Patents

Literature

467 results about "Universal testing machine" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

A universal testing machine (UTM), also known as a universal tester, materials testing machine or materials test frame, is used to test the tensile strength and compressive strength of materials. An earlier name for a tensile testing machine is a tensometer. The "universal" part of the name reflects that it can perform many standard tensile and compression tests on materials, components, and structures (in other words, that it is versatile).

Thermo-mechanical-environmental coupling effect testing device and application from room temperature to ultrahigh temperature

ActiveCN104215521APrecise temperature controlTestable tensile strengthWeighing by removing componentMaterial strength using tensile/compressive forcesPower control systemTest fixture

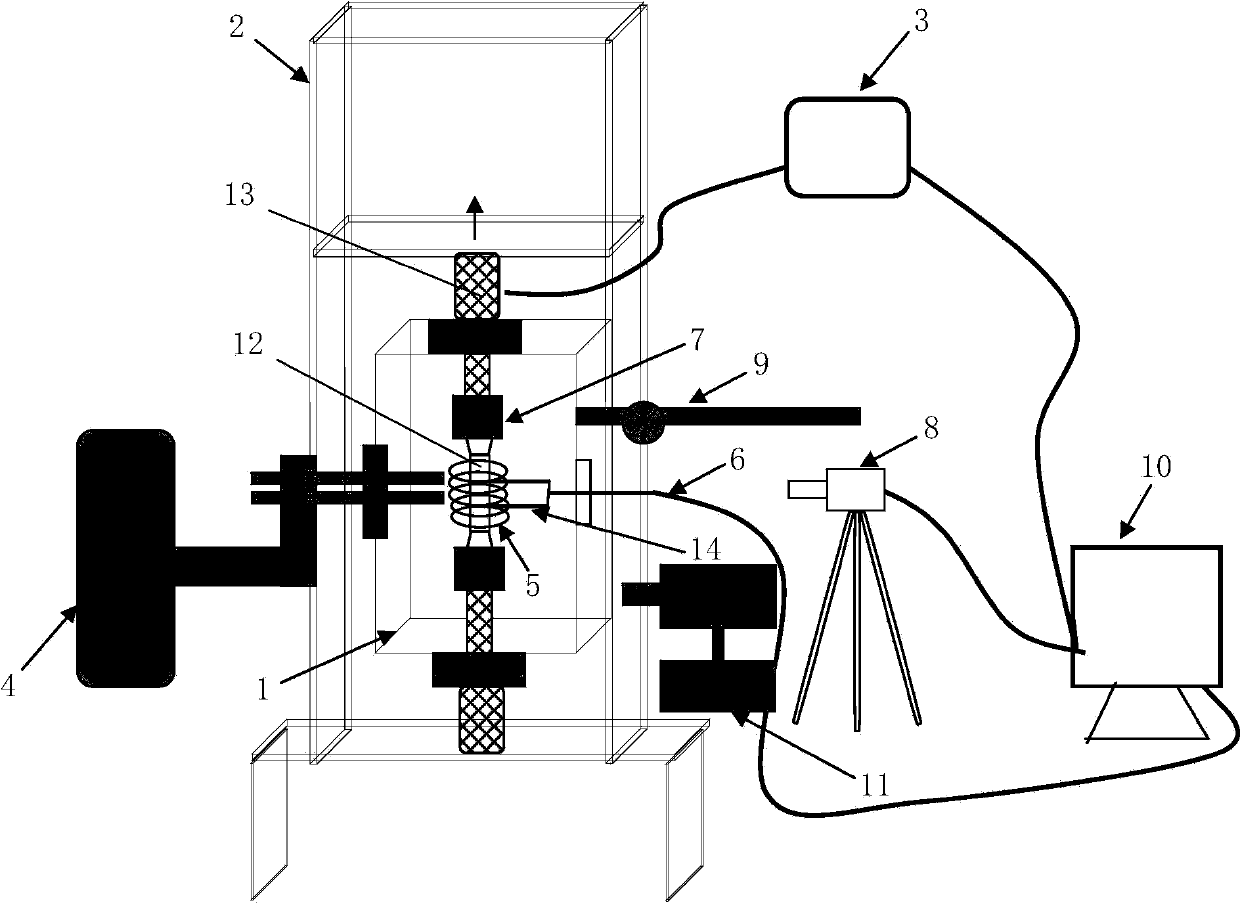

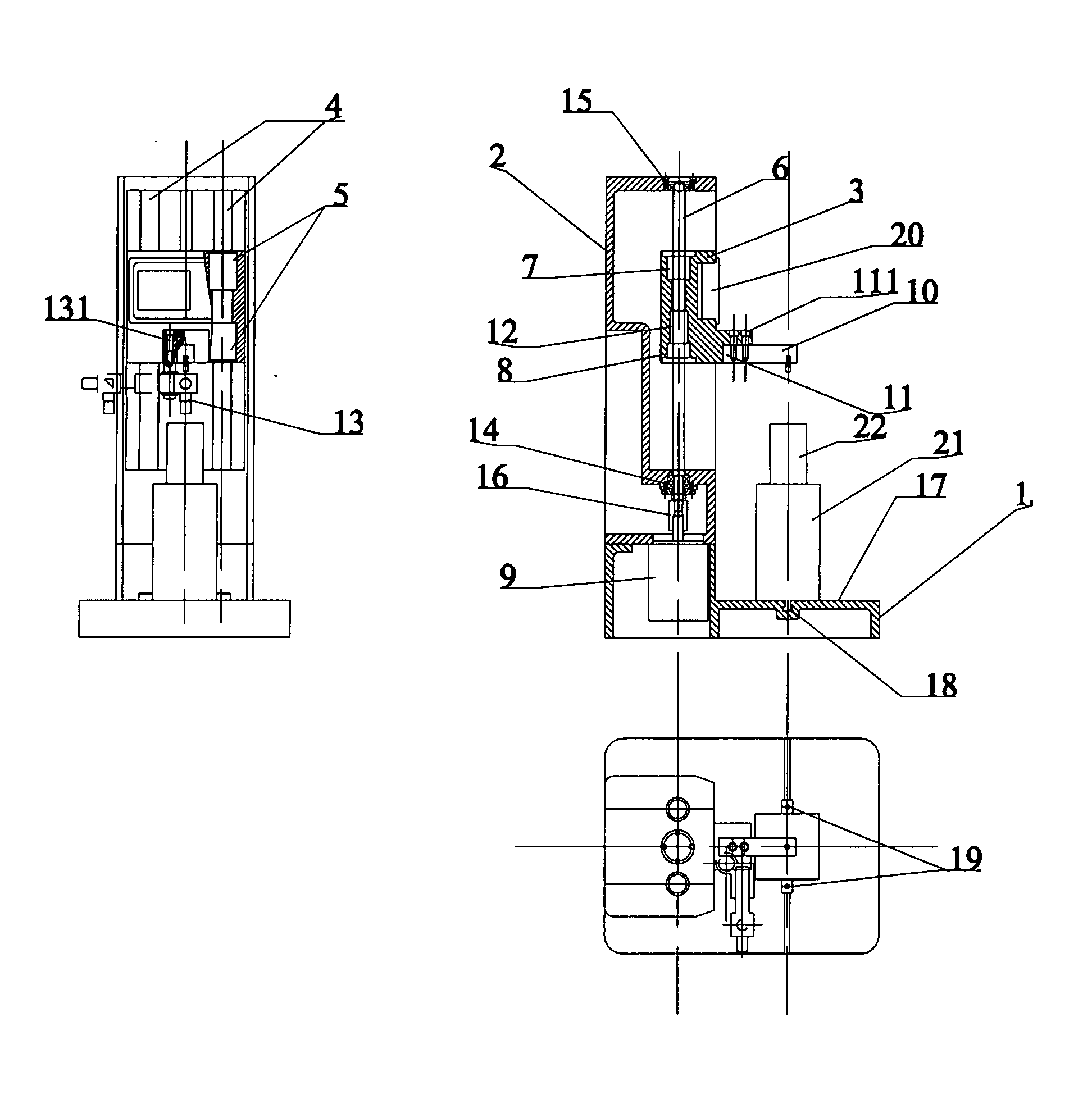

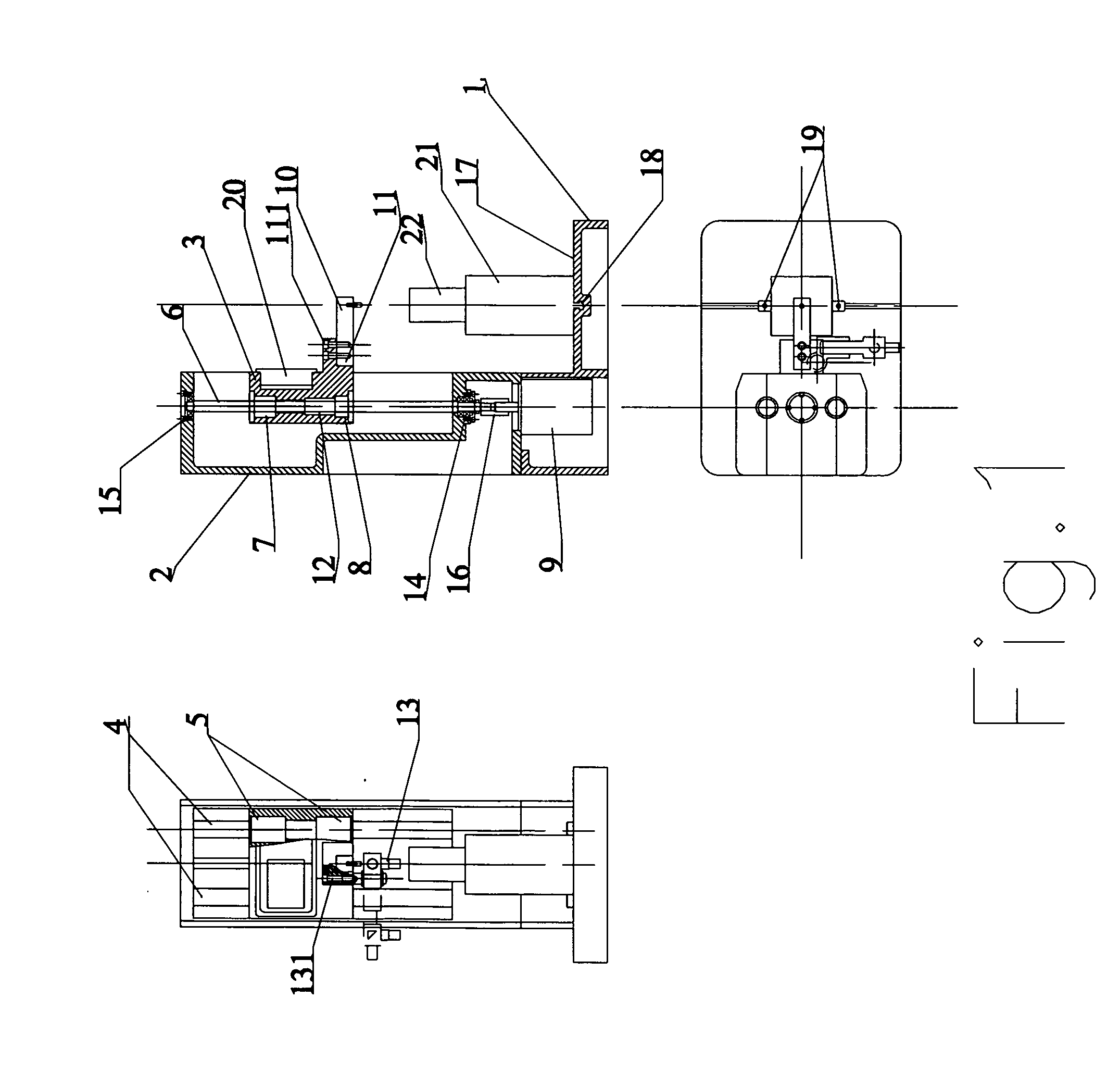

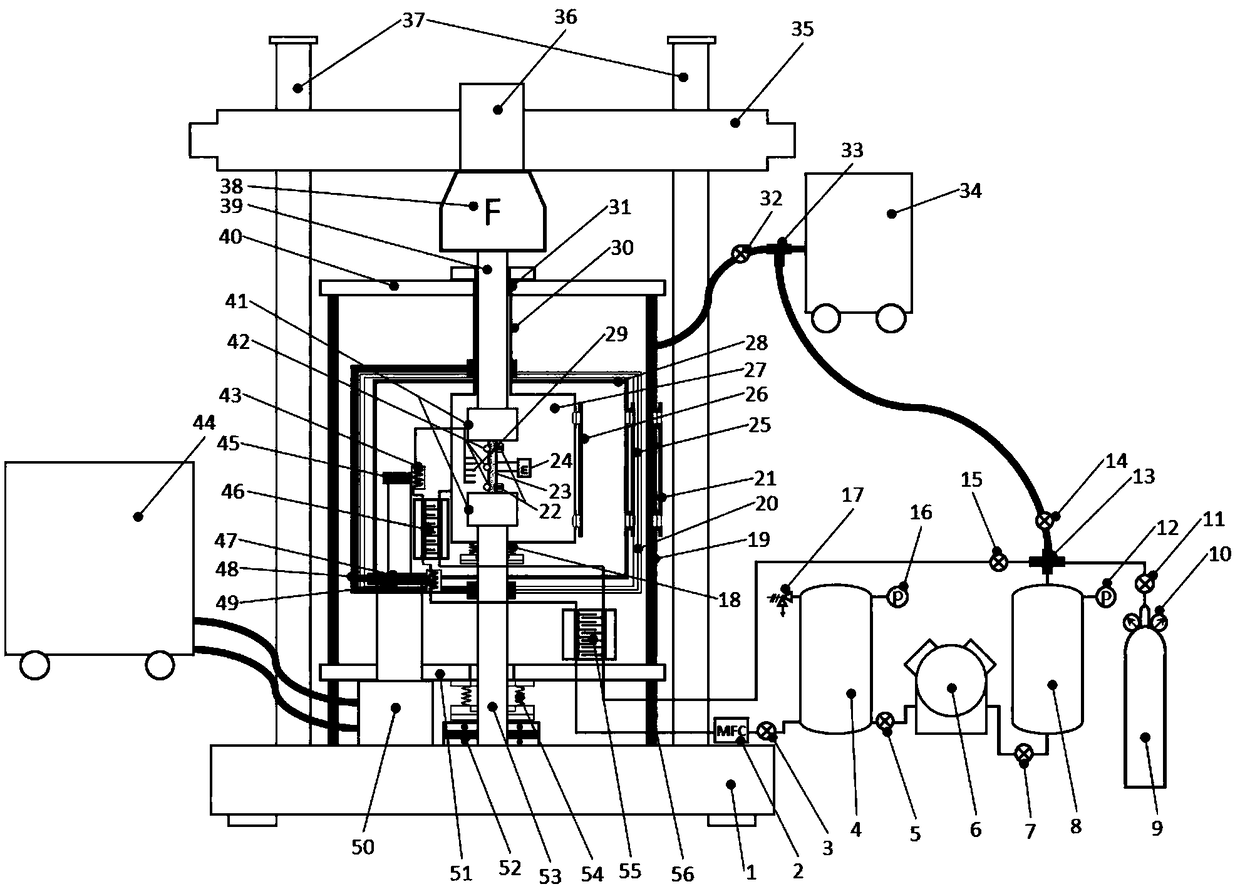

The invention relates to the field of test of mechanical properties of materials and in particular relates to a thermo-mechanical-environmental coupling effect testing device and application from room temperature to ultrahigh temperature. The device comprises an electronic universal testing machine, a loading control system, a power supply control system, an induction heater, a strain measurement system, a sample clamp, a temperature measuring system, a pressure control system, a display and analysis system and a vacuum system, wherein a vacuum cavity in the electronic universal testing machine is in a fully water-cooled design, and various functional windows, such as a sensor connector of the clamp and the electronic universal testing machine, an infrared or thermocouple temperature measuring opening of the temperature measuring system, a pressure control opening of the pressure control system, an induction power supply introduction opening of the power supply control system, an extensometer introduction opening of the strain measurement system and a connector of the vacuum system and the vacuum cavity, are reserved in different parts of the vacuum cavity. The device disclosed by the invention can quantitatively research the thermo-mechanical-environmental coupling effect and has the advantages of diversified tested mechanical property parameters, high sample heating and cooling speed and the like.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

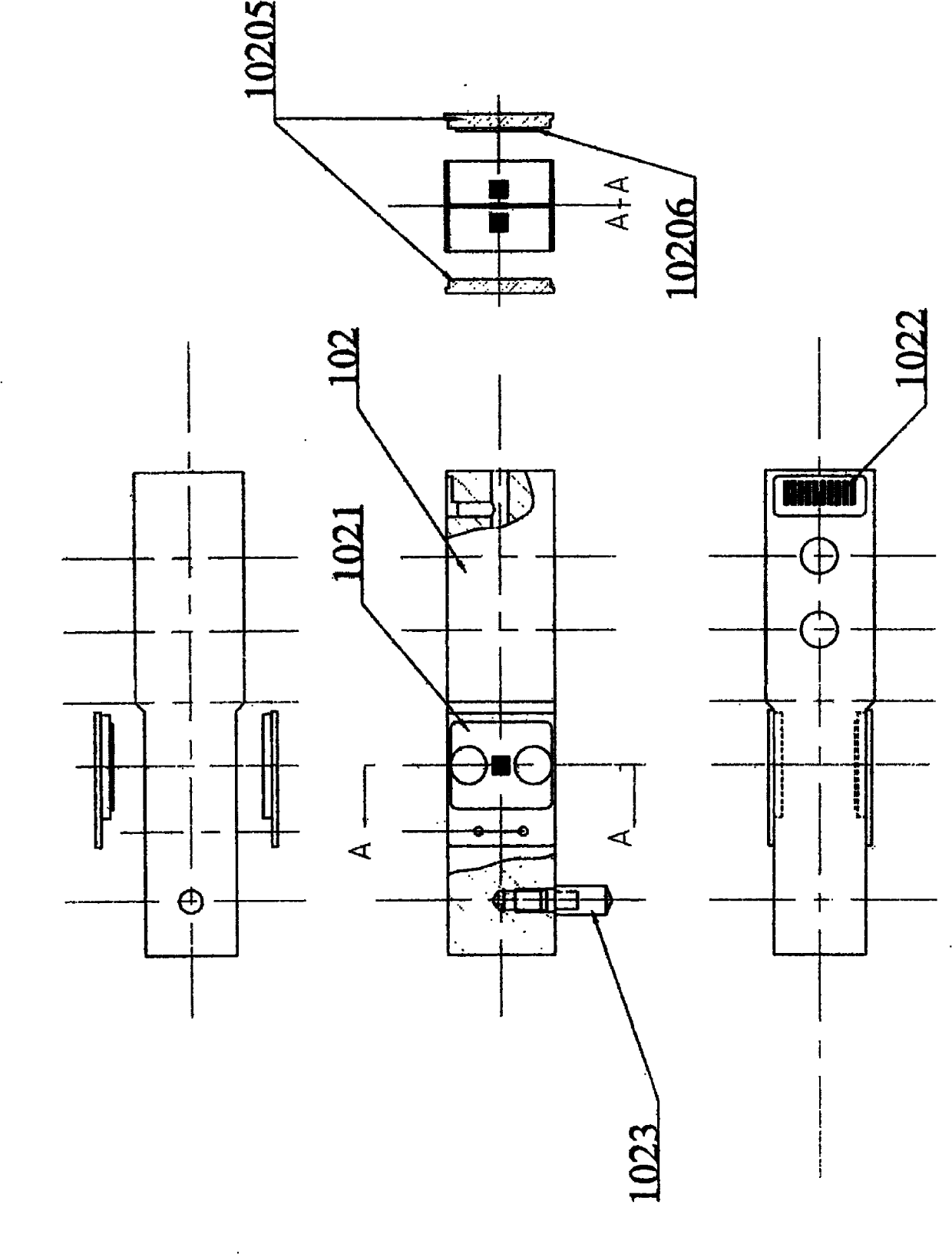

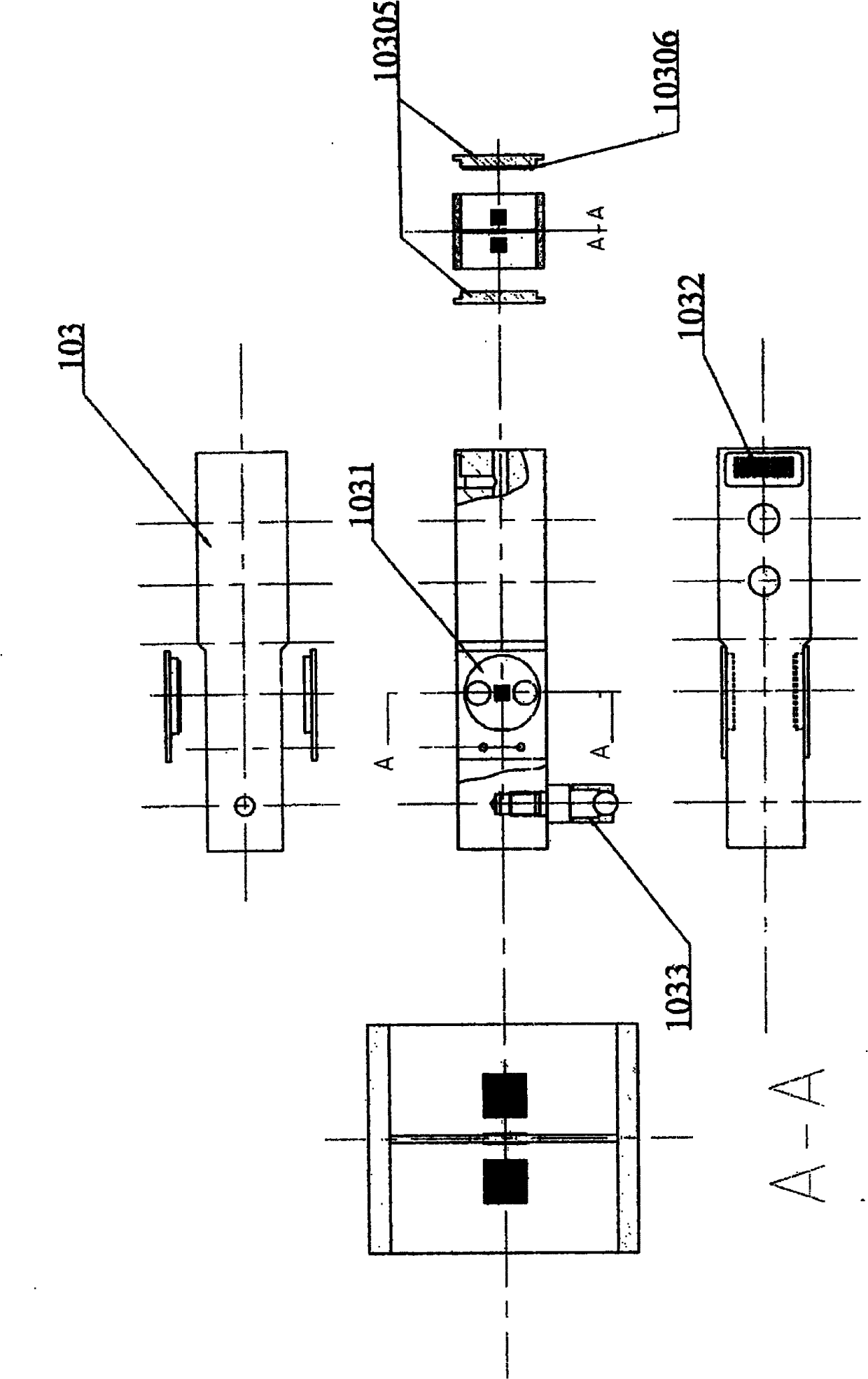

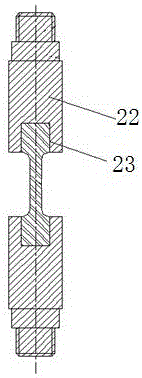

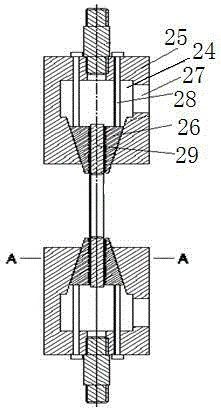

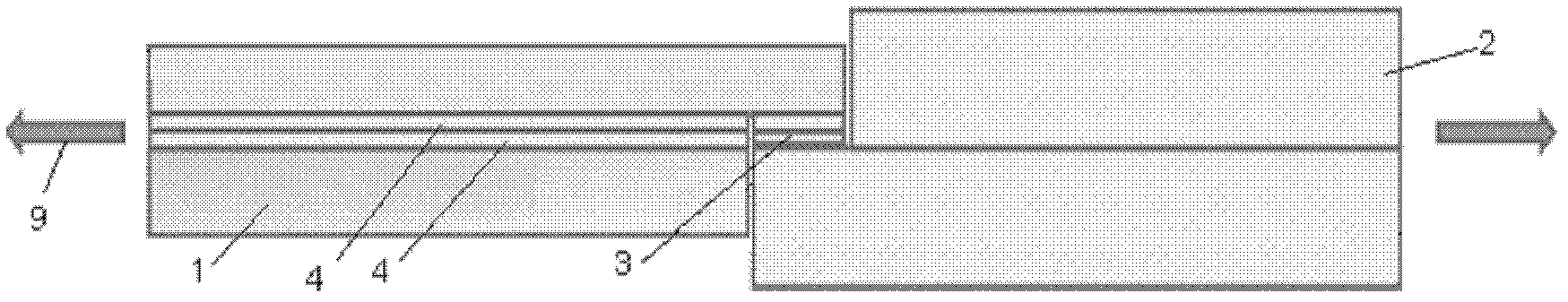

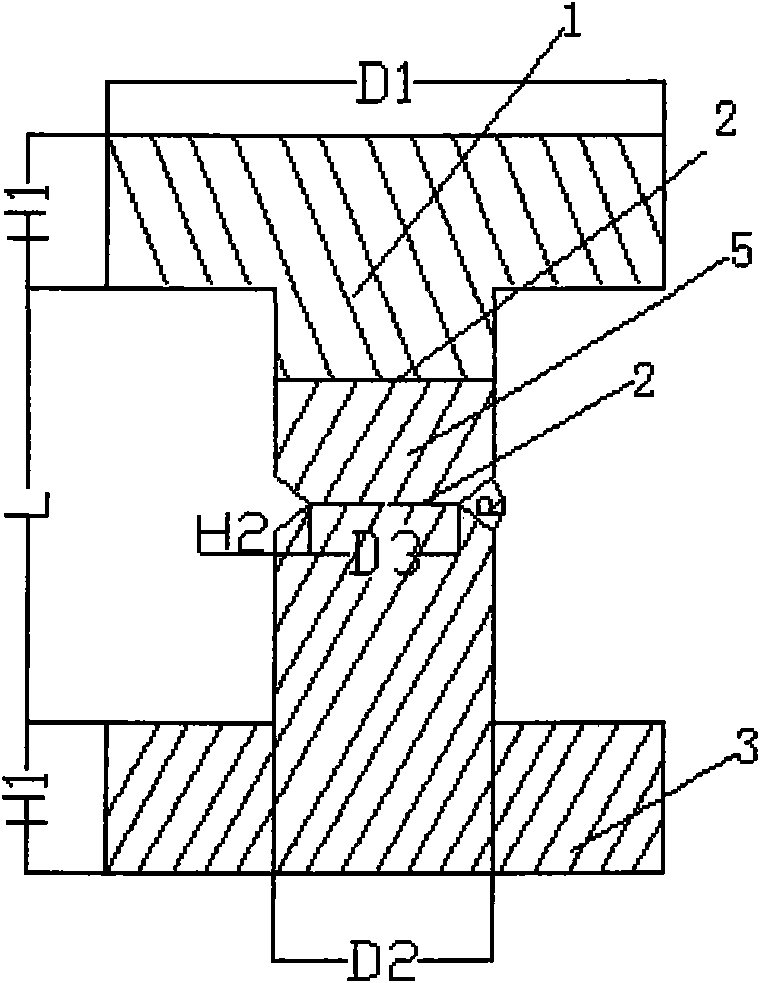

Clamp, device with clamp for testing mechanical property of hyper-elastic material and method

InactiveCN102768149AUniform deformationQuick disassemblyMaterial strength using tensile/compressive forcesData acquisitionHyper elastic

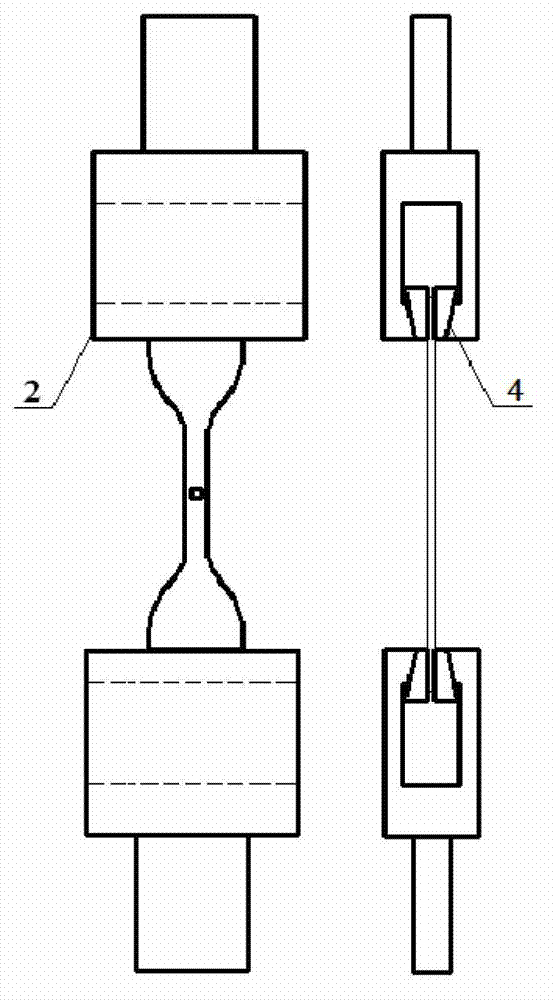

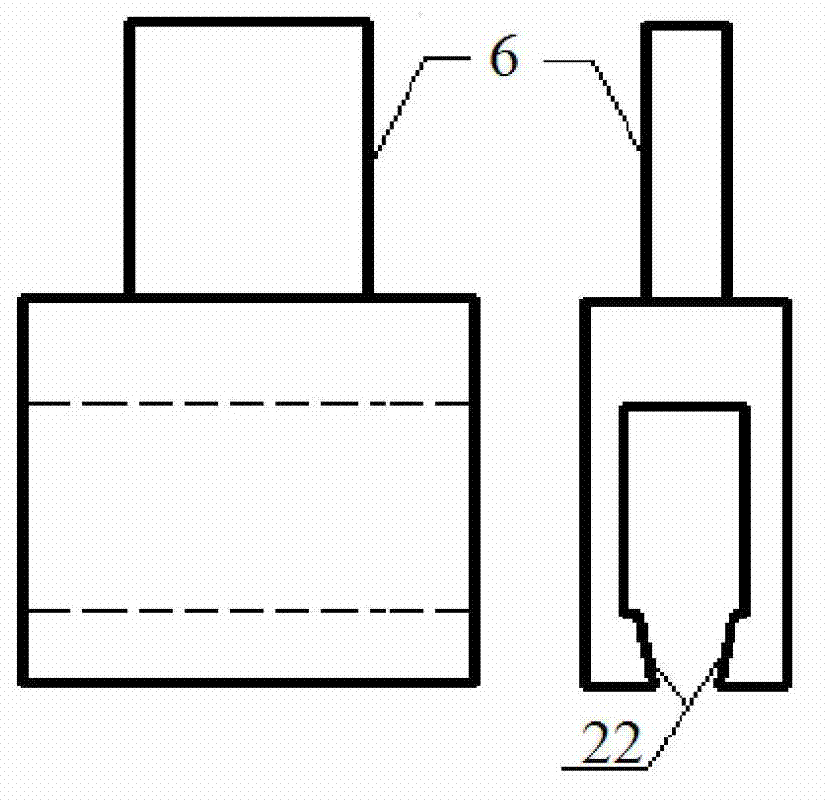

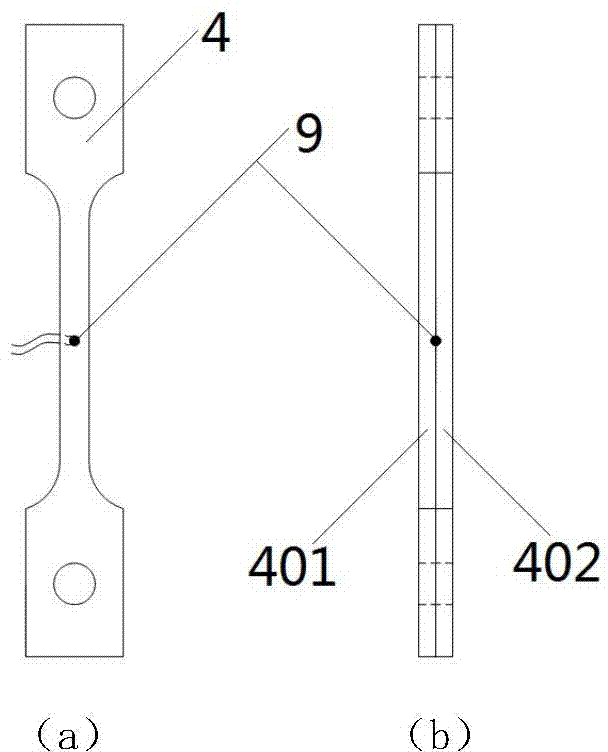

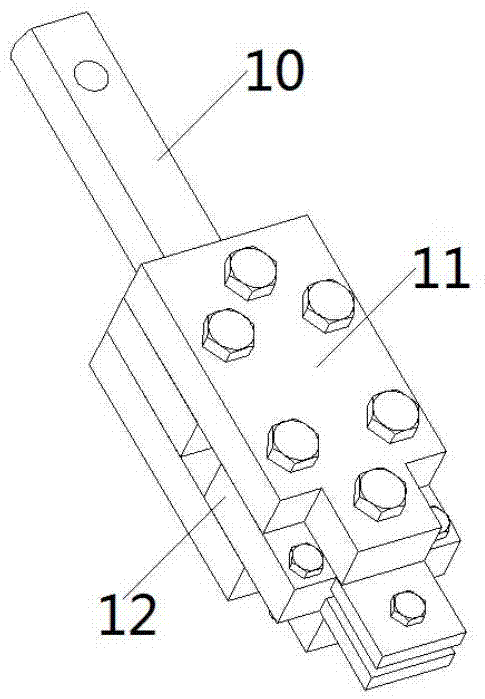

The invention relates to a device and a method for testing mechanical property of a hyper-elastic material. The device mainly comprises a reinforcing piece (4) at the end of a test piece and a test piece clamp, wherein the reinforcing piece (4) has a trapezoidal cross section; a clamping port of the clamp is an inclined surface; the reinforcing piece (4) is adhered to the end of the test piece and is arranged in the clamp, the inclined surface of the clamp tightly clamps the inclined surface of the reinforcing piece (4), and the clamp is self-locked in the tensioning process and is prevented from locally deforming. The device is applied to multiple stress-strain tests of the hyper-elastic material such as uniaxial tension, equally biaxial tension and planar tension (pure shear). Stress data is acquired by a data acquisition system of an electronic universal testing machine, and the strain data is acquired by a charge coupled device (CCD) image acquisition device. Due to the technical scheme, the clamping force is high when the tension is high in the process of tensioning the test piece, so that the test piece is uniformly stressed, more accurate testing data can be obtained, and the mechanical property parameters of the hyper-elastic material obtained accordingly are more reliable.

Owner:TSINGHUA UNIV

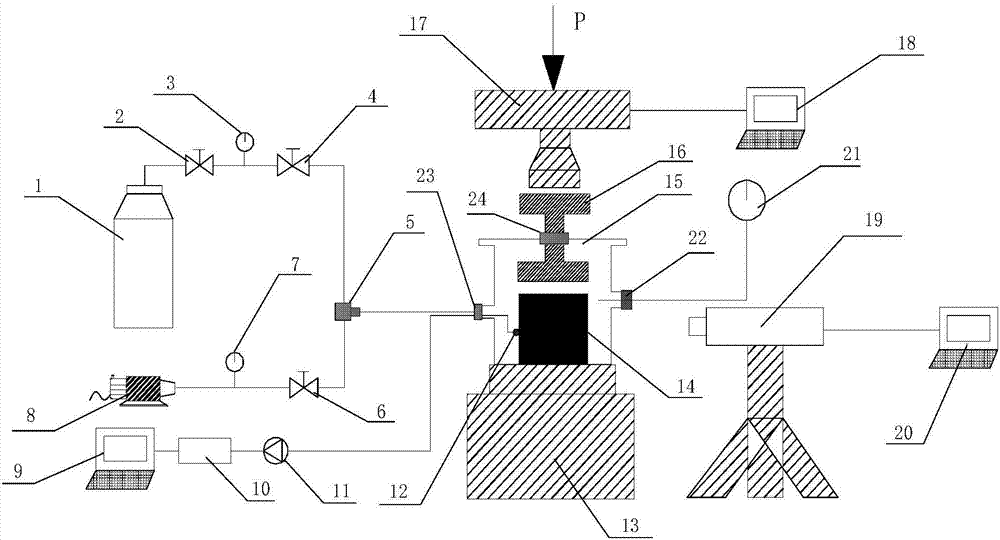

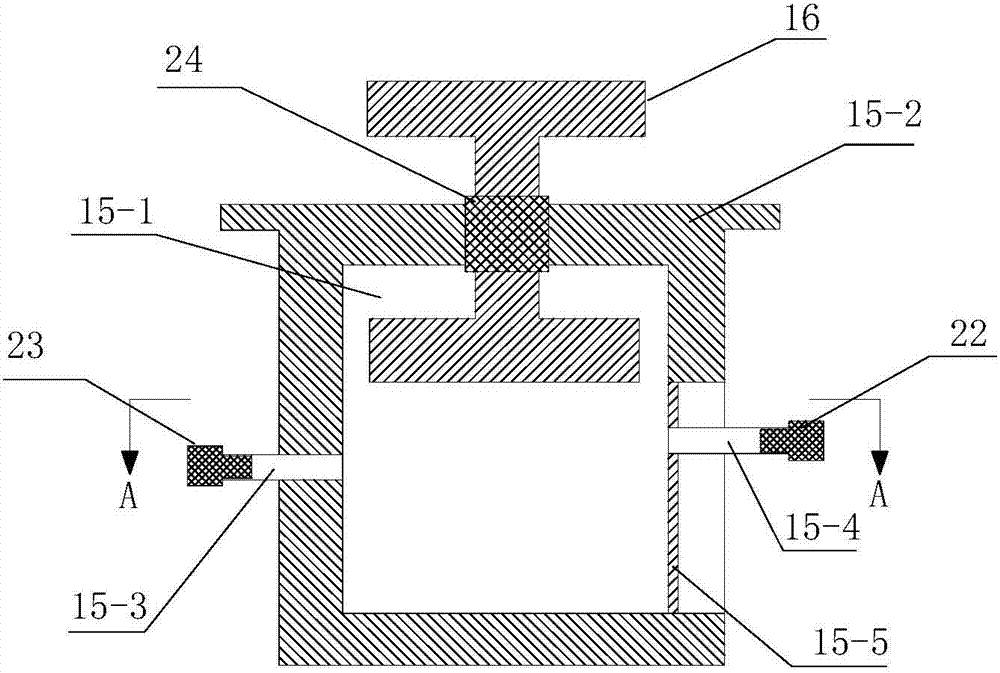

Multi-field coupled environment simulating and online monitoring/observing system

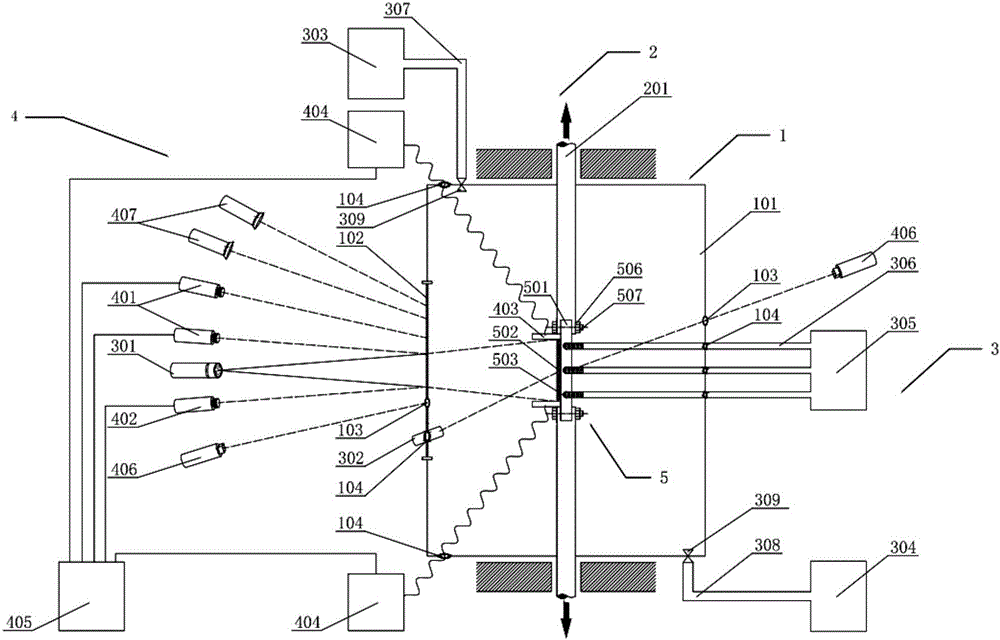

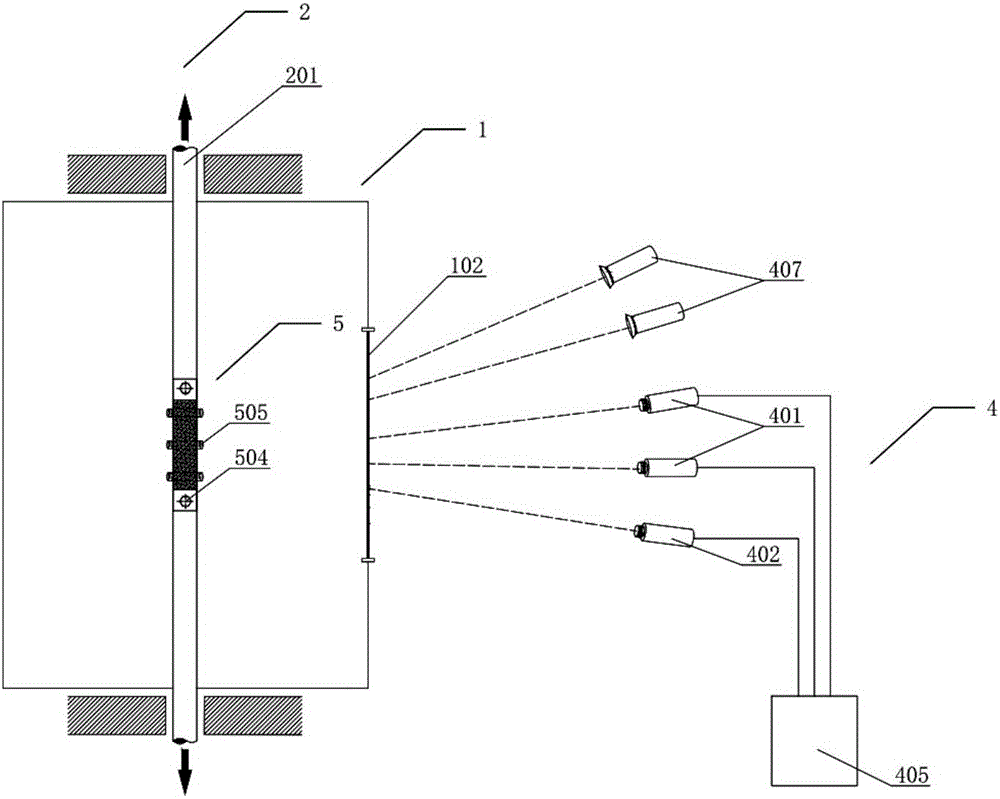

ActiveCN105973690AFast heating and cooling rateIncreased limit temperatureWeather/light/corrosion resistanceMaterial strength using tensile/compressive forcesMulti fieldX-ray

The invention discloses a multi-field coupled environment simulating and online monitoring / observing system. The system comprises: a main body test box provided with a quartz observing window and an infrared window; a mechanical loading module comprising two coaxially arranged mechanical loading shafts and respectively connected with the main shafts of a universal testing machine and a sample clamping device; a multi-field service environment module arranged outside the main body test box and comprising an infrared laser rapid heating device, an X-ray radiation device, a corrosion gas box and a cooling system and respectively used for realizing heating, irradiating, corroding and cooling environments; and a damage online monitoring / observing module comprising a surface / interface strain real-time observation system, an in-situ fracture behavior observation system, a damage signal collecting system and an infrared thermodetector which are arranged outside the main body test box, and damage signal detectors arranged at the upper end and the lower end of a tested sample, and wherein devices contained in the damage online monitoring / observing module are respectively used for real-time capturing of strain information, in-situ fracture image information, damage information and temperature information, and synchronously run through a cynchronous control system.

Owner:XI AN JIAOTONG UNIV

Method for testing electrochemical corrosion of welded pipe seam in high-stress state and sample of welded pipe seam

InactiveCN101608995ACorrosion Resistance EvaluationFix damageWeather/light/corrosion resistanceMaterial electrochemical variablesSalt bridgeAuxiliary electrode

The invention relates to a method for testing electrochemical corrosion of a welded pipe seam in a high-stress state, which utilizes an electronic universal testing machine, an electrolytic cell component comprising a working electrode, an auxiliary electrode, a reference electrode, a salt bridge and the like, and an electrochemical workstation. Under a load stress of between 0 and 800 MPa, the stress change caused by stress relaxation is corrected regularly by a constant potential method or a constant current method to test the circumferential tensile stress of the welded pipe seam and the circumferential tensile stress of the working electrode. A tensile sample is wide and thick at both ends and narrow and thin in the middle part and is provided with connection holes at both ends. A groove corrosion depth d1 and an average corrosion depth d2 of the working electrode are tested under different loads, so a groove corrosion susceptibility coefficient alpha, alpha=d1 / d2, of the working electrode in practical application can be obtained. The method has no stress relaxation, and the stress is convenient to regulate during test; the sample is free from generating plastic deformation or detachment under the load of high stress, and can be used for corrosion test under the condition of high stress; and the electrochemical workstation can be made full use for testing.

Owner:BAOSHAN IRON & STEEL CO LTD

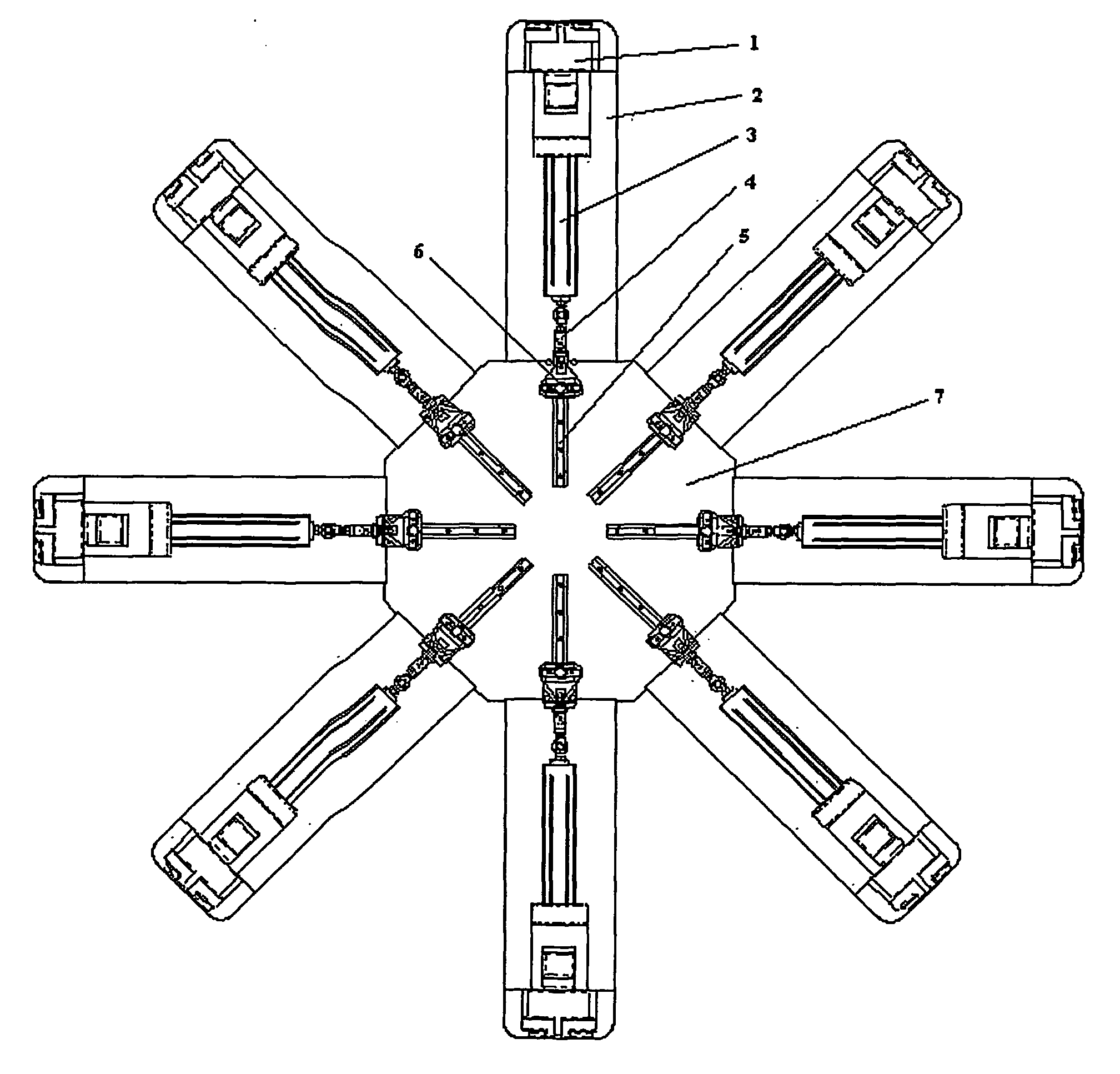

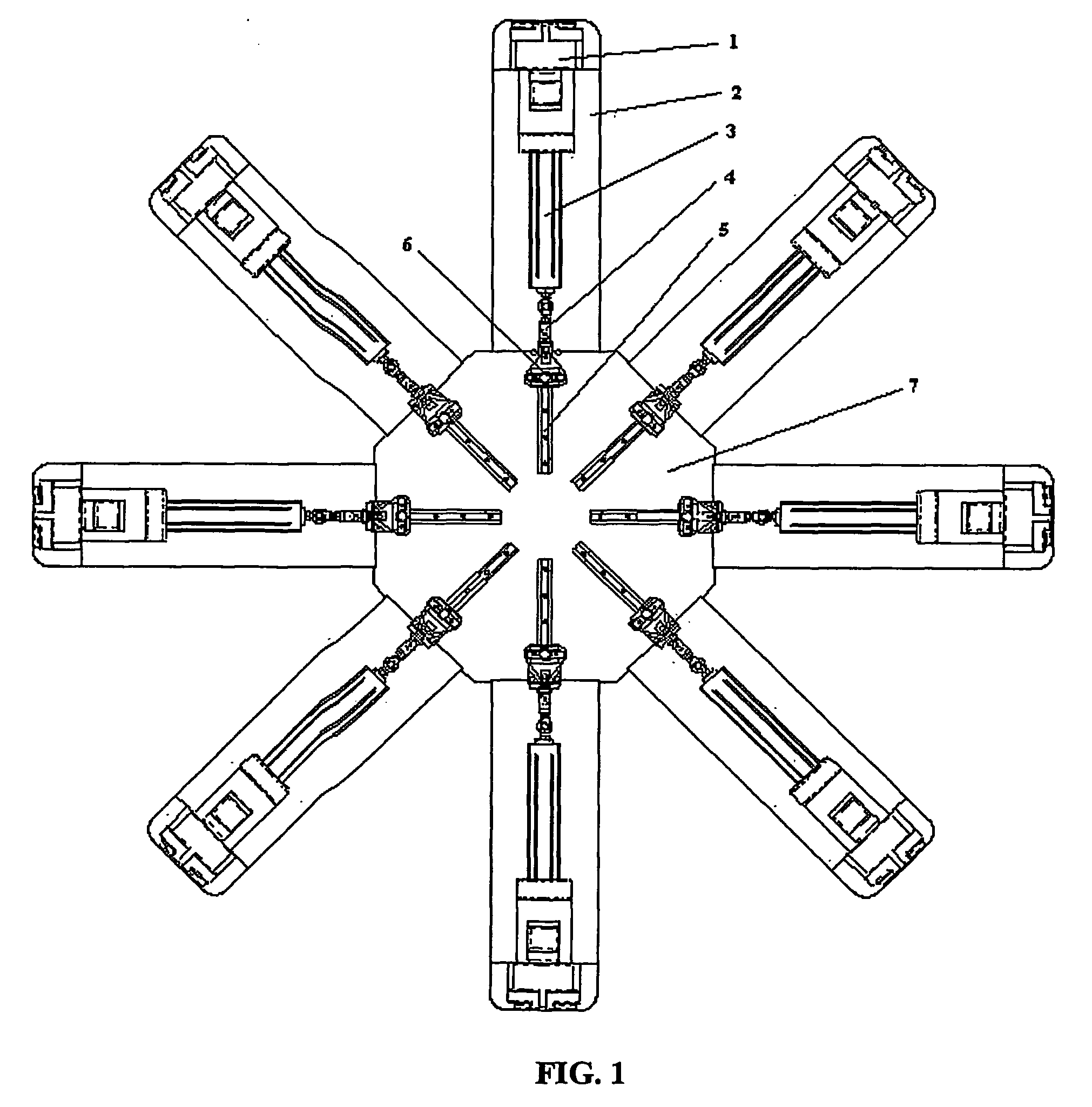

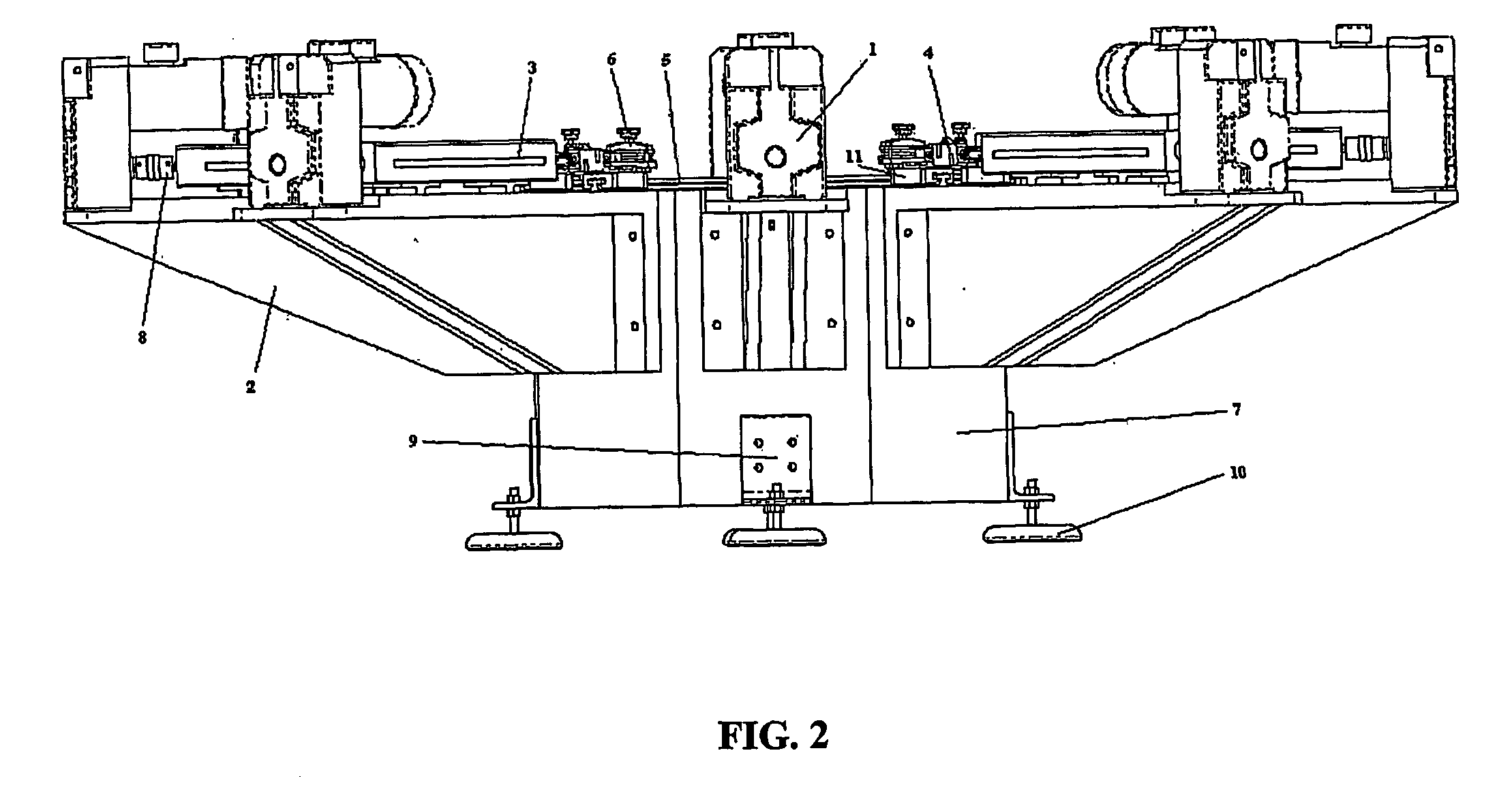

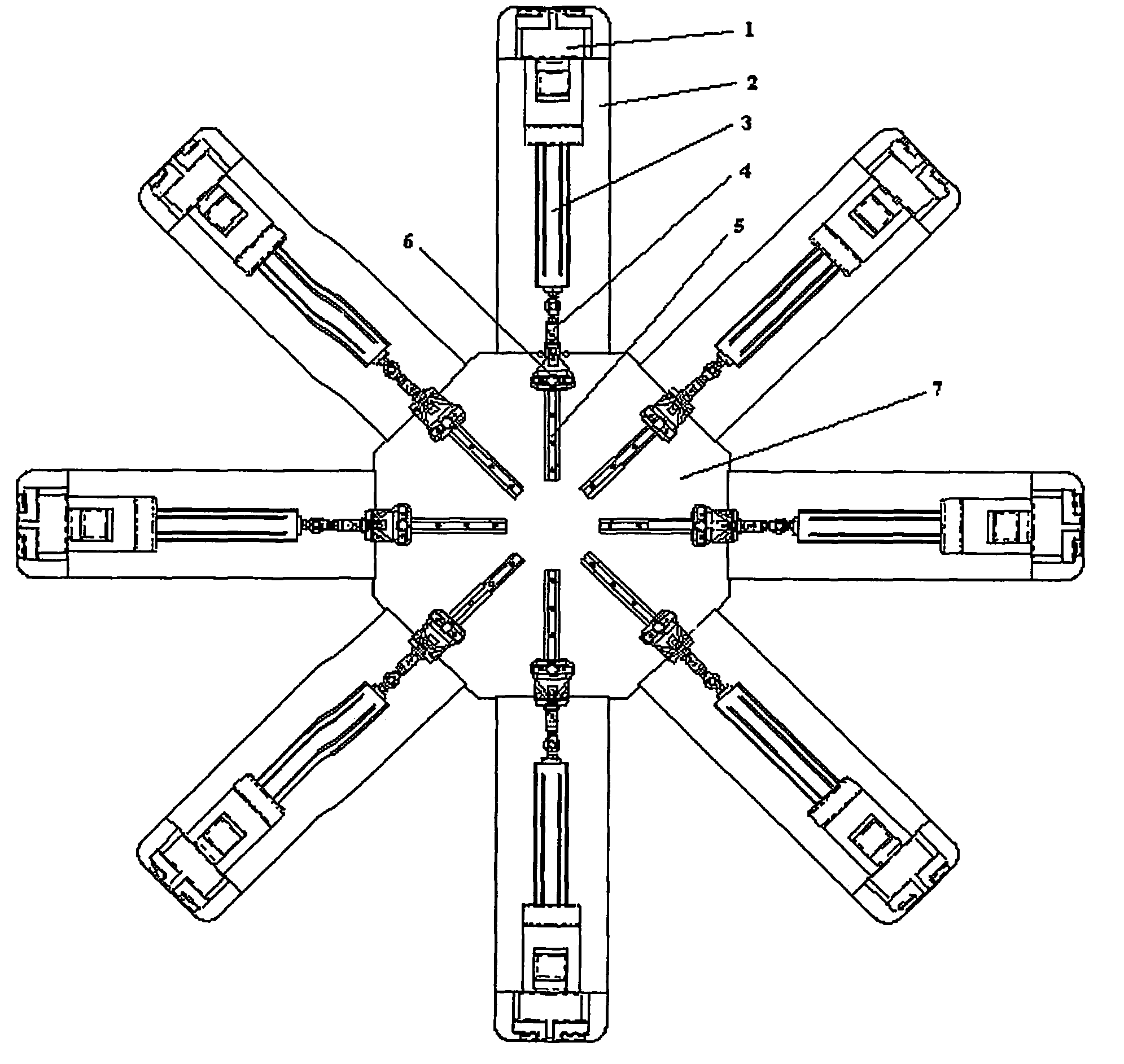

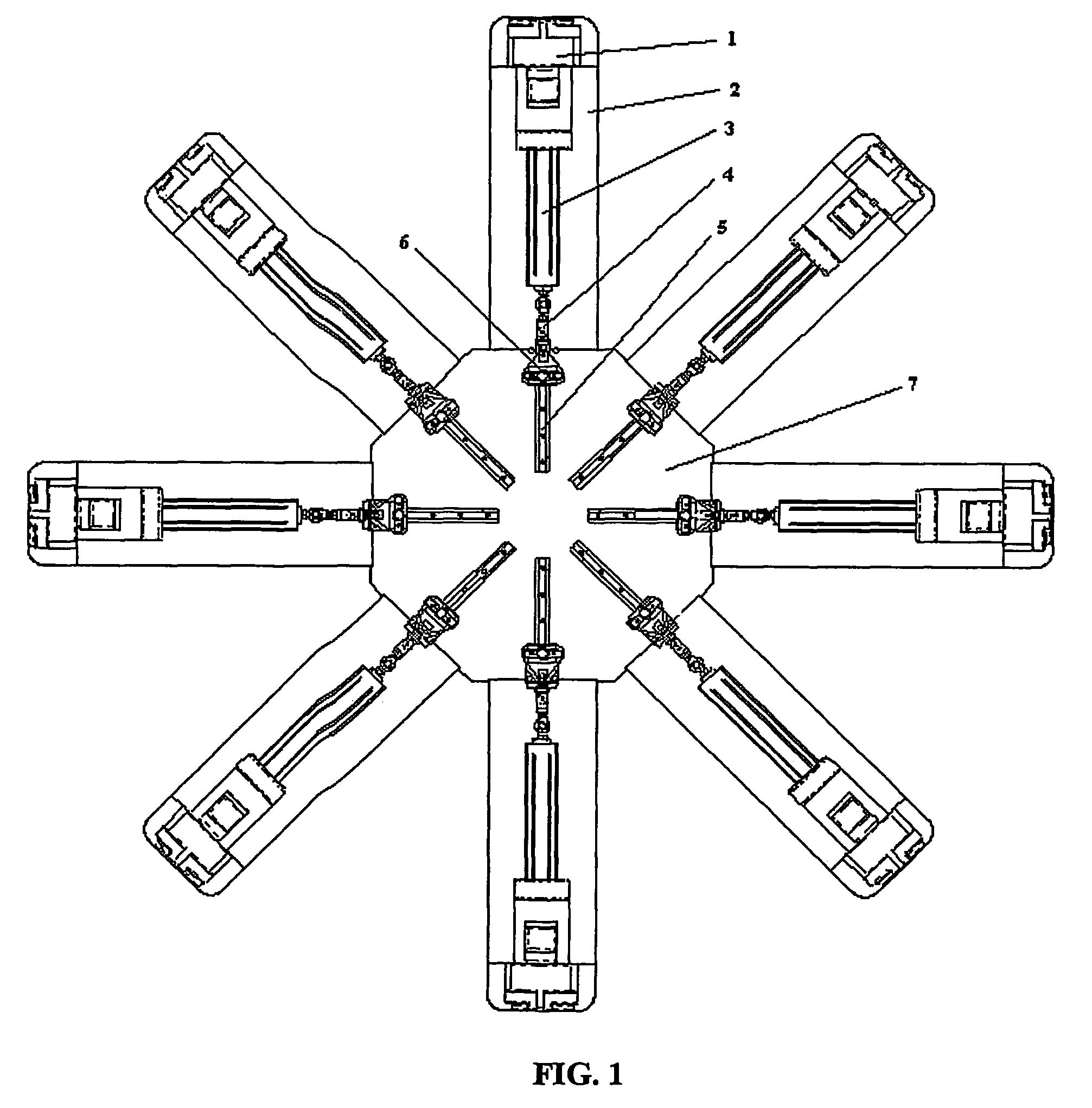

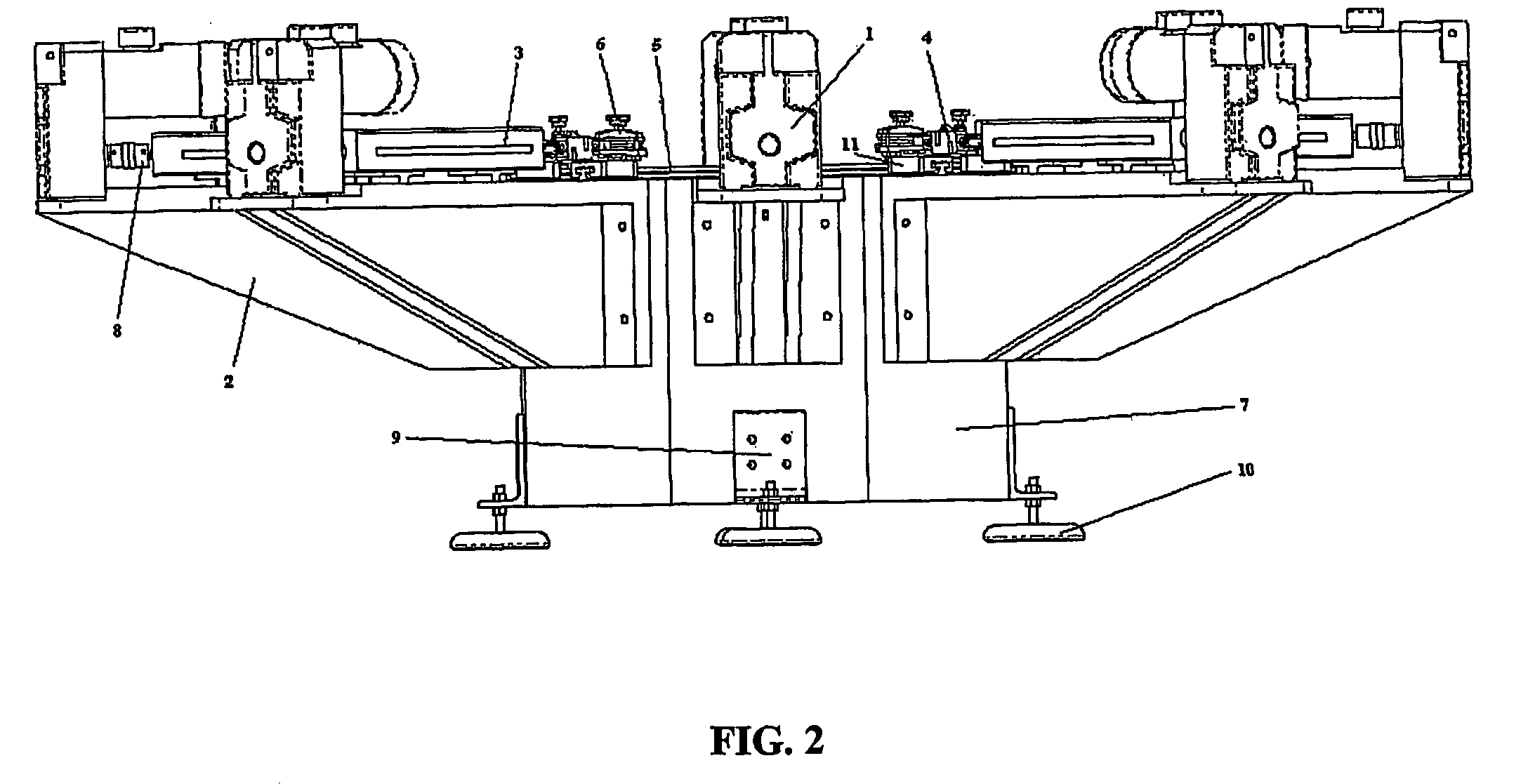

Multiaxial Universal Testing Machine

InactiveUS20080034885A1Reduce speedIncrease torqueMaterial strength using tensile/compressive forcesHorizontal axisElectric machinery

The invention concerns a multiaxial universal testing machine, which allows evaluating the mechanical behaviour and performance of materials with planar structures, such as fabrics, composites and laminates. The machine comprises 4 horizontal axes at 45°, with 8 gripping jaws displaceable along slide rails and moved by the action of 8 independent motors. The connection between a gripping jaw and its respective motor is assured by a linear actuator. The test specimen is fixed by the gripping jaws and can be subject to tensile, compression and fatigue testing, making possible the analysis of the materials behaviour under simultaneous multi-directional loads.

Owner:UNIVERSITY OF MINHO

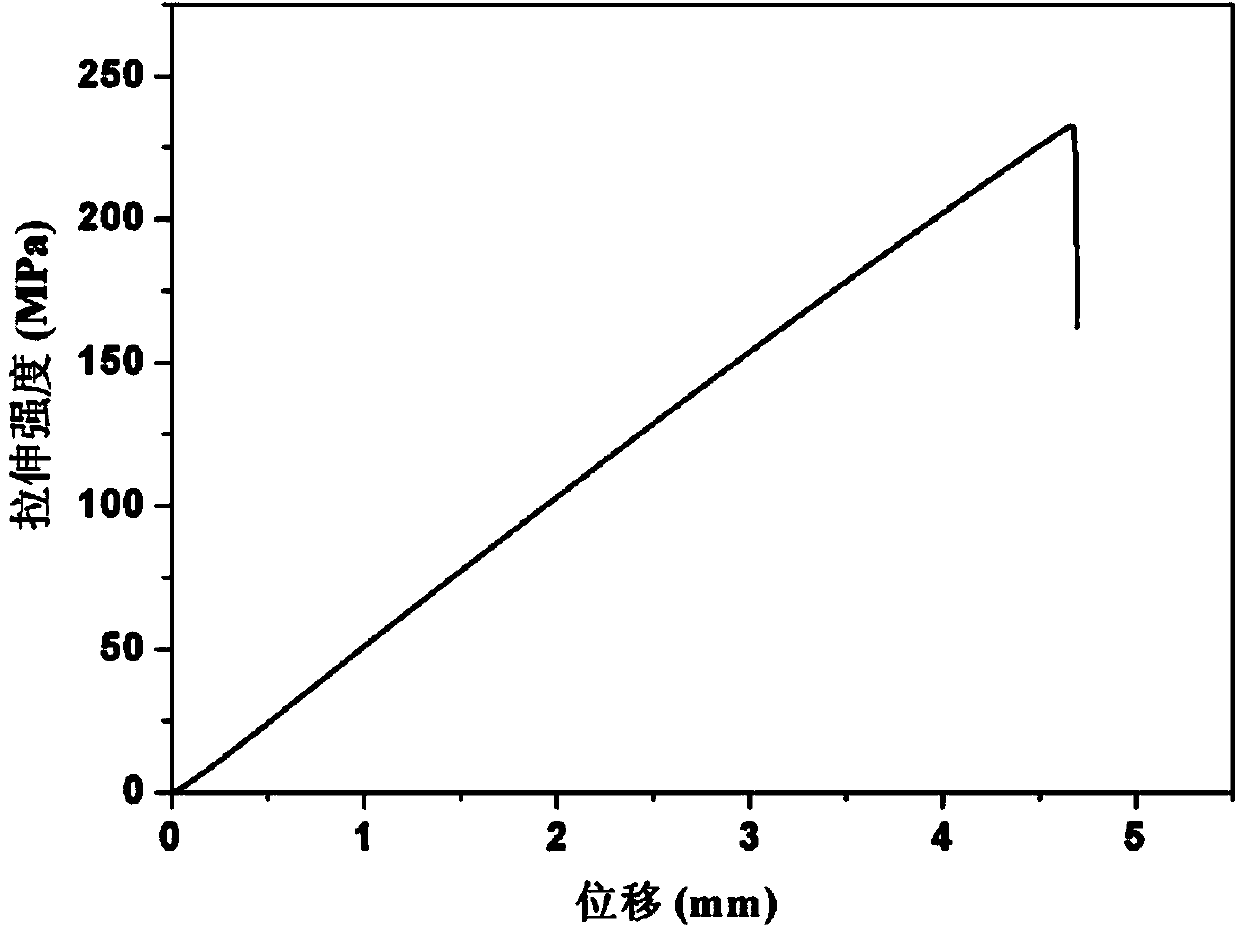

Method for testing mechanical property of braze welding connector

InactiveCN104181052AAvoid human errorEfficient testingMaterial strength using tensile/compressive forcesEngineeringMechanical property

The invention relates to a method for testing a mechanical property of a braze welding connector. The method comprises the following steps: (1) preparing a T-shaped tensile sample; (2) preparing test equipment including an electronic universal testing machine, a clamp, a heating furnace, a temperature control system and a control system; (3) installing the T-shaped tensile sample; (4) testing the mechanical property of a T-shaped tensile sample connector in an environment of the room temperature; (5) testing the mechanical property of the T-shaped tensile sample connector in a high-temperature environment; (6) representing the mechanical property of the connector: integrating a load-displacement curve, dividing the area of a fractured surface to obtain fracture total energy, calculating interface fracture energy (refer to the specification) and a maximal load (refer to the specification) when in fracturing, wherein the interface fracture energy and the maximal load are main parameters representing the mechanical property of the tensile sample. The T-shaped connector sample conforming to the real structure stress situation is provided; the problem that the method for testing the mechanical property of the braze soldering plate-fin structure is in lack and the rest result is incorrect can be solved; the test method is simple, data can be automatically acquired, error in manual operation can be avoided, more efficiency in test can be achieved, and the test result is more accurate.

Owner:EAST CHINA UNIV OF SCI & TECH

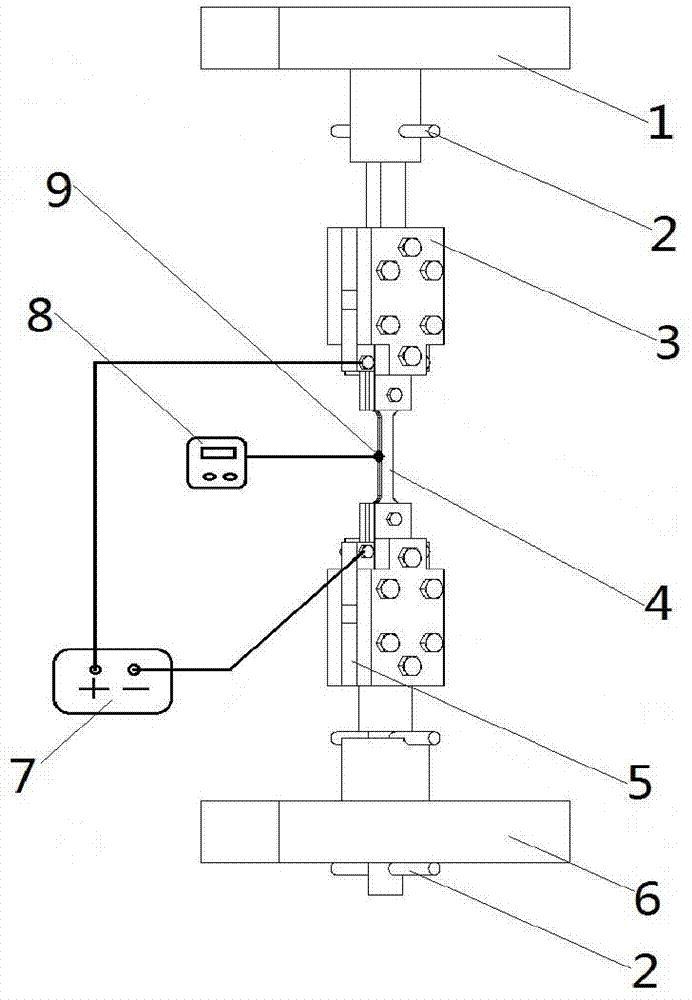

Temperature measurement method for electrified tensile test piece and tensile test device

InactiveCN104515707ASimple structureEasy to fixPreparing sample for investigationMaterial strength using tensile/compressive forcesRoom temperatureEngineering

The invention discloses a temperature measurement method for electrified tensile test pieces and a tensile test device. An electronic universal testing machine with an insulating chuck is used for finishing an electrified unidirectional tensile test of metal test pieces and real-time measurement on the temperatures of the test pieces through thermocouple matching. The method comprises the steps: firstly spraying a protective agent to each of the test pieces to carry out anti-oxidization treatment; after the surface protective coating layers are naturally dried at a room temperature, performing insulating treatment on a thermocouple, clamping the two unidirectional tensile test pieces by the insulating chuck of the electronic universal testing machine, clamping the thermocouple between the two test pieces to ensure that the temperature measured by the thermocouple is the real temperatures of the center positions of the test pieces, electrifying a direct current power supply to heat the test pieces, and measuring the temperatures of the test pieces in real time by a thermocouple temperature measurer; after the test pieces reach the stable temperatures, switching on the electronic universal testing machine to carry out the unidirectional tensile test on the test pieces. Therefore, accurate temperature measurement on the unidirectional tensile test pieces can be guaranteed; furthermore, the test device is simple in structure, short in manufacturing period and low in cost.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

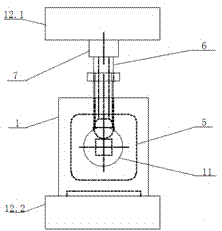

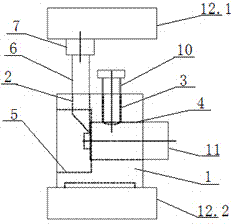

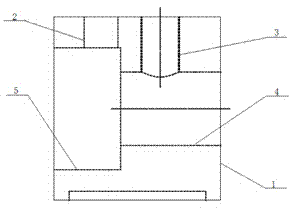

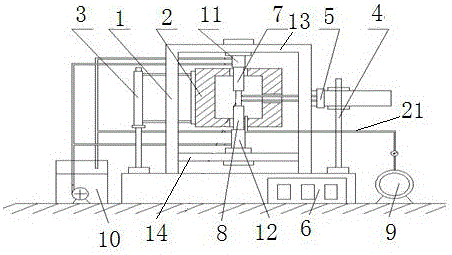

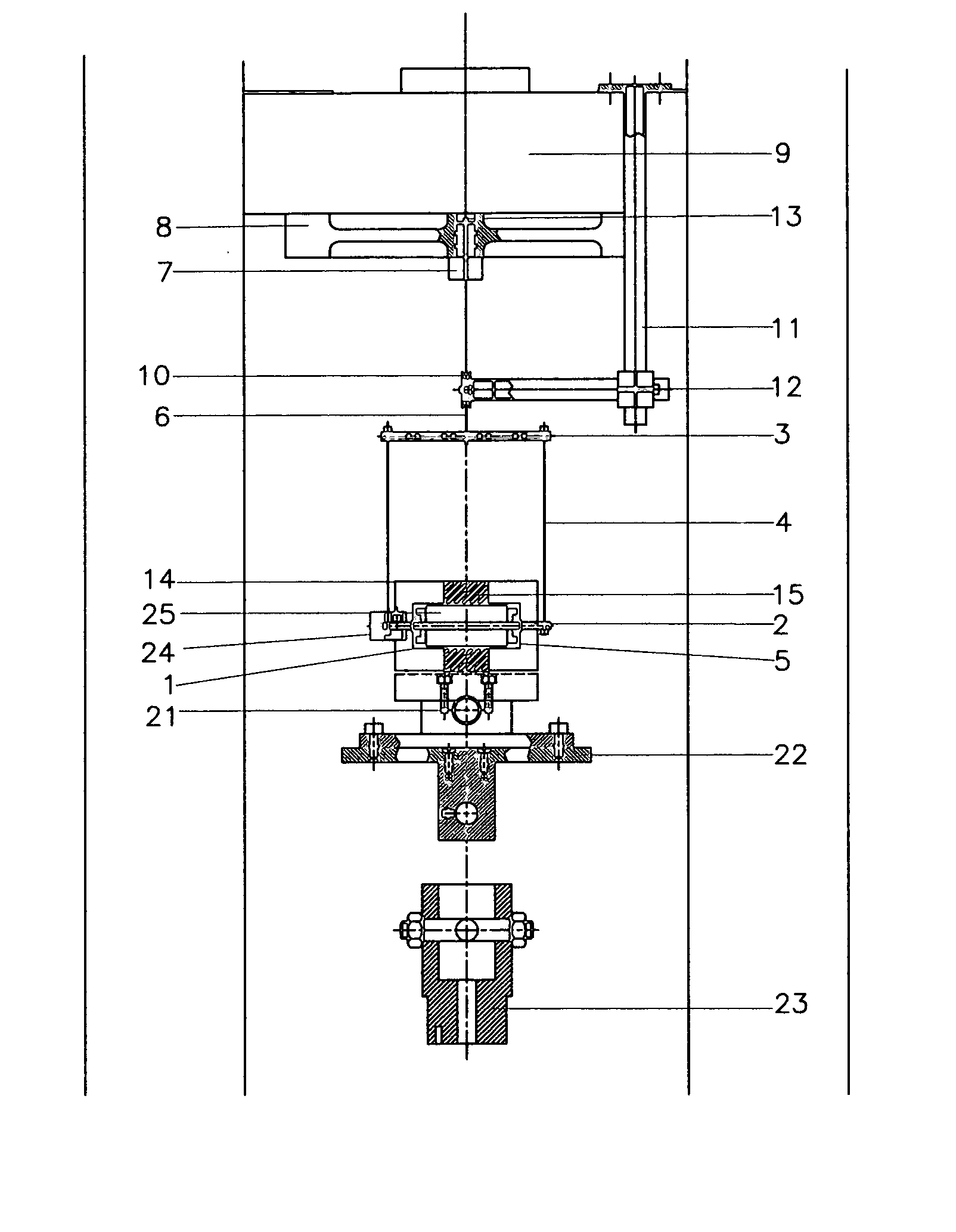

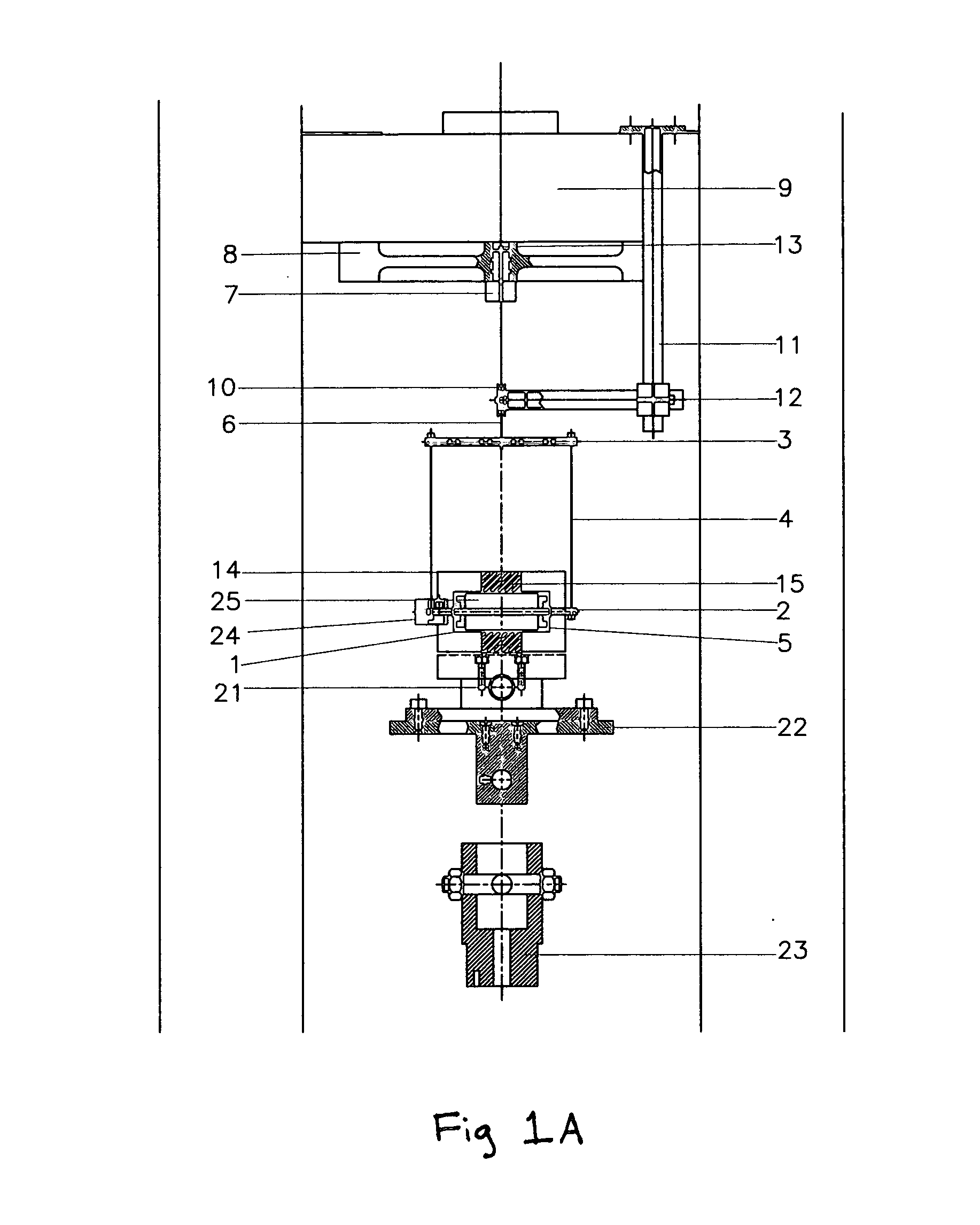

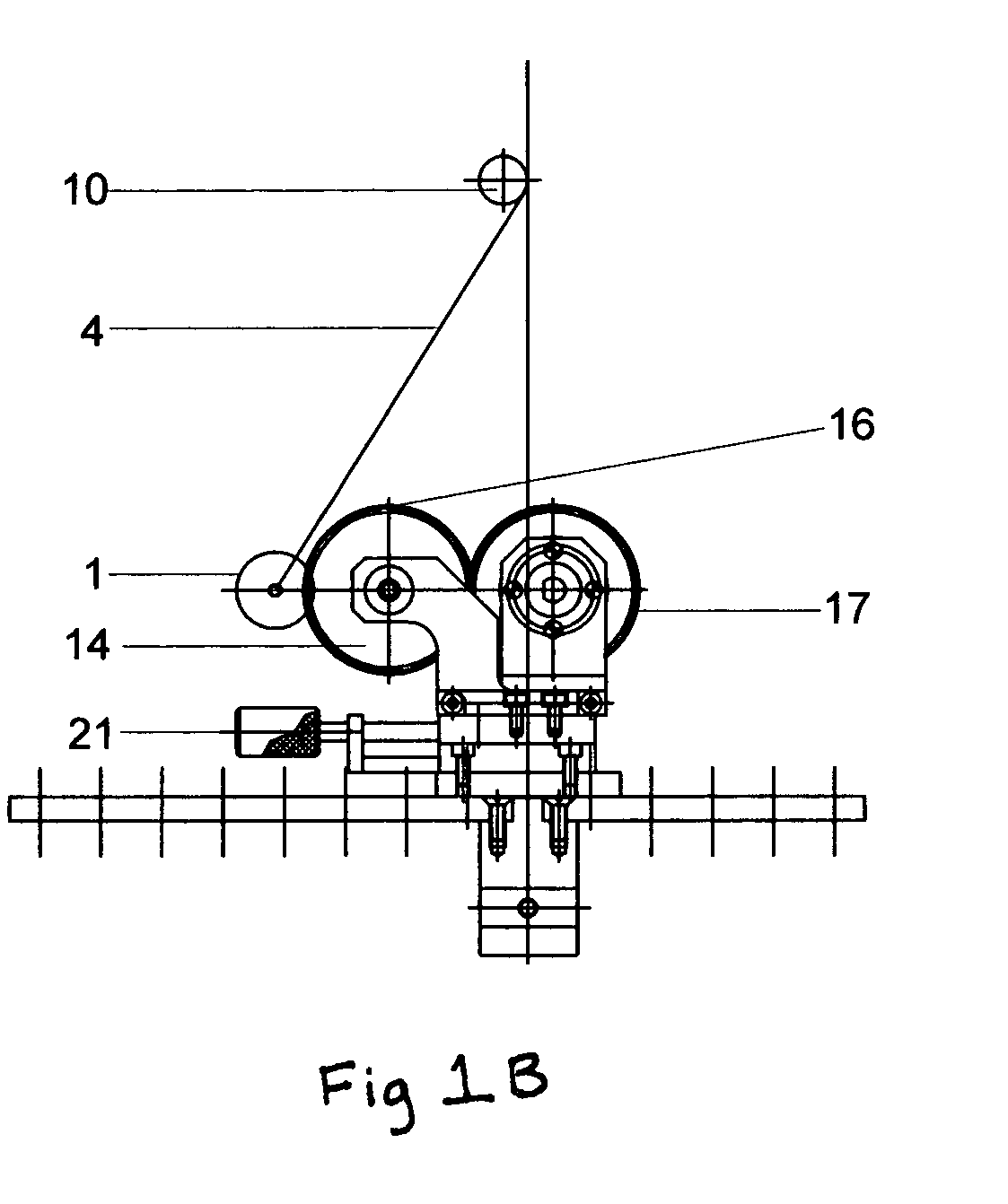

Universal testing machine

ActiveUS20110132078A1Easy to switchEasy to mountMaterial strength using tensile/compressive forcesInvestigating material hardnessDigital dataEngineering

A testing machine includes a stand and a test device. The stand includes a base, box frame, a slide device driven to slide by a motor, and a control system controls the force applied on the test specimen. The test device is coupled at the slide device for performing various hardness tests consisting of Rockwell hardness test, Vickers hardness test, Brinell hardness test, micro-hardness test, and tension-compression test. The test device includes a force sensor and a data processing circuit converting an analog signal of the force sensor into digital data to interface with the control system.

Owner:WUSOMING +1

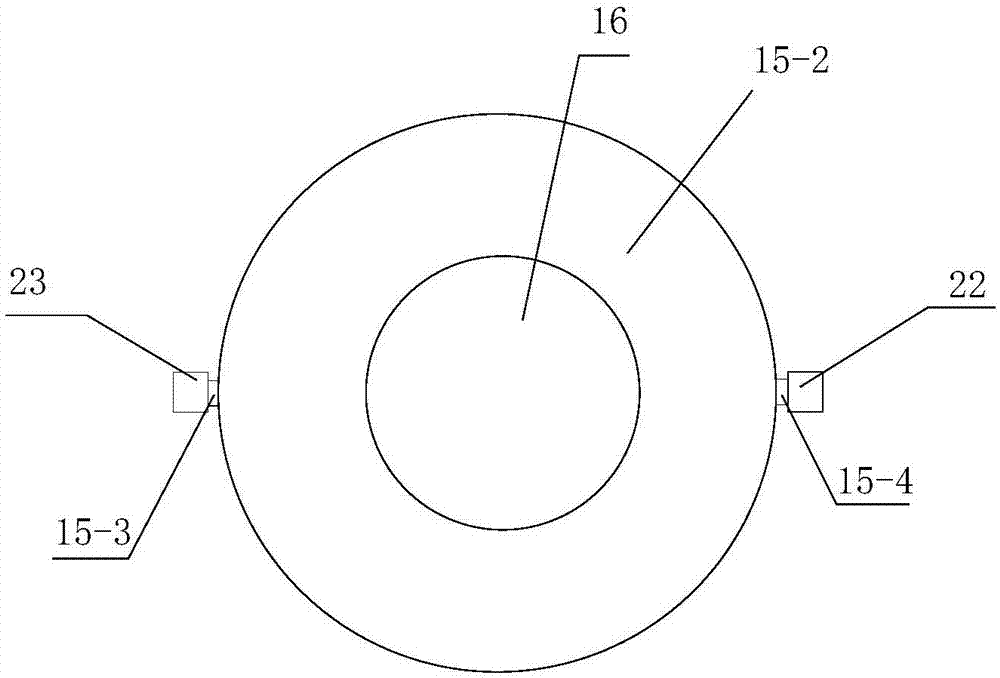

Coal body permeability characteristic testing system and method

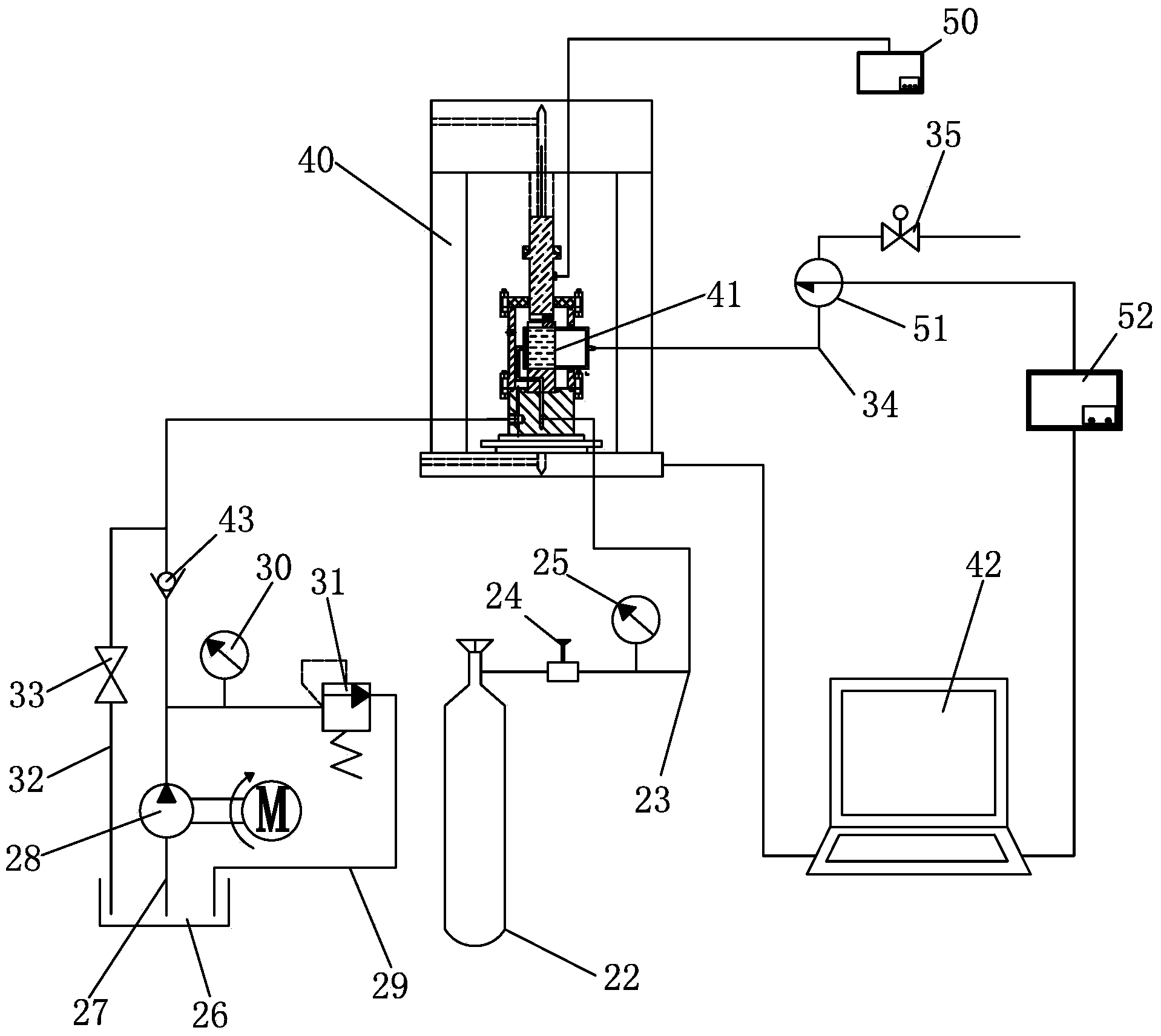

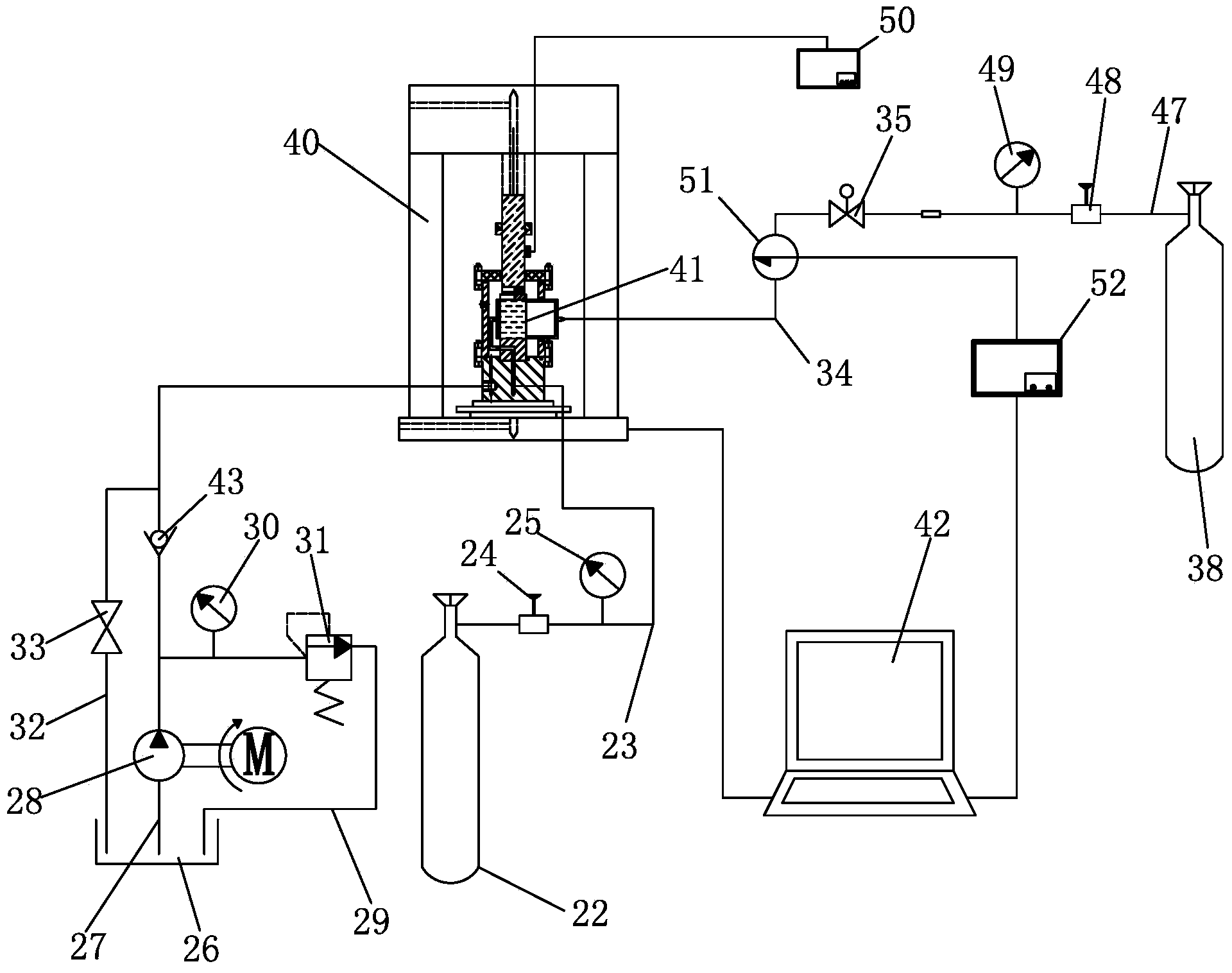

InactiveCN103940719ASimple structureEasy to assemblePermeability/surface area analysisAxial pressureHydraulic pump

The invention discloses a coal body permeability characteristic testing system. The coal body permeability characteristic testing system comprises an electronic universal testing machine, a permeability characteristic testing device, a vibration detecting device, a first gas system, a confining pressure hydraulic system and a computer, wherein the permeability characteristic testing device consists of a lane simulating mechanism and a lane ambient environment simulating mechanism; the lane simulating mechanism comprises a baffle, a breathable plate, a coal rock sample and a U-shaped clamping sleeve; the lane ambient environment simulating mechanism comprises a base, a cylinder tube, a lower pressing head, an upper half concave surface pressing head, an upper half convex surface pressing head and a piston; the first gas system comprises a first gas tank, a first pressure reduction valve and a first gas pressure meter; the confining pressure hydraulic system comprises a confining pressure liquid tank, a hydraulic pump, a unidirectional valve, a confining pressure hydraulic meter and a confining pressure liquid overflow valve. The invention also provides a coal body permeability characteristic testing method. According to the coal body permeability characteristic testing system and method, the axial pressure, the confining pressure and the methane gas pressure are controllable, the gas permeability characteristics influenced by disturbance of a lane coal rock body and a coal mine deep part coal rock body can be tested, and the testing precision is high.

Owner:XIAN UNIV OF SCI & TECH

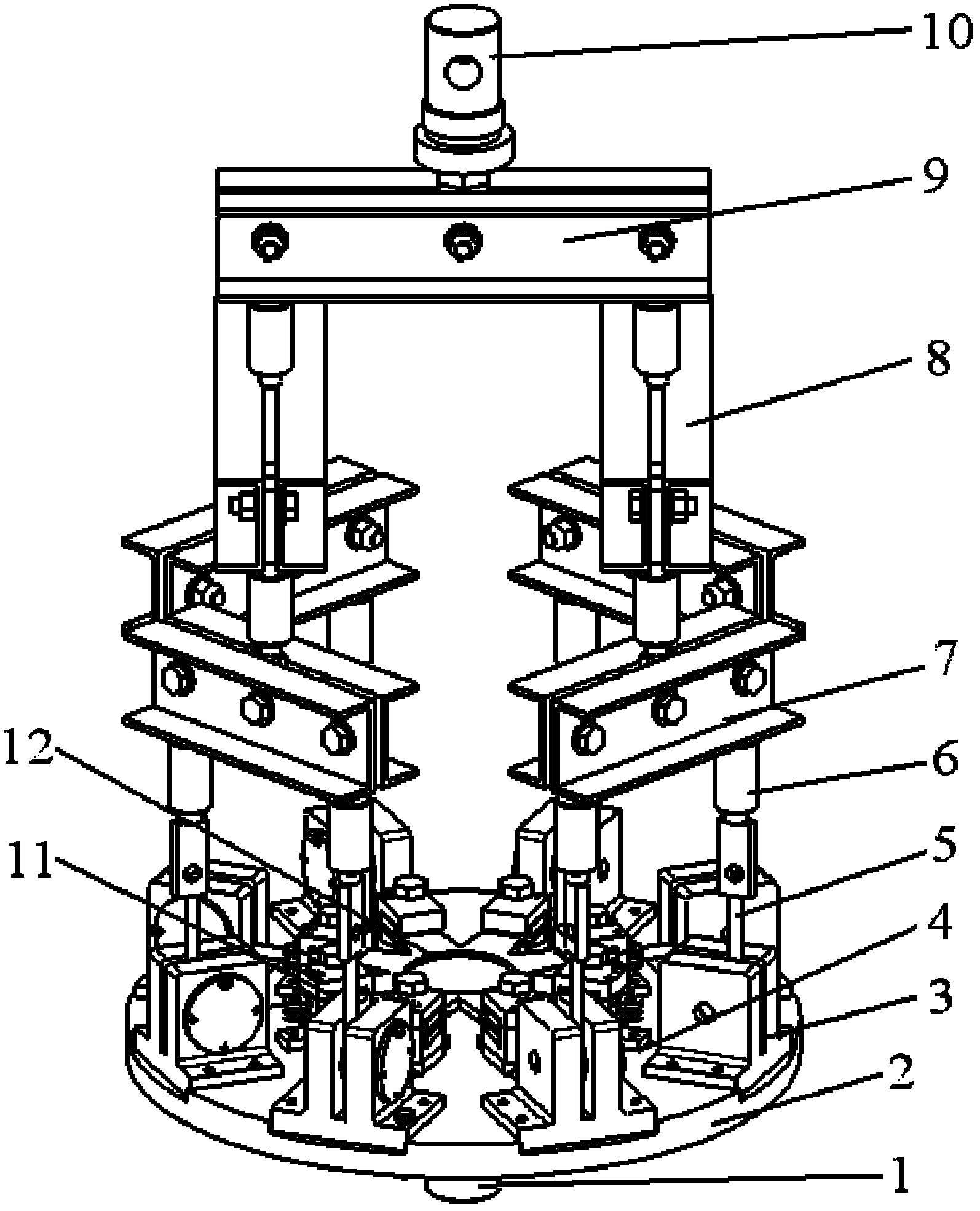

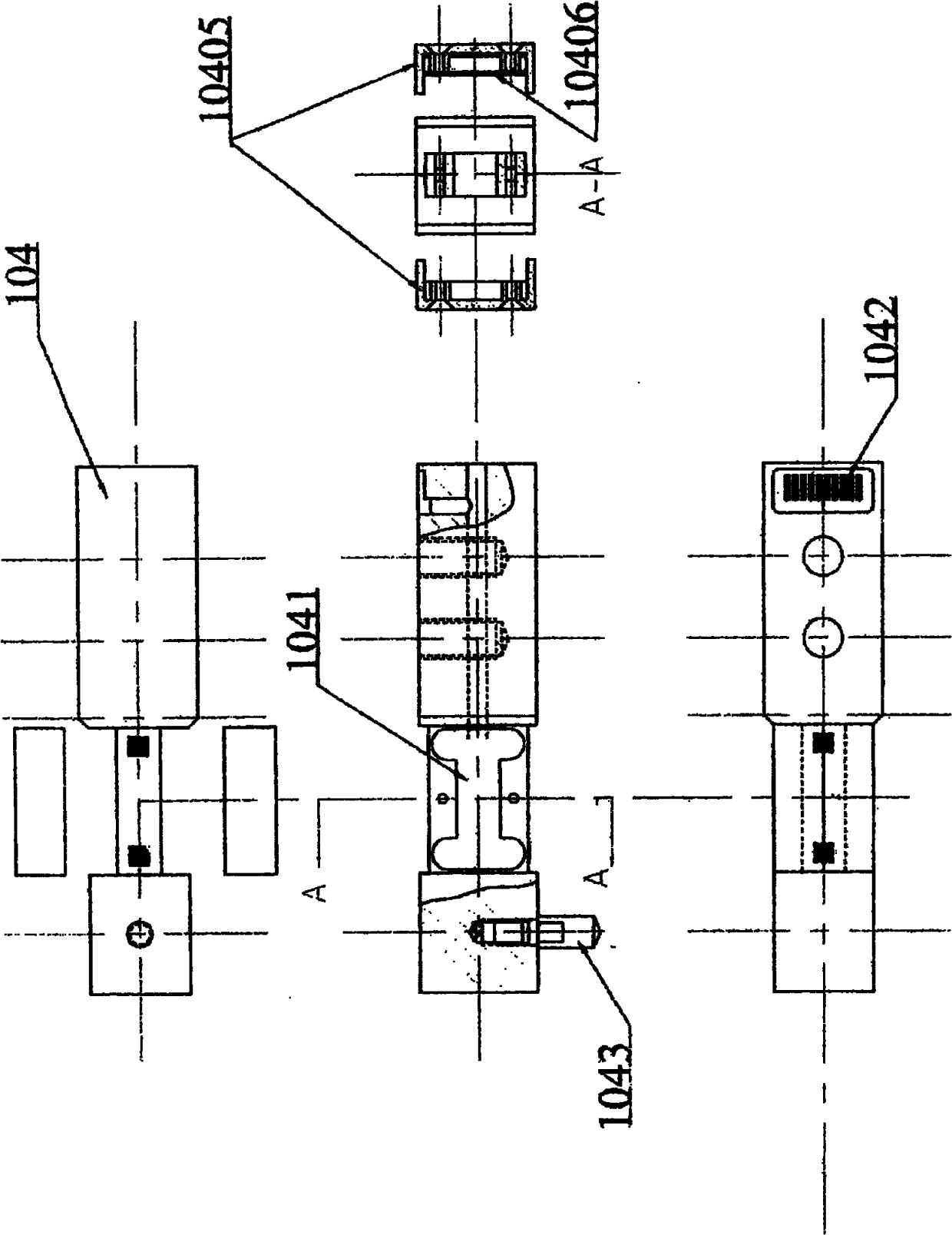

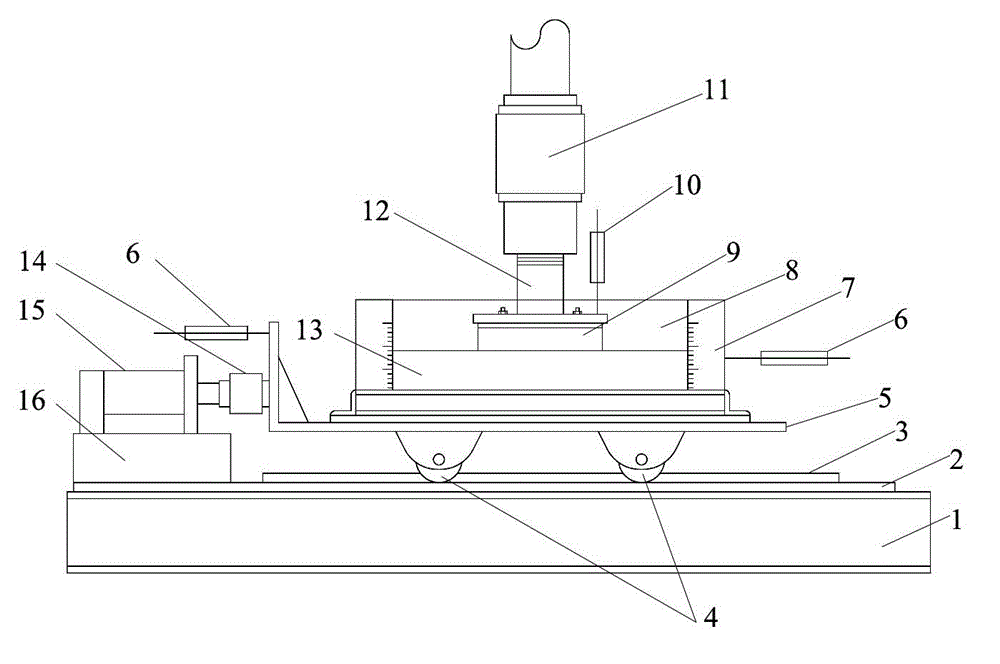

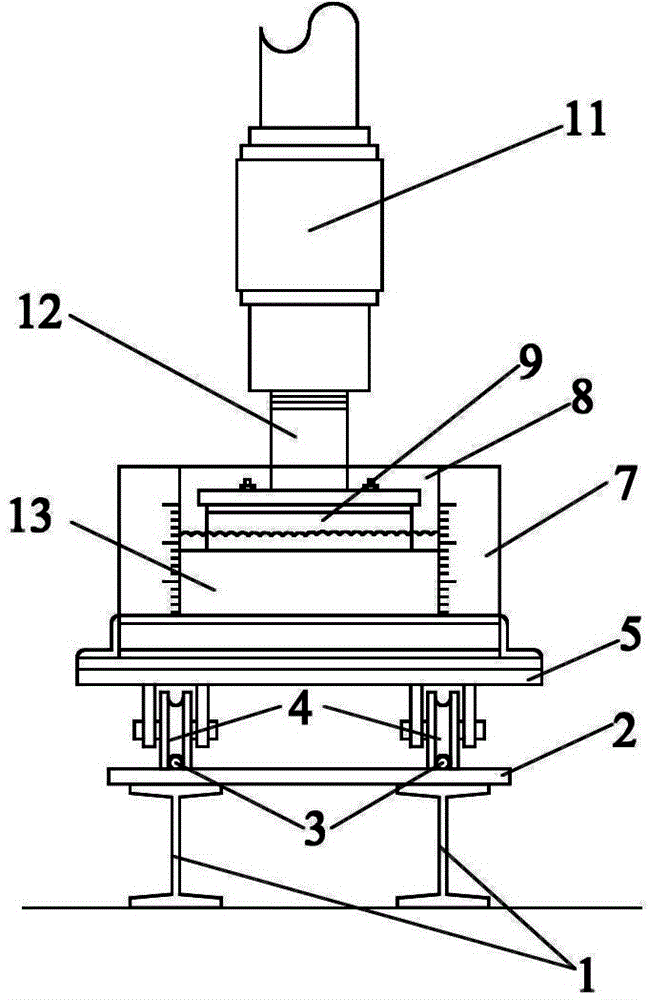

Multiaxial universal testing machine

InactiveUS7509882B2Reduce speedIncrease torqueWork measurementMaterial strength using tensile/compressive forcesElectric machineryHorizontal axis

The invention concerns a multiaxial universal testing machine, which allows evaluating the mechanical behavior and performance of materials with planar structures, such as fabrics, composites and laminates. The machine comprises 4 horizontal axes, each one with 2 arms, resulting in a final arrangement of 8 gripping jaws at 45°, displaceable along slide rails and moved by the action of 8 independent motors. The connection between a gripping jaw and its respective motor is assured by a linear actuator. The test specimen is fixed by the gripping jaws and can be subject to tensile, compression and fatigue testing, making possible the analysis of the materials behavior under simultaneous multi-directional loads.

Owner:UNIVERSITY OF MINHO

Testing device for two-way loading test of material

The invention relates to a testing device for a two-way loading test of a material, which comprises three parts, namely a base, a lever structure and a chuck, wherein the base is arranged at the bottom of the testing device; and the lever structure and the chuck are respectively arranged on the base. Compared with the prior art, the testing device disclosed by the invention has a simple structure, is convenience for maintenance and can be used for conveniently finishing a test object and adjusting the loading proportion; in addition, the testing device can carry out the two-way loading test on a universal testing machine so as to reduce the test cost; and the testing device has the advantages of enough loading precision and the like.

Owner:SHANGHAI JIAO TONG UNIV

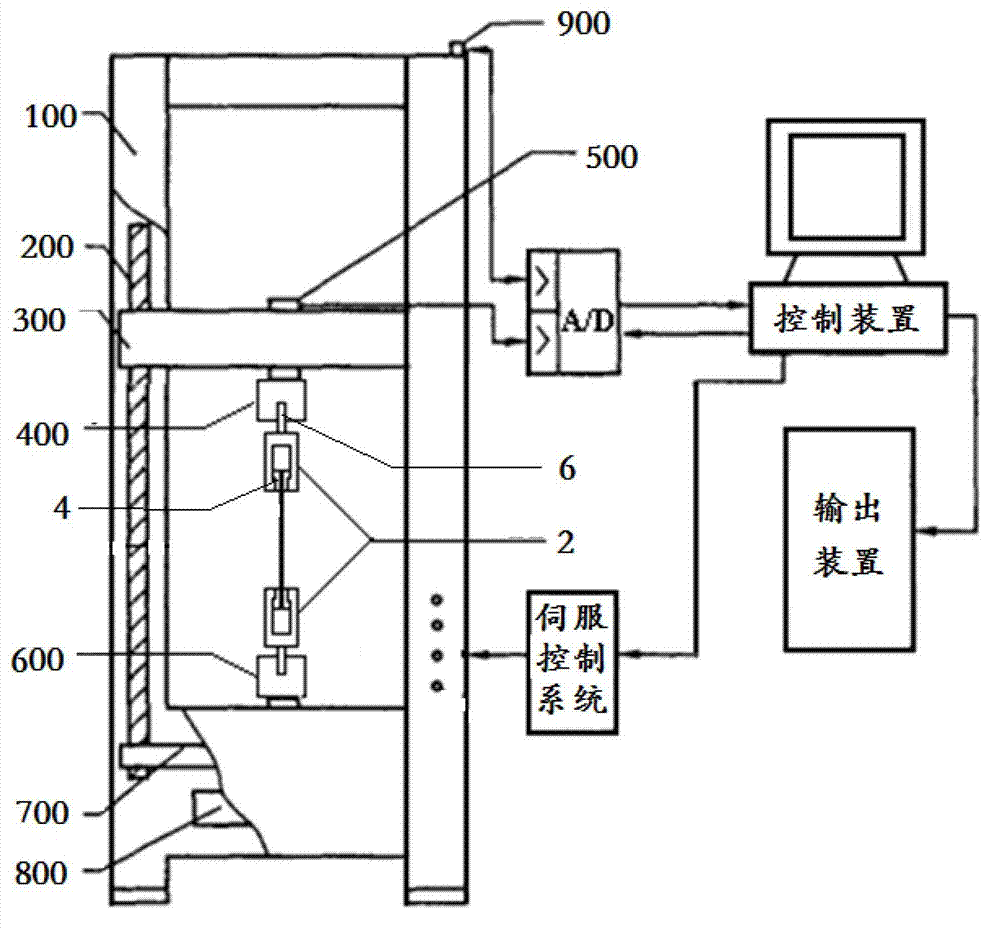

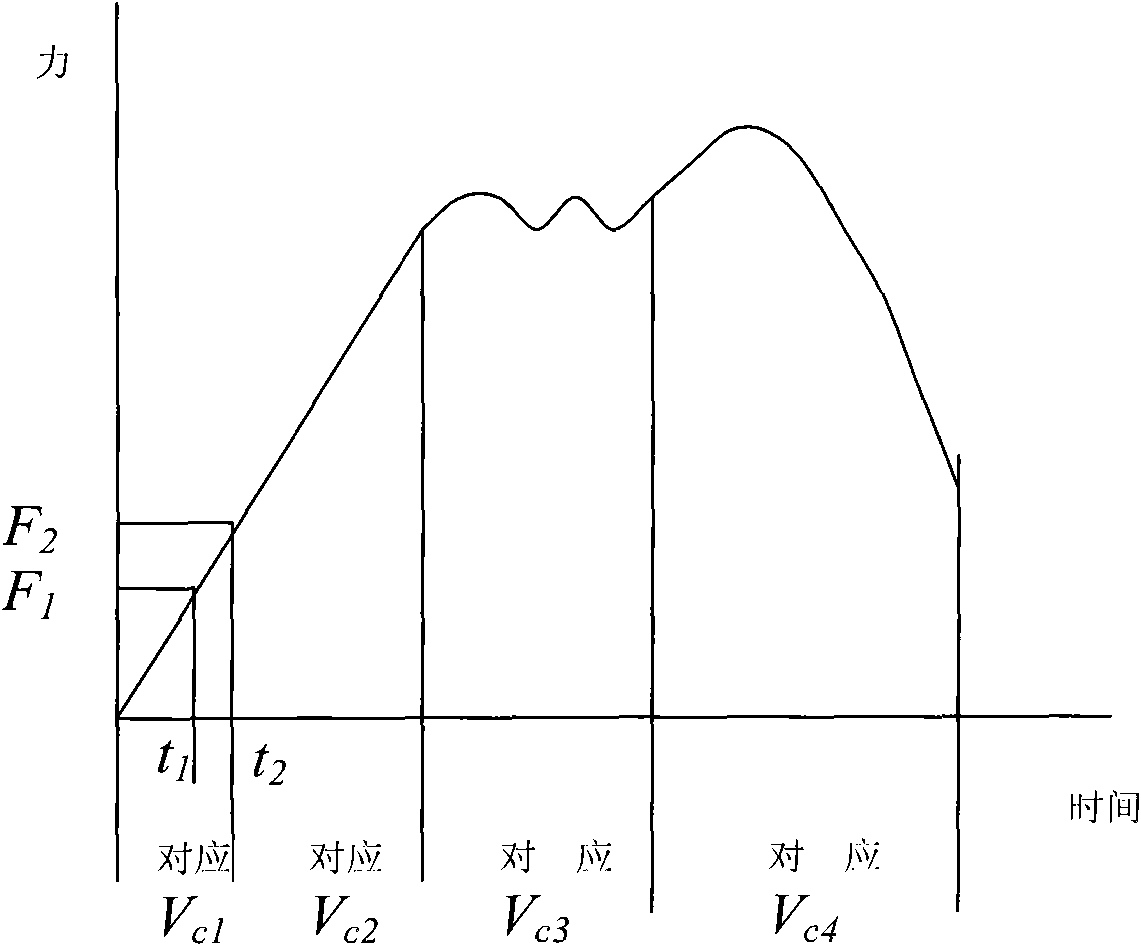

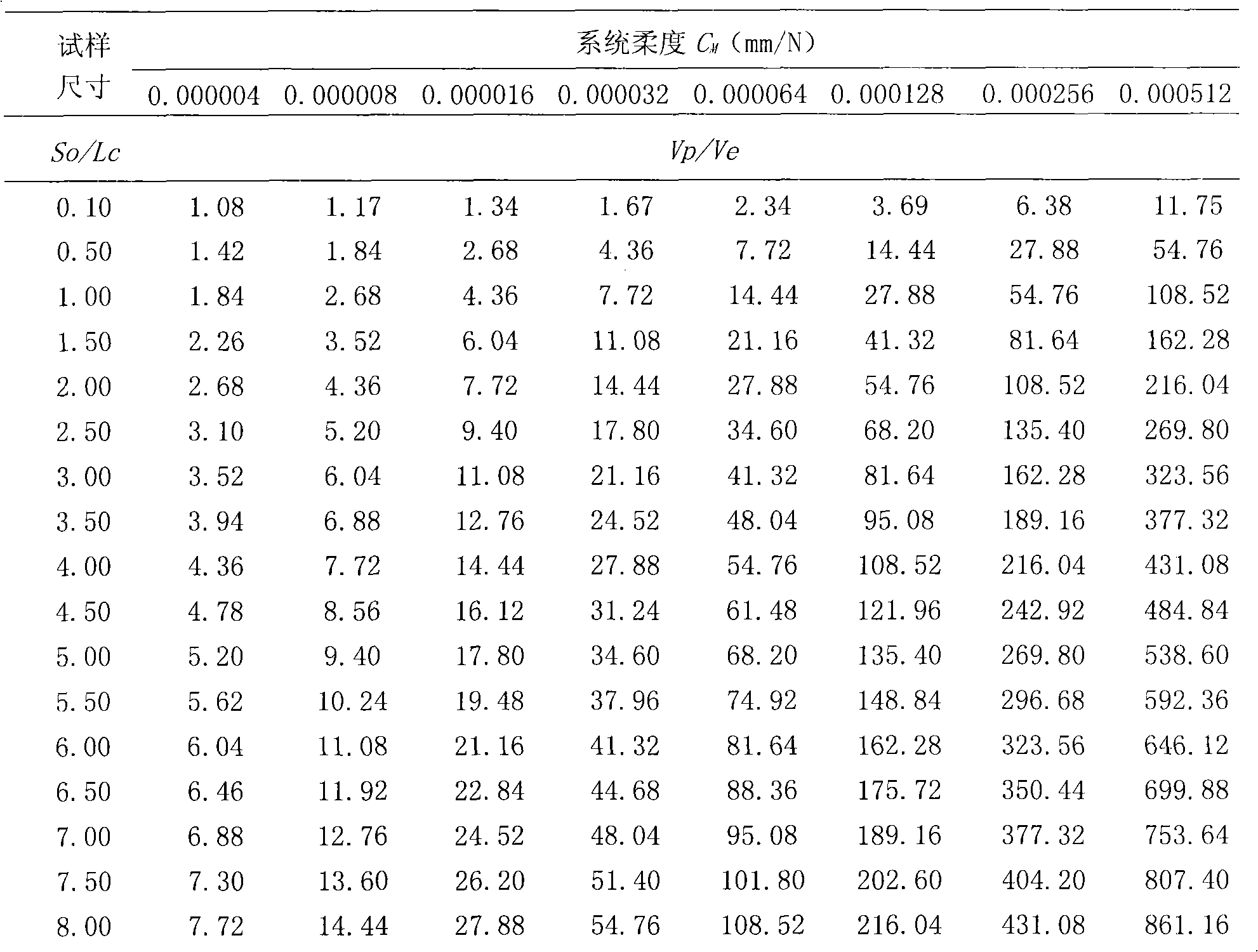

Method for controlling whole-course displacement in program-controlled metal material stretching test

ActiveCN101661271AImprove work efficiencyImprove accuracyMaterial strength using tensile/compressive forcesProgramme control in sequence/logic controllersMathematical modelStress–strain curve

The invention provides a method for controlling whole-course displacement in a program-controlled metal material stretching test. The control method is arranged is a test application program of an electro-hydraulic servo or electronic universal testing machine; the control method comprises the following steps of: displacement control in the first stage, displacement control in the second stage, displacement control in the third stage and the displacement control in the fourth stage. The method has the effects that the control method provides a mathematic model which automatically computes theflexibility of the system in the testing process, and the model is simple and reliable and aims at the system flexibility computation on each testing sample. The whole test is carried out automatically, great convenience is brought to the testing personnel, and the working efficiency and accuracy of the yield strength test are improved obviously. The method is applicable to the requirements on thestretching rates at different stages of various metal material samples; furthermore, rate conversion is smoothly transitional before the yield stage is finished; and the discontinuity is not introduced on the stress-strain curve. The method is applicable to the production, research and technical reconstruction on a stretching testing machine.

Owner:TIANJIN PIPE GROUP CORP

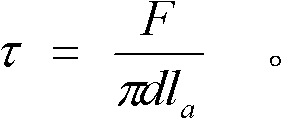

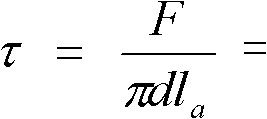

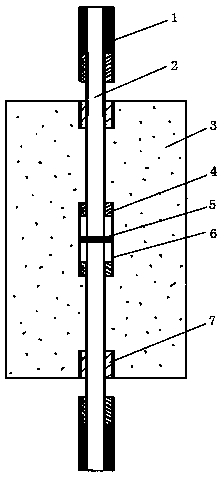

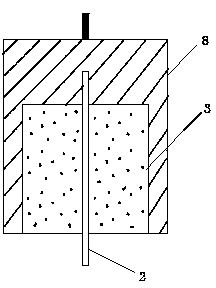

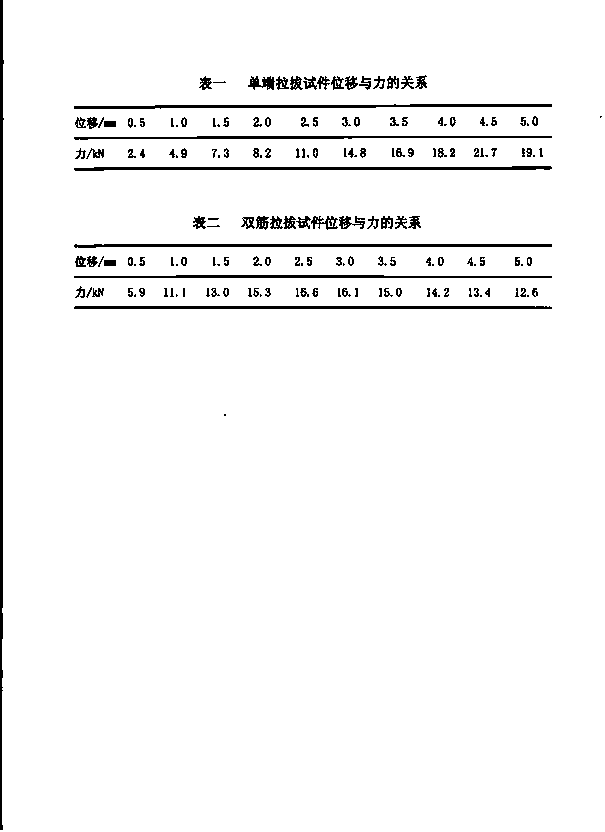

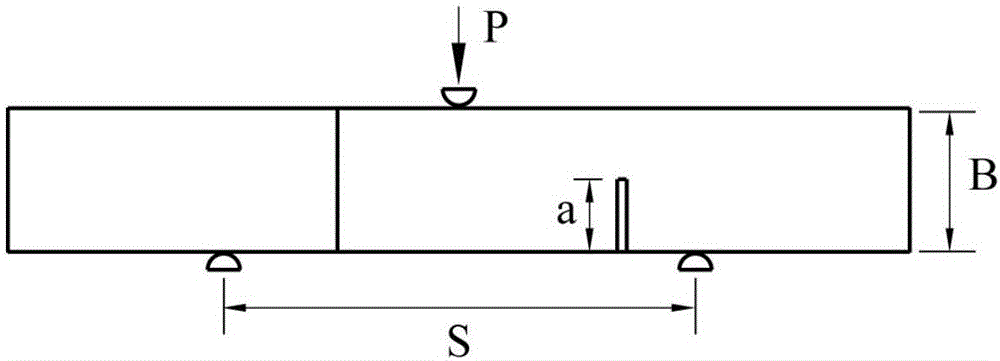

Method for measuring bond strength between high-intensity glass fiber rib and concrete

ActiveCN101819135ASimple test methodLow costUsing mechanical meansMaterial analysisGlass fiberHigh intensity

The invention provides a method for measuring bond strength between a high-intensity glass fiber rib and concrete, which comprises the following steps of: A, pouring test pieces: inserting the high-intensity glass fiber rib into a PVC plastic sleeve in a cubic pouring mold, wherein the lower end of the high-intensity glass fiber rib is positioned in the cubic pouring mold, and the top of the high-intensity glass fiber rib extends out of the cubic pouring mold; B, performing the loading process: after curing the test pieces in a curing chamber to the age, taking the test pieces out for testing, and performing the test on a hydraulic universal testing machine; and C: calculating the bond strength: calculating a bond strength value tau between the high-intensity glass fiber rib and the concrete by the following formula. The measured result obtained by the method can more accurately reflect the bond strength between the high-intensity glass fiber rib and the concrete, and the method for measuring the bond strength between the high-intensity glass fiber rib and concrete has the advantages of simpleness and low cost.

Owner:CHANGSHA UNIVERSITY OF SCIENCE AND TECHNOLOGY

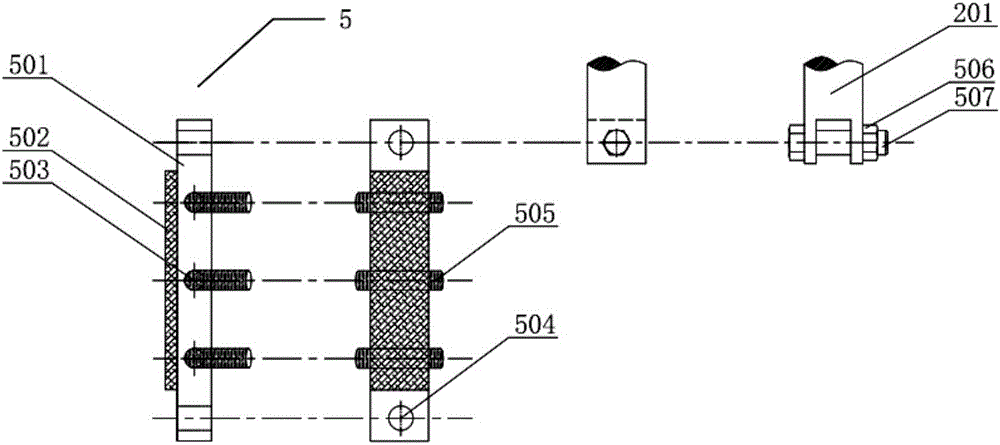

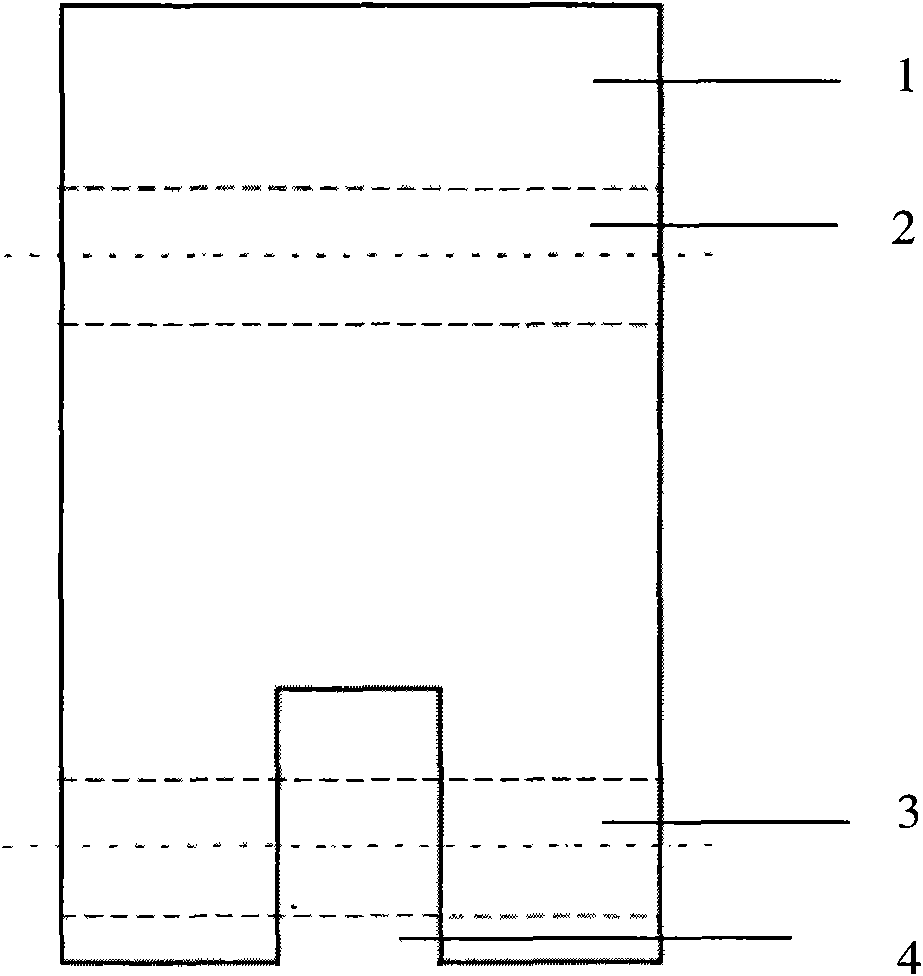

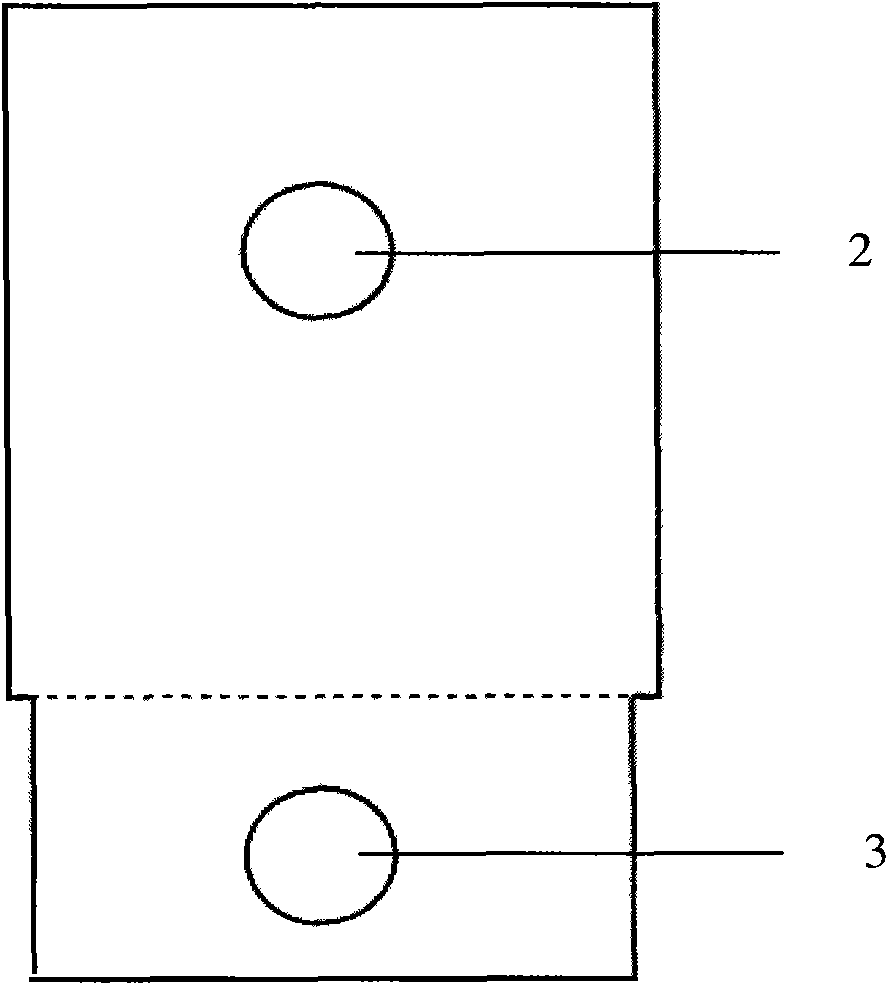

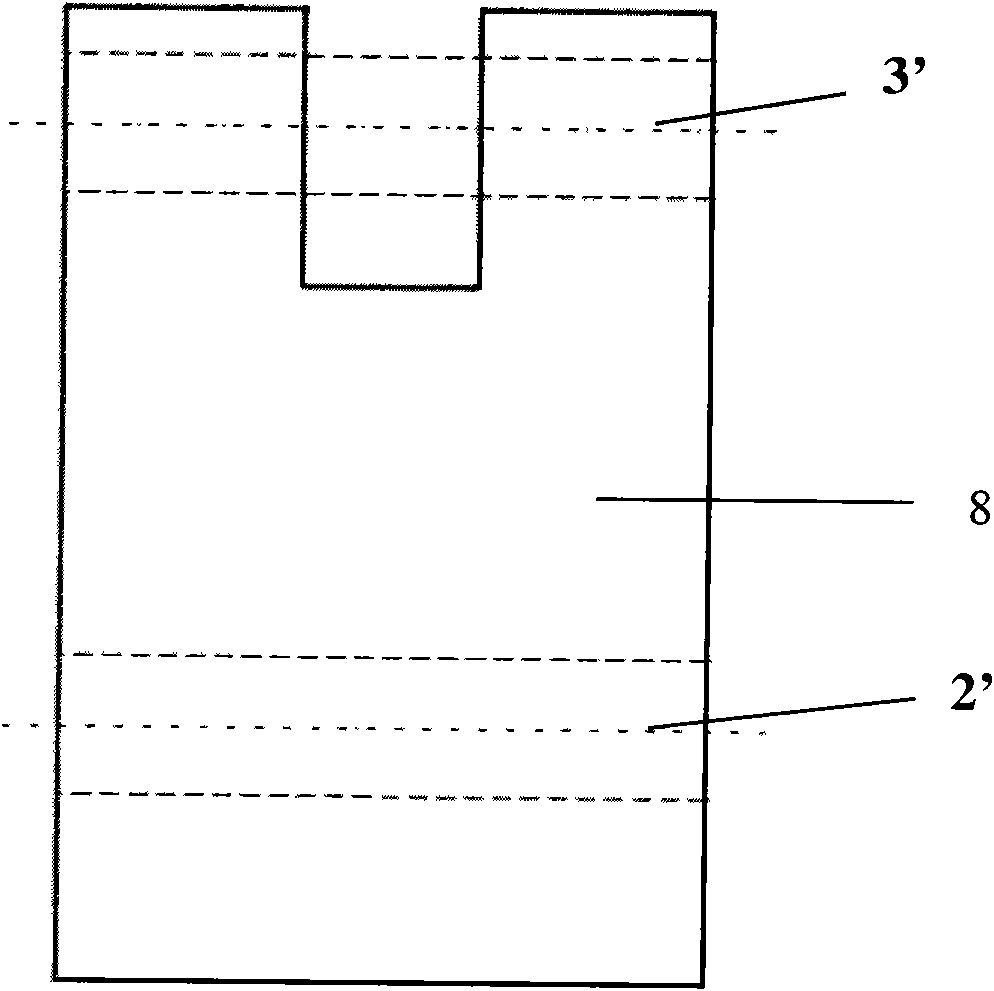

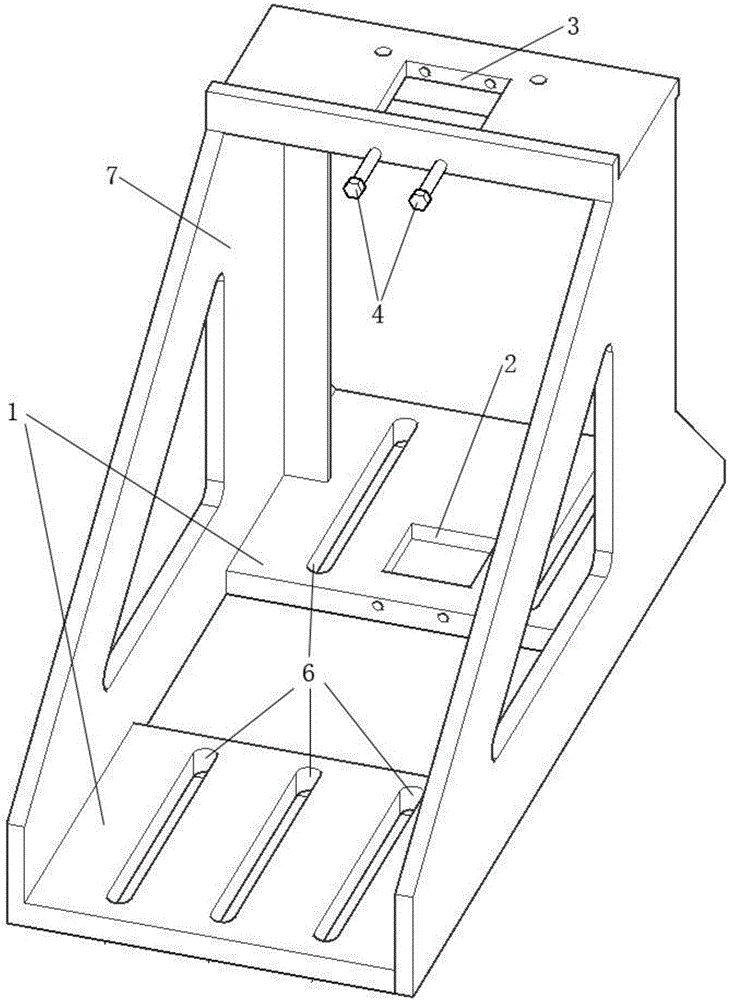

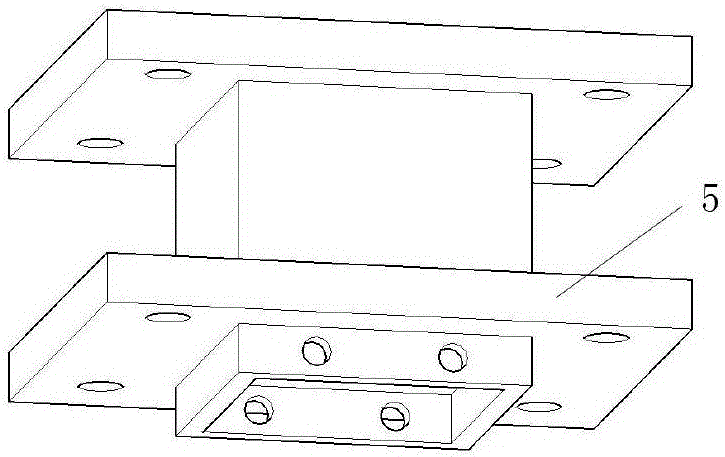

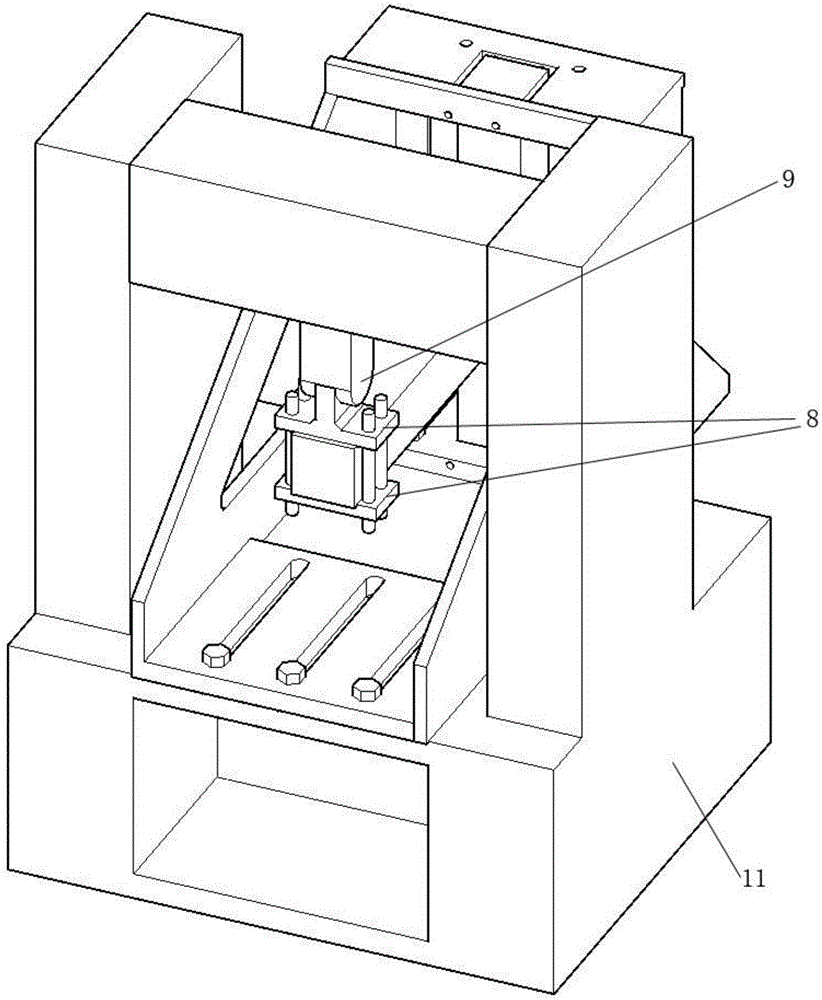

Test device for light steel frame beam column node bearing test

The invention discloses a test device for light steel frame beam column node bearing test. The device includes a device bottom plate assembled and fixed to a universal testing machine, a lower clamp groove provided with a light steel frame beam column, an upper clamp groove, fastening bolts for fixing the light steel frame beam column, an upper cover plate for fixing the light steel frame beam column, a bottom plate long groove for changing the loading point position, side plates connecting the bottom plate with the top plate, clamping plates for beam end loading, a hinge rod for loading an end, a beam column connection node test piece, and a mechanical universal testing machine. The whole test device can not only effectively realize the bearing performance test constraint condition of the beam column node, but also can measure the mechanical parameters of the beam column node test piece under the load by means of a strain gauge, a dial indicator, a displacement sensor, a force sensor or other tools while carrying out the loading, and therefore, the bearing mechanism and the mechanics model can be analyzed and studied. The whole device is clear in construction, convenient to use, and low in cost, and is a novel test device suitable for a miniature light steel beam column node test piece.

Owner:BEIJING UNIV OF TECH

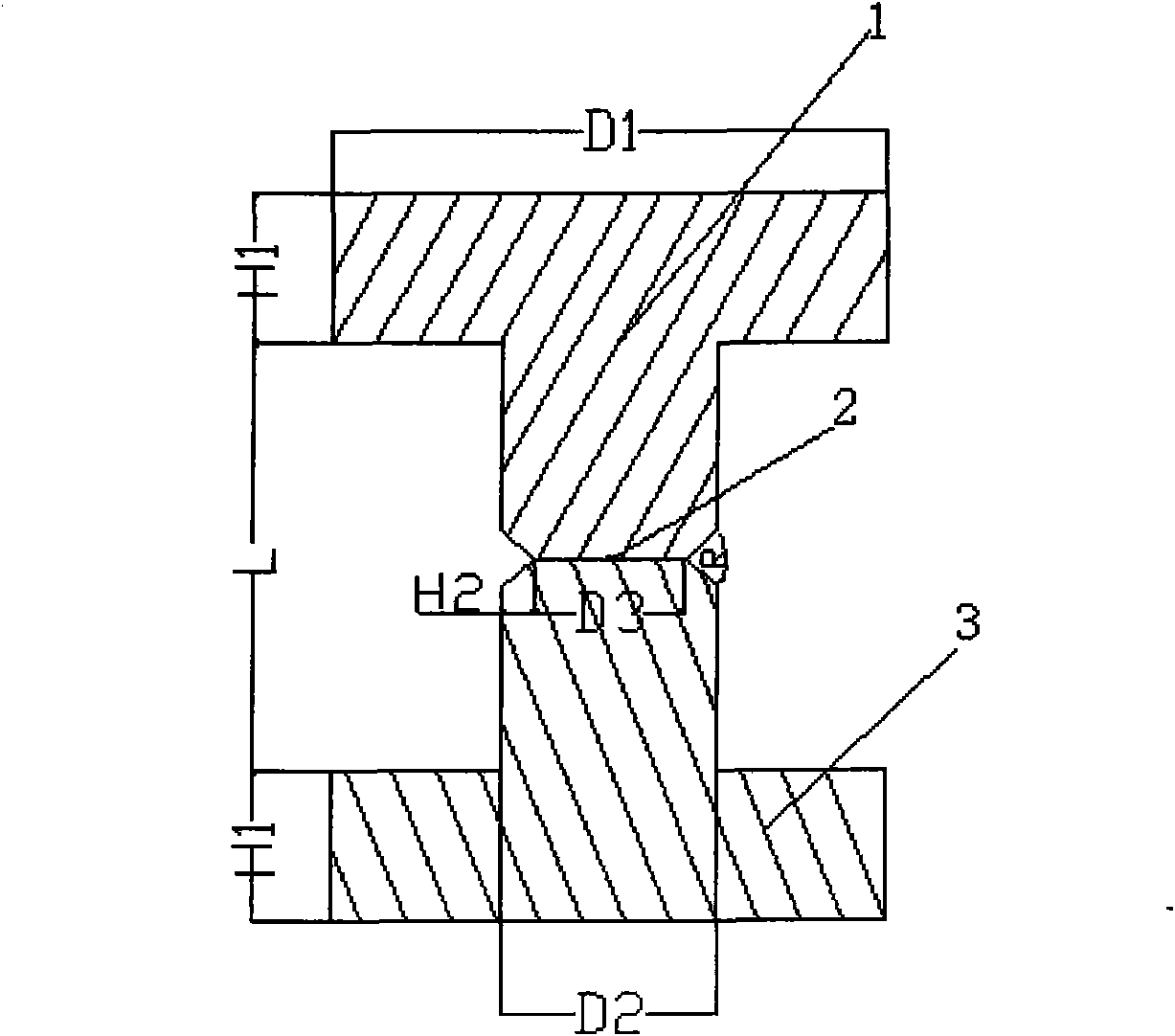

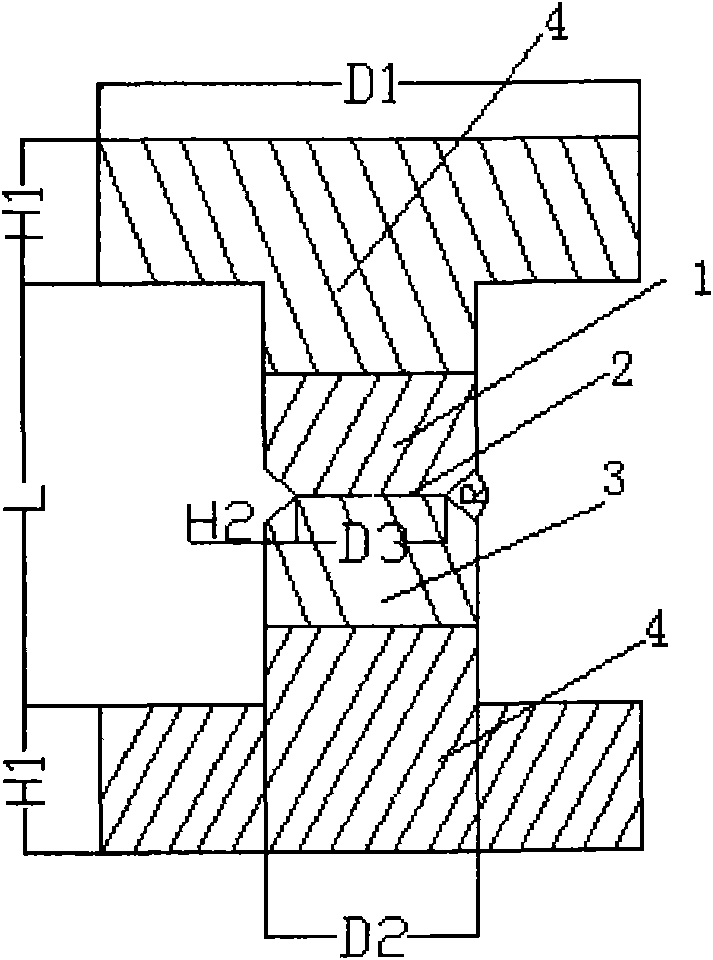

Rigid alloy soldered joint shearing property testing device

InactiveCN104502205AGuaranteed test qualityEasy to processMaterial strength using steady shearing forcesTest sampleEngineering

The invention relates to a rigid alloy soldered joint shearing property testing device which comprises a base, a pressure rod, a lug boss and a fastening screw, wherein the upper surface of a tetragonal structure of the base is provided with a smooth hole and a threaded hole, and the side surface of the tetragonal structure of the base is provided with an unthreaded hole and a square groove; one end of the lug boss contacts with an upper press plate of a universal testing machine, and the other end of the lug boss is connected with the pressure rod; and the pressure rod penetrates through the smooth hole, and the pressure rod exceeds the unthreaded hole positioned on the side surface in length and reaches the lower part of the square groove. The rigid alloy soldered joint shearing property testing device disclosed by the invention can very easily and conveniently complete the soldered joint property testing experiment of a dissimilar material through the traditional universal testing machine and completely ensure the testing quality. According to the rigid alloy soldered joint shearing property testing device, a used test sample is convenient to process, so that the problems that the dissimilar material, especially a material with fragile physical property is difficult to process and the joint property is difficult to test through stretching are solved. A testing method is high in efficiency, reliable and convenient to operate.

Owner:SHANGHAI INST OF TECH

Universal testing machine

ActiveCN102213661AMaterial strength using tensile/compressive forcesInvestigating material hardnessKnoop hardness testDigital data

A testing machine includes a stand and a test device. The stand includes a base, box frame, a slide device driven to slide by a motor, and a control system controls the force applied on the test specimen. The test device is coupled at the slide device for performing various hardness tests consisting of Rockwell hardness test, Vickers hardness test, Brinell hardness test, micro-hardness test, and tension-compression test. The test device includes a force sensor and a data processing circuit converting an analog signal of the force sensor into digital data to interface with the control system.

Owner:吴绍明 +1

Method of FRP reinforced concrete bond slip test

InactiveCN103954200AConsistent bond lengthBond stress decayMechanical measuring arrangementsMaterial analysisRelative displacementDisplacement control

The invention discloses a method of an FRP reinforced concrete bond slip test. The method comprises the steps of determining a test piece for the test, manufacturing a connection structure of an FRP reinforced concrete test piece, selecting a universal testing machine, and determining a loading scheme as one-end loading and determining a loading mode as a displacement control mode. According to the step of manufacturing the connection structure of the FRP reinforced concrete test piece, a test piece component is arranged in the middle of poured concrete, and the test piece component is formed by inserting two FRP ribs into the two ends of a sleeve pipe respectively; the other ends of the two FRP ribs extend out of the sleeve pipe, and a bonding layer is arranged in the middle of the sleeve pipe; the two ends of the sleeve pipe are respectively provided with at least two wedged key blocks which are arranged in the sleeve pipe in the direction of the FRP ribs, and the two FRP ribs extend out of the two ends of the concrete; sleeves are arranged at the matched positions of the extending ends of the two FRP ribs respectively. The sleeves at the upper end and the lower end of the connection structure are fixed on an upper anchor and a lower anchor of the universal testing machine respectively. A data collecting system of the universal testing machine is used for collecting the total displacement of the whole connection structure, and a dial indicator is used for collecting relative displacement of the two FRP ribs and the test piece component, namely the sliding amount of the FRP ribs in the test piece component is obtained.

Owner:SHENYANG JIANZHU UNIVERSITY

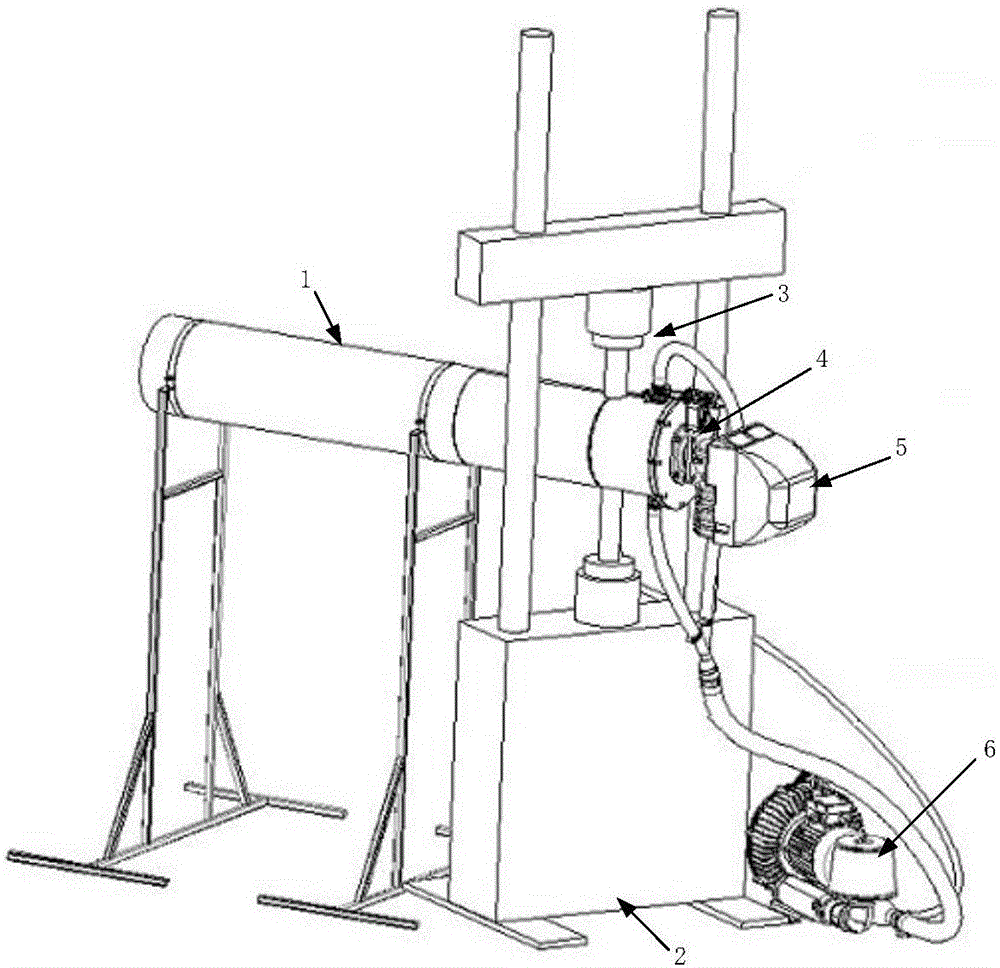

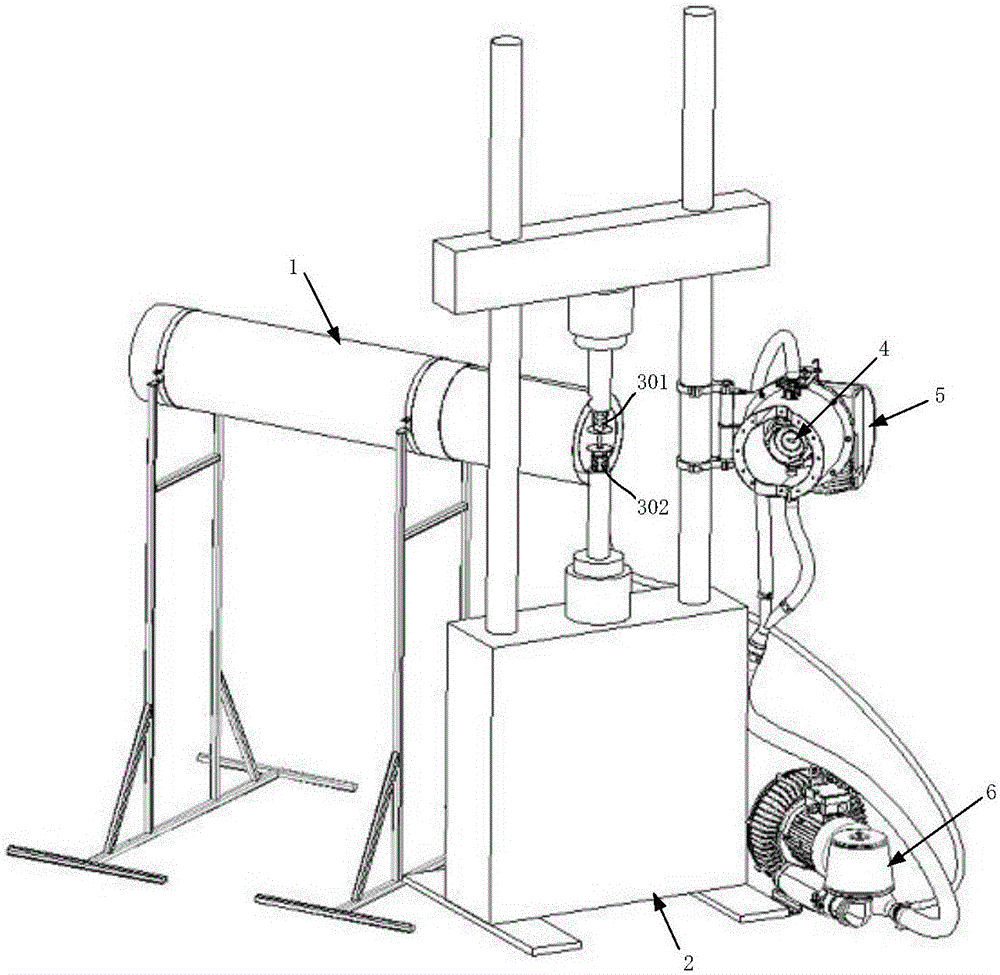

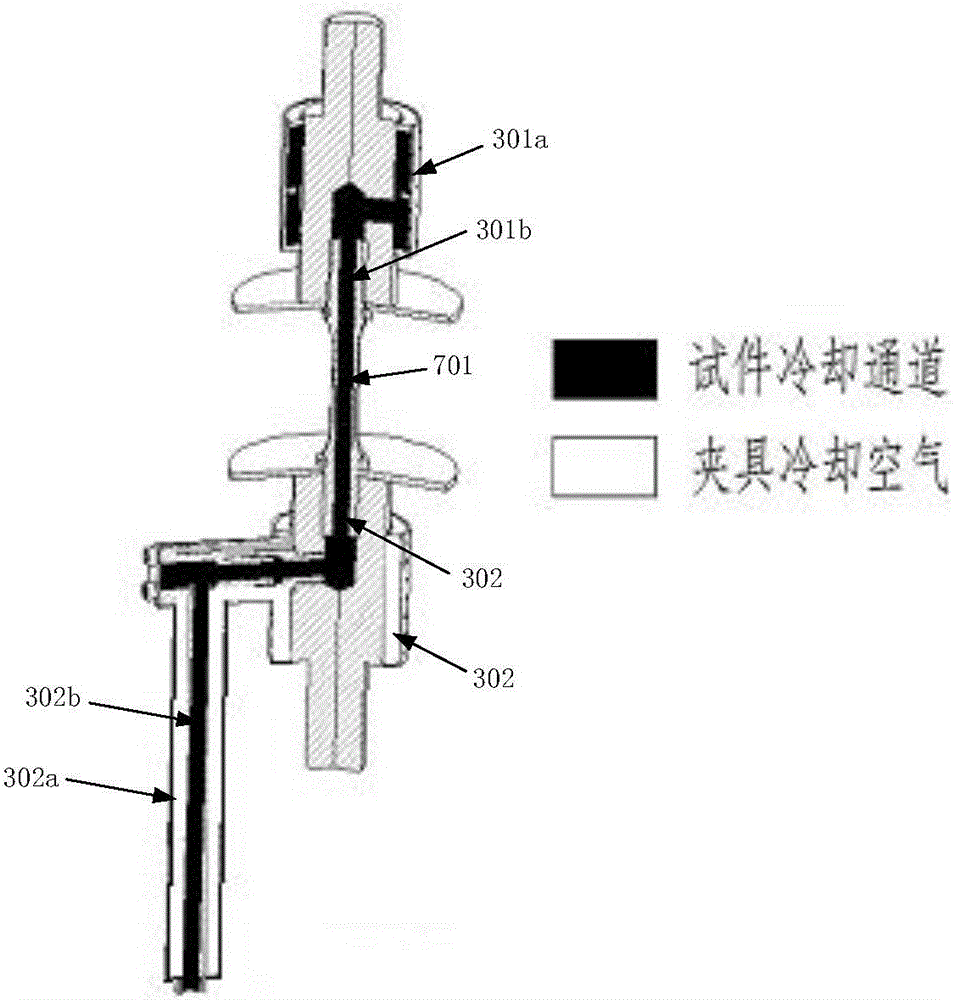

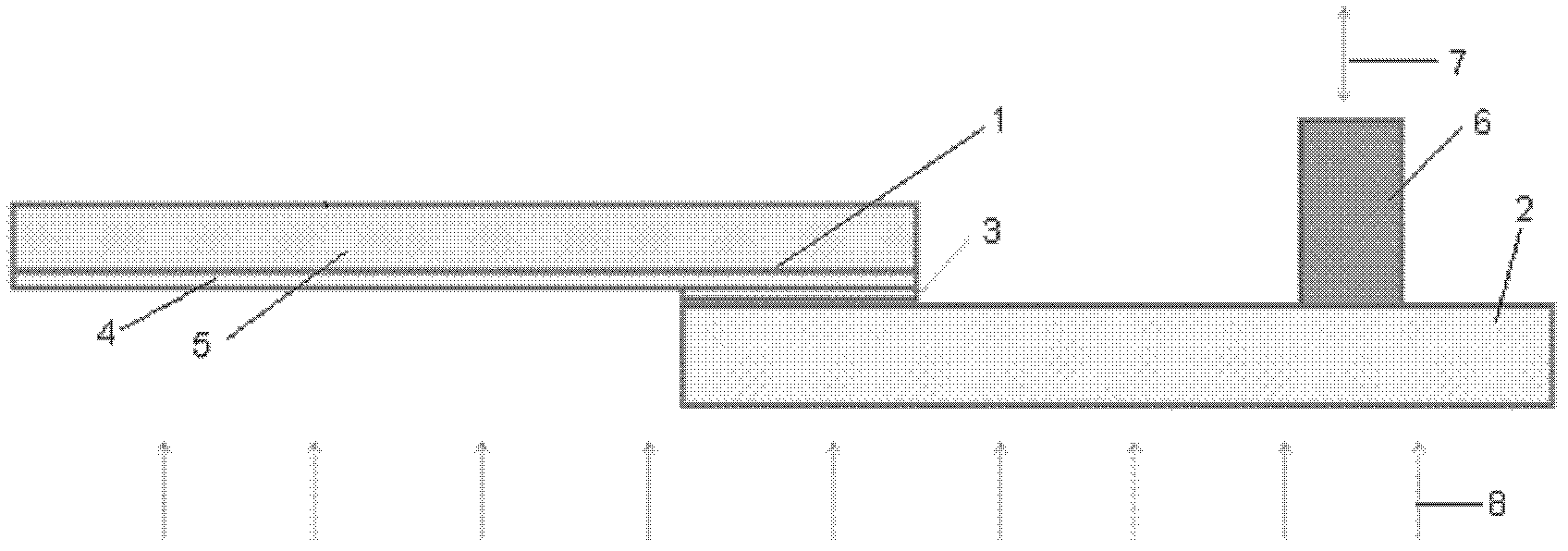

Molybdenum and molybdenum alloy bar/tube high-temperature tensile detection device and method

PendingCN106525603AAvoid oxidation reactionsIncreased stretch detection temperature zoneMaterial strength using tensile/compressive forcesNuclear energy generationTemperature controlAlloy

The invention relates to a molybdenum and molybdenum alloy bar / tube high-temperature tensile detection device and method. The device comprises a universal testing machine, a high-temperature furnace arranged between upper and lower cross beams of the universal testing machine, an extensometer which extends from the side wall of the high-temperature furnace into the furnace, a temperature controller connected with the high-temperature furnace, an upper clamp and a lower clamp which have the same structure, a clamp cooler and an inert atmosphere protector. The device can safely and stably complete the tensile property testing of the molybdenum and molybdenum alloy bar / tube at the temperature of 1200 DEG C, thereby satisfying the high-temperature tensile testing demands and enhancing the reliability of detection data.

Owner:JINDUICHENG MOLYBDENUM CO LTD +1

Shear test device for observing mechanical property of interface between underwater soil and structure

InactiveCN102914475AEasy to manufactureEasy to installMaterial strength using steady shearing forcesTest sampleElectro hydraulic

The invention relates to a mechanical property test device, in particular to a test device for observing the mechanical property of an interface between underwater soil and a structure, which is especially suitable for researching the mechanical property of the interface between the underwater soil and the structure in a hydraulic building (structure). The test device comprises a fixing mechanism, a horizontal movement mechanism, a soil box and a loading system, and an electro-hydraulic servo movable and static universal testing machine is used as a main machine frame. A designed soil material is loaded in the soil box fixed on the horizontal movement mechanism. A structure test block is arranged on an upper chuck of the electro-hydraulic servo movable and static universal testing machine, a normal stress is applied through the vertical loading system, and the shear mechanical behavior of the interface between the underwater soil and the structure under normal stress and complex stress paths can be represented through the horizontal loading system. The normal force and the shear force in the interfere shear test are measured through a load sensor, a vertical displacement meter arranged on the top surface of the structure test sample is used for measuring the normal displacement of the interface in the test, and horizontal displacement meters arranged on two sides of the soil box are used for measuring the shear displacement in the test.

Owner:CHINA UNIV OF MINING & TECH

Simulation experimental apparatus and method for mechanical property of gas-containing coal rock under uniaxial compression

ActiveCN107576774ASimple structureReasonable designPreparing sample for investigationFuel testingGas detectorCoal pillar

The invention discloses a simulation experimental apparatus and method for mechanical property of gas-containing coal rock under uniaxial compression. The apparatus comprises a coal sample container,a stress loading system, a gas filling system, a gas detector, a VIC-3D non-contact full-field strain measuring system and an acoustic emission system, wherein the coal sample container comprises a coal sample container shell and a coal sample placement chamber; the top of the coal sample container shell is connected with a piston in a sealed manner; a first multi-purpose air hole is formed in oneside of the coal sample container shell, and a second multi-purpose air hole and a transparent sight glass are arranged on the other side of the coal sample container shell; and the stress loading system comprises an electronic universal testing machine and a first computer. The method comprises the following steps: 1, performing test sample preparation; 2, establishing a testing apparatus; 3, detecting air tightness of the apparatus; 4, testing in a gas-free environment; and 5, testing in a gas environment. The simulation experimental apparatus disclosed by the invention is reasonable in design, convenient to realize and full in functions, the condition that an underground setting coal pillar is positioned in uniaxial loading can be really reflected, and the simulation experimental apparatus is high in practicality and convenient to popularize and use.

Owner:XIAN UNIV OF SCI & TECH

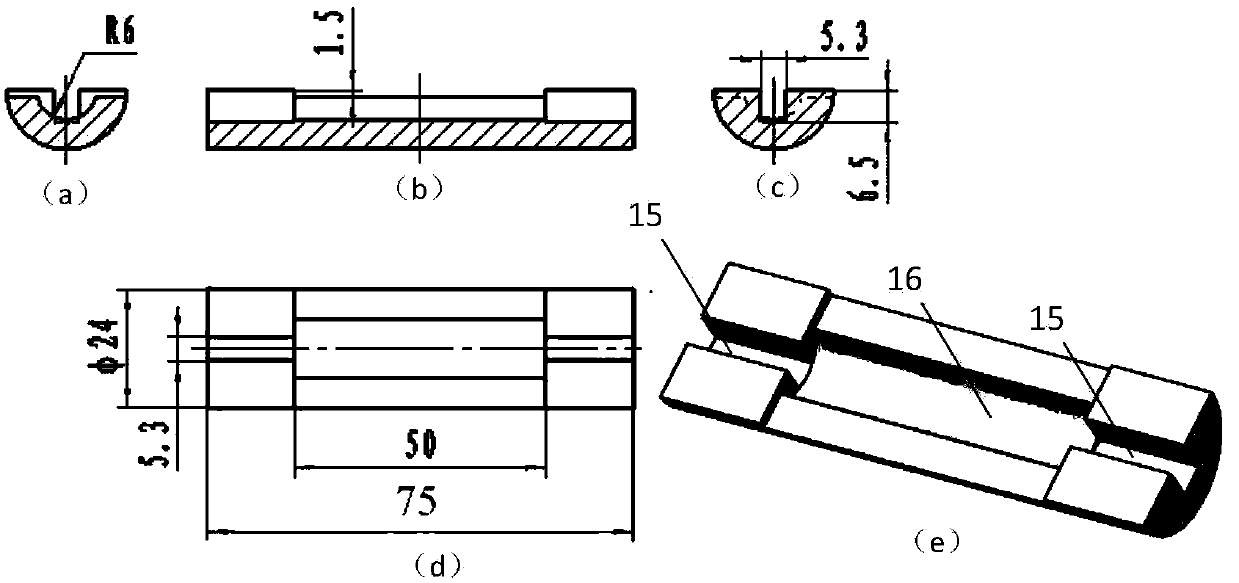

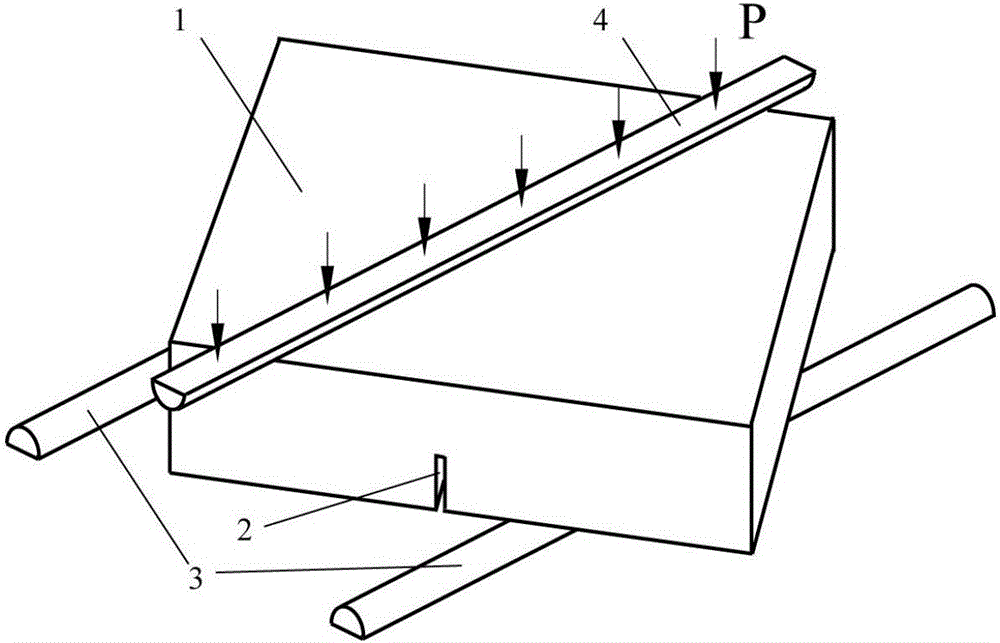

Test piece component and test method of brittle material I-III mixed mode fracture toughness test

InactiveCN106546482ASimple structureEasy to processMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesEngineeringDisplacement control

The invention discloses a test piece component and a test method of a brittle material I-III mixed mode fracture toughness test. The test component comprises a test piece body with a grooving and column bars for supporting and pressing the test piece body, the test piece body is a plate with square and flat surfaces, the grooving passes through the center of the test piece body plate surface, the groove surface of the grooving is parallel to the left and right side surface of the test piece body, and the grooving penetrates the front and back side of the test piece body; the column bars comprise two supporting column bars which are between the plate surface where the test piece body grooving is positioned and a universal testing machine workbench as well as a pressing column bar which is positioned between the other side plate surface of the test piece body and a universal testing machine work head, the supporting column bars and the pressing column bar are column bars with the same structure, and at least one side of each column bar is a straight arc column surface, wherein the surface and the test piece body plate surface form a line contact. During test, the universal testing machine carries out loading by the pressing column bar and the supporting column bars for the test piece body in a displacement control mode till the test piece is failure.

Owner:SICHUAN UNIV

Thermal barrier coating thermal-mechanical fatigue test device for gas environment

ActiveCN106468641AAnalyzing Fatigue LifeEasy to operateMaterial strength using repeated/pulsating forcesCombustorTurbine blade

The invention discloses a thermal barrier coating thermal-mechanical fatigue test device for a gas environment. The device comprises a mounting sleeve, a universal testing machine, a sample loading member, a flame swinging part and a burner. The sample loading member is arranged in the mounting sleeve. The sample loading member is provided with upper and lower connectors. The upper and lower connectors are clamped by upper and lower clamps of the universal testing machine. A sample is fixed between the upper and lower connectors. The flame swinging part is a flame tube driven by a motor to swing and is installed on the end of the mounting sleeve, and the flame tube is located in the mounting sleeve. The burner produces high-temperature gas and sprays the high-temperature gas into the flame tube and the flame is sprayed to a sample through an outlet of the flame tube. By controlling flame tube swinging, a direction of high temperature gas is controlled so that the temperature of the sample produces high and low cyclic change. The test device realizes a fatigue life test on an aeroengine turbine blade thermal barrier coating under the mechanical cycle load and temperature cycle load and provides test data for aeronautical engine life estimation.

Owner:BEIHANG UNIV

Method for measuring combination strength of aluminum film of film aluminum steel composite board and steel substrate

ActiveCN102494998AHigh bonding strengthBinding strength measured directlyPreparing sample for investigationUsing mechanical meansComposite plateUniversal testing machine

A method for measuring combination strength of an aluminum film of a film aluminum steel composite board and a steel substrate aims at solving the problem that the combination strength of the aluminum film of the film aluminum steel composite board and the steel substrate cannot be measured directly and accurately in the prior art. The method includes: using zinc-aluminum brazing filler metal forwelding an aluminum alloy and the aluminum film of the film aluminum steel composite board under anti-vacuum conditions and with the effect of an added heat source and ultrasound, and then performinga stretching and shearing test through an electronic universal testing machine. The method can directly measure the combination strength of the aluminum film of the film aluminum steel composite board and the steel substrate, requires no formula conversion, is easy to operate, needs no expensive experiment and can be applied to the field of mechanical property testing.

Owner:HARBIN INST OF TECH

Method for preparing metal composite material bonding interface separated sample

ActiveCN101957281AEasy to separatePreparing sample for investigationUsing mechanical meansBond interfaceUniversal testing machine

The invention introduces a method for preparing a metal composite material bonding interface separated sample. The method comprises the following steps of: sampling from an entire metal composite material plate; machining the sample to be dumbbell-shaped along thickness direction, wherein the thickness directions of base layer metal and composite layer metal are both the length direction of the dumbbell-shaped sample; placing the bonding interface of the metal composite material at a middle position of the dumbbell-shaped sample; forming a V-shaped groove on the dumbbell-shaped sample; overlapping a bottom cross line of the V-shaped groove with a metal composite material bonding interface line; snapping the bonding interface with a 50-ton universal testing machine to completely separate the bonding interface of the metal composite material; and cutting the sample according to testing requirements. By the method, the bonding interface of the metal composite material with small thickness can be completely separated or a certain bonding interface of a multi-layer metal composite material can be completely separated, so that the problem of difficult complete separation of the metal composite material bonding interface is solved.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

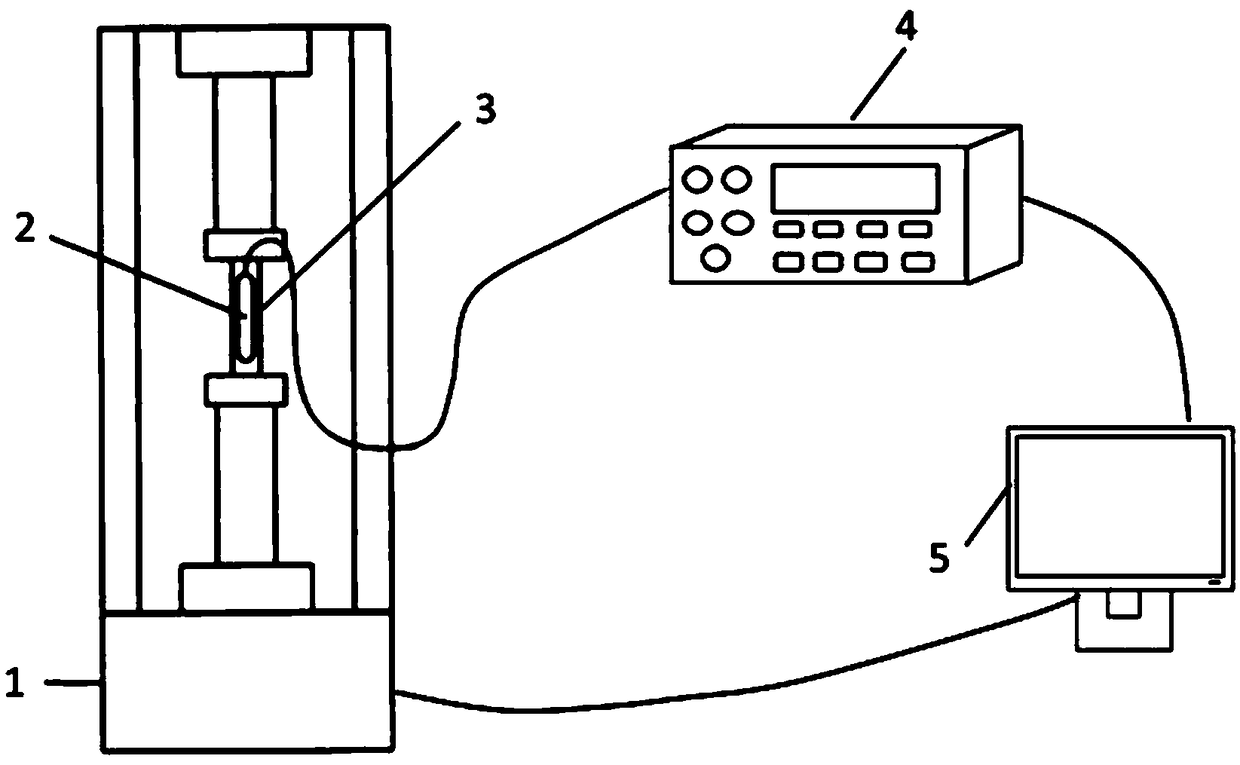

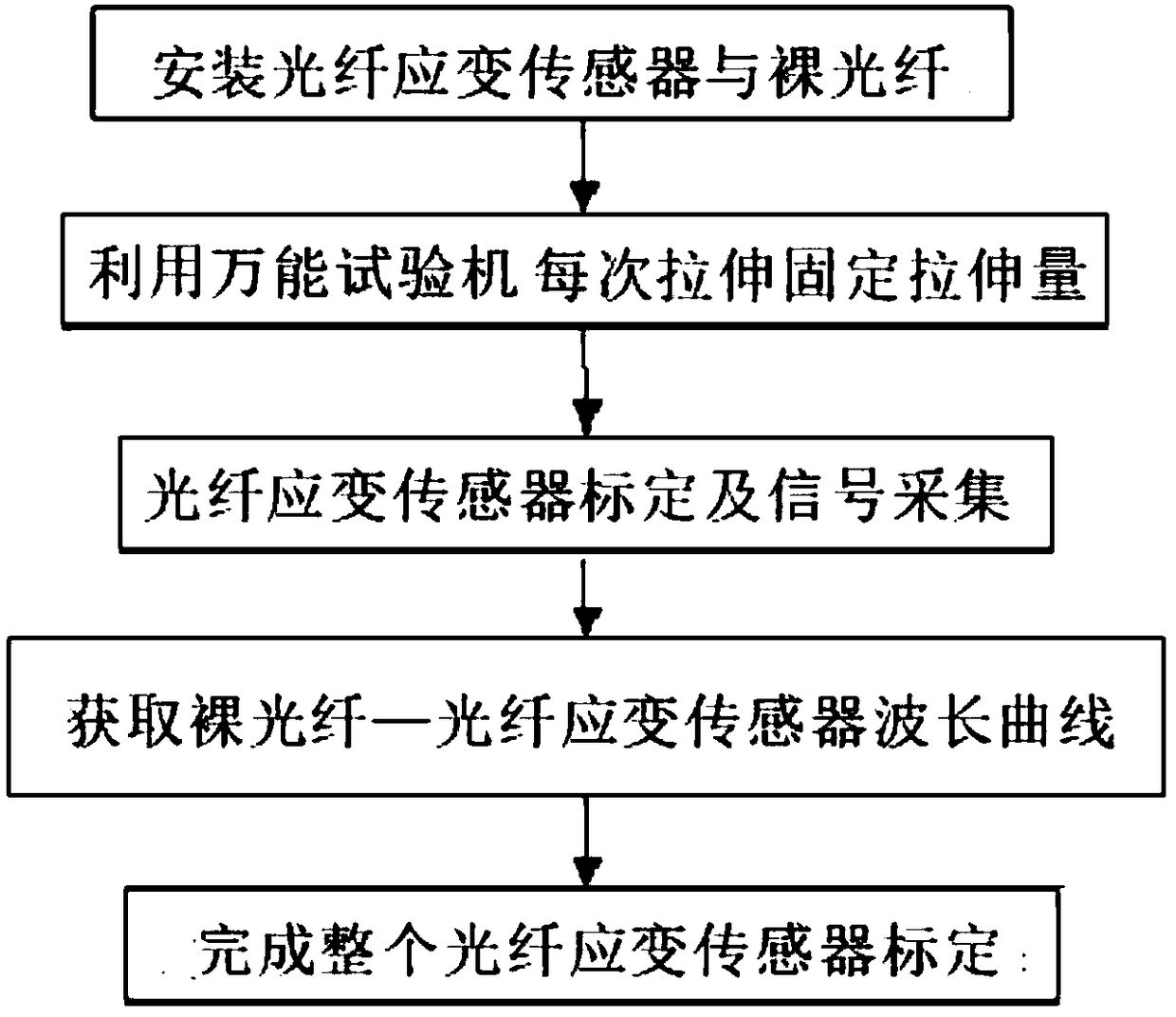

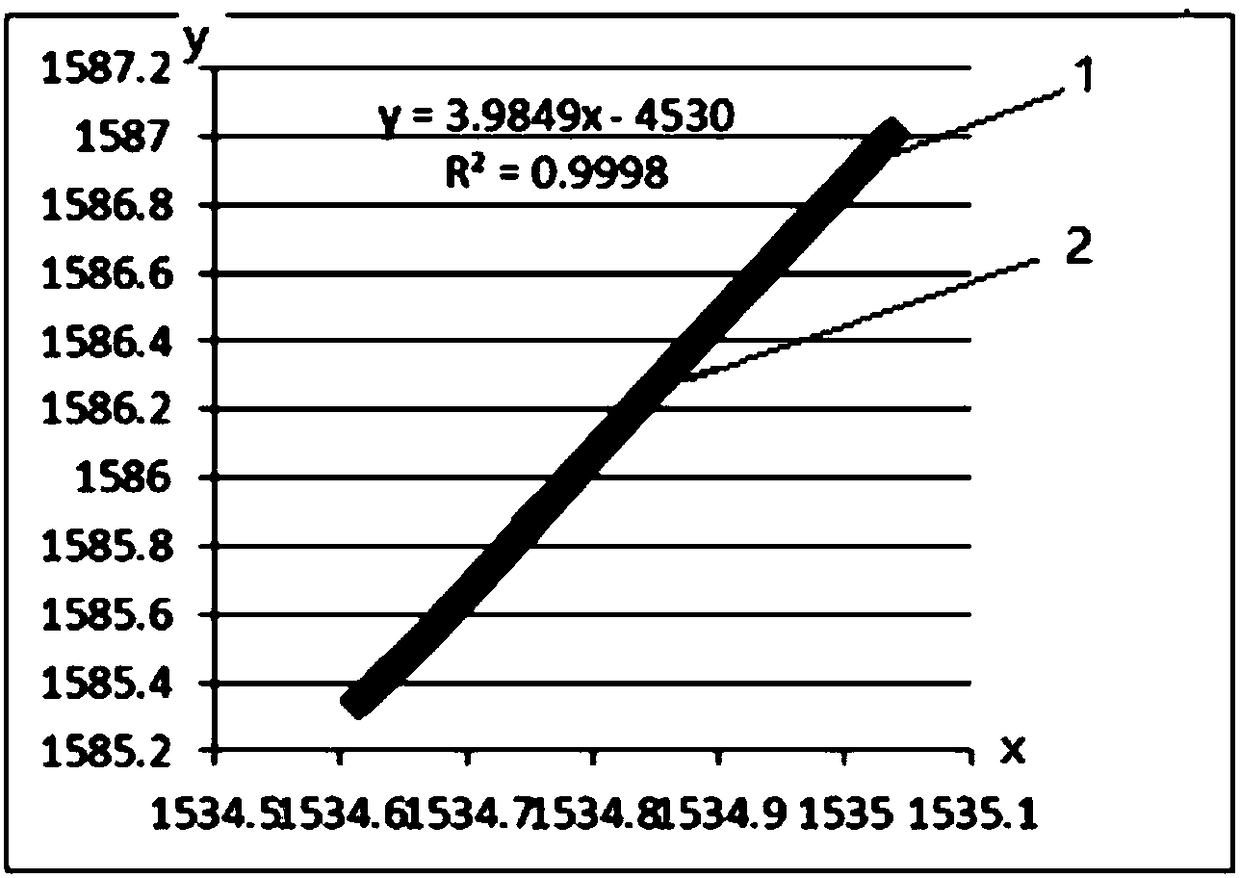

Optical fiber sensor strain sensitivity calibration method based on bare optical fiber

ActiveCN108895978AAvoid errorsAccurately obtain the actual strain sensitivity coefficientUsing optical meansFiber bragg grating sensorFiber gratings

The invention discloses an optical fiber sensor strain sensitivity calibration method based on a bare optical fiber, belongs to the technical field of detection, and relates to the optical fiber strain sensor sensitivity calibration method based on the bare optical fiber. According to the method, an universal testing machine is used as an intermediary, when same force is loaded on a same specimen,same stress-strain is obtained, and the un-packaged bare optical fiber is used as a reference for calibrating a fiber bragg grating stress-strain sensor. In a calibration process, by operating a computer, the force loaded by a loading device every time is controlled, an optical fiber demodulation instrument is controlled to acquire measurement data, calibration data is used for being compared with the bare optical fiber, and the sensitivity of the fiber bragg grating strain sensor is obtained, so that a strain character of the fiber bragg grating sensor is accurately calibrated. The method issuitable for calibrating sensitivity coefficients of any optical fiber strain study sensors, errors caused by the problem of taking conversion from the loaded force to stretching stress, a specimen elasticity modulus range and the like into account are avoided, the calibration precision is greatly improved, moreover, operation is convenient, and the method is fast and easy to popularize.

Owner:DALIAN UNIV OF TECH

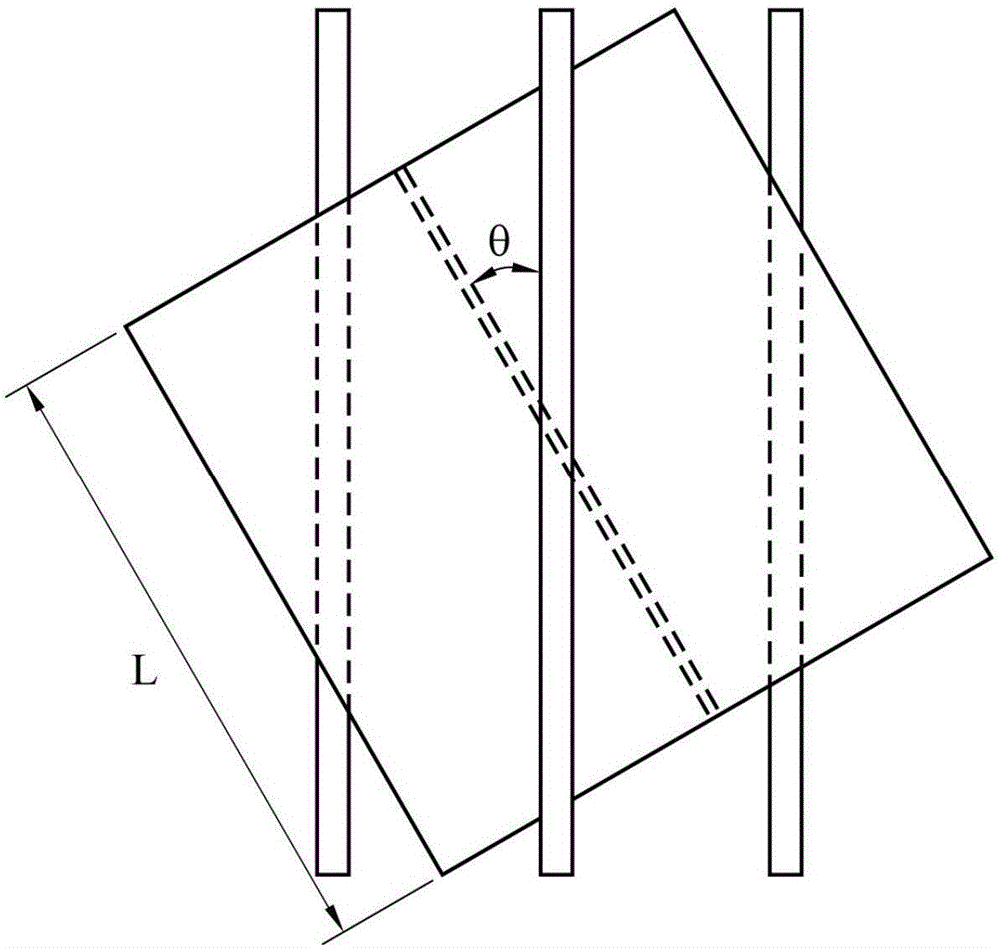

Method and apparatus for testing the rolling tack of pressure-sensitive adhesives

InactiveUS20040083819A1Efficient use ofUniform coatingMaterial strength using tensile/compressive forcesUsing mechanical meansEngineeringRepeatability

A method and apparatus for testing tack of Pressure Sensitive Adhesives (PSA) and other sticky materials is disclosed to simplify the measurement of bonding and debonding procedures. A modified rolling tack test is applied using a device attached on to an Instron Universal Testing machine. By predetermining the angle (position) of a cylindrical probe-roller hanging down to the Instron's cross-head and leaning parallel to a rotary drum covered with tacky substance, the pressure of the probe and its rolling velocity (as an expression for dwell time) can be controlled independently. The ease of execution and its high reproducibility enable the use of the new method to study the experimental tack of adhesive materials.

Owner:YISSUM RES DEV CO OF THE HEBREWUNIVERSITY OF JERUSALEM LTD

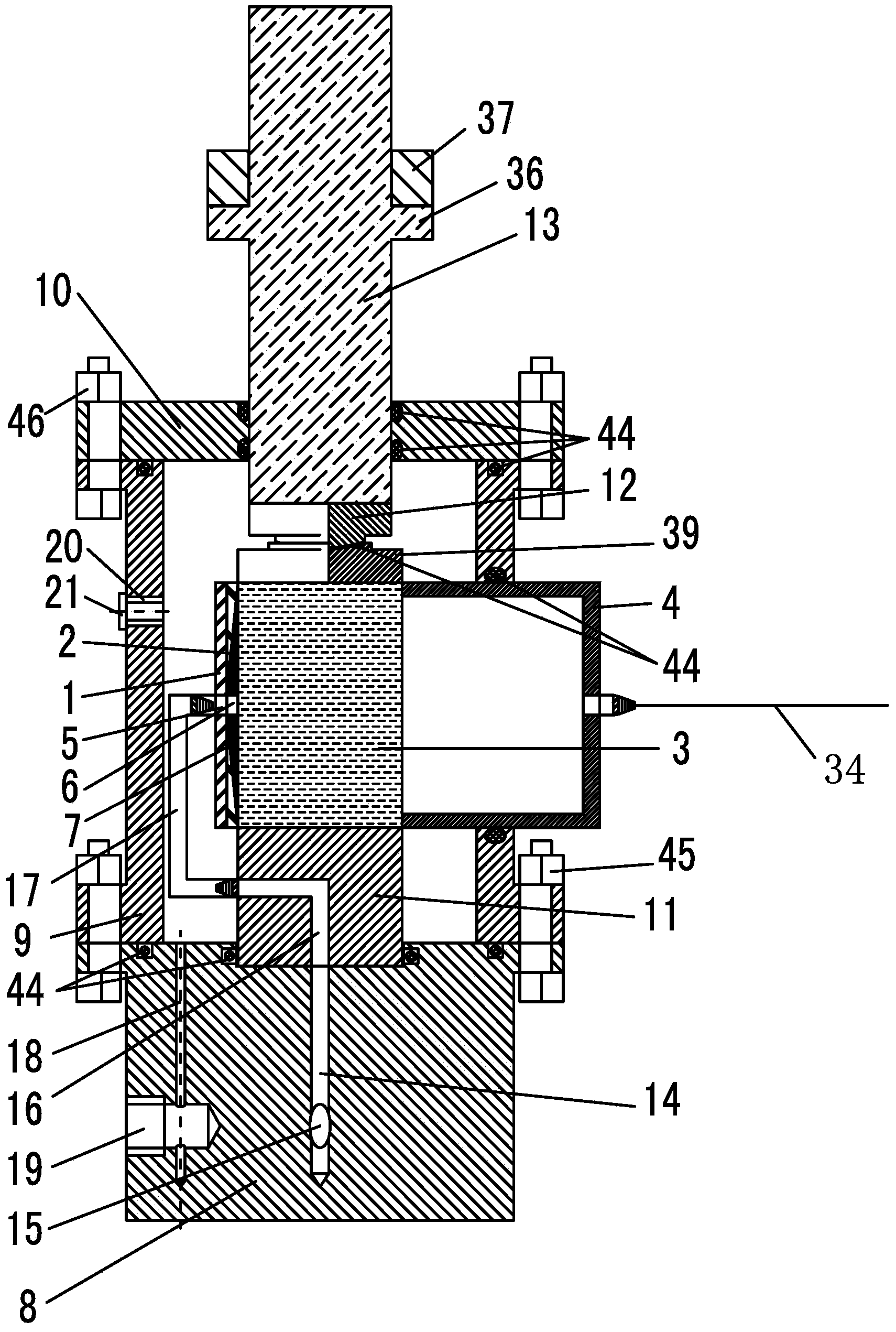

Liquid hydrogen temperature zone material mechanical testing platform based on low-temperature refrigerator and refrigerant circulation

ActiveCN109297804AReduce usageWide temperature rangeLighting and heating apparatusCooling fluid circulationLiquid hydrogenEngineering

The invention relates to the technical field of material mechanical testing, and aims to provide a liquid hydrogen temperature zone material mechanical testing platform based on a low-temperature refrigerator and a refrigerant circulation. The testing platform comprises a universal testing machine, a vacuum insulated dewar cavity, a refrigerant circulation system and a low-temperature refrigeration system. The refrigerant circulation system comprises a nozzle, a secondary cold end heat exchanger, a secondary convection type heat exchanger, a primary cold end heat exchanger, a primary convection type heat exchanger, and a high-pressure gas storage tank, a circulating pump, a low-pressure gas storage tank and a helium bottle arranged outside the universal testing machine. A closed circulation loop is formed through a pipeline, and helium is taken as a refrigerant. According to the liquid hydrogen thermal zone material mechanical testing platform based on low-temperature refrigerator andrefrigerant circulation, the testing of various mechanical properties such as isothermal stretching, compression, bending, shearing, fatigue and fracture toughness of materials in the temperature range of the liquid hydrogen to the room temperature can be realized, the temperature range of the material mechanical test is expanded, and the temperature control precision and stability are improved. Meanwhile, a large amount of waste of helium is avoided, the test cost is greatly reduced, and the use of liquid hydrogen is avoided to improve the safety of the system.

Owner:ZHEJIANG UNIV

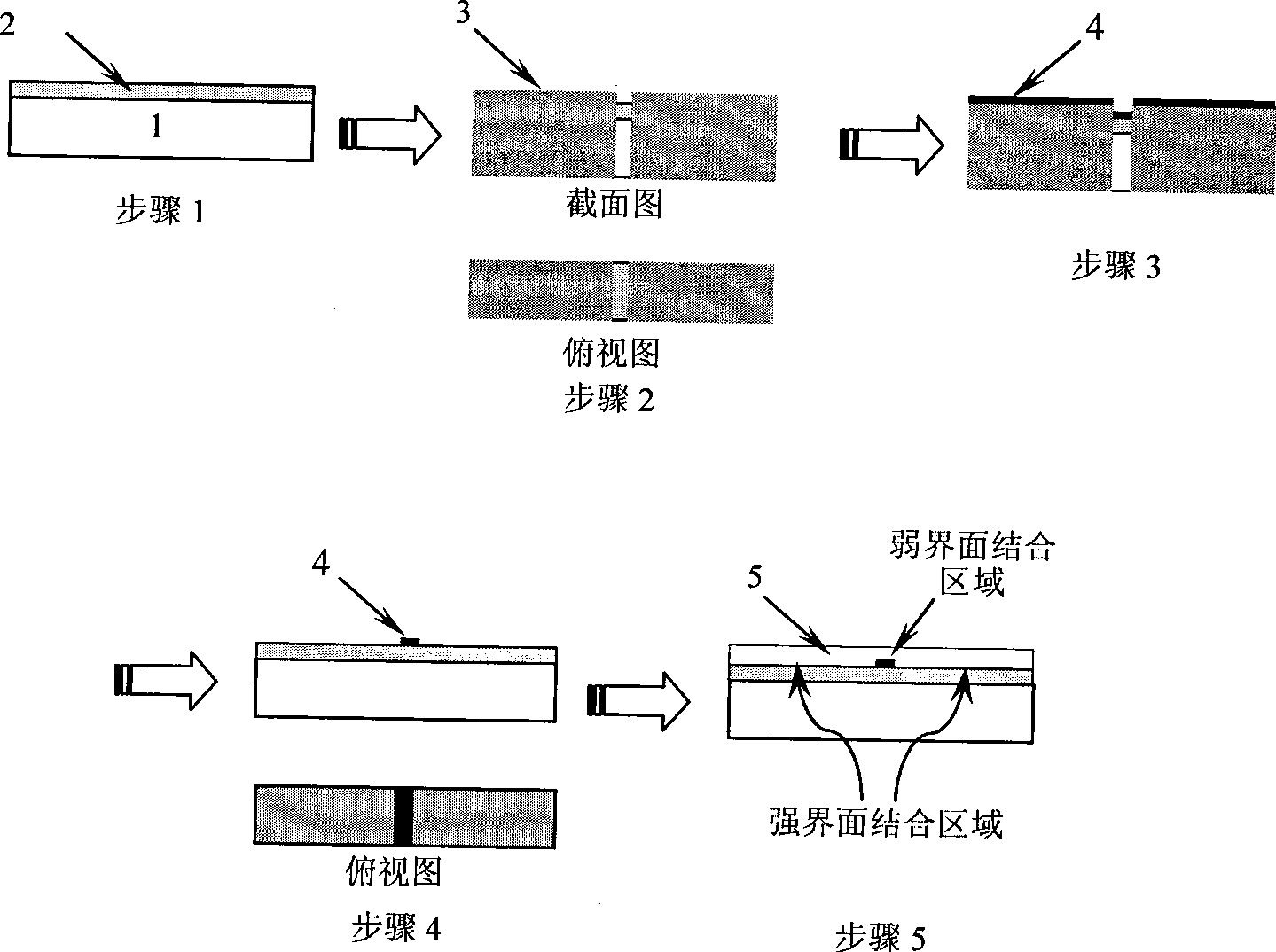

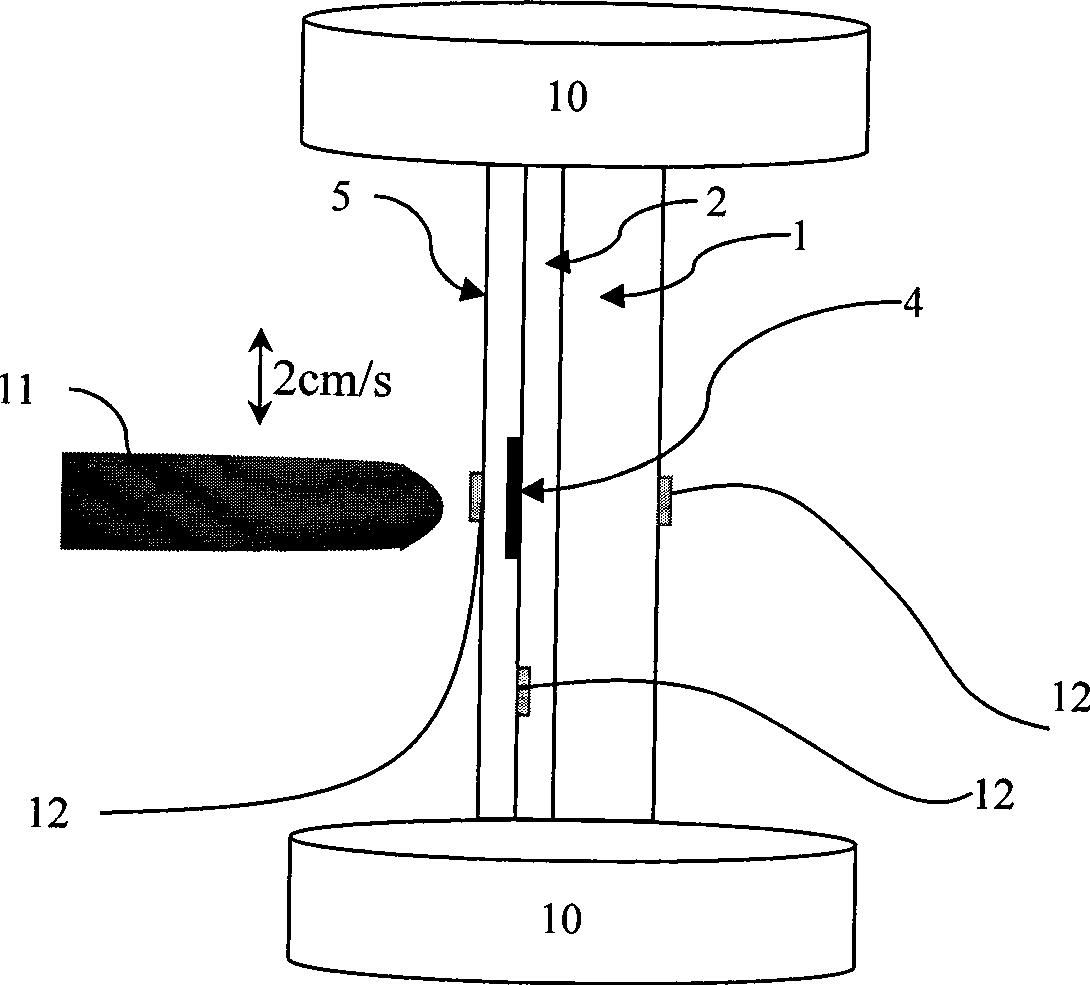

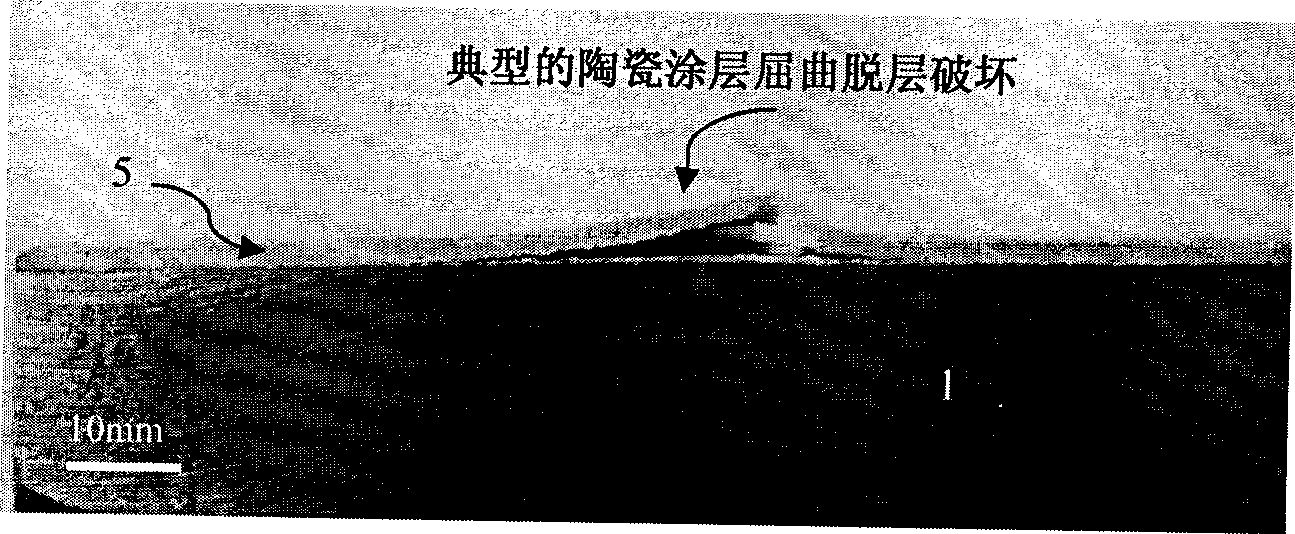

Experiment control method for researching flexion damage of thermal curtain coating interface containing inner embedded interface defect under high temperature environment

InactiveCN101435755AMaterial strength using tensile/compressive forcesUsing mechanical meansCoating systemCeramic coating

The invention discloses an experimental control method for experiments studying the interface buckling failure of thermal barrier coatings containing buried interface defects in high-temperature environment. Experimental equipment needed by the experimental method is as follows: a universal testing machine, an oxyacetylene high-temperature heating device, a thermocouple temperature measurement device, a CCD observation device for coating failure process and a computer. The method mainly comprises the following steps: a certain compressive load is applied in advance to a thermal barrier coating specimen containing interface defects; the method has corresponding requirements on the magnitude and application modes of the load; and residual compressive stress in a thermal barrier ceramic coating is approximately replaced with the compressive load. Therefore, the method is simple to operate and capable of shortening experimental time, thereby providing an important experimental method for analyzing the interface bonding performance of a ceramic layer and a bonding layer and providing a good basis and reference experience for studying the interface buckling problems of film / coating systems in future. The interface-crack critical length a[cr] of the thermal barrier ceramic coating with interface buckling failure is experimentally found to be 3 to 4 millimeters in general.

Owner:XIANGTAN UNIV

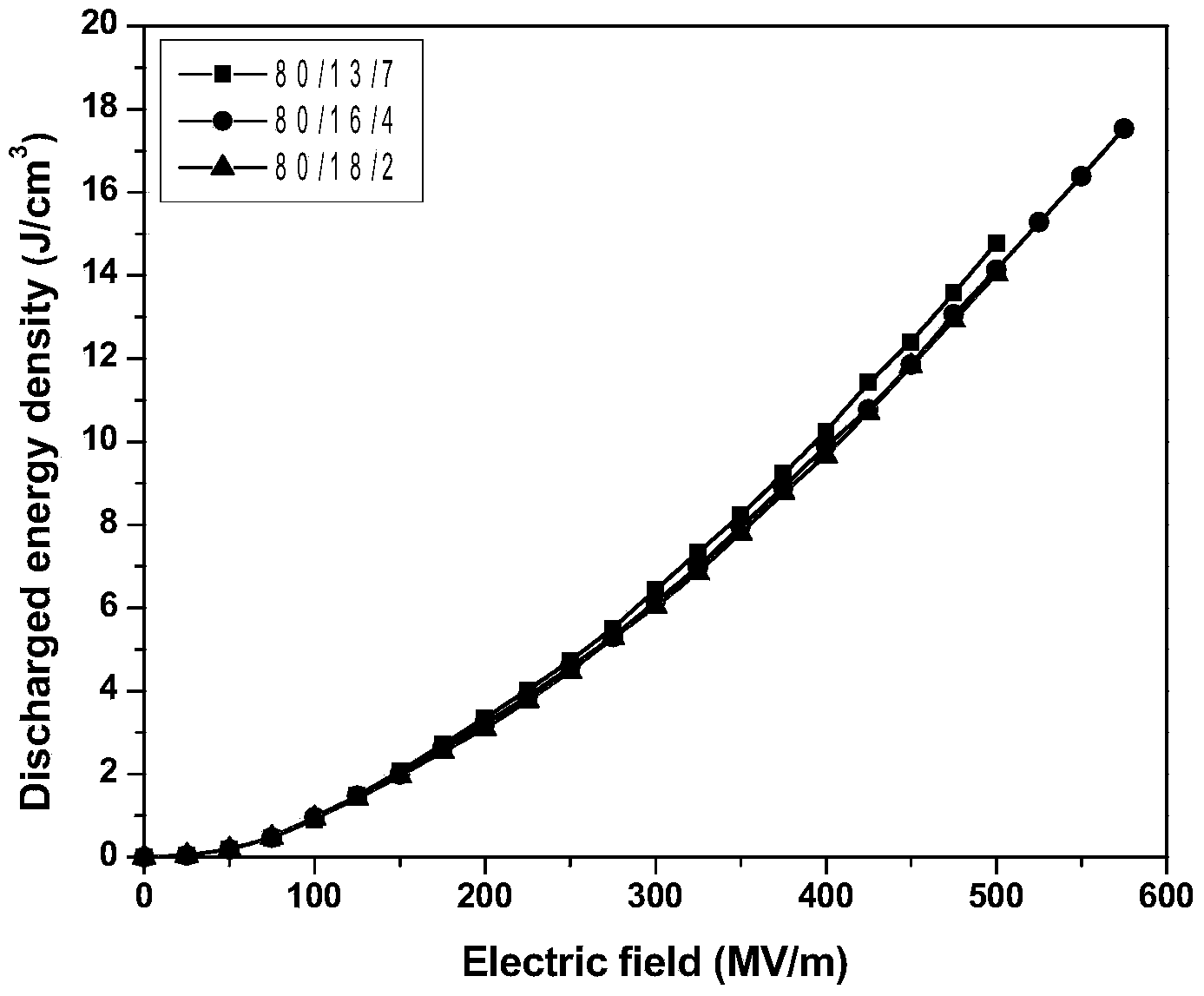

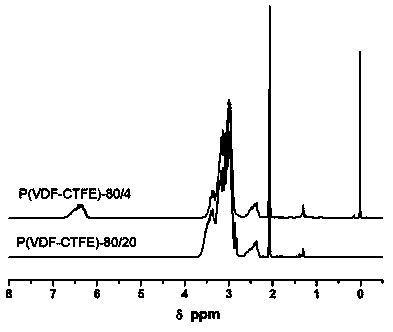

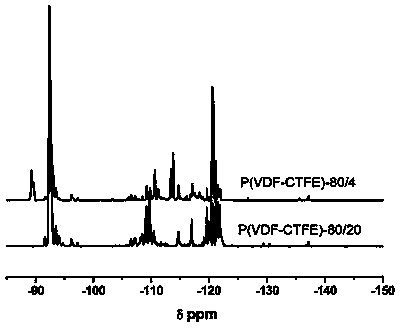

Preparation method for crosslinkable high voltage-resistant high-energy density polyvinylidene fluoride (PVDF) plastic film

The invention provides a preparation method for a crosslinkable high voltage-resistant high-energy density PVDF plastic film. The preparation method comprises the following steps: step 1, adding P(VDF-CTFE) into a boiling flask with three necks, simultaneously adding a solvent and a catalyst and carrying out stirring for a reaction; step 2, dumping a solution finally obtained in the step 1 into a hydrochloric acid beaker and allowing a polymer to be precipitated; step 3, dissolving the polymer obtained in the step 2 in N,N-dimethyl formamide (DMF), adding the radical initiator benzoyl peroxide (BPO) and curing a glass flake on which a polymer film is attached in a baking oven after complete volatilization of the solvent so as to obtain a crosslinked polymer film; and step 4, preparing a dumbbell-like sample from the crosslinked polymer film obtained in the step 3, drawing the sample on a universal testing machine so as to obtain the high voltage-resistant PVDF plastic film. The method provided by the invention overcomes the problem of difficult drawing of a fluorine polymer at a low temperature; moreover, crosslinking is favorable for microcrystallization of a thin film material, which facilitates improvement of breakdown field strength.

Owner:无锡鑫聚电子科技有限公司

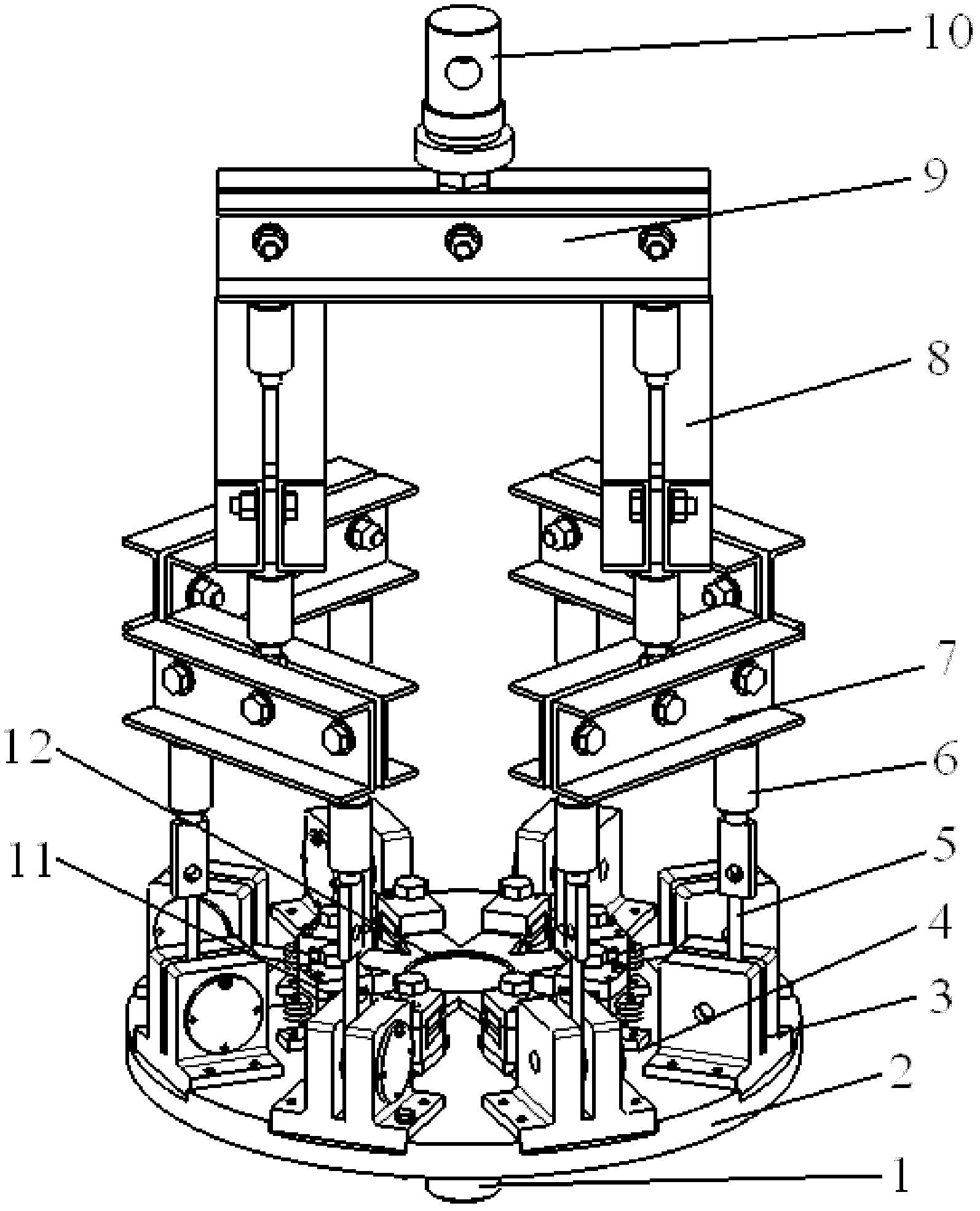

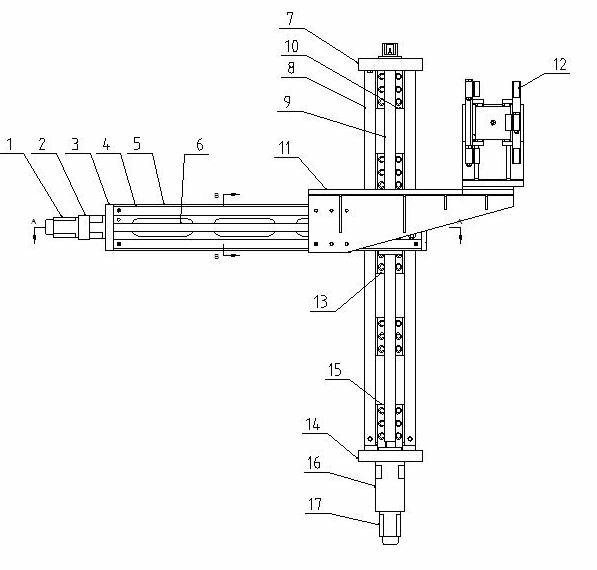

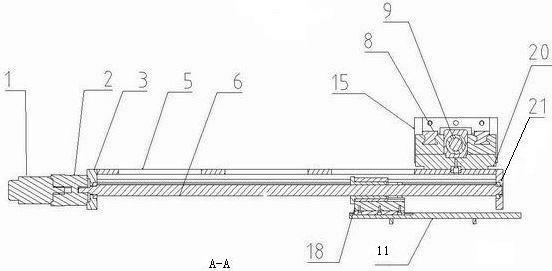

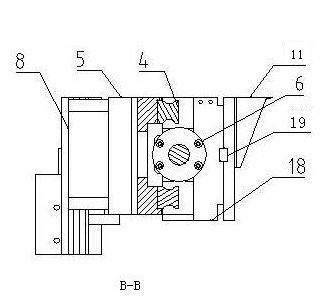

Automatic feeding device of drop-hammer type impact testing machine

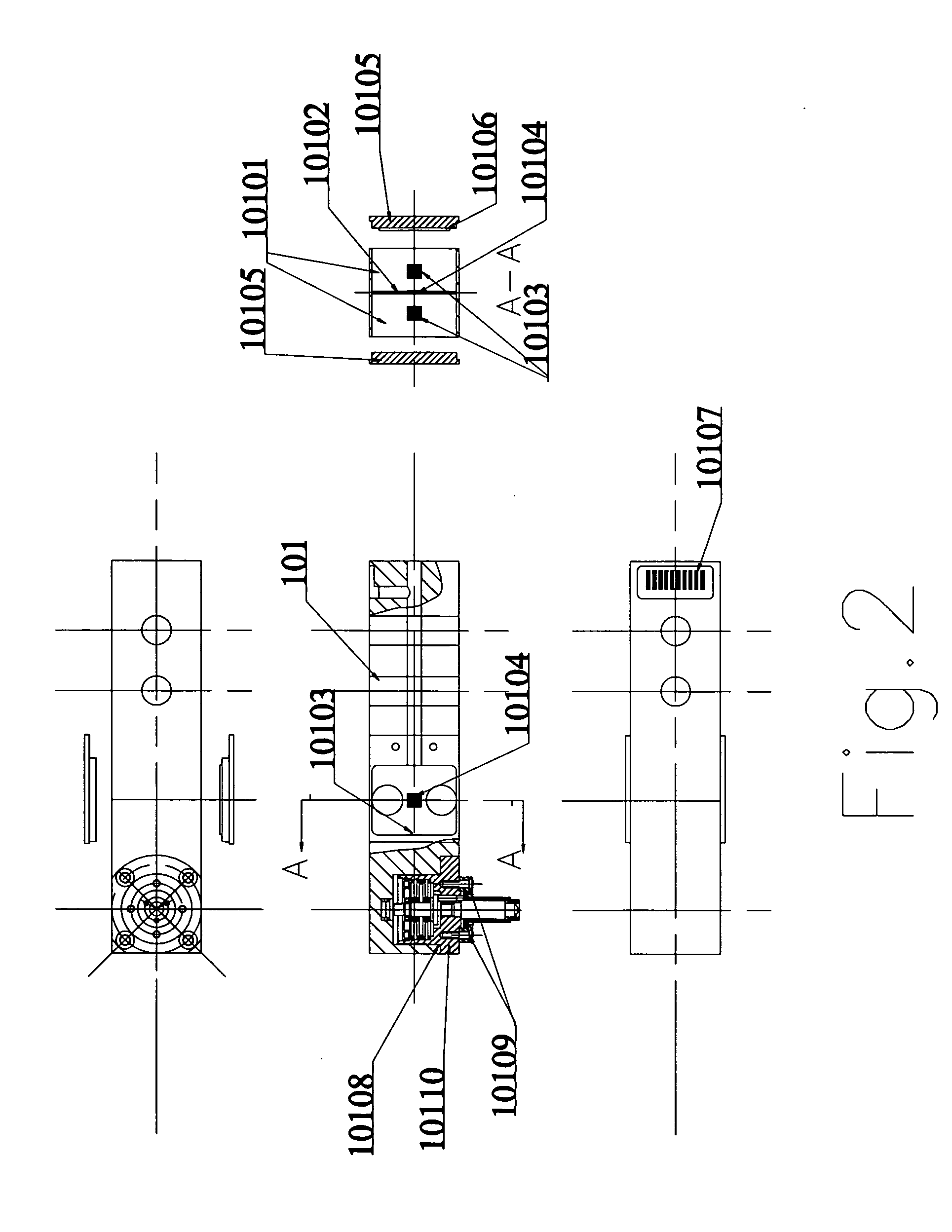

InactiveCN102673953ARapid positioningPrecise positioningConveyorsMaterial strength using single impulsive forceTest sampleBall screw

The invention relates to an automatic feeding device of a drop-hammer type impact testing machine, comprising a transmission mechanism and a test sample gripper, wherein a lifting guide rail pair of the transmission mechanism is fixed on a testing machine vertical column by a connection base, the lifting guide rail pair is slidably connected with a lifting connection bracket, and the lifting connection bracket is sleeved on a lifting ball screw pair; a horizontal connection fixed plate is connected with the lifting connection bracket, a horizontal moving guide rail pair is arranged on the horizontal connection fixed plate, the horizontal moving guide rail pair is slidably connected with a horizontal bracket, and the horizontal bracket is sleeved on a horizontal moving ball screw pair; and a transition bracket is connected to the horizontal bracket, and the test sample gripper is installed on the transition bracket. The automatic feeding device disclosed by the invention is reasonable in structure, convenient to operate and use, high in feeding speed, accurate in location, high in working efficiency, safe and reliable. The automatic feeding device is applicable to automatic feeding of a drop-hammer type impact testing machine, a metal universal testing machine, etc.

Owner:威海市试验机制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com