Integral lowering and demolition method for continuous beam bridge

A bridge pier and integral technology, which is applied in the field of demolition of the entire continuous girder bridge, can solve the problems of high cutting costs, unknown beam section bearing capacity, unfavorable production saving, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

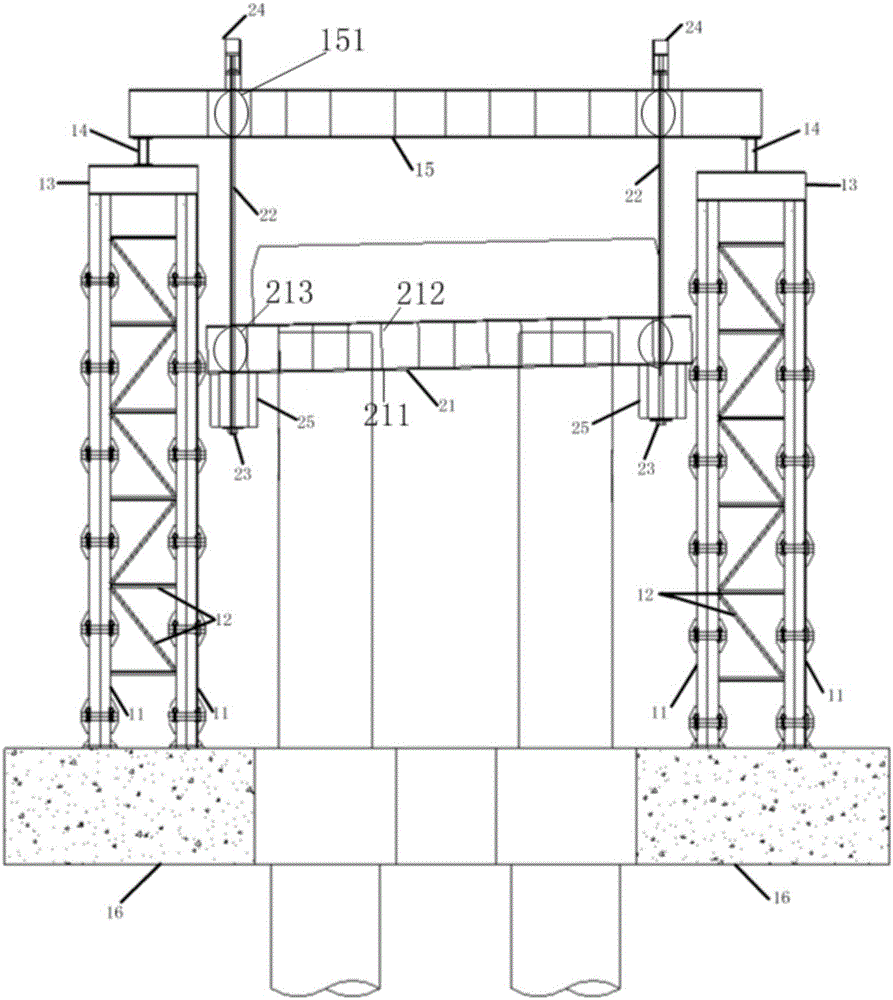

[0029] The preferred embodiments of the present invention are given below in conjunction with the accompanying drawings to describe the technical solution of the present invention in detail.

[0030] The method for lowering and dismantling the entire continuous girder bridge of the present invention comprises the following steps:

[0031] Step 1. Preparation;

[0032] Step 2. Remove the temporary pier system for the whole bridge and install it, which is used for the calculation and design of the temporary pier system for reasonable structural force calculation and design, so as to meet the weight of the main girder of the whole bridge;

[0033] Step 3. Install temporary buttresses and cut the flange of the main girder; design and calculate according to the force characteristics of the entire bridge structure, set up temporary buttresses and temporary buttress connection foundations. abutments or enlarged caps to form a whole to prevent uneven subsidence and deformation of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com