Device for testing plastic deformation capacity of metal glass material

A technology of metallic glass and plastic deformation, applied in the field of metallic glass materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

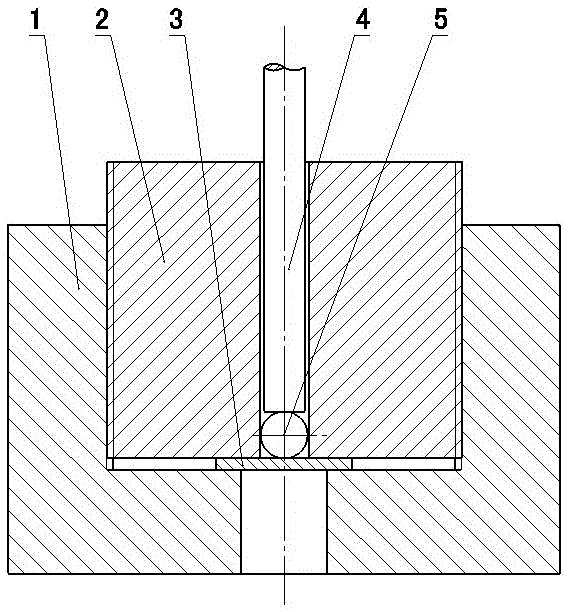

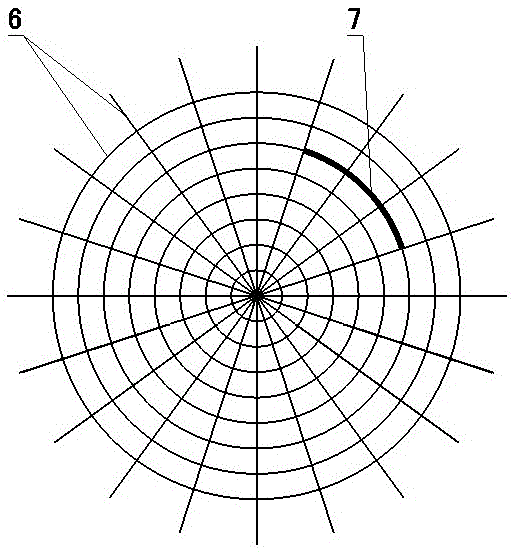

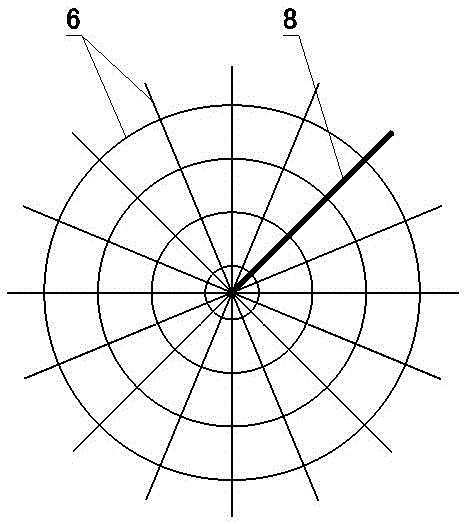

[0015] Such as figure 1 As shown, the present invention has a lower die 1, and a patrix 2 is arranged in the lower die 1, and patrix 2 and lower die 1 all adopt No. 45 steel to make, and screw connection between patrix 2 and lower die 1 is convenient to install and Take out the sample; there is a center hole on the upper die 2 and the lower die 1, and the diameter of the center hole of the lower die 1 is greater than the diameter of the center hole of the upper die 2, and the diameter of the center hole of the lower die 1 is the center hole of the upper die 2 1.5-1.8 times the diameter; a metal glass disc sample 3 is installed between the center hole of the upper mold 2 and the lower mold 1, and the diameter and thickness of the metal glass disc sample 3 can be Ф3mm and 0.2mm respectively; There is a cemented carbide ball 5 on the metal glass disc sample 3, and the cemented carbide ball 5 is YG6 cemented carbide; there is a pressure rod 4 on the cemented carbide ball 5, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com