Method for treating sludge with heavy metals exceeding standard

A technology of heavy metals and heavy metal passivators, applied in sludge treatment, biological sludge treatment, etc., can solve the problem of not meeting the requirements of reduction, stabilization and harmlessness of sludge treatment and disposal, polluting groundwater, and massive infiltration Liquid and other problems, to achieve the effect of reducing land occupation area, improving ecology, and less environmental disturbance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

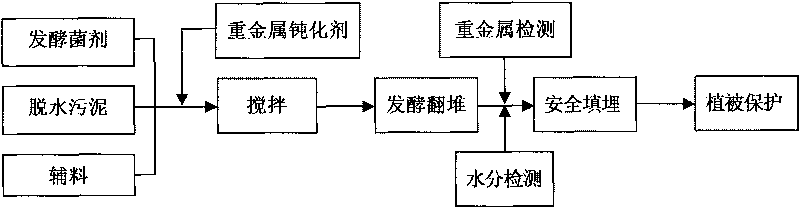

Image

Examples

Embodiment

[0030] Embodiment, the processing of heavy metal content excess sludge

[0031] 1. Preparation of aerobic microbial agent

[0032] The active ingredient of the aerobic microbial agent is composed of aerobic bacteria and facultative aerobic bacteria, and the aerobic bacteria are Bacillus subtilis, Aspergillus niger and Sporidium thermophilic; the facultative aerobic bacteria are thermophilic fat Bacillus and Saccharomyces cerevisiae.

[0033] The above-mentioned 5 kinds of bacteria were all purchased from China Industrial Microorganism Culture Collection Management Center (CICC). The deposit number of Saccharomyces cerevisiae is 2441, and the deposit number of Saccharomyces cerevisiae is 1923.

[0034] Preparation:

[0035] 1. Various bacteria are separately made into powdered active bacteria: inoculate various bacteria (Bacillus subtilis, Bacillus stearothermophilus, Aspergillus niger, Saccharomyces cerevisiae, Sporidium thermophila) into bran for fermentation made.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com