Patents

Literature

167 results about "Heat measurement" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Heat can be measured. That is, the amount of heat given out or taken in can be given a value. One of the units of measurement for heat is the joule. Heat is usually measured with a calorimeter, where the energy in a material is allowed to flow into nearby water, which has a known specific heat capacity.

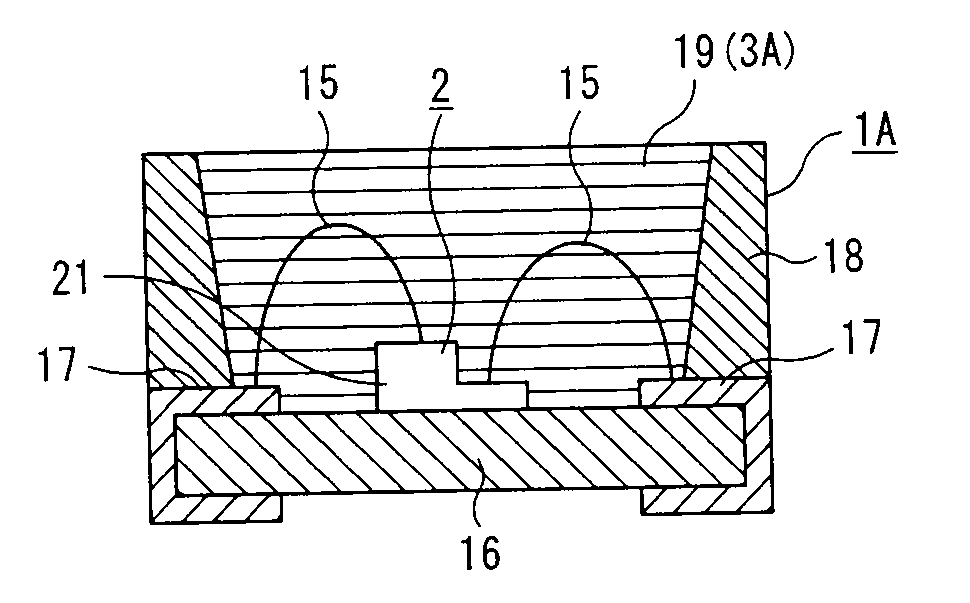

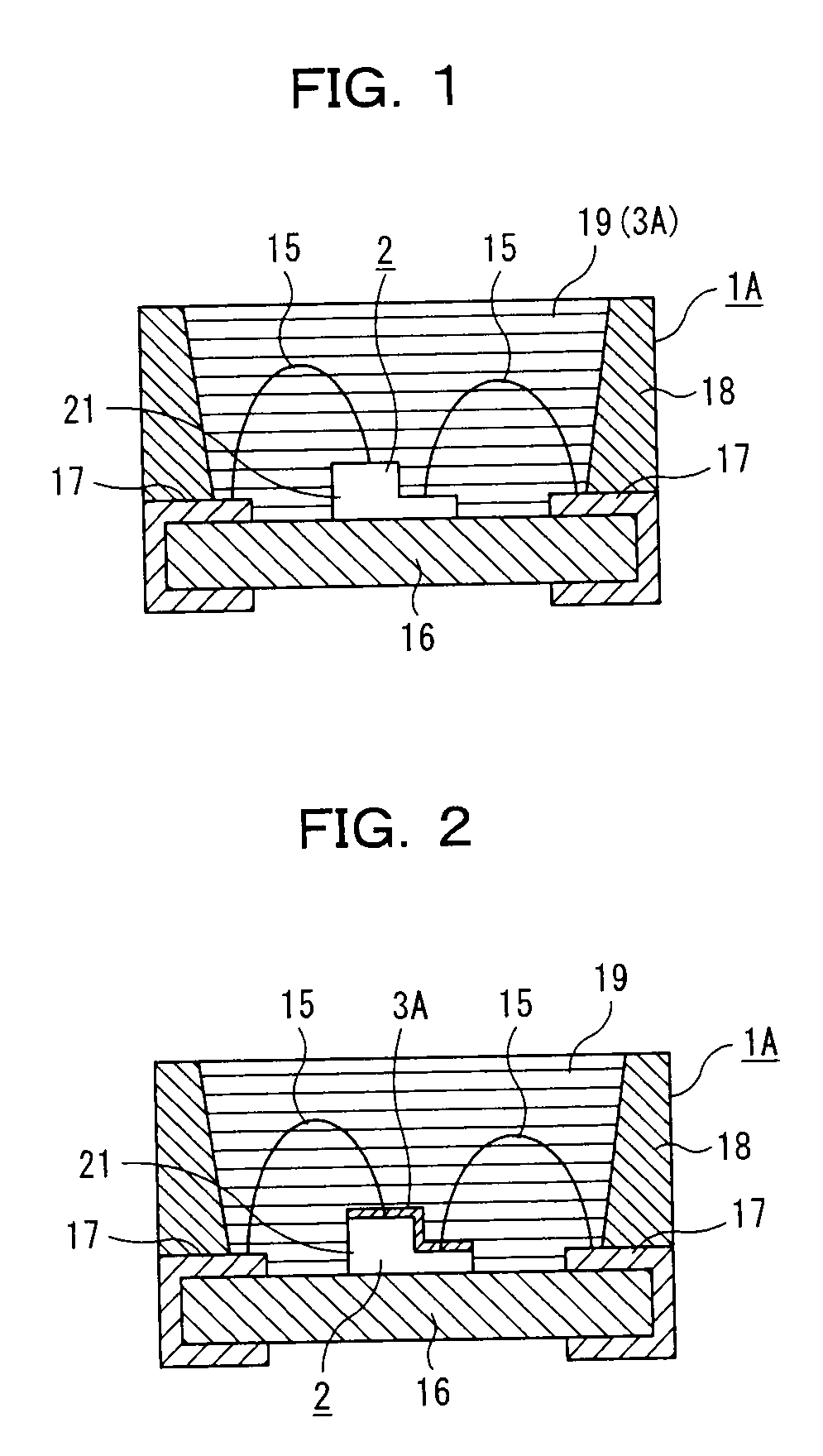

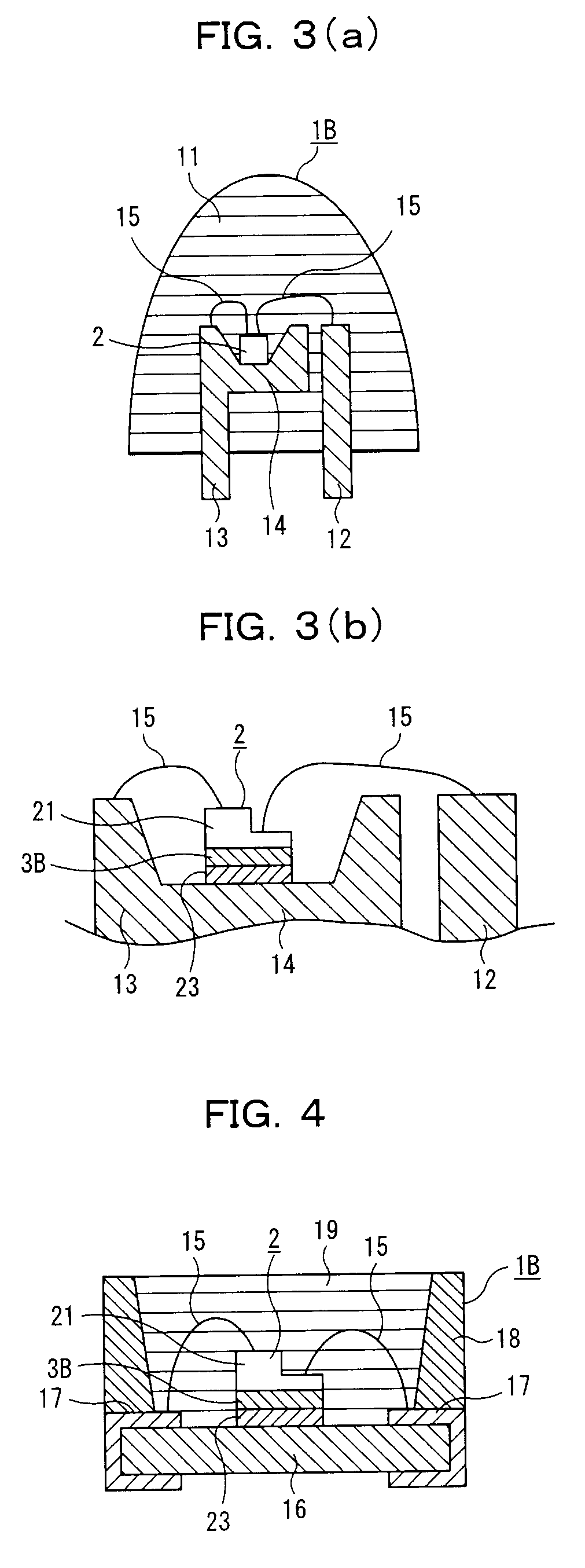

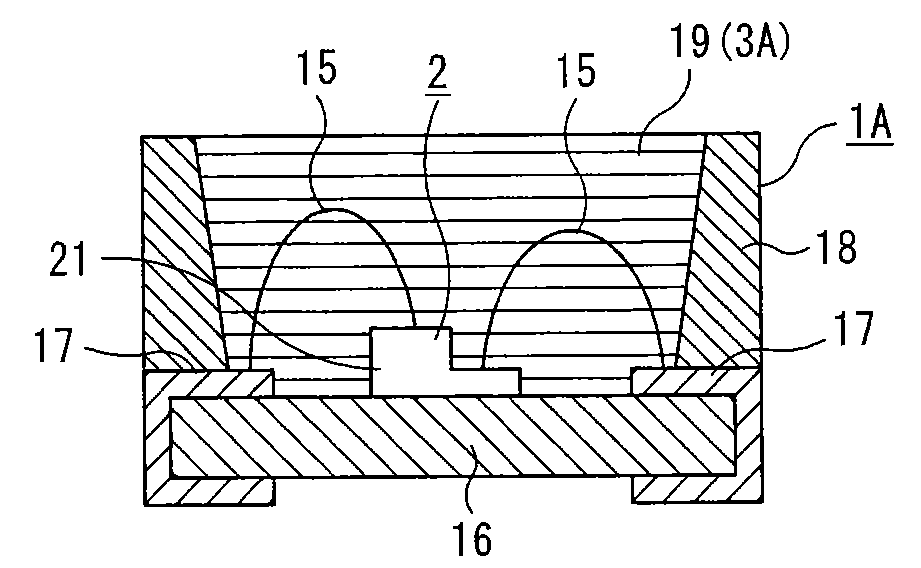

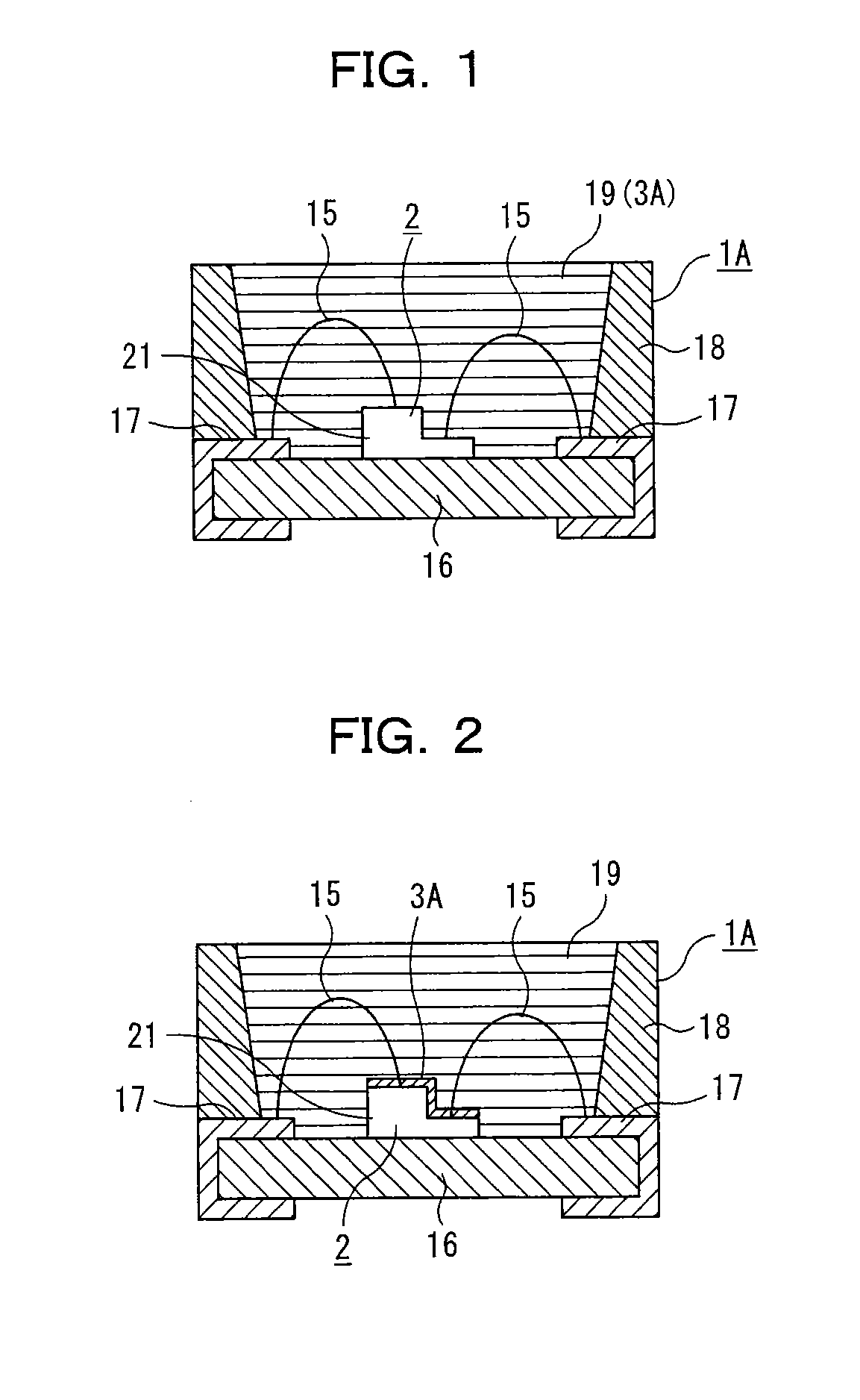

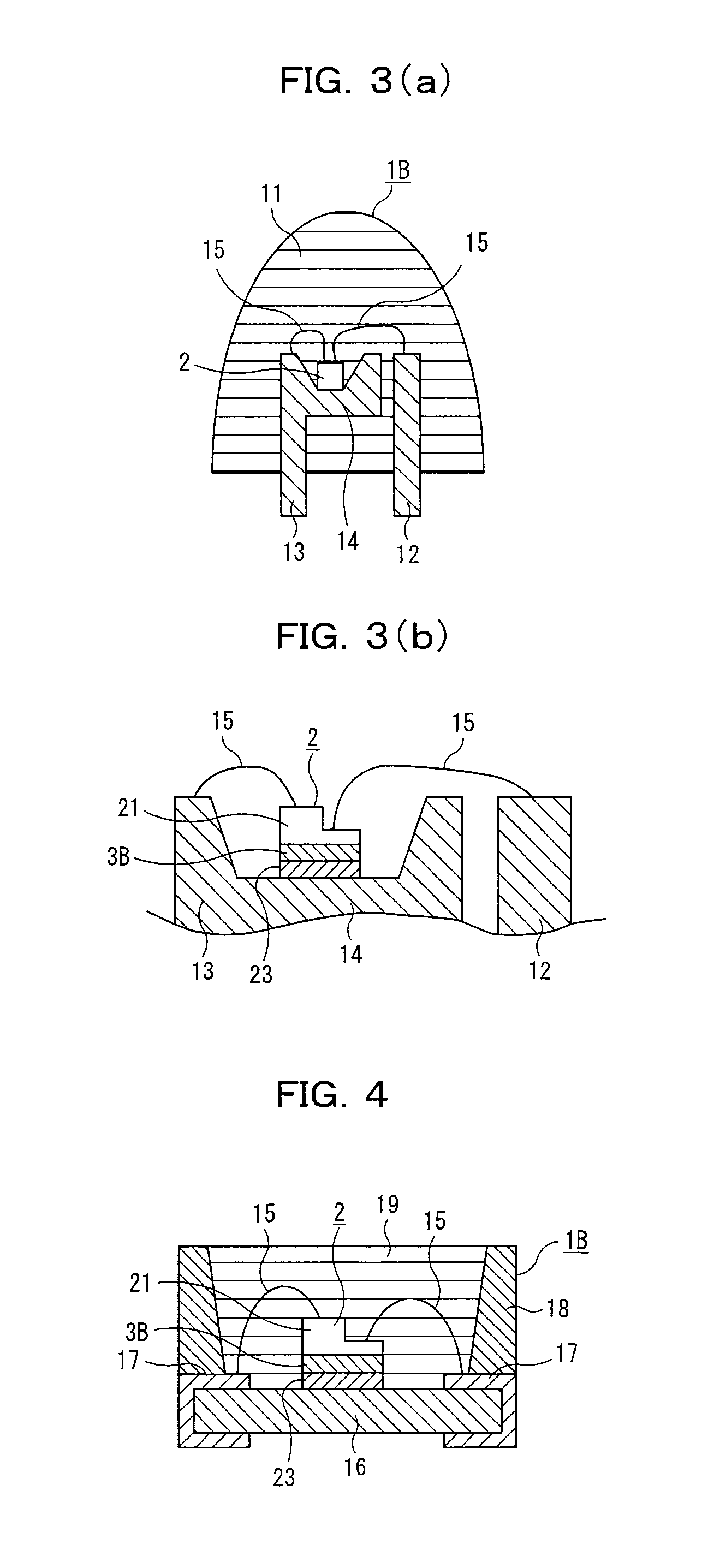

Semiconductor device member, production method of semiconductor-device-member formation liquid and semiconductor device member, and semiconductor-device-member formation liquid, phosphor composition, semiconductor light-emitting device, lighting system and image display system using the same

ActiveUS20090309116A1Improve sealingMaintain performanceSemiconductor/solid-state device detailsSolid-state devicesCrazingDevice material

To provide a semiconductor device member that is superior in heat resistance, light resistance, film-formation capability and adhesion, and is capable of sealing a semiconductor device and holding a phosphor without causing cracks, peelings and colorings even after used for a long period of time, the weight loss at the time of heating, measured by a predetermined weight-loss at-the-time-of-heating measurement method, is 50 weight % or lower and the ratio of peeling, measured by a predetermined adhesion evaluation method, is 30% or lower, in the semiconductor device member.

Owner:MITSUBISHI CHEM CORP

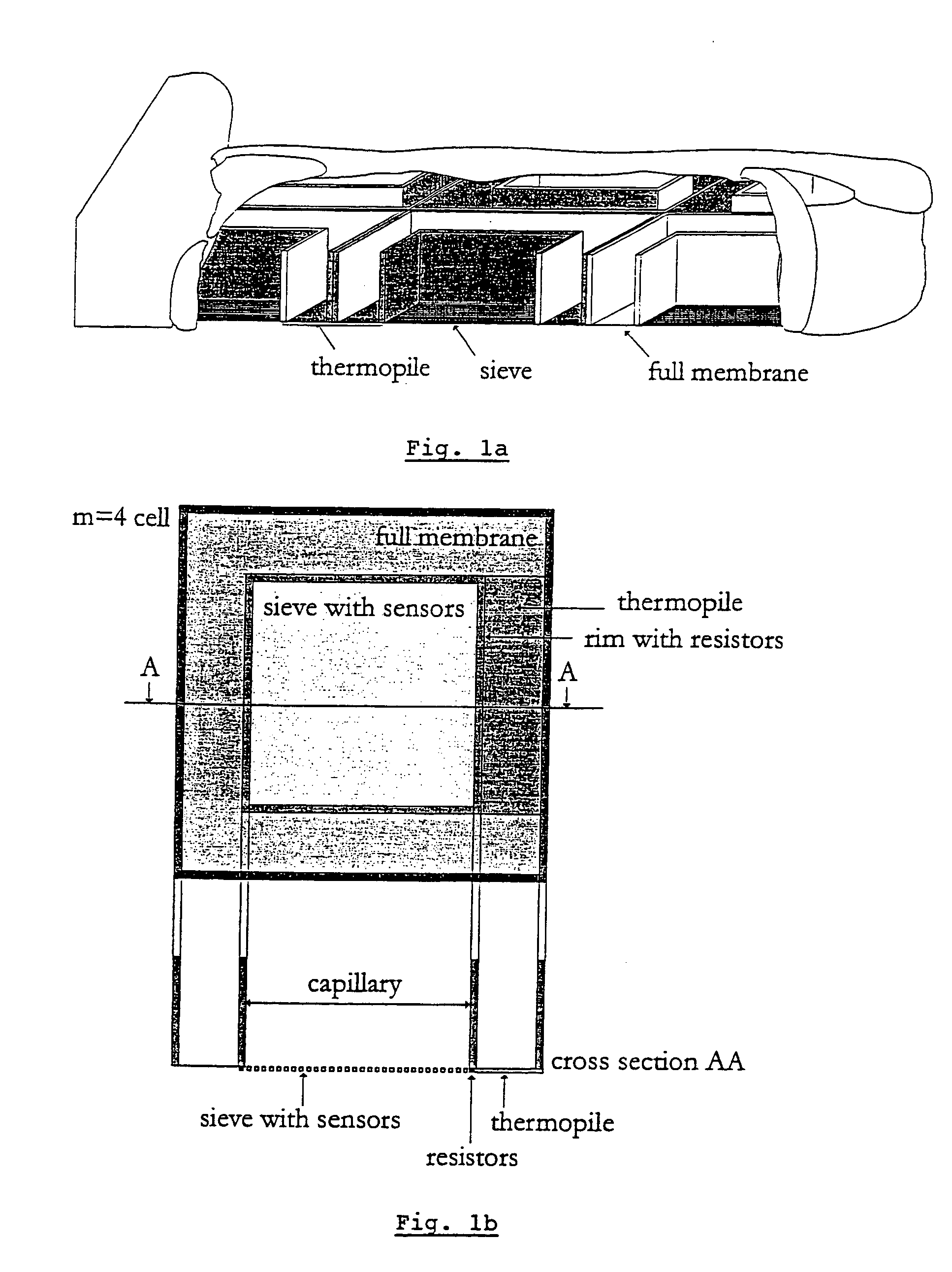

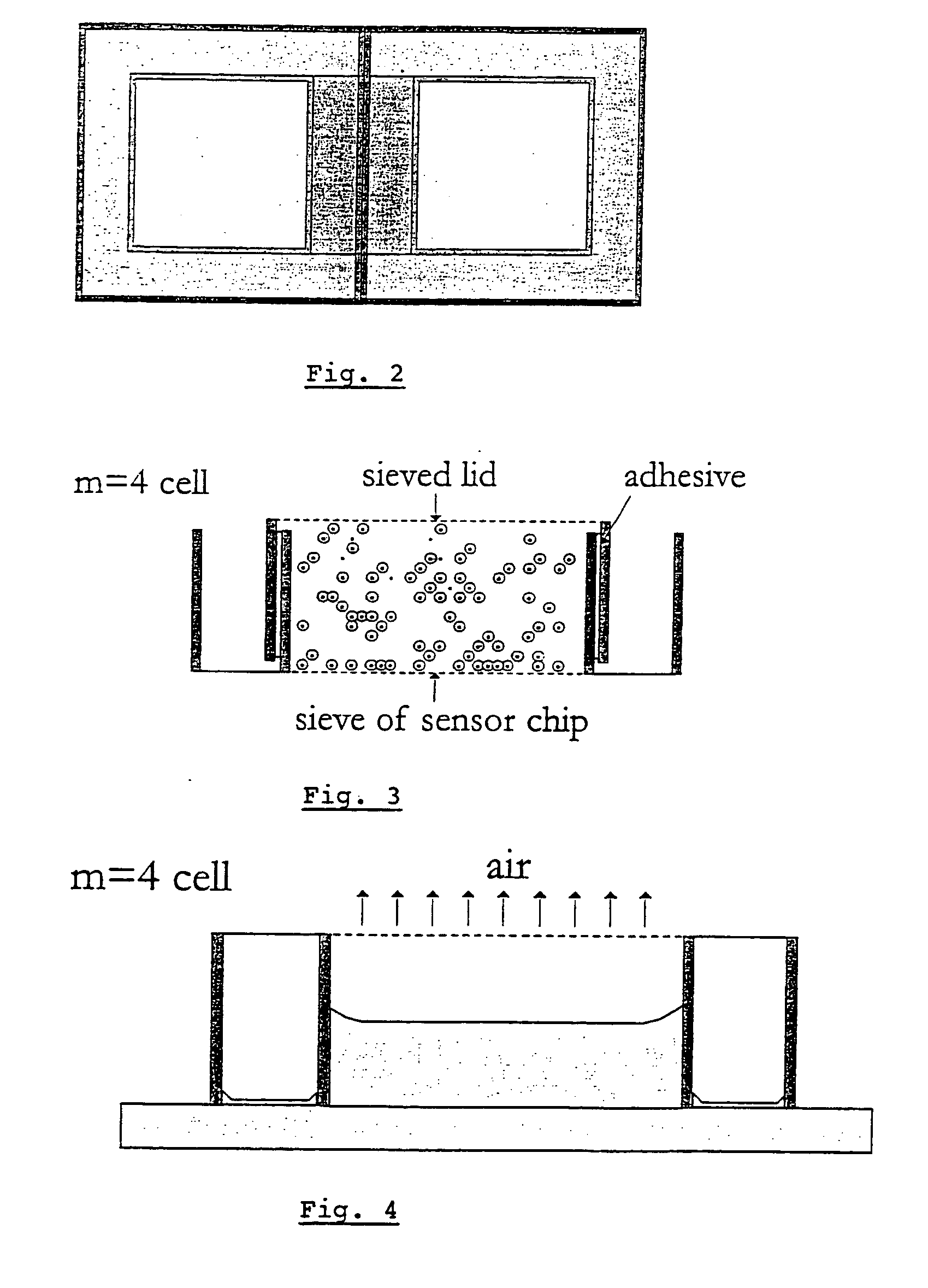

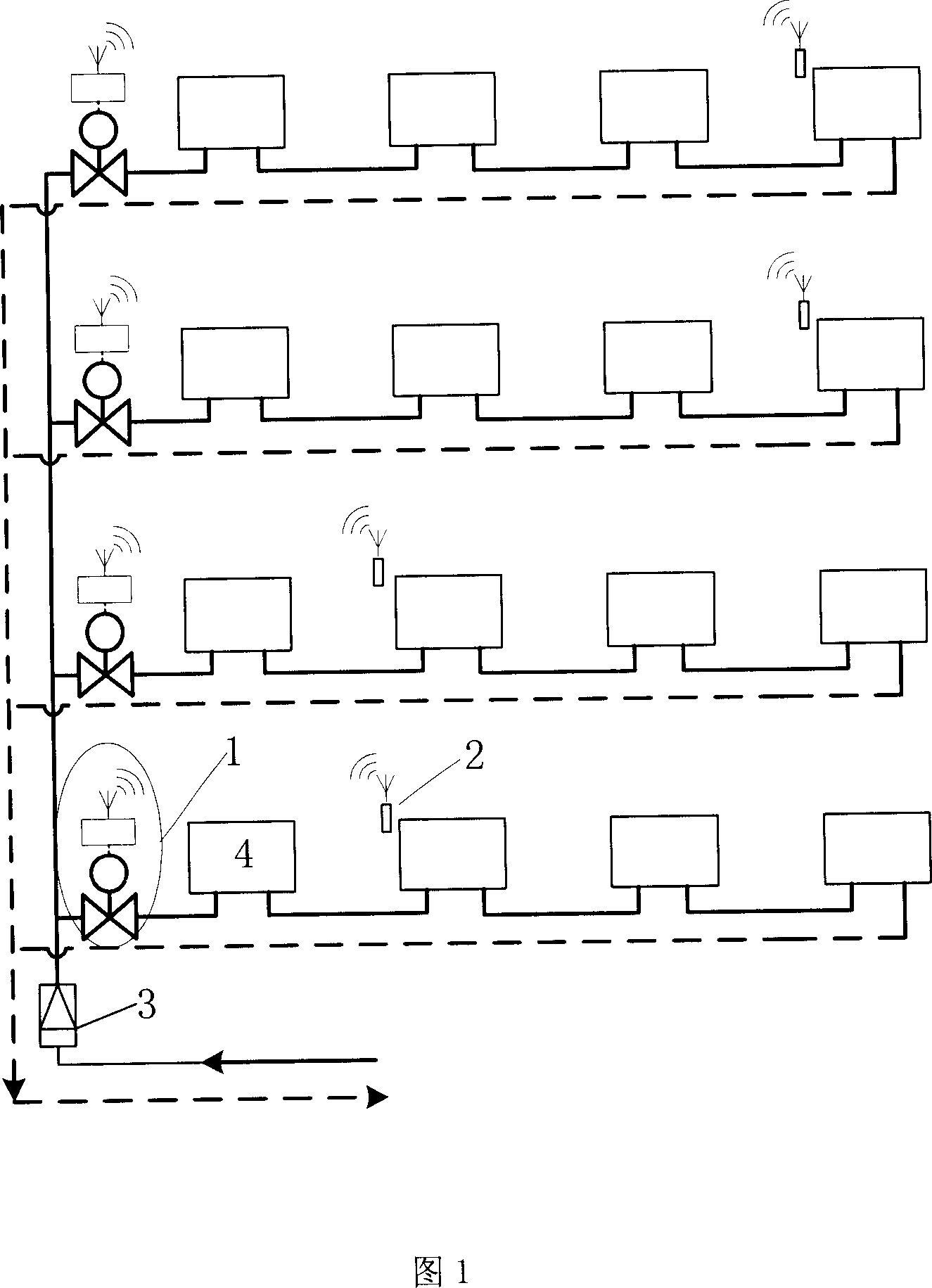

Microphysiometer

InactiveUS20040038228A1Easy to integrateBioreactor/fermenter combinationsBiological substance pretreatmentsChemical stimuliSmall sample

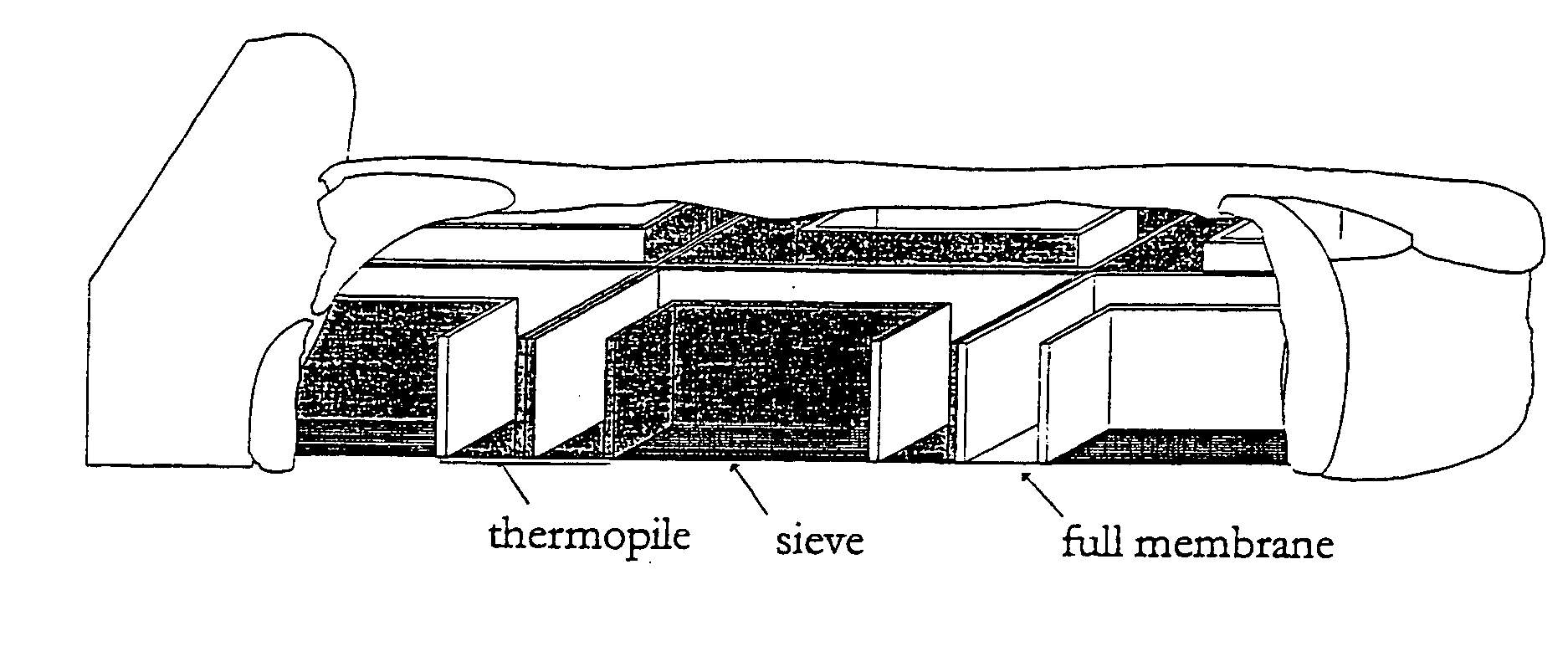

The present invention is related to an array device for monitoring the effect of a physical or chemical stimulus on multiple small samples, said array device comprising a supporting substrate at least two array elements that are separated from each other by a isolation zone, said array elements comprising:.A receiving zone arranged to provide a contact between said one of said samples and said physical or chemical stimulus, said receiving zone having a cross-section smaller than 10 mm..A heat detection means arranged to perform a measurement of heat between said receiving zone and a reference, and said isolation zone being formed by at least part of said supporting substrate characterised in that said supporting substrate has sufficient strength to support said array device and said isolation zone is arranged to thermally isolate said array elements.

Owner:TTP LABTECH

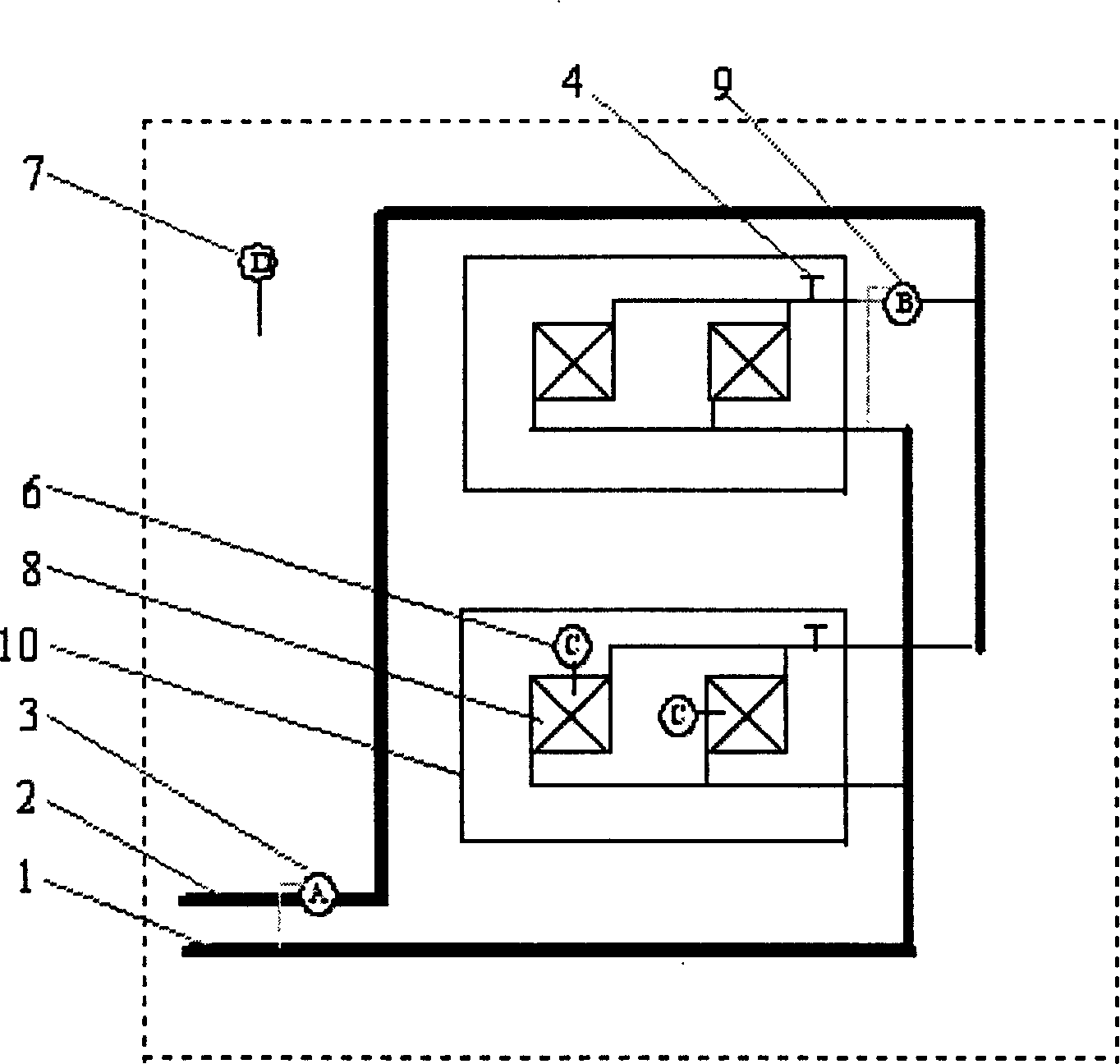

Method and device for simultaneously implementing heat regulation and heat measurement

InactiveCN1952494ASmall heat transfer temperature differenceReduce heat transferLighting and heating apparatusSpace heating and ventilation detailsRoom temperatureEngineering

The invention relates to a method that can accomplish heat adjusting and meter at one time and the equipment, belonging to HVAC area. Said method is that calorimeter is set at the heat inlet of each building to calculate the total heat, which is seen as heat supply charge basis of the building; on-off control valve for room-temperature is set on each said branch pipe of inlet and user can set room-temperature arbitrarily in certain range by the room-temperature controller or put room-temperature controller at any position according to the demand; said room-temperature measures the room temperature and transmits the room-temperature signal measured and set by user to on-off control valve for room-temperature wirelessly and the opening time of valve is calculated and stored by control strategy for building heat characteristic in the on-off control valve so as to adjust on-off control valve for room-temperature with the purpose of controlling room-temperature; and then according to accumulative opening time of on-off control valve for room-temperature and indoor area heat supply for user is allocated. The invention can realize heat adjusting and meter at one time.

Owner:TSINGHUA UNIV

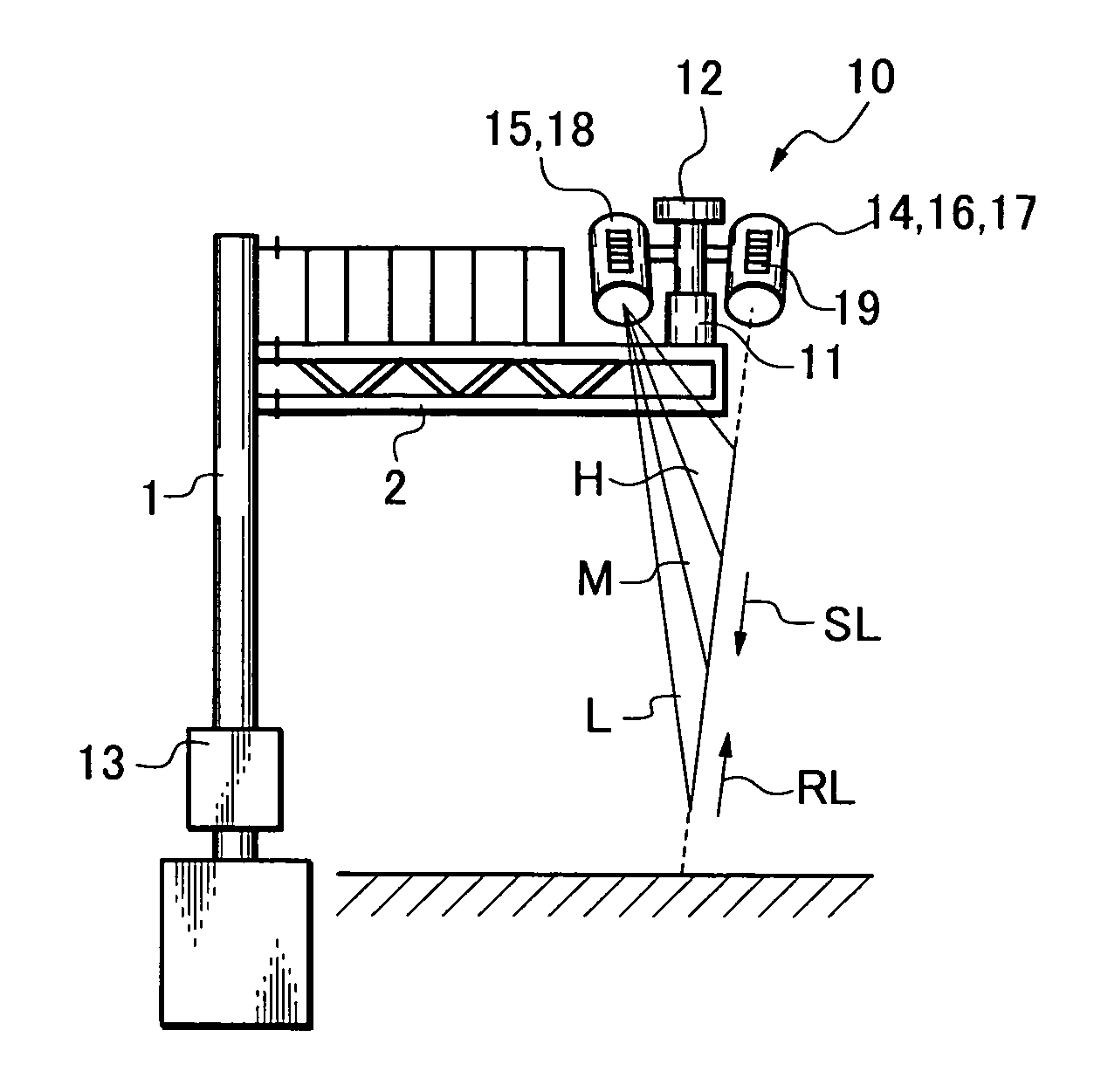

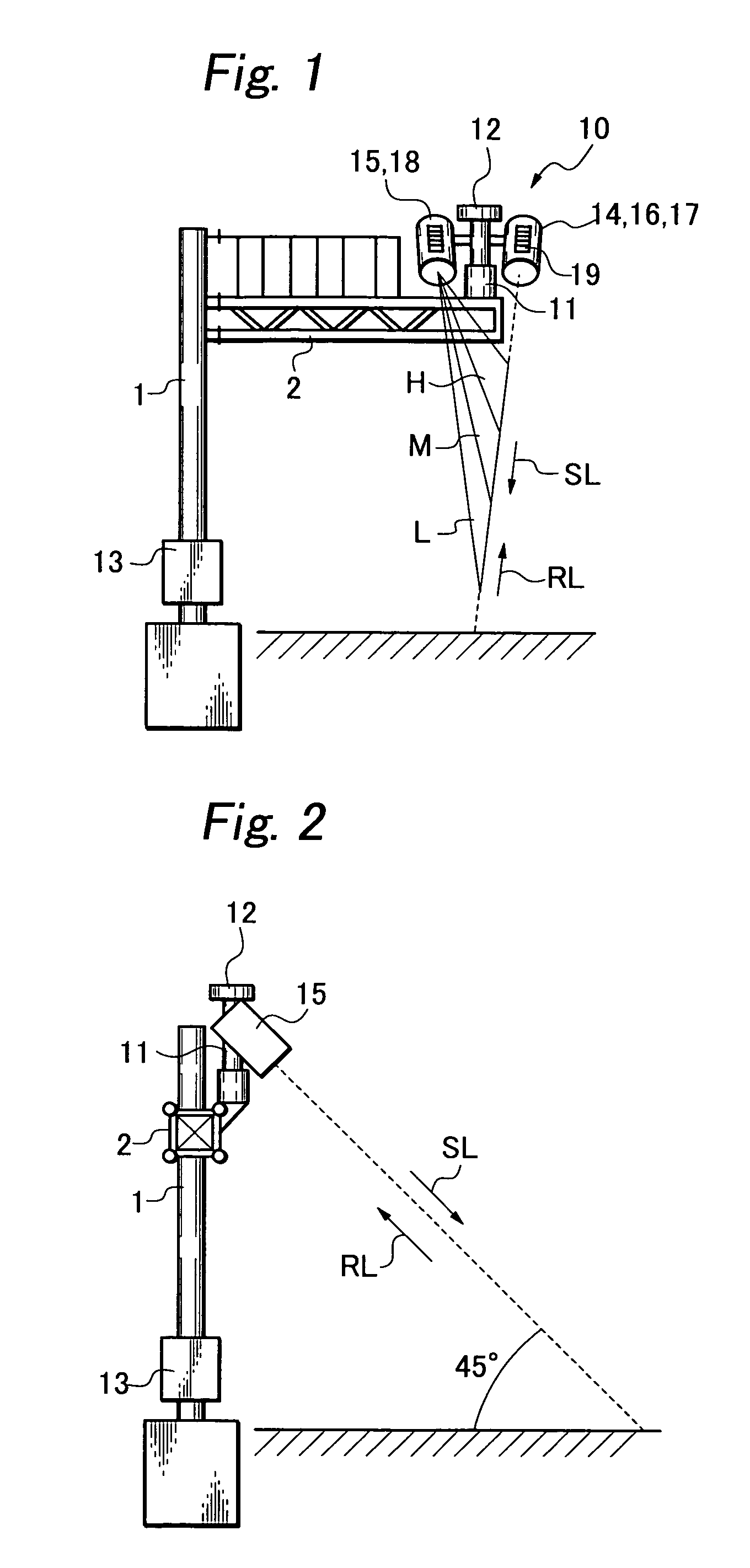

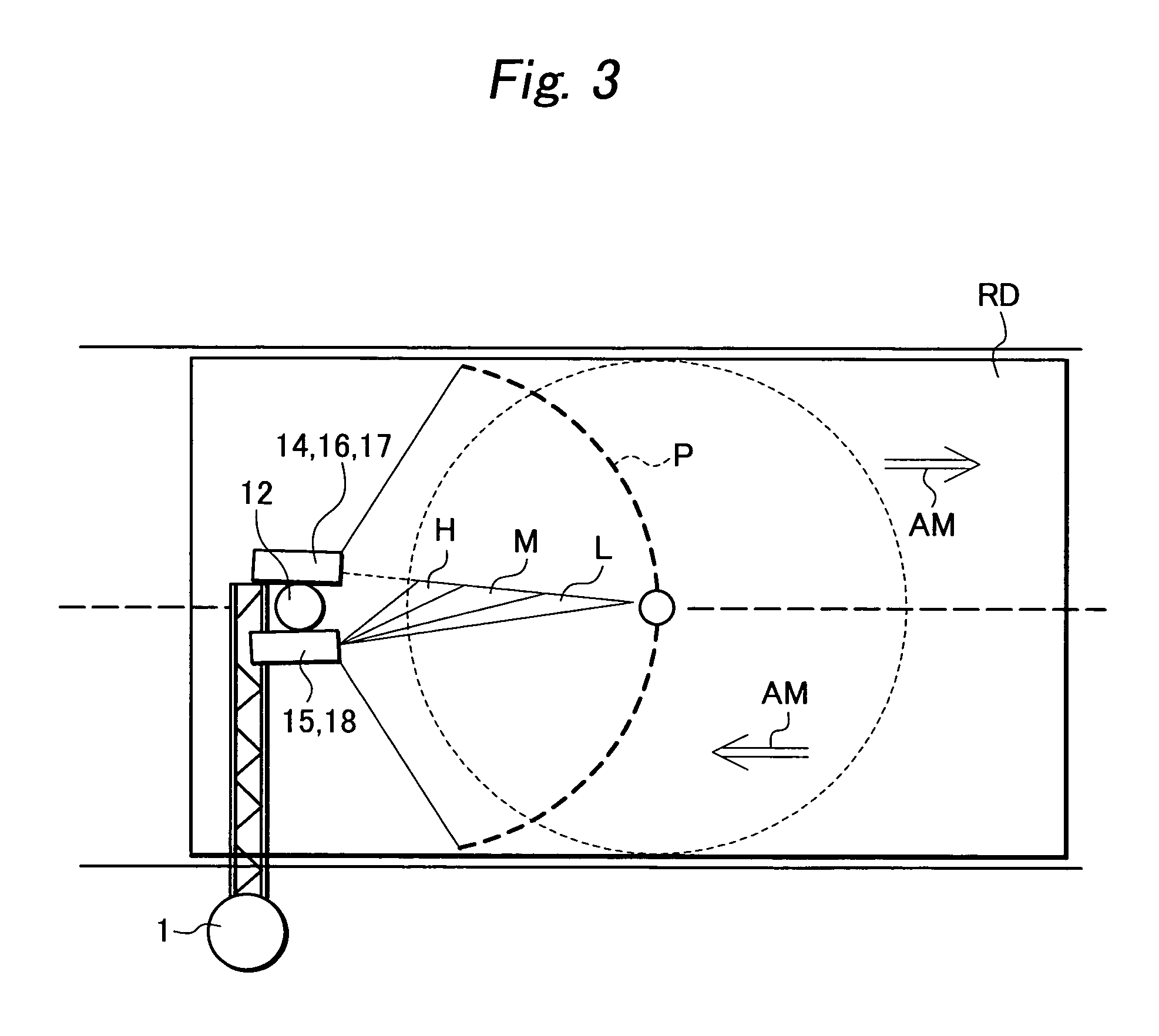

Road surface sensor and monitoring control method for road surface

InactiveUS20050047864A1Don't waste energyRainfall/precipitation gaugesIn situ pavingsSnow meltingEngineering

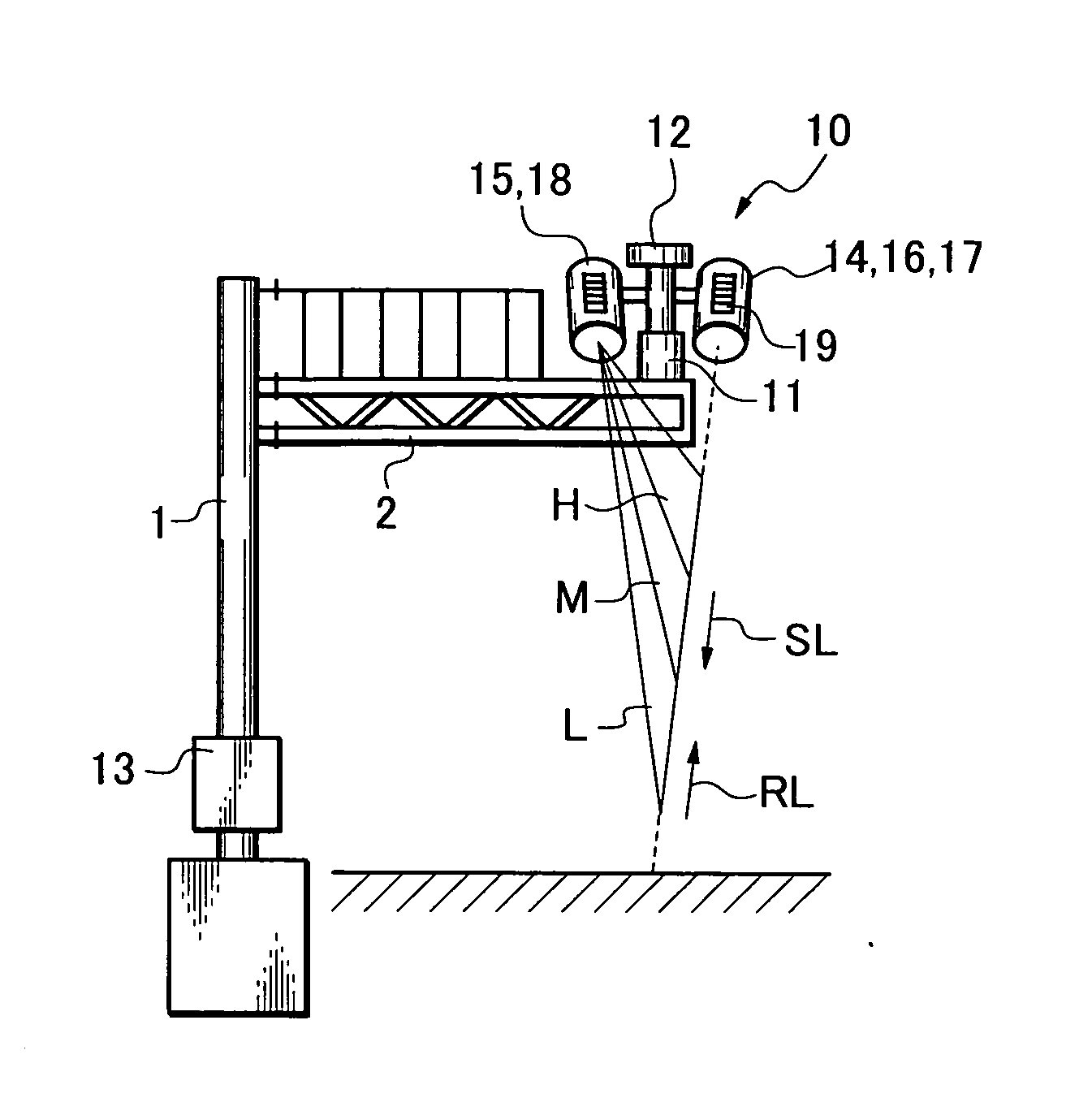

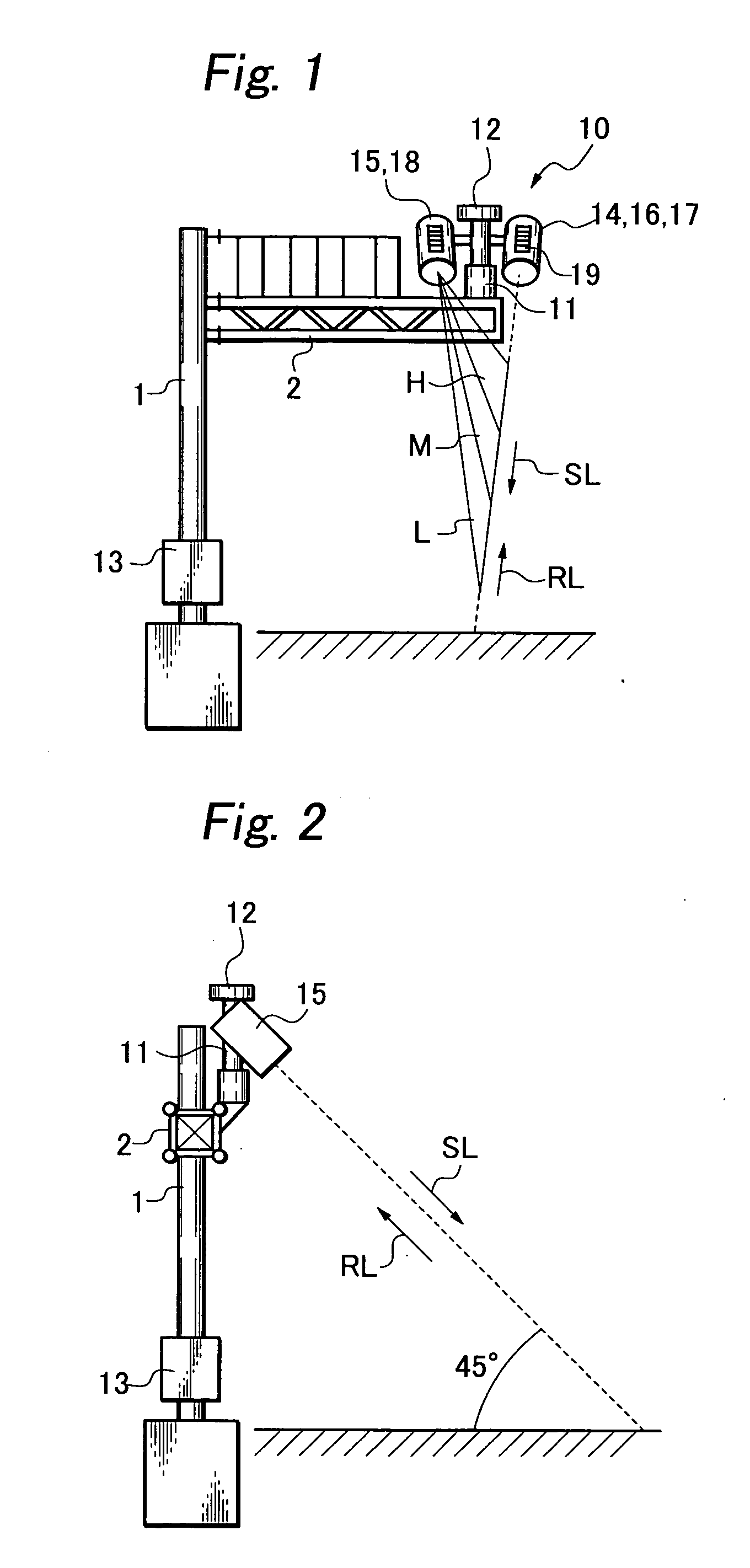

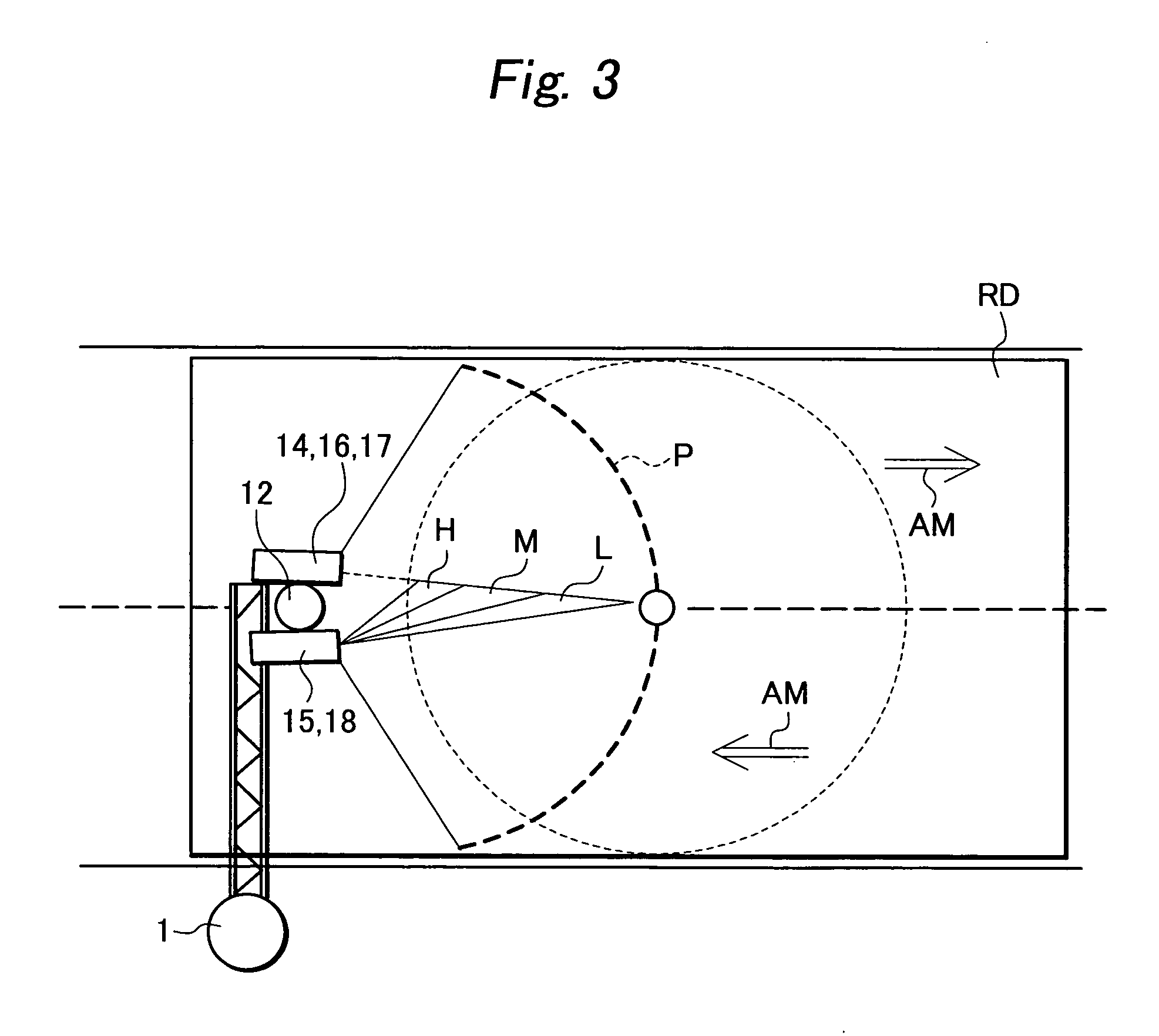

In order to melt snow and prevent freezing without consuming energy wastefully and to monitor a road surface state remotely, a road surface sensor includes: a rotating stand provided so as to be reciprocatingly rotatable upward on the road surface; a snow-melting / freezing heat quantity measurement dummy road surface having an electric heater buried therein and to use as a reference road surface for heat quantity measurement to derive a melting heat quantity for snow falling on the surface and a heat quantity required for freezing prevention; a reference light irradiating / reflected light receiving device that is attached so as to be rotatable with the rotating stand; a space reflected light receiving device; a non-contact road temperature measuring device; a non-contact snow cover depth measuring device; a road surface image pickup device; and a moisture sensor. The reference light irradiating / reflected light receiving device includes a reference light irradiating device for irradiating reference light and a reflected light receiving device for receiving reflected light of the reference light from the road surface, and the reflected light receiving device separates and receives only reflected light of the reference light out of the reflected light from the road surface.

Owner:YAMADA TECH CORP +1

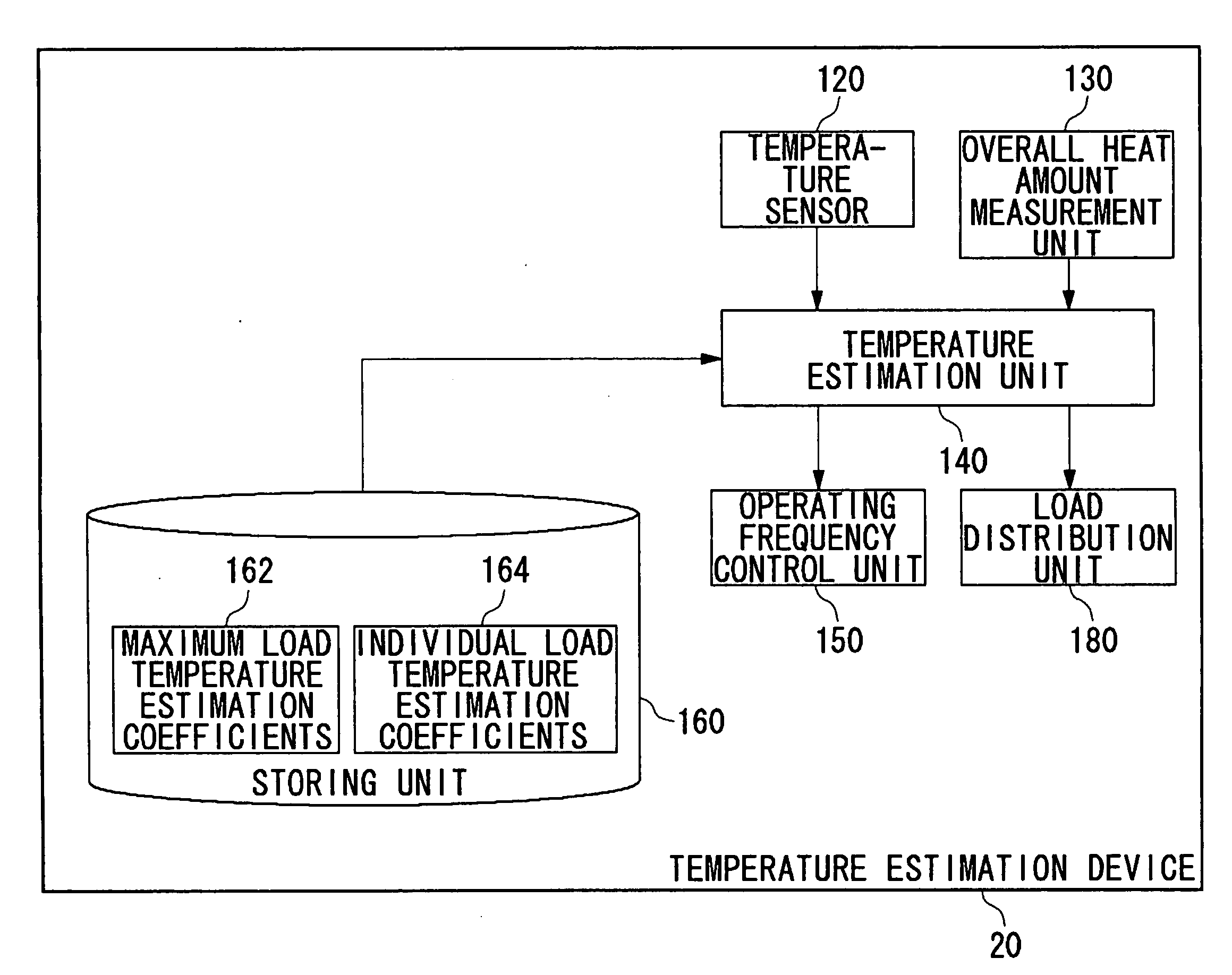

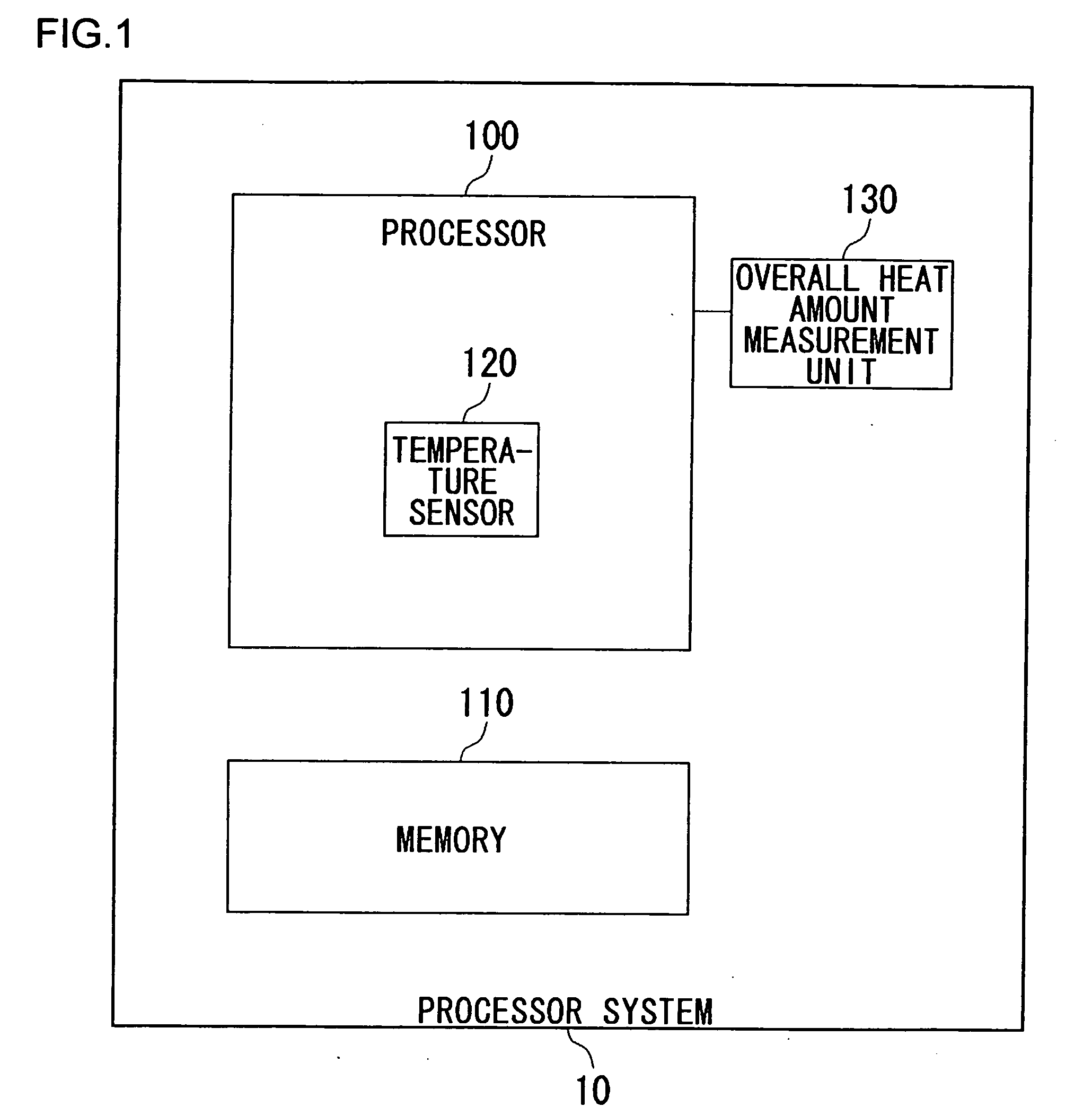

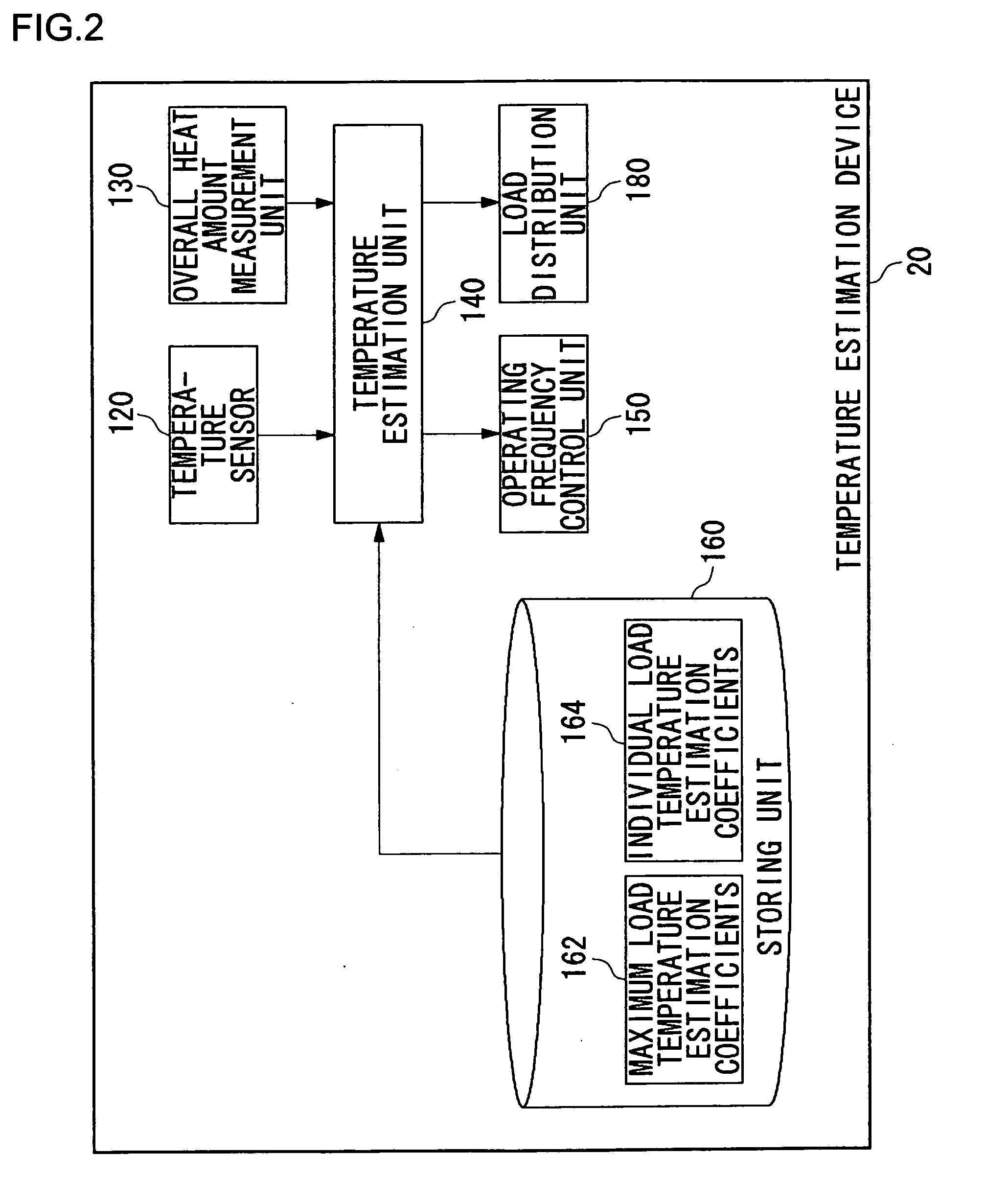

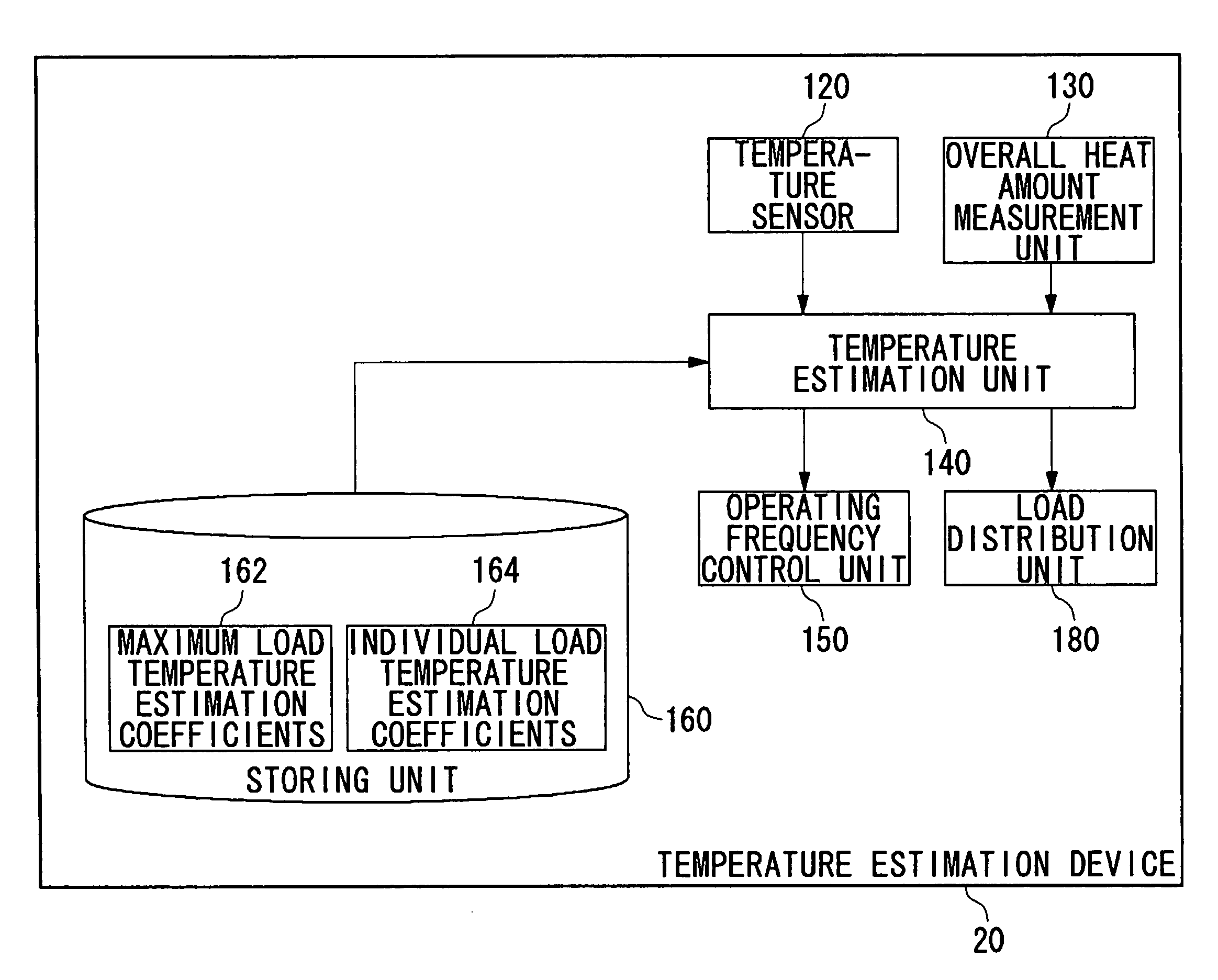

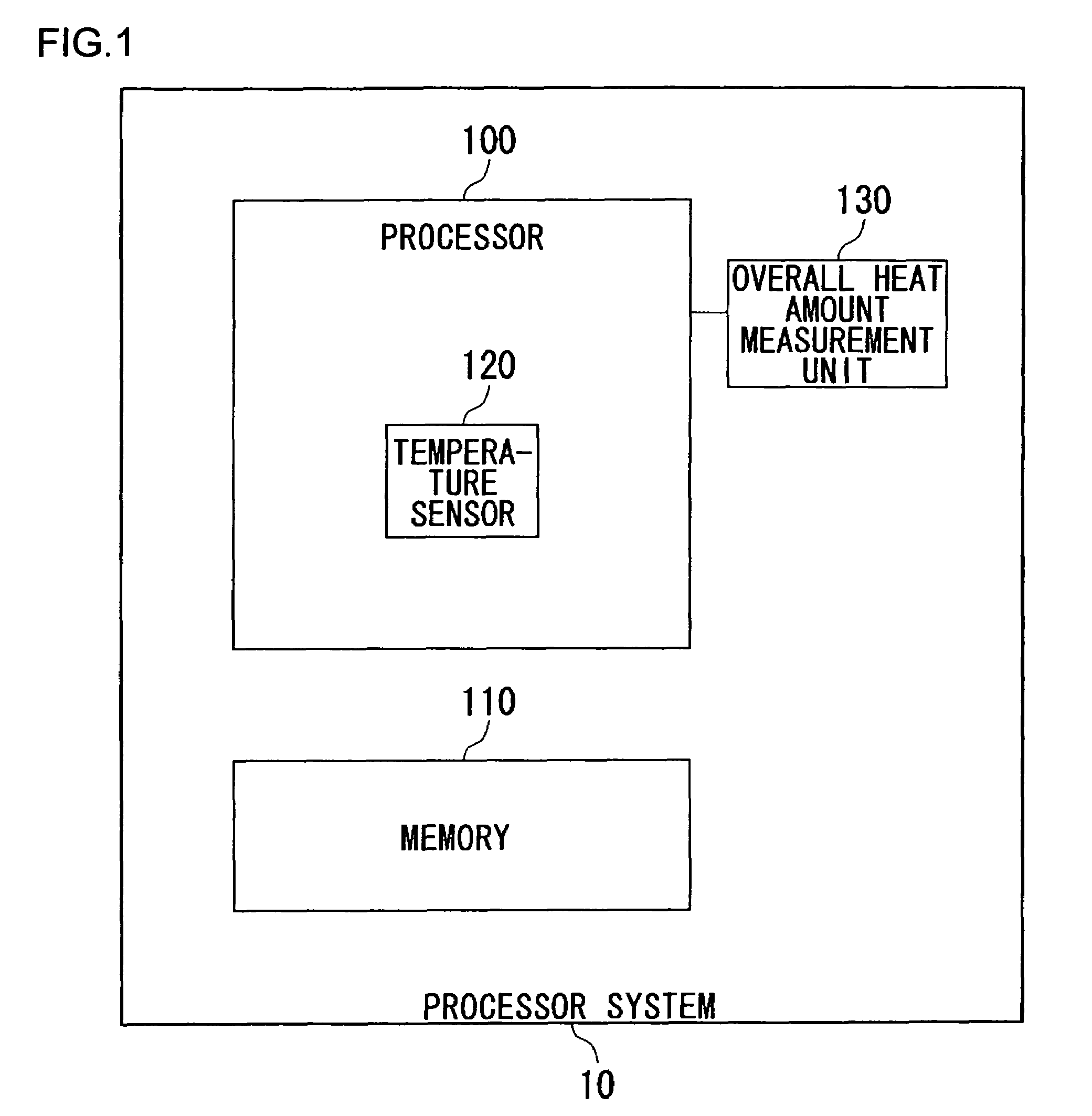

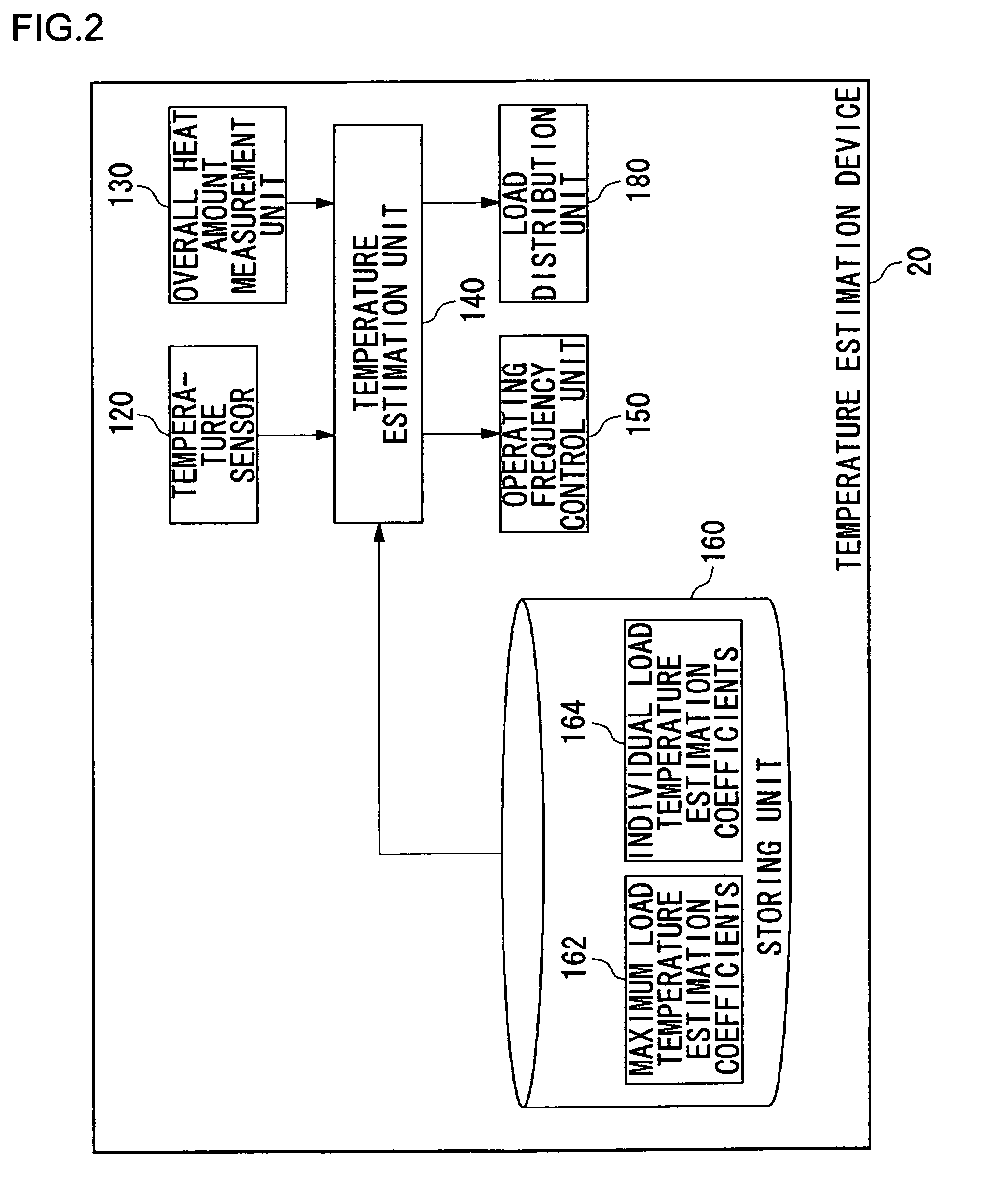

Processor, Processor System, Temperature Estimation Device, Information Processing Device, And Temperature Estimation Method

ActiveUS20080043807A1Accurate graspRelatively small errorThermometer detailsEnergy efficient ICTInformation processingEstimation methods

A temperature sensor measures a temperature of a certain location inside a processor. An overall heat amount measurement unit measures the overall amount of heat of the processor. A temperature estimation unit estimates the temperatures of a plurality of hot spots occurring in the processor based on the temperature of the certain location detected by the temperature sensor, and determines the maximum temperature of the processor. The temperature estimation unit switches between maximum load temperature estimation coefficients and individual load temperature estimation coefficients stored in a storing unit for reference, depending on the overall amount of heat of the processor, and applies them to a temperature estimation function(s) for converting the sensor temperature into the temperatures of the hot spots. An operating frequency control unit exercises control for lowering the operating frequency of the processor when the maximum temperature of the processor estimated by the temperature estimation unit exceeds a predetermined limit temperature.

Owner:SONY COMPUTER ENTERTAINMENT INC

Processor, processor system, temperature estimation device, information processing device, and temperature estimation method

ActiveUS7520669B2Accurate graspRelatively small errorThermometer detailsThermometers using electric/magnetic elementsInformation processingEstimation methods

A temperature sensor measures a temperature of a certain location inside a processor. An overall heat amount measurement unit measures the overall amount of heat of the processor. A temperature estimation unit estimates the temperatures of a plurality of hot spots occurring in the processor based on the temperature of the certain location detected by the temperature sensor, and determines the maximum temperature of the processor. The temperature estimation unit switches between maximum load temperature estimation coefficients and individual load temperature estimation coefficients stored in a storing unit for reference, depending on the overall amount of heat of the processor, and applies them to a temperature estimation function(s) for converting the sensor temperature into the temperatures of the hot spots. An operating frequency control unit exercises control for lowering the operating frequency of the processor when the maximum temperature of the processor estimated by the temperature estimation unit exceeds a predetermined limit temperature.

Owner:SONY COMPUTER ENTERTAINMENT INC

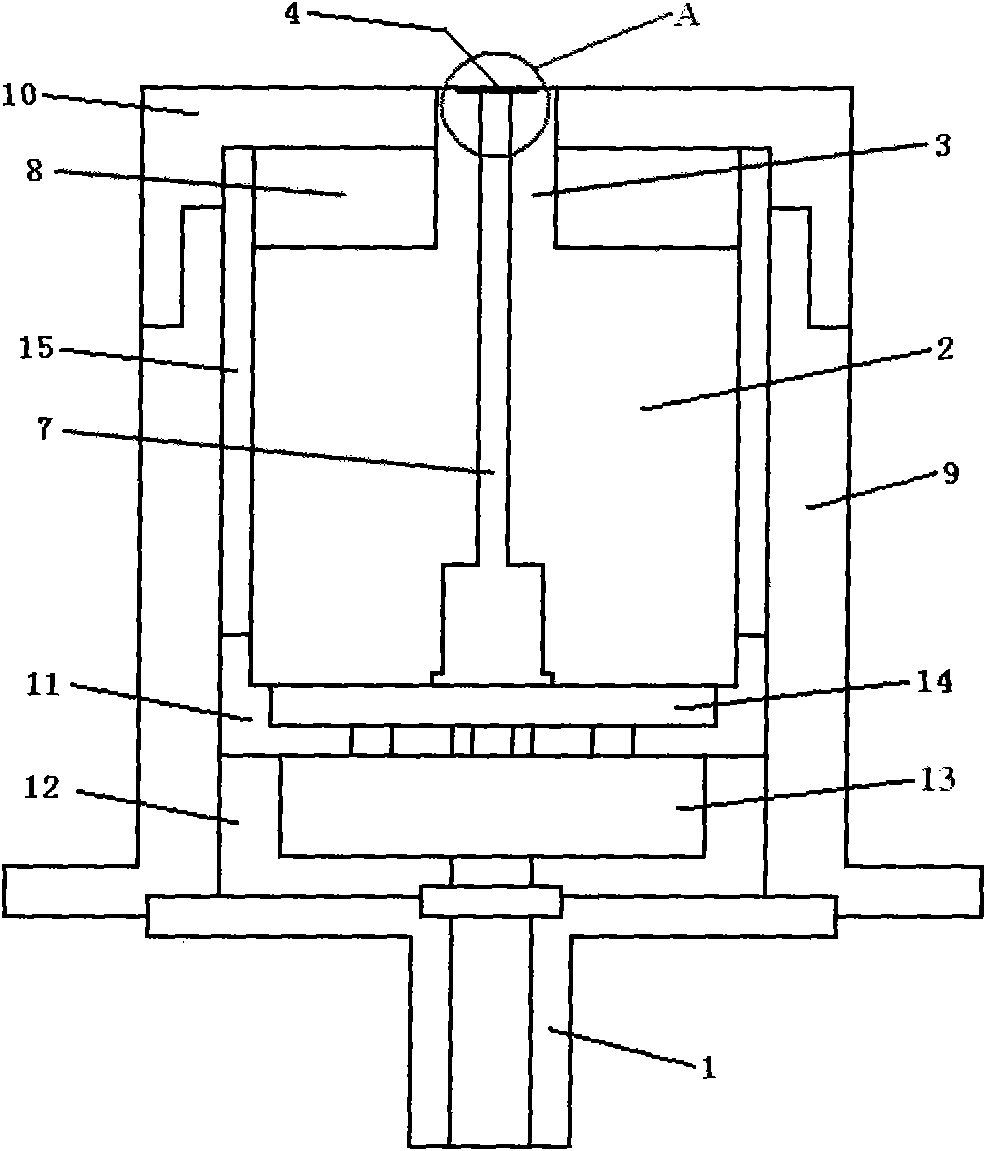

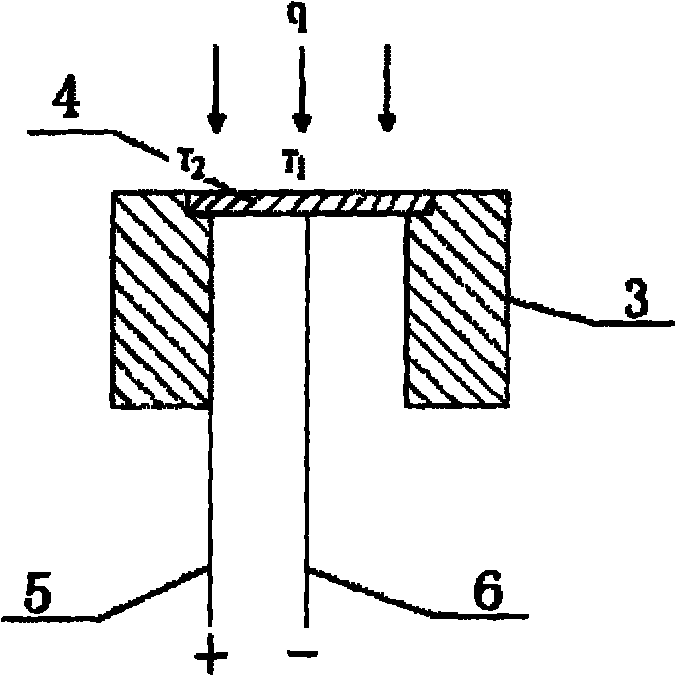

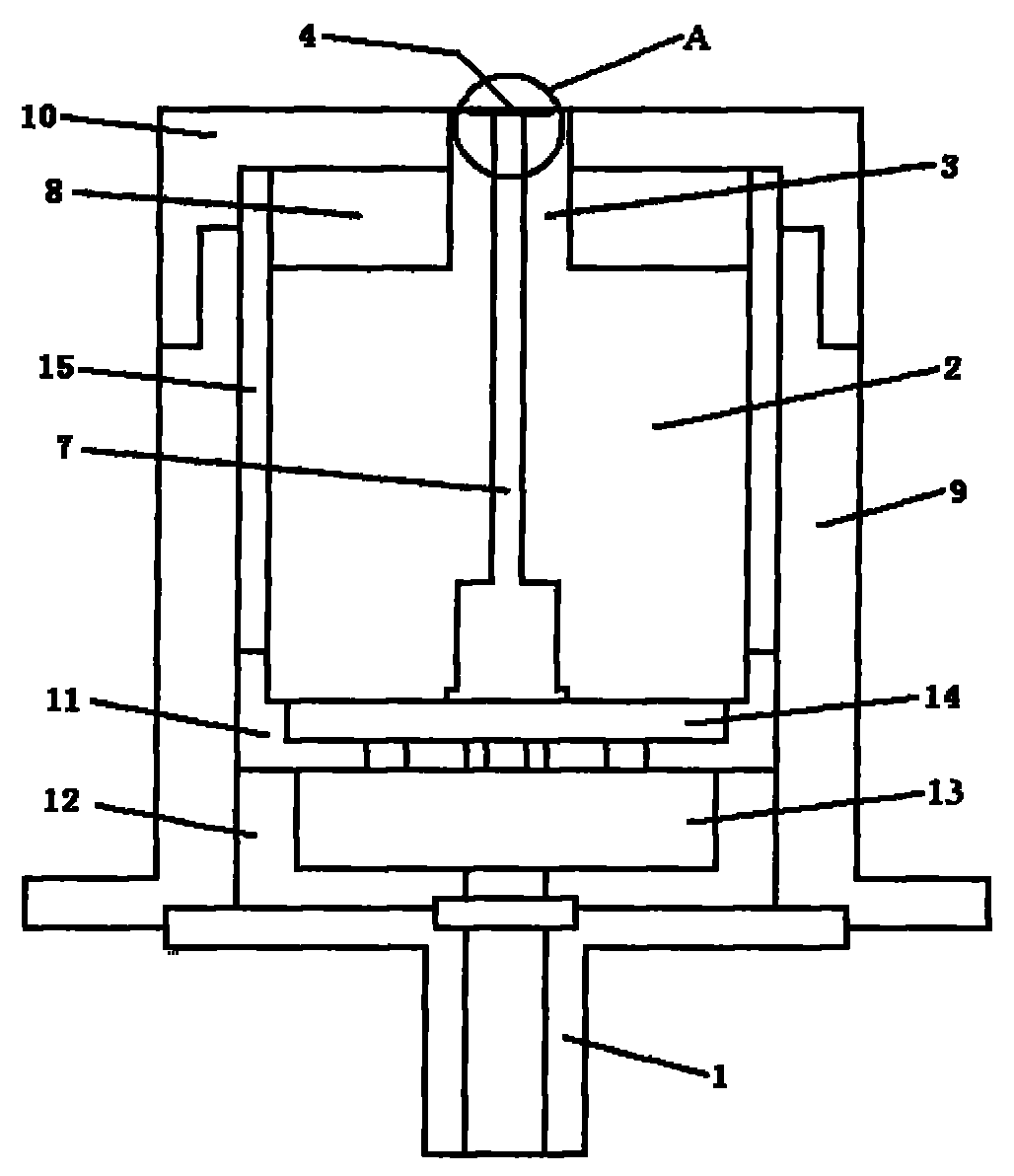

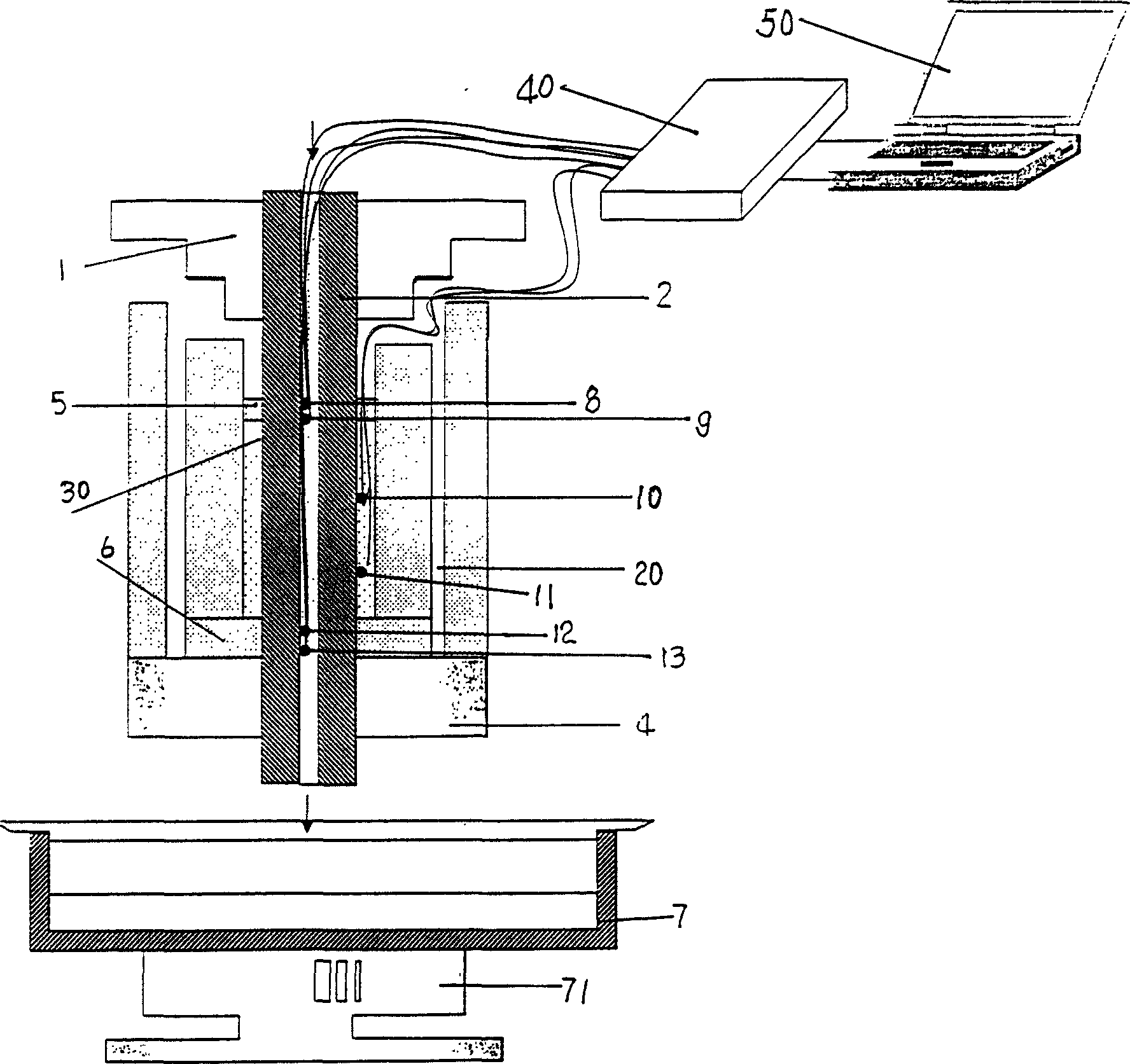

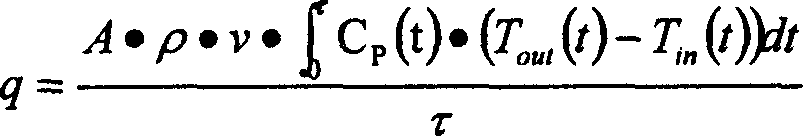

Round chaff type large-scale high-temperature heat flux sensor

InactiveCN101769795AGood insulation structureExtended working hoursPyrometry using electric radation detectorsHeat flowHeat measurement

The invention relates to the field of heat flux measurement, in particular to a round chaff type large-scale high-temperature heat flux sensor. The invention solves the problems that the heat sinking body of the existing round chaff type heat flux sensor is difficult to realize constant temperature, and the like. The round chaff type large-scale high-temperature heat flux sensor comprises a shell with a bottom cover and a heat sinking body, wherein the heat sinking body is composed of a main body and a columnar boss arranged at the center of the top part of the main body, and the top part of the shell is provided with a through hole for inlaying the columnar boss of the top part of the heat sinking body. The columnar boss is inlaid with a round chaff, and the center and the edge of the round chaff are respectively inlaid with lead wires forming thermocouple with the round chaff. The columnar boss is externally sheathed with an adiabatic ring arranged between the main body of the heat sinking body and the shell, and the shell is composed of a tubular shell body and a ceramic top cover. Two disk-shaped ceramic supports are stacked between the bottom part of the main body of the heat sinking body and the bottom cover of the shell, and air adiabatic layers are respectively arranged between the two disk-shaped ceramic supports, between the top disk-shaped ceramic support and the bottom part of the heat sinking body and between the side wall of the main body of the heat sinking body and the inner wall of the shell. With reasonable and optimized structure, the round chaff type large-scale high-temperature heat flux sensor can work for a long time in the high-temperature environment to realize large-scale measurement.

Owner:ZHONGBEI UNIV

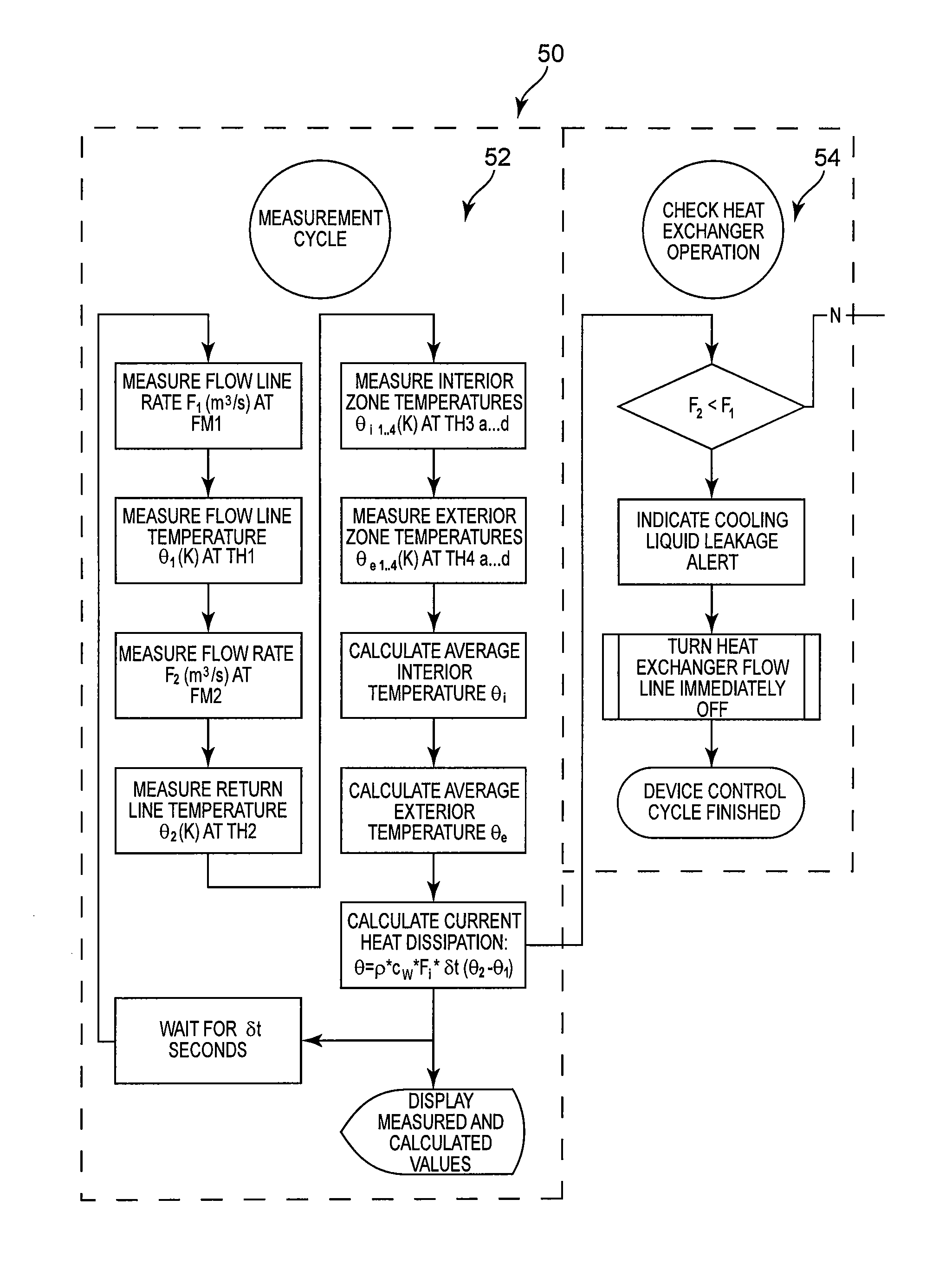

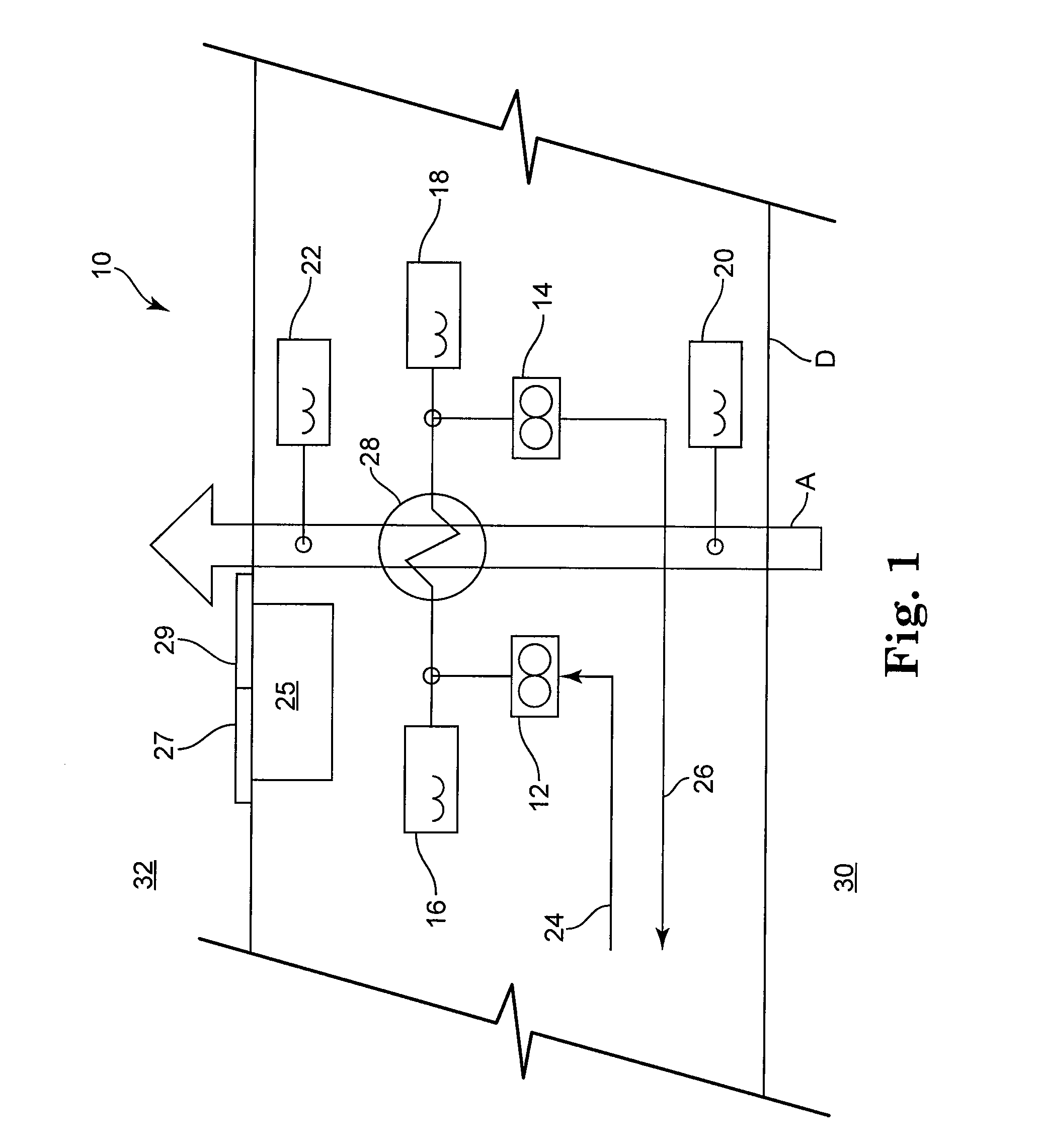

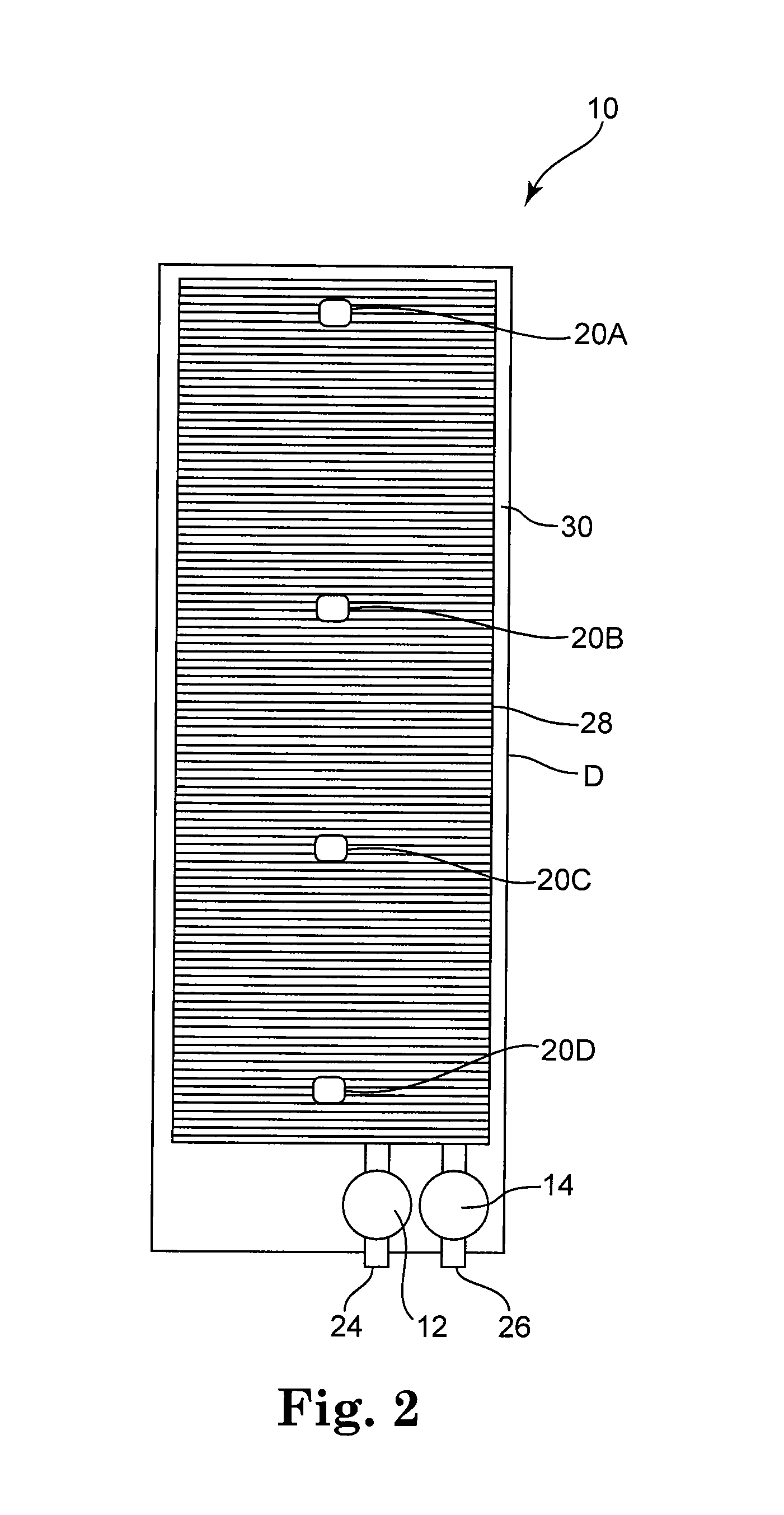

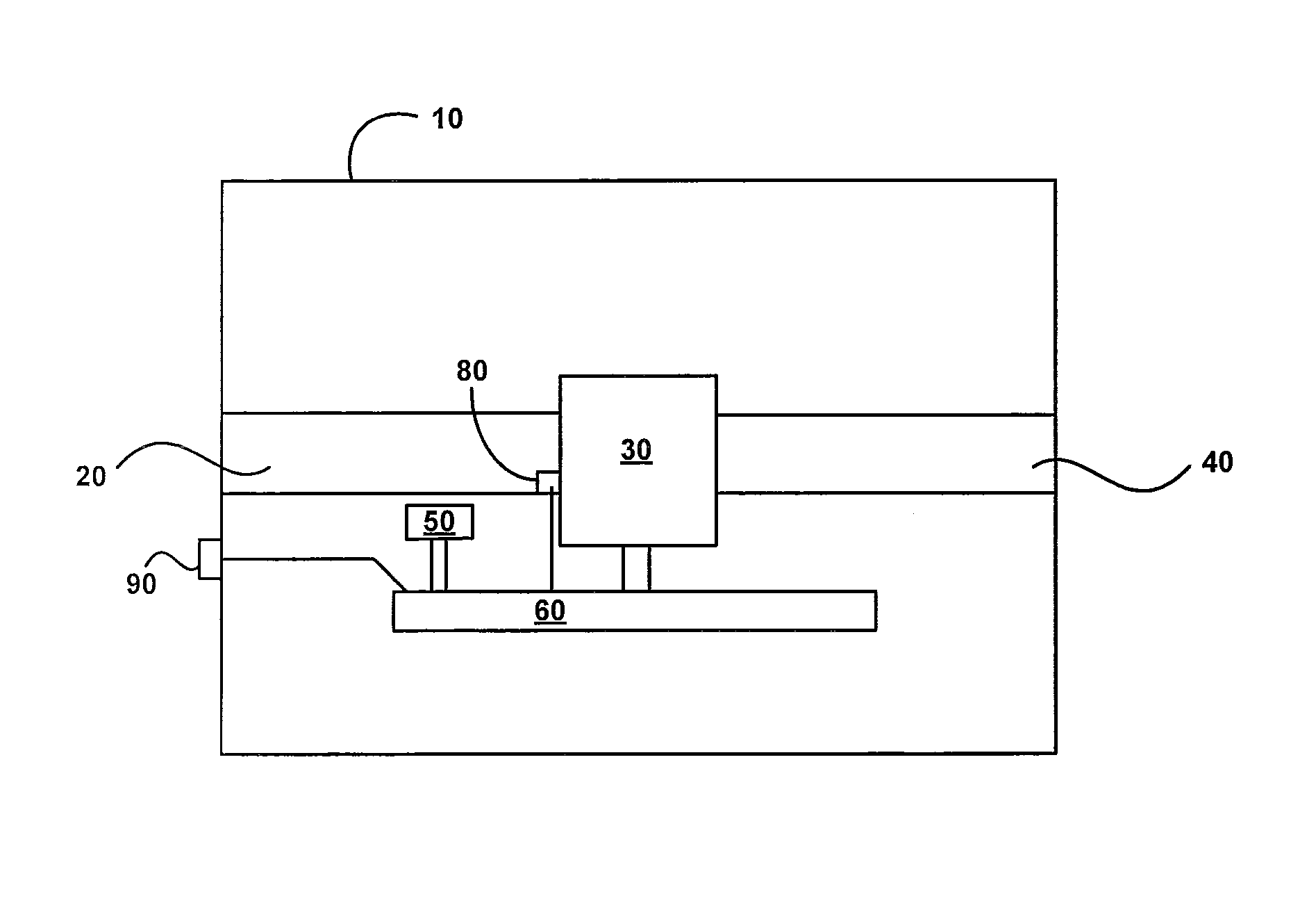

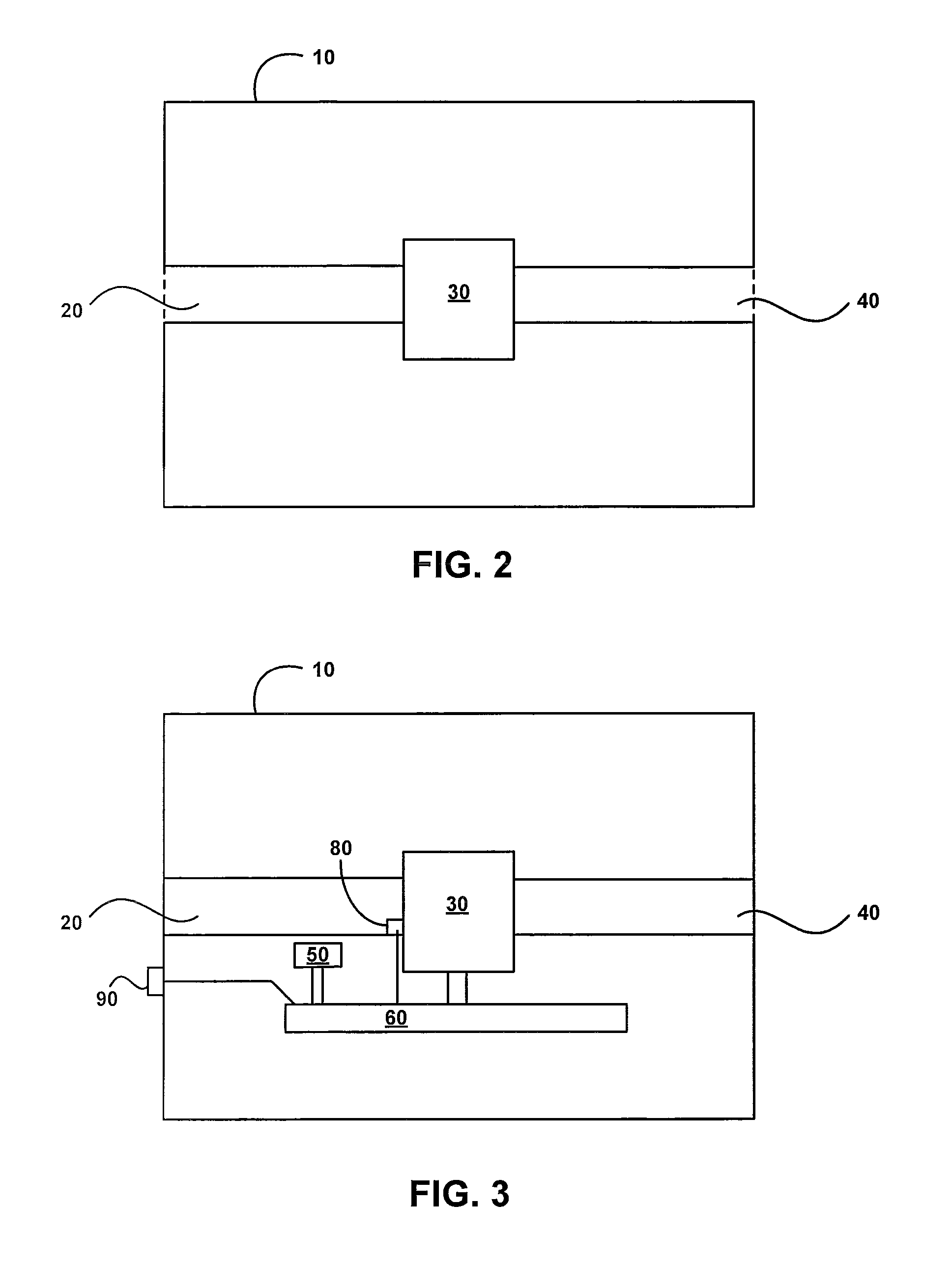

Rear door heat exchanger instrumentation for heat quantity measurement

InactiveUS7548170B1Increase airflowIncrease load levelDomestic cooling apparatusAlarmsComputerized systemTransport medium

A method for controlling operation of a heat exchanger system comprises providing a heat exchanger system mountable to a rear door of a rack mounted computer system, circulating a heat transport medium through the heat exchanger system, detecting leaks in the heat exchanger system by comparing a first flow rate in an inflow line to a second flow rate in a return flow line, emitting a leakage alert and ceasing further circulation of the heat transport medium through the heat exchanger system when the first flow rate exceeds the second flow rate by a predetermined flow amount, optimizing operation of the rack mounted computer system by monitoring an interior temperature of the rack mounted computer system in a plurality of vertical zones, and optimizing operation of the heat exchanger system by comparing a second temperature measured by a second temperature sensor in the return flow line with a predetermined maximum return flow temperature value.

Owner:IBM CORP

Semiconductor device member, production method of semiconductor-device-member formation liquid and semiconductor device member, and semiconductor-device-member formation liquid, phosphor composition, semiconductor light-emitting device, lighting system and image display system using the same

InactiveUS20130037748A1Improve adhesionImprove rendering capabilitiesSemiconductor/solid-state device detailsSolid-state devicesHeat resistancePhosphor

To provide a semiconductor device member that is superior in heat resistance, light resistance, film-formation capability and adhesion, and is capable of sealing a semiconductor device and holding a phosphor without causing cracks, peelings and colorings even after used for a long period of time, the weight loss at the time of heating, measured by a predetermined weight-loss at-the-time-of-heating measurement method, is 50 weight % or lower and the ratio of peeling, measured by a predetermined adhesion evaluation method, is 30% or lower, in the semiconductor device member.

Owner:MITSUBISHI CHEM CORP

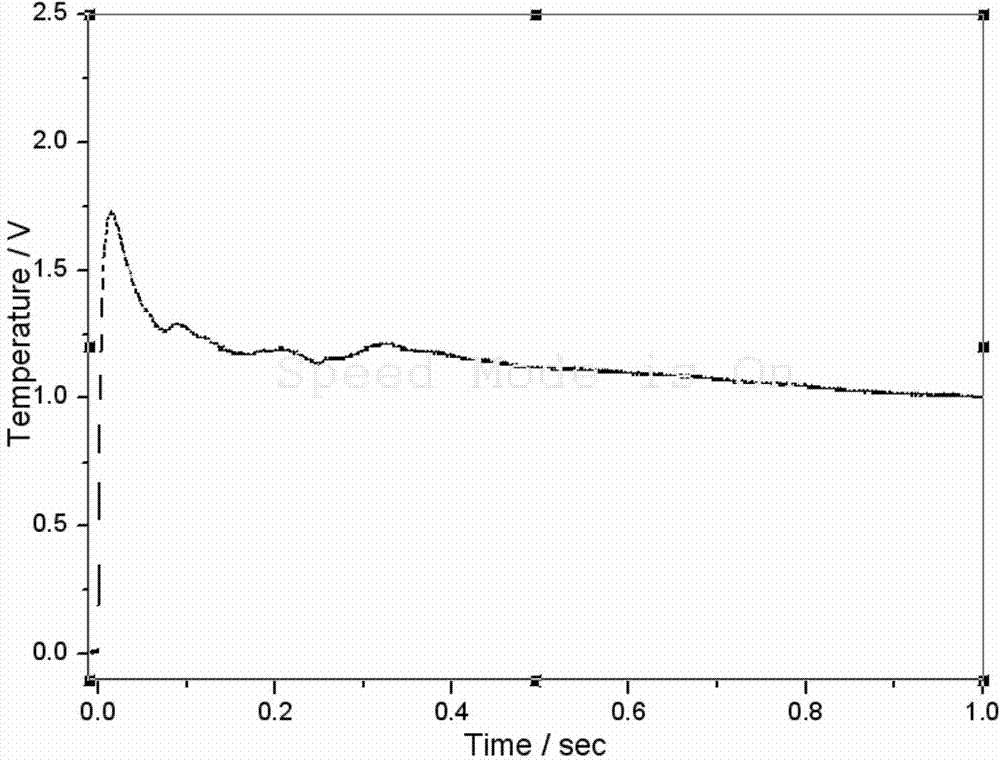

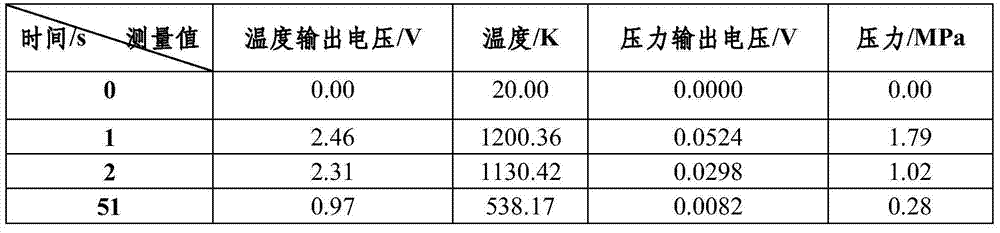

Method for measuring reaction completeness of powdered aluminium during aluminized explosive explosion process

InactiveCN104237306ALow costQuick measurementMaterial exposibilityProcess measurementHeat measurement

The invention discloses a method for measuring reaction completeness of powdered aluminium, and the method can solve the characterized problem of dynamic reaction completeness during an aluminized explosive explosion process. In the method, based on process measurement and combined with an airtight exploder, reacting conditions of powdered aluminium are comprehensively evaluated by measuring and recording temperature and pressure schedule curves during the aluminized explosive explosion process. In comparison with the traditional explosion heat measurement method, the method aims at reaction characteristics and dynamic characteristics of the powdered aluminium. Through the method, the reaction condition of the different-specification powdered aluminium in the phase-condensed aluminized explosive with the same ratio is evaluated along with time.

Owner:XIAN MODERN CHEM RES INST

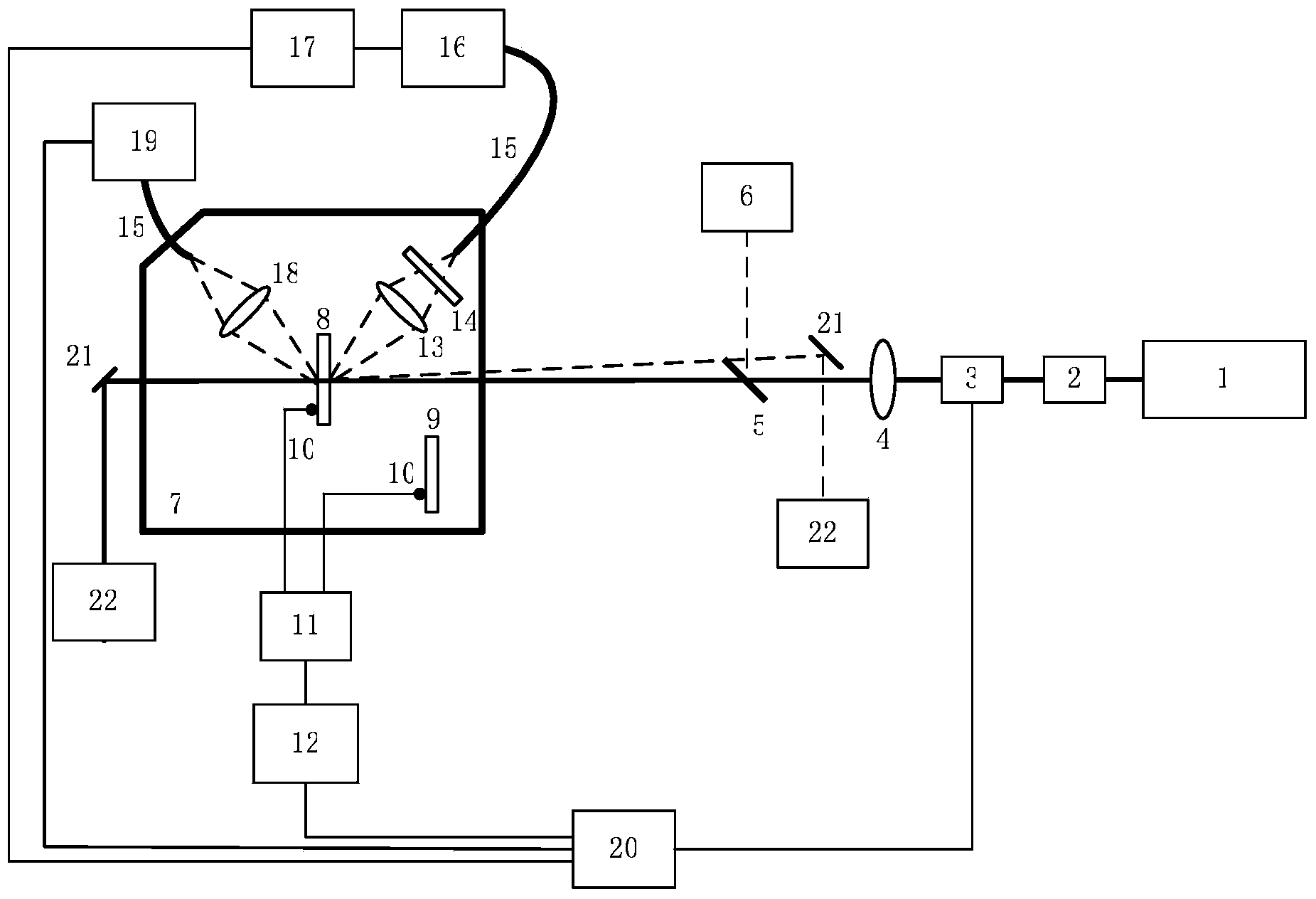

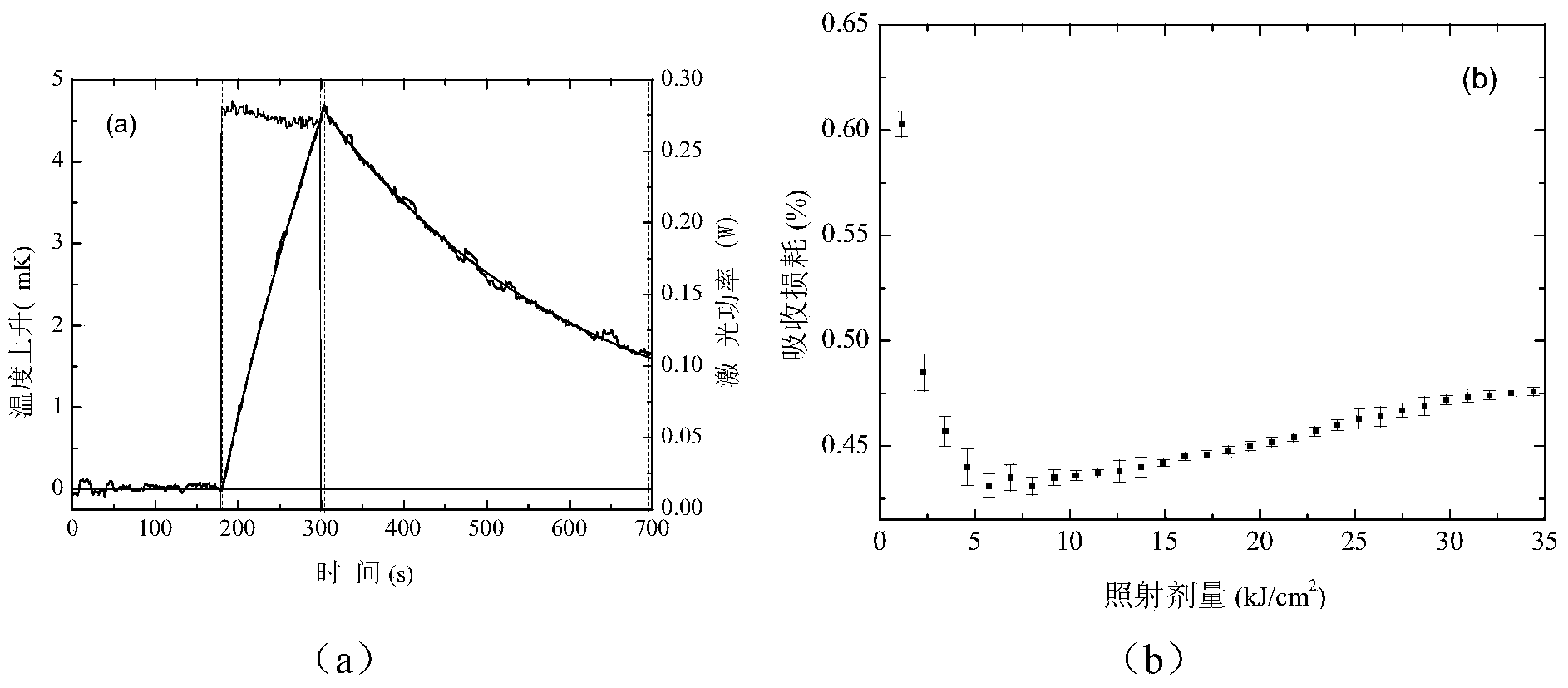

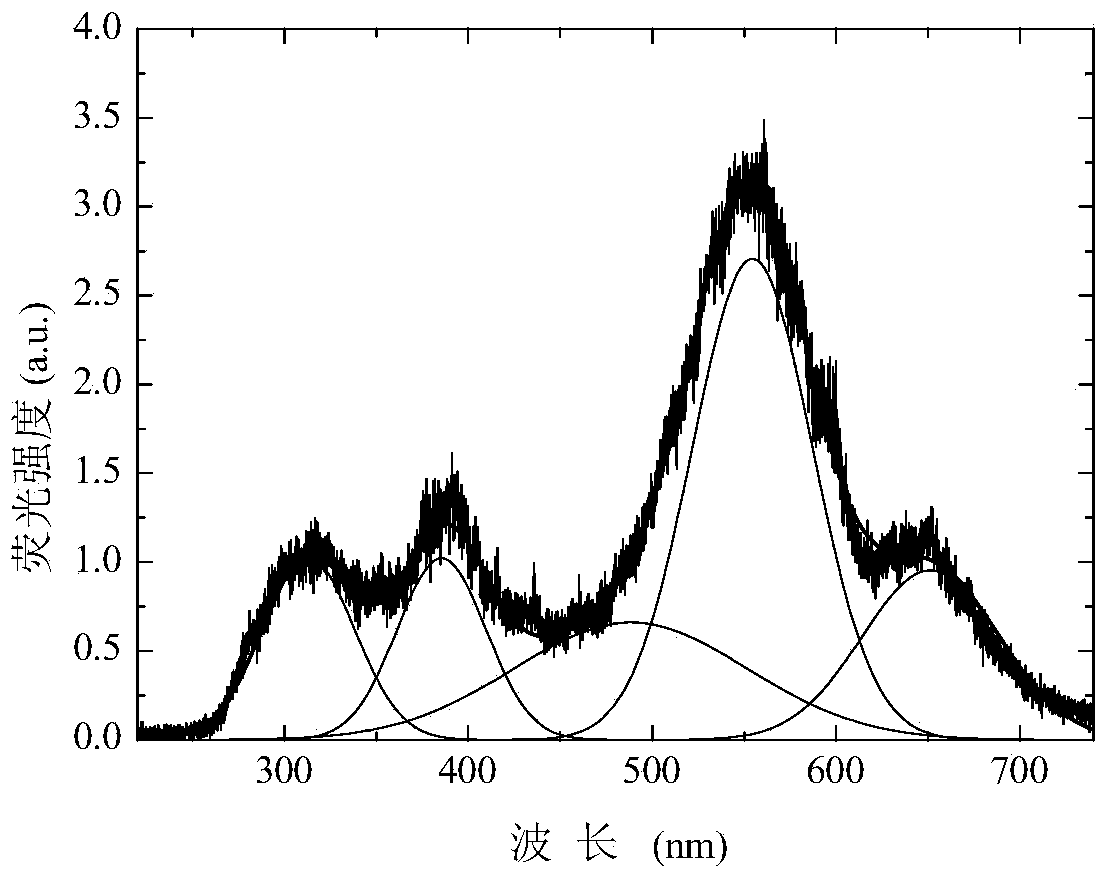

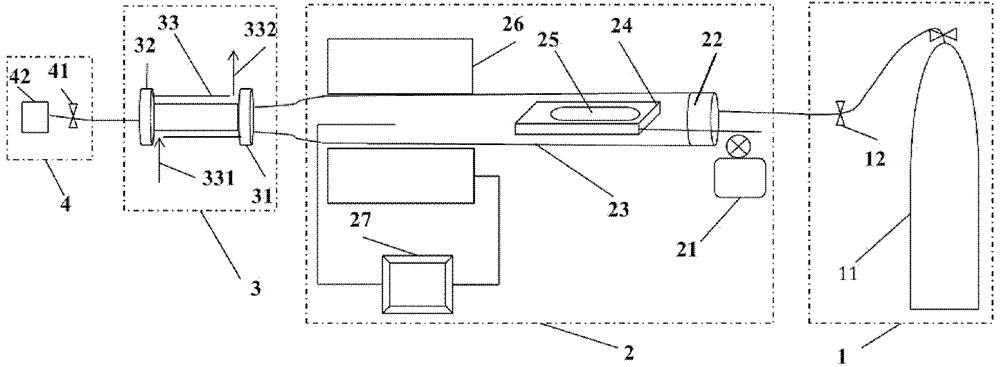

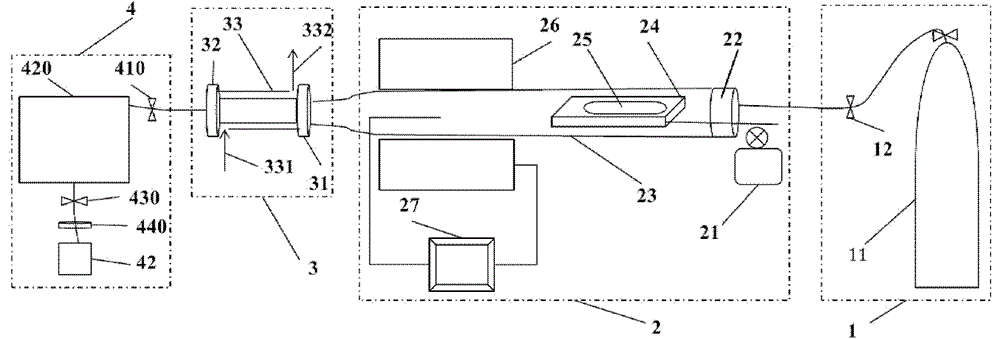

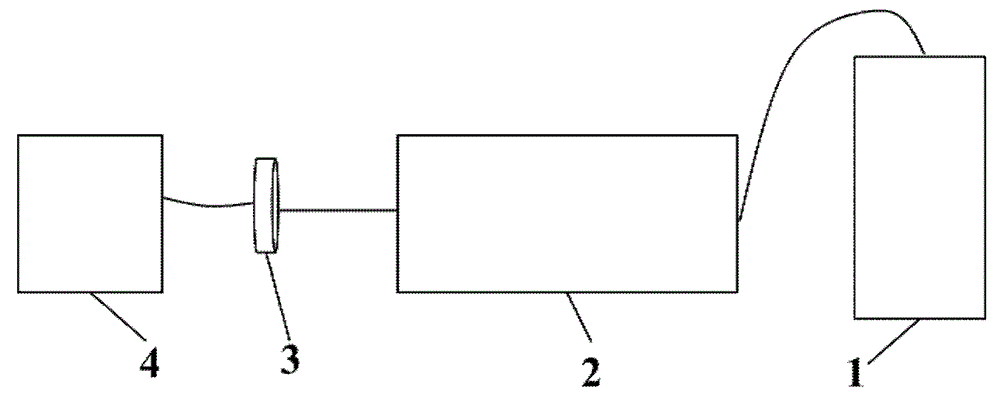

Comprehensive testing method of optical performance of deep ultraviolet optical element

InactiveCN103712782AReal-time monitoring of optical performance stabilityLow costTesting optical propertiesTime changesFluorescence spectrometry

The invention provides a comprehensive testing method of the optical performance of a deep ultraviolet optical element. According to the comprehensive testing method, the absorption loss absolute value of the deep ultraviolet optical element is measured based on the laser heat measurement technology; the fluorescence spectrum of the deep ultraviolet optical element is measured based on the laser-induced fluorescence spectrum technology when the deep ultraviolet optical element is irradiated by a deep ultraviolet laser; the defect level, the contents of doping components and the content of impurities of a material of the deep ultraviolet optical element are measured based on the Raman spectra technology. Through measurement of the absorption loss feature, the fluorescence spectrum feature and the Raman spectral feature of the deep ultraviolet optical element at the deep ultraviolet laser wavelength, the comprehensive optical performance of the deep ultraviolet optical element is estimated. By measuring the real-time change of the absorption loss, the fluorescence spectrum and the Raman spectrum of the deep ultraviolet optical element in the process of deep ultraviolet laser irradiation, the stability of the performance of the deep ultraviolet optical element is monitored. By the adoption of the same device, the optical feature parameters of the deep ultraviolet optical element are measured and the change of the optical feature of the deep ultraviolet optical element in the process of deep ultraviolet laser irradiation is monitored in real time.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

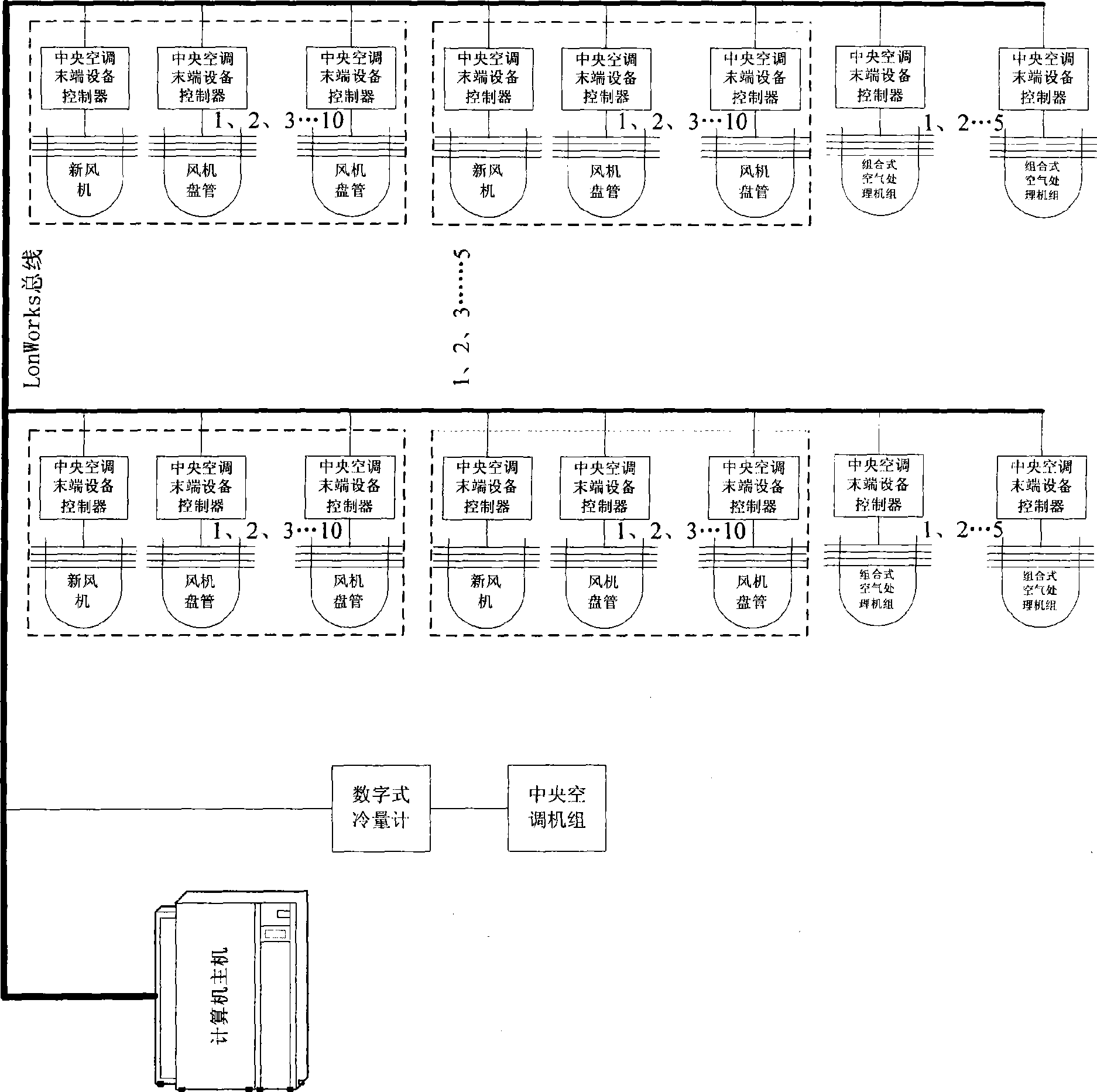

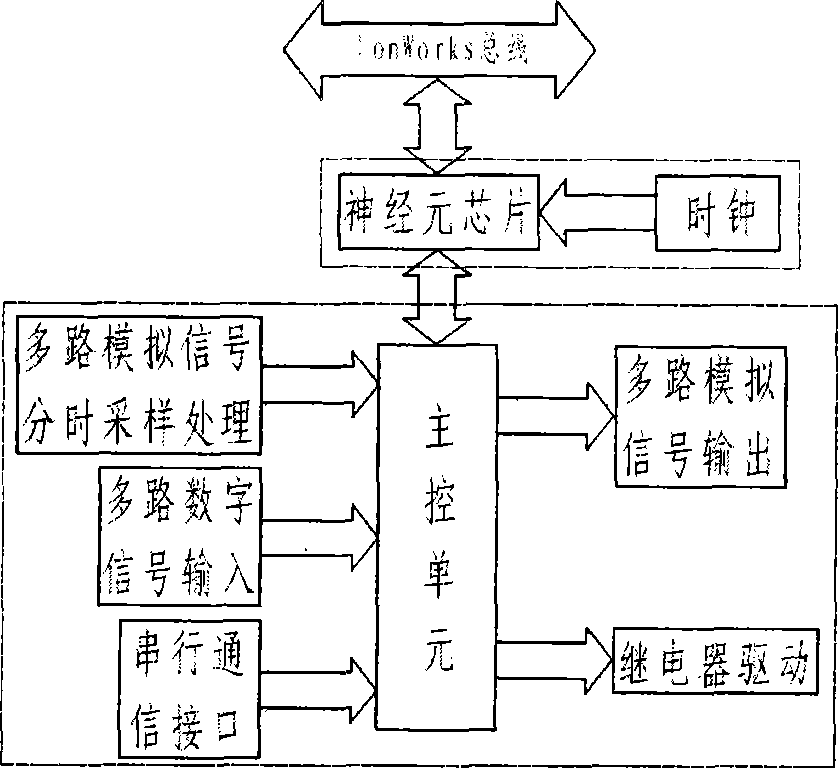

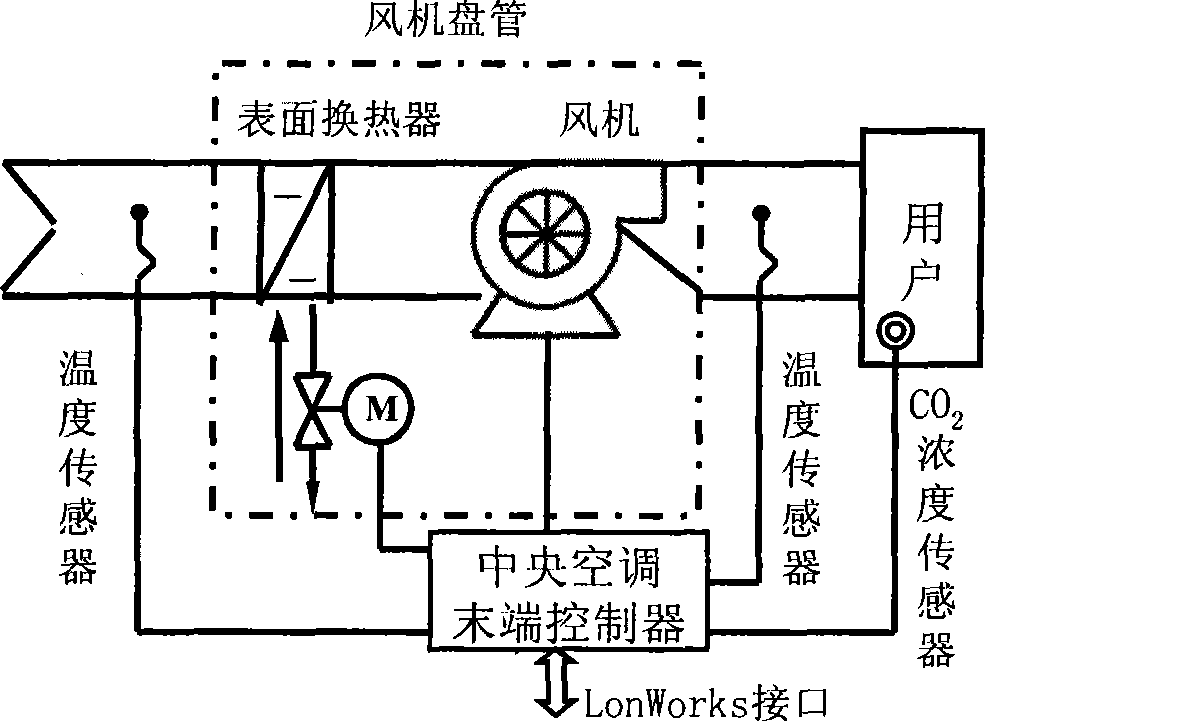

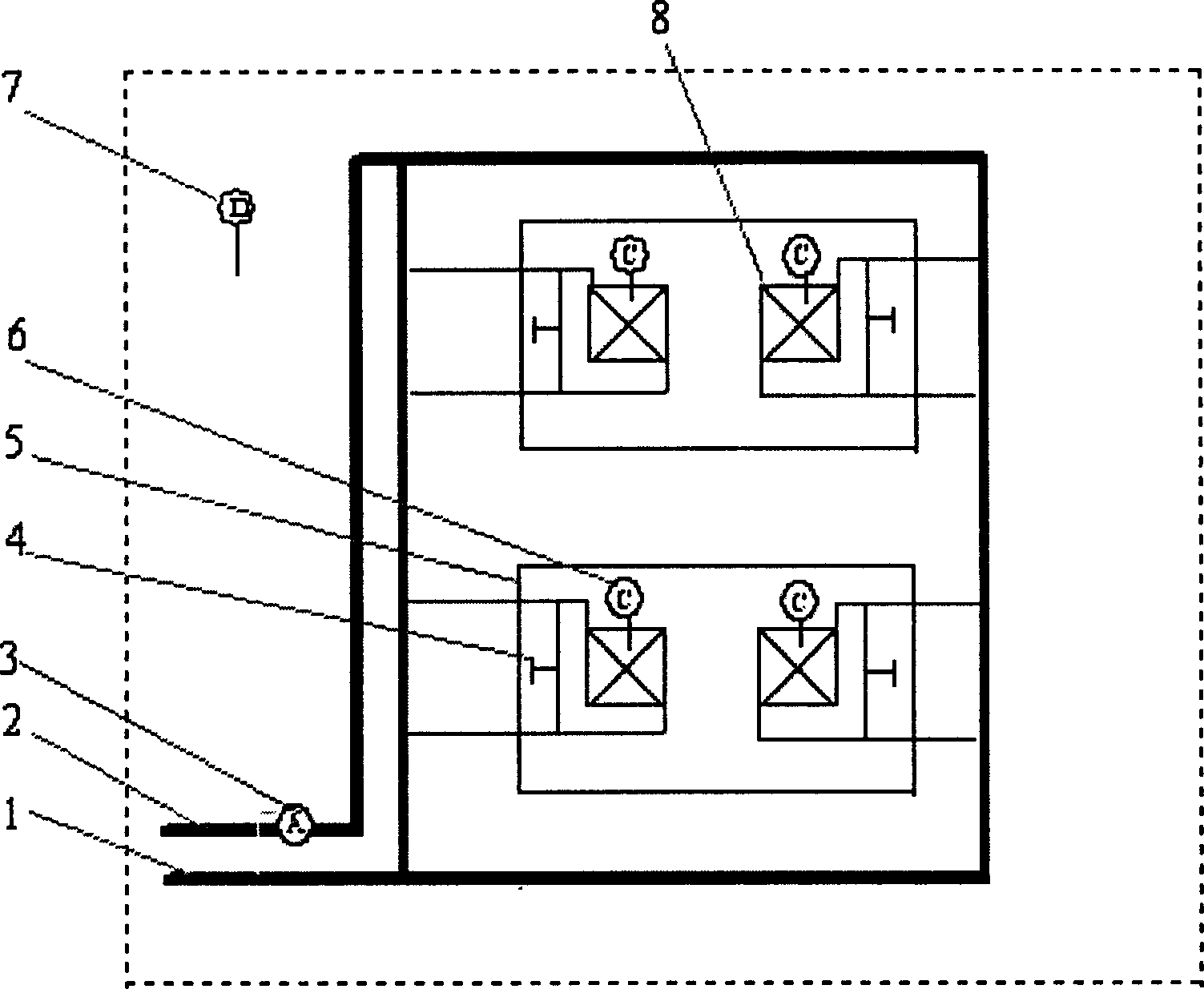

Household metering system for cooling capacity of central air conditioner

ActiveCN101476764AEasy to calculateImprove practicalitySpace heating and ventilation safety systemsLighting and heating apparatusLonWorksTerminal equipment

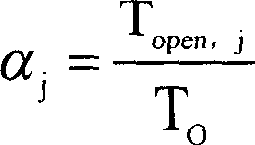

The invention relates to the technical field of heat measurement, in particular to a separated metering system of a central air conditioner. The system comprises a computer hoist machine for providing a management and control platform, central air conditioner terminal controllers and a digital cold calorimeter of a central air conditioner unit, wherein the computer hoist machine is connected with the digital cold calorimeter and the air conditioner terminal controllers through LonWorks interface connection mechanisms to form a control network. The system is characterized in that the control method of the system comprises the following main steps that: central air conditioner terminal equipment controllers carry out time-sharing acquisition of indoor CO2 concentration and the temperature and the humidity of the air at the inlets and outlets of the terminal equipment of the air conditioner system; the enthalpies h1 of the air inlets and the enthalpies h2 of the air outlets of the terminal equipment of the air conditioner system are calculated by using a formula (1) and a formula (2) respectively; at the same time, the mass flow m of the air passing through the terminal equipment is calculated by using a formula (5); quantity W delta T of cold consumed by the terminal equipment within a calculation period is calculated by using a formula (6) and a formula (7) respectively and transmitted to the computer hoist machine; and the computer hoist machine calculates the cold quantity W' to be charged of each piece of terminal equipment according to a formula (8) and stores the W'.

Owner:FOSHAN AKE ELECTRONICS ENG CO LTD

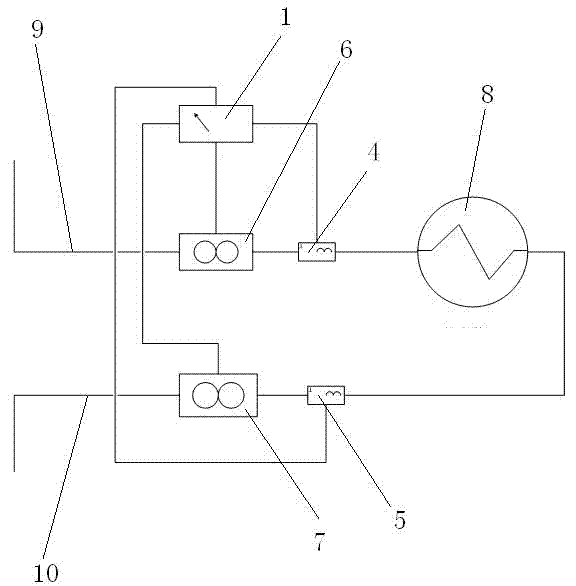

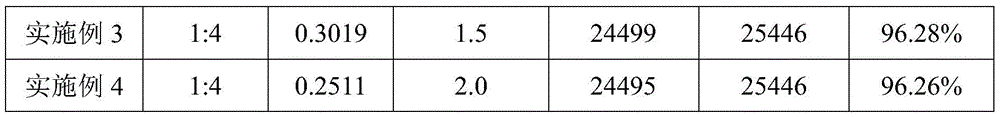

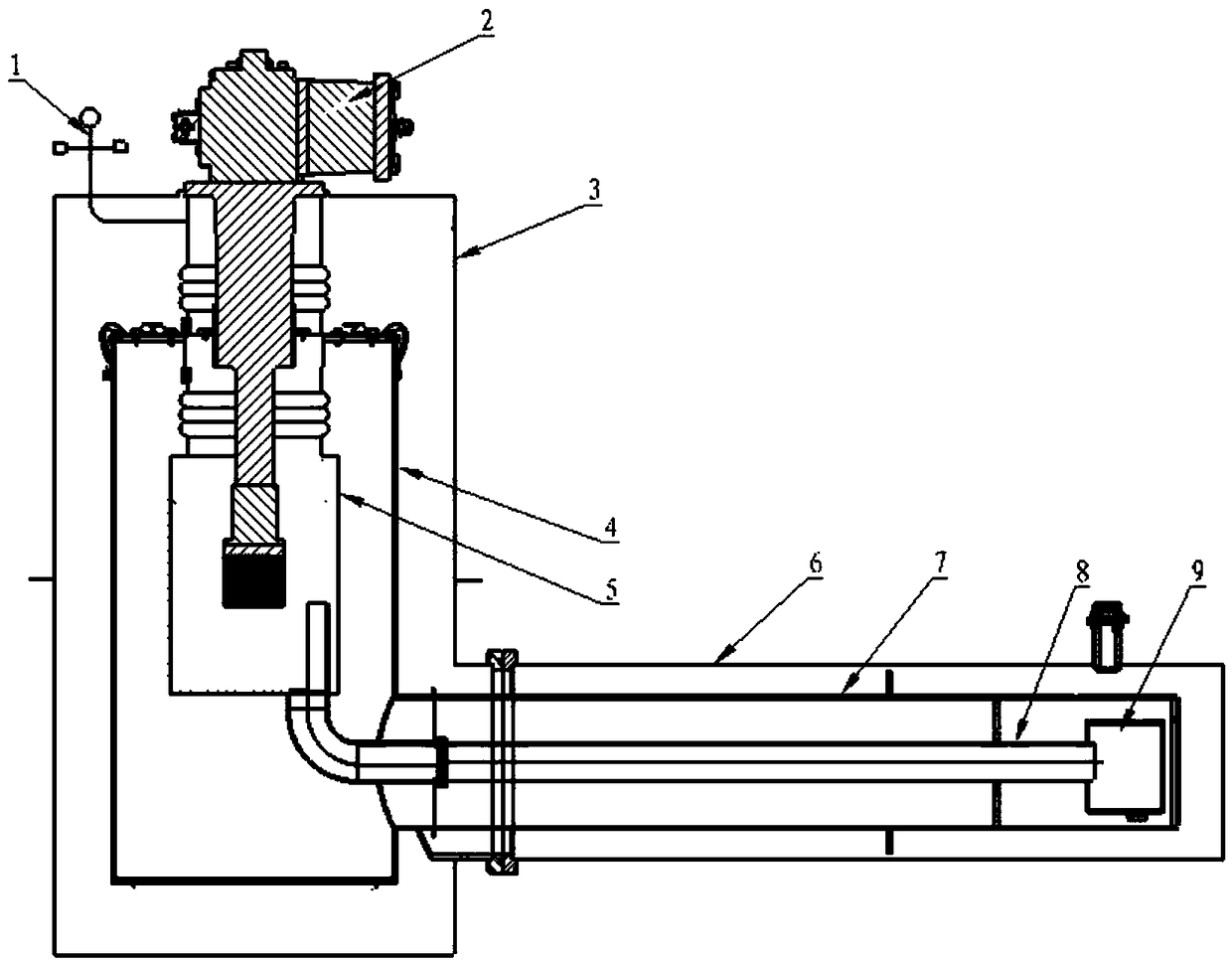

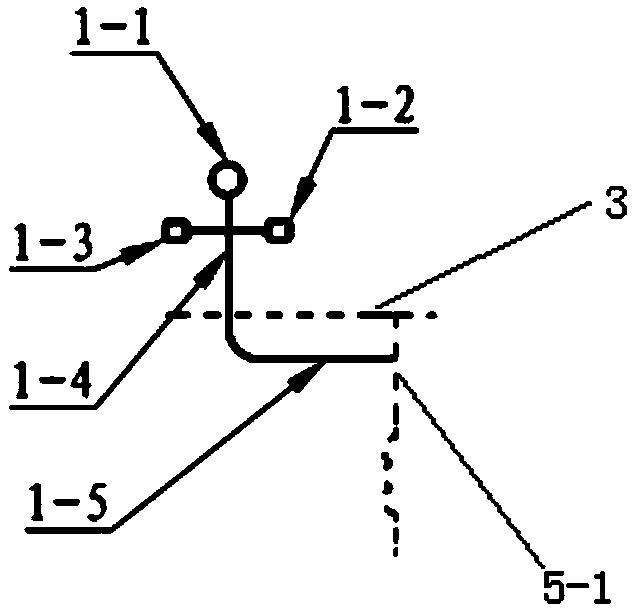

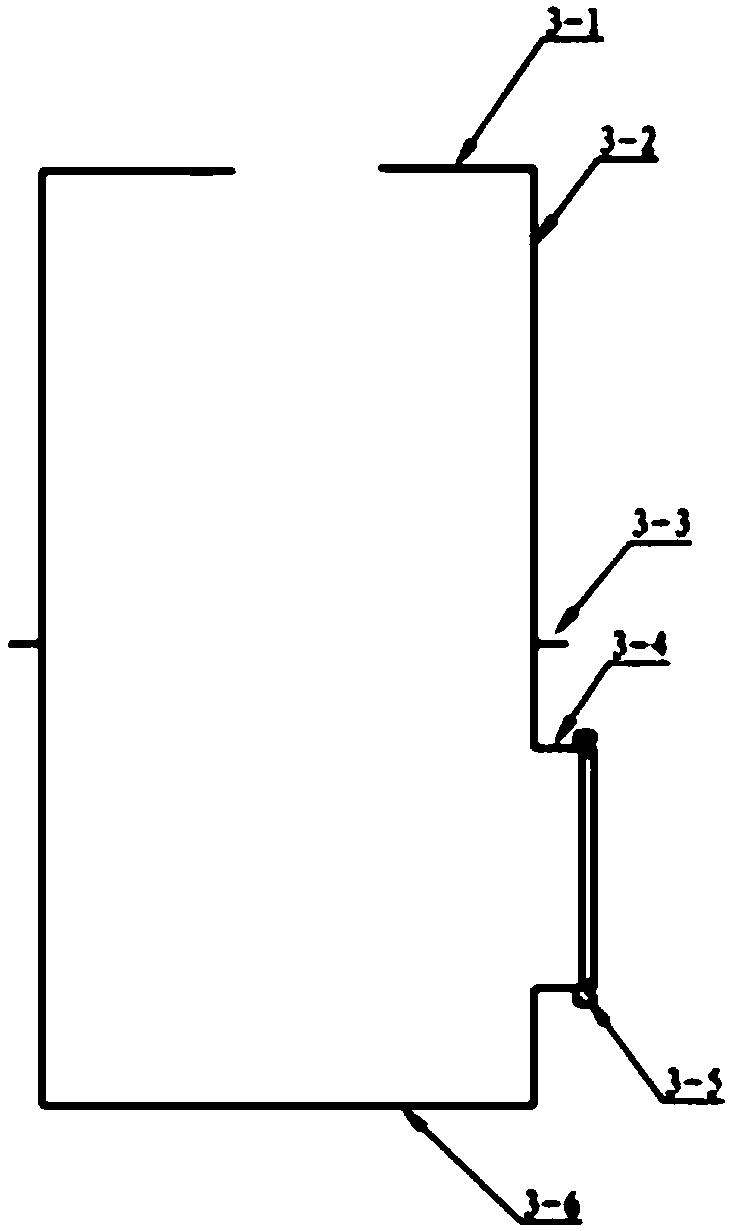

Measurement system and measurement method for heating water loss

A heating water loss measurement system comprises a calculator, a display, a communication module, an incoming water temperature sensor, a return water temperature sensor, an inlet flow meter, a return flow meter, a heat exchanger, an inlet pipeline and a return pipeline. The heat exchanger is disposed between the incoming water temperature sensor and the return water temperature sensor. A heating water loss method of the heating water loss measurement system includes: using the calculator to calculate consumed heat and water loss of the system according to measurement parameters. The heating water loss measurement system and the heating water loss method have the advantages that heat measurement achieves functions of a common heat meter, such as heat calculation and flow-temperature measurement; water loss measurement provides data basis for determining water loss nodes and water loss volume; water loss and heat loss provide data basis for calculation of controlling and heating cost of a heating system; and remote data transmission provides real-time data for real-time monitoring and regulation of the heating system.

Owner:SHENYANG HANGFA HEAT METERING TECH

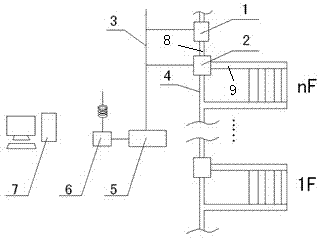

Separate household heating measurement device of serial single-pipe connection type heating pipe network system and method

The invention relates to a separate household heating measurement device of a serial single-pipe connection type heating pipe network system and a separate household heating measurement method. The device comprises a flow meter, a heat integral thermostatic valve, an M_BUS bus, an M_BUS data collector, a DTU (digital transmission unit) and a computer. In the method, heat of a separate household can be measured via measuring heat losses of a heat radiator on each riser, each heat integral thermostatic valve is used for measuring heat losses of the heat radiator connected behind the heat integral thermostatic valve, then the heat calculated by each heat integral thermostatic valve is collected by the M_BUS bus and a data control center, and the heat consumed by the household can be calculated. The layout of the original pipe network needs not to be changed, no punching through walls is needed, the disturbance to households is small, the cost is low, and the problem of separate household heating measurement and energy conservation can be solved with no needs for installation of a heater meter in each household.

Owner:MAXTOR INSTR CO LTD

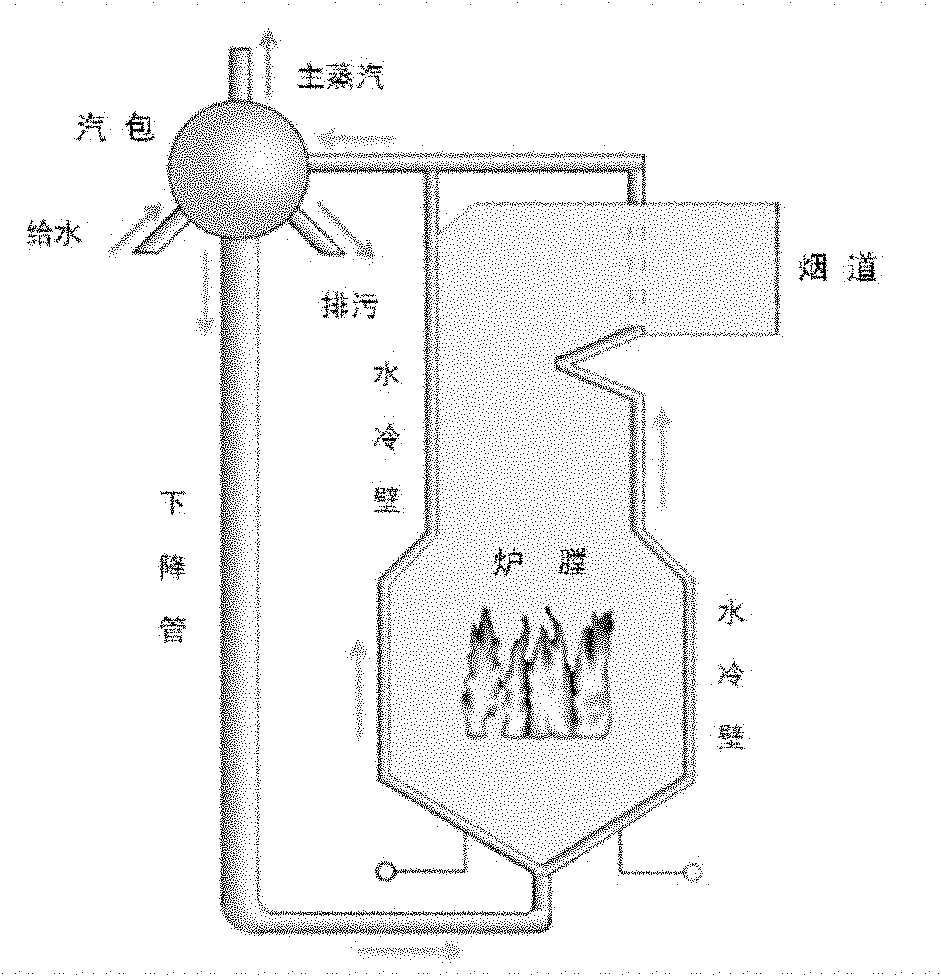

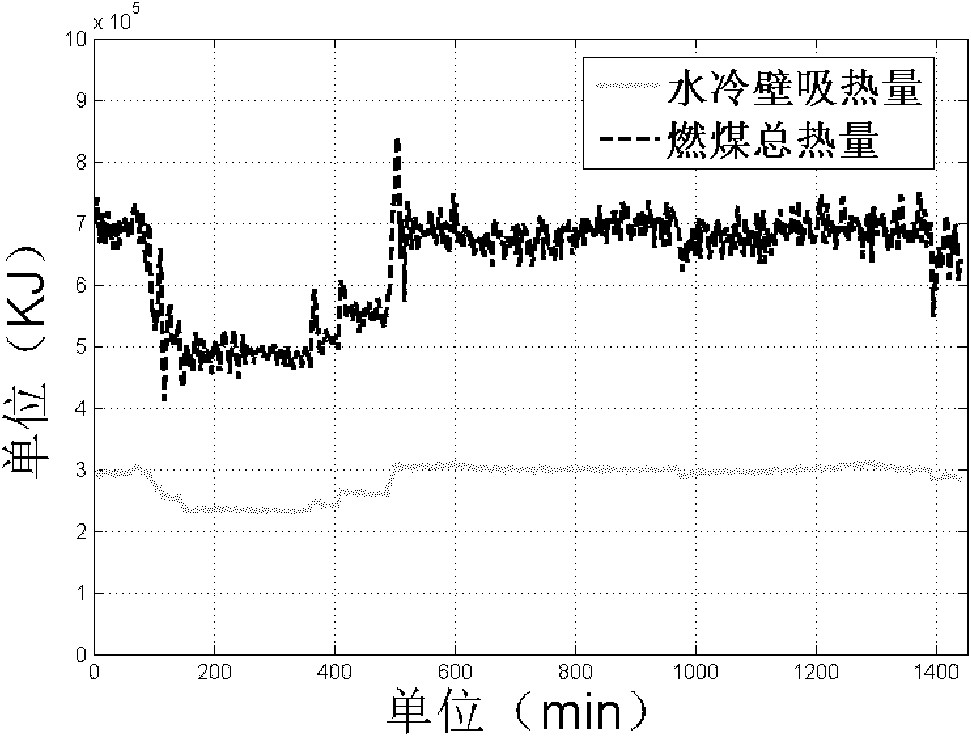

Method for measuring heat absorbed by boiler water cooled wall in real time

The invention relates to a method for measuring heat absorbed by a boiler water cooled wall in real time in the technical field of boiler systems, which comprises the following steps of: 1, obtaining boiler parameters according to the operating standard of a boiler; 2, figuring out a trend curve of heat measured values Qdr changing with the time under the time t by using an IF97 formula; 3, figuring out the proportion of steam to water in a steam pocket and the water cooled wall by using a steam pocket water level model and a water cooled wall steam-liquid recycle ratio model, figuring out the flow and the enthalpy value of a working medium in an outlet of a descending pipe; and 4, figuring out a steam pocket inertia constant Ip by using the steam pocket model, and figuring out the heat absorption real-time measured value Q of the water cooled wall. The invention can be used for one-line measurement on the heat absorption capacity of the water cooled wall of a power plane, and can also be used for on-line recognition of coal heat value and real-time measurement of the boil efficiency.

Owner:SHANGHAI JIAO TONG UNIV

Road surface sensor and monitoring control method for road surface

InactiveUS6979146B2Don't waste energyRainfall/precipitation gaugesIn situ pavingsSnow meltingEngineering

In order to melt snow and prevent freezing without consuming energy wastefully and to monitor a road surface state remotely, a road surface sensor includes: a rotating stand provided so as to be reciprocatingly rotatable upward on the road surface; a snow-melting / freezing heat quantity measurement dummy road surface having an electric heater buried therein and to use as a reference road surface for heat quantity measurement to derive a melting heat quantity for snow falling on the surface and a heat quantity required for freezing prevention; a reference light irradiating / reflected light receiving device that is attached so as to be rotatable with the rotating stand; a space reflected light receiving device; a non-contact road temperature measuring device; a non-contact snow cover depth measuring device; a road surface image pickup device; and a moisture sensor. The reference light irradiating / reflected light receiving device includes a reference light irradiating device for irradiating reference light and a reflected light receiving device for receiving reflected light of the reference light from the road surface, and the reflected light receiving device separates and receives only reflected light of the reference light out of the reflected light from the road surface.

Owner:YAMADA TECH CORP +1

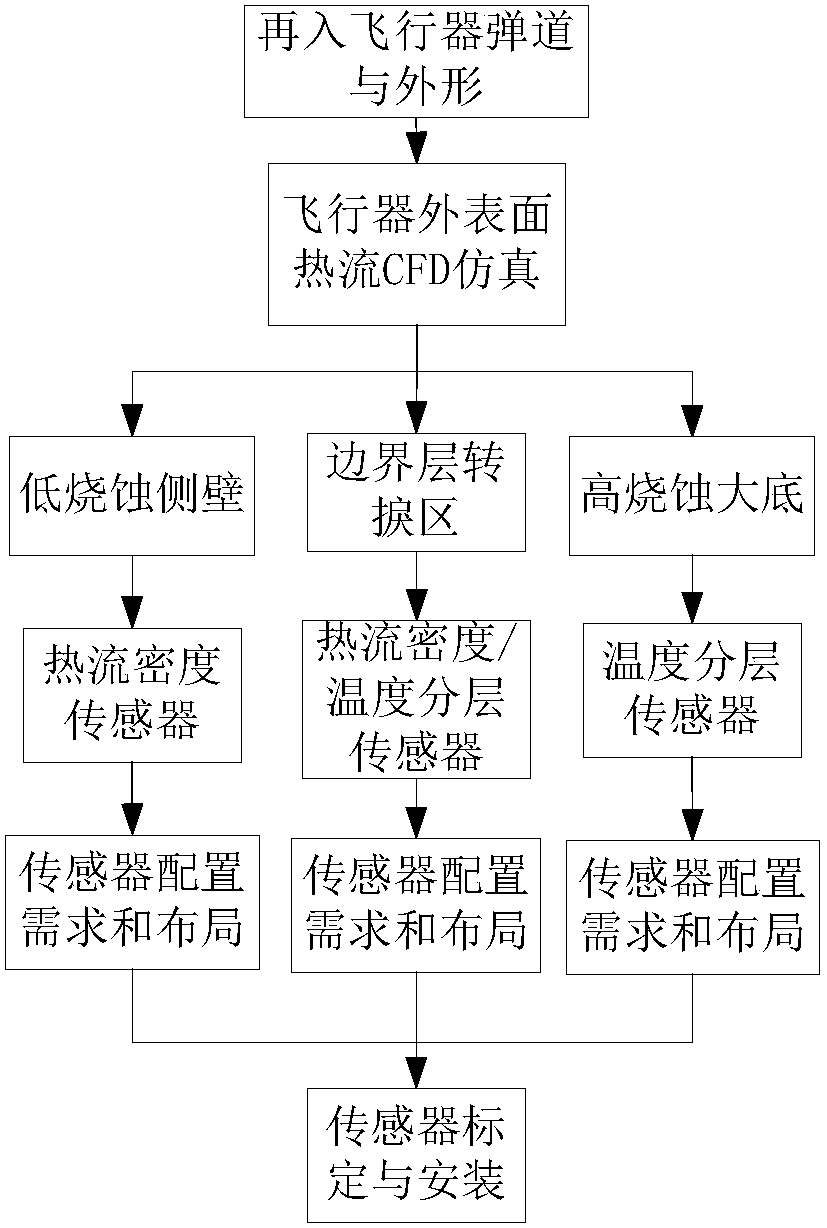

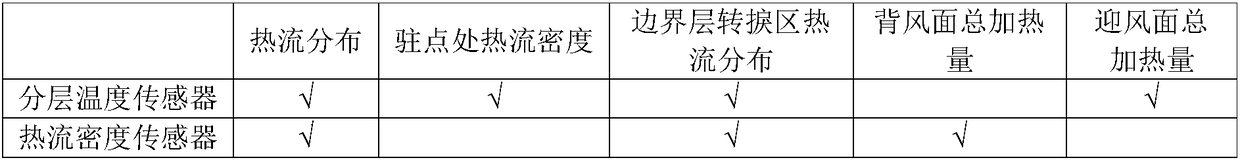

Aerodynamic heat measuring method suitable for blunt body reentry vehicle

InactiveCN108216685ATrue reentry heat flow loadGeometric CADSustainable transportationStagnation pointHeat flow

The invention provides an aerodynamic heat measuring method suitable for a blunt body reentry vehicle. The aerodynamic heat measuring method is used for measuring of surface heat flow distribution ofthe side walls, the large bottom, the stagnation point area and the boundary layer transition area of the blunt body reentry vehicle and measuring of total heating capacity of the windward side and the leeward side. The aerodynamic heat measuring method comprises the following steps that according to the appearance and a reentry trajectory of the blunt body reentry vehicle, simulation analysis onaerodynamic heat load on the surface of the blunt body reentry vehicle is conducted; according to the sizes and distribution of aerodynamic heating heat flows, sensor selecting and measuring range determining are conducted; according to the aerodynamic heat measuring task requirement of the blunt body reentry vehicle, configuration demand analysis of sensors is conducted; sensor layout design is conducted; and sensor calibration and mounting are conducted. According to the aerodynamic heat measuring method, the real reentry heat flow load can be obtained, particularly, real-time data of transition of the boundary layer on the surface of the vehicle can be provided, and guiding significance is achieved on a current calculating analysis model and the ground test technical scheme.

Owner:BEIJING SPACE TECH RES & TEST CENT

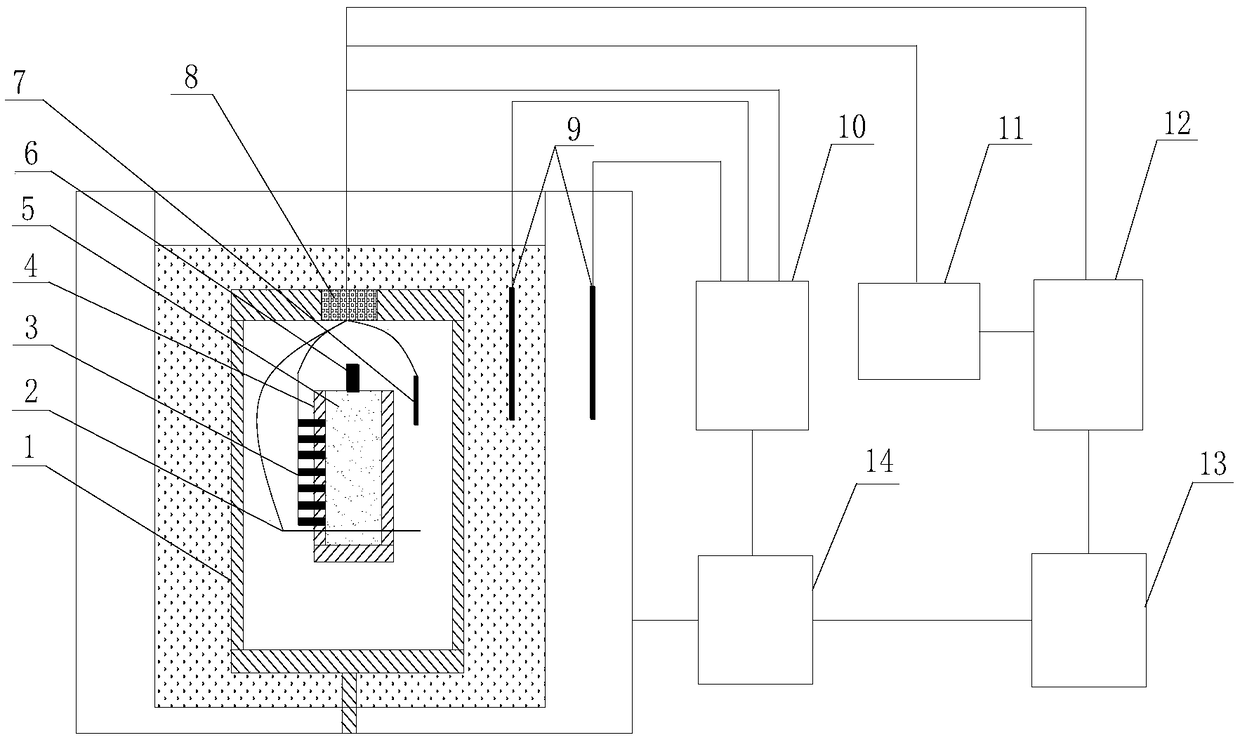

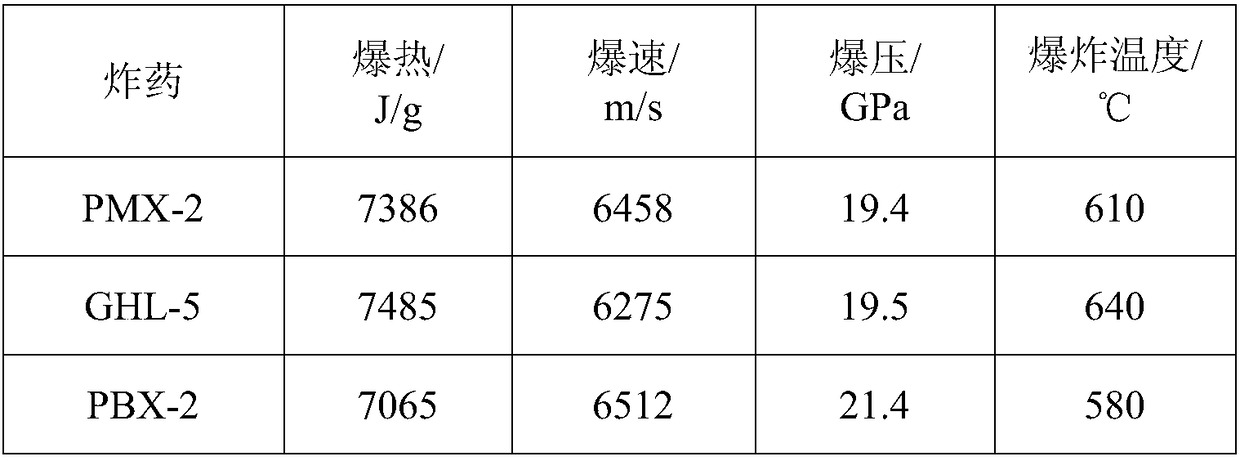

Multi-parameter synchronous measurement method for detonation performances of condensed-phase high explosives

ActiveCN108981503AShort measuring cycleImprove measurement efficiencyAmmunition testingTemperature controlEngineering

The invention discloses a multi-parameter synchronous measurement method for detonation performances of condensed-phase high explosives. In the method, a temperature sensor, an optical fiber probe anda manganese copper piezoresistance sensor are all mounted in an explosion chamber; the explosion chamber is externally provided with a heat measurement system; through once experiment, the synchronous measurement of the detonation velocity, the detonation heat, the detonation pressure and the detonation temperature of explosives is realized; a grain is mounted in an inert shell; the optical fiberprobe is mounted in a positioning hole of the shell; the manganese copper piezoresistance sensor is embedded in the grain; the temperature sensor is mounted in the explosion chamber; and platinum resistors are distributed in inner and outer barrels of the heat measurement system for temperature measurement and temperature control. The method is suitable for synchronous measurement of multiple detonation performance parameters of low-dose condensed-phase high explosives; and through once experiment, the detonation velocity, the detonation heat, the detonation pressure and the detonation temperature of the explosives can be measured, so that the comprehensive evaluation of the detonation performances of the explosives is achieved.

Owner:XIAN MODERN CHEM RES INST

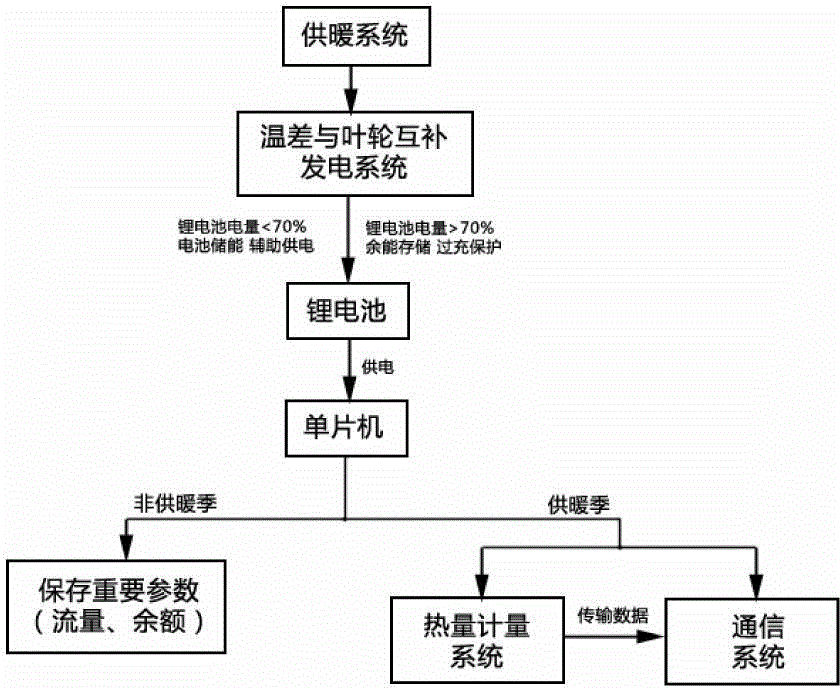

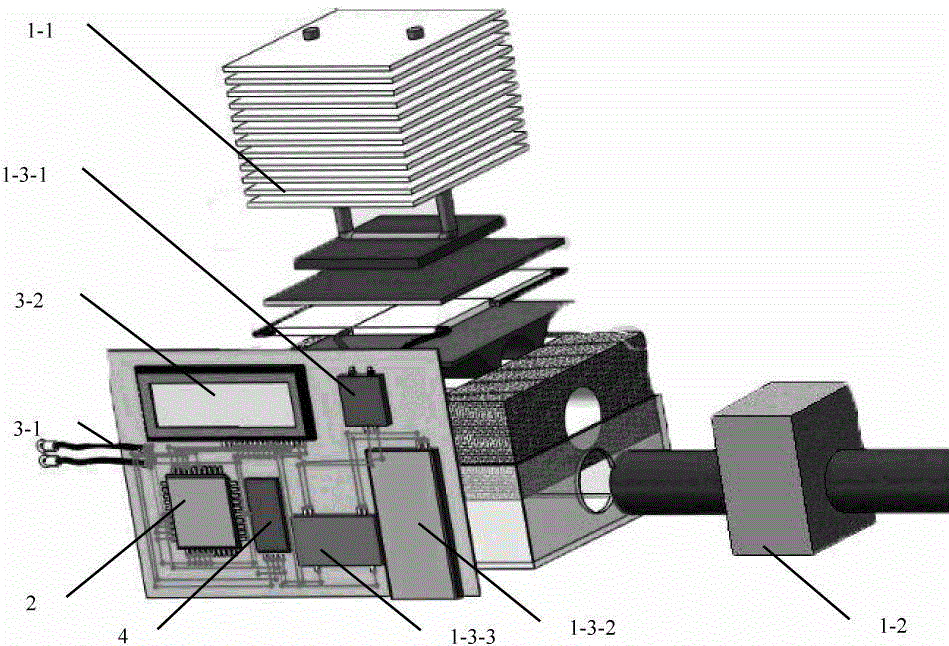

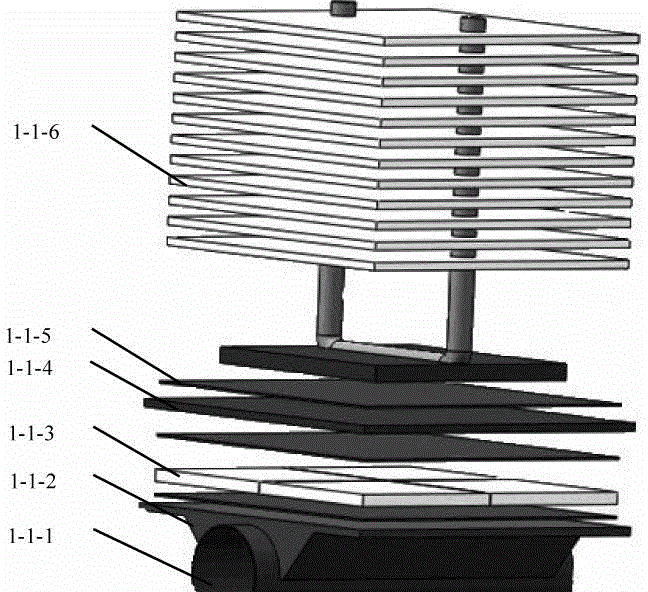

Intelligent remote-transmitting heat meter and working method thereof based on temperature difference and impeller complementary power generation technology

InactiveCN104596671AStable power supplyRealize remote transmission functionBatteries circuit arrangementsElectric powerEngineeringElectric generator

The invention discloses an intelligent remote-transmitting heat meter based on a temperature difference and impeller complementary power generation technology and a working method of the intelligent remote-transmitting heat meter. The intelligent remote-transmitting heat meter is composed of a power supply system, an intelligent control system, a heat measurement system and a communication system, wherein the power supply system collects the dissipated heat energy and the fluid dynamic energy of a pipeline to support the working of the heat measurement system and the communication system, the intelligent control system controls the charge and discharge processes of lithium ion circuits of the power supply system and the switching of working modes of a gauge in different seasons, and the communication system transmits the flow data obtained by the heat measurement system to a user terminal. On the basis of the existing power supply system and the measurement system, since the power generation technology of a power supply system working medium and the temperature difference of the ambient temperature is combined with the power generation technology that a motor is driven by the impeller who is driven by fluid in the pipeline and a wireless remote-transmitting function is increased, the low cost and the energy-saving performance can meet the requirements of times.

Owner:SOUTHEAST UNIV

Tobacco combustion heat measurement apparatus

InactiveCN103983663ASolve the problem that it is difficult to simulate the oxygen-poor combustion environment of cigarettesMaterial heat developmentFiltrationTransmission channel

The present invention discloses a tobacco combustion heat measurement apparatus, which comprises a gas supply device, a combustion device, a filtration device and an analysis device, wherein the combustion device comprises an annular heating furnace and a controller, one quartz pipe end arranged inside the annular heating furnace is a heating end, the other end is a non-heating end, the end is provided with a sealing member, a quartz boat is arranged in the quartz pipe and is pushed by a step motor to move at a uniform speed, the sealing member is provided with two through holes for a gas supply pipeline channel and a step motor transmission channel, the filtration device comprises a high temperature resistance filter directly connected with the gas outlet end of the annular heating furnace, and a second-stage filter communicated with the analysis device, the two stages of the filters are connected through a cooling pipeline, the filtration device is used for filtering particle phase substances and water in the combustion product so as to avoid influence on the analysis device, and the analysis device comprises an oxygen analyser communicated with the second-stage filter through a pipeline. According to the present invention, the accurate measurement of the combustion heat of the tobacco under the stable poor-oxygen combustion state is achieved.

Owner:CHINA TOBACCO ANHUI IND CO LTD

Gas sensor with thermal measurement compensation

ActiveUS9395344B2Analysing fluids using sonic/ultrasonic/infrasonic wavesMaterial thermal analysisProcess engineeringHeat measurement

Owner:VERIS INDS

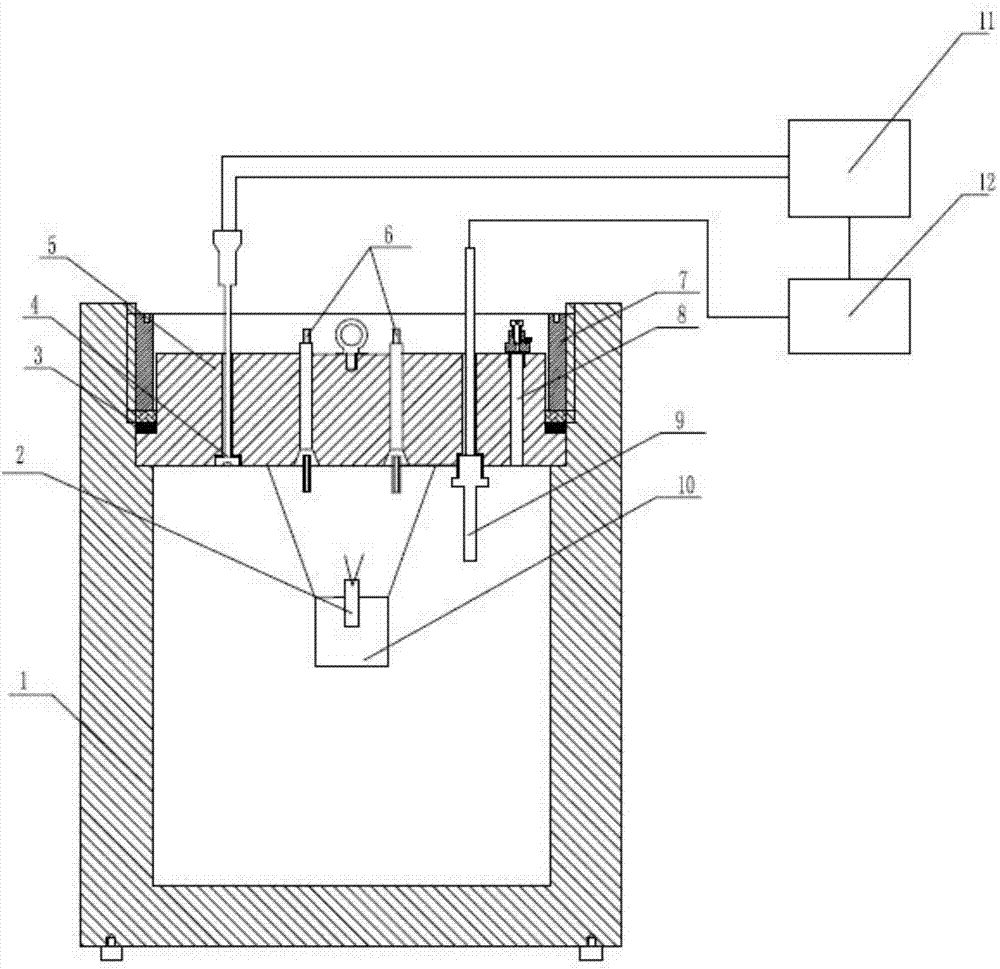

Cylindrical calorimeter based on fluidic heat exchange of fluids

InactiveCN1670519AAccurate measurementHigh precisionMaterial thermal analysisData acquisitionEngineering

This invention provides a column heat measurement device based on fluid flow heat exchanging, which comprises the following: isolation room located inside the sample pool; thick hollow tube through sample pool and isolation room located on the bottom balance of the hollow tube, wherein the balance top is fixed with liquid storage pool; the temperature sensors orderly located on the hollow tube 2 inside wall and outside wall with its conductive wires connected to the data sampler input end, wherein, the data sampler is connected to the computer.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

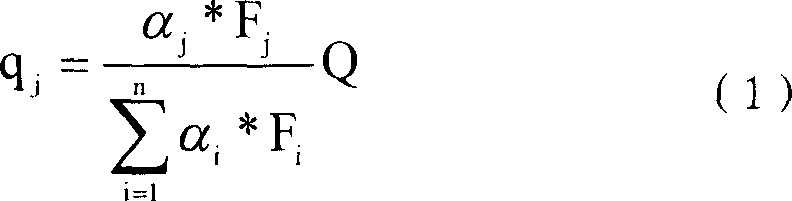

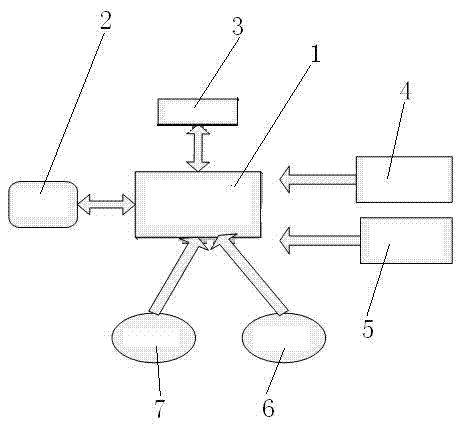

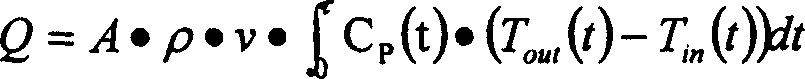

Central heating diverse charging integration method and metering system thereof

InactiveCN1595083AImprove scienceImprove economyTariff metering apparatusCalorimeterEnergy qualityUser charge

This invention relates to a central heating and individual charging integration method and metering system. This invention is based on the ratio of operation charge Z and user consumption general effective heat E of the central heating system within time t to identify the price for each unit of effective heat U. And it identify each user charge of heat Y#-[m, i] according to the multiply of user consumption effective heat and each unit of effective heat price. This invention needn't alter the heating pipe and only locate a outdoor temperature 7 in the central heating area and a heating meter 3 in the entrance of m area and realizes the heat measurement of the I users consumption in the area m through heat meter 9 or heat distribution meter 6. This invention organically integrates the heat supply charge method and heat distribution charge method and imports effective heat to reflect heat supply energy quality and heat supply effect.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

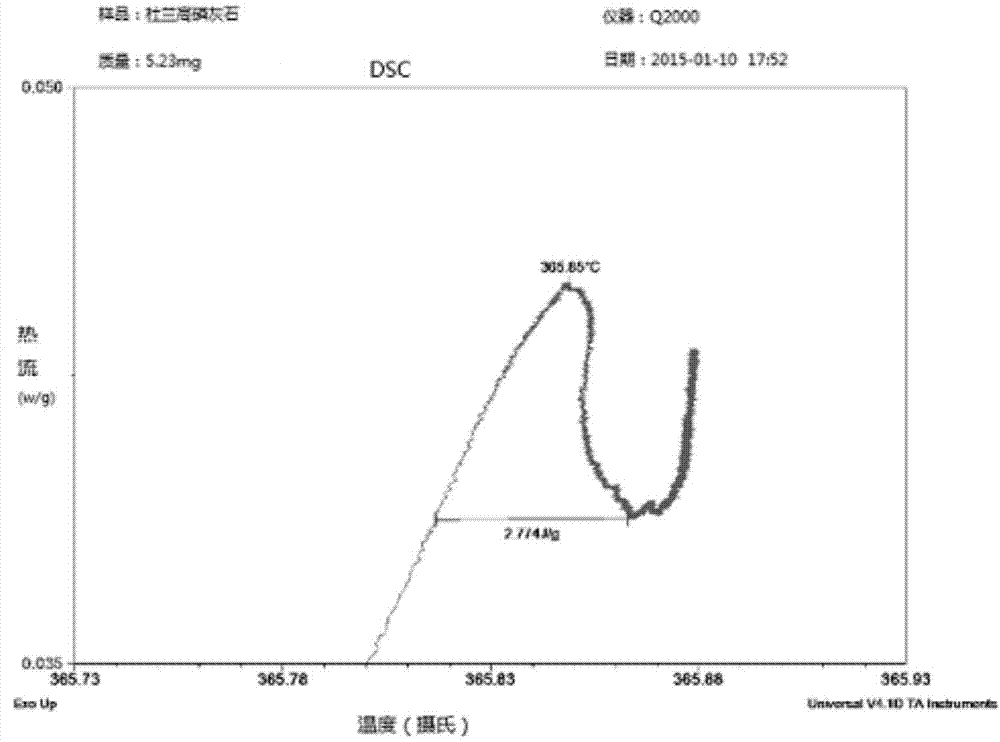

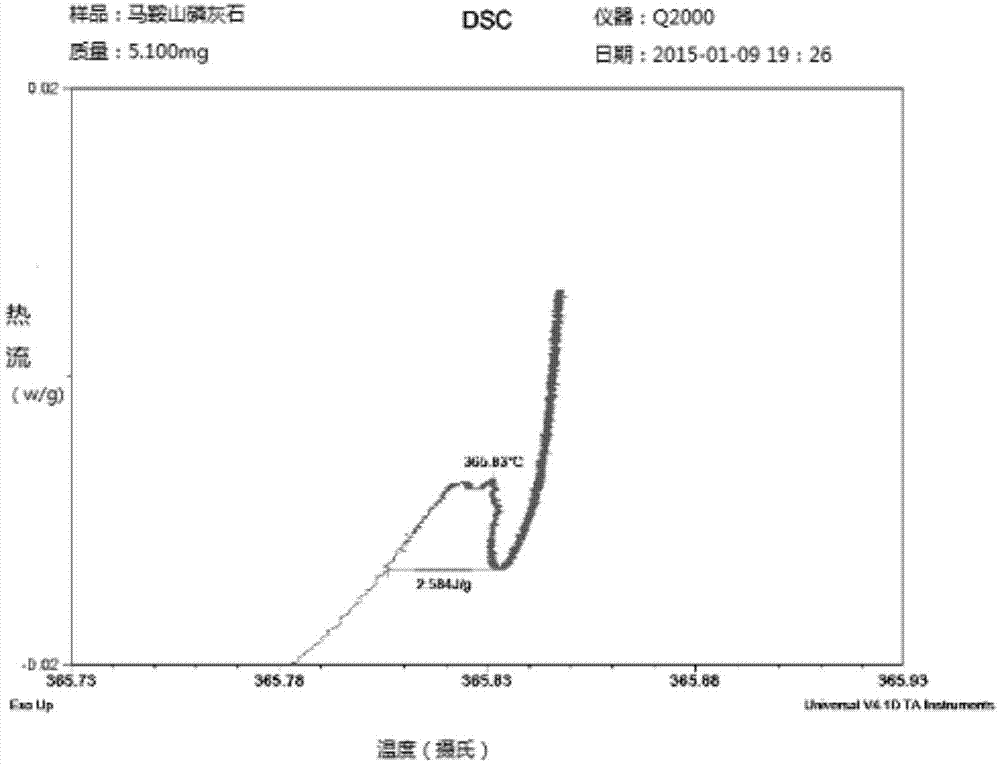

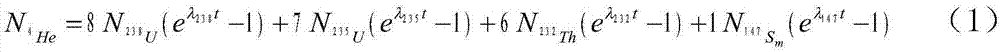

Method for measuring geologic age on basis of thermoanalysis

InactiveCN104749346AEarth material testingSpecial data processing applicationsReference sampleIsotope

The invention discloses a method for measuring a geologic age on the basis of a thermoanalysis. The method comprises the following steps: selecting a reference sample, measuring the average values of <238>U, <232>Th and <147>Sm isotopic contents of the reference sample, calculating the values of N238, N235, N232 and N147<S>, calculating the standard N4<He> of the reference sample, making the isothermal DSC curve of the reference sample by a differential scanning calorimeter, measuring the annealing quality in a unit mass, calculating the annealing heat released by an average of alpha-ion nuclear tracks of the reference sample, then measuring the contents of uranium, thorium and samarium in a sample to be measured, calculating N235, N232 and N147<S>, making the isothermal DSC curve of the sample to be measured by using the differential scanning calorimeter, measuring the annealing heat, calculating the number of the nuclear tracks of the sample to be measured in the unit mass, and finally calculating the geologic age t of the sample to be measured, wherein the geologic environments experienced by the sample to be measured and the reference sample are similar. According to the method disclosed by the invention, a helium measurement is replaced by a heat measurement, and the method is simple and practical.

Owner:XIJING UNIV

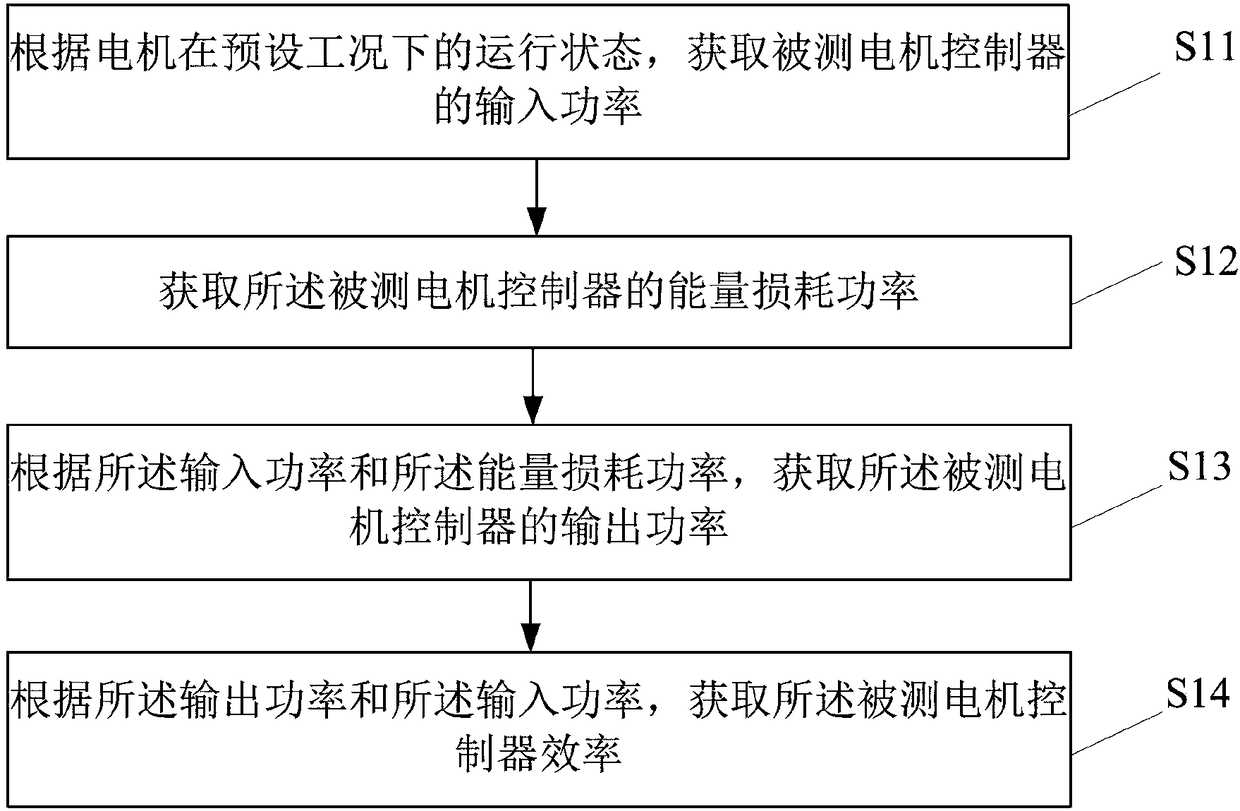

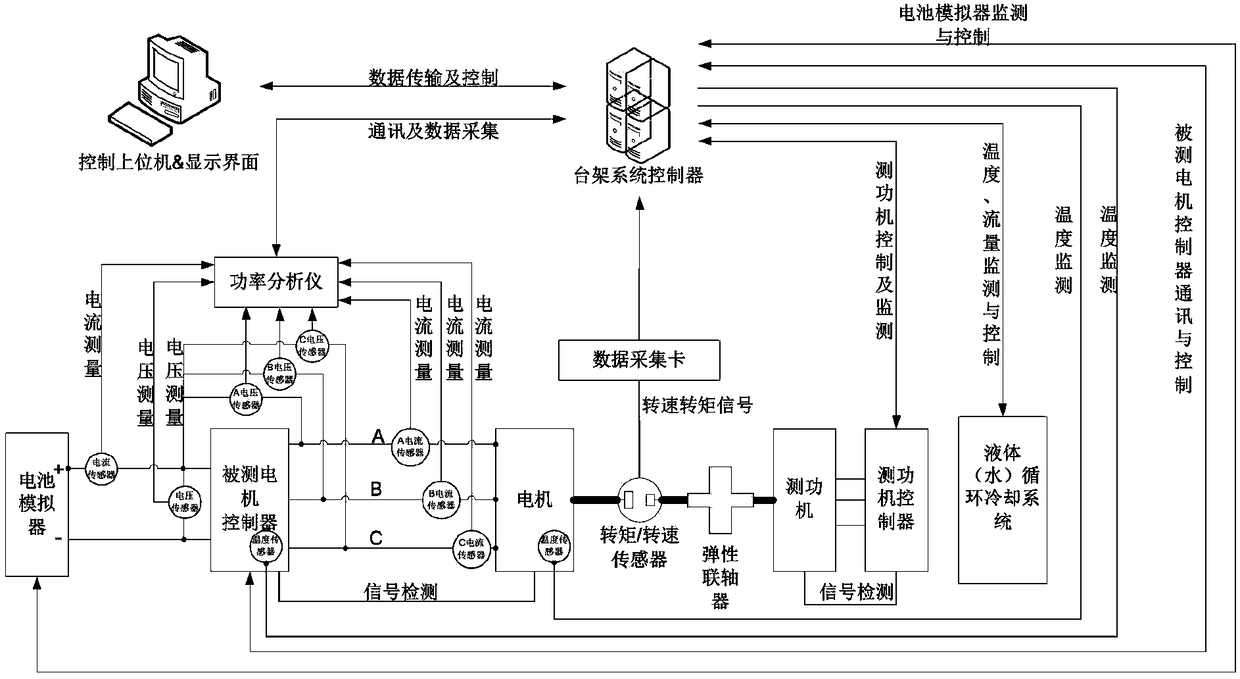

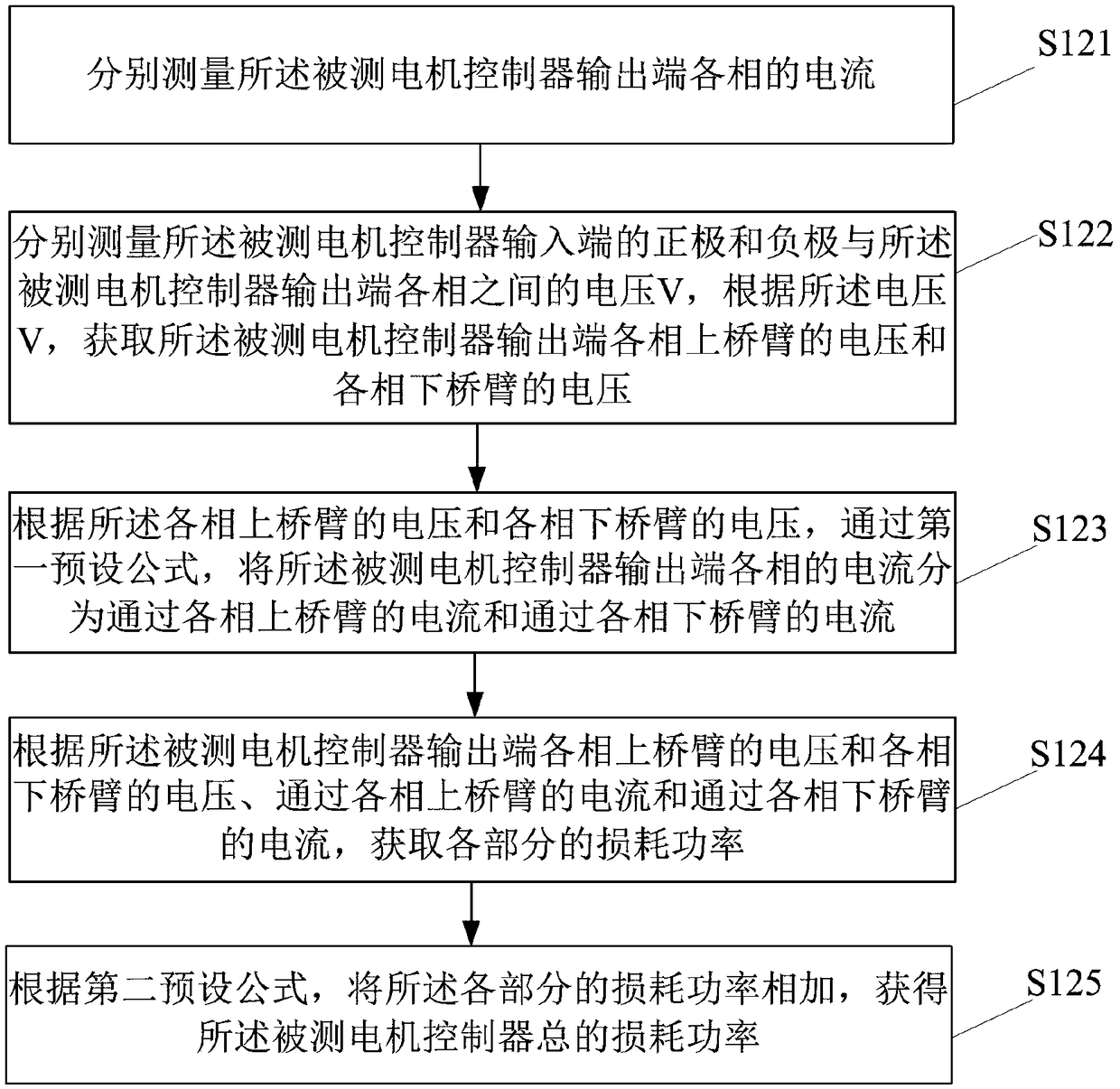

Vehicle motor controller efficiency measuring method, device and system

InactiveCN108614151APower supply testingMotor parameters estimation/adaptationElectric machineMotor controller

The invention relates to a vehicle motor controller efficiency measuring method comprising the steps that the input power of the measured motor controller is acquired according to the operation stateof the motor under the preset condition; the energy loss power of the measured motor controller is acquired; the output power of the measured motor controller is acquired according to the input powerand the energy loss power; and the efficiency of the measured motor controller is acquired according to the output power and the input power. According to the method, the actual operation environmentand condition of the vehicle motor system are considered, and the motor controller efficiency value obtained by testing has high accuracy and low fluctuation in comparison with the conventional measuring method; and the test equipment has simple structure is comparison with the heat measuring method so that the test time can be effectively reduced and the test cost can be reduced.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

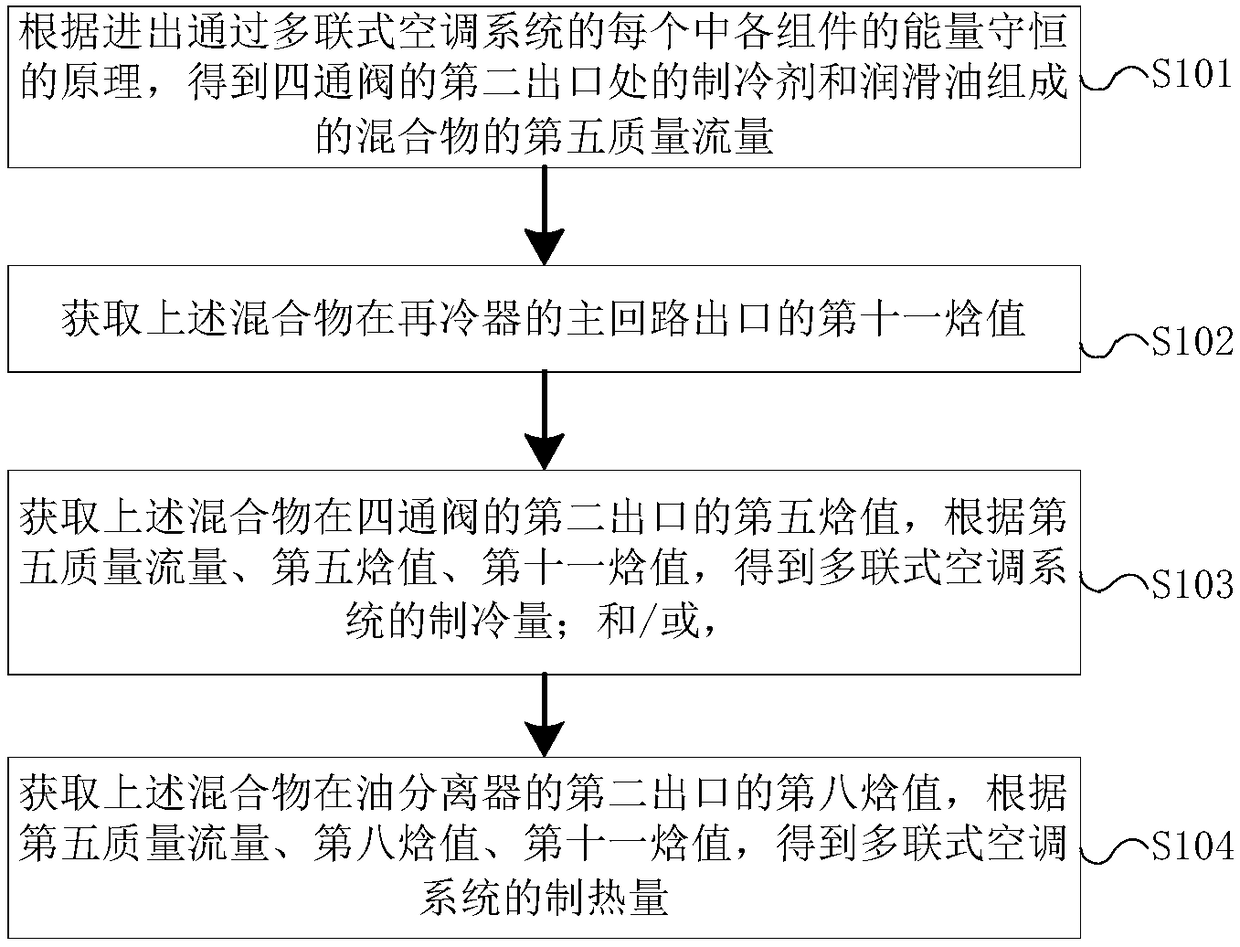

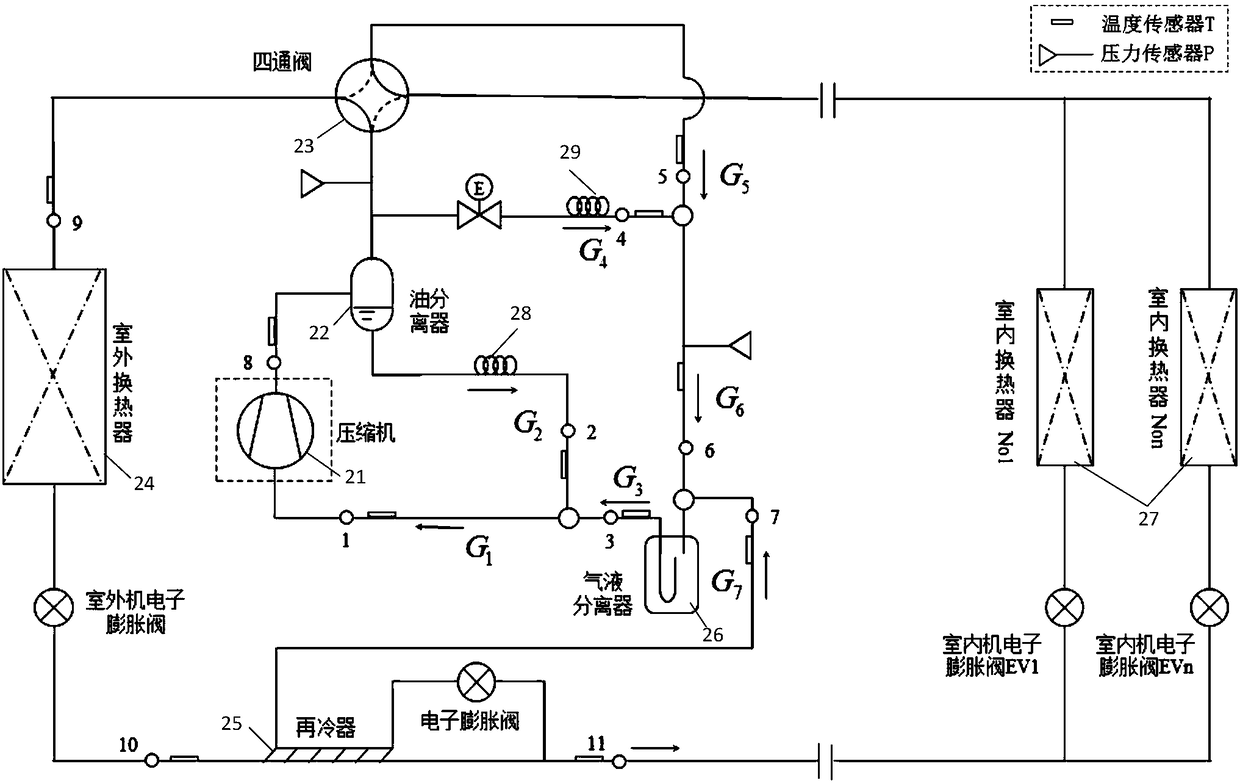

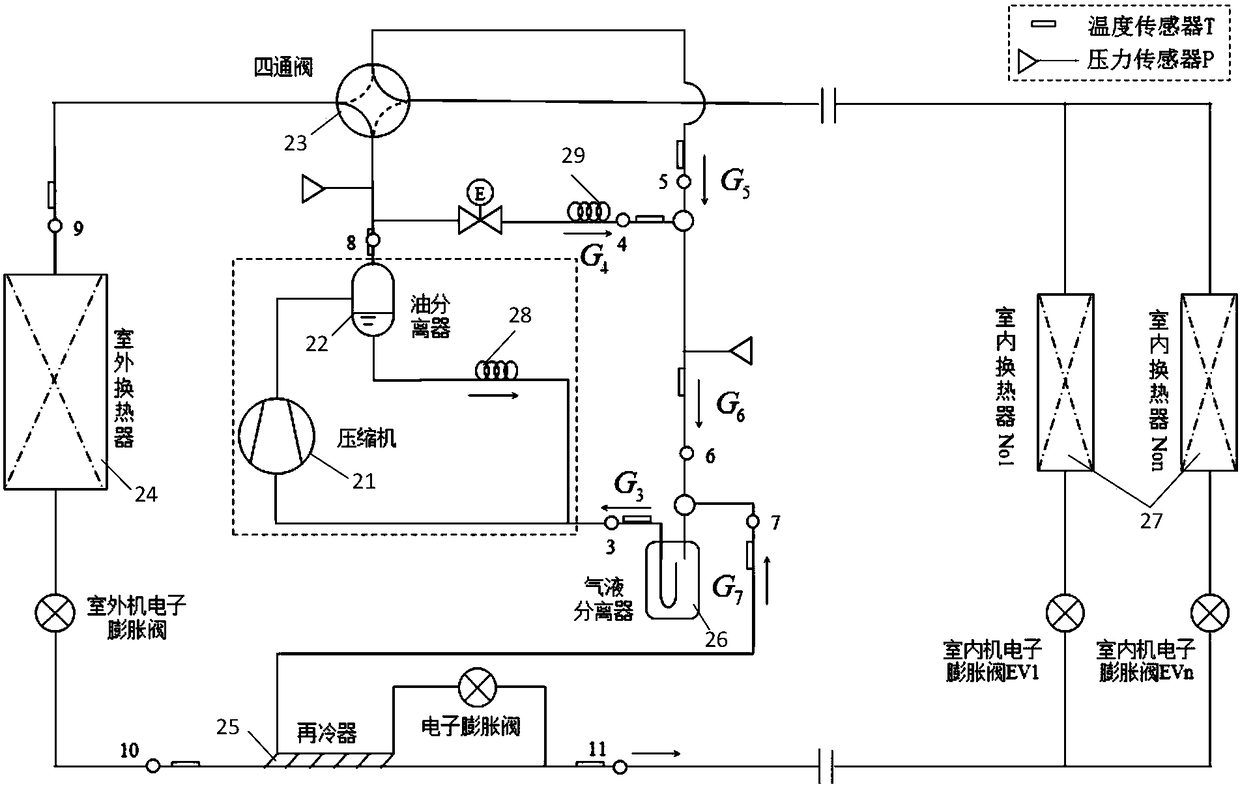

Heat exchange amount measurement method and device for multi-split type air conditioning system

The invention provides a heat exchange amount measurement method and device for a multi-split type air conditioning system. The method includes the following steps that: the fifth mass flow rate of amixture composed of a refrigerant and lubricating oil at the second outlet of a four-way valve is obtained according to the principle of the conservation of energy entering and exiting from componentsin the multi-split type air conditioning system; the eleventh enthalpy value of the mixture at the main loop outlet of a recooler is obtained; the fifth enthalpy value of the mixture at the second outlet of the four-way valve is obtained; the refrigerating capacity of the multi-split type air conditioning system is obtained according to the fifth mass flow rate, the fifth enthalpy value and the eleventh enthalpy value; and / or the eighth enthalpy value of the mixture at the second outlet of an oil separator is obtained, and the heating capacity of the multi-split type air conditioning system is obtained according to the fifth mass flow rate, the eighth enthalpy value and the eleventh enthalpy value. With the heat exchange amount measurement method and device of the invention adopted, the problem that the measurement result of the heat exchange amount of the multi-split type air conditioning system in the prior art is inaccurate can be solved.

Owner:TSINGHUA UNIV

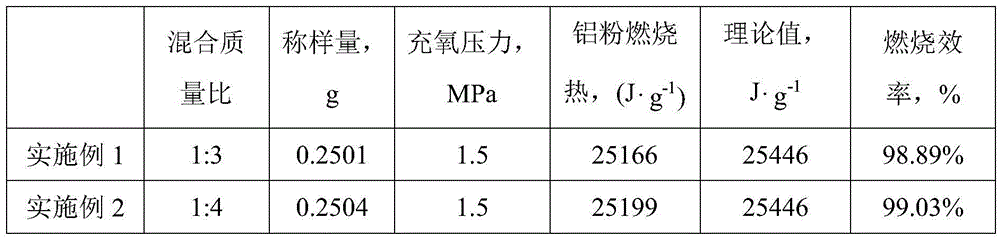

High-activity aluminum powder combustion heat measurement method

InactiveCN105606649AGood application effectGood compatibilityMaterial heat developmentBenzoic acidCombustion

The invention discloses a high-activity aluminum powder combustion heat measurement method. The method includes the following steps of firstly, calibrating a heat metering system of an oxygen bomb calorimeter through benzoic acid so as to obtain the thermal capacity of the system; secondly, mixing aluminum powder with glycidyl azide polymer (GAP) to form a sample; thirdly, weighing the mixed combustion sample, putting the sample in a calorimetric bomb, introducing oxygen, putting the calorimetric bomb in water, making the sample combust in the calorimetric bomb, and accurately measuring the water temperature values before and after combustion; fourthly, calculating the combustion heat value of aluminum powder according to the formula. The method is high in accuracy, safe and feasible, and the experiment basis is provided for thermodynamic calculation and formulation design of aluminum-contained propellant.

Owner:XIAN MODERN CHEM RES INST

Device and method for measuring heat leakage of superconducting magnet low-temperature system

ActiveCN108168738AEasy, fast and efficient measurementSimple structureCalorimeterMeasurement deviceSuperconducting Coils

The invention discloses a device and method for measuring heat leakage of a superconducting magnet low-temperature system, wherein the measuring device comprises a helium injection assembly, a refrigerating assembly, a Dewar middle cylinder assembly, a cold screen middle cylinder assembly, a helium gas input assembly, a Dewar side cylinder assembly, a cold screen side cylinder assembly, a helium output assembly and a heating end assembly. The device is simple in structure and convenient to assemble, and the difference value of the measured refrigerating capacity and the thermal load of the refrigerating machine secondary cold head are the heat leakage of the measured low-temperature system, the measurement result is accurate and reliable, the calculation is simple, and the heat leakage ofthe superconducting magnet low-temperature system can be rapidly and efficiently measured.

Owner:HEFEI CAS ION MEDICAL & TECHNICAL DEVICES CO LTD

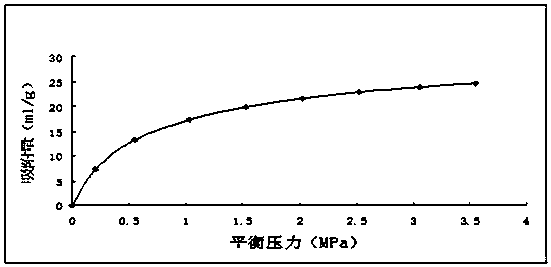

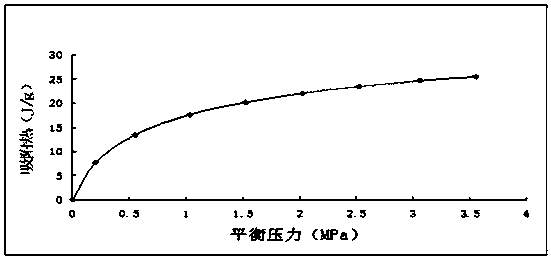

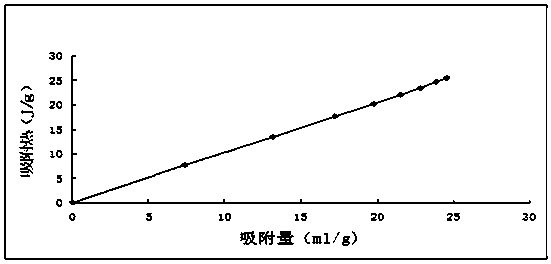

Device for automatically and synchronously measuring adsorption quantity and adsorption heat of high-pressure gas and determination method

ActiveCN108120657AFlexible operationEasy to operateMaterial heat developmentAdsorption equilibriumHeat flux

The invention discloses a device for automatically and synchronously measuring adsorption quantity and adsorption heat of high-pressure gas and a determination method. The device comprises a gas source sample system, a vacuum system, a synchronous adsorption quantity and adsorption heat measurement system and a data acquisition and automation control system. The determination method comprises thefollowing steps: determining a pressure change in the adsorption process by a high-precision pressure sensor in an equilibrium state, reaching adsorption equilibrium under constant temperature control, and combining a gas state equation to calculate the gas adsorption mole number or volume from an initial state to the equilibrium process; and outputting a dynamic curve changing along with time ina heat flux form by adopting a thermoelectric force difference of a multiple stereoscopic thermopile measurement reference cell and a sample cell, and combining a Clausius-Clapeyron equation to calculate the adsorption heat by virtue of instrument parameter correction and integral curves. The measuring device disclosed by the invention is stable, reliable, high in measuring accuracy, high in automation control degree and simple and convenient to operate, and the gas adsorption quantity and adsorption heat in the isothermal gas adsorption process can be synchronously measured.

Owner:CHINA UNIV OF MINING & TECH

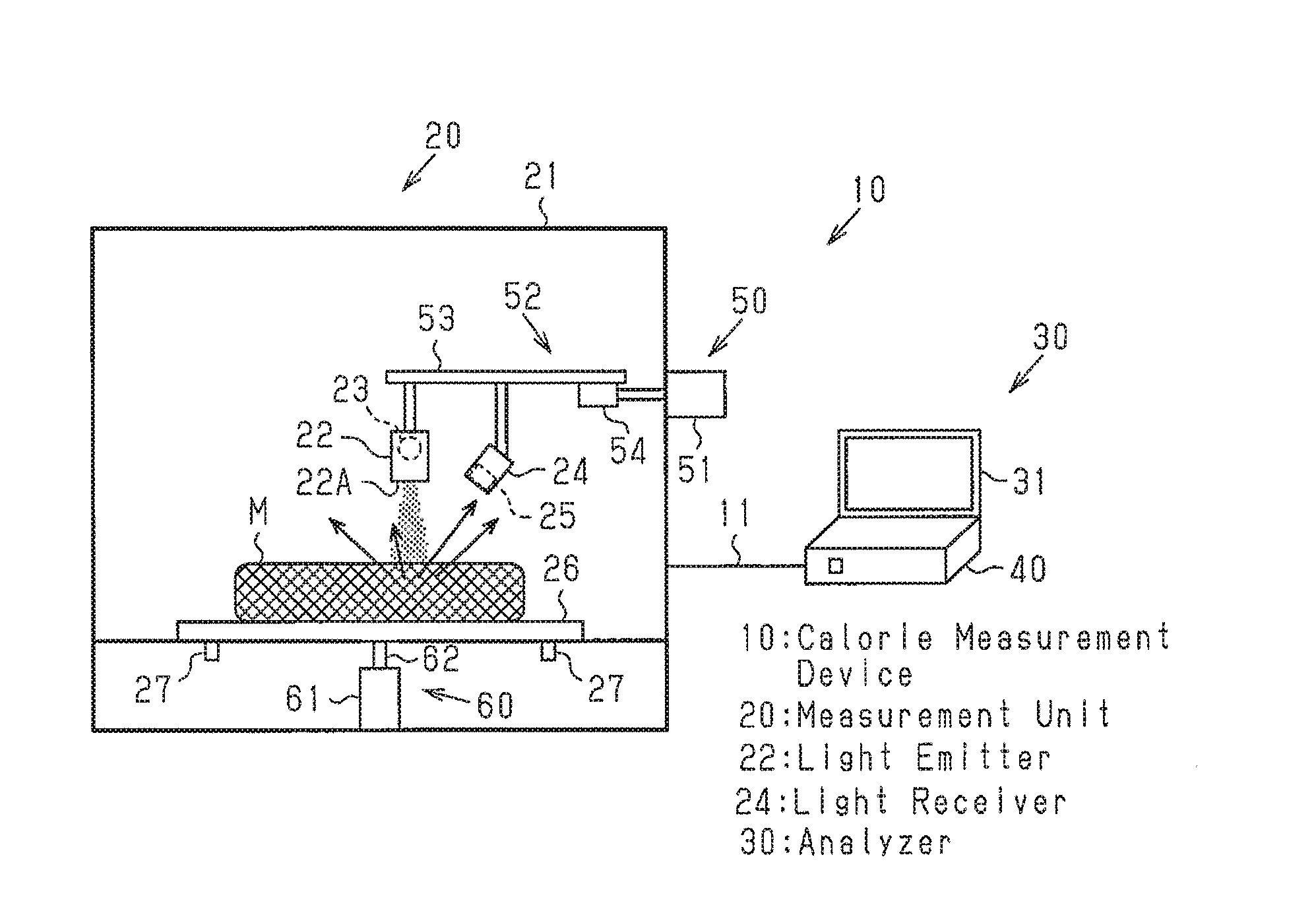

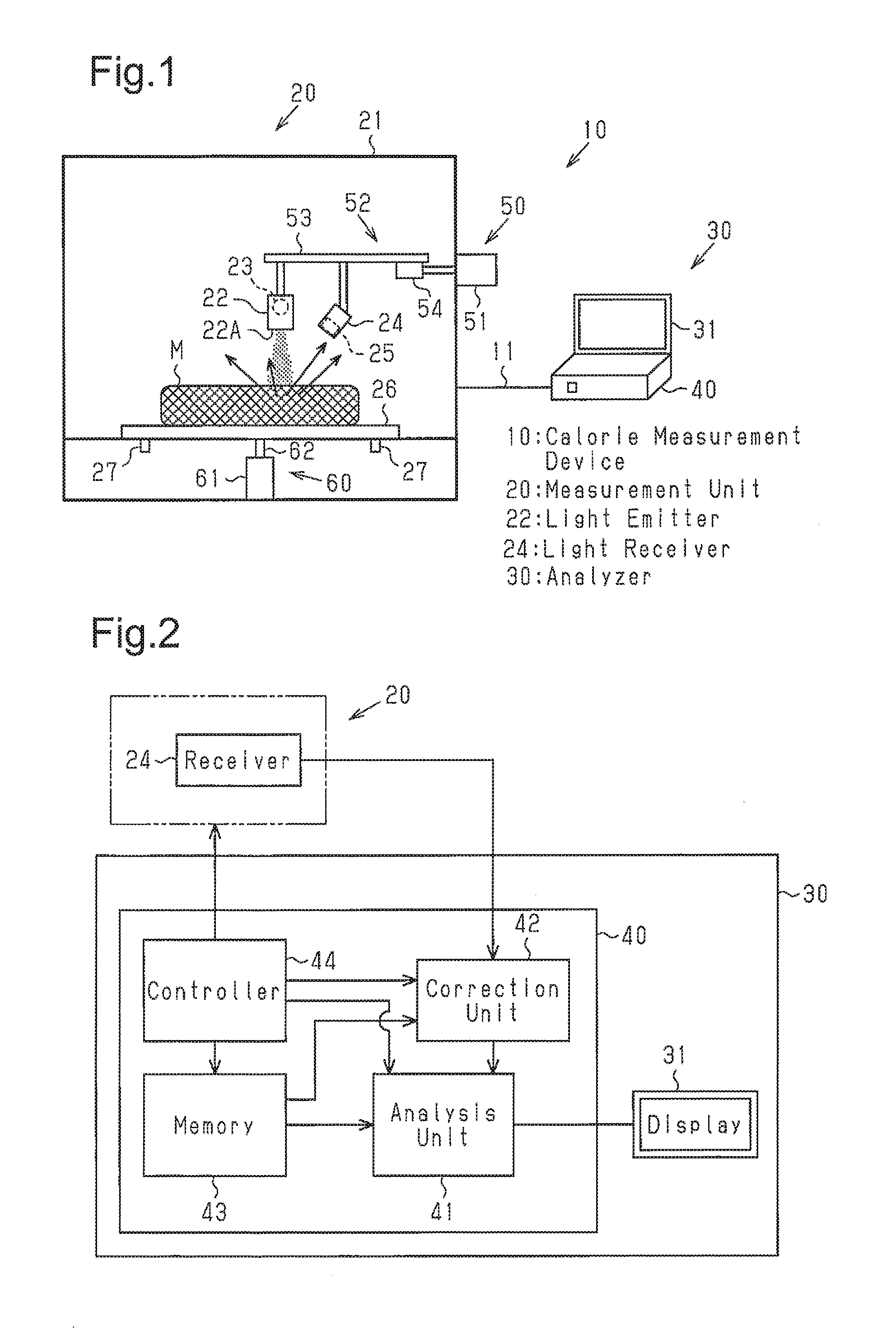

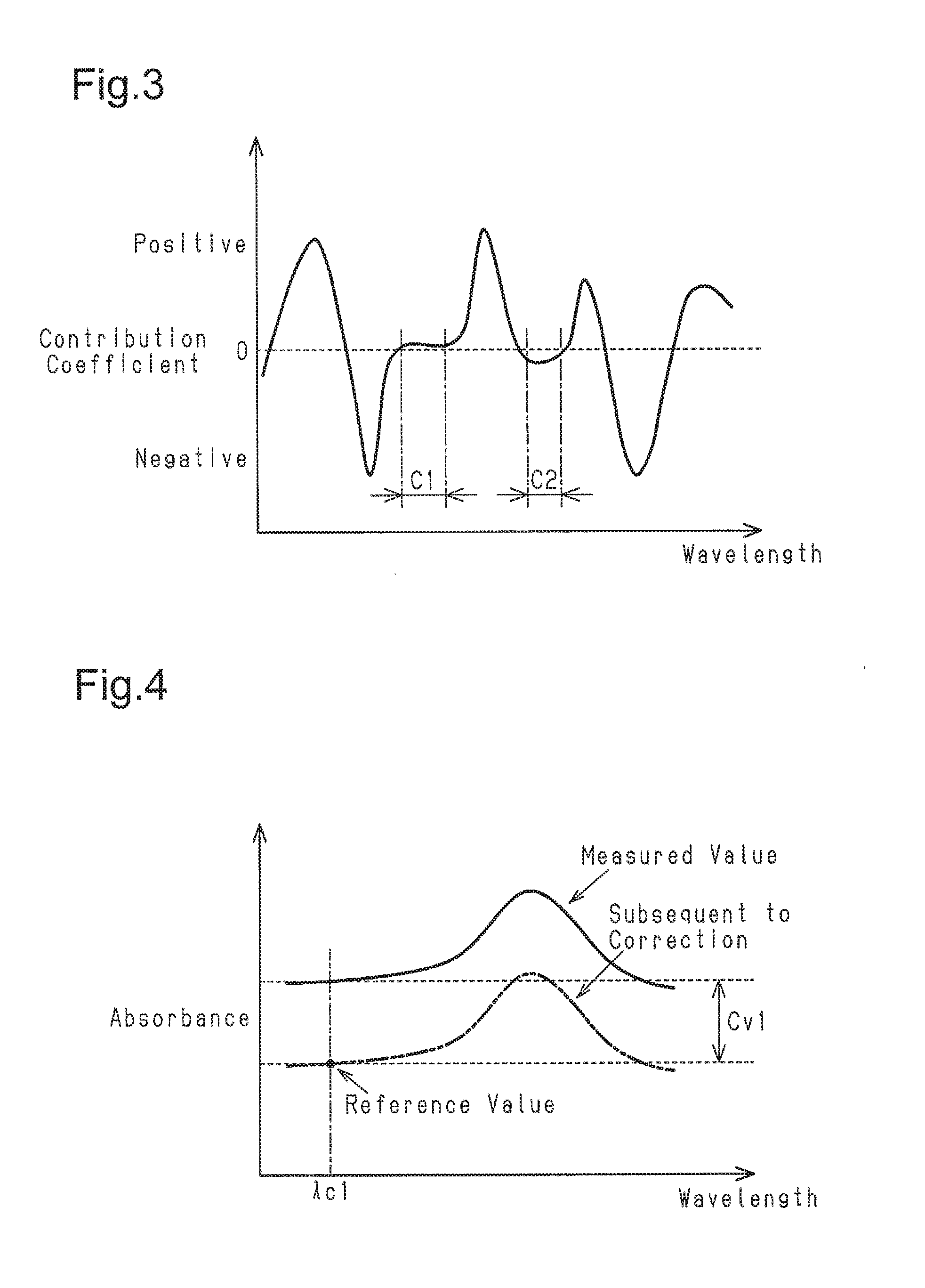

Calorie measurement device

ActiveUS20160313241A1Accurate calculationMaterial analysis by optical meansTesting foodMeasurement deviceLight reflection

This calorie measurement device is provided with the following: a light-emission unit that exposes a food article to light that contains near-infrared wavelengths; a light-reception unit that receives transmitted light that had passed through the food article and / or reflected light that was reflected by the food article; a correction unit that computes a base absorbance for the food article on the basis of the transmitted and / or reflected light and corrects the light intensity measured by the light-reception unit and / or the computed base absorbance on the basis of affecting factors, said affecting factors being those that affect the absorption and reflection of light by the food article but are essentially unaffected by the light-absorption and light-reflection properties of the components of the food article; and an analysis unit that computes an analysis value indicating the caloric content of the food article on the basis of the corrected light intensity measured by the light-reception unit and / or the corrected base absorbance.

Owner:PANASONIC INTELLECTUAL PROPERTY MANAGEMENT CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com