Patents

Literature

277results about How to "Fast deposition rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for repairing crack of cement-based material

ActiveCN103342484APassive repair implementationGuaranteed durabilityBacteriaBiotechnologyMicroorganism

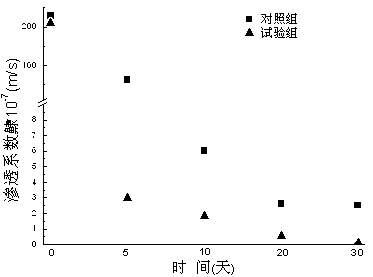

The invention discloses a method for repairing a crack of a cement-based material. According to the method, carbonic anhydrase microorganisms are adopted for generating carbonic anhydrase used for catching CO2, CO2 is promoted to be converted into CO3<2->, and the deposition of calcium carbonate within a surface area of the crack is accelerated; the method has the advantage that the repair speed is faster than that of other methods for repairing the crack through the microorganisms. The method comprises the following steps of: inoculating bacillus mucilaginosus to a culture medium; culturing; preparing bacillus mucilaginosus concentrated bacteria liquid; immobilizing bacteria on carriers; uniformly burying calcium sources into the cement-based material during forming the cement-based material; concentrating the carriers with the bacteria immobilized into a range of 5mm under a surface area of a test part; manufacturing the crack after a part to be tested is cured; transferring into a thermostatic waterbath; continuously charging air for maintaining and repairing. The repair test result shows that the osmotic coefficient is greatly reduced after repairing for 5 days, and the crack is repaired completely after continuously repairing for 30 days.

Owner:SOUTHEAST UNIV

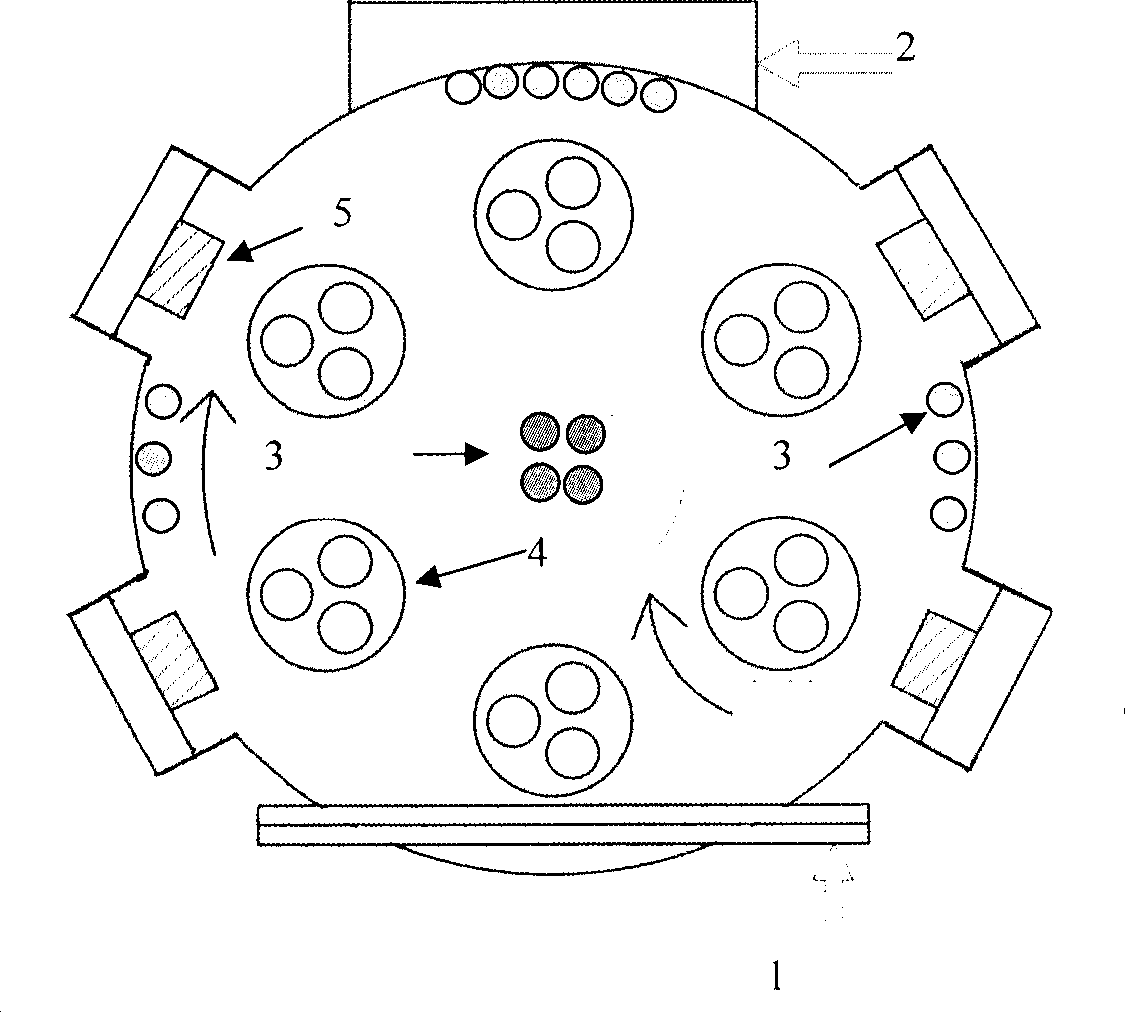

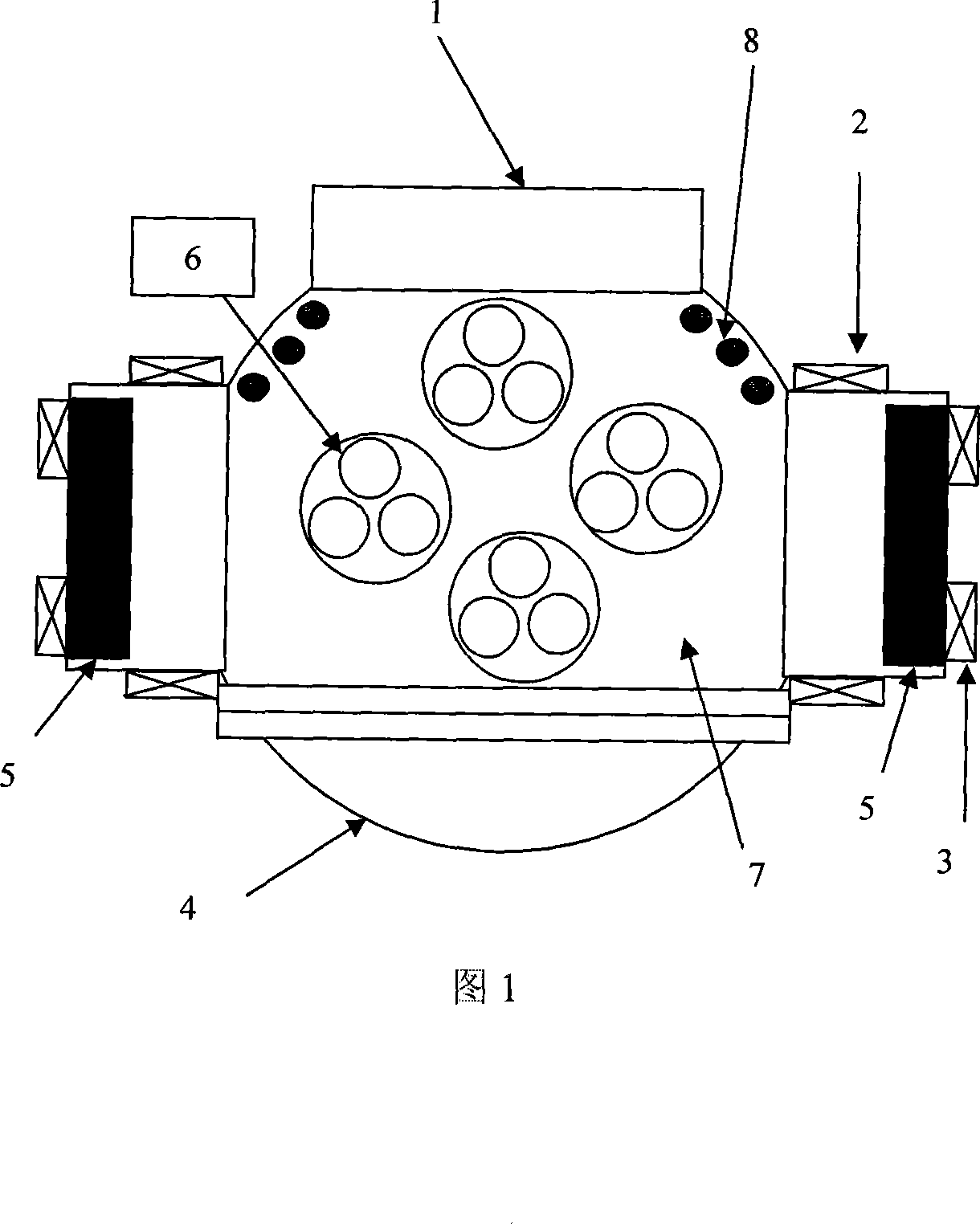

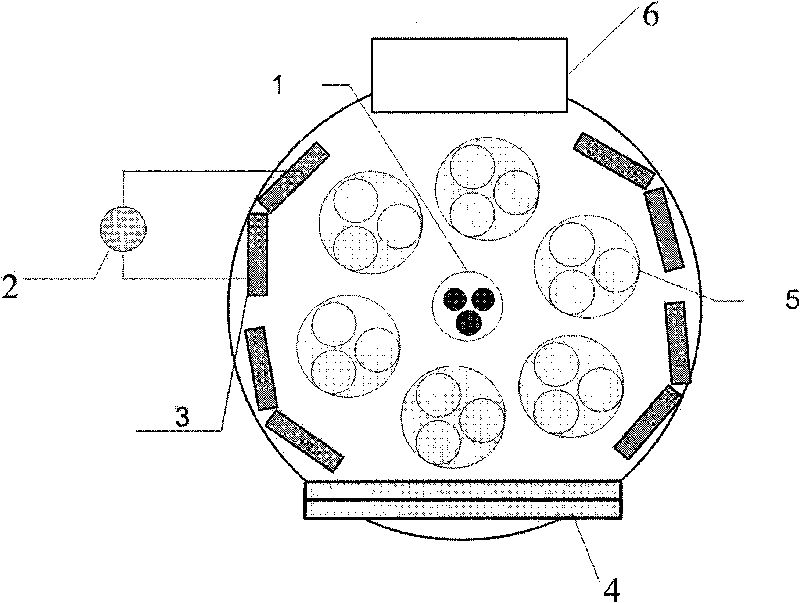

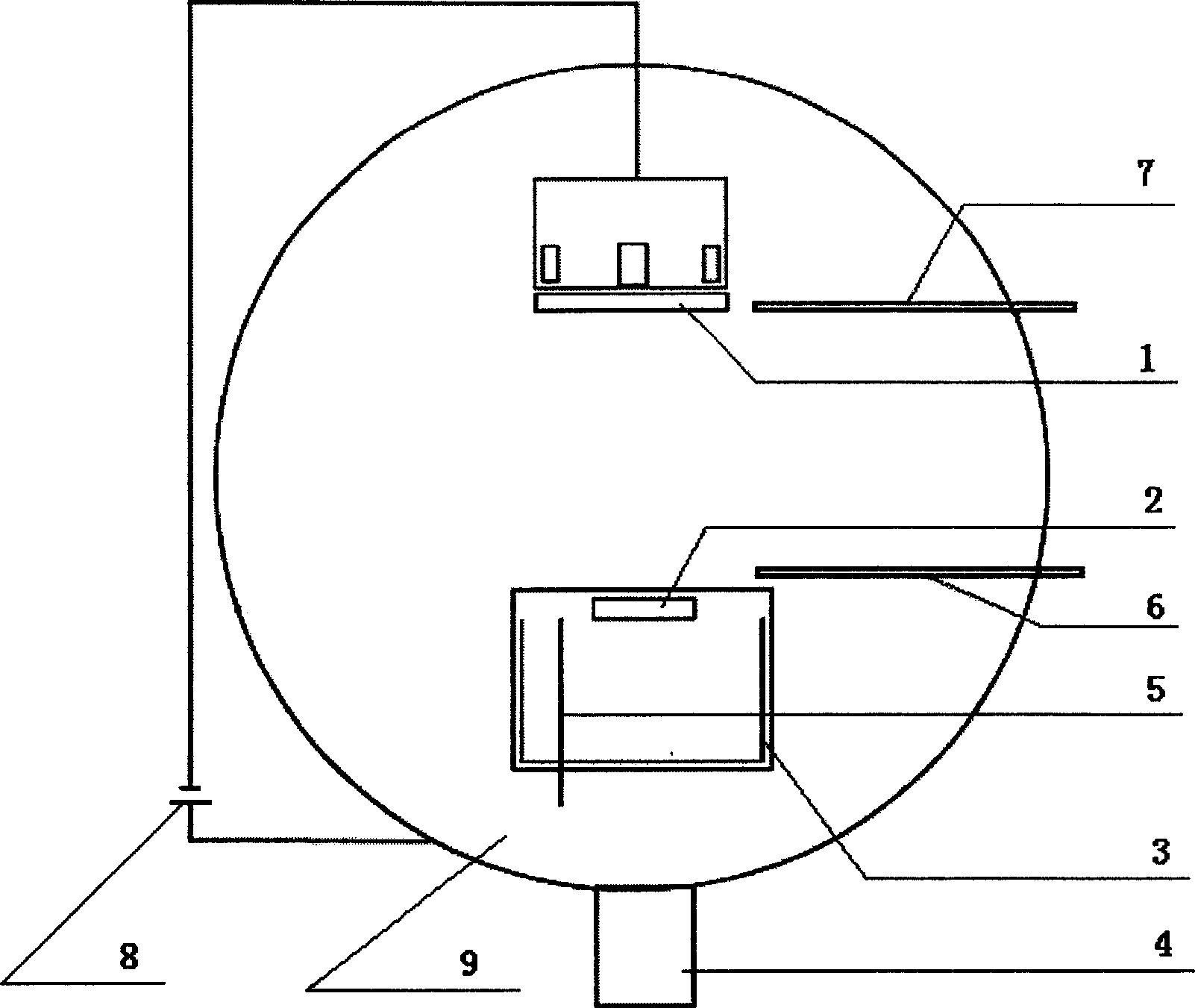

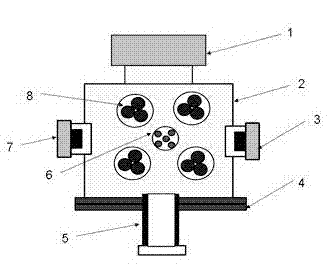

Device for rapid large-area preparation of thin film material and setting method

InactiveCN101158034AReduce defectsAvoid damageSemiconductor/solid-state device manufacturingChemical vapor deposition coatingHigh rateEngineering

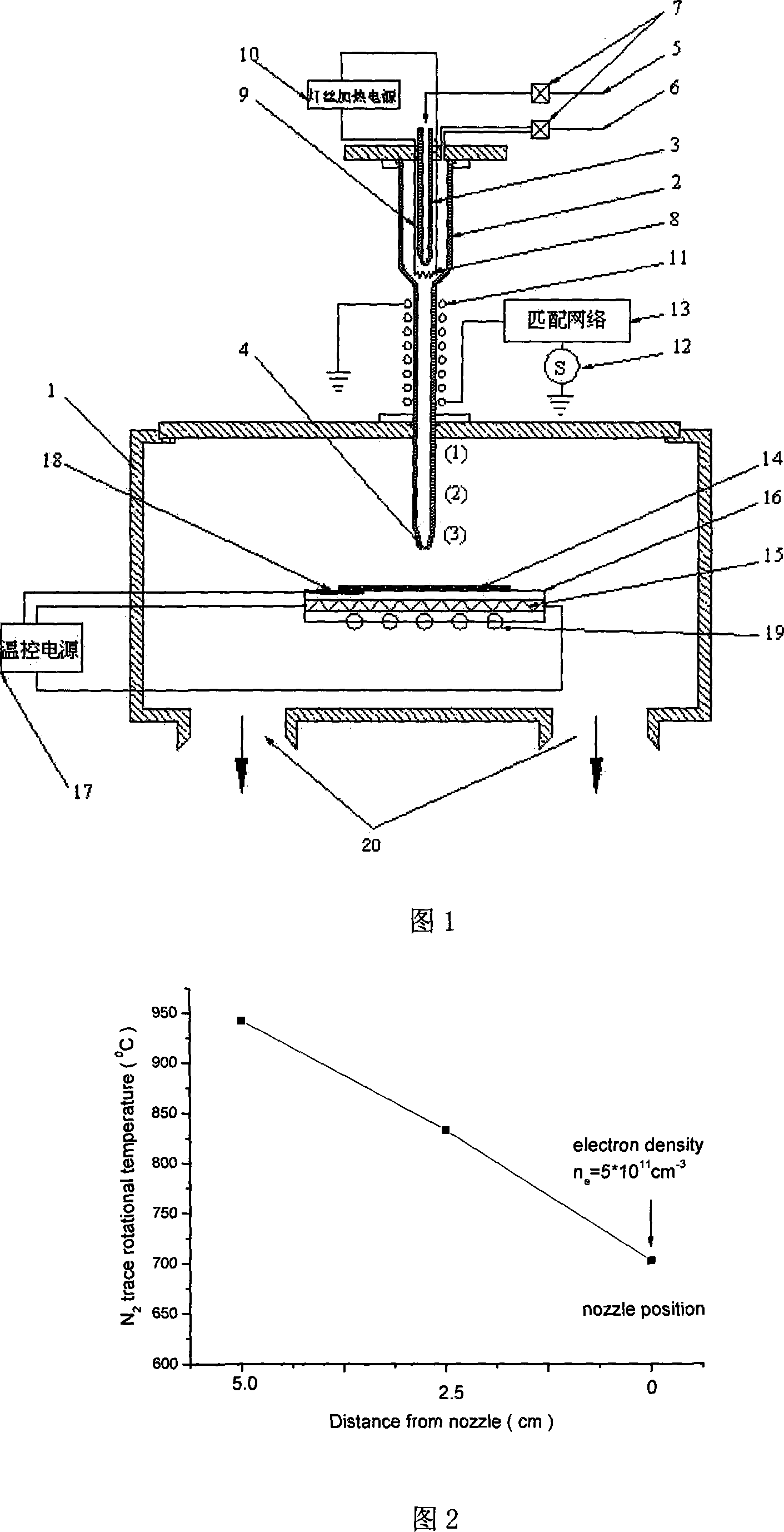

The invention relates to a thin film material preparation device. The invention seals two to four spray pipes which are used for admitting feed gas and fixed on an admitting sediment cavity. The admitting sediment cavity is arranged on a vacuum sediment cavity. The reacting gas or shipping gas is admitted into the spray pipes through air source. A heating wire is arranged around a spout exit of the spray pipes. An inductance coil driven by power supply is provided on an outer wall of the spray pipes. The inductance coil can generate a plasma body. A through sole platform for growing film is provided in the sediment cavity. A rarefying exit pipe is arranged at the lower part or the lower side part of the sediment cavity. The thin film material preparation device of the invention has the advantages of high film forming quality, high rate of sedimentation, low growing temperature and high gas efficiency and so on.

Owner:NANJING UNIV +1

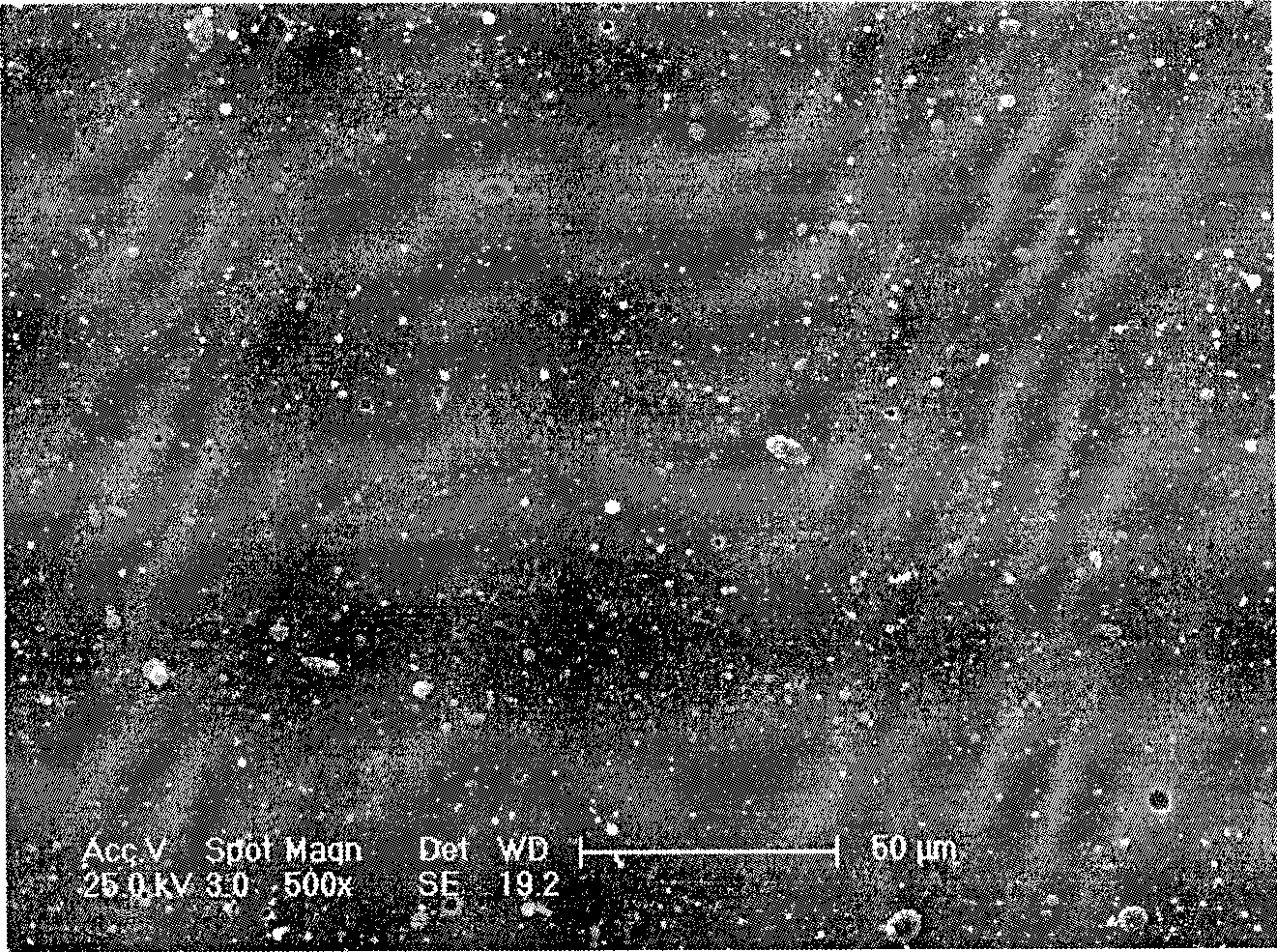

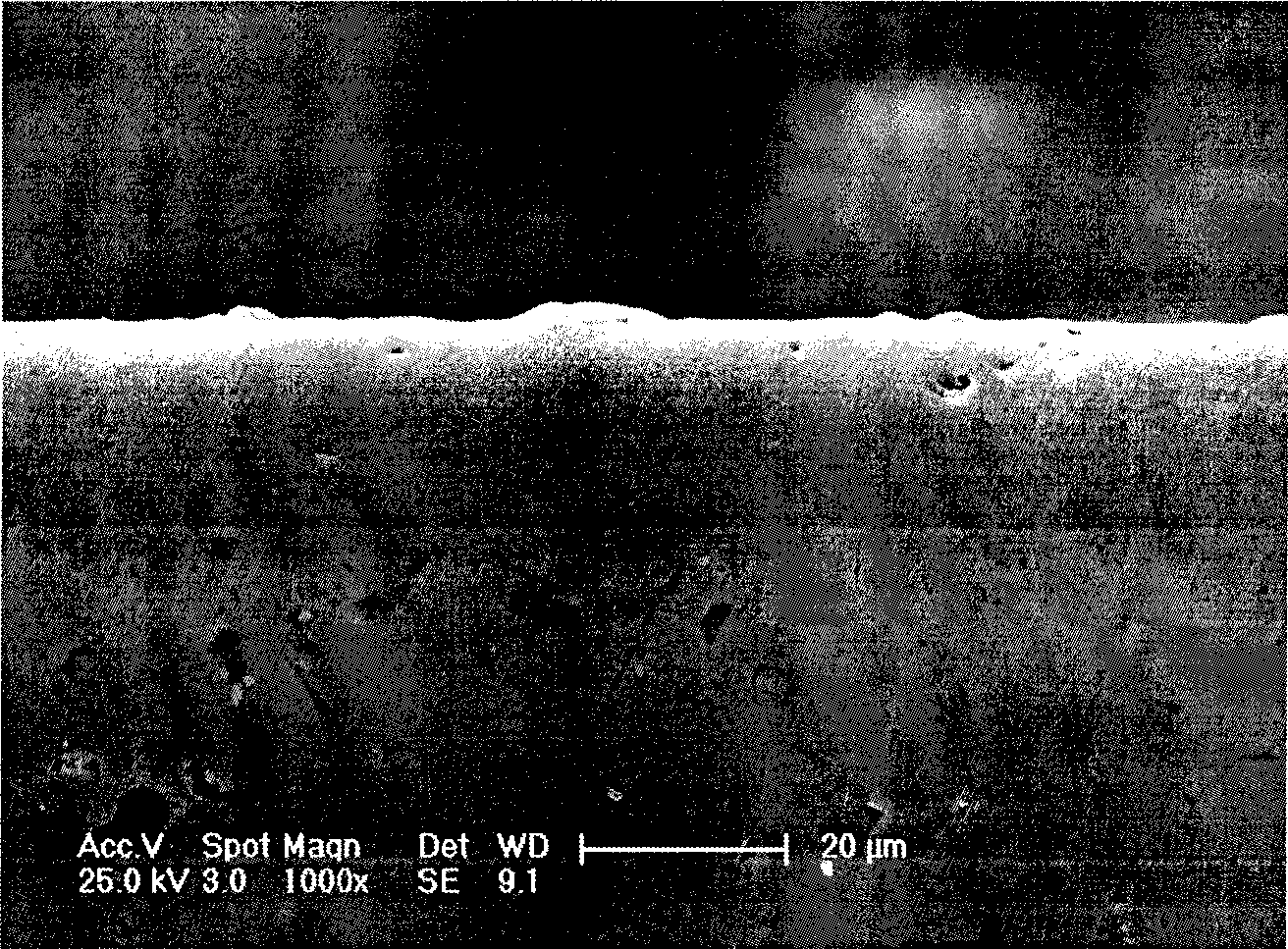

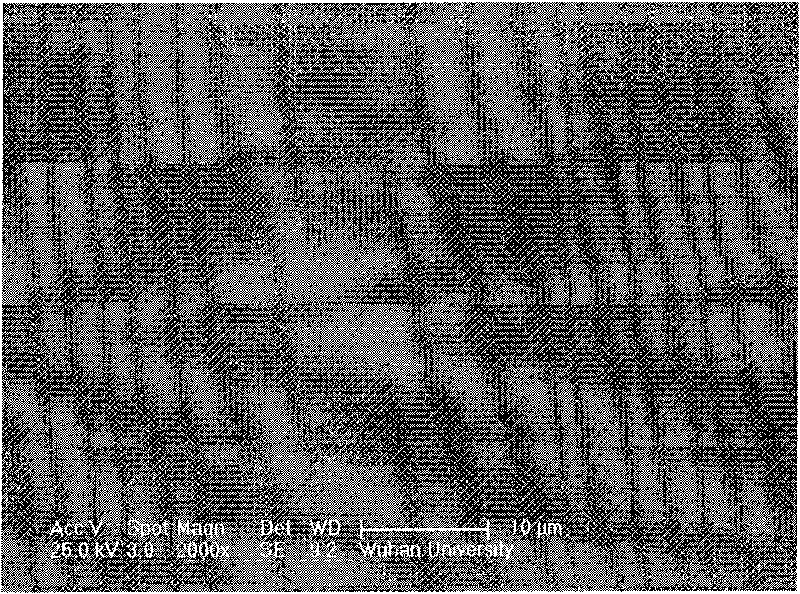

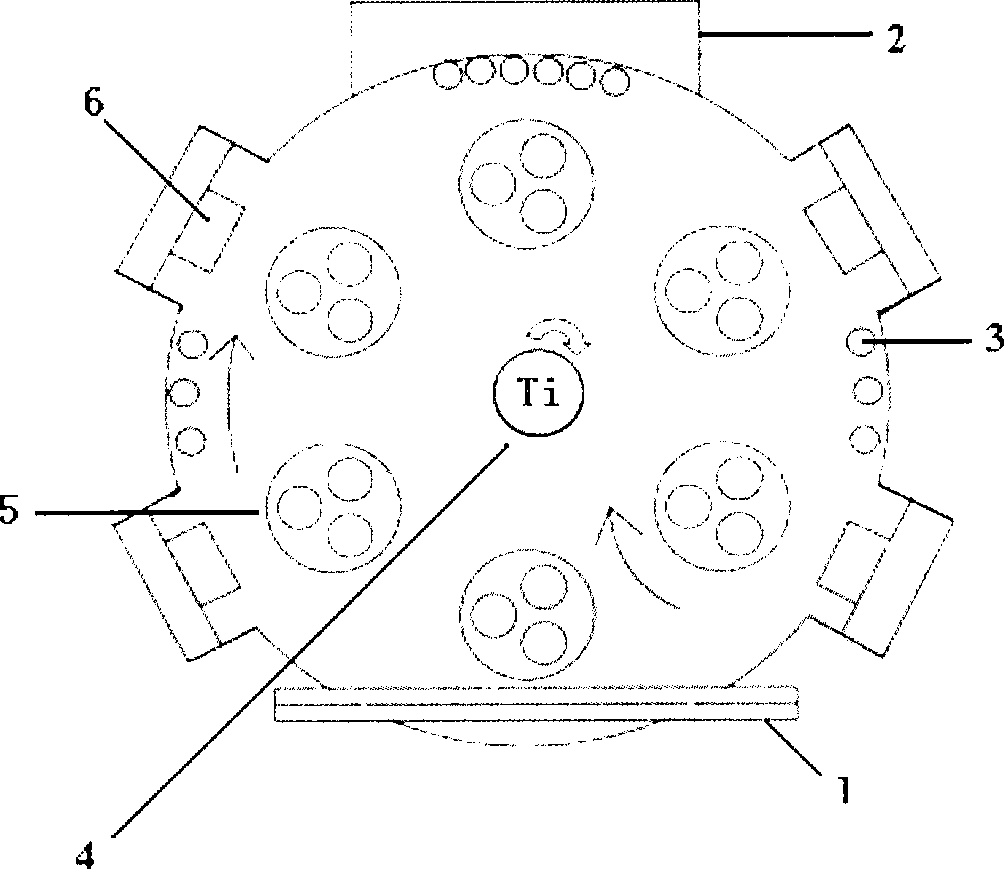

PVD chromium based ceramic composite coating piston ring and method for producing the same

InactiveCN101430004AOvercome the hardnessOvercome uniformity issuesPiston ringsVacuum evaporation coatingCeramic compositePiston ring

The invention discloses a PVD chromium base ceramic composite coating piston ring and a preparation method thereof, and the piston ring is manufactured by plating a chromium base ceramic composite coating on a basal body of the piston ring which is treated by nitriding by adopting high power electric arc discharge method; the chromium base ceramic composite coating is composed of a bonding layer, a main wearing layer and an anti-attrition layer, wherein, the bonding layer is binded with the basal body of the piston ring in a metallurgical way, the main wearing layer is arranged on the bonding layer, and the anti-attrition layer is positioned on the surface of the main wearing layer; the bonding layer is Cr, the main wearing layer is a Cr / CrN multilayer coating formed by the Cr and the CrN which are alternately arranged, and the anti-attrition layer is a Cr / Cr2O3 multilayer coating formed by the Cr and the Cr2O3 that are alternately arranged. The coating structure has reasonable design, and the manufactured coating has good cementing property, high hardness and good lubricating property. Furthermore, the method used for manufacturing the piston ring has no pollution in the preparation process, and overcomes the serious problem of environmental pollution of the conventional electrodeposited chromium; as the manufactured coating has better abrasion resistant and corrosion resistant performance compared with the electrodeposited chromium, the service life of the piston ring is greatly prolonged.

Owner:WUHAN UNIV

A kind of preparation method of metal electrode of crystalline silicon solar cell

ActiveCN102299200AReduce manufacturing costImprove yieldFinal product manufactureSemiconductor devicesSilicon solar cellMetal electrodes

The invention discloses a method for preparing metal electrodes of a crystal silicon solar cell, which comprises the steps that: after the PN junction is prepared on a p-type crystal silicon substrate through diffusion, a silicon nitride antireflection layer is prepared on the surface of a n type emitting electrode, then, a thin Al layer with the thickness being 100nm to 1000nm is prepared on thesurface of a p-type conducting back through the vacuum sputtering technology, the vapor deposition technology or the screen printing technology, in addition, a thin Ag grid line layer with the thickness being 1mum to 5mum is prepared on the surface of the silicon nitride antireflection layer through the screen printing, next, an Al back field seed layer and an Ag grid line seed layer are formed through the traditional high-temperature sintering technology, finally, tin, copper or nickel is electroplated on the Ag grid line seed layer and the Al back field seed layer through the electroplatingprocess, and the metal electrodes are formed after the thickening. Compared with the prior art, the method combines the advantages of the screen printing process, the magnetron sputtering process, the vapor deposition process and the electroplating process, front metal grid line electrodes with high electrical conductivity and low light shielding rate can be obtained, and simultaneously, the consumption of expensive metal Ag can be effectively reduced, so important industrialized application prospects are realized.

Owner:NINGBO INST OF MATERIALS TECH & ENG CHINESE ACADEMY OF SCI

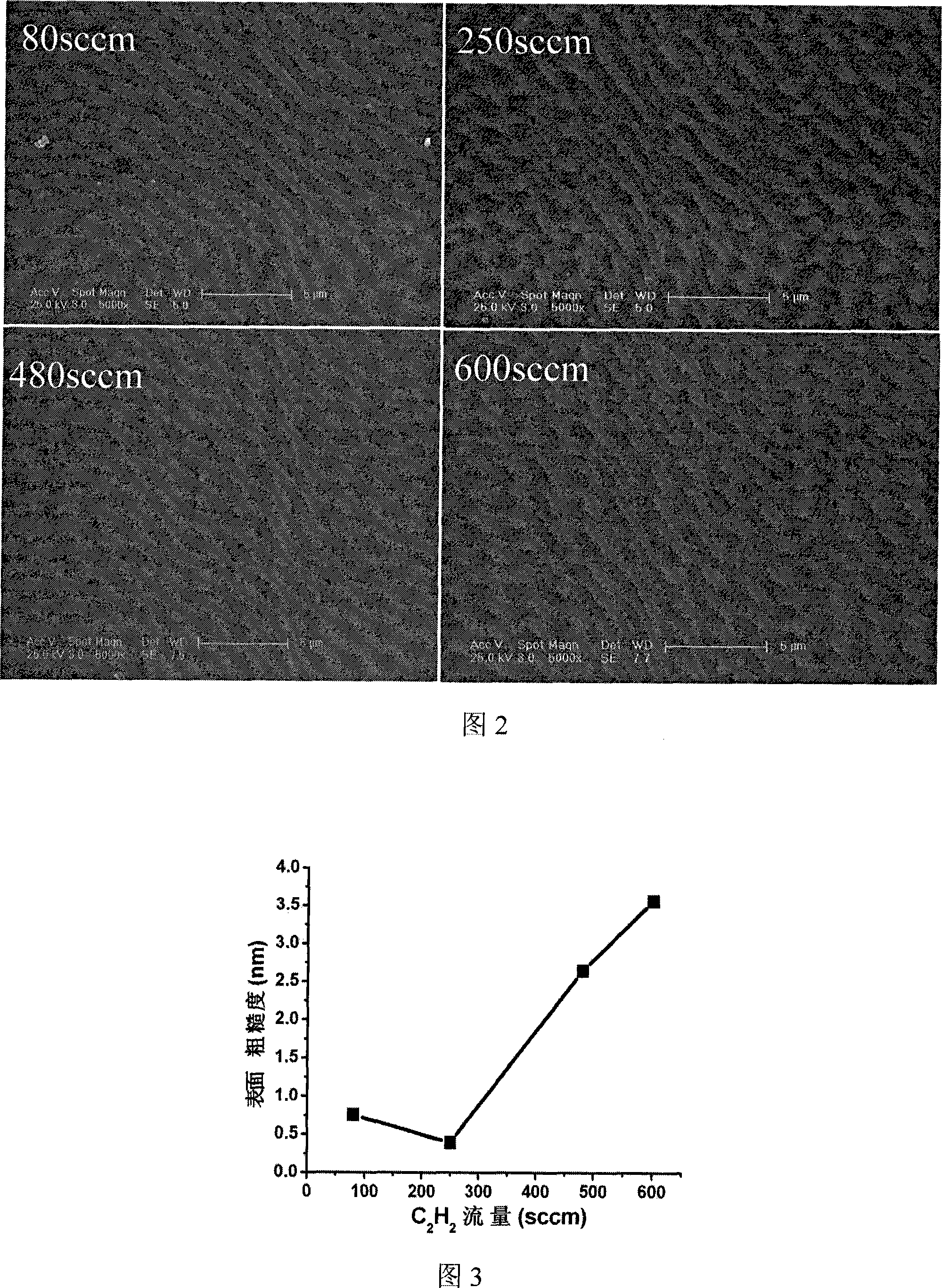

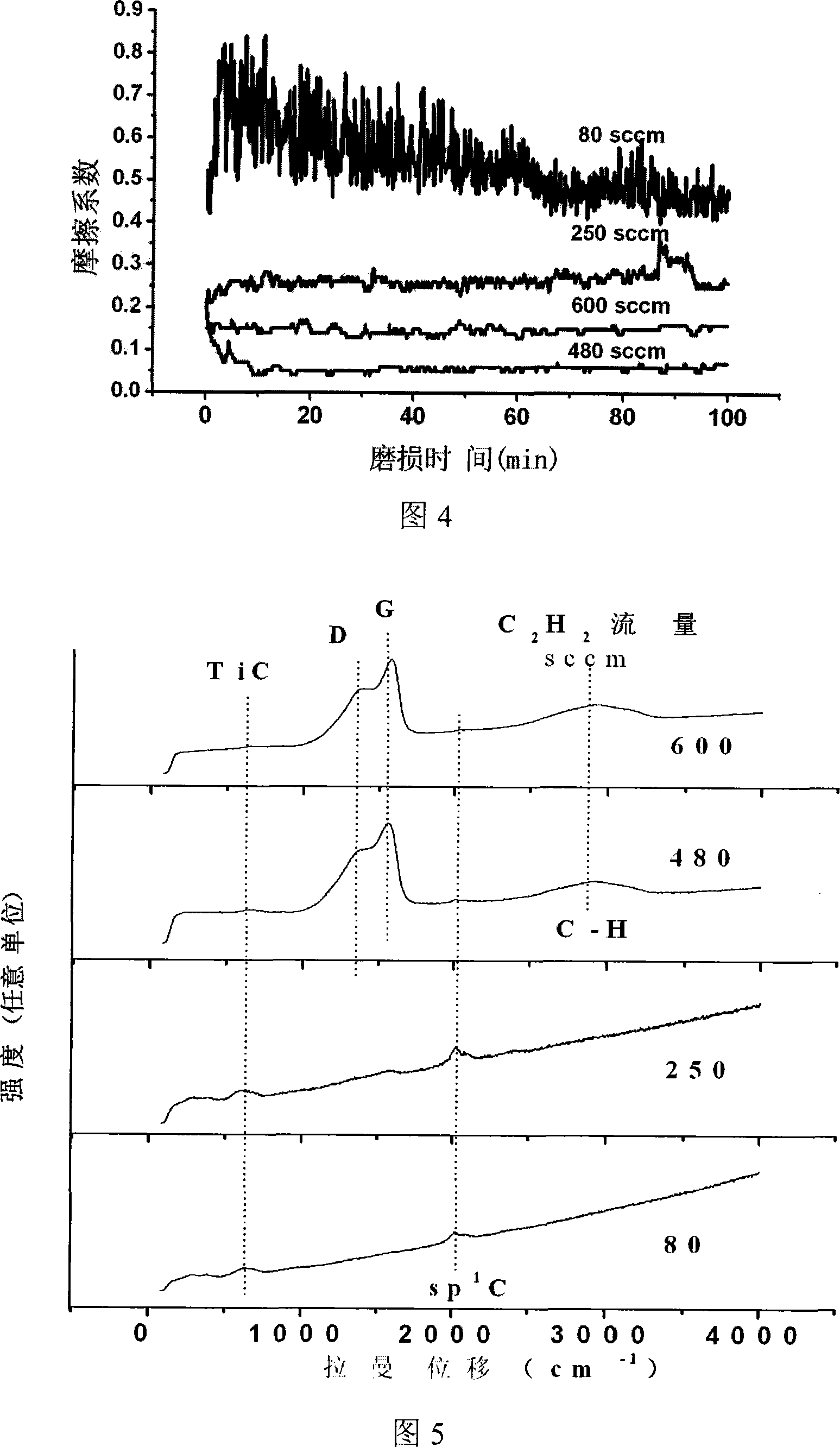

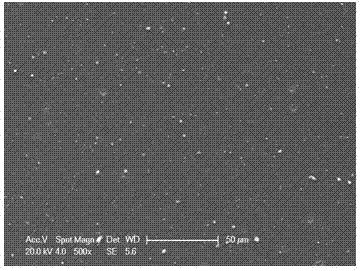

Method for preparing nano composite diamond coating

InactiveCN101113516AIncrease growth rateEliminate pollutionChemical vapor deposition coatingCarbon ionAlloy

The invention discloses a preparation method of a nano complex diamond-like coating layer. The method utilizes the cathode arc discharge controlled by a magnetic field, and excessive ethyne gas is introduced to the front of a metal target, and a metal carbide layer is formed on the target surface, metal carbide can be steamed from the target surface while the arc moves; furthermore, under the function of an auxiliary magnetic field, the front of the arc target utilizes the arc discharge to generate strong plasma ionized ethyne gas, and generate high ionized carbon ions; under the function of bias, the metal carbide steamed from the target surface and carbon ions generated by ethyne form a carbide doped nano complex diamond-like coating layer. The diamond-like coating layer prepared by the invention has the advantages of high coating hardness, strong adhesive force, high coating growing speed and production efficiency, low production cost and simple equipment structure, etc.; the invention can be applied to preparing the diamond-like coating layer of different thickness on all kinds of workpieces such as hard alloy, high speed steel, stainless steel, carbon steel, die steel, etc. according to different using requirements.

Owner:WUHAN UNIV

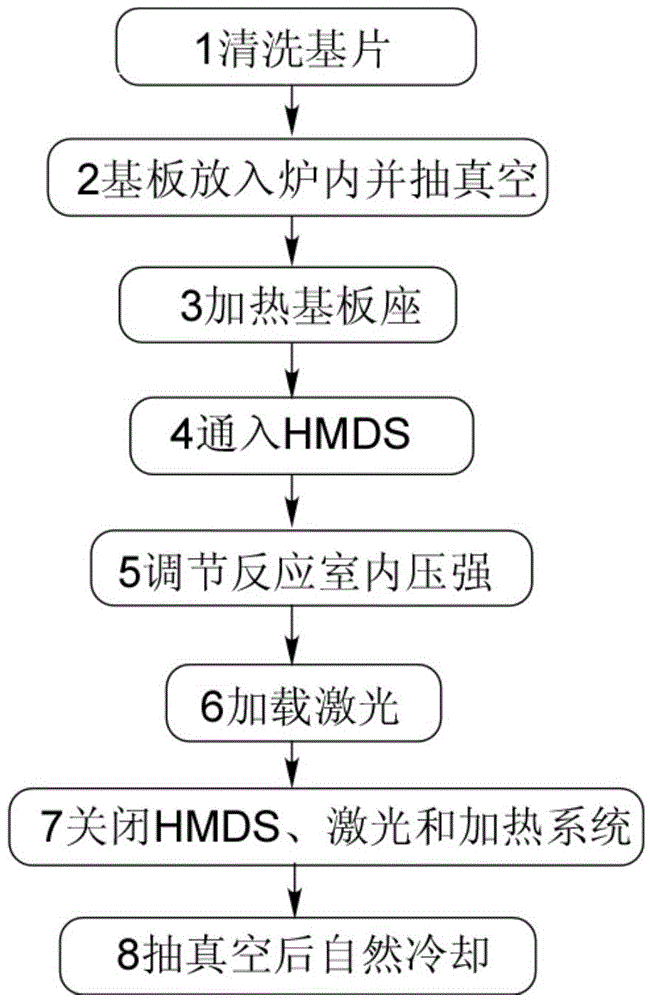

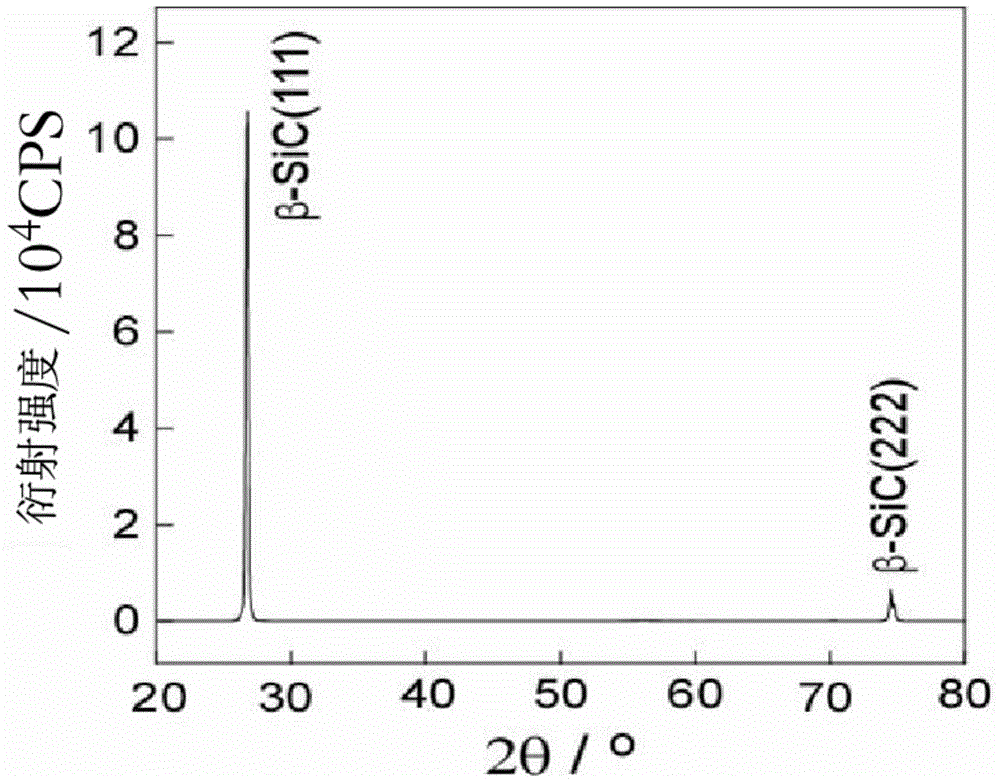

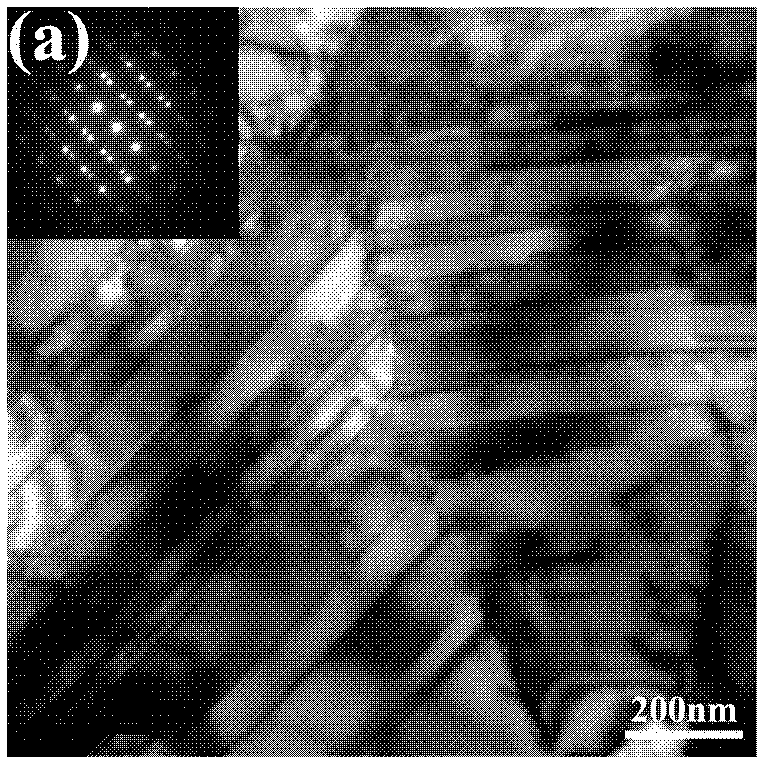

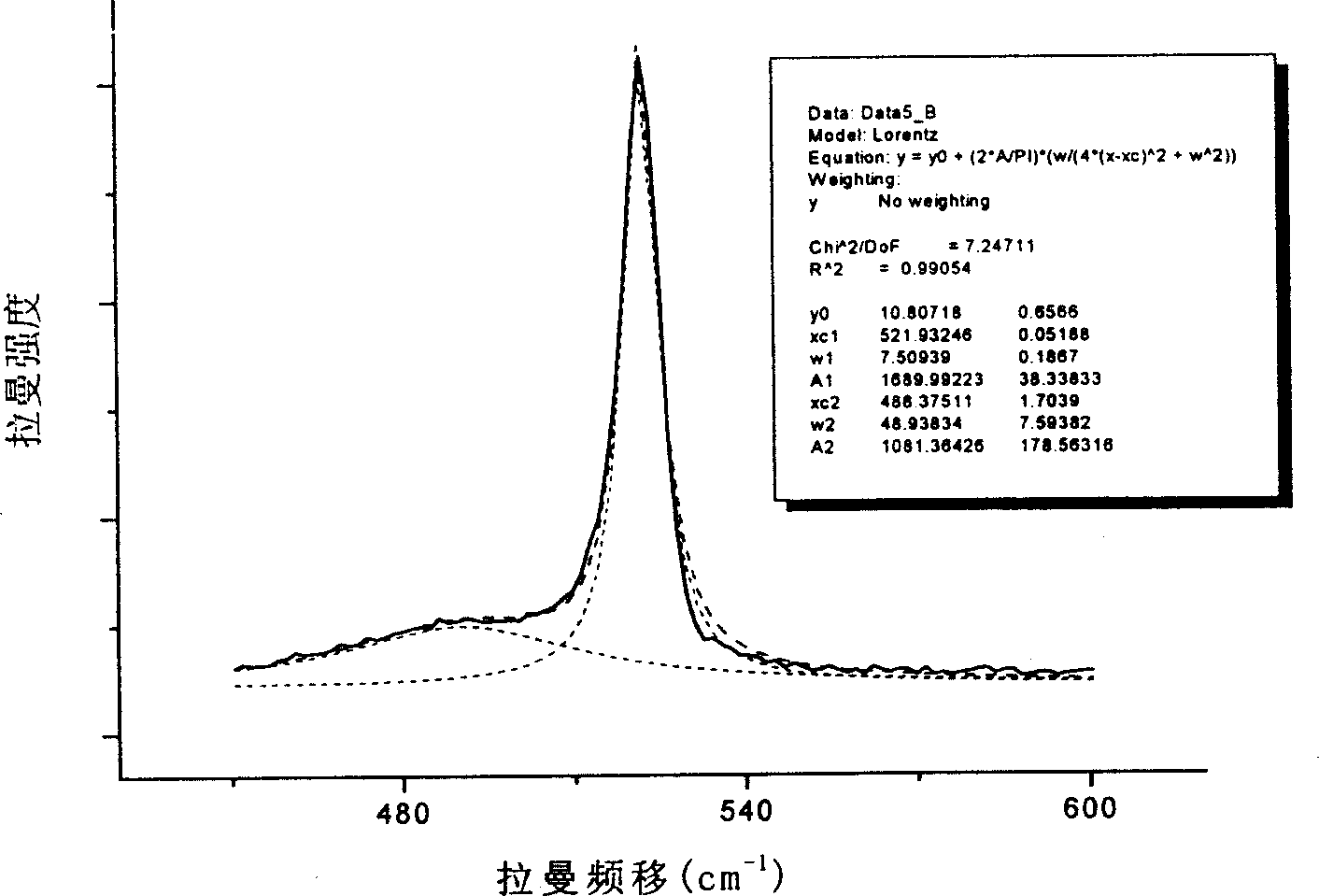

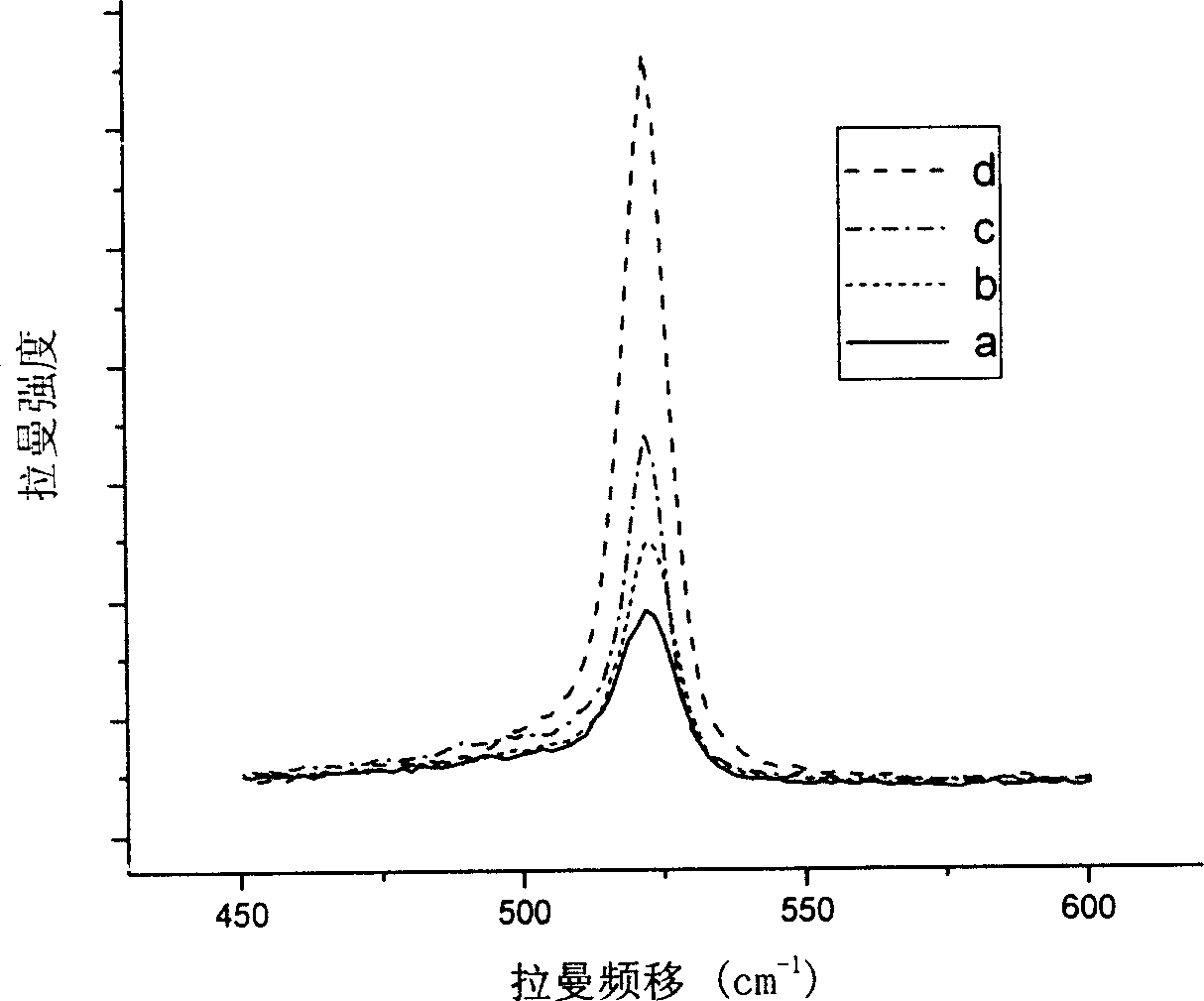

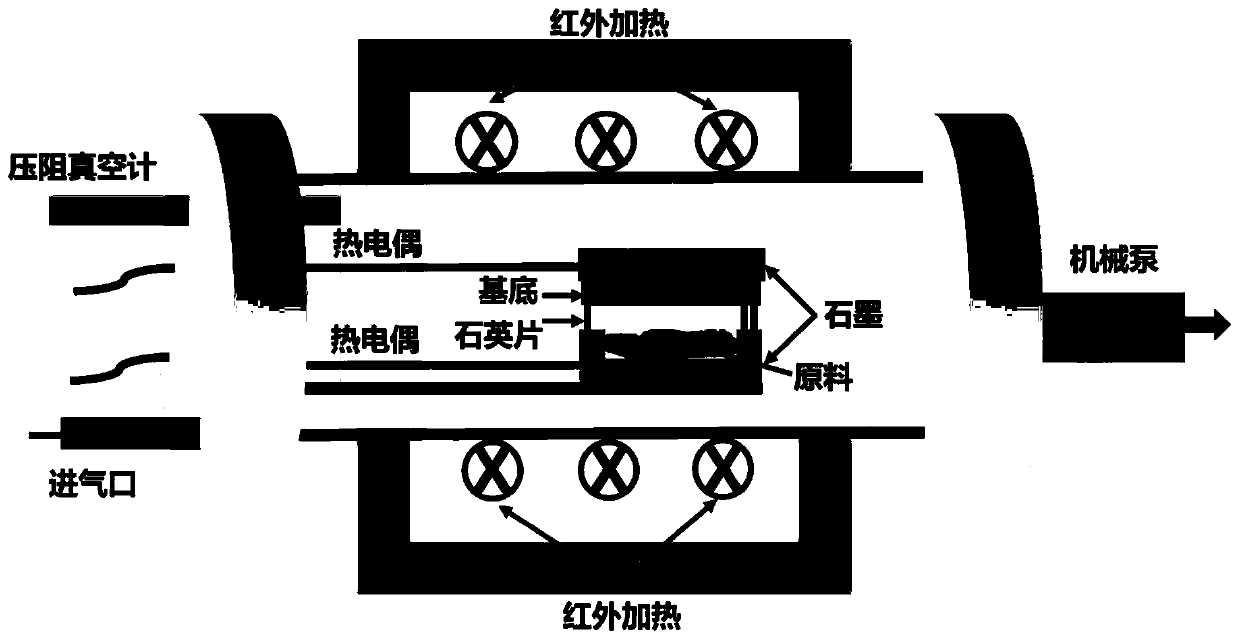

Preparation method of cubic silicon carbide film

ActiveCN104087909AReduce crystal defectsFast deposition rateChemical vapor deposition coatingCubic silicon carbideGas phase

The invention discloses a preparation method of a cubic silicon carbide film. The preparation method comprises the following steps of (1) placing a monocrystalline silicon substrate on a substrate seat of a cold-wall type laser induced chemical vapor deposition device, vacuumizing, and heating the substrate seat to 100-900 DEG C; (2) introducing HMDS-containing carrier gas to a reactor and regulating the vacuum degree to 10-10000Pa, wherein the flux of HMDS is 1-20sccm; (3) loading continuous laser to irradiate the surface of the silicon substrate at the wavelength of 750-1150nm and the power of 10-150W for 1-10min; (4) stopping the introduction of the HMDS-containing carrier gas, closing the laser, stopping heating, vacuumizing, and naturally cooling to room temperature to obtain the cubic silicon carbide film. A planar defect of the cubic silicon carbide film prepared by the invention trends to grow towards the growth direction of the film, and the self-disappearance phenomenon can be generated when adjacent defects meet, so that crystal defects in the material are effectively reduced.

Owner:武汉拓材科技有限公司

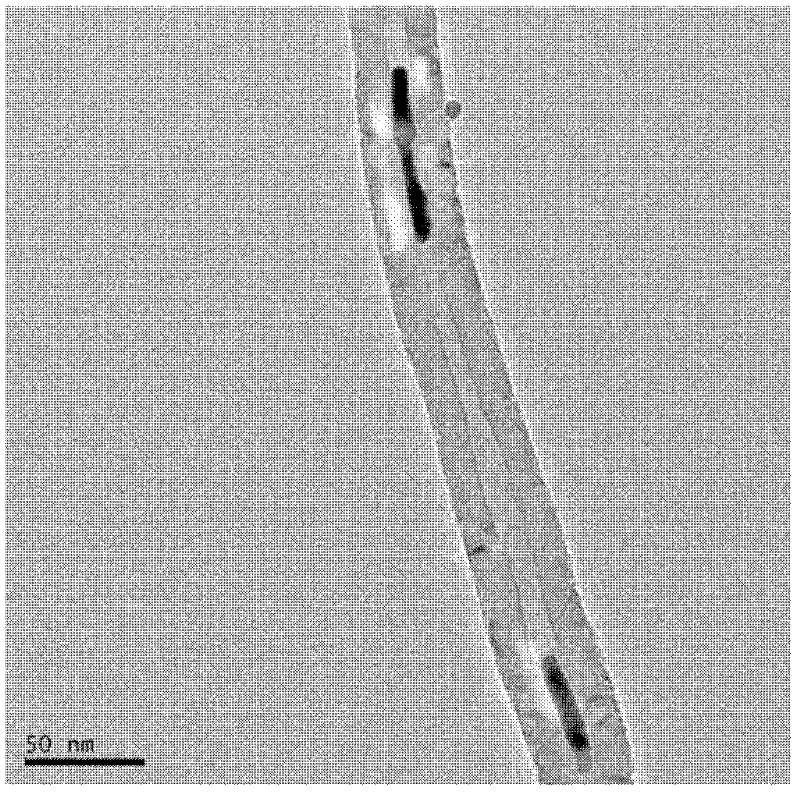

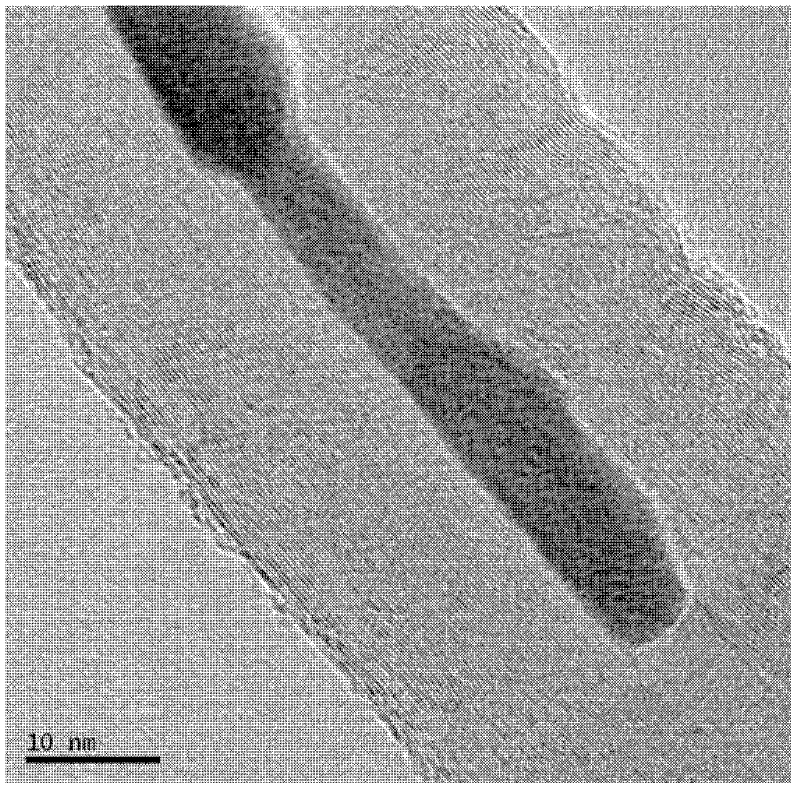

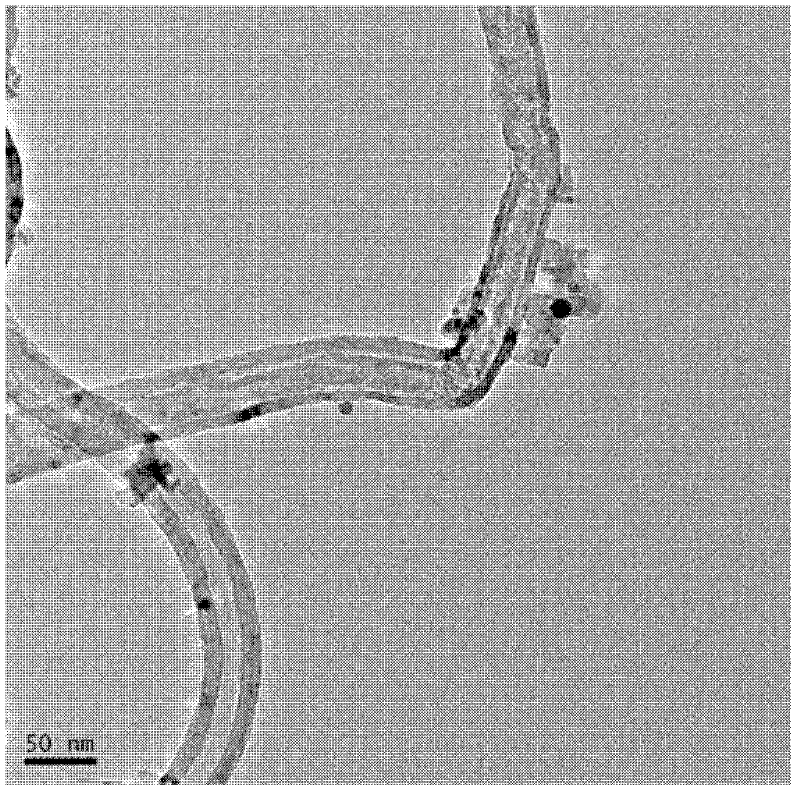

Preparation method of carbon nano tube

InactiveCN102330069ASimple preparation processFast deposition rateNanotechnologyChemical vapor deposition coatingCarbon nanotubeMagnesium

The invention relates to a preparation method of a carbon nano tube. A direct current plasma injection chemical vapour deposition system is adopted for preparing the carbon nano tube. The preparation method comprises the following steps: by taking a mixed solution of nickel nitrite and magnesium nitrite as a catalyst precursor, dropping the mixed solution on a substrate such as molybdenum, zirconium or the like; airing and then placing the substrates on a deposition platform in a cavity of direct current plasma injection chemical vapour deposition equipment; discharging a direct-current arc so that argon and hydrogen form high temperature plasma; decomposing and reducing the catalyst solution by the high temperature plasma, so as to generate a Ni / MgO catalyst; and after hydrocarbon gas isintroduced, cracking the hydrocarbon gas by using the high temperature plasma, and then injecting the cracked hydrocarbon gas on the substrate so that the carbon nano tube is formed in the presence of the catalyst. The preparation method provided by the invention has the advantages that: the catalyst is obtained while the carbon nano tube directly grows, preparation process is simple, deposition speed is fast, and deposition quality is good; and meanwhile, the bamboo-joint-like carbon nano tube is generated, and the prepared carbon nano tube has larger diameter, good crystallinity, no windingand good dispersibility.

Owner:TIANJIN UNIVERSITY OF TECHNOLOGY

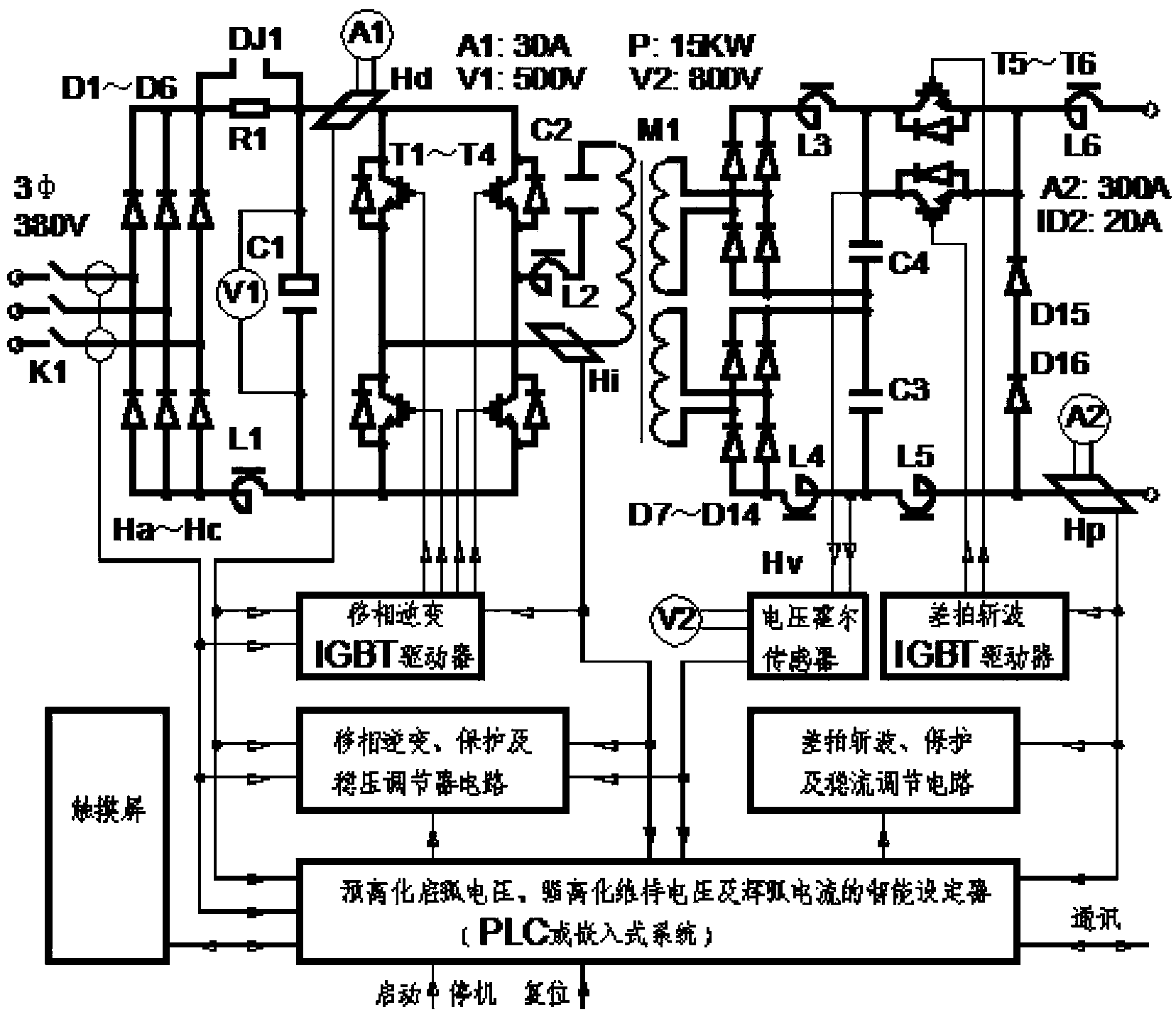

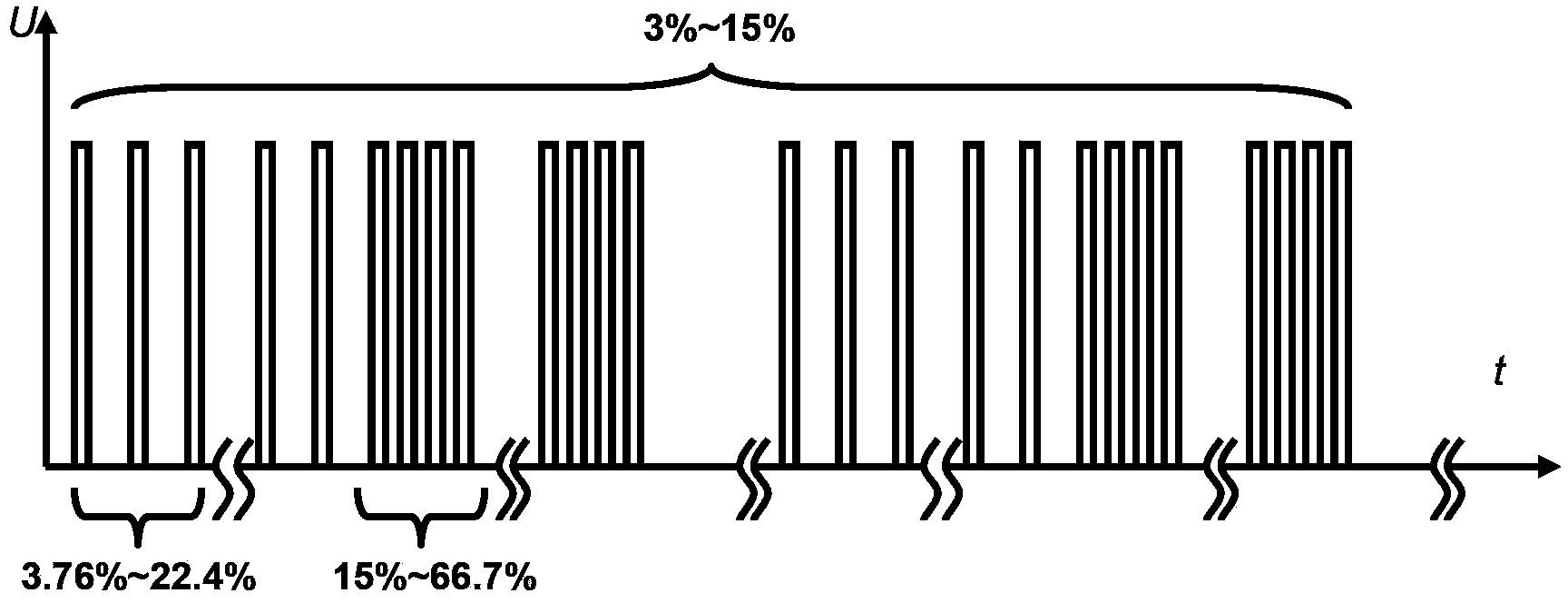

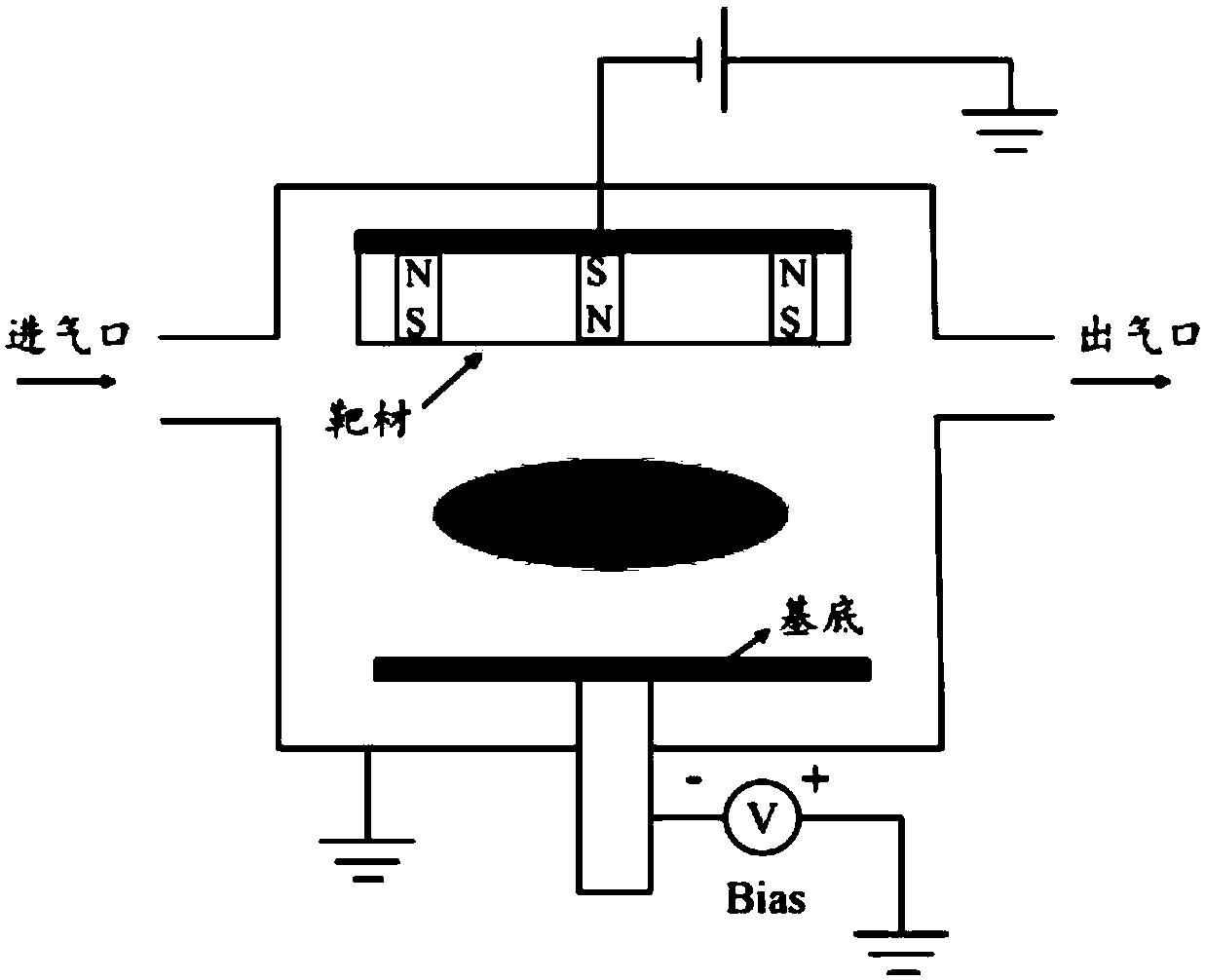

Micro-arc ion plating method

InactiveCN103397304AImprove compactnessGood plating performanceVacuum evaporation coatingSputtering coatingVacuum chamberElectric field

The invention discloses a vacuum plating method integrating advantages of magnetron sputtering and multiple-arc ion plating, in particular to a micro-arc ion plating method. The method comprises the steps as follows: a high-frequency impulse electric field with negative 1,200 V to negative 900 V output voltage, 0.5 KHz-60 KHz frequency and 0.5 mu s-30 mu s pulse width is firstly established, a high-frequency impulse signal output from the high-frequency impulse electric field is modulated by an adjustable inductance attenuation and a digital logic circuit and loaded to a rectangular cathode target with an area of 300 mm*100 mm and two ends of an anode vacuum chamber casing with a volume of Phi 450 mm *H 400 mm, and argon (Ar) gas charged into a vacuum chamber is subjected to an ion plating process when volt-ampere characteristics of negative 900 V to negative 600 V voltage, 100 A-300 A current, 1 ms-5 ms pulse width and 3%-15% duty ratio are generated during discharge. The method is simple and stable; and by means of the method, the yield is high, and industrial production can be realized.

Owner:NANJING HAORANG ENVIRONMENT SCI & TECH

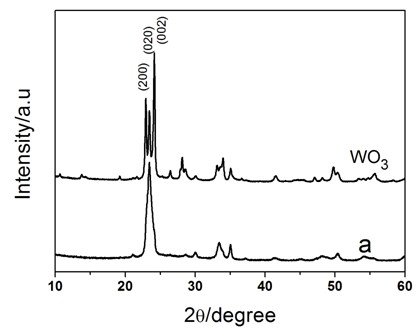

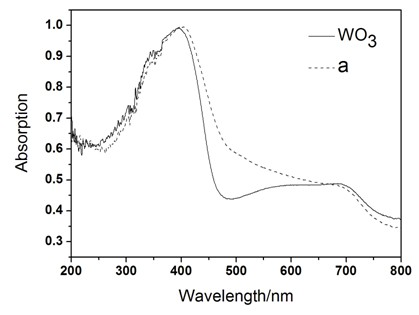

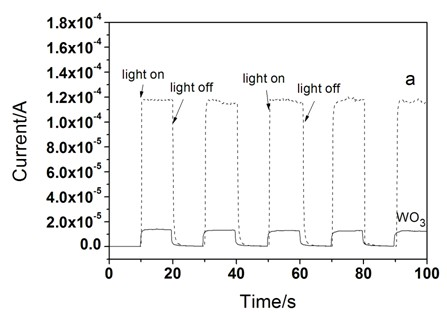

Preparation method for iron-doped tungsten trioxide photoelectrode

InactiveCN102691071AAbsorption BandwidthInhibitory complexElectrolytic inorganic material coatingElectrodesMuffle furnacePt element

The invention discloses a preparation method for an iron-doped tungsten trioxide photoelectrode. The preparation method comprises the following steps: firstly, preparing an amorphous tungsten oxide film: feeding an ITO (Indium Tin Oxide) conductive glass as a work electrode, a platinum gauze electrode as a counter electrode and a saturated calomel electrode as a reference electrode into electrolyte for electrodeposition to obtain the amorphous tungsten oxide film and drying the amorphous tungsten oxide film for later use; secondly, doping iron by using an impregnating method: feeding the amorphous tungsten oxide film obtained in the first step into 0.005mol / L Fe(NO3)3 solution and impregnating for 20-40 minutes to obtain an iron-doped tungsten oxide film, taking out the iron-doped tungsten oxide film and flushing the iron-doped tungsten oxide film with distilled water and drying the iron-doped tungsten oxide film in air; and thirdly, calcining: feeding the iron-doped tungsten trioxide photoelectrode in the second step into a muffle furnace, calcining the iron-doped tungsten trioxide photoelectrode at high temperature of 450DEG C for 3 hours, cooling the calcined iron-doped tungsten trioxide film at room temperature and then taking out to obtain the iron-doped tungsten trioxide photoelectrode. The photoelectric conversion efficiency and the photoelectric catalytic activity of the iron-doped tungsten trioxide photoelectrode are remarkably improved; the adopted experiment equipment is simple and easy to operate; and the used raw materials are abundant in natural word and low in cost and also have the advantages of environment friendliness and the like.

Owner:ZHEJIANG UNIV

Method for preparing film specimen in use for transmission electron microscope

InactiveCN1696334AReduce temperature riseAvoid damagePreparing sample for investigationVacuum evaporation coatingAlloyMetal

A process for preparing the film specimen of transmission electron microscope includes preparing metal or alloy film by magnetically controlled sputter, punching on said film to obtain circular film, and thinning it by dual-spray method or ion method.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

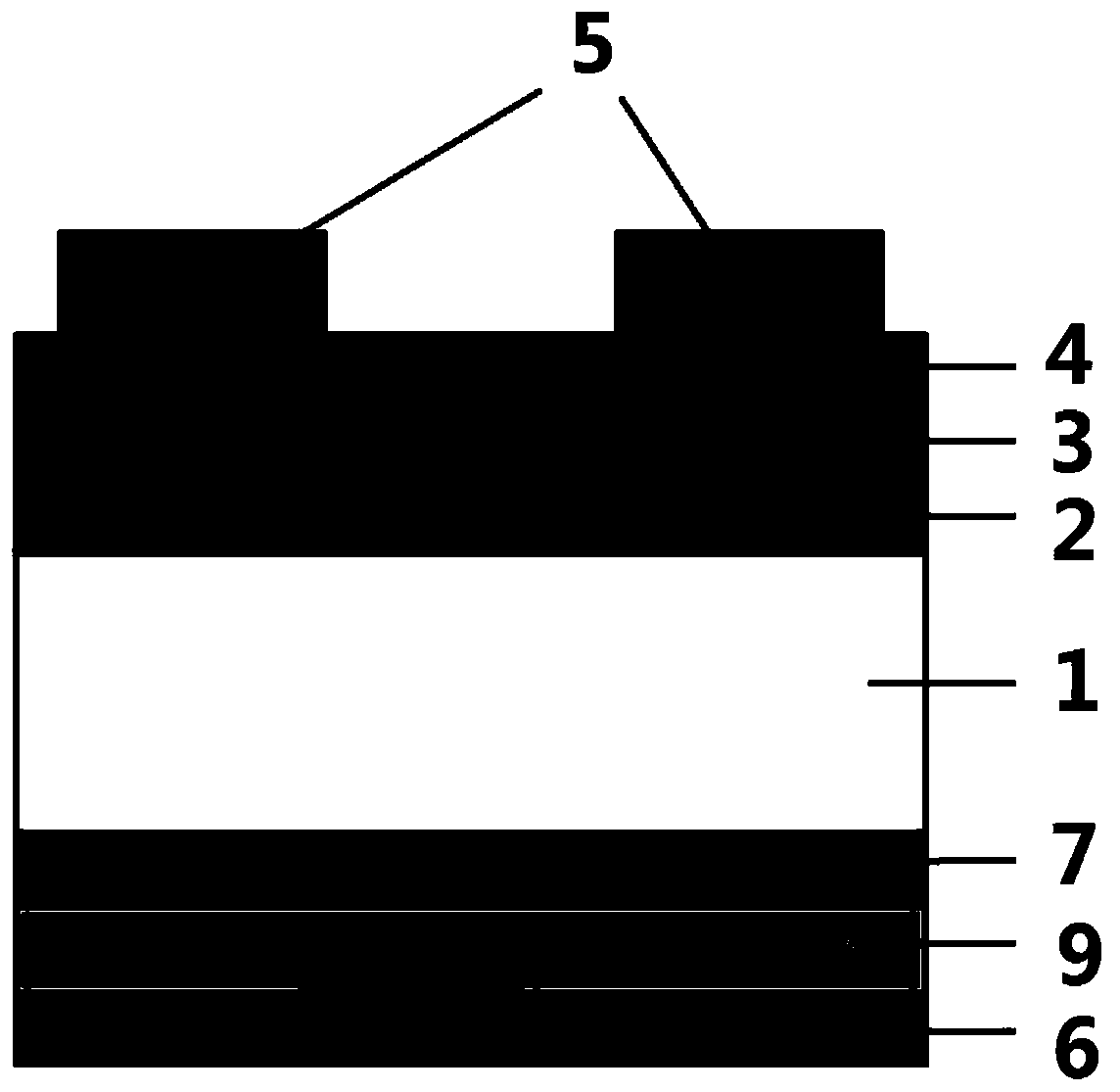

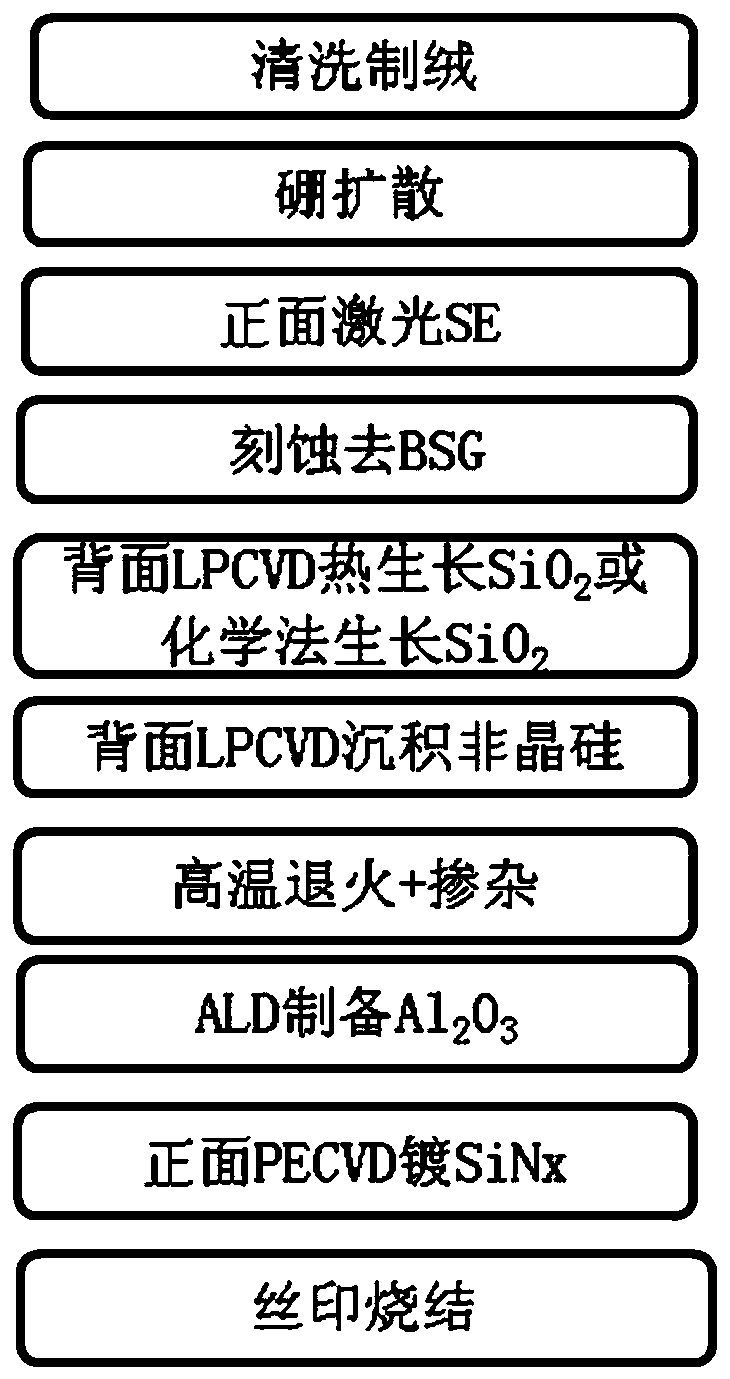

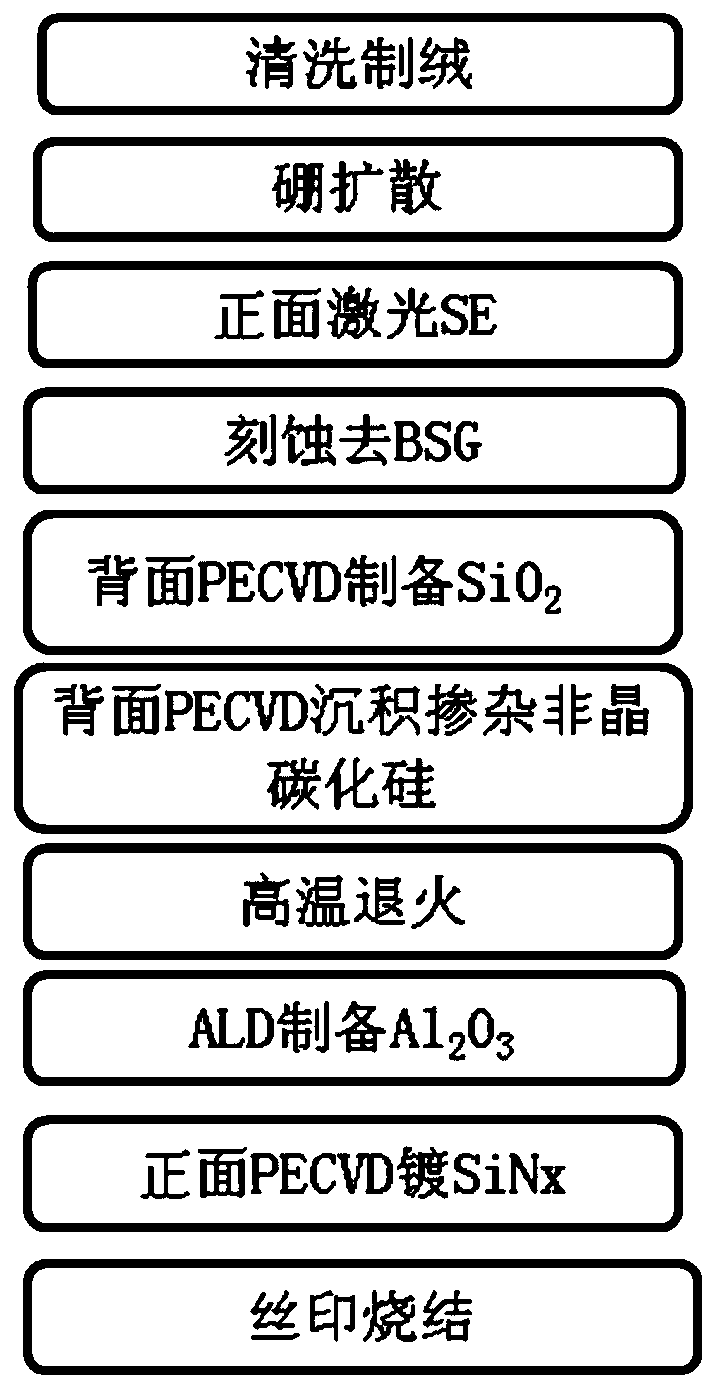

Method for preparing back fully-passivated contact solar cell by utilizing tubular PECVD and back fully-passivated contact solar cell

InactiveCN111106183AThere will be no plating phenomenonNo burstFinal product manufacturePhotovoltaic energy generationScreen printingEngineering

The invention discloses a method for preparing a back fully-passivated contact solar cell by utilizing tubular PECVD and the back fully-passivated contact solar cell. The method comprises the steps of carrying out pre-cleaning, double-sided texturing, front boron diffusion, front laser selective doping, secondary cleaning and back polishing on a silicon wafer; depositing a silicon dioxide thin film layer and a phosphorus-doped amorphous silicon carbide thin film layer on the back surface of the tubular PECVD equipment, and performing annealing treatment to convert amorphous silicon carbide into microcrystalline silicon carbide; depositing an Al2O3 passivation layer and an antireflection layer; and performing silk-screen printing and sintering to obtain the back fully-passivated contact solar cell. The method disclosed by the invention has the advantages of simple process, convenience in operation, low cost, good compatibility with the existing production line, good preparation controllability, high preparation efficiency, good safety and the like, can be used for preparing the high-efficiency back fully-passivated contact solar cell, is suitable for large-scale preparation, is beneficial to industrial application, and has a very high use value and a very good application prospect.

Owner:HUNAN RED SUN PHOTOELECTRICITY SCI & TECH

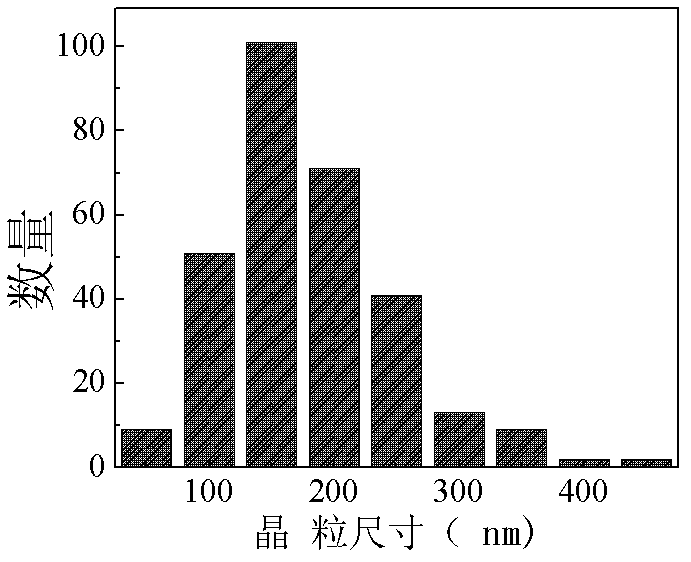

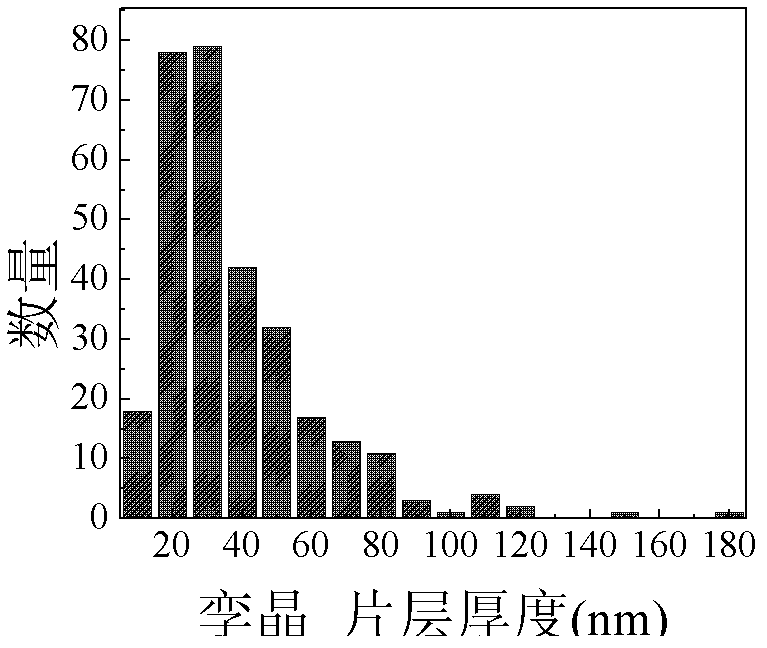

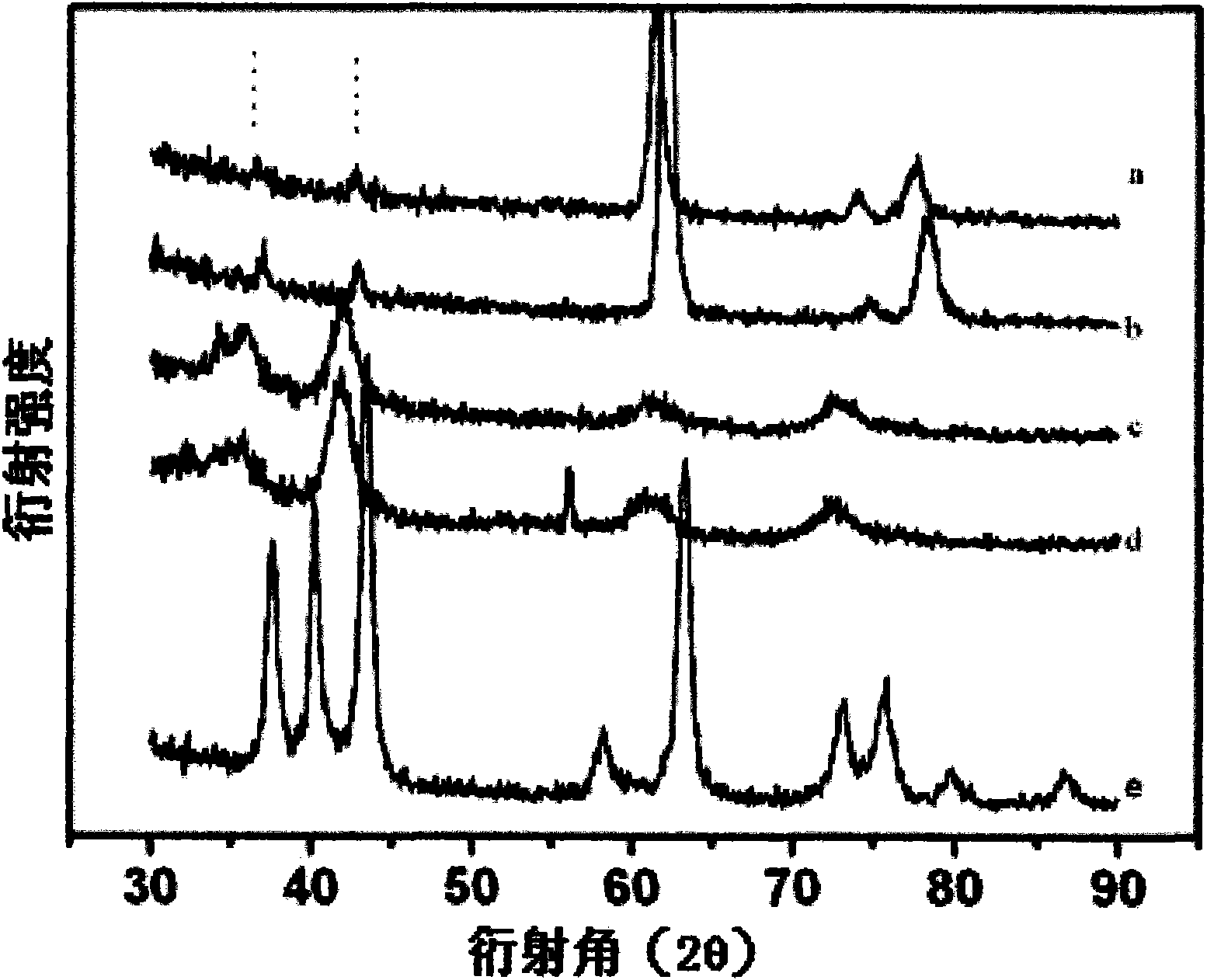

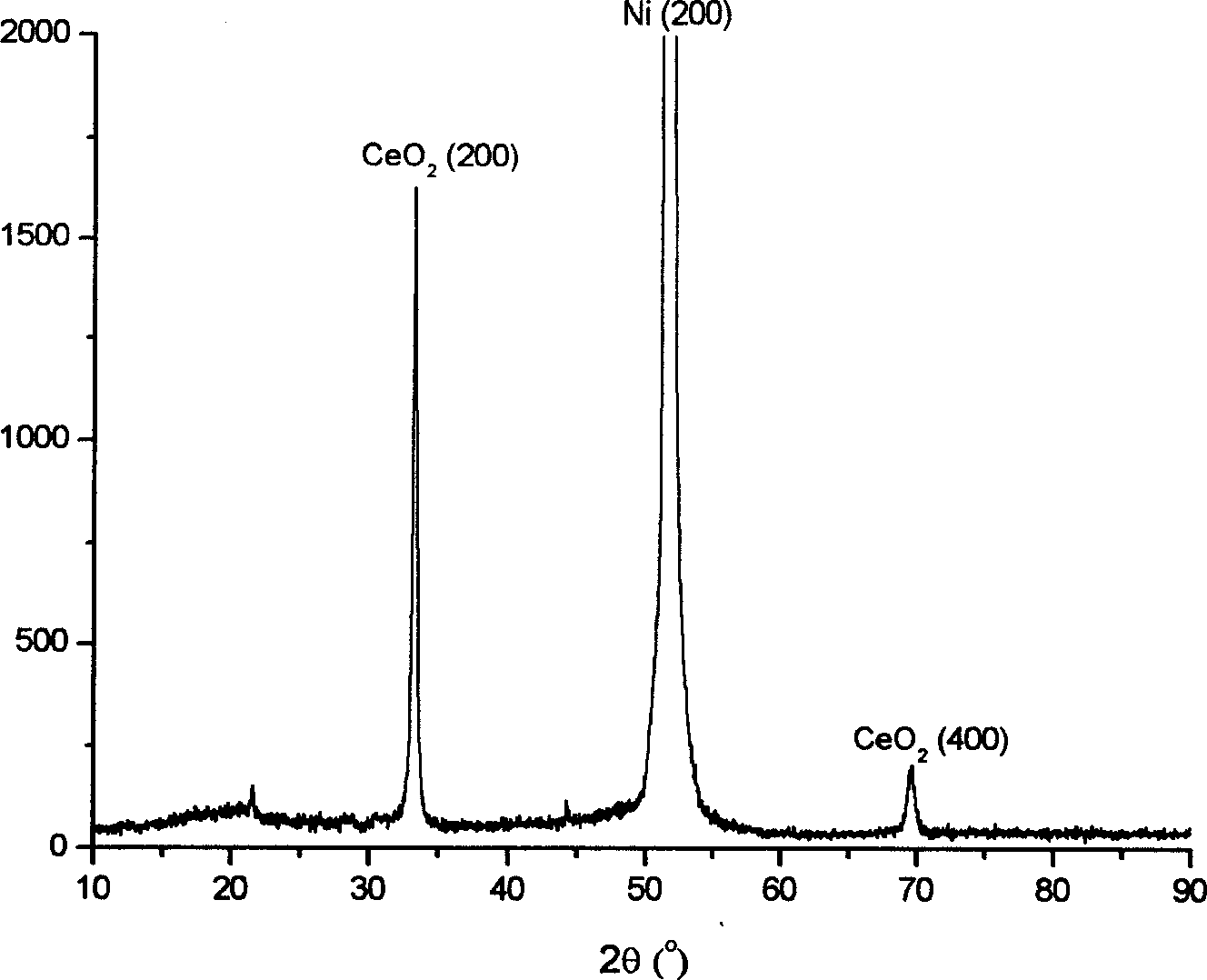

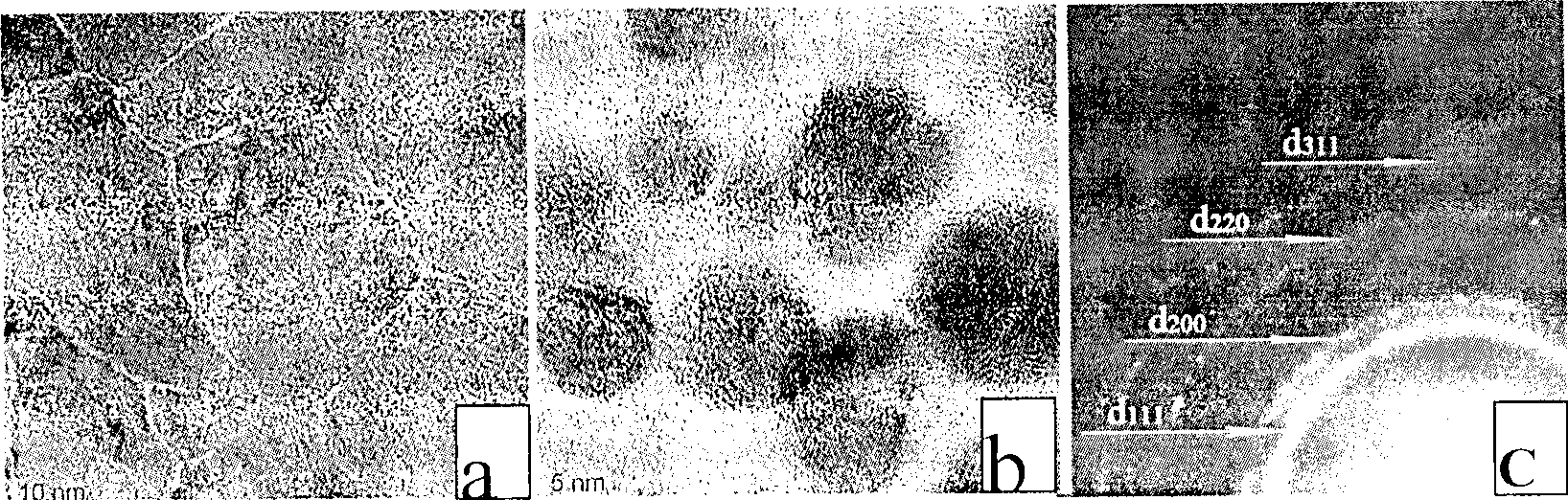

Nanocrystalline nickel with high-density twin structure and preparation method thereof

The invention relates to a preparation method of a nanocrystalline bulk metallic material, in particular to nanocrystalline nickel with a high-density twin structure and a preparation method thereof. The nickel material with the high-density twin structure prepared by direct current electrodeposition technology comprises grains with the thickness of from 20 nm to 500 nm in a microstructure, wherein each nano-crystal comprises a high-density twin lamella structure, and the thickness of each twin lamella is 10 nm to 200 nm, and the length of each twin lamella penetrates through the whole grain; and the grain with the twin lamella structure accounts for 50% to 100% of the whole sample grains. Compared with the prior art, the nanocrystalline nickel with the twin structure has excellent mechanical properties, the room-temperature tensile yield strength can be up to 1.6GPa to 2.0GPa, the breaking strength is 1.9GPa to 2.29GPa, the fracture elongation can be up to 6.5%, the nano-indentation hardness can be up to 3.3GPa to 3.8GPa, and the nano-indentation modulus of elasticity is 150GPa to 240GPa.

Owner:BEIJING UNIV OF TECH

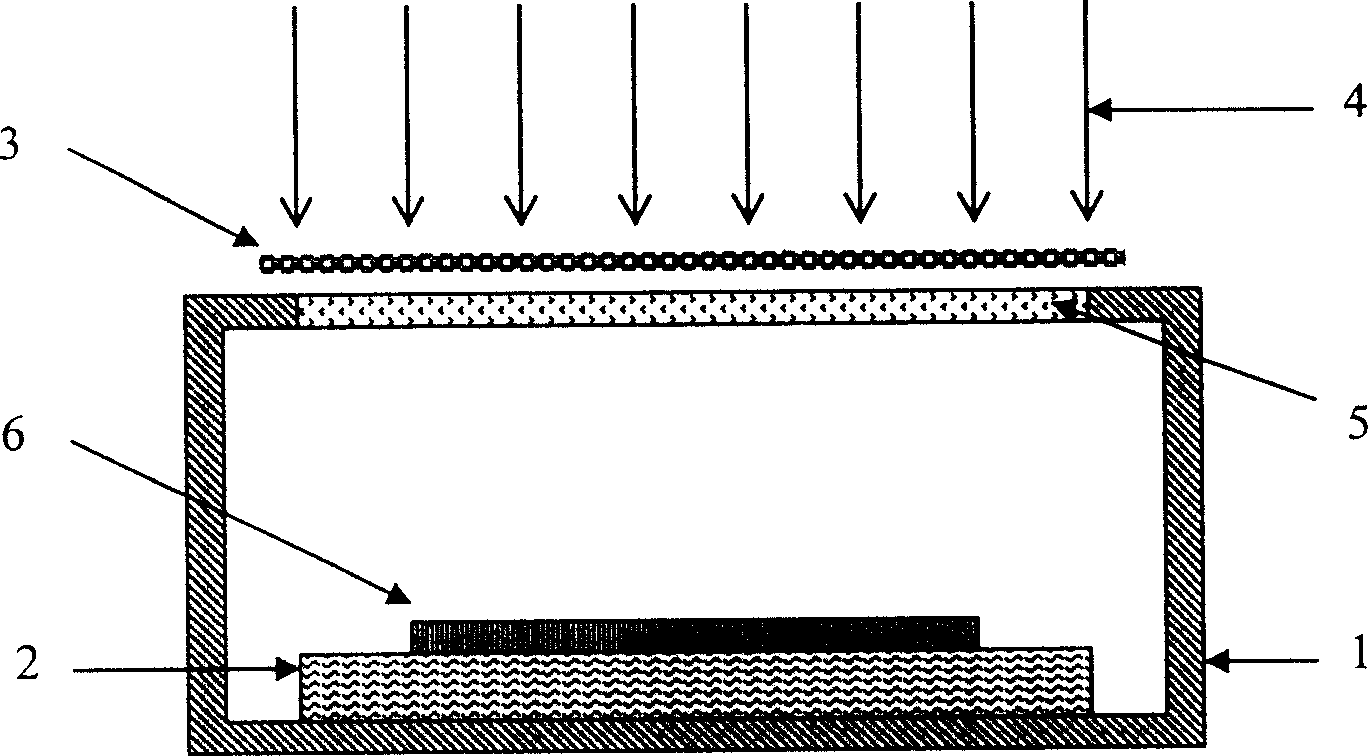

Method for preparing microlite silicon

InactiveCN1727526AOvercome the disadvantage of low deposition rateMature technologyPolycrystalline material growthSemiconductor/solid-state device manufacturingThermal energySemiconductor materials

A process for preparing microcrystal silicon includes preparing non-crystal silicon film on glass substrate, putting it in vacuum annealing furnace, and vacuum annealing while radiating it by ultraviolet ray for phase change to obtain microcrystal silicon film. Its advantages are high speed and high crystallinity.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

Method for preparing compound diamond-like carbon coating by using medium-frequency magnetic-control glow discharge method

InactiveCN101701332AHigh hardnessImprove the lubrication effectVacuum evaporation coatingSputtering coatingCarbon ionDiamond-like carbon

The invention relates to a method for preparing a nano compound diamond-like carbon coating, which is realized in a way that: glow discharge is produced by using a medium-frequency magnetic-control sputtering target; argon and excessive hydrocarbon gases are introduced, so that the metal on the target surface reacts with the hydrocarbon gases to produce metallic carbides; when the argon ions bombard the target surface, the target surface sputters the metallic carbides; strong plasma produced by the glow discharge of the target surface ionize the hydrocarbon gases, so that the hydrocarbon gases produce highly-ionized carbon ions; and the carbides sputtered from the target surface and the highly-ionized carbon ions produced from the hydrocarbon gases form a high-hardness carbide-doped nano compound diamond-like carbon coating on a workpiece surface. The coating prepared by the invention has the characteristics of high hardness, strong adhesive force, high growth speed, high production efficiency, low depositing temperature, low production cost, simple equipment structure and the like; and diamond-like carbon coatings with different thicknesses can be prepared on hard alloy, high-speed steel and various other workpieces.

Owner:WUHAN UNIV

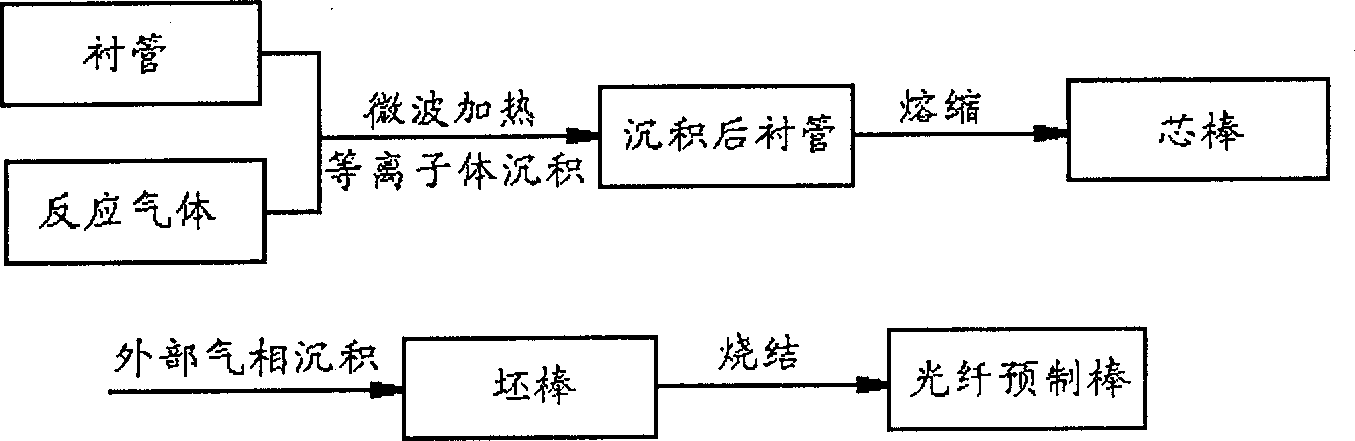

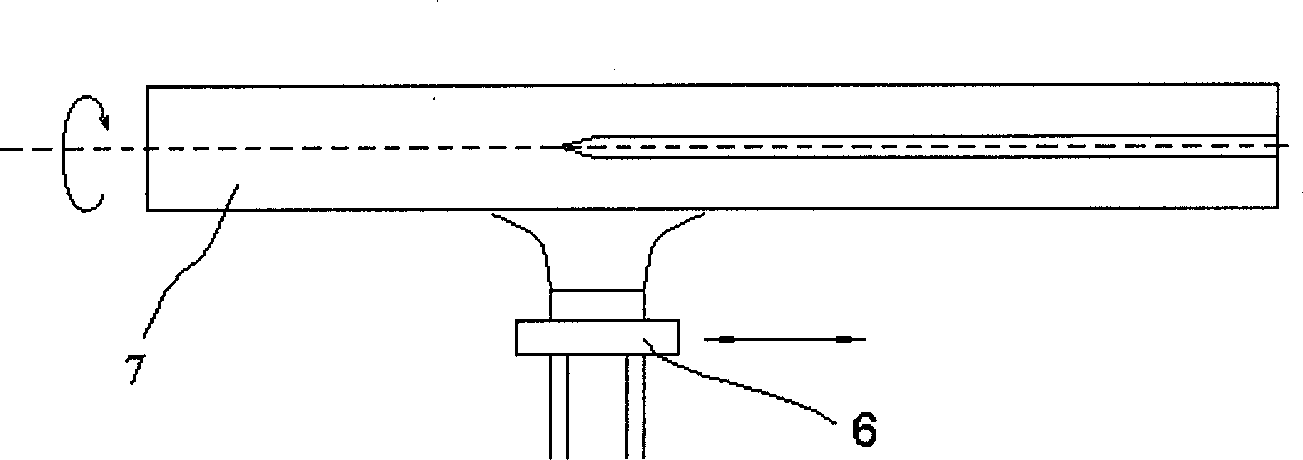

Manufacture of prefabricated fiber rod

InactiveCN1337367AEfficient integrationPrecise control of waveguide structuresGlass making apparatusFiberGas phase

The production method of optical fibre preform includes the following steps: A. adopting plasma chemical vapor phase deposition method to prepare core rod; B. adopting outside vapor phase deposition method to prepare cladding, i,e, obtaining blank rod; and C. sintering blank rod to obtain the optical fibre preform. It can accurately control optical fibre waveguide structure, and possesses the advantages of high raw material utilization rate, short production period and high production efficiency.

Owner:YANGTZE OPTICAL FIBRE & CABLE CO LTD

Tungsten nitride based ternary nano composite super-hard film material and preparation method thereof

InactiveCN101624295ANo holesNo crackVacuum evaporation coatingSputtering coatingNitrogenTungsten nitride

The invention discloses a tungsten nitride based ternary nano composite super-hard film material and a preparation method thereof. The material is a nano composite super-hard film which is covered on a substrate and has a chemical formula of WxM1-xN, wherein in the nano composite super-hard film, W represents tungsten metal, M represents metal replacement, N represents nitrogen, and the value range of the x is 0.06 to 0.72; and the film consists of the tungsten metal, nitride solid solution phase of the M metal and tungsten metal phase or consists of tungsten nitride phase, tungsten metal phase and M metal phase, the grain size of the film is 4 to 30 nanometers, and the thickness of the film is 3 to 7mu m. The method comprises the following steps: firstly, placing a composite target consisting of the tungsten metal and the metal replacement and the substrate on a cathode and in a sample stage in a vacuum chamber of magnetron sputtering equipment respectively; after the vacuum degree of the vacuum chamber is less than or equal to 1*10<-3> pa and the temperature of the substrate reaches 350 and 450 DEG C, making the vacuum chamber in argon-nitrogen mixed atmosphere, sputtering the composite target for 60 to 120 minutes to obtain the tungsten nitride based ternary nano composite super-hard film material. The film material and the preparation method can be widely applied in the fields of mechanical manufacture, automobile and textile industry, geologic drilling, die industry and the like.

Owner:HEFEI INSTITUTES OF PHYSICAL SCIENCE - CHINESE ACAD OF SCI

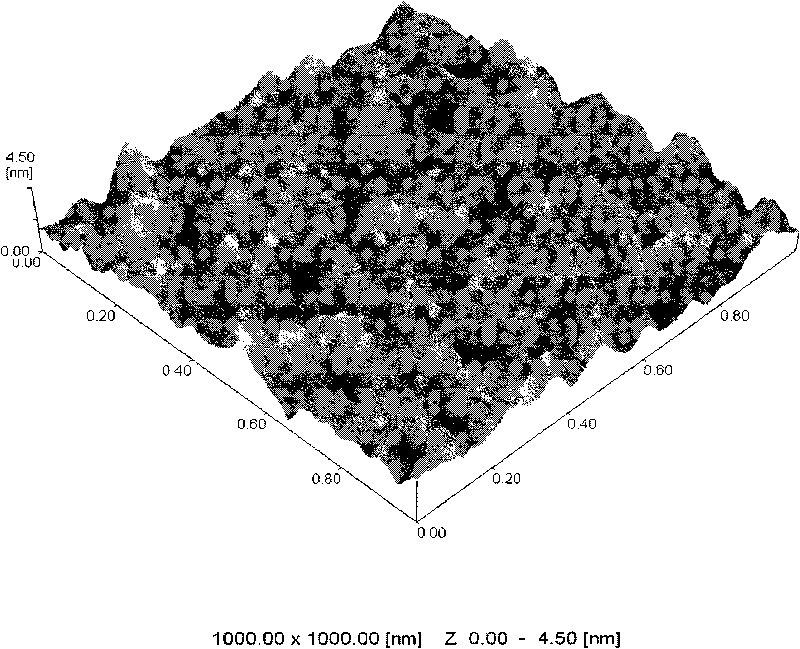

Prepn process of metal oxide film

InactiveCN1740377AHave a single orientationSmall sizeVacuum evaporation coatingSputtering coatingSputteringEvaporation

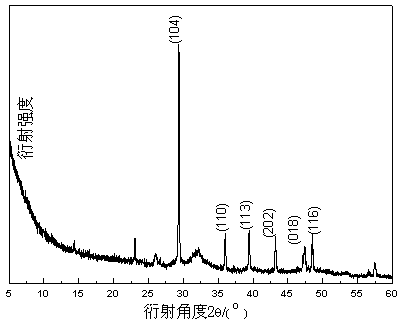

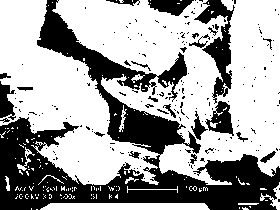

The present invention relates to material technology, and is especially The preparation process of transition layer oxide film for superconductive belt. The process of the present invention can grow oxide film with excellent texture and high surface flatness fast. The process includes the following steps: 1. depositing metal film on metal substrate with texture characteristic via evaporation, sputtering or pulse laser deposition; 2. oxidizing the film while controlling the oxygen pressure component, annealing temperature and annealing time to control the orientation and surface flatness of the oxide film and form oxide film with biaxial texture characteristic; and 3. lowering the temperature. The transition layer oxide film has excellent texture and high surface flatness and the deposition rate may reach 0.3 nm / s, so that the present invention provides way for fast industrial growth of the second generation of transition layer oxide film for high temperature superconductive belt.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

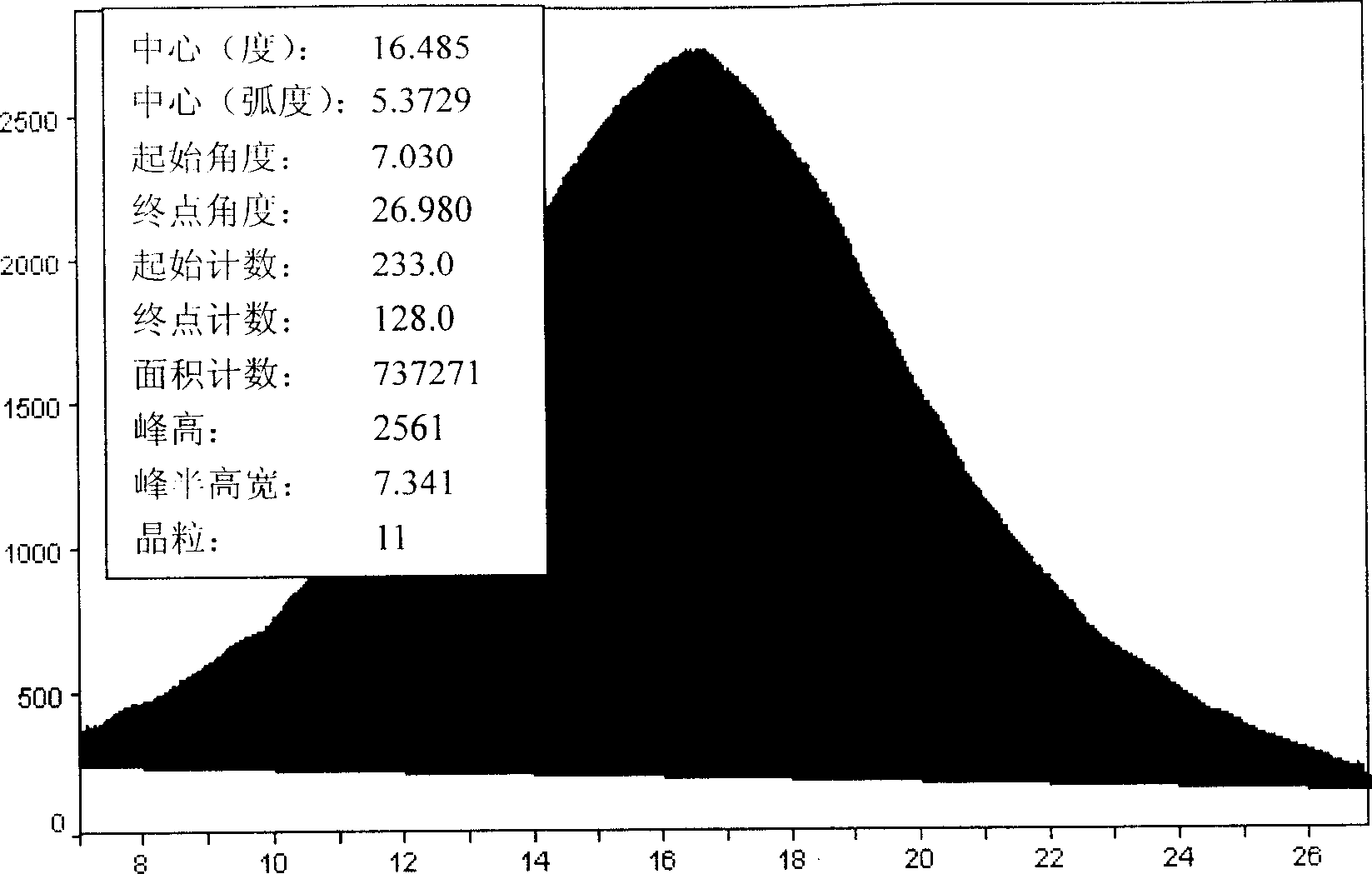

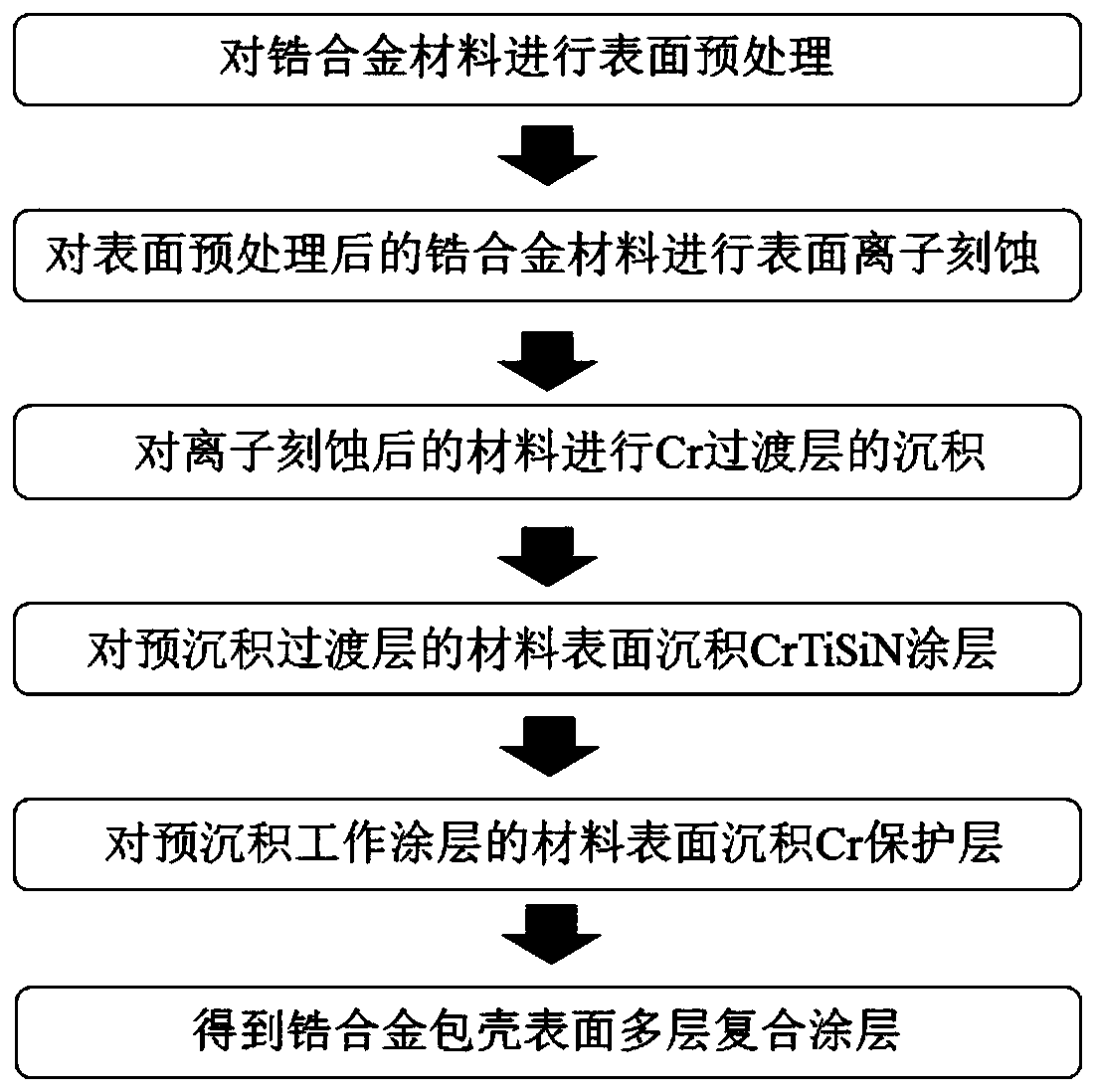

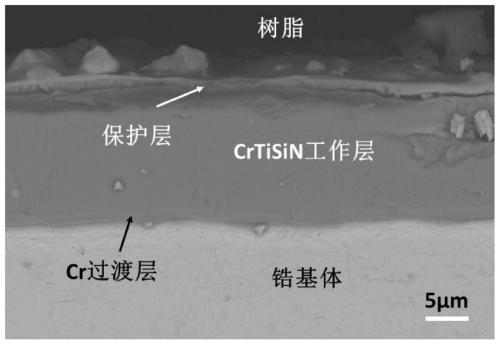

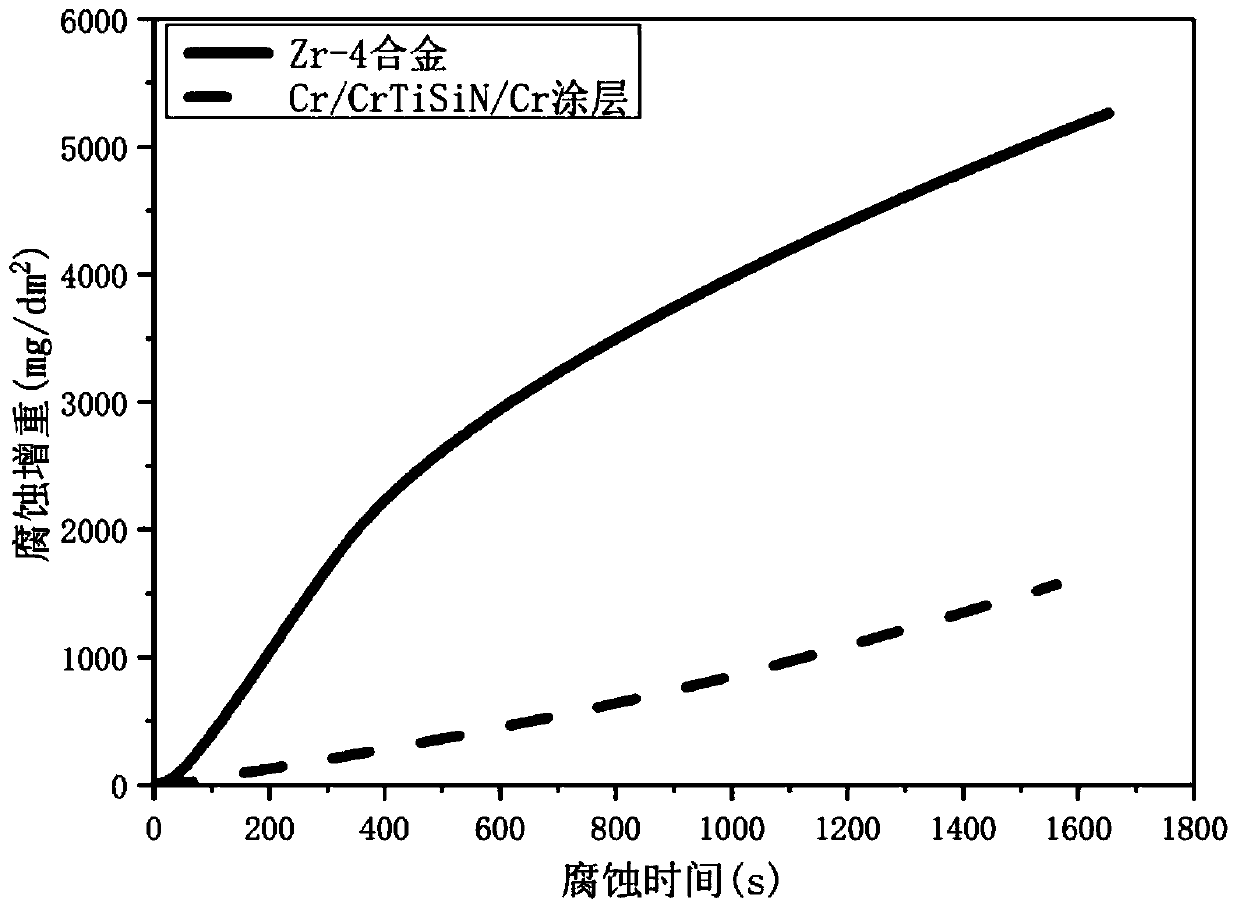

Multilayer composite coating of zirconium alloy cladding surface, and preparation method thereof

ActiveCN111172503AImprove economyUniform thicknessVacuum evaporation coatingSputtering coatingFrettingNitrogen gas

The invention discloses a multilayer composite coating of a zirconium alloy cladding surface, and a preparation method thereof. According to the method, a multi-arc ion plating technology is adopted,and zirconium alloy materials are used as a base; high purity nitrogen is used as reaction gas, and high purity argon is used as protective gas; the vacuum degree, arc current, temperature, depositiontime, gas flow and other parameters of a vacuum chamber are regulated; and a three-layer composite coating, using Cr as a transition layer, a CrTiSiN as a working coating and Cr as a protective coating, are formed on the surface of the zirconium alloy materials through deposition. The coating is uniform and compact, and the binding force between the coating and the zirconium alloy base is strong;the cladding integrity is ensured, and generation of hydrogen is inhibited; and hydrogen explosion is avoided. The coating is extremely high in hardness, and the friction resistance of zirconium alloy can be improved effectively; the a cladding pipe is prevented from being failed due to fretting wear, and the safety and accident tolerance of a reactor are improved.

Owner:XI AN JIAOTONG UNIV

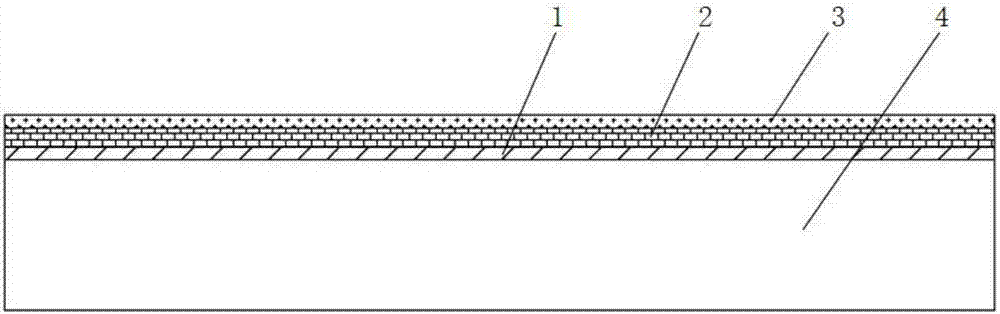

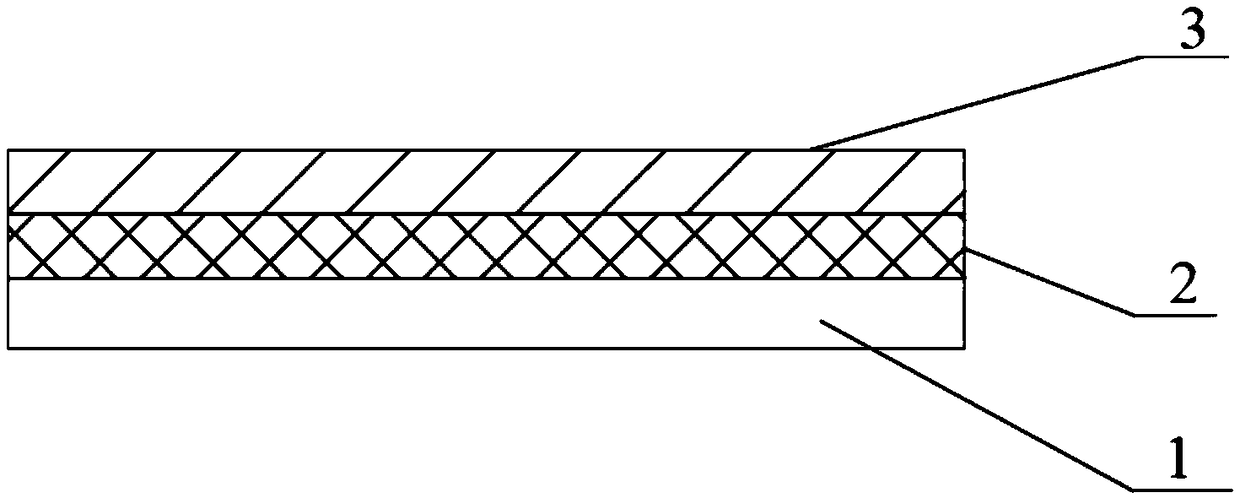

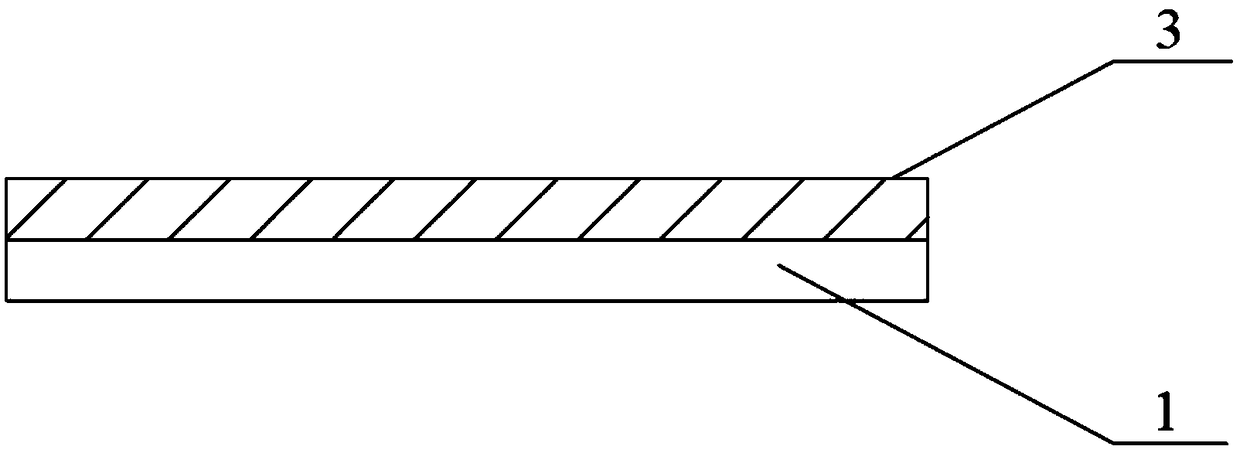

Composite thick film based on diamond-like carbon thin film and coating method of composite thick film

PendingCN107022761AReduce internal stressIncrease internal stressVacuum evaporation coatingSputtering coatingCarbon layerFilm base

The invention discloses a composite thick film based on a diamond-like carbon thin film and a coating method of the composite thick film. The composite thick film comprises a metal base layer, a transition layer and a diamond-like carbon layer which are successively formed from the surface of a substrate to the outside, wherein the transition layer is a mixture layer which is formed by stacking two film layers in a staggered manner by simultaneously using a magnetron sputtering technology and an enhanced type cathode arc technology; and the thickness of the diamond-like carbon layer is between 1 mu m and 10 mu m. The composite thick film is exquisite in design and simple in structure; the transition layer has the structure which is formed by stacking the two film layers in the staggered manner, the advantages of small internal stress of a magnetron sputtering film layer and large hardness of an enhanced type cathode arc film layer are played fully, large hardness and small internal stress of the transition layer are combined effectively, large hardness and small stress facilitate increasing of the thickness of the diamond-like carbon layer, and the thickness of the finally formed composite thick film reaches 20 mu m or above; and moreover, huge stress caused by a thick film function layer can be buffered effectively, therefore, the binding force of the composite thick film and the substrate is guaranteed, and meanwhile, surface defects of the composite thick film can be reduced effectively.

Owner:STARARC COATING TECH SUZHOU

Phosphorus chemical nickel plating concentrated solution and plating process

ActiveCN104328395AFast deposition rateGood bath stabilityLiquid/solution decomposition chemical coatingSodium phosphatesPolyethylene glycol

The invention discloses a phosphorus chemical nickel plating concentrated solution and a plating process, the concentrated solution comprises three parts of an A solution, a B solution and a C solution, a main salt, a brightening agent, an accelerating agent and deionized water are mixed into the A solution at room temperature; a first buffer, a first complexing agent, sodium hypophosphite, a stabilizer, polyethylene glycol 6000, a brightening agent and deionized water are mixed into the B solution at room temperature; a second buffer, a second complexing agent, the stabilizer, the sodium hypophosphite, the polyethylene glycol 6000, the accelerating agent, the brightening agent, ammonia and the deionized wate are mixed r at room temperature into the C solution; the A solution and the B solution are used for grooving, and the A solution and the C solution are used for replenishment. According to the volume percentage, the A solution, the B solution, and dilution water are mixed into a chemical nickel plating solution for plating, the nickel content in the nickel plating solution is lower than 4.0g / L, and the A solution and the C solution are replenished. When the concentrated solution is used for nickel plating, deposition rate is quick, coating hardness and wear resistance are high, and the concentrated solution is suitable for chemical nickel plating of aluminum alloy, all kinds of iron alloy, copper alloy, nickel iron alloy, nickel copper alloy and some non conductive substrates.

Owner:JINCHUAN GROUP LIMITED

Method of coating metal layer on roller surface of biroller thin belt continuous casting machine

InactiveCN1693538AImprove wear resistanceImprove thermal fatigue resistanceElectrolytic coatingsNanoparticleMetal

Owner:CHONGQING UNIV

CN-MCN superhard self-lubricating nano-composite coating and preparation method thereof

InactiveCN102864411AHigh hardnessReduce internal stressVacuum evaporation coatingSputtering coatingHardnessIonization

The invention discloses a CN-MCN superhard self-lubricating nano-composite coating and a preparation method thereof. An electric arc discharge method and a hollow cathode electric arc discharge carbon source combination method are adopted to generate a combination layer, a transition layer, a supporting layer and a lubricating layer to sequentially form the nano-composite coating. The preparation method has the advantages of being high in ionization rate, simple in coating device structure, high in deposition rate and the like. The prepared CN-MCN superhard self-lubricating nano-composite coating is high coating hardness, strong in adhesive power, good in self-lubricating property, high in coating growing speed and production efficiency, low in production cost and friction coefficient and good in coating toughness and can remarkably improve the abrasion-resisting and lubricating performance of processing cutters, dies and mechanical parts. In addition, the preparation method is simple, industrial production is easily achieved, and the CN-MCN superhard self-lubricating nano-composite coating has good application prospect.

Owner:SHENZHEN YUANSIDACHENG TECH

Preparation method of thick tungsten coating material and tungsten coating material

InactiveCN103484830AHigh densityHigh hardnessChemical vapor deposition coatingMetal layered productsGradient materialThermal expansion

The invention relates to a preparation method of a thick tungsten coating material. Chemical vapor deposition method is used, and a tungsten coating is deposited on a base material by using hydrogen for reduction of tungsten hexafluoride. The deposition rate is 0.4-1 mm / h, and the tungsten coating thickness is greater than or equal to 1 mm. The invention also relates to a tungsten coating material including pure copper or copper alloy, an adaptation layer and the tungsten coating; the adaptation layer is 1-5 layers of a tungsten copper gradient material, and the thickness of each layer is 0.5 - 1.5mm; the tungsten content of the tungsten copper gradient material closed to the tungsten coating side is 50-90wt.%; the tungsten contents of the middle layers of tungsten copper gradient material decrease successively, and the copper contents increase successively; and the copper content of the tungsten copper gradient material closed to the copper or copper alloy side is 50-90wt.%. In the tungsten coating material, a pure tungsten coating-adaptation layer-copper based material method is used, through adoption of the adaptation layer, the thermal expansion coefficient mismatch problem between tungsten and copper can be solved, and the thermal stress of the coating and the base can be reduced.

Owner:SOUTHWESTERN INST OF PHYSICS +1

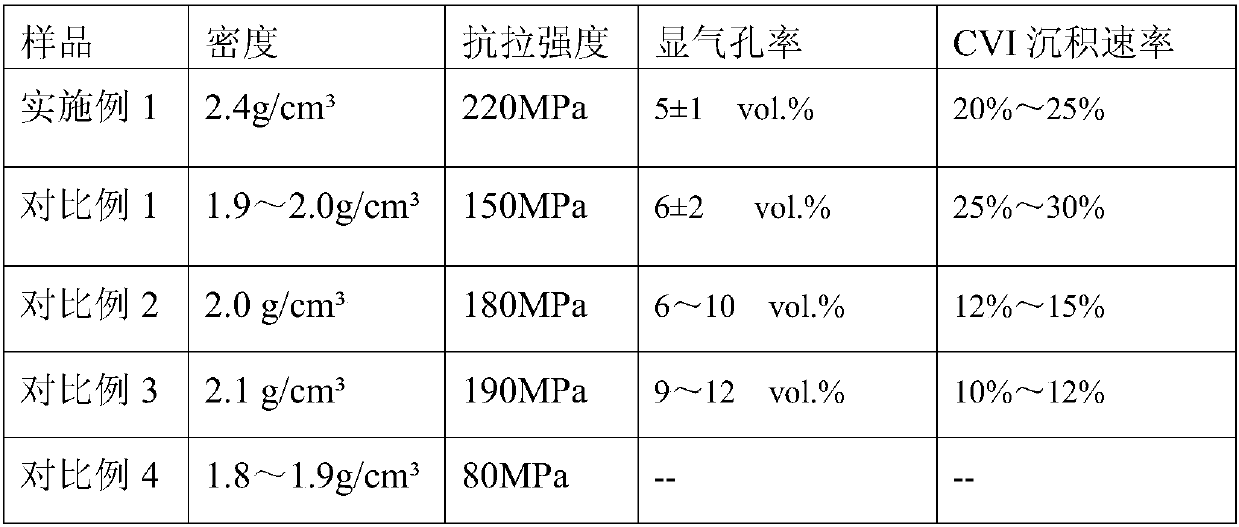

Preparation method of long-fiber carbon ceramic fastener

The invention provides a preparation method of a long-fiber carbon ceramic fastener. The method comprises the following steps: alternately laying long-fiber non-weave cloth and short-fiber mesh tire,wherein the included angle between every two adjacent layers of long-fiber non-weave cloth is 90 degrees along the fiber direction, needling for once when each layer of short-fiber mesh tire is laid,and weaving a three-dimensional needled preform; densifying the obtained preform to 1.4-1.5g / cm<3> in precursor gas by means of pressure differential chemical vapor permeation to obtain a C / C complex;then, carrying out high-temperature heat treatment in protective gas; finally, putting the product into silicon powder, and carrying out high-temperature melting silicon infiltration, and machining and molding to obtain the long-fiber carbon ceramic fastener with the density of 2.2-2.4g / cm<3>. The preparation method provided by the invention is short in preparation period, low in residual porosity, rapid in densifying amplitude, low in cost and environmentally-friendly; the prepared carbon ceramic fastener is high in strength and volume density and better in high temperature resistance and corrosion resistance.

Owner:山东道普安制动材料有限公司

Method for preparing Ti-Si-N nanocrystalline-amorphous composite superhard coating

InactiveCN101457359AOvercome expensiveFast deposition rateVacuum evaporation coatingSputtering coatingCemented carbideIon

The invention discloses a method for preparing a Ti-Si-N nano-crystal-noncrystalline composite ultra-hard coating. The method employs high-density arc discharge controlled by a magnetic field to lead the Ti arc target to evaporate Ti; nitrogen and steam are ventilated so as to react with Ti to generate TiN; meanwhile, silane (SiH4) is inlet and decomposed to Si ions and H ions; the Si ions react with the nitrogen to generate Si3N4. Under bias pressure, the TiN crystal and the SiN4 competitively grow on the workpiece substrate simultaneously to form a film, thus generating the Ti-Si-N nano-crystal-noncrystalline composite coating. The prepared Ti-Si-N nano-crystal-noncrystalline composite coating has the advantages of high hardness, strong adhesion, fast growth speed of coating, high production efficiency, low production cost, simple structure of coating equipment, and the like; according to the use requirement, the preparation of the Ti-Si-N nano-crystal-noncrystalline composite coating of different thickness can be carried out on various workpieces such as hard alloy, stainless steel, carbon steel, and the like.

Owner:WUHAN UNIV

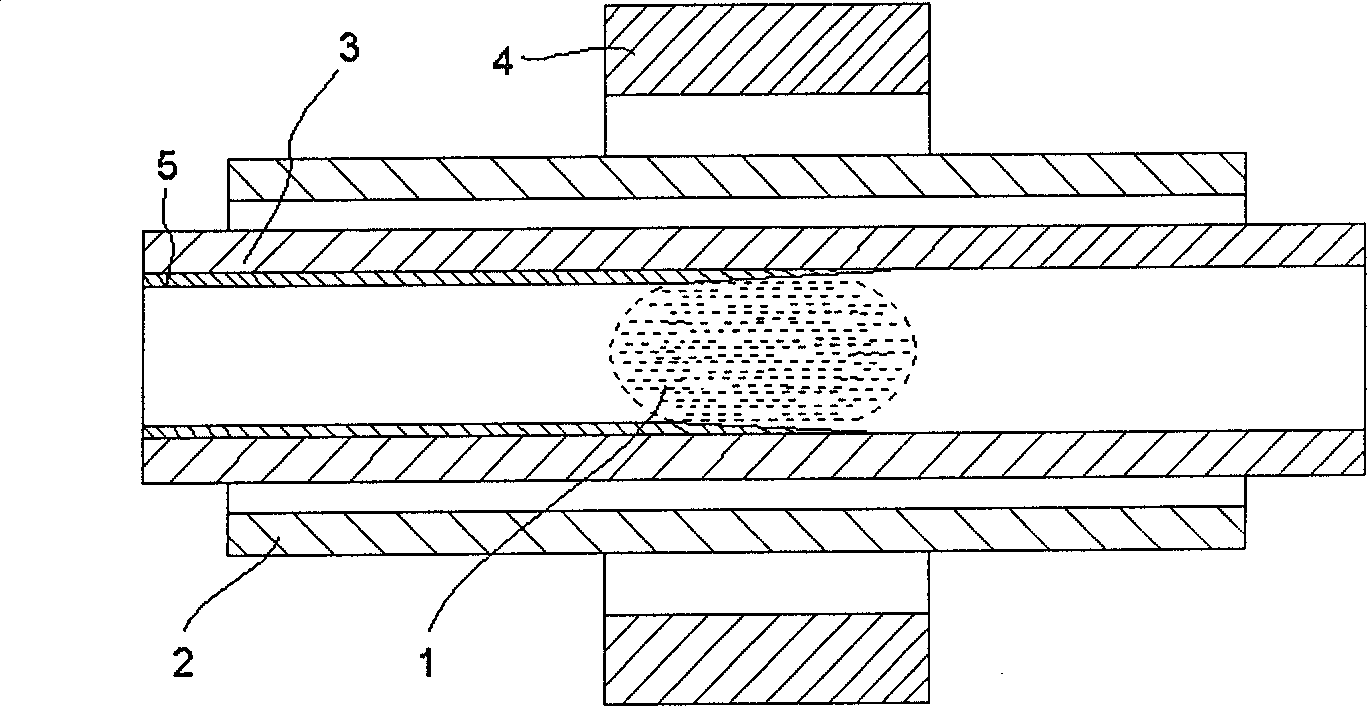

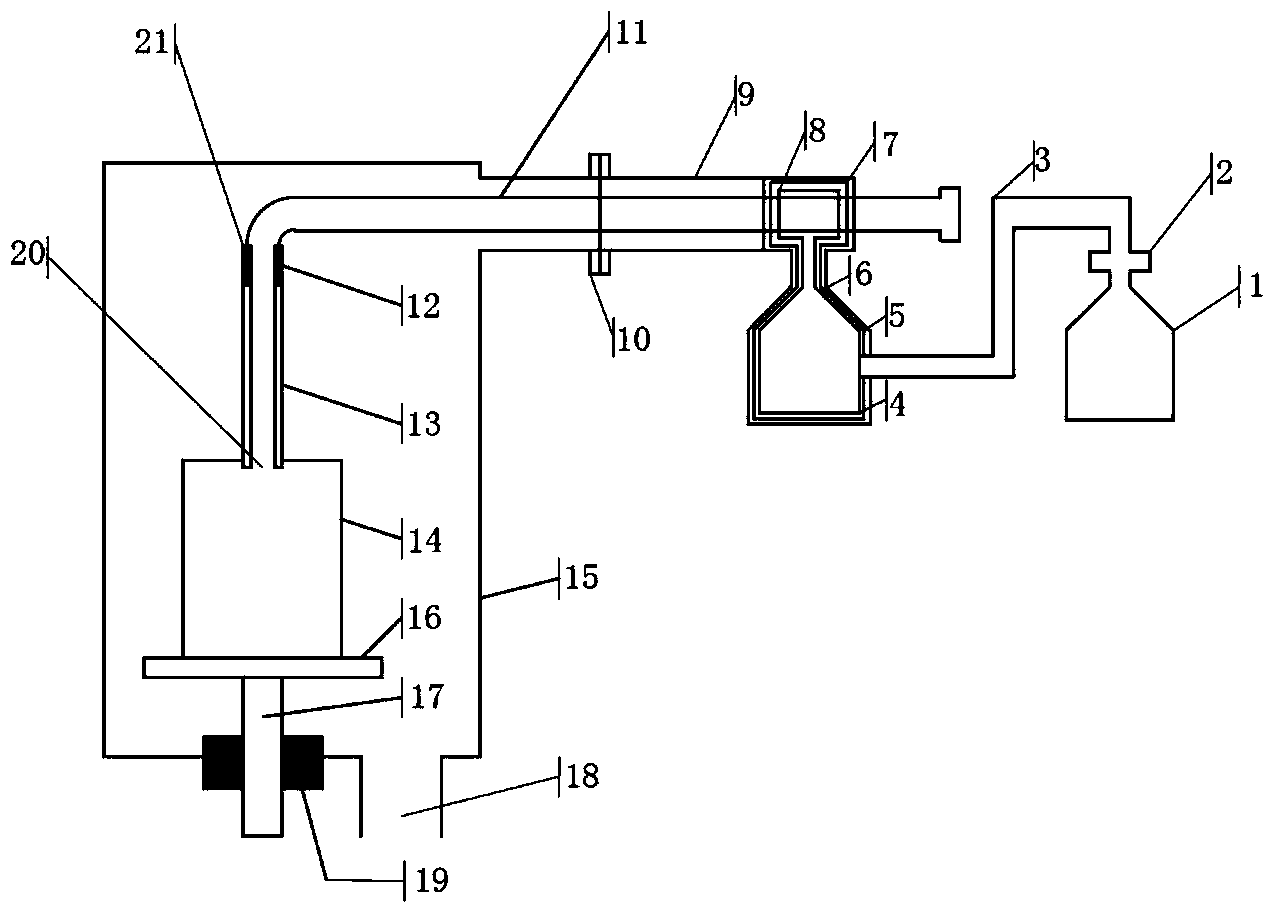

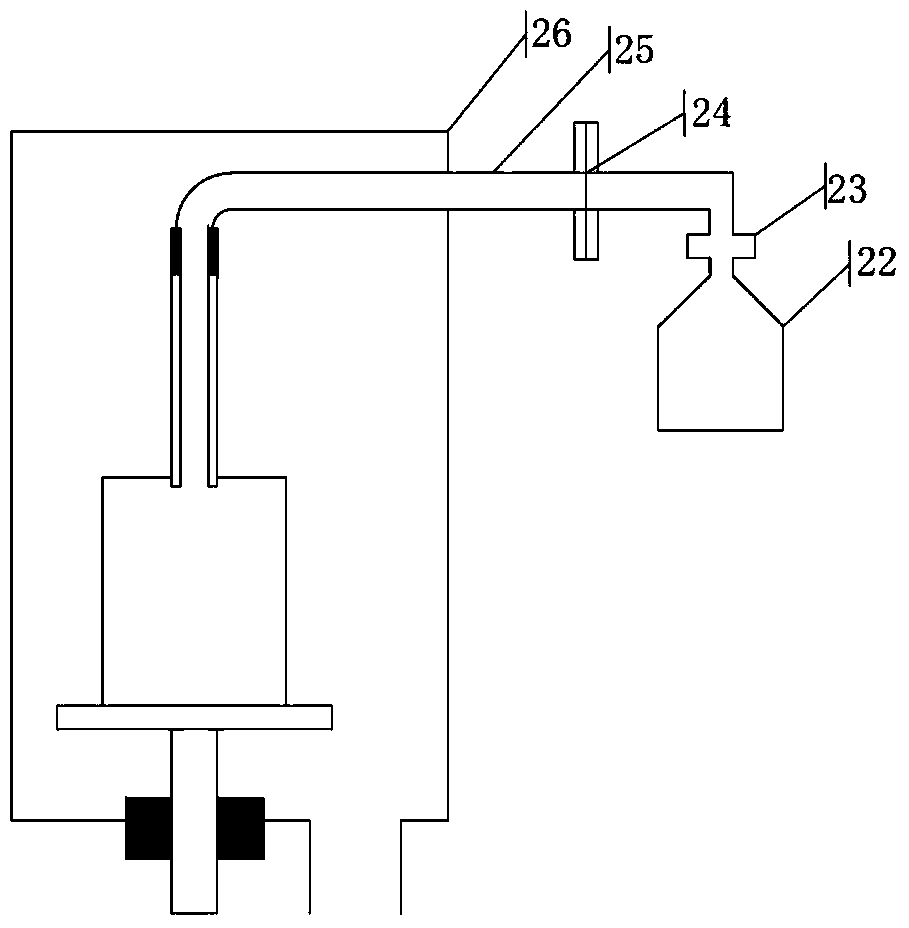

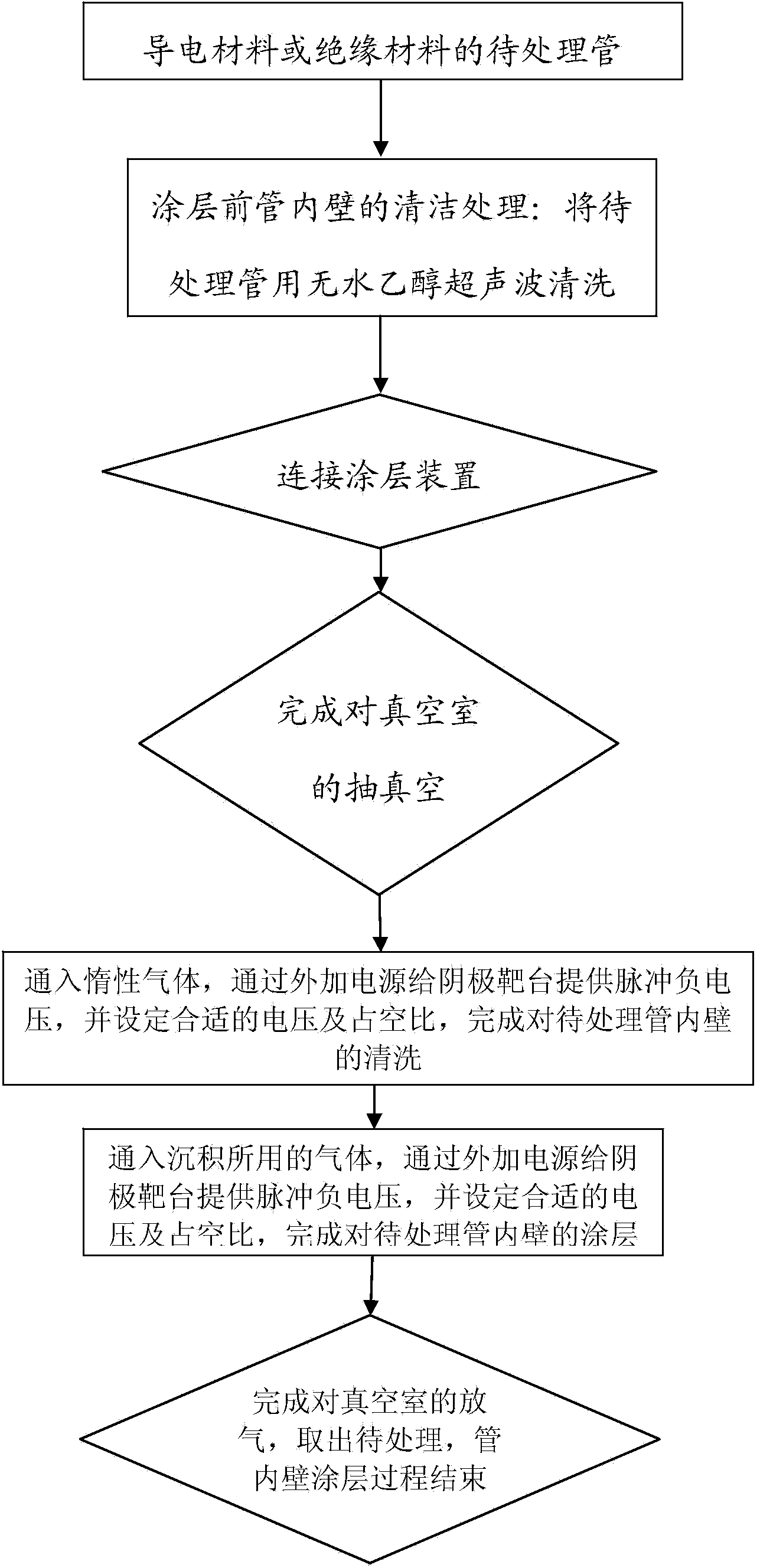

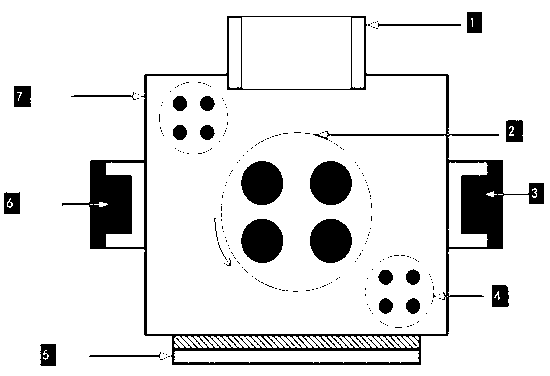

Method for coating inner wall of electron-enhanced plasma discharge tube

InactiveCN103952677AHigh densityFast deposition rateLiquid surface applicatorsVacuum evaporation coatingEngineeringVacuum chamber

The invention provides a method for coating the inner wall of an electron-enhanced plasma discharge tube. The method comprises the following six steps: 1, performing cleaning treatment on the inner wall of the tube to be treated before coating; 2, assembling a device for coating the inner wall of the electron-enhanced plasma discharge tube; 3, completing vacuum supply to a vacuum chamber, introducing an inert gas via an inert gas feed pipeline and feeding the inert gas into an insulating cover via the tube to be treated, and controlling the flow of the inert gas introduced into the vacuum chamber by use of a quality / flow controller; 4, providing negative impulse voltage to a cathode target table by virtue of external power supply and setting predetermined voltage value and duty ratio, thereby completing the cleaning of the inner wall of the tube; 5, introducing gaseous-state or vapor-state particles for deposition via a particle feed pipeline, providing the negative impulse voltage to the cathode target table by virtue of the external power supply and setting predetermined voltage value and duty ratio, thereby completing the coating of the inner wall of the tube; and 6, completing degassing of the vacuum chamber, taking out the tube to be treated and then completing the coating of the inner wall of the tube. The method has practical value in the surface material modification field.

Owner:BEIHANG UNIV

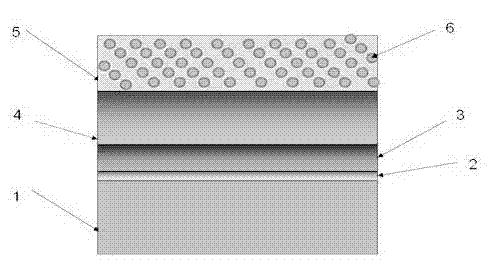

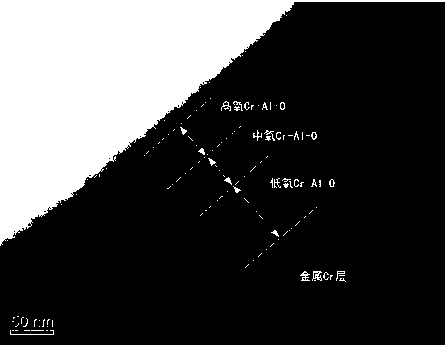

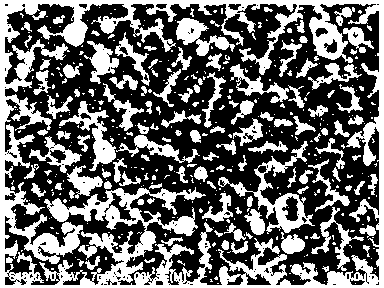

Nano composite Cr-Al-O (chromium-aluminum-oxygen) solar spectrum selective absorption coating and preparation method thereof

InactiveCN103255377AOvercome the problem of heavy metal pollutionImprove adhesionSolar heat devicesVacuum evaporation coatingPhysicsChemistry

The invention discloses a nano composite Cr-Al-O (chromium-aluminum-oxygen) solar spectrum selective absorption coating and a preparation method thereof. The absorption coating is characterized in that an infrared high reflection layer, a low oxygen absorption layer, a medium oxygen absorption layer and a high oxygen antireflection layer are sequentially deposited on a stainless steel substrate. According to the preparation method of the coating, an electric arc discharging method is adopted to sequentially deposit the infrared high reflection layer, the low oxygen absorption layer, the medium oxygen absorption layer and the high oxygen antireflection layer on the substrate. The coating is reasonable in structure design. The prepared Cr-Al-O composite coating has an absorption ratio of 0.92 to 0.94, a transmitting rate of 0.15 to 0.22, good heat stability and high adhesive force. Meanwhile, the preparation process is free from pollution, the severe environmental pollution problem of the conventional electroplating method is overcome, the problems of the magnetron sputtering method, such as poor heat stability and the high-temperature adhesive force of coating and the problem of the evaporation technology that uniformity of the coating is poor can be solved, and the nano composite Cr-Al-O solar spectrum selective absorption coating is expected to be applied to the medium-high-temperature solar utilization field.

Owner:WUHAN UNIV

Long-term firm durable hydrophobic coating as well as preparation method and application thereof

ActiveCN108977782AEnhanced condensation heat transferIncrease ionization rateVacuum evaporation coatingSputtering coatingRare earthMechanical property

The invention relates to the technical field of hydrophobic coatings, in particular to a long-term firm durable hydrophobic coating as well as a preparation method and application thereof. The long-term firm durable hydrophobic coating comprises a rare earth metal transition layer and a rare earth oxide coating, wherein the rare earth metal transition layer is deposited between a base and the rareearth oxide coating, the material of the rare earth metal transition coating is a rare earth metal which is corresponding to the rare earth oxide coating, and the base is a metal base or a nonmetal base. The hydrophobic coating provided by the invention has a good mechanical property, a thermodynamic property, corrosion resistance and a long-term firm durable characteristic, and particularly canbe applied in a severe environment, so that the application of a hydrophobic rare earth oxide coating is greatly promoted in different fields.

Owner:HANGZHOU DIANZI UNIV

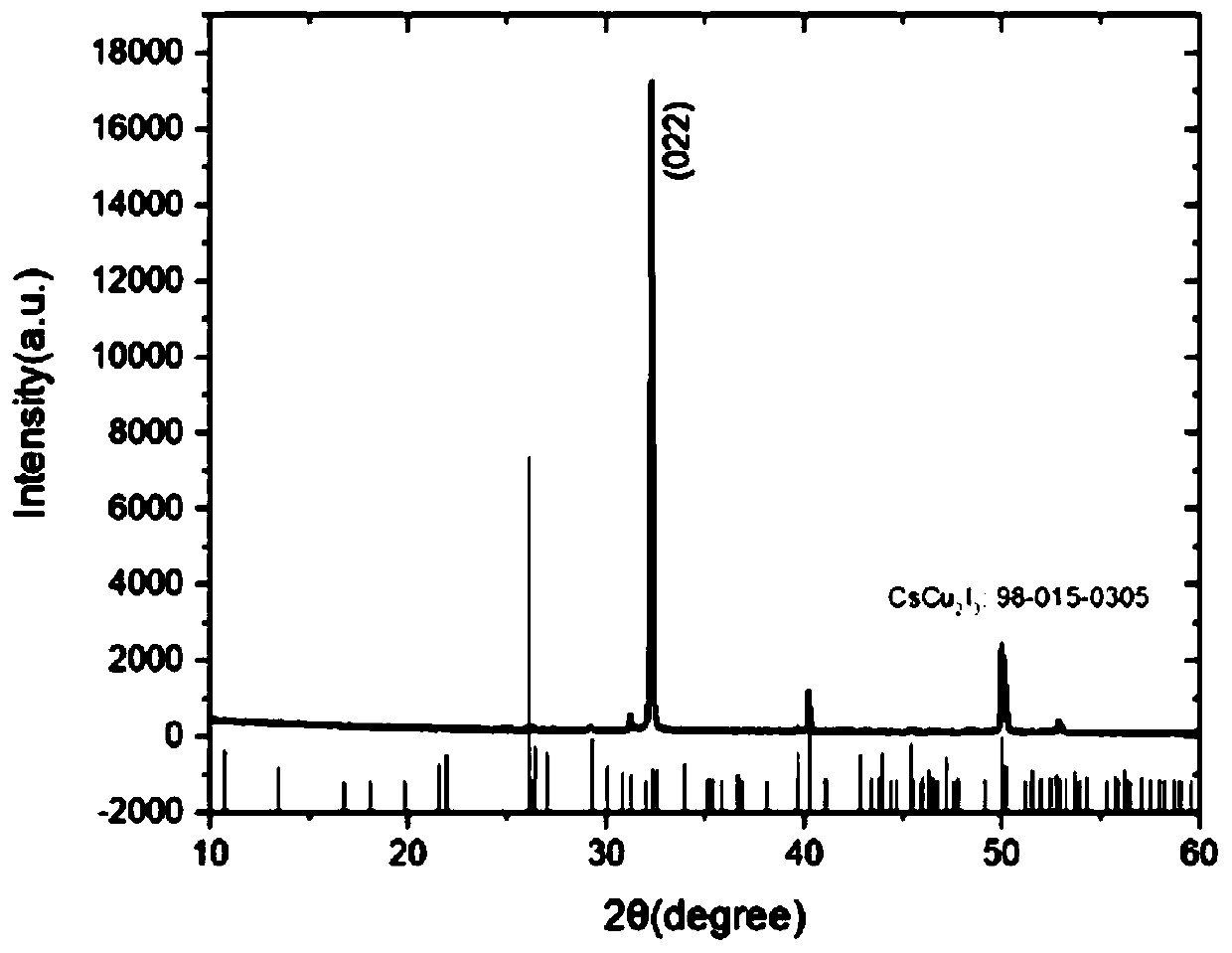

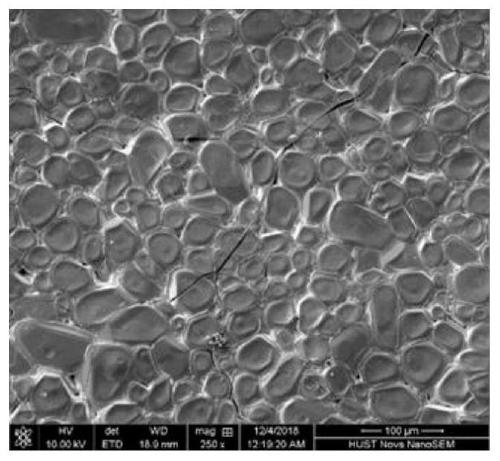

Method for preparing inorganic scintillator film

ActiveCN109991649AIncrease profitPromote growthX/gamma/cosmic radiation measurmentLuminescent compositionsAdhesion forceEffective solution

The invention discloses a method for preparing an inorganic scintillator film. The method comprises the following steps of using an AxByXz powder raw material as an evaporation source; by using a substance sublimation principle, firstly performing vacuum pumping treatment on a deposition cavity containing the raw material and a substrate; then, heating the raw material and the substrate in the vacuum environment so that the AxByXz material is deposited onto the substrate; and thus obtaining an AxByXz inorganic scintillator film, wherein the A is a univalent alkali metal cation; the B is any one element from Cu and Ag; the X is a univalent halogen anion; and the ratio of the x to the y to the z is 1:1:2 or 1:2:3 or 2:1:3 or 3:2:5. The preparation method has the advantages that the operationis simple; the deposition speed is high; the cost is low; the large-area mass synthesis can be realized; and the obtained inorganic scintillator film layer has the advantages of uniformity, compactness, high crystallinity degree, good orientation performance, strong adhesion force with the substrate and excellent x-ray response performance. The invention provides an effective solution for the preparation of an inorganic scintillator thick film, and further provides an effective measure for the integration of a backend scintillator detector; and the market application potential is great.

Owner:HUAZHONG UNIV OF SCI & TECH

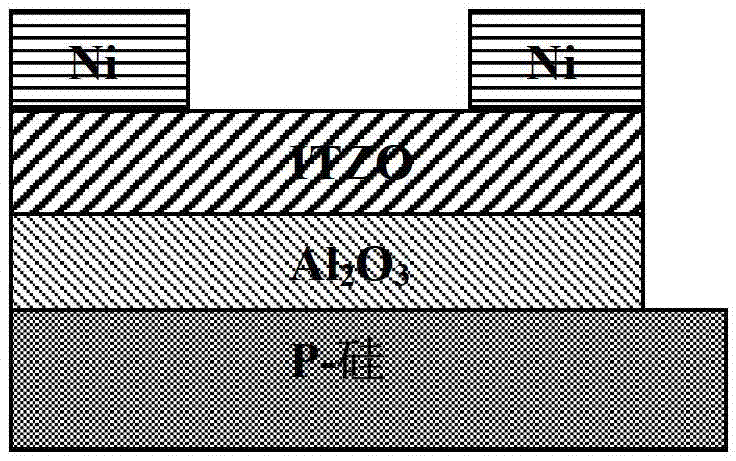

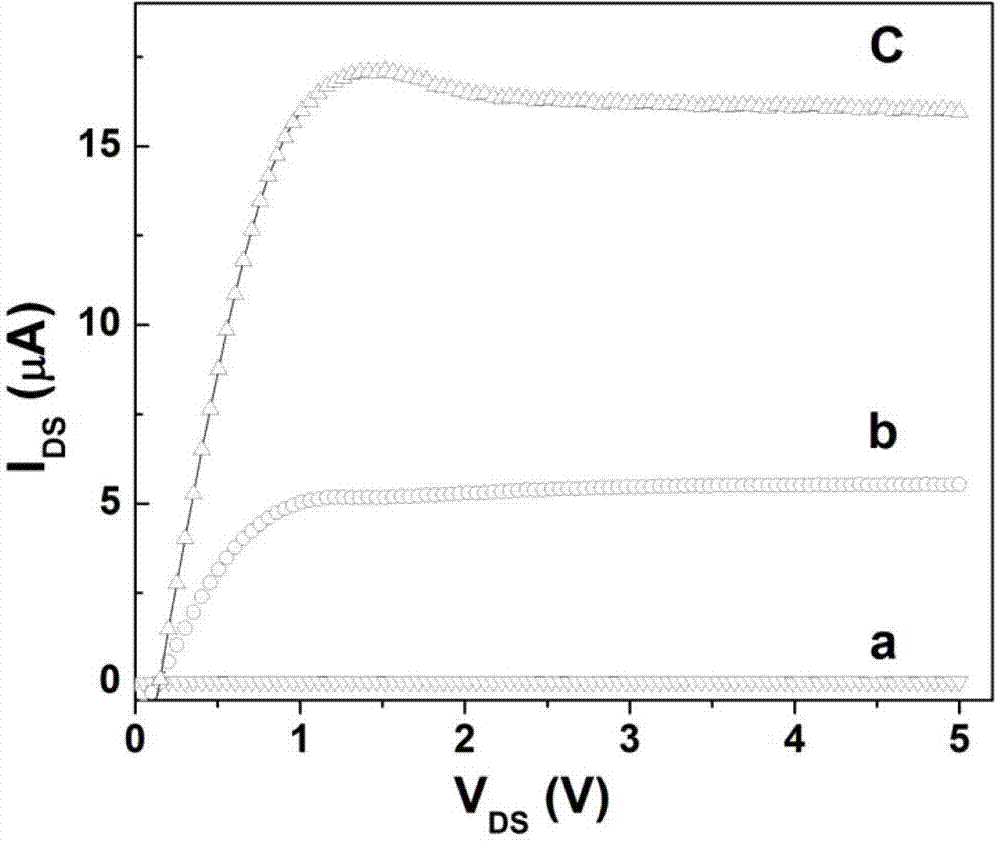

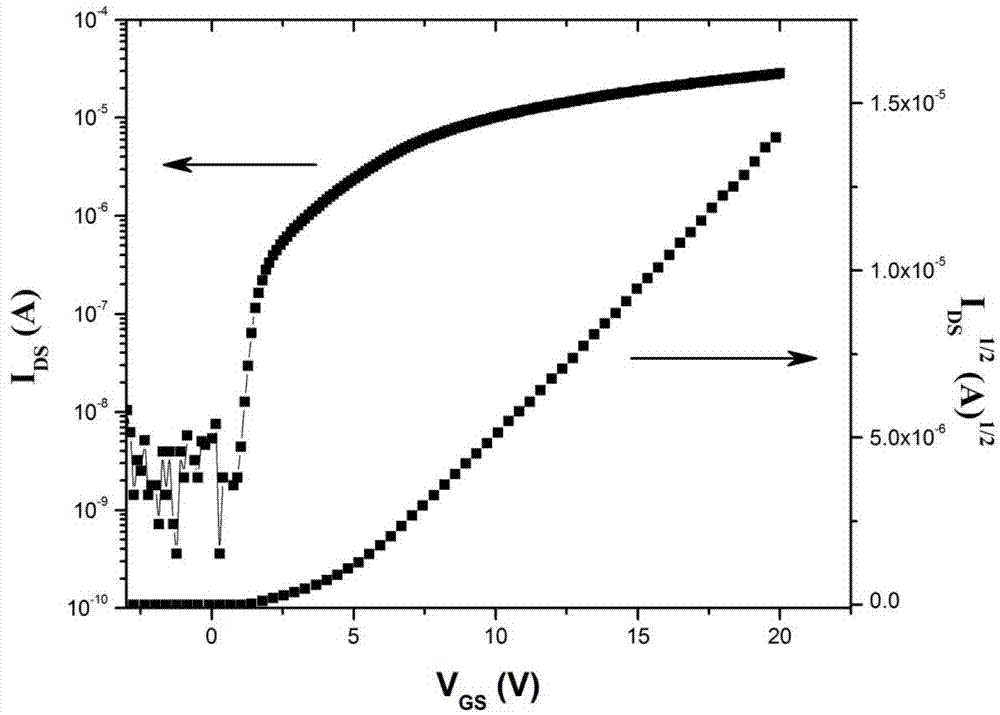

Production method of alloy oxide thin-film transistor

InactiveCN103117226AImprove flatnessExcellent deposition uniformity and consistencySemiconductor/solid-state device manufacturingIndiumOxide

The invention belongs to the technical field of production of semiconductor material thin-film transistors and relates to a production method of an alloy oxide thin-film transistor. After a P-type silicon substrate and an aluminum oxide ceramic target are placed in an existing pulse laser ablation device, the aluminum oxide ceramic target is subjected to pulse laser ablation and an aluminum oxide ceramic target film sample is formed on the P-type substrate by deposition. The surface of the Al2O3 ceramic target film sample is cleaned, ITZO (indium tin zinc oxide) semiconductor channel layer is made on the surface of a gate medium layer of the cleaned Al2O3 ceramic target film sample, TFT (thin film transistor) channels different in length and width are made by photoetching, and alloy semiconductor film channel layer material is deposited on a high-k gate medium layer at room temperature by radio frequency magnetron sputtering technology. Ni is deposited at room temperature by ion beam sputtering technology to form a source electrode and a drain electrode. The source electrode and the drain electrode are obtained after photoresist is stripped, and the alloy oxide thin-film transistor is obtained after annealing. The production process is simple, the principle is reliable, production performance is fine, production is environment-friendly, and the production method is low in cost and widely applicable.

Owner:QINGDAO UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com