Patents

Literature

994 results about "Beam bridge" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Beam bridges, also known as stringer bridges, are the simplest structural forms for bridge spans supported by an abutment or pier at each end. No moments are transferred throughout the support, hence their structural type is known as simply supported.

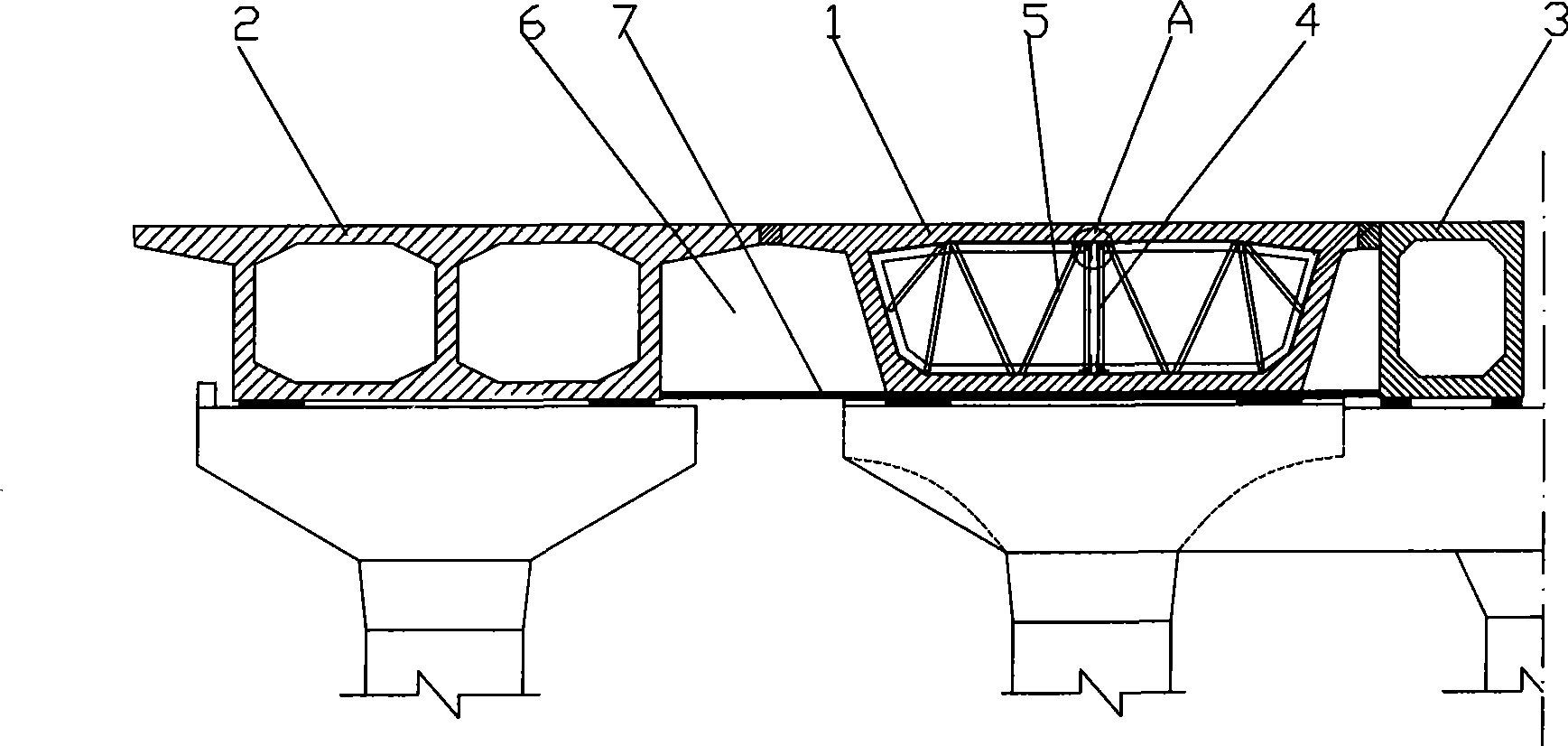

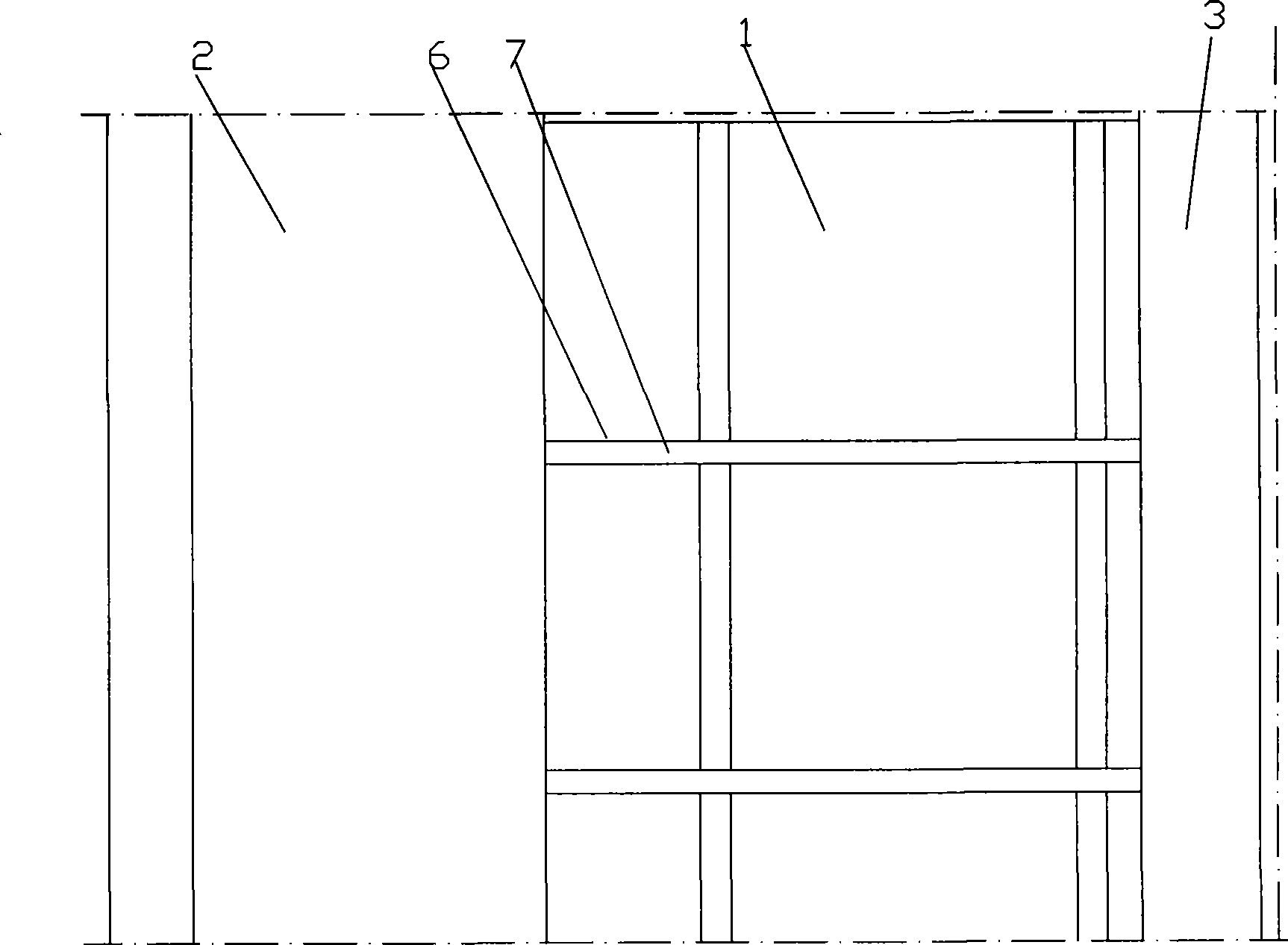

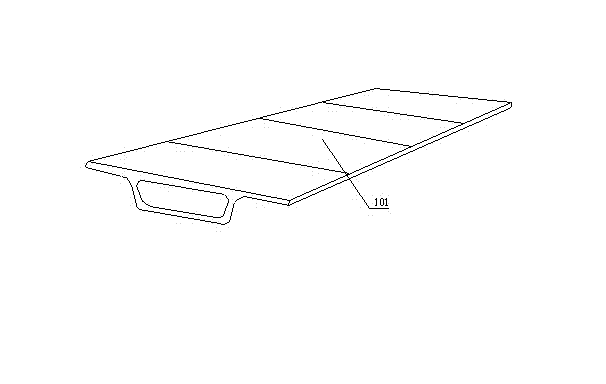

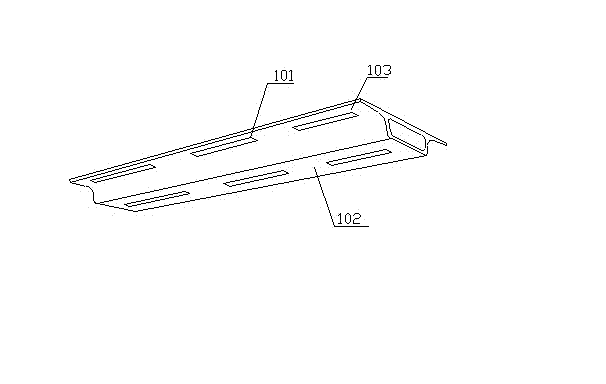

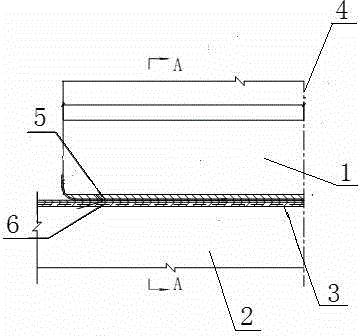

Concrete box girder bridge widening and reinforced structure and construction method thereof

InactiveCN101424075AImprove the state of stressClear forceBridge erection/assemblyBridge strengtheningSocial benefitsReinforced concrete

The invention discloses a widening and reinforcing structure for a concrete box girder bridge and a method for constructing the same. The widening and reinforcing structure comprises a new box girder I and a new box girder II which are parallel with the original box girder bridge and are positioned at two sides of the original box girder bridge; and the box girder of the new box girder I and the box girder of the new box girder II are in rigid connection with box girder flanges of the original box girder bridge. The new box girders share part of the load of the original box girder so that the internal force and the deformation (or the stress of a control point) of a controlled cross section of the original box girder bridge are reduced by about 20 percent; and the generation and the development of cracks on a crest slab, a bottom plate and a web plate of the original box girder bridge can be effectively inhibited. The widening and reinforcing structure is simple, has slight damage to the original box girder bridge, and does not increase obvious structure deadweight substantially. The method for widening and reinforcing constructions is simple and convenient; the reinforced concrete box girder bridge has a reliable structure; the construction period is relatively short; the impact on the road traffic is relatively small; and the damage to the natural environment and the bad social impact caused by the demolition of an old bridge are avoided, thus the method has good comprehensive technical, economic and social benefits.

Owner:CHONGQING JIAOTONG UNIVERSITY

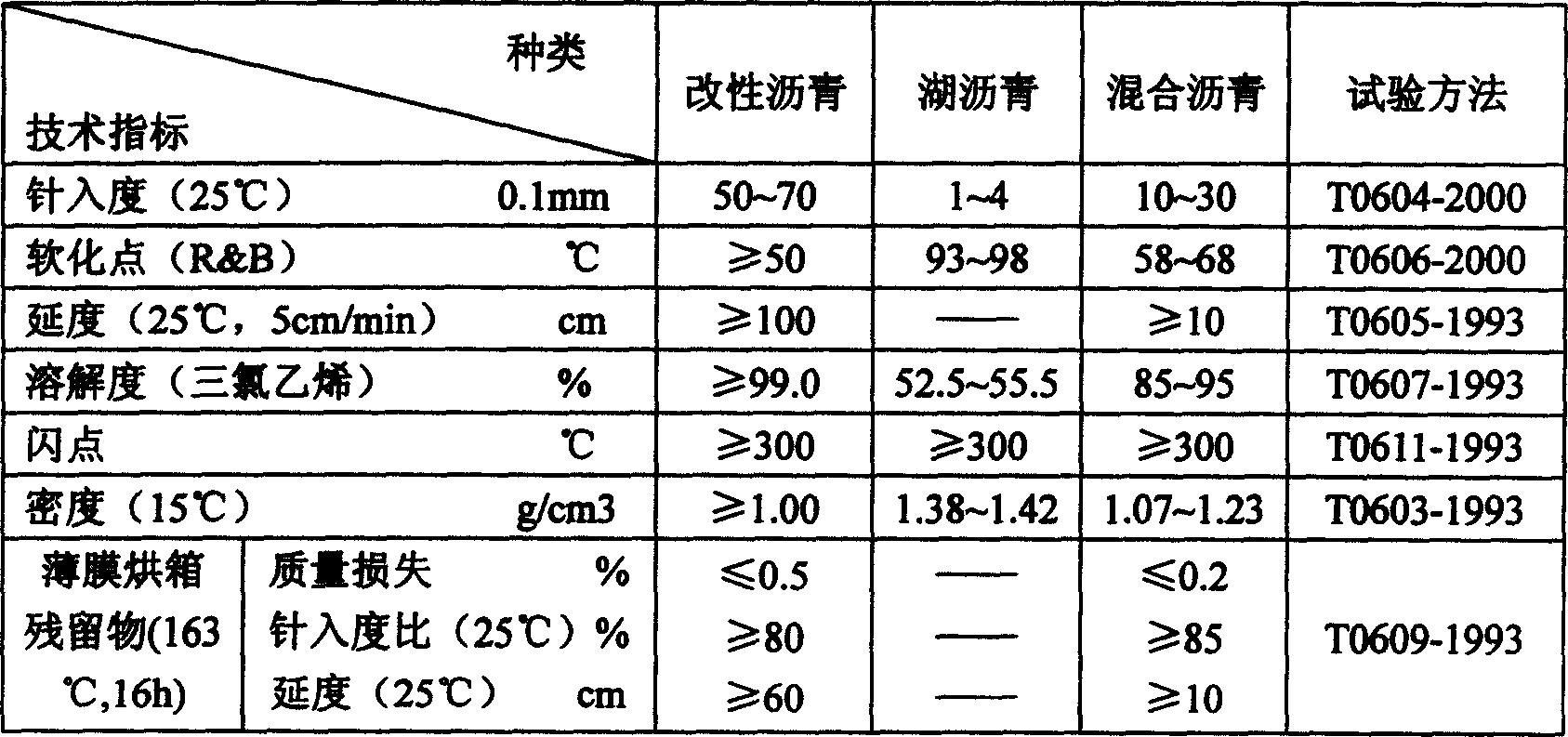

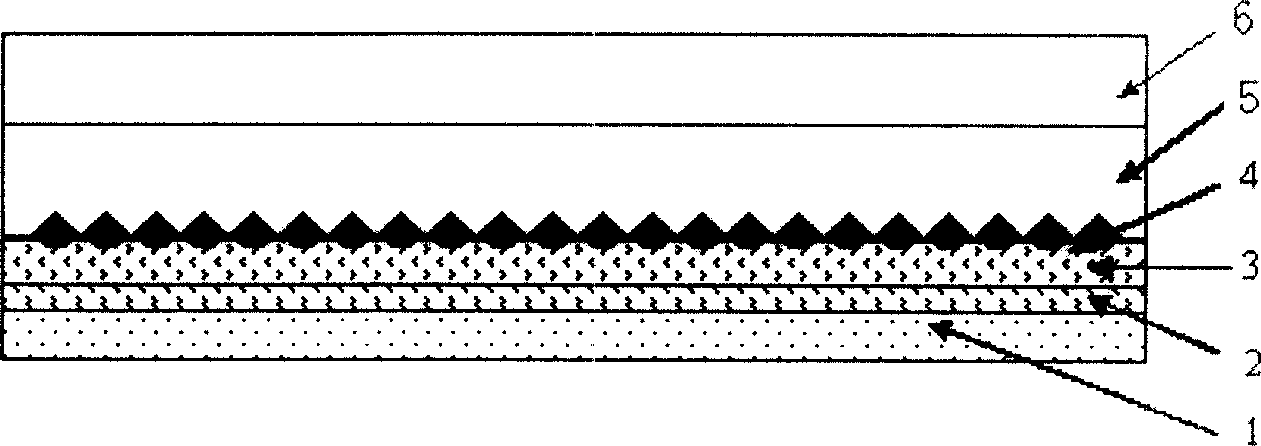

Method for paving resin filling type asphalt concrete steel box-beam bridge deck combined structure

ActiveCN101200873AHigh strengthChemically stableBridge structural detailsBuilding insulationsSheet steelSurface layer

The present invention relates to a paving method of the paving layer of the bridge deck of a steel box girder bridge. A resin infusion type paving method of the composite structure of the asphalt concrete steel box girder bridge deck includes three steps: (1) the sand blasting and the derusting of the steel plates of the steel box girder bridge deck; (2) the preparation of materials: (a) the preparation of high-viscosity modified asphalt; (b) mineral aggregate gradation; (c) the preparation of large pored asphalt concrete; (d) the preparation of thermoset resin grouting material; (3) The pavement of the paving layer of the bridge deck: (a) The large pored asphalt concrete is paved on the steel plates of the steel box girder bridge deck, the pavement thickness is 2cm to 4cm, and after final pressure, a large pored asphalt concrete skeleton layer is formed; (b) While the large pored asphalt concrete skeleton layer is still in a hot state, the thermoset resin grouting material is grouted into the large pored asphalt concrete skeleton layer; (c) After the maintenance of three days, a layer of bonding oil is sprinkled, and an asphalt abrasion surface layer with the thickness of 4cm is paved. The paving method is characterized in good interface cohesive property and simple and convenient construction process.

Owner:WUHAN MUNICIPAL CONSTR GROUP

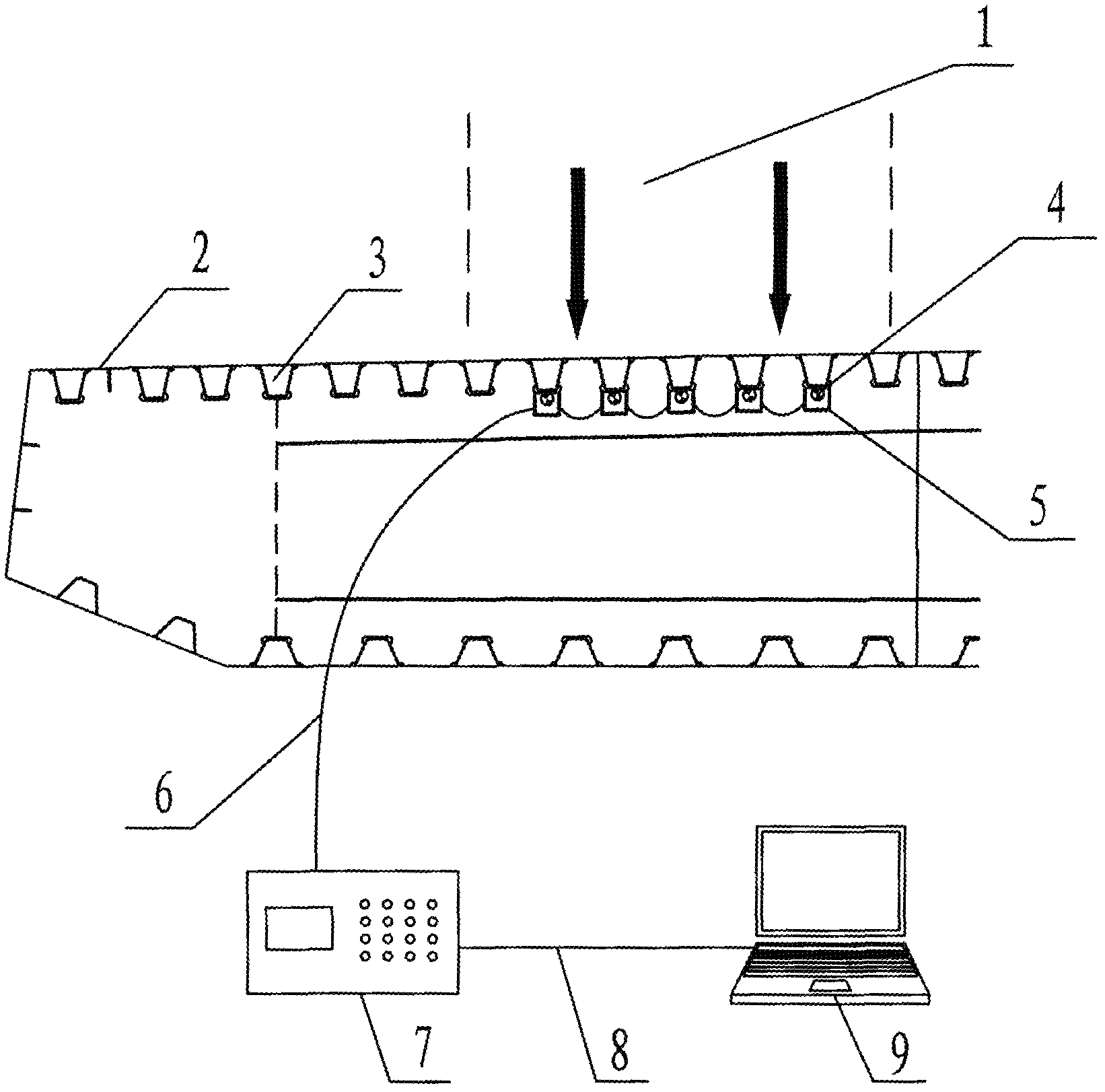

Beam bridge displacement dynamic measurement system and measurement method based on strain gauges

InactiveCN101865683AMeet the requirements of engineering precisionMeasurement devicesMeasuring instrumentStrain gauge

The invention relates to a beam bridge displacement dynamic measurement system based on strain gauges, the system comprises the strain gauges that are used for measuring strain in real time and an acquisition device that is used for acquiring strain data in real time; the system is characterized in that the strain gauges are arranged on a bridge to be measured along the beam longitudinal direction at an equal interval, the strain gauges of each span have at least 5 groups, each group has two strain gauges, and the strain gauges are arranged along the beam height; and the system also comprises a strain data processing device which is used for processing the acquired strain data, thus obtaining the curvature of a bridge deflection line, and then a deflection function is fitted by using curvature data, thus finally obtaining a bridge deflection function and the dynamic displacement at any point of the bridge. Starting from the basic definitions of displacement and strain, a beam bridge displacement dynamic measurement method based on the strain gauges is formed by establishing the inner relationship between the displacement and the strain. The method does not need any displacement measuring apparatus and only utilizes the existing strain data to analyze the bridge displacement in real time and to form dynamic response of the displacement.

Owner:JILIN UNIV

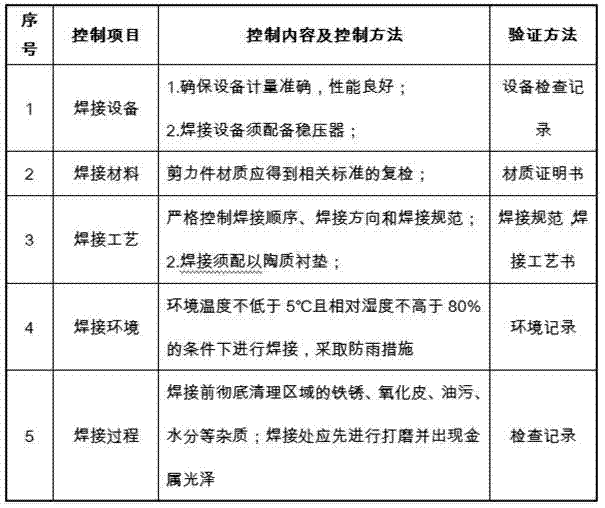

Integral erection construction method of 60m steel box girder

ActiveCN102797226AGuaranteed operational safetySolve the problems of installation and constructionBridge erection/assemblyOperation safetySteel box girder

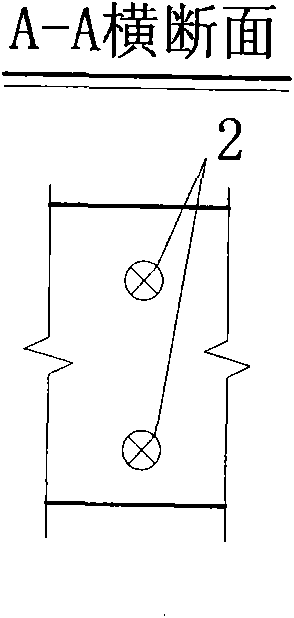

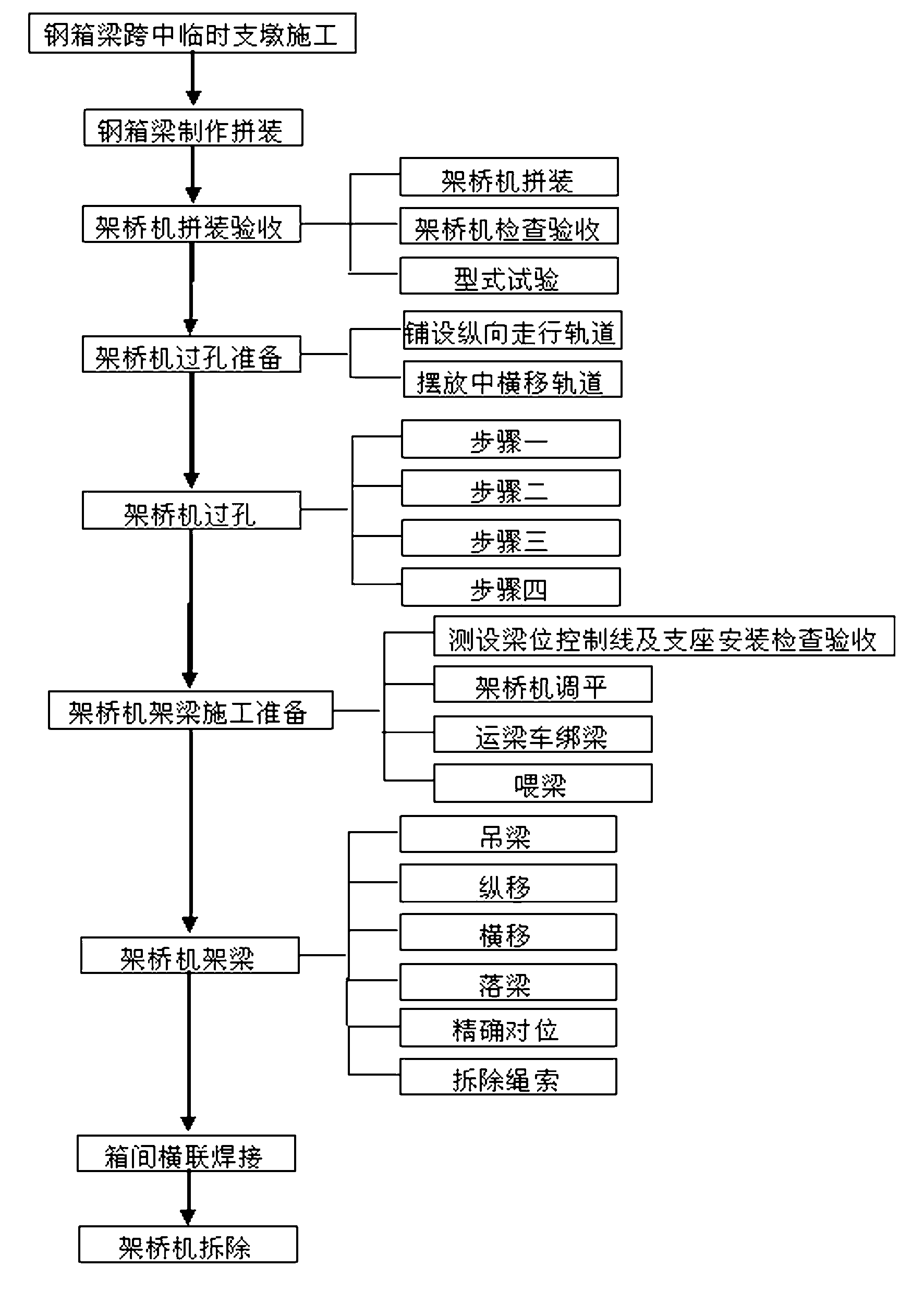

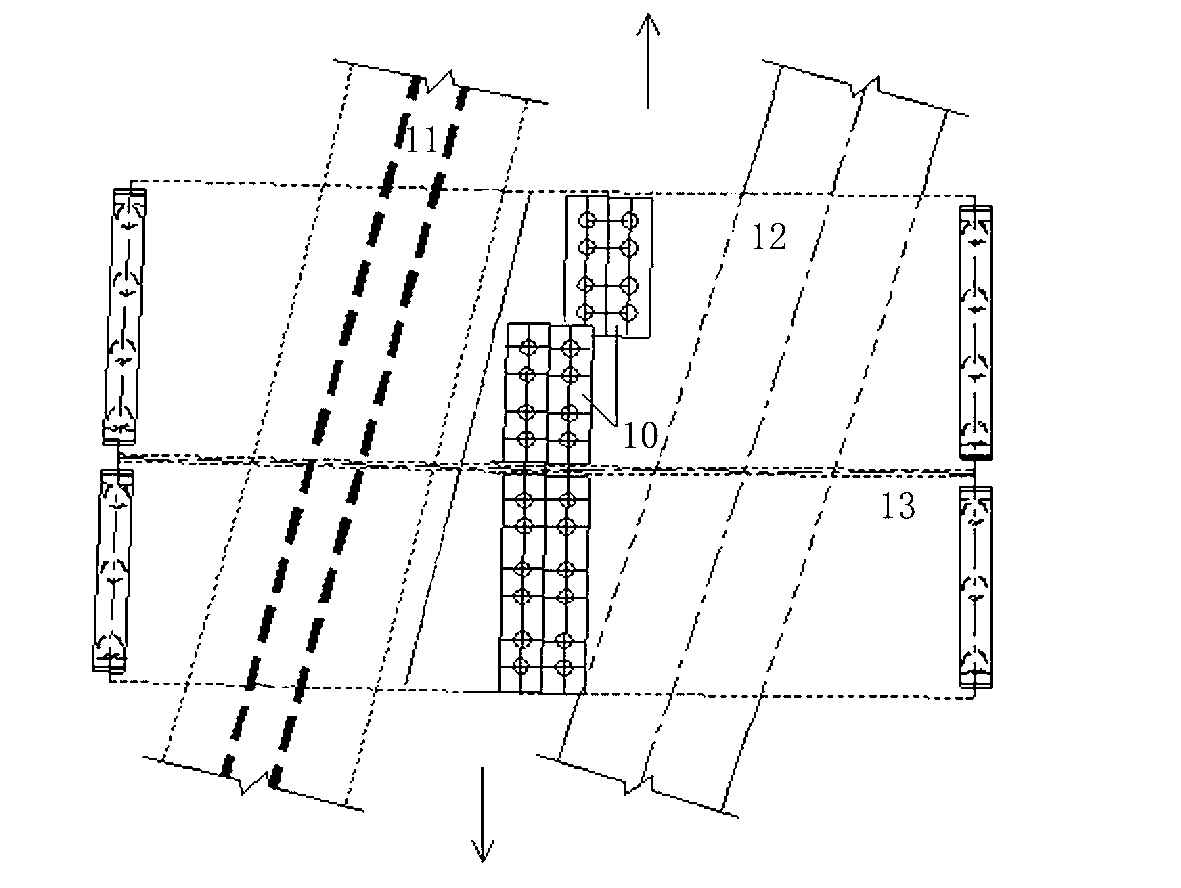

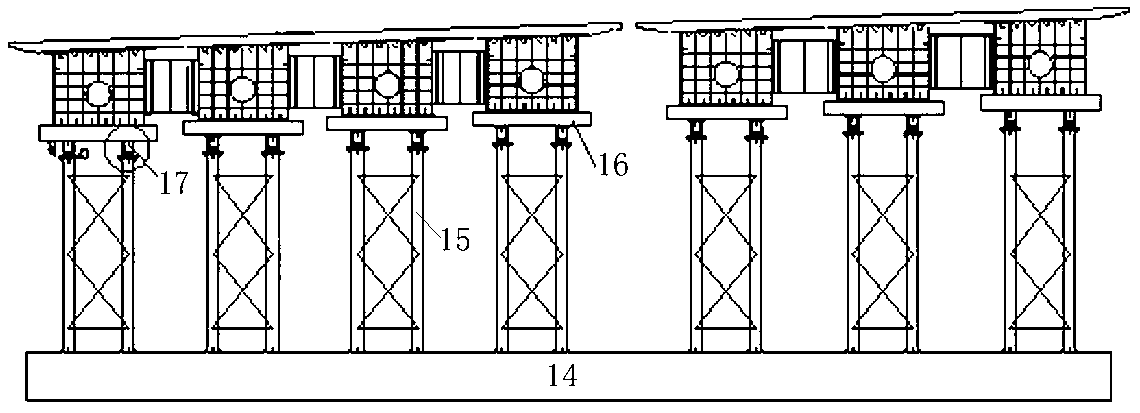

The invention belongs to the technical field of the construction of large bridge bodies, and specifically relates to an integral erection construction method of a 60m steel box girder, which reduces the influence of the construction of long-span steel box girders to communications and transportation and surrounding structures. The method comprises the following steps of: midspan construction of temporary pillar of steel box girder, steel box girder assembling manufacturing, bridge girder erection machine assembling and checking, hole passing of the bridge girder erection machine, preparation for girder erection of the bridge girder erection machine girder and girder erection, transverse welding among boxes, and bridge girder erection machine dismantling. In the method, a hollow box-shaped double-beam bridge girder erection machine is used for carrying out the construction of the steel box girder so as to efficiently solve the construction problem that the 60m and 230t steel box girder simultaneously spans over railways and roads; and the method ensures the operation safety of the conventional railways and national roads and minimizes the influence of the construction to railways and national roads.

Owner:CHINA RAILWAY SIXTH GRP CO LTD

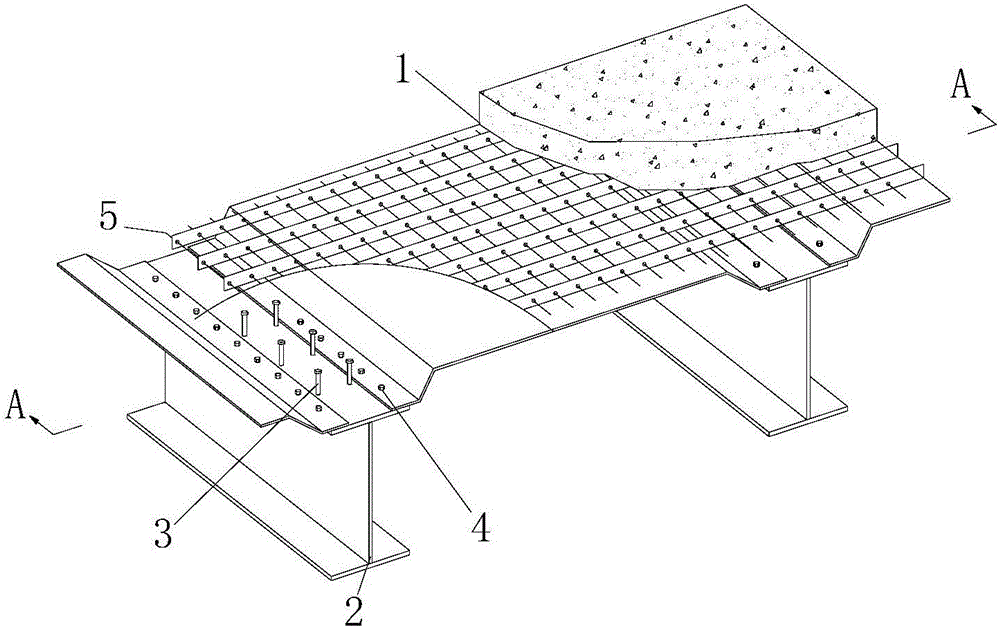

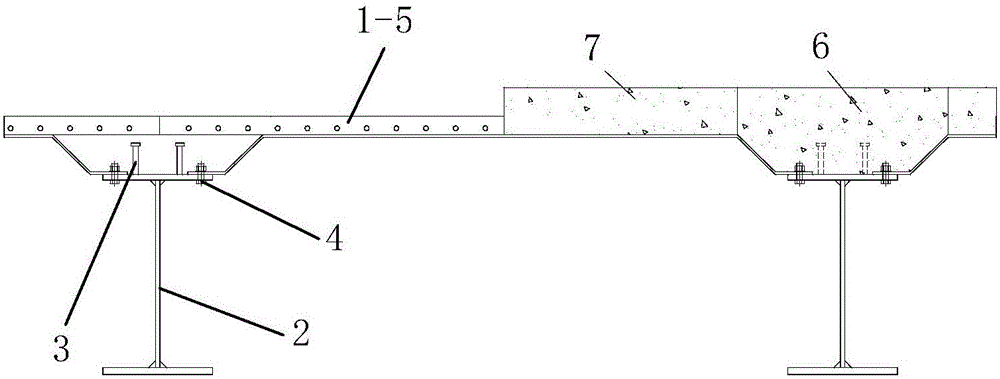

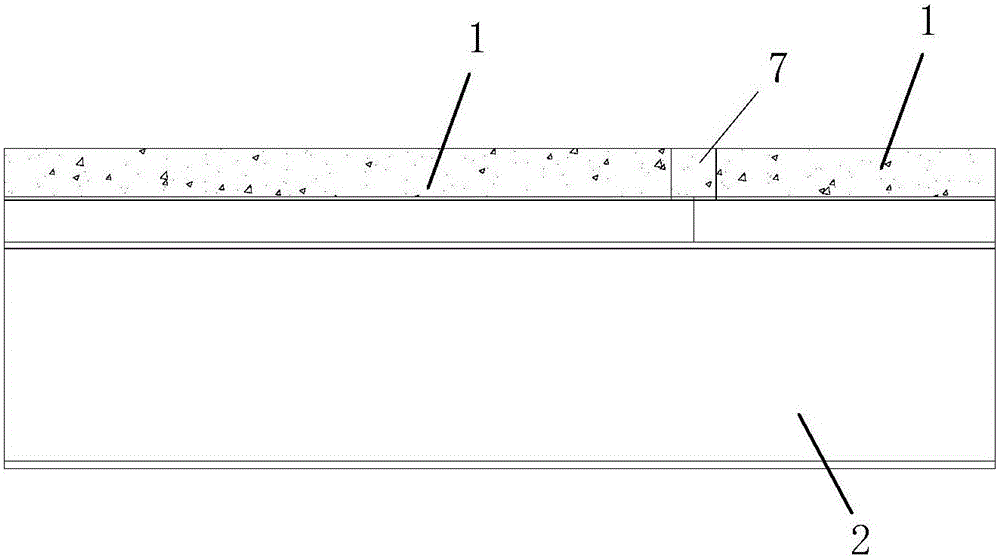

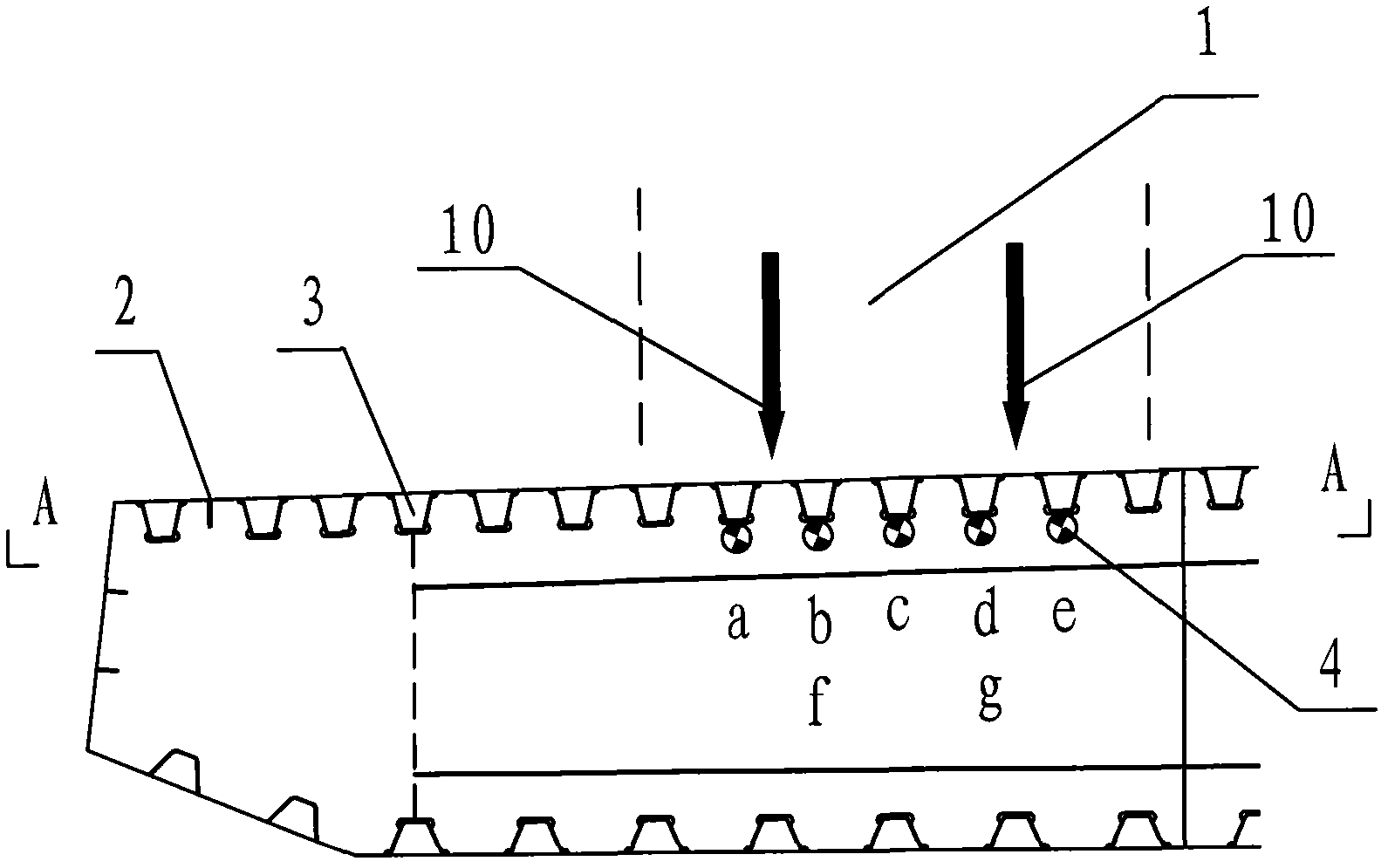

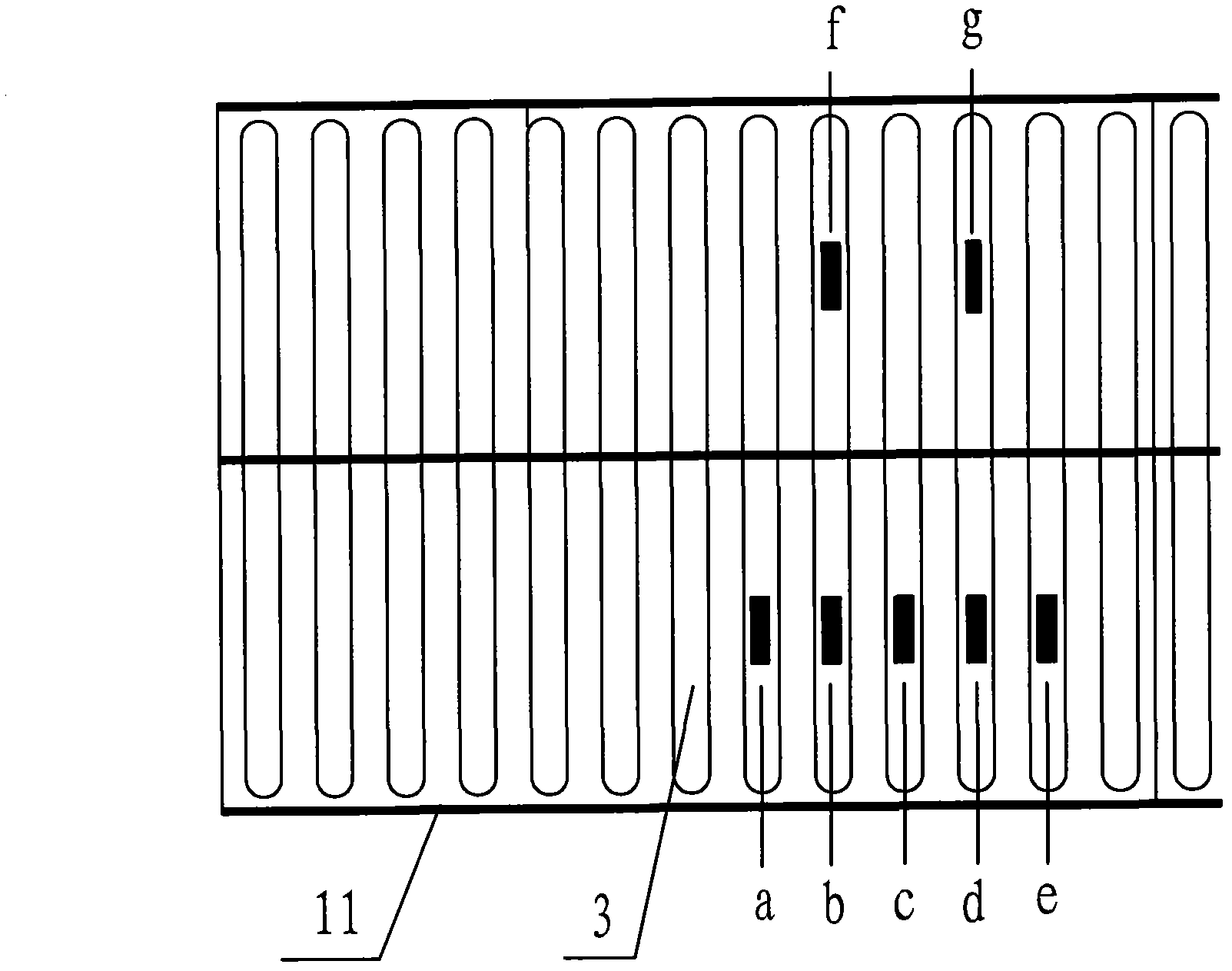

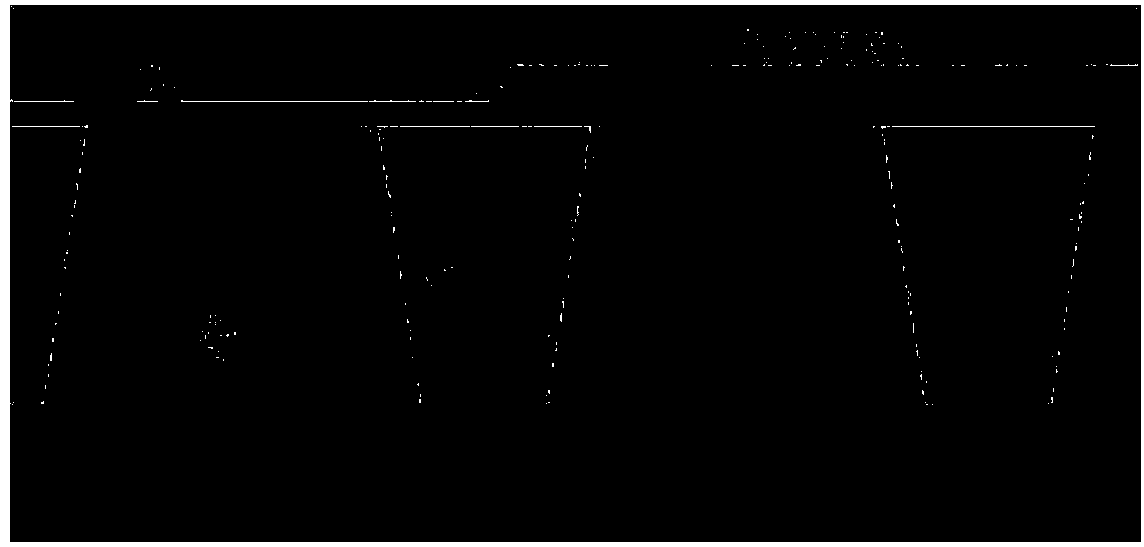

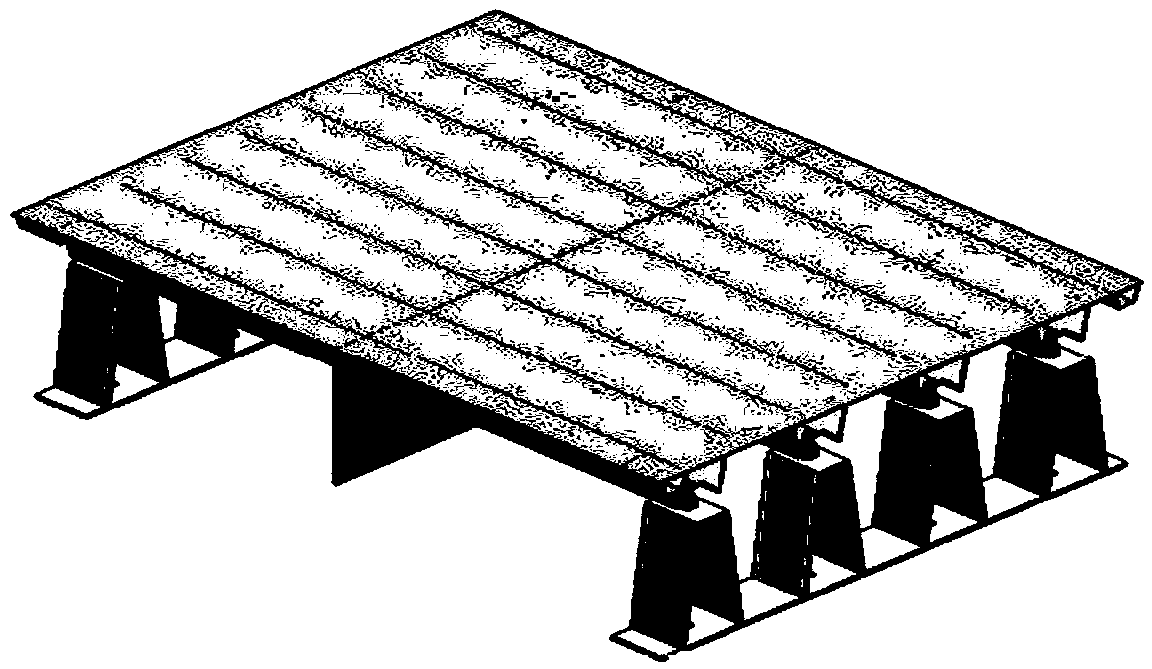

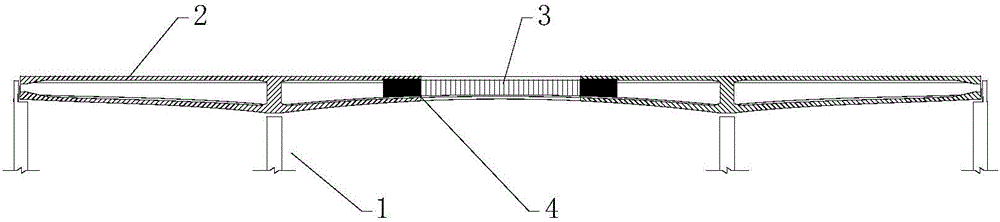

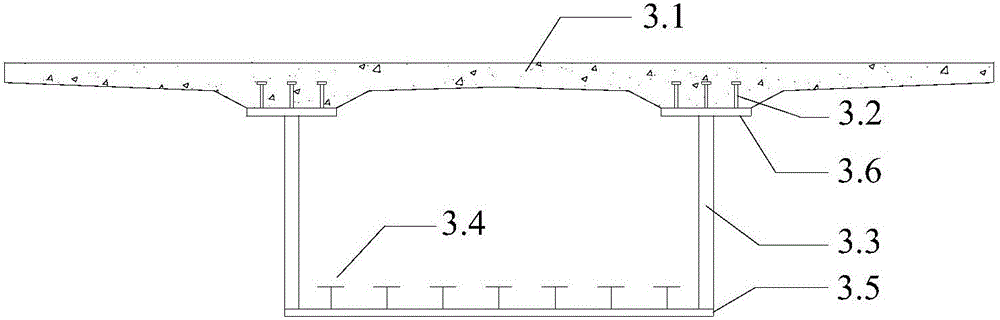

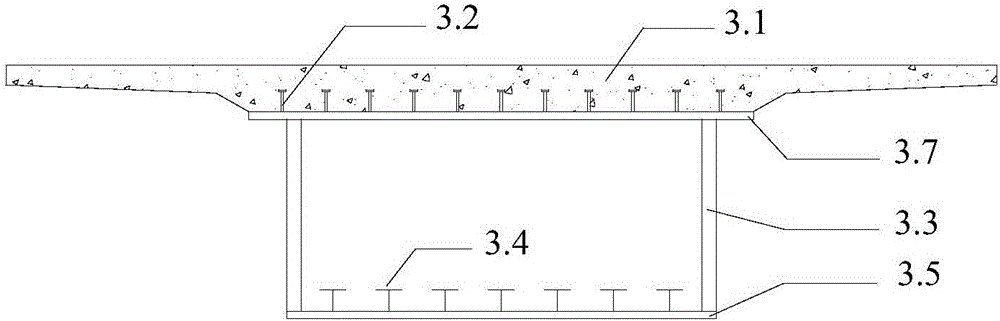

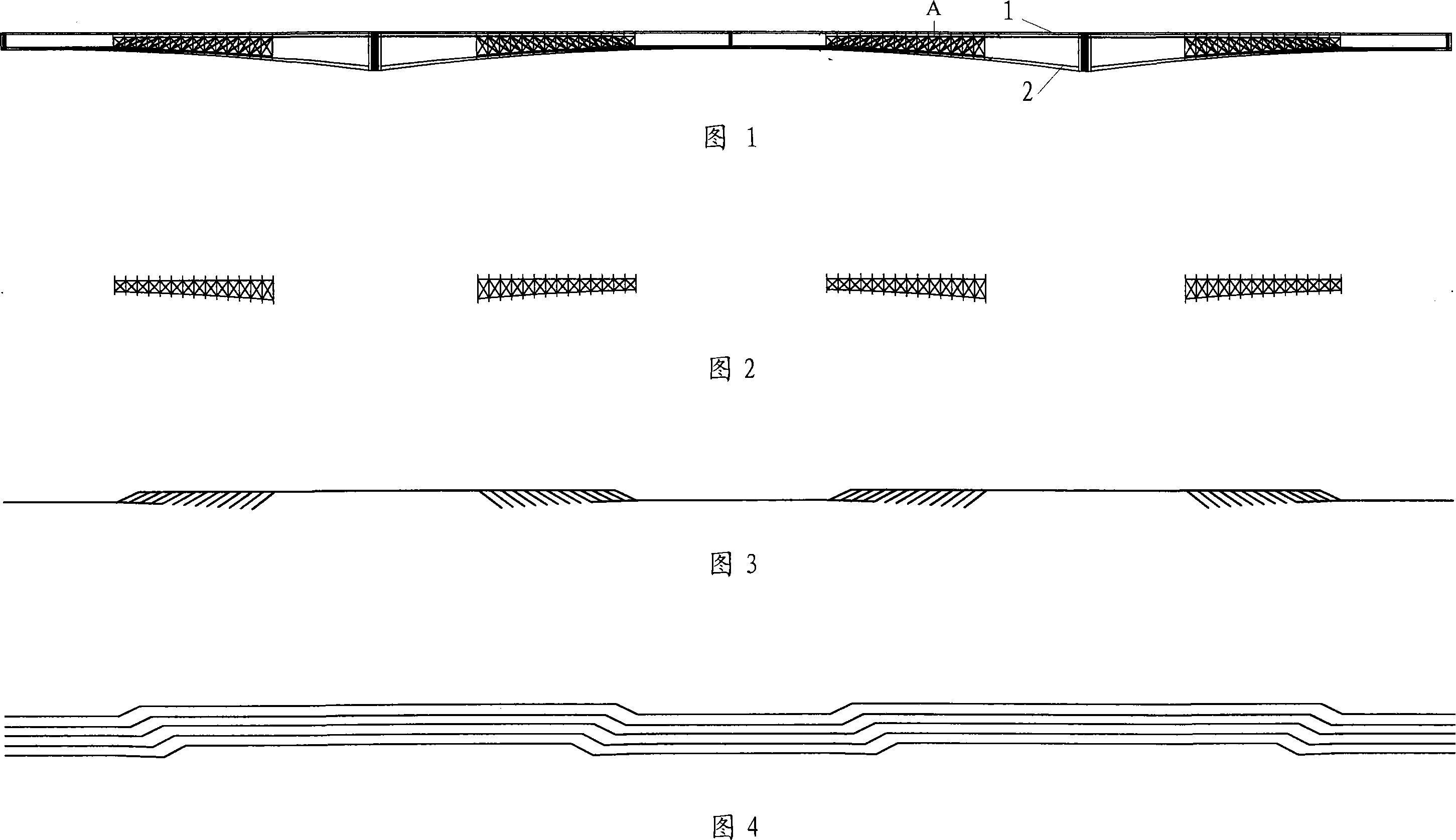

Assembly type steel plate combined beam bridge based on reinforced concrete combined bridge deck slab and construction method of assembly type steel plate combined beam bridge

InactiveCN106149540ASimple structureReasonable designBridge structural detailsBridge erection/assemblyReinforced concreteBridge deck

The invention discloses an assembly type steel plate combined beam bridge based on a reinforced concrete combined bridge deck slab and a construction method of assembly type steel plate combined beam bridge. The steel plate combined beam bridge comprises a main beam supporting structure composed of multiple main steel beams, and multiple reinforced concrete combined bridge deck slab sections installed on the main beam supporting structure from front to back, wherein the multiple main steel beams are I-beam main beams distributed in the longitudinal bridge direction. The reinforced concrete combined bridge deck slab sections comprise multiple reinforced concrete combined bridge deck slab units distributed from left to right. Longitudinal cast-in-place concrete structures are evenly distributed over the main steel beams. The construction method includes the steps of firstly, bridge lower portion supporting structure construction, secondly, main steel beam erection construction, thirdly, reinforced concrete combined bridge deck slab section installation, fourthly, longitudinal connecting reinforcing steel bar penetration, and fifthly, longitudinal cast-in-place concrete structure pouring construction. The assembly type steel plate combined beam bridge is reasonable in design, easy and convenient to construct, good in use effect, excellent in mechanical performance, high in installing and detaching construction speed, short in construction period and capable of effectively solving the problem that the main beam interval is too large.

Owner:CHANGAN UNIV

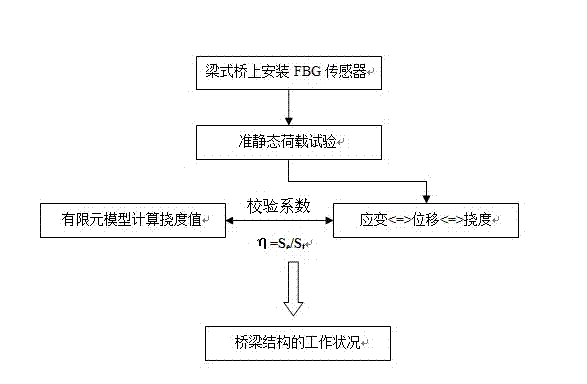

Beam bridge state evaluation method

ActiveCN103048102AAccurate assessmentReduce the difficulty of post-analysisElasticity measurementFiber Bragg gratingHeavy load

The invention relates to a beam bridge state evaluation method, which comprises the following steps of: 1) installing an FBG (fiber bragg grating) sensor on a beam bridge to be detected; 2) carrying out a quasi static load experiment on the beam bridge to be detected to obtain a control point deflection value; 3) comparing the control point deflection value obtained in the step 2 with a control point deflection value obtained by a finite element calculation model to obtain a beam bridge correction coefficient h; and 4) judging the working situation of the bridge structure according to the beam bridge correction coefficient h calculated in the step 3. The elevation method disclosed by the invention is convenient and practical; light load is used for replacing heavy load to lower the experiment expenditure; traffic interruption time is reduced; quasi static load or dynamic load is used for replacing static load; the analytical algorithm of the load experiment result can be directly obtained from a quasi static load experiment result so as to greatly lower the later-stage analysis difficulty of the quasi static load experiment data; and a quick load experiment method is used for replacing the traditional load experiment method.

Owner:JSTI GRP CO LTD

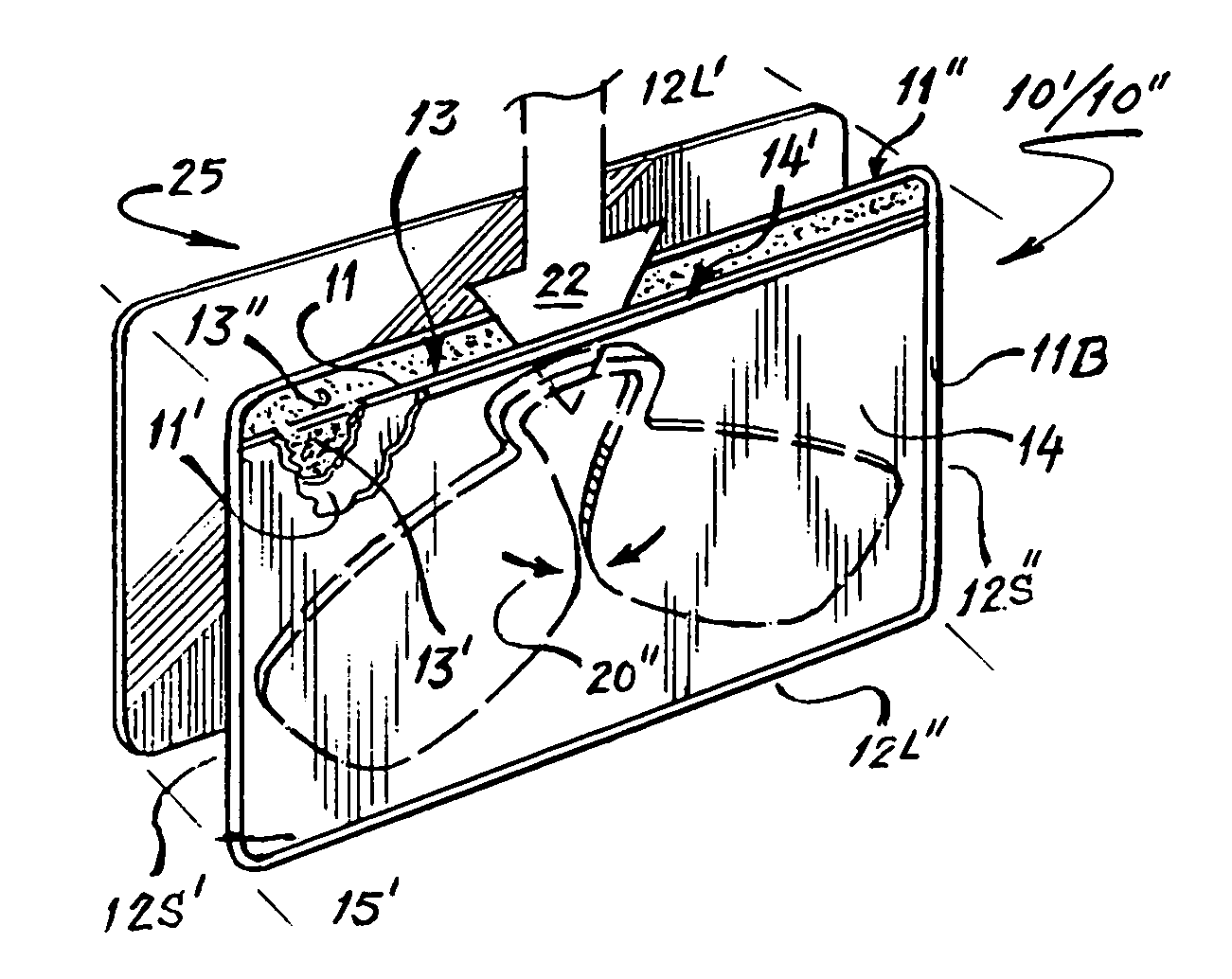

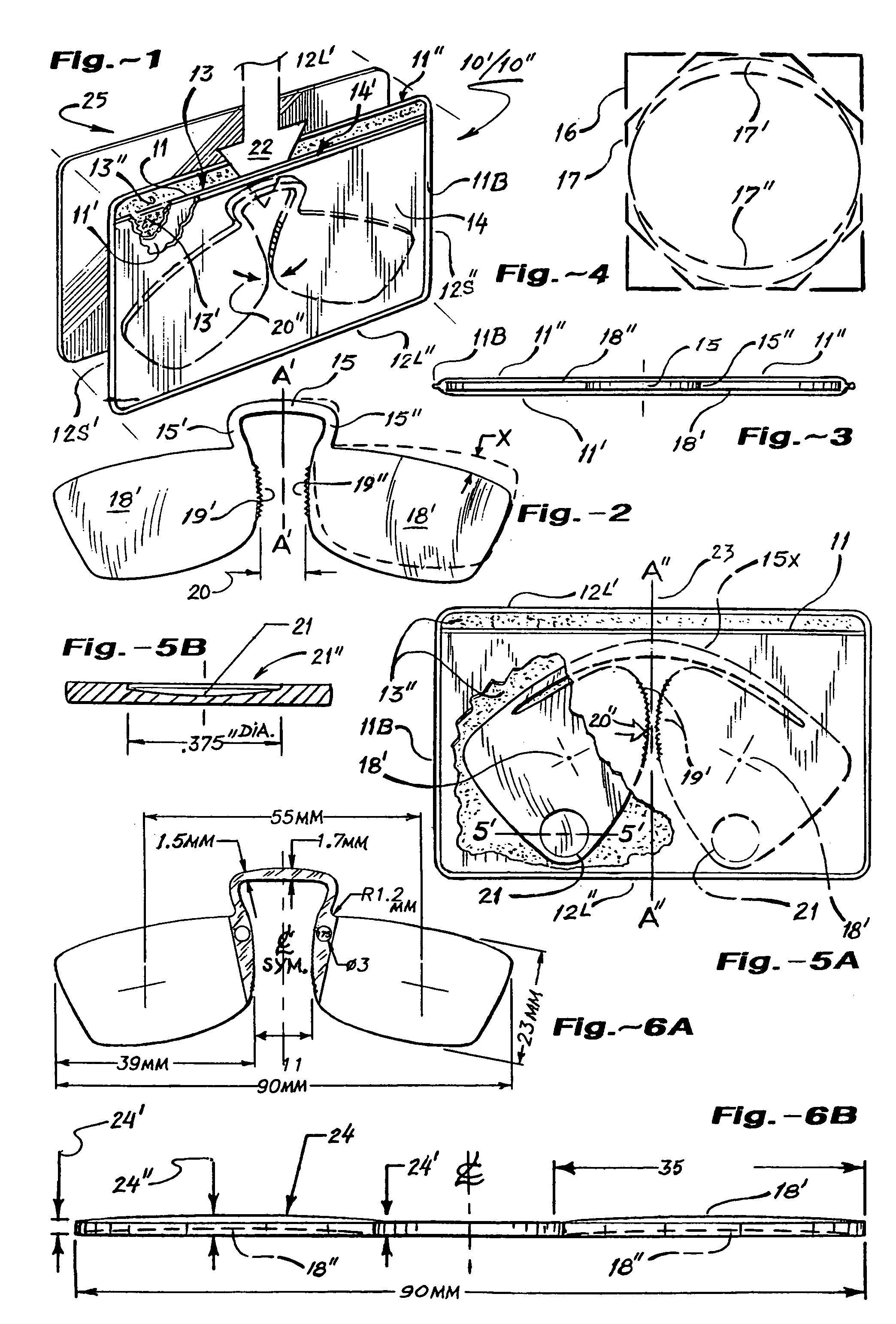

Credit-card modular two-component wallet-reader set

InactiveUS7117990B2Reduce the cross-sectional areaGreat torsional resistancePursesLuggageCredit cardModularity

A credit card modularized set having a flexible stow envelope for receiving a companion nose-clasping type reading glasses, with a length and width approximately that of a conventional credit card; wherein as the set is stacked within a group of conventional credit cards, no portion of the set is substantially protrusive nor recessive of the stacked group. The reading glasses component has a special beam bridge portion having a square cross-sectional shape thereby affording maximum torsional resistance for its diminutive size plus a laterally tapering cross section evenly distributing any imposed bending loads. The modularized set has a minimal thickness enabling its user to slip the set conveniently within the user's wallet modularly among the user's credit cards for ready availability.

Owner:PRESBY

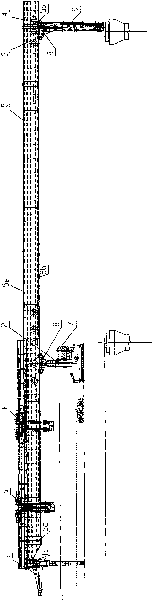

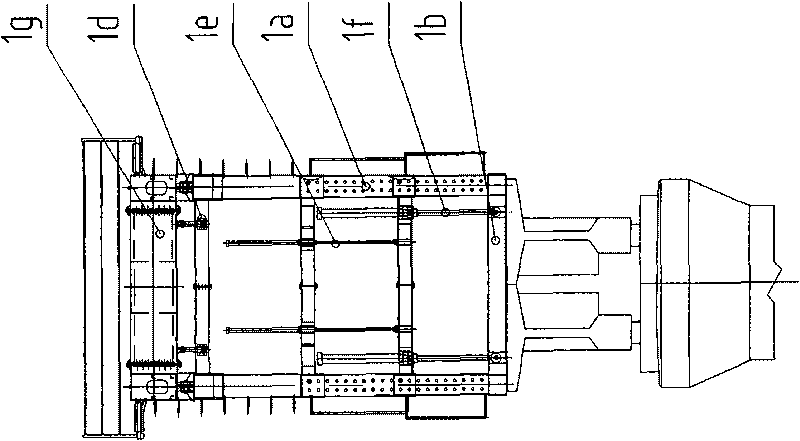

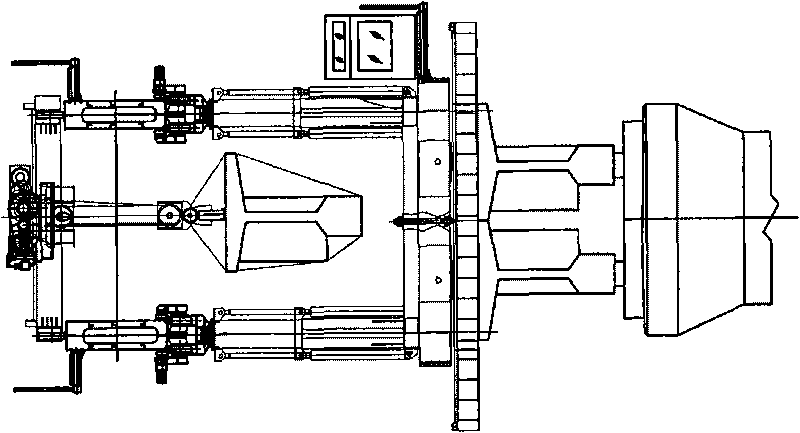

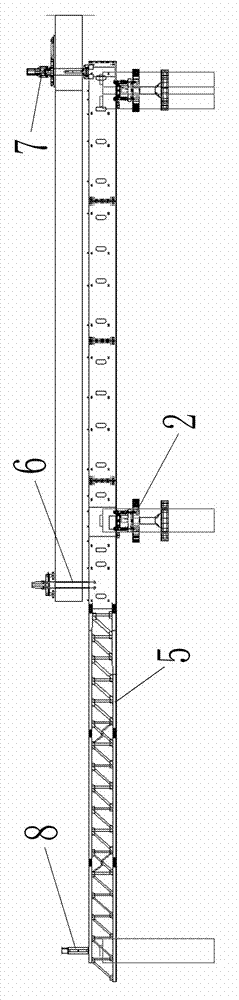

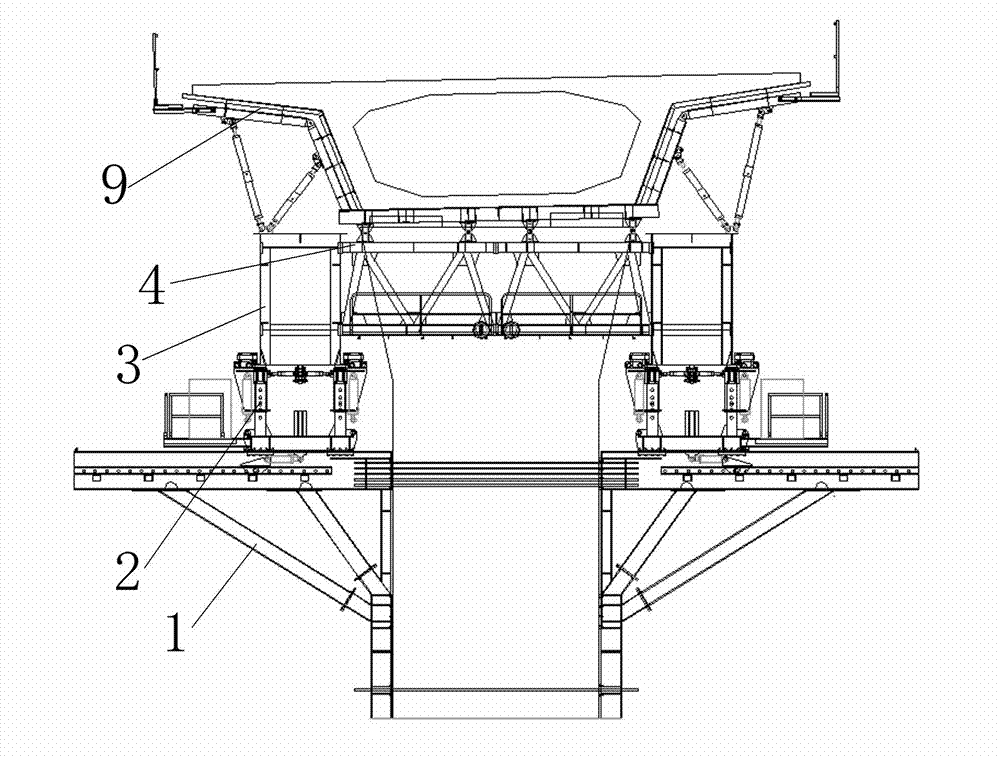

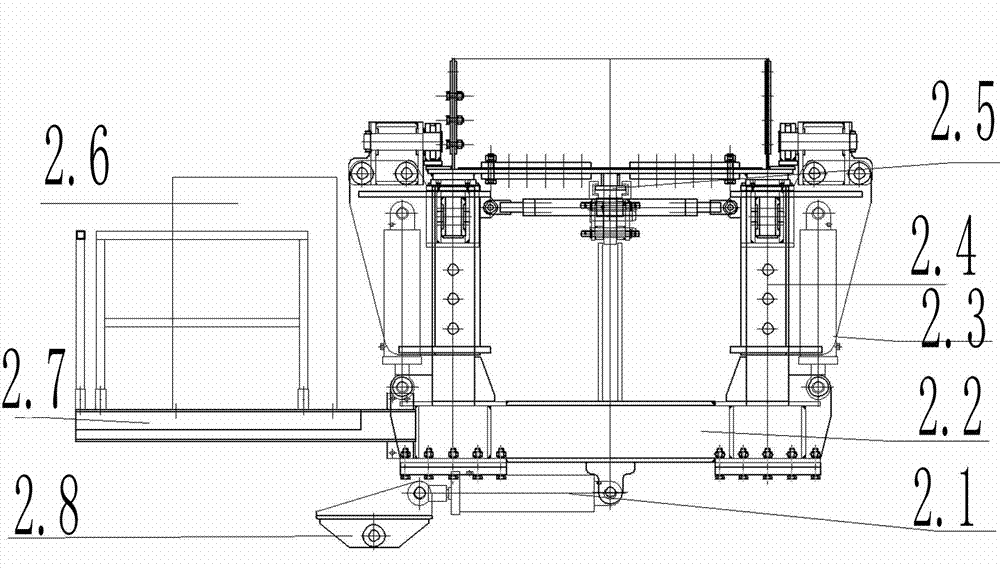

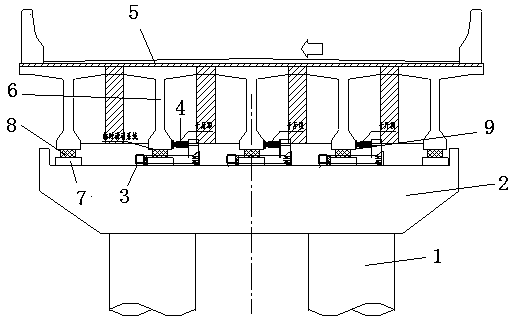

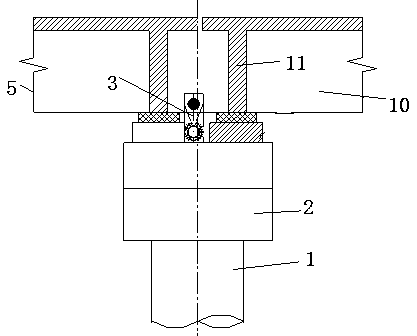

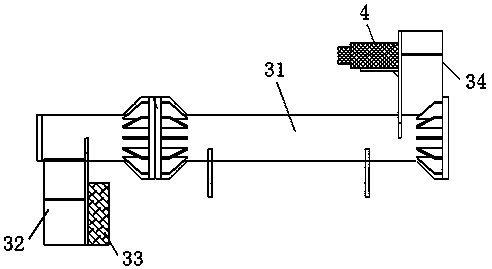

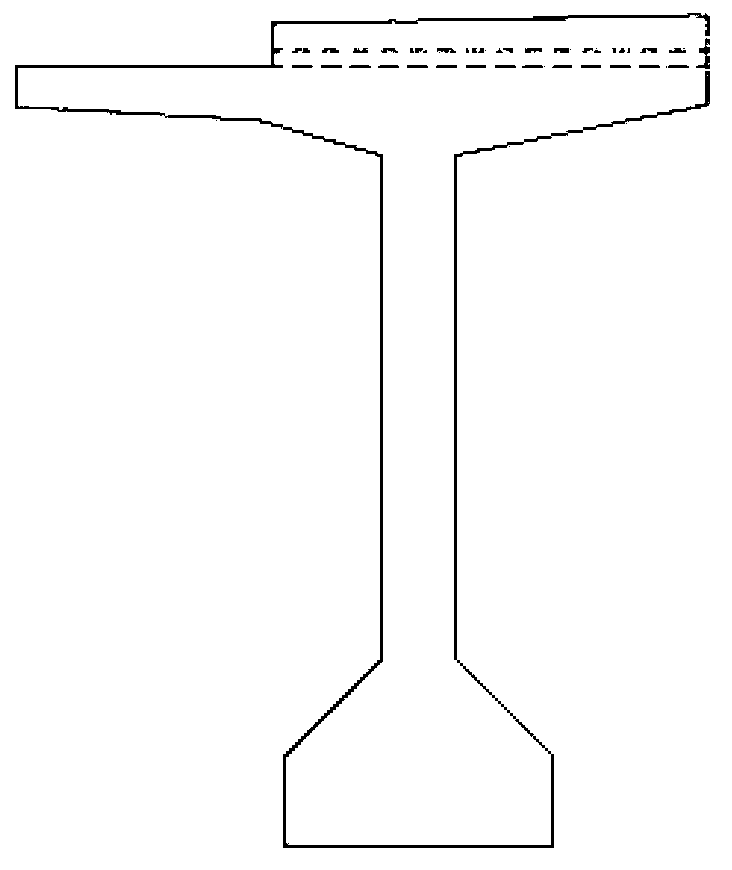

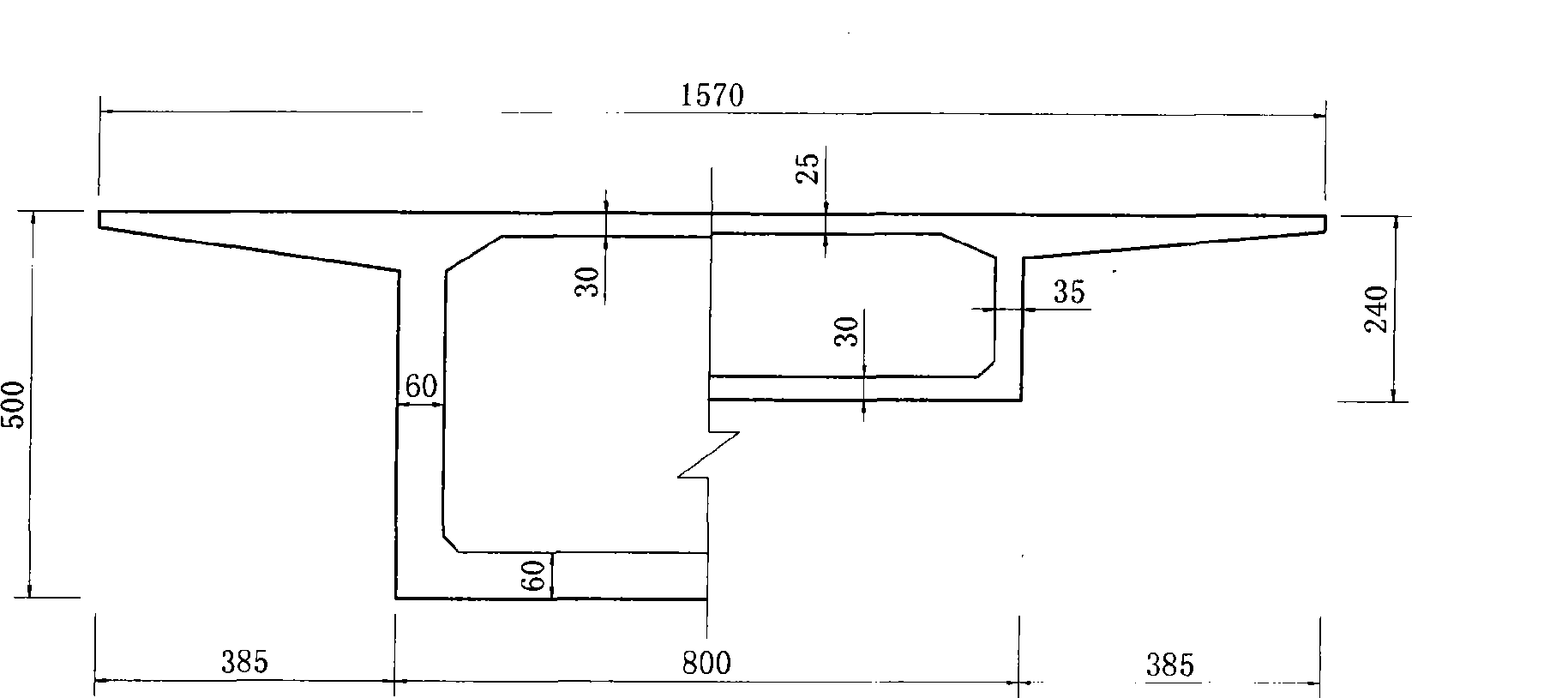

Highway-railway dual-purpose box-shaped double-beam T-shaped beam bridge girder erection machine

ActiveCN101736696AReduce the overall heightLower the altitudeBridge erection/assemblyShaped beamStructural engineering

The invention relates to a highway-railway dual-purpose box-shaped double-beam T-shaped beam bridge girder erection machine, comprising a rear ground jack (1), a middle ground jack (2), a front ground jack (3), an auxiliary ground jack (4), a dual-main beam (5), a front and rear hanging beam trolley (6), an electric appliance and operating system (7), a front and middle ground jack carrier roller (8) and a hydraulic system (9). The bridge girder erection machine has strong adaptability to the technical characteristics of bridges and circuits, thereby having wide popularization and application value. The bridge girder erection machine is suitable for erecting highway T-shape beams and is also suitable for railway T-shape beams.

Owner:ZHENGZHOU NEW DAFANG HEAVY IND & TECH

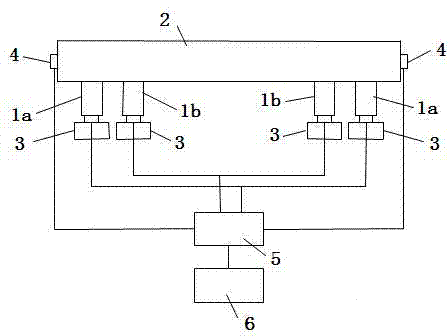

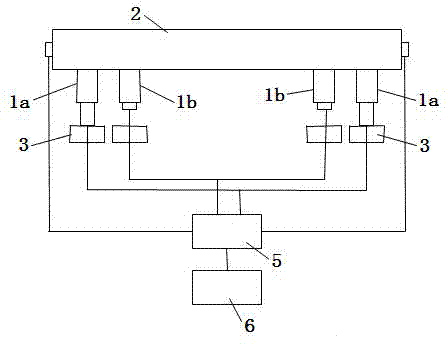

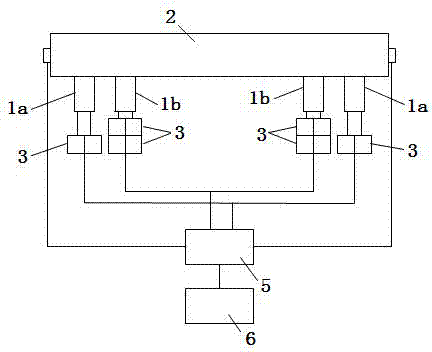

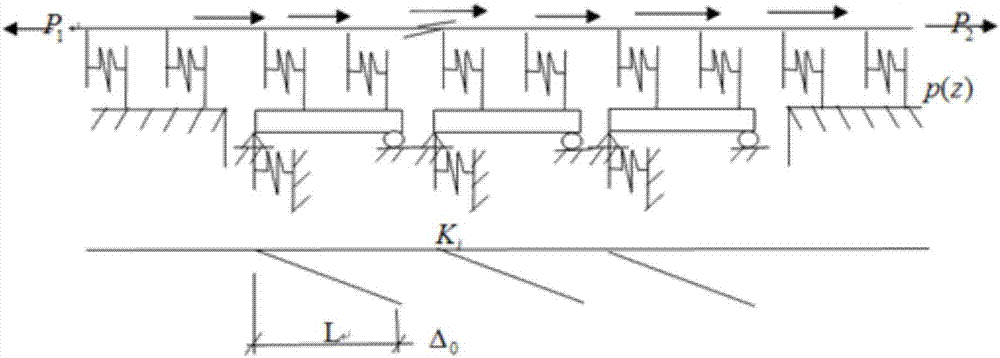

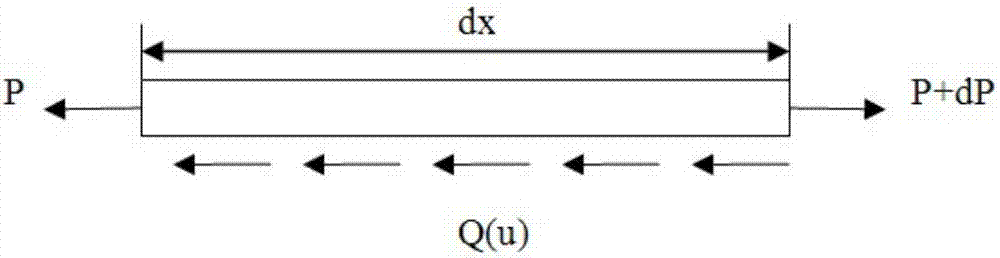

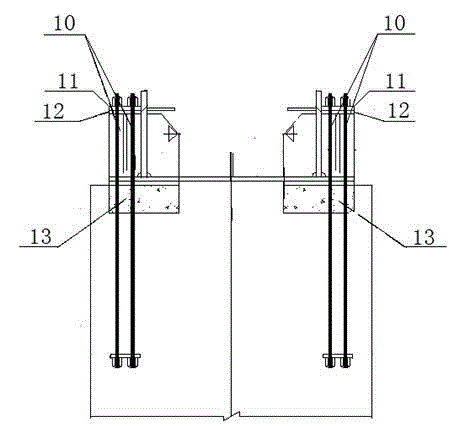

Slope-variable proportional alternate jacking construction method for continuous beam bridges

ActiveCN103205940AEliminate compressionEliminate height differenceBridge erection/assemblyBridge strengtheningHydraulic pumpContinuous beam

The invention discloses a slope-variable proportional alternate jacking construction method for continuous beam bridges. The slope-variable proportional alternate jacking construction method includes setting two groups of jacks capable of actively applying jacking force at the bottom of a bridge structure corresponding to fronts and backs of a pier and an abutment; enabling a control panel to control a hydraulic pump station to drive the two groups of jacks to carry out slope-variable proportional alternate jacking; and plugging temporary steel support cushion blocks at bottoms of one group of jacks when the other group of jacks performs jacking so as to eliminate height differences among various support points. The slope-variable proportional alternate jacking construction method has the advantages that the safety of the bridge structure is effectively guaranteed in a jacking procedure; and the requirement on a design gesture of an existing beam is met by the continuous slope-variable proportional alternate jacking method, and accordingly the purpose of modifying an existing bridge is achieved.

Owner:CHENGDU CONSTR ENG GROUP CORP

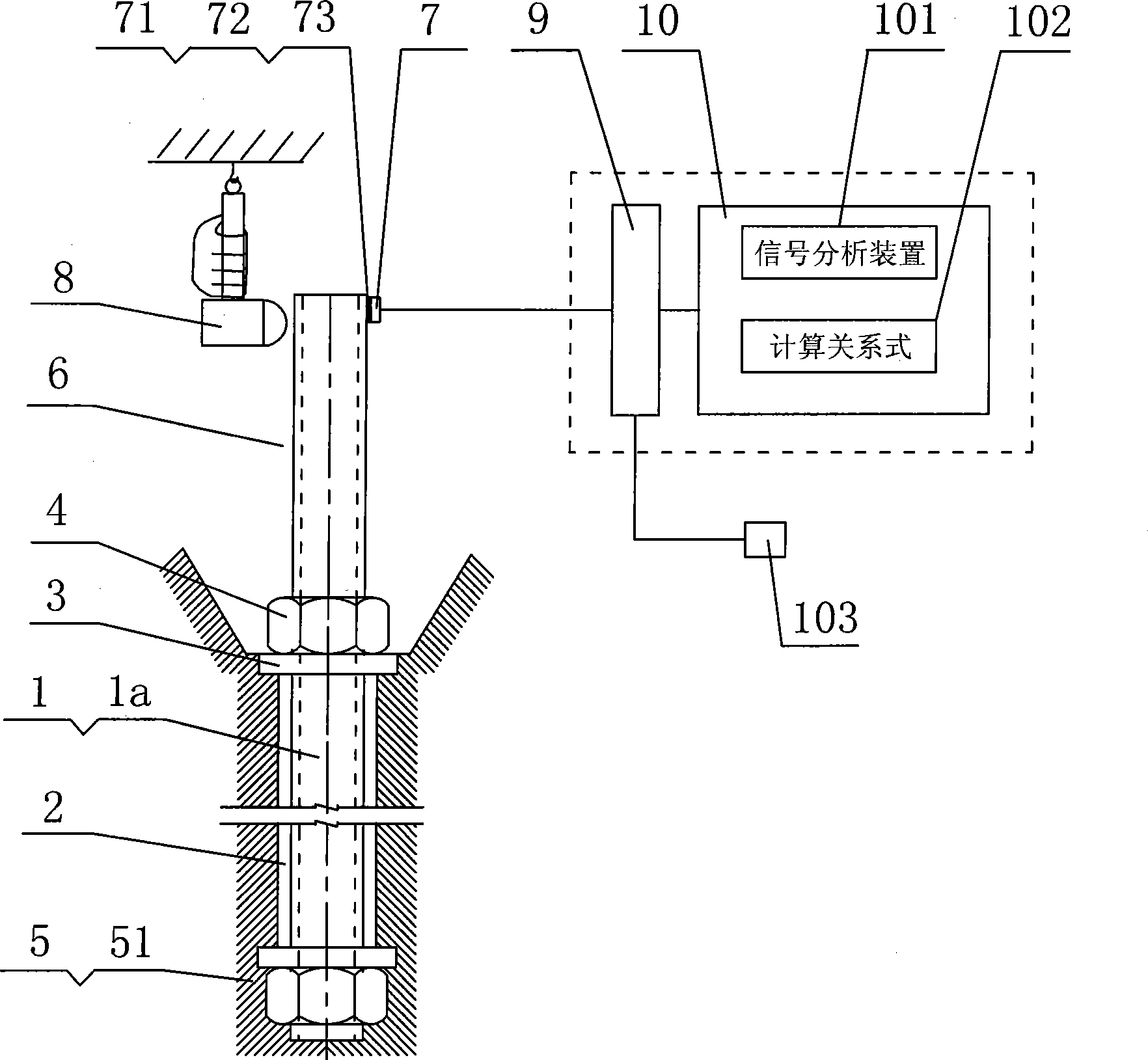

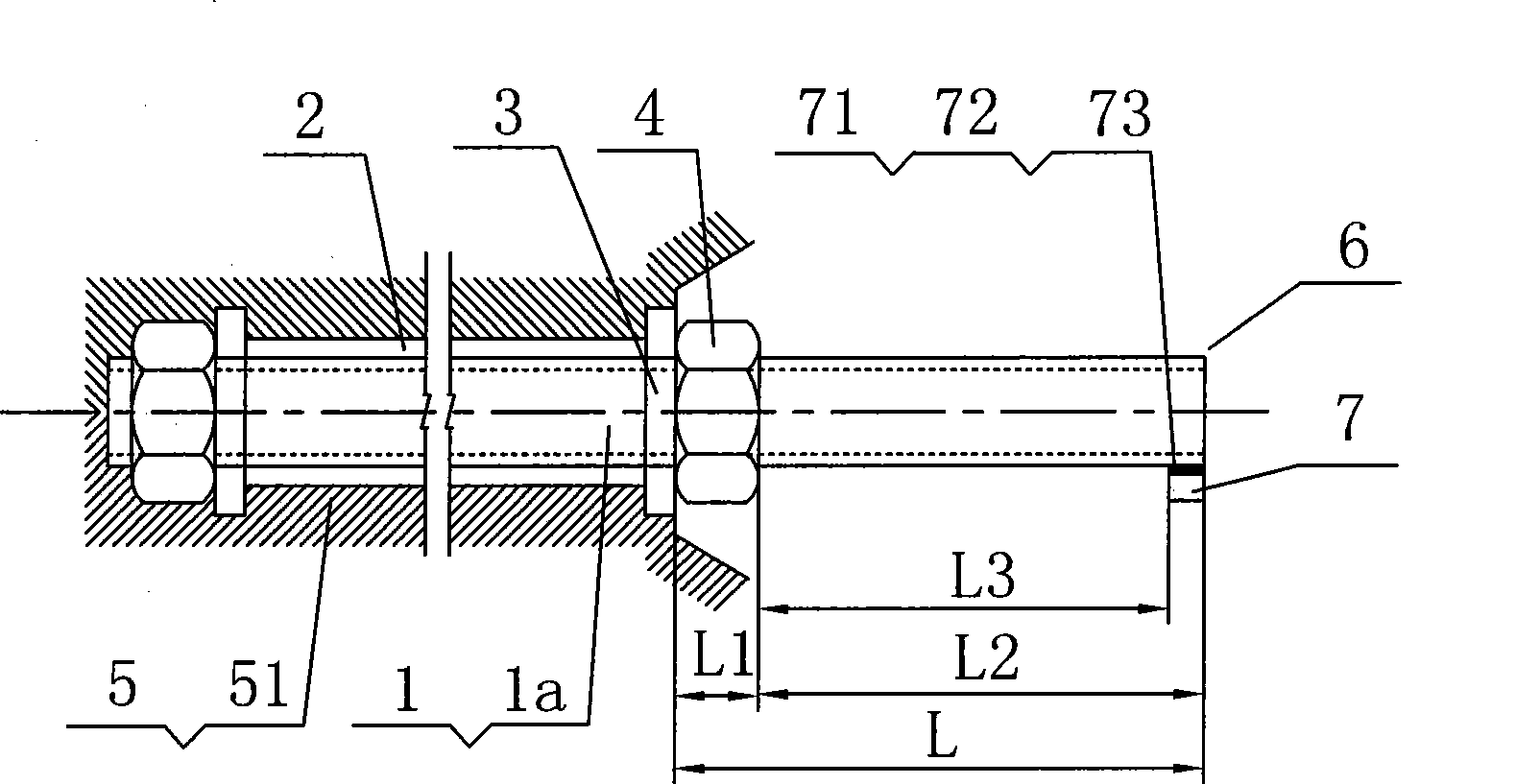

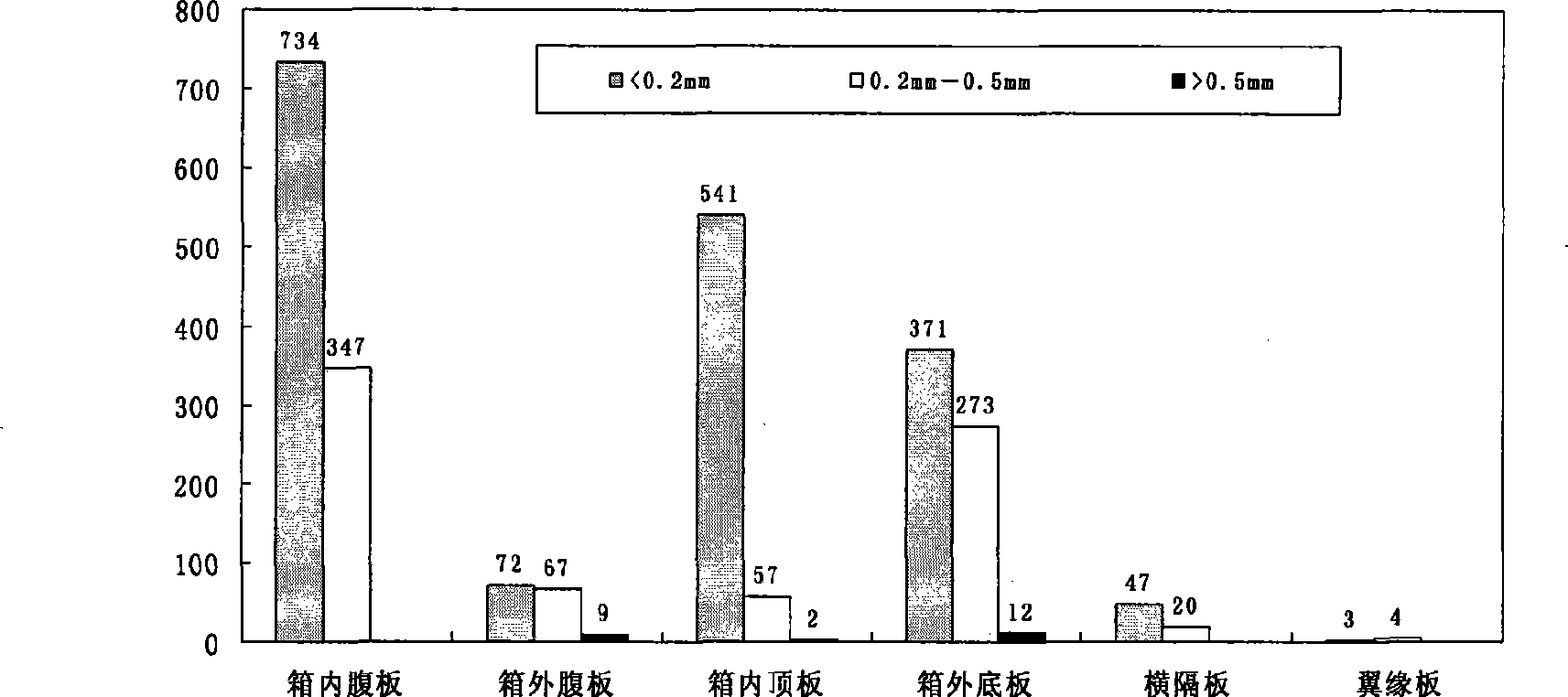

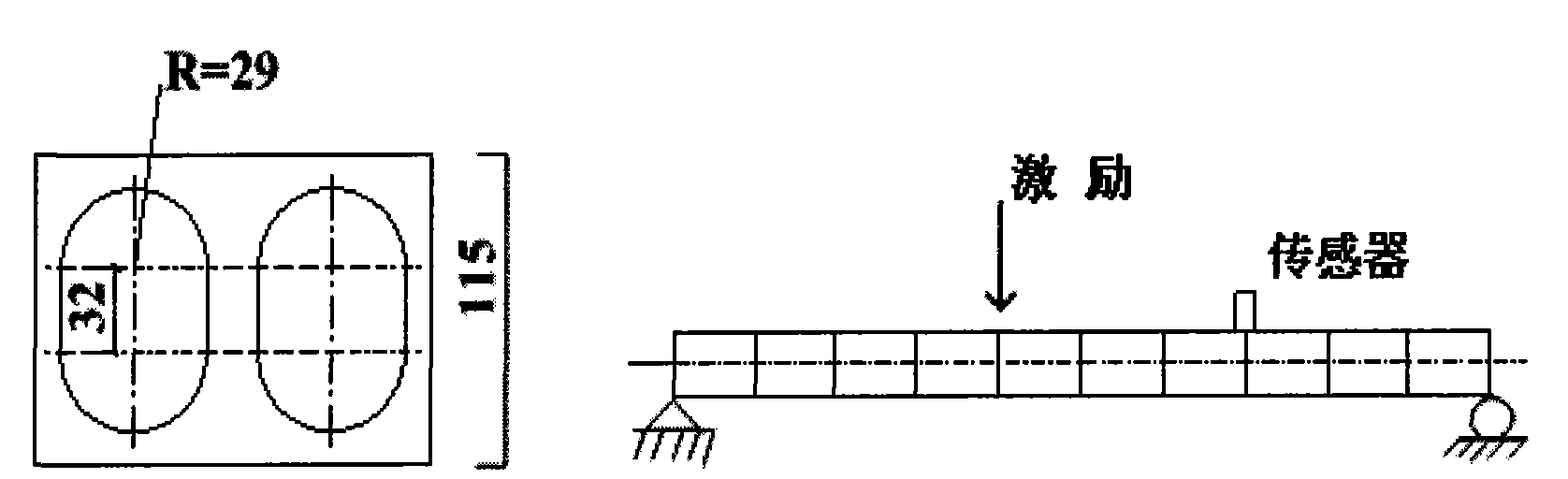

Detecting based on concrete box beam bridge web vertical pre-stress rib stretching force

ActiveCN101419104ARealize detectionSimple structureApparatus for force/torque/work measurementData acquisitionPre stressing

The invention relates to a system for detecting the tensioning force of a vertical presstressed reinforcing steel of a concrete box girder bridge web plate, which comprises a reinforced bar, a corrugated sleeve and nuts, wherein the lower part of the reinforced bar is vertically embedded into the concrete box girder bridge web plate and stretched into the vertical presstressed reinforcing steel; the upper part of the vertical presstressed reinforcing steel is provided with an exposed section; the exposed section is provided with an acceleration transducer and an exciter and electrically connected with a data acquisition unit, a notebook computer and a power supply; a signal analysis device which is used for being connected with the data acquisition unit is arranged and operated inside the notebook computer; the exciter obtains a command of the notebook computer to make the exposed section of the vertical tendon vibrate, converts the vibration into the natural frequency of the exposed section of the vertical presstressed reinforcing steel through the signal analysis device, and acquires the tensioning force between two nuts of the vertical presstressed reinforcing steel by application of a calculation relational expression. The detection system overcomes the defect that the prior system for detecting the tensioning force of the vertical presstressed reinforcing steel of a concrete box girder bridge can not meet the demand of on-scene large-area detection of the quality of the tensioning force of the vertical presstressed reinforcing steel, and is suitable for detecting the vertical presstressed reinforcing steel of the large-span prestressed concrete box girder bridge web plate.

Owner:HUNAN UNIV OF SCI & TECH

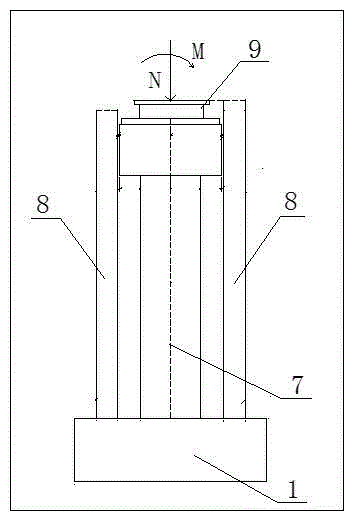

Descending bracket self-mobile model framework bridge fabrication machine

The invention discloses a descending bracket self-mobile model framework bridge fabrication machine, and relates to a bridge fabrication machine. A middle lifting point cross beam takes place and finishes primary blanking together with a C beam and a traveling trolley system, so that conversion of a stressing system from the lower part to the upper part is realized. The front end of a nose bridge is driven by a front supporting cross beam system to be jacked in place. A bracket is driven by the traveling trolley system to move out transversely, move longitudinally to travel and move transversely to take place. The middle lifting point cross beam and the C beam together finish secondary blanking, a middle lifting point cross beam lifting rod is removed, the mobile die framework moves transversely to open, moves longitudinally to travel, moves transversely to close and jacks in place, and the C beam 7 is removed; and finally concrete is poured. Thus, through stressing system conversion of the bracket, the traveling trolley system, the middle lifting point cross beam and the C beam, the use at construction sites of continuous beams at sites of intertidal zones, canyons, urban viaducts, river-crossing bridges and cross-sea bridges with limited construction conditions and high construction difficulty, where the auxiliary hoisting equipment cannot reach, can be realized.

Owner:SHANDONG LUQIAO GROUP

Vehicle load dynamic weighing method for orthotropic bridge deck steel box girder bridge

ActiveCN102628708ADoes not affect drivingHigh sampling frequencyUsing optical meansSpecial purpose weighing apparatusCross correlation analysisBridge deck

The invention discloses a vehicle load dynamic weighing method for an orthotropic bridge deck steel box girder bridge, which relates to the field of bridge health monitoring. The method comprises the following steps of: mounting a fiber grating strain sensor at the bottom of a U-shaped rib of an internal top plate of an orthotropic bridge deck steel box girder; measuring longitudinal bridge strain of the U-shaped rib when a vehicle passes through the position of the sensor; converting the strain into an optical signal by the sensor; demodulating the optical signal by using a fiber grating demodulator; carrying out cross-correlation analysis on actually measured strains of measuring points on the same U-shaped rib in the steel box girder at different sections so as to determine vehicle speed of the vehicle; analyzing actually measured strain area vectors of measuring points on different U-shaped ribs in the steel box girder at the same section; and carrying out angle Cosine distance analysis by using a strain effect linear area vector of the U-shaped rib of the steel box girder so as to figure out transverse acting position and weight of each vehicle on a running lane. The vehicle load dynamic weighing method for the orthotropic bridge deck steel box girder bridge, disclosed by the invention, has the advantages of convenience for mounting, low manufacturing price, no need of interrupting transportation, no excavation or damage of the road surface and capability of achieving nondestructive and automatic dynamic weighing of the bridge vehicle load.

Owner:CHINA RAILWAY BRIDGE SCI RES INST LTD +1

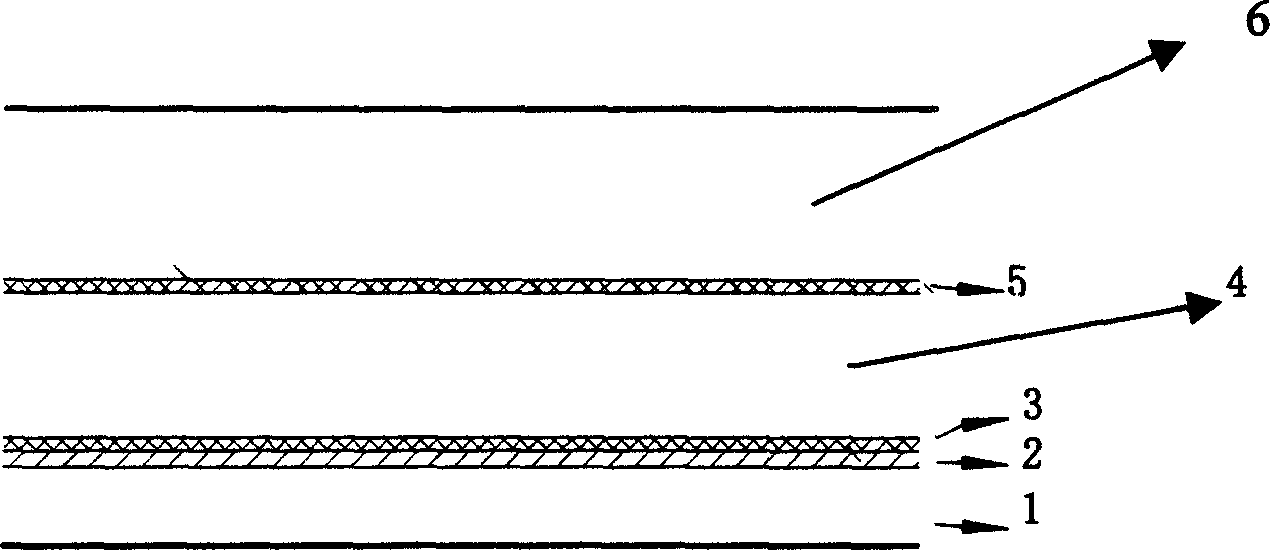

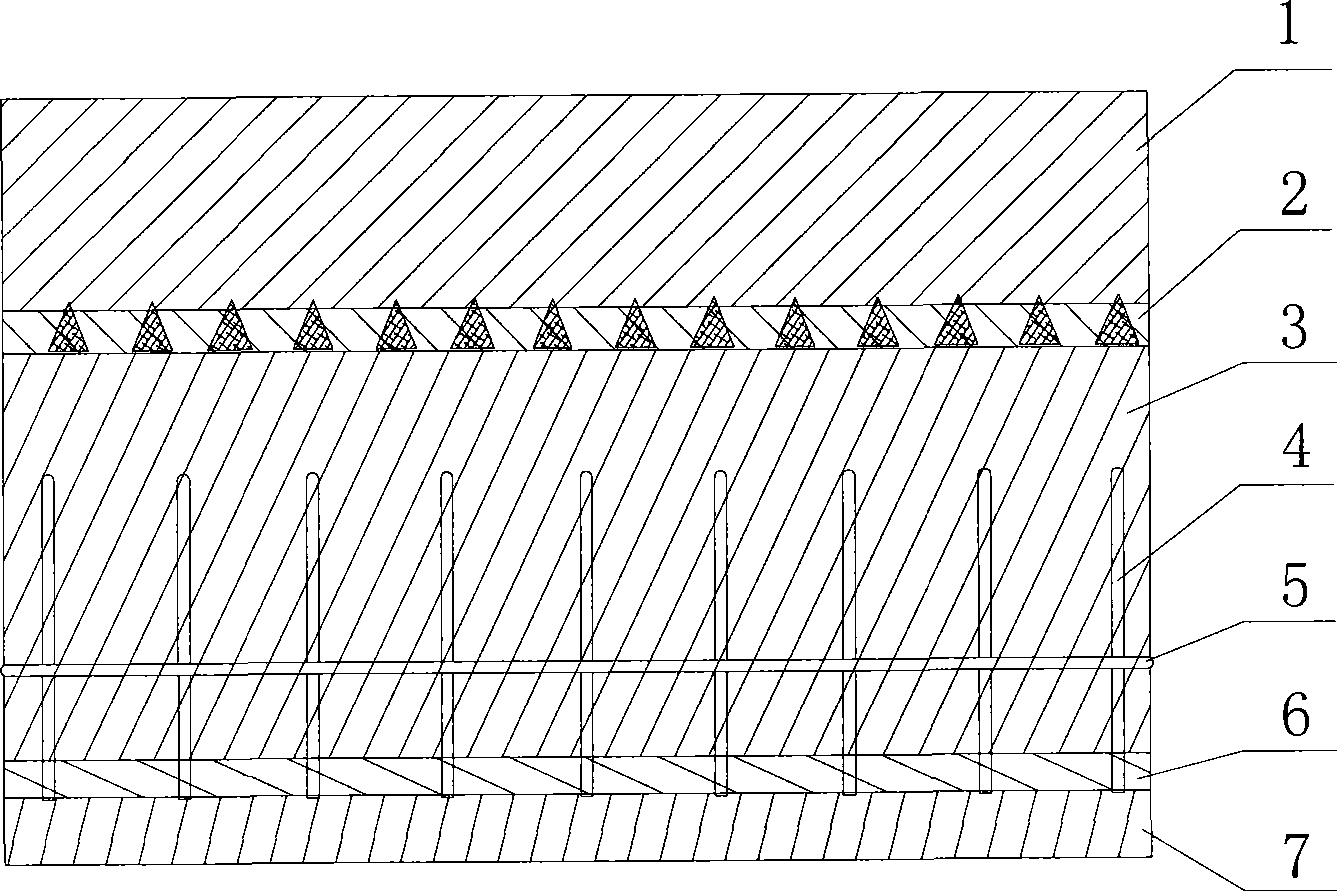

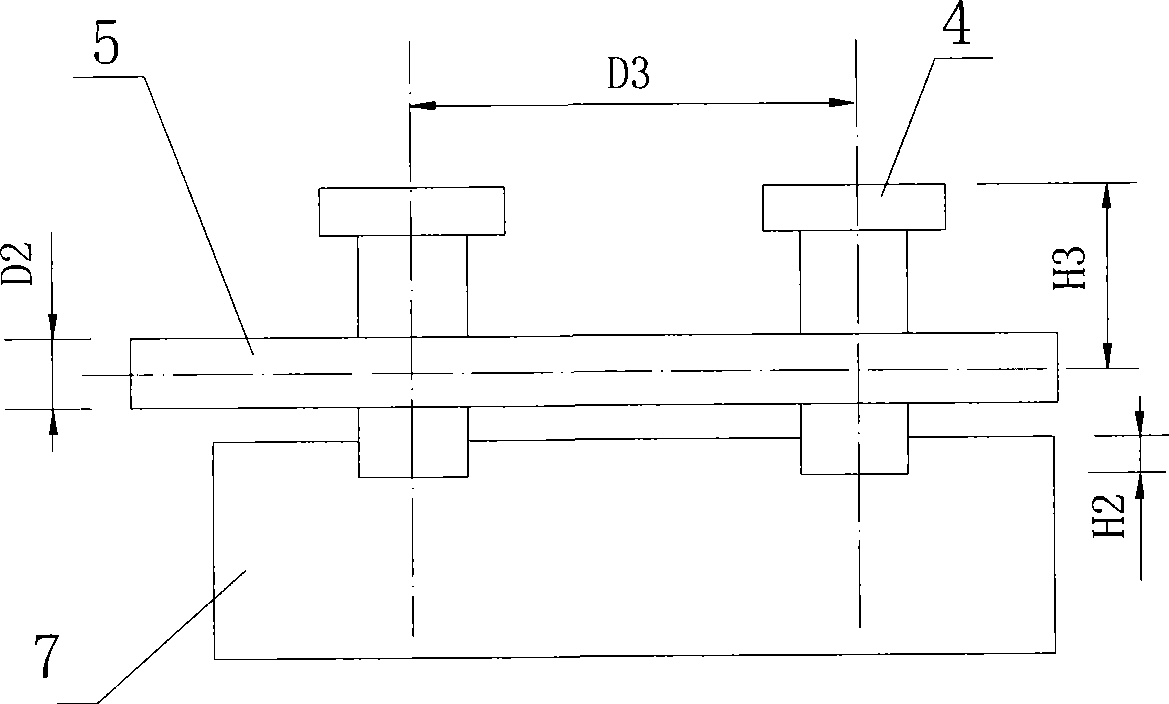

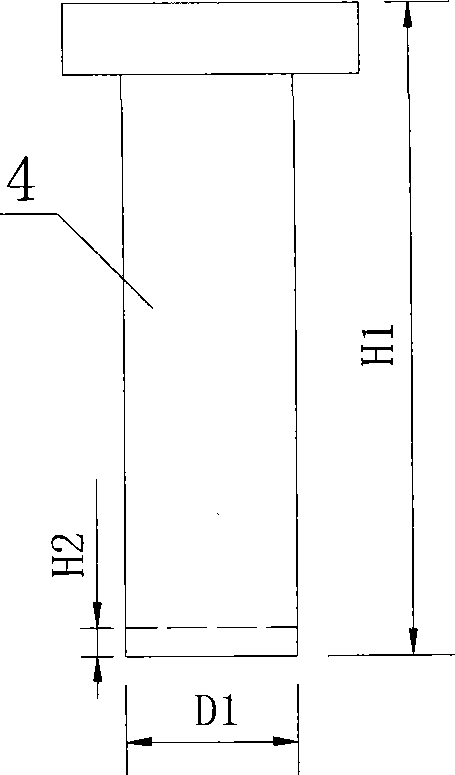

Method for establishing temperature field model of steel box beam bridge road system under high-temperature asphalt concrete paving

ActiveCN103726434AReflect the temperature field distributionIncrease reflectionBridge structural detailsRoads maintainenceThermal insulationInterfacial thermal resistance

The invention provides a method for establishing a temperature field model of a steel box beam bridge road system under high-temperature asphalt concrete paving. The model comprises a paving layer (1), a steel bridge panel (2), U-shaped ribs (4) and diaphragm plates (5). An interface thermal resistor (3) is arranged between the paving layer (1) and the steel bridge panel (2) and is used for reflecting a barrier effect of an adhesive layer in an adhesive layer-paving composite structure on temperature transfer. The method comprises the following steps: acquiring the optimal interface thermal resistance by using a test-numerical simulation mixed parameter analysis method and combining a numerical optimization technology; establishing an actual bridge numerical model, setting a movable temperature load (6) to simulate the paving construction process, and calculating and analyzing the temperature field distribution condition of the steel box beam bridge road system. The method mainly depends on finite element modeling, a thermal insulation effect of the adhesive layer can be well reflected, and the paving construction process can be really simulated. Compared with field measurement, the method is simple and feasible, different working conditions can be simulated, and the temperature field distribution condition of the steel box beam bridge road system can be accurately reflected.

Owner:SOUTHEAST UNIV

Deviation correcting and resetting method for transverse deviation of beam bodies of beam bridge

InactiveCN103821092AIncrease stiffnessAvoid destructionBridge erection/assemblyBridge strengtheningBeam bridgePhysics

The invention discloses a deviation correcting and resetting method for transverse deviation of beam bodies of a beam bridge. The method comprises the steps that 1) horizontal transverse action force enabling the beam bodies to deviate is eliminated; 2) a whole binding beam body of a unit where the deviated beam bodies are located is temporarily fixed and bound to form a stress whole, and meanwhile the beam bodies of the unit and beam bodies of adjacent bridge spans on the two sides of the beam bodies are disconnected; 3) jacking devices are arranged at the tops of all piers corresponding to the temporarily fixed and bound deviated unit, and the corresponding deviated beam bodies are jacked synchronously; 4) a temporary sliding support is arranged in a clearance formed through jacking in the step 3); 5) reaction frames and deviation correction jacks are arranged on support cushion stone at the tops of the piers corresponding to all the beam bodies of the deviated unit, and all the deviation correction jacks transversely push the beam bodies to be reset; 6) after deviation correction is carried out in place, the beam bodies are finally rehabilitated. The deviation correction push thrust of the method is reduced exponentially, the damage of subsidiary stress generated in the deviation correction process to the structure of the beam bodies is avoided, construction is convenient, the construction period is short, and cost is low.

Owner:武汉中交试验检测加固工程有限责任公司

Sound-barrier simply-supported T-beam bridge

ActiveCN103061242AImprove integrityReduce workloadNoise reduction constructionBridge structural detailsSound barrierT-beam

The invention relates to the technical field of railway bridges and particularly discloses a sound-barrier simply-supported T-beam bridge which comprises a plurality of simply supported T-beams. Each simply supported T-beam is formed by connecting a plurality of simply supported T-beam units end to end. The simply supported T-beams are transversely connected through transverse partitions, wet joints and concrete. Concrete cast-in-place decks are arranged outside the simply supported T-beams on two sides. The upper surfaces of the simply supported T-beams, the upper surfaces of concrete connections and the upper surfaces of the concrete cast-in-place decks form an integral bridge deck. The whole integral bridge deck is provided with transverse prestressed bars. Sound-barrier column foundations are arranged outside the concrete cast-in-place decks, and sound-barrier columns are arranged at the sound-barrier column foundations. A sound barrier is arranged between each two adjacent columns. The performance of the railway bridge is improved, the railway bridge meets the requirement of providing the sound barrier by the aid of the integral bridge deck, sound barrier absorbs or isolates noise generated in running process of trains and the influence of the trains upon lives of nearby residents is reduced.

Owner:CHINA RAILWAY ENG CONSULTING GRP CO LTD

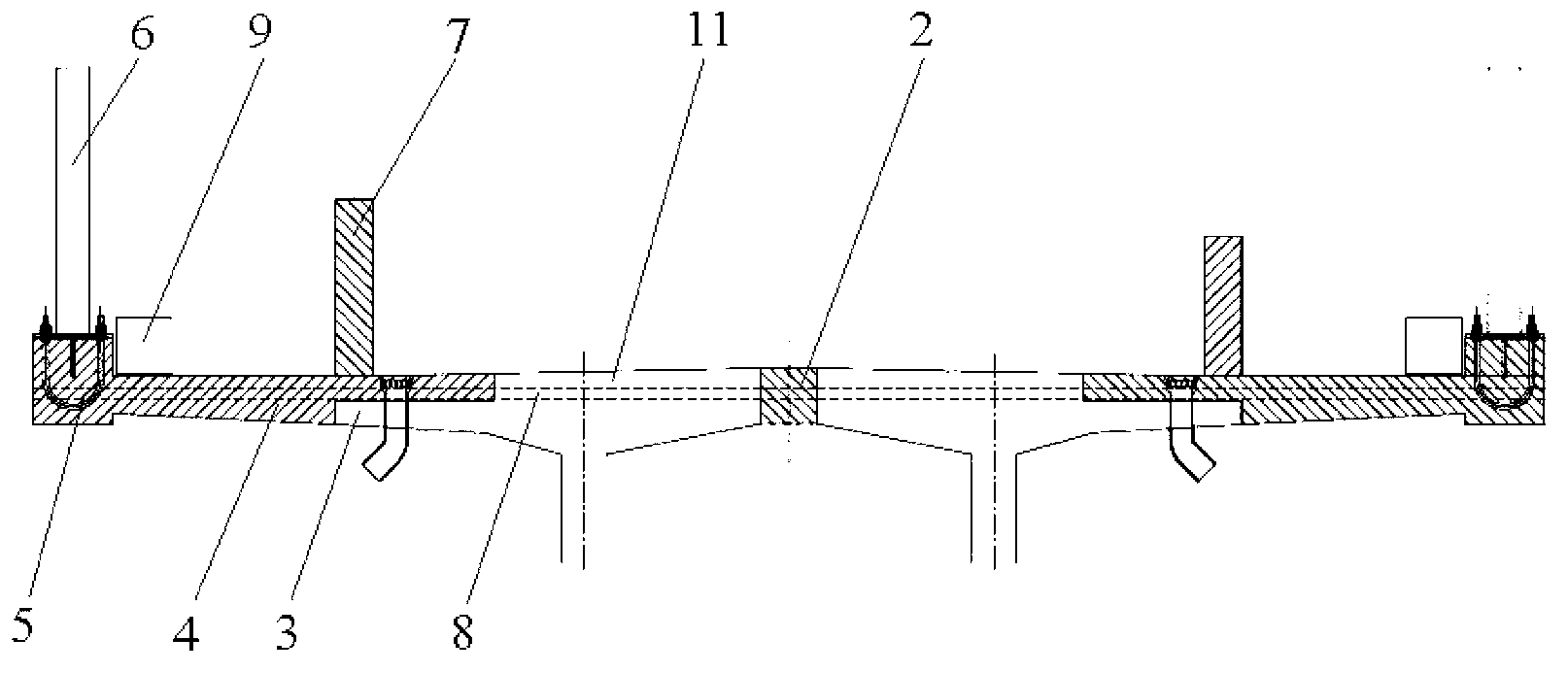

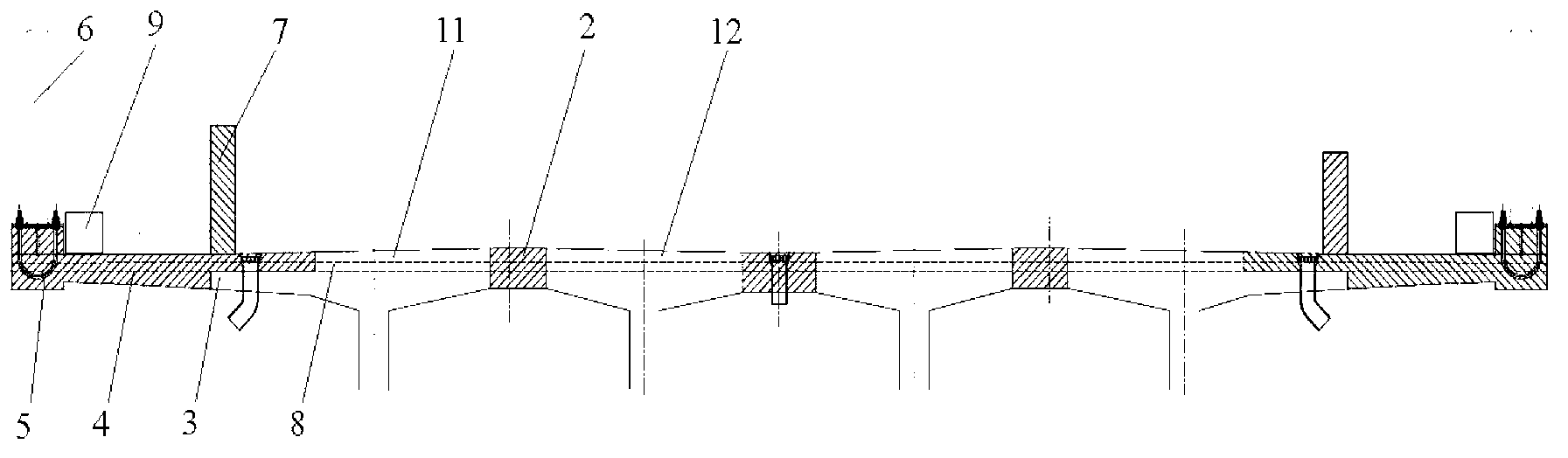

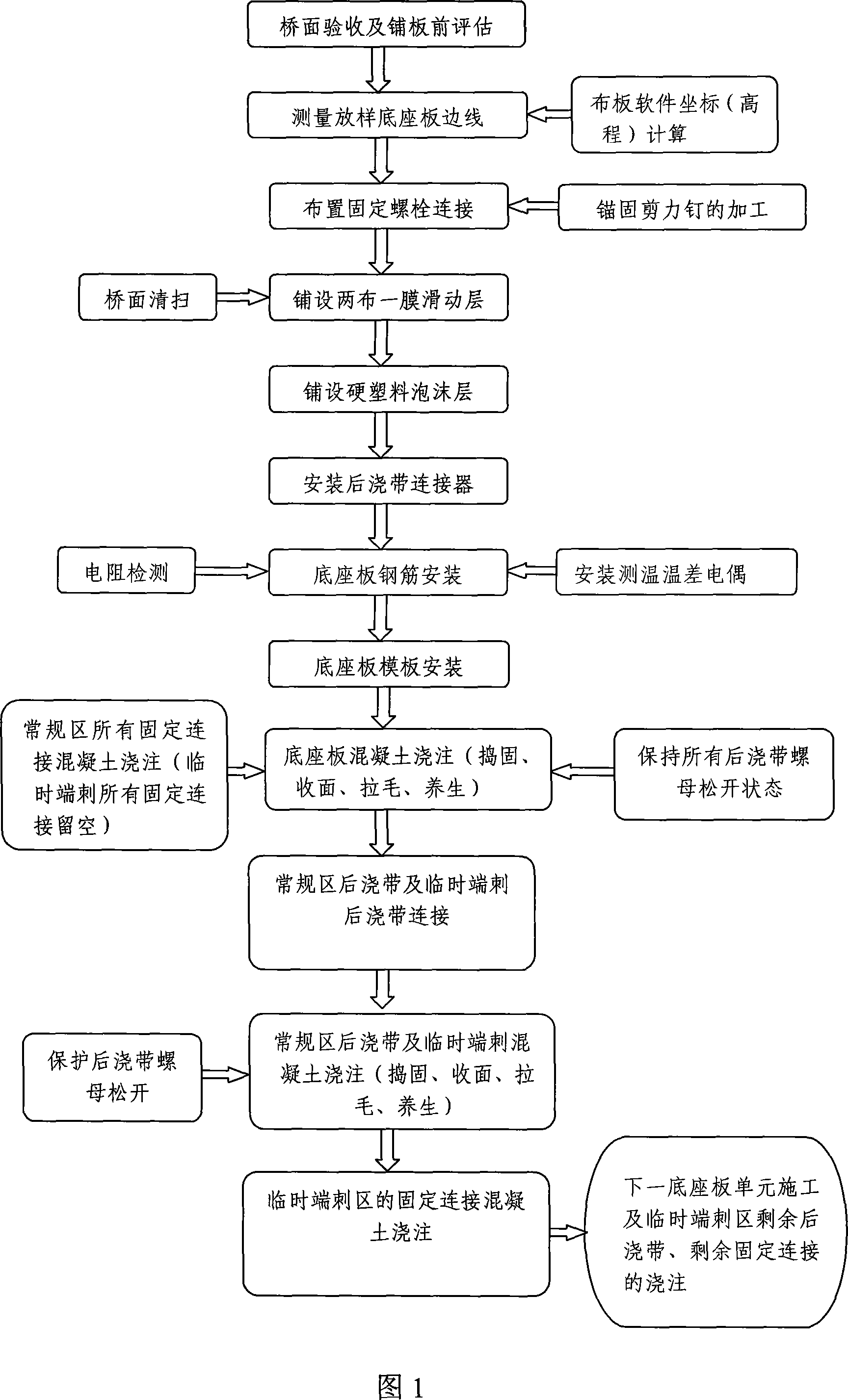

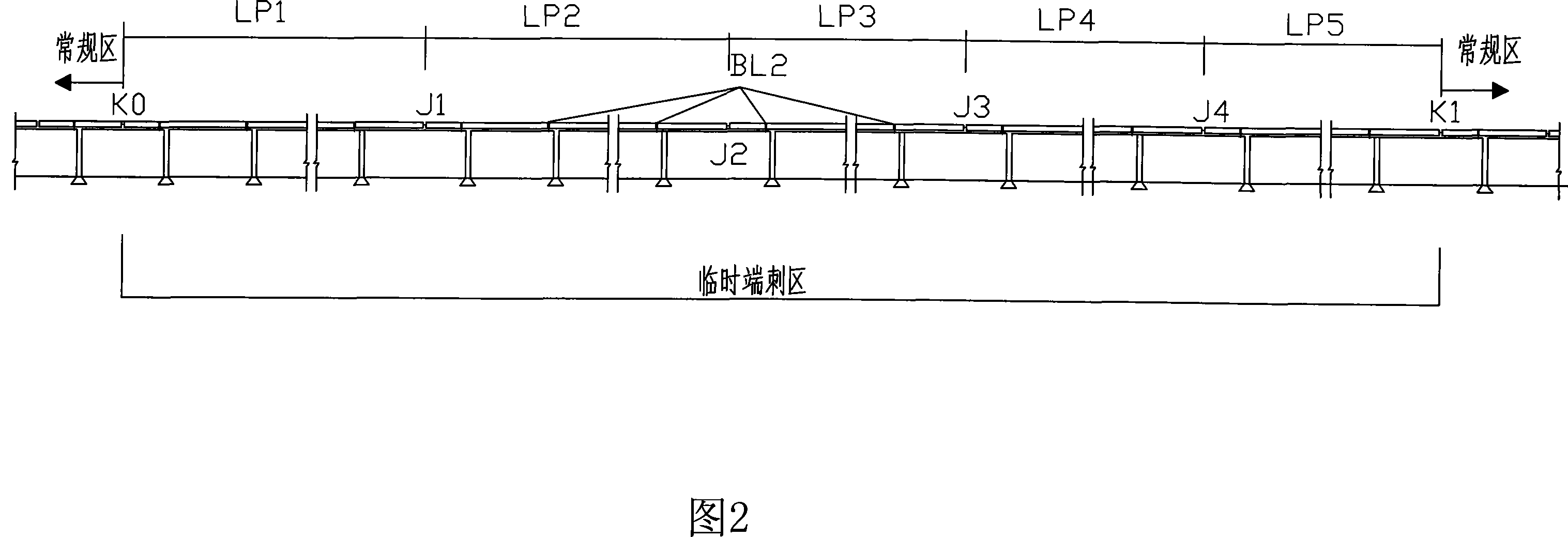

Unballasted track bed plate construction method

ActiveCN101195983ASolve technical difficulties in constructionImprove construction qualityRailway track constructionArchitectural engineeringBridge deck

The invention relates to a construction method of the bottom seat plate of the ballastless track, which belongs to a construction process method of tracks. The purpose of the invention is to provide a reliable construction method of the bottom seat plate of the ballastless track on bridges to meet the quality and accuracy requirement of the bottom seat plate of the ballastless track. The construction method comprises the following steps: step one, firstly, the bridge floor is checked and accepted and assessed before planking; secondly, the stakingout connecting line of the bottom seat plate is measured; thirdly, the connection of the fixed bolt is arranged; fourthly, a sliding layer with two cloth and one film is laid on the bridge floor of the box-beam bridge; step two, a hard plastics foam layer is laid on the two ends of the beam slot; step three, a post casting strip connector is installed; step four, firstly, tooth socket welding studs are installed; secondly, bottom seat plate reinforcing bars are installed; step five, bottom seat plate mould plates are installed; step six, the concrete of the bottom seat plate is cast; step seven, the cast post casting strip and the welding stud tooth socket are fixedly connected, and the connection of the bottom seat plates is completed.

Owner:CHINA RAILWAY NO 2 ENG GRP CO LTD

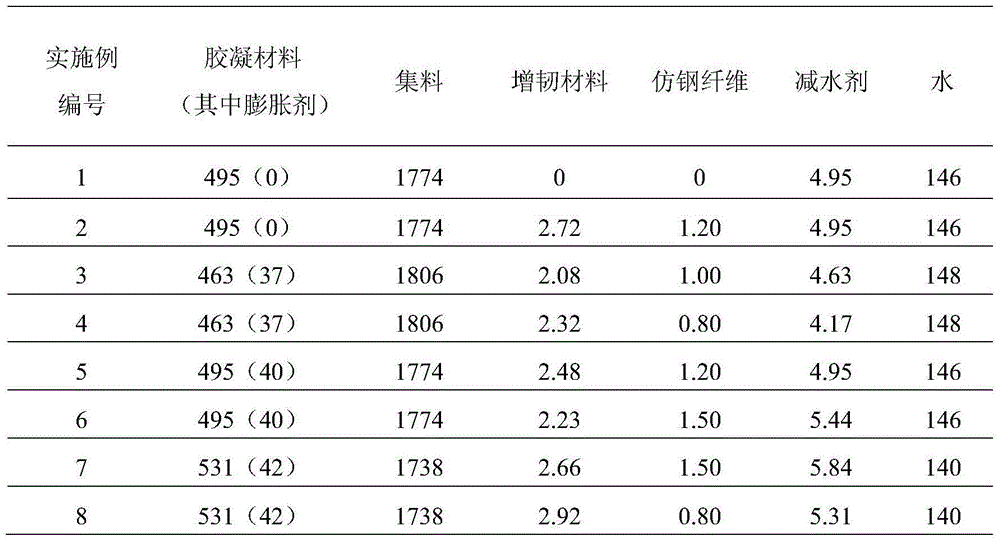

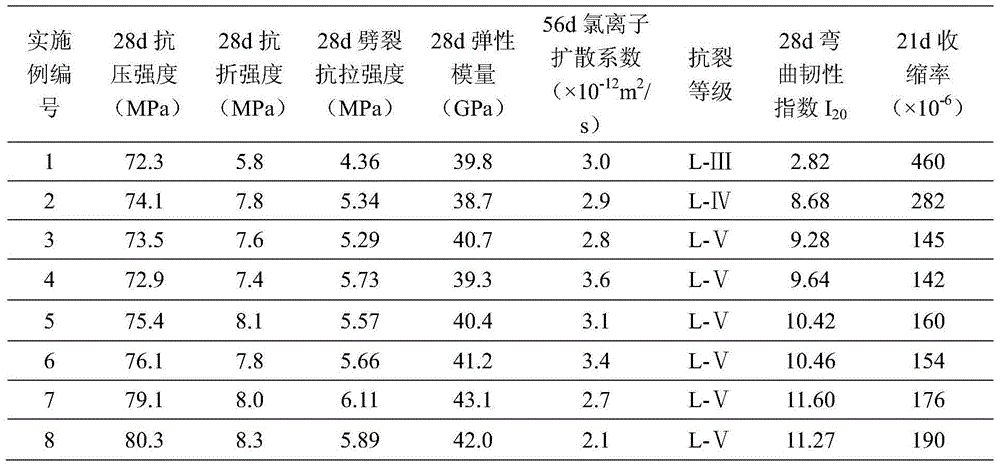

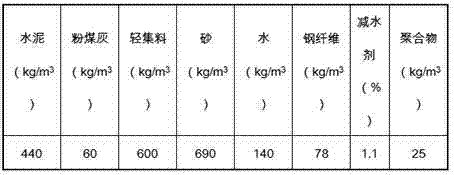

Micro-expansion fiber reinforced concrete and preparation method thereof

The invention discloses micro-expansion fiber reinforced concrete for a steel-concrete combined beam bridge panel wet joint and a preparation method of the micro-expansion fiber reinforced concrete, and relates to the preparation field of the micro-expansion fiber reinforced concrete. The micro-expansion fiber reinforced concrete comprises gel materials (cement, coal ash, slag powder and an expanding agent), aggregate, reinforcing materials, imitated steel fibers, a water reducer and water, wherein the 28 compressive strength of the micro-expansion fiber reinforced concrete is not lower than 69.0MPa, the 28d breaking strength of the micro-expansion fiber reinforced concrete is not lower than 7.0 MPa, the 28d splitting tensile strength of the micro-expansion fiber reinforced concrete is not lower than 5.0 MPa, the 28d elasticity modulus of the micro-expansion fiber reinforced concrete is not lower than 36.0 GPa, the cracking resistance level of the micro-expansion fiber reinforced concrete reaches L-IV level, the 28d bending toughness index I20 of the micro-expansion fiber reinforced concrete is not lower than 8, the 56d chlorine ion diffusion coefficient of the micro-expansion fiber reinforced concrete is lower than 4.0*10<-12>m<2> / s, the 21d shrinkage percentage of the micro-expansion fiber reinforced concrete is lower than 200*10<-6>. By using the preparation method, the shrinkage cracking of the micro-expansion fiber reinforced concrete can be effectively avoided, so that the reinforced concrete is relatively compact. The micro-expansion fiber reinforced concrete disclosed by the invention is relatively high in strength, relatively low in shrinkage percentage, good in bending toughness and durability, relatively low in cost and conveniently to widely use.

Owner:THE 2ND ENG CO LTD MBEC +1

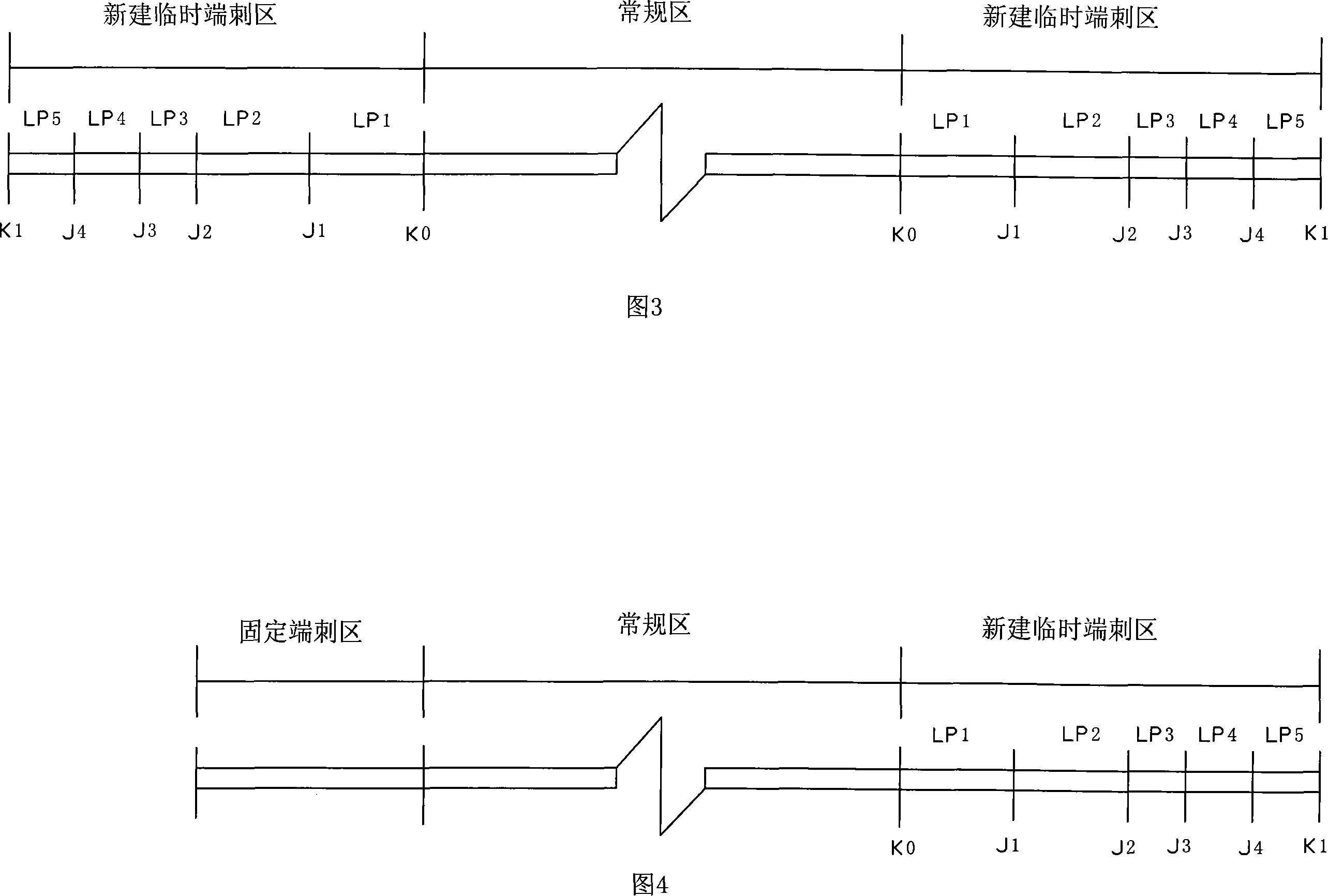

Method for longitudinal stiffness control over high-pier large-span concrete continuous girder bridge and bridge

ActiveCN107201716AMeet vertical and horizontal control standardsProcess stabilityBridge structural detailsEngineeringFixed Bridges

The invention relates to the technical field of high-pier large-span concrete bridges, in particular to a method for longitudinal stiffness control over a high-pier large-span concrete continuous girder bridge and a bridge. The method for longitudinal stiffness control comprises a step a) of establishing a linear bridge pier integrated calculation model; a step b) of applying an analog load; a step c) of analyzing beam track acting force and jointless track stress deformation laws; and a step d) of determining longitudinal rigidity limits of a fixed bridge pier and track treatment measures. Therefore, beam shape arrangement and fixed pier rigidity are determined, a problem that in the prior art, it is difficult to control longitudinal stiffness of the high-pier large-span continuous girder bridge is solved, and the blank of the high-pier large-span girder bridge in the field of longitudinal stiffness control is filled. Meanwhile, normative standards of longitudinal linear stiffness limits of the high-pier large-span concrete continuous girder bridge are established, a reference and a basis are provided for bridge design and construction, so the design cost is reduced, and the actually built bridge meets specific usage environments.

Owner:CHINA RAILWAY ERYUAN ENG GRP CO LTD

Prestressed concrete-corrugated web steel box connecting beam hybrid beam structural system

InactiveCN106400666ASolve crackingReduce the weight of the structureBridge structural detailsBridge materialsCrazingPre stress

The invention discloses a novel hybrid beam structural system. The novel hybrid beam structural system comprises a corrugated web steel box connecting beam segment and prestressed concrete box beam segments. The prestressed concrete box beam segments are located on the two sides of the corrugated web steel box connecting beam segment. The novel hybrid beam structural system is mainly used for a continuous beam bridge or a rigid frame bridge. The midspan part of a main span is the corrugated web steel box connecting beam, the rest part of the main span and sidespans are prestressed concrete box beams, and steel-concrete composite segments are used for connection transition between the prestressed concrete box beams and the corrugated web steel box connecting beam. The novel hybrid beam structural system overcomes the defects of a traditional prestressed concrete box beam unitary system and defects of a traditional steel box beam unitary system, and has the beneficial effects of being good in stress performance and economical efficiency, high in span capacity and the like. According to the structural system, the dead load is effectively reduced, the span capacity is improved, the midspan deflection can be reduced, and the defects that the continuous downwarping and crazing of the midspan of the prestressed concrete box beam, poor stability of an ordinary steel box beam web and poor durability of bridge deck pavement are avoided.

Owner:SOUTHEAST UNIV

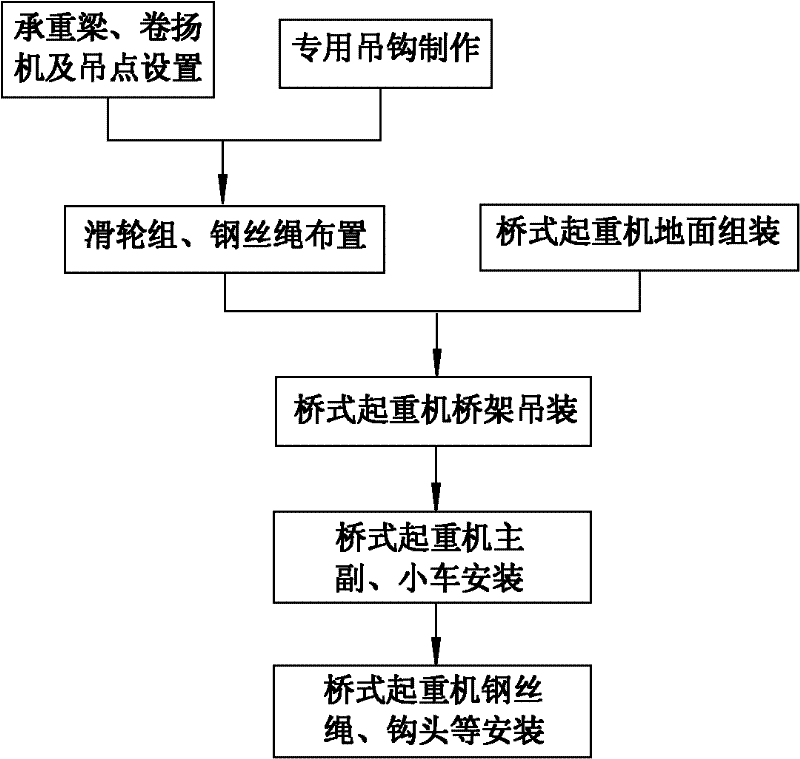

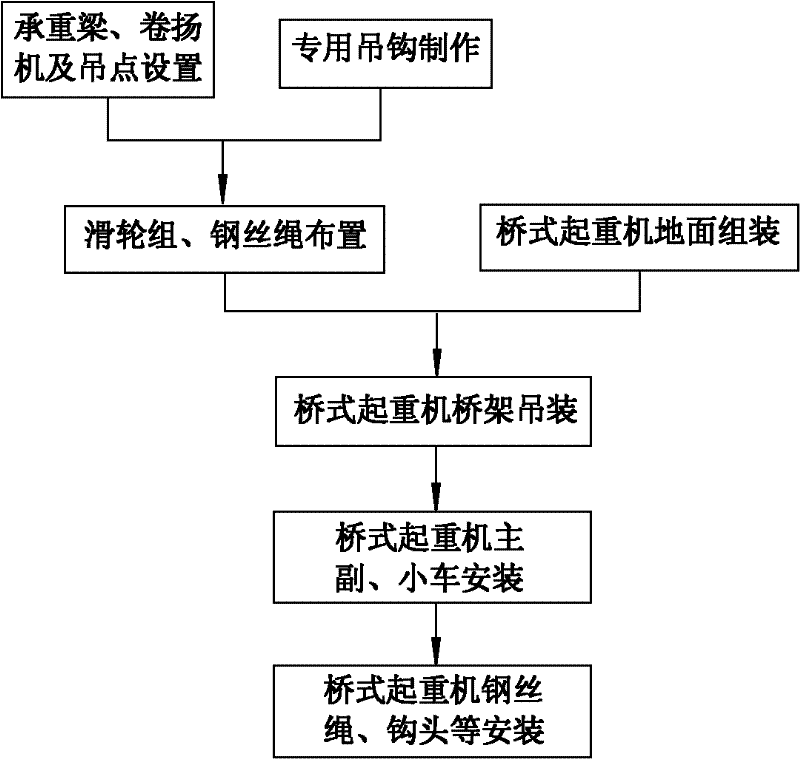

The method of installing the bridge crane by the beam hanging method and the use of this method

InactiveCN102267664ADoes not affect the installation progressReduce investmentTravelling cranesOverhead craneBeam bridge

The invention relates to a method for installing a bridge crane using load-supporting roof beams for hoisting and usage thereof. The invention is characterized in that: hoisting points are arranged on roof beams of a workshop, components of the bridge crane are assembled on the ground on site, and hoists and specified suspenders are used for hoisting the bridge crane; the method mainly comprises the steps of arranging of load-supporting beams for hoisting, hoists and hoisting points, fabrication of the specified suspenders, arranging of assembly pulleys and wire ropes, assembly of the bridge crane on the ground, hoisting of bridge stands of the bridge crane, hoisting of main and assistant trolleys of the bridge crane and installation of the wire ropes and the suspenders. According to the invention, site requirements are low, finished roofing of the workshop does not need to be dismounted, no giant crane is utilized, and facilities purchased and suspenders fabricated at a time can be used repeatedly, thereby saving cost; lifting and suspending with two cranes are avoided, thereby reducing safety risks; components are assembled in place on the ground and hoisted at a time, thereby improving working efficiency and abating risks in high altitude construction; time for actual hoisting is short and operationality is strong; the method is applicable to installation of large and medium-sized bridge cranes without being influenced by sites or hoisting height.

Owner:CHINA FIRST METALLURGICAL GROUP

Structure of felting bridge floor made from steel box girder in large span

InactiveCN1563588AMeet the loadMeet temperature requirementsBridge structural detailsLong spanBituminous concrete

This invention is a structure of long span steel beam and its pave method. It is especially use to pave the bridge directly with the different nature steel plate on the bridge surface. This structure is: the higher layer is epoxy pitch cement, lower layer is pouring pitch cement, on the steel beam bridge surface is water-proof layer, on the layer is lower binding layer, on the lower binding layer is pouring pitch cement layer, on the layer, is higher binding layer, on the layer is epoxy pitch cement. The steps of pavement are: a) Sprinkling water-proof layer on the cleaned and anti-corroded steel bridge surface plate; b) Sprinkling lower binding layer; c) Spread out the mixture pitch materials on; d) Sprinkling higher binding layer; e) Spread out higher layer of epoxy pitch cement; f) When the degree of solidify intensity of epoxy pitch cement reach to 85%, the natural maintained for the steel bridge surface sprinkling are finished.

Owner:SOUTHEAST UNIV

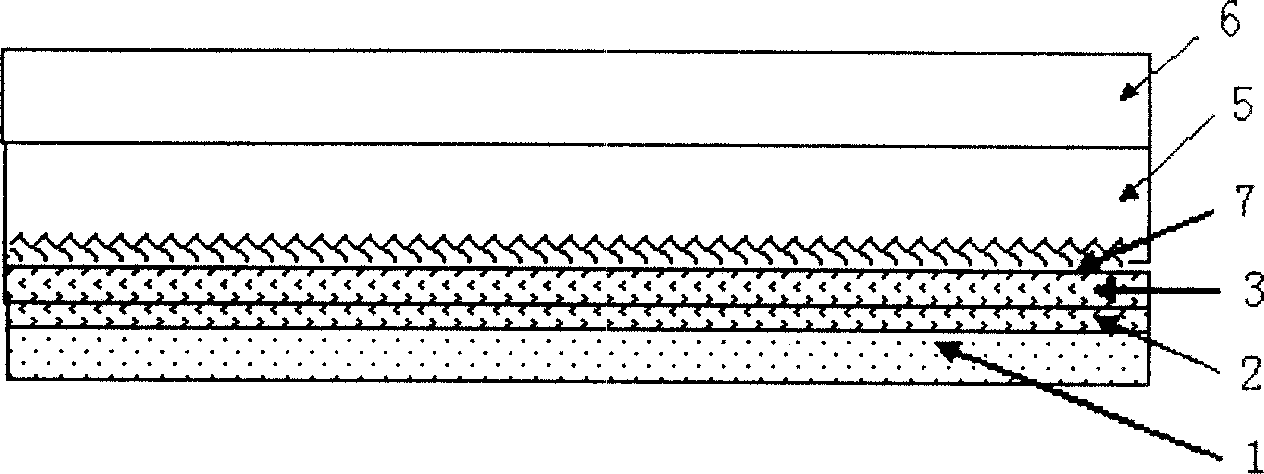

Large-span steel box beam bridge deck pavement layer material gradient structure pavement construction method

InactiveCN104846740AAnti-shear and anti-transition propertiesSolve usabilityBridge structural detailsBridge erection/assemblyFiberMesh reinforcement

The invention discloses a large-span steel box beam bridge deck pavement layer material gradient structure pavement construction method. The method comprises the steps that 1, derusting by sandblast and cleaning processing are conducted on an interface of a steel bridge deck; 2, shearing force parts are welded between a steel plate and a concrete pavement layer; 3, steel rib meshes are paved, and the steel rib meshes are bound to the shearing force parts; 4, high-strength toughening light concrete is poured; 5, a DPS waterproof layer is sprayed; 6, a bond stress absorbing layer is paved; 7, high-viscosity high-elastic SMA-13 bituminous mixtures are paved. According to the large-span steel box beam bridge deck pavement layer material gradient structure pavement construction method, polymers and fibers are added, the light aggregate concrete mix proportion design is optimized, the strength, the toughness, the deformability and the anti-fatigue performance of the light aggregate concrete are strengthened, and an optimal design on the arrangement of the shearing force studs and the steel rib meshes and the reinforcement ratio is conducted.

Owner:NANTONG UNIVERSITY

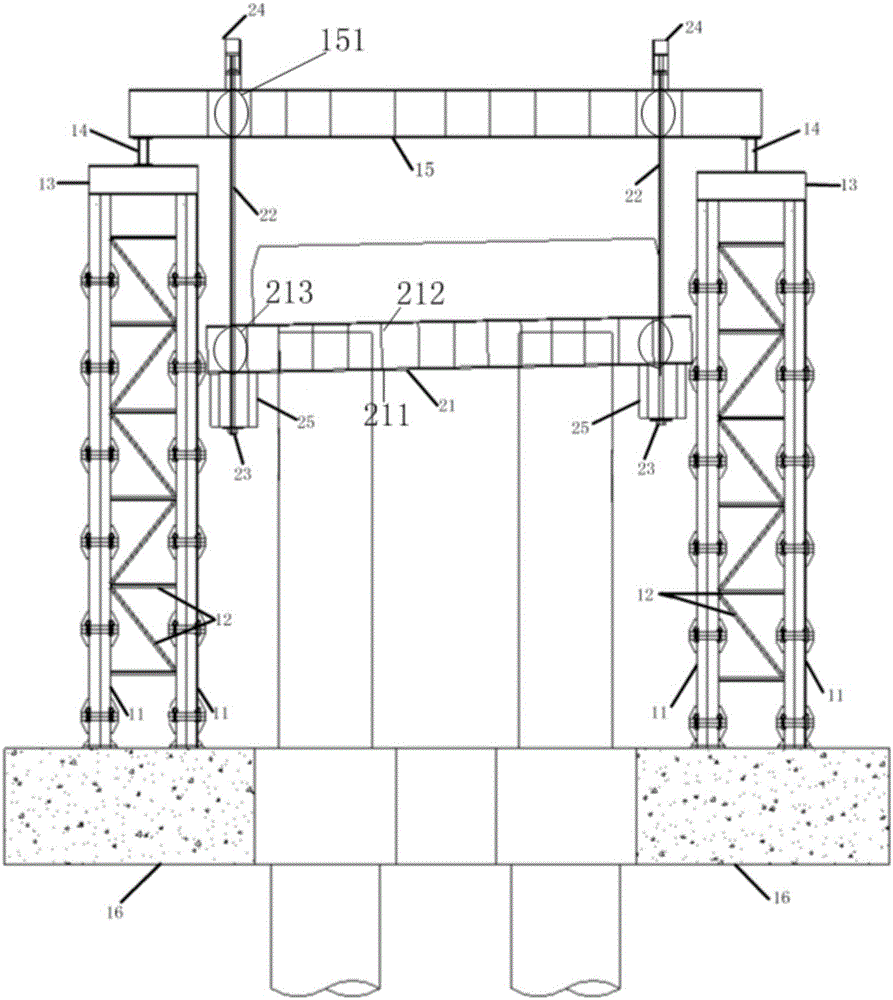

Integral lowering and demolition method for continuous beam bridge

InactiveCN106758887AReduce disturbanceSafe and quick removal methodBuilding repairsBridge strengtheningContinuous beamCost savings

The invention discloses an integral lowering and demolition method for a continuous beam bridge. The method adopts a pier system module and a lowering system module and includes steps: step one, preparing; step two, mounting an integral demolition temporary pier system; step three, mounting temporary piers and cutting main beam flanges; step four, mounting a integral lowering system; step five, synchronously lowering, lifting, constructing and the like. The pier system module comprises steel pipe piles, temporary pier parallel connectors, transverse connection beams, longitudinal distribution beams and the like. The lowering system module comprises dragging beams, a steel stranded lifting rope anchor system, anchor plates, continuous lifting jacks and supporting blocks. The method is applicable to demolition of the high-pier continuous beam bridge large in clearance of span and has advantages of quickness in demolition, safety in construction and cost saving.

Owner:CCCC ROAD & BRIDGE SPECIAL ENG

Horizontal rotating construction method for steel truss beam bridge

ActiveCN104652290AReasonable structureClear forceTruss-type bridgeBridge erection/assemblyReinforced concreteConstruction engineering

The invention discloses a horizontal rotating construction method for a steel truss beam bridge. The horizontal rotating construction method comprises the following steps: constructing a reinforced concrete pile foundation, a cushion cap, a slideway, a main pier and a cap beam in a rotating system by using a conventional construction technology, and mounting a rotating spherical hinge as a core part for rotating; mounting an upper rotating plate on the slideway for construction; constructing the main pier and the cap beam; mounting a permanent support saddle of the main pier; preparing safety measures before rotating; determining a weight scheme before rotating; preparing a jack; rechecking before rotating; performing rotating construction operation. Compared with other processes, the horizontal rotating construction method for the steel truss beam bridge, provided by the invention, has the advantages of high construction speed and low construction cost. The construction of a lower structure can be synchronously finished in the manufacturing process of a steel beam in a factory; the hoisting operation of symmetrical cantilevers can be performed when a spliced site is hardened to reach the traveling strength of cranes like crawler crane; main expenses are rental expenses of the cranes, so the cost is reduced.

Owner:NANTONG ROAD & BRIDGE ENG CO LTD +1

Pavement method for anti-movement composite structure of large-span steel box beam bridge deck

ActiveCN101368368AImprove bindingIncrease stiffnessIn situ pavingsBridge structural detailsSheet steelBridge deck

The invention relates to a method for paving combined anti-push structures on the surface of a large-span steel box girder bridge, including the following steps: 1) pretreating the armor plates of the large-span steel box girder bridge; 2), welding shear studs: welding shear studs on the armor plates of the large-span steel box girder bridge, with an interval at area of (35-45)cm X (35-45)cm between two shear studs; 3) colligating the reinforcement mats: fixing the reinforcement mats at specification of (95-105)cm X (95-105)cm on the shear studs; 4) mineral aggregate grading; 5)preparing and paving cast-type asphalt concrete; 6) paving a waterproof bond coat; and 7)paving anti-skid denoising wearing layer: paving a anti-skid denoising wearing layer at thickness of 3-5cm on the waterproof bond coat. The method has the advantages that cohesiveness at the interfaces is good, the paved layer and the armor plates are strong in coordinated deformability, and construction process is simple and convenient.

Owner:WUHAN MUNICIPAL CONSTR GROUP +1

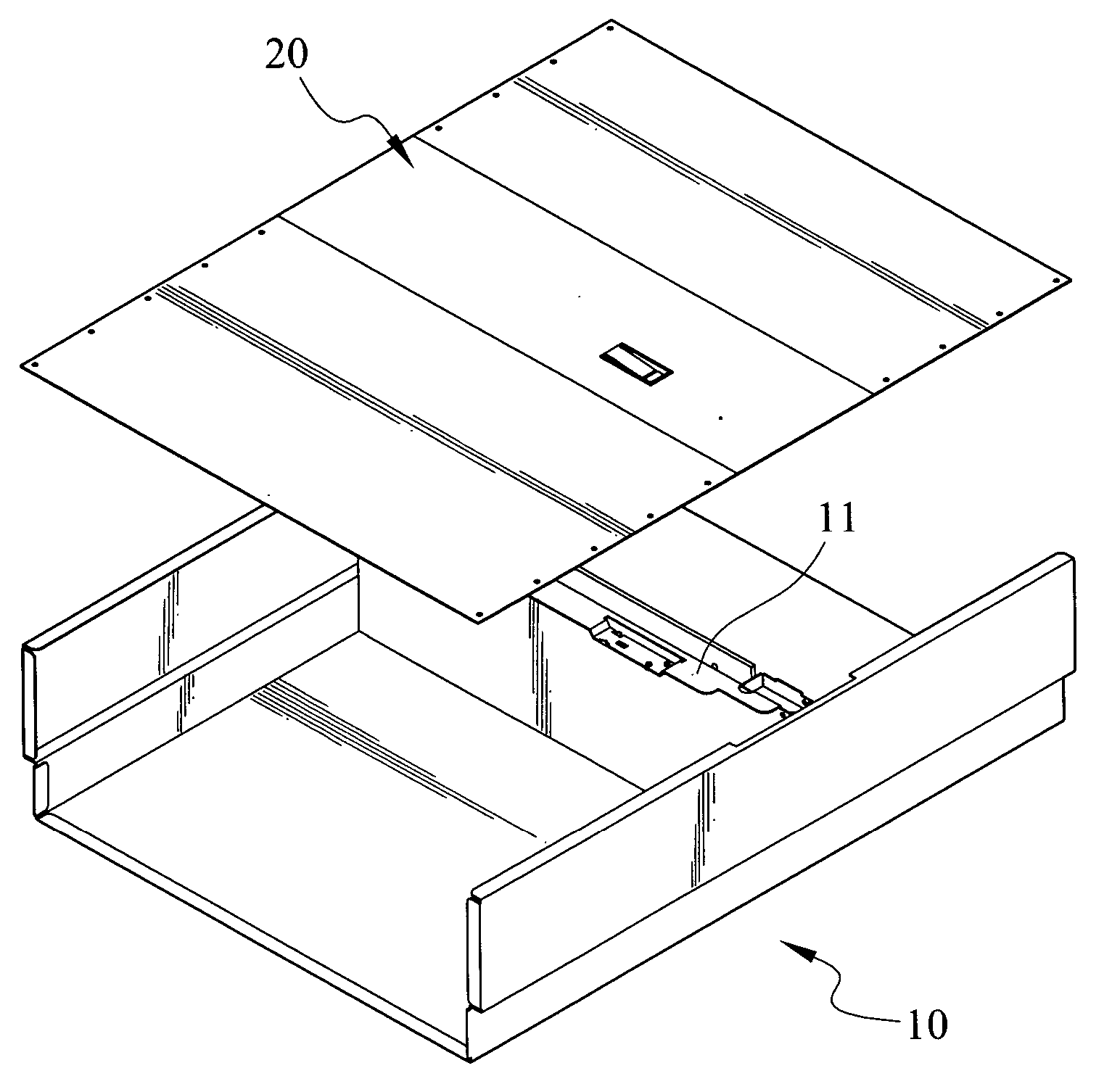

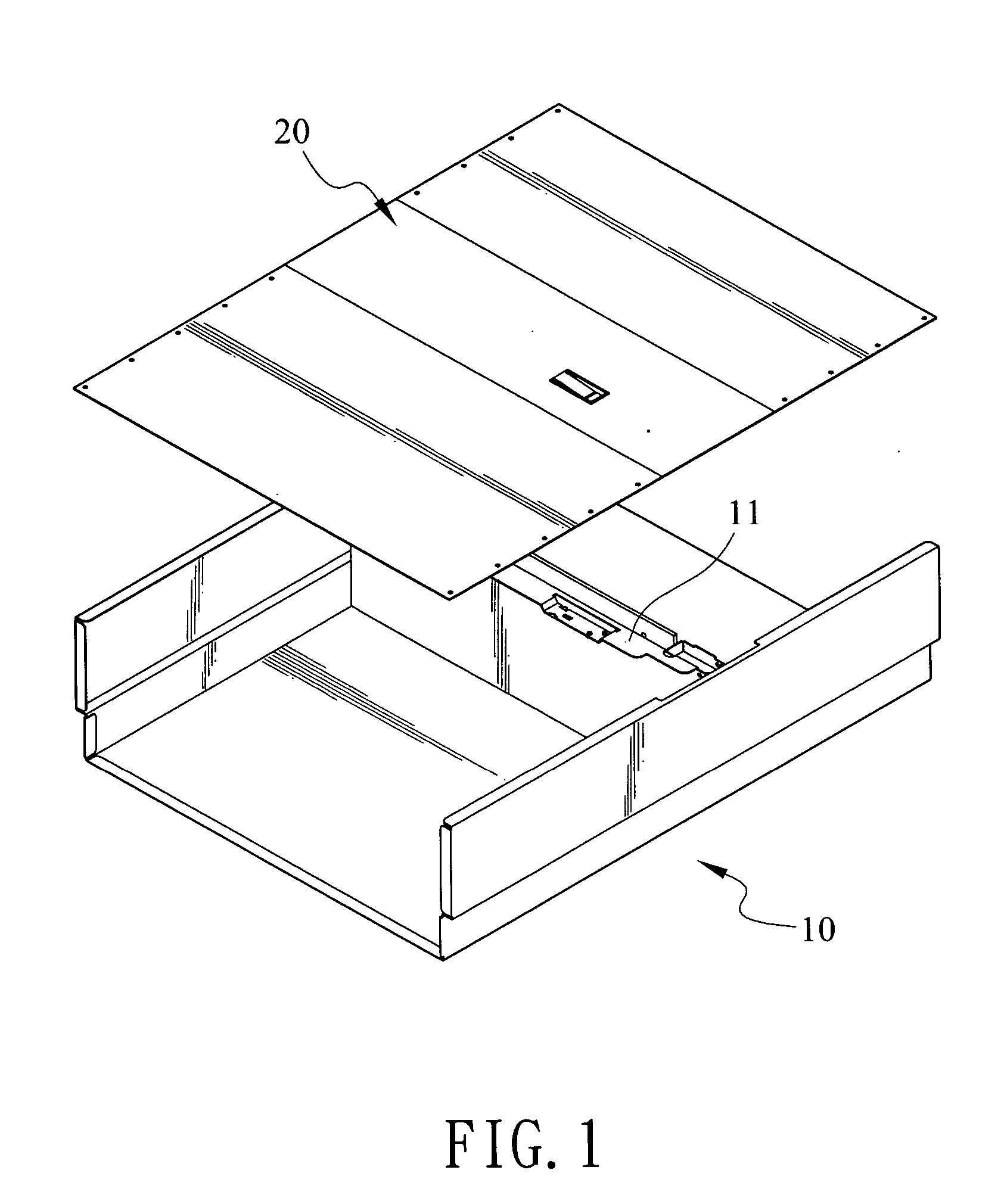

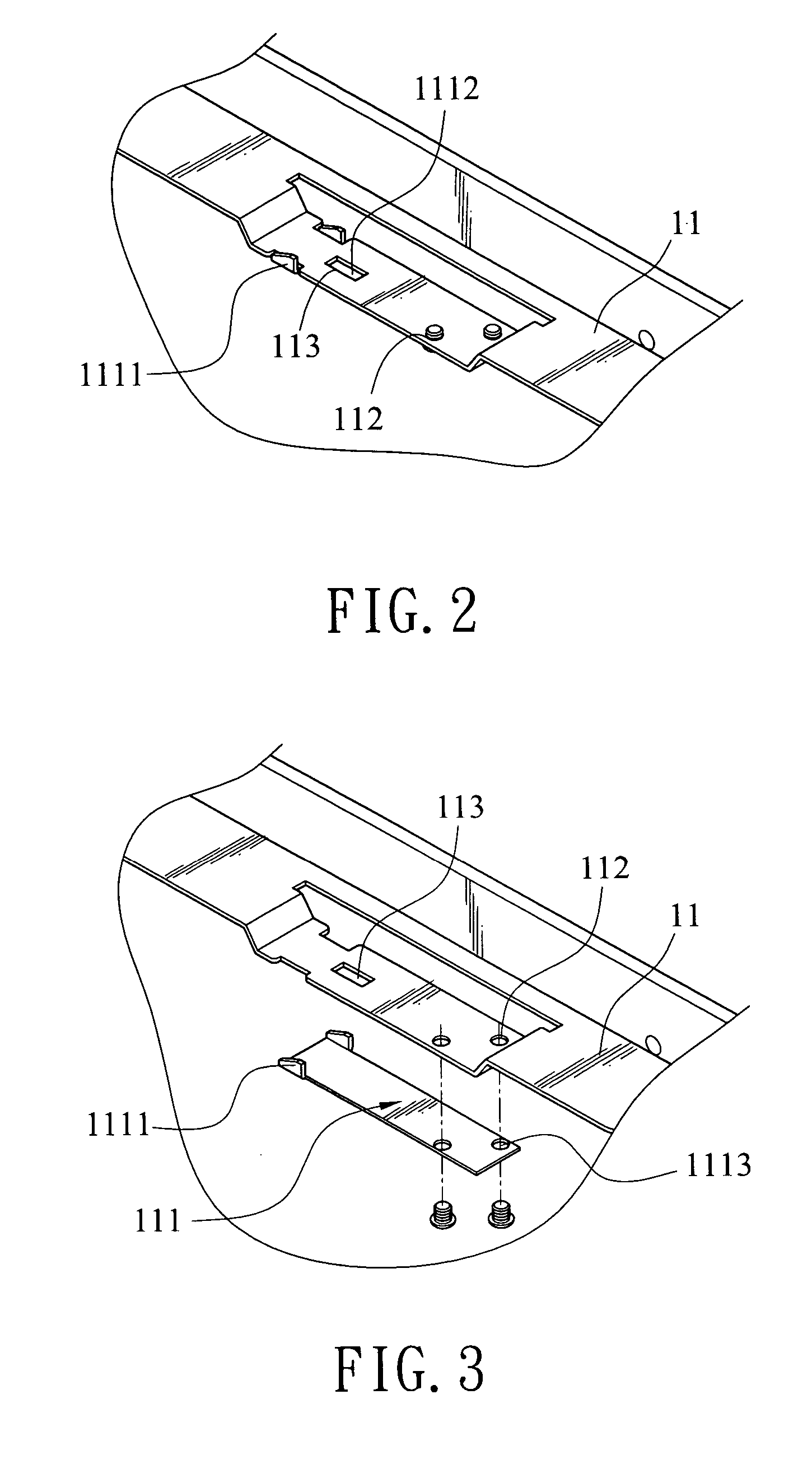

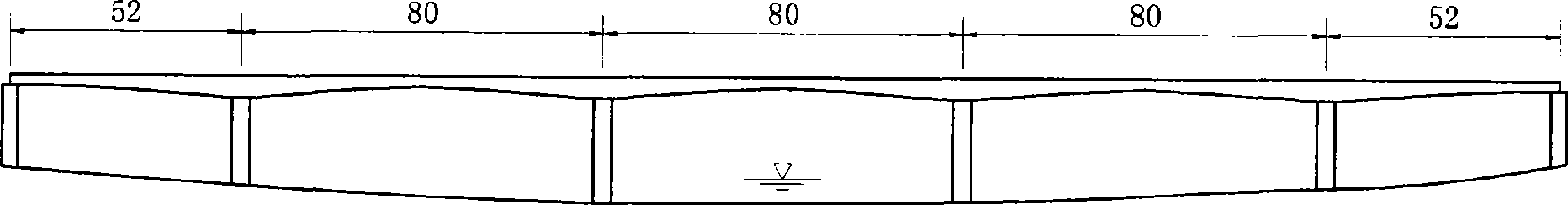

Server rack

InactiveUS20050088068A1Promote repairEasy maintenanceServersCasings/cabinets/drawers detailsCouplingBeam bridge

A server rack for improving opening and closing convenience of computer servers includes a base dock and an upper lid. The base dock has an upper beam bridging two opposite ends thereof. The upper beam has a latch structure. The upper lid is mounted on the based dock and includes a hook structure corresponding to and engageable with the latch structure for coupling the base dock and the upper lid. The latch structure is movable by the hook structure to release the coupling of the base dock and the upper lid. Hence the server rack may be easily opened or closed for replacing the electronic devices in the server during repair operations.

Owner:INVENTEC CORP

Method and apparatus for actively reinforcing wide-span concrete case beam bridge web

ActiveCN101435183AImprove stress statusPrevent extensionBridge erection/assemblyBridge strengtheningElement modelShear stress

The invention relates to a reinforcing and repairing measure for existing concrete box girder bridges, and discloses a method for actively reinforcing a large-span concrete box girder bridge web plate, comprising the following steps: (1) according to the structural parameters of the concrete box girder bridge and by adopting a structural analysis method and corresponding general or special analysis software, a finite element model of a simulated reinforced plate shell concrete box girder bridge is established, thus obtaining the magnitude of the main pulling stress, the vertical stress, the longitudinal stress and the shearing stress of the box girder web plate before reinforcement and the distribution rule thereof; (2) the difference between the main pulling stress and the limited value allowed by the 'Standard' is compared to obtain the target increment value of the vertical stress of the bridge girder, and the actual reinforcement parameters are determined according to the target value; (3) a stretching device is anchored at the upper margin and the lower margin of the concrete box girder web plate, and mild steel wire bundles are tied to carry out stretching; (4) the crank of a hand-operated winch in the stretching device is shaken to respectively stretch every mild steel wire bundle, and when the actual vertical stress increment of the box girder web plate is more than or equal to the theoretical calculated value, a snib is inserted and the stretching hand-operated winch is fixed; and (5) crack is mended.

Owner:广东荣骏建设工程检测股份有限公司

Spreading method for preventing steel box girder bridge face bituminous concrete from being pushed

ActiveCN1710206AExtended service lifePrevention of passage cracking diseaseBridge structural detailsMaterials scienceSteel box girder

The invention relates to a asphalt pavement technique of a steel box beam bridge which features that: sandblasting the steel sheet to remove rust; 2, rust proofing layer pavement, 0.5 -1.5 mm high temperature resistant HBW high intensity glue; 3, water proof adherent layer pavement: 2-3 mm high temperature resistant HBW high intensity glue, and spread basalt particles or cutting steel fiber on before it coagulates; 4, lower layer pavement: coat on rough surface fast cracking modified emulsify asphalt and then spread GC-WHUT high viscosity modified asphalt and fiber contained intensity enhanced SMA-10 asphalt concrete for 2.5-3.5 cm; 5, upper layer pavement spread SMA-13 asphalt concrete over SMA-10 for 3.5 to 45 cm. The invention effectively eliminates cracking and displacing of asphalt concrete system of steel box bridge, lengthening the bridge service life.

Owner:WUHAN MUNICIPAL CONSTR GROUP

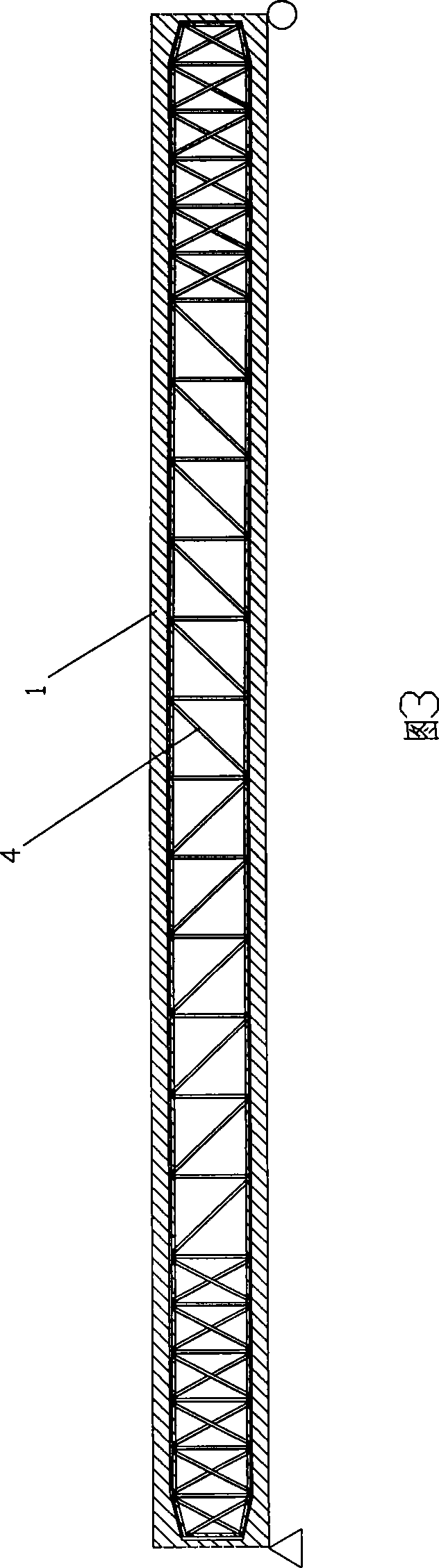

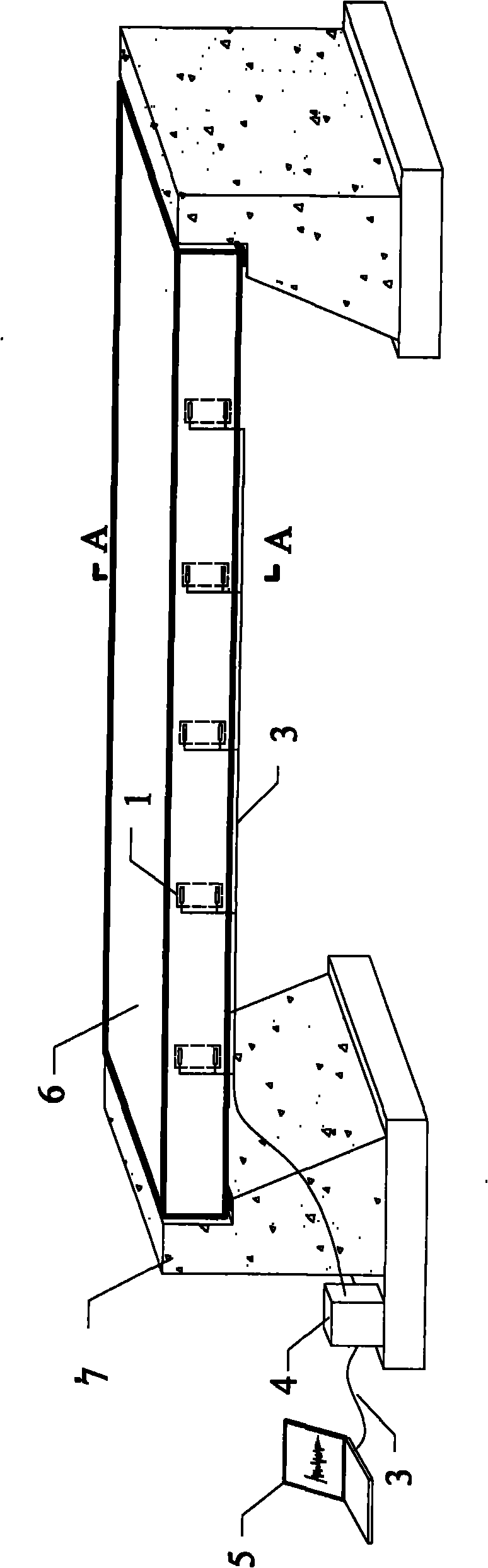

External prestress strengthening method for prestressed concrete box-beam bridge

ActiveCN101230562AFlexible layoutImprove efficiencyBridge erection/assemblyBridge strengtheningPre stressEngineering

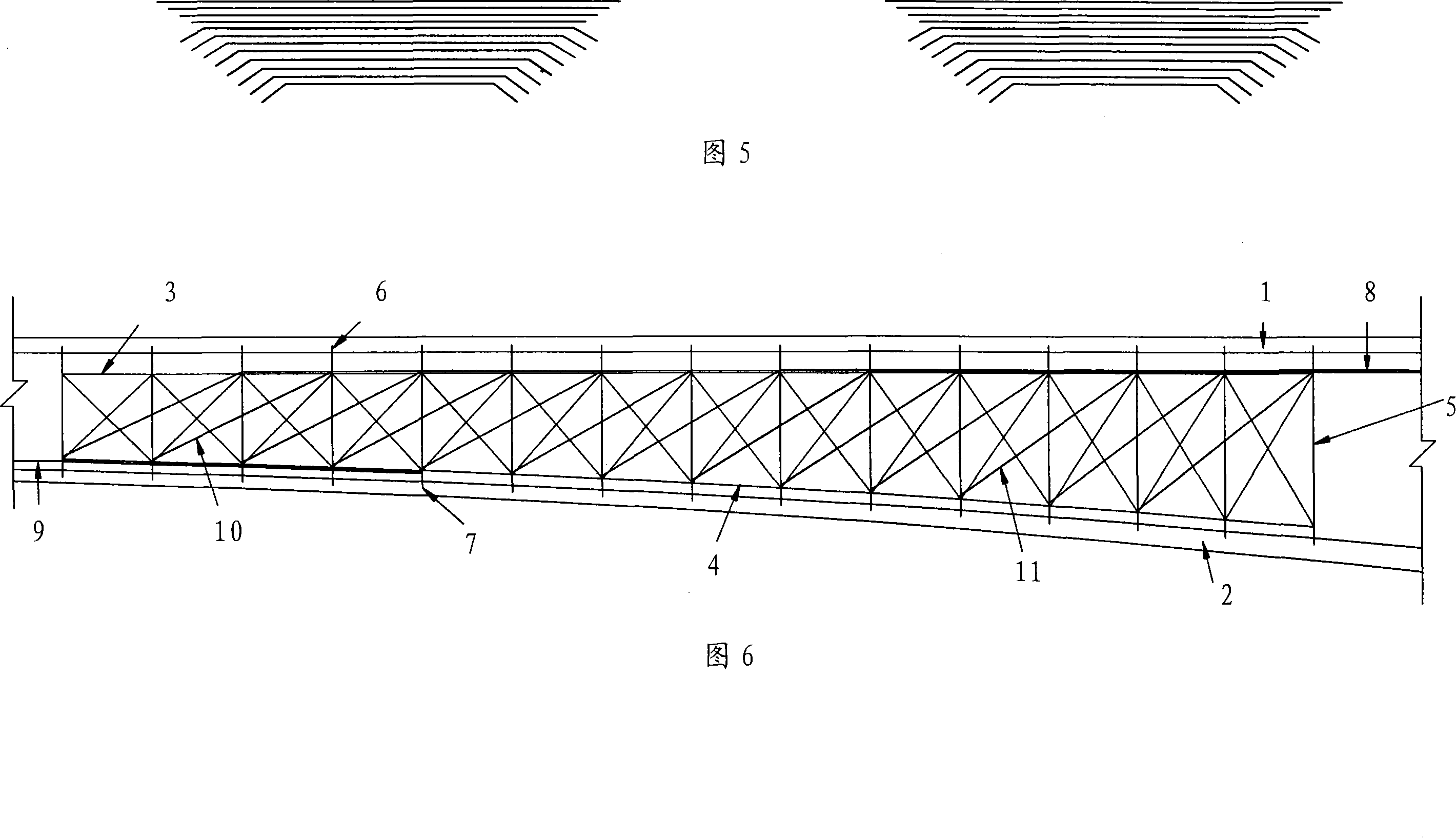

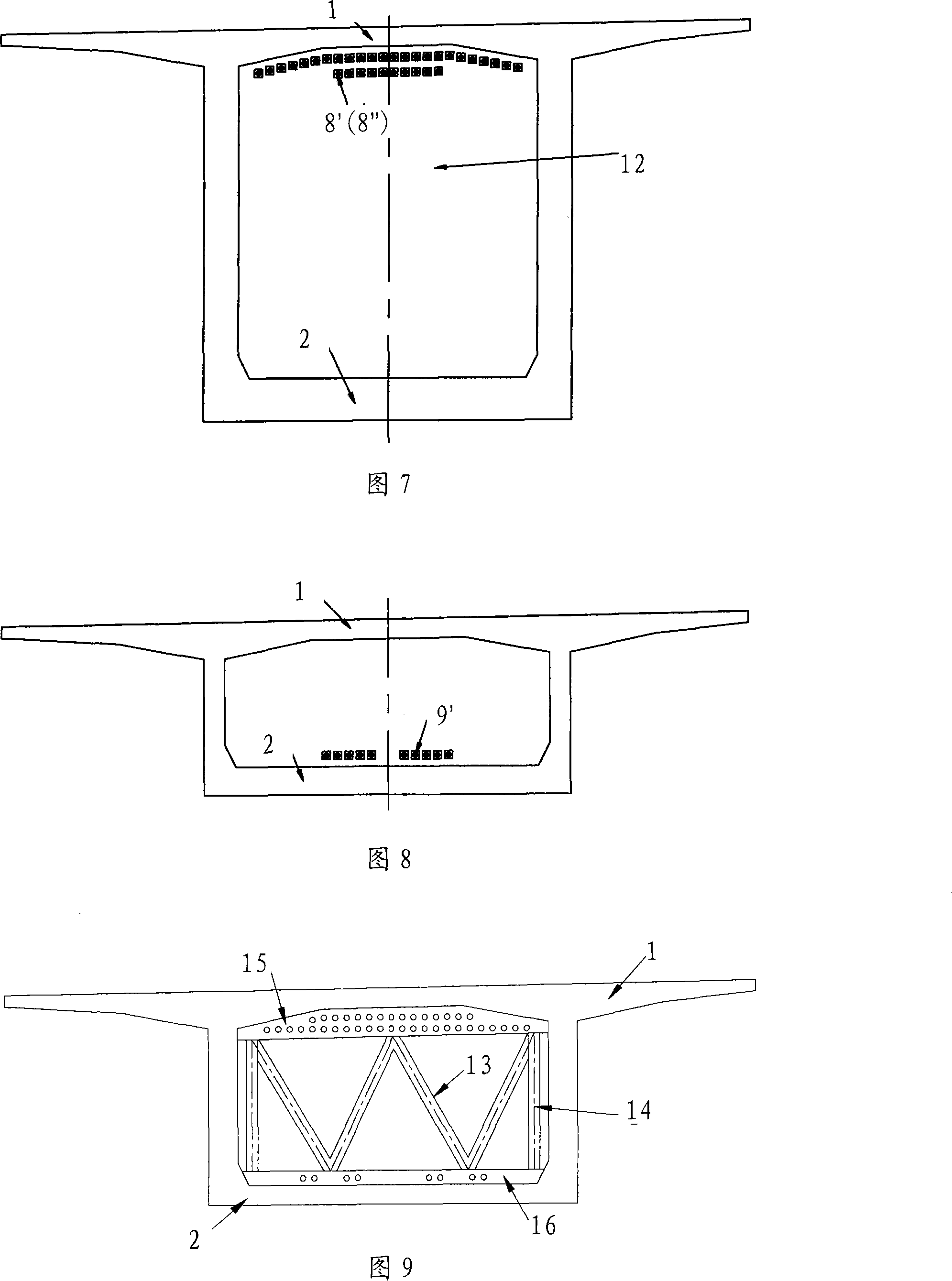

The invention provides a reinforcing method for the prestressing force in vitro, and the reinforcing method aims at a prestressed concrete box girder bridge, and adopts a space steel truss installed inside a box girder as the anchorage and steering configuration of a prestressing force beam in vitro; the prestressing force beam in vitro is distributed under the condition of considering the damnification of the structure based on optimizing the calculating result, and adopts a beam distribution mode of combining a full-length beam and a fulcrum crest slab short beam, wherein, the crest slab short beam can be bended to the lower boom of the steel truss to be anchored to provide a ventral shield with pre-shearing force according to the split situation; the steel truss is distributed according to the requirements of anchorage and steering of the prestressing force beam in vitro, and a girder grillage is respectively arranged in the box girder firmly close to the ventral shield side; each merithal is provided with a horizontal bracing to provide the anchorage and steering configuration of the prestressing force beam in vitro, and at the same time, the rigidity and the shearing resistance bearing capacity of the ventral shield of the concrete box girder are enhanced; the steel truss and the box girder are connected into a whole by adopting a plant ribbon mode, thereby ensuring the dosage and the distribution of the prestressing force beam in vitro to be more flexible, the direction to be stronger and the distribution efficiency of the prestressing force beam in vitro to be high.

Owner:CHINA RAILWAY BRIDGE SCI RES INST LTD +1

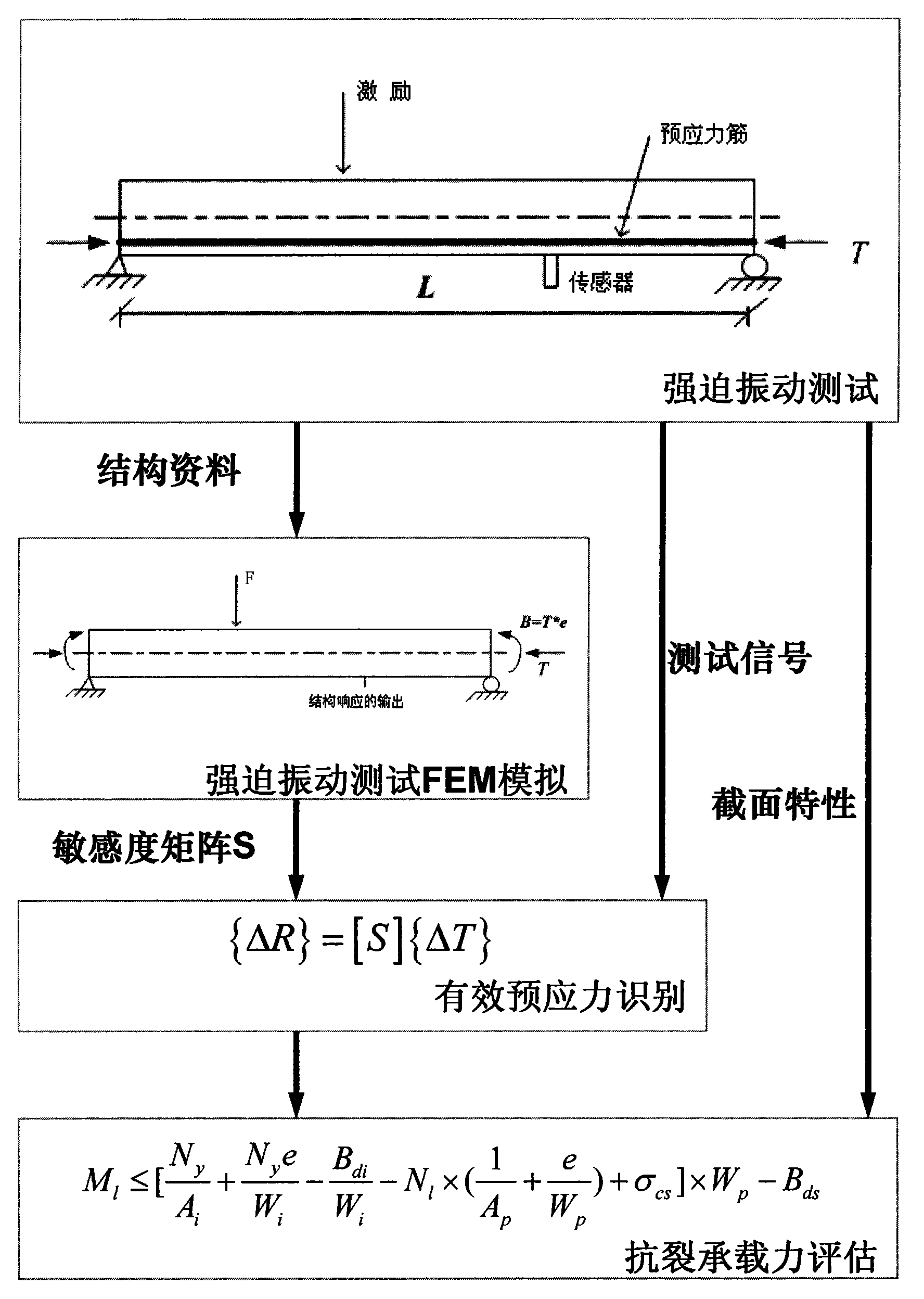

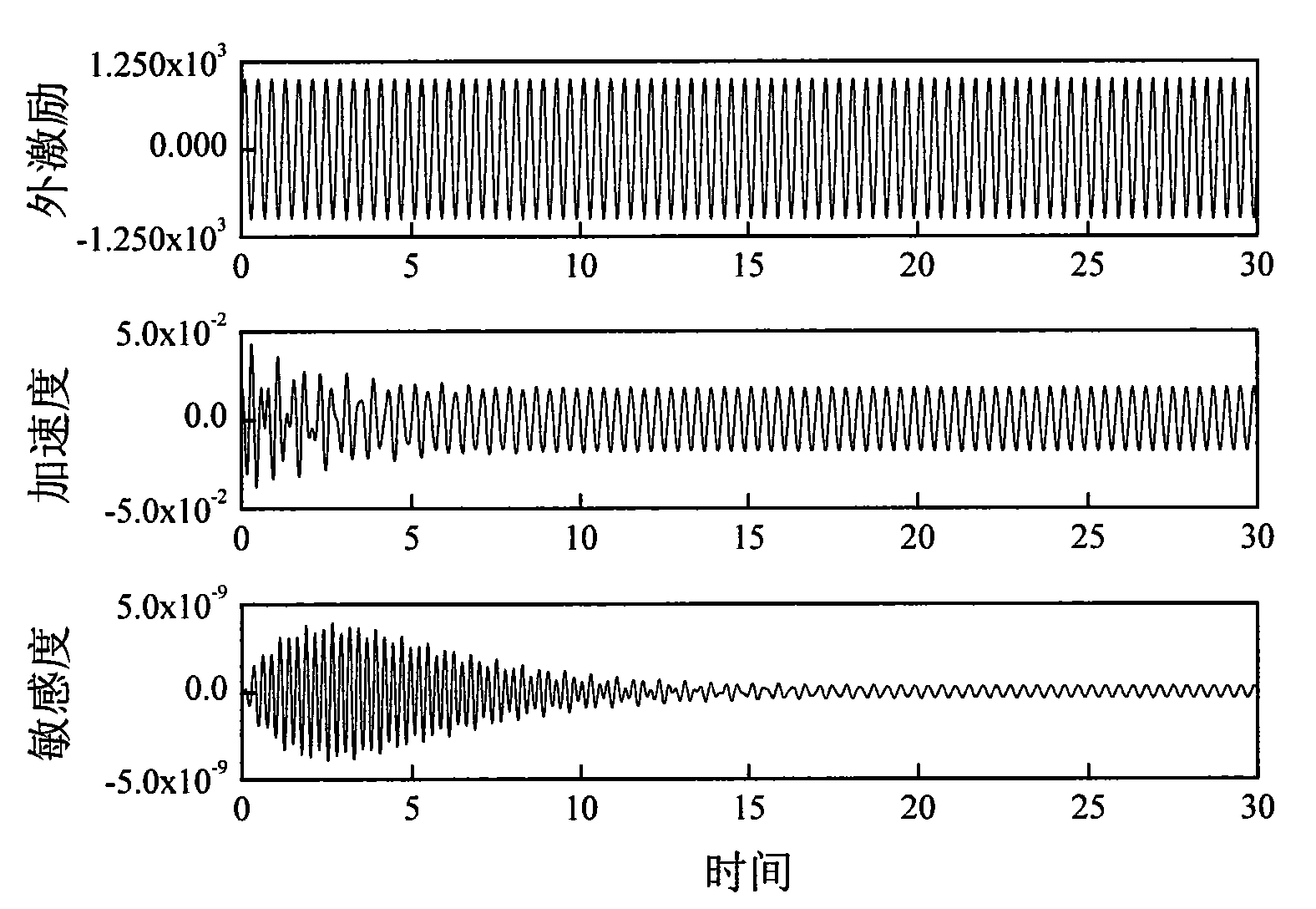

Method for evaluating eccentric straight-line prestressed concrete beam bridge bearing ability based on dynamic measurement process

InactiveCN101587046ANo damageSimple and quick to implementFoundation testingStrength propertiesPrestressed concrete beamPre stress

The invention provides a method for evaluating eccentric straight-line prestressed concrete beam bridge bearing ability based on dynamic measurement process, which includes the steps of: executing forced vibration test for beam bridge structure and acquiring single point vibration movement respond of the structure; establishing structure finite element numeric analysis model for analyzing effect of prestress level to dynamic characteristics of structure; recognizing effective prestress of structure from measured structural power respond variation amount using a method based on sensitivity; calculating anti-crack bearing capacity during test for prestressed concrete beam bridge according to measured effective prestress value. Compared with conventional nondestructive detection method, the method provided by the invention has the advantages of simple and shortcut test process, strict and integral evaluating theory, high precision of test result or the like, and can be conveniently applied to test and evaluation for prestressed concrete beam bridge.

Owner:SHANGHAI TONGJI CONSTR QUALITY INSPECTION STATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com