Organic Rankin cycle and heat pump cycle coupling system

A technology of Rankine cycle and heat pump cycle, applied in the operation mode of machines, mechanical equipment, steam engine devices, etc., can solve the problems of low efficiency of Rankine cycle, weakened electricity, poor economy, etc., to reduce the greenhouse effect and atmospheric Effects of pollution, realization of energy reuse, reduction of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

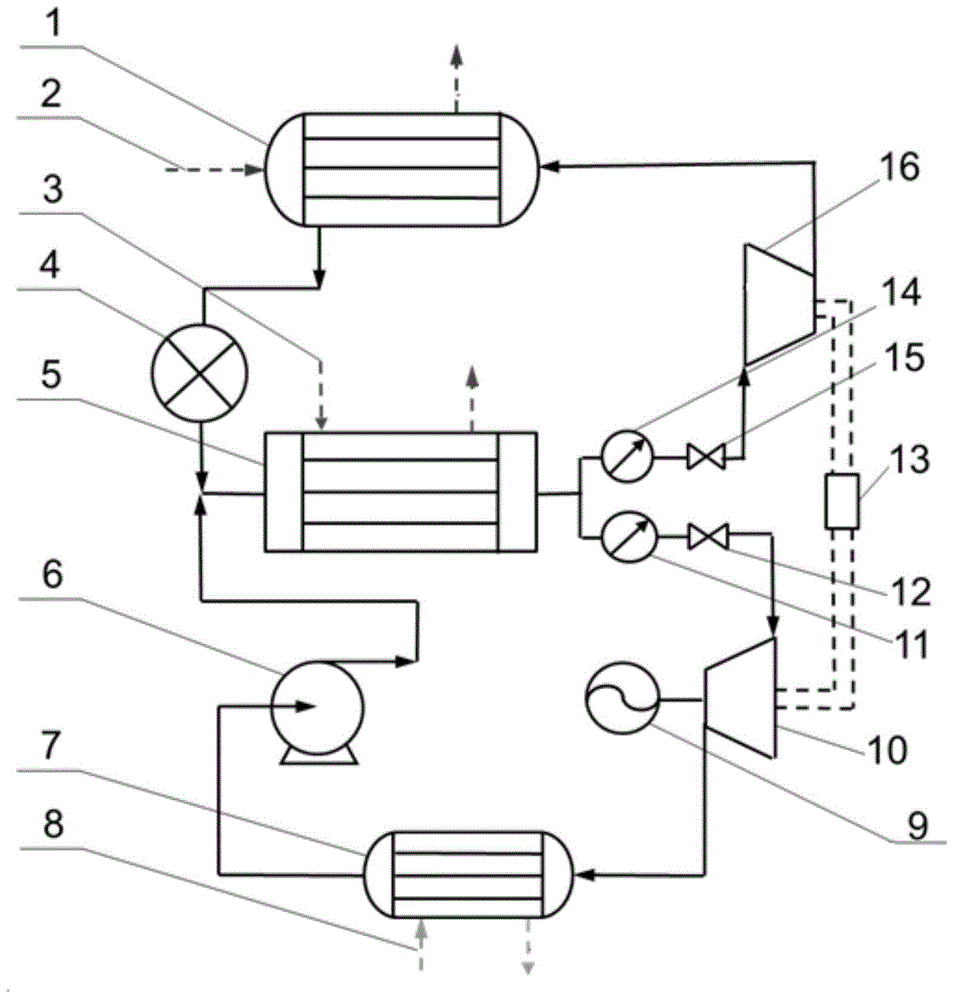

[0034] Such as figure 1As shown, a coupling system of an organic Rankine cycle and a heat pump cycle, the system includes an organic Rankine cycle unit and a heat pump cycle unit coupled to each other, and the organic Rankine cycle unit and the heat pump cycle unit share the same evaporator 5; wherein, The organic Rankine cycle unit includes an evaporator 5, a first flow meter 11, a first flow regulating valve 12, an expander 10, a low-temperature condenser 7 and a working medium pump 6, and the outlet end of the evaporator 5 is sequentially connected with the first pipeline through the first pipeline. The first flow meter 11, the first flow regulating valve 12, the expander 10, the low temperature condenser 7 and the working medium pump 6 are connected, and are connected to the inlet port of the evaporator 5 through the working medium pump 6, forming an organic Rankine cycle loop ; The heat pump cycle unit includes an evaporator 5, a second flow meter 14, a second flow regula...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com