Method for enhancing mechanical properties of cast explosives

A technology of casting explosives and mechanics, which is applied in the direction of explosives, explosives processing equipment, non-explosive/non-thermal agent components, etc. It can solve the problems of difficult dispersion and unsatisfactory modification effect, and achieve uniform and stable distribution and good mechanical enhancement effect , the effect of reducing energy loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

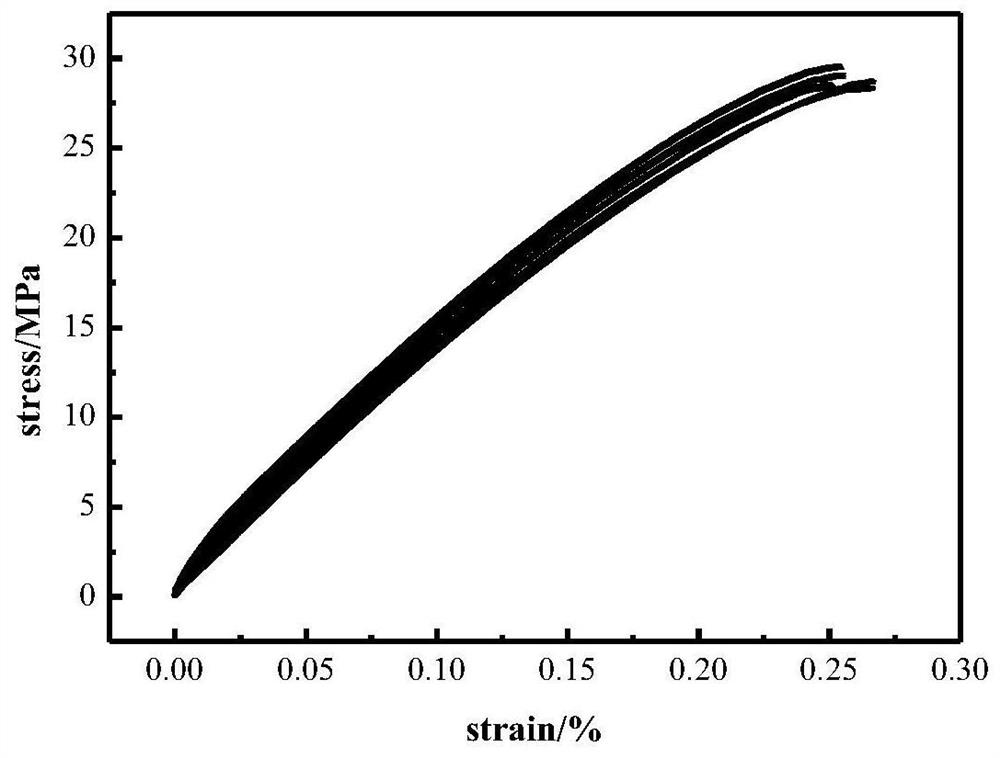

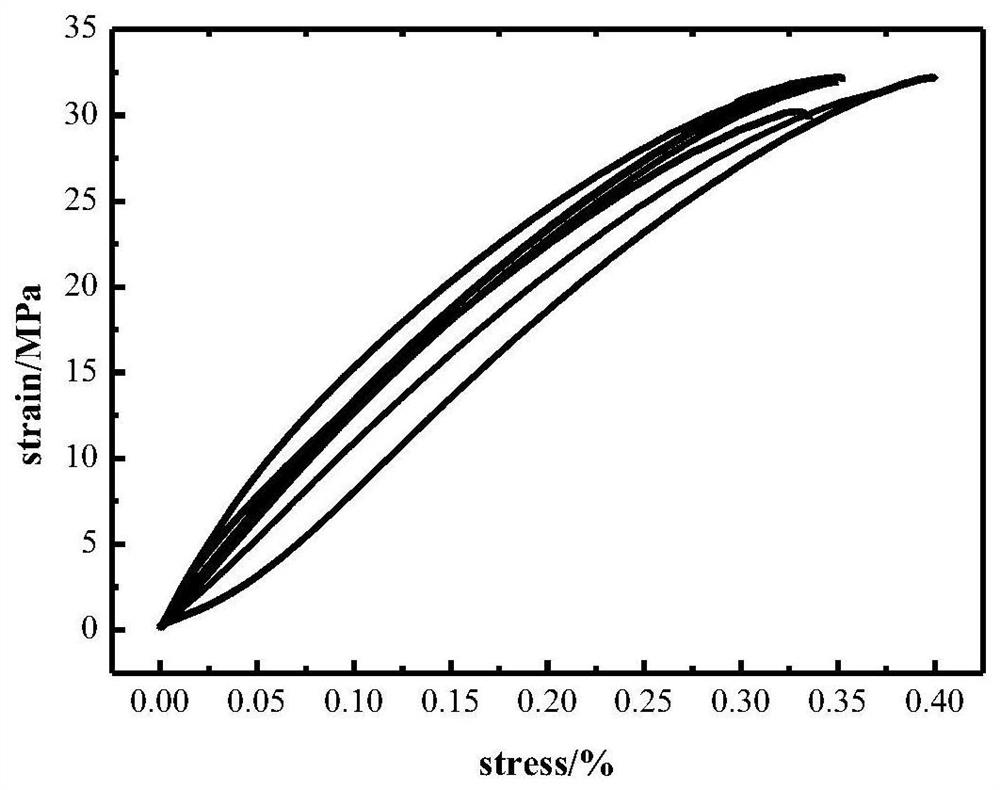

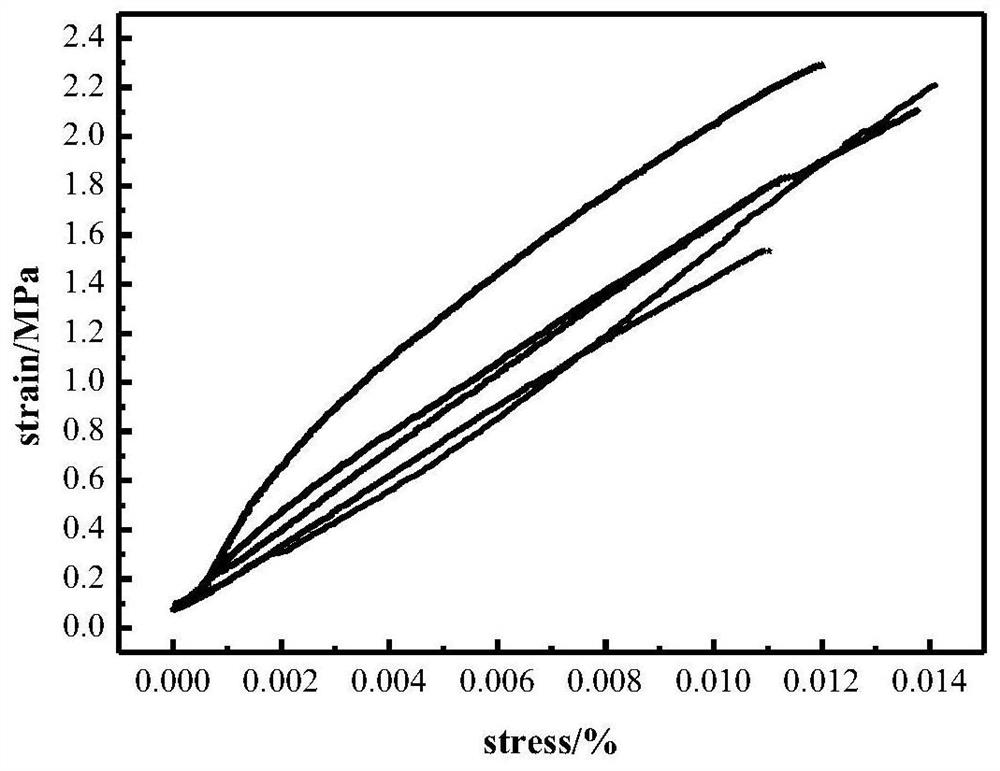

Image

Examples

Embodiment 1

[0025] (1) Weigh a certain amount of DNAN and melt it;

[0026] (2) Add a certain mass of 123 resin / DES to the molten DNAN, the mass ratio of 123 resin to DES is 50:1, the total addition ratio of the modifier is 1% of the total explosive system, and stir for 10 minutes to make it evenly dispersed , the stirring rate is 100rpm;

[0027] (3) Add HMX, Al powder, and AP solid phase components to the above system, with a total mass ratio of 70%, stir for 20 minutes under normal pressure, and stir for 5 minutes under vacuum, with a stirring rate of 45 rpm;

[0028] (4) After the vacuum is released, the above-mentioned materials are cast in a mold, solidified and formed under normal temperature and pressure, and made into a cast explosive.

Embodiment 2

[0030] (1) Take a certain quality of TNT and melt it;

[0031] (2) Add a certain mass of GAP / N100 to the molten TNT, the mass ratio of GAP to N100 is 20:1, the total addition ratio of the modifier is 1.5% of the total explosive system, stir for 10 minutes to make it disperse evenly, stir The speed is 100rpm;

[0032] (3) Add RDX and Al powder to the above system with a mass ratio of 70%, stir for 20 minutes under normal pressure, and stir for 10 minutes under vacuum, with a stirring rate of 50 rpm;

[0033] (4) After the vacuum is released, the above-mentioned materials are cast in a mold, solidified and formed under normal temperature and pressure, and made into a cast explosive.

Embodiment 3

[0035] (1) Take a certain quality of MINI and melt it;

[0036] (2) Add a certain quality of PBT / TDI to the molten MINI, the mass ratio of PBT and TDI is 10:1, the total addition ratio of the modifier is 1% of the total explosive system, stir for 10 minutes to make it disperse evenly, stir The speed is 100rpm;

[0037] (3) Add RDX and Al powder to the above system, add other components with a mass ratio of 65%, stir for 20 minutes under normal pressure, and stir for 10 minutes under vacuum, with a stirring rate of 30 rpm;

[0038] (4) After the vacuum is released, the above-mentioned materials are cast in a mold, solidified and formed under normal temperature and pressure, and made into a cast explosive.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com