Vertical type earth work grille

A geogrid and vertical technology, applied in the field of vertical geogrid, can solve the problems of inability to reduce post-construction settlement, inability to apply special buildings with high seismic resistance levels, inability to determine the lateral displacement of soil, etc. Improved uniform settlement, reduced post-construction settlement, and improved frictional resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

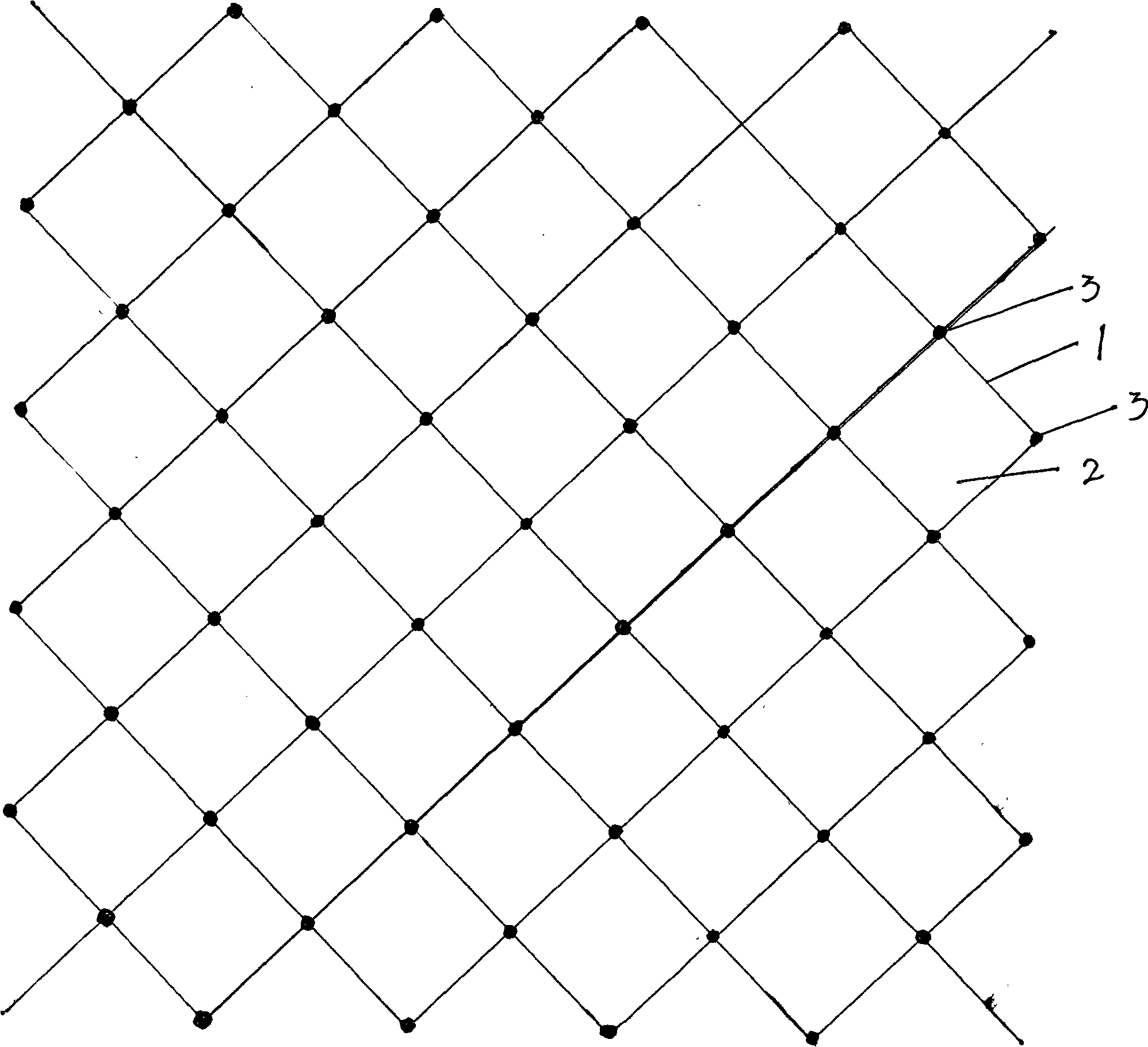

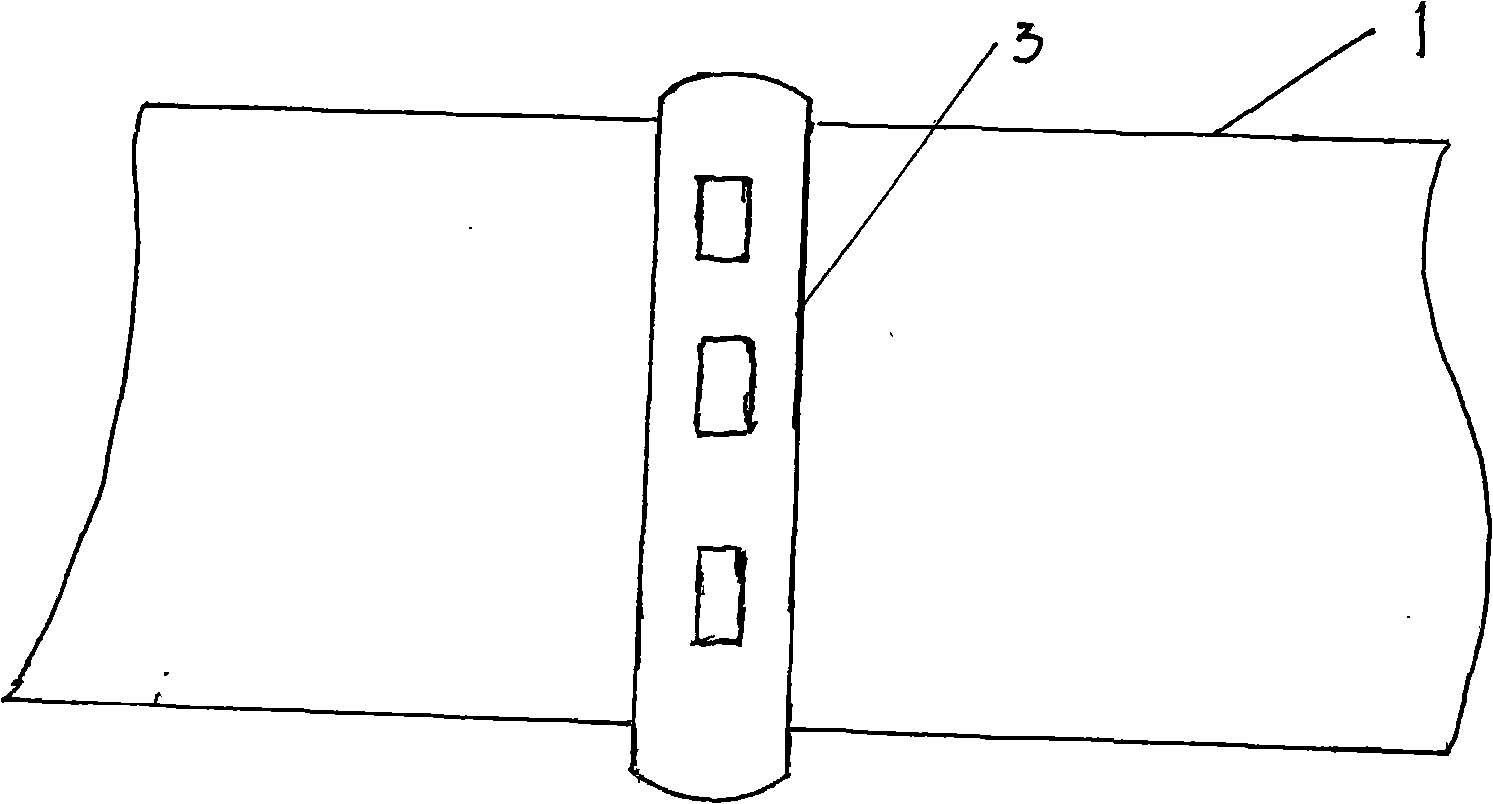

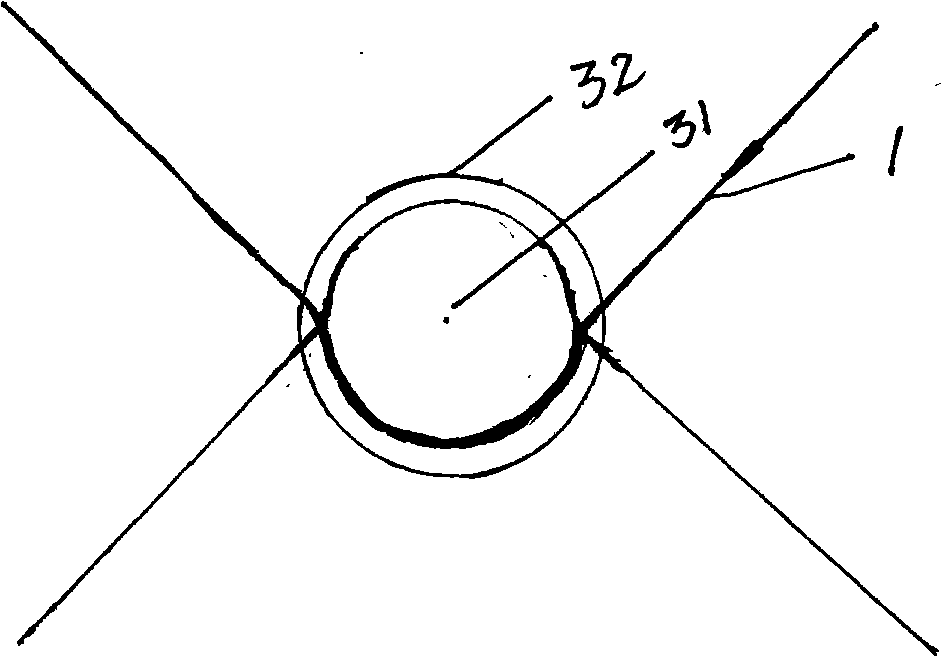

[0009] Vertical geogrid, including polyester rib belt 1, polyester rib belt 1 is arranged vertically, polyester rib belt is arranged in a 45-degree twill pattern, polyester rib belt 1 constitutes a diamond-shaped cell 2, and two polyester ribs are connected. The belt is disposed with an injection joint 3, the injection joint is integrally injection-molded by the middle cylindrical pin 31 and the peripheral firmware 32, and the two polyester rib belts 1 that are handed over are arranged in a parallel row, and several sets of upper and lower cracks are opened at the corresponding positions. A strip-shaped rib is formed between each group of upper and lower slits, and the columnar pin 31 is passed through the space formed by the strip-shaped rib and the rib strip.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com