Adhesive system suitable for insensitive munitions and preparation method

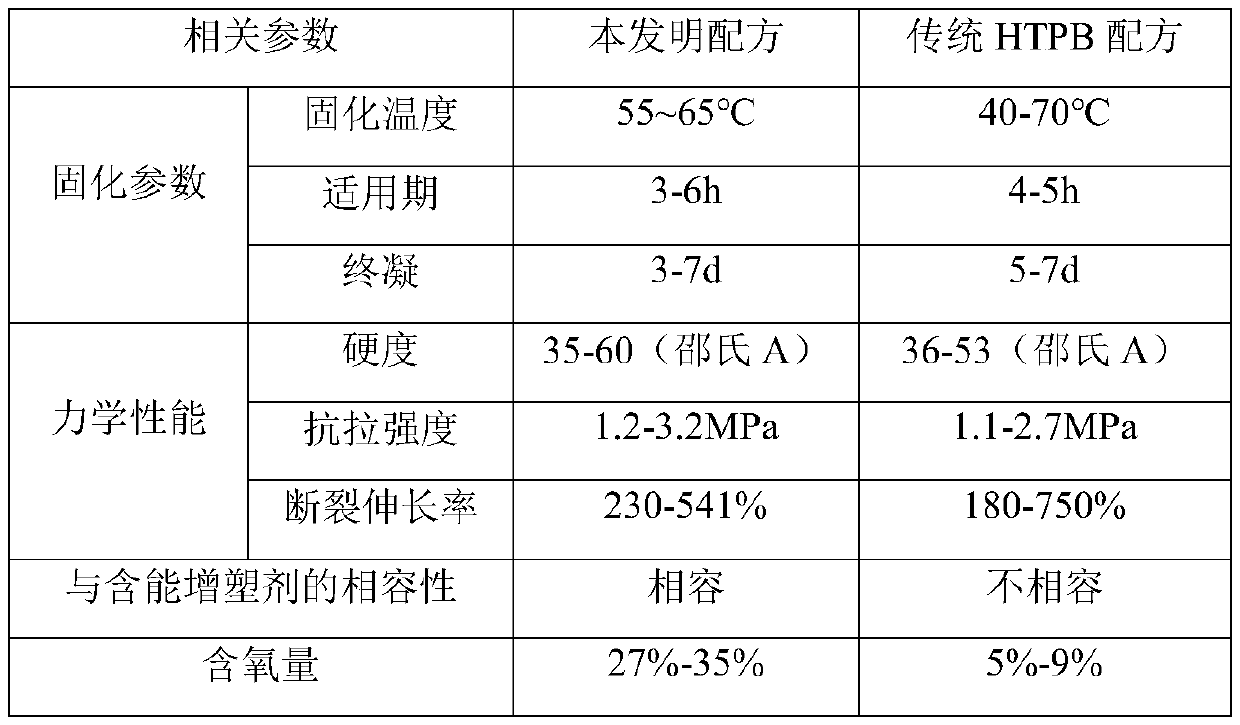

A binder and system technology, applied in the direction of non-explosive/non-thermal agent components, non-explosive fillers/gelling agents/thickeners, explosives, etc., can solve the problem of affecting the energy output of the ammunition system, reducing ammunition sensitivity, ammunition energy, etc. reduce problems, achieve the effect of increasing dosage, improving insensitivity, and increasing energy output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A suitable insensitive ammunition binder system, consisting of the following raw materials by weight: 30g of hydroxyl-terminated block copolyether HTPE, 3.6g of multifunctional isocyanate N-100, 25g of butyl nitrate ethyl nitramine Bu-NENA, catalyst Dibutyltin Dilaurate T 12 Appropriate amount.

[0027] A preparation method suitable for insensitive ammunition binder system:

[0028] (1) Raw material pretreatment. The hydroxyl-terminated polyether and butyl nitrate ethyl nitramine were respectively placed in a rotary evaporator, the temperature was controlled at 80 °C, the vacuum degree was below 0 MPa, the rotary evaporator speed was adjusted to 60 rpm, and the rotary evaporator was 2 hours. Preheat the dehydrated hydroxyl-terminated polyether, butyl nitrate ethyl nitramine, and curing agent multifunctional isocyanate in an oven at 45°C for later use.

[0029] (2) Suitable for the preparation of insensitive ammunition binder system. Accurately weigh the pretreated h...

Embodiment 2

[0031] A binder system suitable for insensitive ammunition, consisting of the following raw materials by weight: 30g of hydroxyl-terminated block copolyether HTPE, 1.98g of multifunctional isocyanate N-100, 1.15g of isophorone diisocyanate IPDI, bis(2, 2 dinitropropanol) acetal / bis(2,2 dinitropropanol) formal BDNPA / BDNPF 20g, catalyst tris-(ethoxyphenyl bismuth)TEPB appropriate amount.

[0032] A preparation method suitable for insensitive ammunition binder system:

[0033] (1) Raw material pretreatment. Put hydroxyl-terminated polyether and bis(2,2-dinitropropanol) acetal / bis(2,2-dinitropropanol) formal in a rotary evaporator, control the temperature at 85°C and vacuum to -0.05MPa, adjust the rotating speed to 60rpm, and rotate for 2h. The dehydration-treated hydroxyl-terminated polyether and bis(2,2 dinitropropanol) acetal / bis(2,2 dinitropropanol) formal and curing agent multifunctional isocyanate and isophor Ketone diisocyanate was preheated in an oven at 50°C and set as...

Embodiment 3

[0036] An adhesive system suitable for insensitive ammunition, consisting of the following raw materials: 30g of hydroxyl-terminated block copolyether HTPE, 3.6g of multifunctional isocyanate N-100, 25g of diethylene glycol dinitrate DEGDN, catalyst three - (ethoxyphenyl bismuth) TEPB qs.

[0037] A preparation method suitable for insensitive ammunition binder system:

[0038] (1) Raw material pretreatment. The hydroxyl-terminated polyether and diethylene glycol dinitrate were respectively placed in a rotary evaporator, the temperature was controlled at 80°C, the vacuum degree was -0.05MPa, the rotational speed of the rotary evaporator was adjusted to 70rpm, and the rotary evaporator was 2h. Preheat the dehydration-treated hydroxyl-terminated polyether, diethylene glycol dinitrate, and curing agent multifunctional isocyanate in an oven at 50°C for later use.

[0039](2) Suitable for the preparation of insensitive ammunition binder system. Accurately weigh the pretreated hyd...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com