Heat treatment and surface treatment method of mold steel SDCM1 for hot stamping

A surface treatment, die steel technology, applied in coating, metal material coating process, solid-state diffusion coating, etc., can solve the problem that nitrided parts cannot withstand too high contact stress and impact load, long nitriding cycle, and high cost problem, to achieve the effect of enhanced wear resistance, improved surface strength, equipment and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0054] In this embodiment, a die steel SDCM1 for hot stamping is carried out for heat treatment and surface treatment. The specific process is as follows:

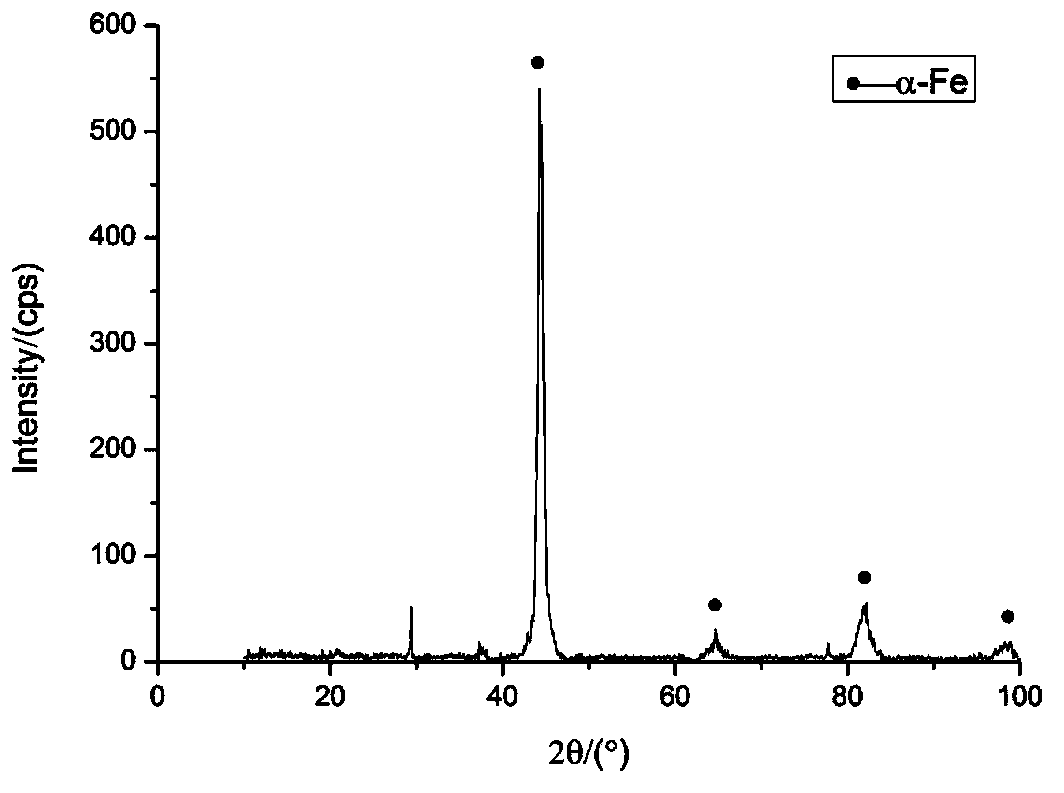

[0055] (a) Heat treatment process: Quenching at 1020°C, tempering at 595°C for 2 hours, and then tempering at 595°C for 2 hours. Under the conditions of this heat treatment process, the hardness and impact toughness: the hardness value is 51HRC, and the impact toughness value is 180J. Quenched and tempered microstructure such as figure 1 shown.

[0056] (b) Plasma nitriding process: voltage 850V, atmosphere ratio NH3:Ar=1:9, furnace pressure 450Pa, nitriding temperature 530°C, nitriding time 8h. After nitriding, the surface hardness is 810HV0.3, and the thickness of the nitriding layer is 225μm.

Embodiment 2

[0058] In this embodiment, a die steel SDCM1 for hot stamping is subjected to heat treatment and surface treatment. The specific process is as follows:

[0059] (a) Heat treatment process: Quenching at 1025°C, tempering at 600°C for 2 hours, and then tempering at 600°C for 2 hours. Under the conditions of this heat treatment process, the hardness and impact toughness: the hardness value is 51HRC, and the impact toughness value is 190J.

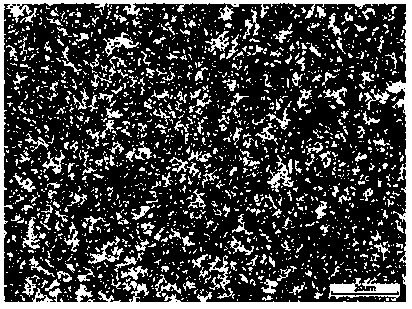

[0060] (b) Plasma nitriding process: voltage 880V, atmosphere ratio NH3:Ar=1:9, furnace pressure 525Pa, nitriding temperature 540°C, nitriding time 8h. After nitriding, the surface hardness is 860HV0.3, and the thickness of the nitrided layer is 264μm. figure 2 It is the metallographic 200× photo of the die steel section after heat treatment and surface treatment in this embodiment.

Embodiment 3

[0062] In this embodiment, a die steel SDCM1 for hot stamping is carried out for heat treatment and surface treatment. The specific process is as follows:

[0063] (a) Heat treatment process: Quenching at 1030°C, tempering at 605°C for 2 hours, and then tempering at 605°C for 2 hours. Under the conditions of this heat treatment process, the hardness and impact toughness: the hardness value is 52HRC, and the impact toughness value is 200J.

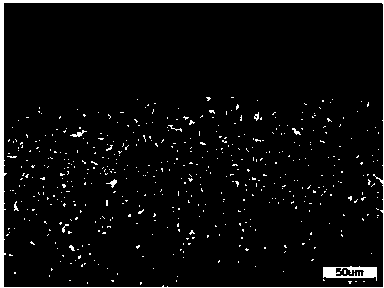

[0064] (b) Plasma nitriding process: voltage 900V, atmosphere ratio NH3:Ar=1:9, furnace pressure 450Pa, nitriding temperature 550°C, nitriding time 6h. After nitriding, the surface hardness is 850HV0.3, and the thickness of the nitriding layer is 190μm. image 3 It is the scanning electron microscope and point component analysis of the mold steel section after heat treatment and surface treatment in embodiment 3; Figure 4 Scanning electron microscope photos and EDS energy spectrum analysis for plasma surface nitriding; Figure 5 It is em...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness value | aaaaa | aaaaa |

| Impact toughness value | aaaaa | aaaaa |

| Impact toughness value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com