Patents

Literature

33 results about "Residual porosity" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

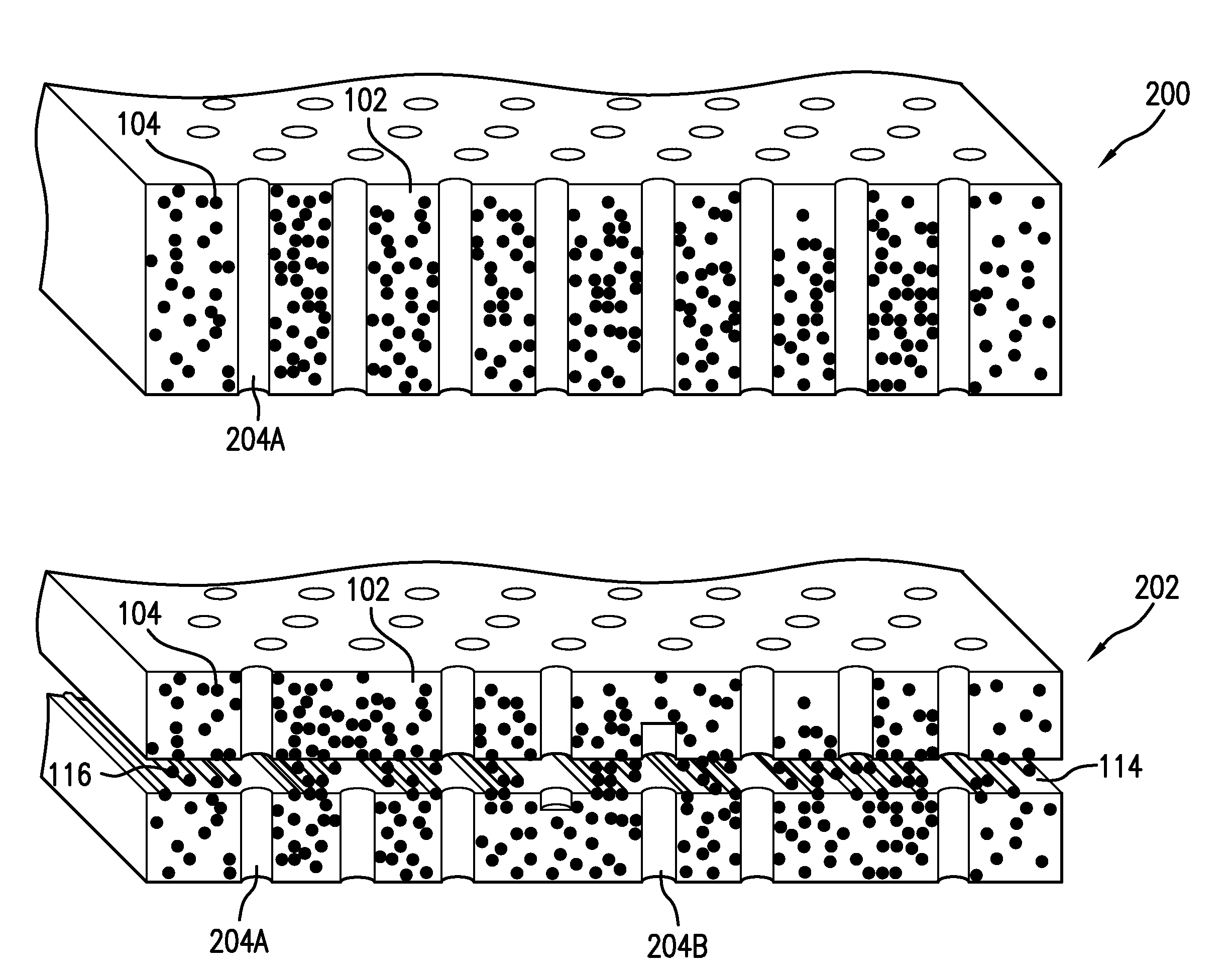

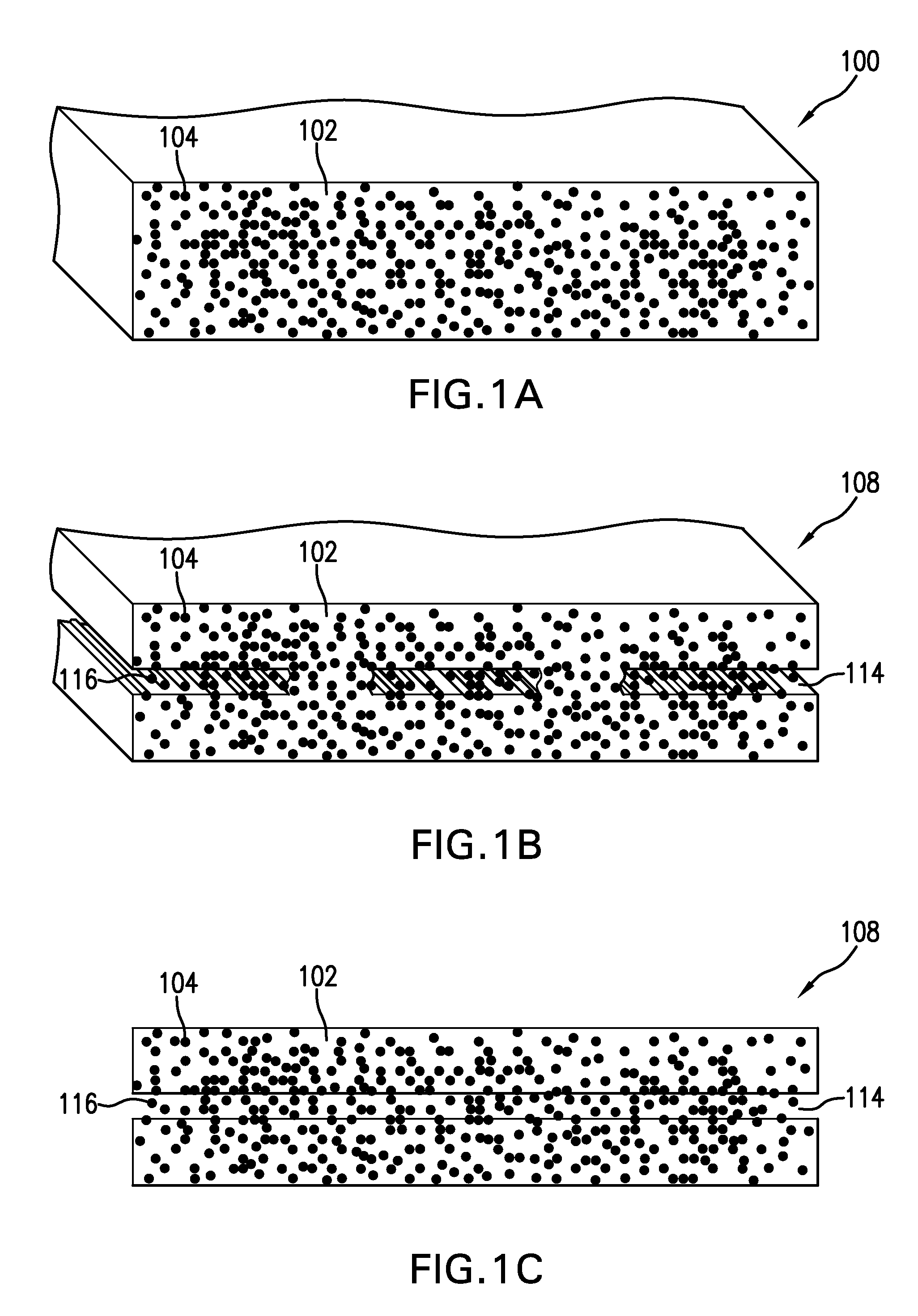

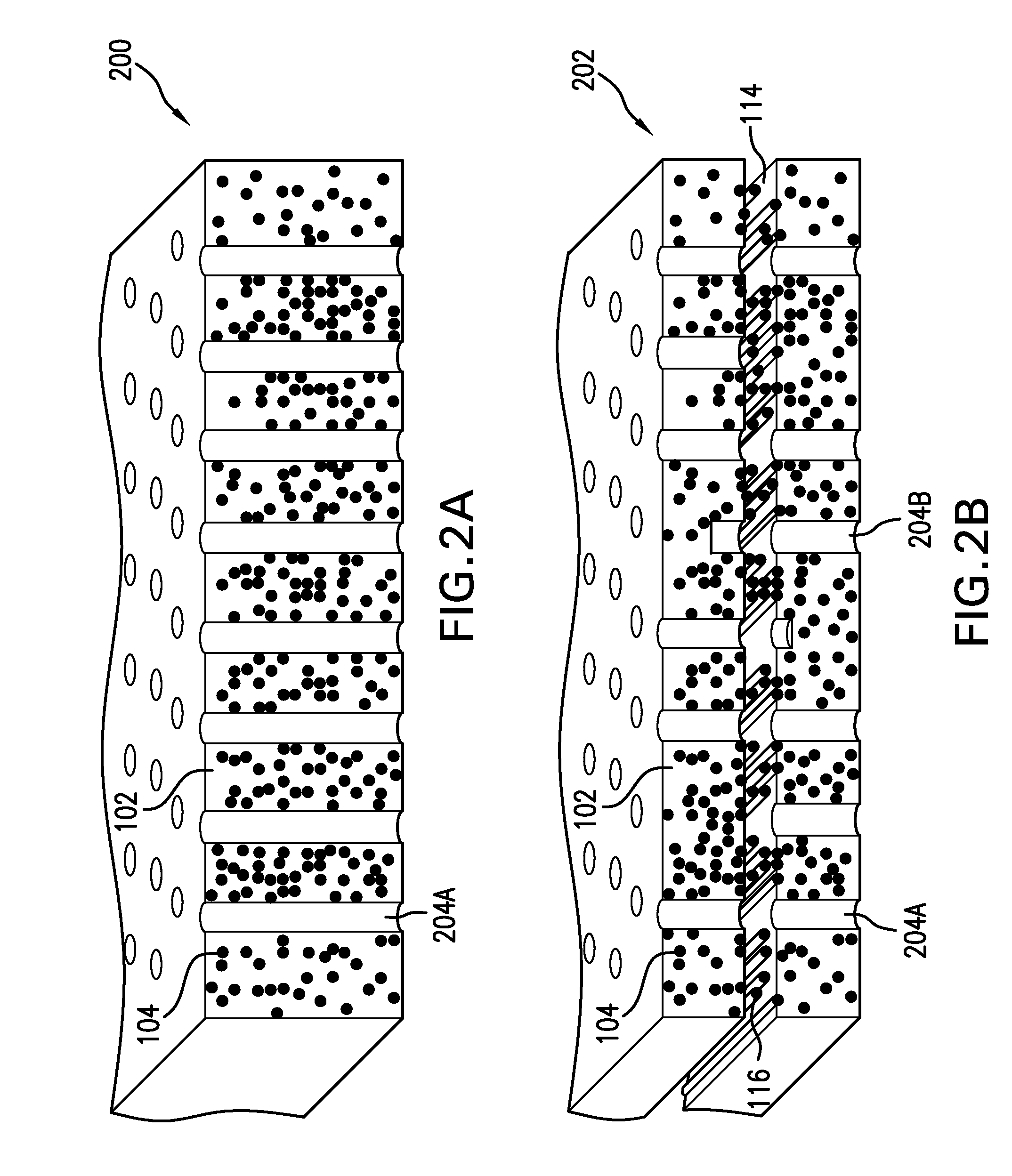

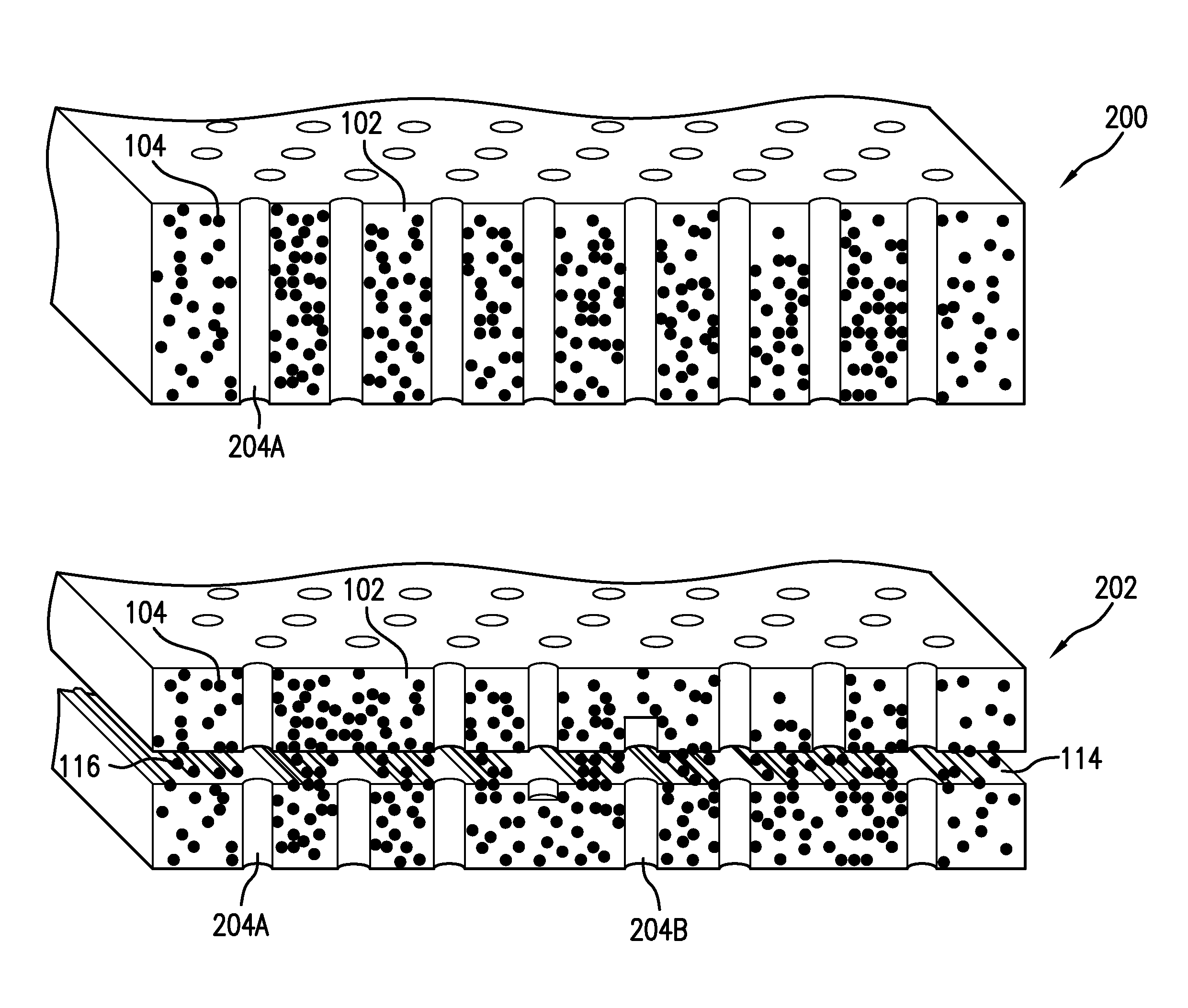

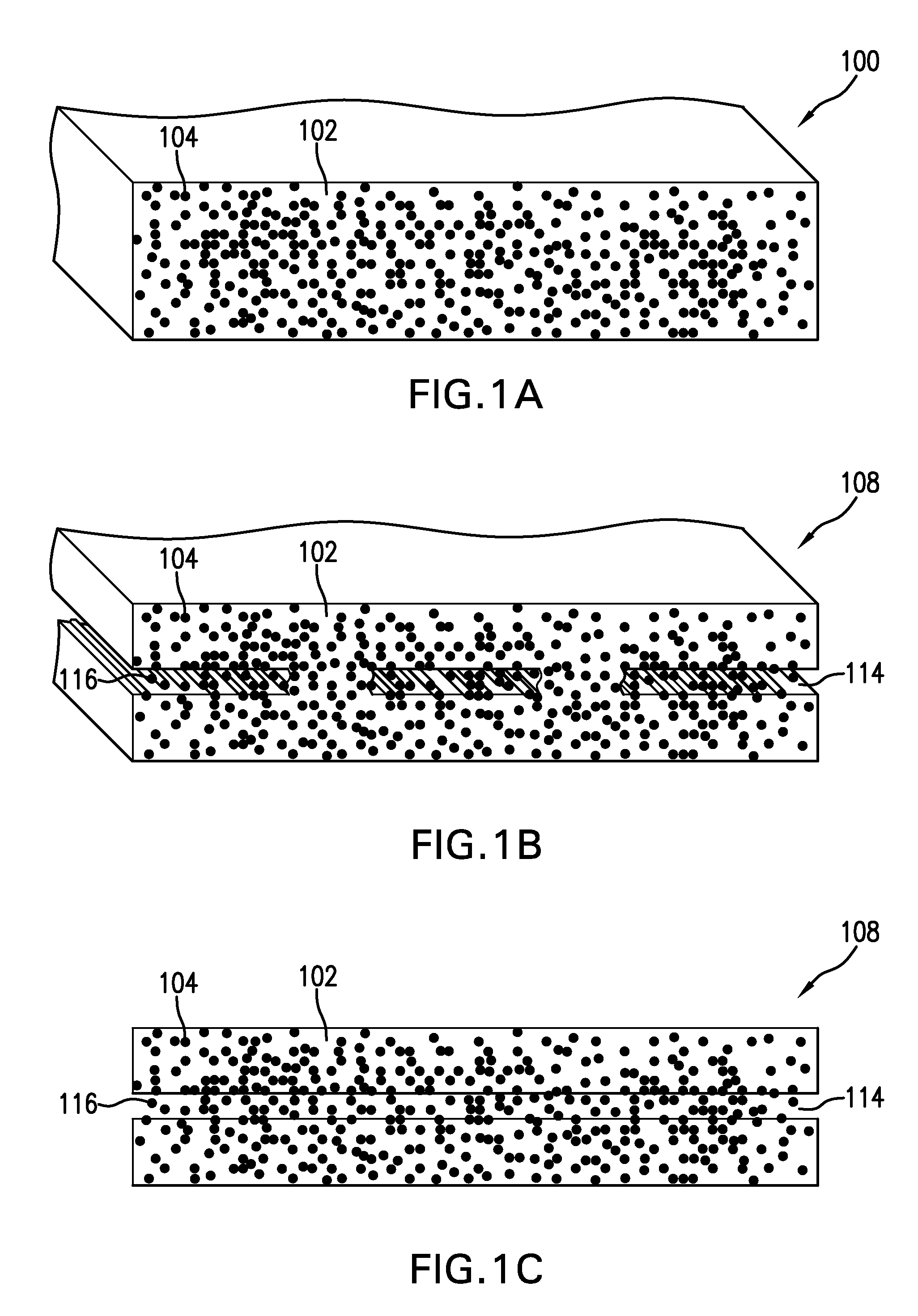

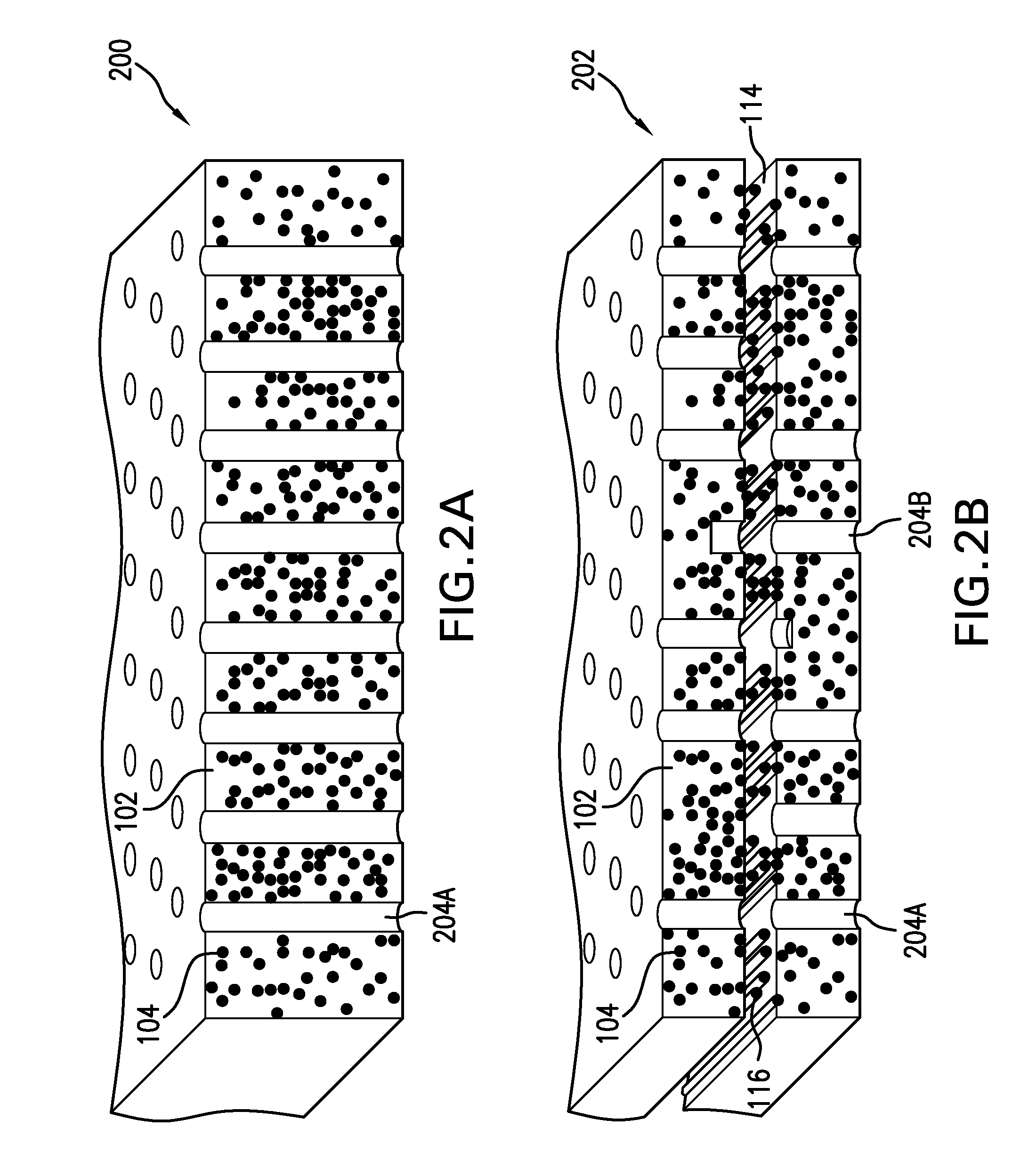

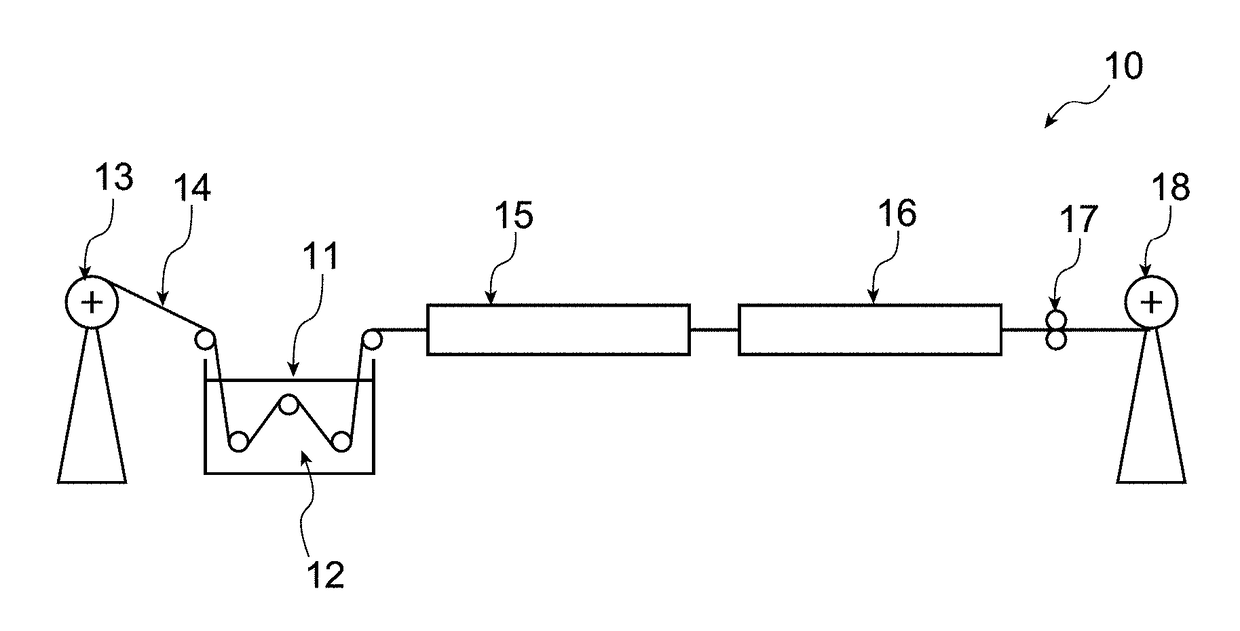

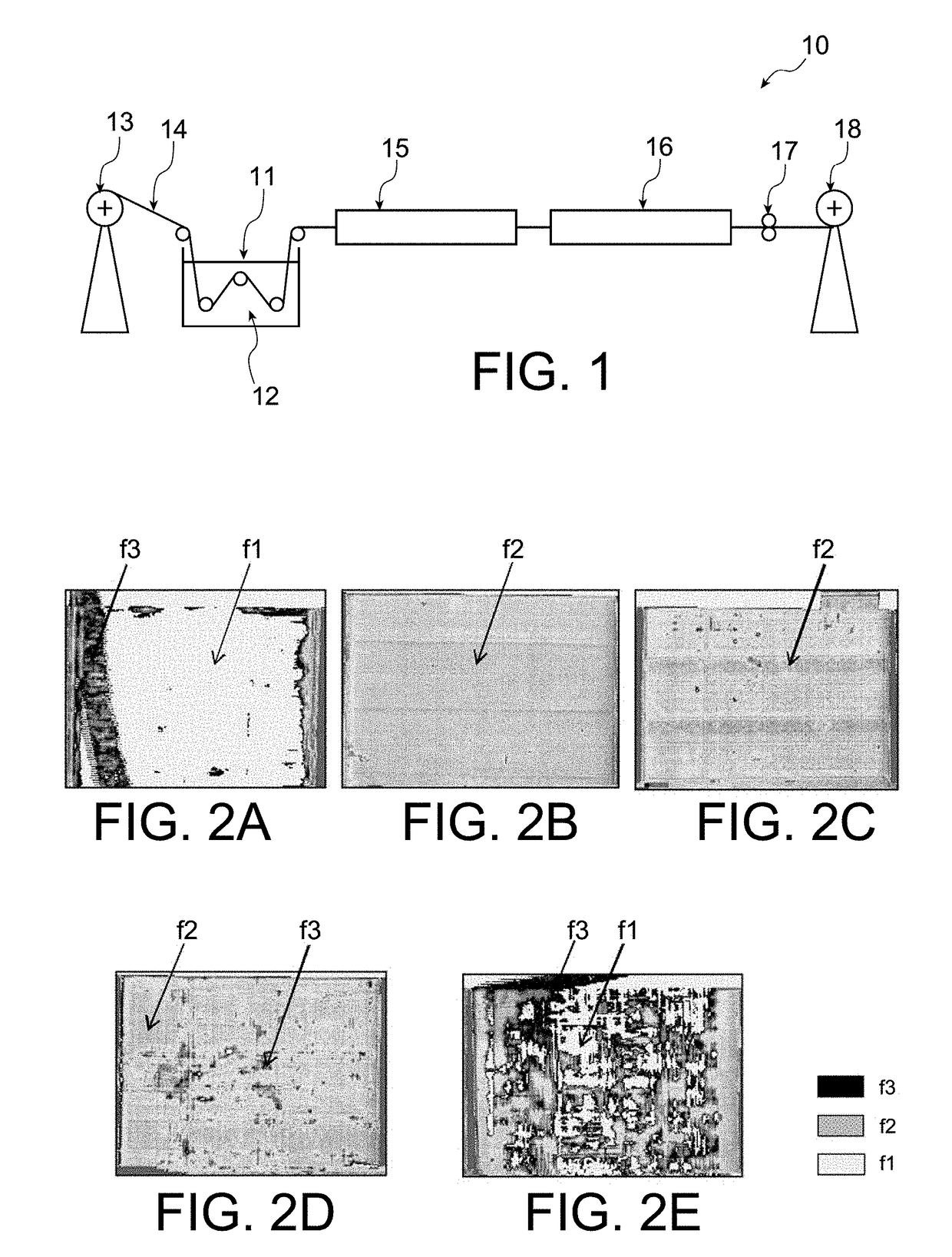

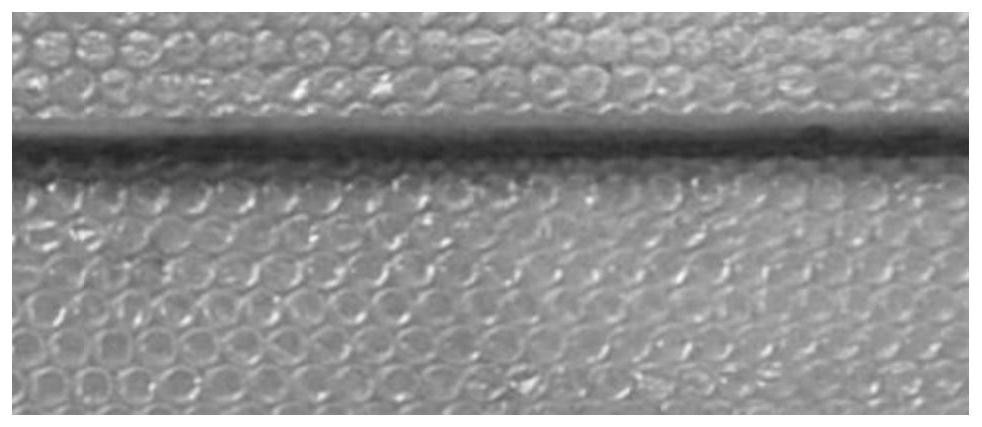

Prepregs with improved processing

ActiveUS20100098906A1Good removal effectLamination ancillary operationsSynthetic resin layered productsMaterial PerforationComposite structure

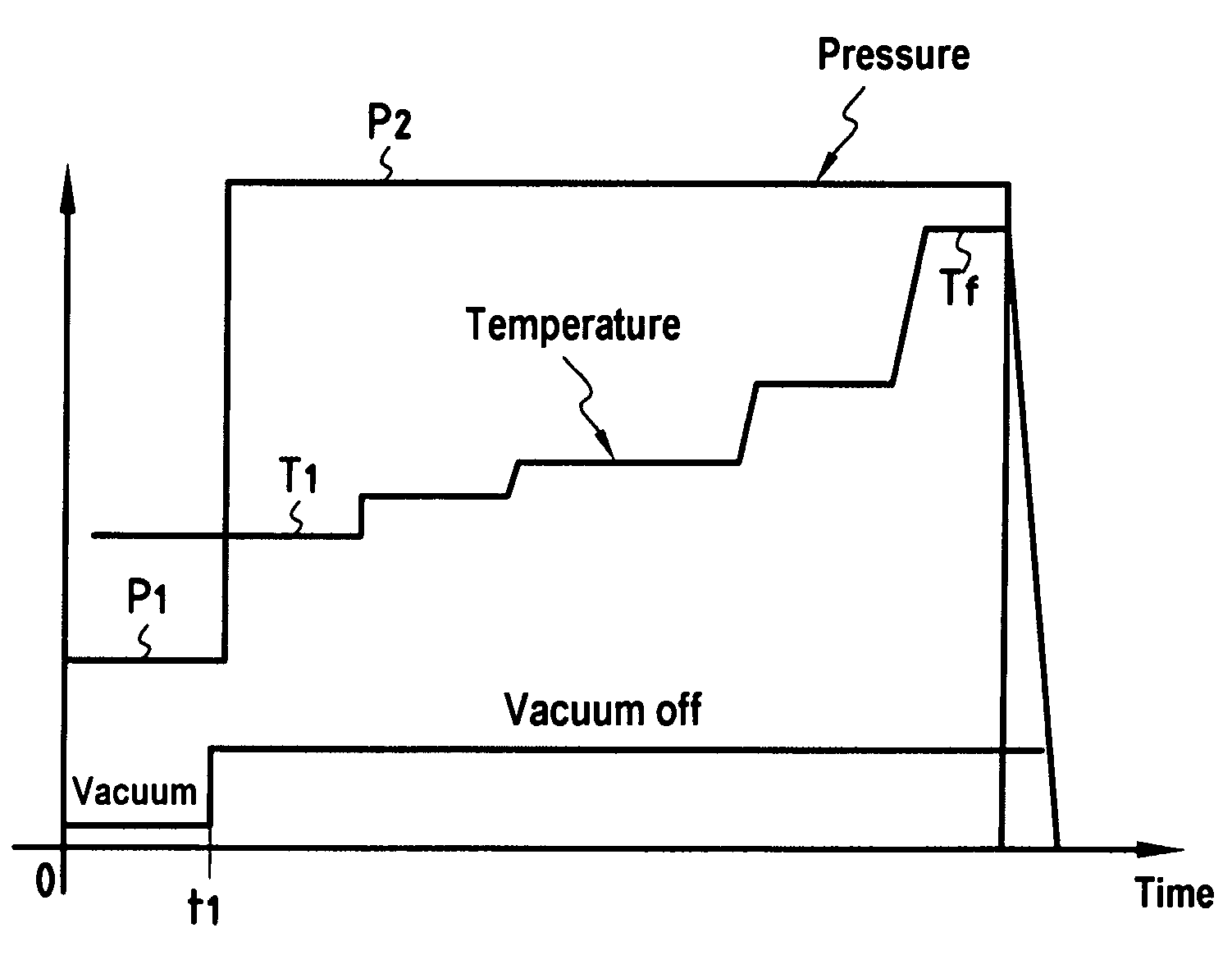

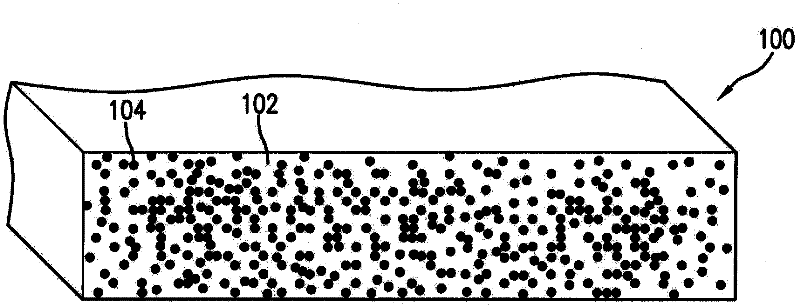

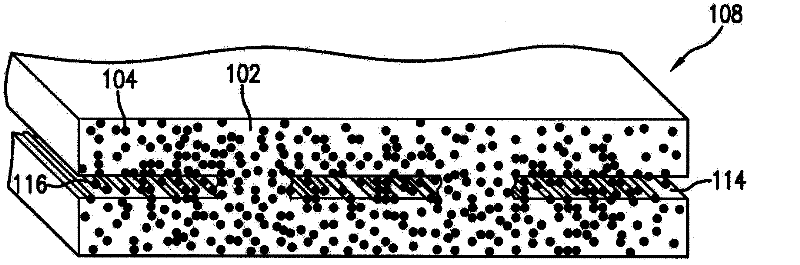

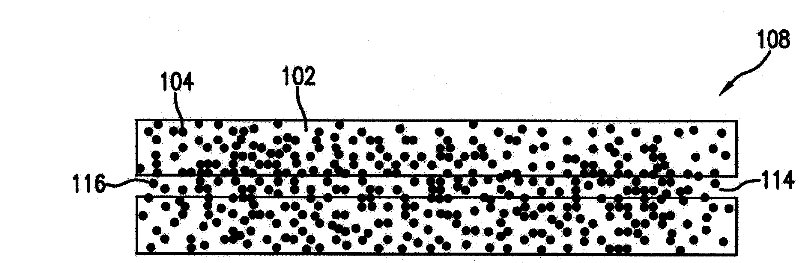

Systems and methods for the fabrication of prepregs possessing enhanced ability for the removal of gases from within prepregs and prepreg layups prior to and / or during at least a portion of consolidation and cure process to form composite structures are disclosed. In certain embodiments, perforations of selected configurations may be introduced into the prepregs prior to, during, and after layup. The perforations provide routes for gases trapped within and between the perforated prepregs and prepreg lay-ups to escape during consolidation and cure process, reducing the residual porosity within the resulting composite. For example, composites having residual porosities less than 10 vol. %, on the basis of the volume of the composite, may be achieved in this manner.

Owner:CYTEC TECH CORP

Method for manufacturing fully dense metal sheets and layered composites from reactive alloy powders

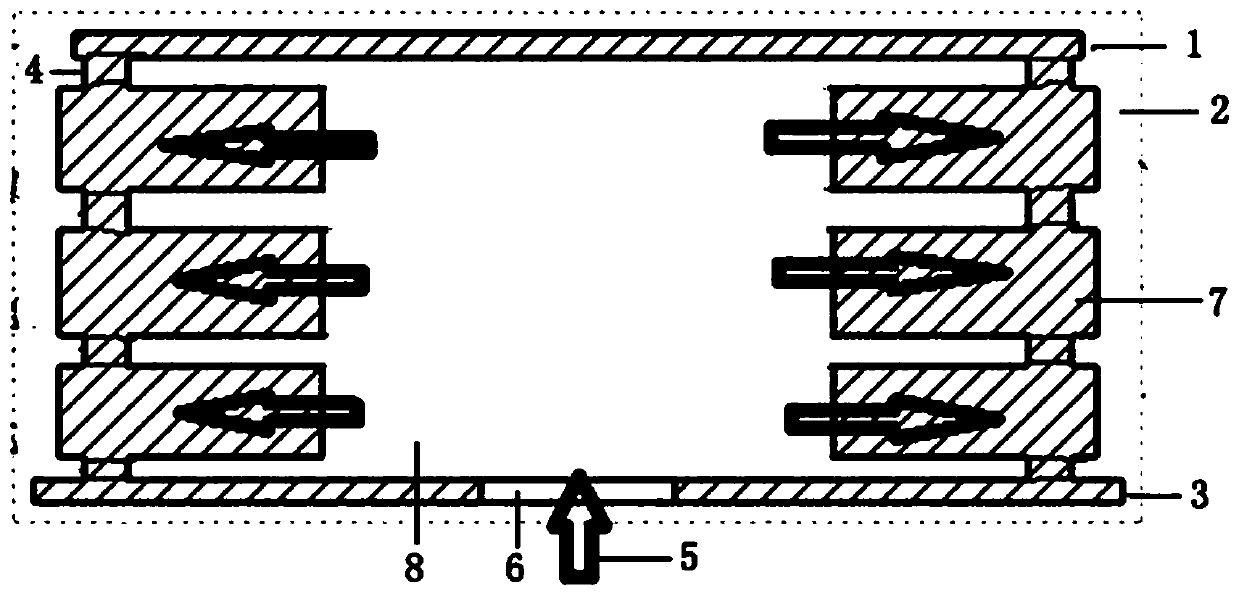

InactiveUS20040096350A1Improve mechanical propertiesReduce residual porosityIncreasing energy efficiencyWelding/cutting media/materialsTi 6al 4vVolumetric Mass Density

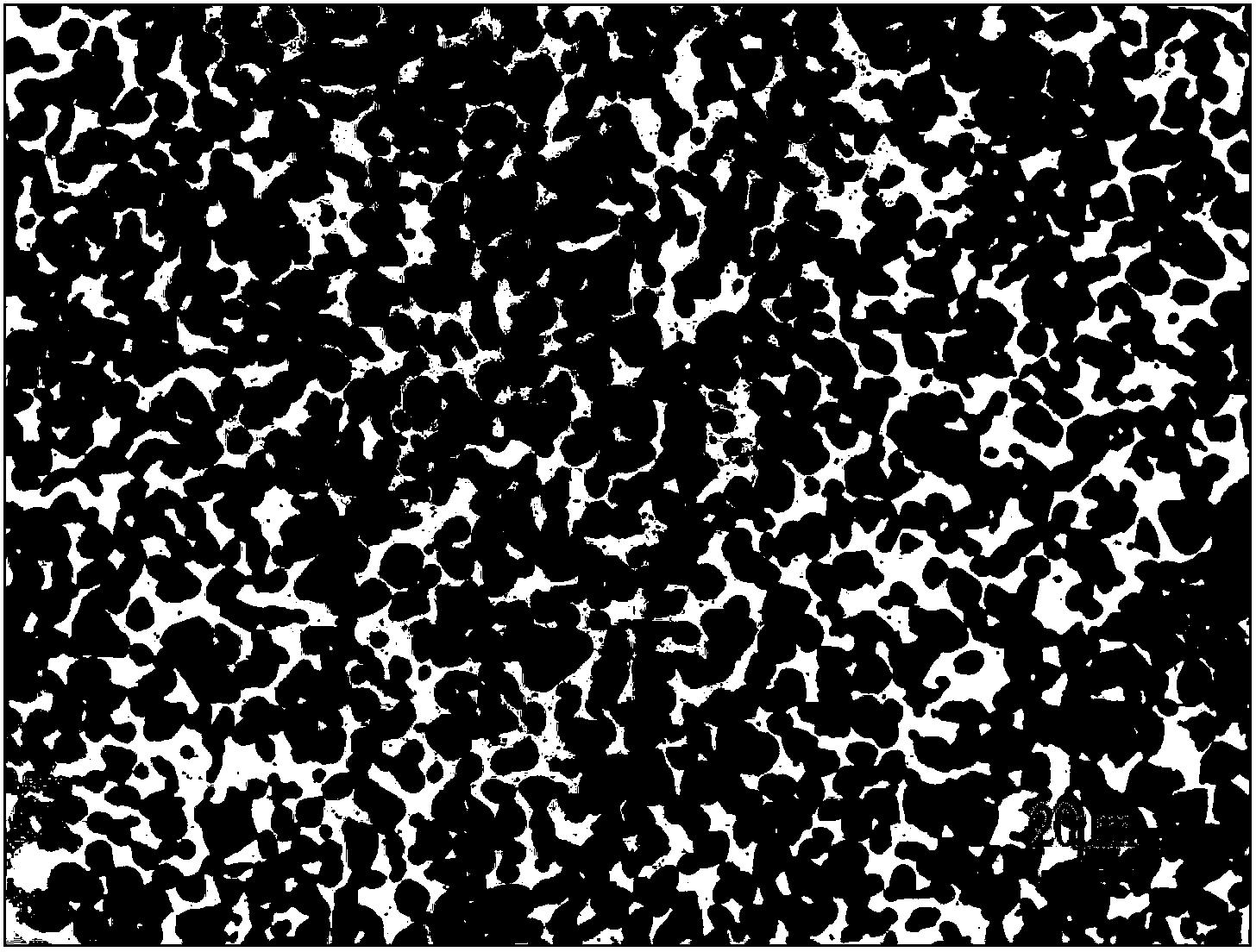

The method is suitable for the manufacture of flat or shaped titanium aluminide articles and layered metal matrix composites such as lightweight plates and sheets for aircraft and automotive applications, thin cross-section vanes and blades, composite electrodes, heat-sinking lightweight electronic substrates, bulletproof structures for vests, partition walls and doors, as well as for sporting goods such as helmets, golf clubs, sole plates, crown plates, etc. The method includes the following steps: (a) forming a porous preform of the reactive powder alloy or a porous multi-layer composite preform consisting of reactive powder metals and alloys by consolidation using at least one method selected from low-temperature loose sintering in vacuum, high-temperature loose sintering in vacuum, low-pressure sintering in an inert gas, cold pressing, direct powder rolling, isostatic or die pressing, and other means of room temperature and warm temperature consolidation, and / or combination thereof, to provide the density not less than 25% from the theoretical density of said reactive alloy; (b) hot consolidating by hot pressing said preform, hot rolling, hot isostatic pressing, or hot extrusion to obtain the density of 98-100% from the theoretical density of said reactive alloy; (c) additional sintering and / or annealing at the temperature being at least 900° C. to decrease the residual porosity, control the microstructure, and improve the mechanical properties, especially ductility and / or plasticity of the resulting metal sheets or layered composites. The hot pressing is carried out at the temperature ranging 950-1700° C., preferably at 1250-1450° C., and at pressure ranging 50-350 kg / cm<2>. The HIP is carried out at the temperature ranging 1250-1350° C. and at pressure ranging 15000-40000 psi. The layered composite preform is manufactured by individual loose sintering, one layer of the composite at a time, and assembling them in the desired order. The composite consists of layers of titanium and / or titanium hydride, Ti-6Al-4V alloy, alpha-titanium aluminide alloy, beta-titanium aluminide alloy, and gamma-titanium aluminide alloy in any combinations.

Owner:ADVANCED MATERIALS PRODS

Compact dispersion-strengthened copper-base composite material

The invention relates to a compact dispersion-strengthened copper-base composite material and a preparation method thereof. The compact dispersion-strengthened copper-base composite material is composed of a copper alloy base and Al2O3 particles which are uniformly dispersed in the copper alloy base. Composite metals are added into the copper-alumina master alloy, and a vacuum induction hot-pressing furnace or low-pressure isostatic sintering furnace is adopted for sintering to maximally eliminate the residual porosity and defects in the alloy, so that the sintered billet basically reaches the theoretical density. The prepared dispersion-strengthened copper product has the advantages of high electric conductivity, high softening temperature resistance and high compactness, and can achieve more than 99.5% of theoretical density.

Owner:YANTAI WANLONG VACUUM METALLURGY

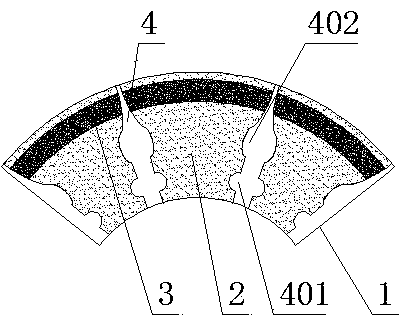

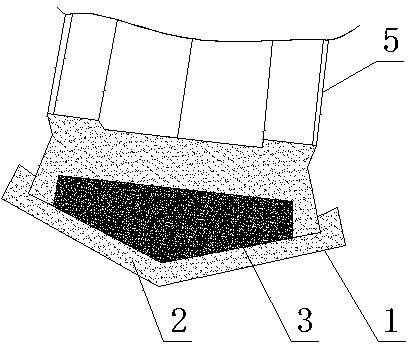

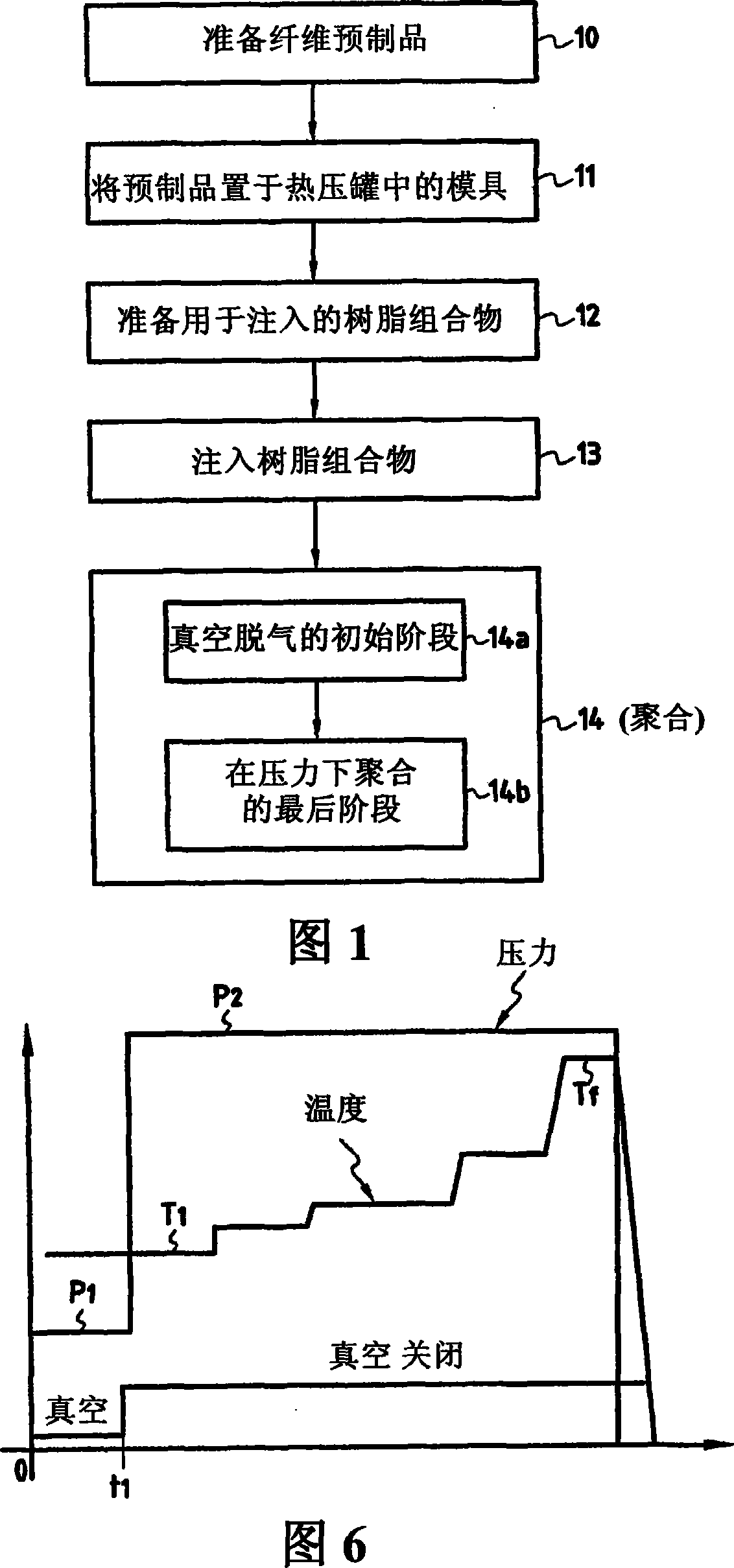

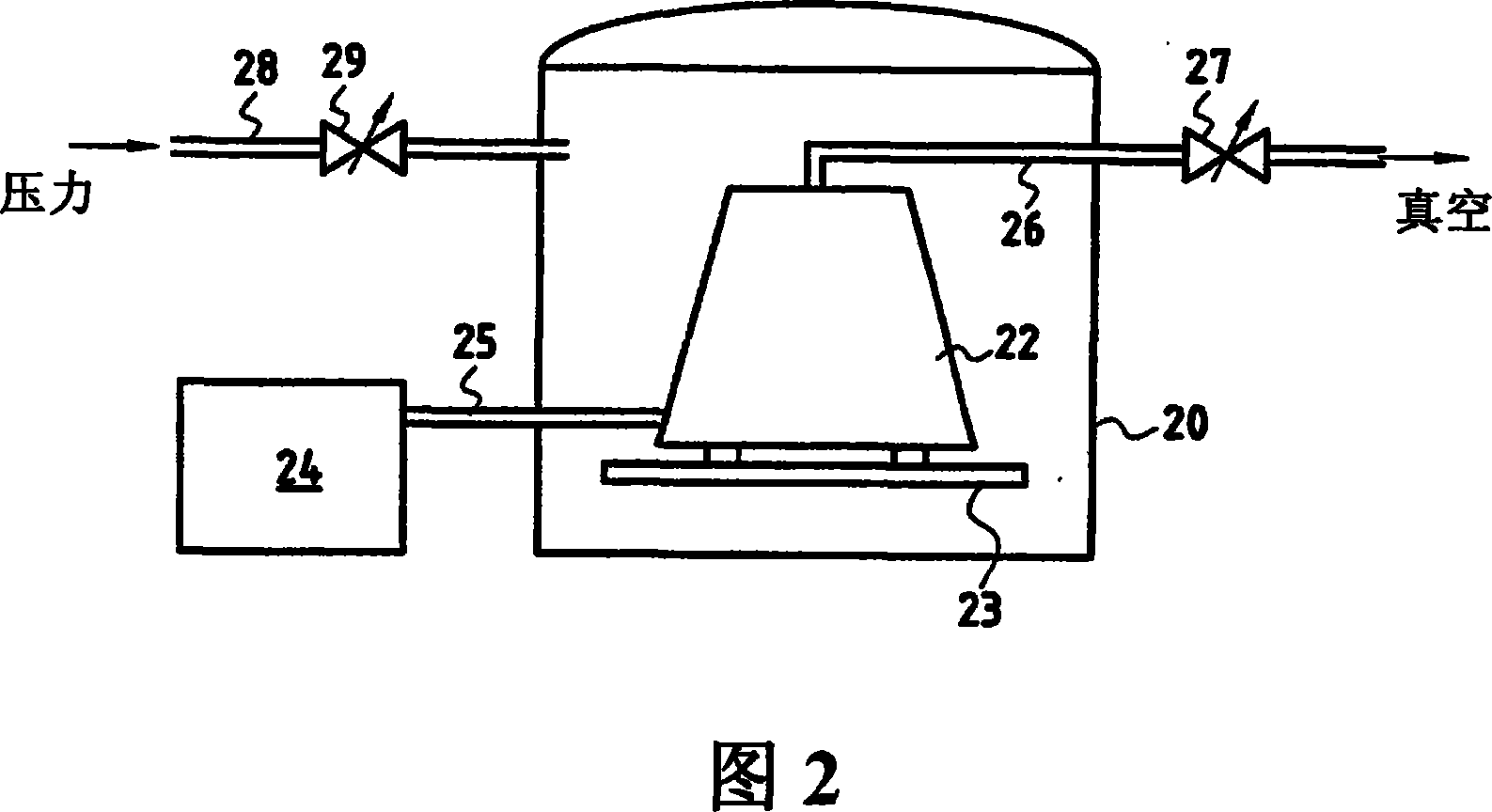

Densification of fibrous structures by resin transfer moulding for making thick parts of composite material

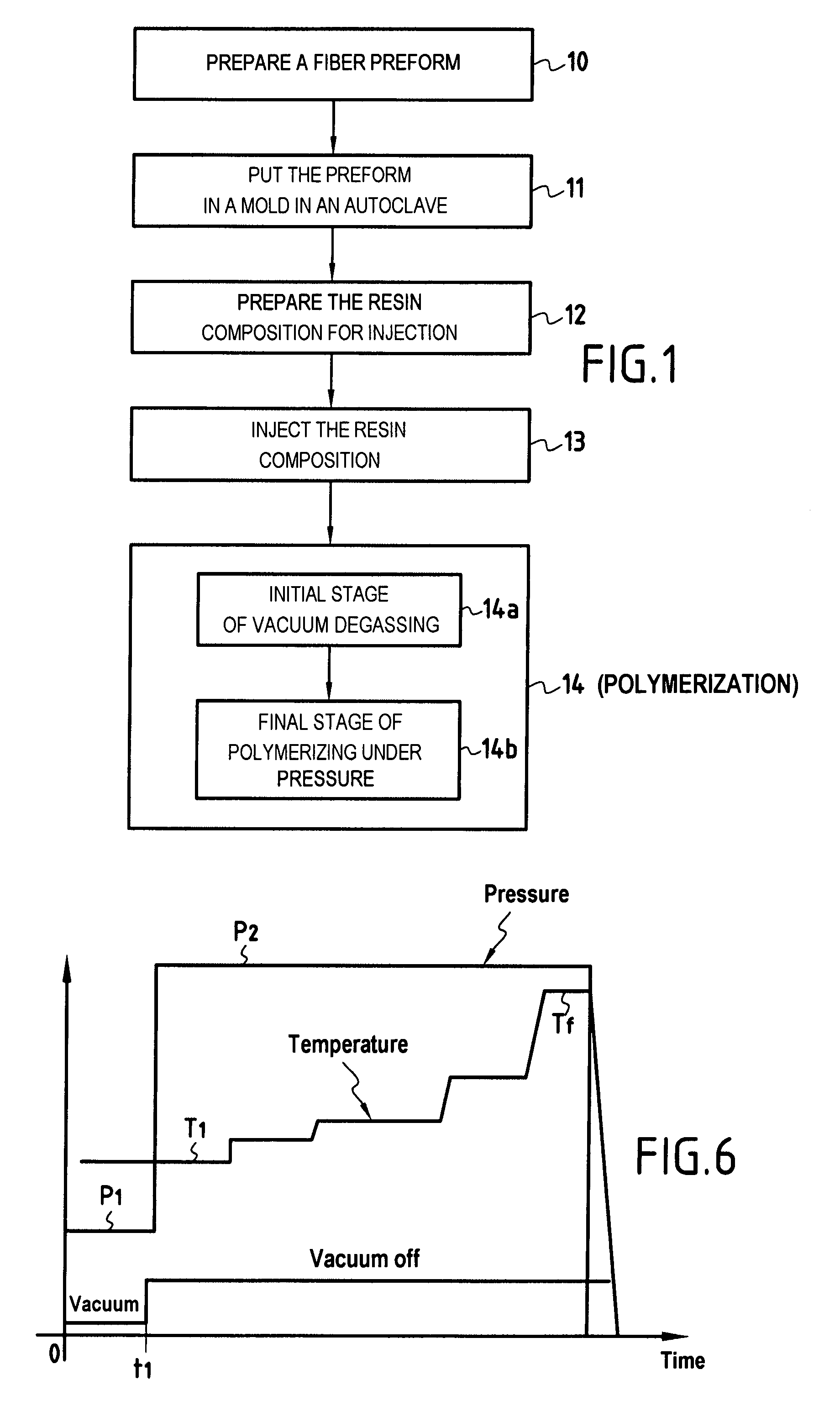

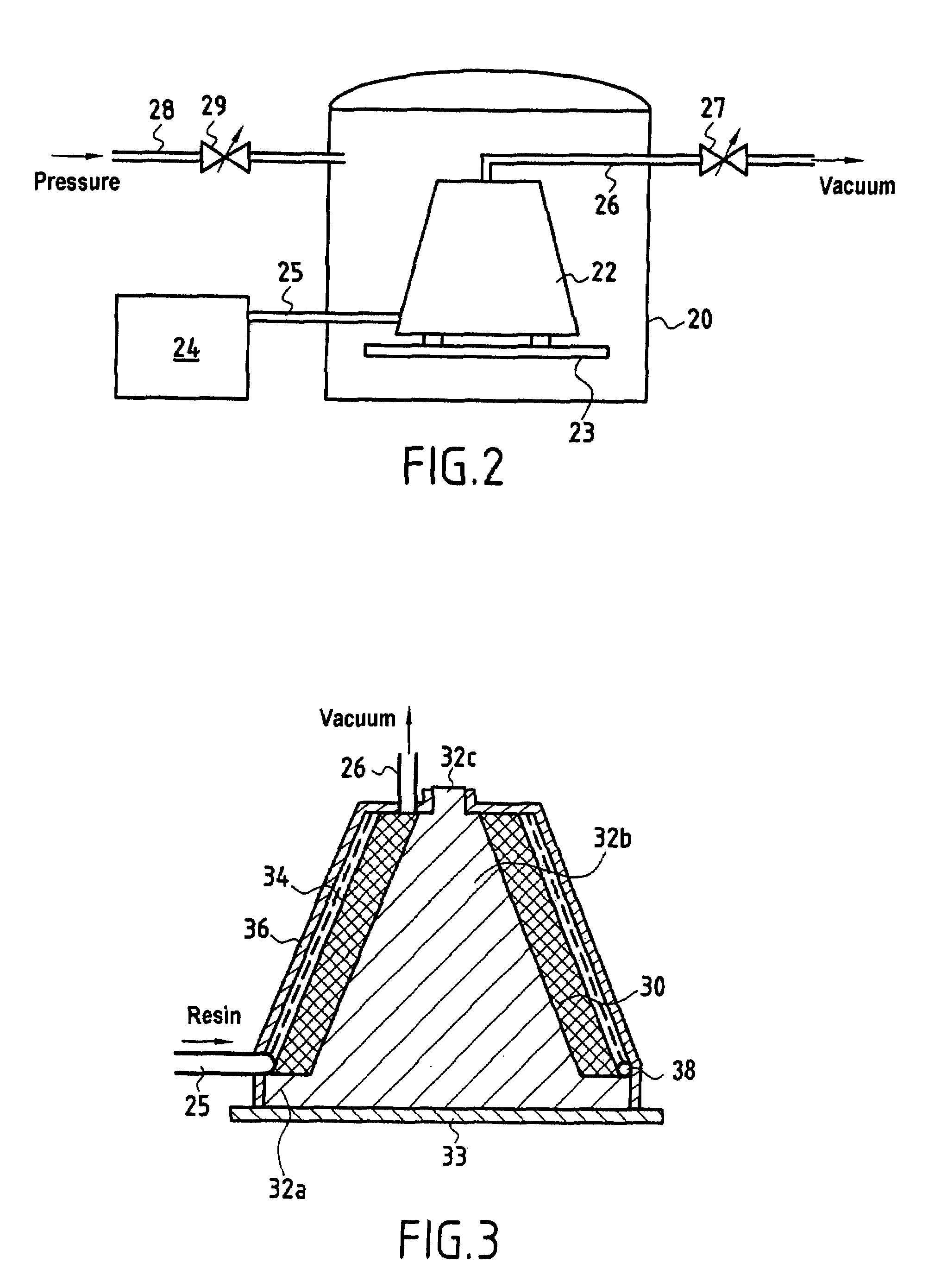

InactiveUS7727448B2Reduce porosityStiffen the fiber structureConfectioneryWood working apparatusShell moldingPolyresin

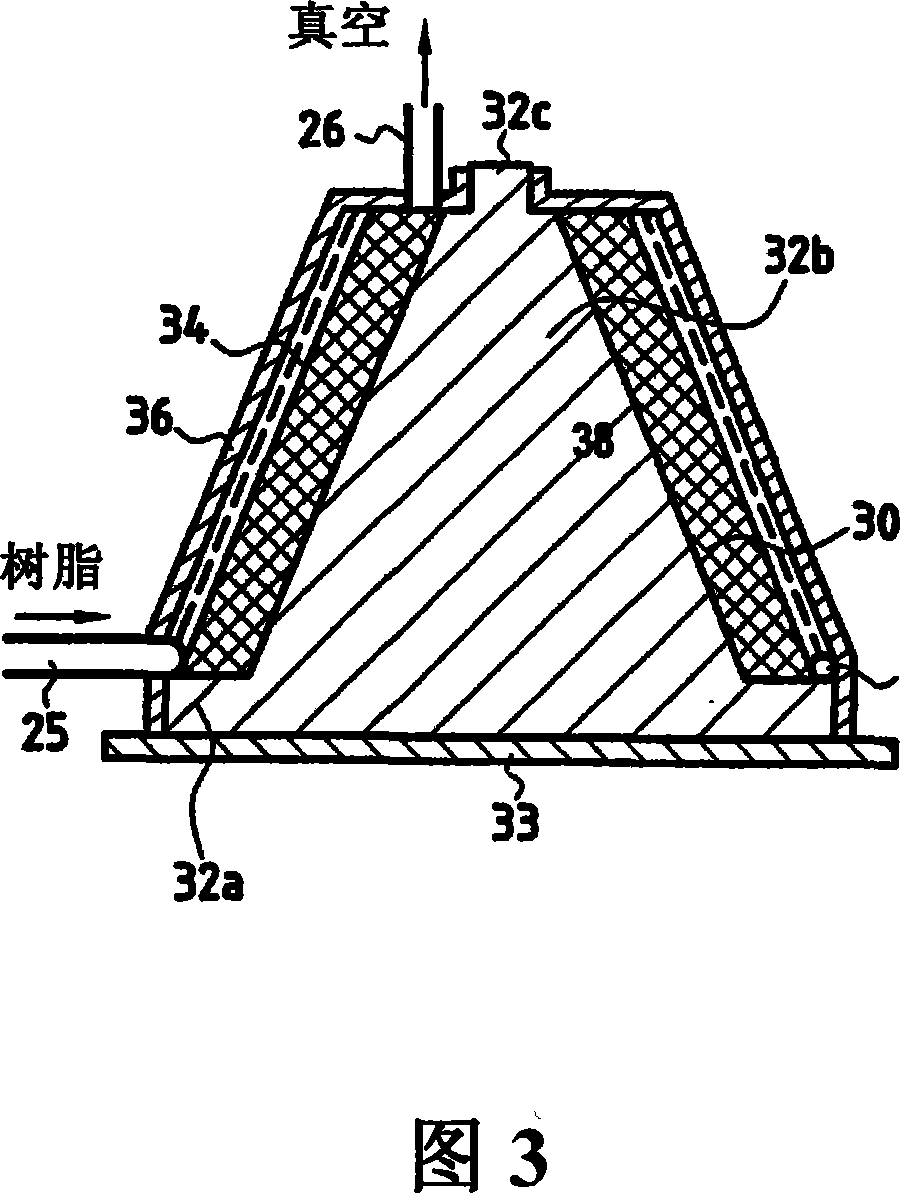

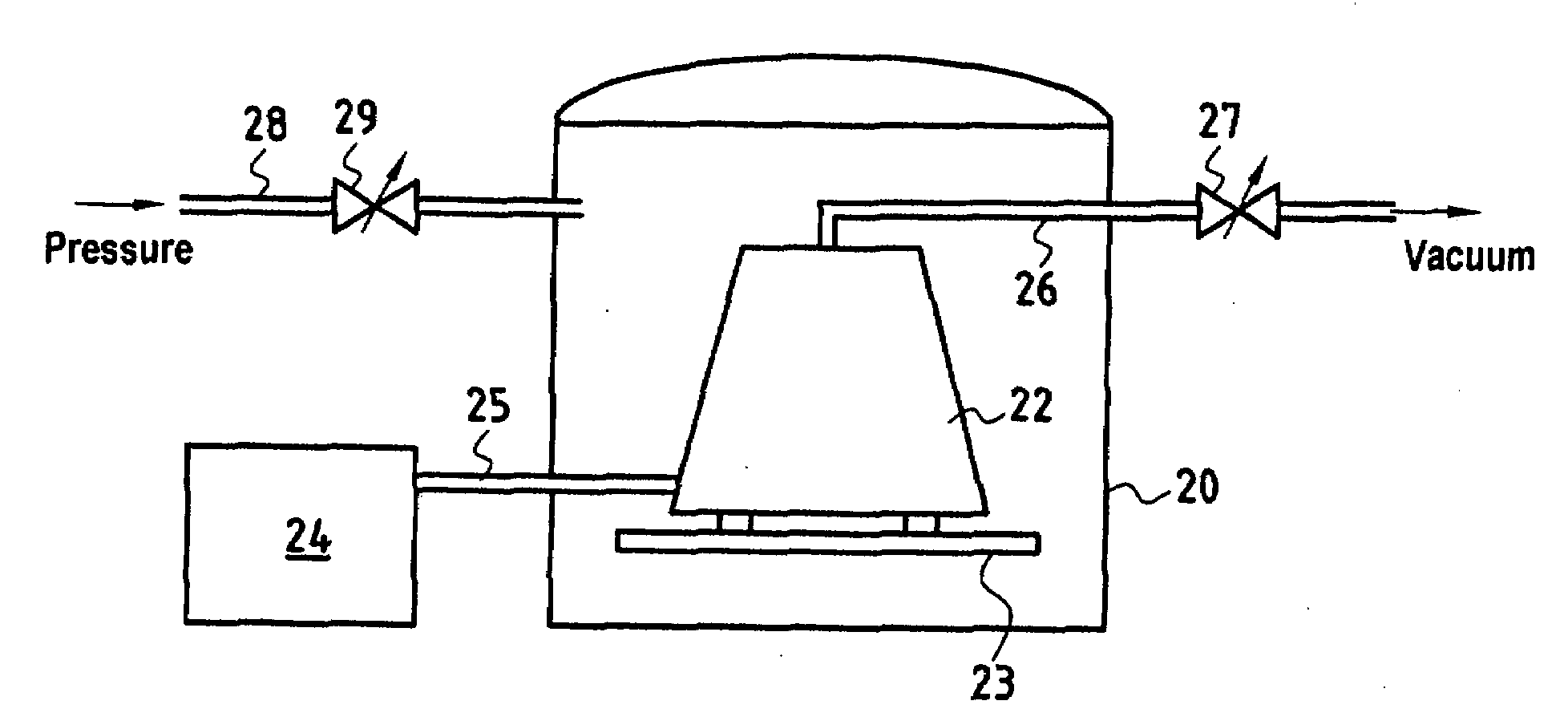

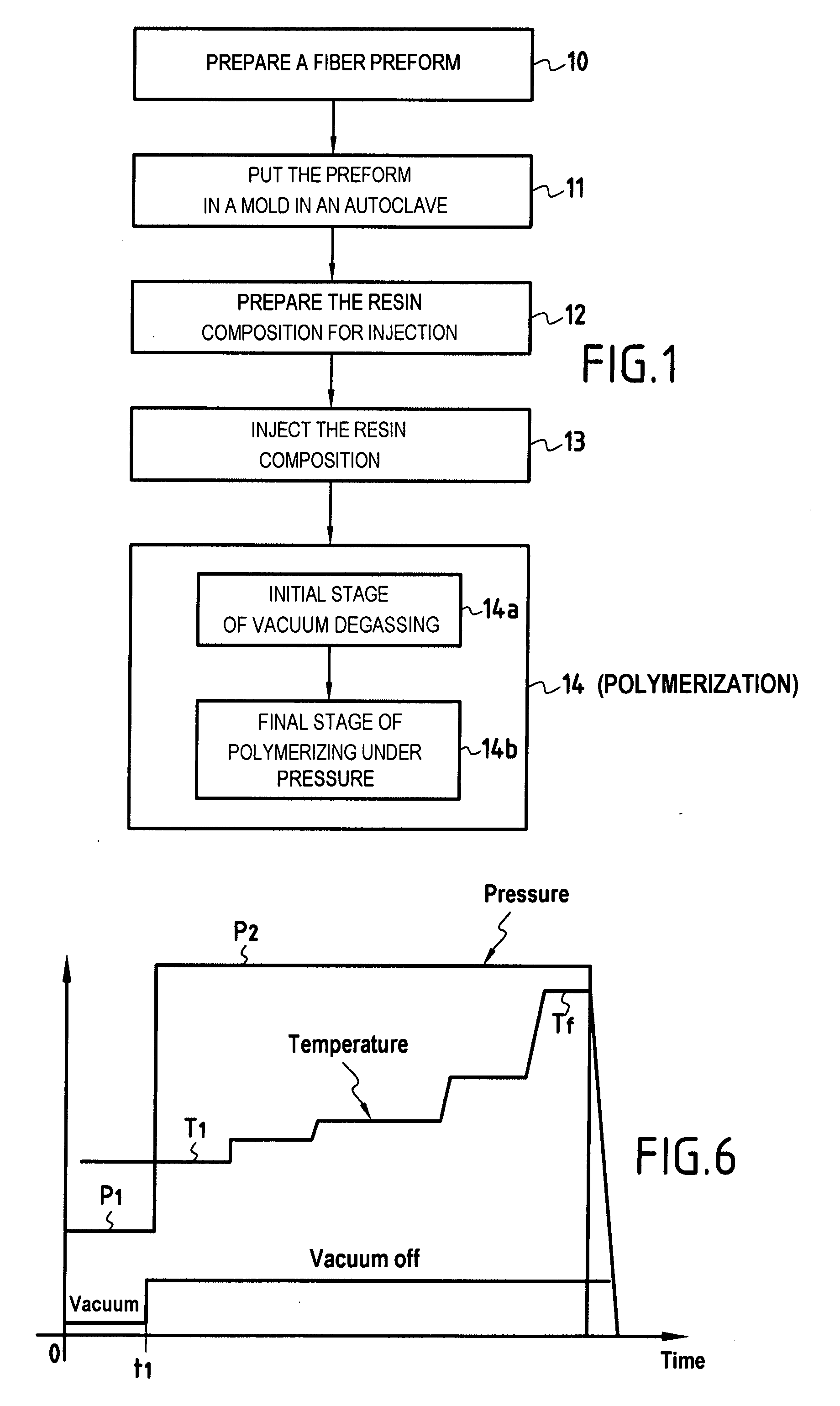

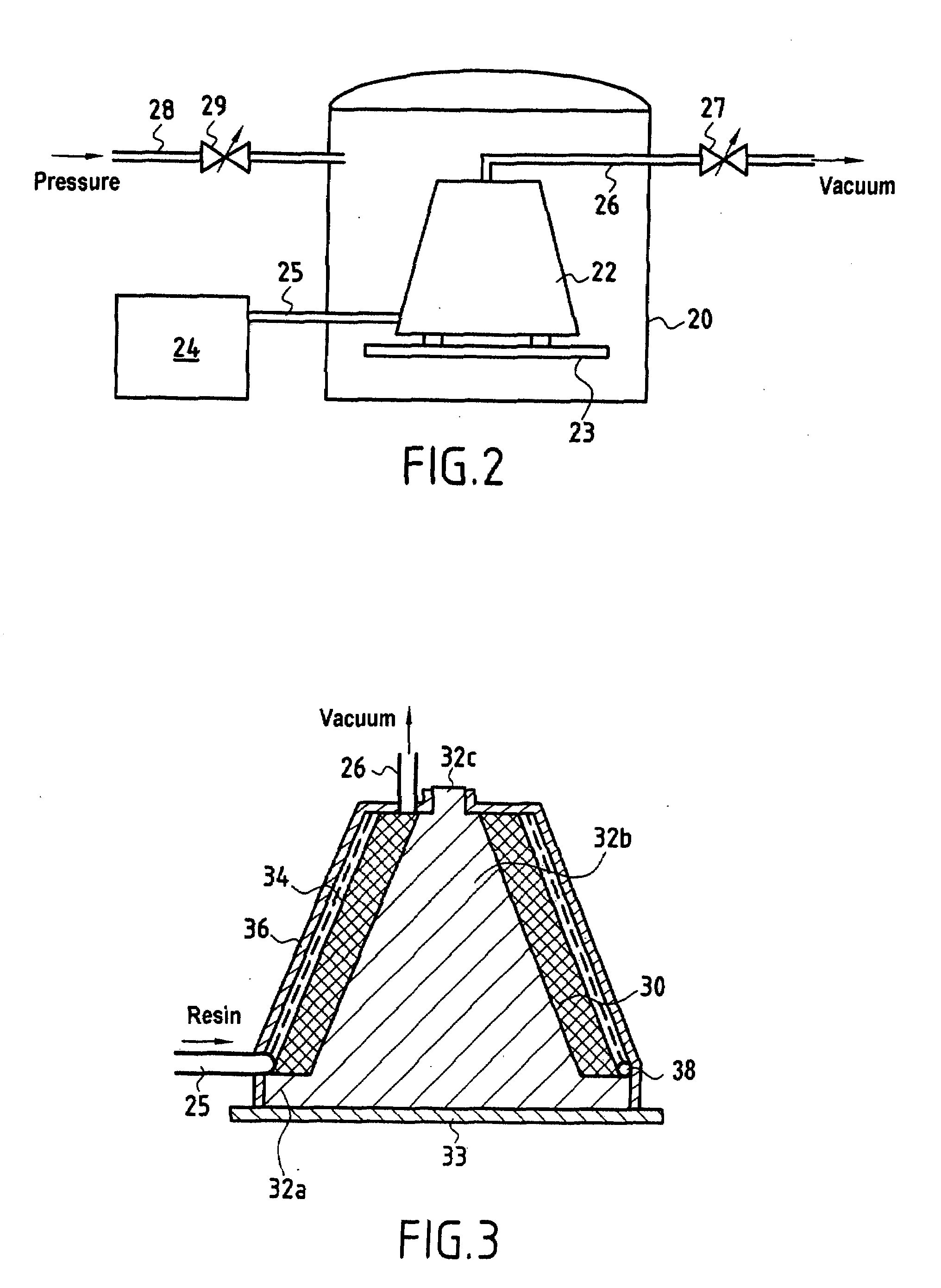

A fiber structure for forming the reinforcement of a part to be made is placed in a mold (22) having at least one wall formed by a flexible membrane, and then a resin composition is injected into the mold, the composition having a volatile material content of less than 25% by weight and being at a temperature of a value such that its viscosity lies in the range 0.1 Pa·s to 0.3 Pa·s. The resin is polymerized in the mold placed in an enclosure (20) with temperature being raised progressively and with polymerization including at least a final stage of polymerization under pressure in order to obtain a composite material part presenting residual porosity of less than 11% by volume.

Owner:GERAKL

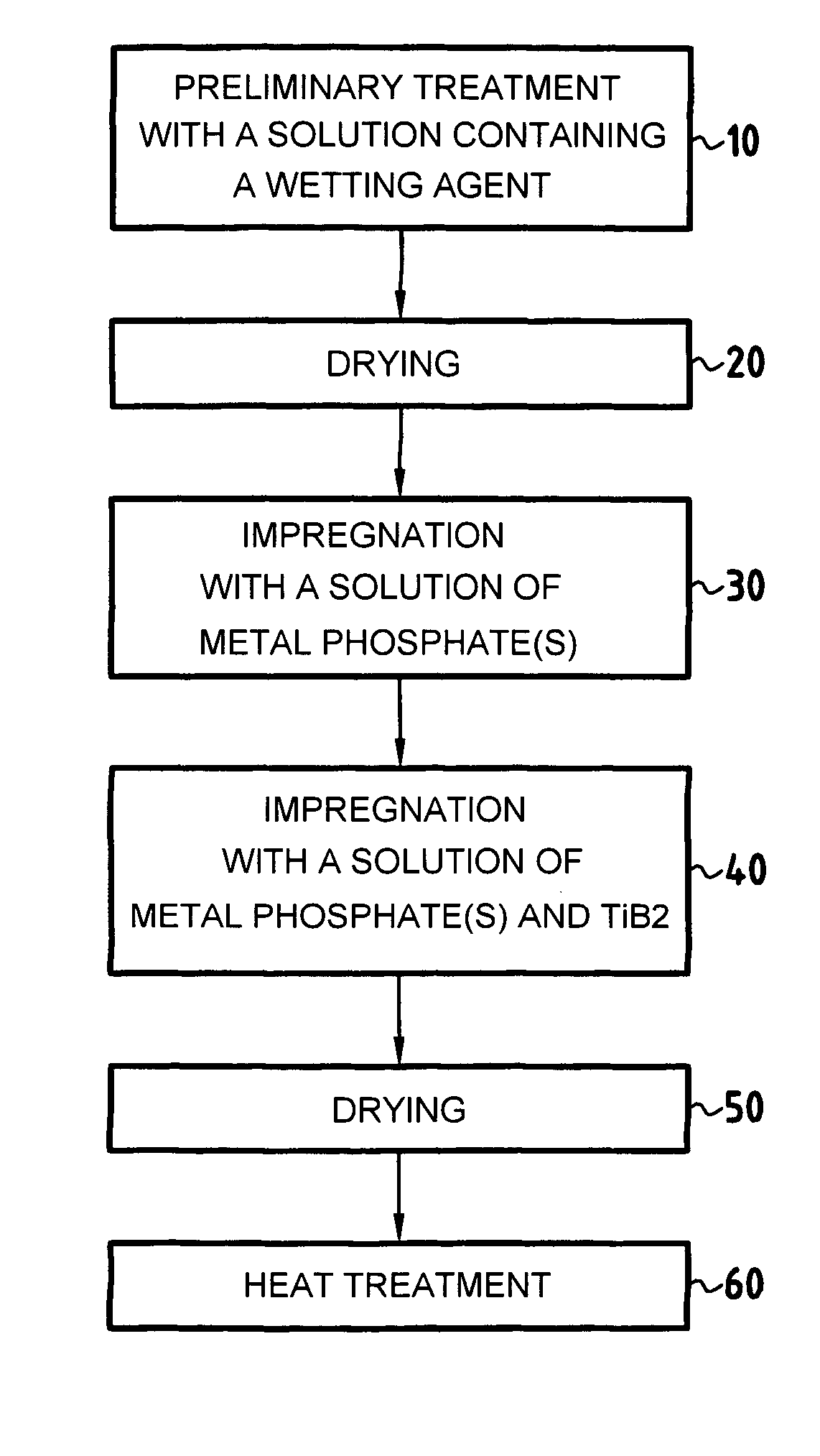

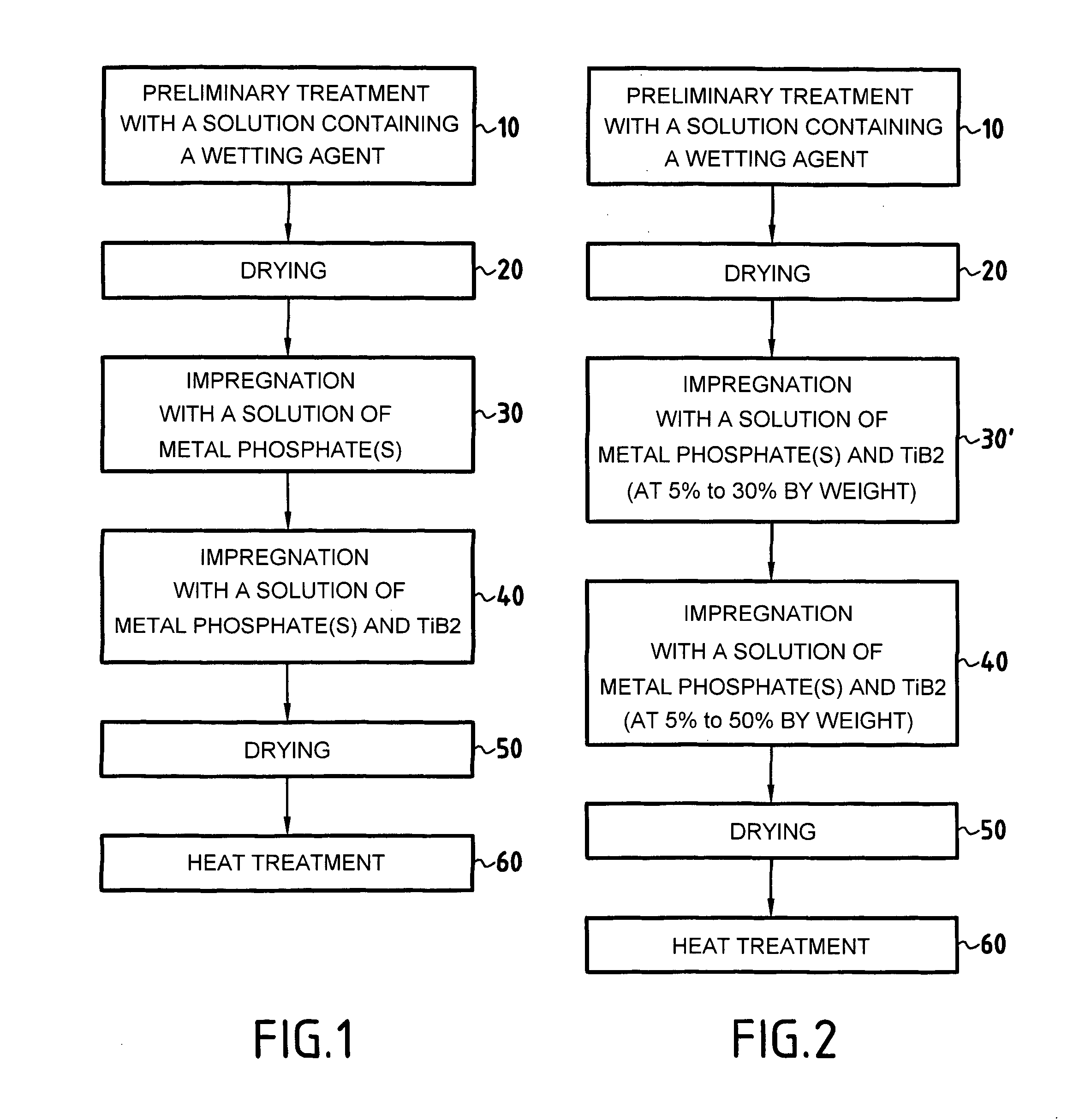

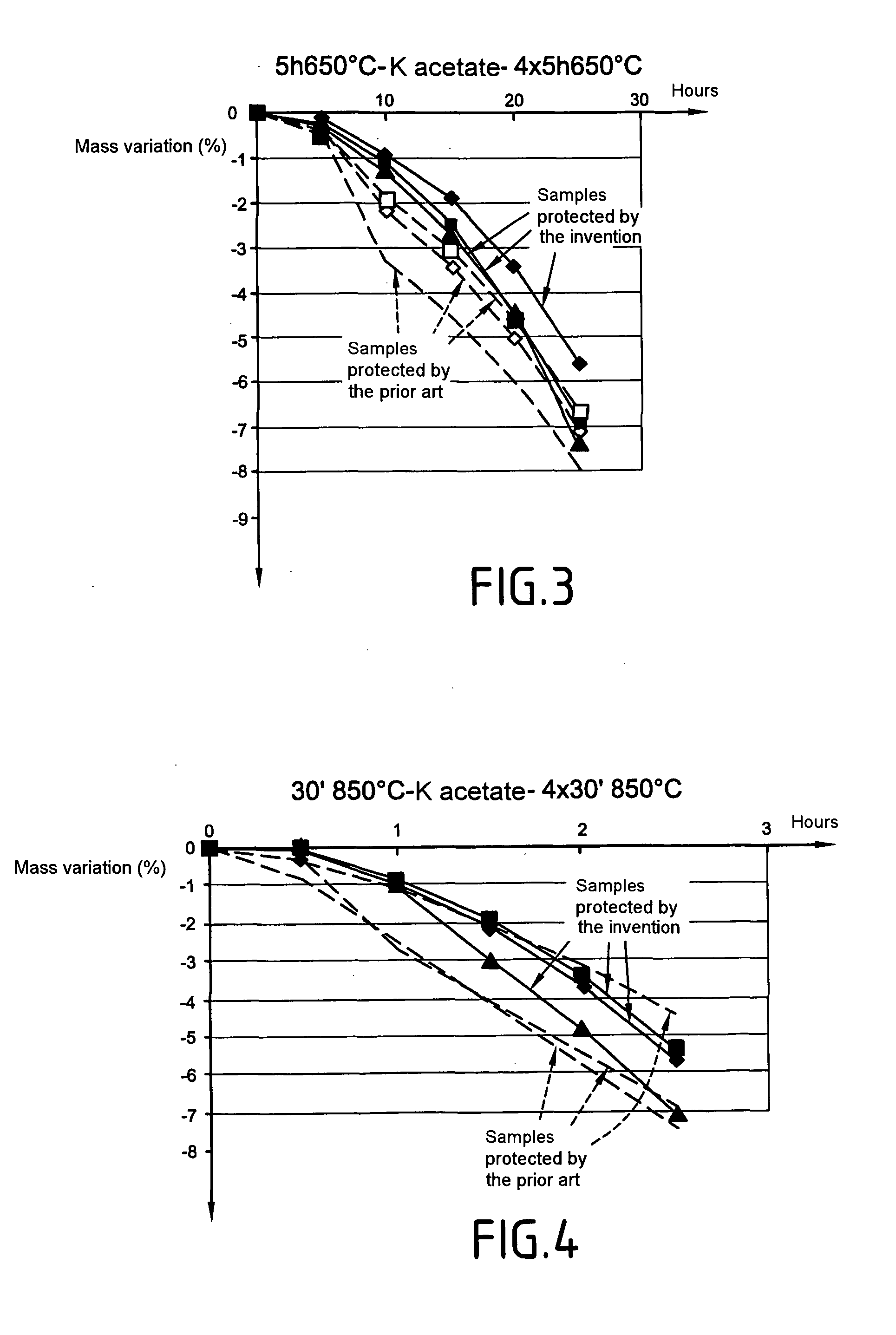

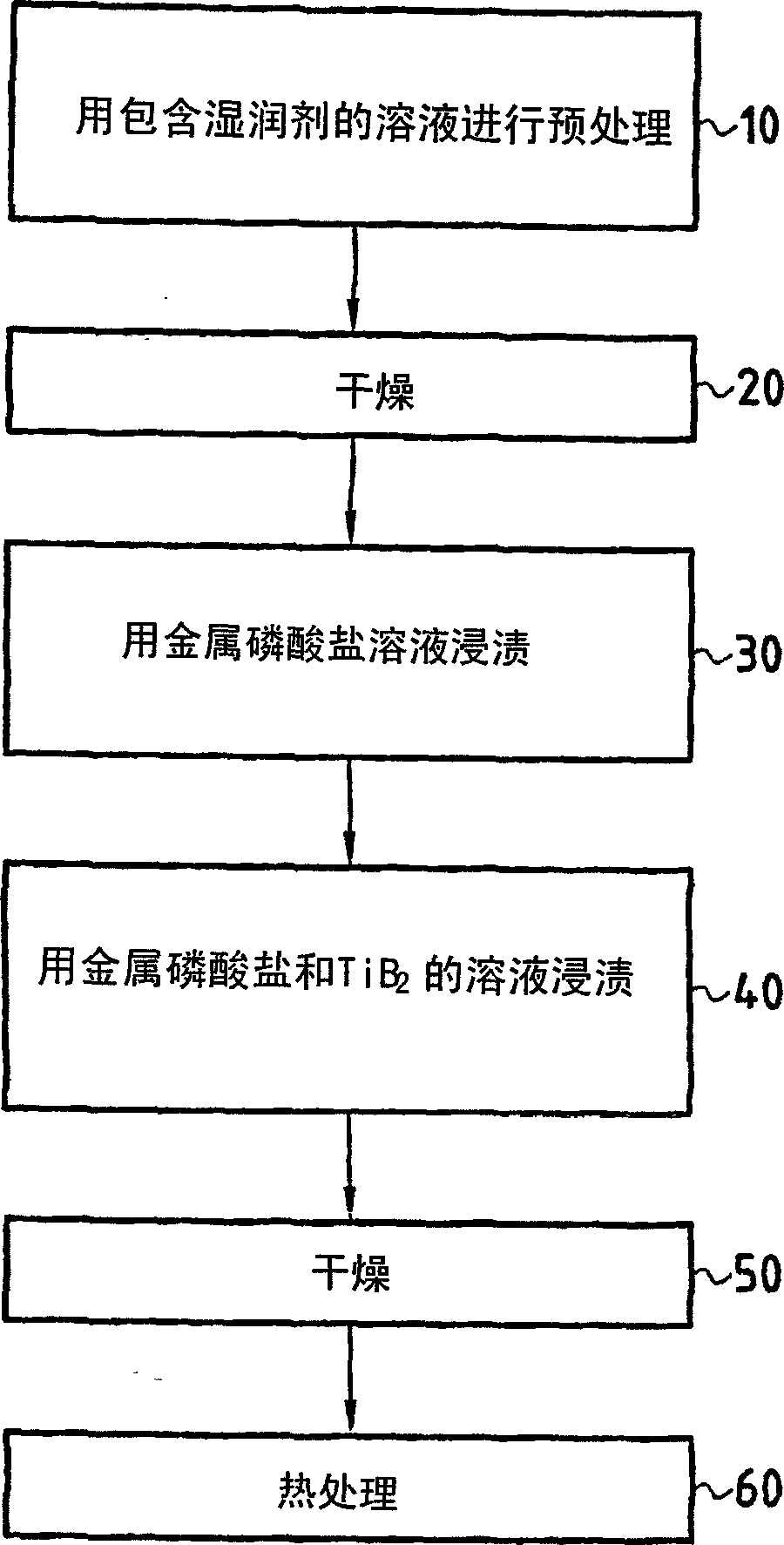

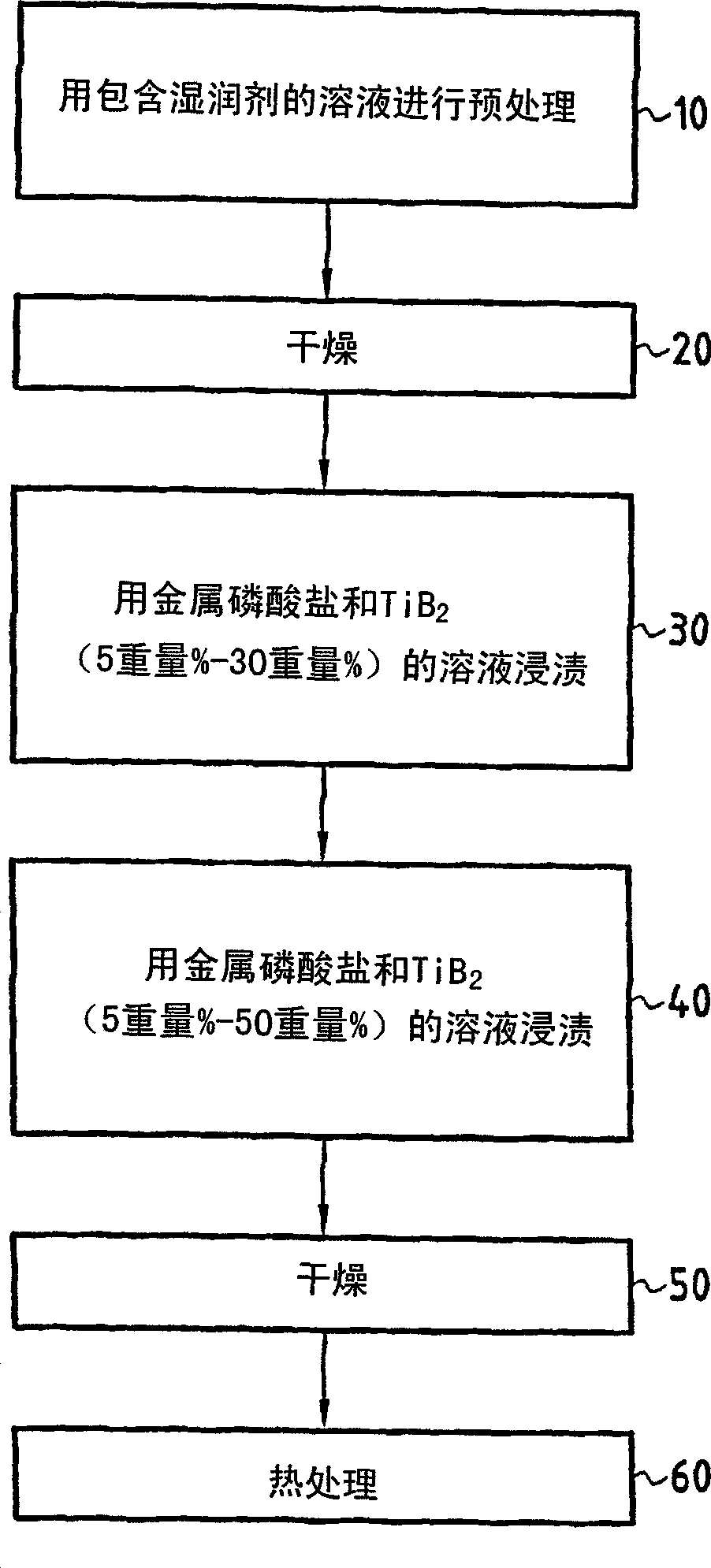

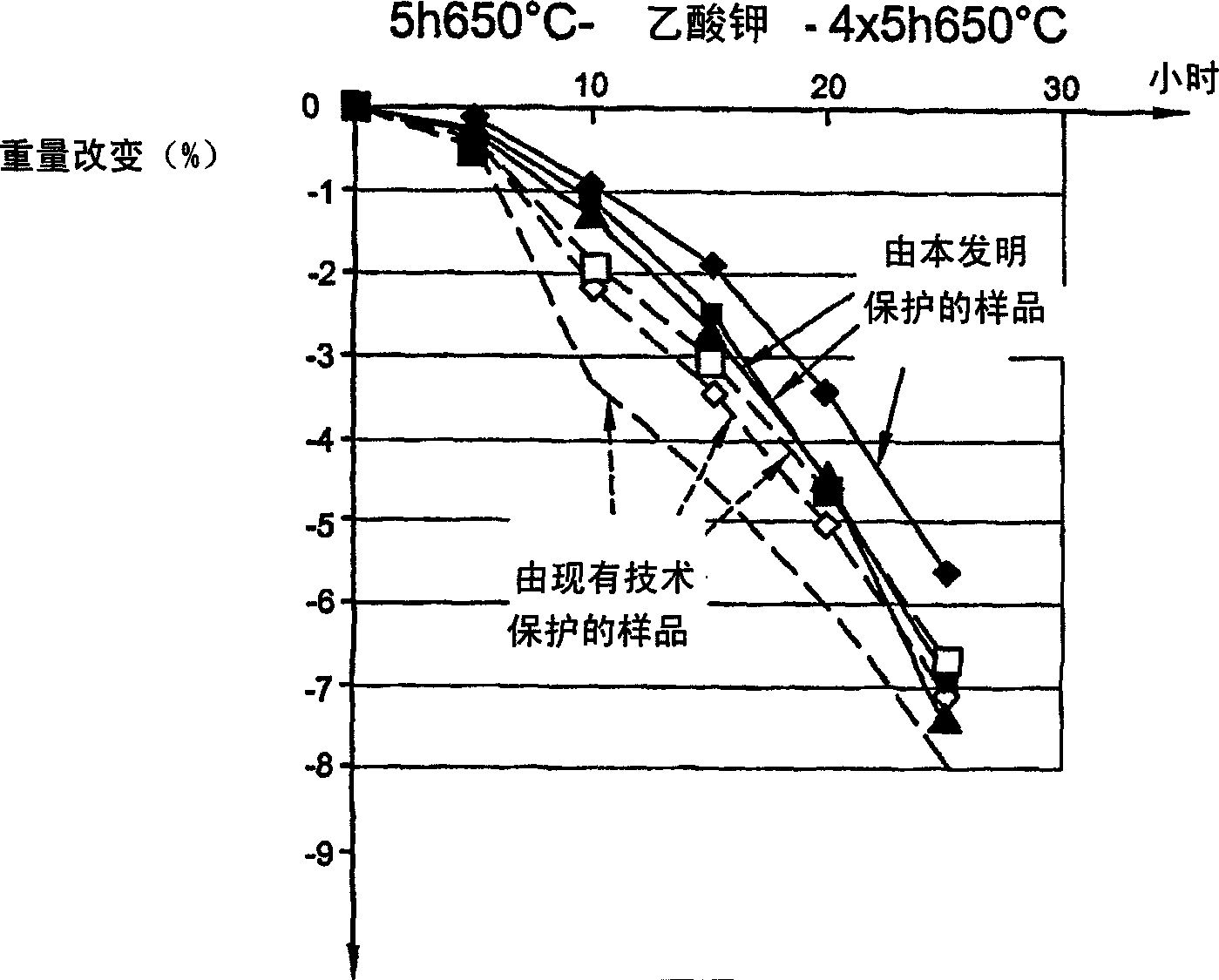

Protection Against the Oxidation of Composite Material Parts Containing Carbon and Parts thus Protected

InactiveUS20070199626A1Easy to implementEfficient methodSolid state diffusion coatingFriction liningCarbon compositesPhosphate

A part made of a composite material containing carbon, having an open internal residual porosity is protected against oxidation by performing at least one stage in which an impregnating composition is applied, said impregnating composition containing at least one metal phosphate and titanium diboride. Efficient protection against oxidation is thus obtained at temperatures of more than 1000° C., also in the presence of a carbon oxidation catalyst and in a damp medium.

Owner:MESSIER BUGATTI INC

Prepregs with improved processing

Systems and methods for the fabrication of prepregs possessing enhanced ability for the removal of gases from within prepregs and prepreg layups prior to and / or during at least a portion of consolidation and cure process to form composite structures are disclosed. In certain embodiments, perforations of selected configurations may be introduced into the prepregs prior to, during, and after layup. The perforations provide routes for gases trapped within and between the perforated prepregs and prepreg lay-ups to escape during consolidation and cure process, reducing the residual porosity within the resulting composite. For example, composites having residual porosities less than 10 vol. %, on the basis of the volume of the composite, may be achieved in this manner.

Owner:CYTEC TECH CORP

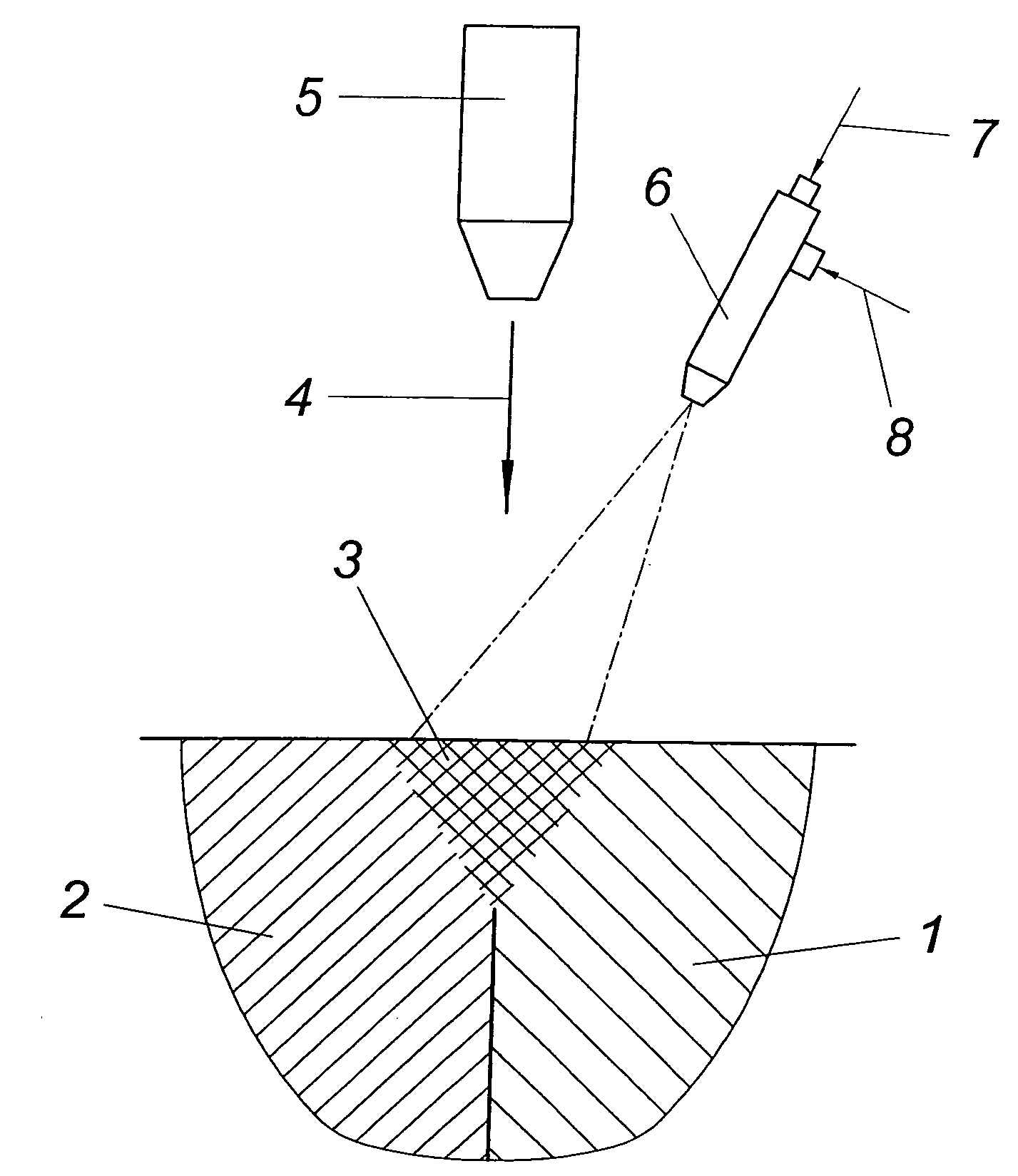

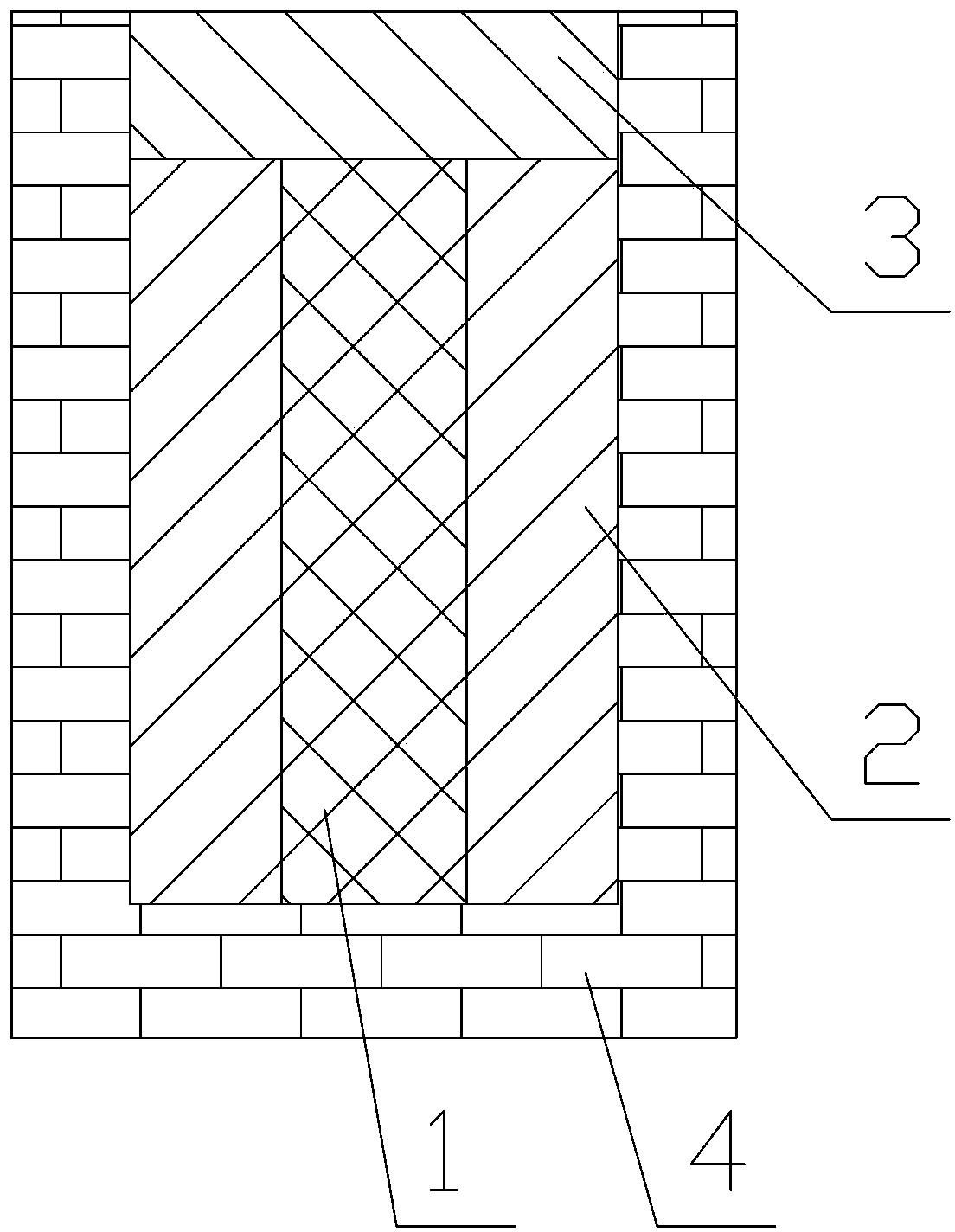

Preparation method for metal-based ceramic composite material grinding roller of vertical grinding machine

ActiveCN103736549AImprove wear resistanceExtended service lifeGrain treatmentsIron powderCeramic composite

The invention provides a preparation method for a metal-based ceramic composite material grinding roller of a vertical grinding machine. A grinding roller base body is sleeved with a roller sleeve which is composed of a high-chromium alloy lining plate and a ceramic lining plate made of a metal-based ceramic enhanced material, wherein the metal-based ceramic enhanced material is composed of 10%-40% of corundum and 60%-90% of iron powder; the high-chromium alloy lining plate and the ceramic lining plate, and the roller sleeve and the grinding roller base body are solidified into a whole body by pouring steel liquid; the preparation method of the grinding roller comprises the following steps: when the corundum and the iron powder are mixed and combusted until the iron powder is completely smelted, the mixture of the corundum and the iron powder is put into a mould for preparing the ceramic lining plate; the ceramic lining plate is placed in a groove in the high-chromium alloy lining plate and the steel liquid is poured to prepare the roller sleeve; the grinding roller base body is sleeved with the roller sleeve and the steel liquid is poured so that the roller sleeve and the grinding roller base body are solidified into the whole body. According to the preparation method, the steel liquid can be immersed into ceramic grains in the ceramic lining plate and covers the ceramic grains so that a ceramic phase and a metal phase are uniformly distributed; the residual porosity after baking is reduced and the wear resistance is high.

Owner:洛阳鹏飞耐磨材料股份有限公司

Densification of fibrous structures by resin transfer moulding for making thick parts of composite material

The invention relates to a method of placing a reinforced fiber structure for forming a part to be manufactured in a mold (22) having at least one wall formed by a flexible film and injecting a resin composition into the mold , the composition has a volatile material content of less than 25% by weight and allows a temperature value of its viscosity in the range of 0.1 Pas to 0.3 Pas. The polymerisation of the resin is carried out in a mold placed inside a hood (20), with a gradual increase in temperature and comprising at least one final polymerisation stage under pressure, in order to obtain a resin composed of Components made of composite materials.

Owner:GERAKL

Densification of Fibrous Structures by Resin Transfer Moulding for Making Thick Parts of Composite Material

InactiveUS20080128938A1Reduce decreaseReduce porosityConfectioneryWood working apparatusShell moldingViscosity

A fiber structure for forming the reinforcement of a part to be made is placed in a mold (22) having at least one wall formed by a flexible membrane, and then a resin composition is injected into the mold, the composition having a volatile material content of less than 25% by weight and being at a temperature of a value such that its viscosity lies in the range 0.1 Pa·s to 0.3 Pa·s. The resin is polymerized in the mold placed in an enclosure (20) with temperature being raised progressively and with polymerization including at least a final stage of polymerization under pressure in order to obtain a composite material part presenting residual porosity of less than 11% by volume.

Owner:GERAKL

Method for manufacturing fully dense metal sheets and layered composites from reactive alloy powders

InactiveUS7566415B2Improve mechanical propertiesReduce residual porosityIncreasing energy efficiencyWelding/cutting media/materialsTi 6al 4vVolumetric Mass Density

Owner:ADVANCED MATERIALS PRODS

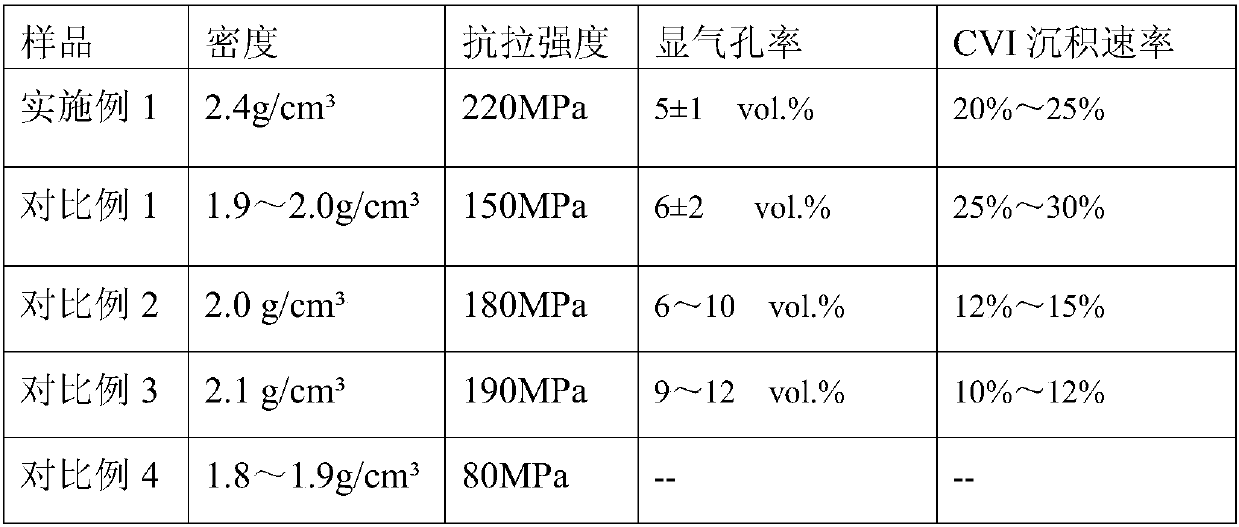

Preparation method of long-fiber carbon ceramic fastener

The invention provides a preparation method of a long-fiber carbon ceramic fastener. The method comprises the following steps: alternately laying long-fiber non-weave cloth and short-fiber mesh tire,wherein the included angle between every two adjacent layers of long-fiber non-weave cloth is 90 degrees along the fiber direction, needling for once when each layer of short-fiber mesh tire is laid,and weaving a three-dimensional needled preform; densifying the obtained preform to 1.4-1.5g / cm<3> in precursor gas by means of pressure differential chemical vapor permeation to obtain a C / C complex;then, carrying out high-temperature heat treatment in protective gas; finally, putting the product into silicon powder, and carrying out high-temperature melting silicon infiltration, and machining and molding to obtain the long-fiber carbon ceramic fastener with the density of 2.2-2.4g / cm<3>. The preparation method provided by the invention is short in preparation period, low in residual porosity, rapid in densifying amplitude, low in cost and environmentally-friendly; the prepared carbon ceramic fastener is high in strength and volume density and better in high temperature resistance and corrosion resistance.

Owner:山东道普安制动材料有限公司

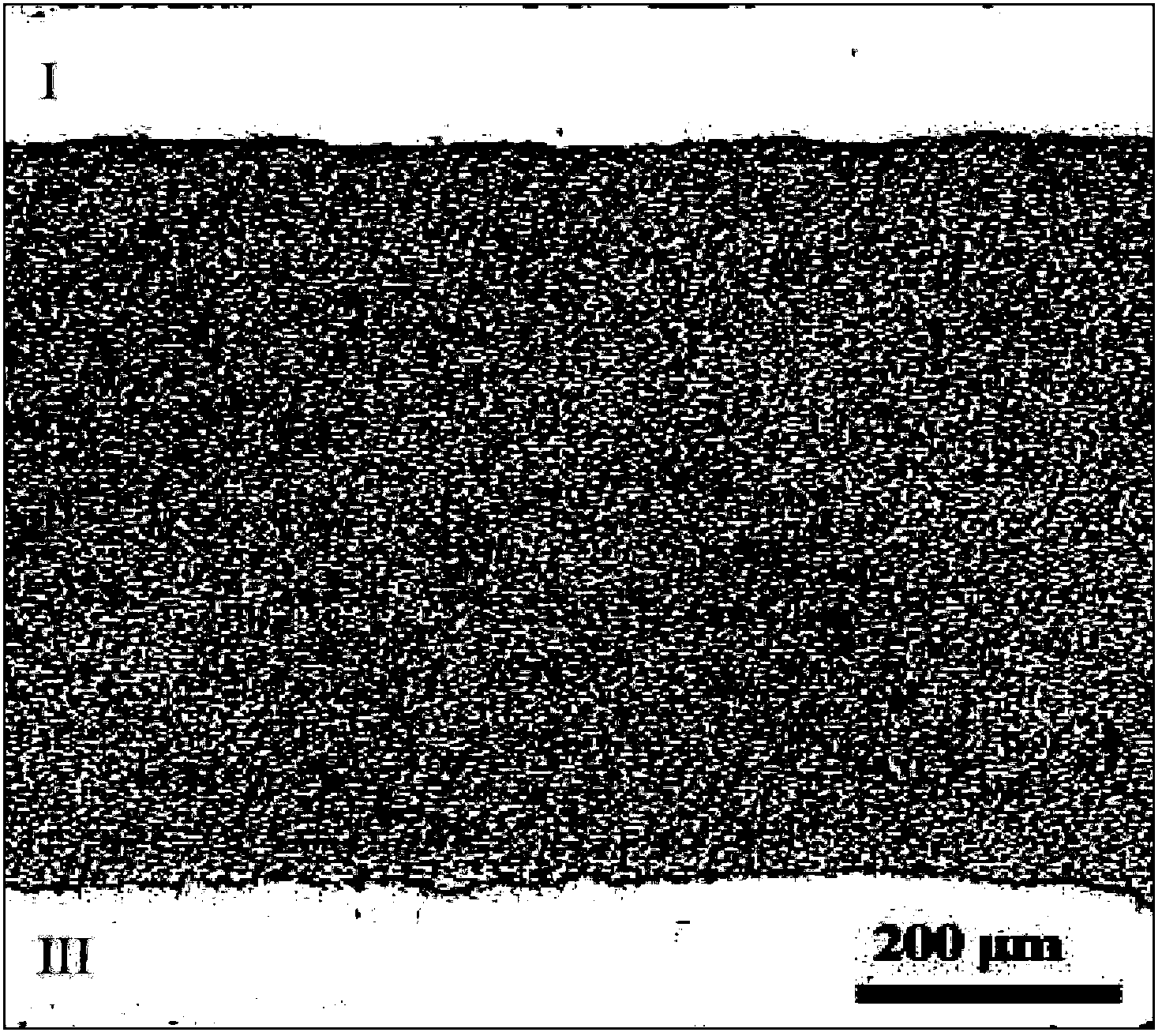

Method for preparing Cu/MoCu/Cu three-layer composite plate blank

ActiveCN103143714AControl the amount of infiltrationAccurate control of copper contentMetal layered productsHydrogen atmosphereCopper

The invention provides a method for preparing a Cu / MoCu / Cu three-layer composite plate blank. The method comprises the following steps of: I, evenly mixing molybdenum powder with copper powder to obtain molybdenum-based composite powder; II, pressing the molybdenum-based composite powder into a molybdenum-based composite plate blank by adopting an oil press; III, paving the molybdenum-based composite plate blank between two first copper plates to form a composite plate, then, putting the composite plate in a graphite crucible, and paving a second copper plate at the top part of the composite plate; and IV, performing infiltration under the protection of a hydrogen atmosphere, and performing surface coping treatment after furnace cooling to obtain the Cu / MoCu / Cu three-layer composite plate blank. The method for preparing the Cu / MoCu / Cu three-layer composite plate blank is short in process route and low in processing cost. An infiltration process and a composite process can be finished simultaneously, and therefore, the Cu / MoCu / Cu three-layer composite plate blank is prepared at one step. The Cu / MoCu / Cu three-layer composite plate blank prepared by adopting the method provided by the invention is strong in interface bonding force, low in residual porosity and easily controllable and adjustable in copper content, and is suitable for large-scale industrial production.

Owner:西安宝德九土新材料有限公司

Compact quartz sandstone porosity recovery simulating method

InactiveCN108363115ASave human effortSave material costGeological measurementsMathematical modelQuartz

The invention provides a compact quartz sandstone porosity recovery simulating method. According to the invention, a compact quartz sandstone porosity compaction model in an early diagenesis phase isestablished; a compact quartz sandstone cementing contraction model is established; a compact quartz sandstone acidification pore retaining model is established; compact quartz sandstone porosity recovery simulation is performed, stage division is performed according to diagenesis, boundary conditions of the compaction model and the cementing model are found, an acidification window is set, petrography data is input and simulation precision and conditions are set for solving; three influence results are obtained through iteration solution and a simulation result is exported, and a compact quartz sandstone porosity evolutionary process is obtained. According to the invention, by adopting a method for calculating the quartz cementing progress to perfrom simulation study on quartz sandstone porosity, real time modification on residual porosity is performed through porosity mathematic models describing a compaction process and an acidification process, and simulation process proceeds segment by segment through fine analysis on diagenetic stages, so that change of porosity in the diagenetic process is described accurately.

Owner:XI'AN PETROLEUM UNIVERSITY

Protection against the oxidation of composite material parts containing carbon and parts thus protected

A part made of a composite material containing carbon, having an open internal residual porosity is protected against oxidation by performing at least one stage in which an impregnating composition is applied, said impregnating composition containing at least one metal phosphate and titanium diboride. Efficient protection against oxidation is thus obtained at temperatures of more than 1000 DEG C, also in the presence of a carbon oxidation catalyst and in a damp medium.

Owner:SNECMA PROPULSION SOLIDE

Prepregs with improved processing

Systems and methods for the fabrication of prepregs possessing enhanced ability for the removal of gases from within prepregs and prepreg layups prior to and / or during at least a portion of consolidation and cure process to form composite structures are disclosed. In certain embodiments, perforations of selected configurations may be introduced into the prepregs prior to, during, and after layup. The perforations provide routes for gases trapped within and between the perforated prepregs and prepreg lay-ups to escape during consolidation and cure process, reducing the residual porosity within the resulting composite. For example, composites having residual porosities less than 10 vol. %, on the basis of the volume of the composite, may be achieved in this manner.

Owner:CYTEC TECH CORP

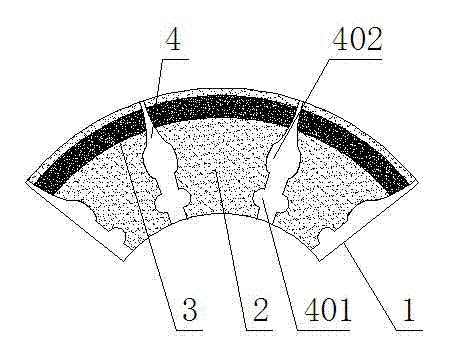

Sintered gearwheel

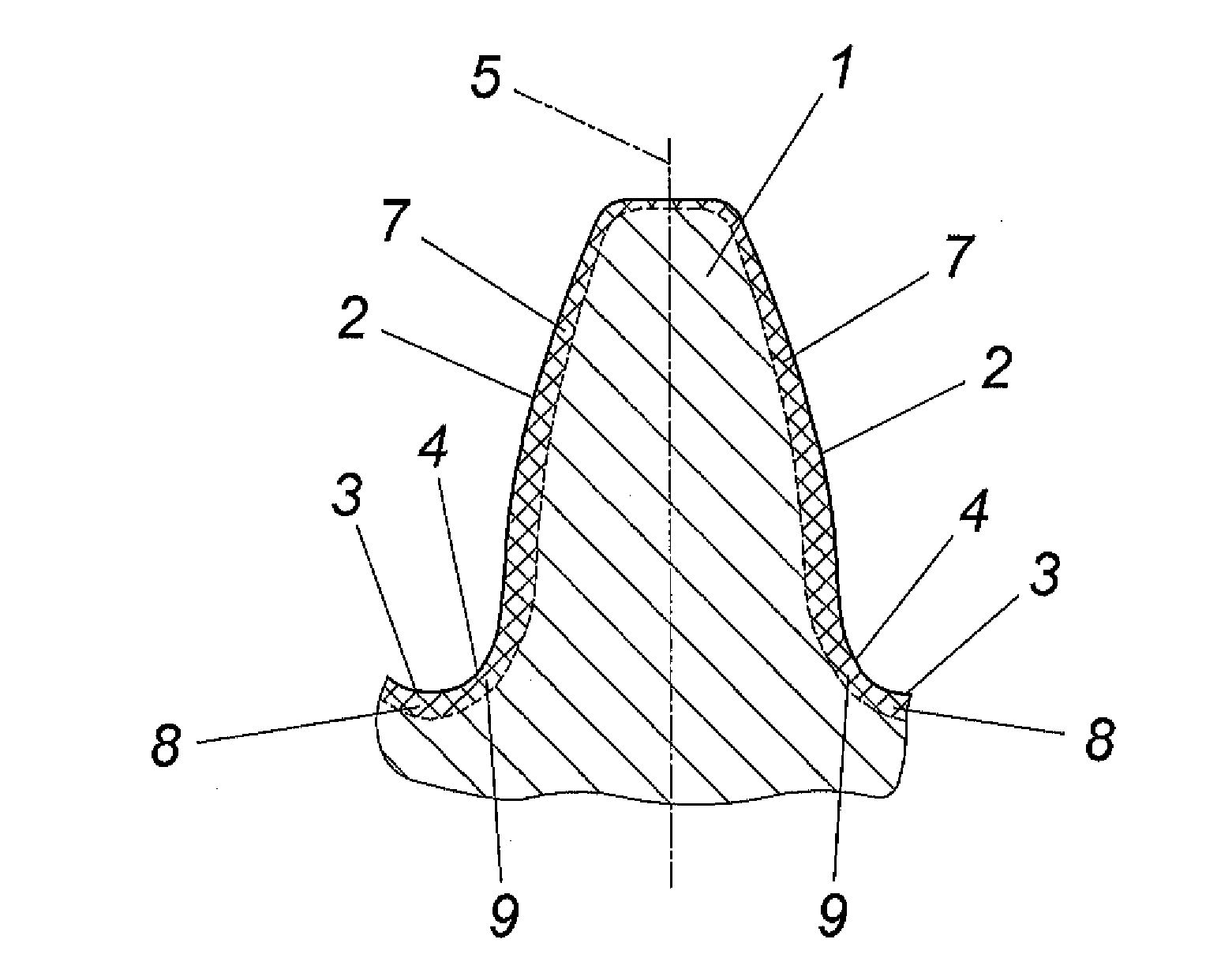

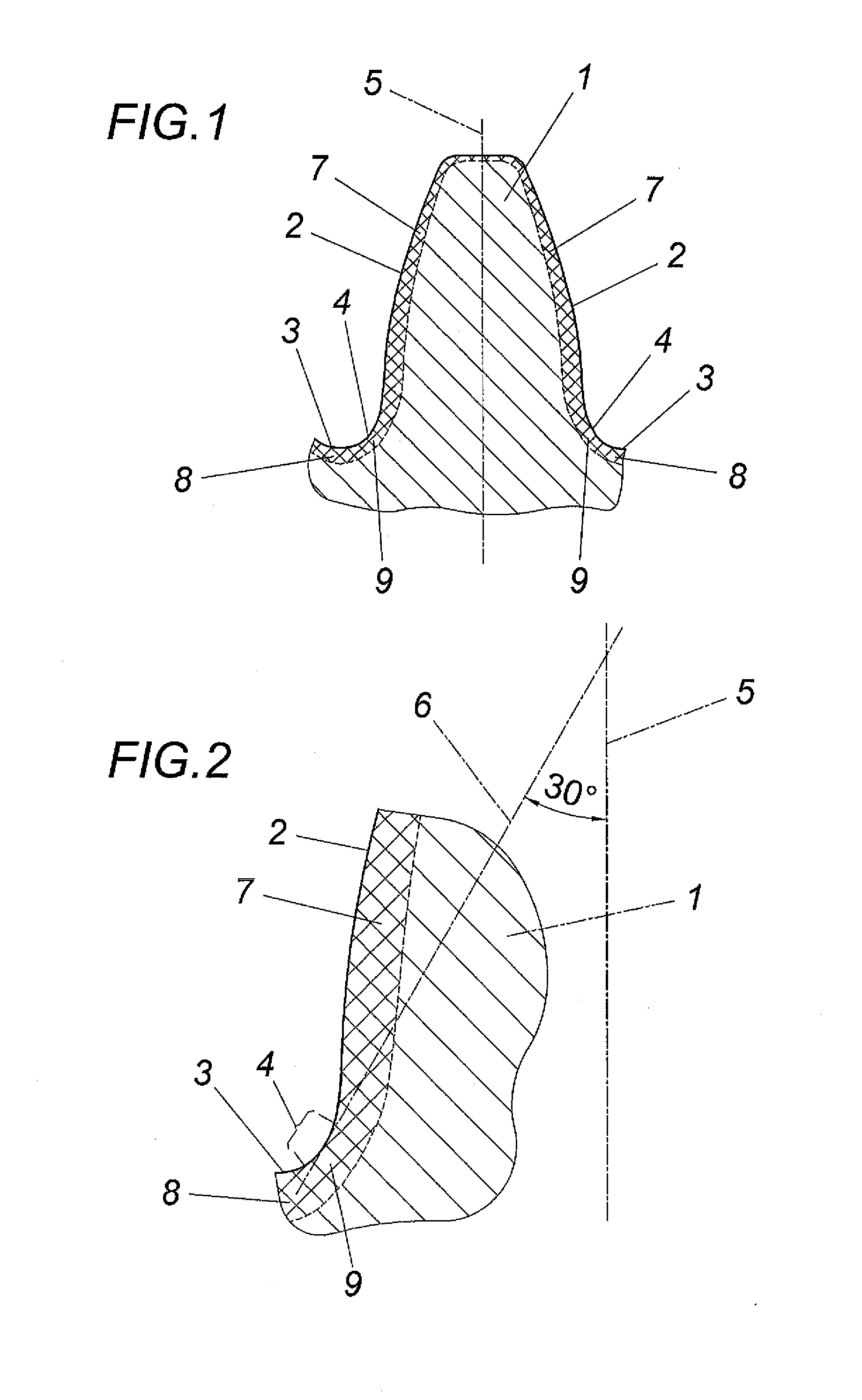

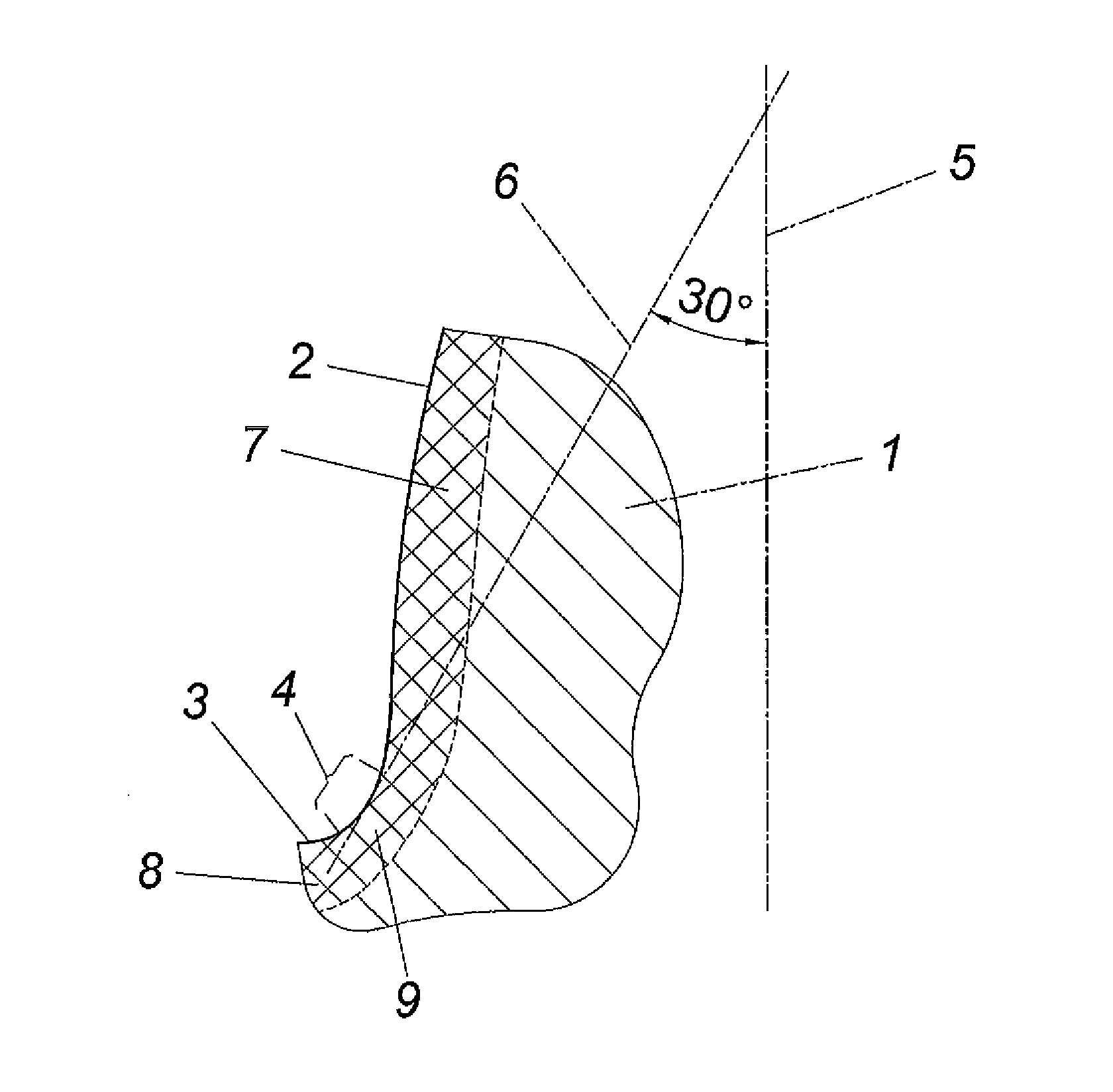

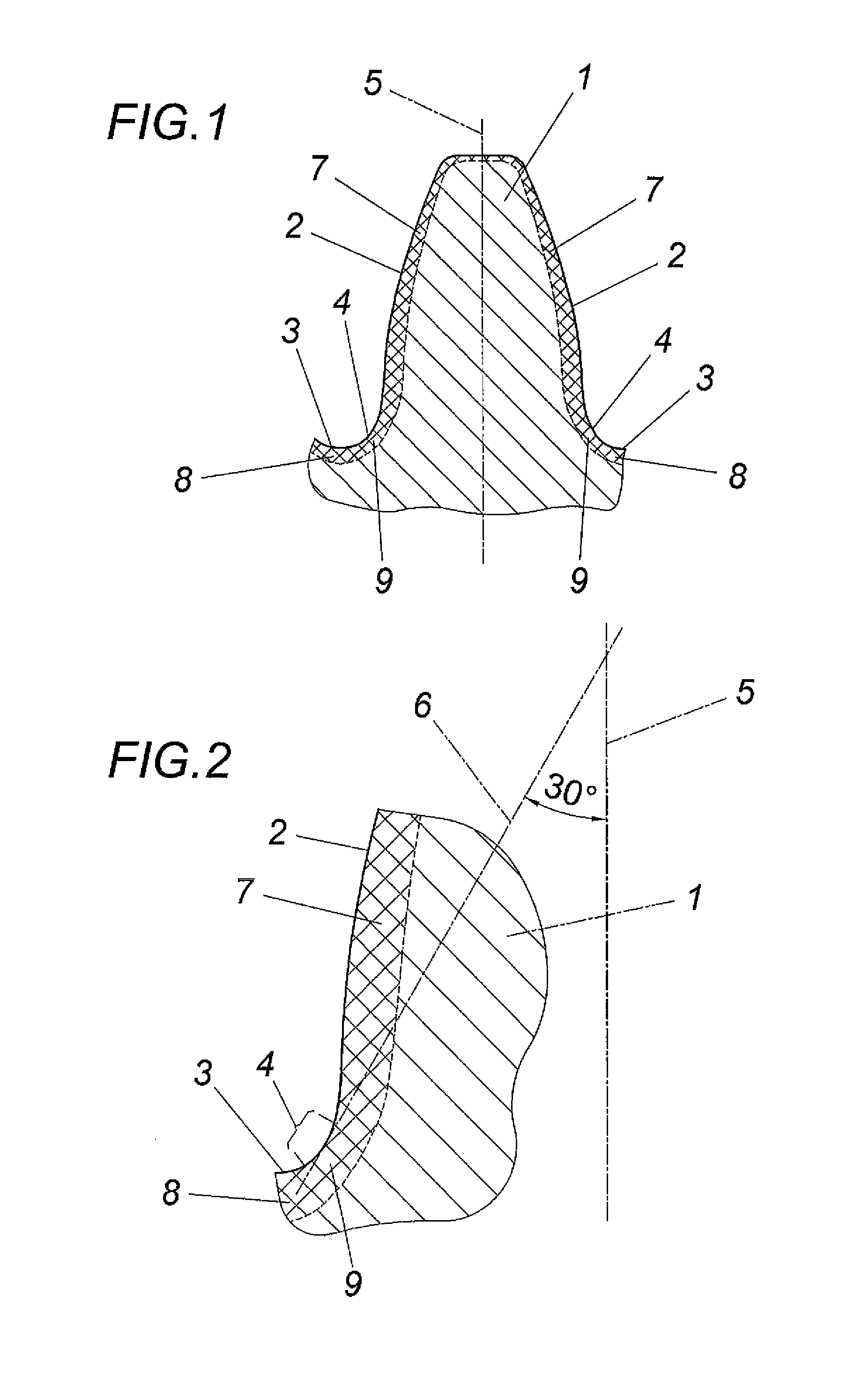

InactiveUS20130008278A1Improve carrying capacityReduce thicknessPortable liftingGear wheelsSurface layerMetallurgy

A sintered gearwheel is described having teeth (1) which, in the flank and root region (2, 3), comprise a compacted surface layer (7, 8, 9) which is continuous in the transition portion (4) between the flank and root region (2, 3) and has a residual porosity of less than 10%. In order to increase the load-bearing capacity it is proposed that the compacted surface layer (9) is formed with a lower thickness in the transitional portion (4) between the flank and root region (2, 3) than in the adjacent flank and root regions (2, 3).

Owner:MIBA SINTER AUSTRIA

Sintered gearwheel

InactiveUS8984981B2Improve carrying capacityReduce thicknessPortable liftingGear wheelsSurface layerMetallurgy

Owner:MIBA SINTER AUSTRIA

Aqueous impregnation bath for reinforcement fibres and uses thereof

The invention relates to an aqueous impregnation bath for reinforcement fibres for manufacturing prepregs having a thermoplastic matrix, resulting in highly satisfactory consolidation, in terms of residual porosity, of the composite material parts manufactured using the prepregs. The impregnation bath includes a least one thermoplastic polymer, a surfactant and water, and is characterised in that the surfactant is an ethoxylated stearyl alcohol of formula: HO—(CH2—CH2—O)n—CH2—(CH2)16—CH3 wherein n is 100. The invention also relates to a method for impregnating reinforcement fibres using the impregnation bath, to a method for manufacturing a prepreg having a thermoplastic matrix using the impregnation method, and to a method for manufacturing a part made of a composite material having a thermoplastic matrix using the method for manufacturing a prepreg. The invention is useful in any field for manufacturing parts made of composite materials and, specifically, in the aeronautical, space, rail, shipping and automotive industries.

Owner:ARIANEGRP SAS

Manufacturing method of positive plate of fiber-type cadmium-nickel storage battery

InactiveCN105322142ALarge remaining porosityReduce weightAlkaline accumulator electrodesNitrateNickel substrate

The invention discloses a manufacturing method of a positive plate of a fiber-type cadmium-nickel storage battery. The method comprises the following steps: (1) selecting a fiber nickel substrate; (2) preparing a nickel nitrate solution and a sodium hydroxide solution; (3) putting the fiber nickel substrate into a vacuum tank through a dipping rack, opening a vacuum pump to vacuumize the vacuum tank, opening a corresponding transfer valve to pump the nickel nitrate solution which is insulated in a dissolving tank into the vacuum tank by the vacuum pump after vacuumizing, closing a vacuum valve and opening an air inlet valve when an upper limit of the liquid level is reached; (4) closing the air inlet valve; (5) opening the air inlet valve, and introducing air into a nickel nitrate vacuum dipping tank, loosening a screw of the dipping tank, opening an upper cover, and hoisting the dipping rack; and (6) putting the dipping rack which is hoisted out from the nickel nitrate vacuum dipping tank into a mercerization tank by a crane, sequentially putting the mercerized dipping rack into four washing tanks by the crane and opening circulating water in the washing process; and (7) circulating the steps, measuring the increment in weight and finishing preparation after reaching the requirements. The manufactured positive plate has the advantages of high residual porosity, no fines removal, light weight and high charging efficiency.

Owner:河南新太行电源股份有限公司

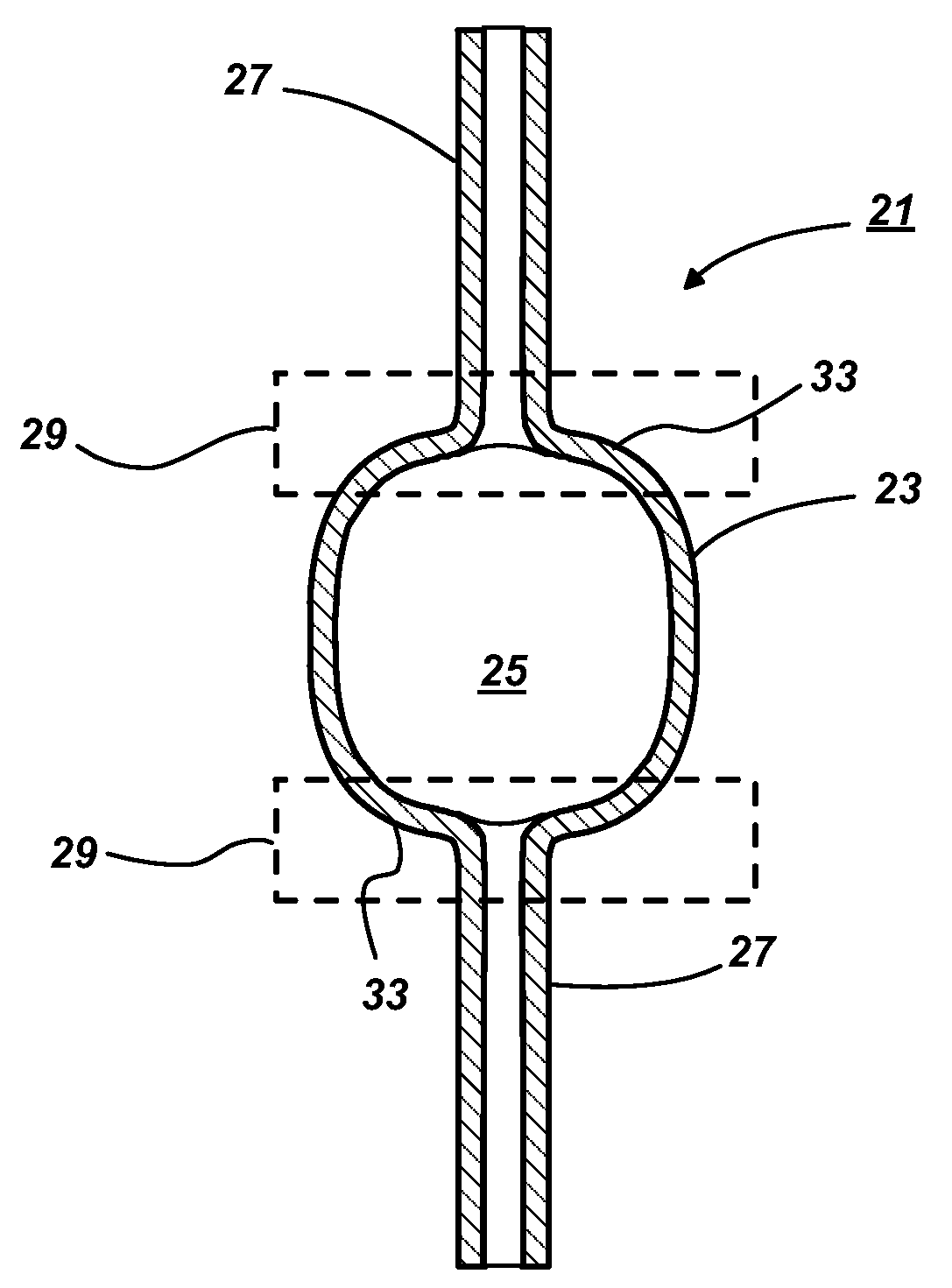

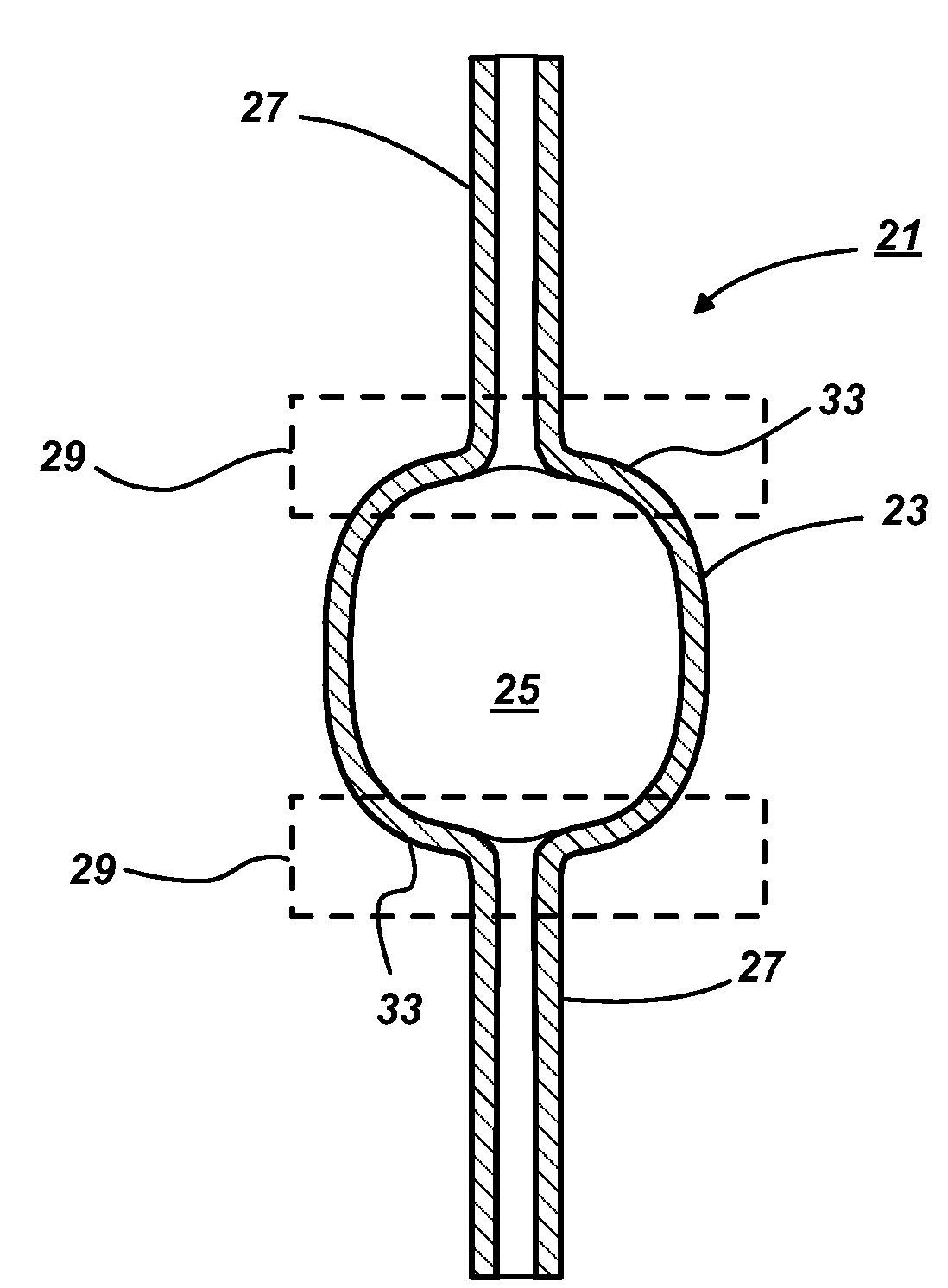

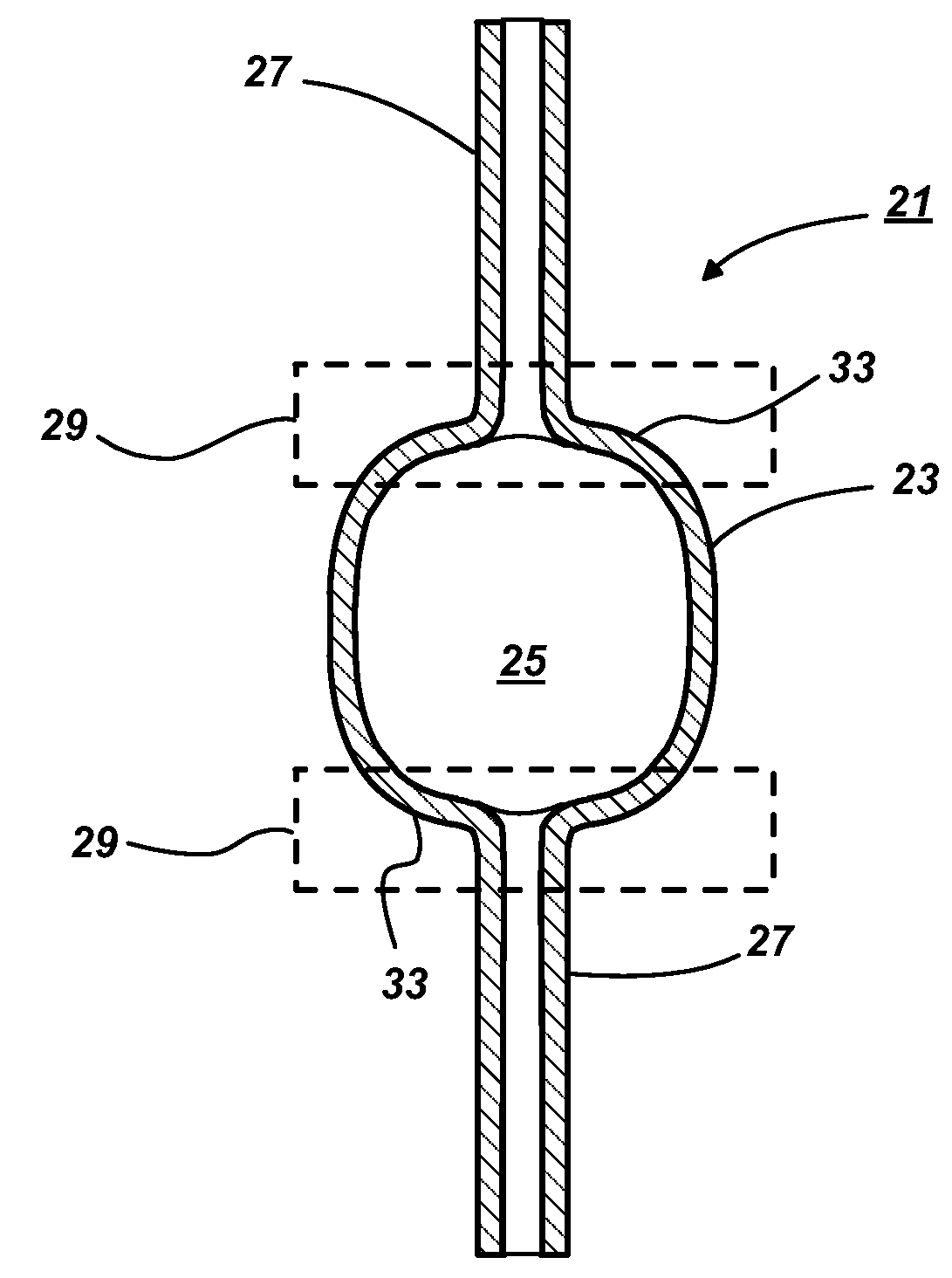

Ceramic discharge vessel having an opaque zone and method of making same

InactiveUS8040061B2Low emissivityIncrease temperatureVessels or leading-in conductors manufactureSolid cathode detailsEmissivityHigh intensity

An opaque zone in the polycrystalline (PCA) discharge vessel of a high intensity discharge lamp may be made by creating residual pores in predetermined regions of the final-sintered discharge vessel. The control over the placement of the opaque zone is achieved by forming a carbonaceous residue in a specific region of the discharge vessel prior to final sintering. During sintering, the carbonaceous material causes residual porosity in the sintered PCA. The higher emissivity of the opaque PCA provides localized cooling in order to provide more control over the condensate behavior in the discharge vessel.

Owner:OSRAM SYLVANIA INC

Ceramic Discharge Vessel Having an Opaque Zone and Method of Making Same

InactiveUS20090066251A1Low emissivityIncrease temperatureVessels or leading-in conductors manufactureSolid cathode detailsEmissivityHigh intensity

An opaque zone in the polycrystalline (PCA) discharge vessel of a high intensity discharge lamp may be made by creating residual pores in predetermined regions of the final-sintered discharge vessel. The control over the placement of the opaque zone is achieved by forming a carbonaceous residue in a specific region of the discharge vessel prior to final sintering. During sintering, the carbonaceous material causes residual porosity in the sintered PCA. The higher emissivity of the opaque PCA provides localized cooling in order to provide more control over the condensate behavior in the discharge vessel.

Owner:OSRAM SYLVANIA INC

Ceramic matrix composite slender thin-wall pipe fitting preparation method, ceramic matrix composite slender thin-wall pipe fitting based on method and application of pipe fitting

ActiveCN114057502AImprove air tightnessSimple processOptical rangefindersNuclear energy generationPipe fittingSlurry

The invention relates to a ceramic matrix composite slender thin-wall pipe fitting preparation method, a ceramic matrix composite slender thin-wall pipe fitting based on the method and application of the pipe fitting. The problems that existing methods cannot achieve forming of a Cf / SiC or SiCf / SiC ceramic matrix composite fiber preform with the ultra-long diameter ratio and the ultra-thin wall thickness, and a prepared Cf / SiC or SiCf / SiC ceramic matrix composite cannot meet the out-of-pile and in-pile examination requirements due to the fact that the residual porosity is large are solved. The method comprises the following steps: firstly, preparing a Cf / SiC or SiCf / SiC composite pipe fitting as a middle layer of a target pipe fitting; secondly, dipping a middle layer of the processed ceramic matrix composite thin-walled thin-walled pipe fitting into the SiC whisker slurry, and densifying; then preparing a SiC ceramic inner layer and a SiC ceramic outer layer on the inner wall and the outer wall of the middle layer of the compact ceramic-based composite thin-walled pipe fitting correspondingly; and finally, polishing the inner layer and the outer layer of the prepared pipe fitting. The pipe fitting prepared by the method is relatively high in air tightness, and meets the related examination application requirements of a fuel cladding pipe for a gas cooled reactor and a fuel cladding pipe for a pressurized water reactor.

Owner:XIAN XINGUI CERAMIC COMPOSITE MATERIAL CO LTD

A Dense Dispersion Strengthened Copper Matrix Composite

The invention relates to a compact dispersion-strengthened copper-base composite material and a preparation method thereof. The compact dispersion-strengthened copper-base composite material is composed of a copper alloy base and Al2O3 particles which are uniformly dispersed in the copper alloy base. Composite metals are added into the copper-alumina master alloy, and a vacuum induction hot-pressing furnace or low-pressure isostatic sintering furnace is adopted for sintering to maximally eliminate the residual porosity and defects in the alloy, so that the sintered billet basically reaches the theoretical density. The prepared dispersion-strengthened copper product has the advantages of high electric conductivity, high softening temperature resistance and high compactness, and can achieve more than 99.5% of theoretical density.

Owner:YANTAI WANLONG VACUUM METALLURGY

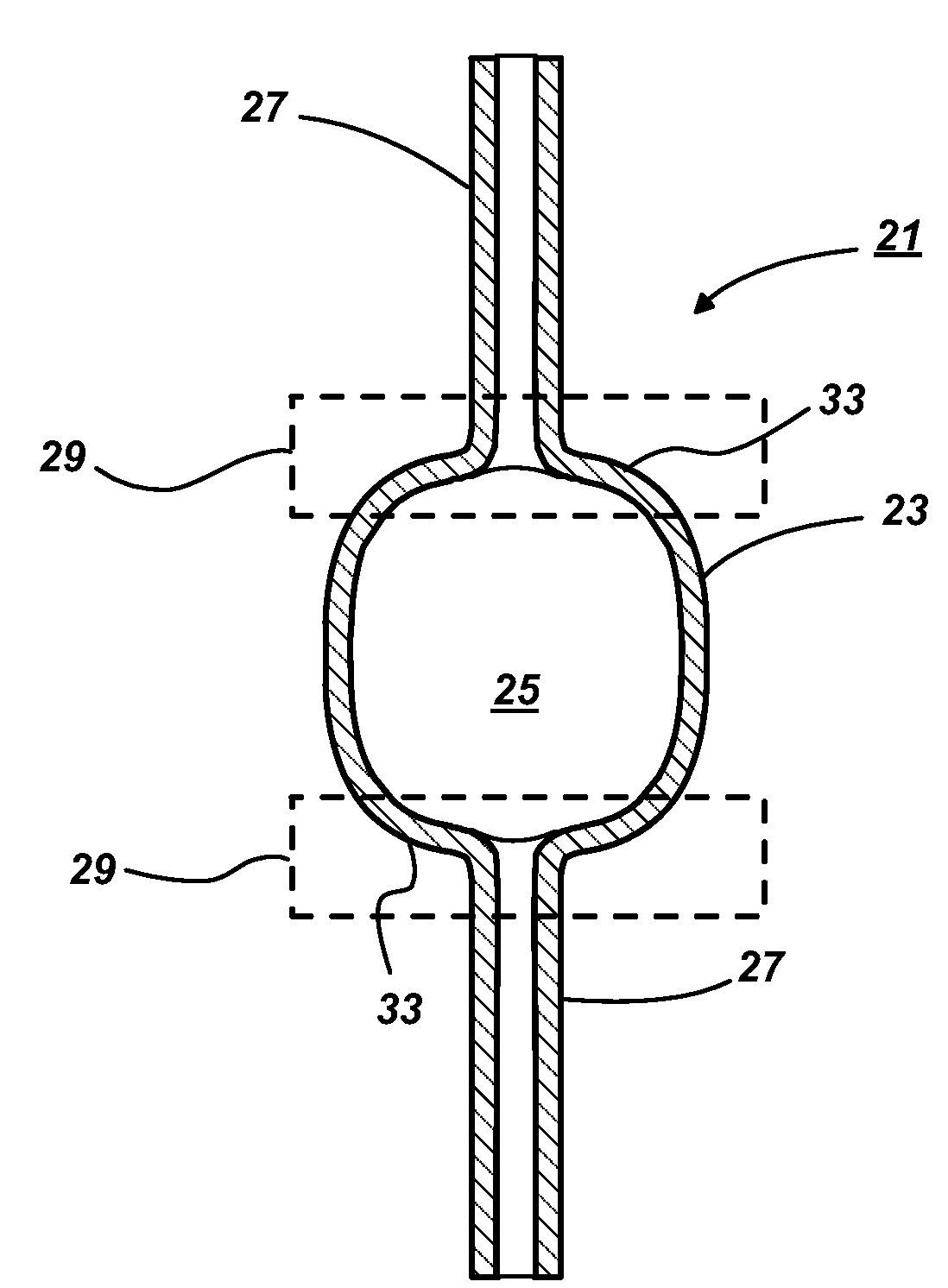

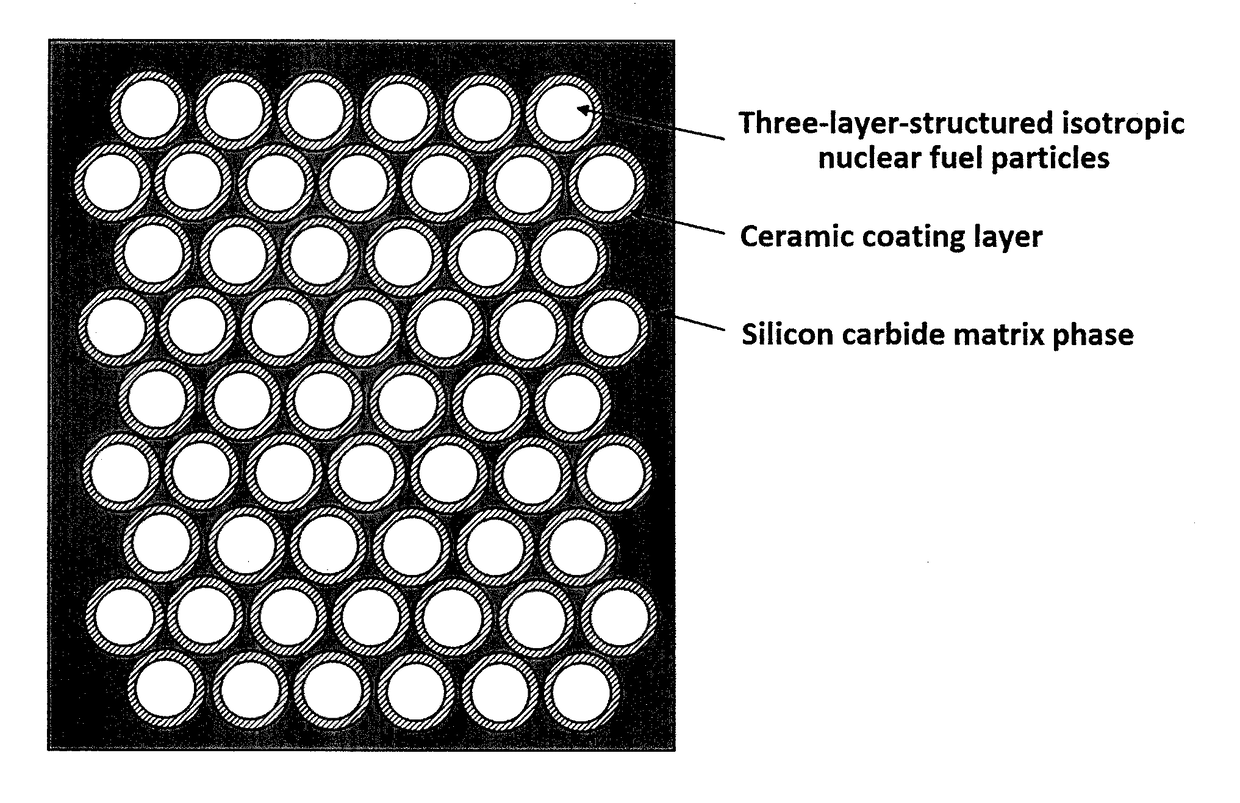

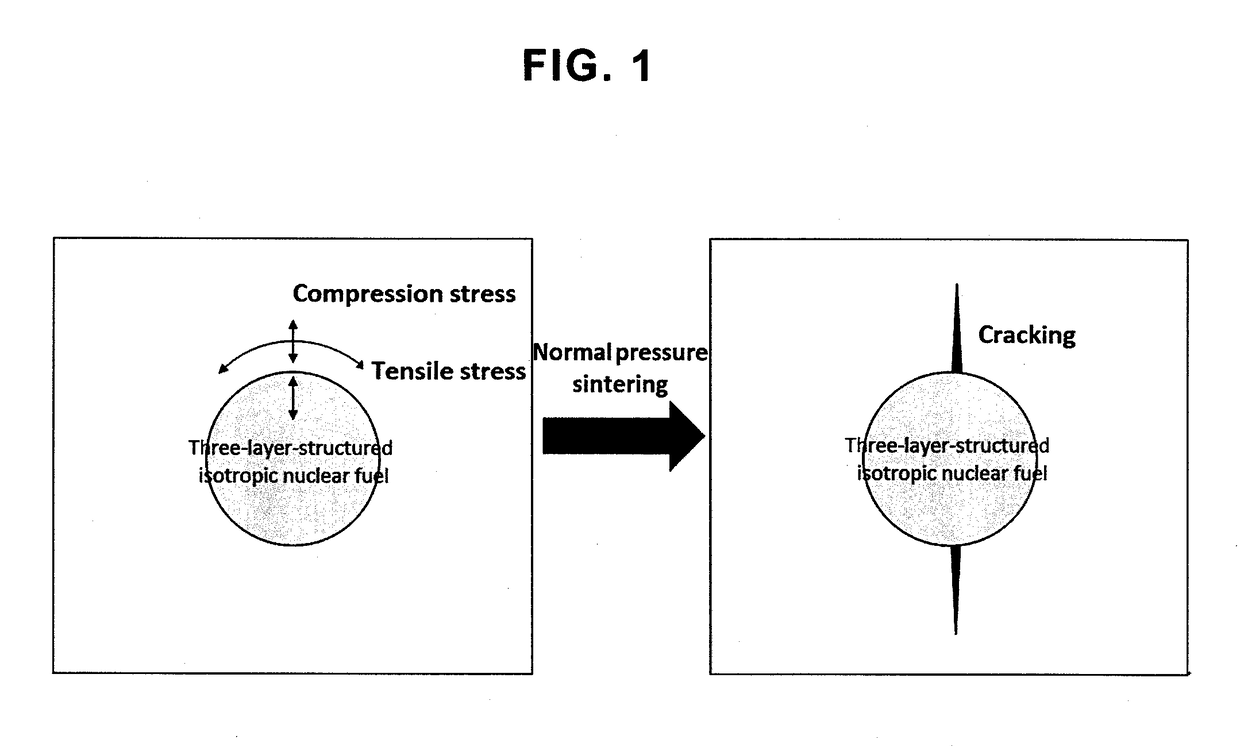

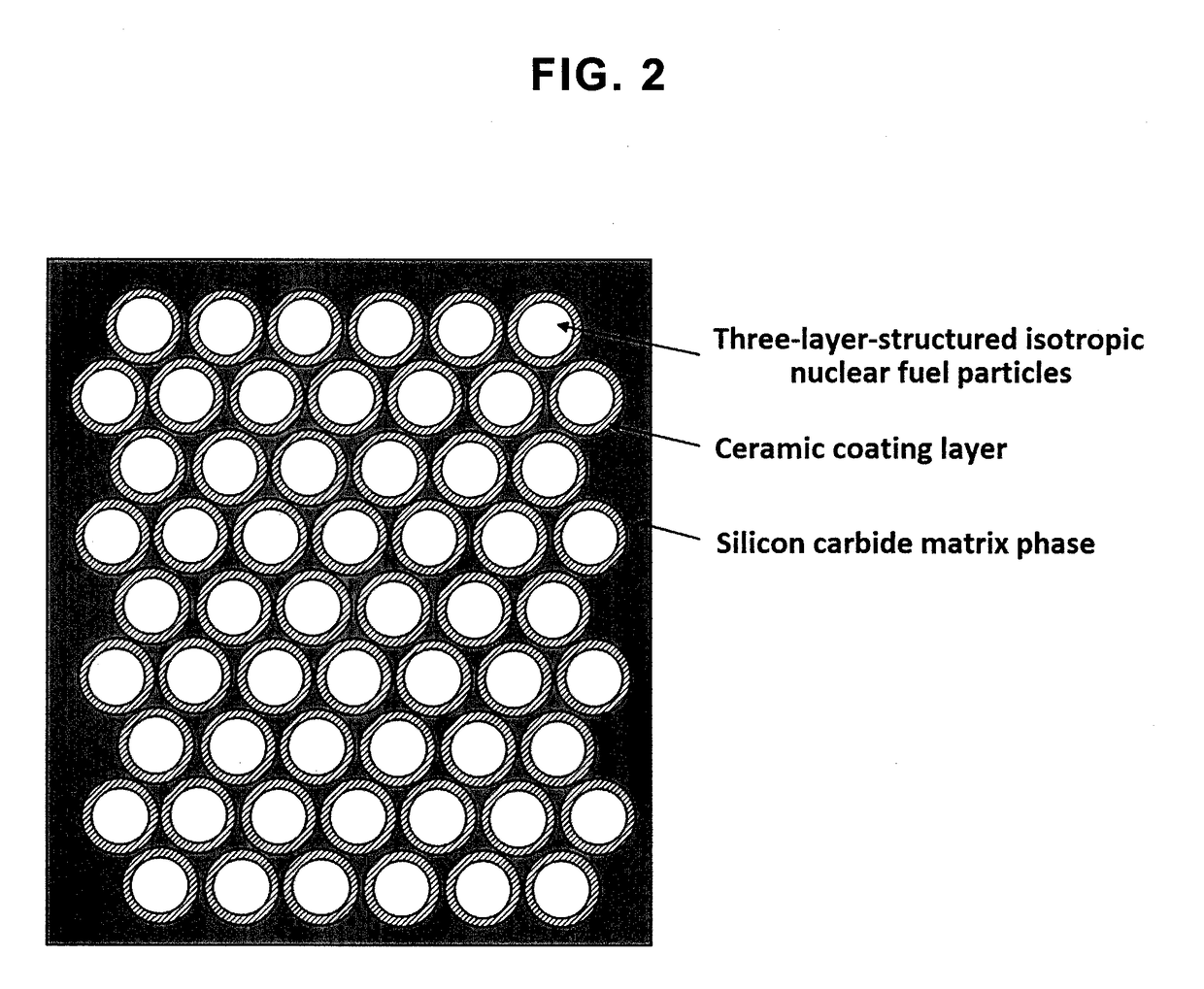

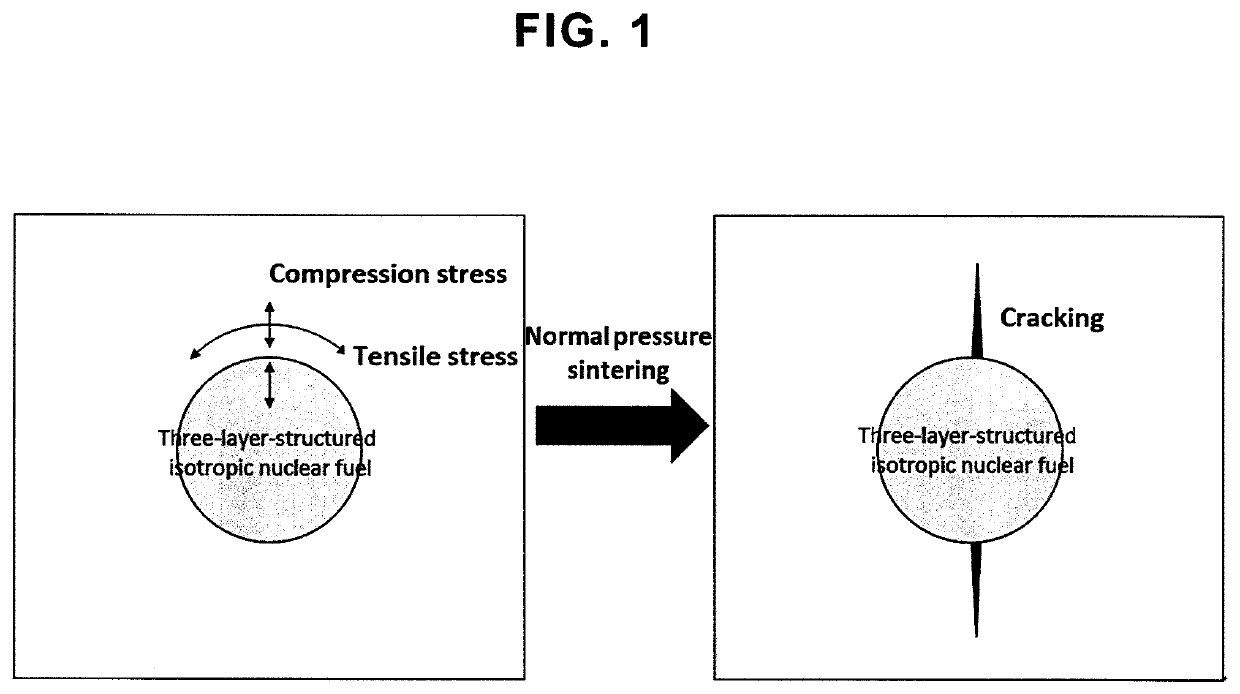

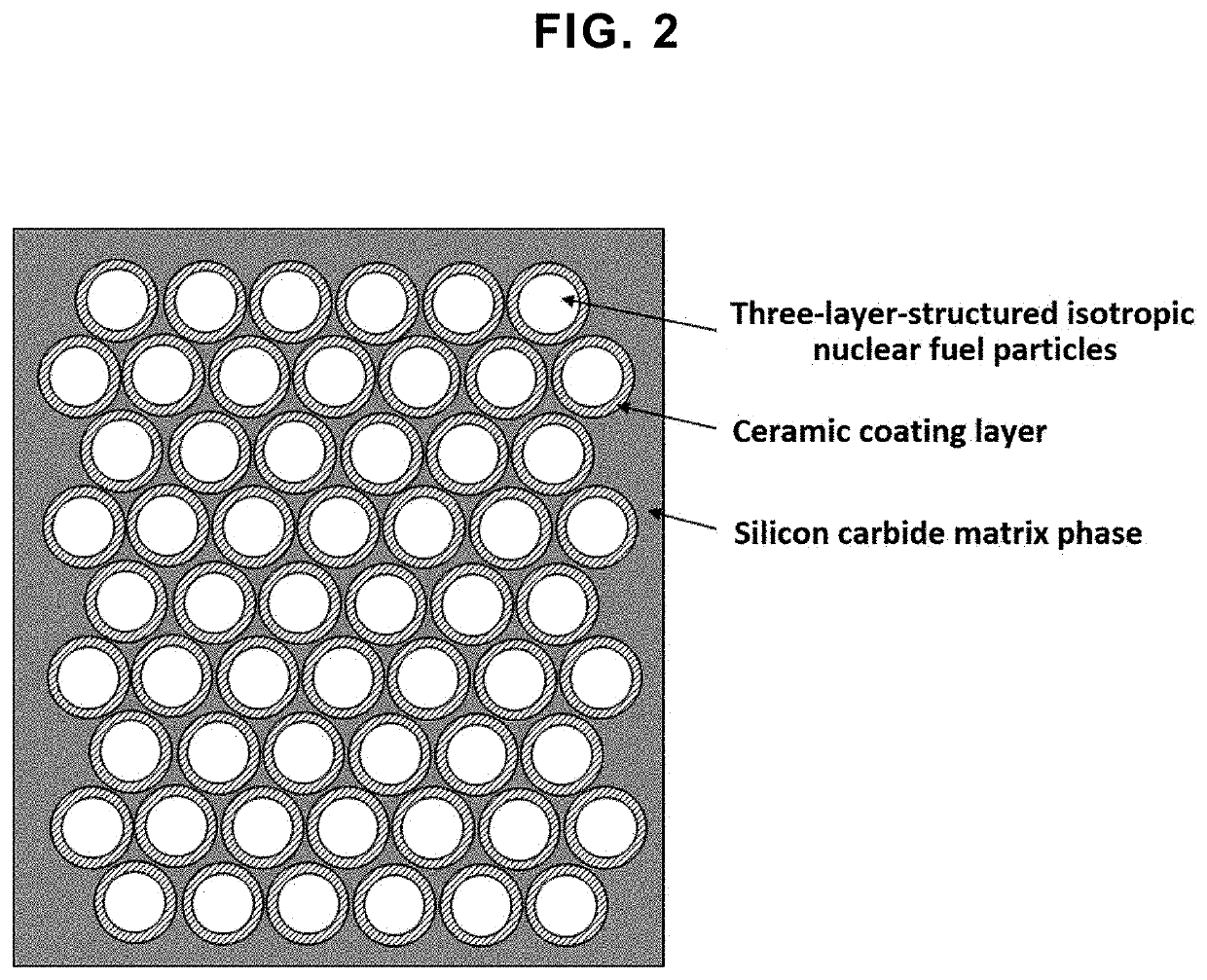

Fully ceramic capsulated nuclear fuel composition containing three-layer-structured isotropic nuclear fuel particles with coating layer having higher shrinkage than matrix, material thereof and method for preparing the same

ActiveUS20180233239A1Avoid crackingAvoid poresFuel elementsNuclear energy generationSintering shrinkageSilicon

The present invention relates to a method for preparing a fully ceramic capsulated nuclear fuel material containing three-layer-structured isotropic nuclear fuel particles coated with a ceramic having a composition which has a higher shrinkage than a matrix in order to prevent cracking of ceramic nuclear fuel, wherein the three-layer-structured nuclear fuel particles before coating is included in the range of between 5 and 40 fractions by volume based on after sintering. More specifically, the present invention provides a composition for preparing a fully ceramic capsulated nuclear fuel containing three-layer-structured isotropic particles coated with the substance which includes, as a main ingredient, a silicon carbine derived from a precursor of the silicon carbide wherein a condition of ΔLc>ΔLm at normal pressure sintering is created, where the sintering shrinkage of the coating layer of the three-layer-structured isotropic nuclear fuel particles is ΔLc and the sintering shrinkage of the silicon carbide matrix is ΔLm; material produced therefrom; and a method for manufacturing the material. The residual porosity of the fully ceramic capsulated nuclear fuel material is 4% or less.

Owner:UNIV OF SEOUL IND COOP FOUND +1

A kind of preparation method of long-fiber carbon ceramic fastener

ActiveCN107793172BIncrease deposition rateIncrease contentFiber orientationChemical vapor infiltration

The invention provides a preparation method of a long-fiber carbon ceramic fastener. The method comprises the following steps: alternately laying long-fiber non-weave cloth and short-fiber mesh tire,wherein the included angle between every two adjacent layers of long-fiber non-weave cloth is 90 degrees along the fiber direction, needling for once when each layer of short-fiber mesh tire is laid,and weaving a three-dimensional needled preform; densifying the obtained preform to 1.4-1.5g / cm<3> in precursor gas by means of pressure differential chemical vapor permeation to obtain a C / C complex;then, carrying out high-temperature heat treatment in protective gas; finally, putting the product into silicon powder, and carrying out high-temperature melting silicon infiltration, and machining and molding to obtain the long-fiber carbon ceramic fastener with the density of 2.2-2.4g / cm<3>. The preparation method provided by the invention is short in preparation period, low in residual porosity, rapid in densifying amplitude, low in cost and environmentally-friendly; the prepared carbon ceramic fastener is high in strength and volume density and better in high temperature resistance and corrosion resistance.

Owner:山东道普安制动材料有限公司

Preparation method for metal-based ceramic composite material grinding roller of vertical grinding machine

ActiveCN103736549BHigh strengthImprove high temperature resistanceGrain treatmentsIron powderCeramic composite

The invention provides a preparation method for a metal-based ceramic composite material grinding roller of a vertical grinding machine. A grinding roller base body is sleeved with a roller sleeve which is composed of a high-chromium alloy lining plate and a ceramic lining plate made of a metal-based ceramic enhanced material, wherein the metal-based ceramic enhanced material is composed of 10%-40% of corundum and 60%-90% of iron powder; the high-chromium alloy lining plate and the ceramic lining plate, and the roller sleeve and the grinding roller base body are solidified into a whole body by pouring steel liquid; the preparation method of the grinding roller comprises the following steps: when the corundum and the iron powder are mixed and combusted until the iron powder is completely smelted, the mixture of the corundum and the iron powder is put into a mould for preparing the ceramic lining plate; the ceramic lining plate is placed in a groove in the high-chromium alloy lining plate and the steel liquid is poured to prepare the roller sleeve; the grinding roller base body is sleeved with the roller sleeve and the steel liquid is poured so that the roller sleeve and the grinding roller base body are solidified into the whole body. According to the preparation method, the steel liquid can be immersed into ceramic grains in the ceramic lining plate and covers the ceramic grains so that a ceramic phase and a metal phase are uniformly distributed; the residual porosity after baking is reduced and the wear resistance is high.

Owner:洛阳鹏飞耐磨材料股份有限公司

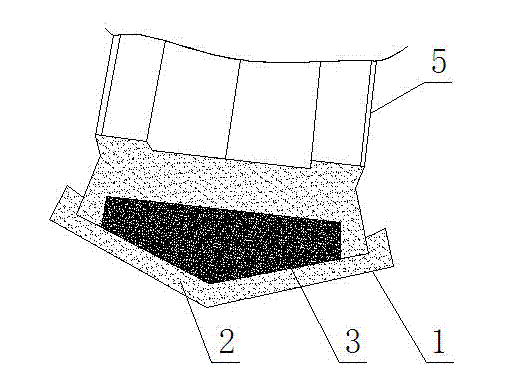

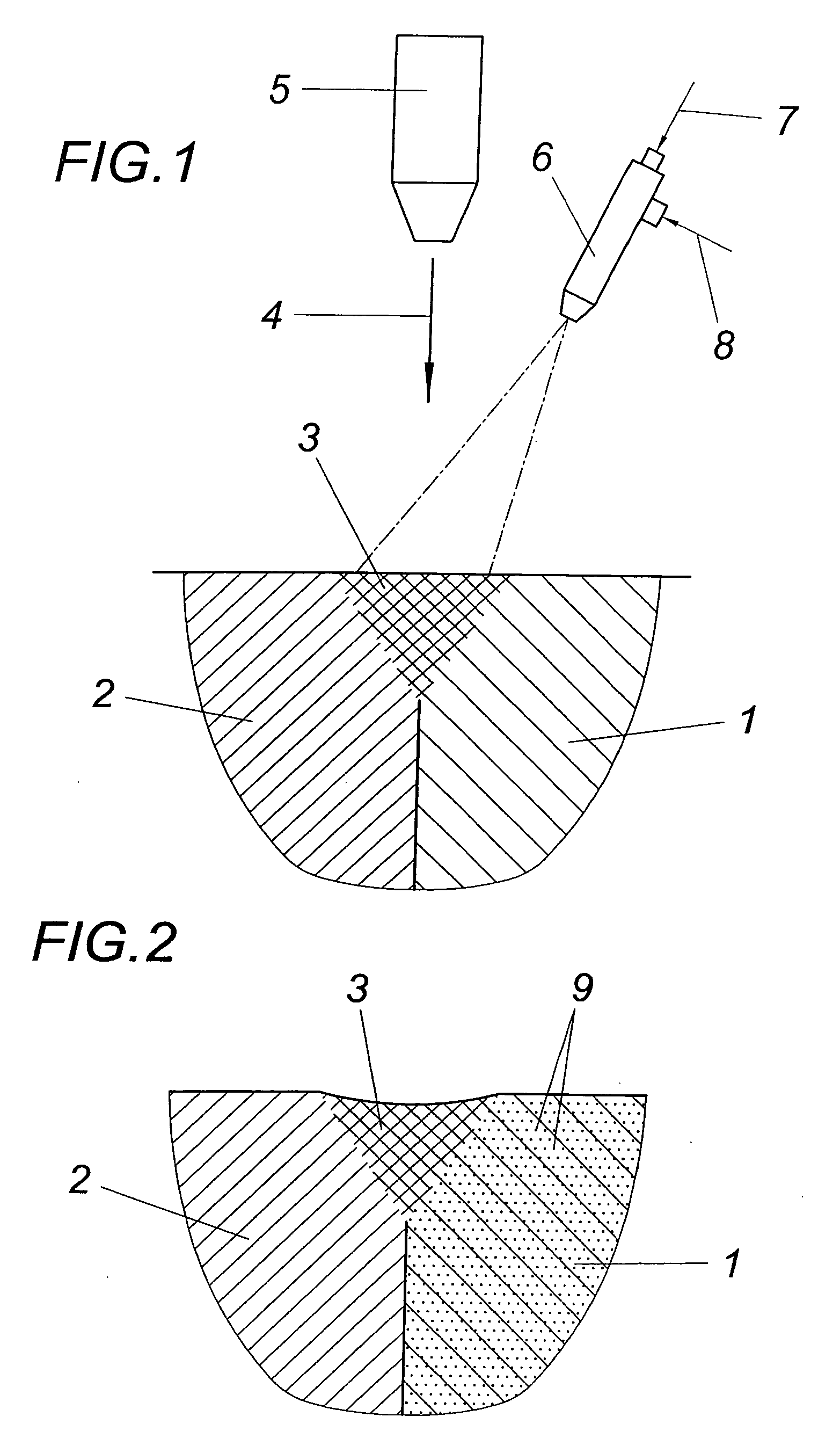

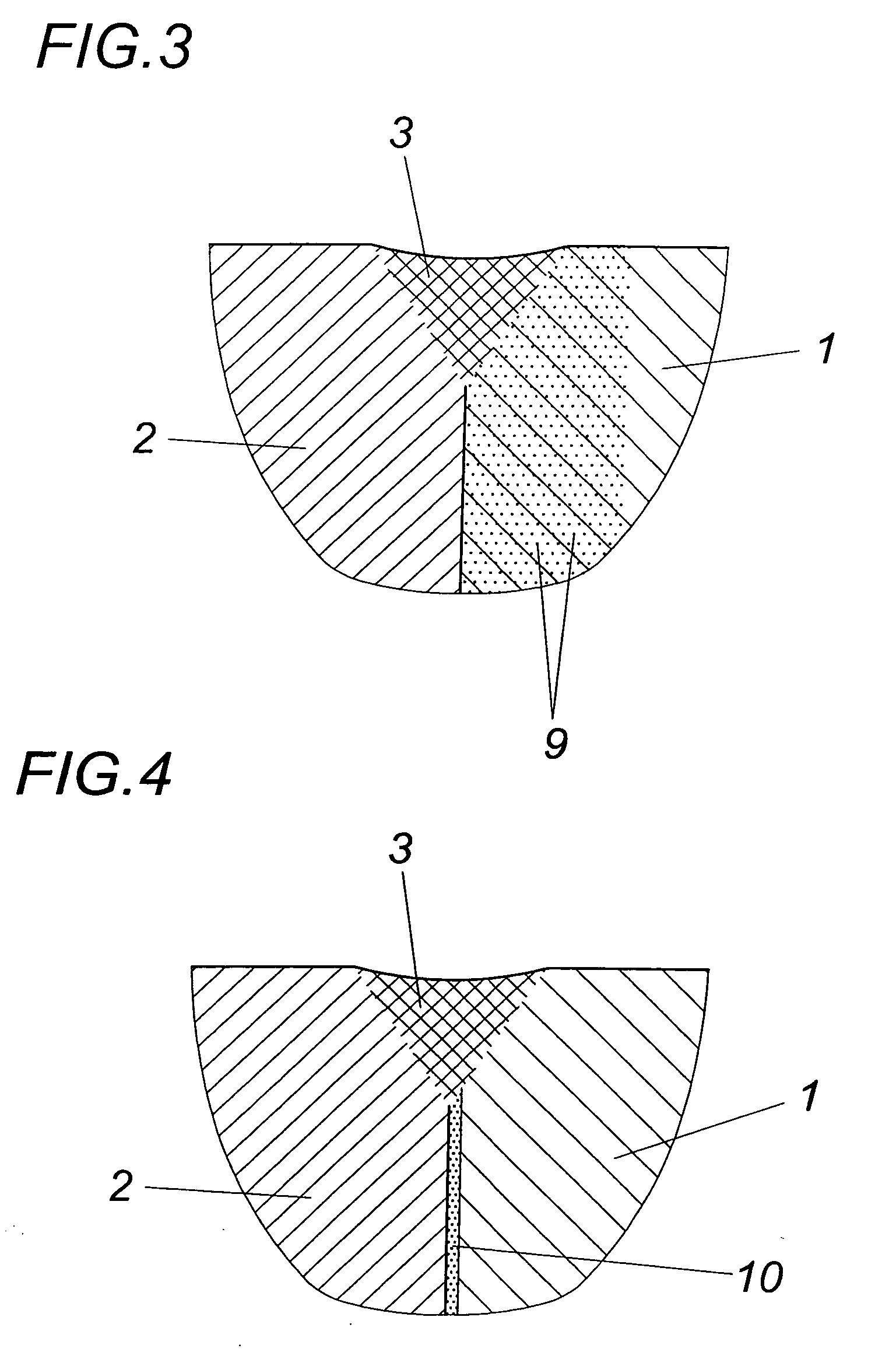

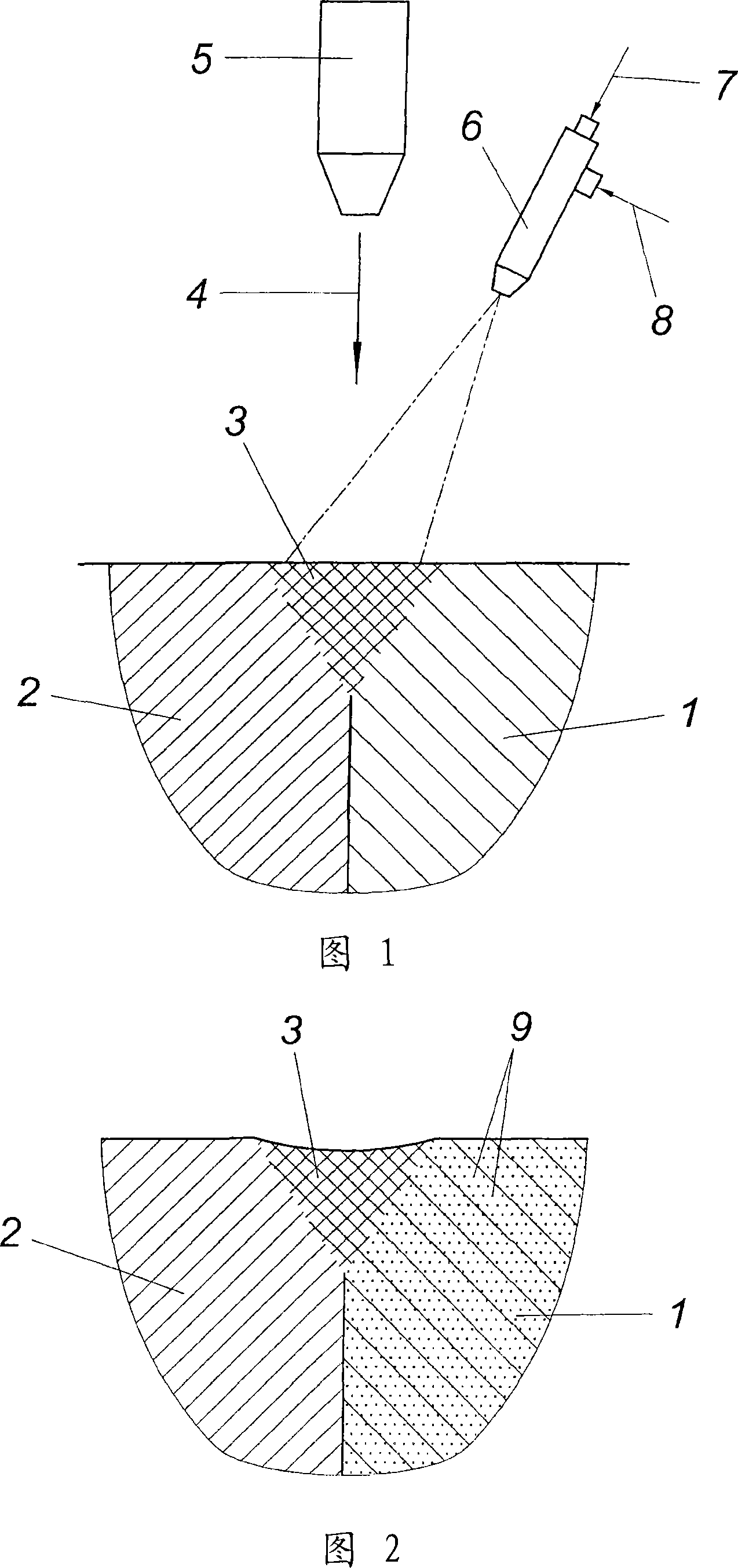

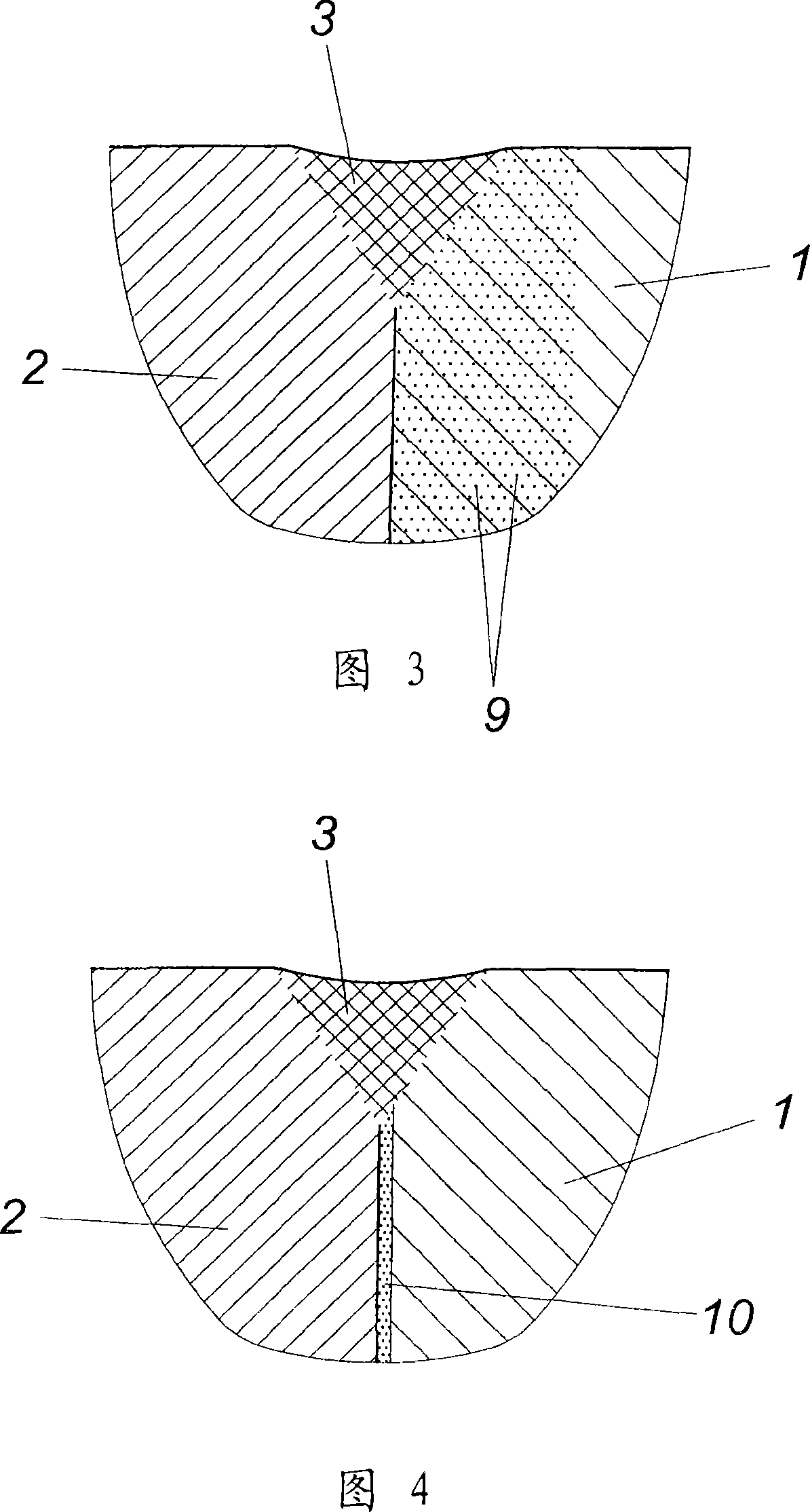

Method for Welding a Sintered Shaped Body

InactiveUS20080197119A1Increase widthEasy solder connectionWelding/cutting media/materialsWelding/soldering/cutting articlesWeld seamLaser beams

A method is described for welding a sintered molded body (1) which comprises a residual porosity and which is molten in the region of the later weld seam (3) by a laser beam (4). In order to obtain dense weld seams it is proposed that during the melting of the molded body (1) the atmospheric oxygen is bound at least substantially by a deoxidizer from the pores of the molded body (1) in the area of the weld seam and is embedded in the form of finely dispersed oxides in the weld seam (3).

Owner:MIBA SINTER AUSTRIA

Method for preparing Cu/MoCu/Cu three-layer composite plate blank

ActiveCN103143714BControl the amount of infiltrationAccurate control of copper contentMetal layered productsHydrogen atmosphereCopper

The invention provides a method for preparing a Cu / MoCu / Cu three-layer composite plate blank. The method comprises the following steps of: I, evenly mixing molybdenum powder with copper powder to obtain molybdenum-based composite powder; II, pressing the molybdenum-based composite powder into a molybdenum-based composite plate blank by adopting an oil press; III, paving the molybdenum-based composite plate blank between two first copper plates to form a composite plate, then, putting the composite plate in a graphite crucible, and paving a second copper plate at the top part of the composite plate; and IV, performing infiltration under the protection of a hydrogen atmosphere, and performing surface coping treatment after furnace cooling to obtain the Cu / MoCu / Cu three-layer composite plate blank. The method for preparing the Cu / MoCu / Cu three-layer composite plate blank is short in process route and low in processing cost. An infiltration process and a composite process can be finished simultaneously, and therefore, the Cu / MoCu / Cu three-layer composite plate blank is prepared at one step. The Cu / MoCu / Cu three-layer composite plate blank prepared by adopting the method provided by the invention is strong in interface bonding force, low in residual porosity and easily controllable and adjustable in copper content, and is suitable for large-scale industrial production.

Owner:西安宝德九土新材料有限公司

Method for welding a sintered shaped body

InactiveCN1988980AWelding/cutting media/materialsWelding/soldering/cutting articlesWeld seamLaser beams

The invention relates to a method for welding a sintered shaped body (1), which has a residual porosity and which is melted in the area of a subsequent weld seam (3) by a laser beam (4). In order to obtain tight weld seams, the invention provides that, during the melting of the shaped body (1), the atmospheric oxygen from the pores of the shaped body (1) is at least largely bound in the weld seam area by means of a deoxidizing agent, and is embedded in the weld seam (3) in the form of finely dispersed oxides.

Owner:MIBA SINTER AUSTRIA

Fully ceramic capsulated nuclear fuel composition containing three-layer-structured isotropic nuclear fuel particles with coating layer having higher shrinkage than matrix, material thereof and method for preparing the same

ActiveUS11004570B2Avoid crackingReduce fuel temperatureFuel elementsNuclear energy generationPhysical chemistryAll ceramic

The present invention relates to a method for preparing a fully ceramic capsulated nuclear fuel material containing three-layer-structured isotropic nuclear fuel particles coated with a ceramic having a composition which has a higher shrinkage than a matrix in order to prevent cracking of ceramic nuclear fuel, wherein the three-layer-structured nuclear fuel particles before coating is included in the range of between 5 and 40 fractions by volume based on after sintering. More specifically, the present invention provides a composition for preparing a fully ceramic capsulated nuclear fuel containing three-layer-structured isotropic particles coated with the substance which includes, as a main ingredient, a silicon carbine derived from a precursor of the silicon carbide wherein a condition of ΔLc>ΔLm at normal pressure sintering is created, where the sintering shrinkage of the coating layer of the three-layer-structured isotropic nuclear fuel particles is ΔLc and the sintering shrinkage of the silicon carbide matrix is ΔLm; material produced therefrom; and a method for manufacturing the material. The residual porosity of the fully ceramic capsulated nuclear fuel material is 4% or less.

Owner:UNIV OF SEOUL IND COOP FOUND +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com