Patents

Literature

46results about How to "Low service life" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

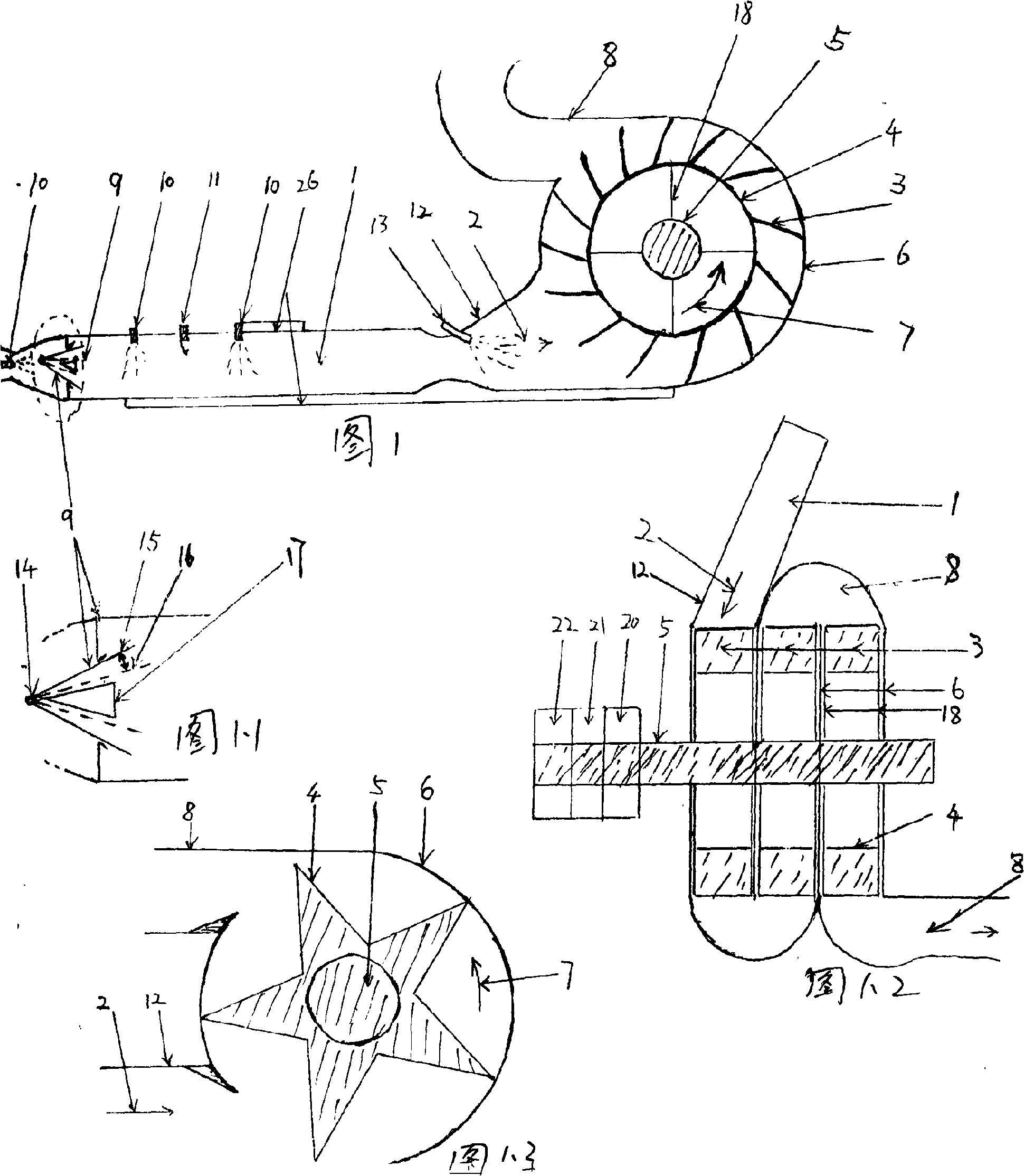

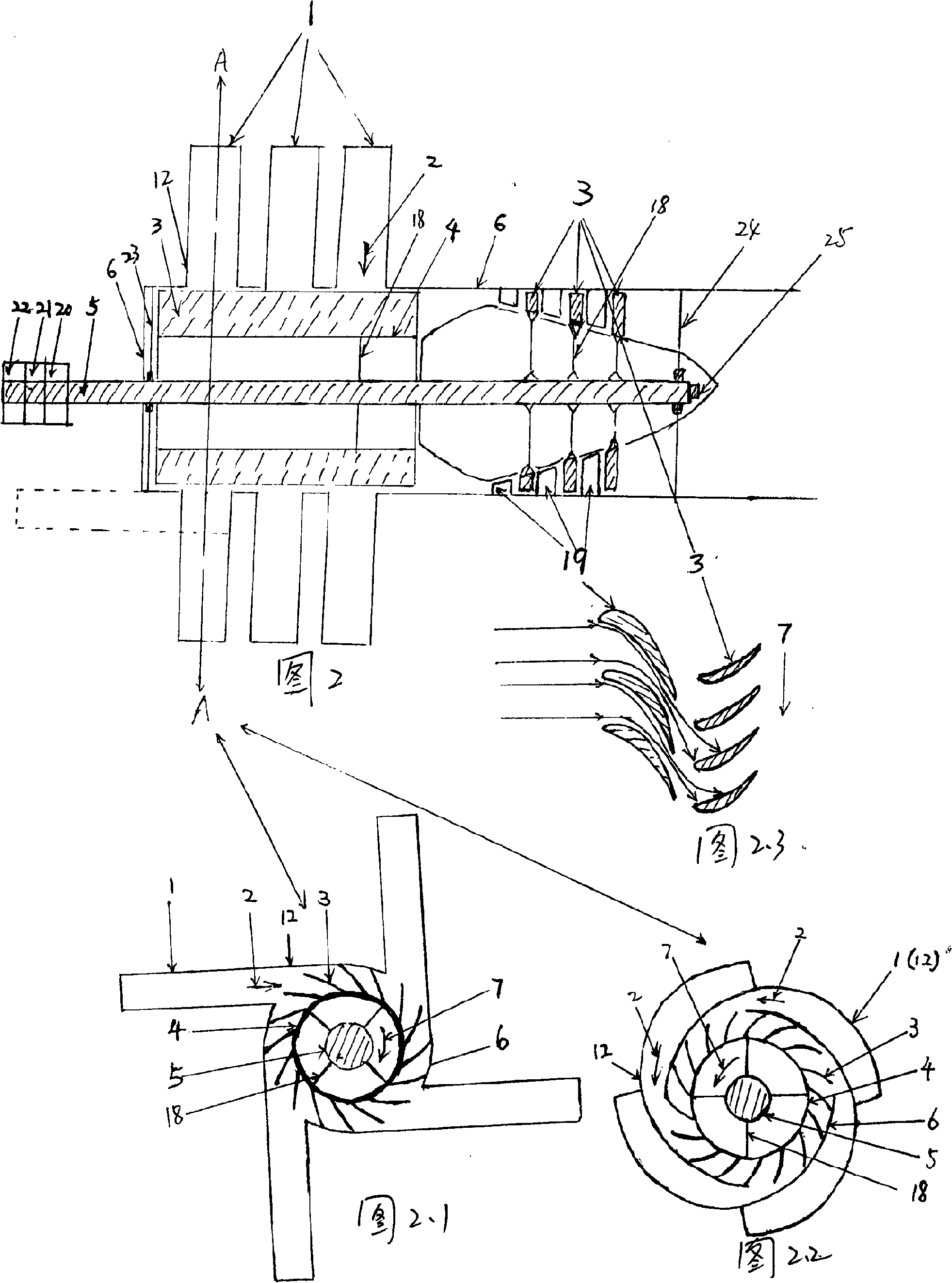

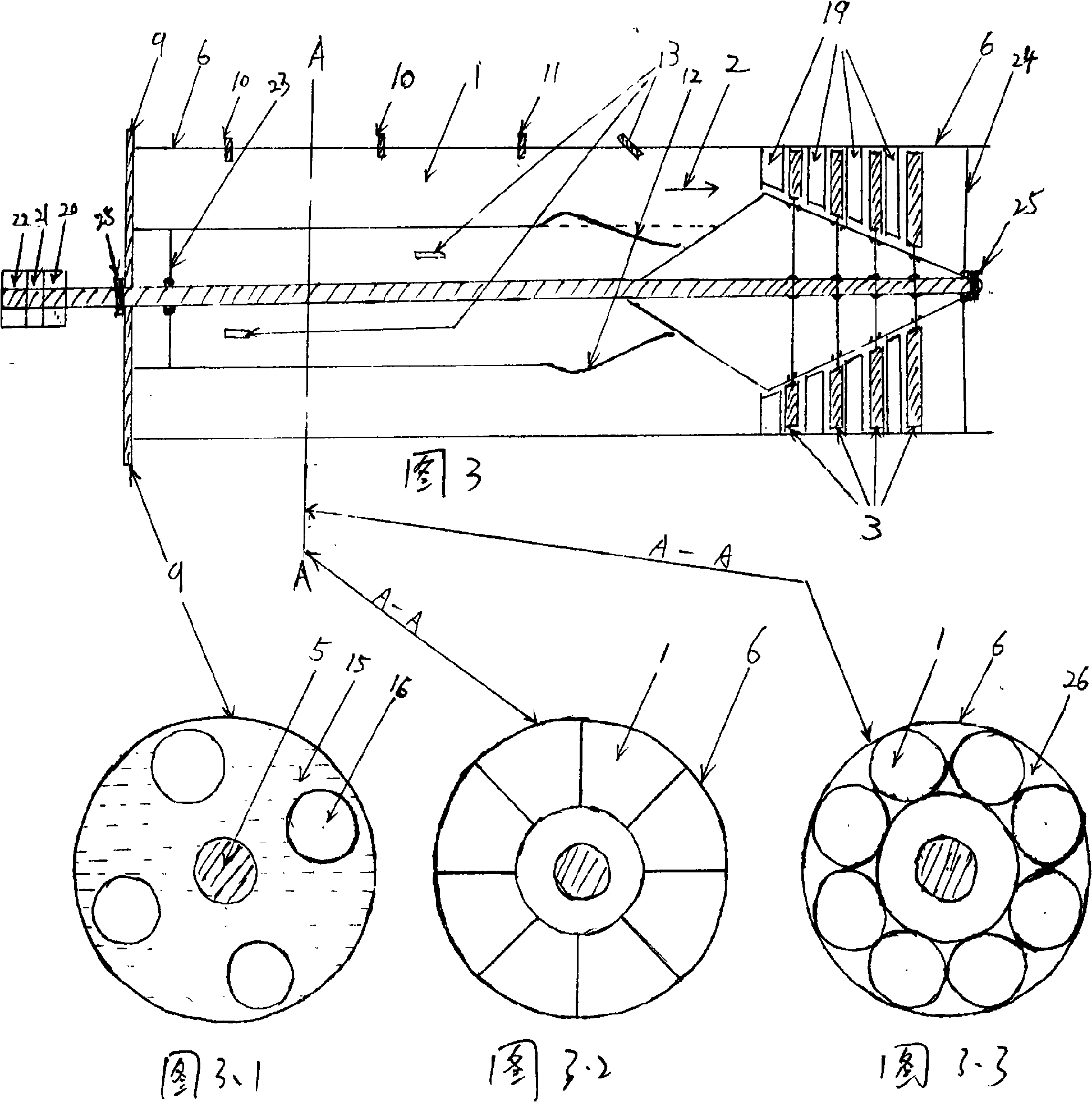

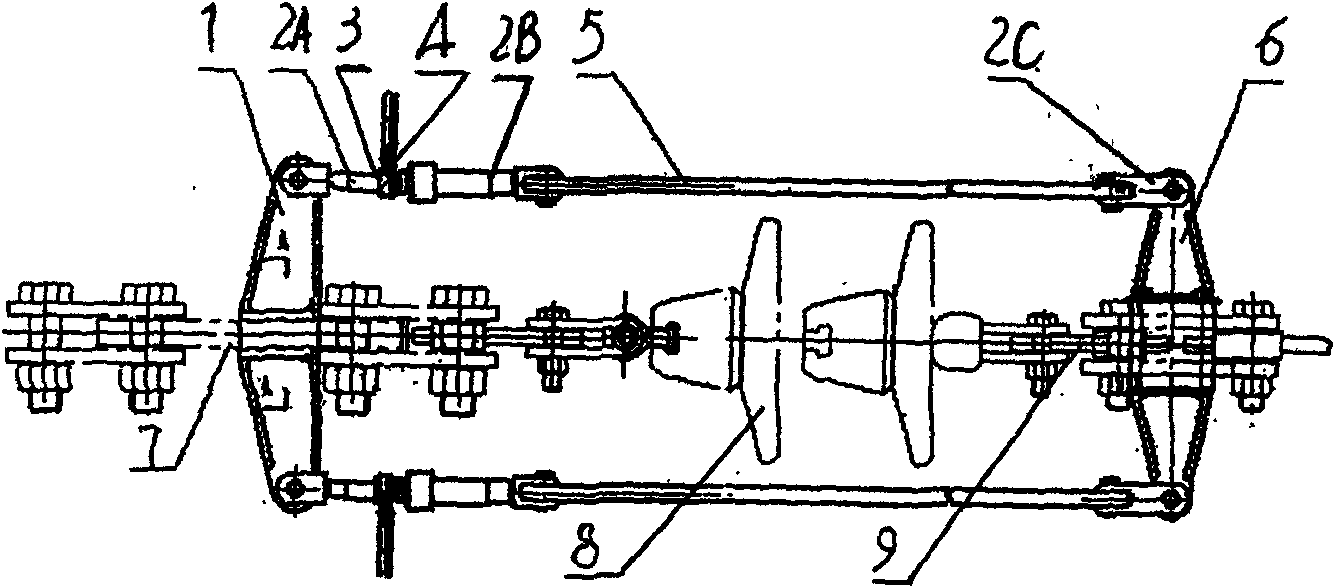

Pulse knock rotor spindle engine

InactiveCN101338702AIncrease useSingle purposeTurbine/propulsion engine coolingGas turbine plantsHigh pressureSubmarine

The present invention relates to a pulse detonation rotor shaft engine. In the technical proposal, the pulse detonation rotor shaft engine mainly consists of a pulse detonation engine, a rotor and an output shaft; propulsive gas with the high temperature and high pressure expansion of pulse which is ejected when the pulse detonation engine works is used as a power source to push the rotor to rotate; the rotor drives the output shaft to rotate; a pulse detonation rotor shaft engine uses the output shaft to output most energy produced by the pulse detonation engine by outputting torsion continuously; the output shaft drives various kinds of loads to work. The pulse detonation rotor shaft engine has the beneficial effects as follows: firstly, the pulse detonation rotor shaft engine can be used as a shaft engine to be widely applied in various kinds of dynamic systems, such as ship, submarine, tank, tractor, automobile, train, and the like and has wide purposes; secondly, the pulse detonation rotor shaft engine overcomes the disadvantage of the large noise of the prior pulse detonation engine; thirdly, compared with a piston type engine, the pulse detonation rotor shaft engine has the obvious advantages of simple structure, low cost, high reliability, long service life, light weight, less fraction resistance loss, etc.

Owner:RUGAO HUAYANG ALUMINUM PROD

Foamed cement heat insulating material for exterior wall and preparation method thereof

The invention relates to a foamed cement heat insulating material for an exterior wall. The foamed cement heat insulating material is prepared by using the following raw materials in parts by weight: 150-250 parts of sulphoaluminate cement, 0-0.5 part of water reducing agent, 2-5 parts of waterproof agent, 7-13 part of foaming agent, 0.5-3 parts of foam stabilizer, 0.5-3 parts of fiber and 60-135 parts of water. The foamed cement heat insulating material for the exterior wall has the advantages of high economy and practicability, light weight, high strength, good heat insulating performance, high waterproof, fireproof and anti-freezing performance and long service life.

Owner:薛一冰

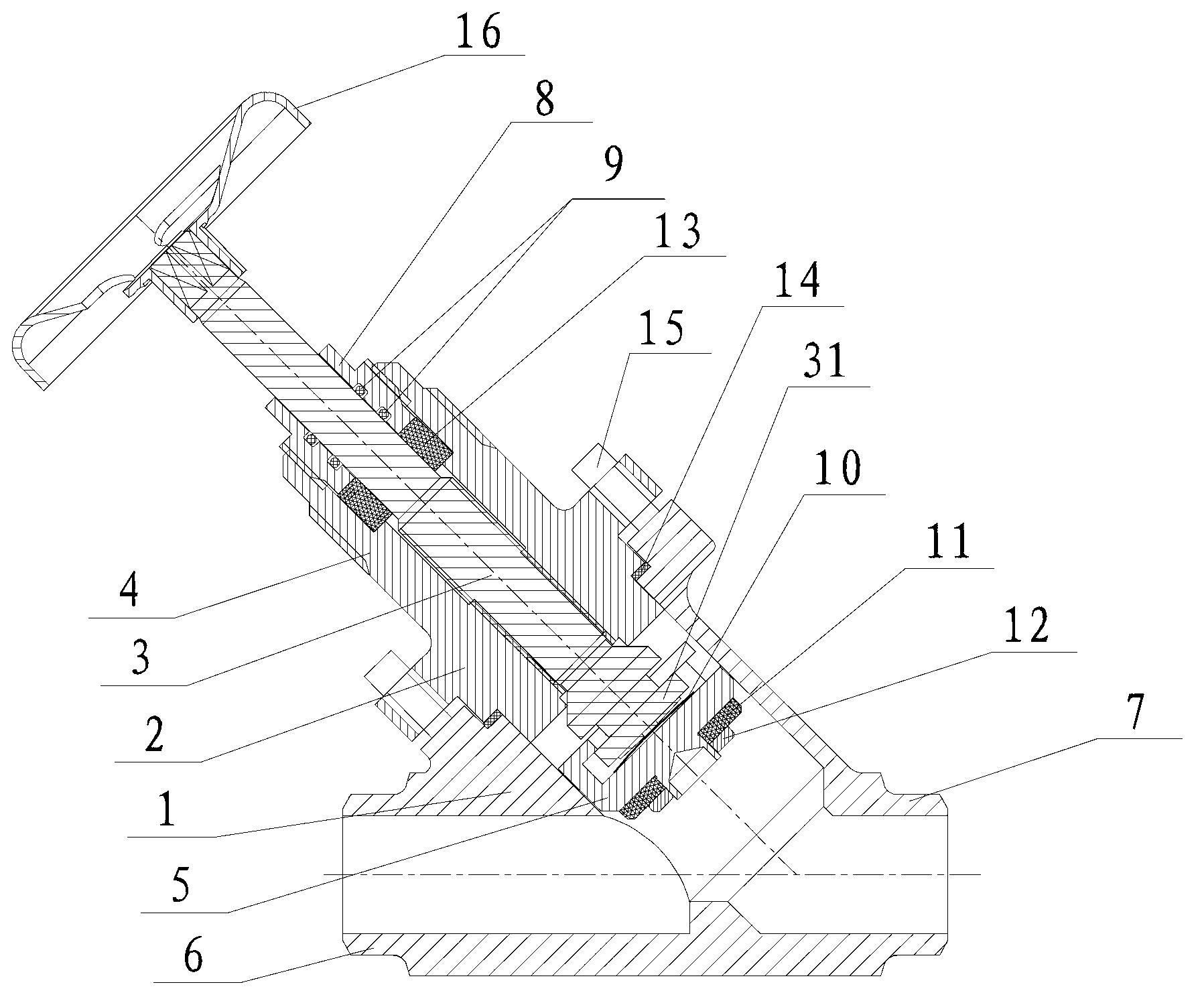

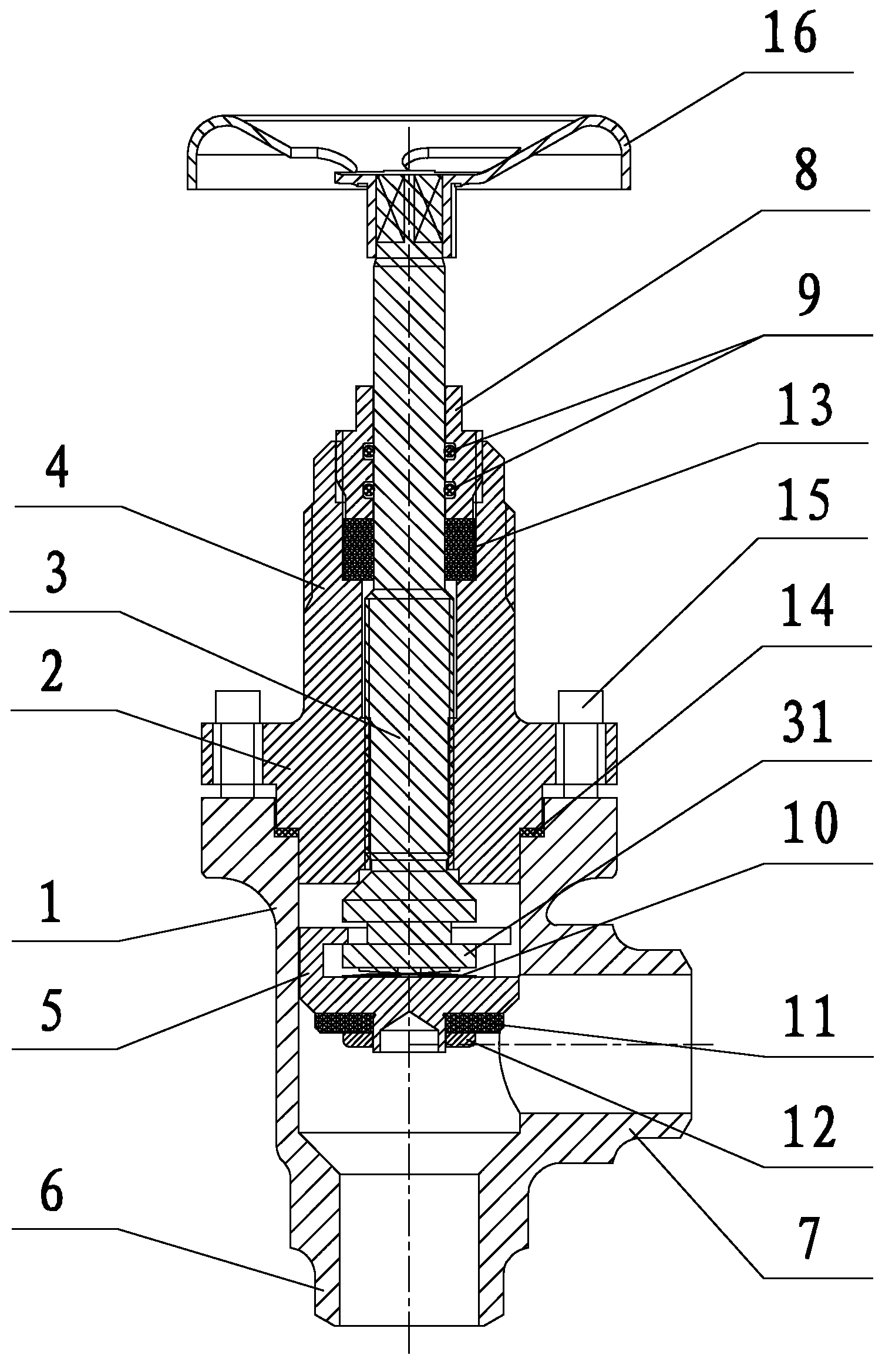

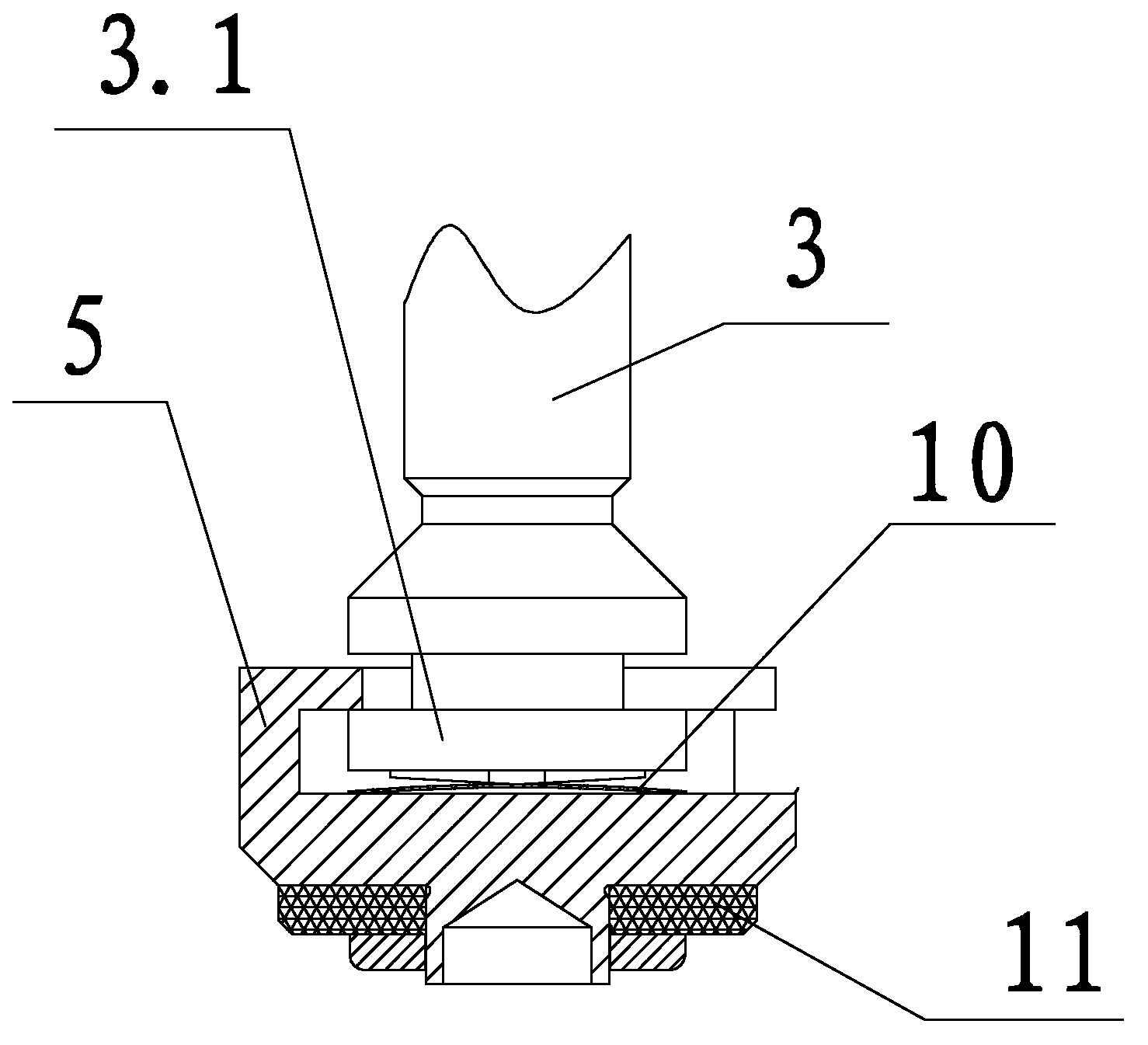

Steel forged refrigeration valve

InactiveCN103062419ACompact structureLarge circulation capacitySpindle sealingsLift valveRefrigerantValve stem

The invention relates to a valve, in particular to a steel forged valves including ammonia valves fluorine valves and the like which are applicable to all universal refrigerants, and mainly solves the problem that the refrigerant use for refrigeration utilizing a conventional valve is prone to leak since a bonnet mounted into a valve seat is eccentric and the conventional valve seat has multiple welding points. The steel forged refrigeration valve comprises a valve seat, a bonnet, a valve stem, a valve stem sleeve, a valve flap and a sealing cover, wherein the bonnet is in bolted connection with the valve seat, the valve stem sleeve is arranged on the bonnet, a clamp groove formed by an upper U-shaped chute and a lower U-shaped chute is arranged on the valve flap which is in clamping connection with the valve stem via the clamp groove, an elastic gasket is arranged between the valve stem and the valve flap, the valve flap and a valve body are enabled to be automatically adjusted concentrically, a valve flap gasket contacts with a sealing surface of the valve seat via a conical surface to form sealing, double O-shaped rubber sealing rings are arranged between the valve stem and the sealing cover for sealing, the valve stem sleeve is arranged on the valve bonnet, the sealing cover is arranged on the valve stem sleeve, and a bonded gasket seal is arranged between the sealing cover and the valve stem cover to improve sealing performance.

Owner:CHANGZHOU AMG REFRIGERATION EQUIP

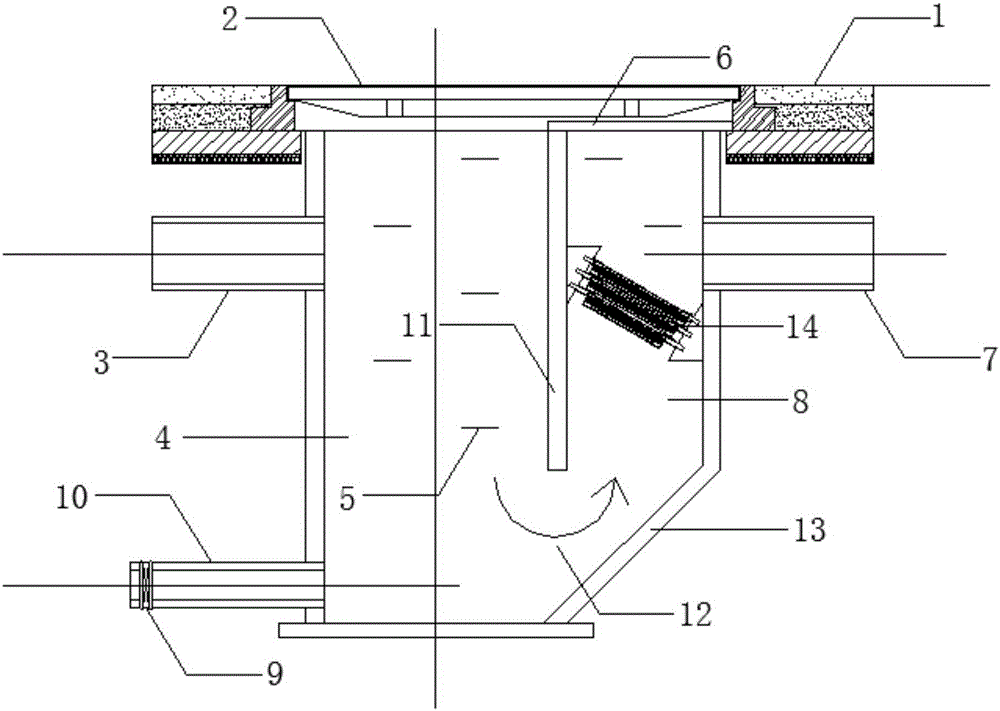

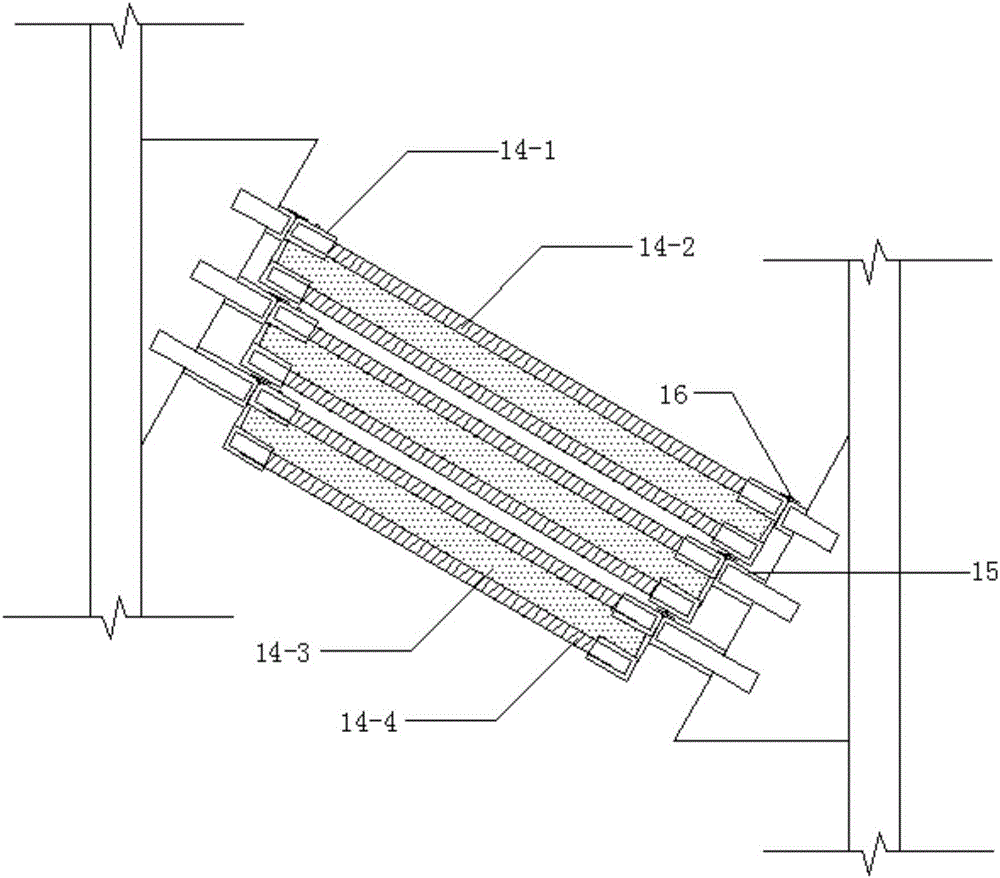

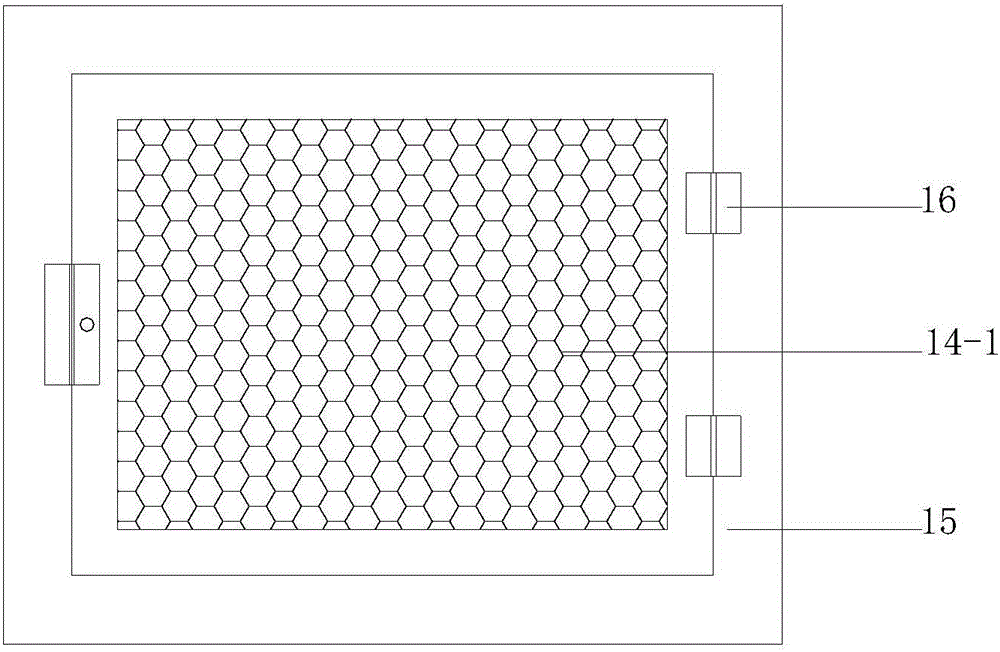

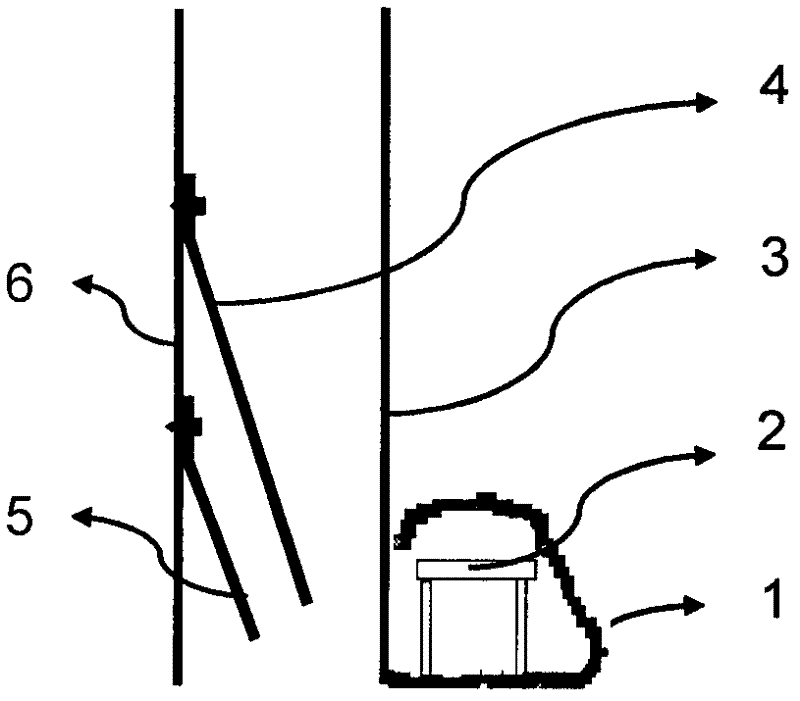

Rainwater filtering and storage device

InactiveCN105089102AEasy to cleanEasy to replaceFatty/oily/floating substances removal devicesSewerage structuresSludgeEngineering

The invention discloses a rainwater filtering and storage device. The rainwater filtering and storage device comprises a rainwater well, wherein the rainwater well is provided with a water inlet pipe, a water outlet pipe and a well lid, a partition wall with the suspending bottom is arranged in the rainwater well for separating the rainwater well into a rainwater collecting well and a filtering well, a seal cover is arranged on the top of the filtering well, a flow passing channel for communicating the rainwater collecting well and the filtering well is formed below the partition wall, the bottom of the filtering well is a slope gradually descending towards the bottom of the flow passing channel from the wall of the filtering well, the water outlet pipe is positioned on the wall of the filtering well, the water inlet pipe is positioned on the wall of the rainwater collecting well, the upper part of the filtering well is provided with a filtering structure which is positioned below the water outlet pipe, the bottom of the wall of the rainwater collecting well is connected with a mud sludge discharge pipe, and a sluice valve is arranged on the mud sludge discharge pipe. The reverse filtering structure is adopted inside the rainwater well, the structure is simple, the construction is easy, the filtering effect is obvious, and the filtering structure is easy to wash, clean and replace.

Owner:TIANJIN UNIV

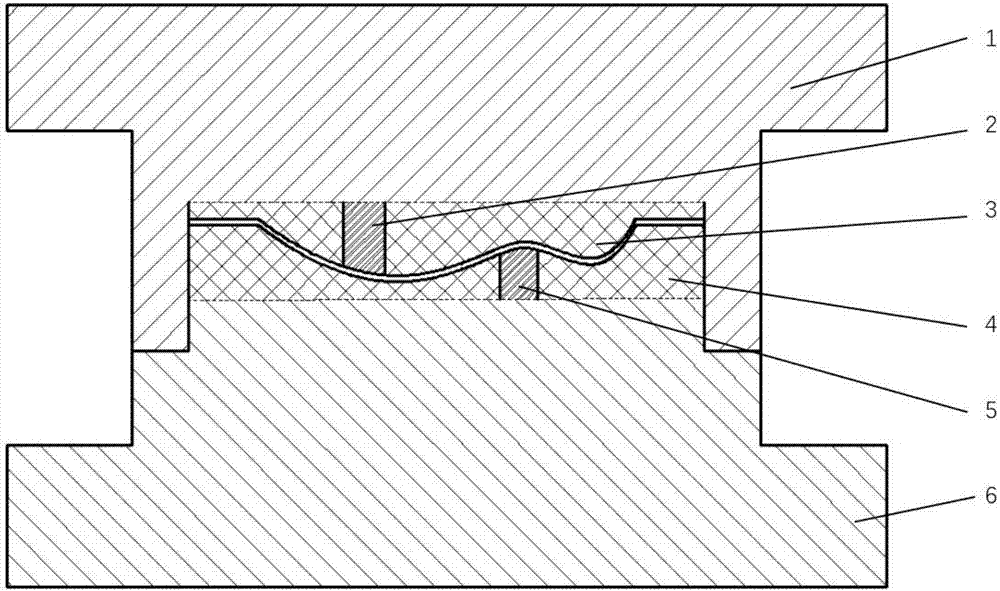

Rapid manufacturing method for metal 3D printing injection mold of structure facing gradient space

ActiveCN107186215ALow service lifeLow and high service lifeAdditive manufacturing apparatusIncreasing energy efficiencyWater channelSpatial structure

The invention provides a rapid manufacturing method for a metal 3D printing injection mold of a structure facing a gradient space. The rapid manufacturing method comprises the steps that the injection mold is designed according to the characteristics of an injection molded part at first, meanwhile, the injection mold is partitioned according to the service characteristics and the molding characteristics of the injection mold in the injection molding process, decoupling optimization is conducted, and the injection mold is divided into a molding area, a supporting area and a function area; then the molding area of the injection mold is manufactured through a metal 3D printing mode; the supporting area of the injection mold is manufactured through a machining mode; the function area of the injection mold is manufactured through a metal 3D printing mode and is a molding insert or a cooling insert with a conformal cooling water channel; and the molding area, the supporting area and the function area are fastened and connected in a bolted connection or inserted connection mode finally. According to the rapid manufacturing method for the metal 3D printing injection mold of the structure facing the gradient space, the manufacturing efficiency of the injection mold is improved, the service life of the injection mold is prolonged, meanwhile, the cooling rate of the injection mold is increased so that the injection molding efficiency can be significantly improved, and the problem that the inconsistency is required by the material performance in the service process is solved.

Owner:XIAN LIANCHUANG ADVANCED MFG A SPECIALIZED INCUBATOR CO LTD

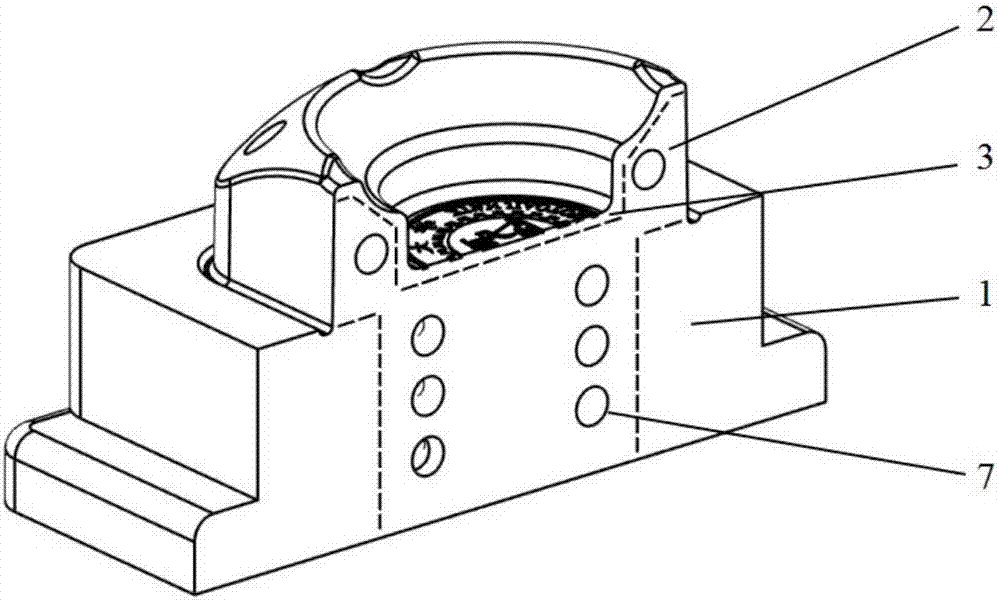

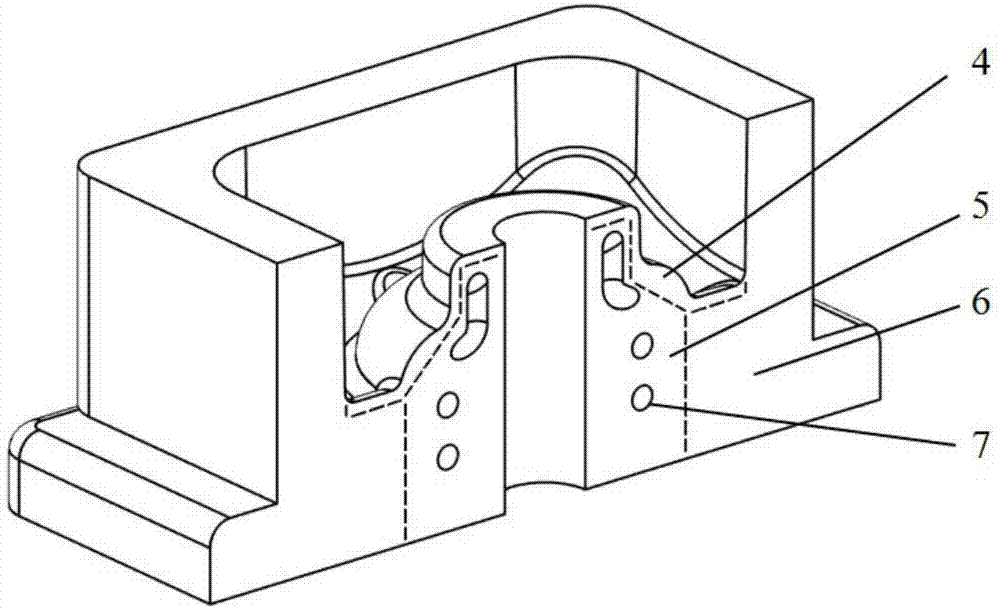

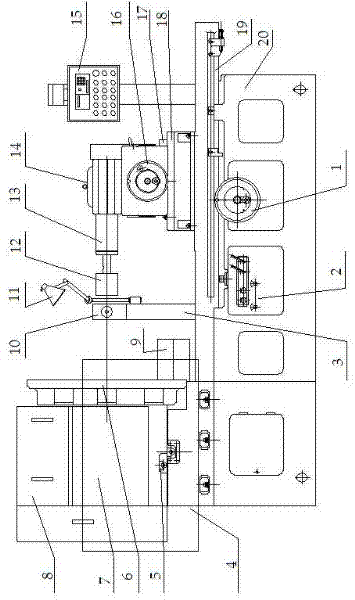

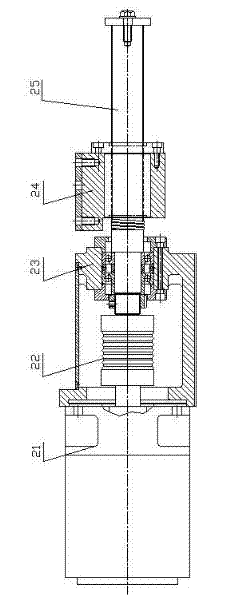

CNC (Computerized Numerical Control) automatic internal grinding machine for bearing ring

InactiveCN102211299ACompact structureImprove rigidityRevolution surface grinding machinesAbrasive surface conditioning devicesNumerical controlControl system

The invention relates to a CNC (Computerized Numerical Control) automatic internal grinding machine for a bearing ring. The internal grinding machine comprises a lathe body, a reciprocating worktable, a grinding wheel shaft assembly, a workpiece axle box, a grinding wheel dresser, a longitudinal feed transmission mechanism, a transverse feed transmission mechanism, a cooling system, a hydraulic lubrication system, a CNC control system host and operating panel, and an electrical control system, wherein the reciprocating worktable, the grinding wheel dresser and the workpiece axle box are arranged on the lathe body; the grinding wheel shaft assembly is arranged on the reciprocating worktable; the longitudinal feed transmission mechanism and the hydraulic lubrication system are arranged inside the lathe body; the transverse feed transmission mechanism is arranged on a grinding wheel seat; the cooling system and the electrical control system are arranged at the rear side of the lathe body; the CNC control system host and operating panel is arranged above the reciprocating worktable; and the reciprocating worktable is arranged on a guide rail of the lathe body. The CNC automatic internal grinding machine for the bearing ring, provided by the invention, has the outstanding advantages of simple and compact structure, strong static and dynamic rigidities, locating precision, good performances of anti-vibration and vibration reduction, good precision retentivity, light friction and abrasion, long service life, easiness for operation and maintenance, safety, saving energy, environment friendliness, attractive appearance and the like.

Owner:大连沃飞亚装备制造有限公司

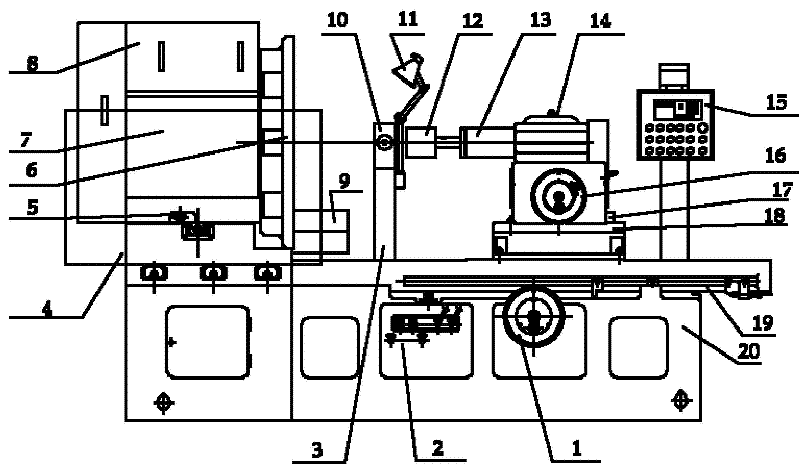

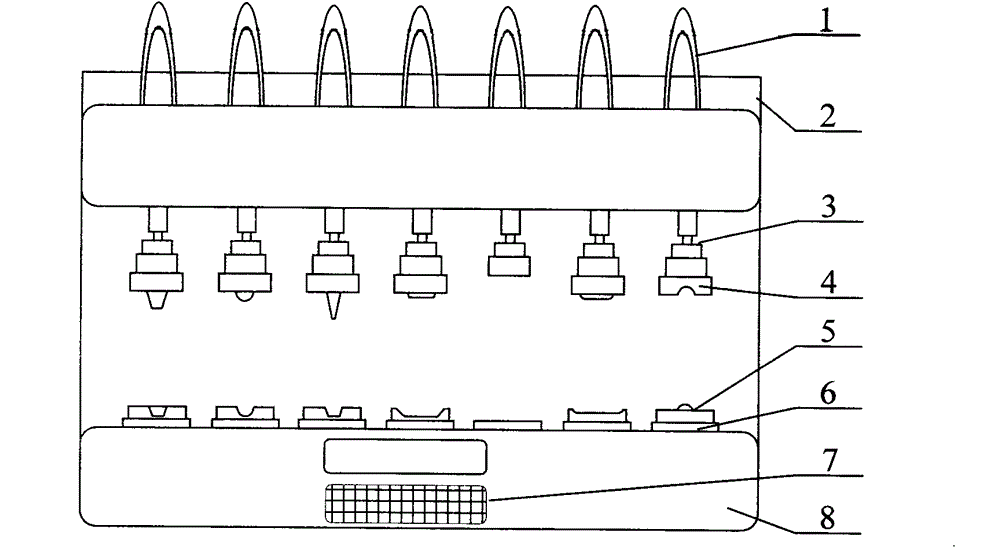

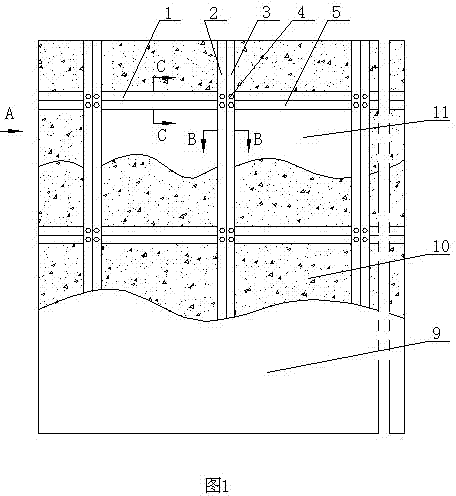

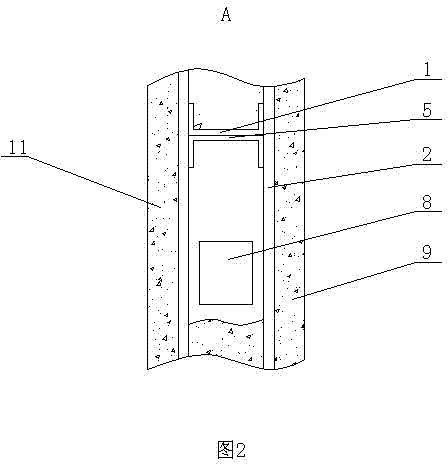

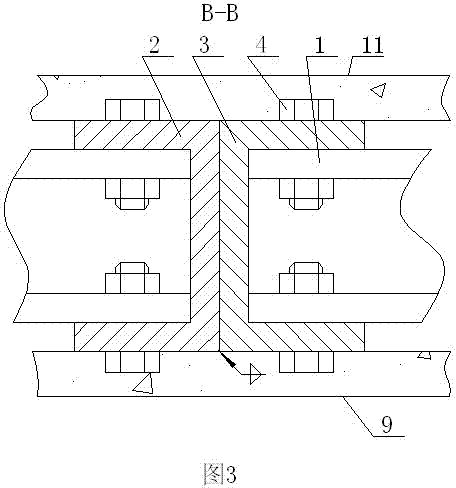

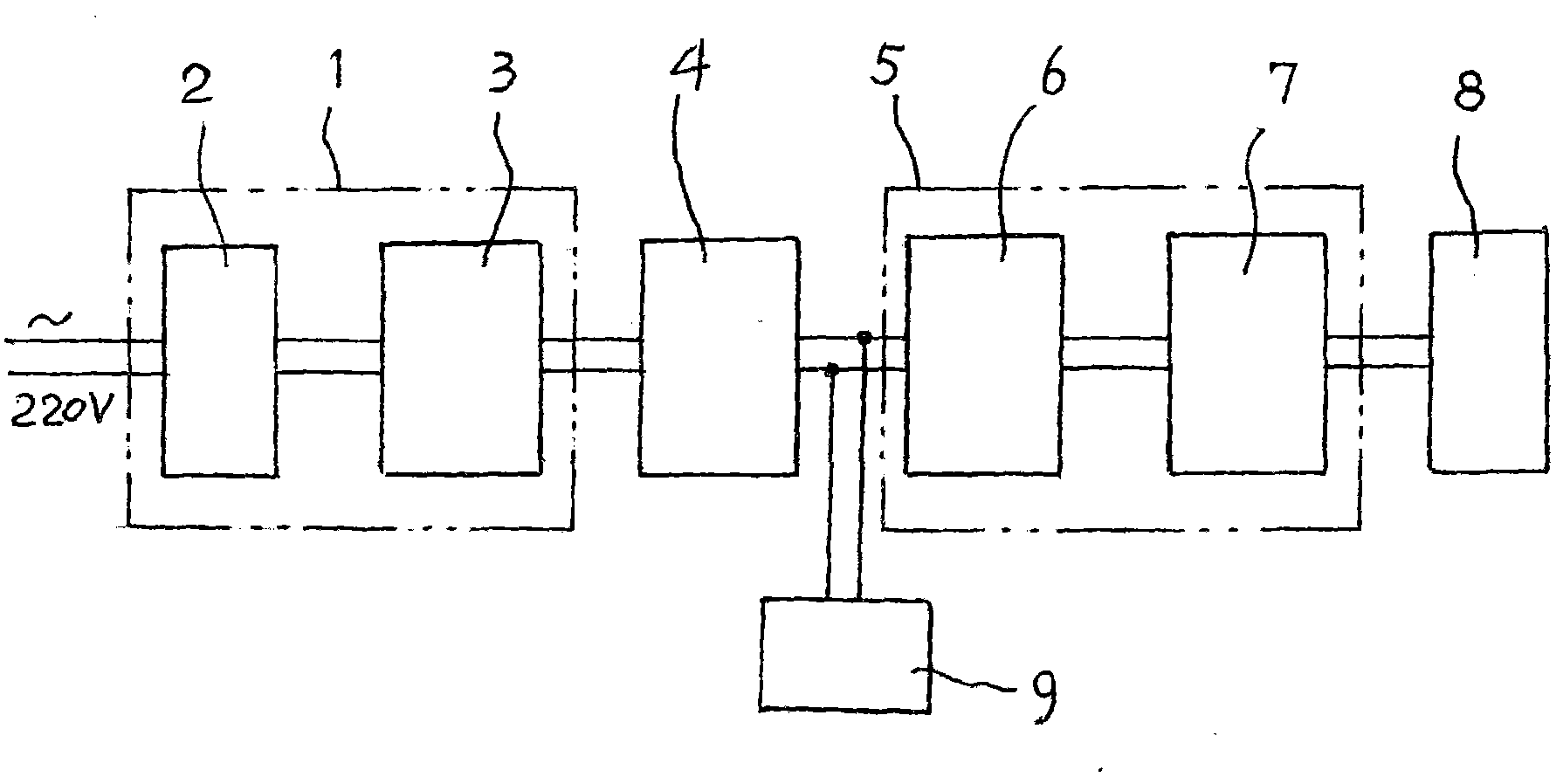

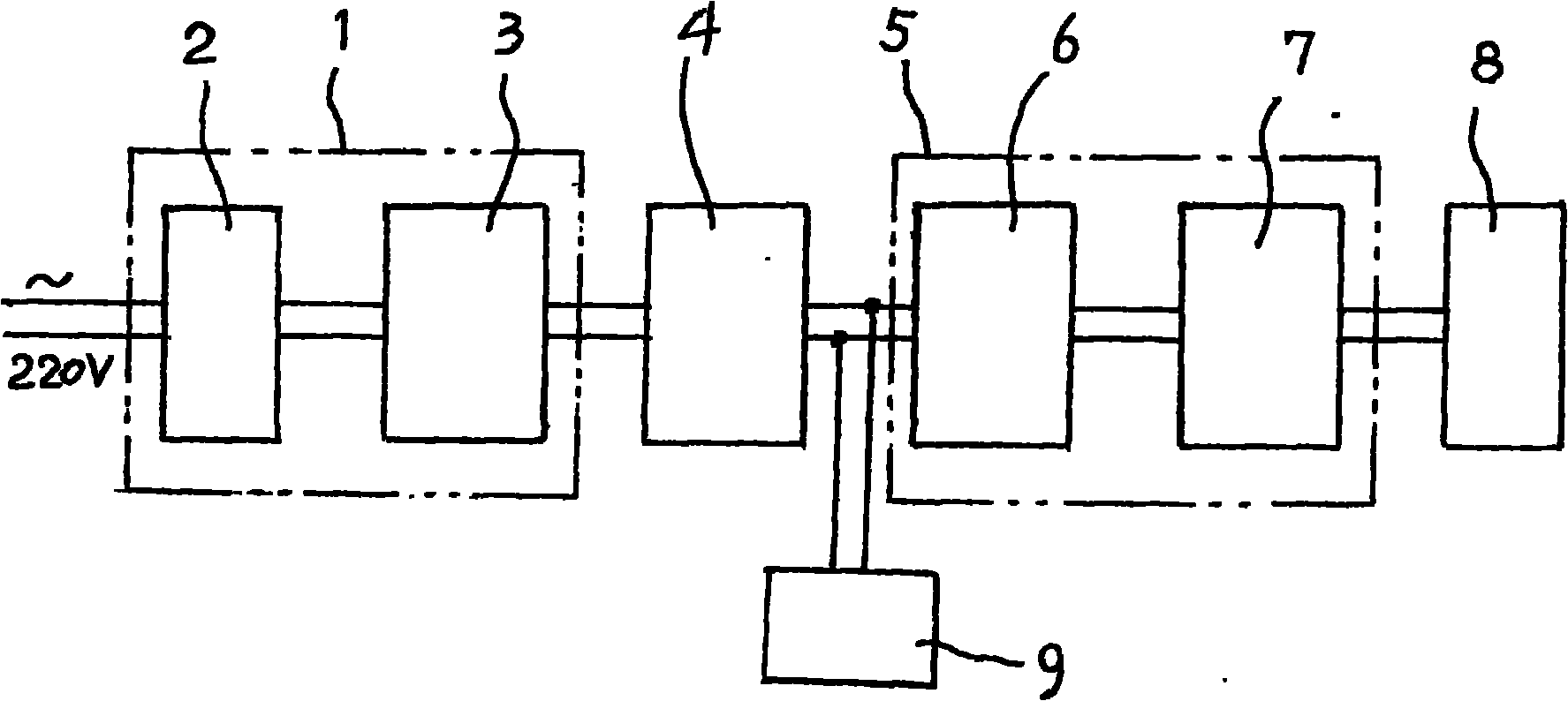

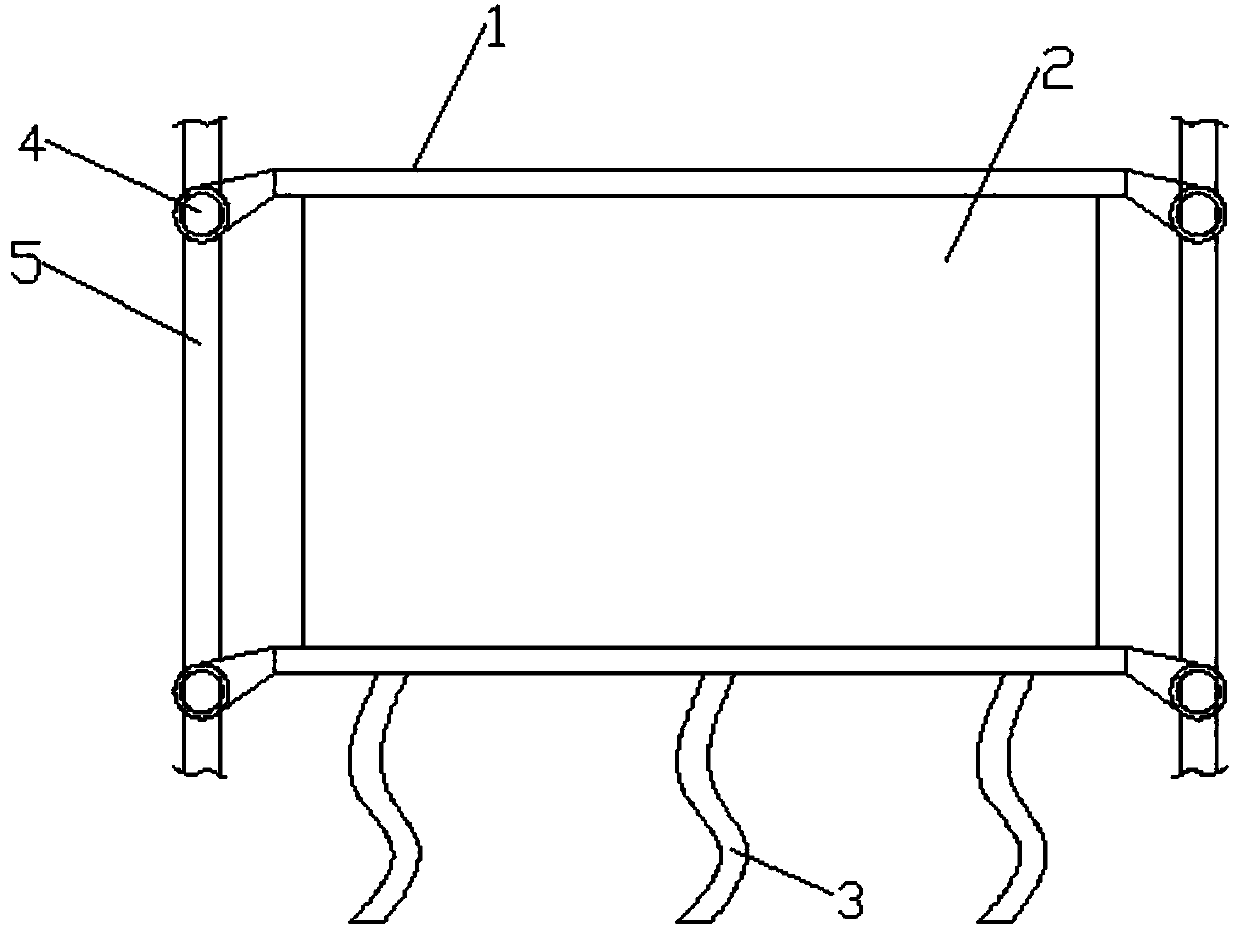

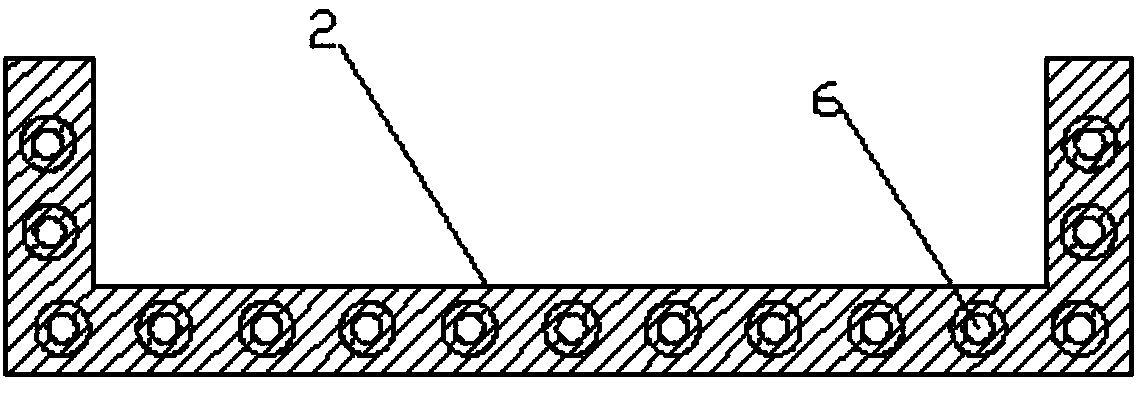

Straightly-arranged multi-station punching machine

The invention relates to a straightly-arranged multi-station punching machine. The straightly-arranged multi-station punching machine comprises hydraulic devices (1), a machine body (2), more than two groups of mold heads (3) and a working platform (8), wherein the working platform (8) is arranged at the middle part of the machine body (2), and the mold heads (3) in straight arrangement are mounted above the working platform (8) and are connected with the hydraulic devices (1). Multiple groups of punching machine stations are arranged straightly, centralized control and operation are adopted, and punching molds can be respectively arranged on the independent stations, so that multiple continuous related punching processing processes can be continuously completed on the same equipment, or multiple different punching processes can be carried out on one workpiece; the use is accurate and fast, the rate of finished products of workpieces can be increased, and the productivity is increased, so that the straightly-arranged multi-station punching machine is very practical; the overall layout is reasonable, the size is small, the weight is light, the operation is simple, convenient and flexible, the service life is long, and the universality is strong, so that the punching machine is convenient, durable and safe; and the punching machine can be operated by one person only, so that the processing quality can be improved, and the processing efficiency can be increased.

Owner:新疆帅府高新技术有限公司

Efficient wood particle active carbon for automobile carbon tank and preparation method thereof

ActiveCN107140636AImprove efficiencyHigh purityNon-fuel substance addition to fuelCarbon compoundsSodium BentoniteDesorption

The invention discloses wood particle active carbon for an automobile carbon tank and a preparation method thereof, and belongs to the fields of active carbon for the automobile carbon tank and the preparation method of the active carbon. The weight ratio of major raw material ingredient of wood active carbon powder to organic sodium-based bentonites to water is 1:(0.2 to 0.25):(0.8 to 1.0); the three kinds of raw materials are uniformly stirred and are then pelleted; after pelleted particles are dried, physical activation is performed to obtain the wood particle active carbon; the wood active carbon powder is formed by mixing aged wood chips and thermal-process food stage phosphoric acid with the concentration being 85 percent according to a weight ratio of 1:(1.2 to 1.5) through fully stirring, still soaking, high-temperature carbonization activation, recovery, rinsing, drying and powder preparation. The preparation method comprises two major work procedures of wood active carbon powder preparation and wood particle active carbon preparation. The product strength is high; the effective aperture pore volume is more developed; the distribution is more uniform; the adsorption and desorption performance is good; the gas flowing resistance is small.

Owner:湖南御洁新材料科技有限公司

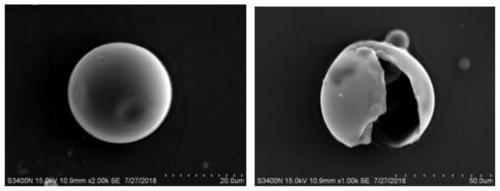

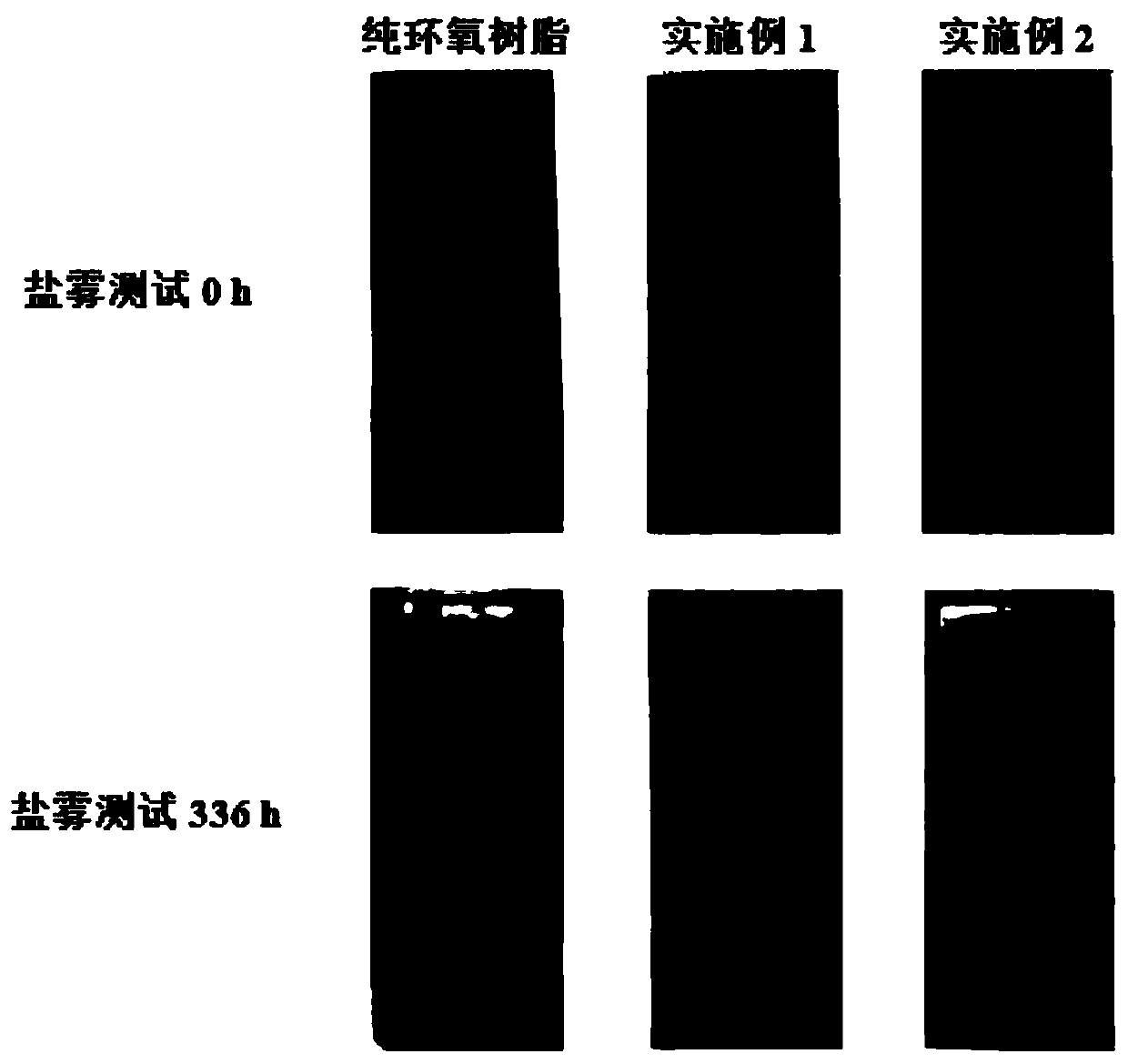

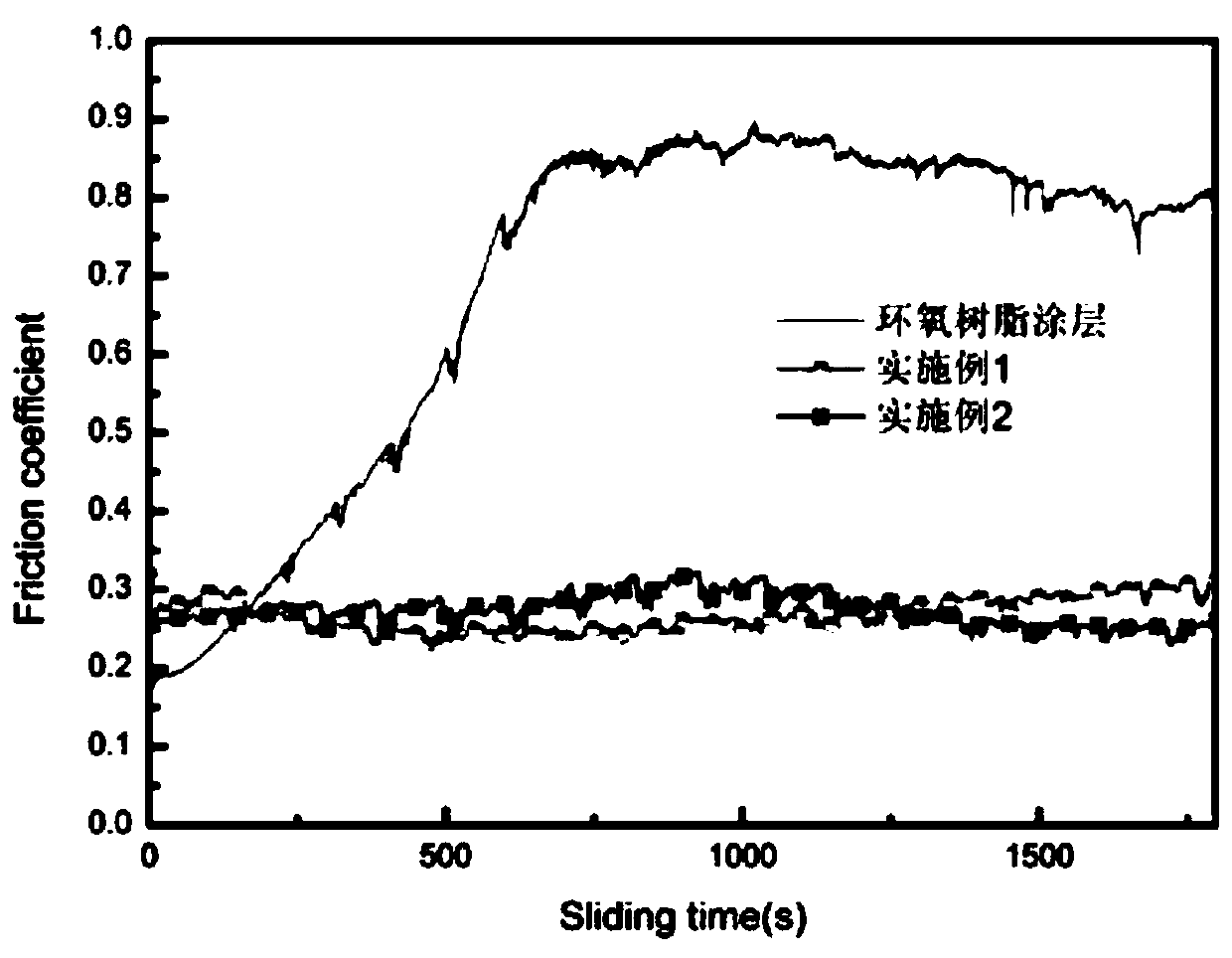

Self-repairing self-lubricating bifunctional anticorrosive coating and preparation method thereof

InactiveCN109971311AReduce harmExtended service lifeAnti-corrosive paintsEpoxy resin coatingsChemical structureLinseed oil

The invention discloses a self-repairing and self-lubricating bifunctional anticorrosive coating and a preparation method thereof and relates to the technical field of intelligent coatings. The anticorrosive coating comprises high-molecular resin and self-repairing and self-lubricating bifunctional microcapsules loaded in the resin. The bifunctional microcapsules are prepared by taking polyurethane as a wall material and linseed oil as a core material and adopting an interfacial polymerization method. The prepared bifunctional microcapsules have smooth and flat surfaces and are narrow in particle size distribution, high in core material content, stable in chemical structure, good in thermal stability and good in compatibility with high-molecular resin. The self-repairing and self-lubricating bifunctional anti-corrosion coating can respond to damage in time, self-lubrication and self-repair of the anti-corrosive coating are effectively achieved, and service life of the coating is prolonged.

Owner:GUANGXI UNIV +1

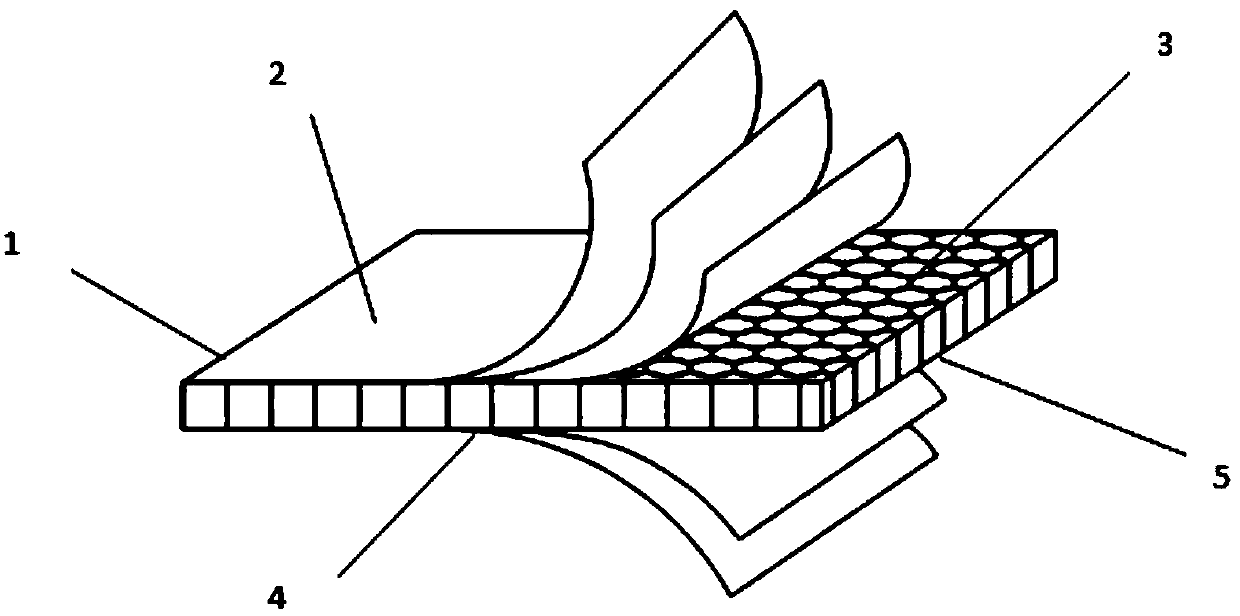

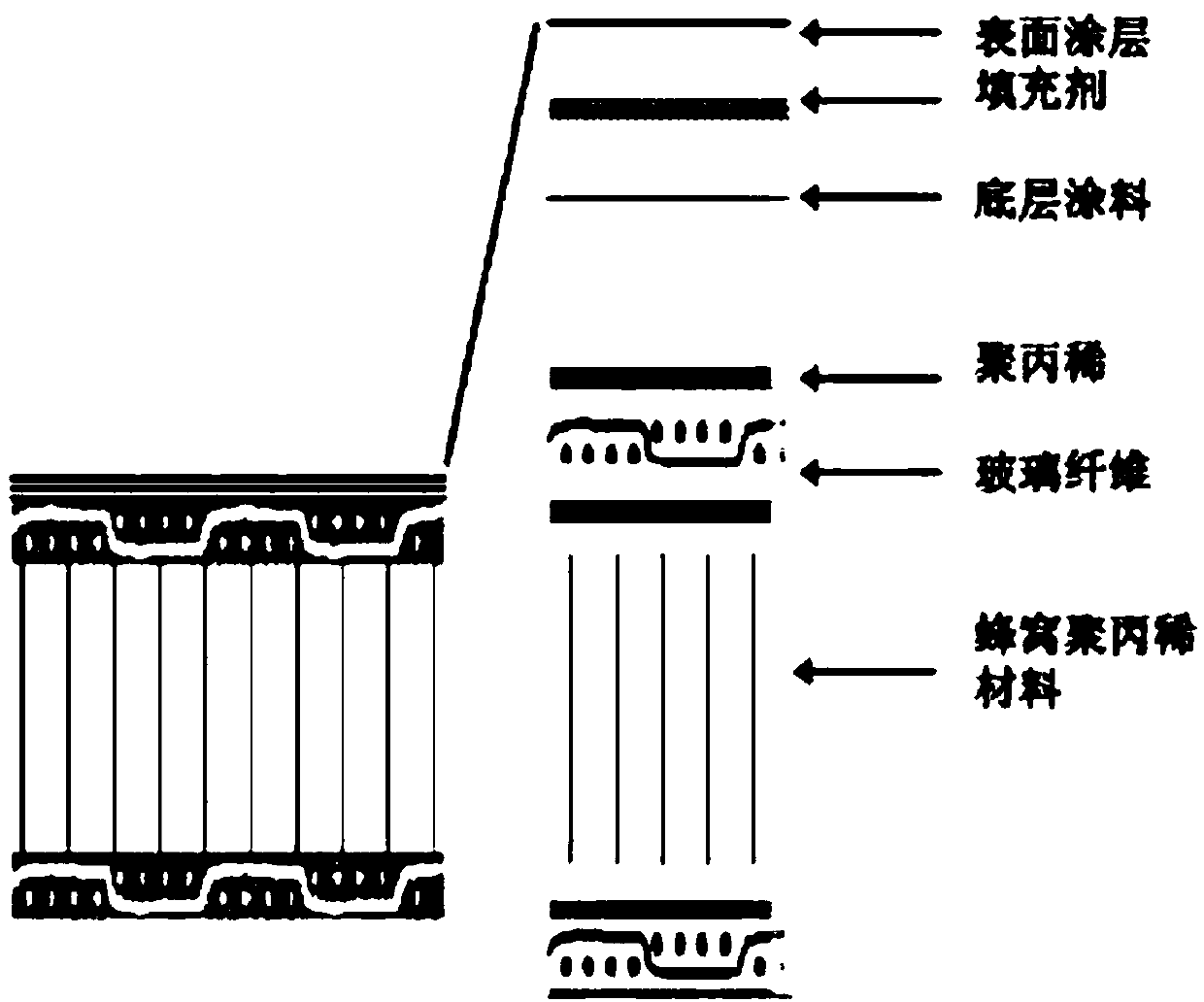

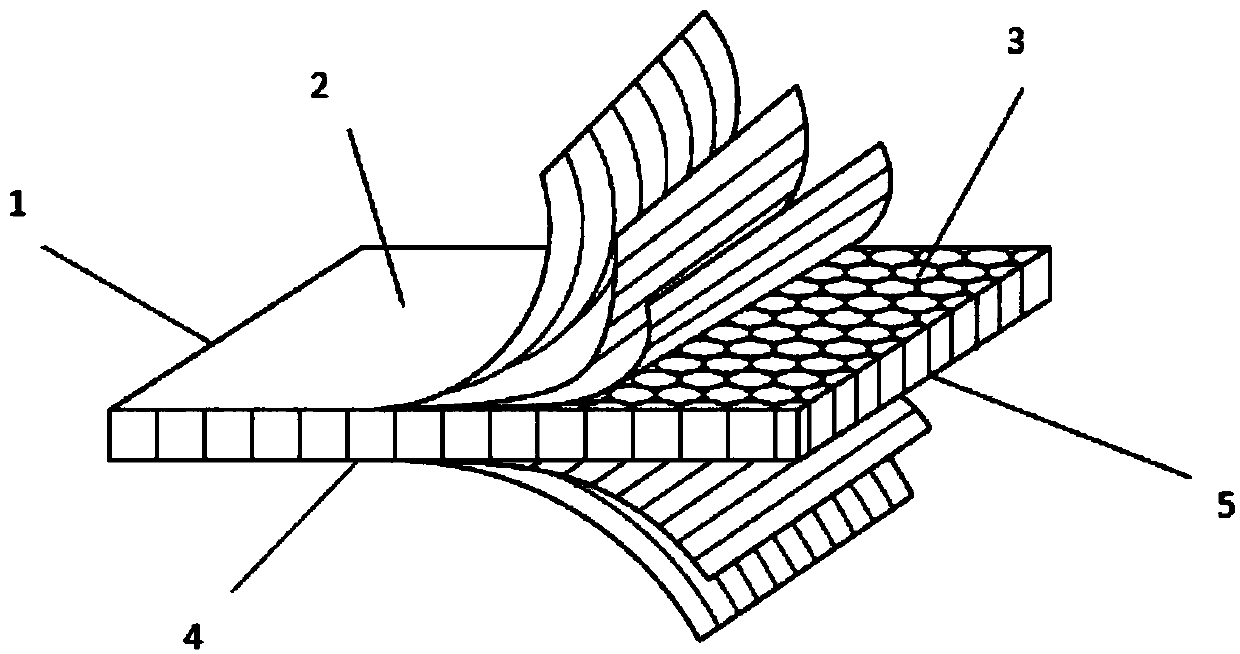

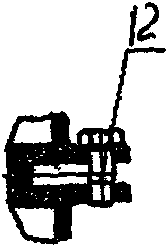

Novel lightweight environment-friendly pedal of scaffold for building, and production process thereof

InactiveCN108045049ALow costHigh degree of automationSynthetic resin layered productsLaminationGlass fiberFiber

The invention relates to a novel lightweight environment-friendly pedal of a scaffold for building. The pedal comprises a board, a top skin, a polypropylene honeycomb core material, a bottom skin, anda finished board, wherein the board is of a three-layer sandwich structure; the top skin and the bottom skin are both prepared by compounding multiple layers of continuous glass fiber polypropylene reinforced unidirectional prepreg tape; the pure polypropylene honeycomb core material is arranged at the center; and the skin of the continuous glass fiber polypropylene reinforced unidirectional prepreg tape is prepared polypropylene and continuous glass fibers through compounding, and the skin with a thickness of 0.6 to 2.0 mm and the pure polypropylene honeycomb core are subjected to hot-melting bonding on the finished board. The novel surface layer reinforcing material, i.e., the continuous glass fiber polypropylene reinforced unidirectional prepreg tape, is utilized in the invention, andhas strength and other properties several times better than those of short fiber felt or long fiber composite materials, and the high performance leads to reduction in used materials; i.e., under thecondition of same physical properties, the pedal using the continuous glass fiber polypropylene reinforced unidirectional prepreg tape saves more materials and is reduced in material cost.

Owner:浙江遂金复合材料有限公司

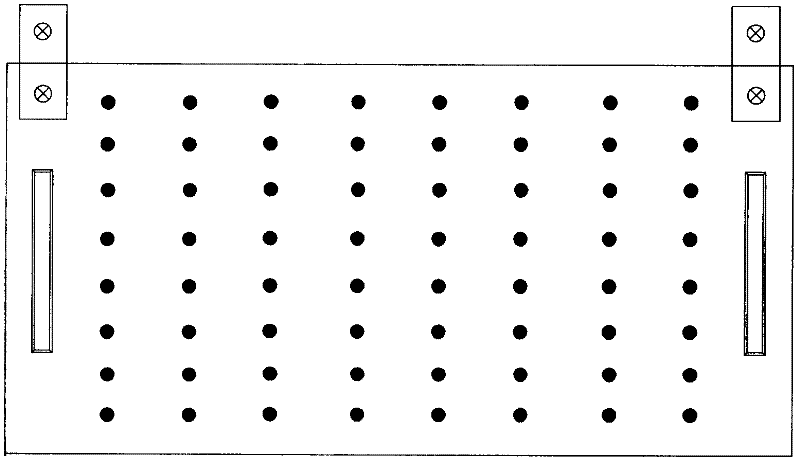

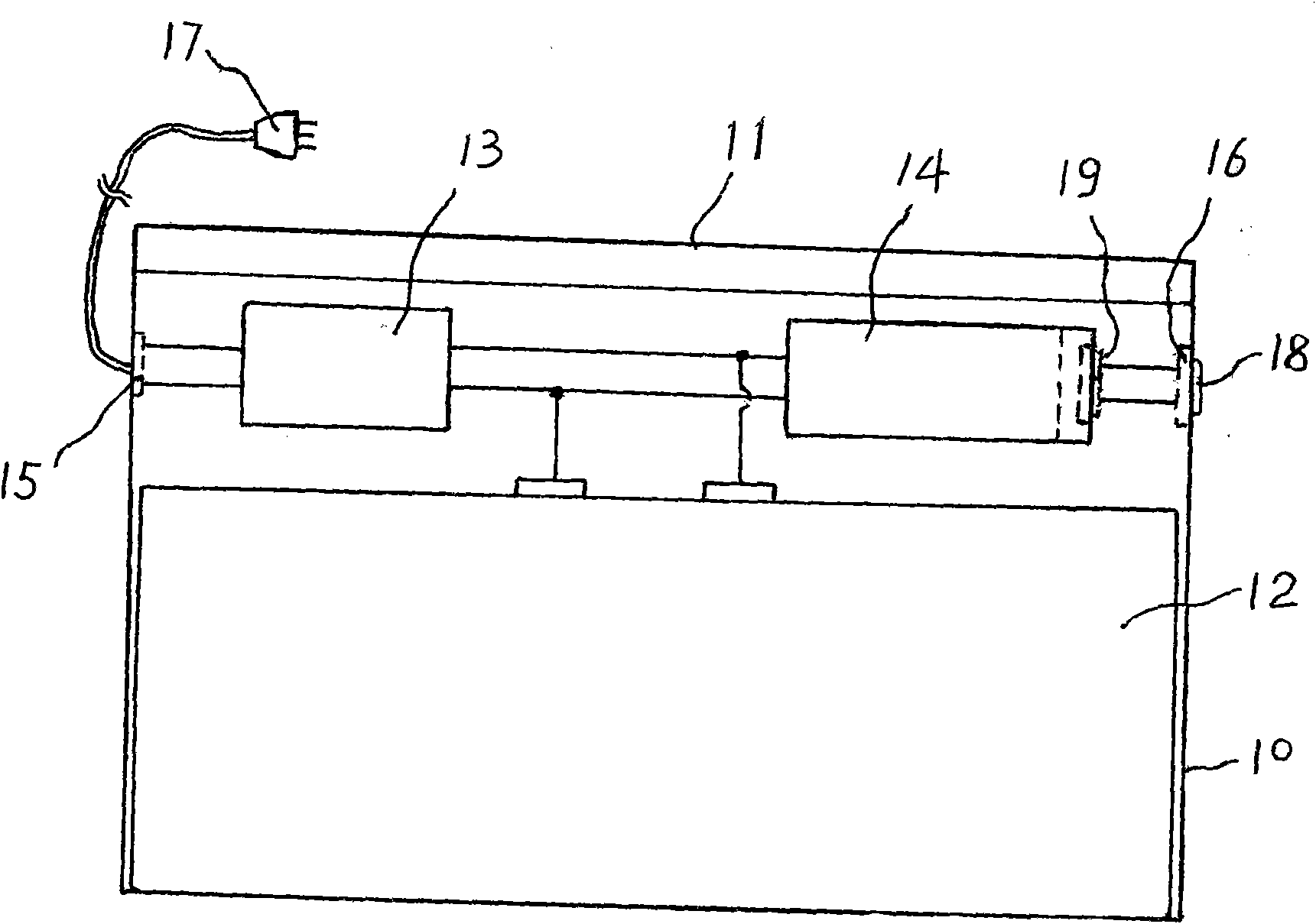

Device and method for simulating dynamic flame and simulated carbon bed

InactiveCN102162618ASimple structureThinElectric lightingElectric light circuit arrangementEnvironmental resistancePoint light source

The invention relates to a device for simulating dynamic flame and a simulated carbon bed. The device comprises a simulated flame light source, an imaging screen, a flame template, the simulated carbon bed and a carbon bed light source, wherein the flame template is arranged between the simulated flame light source and the imaging screen; at least the top and the lateral surface of the simulated carbon bed can transmit light, and the simulated carbon bed is placed in front of the imaging screen or between the imaging screen and the flame template; and the carbon bed light source is placed in the simulated carbon bed. The device is characterized in that: point light source arrays are adopted in the carbon bed light source and the simulated flame light source, and power supplies among the luminous bodies in the point light source arrays are independent with one another; and the device for simulating the dynamic flame and the simulated carbon bed also comprises an electric control devicefor controlling the magnitude of power supply voltage and the power supply time of each luminous body in the carbon bed light source and the simulated flame light source. Compared with the prior art,the device has the advantages of simple structure, no noise, low thickness, light weight, energy conservation, environment friendliness, long service life, strong third dimension of the simulated flame, easily changed flame shape and size and more vivid form.

Owner:宁波高博科技有限公司

High elasticity bat

A high-elasticity wadding is made of laminar polyester fibre floss and spherical polyester fibre cotton through hot pressing. Its advantages are high elasticity and air permeability and excellent insulating performance.

Owner:山东泰鹏新材料有限公司

Light steel concrete construction method

InactiveCN104763149ALow service lifeImprove insulation effectWallsBuilding material handlingCalcium silicateFoam concrete

The invention provides a light steel concrete construction method. The method is that a wall body is supported through a steel joist structure; fiber calcium silicate sheets or fiber cement plates are respectively fixed on two side surfaces of a steel joist; foam concrete is poured in the middle part of the wall body; the steel joist structure is formed by connecting longitudinal supporting frameworks and transverse supporting frameworks, wherein the longitudinal supporting framework is formed by integrally clinging and connecting two bottom plates of two groove type profile steels; two side surfaces of the longitudinal supporting framework are groove shaped; the transverse supporting frameworks are supported through the groove type profile steel; one end of the groove type profile steel is inserted into a groove in one side of one longitudinal supporting framework and fixed to the groove, and while the other end of the groove type profile steel is inserted into the groove in one side of another longitudinal supporting framework and fixed to the groove; through holes are formed in the groove type profile steels. The method has the advantages that the wall body is free of cracks and water penetration; an insulation layer is integrated with the wall body structure, so that the insulation effect is good, and the weight is light; the insulation layer of a concrete beam or a concrete column is integrated with the inner structure of the wall body.

Owner:张作岩

Portable-type domestic charge-discharge power supply box device

InactiveCN102044899ASolve urgent needsReduce weightBatteries circuit arrangementsElectric powerPower inverterElectricity

The invention relates to a portable-type domestic charge-discharge power supply box device. A charge device, a storage battery and a discharge power supply device are uniformly arranged in a box body, the charge device comprises a power input port and a charger provided with a voltage transformation rectification circuit, the power input port is connected with a commercial power socket served as a charge power supply through a lead plug, an output end of the charger is connected with an input port of the storage battery, the discharge power supply device comprises an inverter and a power output port, the power output port comprises a power socket or a power socket set electrically connected with an output end of the inverter, and the input port of the inverter is connected with the output port of the storage battery through a lead. The invention is convenient and safe to use, convenient to move and simple to install and maintain, has light weight, long service life and high cost performance, can provide longer alternating current power supply for users in time under the condition of temporary outage or sudden power cut, and can substitute a domestic small-sized diesel engine generator and has the functions of the domestic small-sized diesel engine generator.

Owner:林福长

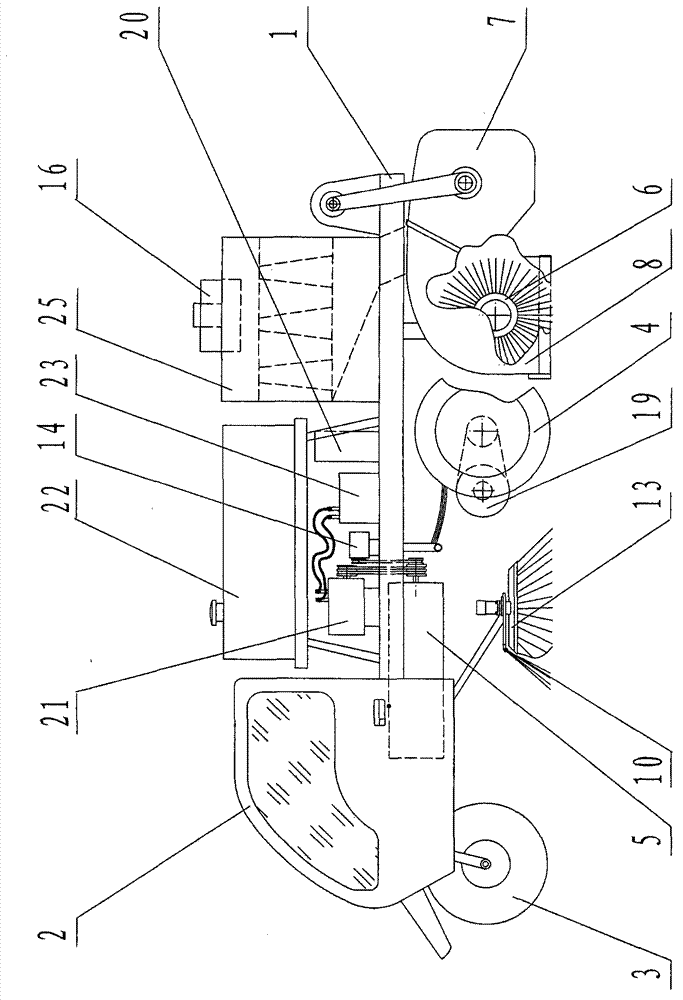

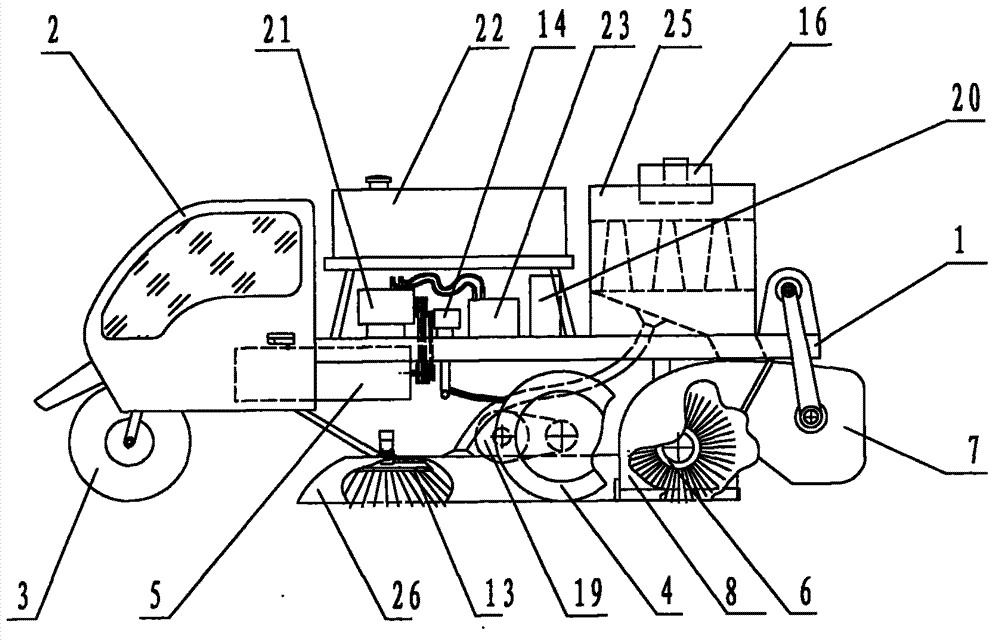

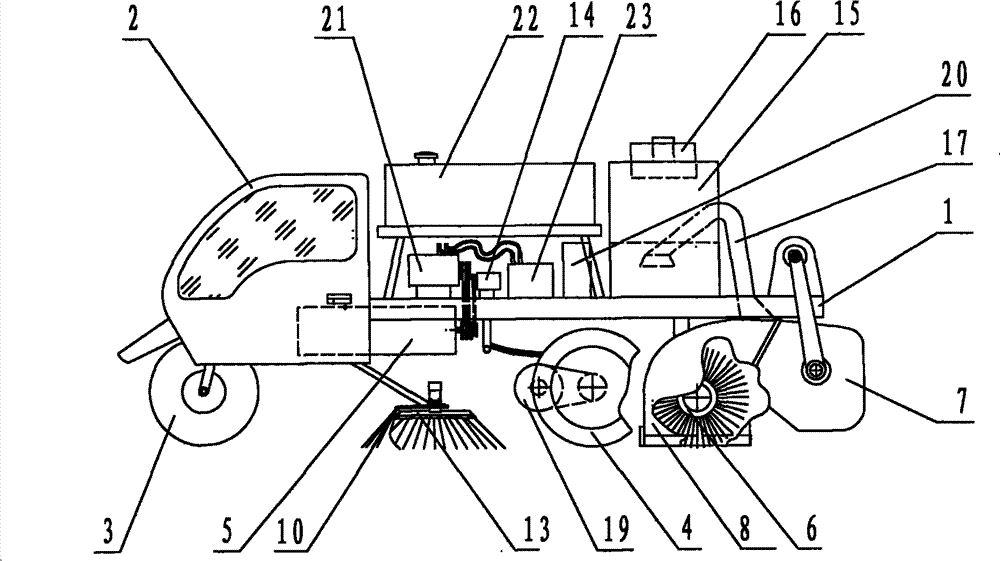

Three-wheeled road sweeper

InactiveCN103205948AReduce energy consumptionReduce configuration capacityRoad cleaningRoad sweeperDust control

The invention provides a mechanical electric hybrid power driven three-wheeled road sweeper which is provided with two power sources of an engine and a storage battery. Under the circumstance of driving a vehicle-mounted working device, the engine further drives a generator to be connected with a drive motor controller, the generator is further connected with the storage battery, the storage battery can be connected with an external charger and connected with the drive motor controller, and the motor controller is connected with a drive motor A to drive the road sweeper to travel at variable speed. Part, of instantaneous generating capacity of the generator, more than requirement of the motor A is used for charging the storage battery, part of the instantaneous generating capacity of the generator, less than the requirement of the motor A is replenished by the storage battery, and the storage battery changes in floating charge and discharge. The three-wheeled road sweeper is small, flexible in steering, high in work capacity, good in dust control effect, more suitable for sweeping bicycle lanes and sidewalks as compared with four-wheeled road sweepers, particularly suitable for sweeping urban roadways, air-conditioned, free of pollution of vehicle exhaust and dust to operators, and capable of working continuously limitlessly as compared with pure electric road sweepers.

Owner:赵国贵

Wood-pellet active carbon and preparation method thereof

The invention discloses wood-pellet active carbon and a preparation method thereof, and belongs to the field of active carbon for a car carbon tank and a preparation method for the active carbon. Thewood-pellet active carbon adopts main raw material components of wooden activate carbon to organic sodium-based bentonite to water of 1 to (0.2-0.25) to (0.8-1.0), the three raw materials are uniformly mixed and then are pelletized, and are physically activated after being pelletized and dried in air to prepare the wood-pellet active carbon; the wood active carbon is prepared by mixing aged saw dust and hot-process food-stage phosphoric acid with concentration of 85% in a weight ratio of 1 to (1.2-1.5); the raw materials are sufficiently stirred and stewed, are carbonized and activated at a high temperature, are recycled, are rinsed, are dried in air and are prepared into powder. The preparation method comprises two main processes of preparing wood active carbon powder and preparing wood-pellet active carbon. The wood-pellet active carbon is high in product strength, is more advanced in effective aperture pore volume, is more uniform in distribution, is good in adsorption and desorption performance, and is small in gas flowing resistance.

Owner:玉山县三清活性炭有限公司

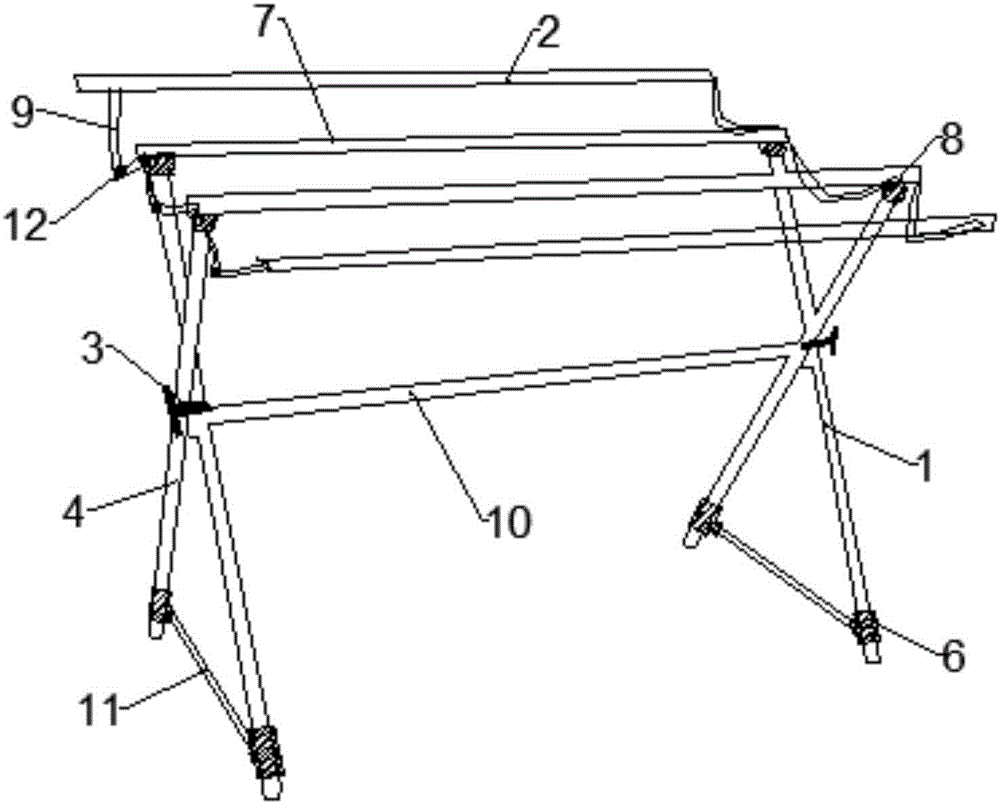

Novel carbon high-strength laundry rack

InactiveCN106319896AEasy connectionLight in massOther drying apparatusTextiles and paperCarbon steelLaundry

The invention discloses a novel carbon high-strength laundry rack. The novel carbon high-strength laundry rack comprises supporting frames and suspending frames. Rotating shafts and supporting legs are fixedly installed on the upper surfaces of the supporting frames, plastic sleeves are also arranged on the upper sides and the lower sides of the rotating shafts, the supporting legs penetrate through the plastic sleeves and are fixedly connected with the rotating shafts installed in the middles of the plastic sleeves, two-opening sleeves are fixedly installed at the bottom ends of the four supporting legs, and the supporting legs are fixedly installed at the tops of the two-opening sleeves; the suspending frames are fixedly installed at the tope ends of the supporting frames, cloth hanging rods are arranged on the surfaces of the suspending frames, support brackets are fixedly installed at the top ends of the supporting frames, folding devices are arranged on the two sides of the suspending frames, and adjustable bolts are fixedly installed at the bottom ends of the folding devices. The cloth hanging rods and the supporting legs of the novel carbon high-strength laundry rack are made from high-carbon carbon steel materials, the strength high, and the rusting-resistant performance is good; compared with a common laundry rack, folding is more convenient, and the novel carbon high-strength laundry rack is suitable for the family life.

Owner:WUHU SUNRISE NEW BUILDING MATERIALS TECH

Aluminum alloy template system receiving template embedded device

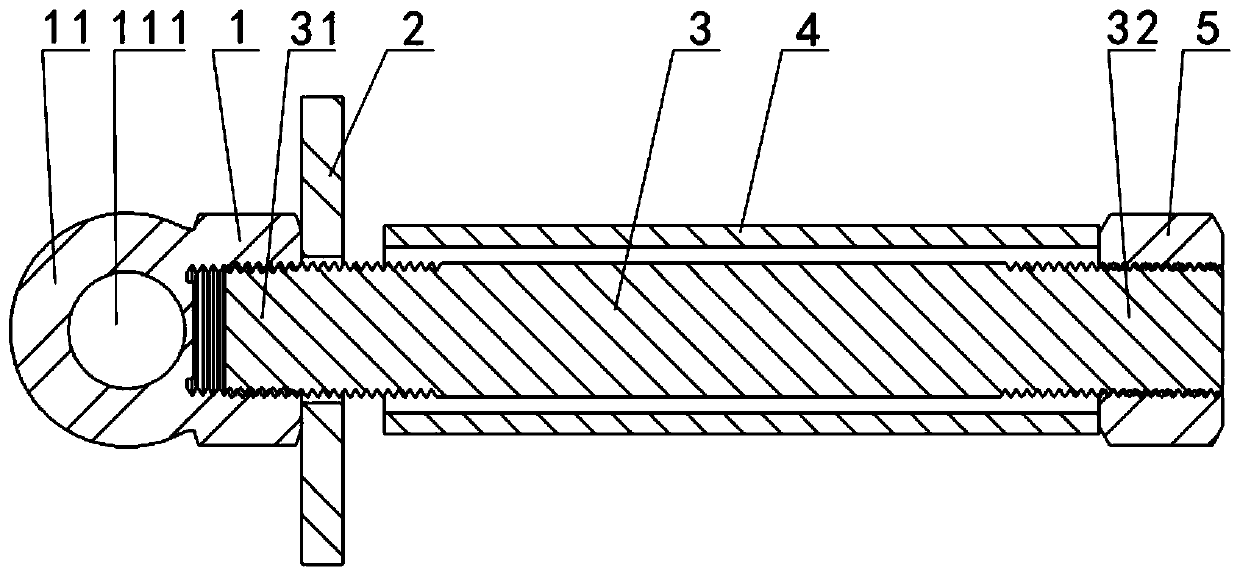

PendingCN110043033ALow costSimple structureAuxillary members of forms/shuttering/falseworksEngineeringScrew thread

The invention discloses an aluminum alloy template system receiving template embedded device which comprises a threaded rod, a screw cap, a gasket, a nut and a sleeve. A first threaded section and a second threaded section are arranged at the two ends of the threaded rod correspondingly, the threaded directions of the first threaded section and the second threaded section are opposite, the gasketand the screw cap sleeve the first threaded section from inside to outside, the nut sleeve the second threaded section, the sleeve sleeves the middle section of the threaded rod and is positioned between the gasket and the nut, a convex part is arranged at the outer end of the screw cap, a through hole is formed in the convex part, and the axial direction of the through hole is perpendicular to the axial direction of the threaded rod. According to the aluminum alloy template system receiving template embedded device, the threads with opposite directions are arranged at the two ends of the threaded rod, and the threaded rod can be driven to rotate and withdraw from the nut by rotating the screw cap after pouring is completed, so that the threaded rod, the screw cap and the gasket can be reused, and the loss cost is reduced; the through hole in the convex part of the screw cap can be matched with non-professional tools such as a common tapered rod or an iron rod to realize disassembly, disassembly can further be realized by professional tools such as wrenches, and the aluminum alloy template system receiving template embedded device is very convenient.

Owner:GUANGDONG ZHONGKE CONSTR

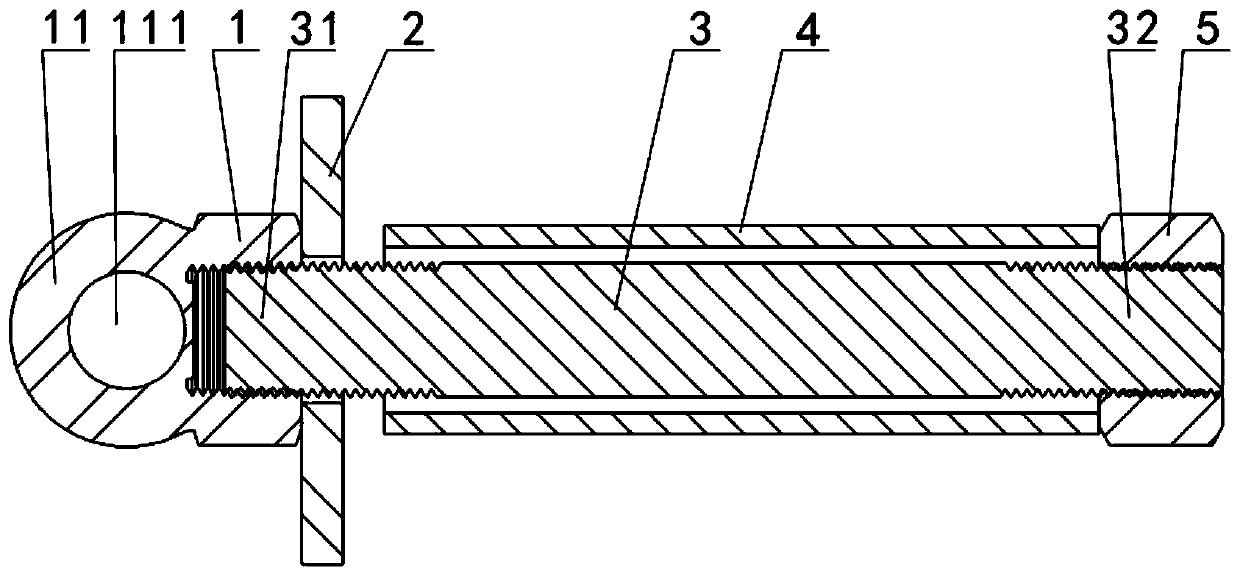

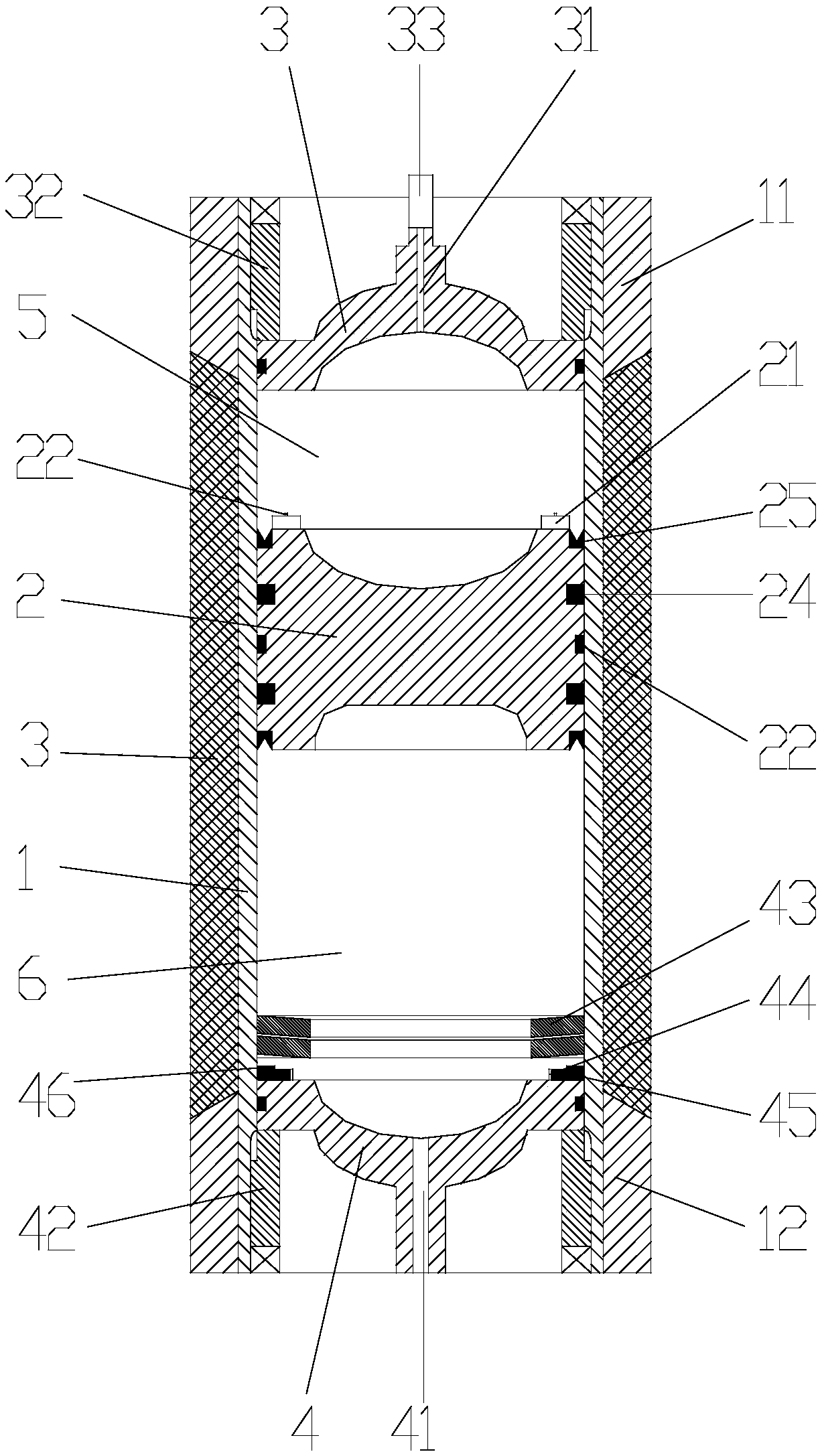

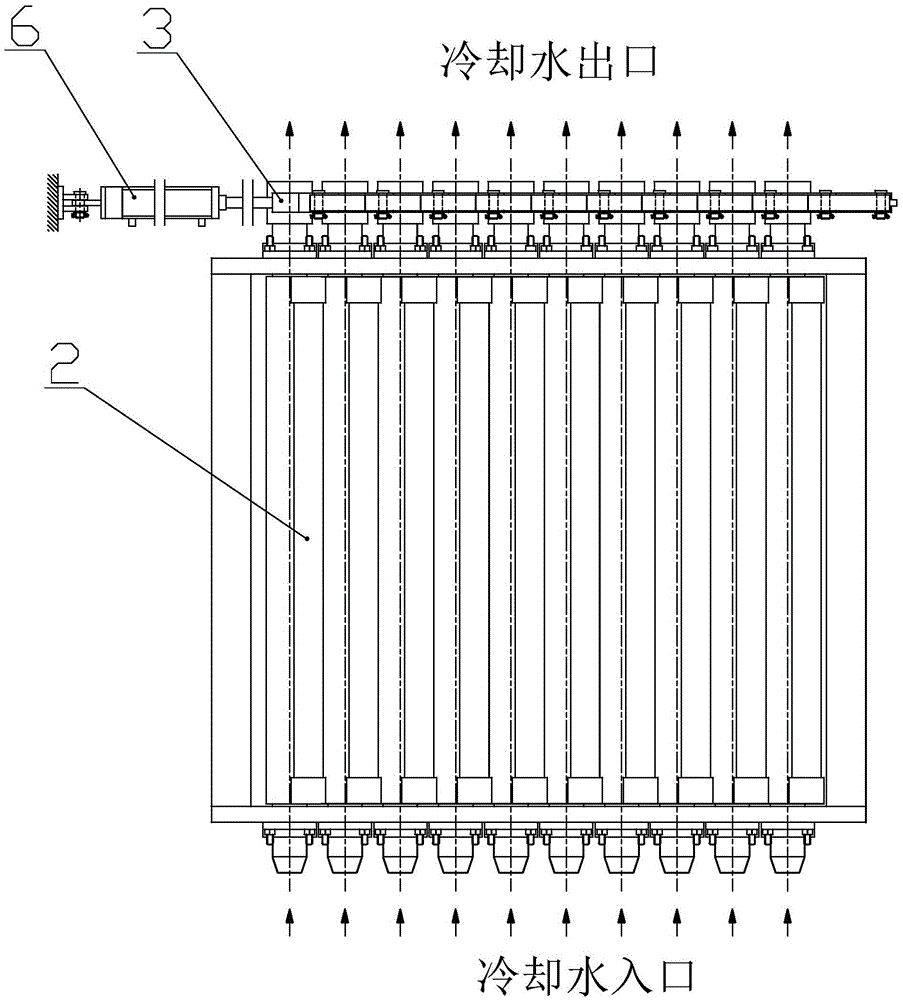

Novel winding type energy accumulator

The invention discloses a novel winding type energy accumulator. The accumulator comprises a cylinder body of the energy accumulator, a piston arranged in the cylinder body, a gas cover arranged abovethe cylinder body, and an end cover arranged below the cylinder body; the cylinder body is divided into an upper gas cavity and a lower oil cavity through the piston, the gas cover is provided with agas port communicating with the gas cavity, and the end cover is provided with an oil port communicating with the oil cavity; and the piston freely slides in the cylinder body under the action of pressure fluctuation of the oil cavity and the gas cavity, and initial pressure is derived from inert gas inflated into the gas cavity and having a predetermined pressure; and an upper locknut is arranged above the gas cover, the gas cover is connected with the upper portion of the cylinder body through the upper locknut, and an inflation valve is further arranged on the gas port. The energy accumulator is simple in structure, convenient to machine, good in sealing performance, free of process difficulties, convenient to install and set and capable of being popularized and used.

Owner:张劲

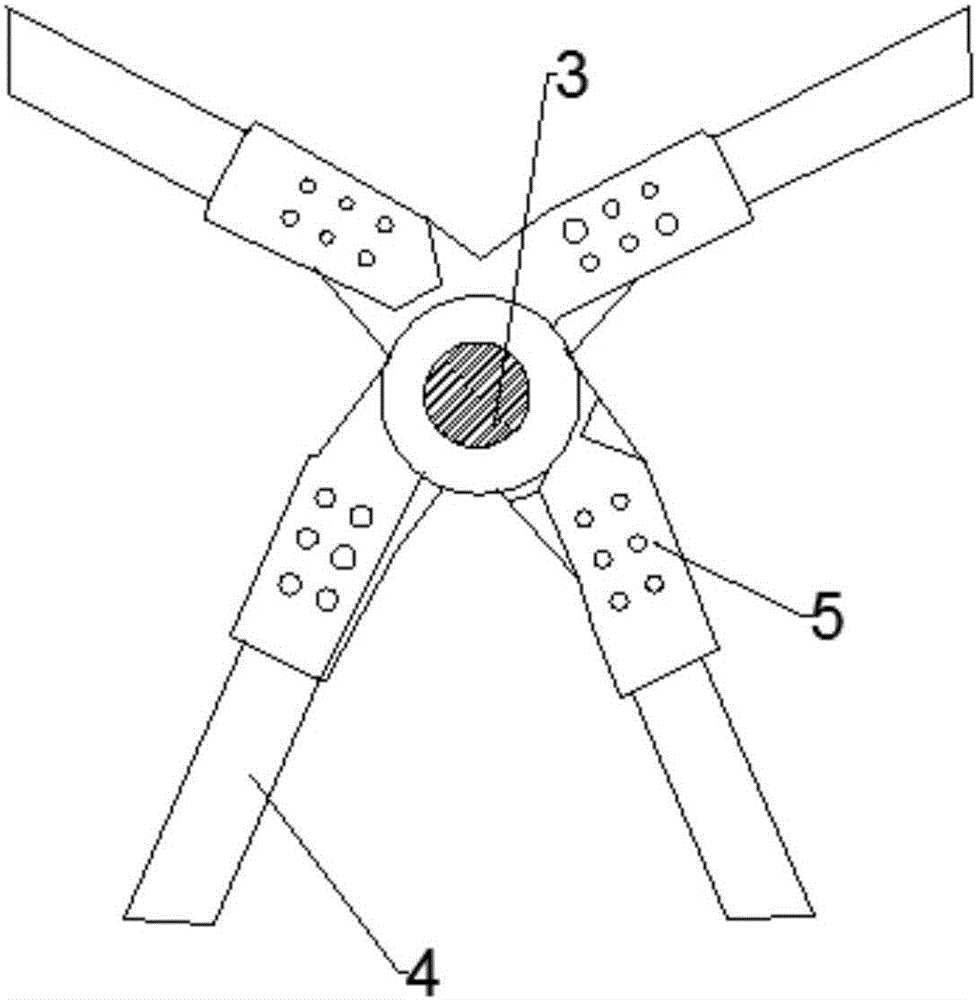

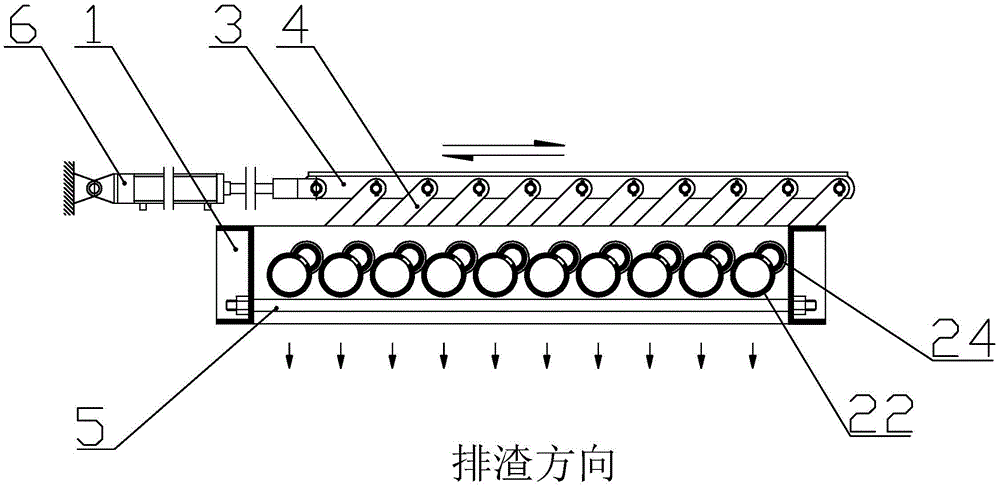

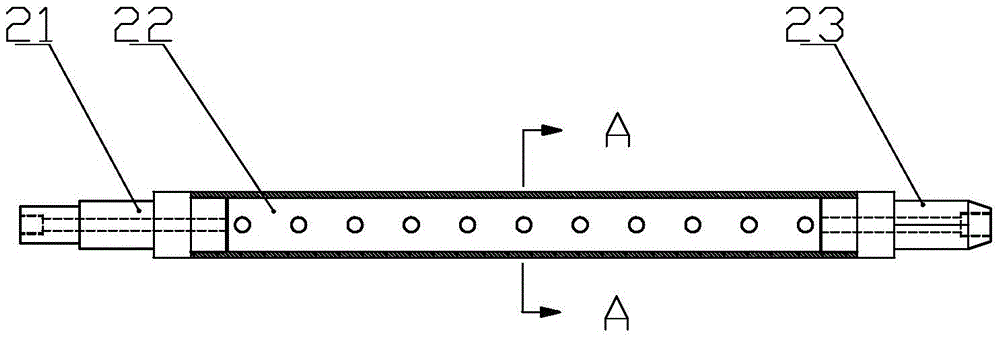

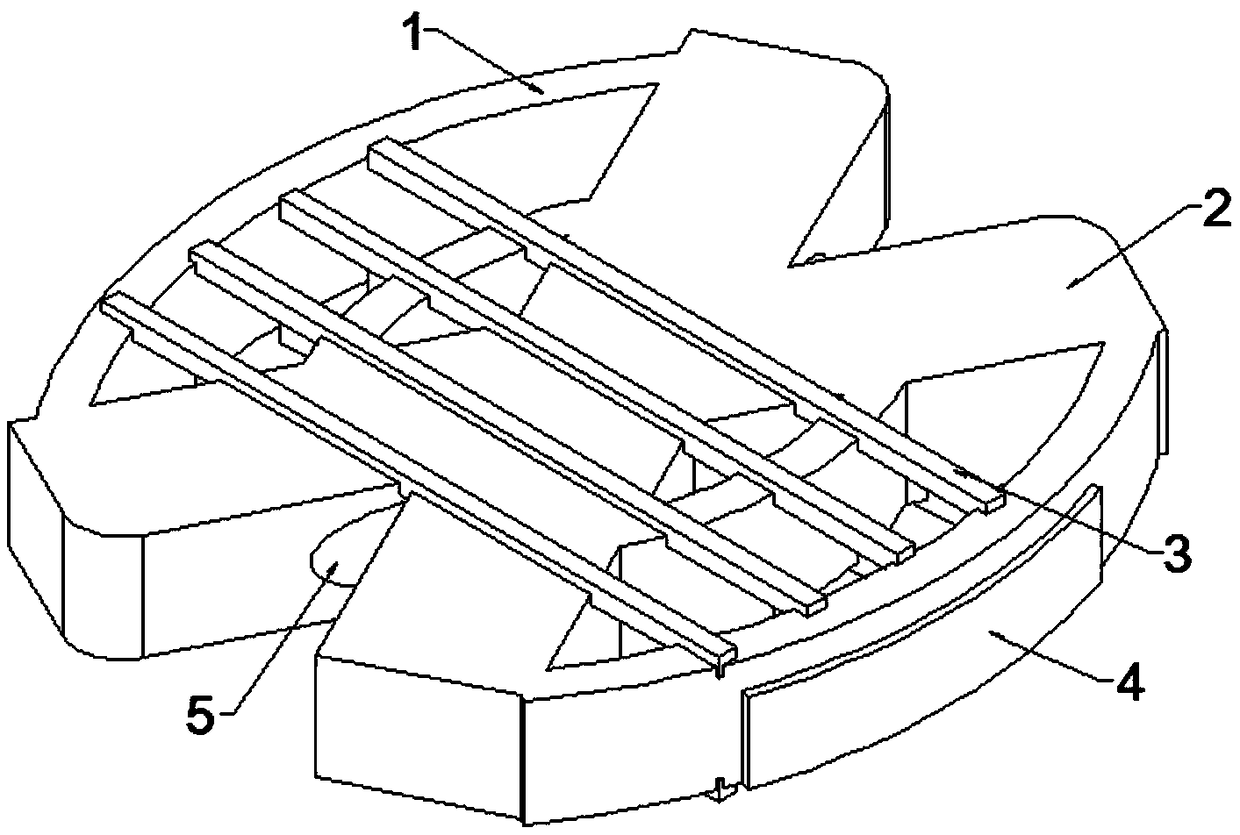

Reciprocating grate of biomass gasification furnace

The invention discloses a reciprocating grate of a biomass gasification furnace. The reciprocating grate of the biomass gasification furnace comprises a support and a plurality of grate bridges which are installed in the support side by side. A swing arm is fixedly connected to the end of each grate bridge. All the swing arms are connected with the same linkage rod. One end of the linkage rod is connected with a power source through a push-and-pull power head. The linkage rod is pushed and pulled by the power source through the push-and-pull power head to pull the swing arms to reciprocate, and then the grate bridges are driven to rotate in a reciprocating mode, so that gaps between the grate bridges are made to become large and small alternately. The reciprocating grate of the biomass gasification furnace is compact in structure and easy and convenient to operate, and the slag discharge gaps can change dynamically; the ash passing capacity is high, and the wind resistance is small; the covering performance is good when deslagging is not conducted; due to the fact that the reciprocating grate is of a hollow structure, the weight is low; the service life of equipment is long; the reciprocating grate can turn in a reciprocating mode so that connection of water pipes can be simplified, and the fault rate is decreased; continuous deslagging can be conducted without stopping the furnace, and thus the production stability is guaranteed; the labor intensity of operators is relieved, fuel waste caused by starting of the stopped furnace is also reduced, and accordingly economic benefits are greatly increased.

Owner:ZHUHAI BOKELAI ENERGY TECH

Household garbage regeneration disposal process and recycled concrete product thereof

InactiveCN104628281AThe production process is simpleEasy to implementSolid waste managementBuilding materialEnvironmental resistance

The invention discloses a household garbage regeneration disposal process. The process comprises the following steps: (1) collecting; (2) carrying out air separation; (3) carrying out first-stage crushing; (4) carrying out magnetic separation; (5) carrying out water separation; (6) carrying out second-stage crushing, so as to obtain a gravel product of 5-25mm. The invention further discloses a recycled concrete product made from the gravel product prepared by the household garbage regeneration disposal process. The household garbage regeneration disposal process disclosed by the invention is simple and easy in production process and easy in realization, can be used for solving the problem of regeneration utilization of household and construction wastes, and is used for rapidly producing the gravel product applicable to building materials; buildings constructed from the product produced by the process are good in structural strength, large in weight capacity, long in service life, light in self weight, low in cost, simple and convenient in processing and convenient in production and procurement, and have environment-friendly and economical characteristics, so that the competitive power is increased, and economic and social benefits are good.

Owner:北京鼎创环保有限公司

Plant cultivation method based on assembly type greening

PendingCN113133372AReduced survival rateReduced service lifeHops/wine cultivationTurf growingAgricultural engineeringGene technology

The invention discloses a plant cultivation method based on assembly type greening, and aims to solve the urgent problem about how to quickly and efficiently realize urban greening and ensure the survival rate of plants along with the increasing demands on greening of urban construction. The method comprises the following steps: determination of a cultivated plant, cultivation and shaping, transplanting and installation and later maintenance. The Lianggu assembly type greening is proposed for the first time, green plants are cultivated through a factory cultivator and planted in a customized mode according to a design drawing, and the plants such as flowers, shrubs and arbors can be selected and freely matched to achieve the needed landscape effect. The green plants planted through factory cultivation and soil layers of the green plants are integrally transplanted and installed on site, later maintenance is reduced, and therefore, a five-step integrated assembly mode including Lianggu customized design, Lianggu gene technology cultivation, Lianggu greening installation, Lianggu online detection and Lianggu operation maintenance is formed. With the adoption of the method, the greening coverage rate needed by buildings can be increased, and the building assembly rate is increased to the maximum extent.

Owner:MIANYANG LIANGGU TECH

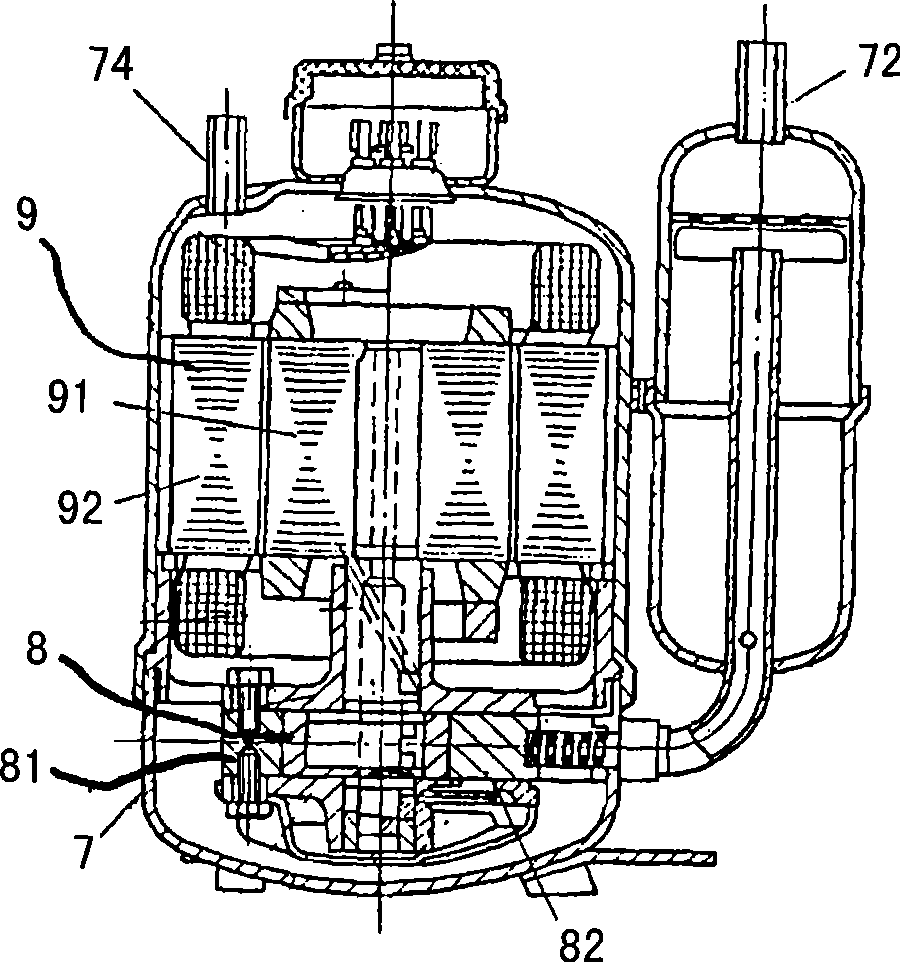

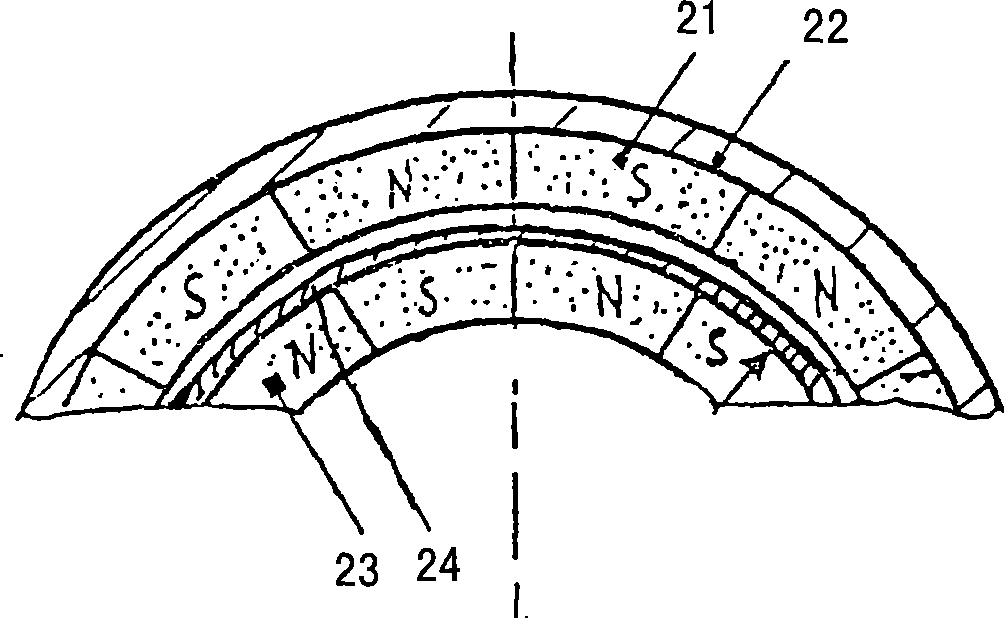

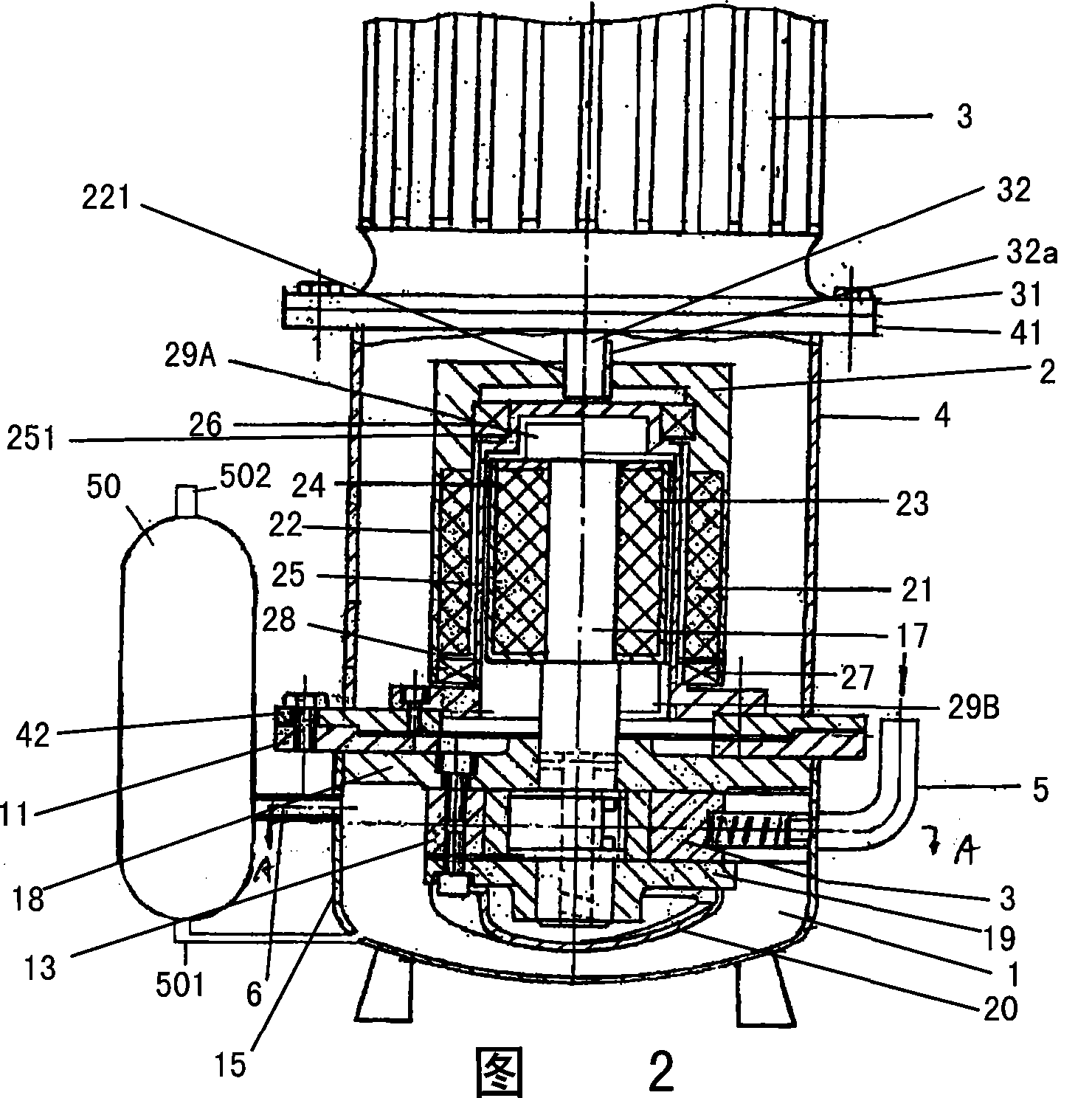

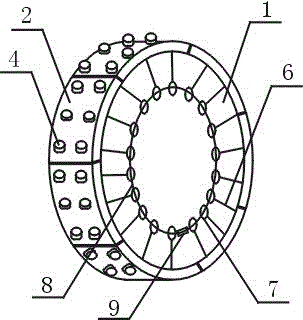

Rolling rotor type cold compressor

InactiveCN101275559BWon't breakPromote environmental protectionRotary piston pumpsRotary piston liquid enginesRefrigeration compressorOzone layer

The invention discloses a rolling rotor type refrigeration compressor, comprising an air inlet pipe, an air outlet pipe, a motor and a rolling rotor type compression device, wherein a magnetic coupling is connected between the motor and the rolling rotor type compression device. The magnetic coupling consists of a shield cover, the opening part of the shield cover is fixedly arranged the mouth ofthe case of the rolling rotor type compression device, and forms a sealing cavity with the case of the compression device. Ammonia can be used as refrigerant of the compressor, the atmospheric ozone layer is not damaged, and no greenhouse effect is caused, therefore, the invention has good environment protection effect. The compressor can be applied to domestic small air conditioners, as well as other fields needing gas compression and including refrigeration.

Owner:崔炳如

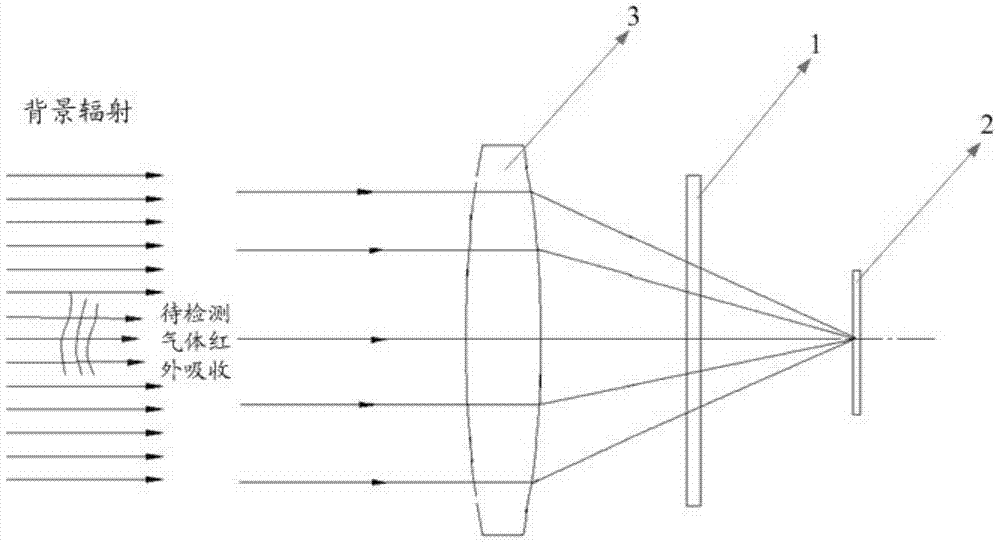

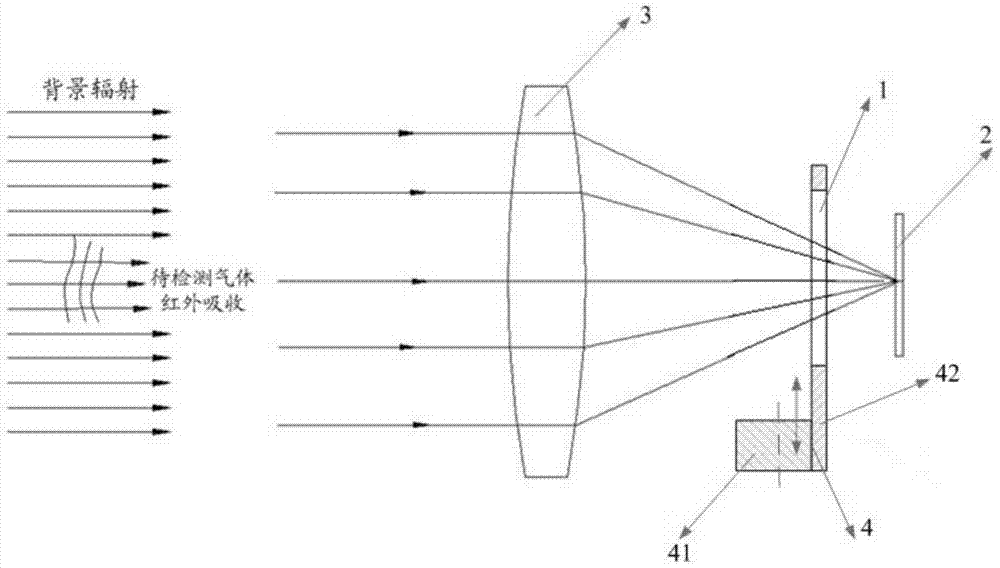

A gas detection device

ActiveCN104568806BEasy to use in different occasionsReduce power consumptionRadiation pyrometryMaterial analysis by optical meansLength waveRefrigeration

The object of the present invention is to provide a gas detection device. Specifically, the gas detection device includes: an optical filter, wherein the transmission band of the optical filter includes the corresponding infrared absorption peak wavelength of the gas to be detected; an uncooled infrared detector is used to acquire and output The infrared imaging information of the light sheet; the infrared lens is used to converge the infrared rays of the object to the uncooled infrared detector. Among them, compared with the prior art, the present invention implements a gas detection device by combining an optical filter with an uncooled infrared detector. The beneficial technical effect of the detector as a detector is mainly reflected in no refrigeration, low power consumption, small size, miniaturization, quick start, more convenient to carry, light weight, long service life, low cost, etc.; and the optical path of the present invention not only It is simple and easy to implement, and also reduces equipment production costs and the like.

Owner:SHANGHAI JUGE ELECTRONICS TECH

Vibration damping automobile luggage rack

InactiveCN107696983AEasy to fixSolve the situation of insufficient spaceSupplementary fittingsWear resistantMechanical engineering

A vibration damping automobile luggage rack comprises two fixed rods, a luggage basket and elastic ropes. Clamping rings are arranged at the both ends of each fixing rod. The luggage basket is arranged between the two fixed rods. The interior of the luggage basket is provided with vibration dampers. The vibration dampers are hollow spherical. The elastic ropes are also arranged on the fixed rods.The vibration damping automobile luggage rack solves the problem that the space inside the automobile is not enough when a large amount of luggage is transported, the storage space of the automobile is increased, the luggage basket and the elastic ropes are arranged, so that the luggage can be fixed conveniently, the vibration dampers are arranged, so that vibration generated during running of theautomobile can be effectively relieved, and the luggage basket is tough and wear-resistant, has a good anti-aging effect and long service life, is lighter in weight when being compared with a metal basket and is not prone to being corroded.

Owner:ANHUI CHENGYOU AUTO PARTS MFG

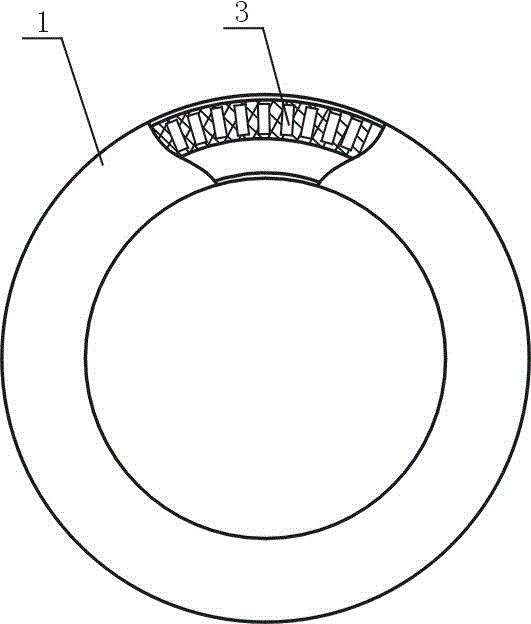

Antiskid inflating-free tire

The invention discloses an antiskid inflating-free tire comprising a tire body. A plurality of antiskid steel sheets are disposed on an outer surface of the tire body. A honeycomb-like airbag is arranged inside a cylindrical surface of the tire body. At least one antiskid columns protruding from the surface of the antiskid steel sheets are arranged on the antiskid steel sheets. Buckling edges are arranged on two sides of each antiskid steel sheet and are buckled with the tire body. The buckling edges are connected to at least one fastening steel wires in the radial direction of the tire body. The other end of each fastening steel wire is sleeved on a fastening steel wire rope through a sleeve ring. The antiskid inflating-free tire is effectively prevented from skid, is prolonged in service life, is free from being punched, is light in weight, is good in elasticity and can reduce fuel consumption of vehicles.

Owner:SHAANXI SHENGHUIYUAN INFORMATION SCI & TECH

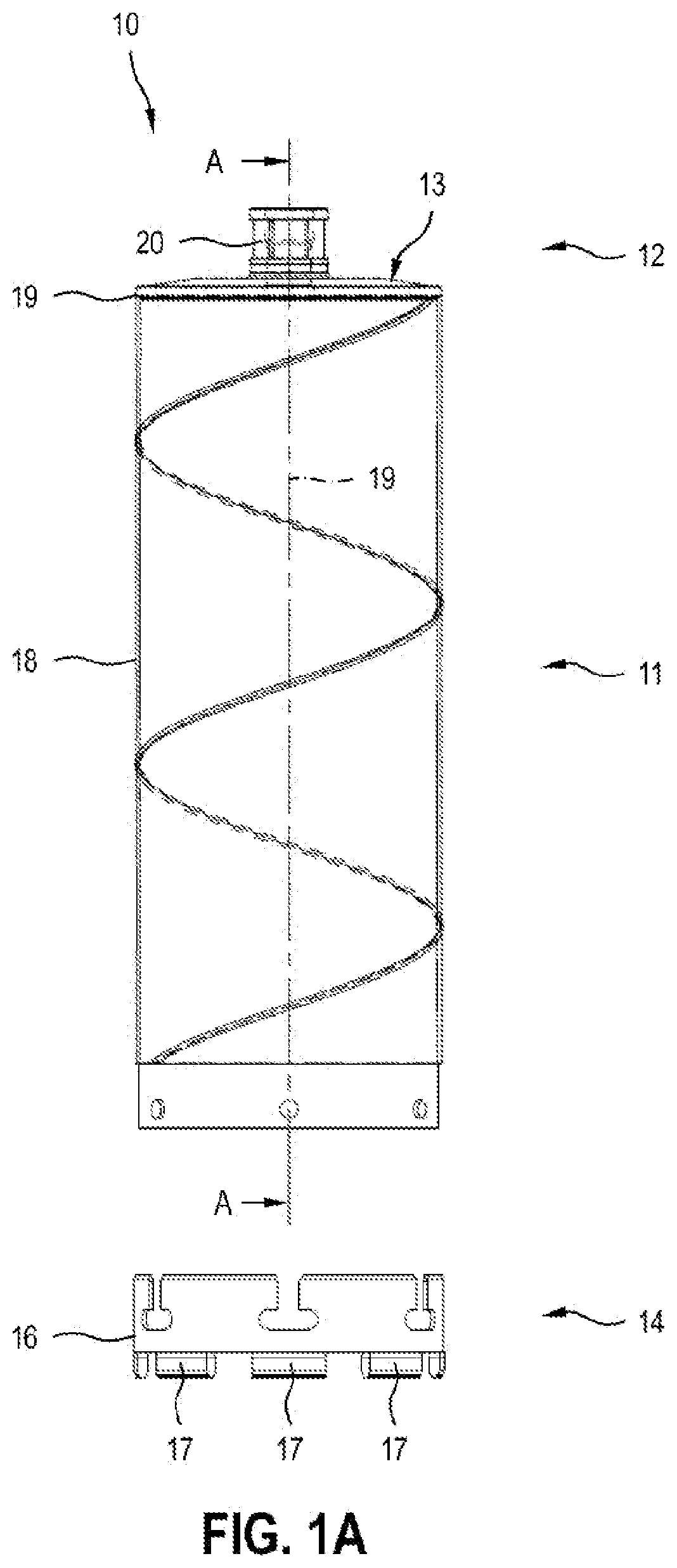

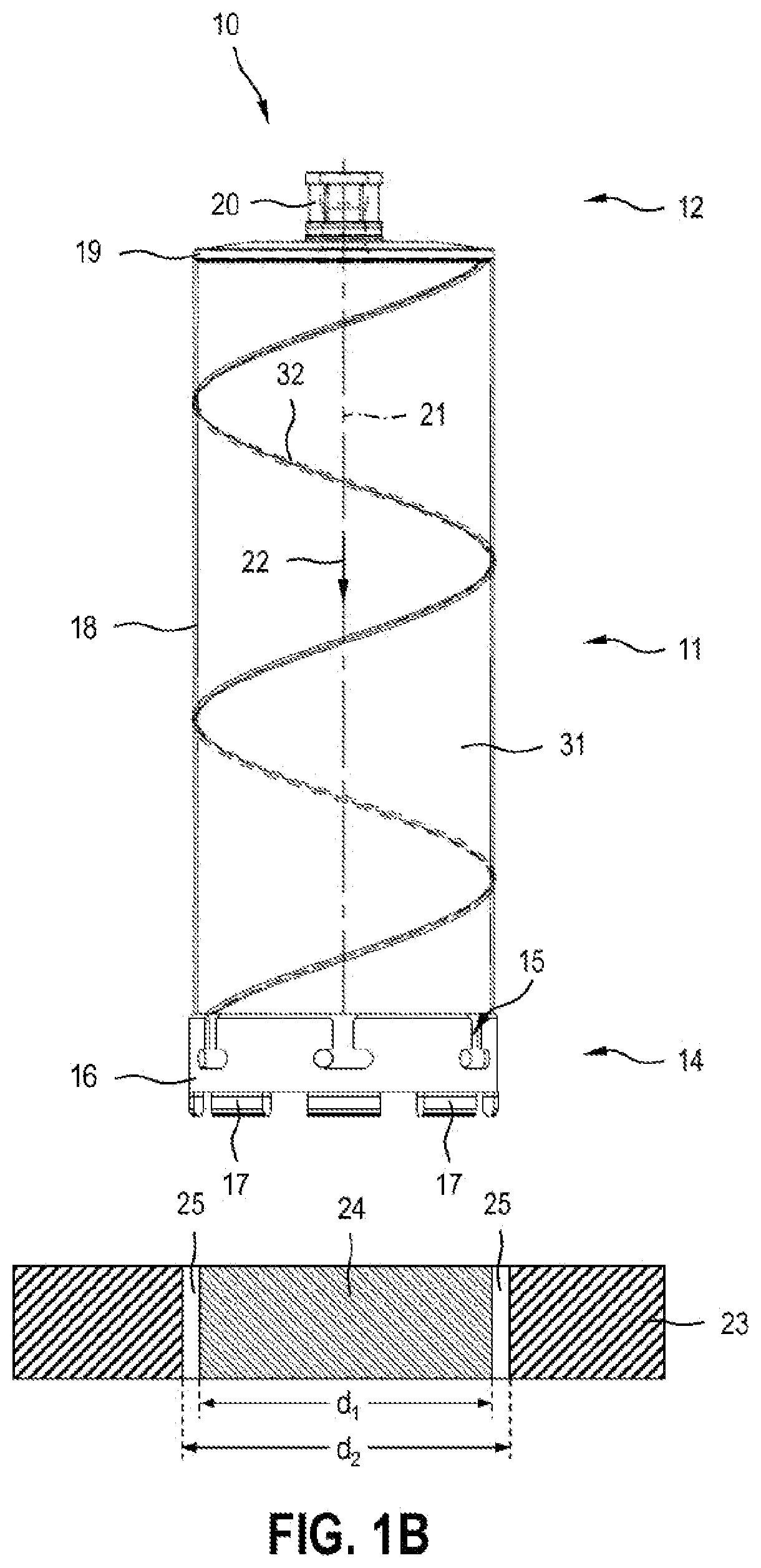

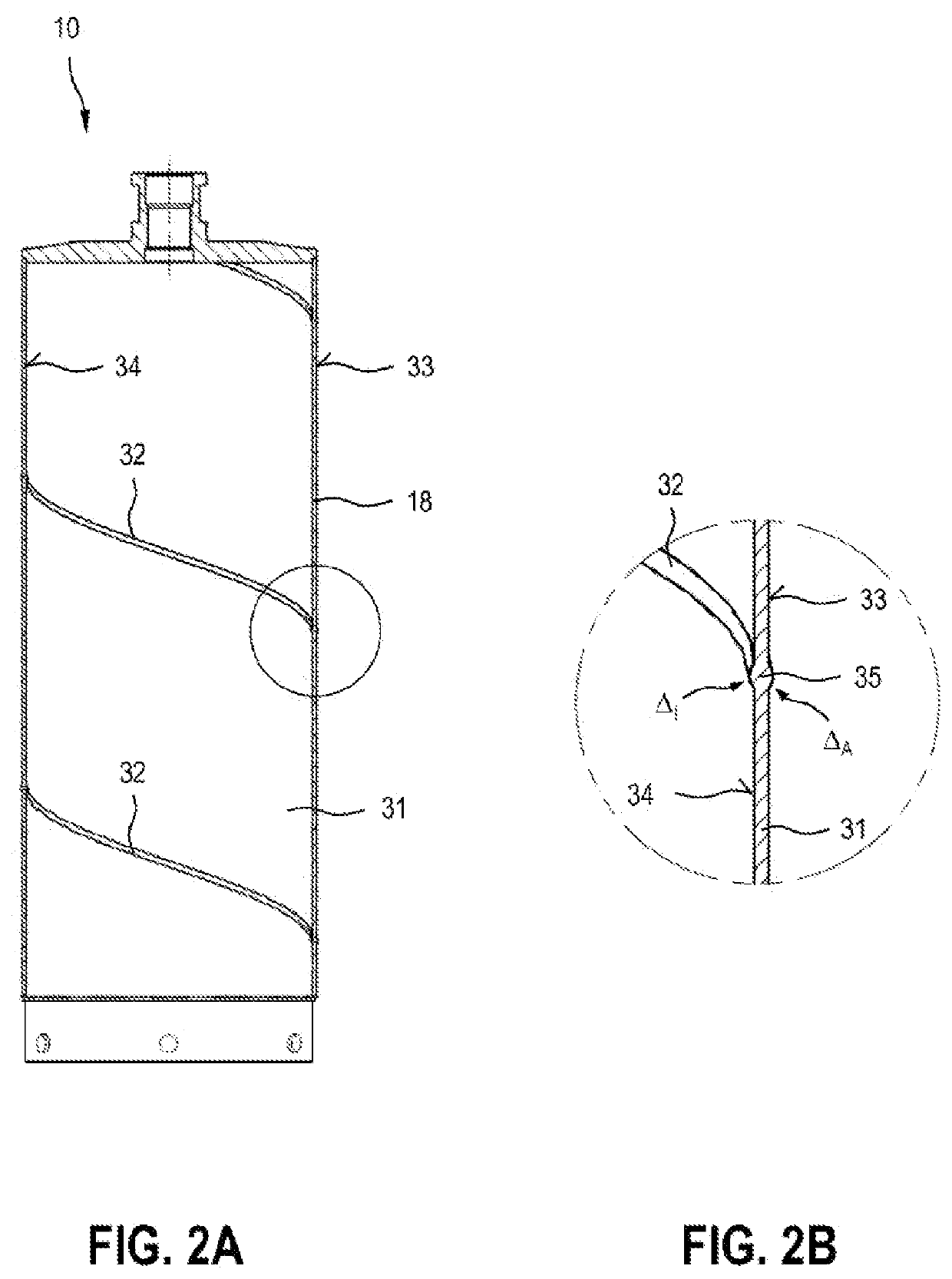

Drill Bit Having a Spiral-Tube-Shaped Drill Shaft and Method for Producing a Spiral-Tube-Shaped Drill Shaft for a Drill Bit

InactiveUS20190366451A1High tensile strengthHigh wear resistanceDrill bitsTool workpiece connectionDrill holeEngineering

Owner:HILTI AG

Tension resistant four-serial string whole composite insulator replacing device

InactiveCN101651308BFor quick maintenanceFor quick replacementSuspension/strain insulatorsApparatus for overhead lines/cablesComposite insulatorsMechanical engineering

Owner:ANHUI ELECTRIC POWER TRANSMISSION & TRANSFORMATION ENG

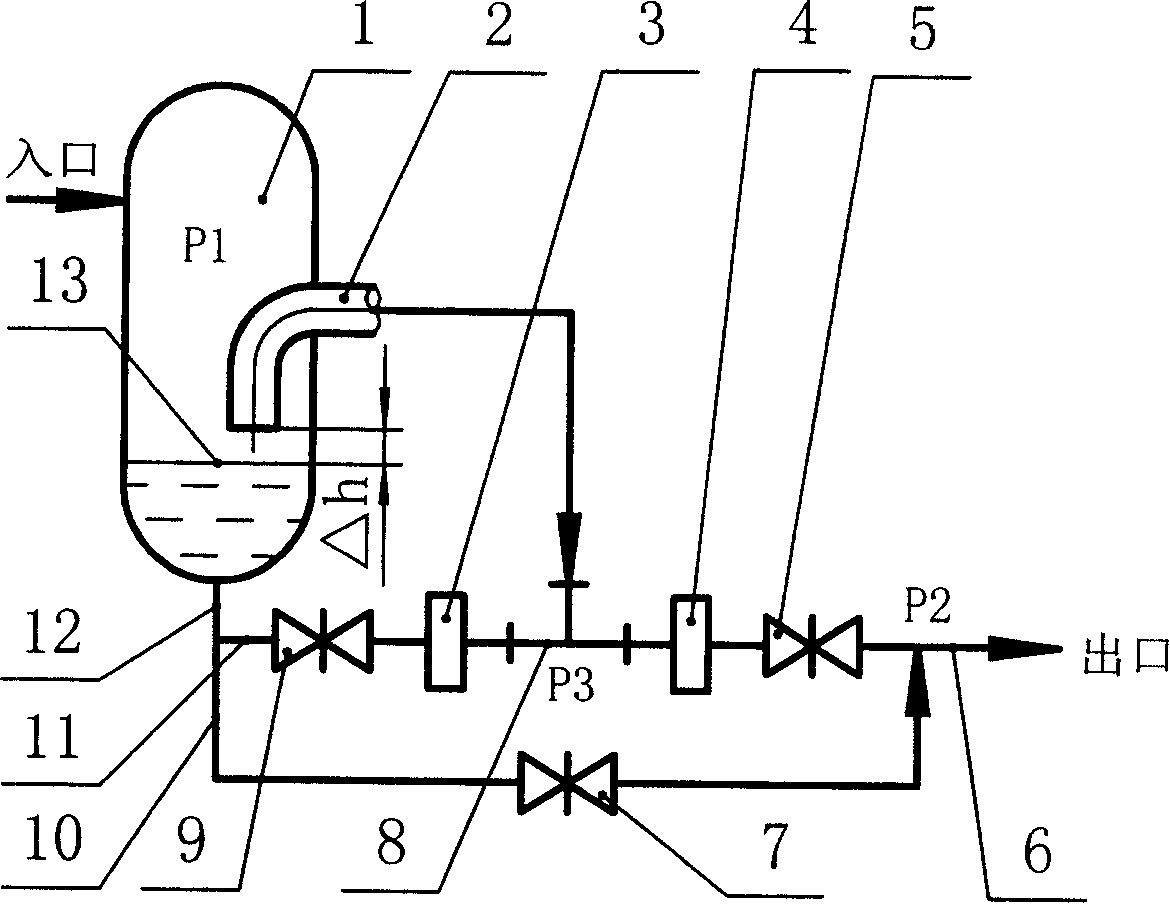

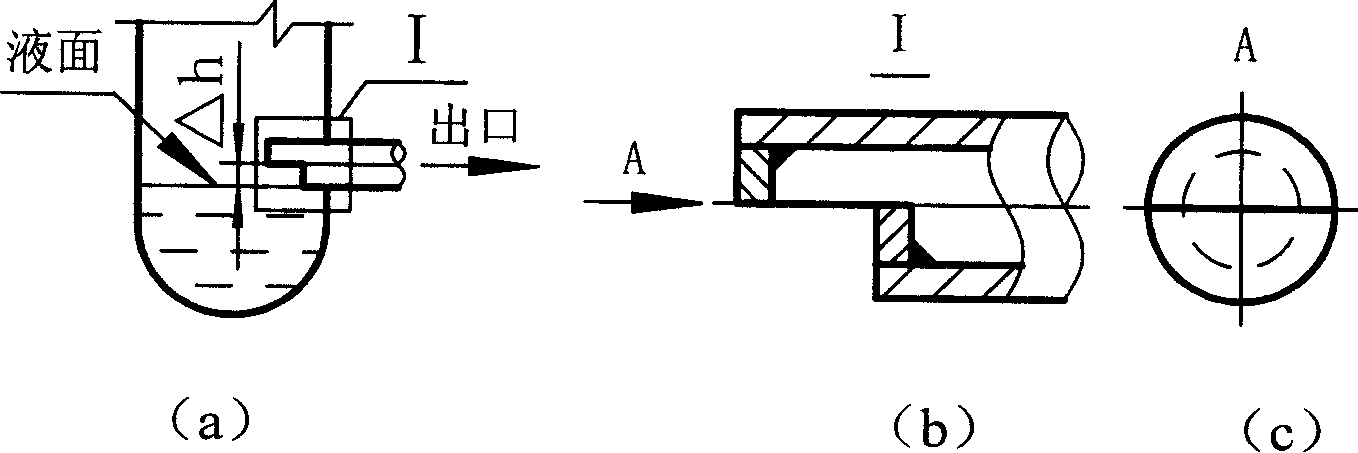

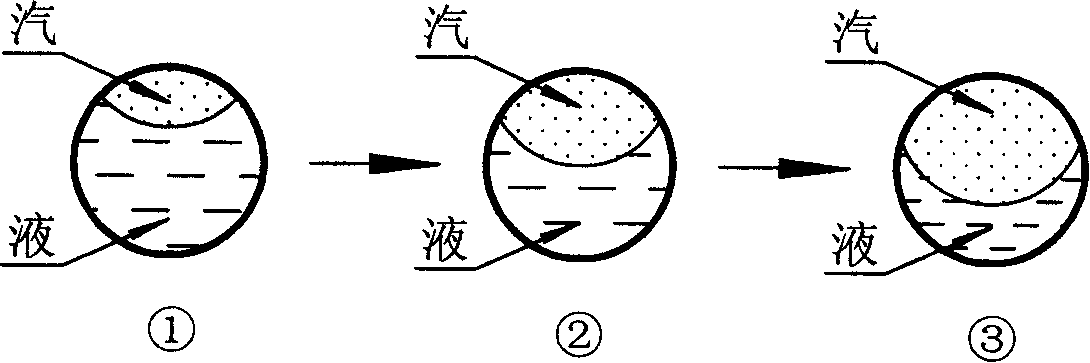

Separated two pbase flow liquid level controller

InactiveCN100386704CTo achieve the purpose of liquid level controlLiquid level stabilityLevel controlEngineeringFluid level

The present invention disclosed a split type two-phase fluid level controller. It is composed of industrial container, steam flow transmitter, throttling pressure-reducing element and two-phase fluid controller. Said invention utilizes the flowing characteristics of steam and liquor two-phase fluid to change the capability for outputting liquor so as to attain the goal of controlling level.

Owner:XI AN JIAOTONG UNIV

Light-and-convenient-type pedal

The invention provides a light-and-convenient-type pedal which comprises a pedal main body. The pedal main body comprises two mutually-crossed X-shaped steel supporting strip blocks. Mounting holes used for being fixedly connected with a mounting shaft of the light-and-convenient-type pedal are formed in the supporting strip blocks, and arc-shaped supporting ribs are fixedly connected between thetwo adjacent supporting strip blocks in the direction perpendicular to the central axes of the mounting holes. The thicknesses of the supporting ribs are the same as those of the supporting strip blocks, and strip-shaped grooves are formed in the upper end face of the pedal main body. Anti-slip strips made of elastic anti-slip rubber are connected into the strip-shaped grooves in a clamped mode. The light-and-convenient-type pedal has the beneficial effects that the mechanical strength of the pedal main body can be remarkably improved through steel materials, and thus the contribution is madefor prolonging of the service life of the pedal; and through the crossed structure of the supporting strip blocks, the structure of the pedal main body is simplified while it is ensured that the pedalmain body has the high mechanical strength, so that the pedal main body has the functions of being convenient to machine and use.

Owner:天津锐雯科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com