Novel gearbox

A kind of gear box, a new type of technology, applied in the direction of gear lubrication/cooling, belt/chain/gear, transmission parts, etc., can solve the problem of oil leakage phenomenon, bearing axial clearance adjustment process, complexity and other problems, to improve life and lubrication quality , Improve the service life, the effect of smooth oil return

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

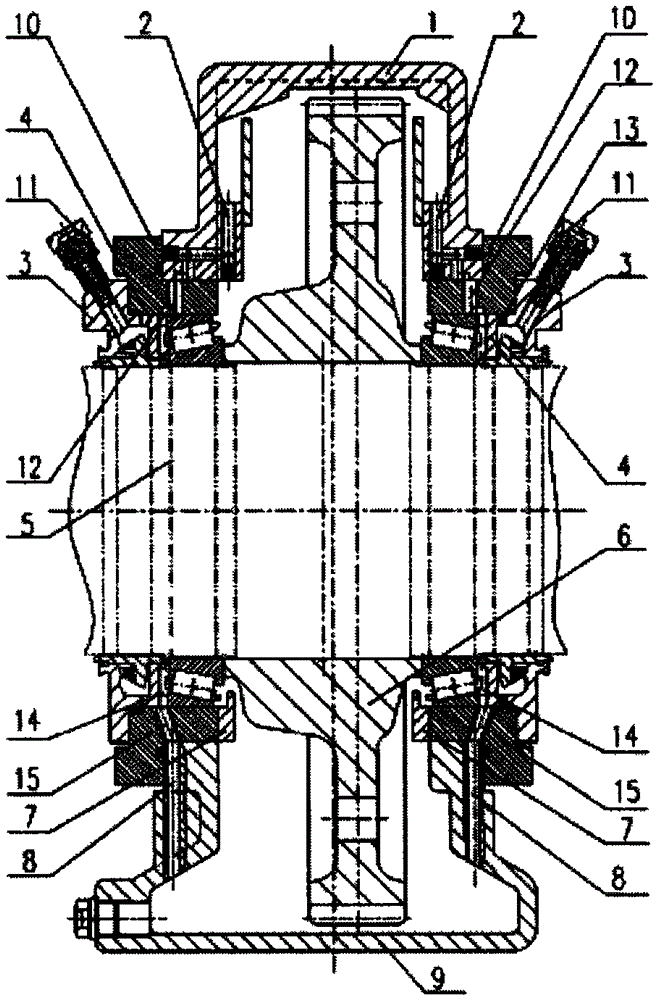

[0018] A gear box, the driven gear 6 and the inner ring of the driven gear bearing are installed on the axle 5, the outer ring of the driven gear bearing is installed on the bearing bush 10, the bearing bush 10 is connected with the gearbox, and the bearing bush 10 The provided bushing oil inlet passage 12 is used to communicate with the upper casing upper oil inlet passage 2 on the upper casing 1 to form an oil inlet passage for lubricating the bearing. The liner oil return passage 15 provided on the bearing bush 10 is used to cooperate with the lower case upper oil return passage 8 on the lower case 9 to form an oil return passage for lubricating the bearing. A respirator 11 is installed on the outer end caps 3 on both sides, and an axial gap adjustment ring 13 is arranged beside the bearing retaining ring 4 .

[0019] When the gearbox is in operation, lubricating oil splashes onto the top wall of the upper box body 1, and then flows into the oil inlet passages 2 on the uppe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com