Patents

Literature

37results about How to "Extended stability" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

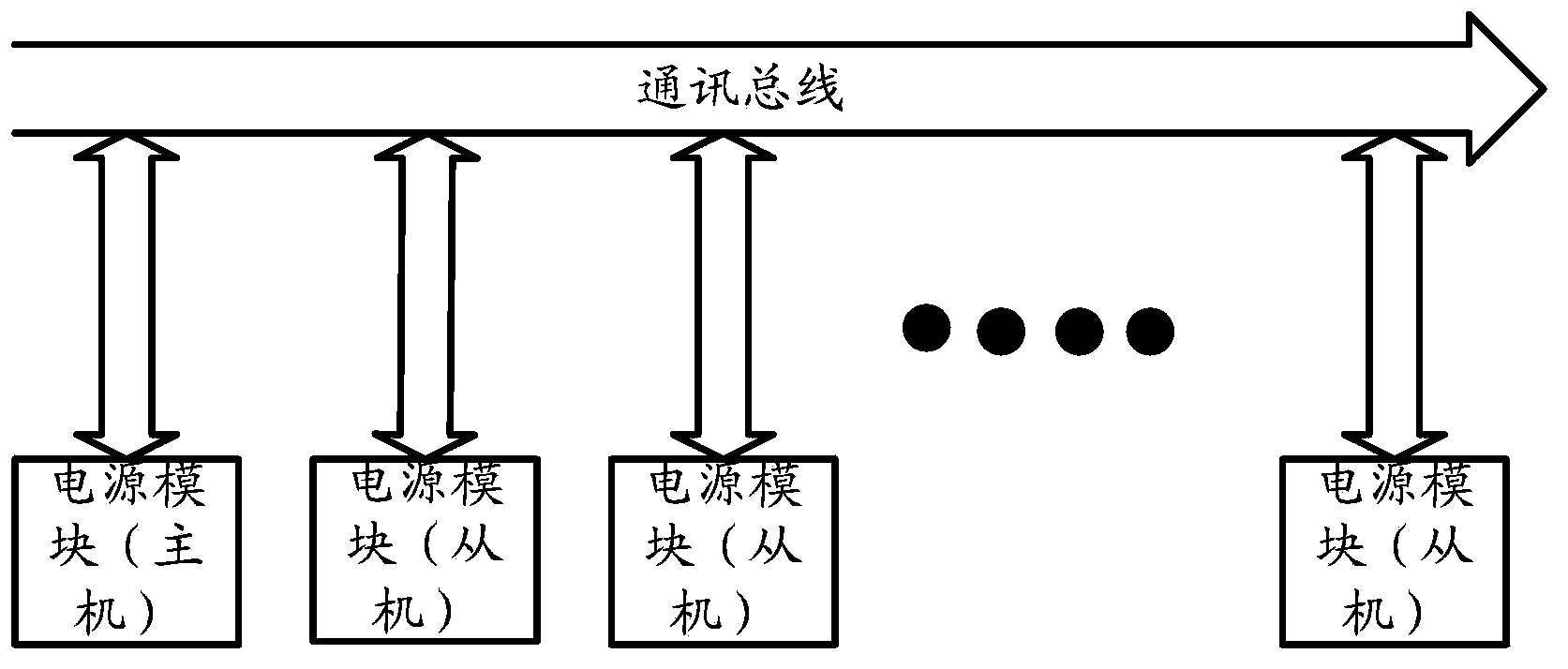

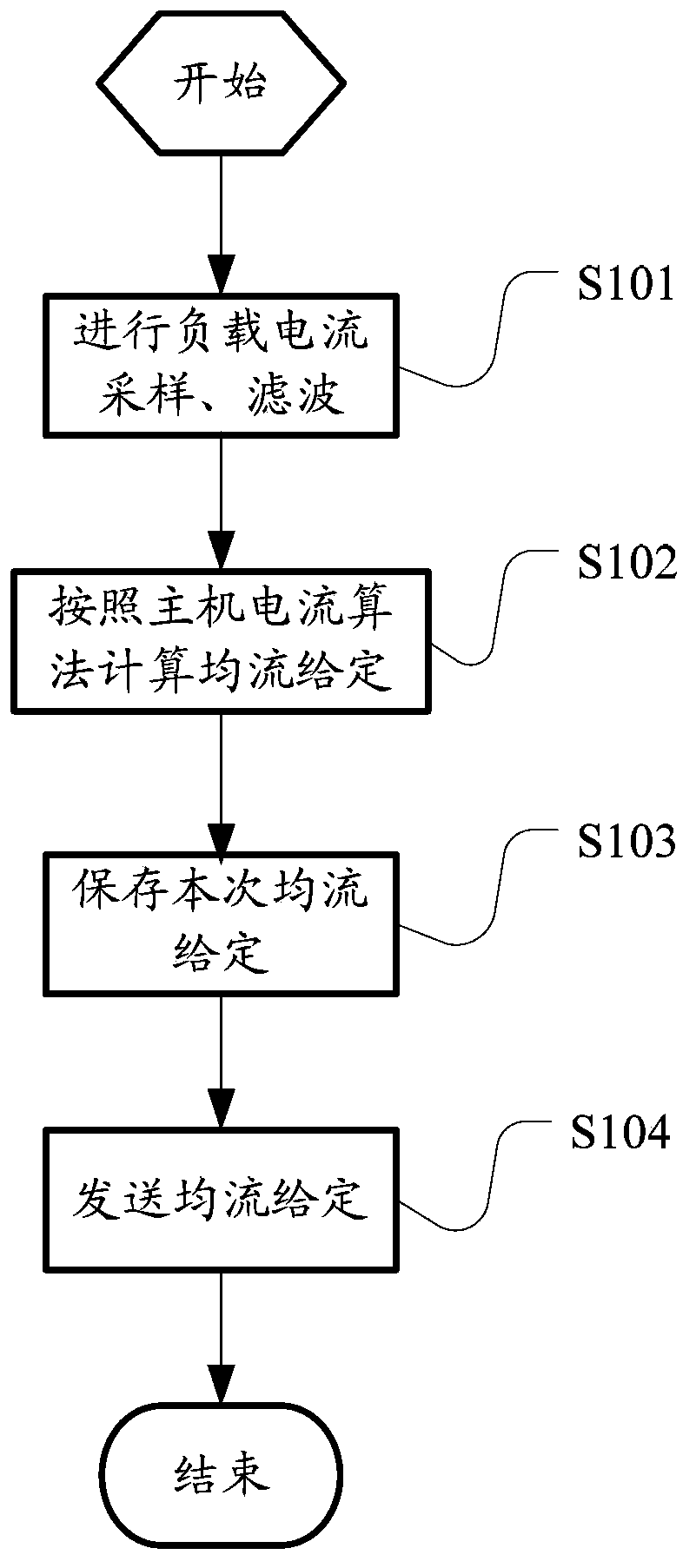

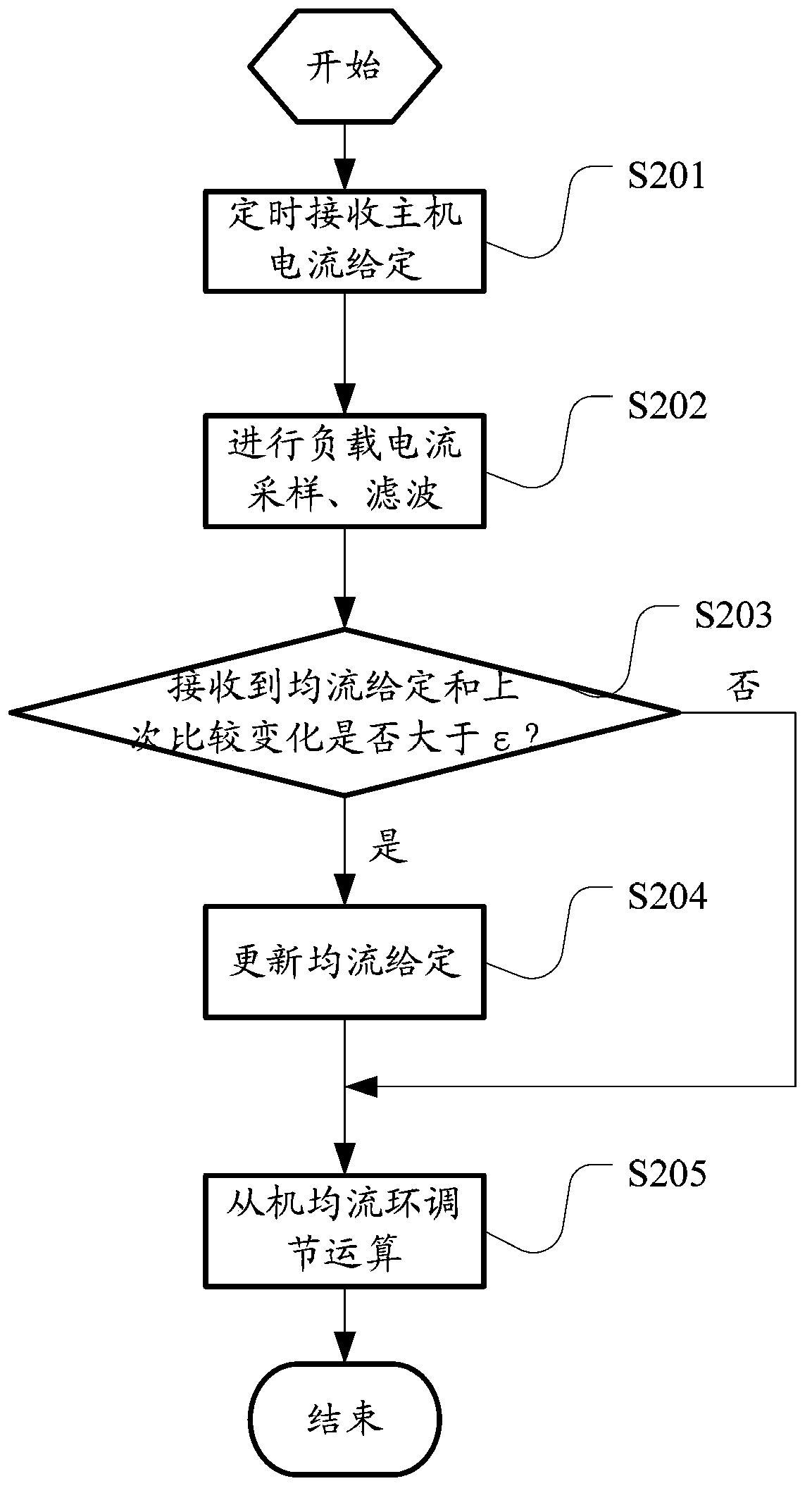

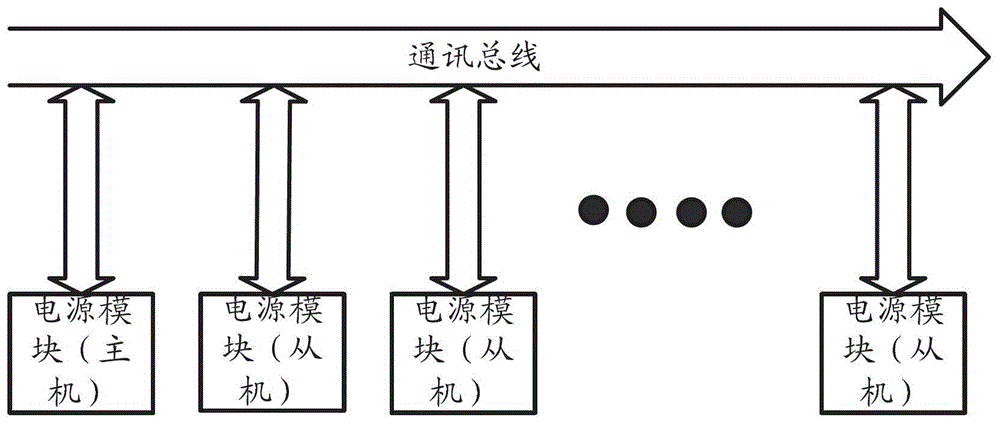

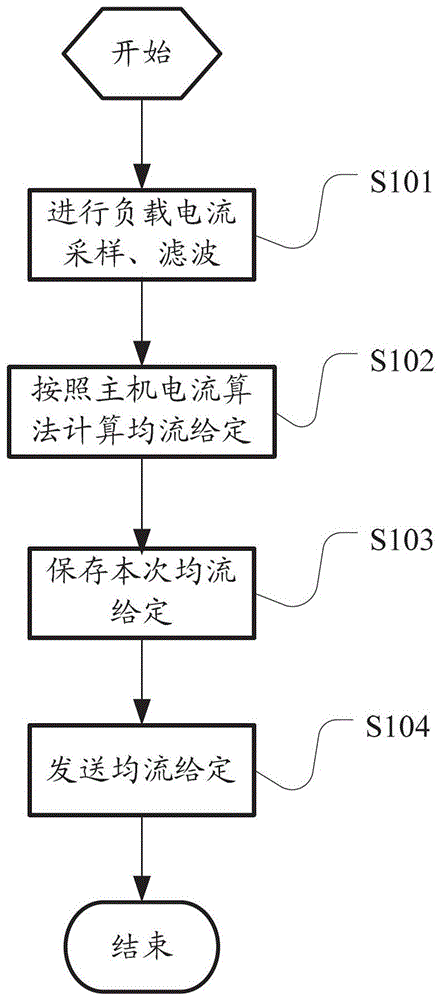

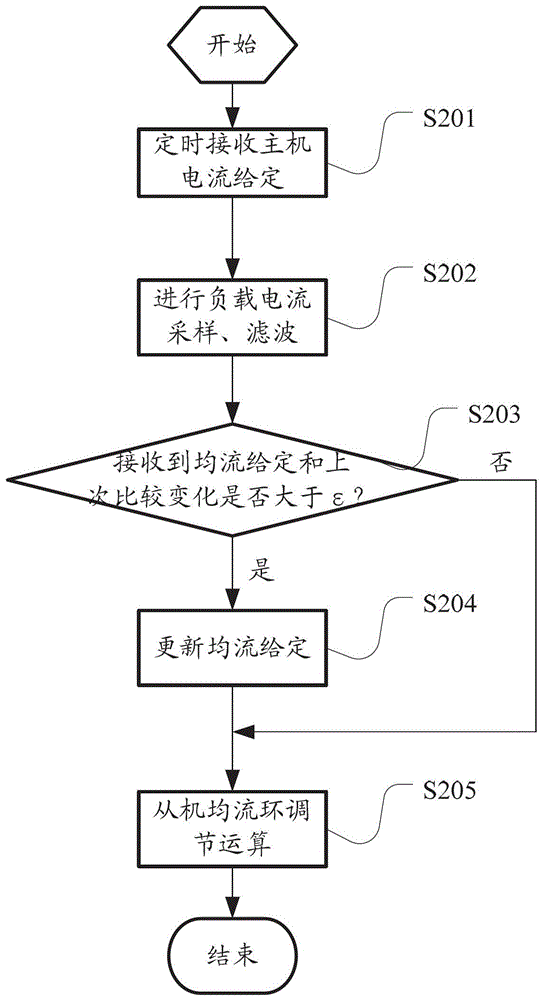

DC converter digital parallel current equalizing method and system

ActiveCN103780078ADestroy convergenceExtended stabilityDc-dc conversionElectric variable regulationEngineeringElectric current

The invention discloses a DC converter digital parallel current equalizing method and system. The method comprises that: a host periodically acquires present load current and calculates a present current equalizing set value and issues the value in combination with last time current equalizing set values issued to multiple parallel-connected slaves last time; and whether load current adjustment of each slave is executed is judged by each slave according to the acquired present current equalizing set value and the stored current equalizing set value last time, and when a difference value between the present current equalizing set value and the current equalizing set value last time is greater than or equal to the preset minimum current equalizing error threshold value, the load current adjustment of the slaves is executed according to the present current equalizing set value, wherein the minimum current equalizing error threshold value can be set as zero. With application of the method, the DC converter digital parallel current equalizing system can still operate stably even interference appears or loads are switched so that great robustness is realized.

Owner:ZTE CORP

Zirconium oxide refractory with homogeneous micro-crystallized structure and preparation method thereof

The invention discloses a zirconium oxide refractory with a homogeneous micro-crystallized structure. The raw materials of the zirconium oxide refractory comprise the following components by weight percent: 92-96wt% of fused monoclinic zirconium oxide, 4-8wt% of compound stabilizer and sintering aid and 0-1wt% of yellow dextrin. Simultaneously, the invention also discloses a preparation method ofthe zirconium oxide refractory. The preparation method comprises the following steps of: firstly, mixing the raw material dry powder for 1-2 minutes by adopting a high-speed mixing and pelleting machine; after additionally adding 8-12wt% of combining agent, carrying out high-speed pug milling for 5-8 minutes, and then cutting for 1-3 minutes at a high speed; after boiling drying and screening, pelleting, and pressing and forming at the pressure of 150-200MPa; drying a formed green body for 12-24 hours at the temperature of 110 DEG C; and calcining for 2-3 hours at the temperature of 1600-1650DEG C. The zirconium oxide refractory of the invention has the advantages of high temperature and high strength, low apparent porosity, small pore aperture, good scouring resistance and stripping resistance and strong thermal shock resistance. The zirconium oxide refractory of the invention not only can adapt to longevity requirements of a steel ladle, an intermediate ladle sliding plate and a continuous casting sizing water gap but also can be used as longevous kiln furniture.

Owner:ZHEJIANG ZILI HIGH TEMPERATURE TECH CO LTD

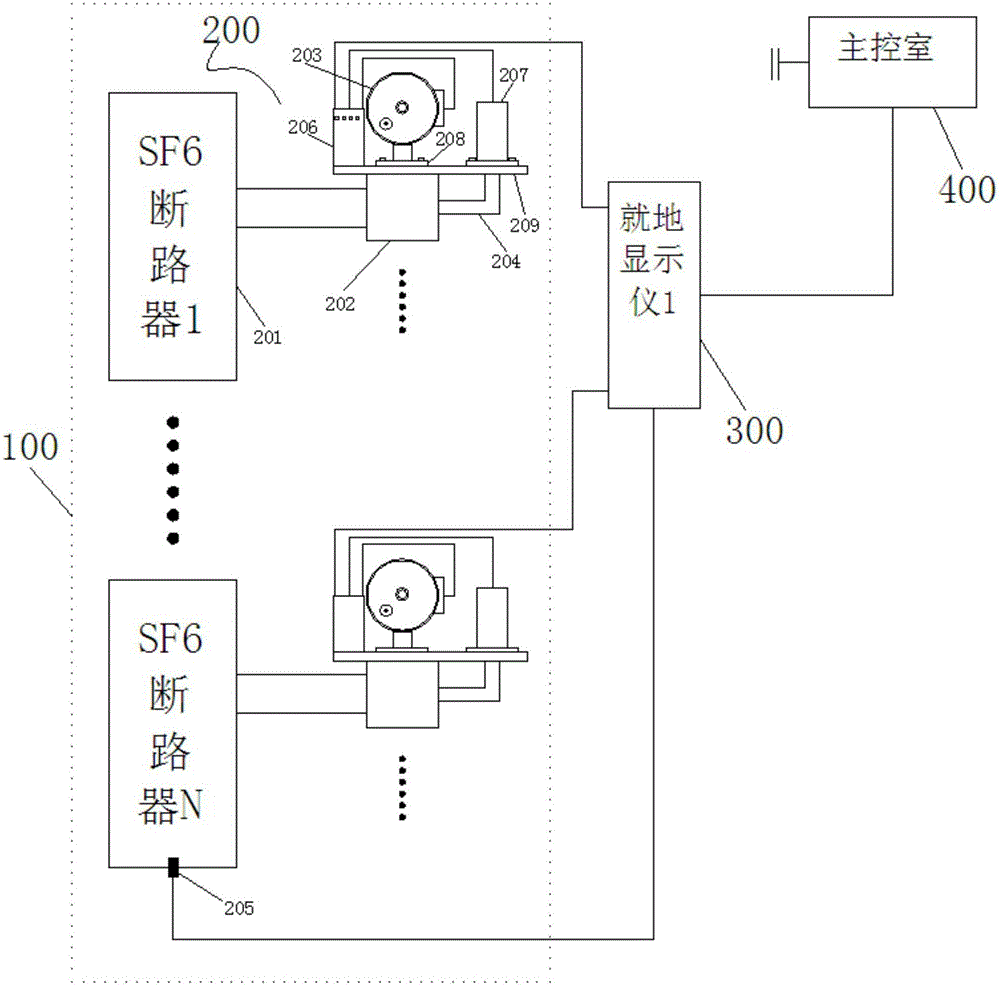

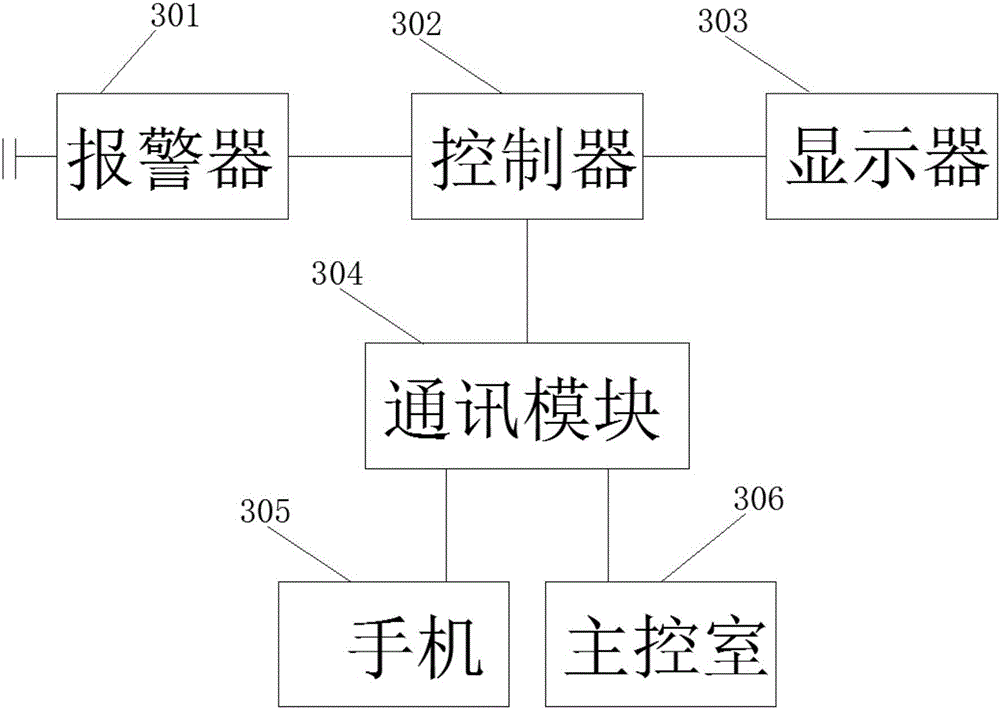

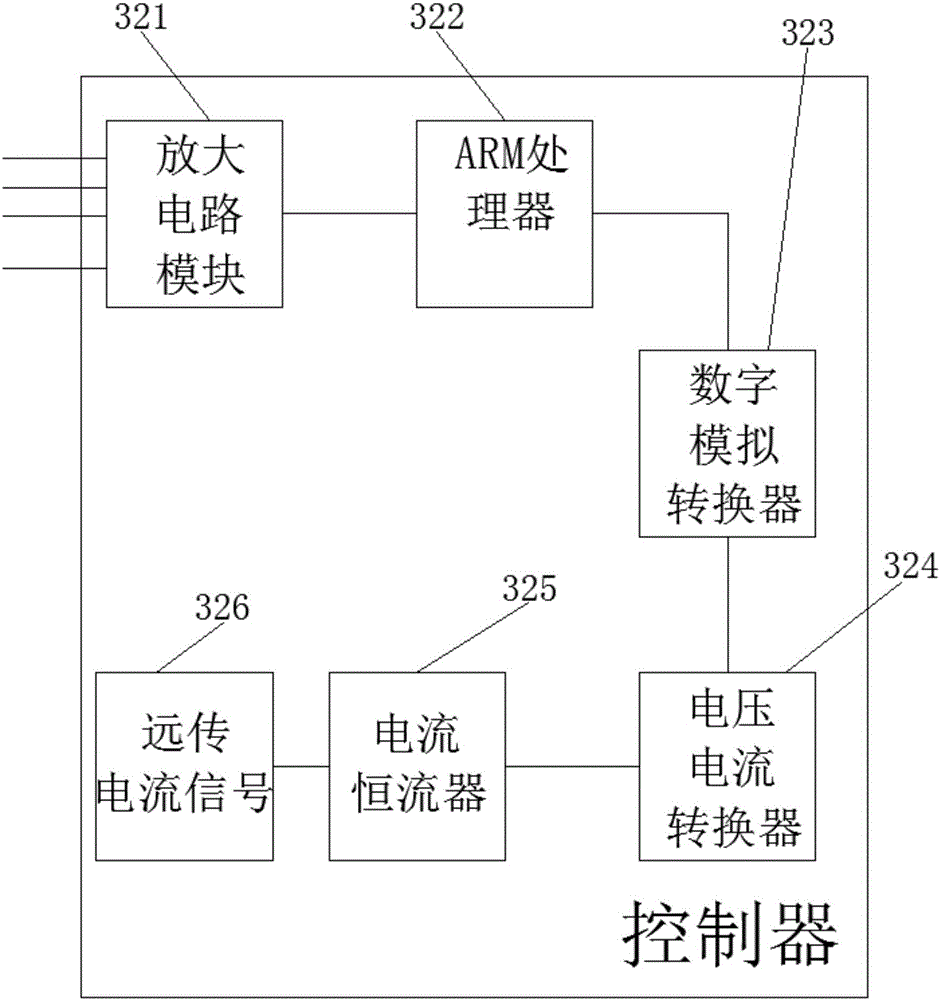

Onsite display instrument-based GIS sulfur hexafluoride density online monitoring system

InactiveCN106596329AWill not cause fragile phenomenaNeat wiringThermometers using electric/magnetic elementsUsing electrical meansElectricitySulfur hexafluoride

The invention discloses an onsite display instrument-based GIS sulfur hexafluoride density online monitoring system. A monitoring pipeline is provided with a gas exporting tee joint; one outlet of the gas exporting tee joint communicates with the gas collecting opening of a sulfur hexafluoride density meter; another outlet of the gas exporting tee joint communicates with the collecting opening of a pressure collecting sensor; the system also includes a horizontally mounted mounting platform, and the sulfur hexafluoride density meter and the pressure collecting sensor are respectively mounted on the mounting platform through mounting flanges, and are vertical to the mounting platform; the mounting platform positioned on the side surface of the sulfur hexafluoride density meter is provided with a wiring terminal strip, and the wiring terminal strip is electrically connected to the signal input channel of an onsite display instrument; and the quantity of SF6 breakers is more than one, and a gas chamber shell of one of the SF6 breakers in the same indoor environment is provided with a temperature sensor used for measuring the gas temperature in the SF6 breaker gas chamber.

Owner:HUANENG INT POWER CO LTD YUHUAN POWER PLANT +1

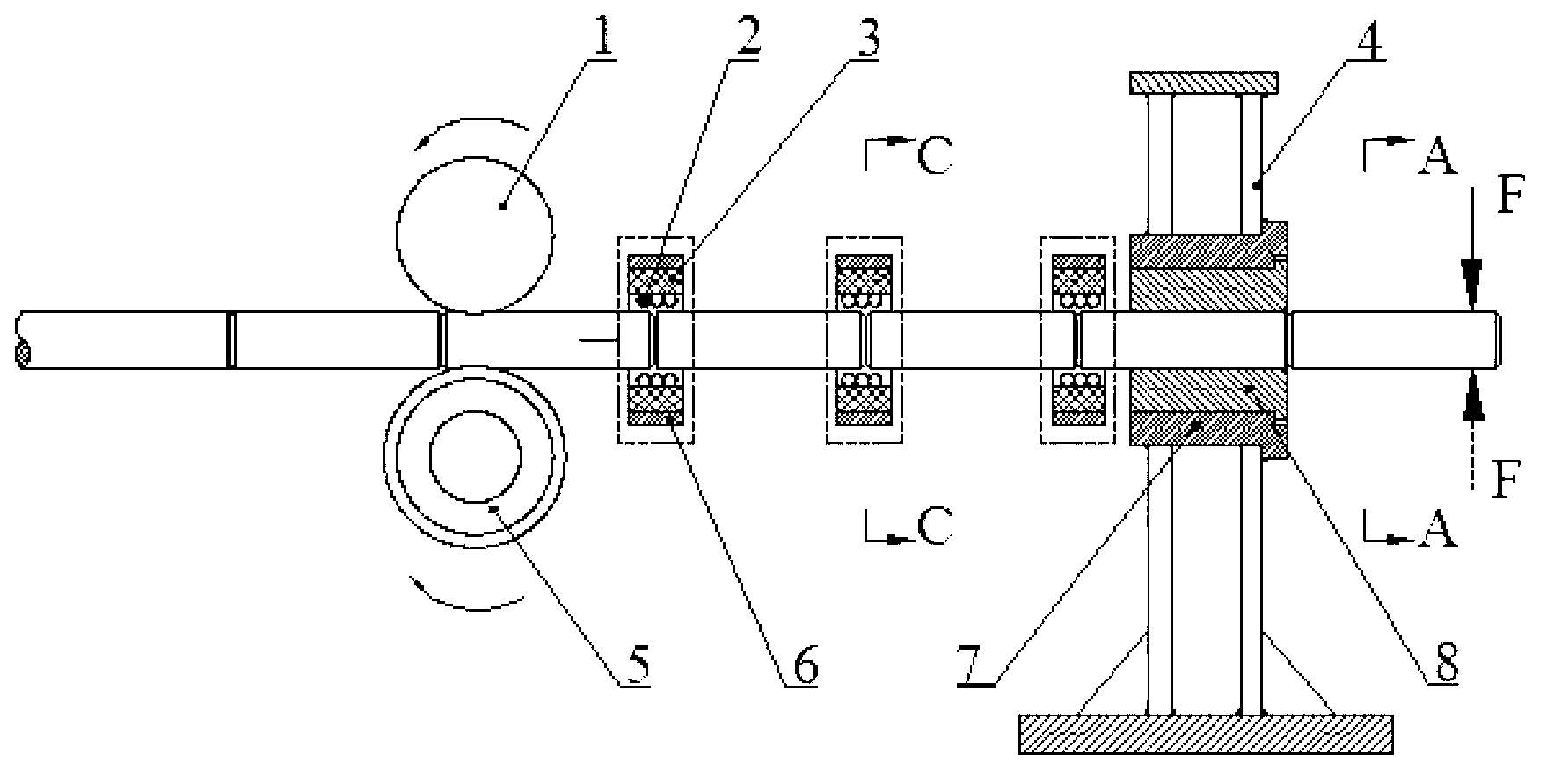

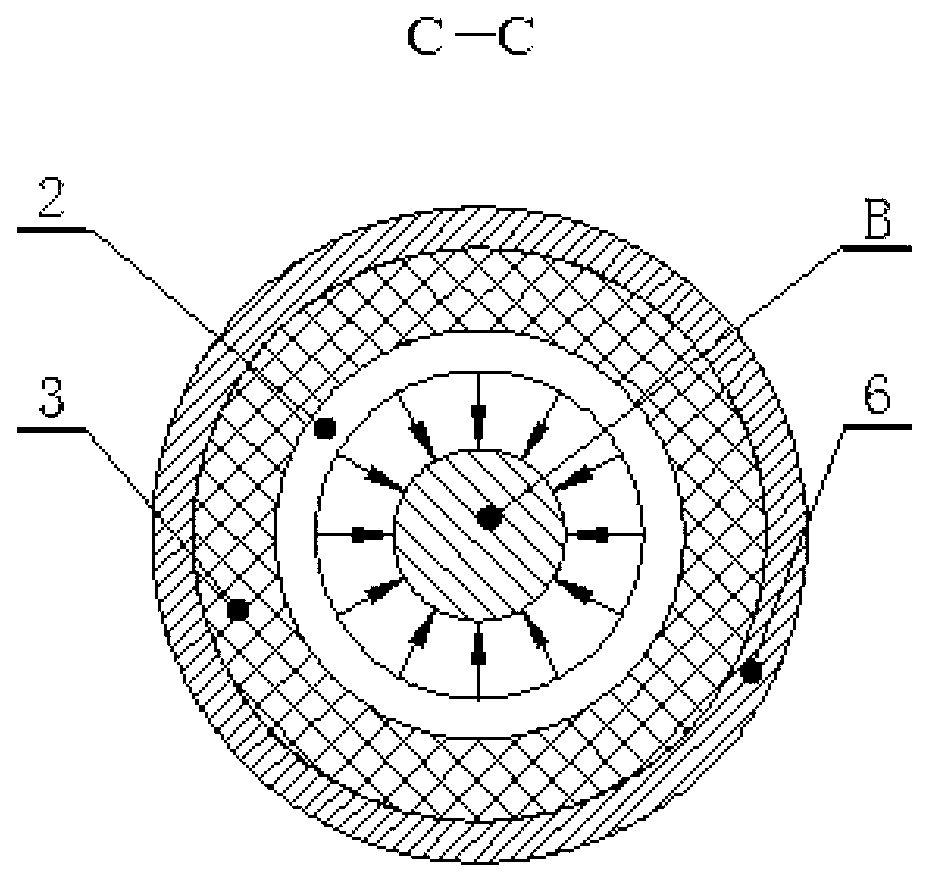

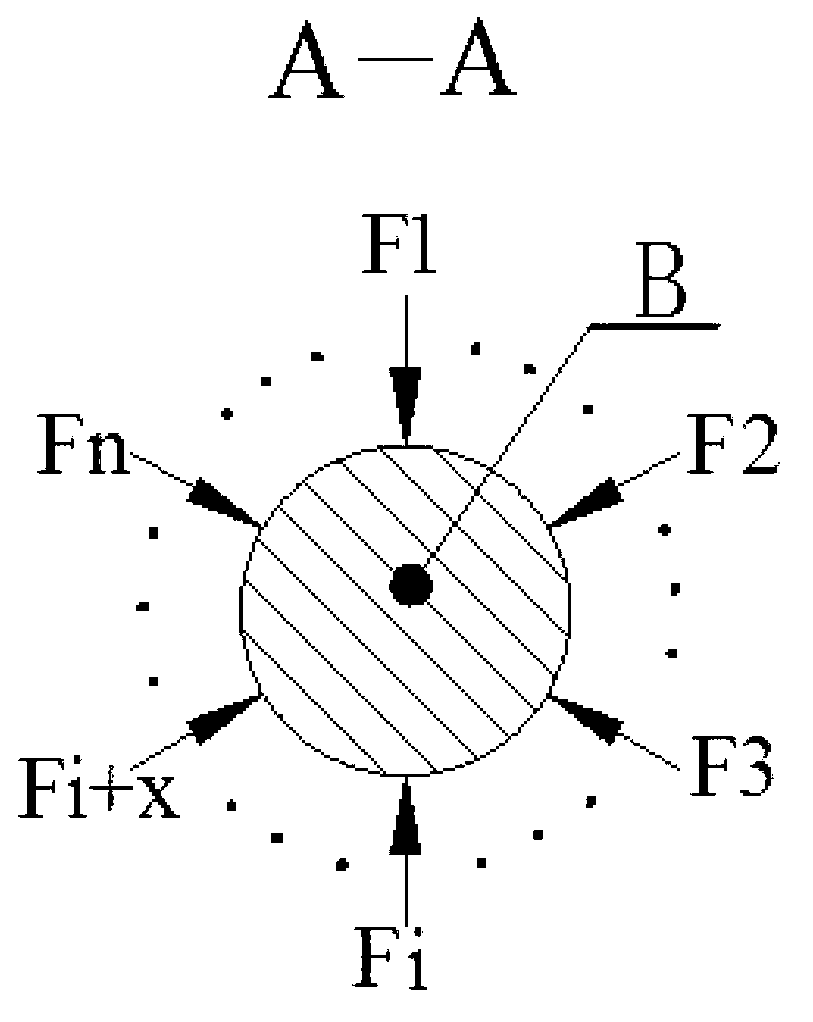

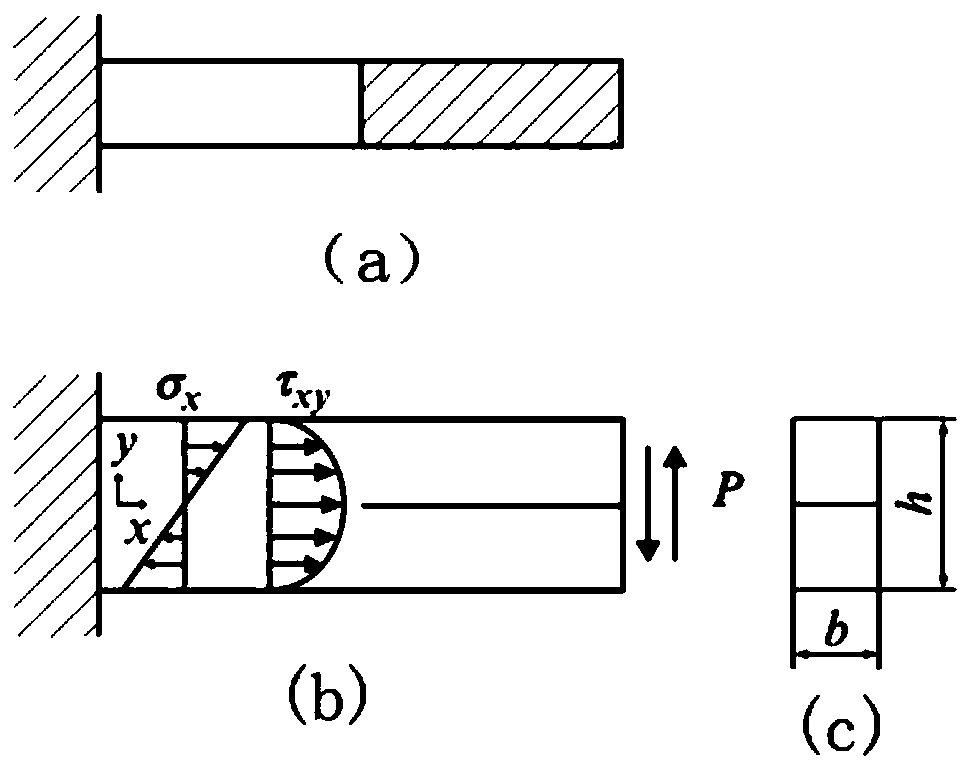

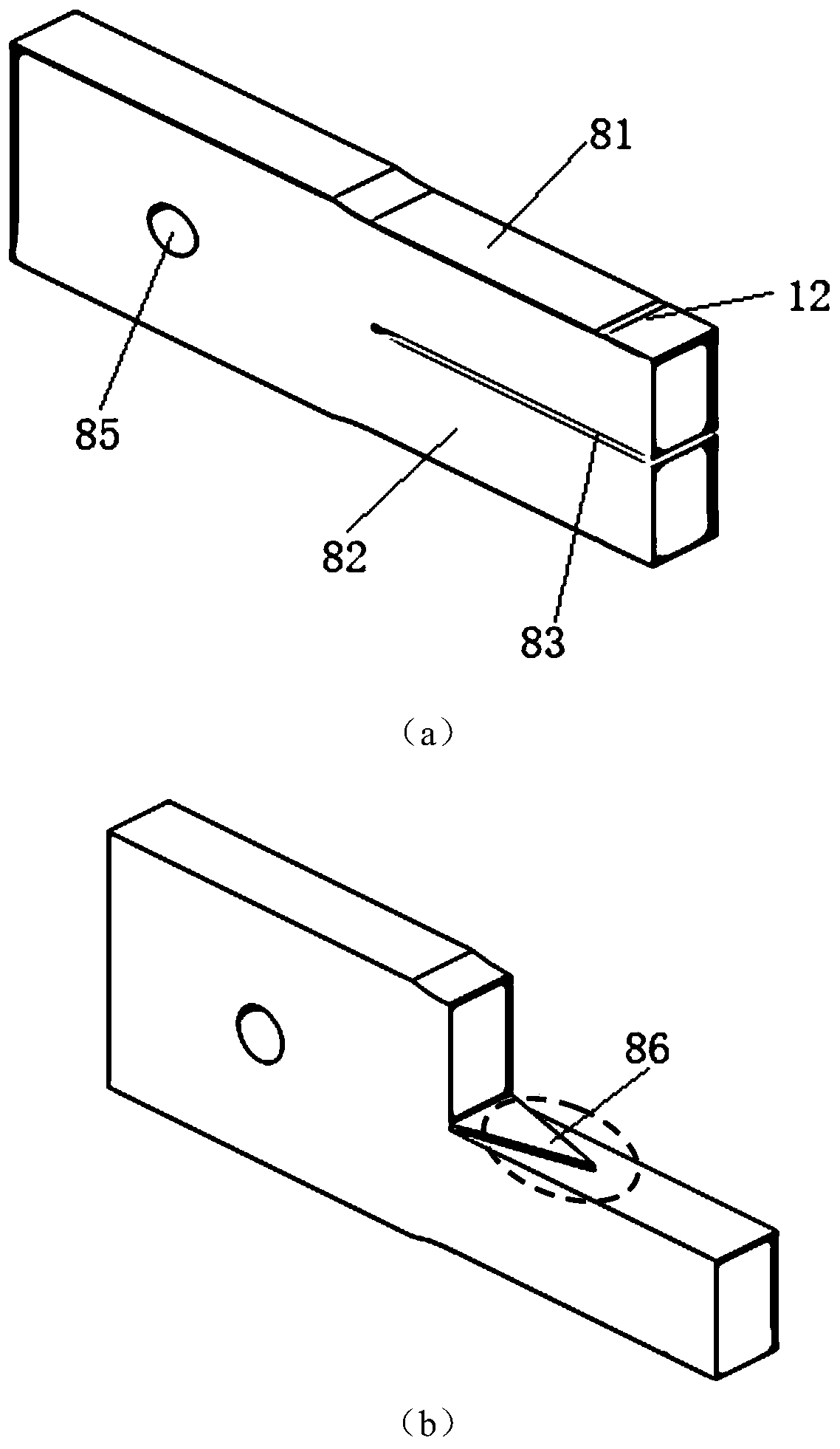

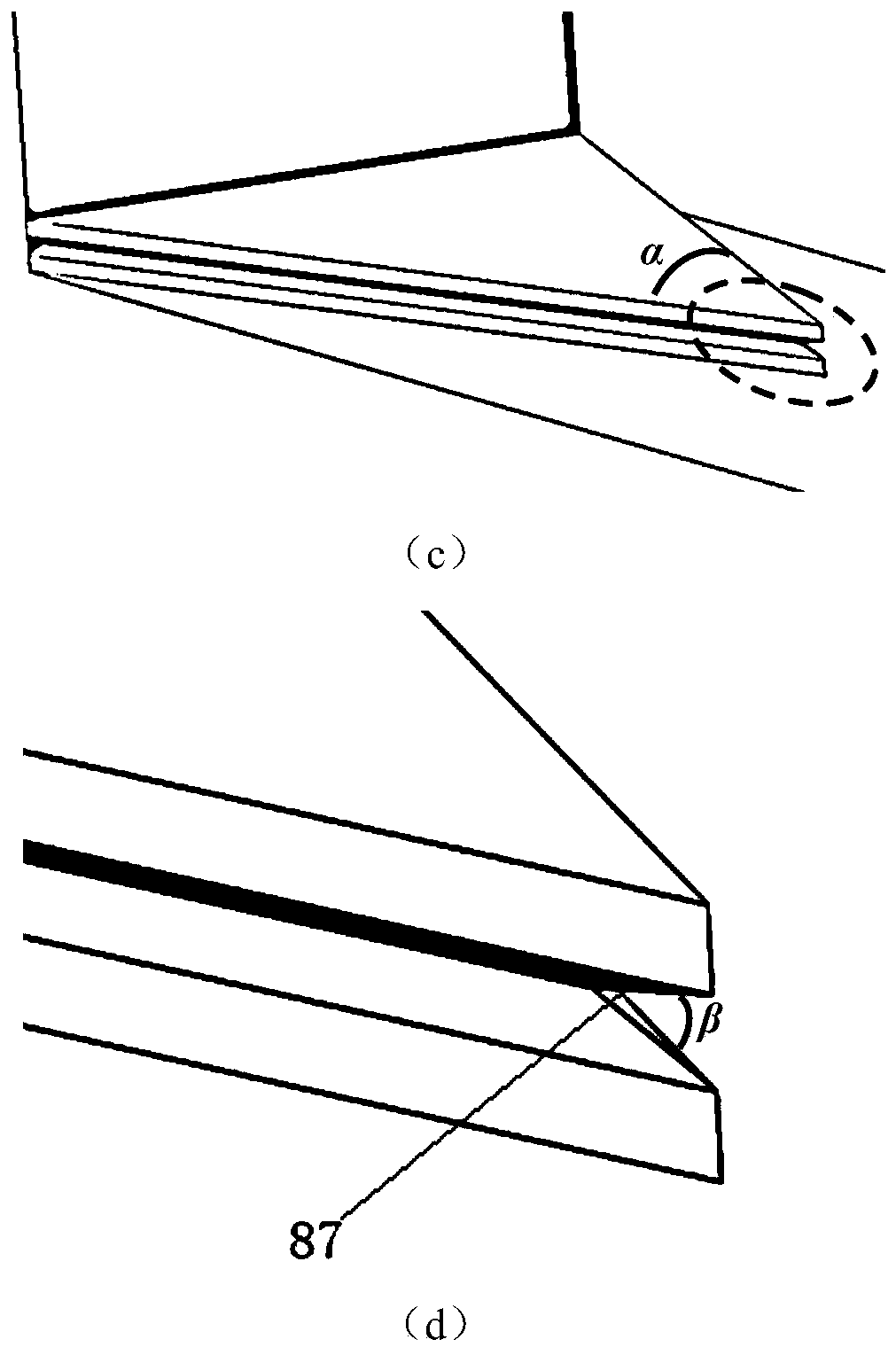

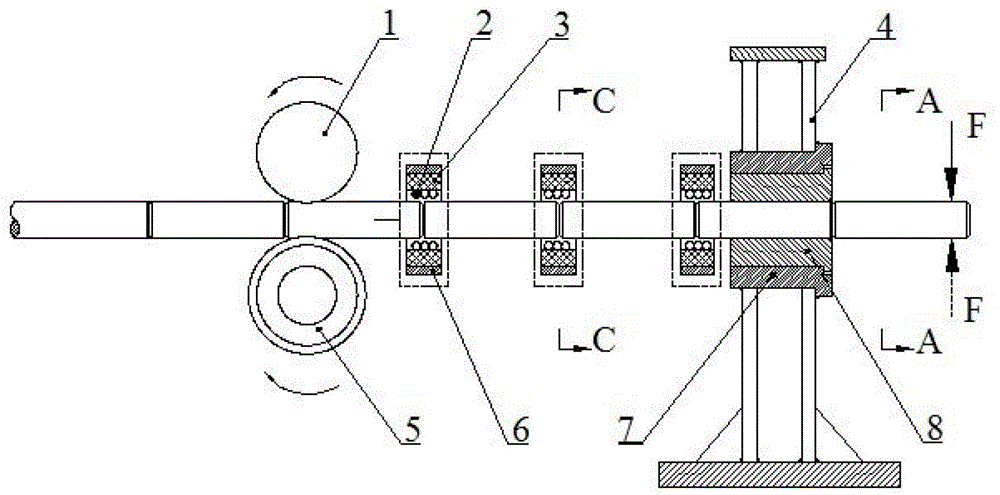

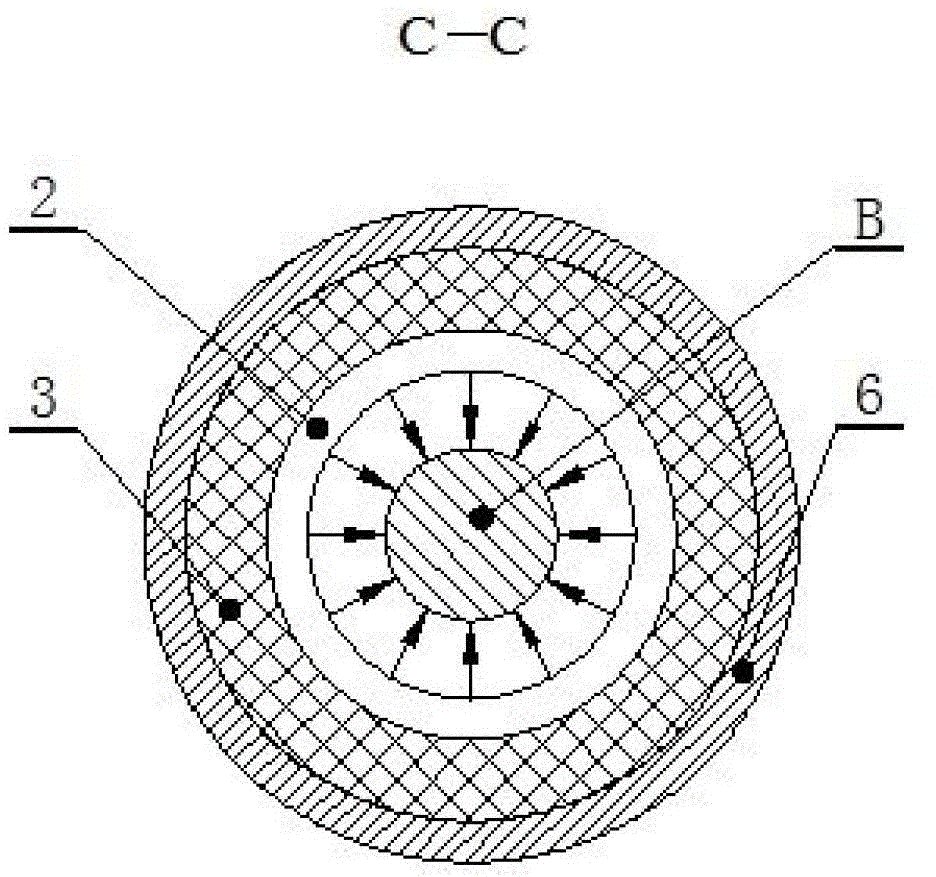

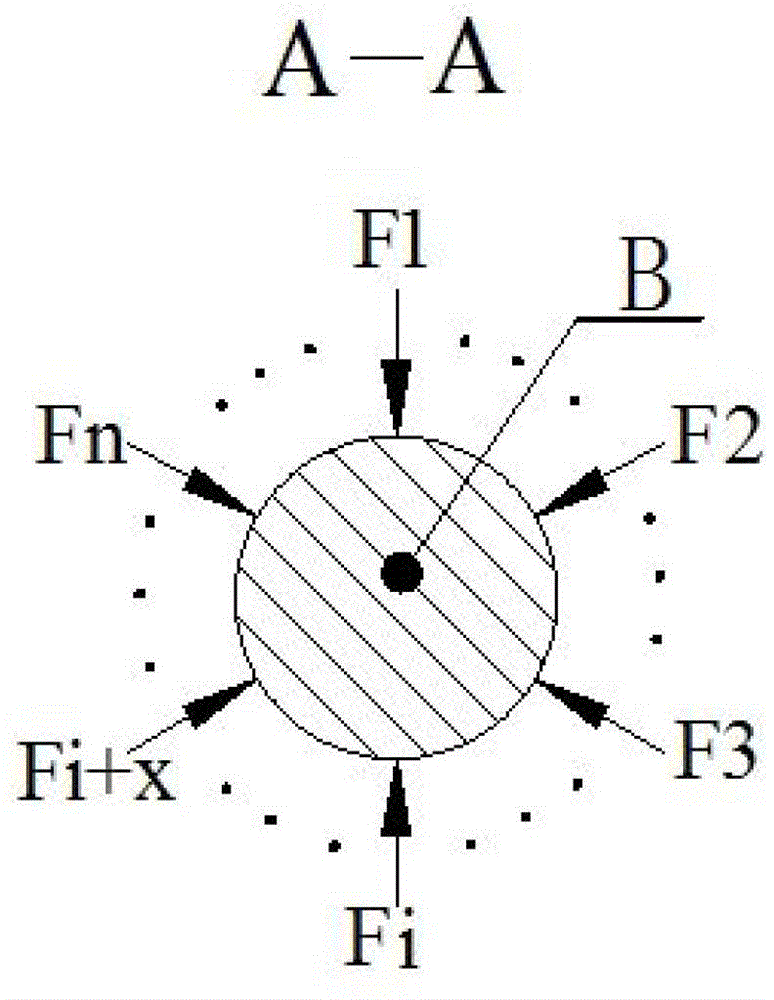

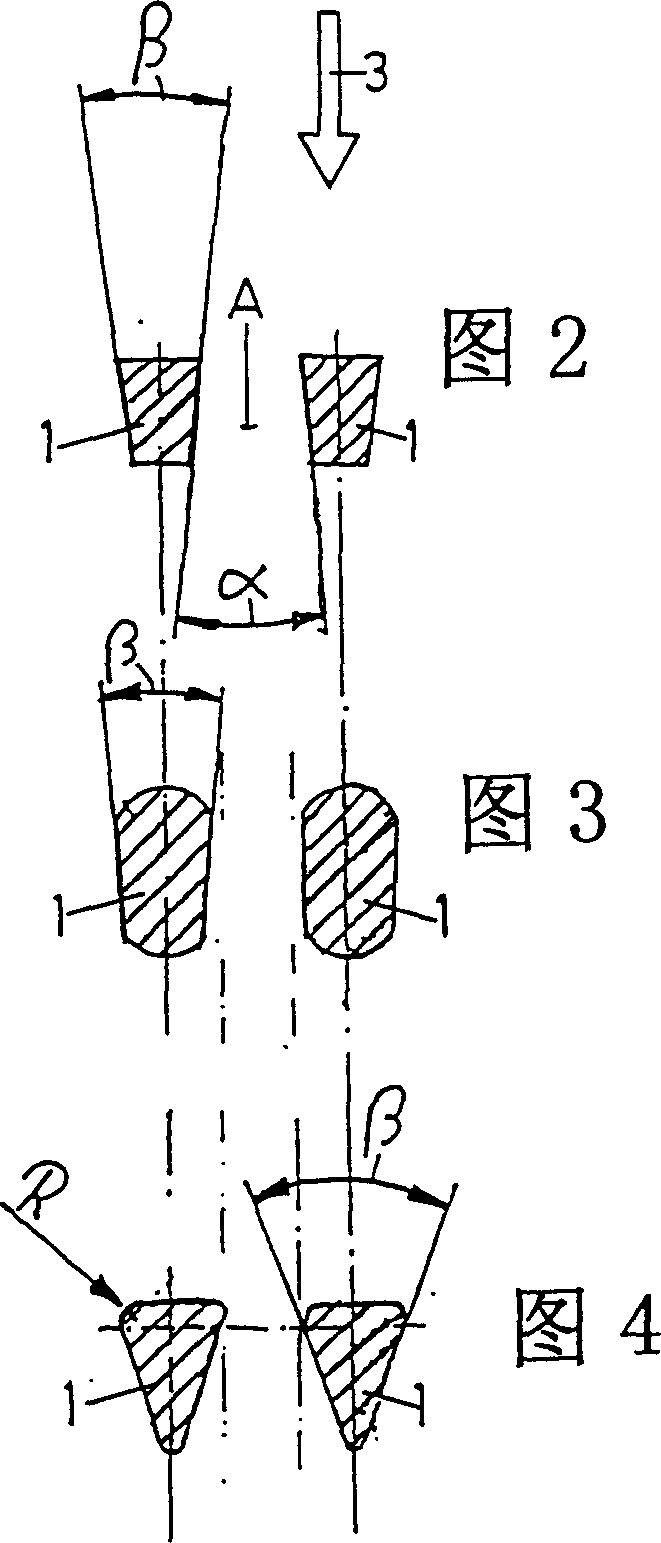

Low-stress and high-efficiency precise blanking method for medium-high frequency inductive heating of rod tube material

ActiveCN103008433AGerminate fastExtended stabilityShaping toolsMetal-working feeding devicesThermodynamicsEngineering

A low-stress and high-efficiency precise blanking method for medium-high frequency inductive heating of a rod tube material is characterized in that the rod tube material is put on a feeding mechanism and then is fed in an inductive heating device; the inductive heating device can control heating time and a surface layer heating depth in a V-shaped groove of the rod tube material through adjusting parameters, such as heating frequency, current magnitude and the like, so as to finish quick heating to the V-shaped groove of the rod tube material; and then, the heated rod tube material is fed in a blanking mechanism, and is fixed by a rod tube material fixing sleeve; circular periphery loads are loaded in the radial direction of the rod tube material; and blanking is implemented by using a stress concentration effect, a heat stress effect and a fatigue break mechanism of the rod tube material. The method has the advantages of high efficiency, low energy consumption, material conservation and good blanking quality.

Owner:XI AN JIAOTONG UNIV

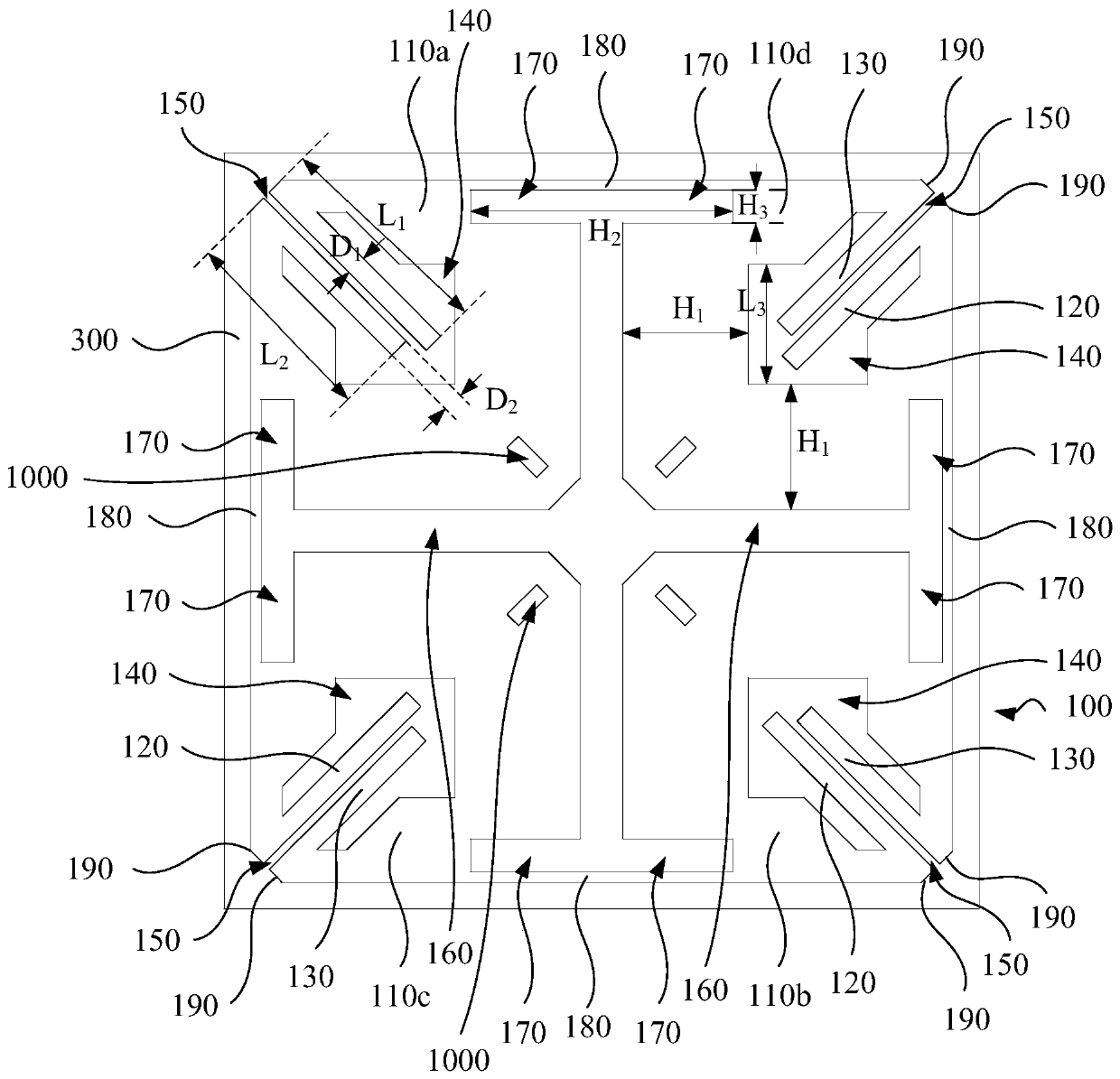

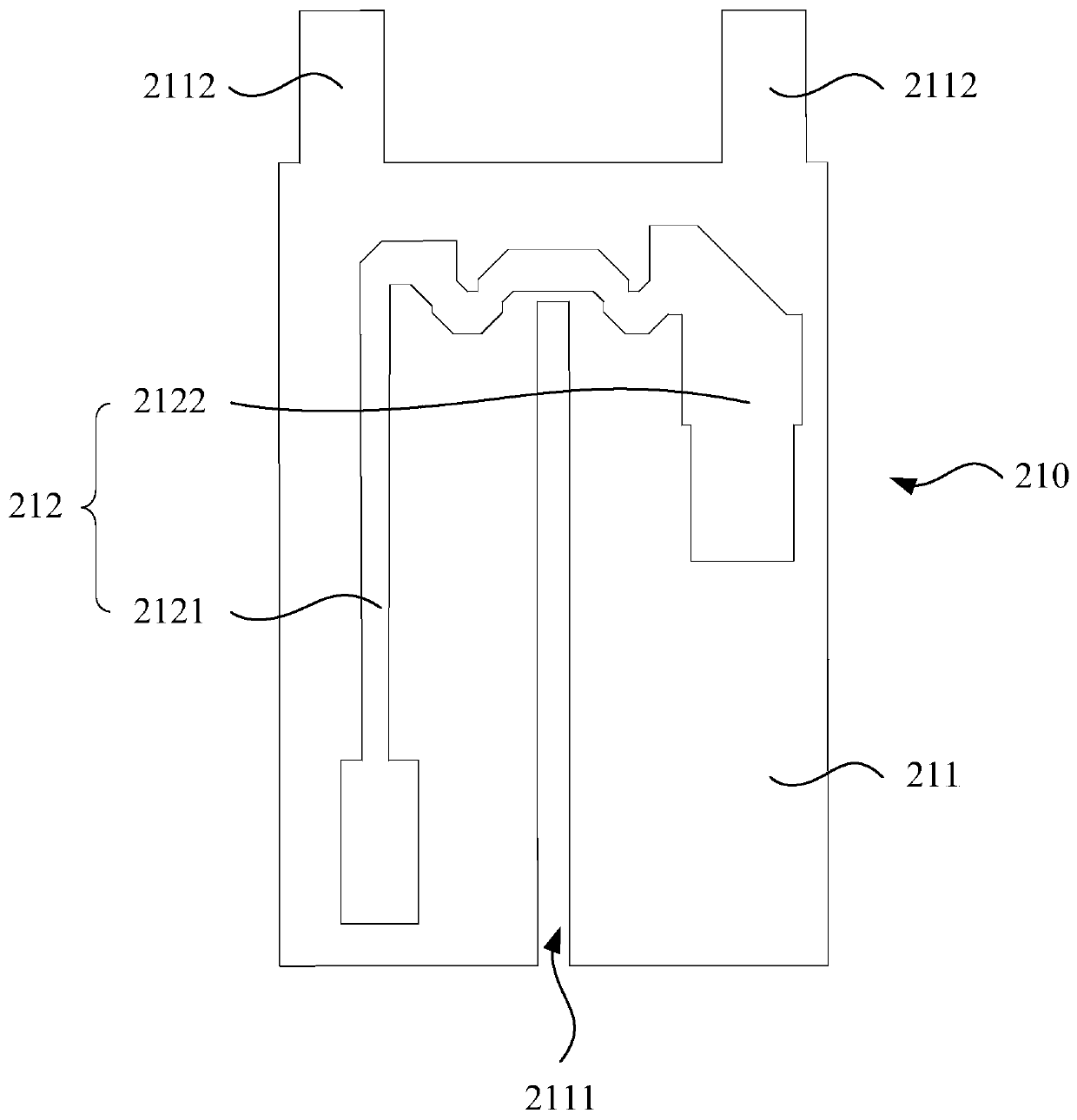

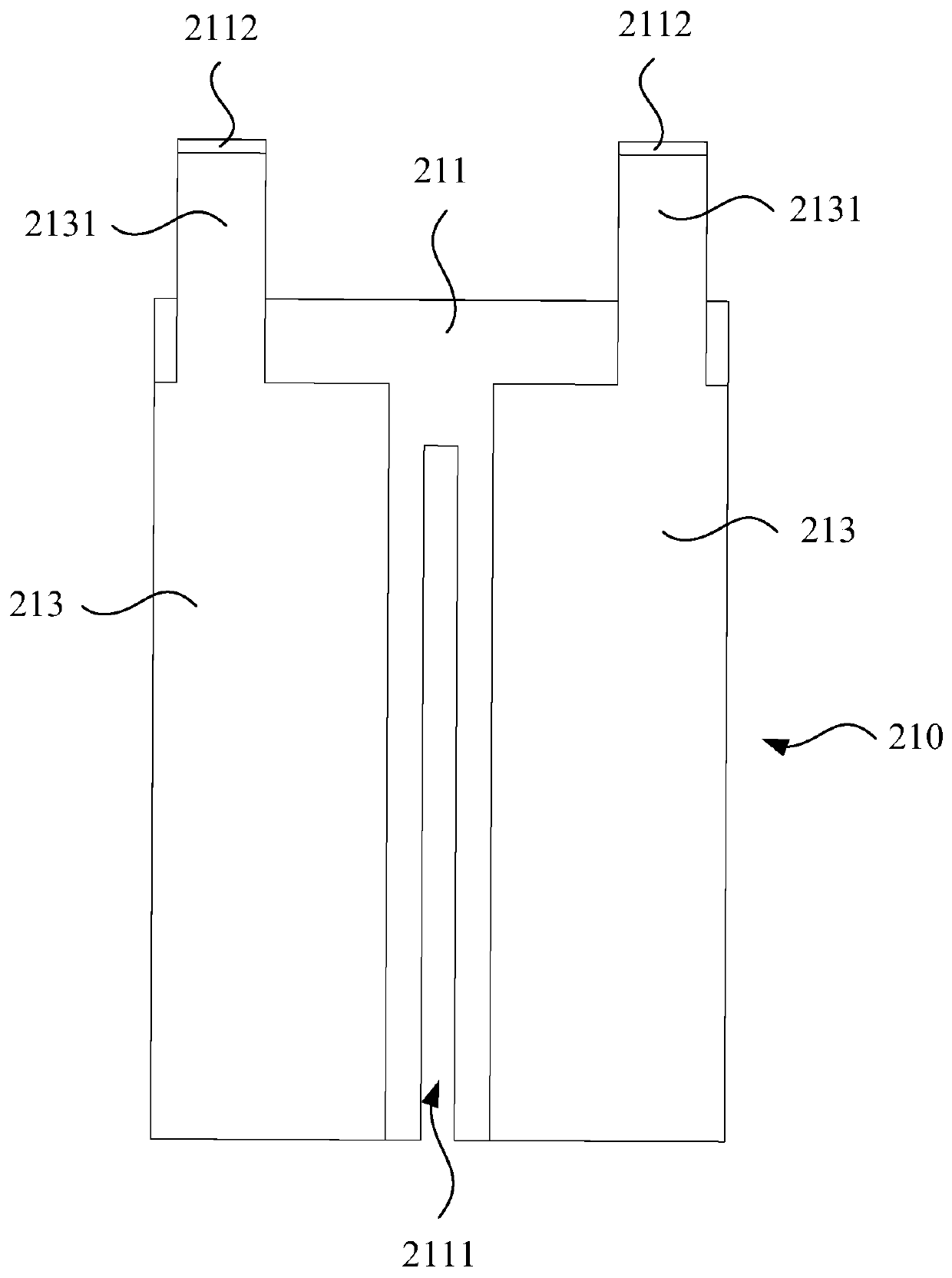

5G antenna and radiation unit thereof

ActiveCN111129750ASimple structureEasy to processParticular array feeding systemsRadiating elements structural formsEngineeringMechanical engineering

The invention discloses a 5G antenna and a radiation unit thereof, the radiation unit comprises two groups of polarized orthogonal dipoles, each group of dipoles comprises two radiation arms which areoppositely arranged at an interval, and each radiation arm is provided with a first expansion branch knot and a second expansion branch knot which are arranged at an interval. The radiation unit canrealize expansion of a working frequency band and has good radiation performance. In this way, the 5G antenna adopting the radiation unit is good in radiation performance.

Owner:COMBA TELECOM TECH (GUANGZHOU) CO LTD

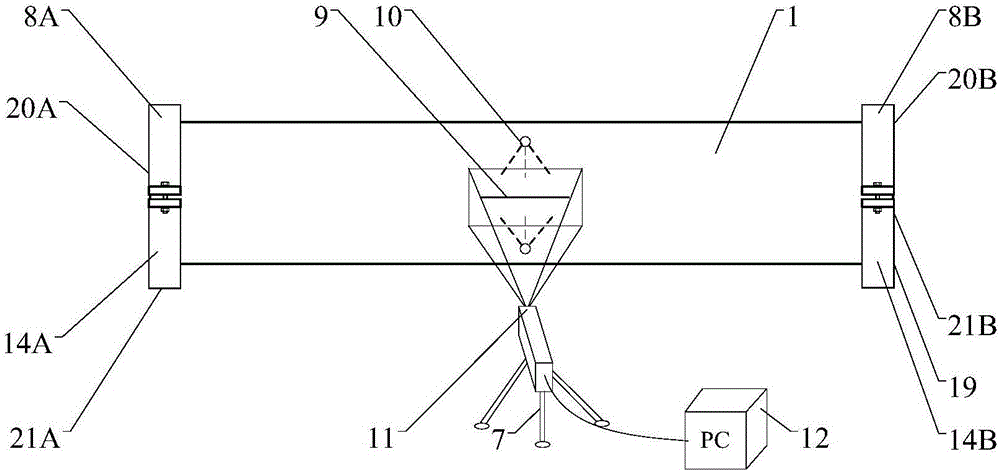

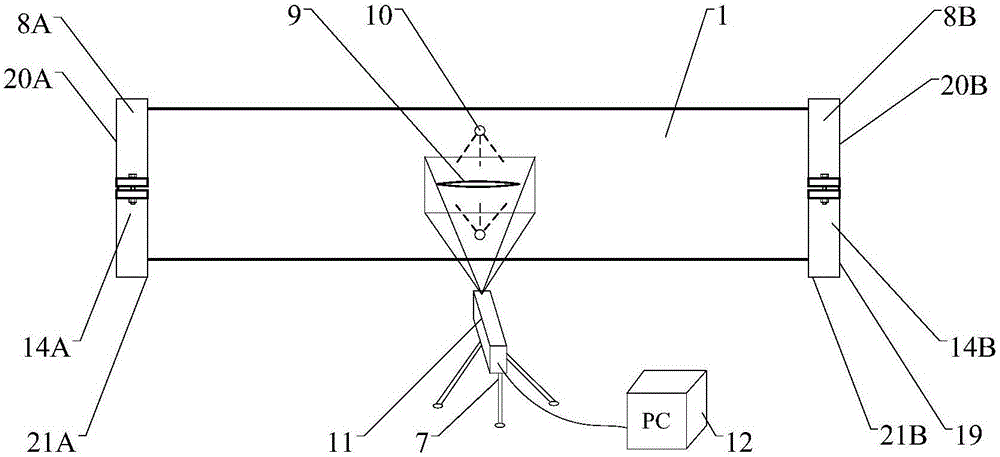

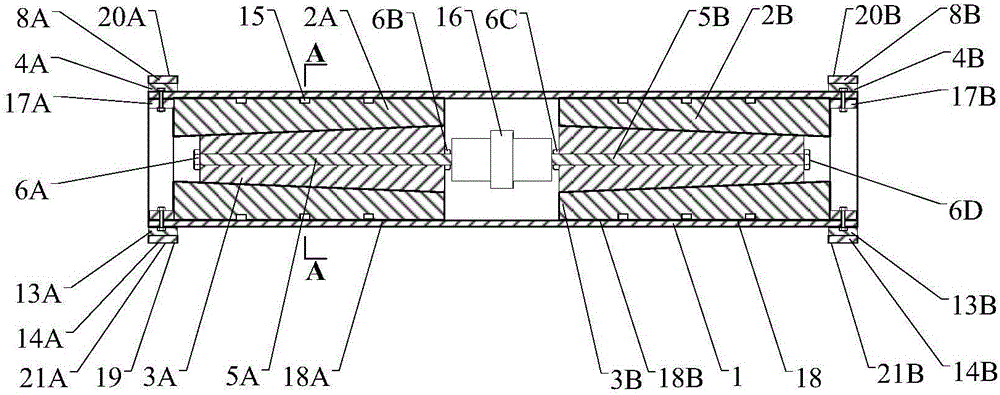

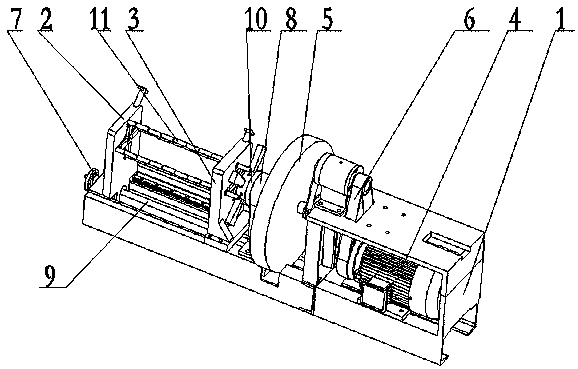

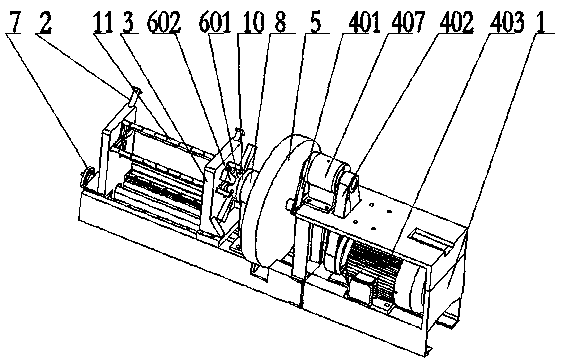

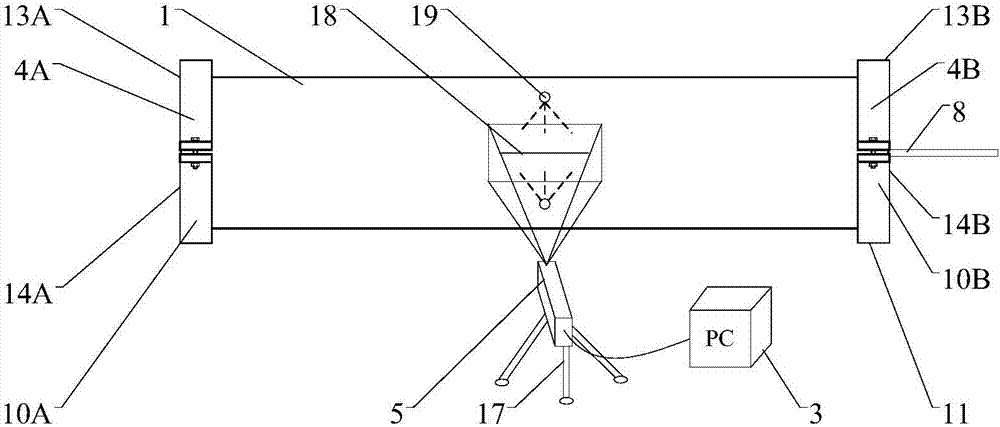

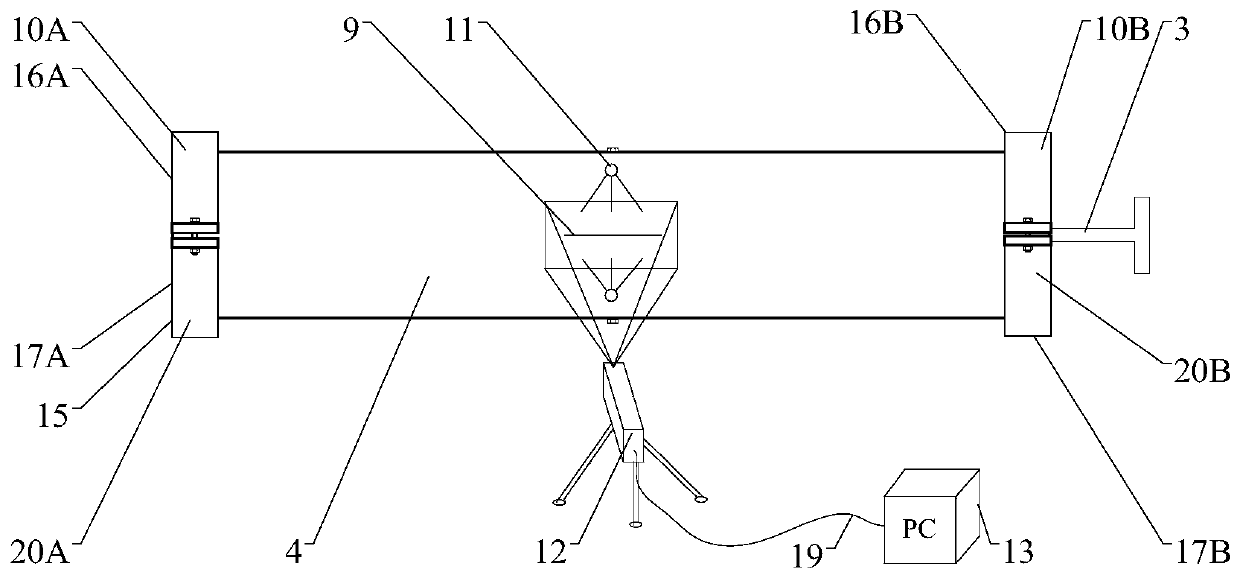

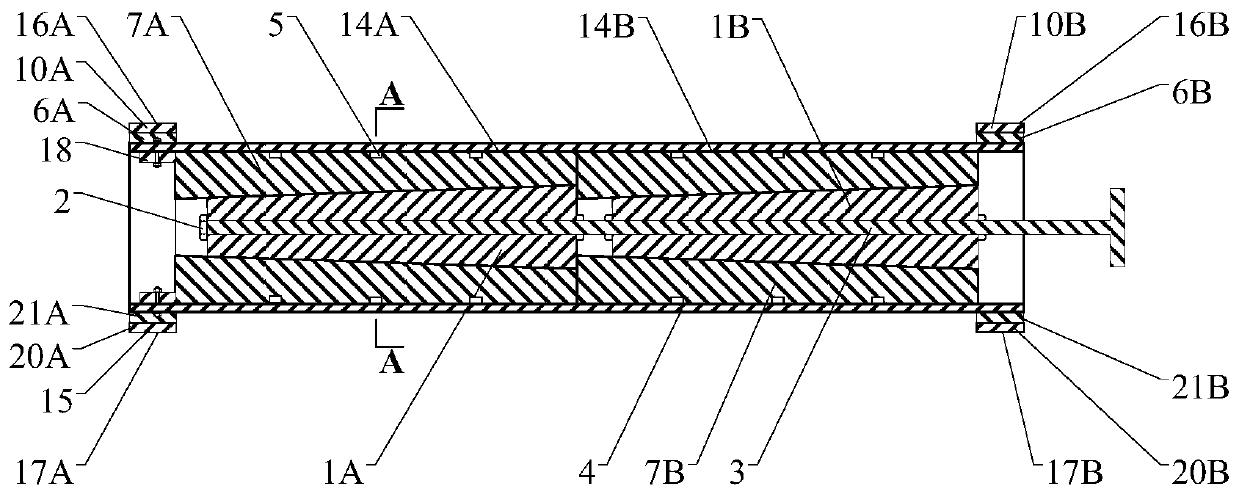

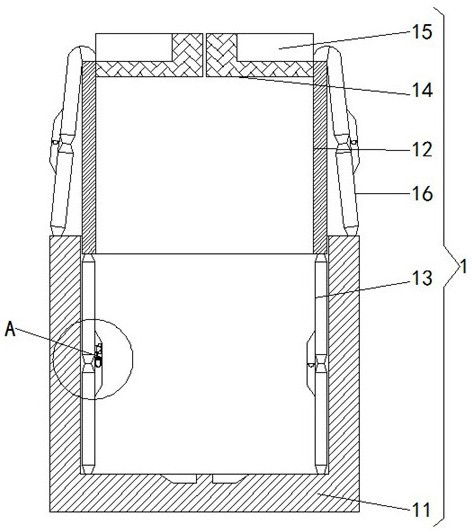

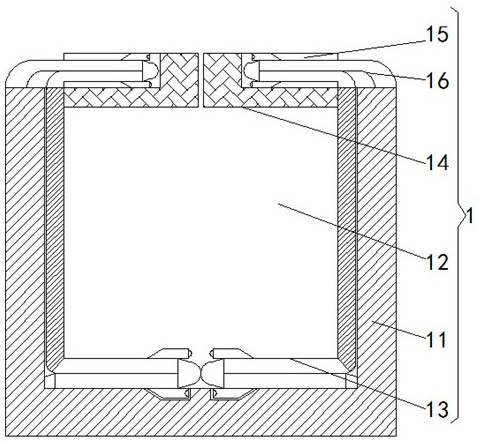

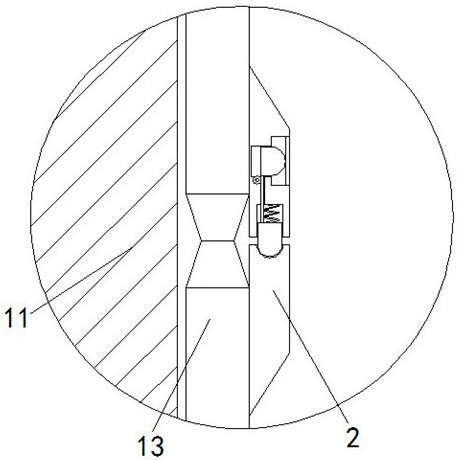

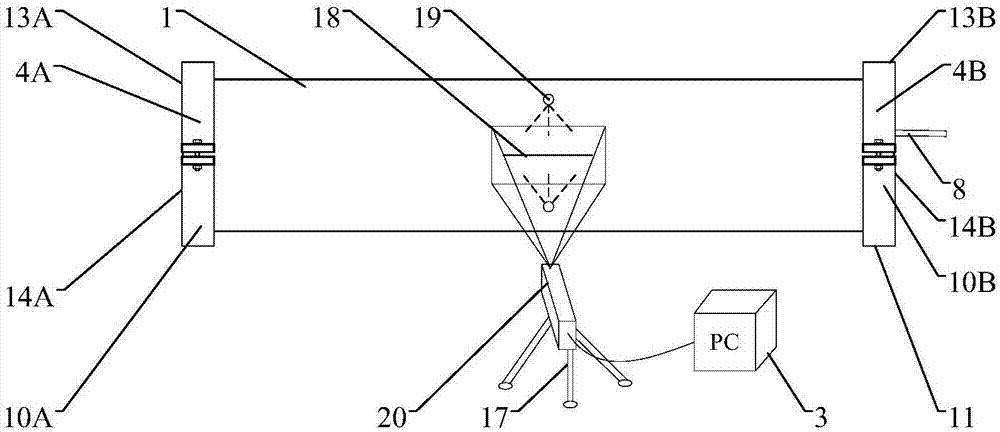

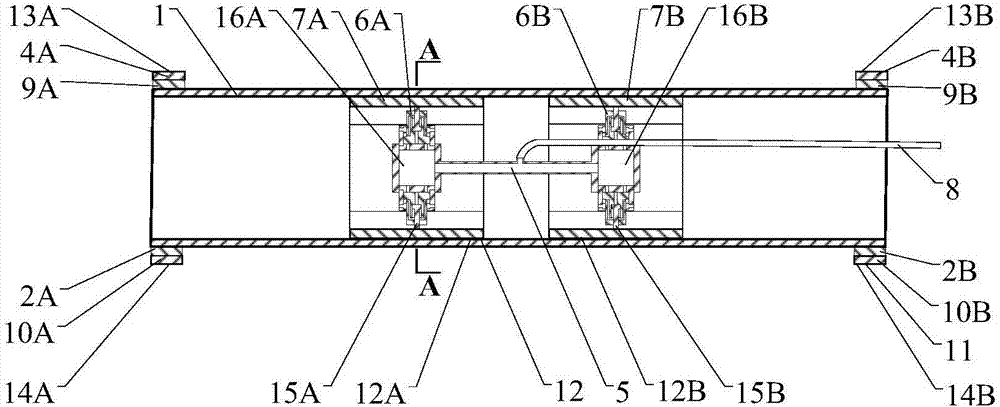

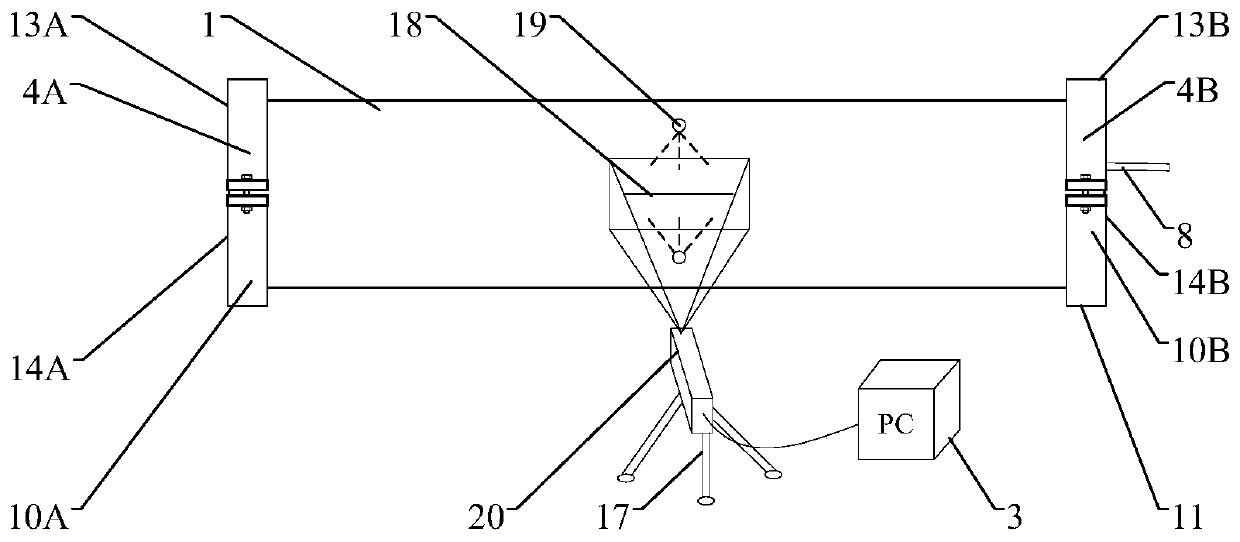

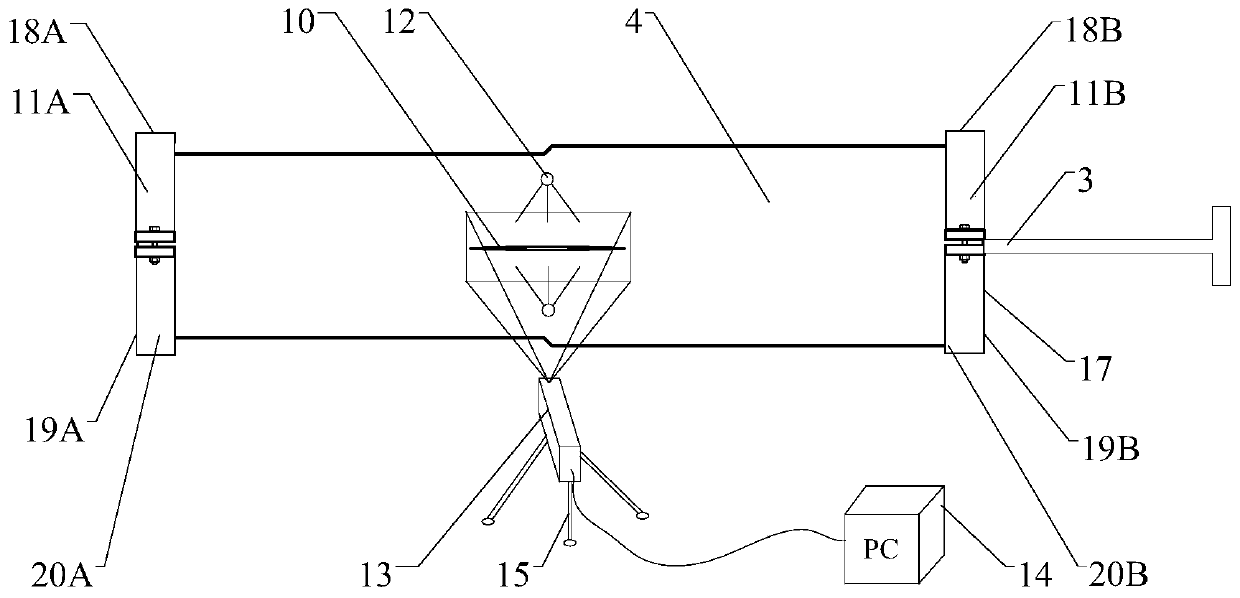

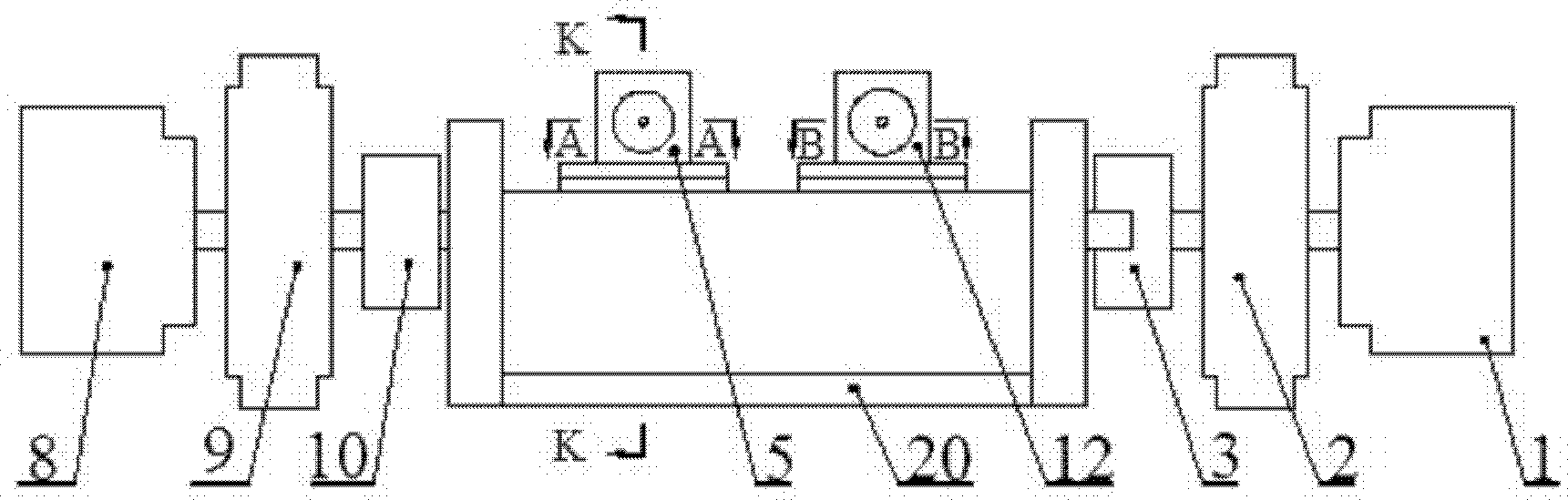

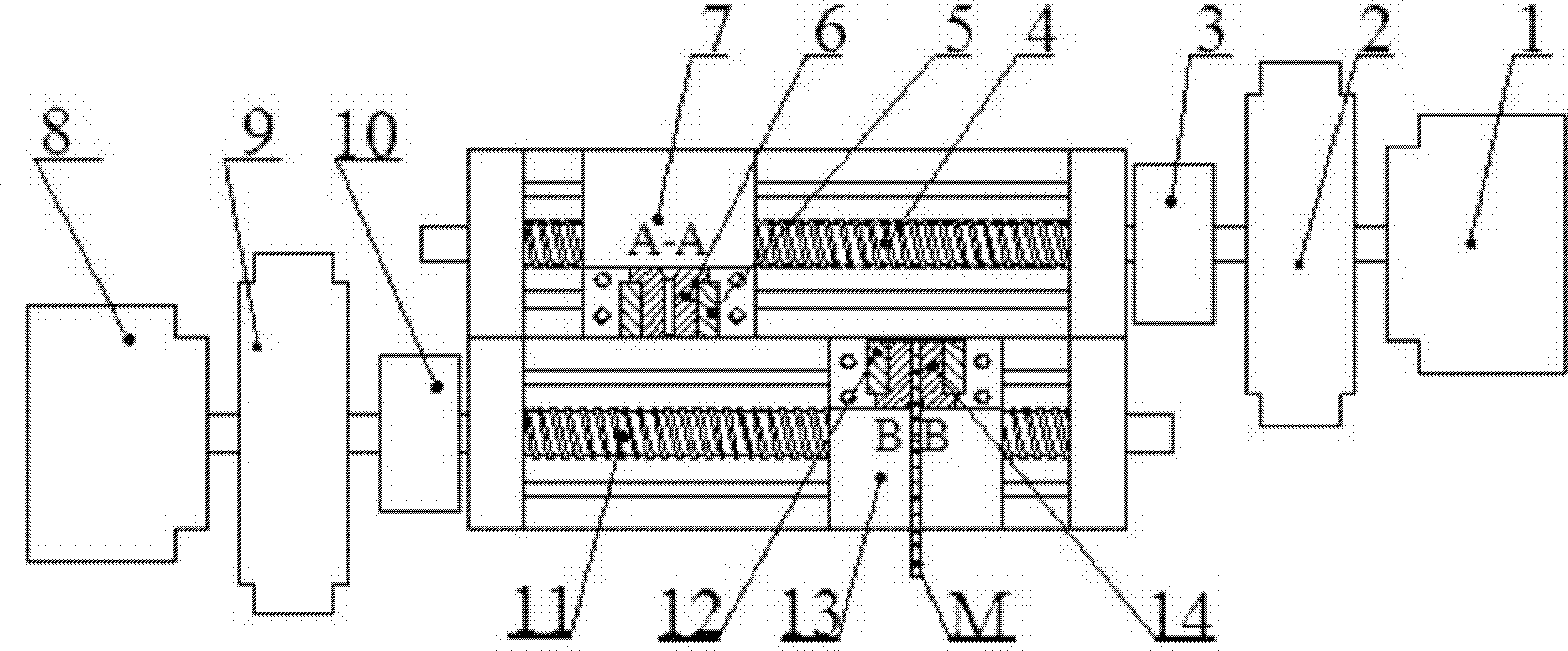

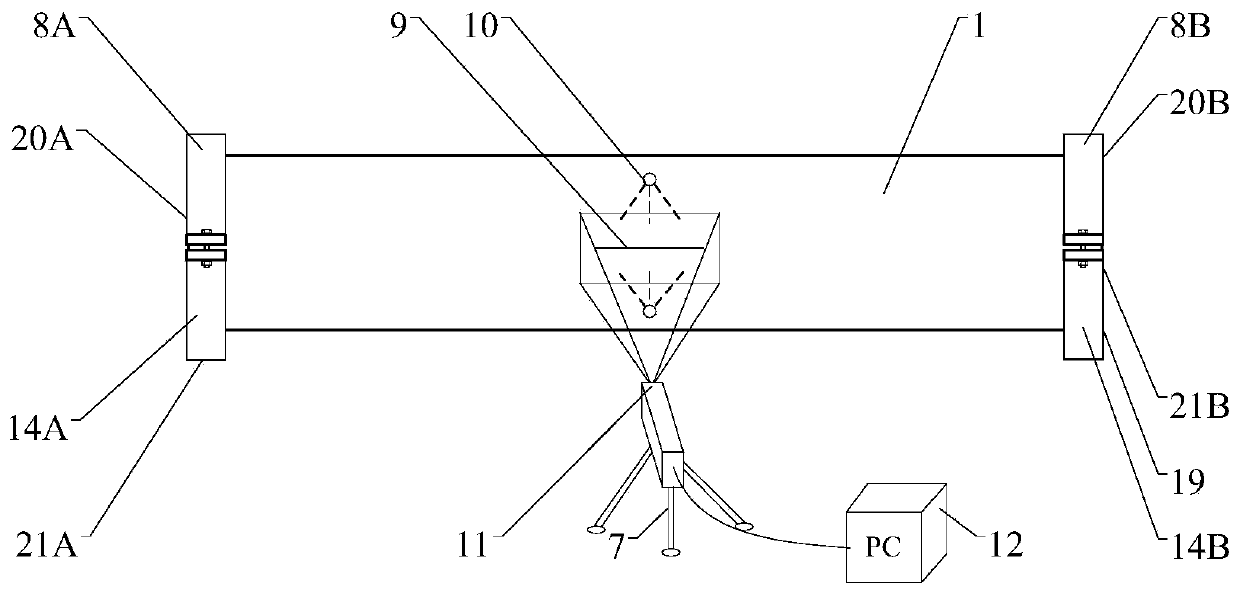

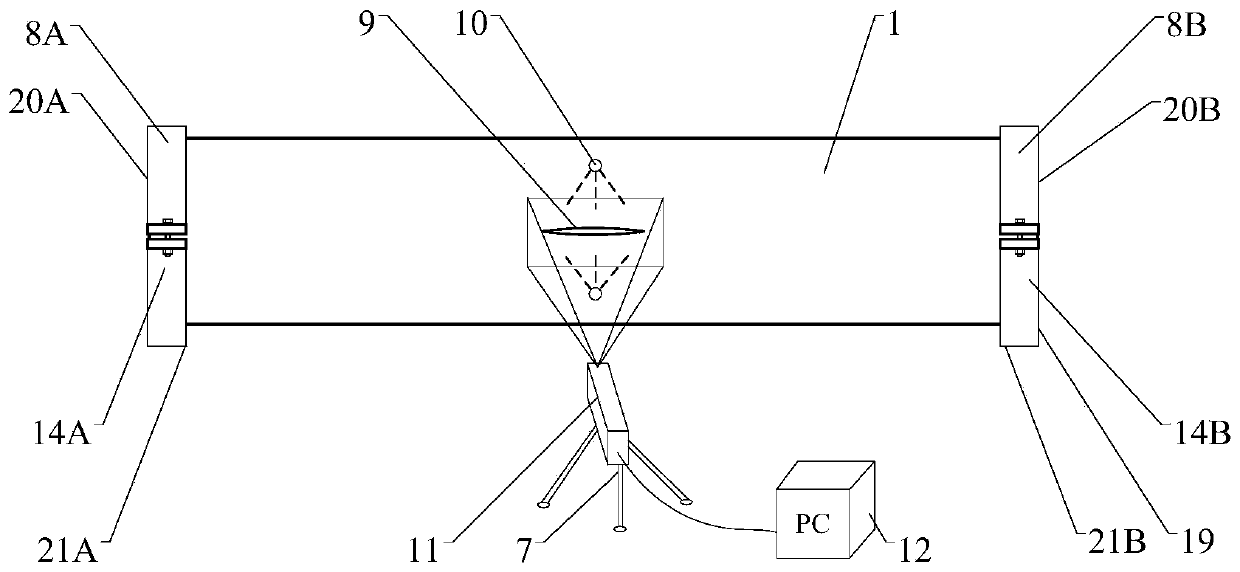

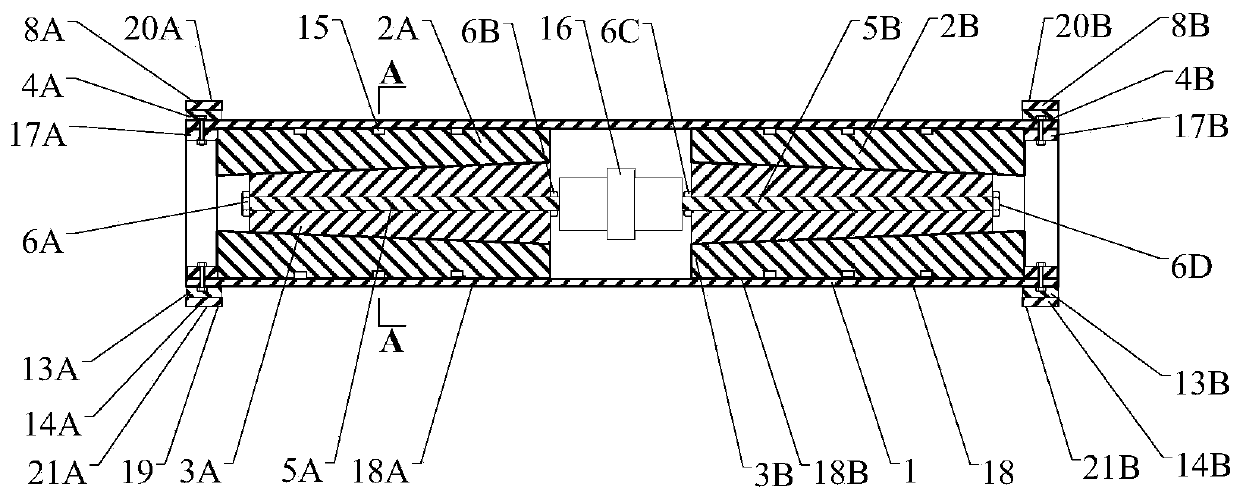

Bi-directional driving type pipeline fracture simulation experiment device and experiment method

ActiveCN106840886ASmall size errorGuaranteed reliabilityMaterial strength using tensile/compressive forcesFull scalePipe support

The invention relates to a bi-directional driving type pipeline fracture simulation experiment device, which comprises a pipeline support system, a pipeline expansion support system and a DIC test system, wherein an axial penetrating precast crack is formed in the side wall of an experiment pipe section; the precast crack is symmetrical about the axial middle surface of the experiment pipe section; the pipeline support system supports the two ends of the experiment pipe section; the pipeline expansion support system performs expansion support on the side wall of the experiment pipe section through pull rod or lead screw traction, so that the experiment pipe section fracture is caused; the DIC test system observes the fracture process of the experiment pipe section in real time. The bi-directional driving type pipeline fracture simulation experiment device has the advantages that an experiment test specimen is a full-scale pipeline test specimen, and is directly cut from the pipeline; the error is reduced; the data reliability is ensured; a hydraulic cylinder or an electric motor driving device is used for experiment; the work risk is reduced; the cost is reduced; the opening speed of a fan-shaped block can be controlled by controlling the moving speed of a pull rod and a lead screw; meanwhile, the expansion speed of the crack is controlled; the accuracy of the obtained data is guaranteed.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

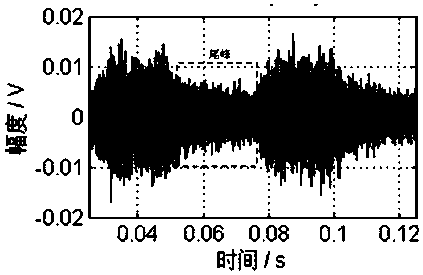

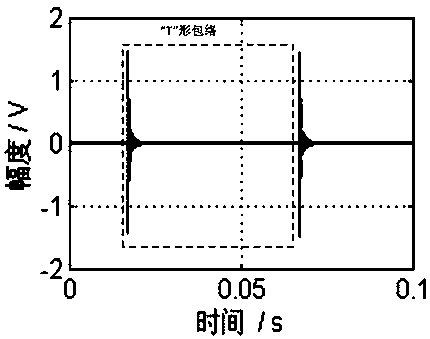

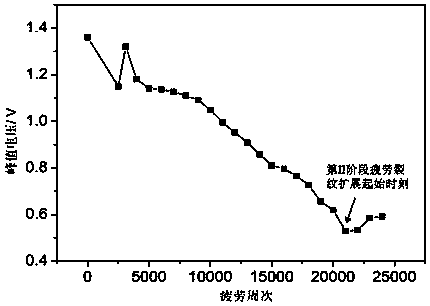

Magnetoacoustic emission detection method for fatigue damage of ferromagnetic metal component

PendingCN111537599AExtended stabilityFailure warningMaterial analysis using acoustic emission techniquesProcessing detected response signalFatigue damageSquare waveform

The invention relates to a magnetoacoustic emission detection method for fatigue damage of a ferromagnetic metal component. The method comprises the steps of firstly, generating an excitation magneticfield by using a sine wave voltage signal, gradually increasing a loading voltage until a bimodal envelope magnetoacoustic emission signal with an obvious tail peak is obtained, and taking a corresponding voltage peak value as a reference voltage; then, generating an excitation magnetic field by using a square wave voltage signal equal to or higher than a reference voltage, and acquiring a magnetoacoustic emission signal with a T-shaped envelope; and thirdly, calculating the average value of peak-to-peak values of the magnetoacoustic emission signal in multiple periods to serve as a characteristic parameter, and enabling the characteristic parameter to have inflection point change along with the development of the initiation and expansion of the fatigue crack, thereby identifying the initiation and expansion of the fatigue micro-crack, and giving a timely early warning for the failure of the component. According to the invention, the T-shaped envelope signals are obtained through square wave voltage excitation, the waveform of the T-shaped envelope signals is clear and easy to distinguish, on the basis that the reference voltage ensures enough magnetic field intensity, the anti-noise capacity of MAE is greatly improved, MAE fatigue monitoring engineering application is achieved, and the detection result is stable and reliable.

Owner:CHINA SPECIAL EQUIP INSPECTION & RES INST

Precision blanking machine with features of high efficiency, cyclical impact and low stress

ActiveCN108620664AAutomatically change the acting torqueExtended stabilityNibbling shearing machinesShearing machine accessoriesStress concentrationCoupling

The invention provides a precision blanking machine with the features of high efficiency, cyclical impact and low stress, and relates to the technical field of machining. The lower part of an impact block is provided with equidistant grooves matched with first spiral wire coils; in the working process of the precision blanking machine, when the bottom of a V groove formed in a bar to be fed is cracked due to the stress concentration effect, a small motor is started to work, and small rotating shafts are driven to rotate by the small motor through couplings; since the small rotating shafts arefixed to the spiral wire coils, the spiral wire coils are rotated with the small rotating shafts; through cooperation between spiral wire bulges on the spiral wire coils and the equidistant grooves atthe lower part of the impact block, the impact block can be moved up and down, so that the applied moment on the bar is changed automatically; and the position of the load application point on the bar is regulated automatically, so that the bar can be stably expanded in the expansion stage through change of the position of the load application point in the expansion process, and the blanking section quality of the bar is improved.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

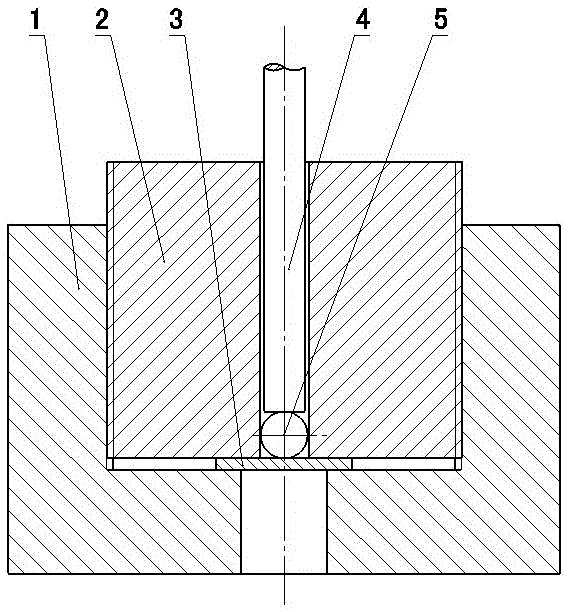

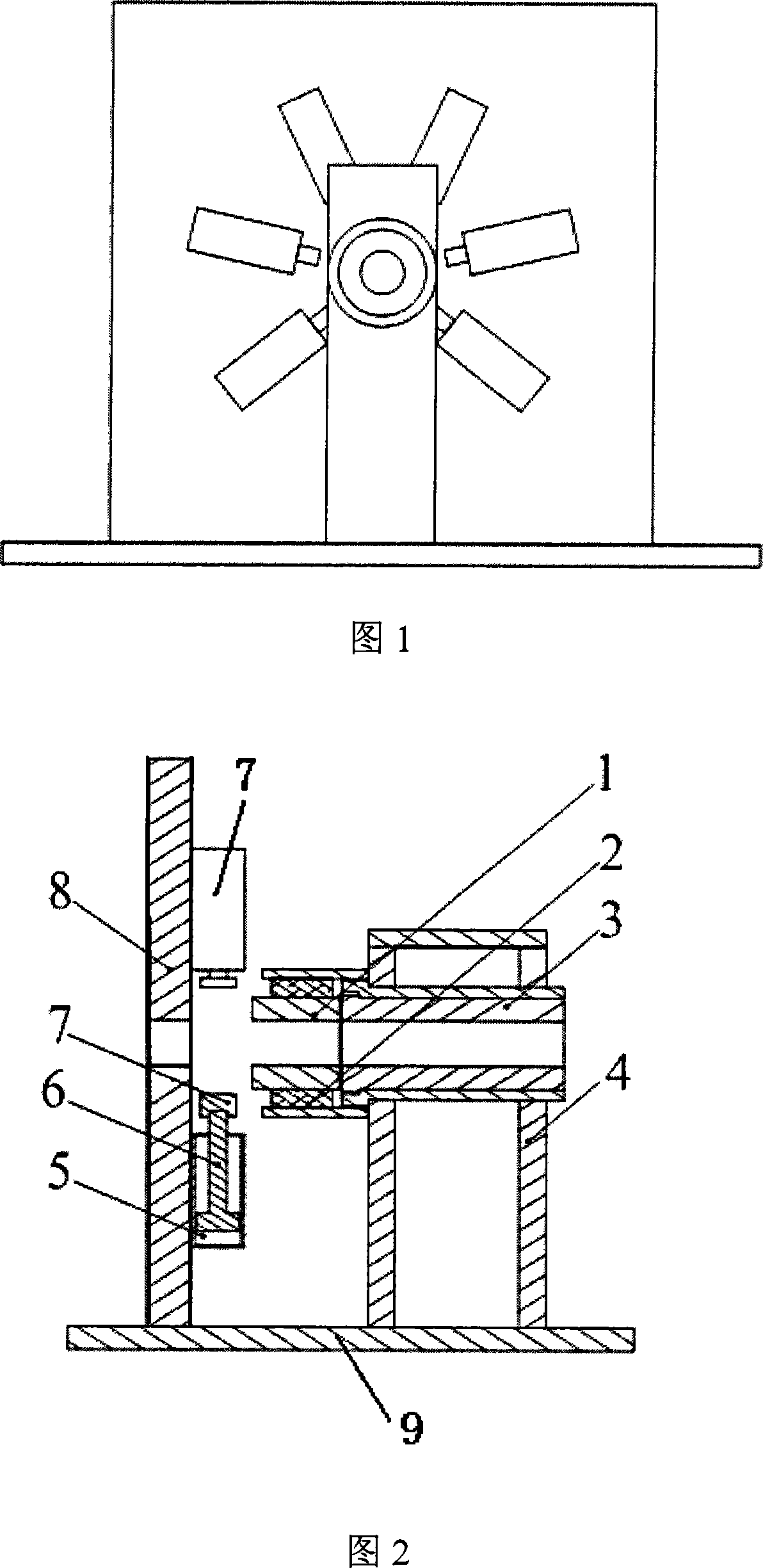

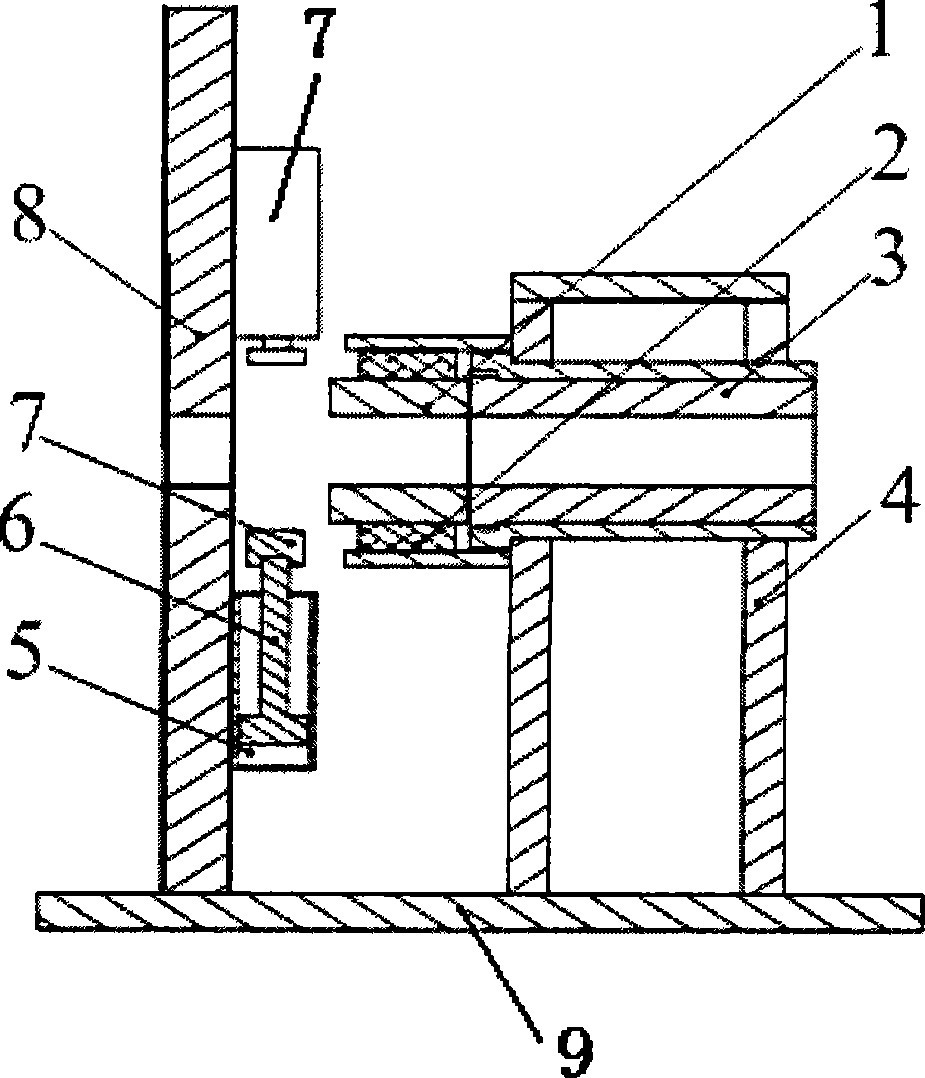

Device for testing plastic deformation capacity of metal glass material

A device for testing the plastic deformation capacity of a metal glass material comprises a lower mold. An upper mold is arranged in the lower mold. The upper mold and the lower mold are connected in a threaded mode. The upper mold and the lower mold are each provided with a central hole. A metal glass wafer sample is arranged between the central holes of the upper mold and the lower mold. A hard alloy ball is arranged on the metal glass wafer sample. A pressing rod is arranged on the upper face of the hard alloy ball. Pressure is exerted by the pressing rod on the hard alloy ball. The hard alloy ball exerts pressure on the metal glass wafer sample so that deformation and breakage appearance can be produced, and then the ductile-brittle performance of the metal glass wafer sample is achieved. The device has the advantages that the metal glass wafer sample required by the testing device is small in size and only has a diameter of 3*0.2 mm, and the requirement for testing the plastic deformation cavity of an ordinary metal glass material can be met; by means of the testing device, remarkable plastic deformation can be produced on tough metal glass, the ductile-brittle performance of different metal glass materials can be conveniently and rapidly distinguished, and the plastic deformation capacity and the ductile-brittle performance of metal glass can be judged only according to the stroke of the pressing rod.

Owner:LIAONING UNIVERSITY OF TECHNOLOGY

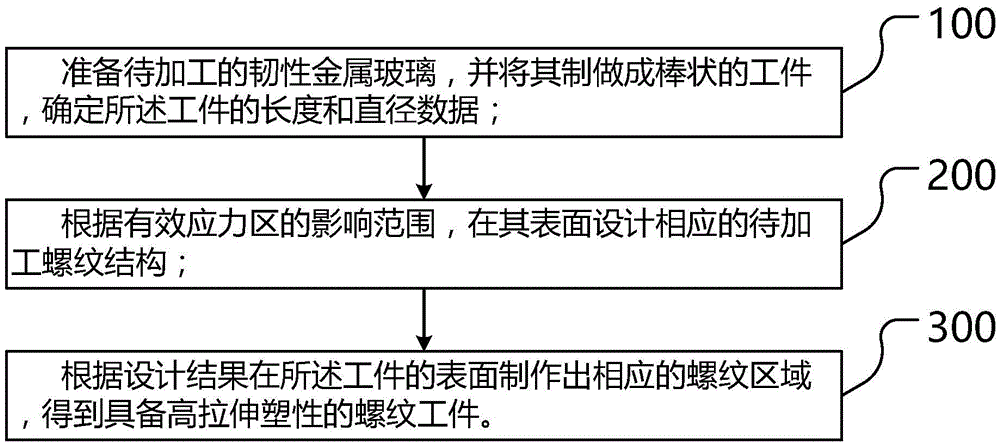

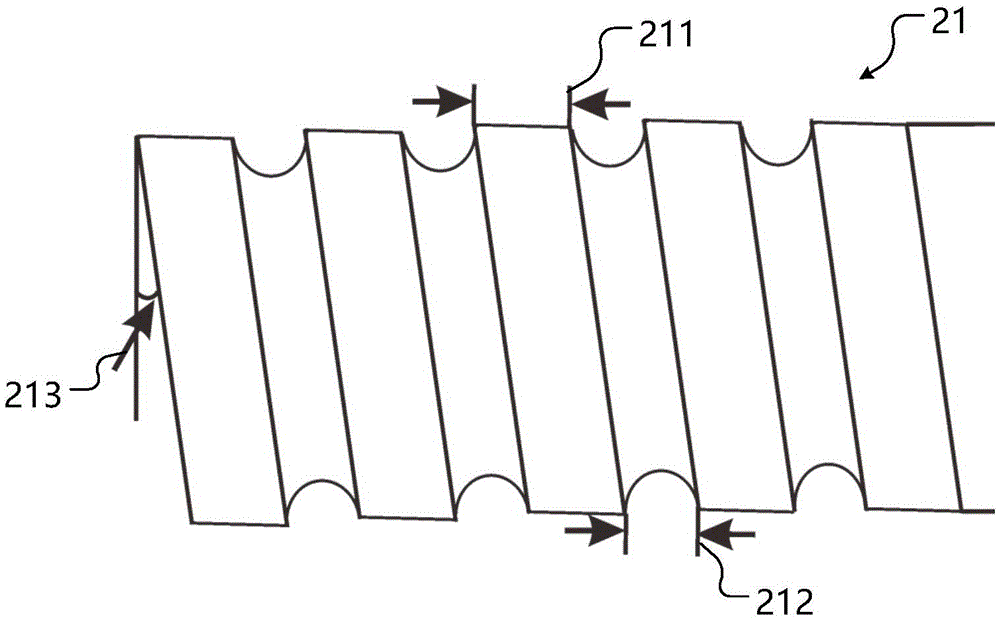

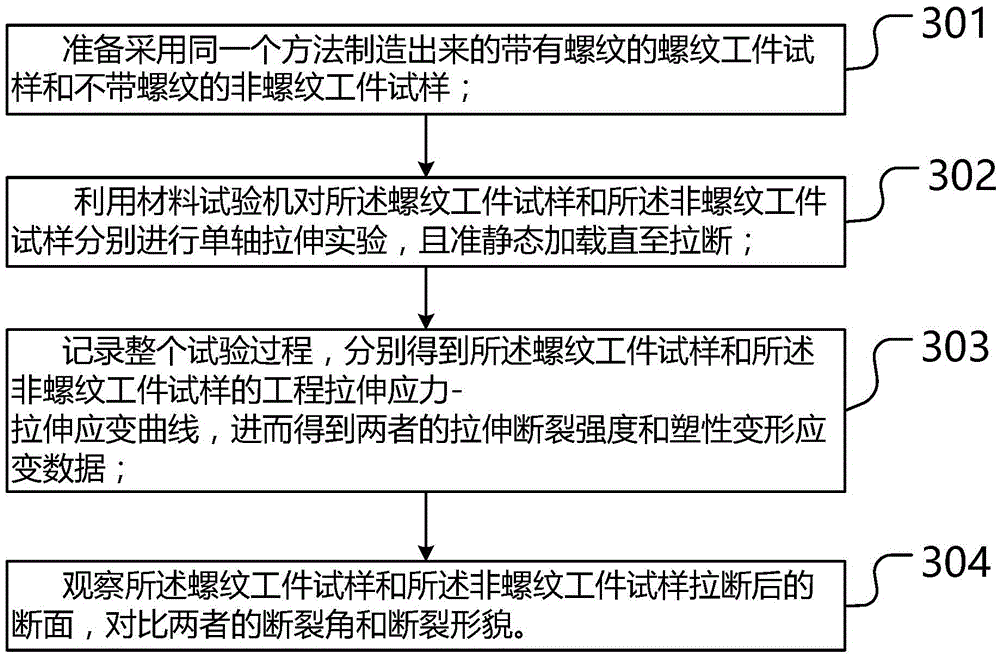

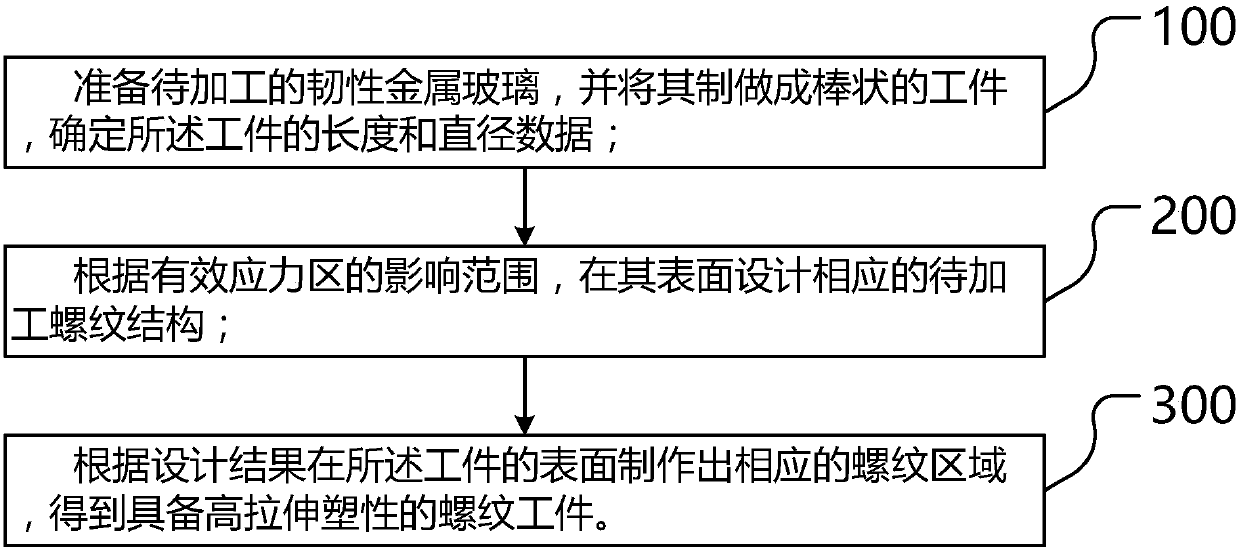

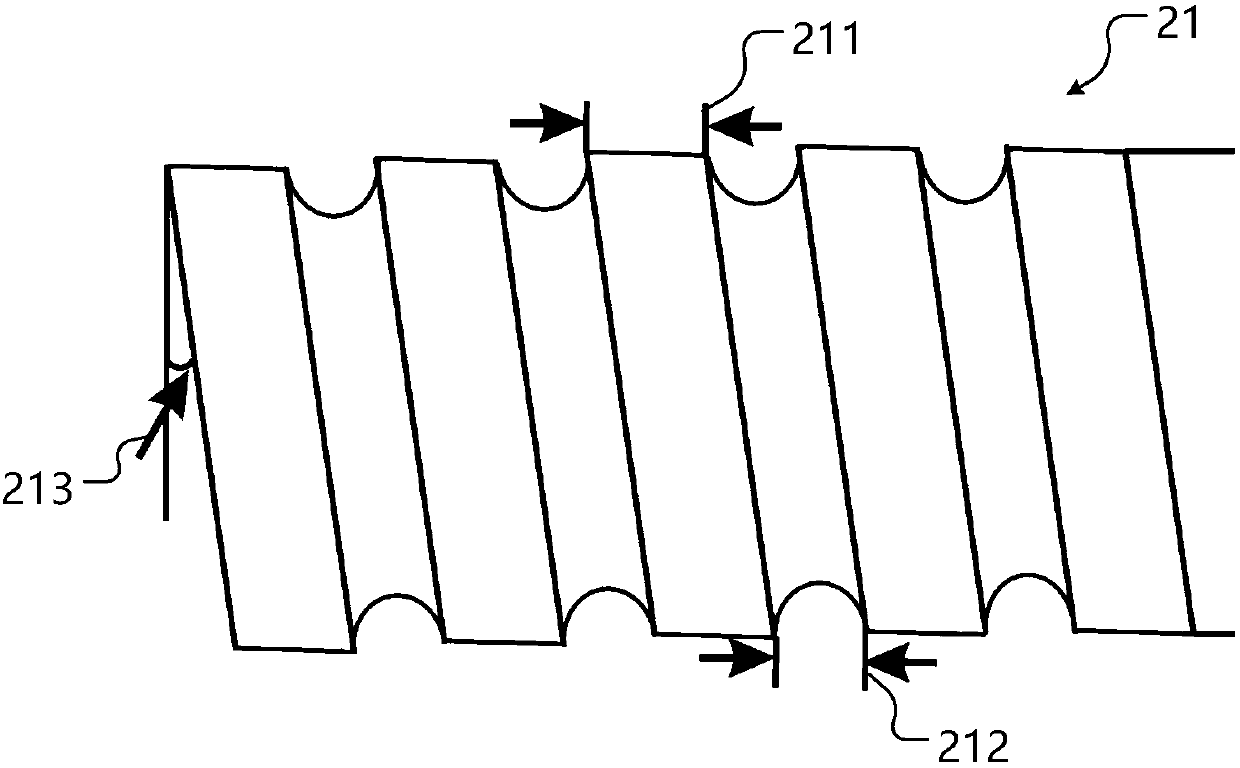

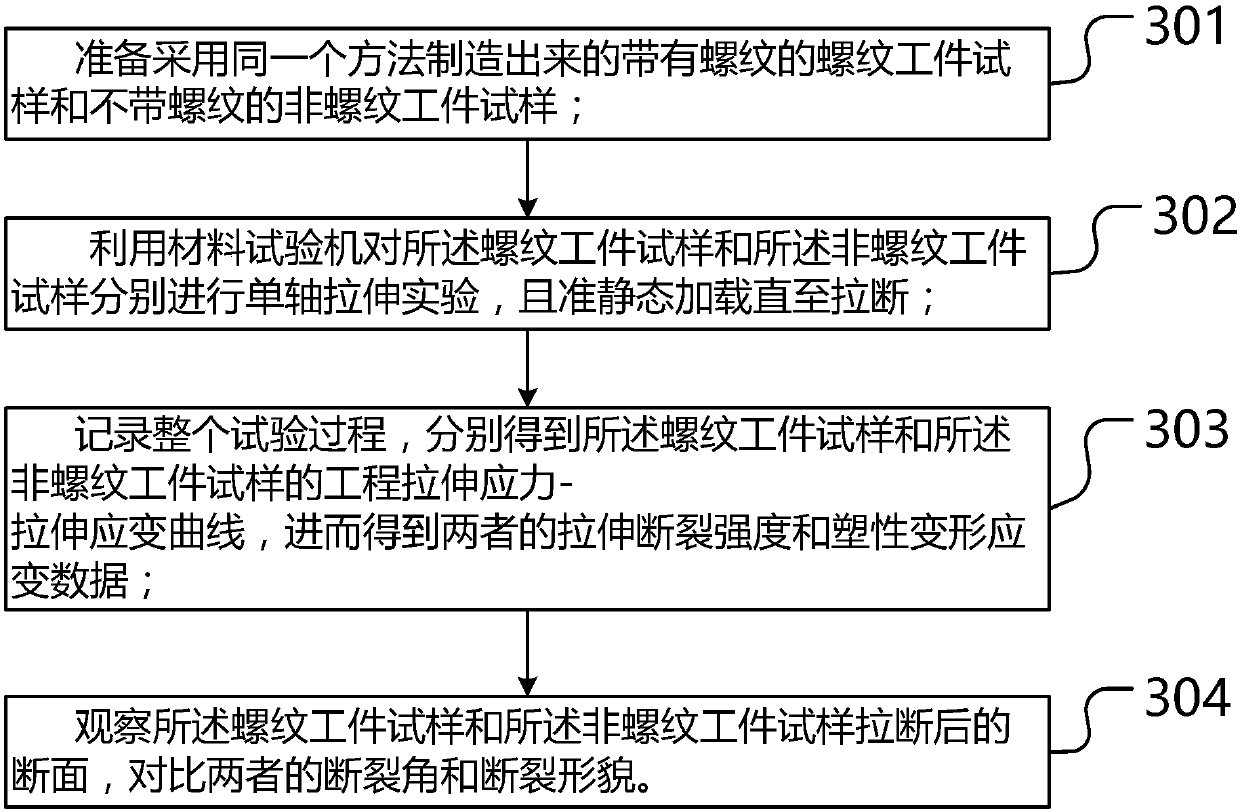

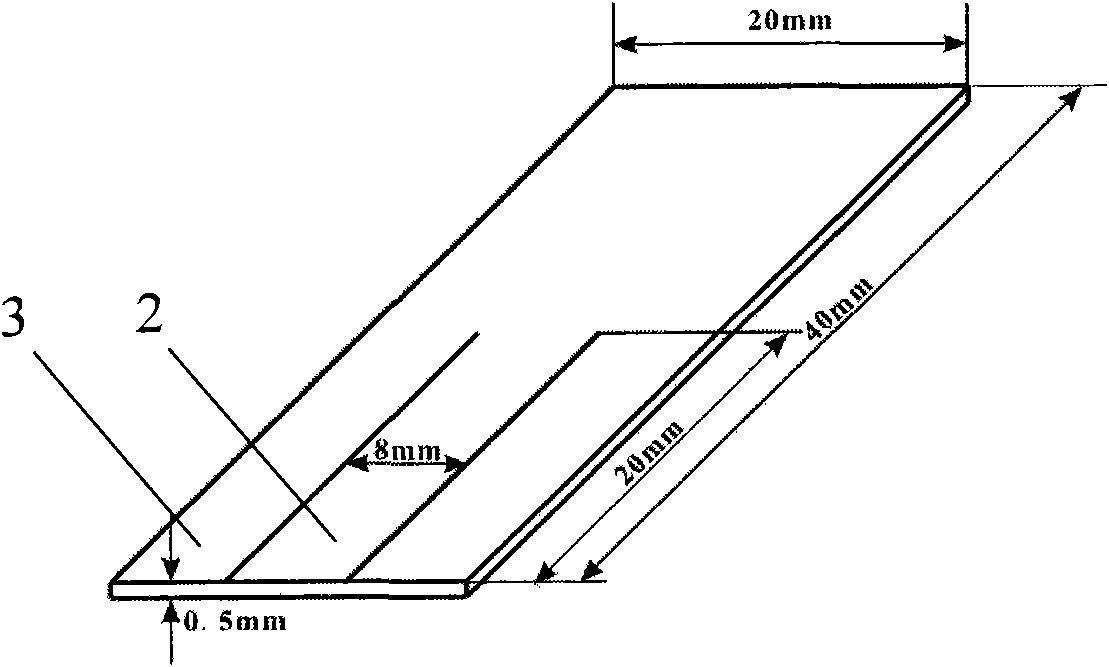

Method for making tough metallic glass generate macroscopic stretching plasticity

The invention provides a method for making tough metallic glass generate macroscopic stretching plasticity. The method comprises the following steps: 1, preparing tough metallic glass to be processed, making the tough metallic glass into a rodlike workpiece, and determining the length and diameter data of the workpiece; 2, according to the influential scope of the effective stress area, designing a corresponding thread structure to be processed on the surface of the workpiece; 3, fabricating the corresponding thread area on the surface of the workpiece according to the design result, so that the threaded workpiece high in stretching plasticity is obtained. According to the method, the thread structure is utilized, the tough metallic glass can be excited to generate multiple shear bands in the uniaxial stretching state, in addition, through the geometric hindrance and limitation effect of the surface micro-thread structure, expansion of the main shear band can be stabilized, and macroscopic stretching plastic deformation is caused.

Owner:广东空天科技研究院

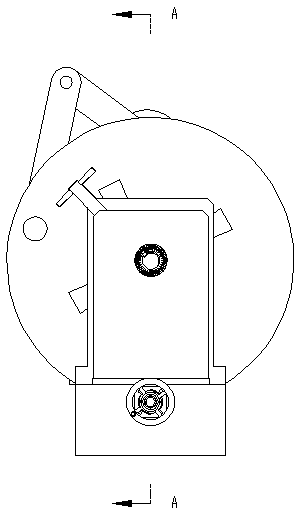

Pneumatic radial impact blanking machine

The invention discloses a pneumatic radial impact high-efficiency precise blanking press. The blanking press at least comprises a pneumatic radial impact blanking device and a bar stock fixing device; wherein, the pneumatic radial impact blanking mechanism adopts a cylinder piston to drive a blanking die so as to impact the bar stock; the invention has the advantages of high frequency, adjustablefrequency, adjustable impact force, economy, practicability and convenience, etc. The invention can achieve the precise blanking according to the bar stocks with different materials and different dimensions.

Owner:XI AN JIAOTONG UNIV

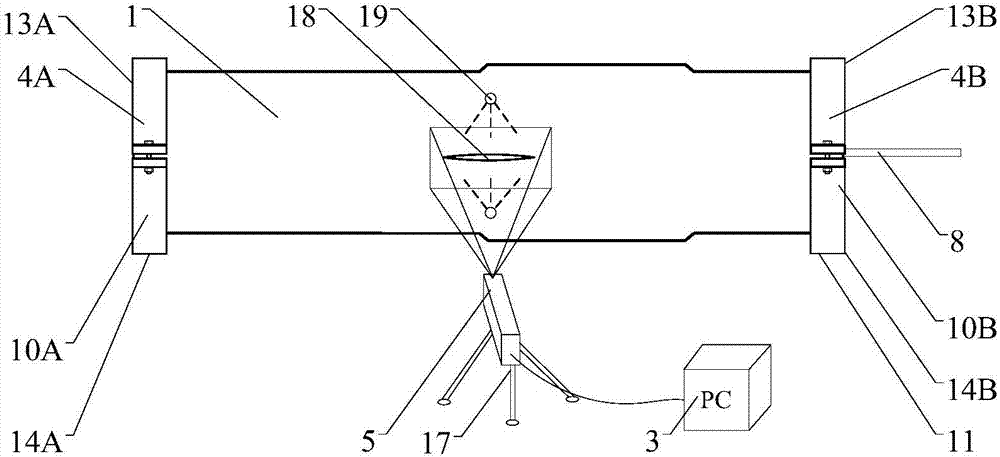

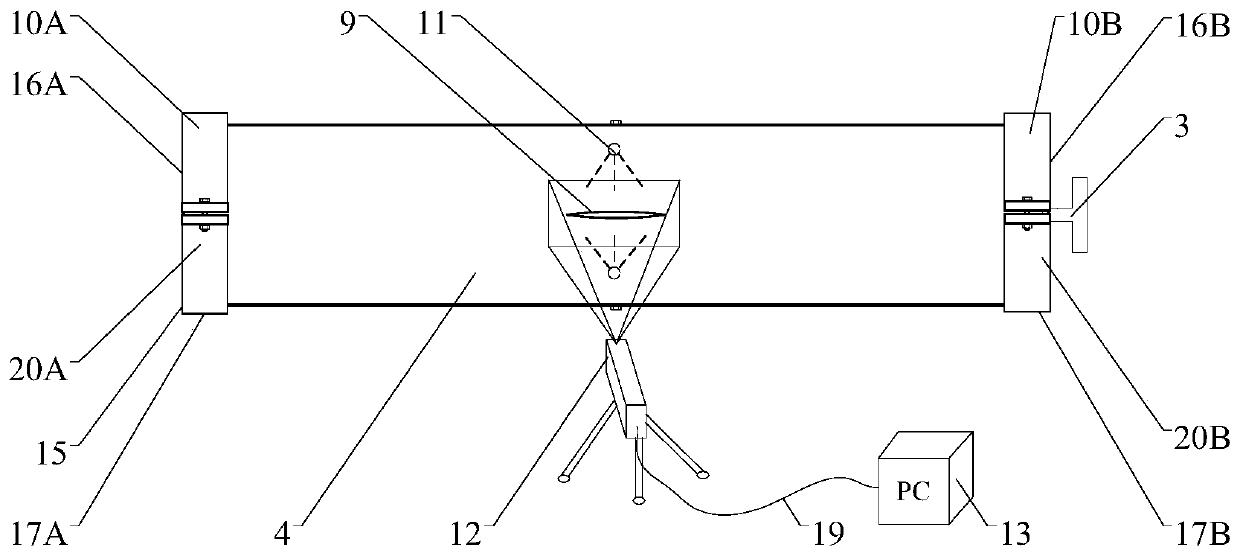

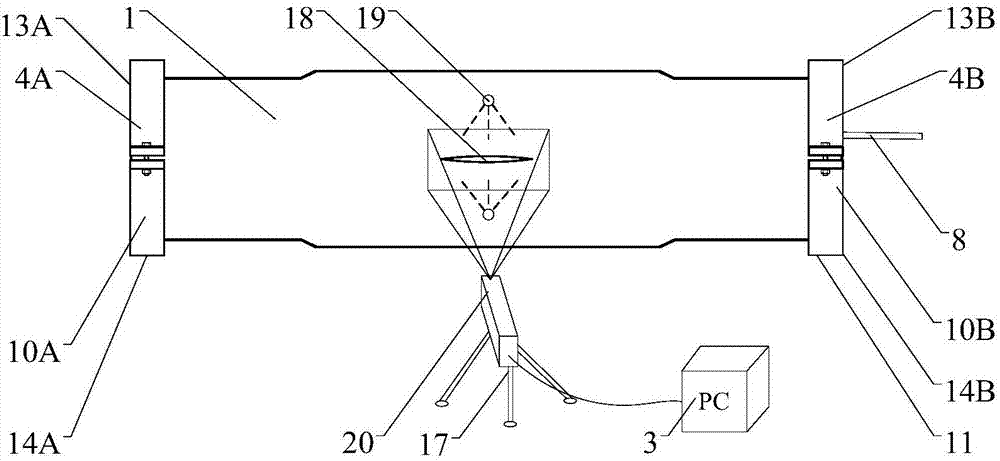

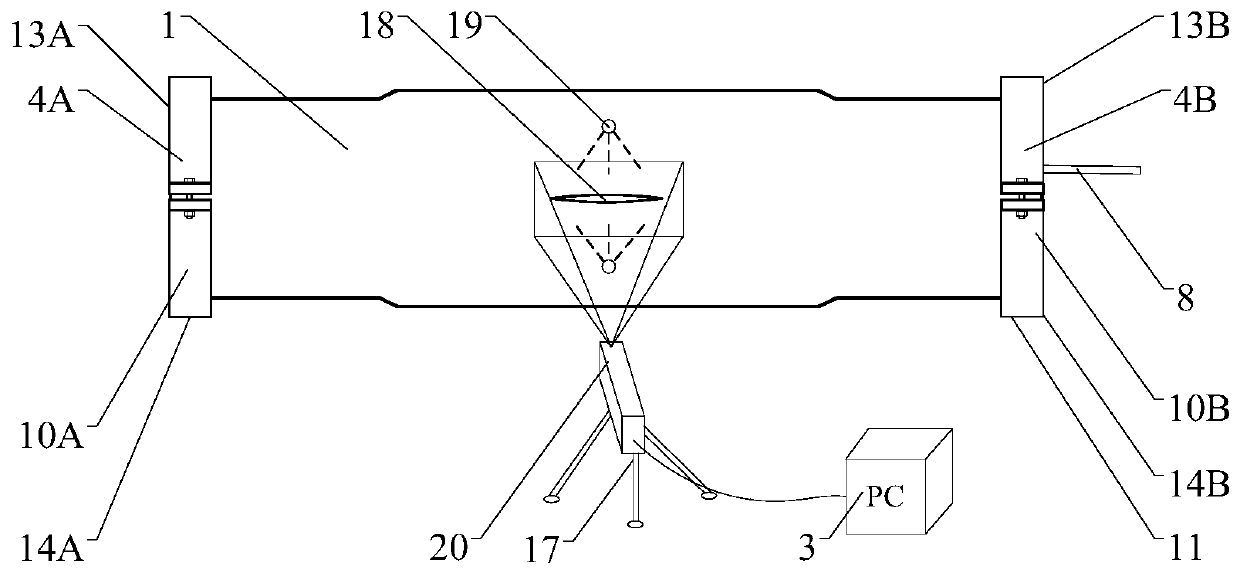

One-way hydraulic diameter-expanding pipeline breakage simulation experiment device and method

InactiveCN106989996AGuaranteed reliabilitySmall size errorMaterial strength using tensile/compressive forcesSupporting systemEngineering

The invention relates to a one-way hydraulic diameter-expanding pipeline breakage simulation experiment device which comprises a pipeline supporting system, a pipeline expanding system, an oil incoming pipe and a DIC testing system. The pipeline supporting system supports two ends of an experimental pipe section, the side wall of the experimental pipe section is provided with axially-penetrating precracks which are symmetric according to an axial middle plane of the experimental pipe section, the inner end face of the pipeline expanding system is coincident with the axial middle plane of the experimental pipe section, incoming oil of the oil incoming pipe provides hydraulic power to the pipeline expanding system, and the DIC testing system observes the breakage process of the experimental pipe section in real time. A hydraulic driving device is adopted for an experiment, so that working risk is lowered, and cost is reduced; during the experiment, opening speed of a fan-shaped block and expanding speed of the cracks can be controlled by controlling moving speed of an extensible rod, so that accuracy of acquired data is ensured; the fan-shaped block is long enough and contacts with a pipe wall uniformly in the process of expanding, so that stable expanding of the cracks during the experiment is guaranteed.

Owner:无锡市弘泰检测科技有限公司

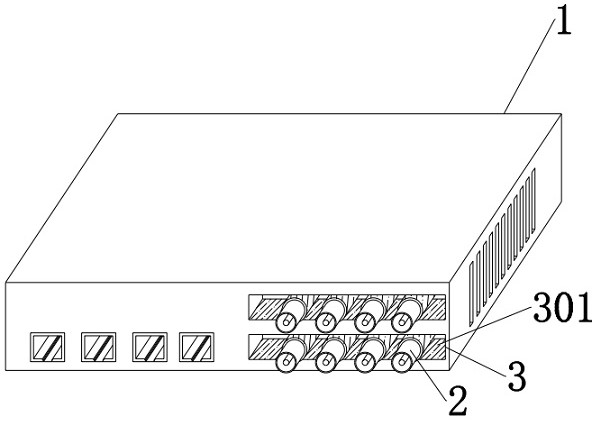

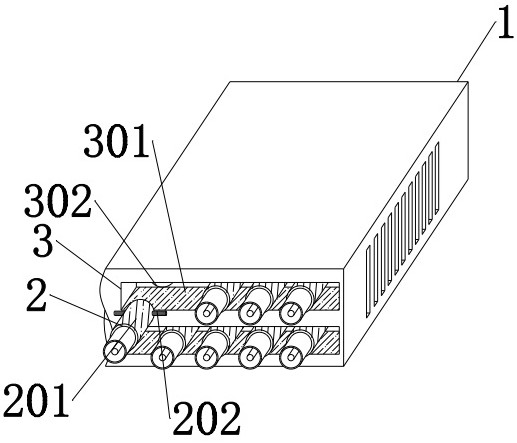

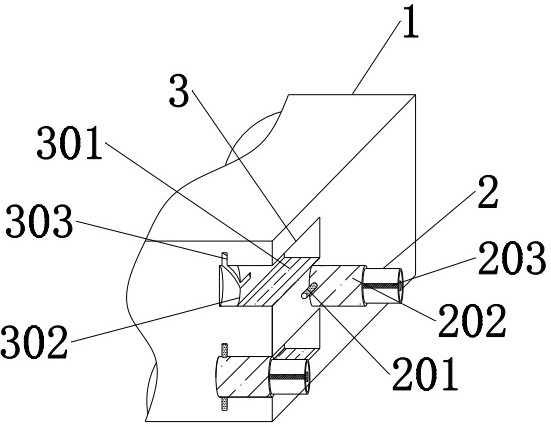

Comprehensive multi-service optical transceiver

PendingCN114040610AExtended stabilityNo offsetCoupling device connectionsCasings/cabinets/drawers detailsRotational axisTransceiver

A comprehensive multi-service optical transceiver comprises a main body and a plug port, one side of the main body is provided with the plug port in an embedded mode, the plug port is arranged in a displacement groove in one side of the main body in an embedded mode for connection, one side of the plug port is provided with a rotating shaft in an embedded mode, and the two sides of the rotating shaft are fixedly connected with circular shaft protruding blocks. Arc blocks are embedded in the two sides of the middle of the plug port, and an embedding groove is formed in an inner opening of the displacement groove. According to the device, the part formed by combining the arc blocks in the plug port can be extruded to be automatically separated and expanded when the connected cable connector is large, and extrusion clamping is generated through the reset thrust of the device, so that the plug port can adapt to cable connectors of various sizes in a more variable manner.

Owner:深圳市锦昊安科技有限公司

A method for producing macroscopic tensile plasticity in ductile metallic glass

The invention provides a method for making tough metallic glass generate macroscopic stretching plasticity. The method comprises the following steps: 1, preparing tough metallic glass to be processed, making the tough metallic glass into a rodlike workpiece, and determining the length and diameter data of the workpiece; 2, according to the influential scope of the effective stress area, designing a corresponding thread structure to be processed on the surface of the workpiece; 3, fabricating the corresponding thread area on the surface of the workpiece according to the design result, so that the threaded workpiece high in stretching plasticity is obtained. According to the method, the thread structure is utilized, the tough metallic glass can be excited to generate multiple shear bands in the uniaxial stretching state, in addition, through the geometric hindrance and limitation effect of the surface micro-thread structure, expansion of the main shear band can be stabilized, and macroscopic stretching plastic deformation is caused.

Owner:广东空天科技研究院

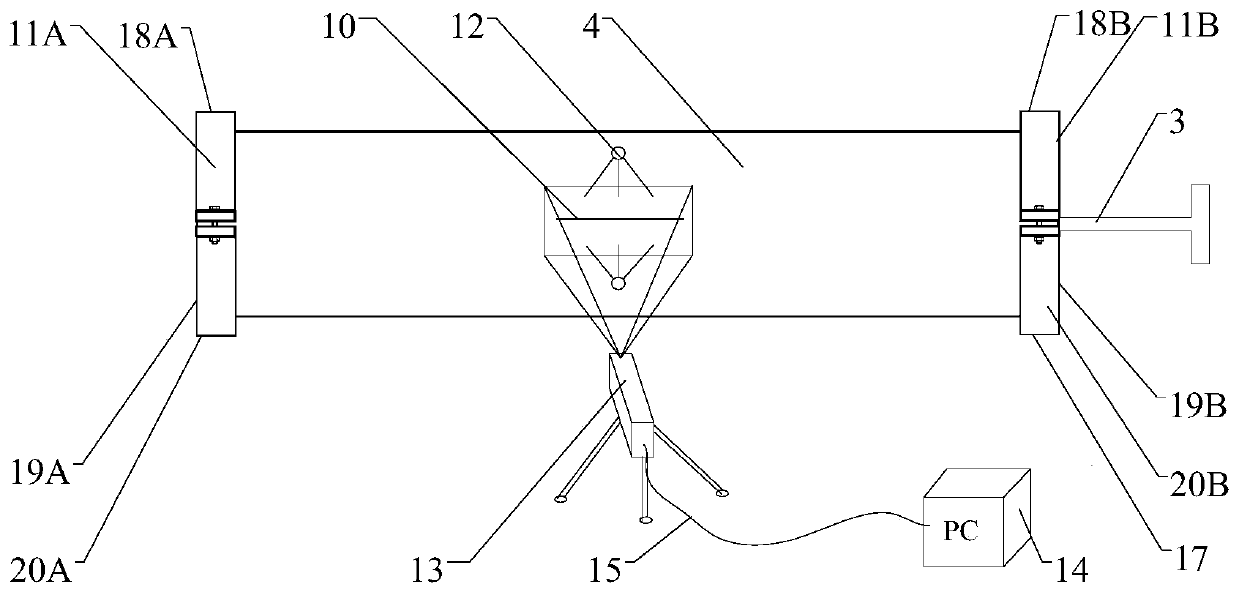

One-way hydraulically driven fully cracked pipeline fracture simulation experimental device and experimental method

ActiveCN106950114BGuaranteed reliabilitySmall size errorMaterial strength using tensile/compressive forcesSupporting systemExperimental methods

The invention relates to a unidirectional hydraulic drive type full crack pipeline fracture simulation experimental facility, which comprises a pipeline support system, a pipeline extension system, a pull bar, and a DIC test system. The lateral wall of an experimental pipeline section is provided with an axially penetrated prefabricated crack, which is symmetric relative to axial middle surface of the experimental pipeline section. The pipeline support system supports two ends of the experimental pipeline section. The pipeline extension system is pulled by the pull bar to carry out a simulation experiment. The DIC test system monitors the fracture process of the experimental pipeline section in real time. The adopted full size pipeline sample is directed taken from a pipeline, the error is reduced, and the data reliability is guaranteed. A hydraulic driven device is adopted, and the risk and cost are reduced. The expansion speed of a sector block is controlled by controlling the moving rate of the pull bar, at the same time, the expansion speed of the crack is controlled, and the data accuracy is ensured. The sector block has an enough length, so during the expansion process, the sector block evenly contacts with the pipeline wall, and the stable expansion of the crack during the experiment process is guaranteed.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

High-strength telescopic carton

The invention provides a high-strength telescopic carton. The high-strength telescopic carton comprises a telescopic mechanism, the telescopic mechanism comprises an outer box, an inner box is slidably connected to the interior of the outer box, a reinforcing plate is fixedly connected to the bottom of the inner box, a cover plate is fixedly connected to the top of the inner box, a storage groove is formed in the top of the cover plate, and the outer side of the inner box is fixedly connected with a supporting plate. According to the high-strength telescopic carton, the inner box is pulled to slide towards the outer side of the outer box, the inner box enables the overall volume of the carton to be increased, meanwhile, the inner box drives the reinforcing plates to swing, the reinforcing plates swing to be unfolded, the reinforcing plates enable the inner box to be stably expanded without dislocation, when the reinforcing plates are completely unfolded, the clamping blocks are clamped in the clamping grooves, at the moment, the upper connecting plates and the lower connecting plates are fixed through the clamping blocks, the reinforcing plate can play a supporting role through the upper connecting plate and the lower connecting plate, it is guaranteed that the inner box stretches out stably and does not fall off, and therefore the effects that the volume of the carton can be expanded, and use is convenient are achieved.

Owner:高邮市恒升彩印包装有限公司

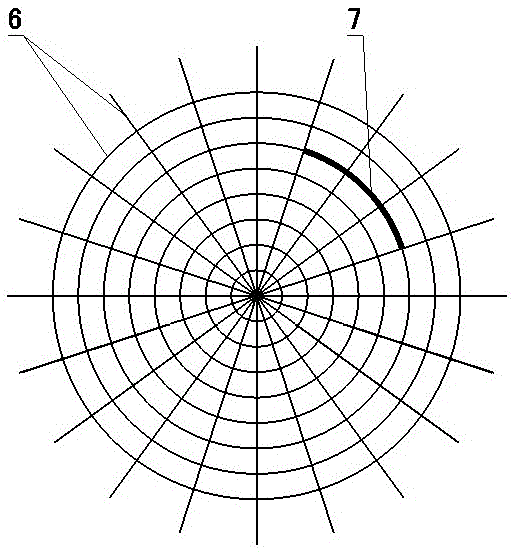

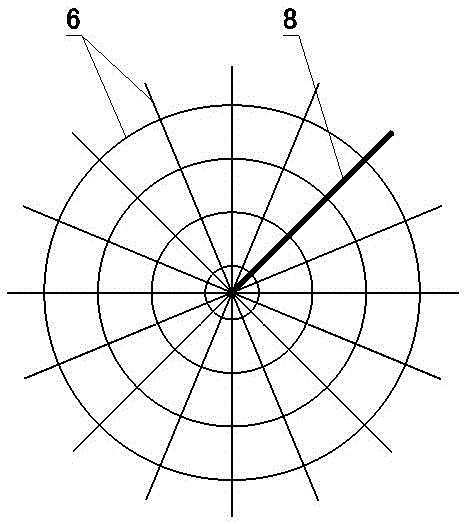

A Method for Measuring the Threshold Value of Stress Intensity Factor of Mode II Crack in Metallic Materials

InactiveCN108613890BExtended stabilityAccurate measurementMaterial strength using repeated/pulsating forcesMetallic materialsEngineering

Owner:SOUTHWEST JIAOTONG UNIV

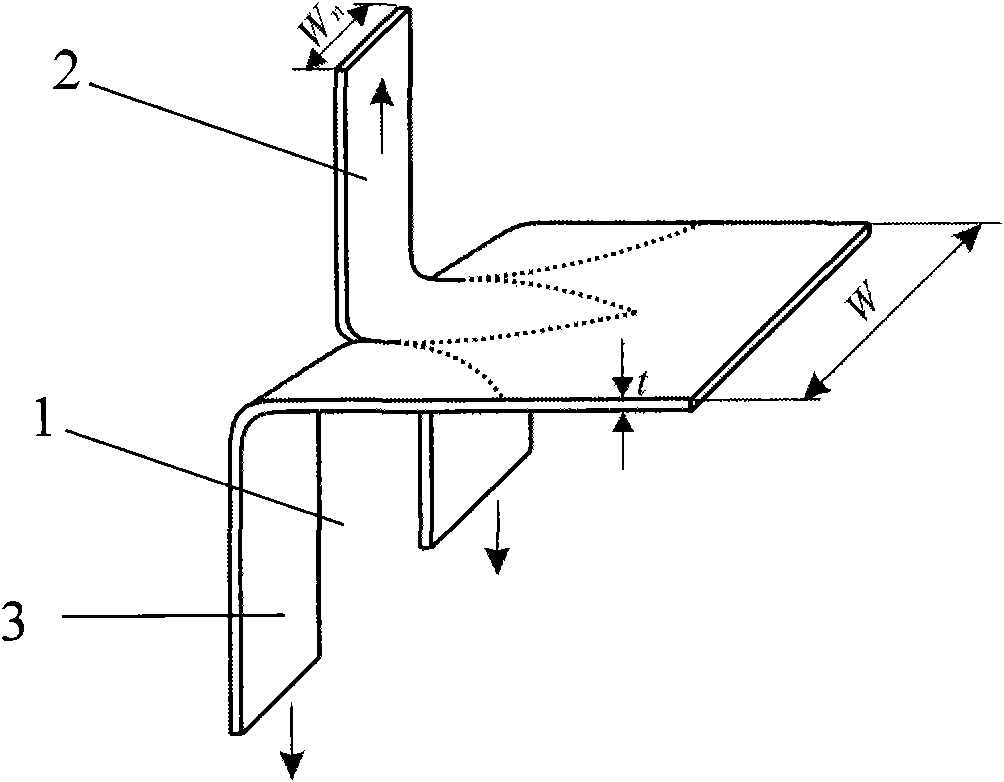

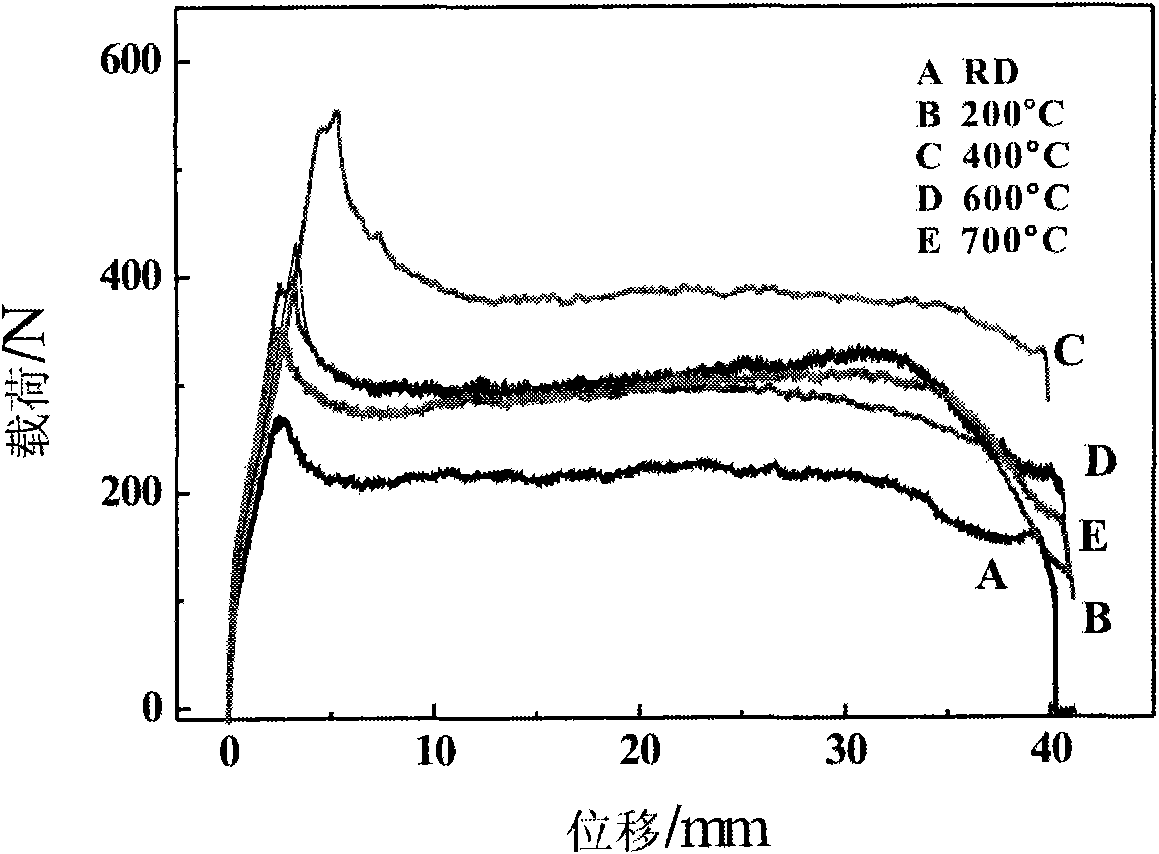

Method for evaluating tearing toughness of ductile metal materials

InactiveCN102374951BExtended stabilityPerfect mechanical propertiesMaterial strength using tensile/compressive forcesCrazingMetallic materials

The invention relates to the field of mechanical property evaluation and characterization of materials, and in particular relates to a method for evaluating the tearing toughness of ductile metal materials. The method is characterized in that through carrying out a tearing test on ductile metal materials by using three-leg trouser-shaped samples, a characteristic that applied loadings in the process of tearing are unchanged is obtained, thereby providing a powerful test basis for the proposition of a tearing toughness concept, thereby obtaining a defined tearing toughness which is shown in a formula as follows: Gamma = FS / 2 t, and used for evaluating the toughness or crack propagation resistance of ductile materials. The tearing test method and the tearing toughness concept provide an effective thought for knowing an inversion relation between the strength and plasticity (toughness) of a material, therefore, a new reference criterion is provided for selecting materials (the strength and plasticity are fitted better) for actual engineering. As for ductile sheet metals, a crack propagation process and a fracture process can be described more accurately by using the tearing toughness, which has a vital significance to the evaluation and characterization of engineering applications and mechanical properties of materials.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

A method for medium-high-frequency induction heating and low-stress precision cutting of rod and tube materials

ActiveCN103008433BGerminate fastExtended stabilityShaping toolsMetal-working feeding devicesStress concentrationSurface layer

A low-stress and high-efficiency precise blanking method for medium-high frequency inductive heating of a rod tube material is characterized in that the rod tube material is put on a feeding mechanism and then is fed in an inductive heating device; the inductive heating device can control heating time and a surface layer heating depth in a V-shaped groove of the rod tube material through adjusting parameters, such as heating frequency, current magnitude and the like, so as to finish quick heating to the V-shaped groove of the rod tube material; and then, the heated rod tube material is fed in a blanking mechanism, and is fixed by a rod tube material fixing sleeve; circular periphery loads are loaded in the radial direction of the rod tube material; and blanking is implemented by using a stress concentration effect, a heat stress effect and a fatigue break mechanism of the rod tube material. The method has the advantages of high efficiency, low energy consumption, material conservation and good blanking quality.

Owner:XI AN JIAOTONG UNIV

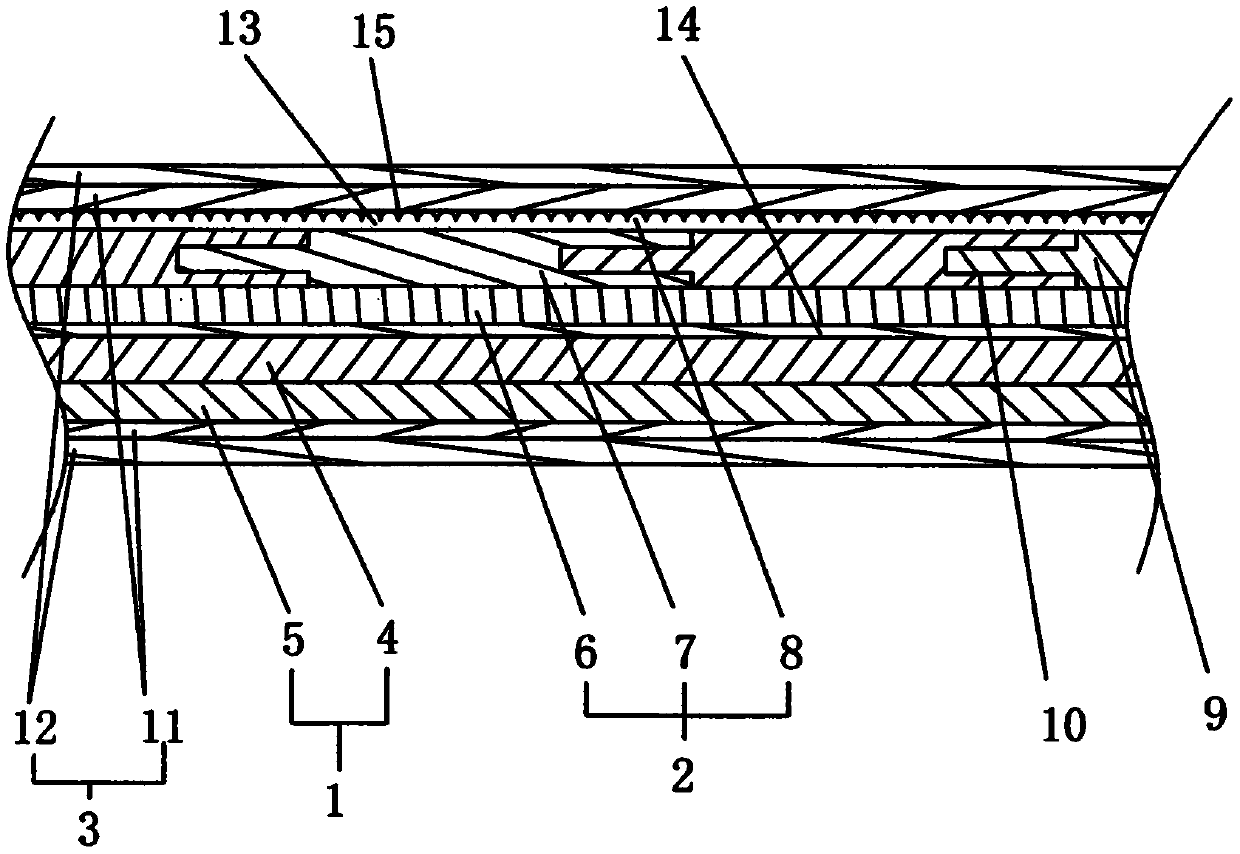

Folding-resistant bobbin paper and processing technology thereof

InactiveCN110952382AExtended stabilityImprove toughness propertiesLamination ancillary operationsSpecial paperPapermakingEngineering

The invention discloses folding-resistant bobbin paper and a processing technology thereof, which are applied to the field of industrial papermaking. The technical problem that the existing bobbin paper is easy to crease and break and has poor toughness is solved. According to the technical scheme, the paper comprises a paper core layer, an extension layer and protective layers; the extension layer is arranged on one side of the paper core layer; the protective layers are respectively arranged on one side of the paper core layer and on the side, far away from the paper core layer, of the extension layer; the paper core layer comprises a raw wood pulp layer and a recycled paper pulp layer; the extension layer comprises a cushion layer, a staggered lamination layer and an adhesion layer which are arranged in sequence, the staggered lamination layer comprises a plurality of continuous fault blocks, an interlayer is arranged at one end of each continuous fault block, and one ends of the adjacent continuous fault blocks are inserted into the interlayers; and the protective layer comprises an elastic cow leather layer and a wear-resistant layer. The toughness of the bobbin paper is improved.

Owner:JIANGSU TIANCHENG PAPER IND

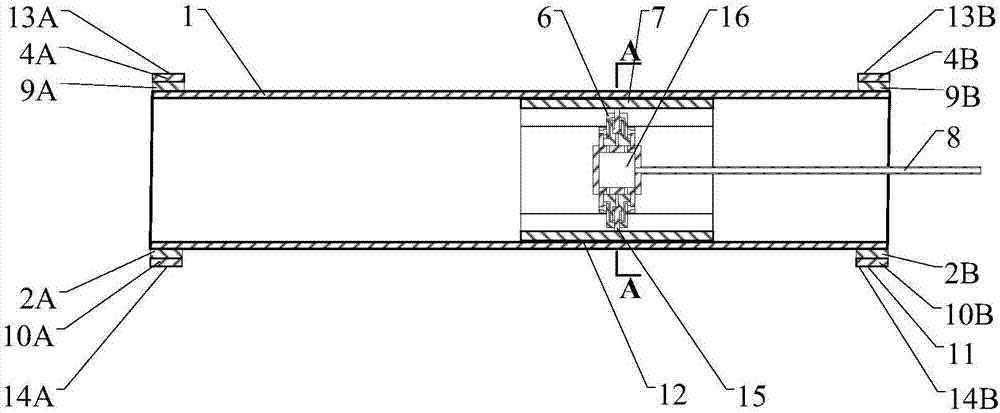

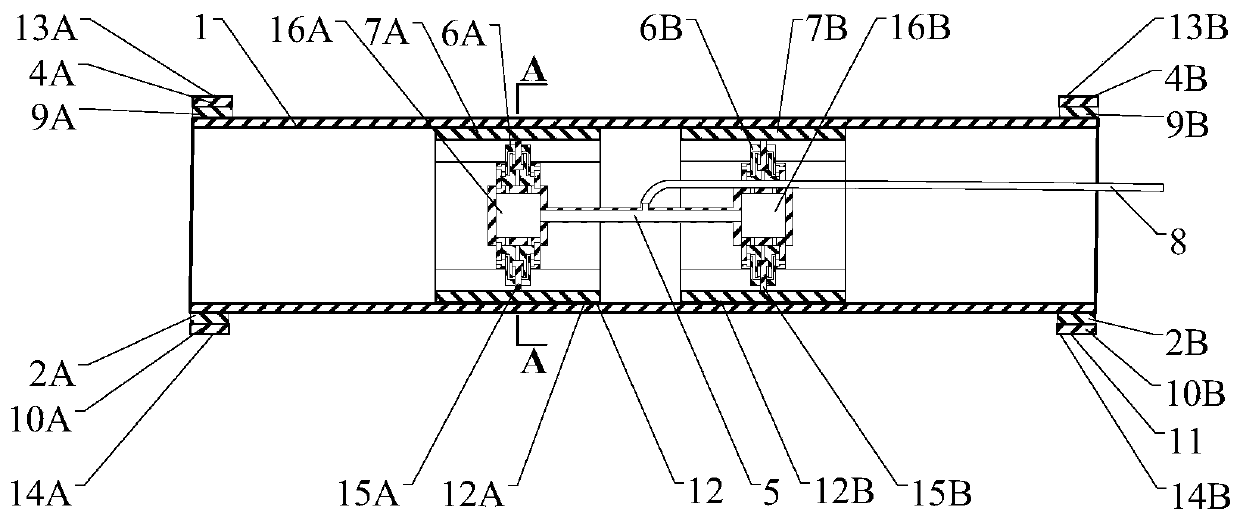

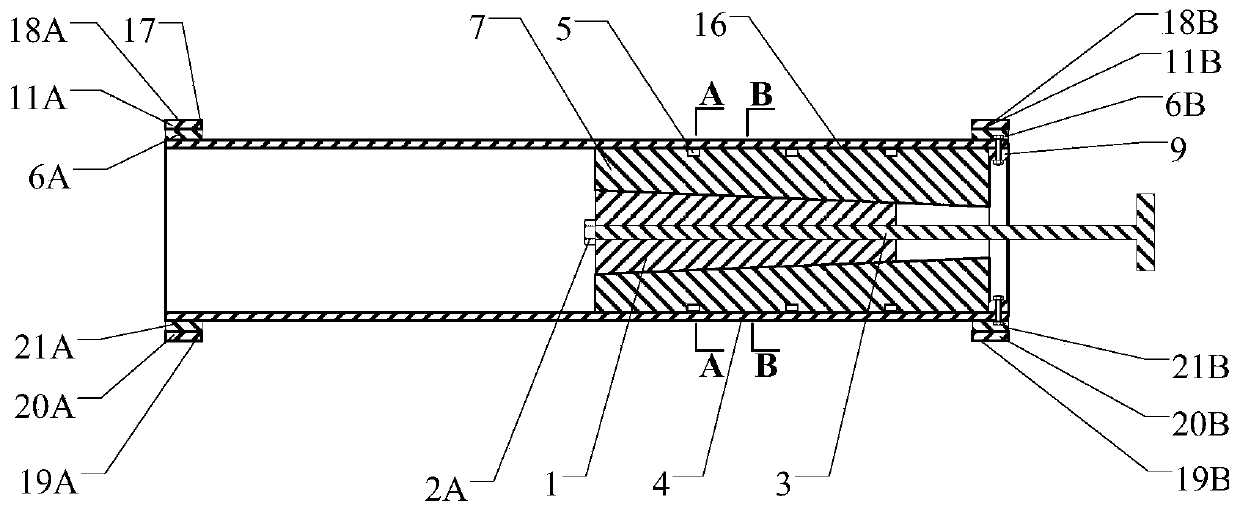

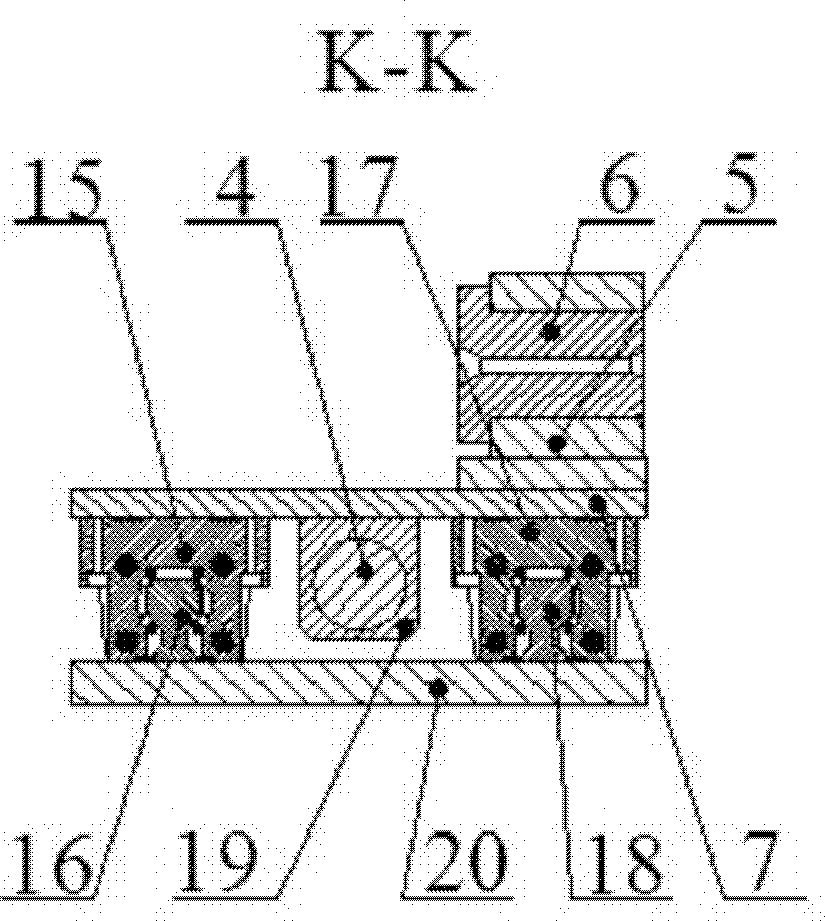

Bidirectional hydraulic hole-expanding type pipeline break simulation experiment device and experiment method

ActiveCN107063868AGuaranteed reliabilitySmall size errorMaterial strength using tensile/compressive forcesSupporting systemPipeline transport

The invention relates to a bidirectional hydraulic hole-expanding type pipeline break simulation experiment device. The experiment device comprises a pipeline support system, a pipeline expanding and supporting system, an oil inlet pipe and a DIC (density indicating controller) testing system, wherein an axial penetrating precrack is formed in the side wall of an experiment pipe section, and is symmetric to the axial center surface of the experiment pipeline section; the pipeline support system is used for supporting both ends of the experiment pipeline section; the pipeline expanding and supporting system is positioned in the experiment pipeline section, and the oil from the oil inlet pipe is used for providing hydraulic power for the pipeline expanding and supporting system; the pipeline expanding and supporting system is used for expanding and supporting the experiment pipeline section, and the precrack is expanded in two directions; the DIC testing system is used for observing the breaking process of the experiment pipeline section in real time. The experiment device has the advantages that the experiment sampling adopts the full-size pipeline sampling, a sample is directly cut from a pipeline, the size error, constraint error and the like are reduced, and the data reliability is guaranteed; by adopting a hydraulic driving device in an experiment, the working risk is decreased, and the cost is reduced; the DIC testing device is used for observing the expanding condition of the crack in real time, and the required data is conveniently obtained.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

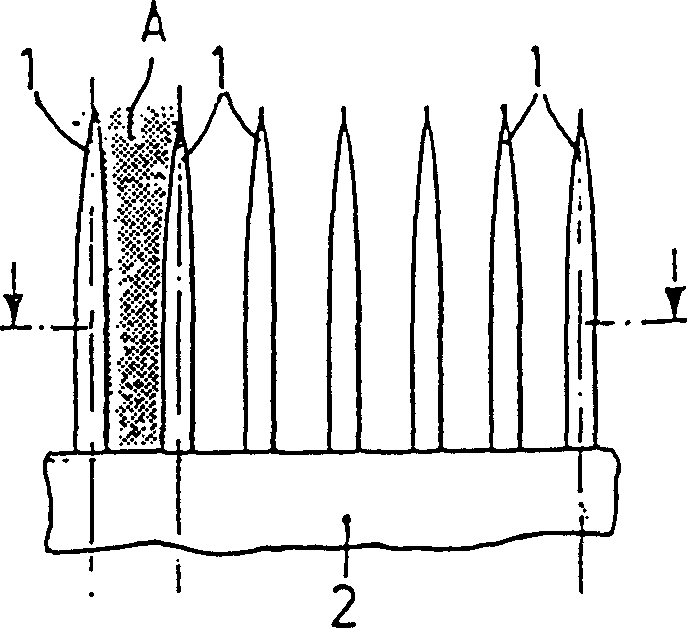

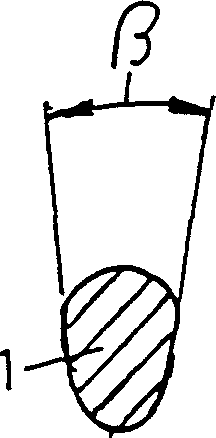

Card clothing for textile machine

Owner:STAEDTLER & UHL

Two-way hydraulic expansion pipe fracture simulation experimental device and experimental method

ActiveCN107063868BGuaranteed reliabilitySmall size errorMaterial strength using tensile/compressive forcesSupporting systemExperimental methods

The invention relates to a bidirectional hydraulic hole-expanding type pipeline break simulation experiment device. The experiment device comprises a pipeline support system, a pipeline expanding and supporting system, an oil inlet pipe and a DIC (density indicating controller) testing system, wherein an axial penetrating precrack is formed in the side wall of an experiment pipe section, and is symmetric to the axial center surface of the experiment pipeline section; the pipeline support system is used for supporting both ends of the experiment pipeline section; the pipeline expanding and supporting system is positioned in the experiment pipeline section, and the oil from the oil inlet pipe is used for providing hydraulic power for the pipeline expanding and supporting system; the pipeline expanding and supporting system is used for expanding and supporting the experiment pipeline section, and the precrack is expanded in two directions; the DIC testing system is used for observing the breaking process of the experiment pipeline section in real time. The experiment device has the advantages that the experiment sampling adopts the full-size pipeline sampling, a sample is directly cut from a pipeline, the size error, constraint error and the like are reduced, and the data reliability is guaranteed; by adopting a hydraulic driving device in an experiment, the working risk is decreased, and the cost is reduced; the DIC testing device is used for observing the expanding condition of the crack in real time, and the required data is conveniently obtained.

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

One-way driving semi-cracked pipeline fracture simulation experimental device and experimental method

ActiveCN106918507BGuaranteed reliabilitySmall size errorMaterial strength using tensile/compressive forcesHydraulic cylinderExperimental methods

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

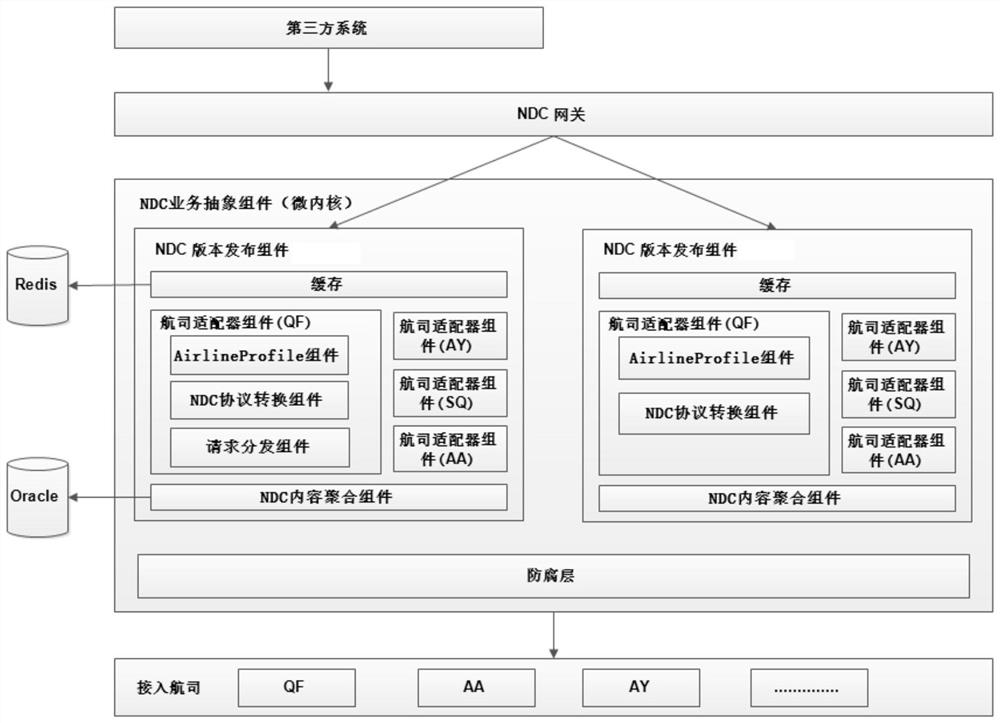

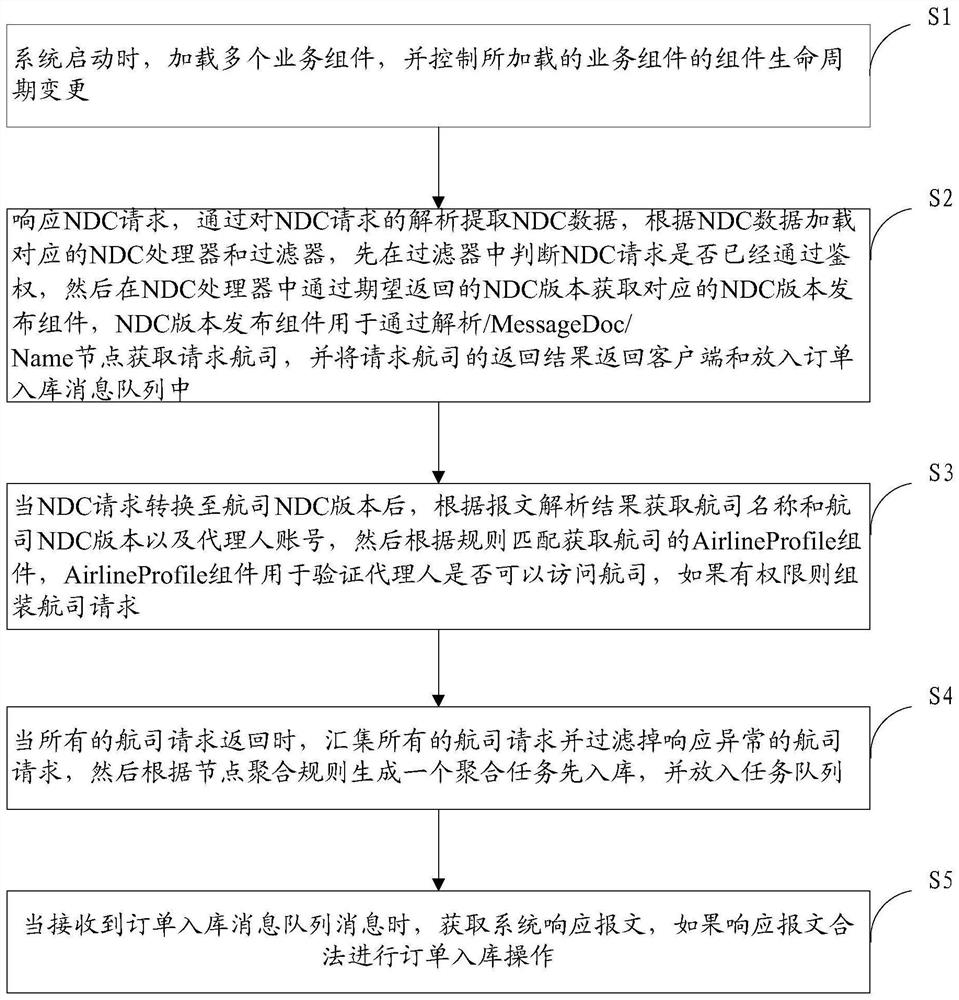

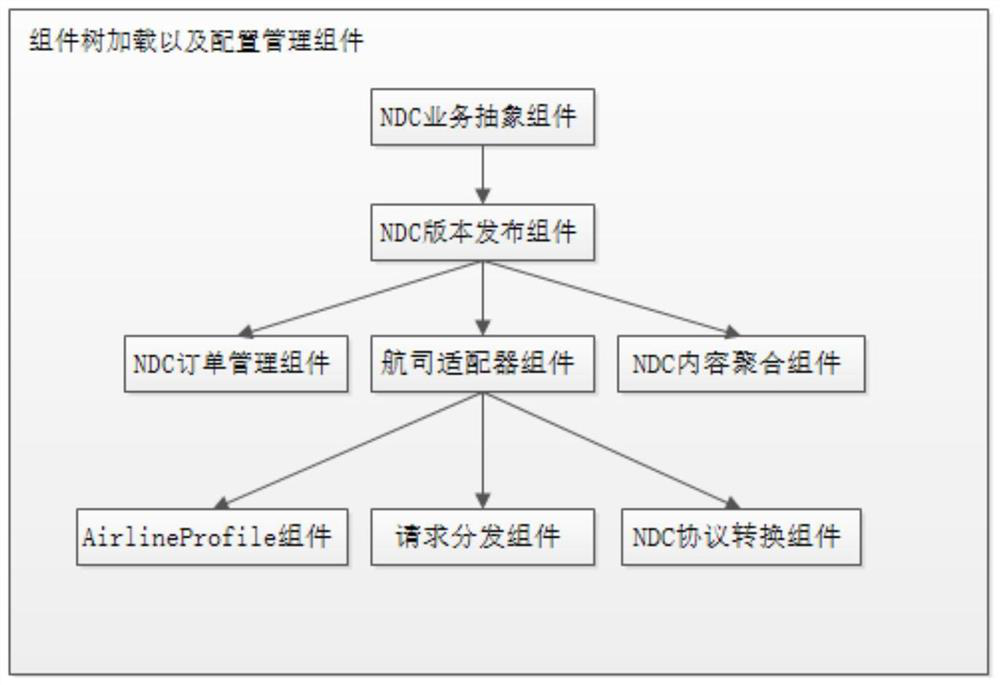

NDC aggregator-oriented NDC processing system and service request processing method thereof

PendingCN112308515AImprove reliabilityExtended stabilityOffice automationPersonalizationOrder management

The invention discloses an NDC aggregator-oriented NDC processing system and a service request processing method thereof. The system comprises a component tree loading and configuration management component, an NDC service abstraction component, an Airline Profile component, at least one airline adapter component, a request distribution component, an NDC content aggregation component, an NDC version release component, an NDC protocol conversion component and an NDC order management component. According to the system, all components in the NDC life cycle are managed in a plug-in microkernel mode, and expansion can be carried out in a simple, efficient, reliable and stable mode; when a new version of NDC interface is newly added, only one NDC message publisher needs to be added, and when a new airline is accessed, only one airline adapter needs to be added, and a large number of personalized business processes are not needed, so that the resource consumption is reduced. In addition, thehigh reliability of the system is guaranteed through the expansion mode, it is guaranteed that the original components are not affected when the system is changed through the isolation between the components, and the performance of the system cannot be reduced due to the fact that an airline is newly accessed.

Owner:TRAVELSKY

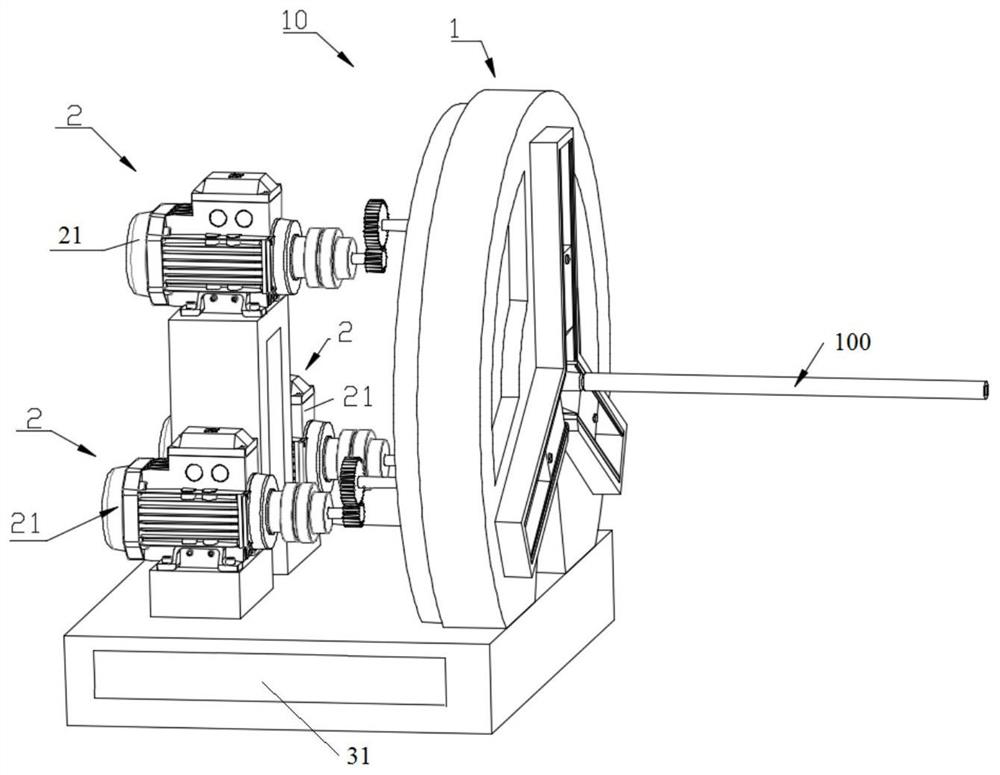

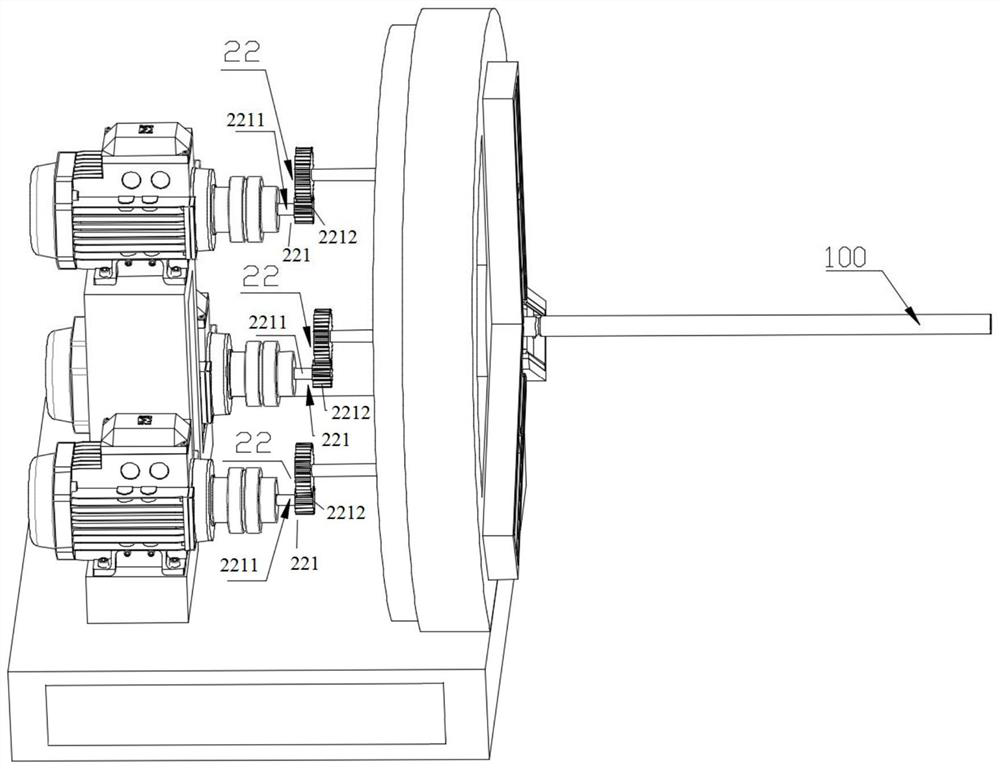

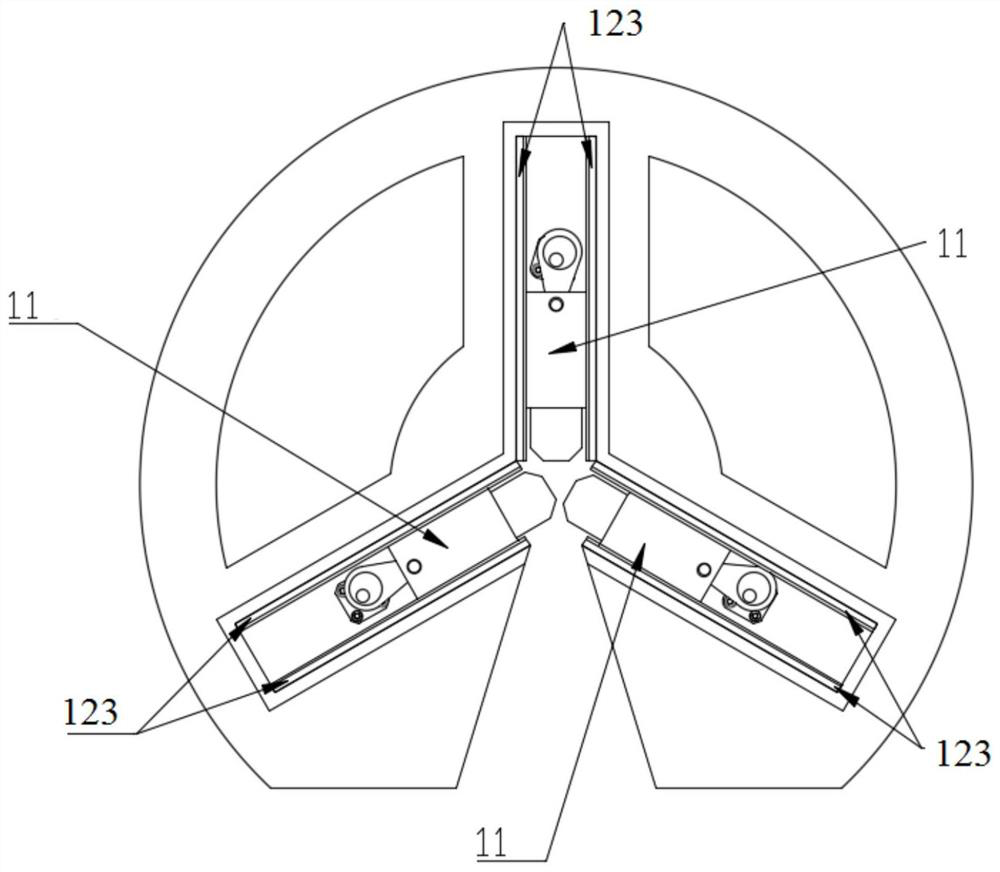

Feeding machine and method for feeding rods and tubes

InactiveCN111673518ASmall shape deformationFlat sectionTube shearing machinesMetal working apparatusHigh energyEnvironmental engineering

The invention discloses a feeding machine and a method for feeding rods and tubes. The feeding mechanism comprises a feeding mechanism and three driving parts. The feeding mechanism includes a box body and three beating blocks, and the three beating blocks are uniformly distributed in the box body at 120 DEG C in the circumferential direction. The three driving parts drive the three beating blocksrespectively. The feeding machine provided by the invention can solve the problems of low feeding efficiency of the existing feeding machine, uneven stress on the rods and tubes during feeding, largecross-sectional deformation, secondary processing of the rods and tubes after feeding, waste generation during the feeding process, waste of raw materials, high energy consumption, and non-compliancewith the concept of green environmental protection.

Owner:XI AN JIAOTONG UNIV

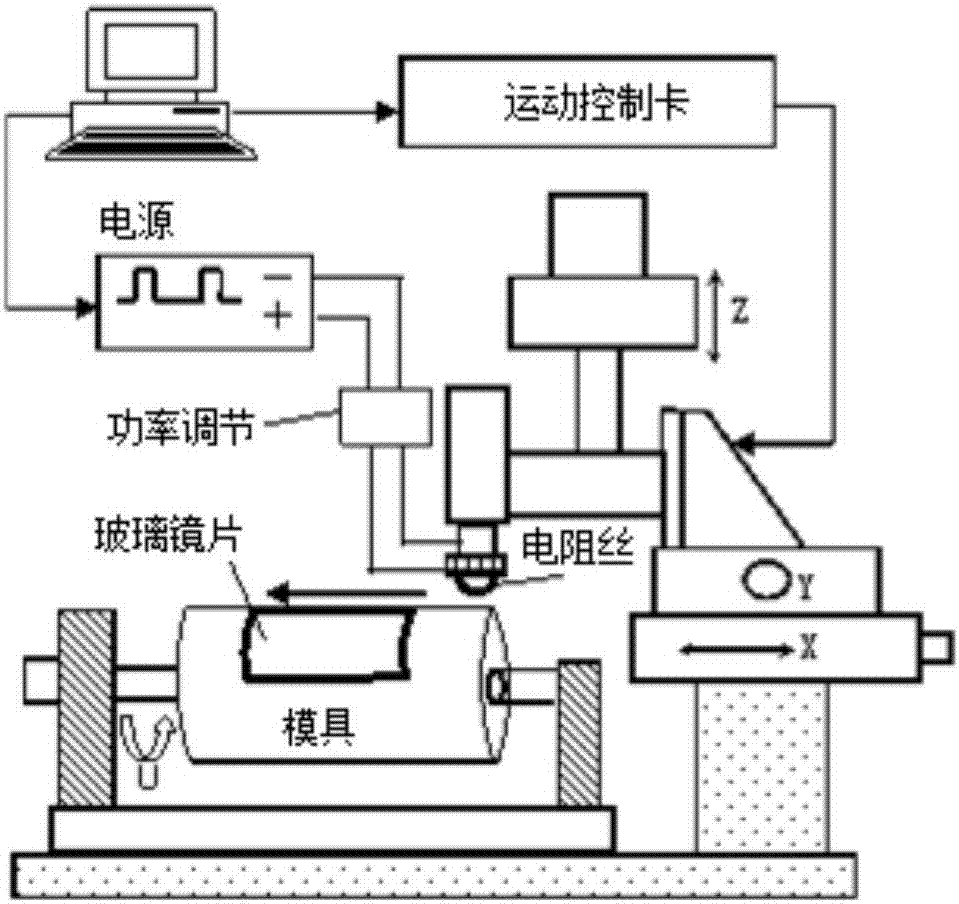

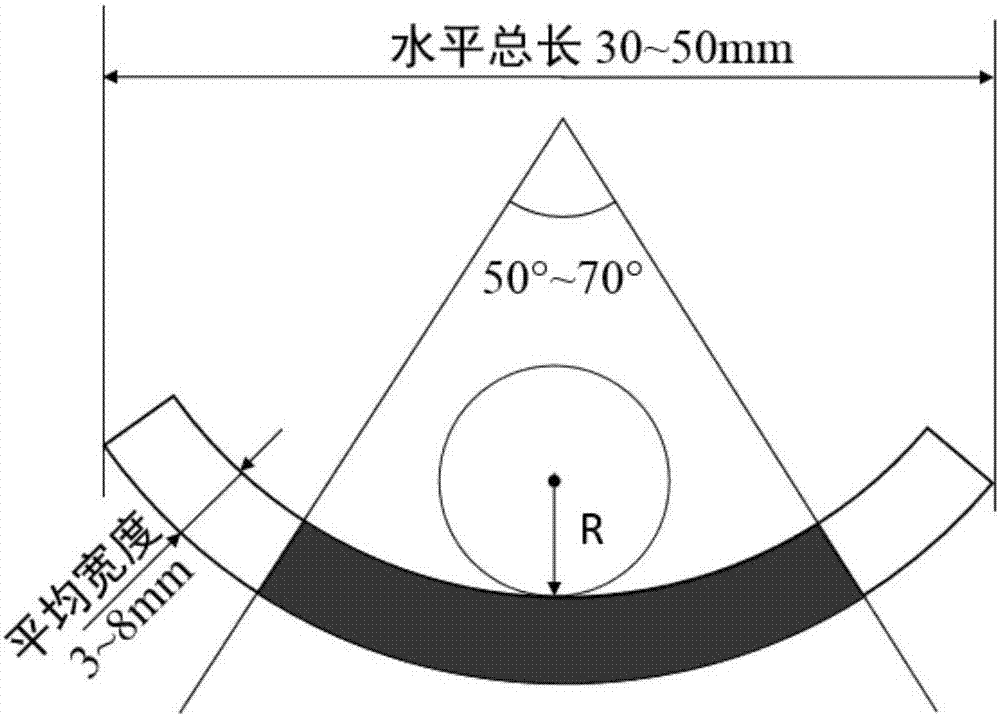

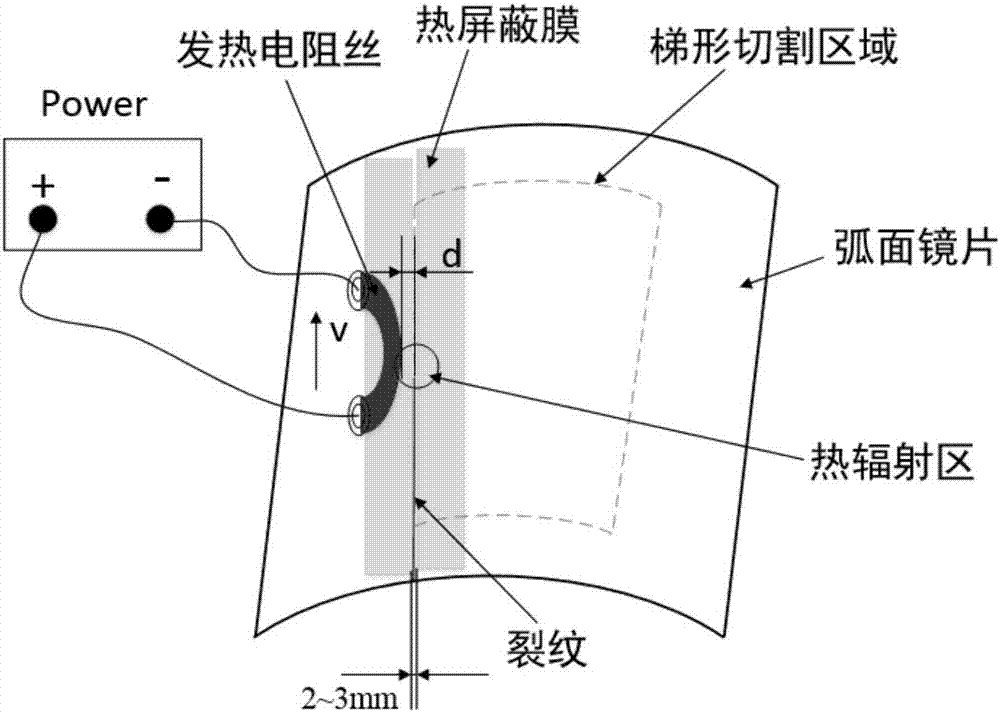

Tiny-crack-free curved glass hot-wire cutting method based on thermal shield membrane

InactiveCN107162400AExtended stabilityImprove straightnessGlass severing apparatusCutting glassWire cutting

The invention relates to a method for hot wire cutting of curved glass without microcracks based on a heat shielding film, which specifically comprises the following steps: (1) building a hot wire cutting device, fixing the curved glass on the mold of the hot wire cutting device, and Mark the cutting position of the prefabricated crack on the surface; (2) Set the heat shielding film symmetrically on both sides of the prefabricated crack cutting position of the curved glass; (3) Move the hot wire directly above the prefabricated crack of the curved glass, and heat the hot wire to the set temperature , and then control the hot wire to move along the expected trajectory and cut cracks on the curved glass. Compared with the prior art, the present invention utilizes the thermal shielding film to control the temperature field generated by the hot wire on the glass surface. The temperature field on the glass surface changes stably and is not easily affected by external environmental factors. The straightness of the cracks cut by wire is higher, which meets the cutting requirements of glass lenses with higher precision requirements.

Owner:TONGJI UNIV

Digital parallel current sharing method and system for DC converters

ActiveCN103780078BDestroy convergenceExtended stabilityDc-dc conversionElectric variable regulationEngineeringElectrical current

The invention discloses a DC converter digital parallel current equalizing method and system. The method comprises that: a host periodically acquires present load current and calculates a present current equalizing set value and issues the value in combination with last time current equalizing set values issued to multiple parallel-connected slaves last time; and whether load current adjustment of each slave is executed is judged by each slave according to the acquired present current equalizing set value and the stored current equalizing set value last time, and when a difference value between the present current equalizing set value and the current equalizing set value last time is greater than or equal to the preset minimum current equalizing error threshold value, the load current adjustment of the slaves is executed according to the present current equalizing set value, wherein the minimum current equalizing error threshold value can be set as zero. With application of the method, the DC converter digital parallel current equalizing system can still operate stably even interference appears or loads are switched so that great robustness is realized.

Owner:ZTE CORP

Opposite-cutting type blanking machine for driving linear motion of double screw rods by AC (Alternating Current) servo motor

The invention relates to an opposite-cutting type blanking machine for driving linear motion of double screw rods by an AC (Alternating Current) servo motor, which comprises a driving mechanism, a blanking radially-loading blanking mechanism and a feeding radially-loading blanking mechanism. The linear motion mode of a ball screw can be utilized to carry out the design of high speed blanking, the linear motion speed of the molds can be improved by the design of the inverse motion of two sets of movable molds, and the blanking process is simple and practical by the design of the instant, rapid motion and the rapid and accurate returning of the molds; the blanking molds can be replaced according to the different process requirements; and rod pipe materials can be preciously discharged by aiming at different materials and different diameters. The opposite-cutting type blanking machine has the advantages of compact structure, high efficiency, low energy consumption and the like and is practical and convenient.

Owner:XI AN JIAOTONG UNIV

Two-way driving pipe fracture simulation experiment device and experiment method

ActiveCN106840886BGuaranteed reliabilitySmall size errorMaterial strength using tensile/compressive forcesHydraulic cylinderSupporting system

Owner:CHINA UNIV OF PETROLEUM (EAST CHINA)

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com