Patents

Literature

82results about How to "Avoid Oil Leakage Problems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

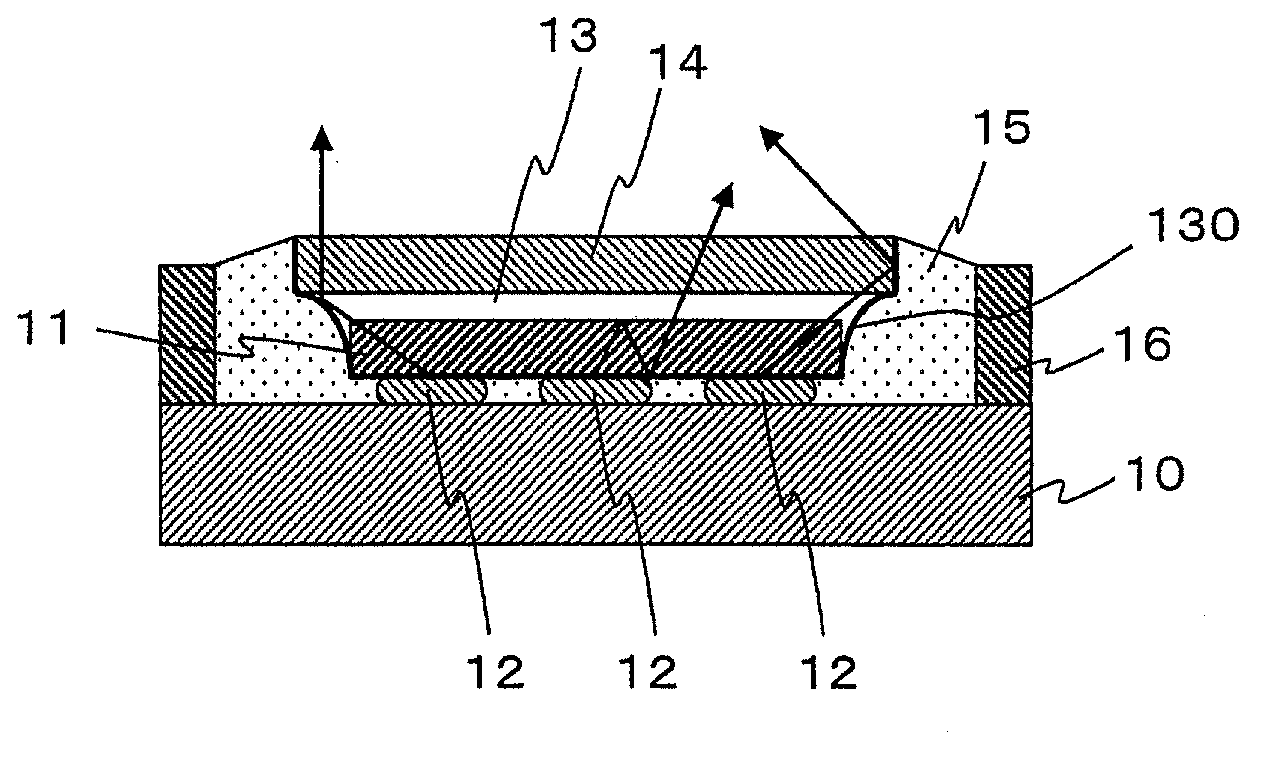

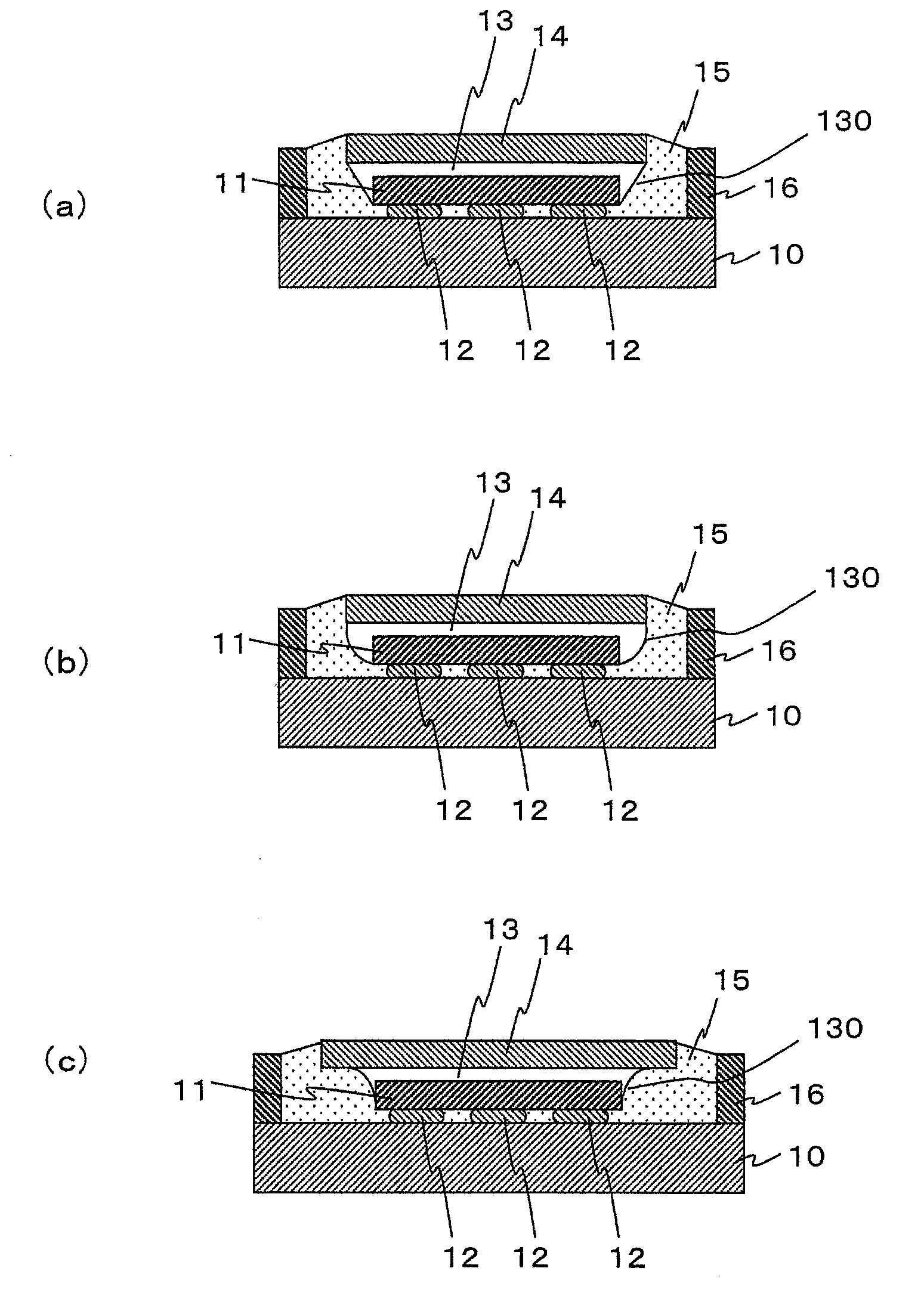

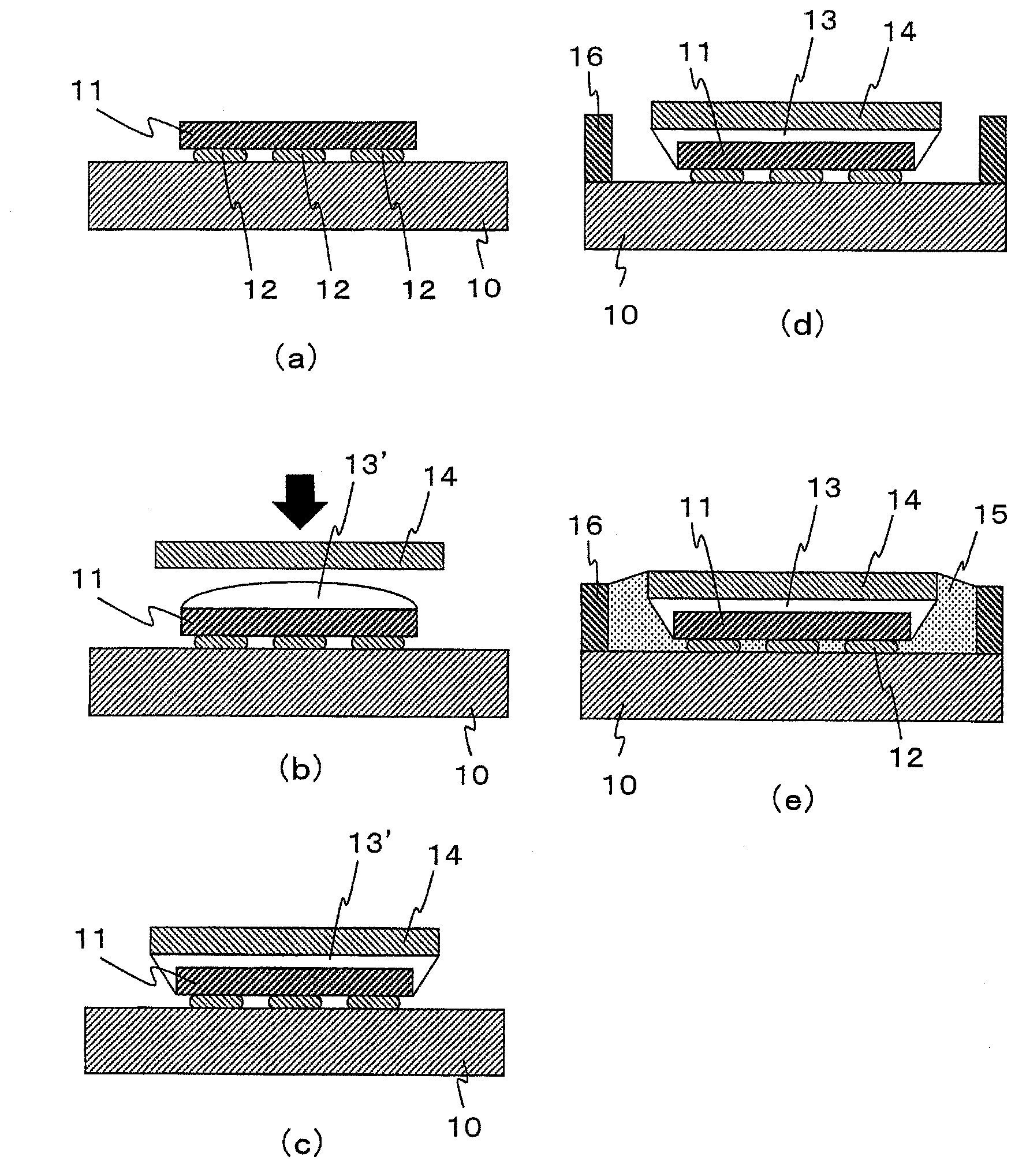

Light emitting device and method for manufacturing the same

InactiveCN102916118AImprove removal efficiencyAvoid Oil Leakage ProblemsSolid-state devicesSemiconductor devicesAlkali metal oxideLight emitting device

The invention provides a light emitting device and method for manufacturing the same. There is provided a method for producing a light emitting device having a small light emitting area and showing high light extraction efficiency. An uncured resin (13) is dropped on either one or both of a light emitting element (11) and a tabular member (14) in such an amount that the resin is maintained on them by surface tension, the light emitting element (11) and the tabular member (14) are piled up with the uncured resin (13) maintained between them and on a side of the light emitting element by surface tension of the uncured resin (13) to form an uncured resin layer (13) having an inclined side 130, and then the resin layer (13) is cured. The tabular member is constituted with a material having an alkali metal oxide content of 0.2% by weight or lower.

Owner:STANLEY ELECTRIC CO LTD

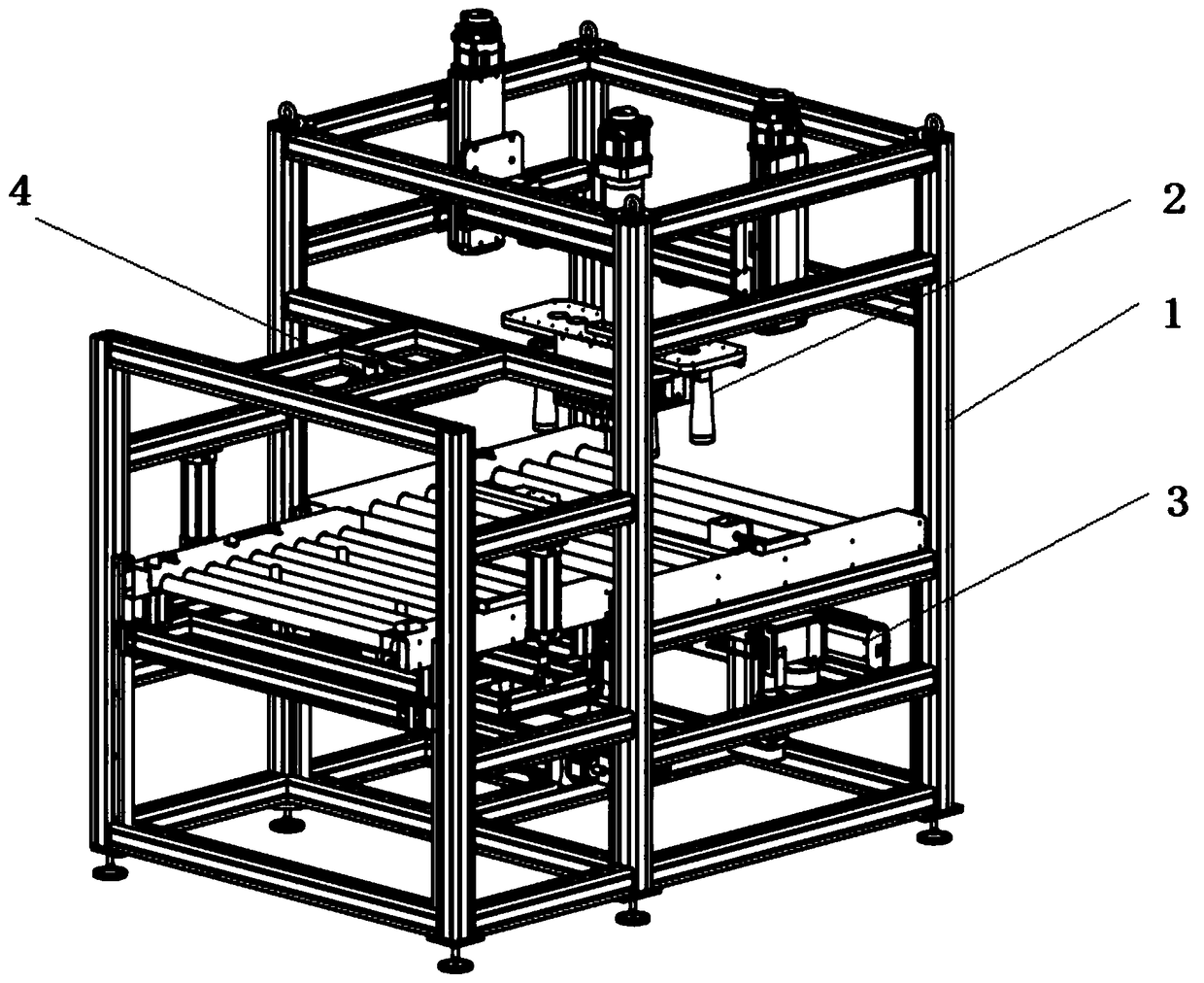

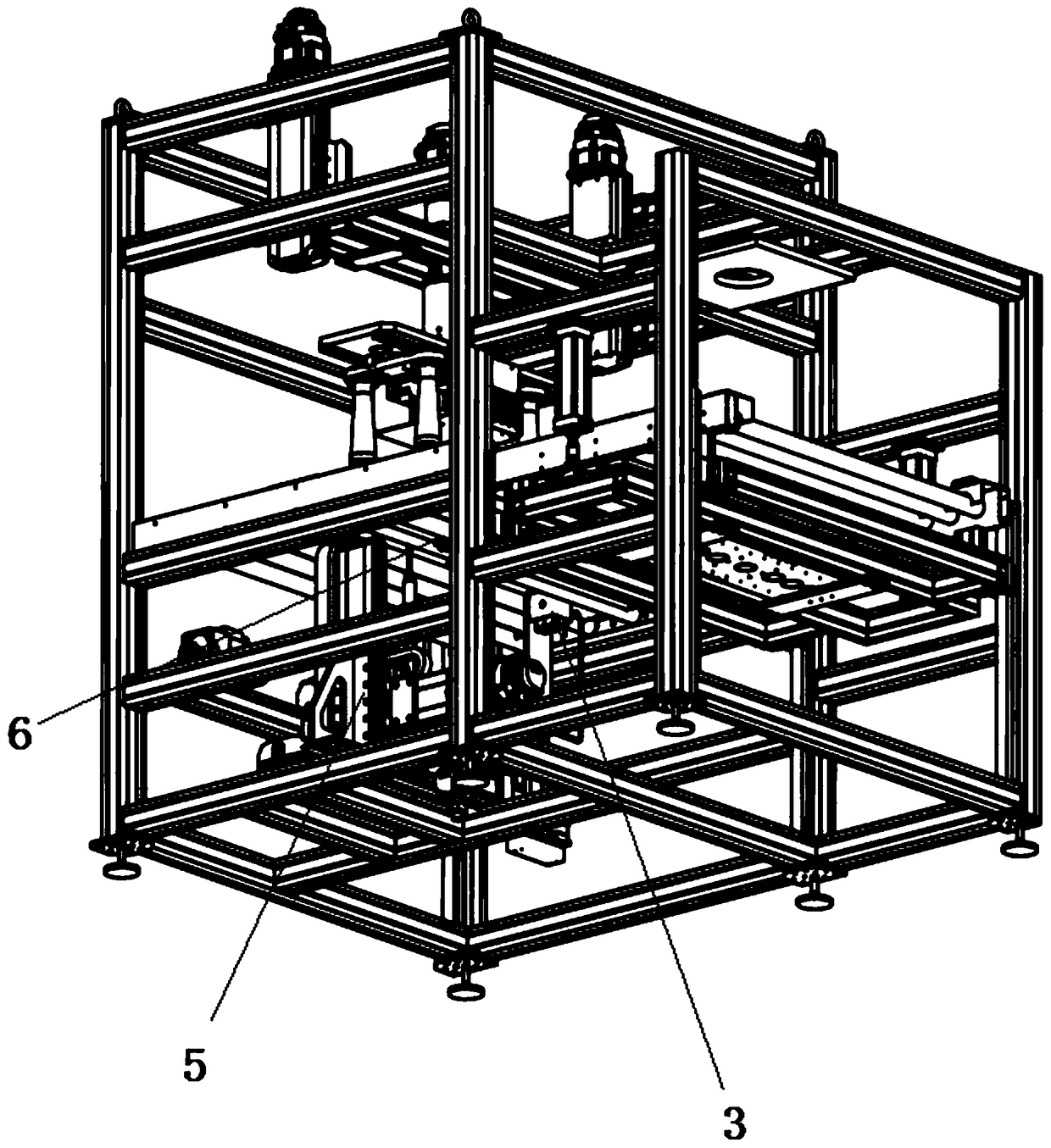

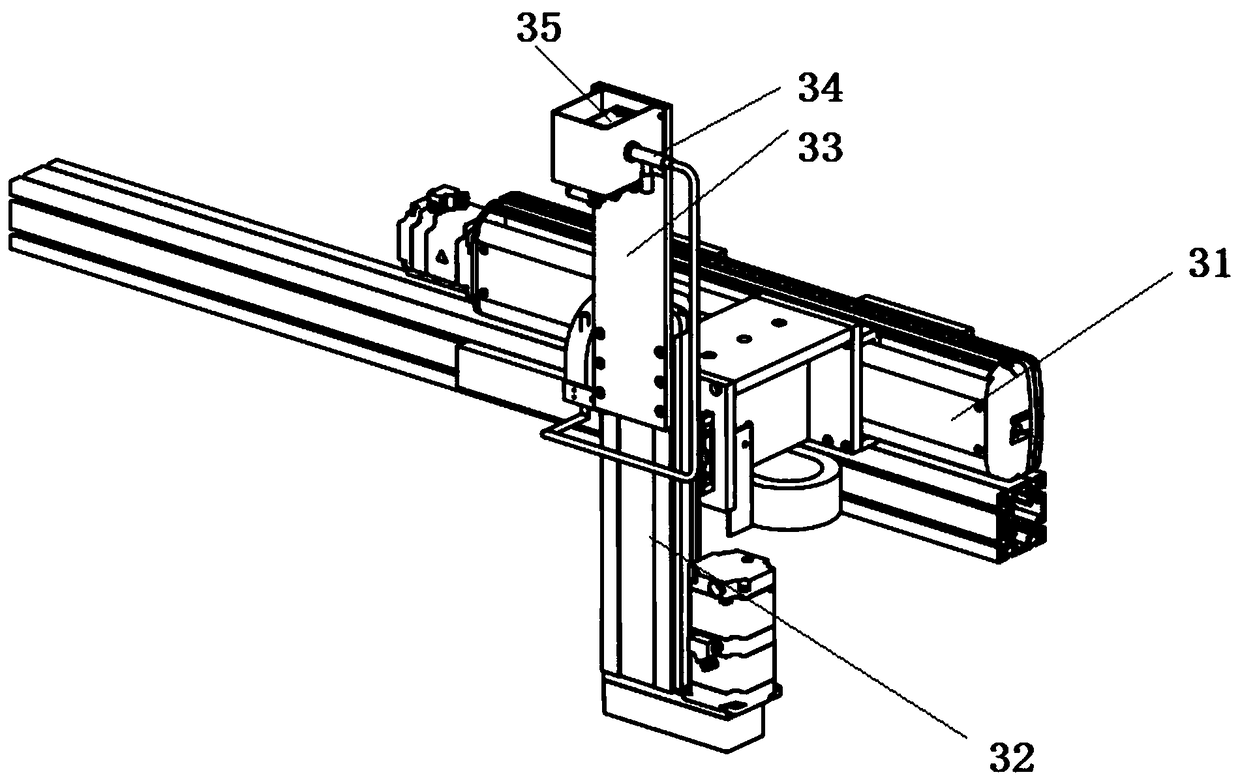

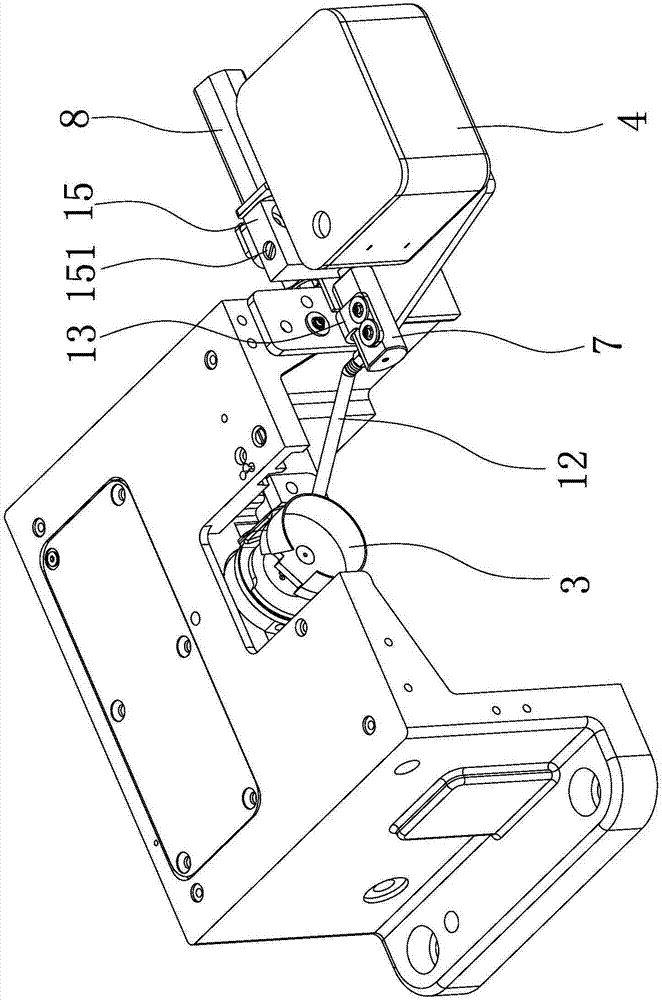

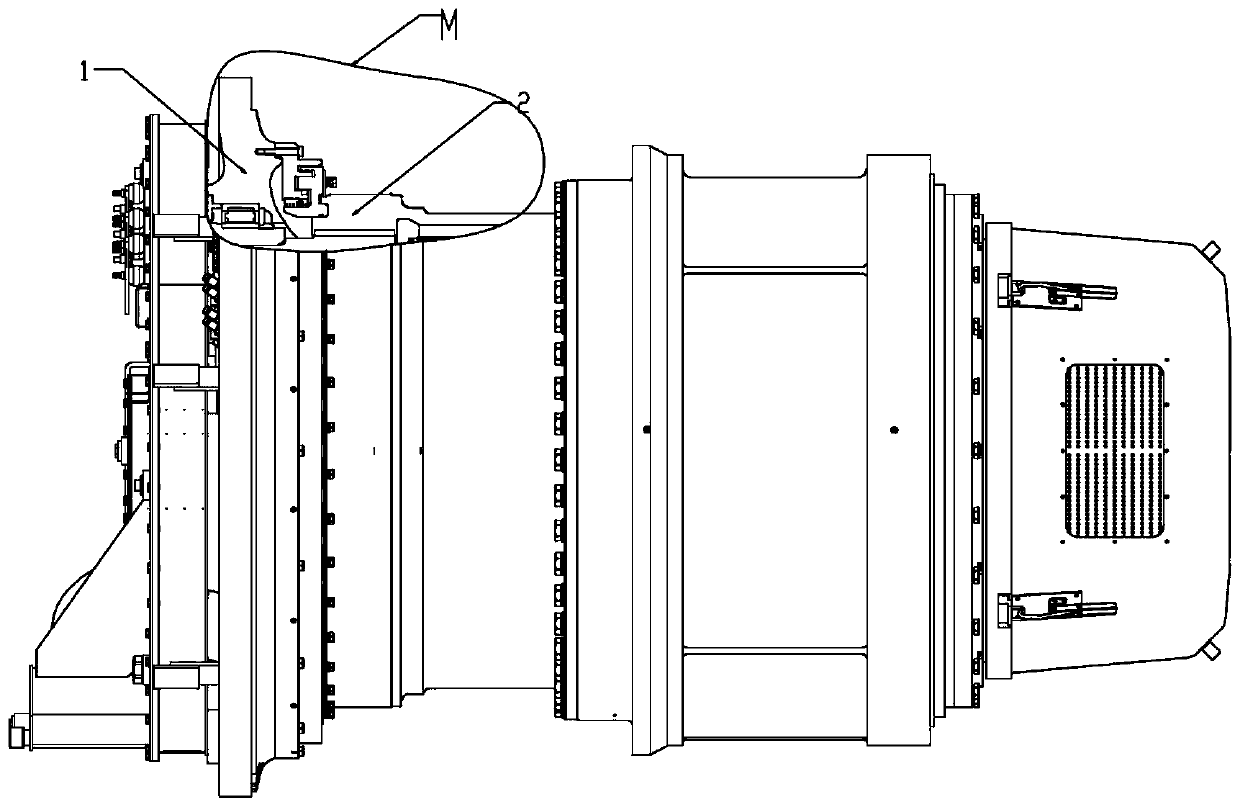

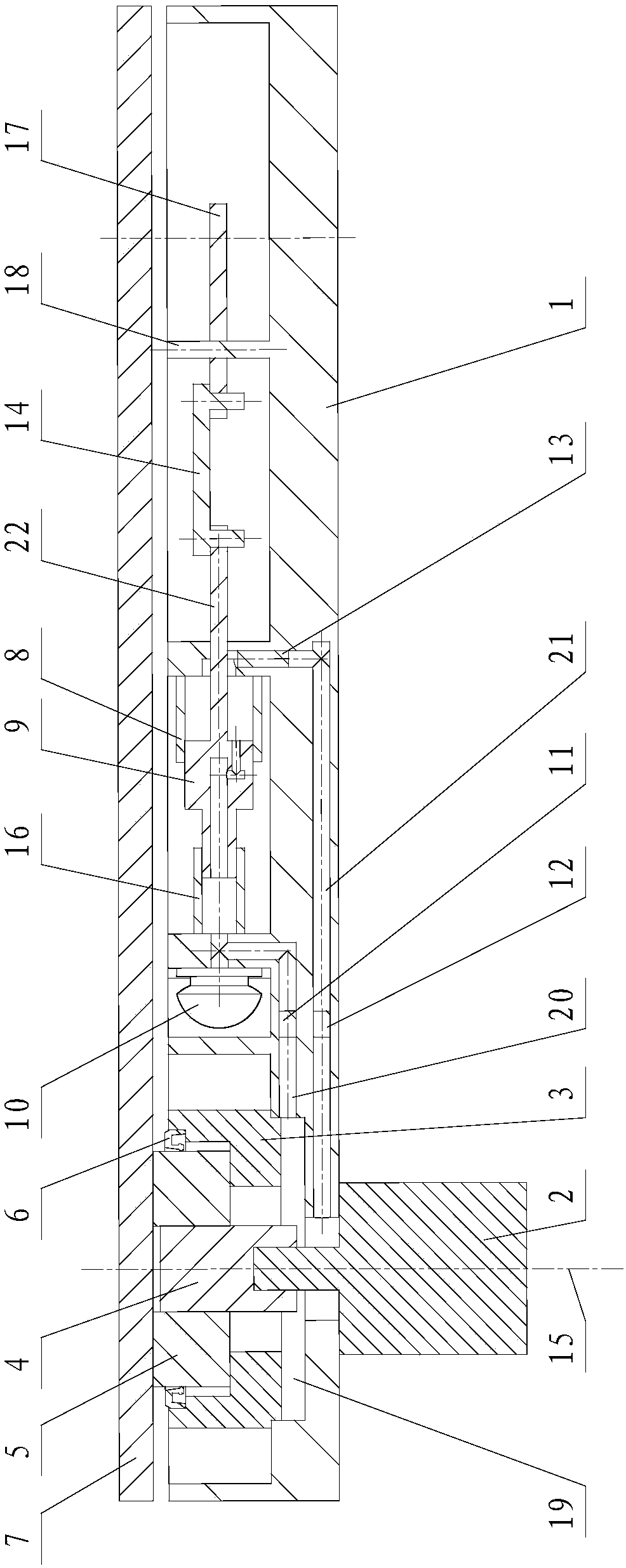

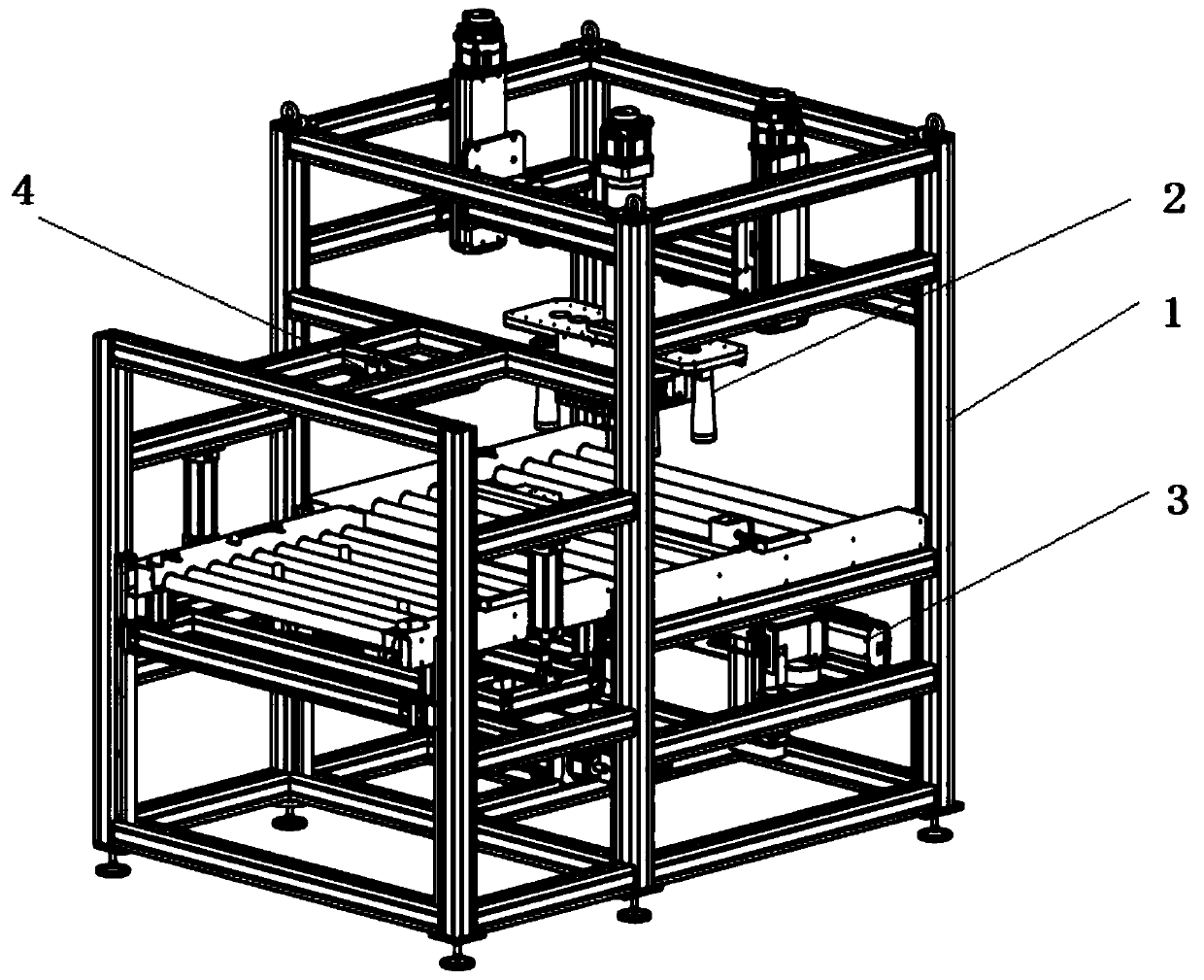

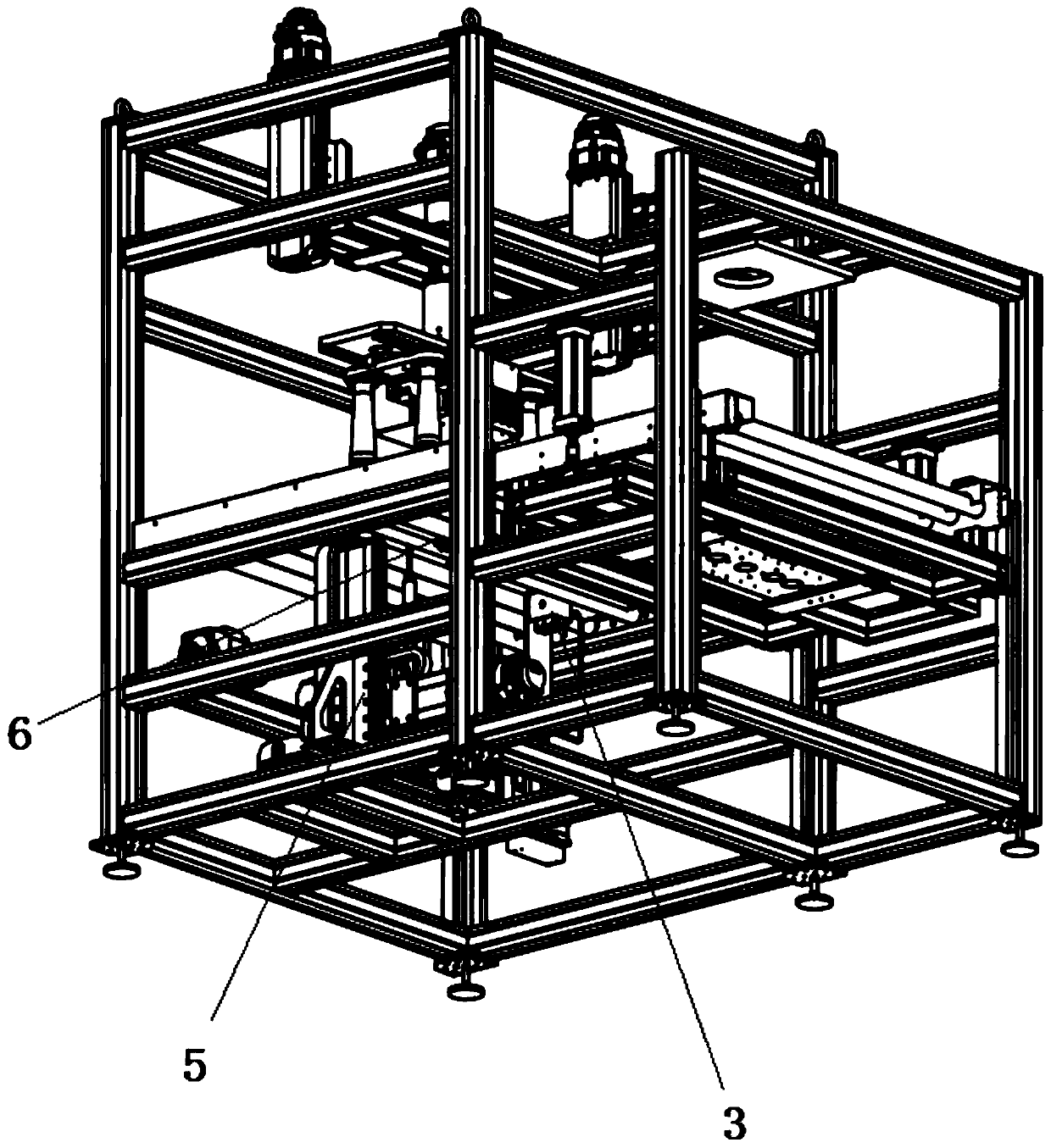

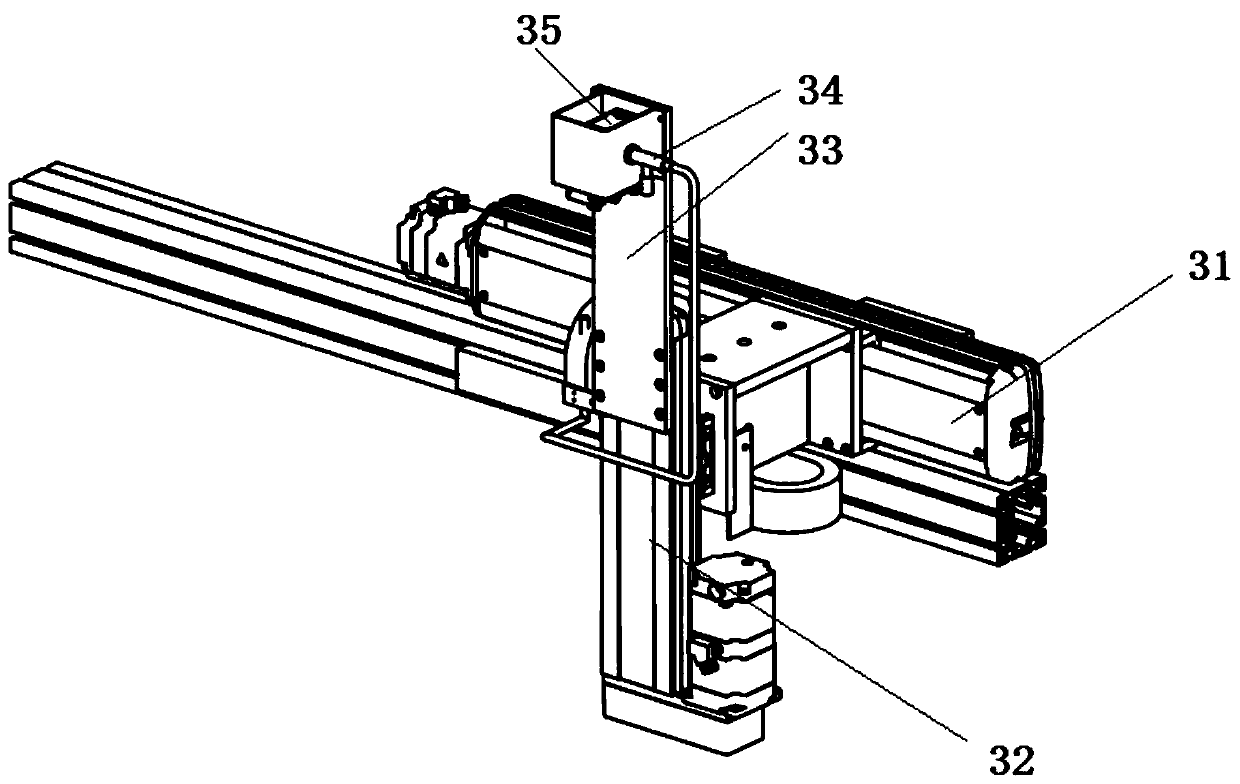

Marking machine with wheel hub type identification function and product tracing method thereof

The invention relates to the technical field of machinery. A marking machine with a wheel hub type identification function comprises a frame, a marking mechanism and a laser scanning mechanism, wherein the frame is provided with a conveying roller way for conveying a wheel hub and a lifting rotating clamping mechanism for clamping the wheel hub to move and rotate along the vertical direction; theframe is provided with a wheel hub type identification device for collecting appearance feature information of the wheel hub; the marking mechanism is arranged on the frame and is located below the conveying roller way, the marking mechanism comprises a pneumatic marking head and a three-dimensional motion assembly driving the pneumatic marking head to conduct three-dimensional motion; and the laser scanning mechanism comprises a laser scanning machine and a two-dimensional motion assembly driving the laser scanning machine to conduct two-dimensional motion in the horizontal and vertical directions, and the two-dimensional motion assembly is connected to the laser scanning machine. By replacing the tradition laser marking head with the pneumatic marking head, two modes of thermal marking and cold state marking are realized and the marking quality is excellent.

Owner:SH INTELLIGENT EQUIP SHANGHAI CO LTD +1

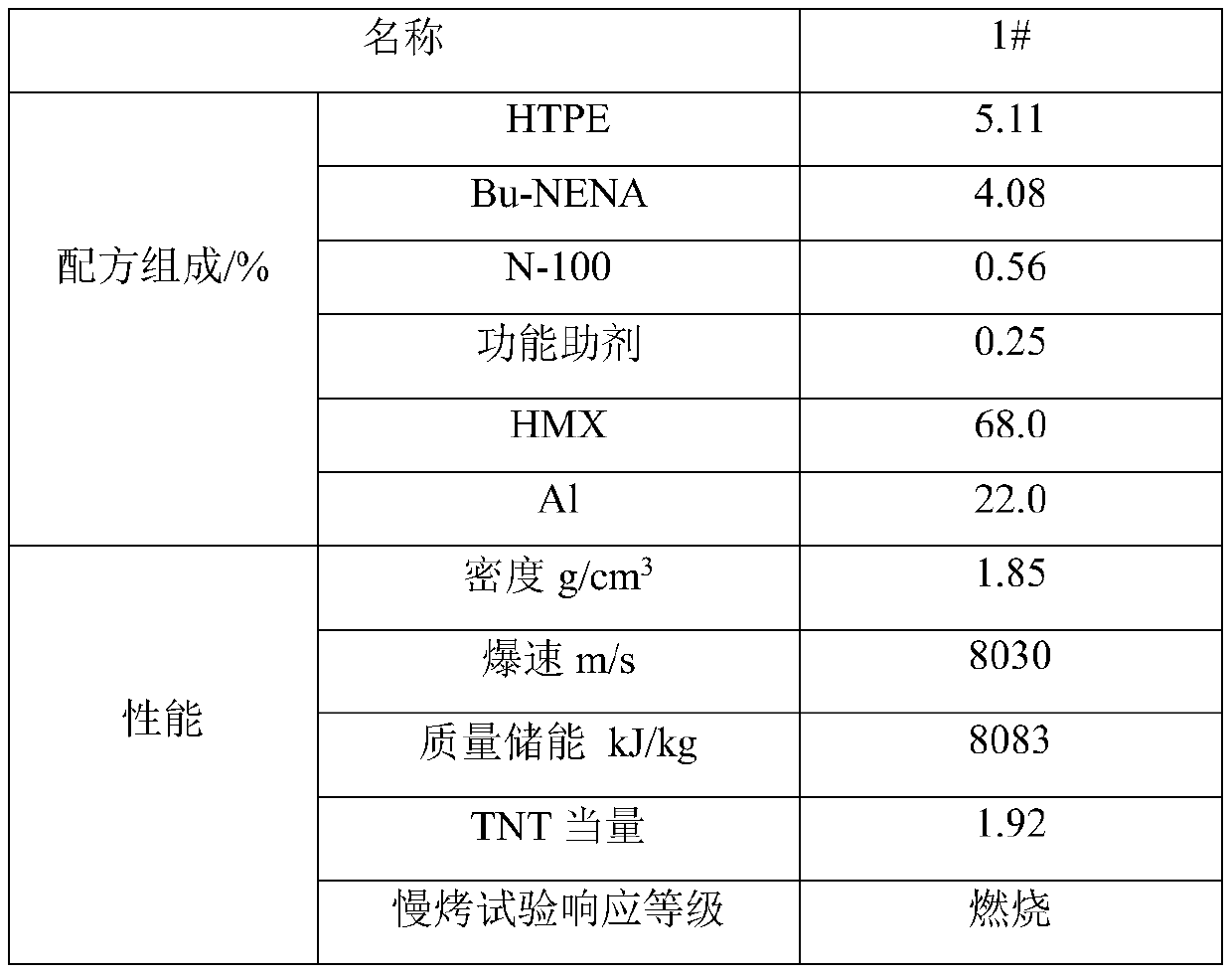

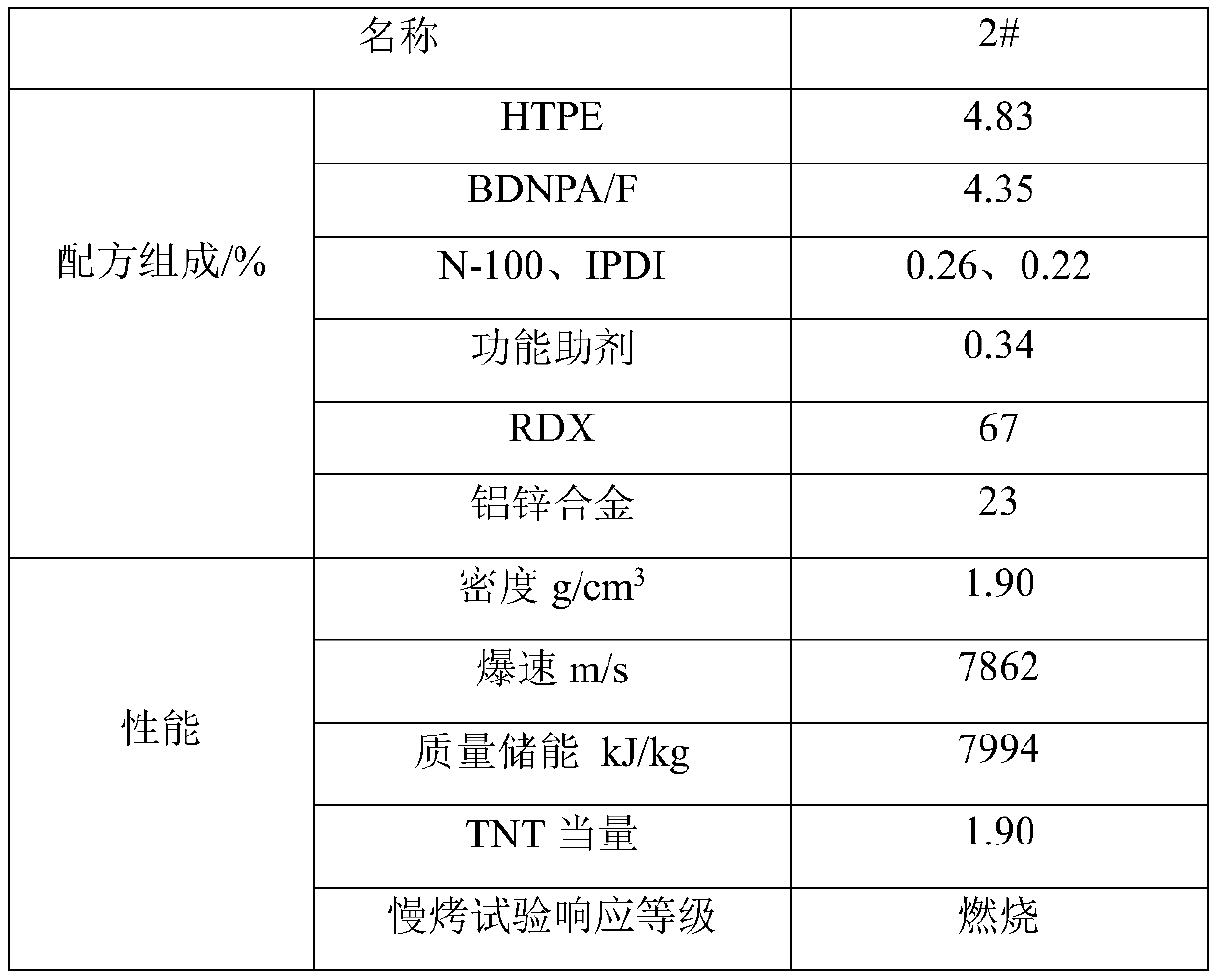

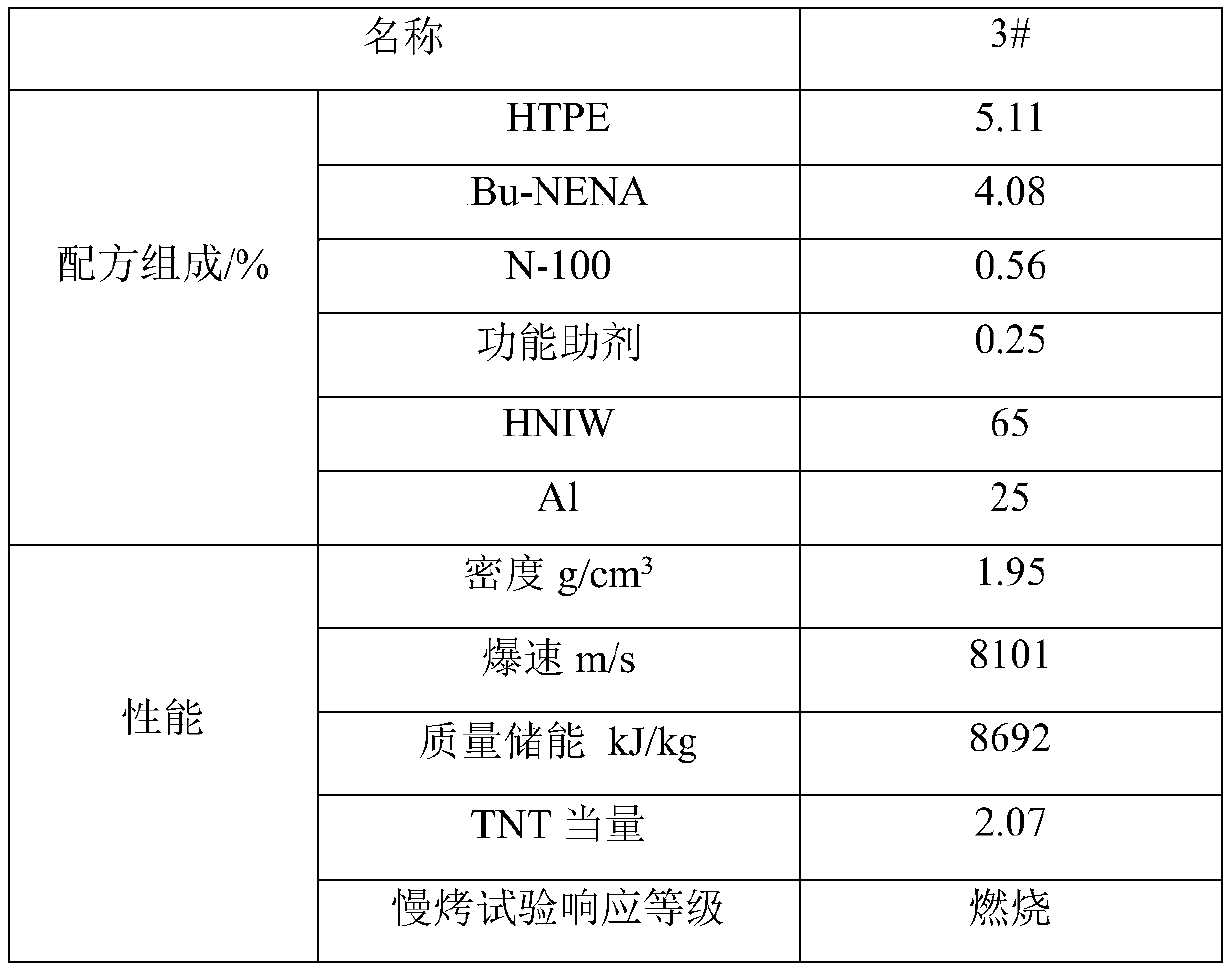

Pouring-type high-energy insensitive explosive and preparation method thereof

ActiveCN110156548AImprove energy characteristicsIncrease energy outputNon-explosive fillers/gelling/thickening agentsAdhesiveHigh energy

The invention relates to a pouring-type high-energy insensitive explosive and a preparation method thereof. In order to solve the problem of a low energy level of traditional butylated hydroxy castingPBX explosives, an energy-containing adhesive and an energy-containing plasticizer are introduced as a binder system, and through addition of high-energy explosives and metal fuel components, the prepared pouring-type PBX explosive has high energy characteristics; the explosive formula has a density greater than 1.85 g / cm<3>, the detonation velocity is greater than 7800 m / s, and the explosive power is that of 1.9 times or above the TNT equivalent; and at the same time, the explosive formula has good low-vulnerability, and especially has mild reactions in slow-speed burning tests, and the reaction level does not exceed a detonation level.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

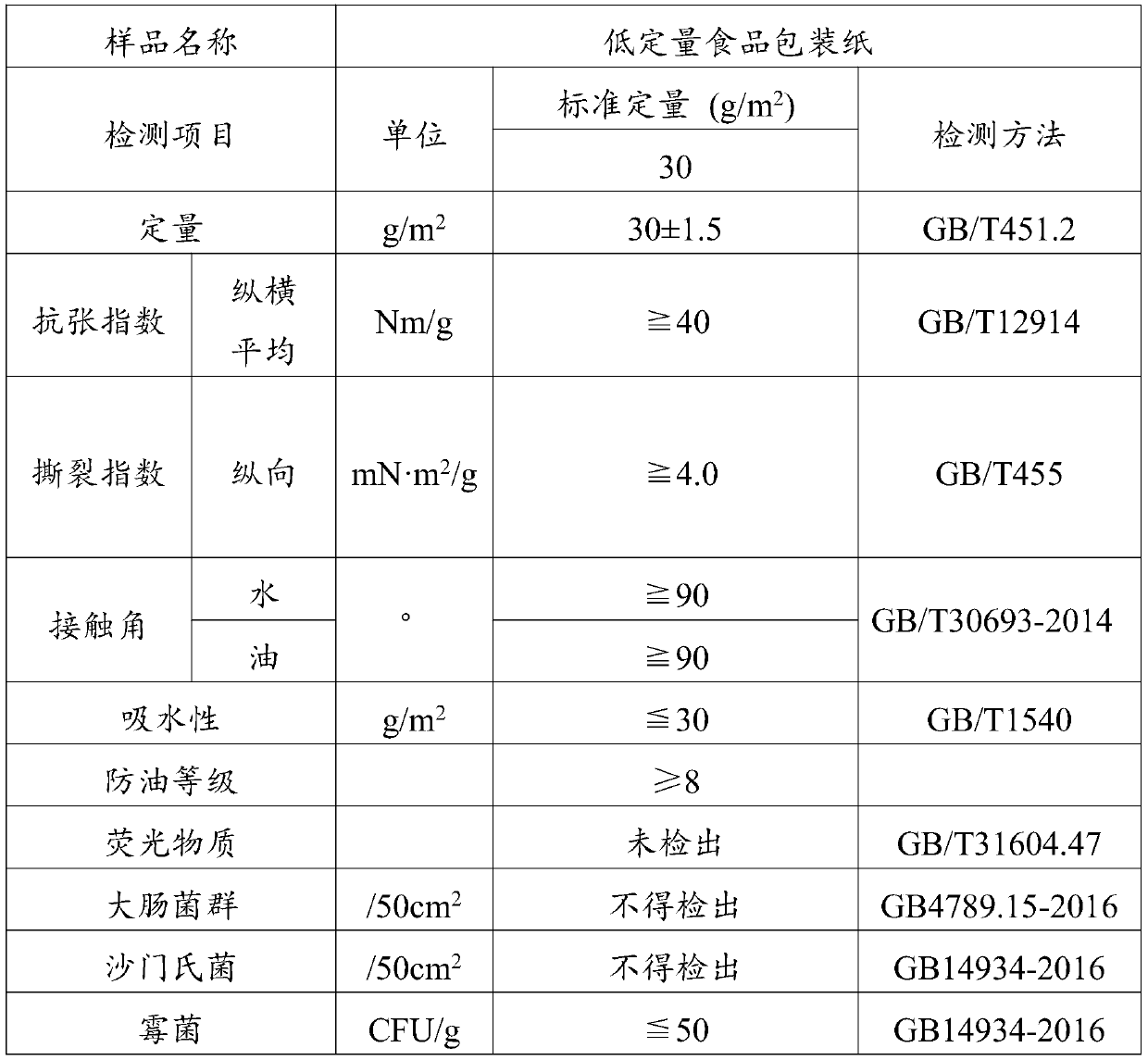

Low-weight food packaging paper added with nanocellulose and manufacturing method thereof

ActiveCN111304967AAvoid breakingReduce manufacturing costWrappersWater-repelling agents additionFood packagingSoftwood

According to the invention, sulfate softwood pulp, sulfate hardwood pulp and domestic bleached or natural-color sterile bamboo pulp are used as raw materials, nano-crystalline cellulose is added intopaper pulp, nano-crystalline cellulose is added into a surface sizing agent, and nano-crystalline cellulose is added into a surface coating solution, so that the strength of the paper is remarkably improved, the use experience of the paper is effectively improved, and the bad experience that food packaging paper such as hamburgers is broken, stuffing leaks out and oil seeps in the use process is prevented. Besides, through repulping, pulping and addition of various chemical additives meeting the GB9685-2016 standard, refined control over the technological process is improved, the high-temperature-resistant, oil-proof, anti-sticking and low-weight food packaging paper is prepared, traditional waxing paper and PE-coated paper materials can be replaced, and it is guaranteed that food making contact with the packaging paper is healthier, safer and more environmentally friendly.

Owner:沈阳思特雷斯纸业有限责任公司

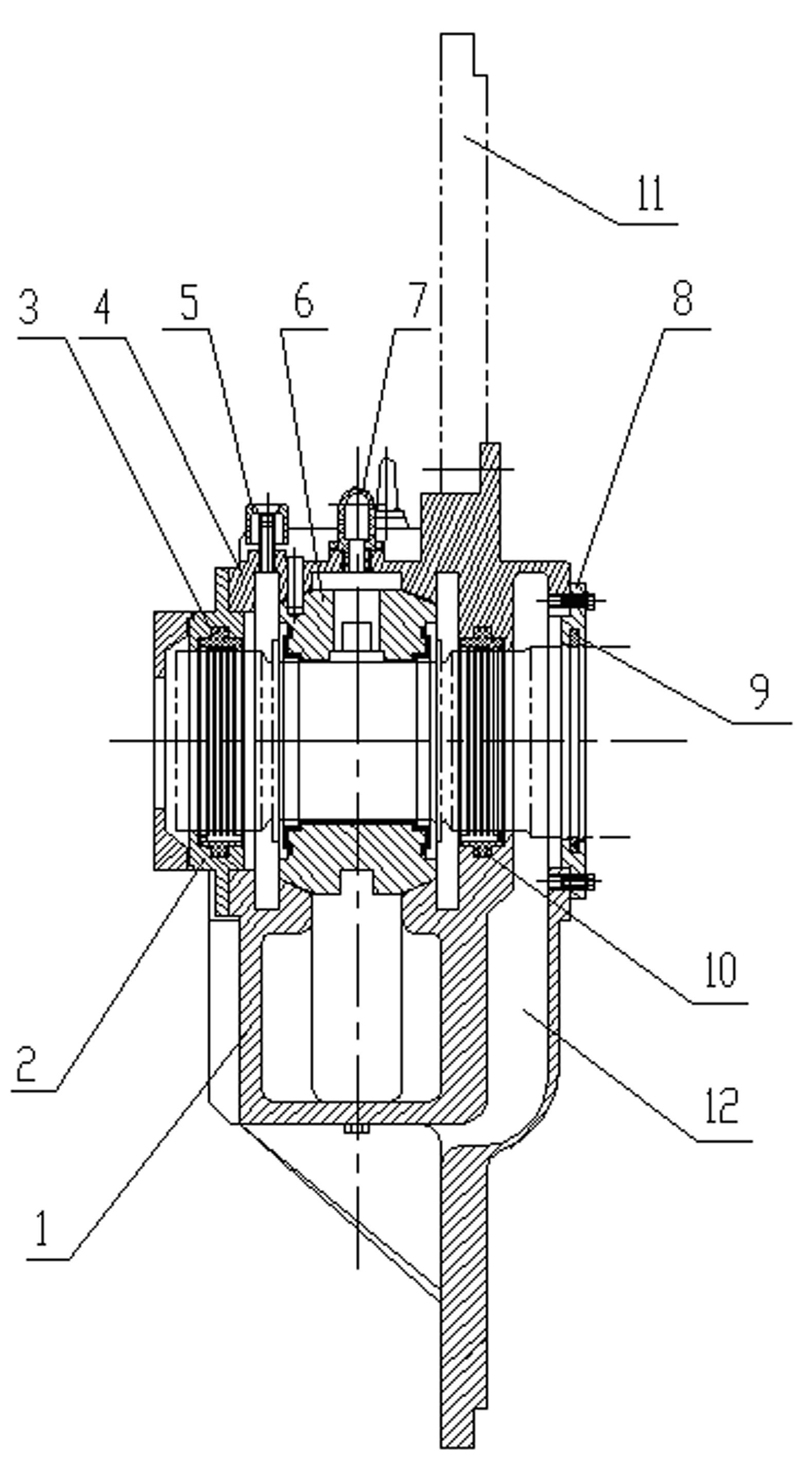

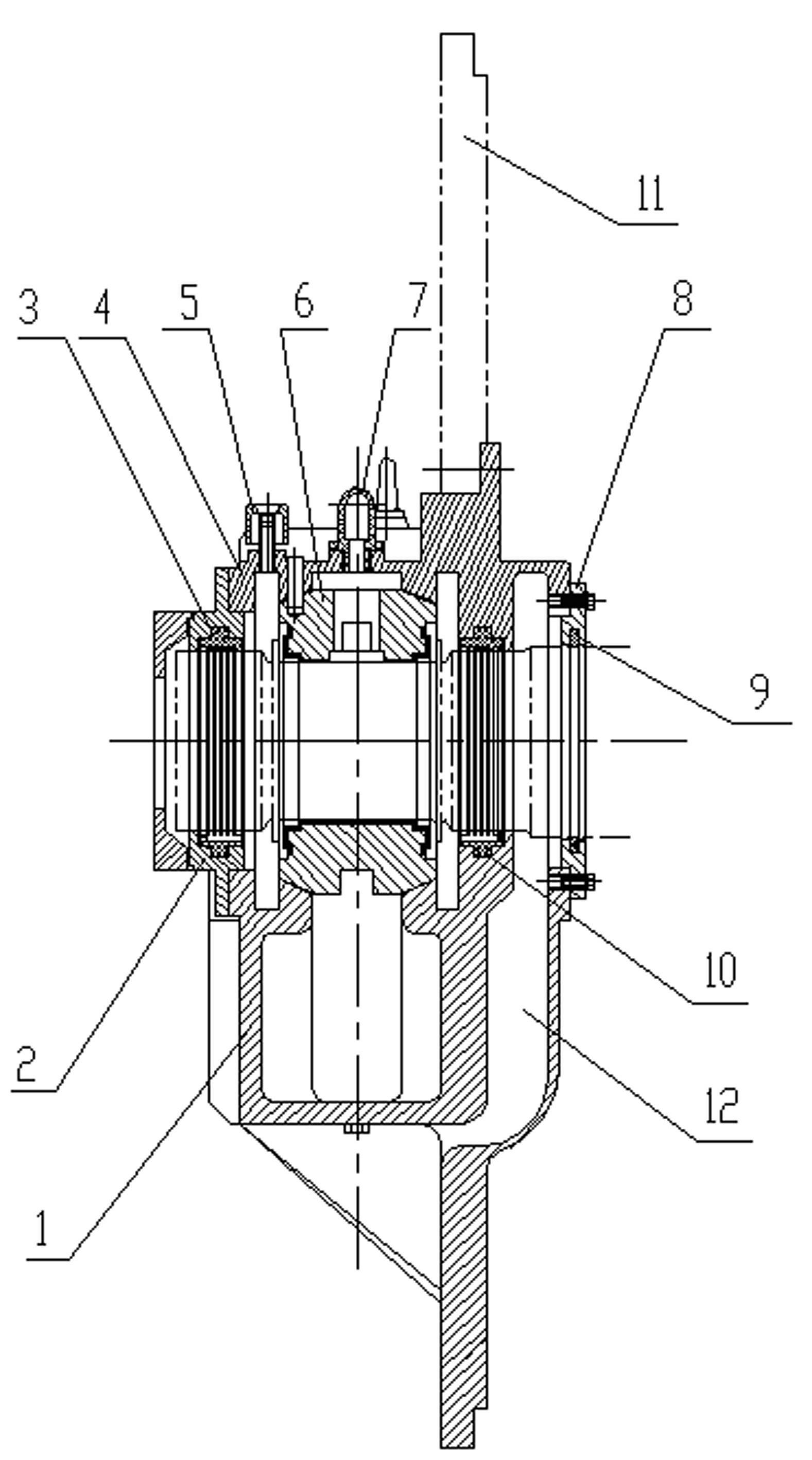

End cover type sliding bearing of high-speed motor

InactiveCN102355079AAvoid oil absorptionAvoid Oil Leakage ProblemsSupports/enclosures/casingsStructural engineeringMotor shaft

The invention discloses an end cover type sliding bearing of a high-speed motor. The end cover type sliding bearing comprises a bearing box, an outer bearing cover, an upper bearing cover, a valve, a bearing bush, an oil inlet pipe, an inner bearing cover and sealing rings, wherein the upper bearing cover and the bearing box form a bisectioned structure; the bearing box is integrated with the lower half of an end cover of the motor; a lower cavity is formed in the sidewall, close to one side of the motor, of the bearing box, and leads to a part below the motor shaft; an upper cavity corresponding to the lower cavity is formed in the sidewall, close to one side of the motor, of the upper bearing cover, and leads to a part above the motor shaft; and after the bearing box and the upper bearing cover are connected, the upper and lower cavities form an airtight cavity which surrounds the motor shaft and is communicated with air. The end cover type sliding bearing of the high-speed motor can prevent oil absorption caused by a negative pressure generated by a fan in the motor around the inner bearing cover of the motor, and effectively prevent oil penetration.

Owner:LANZHOU ELECTRIC CORP

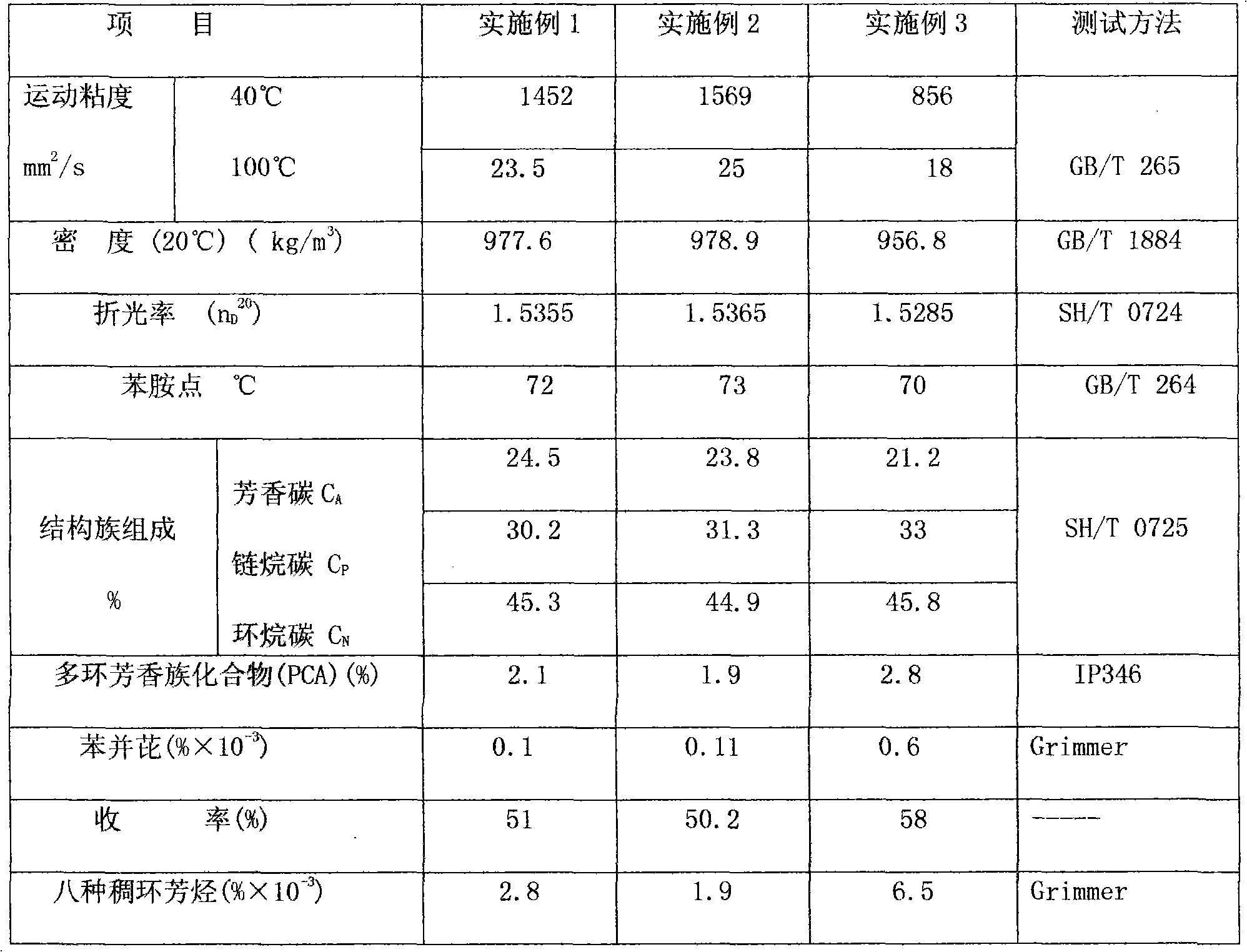

Process for producing environment-friendly aromatic rubber oil

InactiveCN101928595AHigh aromatic contentGood compatibilityTreatment with plural serial refining stagesPolymer scienceSolvent

The invention relates to environment-friendly aromatic rubber oil used in the rubber industry. In the rubber oil, cyclohexane / petroleum ether / HVI150 and dimethyl sulfoxide are used as solvents, and PCA in the oil is extracted by using the selectivity of the dimethyl sulfoxide under a specific condition. The process aims to provide the rubber filling oil which is capable of exerting properties the same as the conventional aromatic oil, does not have the problem of carcinogenicity and has better safety, and a producing method thereof.

Owner:王喜安 +1

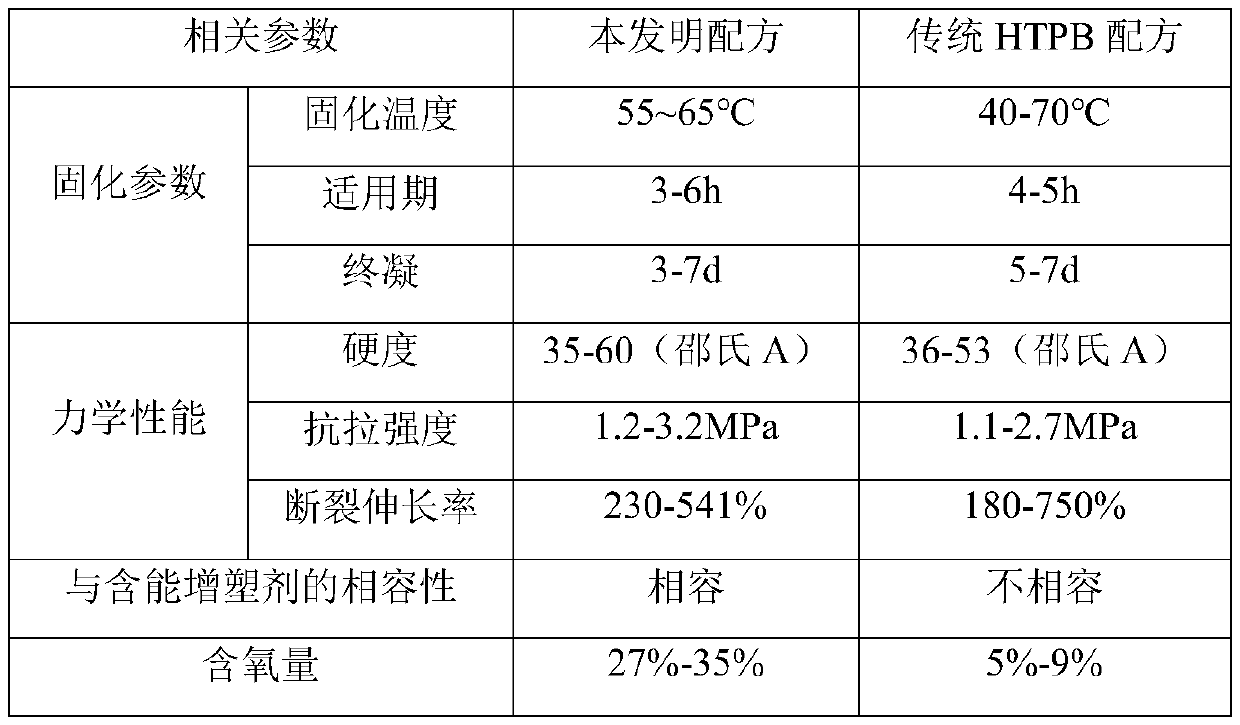

Adhesive system suitable for insensitive munitions and preparation method

InactiveCN110304977AIncrease oxygen contentReduce dosageNon-explosive fillers/gelling/thickening agentsPolyolPlasticizer

The invention provides an adhesive system suitable for insensitive munitions and a preparation method. The adhesive system is prepared by, by weight, 40-50 parts of polyol, 30-60 parts of energetic plasticizer, 5-10 parts of polyisocyanate, 0.0002-0.001 part of catalyst. During preparation, raw material preprocessing including the rotary evaporation dewatering of the polyol and the energetic plasticizer and raw material preheating is performed during preparation, the polyol and the energetic plasticizer are then premixed, and a curing agent is added finally and sufficient and uniform mixing isperformed to perform curing at 55-65 DEG C for 4-7 days. Compared with a traditional hydroxyl-terminated polybutadiene-based (HTPB-based) adhesive system, the adhesive system is high in oxygen content, good in compatibility with the energetic plasticizer, and capable of evidently increasing the energy output of an explosive system; the adhesive system is mild in reaction under a heat stimulationcondition and melts and expand when being heated to break through a munition shell, explosion possibility under the heat stimulation condition is lowered, and munition insensitivity is increased.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

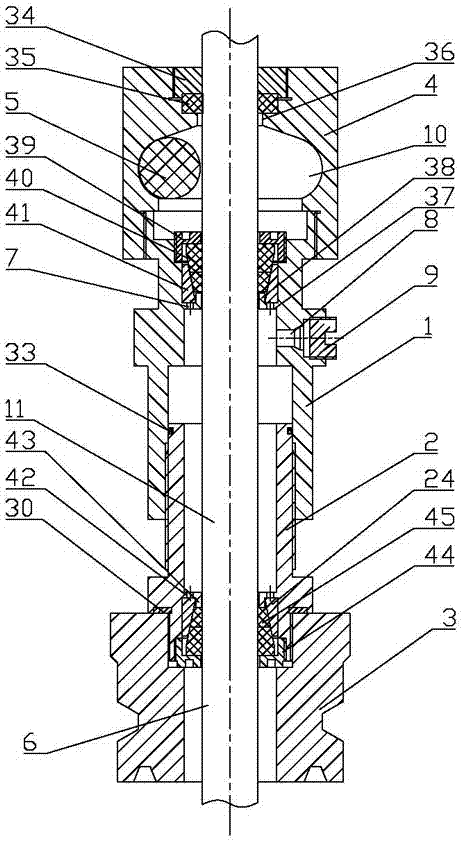

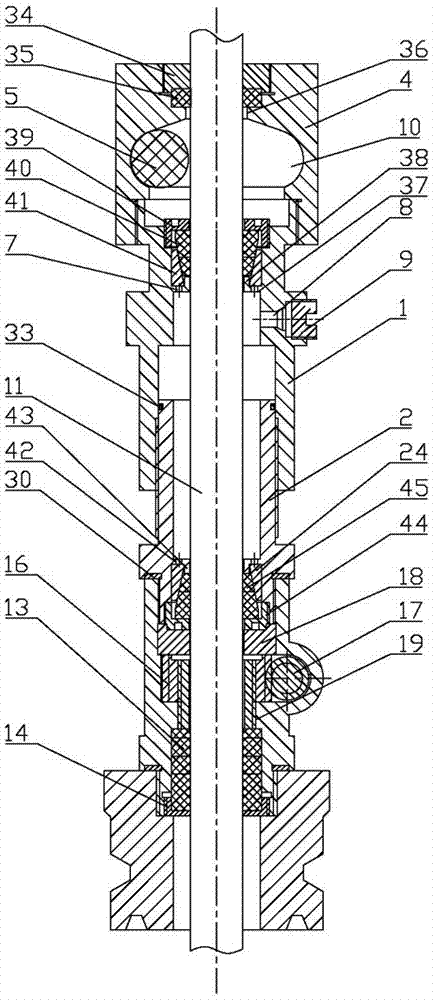

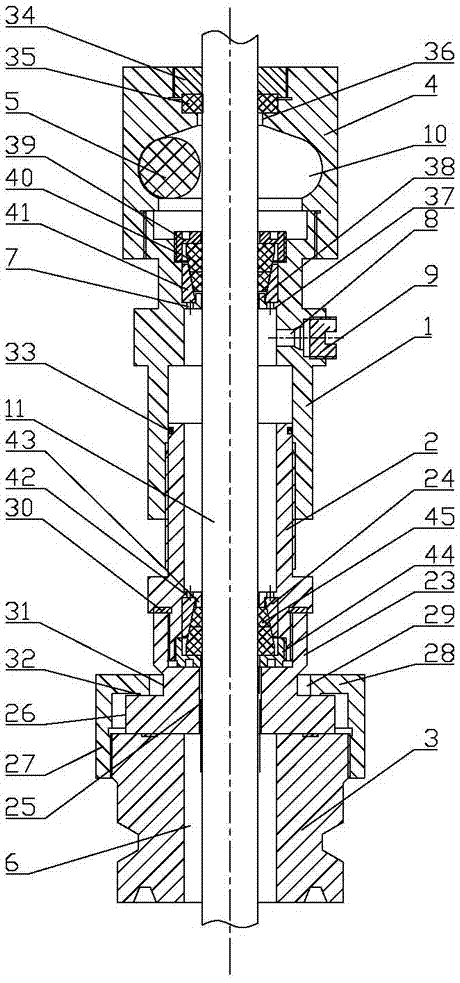

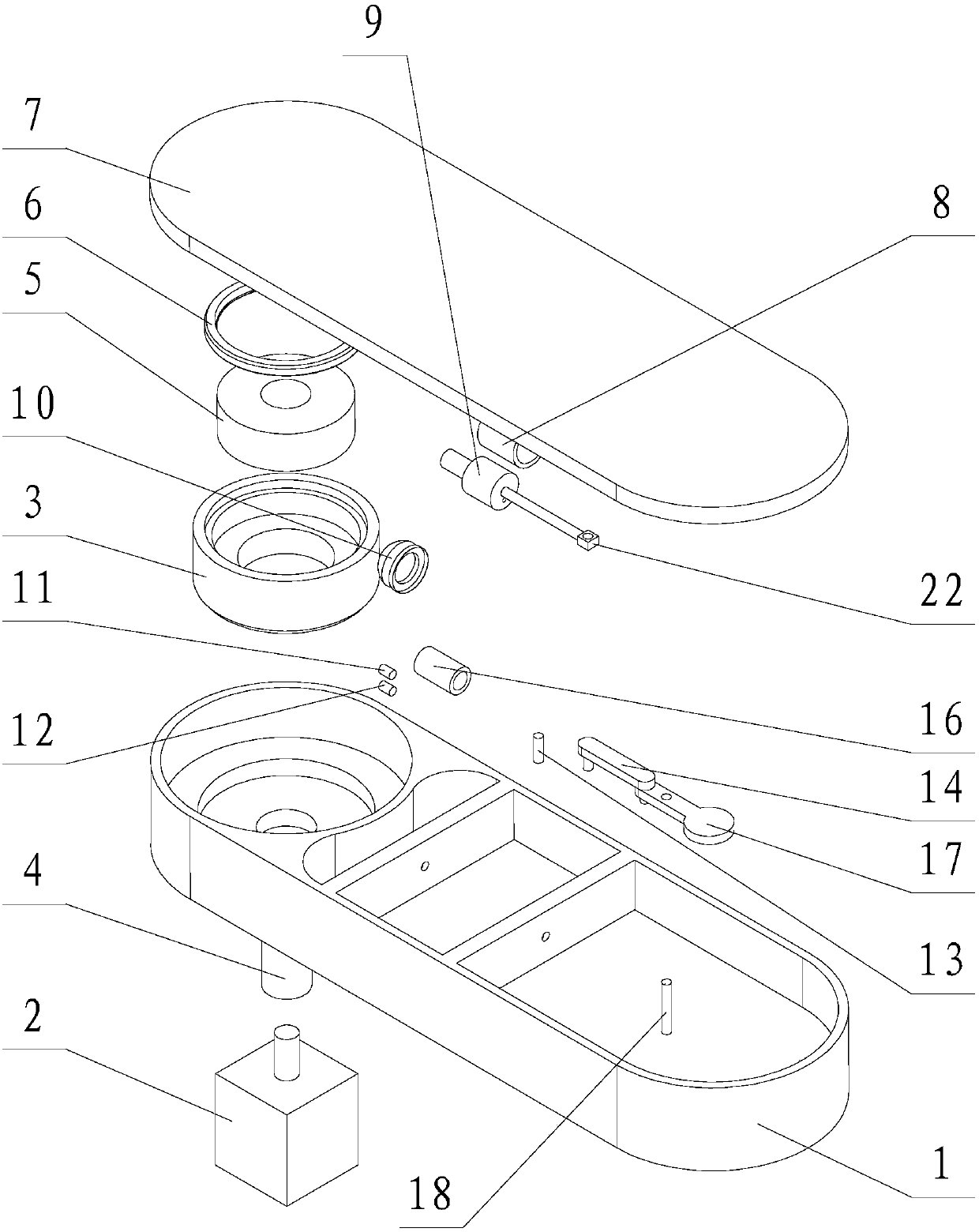

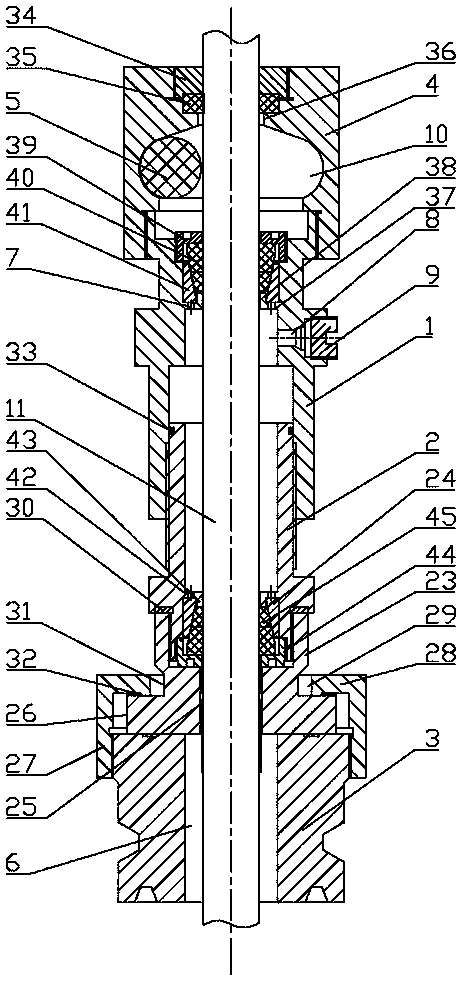

Efficient environmentally-friendly oil-well wellhead sealing device

ActiveCN107165600AEffective against wear and tearPrevent fallingSealing/packingMechanical engineeringPollution

The invention relates to the technical field of oil field wellhead equipment and provides an efficient environmentally-friendly oil-well wellhead sealing device. The device comprises a spraying preventing device body, a packing pressing sleeve, a packing cylinder and a base; a spraying preventing shell, the packing pressing sleeve, the packing cylinder and the base are sequentially and fixedly mounted together from top to bottom; a seat body through hole is formed in the middle of the base; a lower supporting ring seat is fixed to the inner side of the lower portion of the packing cylinder; a lower packing sealing ring sleeve with the top face abutting against the lower supporting ring seat is mounted on the lower portion of the lower supporting ring seat; an upper supporting ring seat is fixed to the inner side of the upper portion of the packing pressing sleeve; and an upper packing sealing ring sleeve with the bottom face sitting on the upper supporting ring seat is mounted on the upper portion of the upper supporting ring seat. According to the efficient environmentally-friendly oil-well wellhead sealing device, the phenomena of oil leakage and environment pollution can be avoided, normal work of whole equipment is ensured, shutting-down and dismounting are not needed in dismounting, mounting and maintaining, and only a pipe plug needs to be opened or closed; oil extraction breaking-off is avoided, and production efficiency is ensured; and meanwhile waste can further be prevented, and the characteristics of being efficient, convenient, rapid, capable of saving time and labor and high in safety efficiency are achieved.

Owner:克拉玛依市三达有限责任公司 +1

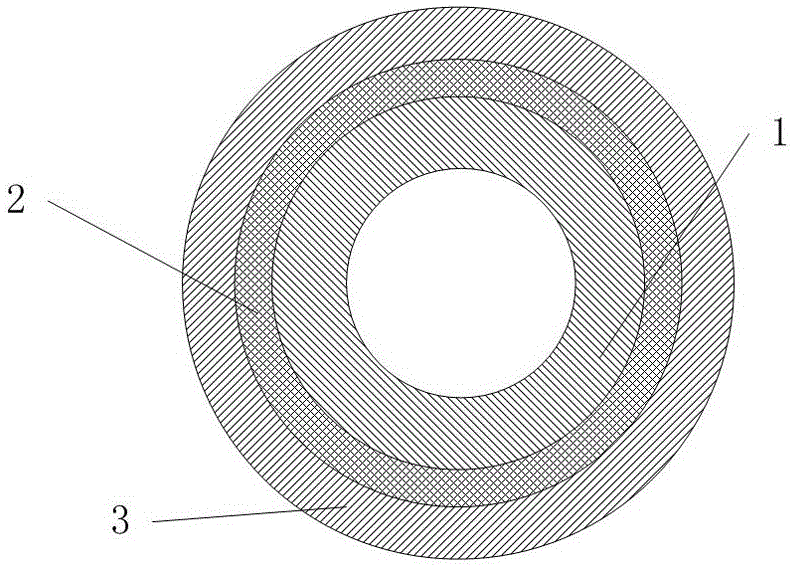

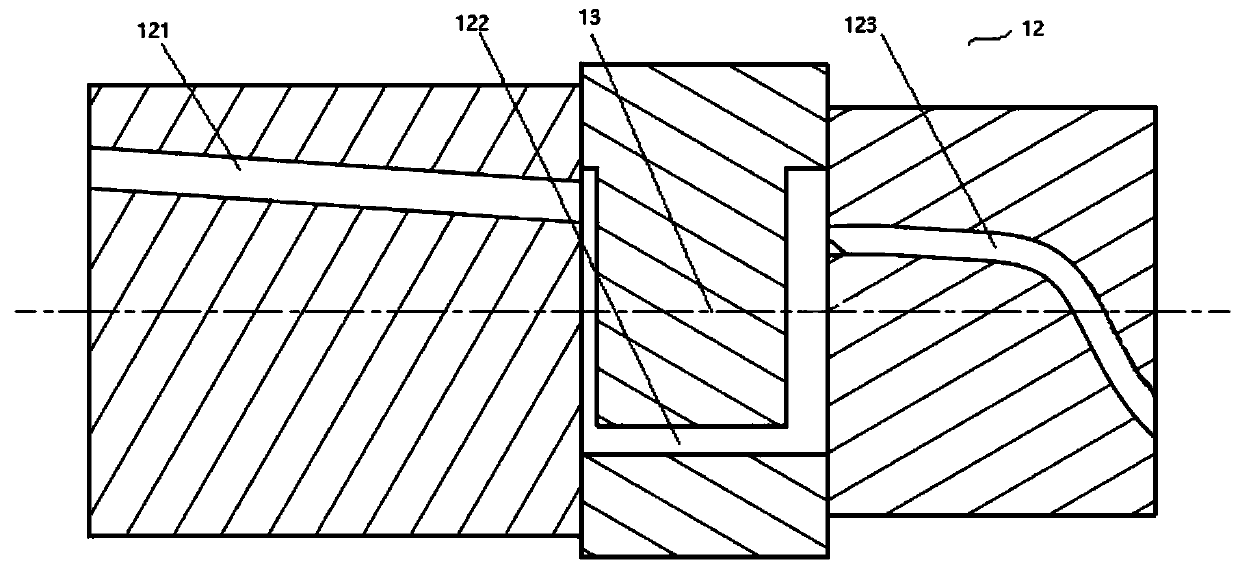

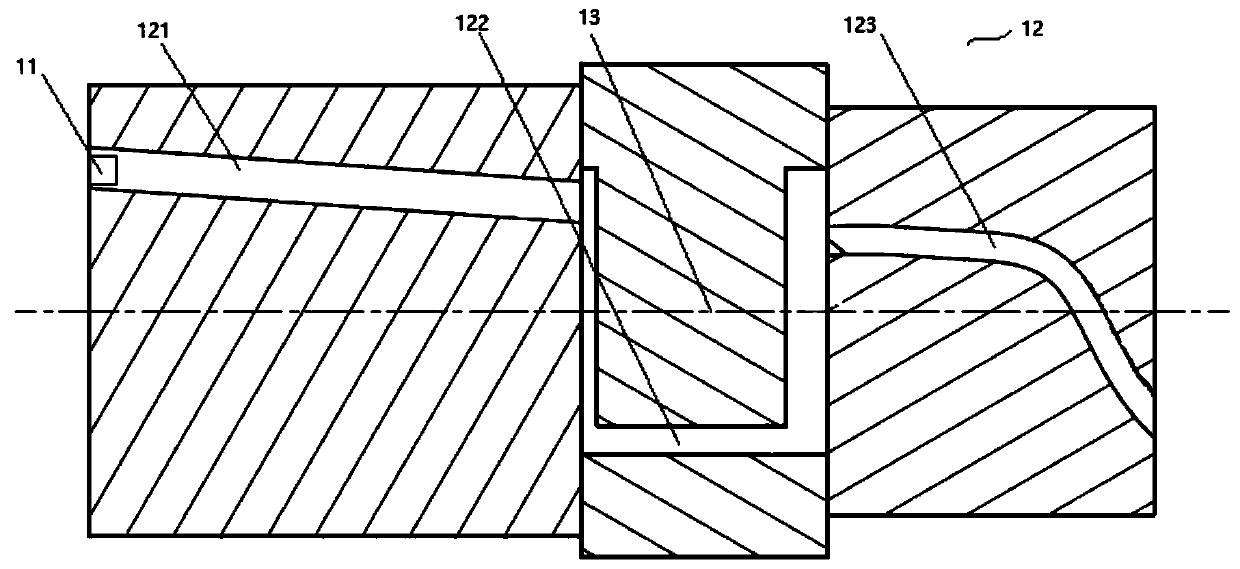

Automobile composite pipe provided with fluorine-containing outer layer and silicon-containing inner layer

InactiveCN106641494AImprove air tightnessAvoid Oil Leakage ProblemsFlexible pipesSilica gelAir tightness

The invention belongs to the field of automobile equipment accessories and particularly relates to an automobile composite pipe provided with a fluorine-containing outer layer and a silicon-containing inner layer. The automobile composite pipe provided with the fluorine-containing outer layer and the silicon-containing inner layer comprises an inner fluorine rubber layer, a reinforcing layer and an outer silica gel layer. The inner wall of the automobile composite pipe provided with the fluorine-containing outer layer and the silicon-containing inner layer is the inner fluorine rubber layer, the reinforcing layer is wrapped around the outer wall of the inner fluorine rubber layer, and the outer silica gel layer is wrapped around the outer wall of the reinforcing layer. According to the automobile composite pipe provided with the fluorine-containing outer layer and the silicon-containing inner layer, the fluorine rubber is resistant to high temperature, good in gas tightness, resistant to oil and capable of effectively protecting a rubber pipe against oil seepage and water seepage, the reliability of a gas inlet rubber pipe and a gas outlet rubber pipe for an automobile can be greatly improved, and the fault rate of the automobile during running can be lowered. The wall thickness consistency and stability of the product are guaranteed, and the adhesion performance between the silica gel layer and the reinforcing layer is improved. Due to the design of the reinforcing layer, the automobile composite pipe provided with the fluorine-containing outer layer and the silicon-containing inner layer has good physical and mechanical properties, oil resistance and acid-base corrosion resistance and can be applied to severe environments, and the service life of the rubber pipe is effectively prolonged.

Owner:QISHENG RUBBER & PLASTIC PROD CO LTD

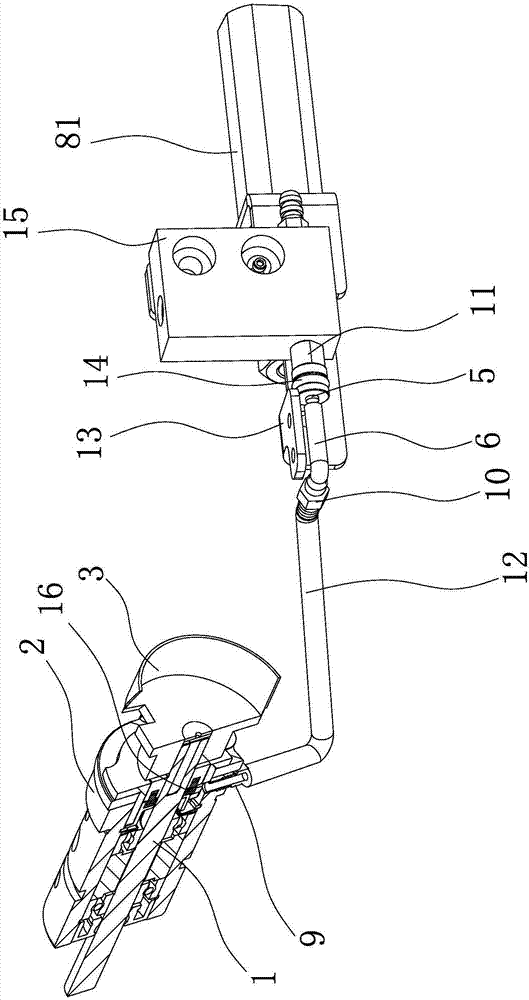

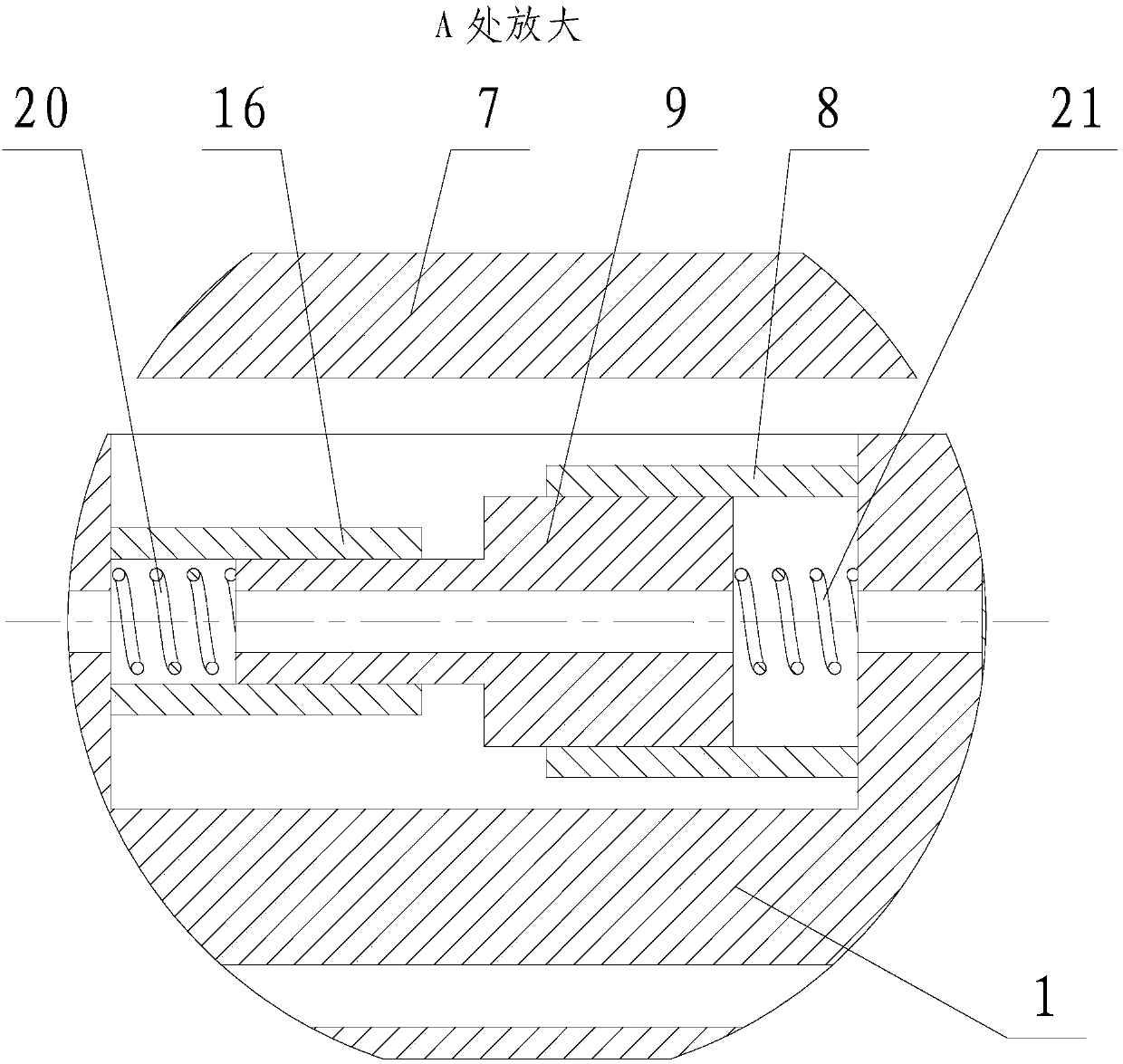

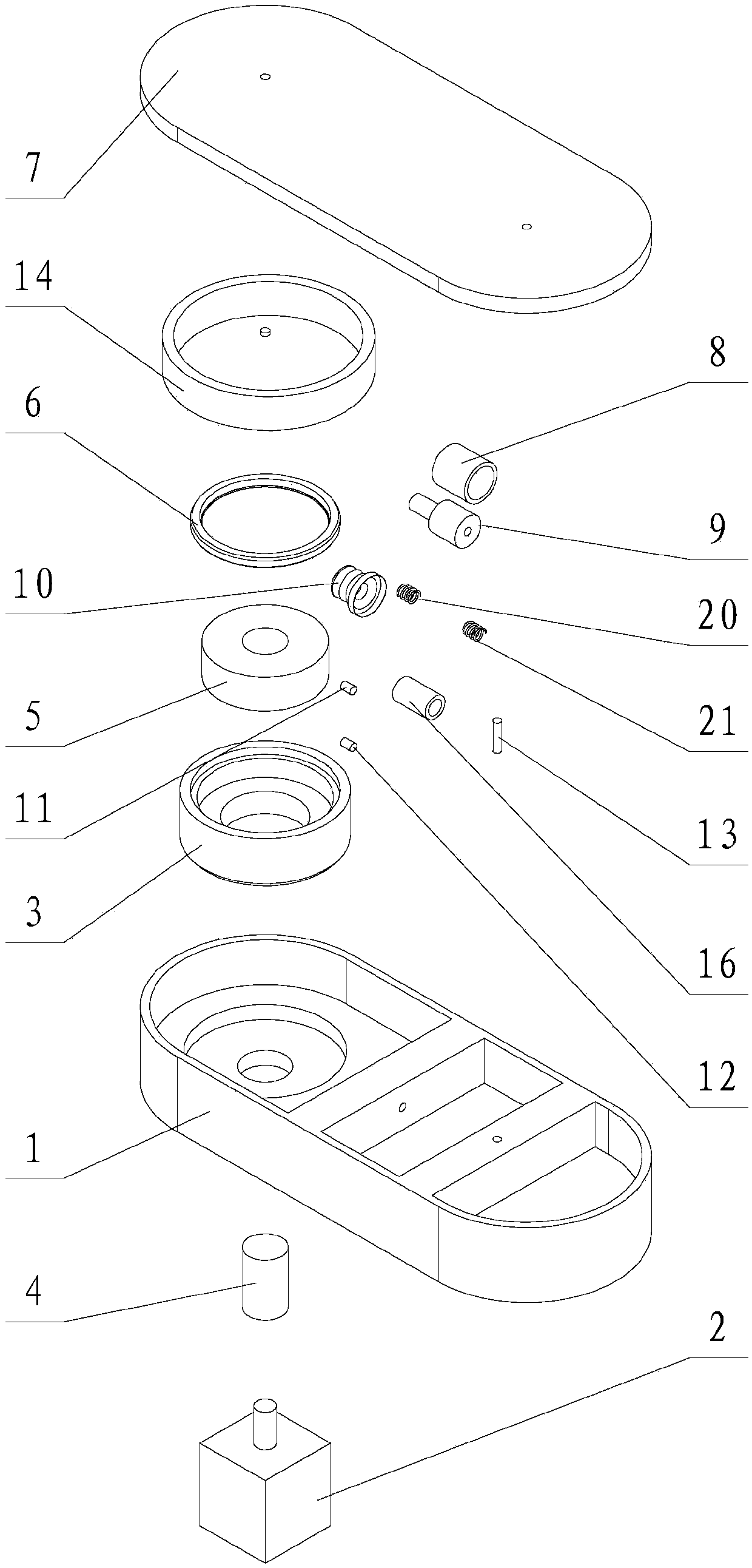

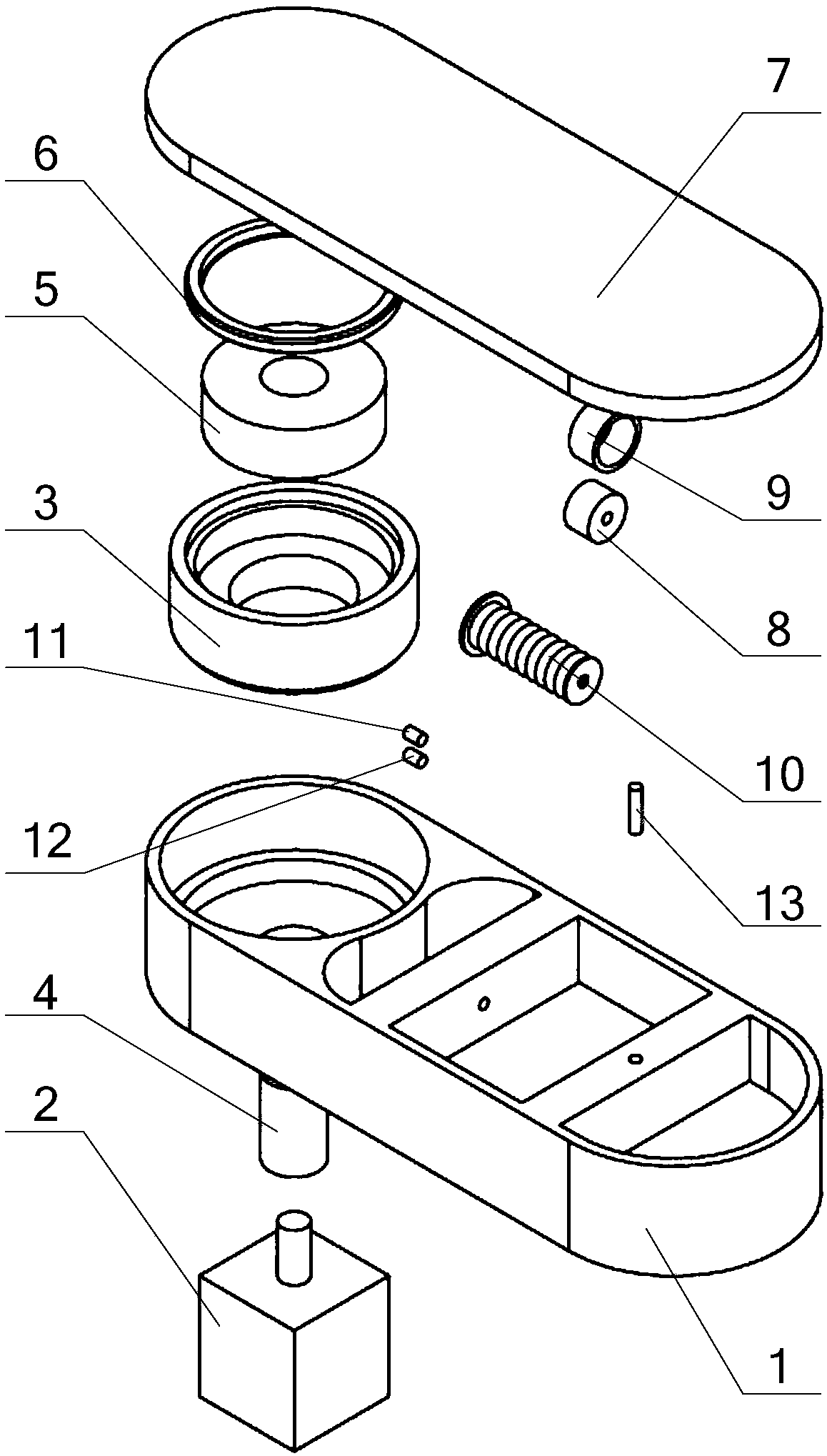

Lubricating structure of rotating shuttle of sewing machine

ActiveCN107254746AAvoid Oil Leakage ProblemsLubrication/cooling devicesStopped workPetroleum engineering

The invention provides a lubricating structure of a rotating shuttle of a sewing machine, and belongs to the technical field of sewing machines. The problem that lubricating oil is easy to accumulate and leak after the rotating shuttle of an existing sewing machine stops working is solved. The sewing machine comprises the rotating shuttle, a rotating shuttle shaft and a shaft sleeve, the rotating shuttle and the shaft sleeve are arranged on the rotating shuttle shaft in a sleeving mode, and an oil inlet is formed in the shaft sleeve; the lubricating structure comprises an oilcan, a first oil line and a second oil line, the inner end of the first oil line is connected with an oil outlet of the oilcan, and the inner end of the second oil line is connected to the oil inlet of the shaft sleeve; the outer end of the second oil line is connected with an oil cut-off base, and the lubricating structure further comprises a driving part connected with the oil cut-off base; the driving part can drive the oil cut-off base to move in a reciprocating mode and make the outer end of the second oil line and the outer end of the first oil line in contact with or separated from each other. According to the structure, the oil cut-off base is arranged, and the phenomenon of oil seepage or oil leakage caused by excessive flowing of lubricating oil at the rotating shuttle can be effectively prevented when the sewing machine stops working.

Owner:浙江耐拓机电科技有限公司

Diesel engine oil pipe seal gasket with high thermal stability

The invention discloses a diesel engine oil pipe seal gasket with high thermal stability. The diesel engine oil pipe seal gasket comprises the following raw materials in parts by weight: 90 to 100 parts of a main material, 4 to 15 parts of a kaolin compound, 8 to 12 parts of coal gangue, 4 to 10 parts of glass fiber, 1 to 2 parts of a cross-linking agent, 1 to 2 parts of tricresyl phosphate, 1 to2 parts of epoxidized fatty acid methyl ester, 0.2 to 0.8 part of chlorinated paraffin, 0.4 o 1.2 parts of disproportionated rosin, 1 to 2 parts of an anti-aging agent SP and 1 to 2 parts of an anti-aging agent AW, wherein the kaolin compound is prepared by adopting the following process: mixing kaolin, sepiolite powder, bentonite, tetrabutyl titanate and water under stirring, adding cocamidopropyl betaine and sodium hydroxide, carrying out uniform mixing, subjecting an obtained mixture to ball milling, filtering, washing and drying so as to obtain the kaolin compound. The diesel engine oil pipe seal gasket provided by the invention has the advantages of excellent thermal stability, good impact-resistant effect, good mechanical properties and excellent seal effect, can effectively preventoil impregnation, greatly improves the work reliability of a diesel engine oil pipe, and facilitates application and popularization.

Owner:全椒县新华机械有限责任公司

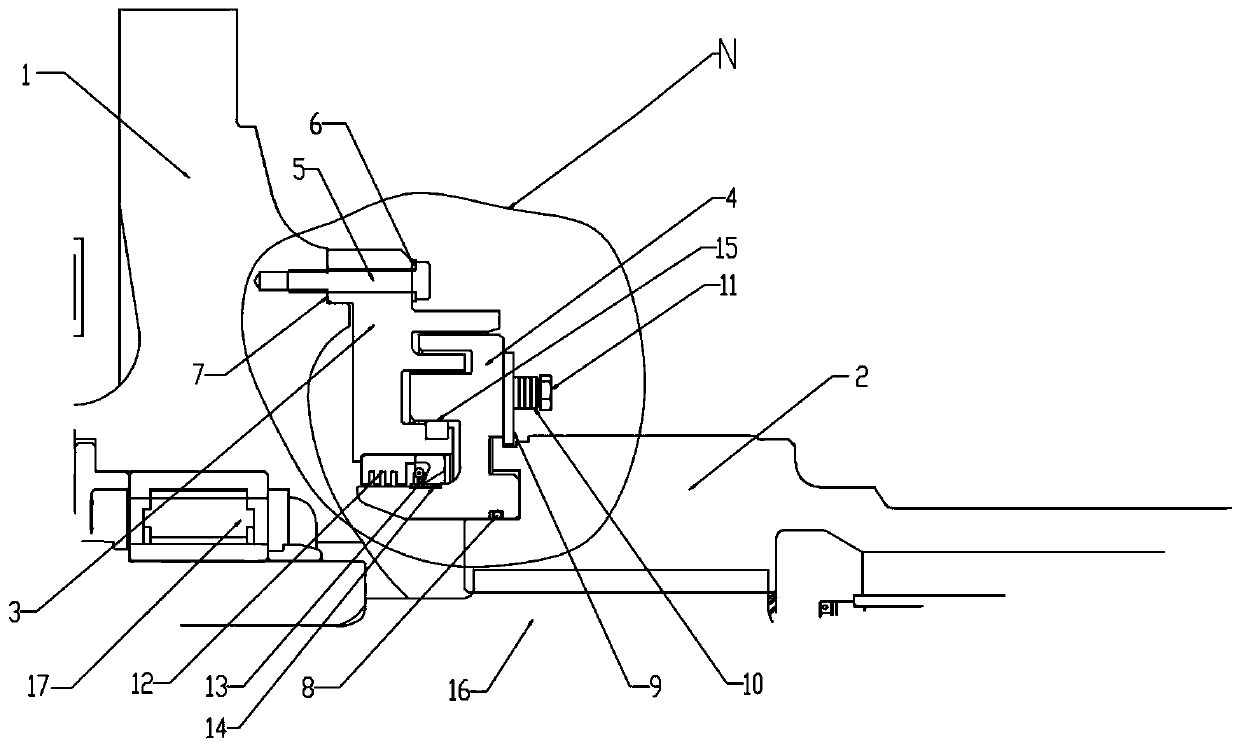

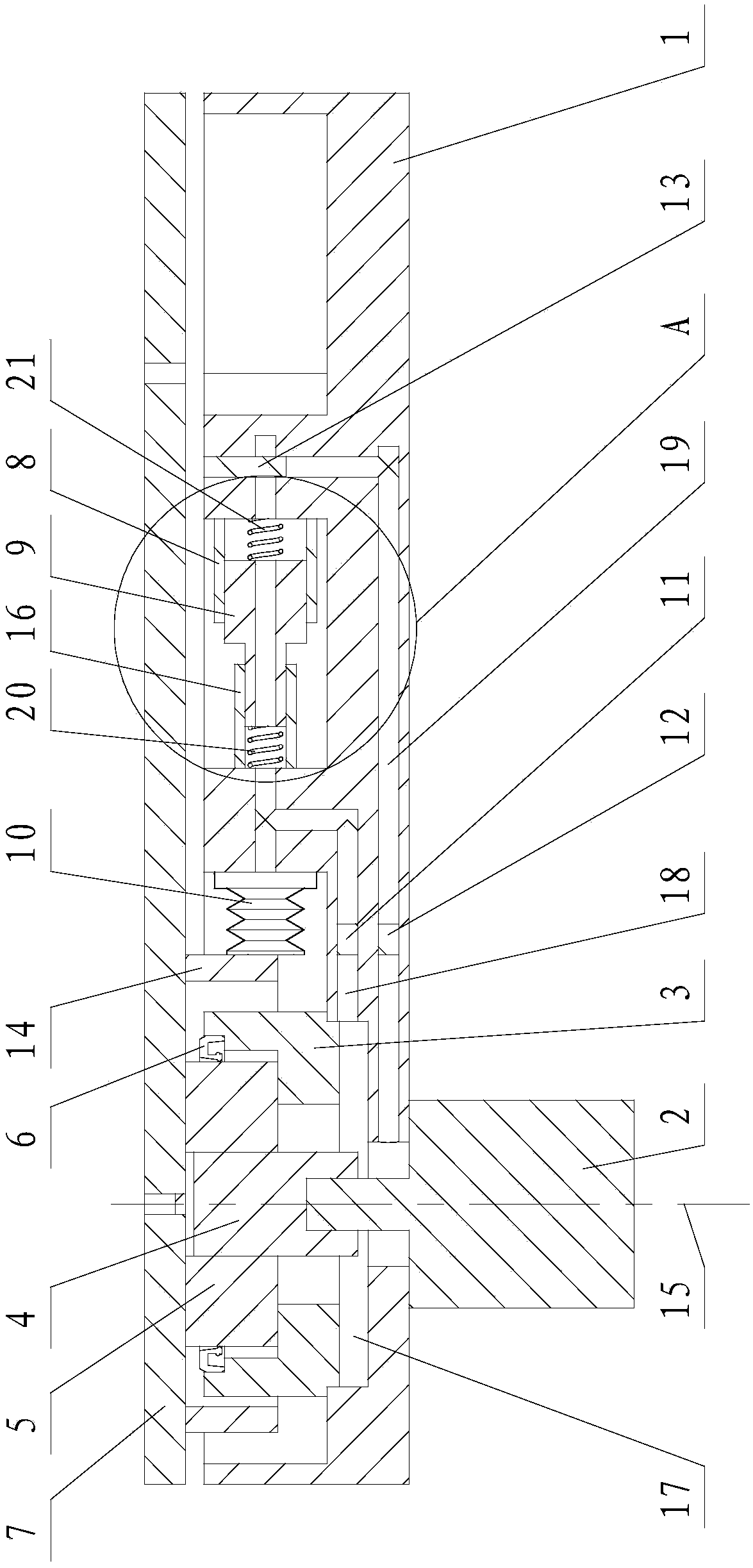

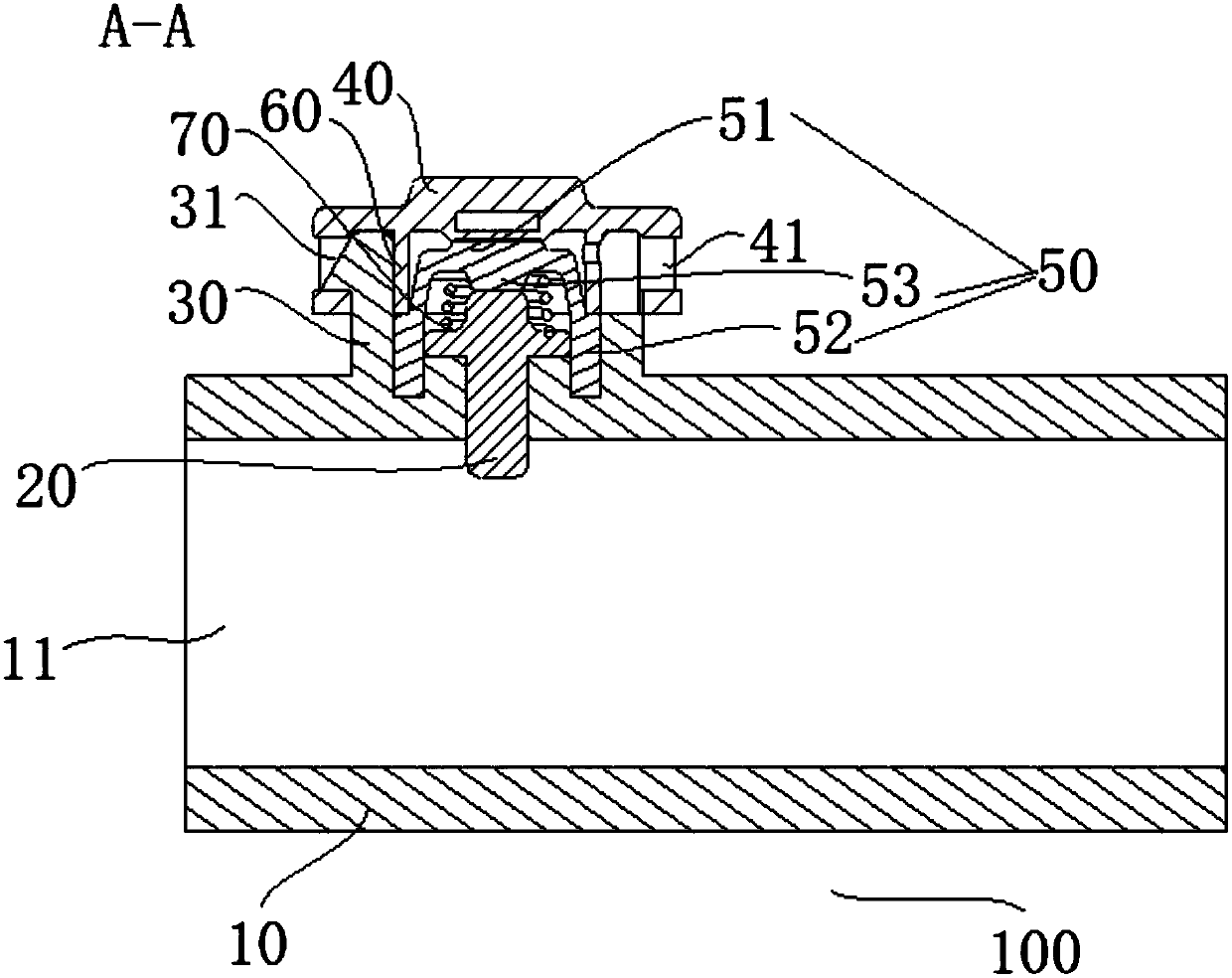

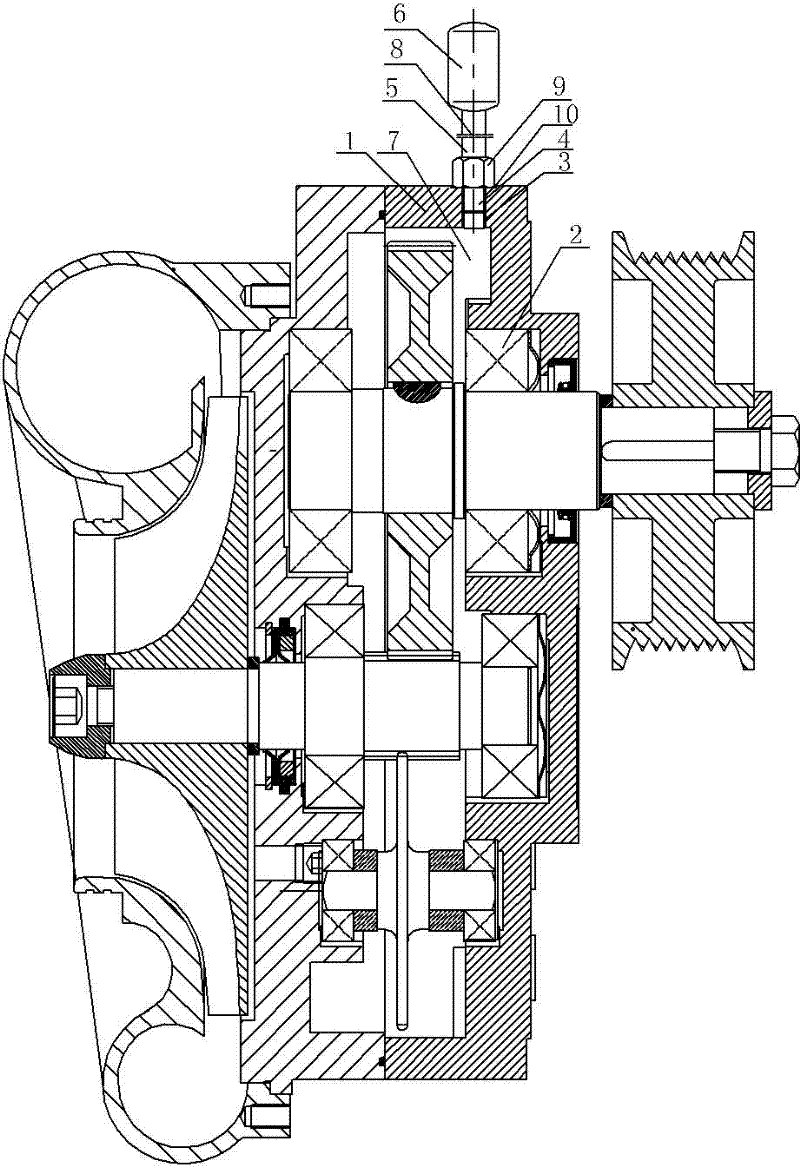

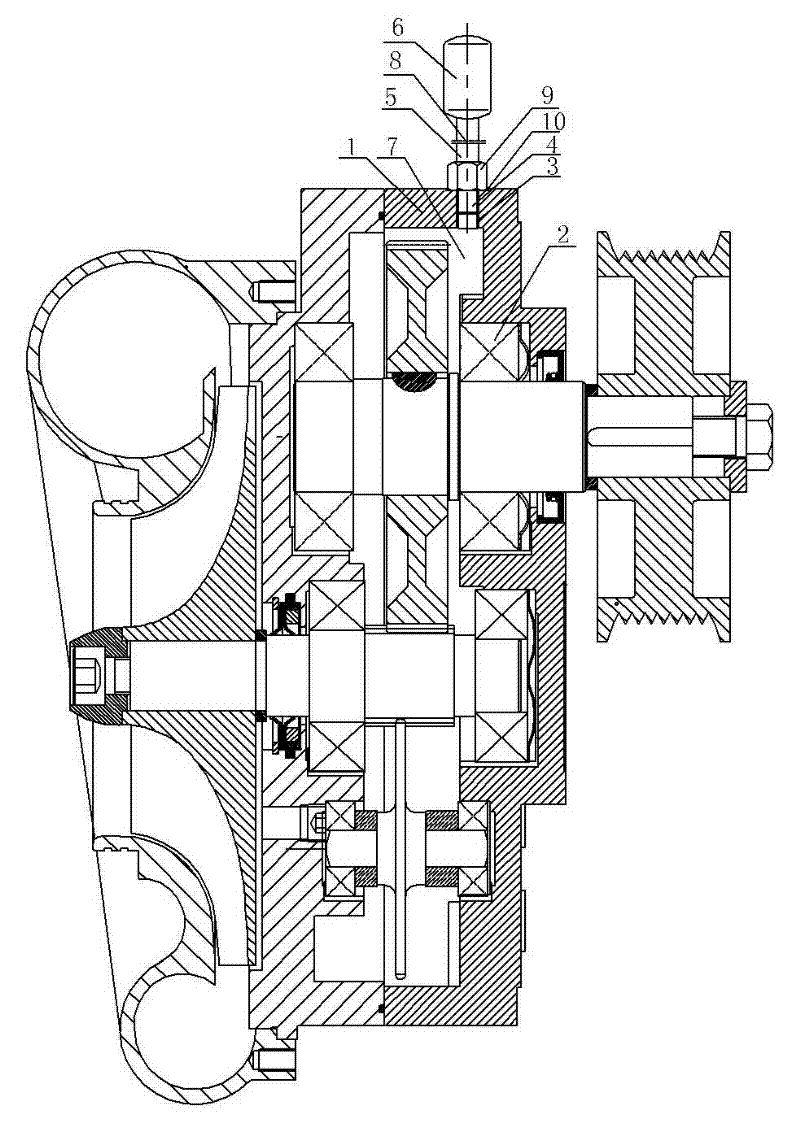

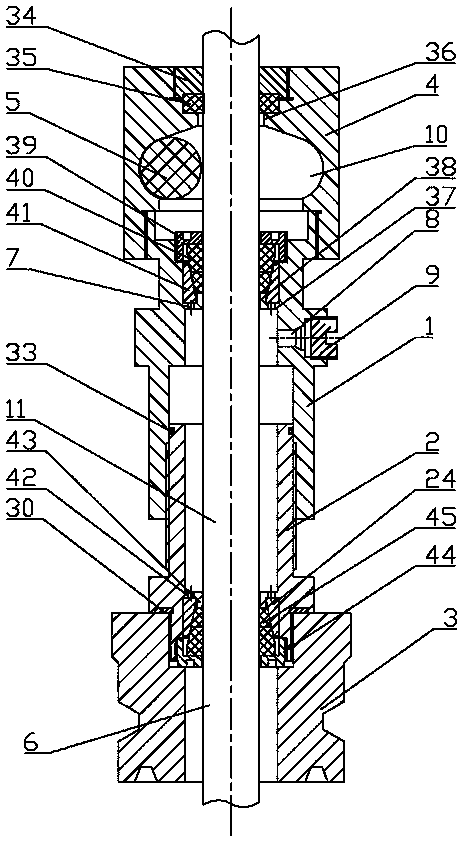

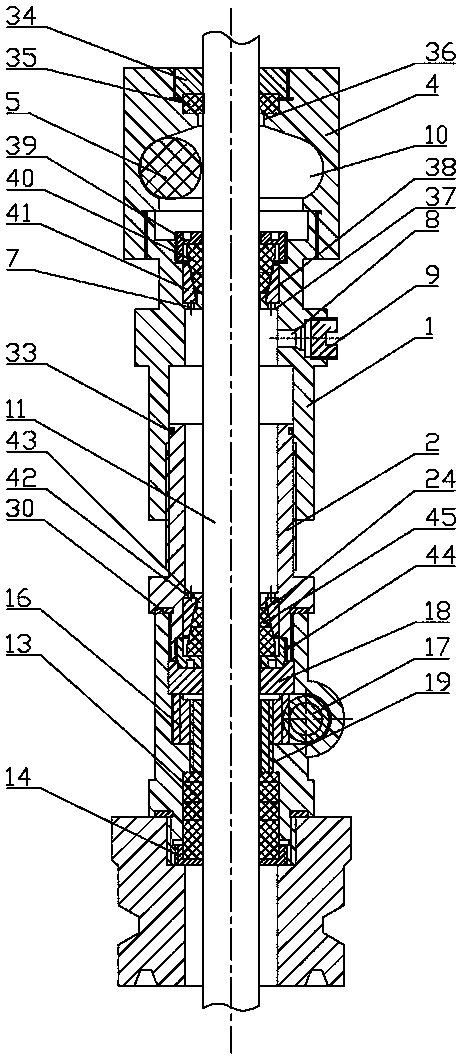

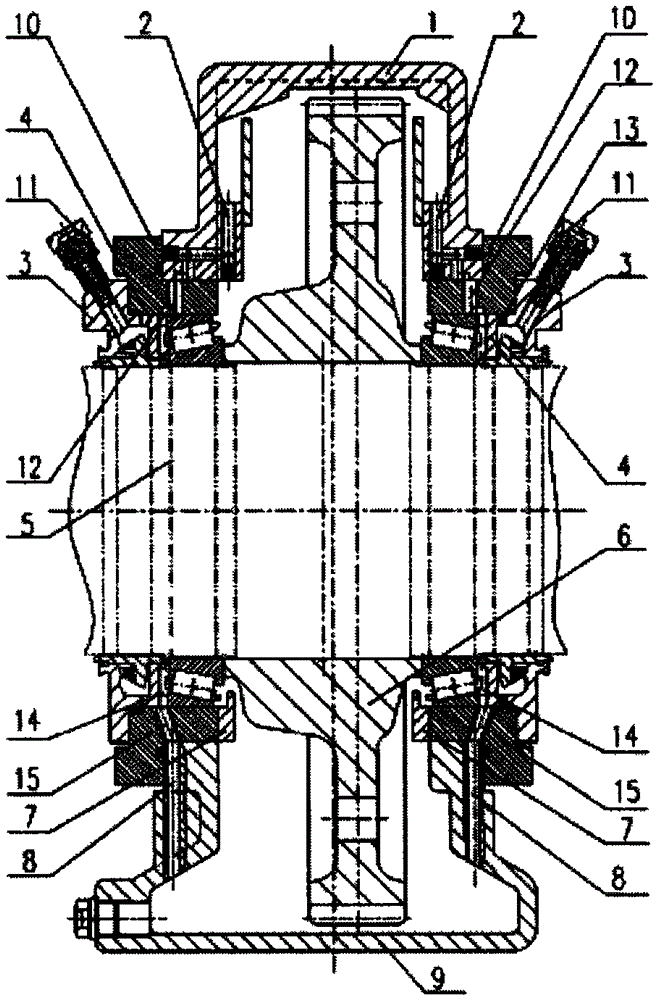

Hub reduction gear combined sealing structure

PendingCN110513465AAvoid Oil Leakage ProblemsImproves sealing reliabilityGearing detailsEngineeringMechanical engineering

The invention relates to a hub reduction gear combined sealing structure, and belongs to the technical field of vehicle transmission. The sealing structure comprises a static ring and a movable ring,wherein the static ring is fixed to a frame; the movable ring is opposite to the static ring, and is fixedly connected to a torsion shaft; the end face of the static ring is provided with at least three rings from outside to inside along the radial direction; the outer circle of the ring on the innermost layer is provided with a clamping groove embedded with a packing; the inner circle of the ringon the innermost layer is in tight fit with a throttling ring and a framework oil seal; the throttling ring is provided with a group of radial extension combs which are arranged at intervals along the axial direction; the end face of the movable ring is provided with a circular lug and a lower edge inner ring which are embedded between adjacent rings to construct a radial labyrinth seal from outside to inside along the radial direction; the inner circumferential surface, opposite to the clamping groove, of the circular lug is in contact with the packing to construct a packing seal; the outercircle of the lower edge inner ring is in contact with the framework oil seal to seal the framework oil seal; and a throttling ring seal is formed at a position opposite to the throttling ring. The quadruple sealing structures perform own functions. Through organic combination, the lip edge of the framework oil seal is always in a stable and reliable sealing state, so that the fatigue failure is avoided effectively, and oil leakage after long-term use is avoided.

Owner:CRRC QISHUYAN INSTITUTE CO LTD

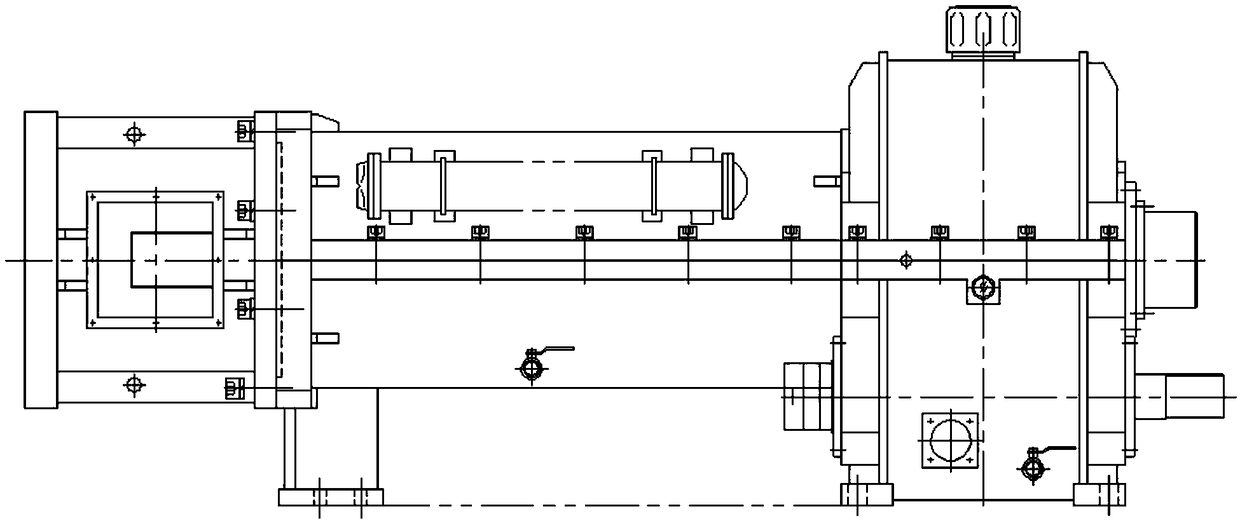

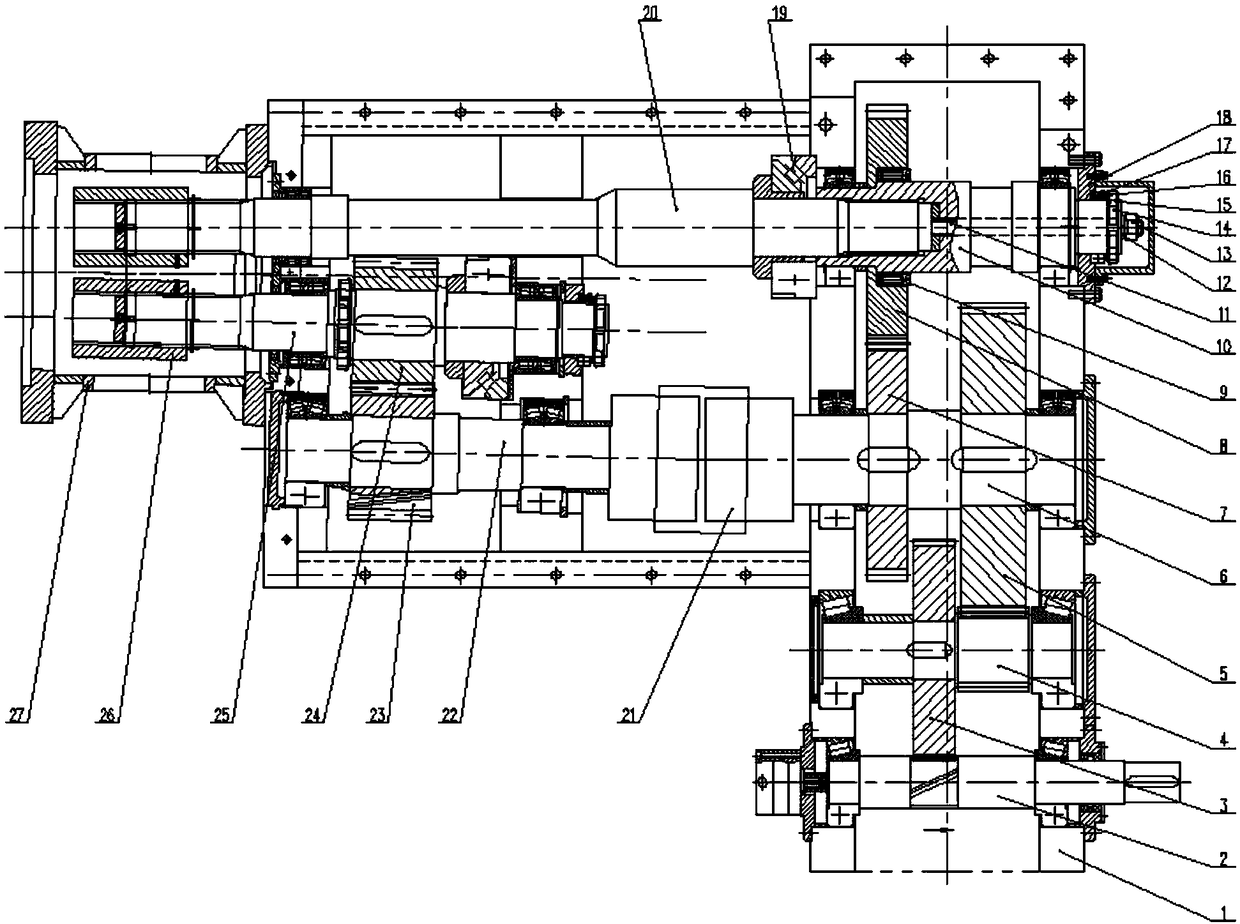

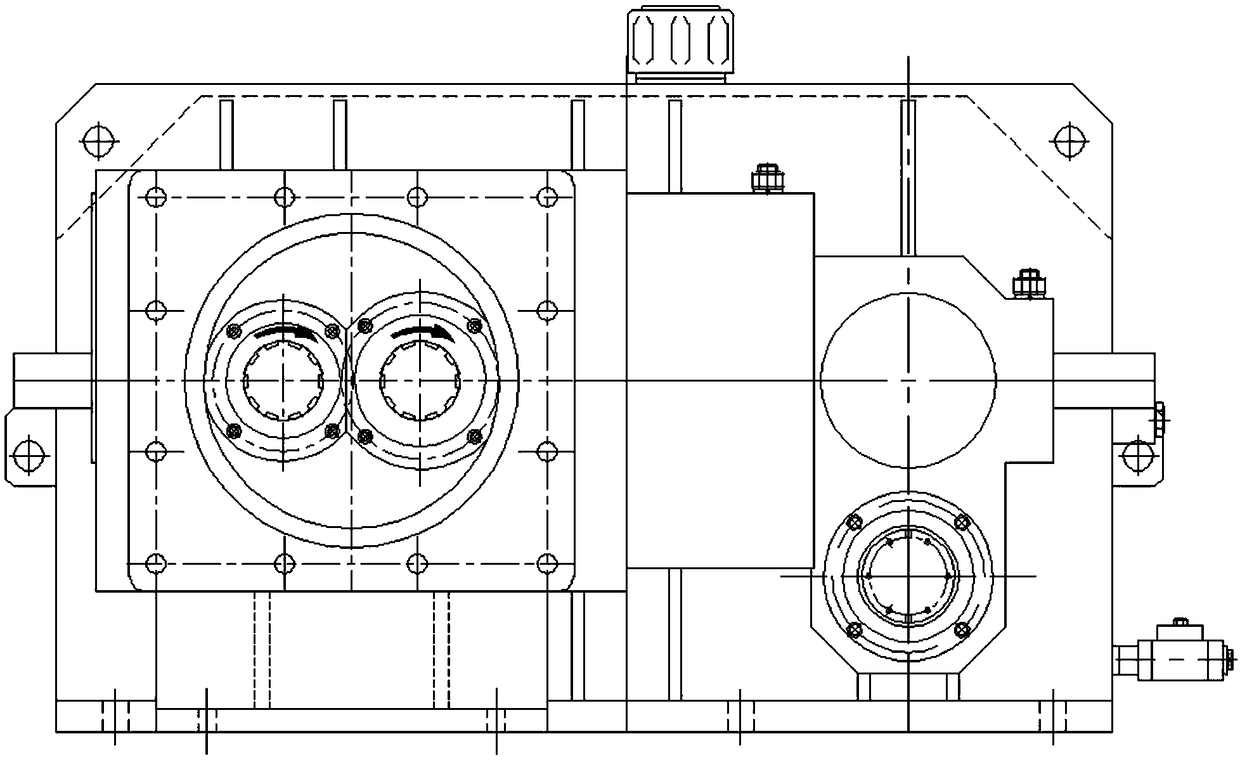

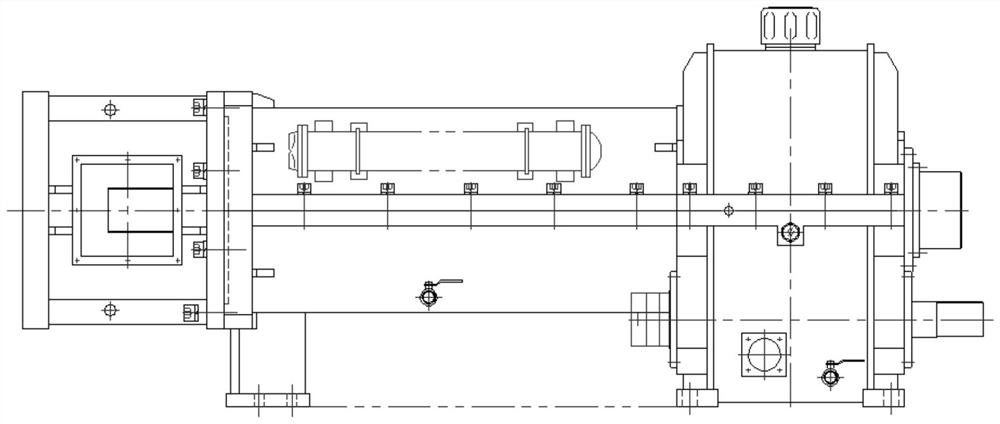

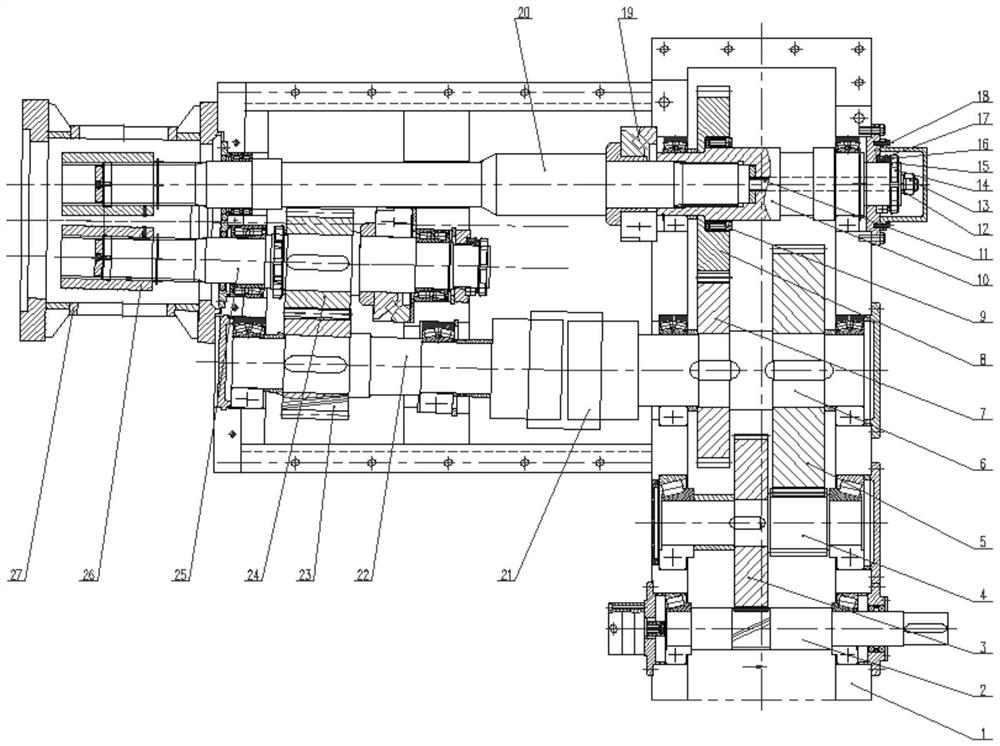

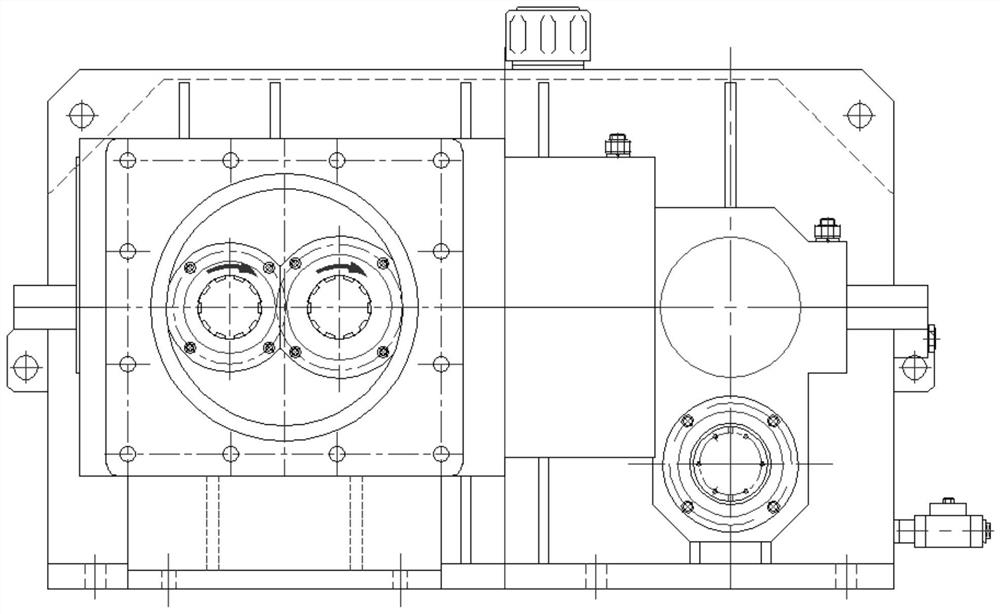

Same direction cone double-gear box adopting flexible shaft coupler

ActiveCN109442003AImprove reliabilityGuaranteed parallelYielding couplingToothed gearingsLeft handedLong axis

The invention relates to a same direction cone double-gear box adopting a flexible shaft coupler. An input shaft, a gear shaft, a first transmission shaft and a second transmission shaft are installedin a transmission box body of a box body in parallel; a small gear is installed on the gear shaft, and is in engaged connection with a gear of the input shaft; the gear shaft is in engaged connectionwith a large gear installed on the first transmission shaft which is provided with a first transition gear; the first transition gear is in engaged connection with a second transition gear installedon the second transmission shaft in a transmission manner; an output long shaft, a third transmission shaft and an output short shaft are installed in a distributing box body of the box body; the first transmission shaft and the third transmission shaft are connected through the flexible shaft coupler; the output long shaft is connected with the second transmission shaft through an involute spline; a left-handed distribution gear is installed on the third transmission shaft; a right-handed distribution gear is installed on the output short shaft; and common cylindrical spiral gear structures are adopted for the left-handed and right-handed distribution gears. According to the same direction cone double-gear box adopting the flexible shaft coupler, the first transmission shaft and the thirdtransmission shaft are connected through the flexible shaft coupler, the installing space is reduced, the torque is high, noise is low, and machining and installing are convenient.

Owner:江阴齿轮箱制造有限公司

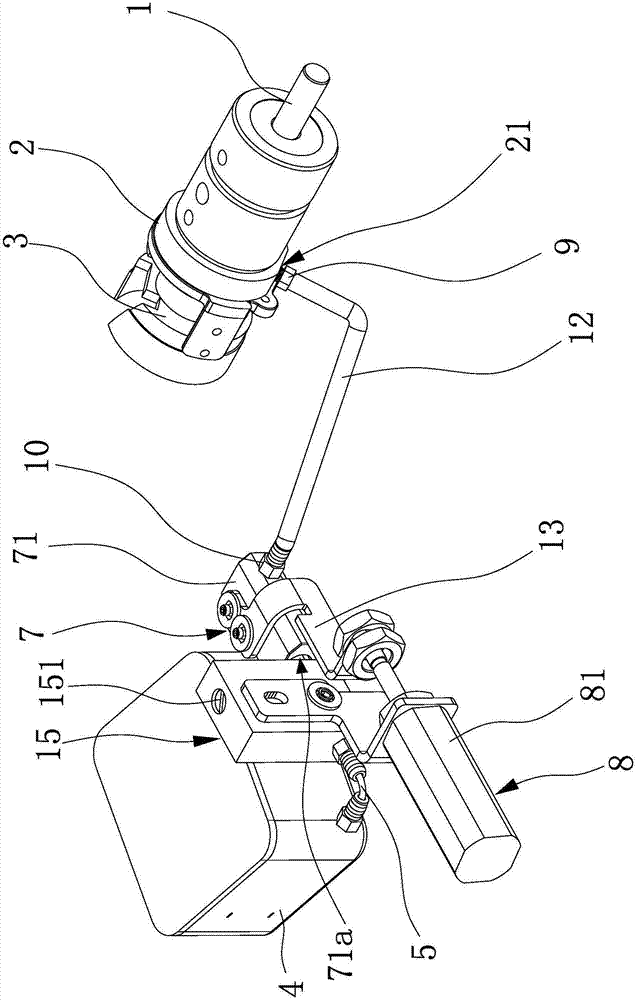

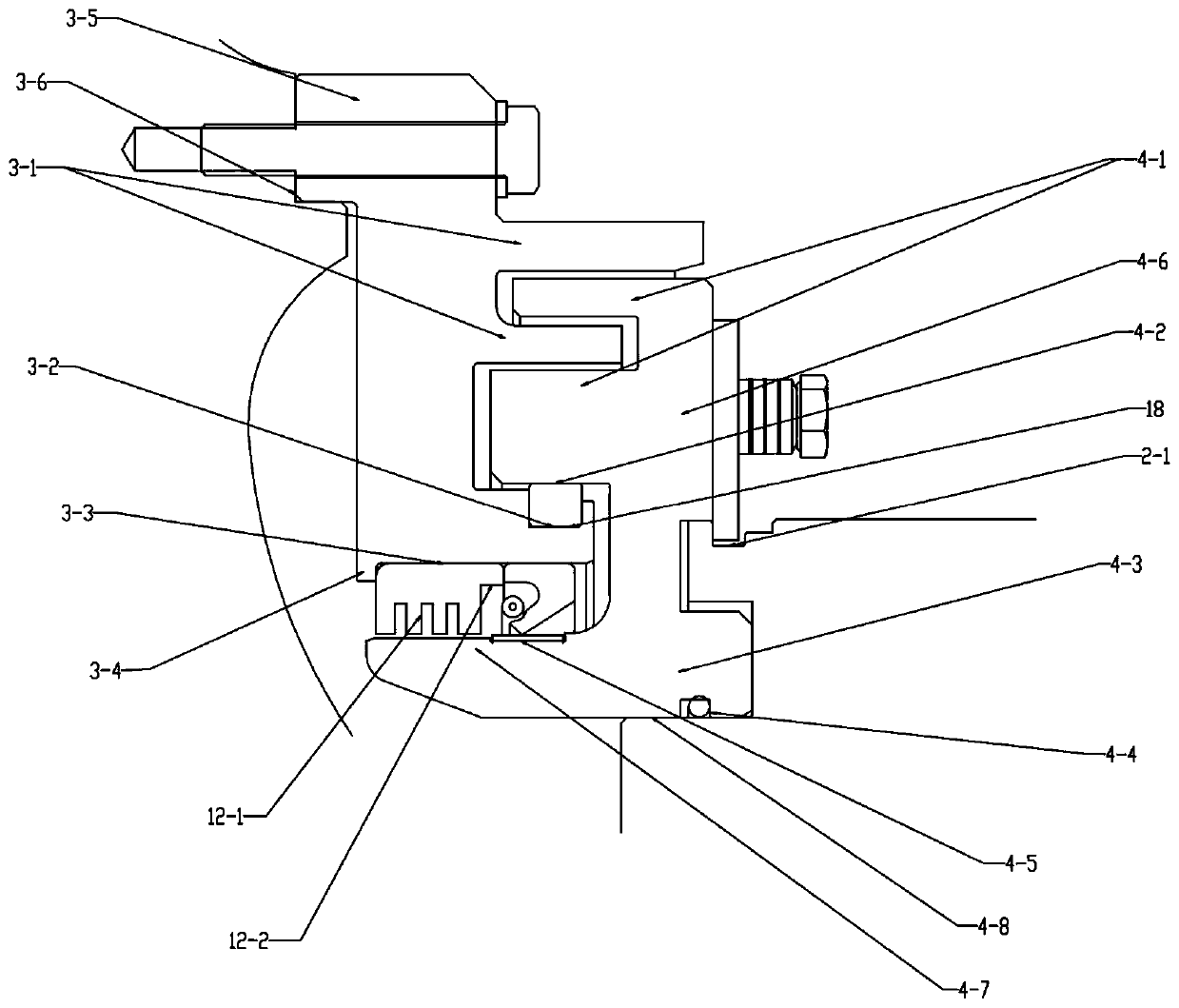

Actuating cam type lubricating self-cleaning mechanism

ActiveCN109807929ALow resistance to joint rotationStable pressureGear lubrication/coolingManipulatorInternal pressureReducer

The invention relates to an actuating cam type lubricating self-cleaning mechanism. A motor is connected to a large arm in a static sealing mode, an output end of the motor is connected with one end of an output shaft of a speed reducer through an input gear shaft of the speed reducer, one end of a shell of the speed reducer is arranged in the large arm in a static sealing mode, the other end of the shell of the speed reducer is connected with the output shaft of the speed reducer in a sealing rotation mode, and the other end of the output shaft of the speed reducer is connected with a small arm in a in static sealing mode; the two ends of an inertia double-head piston are connected with a large cylinder barrel and a small cylinder barrel in a sealing mode to form sliding pairs correspondingly; and a speed reducer inner cavity filled with lubricating grease is arranged in the large arm, the speed reducer inner cavity communicates with the interior of the small cylinder barrel through an oil way A, the interior of the large cylinder barrel communicates with the speed reducer inner cavity through an oil way B, an oil outlet one-way valve allowing oil to flow to the small cylinder barrel only is arranged in the oil way A, an oil return one-way valve allowing oil to flow to the speed reducer inner cavity only is arranged in the oil way B, and a filter element is arranged in the part, close to the large cylinder barrel, of the oil way B. According to the mechanism, the internal pressure of a robot joint can be stabilized, oil leakage is prevented, the energy efficiency is improved, and the energy-saving and environment-friendly effects are better.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

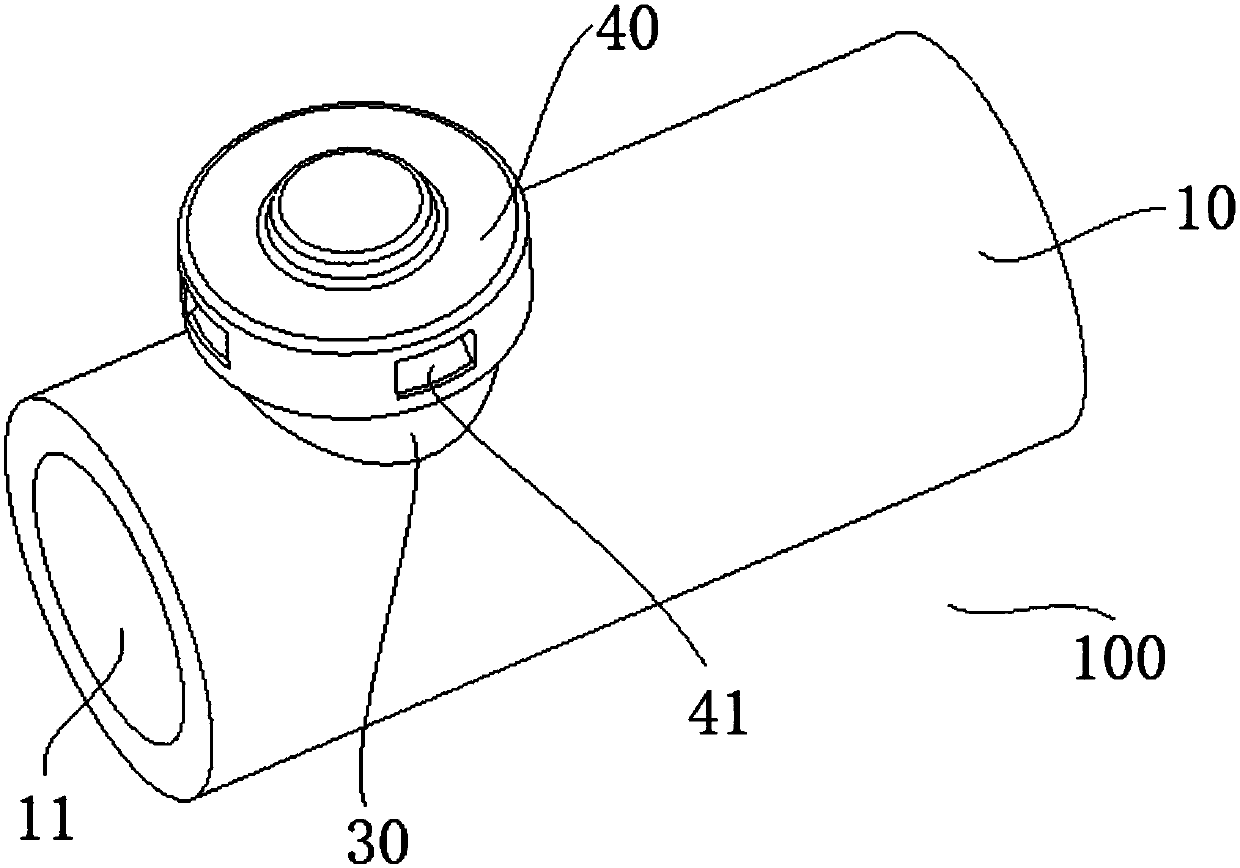

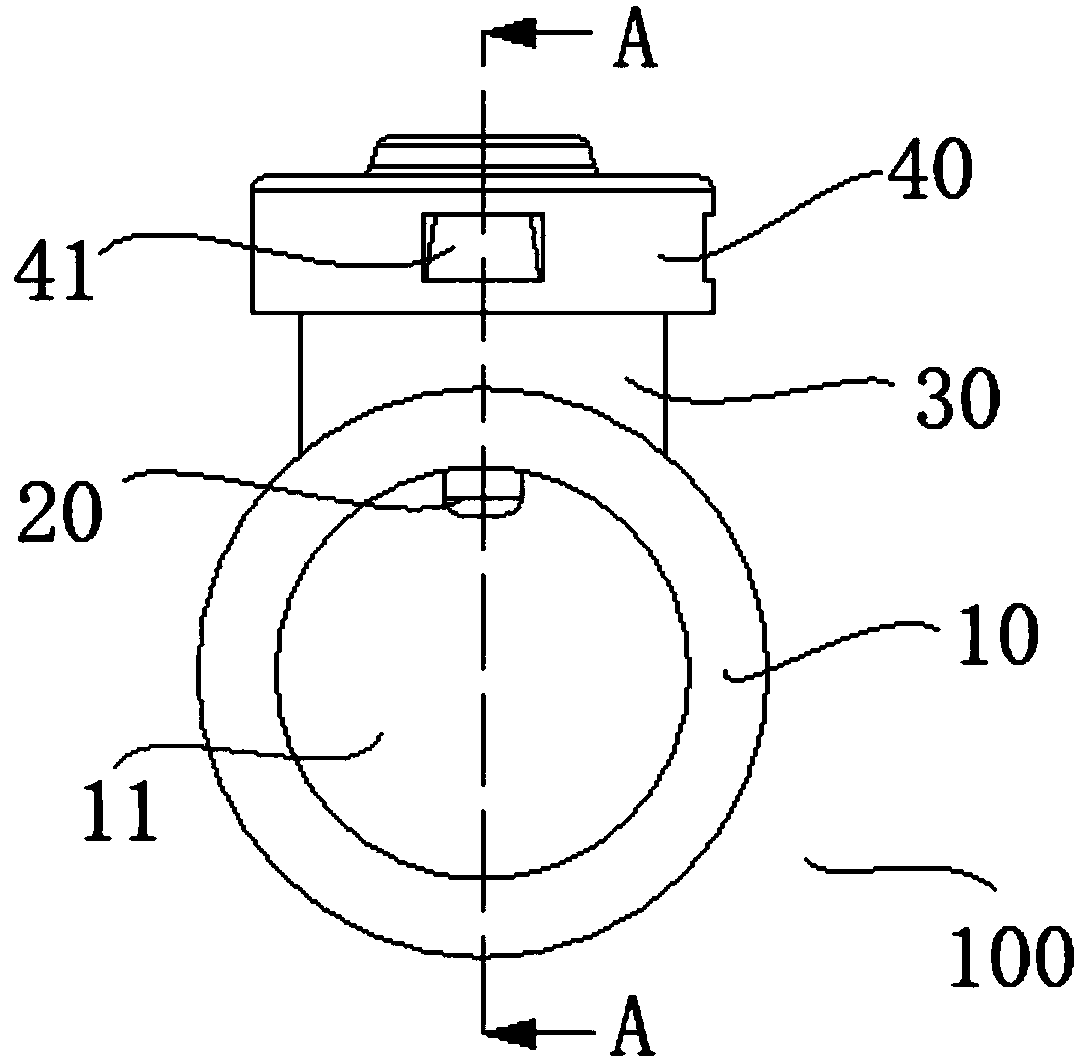

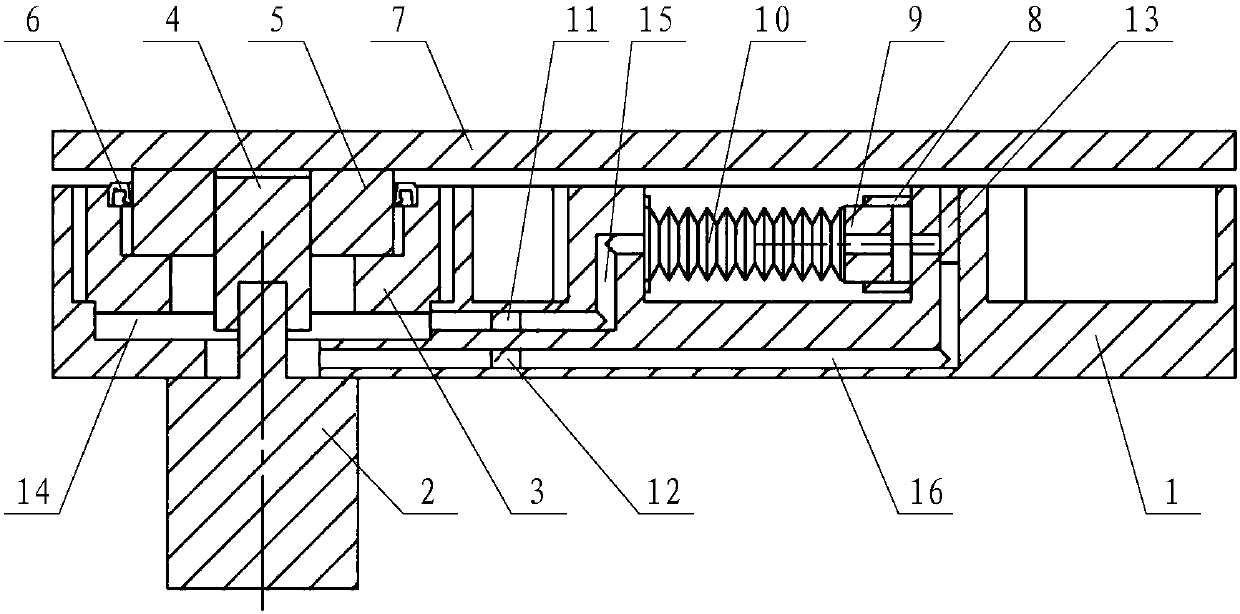

Quick connector of crankcase ventilation system

PendingCN107939477AAvoid Oil Leakage ProblemsPrevent oil spillsMachines/enginesCrankcase ventillationAir filterStructural engineering

The invention provides a quick connector of a crankcase ventilation system. The quick connector comprises an external connecting pipe, an electric switch and a mandrel; the external connecting pipe isformed in a pipe shape; a pipeline passage is formed in the external connecting pipe; one end of the external connecting pipe is connected to an air inlet manifold, and the other end of the externalconnecting pipe is connected to an air filter rubber pipe; a through hole communicating with the pipeline passage is formed in the side wall of the external connecting pipe; the electric switch is arranged outside the external connecting pipe and is adjacent to the through hole; the mandrel capable of moving between a first position and a second position in the axial direction of the through holeis arranged on the external connecting pipe; when the mandrel is located at the first position, at least a part of the mandrel extends into the pipeline passage, the mandrel and the electrical switchare disconnected, and when the mandrel is located at the second position, the mandrel and the electric switch are matched to form a closed electric circuit. The quick connector of the crankcase ventilation system has the advantages that when the air inlet manifold and the air filter rubber pipe are in insertion connection, the mandrel can touch the electric switch and form the closed electric circuit, and therefore normal operation of an engine can be ensured.

Owner:北京汽车动力总成有限公司

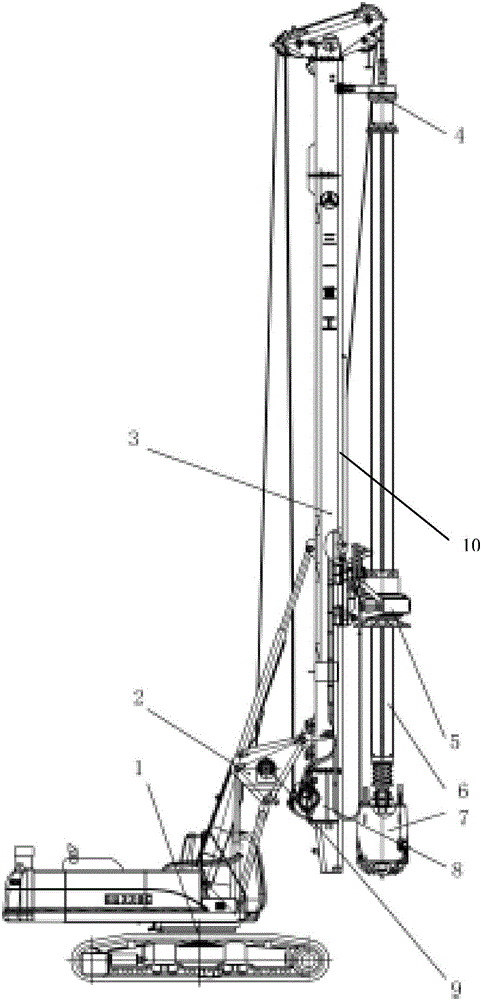

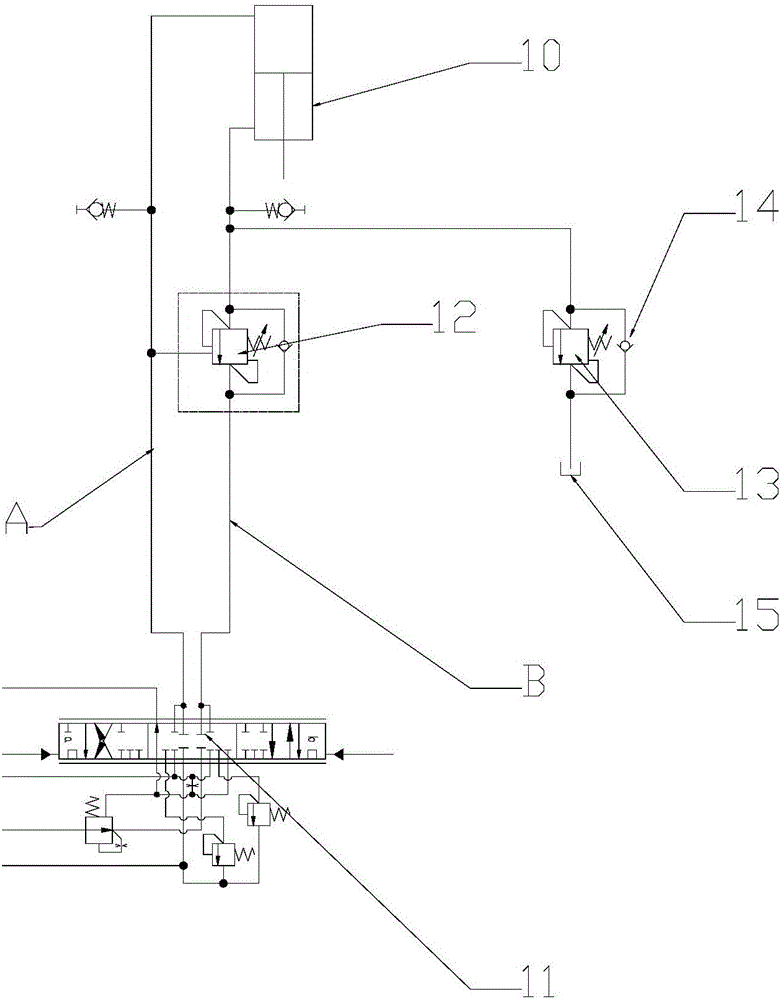

Rotary drilling rig

InactiveCN105089491ASolve the problem of premature damageAvoid Oil Leakage ProblemsConstructionsServomotorsFuel tankPetroleum engineering

The invention discloses a rotary drilling rig comprising a mast and a power head, wherein the mast is provided with a pressurized oil cylinder; one end of the pressurized oil cylinder is connected with the power head; the pressurized oil cylinder is connected with an oil inlet line and an oil return line; the oil return line is connected with an overflow valve; an oil inlet of the overflow valve is connected with the oil return line; and an overflow port of the overflow valve is connected with an oil tank. By using the rotary drilling rig, the problem of oil leakage of the pressurized oil cylinder is solved, a sealing element inside the pressurized oil cylinder is prevented from being damaged, and the service life of the pressurized oil cylinder is greatly prolonged.

Owner:BEIJING SANY HEAVY MASCH CO LTD

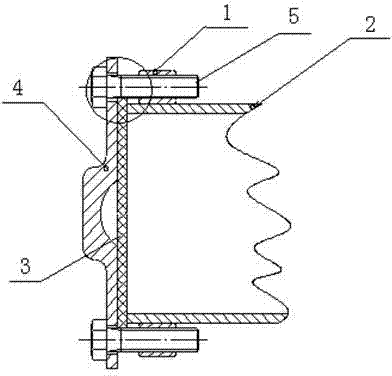

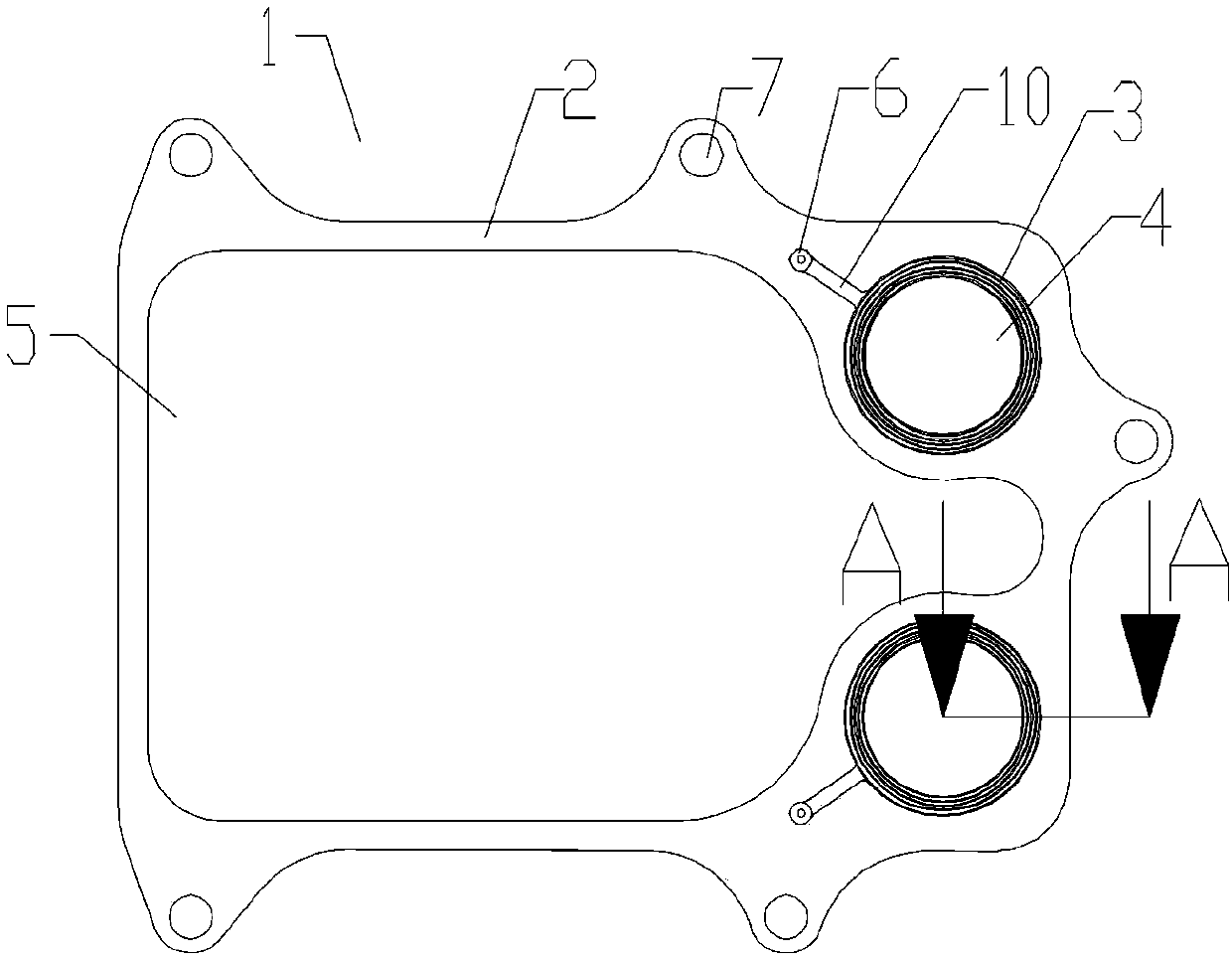

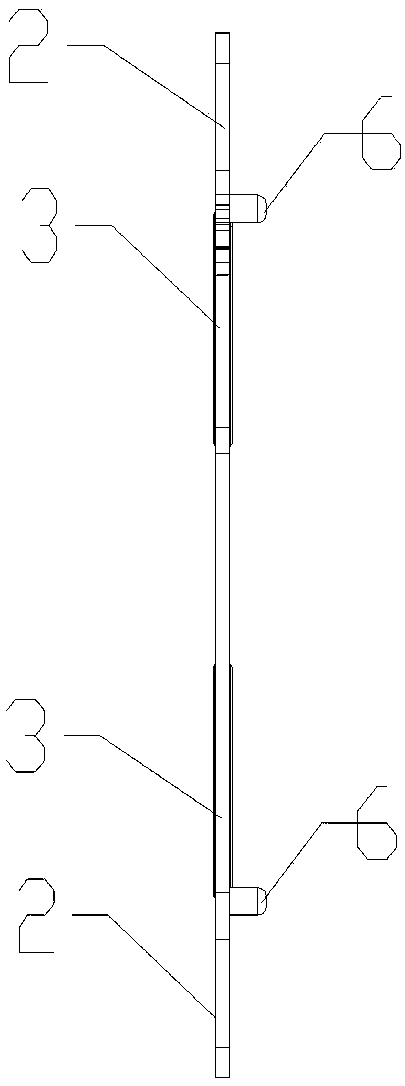

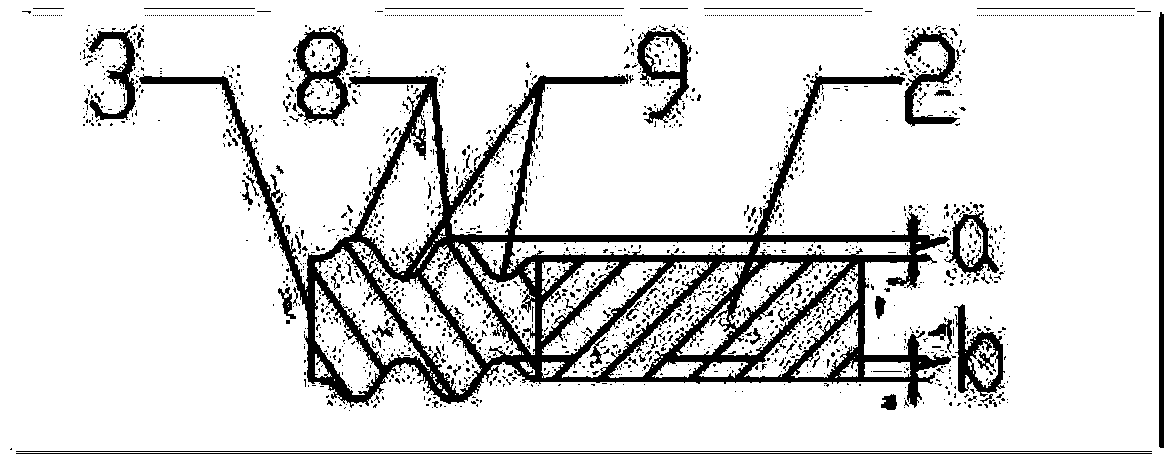

Transformer rectangular pipe opening blocking plate sealing structure and sealing method

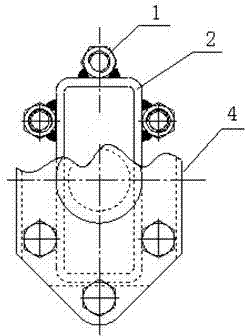

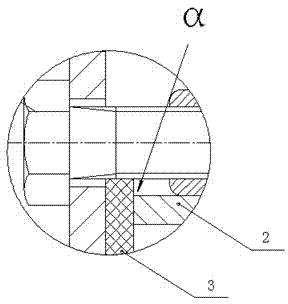

ActiveCN103794334AAvoid Oil Leakage ProblemsGood sealingEngine sealsTransformers/inductances detailsMechanical engineeringTransformer

The invention relates to a transformer rectangular pipe opening blocking plate sealing structure and a sealing method and belongs to the technical field of production of transformers. According to the technical scheme, the transformer rectangular tube opening blocking plate sealing structure comprises hex nuts (1), a rectangular steel pipe, a rubber cushion plate (3), a blocking plate (4) and fastening bolts (5). The hex nuts (1) are fixed to the outer sides of four pipe walls at the opening of the rectangular steel pipe (2). The blocking plate is in a hexagon shape and connected with the rectangular steel pipe (2) through the fastening bolts (5) and the hex nuts (1). The rubber cushion plate is arranged between the blocking plate (4) and the connected rectangular steel pipe. The rubber cushion plate (3) is rectangular and matched with the end face pipe opening of the rectangular steel pipe (2) in size. The transformer rectangular tube opening blocking plate sealing structure has the advantages that the effect of sealing the pipe opening of the rectangular pipe of the transformer is good, oil leak of the transformer is avoided, the materials are greatly saved, the working efficiency is improved and labor intensity of workers is relieved.

Owner:BAODING TIANWEI GROUP TEBIAN ELECTRIC

Improved mechanical turbocharger

InactiveCN102330596AAvoid Oil Leakage ProblemsAvoid oil spillsGear lubrication/coolingMachines/enginesTurbochargerAmbient pressure

The invention provides an improved mechanical turbocharger by which the air pressure in a gear box can be always consistent with the ambient pressure, the temperature in the gear box can be reduced, the lubrication performance of lubricating oil can be ensured, and the occurrence of an oil penetration or leakage phenomenon can be avoided. The improved mechanical turbocharger comprises a gear box, and the gear box is arranged in a shell of the turbocharger; and the improved mechanical turbocharger is characterized in that the shell of the turbocharger is provided with a screwed hole, the screwed hole is a through hole, the inside of the screwed hole is provided with a hydraulic pipe joint, the hydraulic pipe joint is connected with a hydraulic pipe, and the hydraulic pipe is connected with a breathing apparatus.

Owner:WUXI MINGZHU TURBOCHARGER MFG

Passive pendulum bob type lubricating self-cleaning mechanism

The invention relates to a passive pendulum bob type lubricating self-cleaning mechanism. The passive pendulum bob type lubricating self-cleaning mechanism is characterized in that a motor is fixedlyconnected to a big arm in a static sealing manner, the output end of the mechanism is connected with one end of a speed reducer output shaft through a speed reducer input gear shaft, one end of a speed reducer shell is arranged in the big arm in a static sealing mode, the other end of the speed reducer shell is in sealing rotation connection with the speed reducer output shaft, the other end of the speed reducer output shaft is in static sealing connection with a small arm, the two ends of a double-head piston rod are correspondingly connected with a large cylinder barrel and a small cylinderbarrel to form a movable pair and are in sealed connection, a pendulum bob is hinged to the big arm and is connected with the double-head piston rod through a connecting rod, a speed reducer inner cavity is arranged in the big arm, the speed reducer inner cavity communicates with the interior of the small cylinder barrel through an oil way A, the interior of the large cylinder barrel communicateswith the speed reducer inner cavity through an oil way B, an oil outlet one-way valve is arranged in the oil way A, an oil return one-way valve is arranged in the oil way B, and a filter element is arranged in the oil way B close to the large cylinder barrel. According to the passive pendulum bob type lubricating self-cleaning mechanism, the internal pressure of a joint of a robot can be stabilized, oil leakage is prevented, the energy efficiency is reduced, and the energy-saving and environment-friendly effects are better.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

High-efficiency and environmental protection oil well wellhead sealing device

ActiveCN107165600BEffective against wear and tearPrevent fallingSealing/packingEngineeringMechanical engineering

Owner:克拉玛依市三达有限责任公司 +1

Internal circulation type lubricating self-cleaning mechanism

The invention relates to an internal circulation type lubricating self-cleaning mechanism. A motor is connected to a large arm in a static sealing manner, the output end is connected with one end of an output shaft of a speed reducer through an input gear shaft of the speed reducer, one end of a shell of the speed reducer is fixedly arranged in the large arm in a static sealing mode, the other endof the shell of the speed reducer is in sealing rotation connection with the output shaft of the speed reducer, and the other end of the output shaft of the speed reducer is in static sealing connection with a small arm; an inner cavity of the speed reducer is arranged in the large arm, the inner cavity of the speed reducer is in communication with one end of an elastic mechanism through an oil way A, the other end of the elastic mechanism is in communication with the inner cavity of the speed reducer through an oil way B, an oil outlet one-way valve which can only flow to the elastic mechanism is arranged in the oil way A, and an oil return one-way valve which can only flow to the inner cavity of the speed reducer is arranged in the oil way B; and close to the other end of the elastic mechanism, of the oil way B is provided with a filter element. According to the internal circulation type lubricating self-cleaning mechanism, the internal pressure of a robot joint can be stabilized, oil seepage is prevented, the joint rotation resistance of the robot is small, the energy efficiency is reduced, and the energy-saving and environment-friendly effects are better and remarkable.

Owner:SHENYANG SIASUN ROBOT & AUTOMATION

Novel gearbox

InactiveCN106838273AExtend your lifeAvoid failureGear lubrication/coolingEngineeringProcess complexity

The invention discloses a novel gear box. In order to solve the problem of oil leakage and the complex adjustment process of the bearing axial clearance in the existing gear box; the gear box includes a driven gear, a box body, an outer end cover and a bearing retaining ring; It is composed of the lower box body, and the upper box body and the lower box body have corresponding oil passages; there is an outer oil chamber between the bearing retaining ring and the outer end cover, and an inner oil chamber between the bearing retaining ring and the bearing. Cavity; between the box, the bearing retaining ring and the two outer end caps, there are bearing bushes; the bearing bushes are provided with bushings that communicate with the corresponding oil passages on the upper box and the lower box. Sleeve oil passage; the bush oil passage communicates with the inner oil chamber or the outer oil chamber. The invention improves the service life and lubricating quality of the driven gear bearing, reduces the complexity of the process, and improves the assembly efficiency of the gearbox.

Owner:CHANGZHOU KAIFA GUANGMING CASTING FACTORY GENERAL PARTNERSHIP

Gasket mechanism of engine oil cooler of engine and engine

InactiveCN107905886AGood structural sealingImprove sealingSealing arrangements for enginesMachines/enginesGasketLightening holes

The invention discloses a gasket mechanism of an engine oil cooler of an engine and the engine. The gasket mechanism comprises a metal gasket and also comprises a rubber gasket; the metal gasket is used for limiting the compressed degree of the rubber gasket on the inner side; a lightening hole and a gasket oil hole are formed in the metal gasket; the gasket oil hole and an engine oil duct hole are connected; the rubber gasket is arranged on the gasket oil hole in a sleeving manner and a sealing tape is arranged on the rubber gasket for sealing the gap between the engine oil duct hole and thegasket oil hole; grooves are formed around the sealing tape, and after the sealing tape is compressed and deformed, the grooves are used for accommodating deformation generated by compressing the sealing tape. The gasket disclosed by the invention is relatively good in structural sealing property, can be used repeatedly, can prevent oil impregnation as the gasket is aged, and is long in service life; in an assembling process, the gasket mechanism is easily positioned and assembled. Correspondingly, the durability of the engine adopting the gasket mechanism is reinforced.

Owner:NINGBO GEELY ROYAL ENGINE COMPONENTS

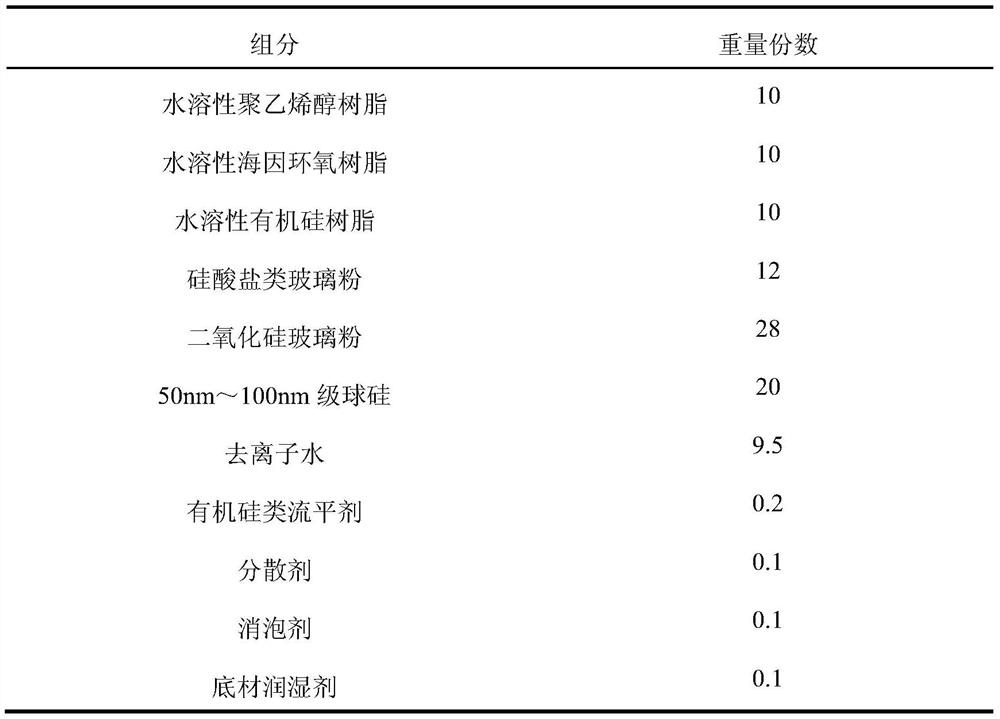

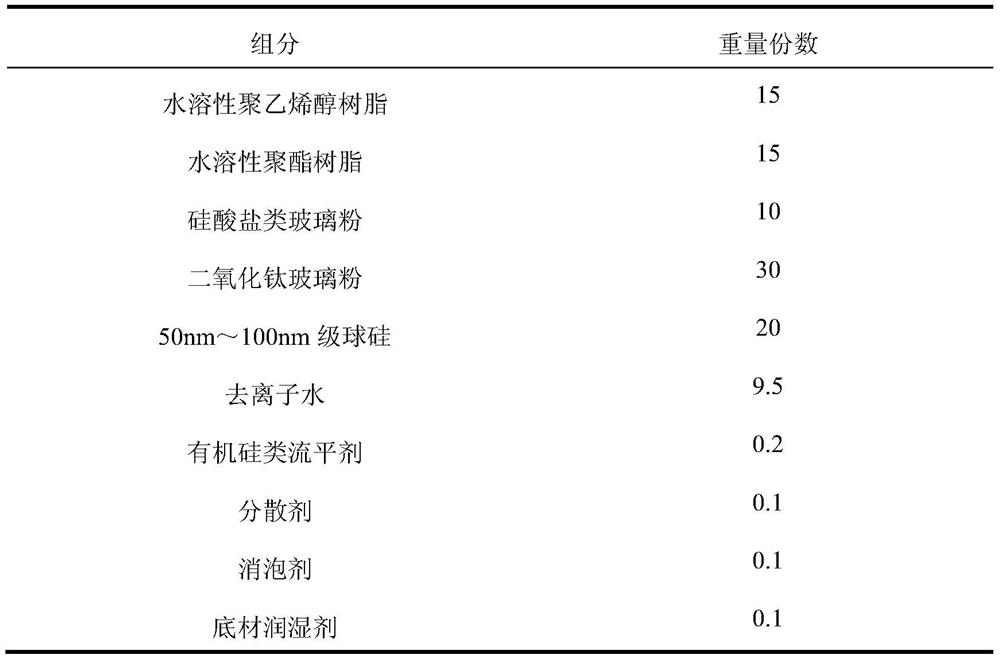

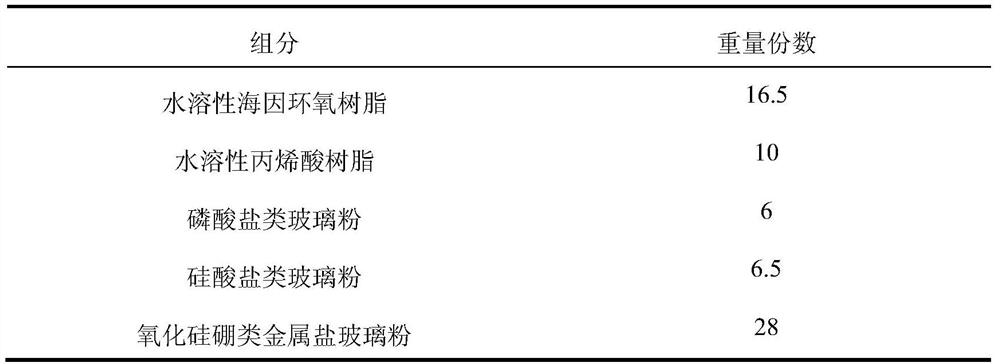

Water-based ink for realizing matte effect of 3D glass as well as preparation method and application of water-based ink

The invention discloses water-based ink for realizing a matte effect of 3D glass as well as a preparation method and an application of the water-based ink, the product is coated on a 2D glass substrate and comprises the following components in parts by weight: 20-35 parts of water-soluble resin, 5-15 parts of glass powder with the melting range of 300-500 DEG C, 15-35 parts of glass powder with the melting range of 500-700 DEG C, 10-25 parts of nanoscale spherical silicon, 5-20 parts of water and 0.01-1.0 part of auxiliaries. According to the water-based ink for achieving the 3D glass matte effect, the water-soluble resin serves as a main carrier of the glass powder with the melting range of 300-500 DEG C, the glass powder with the melting range of 500-700 DEG C and the nanoscale sphericalsilicon, fluidity and leveling property during printing are provided, and the water-soluble resin has good wrapping wettability on the glass powder with different melting ranges and the nanoscale spherical silicon; the adhesive force to a 2D glass substrate is good, and a coating is formed on the surface of the 2D glass after baking, so that the glass powder and the nanoscale spherical silicon with different melting ranges are uniformly and densely distributed on the 2D glass substrate.

Owner:HUNAN SOKAN NEW MATERIAL

Co-rotating bevel double gearbox with flexible shaft coupling

ActiveCN109442003BGuaranteed parallelGuaranteed to be in phaseYielding couplingToothed gearingsDrive shaftGear wheel

The invention relates to a same direction cone double-gear box adopting a flexible shaft coupler. An input shaft, a gear shaft, a first transmission shaft and a second transmission shaft are installedin a transmission box body of a box body in parallel; a small gear is installed on the gear shaft, and is in engaged connection with a gear of the input shaft; the gear shaft is in engaged connectionwith a large gear installed on the first transmission shaft which is provided with a first transition gear; the first transition gear is in engaged connection with a second transition gear installedon the second transmission shaft in a transmission manner; an output long shaft, a third transmission shaft and an output short shaft are installed in a distributing box body of the box body; the first transmission shaft and the third transmission shaft are connected through the flexible shaft coupler; the output long shaft is connected with the second transmission shaft through an involute spline; a left-handed distribution gear is installed on the third transmission shaft; a right-handed distribution gear is installed on the output short shaft; and common cylindrical spiral gear structures are adopted for the left-handed and right-handed distribution gears. According to the same direction cone double-gear box adopting the flexible shaft coupler, the first transmission shaft and the thirdtransmission shaft are connected through the flexible shaft coupler, the installing space is reduced, the torque is high, noise is low, and machining and installing are convenient.

Owner:江阴齿轮箱制造有限公司

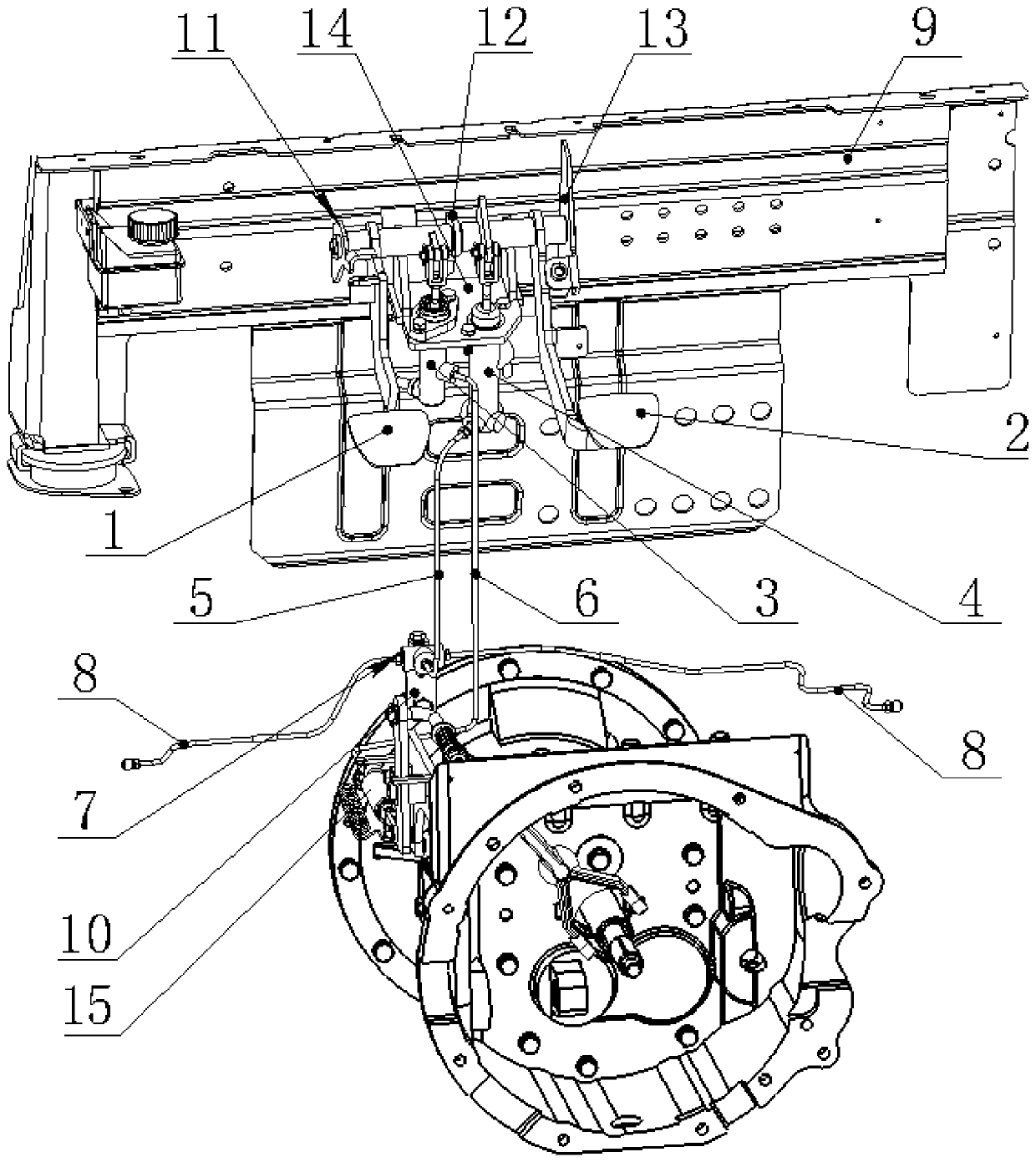

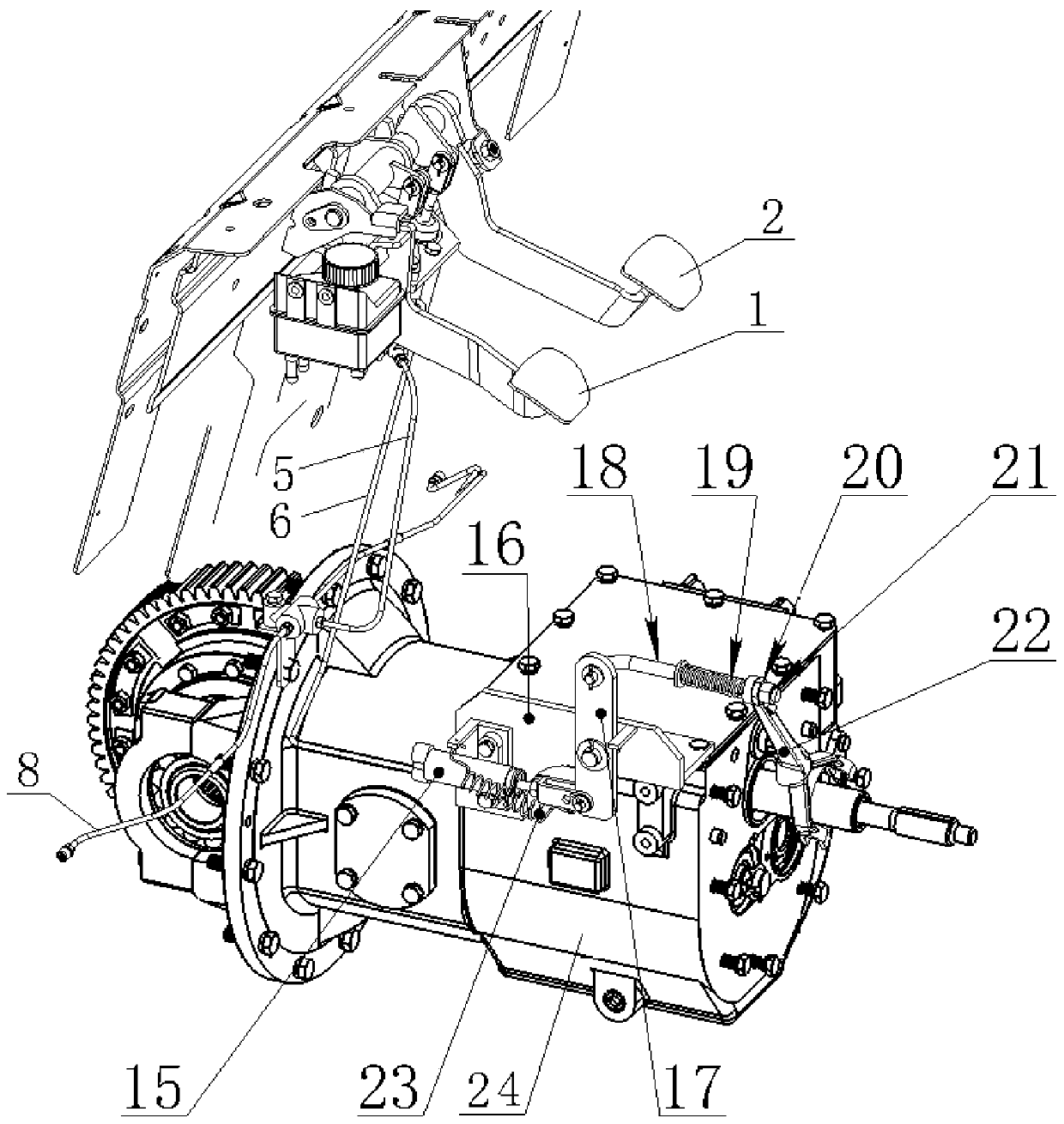

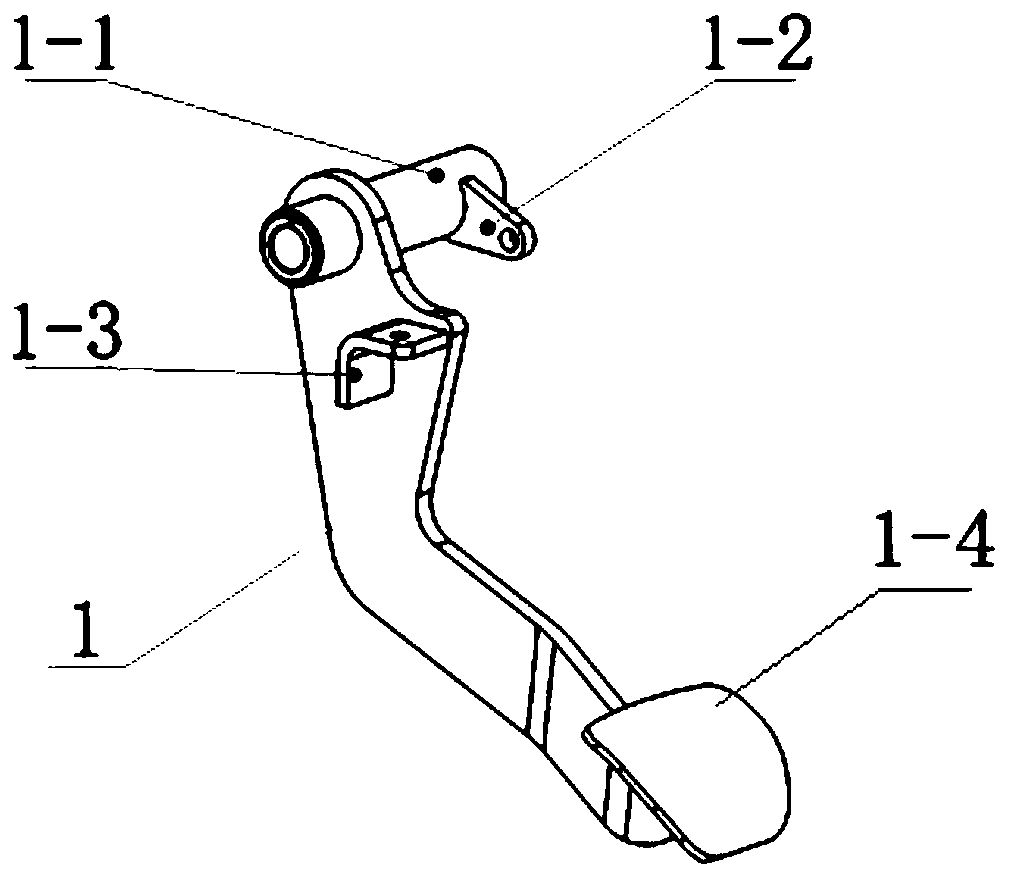

Hydraulic-type clutch and brake control system

PendingCN110697630AResolve the breakExtended service lifeClutchesControlled membersWheel cylinderControl theory

The invention provides a hydraulic-type clutch and brake control system. The hydraulic-type clutch and brake control system comprises a shifting fork, a clutch pedal assembly and a brake pedal assembly, wherein the shifting fork is installed on a gearbox; and the clutch pedal assembly and the brake pedal assembly are installed on a front plate assembly in a coaxial rotating mode. The clutch pedalassembly and the brake pedal assembly are connected with a clutch master cylinder and a brake master cylinder correspondingly. An oil outlet of the clutch master cylinder is connected with an oil inlet of a clutch wheel cylinder through a clutch hose, and an oil outlet of the brake master cylinder is connected with an oil inlet of each brake wheel cylinder through a brake hose. The piston end of the clutch wheel cylinder is fixedly connected with one end of a rocker arm assembly, and the other end of the rocker arm assembly is fixedly connected with one end of a disengaging lever. The other end of the disengaging lever is fixedly connected with the shifting fork. According to the hydraulic-type clutch and brake control system, due to the fact that a limiting compressed spring, a return tension spring, a limiting support and the hoses are connected, the initial gap of a clutch pressure plate is guaranteed while mechanism gaps are eliminated, the service life of the clutch pressure plateis further prolonged and the using safety of vehicles is further improved.

Owner:ANHUI HELI CO LTD

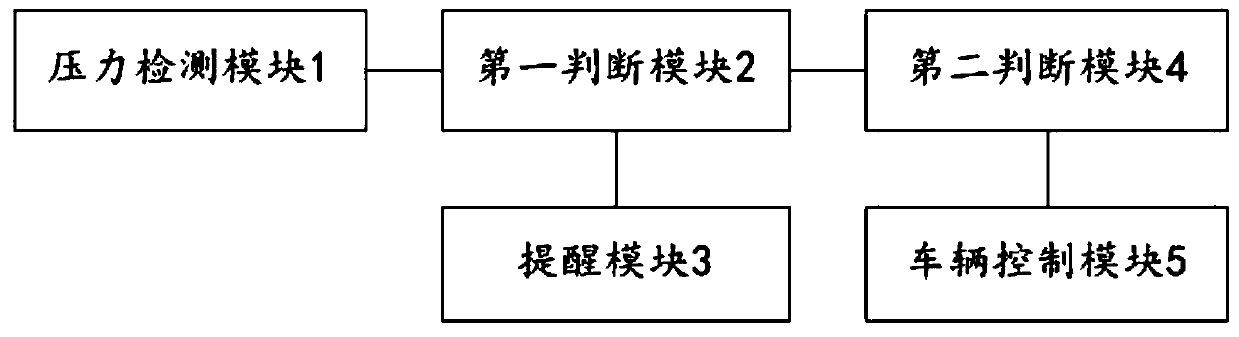

Pressure control device and method and vehicle

ActiveCN111002928AIncrease the function of pressure monitoringAvoid contactSignalling/lighting devicesElectric/fluid circuitDriver/operatorSimulation

The invention discloses a pressure control device and method and a vehicle, which are applied to PTU and / or RDU system pressure control, and the device comprises a pressure detection module which is used for measuring PTU and / or RDU system pressure information in real time; the pressure detection module comprises a ventilation plug and a pressure measurement element, the ventilation plug is connected with the PTU and / or the RDU, the ventilation plug comprises a ventilation groove, the pressure measurement element is arranged in the ventilation groove, and the pressure measurement element is used for measuring pressure information in the ventilation groove in real time; the first judgment module is used for judging whether the pressure information exceeds a first threshold value or not; thereminding module is used for sending first warning information to a driver when the pressure information exceeds a first threshold value; the second judgment module is used for judging whether the pressure information exceeds a second threshold value or not; and the vehicle control module is used for controlling the PTU and / or the RDU to stop working and sending second warning information to thedriver when the pressure information exceeds a second threshold value, so that the system pressure monitoring function is improved, and the protection and safety of the PTU (or the RDU) are improved.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

Marking machine with hub type identification and method for product traceability of the marking machine

The invention relates to the technical field of machinery. A marking machine with a wheel hub type identification function comprises a frame, a marking mechanism and a laser scanning mechanism, wherein the frame is provided with a conveying roller way for conveying a wheel hub and a lifting rotating clamping mechanism for clamping the wheel hub to move and rotate along the vertical direction; theframe is provided with a wheel hub type identification device for collecting appearance feature information of the wheel hub; the marking mechanism is arranged on the frame and is located below the conveying roller way, the marking mechanism comprises a pneumatic marking head and a three-dimensional motion assembly driving the pneumatic marking head to conduct three-dimensional motion; and the laser scanning mechanism comprises a laser scanning machine and a two-dimensional motion assembly driving the laser scanning machine to conduct two-dimensional motion in the horizontal and vertical directions, and the two-dimensional motion assembly is connected to the laser scanning machine. By replacing the tradition laser marking head with the pneumatic marking head, two modes of thermal marking and cold state marking are realized and the marking quality is excellent.

Owner:SH INTELLIGENT EQUIP SHANGHAI CO LTD +1

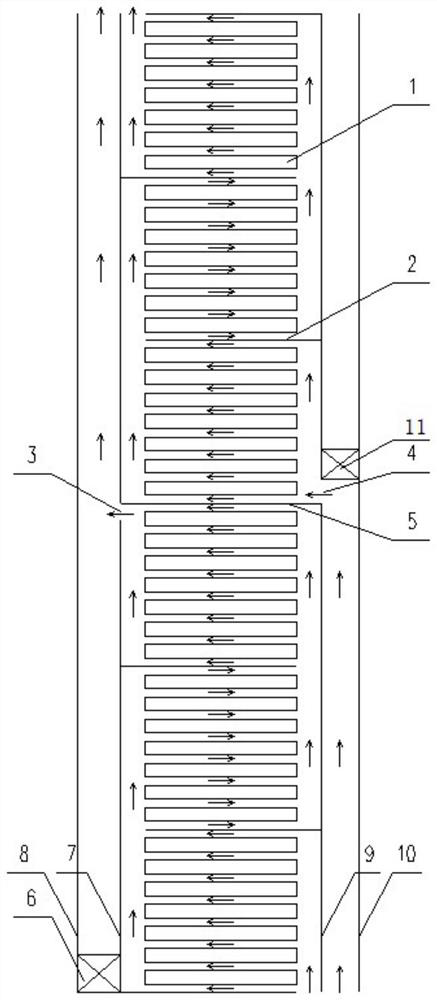

Oil way structure of transformer

ActiveCN112599337AAffect heat dissipationImprove cooling effectTransformers/inductances coolingTransformers/inductances coils/windings/connectionsTransformerEngineering

The invention discloses an oil way structure of a transformer. The oil way structure comprises a plurality of coils and wire cakes, wherein the coils and the wire cakes are sequentially arranged fromtop to bottom; oil baffles are arranged between the coils and the wire cakes; the oil baffles are arranged in a left-right alternating mode, so an S-shaped oil way is formed on the coils and the wirecakes; a first oil duct and a second oil duct are sequentially arranged on the inner sides of the coils and the inner sides of the wire cakes; a third oil duct and a fourth oil duct are sequentially arranged on the outer sides of the coils and the outer sides of the wire cakes; the first oil duct is divided into a lower first oil duct body and an upper first oil duct body, and the lower first oilduct body and the upper first oil duct body do not communicate with each other; and the third oil duct is divided into a lower third oil duct body and an upper third oil duct body. According to the invention, the oil way structure can effectively overcome the problems that since the insulation oil of an existing oil way structure flows through the whole coils, oil at the upper parts of the coils is heated by oil at the lower parts, oil temperature rises, and the heat dissipation, insulation life and operation safety of upper wire cakes are influenced.

Owner:常州西电变压器有限责任公司 +1

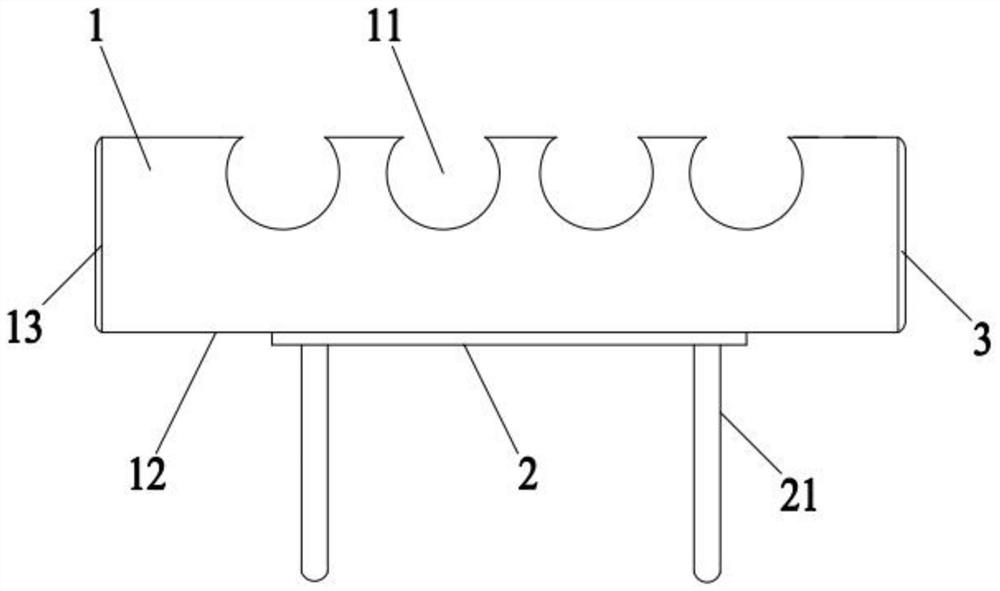

Microporous ceramic heating body

PendingCN113925225AHigh affinityImprove wear resistanceTobacco devicesCeramicwarePorous ceramicsComposite material

The invention relates to the technical field of atomizers, in particular to a microporous ceramic heating body. The microporous ceramic heating body comprises a porous ceramic body and a heating circuit, a plurality of tobacco tar storage grooves are concavely formed in the top of the porous ceramic body at intervals, and the outer surface of the porous ceramic body comprises an atomizing surface located at the bottom of the porous ceramic body and an tobacco tar sealing surface located on the side wall of the porous ceramic body. The outer side surface of the tobacco tar sealing surface is coated with a glass glaze layer, the heating circuit is arranged on the atomizing surface, and the porous ceramic body is prepared by sintering a porous ceramic material. According to the microporous ceramic heating body, the plurality of tobacco tar storage grooves are concavely formed in the upper end face of the porous ceramic body, so that the tobacco tar storage amount and the contact area between tobacco tar and the porous ceramic body can be increased, and the tobacco tar can permeate to an atomizing surface through micropores in the side wall of the porous ceramic body to be atomized;the tobacco tar sealing surface of the side wall of the porous ceramic body is coated with the compact glass glaze layer; the problem that part of tobacco tar leaks through micropores in the side wall of the porous ceramic body can be effectively avoided.

Owner:SHENZHEN HANQINGDA TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com