A solar heat collection system using light guide cables to transmit concentrated light beams

A solar heat collection and optical cable technology, which is applied in the field of solar heat collection systems, can solve the problems that tower heat collection cannot fully and effectively utilize solar energy and unfavorable engineering construction, so as to increase the utilization rate of sunlight, improve system stability, reduce The effect of engineering difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

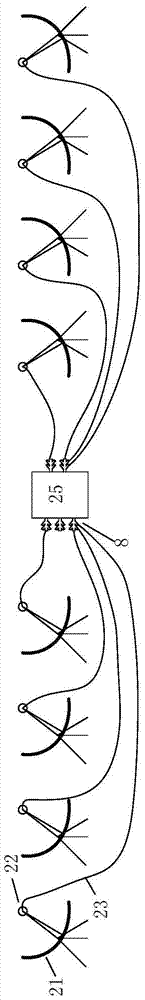

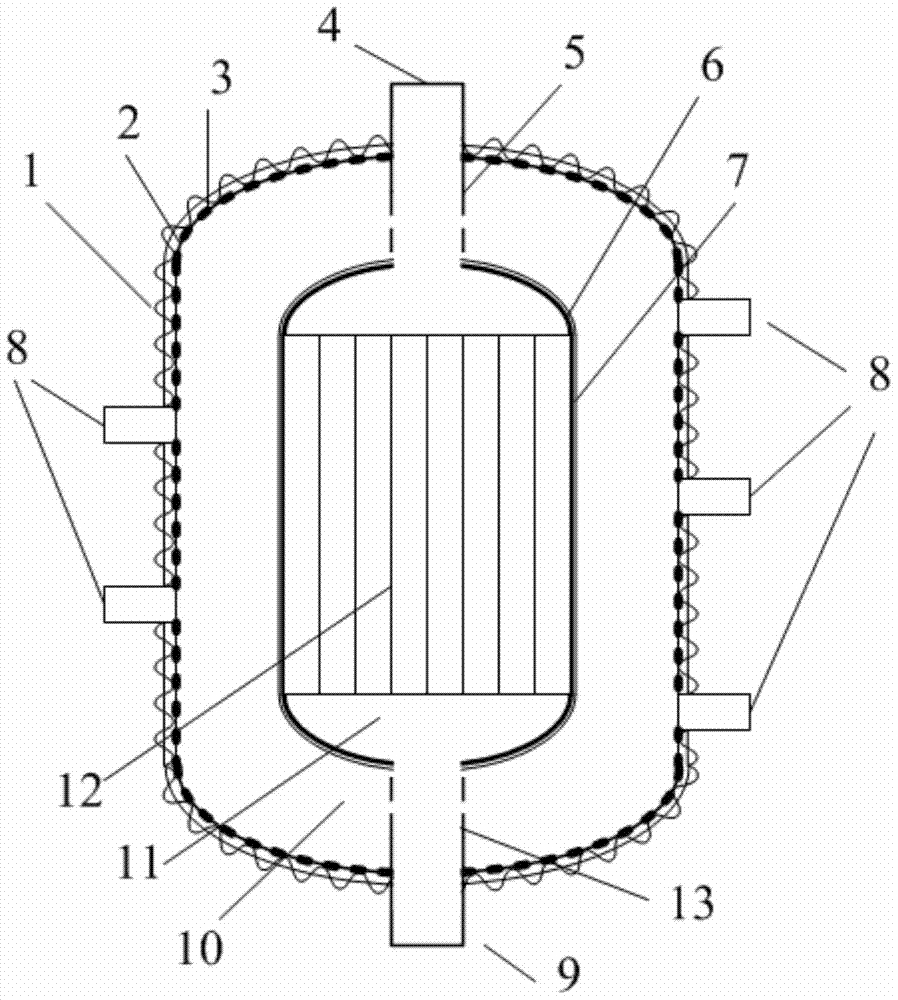

[0030] like figure 1 As shown, the heat collection system of the present invention is composed of a curved condenser lens 21, a light guide head 22, a light guide cable 23, a light receiving head 8, and a heat absorber 25. The system adopts a large number of curved condenser mirrors 21 arranged to form a curved condenser mirror array. Each curved condenser mirror 21 has the same specification and is arranged around the heat absorber 25 according to a certain rule.

[0031] Each curved concentrator 21 can gather the parallel sun rays on its own focal point. The light guide head 22 is positioned at the focal point of the curved concentrator 21. The light guide head 22 is connected to one end of the light guide cable 23, and the other end of the light guide cable 23 is the end. The light receiving head 8 is connected, and the light receiving head ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com