Patents

Literature

167 results about "Shear band" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

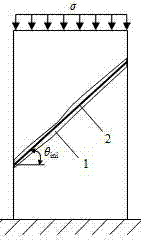

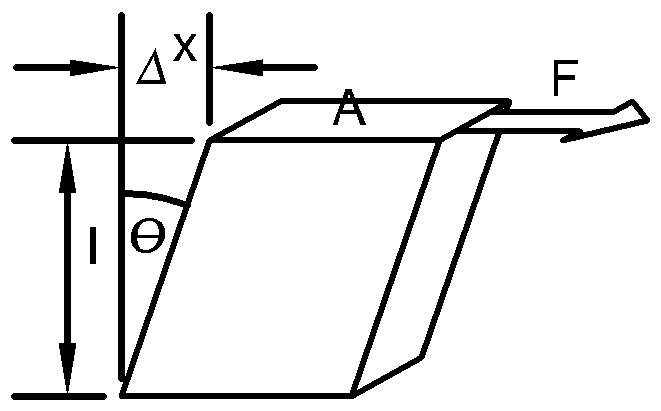

A shear band (or, more generally, a 'strain localization') is a narrow zone of intense shearing strain, usually of plastic nature, developing during severe deformation of ductile materials. As an example, a soil (overconsolidated silty-clay) specimen is shown in Fig. 1, after an axialsymmetric compression test. Initially the sample was cylindrical in shape and, since symmetry was tried to be preserved during the test, the cylindrical shape was maintained for a while during the test and the deformation was homogeneous, but at extreme loading two X-shaped shear bands had formed and the subsequent deformation was strongly localized (see also the sketch on the right of Fig. 1).

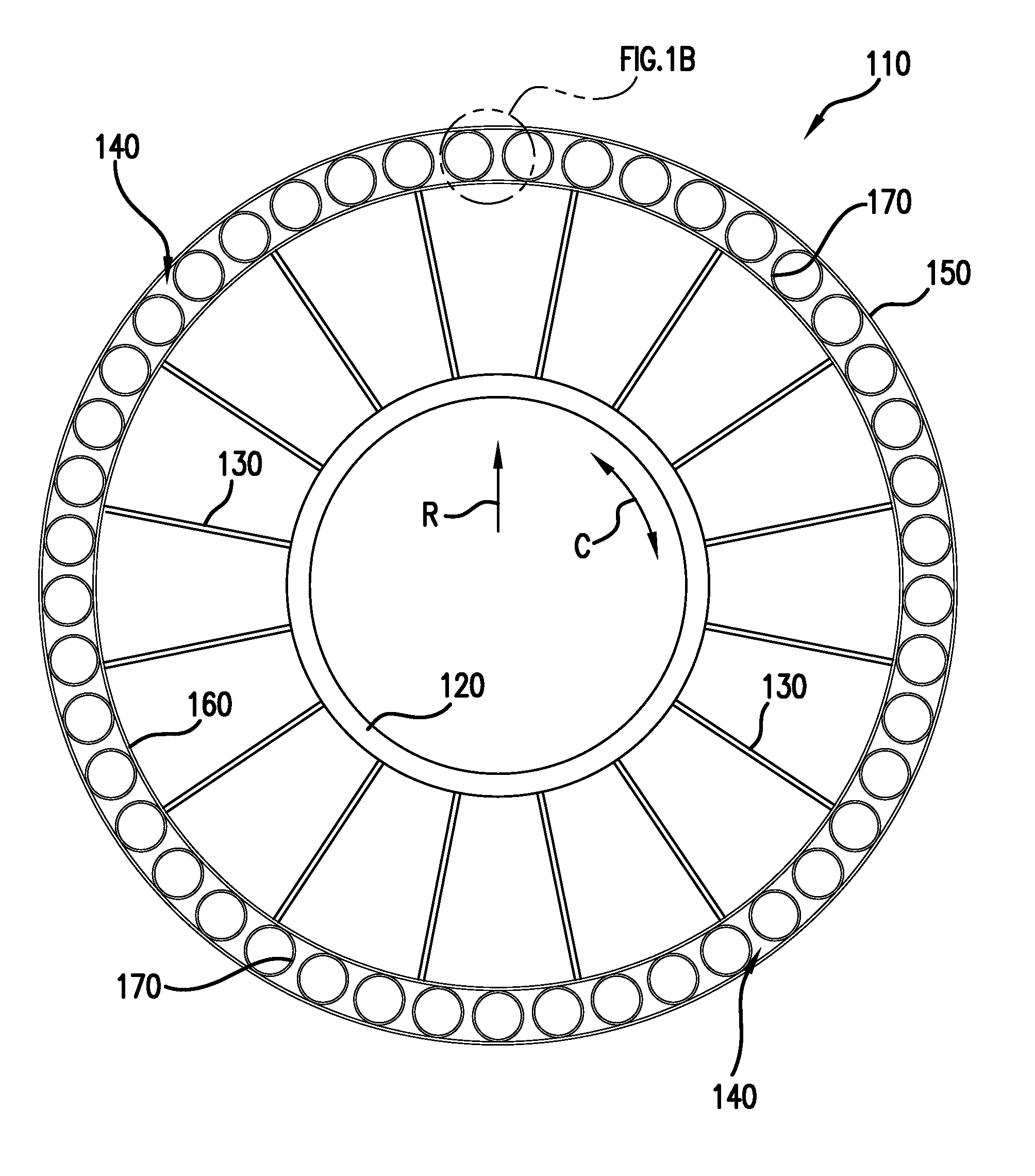

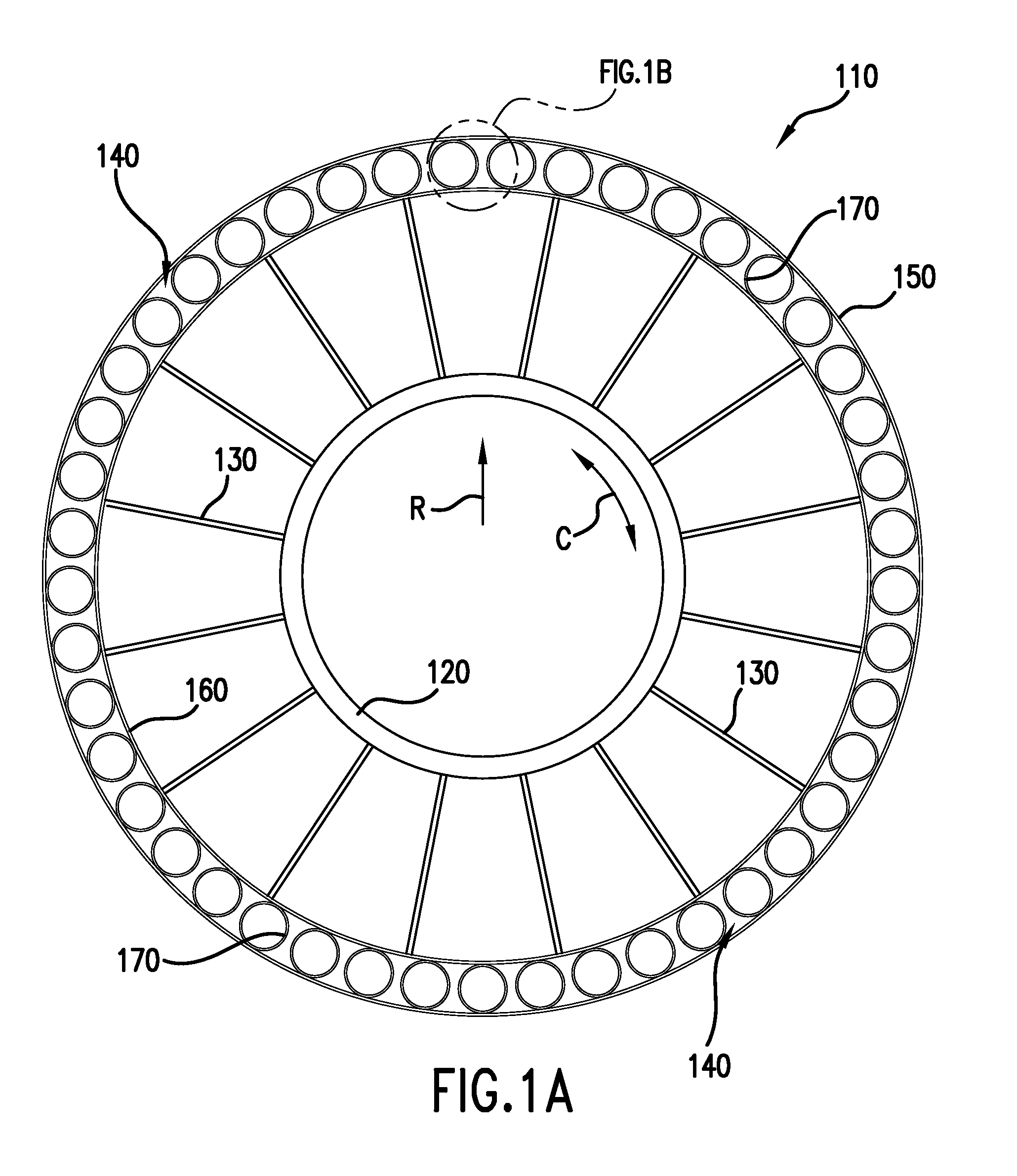

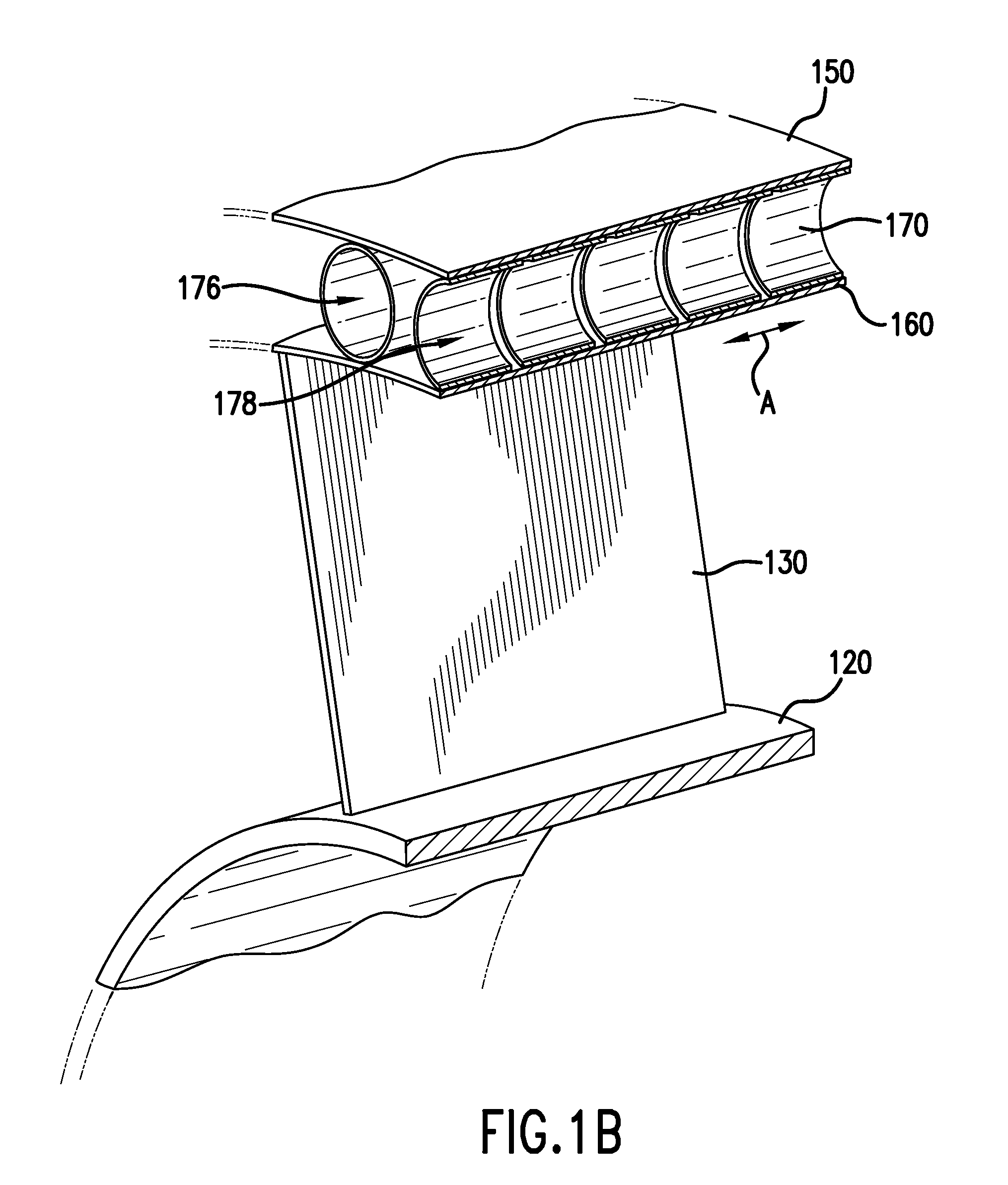

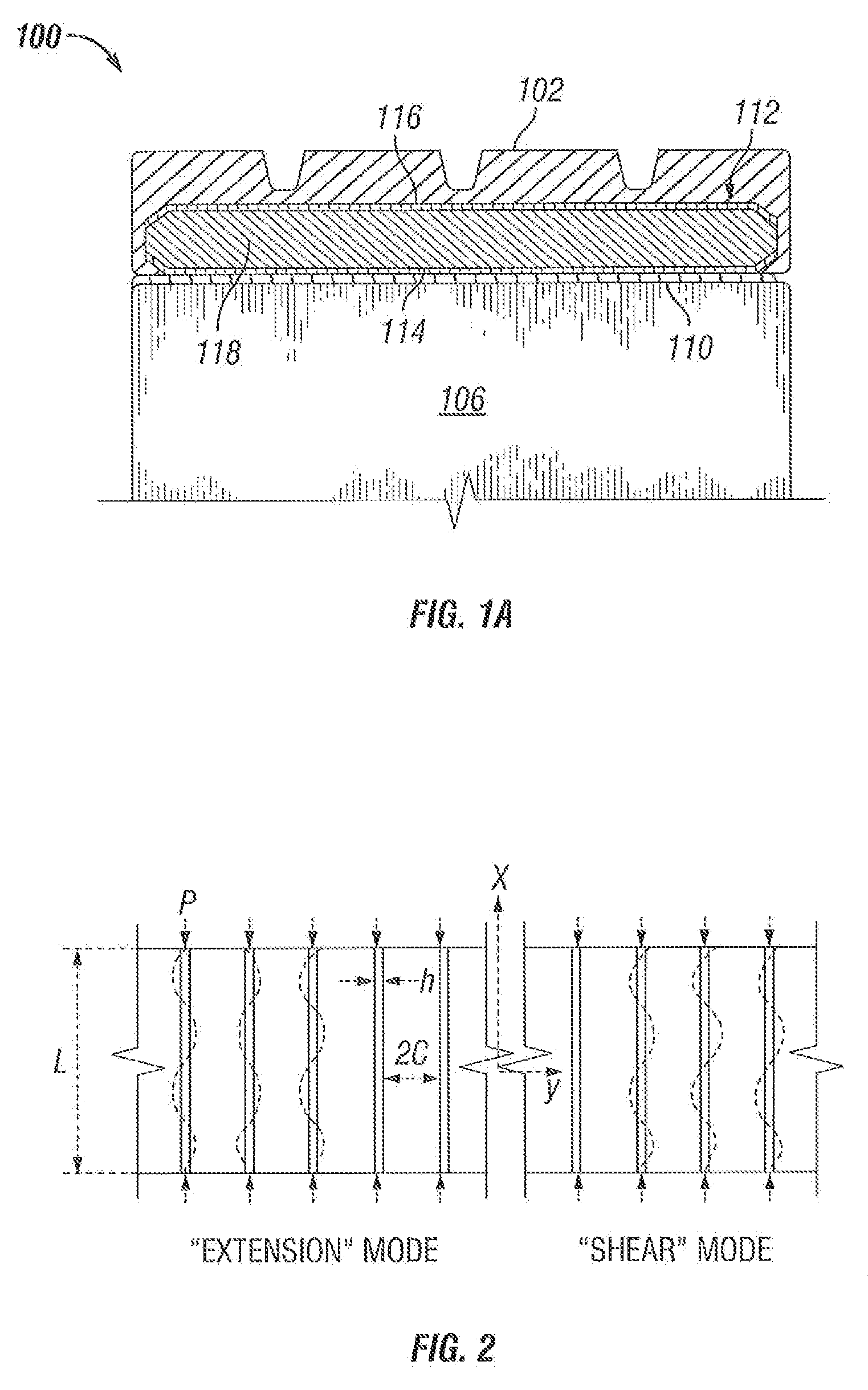

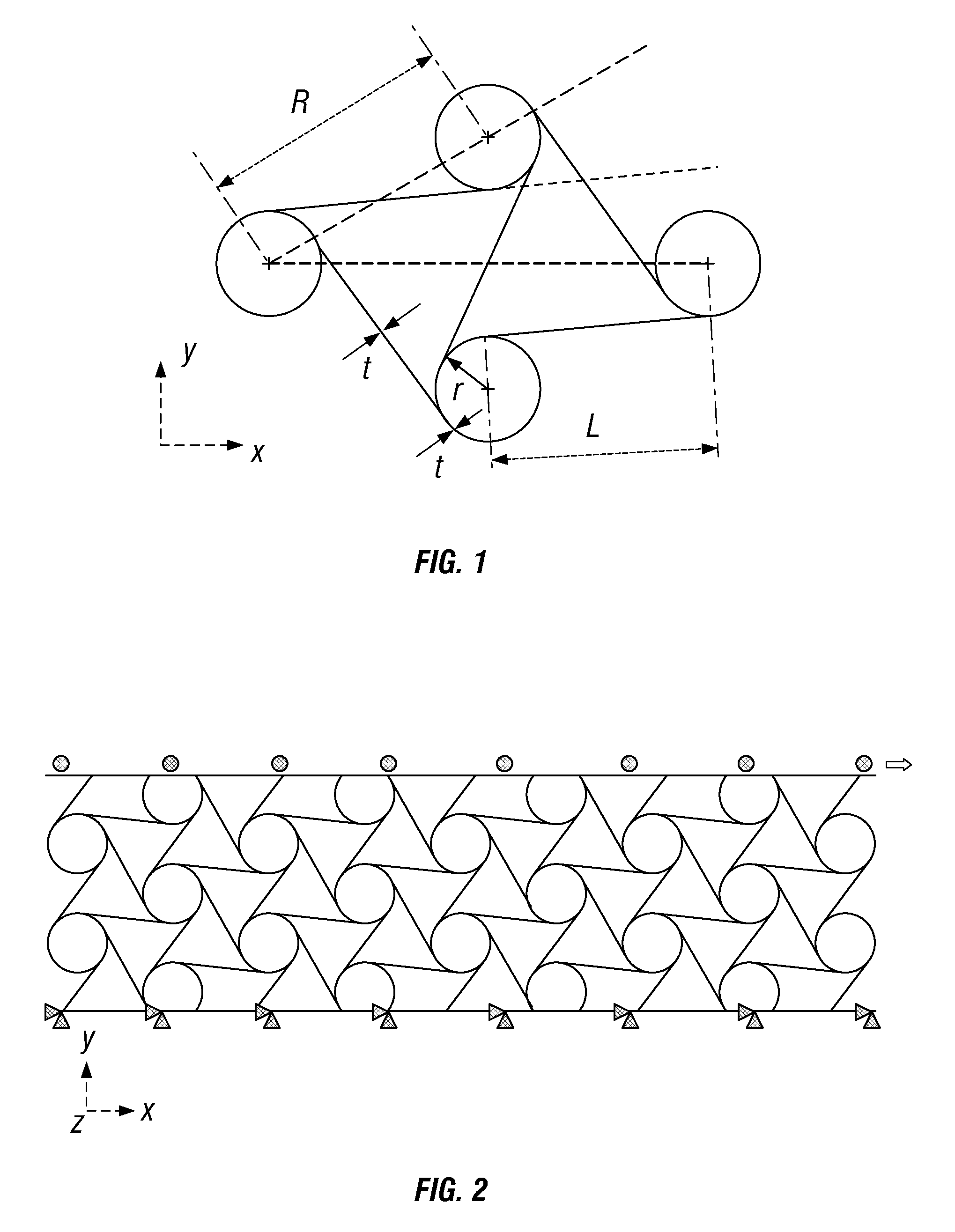

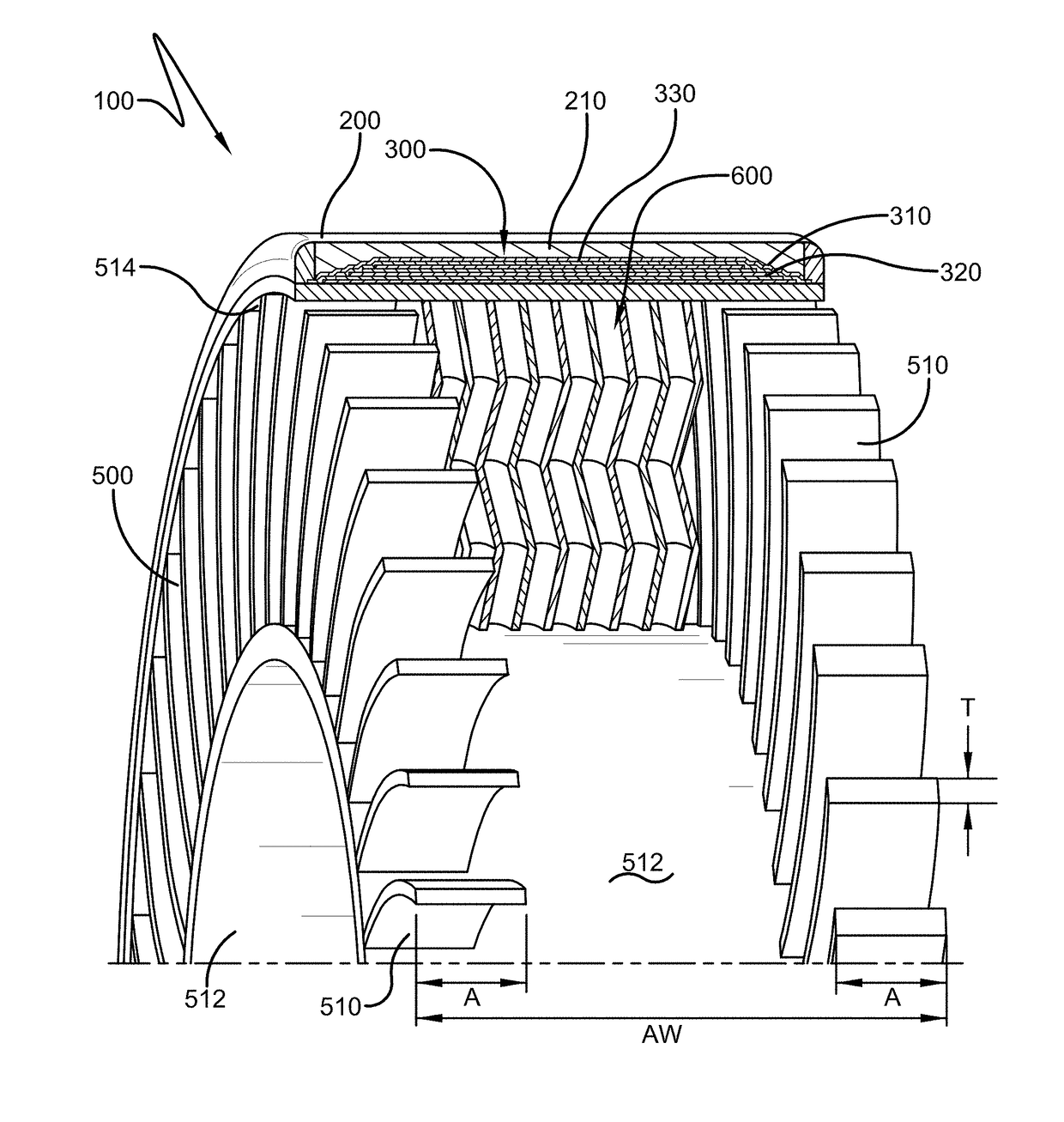

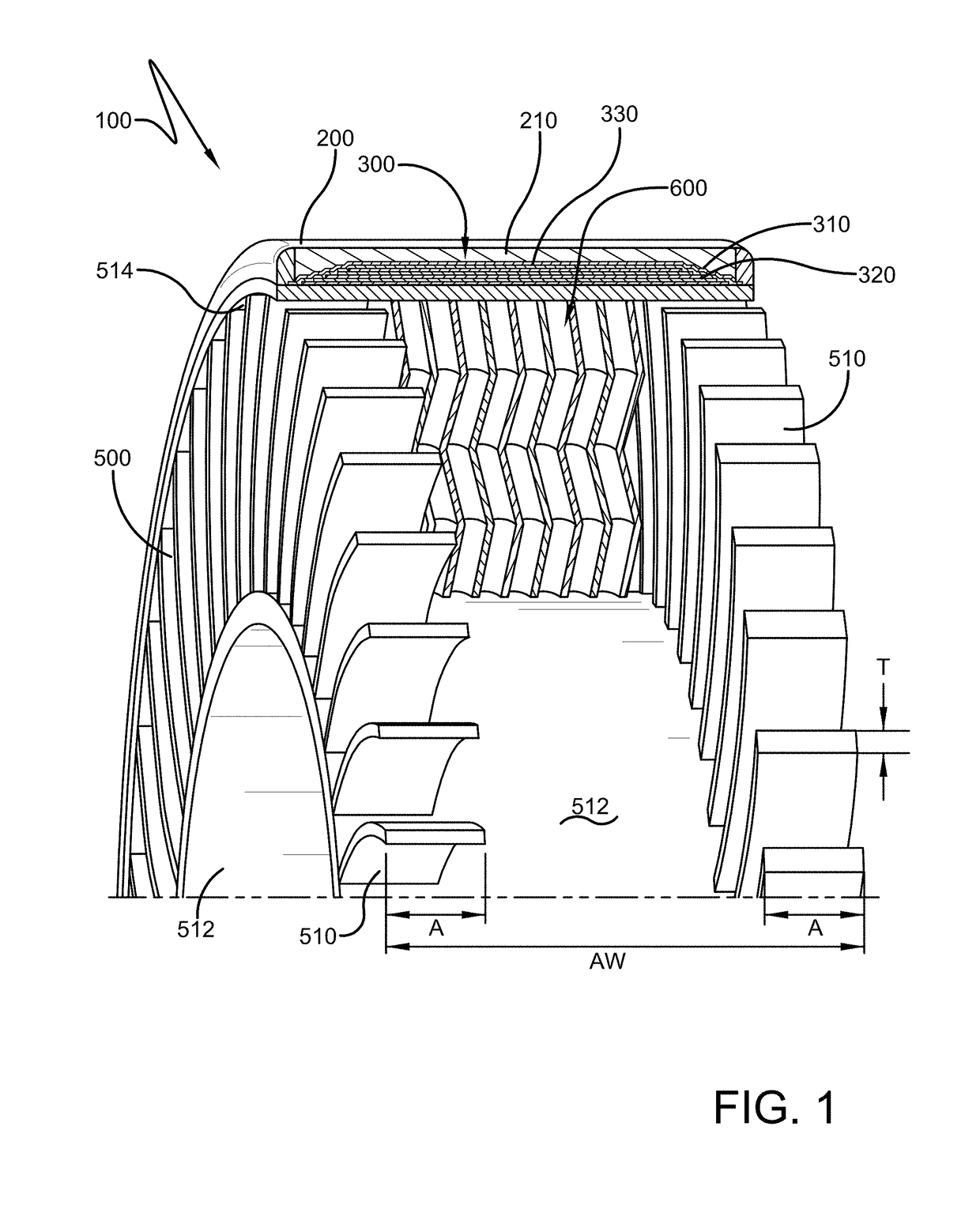

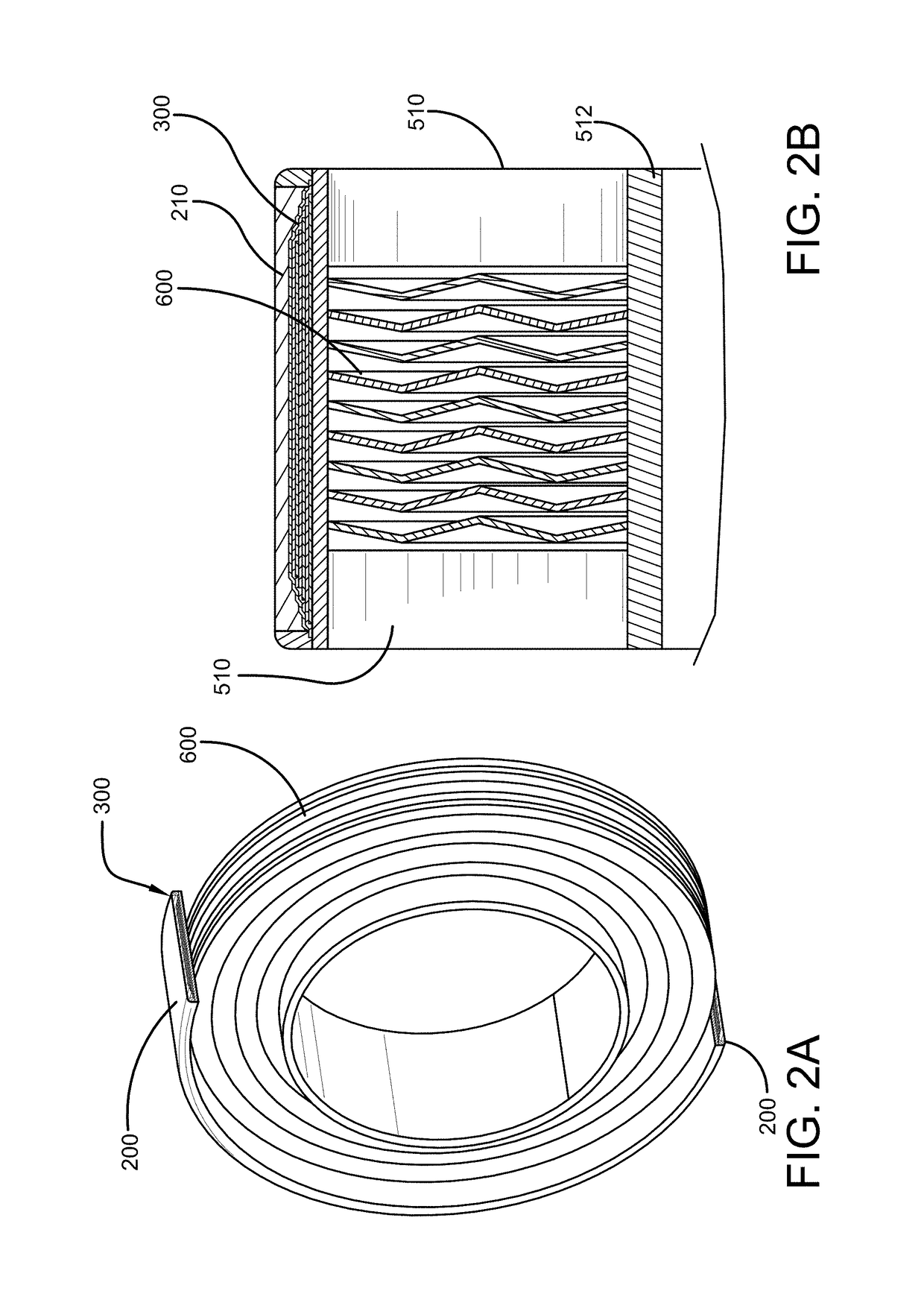

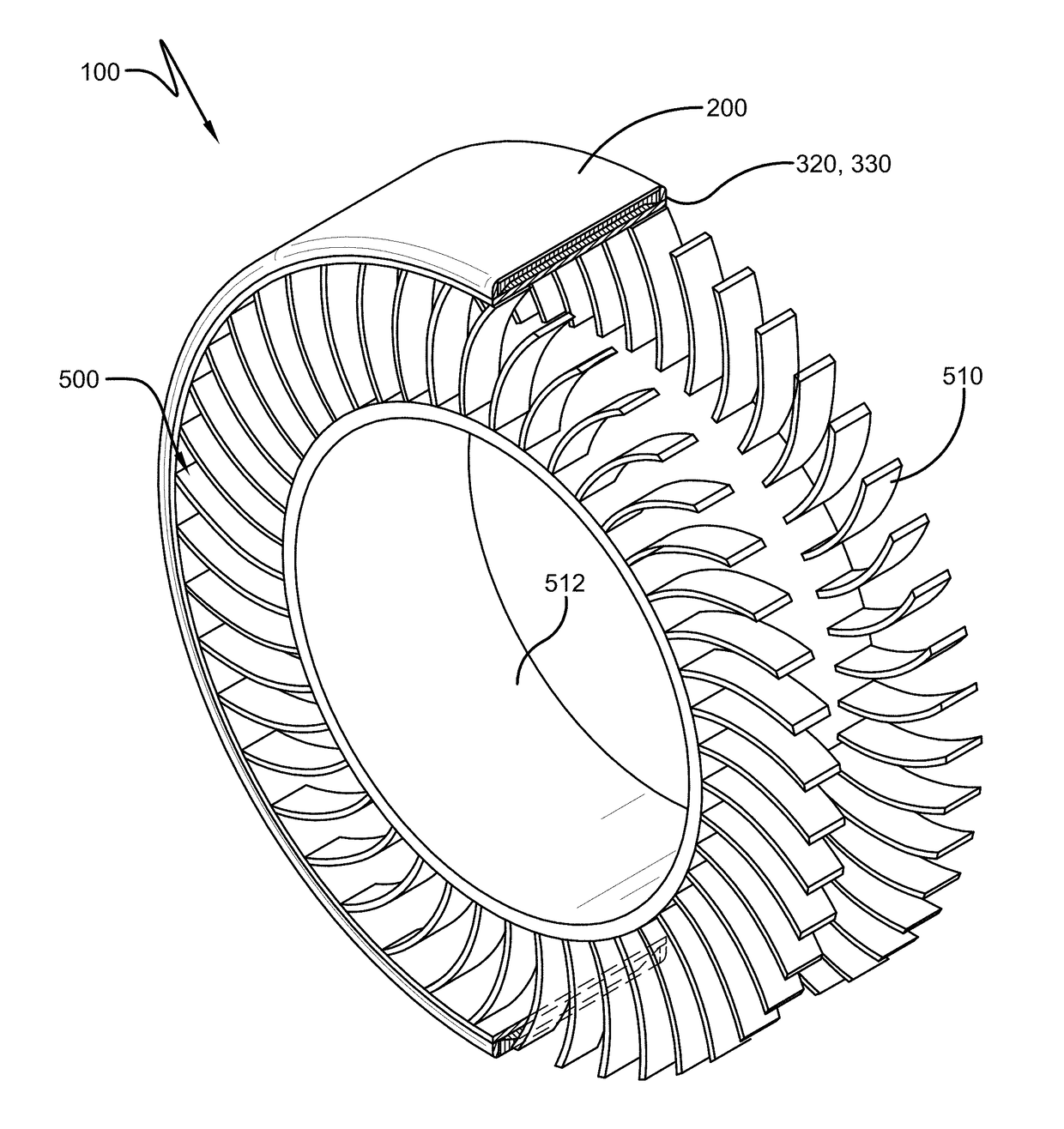

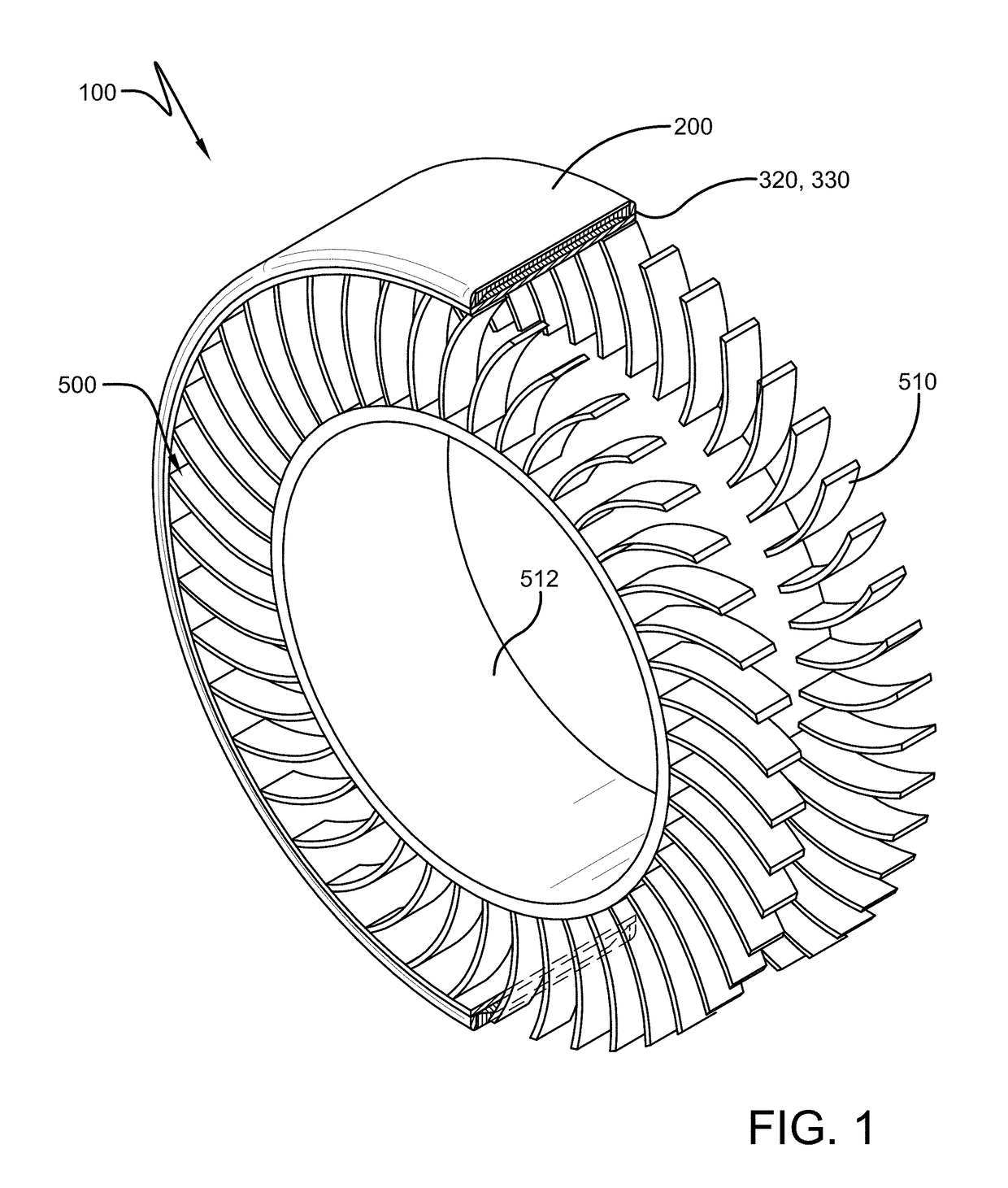

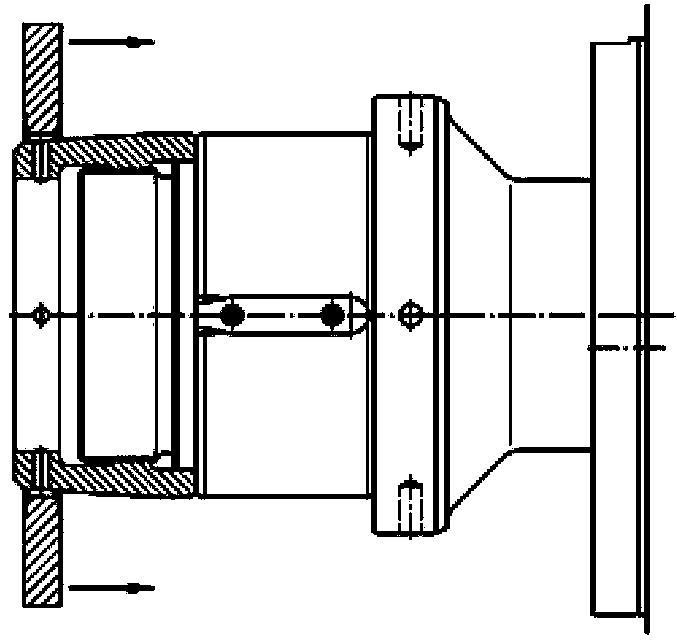

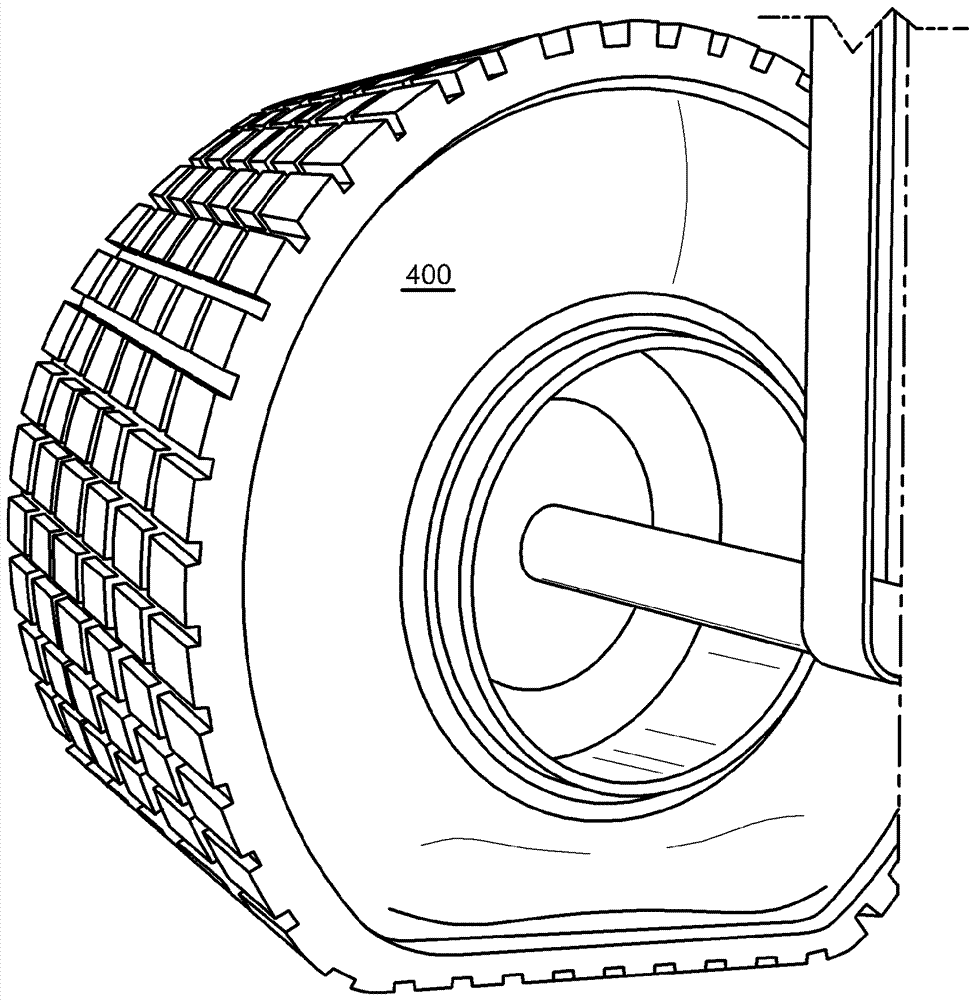

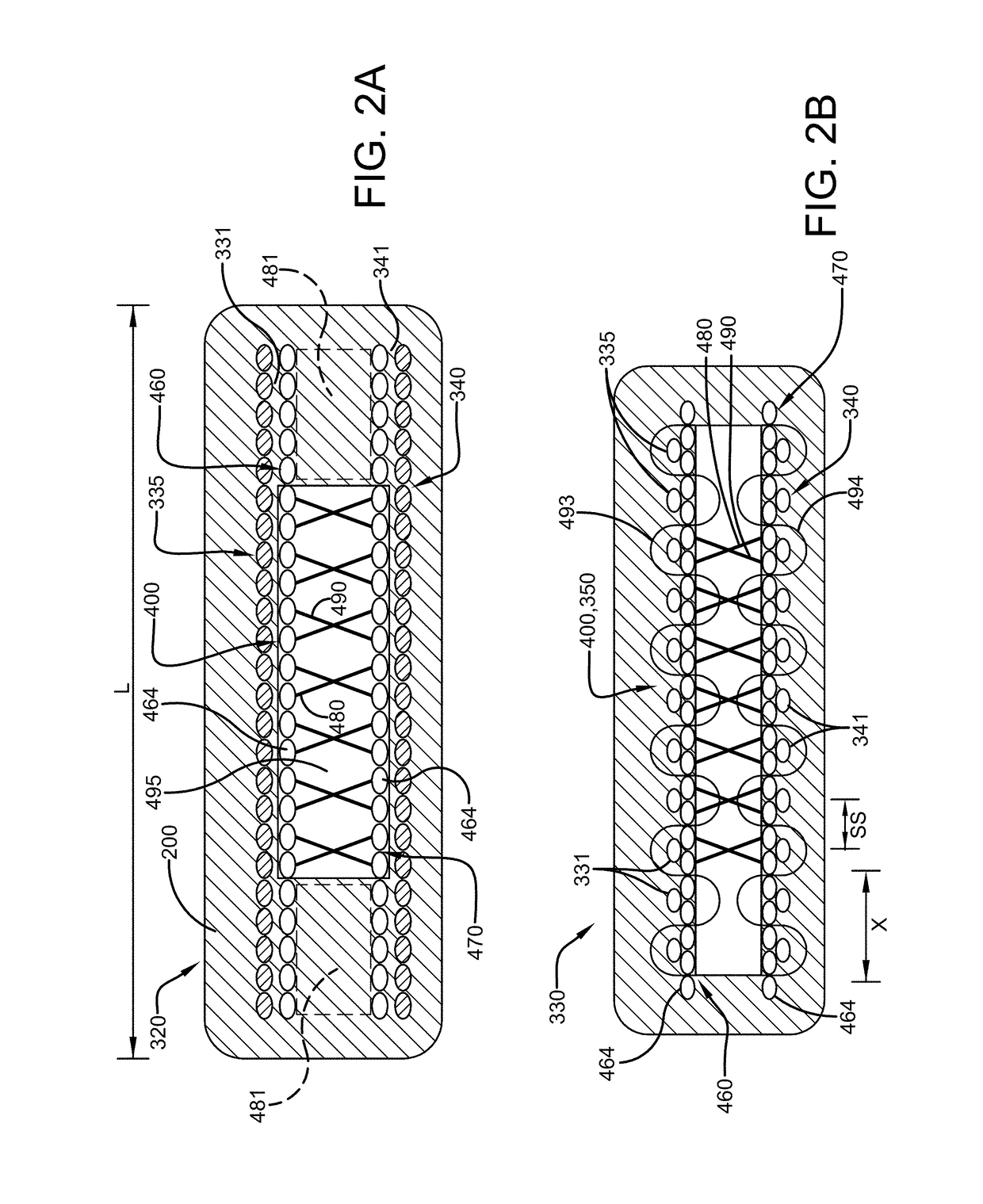

Elastic shear band with cylindrical elements

A shear band that may be used as part of a structurally supported wheel is provided. More particularly, a shear band constructed from resilient, cylindrical elements attached between inextensible members is described. In certain embodiments, the shear band may be constructed entirely or substantially without elastomeric or polymer-based materials. Multiple embodiments are available including various arrangements of the cylindrical elements between the members as well as differing geometries for the cylindrical elements.

Owner:MICHELIN RECH & TECH SA

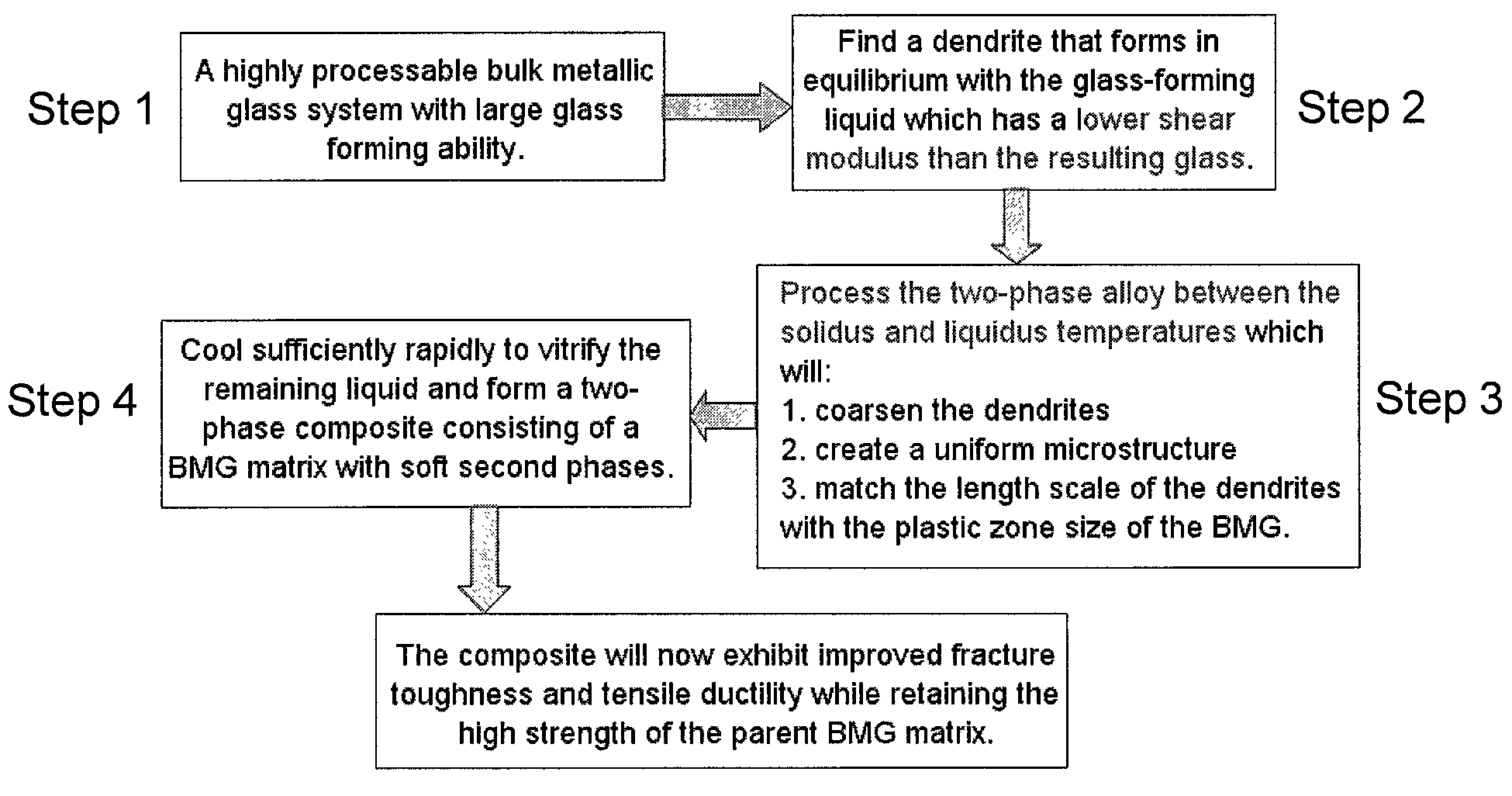

Semi-solid processing of bulk metallic glass matrix composites

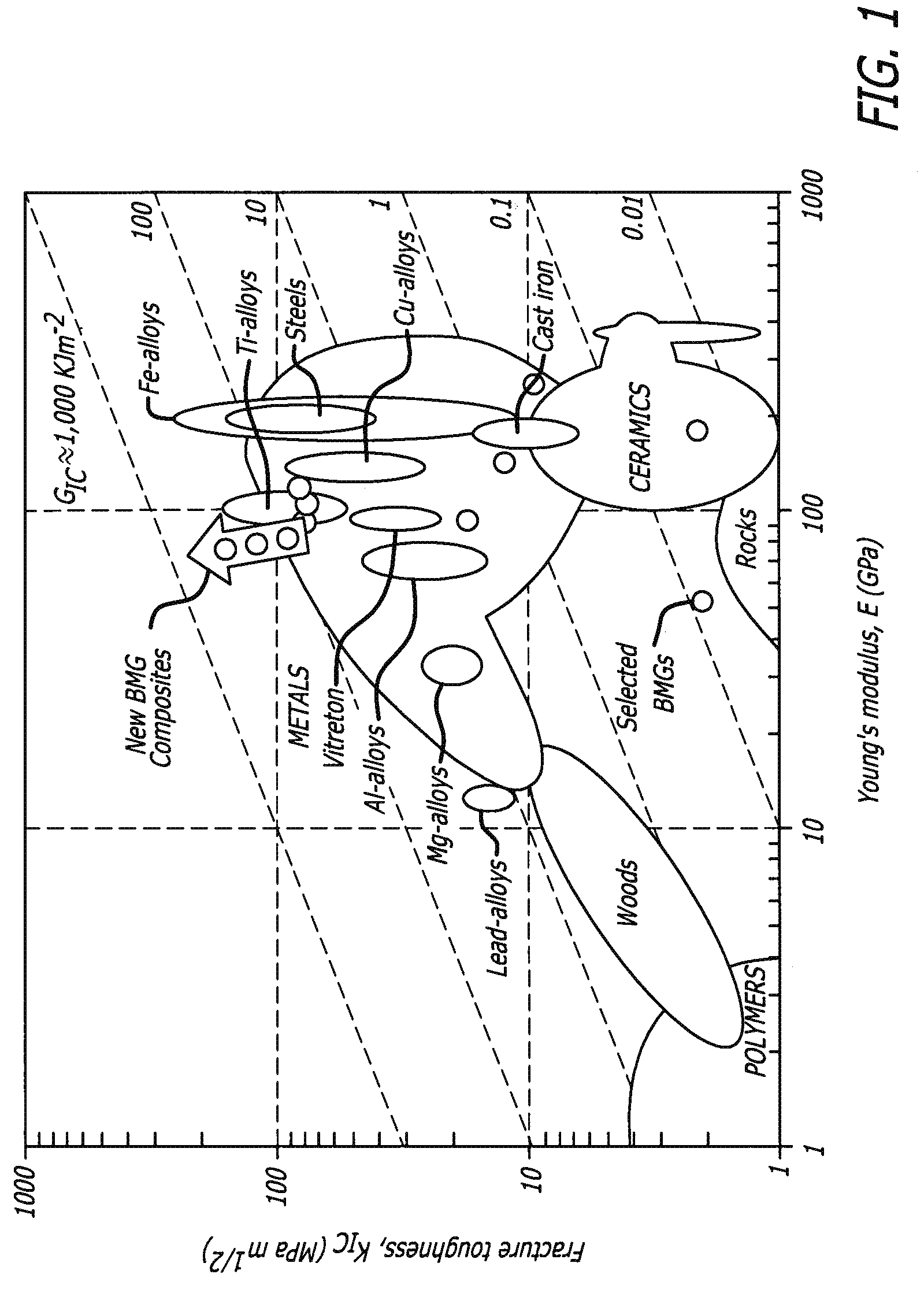

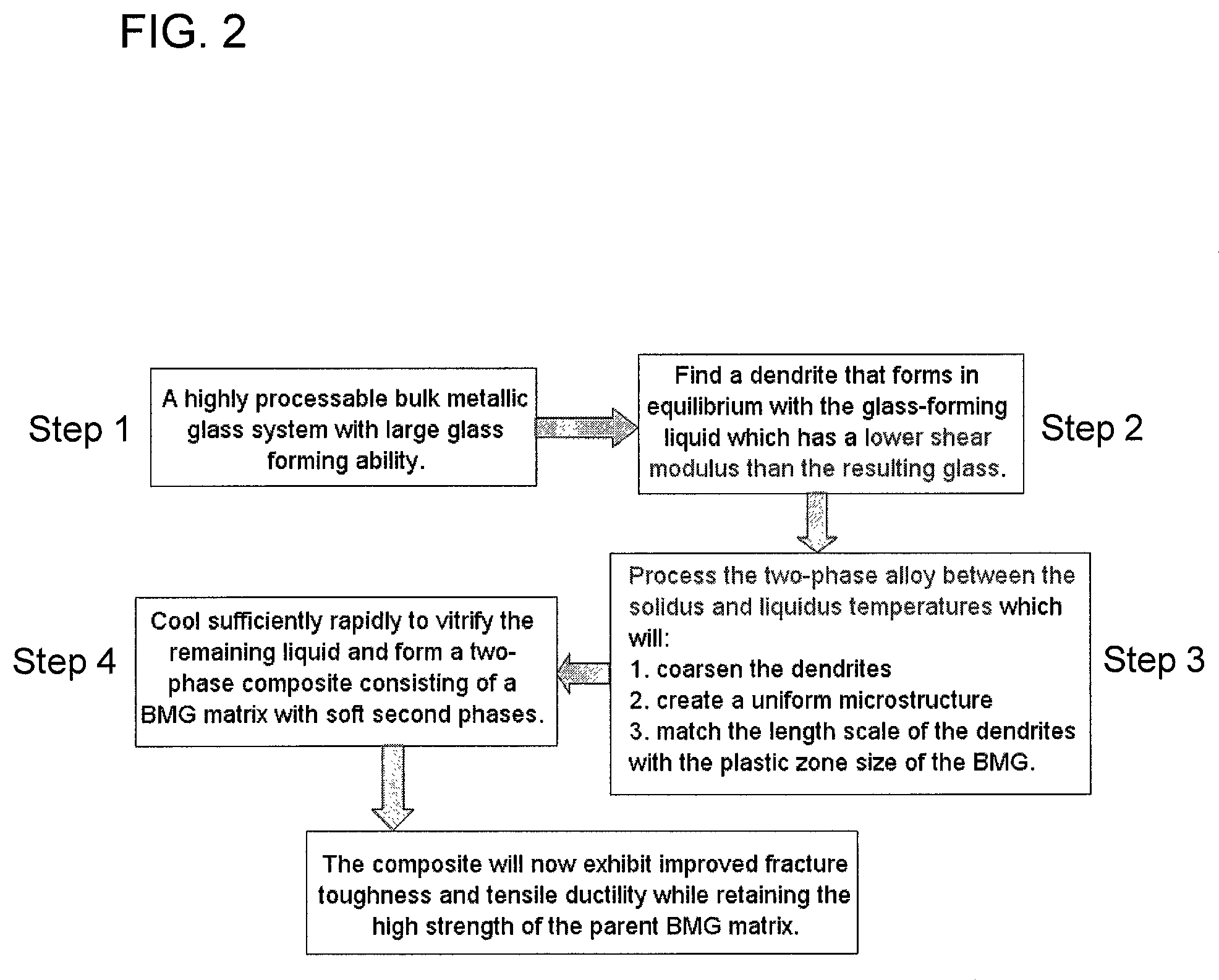

A method of forming bulk metallic glass engineering materials, and more particularly a method for forming coarsening microstructures within said engineering materials is provided. Specifically, the method forms ‘designed composites’ by introducing ‘soft’ elastic / plastic inhomogeneities in a metallic glass matrix to initiate local shear banding around the inhomogeneity, and matching of microstructural length scales (for example, L and S) to the characteristic length scale RP (for plastic shielding of an opening crack tip) to limit shear band extension, suppress shear band opening, and avoid crack development.

Owner:CALIFORNIA INST OF TECH

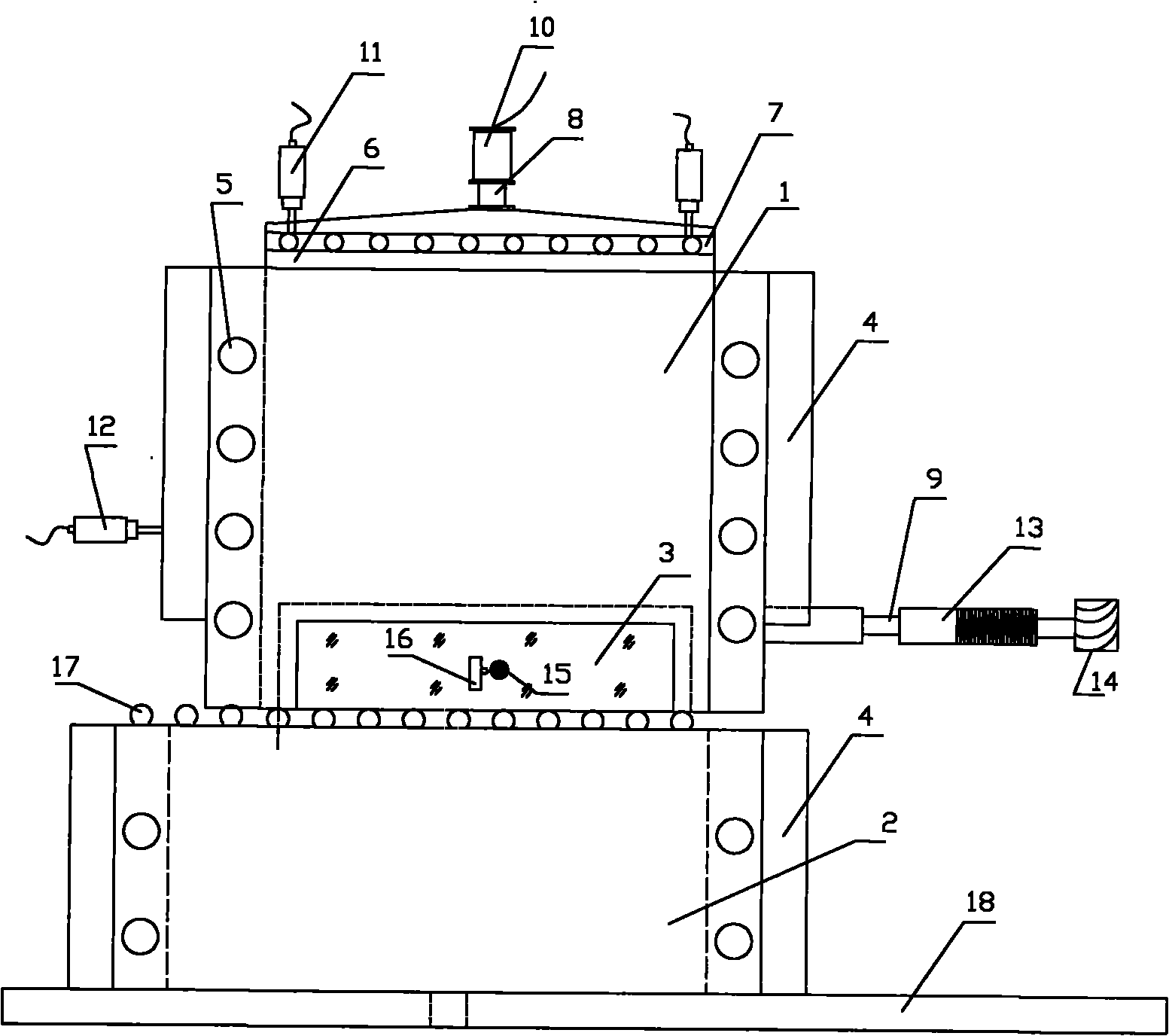

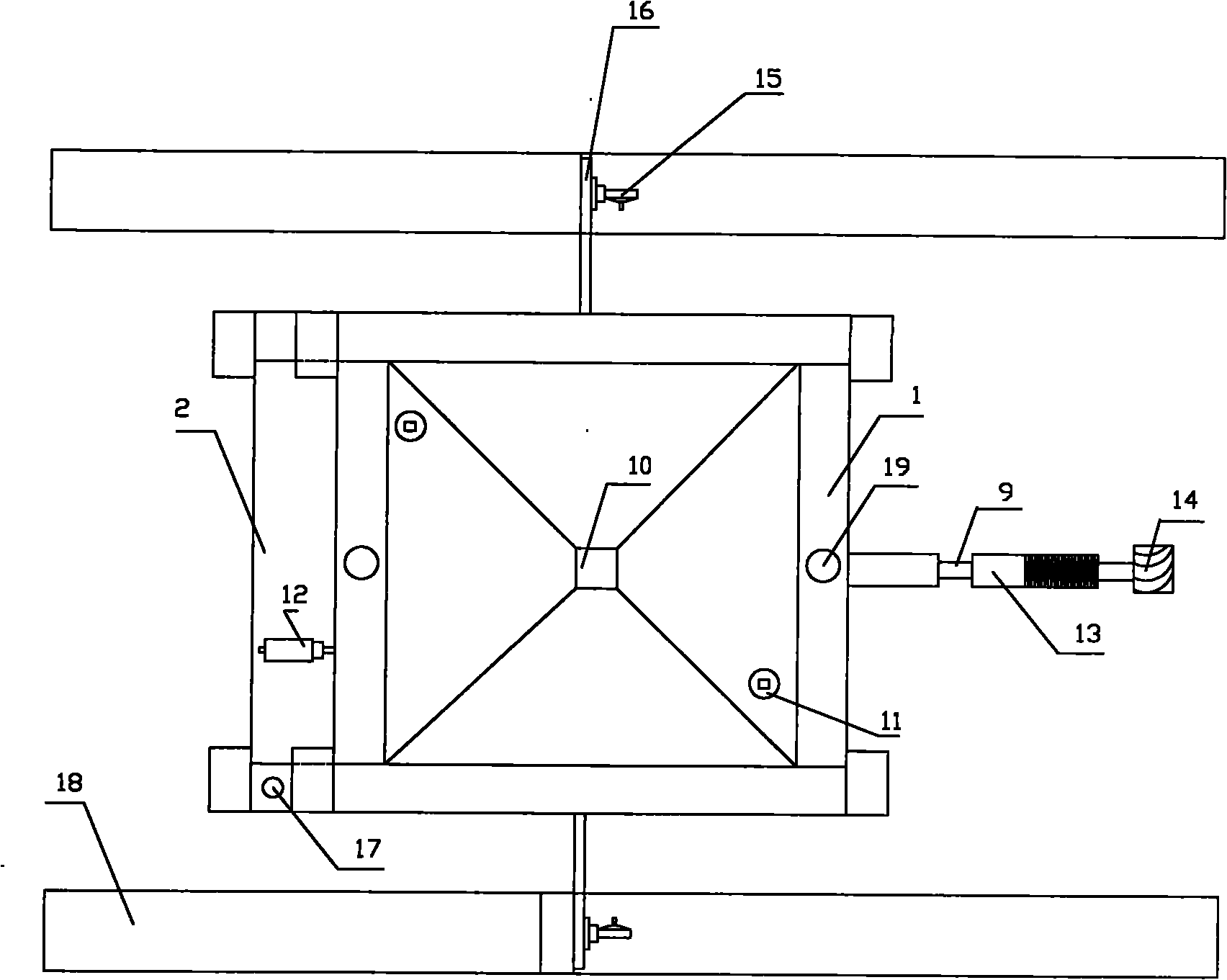

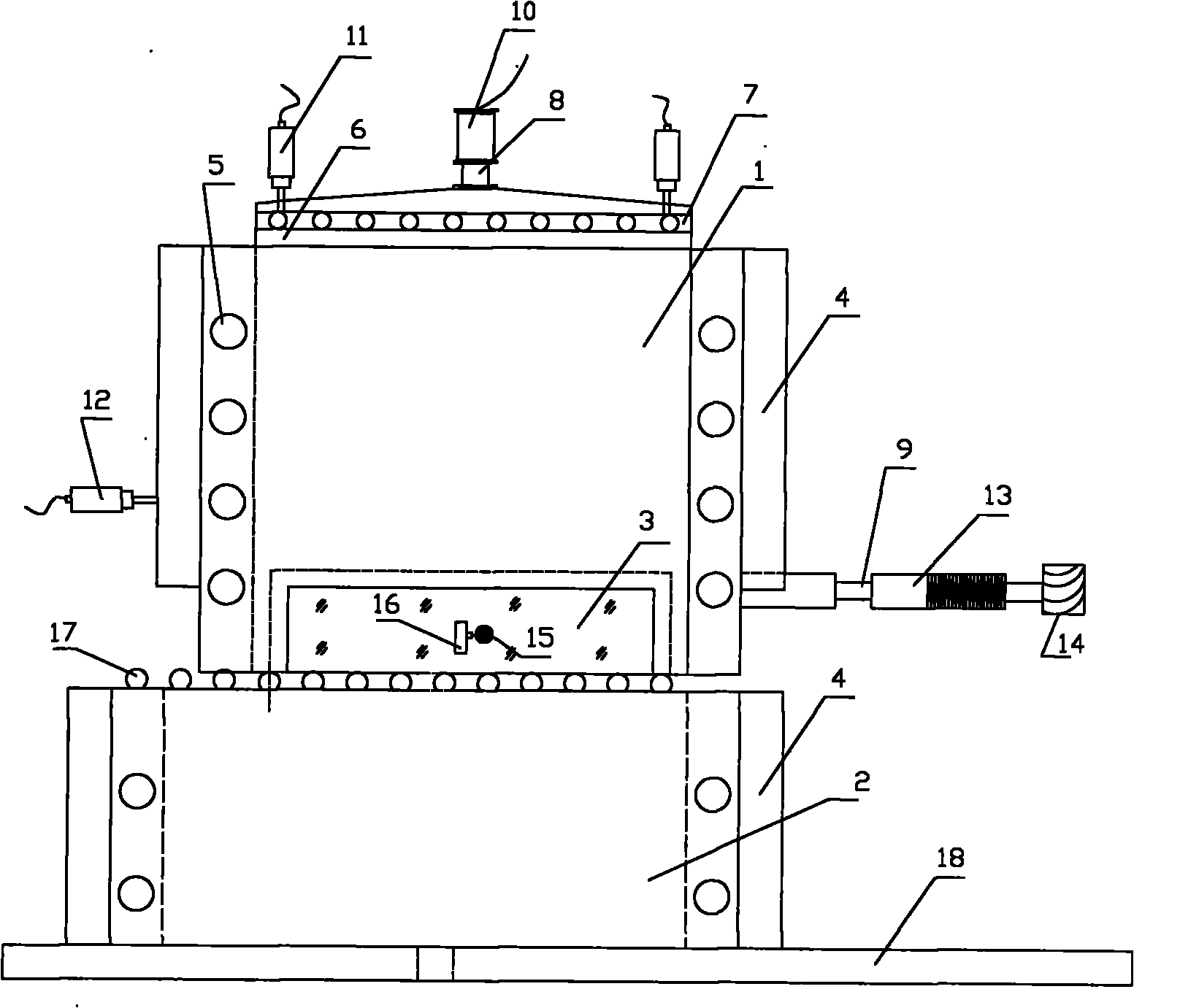

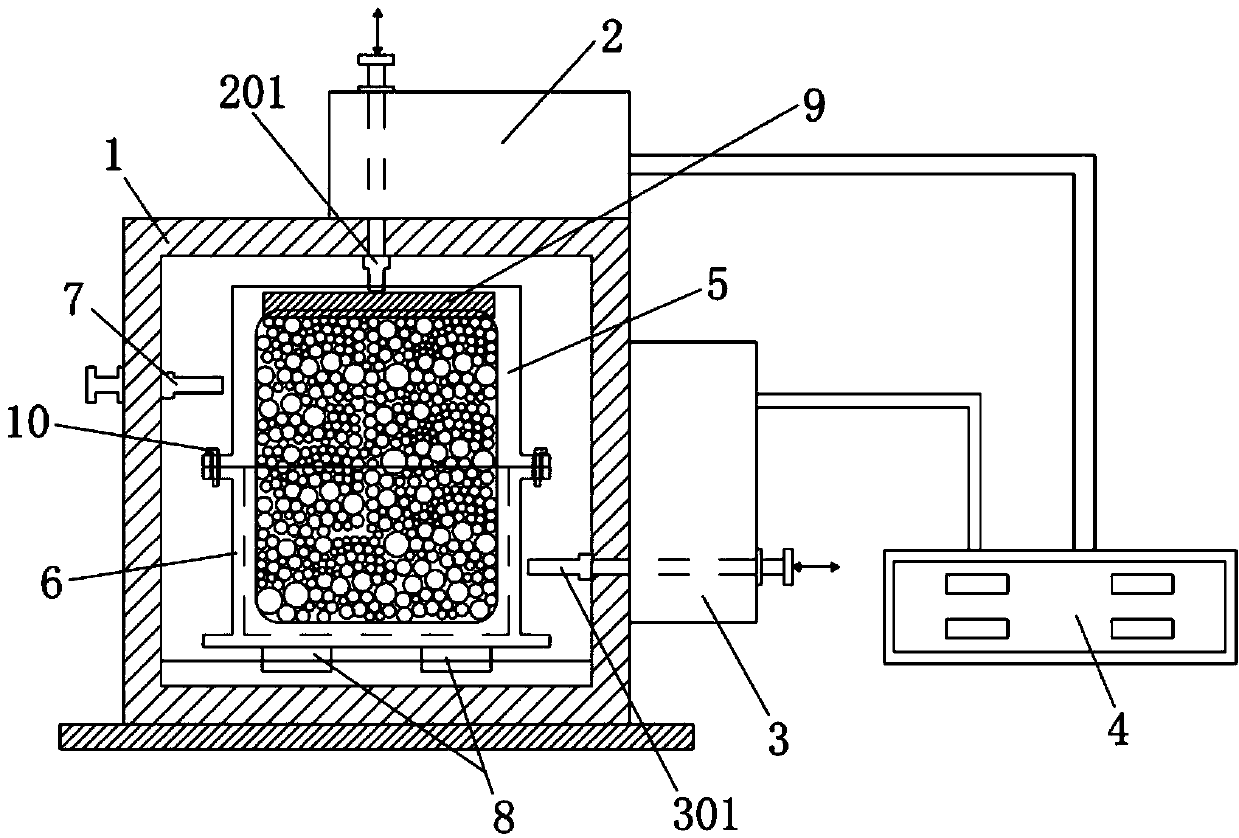

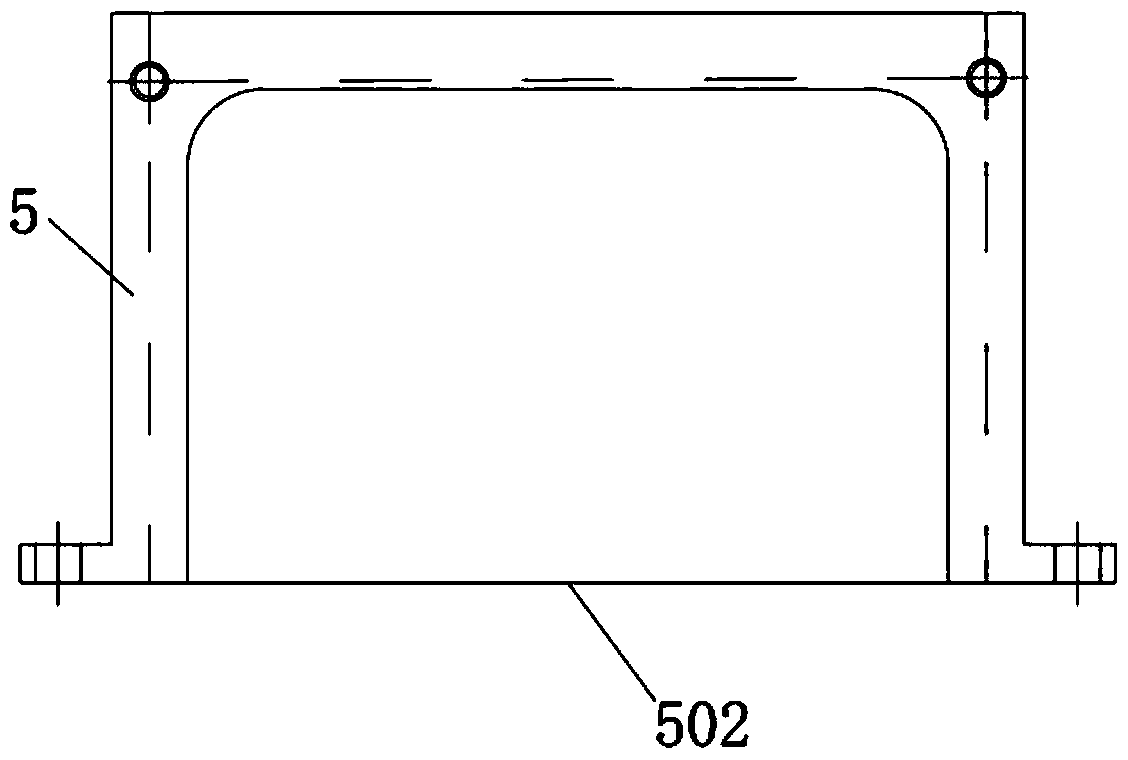

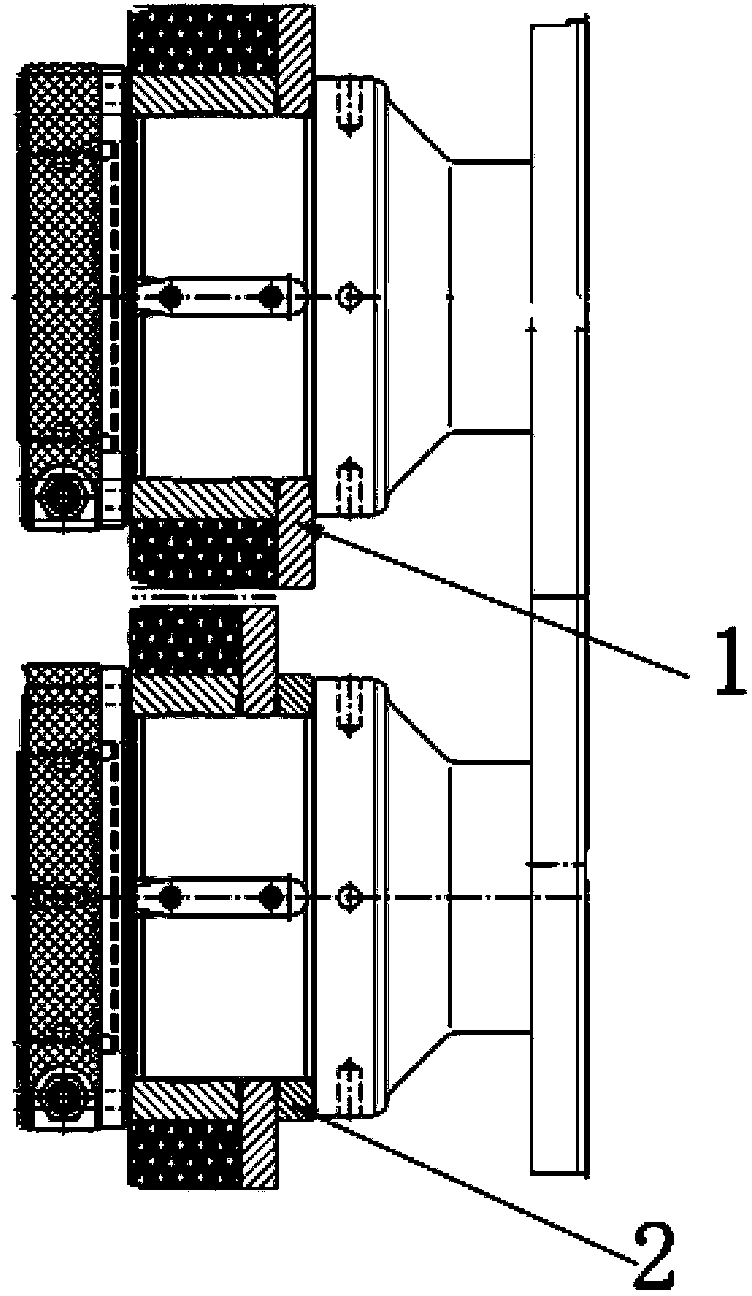

Earth-structure interaction contact surface shearing test visualization device

InactiveCN101846606ARealize a full range of observationAchieve distortionMaterial strength using steady shearing forcesData acquisitionEngineering

The invention relates to an earth-structure interaction contact surface shearing test visualization device. The device mainly comprises an upper shear box (1), a lengthened lower shear box (2), a perspective window (3), a camera head (15), a connecting seat (16) and the like. The device shoots the shear band deformation and the earth grain change process in the whole shear test process by using the camera chain to acquire a series of shear band digital images at different time points and a whole-journey video, and provides references for quantitative analysis tests on the range, deformation and thickness of the earth-structure contact surface shear band. The invention has the characteristics of reasonable structure, convenient disassembly, high test load, large sample dimension, visualized shear test process, automatic data acquisition and the like, and ensures the rigidity of the shear box while realizing the overall visualized observation on the contact surface shear band. The invention can be widely used in contact surface mechanical parameter testing, and qualitative and quantitative analysis on the macroscopic and microscopic properties of the shear band under the earth-structure interaction in geotechnical engineering.

Owner:INST OF ROCK AND SOIL MECHANICS - CHINESE ACAD OF SCI

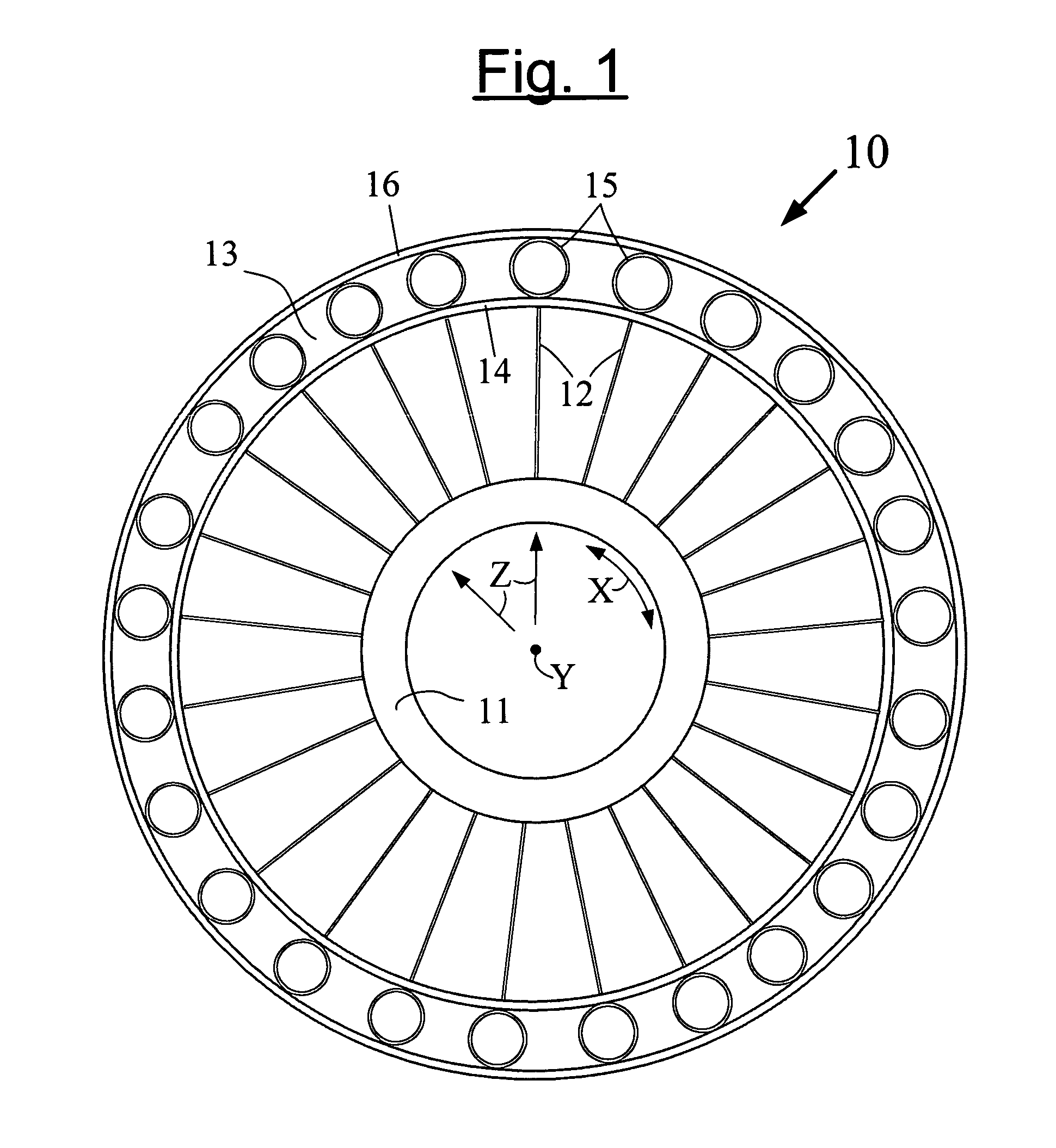

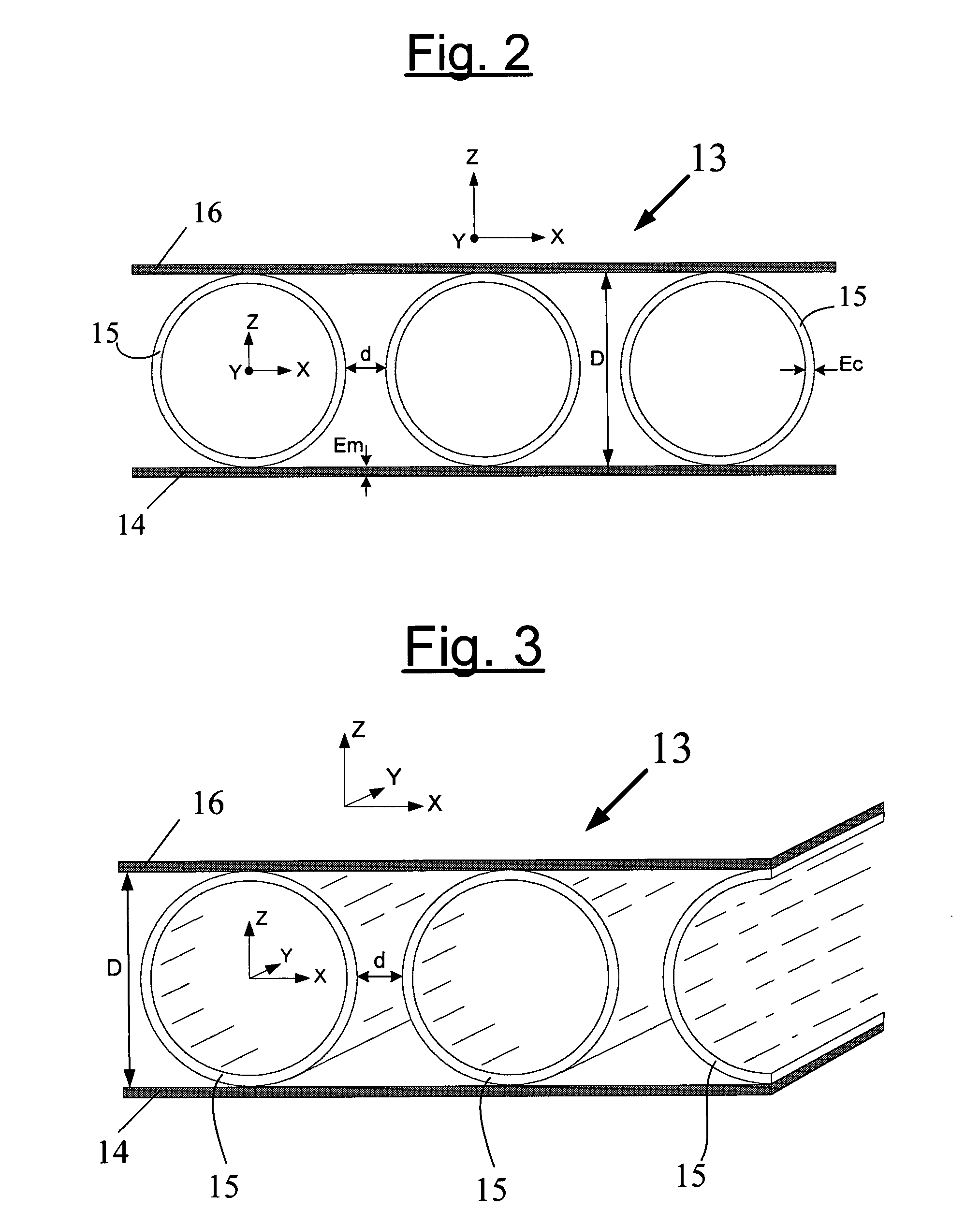

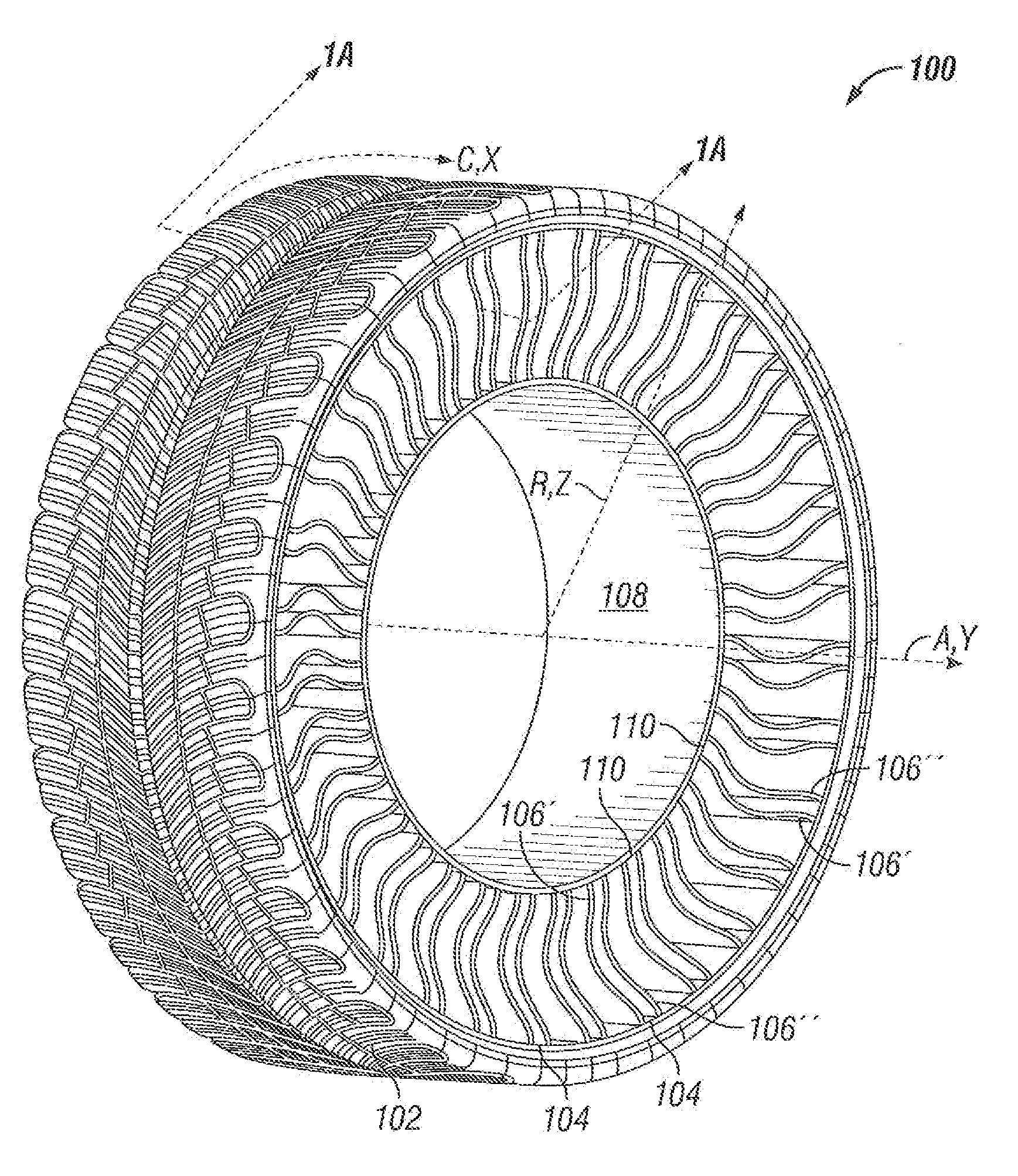

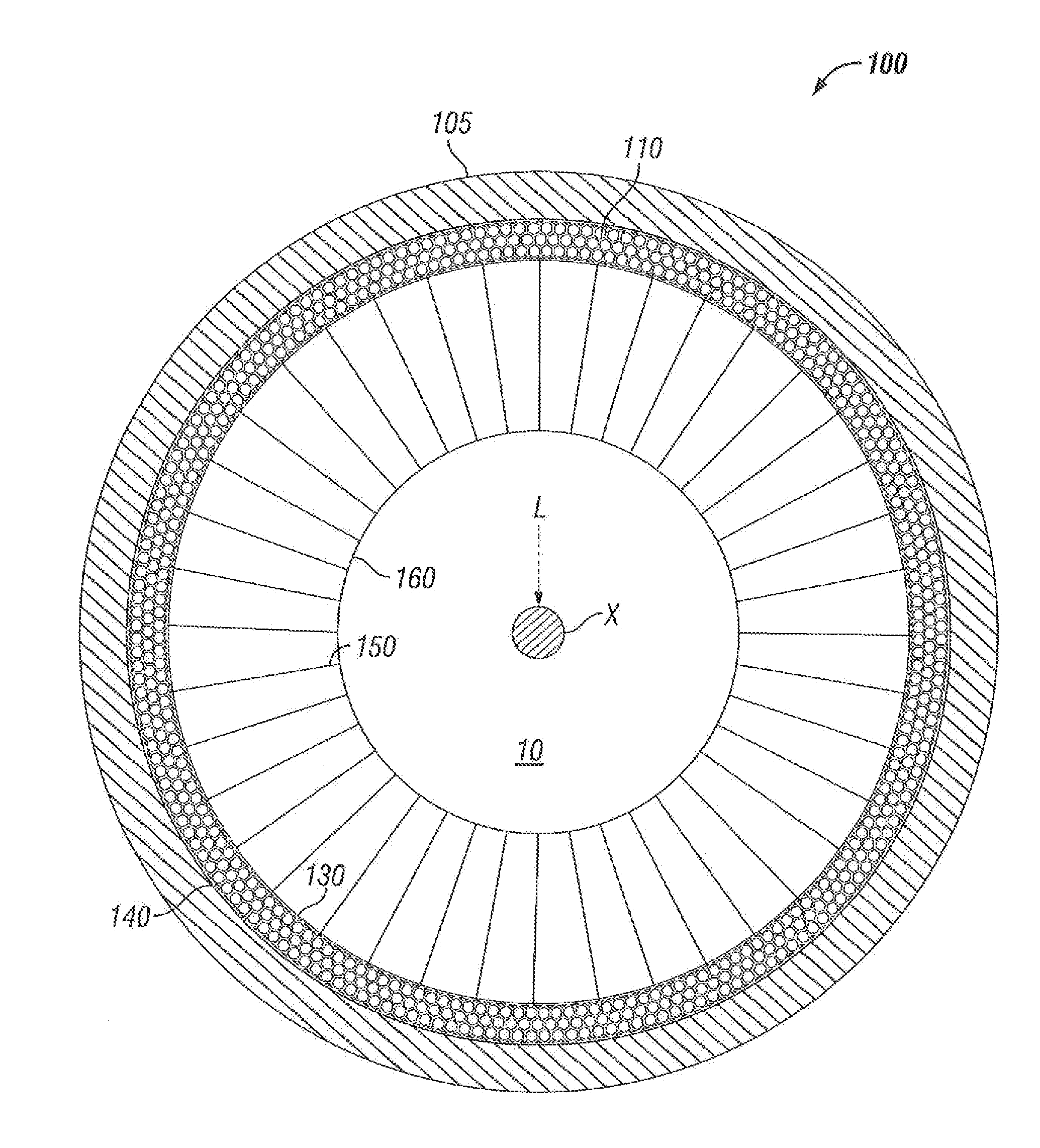

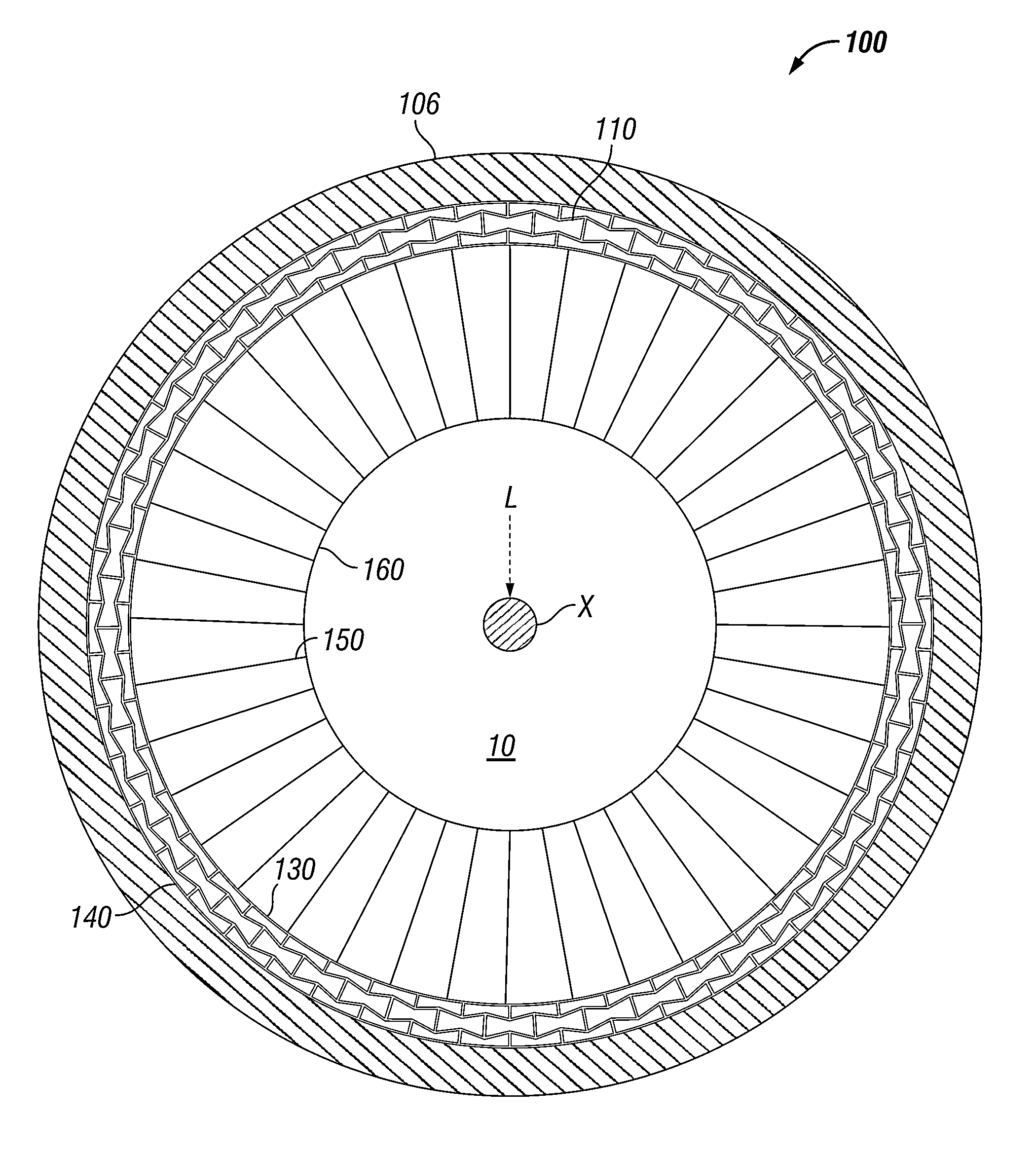

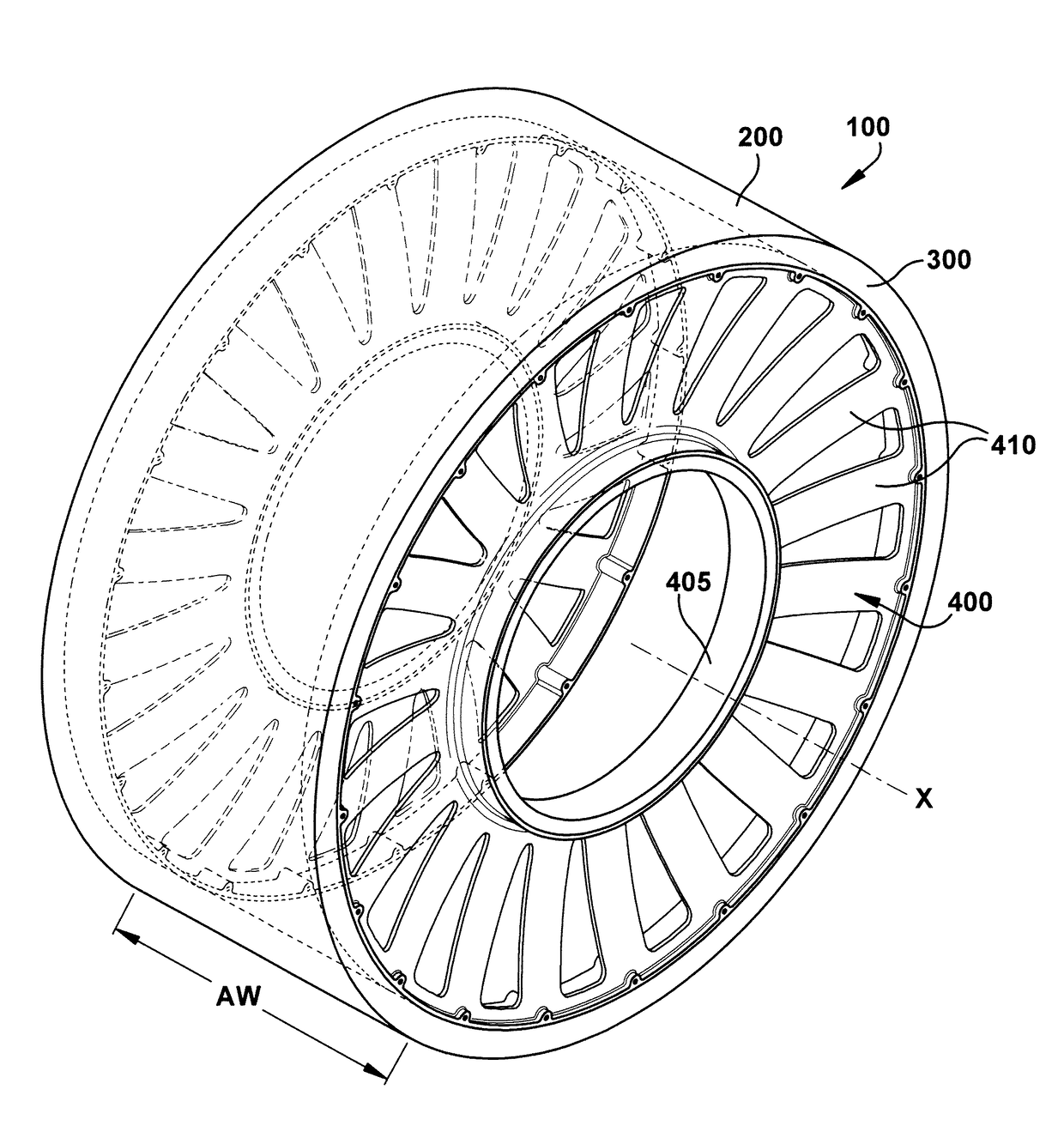

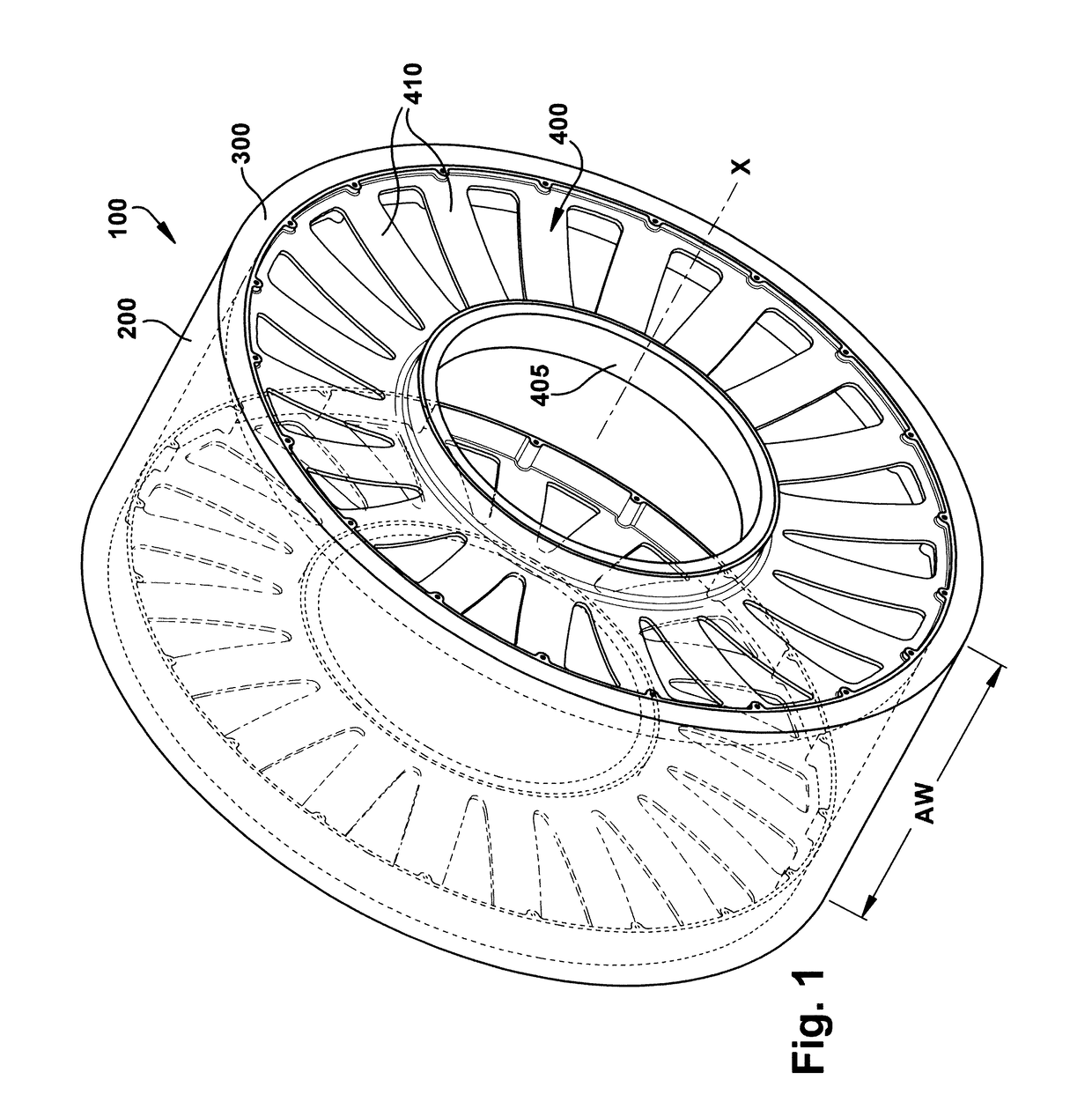

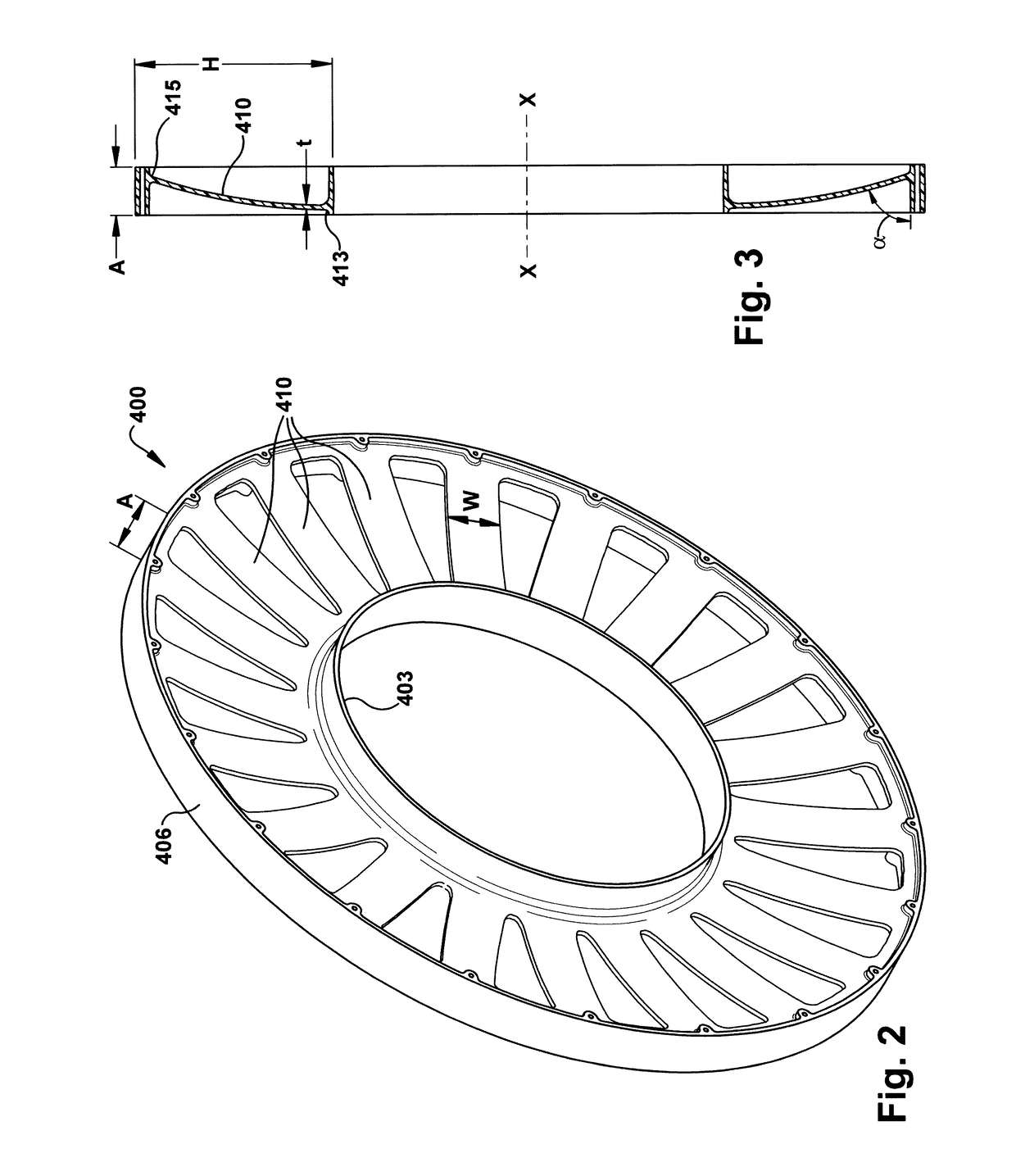

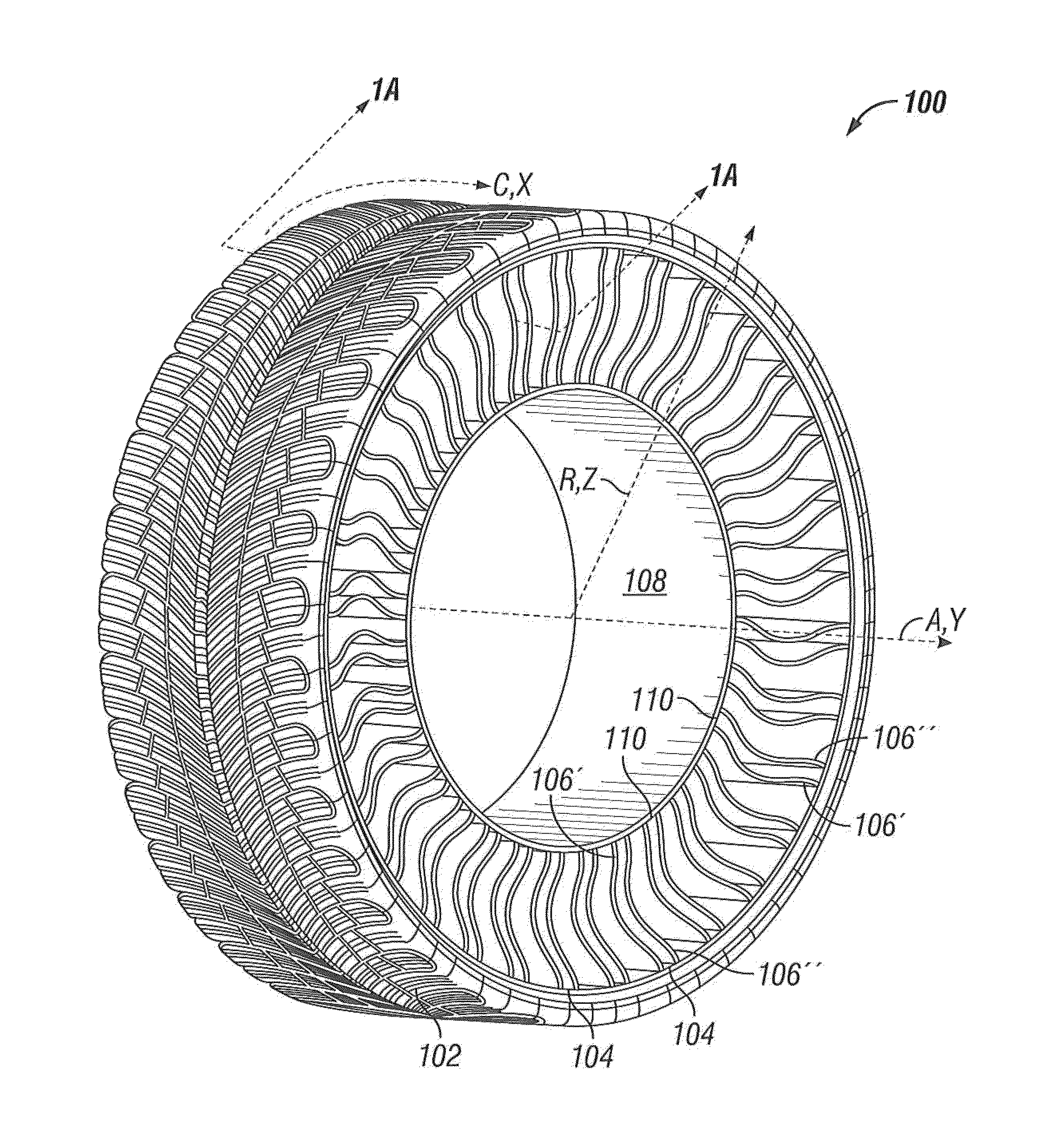

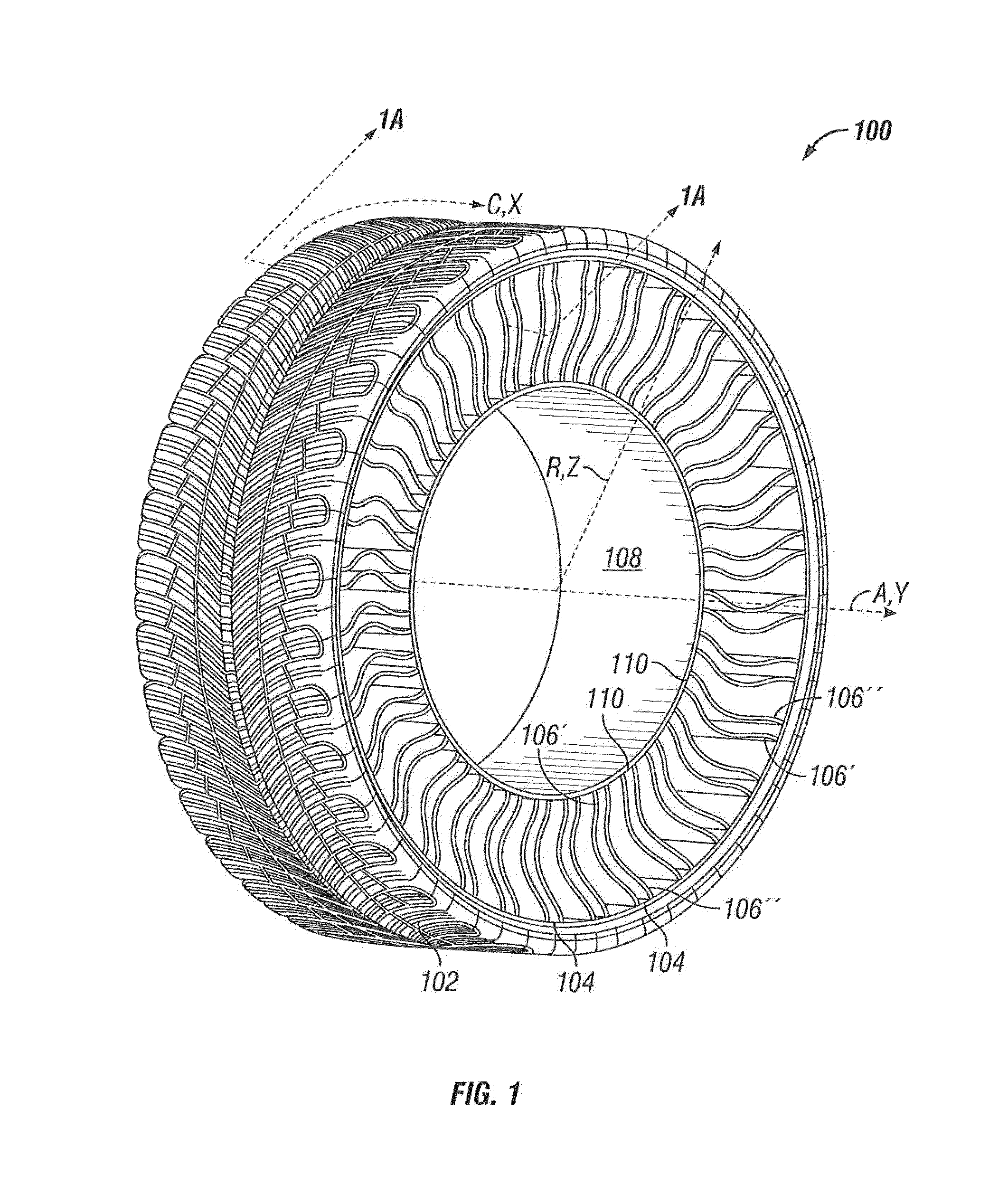

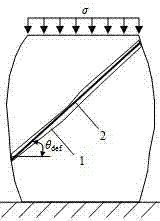

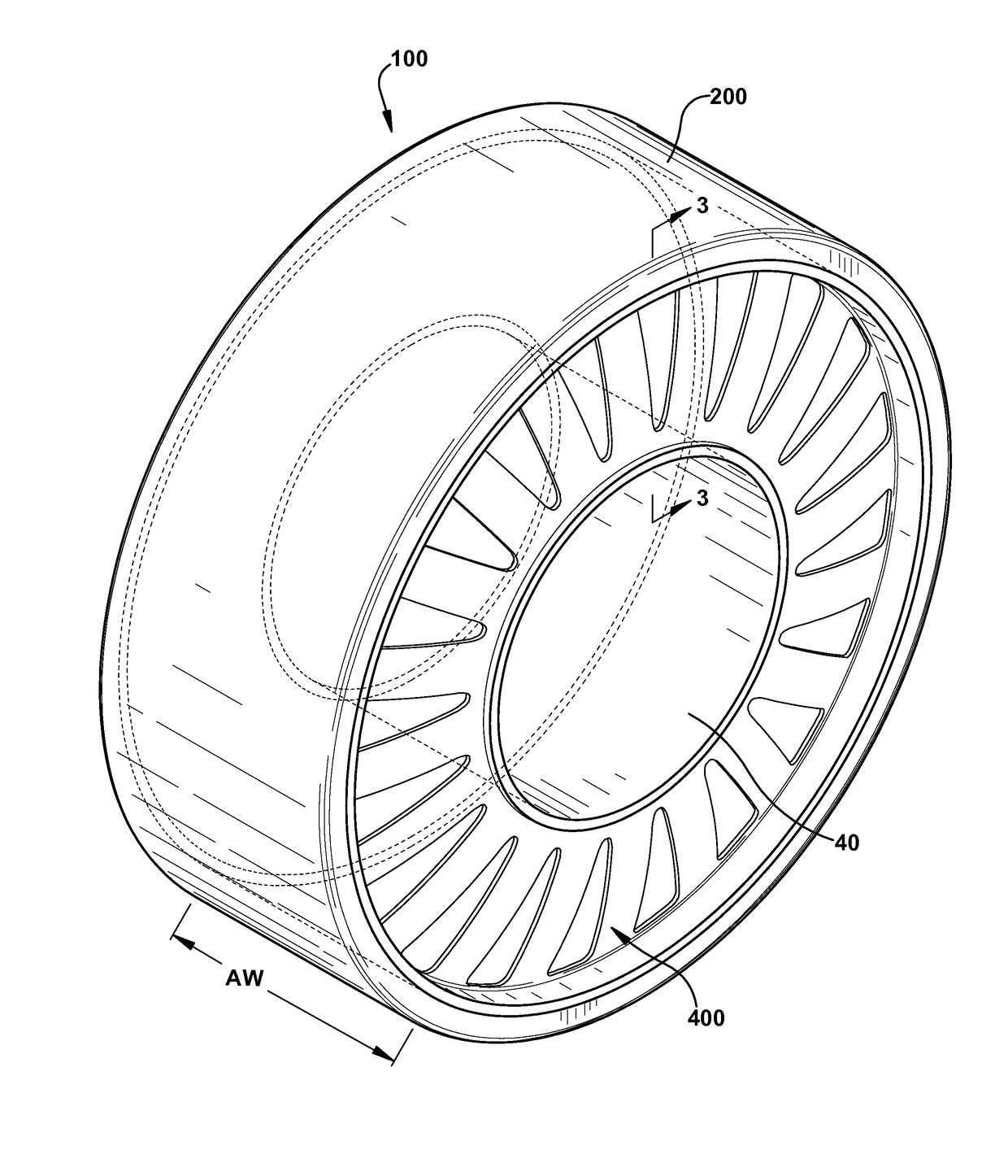

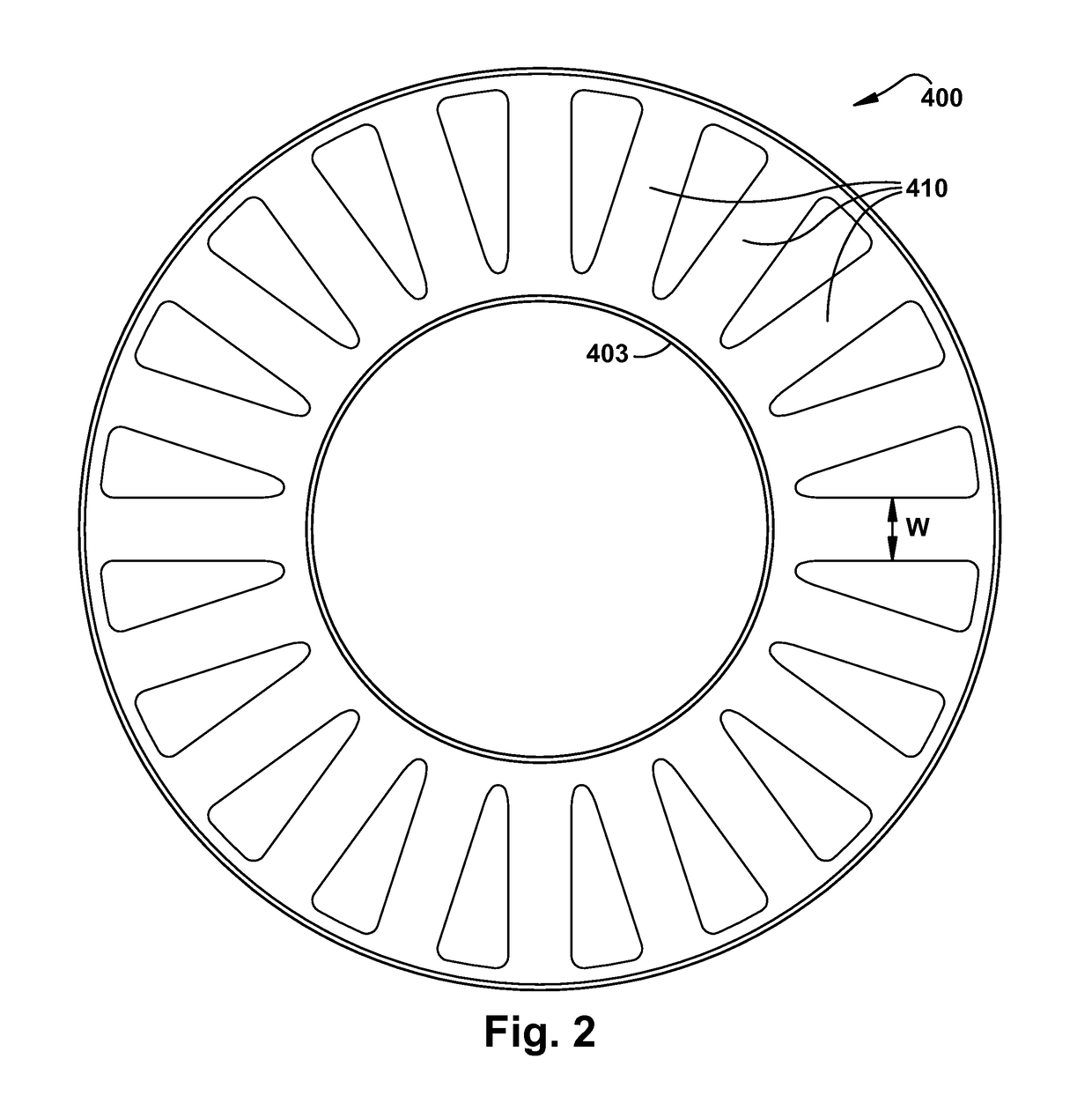

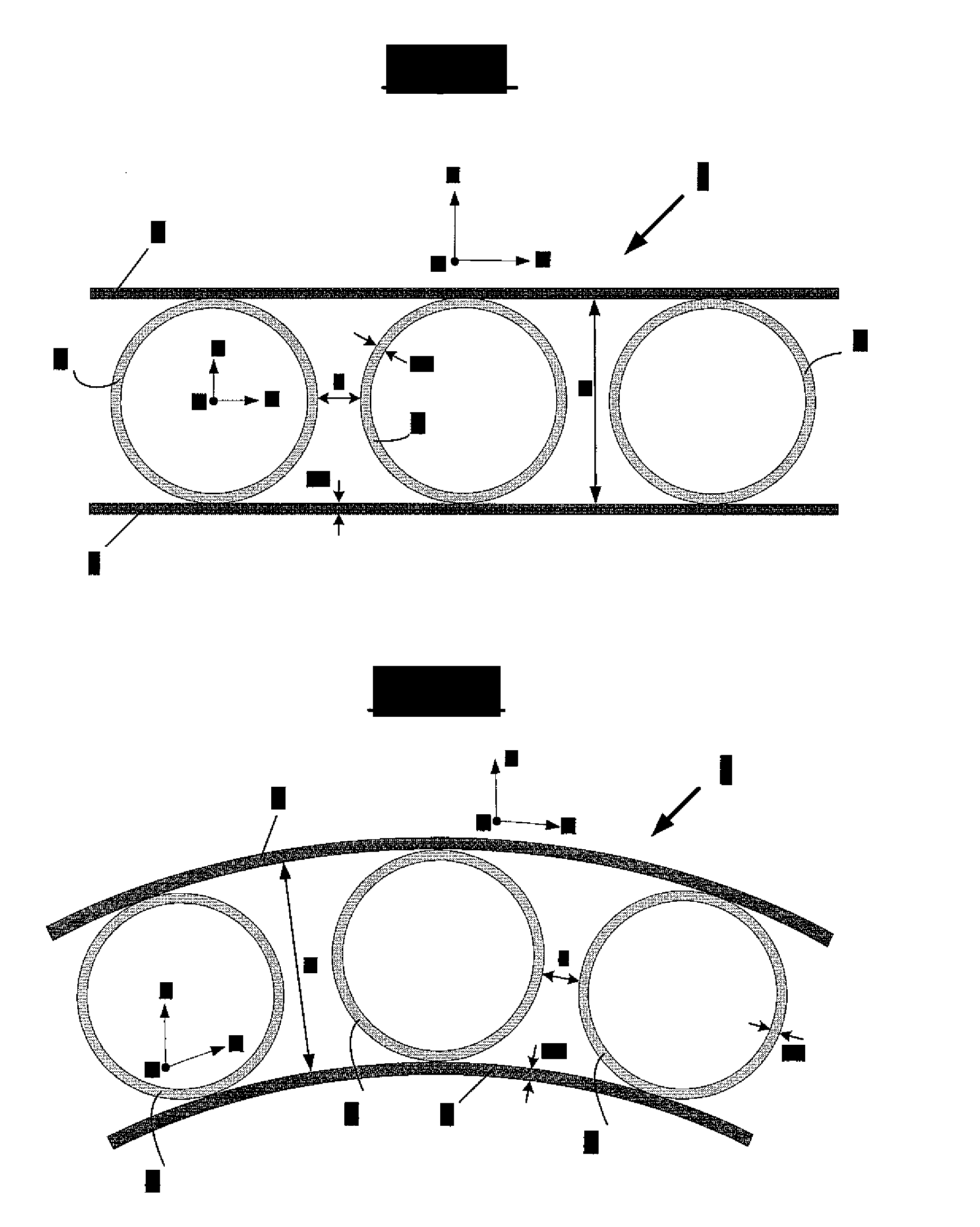

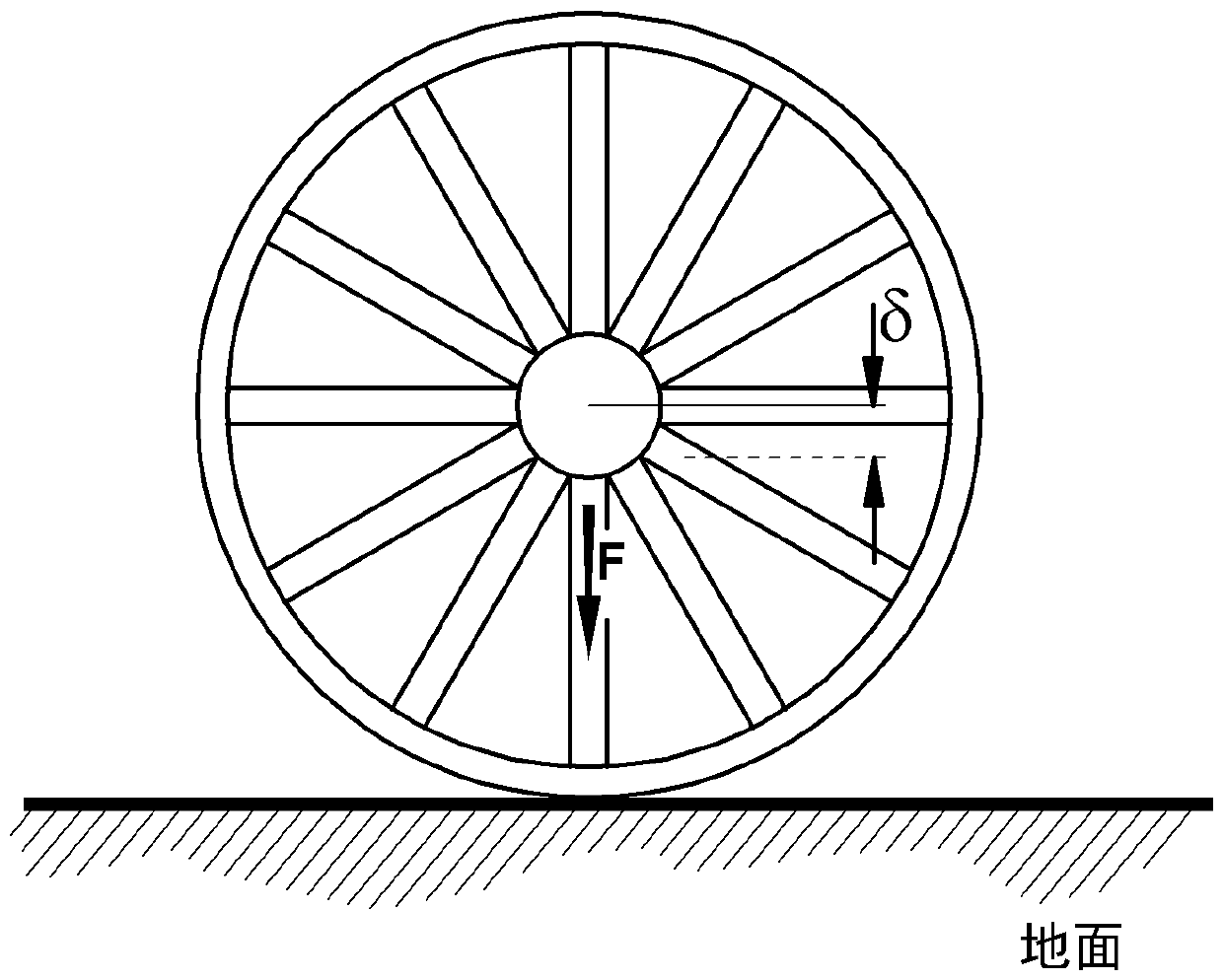

Non-Pneumatic Elastic Wheel

ActiveUS20100307653A1Improve staminaIncrease resistanceNon-inflatable tyresNon-metallic wheel bodyFiberResin matrix

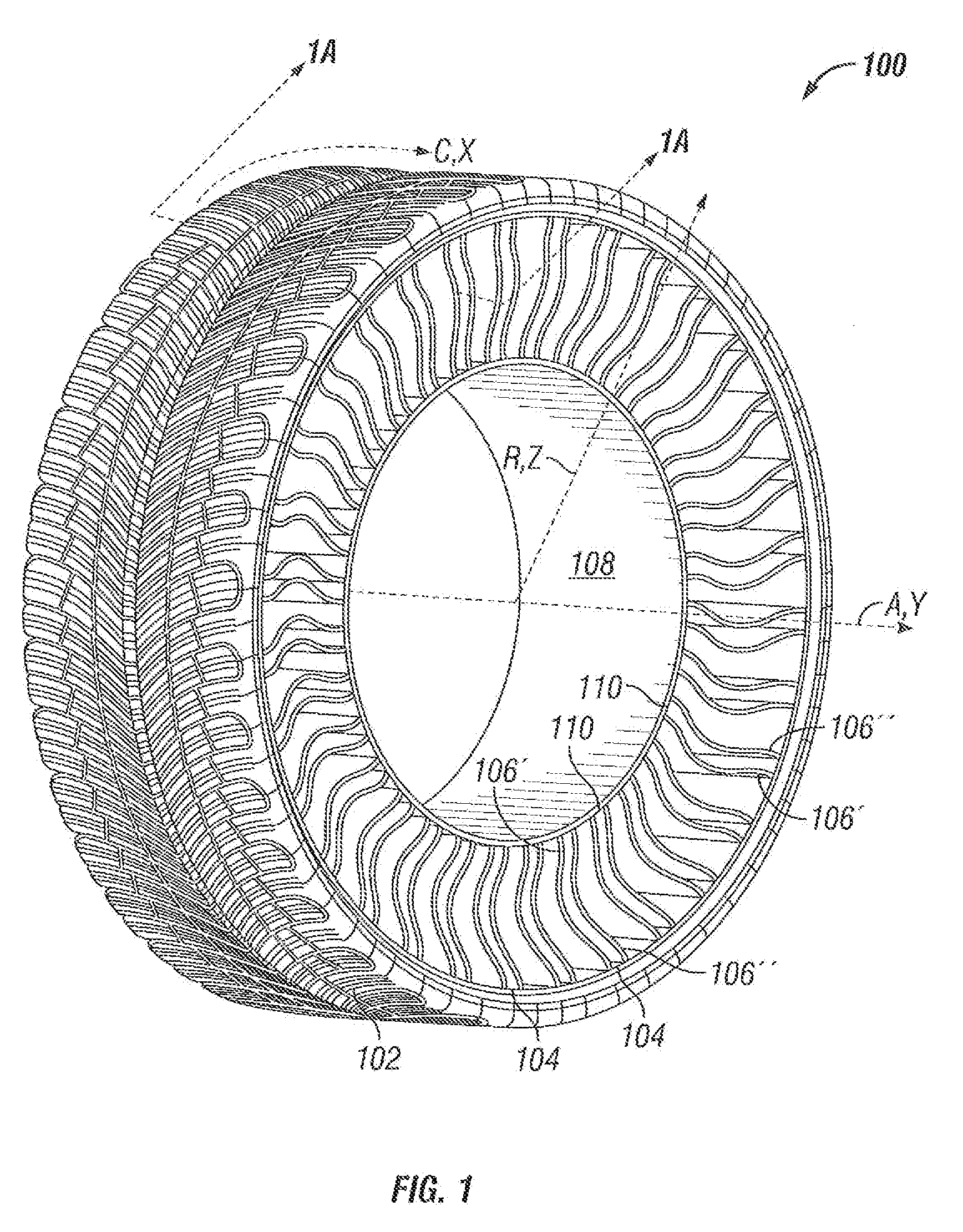

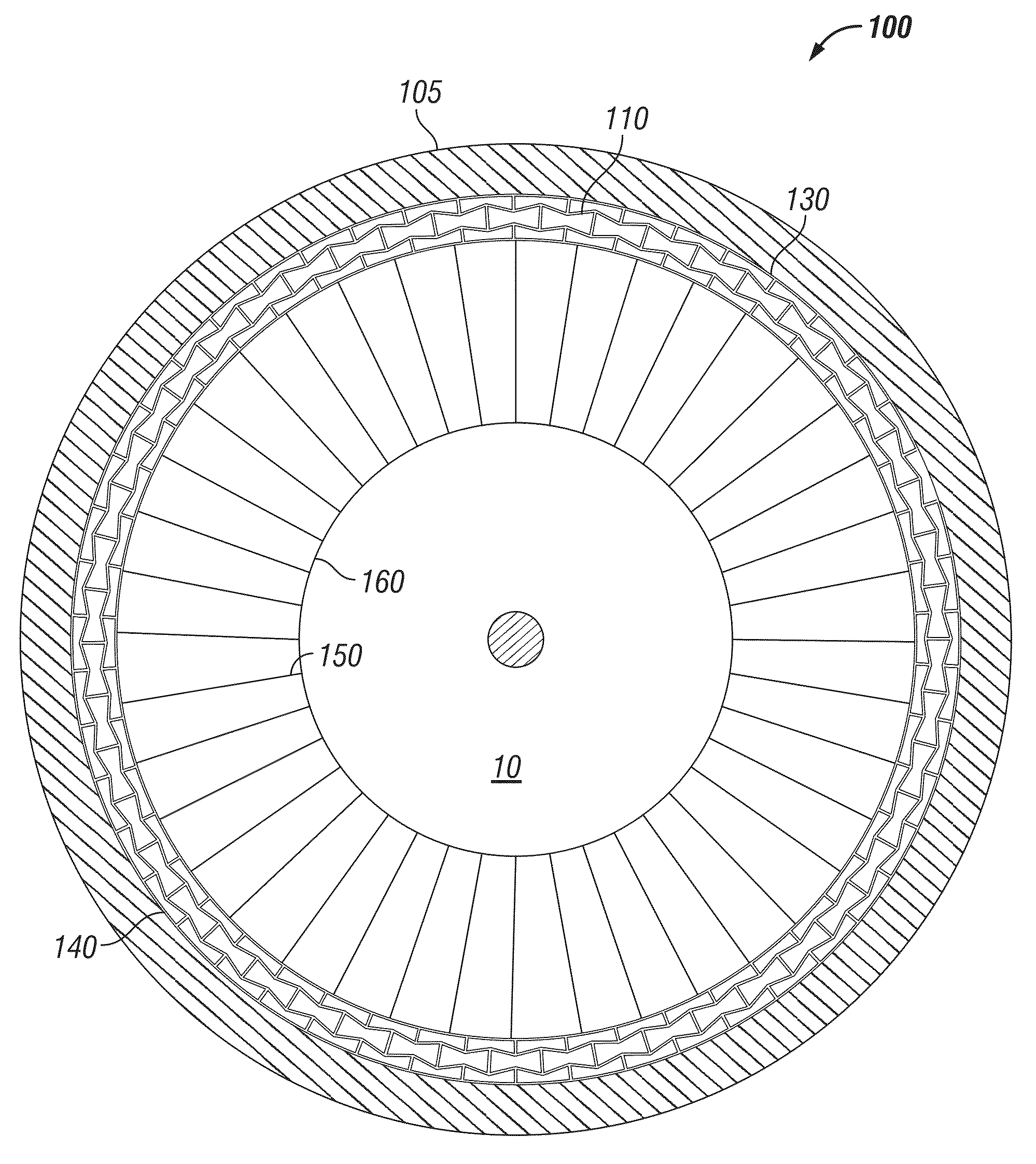

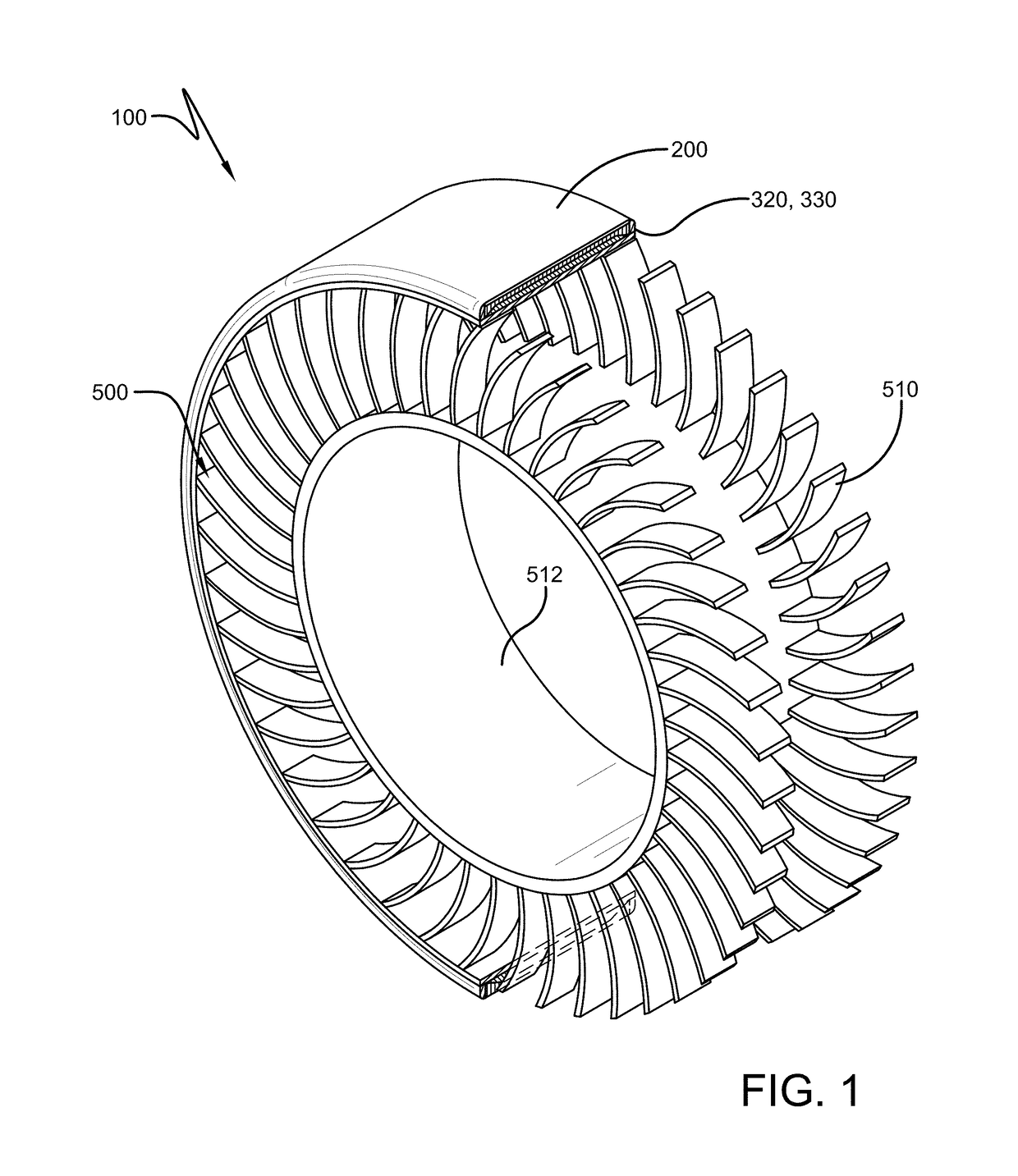

Non-pneumatic resilient wheel (10), that is supported structurally and defines three perpendicular directions, circumferential (X), axial (Y) and radial (Z), this wheel comprising: a hub (11); an annular band referred to as a shear band (13) comprising at least one inner circumferential membrane (14) and one outer circumferential membrane (16) that are oriented in the circumferential direction X; and a plurality of support elements (12) that connect the hub (11) to the inner circumferential membrane (14)U. The two membranes (14, 16) are connected to one another by means of a series, that extends in the circumferential direction (X), of cylinders (15) referred to as connection cylinders, said connection cylinders (15) being non-touching in the circumferential direction X and having their generatrix oriented in the axial direction Y. The connection cylinders (15) are composite cylinders comprising fibres embedded in a resin matrix.

Owner:MICHELIN RECH & TECH SA +1

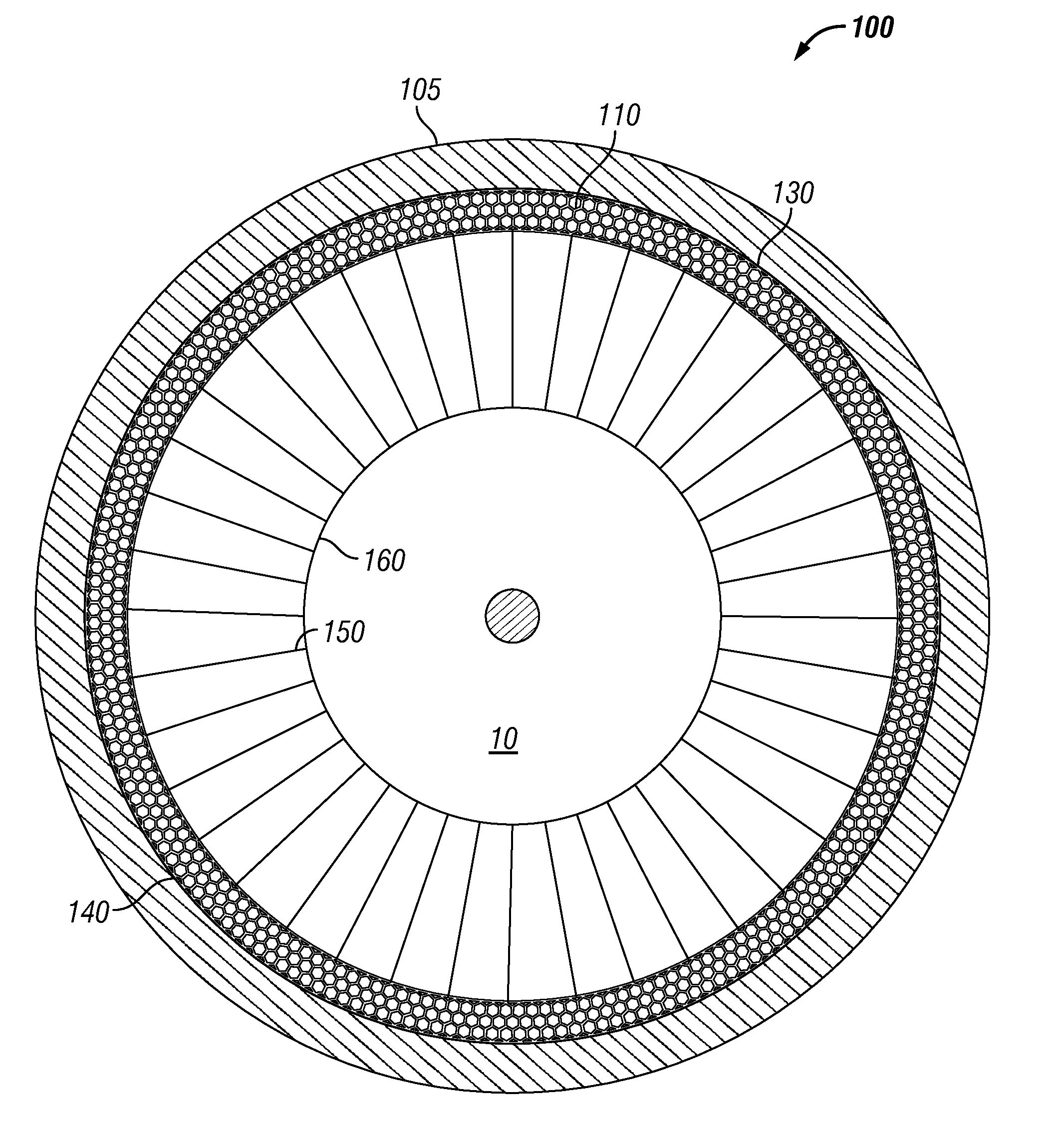

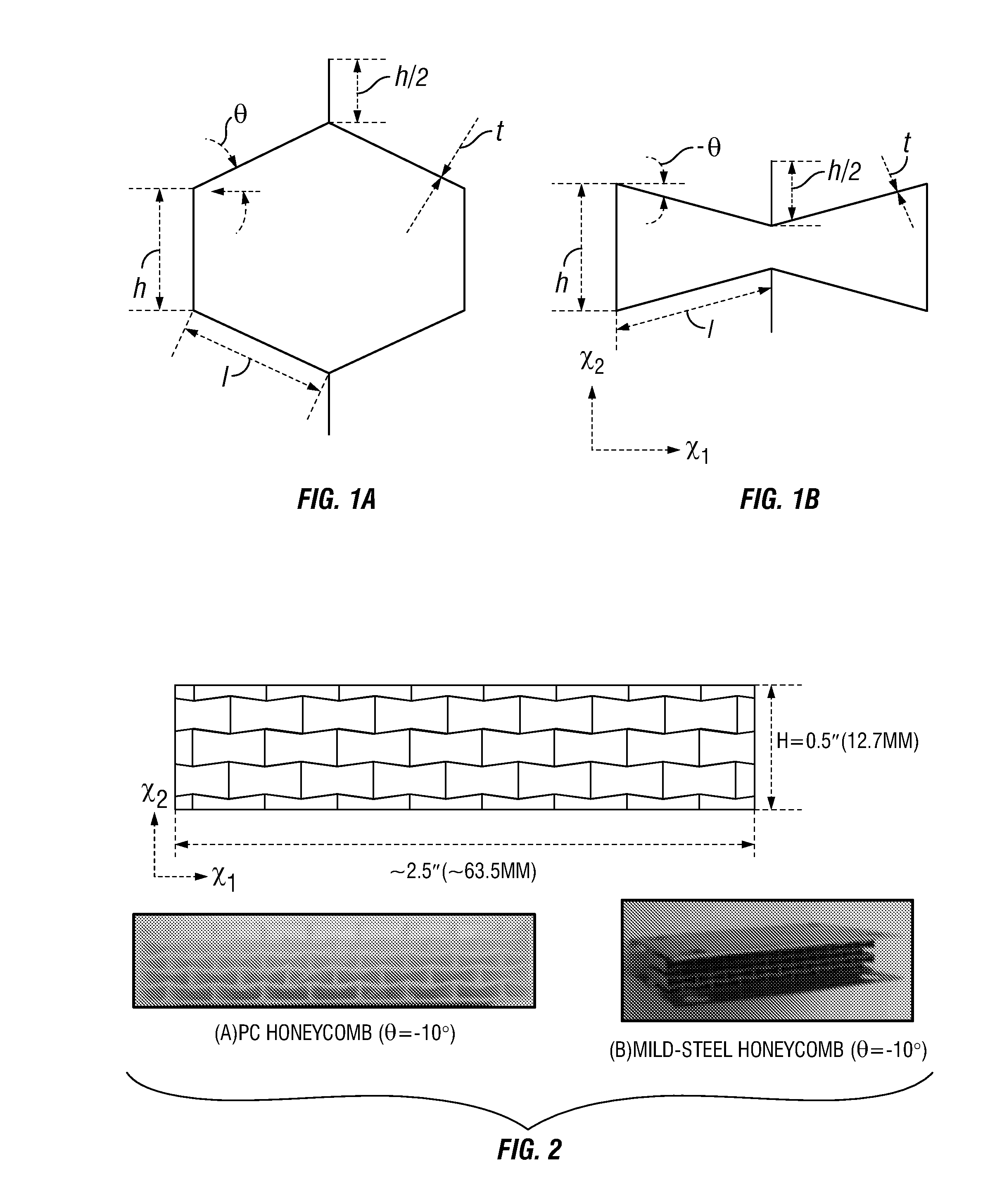

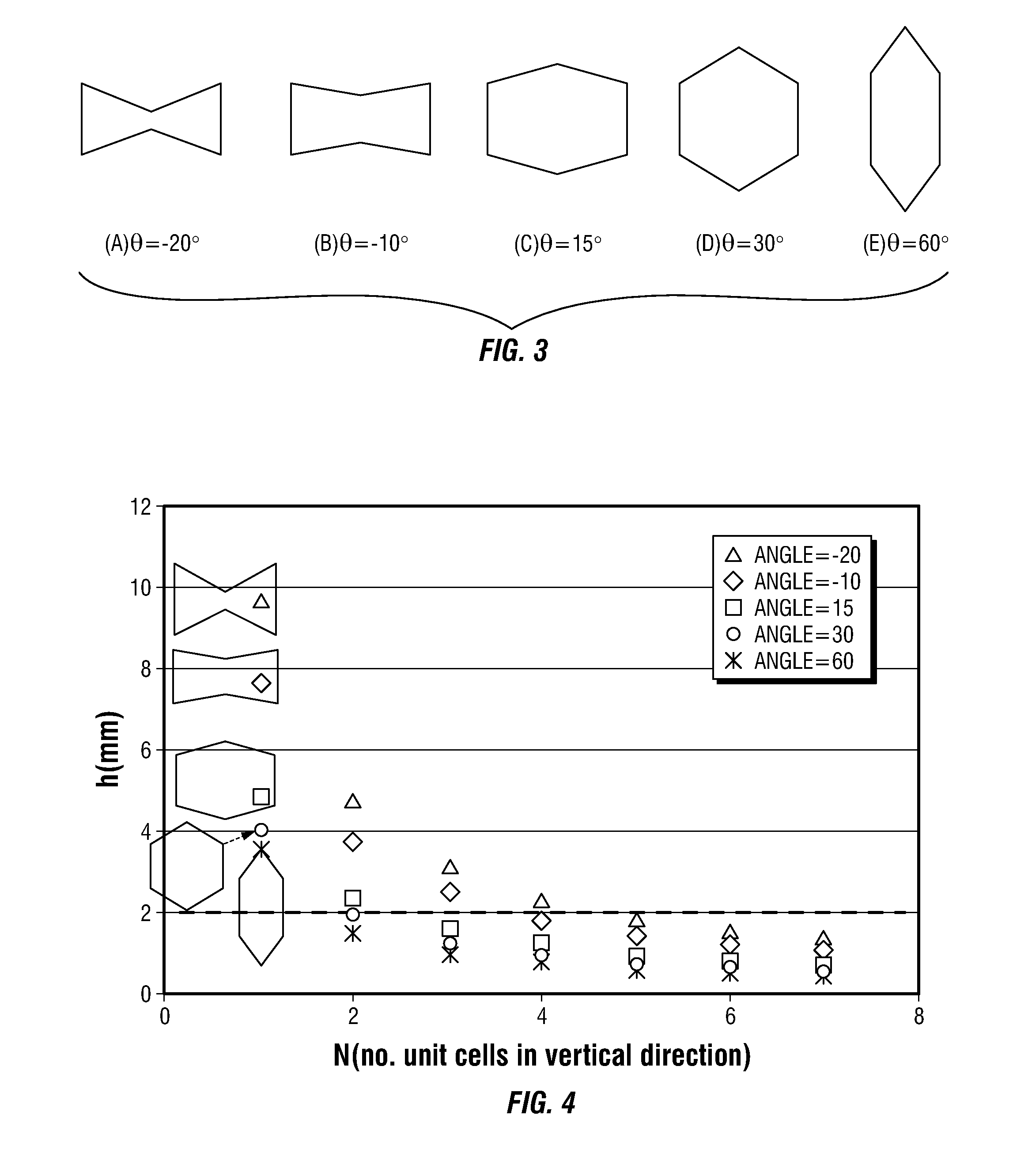

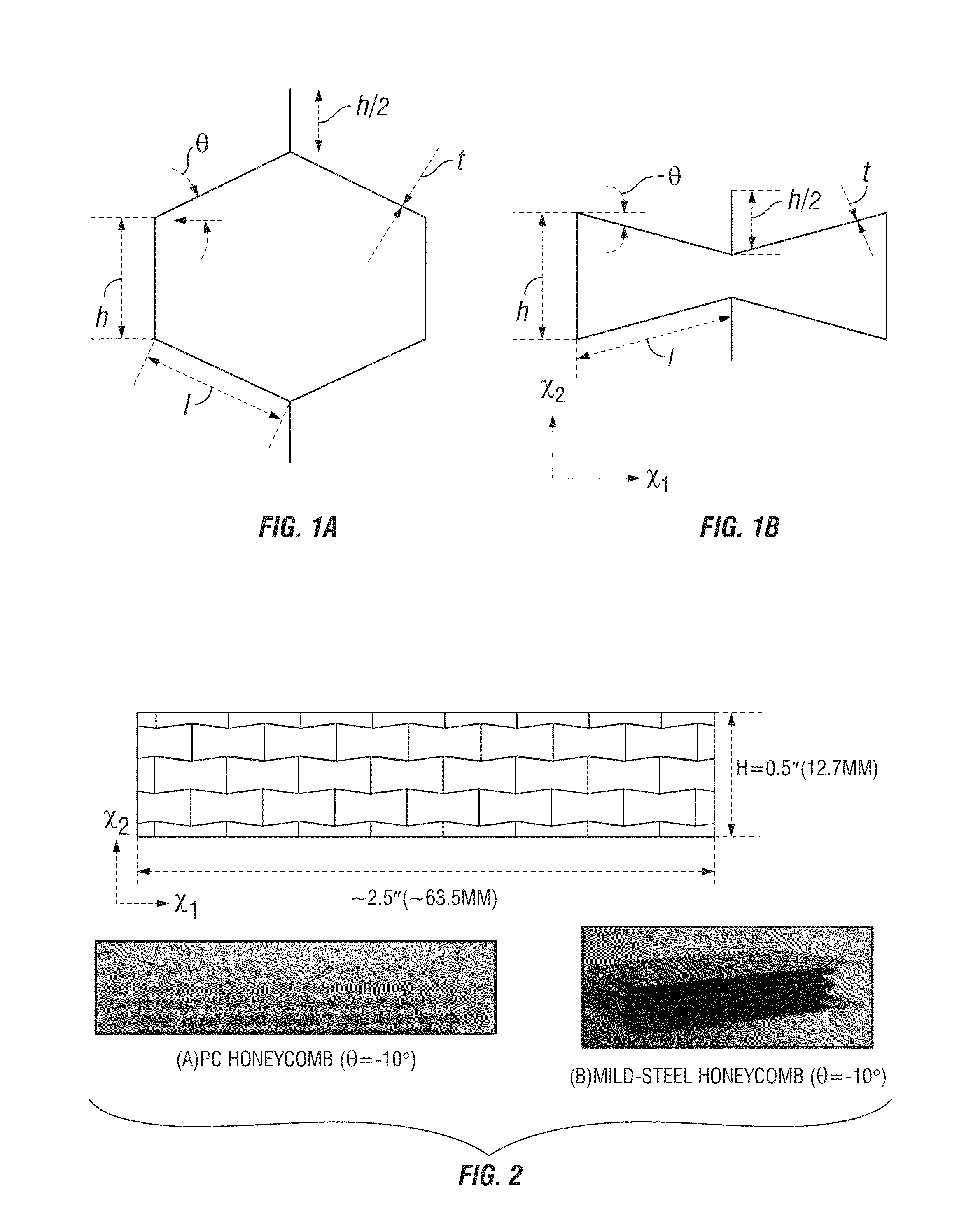

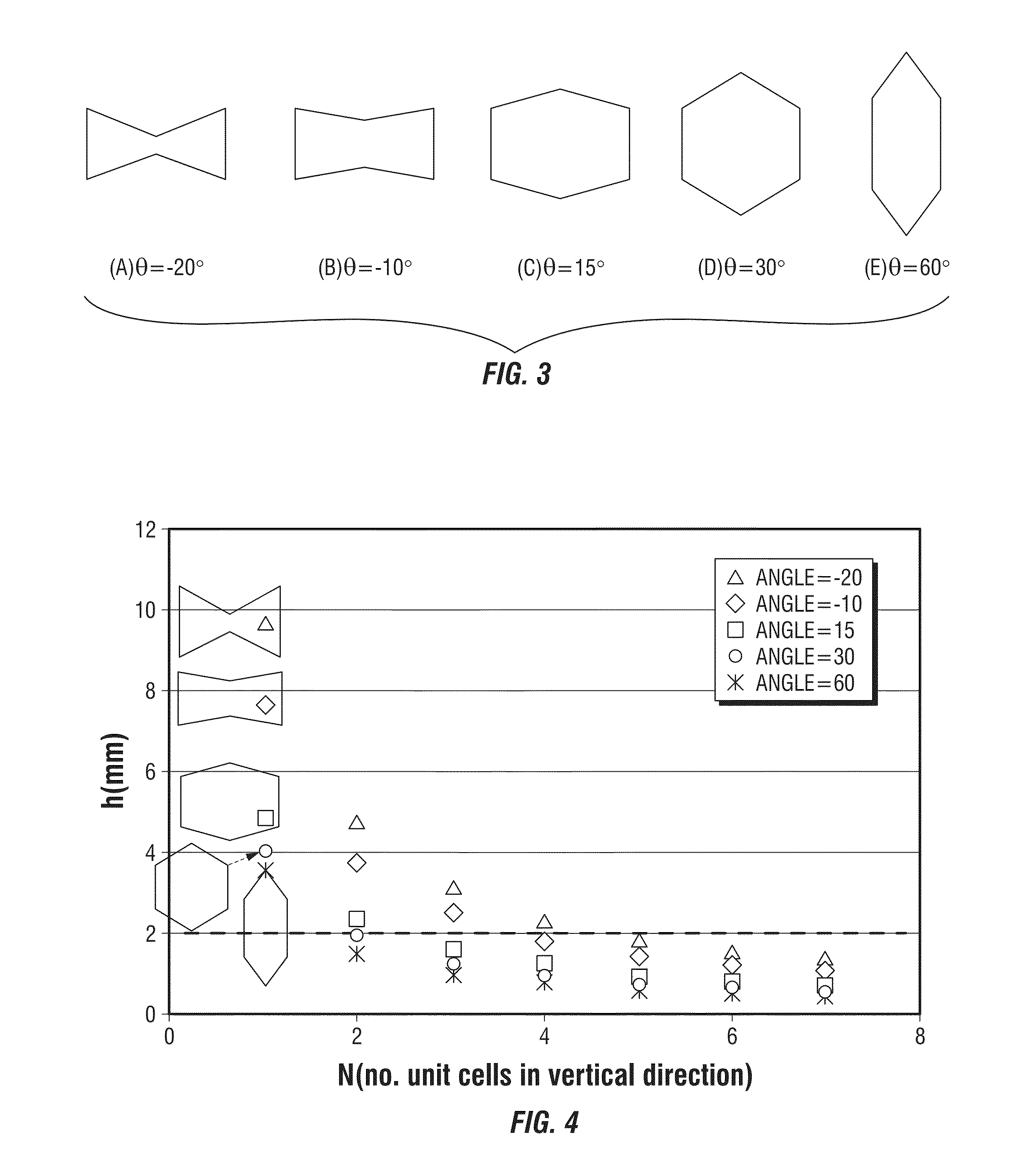

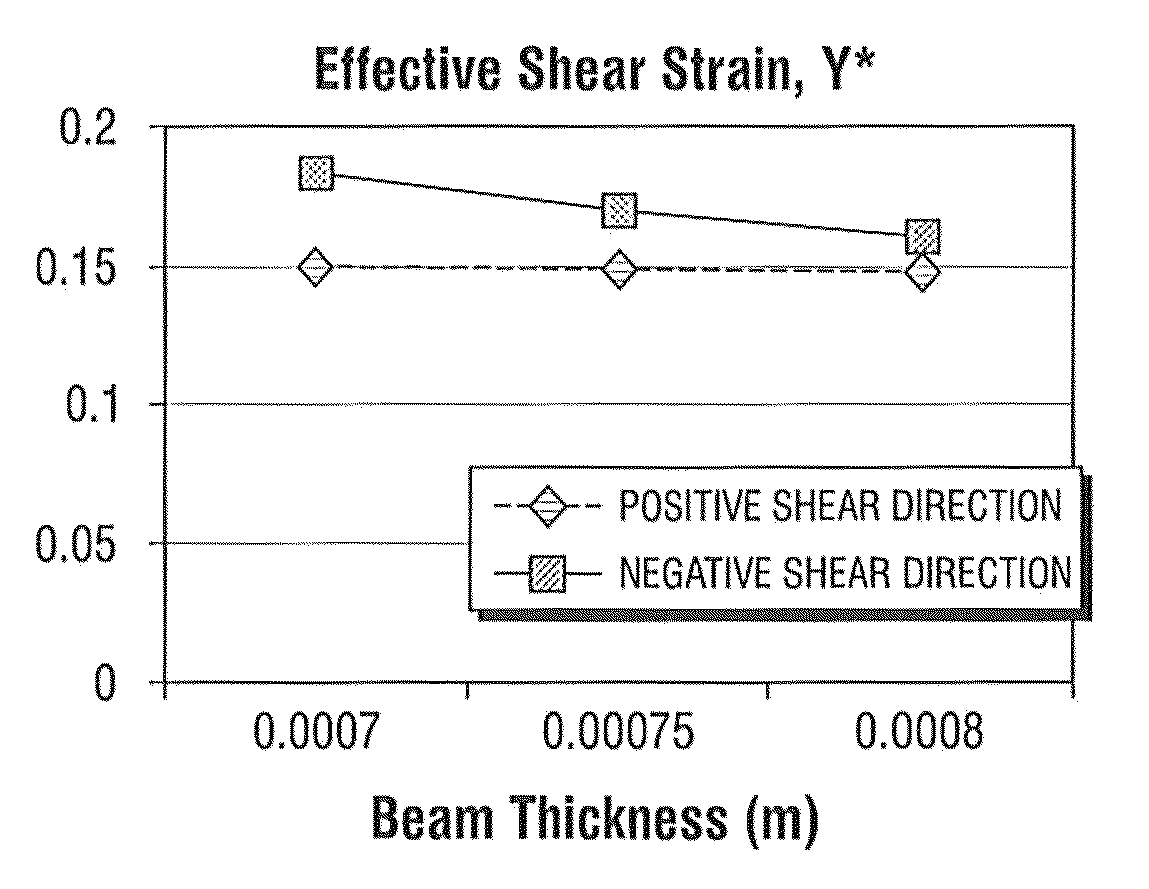

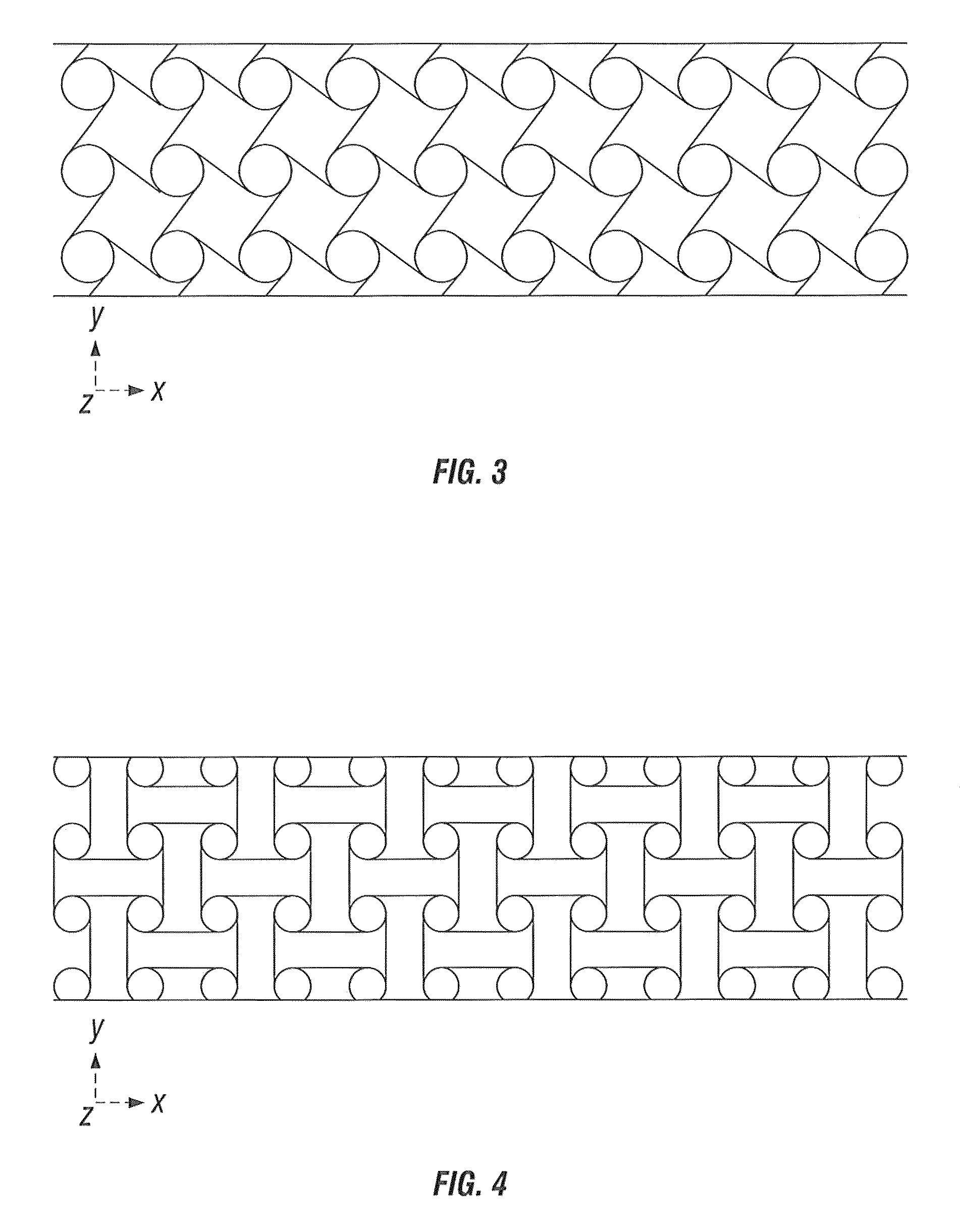

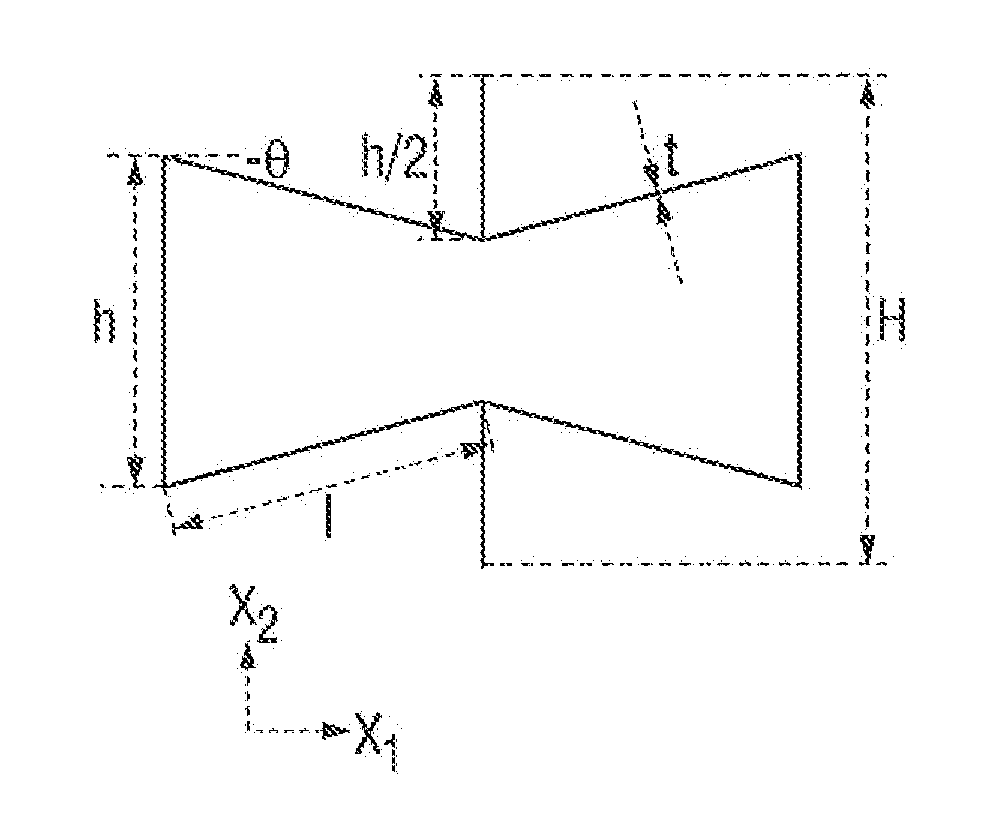

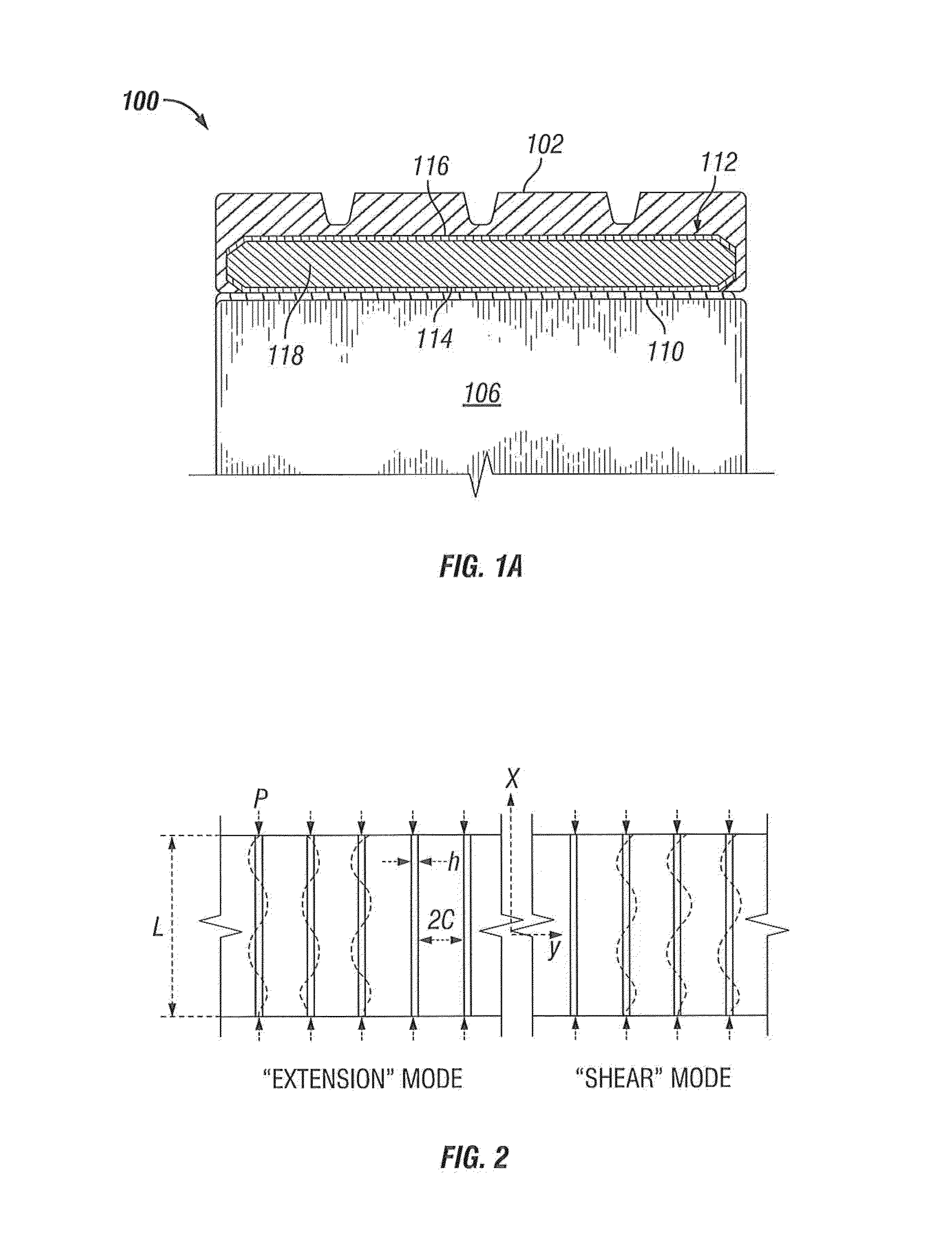

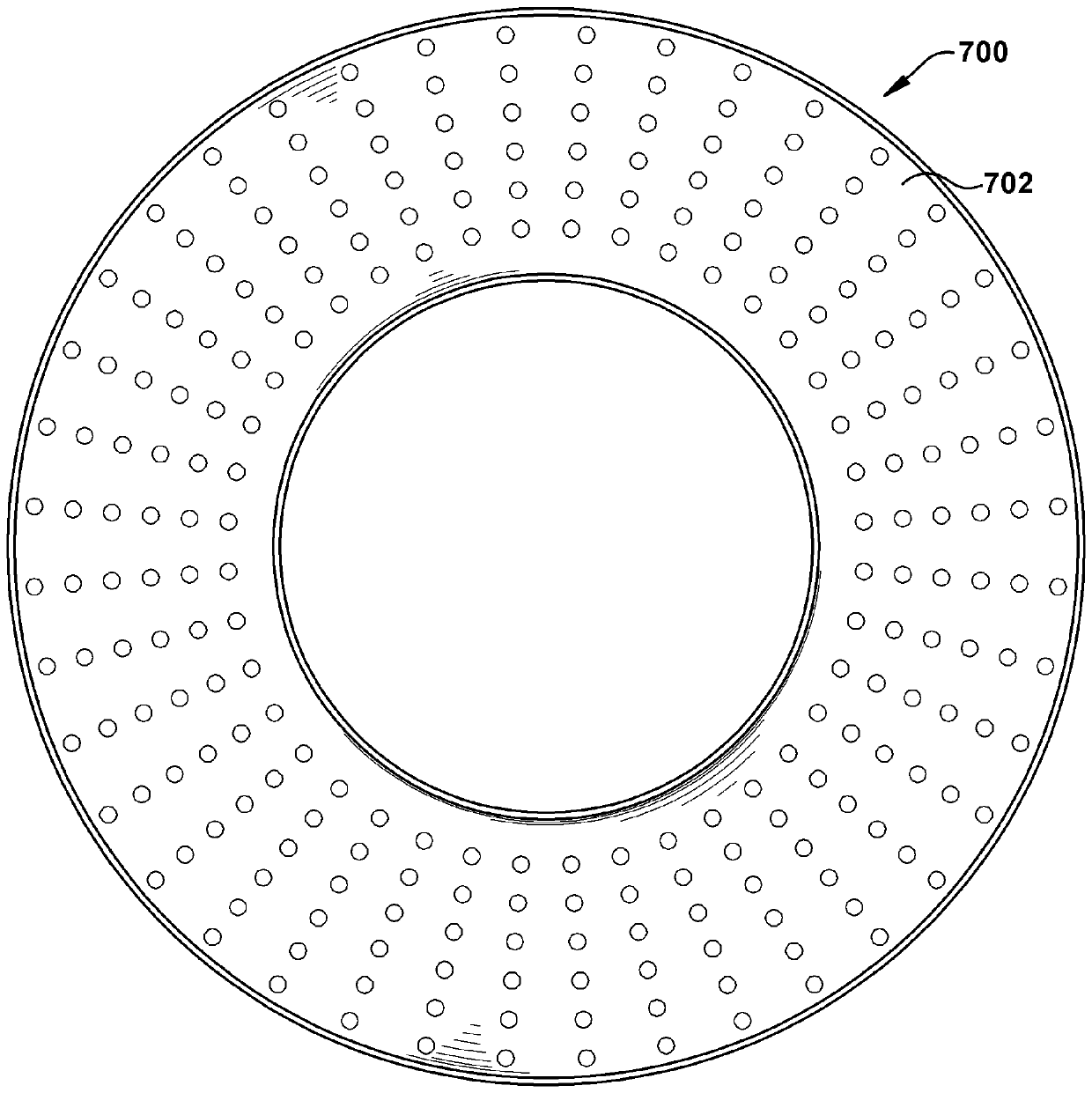

Honeycomb structures for high shear flexure

The present invention provides an improved shear band for use in non-pneumatic tires, pneumatic tires, and other technologies. The improved shear band is uniquely constructed of honeycomb shaped units that can replace the elastomeric continuum materials such as natural or synthetic rubber or polyurethane that are typically used. In particular, honeycomb structures made of high modulus materials such as metals or polycarbonates are used that provide the desired shear strains and shear modulus when subjected to stress. When used in tire construction, improvements in rolling resistance can be obtained because of less mass being deformed and reduced hysteresis provided by these materials. The resulting mass of the shear band is greatly reduced if using low density materials. Higher density materials can be used (such as metals) without increasing mass while utilizing their characteristic low energy loss.

Owner:MICHELIN NORTH AMERICA

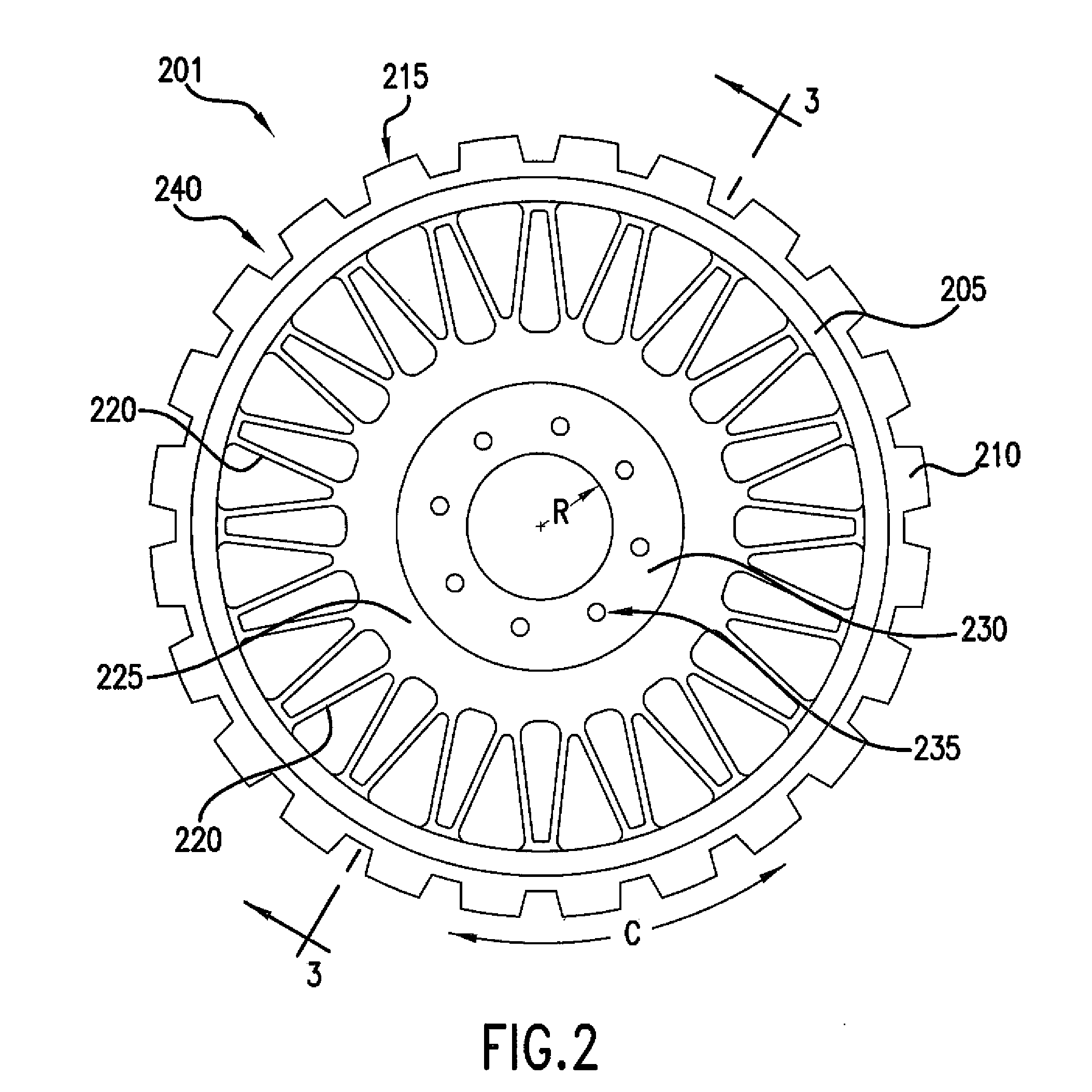

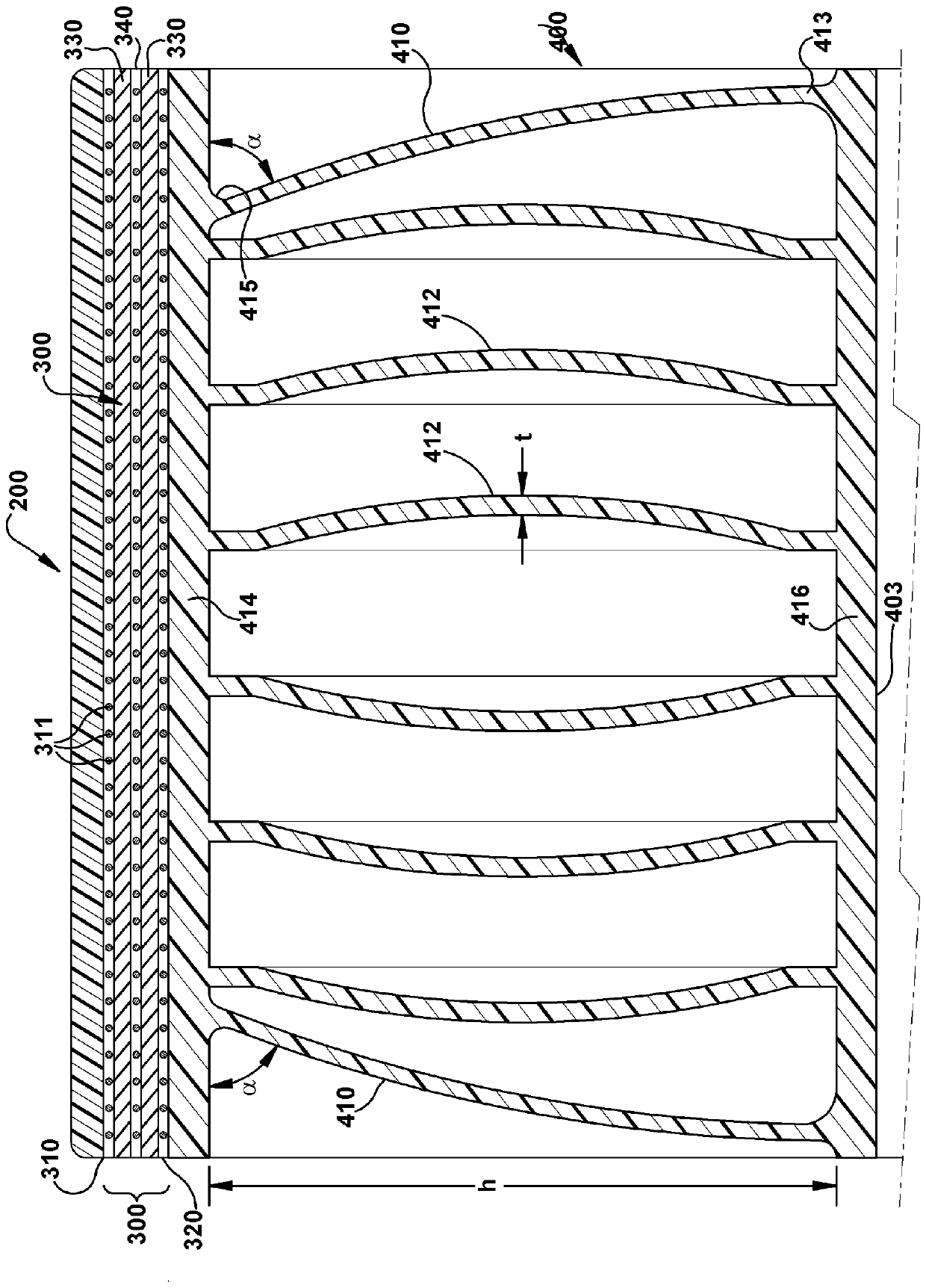

Controlled buckling of a shear band for a tire

This invention relates generally to shear band of a tire that has means for inducing buckling when the tire is subjected to high deformations, and, more specifically, to a tire that has a shear band with at least one membrane that has a reinforcement having predetermined configurations for controlling the buckling behavior of the reinforcement when the membrane is subjected to compressive stress.

Owner:MICHELIN RECH & TECH SA +1

Shear band with interlaced reinforcements

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

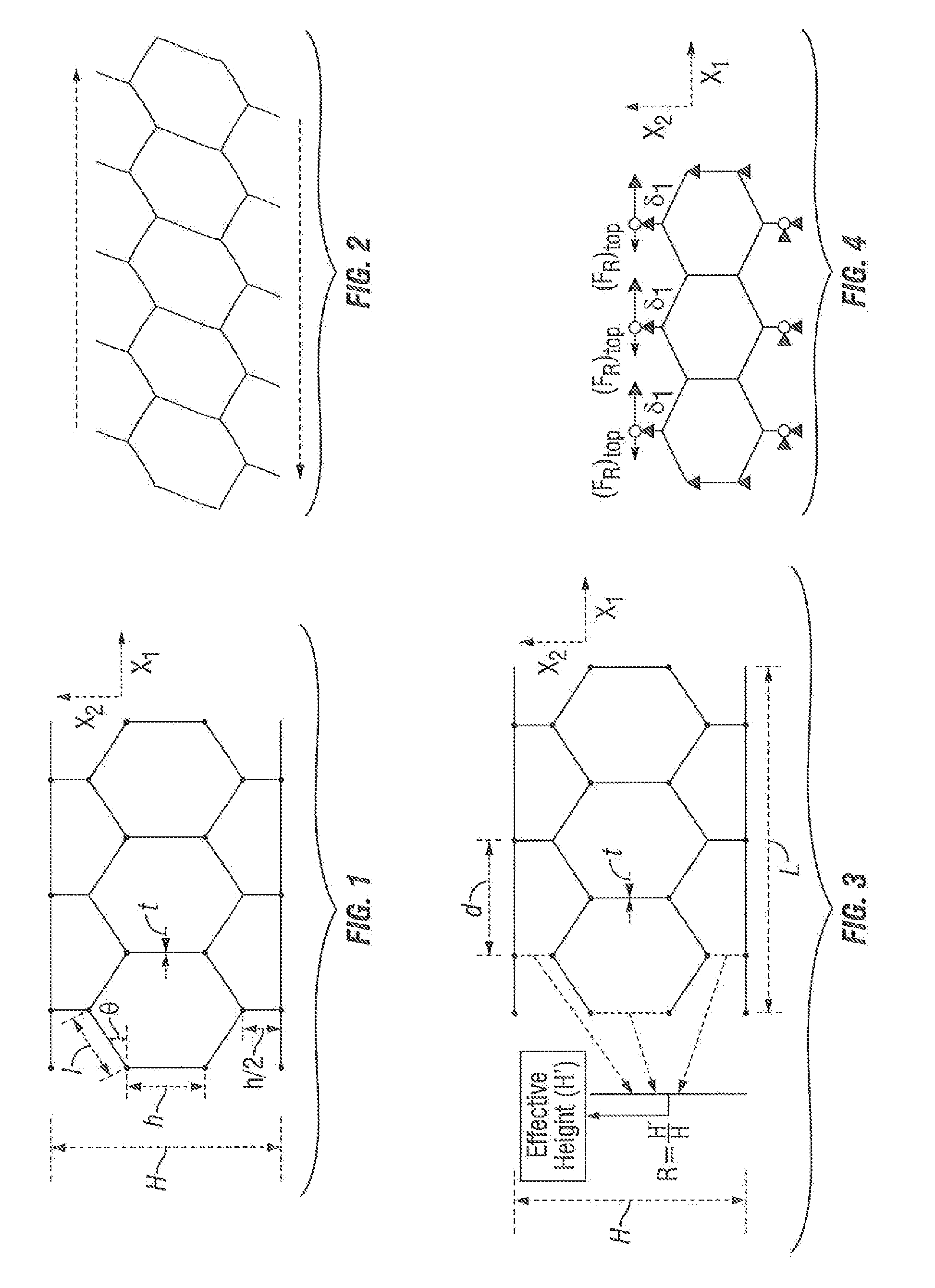

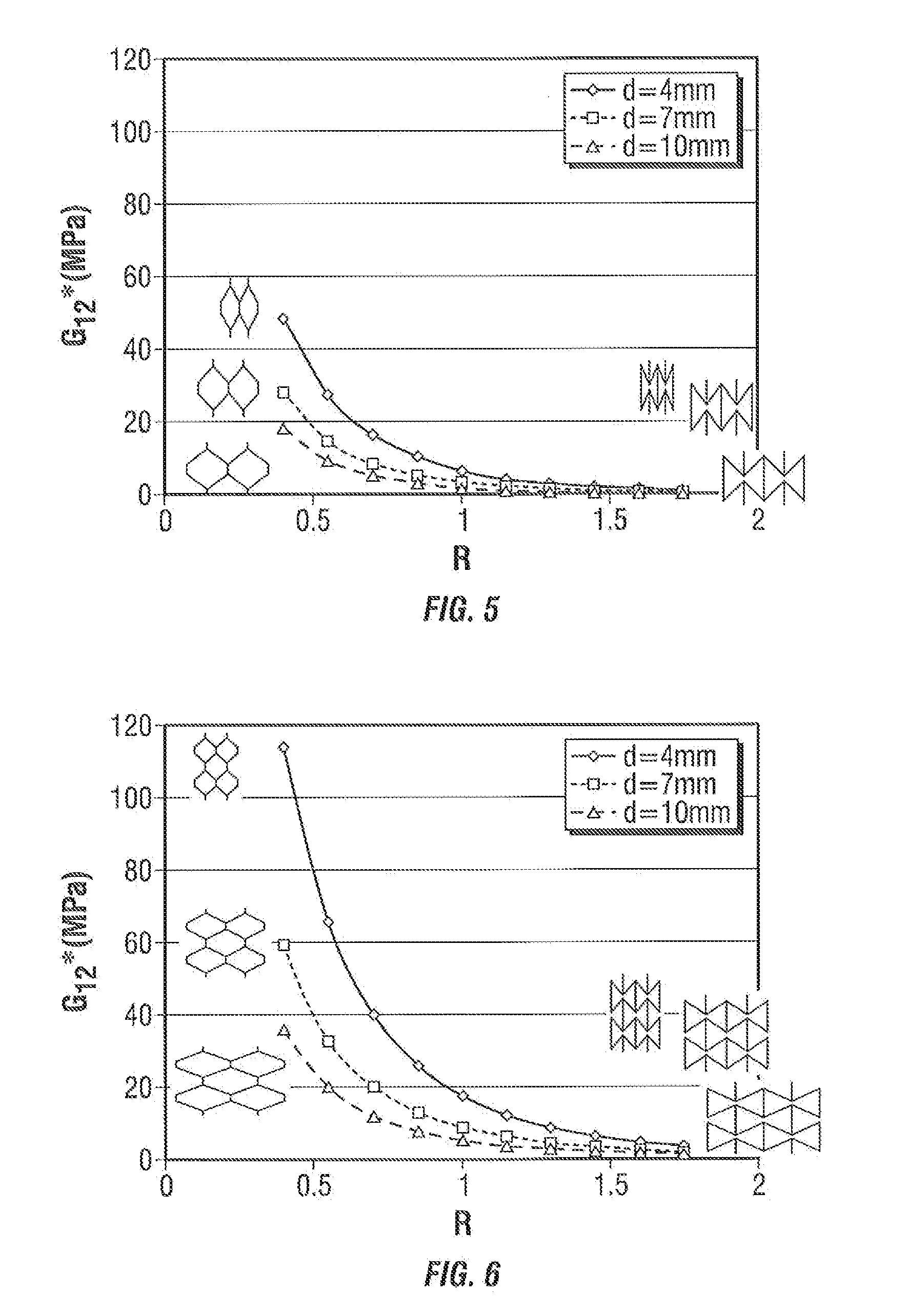

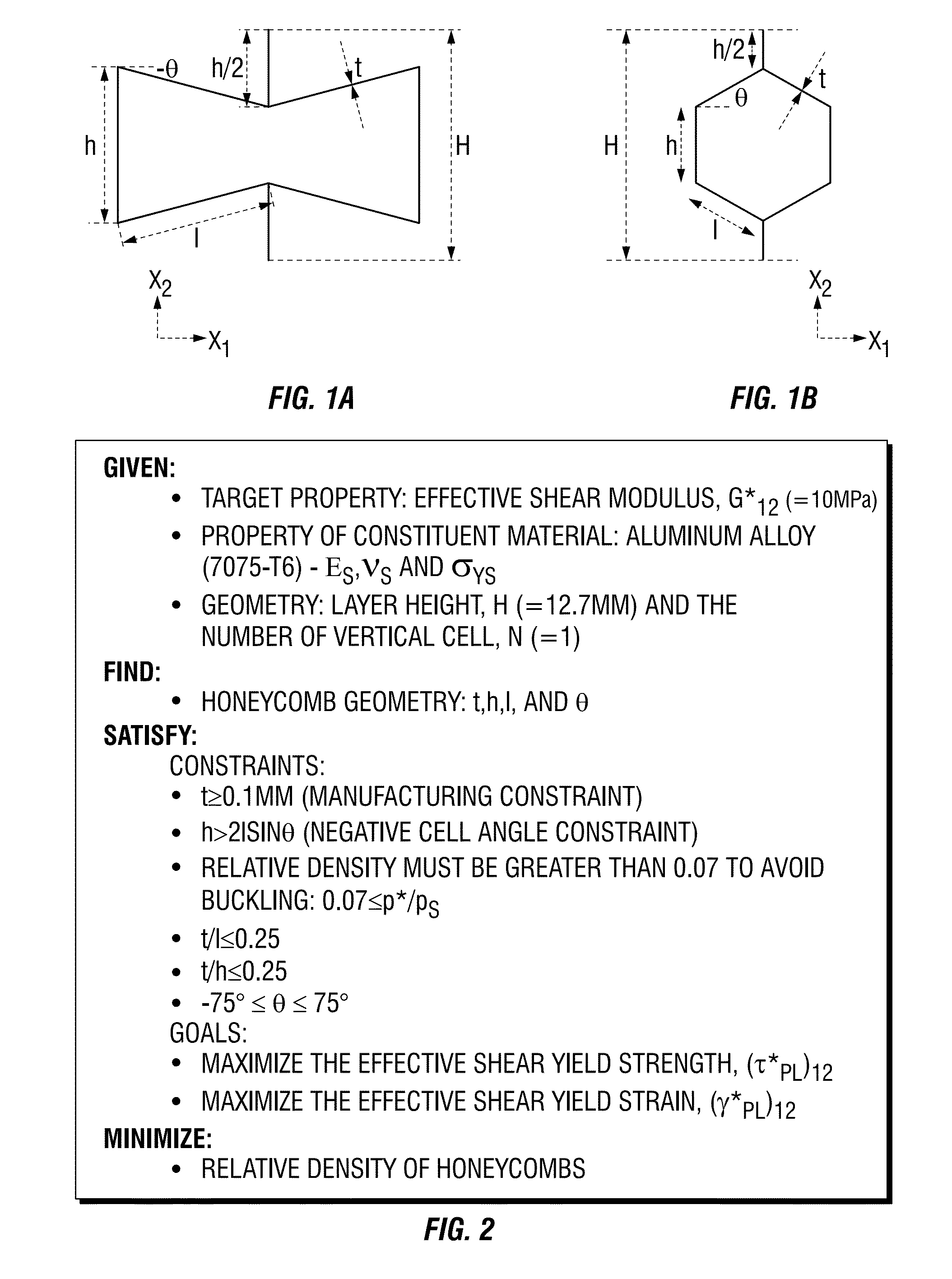

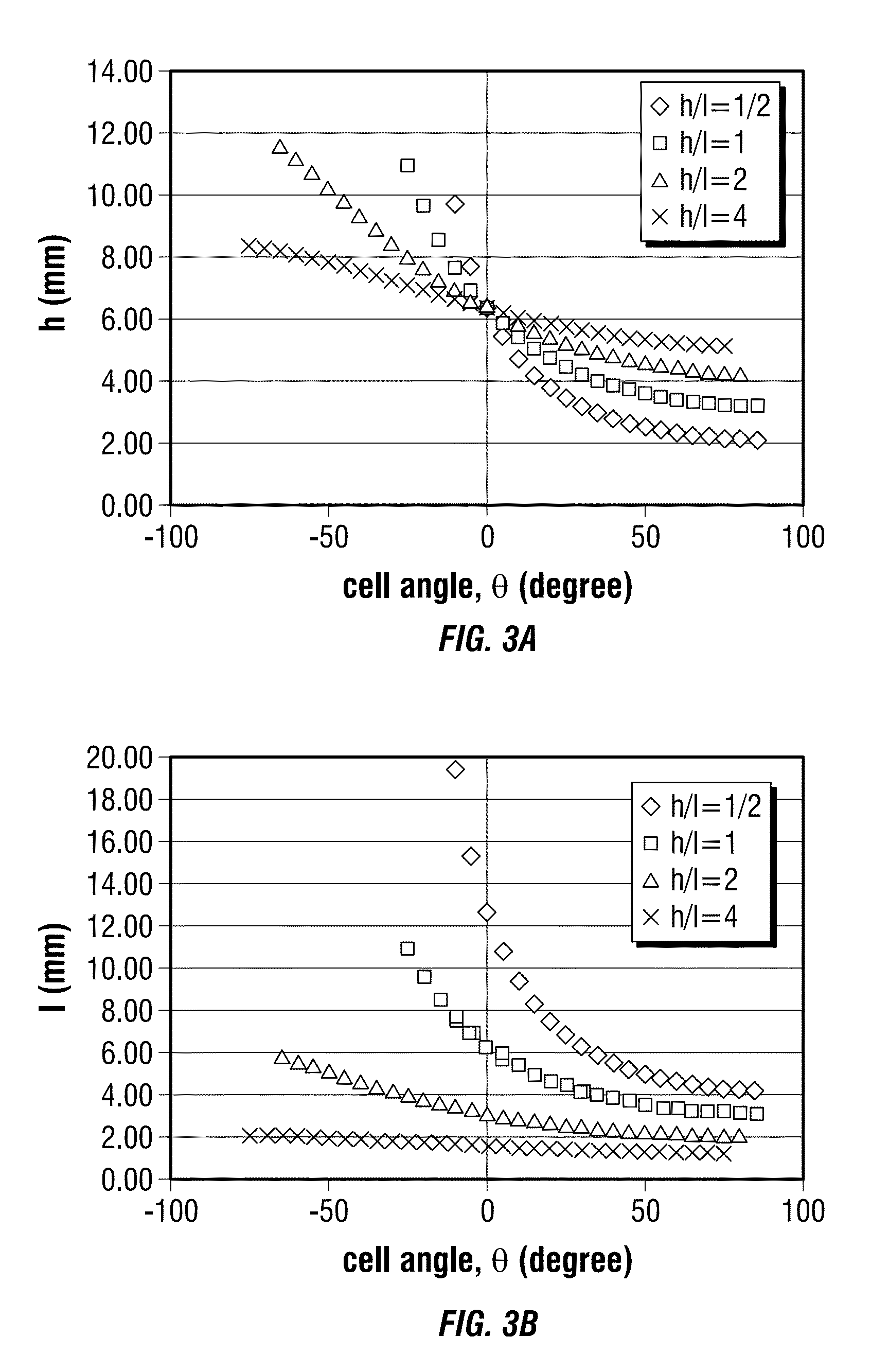

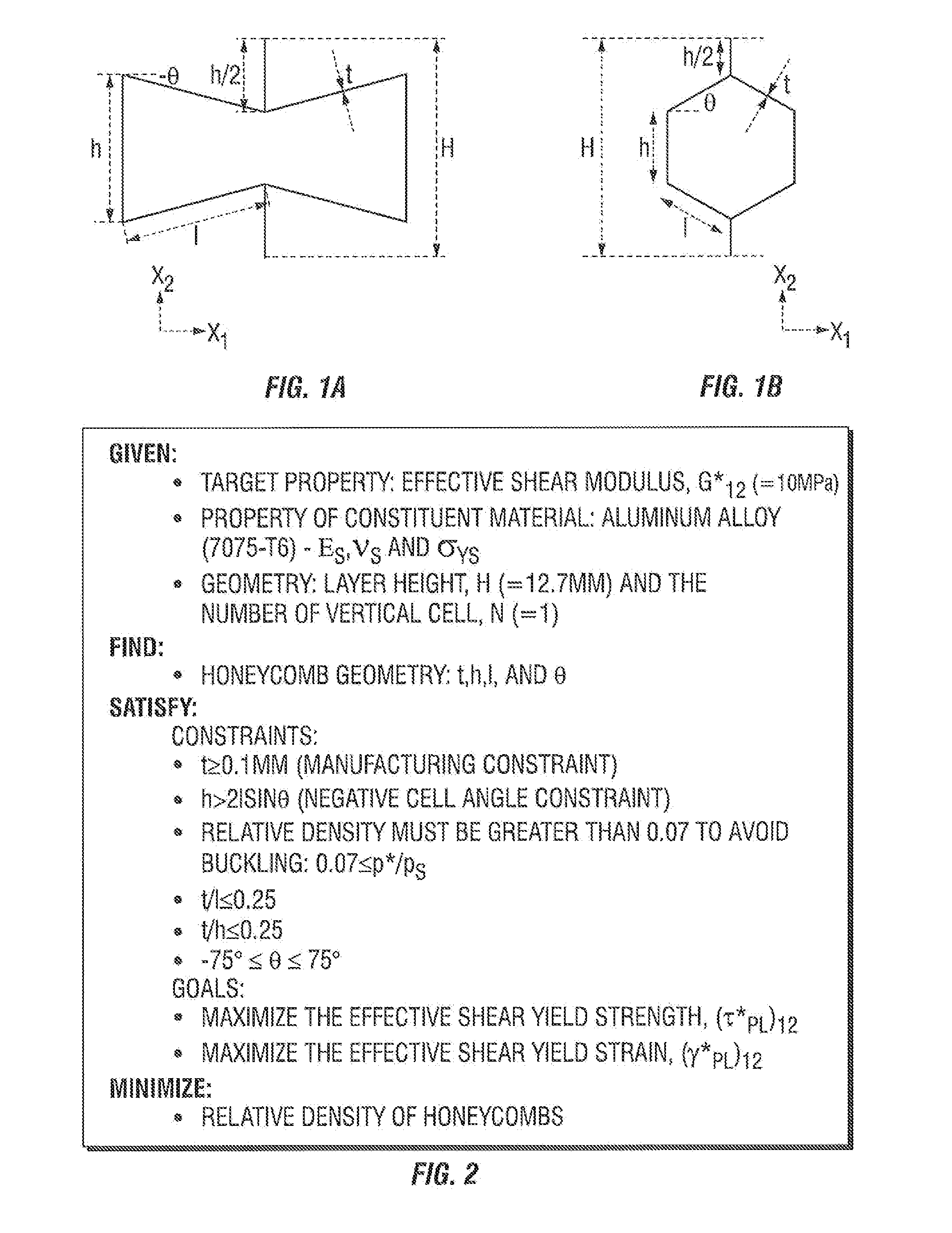

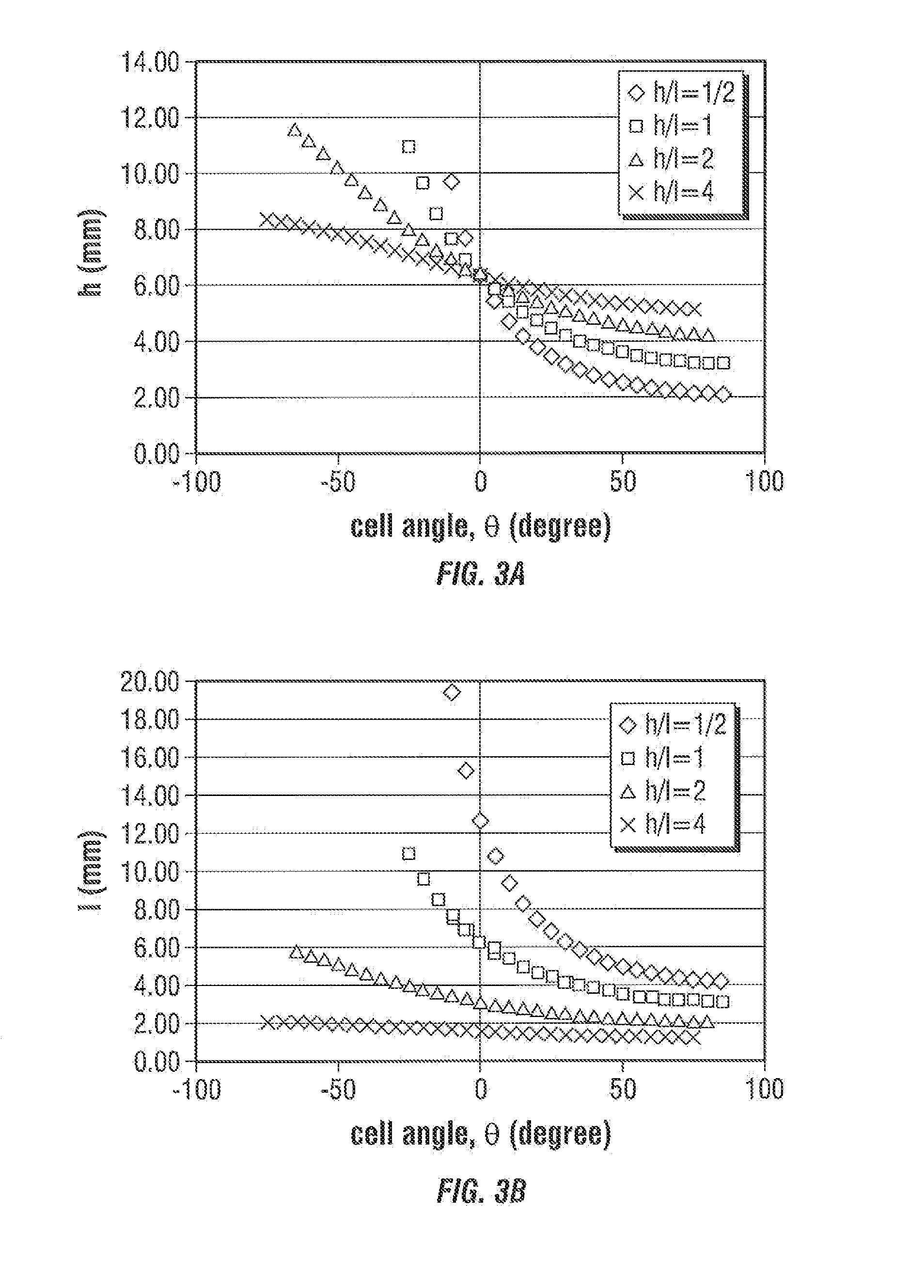

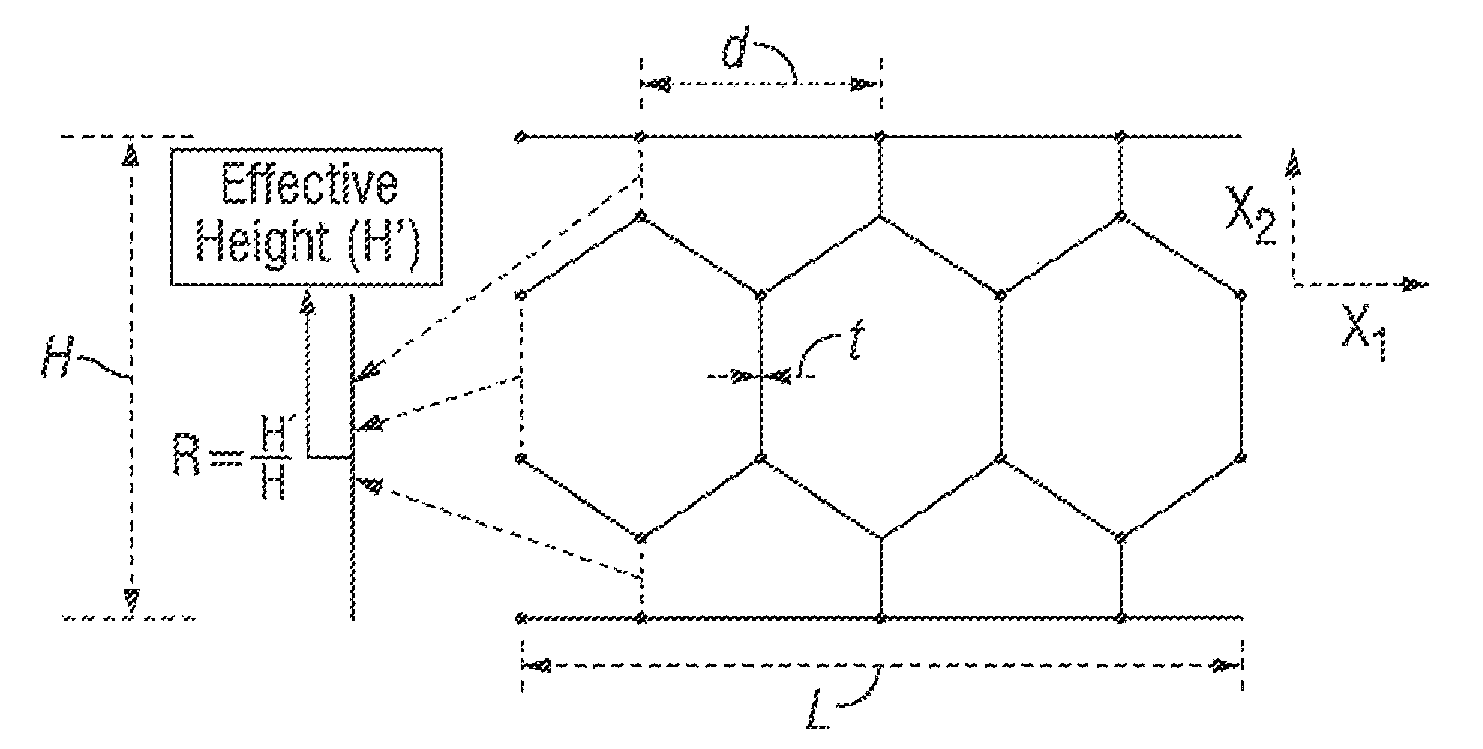

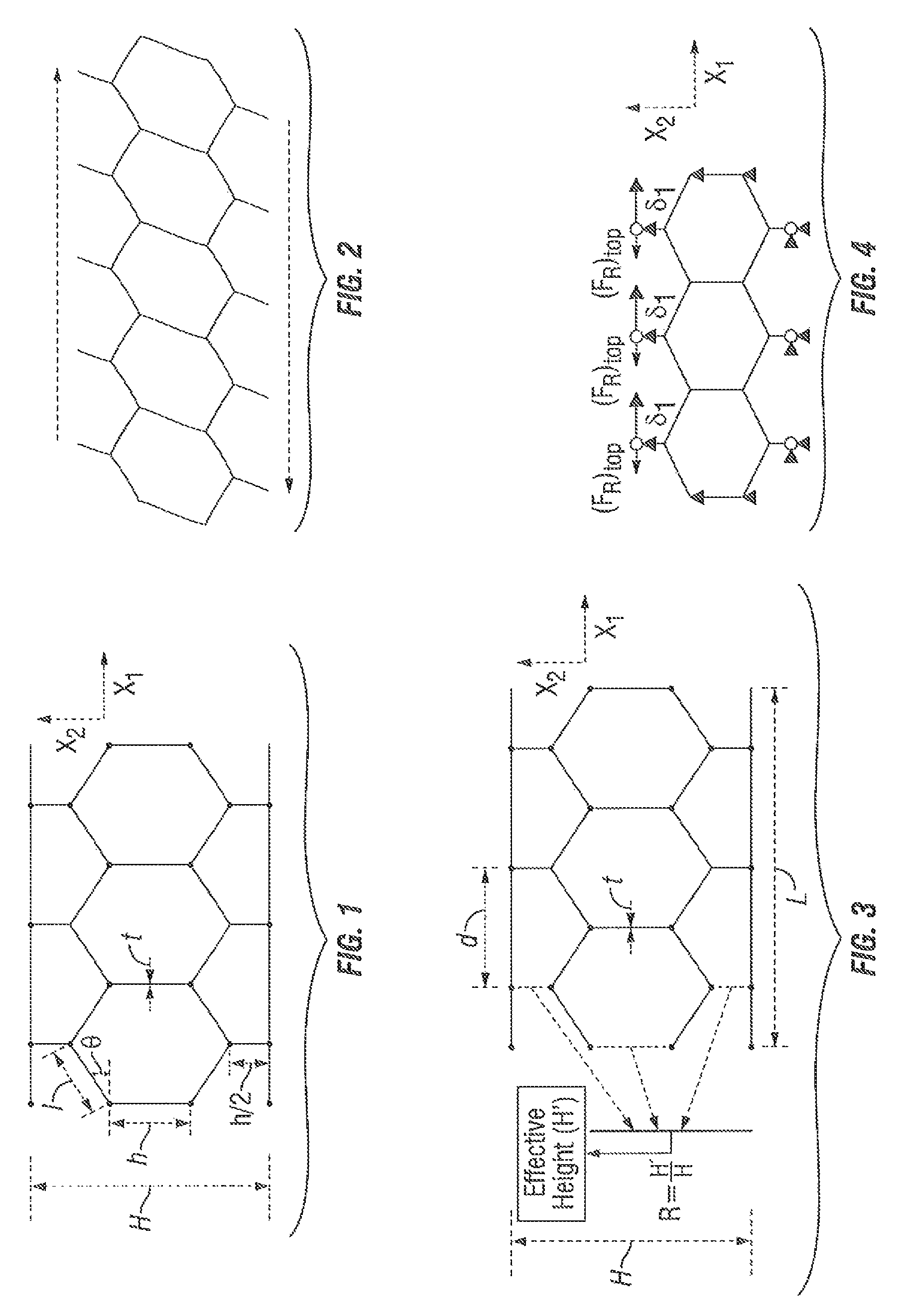

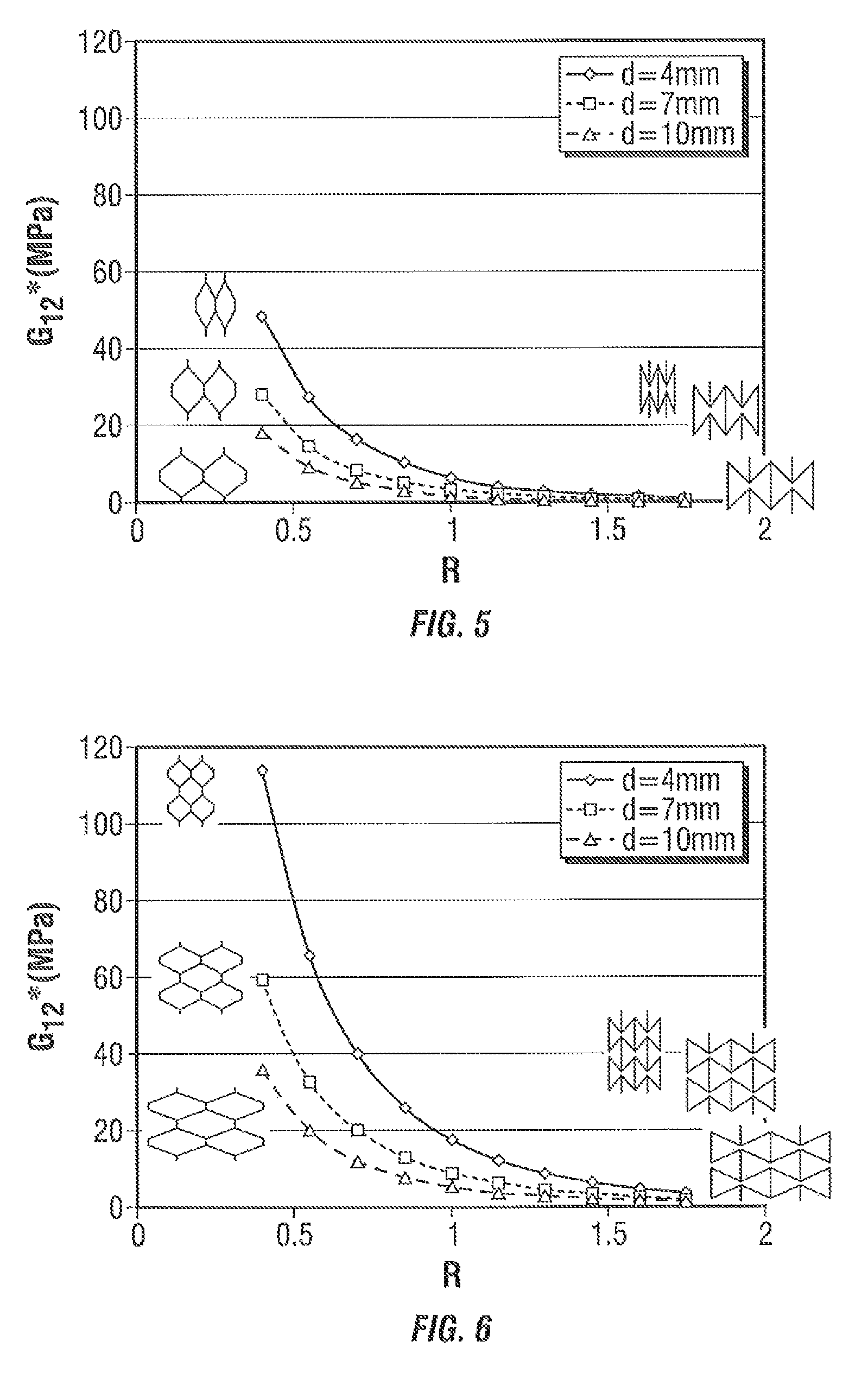

Method to design honeycombs for a shear flexible structure

A design method for optimizing the shear layer of a shear band for use in a tire is provided. The shear layer has a honeycomb configuration and the design method optimizes the dimensions of the honeycomb.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN +1

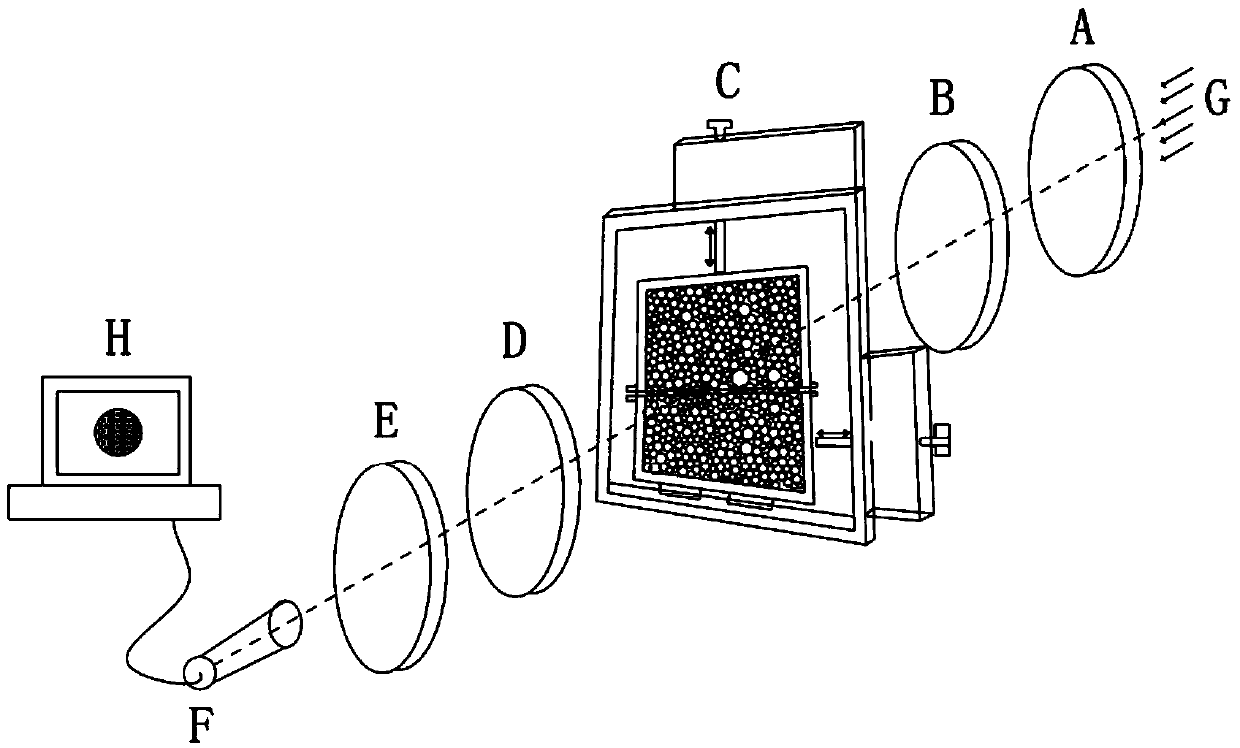

Visualization testing method and device for granular material mechanics experiment

InactiveCN103630441AHigh transparencyIntuitive visualization of medium characteristic testMaterial strength using tensile/compressive forcesMaterial strength using steady shearing forcesSize changePolarizer

The invention discloses a visualization testing method and device for a granular material mechanics experiment. The method comprises the following steps: putting luminous millimeter-sized granules into a visualization loading device capable of applying a compression / shear load; starting a light source to propagate light emitted by the light source along a polarizer, a quarter-wave plate, the visualization loading device, a quarter-wave plate, an analyzer and a camera in sequence; and applying the compression load, the shear load or the combination of the compression load and the shear load to the granules according to corresponding experimental requirements. In a loading process, fringes which are alternately dark and bright are formed in an image acquired by the camera; according to a stress-optical law, the size change of the stresses at different positions in the millimeter-sized granules can be directly observed through the density of the fringes or the light intensity; and after the image acquired by the camera is processed, the stress distribution in granular media can be identified and metered, and the contact stress between the granules, the thickness and angle of shear bands in the granular media and the distribution and trend of mechanical chains can be visualized.

Owner:SOUTH CHINA UNIV OF TECH

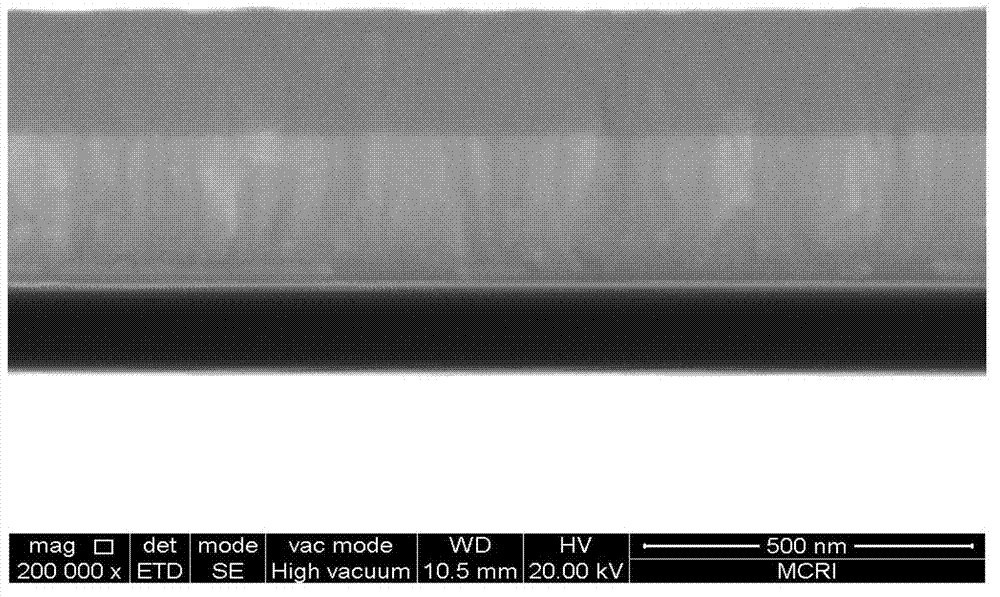

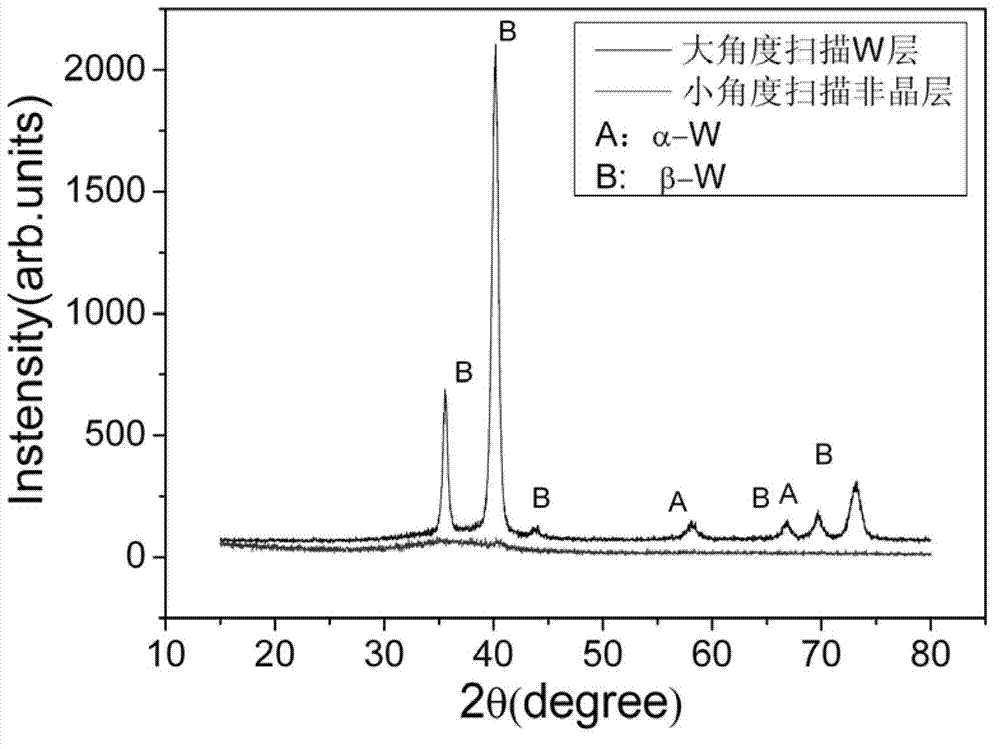

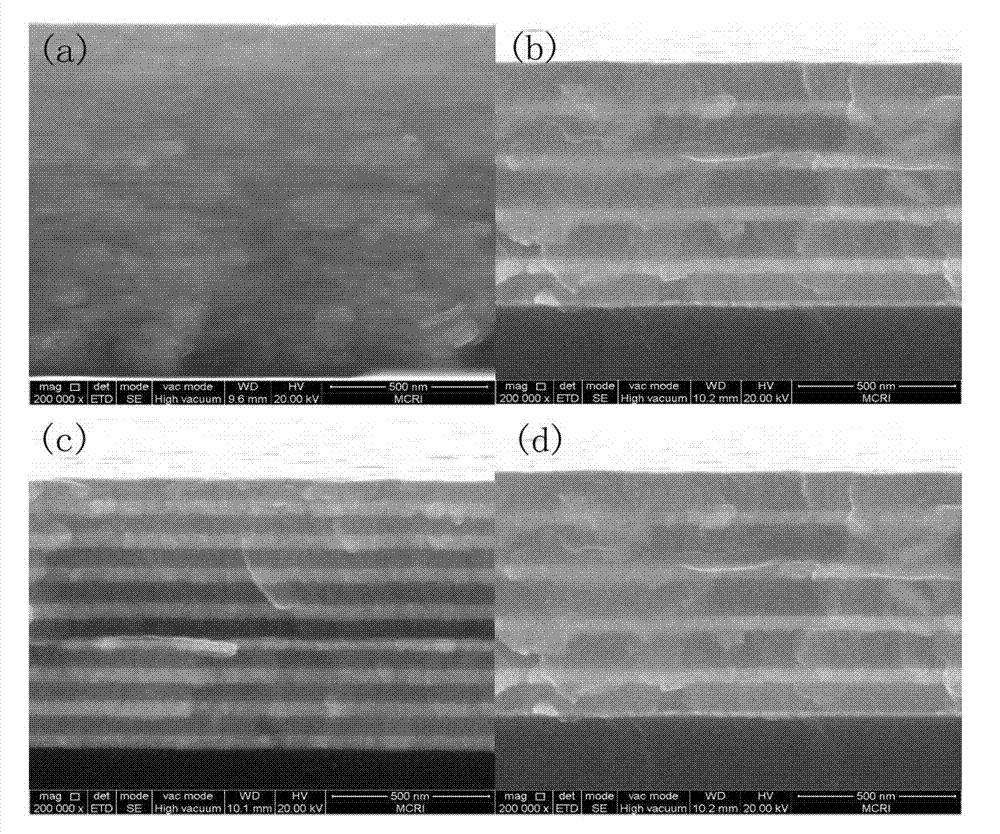

Method for preparing amorphous/nanometer crystal multilayer-structure film

InactiveCN102925869AClear structureClear interfaceVacuum evaporation coatingSputtering coatingAlloyShear band

The invention discloses a method for preparing an amorphous / nanometer crystal multilayer-structure film. The amorphous / nanometer crystal multilayer-structure film is characterized in that the amorphous / nanometer crystal multilayer-structure film is composed of two entirely different crystal structures of a nanometer crystal structure and an amorphous structure, and has a multilayer structure composed of alternately overlapped amorphous layers and nanometer crystal layers. The amorphous / nanometer crystal multilayer-structure film prepared by the method has a compact film structure and clear interface layers. The method realizes control of a blending proportion of amorphous layers and nanometer crystal layers by control of thickness sizes (reaching to nanoscale) of different film layers thereby changing a blending proportion and even gradually changing a blending proportion, provides a novel research method for shear band deformation and size effects of a micro-amorphous alloy, provides a novel approach for improvement of mechanical properties such as ductility and toughness of an amorphous alloy thereby providing possibility for preparation of a mechanical property-controllable amorphous / nanometer crystal composite material, has simple processes and a low cost, and can be industrialized and popularized easily.

Owner:昆山昊盛泰纳米科技有限公司

Shear compliant hexagonal meso-structures having high shear strength and high shear strain

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

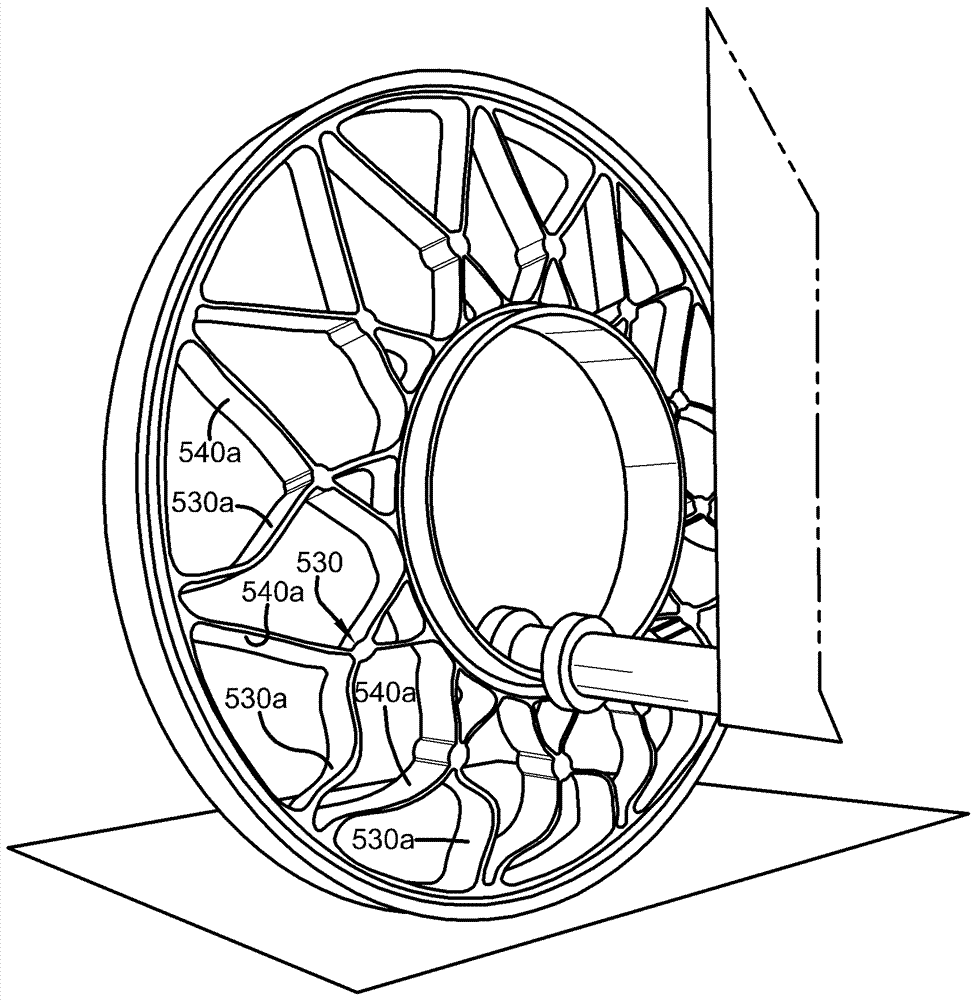

Non-pneumatic tire

A structurally supported tire includes a ground contacting annular tread portion, an annular shear band and two or more spokes.

Owner:THE GOODYEAR TIRE & RUBBER CO

Honeycomb structures for high shear flexure

The present invention provides an improved shear band for use in non-pneumatic tires, pneumatic tires, and other technologies. The improved shear band is uniquely constructed of honeycomb shaped units that can replace the elastomeric continuum materials such as natural or synthetic rubber or polyurethane that are typically used. In particular, honeycomb structures made of high modulus materials such as metals or polycarbonates are used that provide the desired shear strains and shear modulus when subjected to stress. When used in tire construction, improvements in rolling resistance can be obtained because of less mass being deformed and reduced hysteresis provided by these materials. The resulting mass of the shear band is greatly reduced if using low density materials. Higher density materials can be used (such as metals) without increasing mass while utilizing their characteristic low energy loss.

Owner:MICHELIN NORTH AMERICA

Chiral honeycomb meso-structures for shear flexure

A shear layer for a shear band that is used in a tire is provided that has multiple cells having a chiral configuration. The chiral configuration may be hexagonal or tetrachiral or have other configurations.

Owner:MICHELIN RECH & TECH SA +1

Shear compliant hexagonal meso-structures having high shear strength and high shear strain

A shear layer for a shear band that is used in a tire is provided that has multiple cells or units having an auxetic configuration and that are constructed from aluminum or titanium alloys. The cells may have an angle of −10°.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN +1

Controlled buckling of a shear band for a tire

This invention relates generally to shear band of a tire that has means for inducing buckling when the tire is subjected to high deformations, and, more specifically, to a tire that has a shear band with at least one membrane that has a reinforcement having predetermined configurations for controlling the buckling behavior of the reinforcement when the membrane is subjected to compressive stress.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

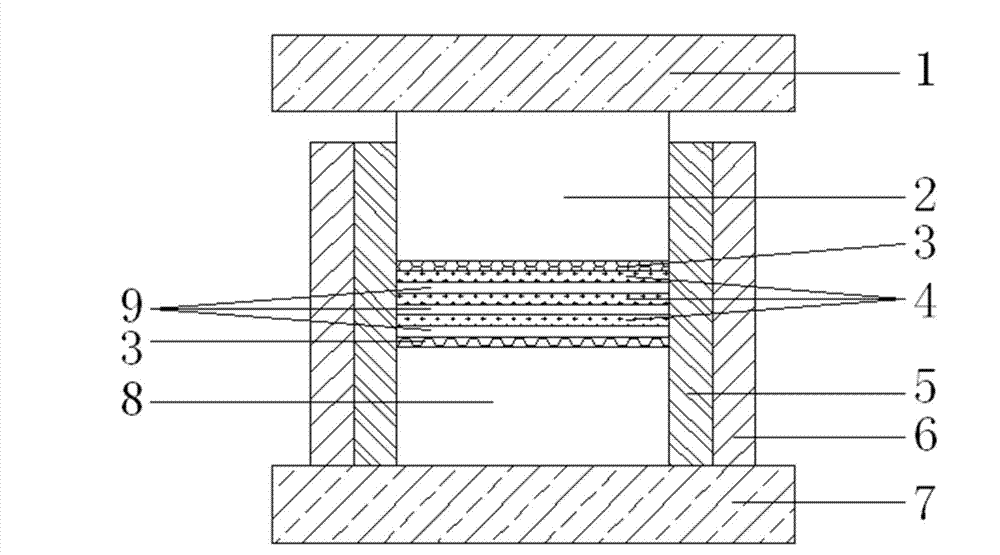

Method for manufacturing multi-layer amorphous alloy and crystal metal composite structure through diffusion welding

InactiveCN102886599AAvoid brittlenessImprove shear resistanceNon-electric welding apparatusShear capacityAlloy

The invention discloses a method for manufacturing a multi-layer amorphous alloy and crystal metal composite structure through diffusion welding. The method comprises the following steps of: cutting, grinding and cleaning an amorphous alloy sheet and a crystal metal sheet, assembling and fixing the amorphous alloy sheet and the crystal metal sheet so as to form a fixed workpiece, and welding the fixed workpiece in a vacuum diffusion furnace. According to the composite structure, extension of a shear band of an amorphous alloy material in the shearing process can be blocked, so that the problem that the pure amorphous alloy material has high brittleness is solved, and the shear resistance is improved. In addition, the welded amorphous alloy material can continuously keep the amorphous characteristics, compared with that of the pure amorphous alloy material, the shear resistance of the composite structure material is greatly improved, the toughness is improved, and the welded sheet is high in surface quality and reliable in connection.

Owner:HUAZHONG UNIV OF SCI & TECH

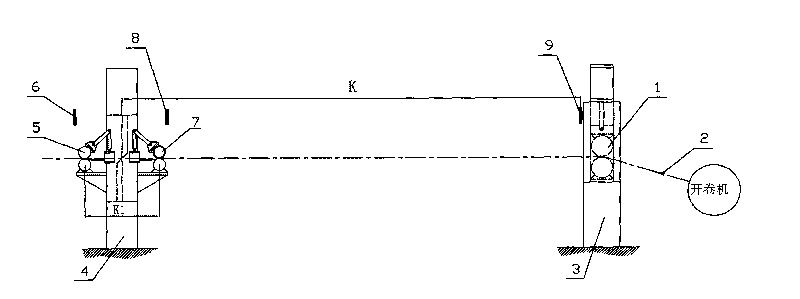

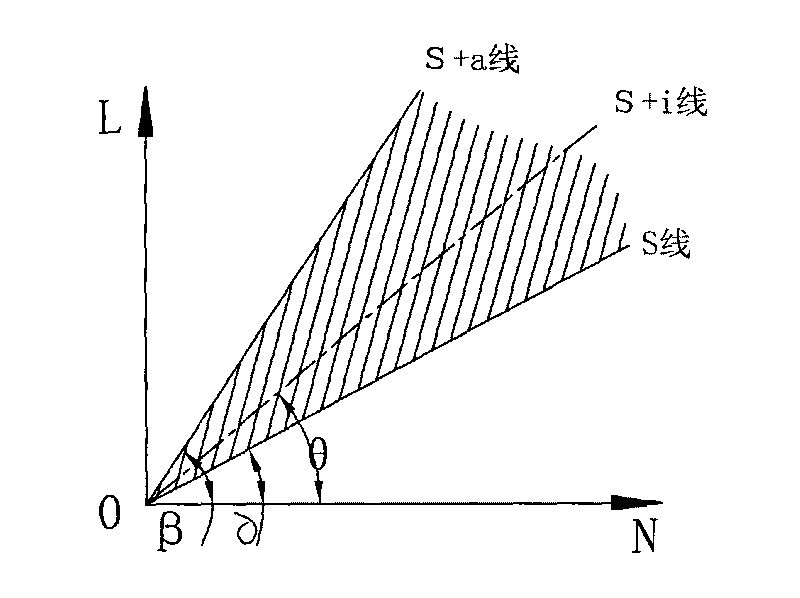

Method for preventing broken pieces of band tail from blocking shearing when shearing band tail of cold rolled strip steel production unit

ActiveCN101716597ACard cutting preventionSmooth cut completeRoll mill control devicesMetal rolling arrangementsAutomatic controlStrip steel

The invention belongs to the field of automatic control of metallurgical cold rolling, in particular to a method for preventing broken pieces of a band tail from blocking shearing when shearing the band tail of a cold rolled continuous strip steel production unit. The method comprises the steps of calculating the distance of the band tail from an inlet to a photoelectric tube at an outlet of a pinch roller and further calculating the total length L1 of the residual band tail which nees to be sheared (when carrying out first-cut shearing, L1=L); the ideal length l of each broken piece is in a range, the number N of shearing cuts is constantly adjusted according to the total length L of the residual waste material to be sheared, thereby always leading the value of L / N to fall in the range of l and further ensuring that each broken piece of the sheared band tail, including the last piece can smoothly pass through a pair of shears at the inlet and be conveyed into a waste material device (which can prevent the broken pieces of the band tail from blocking shearing). The method can prevent the broken pieces of the band tail from blocking shearing when shearing the band tail of the cold rolled strip steel production unit.

Owner:WISDRI WUHAN AUTOMATION

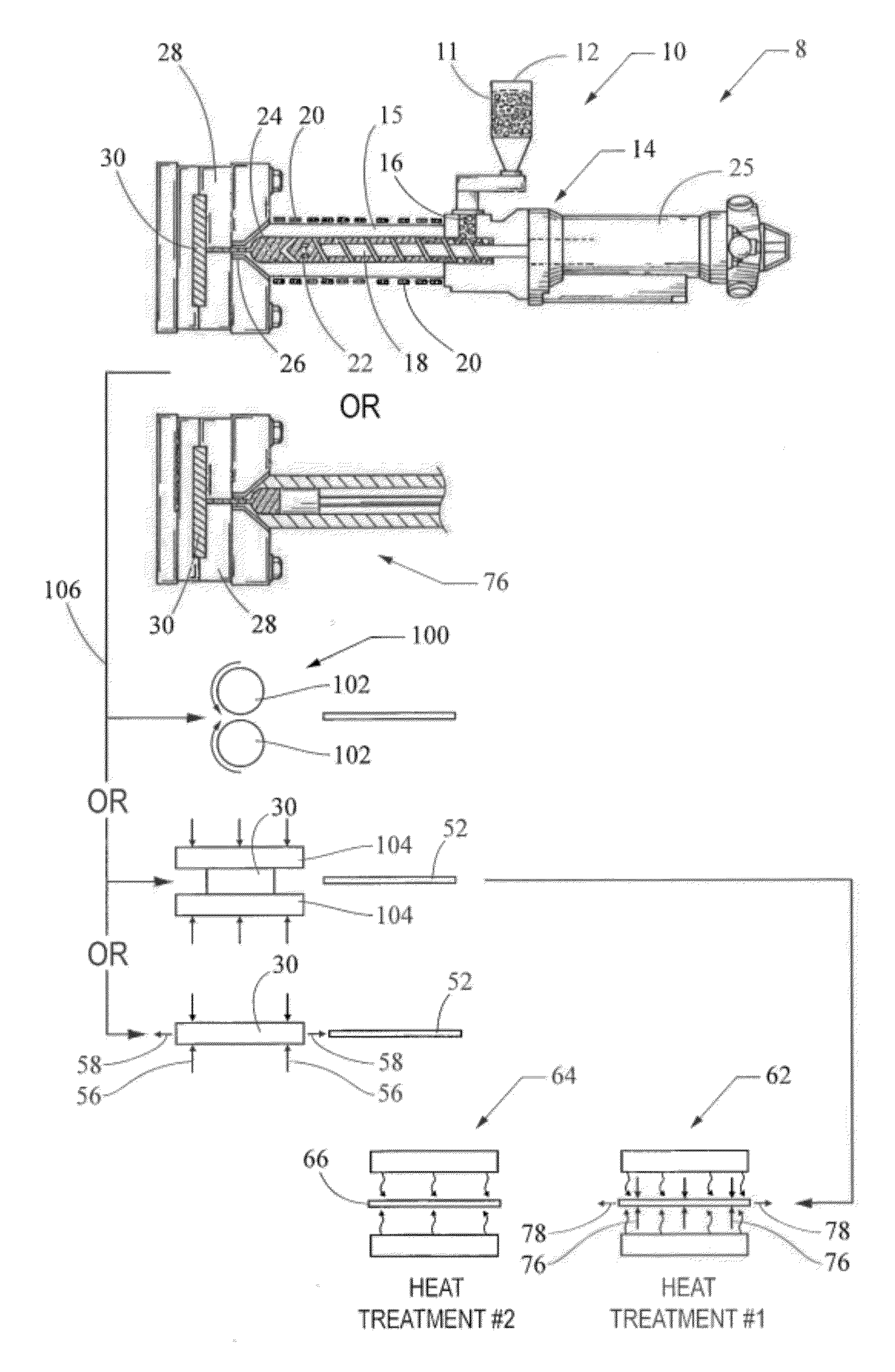

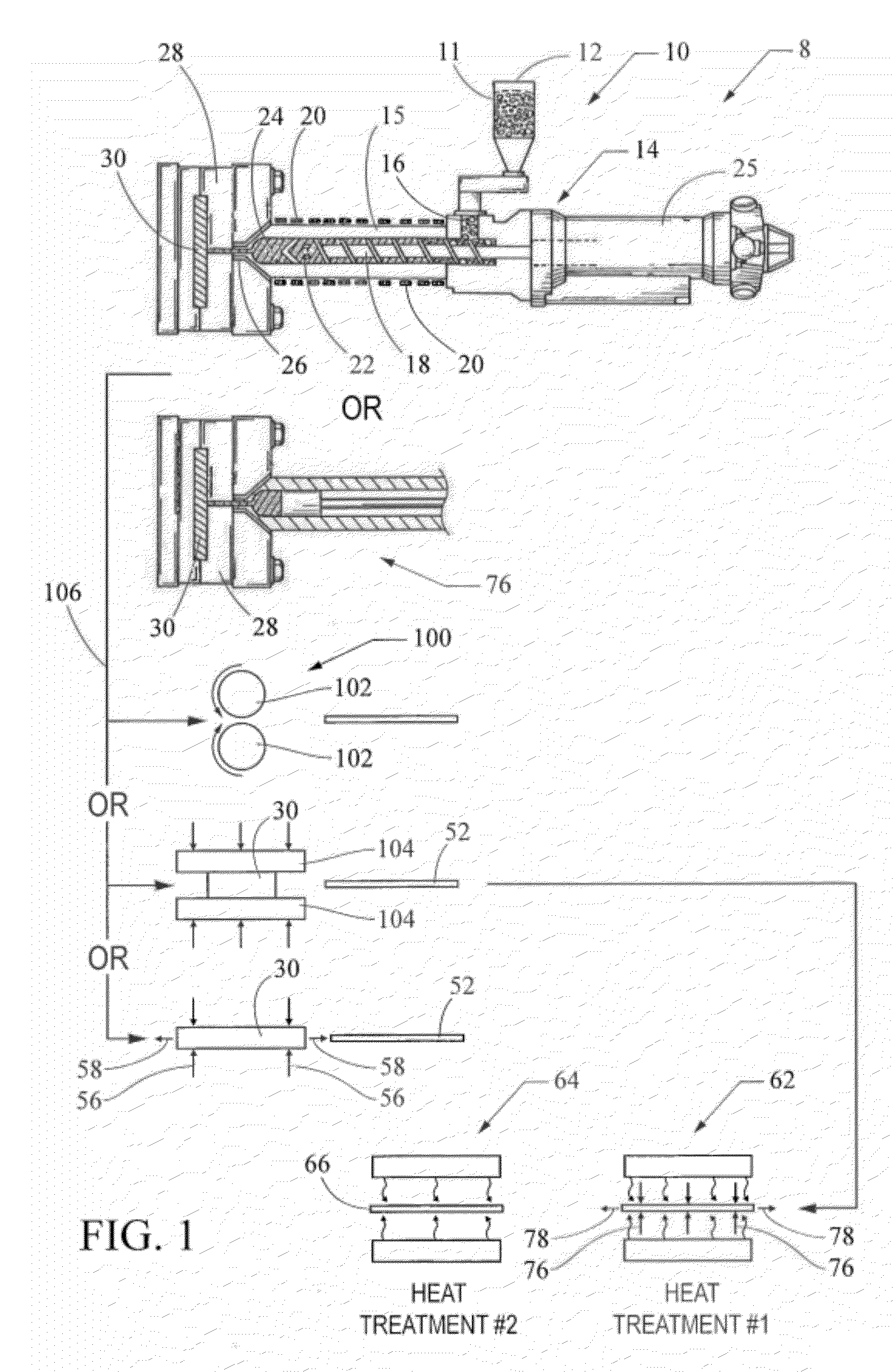

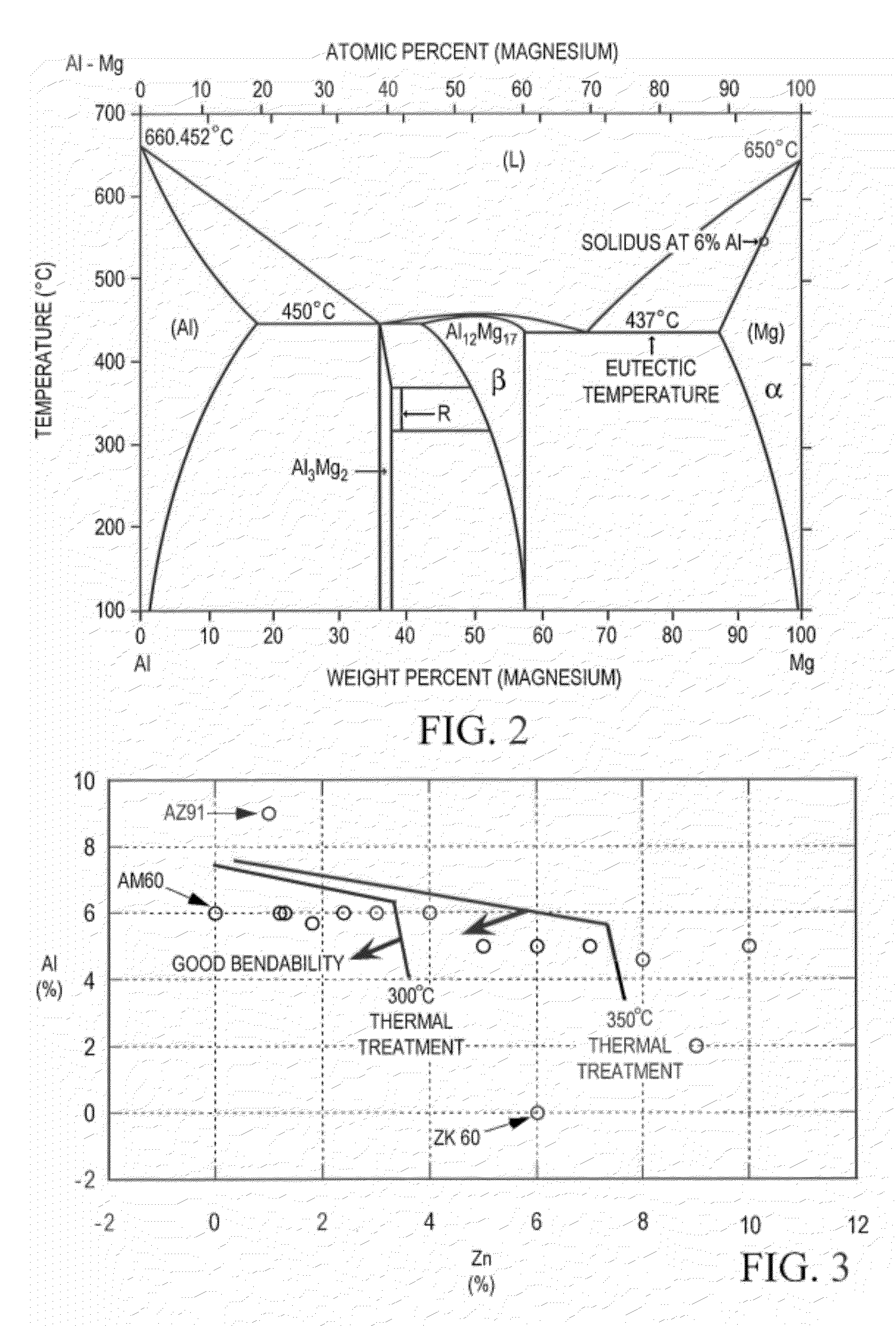

Method and apparatus of forming a wrought material having a refined grain structure

ActiveUS20120305145A1Provide formabilityProvide impact resistanceMould handling/dressing devicesMetal alloyShell molding

A method of forming a wrought material having a refined grain structure is provided. The method comprises providing a metal alloy material having a depressed solidus temperature and a low temperature eutectic phase transformation. The metal alloy material is molded and rapidly solidified to form a fine grain precursor that has fine grains surrounded by a eutectic phase with fine dendritic arm spacing. The fine grain precursor is plastic deformed at a high strain rate to cause recrystallization without substantial shear banding to form a fine grain structural wrought form. The wrought form is then thermally treated to precipitate the eutectic phase into nanometer sized dispersoids within the fine grains and grain boundaries and to define a thermally treated fine grain structure wrought form having grains finer than the fine grains and the fine dendritic arm spacing of the fine grain precursor.

Owner:THIXOMAT

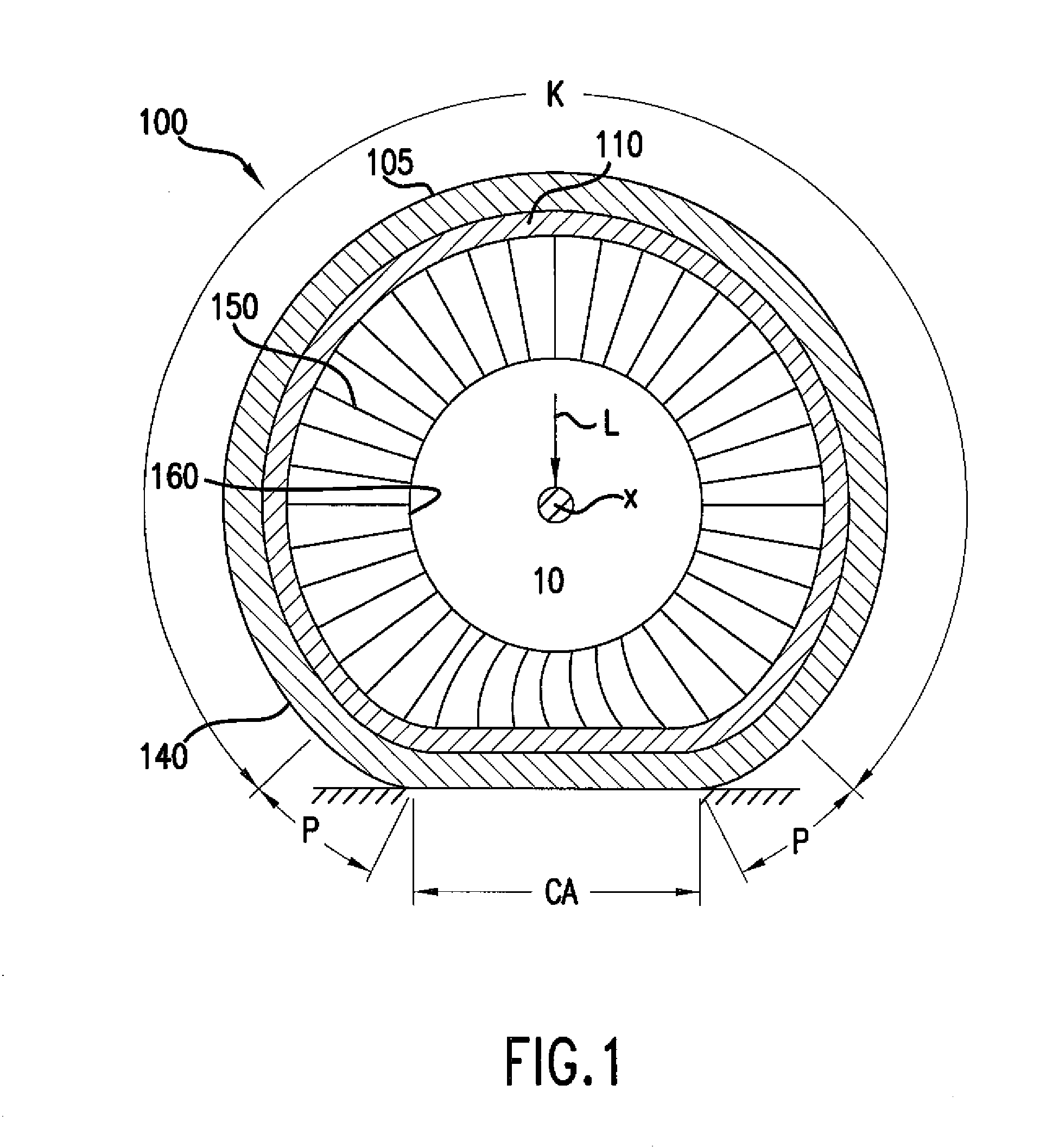

Non-pneumatic tire

A non-pneumatic tire is described that includes a ground contacting annular tread portion, a shear band, wherein the shear band is formed of a first and second inextensible layer, and a low modulus material positioned between the first and second inextensible layer. The non-pneumatic tire further includes a connecting web positioned between a hub and the shear band, wherein the connecting web is formed of one or more spokes extending from an inner ring to an outer ring, wherein the one or more spokes are formed from a material reinforced with a three dimensional spacer structure.

Owner:THE GOODYEAR TIRE & RUBBER CO

Method for observing rock and soil sample shear band inclination angle evolution rules under two types of formation conditions

InactiveCN104848838AFully automatedQuick measurementIncline measurementClassical mechanicsComputational physics

The invention provides a method for observing rock and soil sample shear band inclination angle evolution rules under original and real-time formation conditions. The method includes acquiring a digital image, comprising speckle surfaces, of a sample by shooting devices under a loading condition; by a digital image correlation method, acquiring maximum shear strain fields of the sample under the original and real-time formation conditions; by an interpolation method, acquiring maximum shear strain fields good in smoothness in an area comprising measured shear bands; deleting redundant data according to roughly-estimated widths and inclination angles of the measured shear bands to acquire positions of all points on center lines of the measured shear bands, and acquiring inclination angles of planer shear bands and spatial shear bands by a fitting method. The method has the advantages that the rules that the shear band inclination angles evolve according to stress, strain and time under the original and real-time formation conditions can be acquired; automated, rapid and accurate measurement of the shear band inclination angles can be achieved; the method is suitable for measuring the inclination angles of plane inclination strain concentration bands and spatial shear planes of various materials.

Owner:LIAONING TECHNICAL UNIVERSITY

Non-pneumatic tire

A structurally supported tire includes a ground contacting annular tread portion; a shear band, and a connected spoke disk connected to the shear band. The connected spoke disk has two or more circumferential spokes joined together by a connecting web, wherein the spring rate of the connected spoke disk is greater than the spring rate of the shear band.

Owner:THE GOODYEAR TIRE & RUBBER CO

Method to design honeycombs for a shear flexible structure

A design method for optimizing the shear layer of a shear band for use in a tire is provided. The shear layer has a honeycomb configuration and the design method optimizes the dimensions of the honeycomb.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN

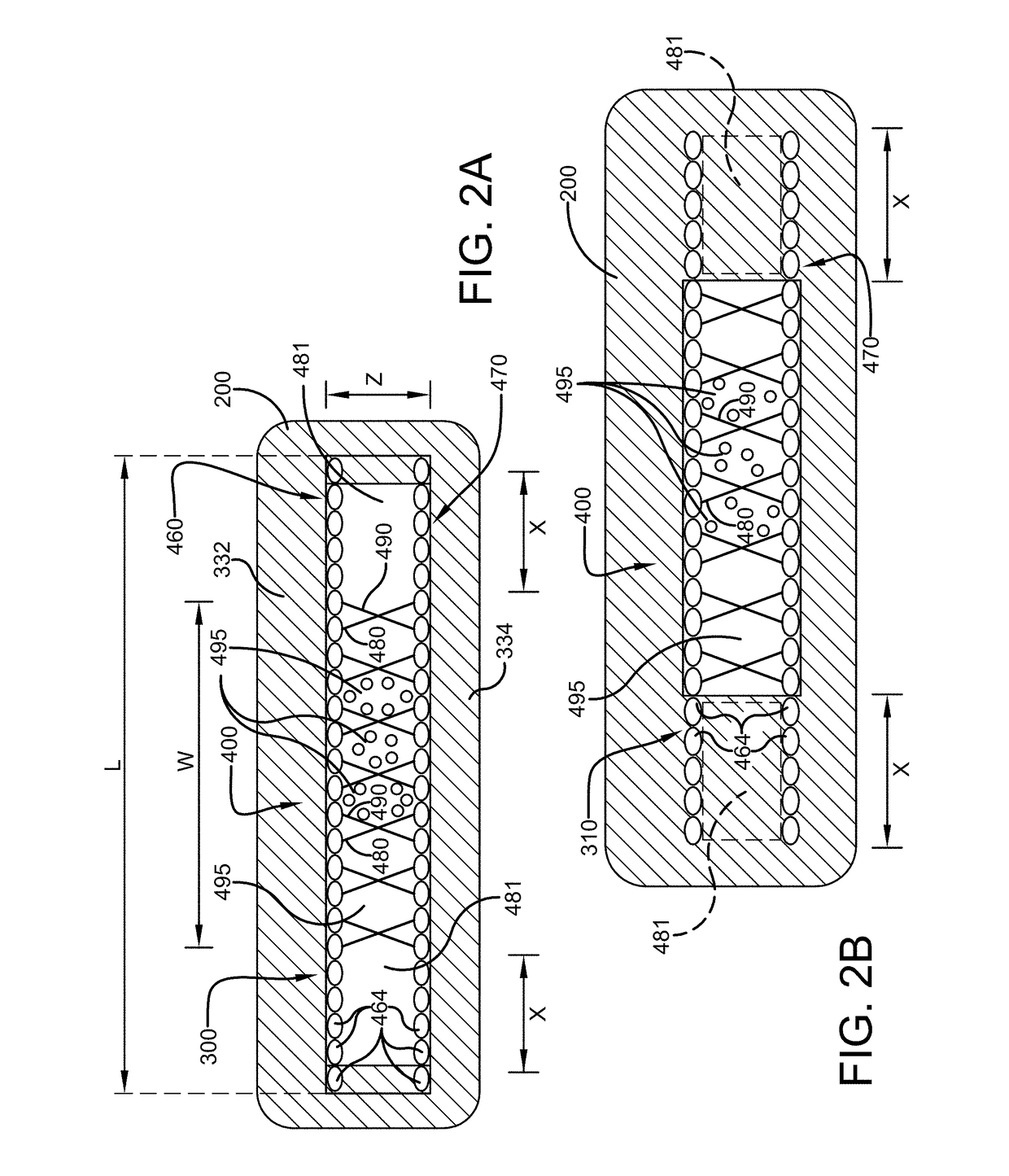

Shear band and non-pneumatic tire

ActiveUS20170297371A1Ornamental textile articlesNon-inflatable tyresGround contactThermoplastic elastomer

A shear band and a non-pneumatic tire is described which includes a ground contacting annular tread portion; a shear band, and a connecting web positioned between a hub and the shear band. The shear band is preferably comprised of a three-dimensional spacer fabric having a first and second layer connected by connecting members. The three-dimensional spacer fabric has a defined depth. The three-dimensional spacer structure further includes a plurality of cells formed between the connecting members, and wherein one or more of the cells are filled with a filler material. The filler material may be foam or a thermoplastic elastomer.

Owner:THE GOODYEAR TIRE & RUBBER CO

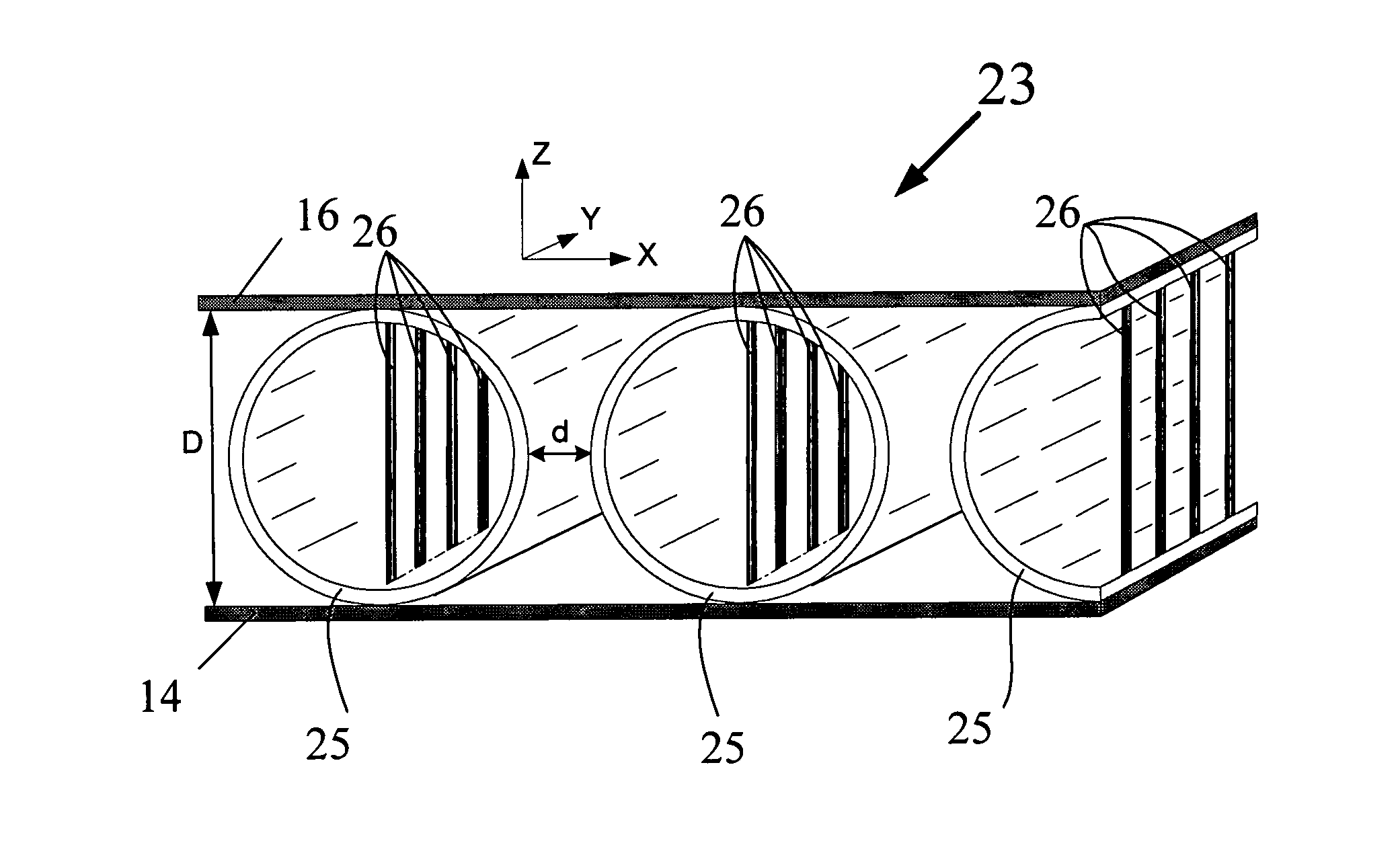

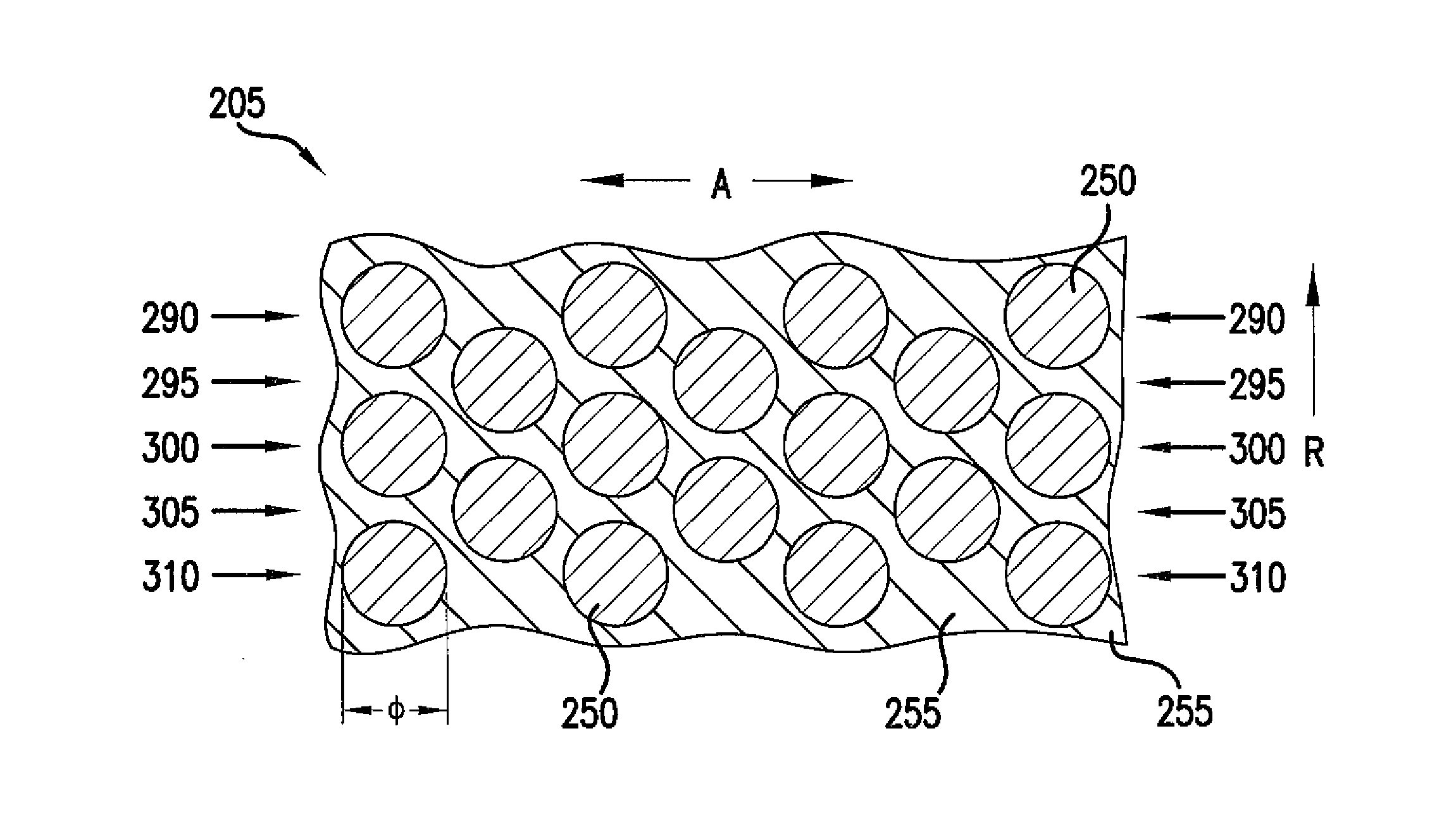

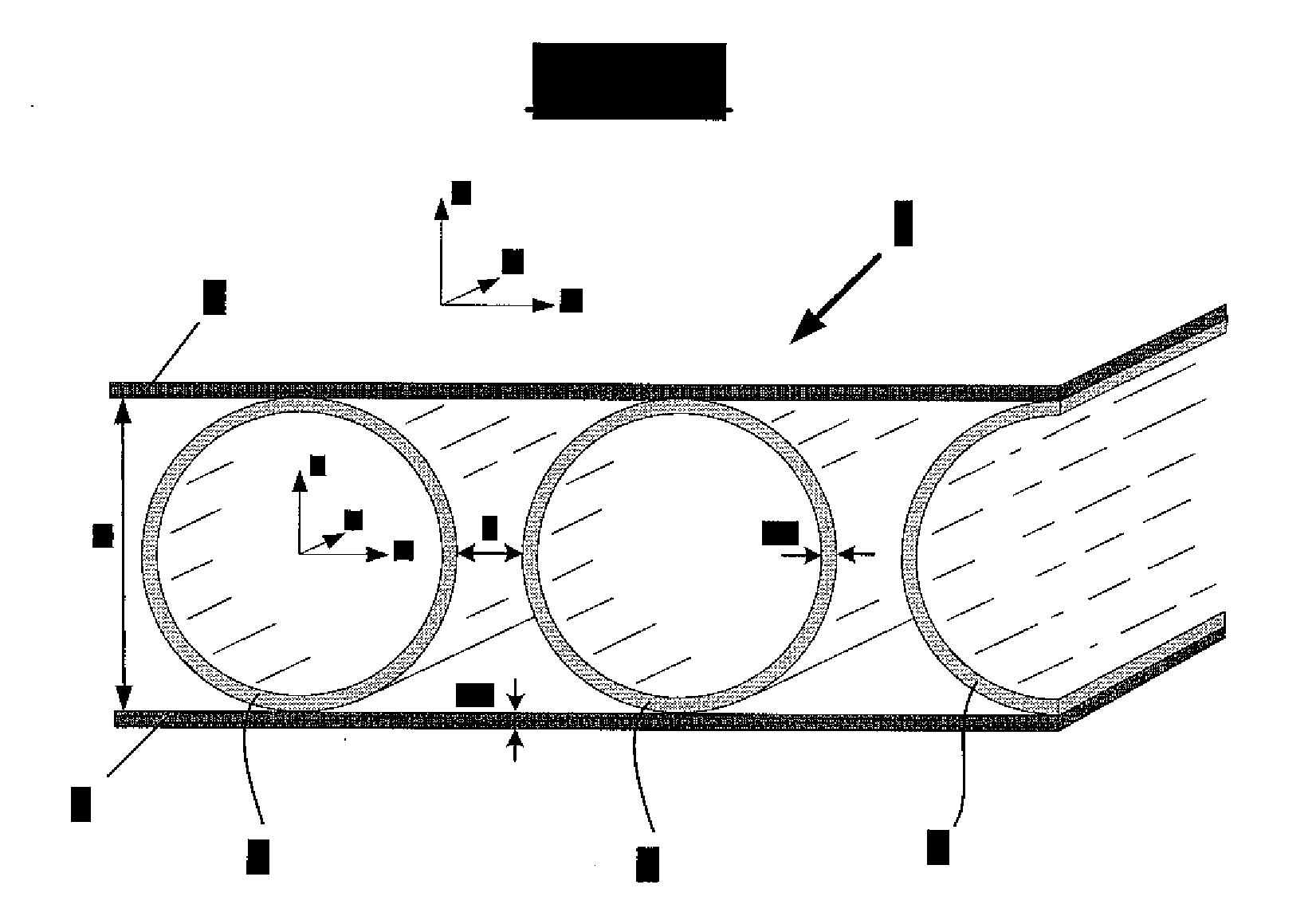

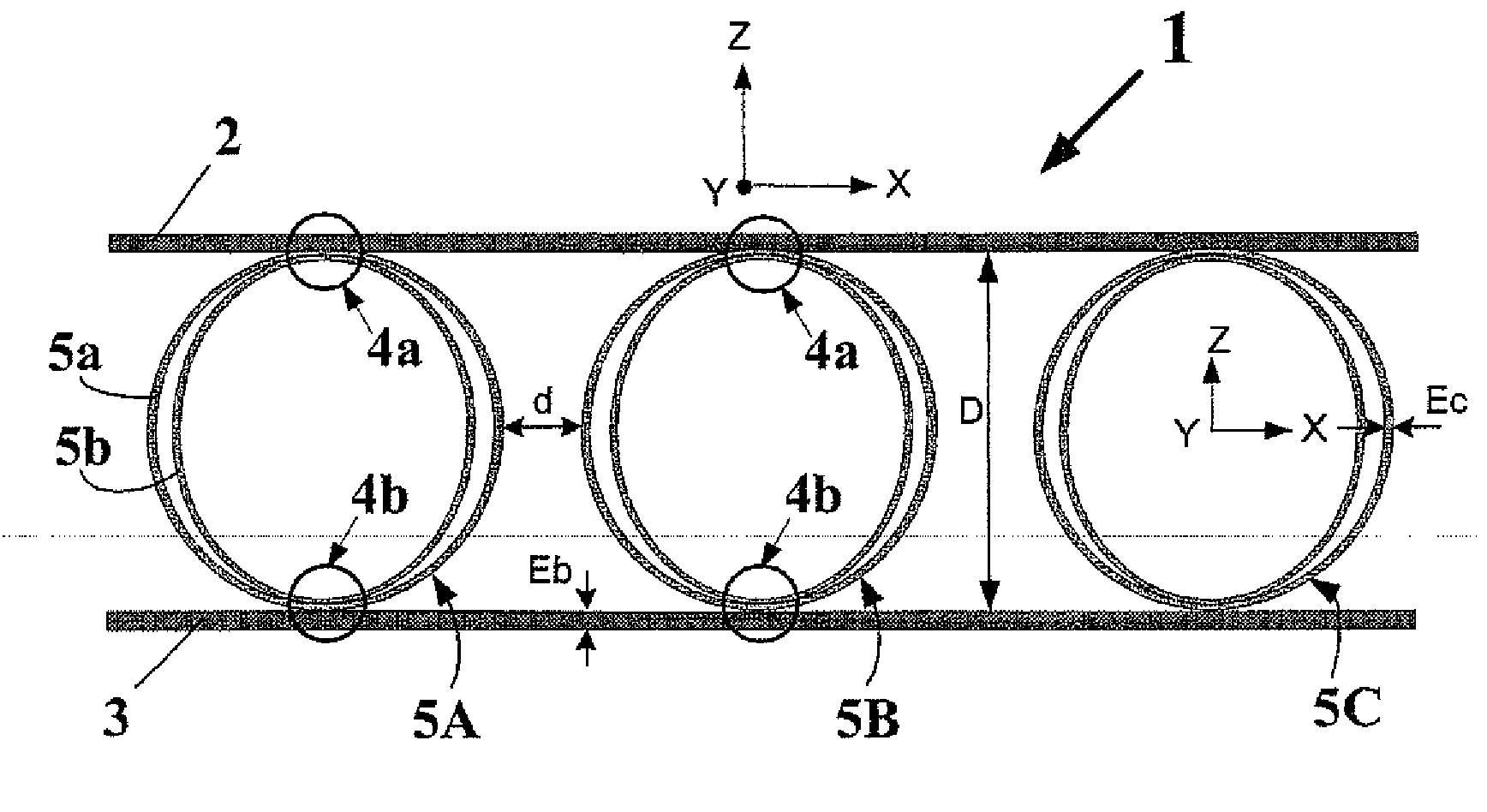

Composite Laminated Product

ActiveUS20100260967A1Overcomes drawbackWide temperature rangeLayered productsNon-inflatable tyresFiberHigh resistance

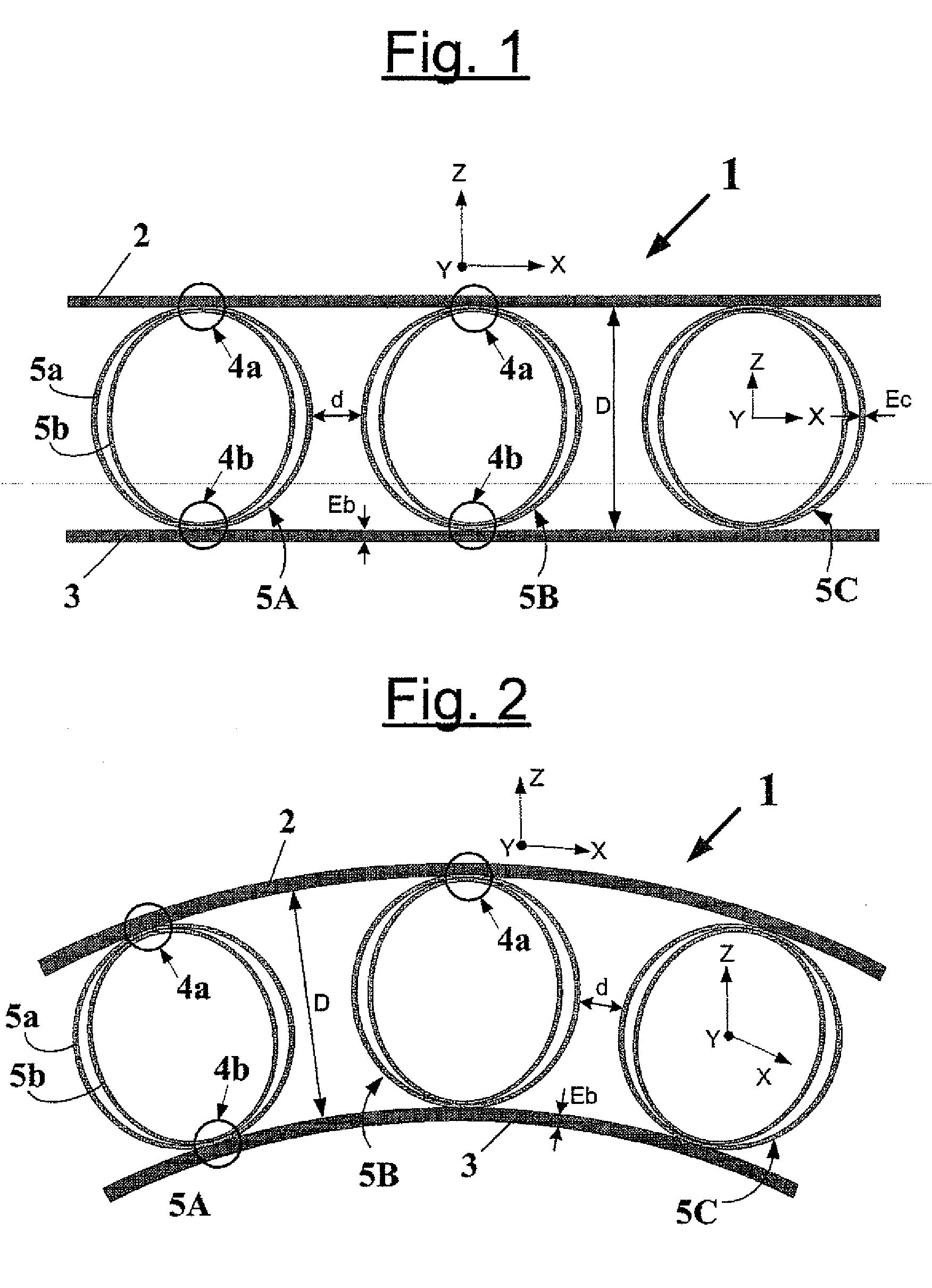

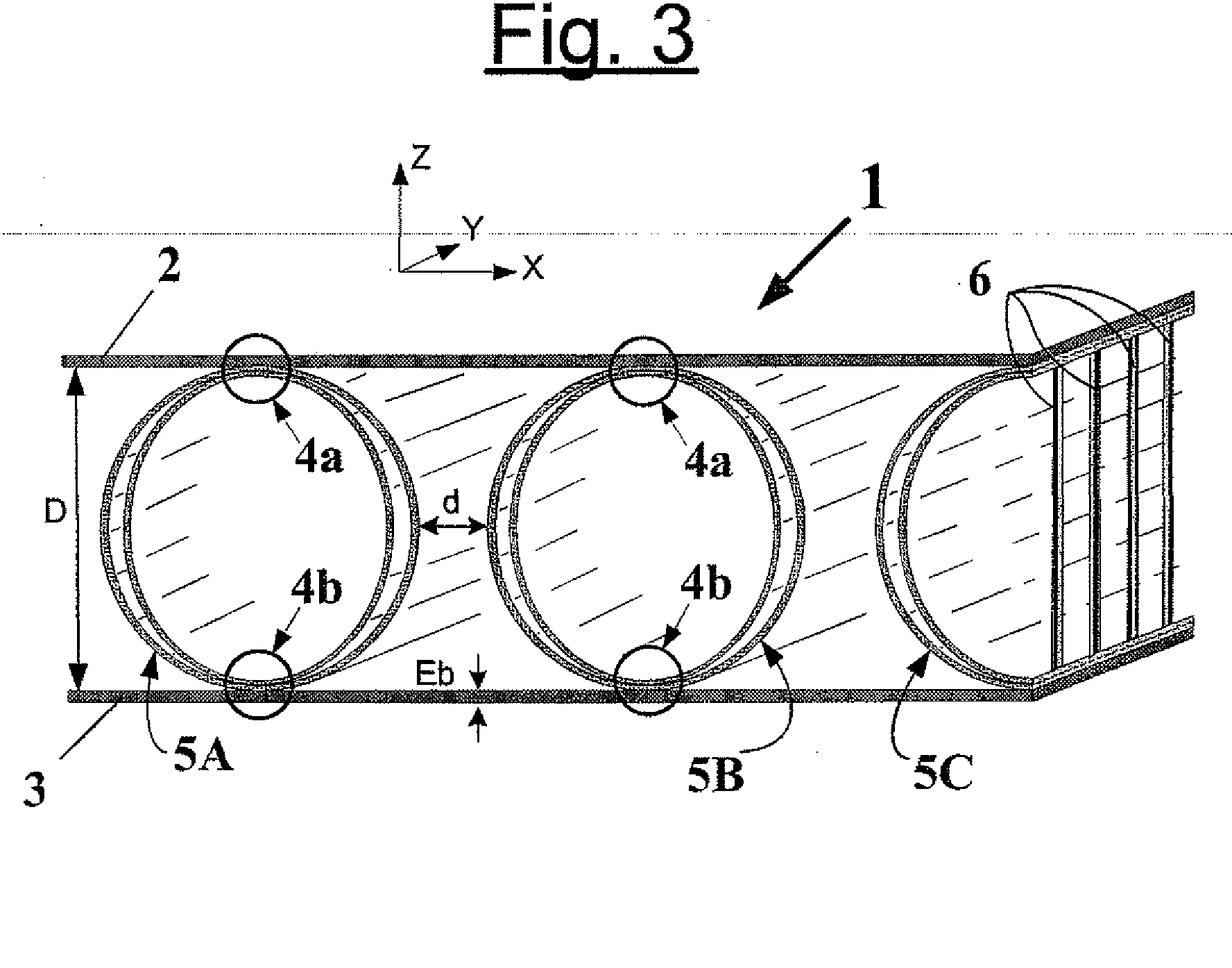

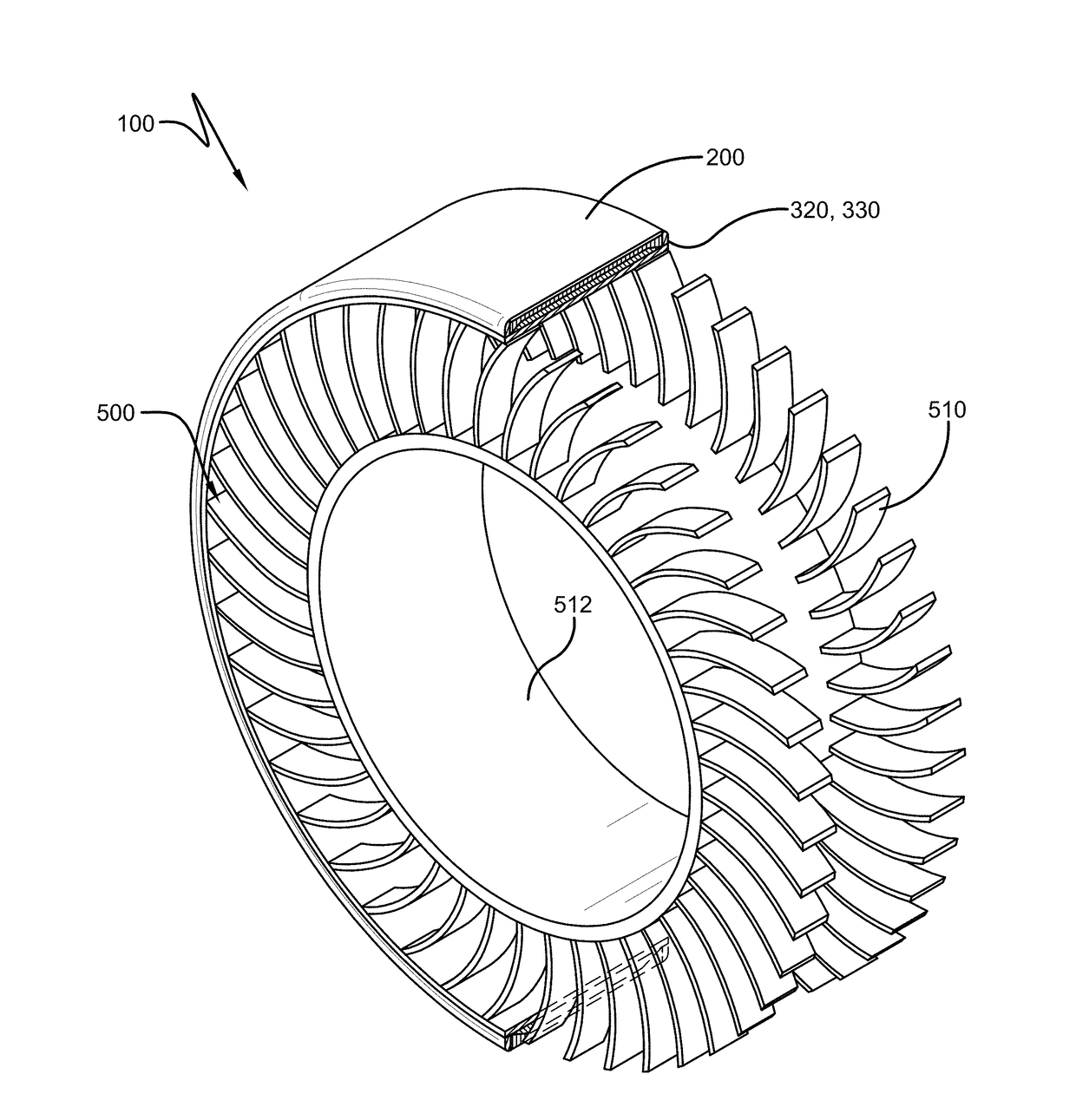

Composite laminated product (1) that forms a deformable cellular structure, comprising: an upper band (2) and a lower band (3) both oriented in the same main direction (X); and between the two bands (2, 3) and connecting the latter, a series that extends in the direction X, of cylinders (4) referred to as connection cylinders, said connection cylinders (4) being non-touching in the direction X and having their generatrix oriented along an axis Y perpendicular to the direction X. The connection cylinders are composite cylinders comprising fibres embedded in a resin matrix. Such a laminated product can be used as an elastic beam having a high resistance to flexural / compressive stresses and having a high endurance to such repeated or alternated stresses, in particular as a shear band in a non-pneumatic resilient wheel.

Owner:MICHELIN & CO CIE GEN DES ESTAB MICHELIN +1

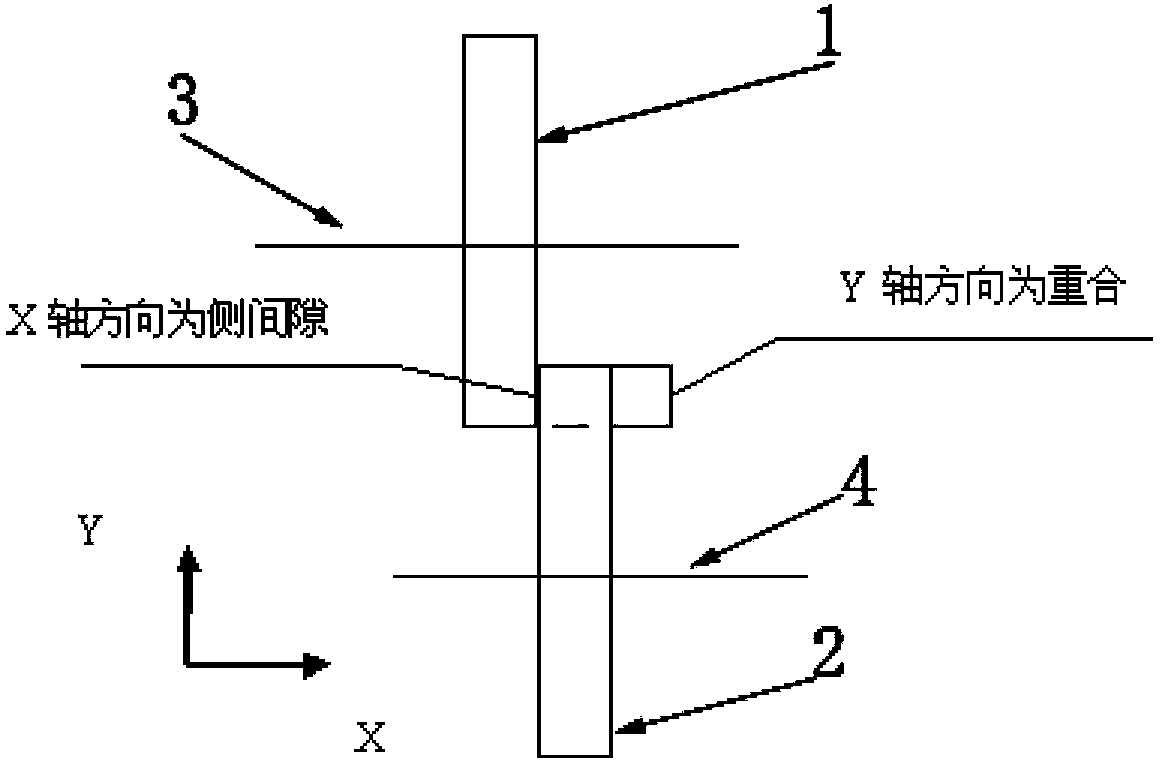

High-yield-strength oriented silicon steel shearing process

The invention provides a high-yield-strength oriented silicon steel shearing method. According to the method, the tensile force for shearing band steel at a disc shear is stabilized by virtue of controlling tensile forces of an unwinder and a reeling machine, and the purpose of stably shearing is achieved by virtue of reducing shaking. The tensile force numeric area of the unwinder is 15+ / -2N / mm<2>, and the tensile force numeric area of the reeling machine is 17+ / -2N / mm<2>; the front and rear parts of the disc shear are respectively provided with a pair of tensile force stabilization control rolls; lateral clearances and superposition amount of the disc shear are set and subsumed into a control program by virtue of a standard setting module, so as to control the oriented silicon steel trimming quality. The shearing process is especially applicable to producing the oriented silicon steel with the yield strength of 300-330N / mm<2>, the tensile strength of 335-355N / mm<2> and the thickness of 0.22-0.33mm, improving the oriented silicon steel trimming quality, and avoiding trimming defects such as broken fracture and poor trimming, namely flying spurs and excessive burrs at edge parts.

Owner:BAOSHAN IRON & STEEL CO LTD

Non-Pneumatic Tire

The invention relates to a non-pneumatic tire. A structurally supported tire includes a ground contacting annular tread portion; a shear band, and a connected spoke disk connected to the shear band. The connected spoke disk has two or more circumferential spokes joined together by a connecting web, wherein the spring rate of the connected spoke disk is greater than the spring rate of the shear band.

Owner:THE GOODYEAR TIRE & RUBBER CO

Non-pneumatic tire

Owner:THE GOODYEAR TIRE & RUBBER CO

Composite Laminate Product

ActiveUS20110104428A1Overcomes drawbackSynthetic resin layered productsNon-inflatable tyresFiberHigh resistance

A laminated product (1) that forms a deformable cellular structure, comprising: an upper band (2) and a lower band (3) both oriented in the same main direction (X); and between the two bands and connecting the latter in zones (4a, 4b) referred to anchoring zones, a series (5A, 5B, 5C) that extends in the direction X, of cylindrical structures (5) referred to connecting cylindrical structures that are non-touching in the direction X. Each connecting cylindrical structure (5) comprises a plurality of preferably concentric elementary cylinders (5a, 5b) having their generatrix oriented along an axis Y perpendicular to the direction X, said elementary cylinders being fitted one inside the other and interconnected to one another in each anchoring zone (4). Said elementary cylinders are especially composite cylinders comprising fibres embedded in a resin matrix. Such a laminated product can be used as an elastic beam having a high resistance to flexural / compressive stresses and having a high endurance to such repeated or alternated stresses, in particular as a shear band in a non-pneumatic resilient wheel.

Owner:MICHELIN RECH & TECH SA +1

Shear band and a non-pneumatic tire

A shear band comprising a three-dimensional spacer structure, wherein the three-dimensional spacer structure is formed from a first and second layer of material, each layer of material having first reinforcement members which extend in a first and direction, and second reinforcement members which extend in a second direction, wherein each layer of material is connected to each other by a plurality of connecting reinforcement members which extend in a third direction, wherein the shear band further comprises a first membrane layer located radially outward of the three-dimensional spacer structure. The invention further comprises a non-pneumatic tire which includes the above described shear band.

Owner:THE GOODYEAR TIRE & RUBBER CO

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com