Magnesium-based high-entropy alloy with high toughness and high hardness and preparation method

A high-entropy alloy, high-strength toughness technology, applied in the field of alloys, can solve the problems of high brittleness of high-entropy alloys, achieve high mixing entropy and ensure uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

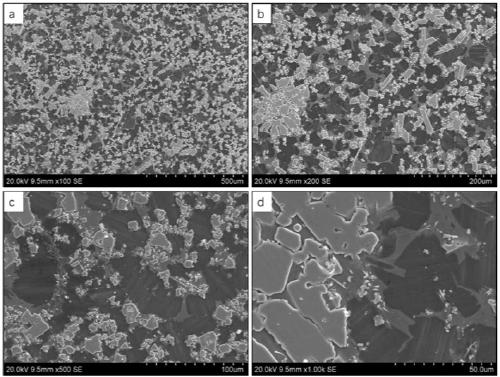

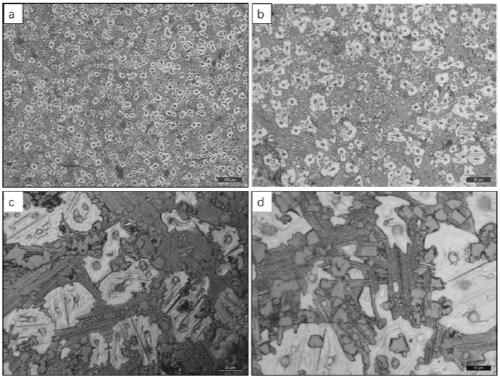

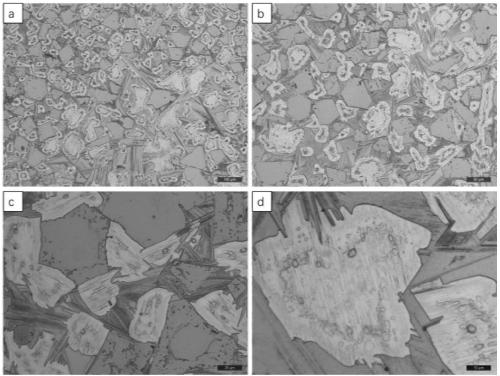

Image

Examples

Embodiment 1

[0028] A method for preparing a magnesium-based high-entropy alloy with high strength, toughness and high hardness, comprising the following steps: according to the atomic percentage (at.%) Mg: 35%, Al: 25%, Gd: 20%, and Y in the magnesium-based high-entropy alloy: 10%, Zn: 10%, 5.43g of Al ingot and 5.26g of Zn ingot with a purity of 99.9wt.%, 23.85g of Mg-30Y master alloy and 84.36g of Mg-30Gd master alloy were placed in a crucible for melting. The melting temperature is 760°C (holding temperature for 15 minutes), and the casting temperature is 740°C. Cast alloy liquid into graphite mold (water cooling) to get Mg 35 Al 25 Gd 20 Y 10 Zn 10 alloy ingot. The obtained alloy ingot was measured by a microhardness tester (load 29.42N, holding time 10 seconds), and the hardness was HV115.6. The obtained alloy ingot was compressed and measured by a UTM-5305 electronic universal testing machine, and the compressive strength at room temperature was 496.65 MPa, and the elongation ...

Embodiment 2

[0030] A method for preparing a magnesium-based high-entropy alloy with high strength, toughness and high hardness, comprising the following steps: according to the atomic percentage (at.%) Mg: 35%, Al: 20%, Gd: 20%, and Y in the magnesium-based high-entropy alloy: 10%, Zn: 15%, 4.21g of Al ingot and 7.65g of Zn ingot with a purity of 99.9wt.%, 23.13g of Mg-30Y master alloy and 81.83g of Mg-30Gd master alloy were placed in a crucible for melting. The melting temperature is 760°C (holding temperature for 15 minutes), and the casting temperature is 740°C. Cast alloy liquid into graphite mold (water cooling) to get Mg 35 Al 20 Gd 20 Y10 Zn 15 alloy ingot. The obtained alloy ingot was measured by a microhardness tester (load 29.42N, holding time 10 seconds), and the hardness was HV103.3. The obtained alloy ingot was compressed and measured by a UTM-5305 electronic universal testing machine, and the compressive strength at room temperature was 481.48 MPa, and the elongation wa...

Embodiment 3

[0032] A method for preparing a magnesium-based high-entropy alloy with high strength, toughness and high hardness, comprising the following steps: according to the atomic percentage (at.%) Mg: 30%, Al: 25%, Gd: 20%, and Y in the magnesium-based high-entropy alloy: 15%, Zn: 10%, 4.128g of Al ingot and 4.002g of Zn ingot with a purity of 99.9wt.%, 27.20g of Mg-30Y master alloy and 64.16g of Mg-30Gd master alloy were placed in a crucible for melting. The melting temperature is 760°C (holding temperature for 15 minutes), and the casting temperature is 740°C. Cast alloy liquid into graphite mold (water cooling) to get Mg 30 Al 25 Gd 20 Y 15 Zn 10 alloy ingot. The obtained alloy ingot was measured by a microhardness tester (load 29.42N, holding time 10 seconds), and the hardness was HV123.7. The obtained alloy ingot was compressed and measured by a UTM-5305 electronic universal testing machine, and the compressive strength at room temperature was 458.23 MPa, and the elongatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com