Thermoelectric device performance testing device

A technology for thermoelectric devices and testing devices, applied in the direction of measuring devices, testing of machine/structural components, instruments, etc., can solve the problems of inability to test non-standard thermoelectric devices, and achieve the effect of complete functions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

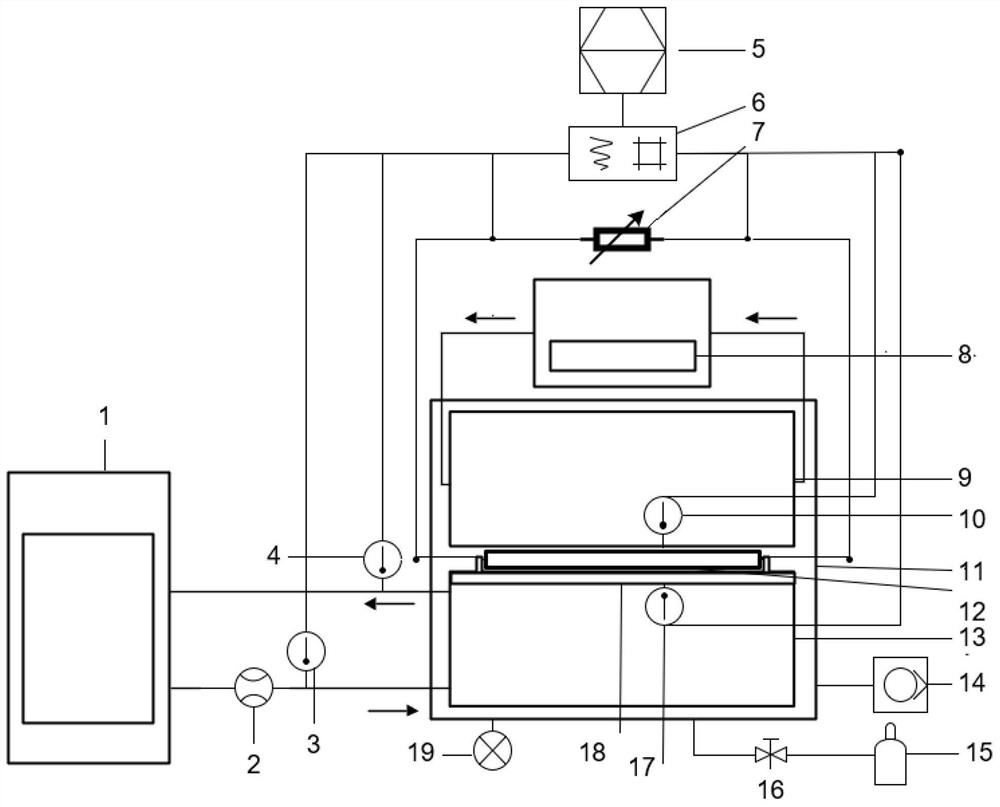

[0040] Such as figure 1 As shown, a device for performance testing of thermoelectric devices in a wide size range includes a test module, a data acquisition and processing module, an atmosphere control module and a data processing terminal 5 .

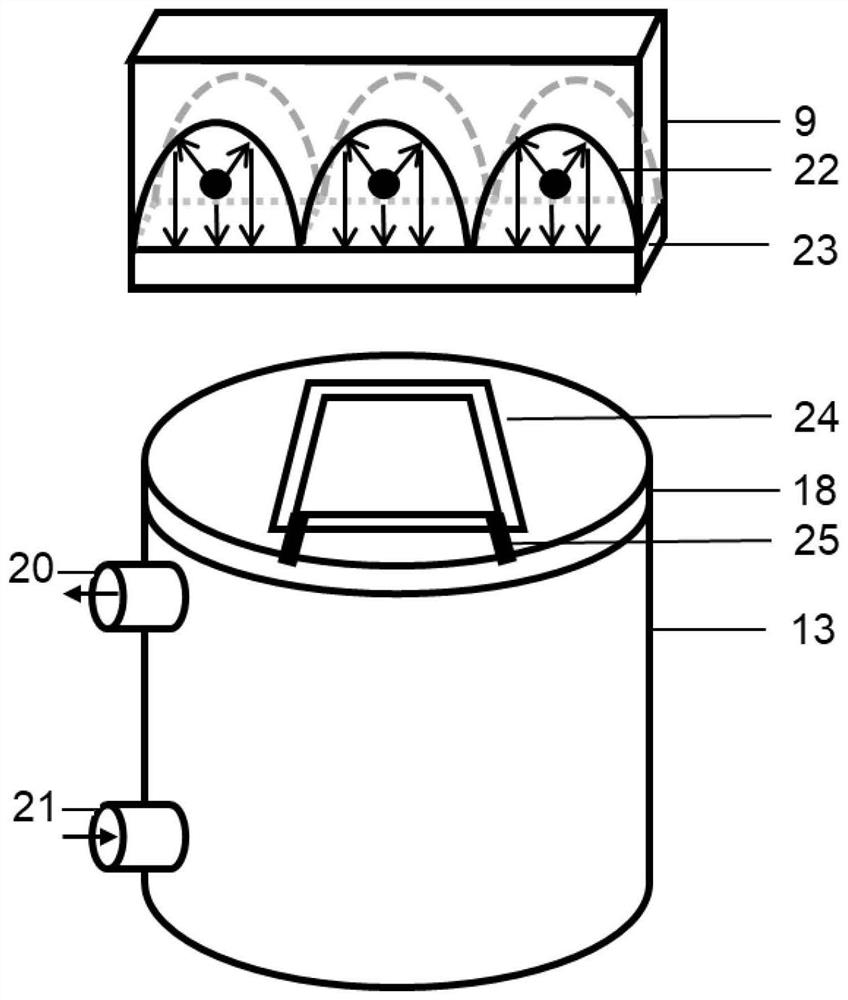

[0041] Such as figure 2As shown, the test module is used to test and collect thermoelectric performance data of the thermoelectric device 12 to be tested under different temperature differences and atmospheric conditions. The test module includes a test chamber 11 , a constant temperature circulator 1 , a flow rate control module 2 , an inlet temperature sensor 3 , an outlet temperature sensor 4 and a circulating water cooler 8 . The flow rate control module 2 adopts a mass flow controller. The test cavity 11 is a sealed cuboid structure, made of 304 stainless steel; the test cavity 11 is also provided with a heating platform 9 and a cooling platform 13, and the heating platform 9 is used to provide the temperature of the hot end of...

Embodiment 2

[0047] Such as Figure 4-Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that the device for performance testing of thermoelectric devices in a wide range of sizes in this embodiment adopts a test platform (groove) 26, and uses an engraved groove 27 as a fixed groove to The thermoelectric device 12 is fixed in the middle, and is used to realize the test of the low-thickness test sample.

Embodiment 3

[0049] Such as Figure 6 As shown, the difference between this embodiment and Embodiment 2 is that the system device for performance testing of thermoelectric devices in a wide size range in this embodiment uses a liquid flow meter 28 and a ball valve 29 instead of a mass flow controller, that is, a flow rate control module 2 A liquid flow meter 28 and a ball valve 29 are used.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com