High-activity aluminum powder combustion heat measurement method

A measurement method and combustion heat technology, applied in the direction of material heat development, etc., can solve the problems of incomplete combustion, aluminum powder prone to agglomeration, ablation, etc., to avoid damage to the instrument, ensure the safety and smoothness of the experiment, and reduce the combustion rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

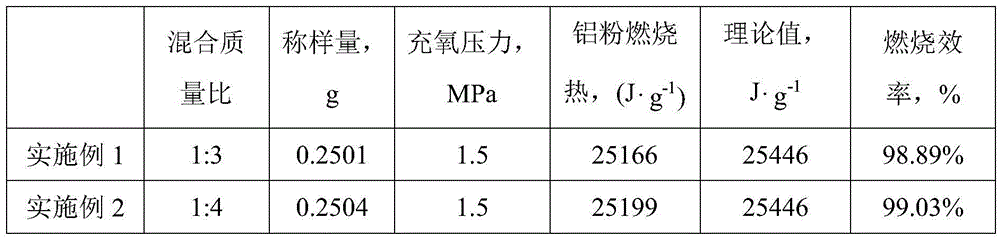

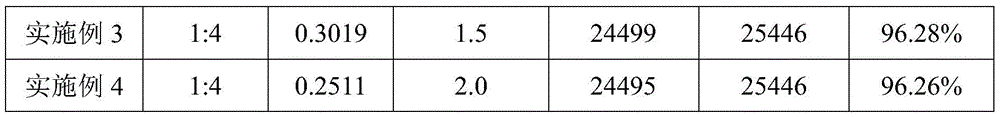

Embodiment 1

[0014] Use benzoic acid to calibrate the calorimetric system of the oxygen bomb calorimeter for many times, take the average value of 5 test results with a range not exceeding 40J / K as the heat capacity of the system, and obtain E=14511.2J / K; put the newly opened Aluminum powder (50nm, active aluminum content 82%) and GAP were uniformly mixed according to 1:3 (mass ratio) for sample preparation, and 0.2501g of burning sample was weighed and placed in a calorimeter bomb, filled with excess oxygen, and then the amount Put the heat bomb in a certain amount of water, let the sample burn in the calorimeter bomb, and accurately measure the temperature rise value of the water (T n -T 0 ); then follow the formula Calculate the heat of combustion of aluminum powder. The oxygenation pressure is 1.5MPa. Take the average value of the two groups of tests as the heat of combustion of the aluminum powder, and the results are shown in Table 1.

Embodiment 2

[0016] Use benzoic acid to calibrate the calorimetric system of the oxygen bomb calorimeter for many times, take the average value of 5 test results with a range not exceeding 40J / K as the heat capacity of the system, and obtain E=14511.2J / K; put the newly opened Aluminum powder (50nm, active aluminum content 82%) and GAP were uniformly mixed according to 1:4 (mass ratio) for sample preparation, weighed 0.2504g of burning sample and placed it in a calorimeter bomb, filled with excess oxygen, and then weighed Put the heat bomb in a certain amount of water, let the sample burn in the calorimeter bomb, and accurately measure the temperature rise value of the water (T n -T 0 ); then follow the formula Calculate the heat of combustion of aluminum powder. The oxygenation pressure is 1.5MPa. Take the average value of the three groups of tests as the heat of combustion of the aluminum powder, and the results are shown in Table 1.

Embodiment 3

[0018] Use benzoic acid to calibrate the calorimetric system of the oxygen bomb calorimeter multiple times, take the average value of the 5 test results with a range not exceeding 40J / K as the heat capacity of the system, and obtain E=14511.2J / K; put the newly opened Aluminum powder (50nm, active aluminum content 82%) and GAP were uniformly mixed according to 1:4 (mass ratio) for sample preparation, and 0.3019g of burning sample was weighed and placed in a calorimeter bomb, filled with excess oxygen, and then the amount Put the heat bomb in a certain amount of water, let the sample burn in the calorimeter bomb, and accurately measure the temperature rise value of the water (T n -T 0 ); then follow the formula Calculate the heat of combustion of aluminum powder. The oxygenation pressure is 1.5MPa. Take the average value of the three groups of tests as the heat of combustion of the aluminum powder, and the results are shown in Table 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com