Patents

Literature

92results about How to "Small size limit" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

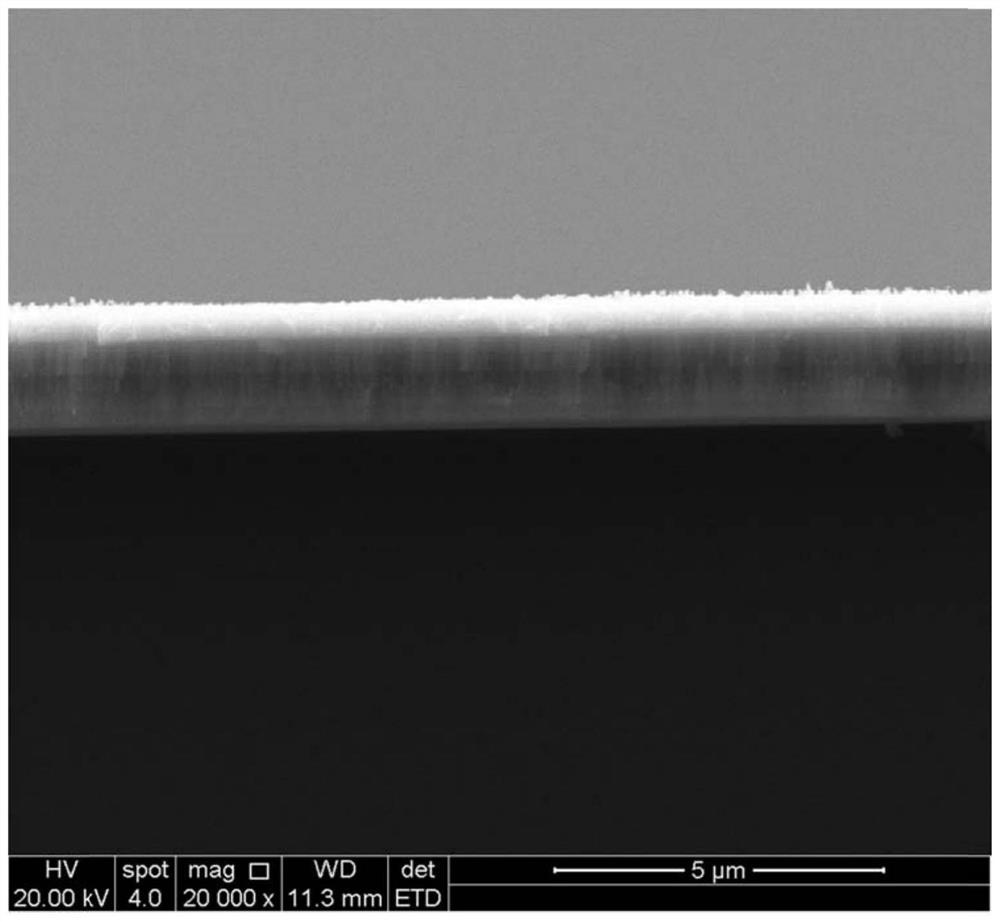

Hot stamping die steel and production method thereof

InactiveCN104928586AImprove the quality of heat treatmentImprove strength and toughnessSolid state diffusion coatingHot stampingHardness

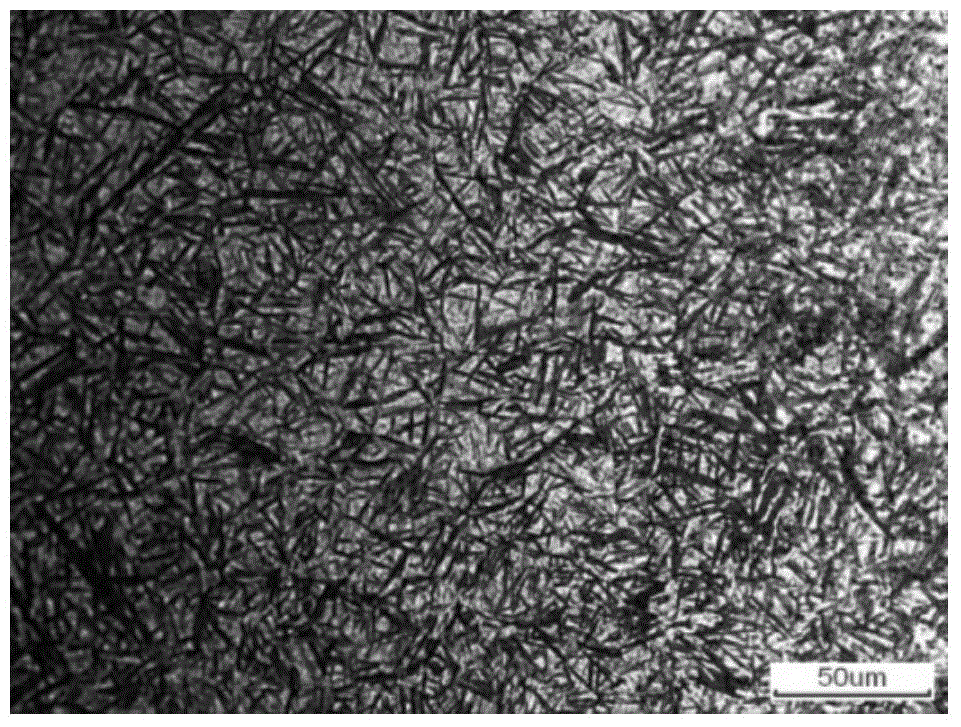

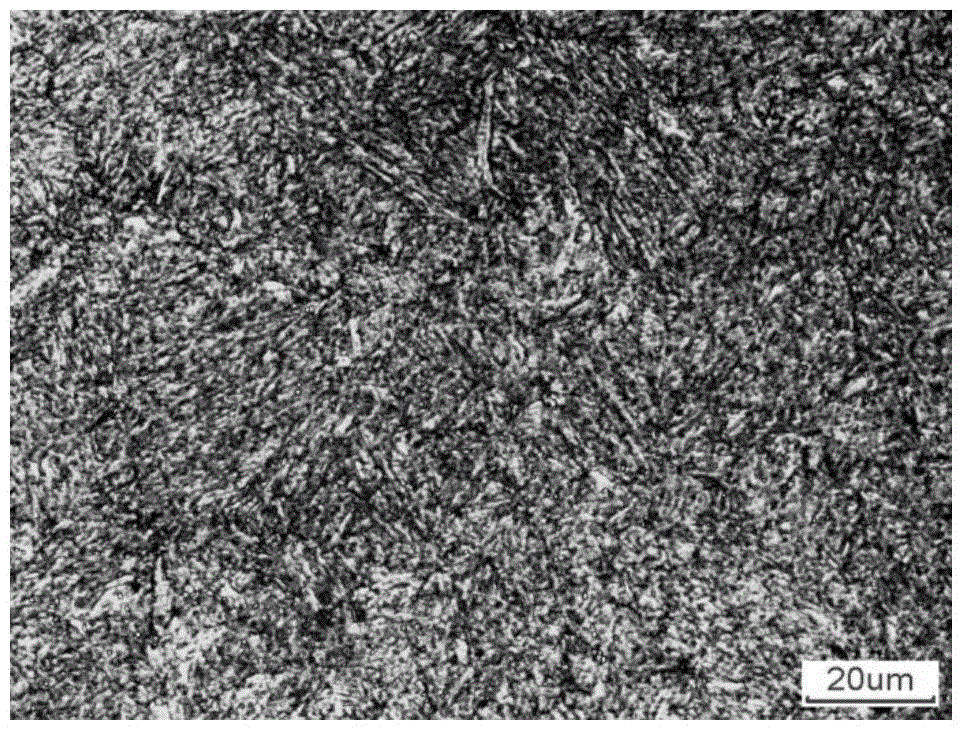

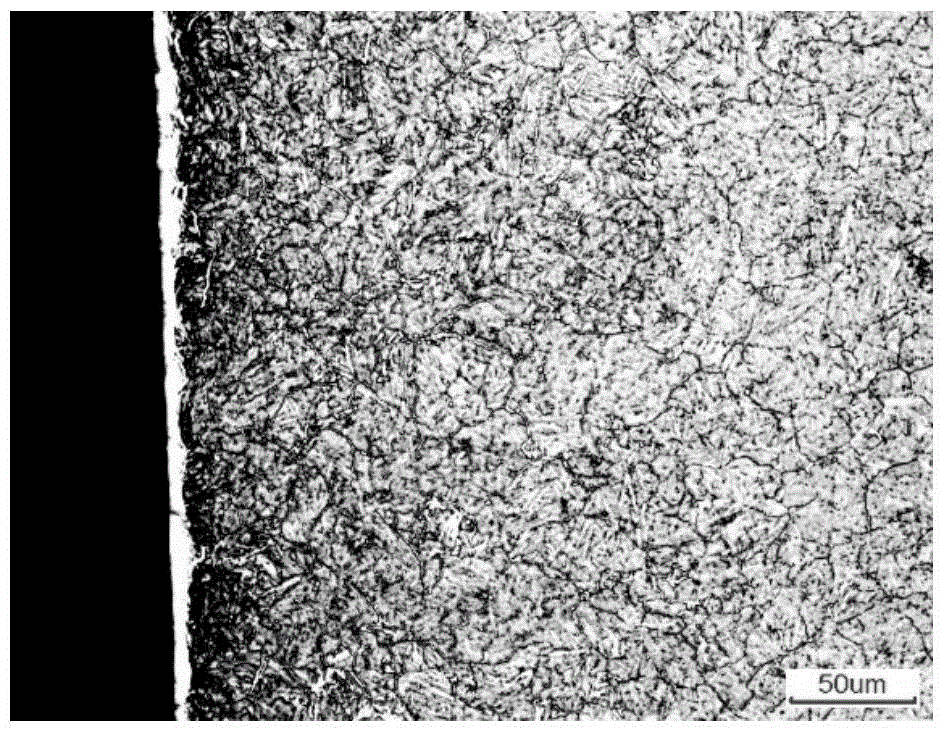

The invention provides hot stamping die steel and a production method thereof. The hot stamping die steel is composed of, by weight, 0.45-0.50% of C, 0.1-0.3% of Si, 0.1-0.3% of Mn, 2.0-2.3% of Cr, 2.3-2.5% of Mo, 0.8-1.0% of V, smaller than or equal to 0.03% of P, smaller than or equal to 0.03% of S and the balance Fe and other inevitable impurities and meets the relational expressions that Mo / Cr=1-1.25 and V / Cr=0.35-0.43. By means of the electroslag remelting process, the ultrafine thermal treatment process, the vacuum thermal treatment process and the plasma nitriding surface treatment process, the produced and obtained hot stamping die steel is low in cost and high in comprehensive performance; the hot stamping die steel has a thermal conductivity coefficient of 34.3 W / m.k, quenching and tempering hardness of 50-53 HRC, ballistic work of 180-210 J, surface hardness of 850-1040 HV0.3 and diffusion thickness of 230-300 microns, and a white bright layer is ceaseless after nitriding.

Owner:BAOSHAN IRON & STEEL CO LTD

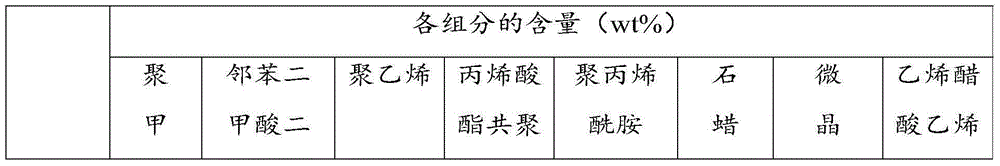

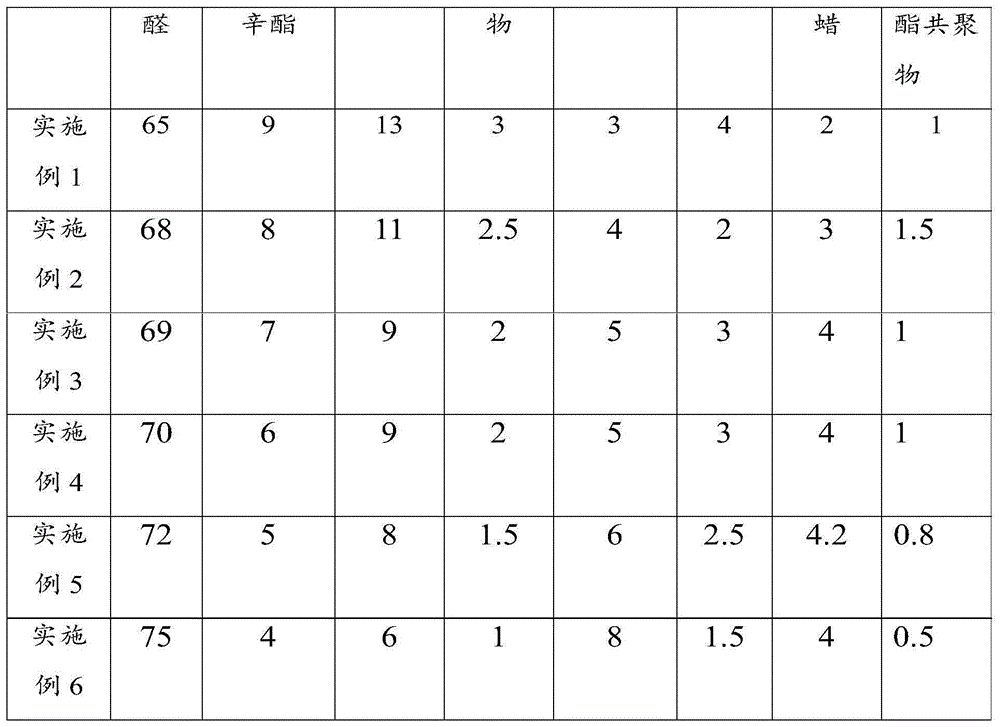

Binding agent for powder injection moulding, preparation method and application method of binding agent

The invention provides a binding agent for powder injection moulding, a preparation method of the binding agent and an application method of the binding agent. The binding agent is mainly prepared from the following components in percentage by mass: 65 to 75 percent of polyformaldehyde, 4 to 9 percent of dioctyl phthalate, 6 to 13 percent of polyethylene, 1 to 3 percent of acrylate copolymer, 3 to 8 percent of polyacrylamide, 1.5 to 4 percent of paraffin, 2 to 6 percent of microcrystalline wax and 0.5 to 2 percent of ethylene vinyl acetate copolymer. In the binding agent provided by the invention, multiple types of components are combined through scientific compatibility, so that the compatibility between metal powder or ceramic powder and the binding agent can be obviously improved, and meanwhile, the binding agent can be quickly removed in a degreasing process without causing the defects of bubbling and cracking of a green body, so as to guarantee the quality of the green body.

Owner:王有才

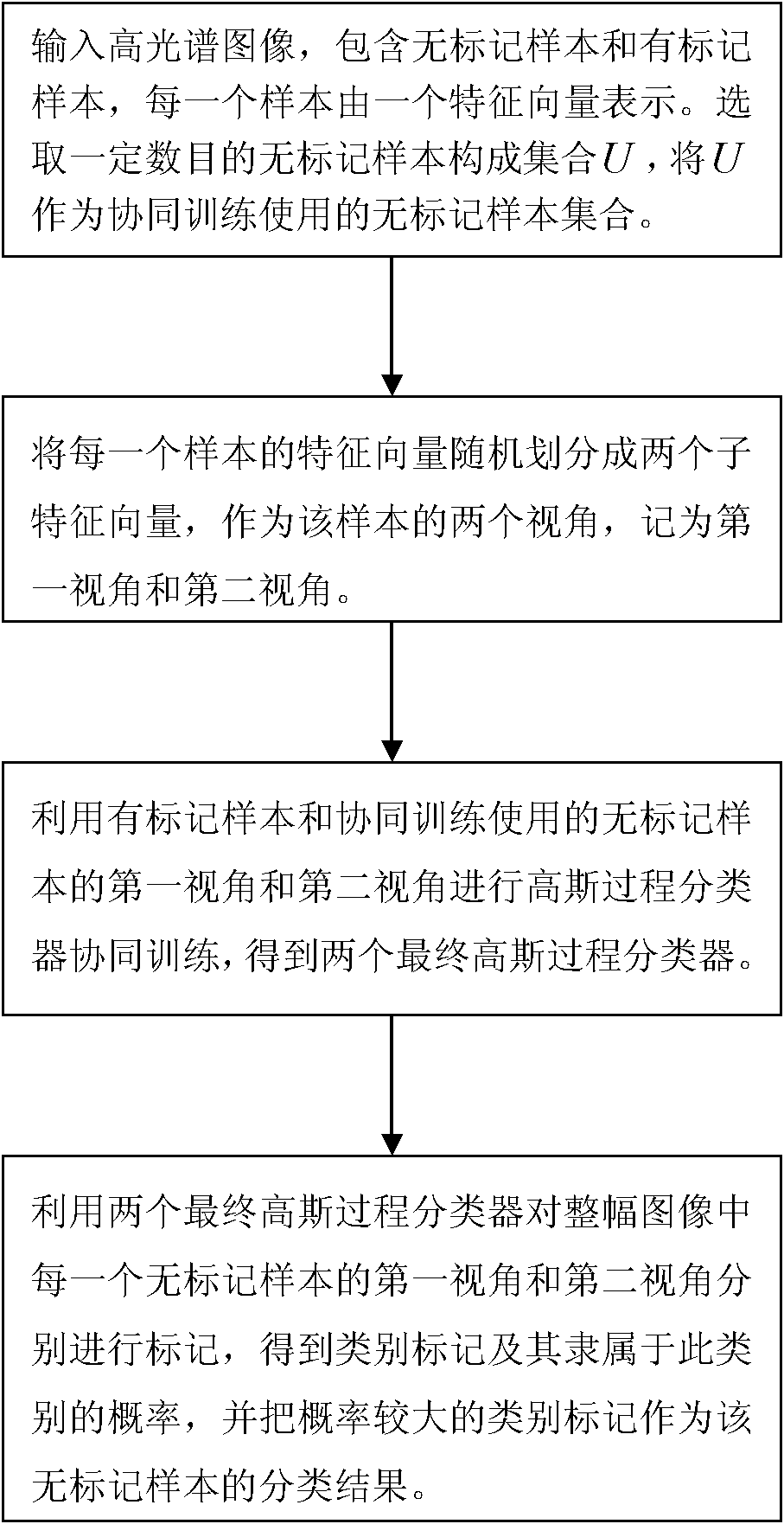

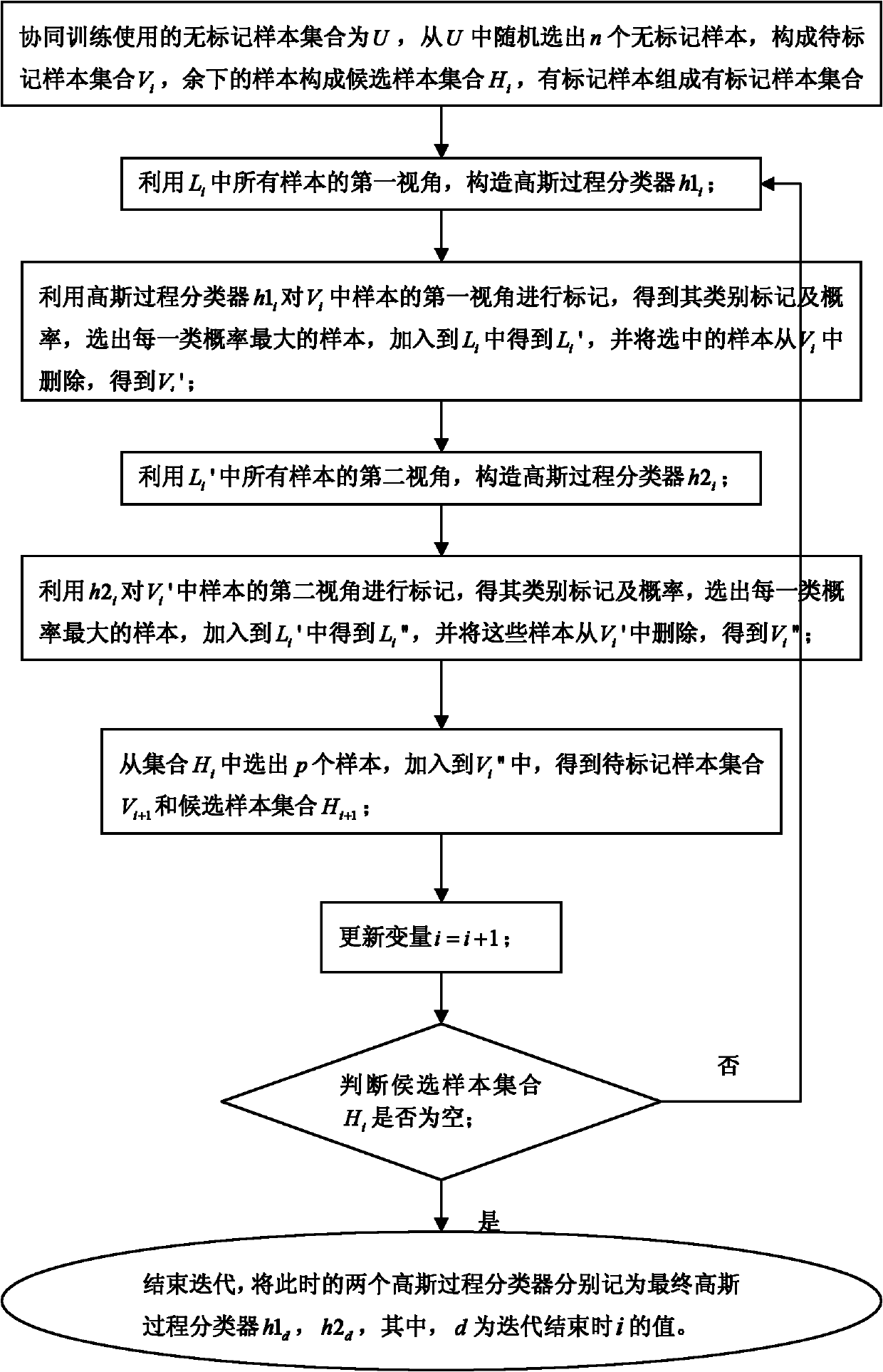

Hyper-spectral image classification method based on Gaussian process classifier collaborative training algorithm

InactiveCN102208037AImprove classification accuracyImprove performanceCharacter and pattern recognitionFeature vectorImaging processing

The invention provides a hyper-spectral image classification method based on a Gaussian process classifier collaborative training algorithm-. The method belongs to the technical field of image processing, and mainly solves the problem of low classification precision when the number of marked samples of hyper-spectral data is small in the prior art. The method comprises the following implementation processes of: firstly, randomly dividing feature vectors of samples into two sub feature vectors which are used as two visual angles of the samples; performing Gaussian process classifier collaborative training by using the two visual angles of partial non-marked samples and existing marked samples to obtain two final Gaussian process classifiers; and marking the two visual angles of all the non-marked samples by using the two final Gaussian process classifiers respectively, wherein the class mark with higher probability is used as the classification result of the non-marked samples. The method applied to hyper-spectral image classification can be used for remarkably improving the classification accuracy under the condition of small marked sample number.

Owner:XIDIAN UNIV

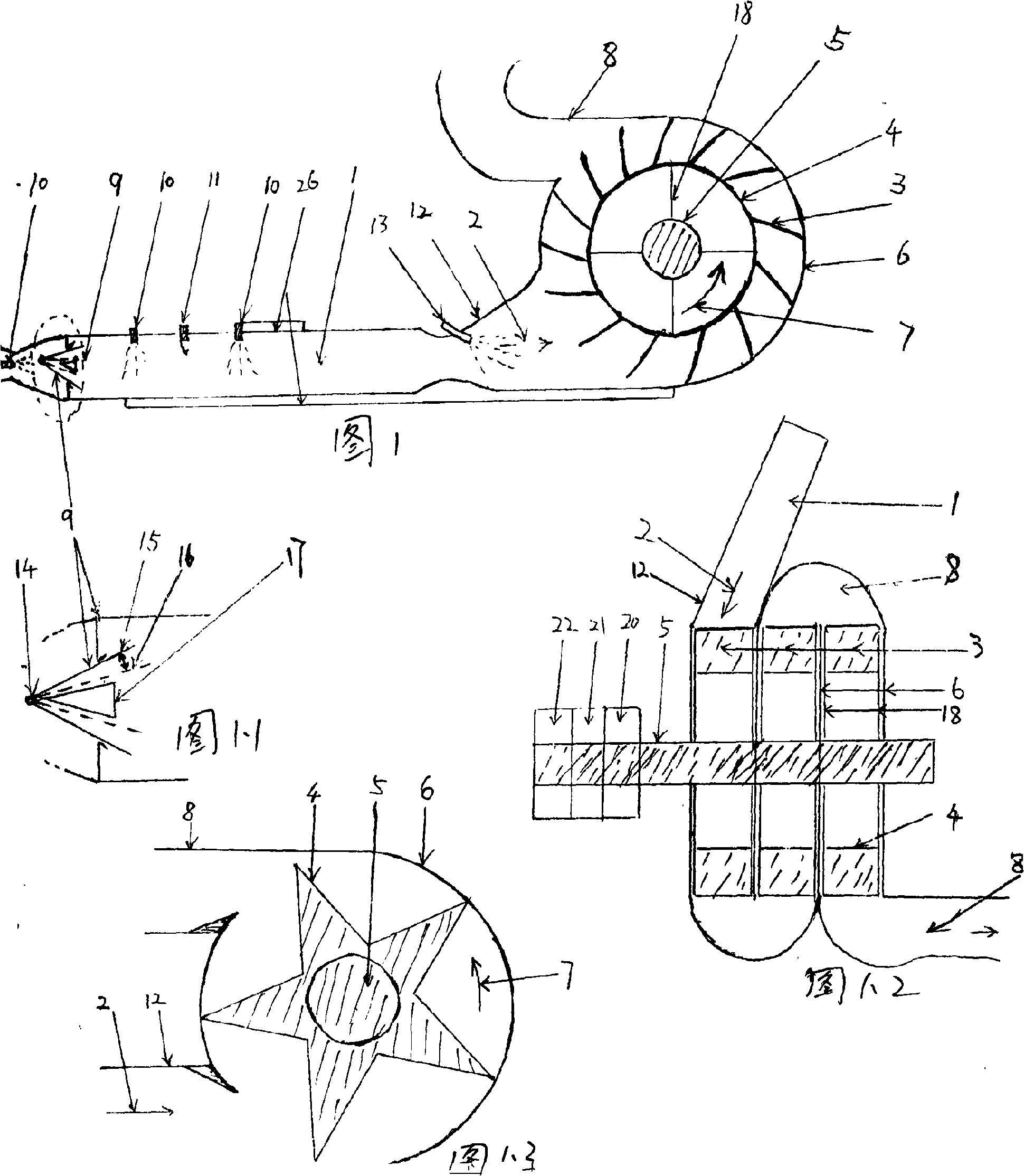

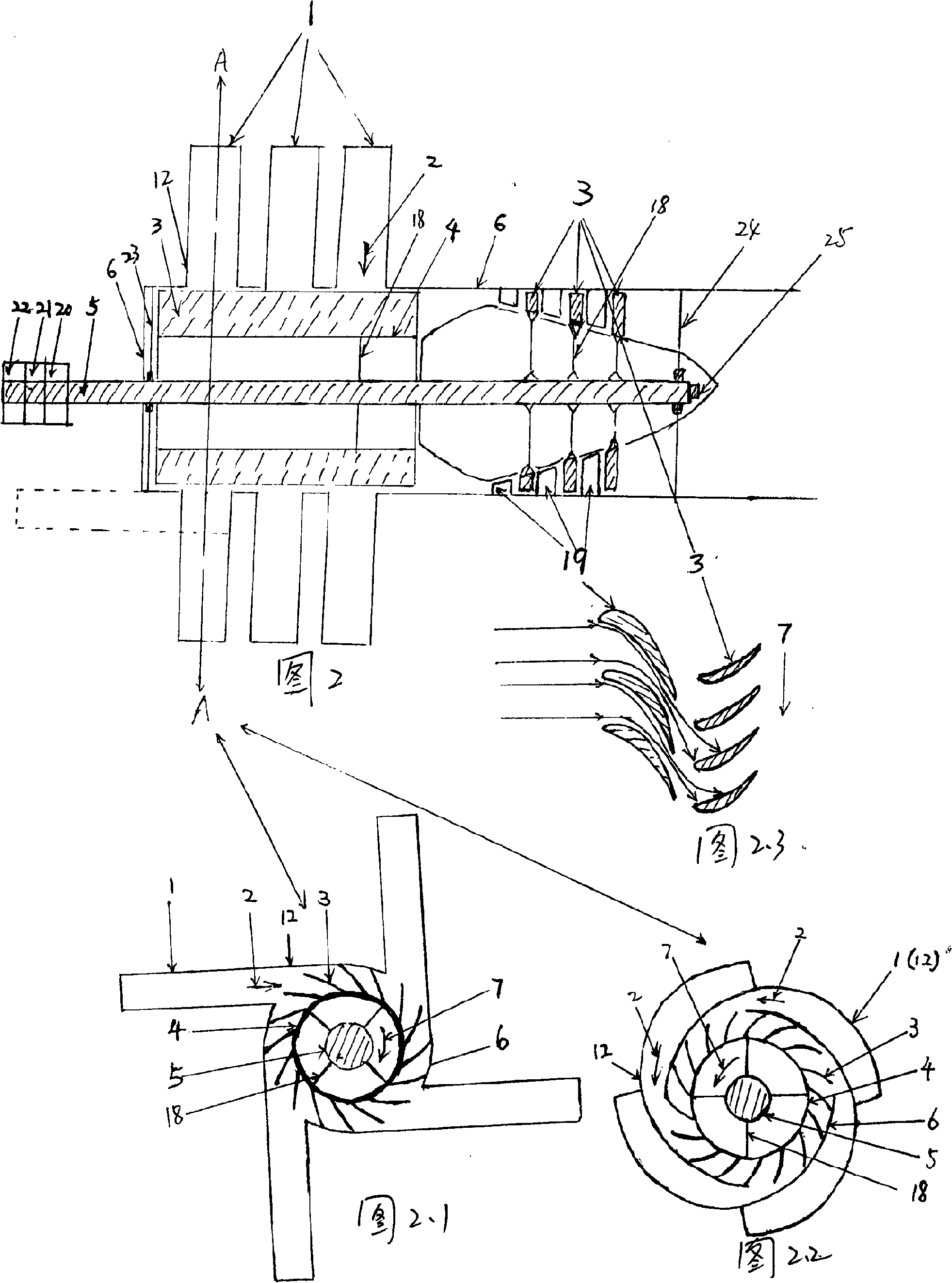

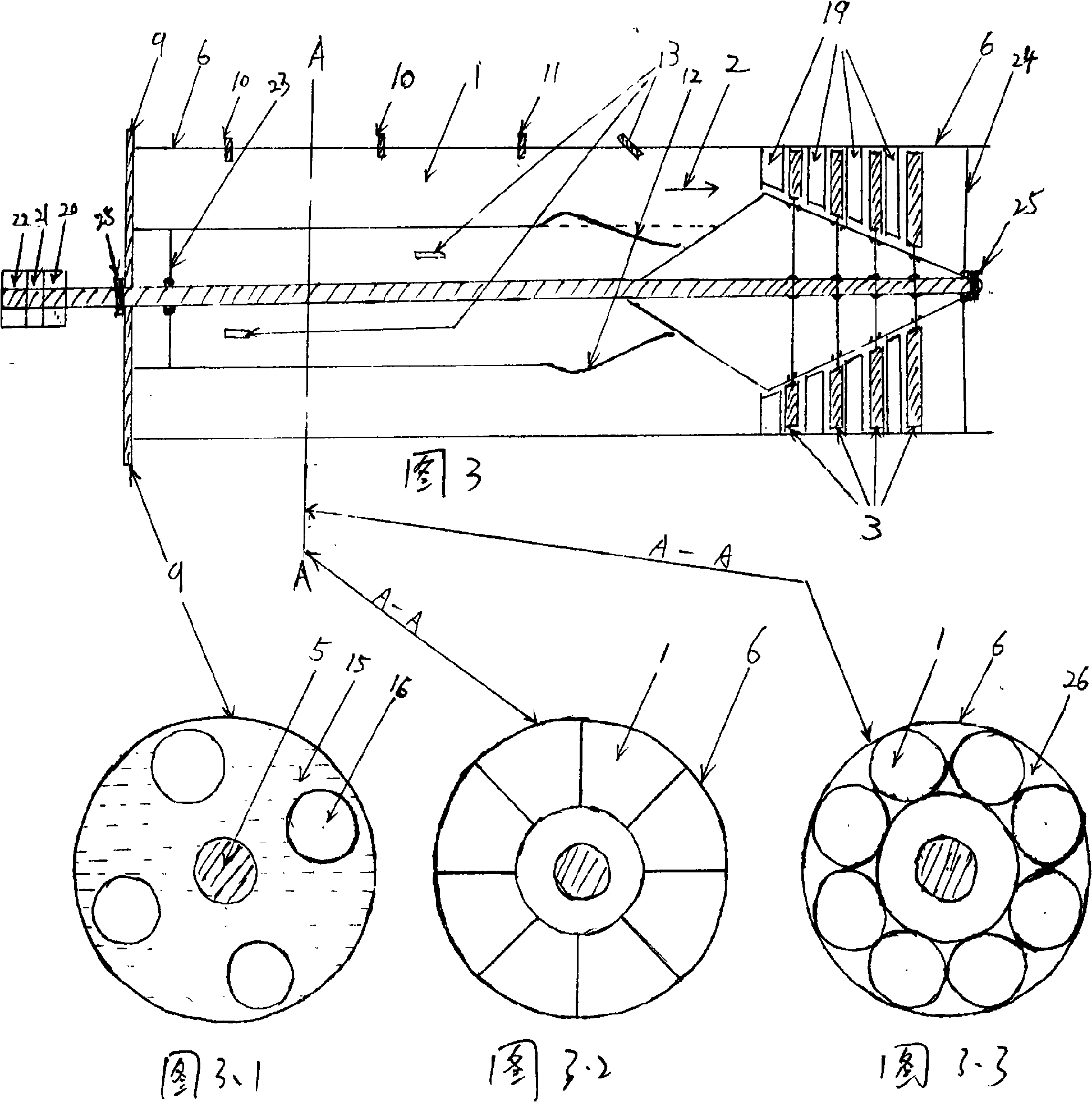

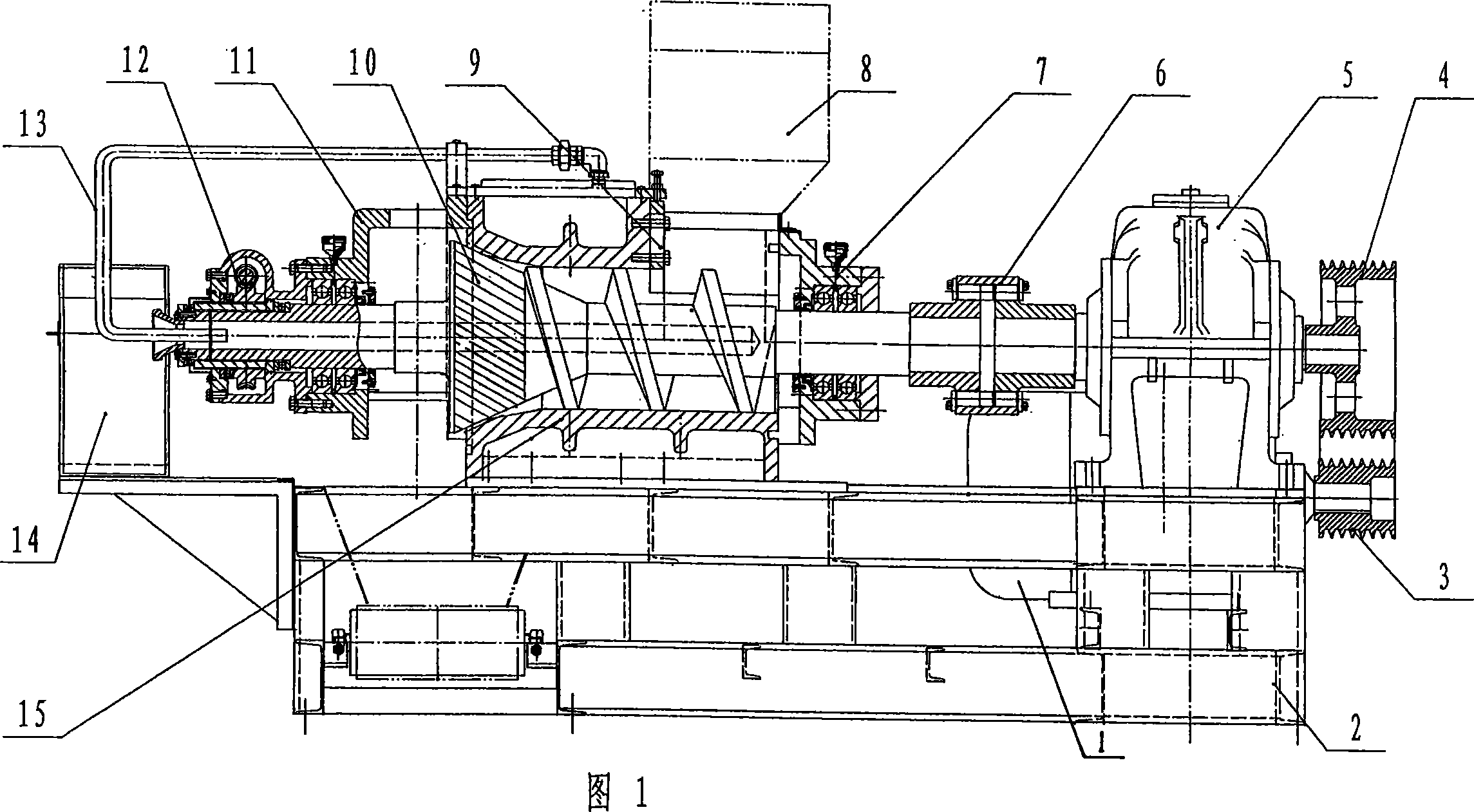

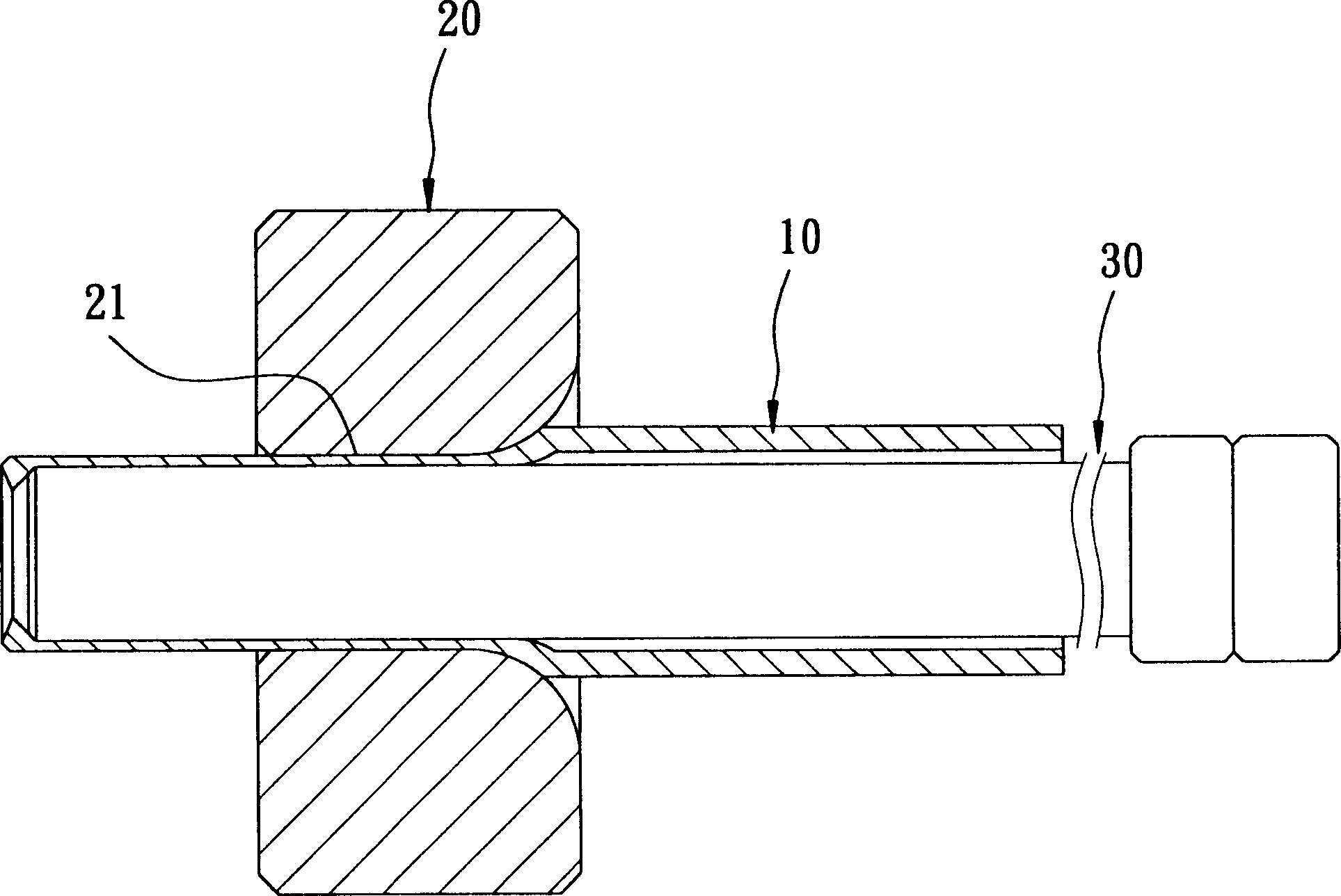

Pulse knock rotor spindle engine

InactiveCN101338702AIncrease useSingle purposeTurbine/propulsion engine coolingGas turbine plantsHigh pressureSubmarine

The present invention relates to a pulse detonation rotor shaft engine. In the technical proposal, the pulse detonation rotor shaft engine mainly consists of a pulse detonation engine, a rotor and an output shaft; propulsive gas with the high temperature and high pressure expansion of pulse which is ejected when the pulse detonation engine works is used as a power source to push the rotor to rotate; the rotor drives the output shaft to rotate; a pulse detonation rotor shaft engine uses the output shaft to output most energy produced by the pulse detonation engine by outputting torsion continuously; the output shaft drives various kinds of loads to work. The pulse detonation rotor shaft engine has the beneficial effects as follows: firstly, the pulse detonation rotor shaft engine can be used as a shaft engine to be widely applied in various kinds of dynamic systems, such as ship, submarine, tank, tractor, automobile, train, and the like and has wide purposes; secondly, the pulse detonation rotor shaft engine overcomes the disadvantage of the large noise of the prior pulse detonation engine; thirdly, compared with a piston type engine, the pulse detonation rotor shaft engine has the obvious advantages of simple structure, low cost, high reliability, long service life, light weight, less fraction resistance loss, etc.

Owner:RUGAO HUAYANG ALUMINUM PROD

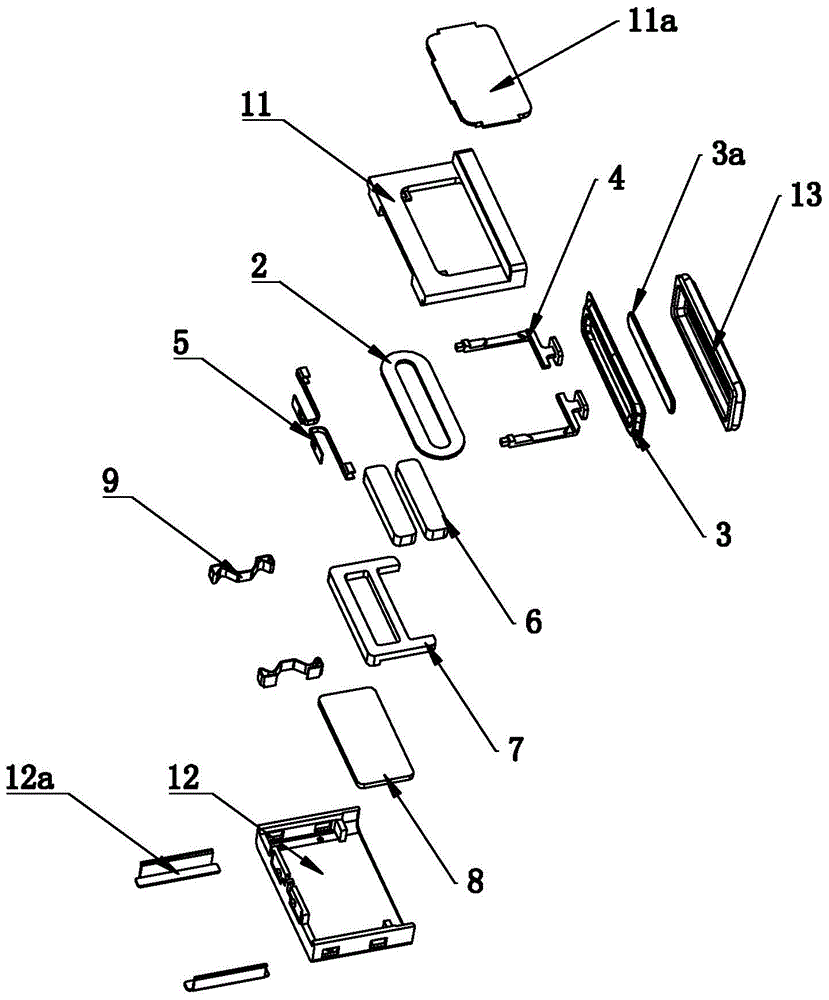

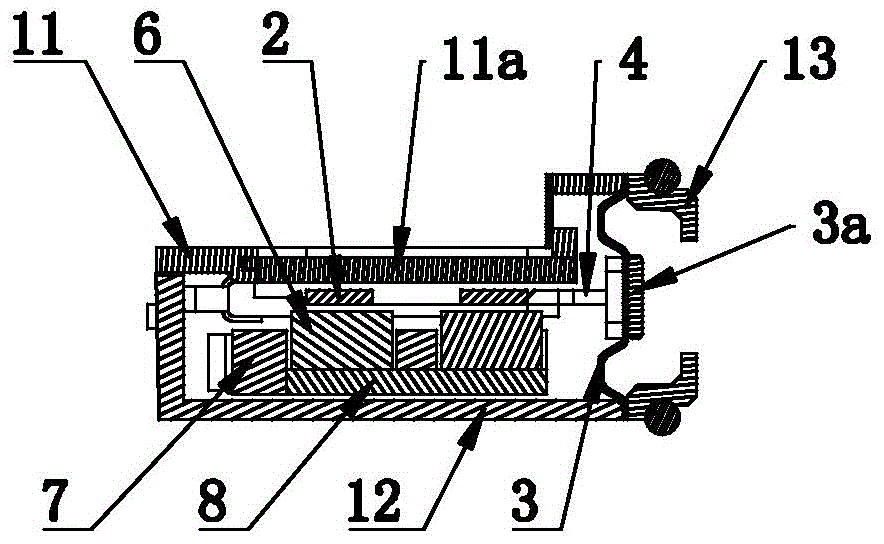

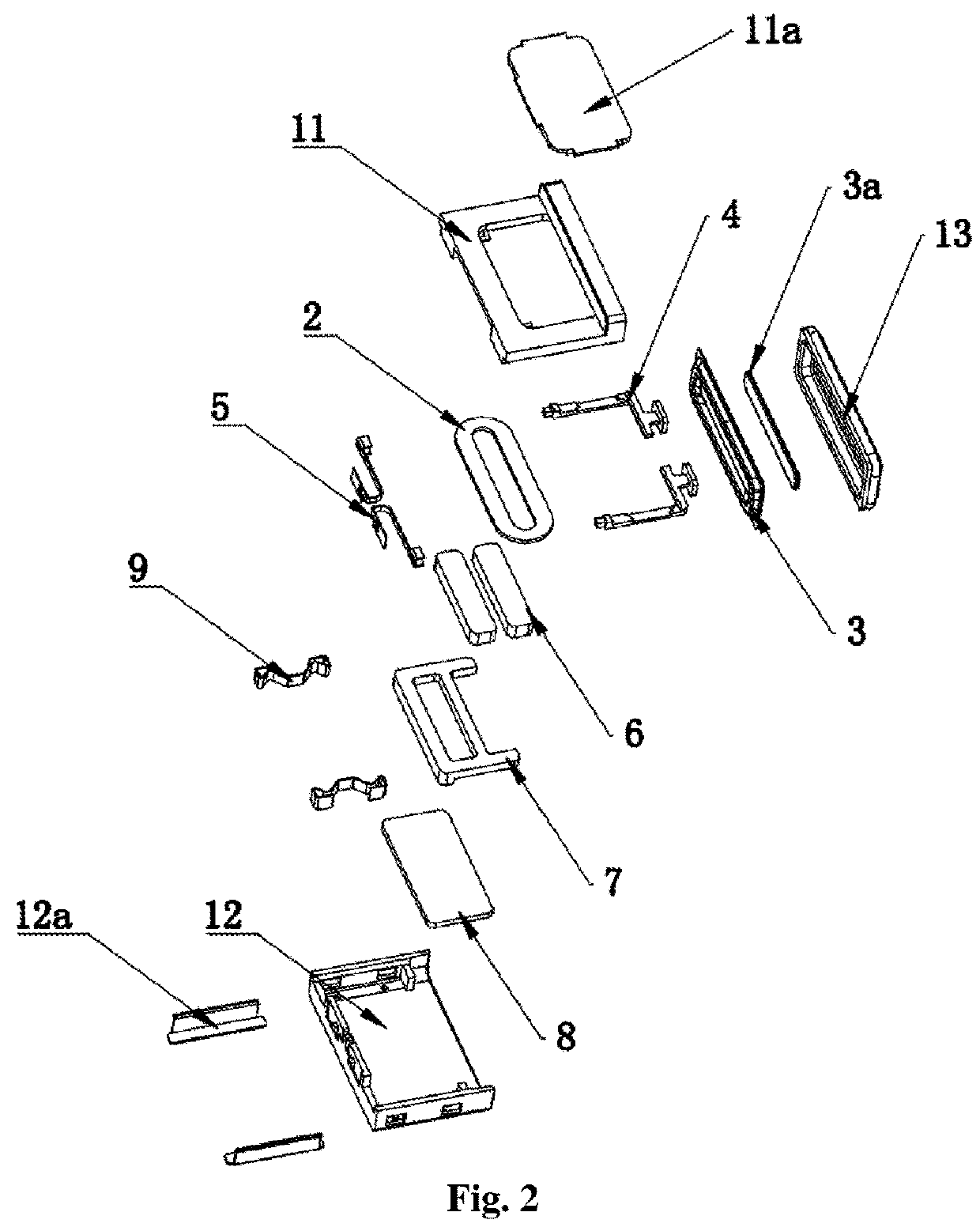

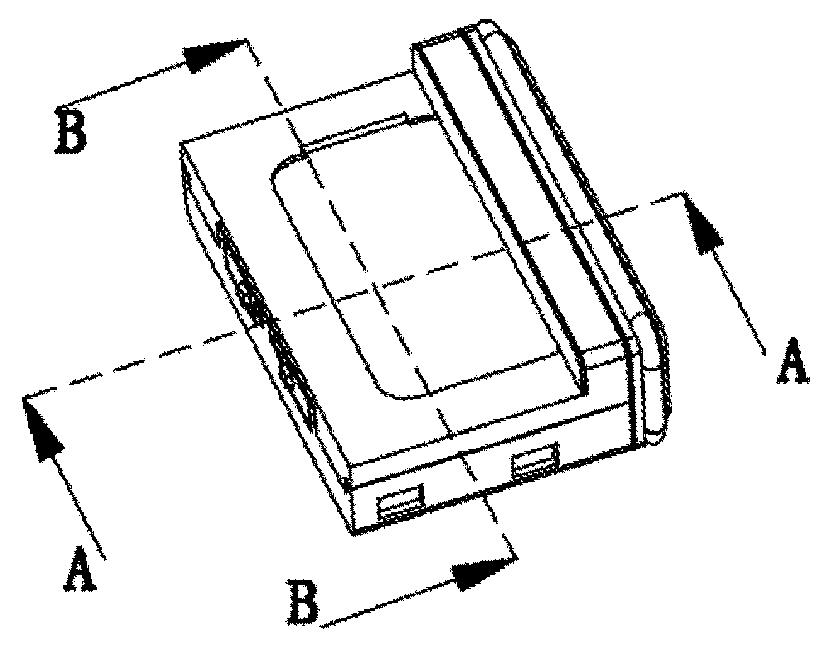

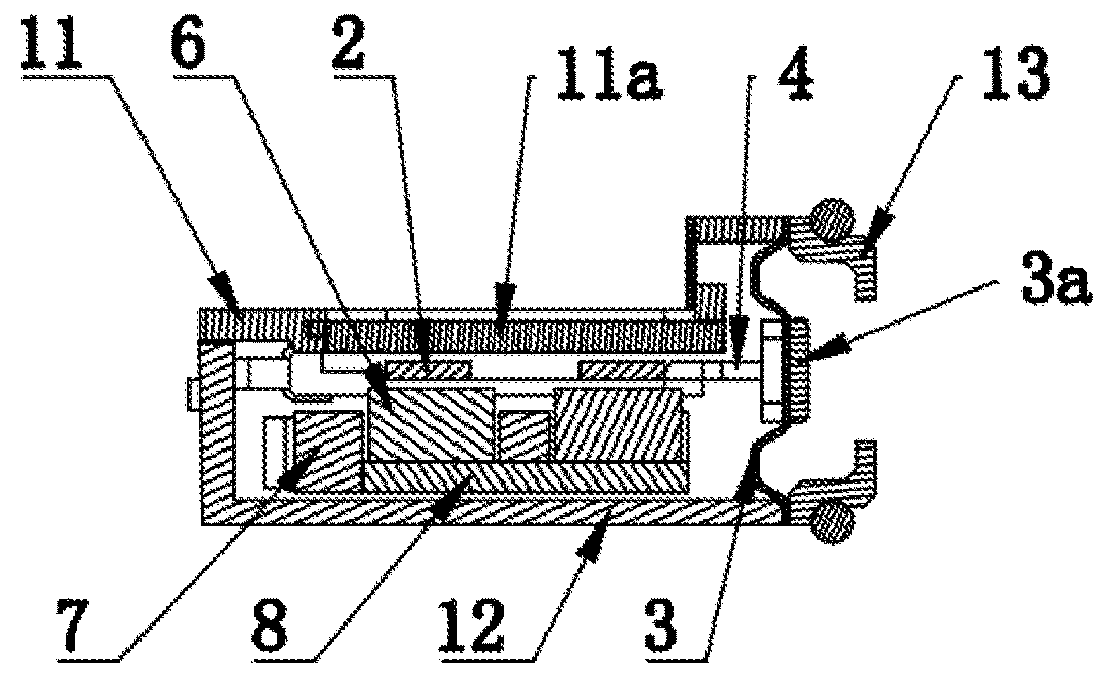

Vibrating sound production device

InactiveCN104883649AGuaranteed sound effectFunction as vibrationLoudspeaker transducer fixingLoudspeakersSound productionVoice coil

The invention discloses a vibrating sound production device. Sound outlet holes of the vibrating sound production device are arranged at a side surface, a vibrating diaphragm corresponds to the sound outlet holes in position, a flat voice coil is vertical with the vibrating diaphragm, magnets are parallel to the voice coil, a vibrating direction of the voice coil avoids the thickness direction, vibrating directions of the magnets and a mass block also avoid the thickness direction, and the mass block is fixedly combined with a shell through elastic pieces, thereby being conducive to reducing the product thickness, improving the product performance and simplifying the production process of products. Therefore, the vibrating sound production device disclosed by the invention has the advantages of high thinning design, good performance and simple assembly.

Owner:GOERTEK INC

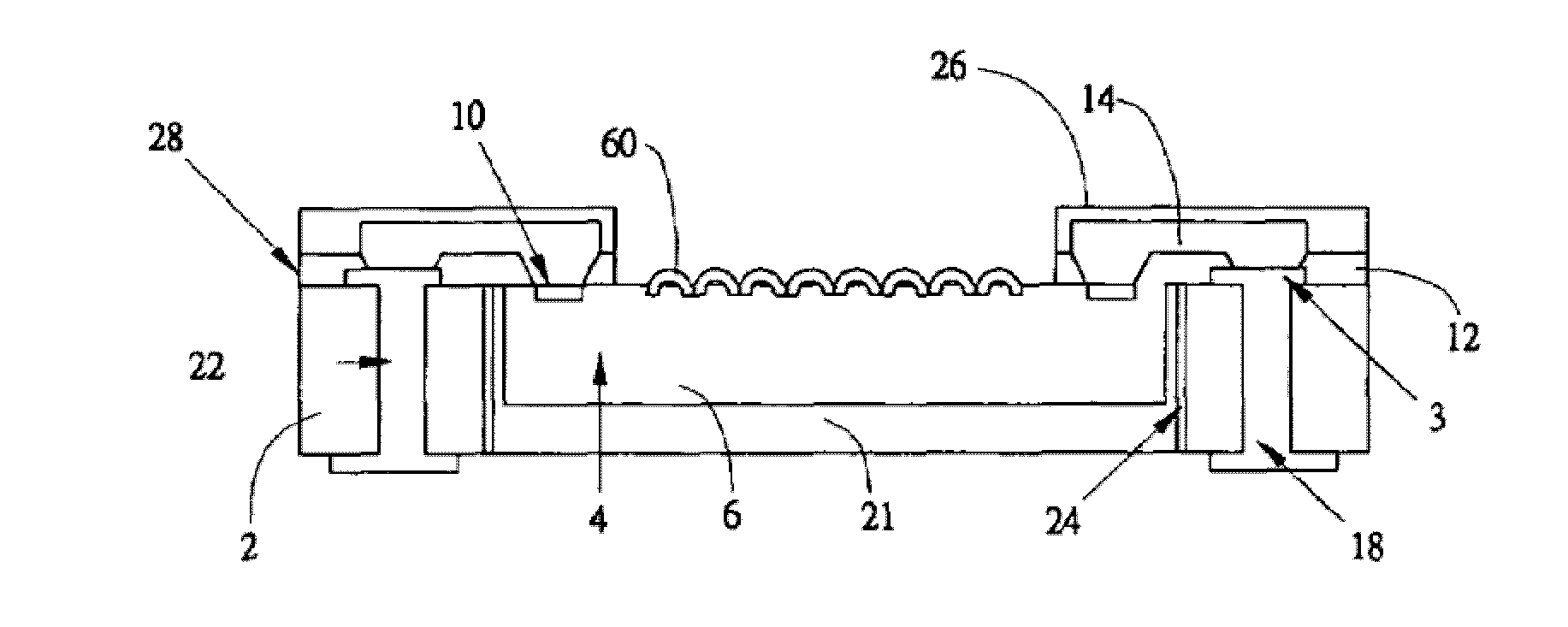

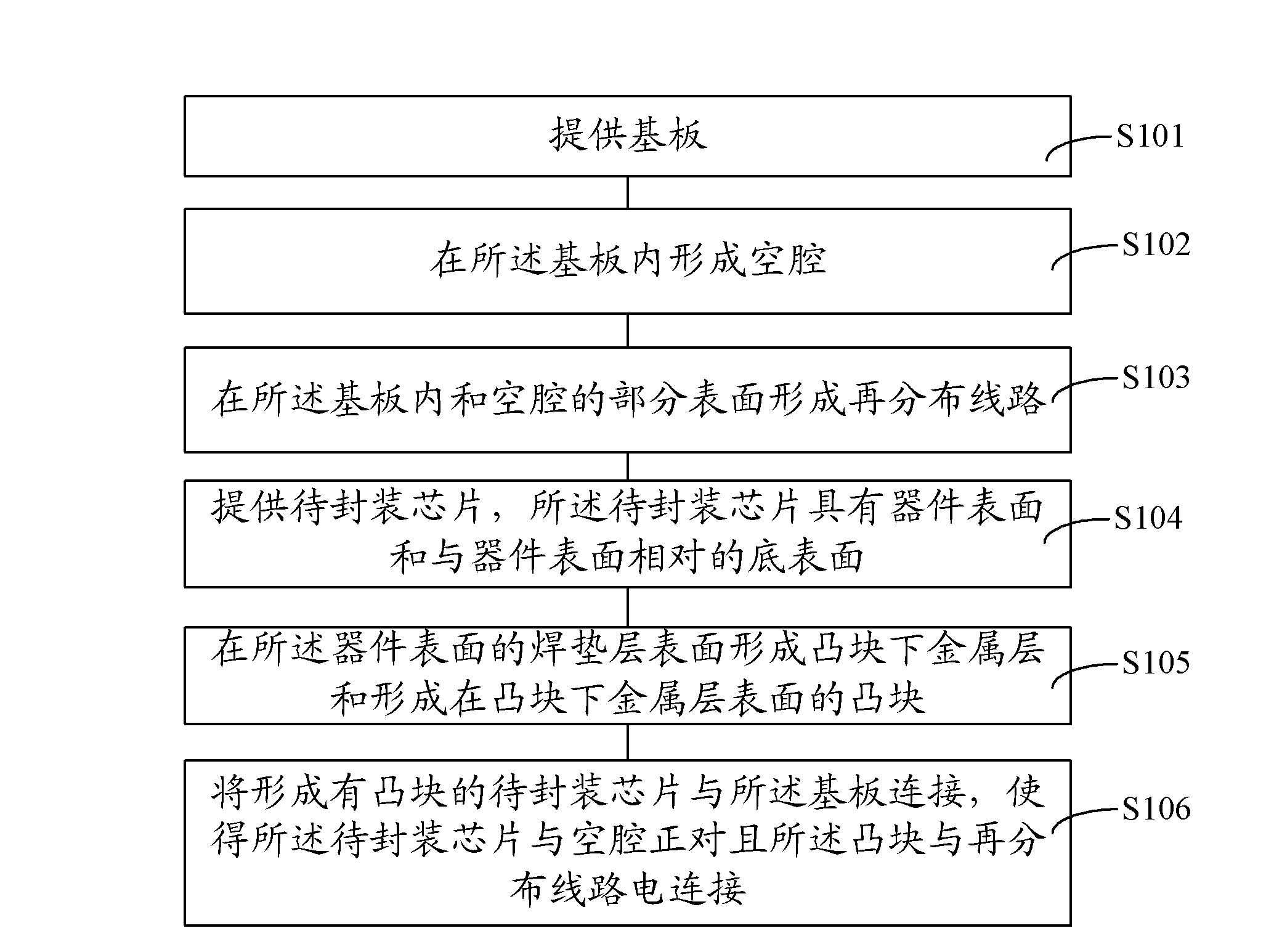

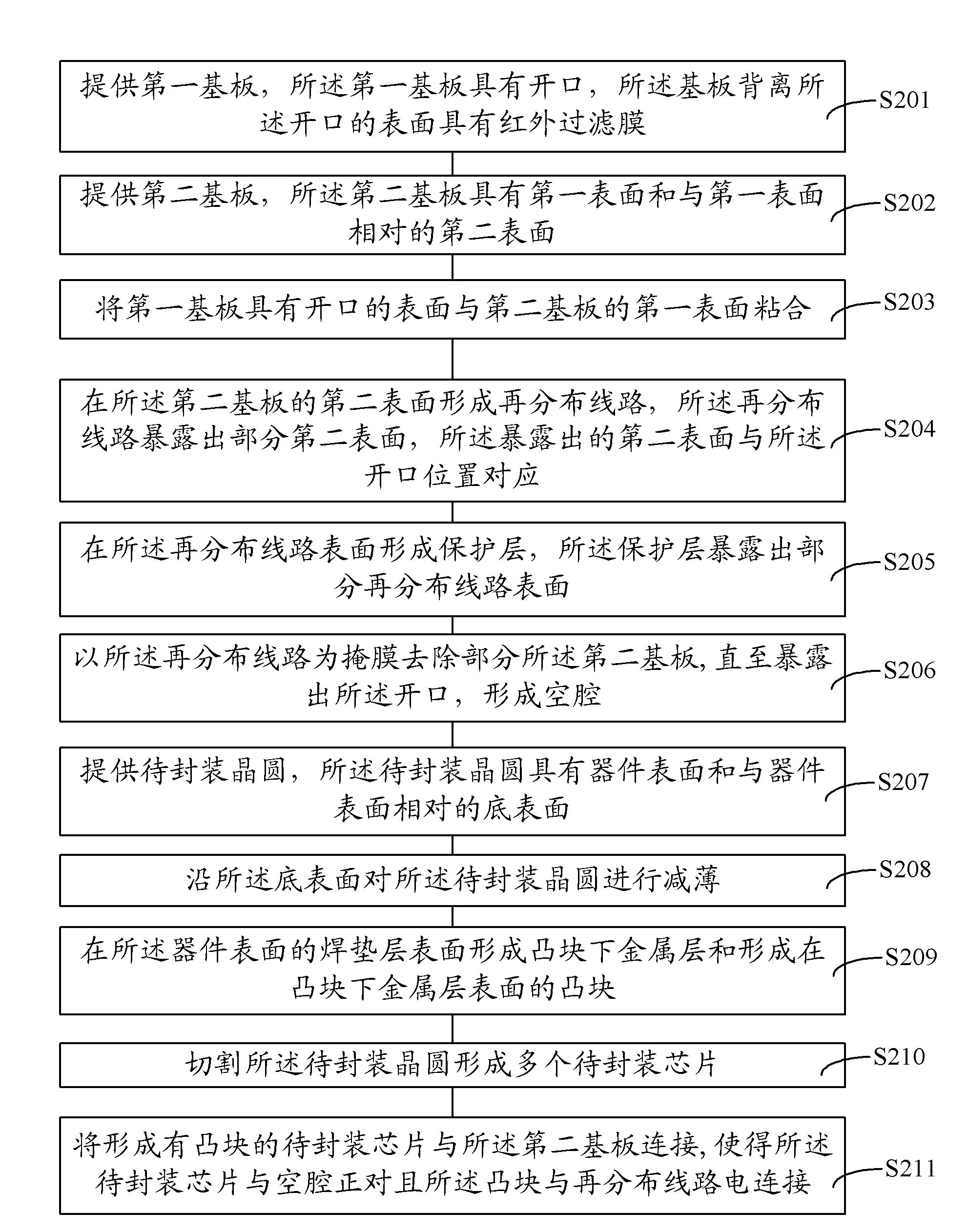

Wafer-level packaging structure and method of forming the same

ActiveCN102280391ASimple structureSimple processSemiconductor/solid-state device detailsSolid-state devicesStructure formationElectrical and Electronics engineering

The invention provides a wafer level package structure and a formation method thereof. The method comprises the following steps: providing a substrate; forming a cavity in the substrate; forming a redistribution line in the substrate and on part surface of the cavity; providing a chip to be packaged, wherein the chip has a device surface and a basal surface opposite to the device surface; formingan Under Bump Metal on a soldering pad layer surface of the device surface and forming a bump on a surface of the Under Bump Metal; connecting the chip to be packaged with the substrate such that thechip to be packaged faces the cavity and the bump is electrically connected with the redistribution line. The wafer level package structure in the invention has the advantages of a simple structure, high packaging quality, and high compatibility in subsequent combination with PCB plate process. The wafer level package structure formation method in the invention has the advantages of simple process sequence and low cost.

Owner:CHINA WAFER LEVEL CSP

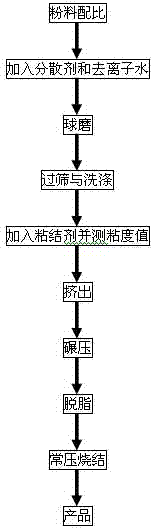

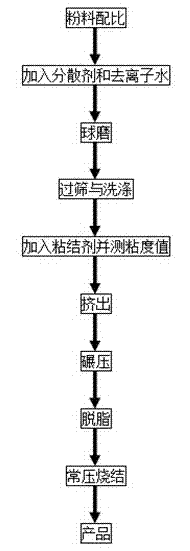

Preparation method of large-size ITO target material

The invention relates to a preparation method of a large-size ITO target material, and belongs to the technical field of transparent conductive film target materials. The technology can prepare a large-size ITO target material by traditional extrusion equipment, rolling equipment, and sintering equipment; the process comprises the following steps: appropriately proportioning ITO powder with different particle sizes, adding a proper forming agent, performing extrusion, rolling, degreasing, and sintering to obtain the ITO target material with high density. The advantage of the process is that the size of the ITO target material can be designed according to market demand.

Owner:KUNMING UNIV OF SCI & TECH

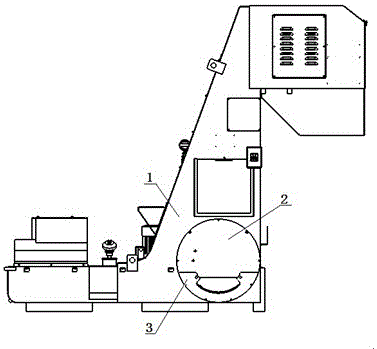

Scrap tire rubber bould crusher

InactiveCN101077599ASmall size limitReduce consumptionPlastic recyclingGrain treatmentsReducerCrusher

The machine for crushing waste tyre and other rubber product initially consists of one pedestal, one motor, one speed reducer and one crushing mechanism. It features the cutting mechanism comprising the fixed blade in the feeding port of the crushing chamber and the spiral feeding blades in the work rotor. The machine has both cutting and crushing functions, and is suitable for direct crushing of various kinds of waste tyre, especially waste radial tyre with steel wire.

Owner:黄子盛

Vibration sound-producing apparatus

ActiveUS20180184209A1Reduce occupancyConducive to thin designLoudspeaker transducer fixingLoudspeakersAcousticsMagnet

Disclosed is a vibration sound-producing apparatus. A sound output aperture of the vibration sound-producing apparatus is provided at a lateral surface. A diaphragm corresponds to the position of the sound output aperture. A flat sound coil is perpendicular to the diaphragm. A magnet is parallel to the sound coil. The vibrating direction of the sound coil avoids a thickness direction. The vibrating direction of the magnet and a mass block also avoids the thickness direction. The mass block is fixedly joined to a housing via a flexible piece. This facilitates reduced product thickness, increased product performance, and a simplified product production process. Therefore, the vibration sound-producing apparatus of the present invention has the advantages of a great thickness-reduced design, great performance, and simple assembly.

Owner:GOERTEK INC

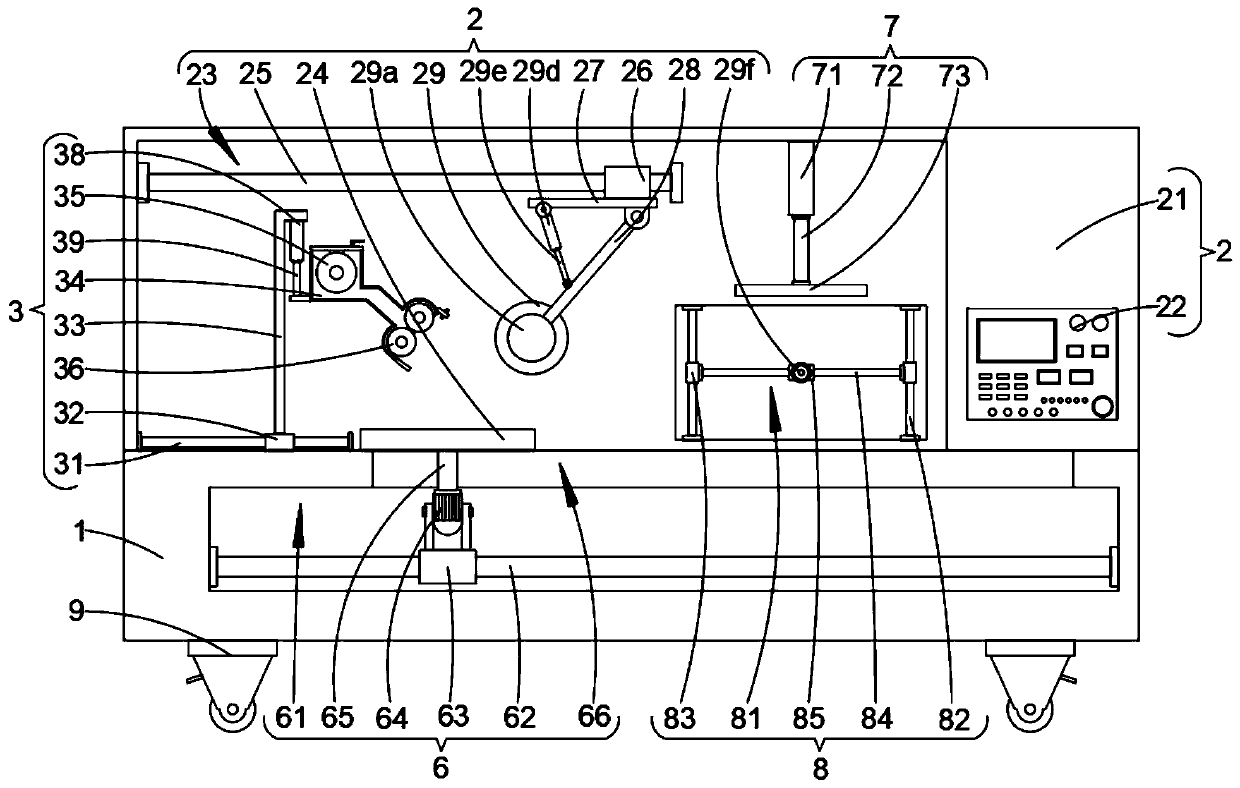

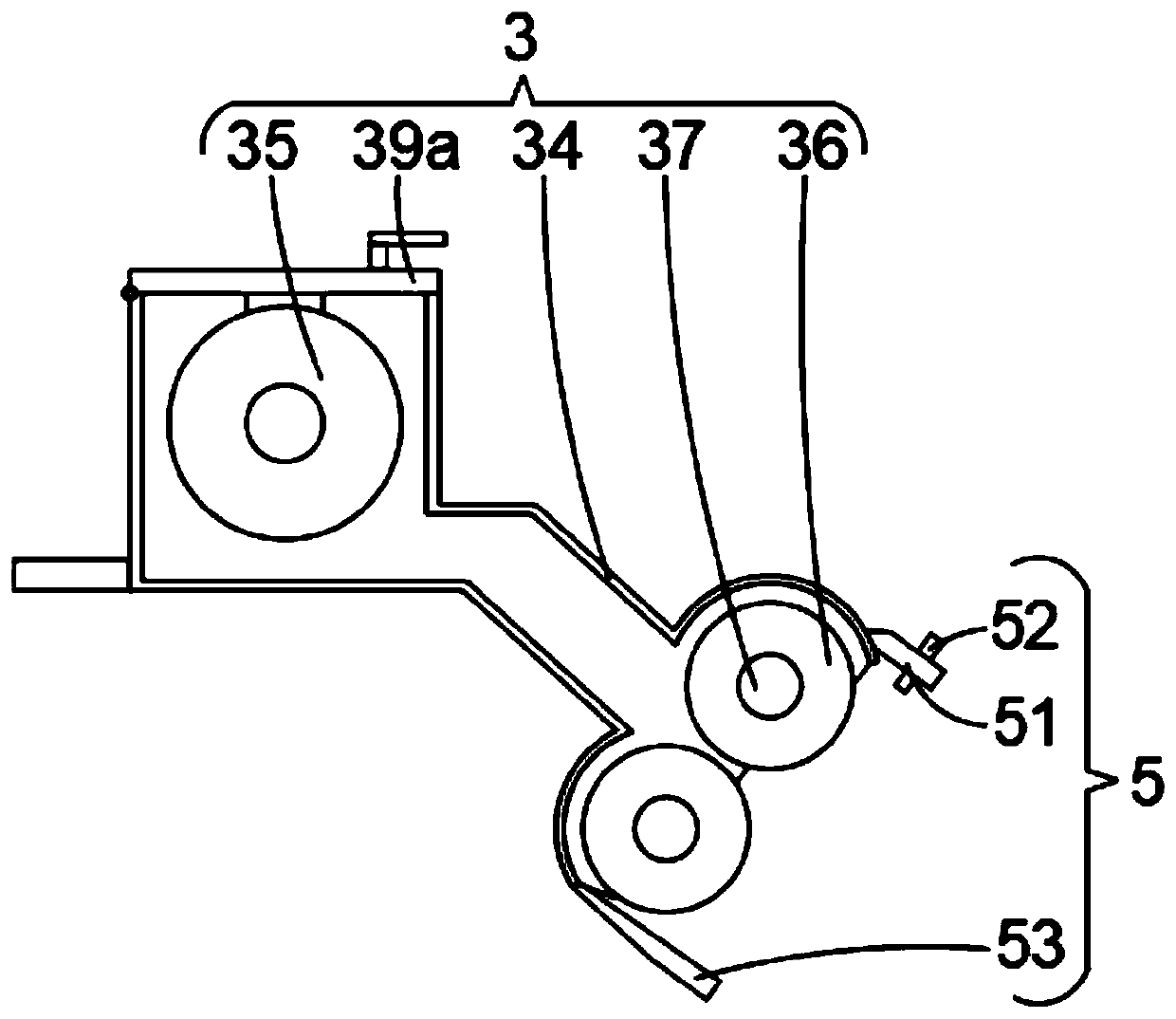

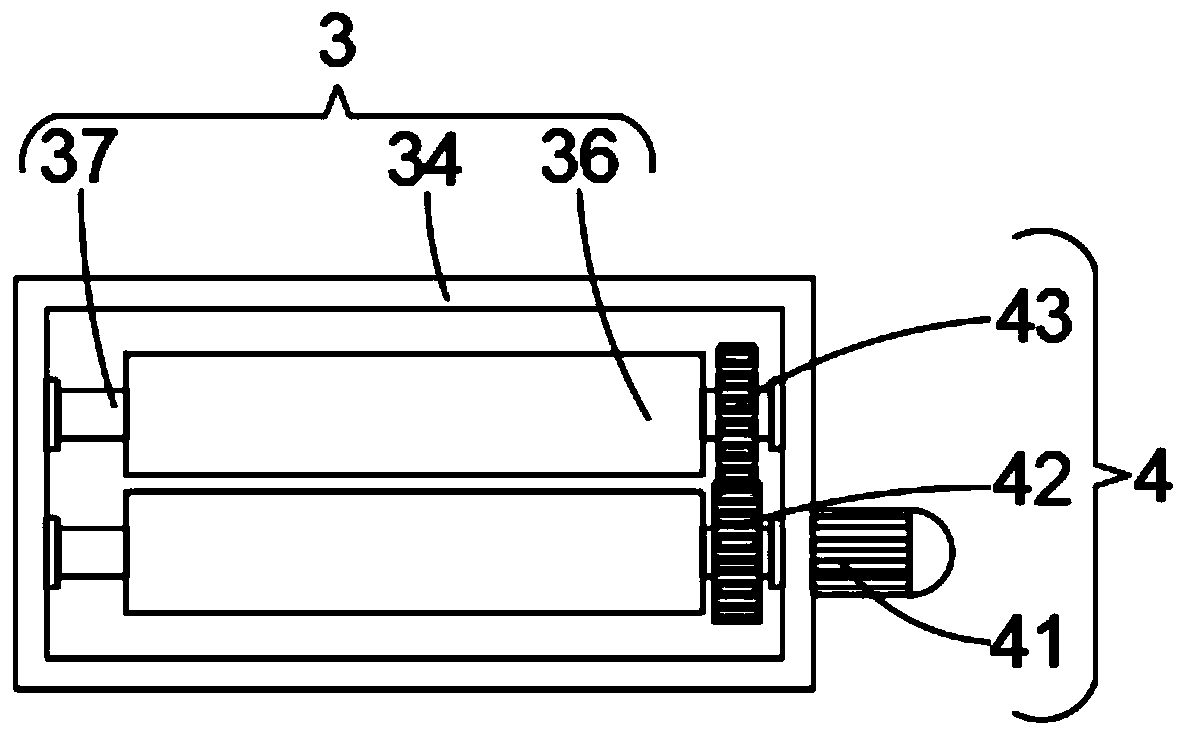

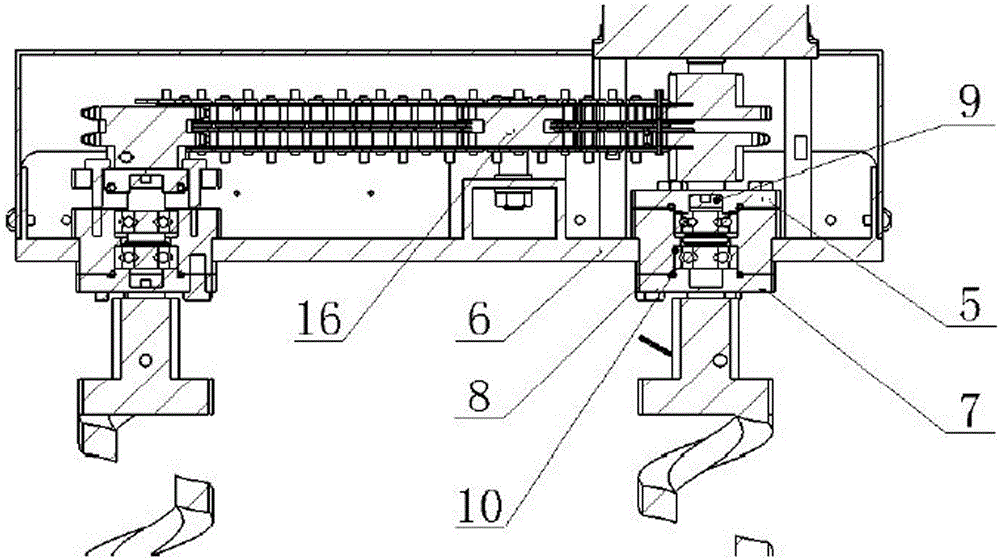

Ultrasonic solidification-friction stir composite added material manufacturing device and application method

ActiveCN110587166APromote interdiffusionImprove mechanical propertiesAdditive manufacturing apparatusWelding apparatusNumerical controlMetal foil

The invention provides an ultrasonic solidification-friction stir composite added material manufacturing device and an application method. The ultrasonic solidification-friction stir composite added material manufacturing device comprises a shell, a machining mechanism, a metal foil conveying mechanism, a driving mechanism, a cutting mechanism, a movable steering mechanism, an extrusion mechanism,an adjusting mechanism and locking universal wheels; the machining mechanism is fixedly connected into the shell; and the machining mechanism comprises a numerical control machining center, a controlpanel, a machining cavity, a substrate, a first electric slide rod, a first electric slide sleeve, a mounting plate, a connecting plate, a machining head, a transducer, an amplitude change rod, an insulation sleeve, a first cylinder, a first piston rod and a friction stir head. The ultrasonic solidification-friction stir composite added material manufacturing device can prepare high-performance metal samples; the mechanical performances of the samples are higher than forgings by 20-50%; and the device is low in size limiting, can machine large-size complex-structured parts, can from more thantwo metal materials according to working conditions and typical performance requirements of parts, and realizes preparation of heterogeneous / gradient function materials.

Owner:ZHEJIANG OCEAN UNIV

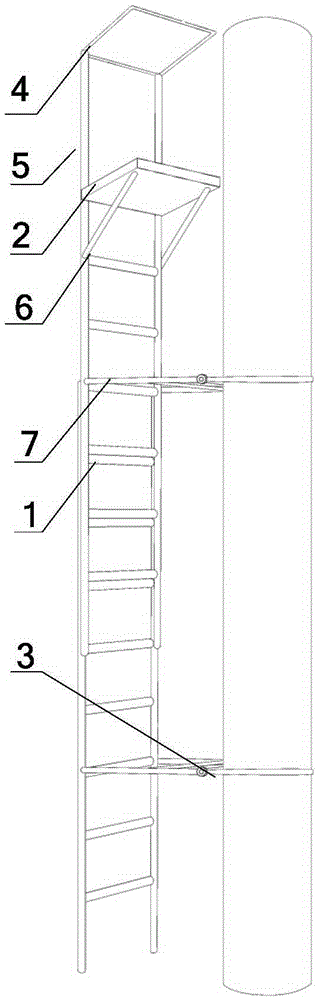

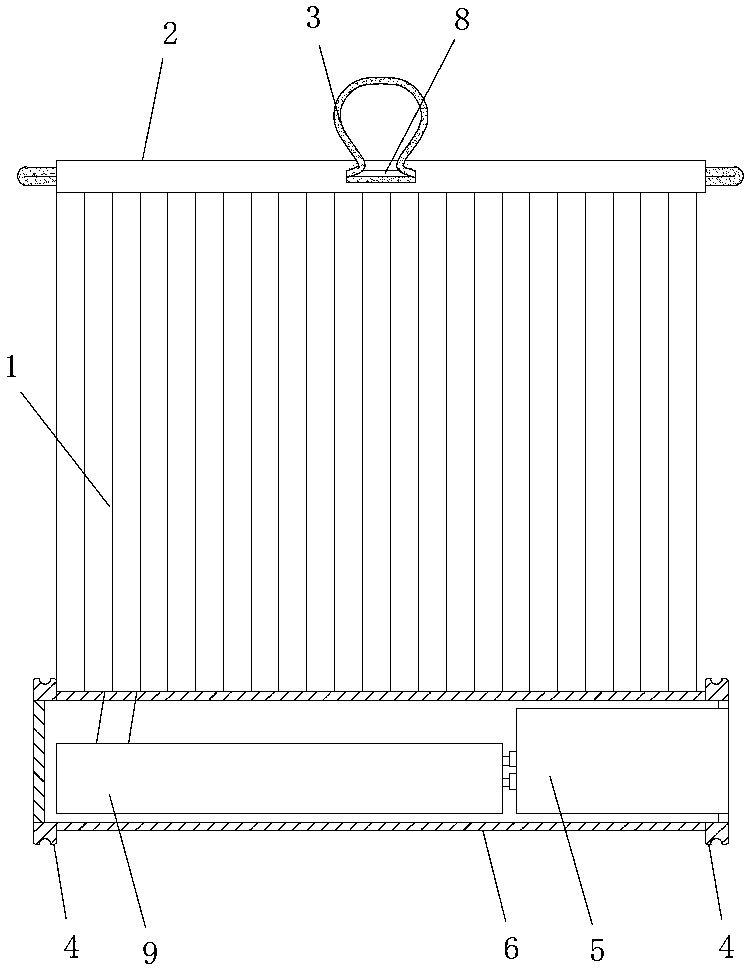

Column holding maintenance platform

The invention provides a column holding maintenance platform. The column holding maintenance platform comprises a climbing ladder (1) vertically arranged and a working pedal (2) mounted at the upper end of the climbing ladder (1) and perpendicular to the extending direction of the climbing ladder (1), and further comprises at least two column holding pieces (3) positioned on the side surface of the climbing ladder (1) and connected with the climbing ladder (1); the column holding pieces (3) include column holding cross bars connected with the climbing ladder (1) and column holding movable pieces detachably connected with the column holding cross bars through at least one end; and the column holding cross bars and the column holding movable pieces are fixedly connected to tightly hold stand columns to be climbed. In high-altitude operation, operators can climb on the working pedal (2) through the climbing ladder (1) to realize corresponding maintenance operations; and compared with a traditional scaffold maintenance platform, the column holding maintenance platform can effectively reduce the limit of construction environment size, is convenient for installation and use, and largely shortens the high-altitude operation time.

Owner:STATE GRID CORP OF CHINA +2

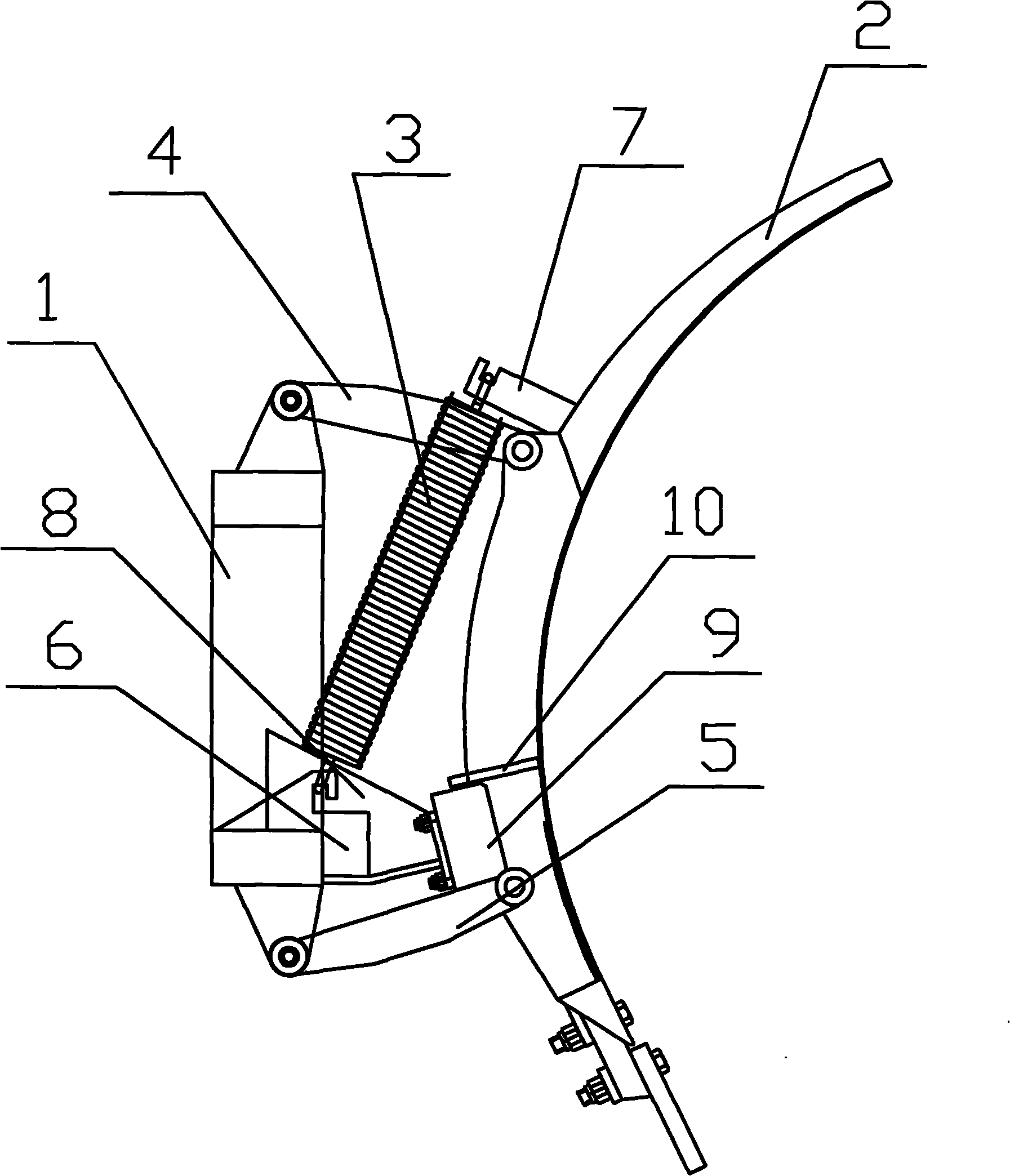

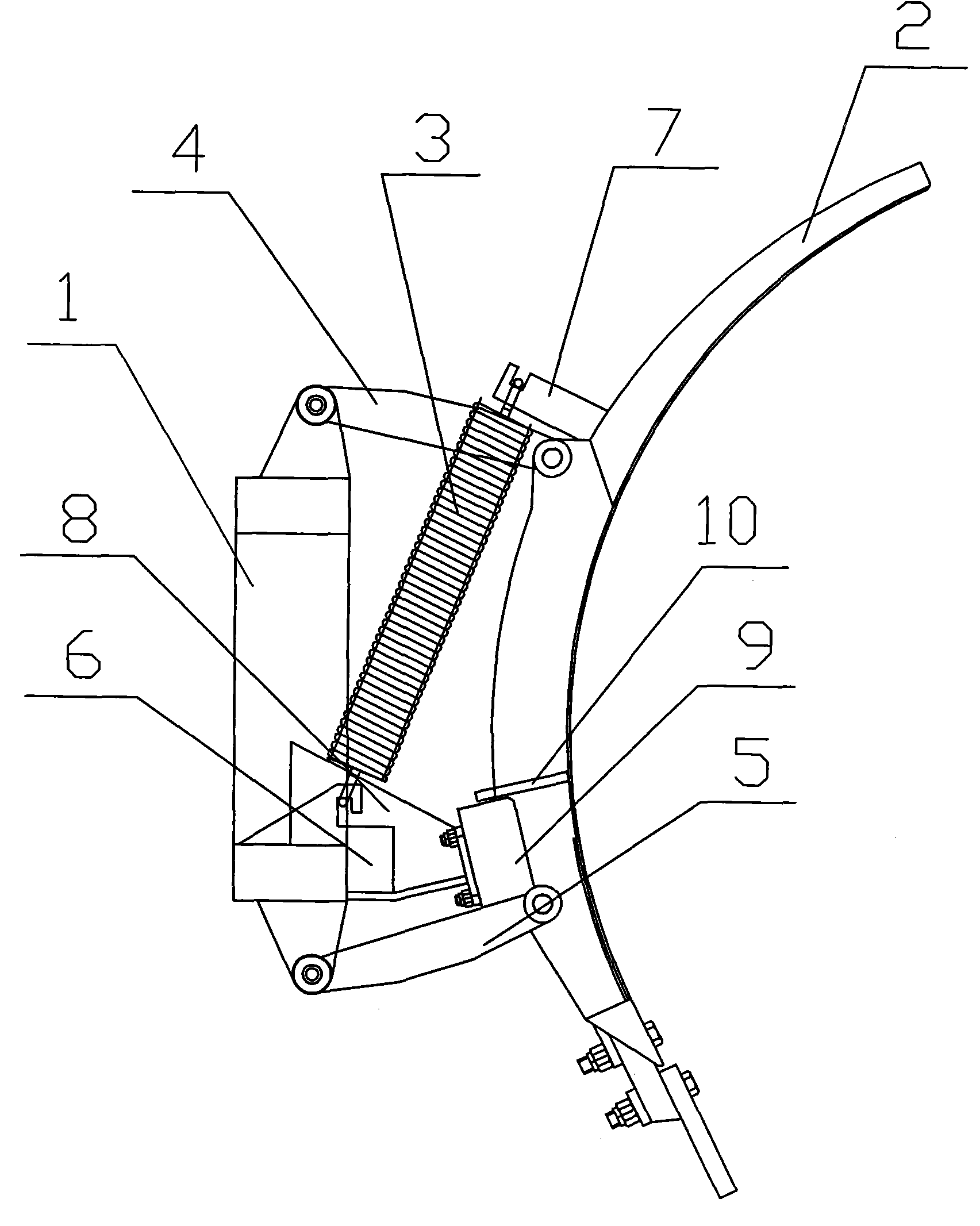

Obstacle avoidance mechanism of shovel board for snow pushing device

InactiveCN101942818AImprove the level ofRapid responseSnow cleaningAgricultural engineeringObstacle avoidance

The invention discloses an obstacle avoidance mechanism of a shovel board for a snow pushing device and relates to the technical field of machines. The obstacle avoidance mechanism comprises a frame, the shovel board, a spring, a first connecting rod and a second connecting rod, wherein a first spring hanger is fixedly arranged at the lower part of the frame, the upper end and the lower end of the frame are respectively hinged with the back end of the first connecting rod and the back end of the second connecting rod, the shovel board is arranged in front of the frame, the front end of the first connecting rod is hinged at the upper part of the shovel board, the front end of the second connecting rod is hinged at the lower part of the shovel board, a second spring hanger is arranged at the upper part of the shovel board, one end of the spring is connected on the first spring hanger, the other end of the spring is connected on the second spring hanger, a support is arranged at the lower part of the frame, a position-limiting block is fixedly arranged at the front end of the support, a position-limiting plate is arranged on the shovel board, and the position-limiting block is pushed against below the position-limiting plate. The obstacle avoidance mechanism has sensitive obstacle avoidance reaction, a large regulation range of obstacle avoidance, convenient regulation and high reliability.

Owner:扬州市金威机械有限公司

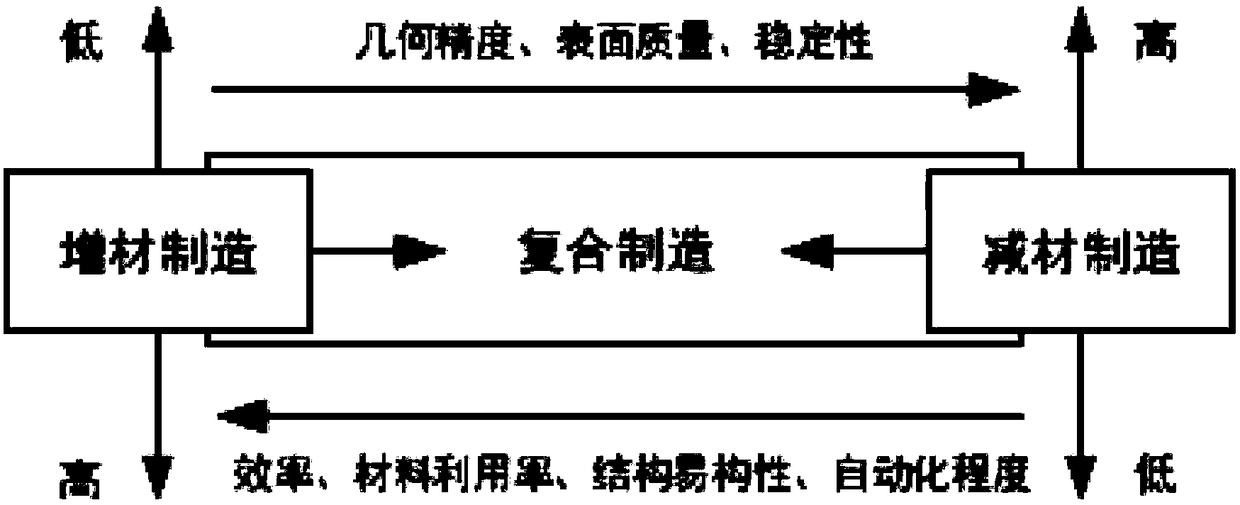

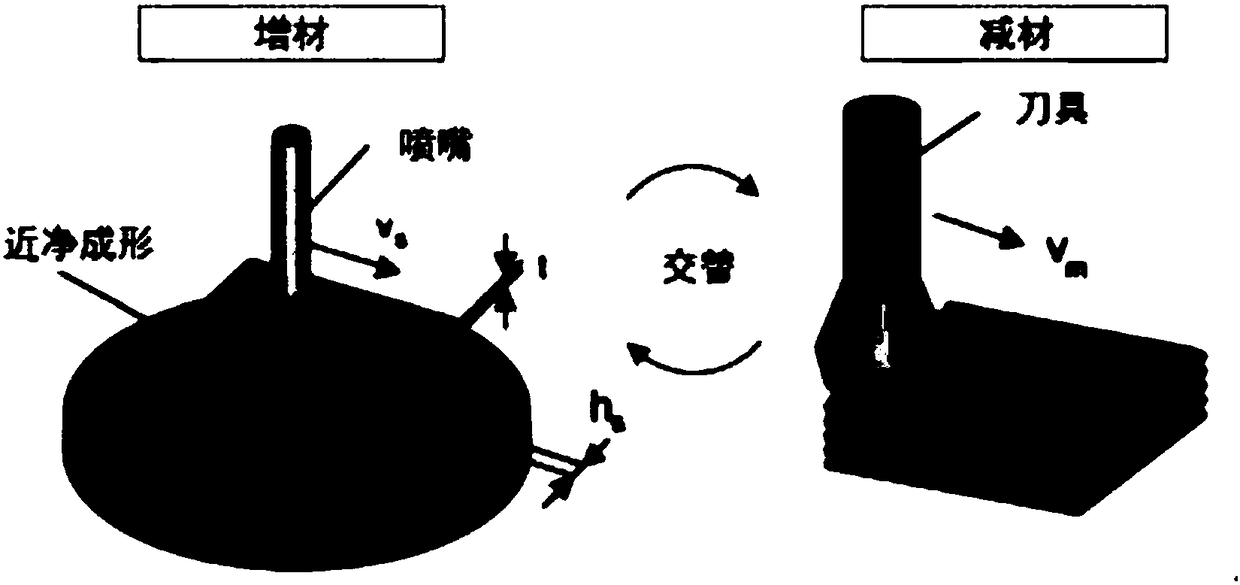

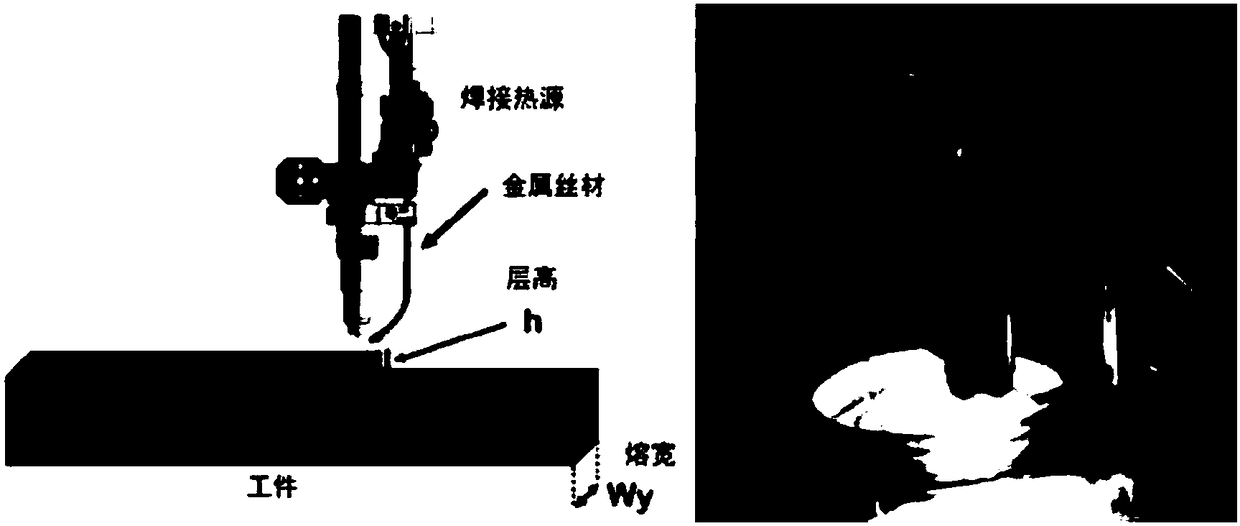

Composite additive, accumulative and subtractive processing device with multi-robot cooperation, and process method

InactiveCN108581490ASmall size limitEasy to fixOther manufacturing equipments/toolsProcedural approachStl file

The invention relates to a composite additive, accumulative and subtractive processing device with multi-robot cooperation, and a process method. The composite processing device comprises three independent industrial robots carrying end effectors with different functions, a robot position changer with two and more degrees of freedoms, and a working table. The manufacturing process comprises the steps of modeling a part to be processed to form three-dimensional data, and generating a standard template library (STL) file required for generating a slice layer under the programmed control; adopting an electric arc produced by a welding machine as a heat source, and through adding welding wires, gradually forming a metal part through line-surface-volume according to a three-dimensional digitalmodel. Through regulating the welding process parameters, different heights and spreading thicknesses of a component section are formed. The composite additive, accumulative and subtractive processingdevice with multi-robot cooperation provided by the invention is compact in structure, wide in processing range and high in product flexibility, has the advantages of high deposition efficiency, highmaterial utilization rate, short integrated manufacturing period, low cost, less limitation on part dimension, easiness in repairing the part and the like, has the capability on in-situ composite manufacturing and forming a large-size part, and achieves the aim of integrally net-shape forming the part.

Owner:BEIJING UNIV OF TECH

Method for fixing sensor

ActiveCN103591972AImprove sensing accuracyImprove sensor sensitivityMeasurement apparatus componentsEpoxyFiber

The invention discloses a method for fixing a sensor. The method includes the steps of using carbon fiber cloth to fix the sensor on the surface of concrete, enabling the carbon fiber cloth to tightly wrap three faces of the sensor through epoxy resin adhesives, reserving a section of the carbon fiber cloth, and after the epoxy resin adhesives are completely solidified, using the reserved carbon fiber cloth to fix the sensor on the surface of the concrete through epoxy resin adhesives. The method for fixing the sensor is easy to operate, high in operating flexibility, small in sensor size limitation, suitable for various complex environments, safe, reliable and good in durability, the sensor can be firmly and tightly fixed to the surface of a concrete structure, the good coupling effect is achieved, damage to the concrete structure is avoided, the sensor can be effectively protected through the fact that the sensor is wrapped by the carbon fiber cloth, the service life of the sensor is prolonged, and the method for fixing the sensor is particularly suitable for health detection of concrete buildings in special environments such as high-speed rail bridges.

Owner:UNIV OF JINAN

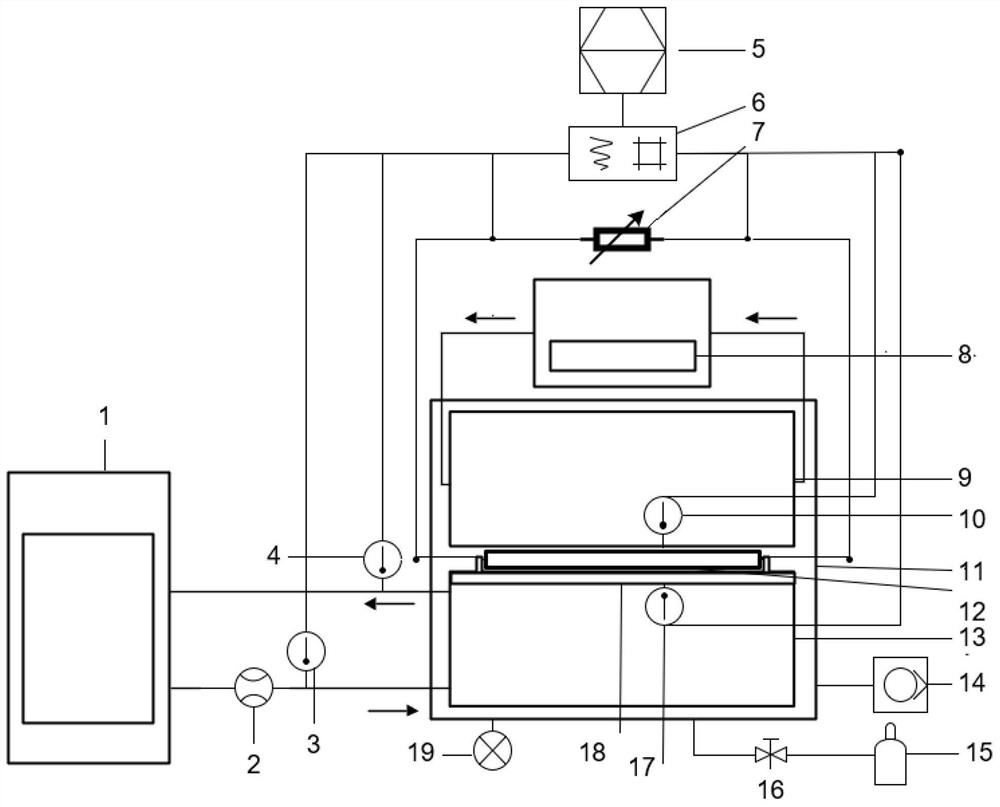

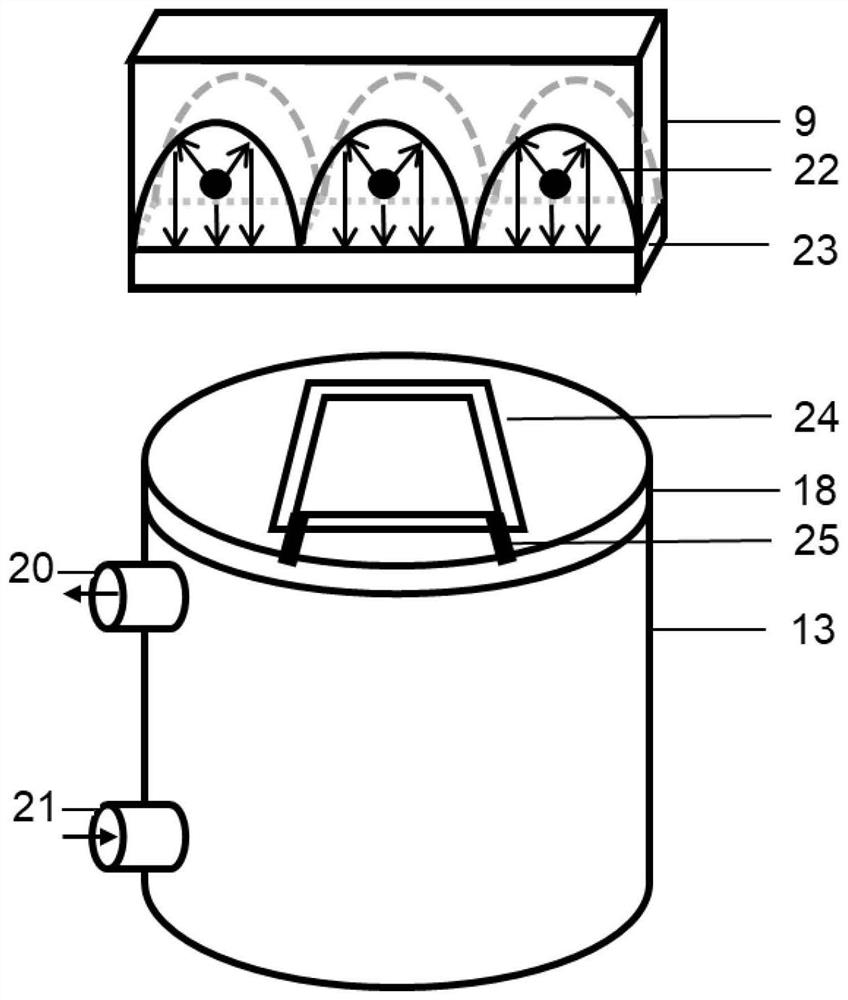

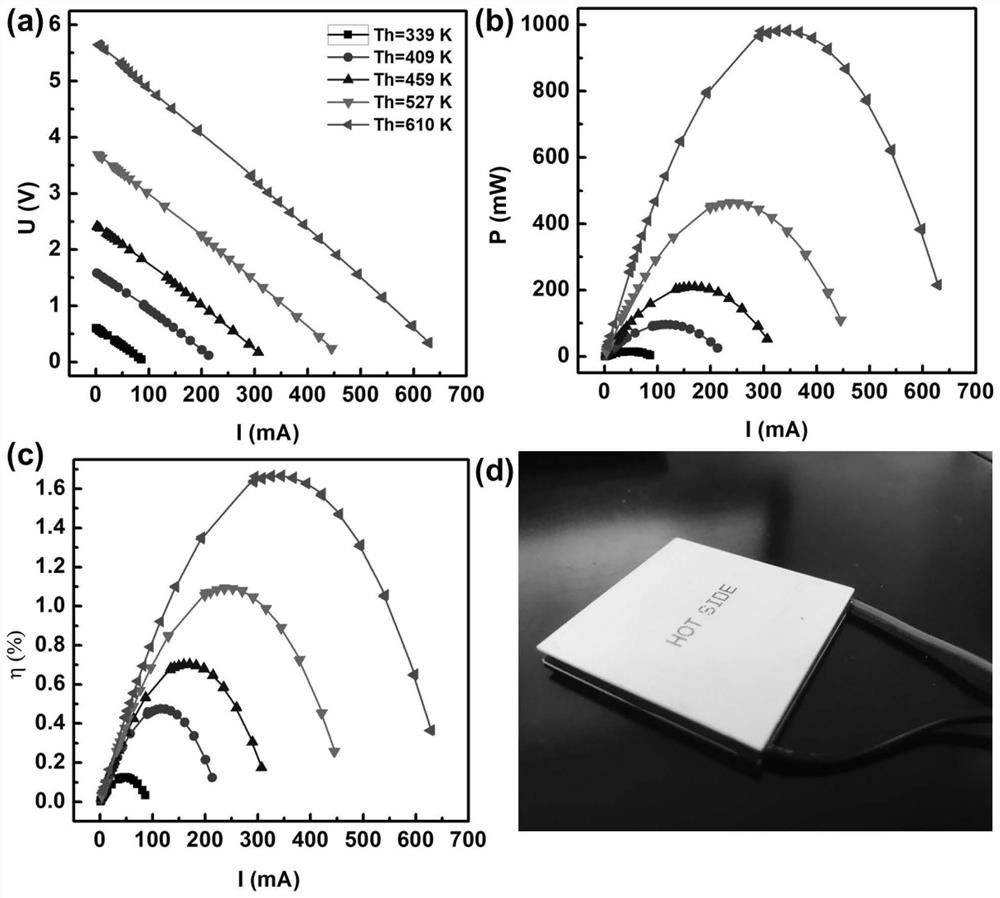

Thermoelectric device performance testing device

InactiveCN111964935AVersatileImprove performanceMaterial heat developmentStructural/machines measurementPhysicsHeat flow

The invention discloses a thermoelectric device performance testing device which comprises a heating platform, a refrigerating platform, a closed testing cavity and a vacuum pump. The method is designed based on a one-dimensional steady-state heat flow method. A to-be-tested thermoelectric device is arranged in a vacuum test cavity. An infrared radiation heating mode (the temperature of the hot end ranges from 20 DEG C to 600 DEG C) is adopted by the hot end; the size limitation of the thermoelectric device to be tested is reduced due to the liquid heat measurement mode (the temperature rangeof the cold end is-50 DEG C to 200 DEG C) of the cold end, and the output power and the conversion efficiency of the thermoelectric device with the wide size range (10mm to 100mm) can be accurately tested; a test can be carried out at the temperature of 0-650 DEG C under a variable temperature difference condition; moreover, the vacuum pump is used for pumping the test cavity into a vacuum cavityfor testing, so that the influence caused by heat convection is avoided. The method has great advantages in accurate testing of the performance of the non-standard thermoelectric device, repeatabilityand stability testing required by commercialization of the thermoelectric device can be achieved, and the method is high in applicability.

Owner:MATERIAL INST OF CHINA ACADEMY OF ENG PHYSICS

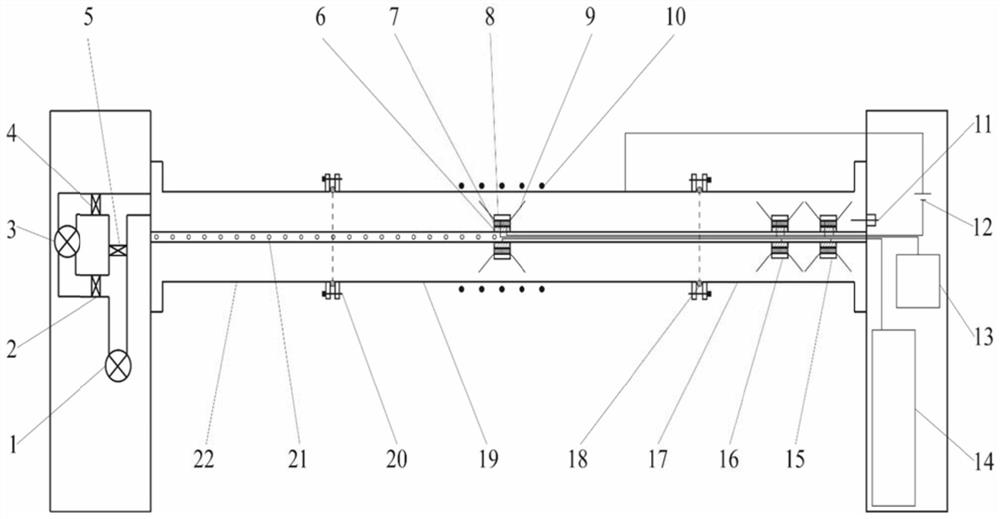

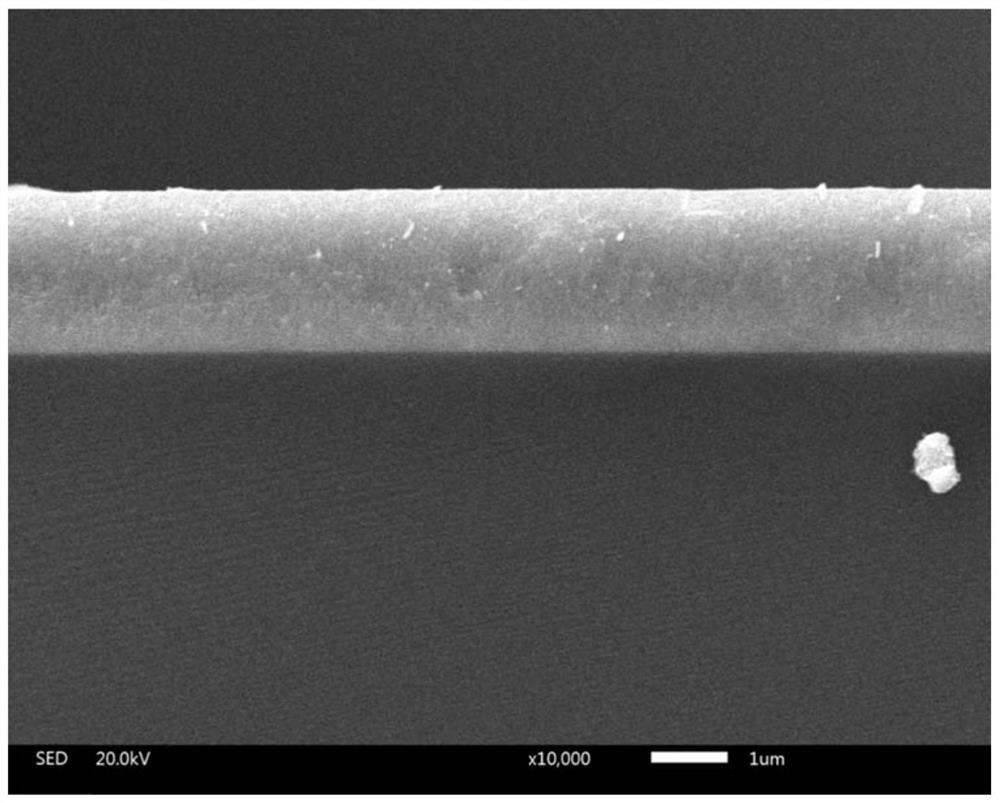

Magnetron sputtering device for coating film on inner wall of pipe with large length-diameter ratio

ActiveCN112680706ASmall size limitEasy to operateNuclear energy generationVacuum evaporation coatingSputteringPipe fitting

The invention discloses a magnetron sputtering device for coating a film on the inner wall of a pipe with a large length-diameter ratio. The magnetron sputtering device comprises a heating system for heating the pipe with the large length-diameter ratio, a vacuum end adapter and a vacuumizing system connected with one end of the pipe with the large length-diameter ratio, a power supply end adapter and a high-power pulse power supply connected with the other end of the pipe with the large-length-diameter-ratio, and a hollow pipe penetrating through the vacuum end adapter, the pipe with the large-length-diameter ratio and the power supply end adapter and located on the central axis of the vacuum end adapter, the large-length-diameter-ratio pipe and the power supply end adapter, a single or multiple annular target systems and a cooling water system, wherein fine holes are evenly distributed in the hollow pipe; the annular target systems are arranged on the hollow pipe in a sleeving manner and can move along the hollow pipe; and the cooling water system is connected with the annular target systems. An annular target material moves back and forth in a pipe fitting along a center shaft to realize uniform film coating of the inner walls of the pipe fittings with different lengths, the target material can be selected from a metal material and a non-metal material, and multiple target materials can be coated with multiple layers of films through cooperative coating of several target systems, and the problem that an existing pipe fitting inner wall coating technology can only achieve single-component film coating is solved.

Owner:WUHAN UNIV OF TECH +1

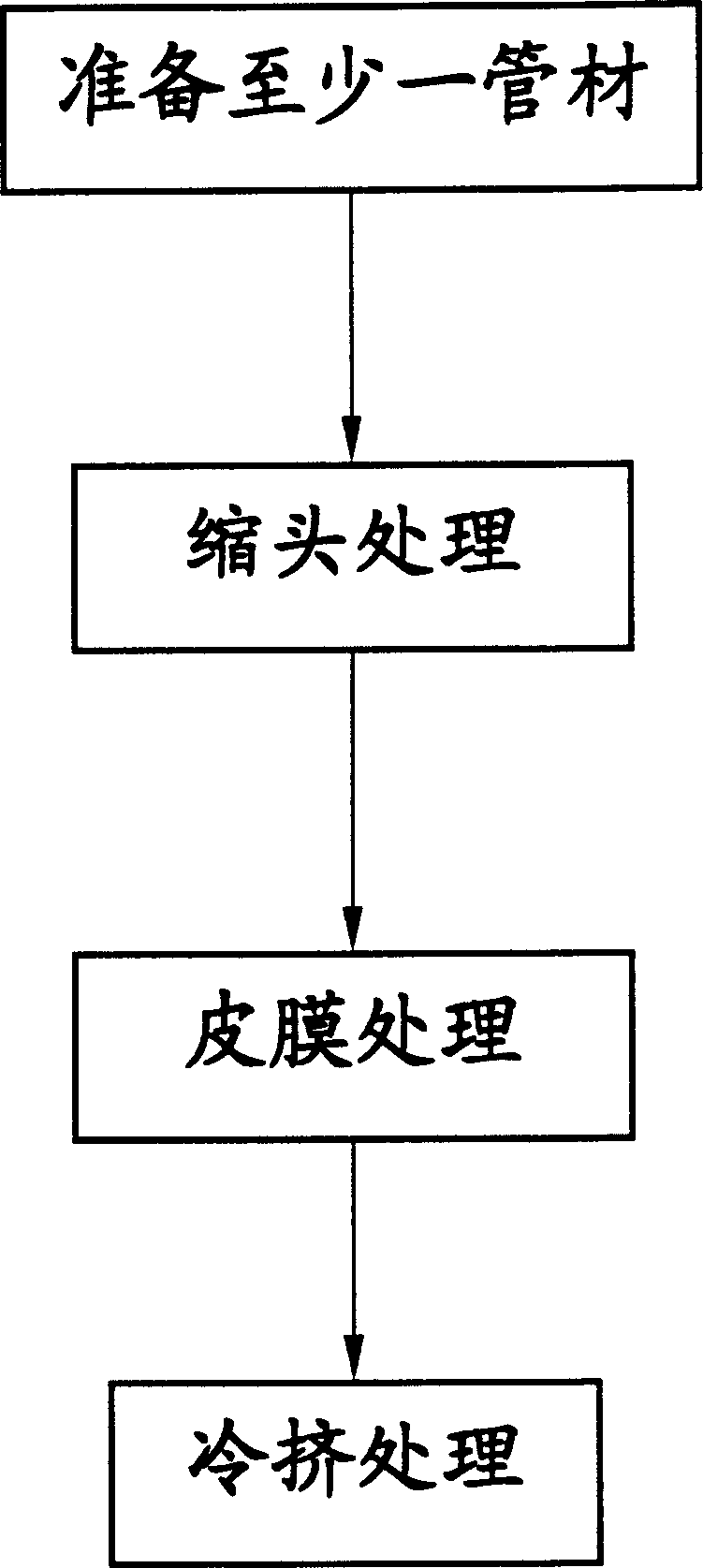

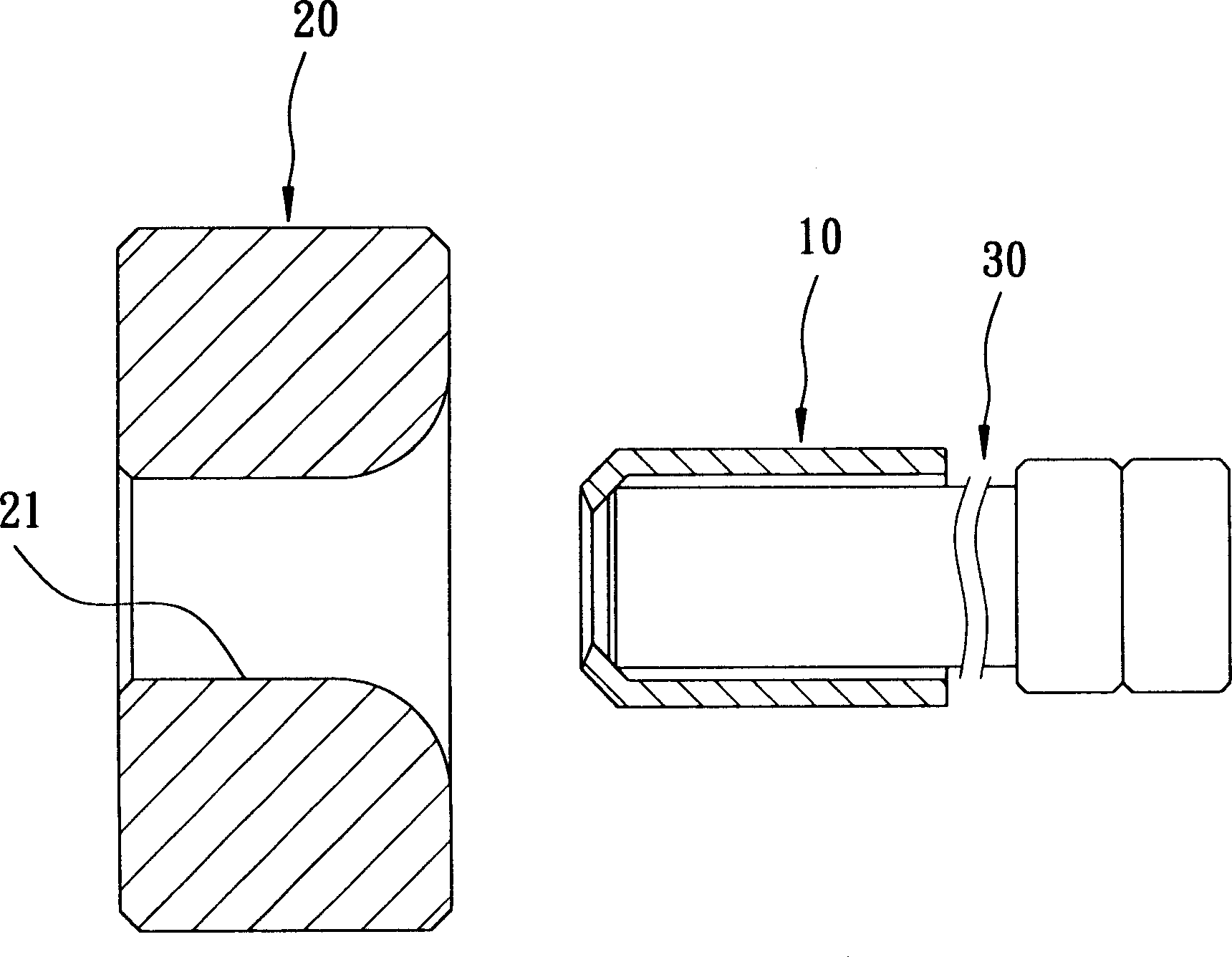

Method for producing aluminium by colol extrusion

InactiveCN1438080ALess prone to processing errorsLess prone to abrasion problemsManufacturing cost reductionWork quality

The method for producing cold-extruded aluminum tube includes: 1. preparing at least a tube material of aluminium; 2. reducing calibre of one end of the tube material and changing it to small; 3. coating said tube material with lubricating agent; 4. cold-extruding treatment; preparing at least one eye mould and at least noe core shaft, inserting the core shaft into said tube material, pushing one end of said tube material which is undergone the process of head-reducing treatment of drive said tube material and make it pass through the mould eye of said eye mould to make said tube material be formed into the required aluminum tube. It can raise working quality and working speed, and can reduce consumption of aluminium material, and can reduce cost.

Owner:LEE CHI ENTERPRISES

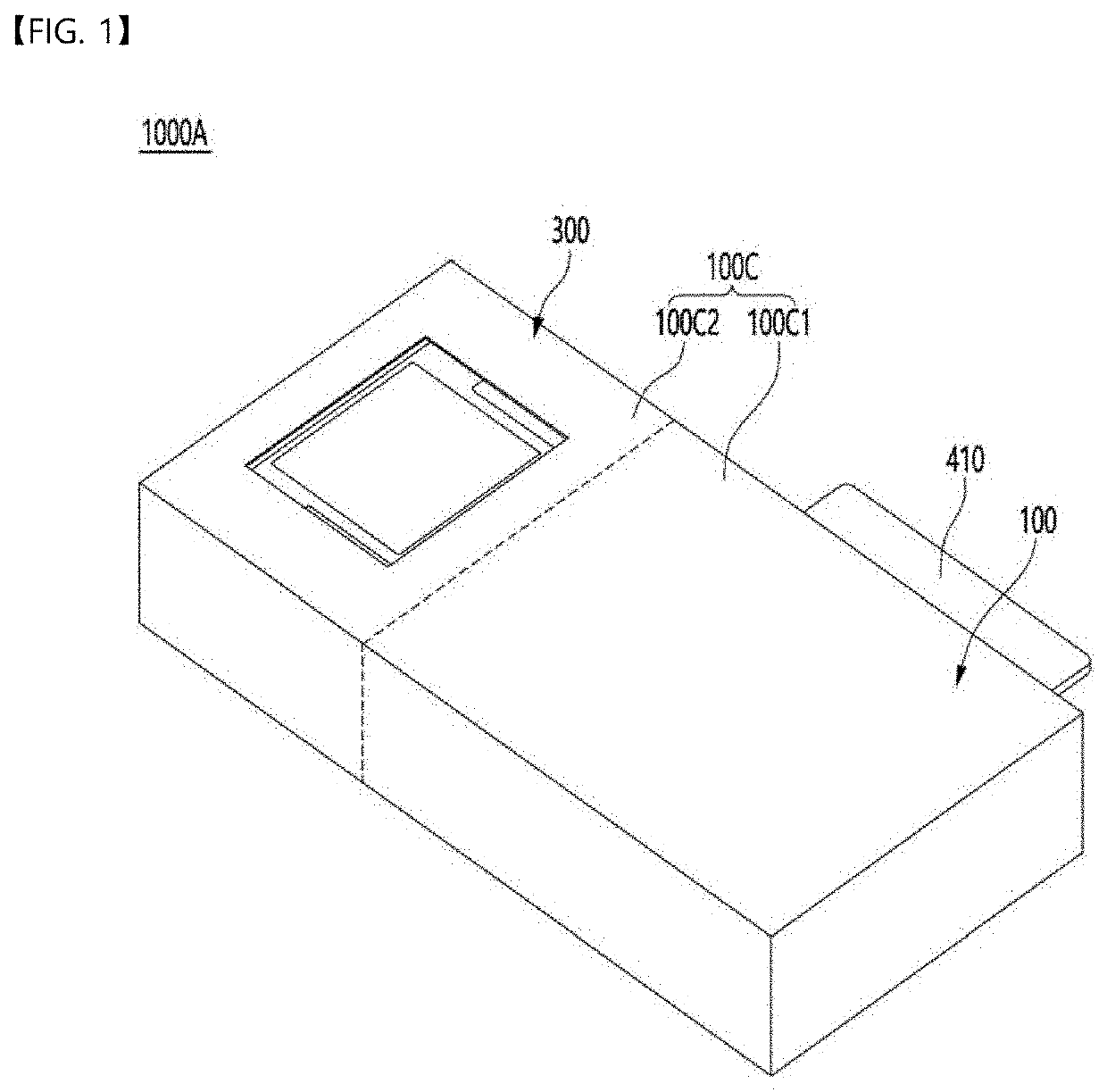

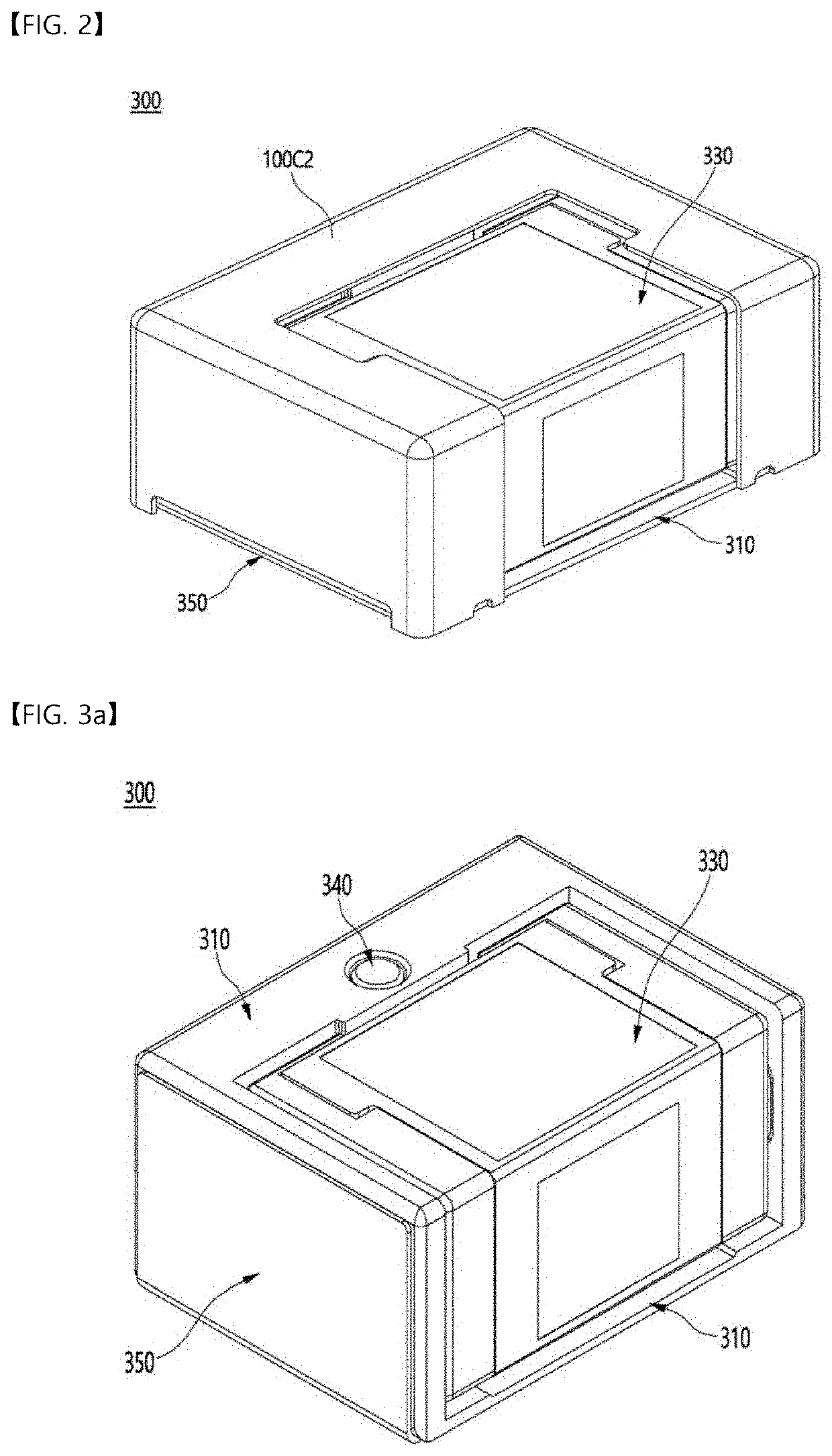

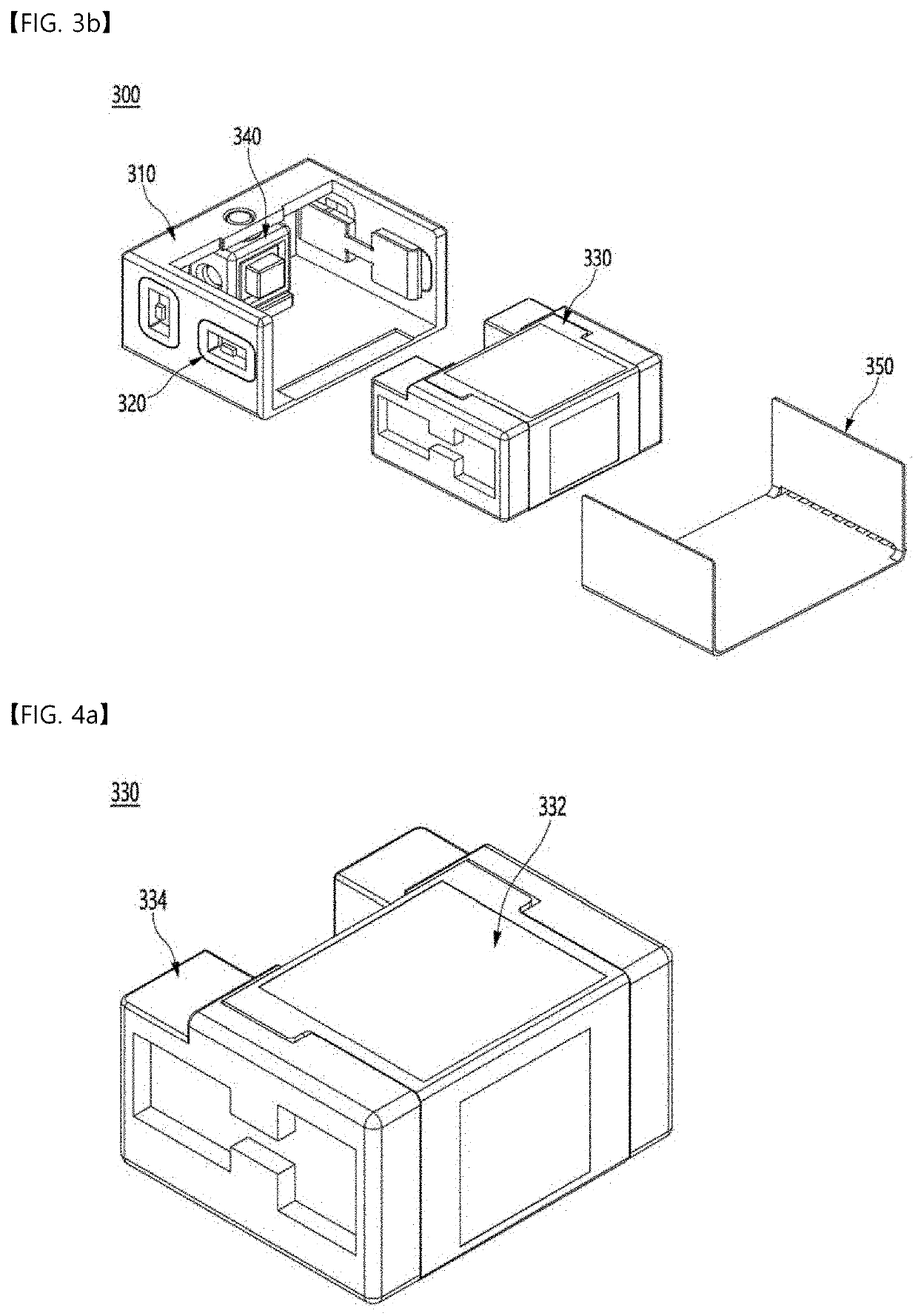

Camera actuator, and camera module and camera device comprising same

PendingUS20220263981A1Small size limitMinimize occurrenceTelevision system detailsPrintersEngineeringCamera module

A camera actuator according to an embodiment can comprise: a housing; a prism unit disposed inside the housing; a driving part for tilting the prism unit; and a rotation unit for tilting the prism unit about a first axis or a second axis. The rotation unit can comprise: a rotation housing; a rotation guide disposed inside the rotation housing; and a guide pin member coupled to the rotation guide.

Owner:LG INNOTEK CO LTD

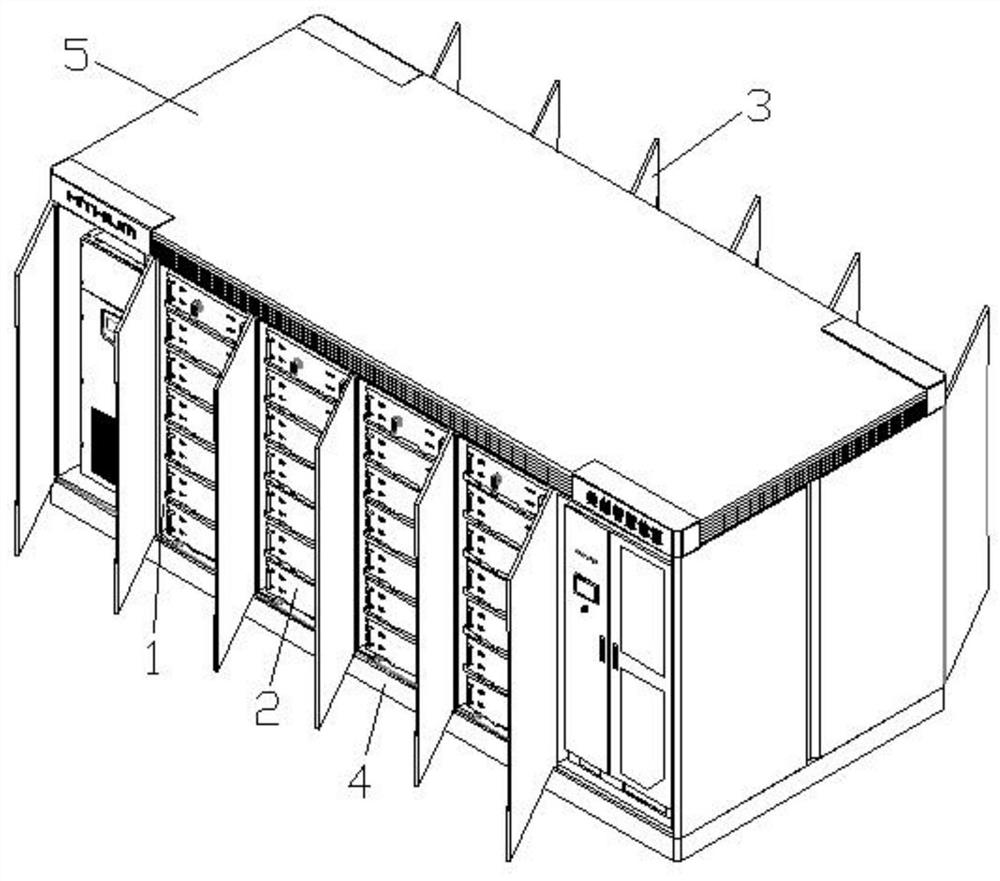

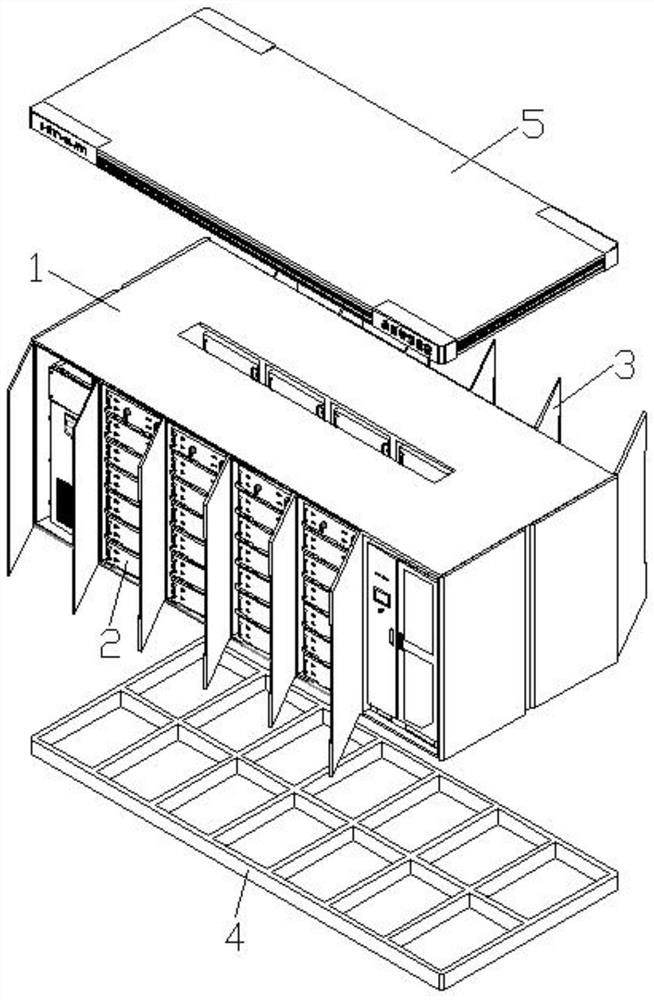

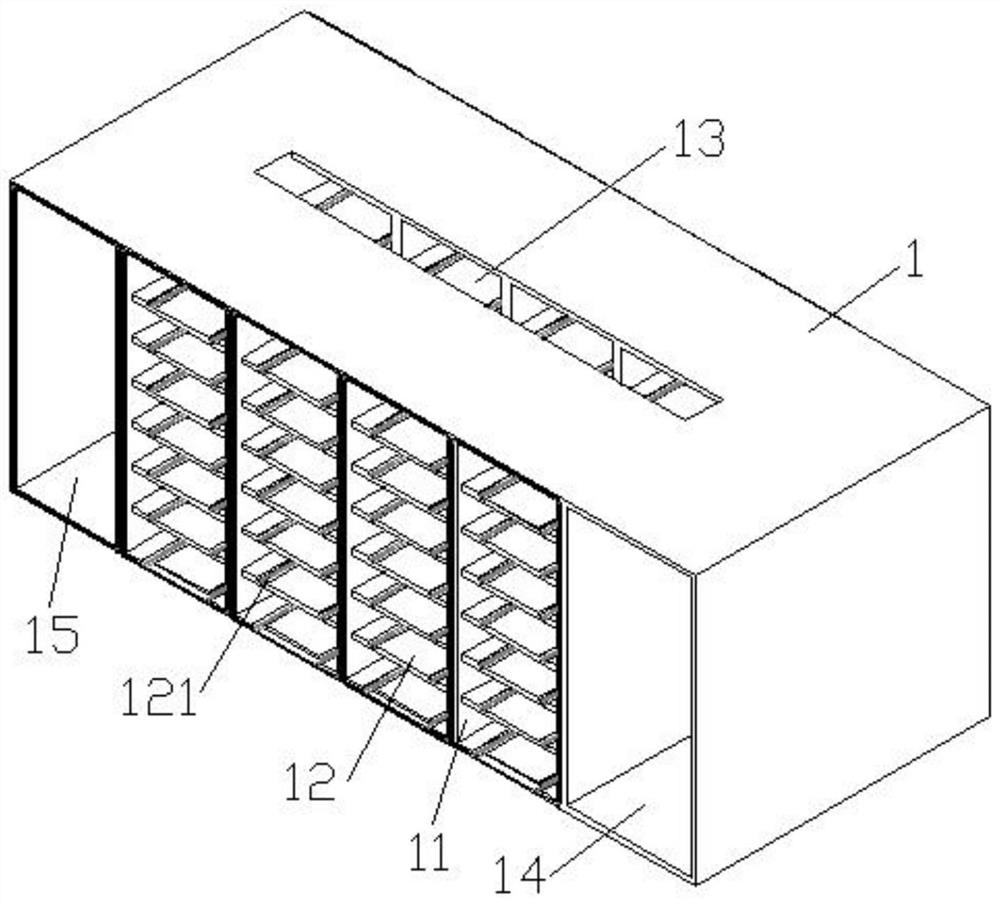

Cabinet type container for energy storage and energy storage system

PendingCN112803099AIncrease profitImprove space utilizationSecondary cellsCell component detailsStructural engineeringMechanical engineering

The invention discloses a cabinet type container for energy storage and an energy storage system. The cabinet type container comprises a cabinet body in the shape of a rectangular box body, the two side faces of the cabinet body in the width direction are of an open structure, a plurality of vertical plates are arranged in the cabinet body in parallel, and all the vertical plates are evenly arranged at intervals in the width direction of the cabinet body. A plurality of transverse plates are uniformly arranged between adjacent vertical plates in parallel at intervals, battery modules are oppositely arranged on each transverse plate at intervals, a rectangular air duct notch is formed in the center of the top surface of the cabinet body, and the air duct notch downwards cuts all the vertical plates and the transverse plates between the two vertical plates located on the outermost side from the top surface of the cabinet body. A plurality of openable cabinet doors are arranged on the two side faces of the cabinet body in the width direction. According to the energy storage system, a traditional maintenance passage is omitted, doors are opened on the two sides, the integral battery rack is adopted, installation and maintenance are convenient and fast, meanwhile, the energy density can be improved, installation of the battery modules on the battery rack is improved, and the structural stability of the energy storage system is improved.

Owner:XIAMEN HAICHEN NEW ENERGY TECH CO LTD

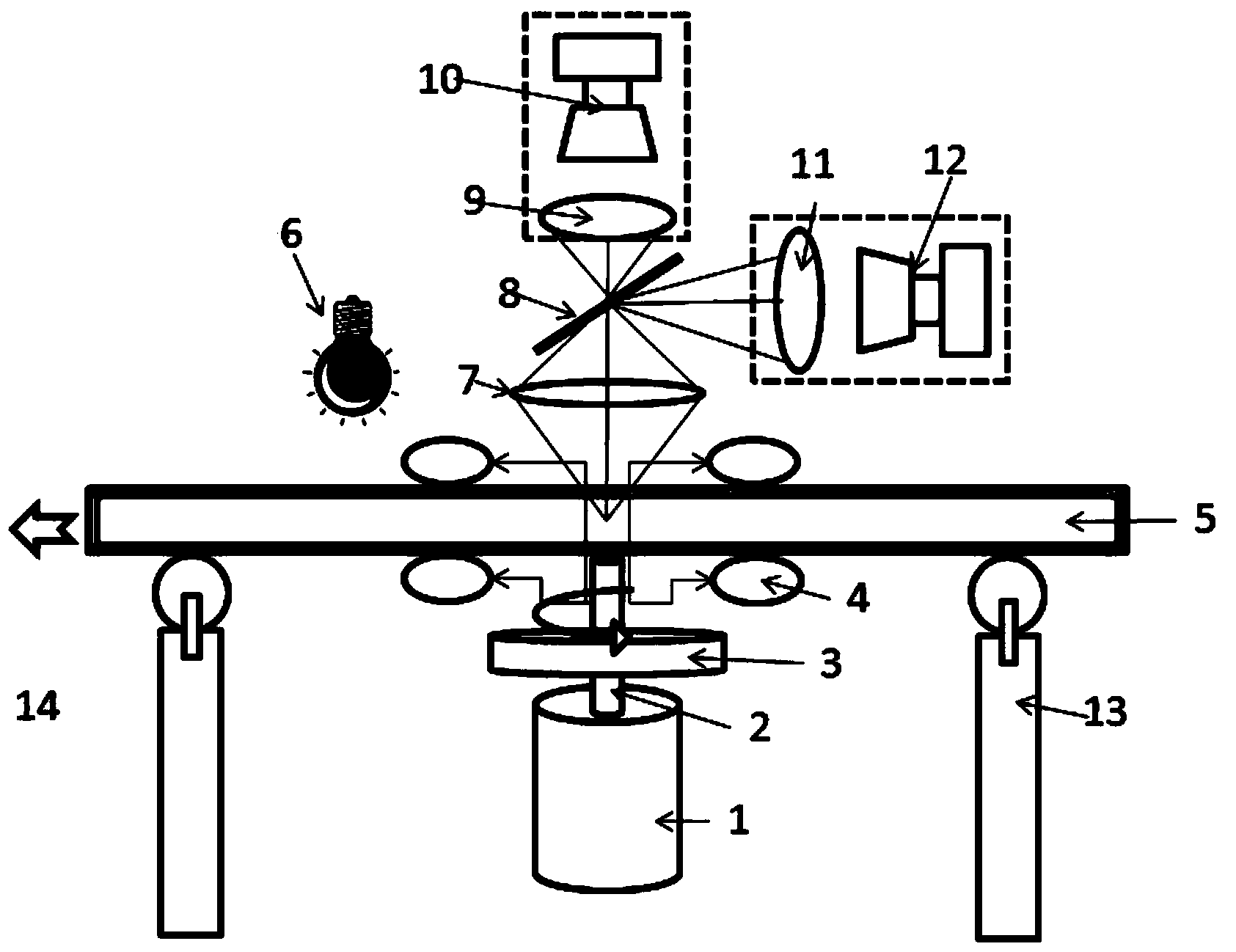

Surface microstructure based high-accuracy length detection method

InactiveCN104034266ASmall size limitReduce restrictionsUsing optical meansMeasurement deviceMagnifying glass

The invention provides a surface microstructure based high-accuracy length detection method and belongs to the high-accuracy length detection field. The surface microstructure based high-accuracy length detection method comprises adjusting a measurement device to be located in a horizontal state and opening a lighting source and an image acquisition system; placing an anti-shaking driving fixture for an object to be detected on the lateral side to be fixed and leveled; enabling a resolution test card to be closely attached to the surface of the object to be detected, adjusting the magnification of a first magnifier group and a second magnifier group to obtain appropriate resolution stripes of images and calculating and displaying the resolution through measurement software due to the fact that the appropriate view fields in respective camera system view fields can be simultaneously occupied by the surface microstructure of the object to be detected due to the transparent resolution test card; starting an image storage system, horizontally moving the object to be detected and displaying and storing data output from camera systems through the system; calculating and storing the displacement of the surface microstructure of the object to be detected between adjacent images through a calculation module according to parameters such as the resolution calibrated through the test card; achieving detection, stopping the image storage system and enabling a direct current motor and an image storage module to stop working.

Owner:CHANGCHUN INST OF OPTICS FINE MECHANICS & PHYSICS CHINESE ACAD OF SCI

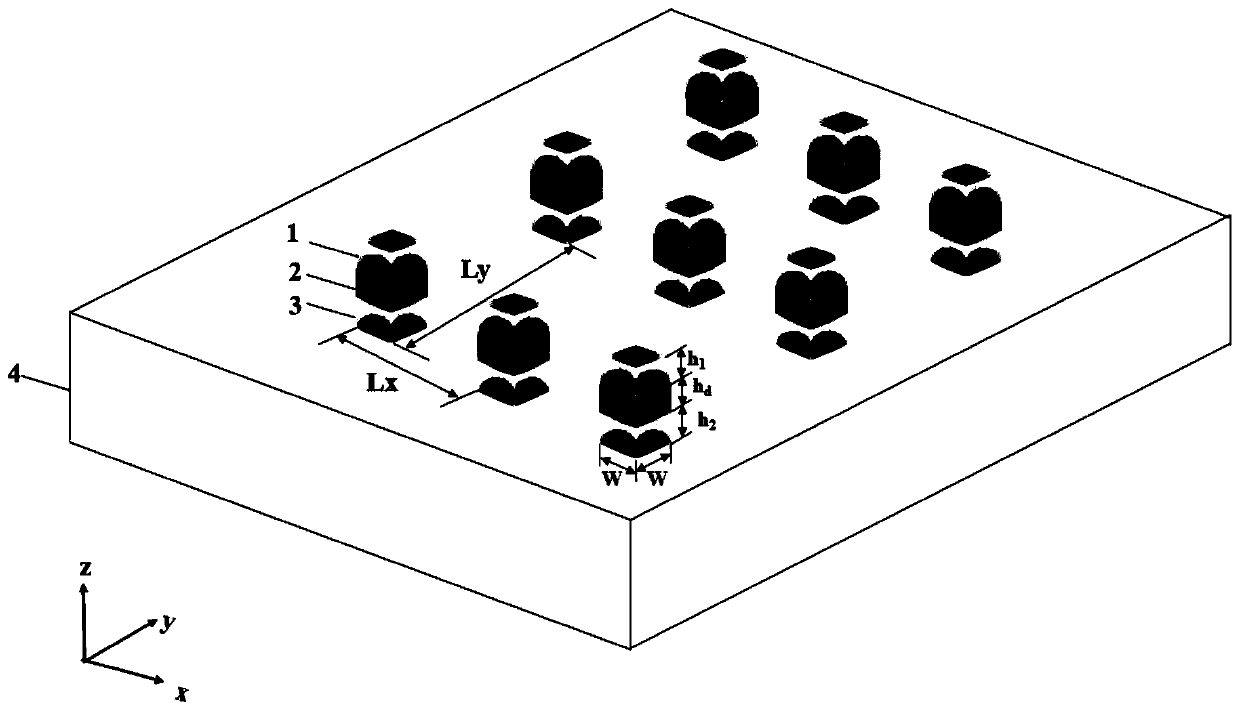

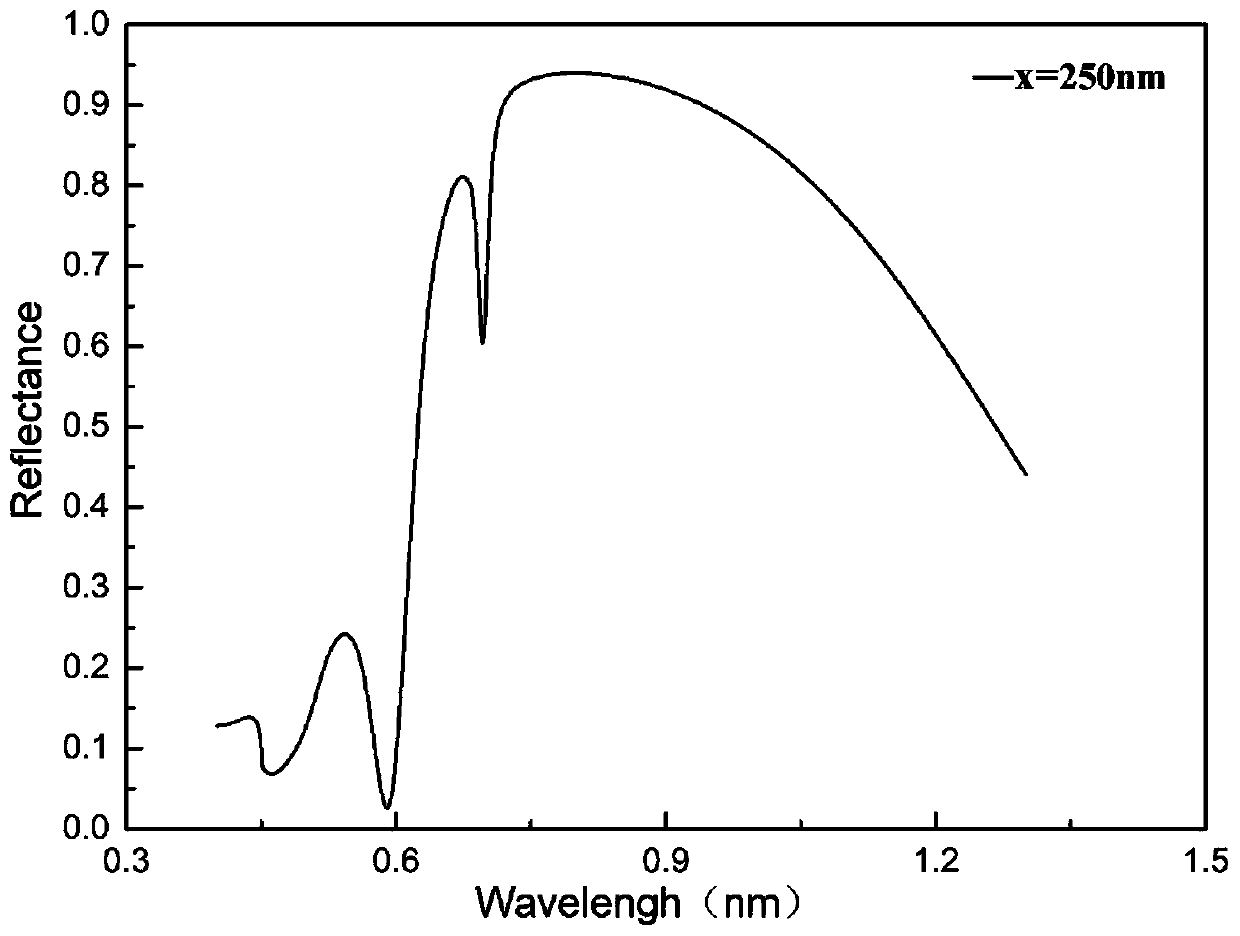

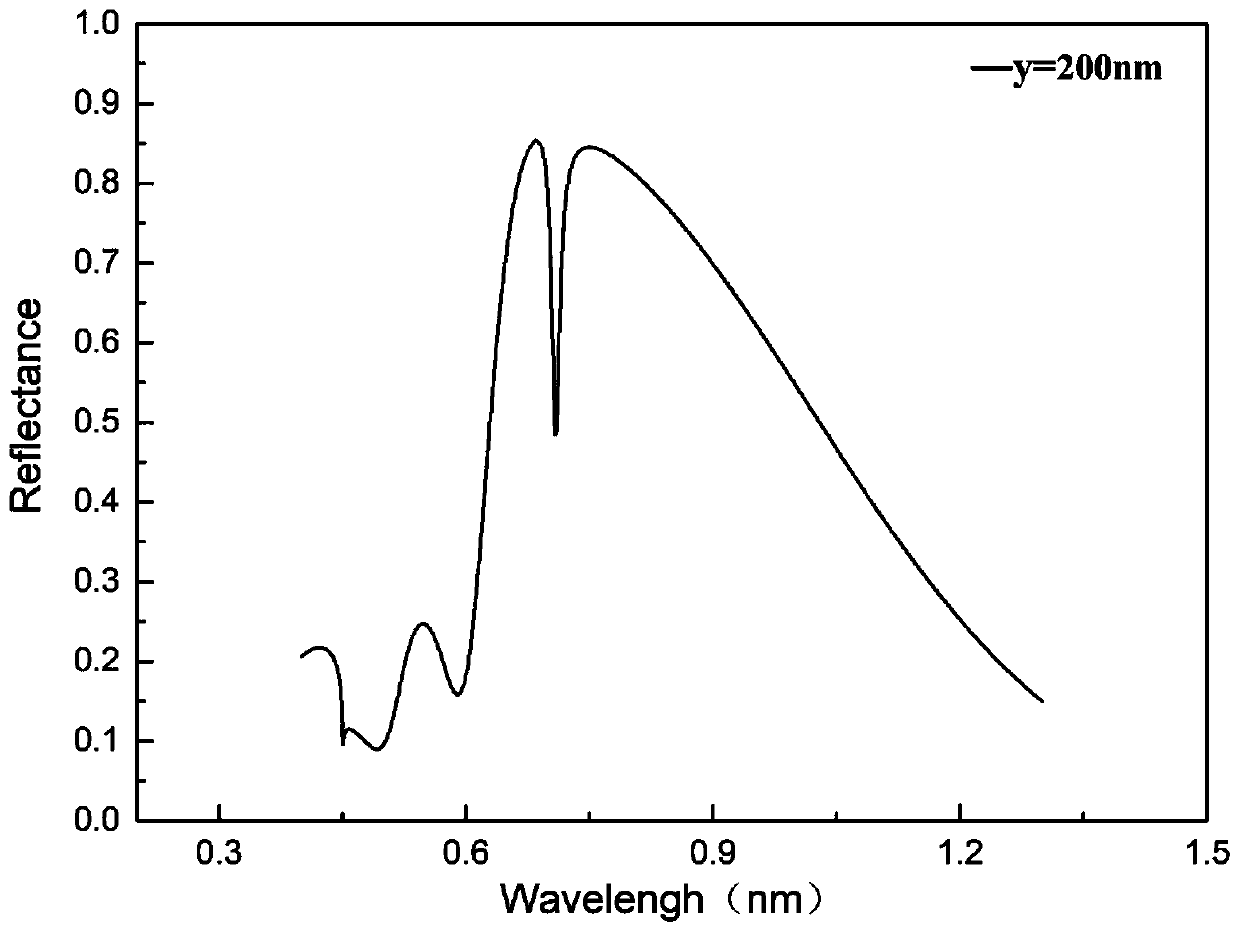

Pressure sensor based on asymmetric period surface plasmon lattice resonance

InactiveCN110926667ASuperior performanceWide range of applicationsForce measurement by measuring optical property variationSurface plasmon polaritonStress sensors

The invention relates to a pressure sensor based on asymmetric period surface plasmon lattice resonance. The sensor comprises a lower-layer PDMS substrate and a nano-structure unit array located abovethe upper-layer PDMS substrate, and each nano-structure unit is formed by closely stacking a top metal ridge, a middle dielectric layer and a bottom metal ridge which are sequentially arranged from top to bottom. In a plane parallel to the lower PDMS substrate, the array period parameter Lx of the nano structure unit in the x direction and the array period parameter Ly of the nano structure unitin the y direction are different from each other. And the external pressure acts on the lower PDMS substrate, so that the change of the surface plasmon resonance wavelength is caused, and a pressure signal is converted into an optical signal for detection. The optical device structure provided by the invention has a very high quality factor, can realize accurate detection of micro deformation pressure, has less limitation on the structure size, and has a wider sensing application range.

Owner:SHENZHEN INST OF ADVANCED TECH CHINESE ACAD OF SCI

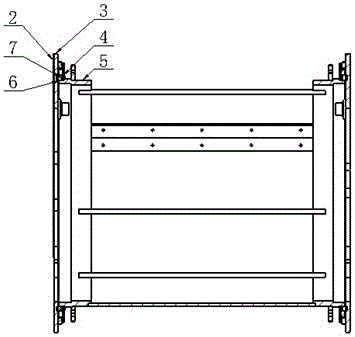

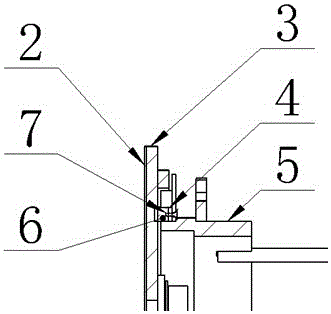

Sealing device of recoil roller chip removal device

ActiveCN105729230AImprove sealingSimple sealing structureEngine sealsMaintainance and safety accessoriesVertical planeFiltration

The invention provides a sealing device of a recoil roller chip removal device. The sealing device of the recoil roller chip removal device comprises a chip removal device body 1, a cover plate 2, a roller end cover 3, a rubber pad 4, a roller 5, packing 6 and self-tapping screws 7. One end of the roller 5 is provided with a vertical part which is perpendicular to the axial direction of the roller. A protruding part which extends in the axial direction of the roller is arranged in the middle of the vertical part. An annular protruding part is formed on the end face of the roller. An annular groove is formed between the annular protruding part and the roller. A circular ring is welded to the inner side face of the roller end cover 3. A labyrinth sealing structure is formed after the roller 5 and the roller end cover 3 are installed, so that primary sealing is achieved. A plurality of holes are formed in the vertical plane of the vertical part, one self-tapping screw 7 is arranged in each hole, the rubber pad 4 is installed on the inner side of the groove, the packing 6 is pressed on the rubber pad 4, and two connectors are fixed to two adjacent self-tapping screws correspondingly. The screws are used for fixing the packing, the situation that a gap is nonuniform due to the rotation of the packing is avoided, and thus filtration is more reliable.

Owner:NINGXIA KOCEL MACHINE TOOL ACCESSORIES

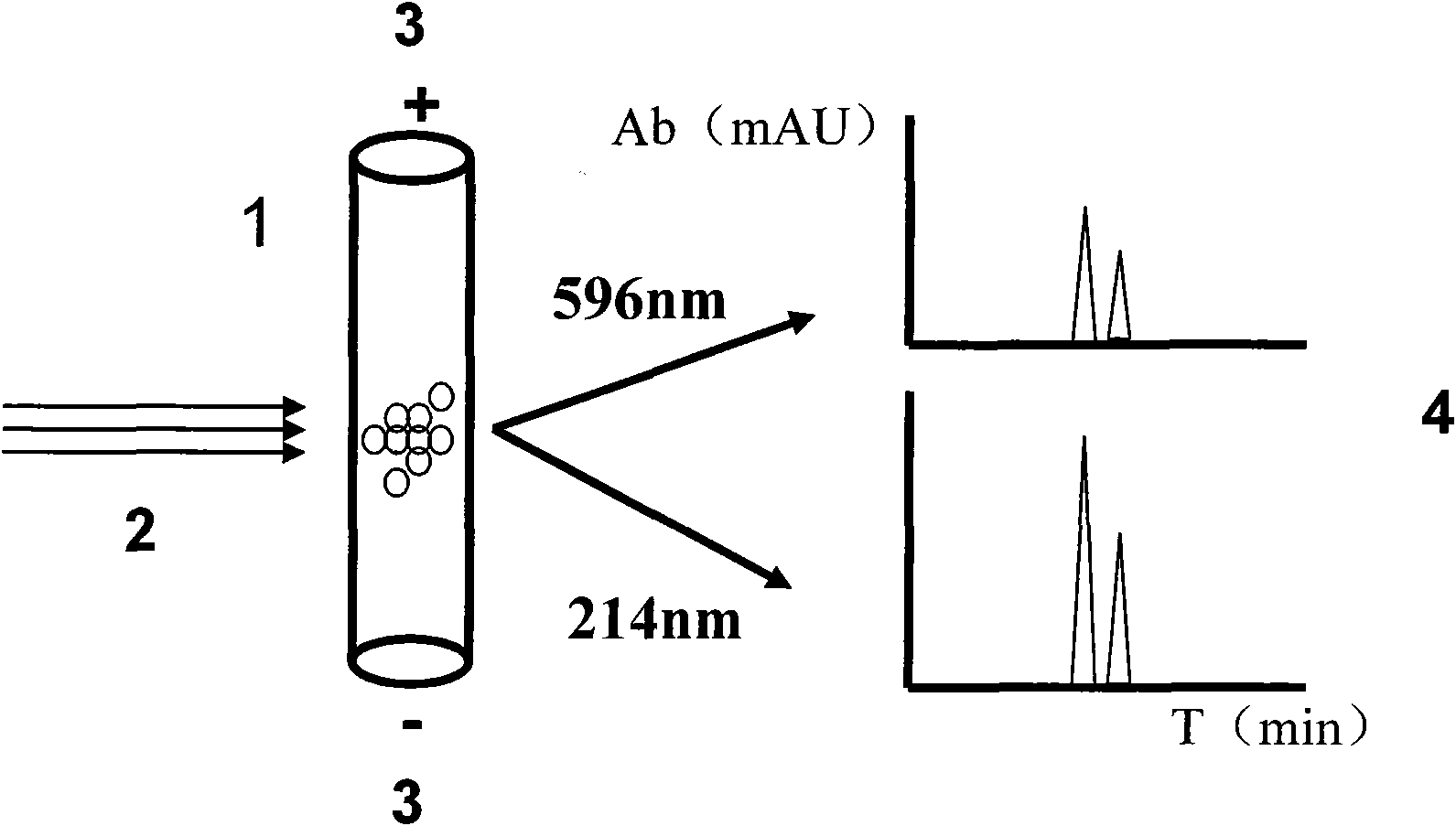

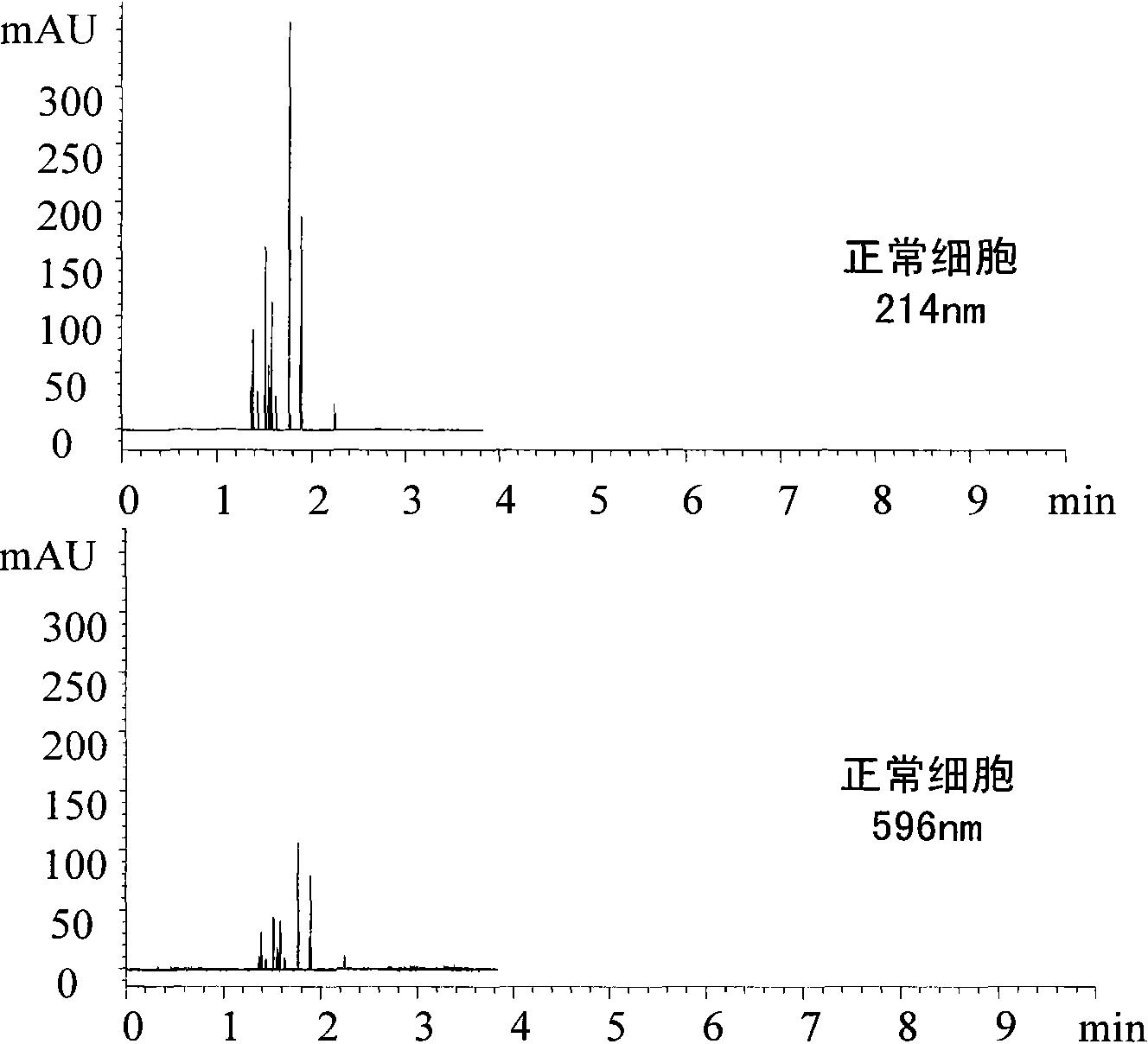

Cytoactive detection method based on capillary zone electrophoresis mode

InactiveCN101782509ARealize quantitative analysisLow costMicrobiological testing/measurementColor/spectral properties measurementsBiological cellCapillary electrophoresis

The invention discloses a cytoactive detection method based on a capillary zone electrophoresis mode, belonging to the technical field of biological cytoactive detection. Firstly, cells to be detected are dyed and fixed to prepare cell suspension with certain concentration; capillary zone electrophoresis (CZE) carries out visible absorption detection of single-wavelength or multiple-wavelength ultraviolet to cells, detected peak area summation represents the light absorption value of cells under the detection wavelength, and a product of the ultraviolet and visible double-wavelength absorption value represents cytoactive. The method of the invention is accurate, quick and simple, has low cost, can qualitatively and quantificationally detect cytoactive, can detect cytoactive and analyze toxicant cytotoxicity and can be applied in relevant fields, such as cytobiology, cytotoxicology, medicine research and development, toxicant cytotoxicity evaluation and the like.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

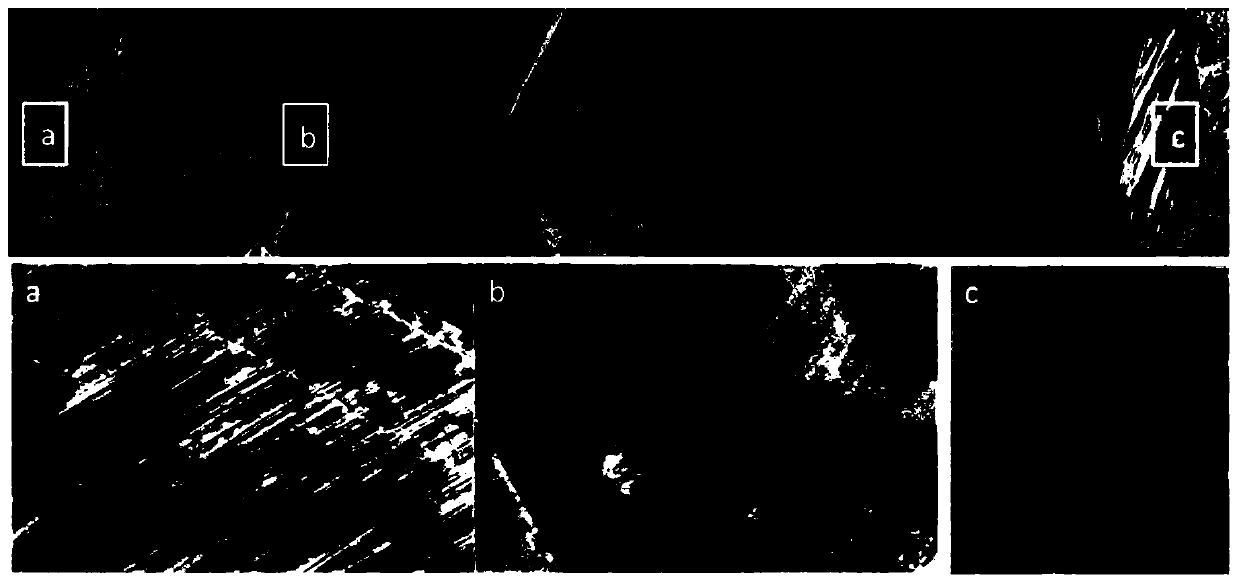

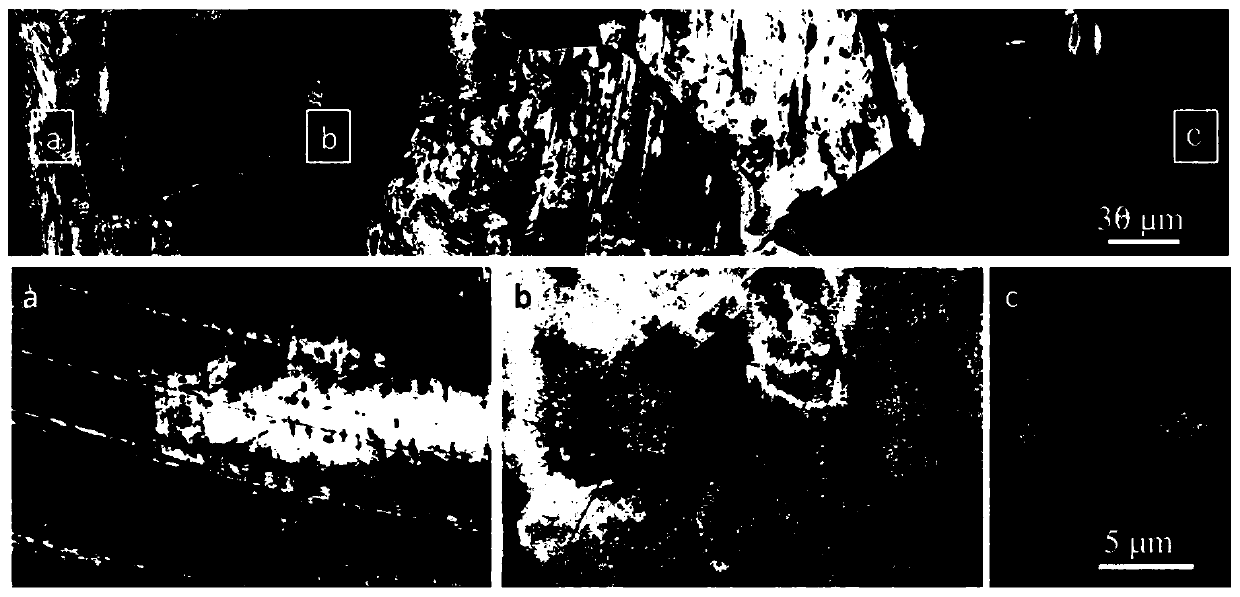

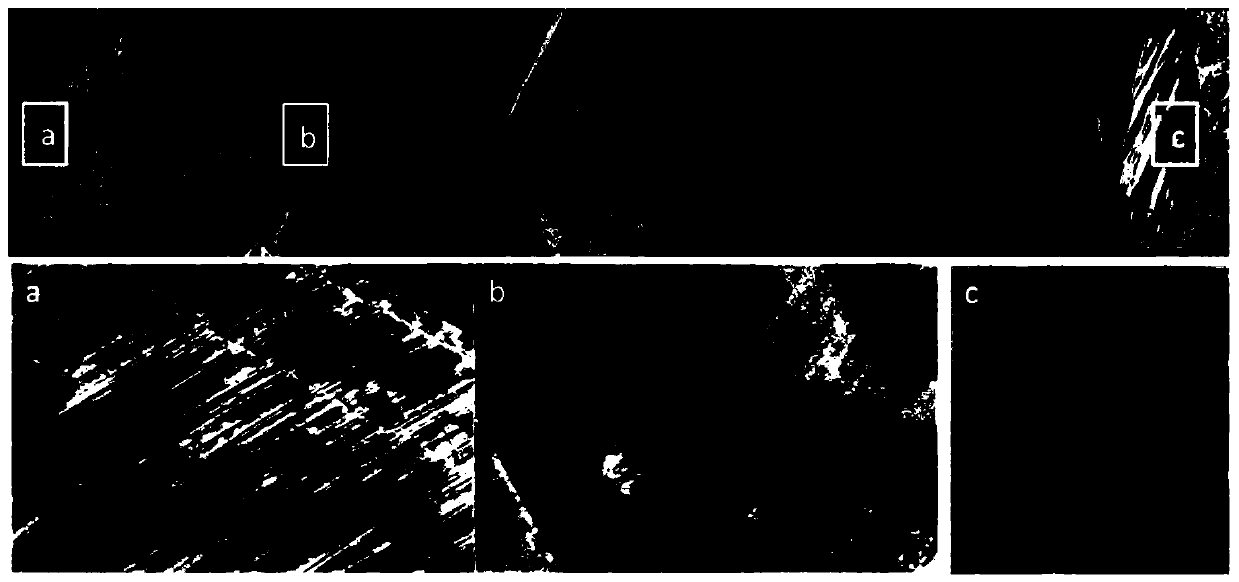

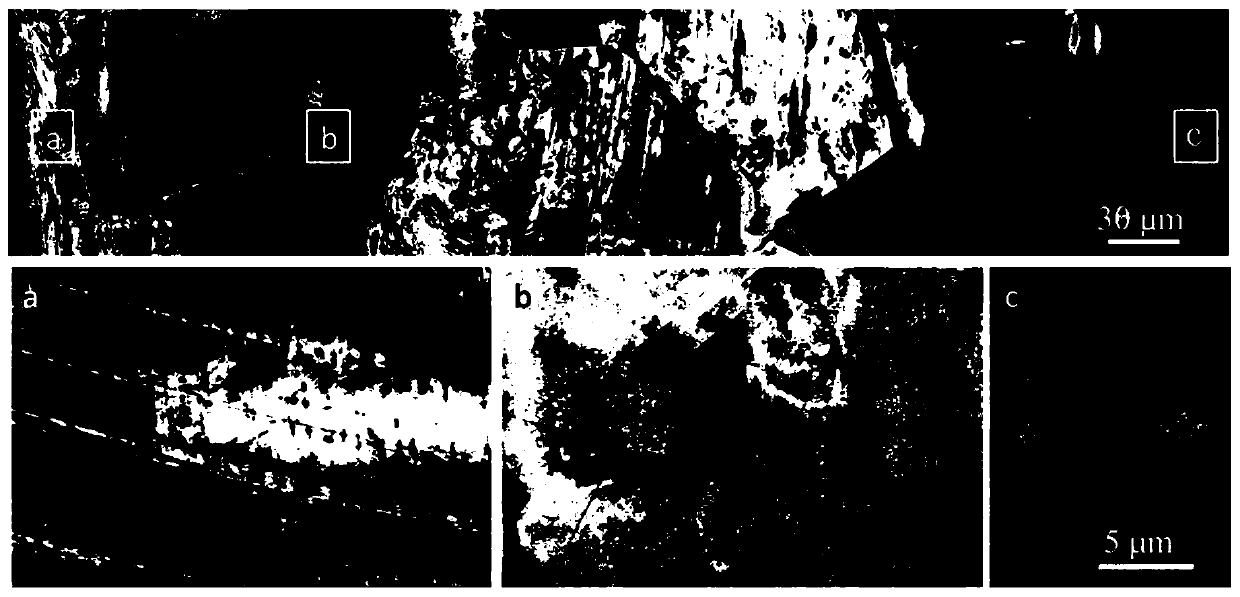

Preparation method of high-strength and high-plasticity 304 austenitic stainless steel with low martensite content

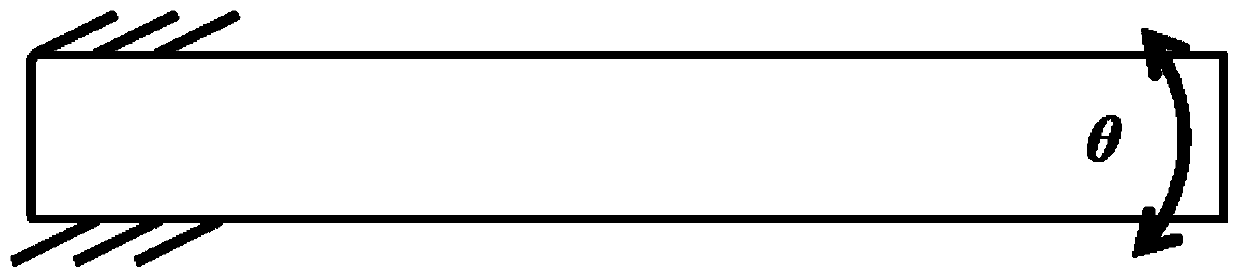

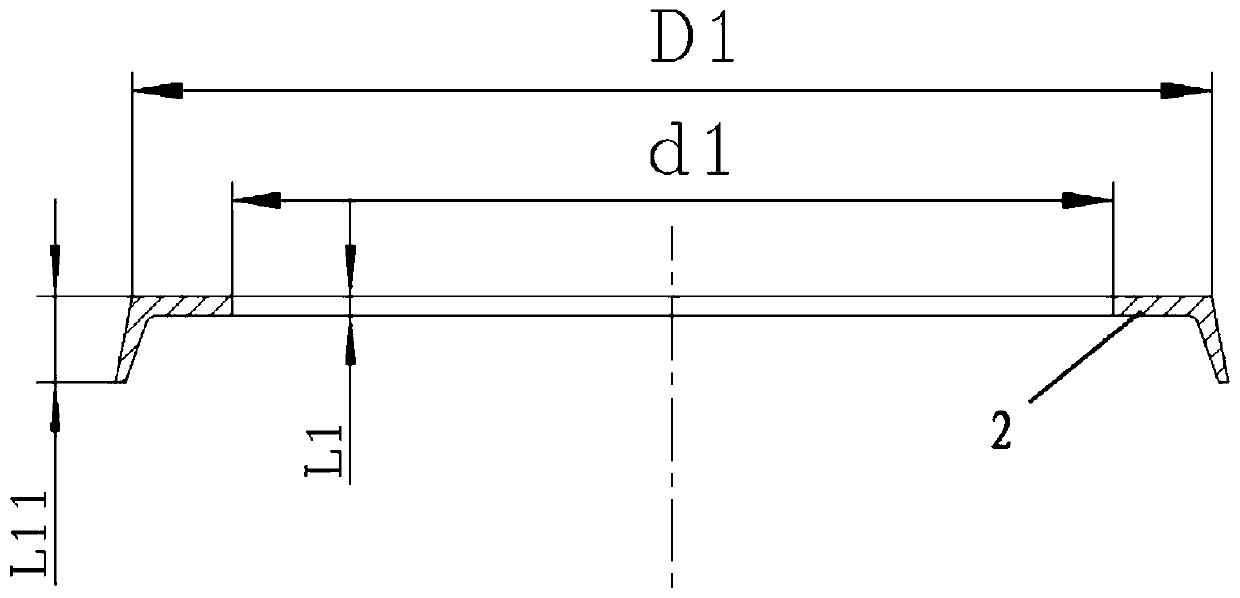

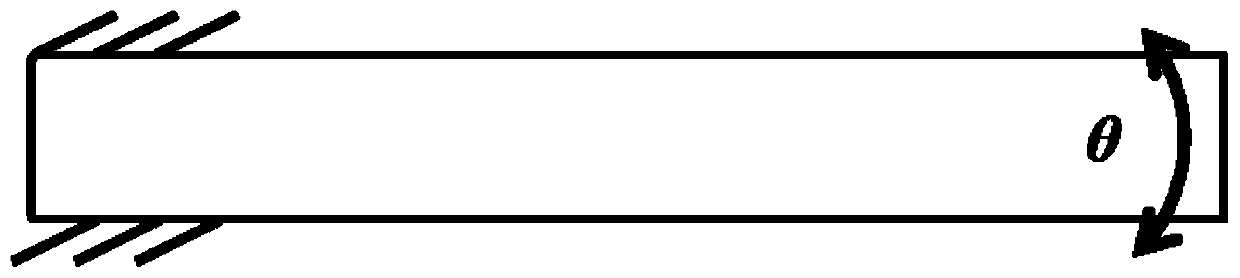

The invention discloses a preparation method of high-strength and high-plasticity 304 austenitic stainless steel with low martensite content, and belongs to the technical field of metal material strengthening. According to the method, small-angle circulating and reciprocating torsional deformation treatment is conducted on a coarse-grain 304 stainless steel bar or pipe, so that dislocation and nano twin crystal deformation microstructures distributed in a gradient mode are introduced into an original coarse-grain structure of 304 stainless steel, and meanwhile, the martensite structure contentof the surface layer of the material is less than 7%; the small-angle cyclic torsional deformation treatment means that one end of the bar or the pipe is fixed, and a force is applied to enable the other end of the bar or the pipe to rotate around the center axis of the bar or the pipe in a reciprocating mode, so one-time reciprocating rotation is one cyclic torsional cycle. Compared with a uniform coarse grain structure with the same components, the material treated by the circulating torsion process is improved by more than 1.5 times in the yield strength, and the metal material has uniformplasticity equivalent to that of coarse grains.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

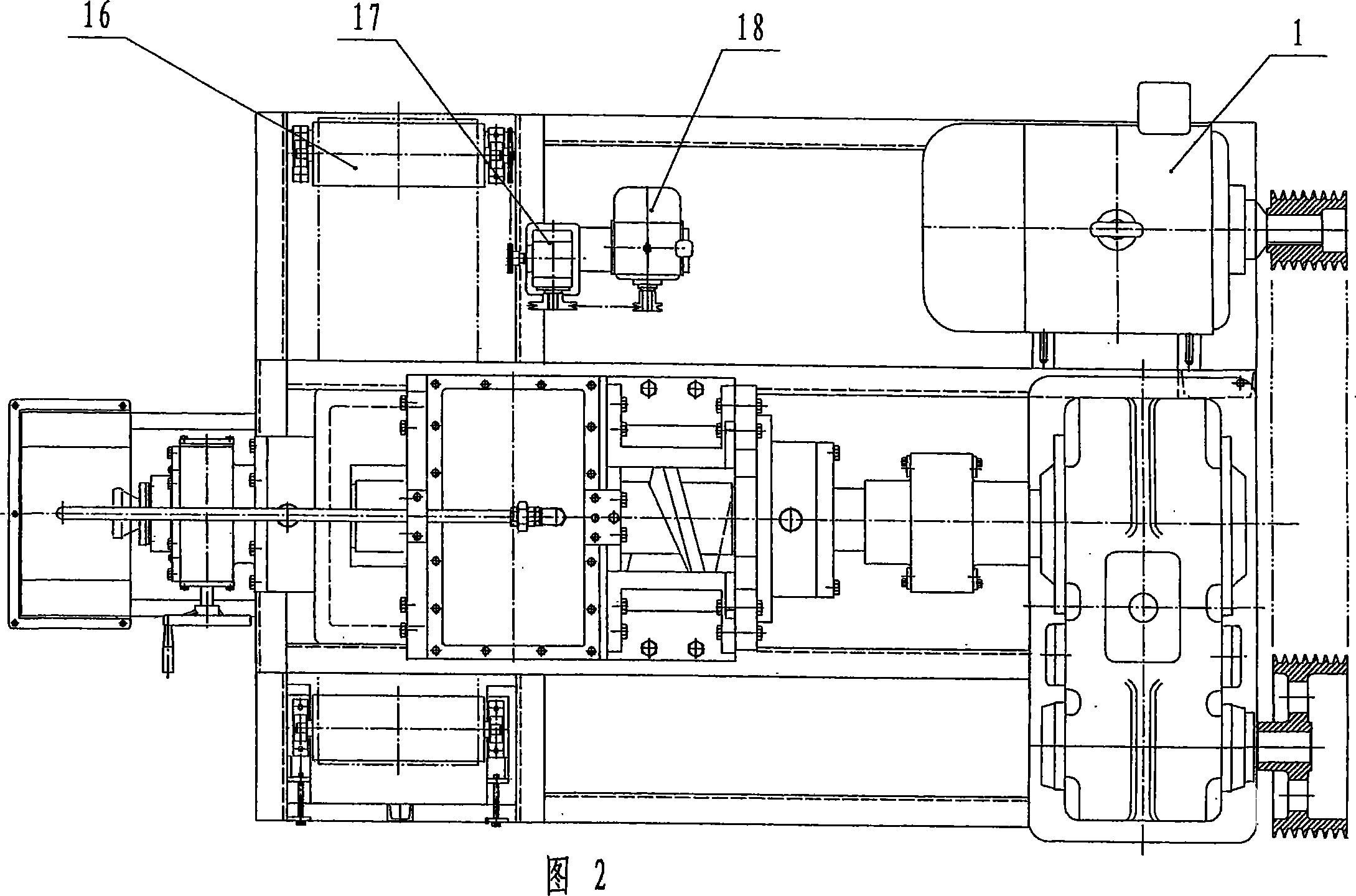

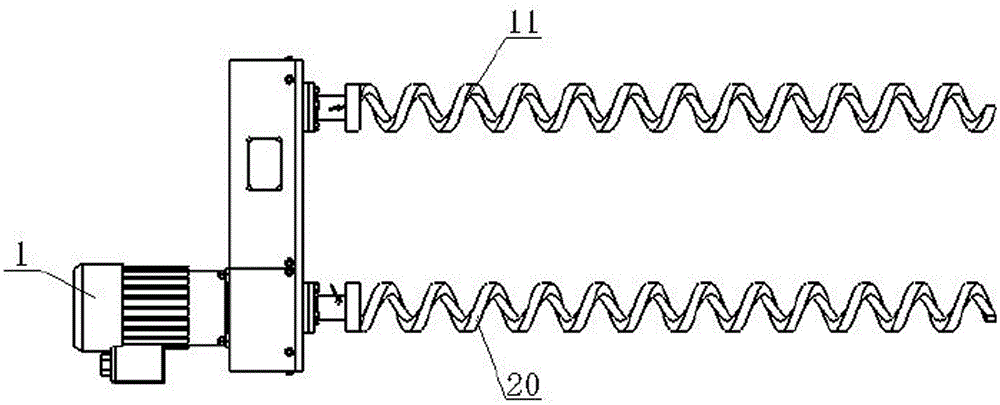

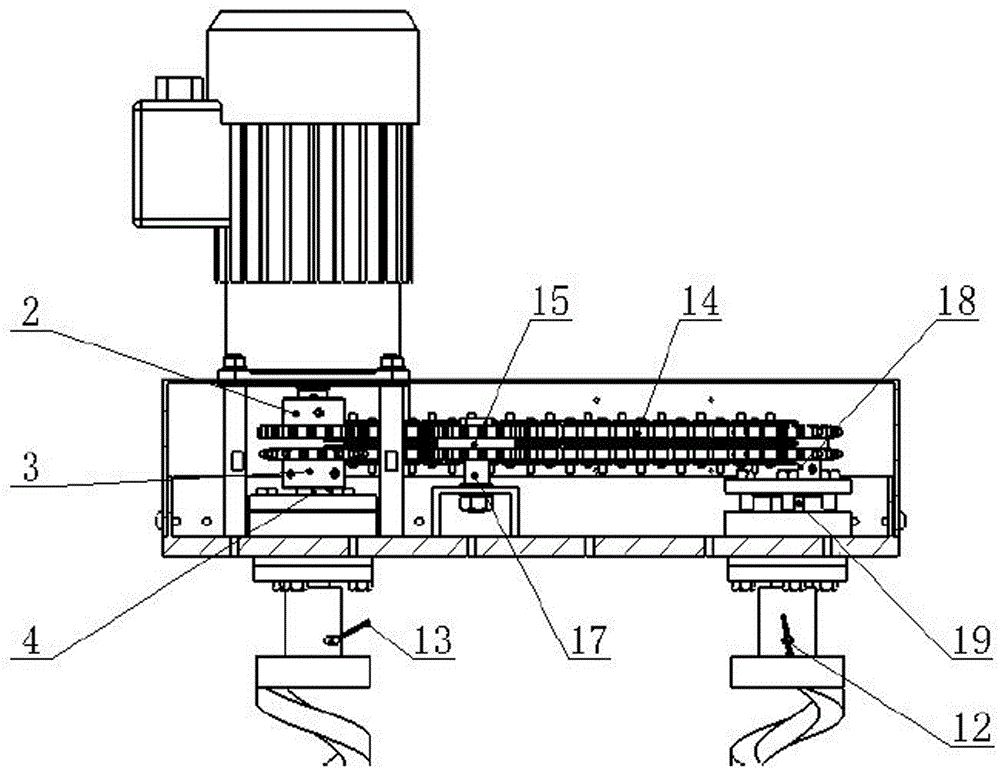

Novel spiral chip remover driving device

ActiveCN105108562AExtended service lifeFix water damageGearingMaintainance and safety accessoriesDrive shaftRoller chain

The invention belongs to the field of mechanical transmission and relates to a novel spiral chip remover driving device. The novel spiral chip remover driving device comprises a driving motor (1), a first driving chain wheel (2), a second driving chain wheel (3), a driving shaft (4), a bearing support (6), a first screw rod (11), a pin shaft (12), a double-row roller chain (14), a tensioning wheel (15), a tensioning bearing (16), a tensioning shaft (17), a double-row-tooth driven chain wheel (18), a driven shaft (19) and a second screw rod (20). According to the technical scheme, the novel spiral chip remover driving device has the beneficial effects that a driving method of meshing double rows of chains with the chain wheels is adopted, the conventional thought that one driving motor can only drive one screw rod to operate in the prior art is changed, the working efficiency is improved, the problem that cutting fluid enters the motor and causes damage of the motor due to wet can be effectively solved, the service life of the motor is prolonged, the cost is reduced. The novel spiral chip remover driving device, compared with a device capable of achieving same function, occupies a smaller area and consumes less energy.

Owner:NINGXIA KOCEL MACHINE TOOL ACCESSORIES

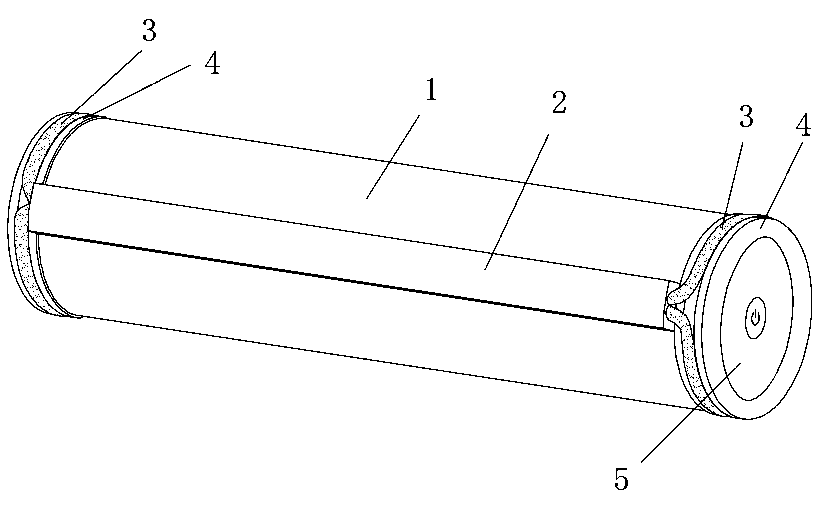

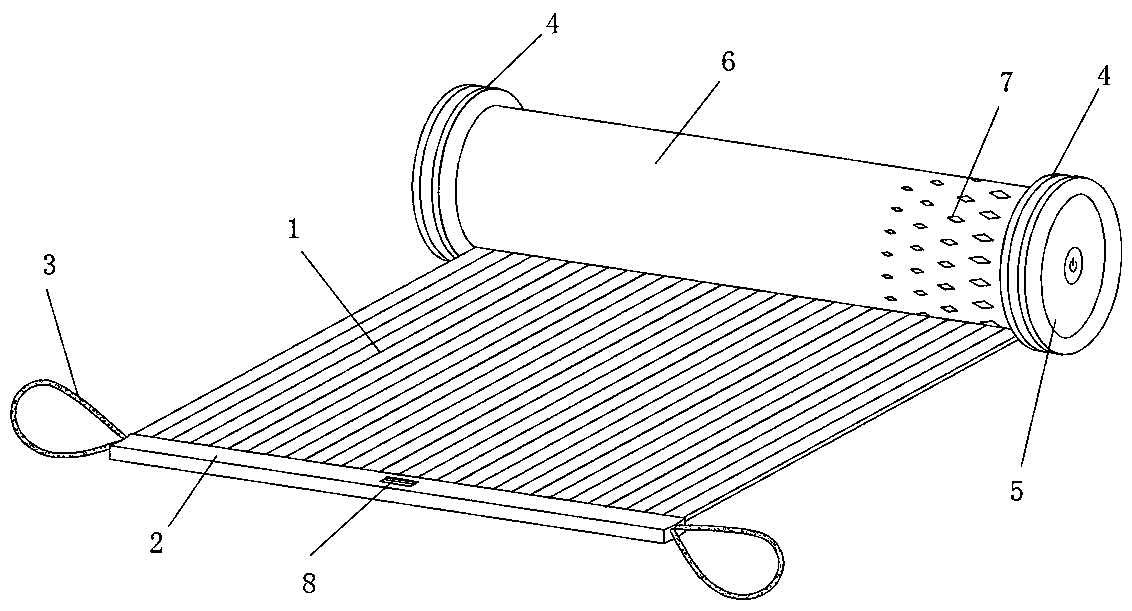

Outdoor solar reel

PendingCN109067347ASmall size limitThe fixing method is simple and reliablePhotovoltaicsPhotovoltaic energy generationSolar cellConductor Coil

The invention relates to an outdoor solar reel, which solves the problem that the size of a flexible solar cell panel is limited and the surface is easy to be damaged due to the existing solar reel peripheral housing. The device has a cylinder core, the cylindrical surface of the cylinder core is wound with a flexible solar cell panel, one end of the flexible solar cell panel is fixed on the outerwall of the cylinder core and is connected with a battery in the cylinder core, The other end is provided with a fixing strip, wherein elastic ropes are pierced through the fixing strip, the elasticropes are pierced out from both ends of the fixing strip and form a collar, the two ends of the cylinder core are provided with fixing parts, the fixing parts are provided with an annular groove, andwhen the flexible solar cell panel is in a rewinding state, the elastic ropes installed in the collar at both ends of the fixing strip are sleeved in the annular groove respectively. The fixing methodof the invention is simple and reliable, and the elastic rope can be pulled out in the middle of the fixing strip and used as a hanging rope suspension; Winding is open, thereby reducing the possibility of scratches; The length of flexible solar panels is adjustable to a certain extent.

Owner:浙江尚越新能源开发有限公司

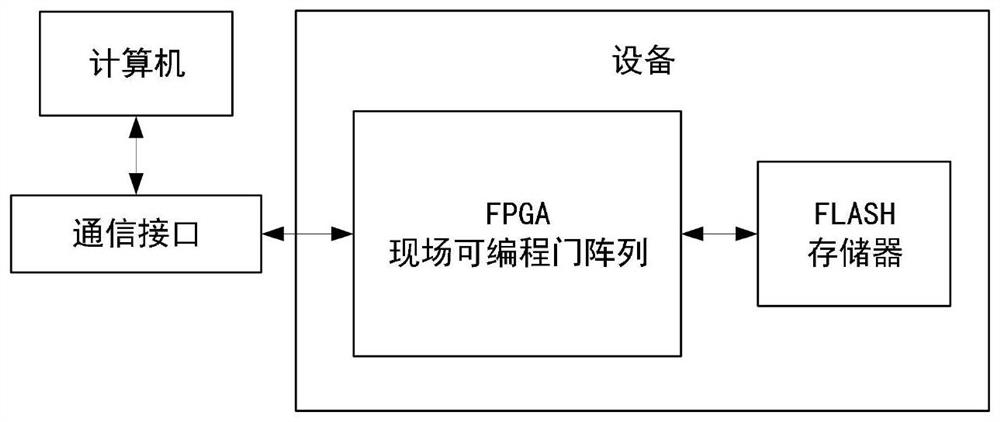

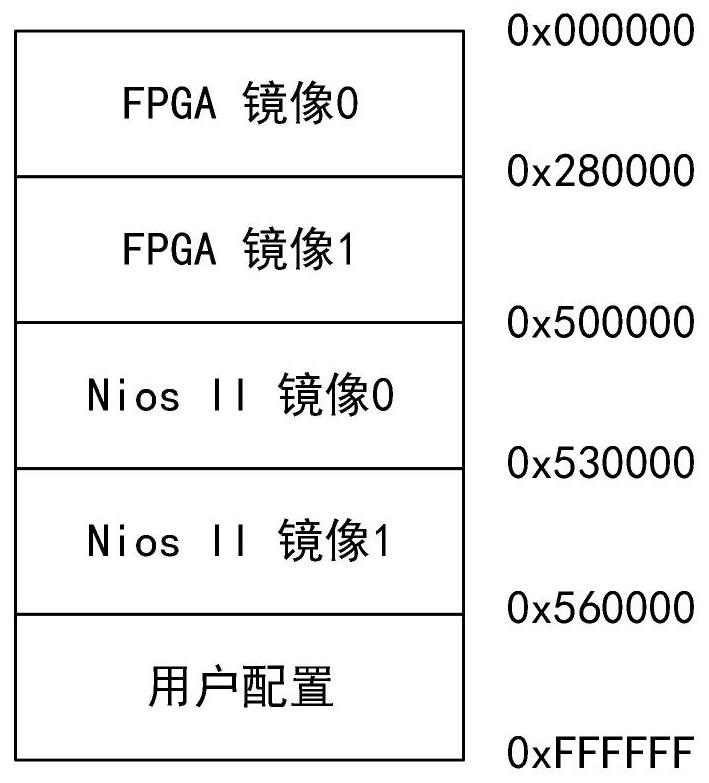

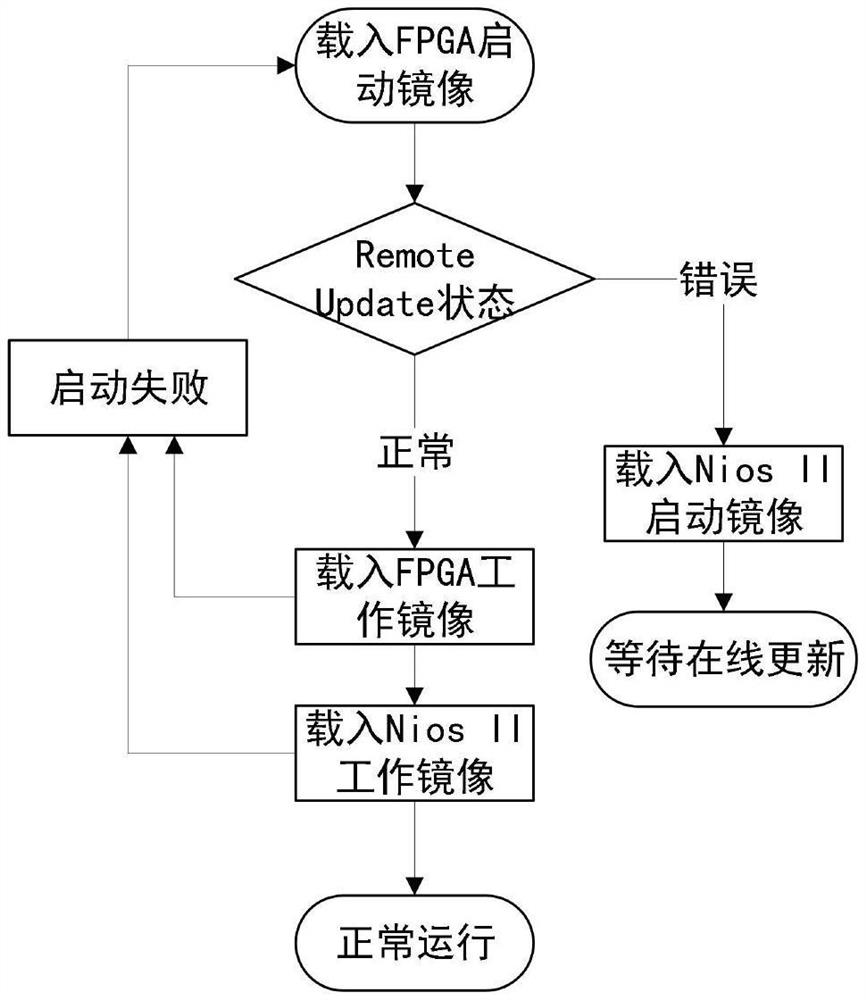

FPGA online upgrading method based on NiosII soft core

PendingCN112148341AConvenient batch updateReduce start-up delayProgram loading/initiatingSoftware deploymentComputer hardwareComputer architecture

The invention discloses an FPGA online upgrading method based on a NiosII soft core, which comprises the following steps: 1, operating the NiosII soft core on an FPGA to be used for responding to an online upgrading instruction and reading and writing a memory; 2, storing two groups of mirror images, namely a starting mirror image and a working mirror image in a memory; 3, loading the starting mirror image after the FPGA is powered on, trying to switch to the working mirror image, and returning to the starting mirror image if the switching fails; and the two groups of mirror images can be upgraded on line. According to the invention, the convenient and stable FPGA online upgrading function can be achieved, it can be guaranteed that the equipment can be started and upgraded again when accidents happen in the upgrading process, in addition, other hardware modules do not need to be added, and therefore cost and equipment size limitation are reduced.

Owner:HEFEI I TEK OPTOELECTRONICS CO LTD

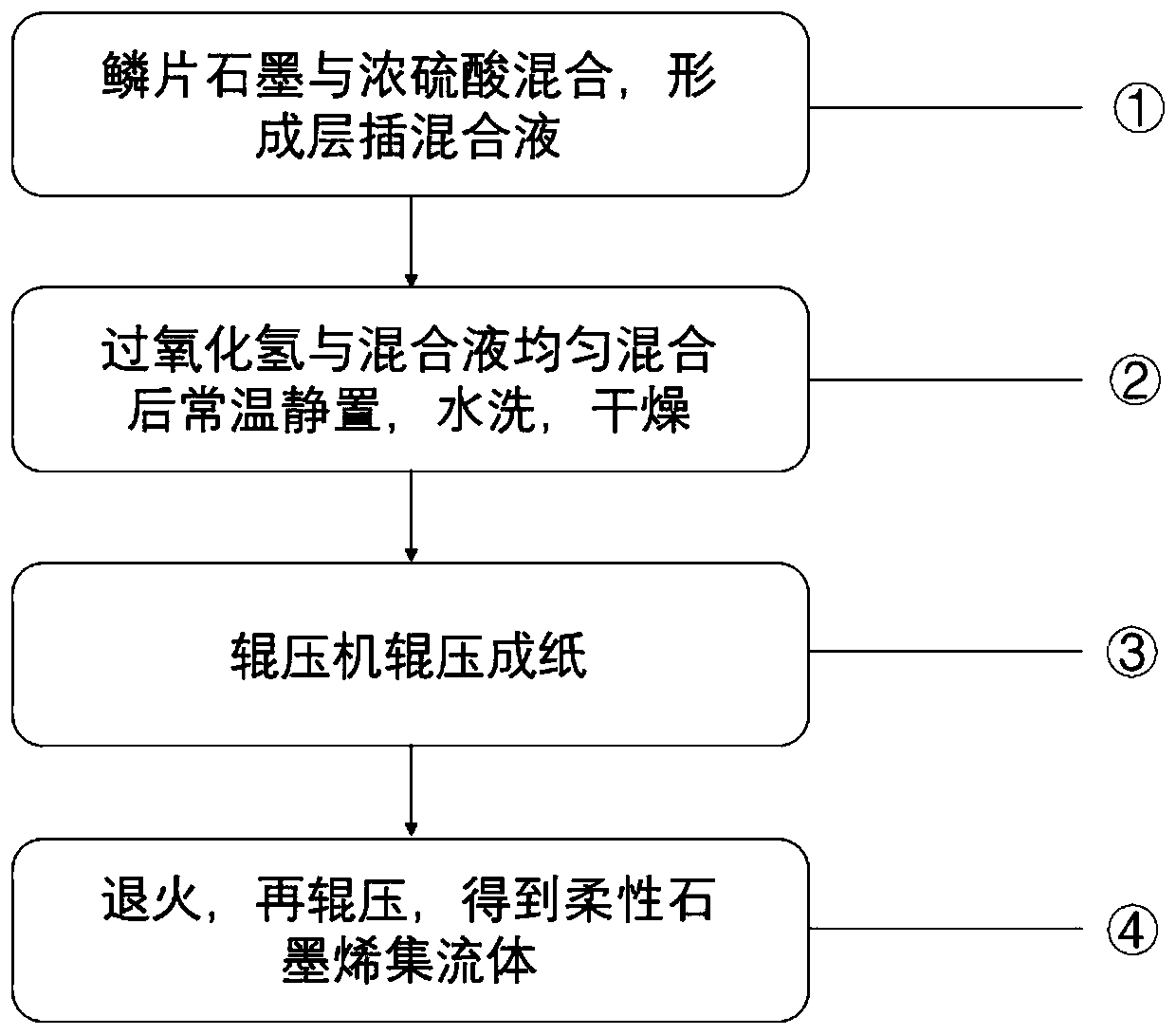

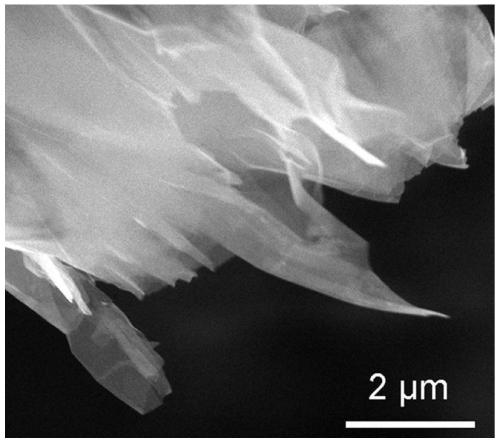

Method capable of obtaining flexible graphene current collectors in batches

InactiveCN111086984AEasy to operateSmall size limitElectrode carriers/collectorsGrapheneChemistryEngineering

The invention discloses a method capable of obtaining flexible graphene current collectors in batches. The method comprises the following steps: (1) mixing concentrated sulfuric acid and crystalline flake graphite so as to prepare a mixed solution; (2) adding hydrogen peroxide with a concentration of 30% into the mixed solution, carrying out stirring, then carrying out standing at a normal temperature, carrying out washing with water, and carrying out drying so as to obtain graphene powder; and (3) rolling the graphene powder into paper by using a rolling technology, then carrying out annealing, and carrying out rolling again so as to obtain flexible graphene paper. According to the preparation method for the flexible graphene current collectors provided by the invention, the flexible graphene current collectors with high conductivity, light weight and hydrophilicity can be obtained in batches by using rolling equipment through simple and low-cost puffing stripping and rolling technologies and preparation from powder to paper.

Owner:SOUTH CHINA UNIV OF TECH

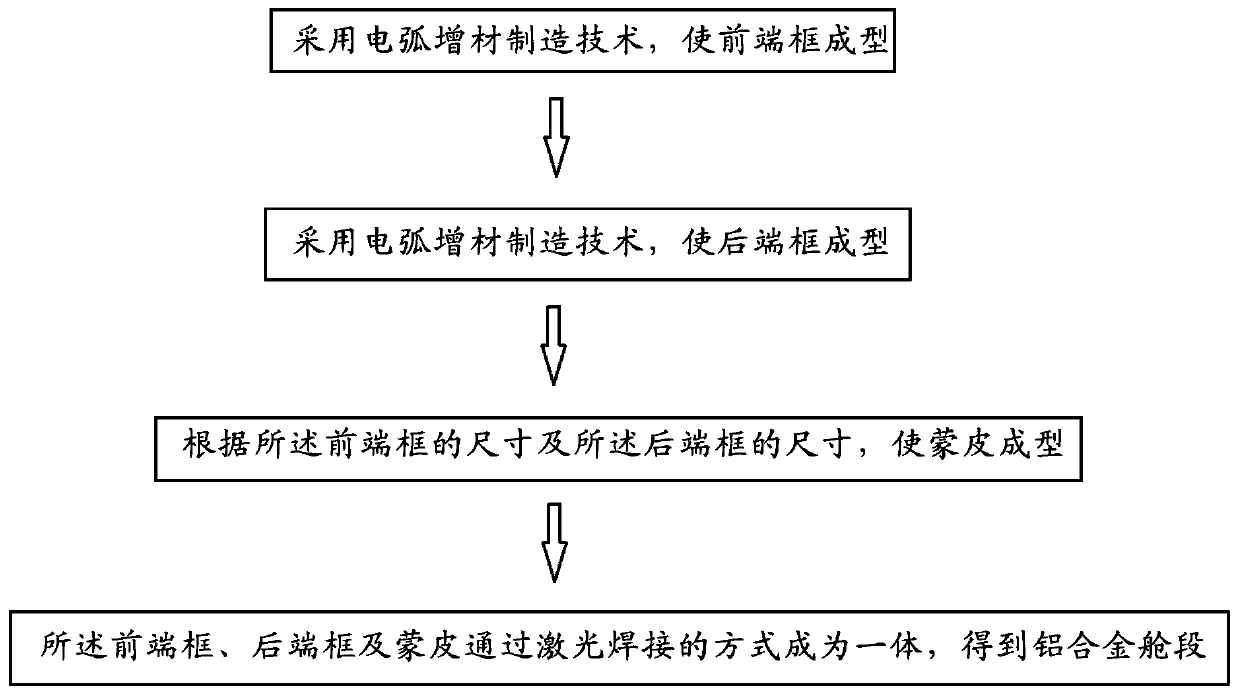

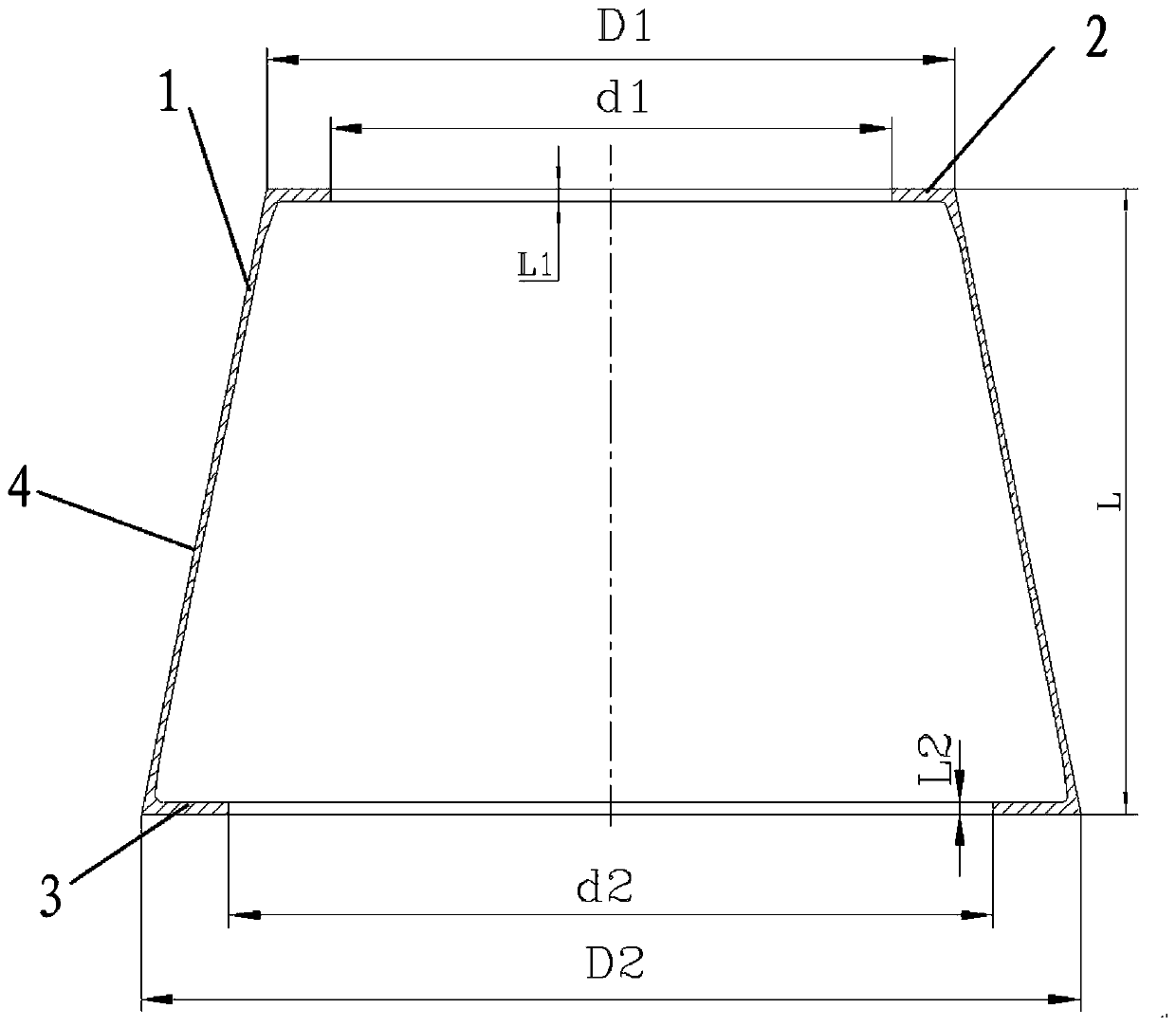

Forming method of aluminum alloy cabin section

ActiveCN111545938ASmall size limitEasy to fixArc welding apparatusLaser beam welding apparatusManufacturing technologyEngineering

The invention discloses a forming method of an aluminum alloy cabin section, and belongs to the technical field of rapid forming. The forming method comprises the steps of forming a front end frame byadopting an electric arc additive manufacturing technology; forming a rear end frame by adopting the electric arc additive manufacturing technology; forming the skin according to the size of the front end frame and the size of the rear end frame; and integrating the front end frame, the rear end frame and the skin in a laser welding mode to obtain the aluminum alloy cabin section. According to the forming method of the aluminum alloy cabin section, forming of an integral metal cabin section shell with the ultra-large diameter of 3.8 m or above can be achieved, the product machining allowanceis reduced, the material utilization rate is increased, the tool structure is simple, the production cost is reduced, and the production cycle is shortened.

Owner:HUBEI SANJIANG AEROSPACE GRP HONGYANG ELECTROMECHANICAL

Cyclic torsion machining process for improving mechanical property of metal material

ActiveCN110923438ADoes not significantly change macroscopic shapeDoes not significantly change surface topographyMetallic materialsGrain structure

The invention discloses a cyclic torsion machining process for improving the mechanical property of a metal material, and belongs to the technical field of metal material strengthening. Specifically,the process comprises the steps: applying small-angle circulating torsional deformation to a metal bar, a pipe or a plate sample, and generating shear shaping strain in gradient distribution from thesurface to the interior of a metal material, so deformation microstructures such as dislocation in gradient distribution and nano twin crystals are introduced, and an original coarse grain structure is reserved, wherein the torsion angle amplitude is between 2 degrees and 30 degrees, and the number of torsion cycles is between 2 and 200. Compared with a uniform coarse grain structure with the samecomponents, the metal material treated by the circulating torsion process is improved by more than 1.5 times in yield strength, and the metal material has uniform plasticity equivalent to that of coarse grains. By utilizing the method, the microstructure with gradient distribution is obtained in the original coarse grain and has high strength and good plasticity matching.

Owner:INST OF METAL RESEARCH - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com