Preparation method for metal-based ceramic composite material grinding roller of vertical grinding machine

A ceramic composite material and metal-based technology, applied in grain processing, etc., can solve the problems of large sintering residual porosity, complex preparation process, strong crack sensitivity, etc., to achieve convenient preparation process, simple preparation process, and low firing temperature Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

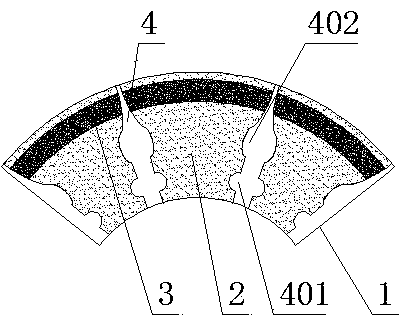

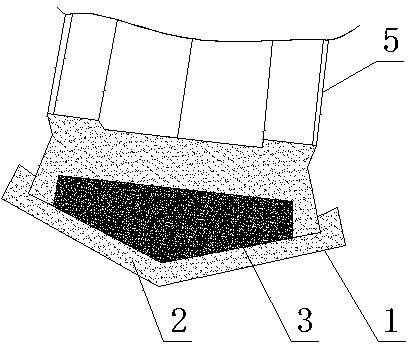

[0023] A method for preparing a grinding roller made of metal-based ceramic composite material for a vertical mill. The base of the grinding roller is covered with a roller cover, and the roller cover is made of a high-chromium alloy liner and a ceramic liner made of a metal-based ceramic reinforcement material. Composition, the metal-based ceramic reinforcement material is composed of corundum and iron powder, the weight ratio of corundum and iron powder is: corundum 10%, iron powder 90%, wherein, the particle size of corundum is 0.35cm, high chromium alloy The lining plate is a fan-shaped plate body, on the surface of the plate body, there are grooves for clamping the ceramic lining plate, and there are gaps on both sides of the plate body, between the high chromium alloy lining plate and the ceramic lining plate 1. The roller sleeve and the grinding roller matrix are solidified by molten steel casting. The preparation method of the grinding roller includes the following step...

Embodiment 2

[0028] A method for preparing a grinding roller made of metal-based ceramic composite material for a vertical mill, wherein the base of the grinding roller is covered with a roller cover, and the roller cover is composed of a high-chromium alloy lining plate and a ceramic lining plate made of a metal-based ceramic reinforcement material , the metal-based ceramic reinforcement material is composed of corundum and iron powder, the weight ratio of corundum and iron powder is: corundum 40%, iron powder 60%, wherein, the particle size of corundum is 0.30cm, high chromium alloy lining The plate is a fan-shaped plate body, on the surface of the plate body, there are grooves for clamping the ceramic lining plate, and there are gaps on both sides of the plate body, between the high chromium alloy lining plate and the ceramic lining plate, The roller sleeve and the grinding roller matrix are solidified by molten steel casting, and the preparation method of the grinding roller includes th...

Embodiment 3

[0033] A method for preparing a grinding roller made of metal-based ceramic composite material for a vertical mill. The base of the grinding roller is covered with a roller cover, and the roller cover is made of a high-chromium alloy liner and a ceramic liner made of a metal-based ceramic reinforcement material. Composition, the metal-based ceramic reinforcement material is composed of corundum and iron powder, the weight ratio of corundum and iron powder is: corundum 35%, iron powder 65%, wherein, the particle size of corundum is 0.25cm, high chromium alloy The lining plate is a fan-shaped plate body, on the surface of the plate body, there are grooves for clamping the ceramic lining plate, and there are gaps on both sides of the plate body, between the high chromium alloy lining plate and the ceramic lining plate 1. The roller sleeve and the grinding roller matrix are solidified by molten steel casting. The preparation method of the grinding roller includes the following step...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com