Patents

Literature

202results about "Non-explosive fillers/gelling/thickening agents" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Family of Modifiable High Performance Electrically Controlled Propellants and Explosives

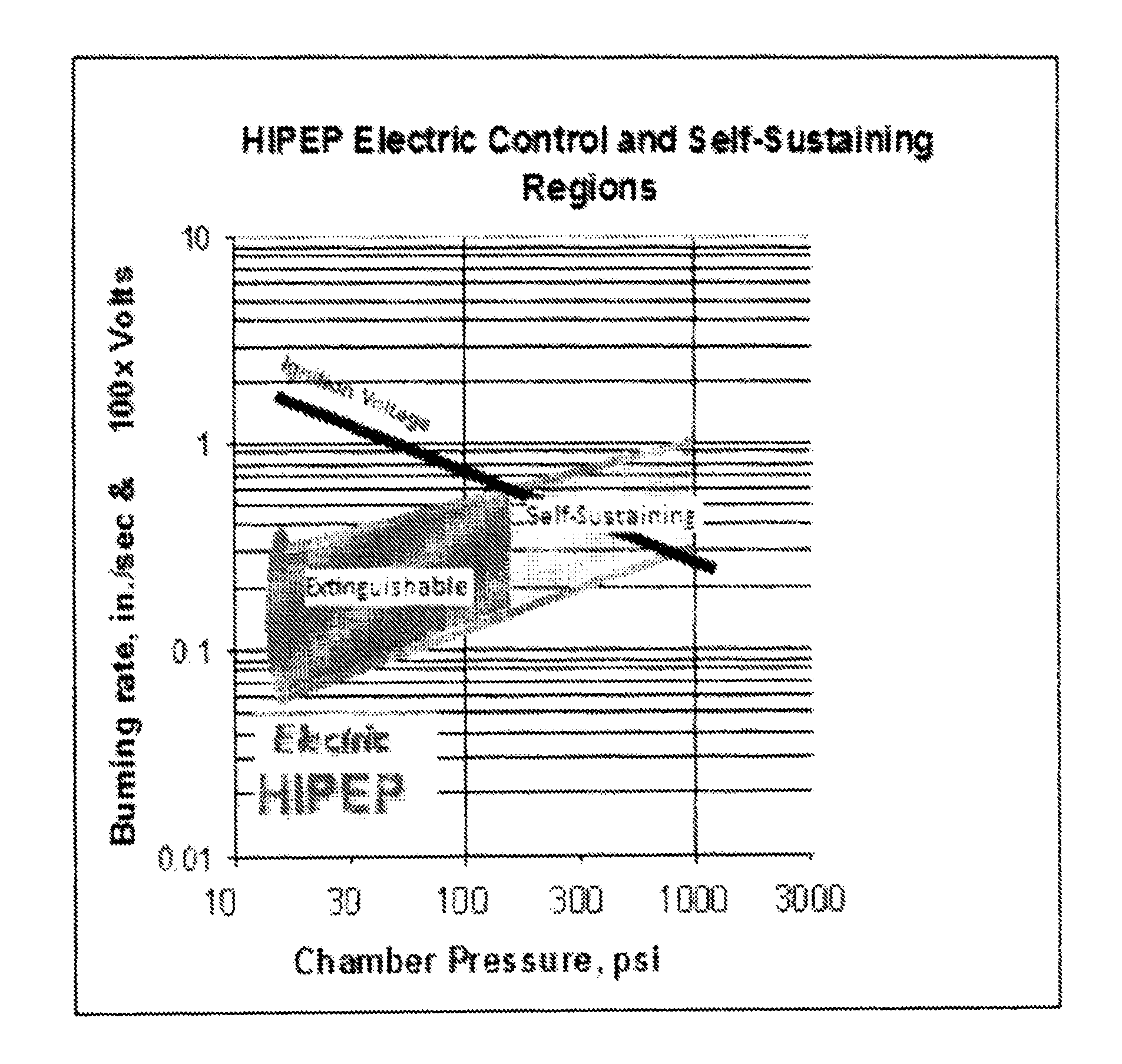

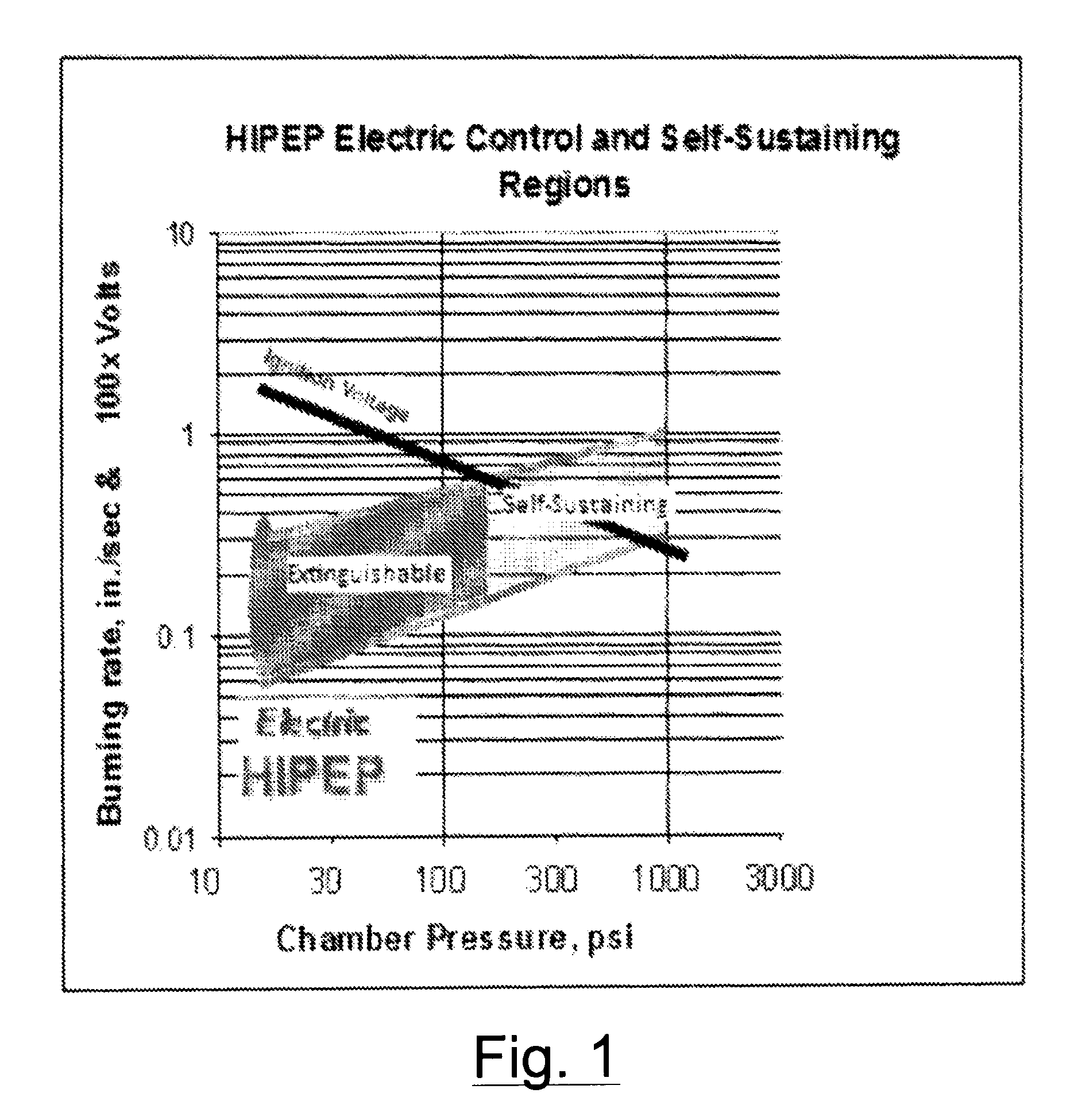

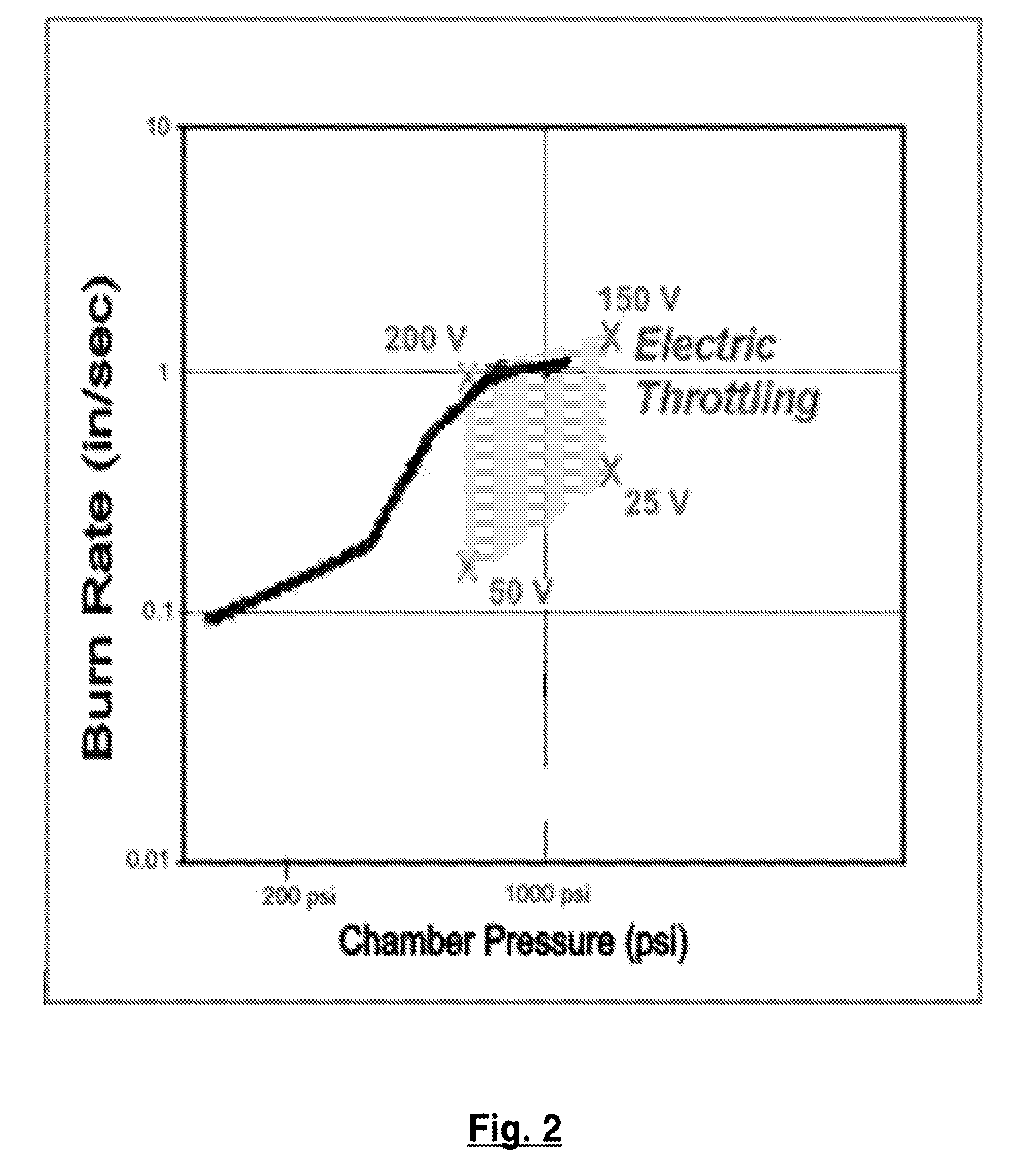

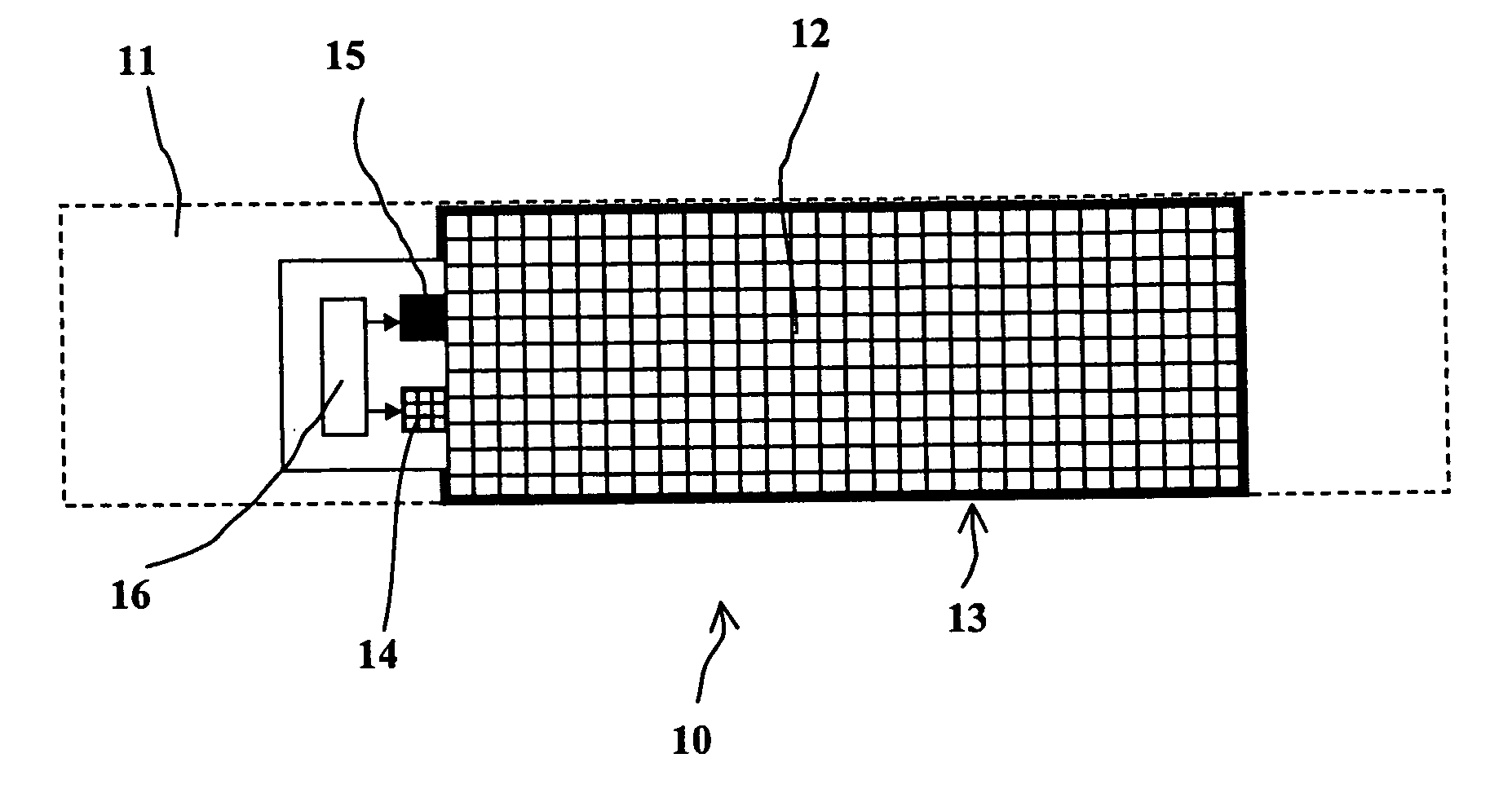

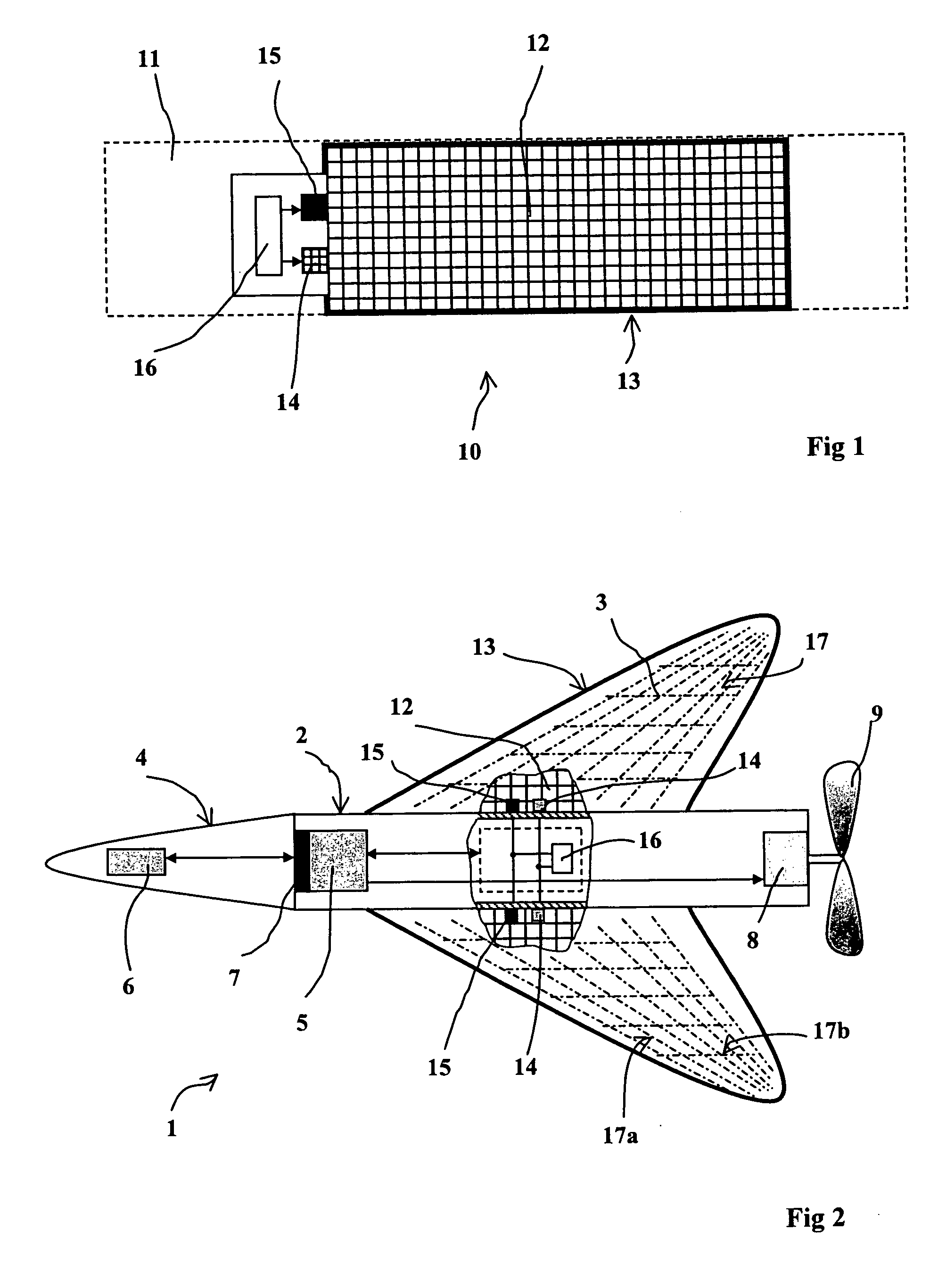

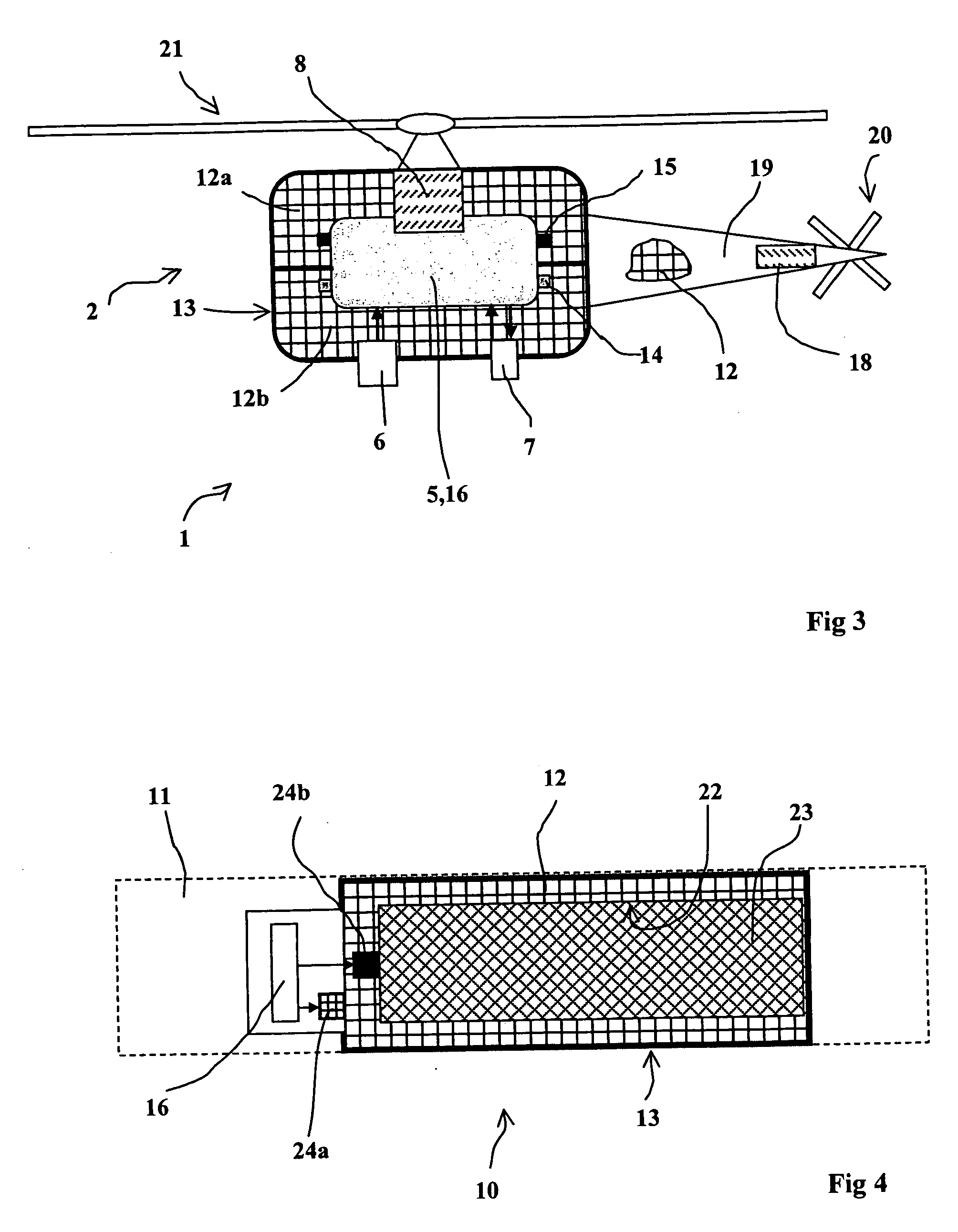

ActiveUS20110067789A1Improve simplicityLow costNon-explosive stabilisersNon-explosive fillers/gelling/thickening agentsElectricityAmbient pressure

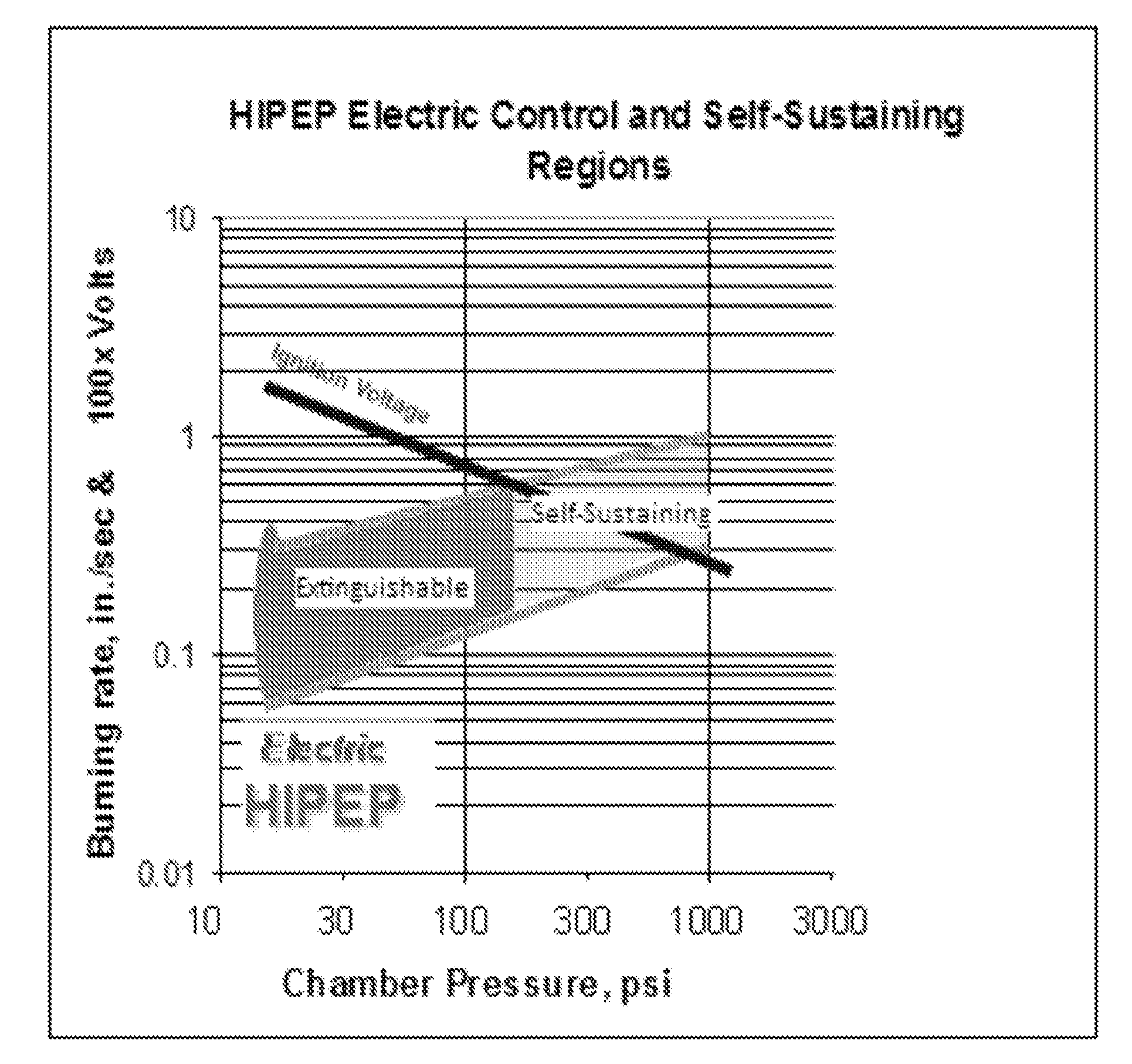

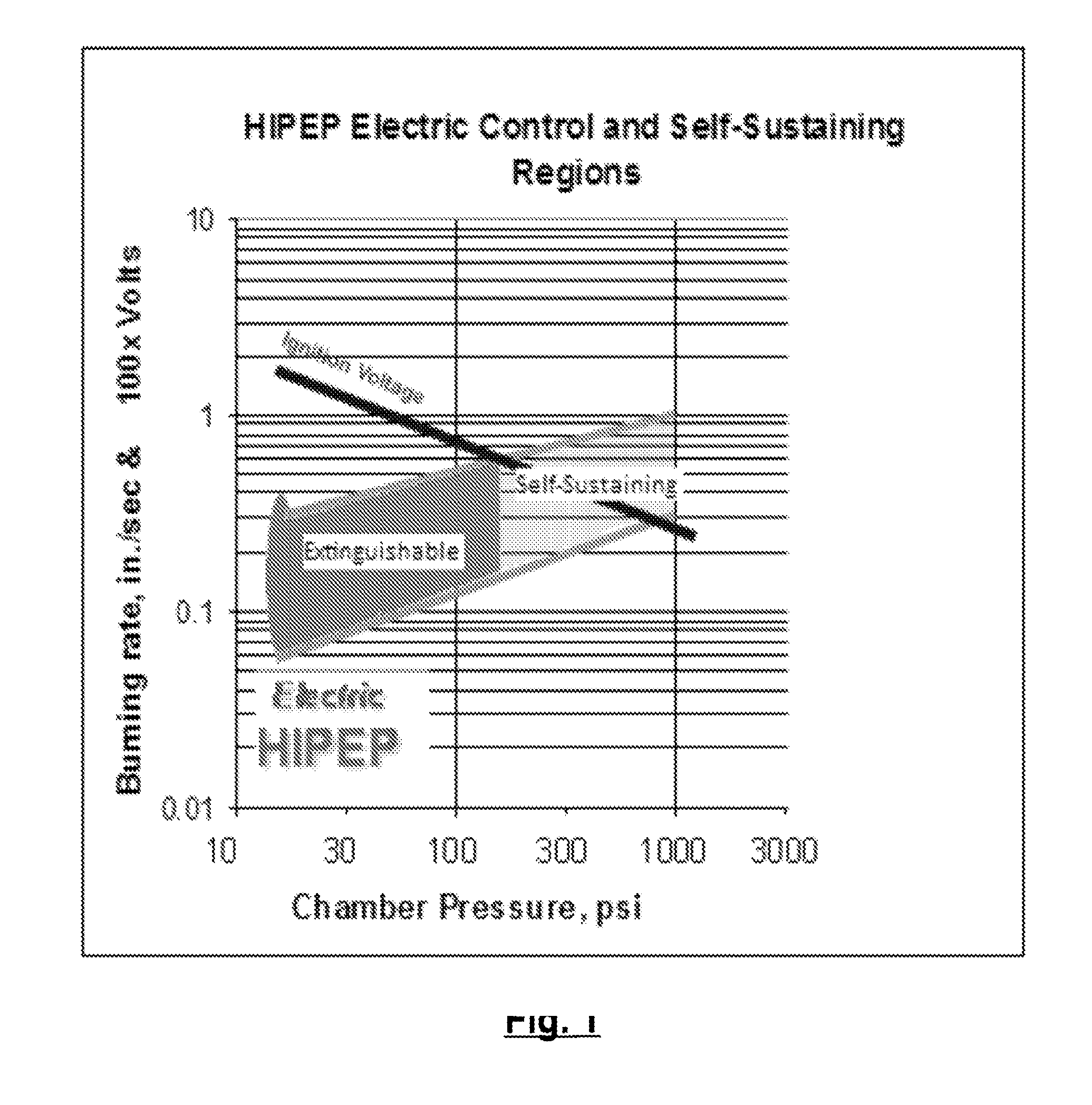

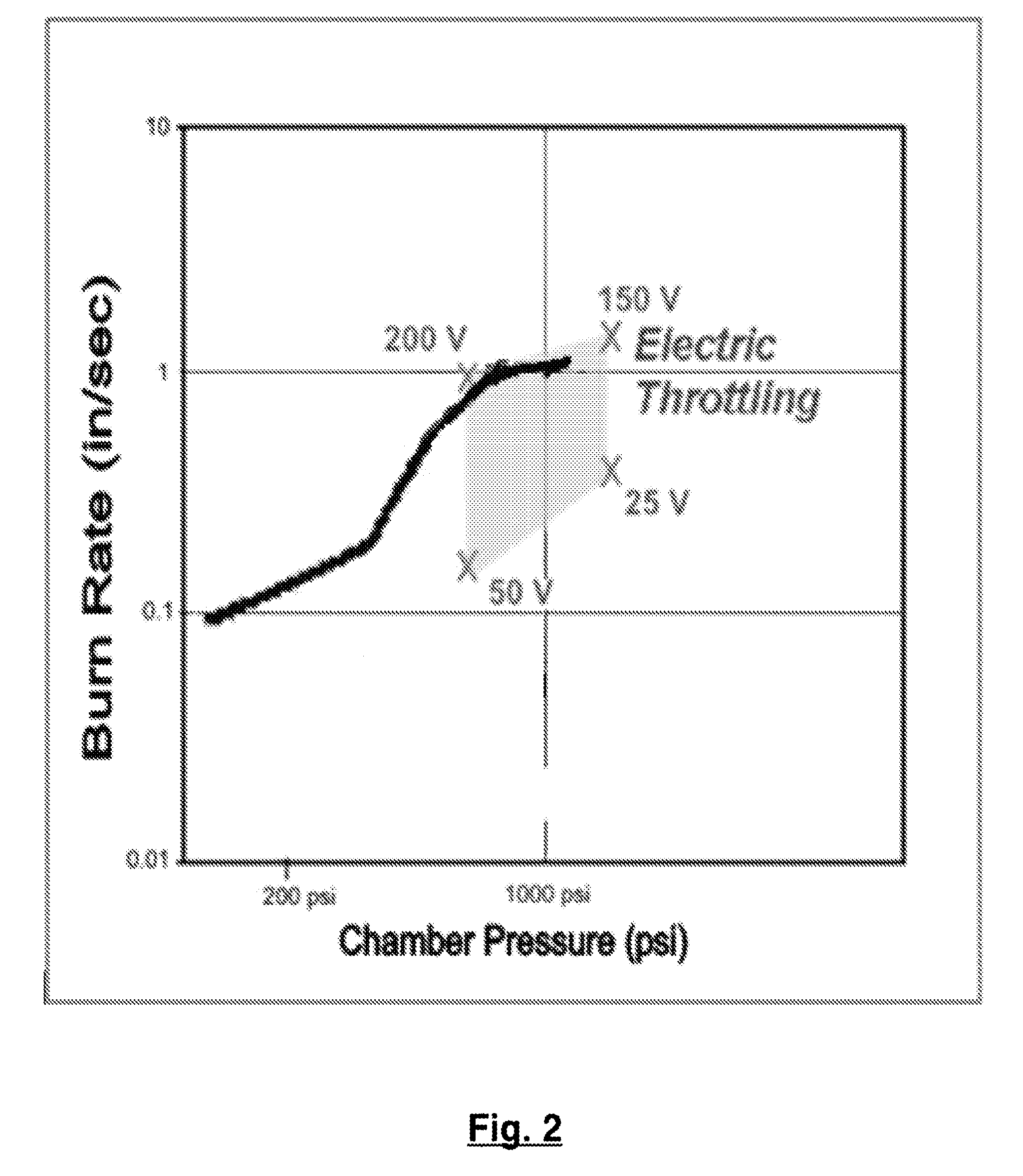

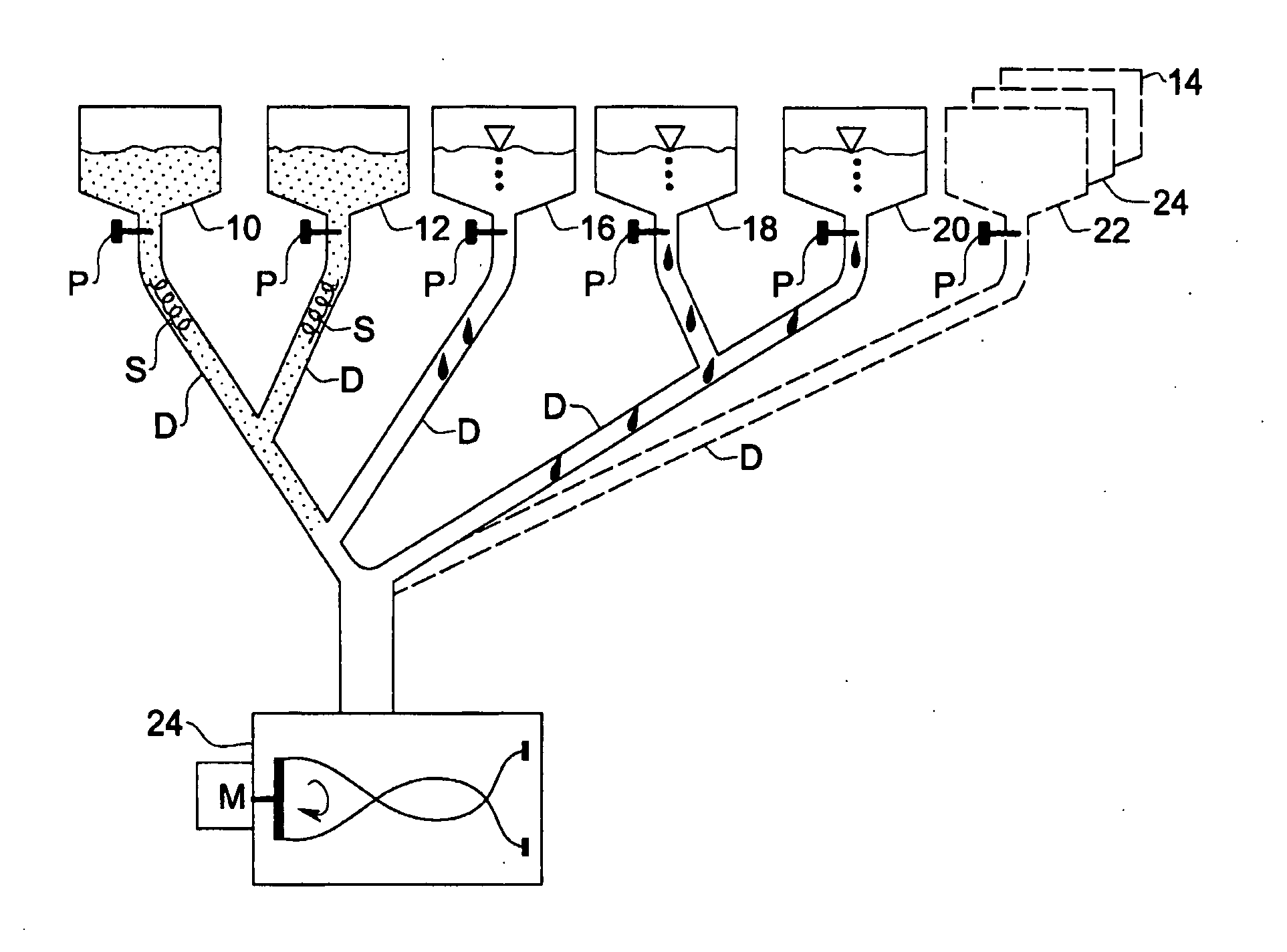

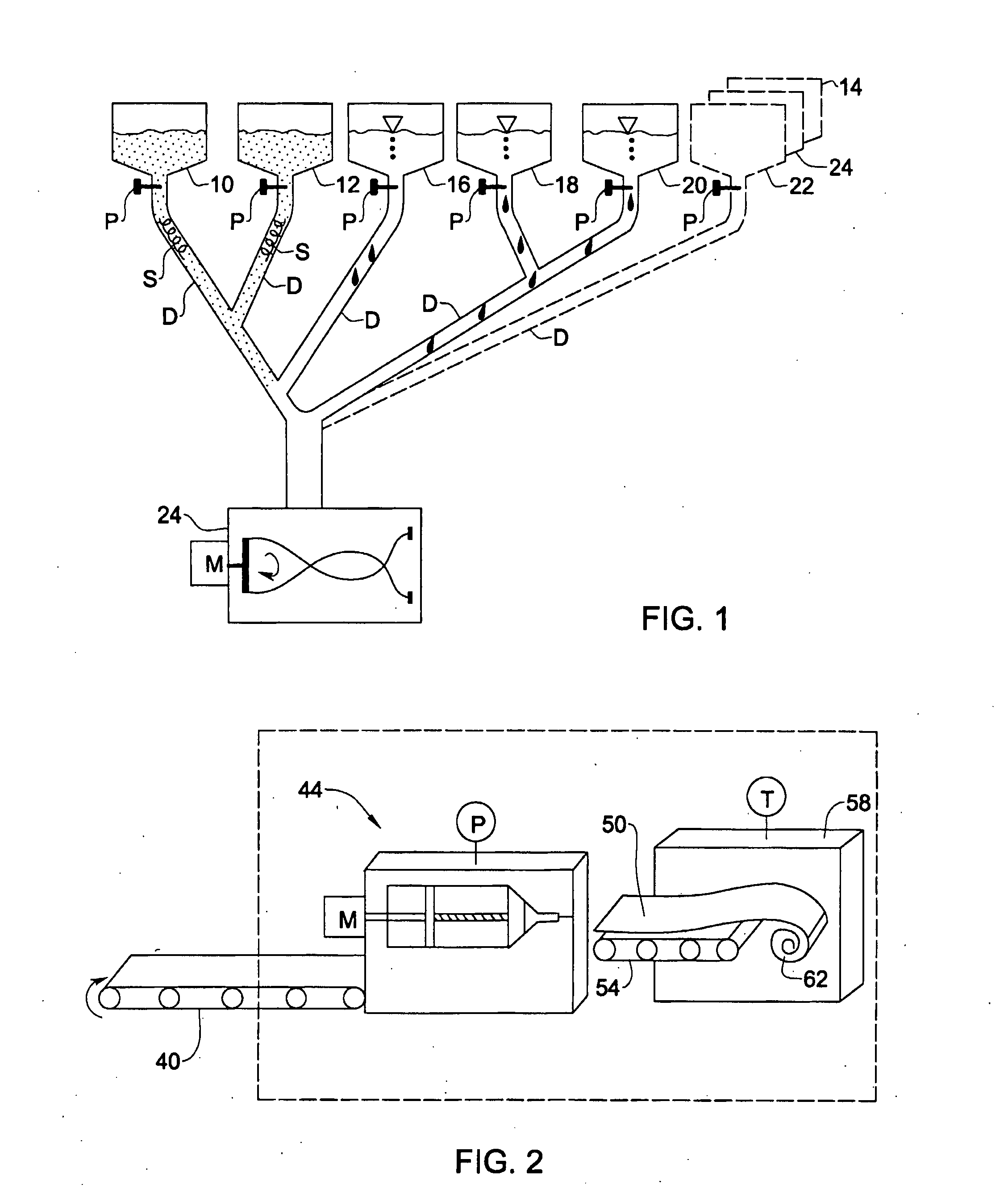

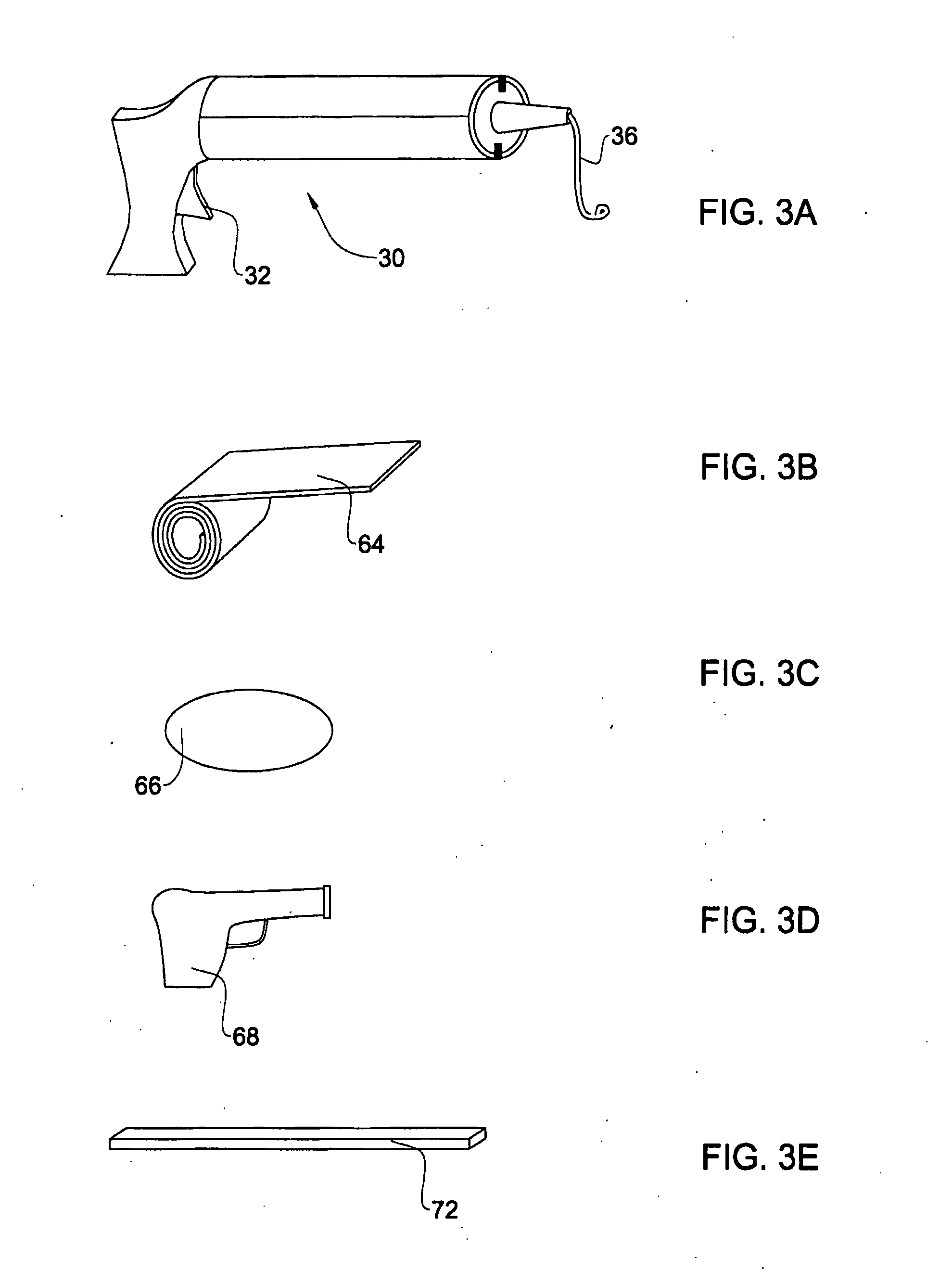

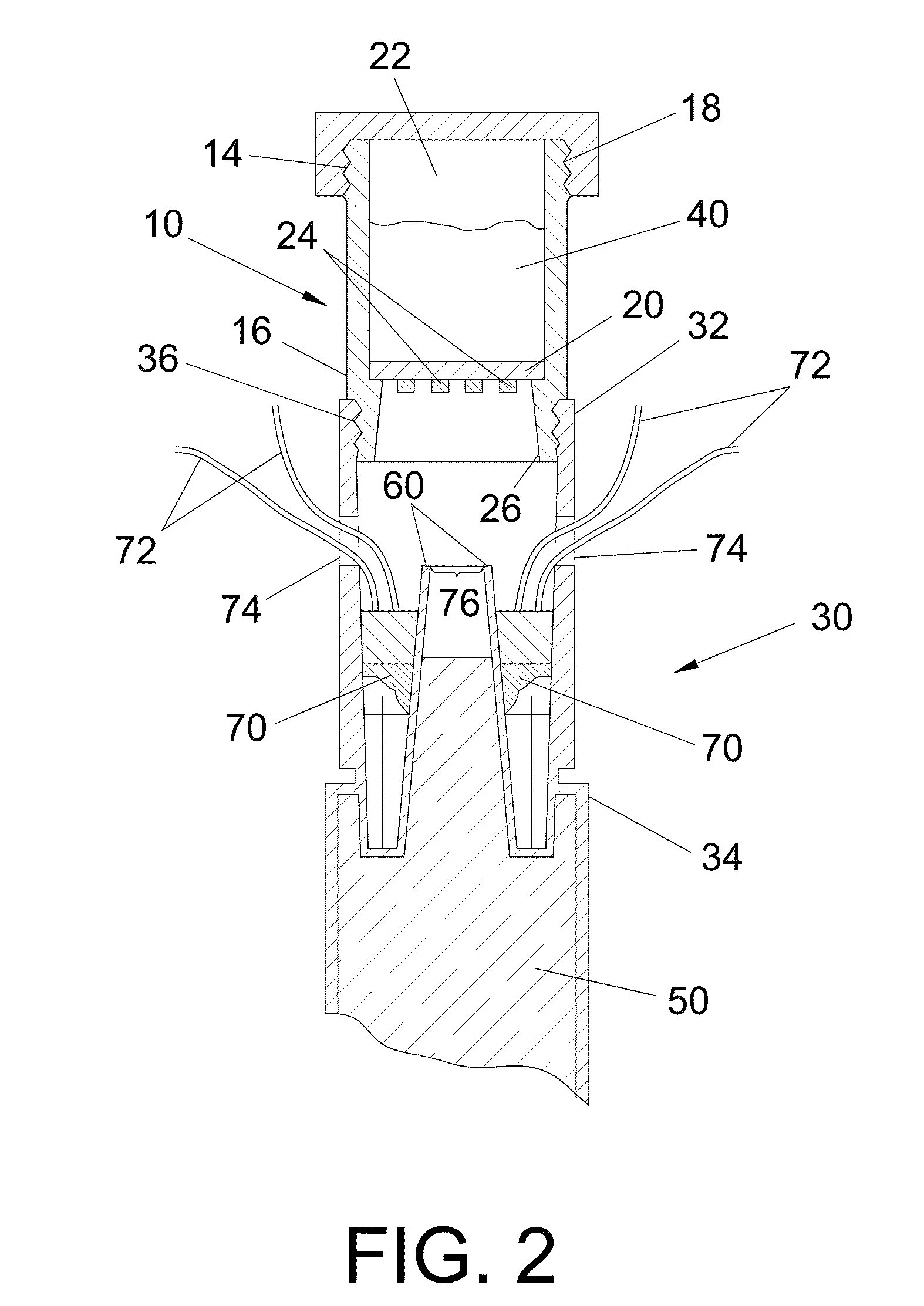

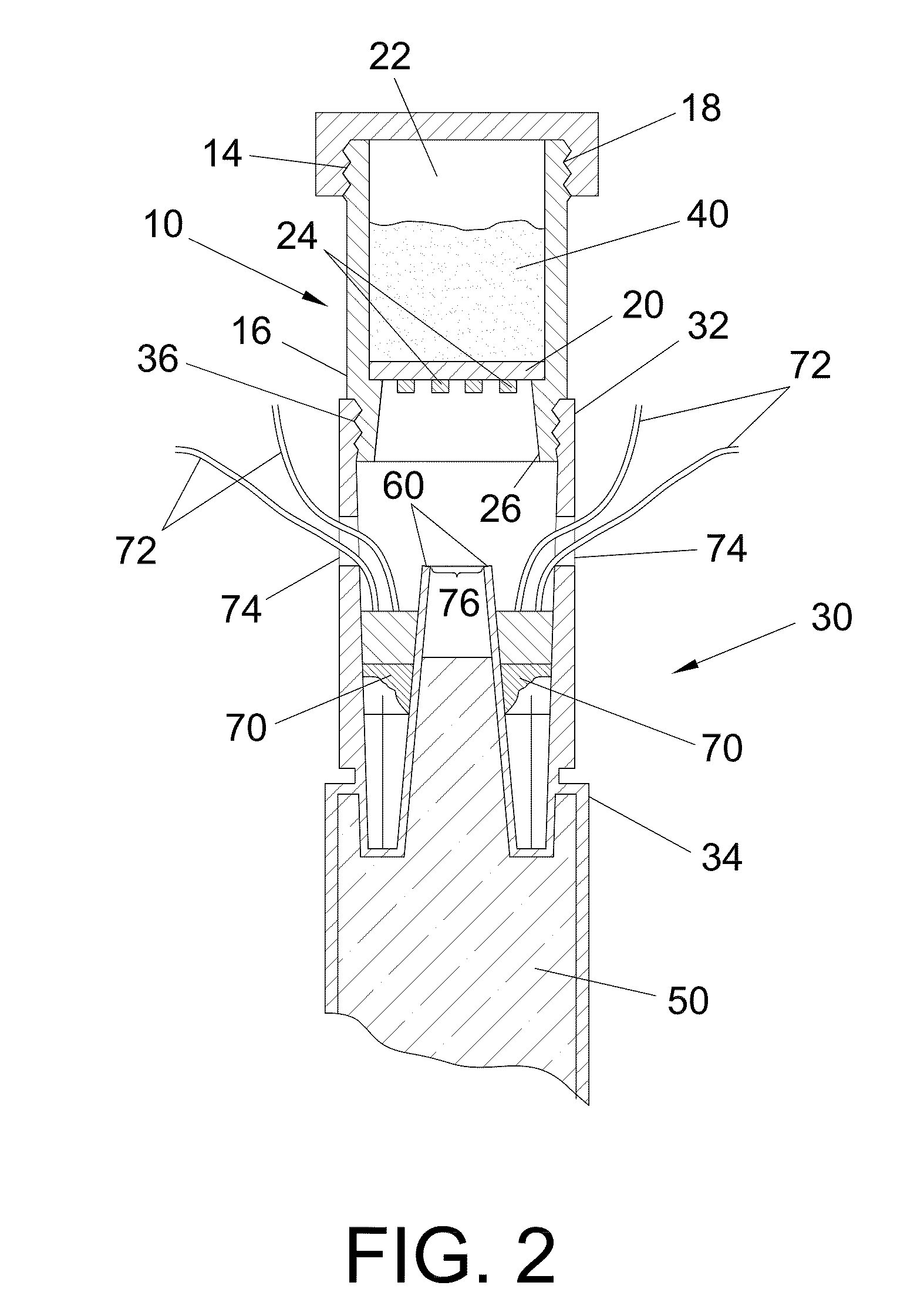

A composition capable of producing either solid propellant grains, liquid or gel monopropellants, all of which are electrically ignitable and capable of sustained controllable combustion at ambient pressure. Additional compositions capable of sustained controllable combustion at elevated pressures are described. Applications for the compositions disclosed herein are provided, and include among other applications use in small micro thrusters, large core-burning solid propellant gains, shaped explosives charges for military application, and pumpable liquids and gel monopropellants or explosives for military, commercial mining or gas and oil recovery. In alternative embodiments the above compositions may also incorporate an energetic nitrate polymer, bum rate modifiers, and / or metal fuel(s). The HIPEP formulation makes it possible to ignite and sustain combustion at ambient and vacuum conditions (a) without continuous electrical power and (b) while providing faster bum rates.

Owner:DIGITAL SOLID STATE PROPULSION

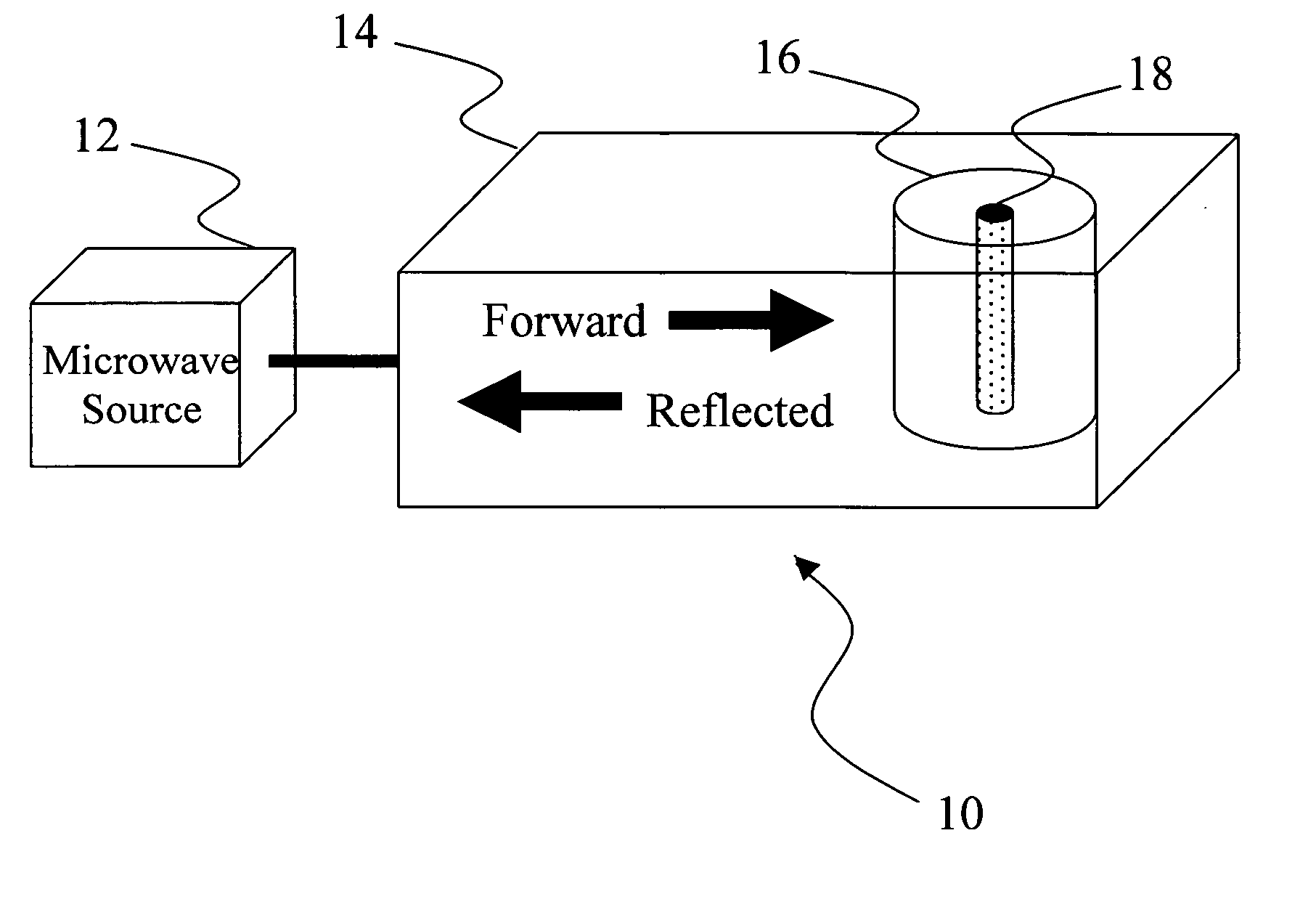

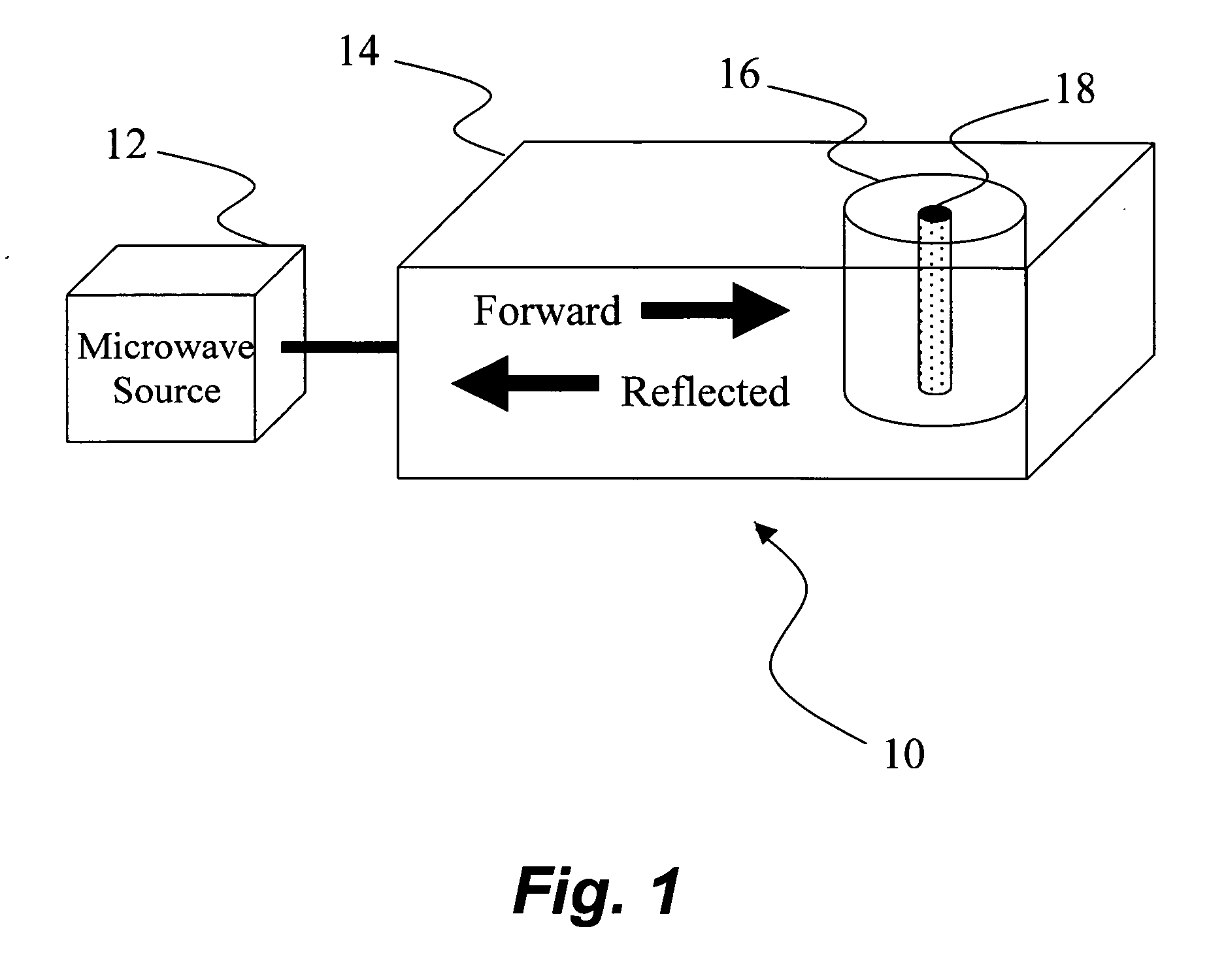

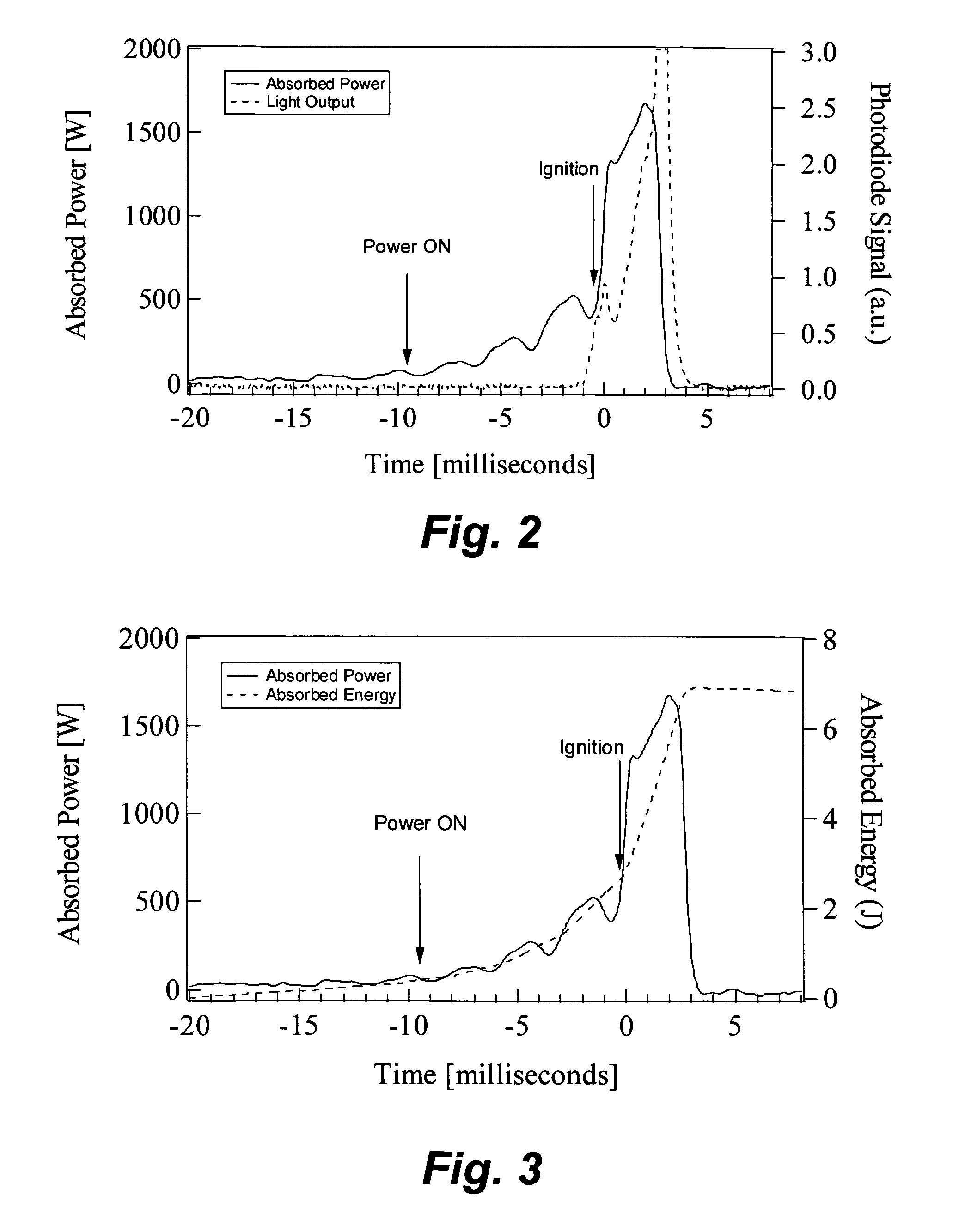

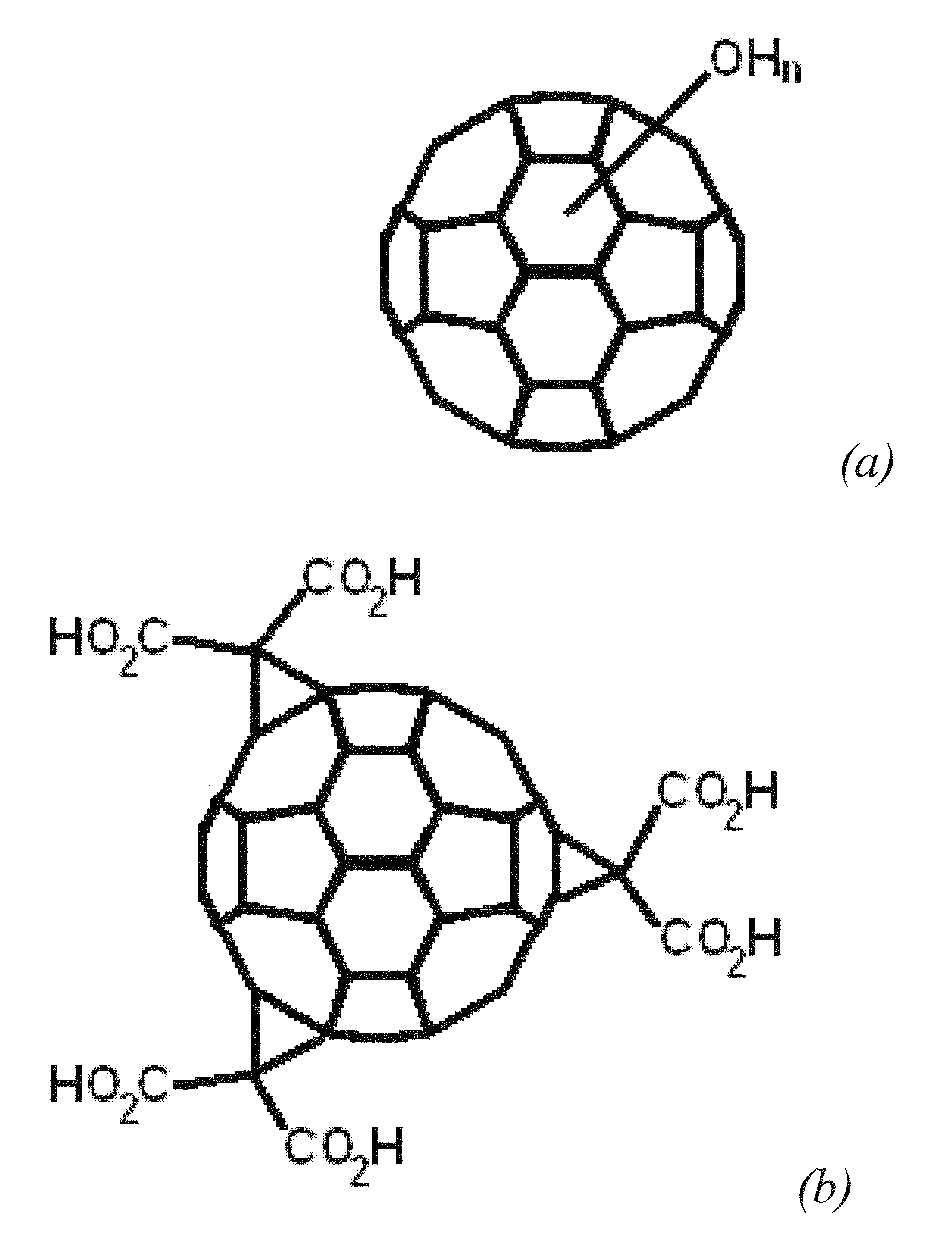

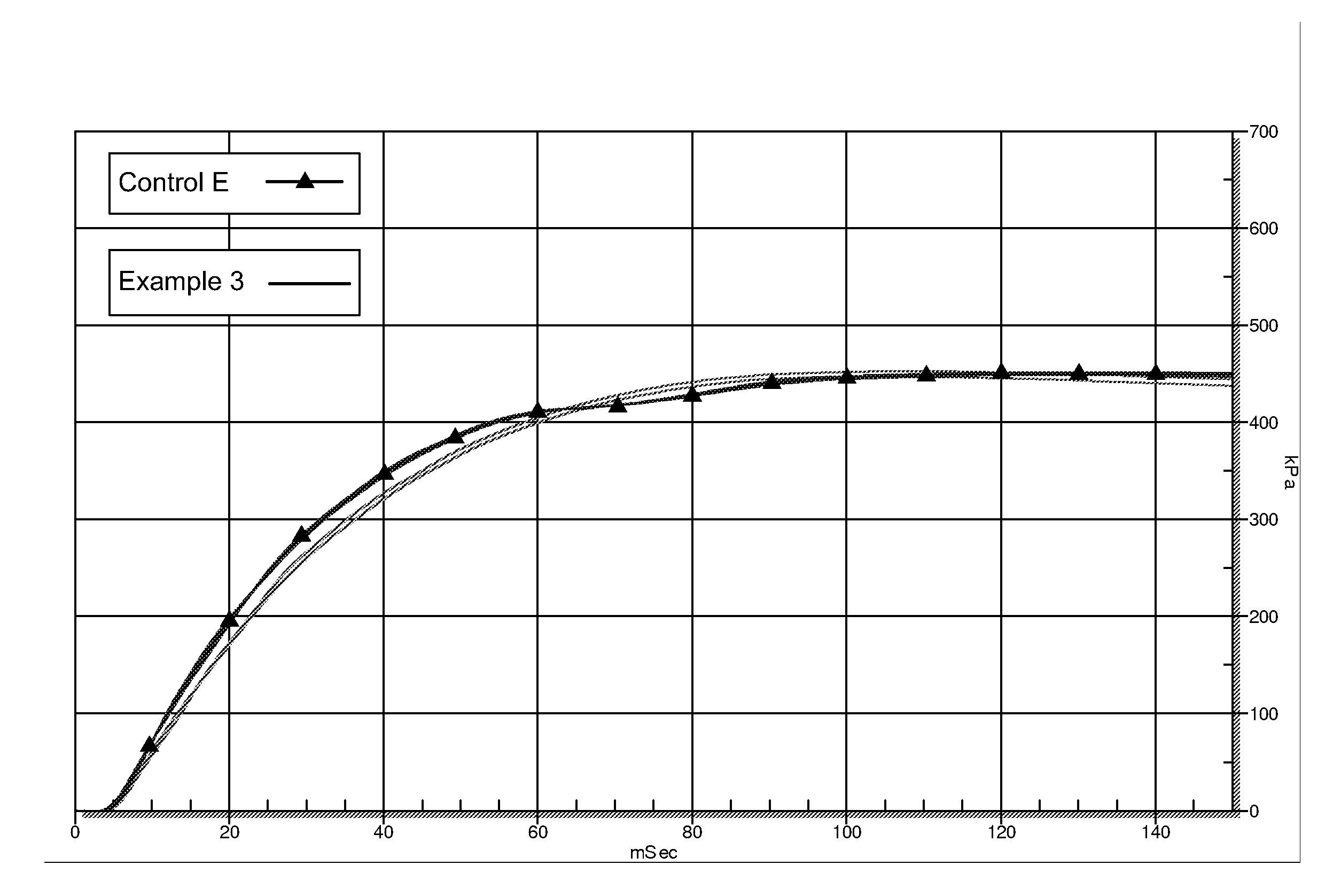

Microwave heating of energetic materials

InactiveUS20060011083A1Material nanotechnologyNon-explosive fillers/gelling/thickening agentsGramDegree Celsius

Mixtures of high explosives with materials that readily absorb microwaves ignite more readily when exposed to microwave energy than the corresponding neat explosives. A charge of HMX (0.5 gram) mixed with carbon nanotubes (1 percent by mass) ignited with 7.5 joules at an average rate of 750 W for 10 milliseconds. To raise a charge of the same mass of neat HMX to an autoignition temperature of 200 degrees Celsius would require much more energy (about 110 joules) for a longer duration (about 150 milliseconds).

Owner:LOS ALAMOS NATIONAL SECURITY

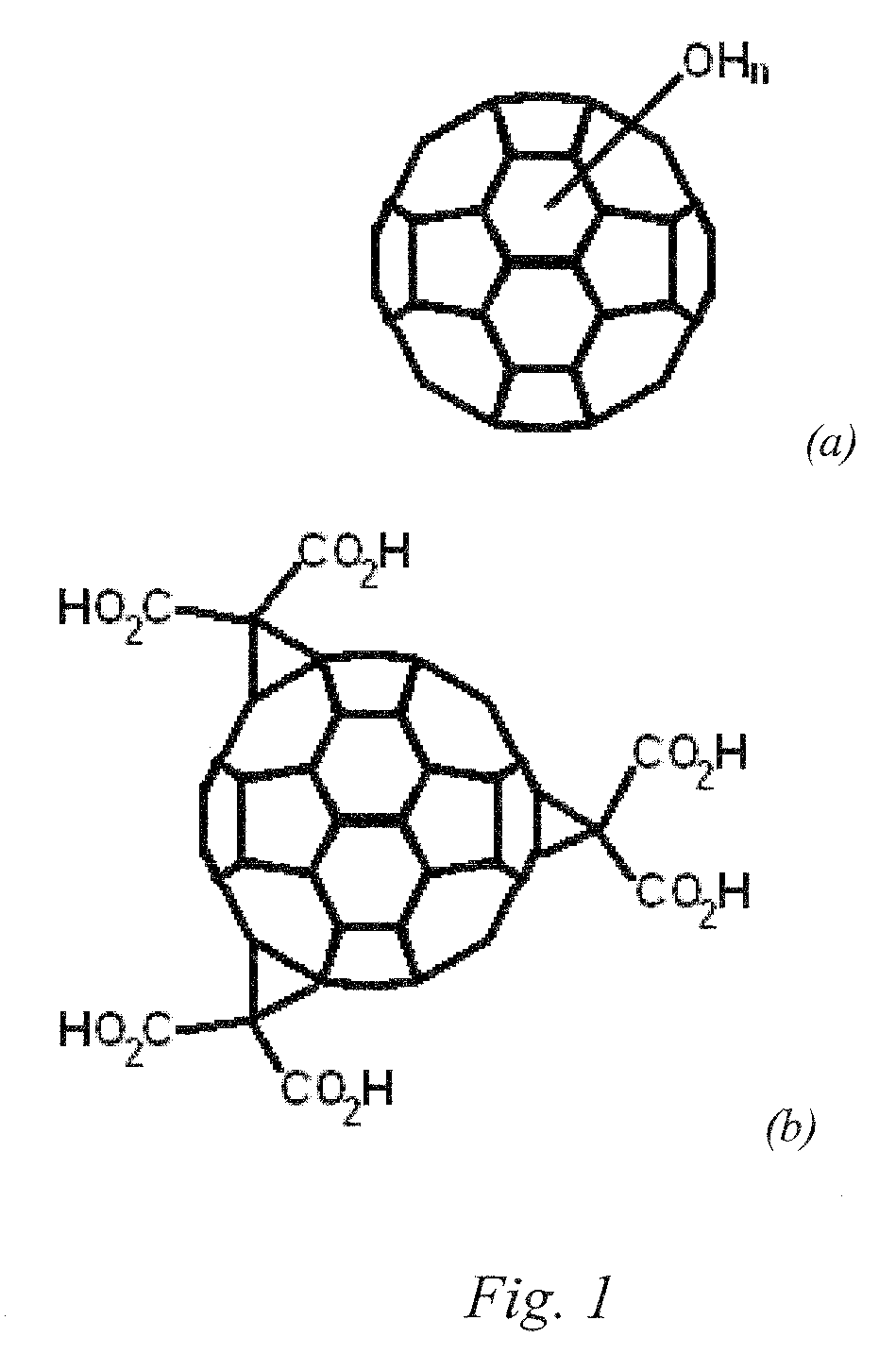

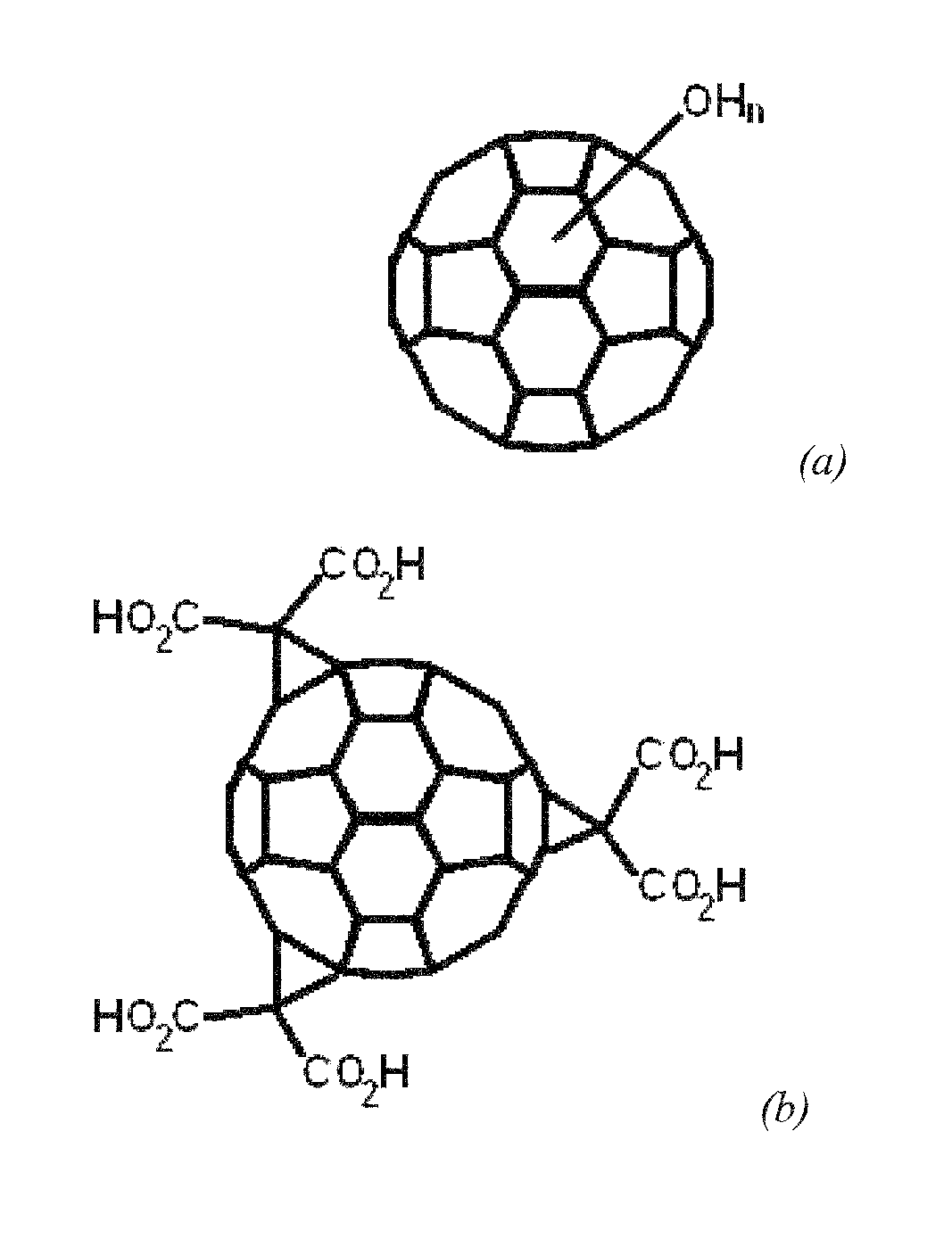

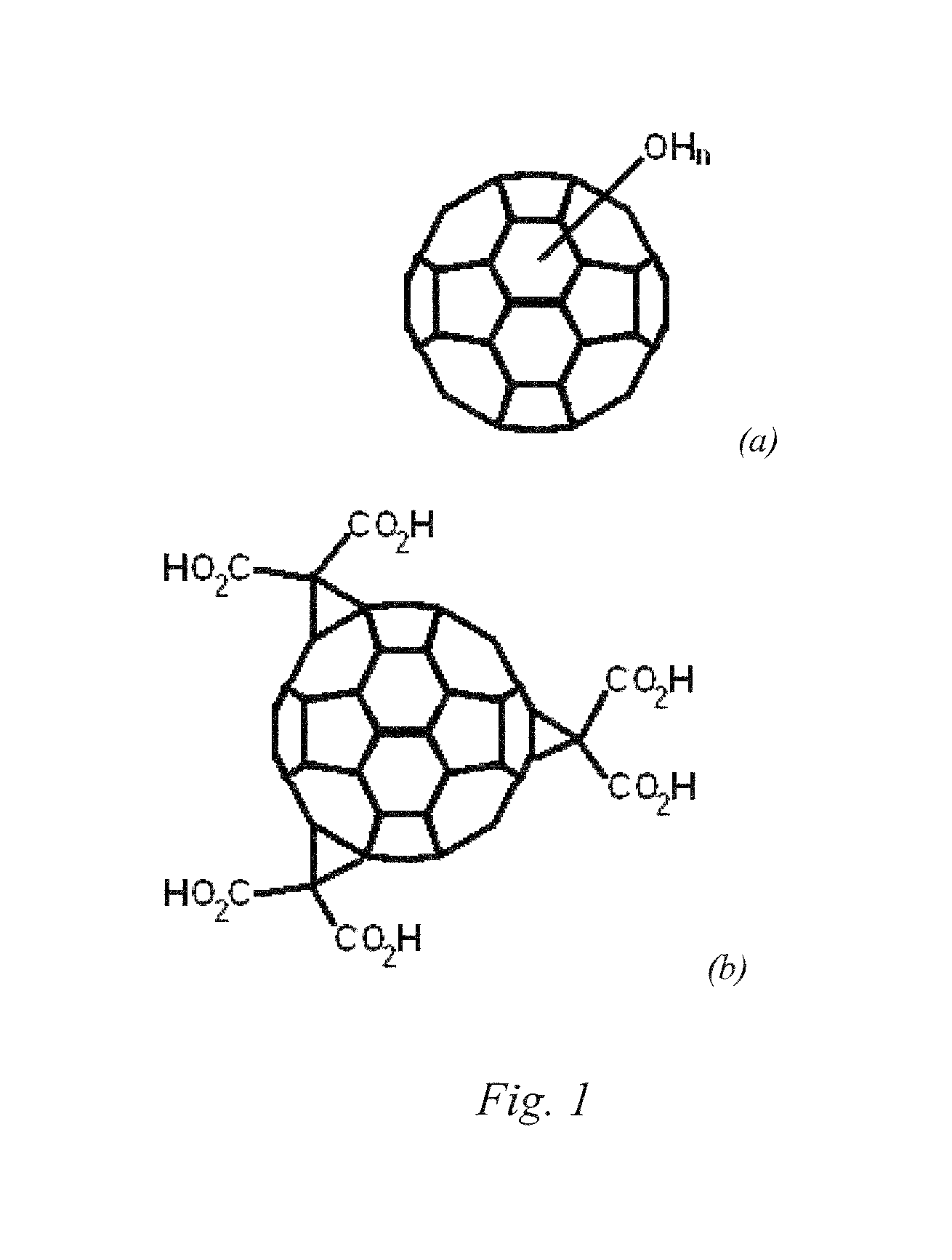

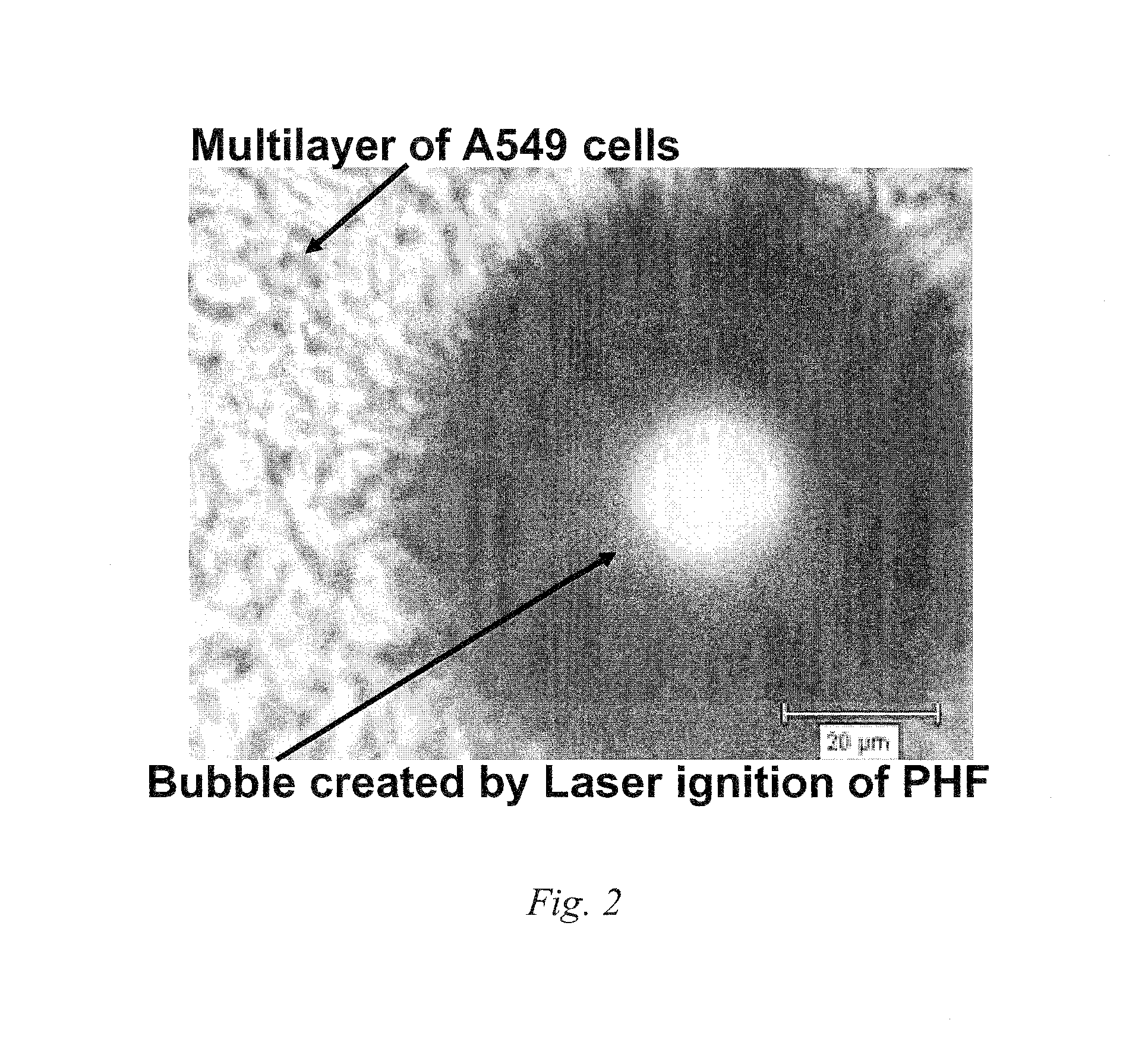

Systems and methods based on radiation induced heating or ignition of functionalized fullerenes

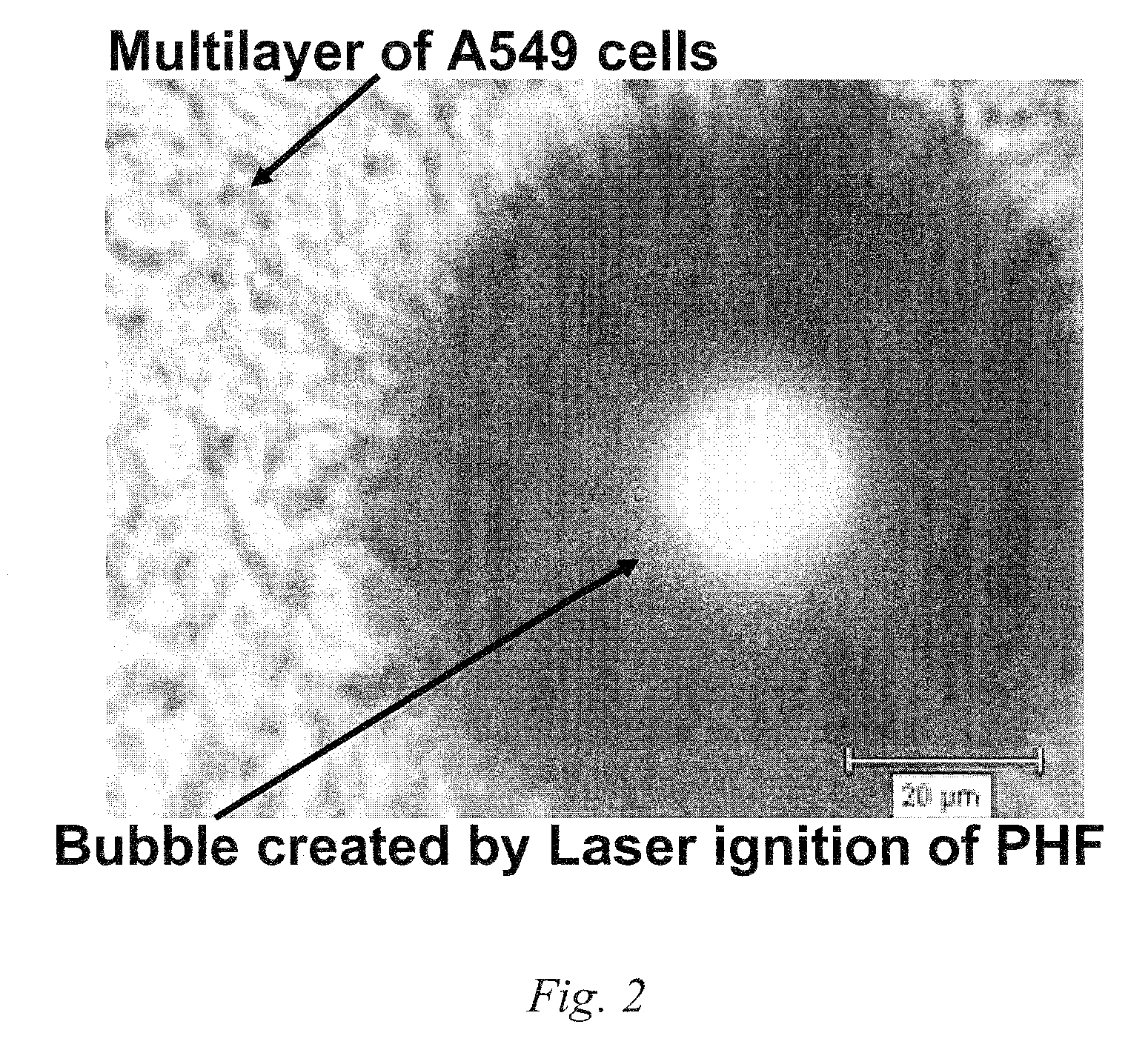

ActiveUS20090302029A1ElectrotherapyNon-explosive fillers/gelling/thickening agentsCancer cellDetonation

A method of irradiating a target region containing at least one fullerene comprising molecule promotes the heating or combustion of the target region. The heating method can be employed in a variety of applications including: selective targeting and destruction of cancer cells, detonation of explosives, ignition of a combustible mixture, photolithographic processes, and writing of optical storage media.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

Family of modifiable high performance electrically controlled propellants and explosives

ActiveUS8888935B2Improve simplicityLow costNon-explosive stabilisersNon-explosive fillers/gelling/thickening agentsElectricityAmbient pressure

A composition capable of producing either solid propellant grains, liquid or gel monopropellants, all of which are electrically ignitable and capable of sustained controllable combustion at ambient pressure. Additional compositions capable of sustained controllable combustion at elevated pressures are described. Applications for the compositions disclosed herein are provided, and include among other applications use in small micro thrusters, large core-burning solid propellant gains, shaped explosives charges for military application, and pumpable liquids and gel monopropellants or explosives for military, commercial mining or gas and oil recovery. In alternative embodiments the above compositions may also incorporate an energetic nitrate polymer, bum rate modifiers, and / or metal fuel(s). The HIPEP formulation makes it possible to ignite and sustain combustion at ambient and vacuum conditions (a) without continuous electrical power and (b) while providing faster bum rates.

Owner:DIGITAL SOLID STATE PROPULSION

High burning rate tactical solid rocket propellant, and related method

InactiveUS8986473B1Improve solubilityNon-explosive fillers/gelling/thickening agentsNitrated acyclic/alicyclic/heterocyclic amine explosive compositionsCombustionHeat conducting

The invention is a composition for a high burning-rate solid rocket propellant, where the composition includes a binder compounded with a soluble energetic additive; a metallic fuel; and an oxidative fuel. The resulting composition has a tactical Class 1.3 hazard rating, and a linear regression rate that is substantially equivalent to a tactical Class 1.1 hazard rating obtainable using solid rocket propellants. The composition may include a heat-conducting element, a plasticizer, a curing component, a combustion catalyst, and curing catalyst.

Owner:THE UNITED STATES OF AMERICA AS REPRESENTED BY THE SECRETARY OF THE NAVY

Simulant material for primary explosives

InactiveUS20090199936A1Reduce sensitivityEasy to useMetal azide explosive compositionsDefence devicesEngineering

Owner:RAFAEL ADVANCED DEFENSE SYSTEMS

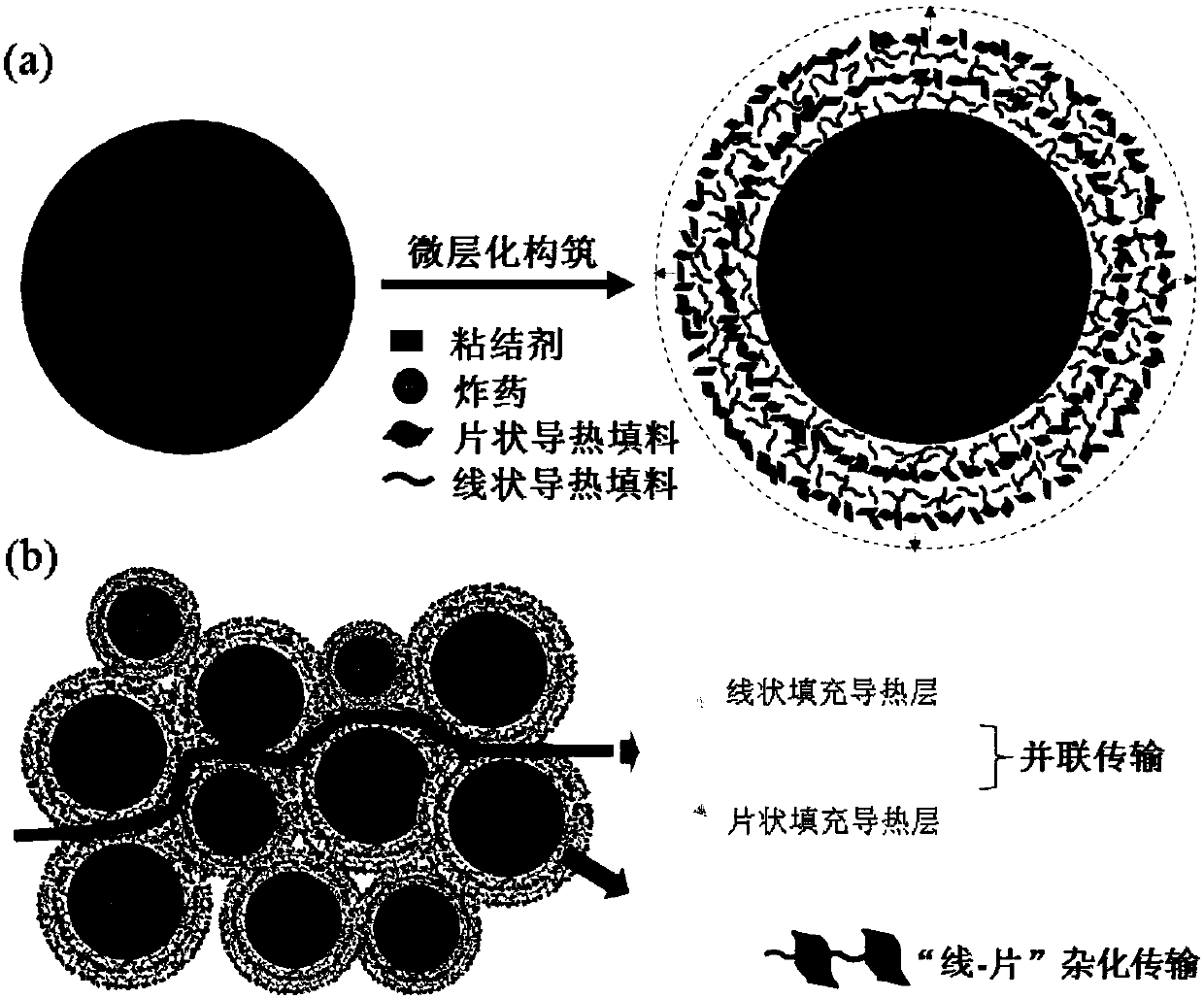

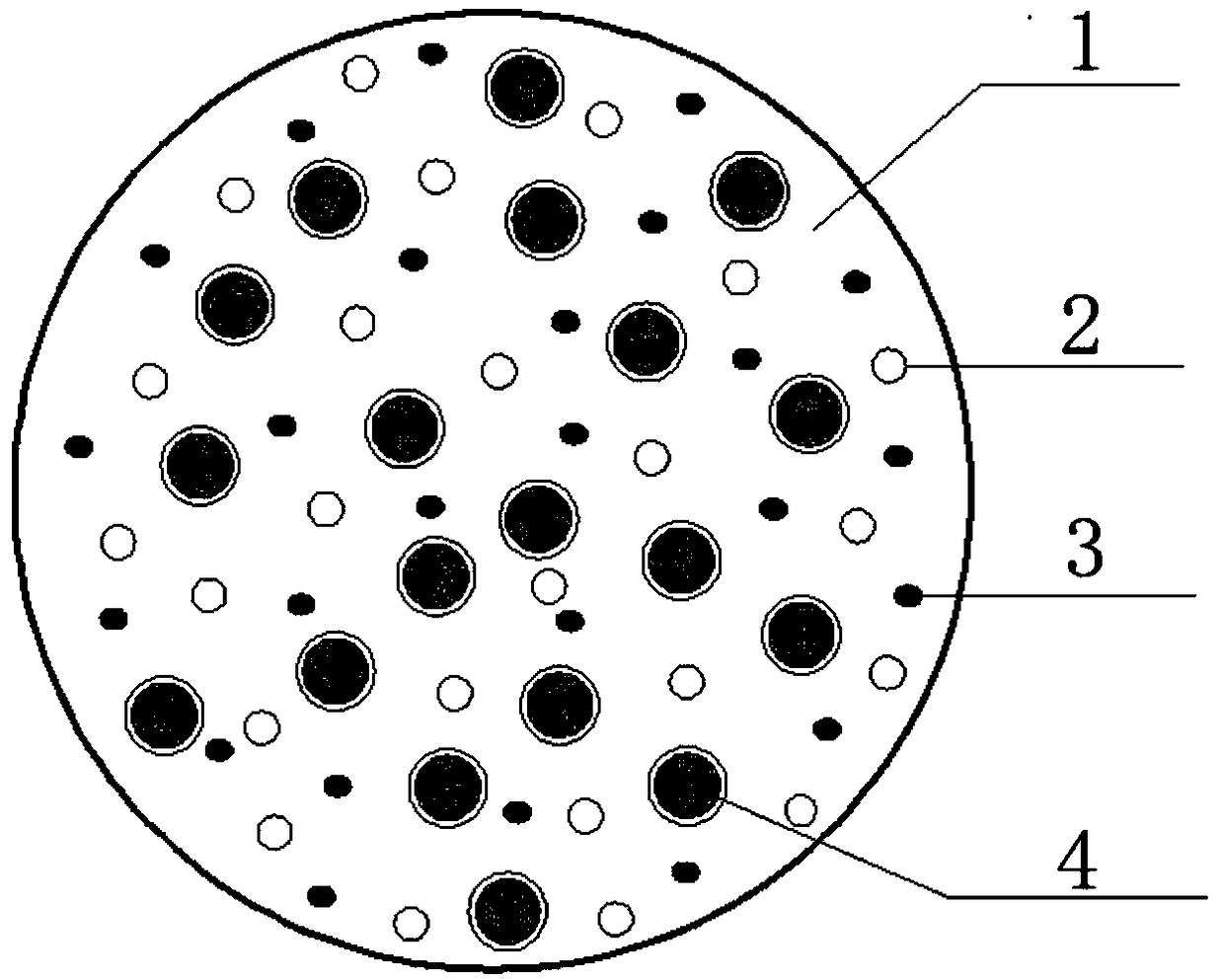

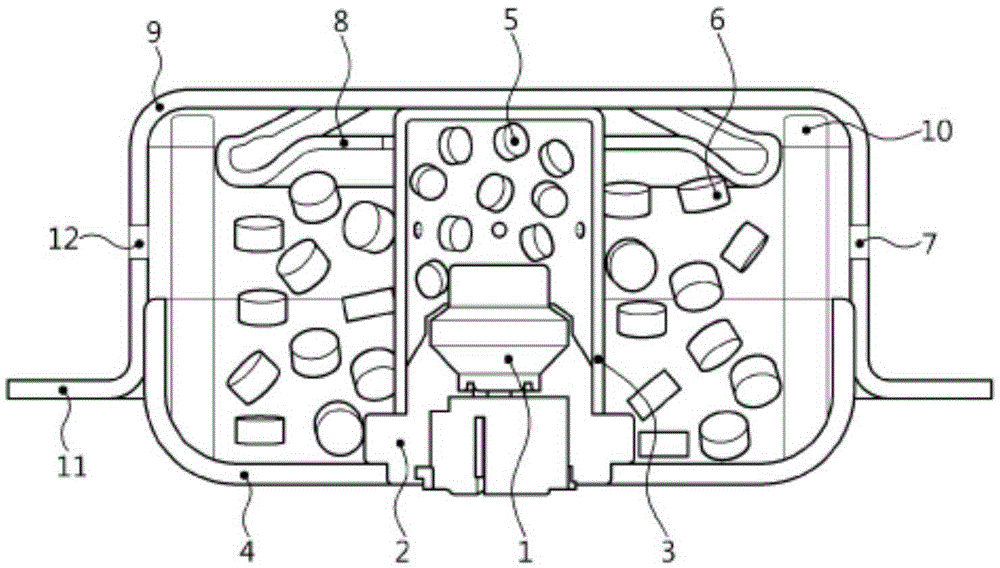

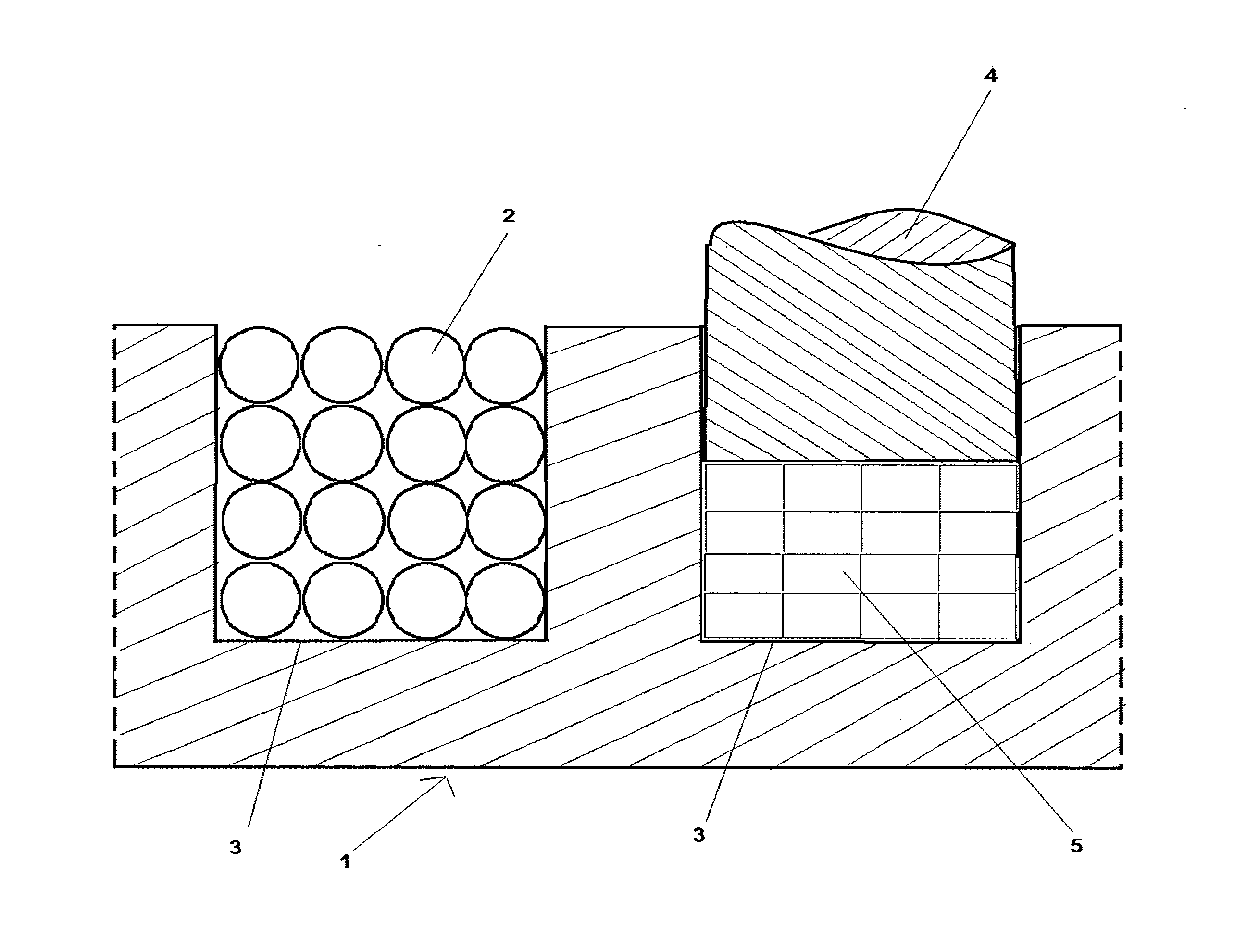

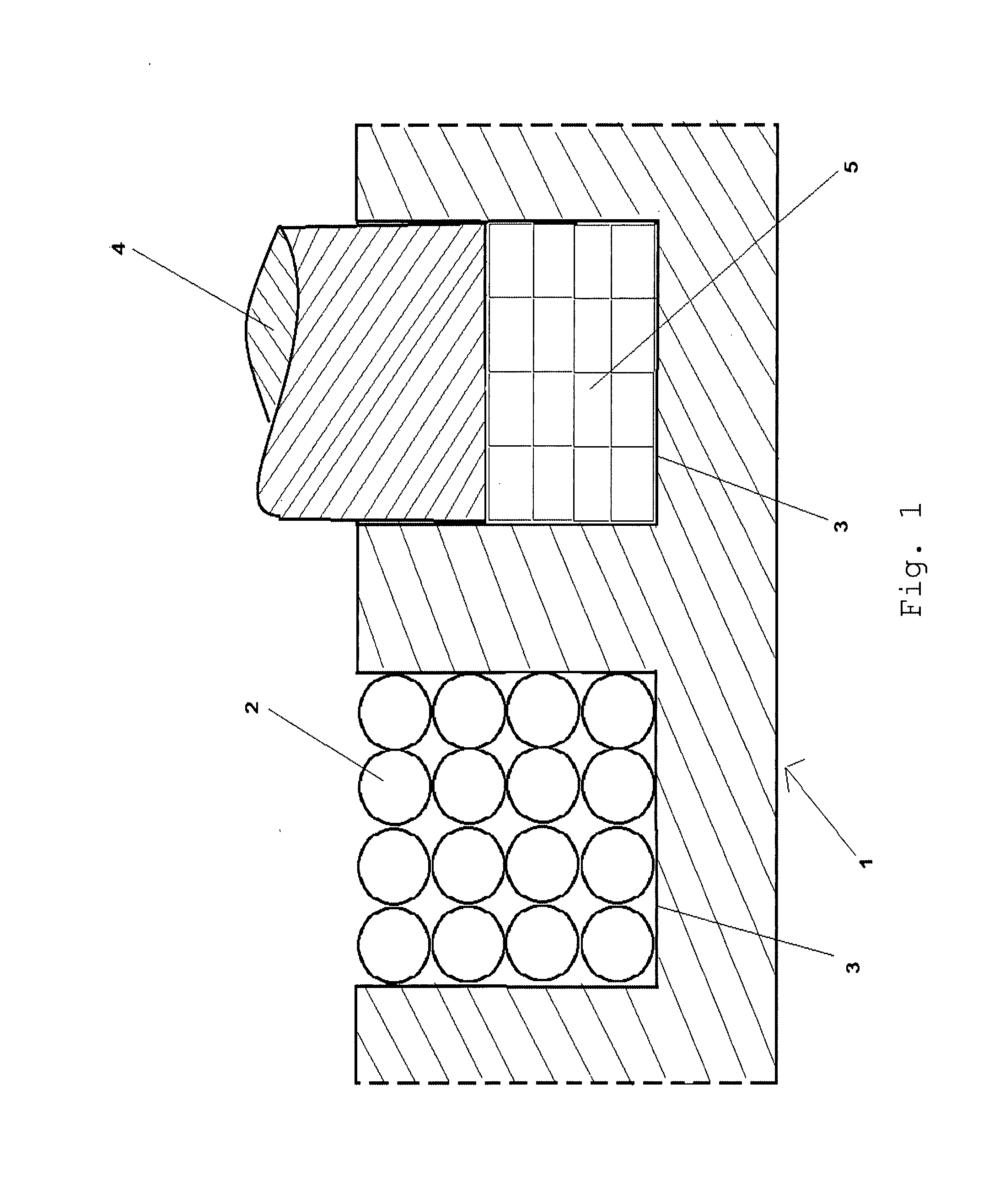

Alternating micro-layered heat conduction PBX mixed explosive and preparation method thereof

ActiveCN107759427AMaximize deliveryEasy to passNon-explosive fillers/gelling/thickening agentsNitrated aromatic explosive compositionsFiberCarbon fibers

The invention discloses an alternating micro-layered heat conduction PBX mixed explosive. The mixed explosive comprises, by weight, 90%-95% of an explosive, 4%-9.8% of a polymer binder and 0.2%-1% ofa heat conduction filler. The heat conduction filler comprises a flake-like heat conduction filler and a linear heat conduction filler. The flake-like heat conduction filler comprises any one of graphene, graphene nanosheets and boron nitride nanosheets. The linear heat conduction filler comprises any one of single-walled carbon nanotubes, multi-walled carbon nanotubes, boron nitride nanotubes andnano-carbon fibers. The invention also provides a preparation method of the alternating micro-layered heat conduction PBX mixed explosive. The preparation method fully utilizes the thermal conductivity characteristics and advantages of the two-dimensional flake-like and one-dimensional linear high thermal conductivity fillers and adopts an ingenious structure control strategy so that the fillersare respectively enriched in the partial layer space to form flake-like and linear thermal conduction layer passages and thus parallel transmission in layers is realized and heat transfer is maximized.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

Novel underground mine gel emulsion explosive and preparation method thereof

ActiveCN108640806AImprove liquidityEasy to automate pumpingNon-explosive fillers/gelling/thickening agentsExplosive ingredient compoundingDetonationEmulsion explosive

Disclosed is a novel underground mine gel emulsion explosive. The explosive is mainly prepared from ammonia nitrate,sodium nitrate,a compound oil phase,water,sensitizer,a viscosity reducer,a thickening agent and a thickening agent wrapping film material. The viscosity reducer is used for reducing the viscosity of the emulsion explosive,pumping resistance is lowered,and it is ensured that the emulsion explosive can be smoothly pumped into a gun hole. Meanwhile,the thickening agent wrapped by micro-capsules is added into the emulsion explosive,in the pumping and spraying charging process of thethickening agent wrapped by micro-capsules,due to the extrusion,friction and spraying collision effects,the micro-capsules are damaged,enable the thickening agent to be exposed,and react with water inthe emulsion explosive,and the viscosity of the underground mine gel emulsion explosive after the explosive reaches the gun hole is enhanced,so that the problem that charging and recharging of the hole are serious on an underground mine is effectively solved. Meanwhile the underground mine gel emulsion explosive is good in detonation performance,and the requirement for storage stability is met.

Owner:ANHUI UNIV OF SCI & TECH

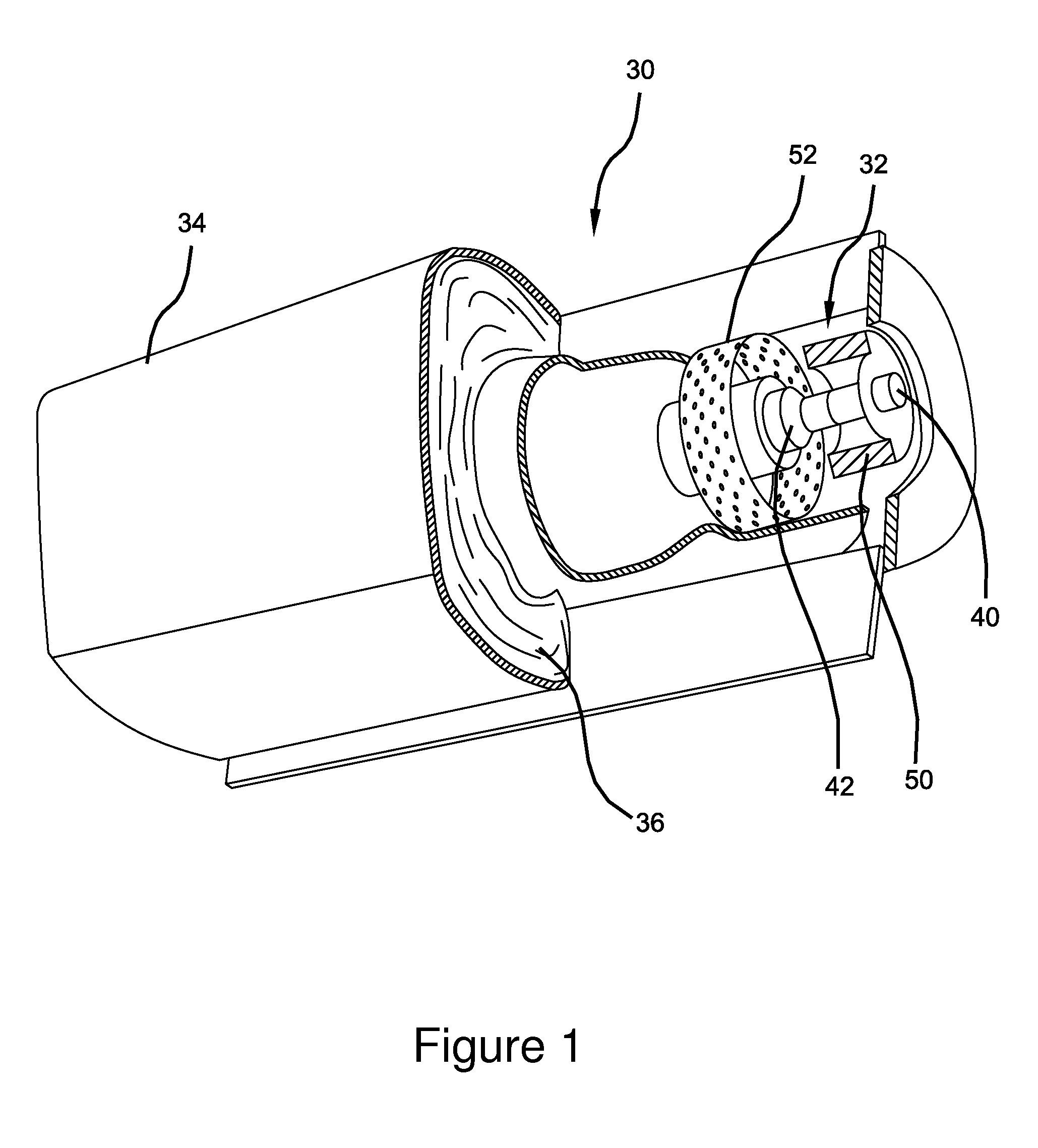

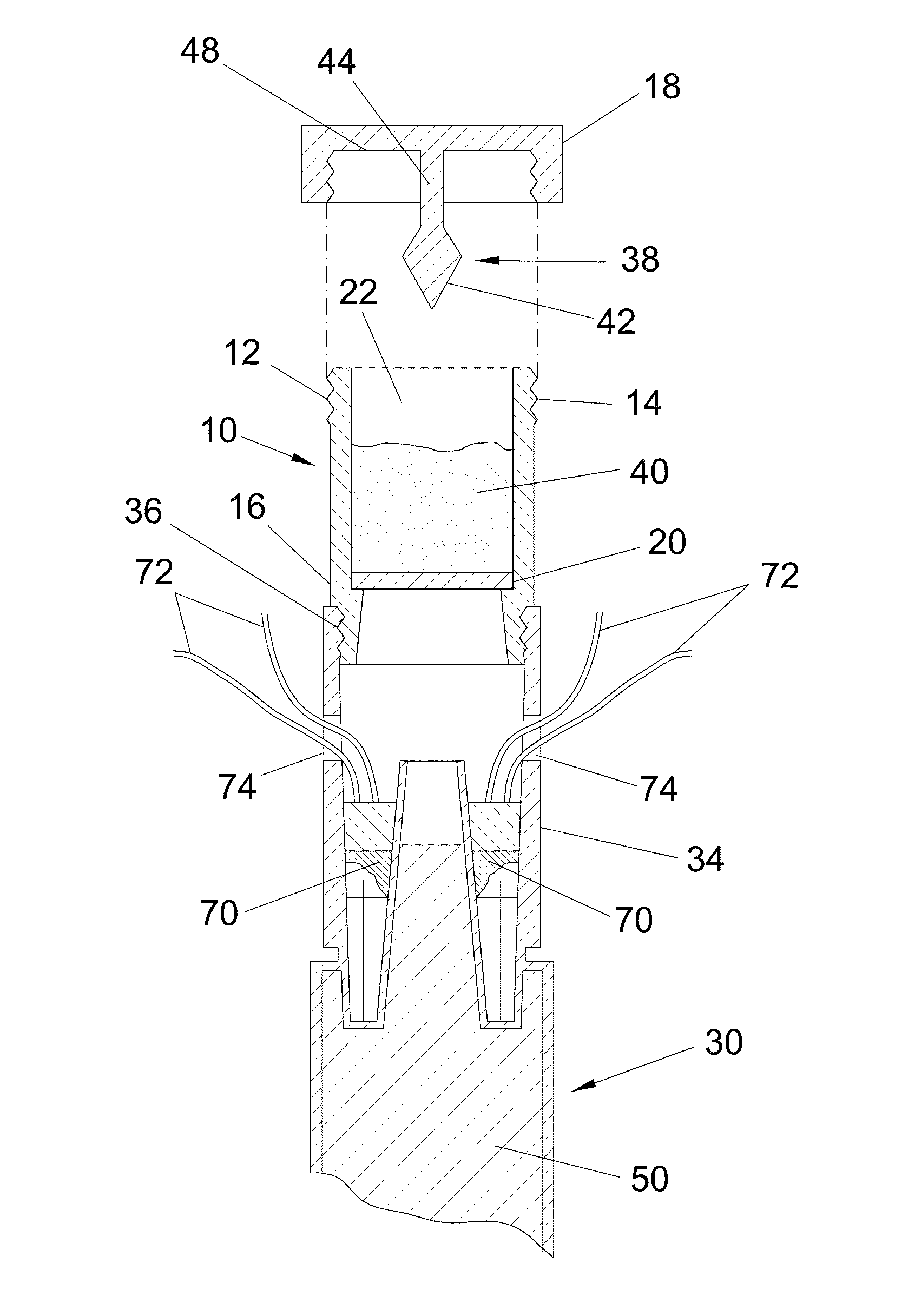

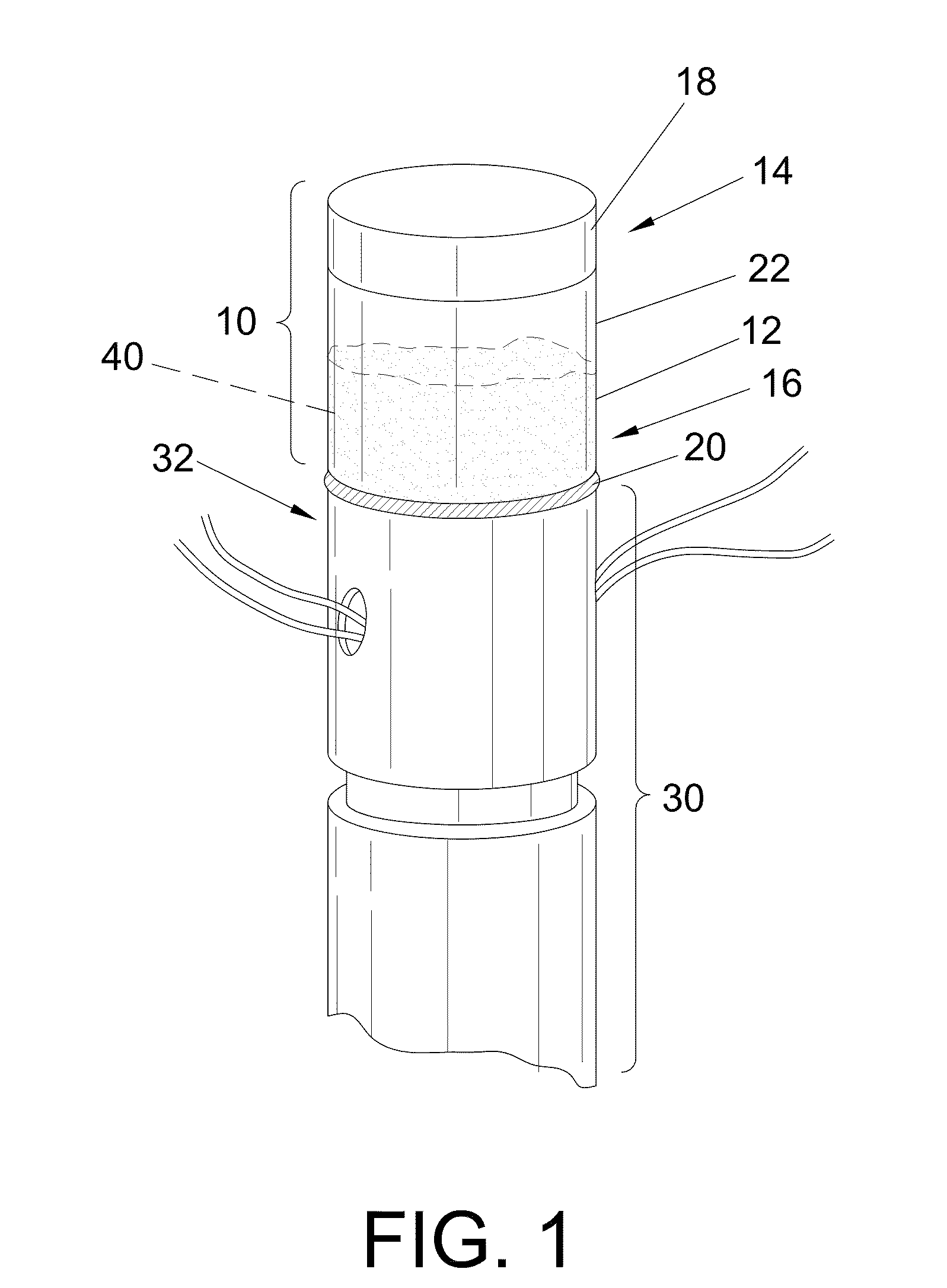

Gas generating compositions having glass fibers

ActiveUS20100116384A1Reduce sensitivity to pressureLessening burn rate pressure sensitivityNon-explosive fillers/gelling/thickening agentsExplosive working-up apparatusGlass fiberBurn rate

Compositions and methods relate to gas generants used in inflatable restraint systems. The gas generant grains include a fuel mixture having at least one fuel and at least one oxidizer, which have a burn rate that is susceptible to pressure sensitivity during combustion. The gas generant composition further includes a plurality of pressure sensitivity modifying glass fiber particles distributed therein to lessen the pressure sensitivity and / or to increase combustion stability of the gas generant. Such gas generants can be formed via spray drying techniques.

Owner:AUTOLIV ASP INC

Thermoplastic composite solid propellant and preparation method thereof

ActiveCN107867962AAchieve moldingImprove securityNon-explosive fillers/gelling/thickening agentsAmmonium perchlorate explosive compositionsInherent safetyPlasticizer

The invention provides a thermoplastic composite solid propellant applicable to a solid booster. The thermoplastic composite solid propellant is prepared from components in percentage by mass as follows: 55%-70% of an oxidant, 10%-20% of a thermoplastic resin adhesive, 10%-20% of a plasticizer, 5%-20% of metal fuel and 3%-8% of auxiliaries. According to the prepared thermoplastic composite solid propellant, relative independence of mixing and pouring, integrated formation of the propellant and secondary formation of engine charge can be realized according to temperature adjustment, and melt mixing and formation of the thermoplastic propellant can be realized at relatively low temperature lower than 90 DEG C, so that inherent safety of preparation of the thermoplastic propellant is greatlyimproved; compared with a traditional thermosetting propellant, crosslinking curing process is omitted, technological process is shortened, recovery and repeated processing of waste products can be realized, and production cost is reduced. The thermoplastic propellant is prepared with a hot melt mixing-cooling formation technology, and application of components absorbing moisture easily in the propellant is realized.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Explosive compositions

InactiveUS20060243362A1Low costGood explosive characteristicNon-explosive fillers/gelling/thickening agentsParticulatesSolvent

A pumpable watergel explosive composition comprises 10 to 40 wt %, based on the total weight of the pumpable explosive composition, of a continuous liquid phase comprising a solvent, a solubilized chemical sensitizer and a gelling agent and 60 to 90 wt %, based on the total weight of the pumpable explosive composition, of a discontinuous solid phase comprising particulate oxidizer salt particles having interstitial spaces between the salt particles. The watergel explosive composition has a density of 1.05-1.4 g / cc and, a shear thinning rheology such that, when subjected to an external force, the explosive composition has a viscosity sufficiently low to render the watergel explosive composition pumpable. The combination of density and low water content provides energy numbers normally associated with more expensive aluminized formulations.

Owner:ETI CANADA INC

Simulant material and method for manufacture thereof

InactiveUS7932089B2Simplified logisticsFast processingDefence devicesFirework simulationsExplosive materialParticulate material

A simulant material for simulating hazardous materials is provided. The simulant material includes a quantity of at least one explosive material and at least one inert material. The simulant material is a non-explosive material and is in the form of a homogenous, flexible and non-particulated material. Also provided is a method for manufacturing such a simulant material.

Owner:STATE OF ISRAEL MINIST OF AGRI & RURAL DEV AGRI RES ORG (A R O) (VOLCANI CENT)

Simultant Material and Method for Manufacture Thereof

InactiveUS20070281358A1Simplified logisticsFast processingDefence devicesFirework simulationsProcess engineeringExplosive material

A simulant material for simulating hazardous materials, comprising a quantity of at least one explosive material and at least one inert material. The simulant material is a non-explosive material and is in the form of a homogenous, flexible and non-particulated material. The invention is also concerned with a method for manufacturing such a stimulant material

Owner:STATE OF ISRAEL MINIST OF AGRI & RURAL DEV AGRI RES ORG (A R O) (VOLCANI CENT)

Nanoparticles prepared using carbon nanotube and preparation method therefor

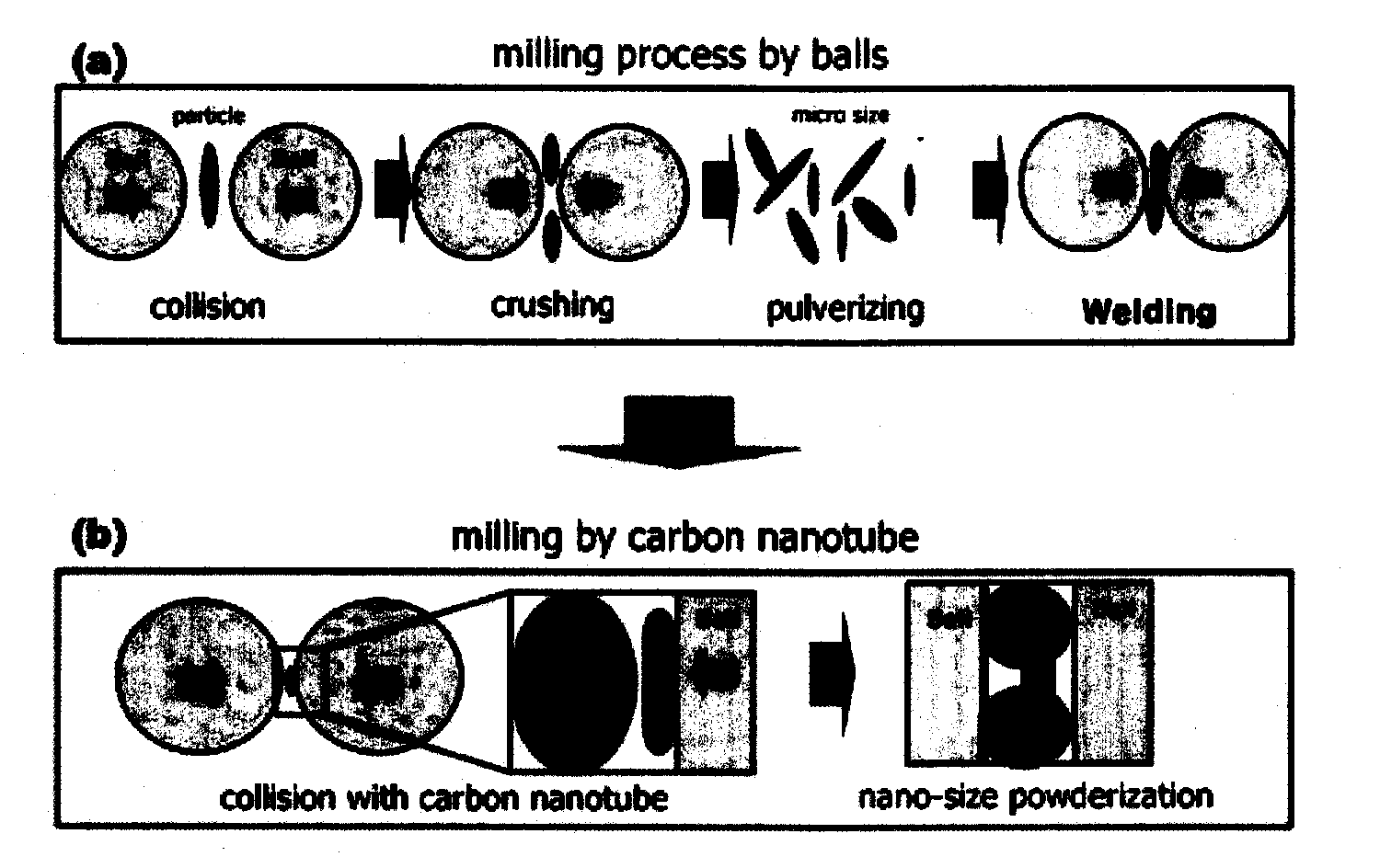

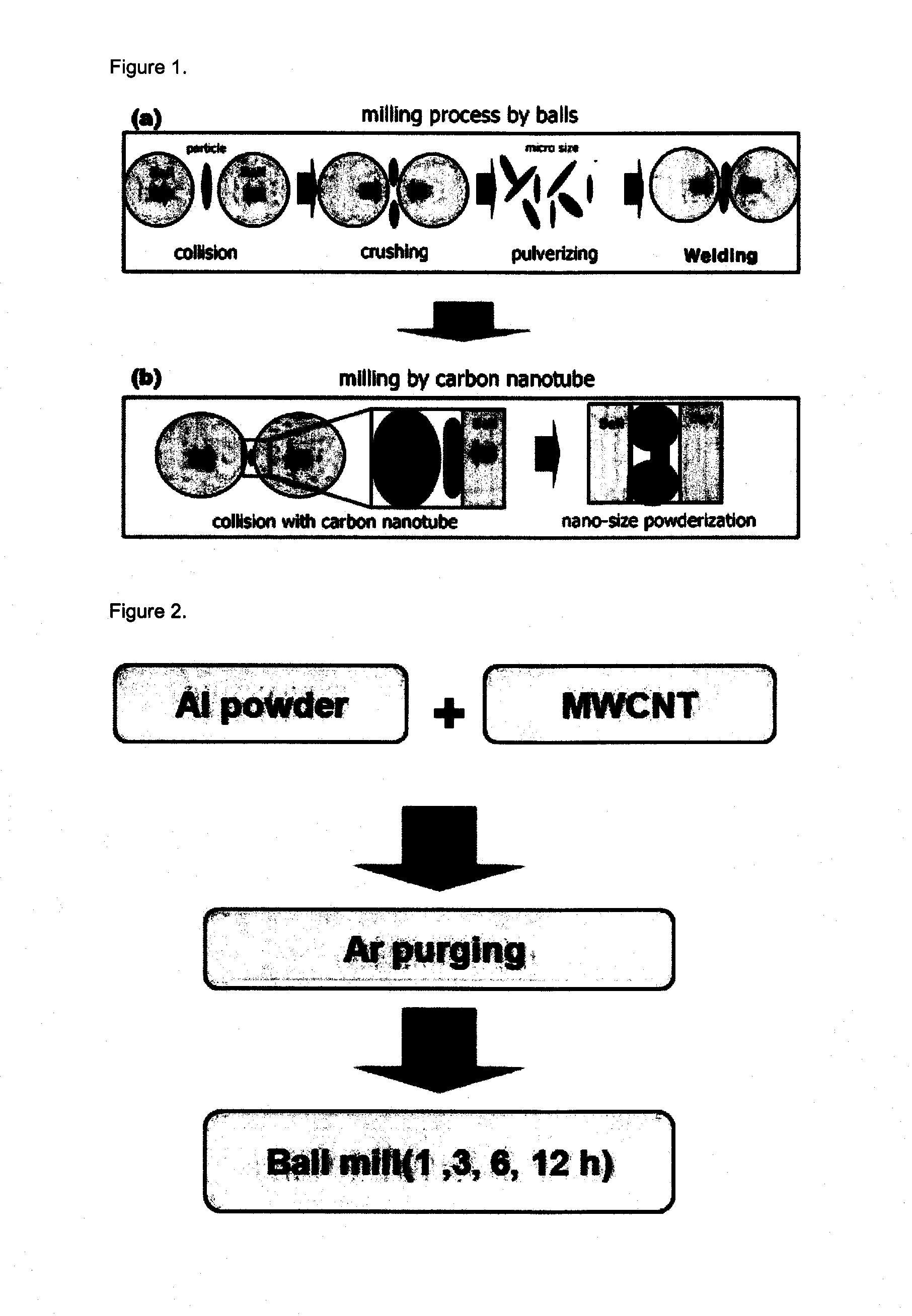

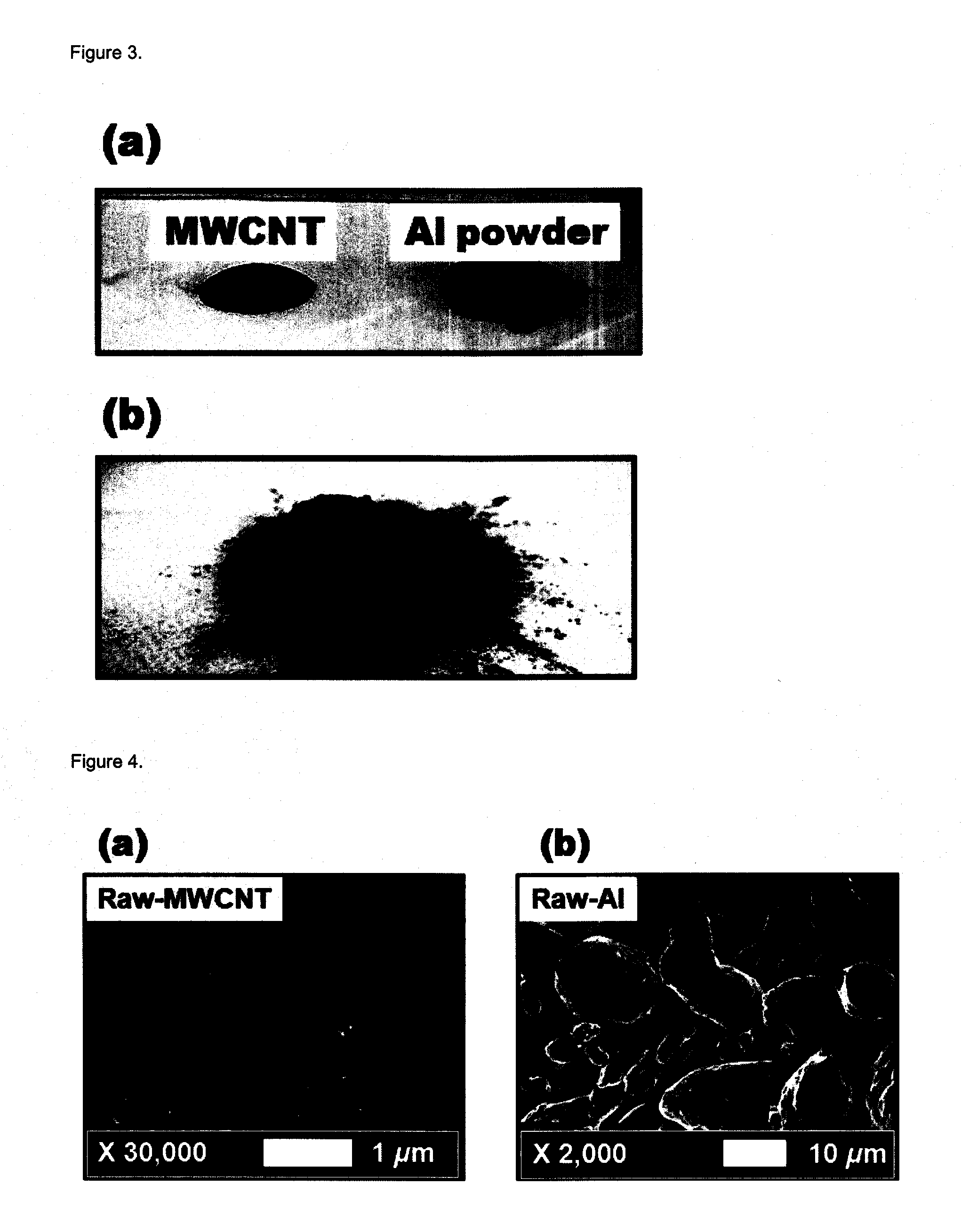

InactiveUS20110309311A1Lightness highlyHighly propertyMaterial nanotechnologyTransportation and packagingNanoparticleCarbon nanotube

Disclosed are a method for preparing a nanoparticle by using a carbon nanotube, and the nanoparticle prepared by the method. In the disclosed method, by using a carbon nanotube having a physically solid structure and a chemically solid bond, a powder particle made of metal, polymer, ceramic or the like is milled to a nano-size. Also, the nanoparticle prepared by the method has a small size and includes the carbon nanotube. Thus, when the method is applied to a highly oxidative metal, the nanoparticle can be applied to related fields requiring ignitability such as solid fuel, gunpowder, and the like. Also, the carbon nanotube has good mechanical properties and electrical conductivity, and thus can be applied to the related products.

Owner:RES & BUSINESS FOUND SUNGKYUNKWAN UNIV +1

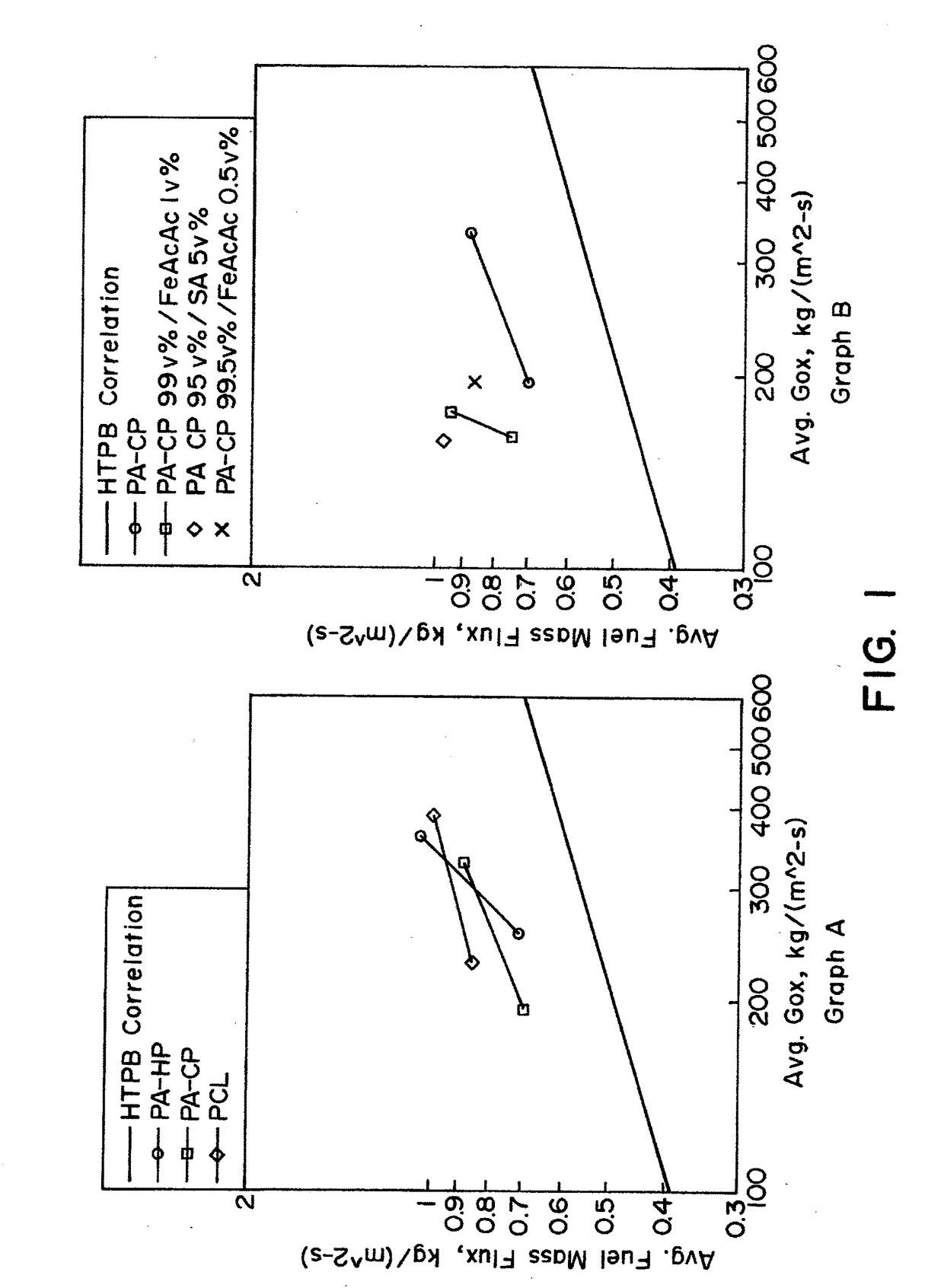

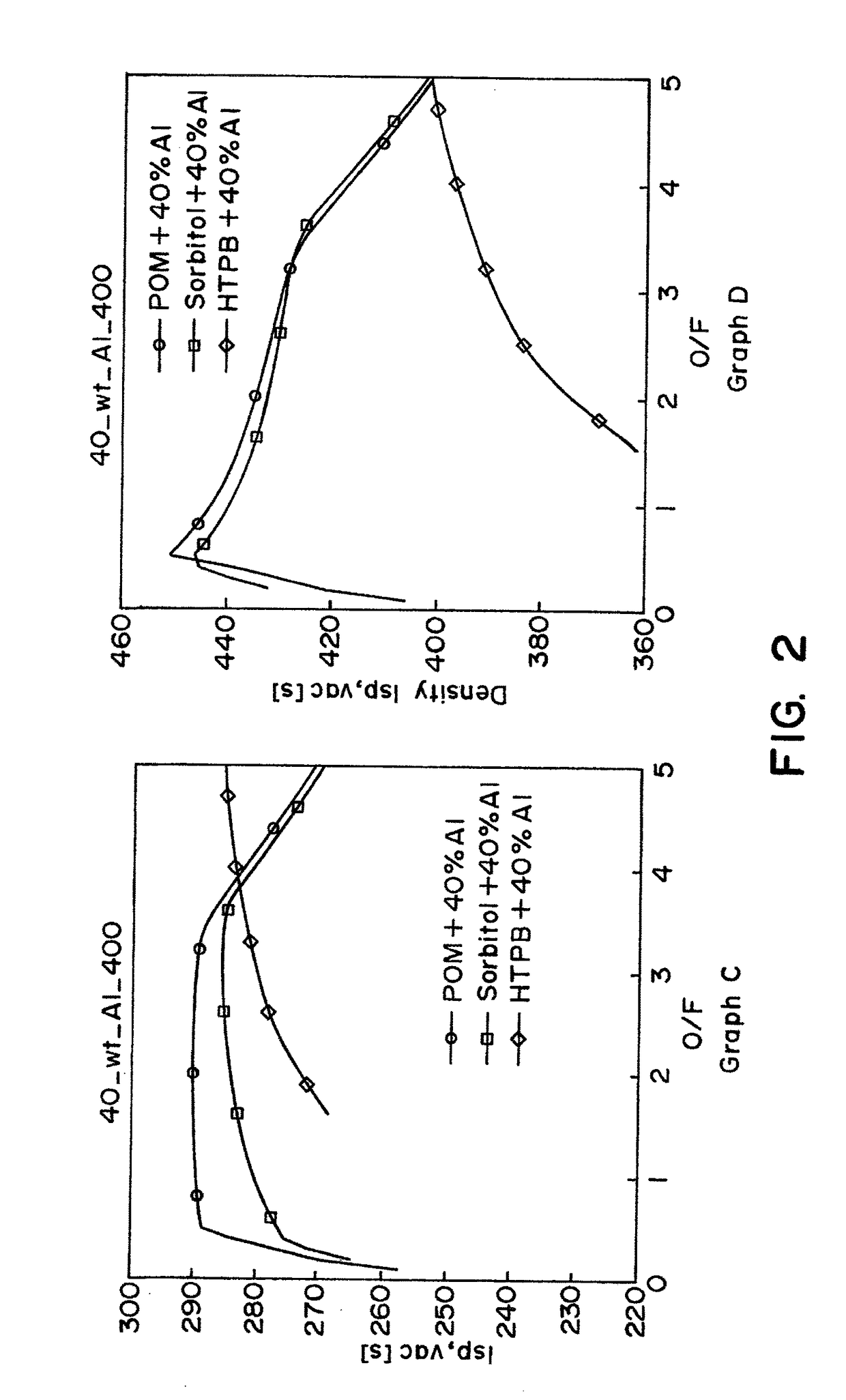

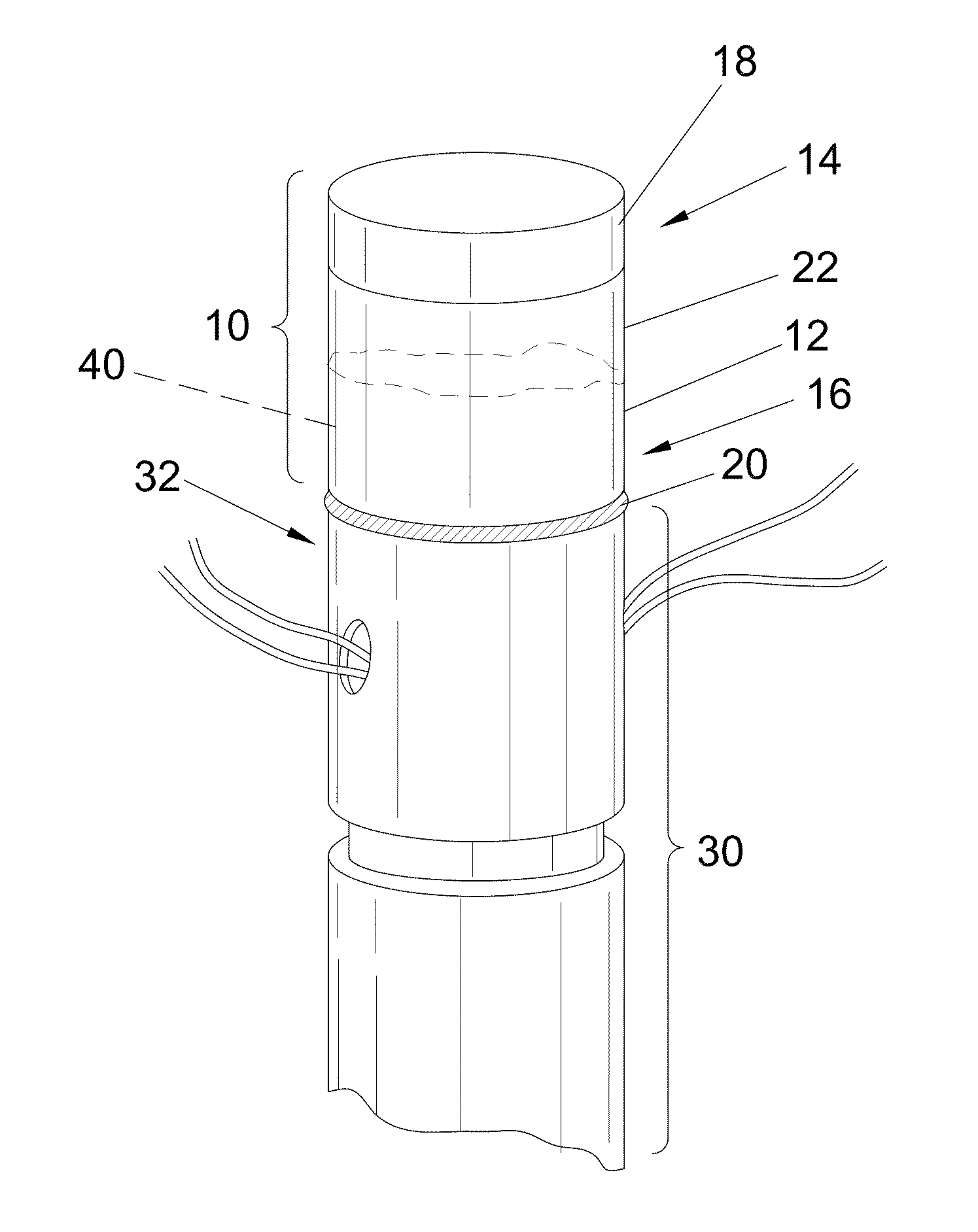

High Density Hybrid Rocket Motor

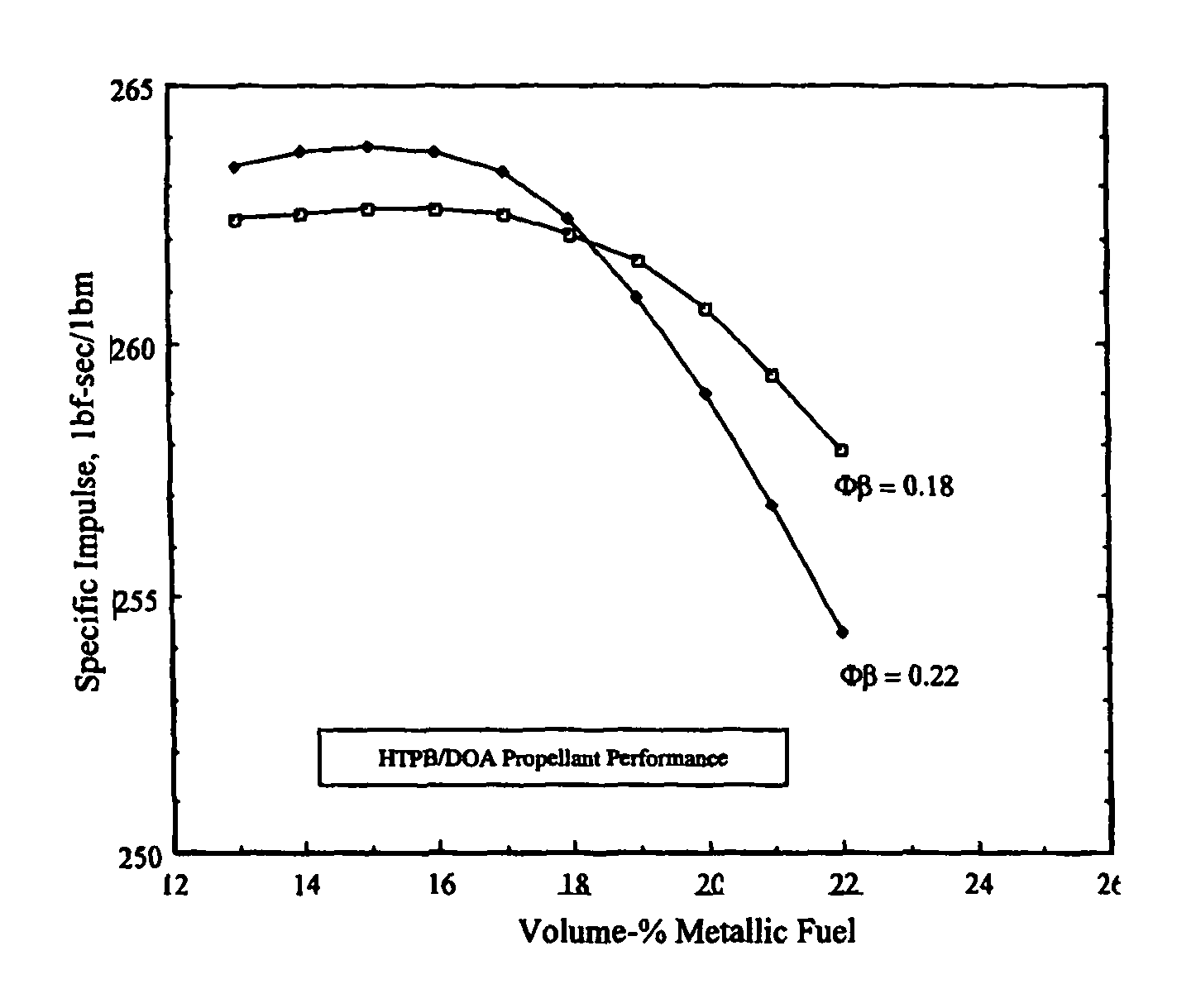

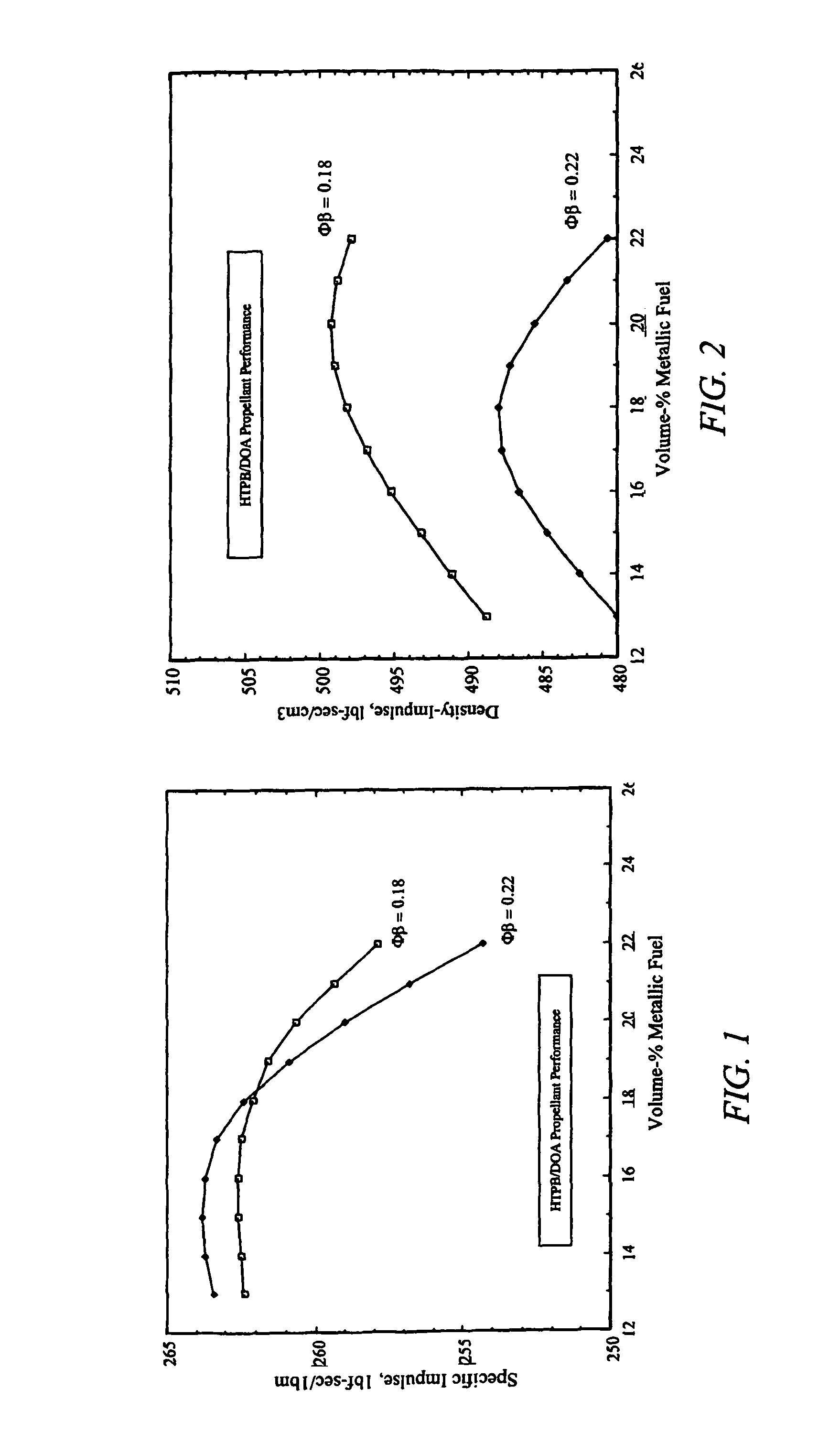

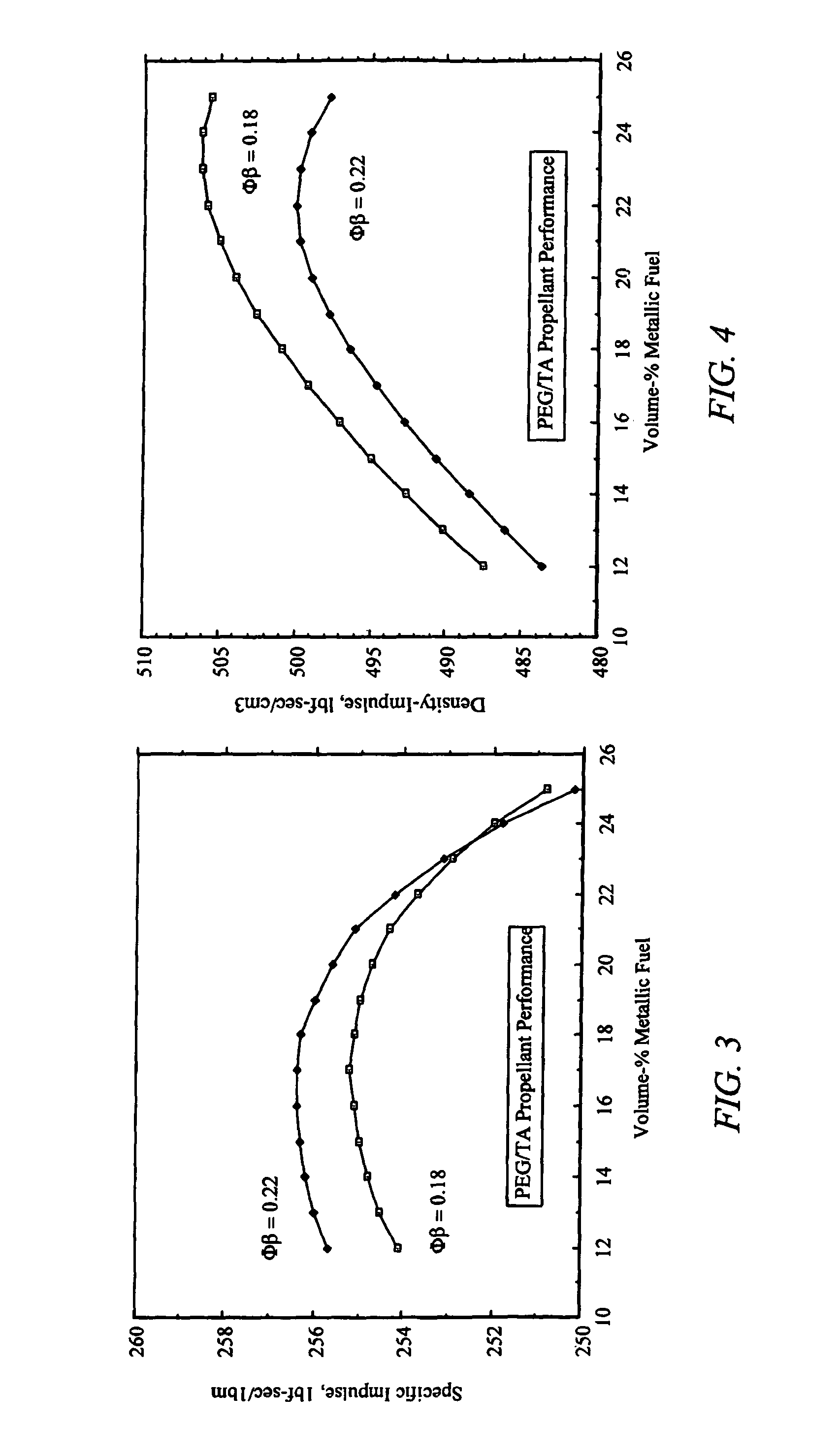

ActiveUS20180118634A1Increasing performance of volumeHigh regression rateNon-explosive stabilisersNon-explosive fillers/gelling/thickening agentsHigh densityVolumetric Mass Density

A high density, generally recognized as safe hybrid rocket motor is described which has a density-specific impulse similar to a solid rocket motor, with good performance approaching or equal to a liquid rocket motor. These high density hybrid motors resolve the packaging efficiency / effectiveness problems limiting the application of safe, low cost hybrid motor technology.

Owner:TERVES

Method for preparing nano metallized explosive

InactiveCN110343020ASolve the difficulty of mixing evenlyImprove energy release characteristicsNon-explosive fillers/gelling/thickening agentsPrillFluoropolymer

The invention discloses a method for preparing a nano metallized explosive. The method for preparingthe nano metallized explosivecomprises the following steps that nano metal powders, an explosive, afluoropolymer, and a binder are added into a mixing tank and sealed, then the mixing tank is placed on a vibration table,a power sourceis turned on, vibration frequency,amplitude, and vibration time are adjusted, mixing is conducted after a start button is activated, mixture of the nano metal powders, the explosive, the fluoropolymer, and the binder is completed according to a set mixing time to form a composite slurry, and a nanometalized explosive composite is obtained after drying. According to the method for preparingthe nano metallized explosive, in order to improve the energy release characteristics of metallized explosives, the nano metal powders and the fluoropolymer are used as fillers to improve capacity and pressure output;at the same time, for the high viscosity and easy agglomeration characteristics of the nano metal powders, the nano metallized explosive is prepared by adopting acoustic resonance mixing technology to achieve uniform mixing between the nano metal powder and explosive particles.

Owner:INST OF CHEM MATERIAL CHINA ACADEMY OF ENG PHYSICS

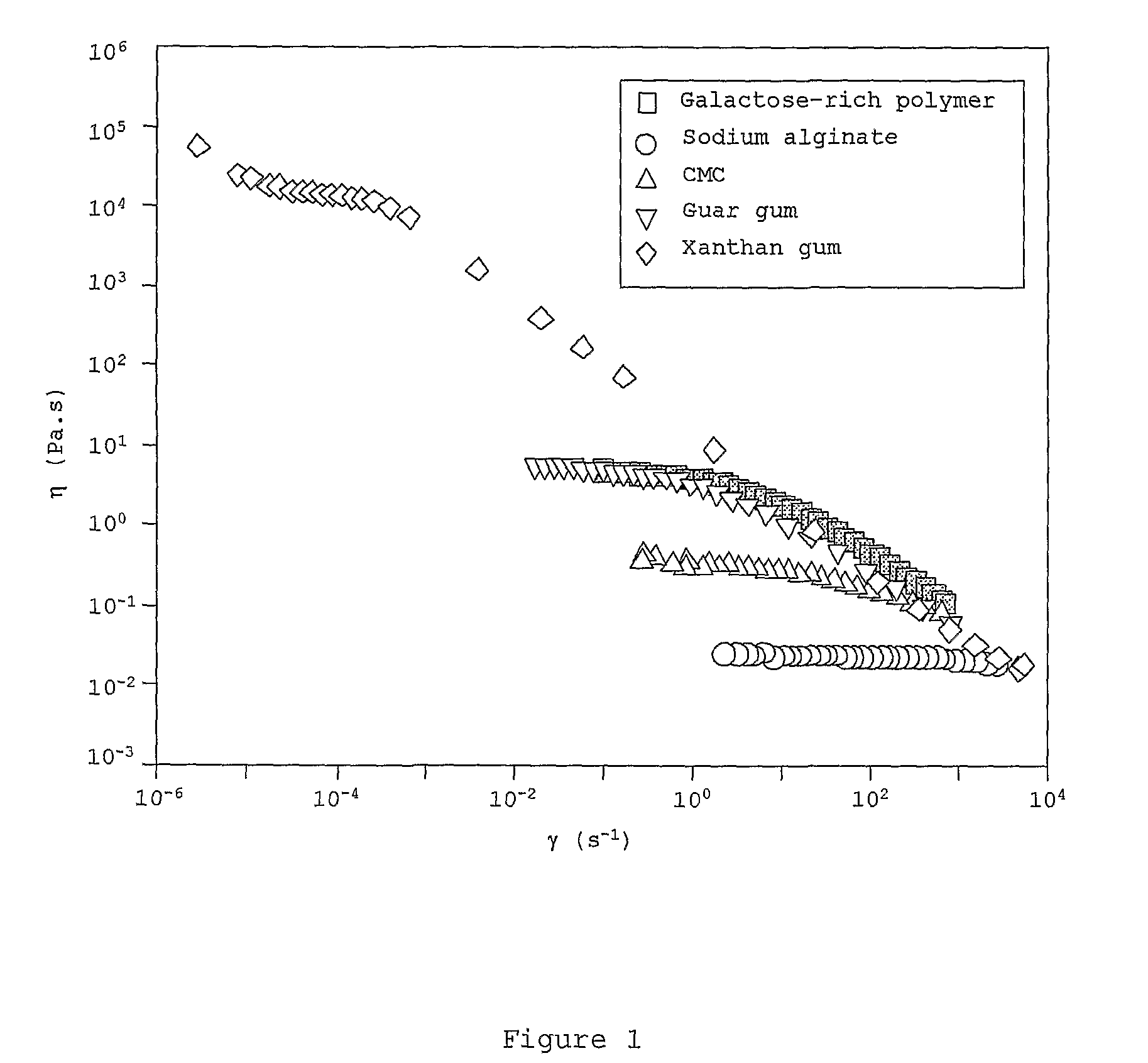

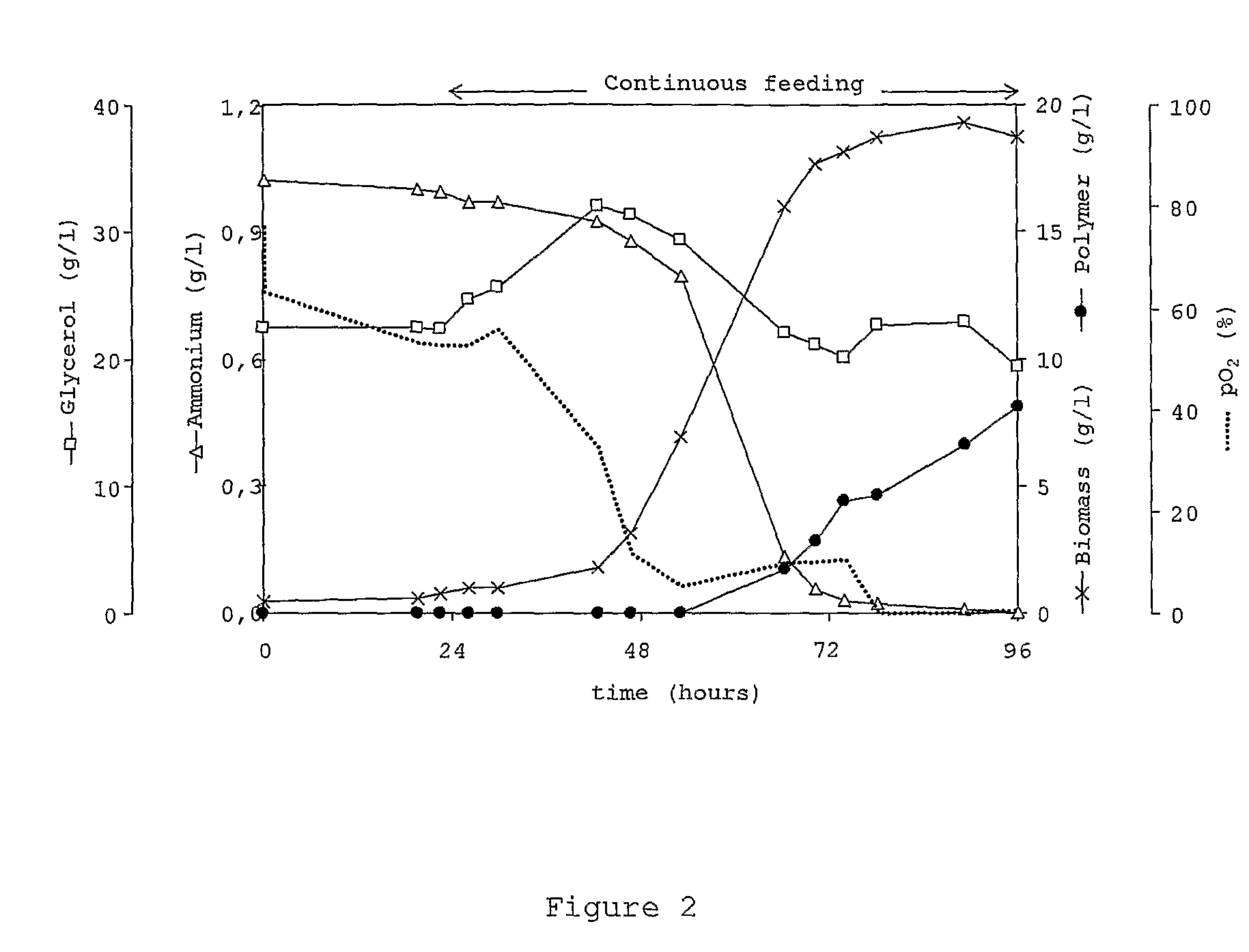

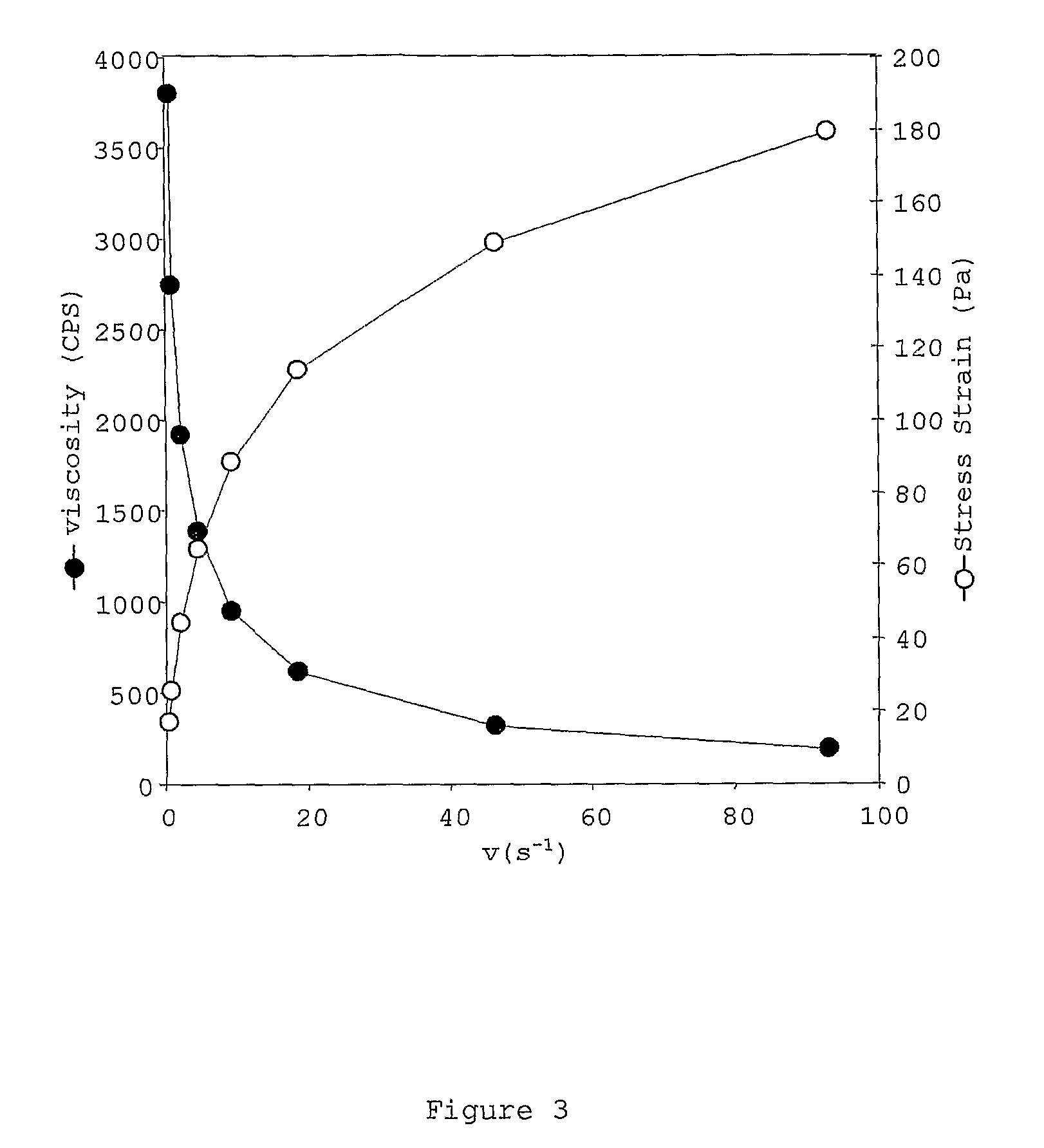

Galactose-rich polysaccharide, process for the production of the polymer and its applications

This invention concerns a biopolymer consisting of a polysaccharide composed of galactose (50-90%), glucose (1-25%), mannose (1-25%) and rhamnose (0.5-20%), which may additionally contain, in trace amounts, xylose, fucose, ribose, arabinose and / or fructose. The galactose-rich polymer also contains non-saccharide components, namely, acyl groups. This invention also concerns a process for the production of the galactose-rich polymer, by microbial fermentation using glycerol or glycerol-rich substrates as carbon source, and recovery of the polymer from the culture broth. From the process for the production of the galactose-rich polymer results the co-production of intracellular biopolymers, namely, polyhydroxyalkanoates. This invention also concerns to the application of the galactose-rich polymer and the products of its partial or complete degradation and / or derivatization, namely, galacto-oligosaccharides, galactose, rhamnose and others, by physical, chemical and / or biological methods, in food, agricultural, textile and paper industries, pharmaceutical and cosmetic products, oil and metal recovery in mining industry, industrial waste treatment and wastewater treatment, among others.

Owner:73100 SETENTA E TRES MIL E CEM LDA

Process For Producing Fine Diamond and Fine Diamond

InactiveUS20090285744A1Good electrical propertiesImprove mechanical propertiesMaterial nanotechnologyPolycrystalline material growthWear particleAliphatic hydrocarbon

The present invention relates to a process for producing a fine diamond characterized by that an explosive composition containing a compound having an aliphatic hydrocarbon ring with 4 to 15 carbons, a fullerenes or a tubular or fiber carbon nanostructure having a diameter of 1 to 100 nm as a carbon raw material is exploded for explosive synthesis, and a fine diamond obtained by said process; the ultrafine particulate diamond of 1 to 3 nm is expected, as a single nano diamond, for application of the fields such as ultrafine processing, the uniform, spherical fine particulate diamond of 0.01 to 100 μm is expected as abrasive grains for polishing in precise processing and the like, and the needle diamond is expected for application in various sensors and the like.

Owner:NIPPON KAYAKU CO LTD

Stabilized energetic water-in-oil emulsion composition

A stabilized water-in-oil energetic emulsion composition comprising a) an aqueous oxidizer phase comprising at least one oxygen supplying component; b) an organic phase comprising at least one organic fuel; c) an emulsifying amount of at least one emulsifying agent suitable for forming a water-in-oil emulsion; and d) an emulsion stabilizer comprising a hydrocarbon polymer, said hydrocarbon polymer having {overscore (M)}n ranging from about 2,000 to about 6,000, provided that said emulsion composition is essentially free of any polyvalent inorganic agent that is capable of cross-linking with the emulsifying agent or the emulsion stabilizer.

Owner:THE LUBRIZOL CORP

Systems and methods based on radiation induced heating or ignition of functionalized fullerenes

A method of irradiating a target region containing at least one fullerene comprising molecule promotes the heating or combustion of the target region. The heating method can be employed in a variety of applications including: selective targeting and destruction of cancer cells, detonation of explosives, ignition of a combustible mixture, photolithographic processes, and writing of optical storage media.

Owner:UNIV OF FLORIDA RES FOUNDATION INC

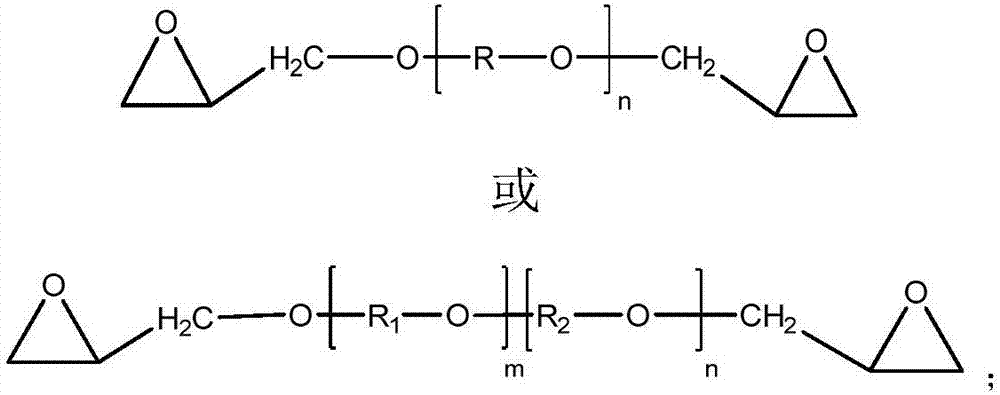

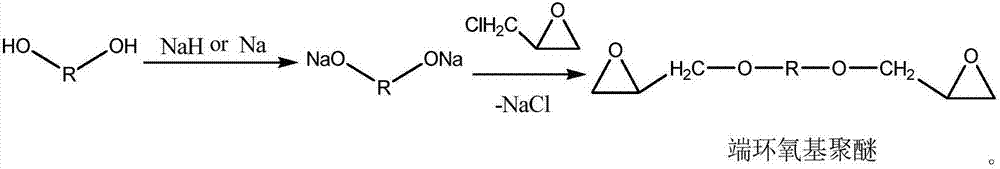

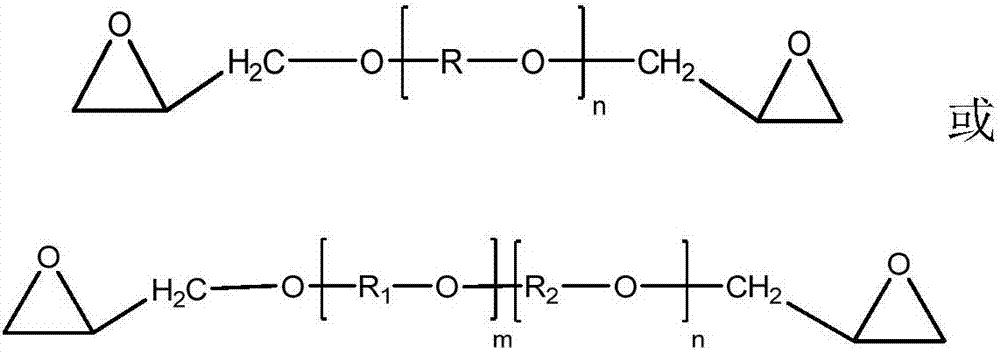

Epoxy-terminated polyether compound as well as preparation method and application thereof

ActiveCN106957423AImprove curing effectMechanical property adjustmentNon-explosive fillers/gelling/thickening agentsPressure gas generationEpoxyAdhesive

The invention relates to an epoxy-terminated polyether compound as well as a preparation method and application thereof and belongs to the field of solid propellants. The compound comprises two epoxy-terminated groups; the preparation method of the epoxy-terminated polyether compound comprises the following steps: taking polyether diol and metal sodium or sodium hydride to react to generate polyether diol sodium; continually taking the polyether diol sodium and epoxy chloropropane to react and removing sodium chloride, so as to synthesize epoxy-terminated polyether. The epoxy-terminated polyether compound keeps good structure and performance of a traditional adhesive and is not sensitive to impurities including water and the like; meanwhile, the epoxy-terminated polyether compound has chemical inertness on novel energy-containing materials including ADN (Ammonium Dinitramide), CL-20, AlH3 and the like and good compatibility; after the compound is solidified, a propellant medicine block has no air pores and relatively good mechanical properties. The preparation method of the epoxy-terminated polyether compound is simple and feasible; a catalyst is not needed and an intermediate does not need to be separated; the epoxy value of the product is easy to control and large-scale production is convenient to realize.

Owner:HUBEI INST OF AEROSPACE CHEMOTECHNOLOGY

Systems and methods for chemical and/or mechanical remediation of nitro compounds and nitrate esters

ActiveUS8585841B2Reduce the likelihood of an explosionReduce the possibilityAmmunition projectilesNon-explosive fillers/gelling/thickening agentsNitro compoundReagent

Owner:MAXAMCORP HLDG SL

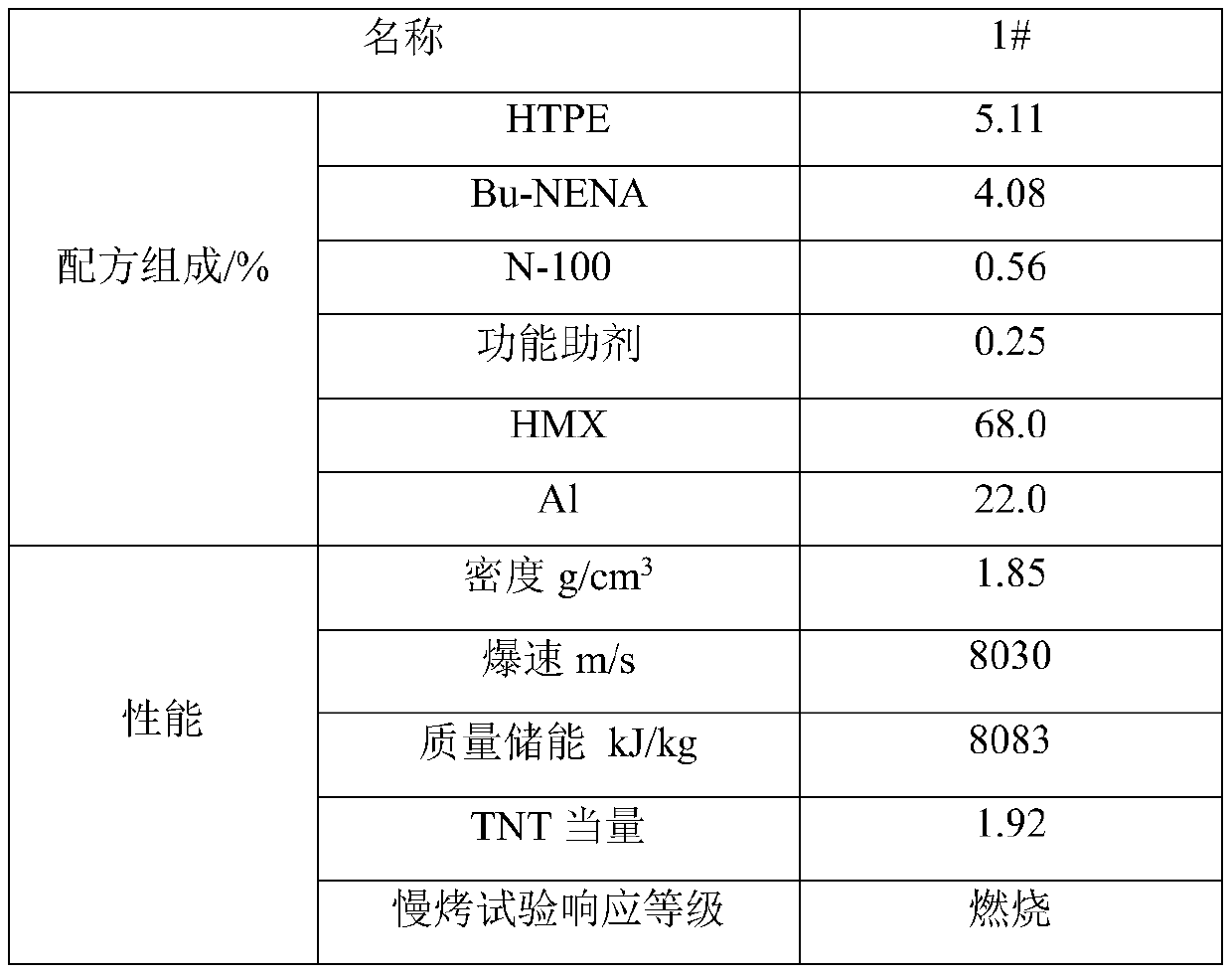

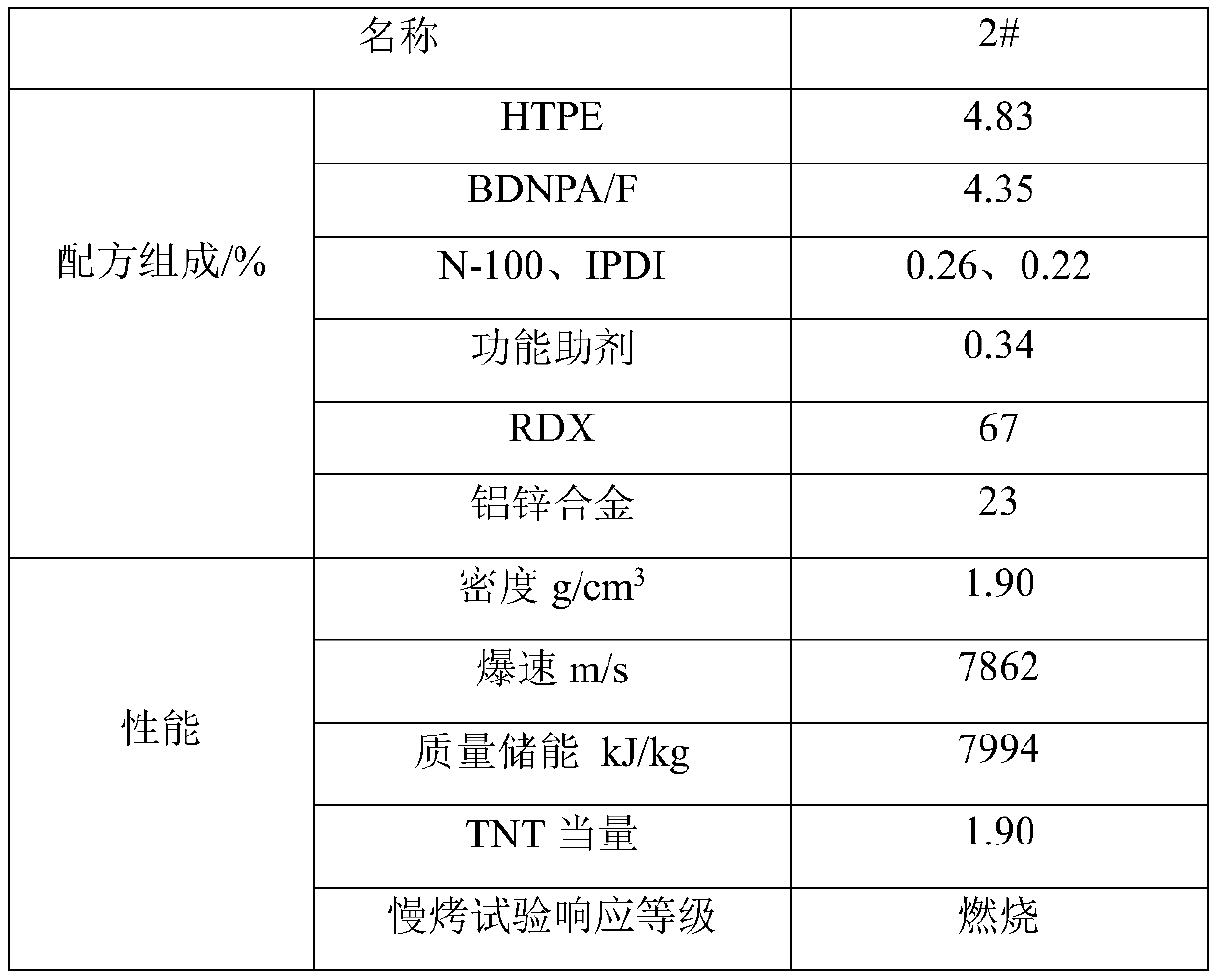

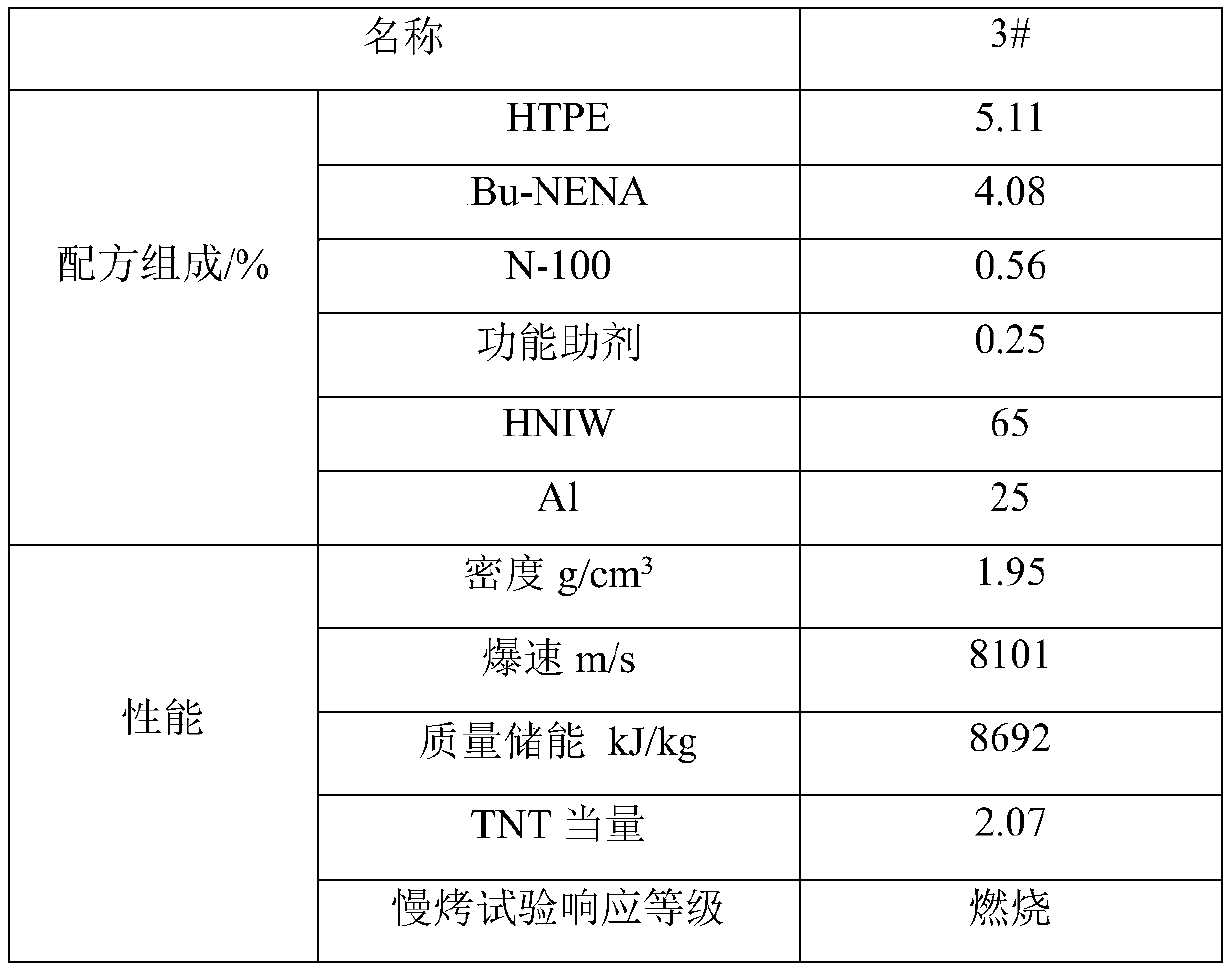

Pouring-type high-energy insensitive explosive and preparation method thereof

ActiveCN110156548AImprove energy characteristicsIncrease energy outputNon-explosive fillers/gelling/thickening agentsAdhesiveHigh energy

The invention relates to a pouring-type high-energy insensitive explosive and a preparation method thereof. In order to solve the problem of a low energy level of traditional butylated hydroxy castingPBX explosives, an energy-containing adhesive and an energy-containing plasticizer are introduced as a binder system, and through addition of high-energy explosives and metal fuel components, the prepared pouring-type PBX explosive has high energy characteristics; the explosive formula has a density greater than 1.85 g / cm<3>, the detonation velocity is greater than 7800 m / s, and the explosive power is that of 1.9 times or above the TNT equivalent; and at the same time, the explosive formula has good low-vulnerability, and especially has mild reactions in slow-speed burning tests, and the reaction level does not exceed a detonation level.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Piece of ammunition or ammunition component comprising a structural energetic material

InactiveUS20060225599A1Possible to produceAmmunition projectilesShotgun ammunitionEngineeringEnergetic material

The invention relates to a piece of ammunition or ammunition component comprising a pyrotechnic load associated with a structure, such as a casing. This ammunition is characterized in that part at least of its structure is made of an energetic material comprising at least one energetic component mixed with at least a first structural reinforcement material.

Owner:GIAT INDS SA

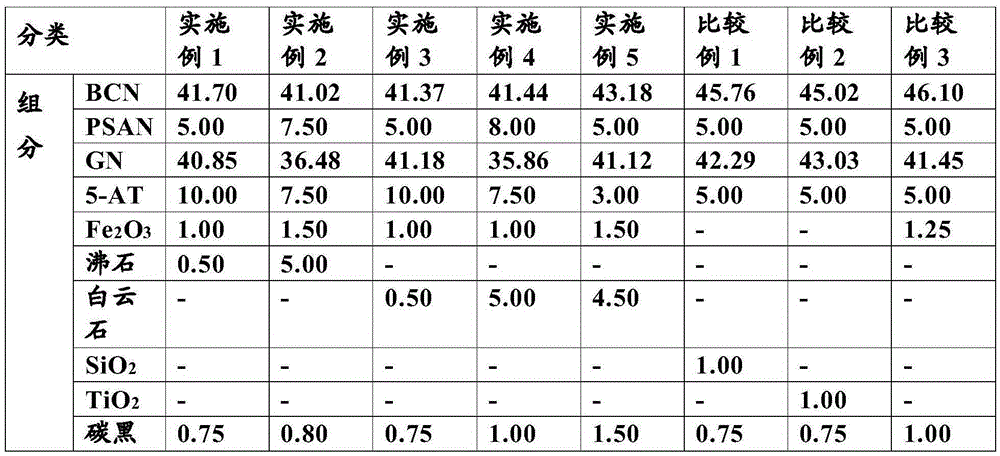

Gas generating agent composition having reduced solid discharge amount of inflator

InactiveCN105358507AThe overall thickness is thinReduce weightNon-explosive fillers/gelling/thickening agentsPedestrian/occupant safety arrangementCombustionSlag

A gas generating agent for an inflator is an explosive composition required for expanding an airbag to protect passengers when a car accident occurs. An electrical signal detected by a sensor due to a car crash may cause the ignition and combustion of an igniter, an ignition charge, and a gas generating agent of the inflator in order. Gases and a high-temperature melting compound generated by the combustion of the gas generating agent are cooled and filtered through a filter to expand the airbag. In order for the high-temperature melting compound to be effectively cooled and filtered through the filter, the high-temperature melting compound must be converted into slag. In the present invention, by converting the high-temperature melting compound into the slag by using zeolite [Na4Al4Si4O25H18] or dolomite [CaMg(CO3)2] as a slag forming agent, and allowing an amount of combustion residuals discharged into the interior of the airbag during the operation of the inflator to be equal to or less than 1g, which is a standard value specified in USCAR-24, damage to the airbag can be prevented and passengers can be effectively protected.

Owner:株式会社三松

Systems and methods for chemical and/or mechanical remediation of nitro compounds and nitrate esters

ActiveUS20110041718A1Reduce the likelihood of an explosionReduce the possibilityAmmunition projectilesNon-explosive fillers/gelling/thickening agentsNitro compoundCompound (substance)

Systems and methods for chemoremediation or mechanical destruction of undetonated explosive materials. An explosive apparatus contains an explosive material in close proximity to a chemical reagent selected for its chemoremediative properties. A barrier is interposed between the explosive material and the chemical reagent to delay the chemoremediation of the explosive material.Alternatively a water expandable material may be incorporated into the explosive material, whereby upon exposure to moisture the water absorbing material will expand sufficiently to fragment the explosive material into initiation insensitive particles. Initiation insensitivity is achieved by incorporation of water, which acts as a desensitizing agent as well as fragmenting the explosive material into particles sufficiently small that they are below the critical diameter for explosive initiation.The present invention also relates to self-degradable, shaped explosive formulations, comprising an explosive material and a water expandable material.

Owner:MAXAMCORP HLDG SL

Ethanol based gel fuel for a hybrid rocket engine

InactiveUS8101032B1Improve propertiesLow costNon-explosive fillers/gelling/thickening agentsLoomsCross-linkCost effectiveness

A cost-effective, renewable ethanol-based solid fuel compound, and method of making the fuel for hybrid rocket engines. Gelling agents, preferably methylcellulose can be used in conjunction with calcium acetate or calcium acetate alone make a stiff plastic out of ethanol to improve its properties for hybrid rocket engine. The increased stiffness of an ethanol-based fuel gel, increases yield stress that allows rapid acceleration of rockets. The low cost bio-fuel based on solidified ethanol rather than expensive petroleum derived substances lowers the cost of volume rocket launches, lowers the cost of access to orbit and provides safer sounding rocket flights into space. The resulting raw gel can further be mixed with a cross linking compound and water to form a stiffer material. Alternatively, the resulting raw gel can be frozen by liquid nitrogen.

Owner:UNIV OF CENT FLORIDA RES FOUND INC

Electrically ignitable caseless propellant charge, the production and use thereof

InactiveUS20160046536A1Improve liquidityGood storage stabilityNon-explosive fillers/gelling/thickening agentsNitrocellulose explosive compositionsElectricityNitrocellulose

Electrically ignitable caseless propellant charge in the form of a caseless propellant tablet (5), characterised in that it is obtainable by mixing together of at least one current-conductive material in dissolved or dispersed form or powder form and graphite in powder form, together with nitrocellulose, with or without addition of further additives, and subsequent compaction to form a propellant tablet, the production and use thereof, and related subject matter of the invention. Uses include: use of the propellant charge in a bolt-driving tool for installing bolts, as an explosive charge in a warning shot device, as a gas-generating element in airbags, for driving cutting devices, for driving pressing devices (for example for squeezing tong-like elements together) or as a propellant charge in small calibre rifles for sporting purposes, or for captive bolt devices for animal slaughtering.

Owner:FISCHERWERKE ARTUR FISCHER GMBH & CO KG

Gas generating composition

InactiveUS20060191614A1Non-explosive fillers/gelling/thickening agentsPressure gas generationO-Phosphoric AcidCompound (substance)

The present invention provides a gas generating composition comprising: (a) a fuel; (b) an oxidizer; and (c) a compound selected from the group consisting of a double salt of phosphoric acid.

Owner:DAICEL CHEM IND LTD

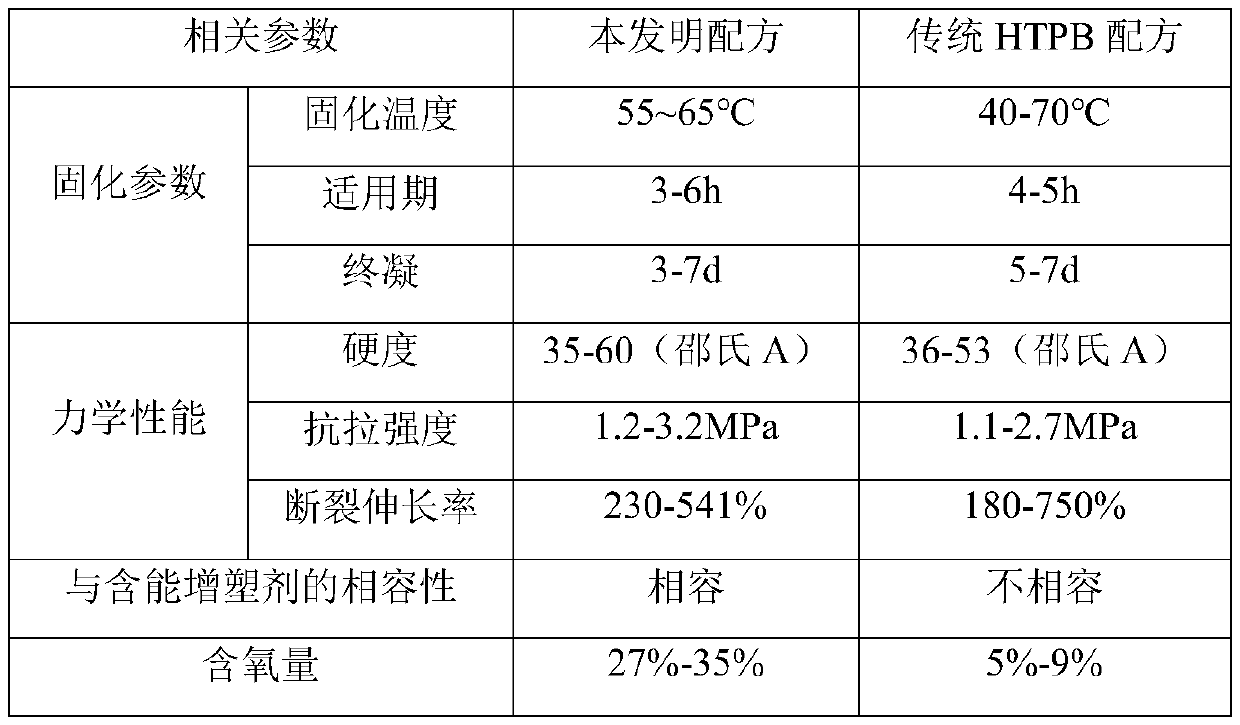

Adhesive system suitable for insensitive munitions and preparation method

InactiveCN110304977AIncrease oxygen contentReduce dosageNon-explosive fillers/gelling/thickening agentsPolyolPlasticizer

The invention provides an adhesive system suitable for insensitive munitions and a preparation method. The adhesive system is prepared by, by weight, 40-50 parts of polyol, 30-60 parts of energetic plasticizer, 5-10 parts of polyisocyanate, 0.0002-0.001 part of catalyst. During preparation, raw material preprocessing including the rotary evaporation dewatering of the polyol and the energetic plasticizer and raw material preheating is performed during preparation, the polyol and the energetic plasticizer are then premixed, and a curing agent is added finally and sufficient and uniform mixing isperformed to perform curing at 55-65 DEG C for 4-7 days. Compared with a traditional hydroxyl-terminated polybutadiene-based (HTPB-based) adhesive system, the adhesive system is high in oxygen content, good in compatibility with the energetic plasticizer, and capable of evidently increasing the energy output of an explosive system; the adhesive system is mild in reaction under a heat stimulationcondition and melts and expand when being heated to break through a munition shell, explosion possibility under the heat stimulation condition is lowered, and munition insensitivity is increased.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com