Patents

Literature

31 results about "Critical length" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

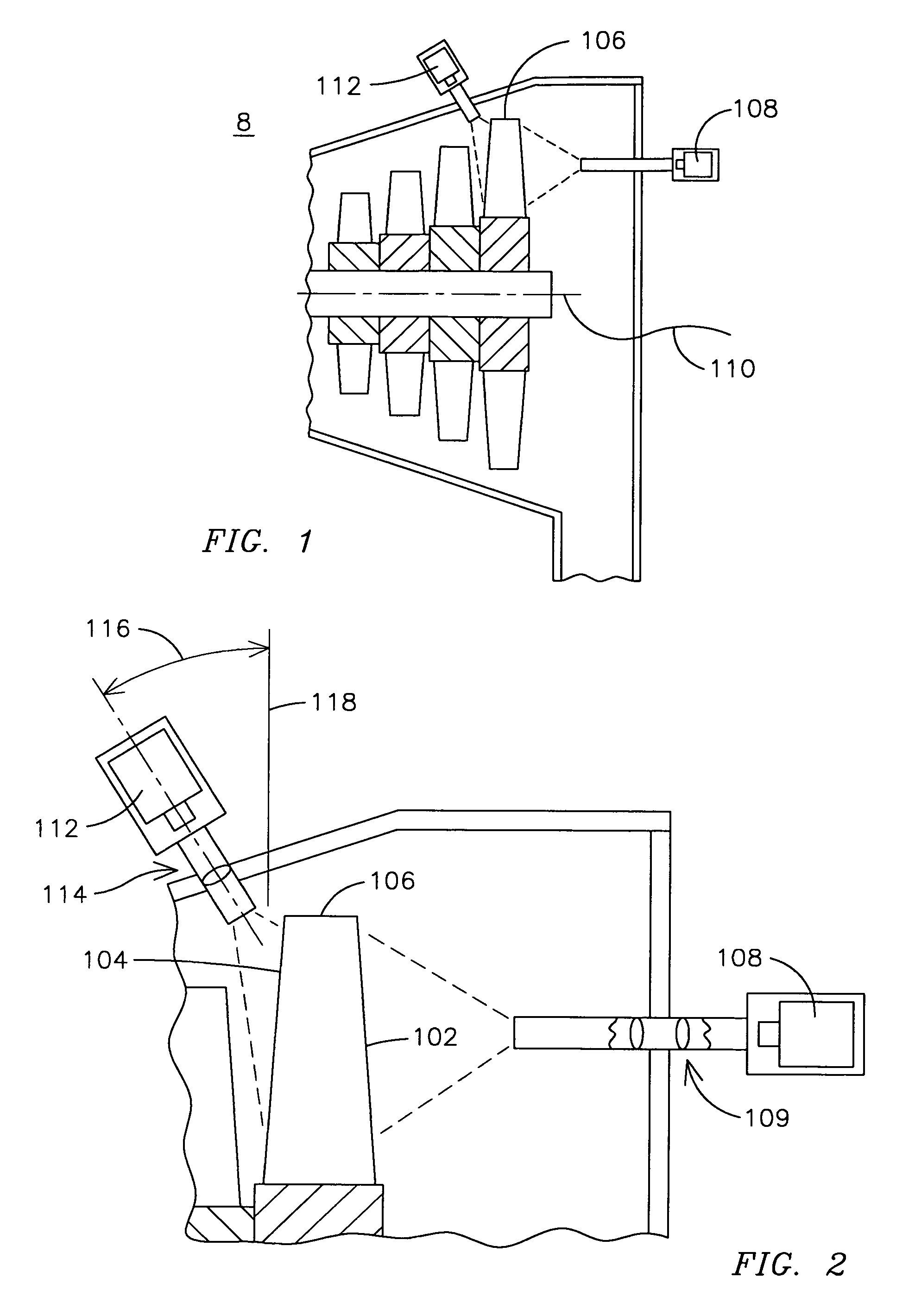

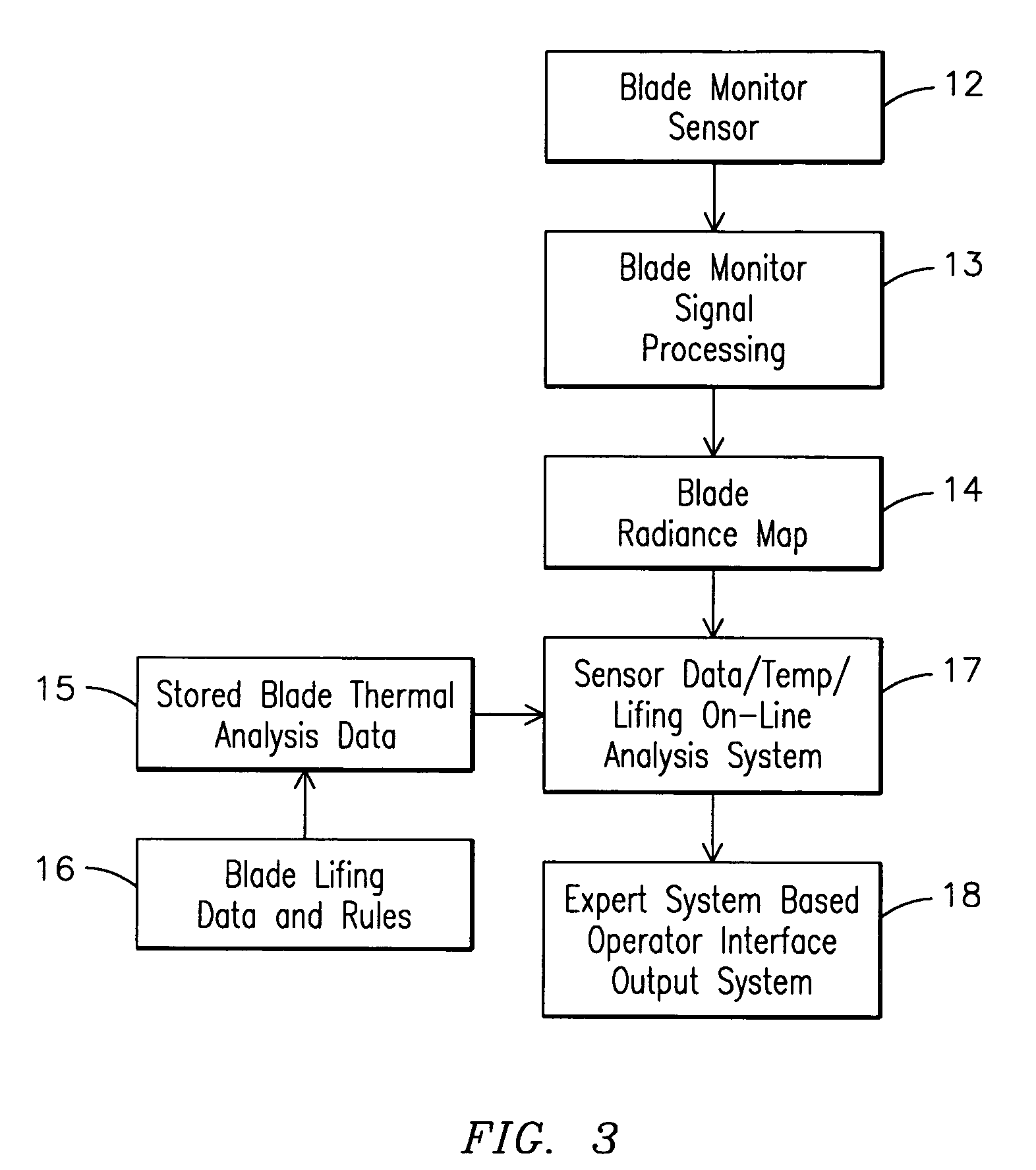

Infrared-based method and apparatus for online detection of cracks in steam turbine components

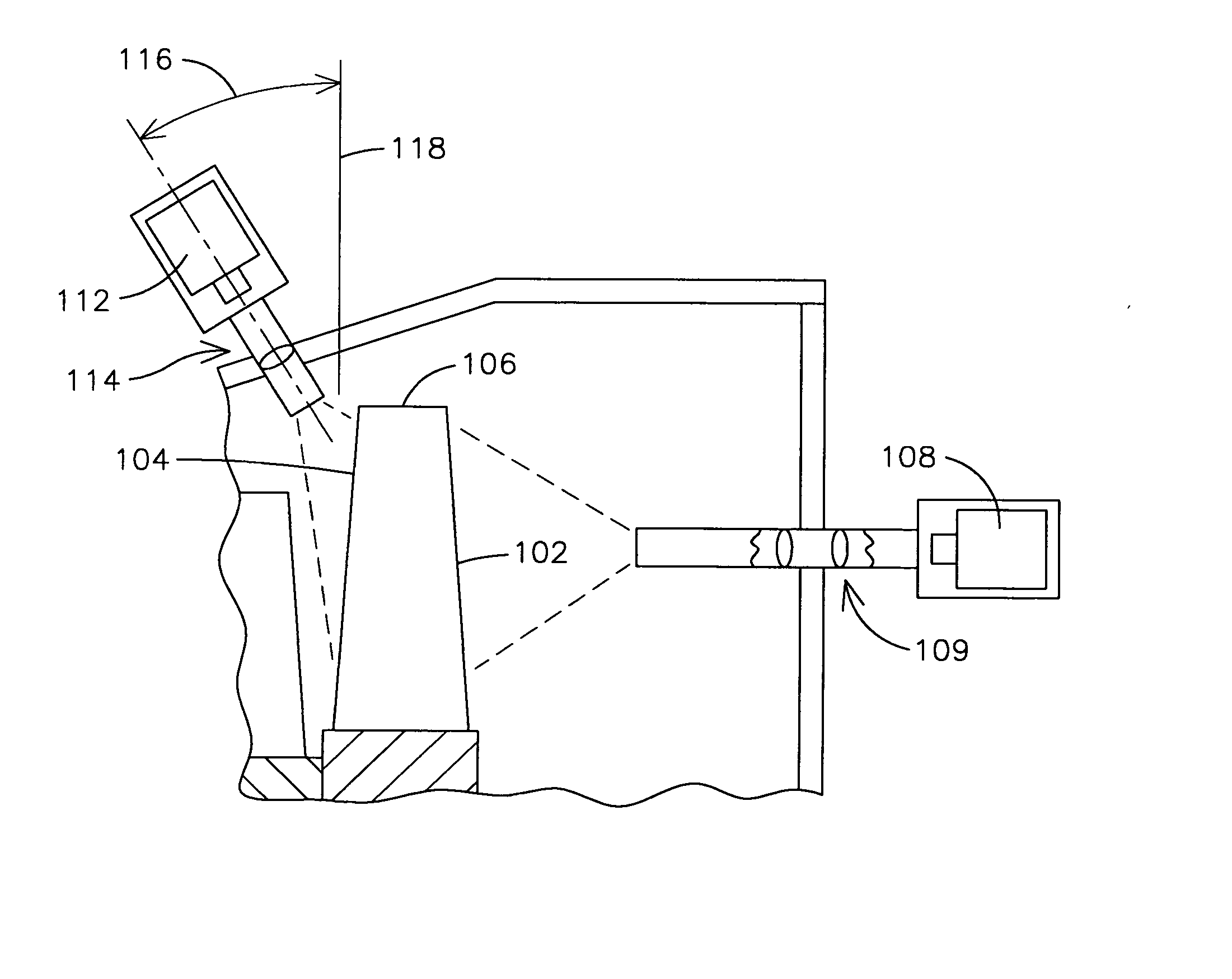

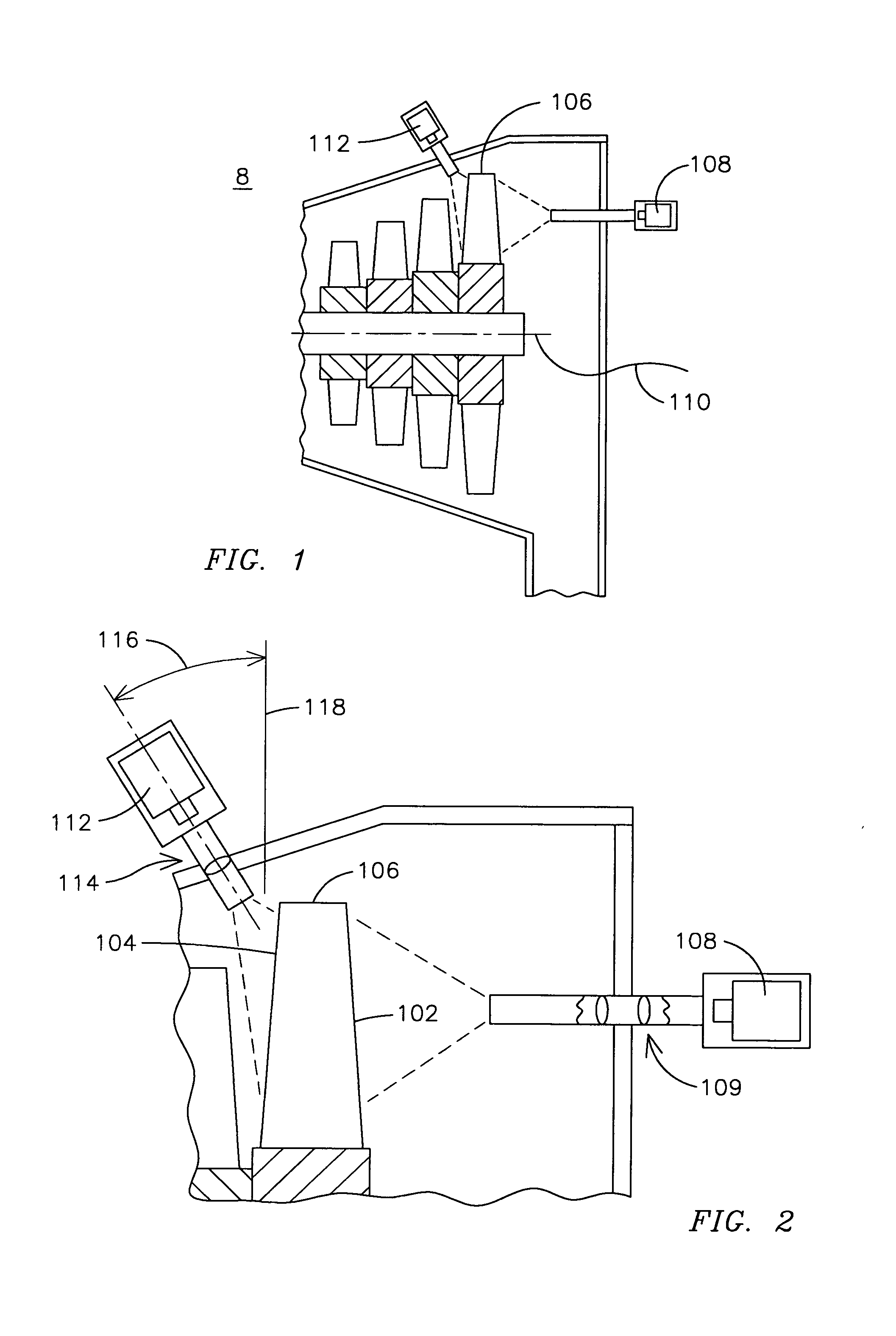

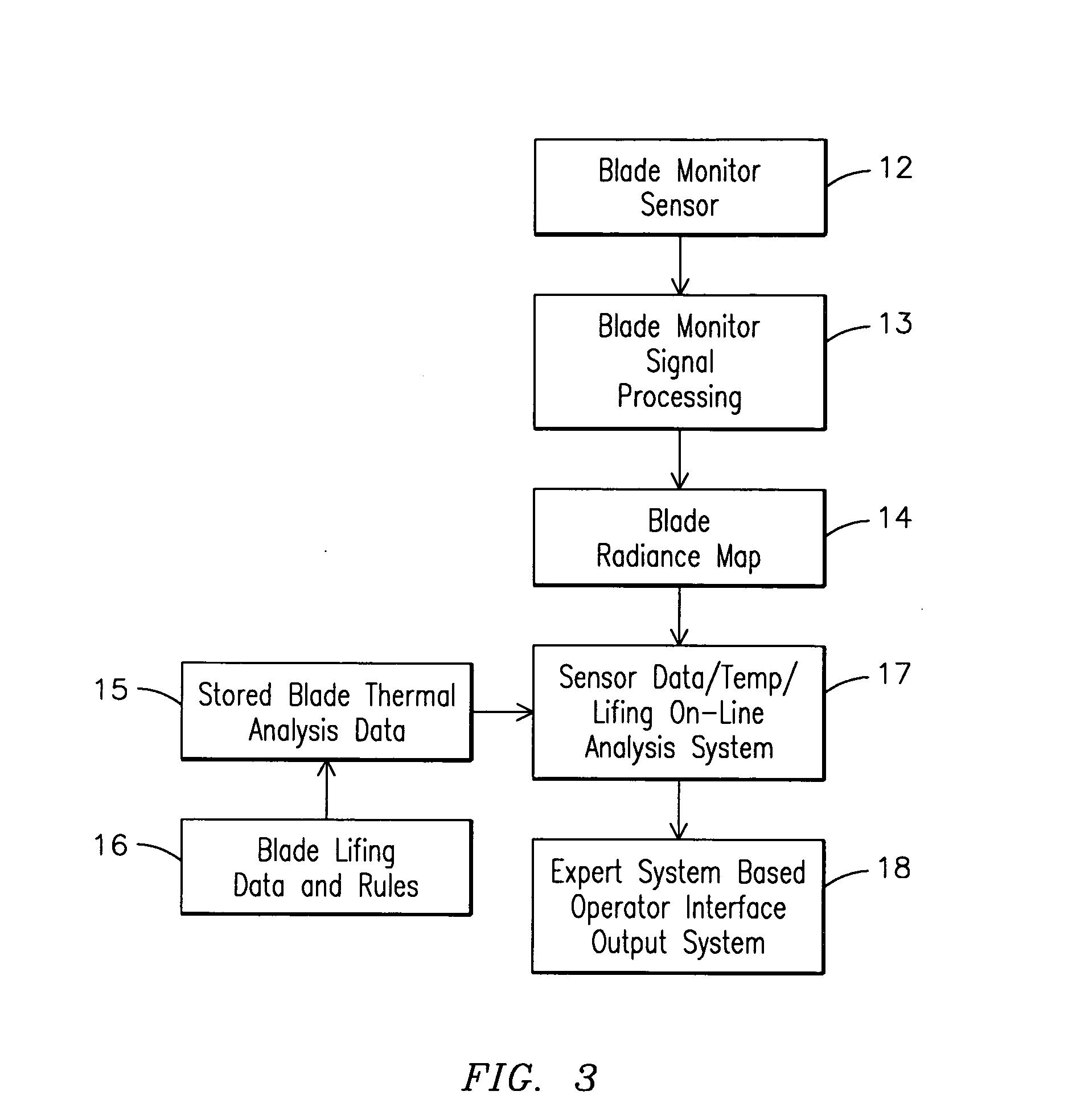

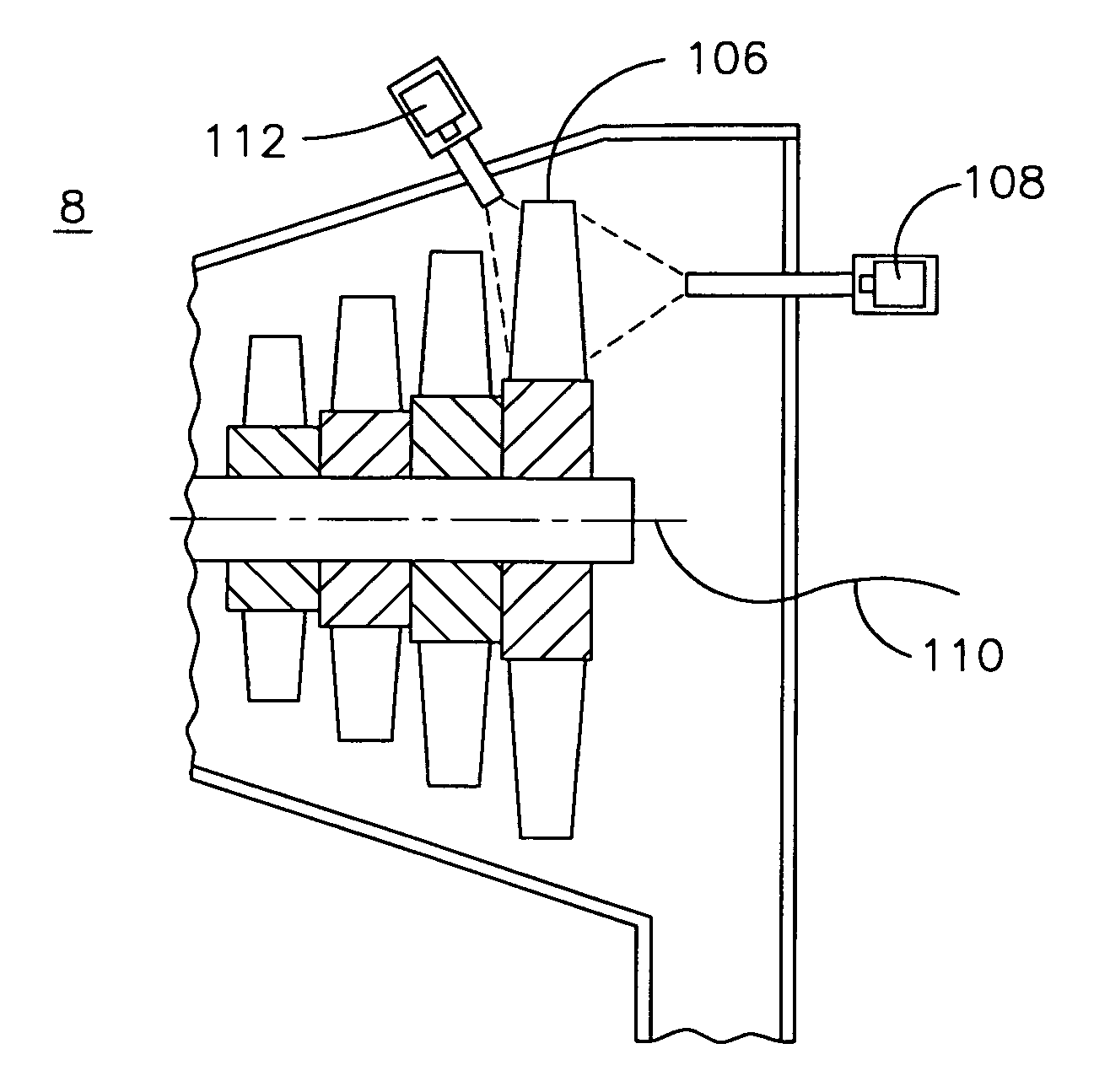

An online method, system, and computer-readable code for remotely monitoring radiant energy emitted from a turbine blade (106), which may be undergoing an incipient degradation, such as a crack, in a relatively low-temperature, and saturated steam environment of the low pressure stage of a steam turbine. The method and system provide sufficient temporal and spatial resolution to obtain high quality infrared images of the blade areas of interest enabling the system to identify the crack at any of those areas of the blade prior to such a crack growing to a critical length.

Owner:SIEMENS ENERGY INC

Infrared-based method and apparatus for online detection of cracks in steam turbine components

Owner:SIEMENS ENERGY INC

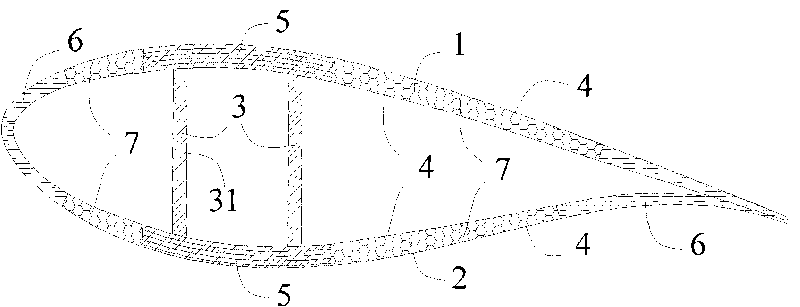

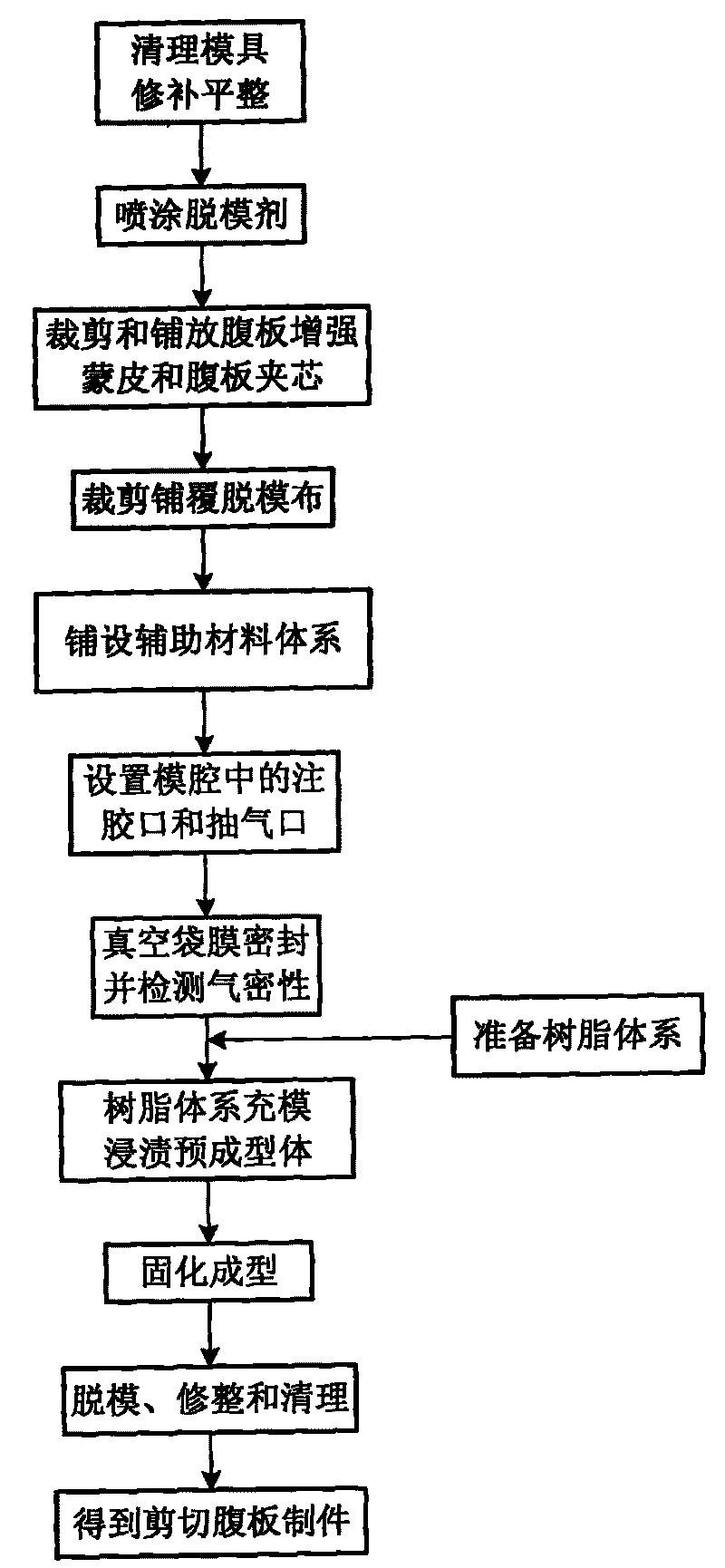

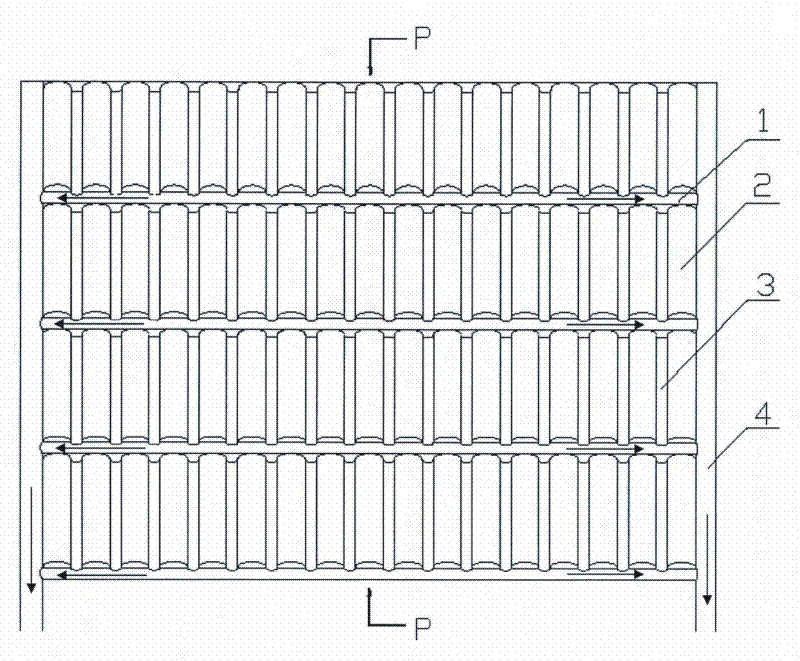

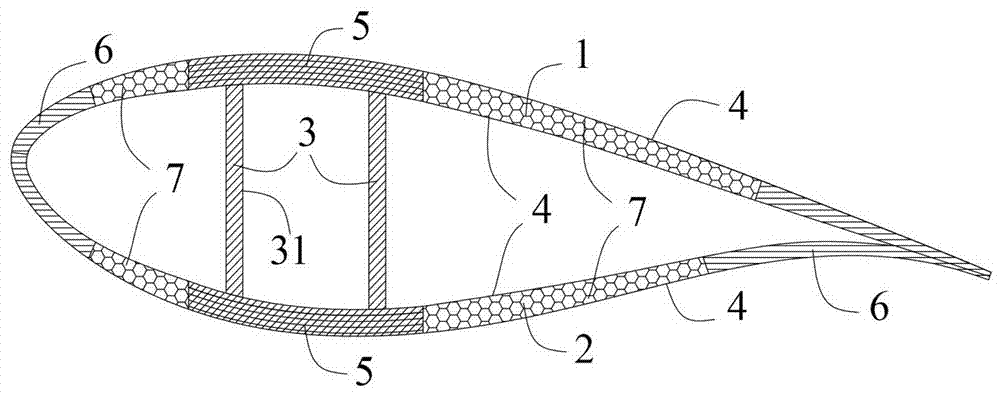

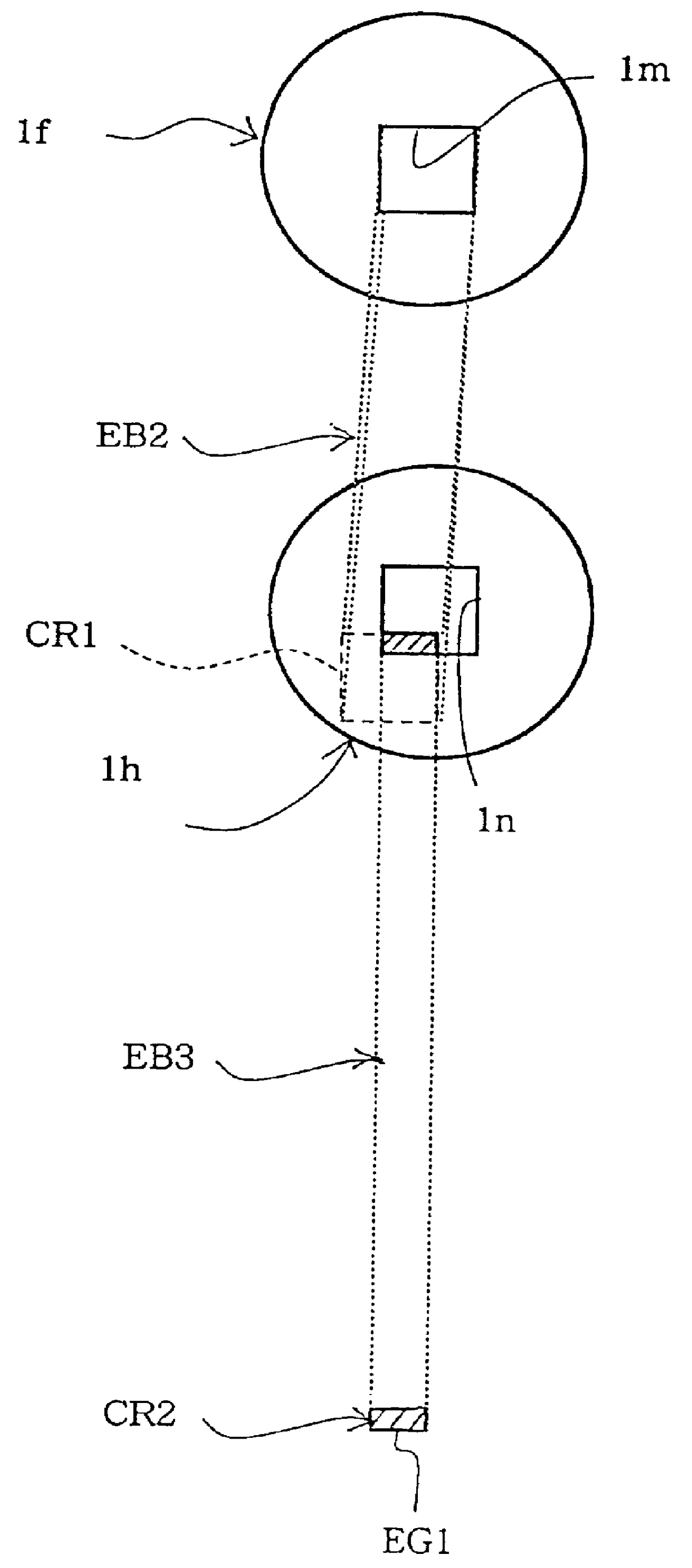

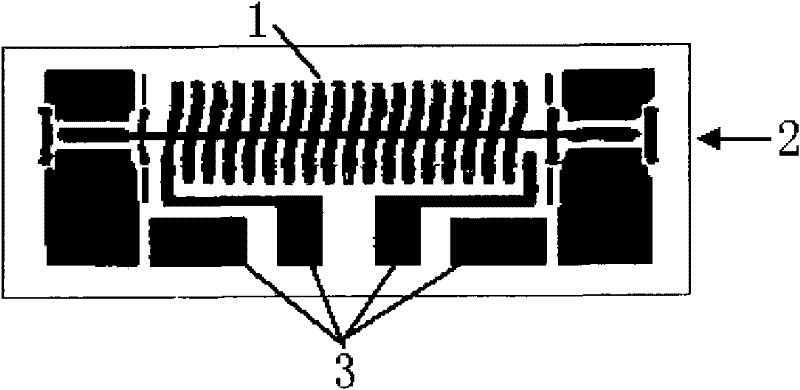

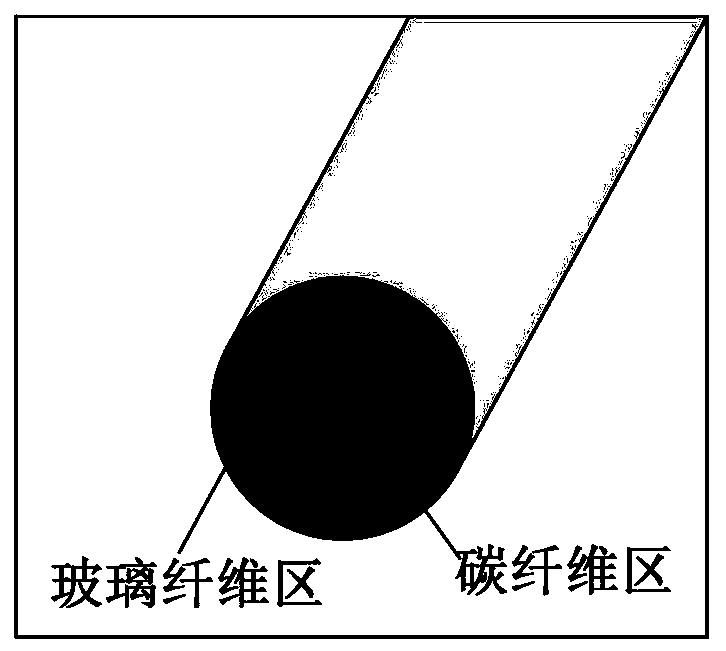

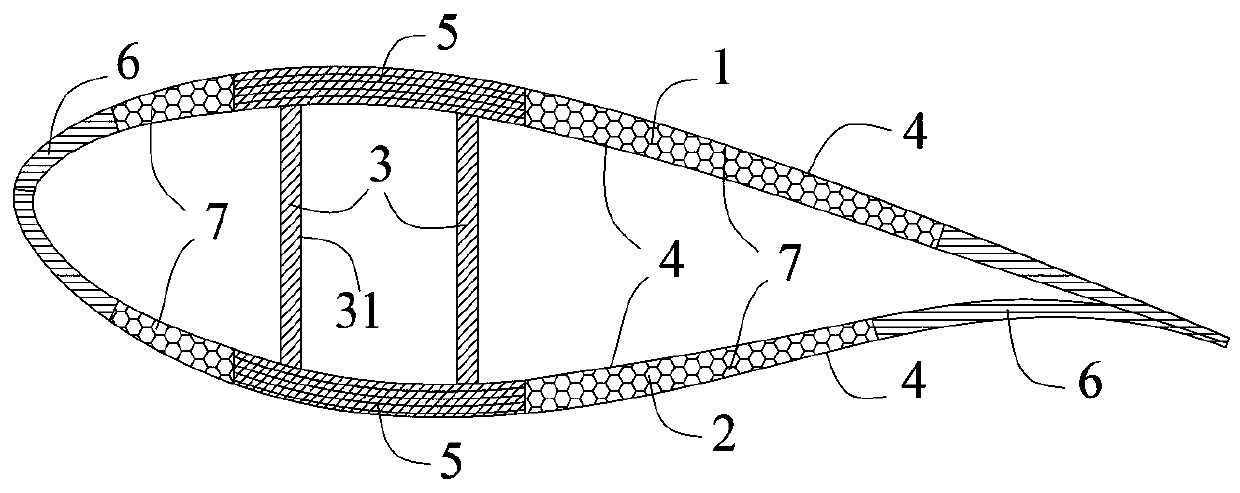

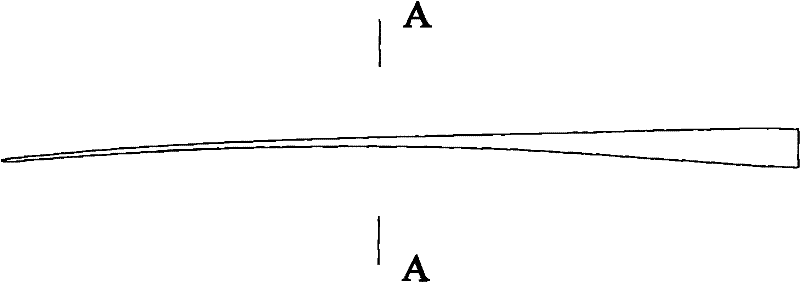

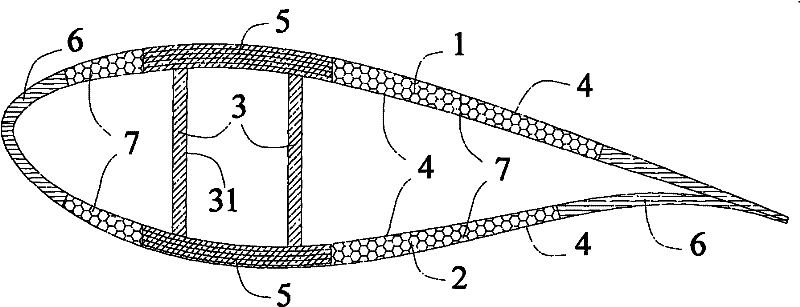

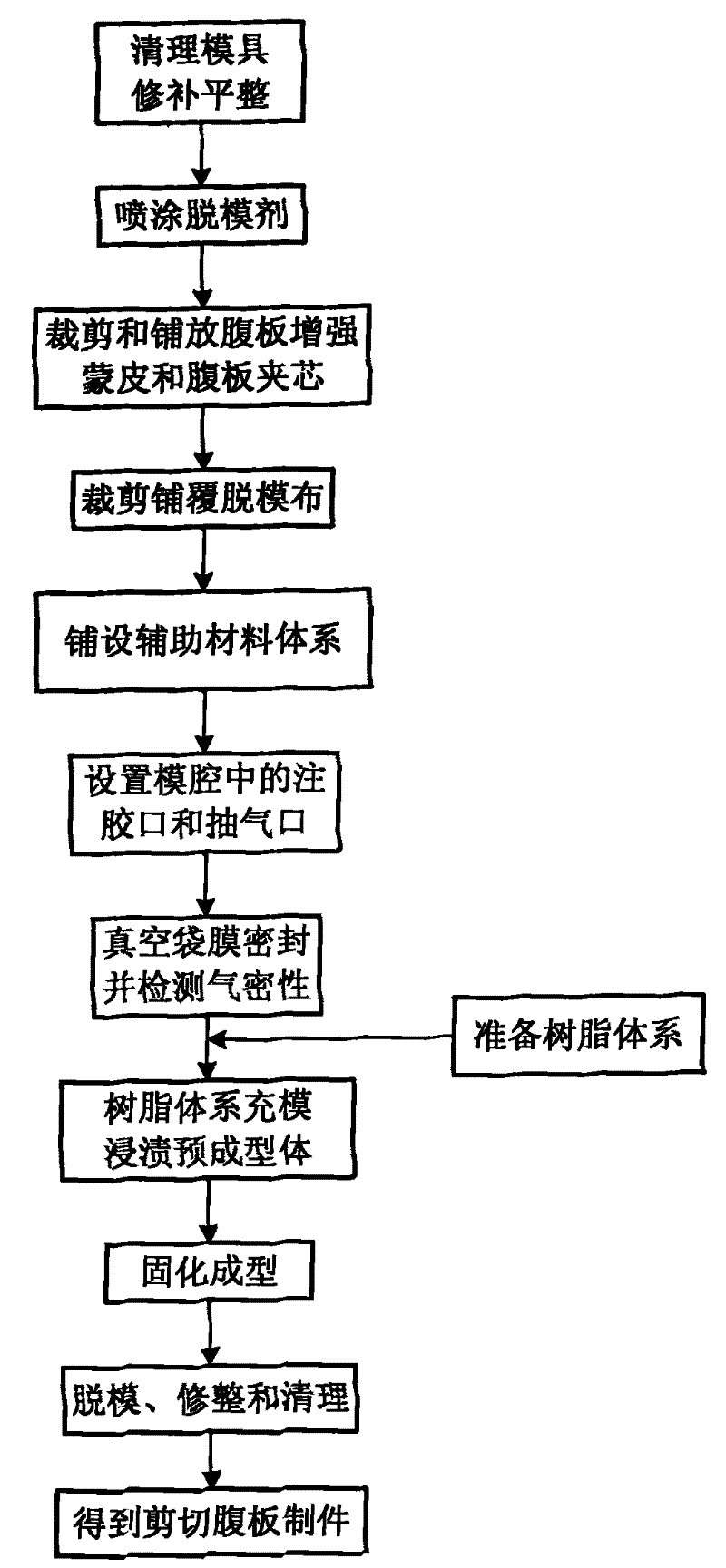

Large-scale composite material wind-power blade and preparation method thereof

ActiveCN101705922ASolve the problem of critical length limitationReduce wasteMachines/enginesWind energy generationElectricityGlass fiber

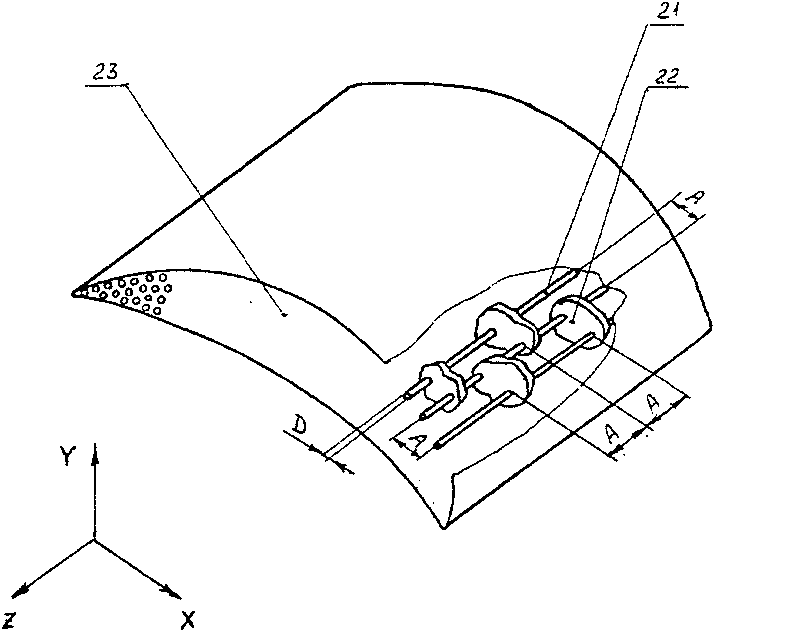

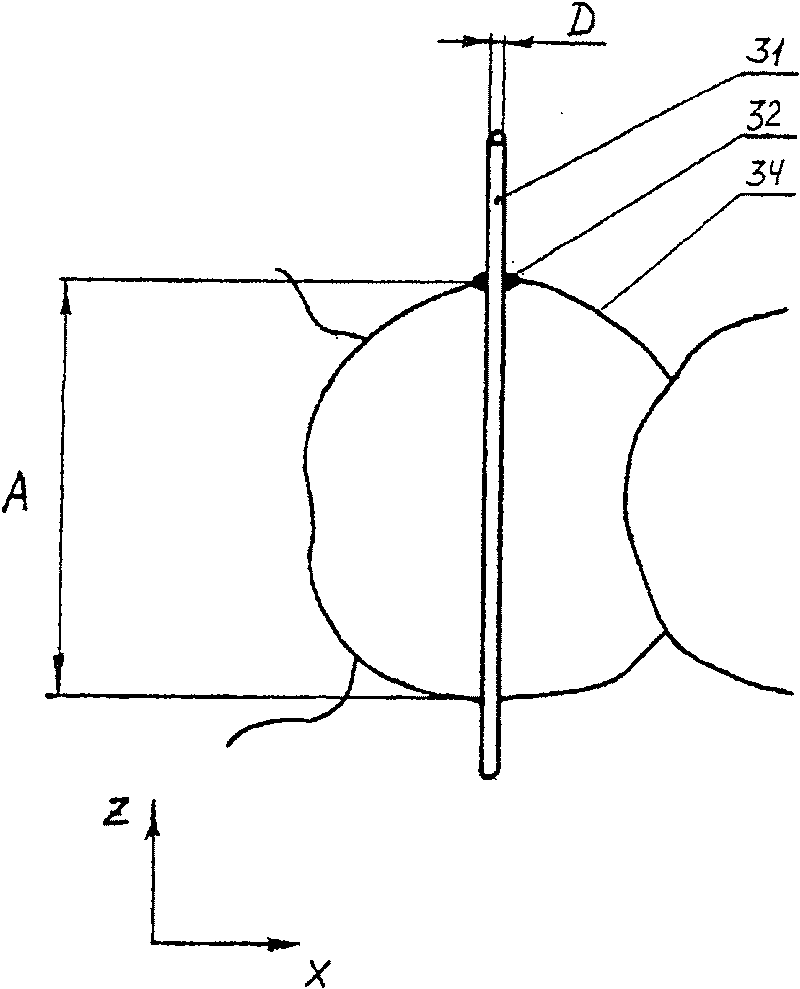

The invention discloses a large-scale composite material wind-power blade which comprises a suction face shell (1), a pressure face shell (2) and a cutting webplate (3) fixedly connected between the two shells, wherein the suction face shell (1) and the pressure face shell (2) are both sandwich type structural parts of an envelope (4) for covering a core material; the core material comprises a main blade bearing beam (5), a flange reinforcement part (6) of the blade and a filling material (7) arranged between the main blade bearing beam (5) and the reinforcement part (6); and the main blade bearing beam (5) and the reinforcement part (6) both use mixtures of carbon fibers / glass fibers as an reinforcement material. The large-scale composite material wind-power blade has the advantages of light weight, extended critical length, excellent mechanical property, and the like.

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

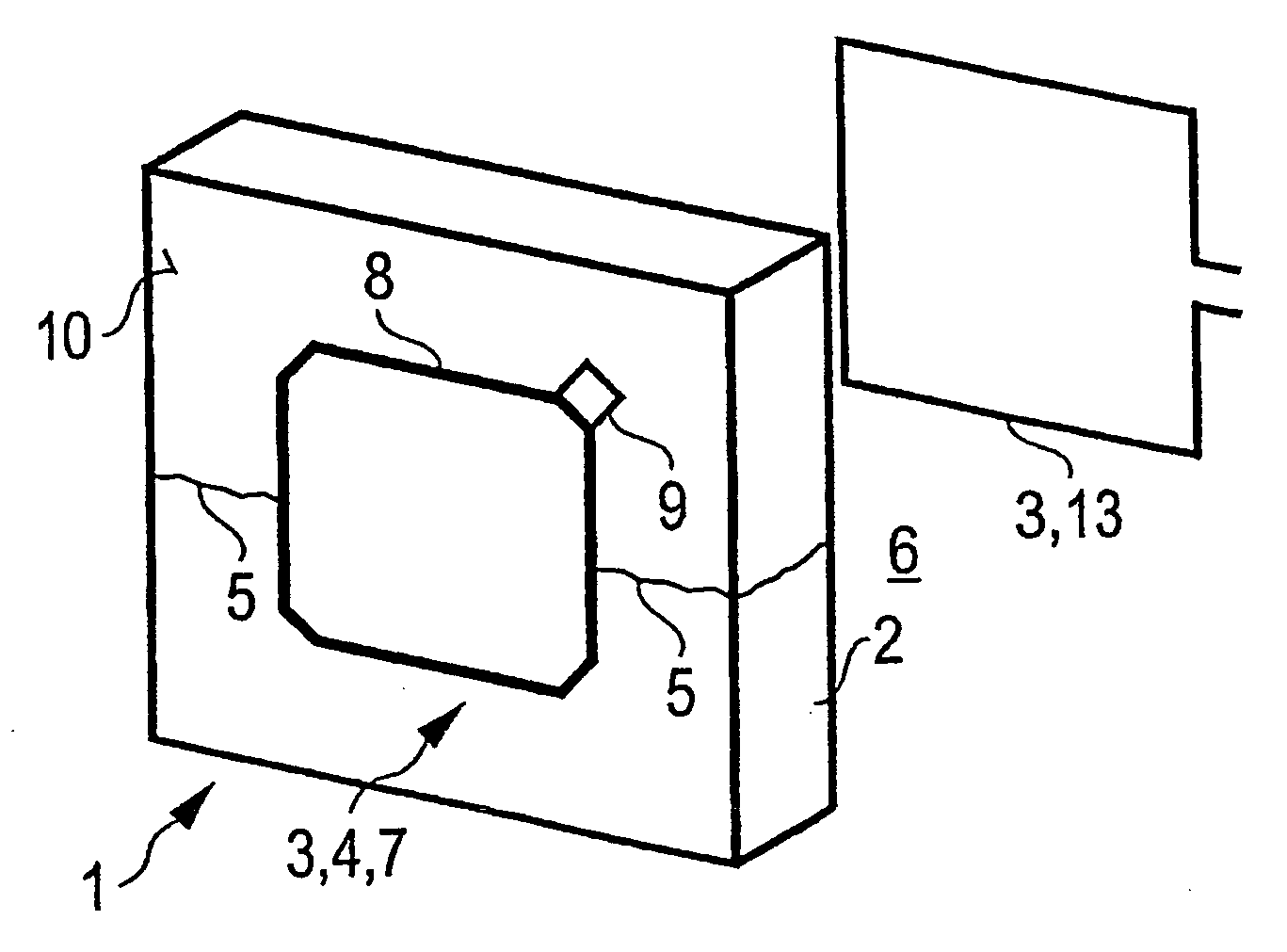

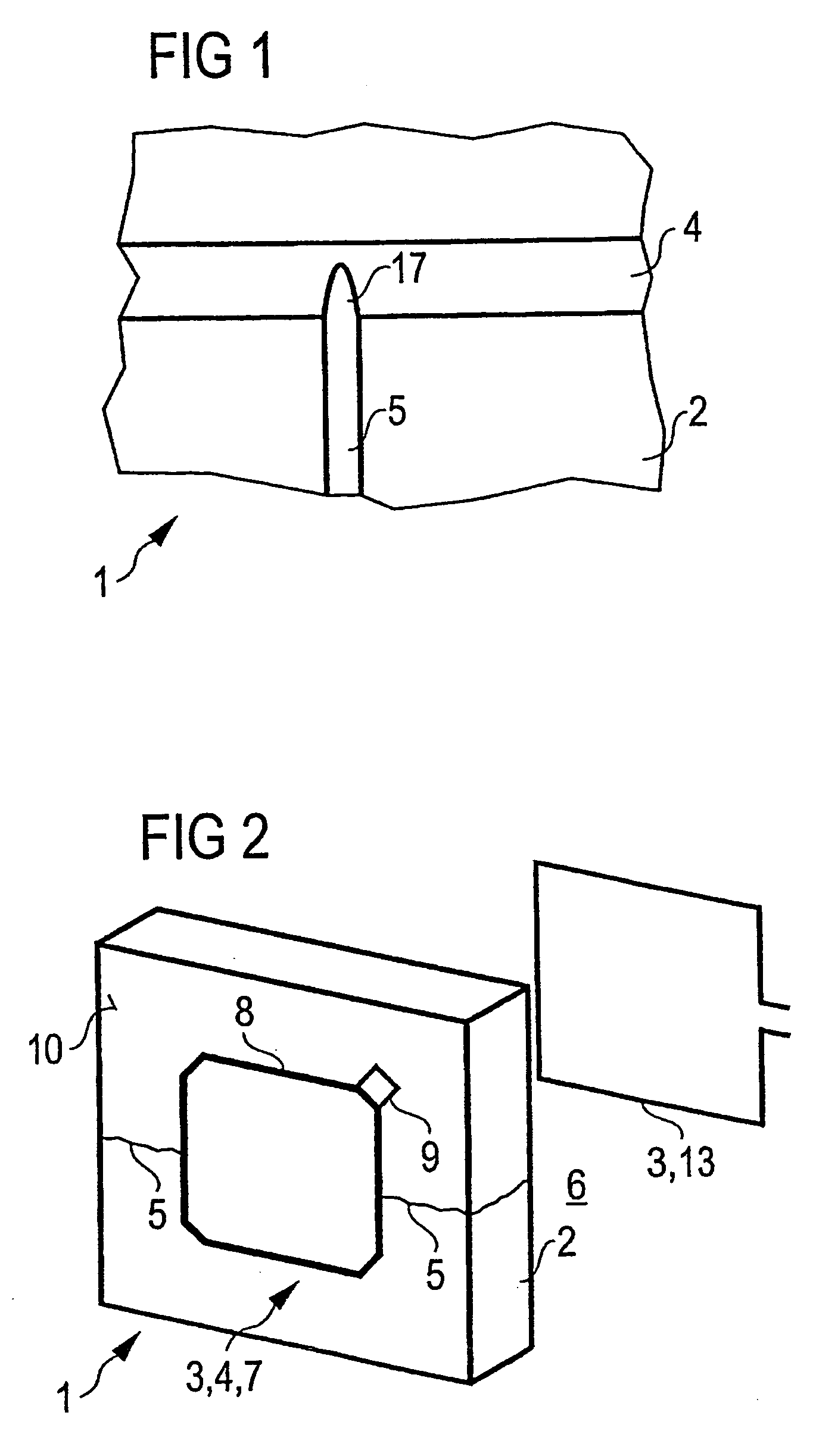

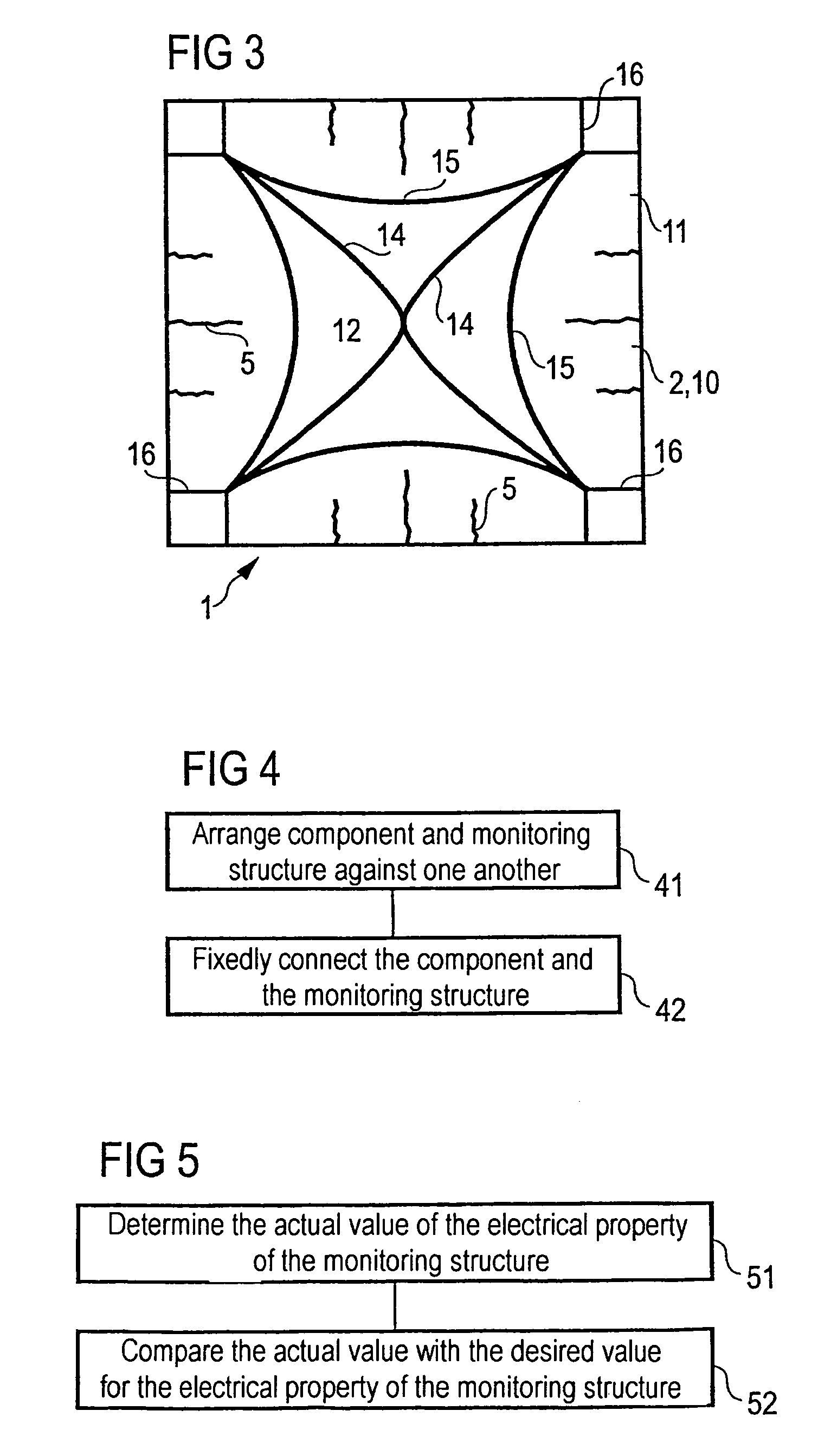

Device for detecting degradation of a component

InactiveUS7141990B2Quick and reliableAnalysing solids using sonic/ultrasonic/infrasonic wavesResistance/reactance/impedenceElectricityElectrical conductor

An apparatus for monitoring the structural integrity of a component. A monitoring structure is applied to a component that is subject to structural degradation. The monitoring structure includes an electrical conductor that becomes cracked if the component becomes structurally degraded. When the component is a ductile metal component that may be degraded by bending, the electrical conductor is formed of a brittle material that cracks when the ductile metal component is bent. When the component is a brittle ceramic heat shield wherein a crack having a critical length is of concern, the electrical conductor is located at a predetermined location wherein a critical length crack in the component will propagate into the conductor. A crack in the electrical conductor is detected with a monitoring device to indicate a degraded structural condition in the component.

Owner:SIEMENS AG

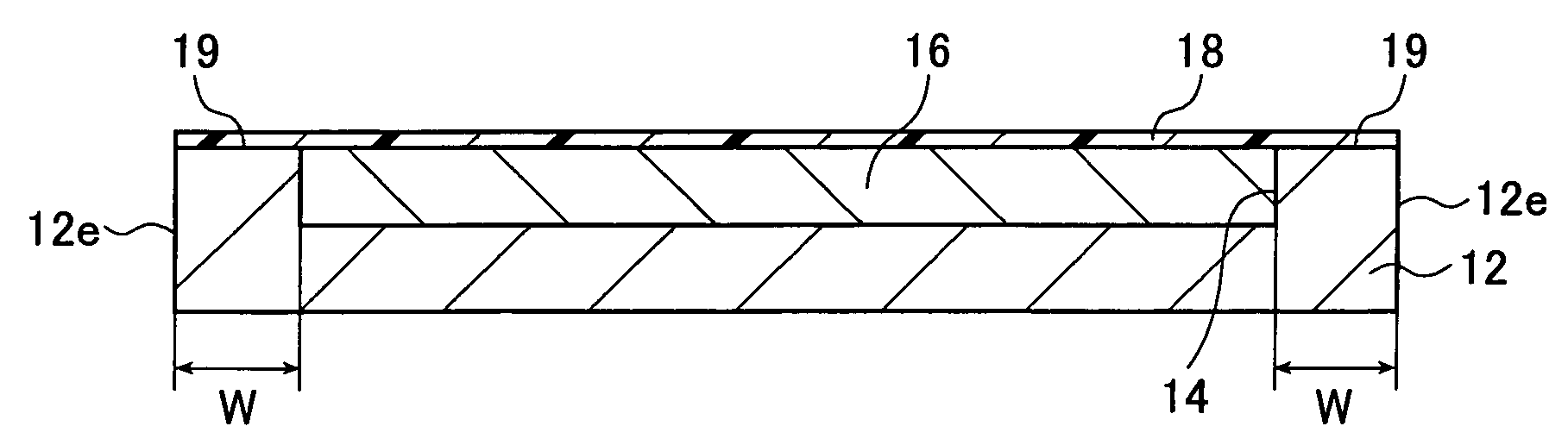

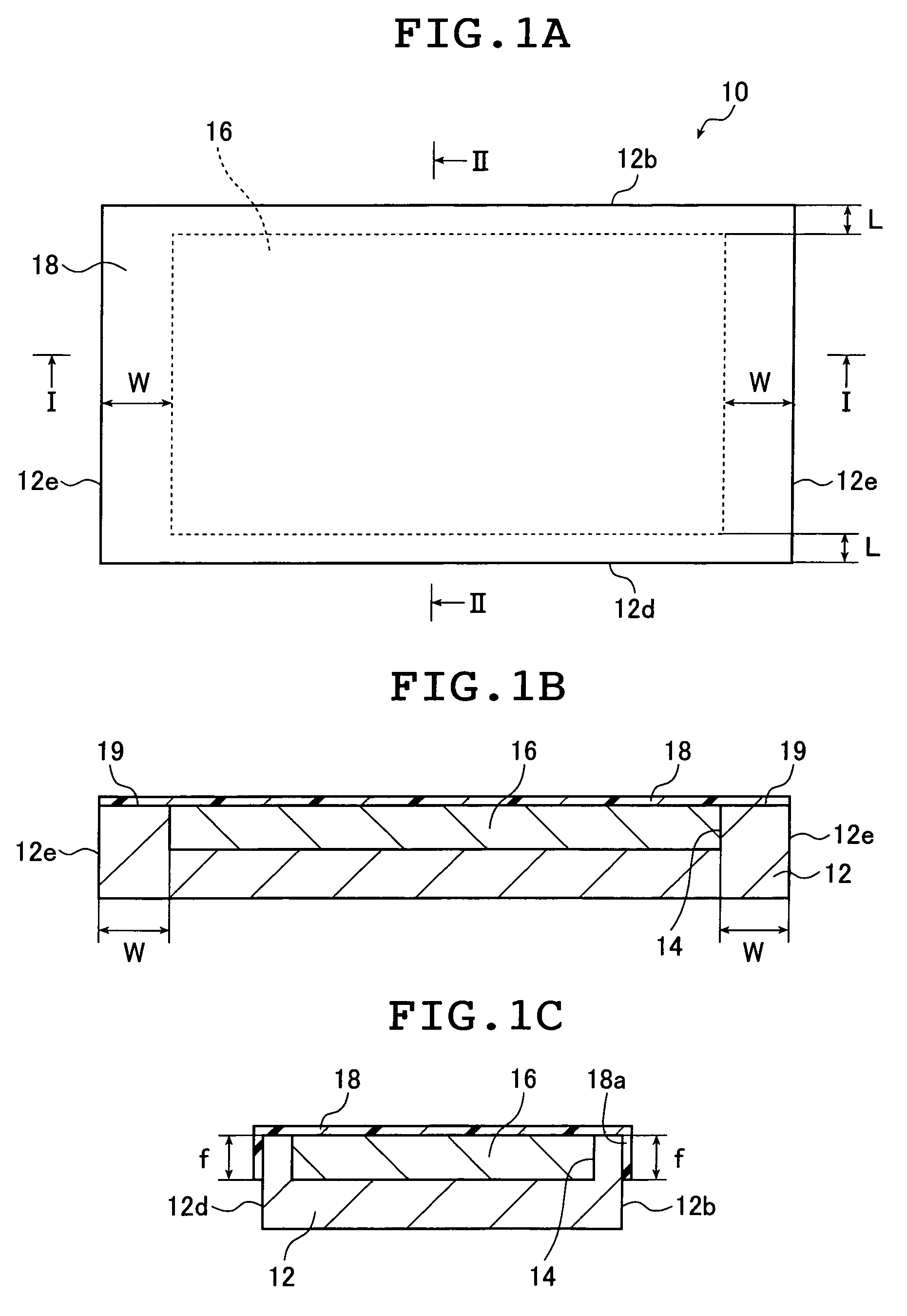

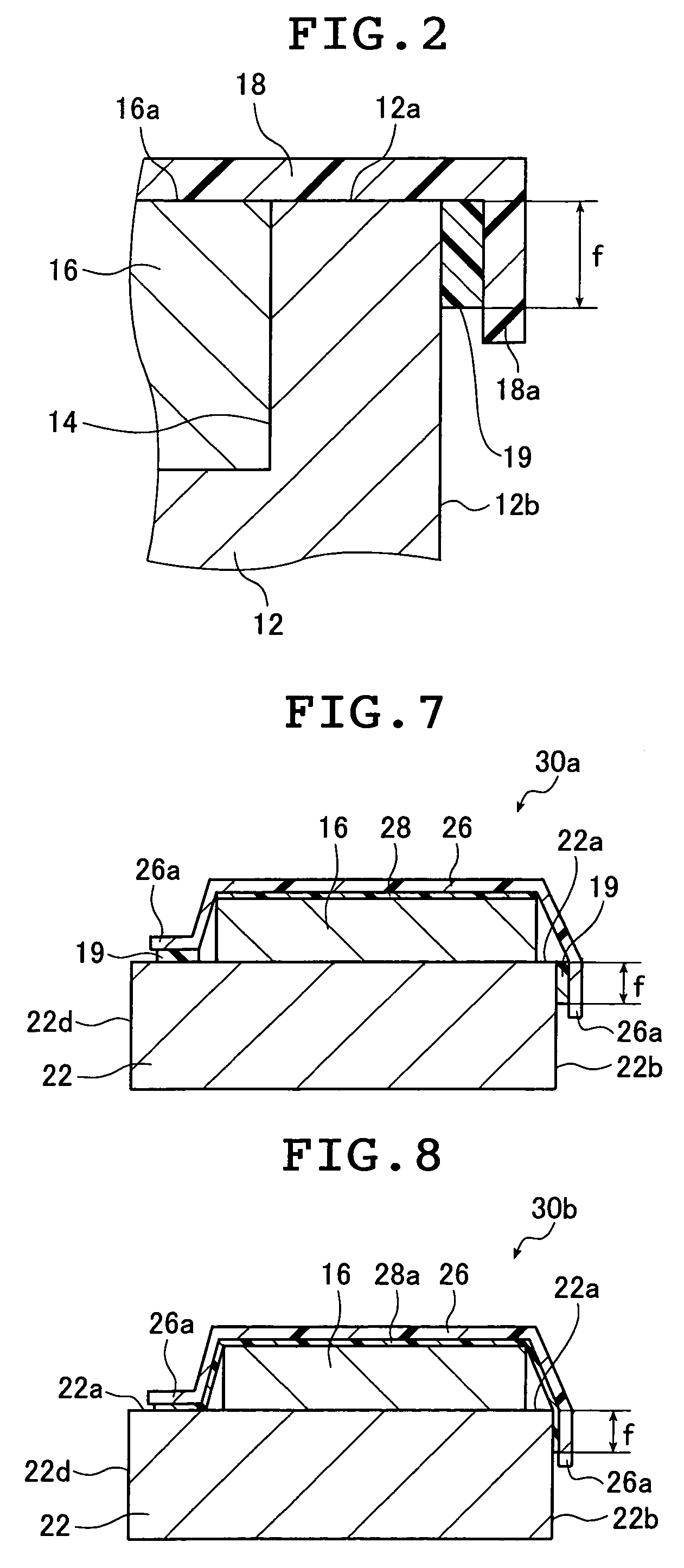

Method of forming electrical interconnects having electromigration-inhibiting segments relative to a critical length

InactiveUS7062850B2Shorten the lengthLower resistanceSemiconductor/solid-state device detailsSolid-state devicesConductive materialsElectromigration

A method of forming an electrical conductor, comprising forming electrically conductive segments incorporating electromigration-inhibiting plugs. A row of windows is formed in a planar surface and electromigraation-inhibiting material is deposited over the planar surface and into the windows to provide electromigration-inhibiting plugs in the windows. The plugs may be formed by depositing an electromigration-inhibiting liner in the windows and then depositing electrically conductive material to fill the windows. Portions of either or both of the plugs and conductive segments are removed such that the plugs and conductive segments have a coplanar surface. The plugs may be formed in windows in an electrically conductive layer defining the conductive segments. Embodiments of the method may be employed in manufacture of integrated circuit conductor.

Owner:SAMSUNG ELECTRONICS CO LTD

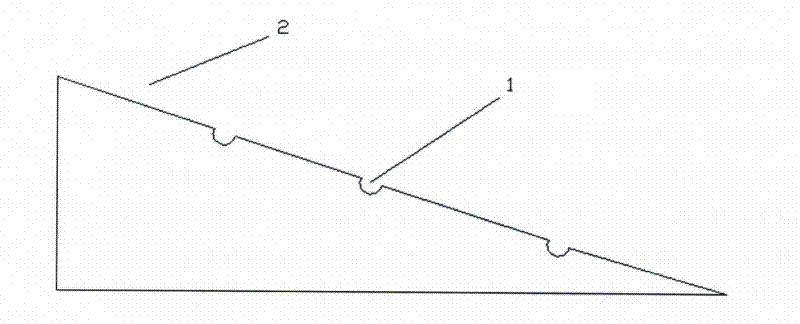

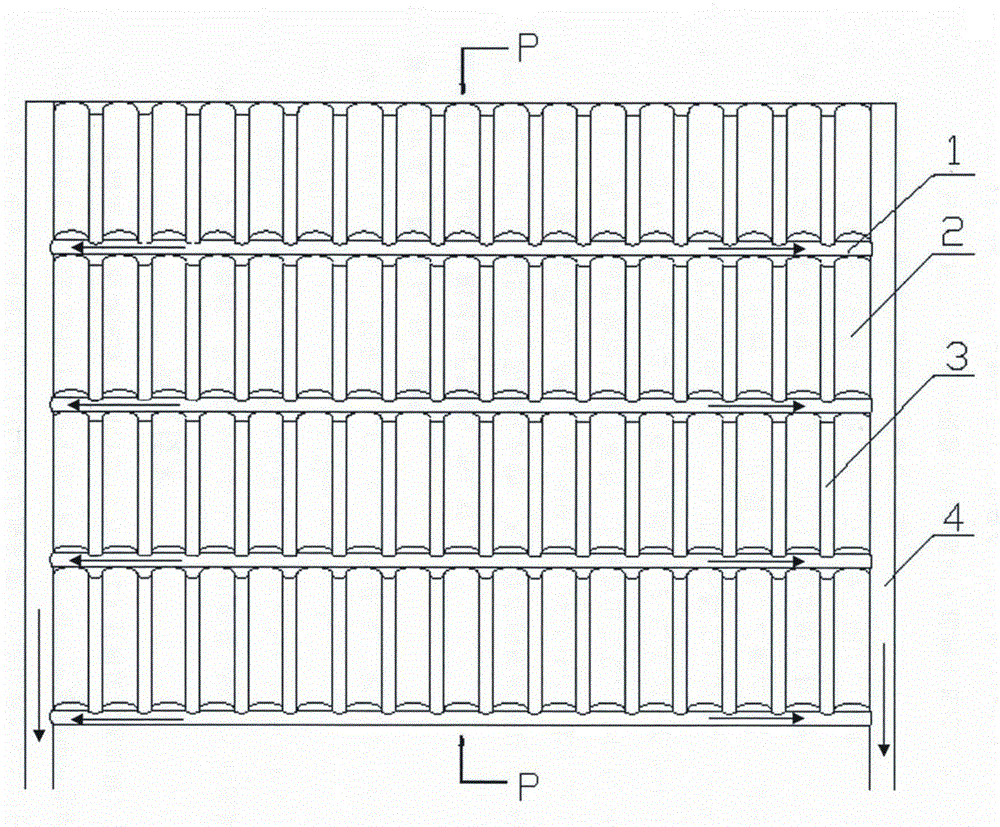

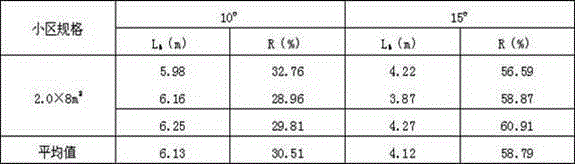

Transverse-furrow and sequential-ridge mellow soil anti-erosion farming method of purple soil slope farmland

InactiveCN102239760AAvoid strong washingReduce churnClimate change adaptationAgriculture gas emission reductionTerrainSlope length

The invention discloses a transverse-furrow and sequential-ridge mellow soil anti-corrosion farming method of a purple soil slope farmland and particularly relates to the field of a soil erosion management technique of the purple soil slope farmland. In the method disclosed by the invention, a transverse furrow is excavated along the contour line on the purple soil slope farmland at the slope length interval which is less than the rill erosion generation critical length of the modified slope surface; the cross section of the transverse furrow is in an arc shape; the formed transverse furrow divides the whole slope farmland plot into multiple small farming units in the transverse slope direction; the two ends of the transverse furrow are connected with the original drainage furrows at the two ends of the slope farmland plot; and the integral farming terrain conditions with alternate furrows and ridges are formed by adopting a sequential-slope ridging farming mode, i.e. alternately farming and ridging in the sequential slop direction and reverse slop direction. The method disclosed by the invention can reduce the water and soil loss and prevent and control the soil erosion of the slope farmland, is beneficial to the enhancement of the water content in the soil of the farmland plot in the descending direction of the transverse furrow, improves the drought resistance of crops, maintains the agricultural productivity of the slope farmland and realizes the sustainable utilization of slope farmland water and soil resources.

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

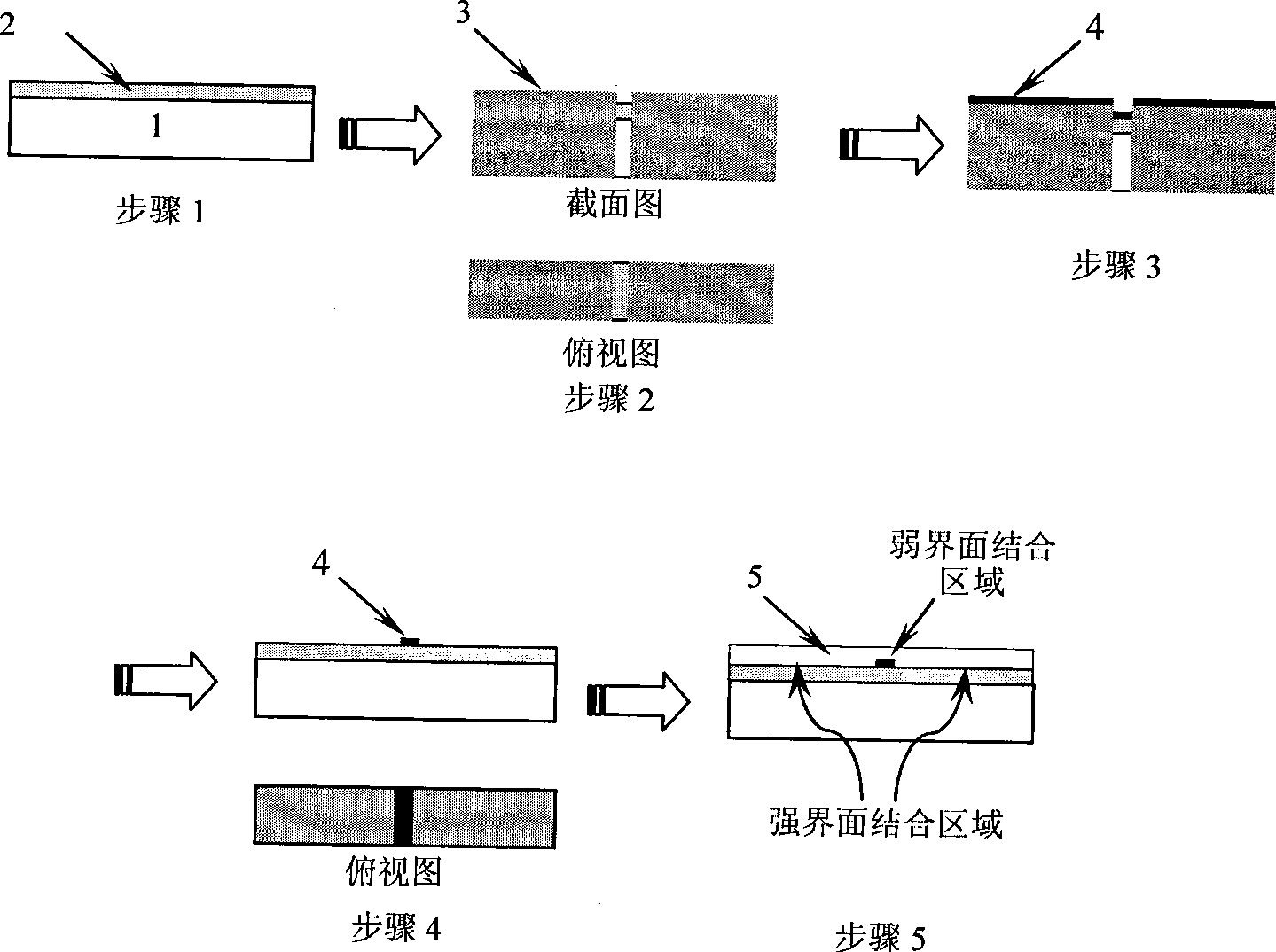

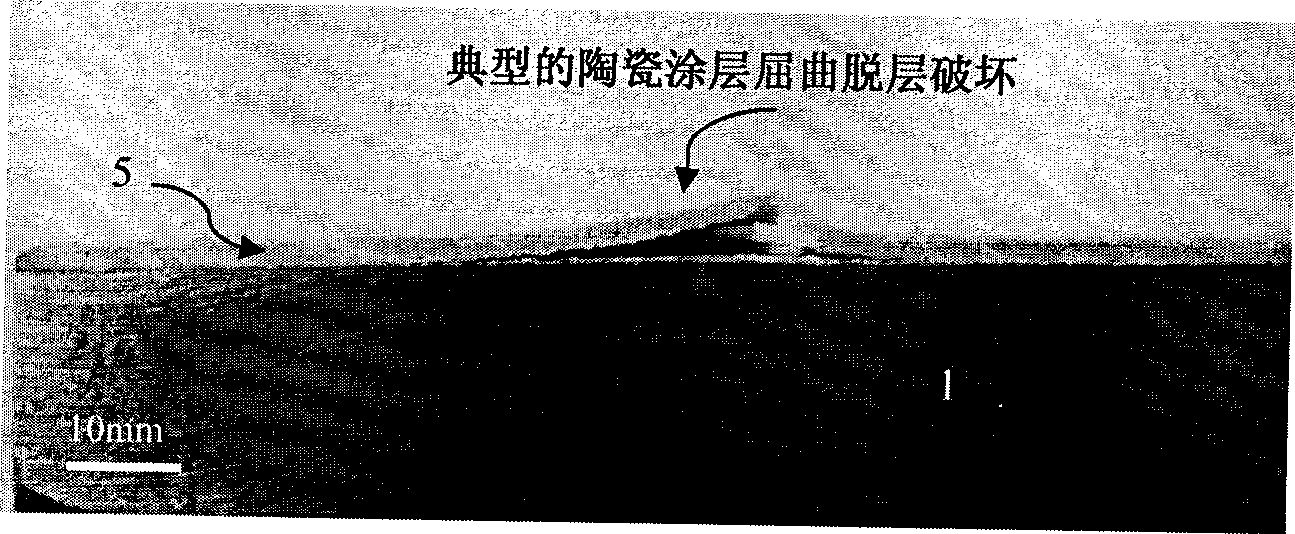

Experiment control method for researching flexion damage of thermal curtain coating interface containing inner embedded interface defect under high temperature environment

InactiveCN101435755AMaterial strength using tensile/compressive forcesUsing mechanical meansCoating systemCeramic coating

The invention discloses an experimental control method for experiments studying the interface buckling failure of thermal barrier coatings containing buried interface defects in high-temperature environment. Experimental equipment needed by the experimental method is as follows: a universal testing machine, an oxyacetylene high-temperature heating device, a thermocouple temperature measurement device, a CCD observation device for coating failure process and a computer. The method mainly comprises the following steps: a certain compressive load is applied in advance to a thermal barrier coating specimen containing interface defects; the method has corresponding requirements on the magnitude and application modes of the load; and residual compressive stress in a thermal barrier ceramic coating is approximately replaced with the compressive load. Therefore, the method is simple to operate and capable of shortening experimental time, thereby providing an important experimental method for analyzing the interface bonding performance of a ceramic layer and a bonding layer and providing a good basis and reference experience for studying the interface buckling problems of film / coating systems in future. The interface-crack critical length a[cr] of the thermal barrier ceramic coating with interface buckling failure is experimentally found to be 3 to 4 millimeters in general.

Owner:XIANGTAN UNIV

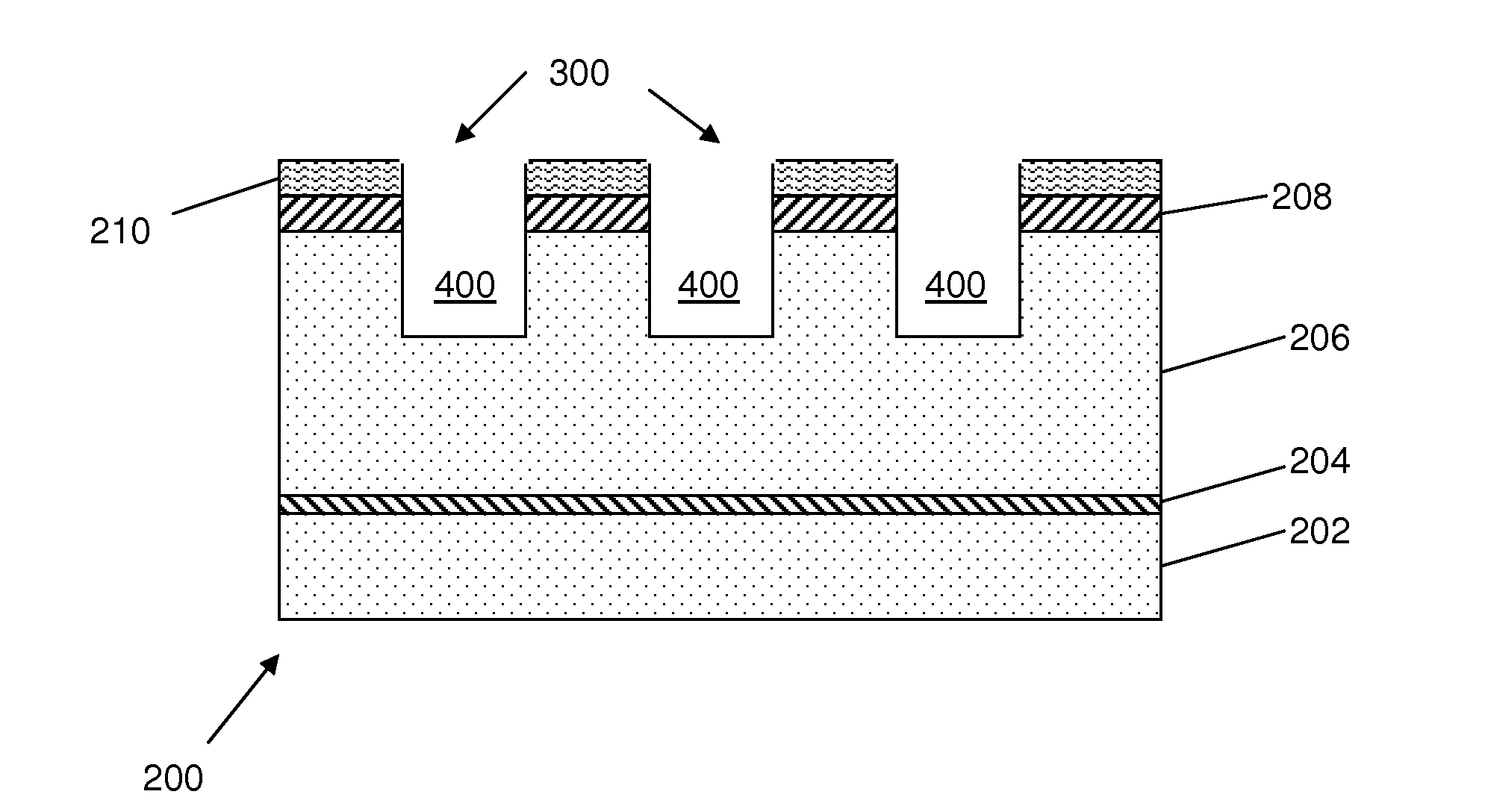

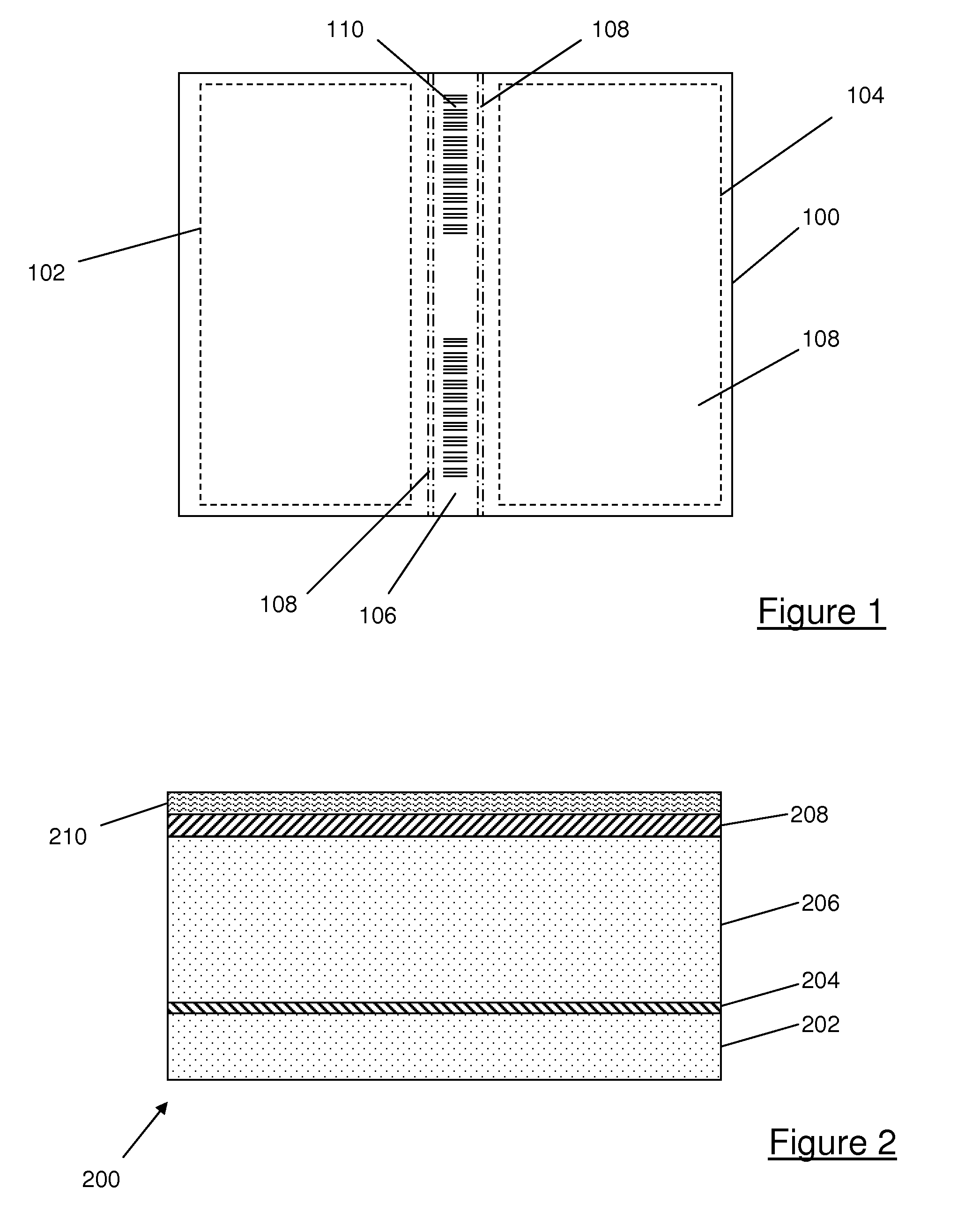

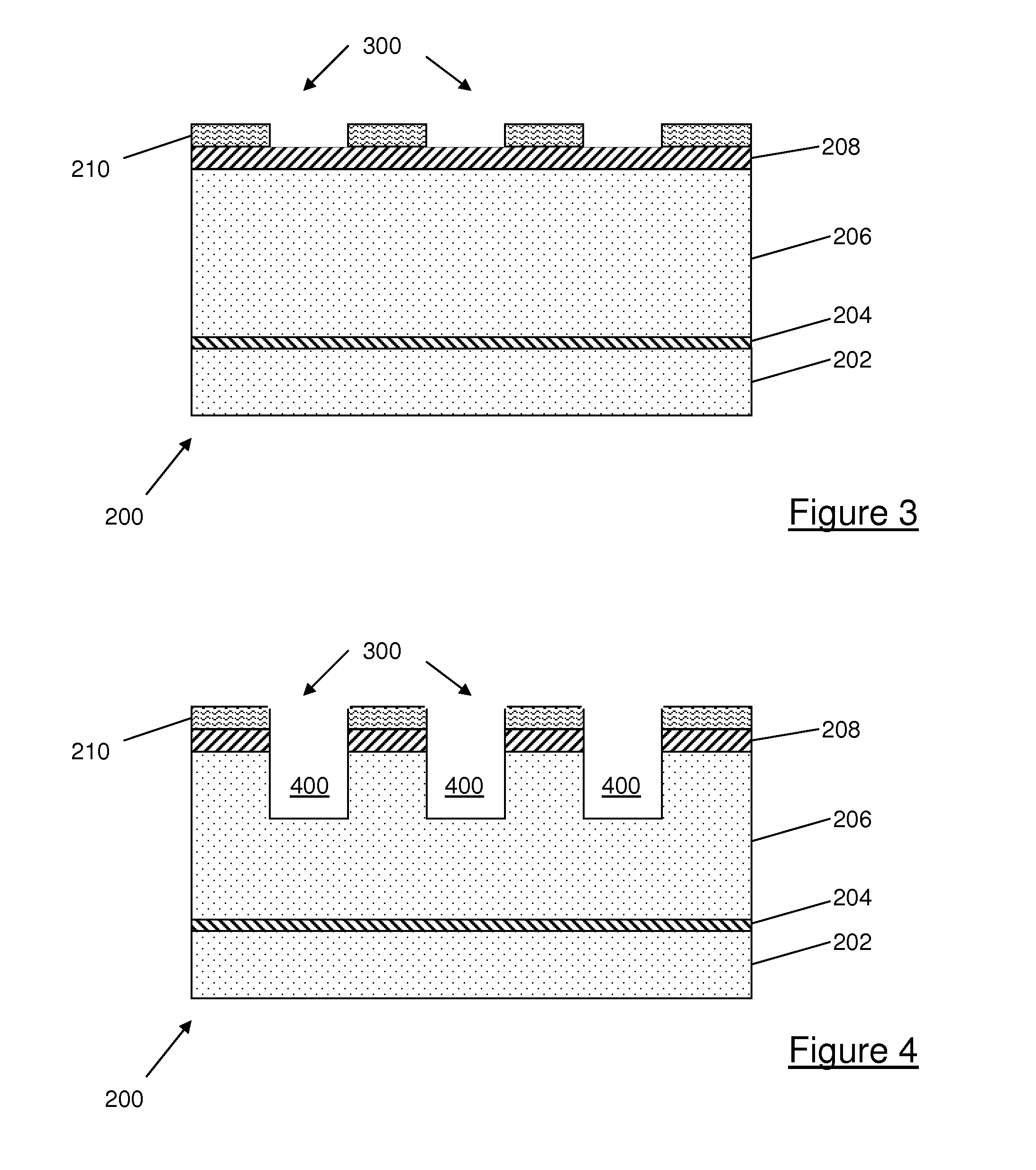

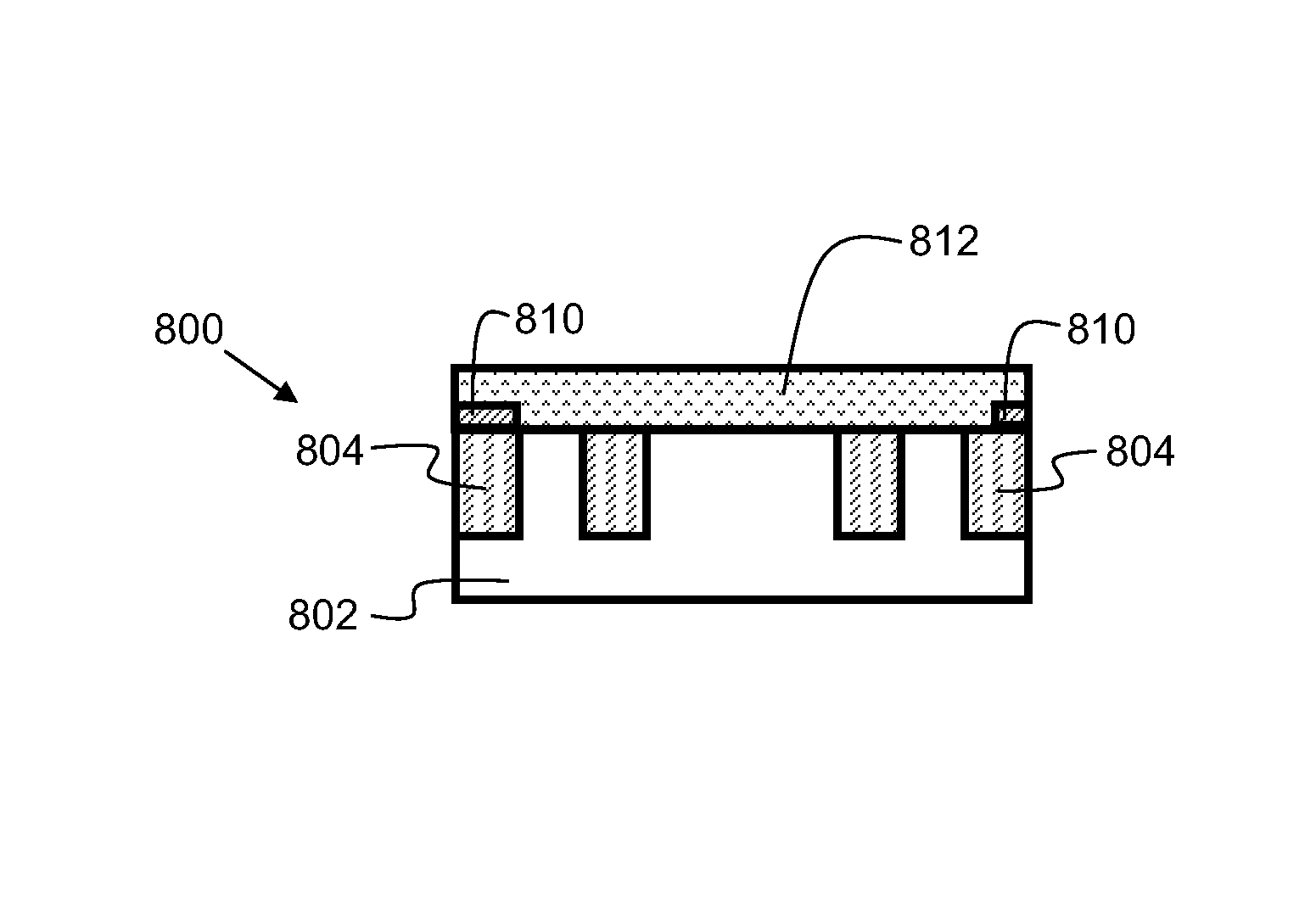

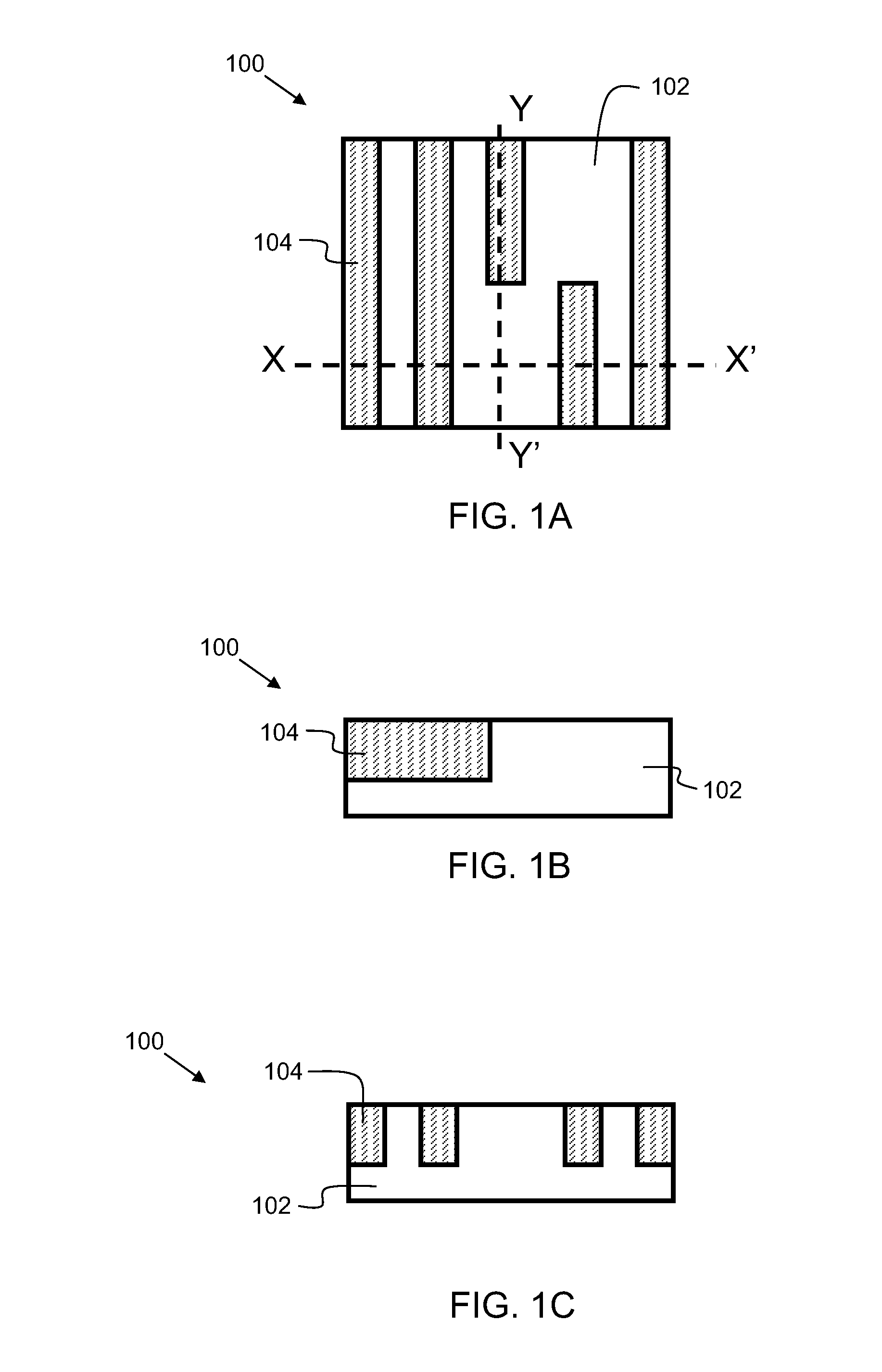

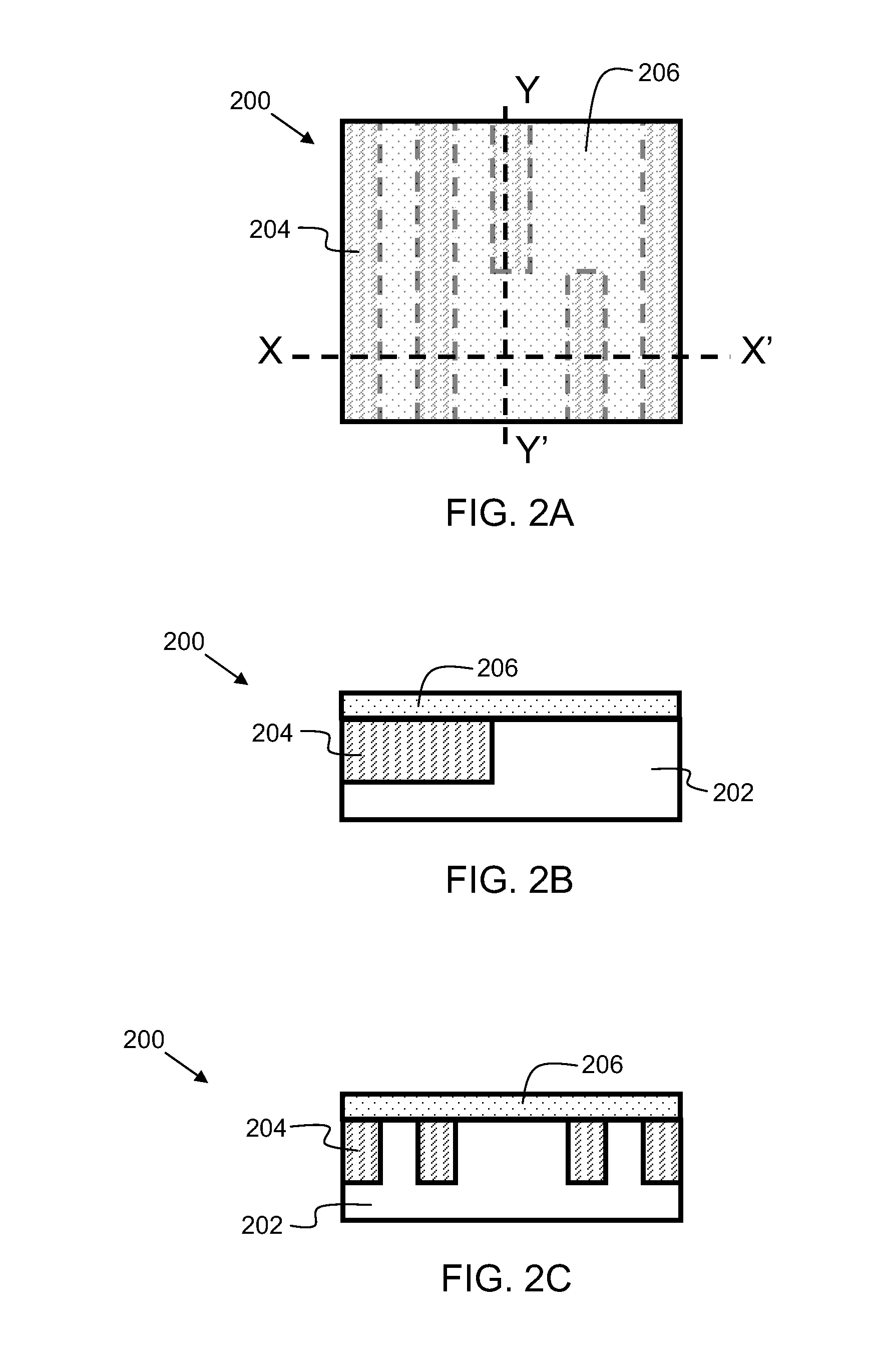

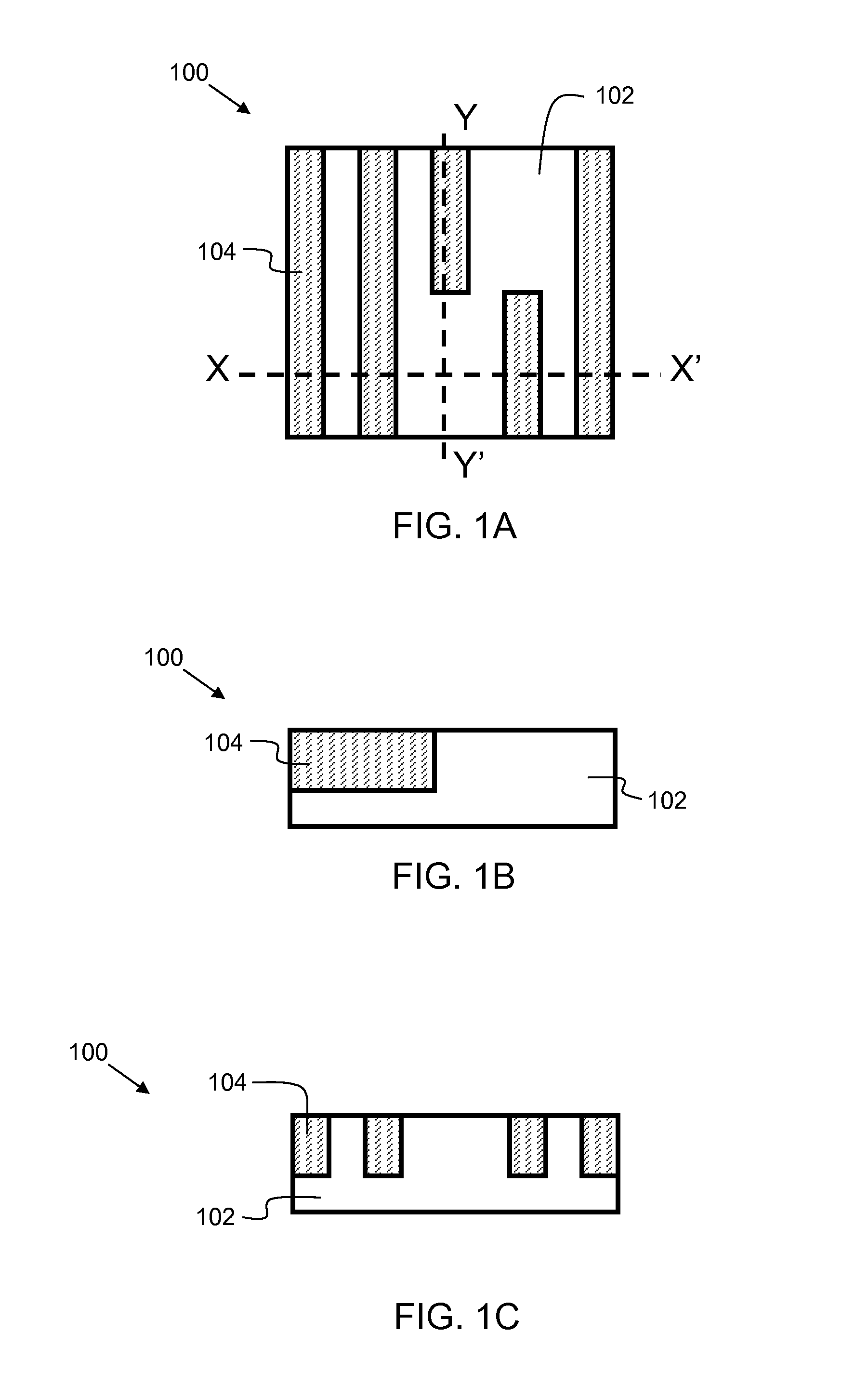

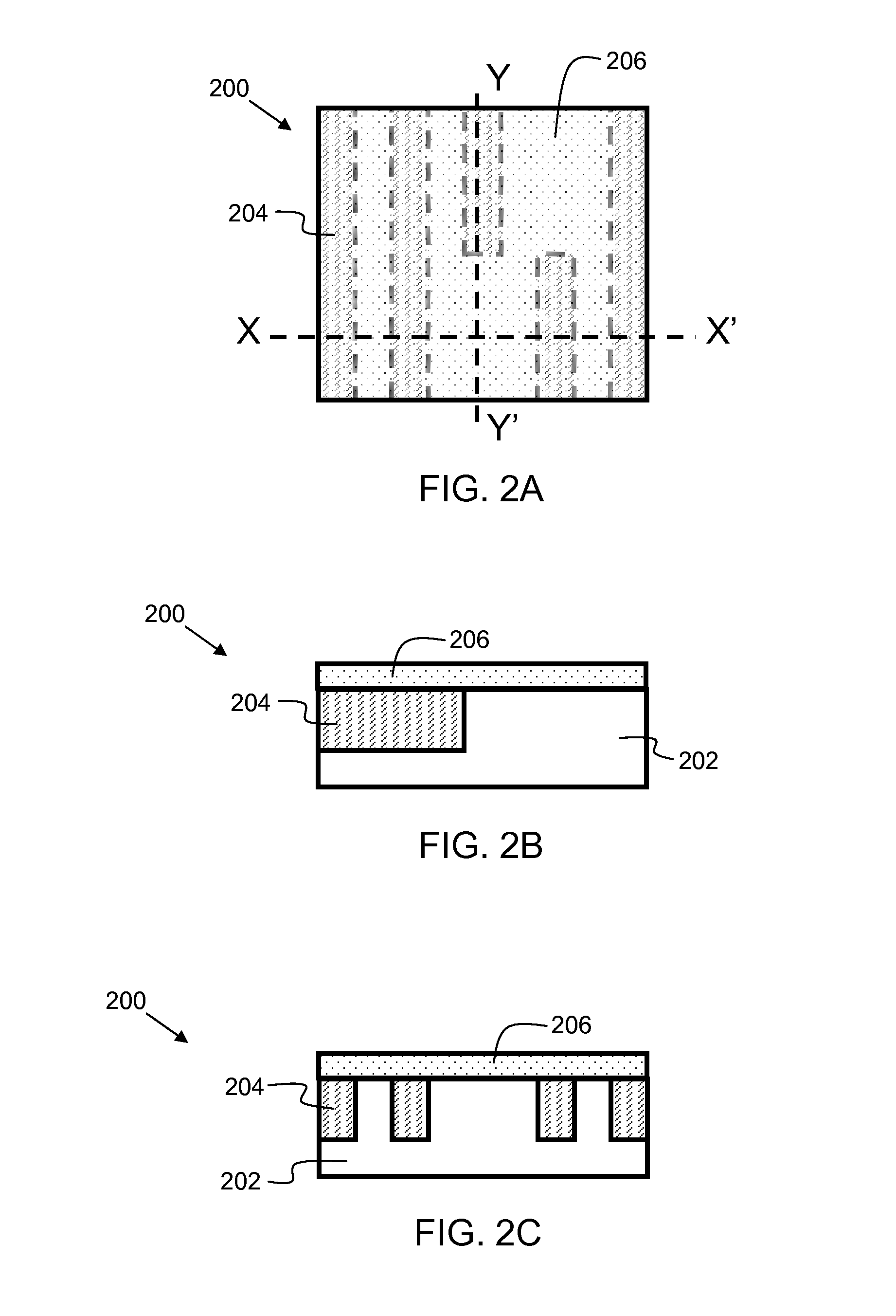

Wafer and method of forming alignment markers

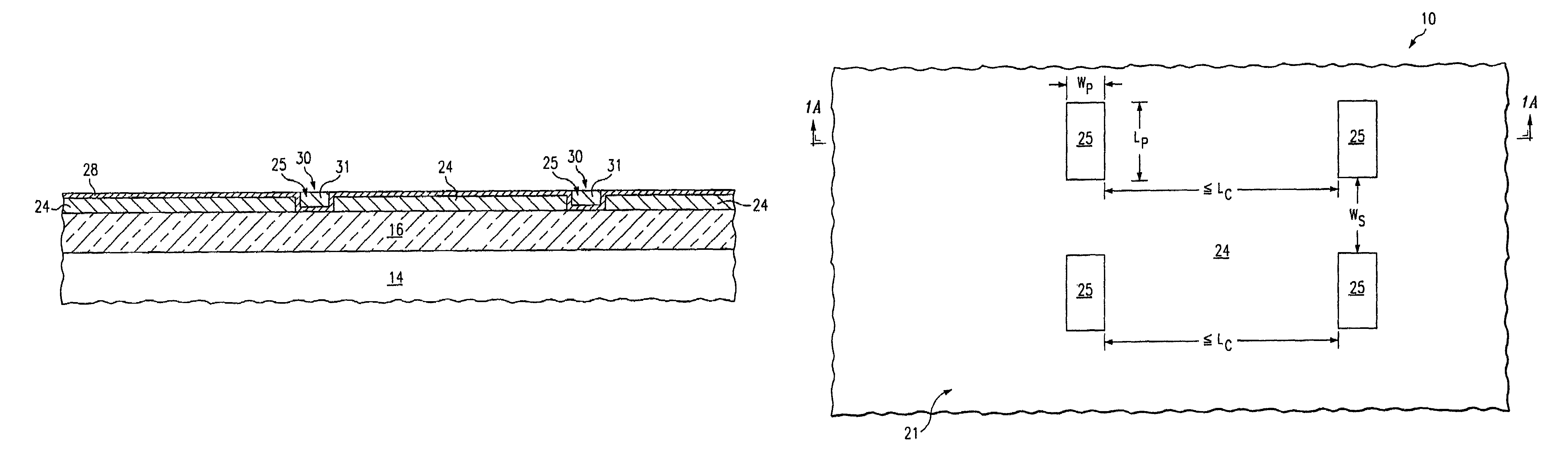

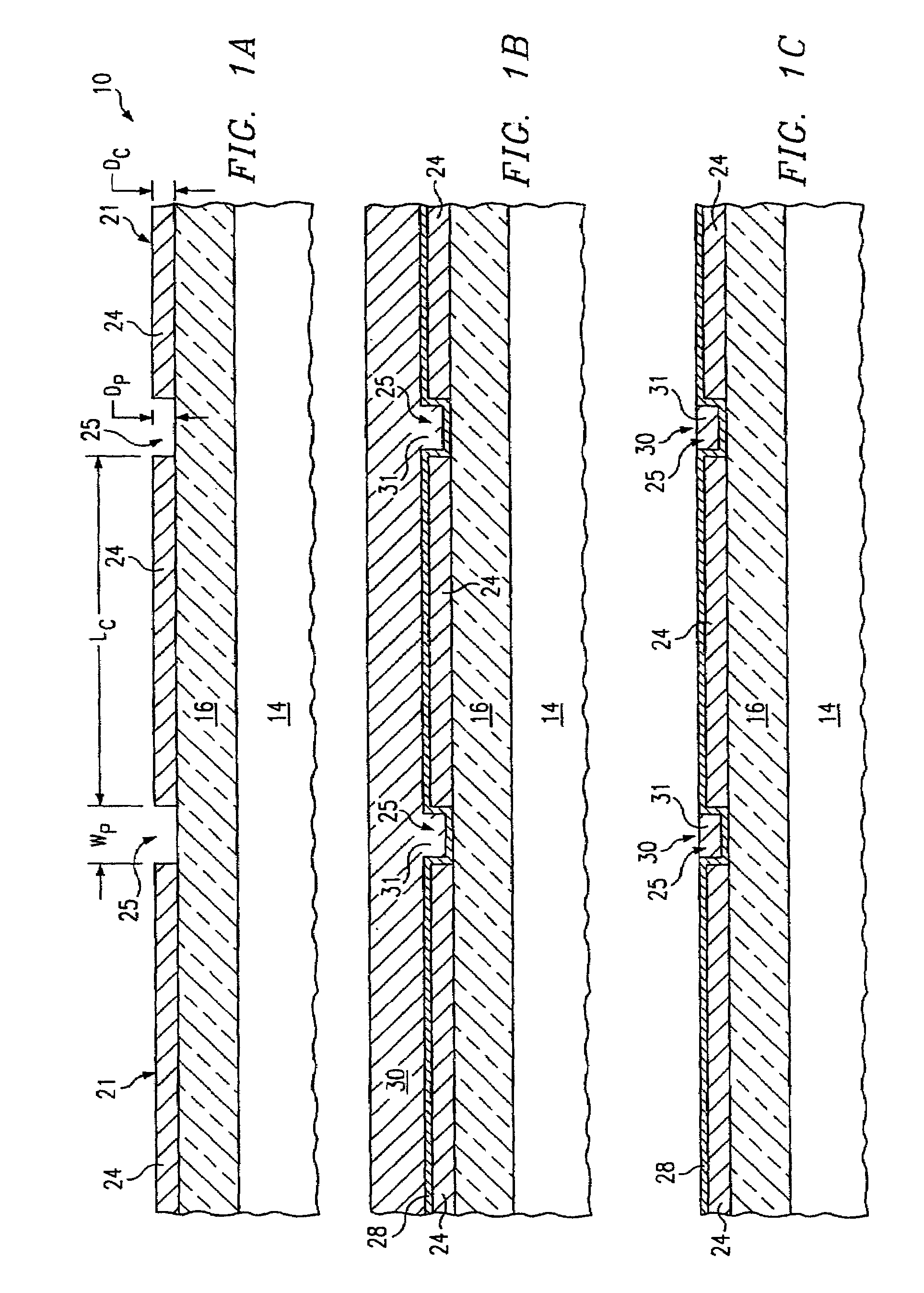

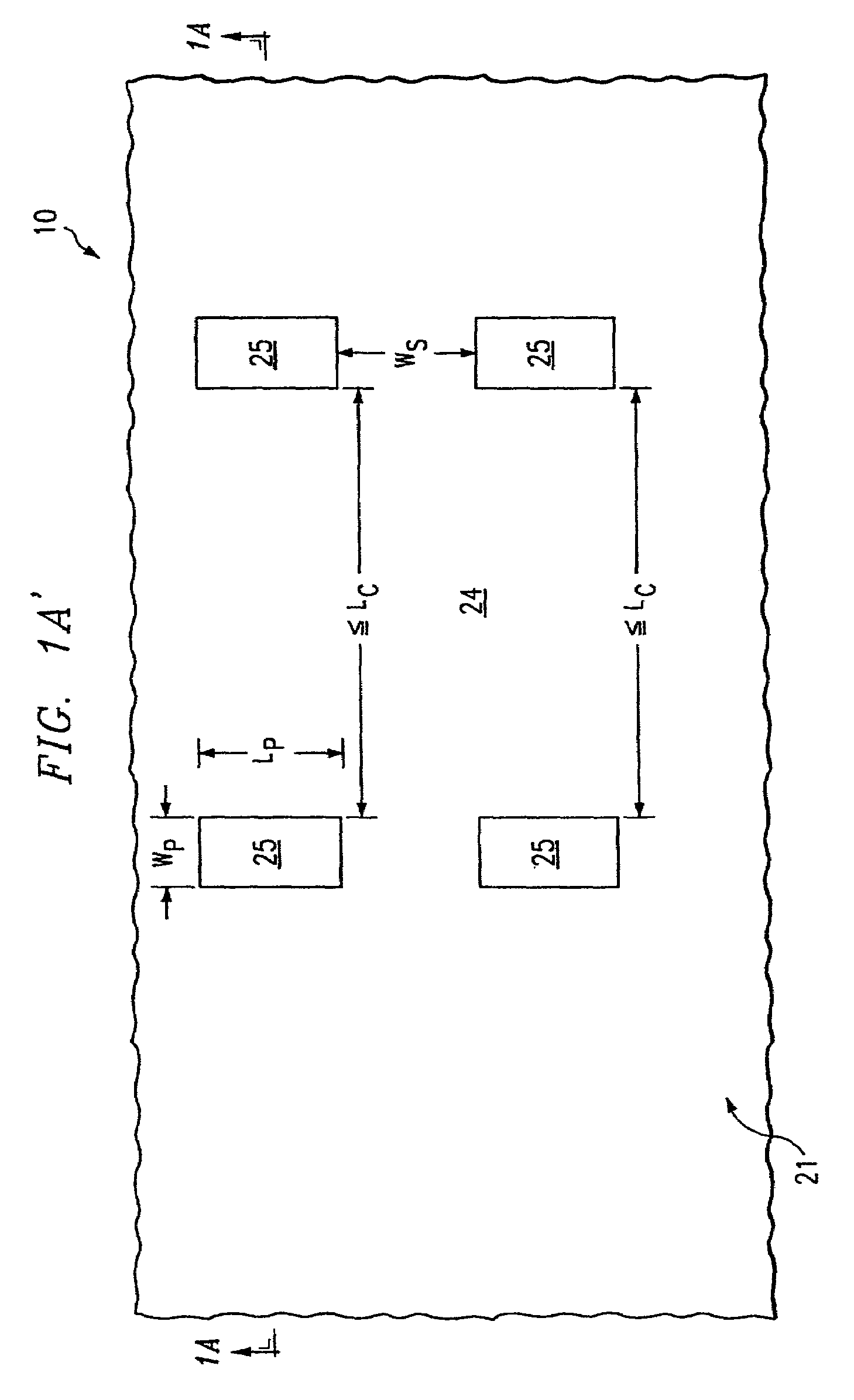

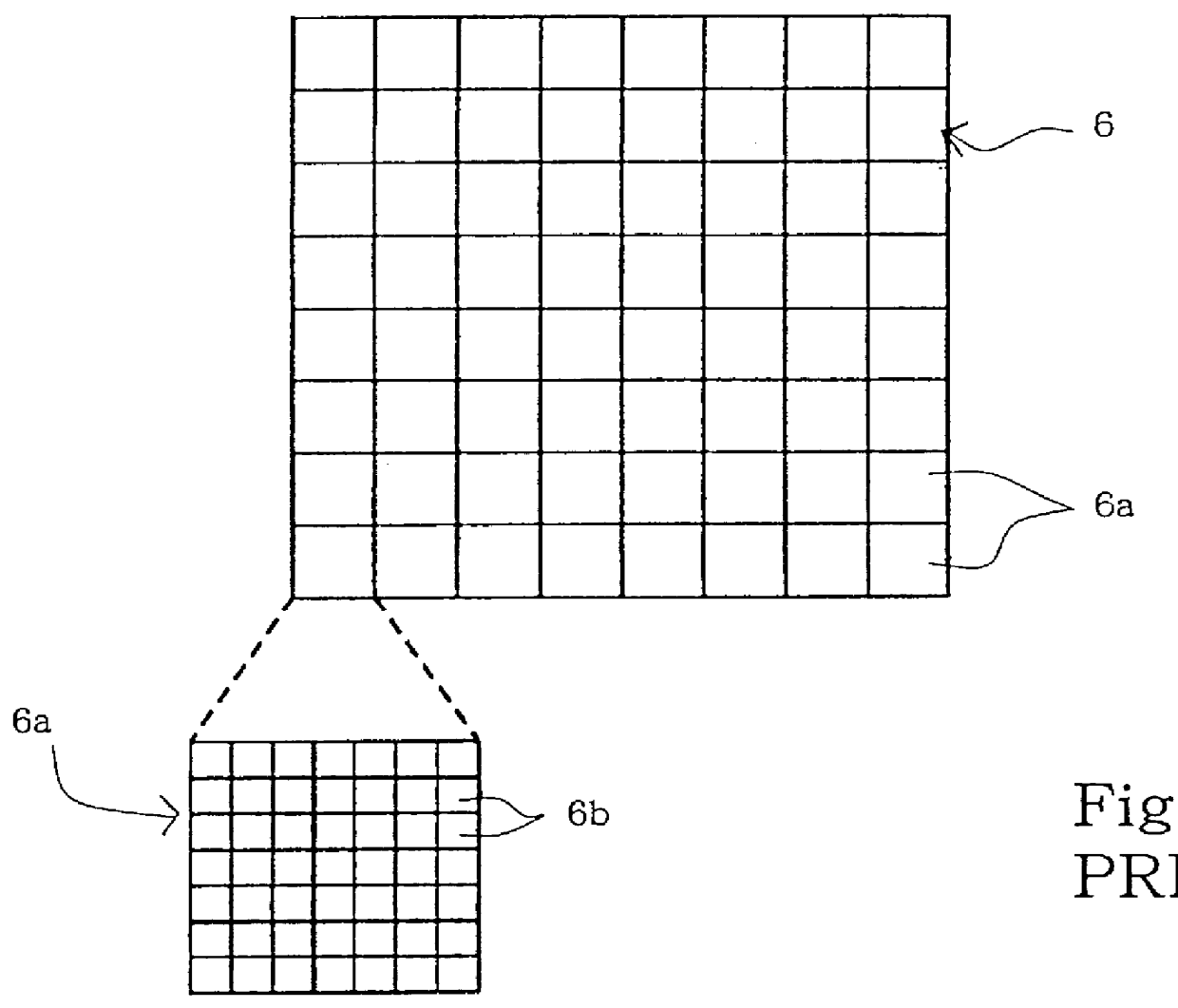

InactiveUS20090134496A1Semiconductor/solid-state device detailsSolid-state devicesEngineeringMechanical engineering

A wafer comprises a multi-layer structure. The multi-layer structure includes a first device structure neighbouring an area for receiving alignment markers. A plurality of alignment markers extend into the multi-layer structure and are located within the area for receiving alignment markers. The plurality of alignment markers is arranged to prevent propagation of a crack, when occurring, beyond a material-dependent critical length in a part of the multi-layer structure corresponding to the area for receiving the alignment structure. The material-dependent critical length is associated with the part of the multi-layer structure.

Owner:FREESCALE SEMICON INC

Monitoring and testing method for electric-transmission-line mountain fire satellite monitoring system

The invention discloses a monitoring and testing method, including acquisition of satellite monitoring sensitivity, for an electric-transmission-line mountain fire satellite monitoring system. The monitoring and testing method includes selecting a testing satellite, an open site, a season, weather, time and orbit azimuth angle conditions, preparing a ground monitoring and measuring device, taking firewood as a flaming material, laying a fire ground at the center of the site, recording coordinates of the fire ground, setting fire to the fire ground before satellite transition, observing a quick satellite view in real time and recording time spent by system preprocessing during satellite transition, repeating fire-point judgment after pre-processing, observing whether the satellite can find the test fire ground or not until finding the critical length of the testing satellite finding the fire ground, and squaring the critical length to acquire the sensitivity of the testing satellite. The monitoring and testing method can be used for acquiring sensitivity, distortionless reception range and fire-point judgment threshold of the monitoring system under the conditions such as different weather and territories, thereby having great guiding significance for operation and accuracy improvement of the electric-transmission-line mountain fire monitoring system.

Owner:STATE GRID CORP OF CHINA +2

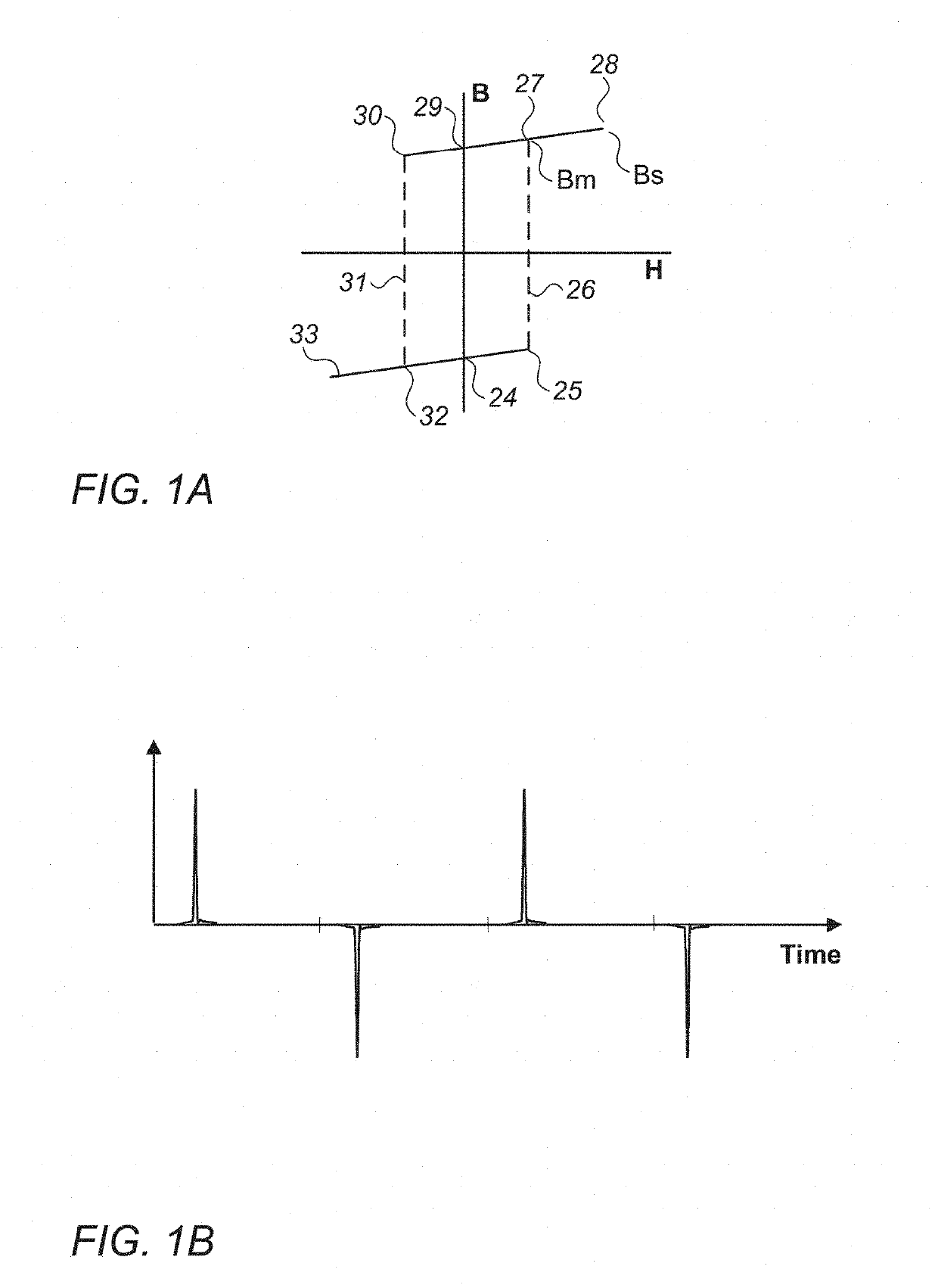

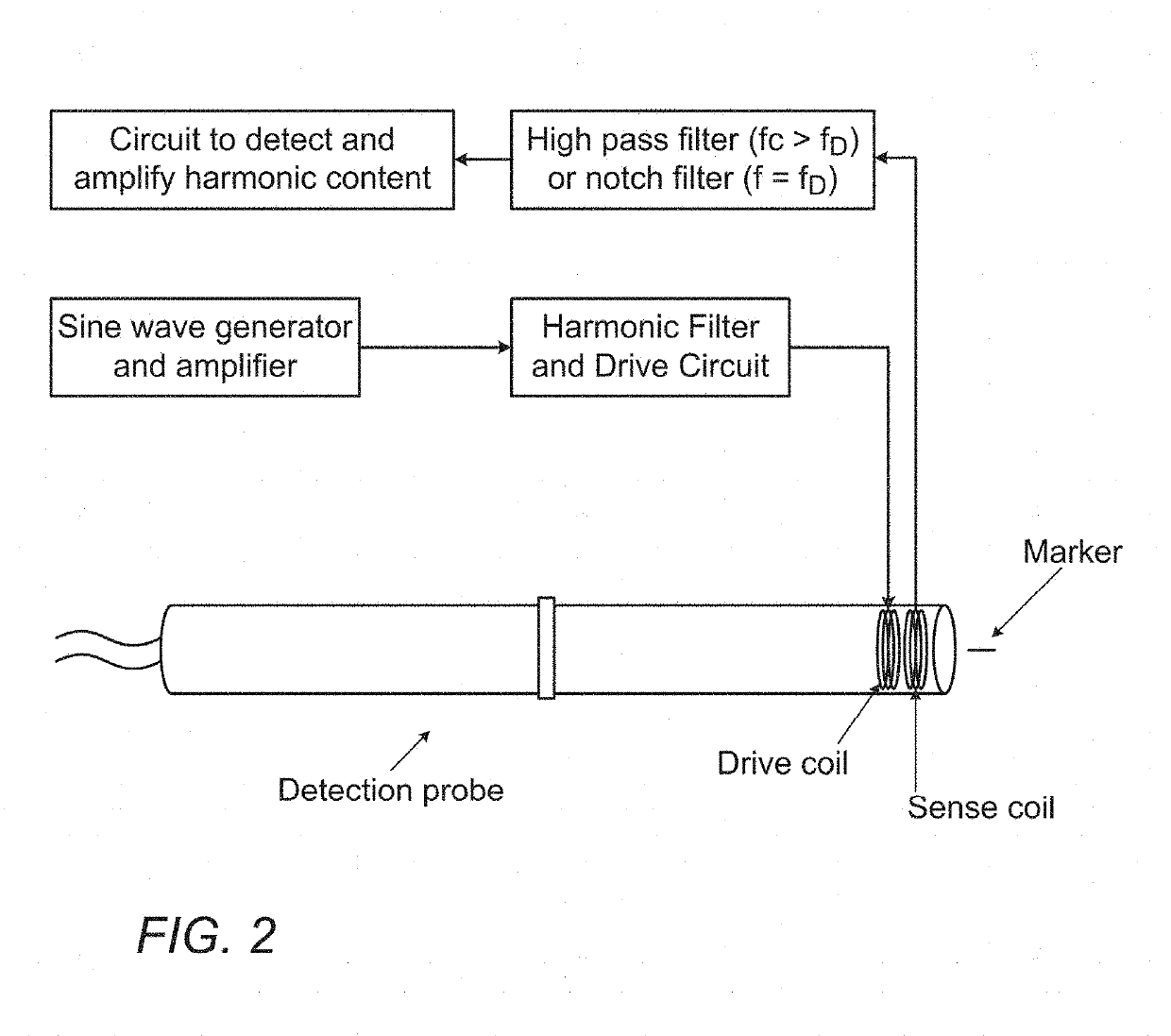

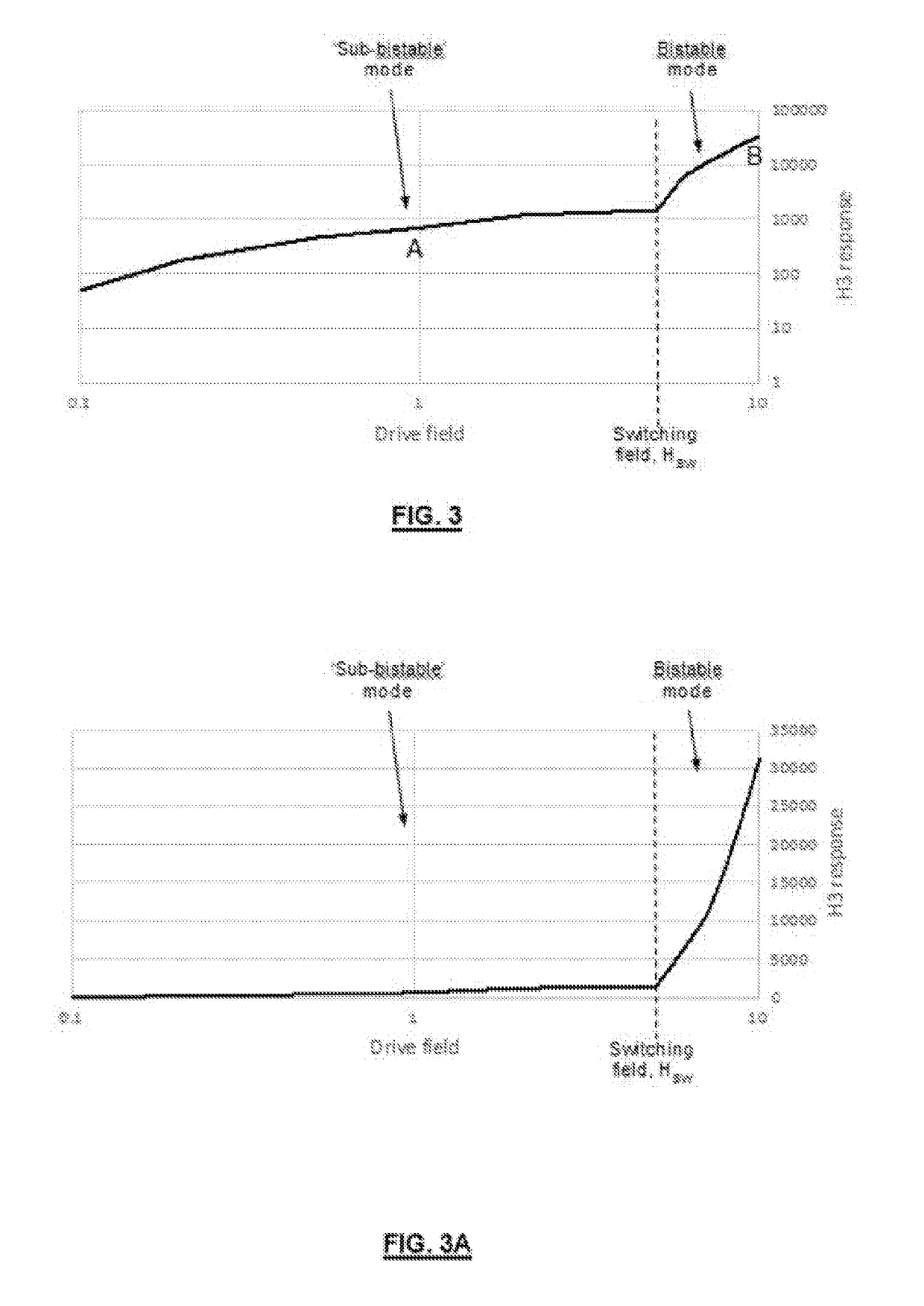

Systems and Methods for Detecting Magnetic Markers for Surgical Guidance

ActiveUS20190223975A1Relieve painQuantity minimizationMagnetisation measurementsSurgical navigation systemsMagnetic markerSurgery procedure

A detection system and method uses an implantable magnetic marker comprising at least one piece of a large Barkhausen jump material (LBJ). The marker is deployed to mark a tissue site in the body for subsequent surgery, and the magnetic detection system includes a handheld probe to excite the marker below the switching field for bistable switching of the marker causing a harmonic response to be generated in a sub-bistable mode that allows the marker to be detected and localised. The marker implanted may also be shorter than the critical length required to initiate bistable switching of the LBJ material.

Owner:ENDOMAGNETICS LTD

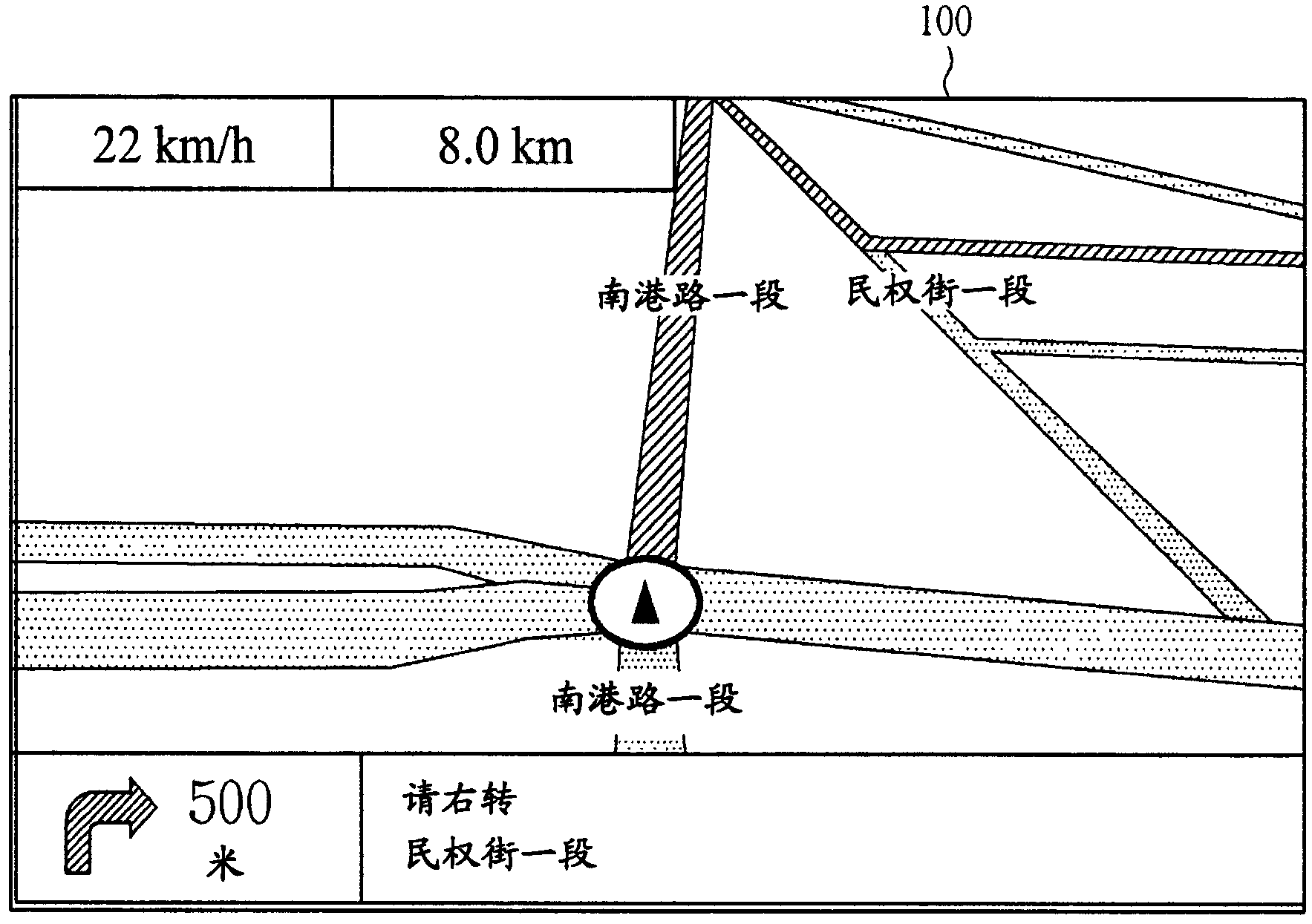

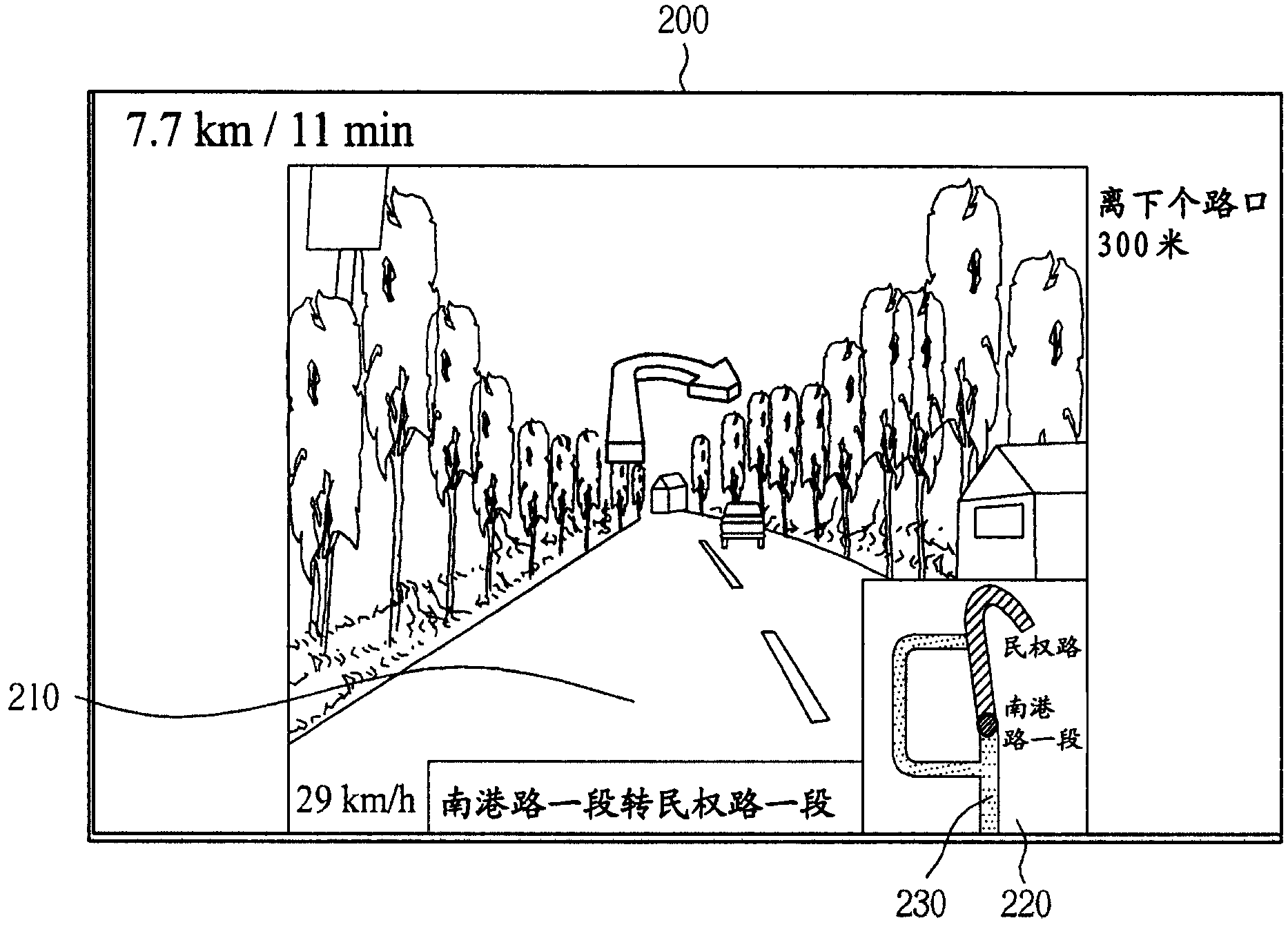

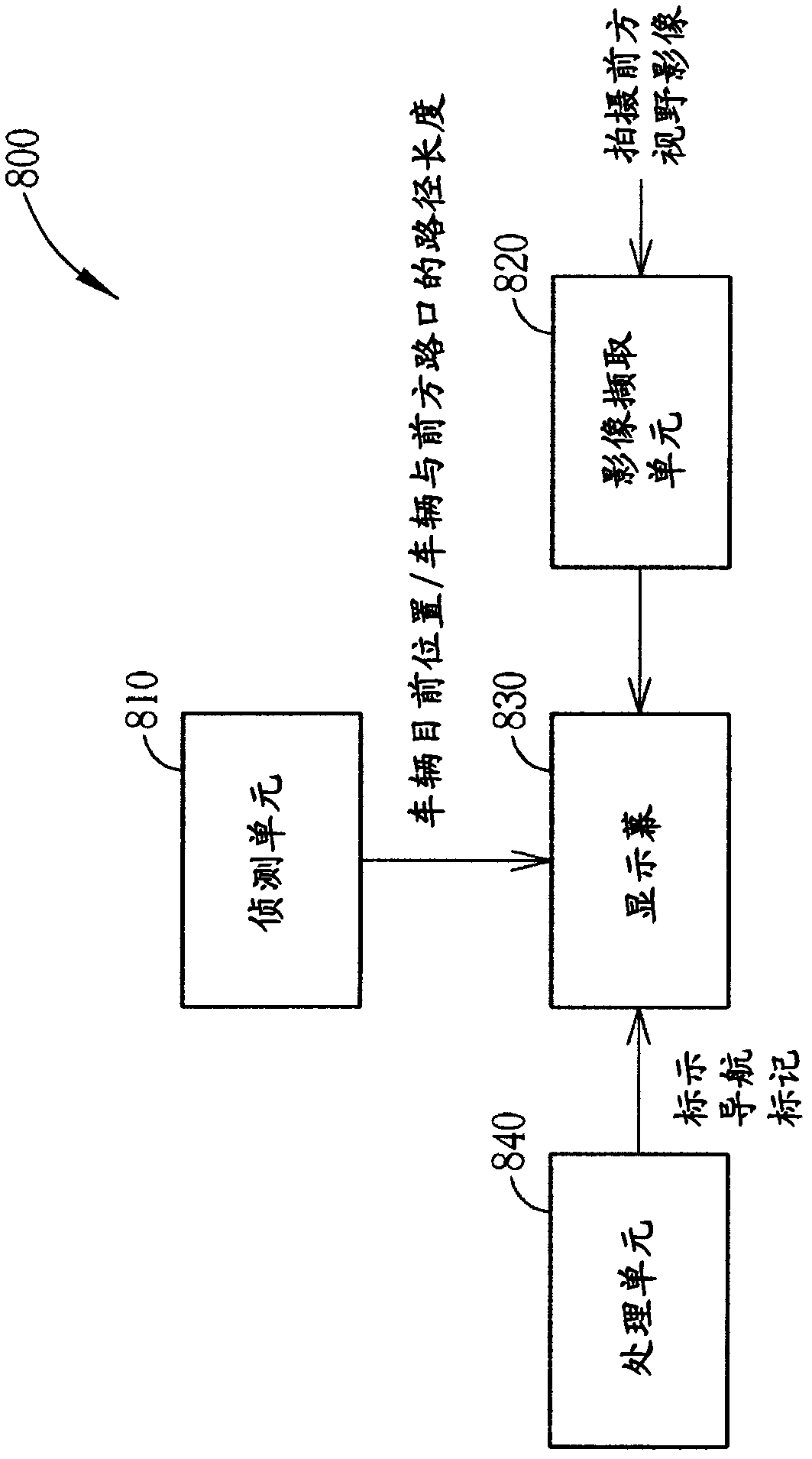

Vehicle navigation method and vehicle navigation system

InactiveCN102636180AShort comprehension timeImprove understandingInstruments for road network navigationEngineeringNavigation system

The invention relates to a vehicle navigation method and a vehicle navigation system. When the vehicle navigation system is navigating, a view image in front of a vehicle is determined to be displayed based on a fact that whether the distance between the current position of the vehicle and a crossroad in front of the vehicle is less than a critical length. If the distance between the current position of the vehicle and the crossroad in front of the vehicle is less than the critical length, the view image in the front is displayed by the navigation system, and a navigation mark is indicated on the front view image based on the map information used by the system and the navigation path determined by the information, thereby accurately guiding a driver to drive on the navigation path.

Owner:MITAC INT CORP

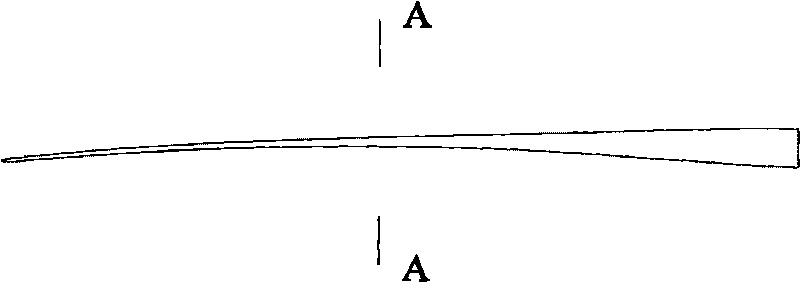

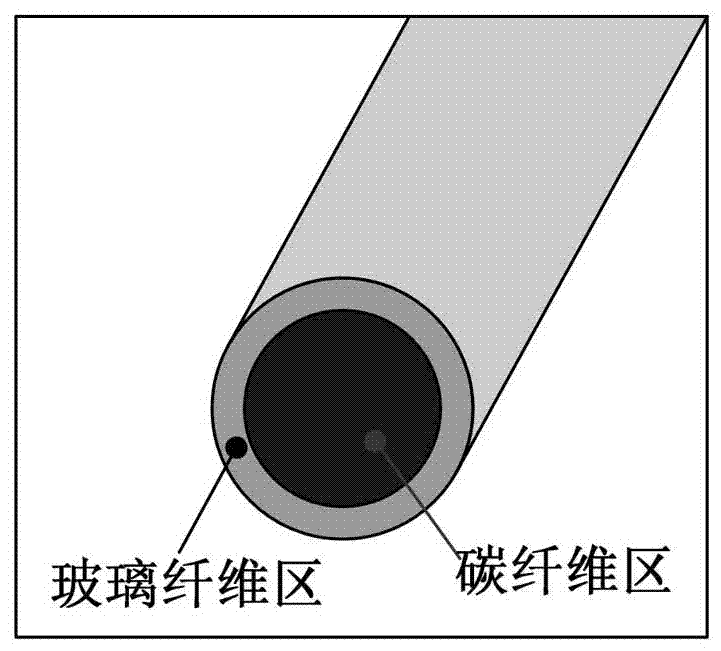

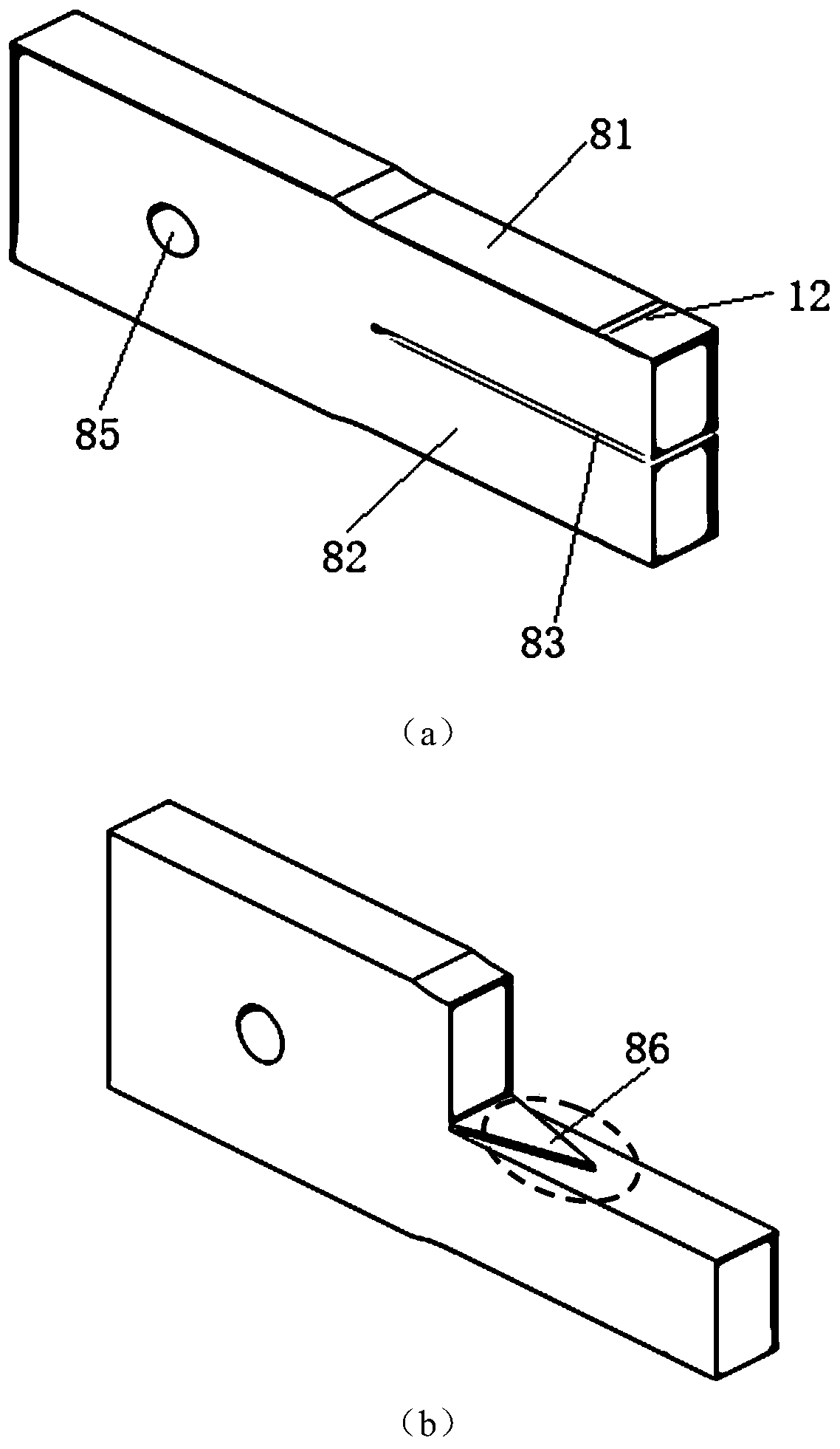

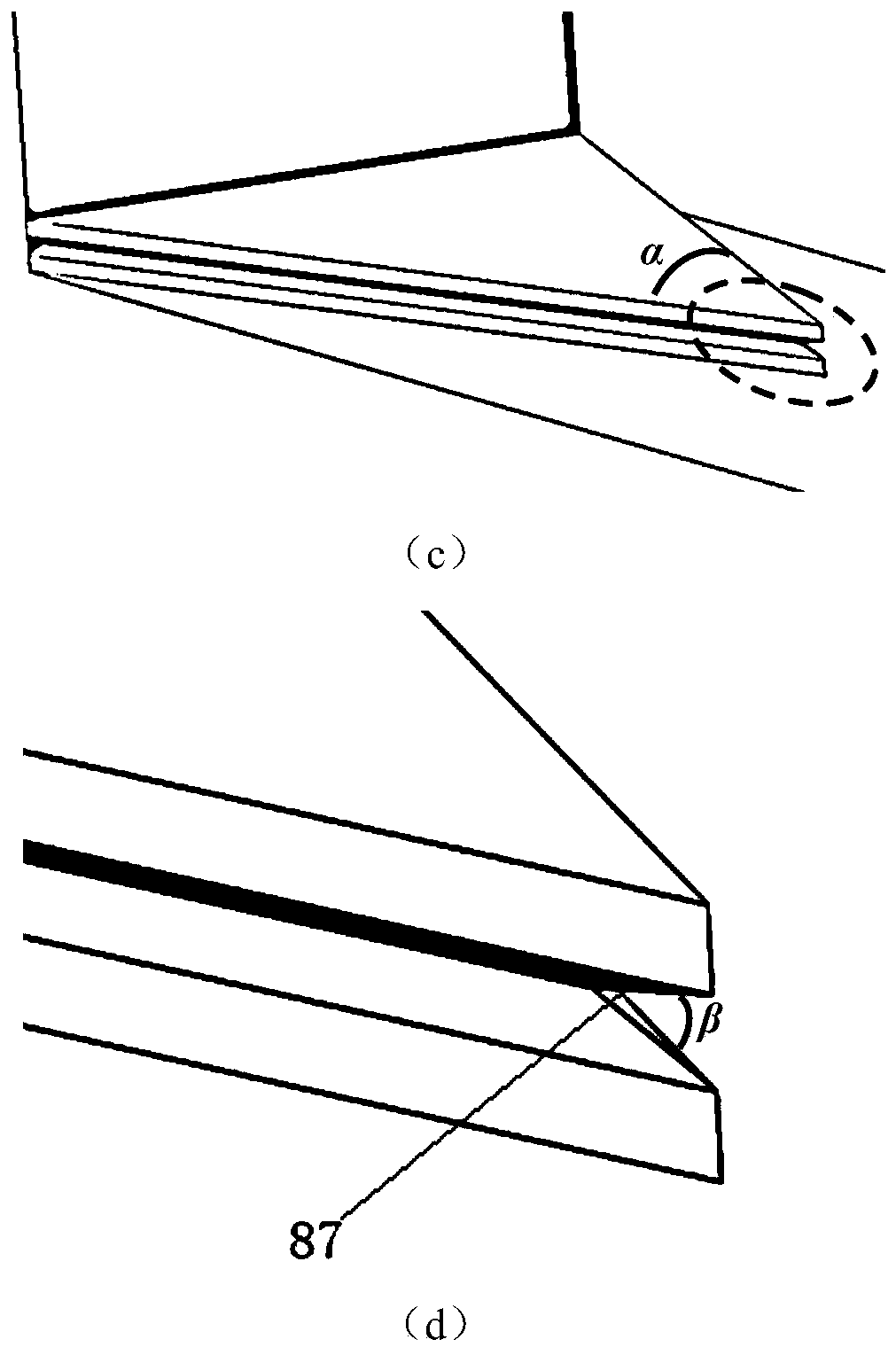

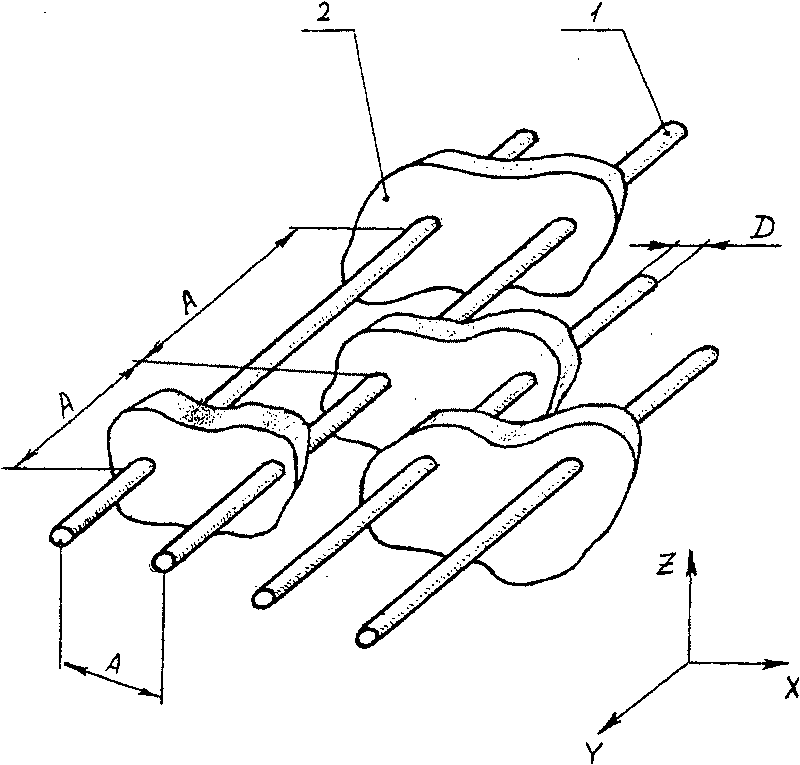

Main bearing beam for large wind power blade, mixed spar composite material wind power blade and preparing method of mixed spar composite material wind power blade

ActiveCN108005846AGuaranteed moldingSolving difficult technical problems in preparationFinal product manufactureMachines/enginesFiberYarn

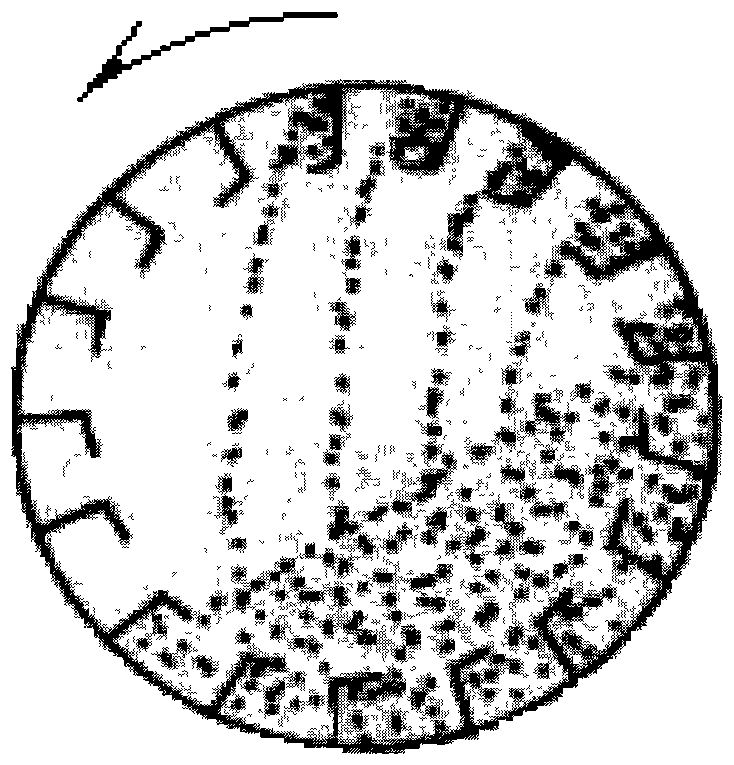

The invention discloses a main bearing beam for a large wind power blade. The main bearing beam is a carbon fiber / glass fiber mixed composite material round bar sectional material combined body, and the combined body is formed through beam bunching and sizing of a plurality of carbon fiber / glass fiber mixed composite material round bar sectional materials via glass fiber felt or yarn. According tothe main bearing beam for the large wind power blade, the combined body is formed through beam bunching of the carbon fiber / glass fiber mixed composite material round bar sectional materials, complementation of carbon fiber performance and glass fiber performance is sufficiently utilized, the beneficial effects of high elasticity and lightness of carbon fiber are brought into sufficient play, therigidity and strength of the main bearing beam are greatly improved, and the critical length of the main bearing beam is increased; meanwhile, the price is greatly reduced compared with the cost of adoption of pure carbon fiber serving as reinforcing materials, and popularization and application of the carbon fiber to the field of the main bearing beam and the wind power blade are better facilitated. The invention further correspondingly provides a mixed spar composite material wind power blade and a preparing method of the mixed spar composite material wind power blade.

Owner:NAT UNIV OF DEFENSE TECH

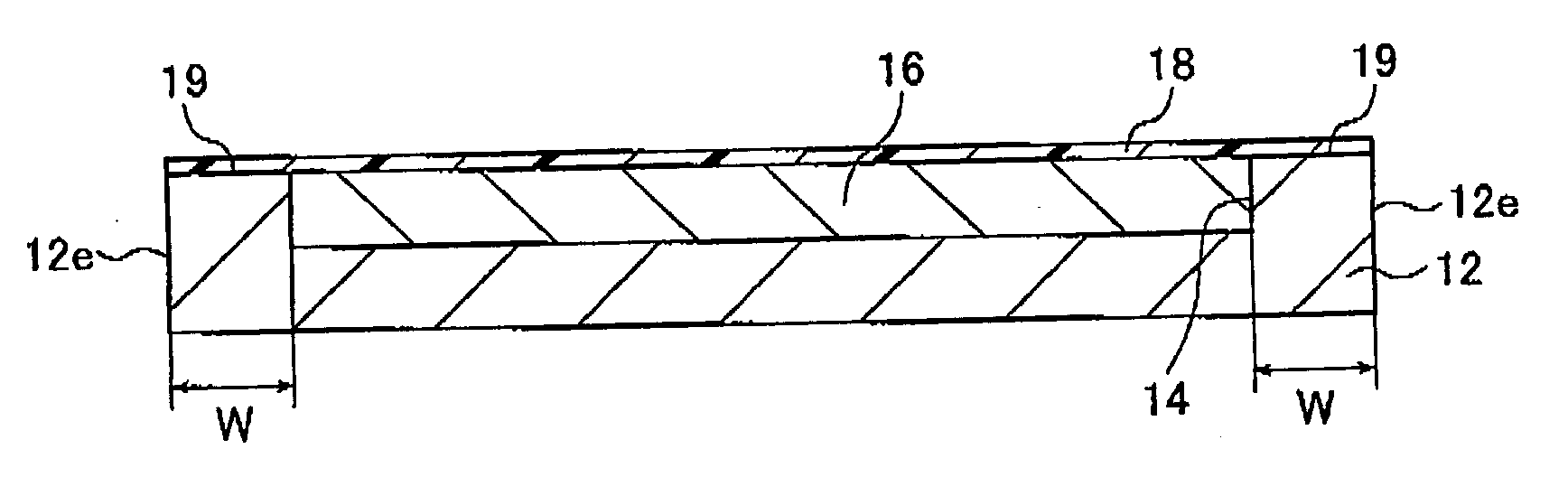

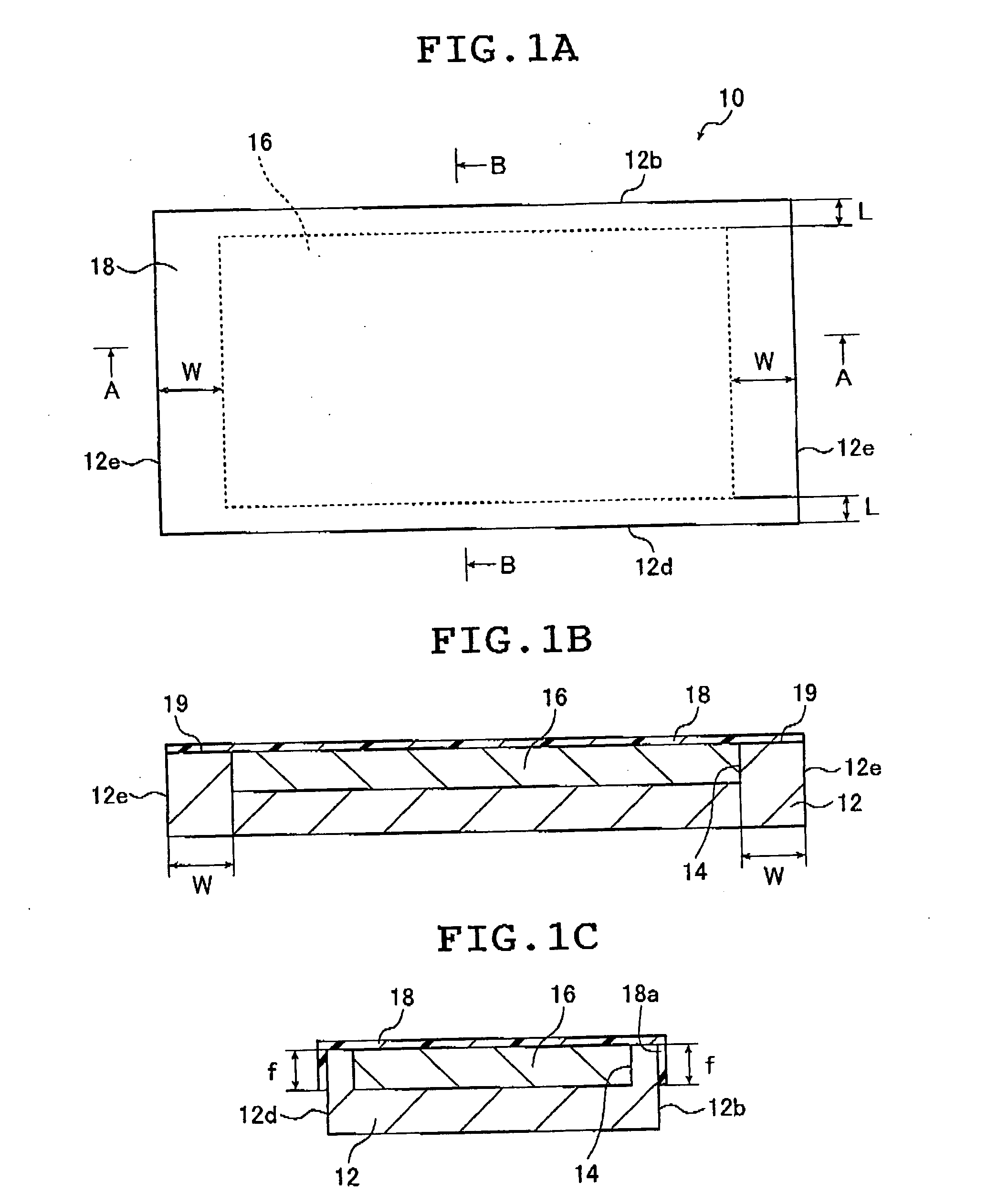

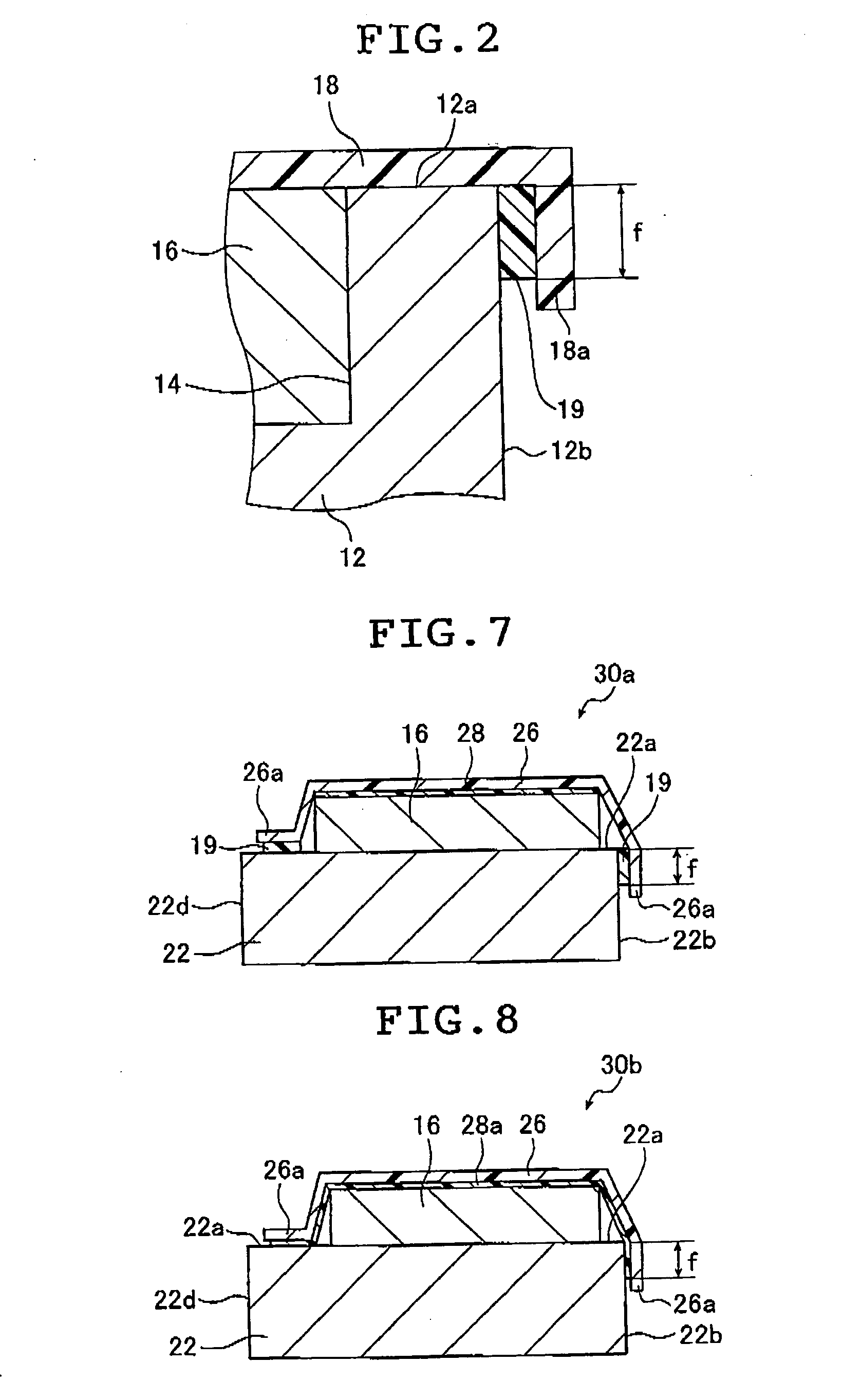

Radiographic image conversion panel for mammography and method of manufacturing the same

InactiveUS20060038135A1Prevent degradationIncrease the areaElectrical apparatusElectroluminescent light sourcesPhosphorFluorescence

The radiographic image conversion panel for mammography includes a stimulable phosphor layer formed on a rectangular substrate having first and second pairs of two parallel sides, and sealed with a moisture-proof protective film. The phosphor layer is positioned on the substrate such that a distance from at least one side of the first pair to an adjacent end of the phosphor layer is shorter than a critical bonding length being a shortest bonding length long enough to provide a predetermined level of moisture-proof effect and distances from two sides of the second pair to adjacent ends of the phosphor layer are not shorter than the critical length. A seal bonding layer is formed in areas of the second distance, and on a side surface having the at least one side or on the side surface and a rear surface of the substrate. The phosphor layer may be formed in a recess formed in the substrate.

Owner:FUJIFILM CORP +1

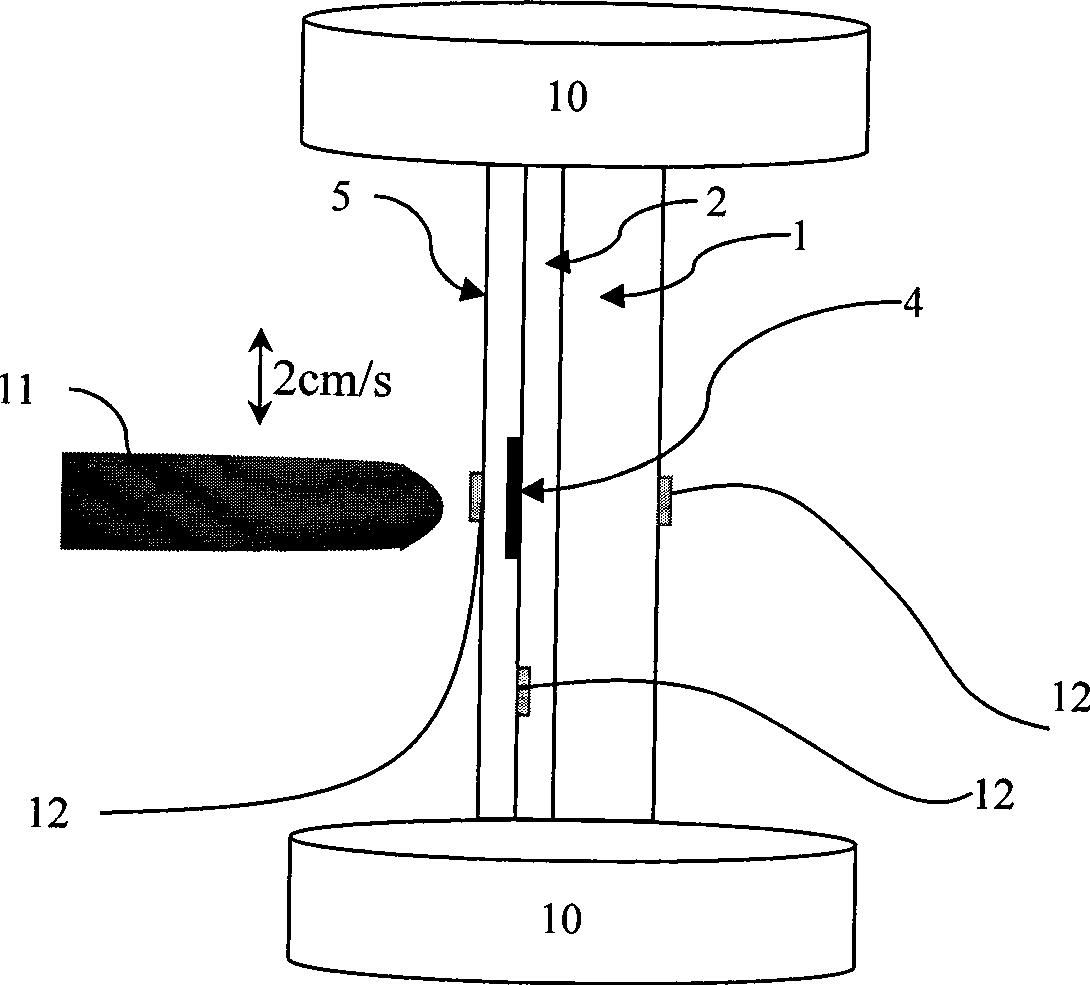

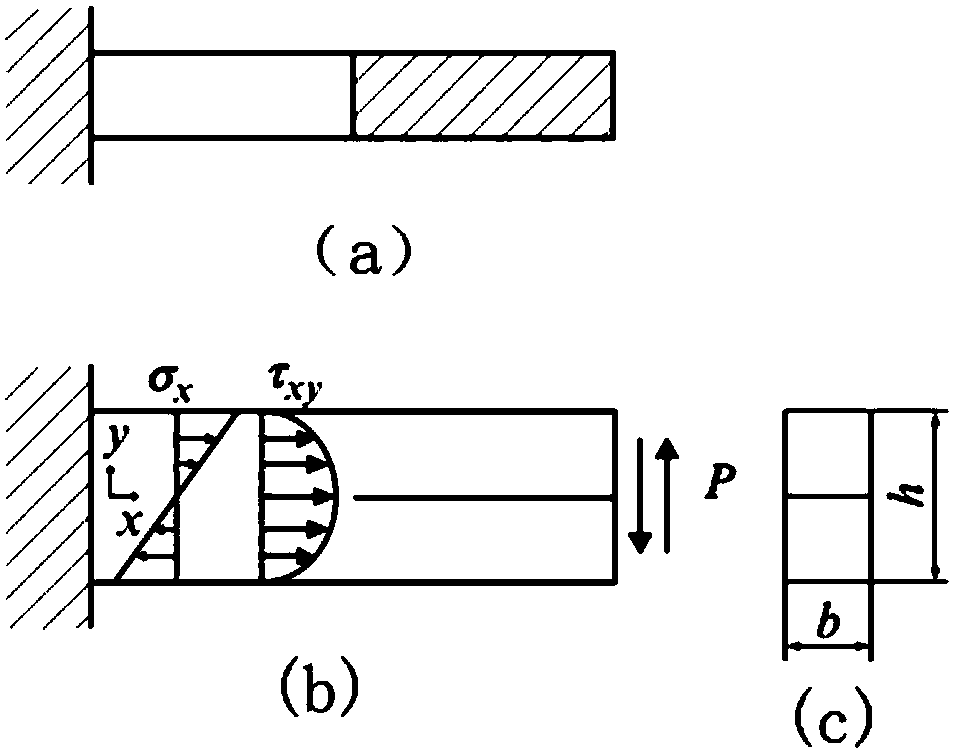

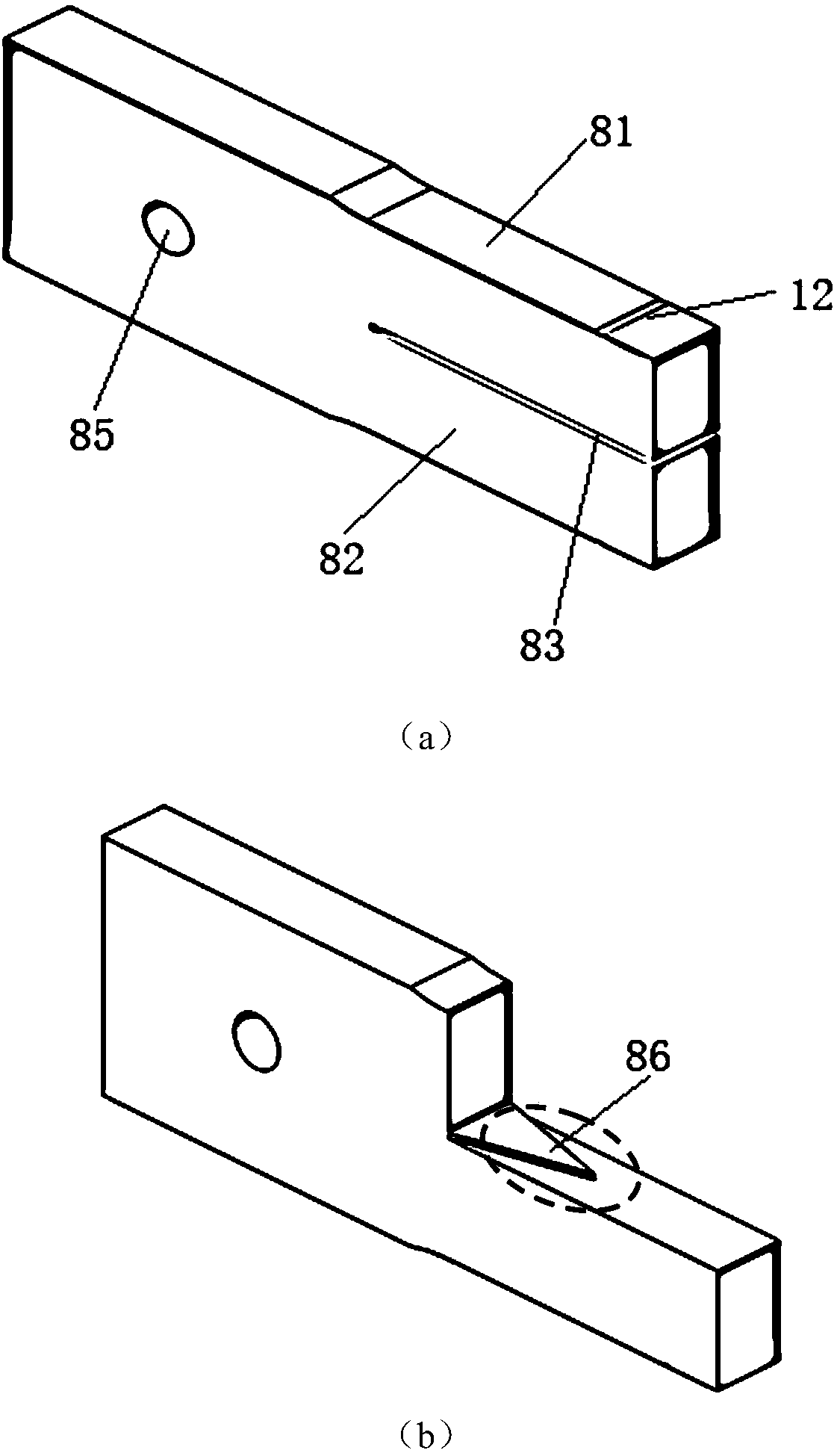

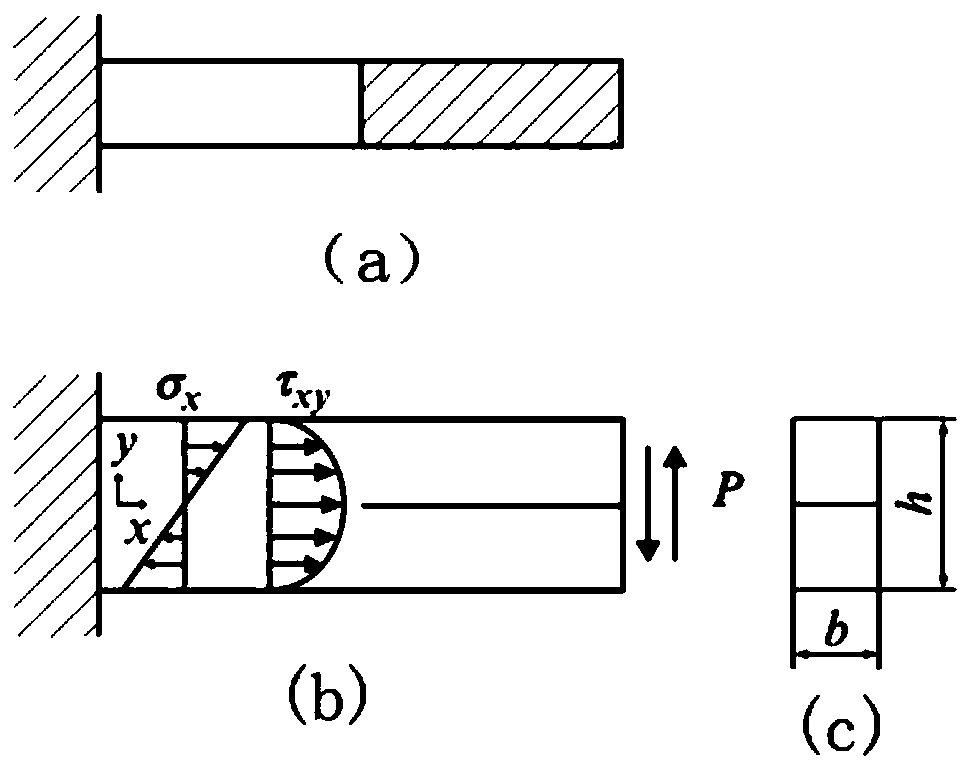

Method for measuring type II crack stress intensity factor threshold value of metal material

InactiveCN108613890AExtended stabilityAccurate measurementMaterial strength using repeated/pulsating forcesShear stressVertical edge

The invention discloses a method for measuring type II crack stress intensity factor threshold value of a metal material. The left end of a test sample is fixed through a test sample fixing mechanism,a horizontal gap extending from the right end face to the center is formed in the right end of the test sample, a triangular crack producing and expanding part with a tip facing towards the right endface is formed in the internal end part of the crack, a V-shaped notch is formed in a vertical edge in the tip position, and a supporting rod is inserted into the gap; stress conducting rods are arranged between an upper clamping part and an upper cantilever as well as a lower clamping part and an lower cantilever of a clamping part; a fatigue test machine applies reciprocating load through an upper column body at the upper part of the upper clamping part; after the test ends up, the test sample is split in perpendicular to the end face, the Type II crack is observed, the stress intensity factor amplitude corresponding to the critical length of the Type II crack is calculated, and the value is the Type II crack stress intensity factor threshold value of the metal material. By the method,production of the crack on the neutral surface is guaranteed, the shear stress is guaranteed to be reduced along with the increment of the length of the crack, and stable expansion of the crack alongthe neutral surface of the test sample is guaranteed.

Owner:SOUTHWEST JIAOTONG UNIV

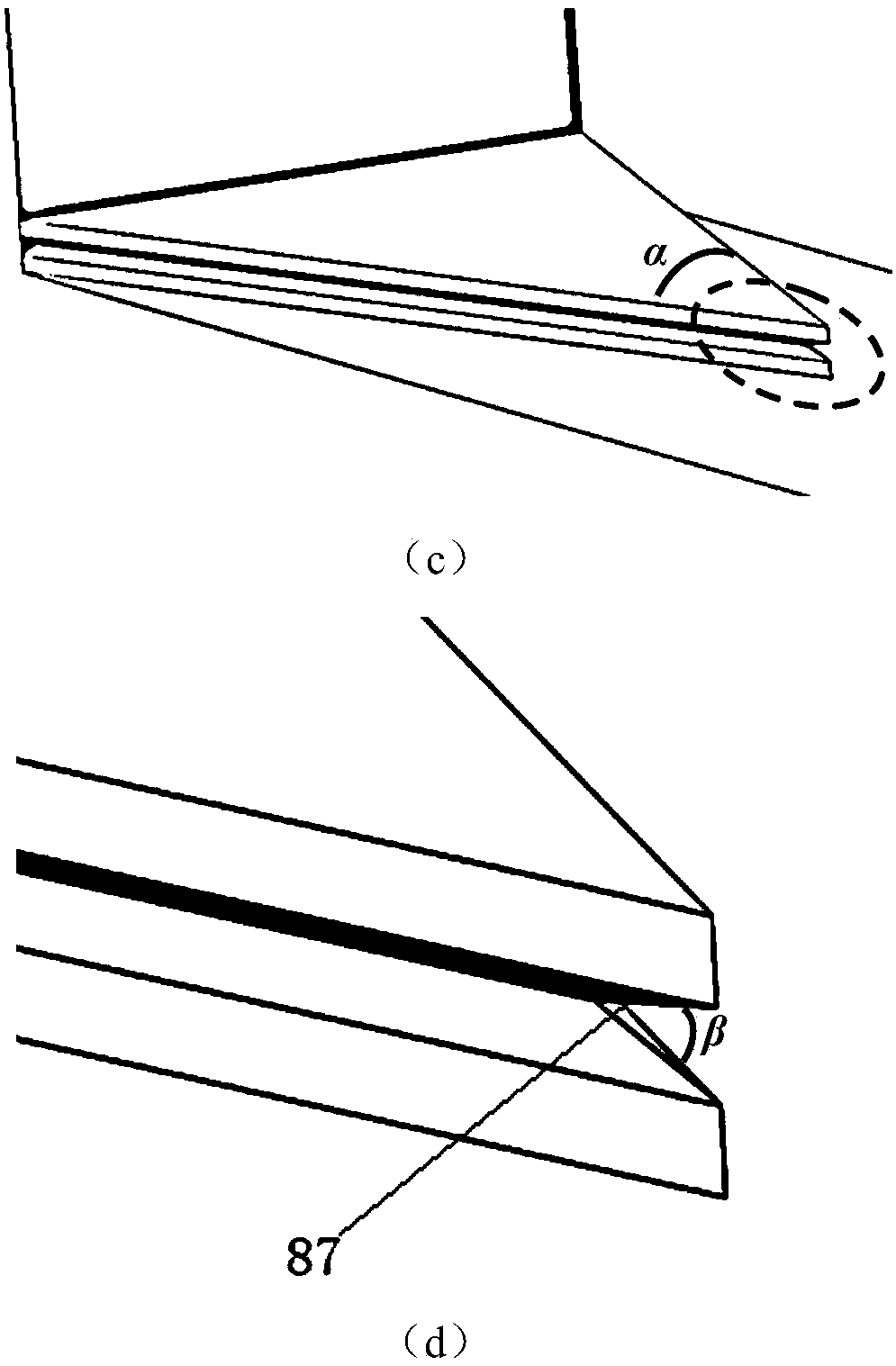

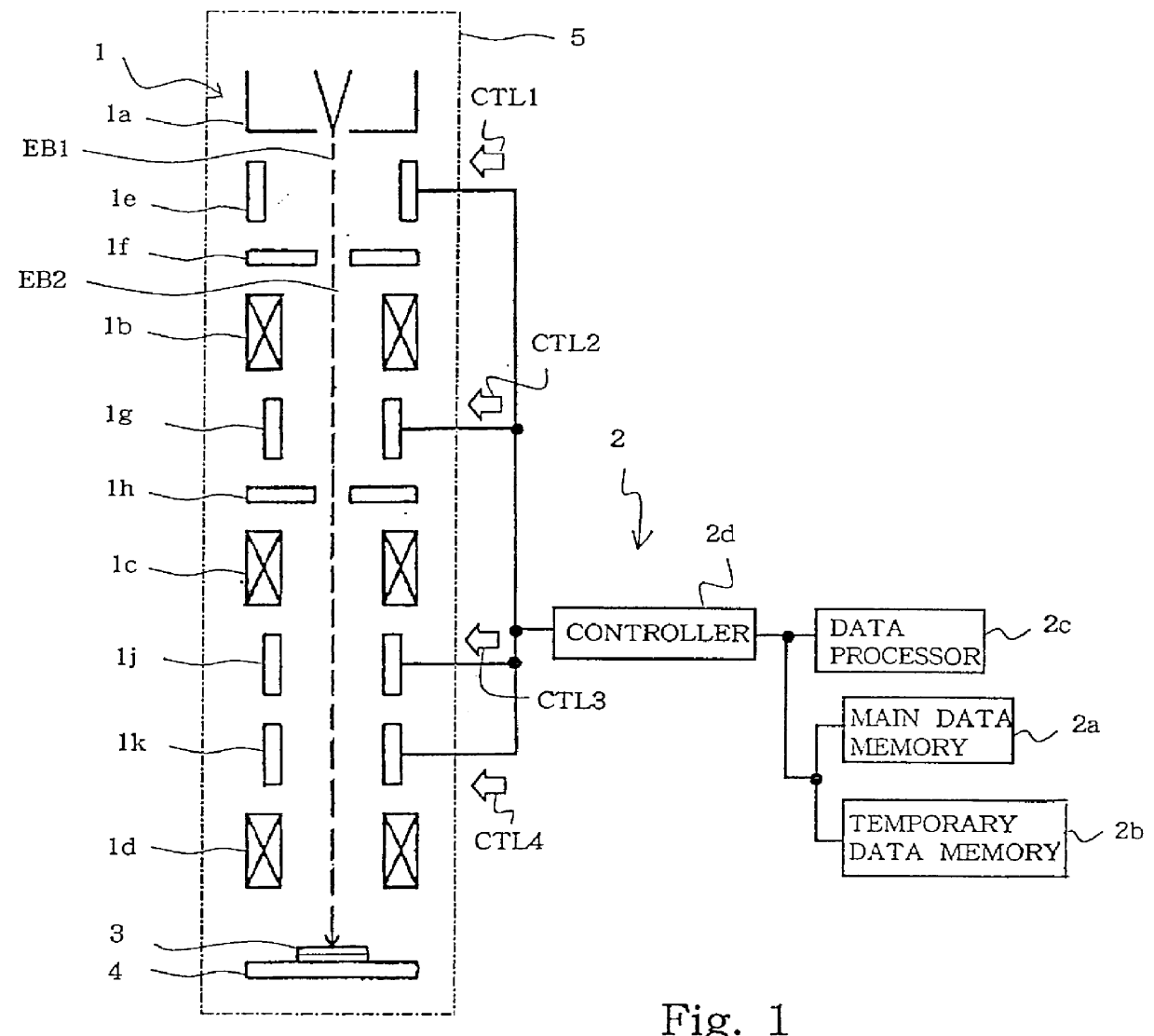

Method of writing cross pattern in adjacent areas of layer sensitive to charged particle beam for improving stitching accuracy without sacrifice of throughput

InactiveUS6066854AImprove stitching accuracyElectric discharge tubesSemiconductor/solid-state device manufacturingCharged particle beamThroughput

A data processor compares a length of a pattern to be written into a layer sensitive to a charged particle beam with a critical length equal to the maximum length of a cross section of the charged particle beam or the maximum length of a variable sub-field to see whether or not the pattern is written through a radiation of the maximized cross section or through a radiation onto the maximized sub-field, and a main deflector and a sub-deflector guide a shot of charged particle beam to the layer if the answer is positive so that the pattern is prevented from deformation due to a low stitching accuracy.

Owner:NEC ELECTRONICS CORP

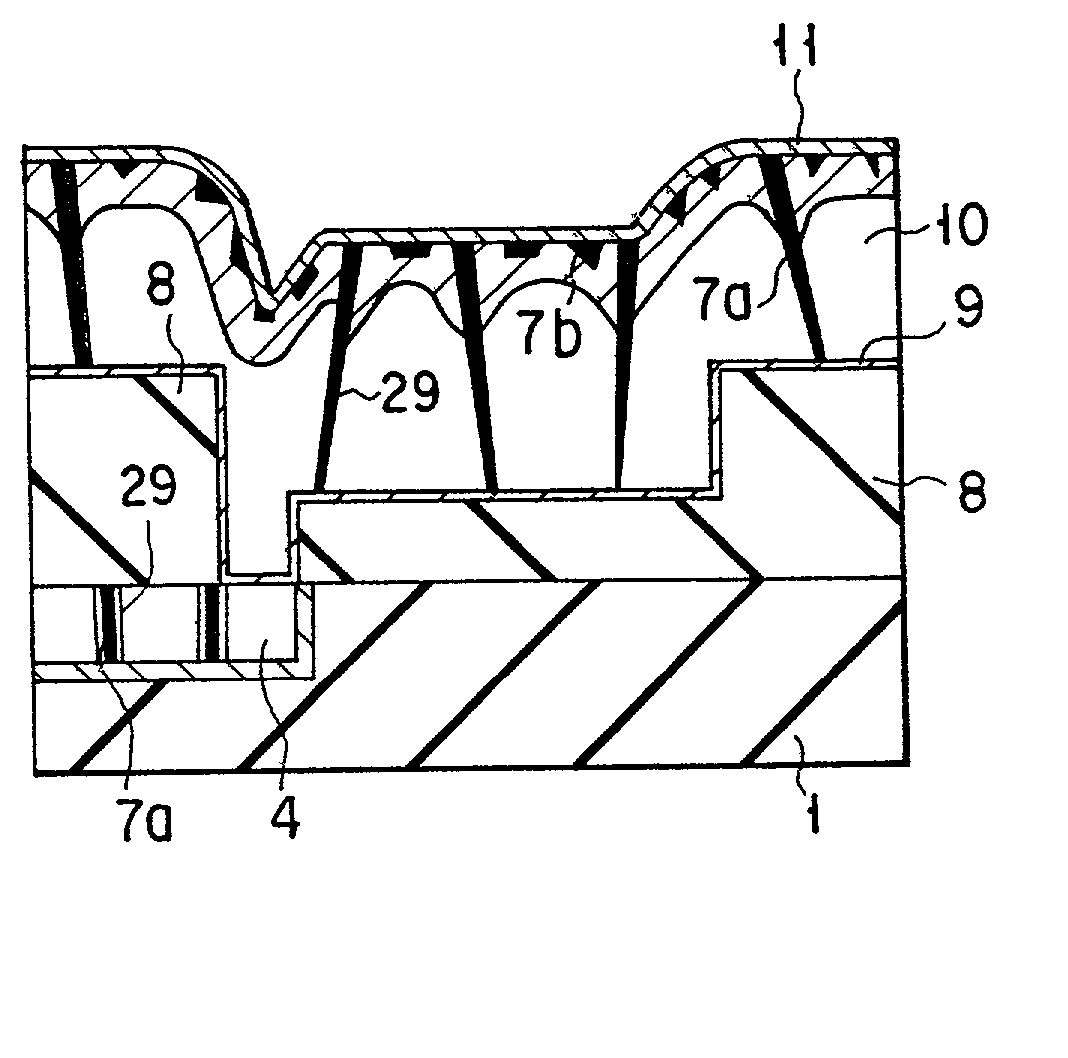

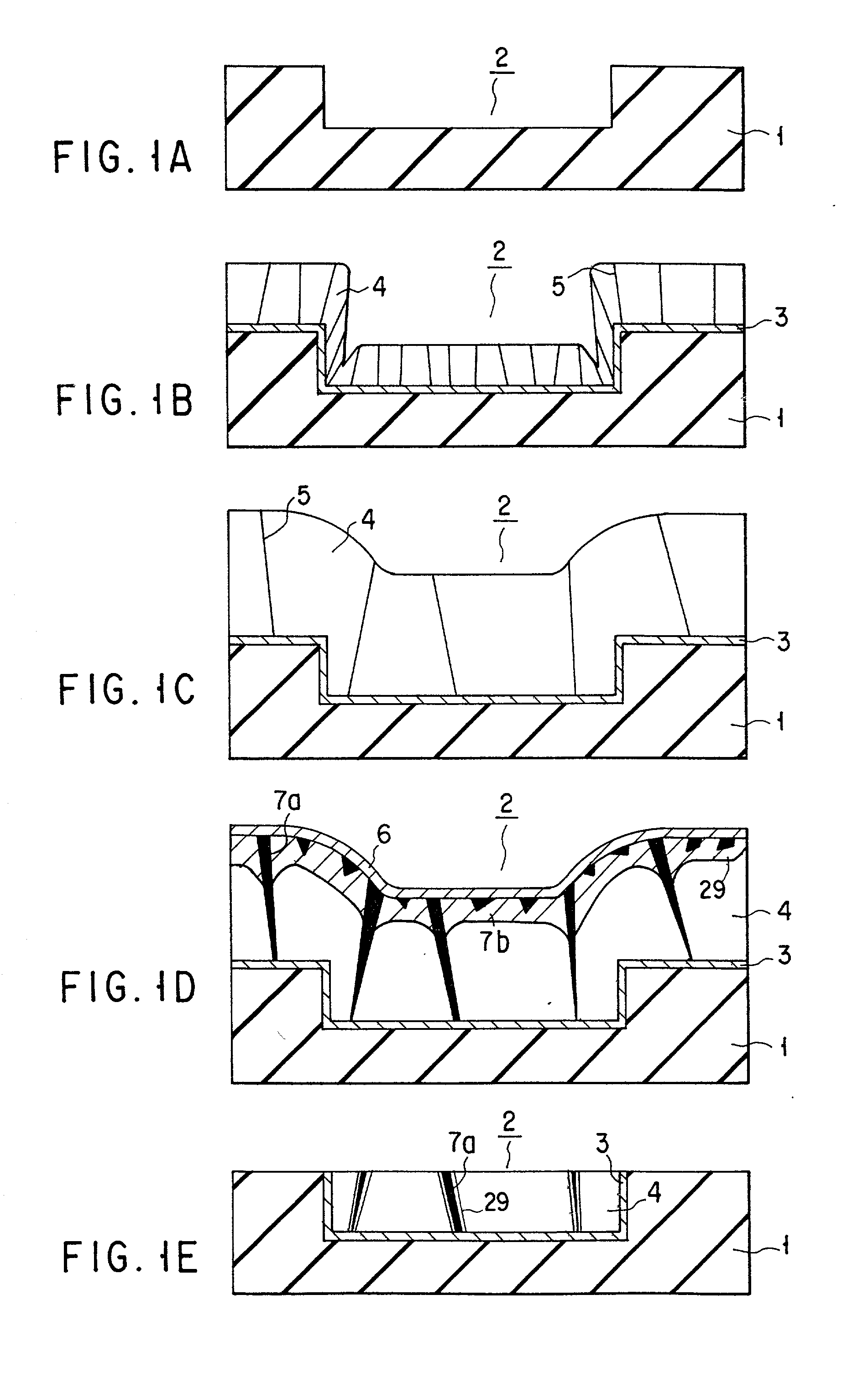

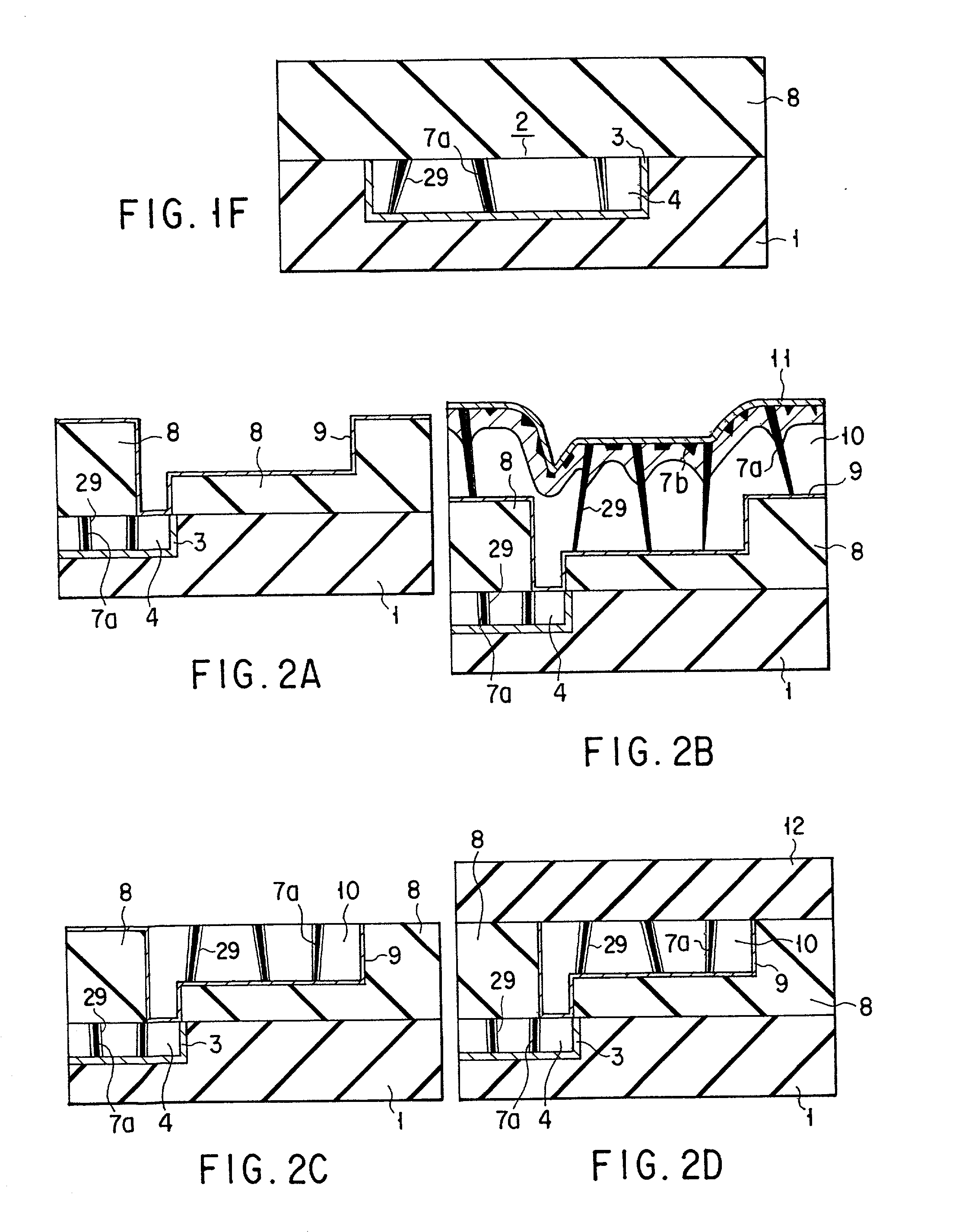

Semiconductor device and manufacturing method thereof

InactiveUS20020130415A1Increasing interconnection resistancePrevent precipitationSemiconductor/solid-state device detailsSolid-state devicesDevice materialEngineering

A semiconductor device manufacturing method of the this invention having the step of forming an interlayer insulating film on a semiconductor substrate, the step of making interconnection groove in the interlayer insulating film, the step of filling the inside of the interconnection groove with a conductive film which is made of a first substance and is thicker than the depth of the interconnection groove, the step of thermally stabilizing the size of crystal grains in an Al film either at the same time or after the Al film has been formed, the step of forming a Cu film on the Al film, the step of selectively forming .theta. phase layers in a crystal grain boundary of the Al film by causing Cu to selectively diffuse into the crystal grain boundary of Al film and of allowing the .theta. phase layers to divide the Al film in the interconnection groove into fine Al interconnections shorter than the Blech critical length, and the step of removing the Al film and Cu film outside the interconnection groove.

Owner:KK TOSHIBA

Radiographic image conversion panel for mammography and method of manufacturing the same

InactiveUS7417237B2Prevent degradationIncrease the areaX-ray/infra-red processesElectrical apparatusTectorial membraneFluorescence

Owner:FUJIFILM CORP +1

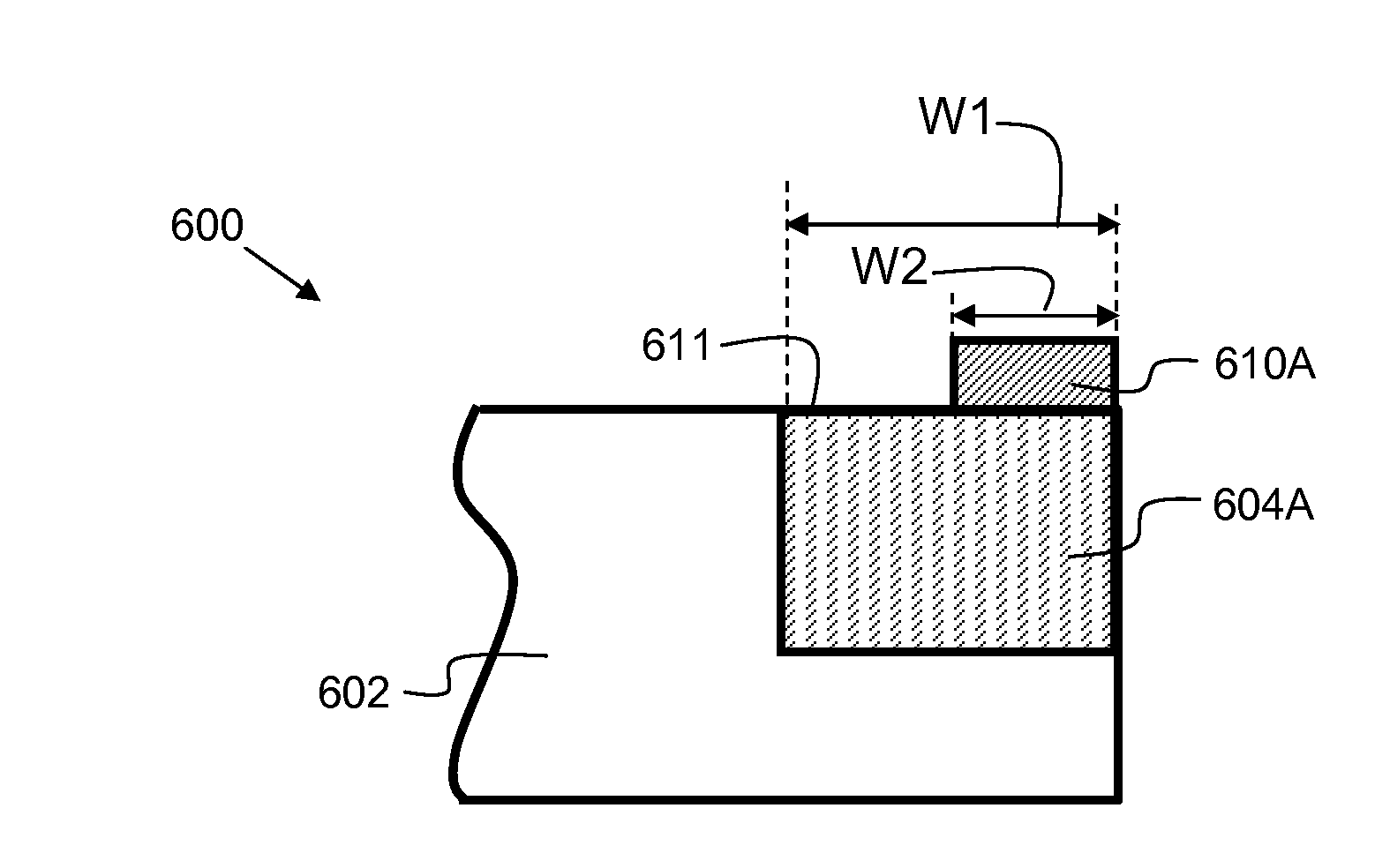

Random local metal cap layer formation for improved integrated circuit reliability

InactiveUS8906799B1Semiconductor/solid-state device detailsSolid-state devicesElectricityLength effect

A method and structure for preventing integrated circuit failure due to electromigration and time dependent dielectric breakdown is disclosed. A randomly patterned metal cap layer is selectively formed on the metal interconnect lines (typically copper (Cu)) with an interspace distance between metal cap segments that is less than the critical length (for short-length effects). Since the diffusivity is lower for the Cu / metal cap interface than for the Cu / dielectric cap interface, the region with a metal cap serves as a diffusion barrier.

Owner:GLOBALFOUNDRIES US INC

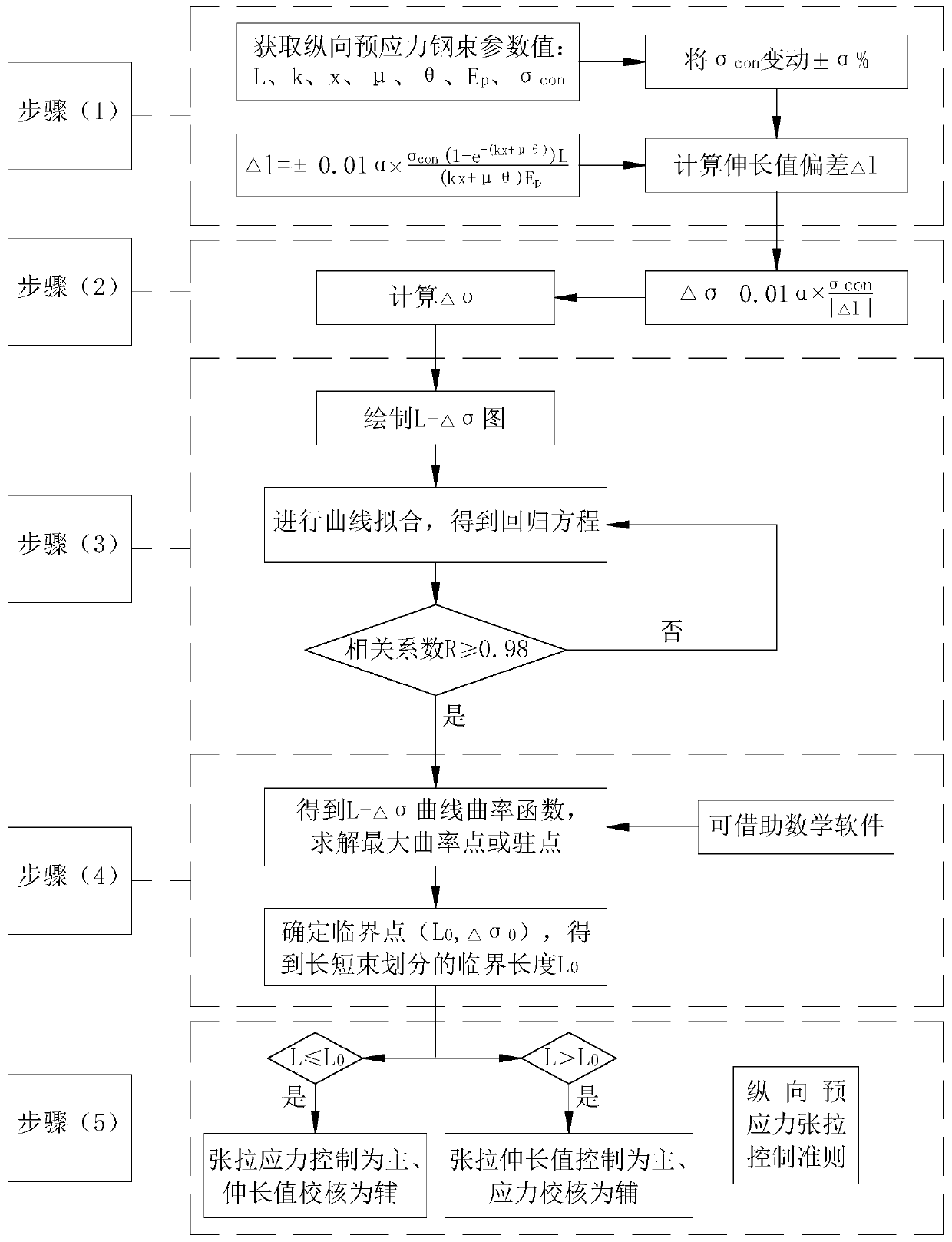

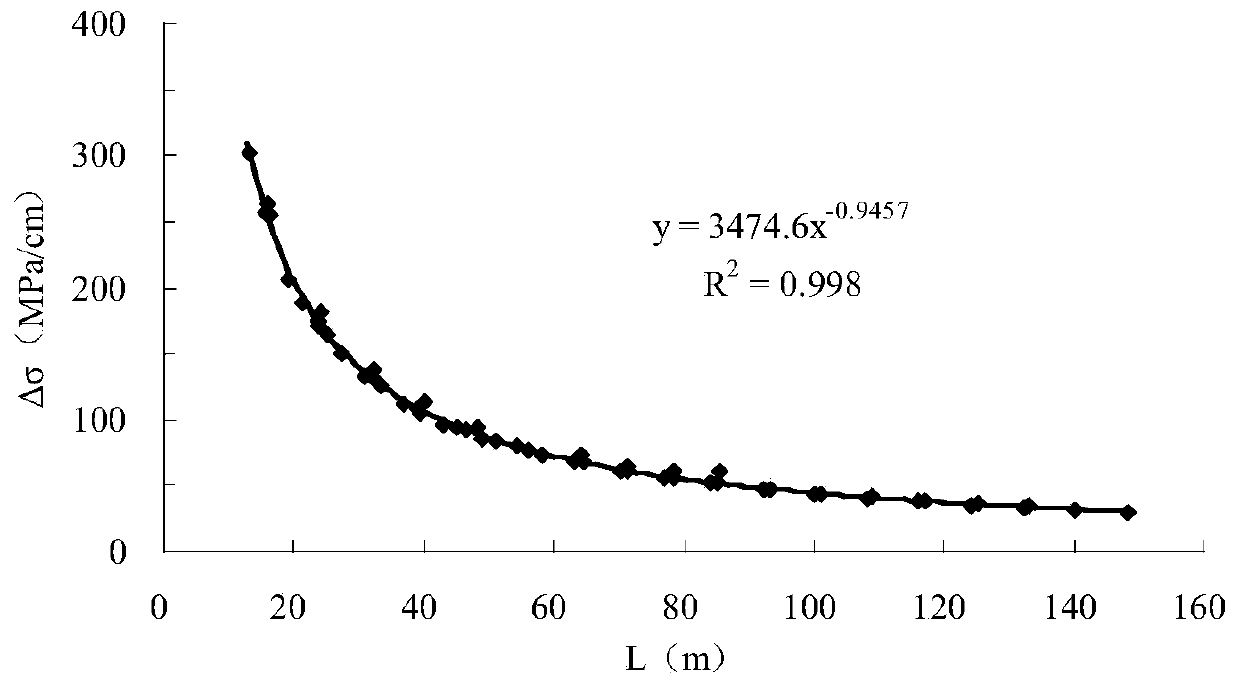

Cantilever construction bridge longitudinal prestress long and short beam division tensioning control method

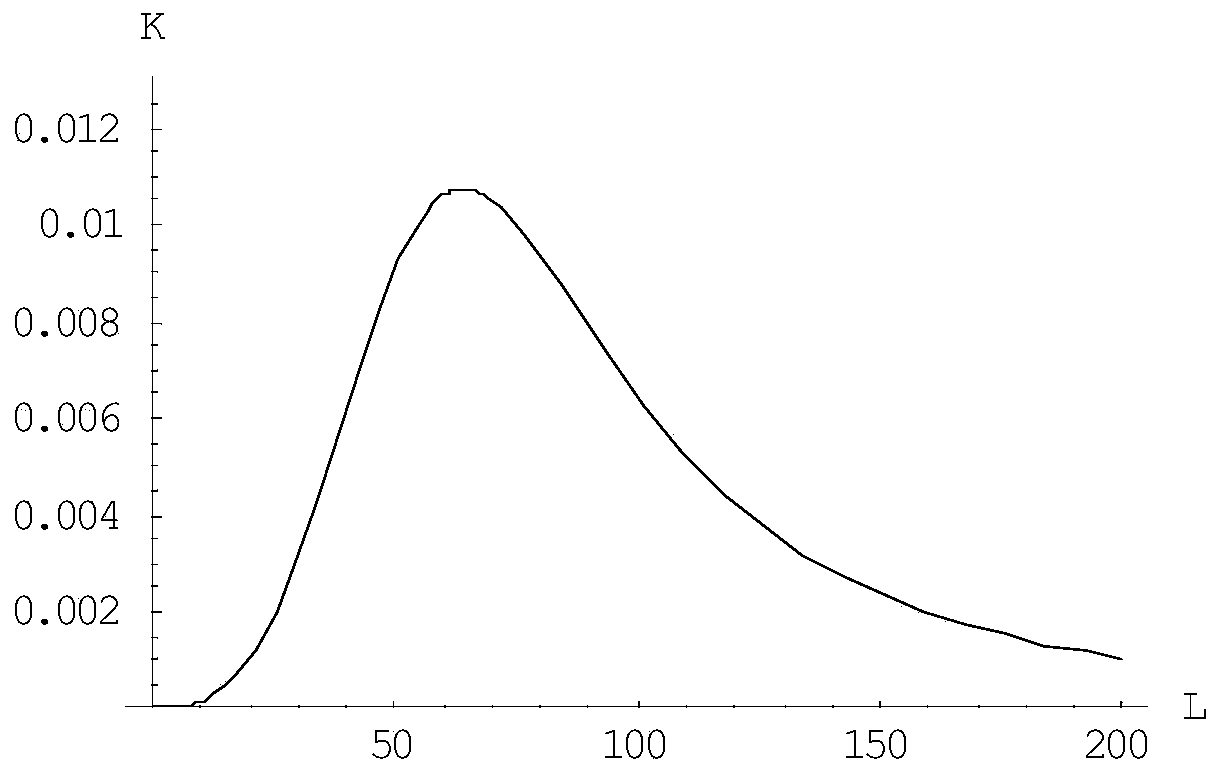

InactiveCN111549682AEasy to controlControl criteria are scientific and reasonableBridge erection/assemblyBuilding material handlingPre stressClassical mechanics

The invention discloses a cantilever construction bridge longitudinal prestress long and short beam division tensioning control method which comprises the following steps: (1) acquiring bridge longitudinal prestress steel beam parameters and parameter values, changing designed tensioning control stress by + / -alpha%, and calculating steel beam elongation value deviation; (2) calculating the tensilestress deviation caused by the unit length elongation value error of the steel bundle; (3) drawing an L-delta sigma relational graph and carrying out curve fitting, wherein the correlation coefficient should be greater than or equal to 0.98; (4) solving the maximum curvature point or stationary point, namely a critical point, of the fitting curve, and taking the corresponding steel beam length L0as the critical length of long and short beam division; and (5) proposing a prestress tension control criterion based on the critical length as a threshold value. The method has the beneficial technical effects that the influence of the steel bundle length difference on stress control is considered, a prestress critical length division method and a tensioning control criterion taking the criticallength as a threshold value are provided, and technical support is provided for tensioning construction of longitudinal prestress of a cantilever construction bridge.

Owner:云南省公路科学技术研究院

Transverse-furrow and sequential-ridge mellow soil anti-erosion farming method of purple soil slope farmland

InactiveCN102239760BAvoid strong washingReduce churnClimate change adaptationAgriculture gas emission reductionTerrainSlope length

The invention discloses a transverse-furrow and sequential-ridge mellow soil anti-corrosion farming method of a purple soil slope farmland and particularly relates to the field of a soil erosion management technique of the purple soil slope farmland. In the method disclosed by the invention, a transverse furrow is excavated along the contour line on the purple soil slope farmland at the slope length interval which is less than the rill erosion generation critical length of the modified slope surface; the cross section of the transverse furrow is in an arc shape; the formed transverse furrow divides the whole slope farmland plot into multiple small farming units in the transverse slope direction; the two ends of the transverse furrow are connected with the original drainage furrows at the two ends of the slope farmland plot; and the integral farming terrain conditions with alternate furrows and ridges are formed by adopting a sequential-slope ridging farming mode, i.e. alternately farming and ridging in the sequential slop direction and reverse slop direction. The method disclosed by the invention can reduce the water and soil loss and prevent and control the soil erosion of the slope farmland, is beneficial to the enhancement of the water content in the soil of the farmland plot in the descending direction of the transverse furrow, improves the drought resistance of crops, maintains the agricultural productivity of the slope farmland and realizes the sustainable utilization of slope farmland water and soil resources.

Owner:INST OF MOUNTAIN HAZARDS & ENVIRONMENT CHINESE ACADEMY OF SCI

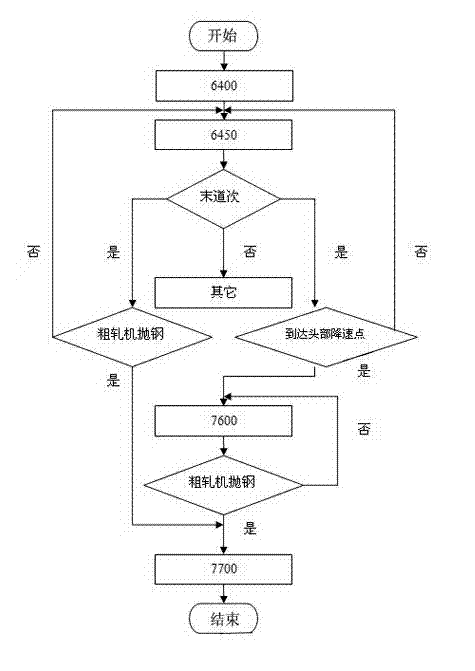

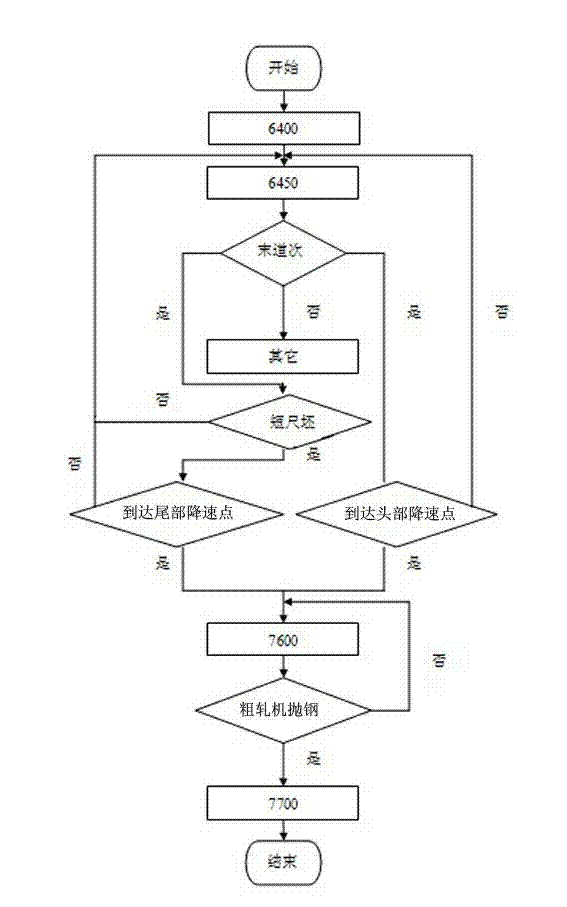

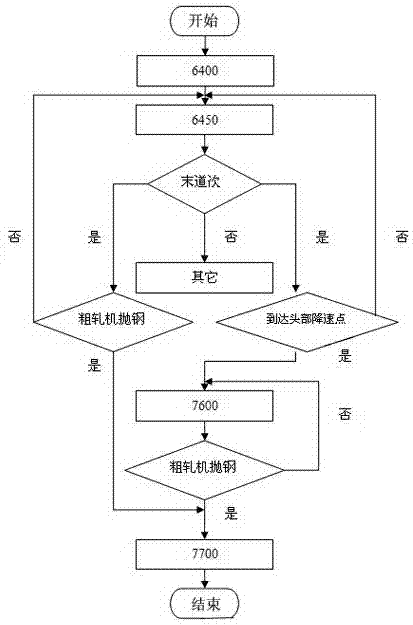

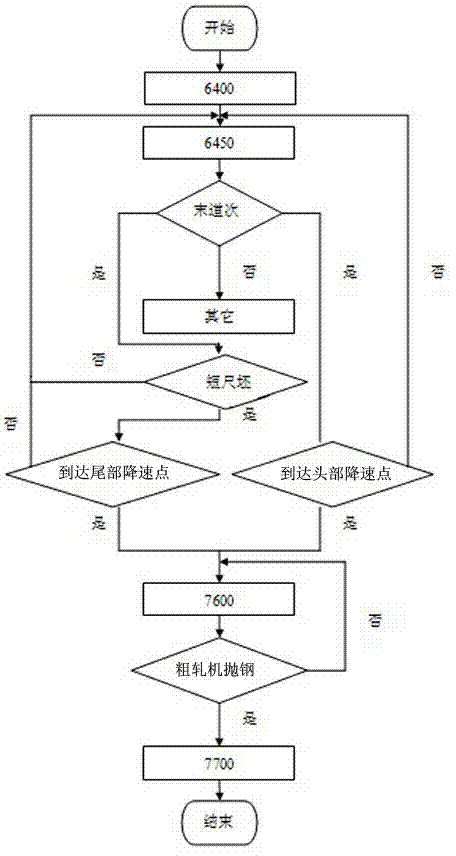

Hot-rolled strip steel rolling technology for preventing high-speed breaking-away of roughing mill

ActiveCN102896149APrecise position controlPrecise speed controlRoll mill control devicesMeasuring devicesStrip millStrip steel

The invention relates to a hot-rolled strip steel rolling technology for preventing high-speed breaking-away of a roughing mill, and belongs to the technical field of steel rolling processes in the metallurgical industry. According to the technical scheme, the technology is characterized by comprising the following steps of: 1, calculating whether a rough-rolled final plate blank is a short blank with the critical length S=S1-S2+S3+k; 2, determining a tail speed reducing point position of the final plate blank: S4=S2-k-S3; and 3, when the actual length of the rough-rolled final plate blank is smaller than the critical length S and the actual tail position of the final plate blank is equal to the tail speed reducing point position S4 of the final plate blank, or when the actual length of the rough-rolled final plate blank is greater than or equal to the critical length S and the actual head position of the final plate blank is equal to the head speed reducing point position S1 of the final plate blank, reducing the speed of the final plate blank, namely reducing the rolling speed of the final plate blank to the hot coil strip penetrating speed till the tail of the final plate blank is broken away. The technology has the advantages of accurately controlling the speed reducing point position and the speed of the final plate blank of the roughing mill, preventing the breaking-away condition of the roughing mill at a high speed, reducing influence on the roughing mill and equipment connected with the roughing mill, ensuring perfectness of the equipment and ensuring normal production.

Owner:TANGSHAN GUOFENG IRON & STEEL

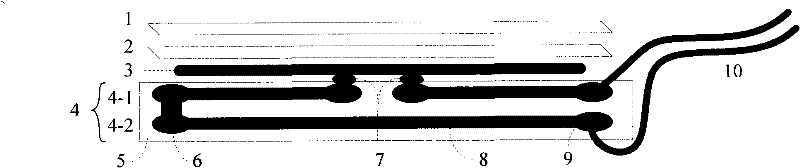

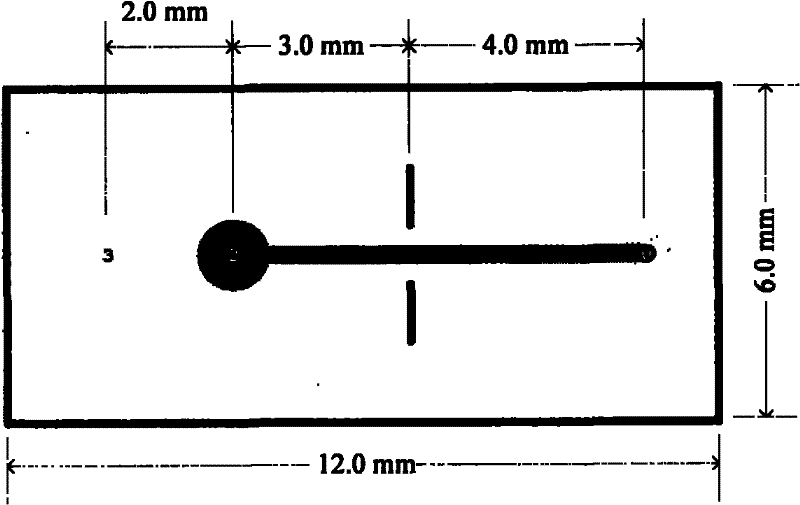

Giant magneto-impedance effect sensing probe based on flexible circuit board

InactiveCN101699309BHigh sensitivityElectromagnetic wave in small spaceMagnetic measurementsFlexible circuitsEngineering

The invention discloses a giant magneto-impedance effect sensing probe based on a flexible circuit board. The sensing probe belongs to the technical field of magnetic field detection and is characterized in that the probe uses a double-layer flexible circuit board comprising two coincident straight wires with a longer length than an end effect critical length of a magnetic alloy wire or belt. Thetwo wires are in short connection through vias at one end, and the other end of each wire leads out a twin conductor by means of a bonding pad to provide a sensing signal. One wire is disconnected for a certain gap in the middle, and the middle section of a magnetic alloy wire or a magnetic alloy belt is accessed on two bonding pads at the two sides of the gap by constant temperature welding spots. The magnetic alloy wire or belt is straightened along the wire direction and attached on the surface of the flexible circuit board by virtue of an inviscid insulating film, and is fixed by a viscous insulating film to constitute the integral sensing probe. The sensing probe has a sensitive giant magneto-impedance effect within 10MHz to 30MHz, and the machined probe has consistent measuring properties and is strong in anti-interference performance when in application.

Owner:TSINGHUA UNIV

A monitoring test method of a transmission line mountain fire satellite monitoring system

The invention discloses a monitoring and testing method, including acquisition of satellite monitoring sensitivity, for an electric-transmission-line mountain fire satellite monitoring system. The monitoring and testing method includes selecting a testing satellite, an open site, a season, weather, time and orbit azimuth angle conditions, preparing a ground monitoring and measuring device, taking firewood as a flaming material, laying a fire ground at the center of the site, recording coordinates of the fire ground, setting fire to the fire ground before satellite transition, observing a quick satellite view in real time and recording time spent by system preprocessing during satellite transition, repeating fire-point judgment after pre-processing, observing whether the satellite can find the test fire ground or not until finding the critical length of the testing satellite finding the fire ground, and squaring the critical length to acquire the sensitivity of the testing satellite. The monitoring and testing method can be used for acquiring sensitivity, distortionless reception range and fire-point judgment threshold of the monitoring system under the conditions such as different weather and territories, thereby having great guiding significance for operation and accuracy improvement of the electric-transmission-line mountain fire monitoring system.

Owner:STATE GRID CORP OF CHINA +2

A Method for Measuring the Threshold Value of Stress Intensity Factor of Mode II Crack in Metallic Materials

InactiveCN108613890BExtended stabilityAccurate measurementMaterial strength using repeated/pulsating forcesMetallic materialsEngineering

Owner:SOUTHWEST JIAOTONG UNIV

Main bearing beam for large wind power blades, hybrid spar composite wind power blades and preparation method thereof

Owner:NAT UNIV OF DEFENSE TECH

Hot-rolled strip steel rolling technology for preventing high-speed breaking-away of roughing mill

ActiveCN102896149BPrecise position controlPrecise speed controlRoll mill control devicesMeasuring devicesStrip millStrip steel

The invention relates to a hot-rolled strip steel rolling technology for preventing high-speed breaking-away of a roughing mill, and belongs to the technical field of steel rolling processes in the metallurgical industry. According to the technical scheme, the technology is characterized by comprising the following steps of: 1, calculating whether a rough-rolled final plate blank is a short blank with the critical length S=S1-S2+S3+k; 2, determining a tail speed reducing point position of the final plate blank: S4=S2-k-S3; and 3, when the actual length of the rough-rolled final plate blank is smaller than the critical length S and the actual tail position of the final plate blank is equal to the tail speed reducing point position S4 of the final plate blank, or when the actual length of the rough-rolled final plate blank is greater than or equal to the critical length S and the actual head position of the final plate blank is equal to the head speed reducing point position S1 of the final plate blank, reducing the speed of the final plate blank, namely reducing the rolling speed of the final plate blank to the hot coil strip penetrating speed till the tail of the final plate blank is broken away. The technology has the advantages of accurately controlling the speed reducing point position and the speed of the final plate blank of the roughing mill, preventing the breaking-away condition of the roughing mill at a high speed, reducing influence on the roughing mill and equipment connected with the roughing mill, ensuring perfectness of the equipment and ensuring normal production.

Owner:TANGSHAN GUOFENG IRON & STEEL

Large-scale composite material wind-power blade and preparation method thereof

ActiveCN101705922BSolve the problem of critical length limitationReduce wasteMachines/enginesWind energy generationElectricityGlass fiber

Owner:ZHUZHOU TIMES NEW MATERIALS TECH

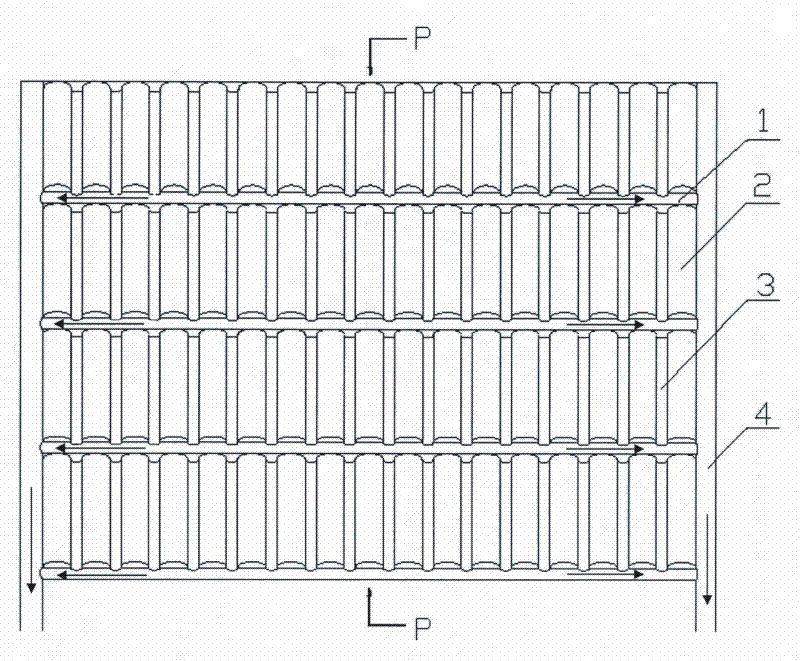

Composite material and production method thereof

Improved composite structure comprises threads distributed within disperse matrix. The structure has increased strength by virtue of distance between the points of support of the thread span, which is deliberately selected to be less than the distance corresponding to the critical lengths corresponding to buckling. The structure is suitable for various articles of manufacture requiring improved the strength-to-weight or rigidity-to-weight ratio in various directions.

Owner:费拉迪米尔·克里亚泽金

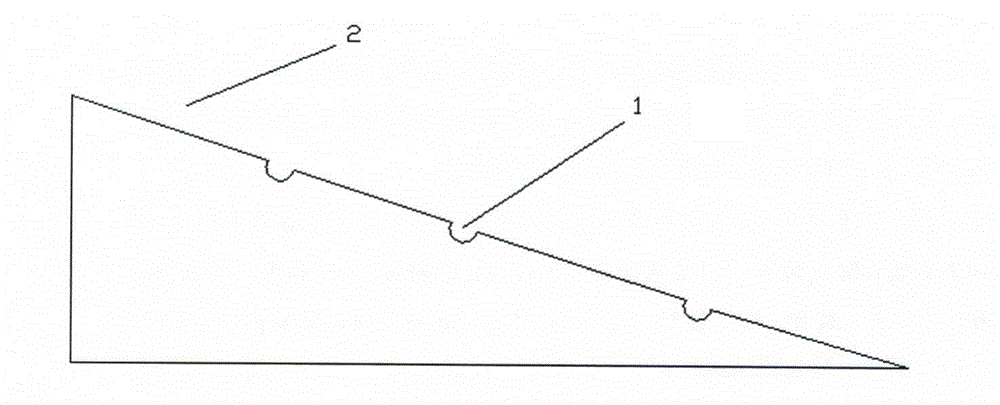

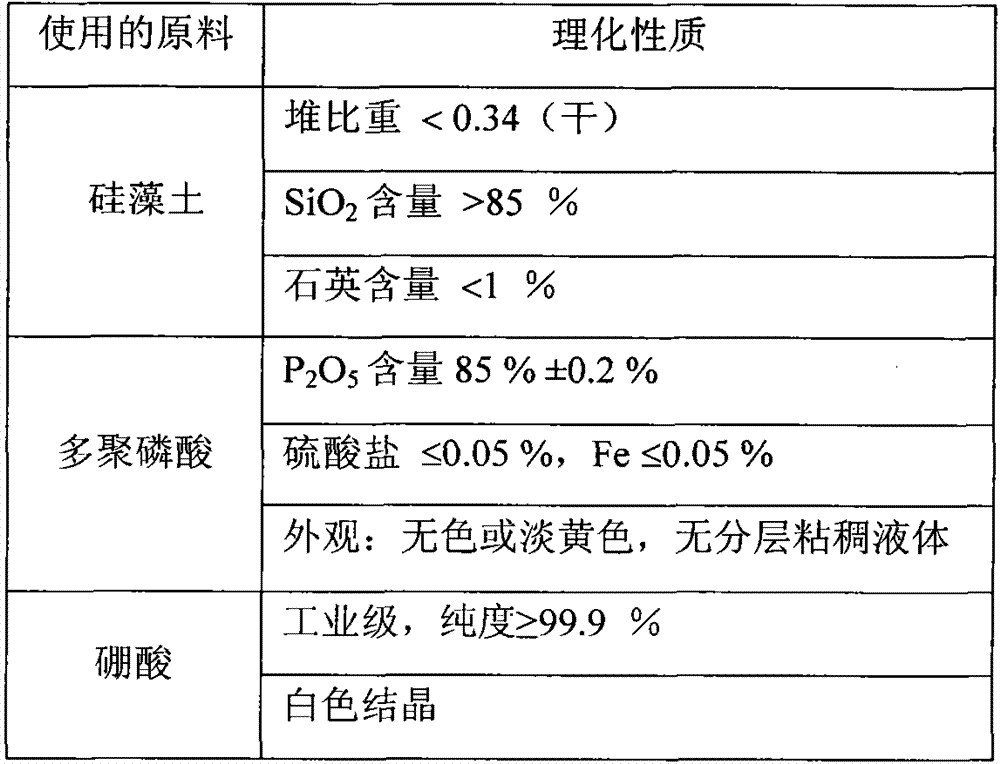

Catalyst roasting - plastic dual-purpose rotary kiln

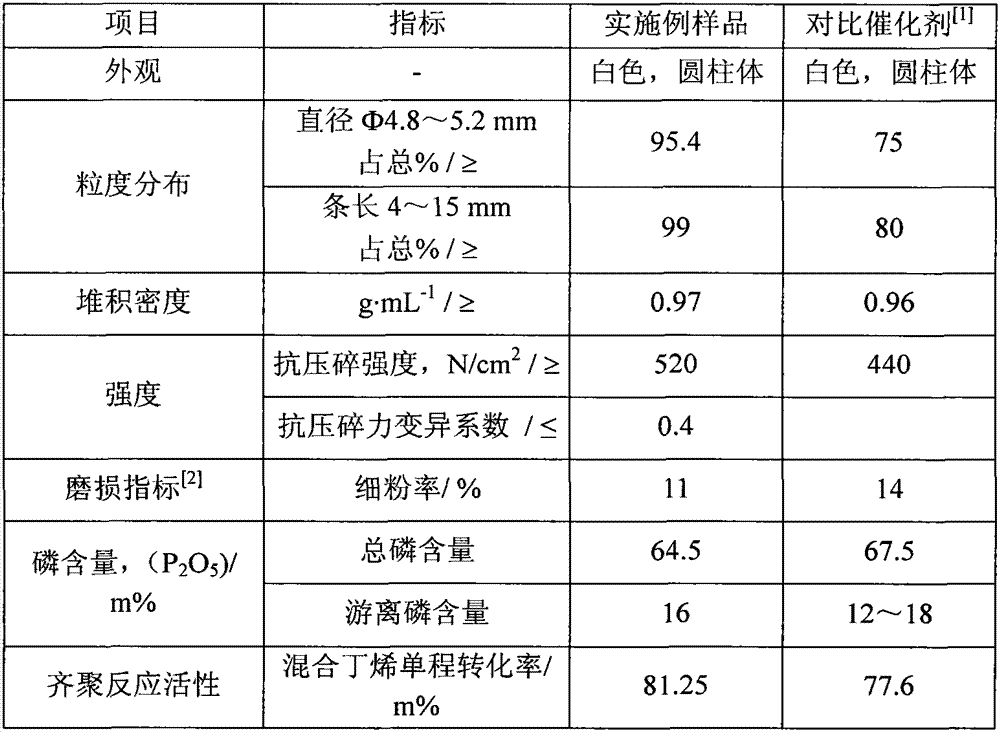

ActiveCN102895982BAvoid breakingBreak will not happenPhysical/chemical process catalystsRotary drum furnacesEffective radiusPhosphoric acid

The invention relates to two processes of roasting and shaping in a preparation process of a solid phosphoric acid catalyst (SPAC). The catalyst is applied to reactions such as oligomerization of low-carbon olefins and alkylation of propylene. In the past, SPAC preparation, roasting and shaping processes were carried out separately. The static method was used for roasting, and the materials could not be fully and evenly heated; the shredder was used for shaping, resulting in low yield of finished products, high crushing loss, high broken particles and powder, and "memory" inside the particles. crack. The inventor proposed the concept of critical strip length and defined the probability function of particle fracture: ζi=k·(Li‑Lcri)α. During the rotation of the kiln, homogeneous strips fall from the top of the built-in lifting board and hit the bottom. The strip length tends to be the same, and the dual-purpose rotary kiln is designed for roasting and shaping. The obtained SPAC particles have a narrow distribution of length and strength, which improves the conversion rate of the catalytic reaction and the selectivity of oligomers, reduces its muddy tendency, and prolongs the operating life. The particle length of the product of the present invention depends on the effective radius (rbs) of the roasting kiln. The present invention can be implemented industrially.

Owner:RACHEM CHINA CO LTD

Random local metal cap layer formation for improved integrated circuit reliability

InactiveUS20150028484A1Semiconductor/solid-state device detailsSolid-state devicesElectricityLength effect

A method and structure for preventing integrated circuit failure due to electromigration and time dependent dielectric breakdown is disclosed. A randomly patterned metal cap layer is selectively formed on the metal interconnect lines (typically copper (Cu)) with an interspace distance between metal cap segments that is less than the critical length (for short-length effects). Since the diffusivity is lower for the Cu / metal cap interface than for the Cu / dielectric cap interface, the region with a metal cap serves as a diffusion barrier.

Owner:GLOBALFOUNDRIES INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com