Patents

Literature

56 results about "Engineering stress" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

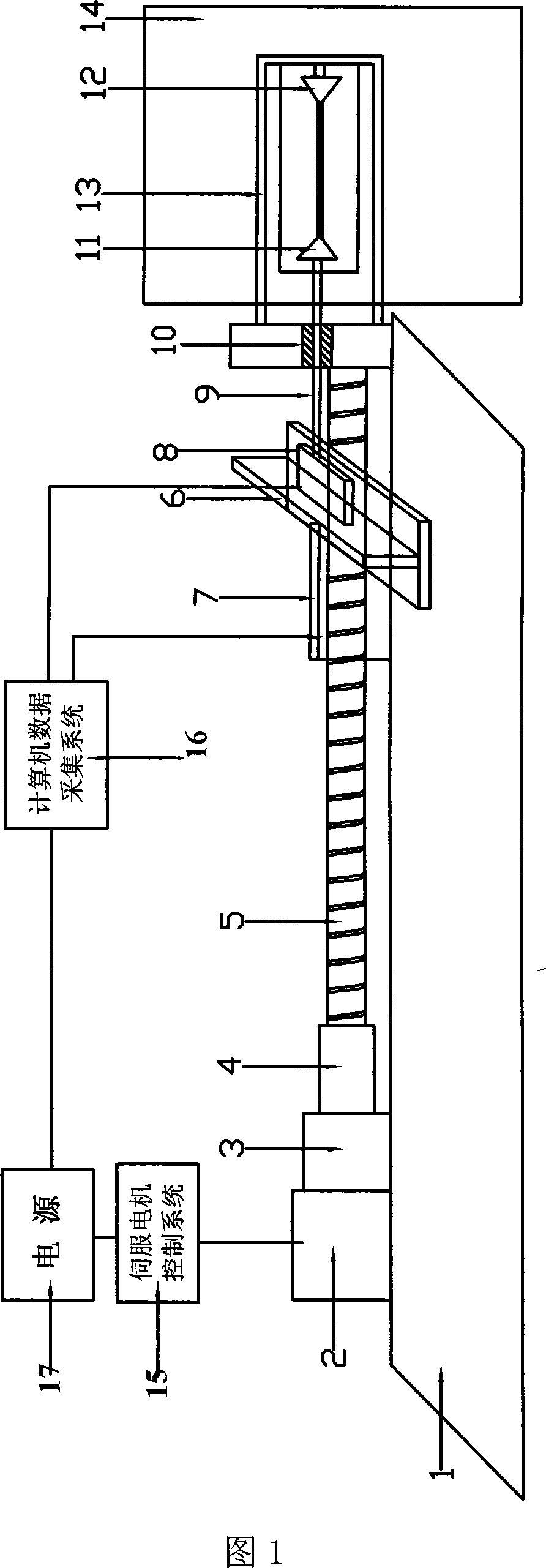

Metal wire material stretching mechanical property testing device

ActiveCN101196450ASimple structureEasy to operateInvestigating material ductilityTest fixtureMechanical property

The invention relates to a metal wire material drawing force performance testing device for testing the drawing force performance of metal wire material, which utilizes measuring the drawing deformation displacement of the metal wire material and the drawing force loaded on the metal wire material, according to the length and diameter of the metal wire material, counts the strain and stress of engineering, and obtains the drawing force performance of the metal wire material according to the gotten engineering stress-strain curve under different temperature. The invention also provides a device used for testing the drawing force of the metal wire material. The device has simple structure, small volume, light weight and low cost, which makes the combining testing accuracy of the method and the device in the invention high. The measured data is reliable and the operation is simple.

Owner:GRIMAT ENG INST CO LTD

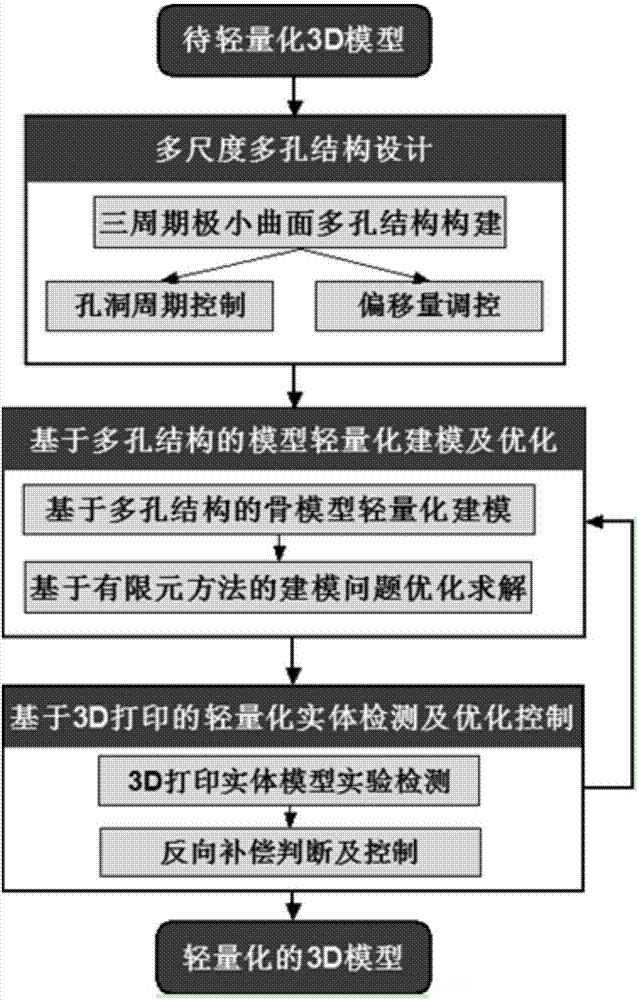

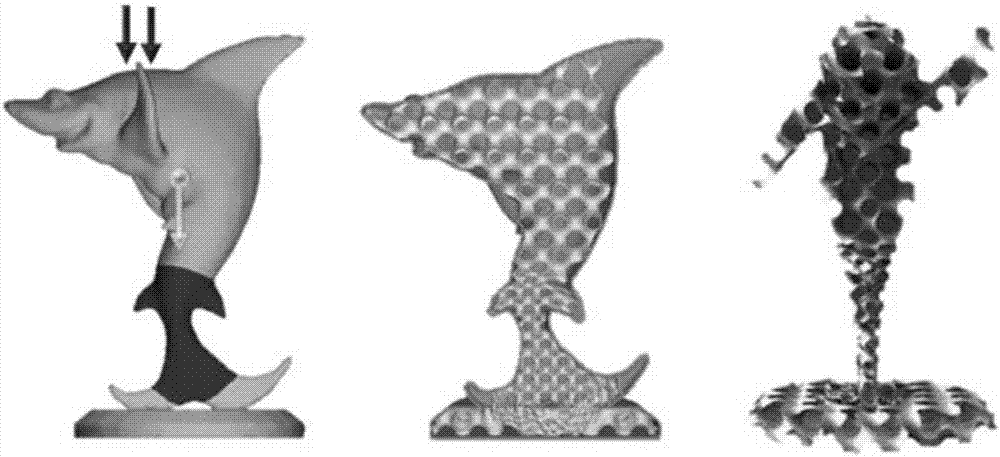

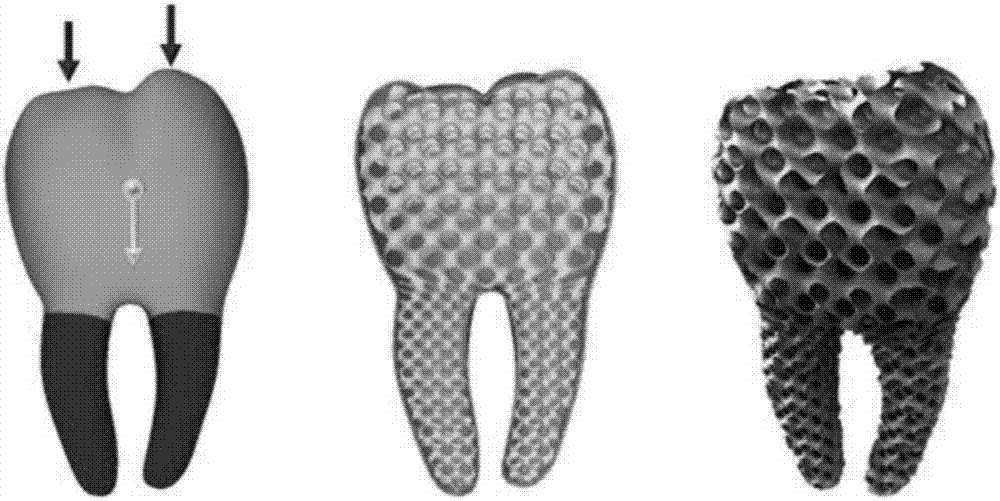

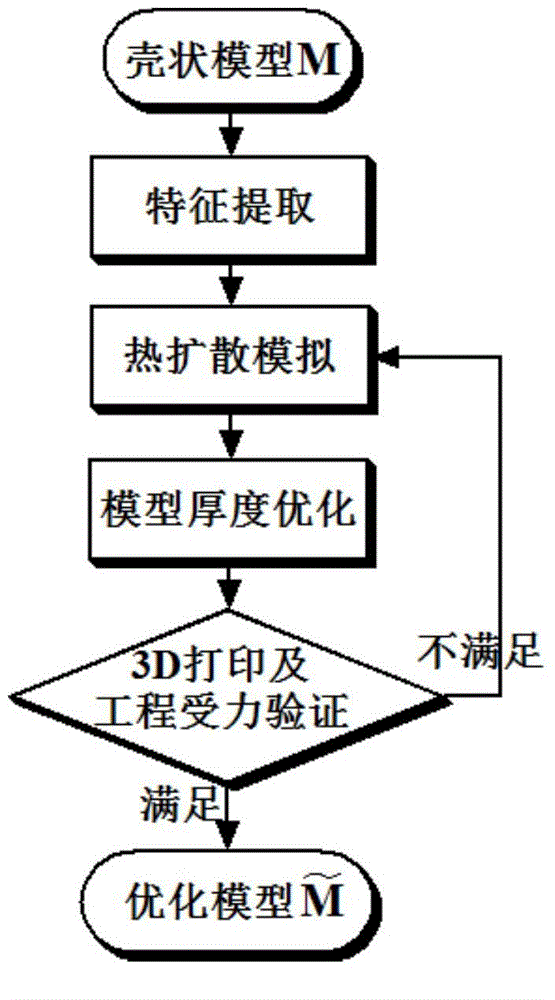

Multi-scale porous structure light weight modeling method oriented to 3D printing

ActiveCN107885945ASmoothWith full connectivityDesign optimisation/simulationSpecial data processing applicationsEngineeringEntity model

The invention discloses a multi-scale porous structure light weight modeling method oriented to 3D printing, and belongs to the field of computer aided design and industrial design manufacture. Undera condition that characteristic constraints and a stress condition are given, through a compact support radial basis function interpolation, a smooth multi-scale porous model is constructed; the multi-scale porous model is applied to light weight modeling, and a feasible solving solution is given; through the 3D printing, an entity experiment model is obtained and is subjected to engineering stress verification; according to engineering verification result analysis, a parameter is corrected to enable the hole change of an optimization model to more approach to practical stress requirements; and through the above loop iteration process, a light weight model which meets stress requirements is obtained. By use of the method, a light weight purpose of the entity model can be truly realized, sothat the light weight design optimization period of the model is greatly shortened, the porous structure obtained by design has the advantages of smoothness, full connectivity, controllability and quasi-self-supporting, and the effectiveness and the manufacturability of light weight can be accurately guaranteed.

Owner:DALIAN UNIV OF TECH

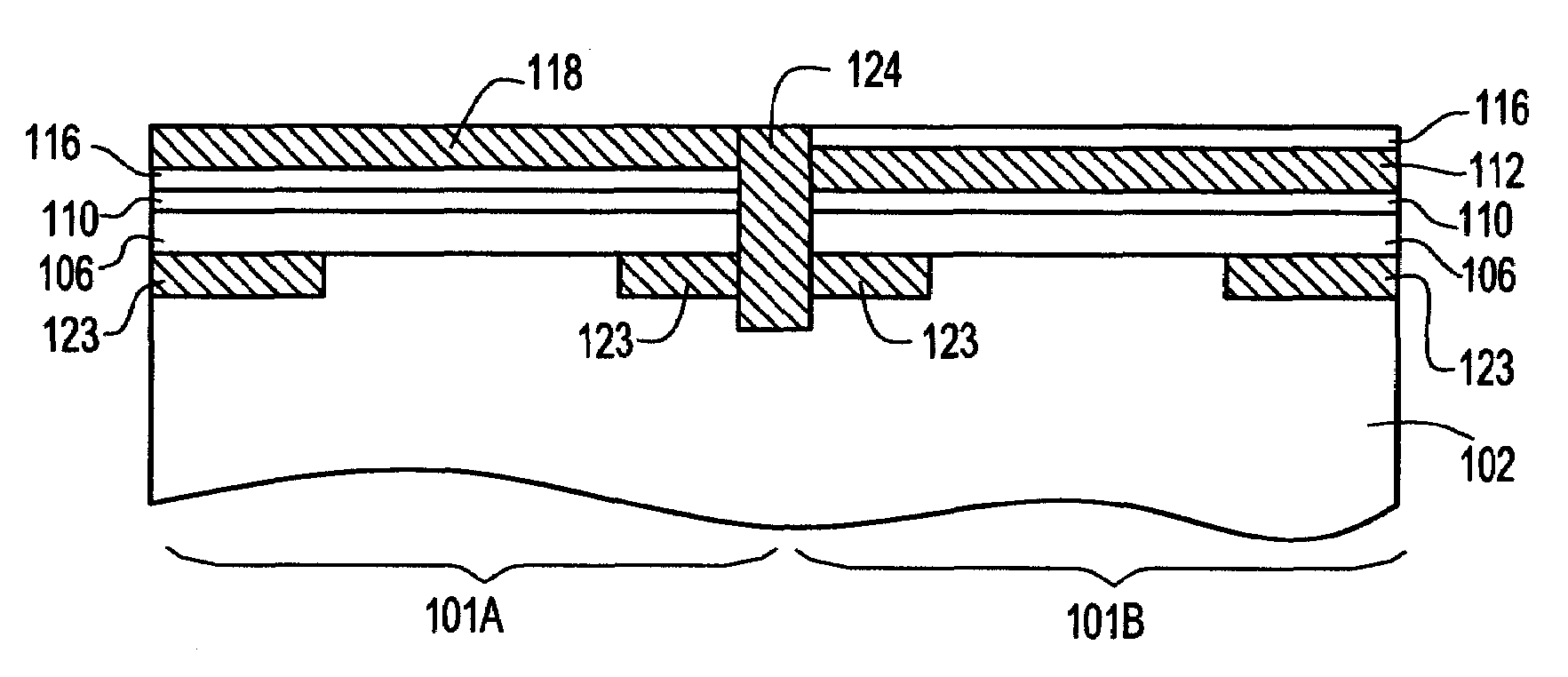

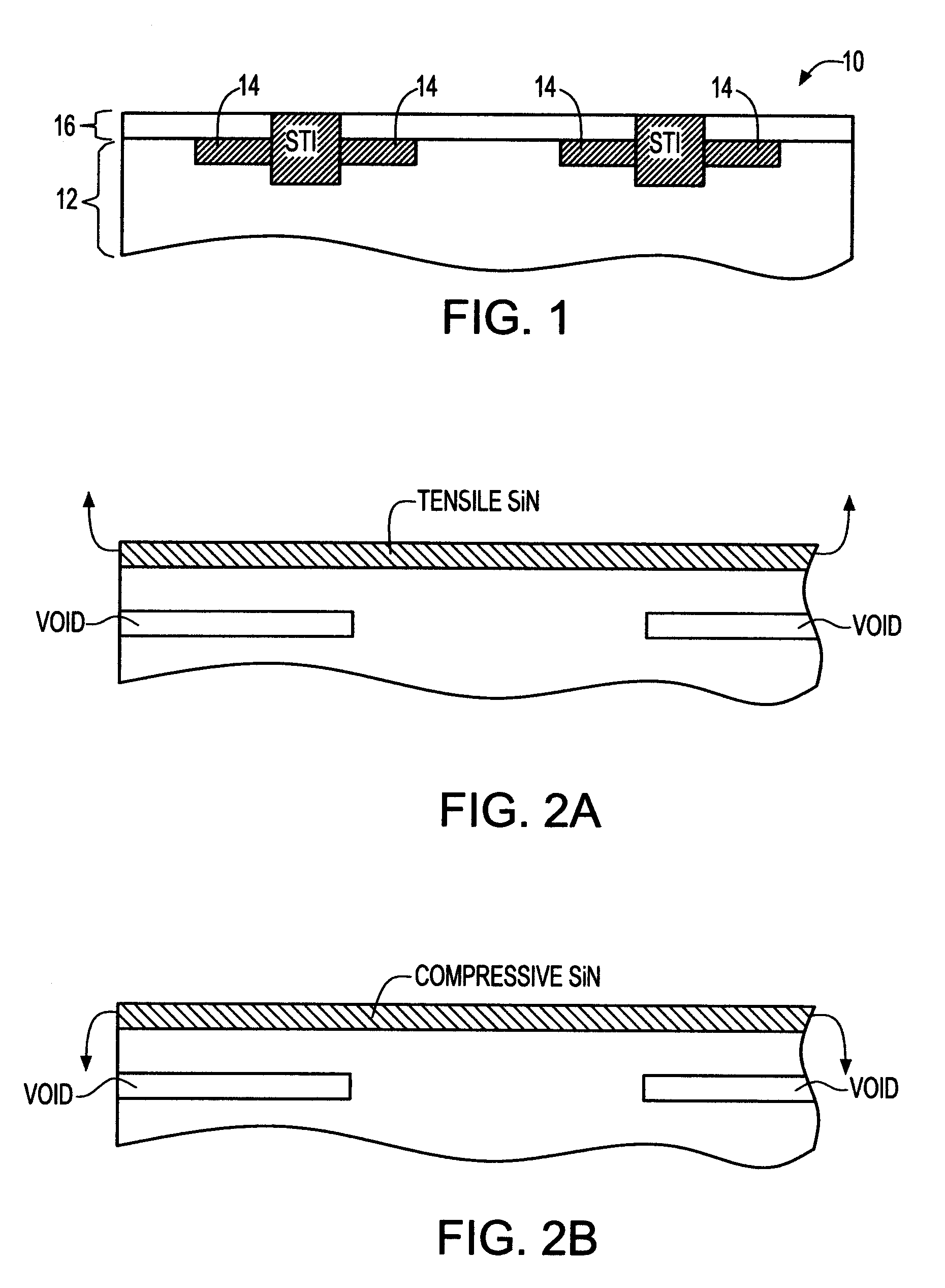

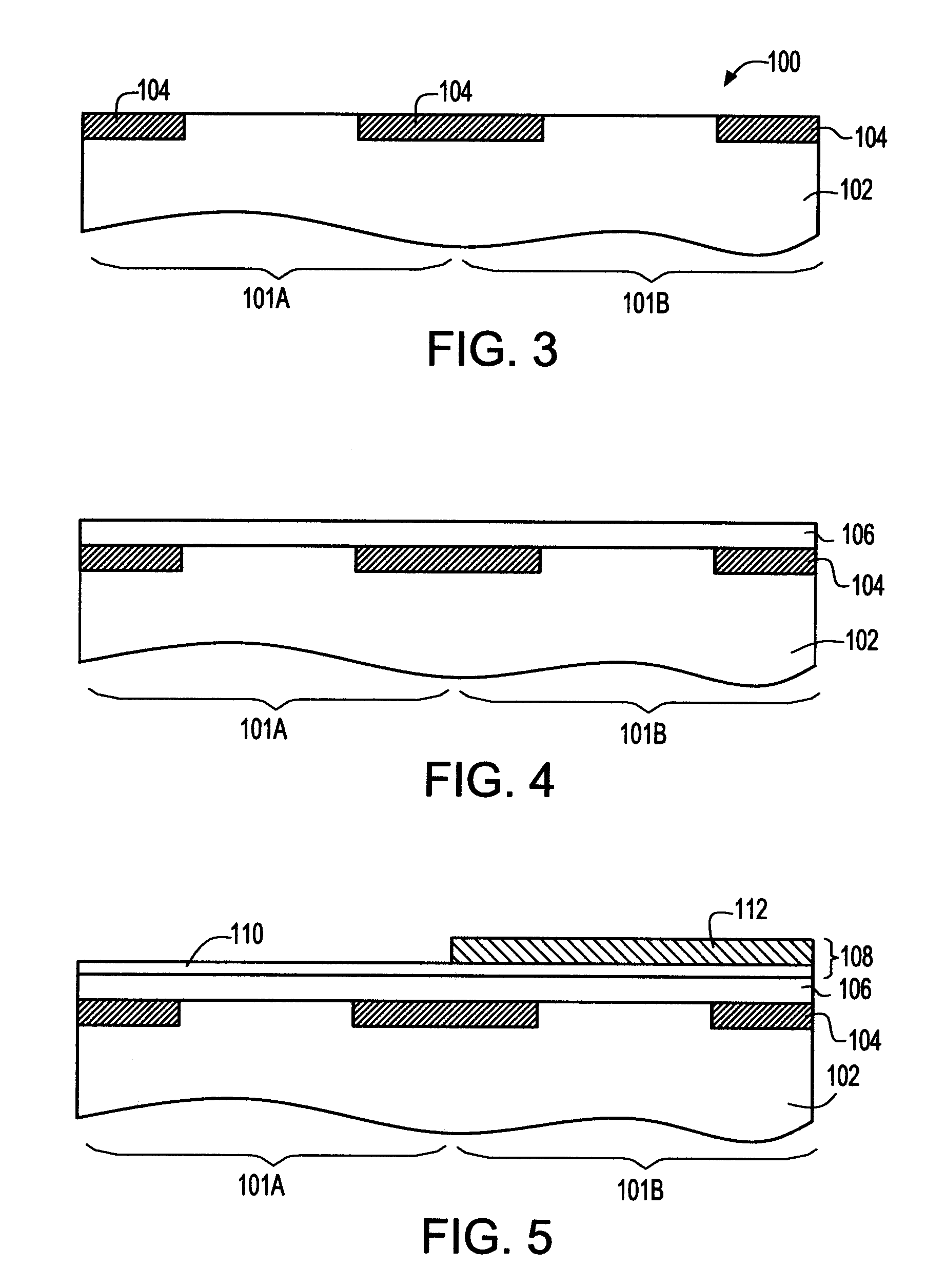

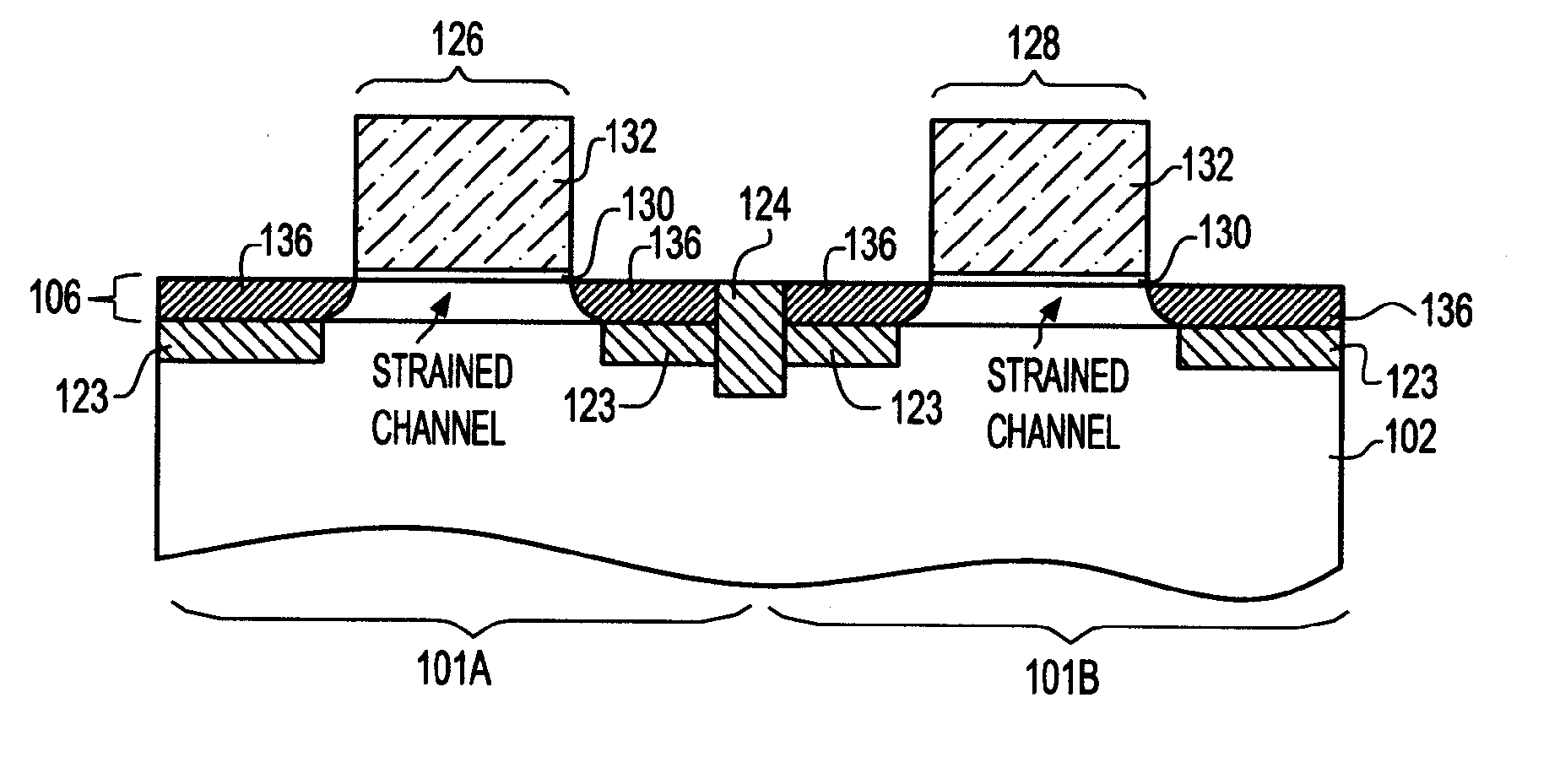

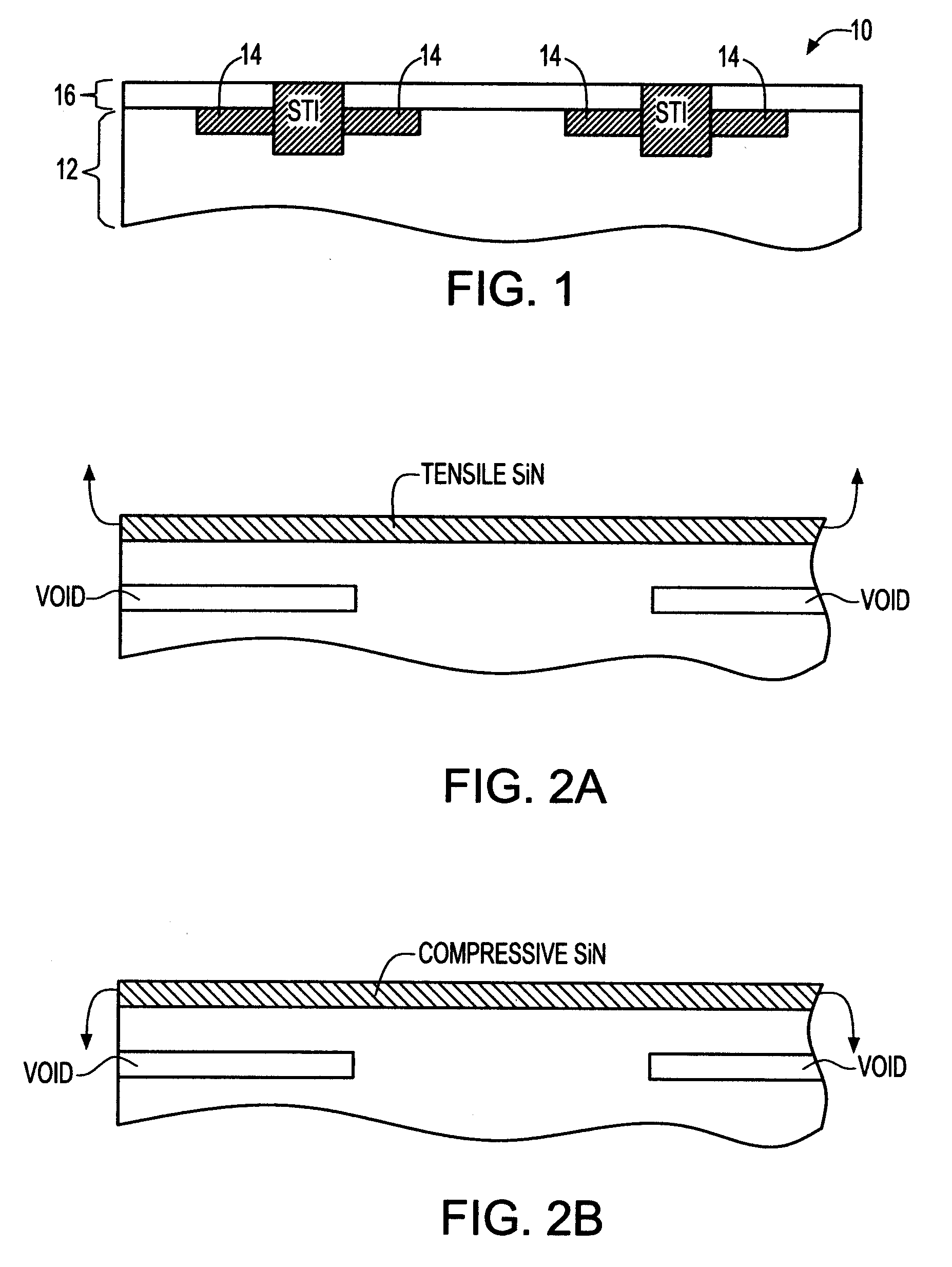

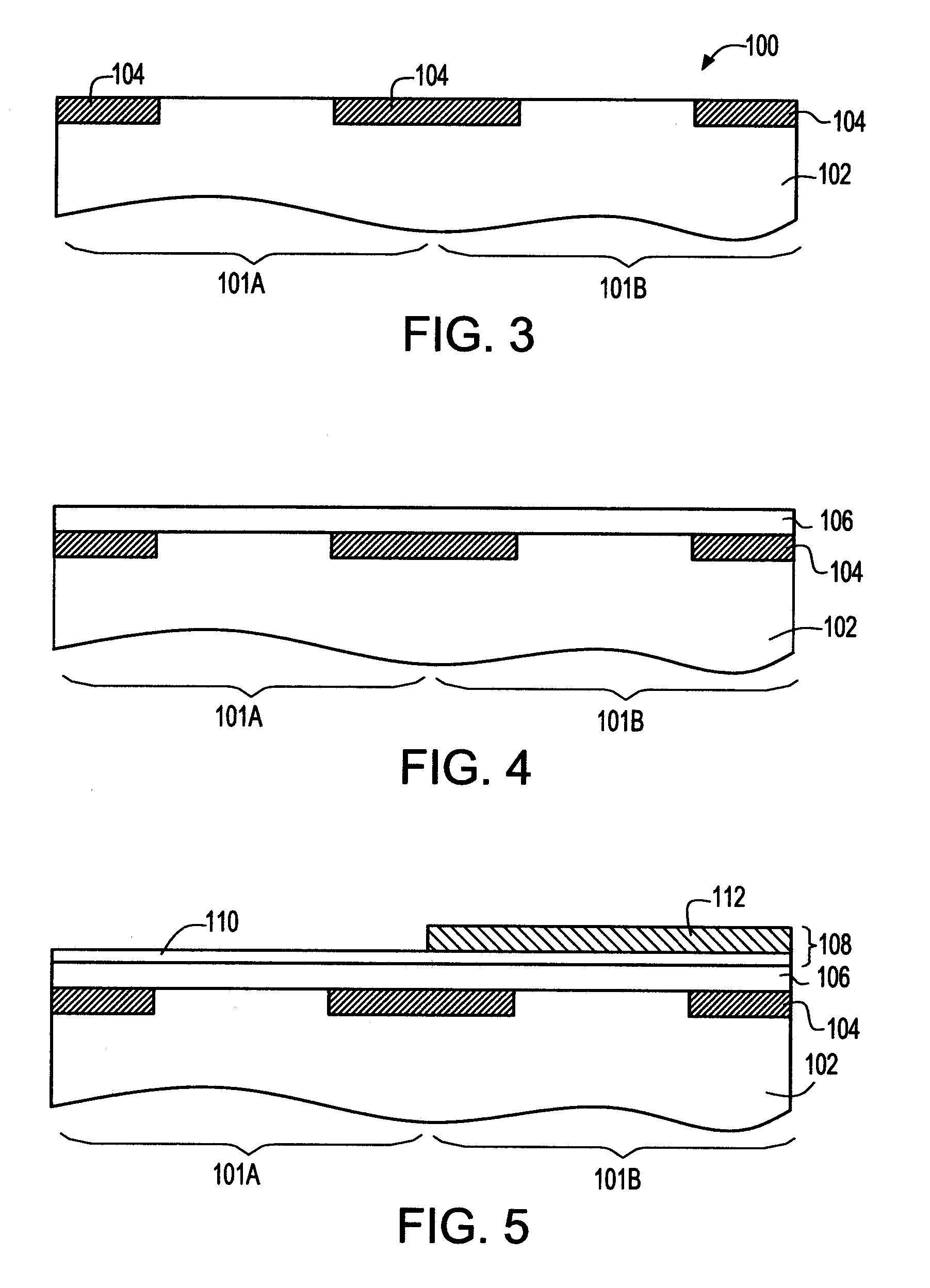

Stress engineering using dual pad nitride with selective SOI device architecture

ActiveUS7202513B1Increase valueSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductorMaterials science

A method for engineering stress in the channels of MOS transistors of different conductivity using highly stressed nitride films in combination with selective semiconductor-on-insulator (SOI) device architecture is described. A method of using compressive and tensile nitride films in the shallow trench isolation (STI) process is described. High values of stress are achieved when the method is applied to a selective SOI architecture.

Owner:GLOBALFOUNDRIES U S INC

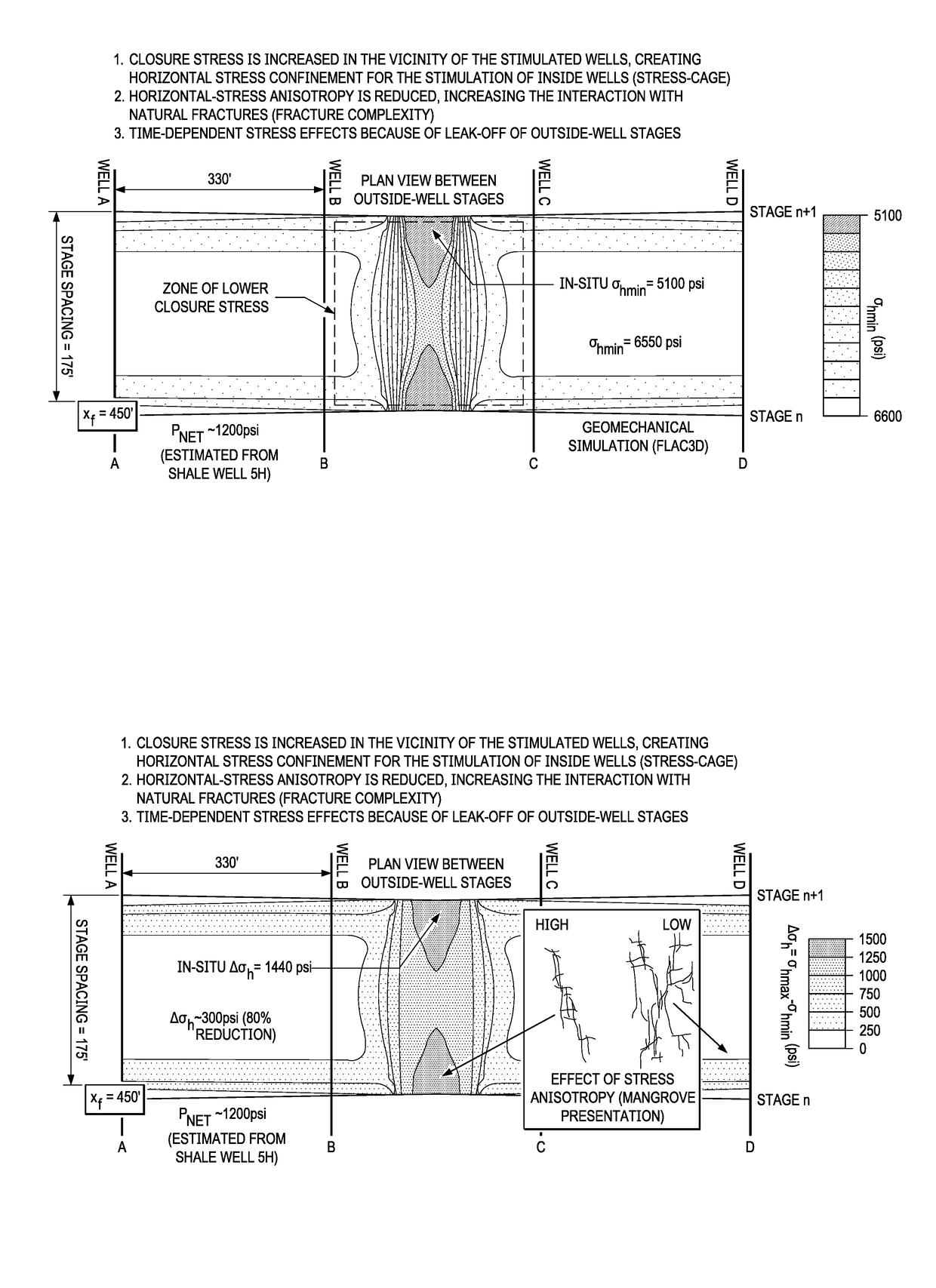

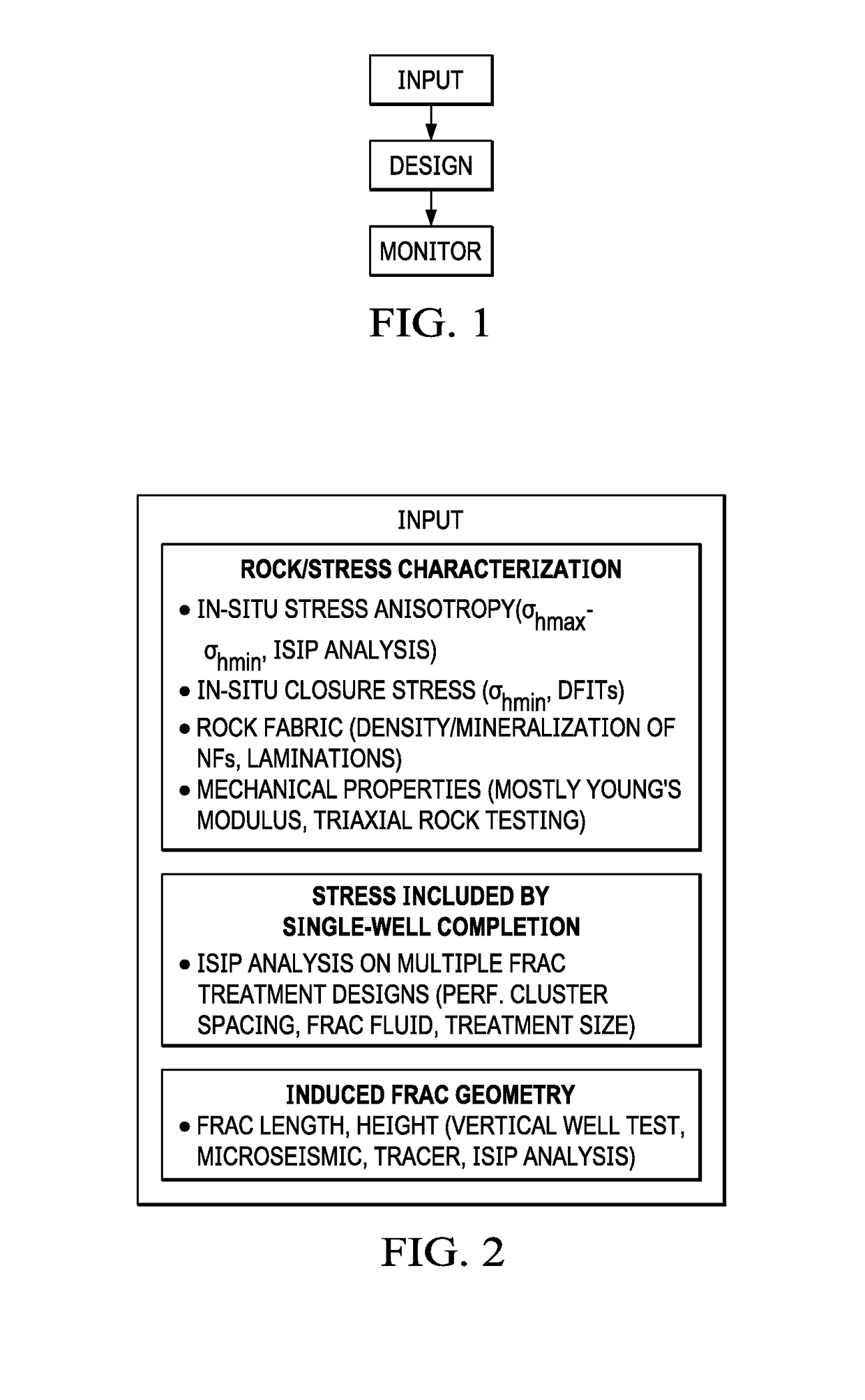

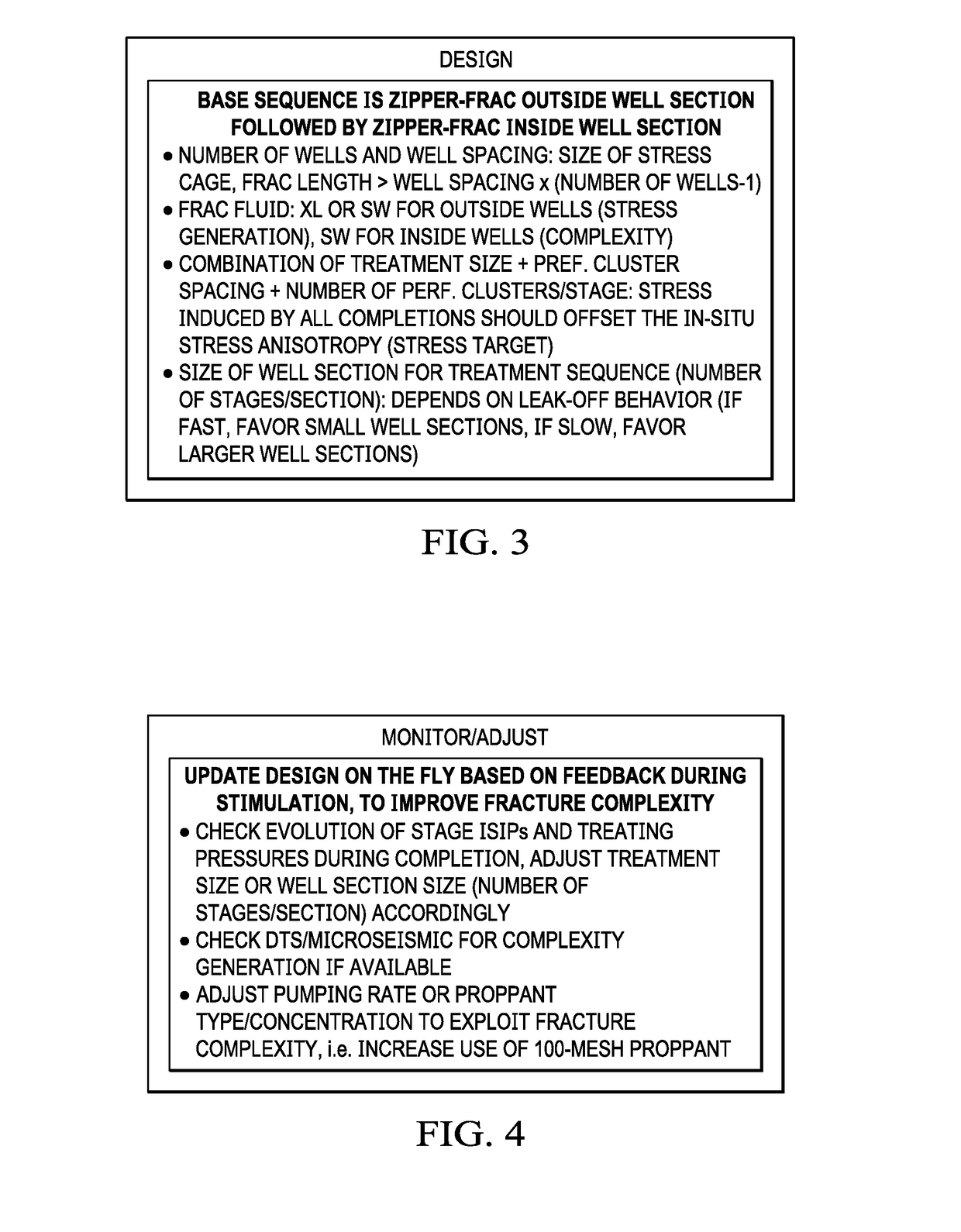

Engineered stress state with multi-well completions

ActiveUS20180149000A1Constrain transverse propagationEnhanced interactionFluid removalProduction rateStressed state

This disclosure describes a method for fracturing a well to improve productivity, by simulating zipper fracturing in such a way as to generate stress cages, thus minimizing anisotropy in a zone where fracture complexity is desired.

Owner:CONOCOPHILLIPS CO

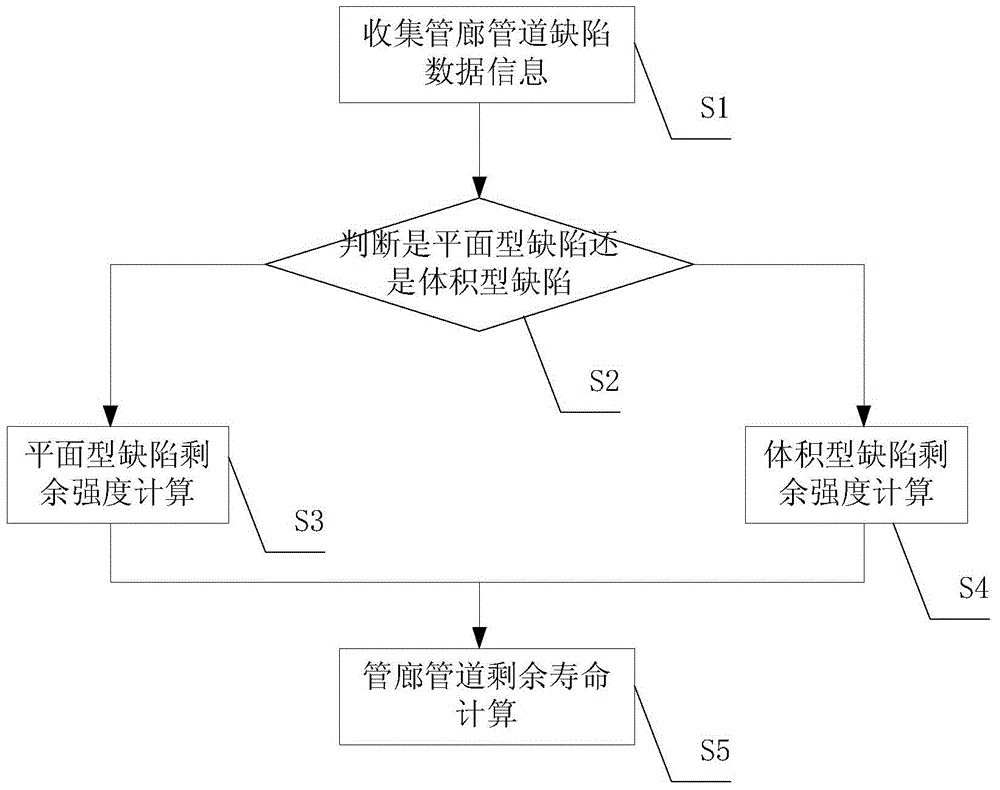

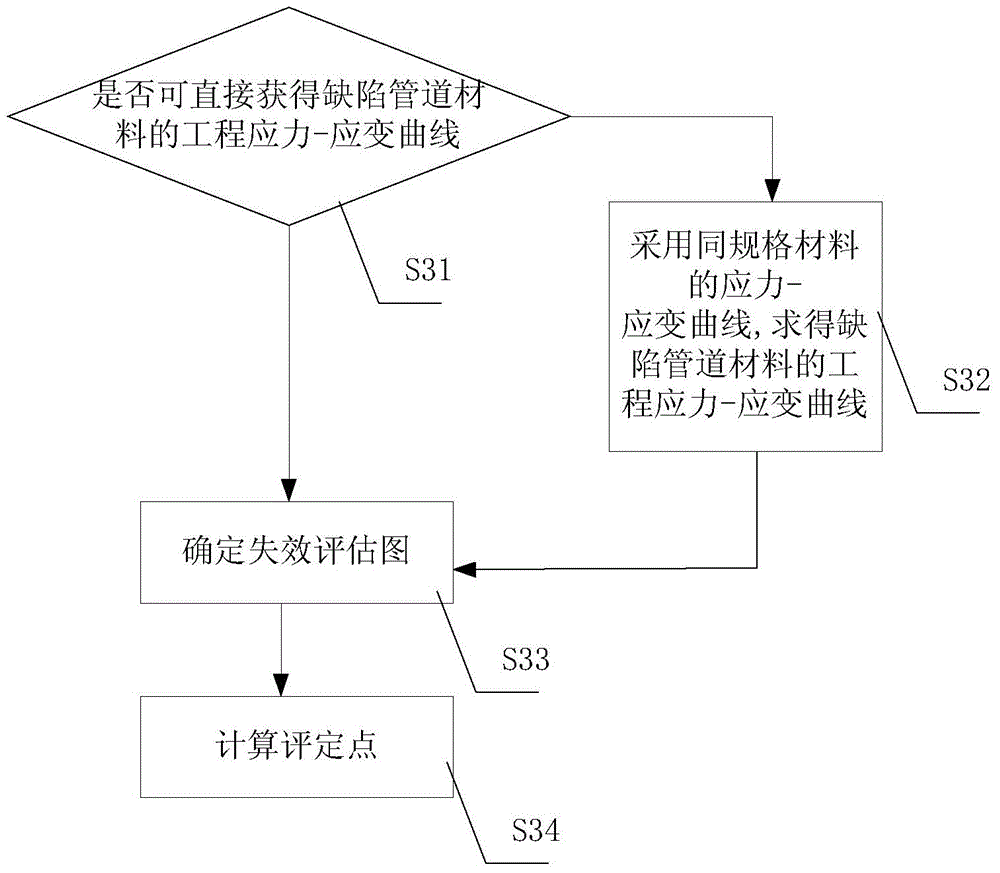

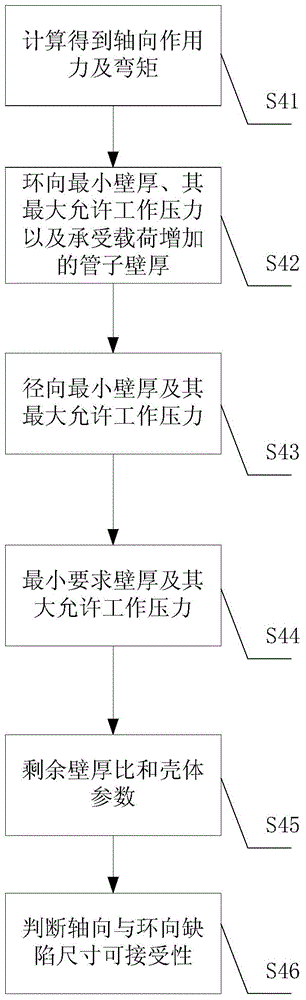

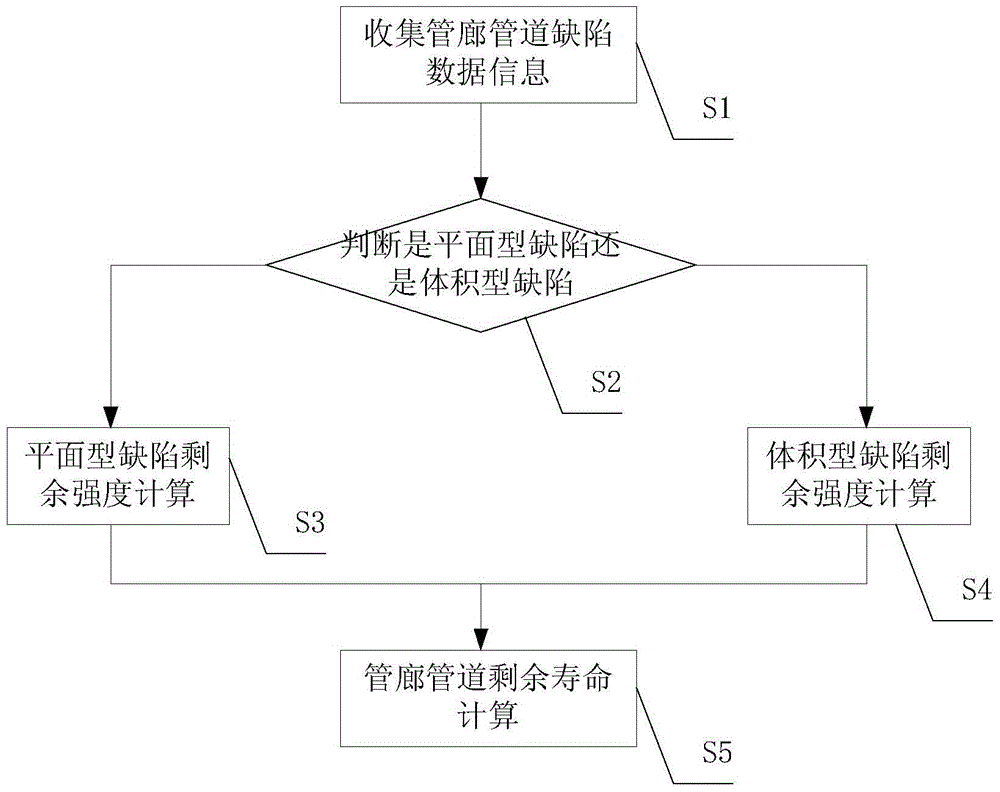

Residual intensity and residual life computing method for pipe gallery pipelines

ActiveCN104807966AGuaranteed safe operationSimple and fast operationMaterial analysisFailure assessmentNormal density

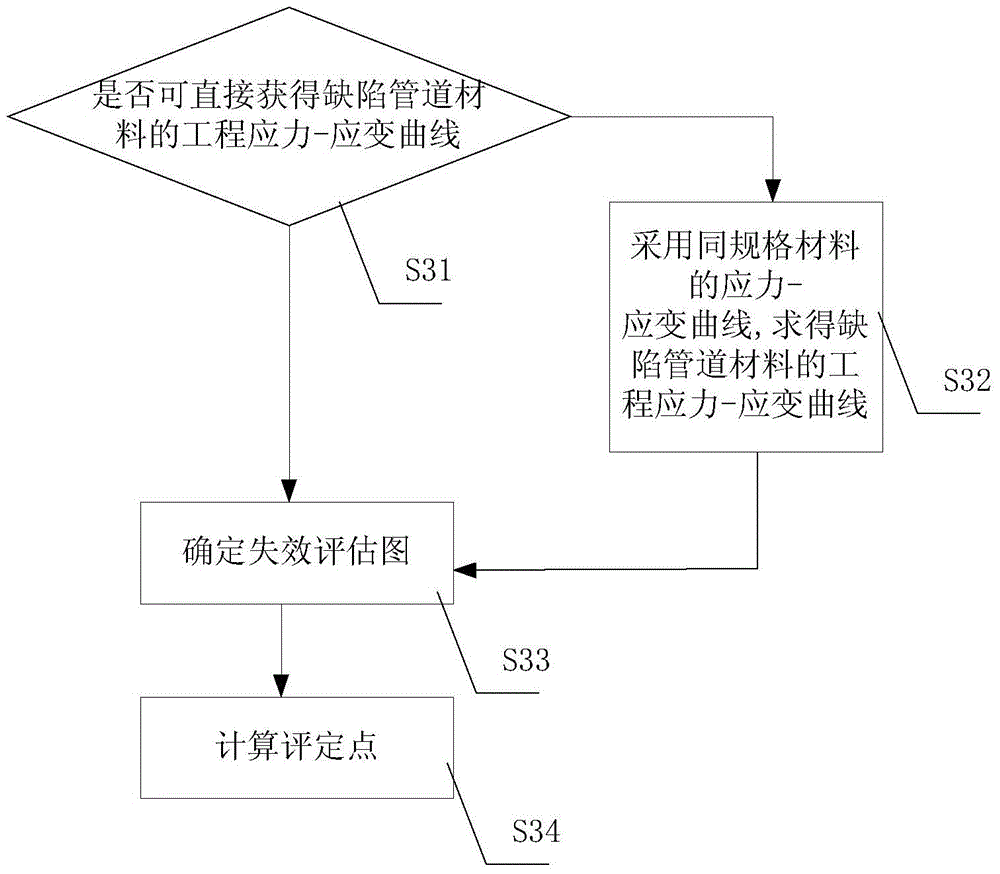

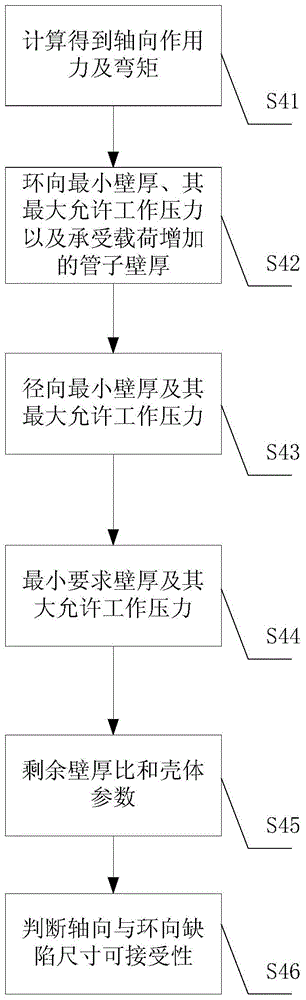

The invention discloses a residual intensity and residual life computing method for pipe gallery pipelines. The residual intensity and residual life computing method comprises the following steps: collecting the data information of defects of the pipe gallery pipelines; judging the defects are plane type defects or volume type defects; for the plane type defects, obtaining the engineering stress-strain curve of a defect pipeline material from the data information of the defects of the pipe gallery pipelines, determining a failure assessment diagram, and then computing assessment points to obtain the residual intensity of the pipe gallery pipelines; for the volume type defects, obtaining the design factors, the weld joint factors and the minimum measurement wall thickness from the data information of the defects of the pipe gallery pipelines, and obtaining the residual intensity of the pipe gallery pipelines through computing; computing basic numerical values according to the data information of the defects of the pipe gallery pipelines, and computing the residual lives of the pipe gallery pipelines according to a maximum value distribution probability density function, a reliability function, maximum corrosion depth point estimation and maximum likelihood estimation. Therefore, the residual intensity and residual lives of the pipelines in a pipe gallery area are effectively and accurately computed and predicted.

Owner:SHANGHAI CHEM IND PARK PUBLIC PIPE RACK

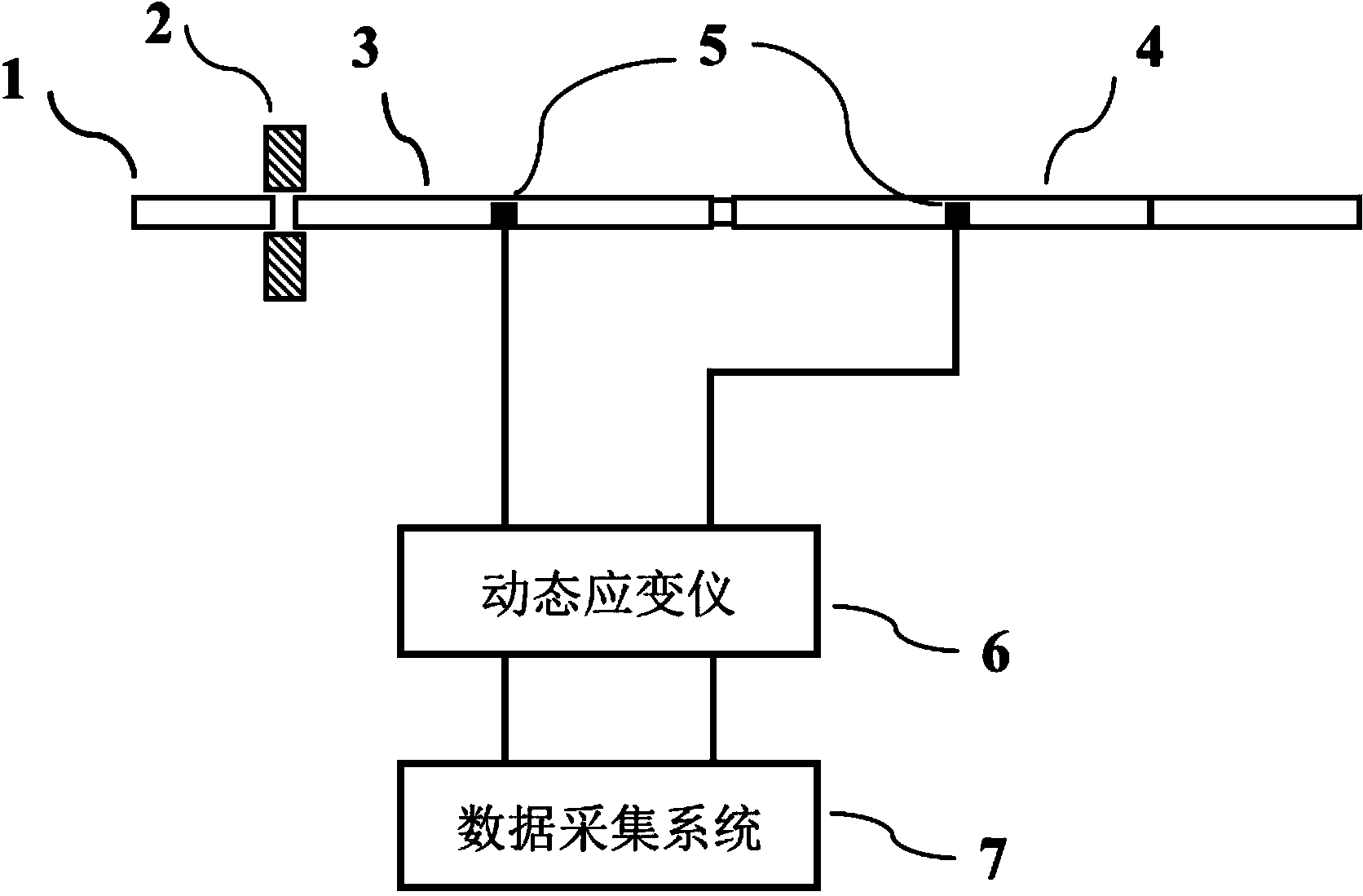

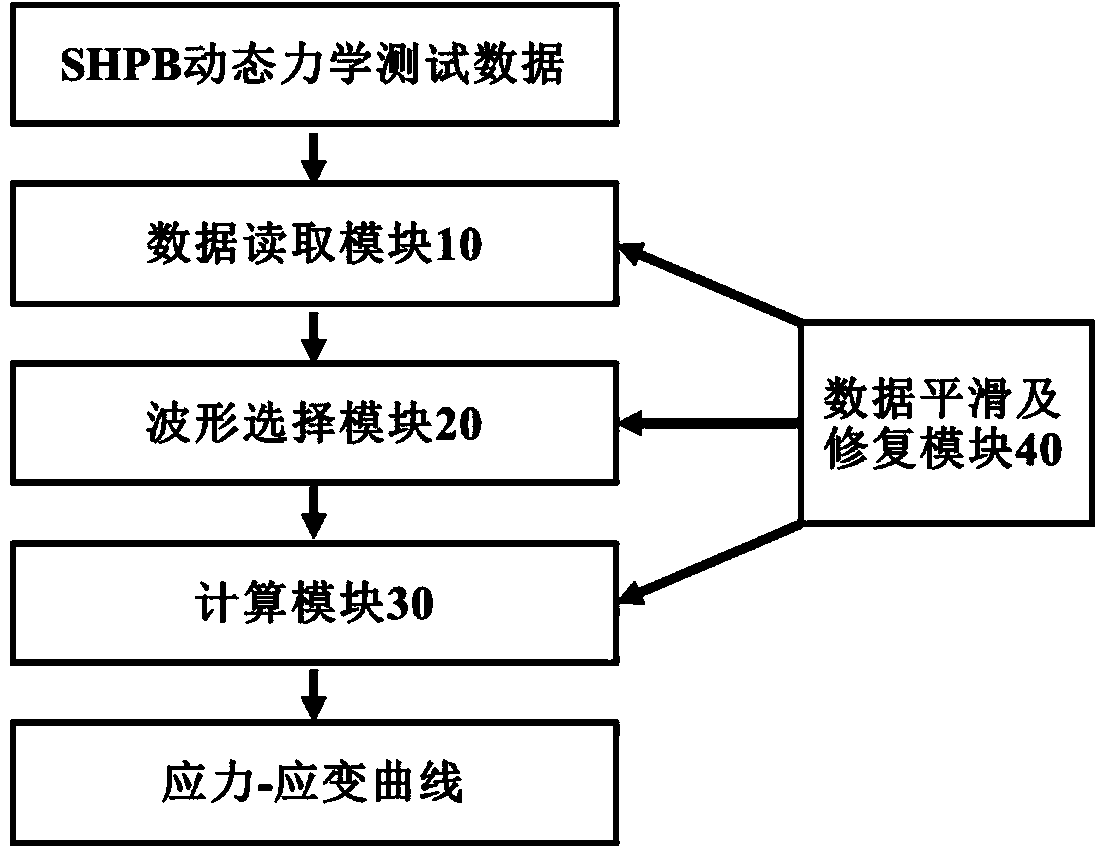

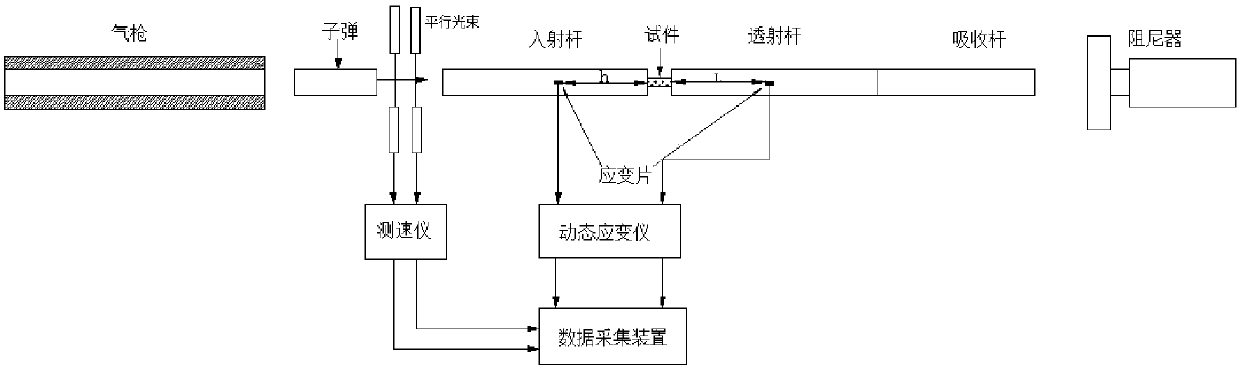

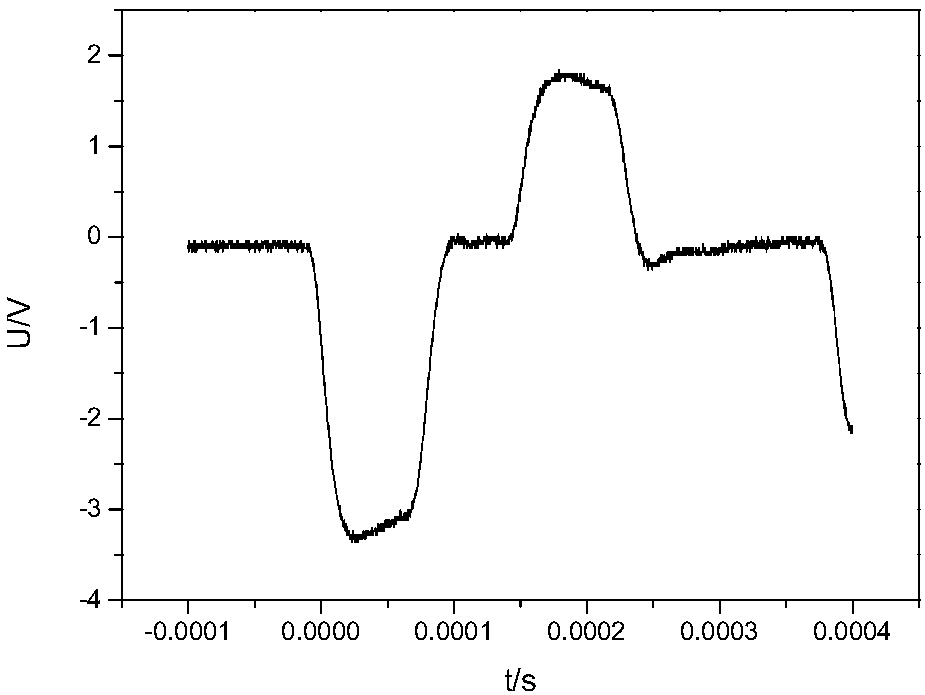

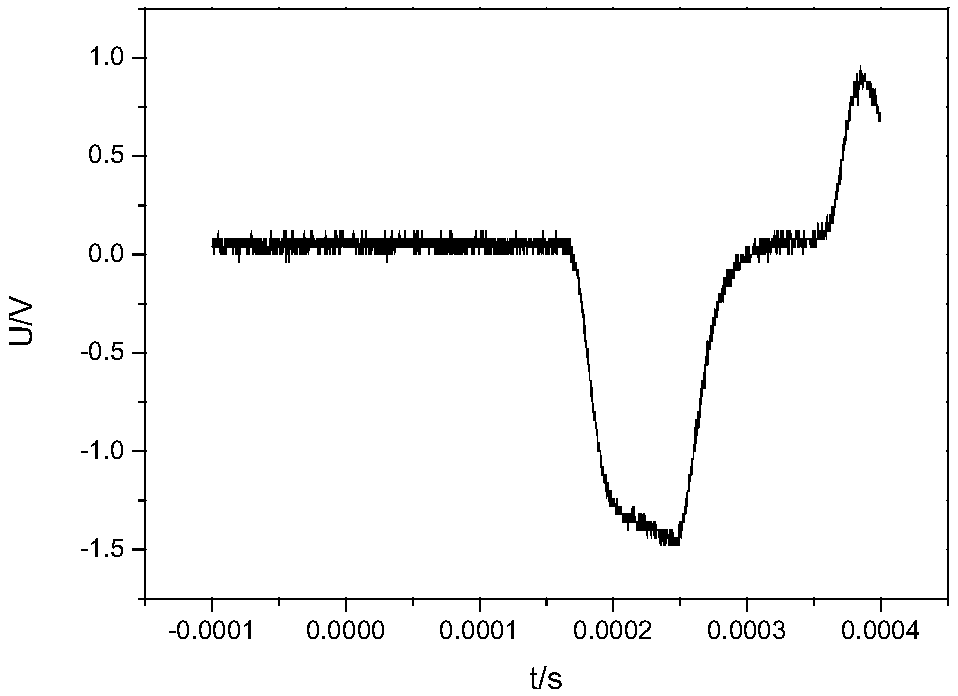

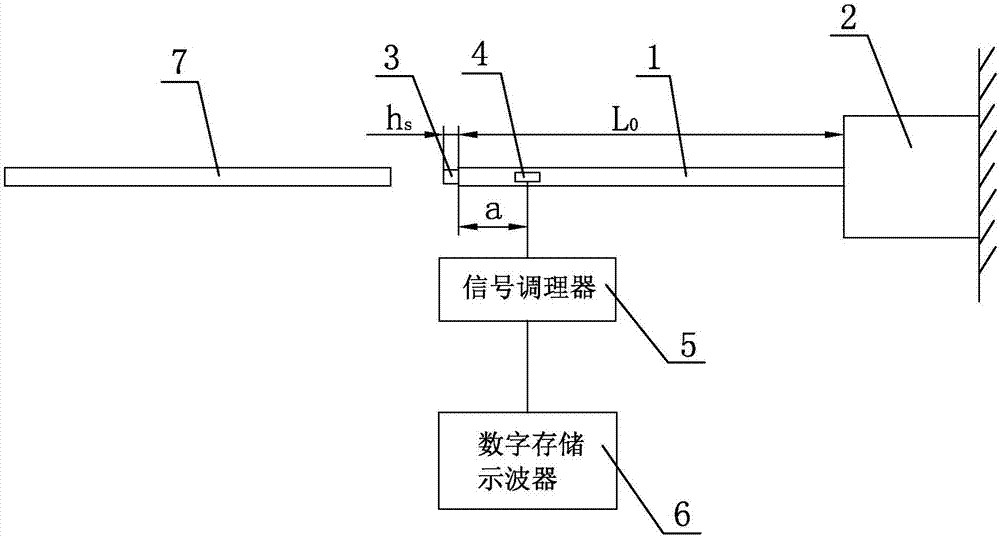

Data processing system based on separated Hopkinson bar dynamical mechanical property test device

InactiveCN104062174ARealize intelligenceFlexible handlingStrength propertiesOperational systemStress–strain curve

The invention discloses a data processing system based on a separated Hopkinson bar dynamical mechanical property test device. The data processing system is characterized in that voltage-time data points obtained by testing the separated Hopkinson bar dynamical mechanical property are first read, then the voltage-time data points are drawn into a voltage-time curve, the tested voltage-time curve is transformed to a needed engineering stress-strain curve and a real stress-strain curve through the human-computer interaction according to a given test parameter or by automatically inputting the parameter and a calculation formula, and the data can be examined, smoothened, modified, intercepted and outputted at any time. By adopting the data processing system, the dynamically compressed test data, the cutting data and the tensile mechanical property test data can be respectively processed; based on the humanized interface of the windows operating system, the intelligentization of the separated Hopkinson bar dynamical mechanical property data processing can be realized, the data is more flexible to process, the operation rate and convenience in operation can be improved, and the practicability is strong.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Stress engineering using dual pad nitride with selective SOI device architecture

ActiveUS20070069294A1Increase valueSolid-state devicesSemiconductor/solid-state device manufacturingSemiconductorMaterials science

A method for engineering stress in the channels of MOS transistors of different conductivity using highly stressed nitride films in combination with selective semiconductor-on-insulator (SOI) device architecture is described. A method of using compressive and tensile nitride films in the shallow trench isolation (STI) process is described. High values of stress are achieved when the method is applied to a selective SOI architecture.

Owner:GLOBALFOUNDRIES US INC

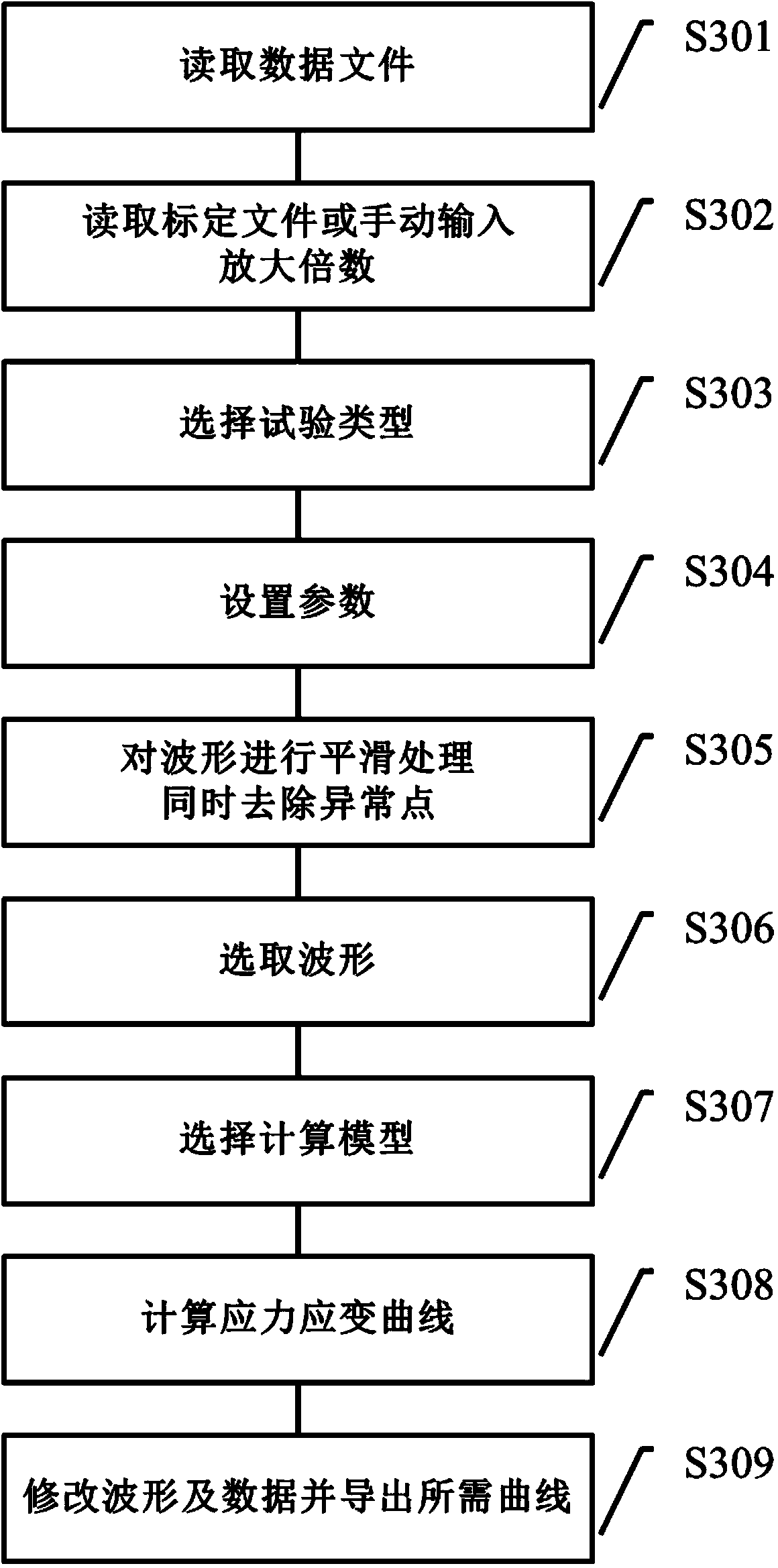

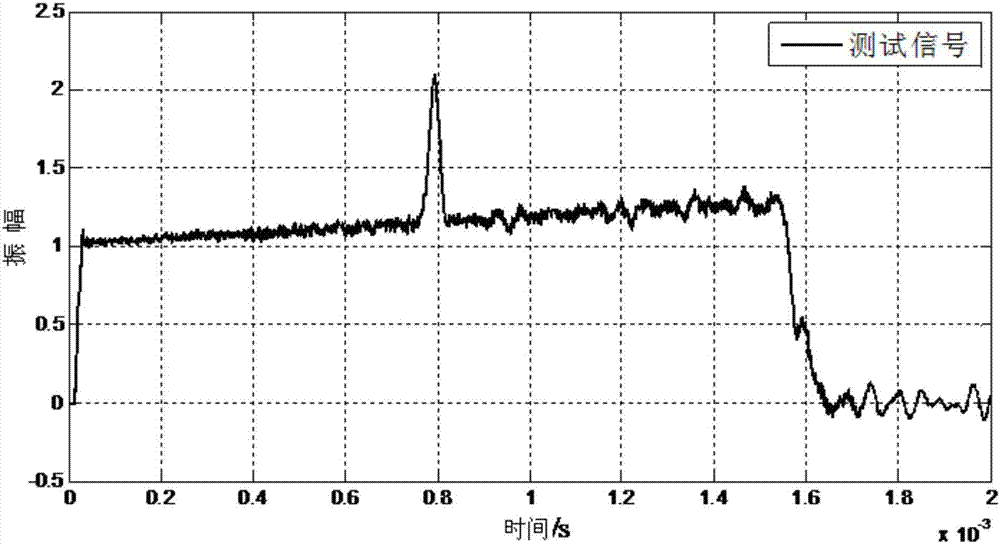

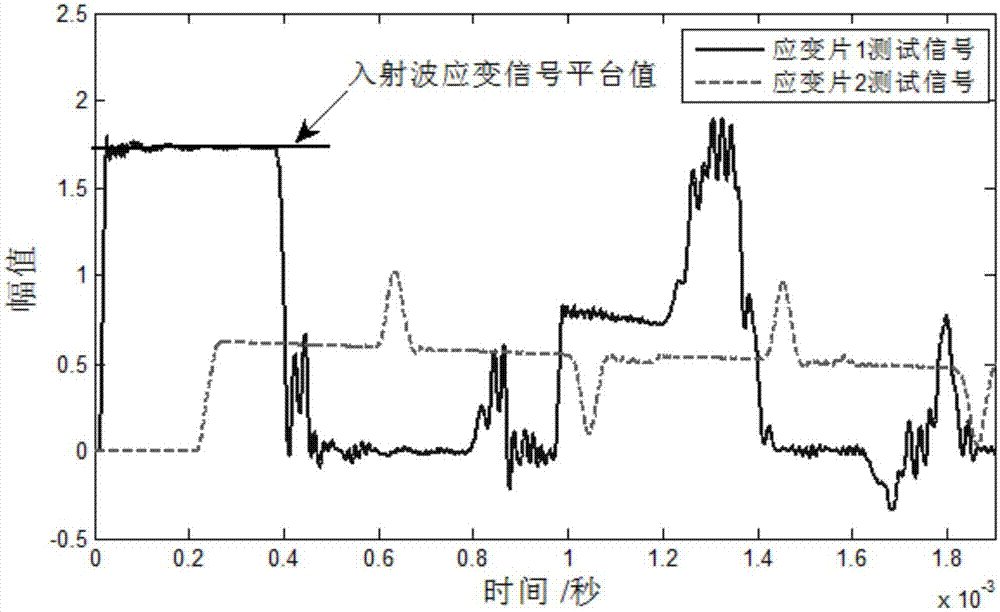

Data processing method based on separated Hopkinson press bar experiment technique

ActiveCN108375501AChoose accuratelyAccurately reflectStrength propertiesProcess dynamicsStress–strain curve

The invention discloses a data processing method based on a separated Hopkinson press bar experiment technique. The method includes the steps: return-to-zero adjustment: performing a wavelike return-to-zero adjustment on a voltage-time curve acquired by a data acquisition unit, and namely, enabling an initial voltage value to keep zero; data smoothing: smoothing the voltage-time curve, and removing abnormal points; waveform selection: selecting head and tail positions of incident waves, reflected waves and transmitted wave, and intercepting waveforms; result calculation: calculating the intercepted waveforms to obtain engineering stress curve, a true stress-strain curve, a stress-time curve, a strain-time curve and a strain rate time curve; data storage: storing all acquired waveforms anddata. The data processing method is applicable to testing data for processing dynamic compressive mechanical properties and has high practicability.

Owner:NANJING UNIV OF SCI & TECH

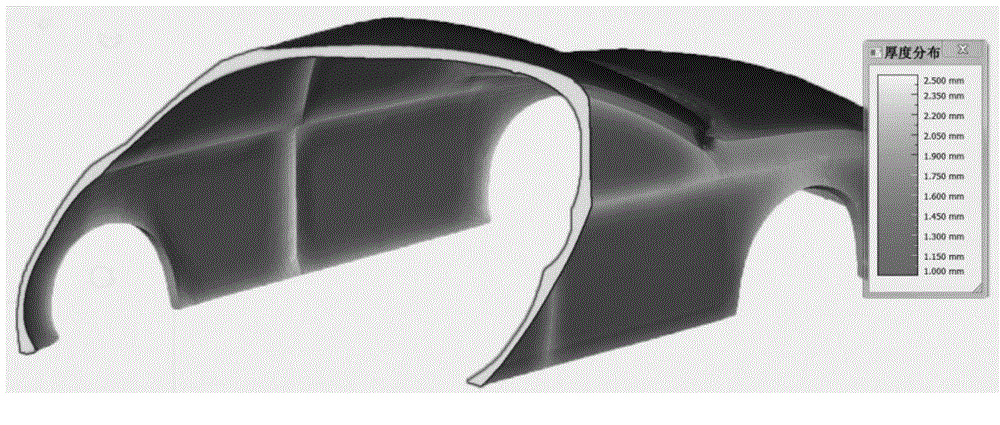

Shell-shaped component light modeling system for 3D (three-dimensional) printing

InactiveCN104881514AHigh speedAchieve lightweightSpecial data processing applications3D modellingStress distributionDiffusion

The invention provides a shell-shaped component light modeling system for 3D (three-dimensional) printing, and belongs to the field of computer aided design and industrial design manufacturing. According to the shell-shaped component light modeling system for 3D printing, stress distribution of a model is simulated through thermal diffusion under the conditions that characteristic constraints and stress working conditions are given, and a simulating numerical value corresponds to the thickness of the model to obtain an initially optimized model; an entity experiment model is obtained through 3D printing and is subjected to engineering stress verification; furthermore, thermal diffusion degree is adjusted through diffusion parameters according to engineering verification conditions, so that the thickness of the optimized model is close to actual stress requirements; and a weight optimized model which meets stress requirements is obtained through a circular iteration process.

Owner:DALIAN UNIV OF TECH

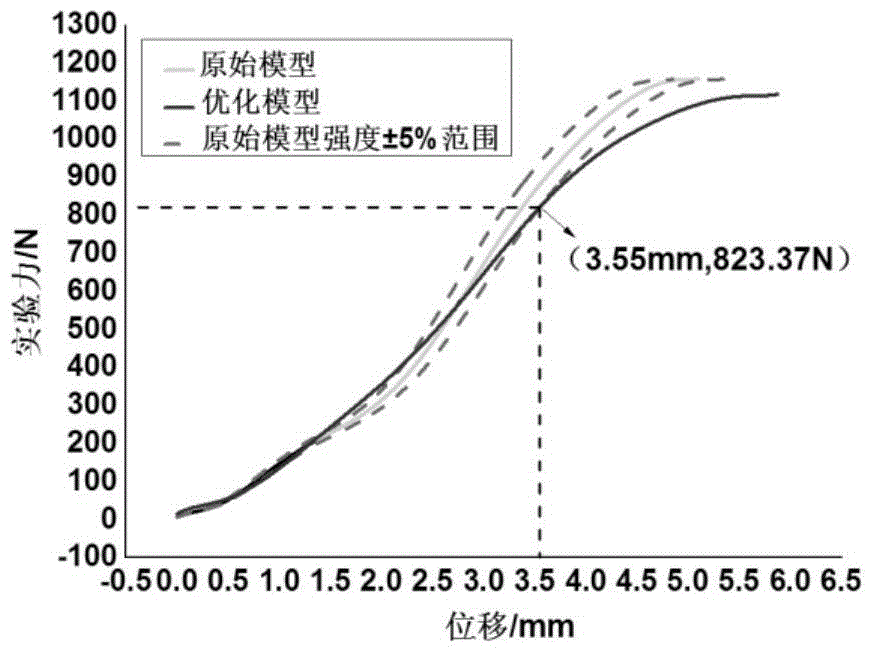

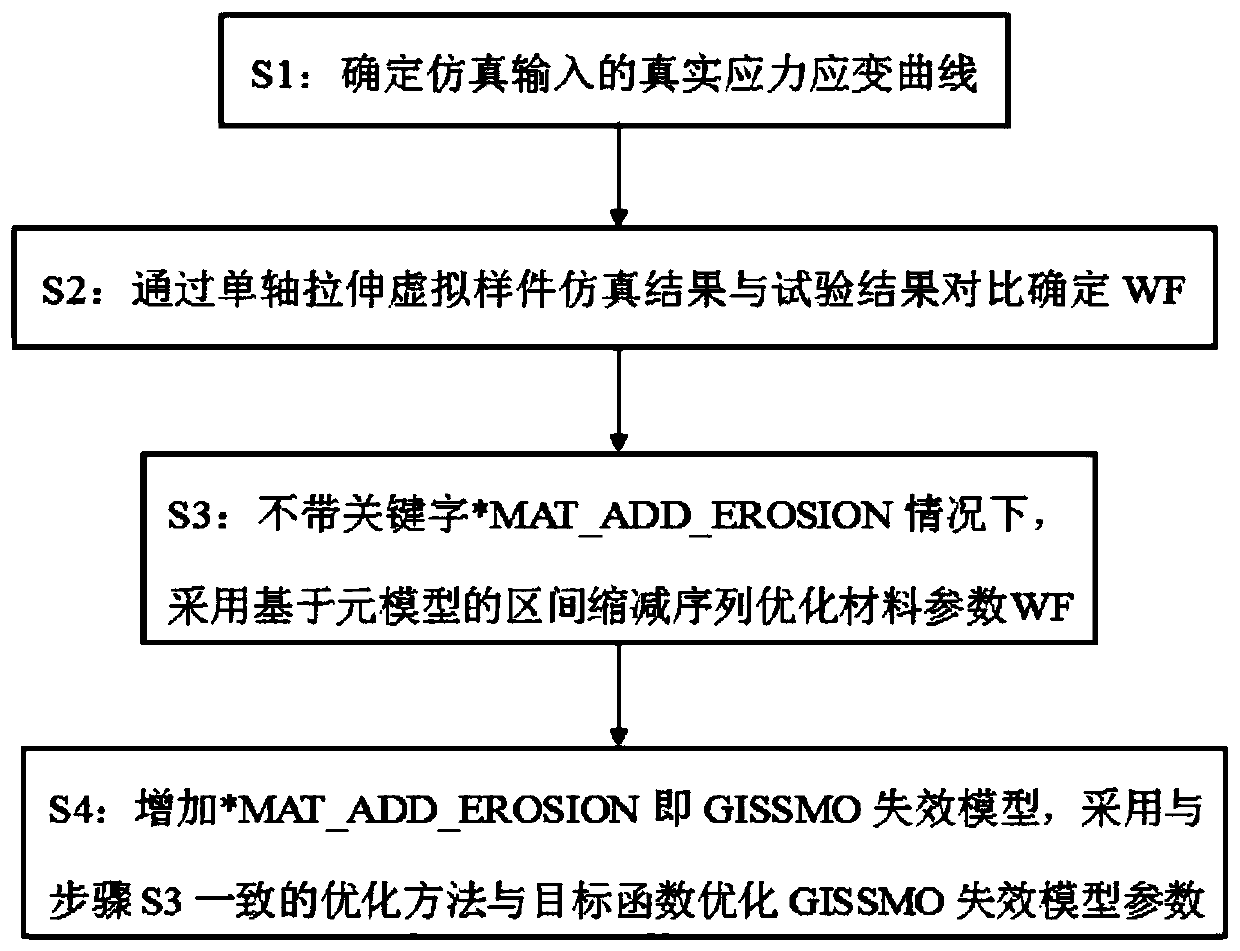

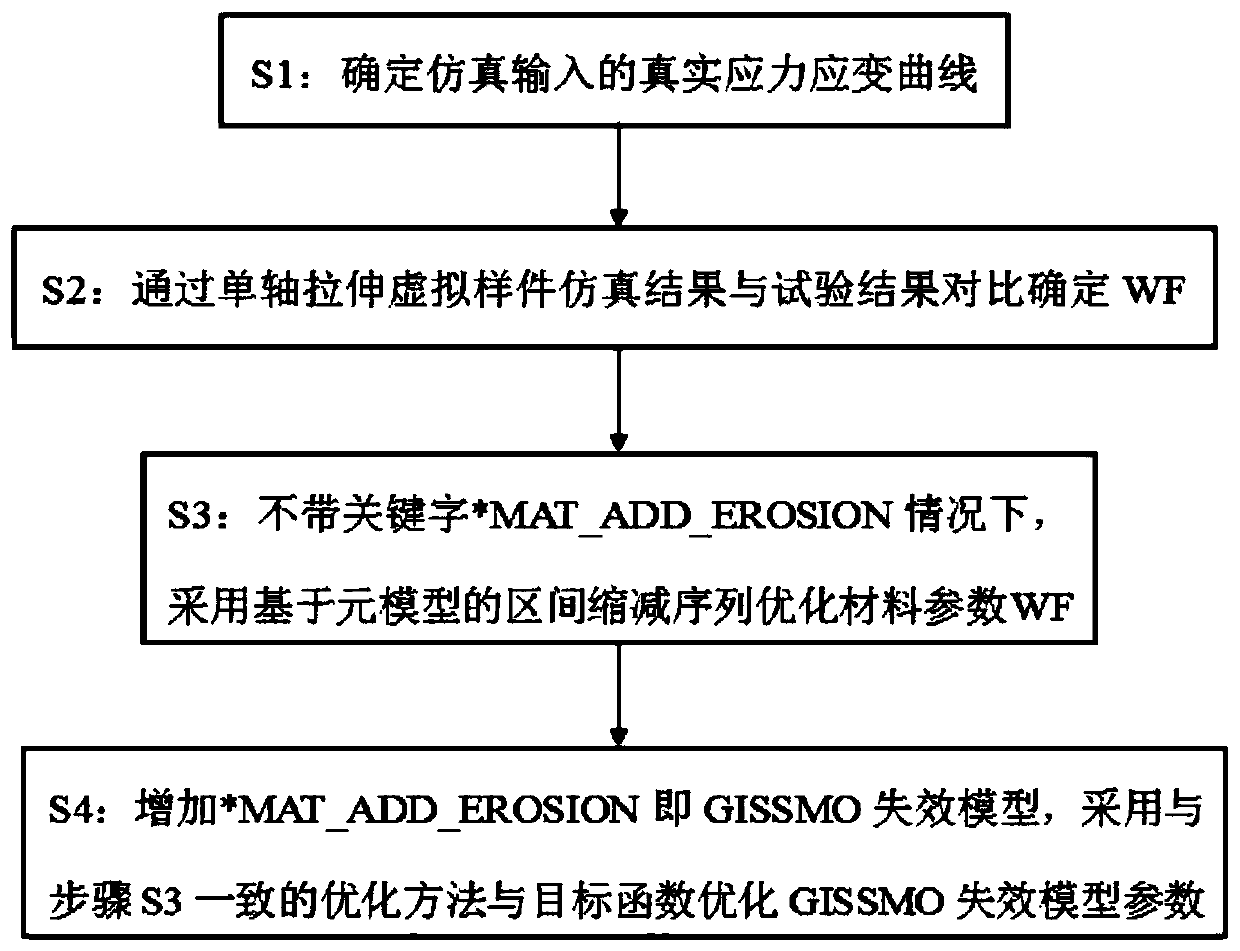

GISSMO material failure model parameter optimization method

ActiveCN111125960AQuick identificationImprove consistencyGeometric CADMaterial strength using tensile/compressive forcesAlgorithmVirtual sample

The invention relates to the technical field of materials, in particular to a GISSMO material failure model parameter optimization method which comprises the following steps: S1, determining a real stress-strain curve of simulation input; s2, comparing the simulation result of the uniaxial stretching virtual sample with the test result to determine the initial range of the WF; s3, under the condition that no keyword * MAT_ADD _ EROSION exists, optimizing the material parameter WF by adopting an interval reduction sequence based on a meta-model; and S4, adding * MATs _ ADD _ EROSION, namely a GISSMO failure model, and optimizing GISSMO failure model parameters by adopting an optimization method consistent with the step S3 and a target function. According to the method, based on a GISSMO failure model provided in commercial finite element software LS-DYNA, GISSMO failure model parameters are reversely solved and calibrated according to material mechanical property test data parameters; by adopting the LS-OPT, material parameters can be quickly identified, so that output engineering stress-strain curves of simulation and test can obtain relatively good consistency, and a reference canbe provided for establishment of a quick, automatic and high-precision failure material library.

Owner:CHINA AUTOMOTIVE ENG RES INST +1

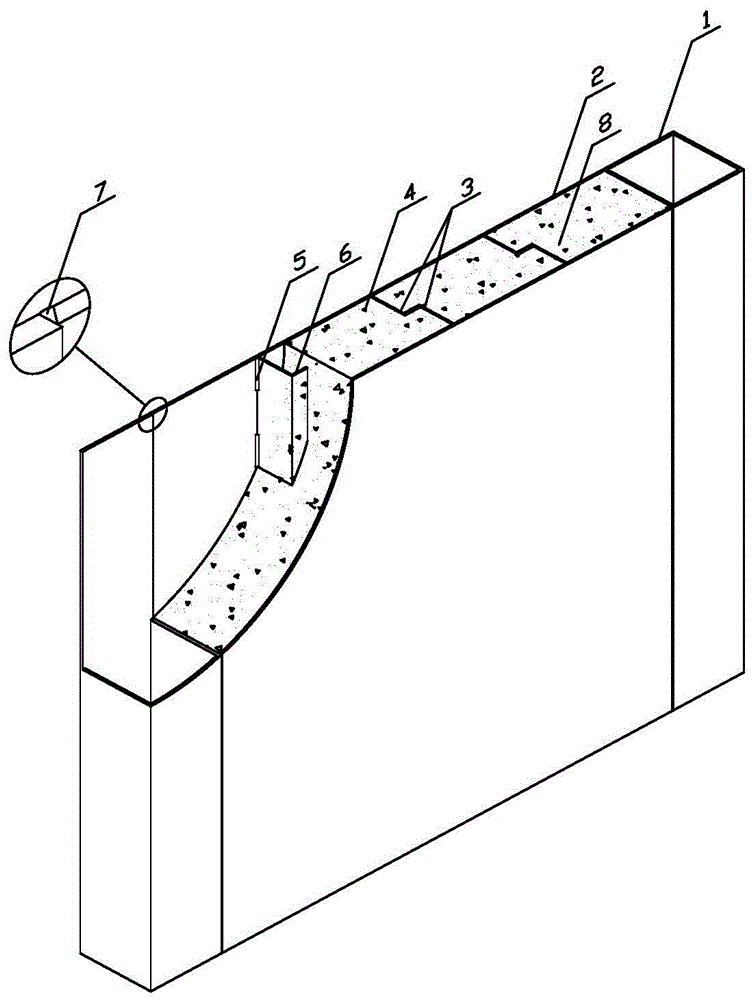

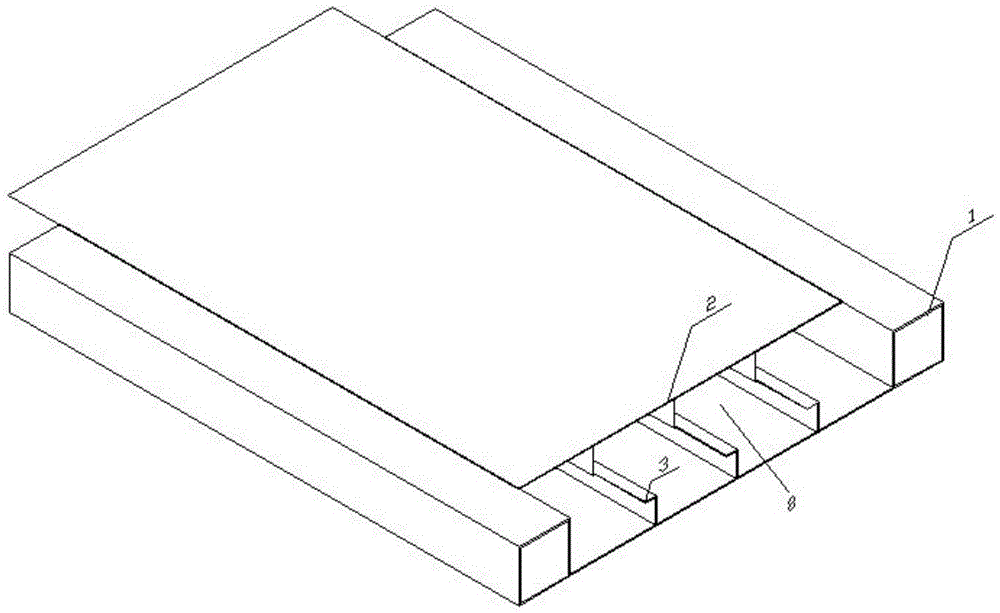

Pull-joint type double-steel-plate composite shear wall

The invention discloses a pull-joint type double-steel-plate composite shear wall, comprising steel pipe columns (steel pipe columns or concrete-filled steel tube columns) respectively arranged at the two ends, a pair of steel plates and at least one pull-joint type connecting piece. The pull-joint type connecting piece is firstly connected with the steel plates by staggered and intermittent one-side fillet welds in a welding way, and then a whole is assembled; the pull-joint type double-steel-plate composite shear wall has the advantages that the composite shear wall is simple in pull-joint structure, has a flat wall surface, and is less in welding workload, easy to operate and convenient to assemble; the stress performance of the composite shear wall is seldom affected by the welding quality since weld joints are positioned at construction parts; the composite shear wall is economical and safe; the steel plates and concrete are strong in cooperative work capability. A straight hook L shape, a sickle hook shape or hump hook shape can be adopted as the pull-joint way of the connecting piece, the pull-joint position can be positioned at the middle or side part of the thickness of the composite wall, and the pull-joint way is flexible and changeable, so that different engineering stress and use requirements are met. Riffled plates can be used as the wallboard steel plates and the pull-joint type connecting piece, so that the binding action between the wall steel plates and the concrete is effectively improved, and the co-working between steel components and the concrete is guaranteed.

Owner:HEFEI UNIV OF TECH +1

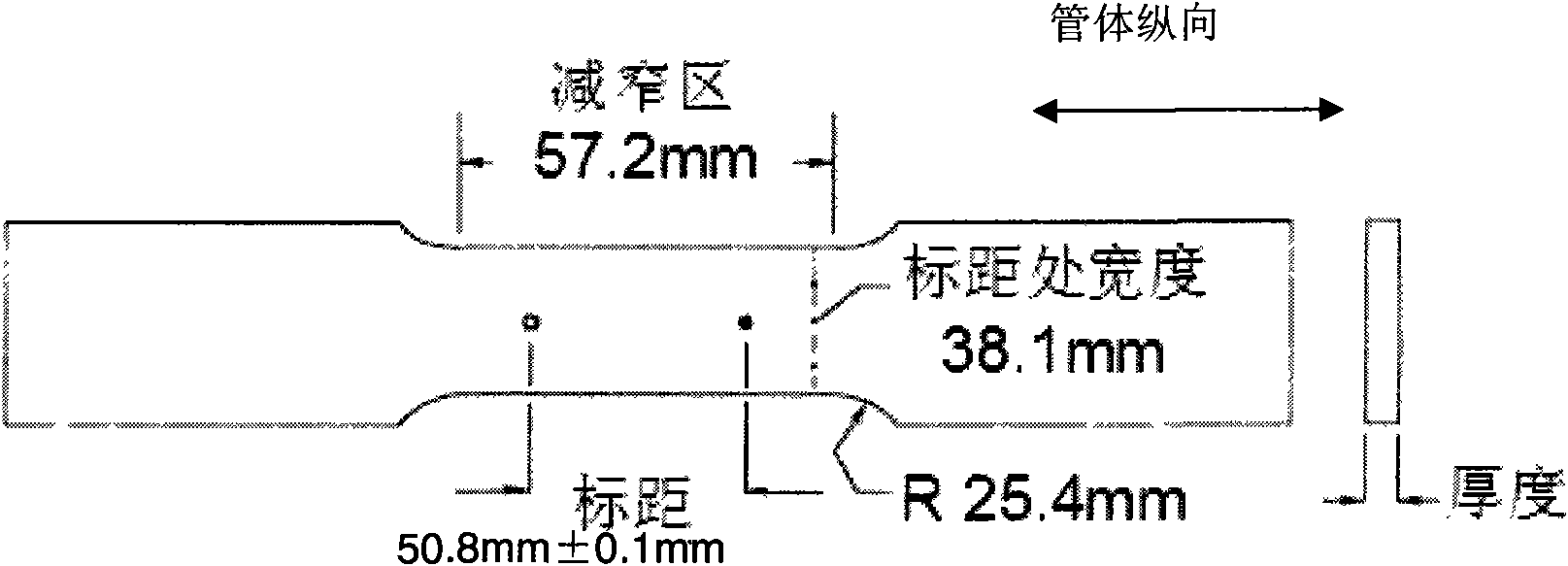

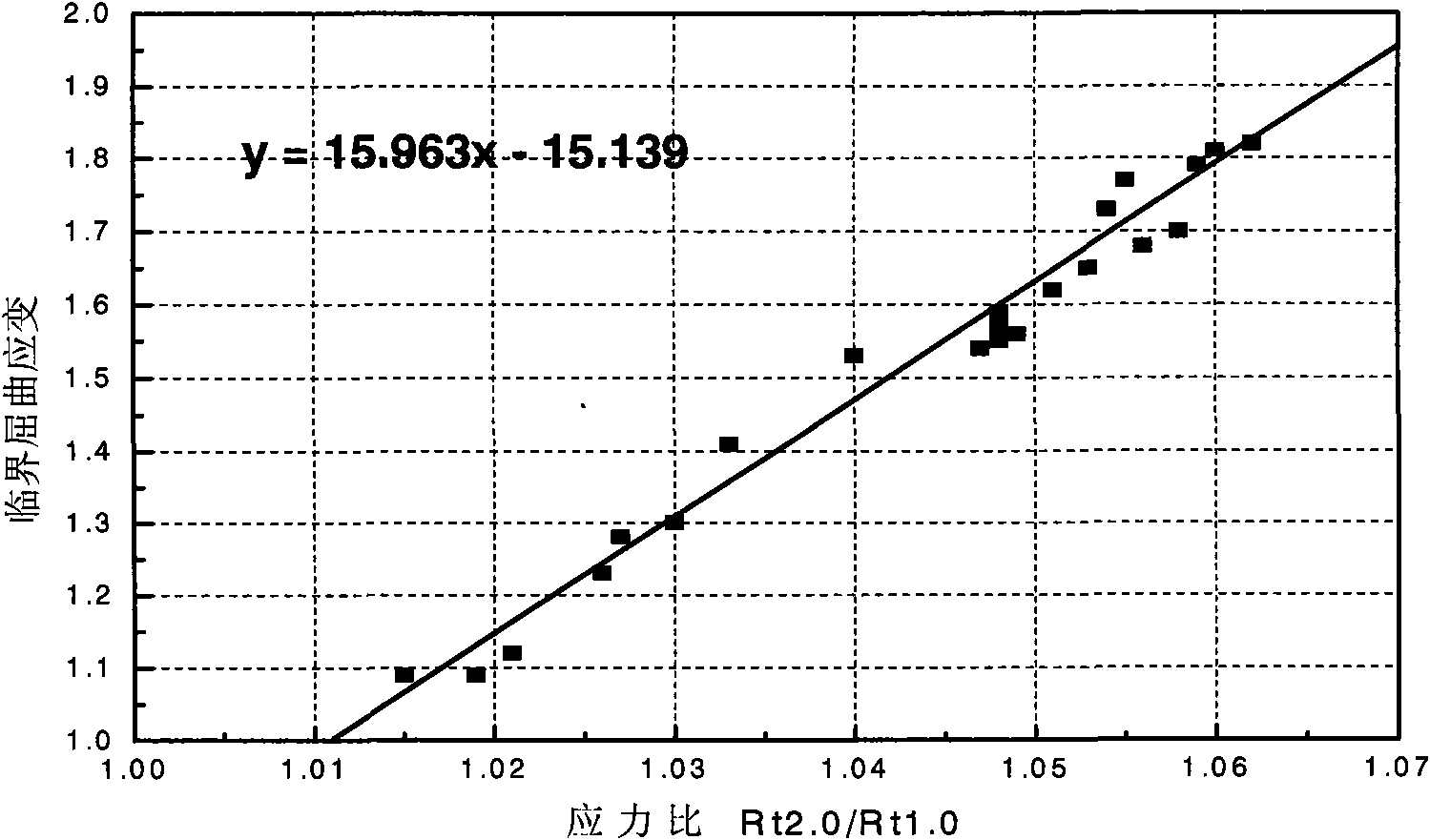

Method for rapidly determining buckling strain capability of steel tube

ActiveCN101923021AQuick determination of critical buckling strainMeet critical buckling strain level requirementsMachine part testingStrength propertiesLine tubingStress ratio

The invention provides a method for rapidly determining the buckling strain capability of a steel tube, belonging to the production control technical field of the high-deformability steel tube for a petroleum and gas pipeline. The method comprises the following steps: taking a longitudinal test piece from the tube, and then obtaining an engineering stress-engineering strain curve by a test; and calculating the critical buckling strain of the steel tube in a bending deformation mode according to a formula: epsiloncrit=15.963*Rt2.0 / Rt1.0-15.139, wherein, the critical buckling strain is average strain that a compression side of the test piece stretches towards two sides over a distance which is twice as long as the external diameter length of the steel tube with a buckled position as a center. The method can help rapidly determine the critical buckling strain of the steel tube in the bending deformation mode by controlling the tensile property of the pipeline steel tube, and can carry out performance control by a conventional production control test according to the stress ratio of the critical buckling strain level so as to produce the steel tube which can meet the requirement for the critical buckling strain level.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

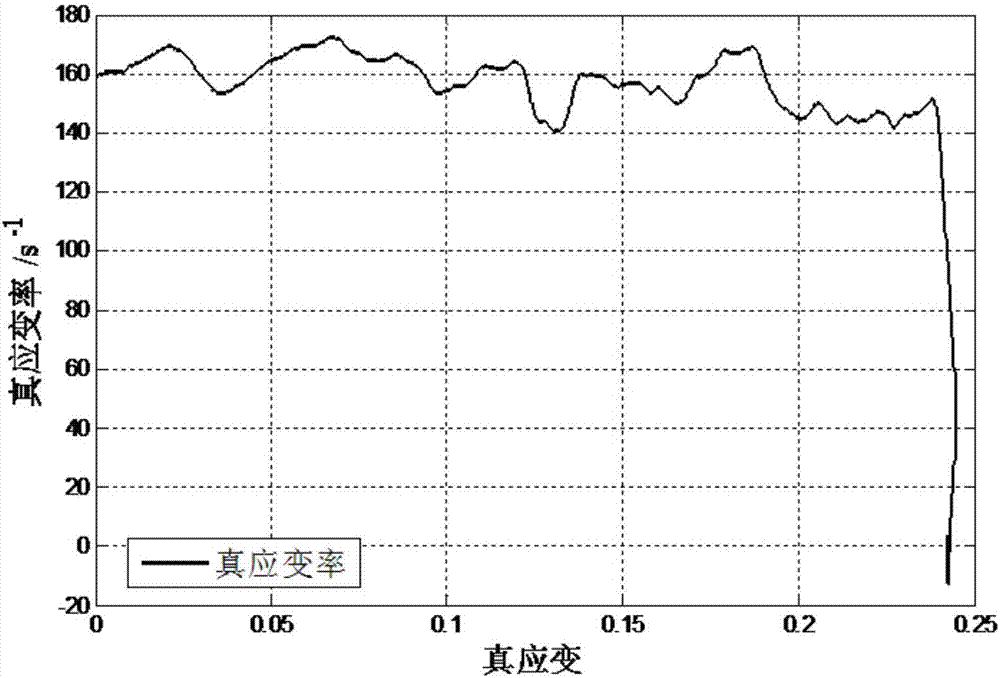

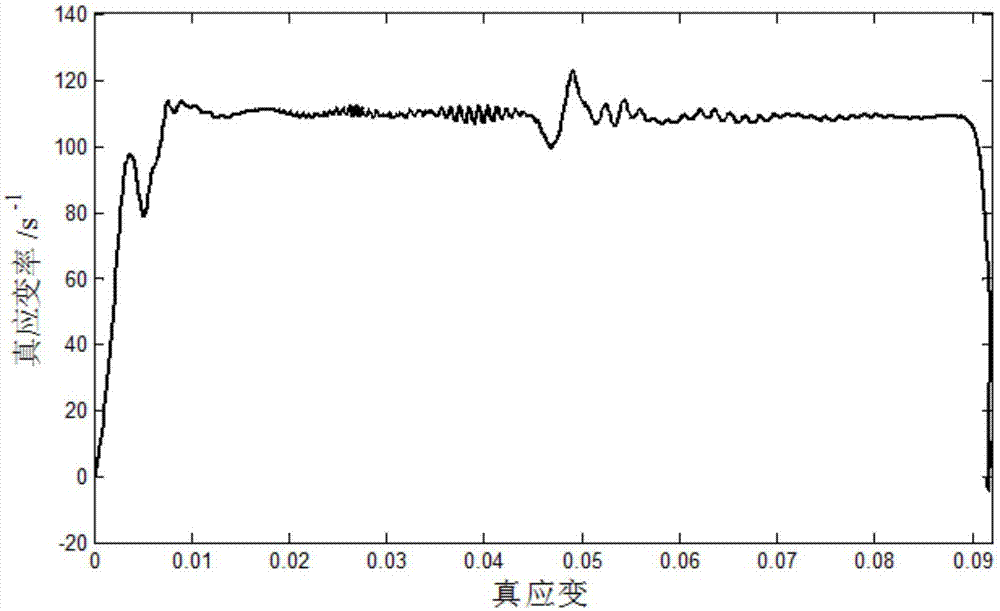

Large-deformation shock compression experimental method for materials

ActiveCN107389476ARealize secondary continuous loadingThe experimental strain rate remains stableMaterial strength using single impulsive forceExperimental methodsEngineering

The invention discloses a large-deformation shock compression experimental method for materials. The large-deformation shock compression experimental method is characterized in that the right end surface of a transmission bar is fixedly connected with a support block, and a piece to be tested is fixed on the left end surface of the transmission bar, and is in tight contact with the left end surface of the transmission bar; two strain gauges which are symmetrical along an axial center surface are fixed to the outer surface, close to the left end, of the transmission bar, an impact bar of which the material, the length and the diameter are all the same as those of the transmission bar is selected, and regulation is performed, so that the impact bar, the piece to be tested, and the transmission bar are coaxial; and then, the impact bar is emitted, the two strain gauges fixed to the transmission bar are used for testing strain signals of the transmission bar, the tested strain signals of the transmission bar are substituted to a relational expression, and treatment is performed, so that a time interval curve about the axial engineering stress, engineering strain and engineering strain rates, of the tested piece during an experiment is obtained. The large-deformation shock compression experimental method has the advantages that a continuous stable experiment strain rate is realized, and under the condition of the biggest strain same as a conventional Hopkinson pressure bar experiment, the strain rate can achieve the 10 S<-1> order.

Owner:NINGBO UNIV

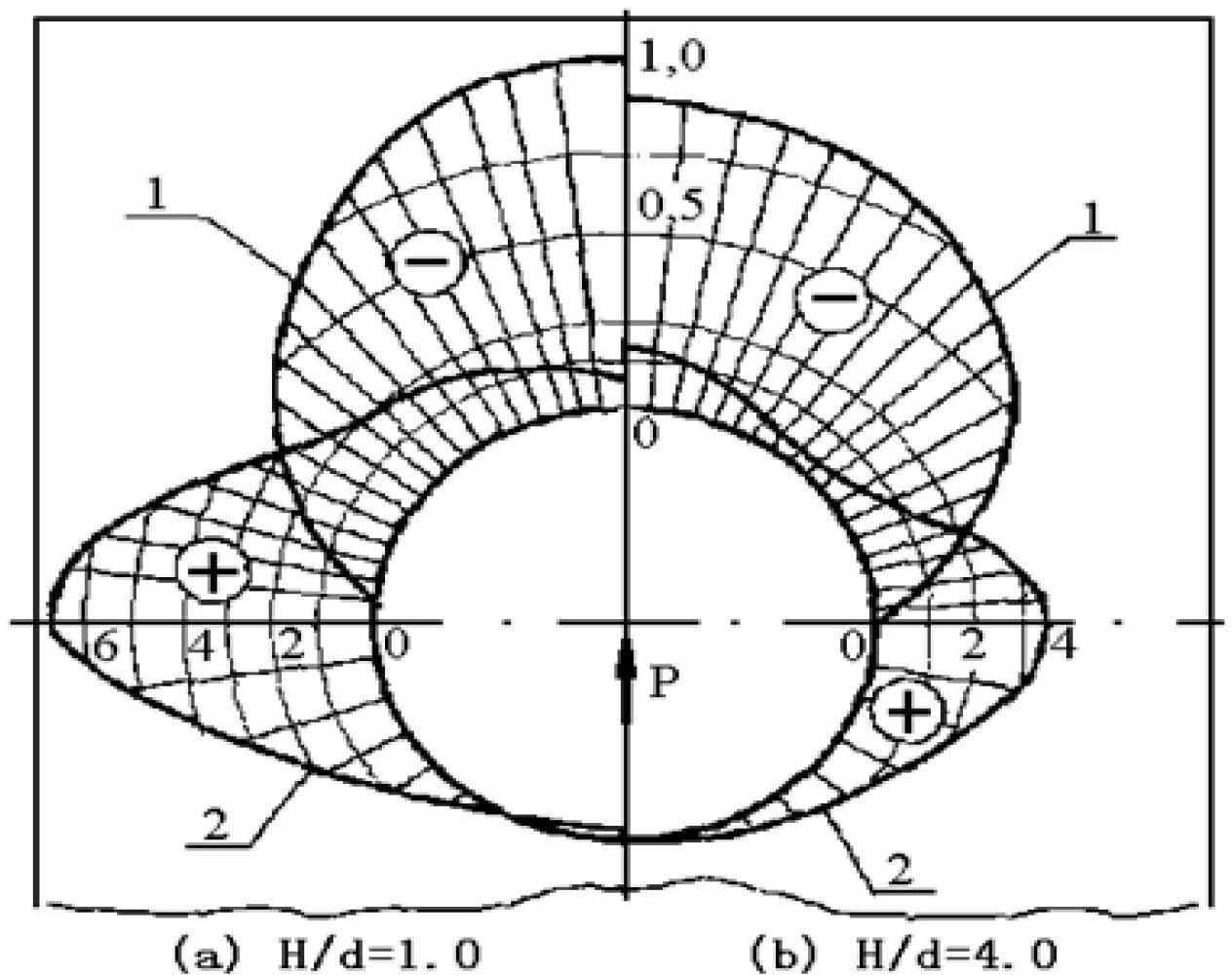

Geosynthetics anisotropism drawing test system and method

ActiveCN104833575AAvoid randomnessRealize the anisotropy test of the mechanical properties of the pull-out testMaterial strength using tensile/compressive forcesEngineeringGeosynthetics

Owner:山西省交通科技研发有限公司

Method for processing material performance of composite material at wet fitting joint

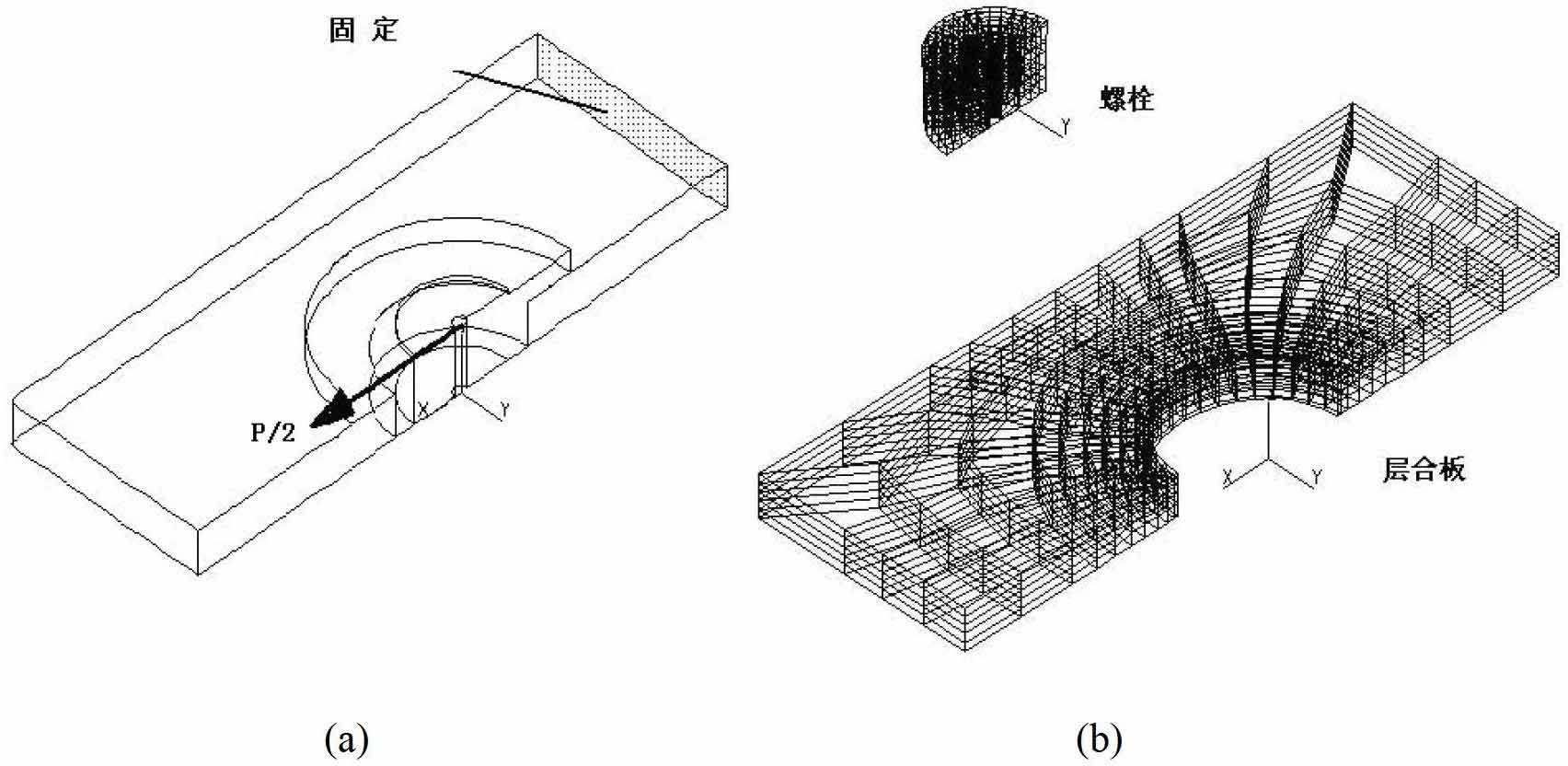

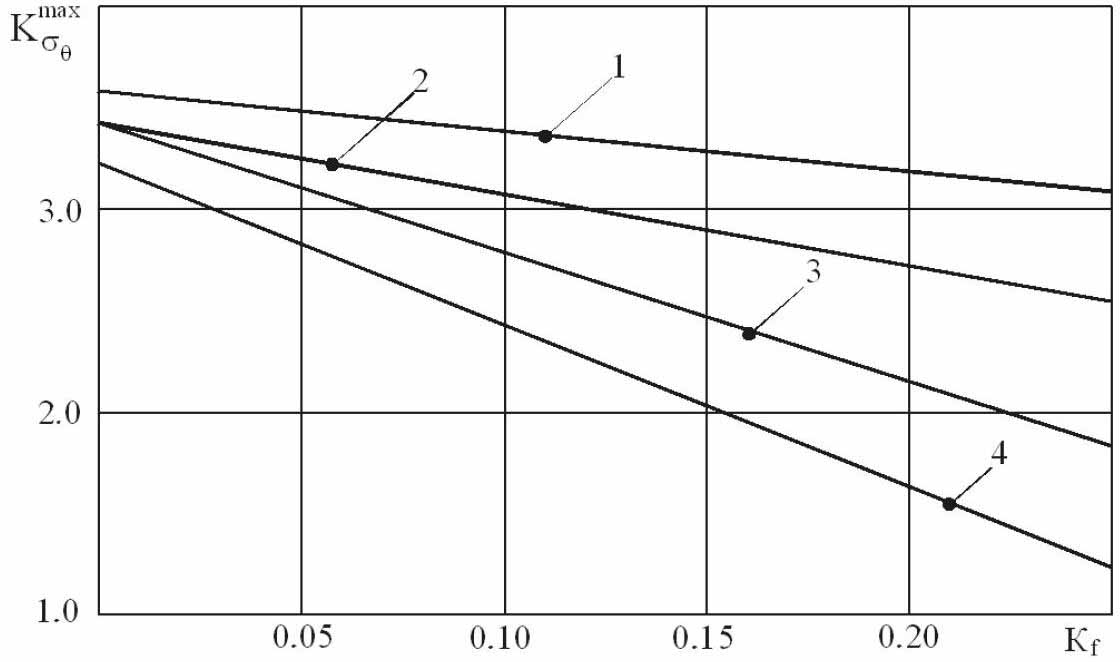

ActiveCN102682170ASolve the problem of insufficient analytical meansHigh engineering application valueSpecial data processing applicationsStress concentrationRadial stress

The invention belongs to a composite material technology, and relates to a method for processing the material performance of a composite material at a wet fitting joint in a mechanical connecting wet assembly process for a composite material structure. The influence of adhesive layer hardness and tightening torque in the mechanical connecting wet assembly process for the composite material structure is analyzed, a material laminate model, an adhesive layer model and a bolt model are analyzed respectively, toroidal and radial stress curves of a hole edge of a composite material laminate are drawn, and a method for analyzing the stress of the composite material hole edge and an engineering stress treatment method are provided, so that the problem of deficiency of analysis means for the influence of the adhesive layer hardness and the tightening torque on the stress concentration of the composite material hole edge in the wet assembly process is solved; and a composite material hole edge stress extraction and treatment method is provided, is helpful for the direct judgment of engineering technical personnel in the stress concentration of the hole edge, and has high engineering application value.

Owner:XIAN AIRCRAFT DESIGN INST OF AVIATION IND OF CHINA

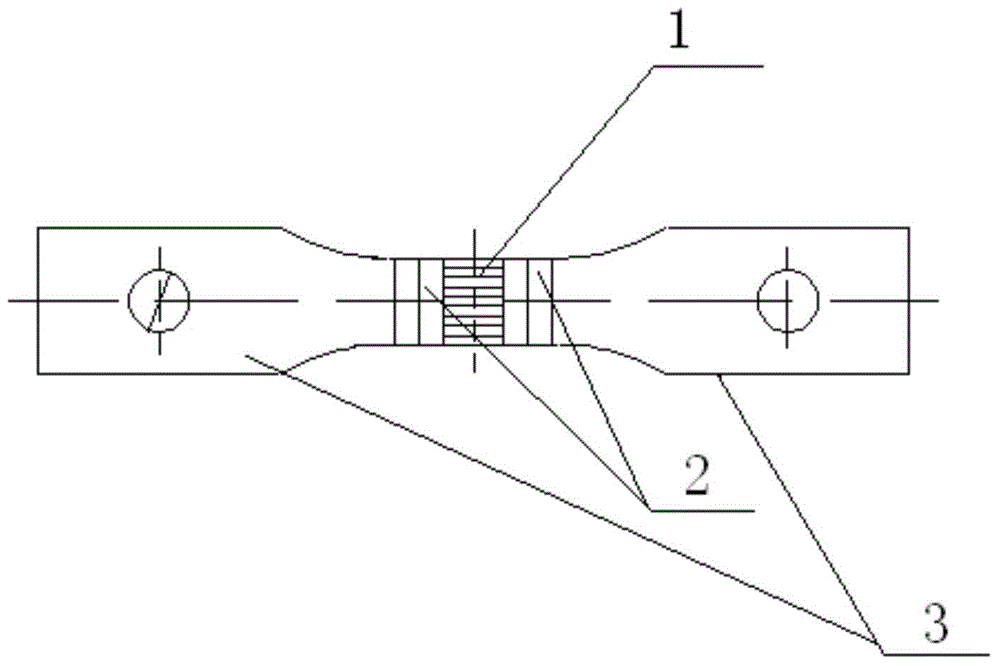

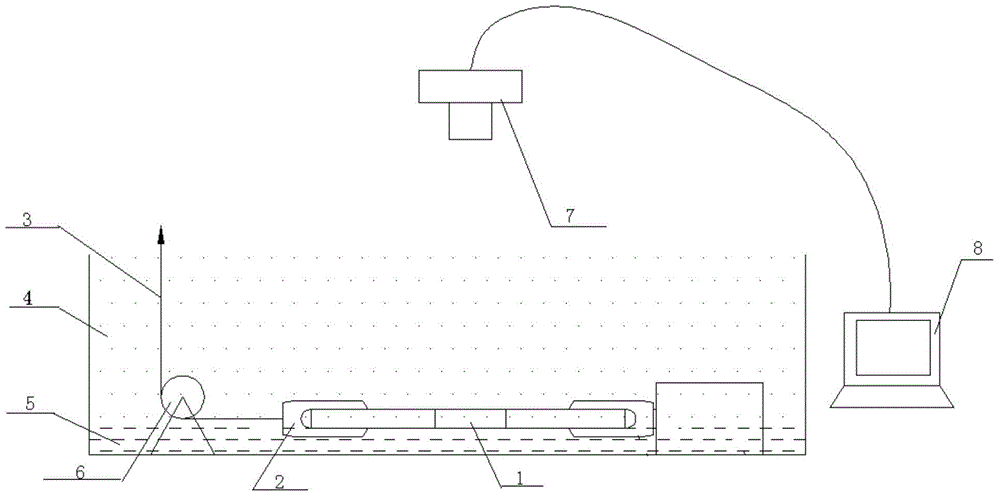

Metal welding test piece low temperature mechanical property optical test method

ActiveCN105628510AAvoid frostImprove accuracyMaterial strength using tensile/compressive forcesHeat-affected zoneData acquisition

The invention belongs to the technical field of structure low temperature mechanical property test analysis and relates to a metal welding test piece low temperature mechanical property optical test method. The optical test method comprises preparing a welding test piece, dividing the welding test piece into a welding zone, a heat influence zone and a base material zone, putting the welding test piece in a low temperature environment, installing a digital camera above the welding test piece at an interval, connecting the digital camera to a data acquisition system through a data line, calculating strain values through speckle images of the welding test piece before and after loading, and calculating engineering stress, test stress, strength limits and elongation of the whole welding test piece and all zones of the welding test piece so that mechanical property parameters of the welding test piece are obtained. The method is suitable for testing mechanical properties of an aluminum alloy, other metals and structures welded through different welding methods in a low temperature environment. The welding test piece is divided into different zones so that the technical problem that the existing optical test method cannot detect mechanical properties in a low temperature environment.

Owner:BEIJING INST OF STRUCTURE & ENVIRONMENT ENG +1

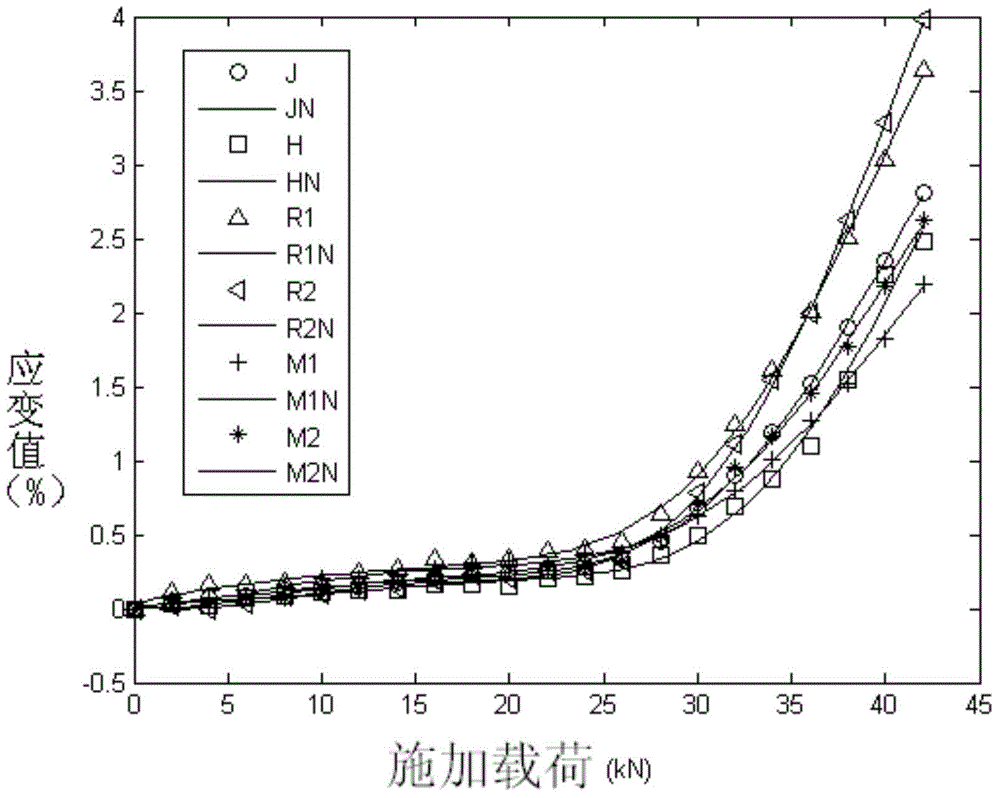

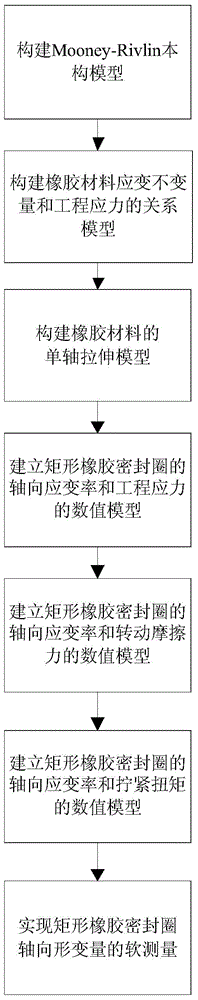

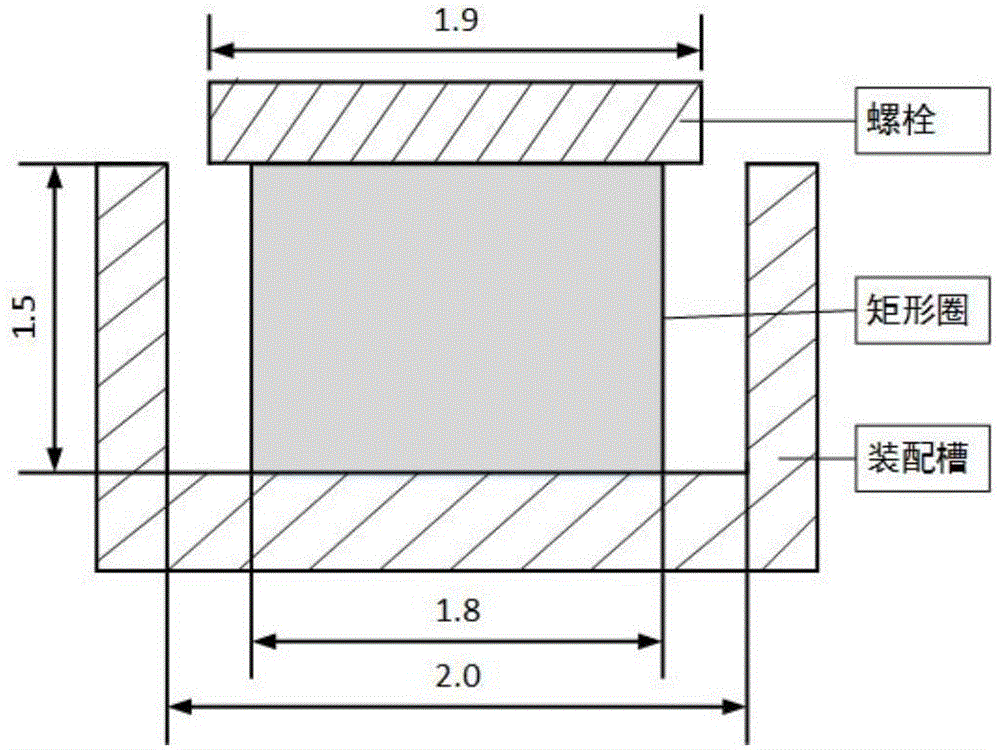

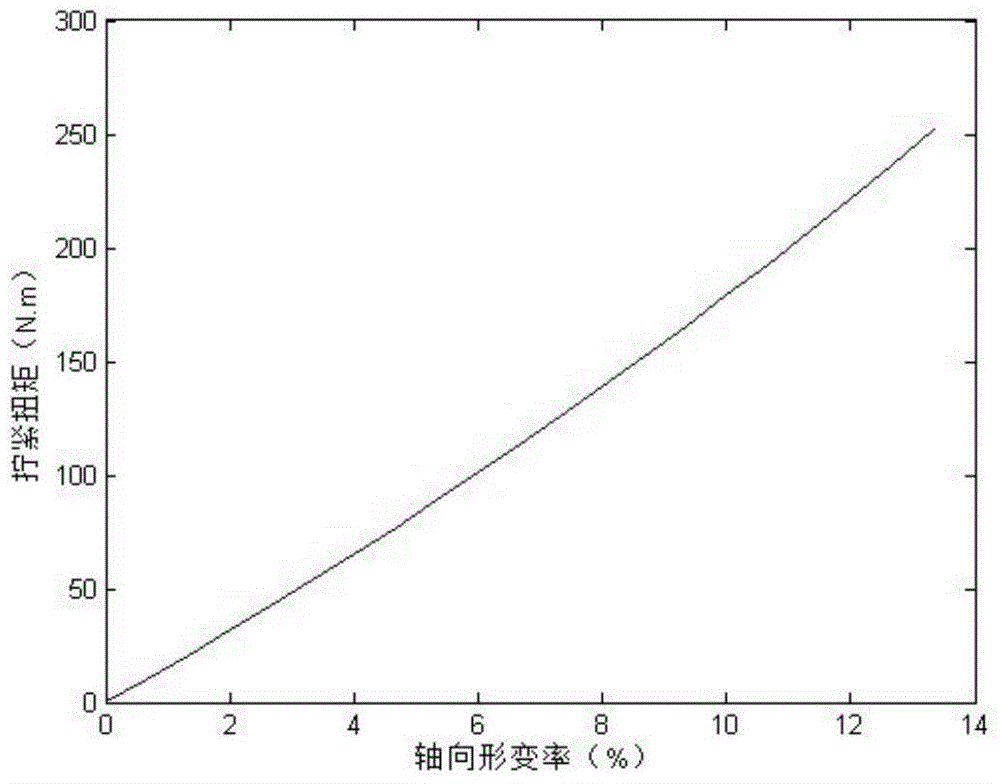

Soft measuring method of axial deformation quantity of rectangular rubber sealing ring based on flexible screwing assembly

The invention relates to a soft measuring method of axial deformation quantity of a rectangular rubber sealing ring based on flexible screwing assembly. The method comprises the following steps that (1) a Mooney-Rivlin constitutive relation model of rubber materials is built; (2) a rubber material strain invariant and engineering stress relation model is built according to the constitutive relation; (3) a single-axis stretching model of rubber materials is built, and the strain invariant expressed by the axial decoration rate is worked out; (4) the strain invariant expressed by the axial decoration rate is substituted into the strain invariant and engineering stress relation model to obtain an axial engineering stress strain relation model; (5) a penalty function is adopted to convert the axial strain rate of the rectangular rubber ring and an engineering stress value model into a rectangular rubber ring axial strain rate and engineering rotation friction value model; (6) the rectangular rubber ring axial strain rate and engineering rotation friction value model is converted into a rectangular rubber ring axial strain rate and screwing torque value model. The method has the advantages that the soft detection of the rectangular rubber sealing ring axial deformation quantity in the flexible screwing assembly is realized.

Owner:CHONGQING UNIV

Method for predicting fatigue strength of metal material by hardening strength and tensile strength

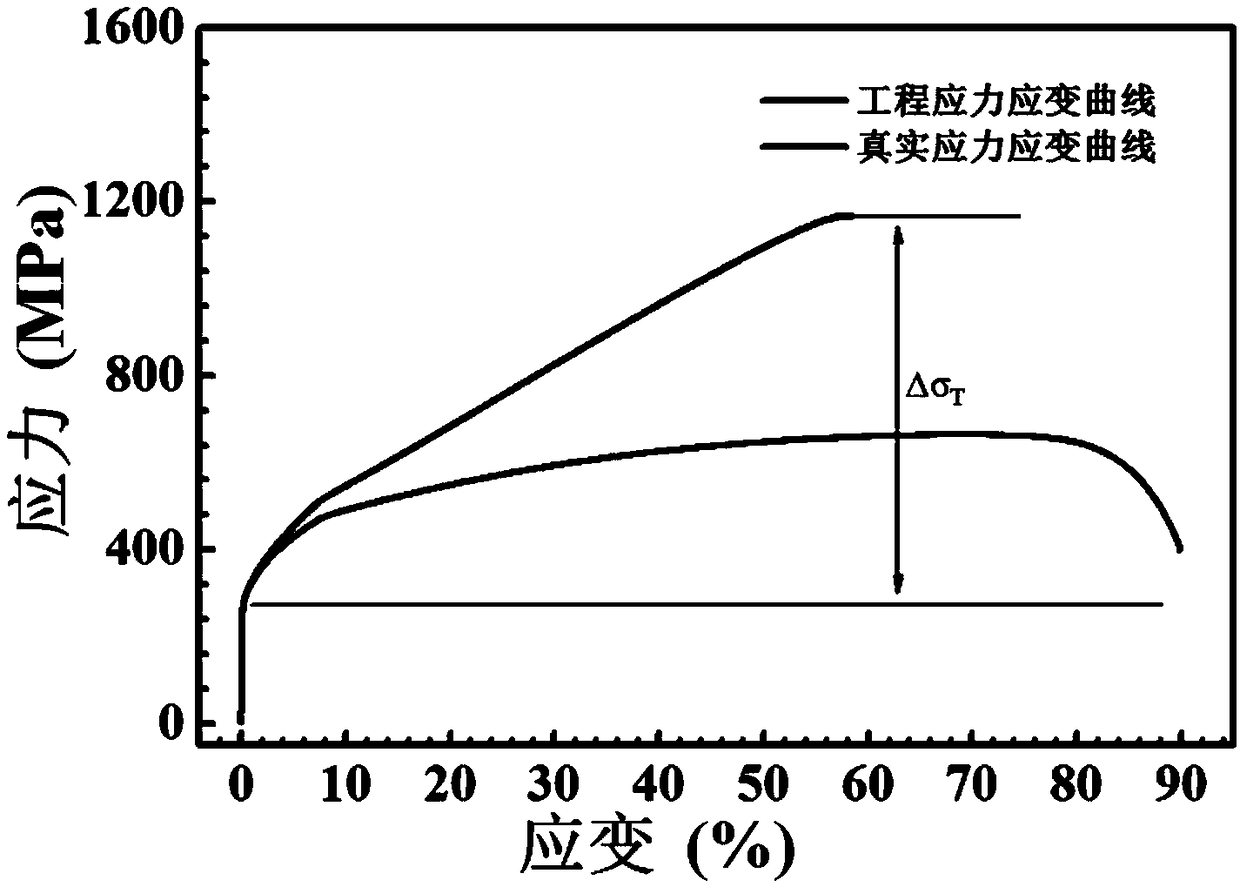

ActiveCN108645706AEffect of fatigue strength, clear physical meaningUniversalMaterial strength using tensile/compressive forcesStress–strain curveMetallic materials

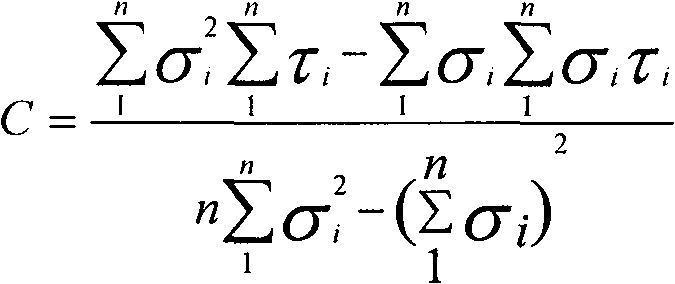

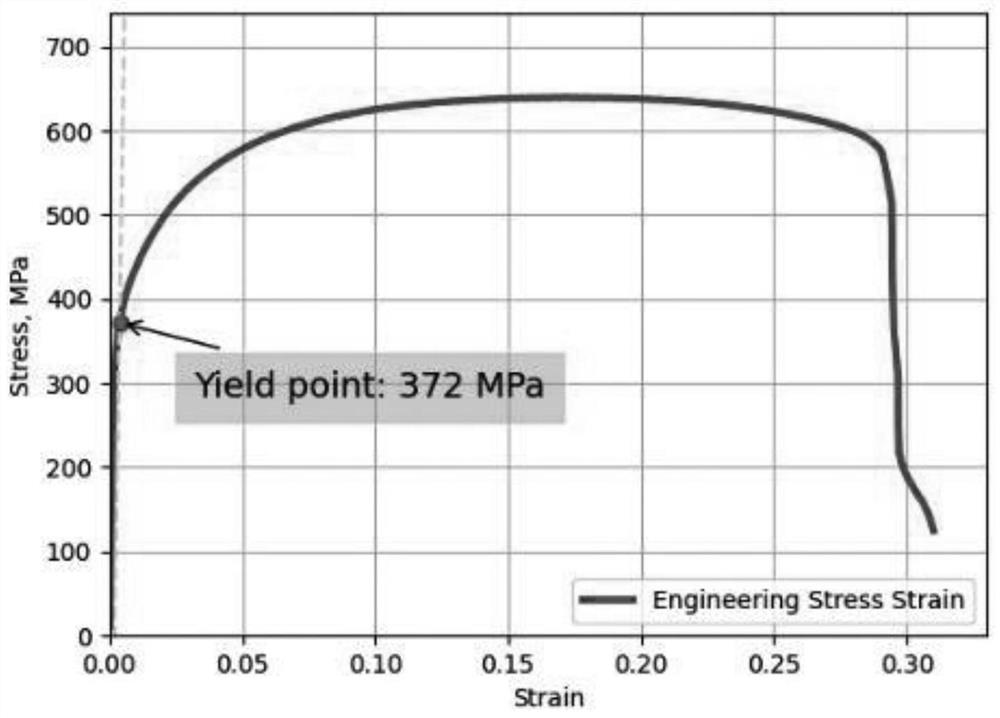

The invention discloses a method for predicting fatigue strength of a metal material by hardening strength and tensile strength, and belongs to the technical field of material science and engineeringapplication. Firstly, a true stress-strain curve is calculated according to an engineering stress-strain curve, work hardening ability parameter, namely the hardening strength can be obtained, and thehardening strength and the tensile strength are combined and fitted by two-parameter least square method to establish the relationship between the fatigue strength and the hardening strength and thetensile strength. The method effectively reduces the experimental amount required for fatigue strength prediction, greatly saves time, money and labor costs, has high accuracy, and can be widely applied to various metal materials with strong work hardening ability.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Direct-shear measuring method of drilling rock mass specimen preparation

ActiveCN101949288ASimple methodEasy to operateBorehole/well accessoriesCore removalRock coreTest sample

The invention relates to a direct-shear measuring method of drilling rock mass specimen preparation, which can solve the problems of high test expenses, long test period and low efficiency effectively and particularly can overcome the defect that specimen preparation is dependent on stonecutters. The method comprises the following steps of: excavating a test adit in a mountain by adopting a bursting method first, and drilling two holes upwards on a test adit bottom board by using a drilling machine, wherein one hole is a shear hole, the other hole is a specimen hole, the centers of the two holes are in the same straight line, the direction of the straight line is consistent with that of engineering stress, and the specimen hole is a test sample drill hole; reserving a rock core in the holes, taking the rock core from the shear hole for arranging a shearing test equipment, and cutting the rock mass on the middle part of the two holes for communicating; determining the drilling depth according to the position of a shear surface, and after completing a drilling workpiece, arranging a steel protective sleeve on a specimen; and arranging normal and shearing loading equipment respectively after the work is finished. The direct-shear measuring method has the advantages of simplicity, convenient operation, low cost, labor and time saving and high efficiency, and is the innovation of the direct-shear test of the site rock mass strength.

Owner:YELLOW RIVER ENG CONSULTING +1

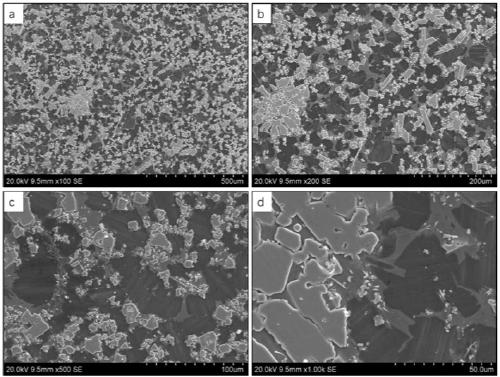

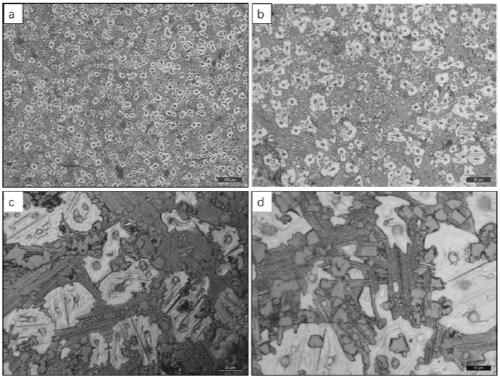

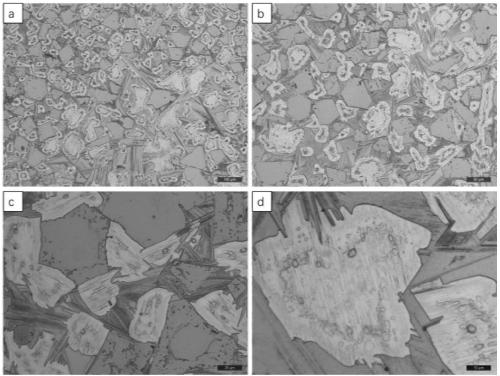

Magnesium-based high-entropy alloy with high toughness and high hardness and preparation method

The invention belongs to the technical field of alloys and discloses a magnesium-based high-entropy alloy with high toughness and high hardness and a preparation method. By taking Mg as a base, and selecting main elements Al, Gd, Y and Zn beneficial to reinforcement and hardness improvement of a magnesium alloy, the magnesium-based high-entropy alloy with high toughness and high hardness and the preparation method are developed. The magnesium-based high-entropy alloy has an engineering stress-strain curve with a remarkable processing hardening characteristic, has microhardness of HV103.3-123.7, room-temperature tension strength of 458.01-496.65MP, and a compression ratio after breakage of 14.83-17.28%, and in addition, the magnesium-based high-entropy alloy disclosed by the invention is simple in preparation method and easy in condition control.

Owner:NORTHEASTERN UNIV

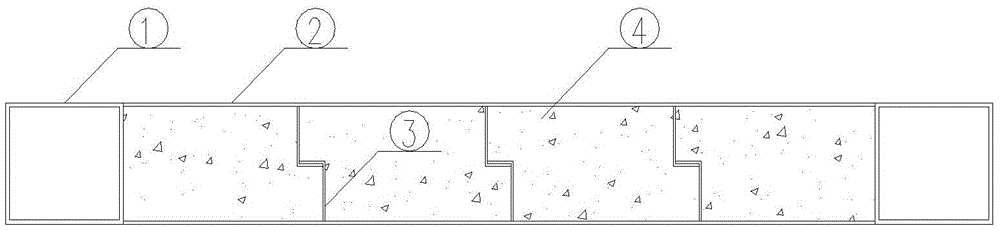

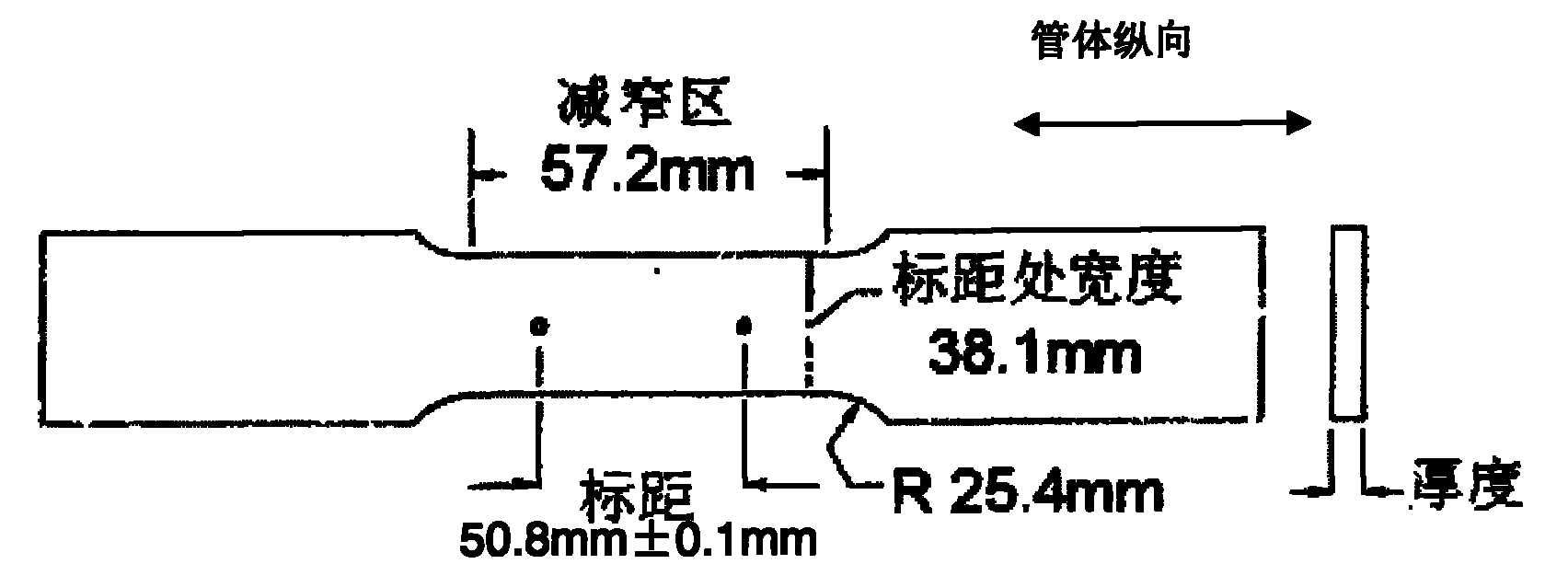

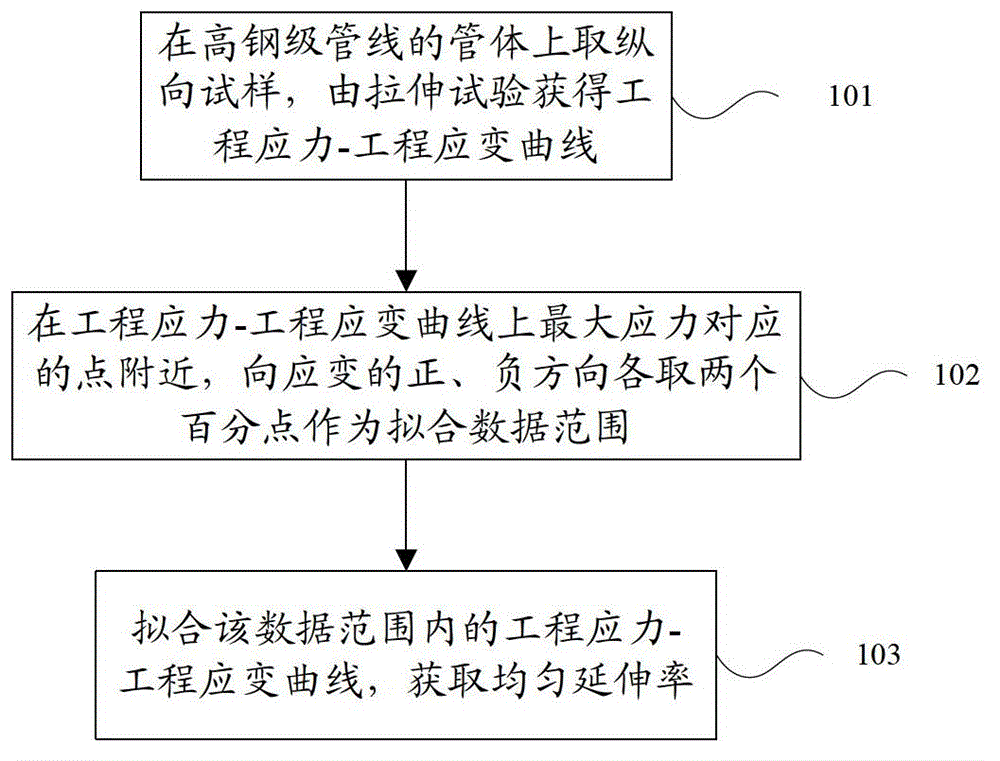

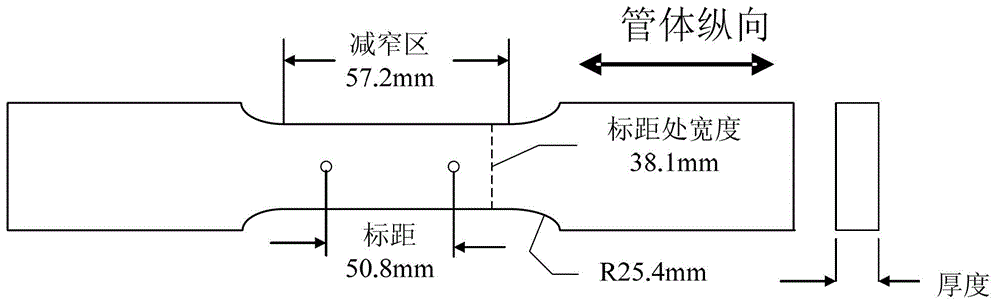

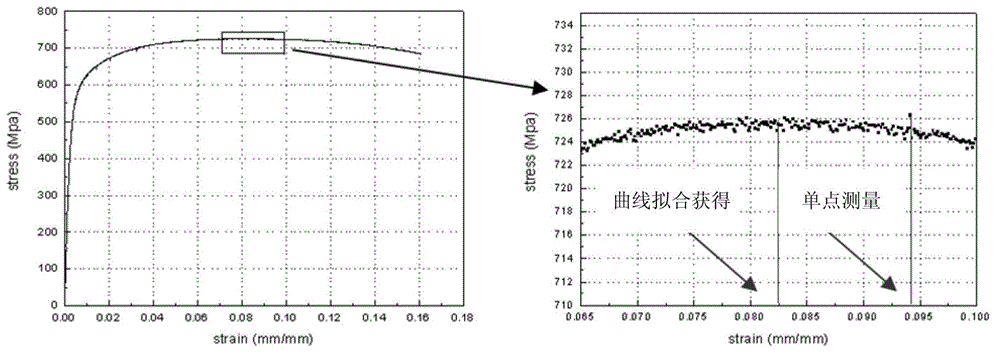

Method and device for determining uniform ductility of hi-grade steel pipeline steel pipe

ActiveCN103335899AUniform elongation valueAvoid misjudgmentInvestigating material ductilityLine tubingTensile testing

The invention discloses a method for determining uniform ductility of a hi-grade steel pipeline steel pipe, and relates to the technology of pipeline steel materials. The method comprises the following steps of: picking a tensile sample on a pipe body of a hi-grade pipeline, and obtaining an engineering stress-engineering stress curve through a tensile test; taking two percent points toward the stress positive and negative directions near points corresponding the biggest press on the engineering stress-engineering stress curve to fit a data range; and fitting the engineering stress-engineering stress curve in the data range, and obtaining the uniform ductility. The invention also discloses a device for determining the uniform ductility of the hi-grade steel pipeline steel pipe. The method for determining the uniform ductility of the hi-grade steel pipeline steel pipe has the advantages that the engineering stress-engineering stress curve of the tensile test is fitted, the mathematical expression of the curve is obtained, the real uniformity ductility numerical value of the material is determined on the foundation, the deformation performance of the steel pipe is objectively judged, and an erroneous judgment is avoided.

Owner:BC P INC CHINA NAT PETROLEUM CORP +1

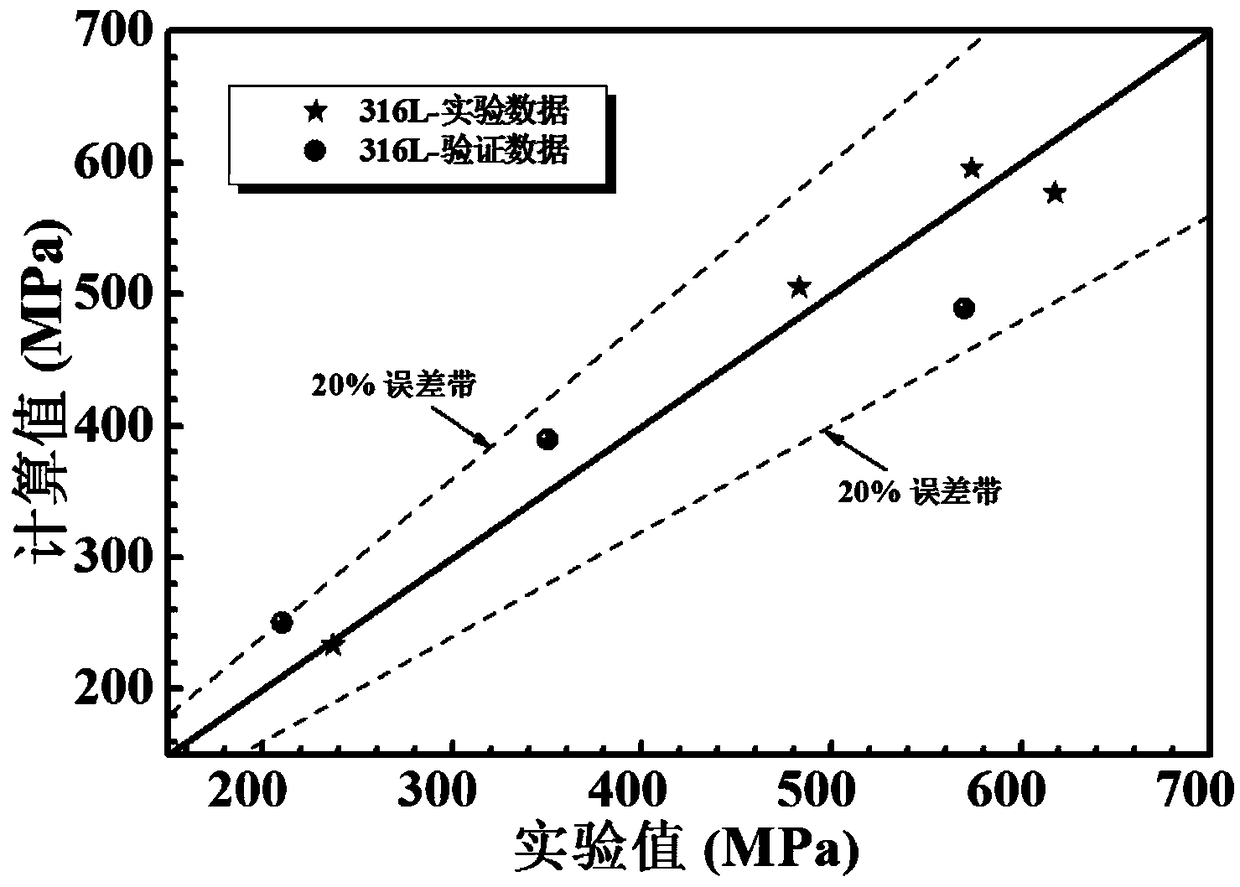

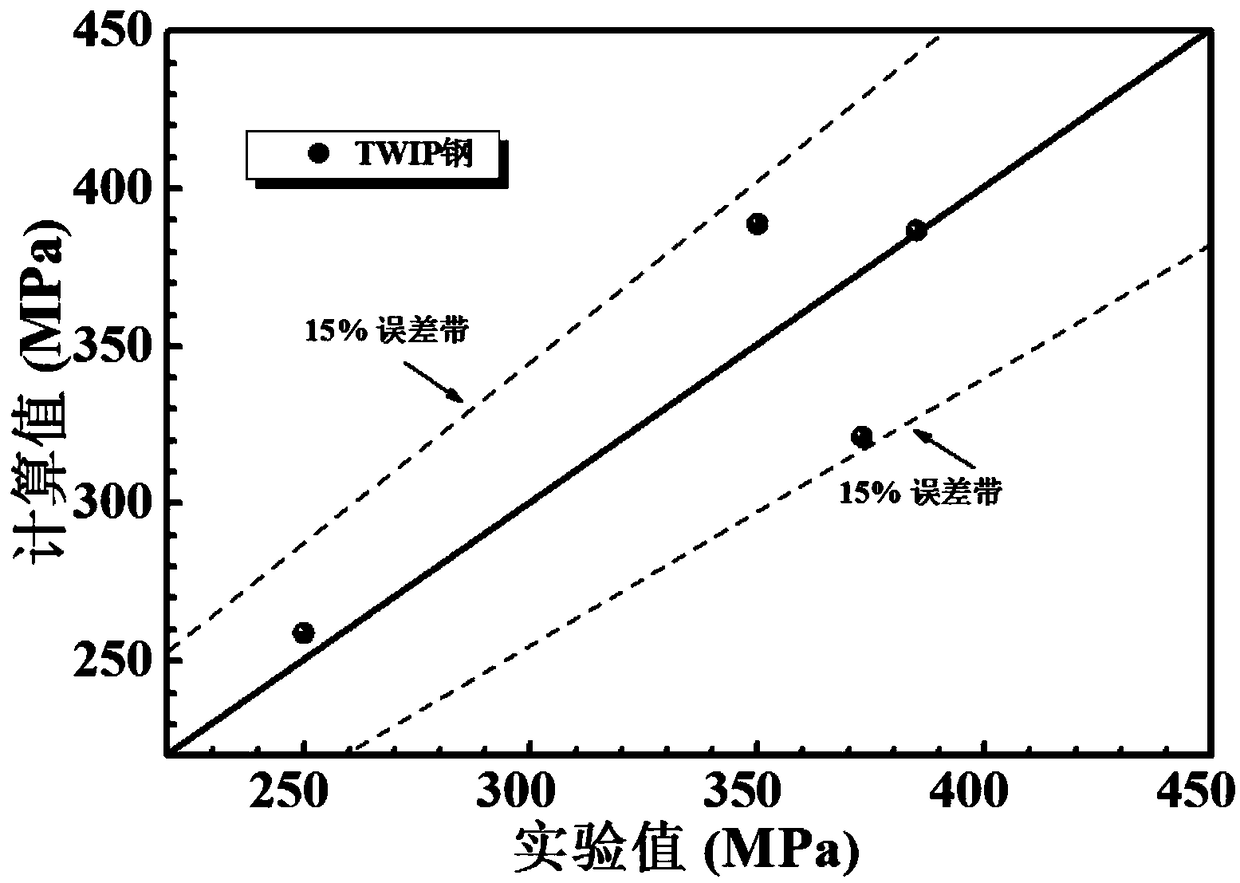

Method for obtaining high-precision hardening model parameters of material in complex stress state

ActiveCN113420391AHigh precisionSolve the problem that the characterization of material properties under different stress states cannot be considered at the same timeGeometric CADMaterial strength using tensile/compressive forcesEngineeringNumerical models

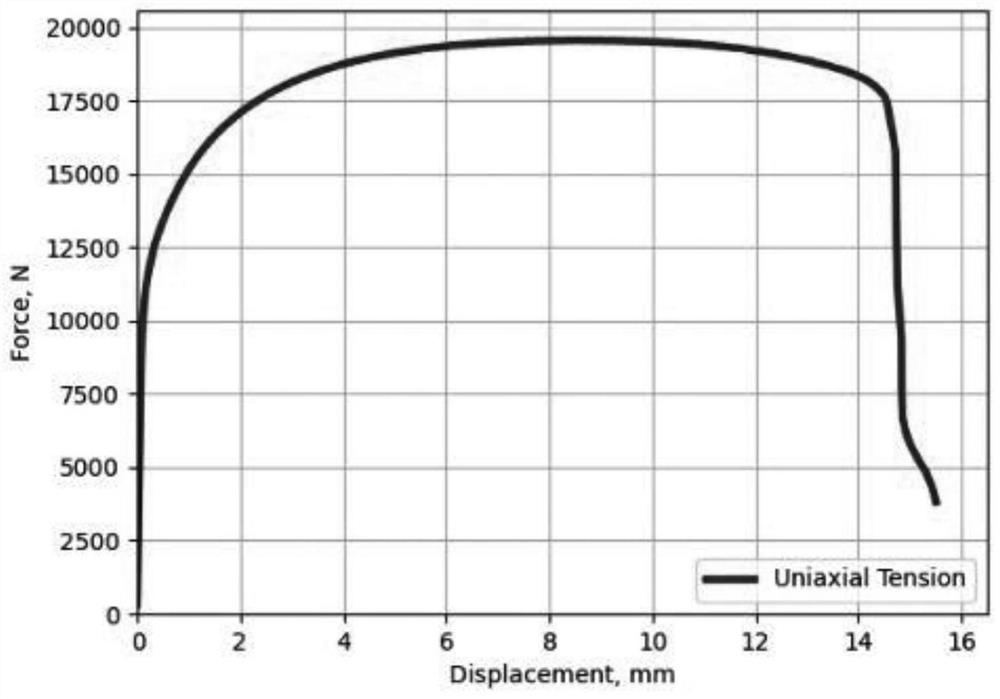

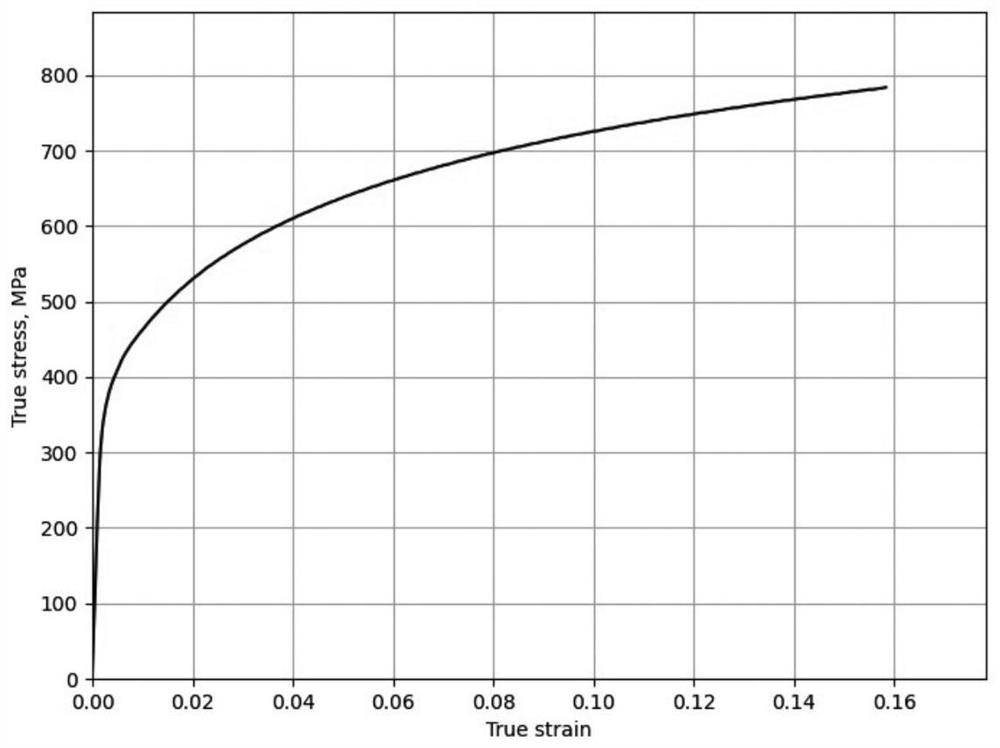

The invention discloses a method for obtaining high-precision hardening model parameters of a material in a complex stress state. The method comprises the following steps: S1, obtaining a force-displacement curve of the material in a uniaxial tensile stress state; S2, calculating an engineering stress-engineering strain curve; S3, calculating a true stress and true strain curve; S4, calculating an effective stress-strain curve; S5, performing fitting epitaxy on the effective stress-strain curve to obtain an epitaxial stress-strain curve; S6, adjusting the line shape of the fitting curve; S7, establishing numerical models for the material samples in different stress states, and comparing force-displacement curves in test and simulation results; and S8, returning to the step S6, and optimizing the weighting coefficient until the benchmarking result in the step S7 meets the requirement. According to the method, material samples in different stress states are subjected to simultaneous benchmarking and optimization iteration to obtain high-precision hardening model parameters, the problem that material performance characterization in different stress states cannot be considered at the same time in the existing hardening model parameter establishing process is solved, and the defects existing in an existing method are overcome.

Owner:北京理工大学重庆创新中心

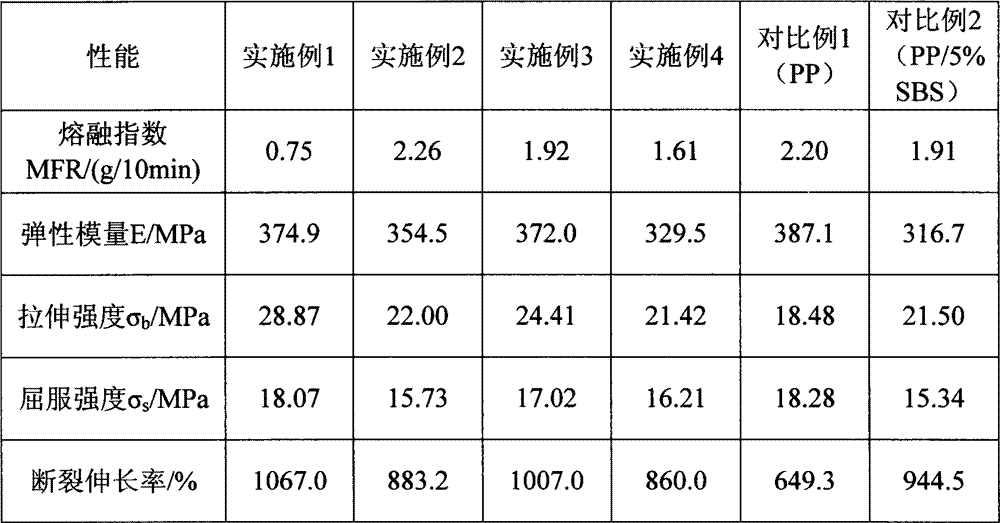

Method for preparing styrene/isoprene in-situ toughened polypropylene

The invention discloses a method for preparing styrene / isoprene in-situ toughened polypropylene, and relates to a method for preparing styrene / isoprene in-situ toughened polypropylene by reactive extrusion. According to the method, raw materials comprise polypropylene, styrene, isoprene and a peroxide initiator. The method is characterized by comprising the following steps of: adding the polypropylene from a main charging hole of a first section of an extruder; injecting styrene, isoprene monomers and the peroxide initiator into a third section of the extruder by a metering pump; and performing melt grafting at the reaction temperature of between 170 and 230 DEG C to obtain the in-situ toughened polypropylene material with high melt strength, wherein the toughness of the polypropylene can be improved obviously under the condition of the low using quantity of the monomers, the breakage elongation can be increased to 65 percent, and tensile strength of the polypropylene is equal to and even higher than that of pure polypropylene; and by the method, a toughening effect of a blending system of the polypropylene and 5 percent of butadiene-styrene-butadiene (SBS) can be achieved. According to the method, a process is simple, easy to control, low in cost and environment-friendly, and the product can be used for foaming and can be used as engineering stressed materials to be applied to the field of automobile industry.

Owner:EAST CHINA UNIV OF SCI & TECH

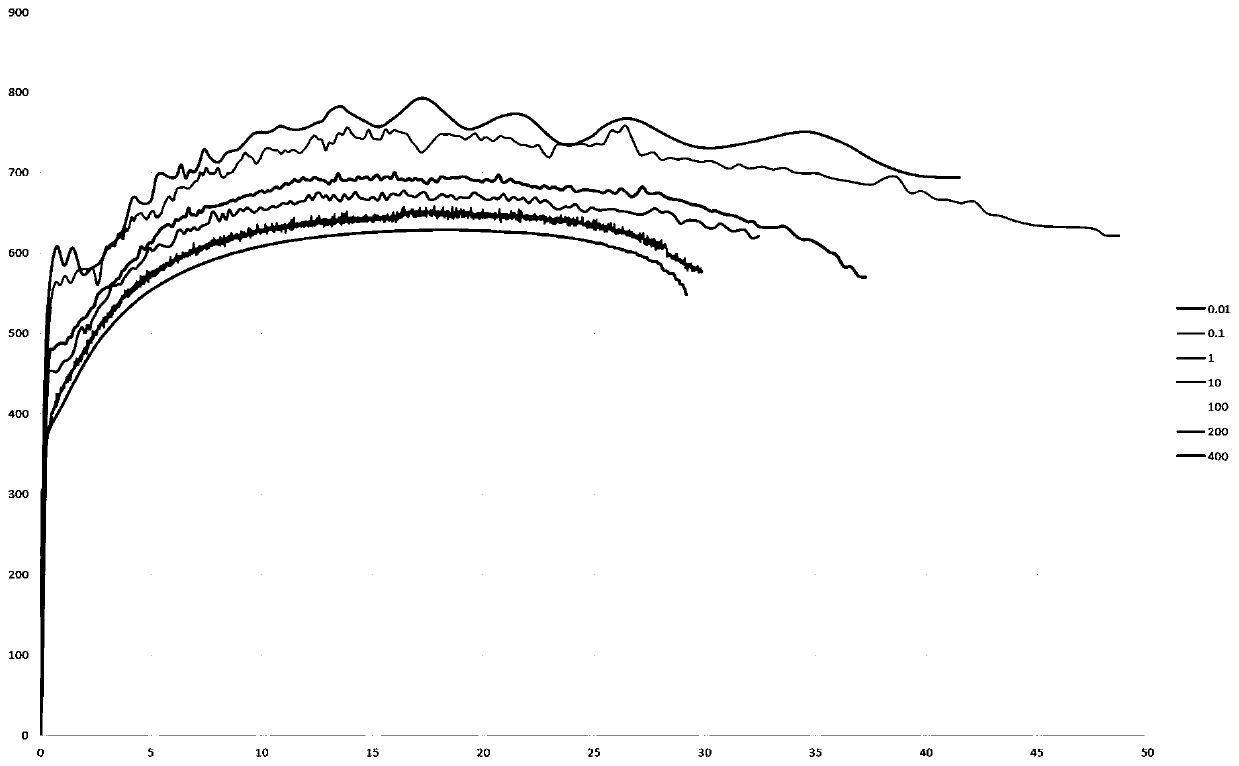

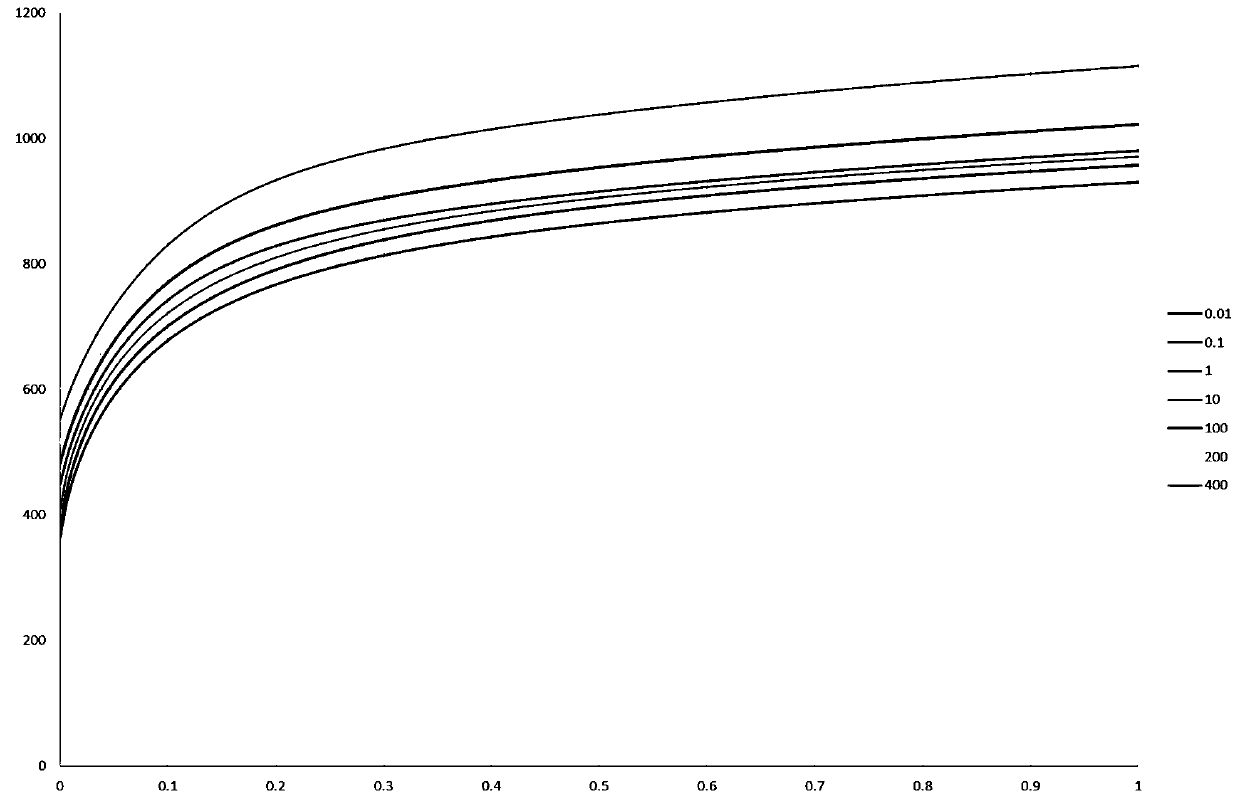

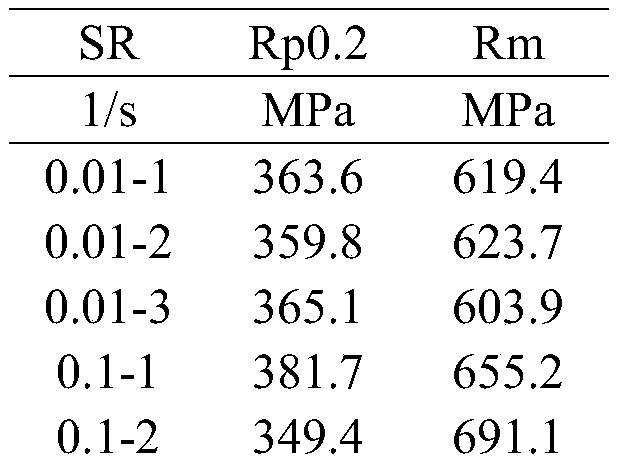

Variable-rate stretching curve evaluation method

ActiveCN111272552AAccurate evaluationNon-overlappingMaterial strength using tensile/compressive forcesClassical mechanicsEngineering

The invention relates to a variable-rate tensile curve evaluation method, which combines a metal dynamic deformation theory with a rheological law, correlates strain rates with yield strength and tensile strength of a material, and evaluates a variable-rate engineering stress-strain curve by actually measuring the yield strength and the tensile strength of each sample at each strain rate by taking0.2%-1% as a standard. Compared with the prior art, the variable-rate tensile curve evaluation method has the beneficial effects that the variable-rate tensile curve evaluation method overcomes the defects that an existing method is large in random error and the like, a reasonable variable-rate engineering stress-strain curve range can be accurately evaluated, processed effective stress-strain curves are not overlapped, and the CAE collision simulation requirement is met.

Owner:ANGANG STEEL CO LTD

A Calculation Method for Residual Strength and Remaining Life of Pipes in Pipe Gallery

ActiveCN104807966BGuaranteed safe operationSimple and fast operationMaterial analysisNormal densityResidual strength

The invention discloses a residual intensity and residual life computing method for pipe gallery pipelines. The residual intensity and residual life computing method comprises the following steps: collecting the data information of defects of the pipe gallery pipelines; judging the defects are plane type defects or volume type defects; for the plane type defects, obtaining the engineering stress-strain curve of a defect pipeline material from the data information of the defects of the pipe gallery pipelines, determining a failure assessment diagram, and then computing assessment points to obtain the residual intensity of the pipe gallery pipelines; for the volume type defects, obtaining the design factors, the weld joint factors and the minimum measurement wall thickness from the data information of the defects of the pipe gallery pipelines, and obtaining the residual intensity of the pipe gallery pipelines through computing; computing basic numerical values according to the data information of the defects of the pipe gallery pipelines, and computing the residual lives of the pipe gallery pipelines according to a maximum value distribution probability density function, a reliability function, maximum corrosion depth point estimation and maximum likelihood estimation. Therefore, the residual intensity and residual lives of the pipelines in a pipe gallery area are effectively and accurately computed and predicted.

Owner:SHANGHAI CHEM IND PARK PUBLIC PIPE RACK

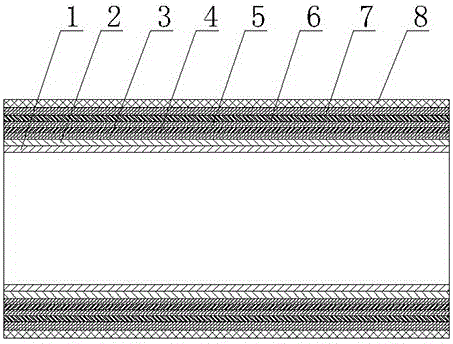

Nano-antibacterial plastic pipe having high-molecular carbon fiber composite skeleton

The invention discloses a nano-antibacterial plastic pipe having a high-molecular carbon fiber composite skeleton. The plastic pipe includes an antibacterial layer, a high density polyethylene layer, a high intensity adhesive agent layer, a metal skeleton layer, a high intensity adhesive agent layer, a fiber skeleton layer, a high intensity adhesive agent layer and a high density polyethylene layer. The pipe of the technical scheme of the invention has the high molecule carbon fiber and coppered steel wire composite skeleton. The high molecule carbon fibers have a low cost and high modulus and intensity, so that the external force resistance of the pipe is effectively improved with low cost and at the same time the engineering stress of fluid inside the pipe is increased. The nano-silver antibacterial plastic is adopted in making a fluid contact surface of the pipe, which can effectively eliminate secondary pollution to water and enables the plastic pipe to have antibacterial and self-cleaning functions.

Owner:JIANGSU XIANGSHENG NEW POWER TECH

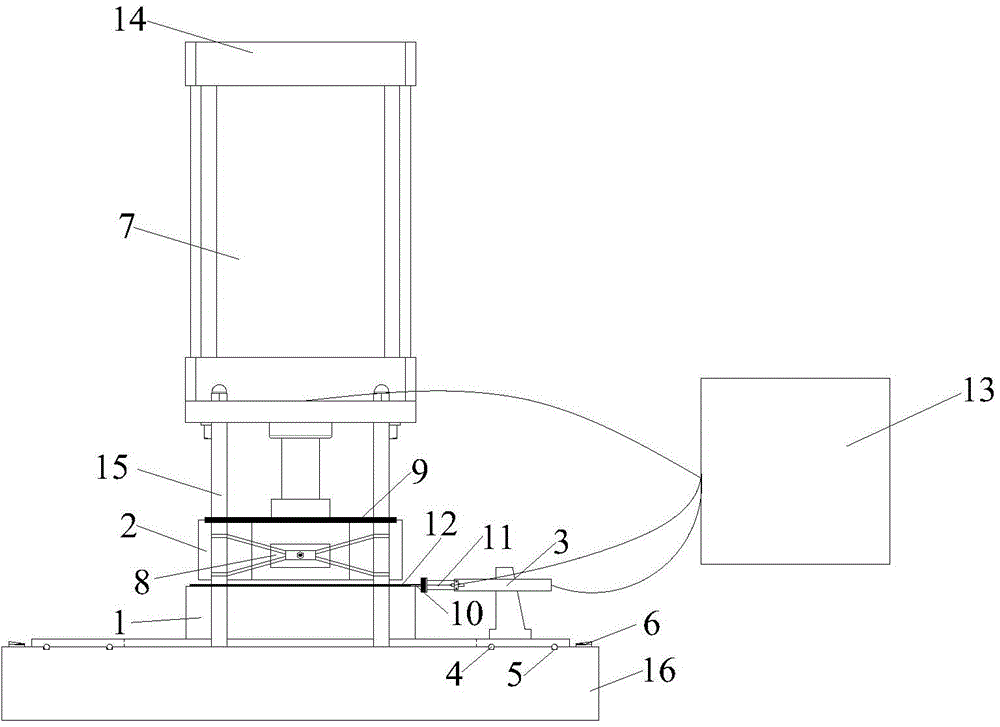

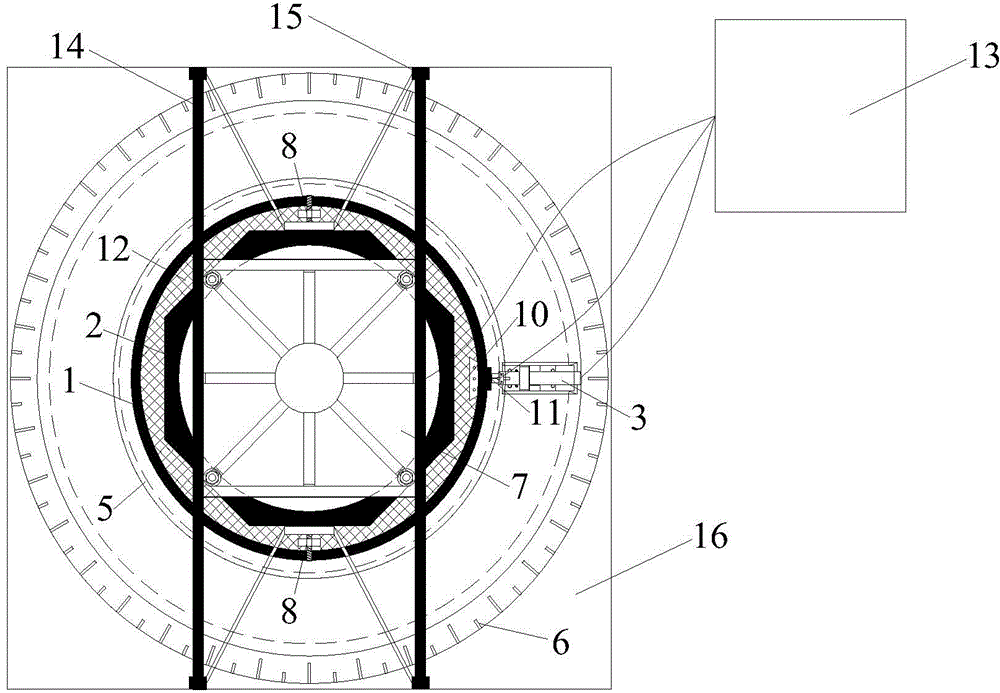

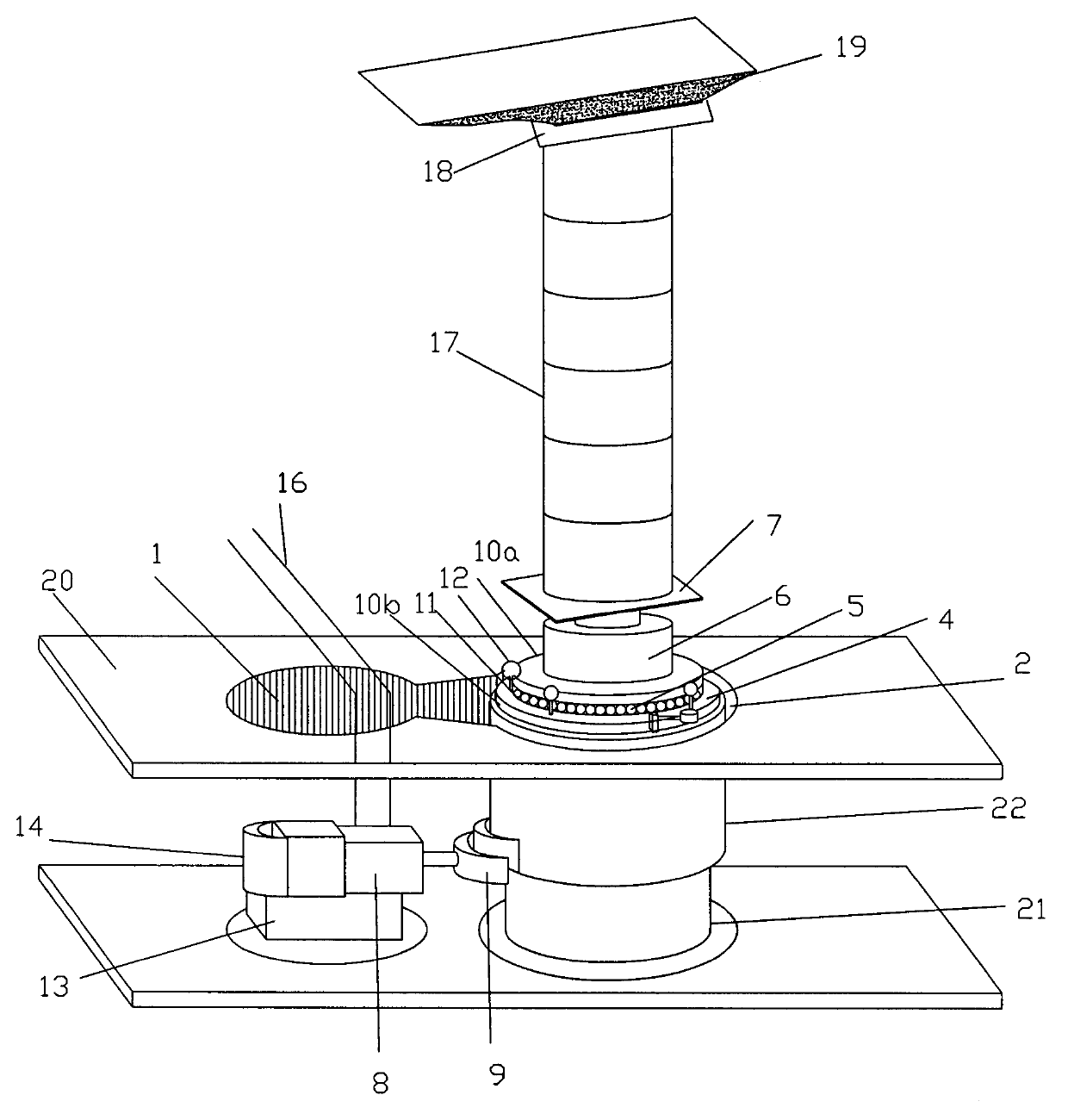

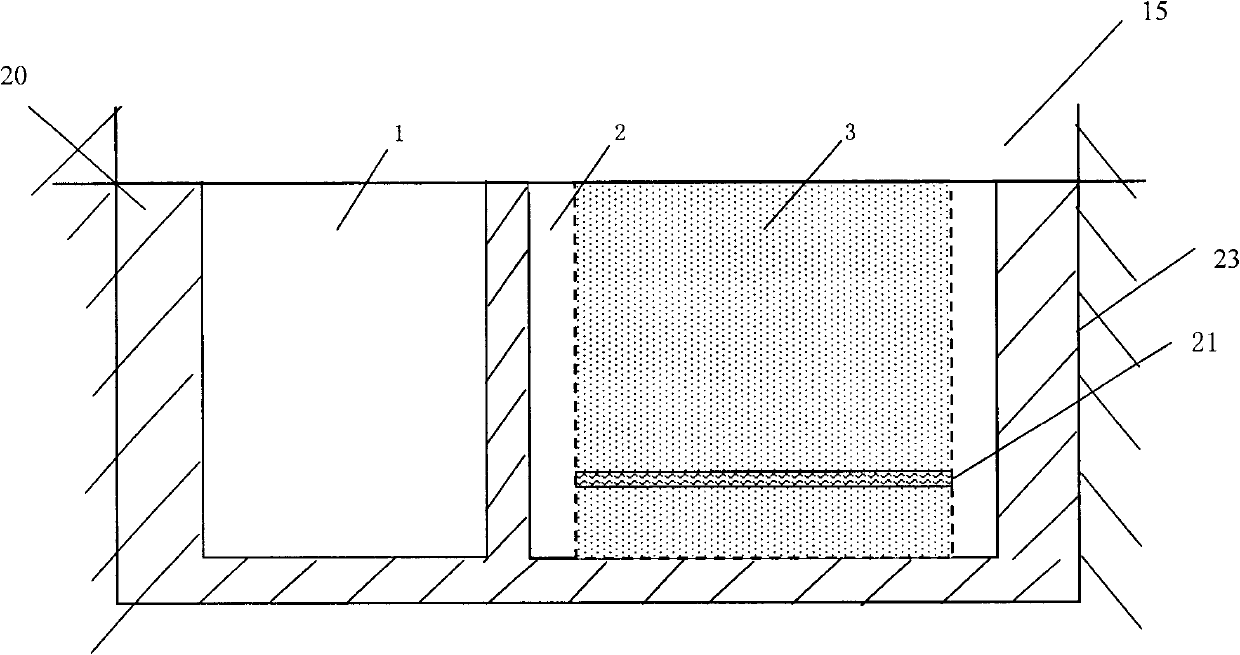

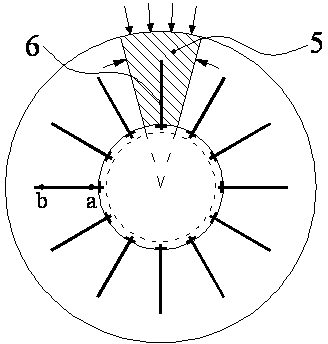

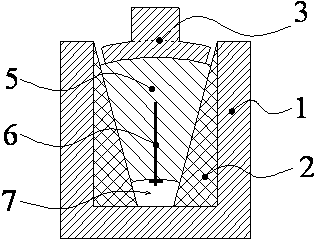

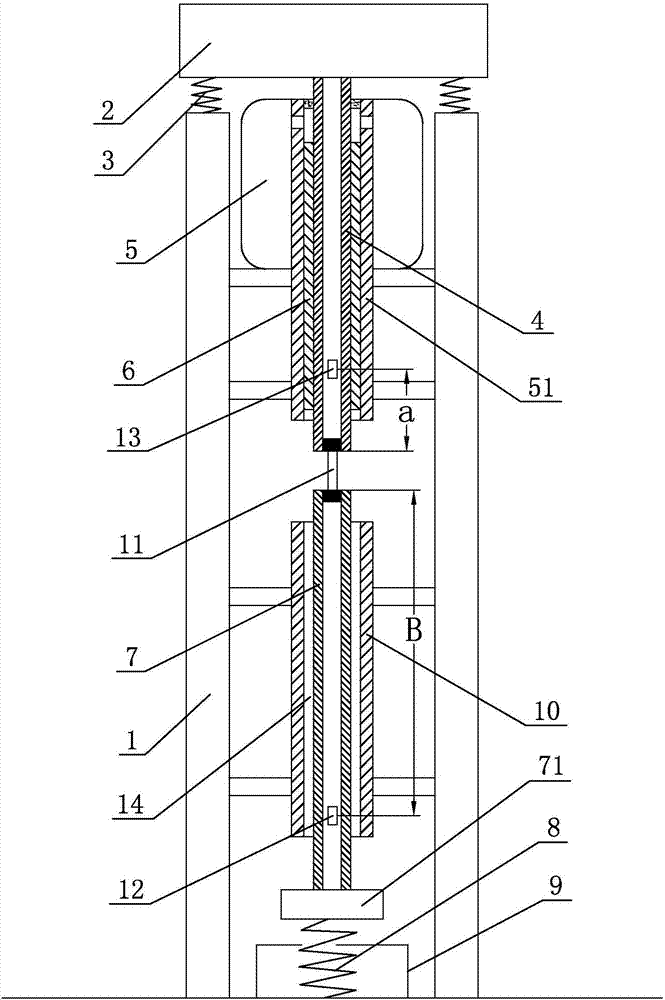

Anchor rod engineering stress simulation experimental device

InactiveCN103471918ASimple structureReduce testing costsMaterial strength using tensile/compressive forcesStress distributionScale model

The invention discloses an anchor rod engineering stress simulation experimental device. The anchor rod engineering stress simulation experimental device comprises a U-shaped groove, a triangular prism cushion block, a loading cushion block, side baffles, an approximately trapezoidal test piece and anchor rod test pieces. The anchor rod engineering stress simulation experimental device can be used for simulating the stress state of an anchor rod in an engineering field, and truly reflecting the interaction process between a surrounding rock and the anchor rod in tunnel engineering to obtain a true stress distribution curve of the anchor rod, so that the anchor rod engineering stress simulation experimental device has great significance on the research on the properties of stress, deformation, damage and the like of a deep high stress anchored rock mass. According to the anchor rod engineering stress simulation experimental device, part of a deeply buried circular tunnel surrounding rock is subjected to analysis, so that compared with an existing whole sectional model test device, large-scale model tests can be carried out, and the test results are closer to those of the anchor rod in the practical application.

Owner:SHANDONG UNIV OF SCI & TECH

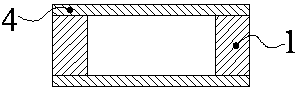

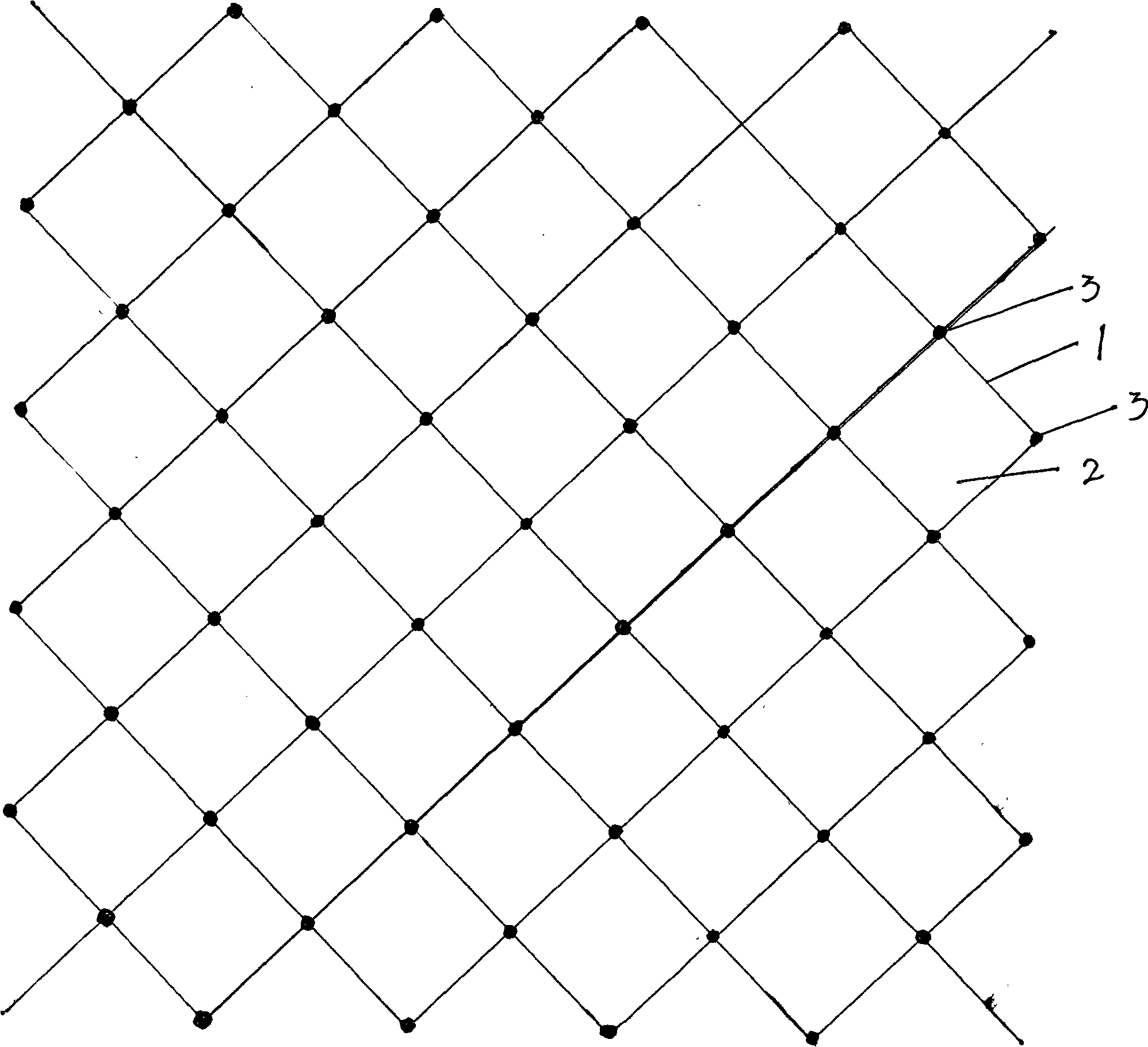

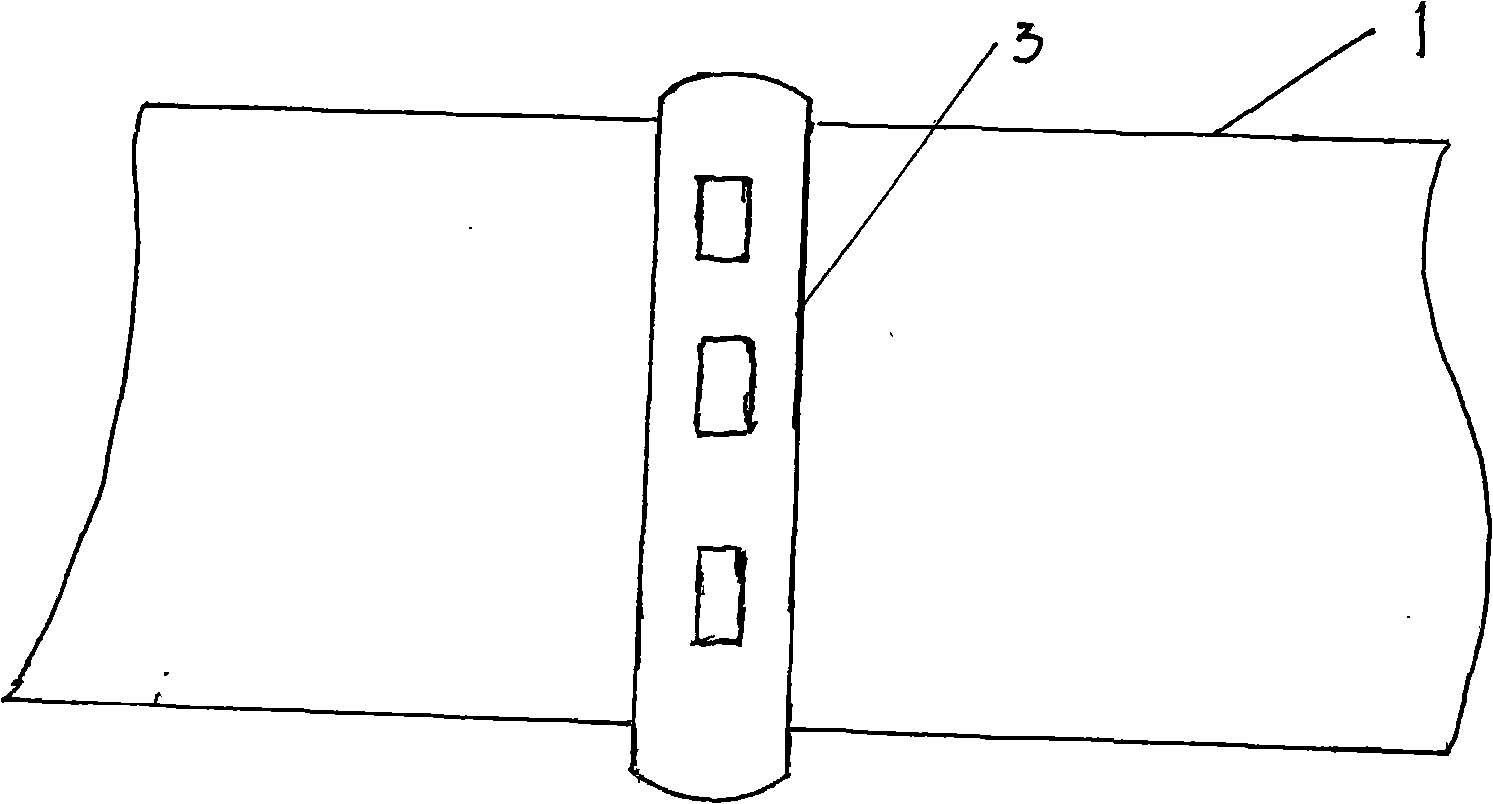

Vertical type earth work grille

InactiveCN101328708AHigh strengthImprove securitySoil preservationInjection molding machineUltimate tensile strength

The invention provides a vertical soil engineering grid, comprising rib belts which are arranged vertically and in a 45-degree cross grain, the space between the rib belts form a rhombus grid cavity, an injection molding node is arranged at the connection position of the two rib belts, the injection molding node is formed by integrated injection molding a middle cylindrical pin and a fixed piece on the periphery, the two connected rib belts are arranged in parallel, a plurality of sets of upper and lower cracks are arranged evenly at corresponding positions, strip rib blocks are formed between each set of upper and lower cracks, and the cylindrical pin is passed through the spaces formed by a plurality of strip rib blocks and rib belts. After the vertical soil engineering grid is paved in a foundation, the stretching resistance, the yield strength, the shearing force, the lock force and the frictional resistance are improved evidently, great intensity of pressure in the construction process can be borne, the soil body compacted density is increased, the soil fixing ability is increased greatly, the uneven sedimentation is improved evidently, the sedimentation after the construction is reduced, the vertical soil engineering grid is anti-chemical erosion, the engineering stress has time effect, the safety is good and the intensity is high.

Owner:JIANGSU XINTAI GEOTECHNICAL TECH CO LTD

Method for testing large deformation impact tension of material

ActiveCN107543751ARealize secondary continuous loadingAchieving Tensile Failure Strain TestingMaterial strength using tensile/compressive forcesLarge deformationIndustrial engineering

The invention discloses a method for testing large deformation impact tension of a material. The method is characterized in that a supporting block is arranged at the upper end of a bracket; a tubulartransmission bar is vertically arranged, and the upper end of the transmission bar is fixedly connected to the supporting block; tubular incident bar which is the same as the transmission bar in theaspects of material, length and diameter is selected and vertically coaxially arranged below the transmission bar; a boss is integrally arranged at the lower end of the incident bar; a tested part isfixed between the lower end of the transmission bar and the upper end of the incident bar; an impact rod is launched to impact the boss which is fixed at the lower end of the incident bar, thus a strain signal can be tested; and the tested signal is substituted into a relation to obtain an axial engineering stress, engineering strain and engineering strain rate time history curve of the tested part in the test. The method has the advantage that the continuous stable test strain rate is achieved; and in addition, the strain rate is up to 10S<-1> order under the maximum stress the same as that of a traditional Hopkinson bar test.

Owner:NINGBO UNIV

Mechanical model of scaffold based on pulling and lifting unloading method and solving method of mechanical model

ActiveCN113569344AImprove accuracyThe solution formula is conciseGeometric CADDesign optimisation/simulationMechanical modelsClassical mechanics

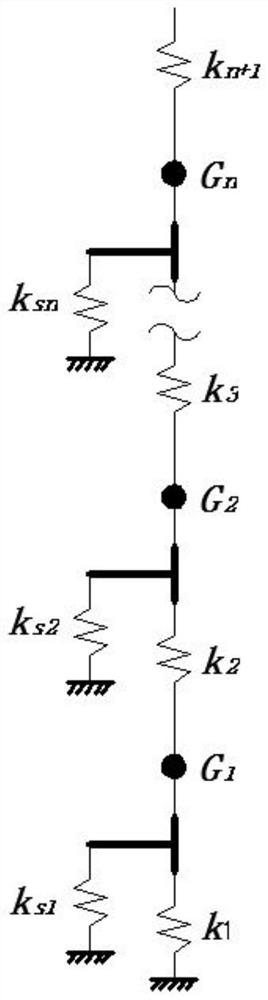

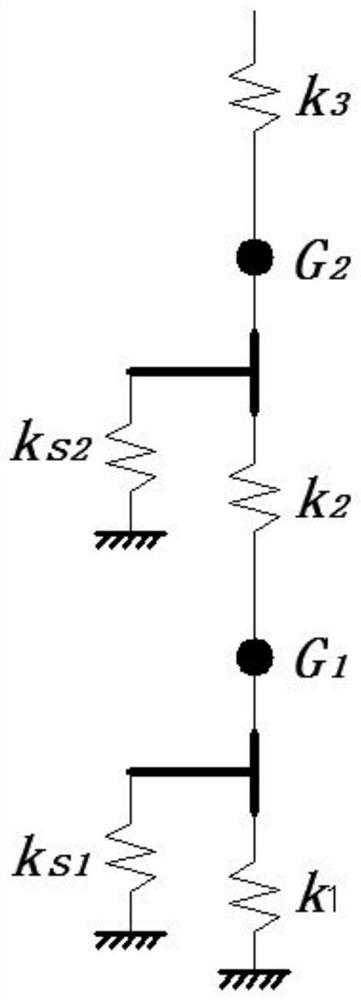

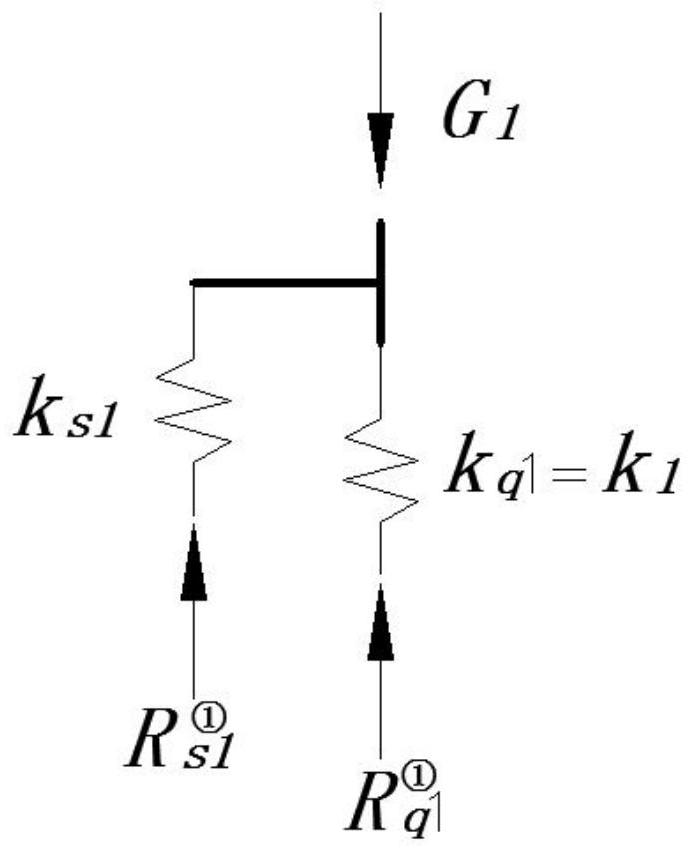

The invention belongs to the technical field of engineering stress calculation, and provides a mechanical model of a scaffold based on a pulling and lifting unloading method and a solving method of the mechanical model. The model mainly comprises a single vertical rod model formed on the basis of an inner vertical rod or an outer vertical rod of the scaffold, wherein the single vertical rod model comprises k1, G1, k2, G2, k3, G3... kn, Gn and kn + 1 which are linearly and sequentially arranged, in which ks1, ks2... ksn are correspondingly connected between k1 and G1... kn and Gn; herein, the k1 is the vertical rigidity of the scaffold at the foundation section; the ks1... ksn is the vertical rigidity of the unloading steel wire rope at the corresponding section of the corresponding scaffold; the G1... Gn are equivalent concentrated vertical loads at the first section... the nth section of the vertical rod respectively; the k1,... kn + 1 are equivalent springs at the first section to the nth section of the vertical rod respectively. According to the method, the stress calculation accuracy and the calculation convenience of the scaffold under the pulling and lifting unloading method can be effectively improved.

Owner:GUANGZHOU CONSTR ENG +3

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com