Patents

Literature

270results about How to "Avoid brittleness" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

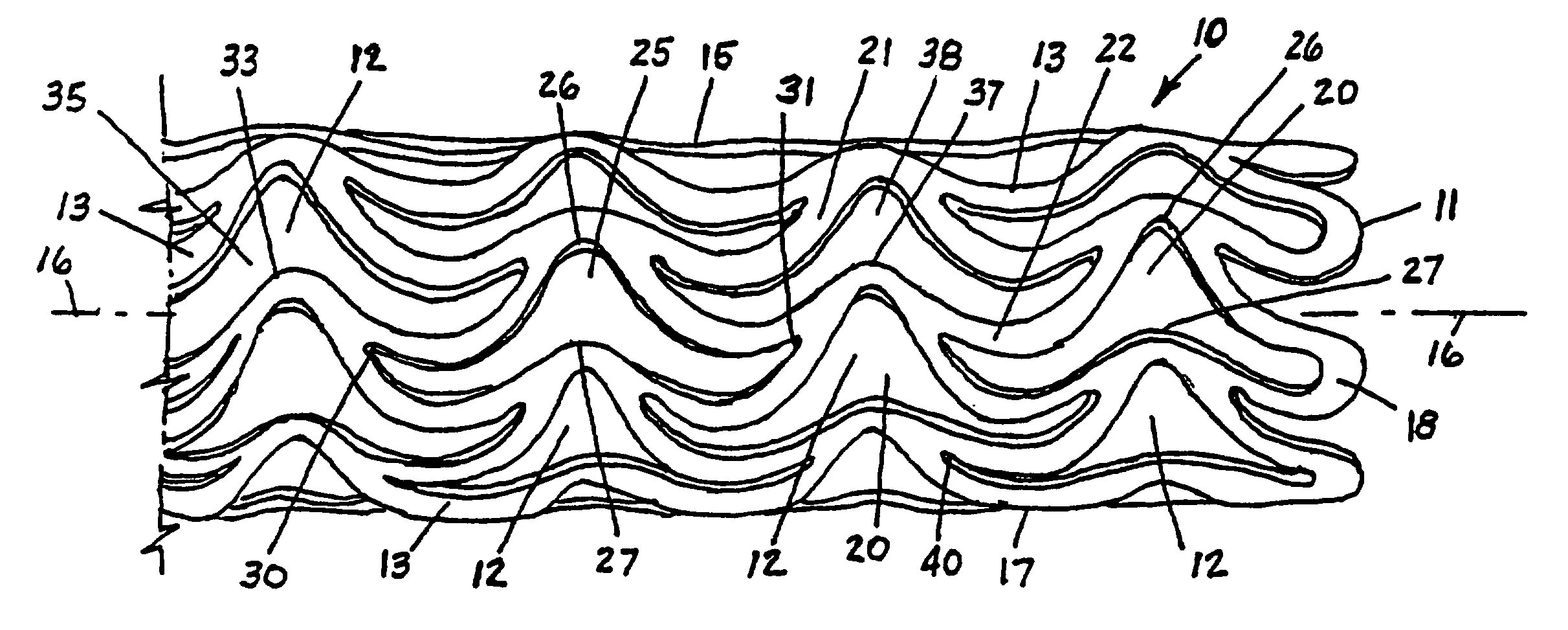

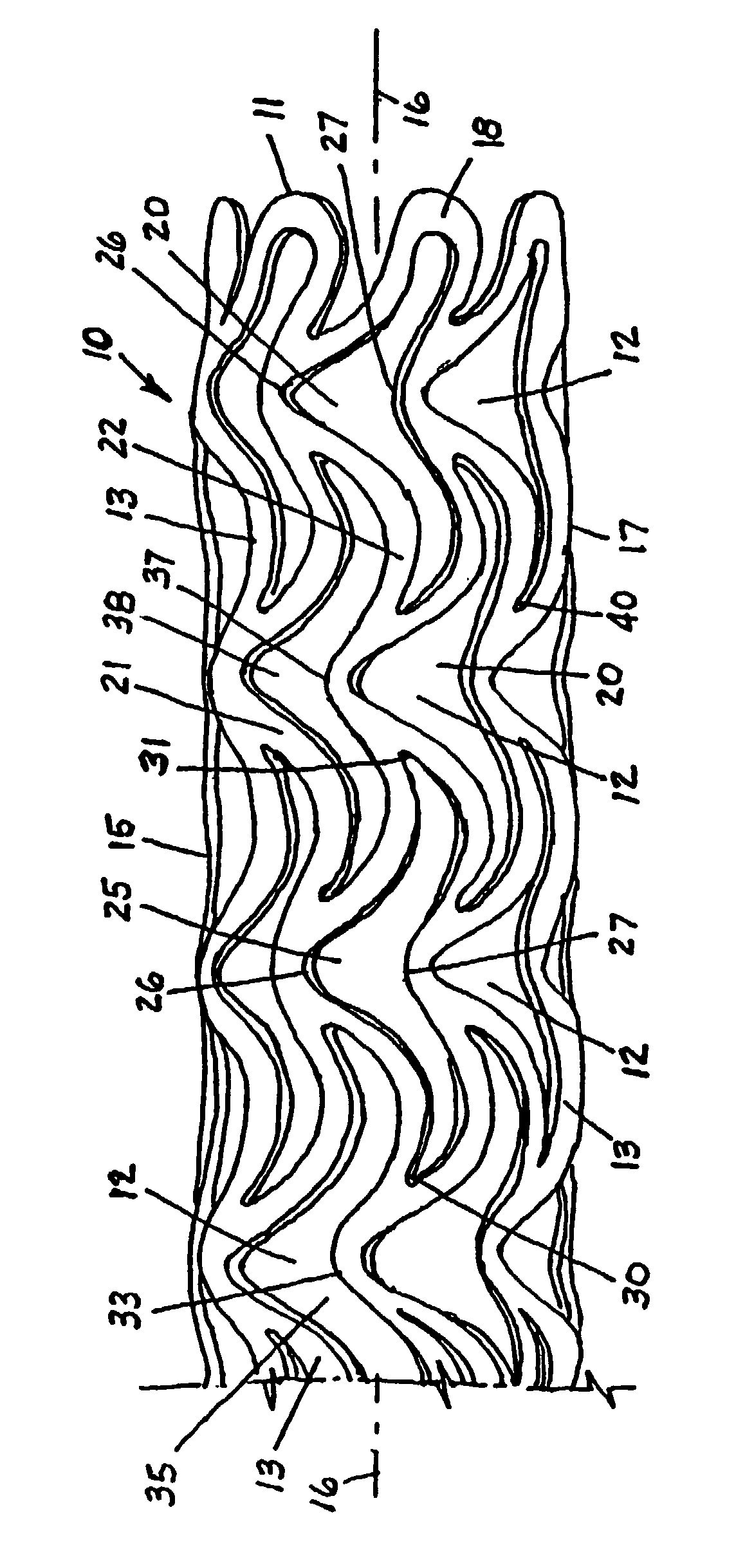

Primarily niobium stent

InactiveUS7101391B2Improved performance structurallyAvoid brittlenessStentsSurgeryNiobium alloyTitanium alloy

In a process of fabricating a stent composed primarily of niobium alloyed with a trace amount of zirconium, tantalum, or titanium for hardening, the stent is annealed under vacuum in a substantially oxygen-free environment. The vacuum is preferably maintained at pressure less than 10−4 millibars, oxygen-content less than about 80 parts per million, and the annealing temperature exceeds 400° C. for at least one hour, and is preferably kept in a range from about 1100–1200° C. for several hours. This may be followed by applying a surface layer of oxide, such as iridium oxide, with a thickness of 299–300 nm to the stent.

Owner:BOSTON SCI SCIMED INC

Waterproof and anti-corrosion repair mortar for polymer cement-based concrete structure

The invention relates to a waterproof and anti-corrosion repair mortar for a polymer cement-based concrete structure, in particular to a cement concrete repair material for a cement concrete structure, which is used for carrying out bonding reinforcement and repair on defects of municipal roads, municipal services, bridges and water conservancy projects (dams and gates). The waterproof and anti-corrosion repair mortar is prepared by mixed materials and water, and the mixed materials comprise the following components in parts by weight: 20-30 parts of portland cement, 0.01-0.05 part of high-performance water-reducing agent, 1-5 parts of high-aluminum cement, 15-30 parts of quartz sand, 25-60 parts of gravel and 1-3 parts of acrylic adhesive powder, 1-3 parts of fiber material, while the using amount of water accounts for 5-14% of the total parts of the mixed materials. Due to the adoption of the technical scheme, the waterproof and anti-corrosion repair mortar has the characteristics of good pressure resistance, high flexural strength, high bonding strength, good durability, convenient and fast construction, fast setting and early strength shrinkage control, and can greatly shorten the repair time and quickly resume the traffic in particular to roads.

Owner:卢建华

Composite material for pultrusion polyurethane resin and preparation method thereof

The invention discloses a composite material for pultrusion polyurethane resin and a preparation method thereof. The composite material is prepared from continuous fiber and polyurethane resin; the continuous fiber is selected from glass fiber or carbon fiber and is 60-85% of the total volume of the composite material in percentage by weight; and the polyurethane resin is 15-40% of the total volume of the composite material in percentage by weight. The resin disclosed by the invention has fast speed during curing, high degree of cross-linking, excellent mechanical property and good wettability to fiber reinforced materials.

Owner:南京聚发新材料有限公司

Active bio piezoelectric ceramic coating layer and method of preparing said coating layer on titanium base body surface

InactiveCN1785439AReduce bond strengthHigh bonding strengthAnodisationImpression capsPlasma electrolytic oxidationMicro arc oxidation

A coated active biologic piezoelectric layer on Ti substrate is prepared from fluorohydroxy apatite (FHA) and barium titanate (BT) through cleaning the surface of Ti substrate, microarc oxidizing to form a porous oxide film layer, and electrophoretic deposition to form a FHABT layer on the surface of Ti substrate. Its advantages are easy control to content of F, high implantation stability, binding power to interface, biocompatibility and bioactivity, and high effect to promote generation of biologic bone and taking part energy conversion in human body.

Owner:HARBIN ENG UNIV

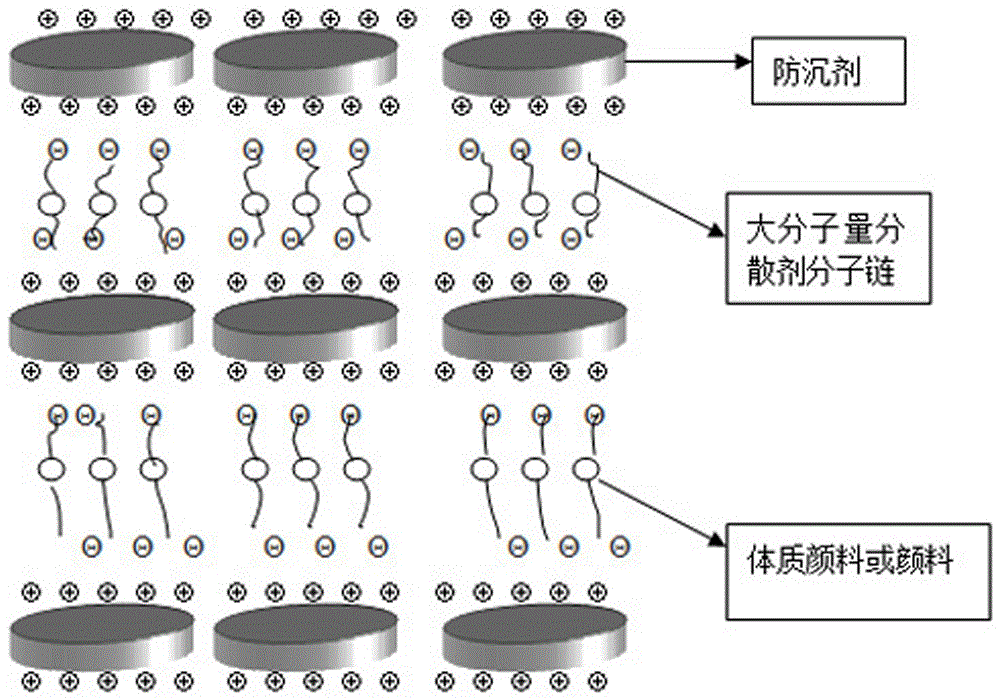

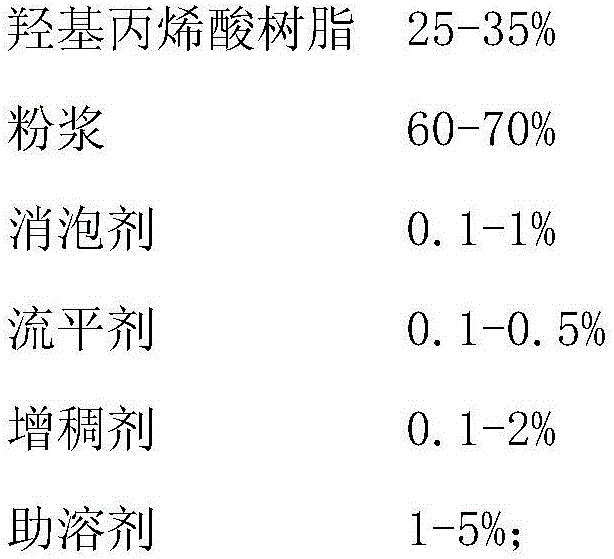

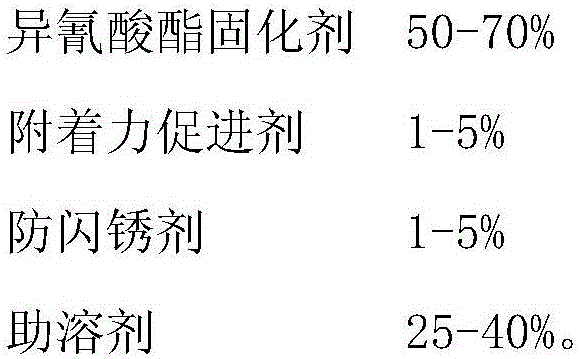

Automobile water-based dual-component middle coating excellent in performance and preparation method thereof

The invention discloses an automobile water-based dual-component middle coating excellent in performance and a preparation method thereof. The water-based middle coating is composed of a component A and a component B. The component A is composed of hydroxy acrylic resin, powder syrup, auxiliaries and cosolvent, wherein powder syrup contains deionized water, amine neutralizer, auxiliaries, extender pigment and pigment. The component B is composed of a curing agent, auxiliaries and cosolvent. After being put in according to the formula of the powder syrup of the component A, materials are dispersed at a high speed for 15 min and then enter a grinding machine to be ground till the granularity is smaller than 30 micron, then powder syrup is obtained, and hydroxy acrylic resin, powder syrup, auxiliaries and cosolvent are evenly mixed to obtain the component A. The component A and the component B are mixed in certain proportion, viscosity is adjusted by adding deionized water, and a middle coating film is obtained through spraying construction. By means of the water-based middle coating, the water-based performance of the automobile middle coating is achieved, the VOC content is greatly decreased, and excellent comprehensive performance is achieved.

Owner:GUANGDONG YATU CHEM

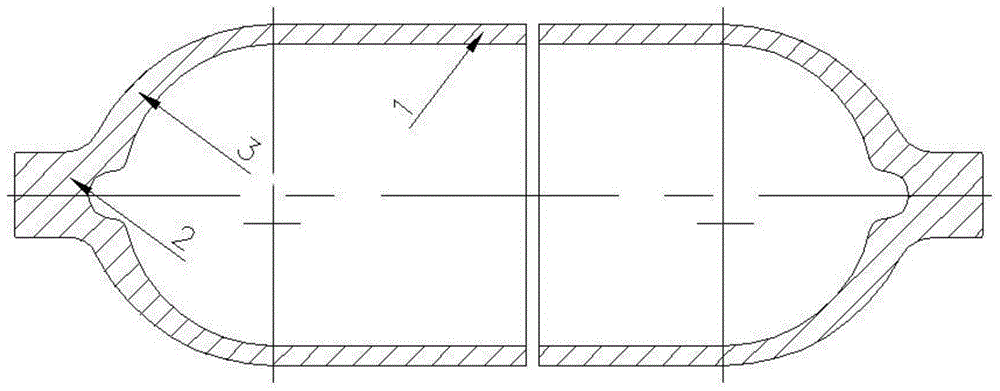

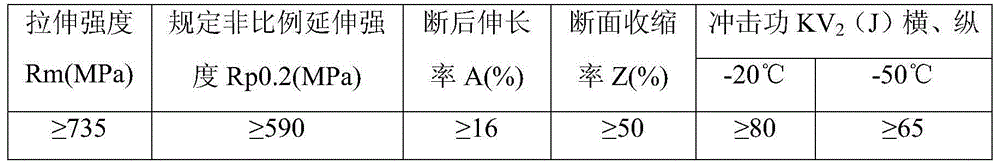

High-pressure seamless 10CrNi3MoV steel cylinder and manufacturing process thereof

ActiveCN104451419AImprove toughnessAvoid brittlenessFurnace typesHeat treatment furnacesHigh probabilityHigh pressure

The invention belongs to the field of machinery manufacturing, particularly relates to a high-pressure seamless 10CrNi3MoV steel cylinder and a manufacturing process thereof, and aims to solve the technical problems of difficulty in manufacturing process determination, poor low-temperature toughness of materials, high probability of deformation and cracking and the like of the current welded type high-pressure seamless 10CrNi3MoV steel cylinder. The scheme is that the high-pressure seamless 10CrNi3MoV steel cylinder adopting seamless 10CrNi3MoV steel pipes as raw materials is provided. The invention further provides a manufacturing process of the high-pressure seamless 10CrNi3MoV steel cylinder. A cylinder body and a seal head of the high-pressure seamless 10CrNi3MoV steel cylinder are seamlessly connected, so that the welding defect is overcome, and meanwhile, with the adoption of the manufacturing process, the low-temperature toughness of steel is further improved.

Owner:CHENGDU GREAT HIGH PRESSURE VESSEL

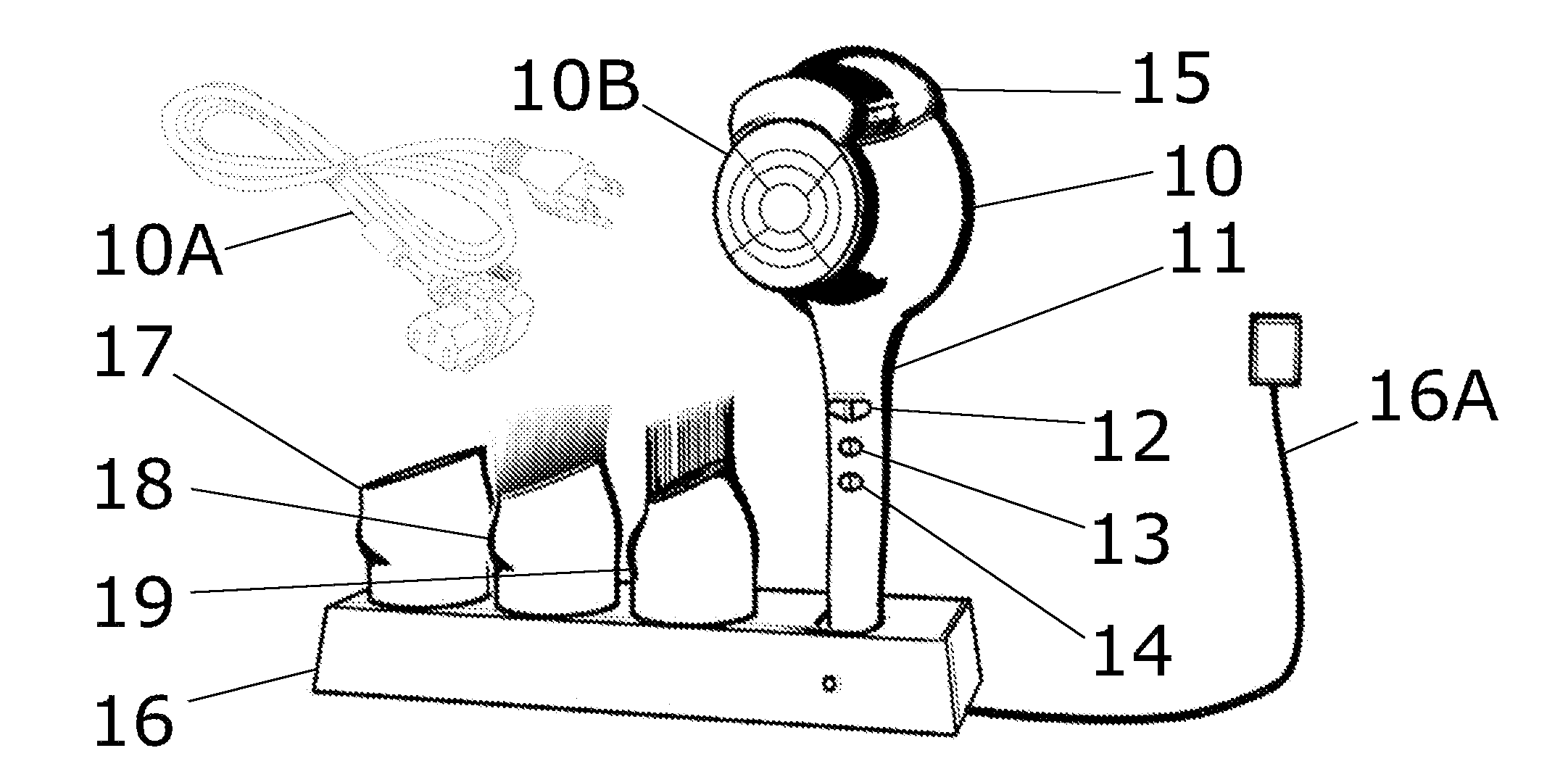

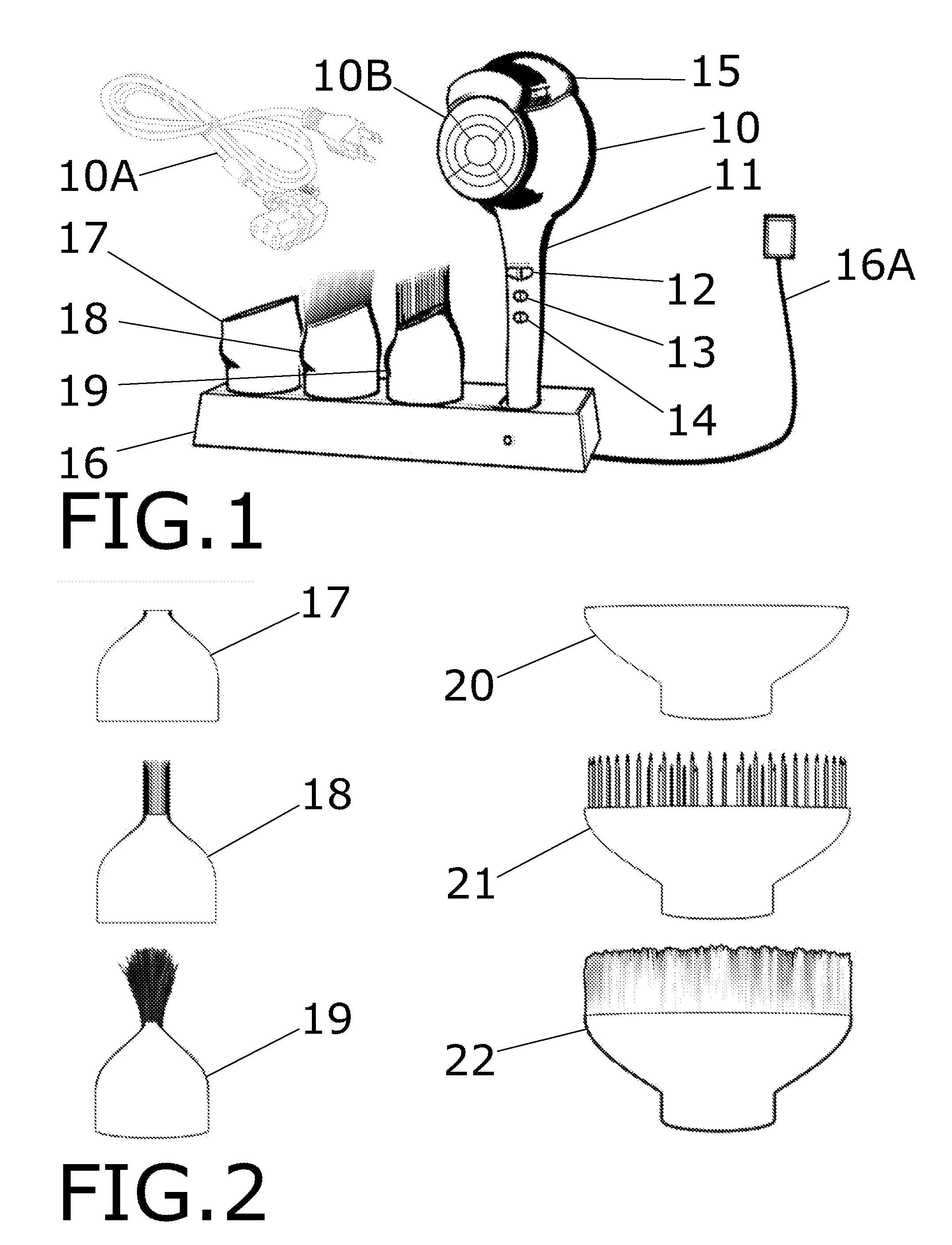

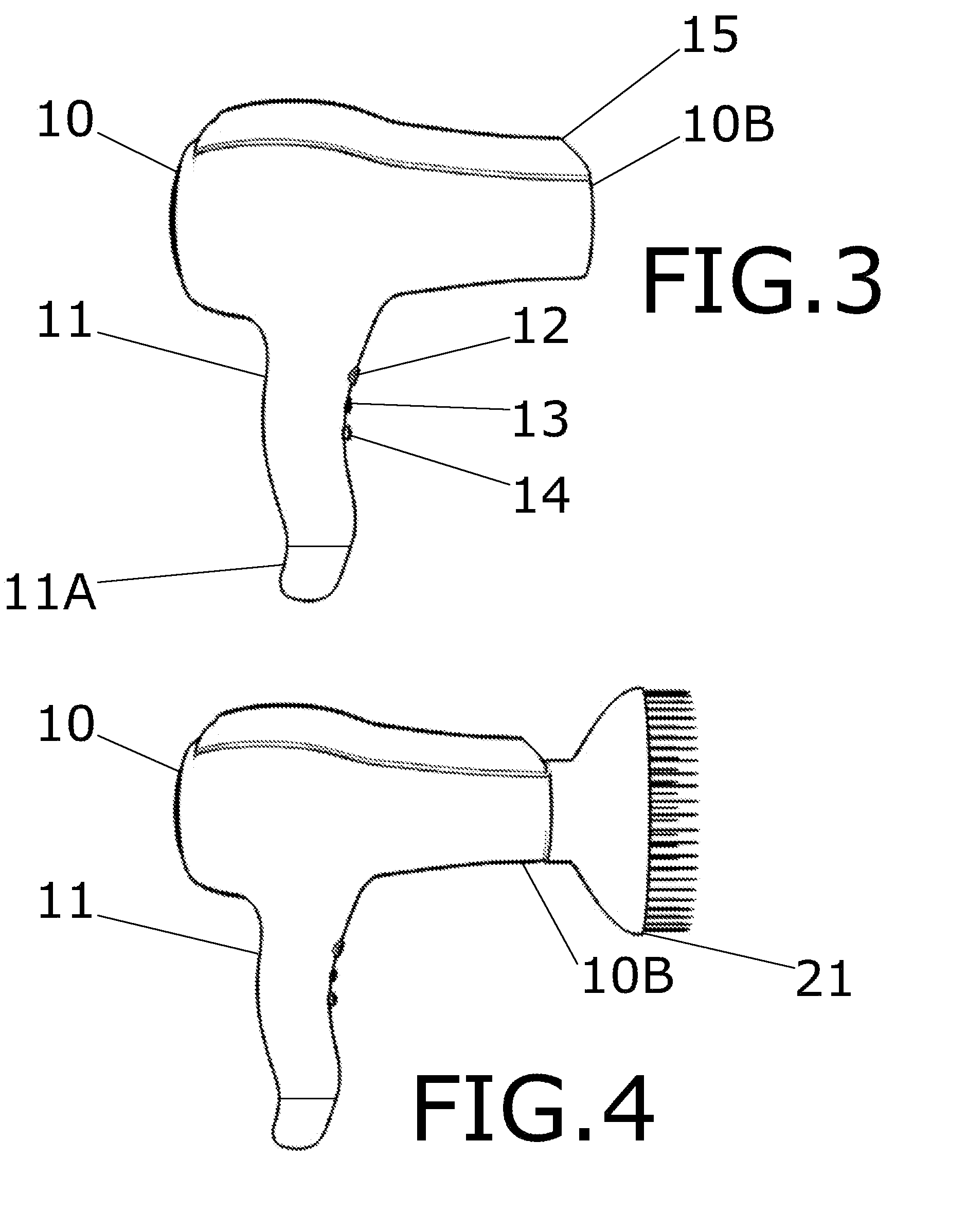

Cordless hair dryer with ionizing solution

ActiveUS20160353854A1Avoid brittlenessAvoid damageBatteries circuit arrangementsNetwork topologiesEngineeringMobile electronics

A hair dryer with an ionizing solution provides a translucent reservoir which contains an ionized solution. The hair dryer heats the solution into a vapor, and may then be used to apply the ionized vapor to a salon client's hair while styling it, to prevent brittleness, damage, and split ends. In one embodiment a cradle is provided for recharging a handheld hair dryer and storing various attachments which are ready for immediate use. When separated from the handheld hair dryer, the cradle transfers electric power to the hair dryer via resonant inductive coupling, creating an oscillating magnetic field which is converted to electric power by components within the hair dryer. A second embodiment provides a standing hair dryer. The hair dryer also provides wireless internet and power outlets for mobile electronic devices.

Owner:THOMAS SHERRON M

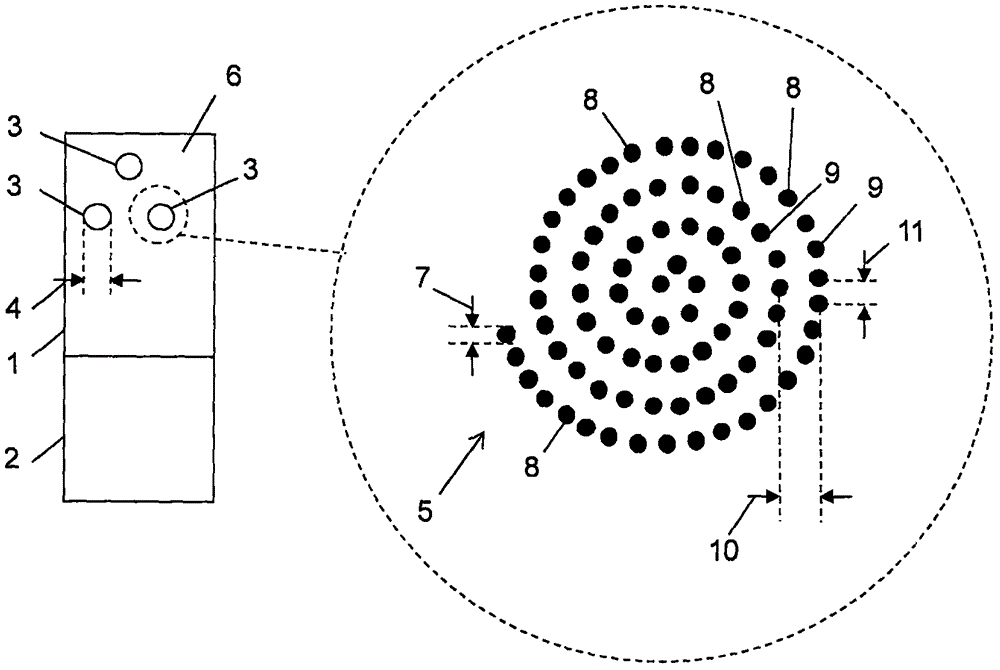

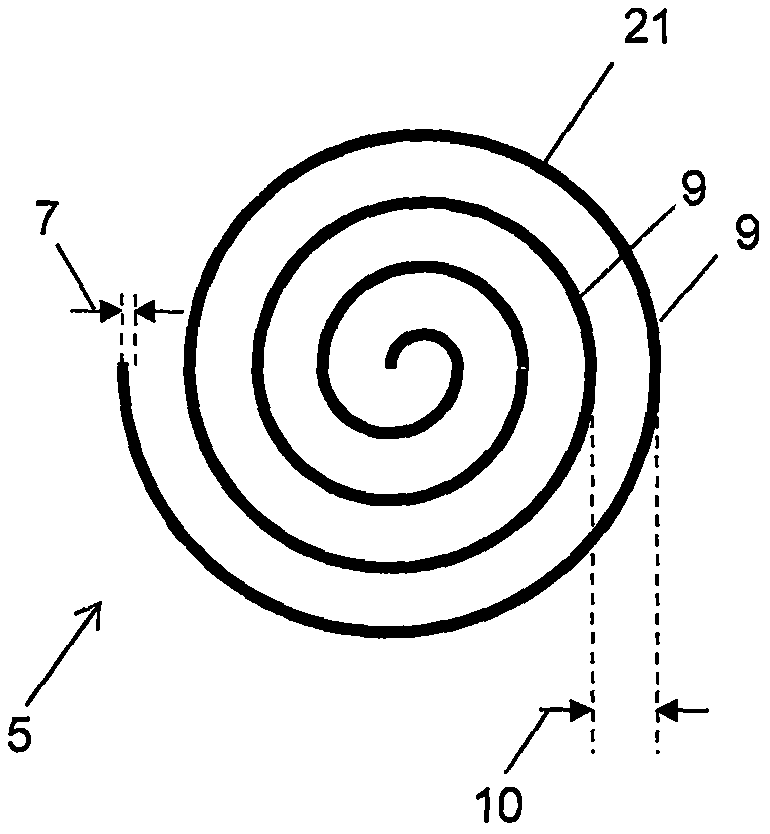

A weld

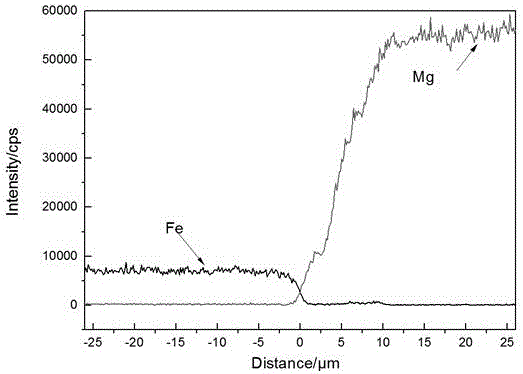

ActiveCN105855706AAvoid generatingImprove efficiencySheet joiningWorkpiece edge portionsMetallic materialsLaser beam welding

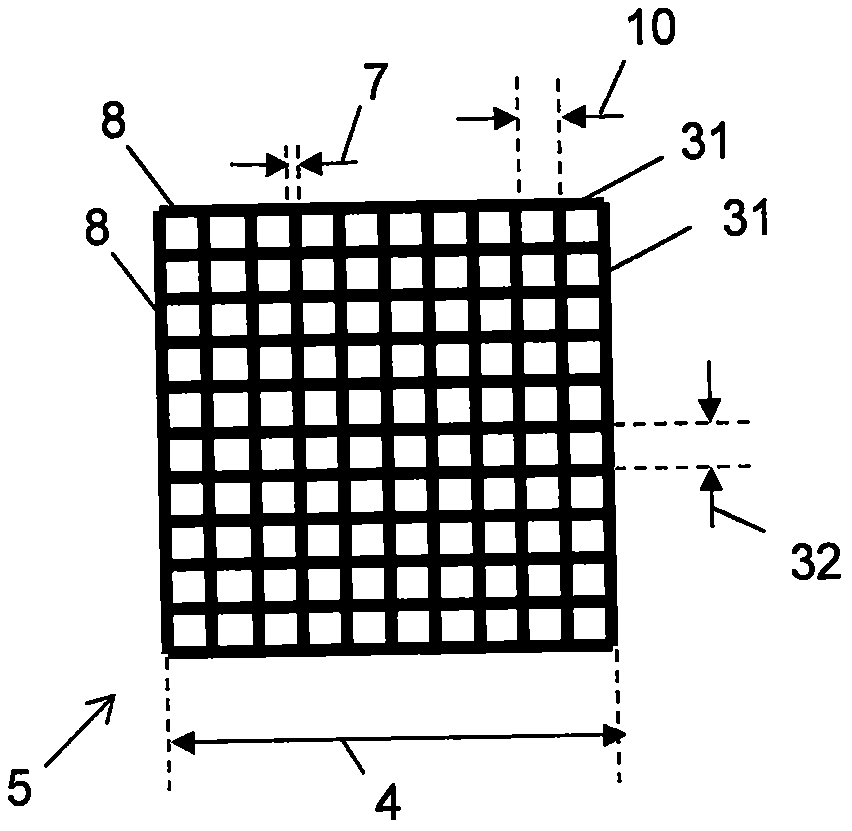

Provided is a weld (3) between a first material (1) and a second material (2), the first material (1) being a first metallic material, and the second material (2) being a second metallic material, the weld (3) has a width (4) between 0.5mm and 7mm, the weld (3) comprises at least one microweld (8), the microweld (8) forms a welding pattern (5) defined parallel to a surface (6) of the first material (1), and the microweld (8) has a characteristic feature size (7) of between 20mum and 400mum.

Owner:SPI LASERS UK

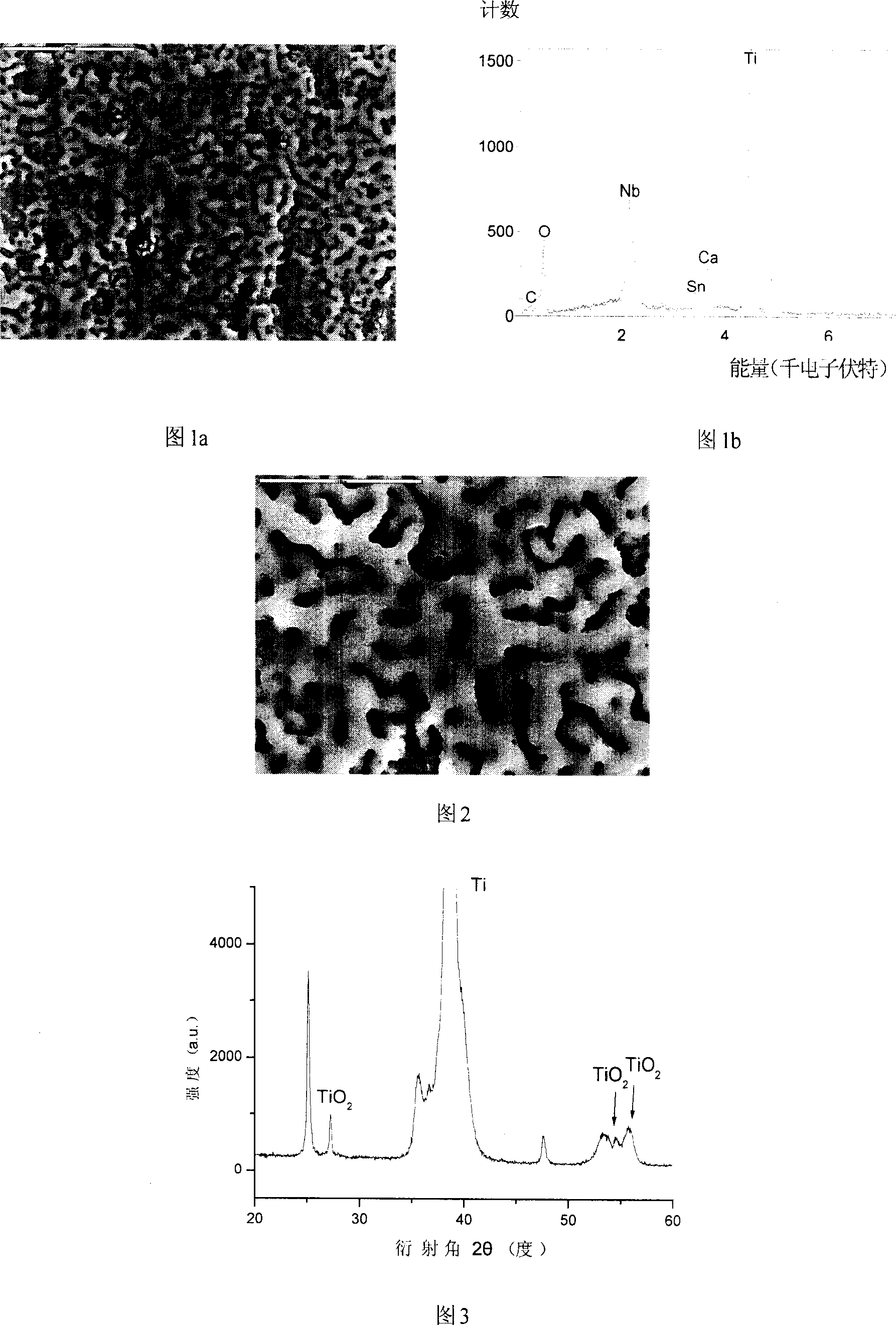

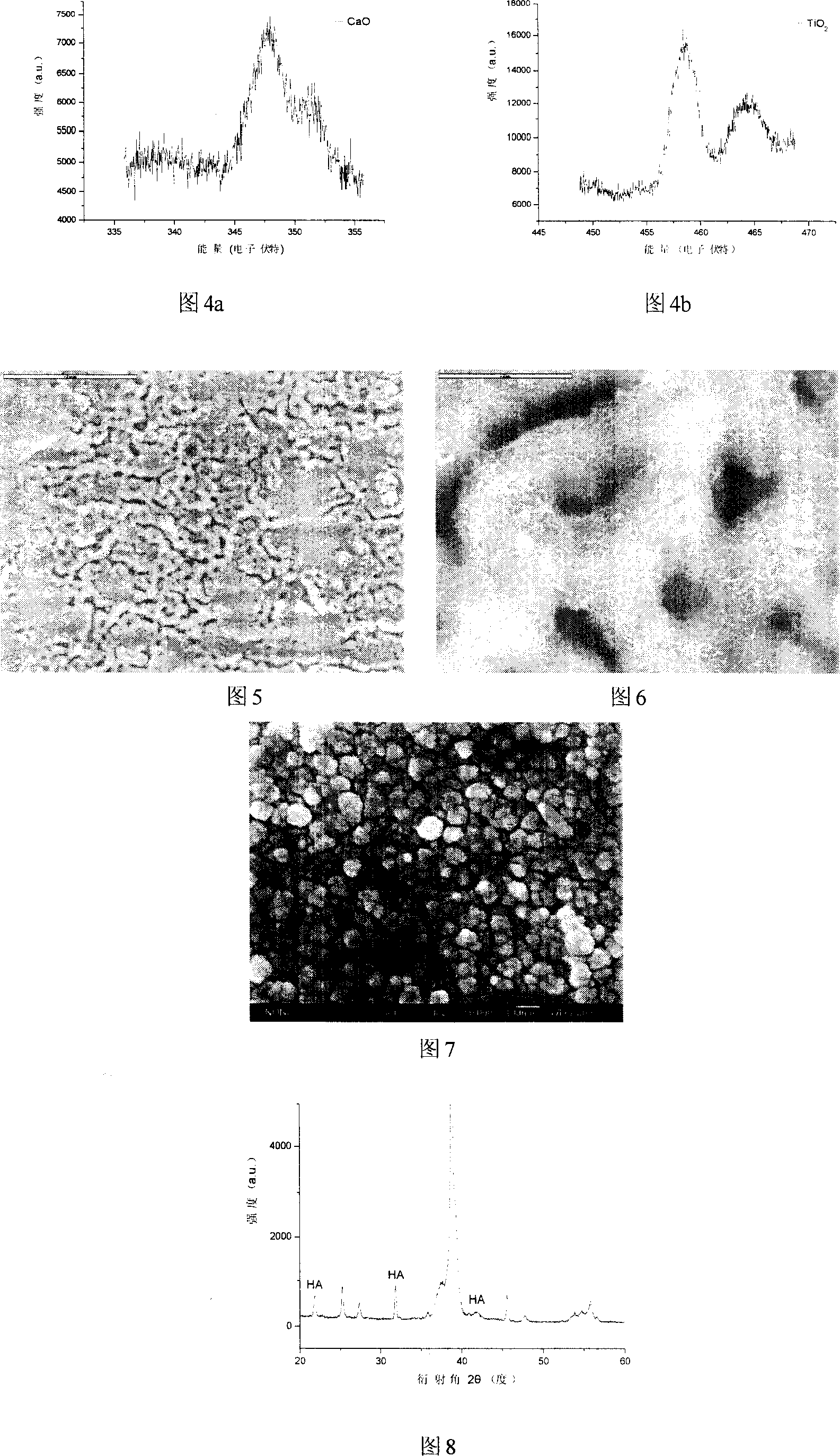

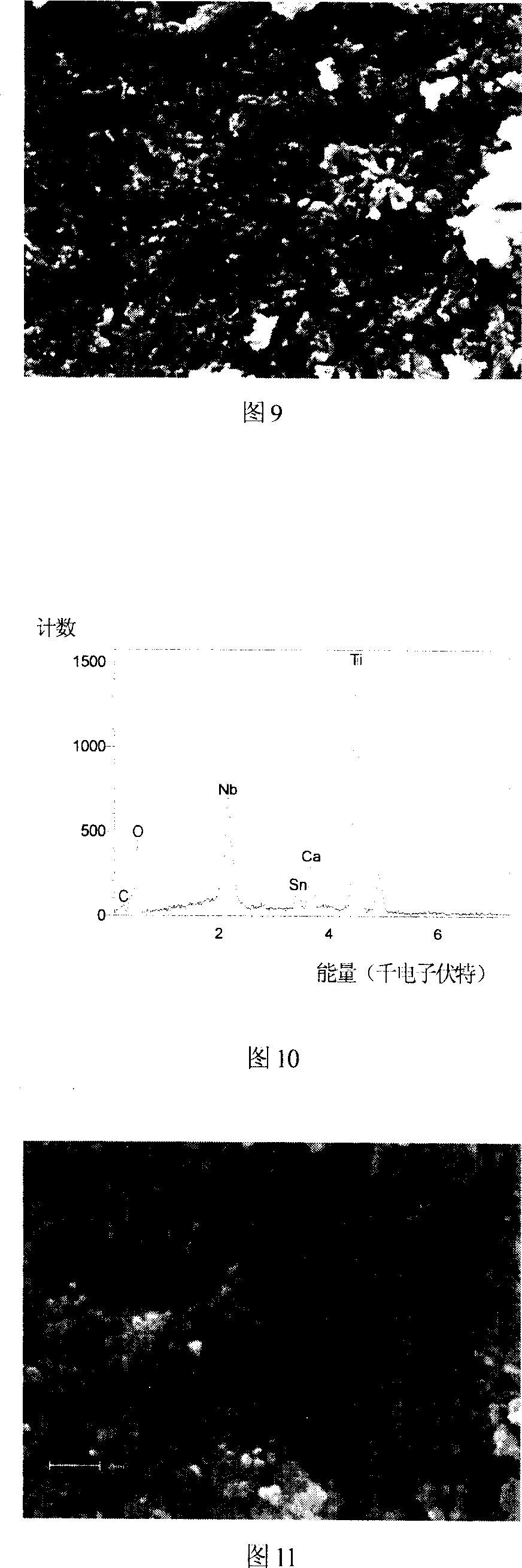

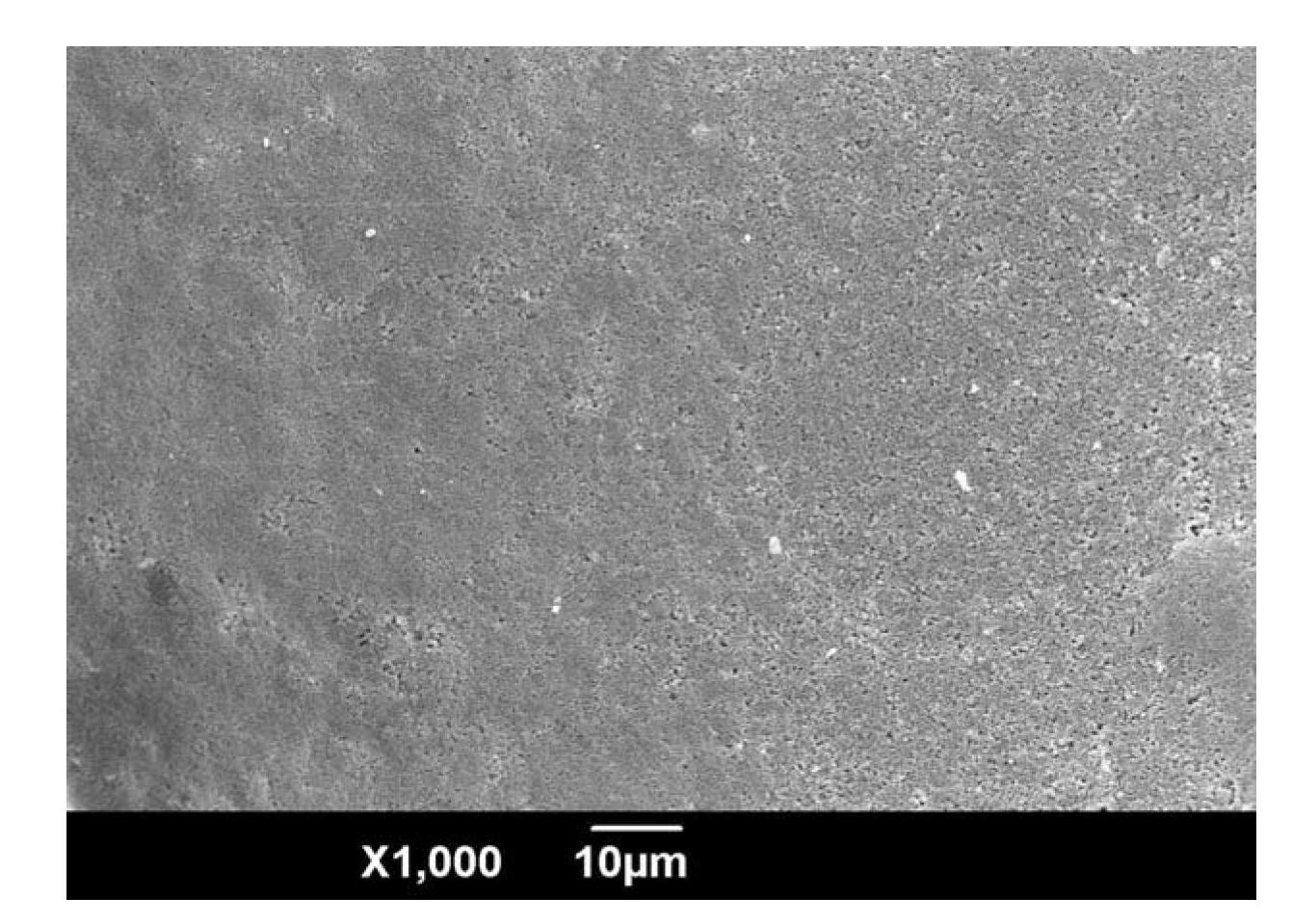

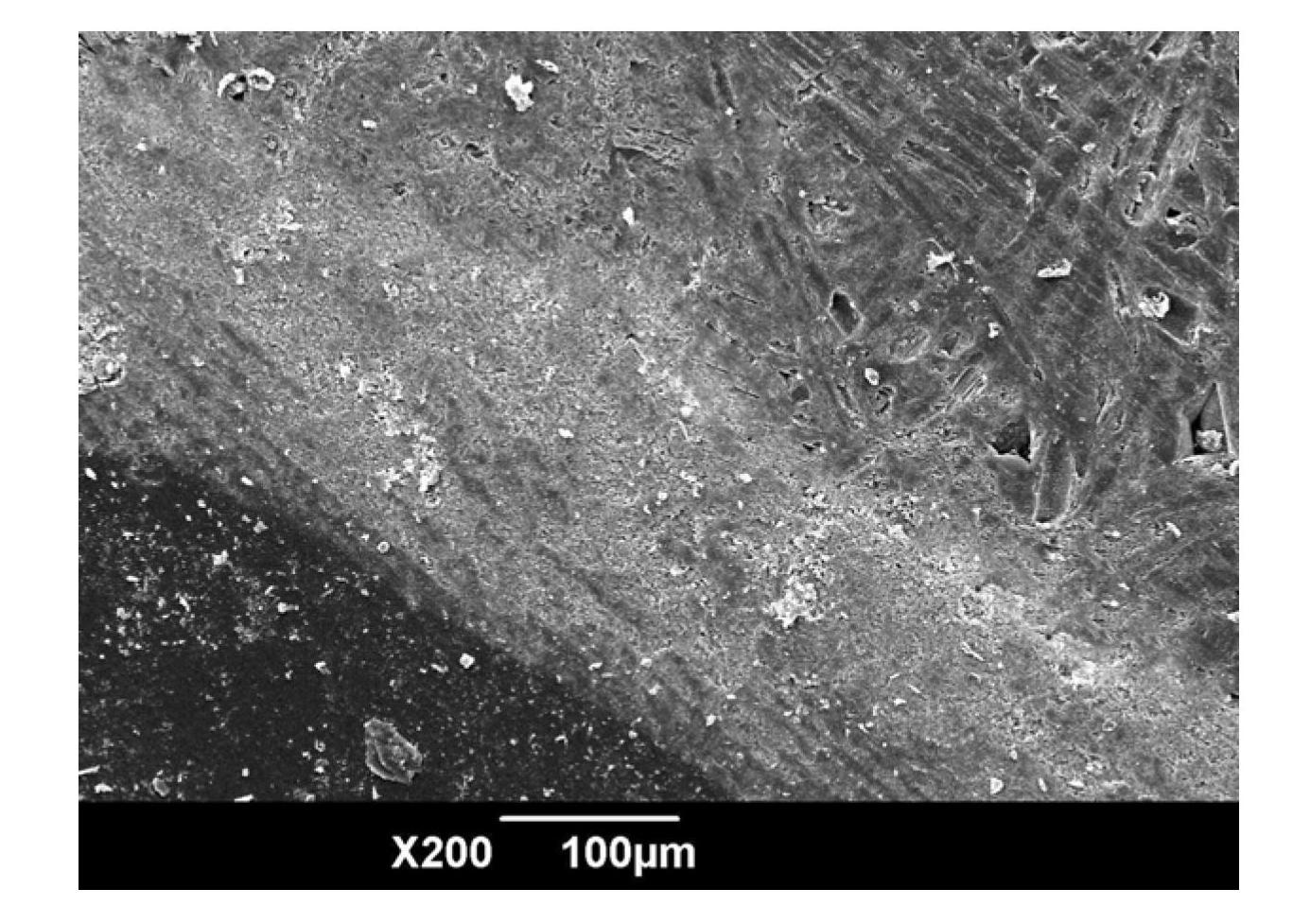

Bioactive coating on surface of Titanium or titanium alloy and its preparing method

InactiveCN1986003AGood biocompatibilityImprove biological activityCoatingsHigh cellBiocompatibility Testing

The present invention relates to bioactive coating on the surface of titanium or titanium alloy and its preparation process. The process includes the following steps: the first anode oxidation, alkali treatment and heat treatment of titanium or titanium alloy to form surface gradient coating in the thickness of 3 micron and comprising one inner thin and compact titania film and one outer porous titania film; introducing Ca element by means of the electrolyte solution into the coating to raise the biocompatibility; boiling in NaOH solution for 1-5 hr to form thin surface sodium titanate and calcium titanate layer; and final depositing a bone-like hydroxyapatite layer. The present invention raises the bioactivity of titanium or titanium alloy surface, and has high binding force of hydroxyapatite layer and high cell adhering capacity.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

High strength seamless steel pipe excellent in hydrogen-induced cracking resistance and its production method

ActiveUS20050167013A1High strength and HIC resistanceIncrease resistanceFurnace typesHeat treatment furnacesCrack resistanceHydrogen

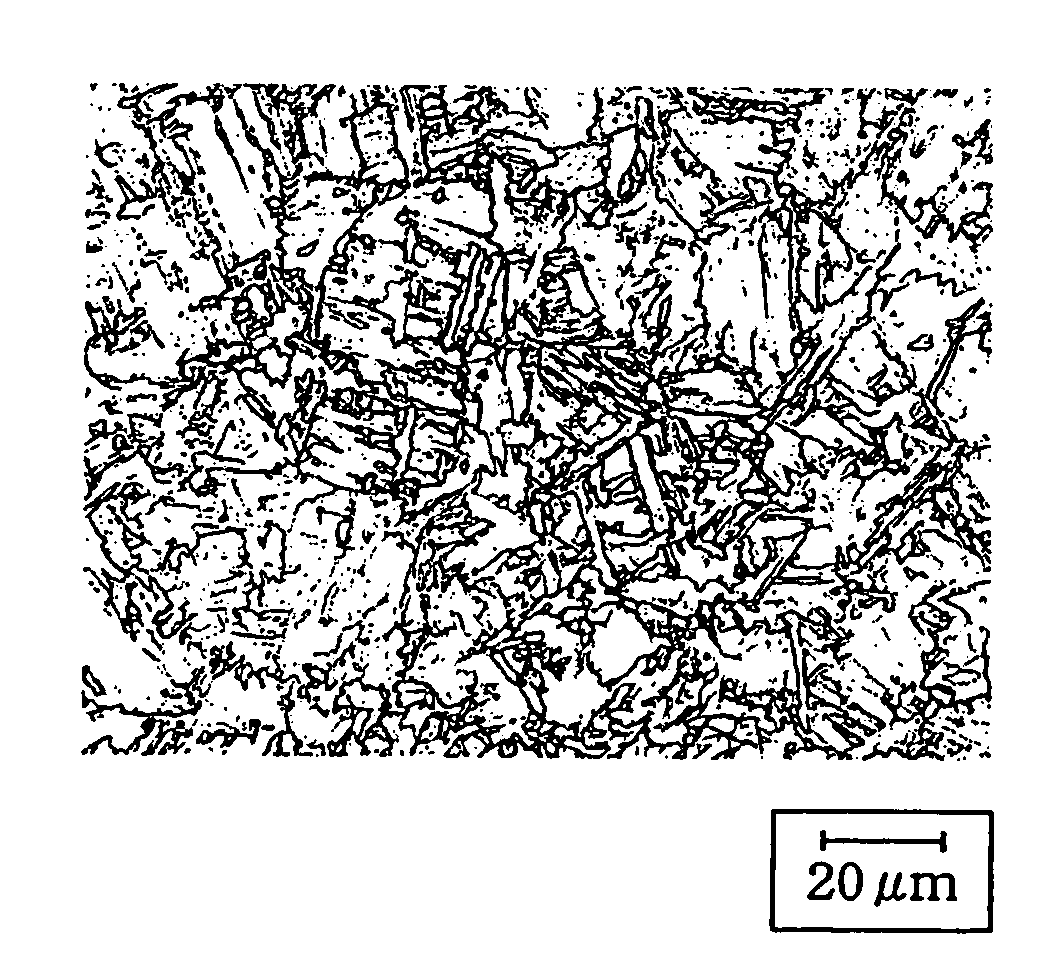

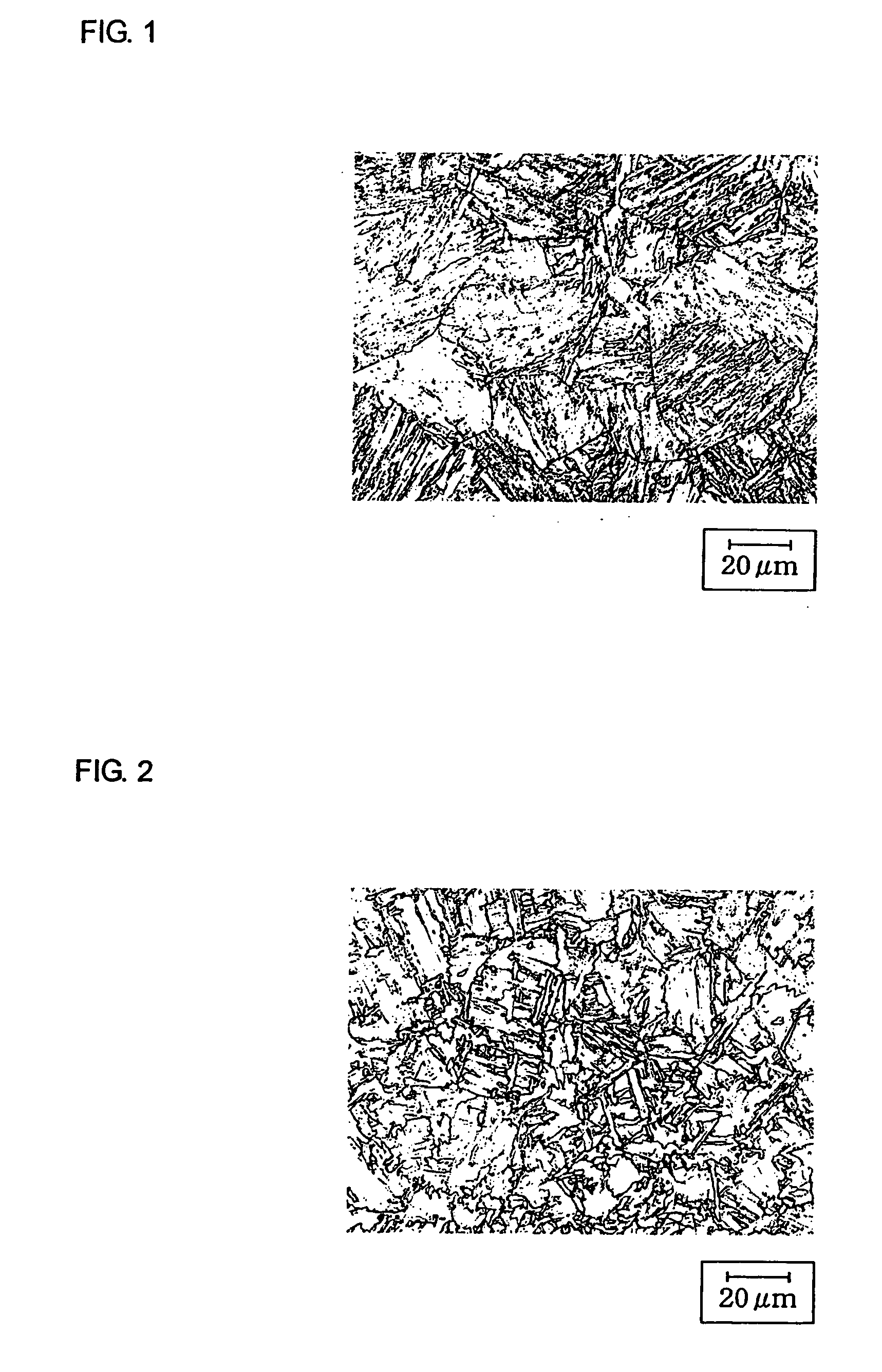

A high strength seamless steel pipe having mgh yield stress and excellent hydrogen-induced cracking resistance, comprises by mass %, C: 0.03-0.11%, Si: 0.05-0.5%, Mn: 0.8-1.6%, P: 0.025% or less, S: 0.003% or less, Ti: 0.002-0.017%, Al: 0.001-0.10%, Cr: 0.05-0.5%, Mo: 0.02-0.3%, V: 0.02-0.20%, Ca: 0.0005-0.005%, N: 0.008% or less and O (Oxygen): 0.004% or less, the balance Fe and impurities. The steel microstructure is bainite and / or martensite and ferrite is precipitated at grain boundaries. The seamless steel pipe can contain at least one of Cu: 0.05-0.5% and Ni: 0.05-0.5%. To produce the pipe, it is desirable to limit a starting temperature of quenching after rolling, a cooling rate and a tempering temperature.

Owner:NIPPON STEEL CORP

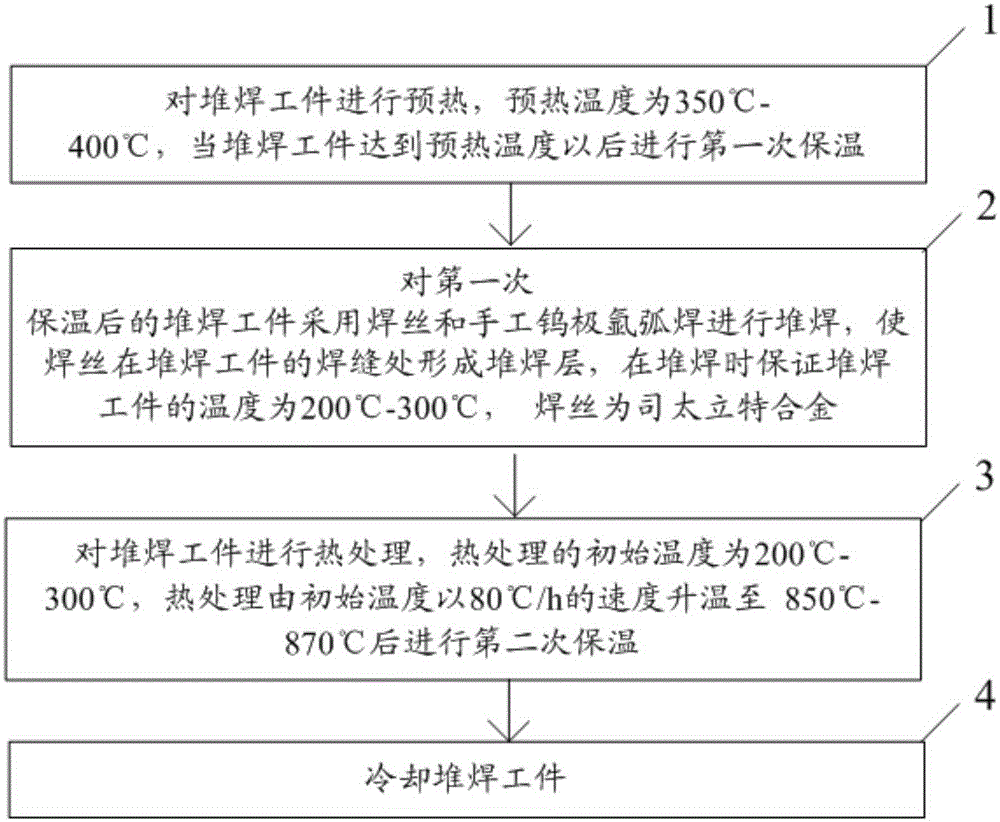

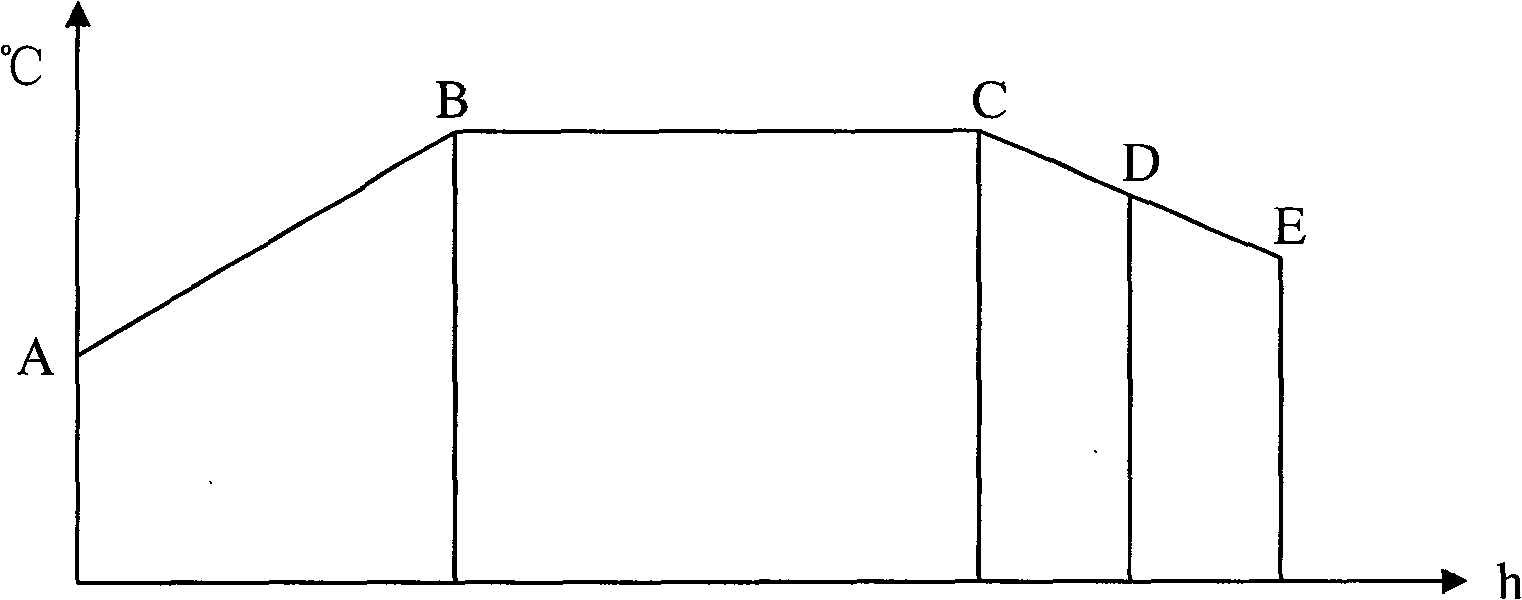

Welding method for conducting build up welding through stellite alloy

InactiveCN105171186AReduce cooling rateSlow coolingArc welding apparatusWelding/cutting media/materialsStellite alloyAlloy

The invention discloses a welding method for conducting build up welding through stellite alloy, and belongs to the field of welding. The method includes the steps that the first time of heat preservation is conducted after a build up welded workpiece is preheated; build up welding is conducted through a welding wire and manual argon tungsten-arc welding by means of the build up welded workpiece after the first time of heat preservation so that the welding wire can form a build up welded layer at the weld joint of the build up welded workpiece, wherein it is ensured that the build up welded workpiece is 200 DEG C to 300 DEG C in the build up welding process, and the welding wire is made of stellite alloy; after welding is completed, thermal treatment is conducted on the build up welded workpiece, wherein the initial temperature of thermal treatment is 200 DEG C to 300 DEG C, and the second time of heat preservation is conducted after the initial temperature of thermal treatment is raised to 850-870 DEG C at the speed of 80 DEG C per hour; and cooing is conducted. According to the method, the build up welded workpiece is preheated, the cooling speed of the weld joint can be decreased through preheating, the welded build up welded workpiece can be slowly cooled, a product is prevented from generating welding cracks especially cold cracks, and meanwhile it can be ensured that the build up welded layer has high strength.

Owner:WUHAN MARINE MACHINERY PLANT

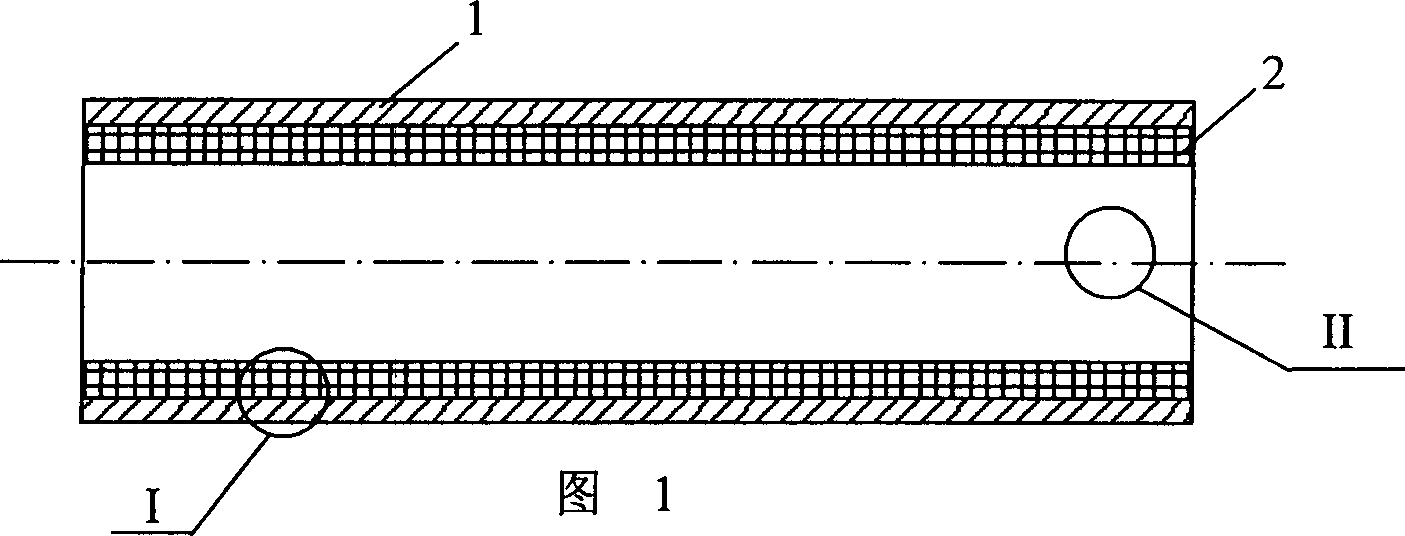

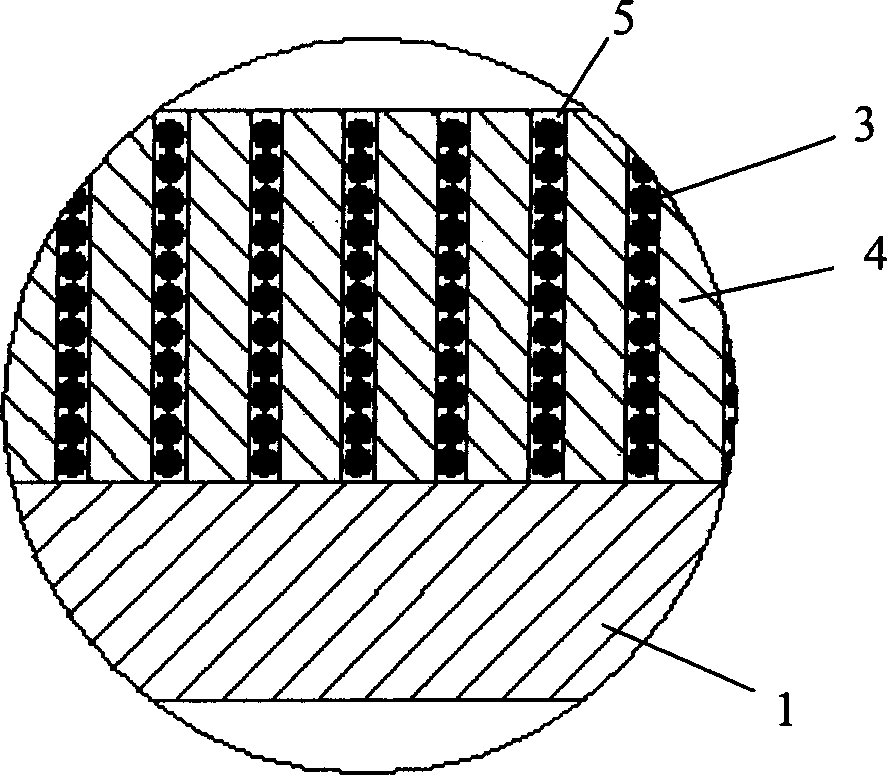

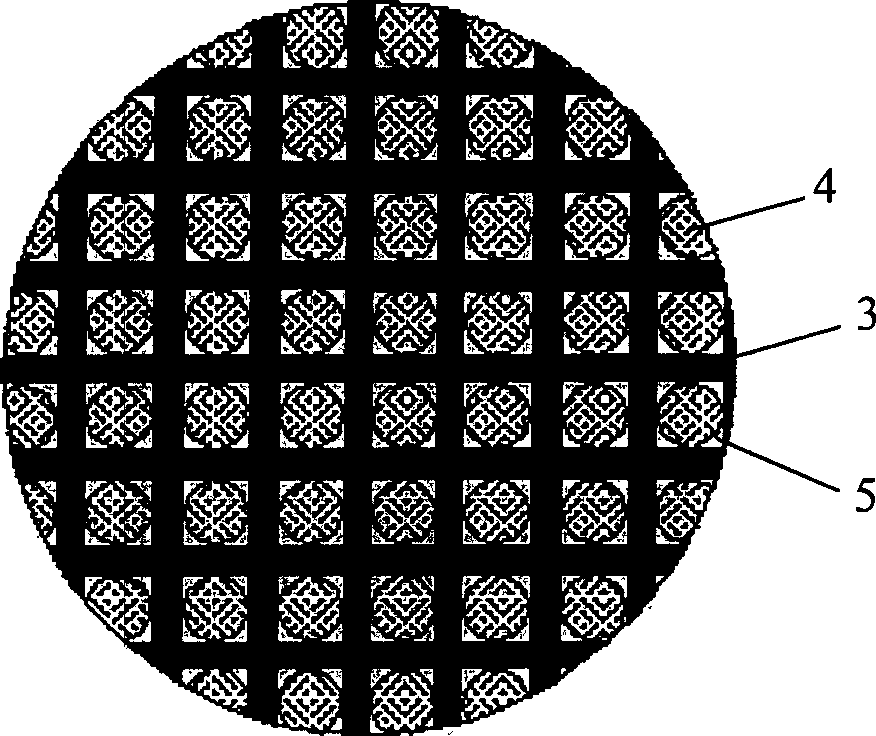

Abrasion proof pipe with ternary composite material as liner and preparing technique thereof

This invention discloses a ternary compound material underlay anti-wearing tube and its process method, which comprises outer steel tube and anti-wearing underlay, wherein, the anti-wearing underlay is composed of metal wire net, ceramics bar and compound materials and the ceramics is imbedded in the metal wire net holes into one part by compound materials. The processed compound materials underlay anti-wearing tube is one of straight tube, bent tube or three-way tube.

Owner:XI'AN UNIVERSITY OF ARCHITECTURE AND TECHNOLOGY

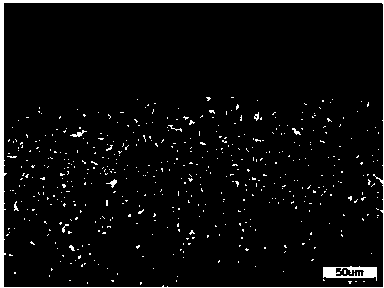

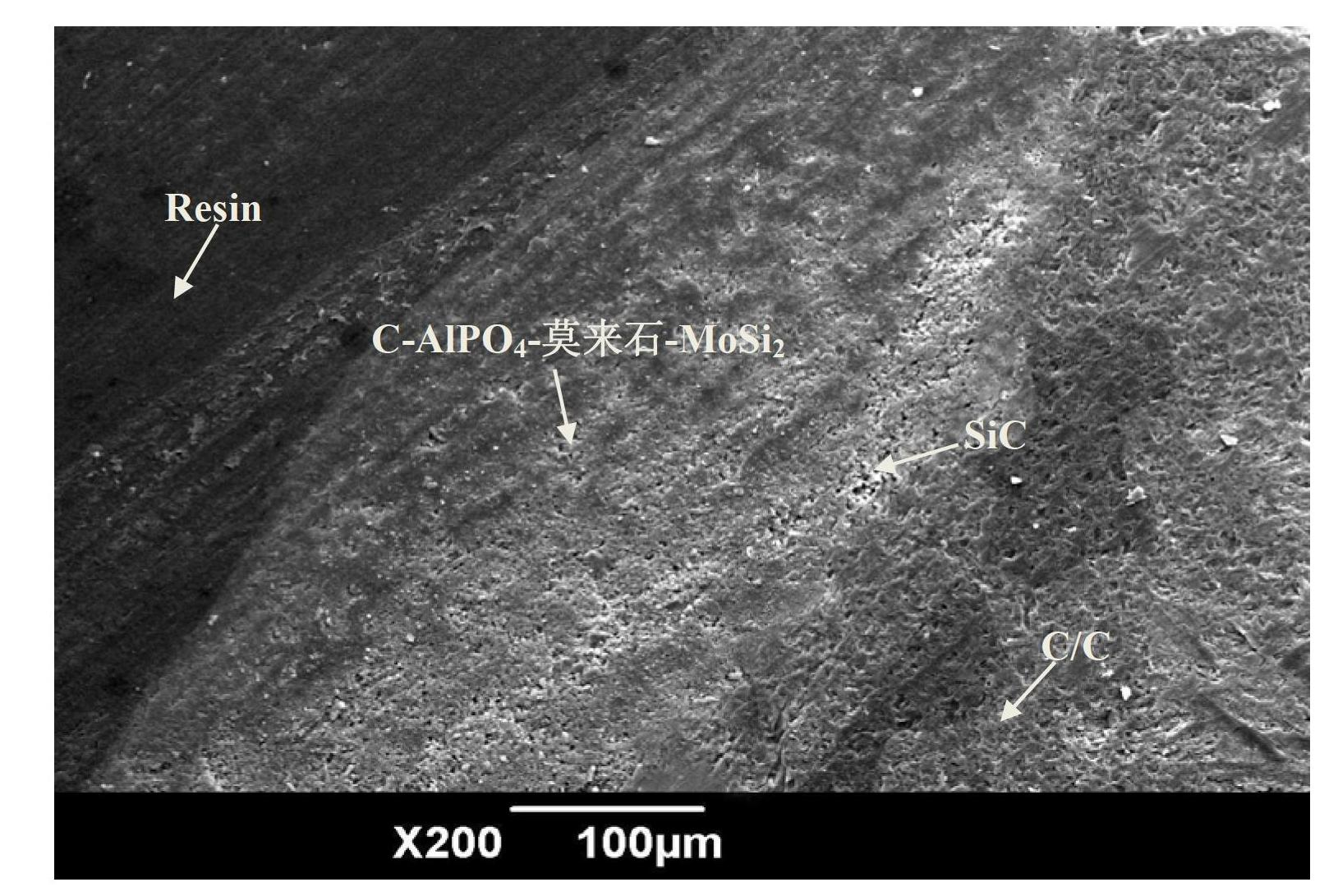

Preparation method of SiC/C-AlPO4-mullite antioxidation coating for C/C composite material

The invention relates to a preparation method of an SiC / C-AlPO4-mullite antioxidation coating for a C / C composite material, which comprises the following steps: mixing silicon powder and graphite powder to obtain powder A; mixing Al2O3 powder, WO3 powder and B2O3 powder to obtain powder B; mixing the powder A and the powder B to obtain embedded powder C; putting a sample in a graphite crucible, adding the embedded powder C, putting the graphite crucible in a vertical vacuum furnace, heating to react while introducing argon as a protective atmosphere, cooling to room temperature, and cleaning with anhydrous alcohol in ultrasonic waves to obtain a silicon carbide transition layer for the C / C composite material; adding the C-AlPO4 and the mullite powder into methanol, adding iodine to obtain a suspension, and putting the suspension in a hydrothermal kettle, wherein the cathode adopts the C / C composite material with the silicon carbide transition layer; and sealing the hydrothermal kettle, putting the hydrothermal kettle in an ultrasonic-microwave generator, depositing, taking out the sample, and drying to obtain the SiC / C-AlPO4-mullite antioxidation coating for the C / C composite material. The composite coating can protect the C / C composite material at 1500 DEG C in static air for 322 hours, and the oxidative weight loss is less than 2%.

Owner:深圳市贝尔新材料科技有限公司

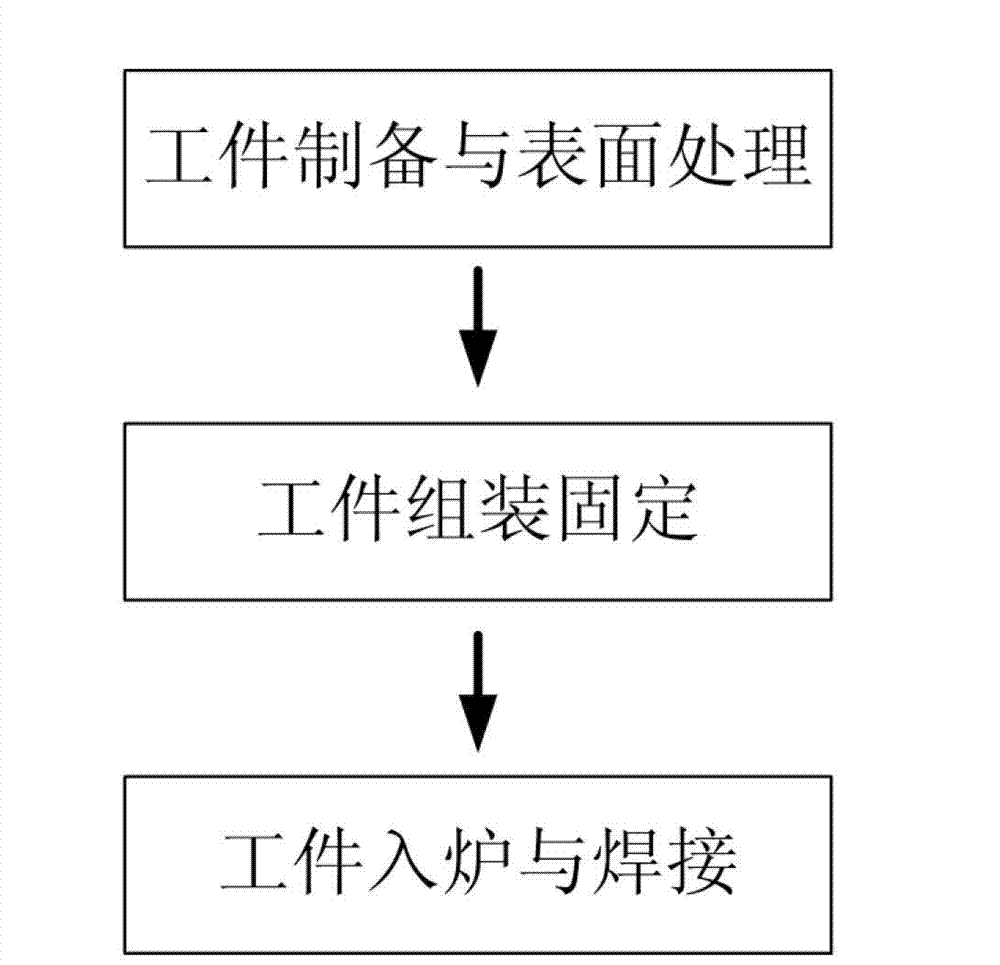

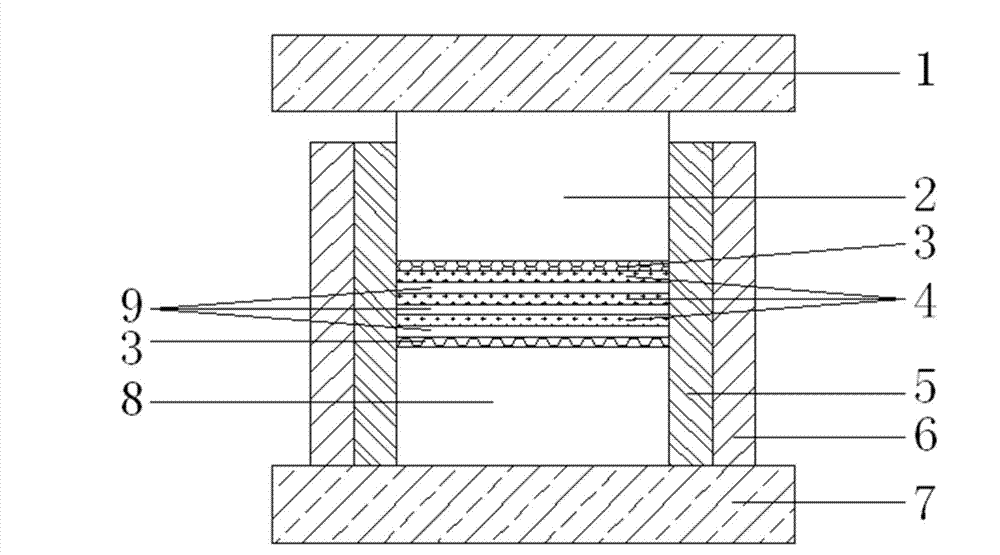

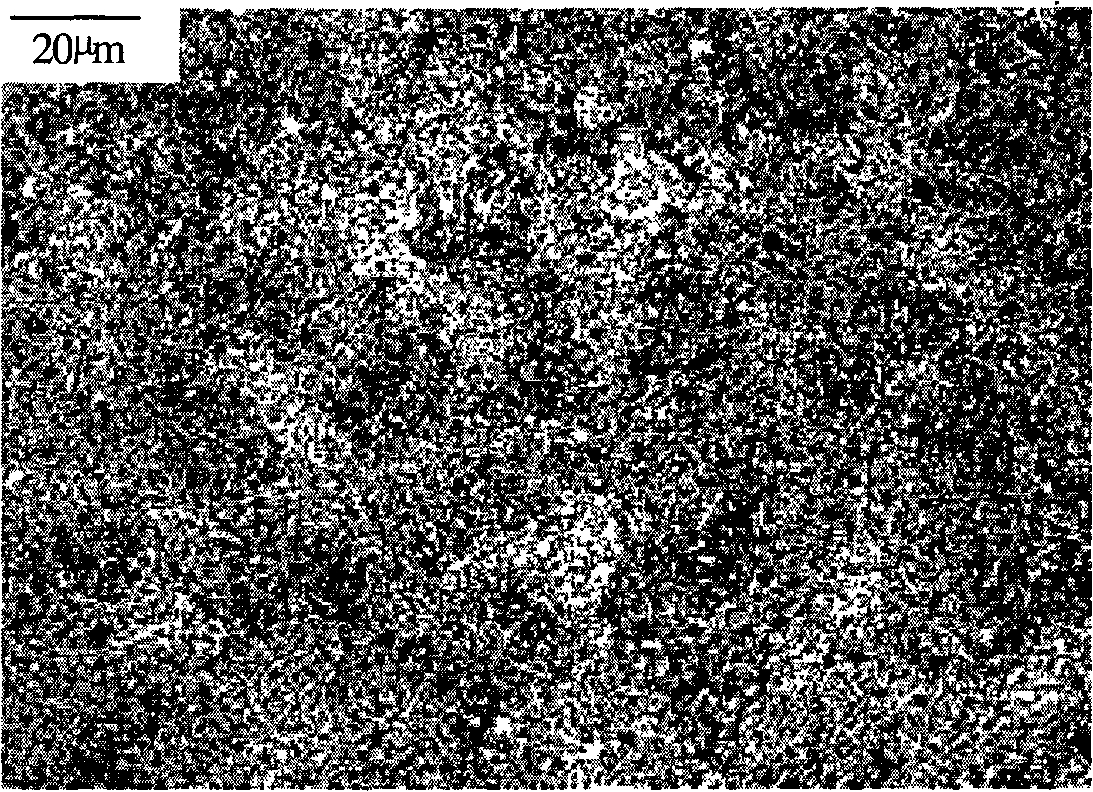

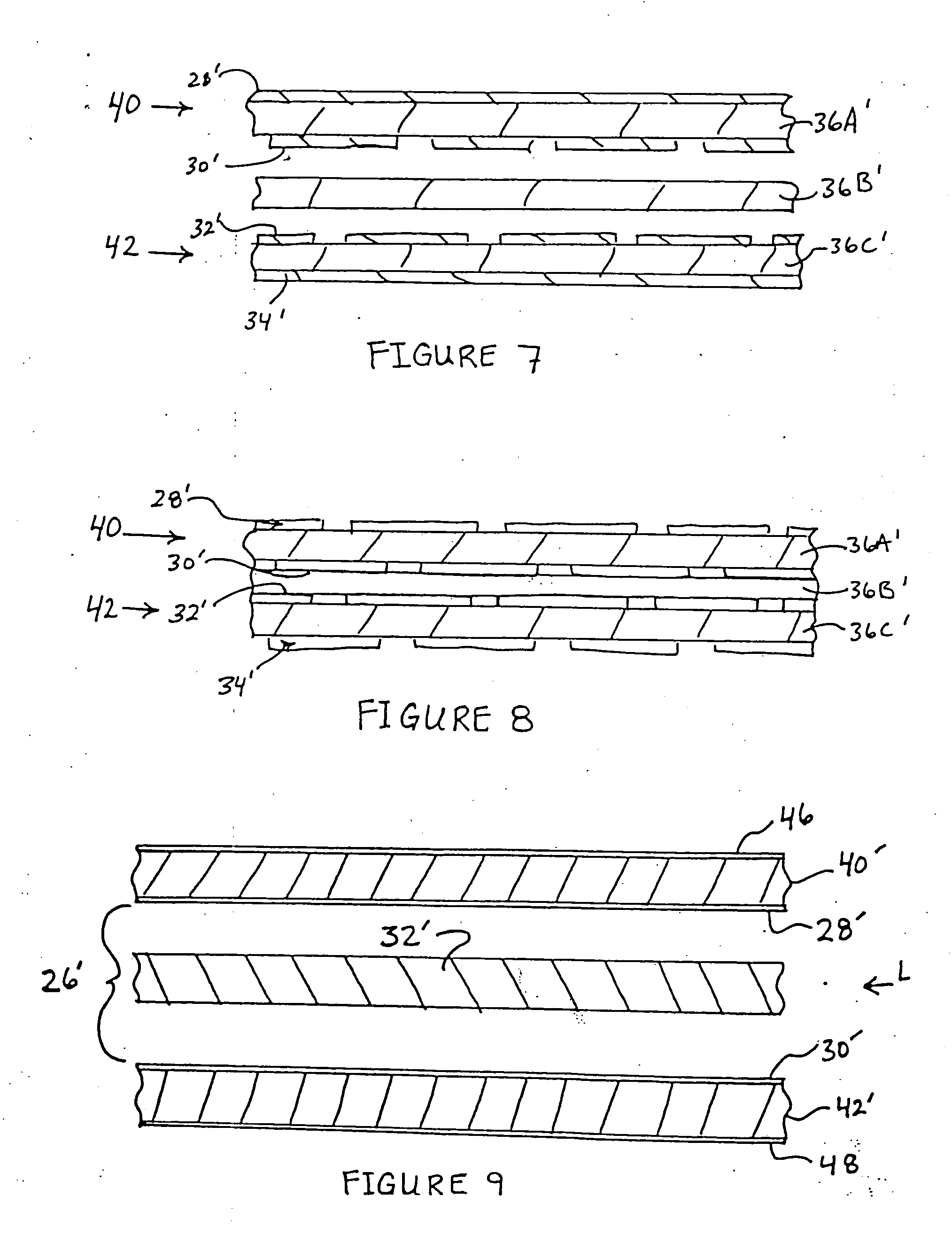

Method for manufacturing multi-layer amorphous alloy and crystal metal composite structure through diffusion welding

InactiveCN102886599AAvoid brittlenessImprove shear resistanceNon-electric welding apparatusShear capacityAlloy

The invention discloses a method for manufacturing a multi-layer amorphous alloy and crystal metal composite structure through diffusion welding. The method comprises the following steps of: cutting, grinding and cleaning an amorphous alloy sheet and a crystal metal sheet, assembling and fixing the amorphous alloy sheet and the crystal metal sheet so as to form a fixed workpiece, and welding the fixed workpiece in a vacuum diffusion furnace. According to the composite structure, extension of a shear band of an amorphous alloy material in the shearing process can be blocked, so that the problem that the pure amorphous alloy material has high brittleness is solved, and the shear resistance is improved. In addition, the welded amorphous alloy material can continuously keep the amorphous characteristics, compared with that of the pure amorphous alloy material, the shear resistance of the composite structure material is greatly improved, the toughness is improved, and the welded sheet is high in surface quality and reliable in connection.

Owner:HUAZHONG UNIV OF SCI & TECH

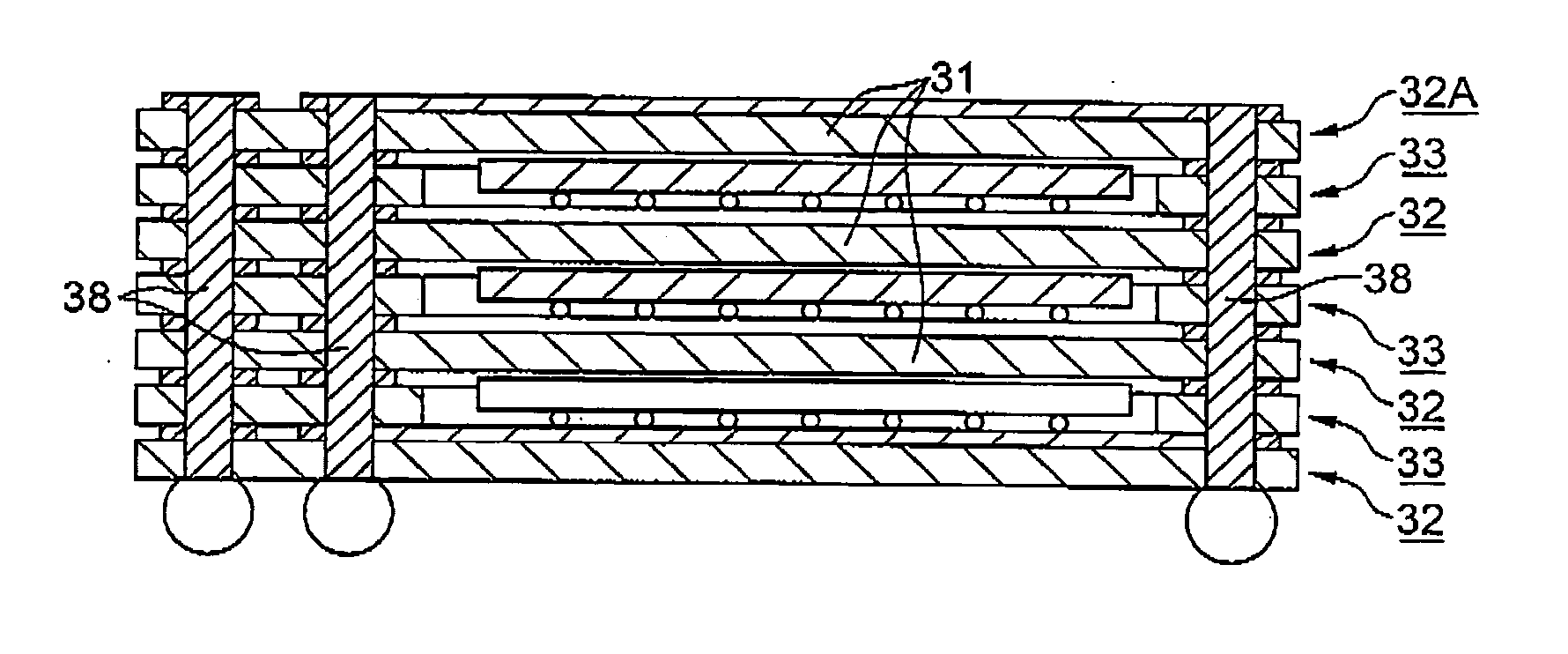

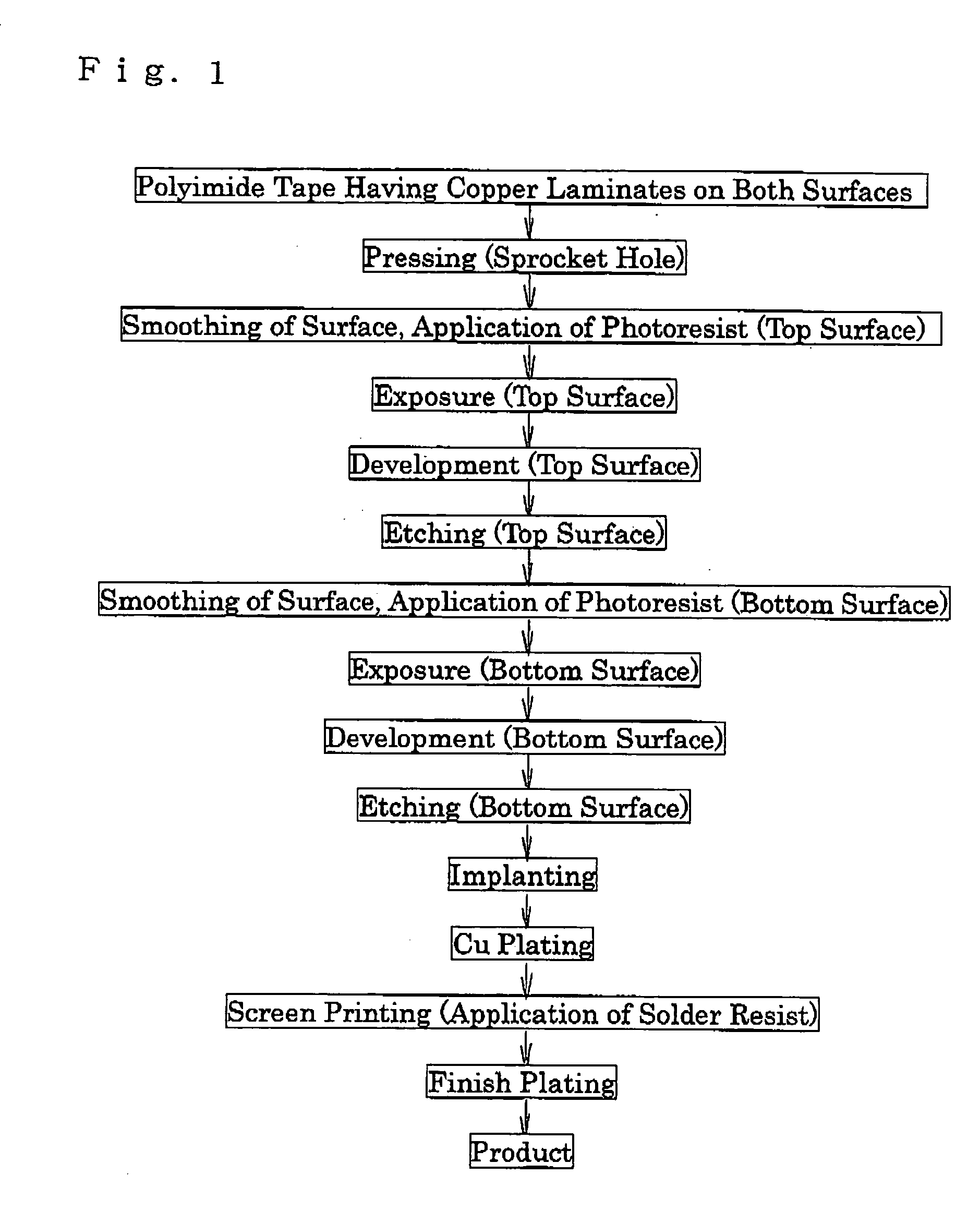

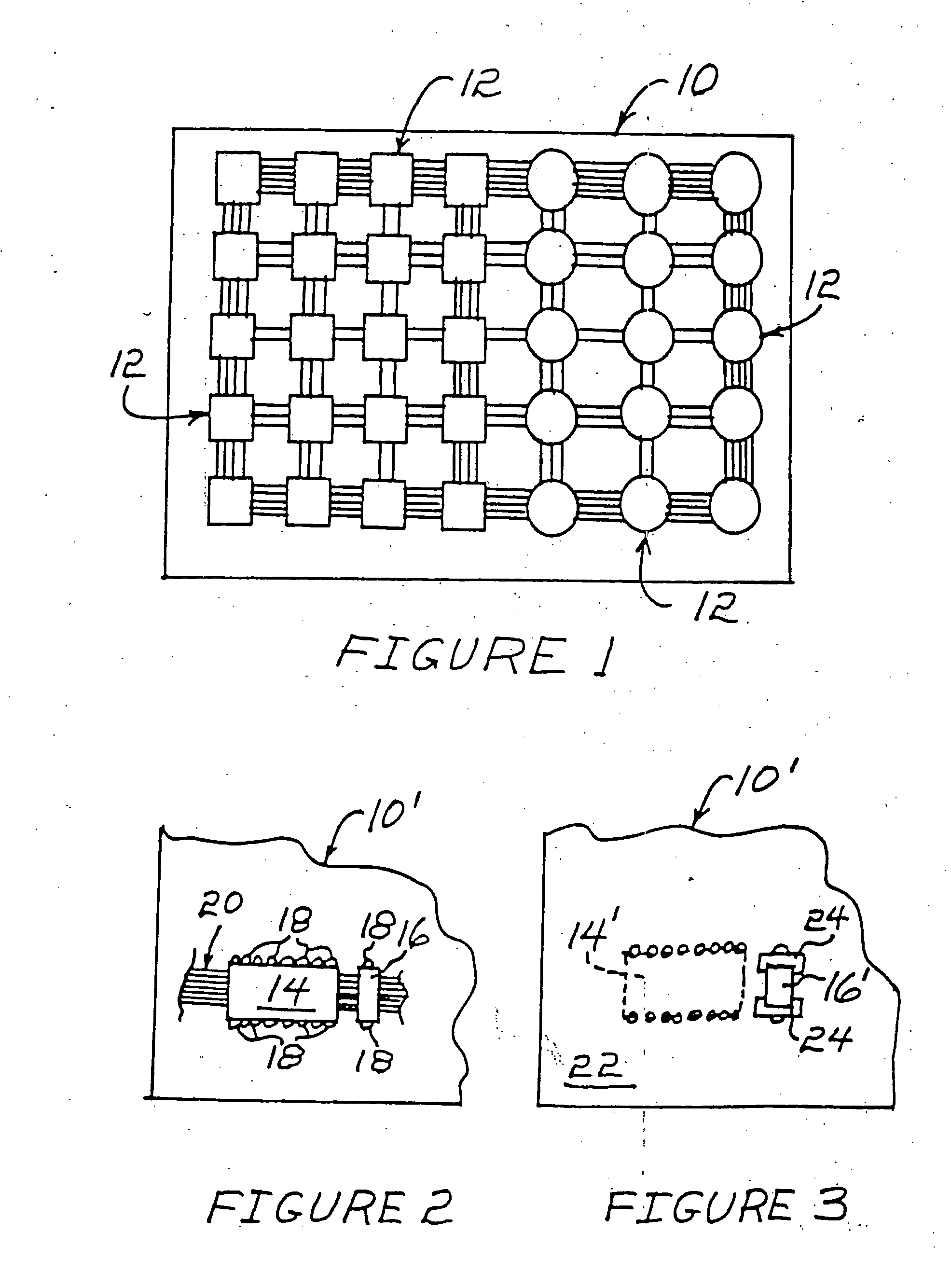

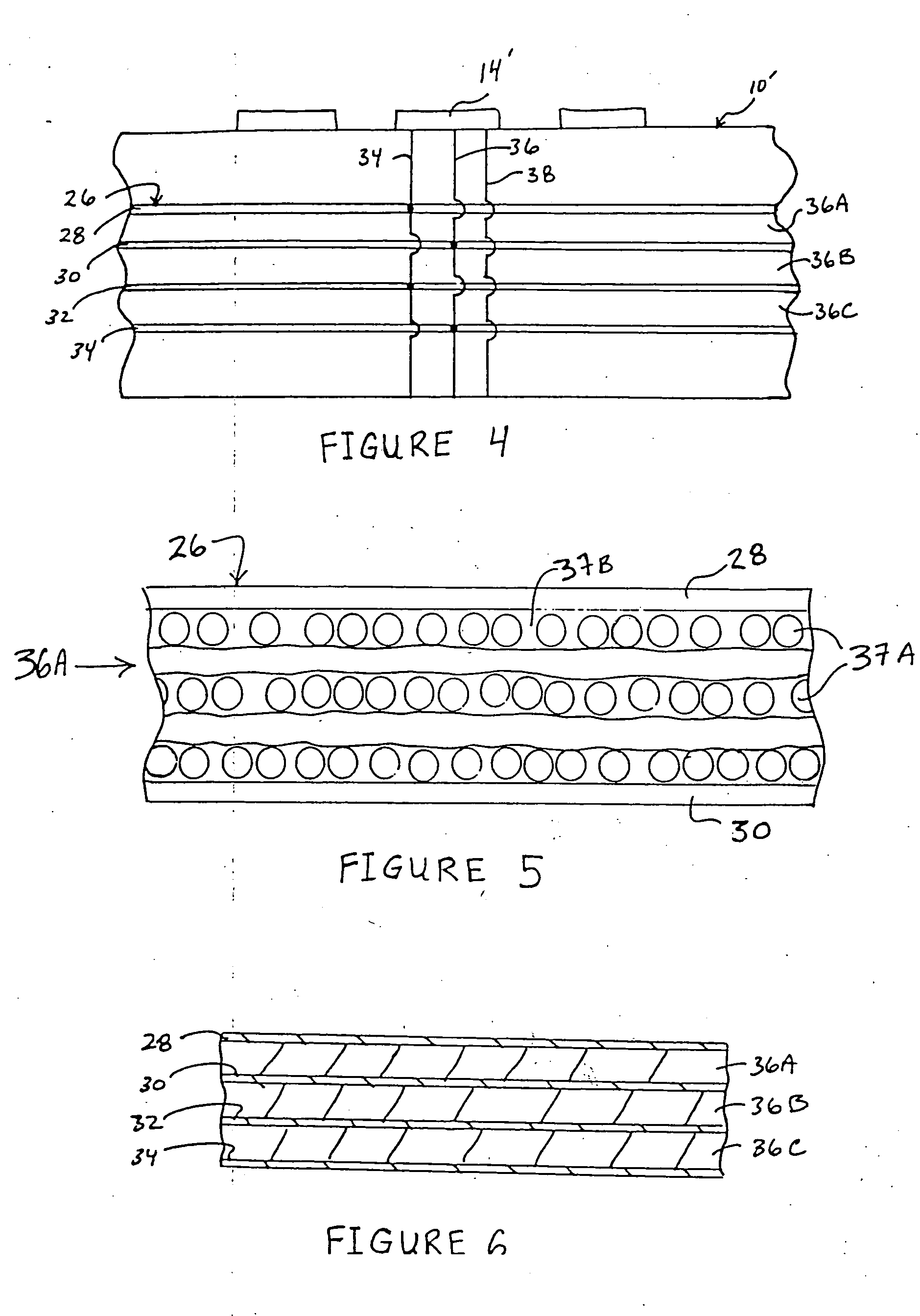

Printed circuit board,its manufacturing method and csp manufacturing method

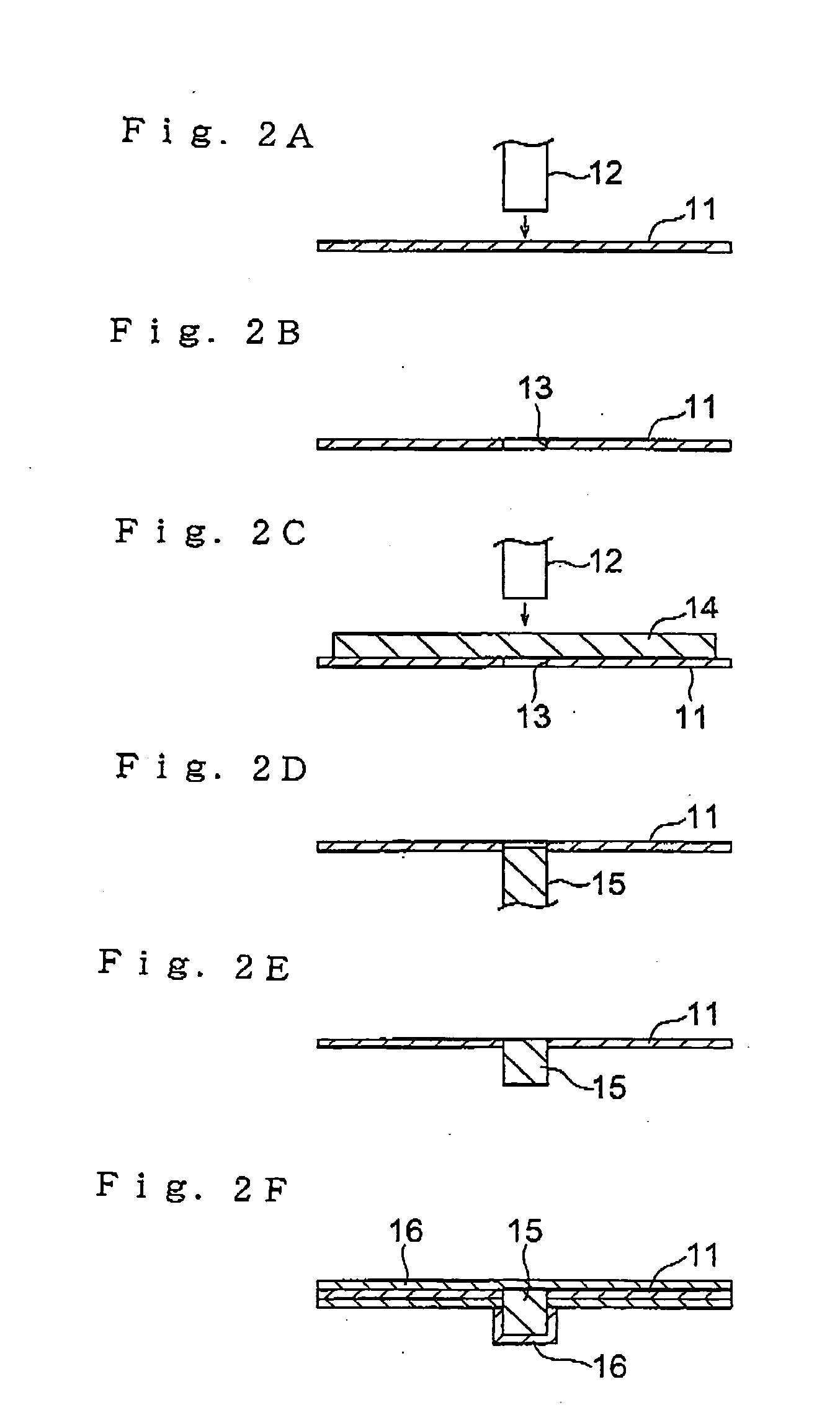

InactiveUS20040099441A1Easy to makeEfficient manufacturingPrinted circuit assemblingSemiconductor/solid-state device detailsElectrical conductorDegrees of freedom

A printed circuit board comprising an insulating substrate, a through-hole formed in the insulating substrate, an implant material filling the through-hole, and a wiring pattern formed on both faces of the insulating substrate and electrically connected with the implant material, characterized in that one face of a conductor wiring layer wherein a bump penetrates from one face to the other face and protrudes is adhered to the insulating substrate so as to be electrically connected to the implant material. This bump conductor wiring layer of this printed circuit board has a large degree of freedom in forming a wiring pattern, through-hole, and bump and is unlike conventional handled separately from the insulating substrate. Therefore, the effect arises that this circuit board is the target of commercial trading by itself.

Owner:MITSUI MINING & SMELTING CO LTD

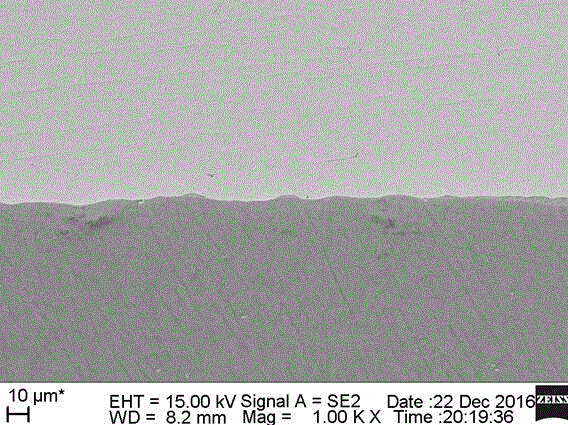

Method for producing a hot-formed and heat-treated steel component that is coated with a metal anti-corrosion coating from a sheet steel product

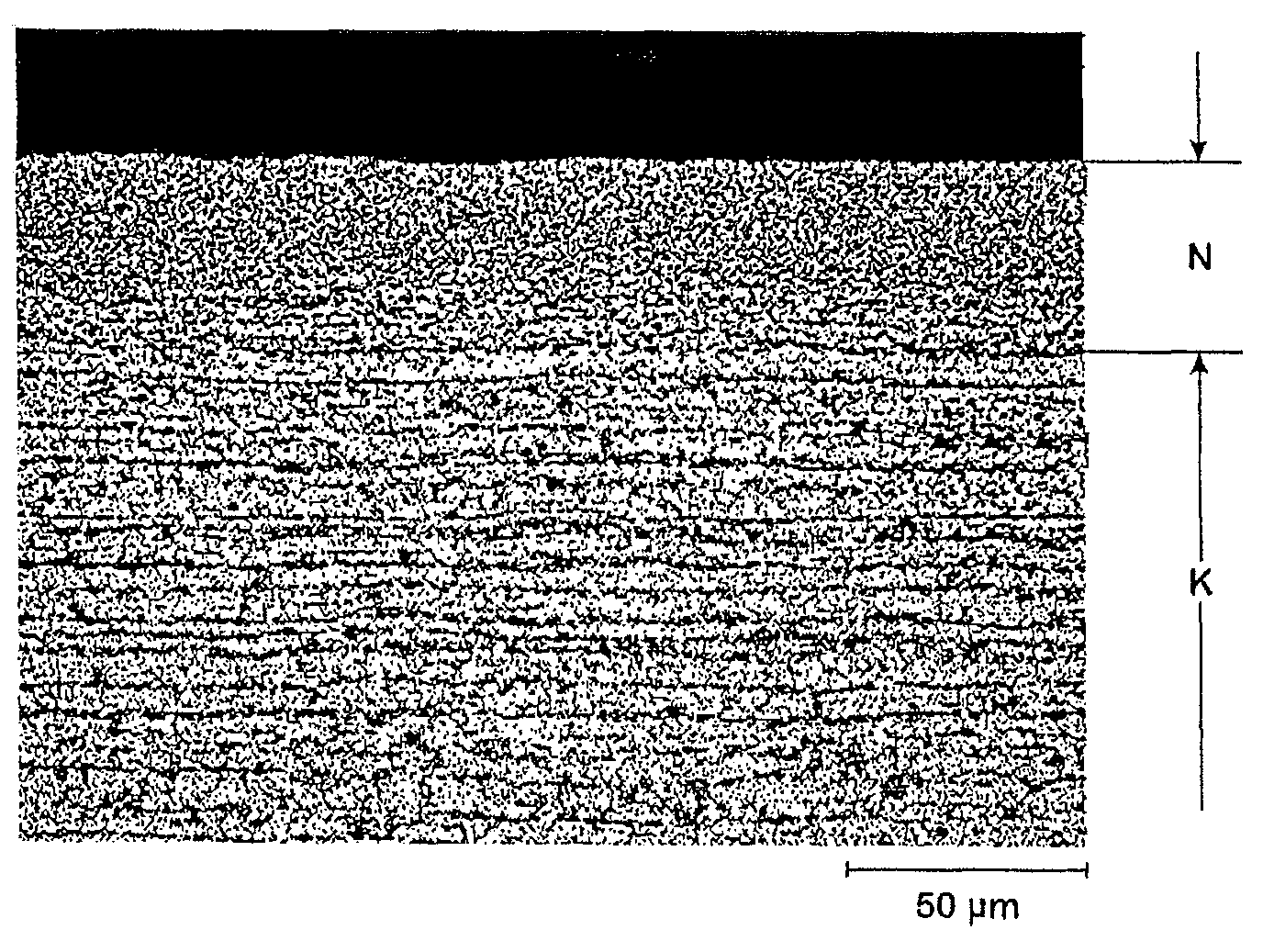

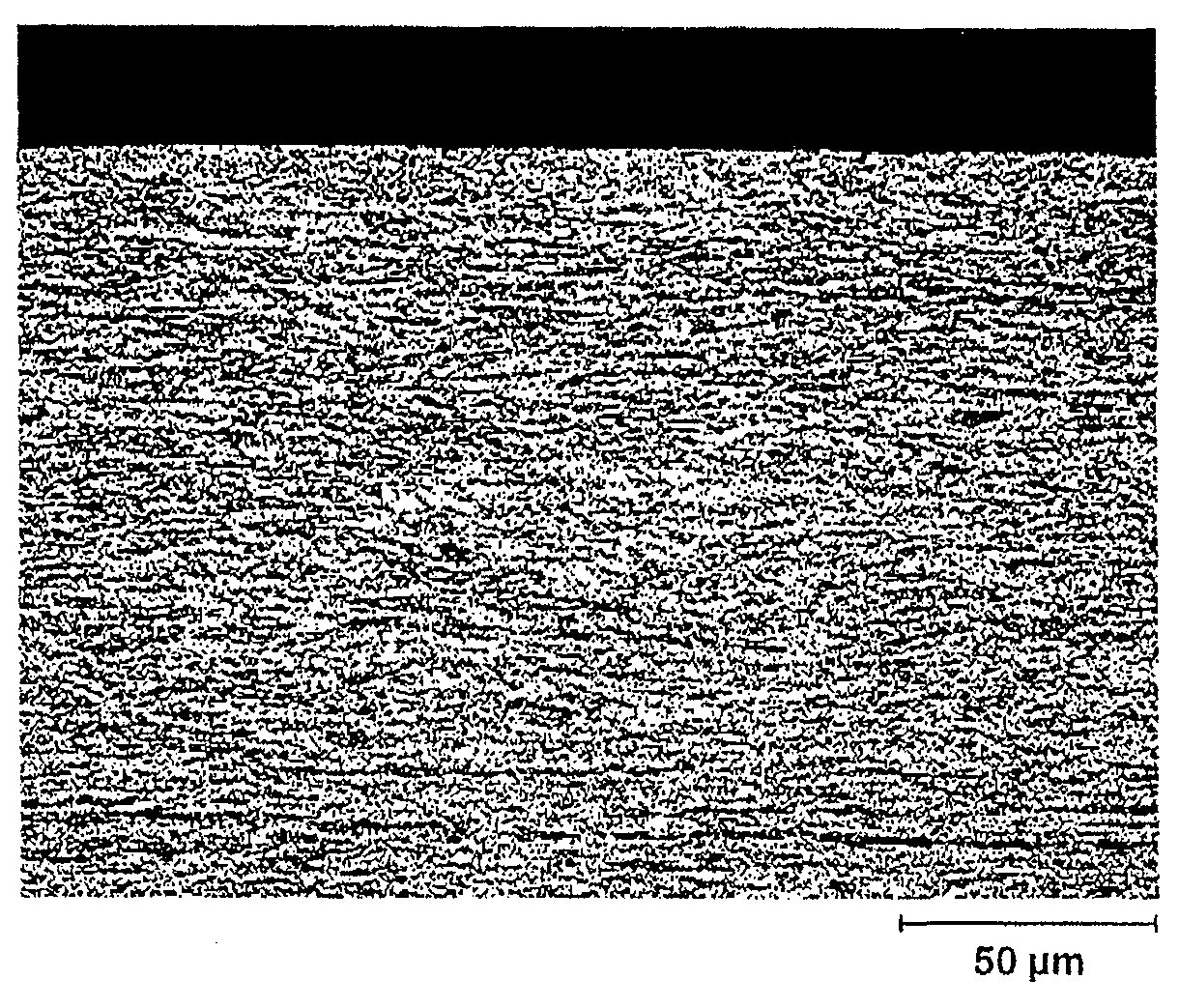

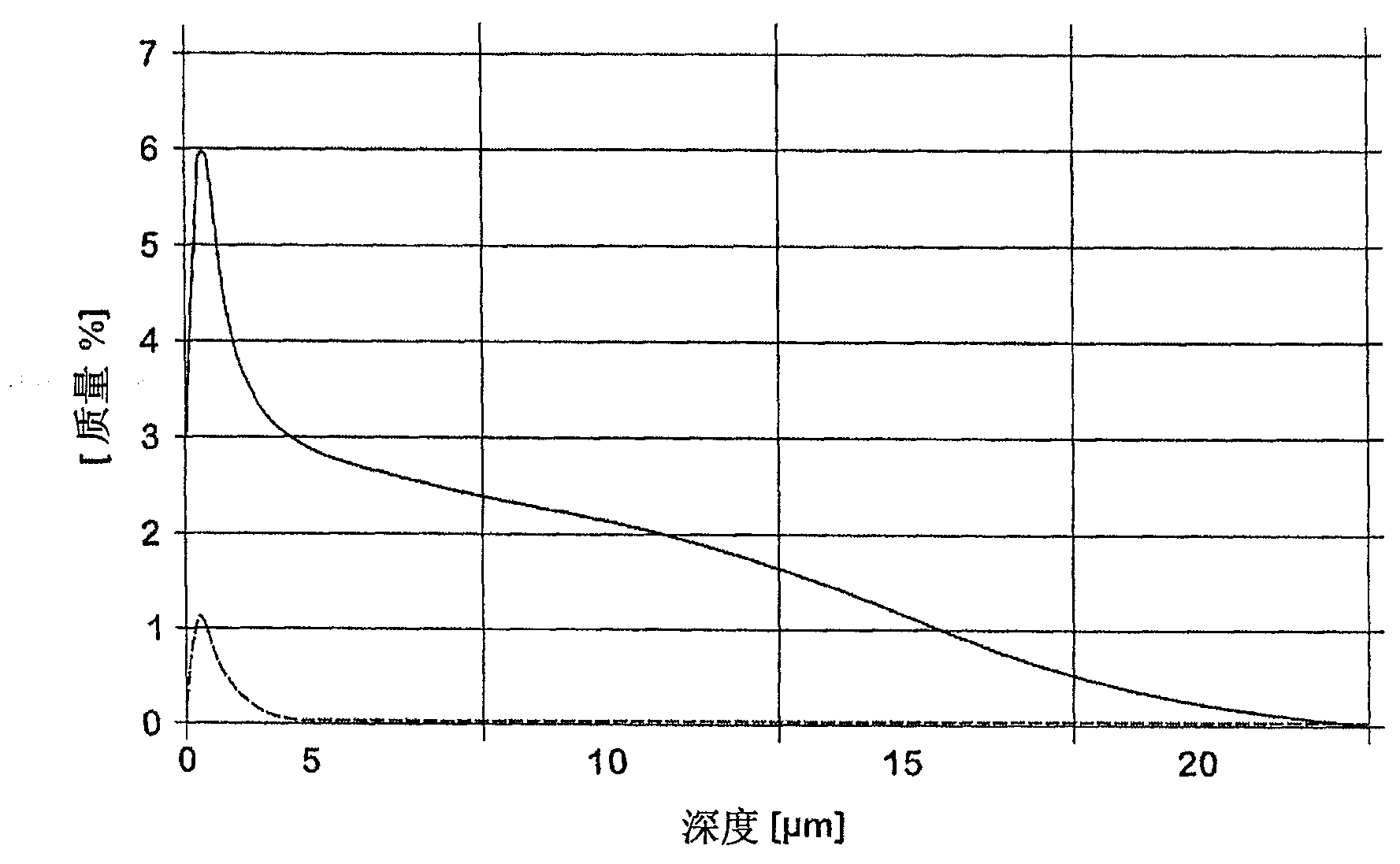

InactiveCN102985570AAvoid brittlenessResist Crack IssuesHot-dipping/immersion processesSolid state diffusion coatingSheet steelNitride

The invention relates to a method for producing a steel component that is coated with a metal protective coating from a sheet steel product comprising at least 0.4 % by weight of Mn. In order to economically generate a high-strength steel component, while minimizing the risk of the development of metal-induced cracks, according to the invention the sheet steel product is annealed in a continuous furnace under an annealing atmosphere containing up to 25% by volume H2, 0.1 - 10% by volume NH3, H2O, the remainder being N2 as well as process-related inevitable impurities, at a dew point ranging between -50 DEG C and -5 DEG C and at a holding temperature of 400 - 1100 DEG C for a holding period of 5 - 600 s. The annealed sheet steel product has a nitride layer (N) 5 - 200 [mu]m thick, the particle size of which is finer than the particle size of the interior core layer (K) of the sheet steel product. After it has been coated with a metal protective layer, a blank is separated from the annealed sheet steel product and is soaked to an austenitizing temperature of 780 - 950 DEG C subsequent to an optional preforming step, is hot-formed to form the steel component and is cooled so quickly that a tempered martensitic structure forms in the sheet steel product.

Owner:THYSSENKRUPP STEEL EURO AG

F304/F304L double-standard stainless steel flange and production process thereof

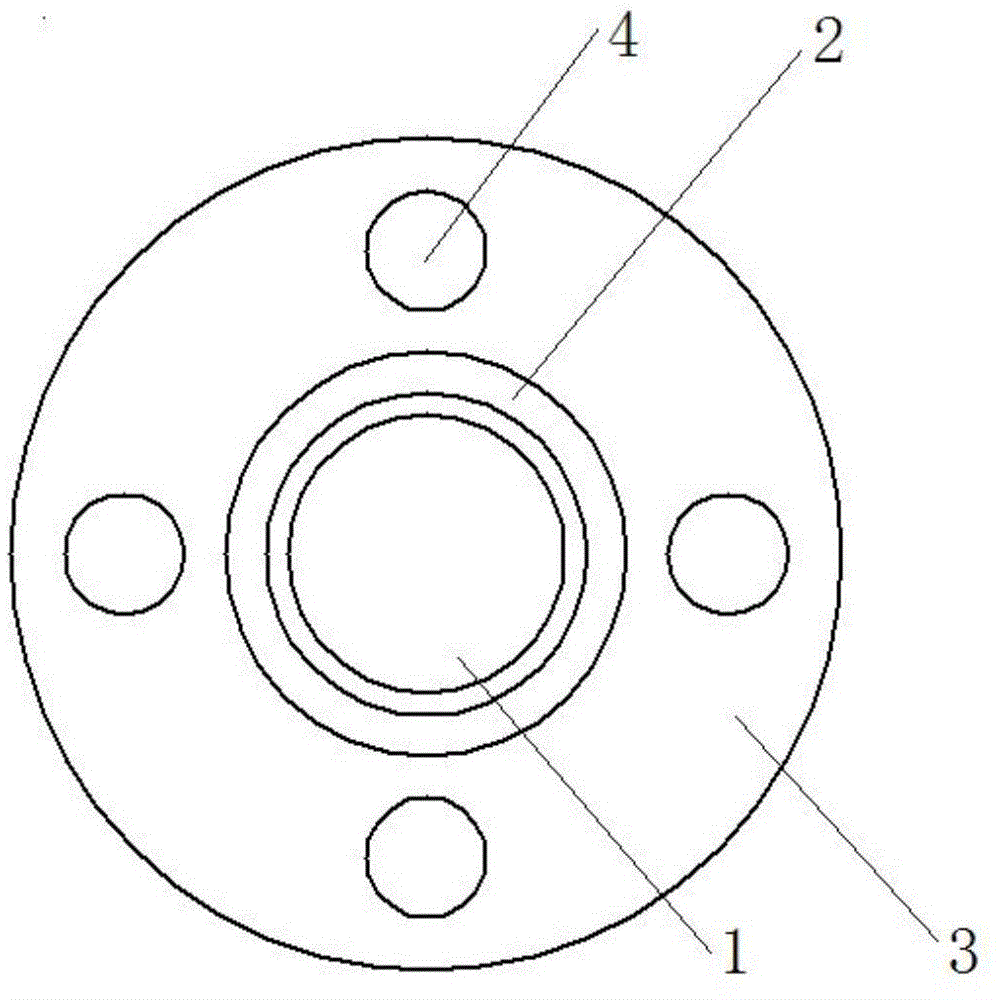

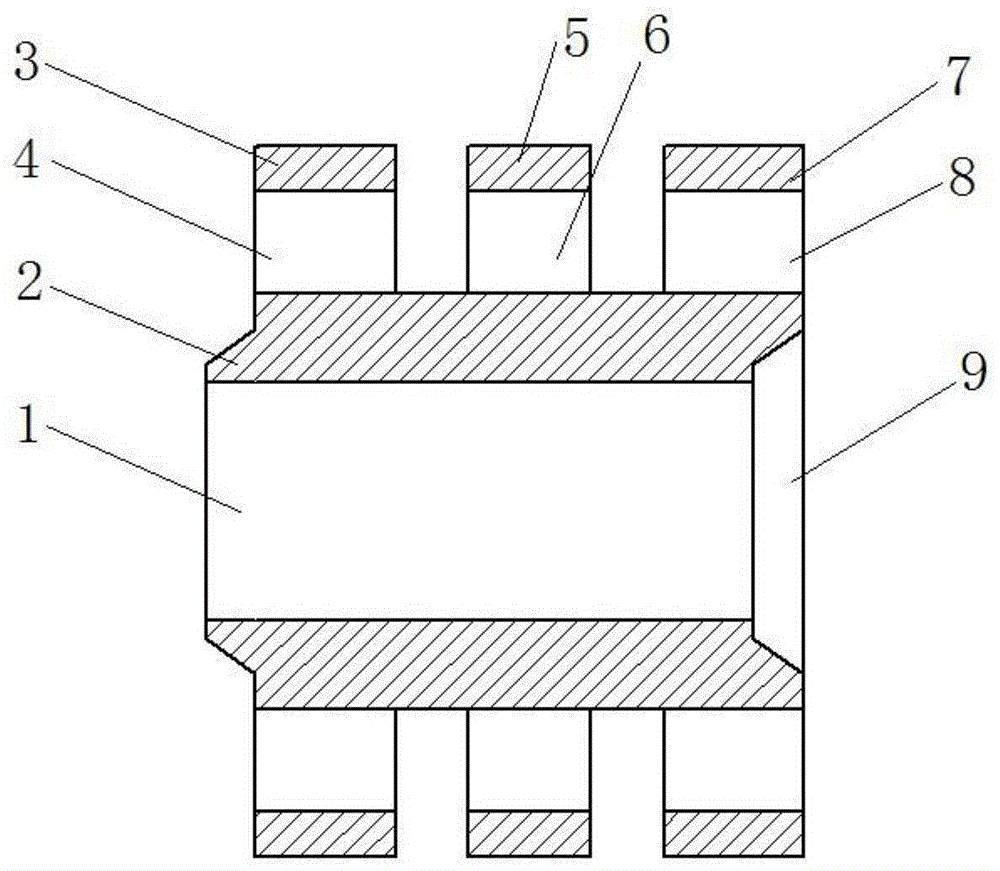

ActiveCN104791562AReasonable structureExquisite designFlanged jointsCircular discSS - Stainless steel

The invention discloses an F304 / F304L double-standard stainless steel flange. The F304 / F304L double-standard stainless steel flange comprises a through hole and a flange plate. The flange plate is of a disc structure, the through hole is formed perpendicular to the flange plate with the center axis of the flange plate serving as the center line, and the edges of the two ends of the through hole are provided with a boss and a groove respectively. The flange plate comprises a front flange plate body, a middle flange plate body and a rear flange plate body which are sequentially arranged in parallel, the diameters of the front flange plate body, the middle flange plate body and the rear flange plate body are equal, the thicknesses of the front flange plate body and the rear flange plate body are equal, at least four fixing holes are evenly formed in each flange plate body, the hole diameters of the front fixing holes, the middle fixing holes and the rear fixing holes are equal, and the positions of the front fixing holes, the middle fixing holes and the rear fixing holes correspond. The invention further discloses a production process of the F304 / F304L double-standard stainless steel flange. The F304 / F304L double-standard stainless steel flange is high in rigidity and strength, resistant to corrosion, ingenious in structural design, high in practicality and long in service life.

Owner:WUXI HUAERTAI MACHINERY MFG

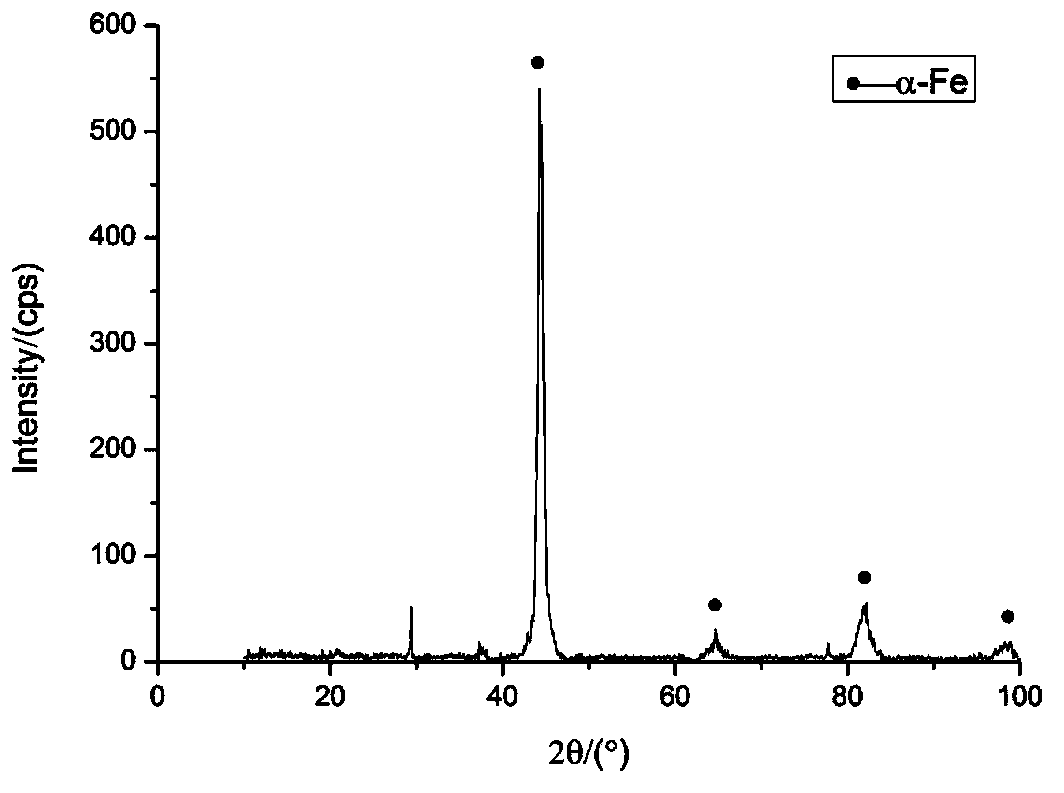

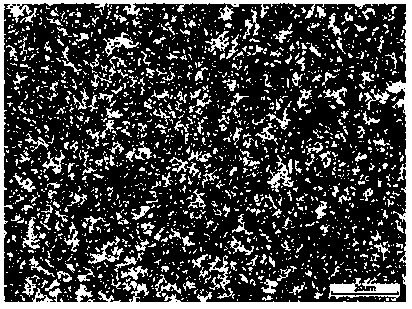

High-toughness ductile blade steel and metallurgical manufacturing method thereof

The invention provides high-toughness ductile blade steel and a metallurgical manufacturing method thereof. The steel comprises the following chemical components in percentage by mass: 0.55 to 0.65 percent of C, 0.30 to 0.60 percent of Mn, 7.20 to 8.20 percent of Cr, 0.75 to 0.98 percent of Si, 1.55 to 1.90 percent of Mo, 0.95 to 1.45 percent of W, 0.20 to 0.40 percent of V, less than or equal to 0.30 percent of Cu, less than or equal to 0.25 percent of Ni, less than or equal to 0.020 percent of P, less than or equal to 0.015 percent of S, and the balance of Fe and inevitable impurities. The steel components can greatly improve the toughness of the steel. In the metallurgical manufacturing method, the temperature of a furnace placed with a steel ingot is between 600 and 800 DEG C, and the heat is preserved after the steel ingot is heated to between 1,140 and 1,160 DEG C; and the forging and cogging starting temperature of a radial forging machine is between 1,000 and 1,080 DEG C, and the forging ending temperature is between 850 and 950 DEG C. The method is simple and convenient to operate, and saves production cost.

Owner:BAOSTEEL SPECIAL STEEL CO LTD

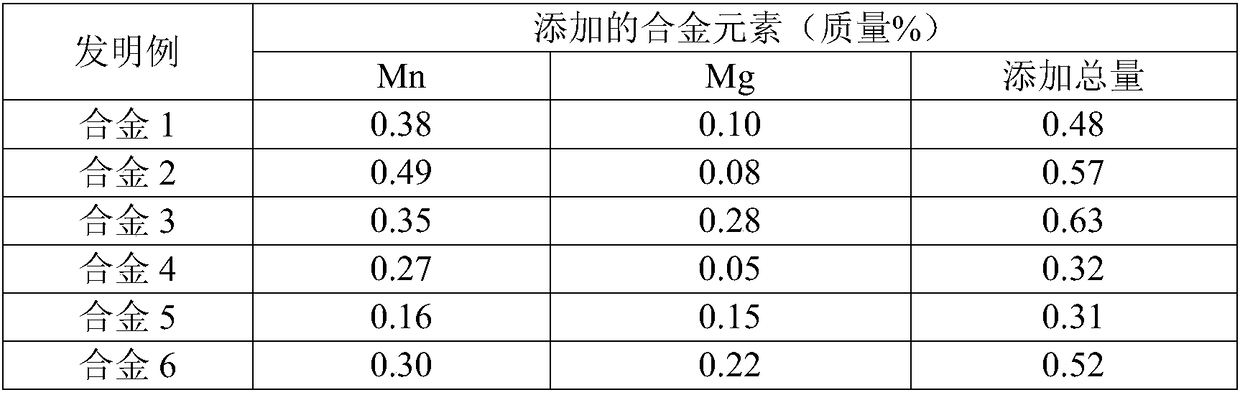

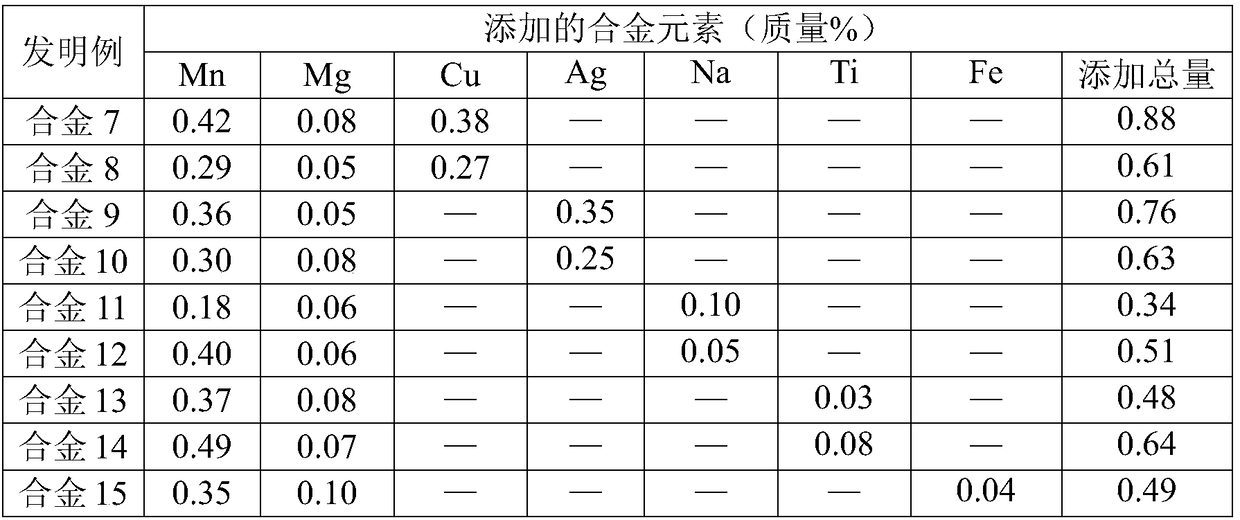

High-strength high-ductility biodegradable Zn-Mn-Mg series zinc alloy and preparation method thereof

The invention relates to high-strength high-ductility biodegradable Zn-Mn-Mg series zinc alloy and a preparation method. The alloy is prepared from the 0.02 to 0.49% of Mn and 0.001 to 0.3% of Mg, wherein Mn is a main alloying element, Mg is a secondary alloying element, and the Mn content is not lower than the Mg content in the alloy; at least one of Na, K, Ca, Sr, Ti, Fe, Cu and Ag elements is selected, the total content of the alloying elements added to the Zn-Mn-Mg series zinc alloy does not exceed 2%, and the balance is Zn. The basic preparation process of the zinc alloy comprises the steps of vacuum directional solidification and extrusion; on the basis of the steps, at least one of the following processing methods can be selected for processing again: two-stage heat treatment, extrusion, rolling, drawing and annealing. According to the preparation process, the processing plasticity of the zinc alloy can be given to the maximum, and multiphase multiscale directional tissues can be obtained, so that the alloy has excellent overall performance. The tensile mechanical properties of the zinc alloy at room temperature include the yield strength of 260 to 430 MPa, the tensile strength of 305 to 580 MPa and the elongation of 18.5 to 55%, and the zinc alloy is suitable for medical implants and is especially suitable for biodegradable stents.

Owner:北京尚宁科智医疗器械有限公司

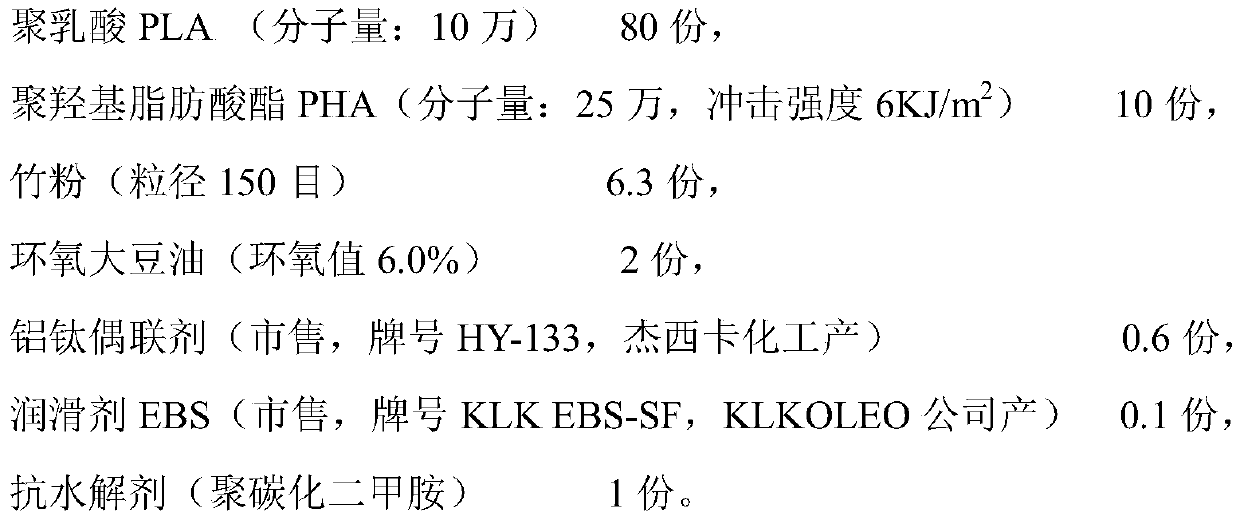

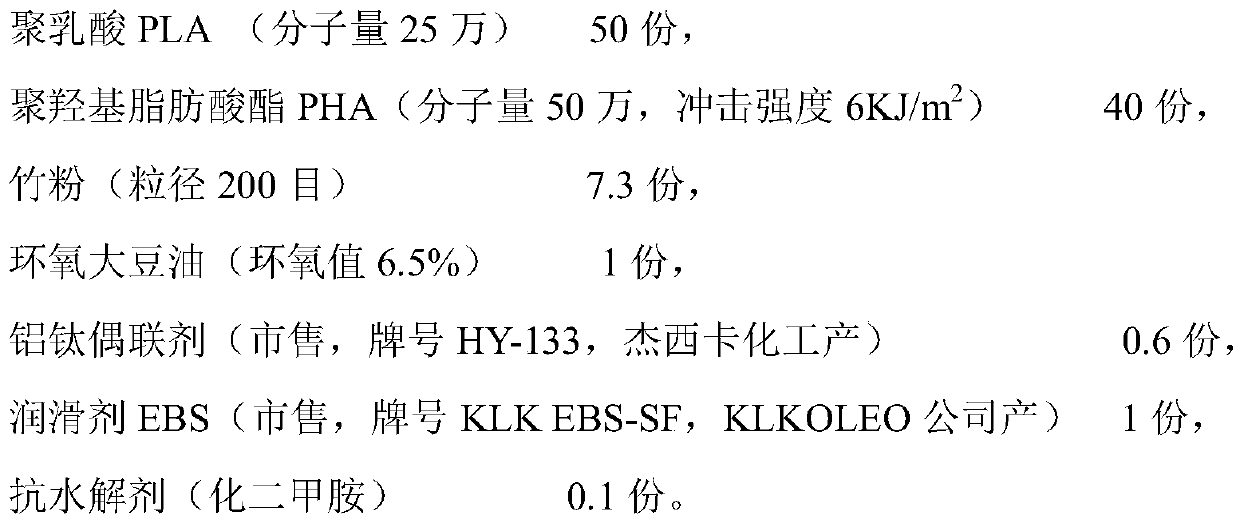

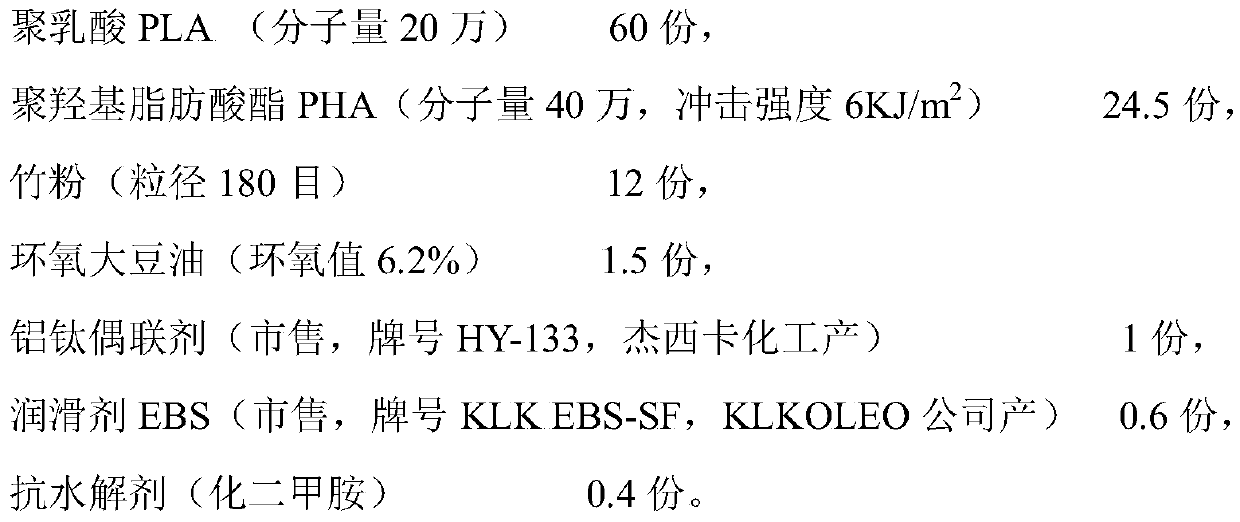

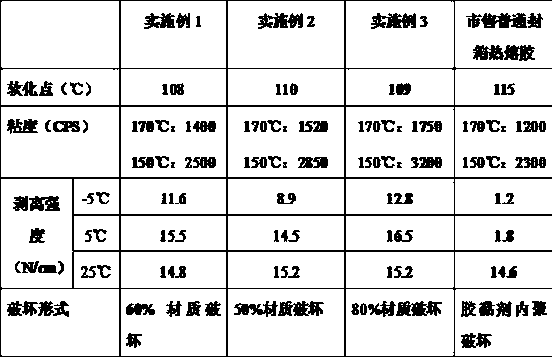

Biodegradable straw and preparation method thereof

ActiveCN111040398AImprove crystallization propertiesIncrease glass transition temperature and thermal stabilitySOYBEAN SEED OILSoybean oil

The invention discloses a biodegradable straw and a preparation method thereof. The straw comprises, by mass, 50%-80% of polylactic acid, 10%-40% of polyhydroxyalkanoate, 3%-12% of bamboo powder, 1%-2% of epoxidized soybean oil, 0.3%-1% of an aluminum-titanium coupling agent, 0.1%-1% of a lubricating agent and 0.1%-1% of an anti-hydrolysis agent. The preparation method comprises the following steps: uniformly stirring the bamboo powder and the aluminum-titanium coupling agent to obtain a bamboo powder pretreated material for later use; sequentially adding the epoxidized soybean oil, the bamboopowder pretreated material, the lubricant and the anti-hydrolysis agent into a resin mixture of the polylactic acid and the polyhydroxyalkanoate at a stirring speed of 100-250 r / min, and uniformly stirring to form a polylactic acid mixture; and adding the polylactic acid mixture into double-screw extrusion equipment, extruding a straw blank, and sequentially carrying out water cooling, air cooling, water removal and cutting on the straw blank under the traction of traction equipment to obtain the biodegradable straw product. The biodegradable straw material can effectively prolong the degradation time of the PLA straw, improve the mechanical properties of the PLA straw, and effectively improve the harmful bacterium inhibition ability of the straw.

Owner:NANJING PRIDE PLASTIC TECH

Manufacturing method of tobacco leaf primary color exsiccata

ActiveCN102410948AKeep the original colorAvoid brittlenessPreparing sample for investigationRetention periodRoom temperature

The invention provides a manufacturing method of a tobacco leaf primary color exsiccate. The method comprises the steps of shaping, color fixing, drying and moisturizing again. The shaping step mainly comprises: orderly overlapping absorbing paper, a moisture absorbent, absorbing paper and a specimen in a specimen holder; orderly overlapping the specimens in n layers (preferably 5-8 layers) according to the above form; fixing color for 15-18 hours at the constant temperature of 45-55 DEG C; drying for 3-6 hours at the constant temperature of 55-65 DEG C; and placing the absorbing paper and specimen in a room temperature environment with relative moisture of more than 70%, moisturizing again for 6-12 hours to obtain the primary color exsiccate. The specimen manufacturing is faster by usingthe method provided by the invention, and 6-8 days are shortened in comparison with the general pressing method, the color retention effect is good, and the color keeps the same in the specimen retention period; the water content is controlled in a range of 8-10% so as to prevent the specimen from brittle rupture and maintain the integrity of the specimen. The manufacturing method provided by theinvention is especially suitable for the manufacturing of the tobacco leaf primary color exsiccate, is especially in favor of storing the primary shape and color of the diseased tobacco leaf, and greatly improves the scientific research value and economy of the specimen.

Owner:YUNNAN ACAD OF TOBACCO AGRI SCI

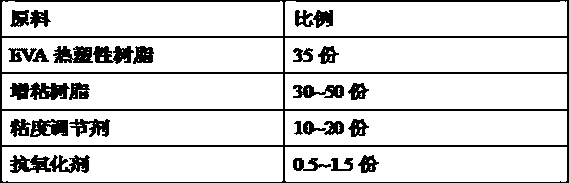

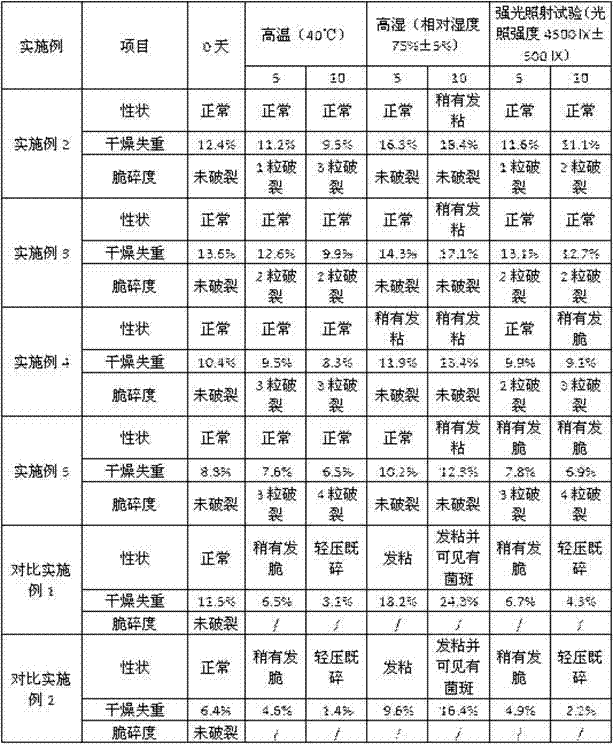

Hot melt adhesive for packaging

InactiveCN108395854AGood compatibilityImprove low temperature bonding performanceNon-macromolecular adhesive additivesMacromolecular adhesive additivesHigh surfacePackaging industry

The invention discloses a hot melt adhesive for packaging, and belongs to the field of adhesives. The hot melt adhesive is prepared at least from the following raw materials in parts by mass: 35 partsof ethylene-vinyl acetate (EVA) resin, 30-50 parts of tackifying resin, 10-20 parts of a viscosity regulator and 0.5-1.5 parts of an antioxidant. The hot melt adhesive provided by the invention has the advantages of environmental friendliness, no toxicity, no heavy metals, fast curing speed, excellent low-temperature resistance, high bonding strength to a carton with high surface paper strength (the wax picking degree of the carton surface paper reaches 20A or above), and the like. The hot melt adhesive solves the problems that cartons are open on a production line and in a warehouse when a conventional EVA hot melt adhesive is applied to the binding of cartons with high surface paper strength, and thus can be widely applied in the automatic packaging industry for food, beverages, beer and other industries.

Owner:朱俊帆

Modified gelatin capsule

ActiveCN103933012AIncrease viscosityEasy to manufactureCapsule deliveryMacromolecular non-active ingredientsViscosityToughness

The invention provides a modified gelatin capsule. Modified gelatin is a gelatin-glutamic acid crosslinked compound. The compound has stronger viscosity compared with gelatin, thus being capable of more easily preparing the capsule; the prepared capsule is longer in shelf life, excellent in toughness and difficult to break.

Owner:HUNAN ER KANG PHARMA

Explosive welding machining method for stainless steel magnesium alloy composite plates

ActiveCN106825898AReduce manufacturing costSimple and fast operationWelding/soldering/cutting articlesNon-electric welding apparatusDetonatorManufacturing technology

The invention discloses an explosive welding method for stainless steel magnesium alloy composite plates, and belongs to the field of manufacturing technologies for composite plates. Composite layers of the stainless steel magnesium alloy composite plates are made of stainless steel, and base layers of the stainless steel magnesium alloy composite plates are made of magnesium alloy. The explosive welding method includes carrying out explosive welding by the aid of expanded ammonium nitrate mixed explosive which is used as an explosive energy source; annealing magnesium alloy plates before explosive welding is carried out, mechanically polishing to-be-bonded surfaces of the stainless steel and the magnesium alloy plates, mounting explosive devices on soil foundations, laying rubber layers on the foundations and remotely detonating the expanded ammonium nitrate mixed explosive by the aid of electric detonators. The explosive welding method has the advantages that the explosive welding method is easy to implement and is economical; the interface bonding rate is 100%, the interface bonding strength is 130.0 Mpa, and accordingly the explosive welding method is a feasible method for manufacturing the stainless steel magnesium alloy composite plates.

Owner:SHANXI YANG MEI CHEM IND MACHINERY

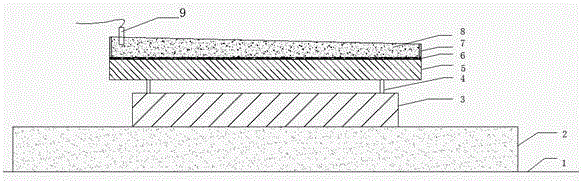

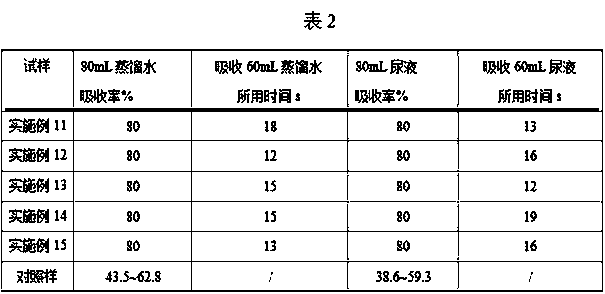

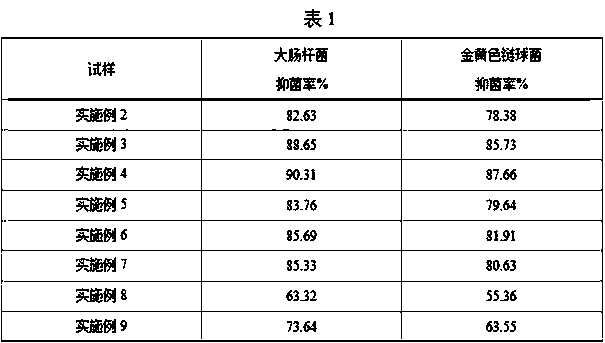

Mutli-layer protective type diaper and method for making diaper

ActiveCN108143542APreserves antimicrobial propertiesAvoid brittlenessAbsorbent padsBandagesSurface layerDeodorant

The invention discloses a multi-layer protective type diaper. The diaper comprises an antibacterial and deodorant fabric layer, a sweat-absorbent and moisture transfer fabric layer, a water-absorptiontype non-woven fabric layer and a surface layer from inside to ouTSide in sequence. The invention further discloses a method for making the multi-layer protective type diaper. The diaper has the advantages of being good in antibacterial effect, high in deodorant capacity and capable of absorbing moisture and releasing sweat.

Owner:DADDY BABY

Zinc plating liquid used for forming thick zinc coating as well as preparation method and application

The invention discloses zinc plating liquid used for forming a thick zinc coating as well as a preparation method and application. 1 L of zinc plating liquid used for forming the thick zinc coating comprises the following ingredients: 60-100 g of zinc chloride, 180-220 g of potassium chloride, 20-35 g of boric acid, 10-20 g of a combined brightener, 0.2-1.2 g of a softening agent, 1-20 mL of an organic solvent and the balance of water. The preparation method comprises the followings steps: dissolving zinc chloride, potassium chloride, boric acid, the combined brightener and the softening agent with a small amount of water, adding the organic solvent, uniformly mixing, and diluting with water so as to form the zinc plating liquid used for forming the thick zinc coating. When the zinc plating liquid used for forming the thick zinc coating is electroplated for 15-120 min under the current density of 1-15 A / dm<2>, the zinc coating with the thickness of 34-100 [mu]m can be obtained on the surface of a metallic matrix, and is compact, uniform, bright and crack-free.

Owner:SHANGHAI INST OF TECH

Resin composition having high dielectric constant and uses thereof

InactiveUS20050009975A1High dielectric constantAvoid brittlenessPrinted circuit aspectsPrinted capacitor incorporationEpoxyPrinted circuit board

The subject invention relates to a resin composition having a high dielectric constant, comprising (a) an epoxy resin, (b) a curing agent, (c) a ceramic powder, and (d) a highly polar modifier. The subject invention further relates to a process for the manufacture of a printed circuit board comprising using the composition of the subject invention as a material for a capacitor material embedded in the printed circuit board.

Owner:ETERNAL MATERIALS CO LTD

Heat treatment and surface treatment method of mold steel SDCM1 for hot stamping

InactiveCN104178771AImprove corrosion resistanceAvoid brittlenessSolid state diffusion coatingQuenchingHot stamping

The invention discloses a heat treatment and surface treatment method of a mold steel SDCM1 for hot stamping. The heat treatment and surface treatment method comprises quenching and tempering; the method comprises the following steps: vacuum heat treatment: the quenching temperature is 1010-1040 DEG C; two times of tempering: the tempering temperature is 580-610 DEG C; and surface plasma nitriding: the voltage is 600-900 V; the atmospheric specific value of NH3 to Ar is 1: (6-10); and the furnace pressure is 133-1066 Pa. A non-compound layer nitriding layer is obtained through controlling such parameters as plasma nitriding atmospheric ratio, nitriding time, furnace pressure, voltage and nitriding temperature. When the surface hardness of the mold is improved, the corrosion resistance, wear resistance and bonding resistance of the mold are optimized. The worn mold can be reused through repairing and secondary plasma nitriding so as to largely prolong the total service life of the mold. The equipment cost is lower; the workpiece size and shape are low in limitation; and the method can be totally applied to the actual production.

Owner:BAOSHAN IRON & STEEL CO LTD

Preparation method of carbon/carbon material C-AlPO4-mullite-MoSi2 composite outer coating layer

The invention relates to a preparation method of a carbon / carbon material C-AlPO4-mullite-MoSi2 composite outer coating layer. The preparation method comprises the steps of: adding mullite powder, C-AlPO4 powder and MoSi2 powder into butanol to obtain suspension A, and adding elementary selenium into the suspension A to obtain solution B; and pouring the solution B into a device which uses a graphite electrode as an anode and a conductive substrate as a cathode for microwave ultrasonic cathode rotation hydrothermal electrophoretic arc-discharge deposition reaction, after the reaction is ended, naturally cooling to room temperature and drying to obtain the final product, i.e. a SiC-C / C test sample protected by the C-AlPO4-mullite-MoSi2 composite outer coating layer. The C-AlPO4-mullite-MoSi2 composite outer coating layer prepared by adopting the method has the advantages of uniform thickness and no surface crack. The preparation method of the C-AlPO4-mullite-MoSi2 composite outer coating layer has the advantages that the preparation period is short, the advantages of hydrothermal, electrophoretic, ultrasonic, microwave and arc-discharge processes are combined, the preparation steps are simple, the operation is convenient to conduct, the raw materials are easy to obtain and the preparation cost is lower.

Owner:XINING GONGJIN NEW MATERIAL TECHNOLOGY CO LTD

Laser drilling method for glass

ActiveCN104759764AImprove drilling efficiencyAvoid brittlenessLaser beam welding apparatusLaser drillingPulse delay

The invention is applicable to the drilling filed of a hard and crisp material, and provides a laser drilling method for glass. The laser drilling method for the glass comprises the steps of dividing a through hole to be laser drilled into a plurality of processing layers, and processing the glass layer by layer by the laser, wherein the process path of each processing layer is an inner cycloidal path. According to the laser drilling method for the glass, the through hole to be laser drilled is divided into the plurality of processing layers, and the process path of each processing layer is the inner cycloidal path, therefore the operation of frequently turning on or off the laser can be reduced, and the blast points at the drilling place or the glass crisp caused by the sudden change of the first and last pulse delay or power of a laser device can be prevented; meanwhile, and the laser drilling efficiency can be greatly improved due to the operation of reducing turning on or off the laser.

Owner:HANS LASER TECH IND GRP CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com