Tension resistant four-serial string whole composite insulator replacing device

A technology of synthesizing insulators and tandem, applied in the direction of suspension/strain insulators, overhead lines/cable equipment, etc., can solve the problems of poor work efficiency, heavy and unsafe tools, and achieve high work efficiency, easy maintenance and replacement, and long service life. long effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

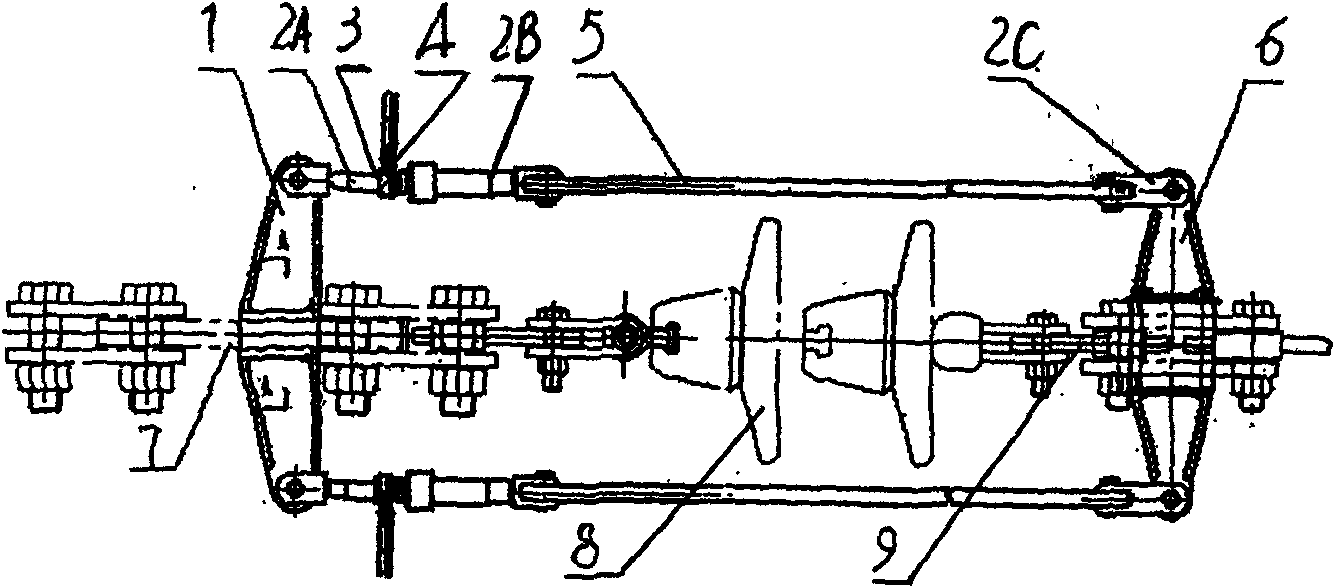

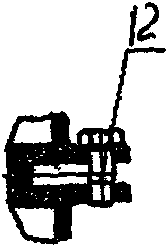

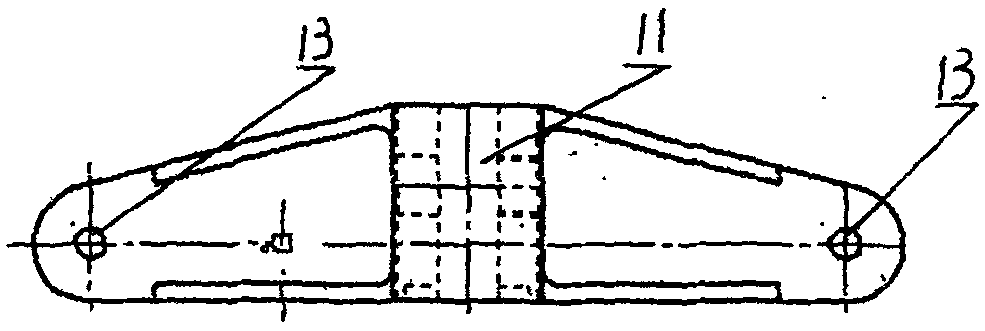

[0012] Such as figure 1 As shown, a strain-resistant four-connected string composite insulator replacement device is composed of front-end airfoil clips, rear-end airfoil clips, screw rods, pull plates and fork-shaped joints. Front airfoil card 1 (see figure 2 , 3 4) The lower part of the center is provided with a horizontal clamping groove 11, the two sides of the lower part of the clamping groove are provided with vertical screw holes 12, and the two wing ends of the front-end airfoil card are respectively provided with screw holes 13. Rear airfoil card 6 (see Image 6 , 7) It consists of two symmetrical components connected by bolts, the groove 61 provided symmetrically in the junction of the two symmetrical components forms a through hole, and the two wing ends of the rear airfoil card are respectively provided with screw holes 63 . A fork joint 2A, a screw rod 3 , a fork joint 2B, a pull plate 5 and a fork joint 2C are sequentially connected between the two wing ends ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com