Vehicle load dynamic weighing method for orthotropic bridge deck steel box girder bridge

An orthotropic bridge and dynamic weighing technology, which is applied in weighing, special scales, optical devices, etc., can solve the problems of resistance strain gauges being susceptible to electromagnetic interference, resistance strain gauge sensitivity reduction, and susceptibility to electromagnetic interference. Achieve the effects of unique anti-electromagnetic interference ability, simple protection measures, and convenient maintenance and replacement of sensors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

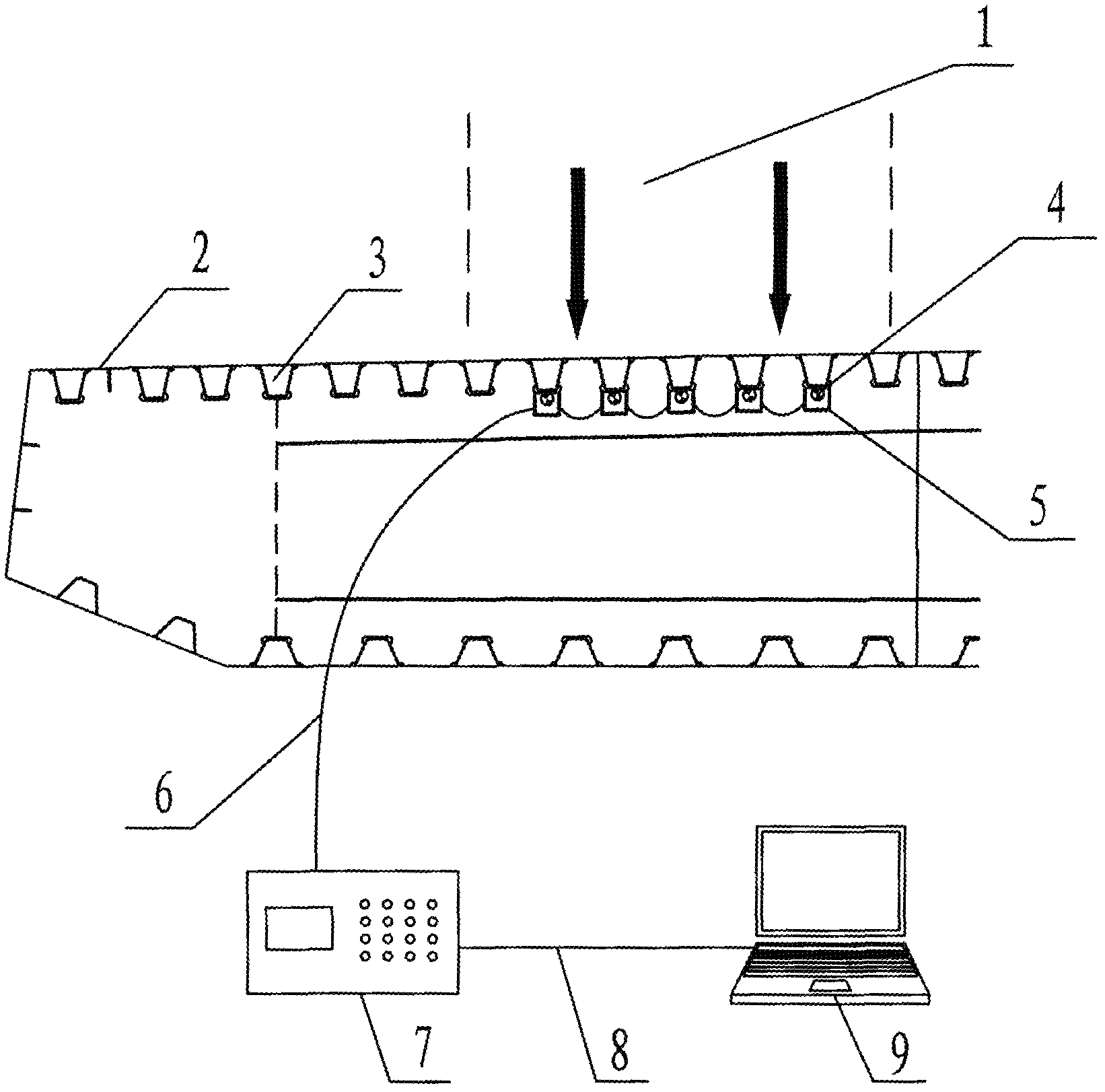

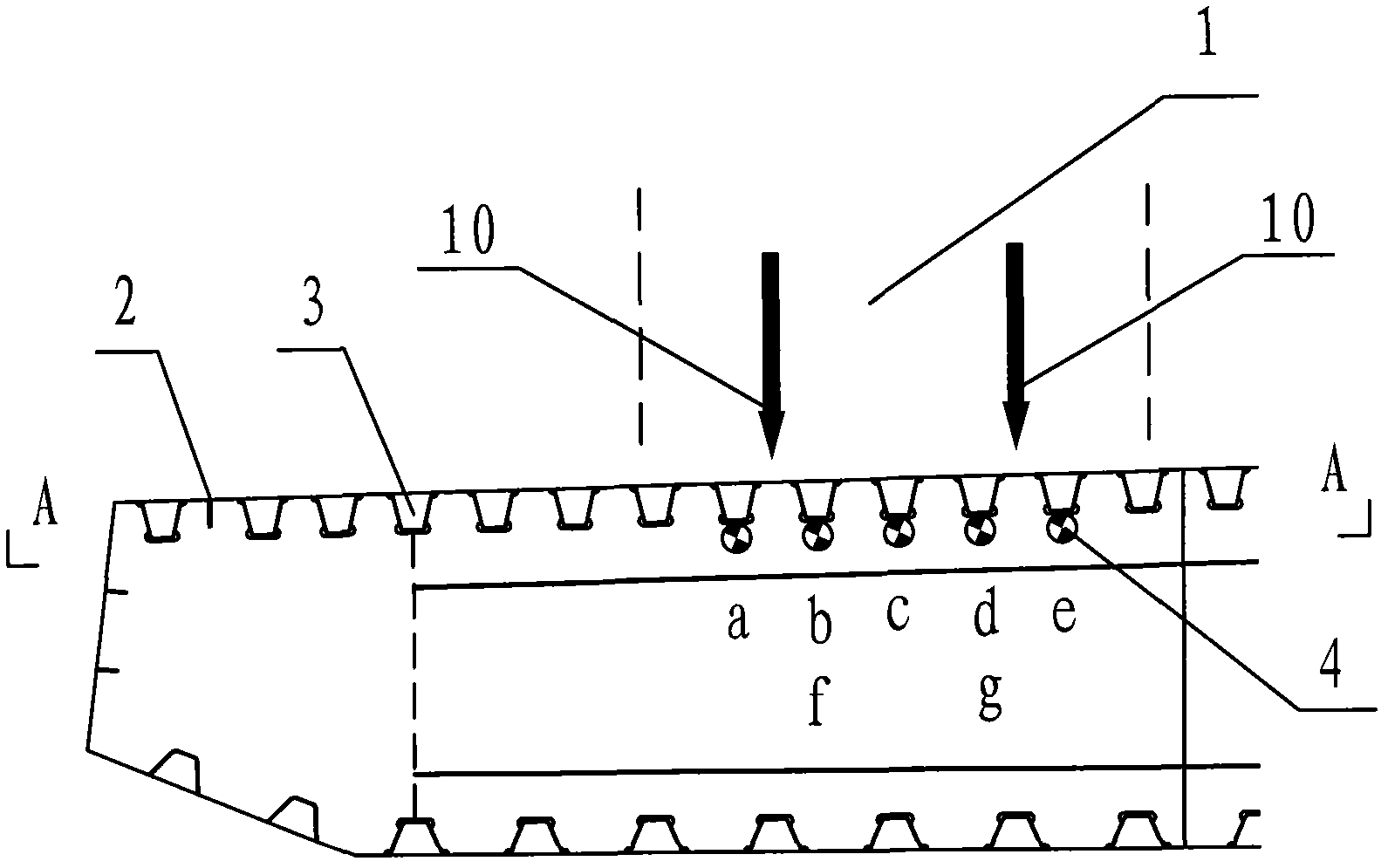

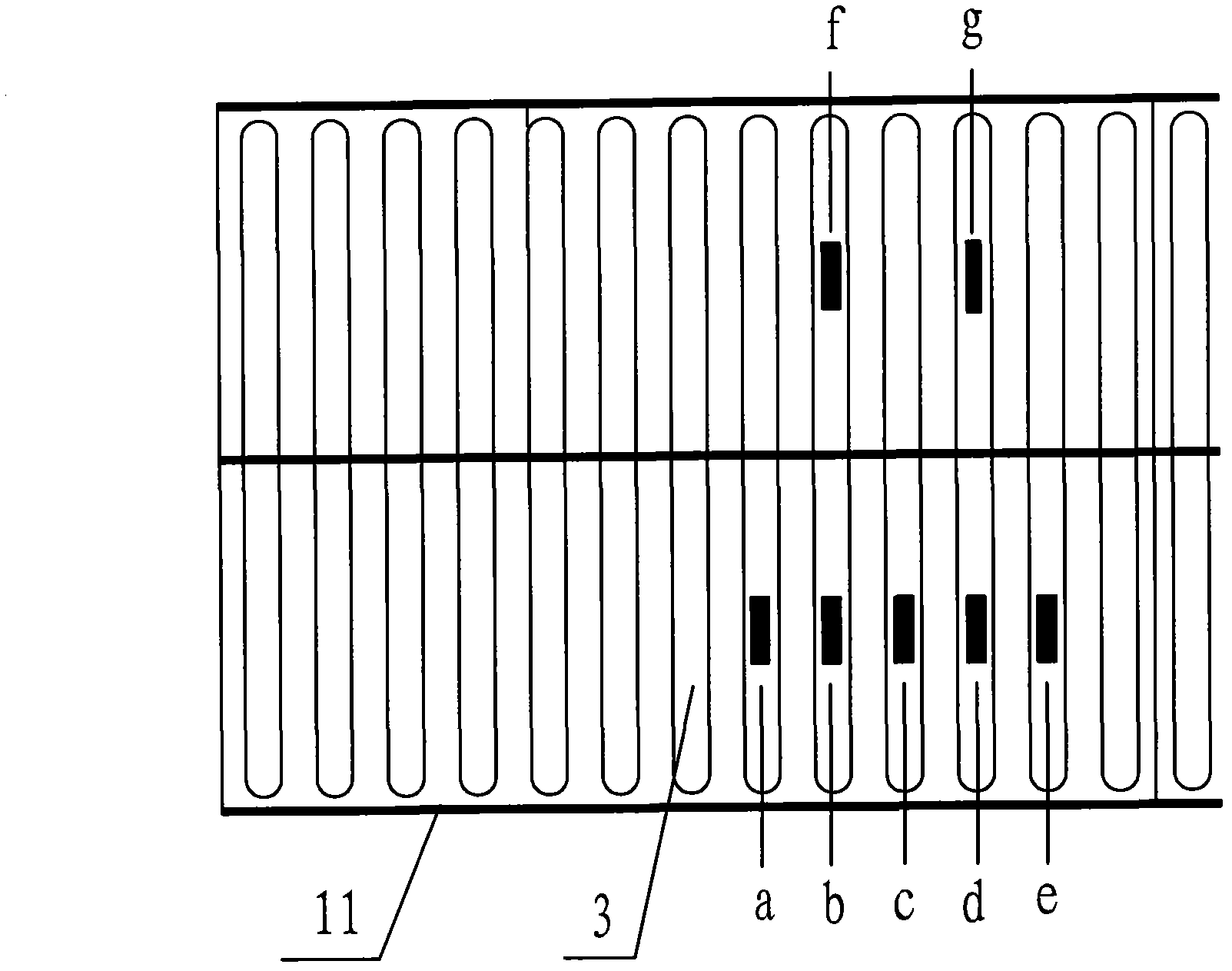

[0029] The present invention will be further described in detail below in conjunction with the drawings and specific embodiments.

[0030] The vehicle load dynamic weighing method for the orthotropic deck steel box girder bridge provided by the embodiment of the present invention includes the following steps:

[0031] A. Arrange at least 6 strain sensors on each traffic lane, of which at least 5 strain sensors are installed on the bottom of at least 5 U-ribs between two transverse diaphragms in the same section of steel box girder in the longitudinal direction. Install a strain sensor at the bottom longitudinal bridge of the U-rib between the two transverse diaphragms in the steel box girder at least 1 strain sensor, and measure the longitudinal strain data of the passing vehicle;

[0032] B. Transmit the measured strain data to the fiber grating demodulator to convert it into an optical signal, and demodulate it through the fiber grating demodulator terminal to calculate the change ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com