Patents

Literature

42 results about "Glycidyl azide polymer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Glycidyl azide polymer (GAP) offers an unique energetic binder and plasticizer system for advanced propellants and plastic bonded explosives (PBX) for achieving higher performance, superior structural integrity and low vulnerability. Its chief advantages are higher density and * To whom all correspondence shpuld be addressed.

Propellant with high energy and low temperature sensitive coefficient of burning

ActiveCN105130720ABoost energy levelsLow burning rate temperature sensitivity coefficientExplosivesAl powderExplosive Agents

A propellant with high energy and low temperature sensitive coefficient of burning comprises 12-15% of an adhesive, 10-13% of a plasticizer, 15-18% of an oxidant, 38-50% of an energetic explosive, 10-18% of a metal fuel and 1.5-2.0% of a small group, wherein the adhesive is glycidyl azide polymer; the plasticizer is triethylene glycol dinitrate or 2,4-dinitro-2,4-diazaalkane; the oxidant is ammonium perchlorate; the energetic explosive is octogen; and the metal fuel is aluminum powder. The propellant has the characteristics of high energy (standard measured specific impulse is greater than 2450N.s / kg) and low temperature sensitive coefficient of burning (not greater than 0.15%K<-1>), and is suitable for tactical missile engines with far required range, strong penetration ability, high reliability and accurate guidance.

Owner:HUBEI INST OF AEROSPACE CHEMOTECH

Polyvinyl alcohol acetal aromatic aldehyde grafting glycidyl azide polymer, preparation method thereof and application thereof

InactiveCN102199301AGreat development potentialGood market prospectsNon-explosive/non-thermic compositionsCross-linkPolymer science

The invention relates to a polyvinyl alcohol acetal aromatic aldehyde grafting glycidyl azide polymer and a preparation method thereof. Polyvinyl alcohol acetal aromatic aldehyde and a glycidyl azide polymer which serve as initiators and diisocyanate serving as a cross-linking agent perform a homogeneous phase cross-linking reaction to obtain the polyvinyl alcohol acetal aromatic aldehyde grafting glycidyl azide polymer. The energetic polymer is used as a toughening elasticizer to be applied in fields of energetic materials such as explosives, propellants, pyrotechics and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

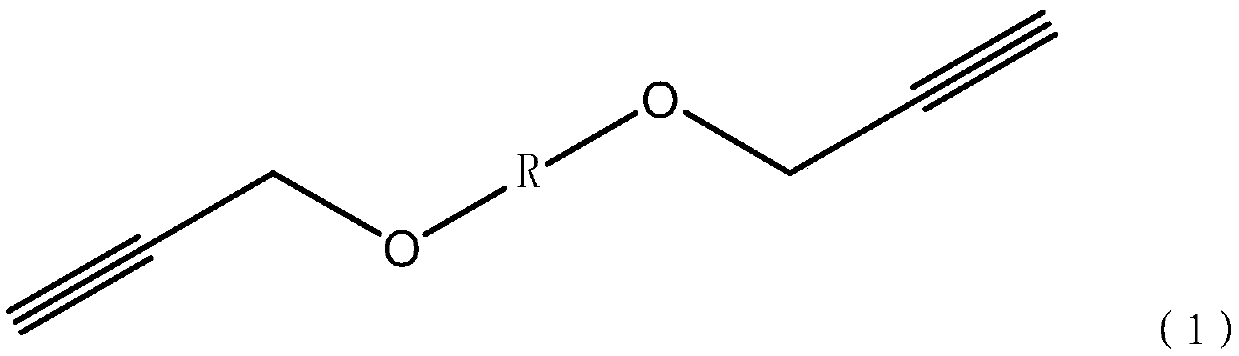

Method for preparing elastomer based on Click reaction

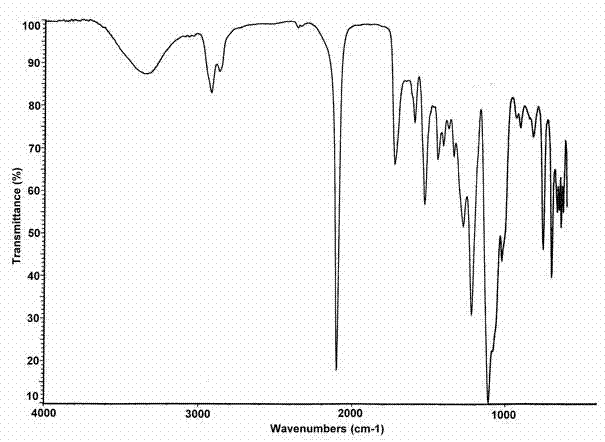

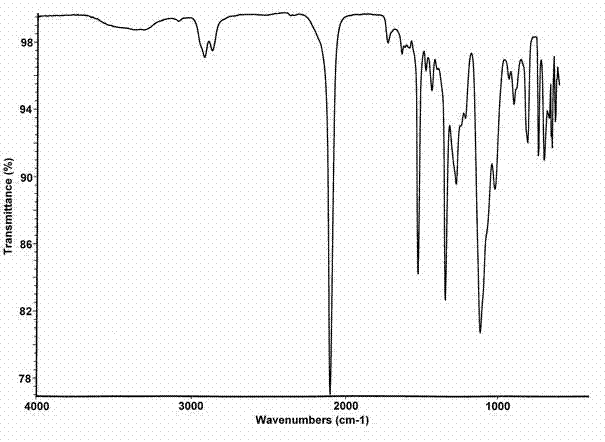

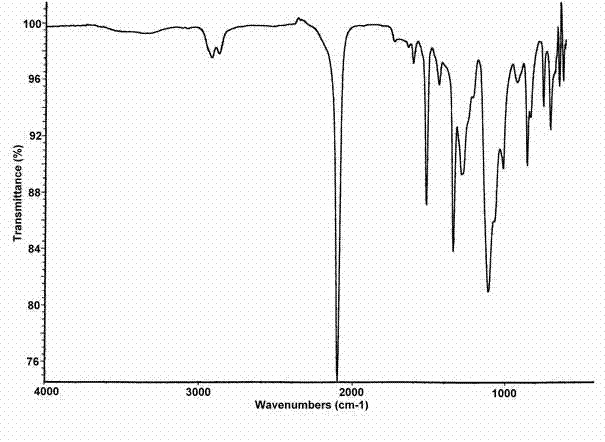

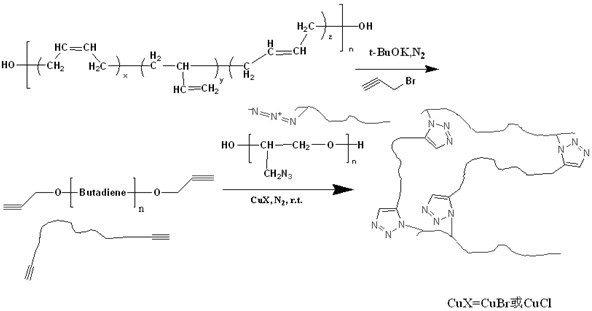

The invention relates to a method for preparing elastomer based on Click reaction. The method for preparing elastomer based on the Click reaction is characterized by including the steps: 1) preparing alkynylation polybutadiene; 2) according to the molar ratio of the total quantity of alkynylation polybutadiene end-C Xi C to N3 in glycidyl azide polymer to cuprous halides being 1:1-4:0.05-0.5, dissolving the alkynylation polybutadiene and the glycidyl azide polymer in tetrahydrofuran, adding glycidyl azide polymer solution into alkynylation polybutadiene solution to obtain mixed solution M, adding the cuprous halides into the mixed solution M under the condition of N2 protection and stirring, keeping the temperature at 0-25 DEG C, and performing reaction away from light for 8-24h to obtainreaction solution N; and 3) performing suction filtration for the reaction solution N, drying filtrate with anhydrous MgSO4, and performing filtration, concentration and solvent volatilization to obtain the elastomer based on the Click reaction. The preparation process is simple, and the elastomer prepared by the method has a good mechanical property.

Owner:碳衡(重庆)生物质新材料有限公司

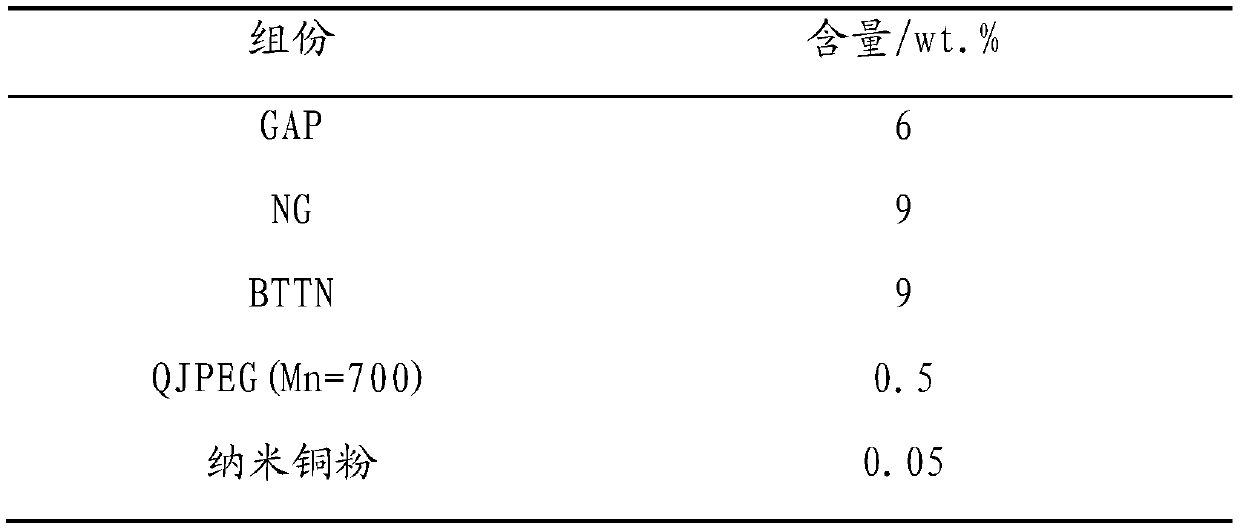

Nonisocyanate-cured azide polyether binder system and propellant

The invention relates to a nonisocyanate-cured azide polyether binder system and a propellant, and belongs to the technical field of solid propellants. The system includes the following components inparts by mass: 54% to 96.6% of a binder, 3.2% to 45.3% of a curing agent, and 0.2% to 1.5% of a curing catalyst, wherein the binder is glycidyl azide polymer (GAP), the curing agent is a bifunctionalor multifunctional alkynyl-terminated polyether, and the curing catalyst is at least one of nano copper powder and a cuprous salt. The propellant provided by the invention has higher curing reaction activity and a faster reaction speed, can be cured at normal temperature, and solves the problem of residual thermal stress of grain solidification; the reaction mechanism is not affected by moisture,and the affect of environmental humidity and the moisture of the raw materials on curing and mechanical properties can be eliminated; and the obtained propellant has excellent mechanical properties, especially has higher elongation, and the elongation can reach 100% or more and is much higher than a level of mechanical properties reported outside China.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

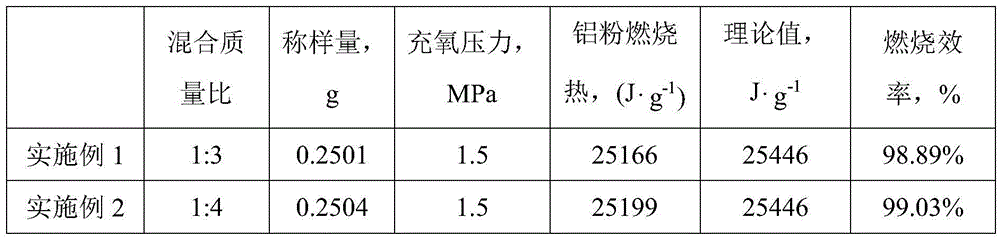

High-activity aluminum powder combustion heat measurement method

InactiveCN105606649AGood application effectGood compatibilityMaterial heat developmentBenzoic acidCombustion

The invention discloses a high-activity aluminum powder combustion heat measurement method. The method includes the following steps of firstly, calibrating a heat metering system of an oxygen bomb calorimeter through benzoic acid so as to obtain the thermal capacity of the system; secondly, mixing aluminum powder with glycidyl azide polymer (GAP) to form a sample; thirdly, weighing the mixed combustion sample, putting the sample in a calorimetric bomb, introducing oxygen, putting the calorimetric bomb in water, making the sample combust in the calorimetric bomb, and accurately measuring the water temperature values before and after combustion; fourthly, calculating the combustion heat value of aluminum powder according to the formula. The method is high in accuracy, safe and feasible, and the experiment basis is provided for thermodynamic calculation and formulation design of aluminum-contained propellant.

Owner:XIAN MODERN CHEM RES INST

Waterproof moisture penetration film preparation method

InactiveCN109825250AFill in the gapsSmall molecular weightPolyureas/polyurethane adhesivesLaminationMoisture penetrationMoisture absorption

The invention discloses a waterproof moisture penetration film preparation method, and belongs to the technical field of high-polymer waterproof materials. The prepared waterproof moisture penetrationfilm comprises gelatinous fiber solution, moisture absorption toughening agents, hot melt adhesives and polytetrafluoroethylene micro-pore films, deeper stripes are vertically distributed on the inner fibrous layers of mulberry barks, the inner fibrous layers are of structures of hollow cavities, have more micro-pores and soaked in moisture absorption coagulating bath, moisture absorption performance of the gelatinous fiber solution is improved, tetrahydrofuran segments are introduced into glycidyl azide polymer to prepare the moisture absorption toughening agents, the toughness and the moisture absorption performance of a moisture penetration film at normal temperature are improved under synergistic effects of the moisture absorption toughening agents and the gelatinous fiber solution, and the moisture penetration performance and the toughness of the whole waterproof moisture penetration film are improved. The prepared waterproof moisture penetration film resists outside water through the polytetrafluoroethylene micro-pore films with low surface energy, the inner layer of the waterproof moisture penetration film is made of moisture absorption toughness materials and can absorb moisture approaching to the inside of skins, and the film has wide application prospects.

Owner:姜向军

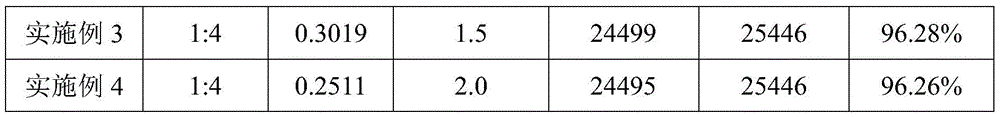

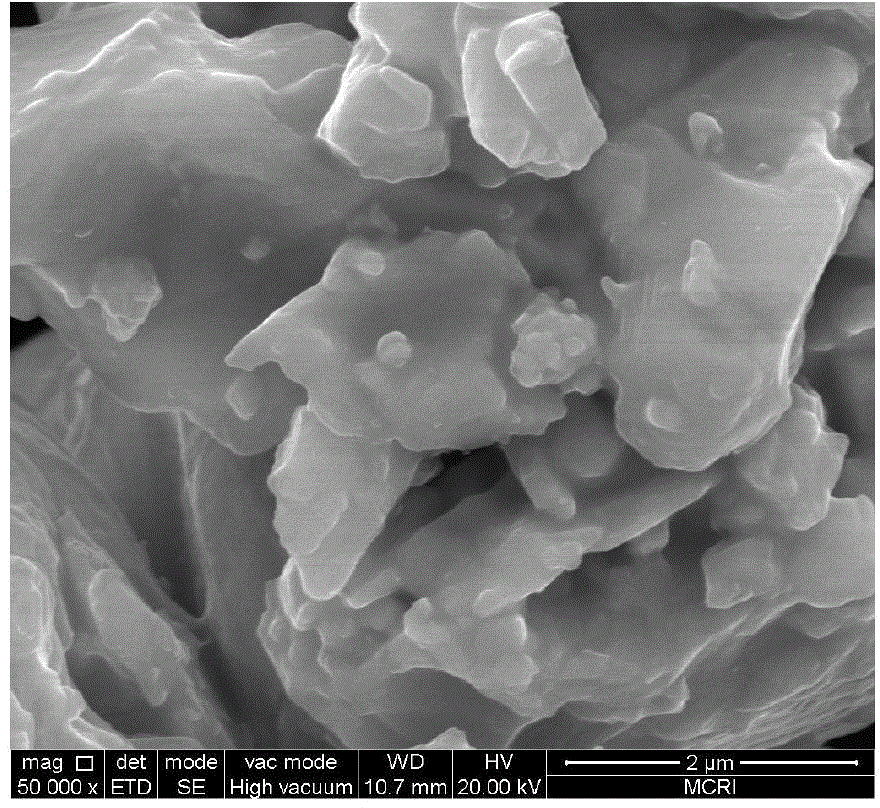

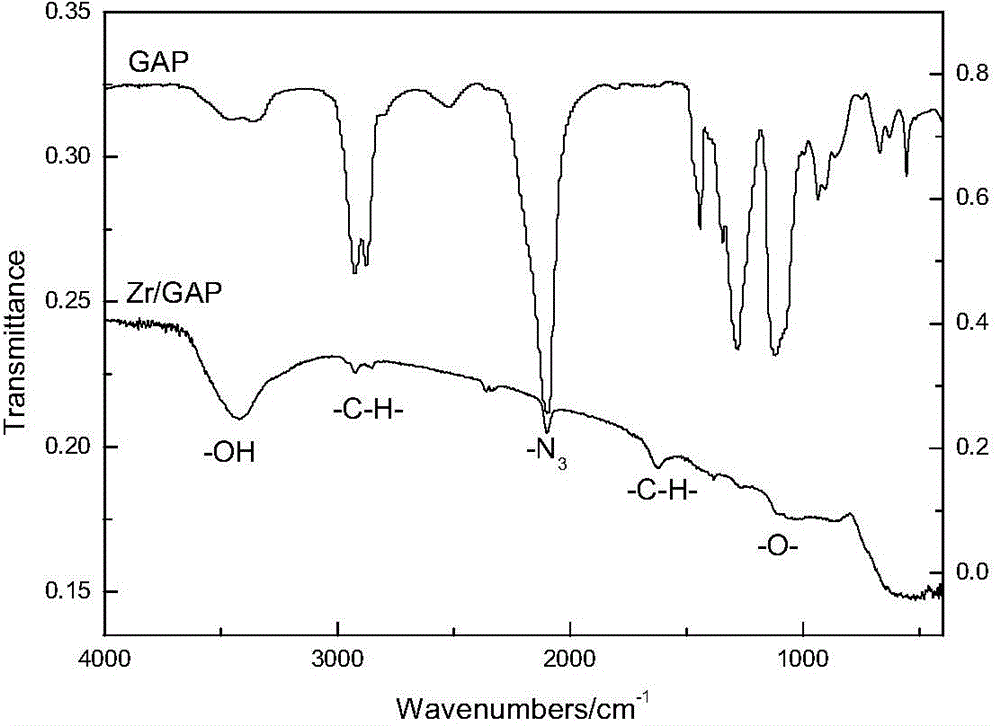

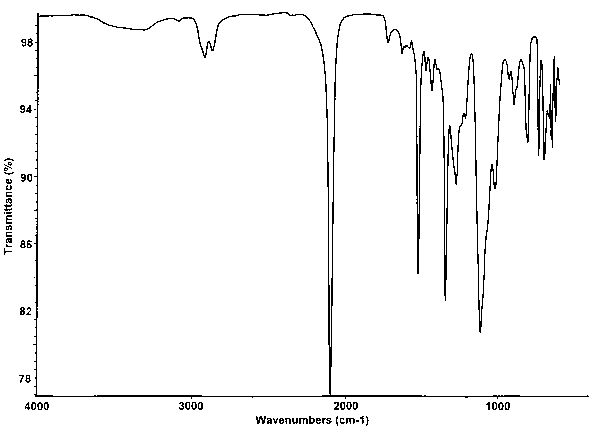

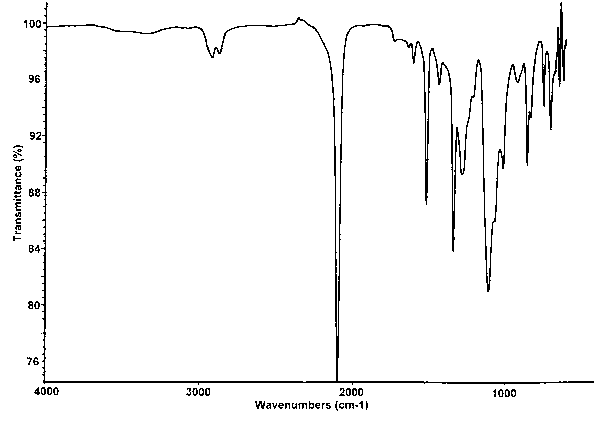

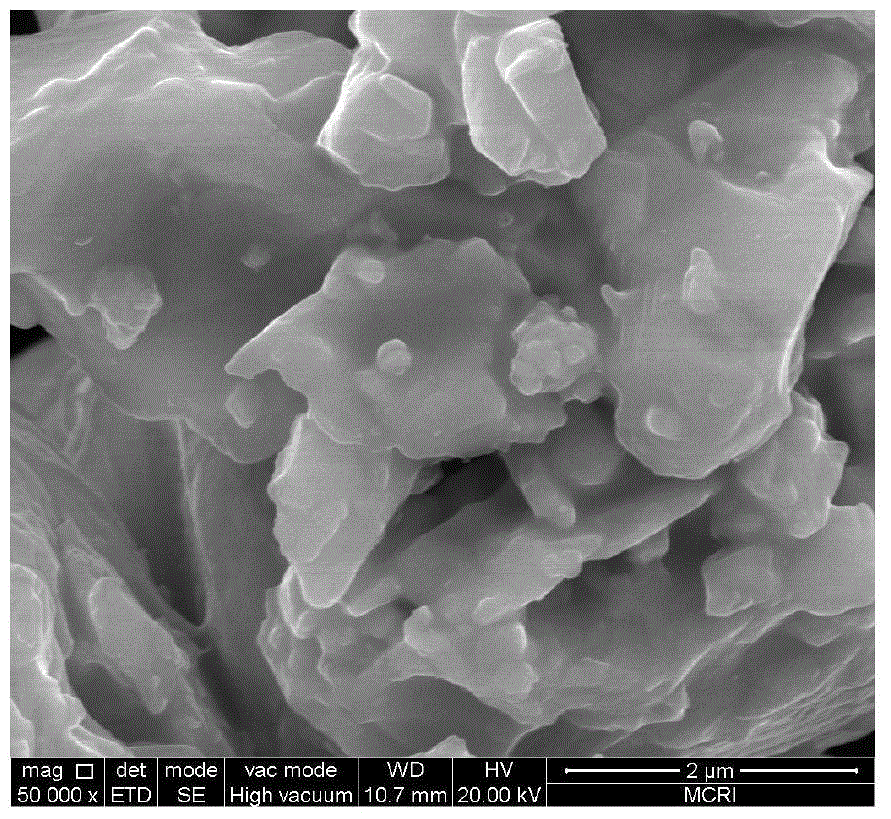

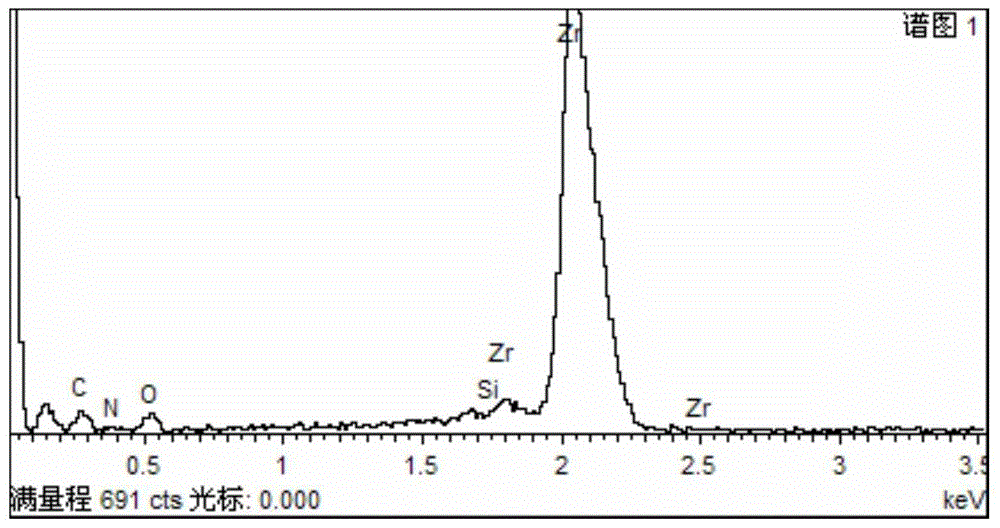

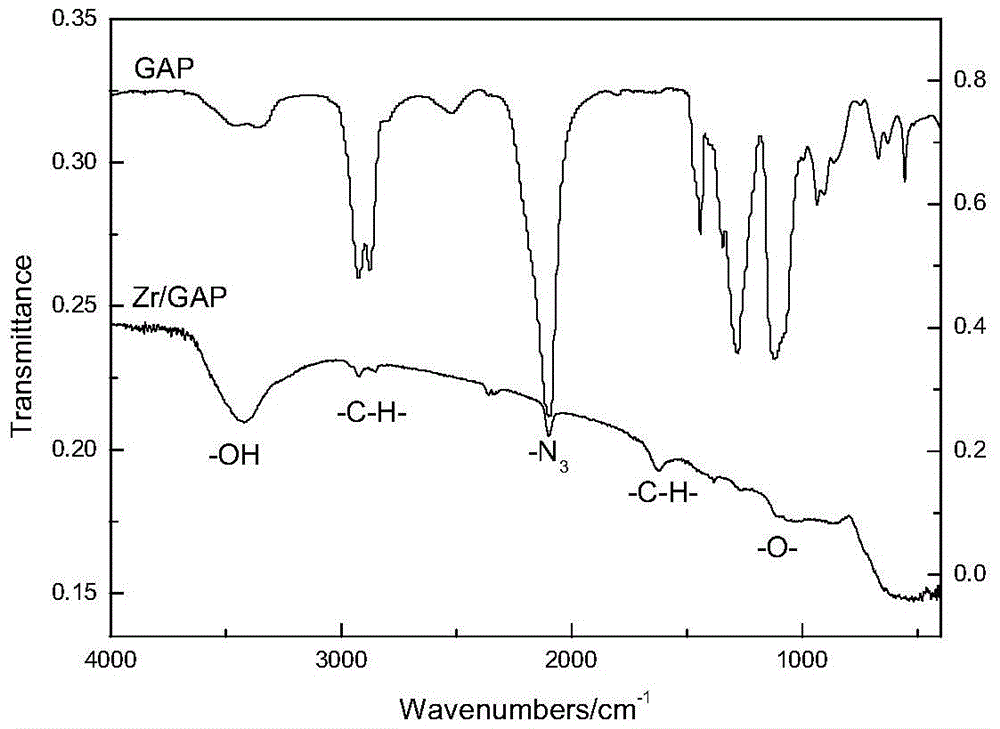

Preparation method of glycidyl azide polymer modified micro-nano zirconium composite particles

ActiveCN104311375AReduced static spark sensitivityImprove the safety of usePressure gas generationRamjetMicro nano

The invention provides a preparation method of glycidyl azide polymer modified micro-nano zirconium composite particles. The preparation method comprises the following steps: (1) pretreatment of zirconium powder; and (2) preparation of the zirconium composite particles. According to the preparation method, the electrostatic spark sensitivity of the prepared zirconium composite particles is obviously reduced relative to the uncoated zirconium powder, so that the safety performance of the zirconium powder is improved to a great extent; the selected coating material glycidyl azide polymer which is used as an energetic adhesive is capable of providing energy during the combustion and has favorable consistency with the components of propellants, so that the practical application of the zirconium powder as a composite propellant fuel to ramjets and volume-limited solid rocket engines is promoted.

Owner:XIAN MODERN CHEM RES INST

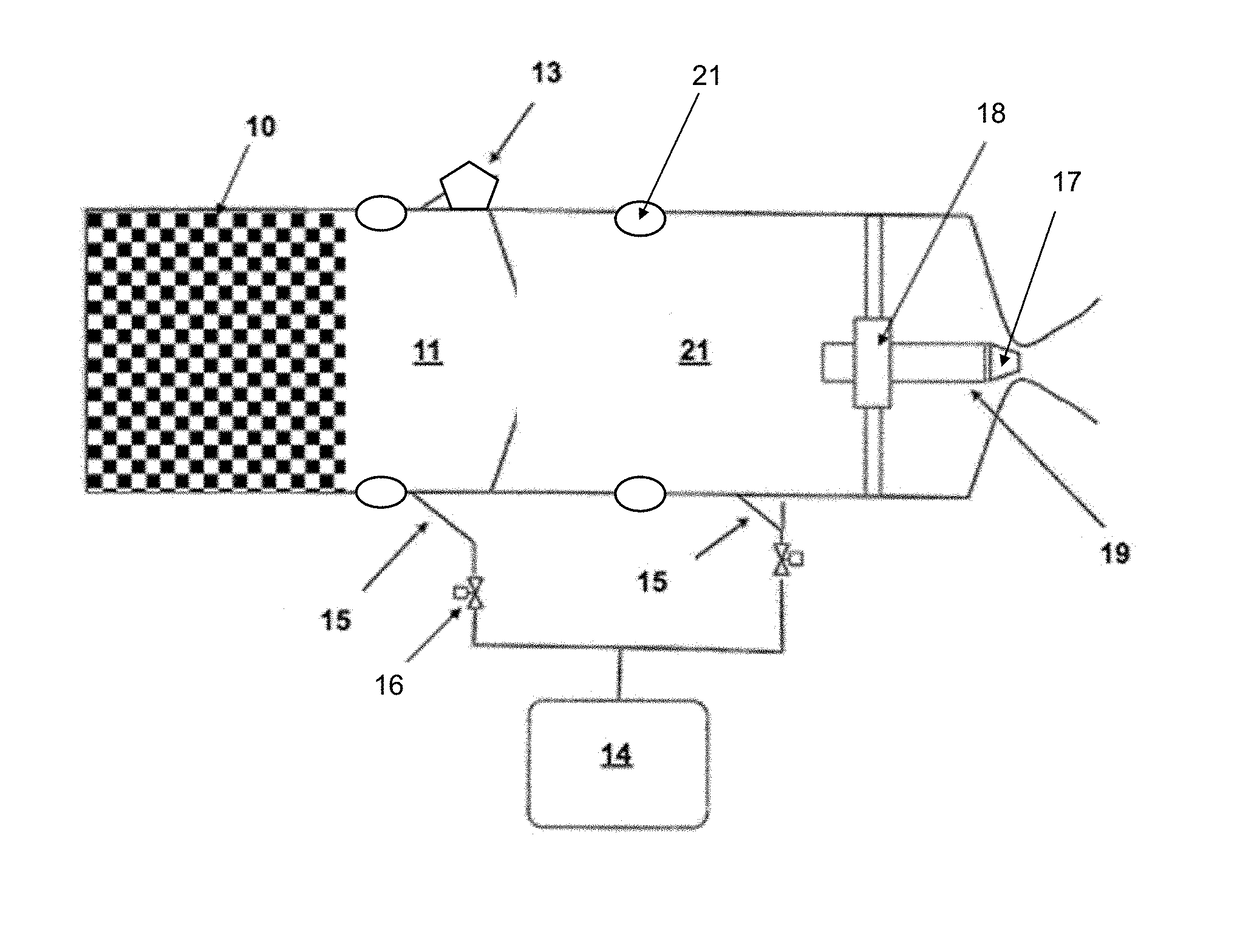

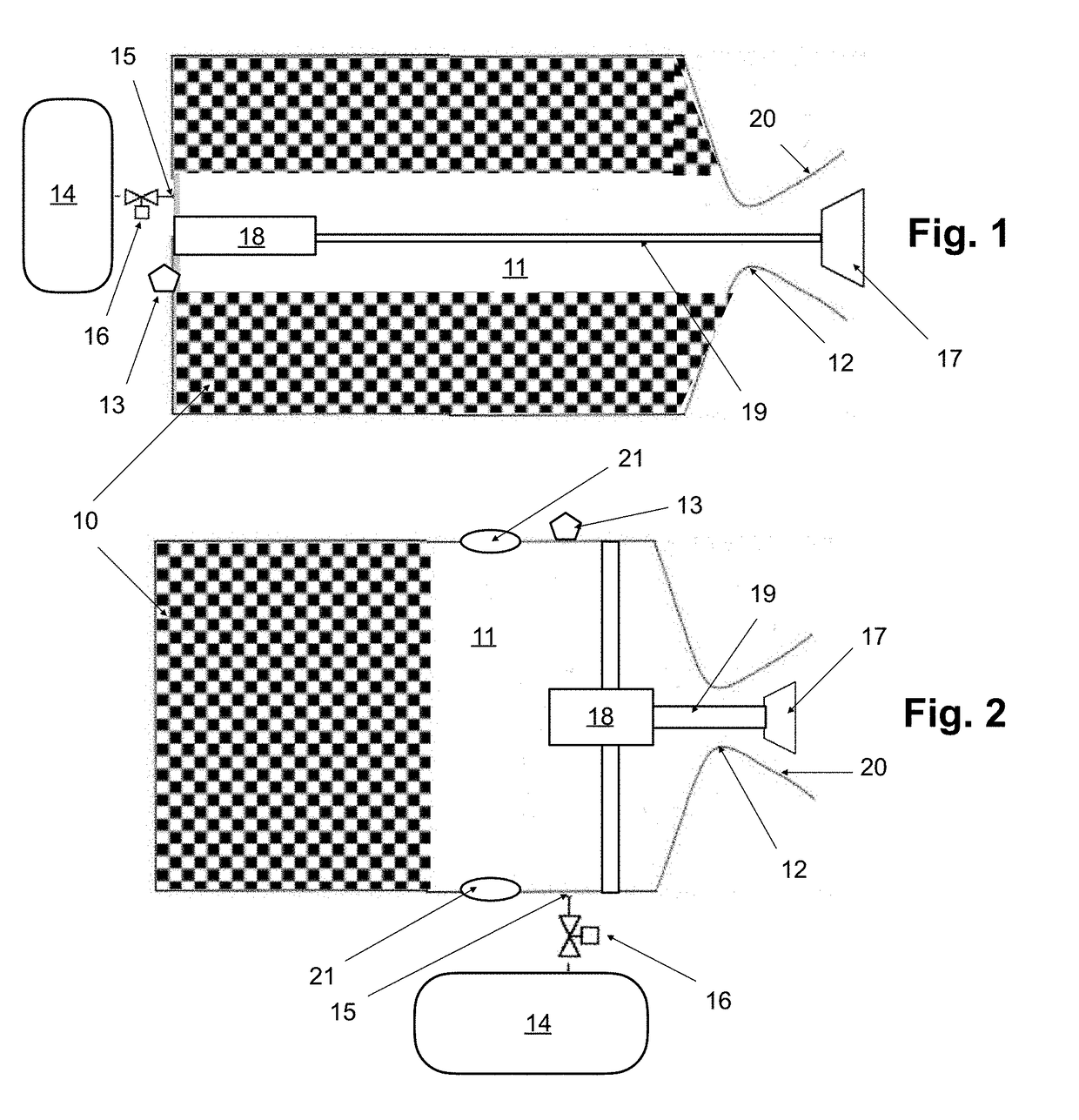

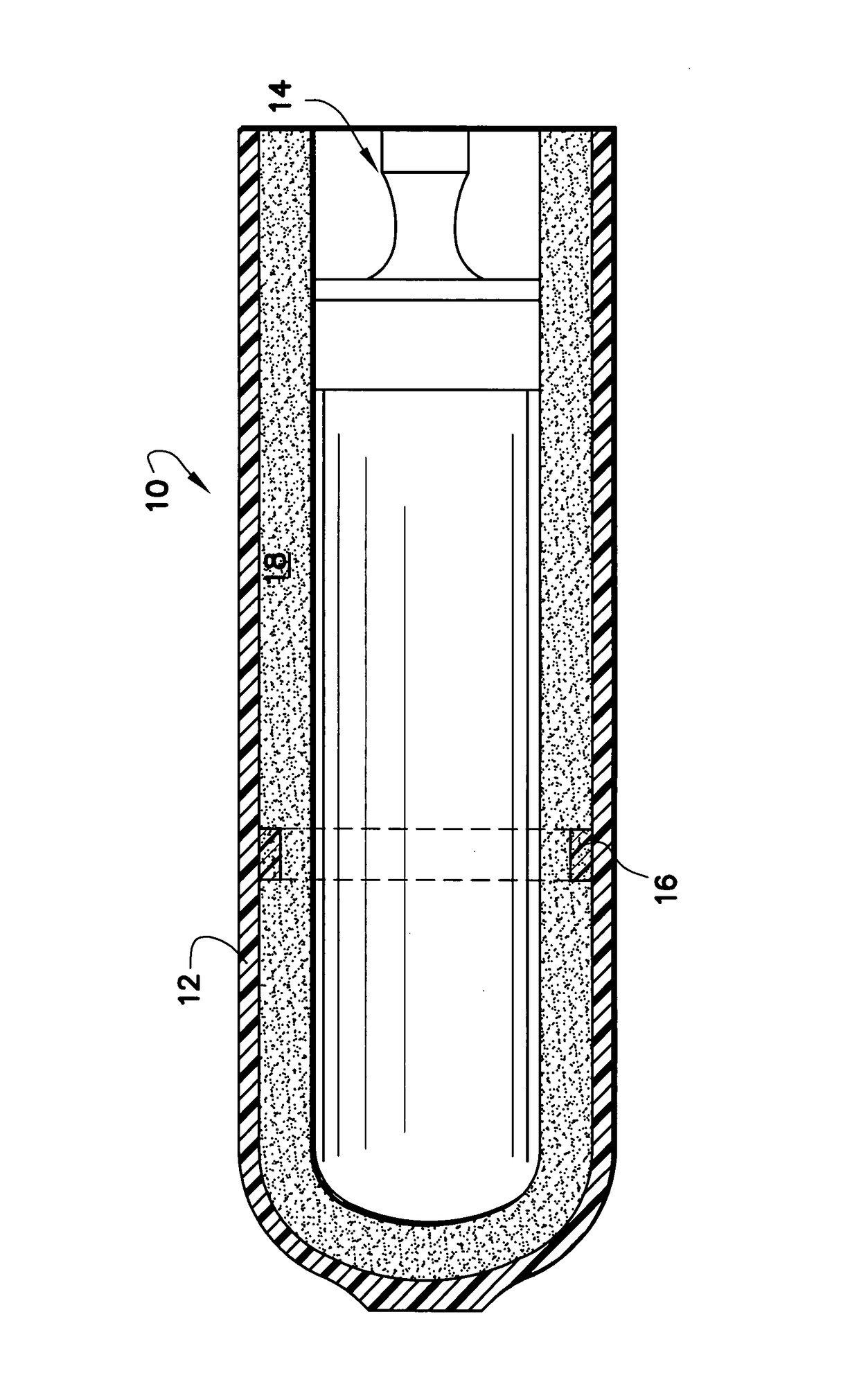

Hybrid Rocket Motor

InactiveUS20180334996A1High regression rateSelf-combustibility (deflagration)Rocket engine plantsPolyethylene glycolGlycidyl azide polymer

Hybrid rocket motors having fuel grains containing glycidyl azide polymer (GAP) produce high regression rates and can be stopped and restarted. The fuel grains also contain carbon and optionally either hydroxyl-terminated polybutadiene (HTPB) or polyethylene glycol (PEG). TGAP self-deflagration in the hybrid rocket motors is controlled by at least one of motor design and the amount of carbon in the fuel grain.

Owner:STREAMLINE AUTOMATION LLC

Combustion performance test method of nanometer aluminum powder

InactiveCN103134899AShorten the development cycleImprove efficiencyChemical analysis using combustionCombustorCombustion chamber

A combustion performance test method of nanometer aluminum powder includes the following steps of mixing the nanometer aluminum powder and glycidyl azide polymer (GAP), fully stirring the nanometer aluminum powder and the glycidyl azide polymer (GAP) to form medicament slurry to be tested, pouring the medicament slurry to be tested into a thin-wall straight plastic tube with one sealed end to form a medicament tube to be tested, fixing the medicament tube to be tested on a medicament frame of a combustion chamber, binding one end, not being sealed, of the medicament tube to be tested with nichrome wire to fix the one end, not being sealed, of the medicament tube to be tested, wrapping the end surface of the end, not being sealed, of the medicament tube to be tested with ignition powder, placing the medicament frame of the combustion chamber bond with the medicament tube to be tested in the combustion chamber of an underwater acoustic emission combustor, pressing an ignition button to conduct a combustion speed test, recording a test result, exhausting air, discharging water, taking out the medicament frame of the combustion chamber, cleaning the medicament frame of the combustion chamber, repeatedly testing each identical sample for five times at a fixed temperature and a fixed pressure point, eliminating abnormal data to obtain an average value which serves as the final test result of the single-point combustion speed, and calculating the combustion pressure exponent and the combustion speed temperature sensitivity coefficient. The combustion performance test method of the nanometer aluminum powder has the advantages of being simple, easy to operate, short in testing period and free from preparing a large number of samples to be tested.

Owner:裴庆

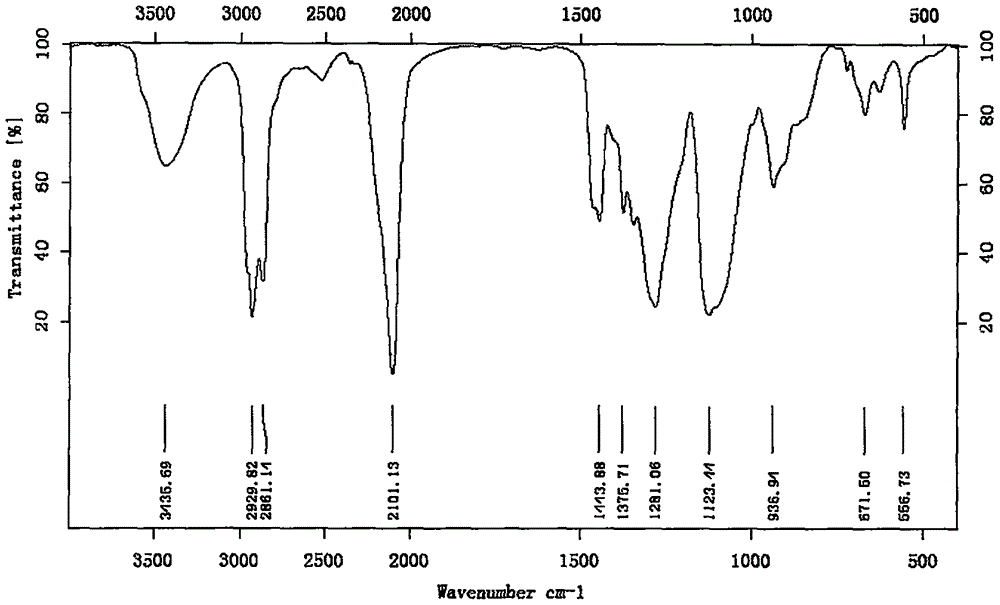

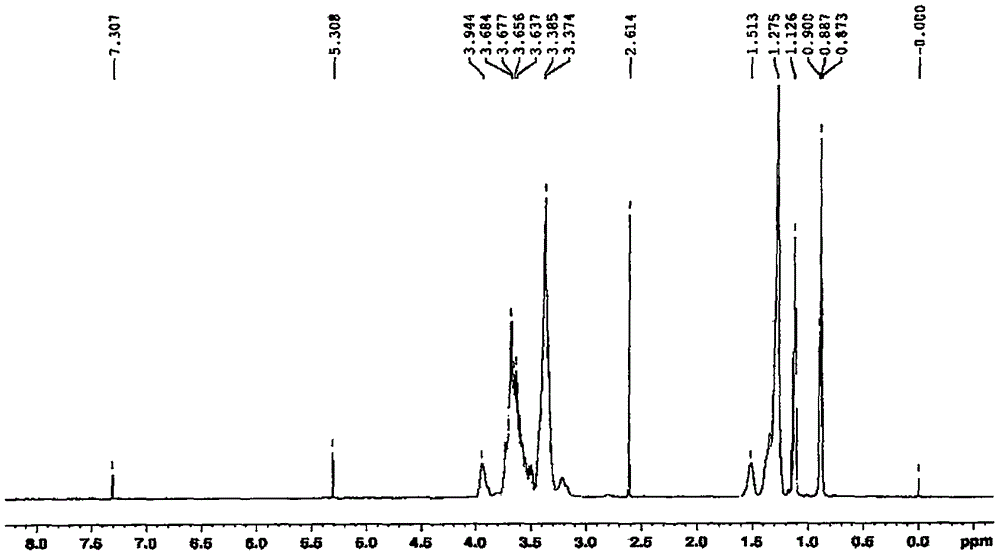

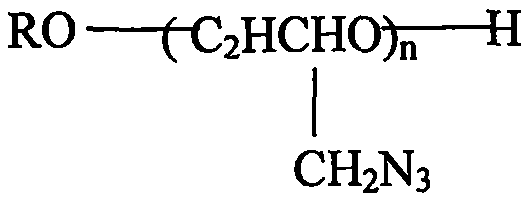

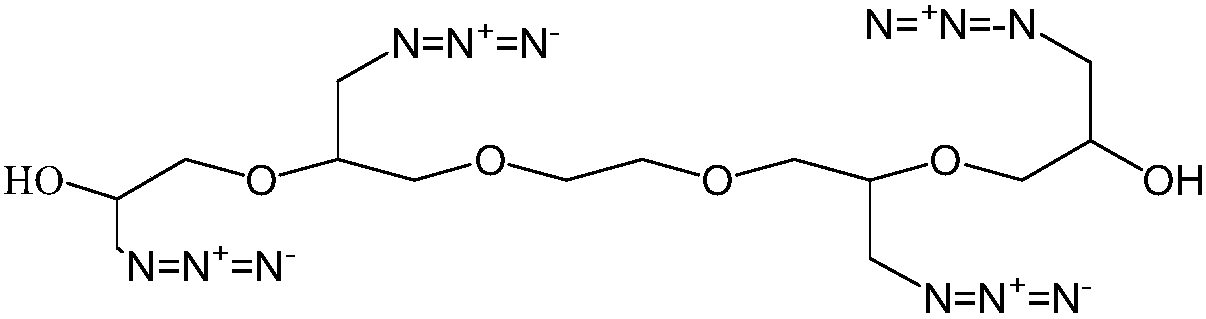

GAP (glycidyl azide polymer) as well as preparation method and application thereof

ActiveCN105884648AImprove solubilityImprove combustion performanceOrganic chemistryLiquid carbonaceous fuelsSolubilityAlicyclic Hydrocarbons

The invention discloses a GAP (glycidyl azide polymer) as well as a preparation method and an application thereof. GAP adopts the structure shown in the specification, wherein n refers to the number of structural units in GAP and ranges from 2 to 8; R refers to an aliphatic group, an alicyclic hydrocarbon group and an aromatic hydrocarbon group comprising hydrocarbons or an ether group comprising carbon-hydrogen-oxygen atoms, and the number of carbon atoms ranges from 1 to 15. GAP is prepared through polymerization of epichlorohydrin and azidation, has the good solubility in fuel oil and can play a relatively good combustion supporting role after a relatively small amount of GAP is added.

Owner:LIMING RES INST OF CHEM IND

A high energy low burning rate temperature sensitive coefficient propellant

ActiveCN105130720BBoost energy levelsLow burning rate temperature sensitivity coefficientExplosivesAlkaneHigh energy

A propellant with high energy and low burning rate temperature sensitivity coefficient, comprising the following components: binder 12%~15%; plasticizer 10%~13%; oxidizer 15%~18%; energetic explosive 38%~50% ;Metal fuel 10%~18%; small component: 1.5%~2.0%. Wherein the binder is polyazide glycidyl ether; the plasticizer is triethylene glycol dinitrate or 2,4-dinitro-2,4-diazaalkane; the oxidizing agent is ammonium perchlorate; The energetic explosive is Octojin; the metal fuel is aluminum powder. The invention has the characteristics of high propellant energy (the standard measured specific impulse is greater than 2450N.s / kg) and low burning rate temperature sensitivity coefficient (the burning rate temperature sensitivity coefficient is not greater than 0.15%K-1), and is suitable for applications requiring long range, A tactical missile engine with strong penetration capability, high reliability and precise guidance.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

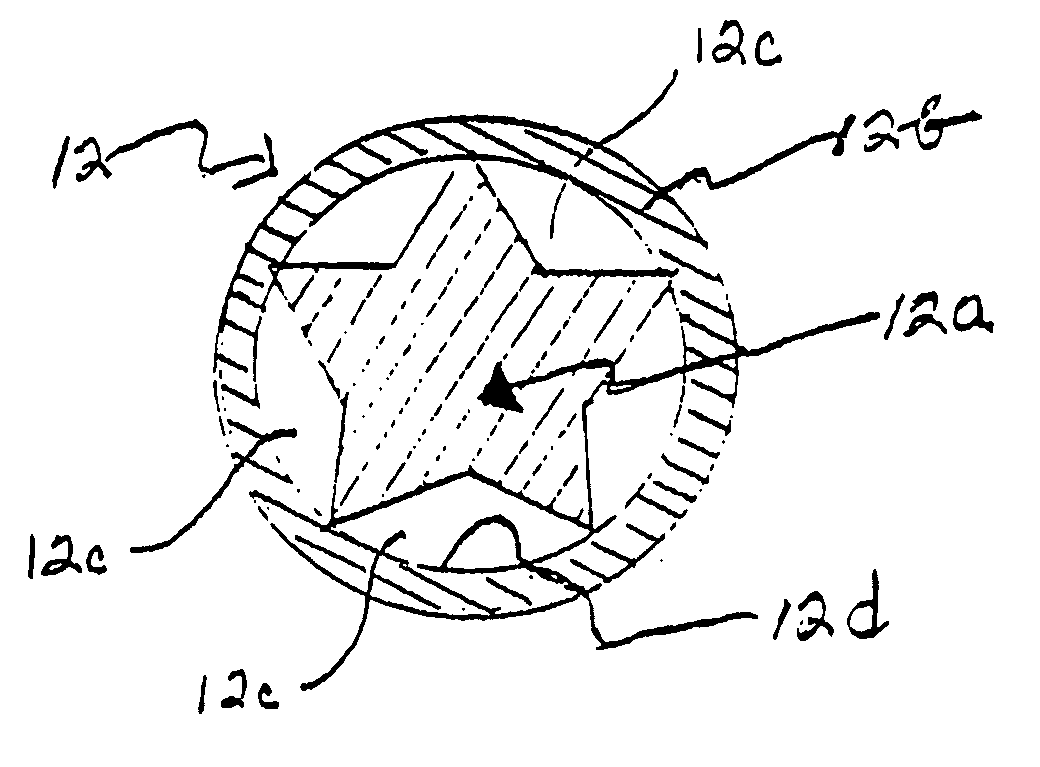

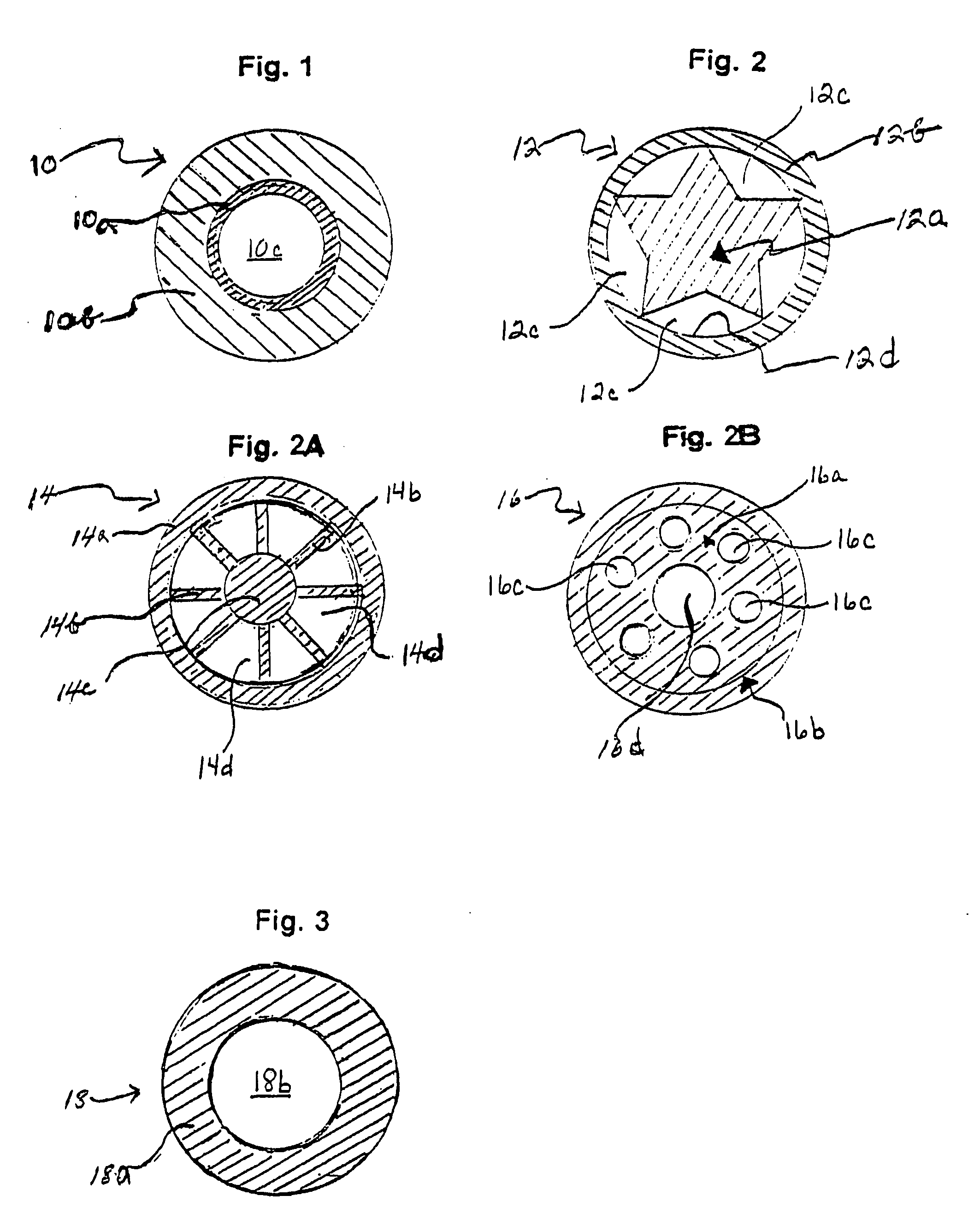

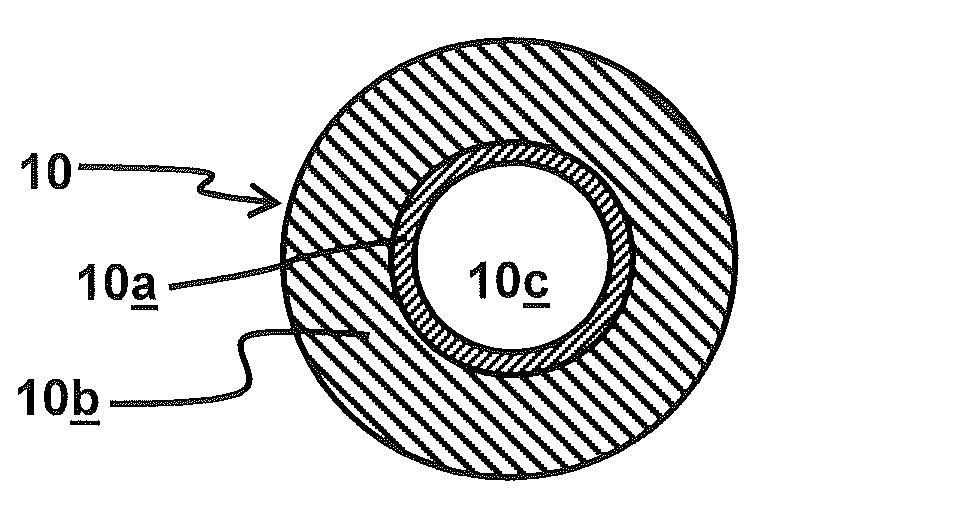

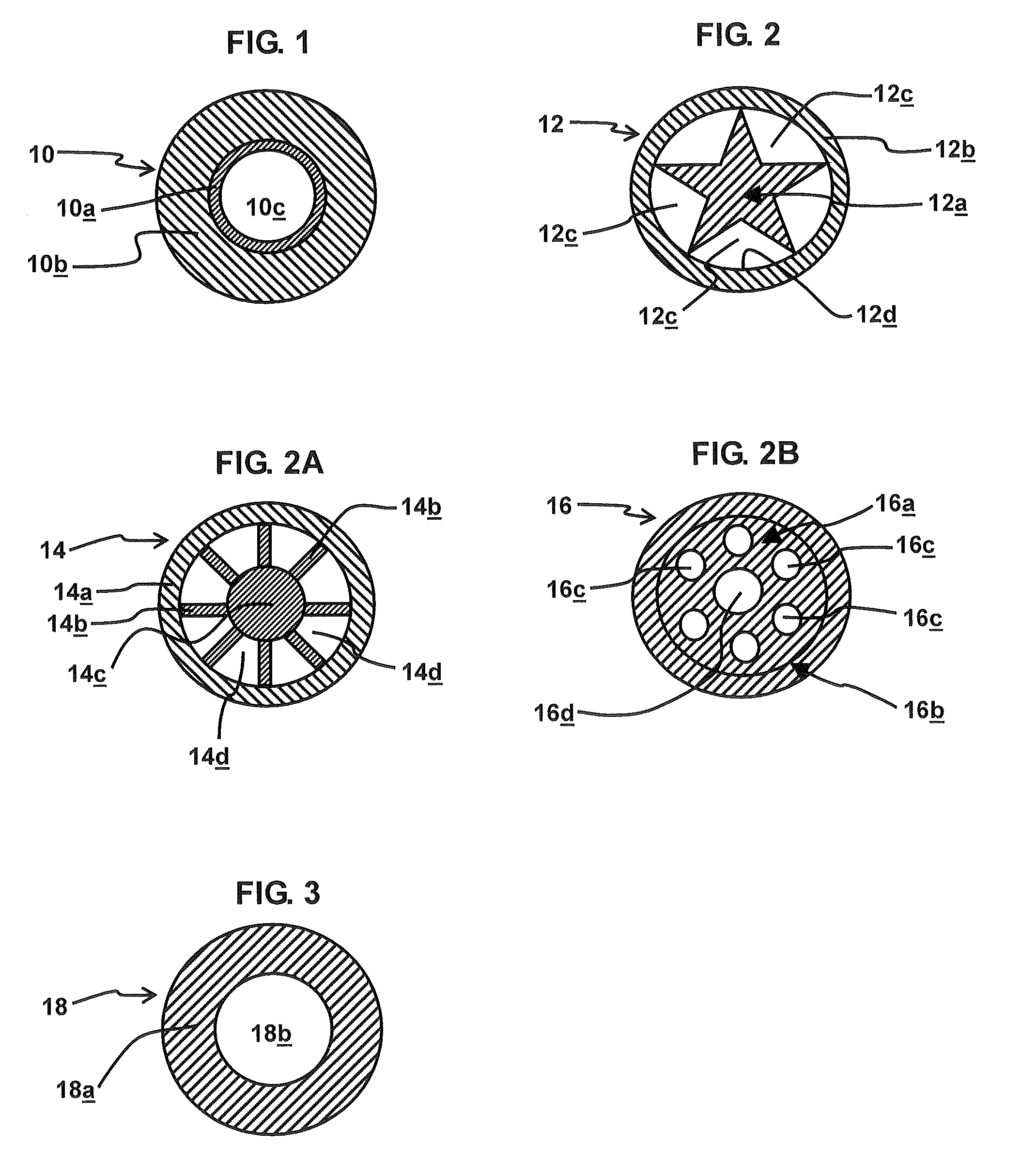

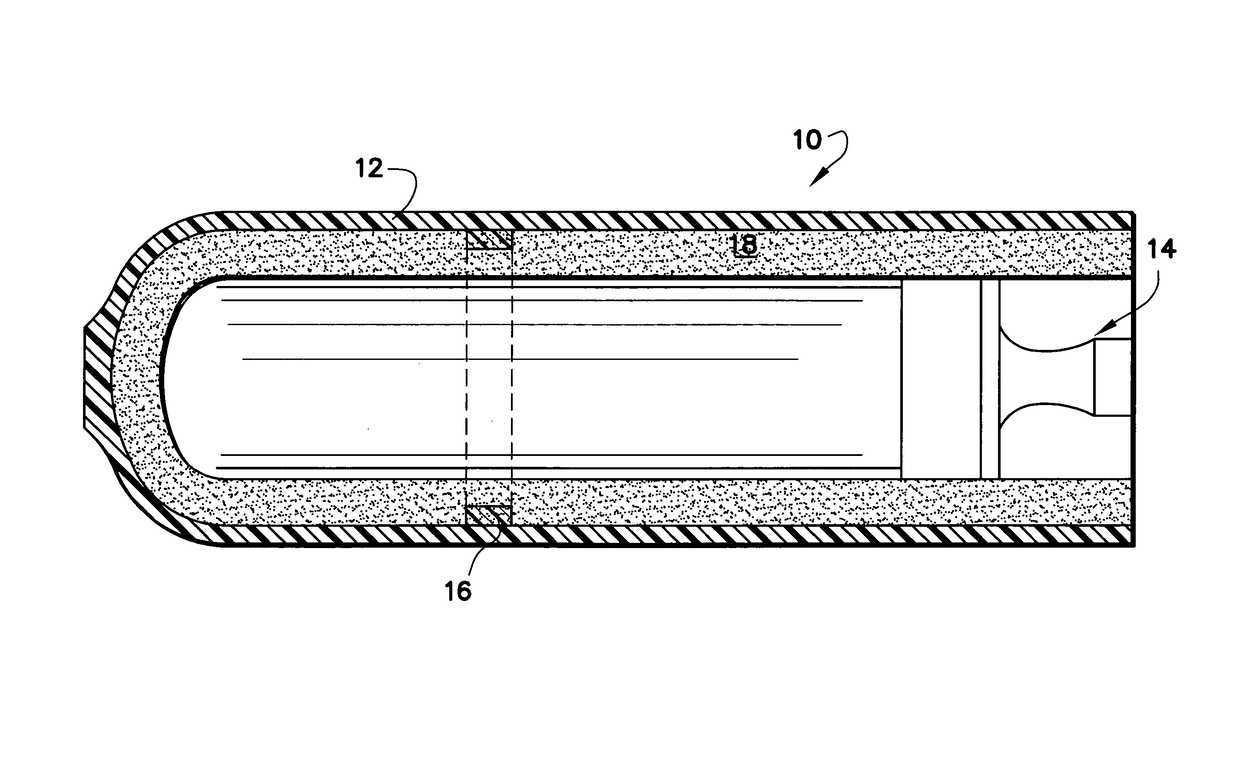

Tubular signal transmission device and method of manufacture

A signal transmission tube may be made by disposing a reactive polymeric material within a confinement tube and leaving a portion of the tube interior unoccupied. The tube may be formed by disposing a layer of paint comprising the reactive polymeric material on the interior surface of the confinement tube, extruding the confinement tube over an elongate rod that comprises the reactive polymeric material. The rod preferably has a high surface area configuration, e.g., the rod may comprise a longitudinal bore therethrough or may be star-shaped, cross-shaped, etc. Alternatively, the signal transmission tube may be made from the reactive polymeric material. Optionally, a sheath may be extruded over the tubular reactive polymeric material. In various embodiments, the confinement tube or sheath may be configured to be fractured or substantially consumed by the reaction of the reactive polymeric material. Optionally, the reactive polymeric material may comprise a glycidyl azide polymer.

Owner:DYNO NOBEL INC

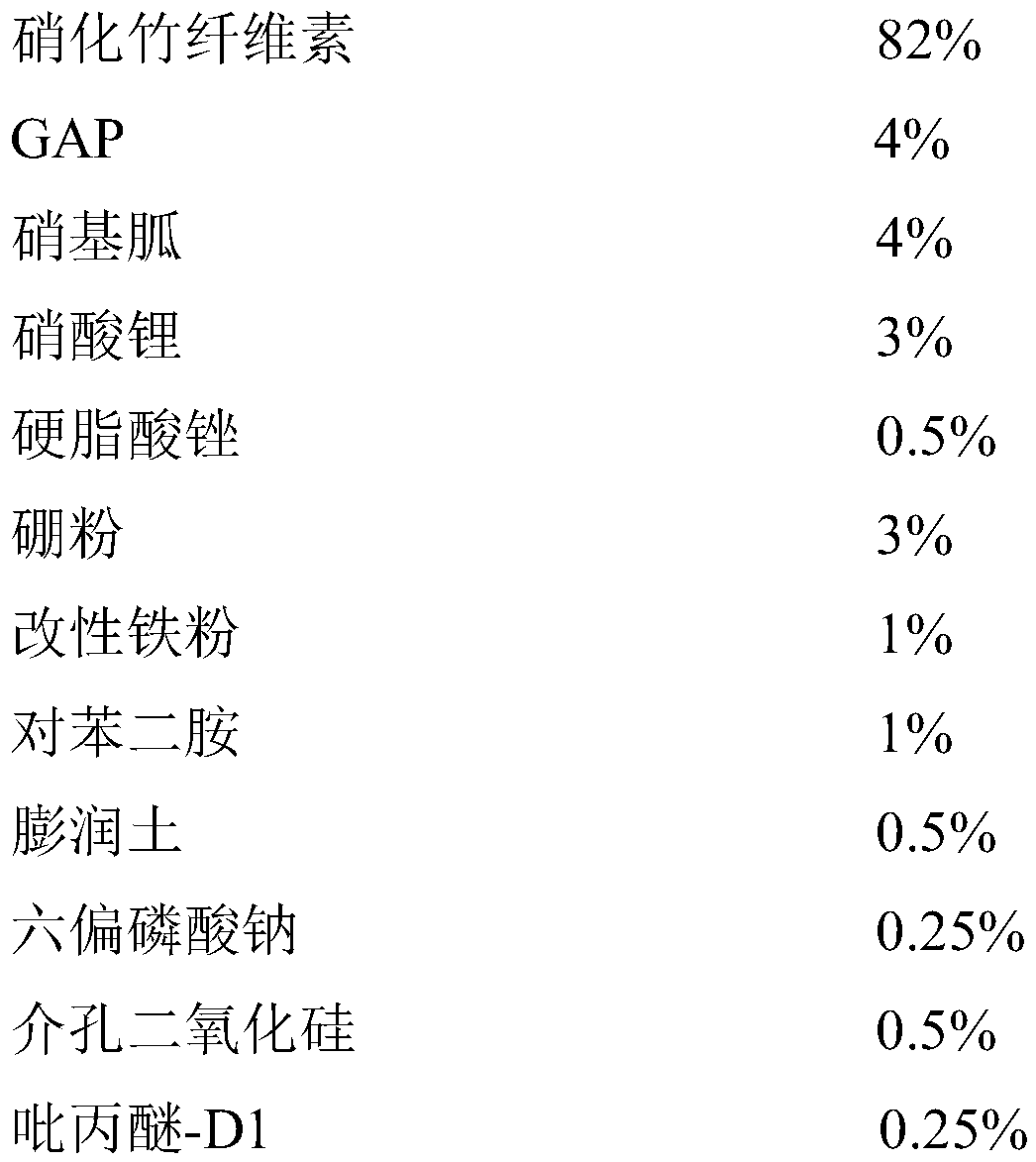

Moisture-proof smokeless sulfur-free propellant for fireworks and preparation method thereof

InactiveCN110845286AHigh launch heightMeet the requirements of environmentally friendly pyrotechnic agentsExplosivesCelluloseSodium phosphates

The invention relates to a moisture-proof smokeless sulfur-free propellant for fireworks and a preparation method thereof, and belongs to the field of environment-friendly pyrotechnic compositions. The moisture-proof smokeless sulfur-free propellant comprises nitrified bamboo cellulose, glycidyl azide polymer, nitroguanidine, a component A, a component B, a component C, modified iron powder, p-phenylenediamine, bentonite, sodium hexametaphosphate, mesoporous silica and pyriproxyl-D1; the moisture-proof smokeless sulfur-free propellant for fireworks provided by the invention is high in emissionheight, smokeless and residue-free when being set off, and can meet the requirements of an environment-friendly pyrotechnic composition. The moisture-proof smokeless sulfur-free propellant has good moisture resistance, oxidation resistance and corrosion resistance, and can be widely applied to various firework products. And the preparation process is simple, easily available in raw materials andsuitable for large-scale production.

Owner:江西吉润花炮新材料科技有限公司

Tubular signal transmission device and method of manufacture

A signal transmission tube may be made by disposing a reactive polymeric material within a confinement tube and leaving a portion of the tube interior unoccupied. The tube may be formed by disposing a layer of paint comprising the reactive polymeric material on the interior surface of the confinement tube, extruding the confinement tube over an elongate rod that comprises the reactive polymeric material. The rod preferably has a high surface area configuration, e.g., the rod may comprise a longitudinal bore therethrough or may be star-shaped, cross-shaped, etc. Alternatively, the signal transmission tube may be made from the reactive polymeric material. Optionally, a sheath may be extruded over the tubular reactive polymeric material. In various embodiments, the confinement tube or sheath may be configured to be fractured or substantially consumed by the reaction of the reactive polymeric material. Optionally, the reactive polymeric material may comprise a glycidyl azide polymer.

Owner:DYNO NOBEL INC

Method for grafting energetic macromolecules on surface of 1,3,5-triamido-1,3,5-trinitrobenzene crystal powder

The invention discloses a method for grafting energetic macromolecules on the surface of 1,3,5-triamido-1,3,5-trinitrobenzene crystal powder. The method comprises the following steps: (1) adding 1,3,5-triamido-1,3,5-trinitrobenzene explosive crystal powder into a dopamine water solution for mechanical stirring, carrying out suction filtration, and drying with inert gas; (2) adding the explosive crystal powder into butyl acetate for mechanical stirring dispersion, then adding toluene diisocynate and dibutyltin dilaurate, carrying out backflow suction filtration, and washing with butyl acetate for three to five times; and (3) adding the explosive crystal powder into butyl acetate for mechanical stirring dispersion, then adding glycidyl azide polymer and dibutyltin dilaurate, carrying out backflow suction filtration, and washing with butyl acetate for three to five times, and carrying out vacuum drying. The invention provides a simple and efficient explosive crystal surface modification new technique, and technical support can be provided for the application of explosive crystals in compound explosives.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

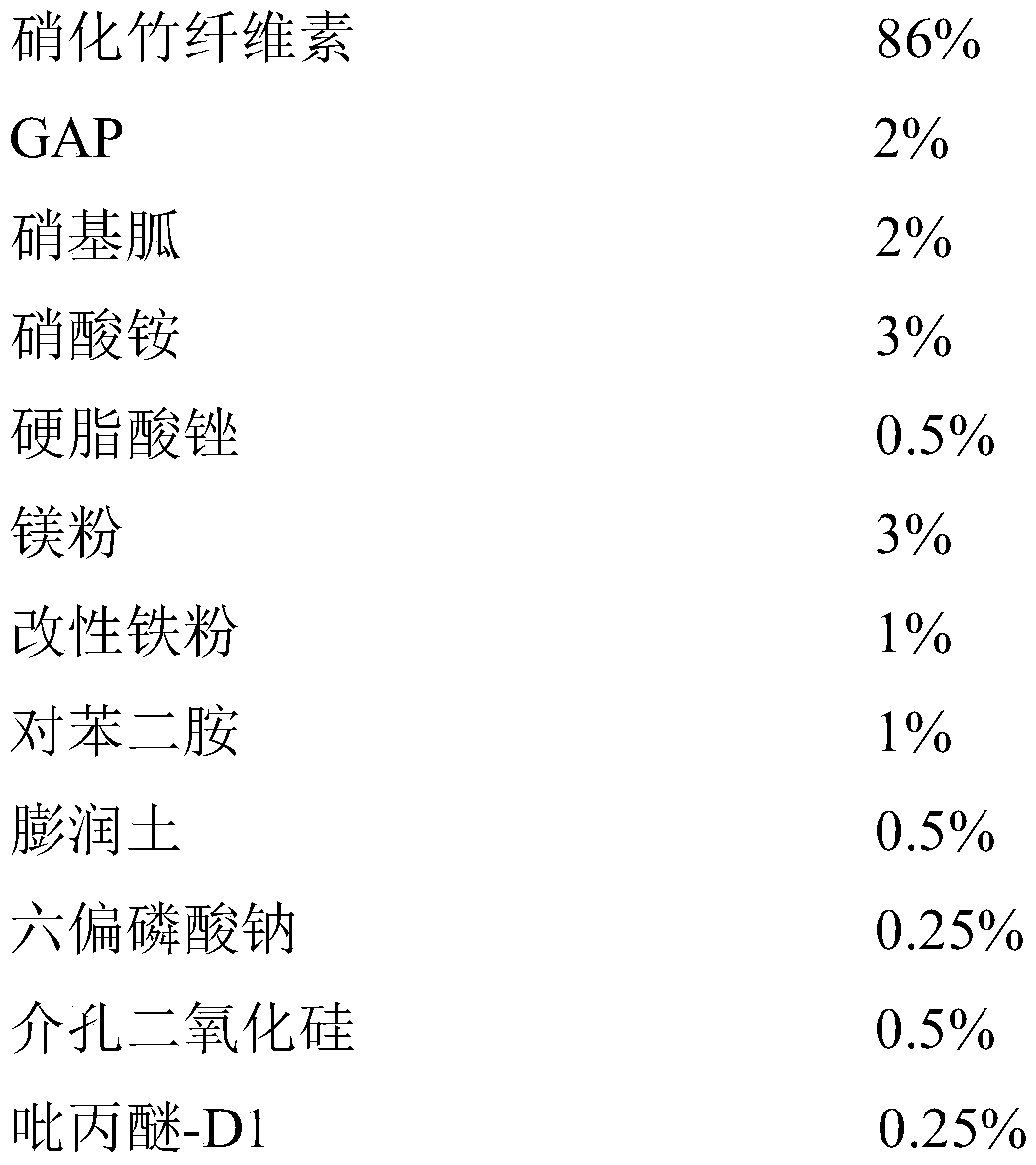

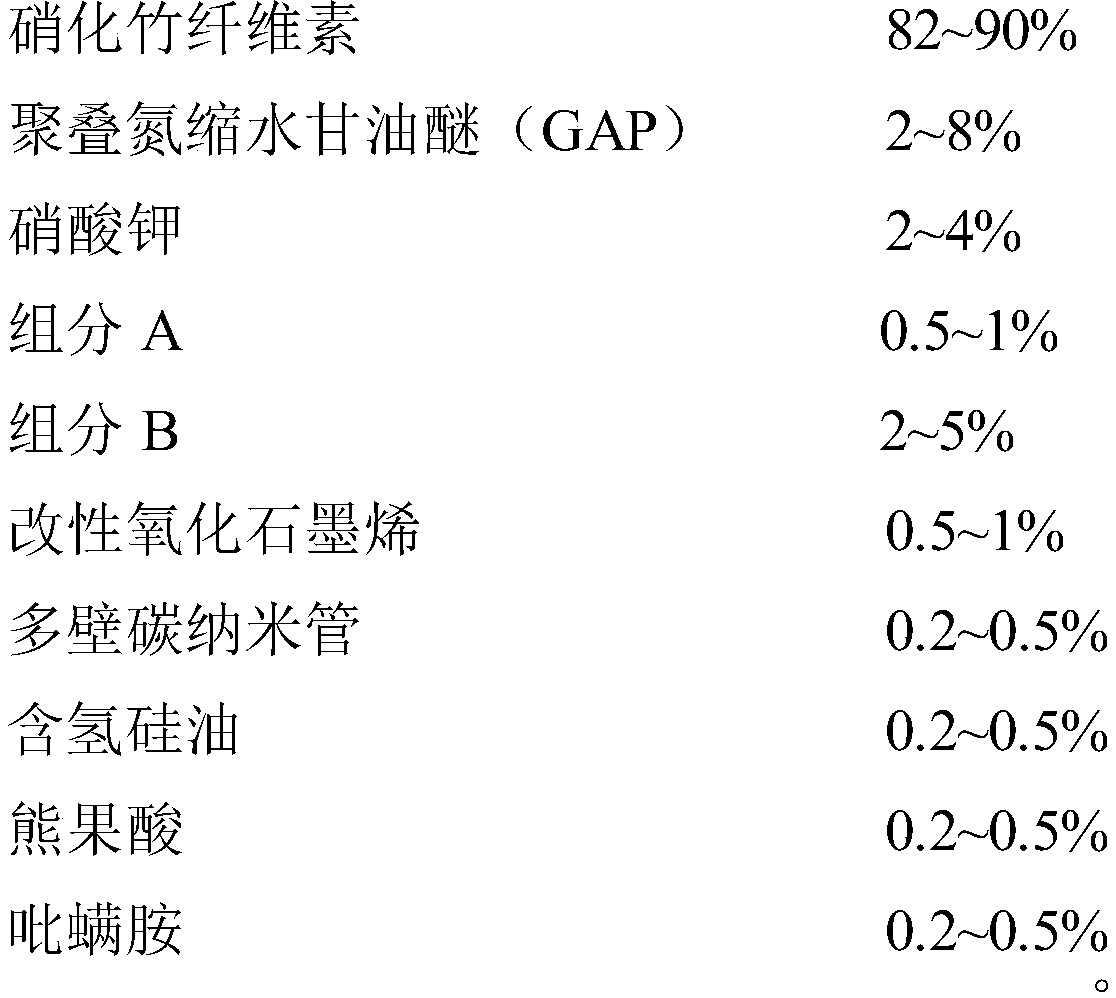

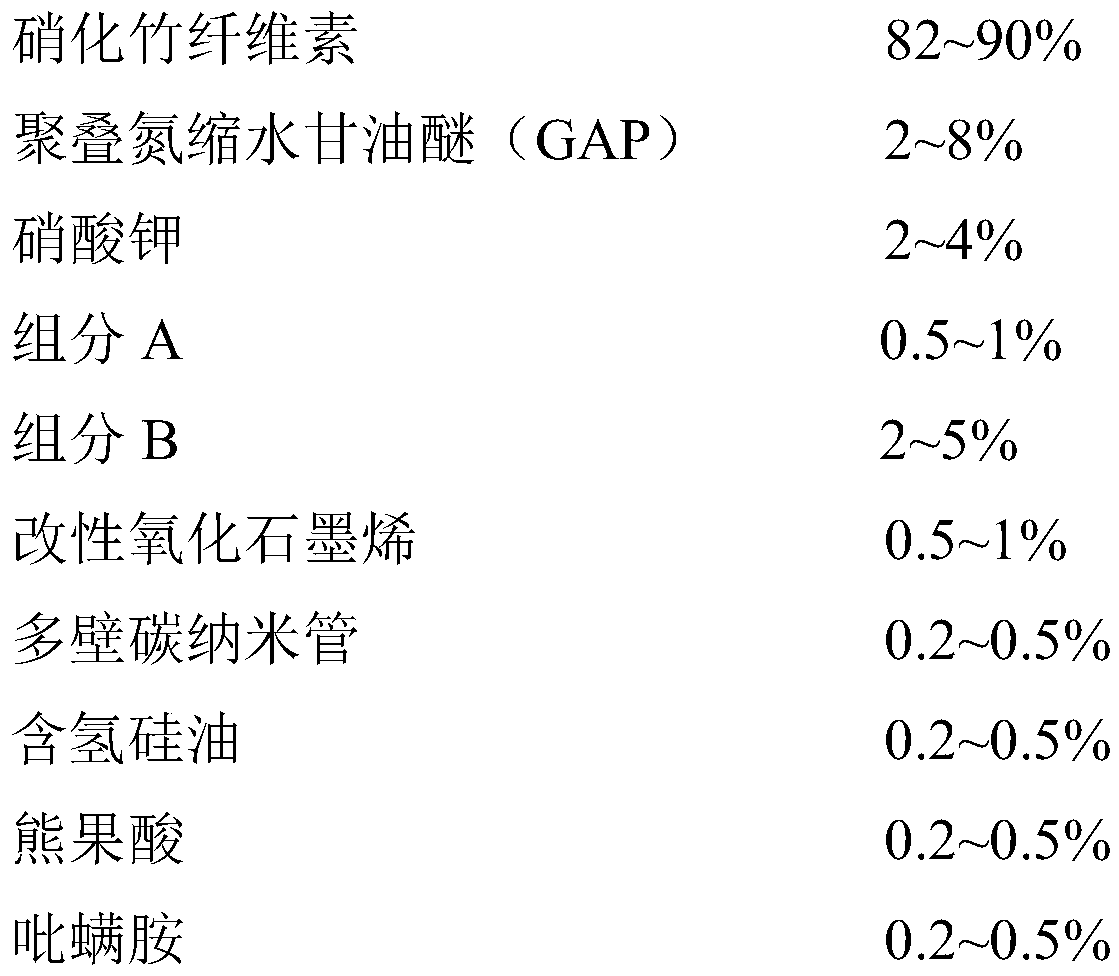

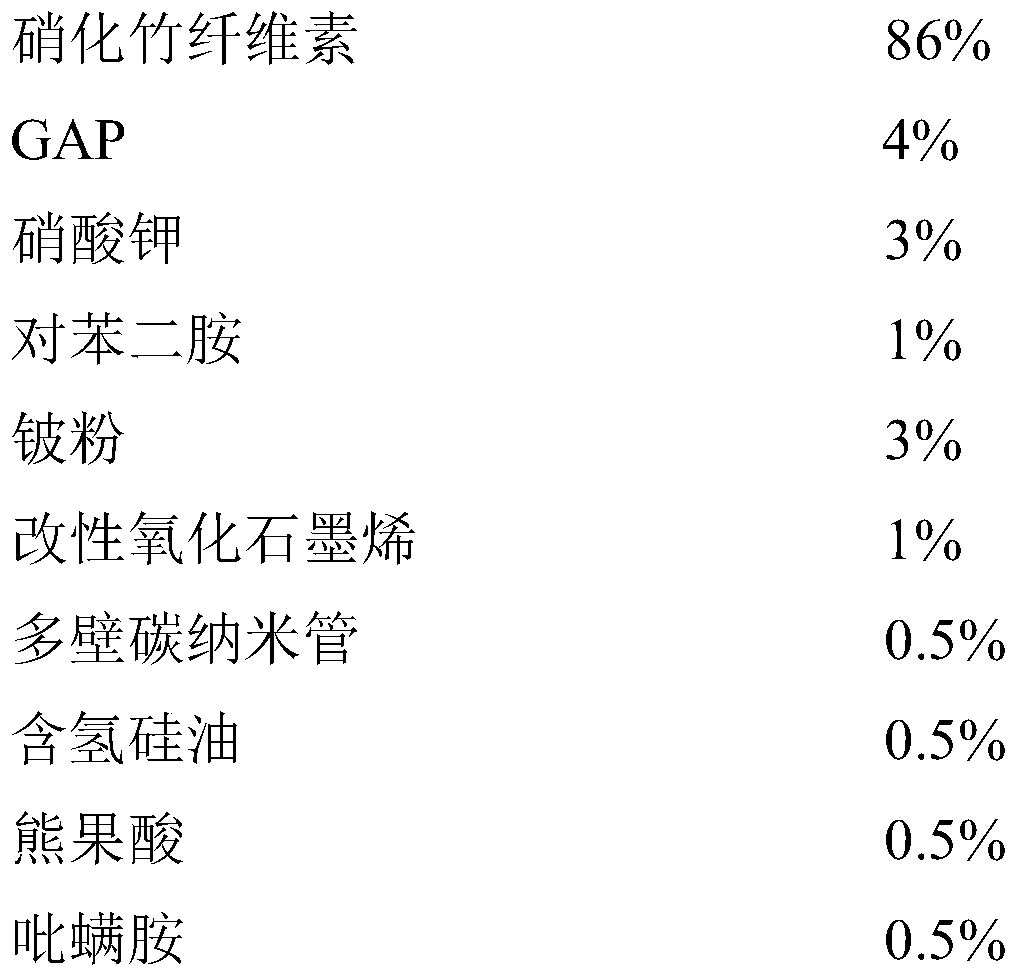

Antistatic, smokeless and sulfur-free propellant for fireworks, and preparation method thereof

InactiveCN110963869AImprove stabilityHigh launch heightExplosive working-up apparatusCellulosePolymer science

The invention relates to an antistatic, smokeless and sulfur-free propellant for fireworks, and a preparation method thereof, and belongs to the field of environmentally-friendly pyrotechnic compositions. The propellant is prepared from nitrified bamboo cellulose, glycidyl azide polymer, potassium nitrate, a component A, a component B, modified graphene oxide, multi-walled carbon nanotubes, hydrogen-containing silicone oil, ursolic acid and tebufenpyrad. The antistatic, smokeless and sulfur-free propellant for fireworks has the advantages of good stability, high emission height during settingoff, no smoke, no residues, meeting the requirements of an environmentally-friendly pyrotechnic composition, and good antistatic, antioxidant and anticorrosive properties, and can be widely applied tovarious firework products. The preparation method has the advantages of simple process, easily available raw materials and suitableness for large-scale production.

Owner:江西吉润花炮新材料科技有限公司

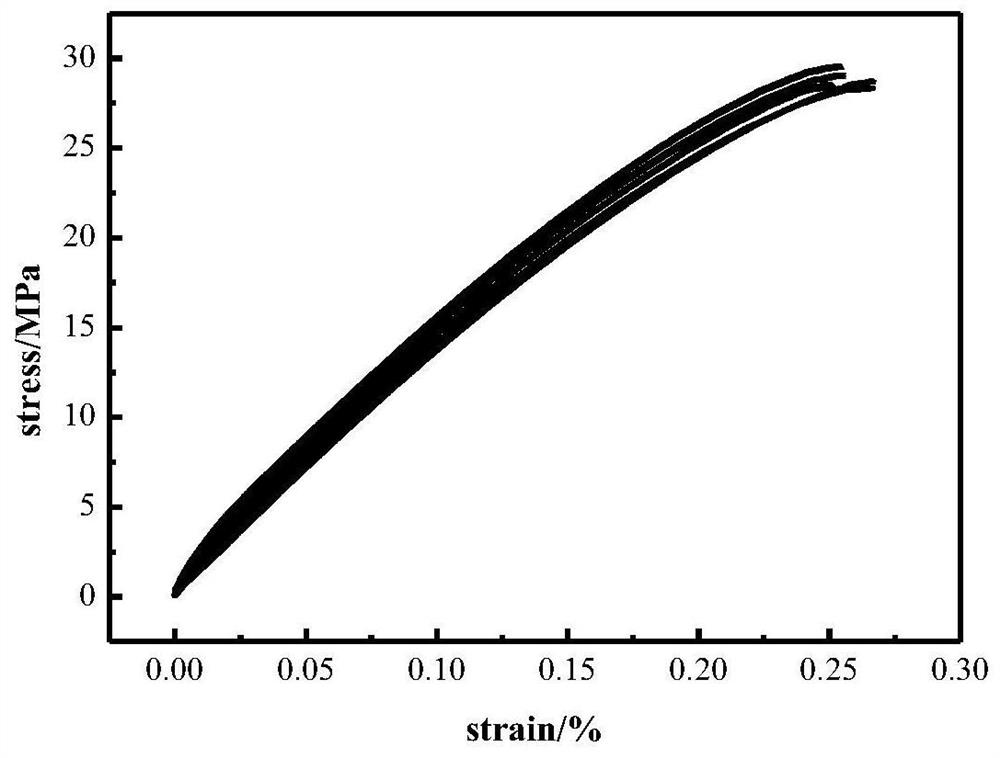

Quickly-cured GAP (Glycidyl Azide Polymer)-based mixture

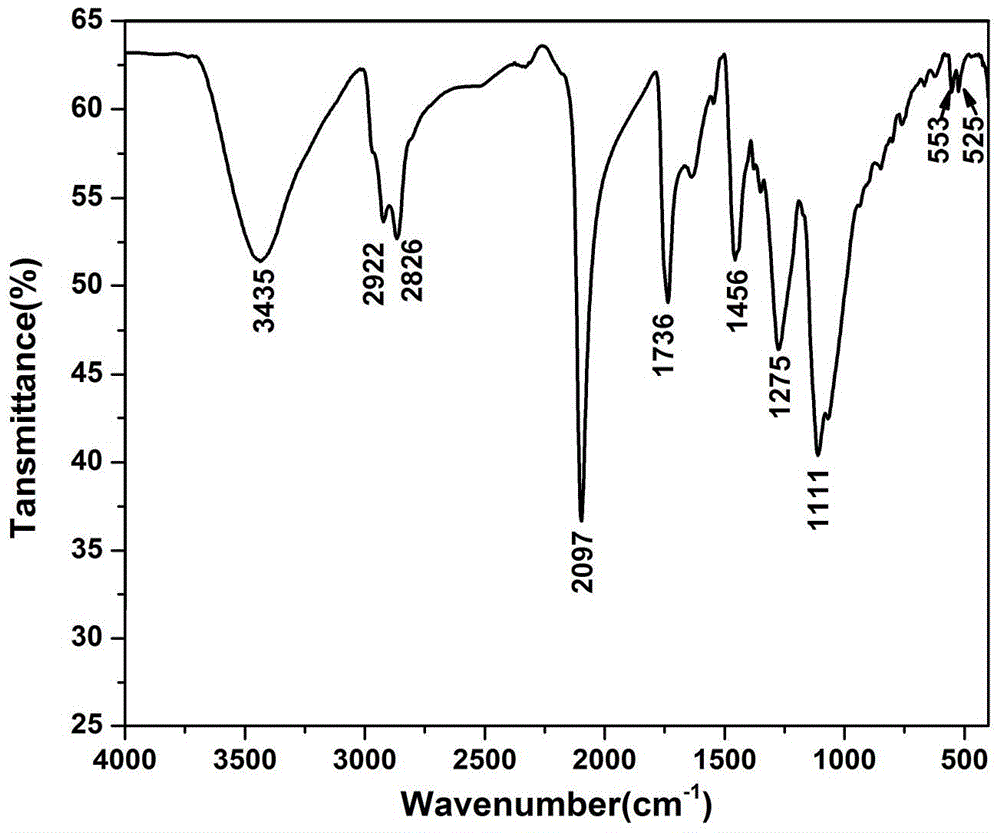

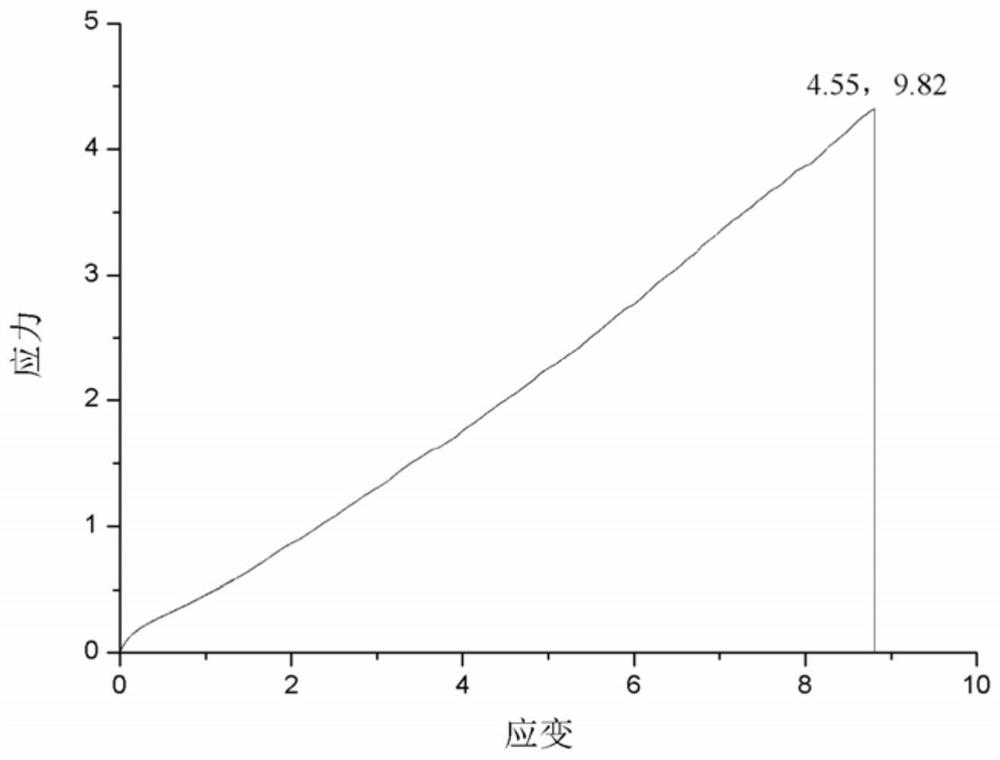

InactiveCN107674192ALow viscosityShort curing timeNon-explosive/non-thermic compositionsPressure gas generationAmbient humidityAlcohol

The invention discloses a quickly-cured GAP (Glycidyl Azide Polymer)-based mixture and aims at solving the problems that an existing cyanate curing agent is long in curing time, and a curing system iseasily affected by ambient humidity. The quickly-cured GAP-based mixture is prepared from the following components in percentage by mass: 88.89 to 91.67 percent of GAP, 8.33 to 11.10 percent of dipropargyl alcohol succinate and 0.001 percent of triphenyl bismuth, wherein the number-average molecular weight of the GAP is 3698g / mol, and the content of N in the GAP is 41.72 percent. The curing timeof a formula is reduced to below 22h, tensile strength of a condensate in the formula is greater than that of a cyanate / GAP curing system, and the viscosity of the condensate in the formula is smallerthan that of the cyanate / GAP curing system. The invention provides a technical means for application of the GAP in an explosive formula.

Owner:XIAN MODERN CHEM RES INST

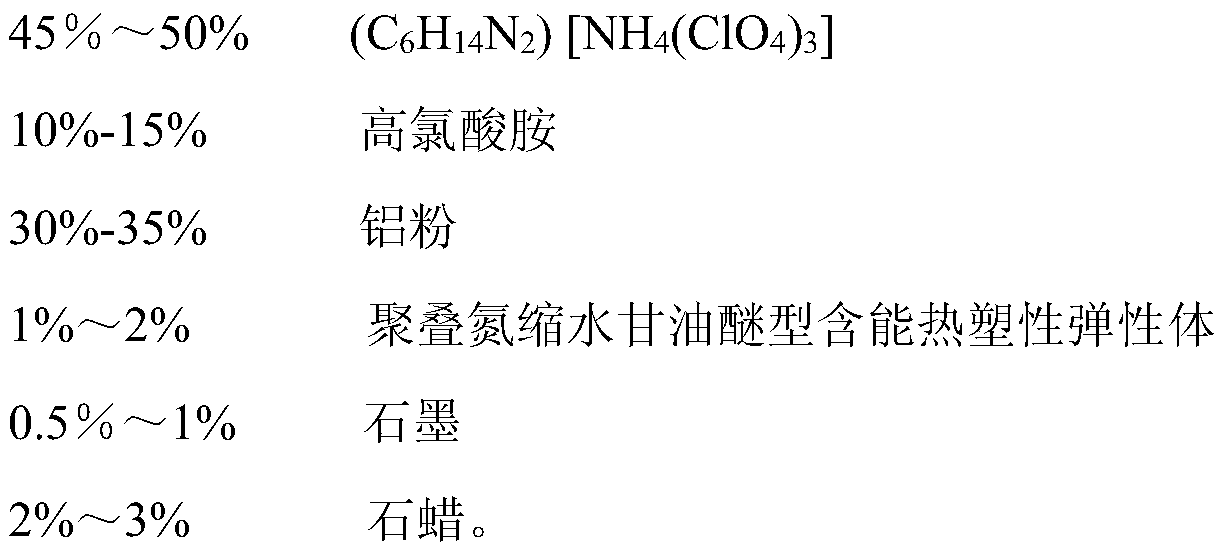

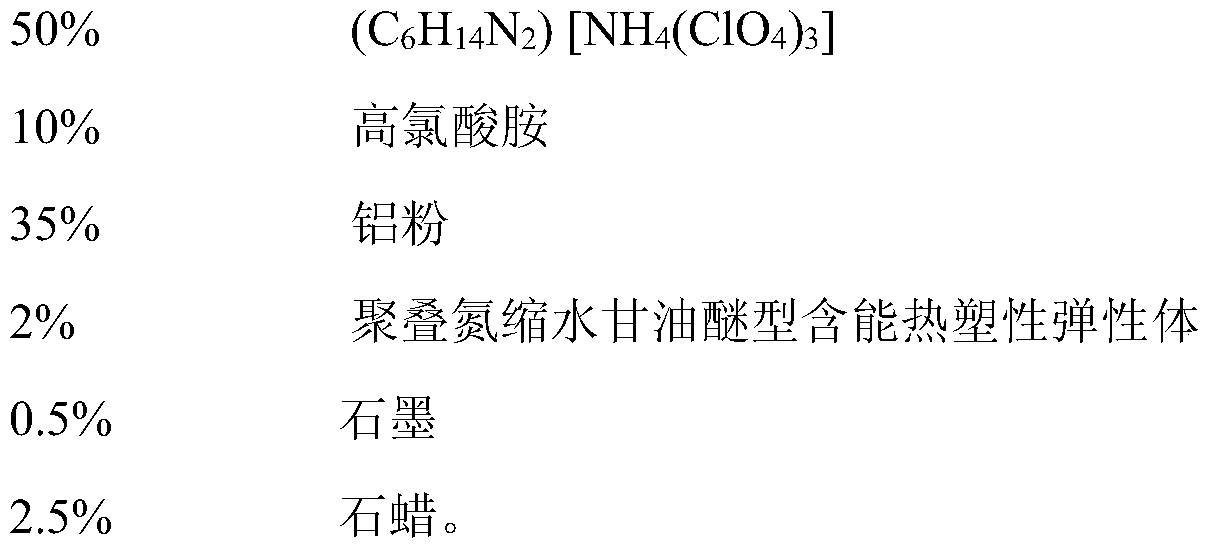

Aluminum-containing explosive composition

ActiveCN111004075ARelatively high molding densityReduced friction sensitivityExplosivesElastomerHigh energy

The invention discloses an aluminum-containing explosive composition, and aims to solve the problems of high mechanical sensitivity and low energy of a (C6H14N2)[NH4(ClO4)3] compound. The aluminum-containing explosive composition comprises (C6H14N2)[NH4(ClO4)3], ammonium perchlorate, glycidyl azide polymer energetic thermoplastic elastomer, aluminum powder, graphite and paraffin, and is relativelylow in mechanical sensitivity and high in explosion heat energy. The aluminum-containing explosive composition is mainly used for air blasting type weapon ammunition charging.

Owner:XIAN MODERN CHEM RES INST

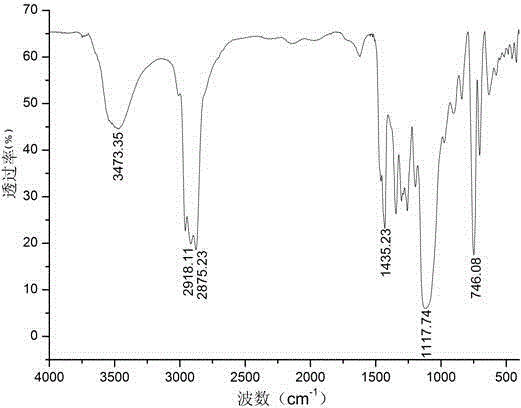

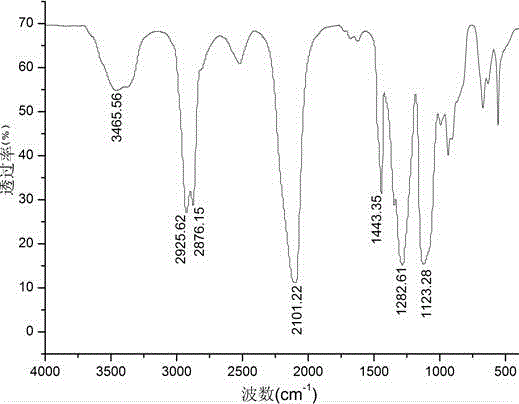

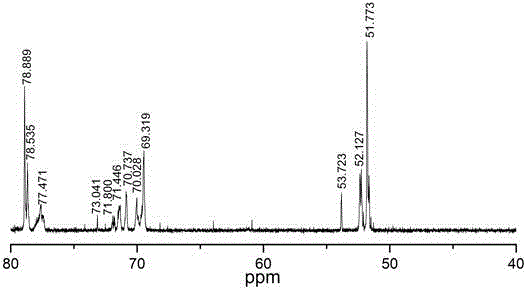

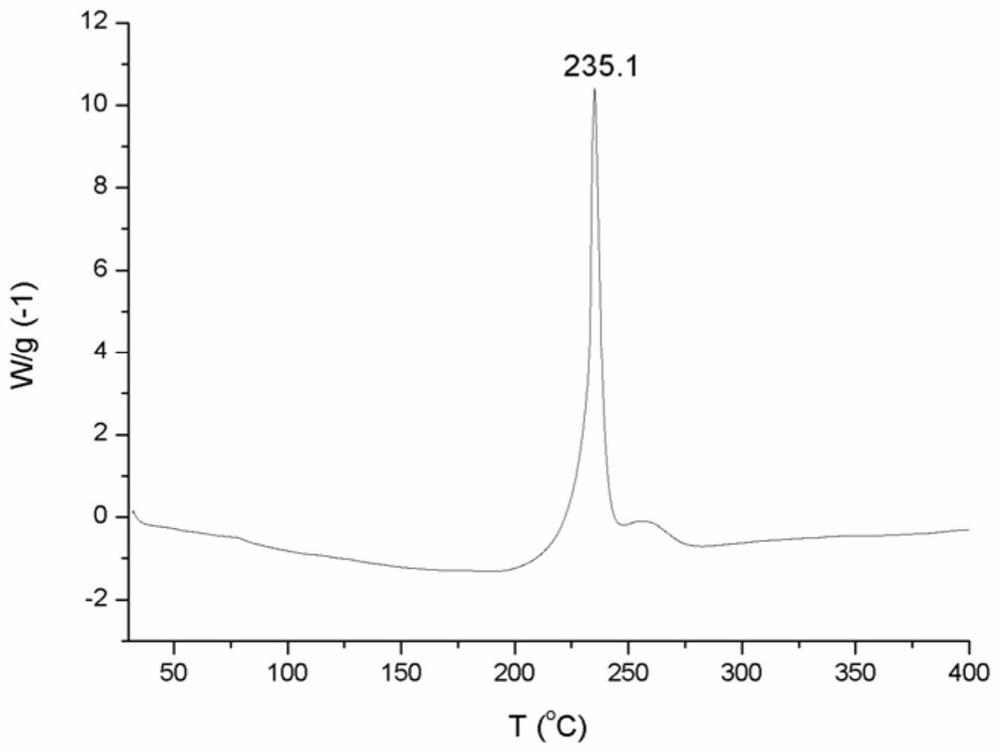

Six-arm type hydroxyl-terminated glycidyl azide polymer preparation method

The present invention relates to an energy-containing plasticizer preparation method, specifically to a six-arm type glycidyl azide polymer preparation method, wherein sorbitol and epichlorohydrin are subjected to a cationic polymerization reaction to synthesize six-arm type poly epichlorohydrin, and under the protection of nitrogen gas, sodium azide and the poly epichlorohydrin are subjected to a substitution reaction so as to synthesize the six-arm type hydroxyl-terminated glycidyl azide polymer. According to the present invention, the initial decomposition temperature is 227.3 DEG C, the azido strong heat release absorption peak appears at the thermal decomposition temperature of 255.7 DEG C, and the 2459 J / g energy is provided; compared with the commonly used energetic plasticizer nitroglycerin, the material of the present invention has good thermal stability, and can significantly improve the thermal stability of the system of the energetic material when being adopted as the plasticizer; and the low molecular weight six-arm type hydroxyl-terminated glycidyl azide polymer can be adopted as the chain extender and the reaction raw material for preparation of the branched glycidyl azide polyurethane.

Owner:SOUTHWEAT UNIV OF SCI & TECH

Controlled autoignition propellant systems

ActiveUS9759162B1Reaction violence is reducedReduce violenceNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsIgnitorsNitroguanidineAutoignition temperature

Solid propellant systems include a main propellant and a secondary propellant in contact with the first propellant that exhibits autoignition temperatures of at least about 100° F. lower than the autoignition temperature of the main propellant. The secondary propellant of the present invention is most advantageously employed with conventional AP-containing solid propellant formulations as the main propellant, especially formulations containing both AP, an energetic solid, and a binder. In especially preferred forms, the secondary propellant will include a nitramine which is at least one selected from nitroguanidine (NQ), cyclotrimethylene trinitramine (RDX) and cyclotetramethylenetetranitramine (HMX), and a binder which is at least one selected from HTPB, HTPE or glycidyl azide polymer (GAP). Most preferably, the secondary propellant will include a combination of nitramines which includes NQ and one of RDX or HMX.

Owner:AEROJET ROCKETDYNE INC

Method for enhancing mechanical properties of cast explosives

InactiveCN112110781AReduce energy lossEvenly distributedNon-explosive fillers/gelling/thickening agentsExplosive working-up apparatusPolymer scienceExplosive Agents

The invention discloses a method for enhancing mechanical properties of a cast explosive. The method is characterized in that a mechanical modifier is added into the cast explosive to enhance the mechanical properties of the cast explosive; the mechanical modifier comprises pentaerythritol acrolein resin, glycidyl azide polymer, 3,3'-diazidomethylepoxybutane-tetrahydrofuran prepolymer and an ethylene oxide-tetrahydrofuran prepolymer; and a prepolymer / curing agent system is added into the molten explosive, and the ratio of a curing agent is regulated, so the modifier is subjected to a curing reaction in a process period of the cast explosive, and a three-dimensional continuous network is formed in the system. The method has the advantages that the original preparation process of the cast explosive is not changed, and mechanical enhancement effect is good; and meanwhile, the energy loss of the explosive is reduced due to the fact that the modifier has an energetic group or an oxygen-enriched structure.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

GAP propellant preparation method for laser micropropulsion

InactiveCN108610222AGuaranteed to draw a lotFast curingNon-explosive/non-thermic compositionsPressure gas generationPorosityColloid

The invention relates to the field of laser micropropulsion of a solid ablation mode, and provides a high-viscosity mixed propellant taking hydroxyl terminated glycidyl azide polymer (GAP) as the mainingredient. The preparation method comprises the following steps that a GAP solution is subjected to pretreatment; at 60 DEG C, nanometer carbon powder, centralite, a curing agent and a curing catalyst are added in sequence, and stirring is conducted in each step; finally, on the condition that the temperature is 60 DEG C, and the vacuum degree is 0.01 MPa, vacuum bubble pumping is conducted for1-1.5 h, standing and curing are conducted, and then a GAP grain is obtained. The operation method is simple and easy to implement, the curing process is mild, and the porosity in GAP mixed propellantcolloid is effectively lowered.

Owner:NANJING UNIV OF SCI & TECH

Polyvinyl alcohol acetal aromatic aldehyde grafting glycidyl azide polymer, preparation method thereof and application thereof

InactiveCN102199301BEasy to prepareEasy to separate and purifyNon-explosive/non-thermic compositionsPolymer scienceExplosive Agents

The invention relates to a polyvinyl alcohol acetal aromatic aldehyde grafting glycidyl azide polymer and a preparation method thereof. Polyvinyl alcohol acetal aromatic aldehyde and a glycidyl azide polymer which serve as initiators and diisocyanate serving as a cross-linking agent perform a homogeneous phase cross-linking reaction to obtain the polyvinyl alcohol acetal aromatic aldehyde grafting glycidyl azide polymer. The energetic polymer is used as a toughening elasticizer to be applied in fields of energetic materials such as explosives, propellants, pyrotechics and the like.

Owner:SOUTHWEAT UNIV OF SCI & TECH

A preparation method of polyazide glycidyl ether modified micro-nano zirconium composite particles

ActiveCN104311375BReduced static spark sensitivityImprove the safety of usePressure gas generationRamjetMicro nano

The invention provides a preparation method of glycidyl azide polymer modified micro-nano zirconium composite particles. The preparation method comprises the following steps: (1) pretreatment of zirconium powder; and (2) preparation of the zirconium composite particles. According to the preparation method, the electrostatic spark sensitivity of the prepared zirconium composite particles is obviously reduced relative to the uncoated zirconium powder, so that the safety performance of the zirconium powder is improved to a great extent; the selected coating material glycidyl azide polymer which is used as an energetic adhesive is capable of providing energy during the combustion and has favorable consistency with the components of propellants, so that the practical application of the zirconium powder as a composite propellant fuel to ramjets and volume-limited solid rocket engines is promoted.

Owner:XIAN MODERN CHEM RES INST

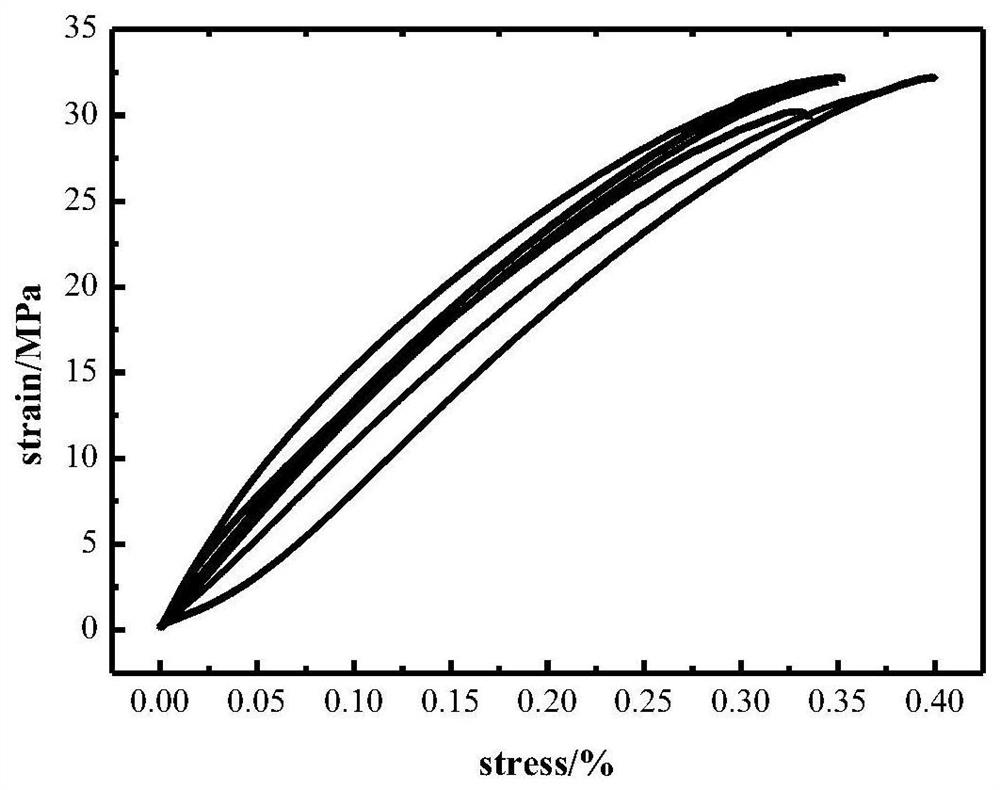

Rapid-curing GAP-based explosive

InactiveCN111018641ALow viscosityShort curing timeNon-explosive fillers/gelling/thickening agentsExplosive working-up apparatusButanedioic acidExplosive Agents

The invention discloses a rapid-curing GAP (glycidyl azide polymer) explosive, and aims to solve the problems that the curing time of an existing cyanate ester curing agent is long, and a curing system is easily influenced by environmental humidity. According to the invention, the rapid-curing GAP explosive is composed of, by mass, 11.11%-11.45% of GAP; 1.04%-1.38% of succinic acid dipropargyl alcohol ester; 5.50% of glycerol triacetate, 30.00% of RDX, 30.00% of AP is, 21.66%-22.34% of AL, and 0.01% of triphenyl bismuth, wherein the number-average molecular weight of GAP is 3698g / mol, and theN content of GAP is 41.72%. The curing time of the formula is reduced to 22 hours or shorter, and a technical means is provided for the application of GAP in the explosive formula.

Owner:XIAN MODERN CHEM RES INST

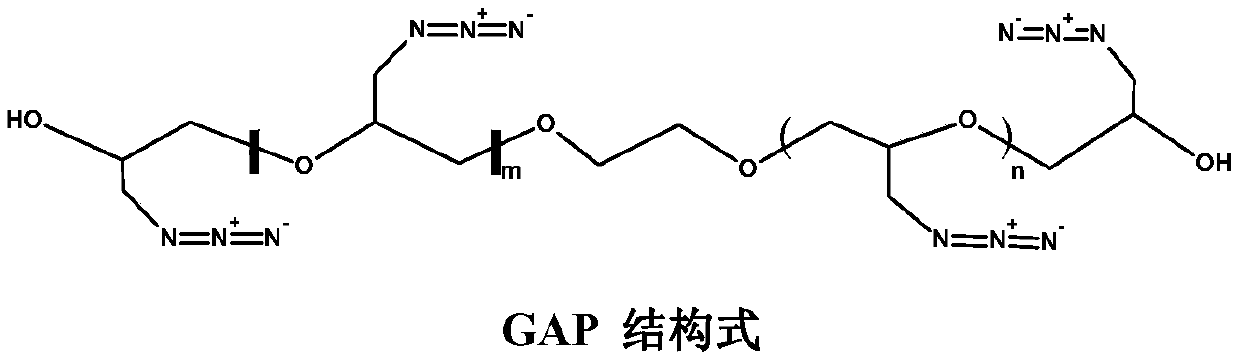

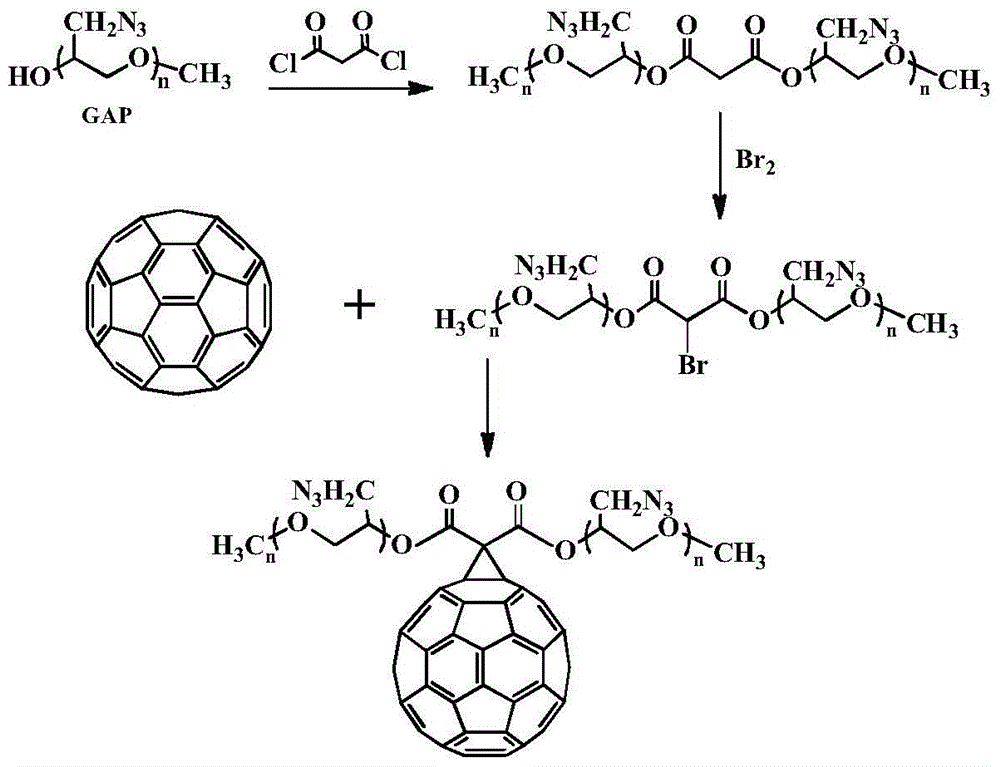

Fullerene polyazide glycidyl ether and its preparation method and application

InactiveCN104371114BBroaden the burn rate rangeHigh energyOrganic-compounds/hydrides/coordination-complexes catalystsPressure gas generationChemical structureMalonate

The invention relates to fullerene polyazide glycidyl ether, a preparation method and applications thereof, wherein the fullerene derivative has the chemical structure formula represented by a formula (1). The invention further provides the preparation method, which comprises that: monomethyl polyazide glycidyl ether and malonyl chloride are adopted as raw materials, an esterification and bromination two-step reaction is performed to prepare brominated malonate di monomethyl polyazide glycidyl ether, and the brominated malonate di monomethyl polyazide glycidyl ether reacts with fullerene to prepare the fullerene polyazide glycidyl ether, wherein the fullerene derivative can be applied in the solid rocket propellant as the novel energetic combustion catalyst. According to the present invention, experiment results prove that the yield of the product can achieve 72%, and the platform combustion speed can be increased by 65% and the pressure index can be reduced to 0.22 through application of the product of the present invention in the solid propellant as the novel combustion catalyst. In the formula (1), n is 1-100.

Owner:SOUTHWEAT UNIV OF SCI & TECH

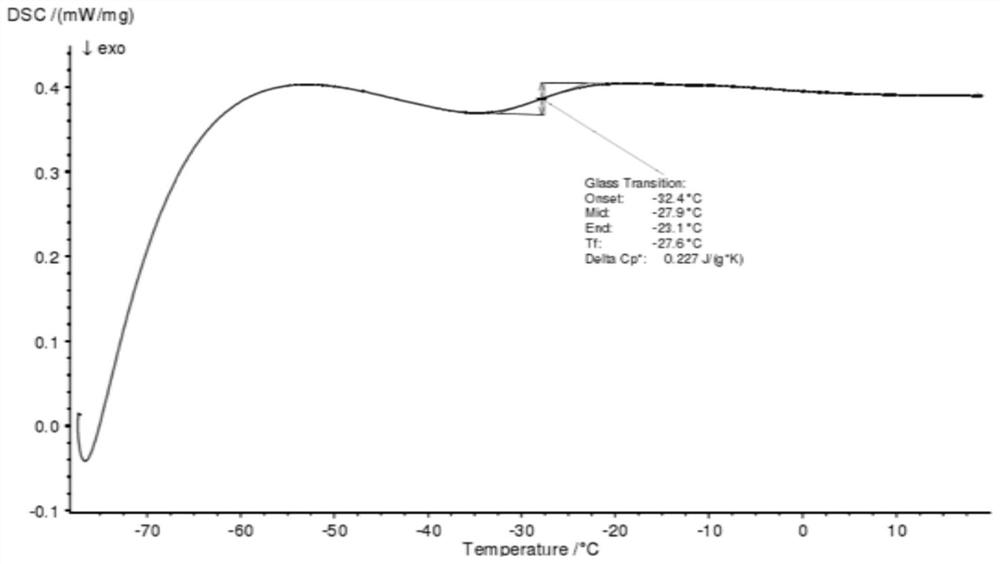

Preparation method of energetic thermoplastic elastomer compound

ActiveCN112062980AGood dispersionImprove thermal stabilityGraphenePressure gas generationElastomerPolymer science

The invention discloses a preparation method of an energetic thermoplastic elastomer compound. The method is used for preparing a 3-aminopropyltriethoxysilane modified graphene oxide / glycidyl azide polymer energetic thermoplastic elastomer compound. The synthesized 3-aminopropyltriethoxysilane modified graphene oxide / glycidyl azide polymer energetic thermoplastic elastomer (GAP-ETPE) compound canimprove the thermal stability of original GAP-ETPE, the thermal decomposition temperature is delayed by 0.6-5.0 DEG C, the glass transition temperature of the original GAP-ETPE is reduced by 1.0-3.3 DEG C, the preparation method is easy, and the cost is low.

Owner:XIAN MODERN CHEM RES INST

Trinitride capable of upgrading quality and effect of fuel and safe and environment-friendly synthesis method

InactiveCN107057782AUniform temperatureDrop ignitionLiquid carbonaceous fuelsFuel additivesSynthesis methodsSodium azide

The invention relates to a trinitride capable of upgrading the quality and effect of fuel. The trinitride is a main product which is obtained from the raw materials of saturated alkyl alcohol or phenol, epichlorohydrin and sodium azide, a few of by-products and a mixture containing an azide catalyst, wherein (1) the main product is glycidyl azide polymer, namely GAP for short; (2) the by-products are a chloride-containing isomer of the glycidyl azide polymer, namely GAP-CL for short; (3) the azide catalyst is a home-made azide catalyst for reaction synthesis in the second step; and (4) an intermediate is polyepichlorohydrin, namely PECH for short, is an intermediate product synthesized by the trinitride, and is not a component of the trinitride, wherein any moL number of a chlorine group is replaced with the sodium azide of which the polymerization number n is 1-8, n is not an integer, and saturated alkyl R is alcohol or phenol with the atom number is 2-18. According to the trinitride, the big problems of security and environmental protection in synthesis are solved, and the production cost and the use cost are greatly reduced.

Owner:聂志守

Composite material used for ultrasonic sensors

The invention discloses a composite material used for ultrasonic sensors. The composite material comprises, by weight, 8-22 parts of organosilicon modified epoxy acrylic prepolymer , 5-15 parts of glycidyl azide polymer, 3-10 parts of a nano-SiO2 / acrylate prepolymer, 30-50 parts of polyethyleneglycol diglycidylether diacrylate, 10-20 parts of methyl diphenylene diisocyanate prepolymer, 20-30 parts of 1,5-hexadiene-3,4-diol and 6-19 parts of 4,4-di(3,4-dicyanophenoxyl)methane. The composite material has the advantages of good impact resistance, good wear and corrosion resistance, and good anti-pollution performance.

Owner:WUXI YONGYI PRECISION CASTING

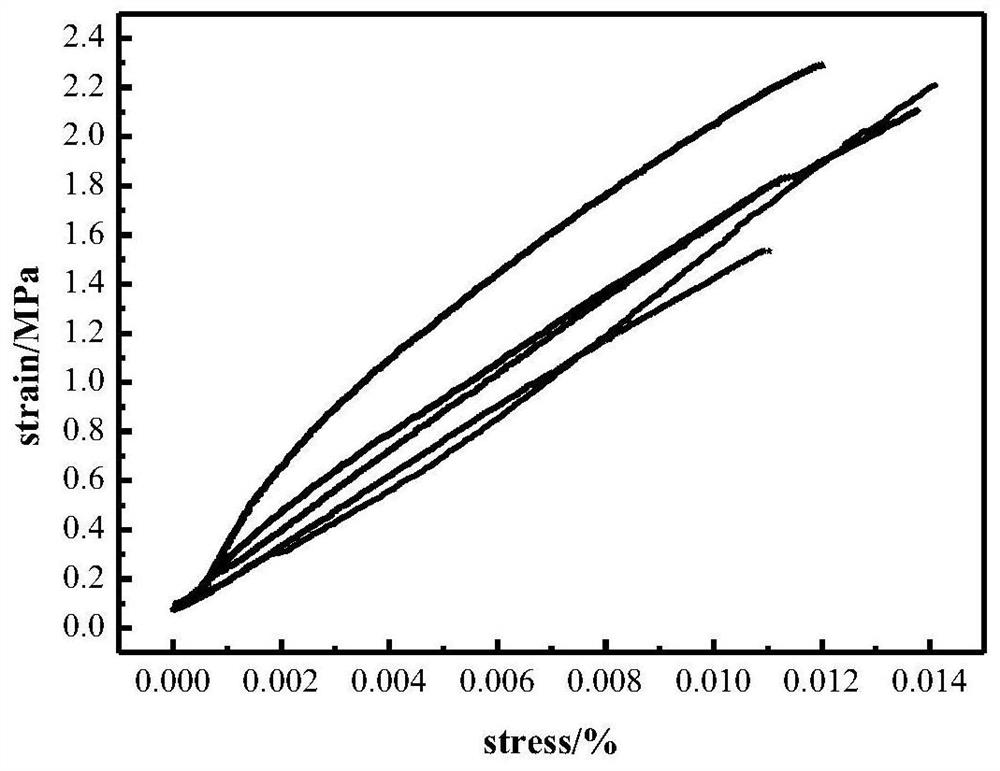

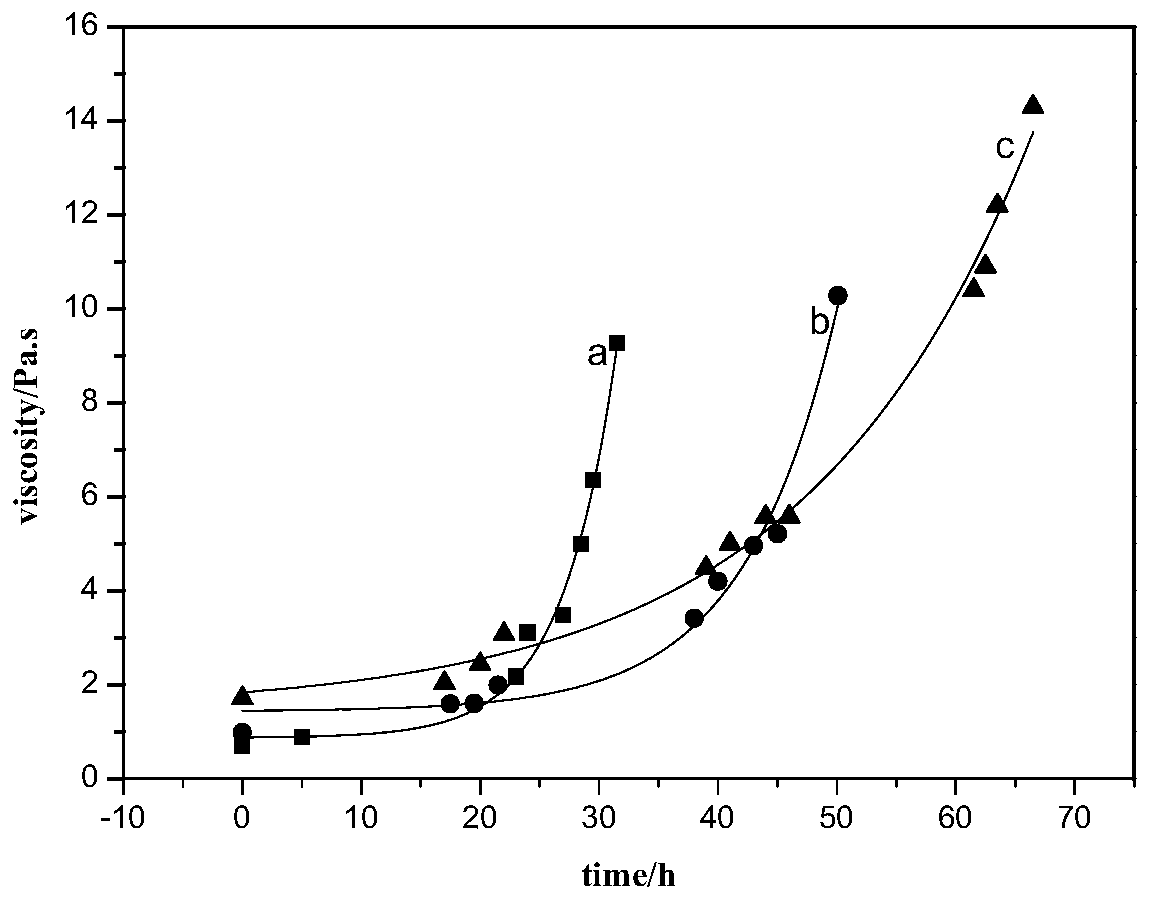

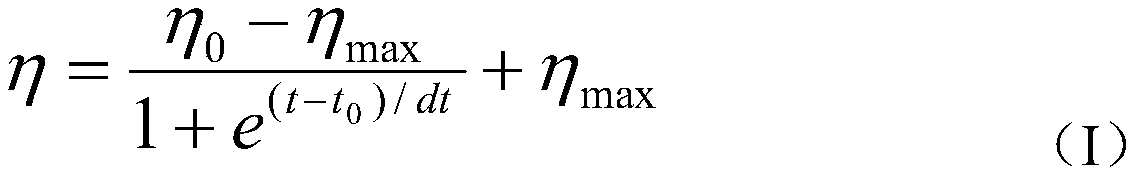

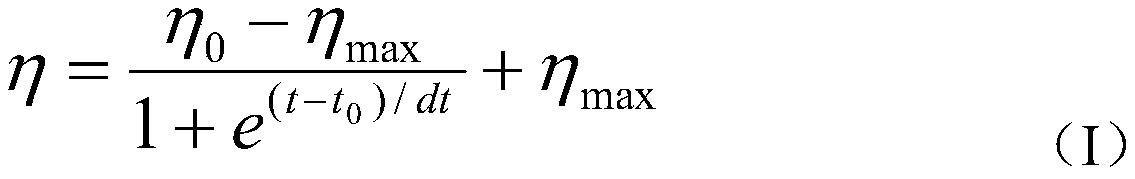

Method for determining relative rate of curing reaction of glycidyl azide polymer adhesive

ActiveCN109799170AReduce usageSolving the Problem of Relative Rates of Cure ReactionFlow propertiesBoltzmann equationAdhesive

The invention provides a method for determining the relative rate of the curing reaction of a glycidyl azide polymer (GAP) adhesive. The method includes testing the viscosity values of the GAP adhesive and a curing agent at different times in the curing reaction according to a rheological method; according to the Boltzmann equation, acquiring a time-dependent curve of the viscosity and each parameter in the equation through fitting; qualitatively determining the relative rate of the curing reaction of the GAP adhesive by a time constant t0 in the equation, wherein the time constant t0 represents that the curing reaction viscosity value reaches 50% to the maximum extent. The method has the advantages that the experiment process is simple, and easy to operate; data are processed quickly, simply and conveniently; the method can be used for determining the relative rate of the curing reaction of the glycidyl azide polymer adhesive.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com