Safety evaluation method for polyethylene gas pipeline under ground contact impact of blasting demolition collapse body

A technology for gas pipeline and safety evaluation, applied in impact testing, testing of machine/structural components, complex mathematical operations, etc., can solve problems such as the difficulty of effective evaluation of hazards, reduce engineering difficulty, strengthen engineering significance, and ensure engineering safety. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

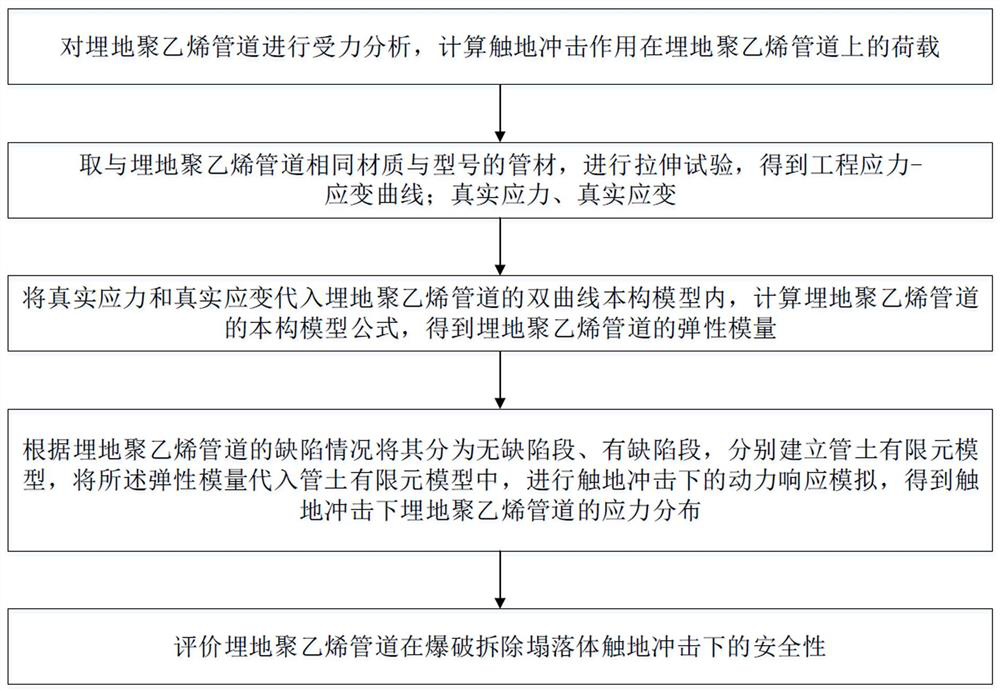

[0093] Such as figure 1 The safety evaluation method for polyethylene gas pipelines under the impact of blasting and demolition collapsed bodies is shown. The PE100 grade HDPE (high density polyethylene) SDR17 (outer diameter / wall thickness = 17) pipeline is used as the research object. The specific evaluation steps include: :

[0094] Step S1: Carry out stress analysis on the buried polyethylene gas pipeline, and calculate the load on the buried polyethylene gas pipeline due to ground impact P P ,Calculated as follows:

[0095]

[0096] In the formula, P max is the maximum impact load on the ground surface; H is the thickness of the covering soil layer above the buried polyethylene gas pipeline; L is the horizontal distance between the ground contact impact load point and the buried polyethylene gas pipeline; where P max The calculation formula is as follows:

[0097]

[0098] In the formula, n is the impact coefficient, V is the velocity of the collapsed bo...

Embodiment 2

[0104] The method for evaluating the safety of polyethylene gas pipelines under the impact of blasting and demolishing collapsed objects on the ground, on the basis of Example 1, the specific implementation process of steps S2-S3 is as follows:

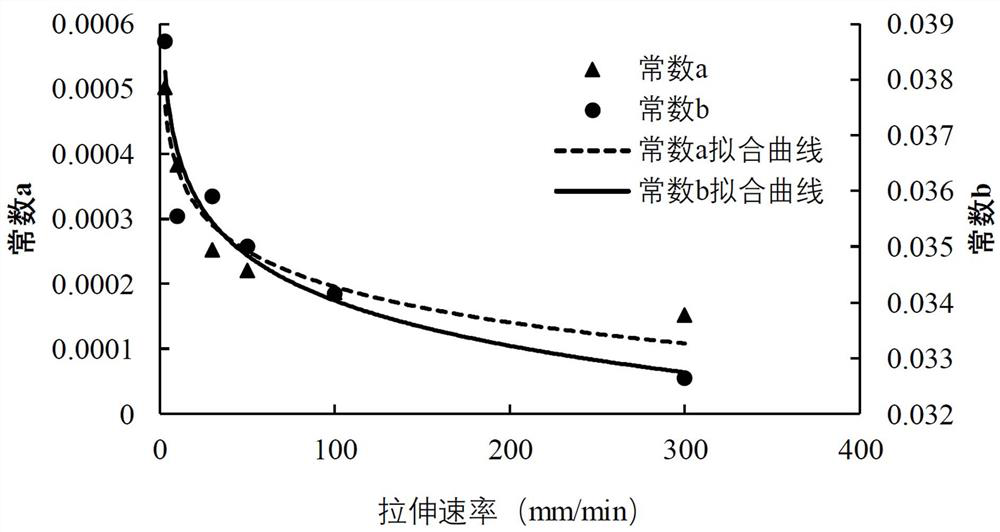

[0105] According to the tensile test results of PE100 grade high-density polyethylene pipes in this embodiment, the engineering stress-strain curve is obtained, and the calculation formula of the yield strength of PE100 under different rates is obtained by fitting:

[0106]

[0107] is the yield stress at the corresponding tensile rate, MPa; v is the uniaxial tensile rate of the pipe, mm / min.

[0108] Substituting different PE100 pipe tensile rates according to this formula can predict the corresponding engineering stress when the pipe yields .

[0109] The real stress at yield can be obtained by substituting the predicted engineering stress into the following formula:

[0110]

[0111] is the engineering stress; is th...

Embodiment 3

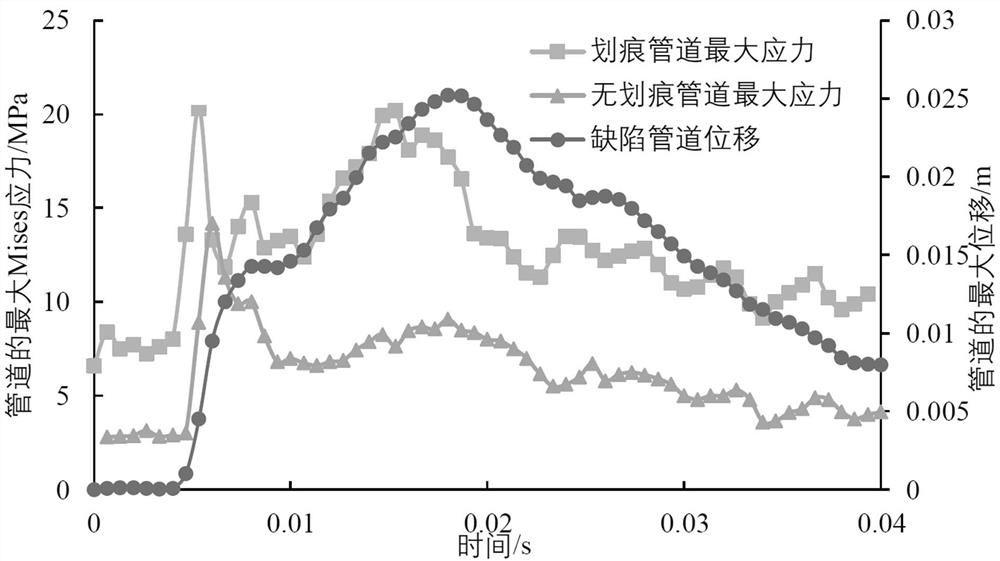

[0127] On the basis of any of the above embodiments, this embodiment refines step S4:

[0128] For the establishment of the pipe-soil finite element model of the pipeline without defects: the Drucker-Prager model is selected, which can well simulate the elastic-plastic state of the material under load impact, and there will be no instability in the calculation of large deformation; The grade selects PE100 gas transmission pipeline, and its density is 951kg / m 3 , the tensile rate of the HDPE pipe under the impact load is about 300mm / min; according to the method described in the above examples, the yield strength of the pipe is 27.4MPa and the modulus of elasticity is 1115MPa. The collapsing body adopts the plane touch-to-ground contact method, and the collapsing body is set as a low-height cuboid, 2m long, 0.5m high, and 1m wide. The pipe diameter is preset to 110mm, the wall thickness is 6.5mm, and the covering soil thickness is 0.8m.

[0129] Fully consolidated constraints a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com