Semiconductor device member, production method of semiconductor-device-member formation liquid and semiconductor device member, and semiconductor-device-member formation liquid, phosphor composition, semiconductor light-emitting device, lighting system and image display system using the same

a semiconductor and semiconductor technology, applied in the direction of semiconductor/solid-state device details, luminescent compositions, chemistry apparatus and processes, etc., can solve the problems of low adhesion, degradation of phosphor or luminous elements, and difficulty in using a semiconductor light-emitting device generally as a power device, so as to improve the performance of the semiconductor device and maintain the performance. , the effect of film-forming ability and adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment a-1

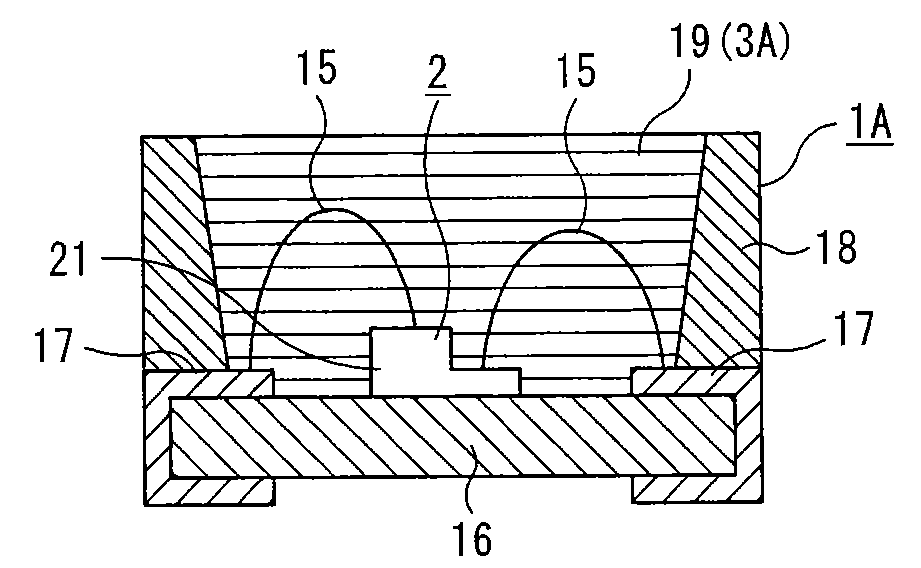

[0603]In light emitting device 1A of the present embodiment, as shown in FIG. 1, luminous element 2 is surface-mounted on an insulating substrate 16 on which printed wiring 17 is carried out. In luminous element 2, a p-type semiconductor layer (not shown) and an n-type semiconductor layer (not shown) in a luminous layer part 21 are connected electrically to printed wirings 17 and 17 via conductive wires 15 and 15 respectively. Conductive wires 15 and 15 have a small cross section so that the light emitted from luminous element 2 may not be blocked.

[0604]As luminous element 2, one that emits light of any wavelengths, from ultraviolet to infrared regions, may be used. In this embodiment, a gallium nitride LED chip is assumed to be used. In luminous element 2, an n-type semiconductor layer (not shown) is formed on the lower side in FIG. 1 and a p-type semiconductor layer (not shown) is formed on the upper side in the same. The upper side of FIG. 1 is assumed to be the front side in the...

embodiment a-2

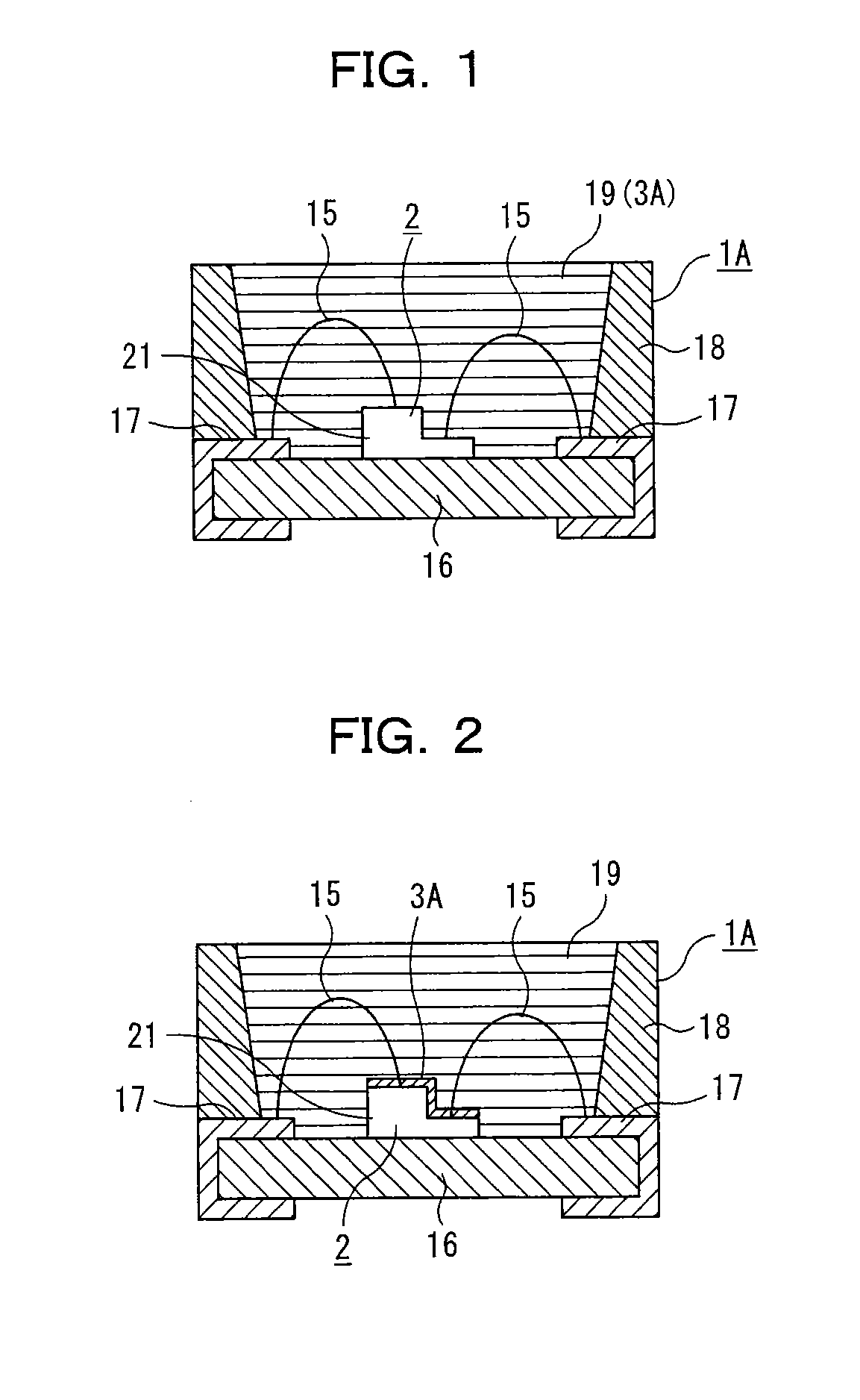

[0608]Light emitting device 1A of the present embodiment is structured, as shown in FIG. 2, in the same manner as the above embodiment A-1, except that the front side of luminous element 2 is covered with transparent member 3A and sealing part 19, formed on member 3A. Sealing part 19 is formed of a material different from that of transparent member 3A. Transparent member 3A on the surface of luminous element 2 is a transparent thin film, functioning as a light extracting film and sealing film. Transparent member 3A can be formed, for example, by coating the above liquid for forming the semiconductor light-emitting device member, by a method of spin coating or the like, during the formation process of a chip of luminous element 2. Meanwhile, the same components as in embodiment A-1 are designated by the same reference numerals to omit redundant explanations.

[0609]Thus, because light emitting device 1A of the present embodiment is also provided with luminous element 2 and transparent ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| cure temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com