically, which comprises an in-parallel pipe group, a control valve, a pH value sensor, a temperature sensor, a light sensor, a water mist sprayer, a liquid level alarm, a pipe pump, an air inlet pipe, an exhaust pipe, a feed pipe, a discharge pipe, a microporous pipe, a liquid storage tank, a cool and heat exchanger, a control panel, a bracket, a lighting facility and the like, wherein the pipe group and the valve are effectively connected in a close way, specific surface area is enlarged simultaneously when the volume of microalgae is enlarged during culturing, and the invention has small ground occupation, effectively uses stereo space and has sufficient air exchange, and utilization rate is increased; during culturing, the invention monitors parameters such as temperature, pH value, concentration of a culture medium, lighting intensity, and the like in real time, provides the best condition for microalgae growth and metabolism, effectively reduces culturing time, avoids danger of outside harmful creatures, and decreases production cost. The bioreactor can be used for culturing microalgae cells in a continuous or semi-continuous way and producing microalgae protein, biodiesel or aquatic baits and other products.

Owner:云南爱尔发生物技术股份有限公司

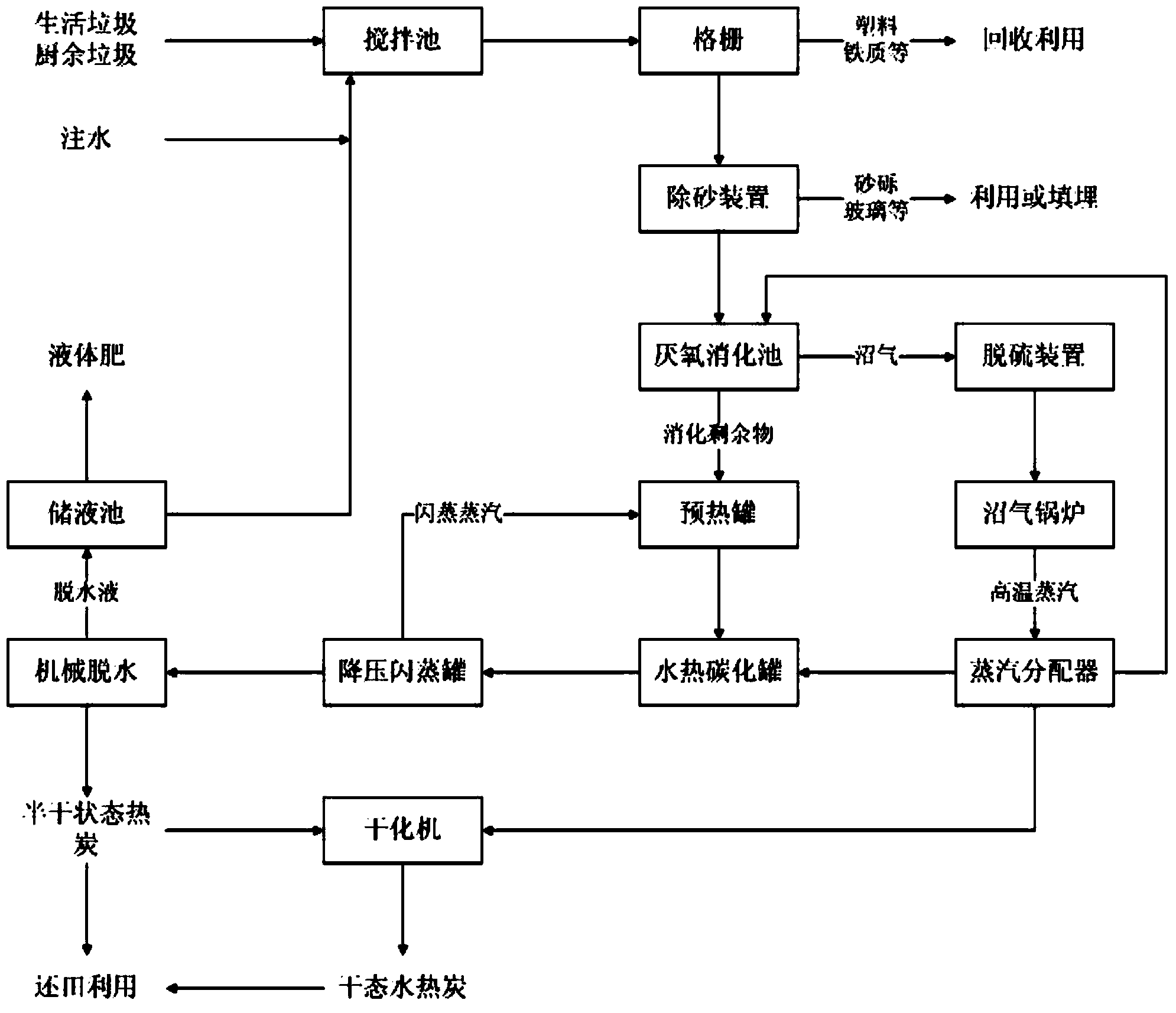

Domestic waste comprehensive treatment method based on anaerobic digestion and hydrothermal carbonization

ActiveCN103722002AIncrease energy densityHigh agronomic valueBio-organic fraction processingSolid waste disposalResource recoveryEnergy regeneration

The invention relates to a municipal solid waste reduction, energy regeneration and recycling method, and discloses a domestic waste comprehensive treatment method based on anaerobic digestion and hydrothermal carbonization. The domestic waste comprehensive treatment method comprises the following steps: slurry treatment, anaerobic digestion, hydrothermal carbonization, dewatering and drying. The domestic waste and kitchen waste are subjected to reduction, energy regeneration and recycling treatment, so that the domestic waste comprehensive treatment method is high in resource recycling degree, low in operation cost, clean and environment-friendly, and can ensure that pathogenic microorganisms in the wastes are completely killed, so that repugnant substances are converted and decomposed, and the domestic waste comprehensive treatment method has good economic value and social value.

Owner:HANGZHOU HUHUI ENVIRONMENTAL PROTECTION TECH

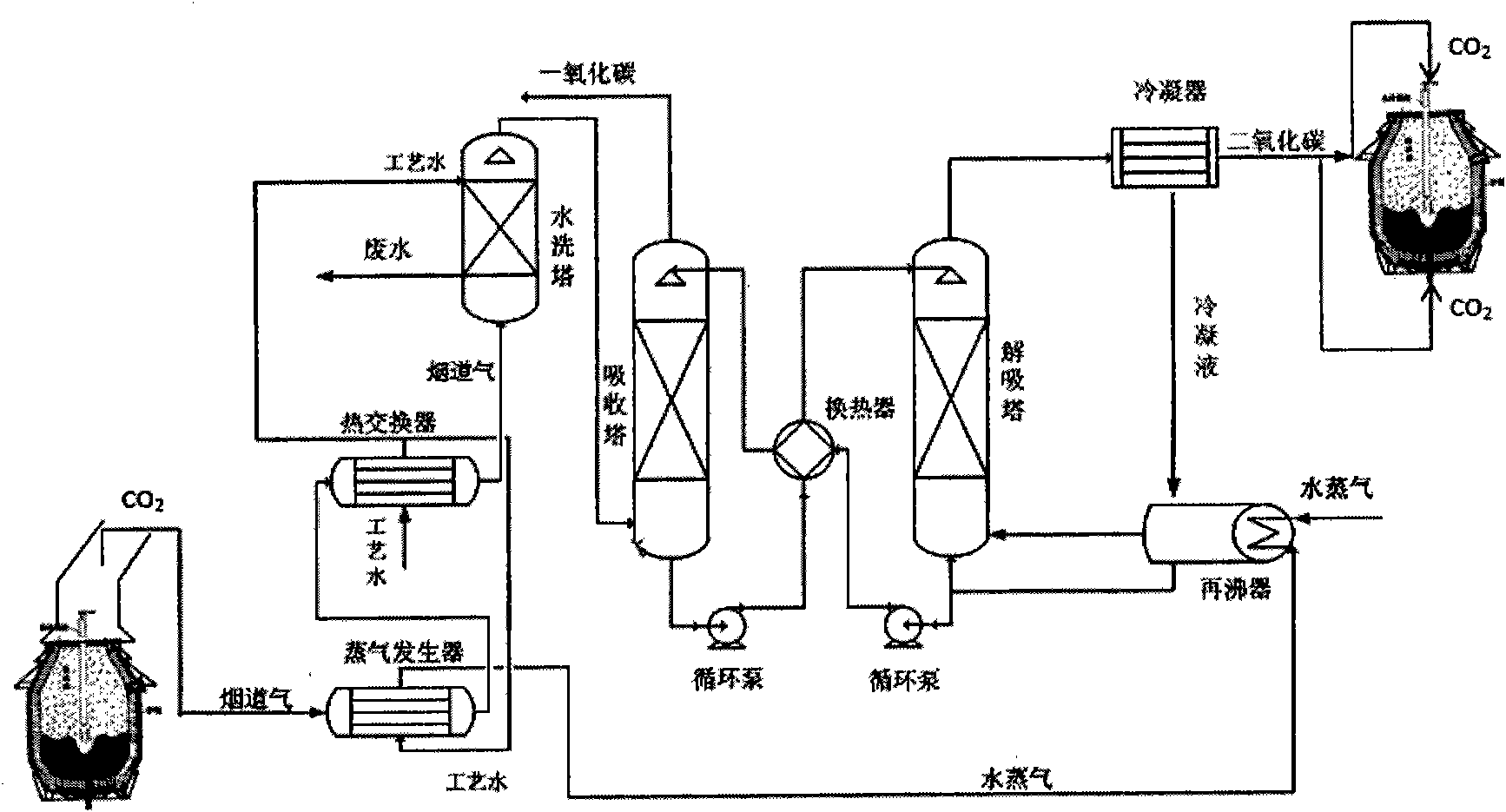

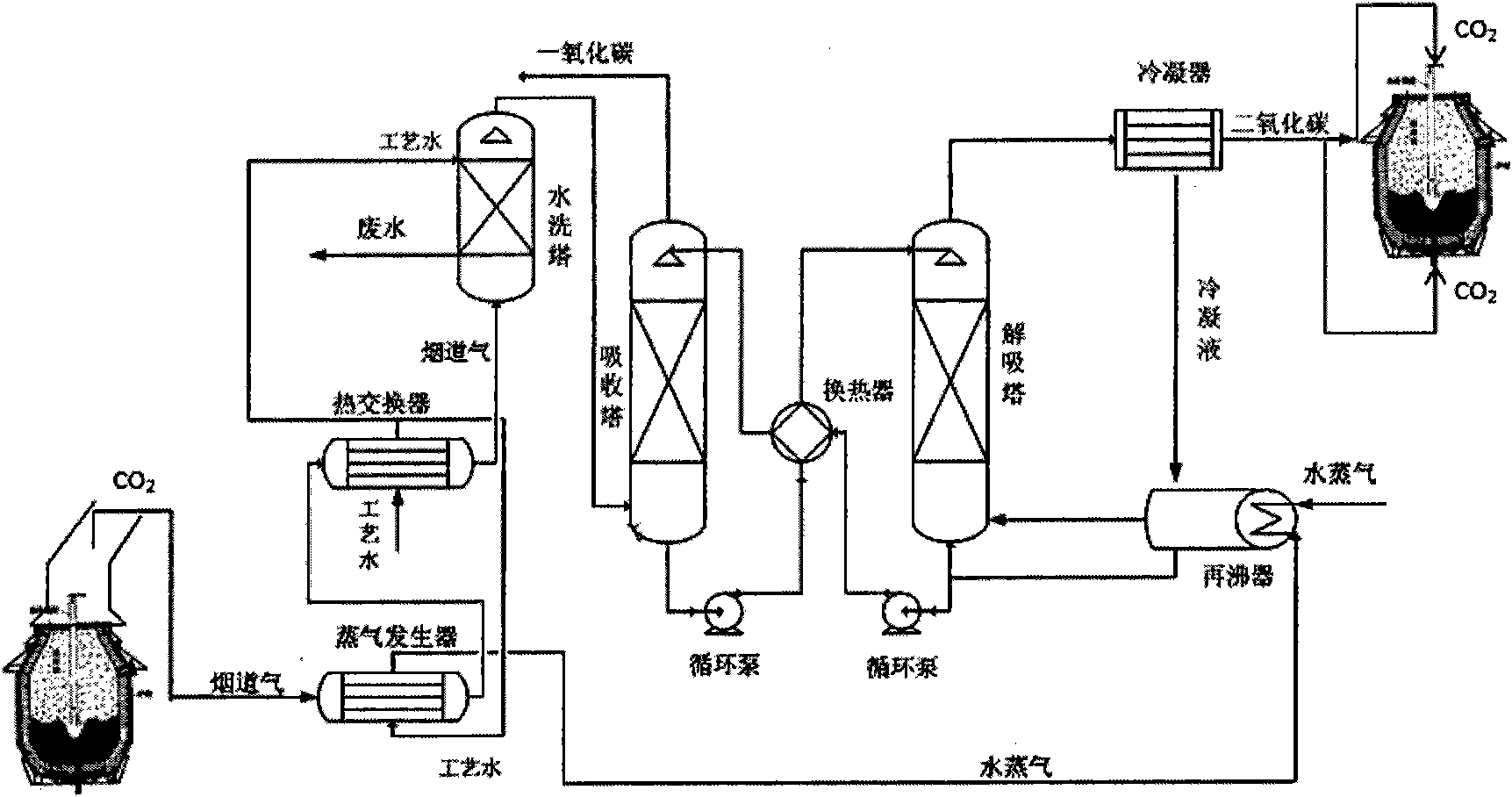

Method for recycling CO2 separated from converter steel-making gas for top blowing and bottom blowing

InactiveCN101818227AHigh carbon contentControl heating rateManufacturing convertersGas emission reductionProduct gasProcess engineering

The invention discloses a method for recycling CO2 separated from converter steel-making gas for top blowing and bottom blowing and belongs to the fields of ferrous metallurgy, energy conservation and environment protection. In the invention, the CO2 in the converter steel-making gas is separated and recycled after being cooled and dedusted; the recovery is 100 to 15,000Nm<3> / h; and the concentration of CO in the converter gas is improved by 5 to 20 percent at the same time. The CO2 serves as a gas source for the top blowing and the bottom blowing of a top and bottom combined blown converter. A chemical absorption separation method is adopted to separate the CO2; steam added with rich liquid is generated by using the residual heat of the converter gas; and almost no additional energy is consumed in the process for separating the carbon dioxide. 1 to 30 percent of the CO2 and 99 to 70 percent of O2 are blown from the top part; pure CO2 or a mixture of the CO2 and N2 or Ar or O2 or gas and the like is adopted in the whole process of the bottom blowing; and the amount of the CO2 is 100 to 3,000Nm<3> / h. The method is applicable to a steel-making process for a 30 to 350 ton converter. By adopting the method, for each ton of steel, 1 to 20 m3 of CO2 emission is reduced synthetically; the soot amount is reduced by 1 to 30 percent; and the content of the CO in the gas is improved to more than 2 to 15 percent.

Owner:UNIV OF SCI & TECH BEIJING

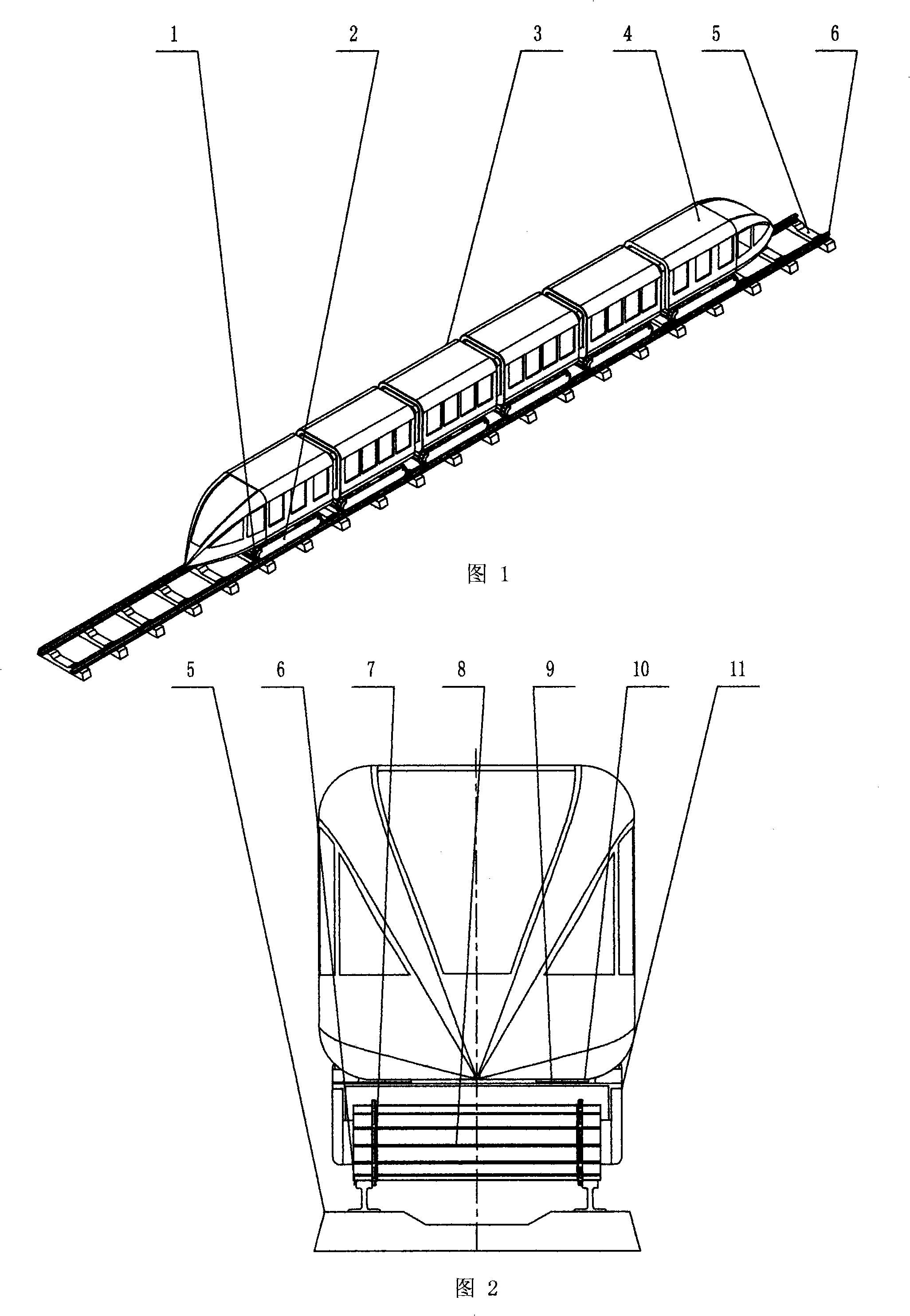

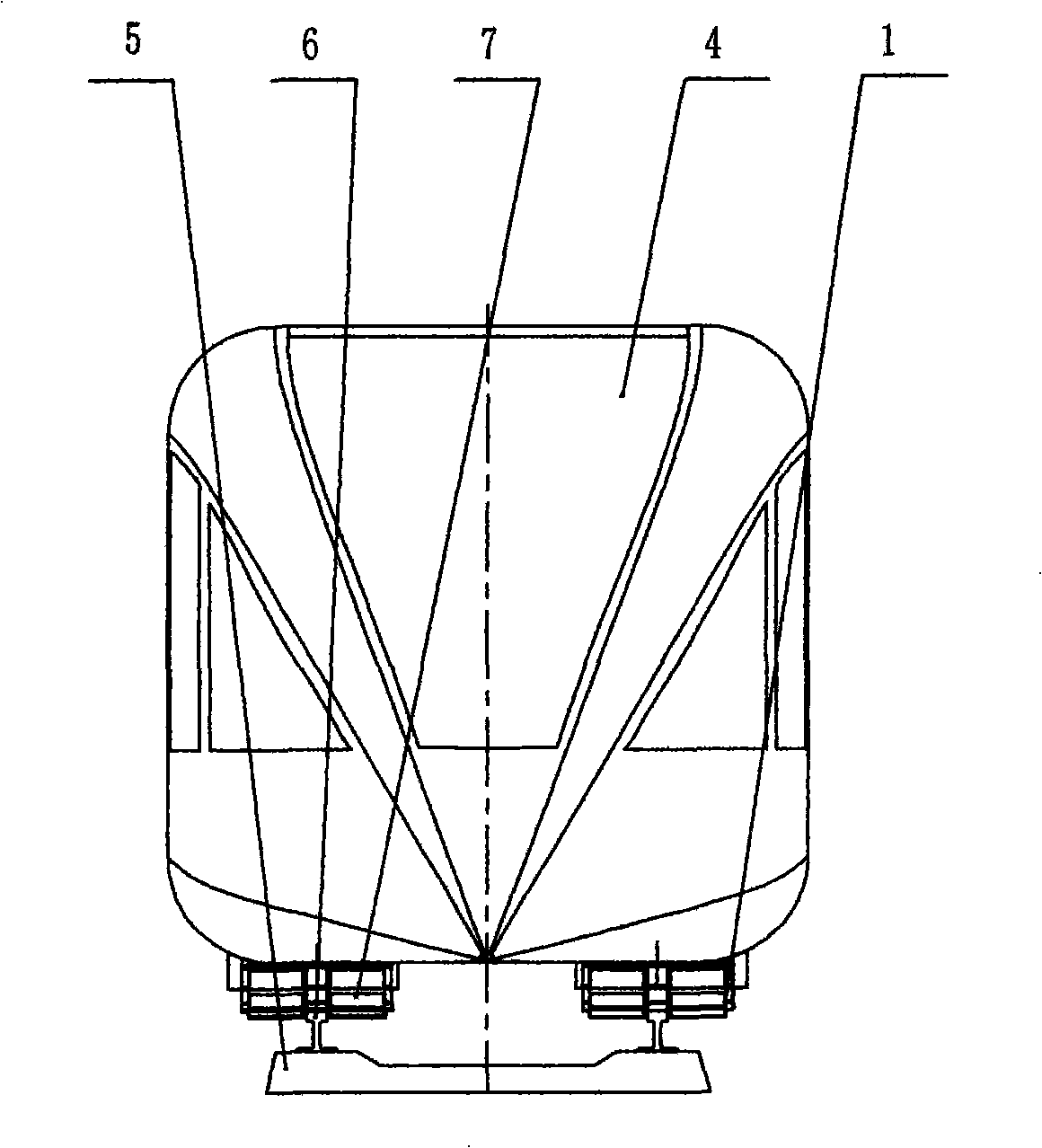

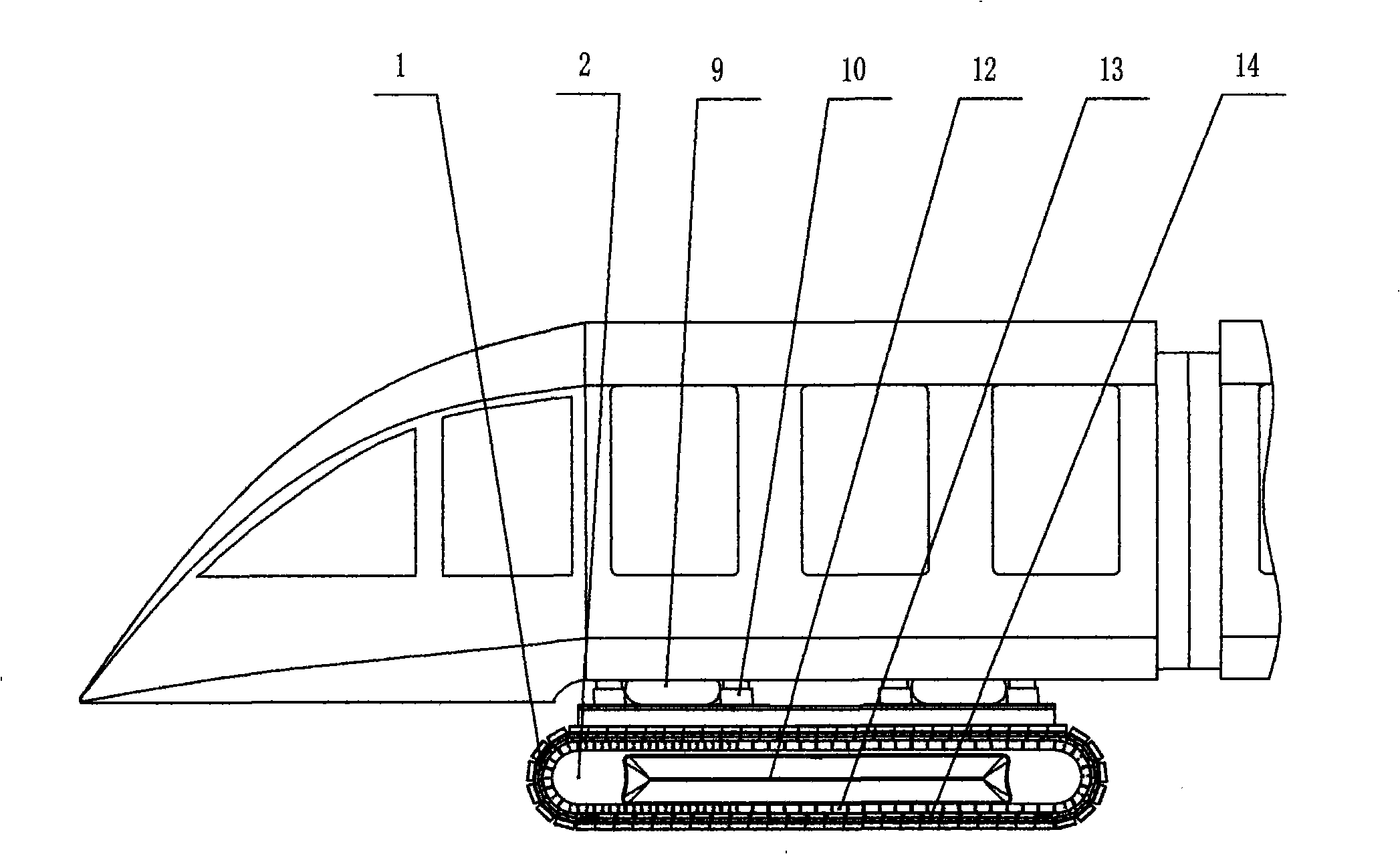

Crawler maglev vehicle and conveyor

InactiveCN101407181ASimple structureLow costEndless track vehiclesElectric propulsionDrive wheelFriction force

The invention provides a tracked magnetic suspension vehicle / a conveyer, which comprise a track, permanent magnets, a suspension seat and a driving wheel. The track is fixedly connected with the permanent magnet or a magnetizer, the suspension seat is fixedly connected with the permanent magnet, and the permanent magnet on the track and the permanent magnet on the suspension seat have homopolarity (or heteropolarity) and are arranged oppositely, generate magnetic suspension repulsive force (or attractive force) opposite to gravitational attraction, reduce or eliminate friction force when a vehicle runs, and reduce energy dissipation. The tracked magnetic suspension vehicle has the advantages of no energy consumption during suspension, low energy consumption during running, and energy saving. The tracked magnetic suspension vehicle achieves trackless magnetic suspension, also can run on a road, and is not limited by railway track any more. The tracked magnetic suspension vehicle also can be used as a magnetic suspension conveyer, and is energy-saving, clean and dustless.

Owner:刘忠臣

Biological carbon soil conditioner and preparation method thereof

ActiveCN101818067AHigh porosityImprove adsorption capacityAgriculture tools and machinesOrganic fertilisersSodium BentoniteSoil organic matter

The invention discloses a biological carbon soil conditioner and a preparation method thereof. The biological carbon soil conditioner mainly comprises the following components in parts by weight: 40-60 parts of biological carbon, 10-25 parts of pumice and 20-45 parts of bentonite, wherein the biological carbon is obtained by performing anaerobic carbonization on at least one of crops straw, wooden meal, deadwood or deciduous leaves at the temperature of 300-1000 DEG C; and the biological carbon soil conditioner is prepared by the following the steps: mixing the raw materials, adding 15-35 parts of water by weight, stirring, extruding, pelletizing and packaging components. The invention can improve soil physicochemical property, enhance soil organic matter content and fertilizer utilization rate, and reduce carbon dioxide burst size.

Owner:沃达农业科技股份有限公司

Device and method for exploiting terrestrial natural gas hydrates through CO2 fracturing and displacing

InactiveCN105545273AKeep abreast of the breakdownStay abreast of penetration ratesConstructionsFluid removalControl systemEngineering

The invention discloses a device and method for exploiting terrestrial natural gas hydrates through CO2 fracturing and displacing. The device is composed of a CO2 control system, a natural gas hydrate control system and a power generation control system; the power generation control system is connected to the CO2 control system and the natural gas hydrate control system, and the CO2 control system is connected with the natural gas hydrate control system. According to the device and method, by combining CO2 dry fracturing with CO2 displacing, the problems that when the hydrates are exploited only by adopting CO2 displacing, the speed and the efficiency are low are solved, hydrate exploiting and greenhouse gas burying and storing are integrated into a whole, and meanwhile the stability of a hydrate layer in the exploiting process is guaranteed. Information such as the pressure, the temperature and the permeability of the hydrate layer can be collected in real time in the fracturing and exploiting process, the exploiting speed of hydrate decomposition gas and improvement treatment on the reservoir permeability are adjusted and controlled according to the information, and therefore the purpose of efficient and safe exploiting is achieved.

Owner:JILIN UNIV

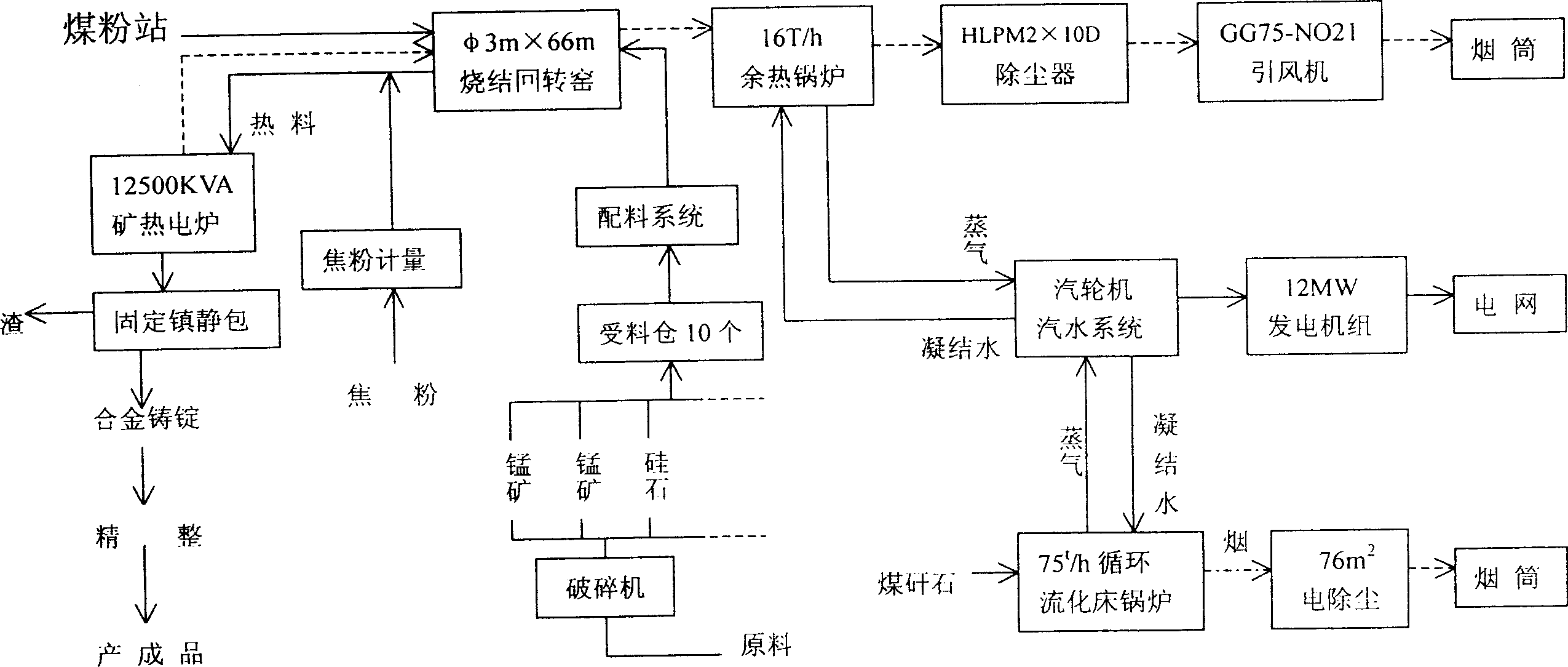

Production method of silicomangan of sintering powder by rotary kiln and hot filling in ore-smelting electric furnace

InactiveCN1912159AIncrease productionReduce power consumptionOther heat production devicesAlloyIron alloys

The invention relates to a manufacture method for siliconmanganese that uses rotary kiln sintering powder and hot charges into mine thermoelectricity furnace. It includes the following steps: mixing, sintering powder, hot charging the 5-70mm diameter powder into mine thermoelectricity furnace and the furnace temperature is 680-900 degree centigrade, melting for 6h to generate siliconmanganese mixed solution and draw a charge, separating the dregs and iron, and casting the alloy molten iron into die equipment.

Owner:偏关县晋电化工有限责任公司

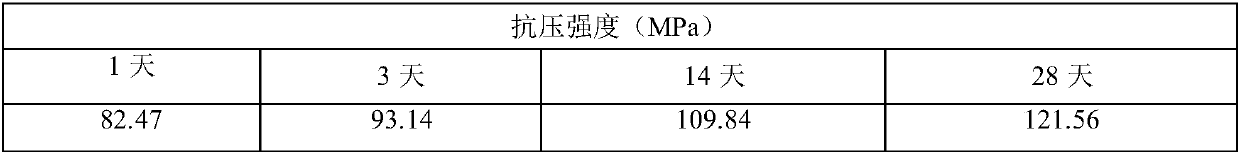

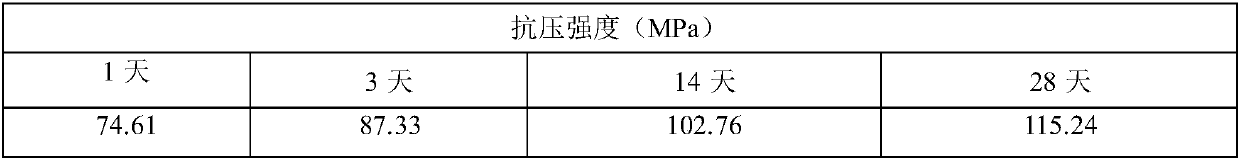

Method for efficiently preparing low-cost carbonized brick by utilizing steel slags

The invention provides a method for efficiently preparing a low-cost carbonized brick by utilizing steel slags, and belongs to the technical field of comprehensive utilization of resources. The methodincludes, firstly, mixing 45-100% of steel slags, 0-30% of desulfurized gypsum and 0-50% of fine aggregate to prepare a solid mixture; then, adding water accounting for 5-25% of the dry basis mass ofthe solid mixture and uniformly stirring; and after pressing and forming, curing the mixture in a carbonization chamber to obtain the steel slag carbonized building material. The method overcomes thedifficult problem of low comprehensive utilization rate of the steel slags, improves the production efficiency in a compression molding mode, absorbs carbon dioxide in industrial waste gas, can further alleviate the greenhouse effect to a certain extent, and has certain economic benefits, environmental benefits and social benefits, so that the prepared building material has excellent early strength and stability.

Owner:UNIV OF SCI & TECH BEIJING

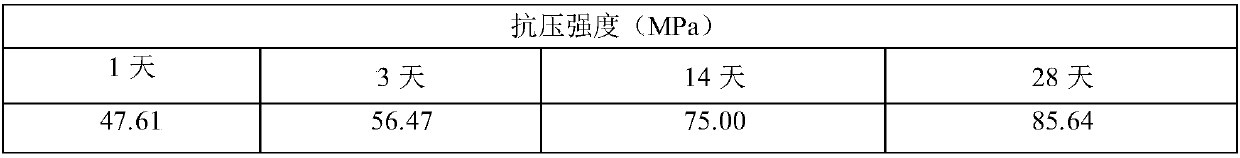

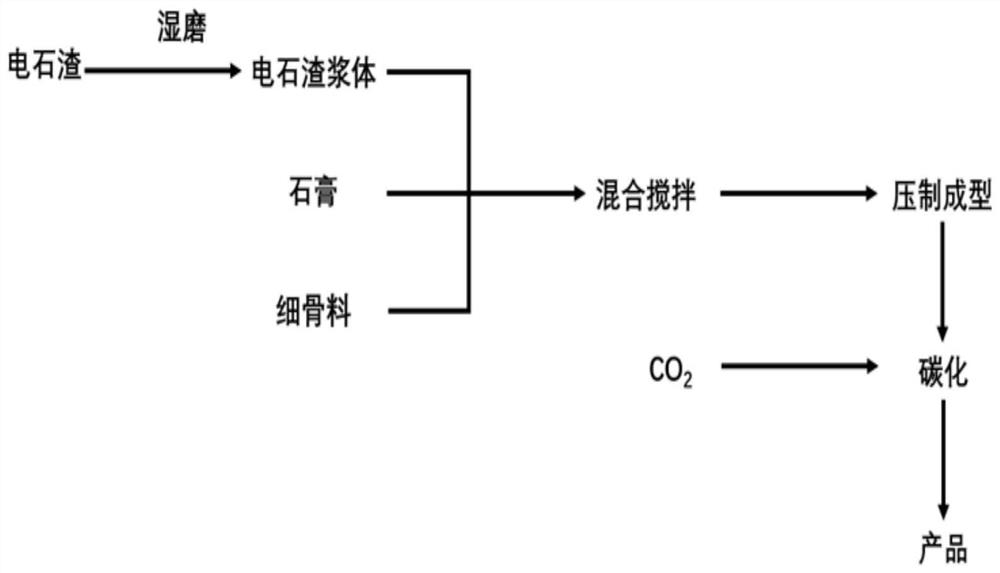

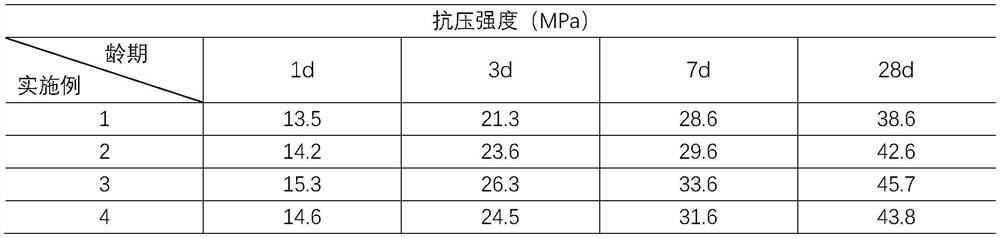

Method for preparing carbonized brick from wet-milling carbide slag

The invention provides a method for preparing a carbonized brick from wet-milling carbide slag. The method comprises the following steps: carrying out wet milling on 150-300 parts of carbide slag and75-150 parts of water to realize refining of carbide slag particles and high alkalinity of a liquid phase; preparing 120-200 parts of wet-milled carbide slag slurry, 10-35 parts of gypsum and 50-120 parts of slag as cementing materials, adding 420-865 parts of fine aggregate and 0-18 parts of wate and fully and evenly stirring the components, press-shaping the the stirred raw materials, and performing maintenance in a carbonization chamber to obtain the wet-milling carbide slag carbonized brick. By adopting the method, gas carbon dioxide can be cured, and environmental pollution caused by industrial waste gas is reduced; by utilizing the advantage that the wet-milling carbide slag is easy to carbonize and is easy to react with carbon dioxide to form calcium carbonate, and precipitate and crystal growth have cohesion, the prepared brick is high in strength and short in curing age, the production efficiency is improved, and the brick can effectively replace a common brick for construction.

Owner:HUBEI UNIV OF TECH

Energy-saving environment-protecting abrasion-proof canned carbon-hydrogen refrigerant

InactiveCN101270274ASolve the problem of cylinder wear and tearLittle effect of loadChemical industryHeat-exchange elementsAlkaneSolubility

The invention relates to an energy-saving environmental-protection type abrasion resistant canned hydrocarbon refrigerant, which comprises propane and isobutane. The energy-saving environmentally-protective abrasion resistant canned hydrocarbon refrigerant is characterized in that the energy-saving environmentally-protective abrasion resistant canned hydrocarbon refrigerant further comprises low temperature refrigeration lubricating oil; the propane accounts for 54 to 65 percent; the isobutane accounts for 30 to 40 percent, and the low temperature refrigeration lubricating oil accounts for 3 to 8 percent. The hydrocarbon refrigerant is prepared by mixing mixed alkane with certain proportion and the low-temperature refrigeration lubricating oil in proper amount, thus effectively solving the problem of the prior hydrocarbon refrigerant that a compressor is abraded frequently and a cylinder bore is scuffed frequently due to the characteristics of being too dry and excellent oil solubility, The hydrocarbon refrigerant with mixed alkane disclosed by the invention belongs to natural working fluid, is free of fluorine without influence on warming-up of the global climate. Compared with R12 and R134a, the freezing point is lower; the latent heat of vaporization is larger; the specific energy of constant entropy compression is smaller so that the compressor works more easily. The flowing property is better; the delivery pressure is lower; the load of the compressor is lower; fuel consumption is reduced and the energy-saving rate can reach 10 percent to 20 percent when the air conditioners are running.

Owner:周飞

Converter steelmaking process by blowing CO2 gas

A converting process that jets carbon dioxide, belonging to ferrous metallurgy field. The process takes oxygen and carbon dioxide or the mixed gas with oxygen and carbon dioxide as gas source, the injection quantity of gas is 1000-120000Nm3 / h, the pressure is 0.4-1.6MPa.The process can make use of carbon dioxide recovered and treated from waste gas that generated by various industrial furnace, and also can exploit natural carbon dioxide as gas source. It suits for steel that the carbon content is 0.01-1.30% in the smelting steel. By using carbon dioxide instead of oxygen, it decreases the burning loss of iron and other metal element during the smelting process, which deducing the production cost and the consumption of oxygen, and therefore plays a positive part in alleviating the green house effect and has a dramatic social benefit.

Owner:UNIV OF SCI & TECH BEIJING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com