Patents

Literature

69results about How to "Smooth oil return" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

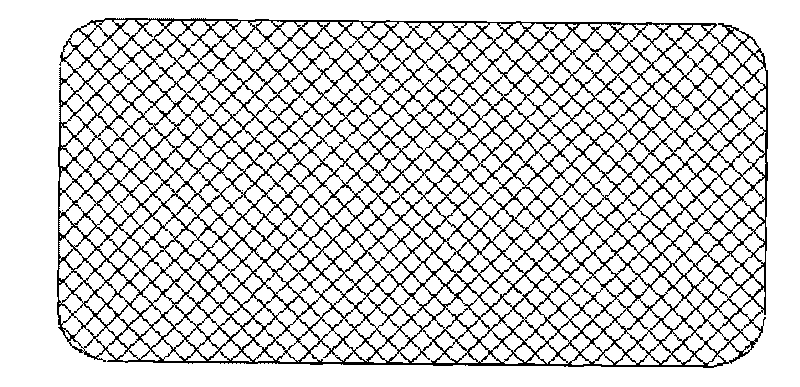

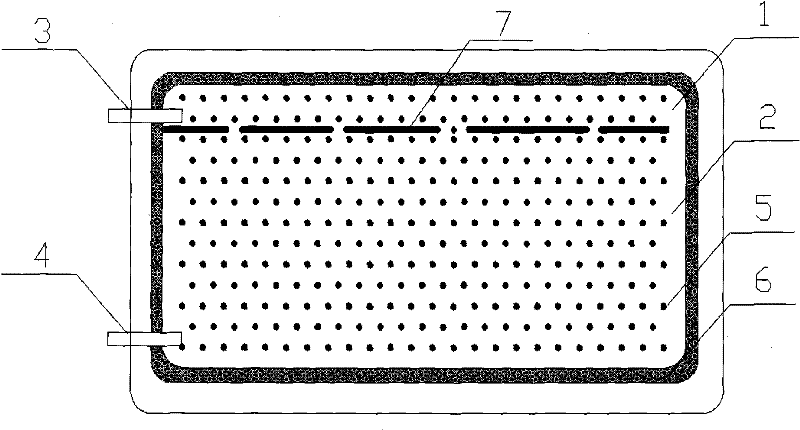

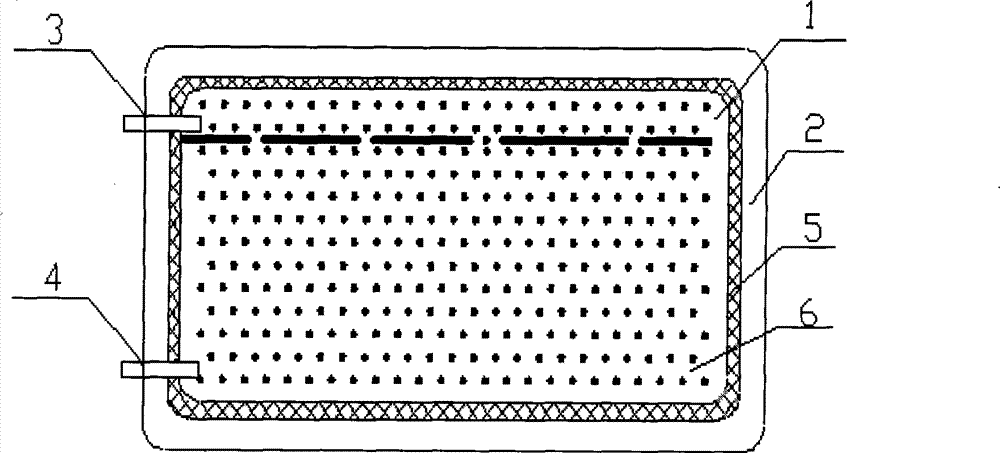

Aluminum honeycomb type evaporation plate and processing molding method thereof

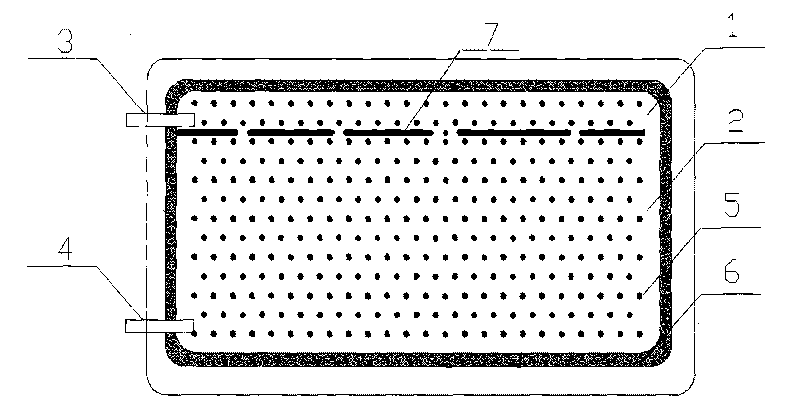

InactiveCN101691978ANot easy to form dead angleLow flow resistanceShaping toolsArc welding apparatusAluminum honeycombEvaporation

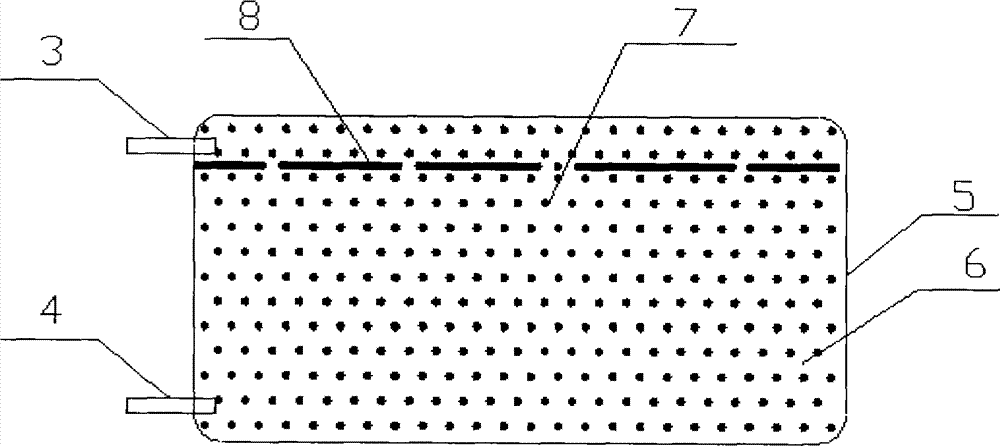

The invention discloses an aluminum honeycomb type evaporation plate and a processing molding method thereof. The evaporation plate adopts a high strength aluminum alloy plate and consists of an upper plate, a lower plate, an inlet pipe and an outlet pipe, wherein the two high strength aluminum alloy plates are overlapped and welded together by a solid-phase stir friction connecting method; the inlet pipe and the outlet pipe are inserted in the upper end and the lower end between the two high strength aluminum alloy plates and are connected with the high strength aluminum alloy evaporation plate body by using an electric arc welding method; and then the evaporation plate is finally molded through a mould and high-pressure bulging technology.

Owner:CHONGQING UNIV

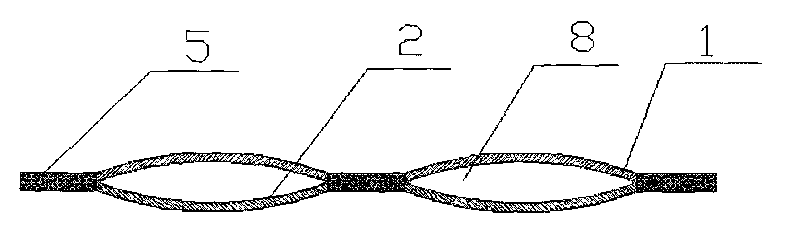

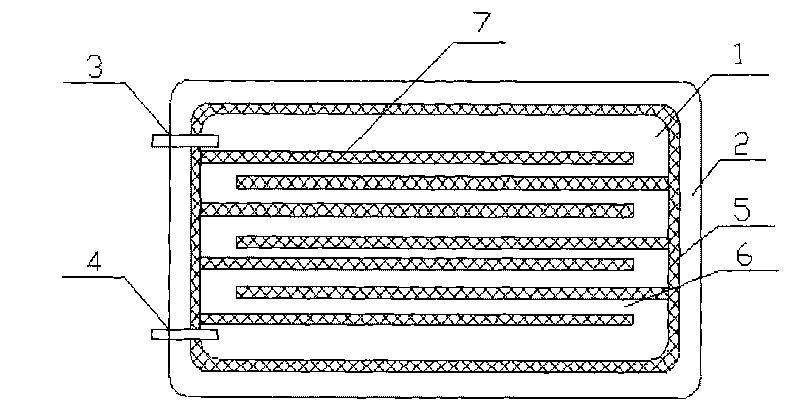

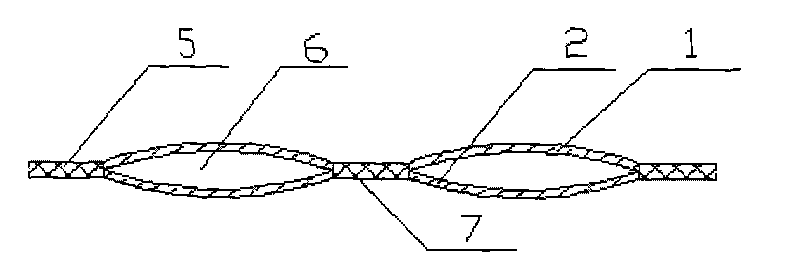

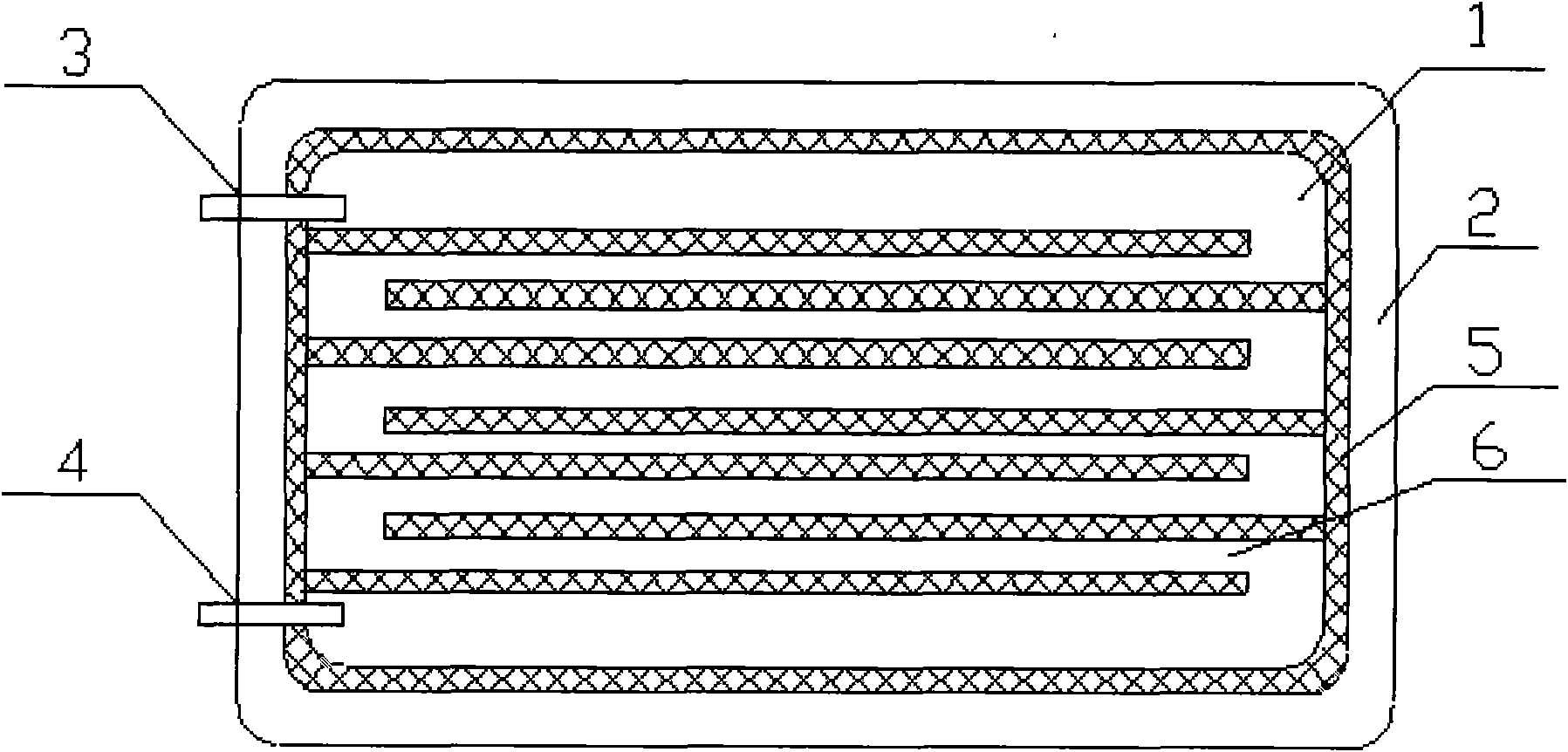

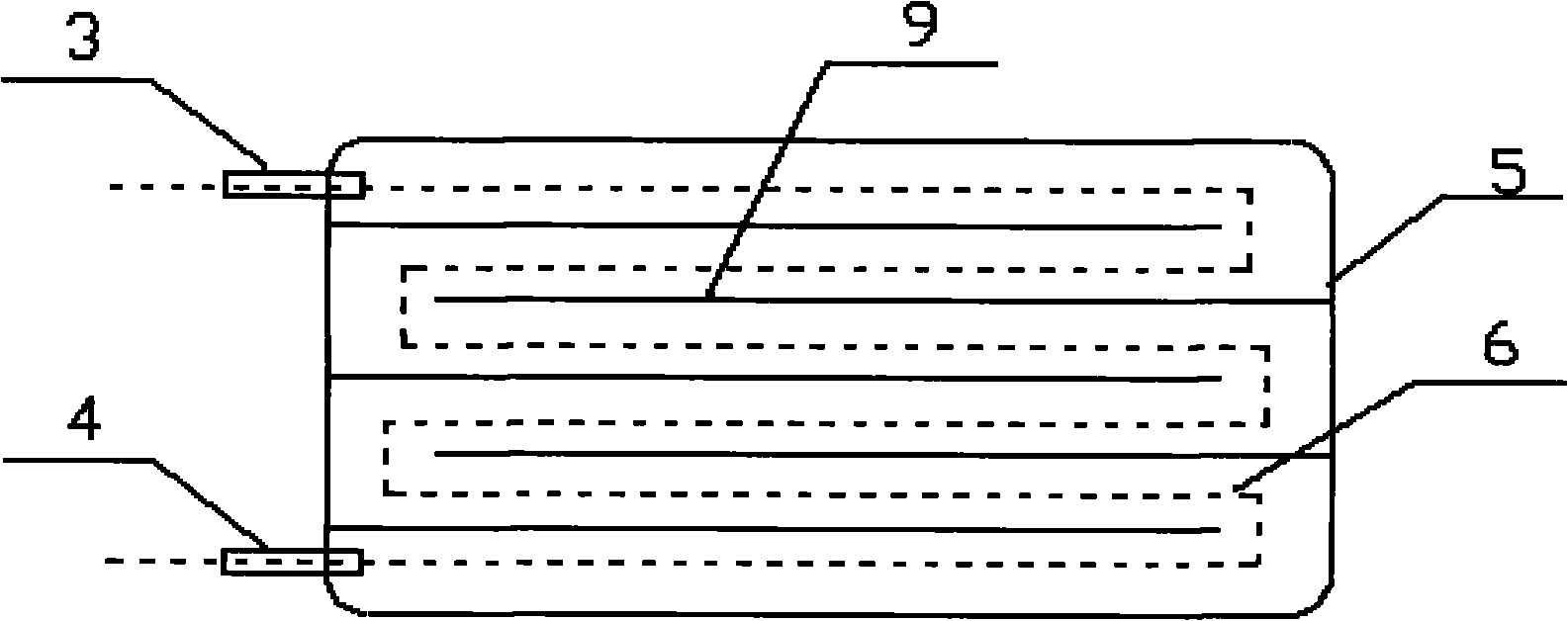

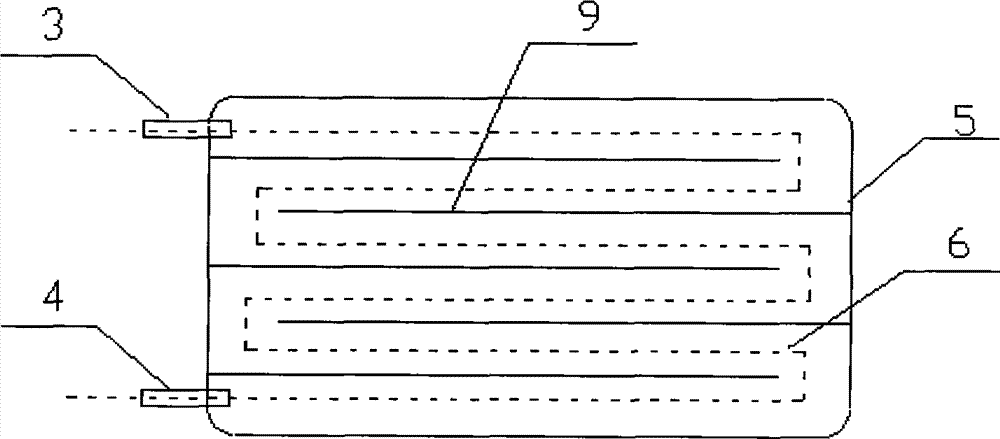

Stainless steel snakelike flow channel cold plate and processing molding method thereof

InactiveCN101691977AReduce pollutionLow soldering temperatureShaping toolsArc welding apparatusElectrical resistance and conductanceCold plate

The invention discloses a stainless steel snakelike flow channel cold plate and a processing molding method thereof. The snakelike flow channel cold plate adopts a stainless steel plate and consists of a stainless steel upper plate, a stainless steel lower plate, an inlet pipe and an outlet pipe, wherein the two stainless steel plates are overlapped and connected by a water-cooling resistance welding method; the inlet pipe and the outlet pipe are inserted in the upper end and the lower end between the two stainless steel plates and are connected with the stainless steel snakelike flow channel cold plate by using an electric arc welding method; and then the snakelike flow channel cold plate is finally molded through a mould and high-pressure bulging technology.

Owner:CHONGQING UNIV

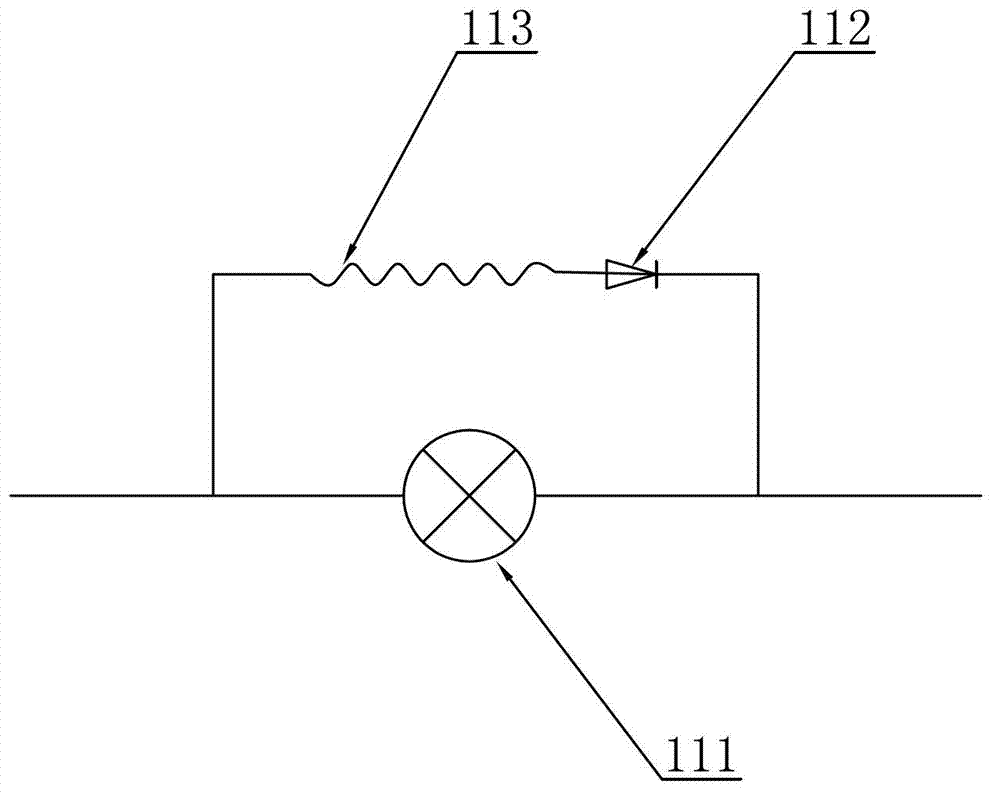

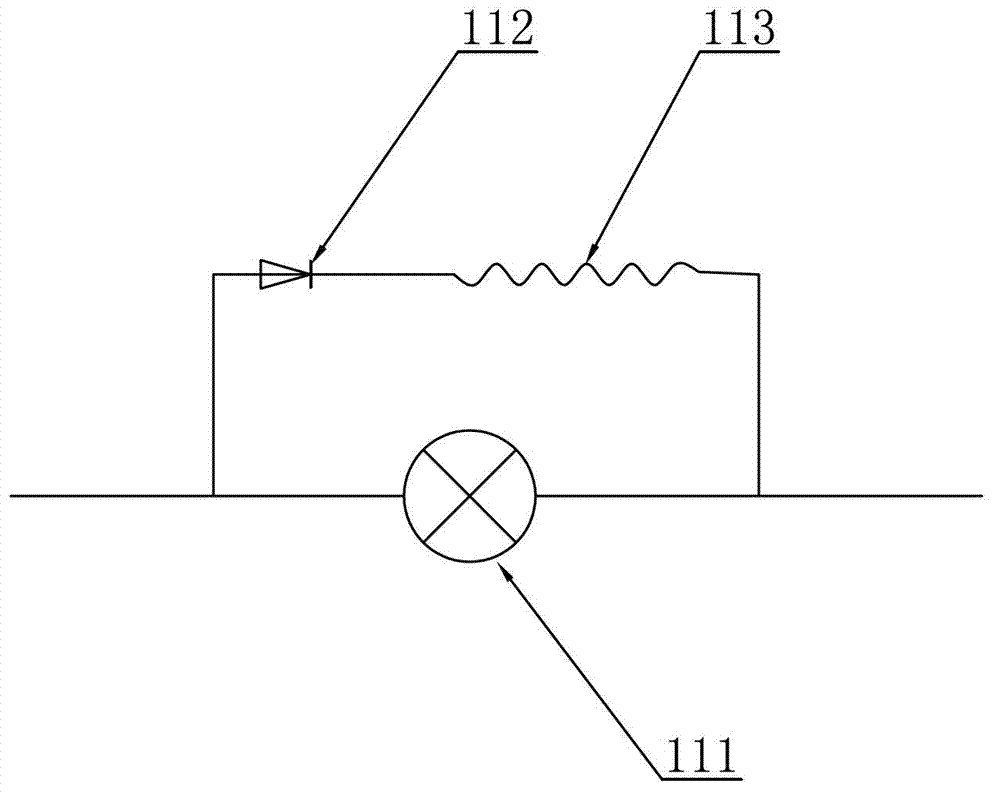

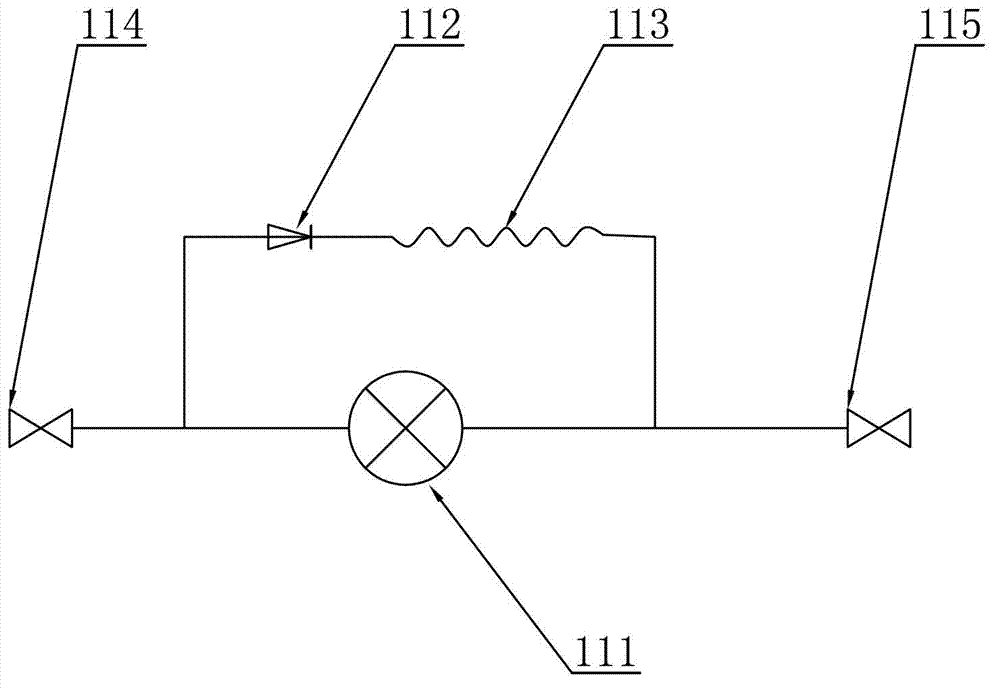

Throttling device and air conditioner adopting same

InactiveCN102767923AImprove sound qualityReduce cavitation effectsNoise suppressionEfficient regulation technologiesCavitationSound quality

The invention discloses a throttling device, which includes an electronic expansion valve, and is characterized in that a one-way valve and a capillary tube are connected to form a bypass over the electronic expansion valve; the one-way valve and the capillary tube are connected in series, so as to form a capillary tube one-way valve assembly. The invention further discloses an air conditioner including the throttling device, which is characterized in that an indoor unit of the air conditioner includes a blower system, and an evaporator component welded on a public pipeline of the throttling device. According to the invention, the one-way valve is closed when the throttling device is used for refrigeration, and is conducted when the throttling device is used for heating; the by-pass capillary tube is adopted to reduce the partial pressure difference of a cooling medium, and reduce the phase change speed of the cooling medium and the cavitation degree, so that ear-piercing noise and cooling medium impulsive vibration caused by the cavitation effect of the cooling medium can be reduced, and the sound quality during the operation of the air conditioner is greatly improved.

Owner:GD MIDEA HEATING & VENTILATING EQUIP CO LTD

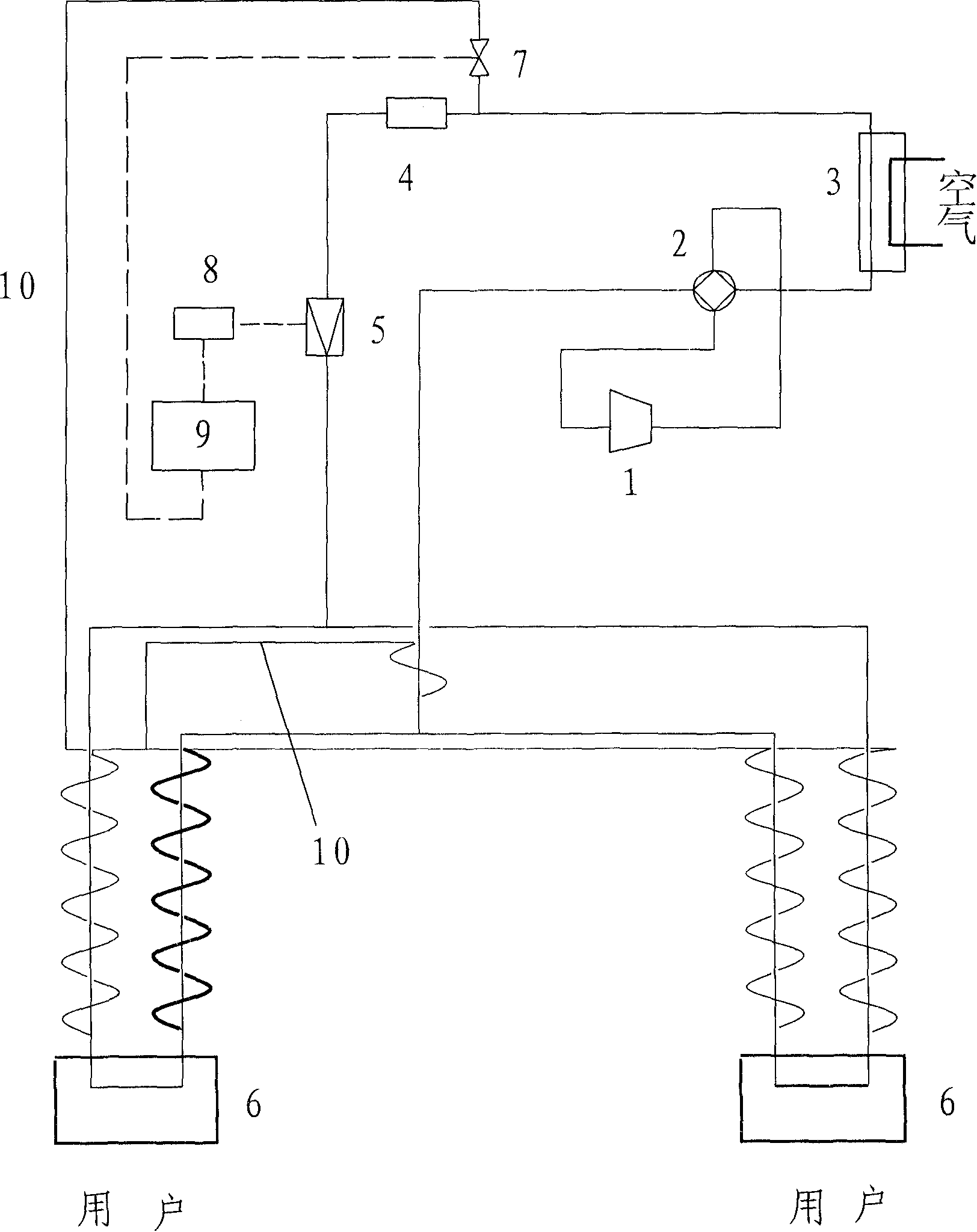

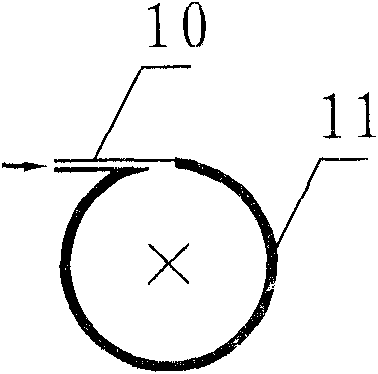

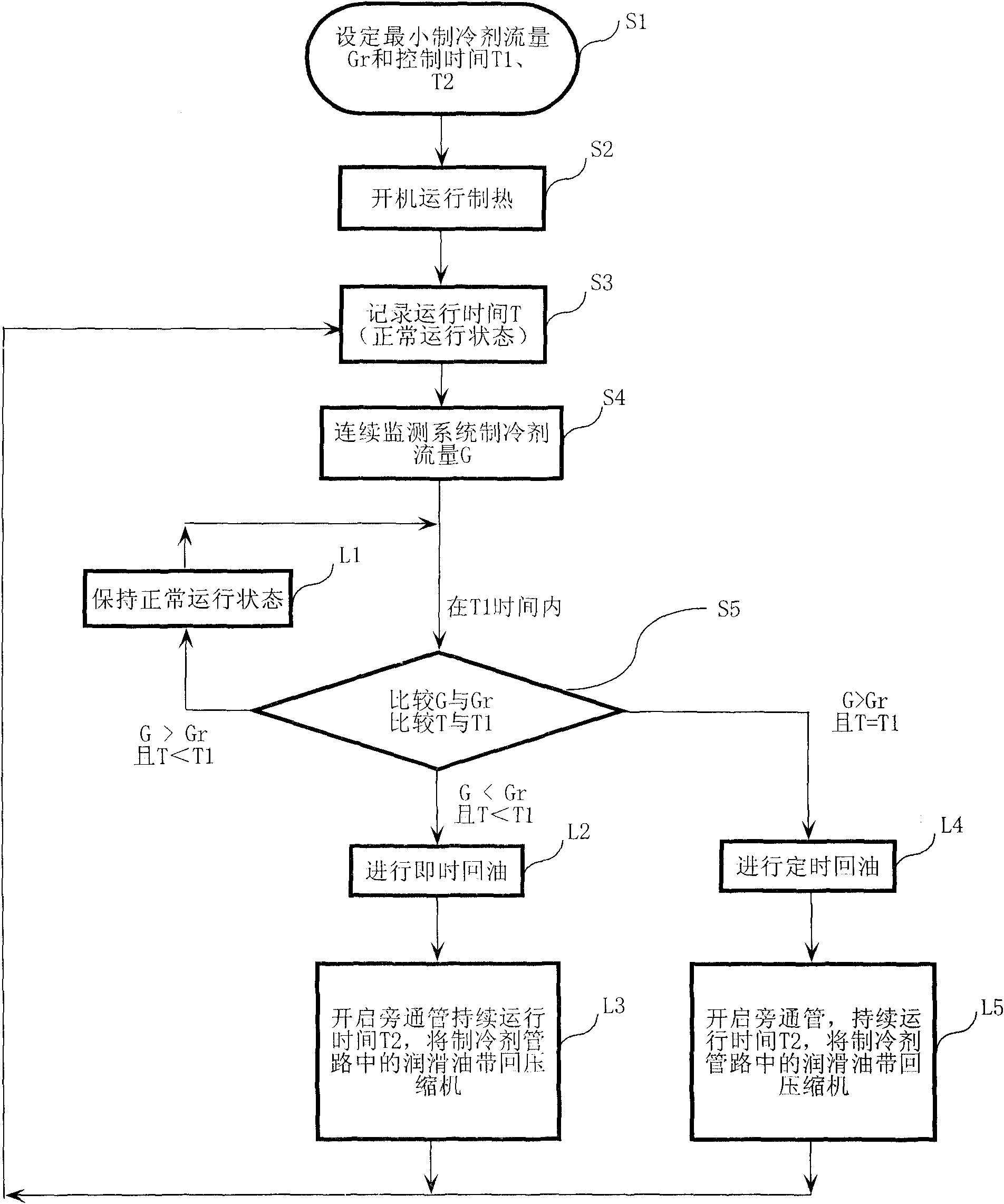

Oil-return control method of large-head long-piping heat pump air conditioning system

ActiveCN101776355AHigh oil contentReduce thicknessCompressorSpace heating and ventilation safety systemsEngineeringAir conditioning

The invention relates to an oil-return control method of a large-head long-piping heat pump air conditioning system, which is characterized in that a bypass pipe is respectively installed between a condenser and the bottom part of an evaporator and between the condenser and the lower part of a compressor air suction pipe of the large-head long-piping heat pump air conditioning system, wherein the bypass pipe is tangentially connected with the condenser and the compressor air suction pipe; the flow rate of refrigerant inside the pipeline and the running time of the system are instantly monitored, when the flow rate of the refrigerant reaches a given quantity and the running time reaches a given time, the bypass pipe is opened, the high-pressure refrigerant liquid is spayed into a lubricant converging area on the bottom part of the evaporator or on the lower part of the air suction pipe in a tangential direction after being throttled by the bypass pipe, so the accumulated lubricant inside the refrigerant pipe with stoppage is brought back to the compressor so as to realize the successful oil return of the system. Under the condition that the normal work of the heat pump air conditioning system is free from being influenced, the oil return efficiency of the system can be effectively improved, the running stability of the system can be improved, the compressor can be prevented from having malfunction because of the oil shortage, and the high-efficient running of the large-head long-piping heat pump air conditioning system can be ensured.

Owner:湖南湖大瑞格能源科技有限公司

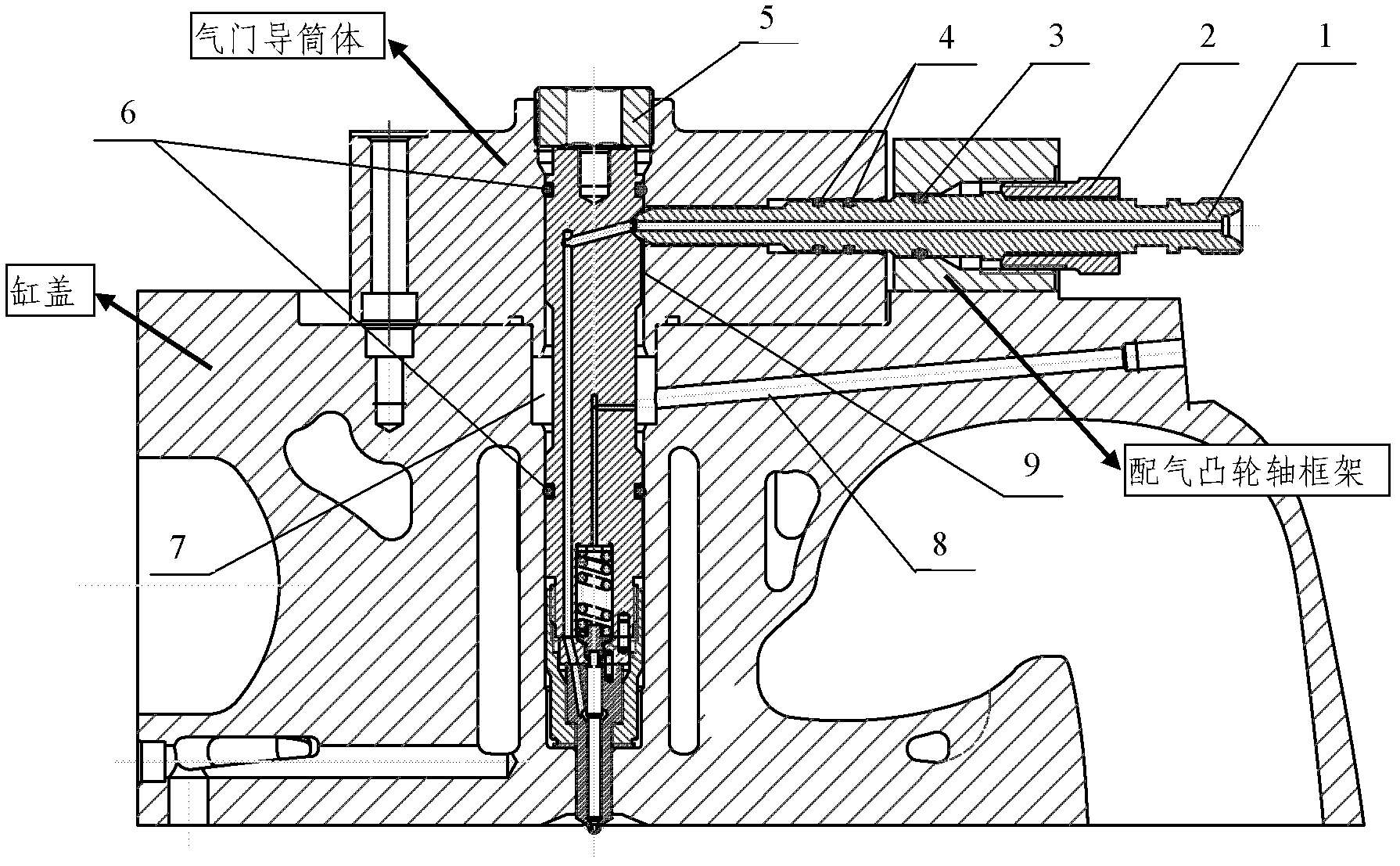

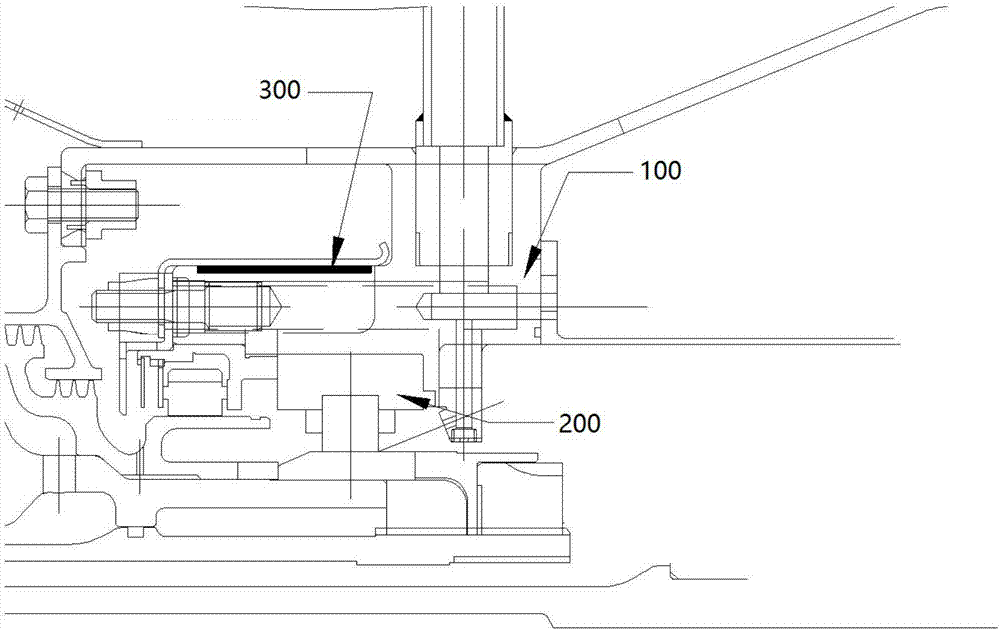

Embedded oil charging structure for high-pressure fuel oil system

InactiveCN102425520AGuaranteed sealing requirementsSmooth oil returnFuel injection apparatusMachines/enginesLateral compressionFuel oil

The invention discloses an embedded oil charging structure for a high-pressure fuel oil system. A lateral oil charging pipe is transversely embedded into a gas distribution camshaft frame and an air valve guide barrel; an oil sprayer is vertically arranged in a cylinder cover and the air valve guide barrel, and is used for charging oil laterally; a lateral oil charging pipe is pressed tightly onto the side wall of the oil sprayer by adopting a lateral compression nut, and is screwed on the gas distribution camshaft frame; an oil sprayer assembly is pressed tightly into a cylinder cover inner hole by adopting a top end compression nut, and is screwed on the air valve guide barrel; two O-shaped sealing rings are distributed on the lateral oil charging pipe and the air valve guide barrel in a matching way; an O-shaped sealing ring is distributed on the lateral oil charging pipe and the gas distribution camshaft frame in a matching way; an O-shaped sealing ring is distributed on the oil sprayer, the air valve guide barrel and the cylinder cover respectively in a matching way; an oil return cavity is communicated with a phi5 oil return channel on the cylinder cover; and an oil leaking groove is formed between the oil charging conical surface of the oil sprayer and the oil return cavity. Due to the adoption of the embedded oil charging structure, a shorter high-pressure oil pipe is realized, the sealing requirements of fuel oil and lubricating oil can be met simultaneously, oil return of the oil sprayer is smooth, and the entire structure is easy to install.

Owner:CHINA NORTH IND GRP NO 70 RES INST

Balance valve

ActiveCN105952702AReduce lossSimple and reasonable structureServomotor componentsMechanical engineeringEnergy loss

The invention discloses a balance valve which comprises a valve body, a main valve element and a one-way valve element. The valve body is provided with a first oil port, a second oil port and a control oil port. A spring seat is arranged at the front end of the valve body. A one-way valve spring is arranged between the spring seat and the one-way valve element in an abutting manner. A valve port corresponding to the second oil port is formed in the front end of the main valve element. An annular conical face in sealing fit with the one-way valve element is arranged on the outer wall of the valve port. An oil passing hole corresponding to the first oil port is formed in the middle portion of the main valve element. The first oil port communicates with the valve port through the oil passing hole. A screw plug is arranged at the rear end of the valve body. A spring set is arranged between the rear end of the main valve element and the screw plug in an abutting manner. The position between the main valve element and the valve body is further sleeved with a guide sleeve corresponding to the control oil port. The guide sleeve and the main valve element are in axial linkage fit. A control oil cavity is formed between the guide sleeve and the valve body. The control oil port communicates with the control oil cavity. The balance valve is simple and reasonable in structure, good in overflowing effect and smooth in oil return, energy losses can be reduced easily, and the work efficiency is improved.

Owner:宁波市镇海天地液压有限公司

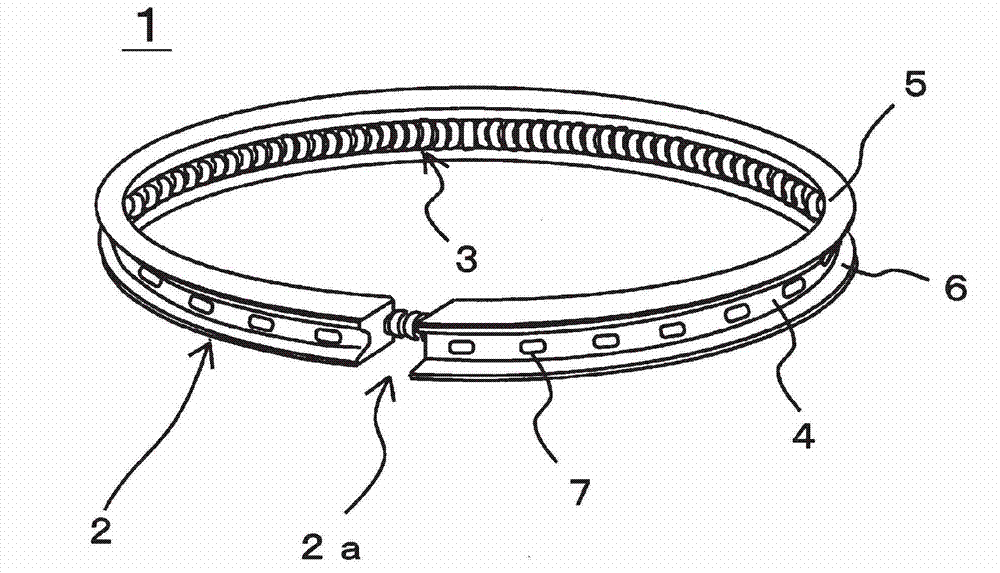

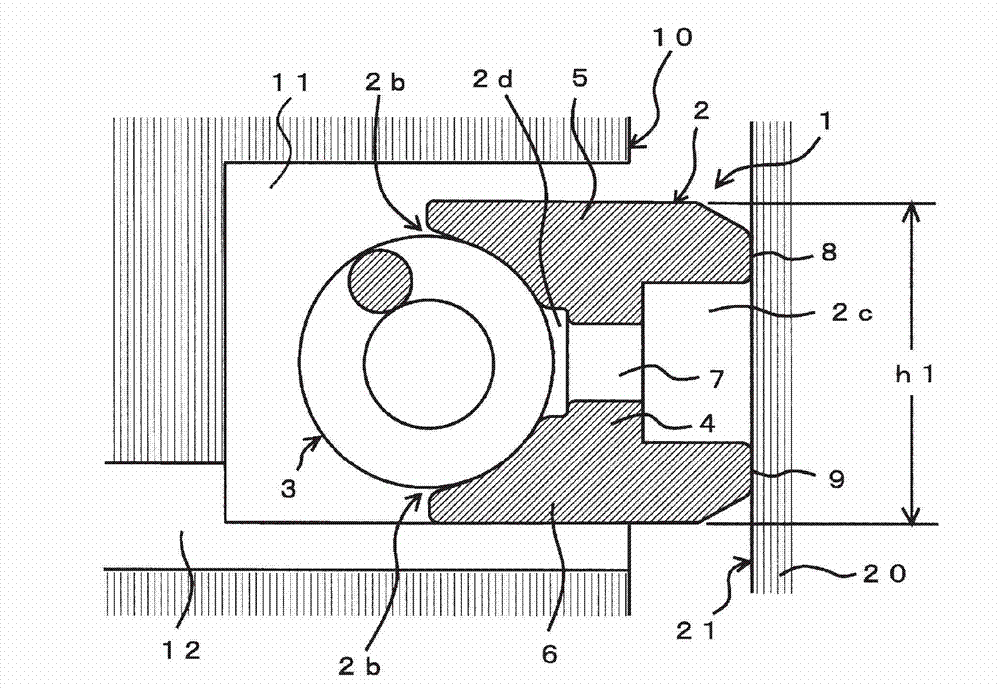

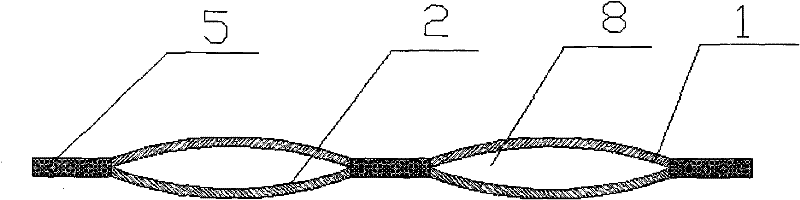

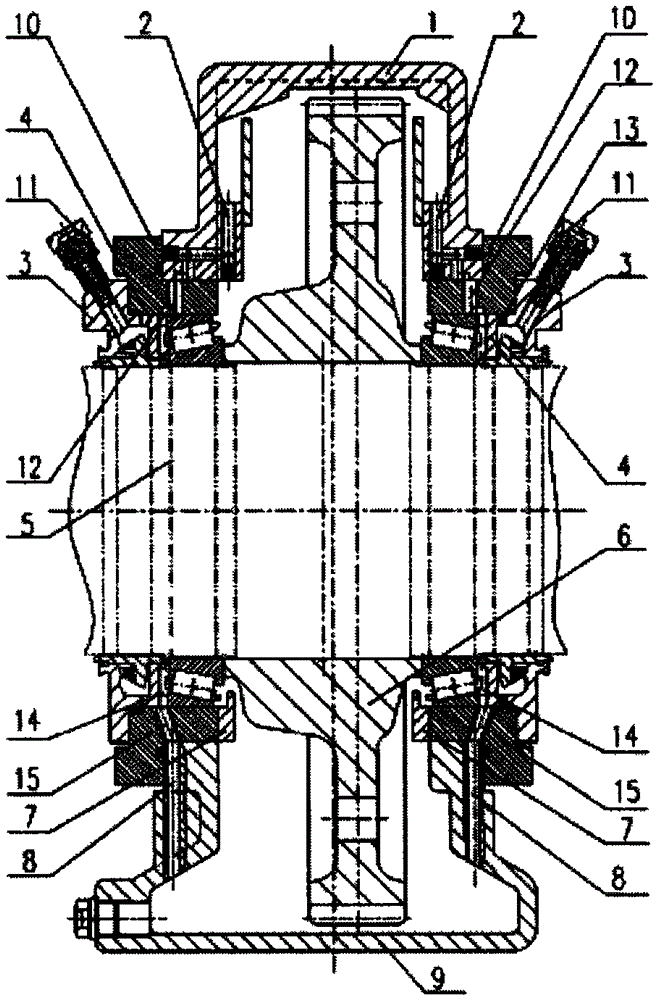

Oil ring for internal combustion engine

ActiveCN102859241AImprove consumption rateSuppression of variation in pressing forcePiston ringsMachines/enginesExternal combustion engineInternal combustion engine

Owner:NIPPON PISTONRING CO LTD

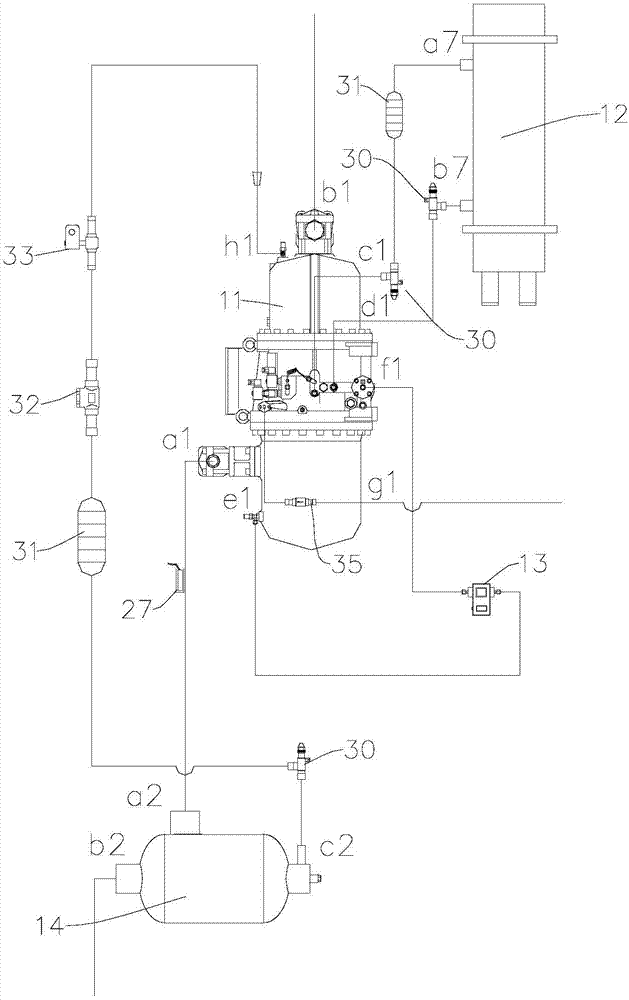

Siphonic water-cooled screw low-temperature solution unit

ActiveCN105674611AImprove operational efficiencyIncrease oil return temperatureMechanical apparatusCompression machines with non-reversible cycleVapor–liquid separatorEngineering

The invention discloses a siphonic water-cooled screw low-temperature solution unit, which comprises a screw compressor, a built-in oil condenser, a gas-liquid separator circulation tank and a siphonic evaporator; a gas outlet of the gas-liquid separator circulation tank communicates with a gas inlet of the screw compressor through a suction pipeline; the gas-liquid separator circulation tank and a delivery valve of the built-in oil condenser communicate with the suction pipeline through an oil return system; a liquid outlet of the built-in oil condenser separately communicates with the gas-liquid separator circulation tank and the siphonic evaporator through a liquid supply system; and the liquid supply system comprises a plurality of sections of liquid supply pipelines, an oil return heat exchanger and an economizer. According to the siphonic water-cooled screw low-temperature solution unit disclosed by the invention, by installing the oil return heat exchanger and the economizer, oil return temperature of the evaporator is increased, and oil return viscosity is reduced, so that oil return of the evaporator is more smooth; meanwhile, liquid refrigerant coming out from the condenser is lowered in temperature to realize a certain supercooling degree, therefore operating efficiency of the unit is increased.

Owner:JIANGXI HAOJIN OUBO AIR CONDITIONING MFG CO LTD

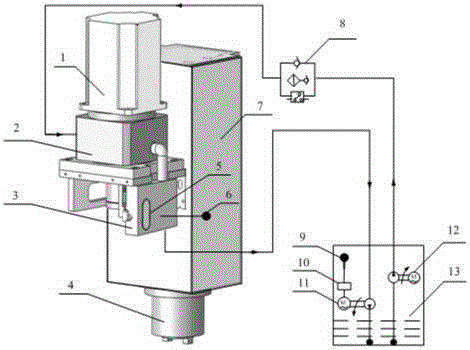

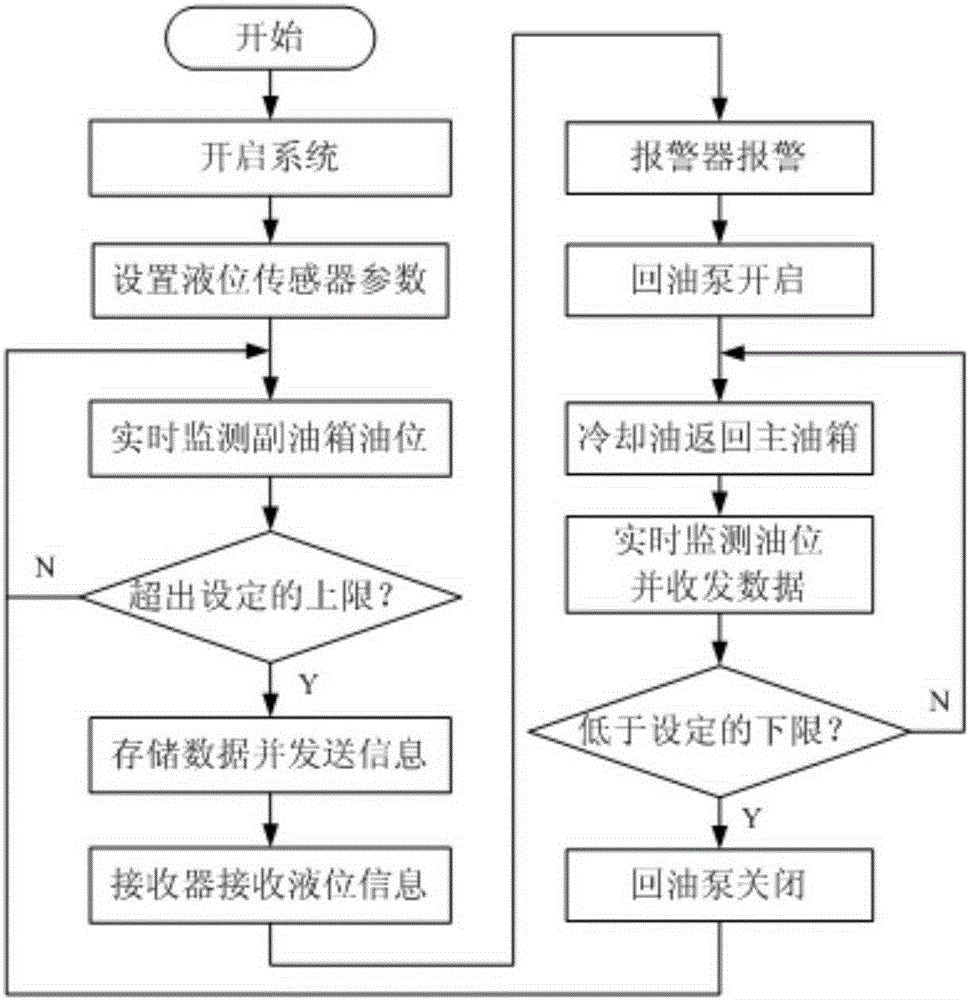

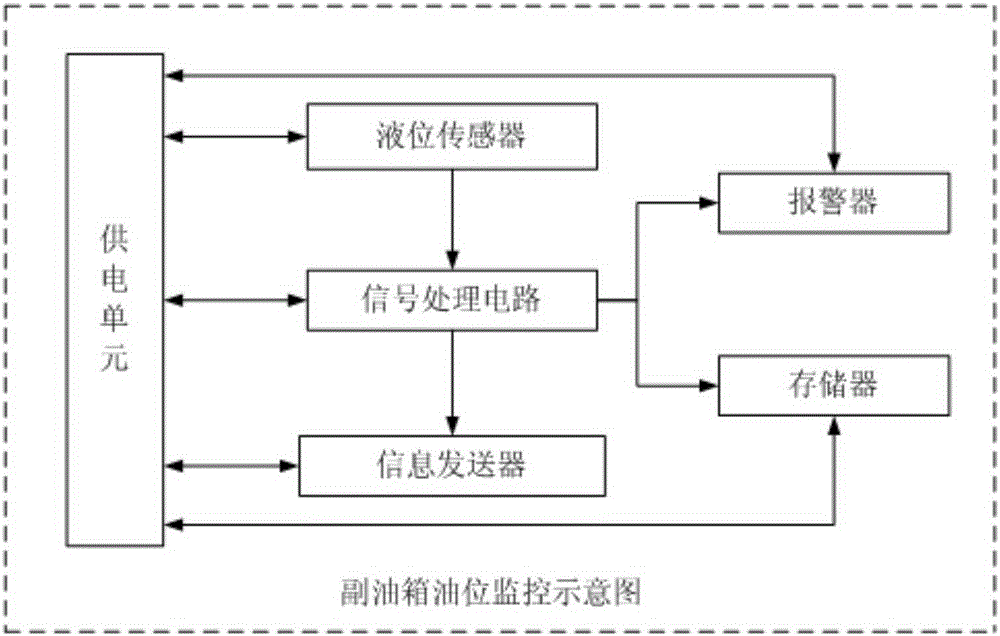

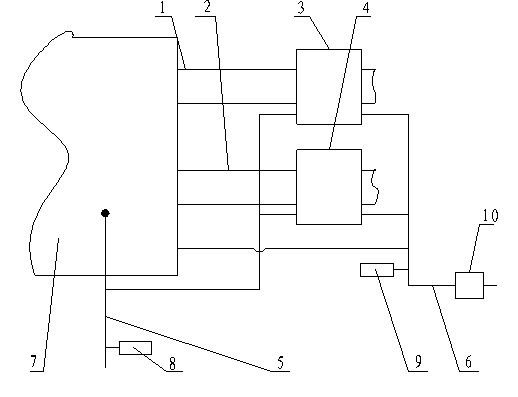

Numerically-controlled machine tool gearbox intelligent oil return system with auxiliary oil tank and working method of numerically-controlled machine tool gearbox intelligent oil return system

InactiveCN105269397ASolve problems that require non-stop workReduce energy consumptionMaintainance and safety accessoriesNumerical controlStopped work

The invention discloses a numerically-controlled machine tool gearbox intelligent oil return system with an auxiliary oil tank and a working method of the numerically-controlled machine tool gearbox intelligent oil return system. The system comprises a gearbox, a main oil tank, the auxiliary oil tank, a filter, an oil pump, an oil scavenger pump, a liquid level sensor, an information receiver, a relay and the like. The auxiliary oil tank is mounted below one side of the gearbox. An oil inlet of the auxiliary oil tank is directly connected with the gearbox. An oil outlet of the auxiliary oil tank is connected to the main oil tank through the oil scavenger pump. The liquid level sensor is mounted in the auxiliary oil tank and controls turn-on and turn-off of the oil scavenger pump by detecting the height of the oil level. If the oil level in the auxiliary oil tank exceeds a set upper limit, the oil scavenger pump is turned on, and cooling oil in the auxiliary oil tank flows back into the main oil tank; when the oil level in the auxiliary oil tank is lower than a set lower limit, the oil scavenger pump stops working. By adopting the numerically-controlled machine tool gearbox intelligent oil return system, a whole oil channel is smooth in oil return, the oil scavenger pump is prevented from working continuously while the cooling effect is guaranteed, energy consumption is reduced, and the intelligent oil return function is achieved.

Owner:NANTONG GUOSHENG INTELLIGENCE TECH GRP CO LTD

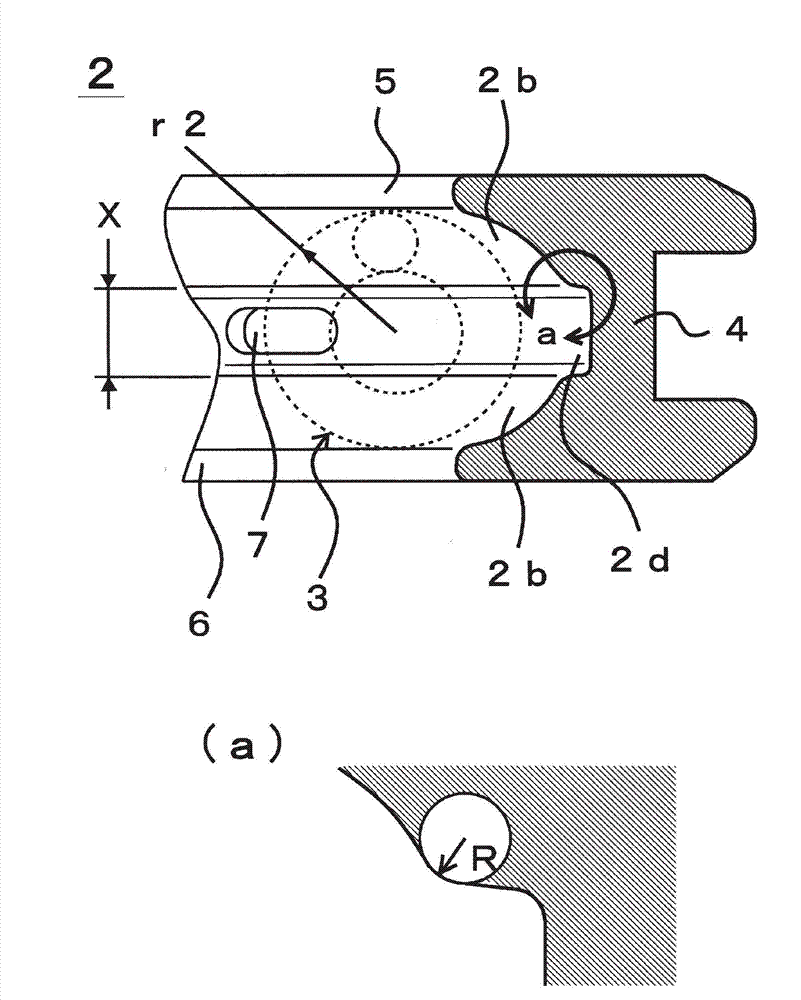

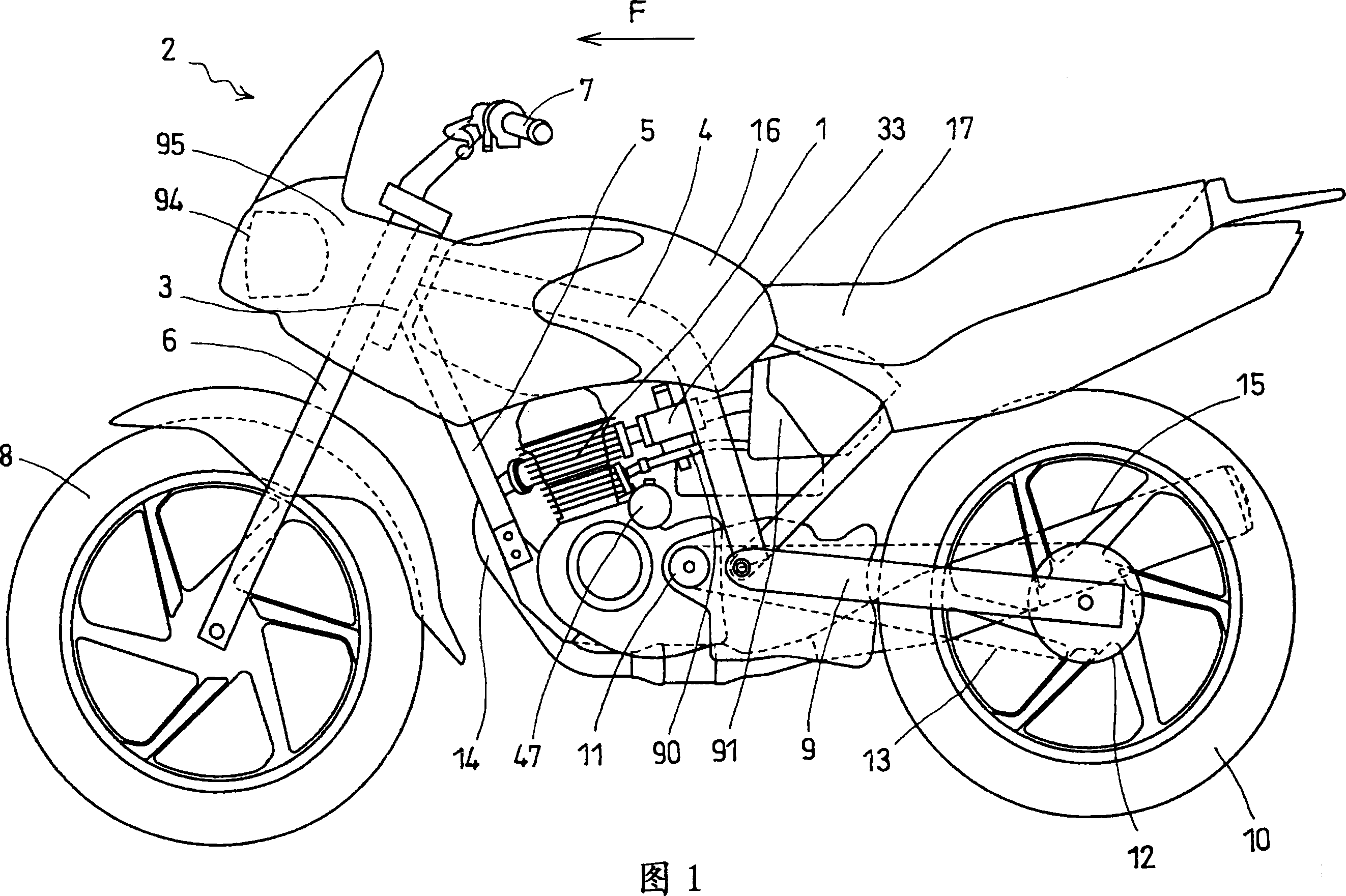

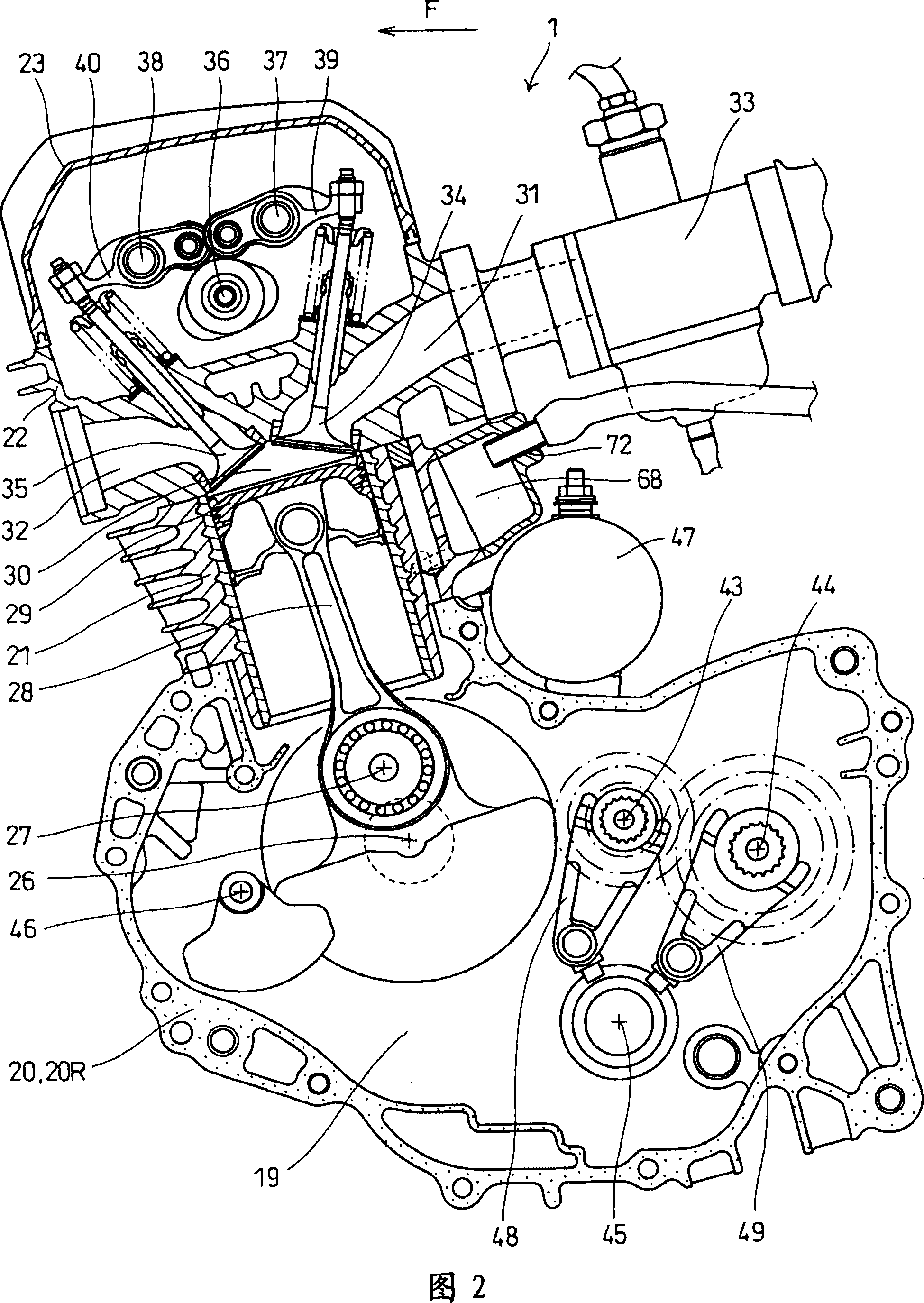

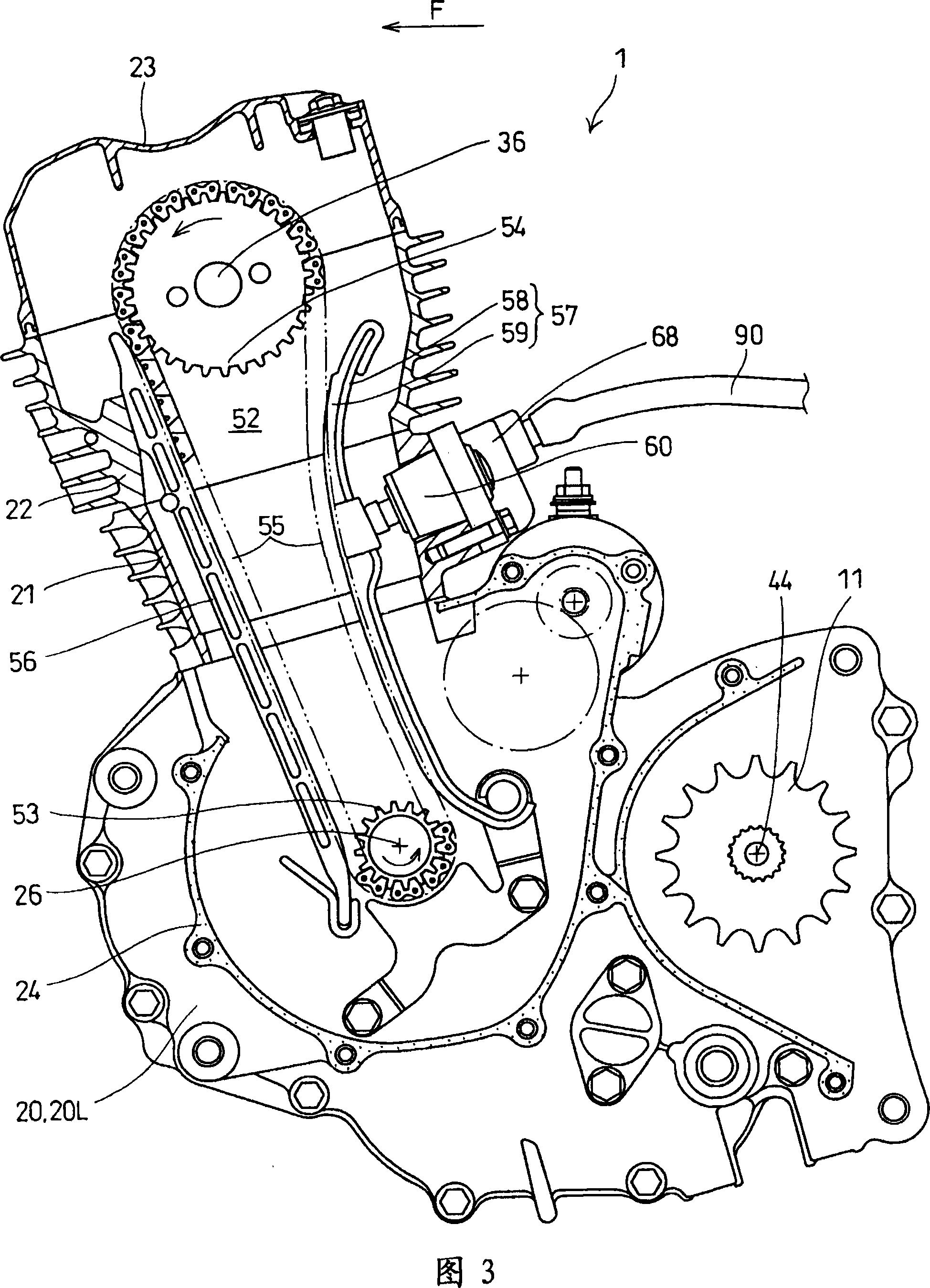

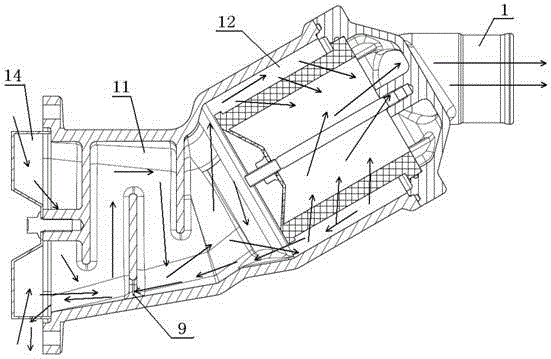

Aerating device for internal combustion engine

InactiveCN101240726AImprove assembly efficiencyReduce condensationMachines/enginesCrankcase ventillationBearing surfaceCylinder block

The present invention provides a ventilation device for an overhead valve type internal combustion engine. The internal combustion engine has a cam chain wound between the crankshaft and the camshaft and is provided with a cam chain tensioner. In the above internal combustion engine, the cam chain is not used to drive the pulley The breather is provided without offsetting the size of the cylinder block. A cam chain tensioner push rod installation support surface is formed on the outer wall of the cylinder block, and on the side of the cam chain tensioner push rod installation support surface, on the cylinder outer wall located in parallel with the above support surface, a The recessed portion which becomes a part of the breather chamber which separates the gas-liquid separation of the blow-by gas discharged from the inside of the internal combustion engine and the joint surface which attaches the cover part of the breather chamber.

Owner:HONDA MOTOR CO LTD

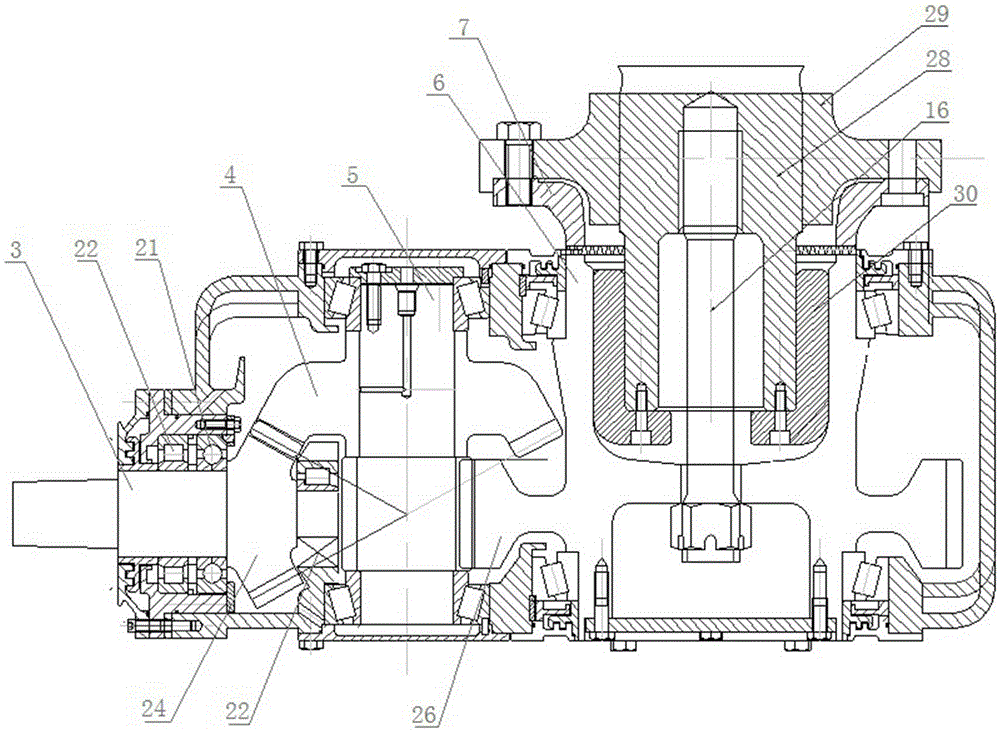

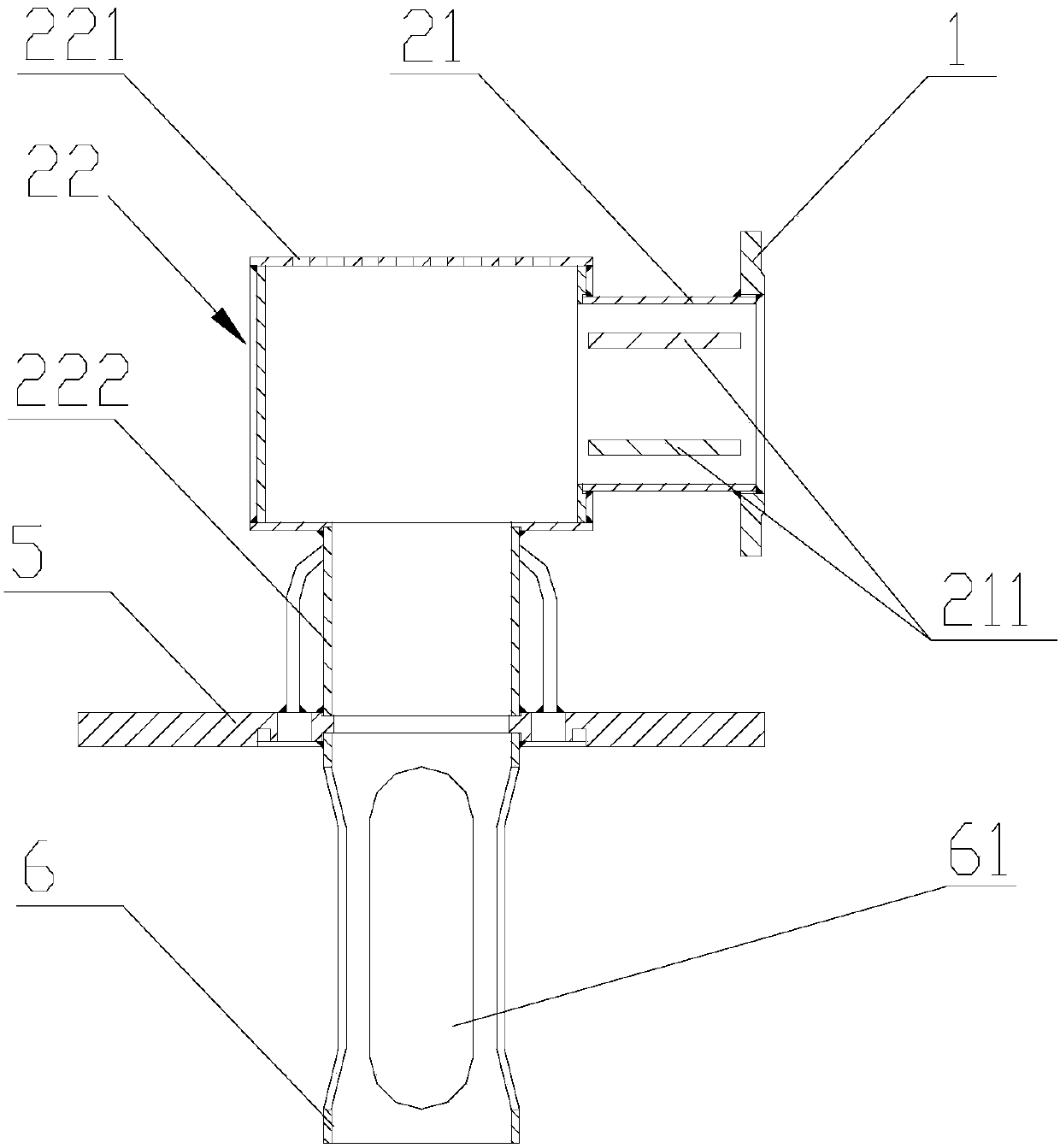

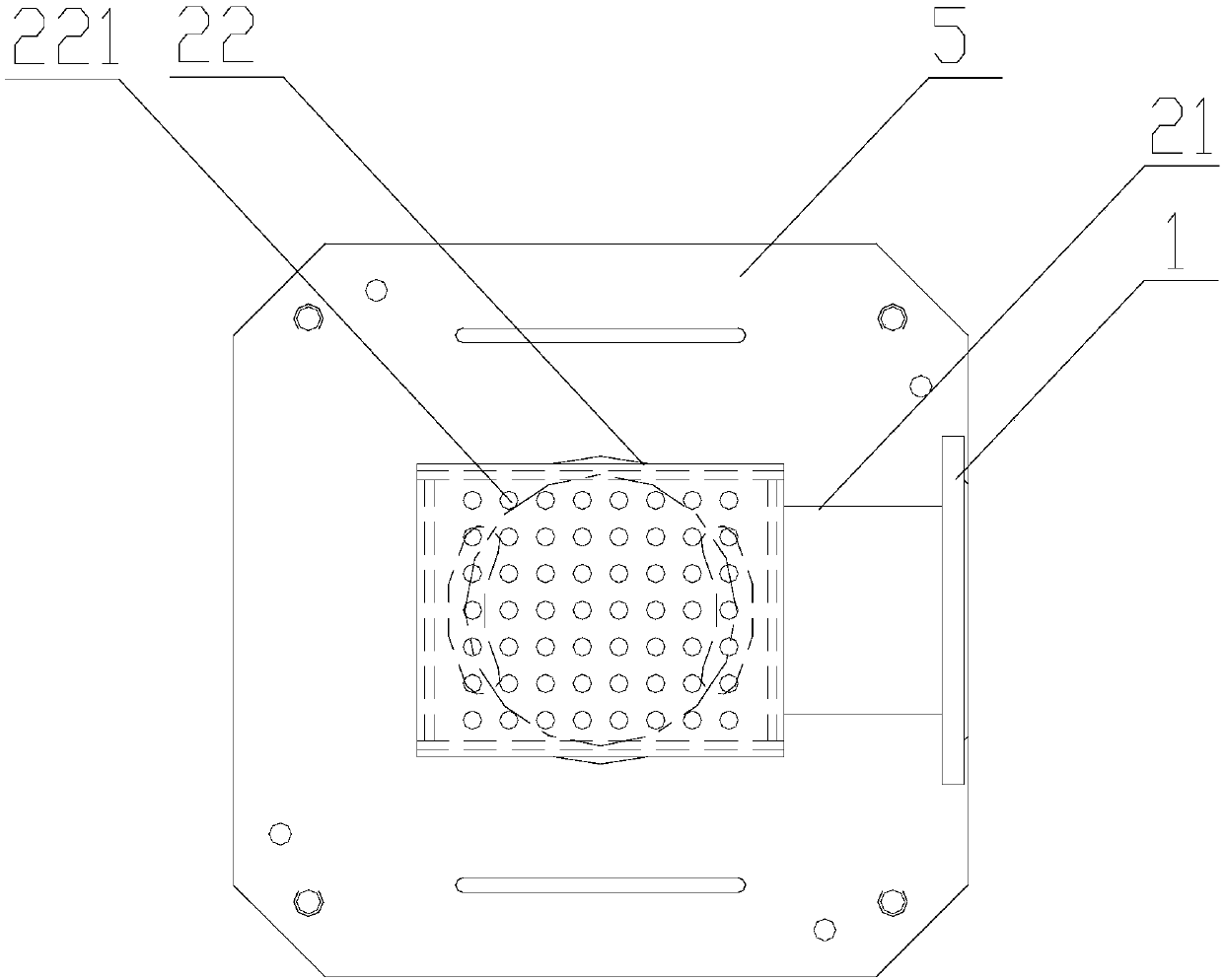

Gearbox used for rail transit vehicle

InactiveCN105422811AEasy installation and maintenanceEasy to installGear lubrication/coolingJoint surfaceSurface tooth

The invention relates to a gearbox used for a rail transit vehicle. Center lines of an input shaft and an output shaft of the gearbox are perpendicular to each other; a middle gear shaft which is parallel to the output shaft is arranged between the input shaft and the output shaft; the input shaft is engaged with a middle bevel gear of the middle gear shaft by virtue of a spiral bevel gear; supporting points at the two ends of the output shaft are hollow shafts; an output big gear is arranged on the output shaft; the middle gear shaft is engaged with the output large gear on the output shaft; an output flange plate is positioned at the output side of the output shaft; a jointed surface of the output flange plate and the output shaft is end surface teeth which are matched with each other; and the output flange plate passes through a central connecting bolt, so that end surface teeth of the jointed surface are engaged with each other. A mounting hole which is in butt joint with the output flange plate is mounted in the central axis of the output shaft, and the central connecting bolt is assembled in the mounting hole; the input shaft is supported on an upper box body by virtue of one four-point ball bearing and two cylindrical roller bearings in a input bearing base; and the two ends of each of the middle gear shaft and the output shaft are respectively supported on a box body by virtue of a bearing in the bearing base.

Owner:南京高精轨道交通设备有限公司

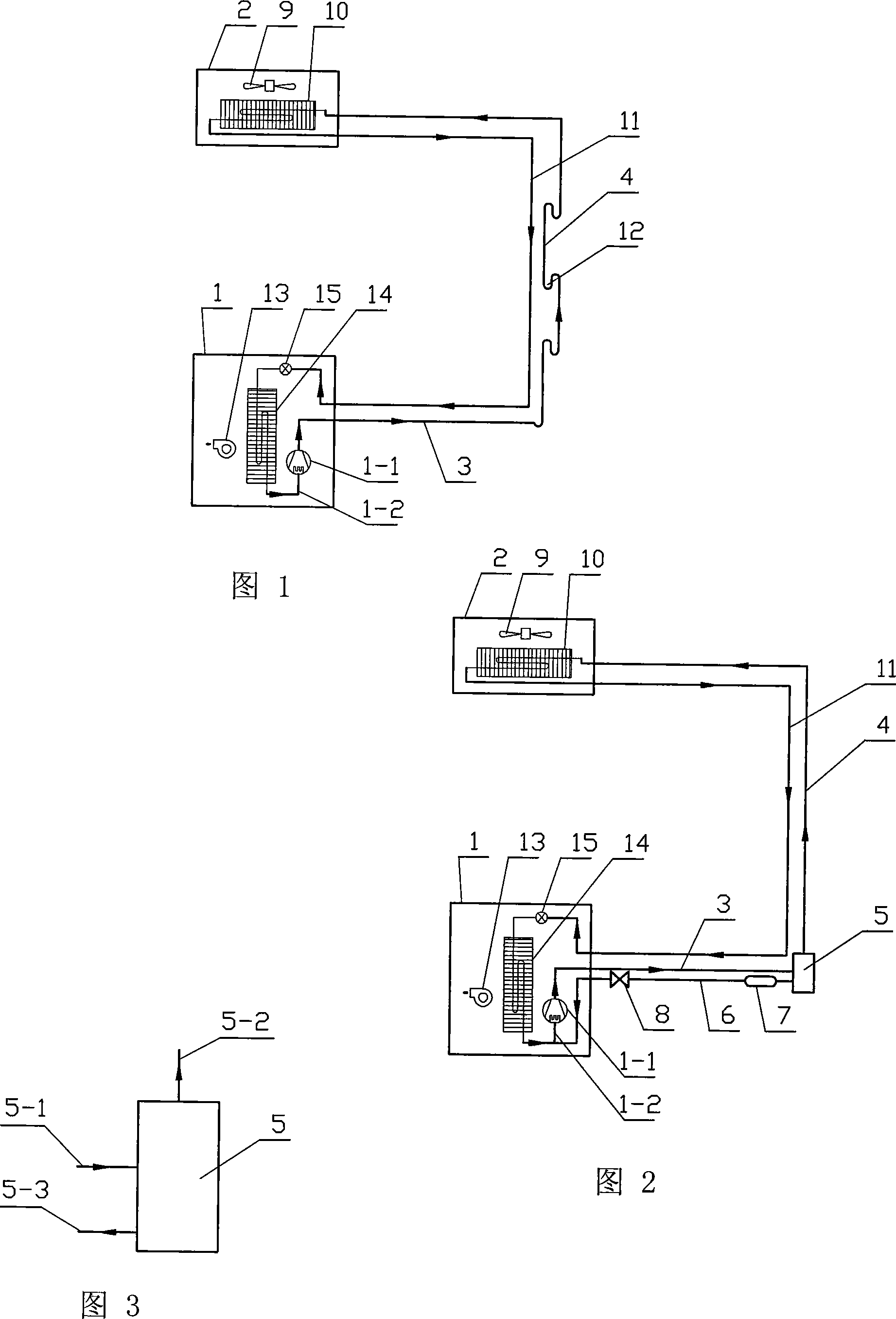

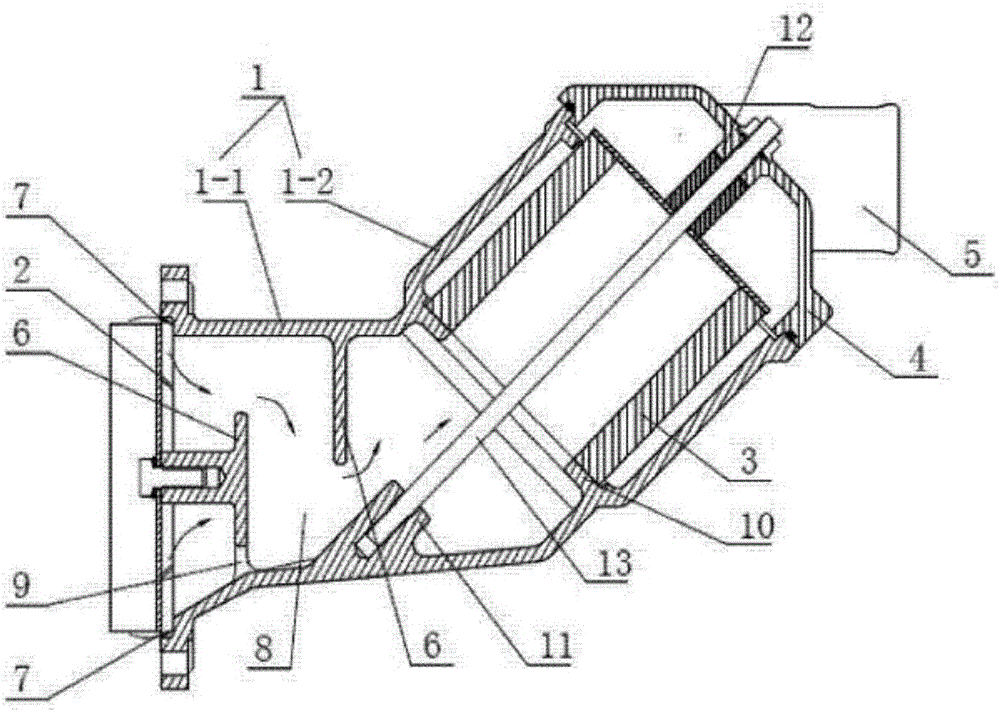

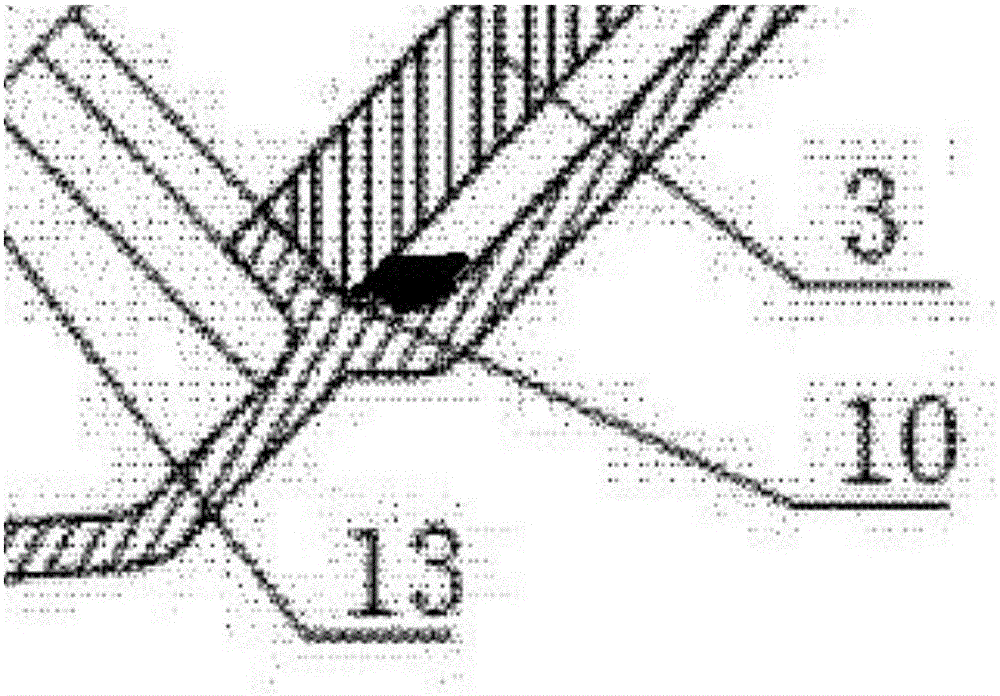

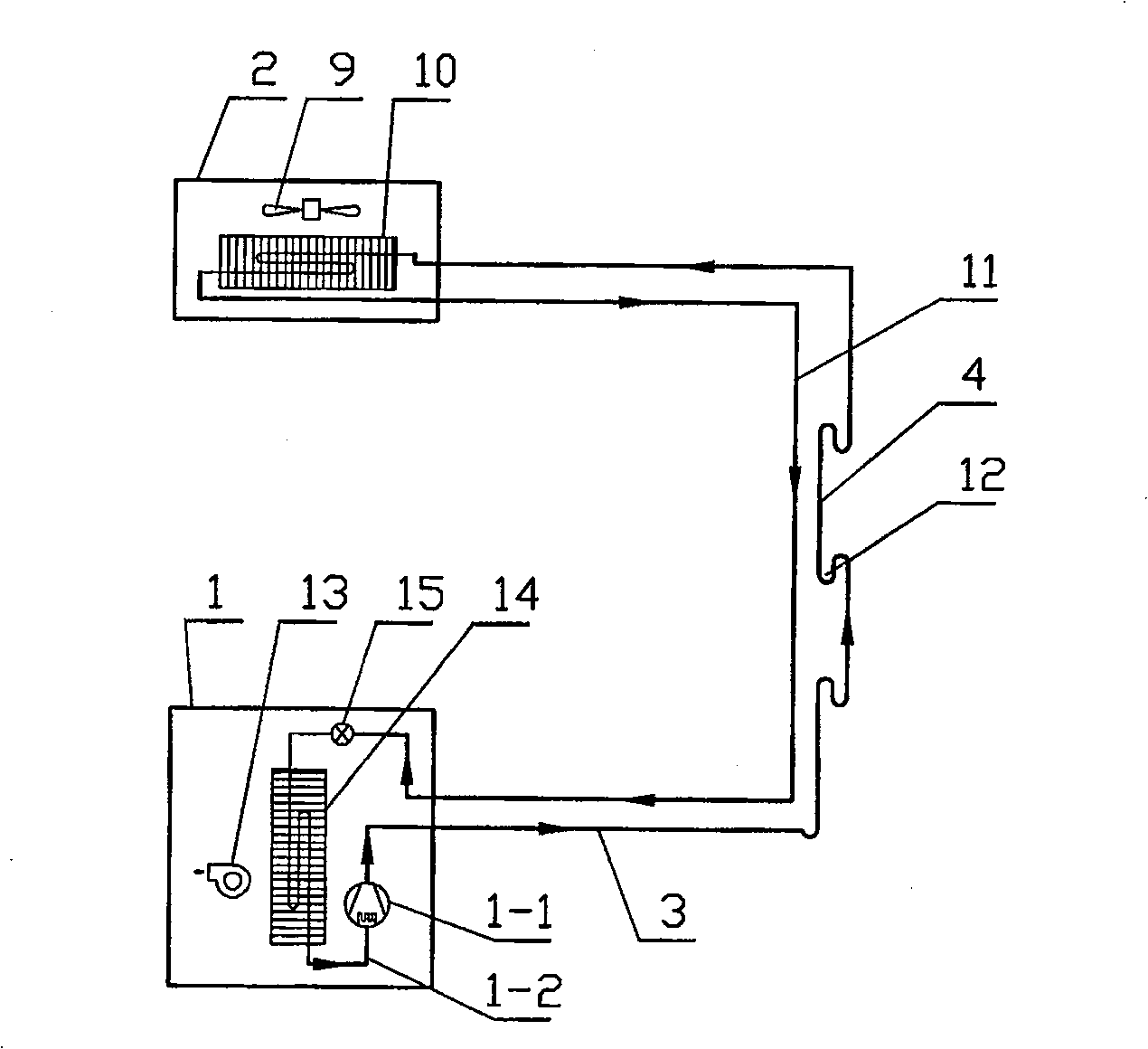

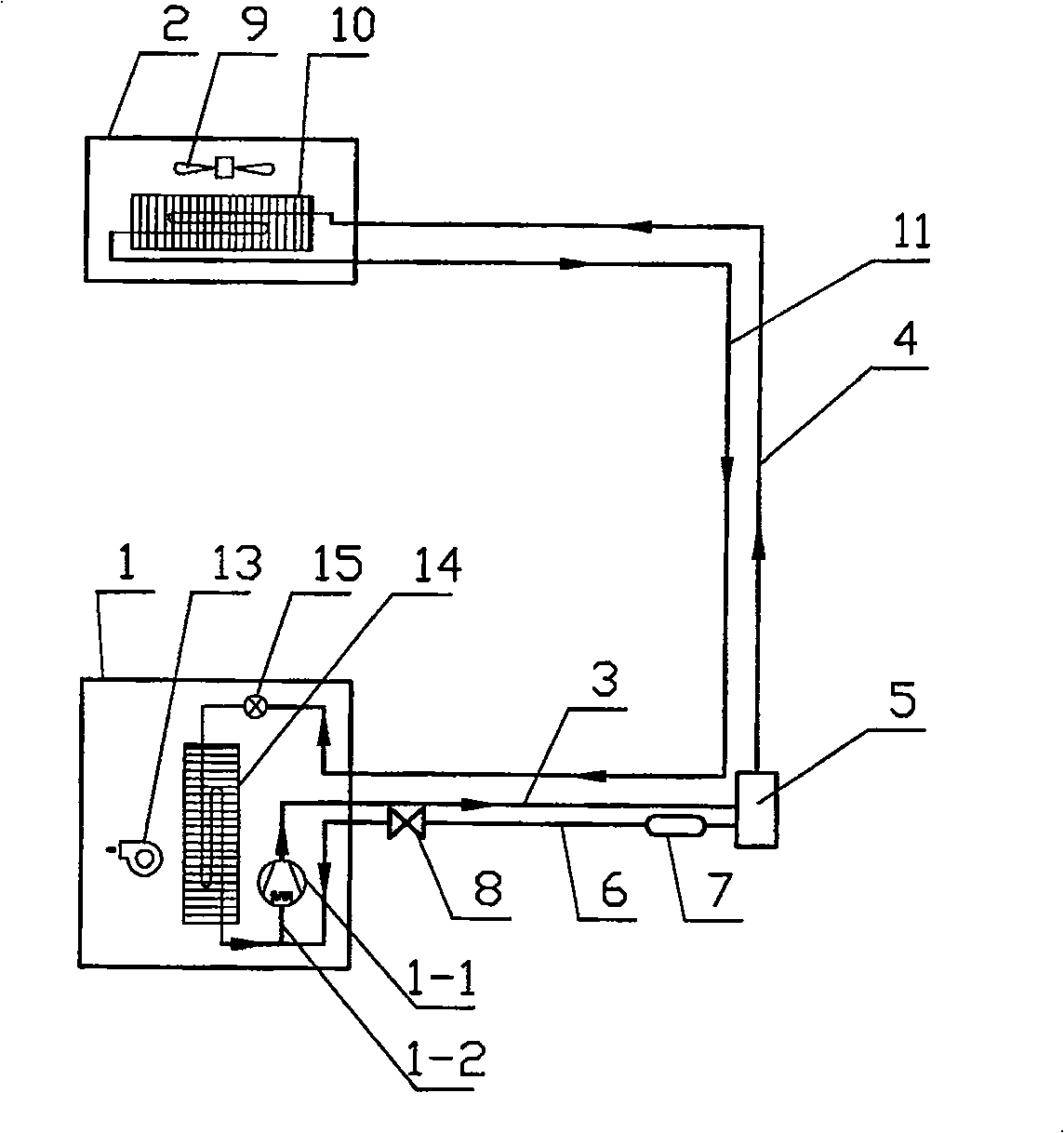

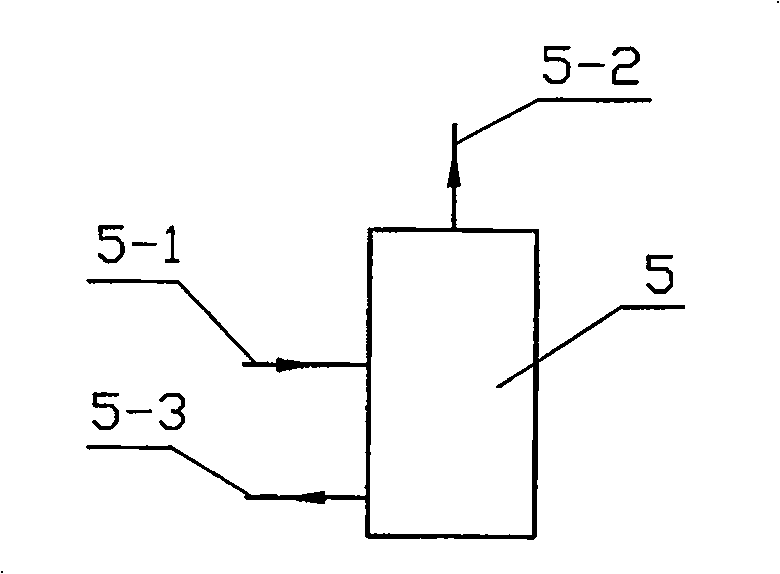

Wind cooling split type air adjusting machine communicate system

ActiveCN101158499ASmooth oil returnReduce design requirementsDucting arrangementsRefrigeration componentsAir conditioningSystem structure

The invention relates to a connection system for an air-cooled split air conditioner. Aiming at the problems that the pipeline has large resistances and the return oil blockage happens to the pipeline when the existing air conditioner has long distance and high fall, the invention provides a connection system for the air conditioner. An exhaust rising pipeline (4) of the invention is a pipeline which is uniformly upward and an oil separator (5) is arranged at the lower end of the exhaust rising pipeline (4). The exhaust inlet (5-1) of the oil separator (5) is connected with an exhaust horizontal pipeline (3) which is extended out from an indoor-machine (1) and the exhaust outlet (5-2) of the oil separator (5) is connected with the exhaust rising pipeline (4) connected to an outdoor-machine (2); the oil return pipe port (5-3) of the oil separator (5) is connected with one end of an oil return pipeline (6) while the other end of the oil return pipeline (6) is connected to the air return pipeline (1-2) of a compressor (1-1) in the indoor-machine (1). The invention has the advantages of small resistance, smooth oil return, simple system structure, easy implementation, easy installation, low cost, small investment, low running and management fees, few occupied building spaces and is beneficial for popularization and utilization.

Owner:AIRSYS REFRIGERATION ENG TECH BEIJING

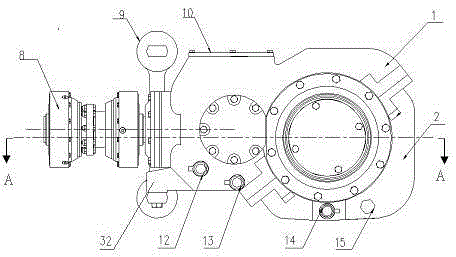

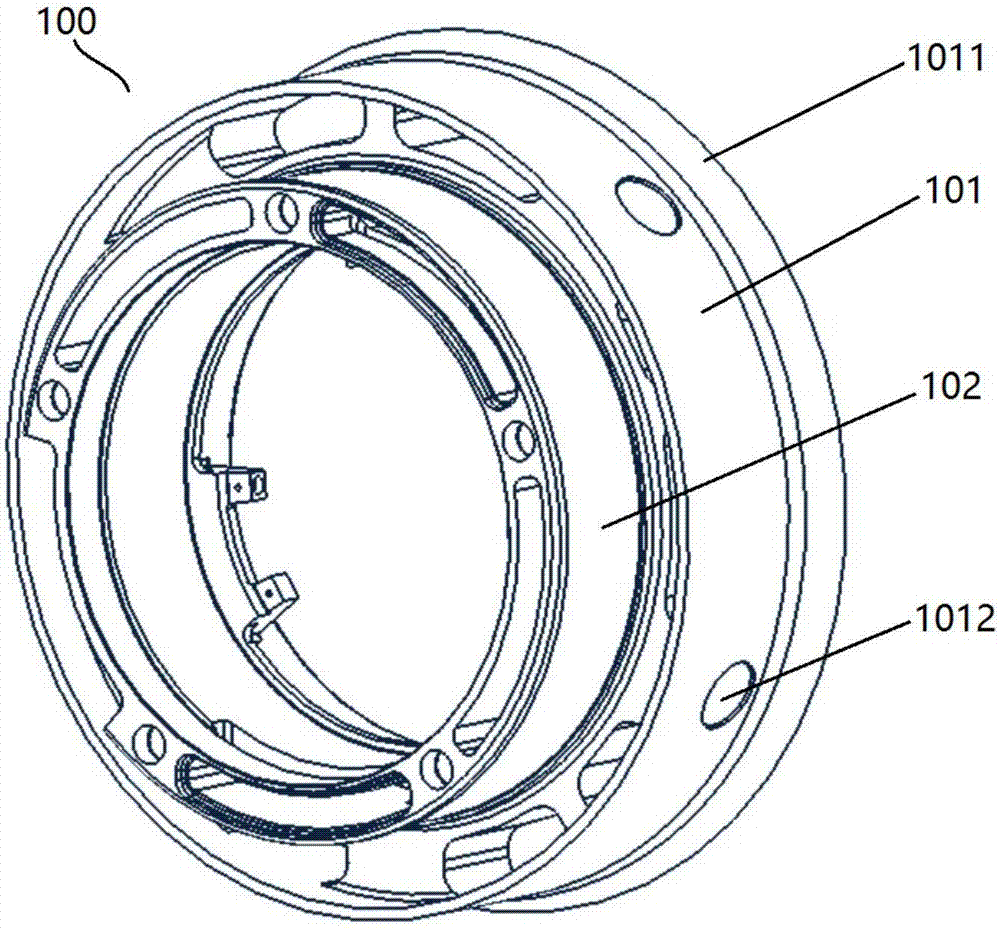

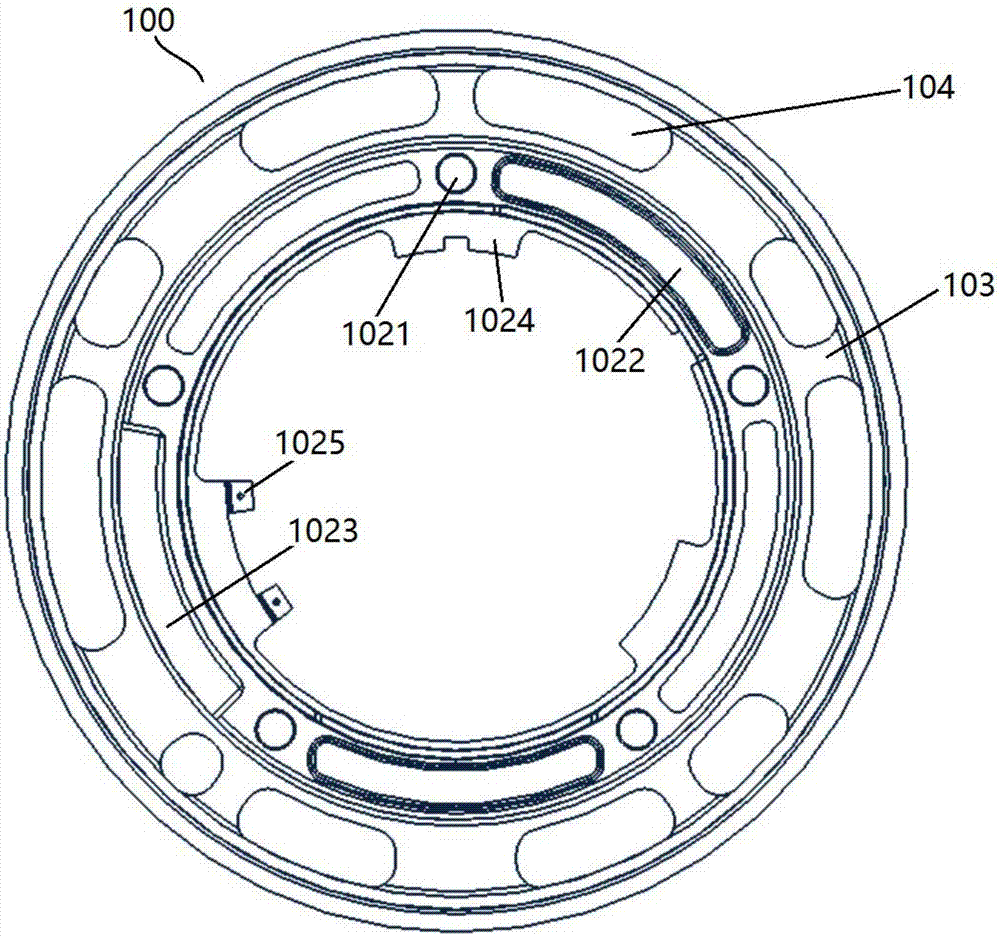

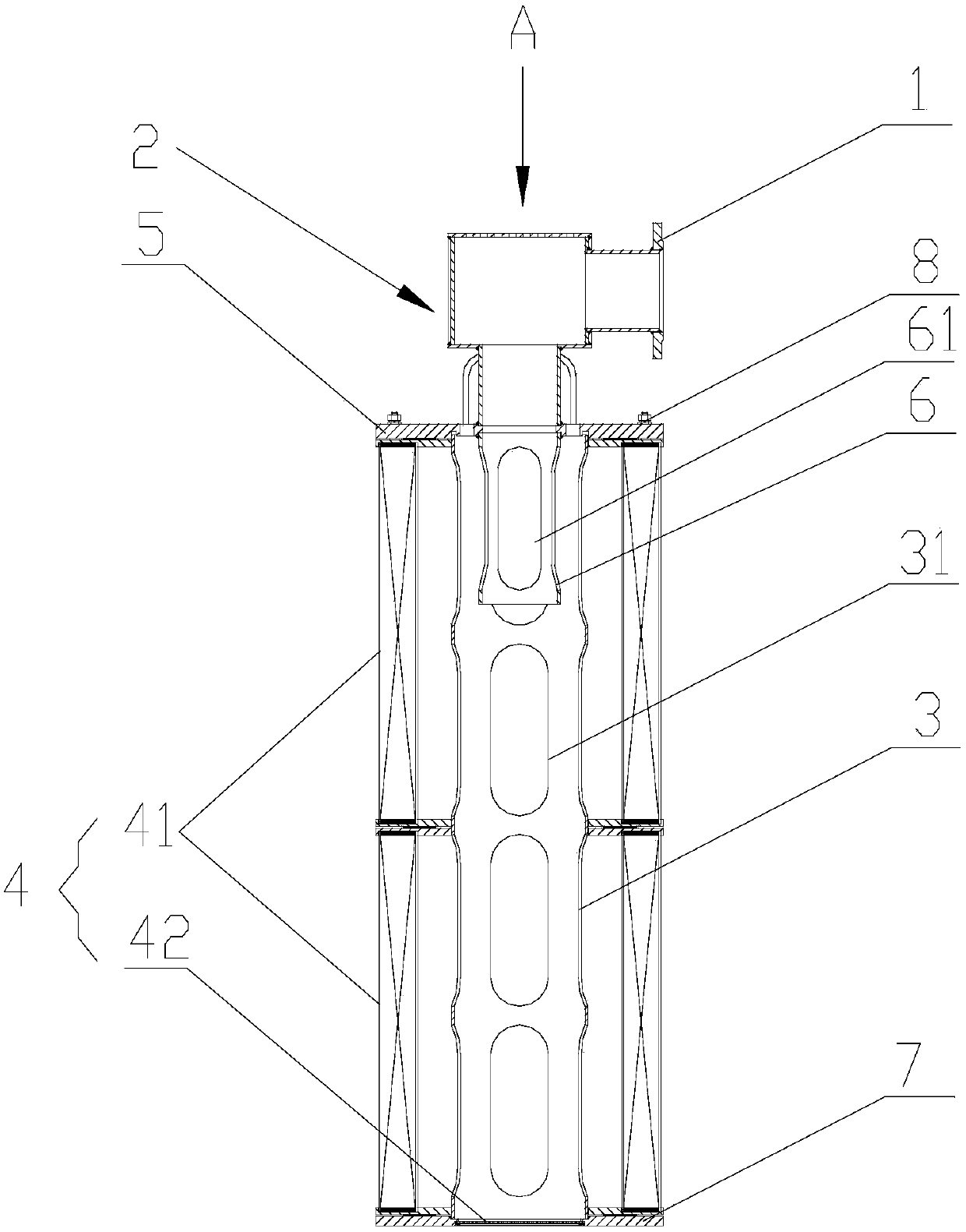

Light bearing base structure

ActiveCN107269397ASimple structureEasy to processTurbine/propulsion engine coolingTurbine/propulsion lubricationCold airShape optimization

The invention relates to a light bearing base structure capable of being applied to such fields as ground gas turbines and aircraft engines; and the structure can realize lubricating oil supply of bearing cavities, lubricating oil returning, cooling gas supply and ventilation between the bearing cavities. The light bearing base structure is provided with a discrete convex rib structure for realizing such functions as lubricating oil supply, lubricating oil returning and cooling gas supply, is provided with a kidney-shaped or shape-optimized cavity structure for realizing such functions as ventilation between the bearing cavities, and is provided with a flange mounting edge and an O-shaped ring mounting groove for realizing a function of sealing lubricating oil in the bearing cavities. The light bearing base structure can relieve the weight of an engine to the greatest extent, optimizes internal space utilization of the engine, and shortens an air way of a secondary air system of the engine; and lubricating oil supply and cold air supply in the bearing base both can realize effective control of the temperature of the lubricating oil in the bearing cavities.

Owner:INST OF ENGINEERING THERMOPHYSICS - CHINESE ACAD OF SCI

Oil-gas separator assembly

InactiveCN106194334AEasy to separateExtended cleaning cycleMachines/enginesCrankcase ventillationProcess engineeringProduct gas

The invention relates to an oil-gas separator assembly. Large-particle oil drops are pre-separated through the matching of oil baffles and a plurality of partition plates, and then, relatively-small-particle oil mists are separated by using a filter element, so that the oil-gas separation effect can be greatly improved, and air pollution can be reduced. The filter element of the oil-gas separator assembly can be directly mounted on an upper sealing cover, gaps exist inside the filter element and a filter cavity, a gas penetrates from the outside to the inside of the filter element, and the bottom of the filter element is closed, so that oil accumulation points generated at the filter element and a low point of the wall of the cavity are eliminated, oil is returned smoothly, the clearing period of the filter element is prolonged, and furthermore, the maintenance cost is reduced.

Owner:WEICHAI POWER CO LTD

Oil returning gas removal device and lubricating oil system

ActiveCN107940224AReduce air contentGuaranteed lubrication effectLubrication containersCavitationFuel tank

The invention discloses an oil returning gas removal device and a lubricating oil system, and relates to the technical field of power devices. The oil returning gas removal device is arranged in an oil tank of the lubricating oil system and comprises a connecting part, an oil returning pipe assembly, a sleeve and a filter assembly; the connecting part is used for mounting the oil returning gas removal device in an oil returning hole in the inner wall of the oil tank, the inlet end of the oil returning pipe assembly is connected with the connecting part, the sleeve is arranged at the outlet endof the oil returning pipe assembly, the sleeve and the oil returning pipe assembly form a continuous pipeline, multiple oil passing holes are formed in the periphery of the wall of the sleeve, the filter assembly is detachably arranged on the circumferential outer side and the bottom of the sleeve, and the filter assembly is provided with a filter net with the hole diameter smaller than 0.3 mm. Oil returning turning over and bubbles generated by traditional gravity oil returning can be avoided, the filter net of the filter assembly can effectively separate bubbles with the diameter above 0.3mm in the oil returning process, the gas containing amount in lubricating oil can be effectively reduced, the lubricating effect of the lubricating oil is ensured, and cavitation noise caused by gas containing of the lubricating oil can be reduced.

Owner:NO 719 RES INST CHINA SHIPBUILDING IND

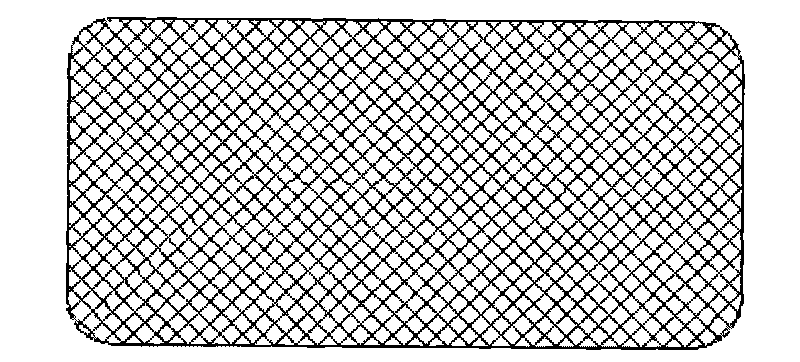

Processing molding method for stainless steel plate type heat exchanger

InactiveCN101691961BReduce pollutionLow soldering temperatureShaping toolsEvaporators/condensersPlate heat exchangerMetallurgy

The invention discloses a stainless steel plate type heat exchanger and a processing molding method thereof. The plate type heat exchanger comprises a snakelike flow channel type and honeycomb flow channel type evaporation plate or a cold plate. The plate type heat exchanger adopts a stainless steel plate and consists of a stainless steel upper plate, a stainless steel lower plate, an inlet pipe and an outlet pipe, wherein the two stainless steel plates are overlapped and connected by a special welding method; the inlet pipe and the outlet pipe are inserted in the upper end and the lower end between the two stainless steel plates and are connected with the stainless steel plate type heat exchanger body by using an electric arc welding method; and then the plate type heat exchanger is finally molded through a mould and high-pressure bulging technology.

Owner:CHONGQING UNIV

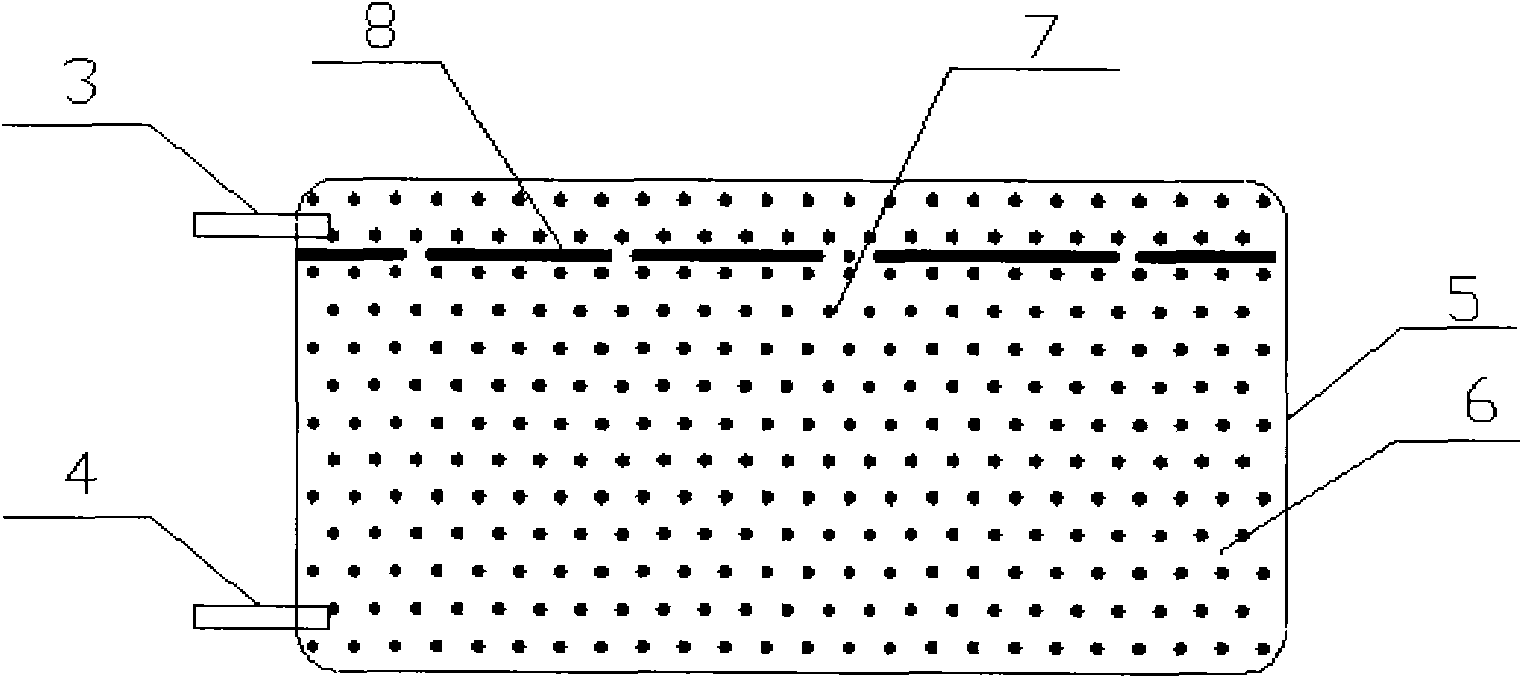

Aluminum honeycomb type evaporation plate and processing molding method thereof

InactiveCN101691978BImprove heat transfer efficiencyReduce weightShaping toolsArc welding apparatusEvaporationAluminum honeycomb

The invention discloses an aluminum honeycomb type evaporation plate and a processing molding method thereof. The evaporation plate adopts a high strength aluminum alloy plate and consists of an upper plate, a lower plate, an inlet pipe and an outlet pipe, wherein the two high strength aluminum alloy plates are overlapped and welded together by a solid-phase stir friction connecting method; the inlet pipe and the outlet pipe are inserted in the upper end and the lower end between the two high strength aluminum alloy plates and are connected with the high strength aluminum alloy evaporation plate body by using an electric arc welding method; and then the evaporation plate is finally molded through a mould and high-pressure bulging technology.

Owner:CHONGQING UNIV

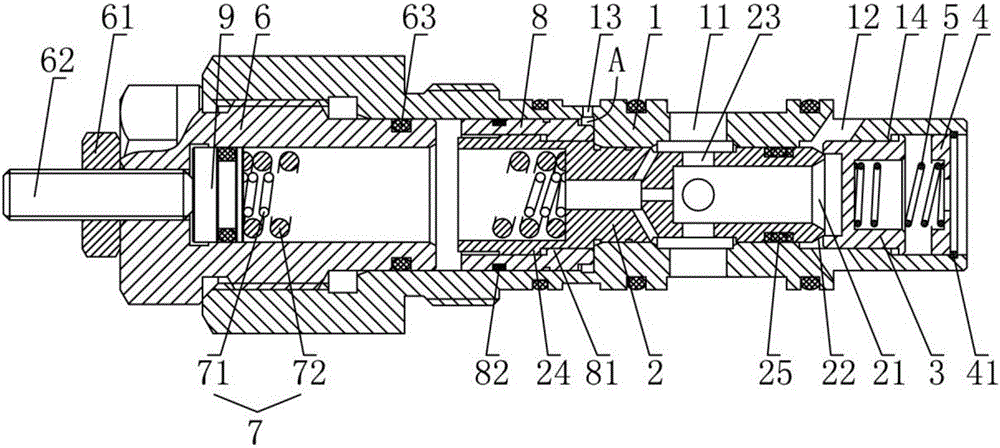

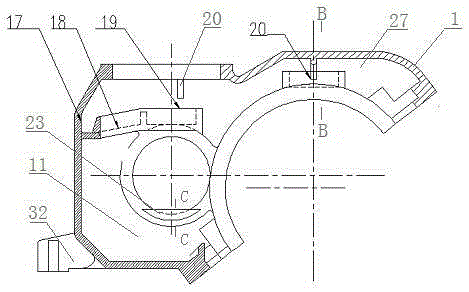

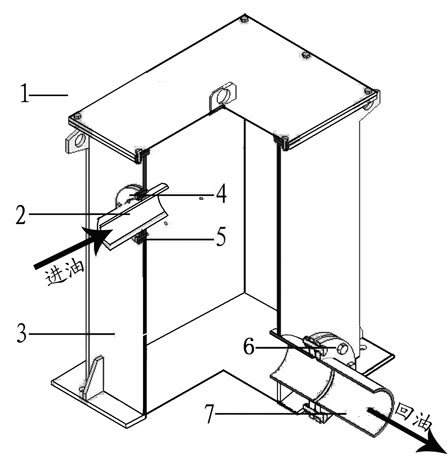

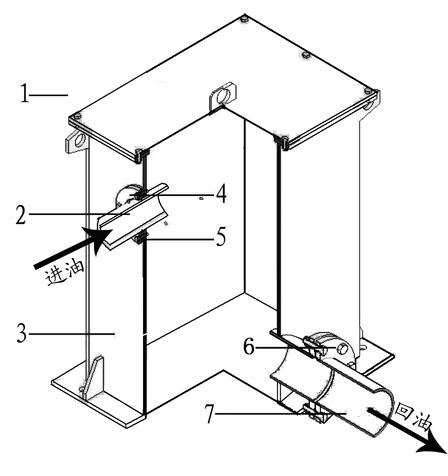

Floating oil return mechanism

The invention relates to the field of metallurgical equipment, in particular to a floating oil return mechanism in a floating decoiler. The mechanism is characterized by at least comprising a sealing box body, a box cover, an oil inlet flange, a rubber sealing gasket, an oil inlet pipe, an oil return flange and an oil return pipe, wherein the oil return pipe is connected with an oil box of a thin oil lubrication station through an intermediate piping; the sealing box body is a welding structural member and fixed on a foundation; the oil inlet flange is fixed on the upper side part of the sealing box body; the oil inlet pipe is in rigid connection with the decoiler body; the oil return flange is fixed right below the sealing box body and connected with the oil return pipe; and the oil inlet pipe floats and stretches in the sealing box body through the guide of the oil inlet flange and the sealing of the rubber sealing gasket in the presence of the drive of the floating decoiler body to ensure that lubricating oil flows in the sealing box body and then flows back to the thin oil lubrication station through the oil return pipe at the bottom of the sealing box body. The floating oil return mechanism has simple structure, guarantees smooth oil return and is completely suitable for the floating oil return working conditions of the floating decoiler.

Owner:CHINA NAT HEAVY MACHINERY RES INSTCO

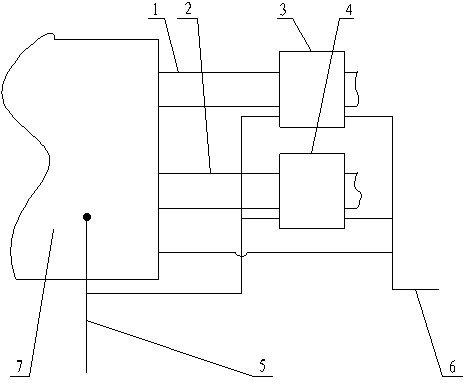

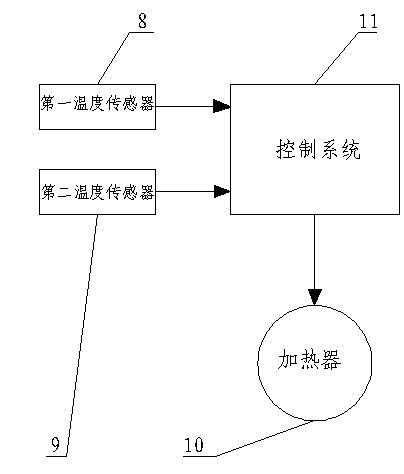

Temperature control device for lubricating oil return

InactiveCN104197180ASmooth oil returnImprove lubricating propertiesLubrication elementsTemperature controlControl system

The invention discloses a temperature control device for lubricating oil return. The temperature control device comprises a first temperature sensor, a second temperature sensor, a heater and a control system. The first temperature sensor is installed on an oil inlet pipe, and the second temperature sensor and the heater are sequentially installed on an oil return pipe. The first temperature sensor and the second temperature sensor are respectively connected with the control system. The heater is controlled by the control system. The temperature control device has the following advantages that the control system automatically adjusts the heater according to temperature data, it can be guaranteed that thin lubricating oil smoothly returns, and the lubricating characteristic of a lubricating system is improved.

Owner:蔡宏磊

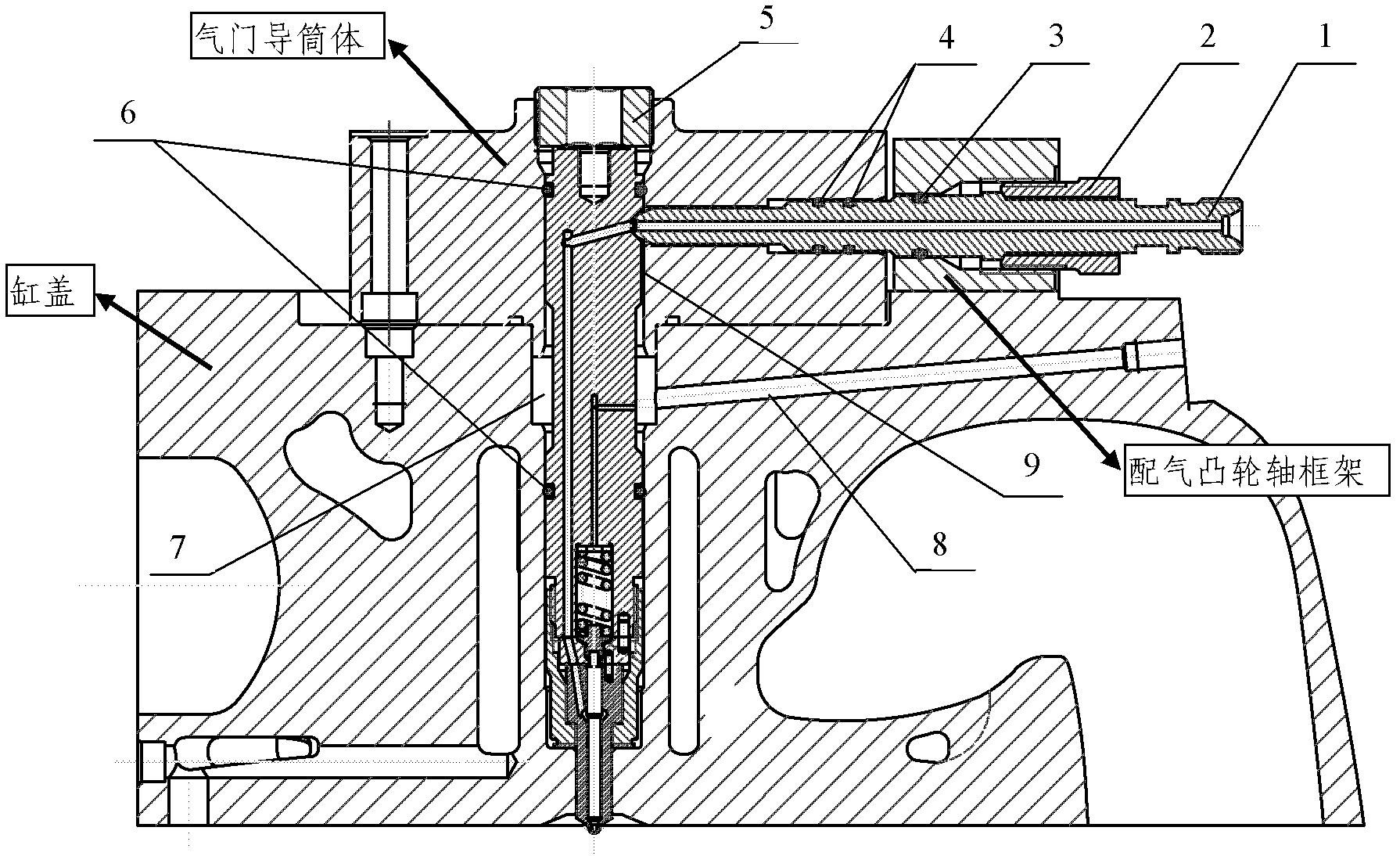

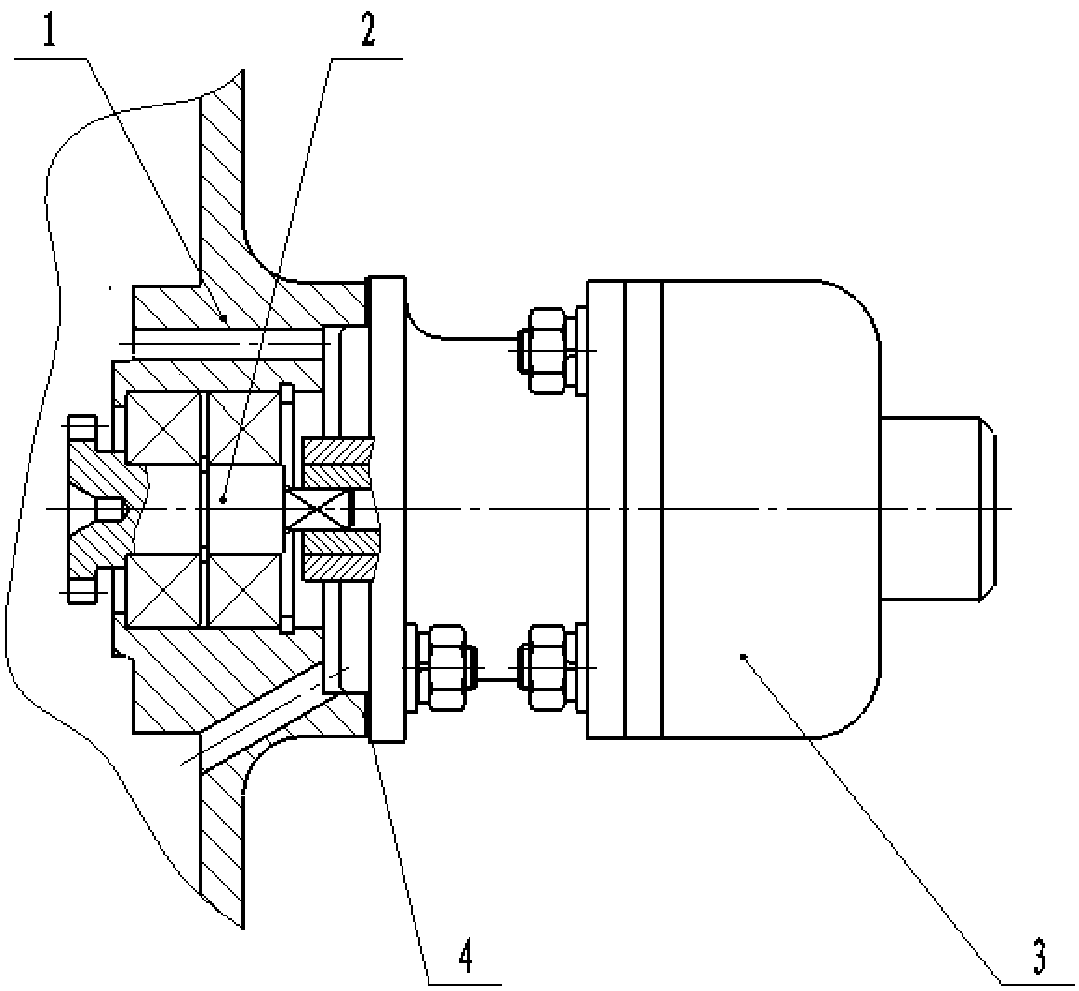

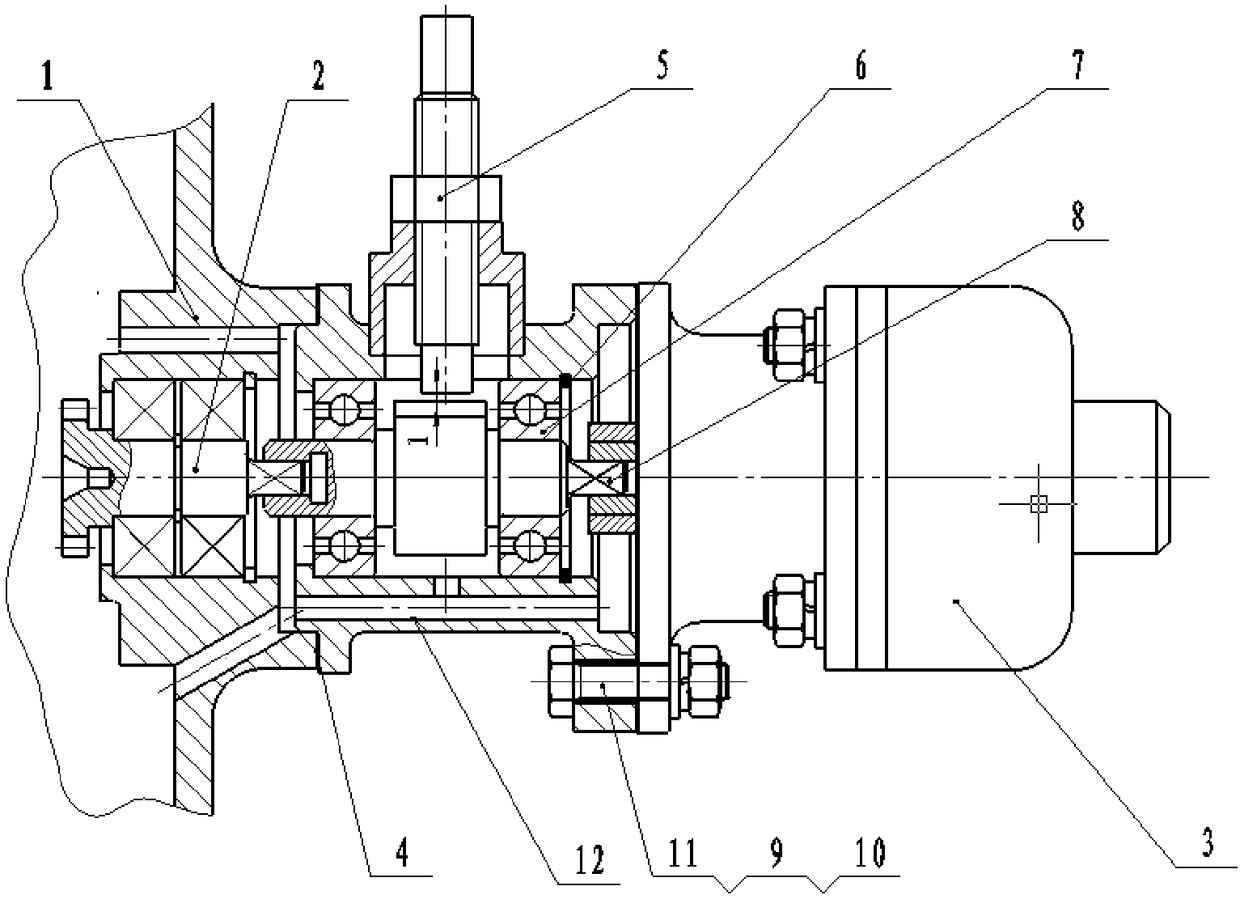

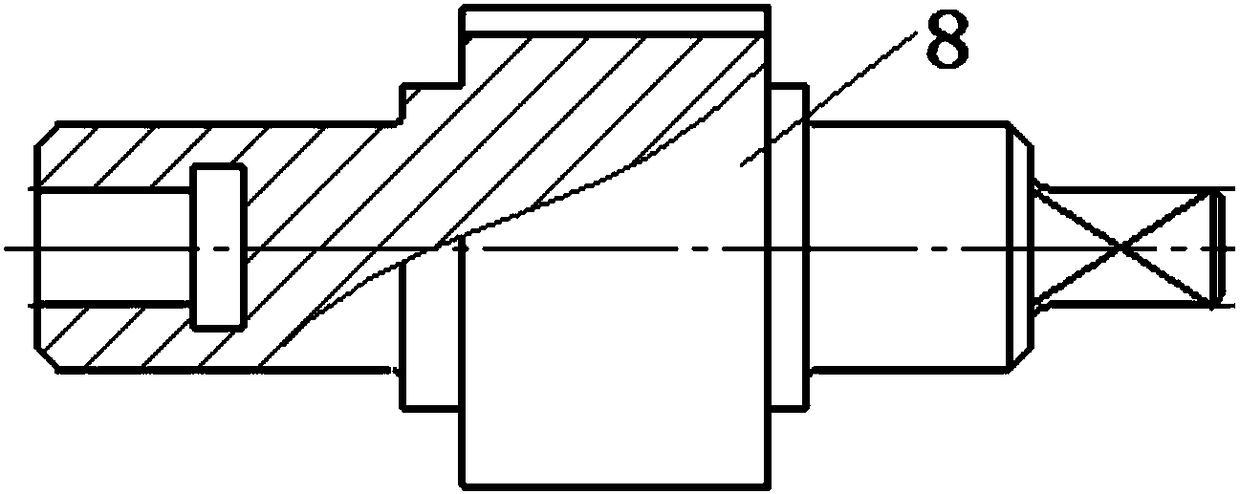

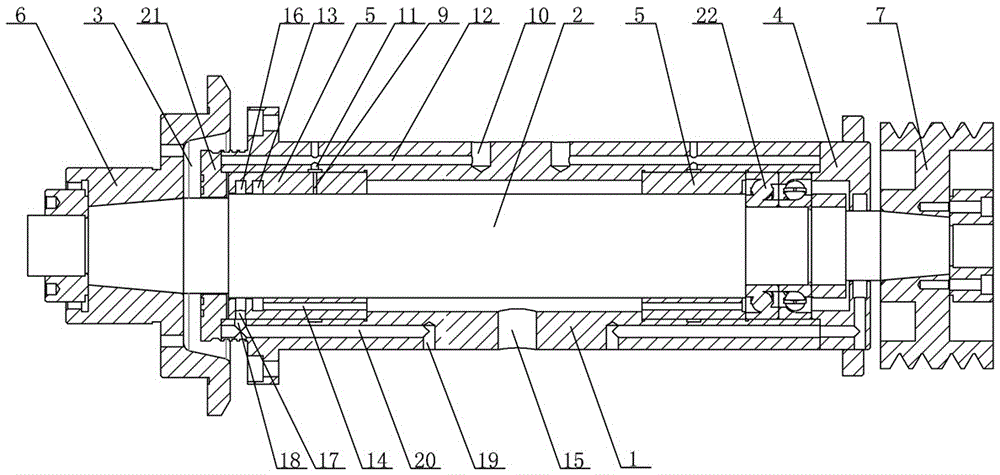

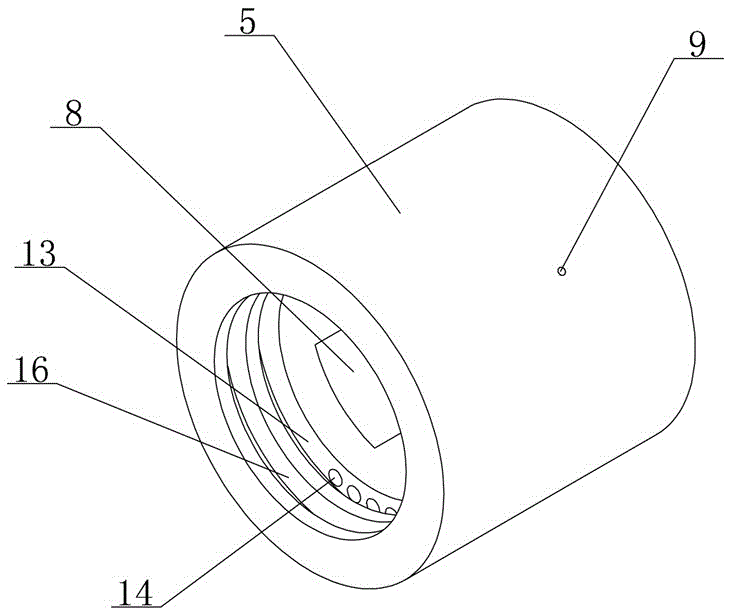

Device for testing input speed of aeroengine centrifugal sensor

ActiveCN108120848ASimple structureImprove accuracyDevices using electric/magnetic meansTest inputData acquisition

The invention discloses a device for testing the input speed of an aeroengine centrifugal sensor. The device is provided with a change-over seat between an engine accessory casing and the centrifugalsensor, the change-over seat is provided with a through hole, then two ends of a counting gear shaft installed in the change-over seat are respectively connected with an input shaft of the centrifugalsensor and a driven gear shaft in the engine accessory casing, the middle of the counting gear shaft is provided with counting teeth, the side wall of the change-over seat is provided with an eddy current sensor mounting hole, a probing head of the eddy current sensor directly faces towards the counting teeth on the counting gear shaft so as to perform signal acquisition on the speed of the counting gear shaft, and the counting gear shaft is connected with the driven gear shaft and capable of coaxially rotating, so that data acquisition for the speed of the counting gear shaft is the speed ofthe driven gear shaft and the actual input speed of the centrifugal sensor. The device is simple in structure, authentic and reliable in data, does not need to modify the structure of the engine accessory casing and the centrifugal sensor, and greatly improves the detection and data accuracy of the input speed of the aeroengine centrifugal sensor.

Owner:AECC AVIATION POWER CO LTD

Novel gearbox

InactiveCN106838273AExtend your lifeAvoid failureGear lubrication/coolingEngineeringProcess complexity

The invention discloses a novel gear box. In order to solve the problem of oil leakage and the complex adjustment process of the bearing axial clearance in the existing gear box; the gear box includes a driven gear, a box body, an outer end cover and a bearing retaining ring; It is composed of the lower box body, and the upper box body and the lower box body have corresponding oil passages; there is an outer oil chamber between the bearing retaining ring and the outer end cover, and an inner oil chamber between the bearing retaining ring and the bearing. Cavity; between the box, the bearing retaining ring and the two outer end caps, there are bearing bushes; the bearing bushes are provided with bushings that communicate with the corresponding oil passages on the upper box and the lower box. Sleeve oil passage; the bush oil passage communicates with the inner oil chamber or the outer oil chamber. The invention improves the service life and lubricating quality of the driven gear bearing, reduces the complexity of the process, and improves the assembly efficiency of the gearbox.

Owner:CHANGZHOU KAIFA GUANGMING CASTING FACTORY GENERAL PARTNERSHIP

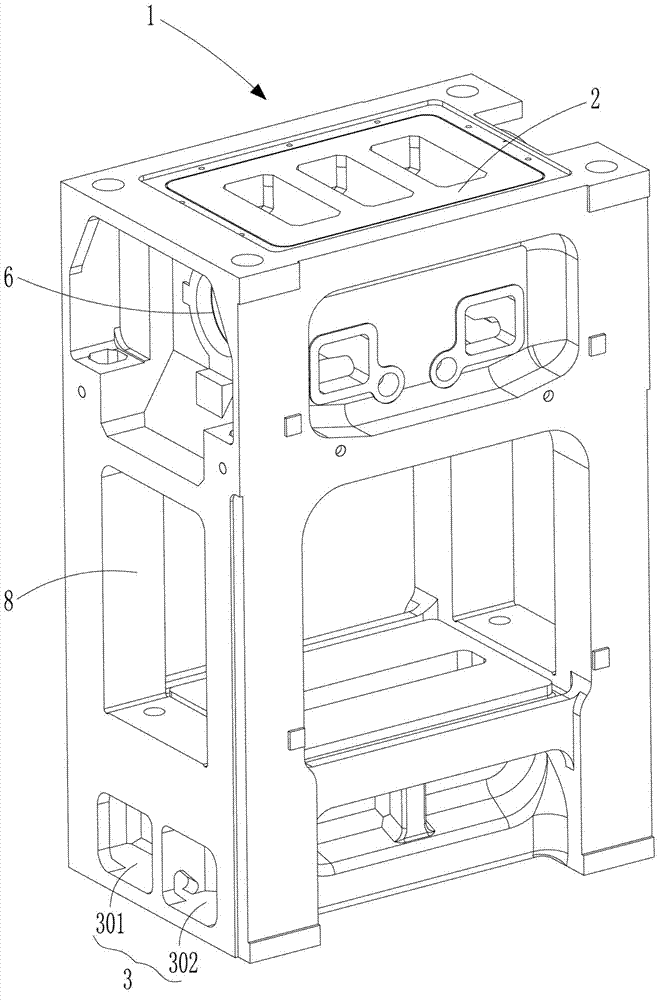

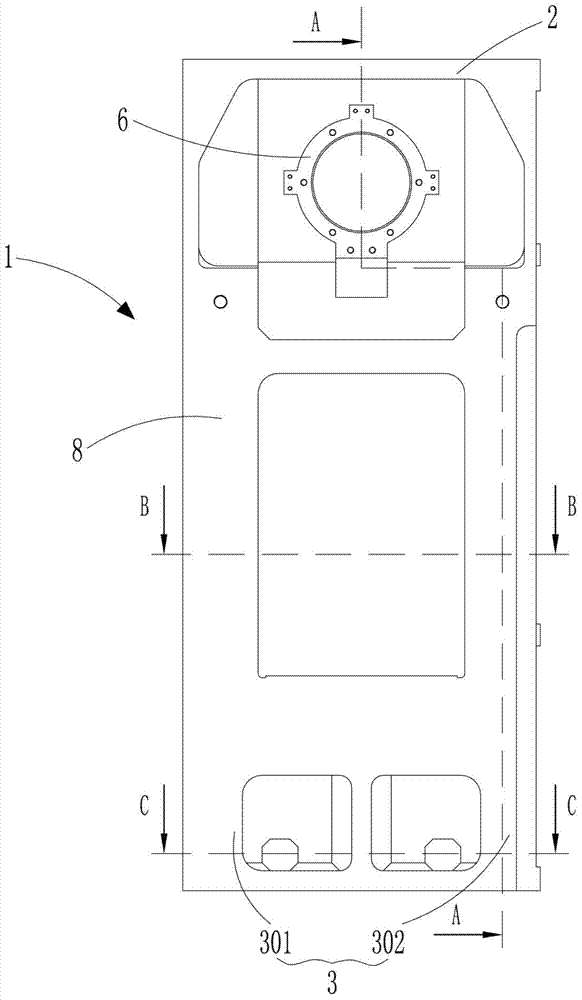

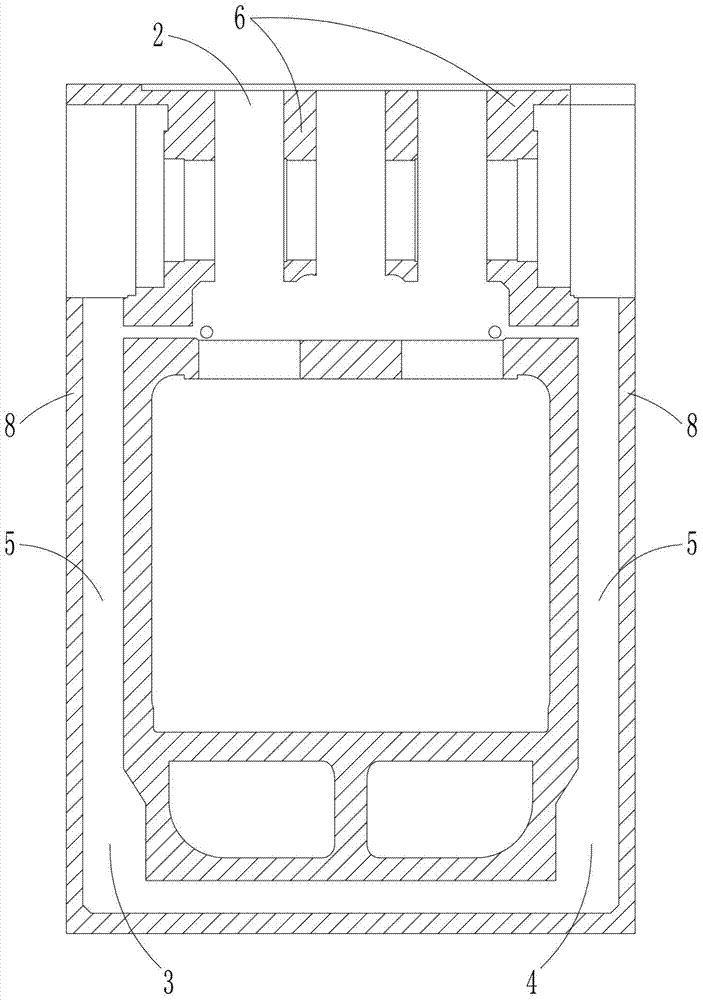

Integrated high-speed punch press body

ActiveCN103692687ASolve the problem of damaged oil leakageUniform temperaturePressesEngine lubricationPunch pressThermal deformation

The invention discloses an integrated high-speed punch press body. The whole punch press body is integrally cast and comprises a main body, a crank case arranged on the main body, a main oil tank and an auxiliary oil tank, wherein the main oil tank and the auxiliary oil tank are arranged on the main body. The main body is provided with four stand columns, and cavities are formed inside the stand columns to form oil return pipes which communicate the main oil tank and the crank case as well as the auxiliary oil tank and the crank case; a bearing block is arranged inside the crank case; an oil channel which communicates the insides of the main oil tank and the auxiliary oil tank is arranged between the main oil tank and the auxiliary oil tank. Being integrally formed through the casting technology, the whole integrated high-speed punch press body is better in integral rigidity and accordingly solves the influence of assembly errors on precision; the oil return pipe of lubricant oil is integrated inside the integrated punch press body and accordingly is fully sealed without contact with joint guide pipes, further the problem of breakage and oil leakage of the guide pipes can be solved; besides, the thickness of the oil return pipes is larger than the diameter of traditional rubber pipes, so that oil return can be more smooth; the oil tank channel achieves mixing and circulation of the lubricant oil in the main oil tank and the auxiliary oil tank, so that the temperature of every portion of a punch press can be uniform and further thermal deformation can be avoided.

Owner:苏州欧利锦高速精密冲床科技有限公司

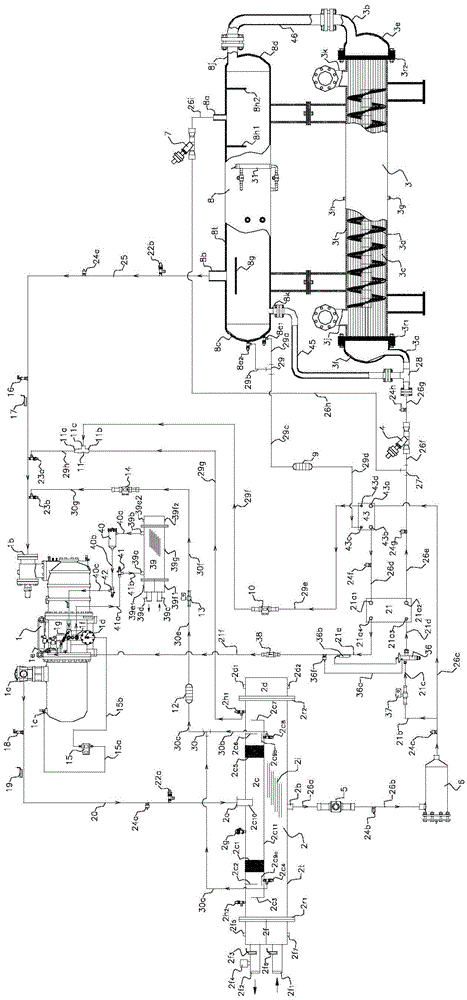

Wind cooling split type air adjusting machine communicate system

ActiveCN100516693CReduce resistanceSmooth oil returnDucting arrangementsRefrigeration componentsAir conditioningSystem structure

An air-cooled split-type air conditioner connection system, aiming at the problems of large resistance and poor oil return in the pipeline when the air conditioner is installed over a long distance and with a high drop, the invention provides an air conditioner connection system, its The exhaust rising pipeline (4) is a consistent upward pipeline, and an oil separator (5) is installed at the lower end of the exhaust rising pipeline (4), and the exhaust inlet (5-1) of the oil separator (5) It is connected with the exhaust horizontal pipeline (3) coming out of the indoor unit (1), and the exhaust outlet (5-2) of the oil separator 5 is connected with the exhaust rising pipeline (4) going to the outdoor unit (2); The oil return pipe interface (5-3) of the oil separator (5) is connected to one end of the oil return line (6), and the other end of the oil return line (6) is connected to the compressor (1-1) in the indoor unit (1) on the air return line (1-2). The invention has the advantages of small resistance, smooth oil return, simple system structure, easy implementation, easy installation, low cost, low initial investment, low operation and management costs, less building space occupation, and low cost, which is beneficial to popularization and application.

Owner:AIRSYS REFRIGERATION ENG TECH BEIJING

Processing molding method of magnesium alloy plate type heat exchanger

InactiveCN101691962BImprove heat transfer efficiencyReduce weightShaping toolsEvaporators/condensersEvaporationHoneycomb

Owner:CHONGQING UNIV

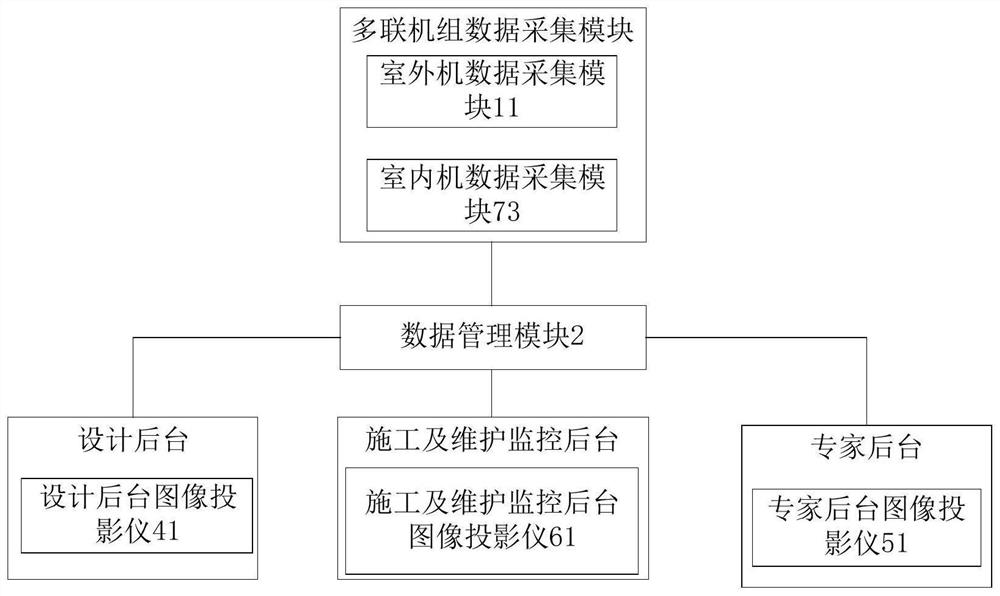

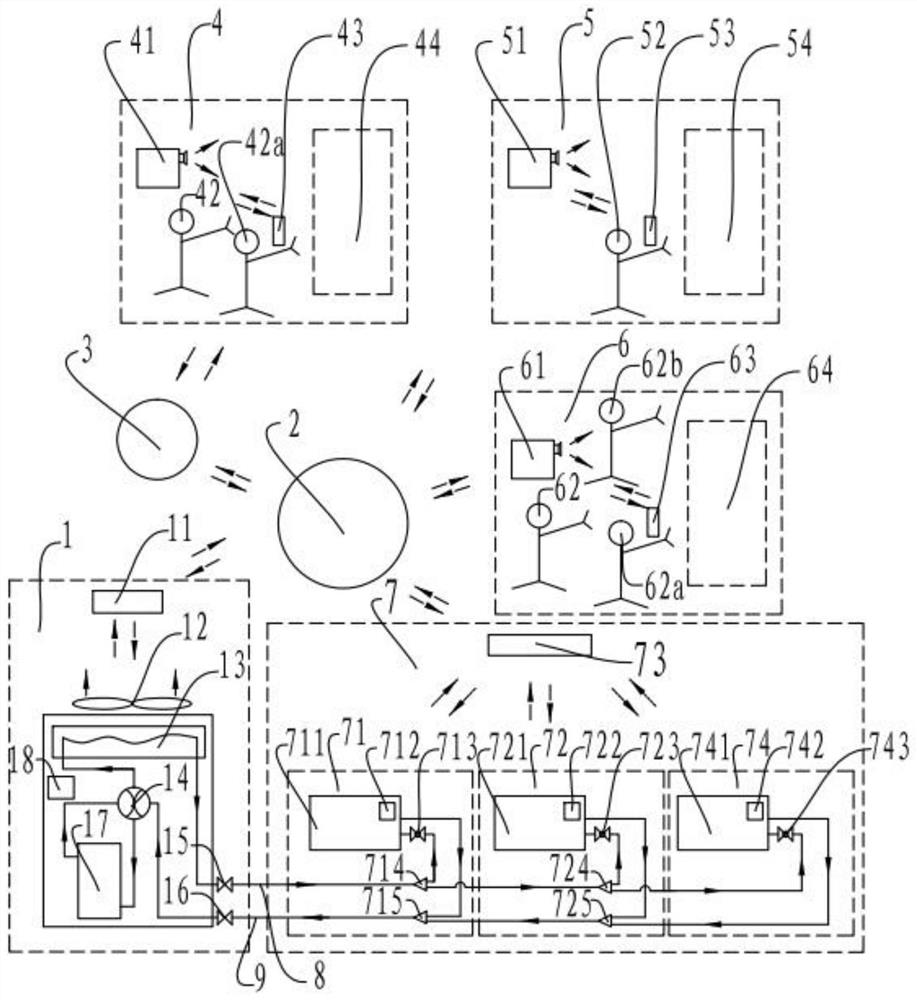

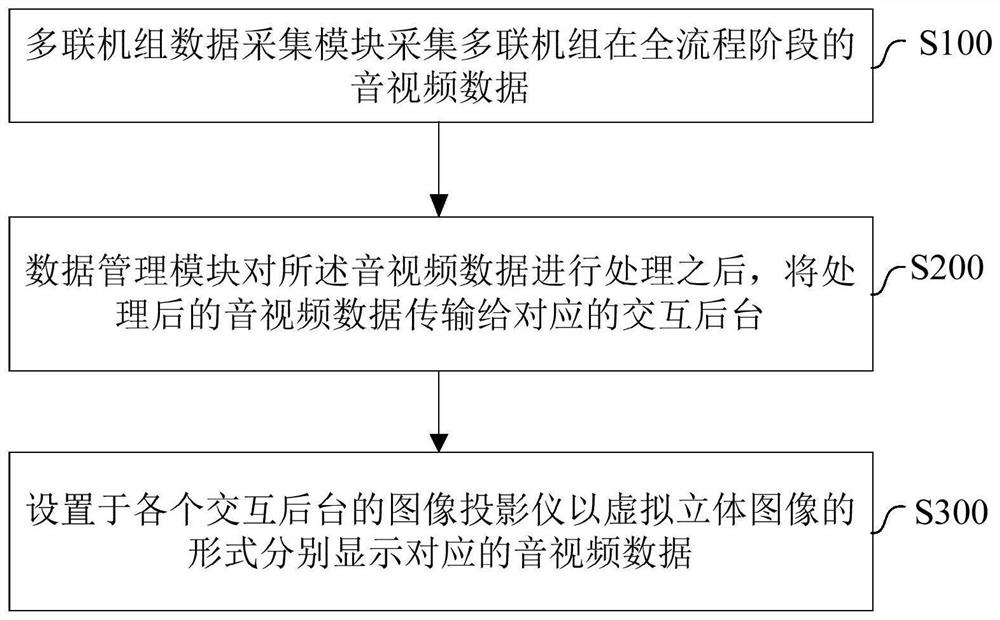

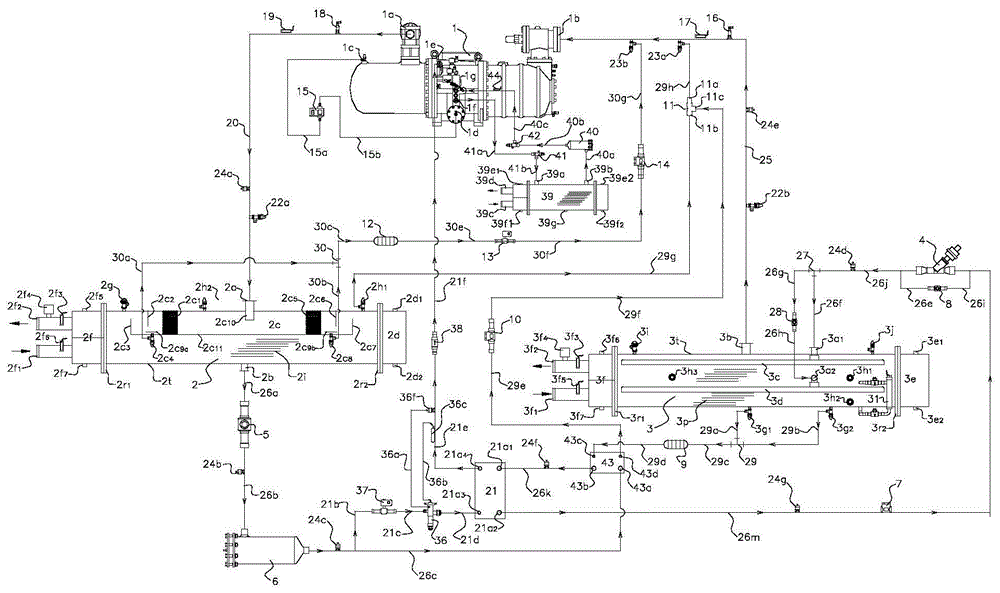

Multi-connected unit remote installation and maintenance method and system based on 5G network

PendingCN113405209AEasy to observeSimplified display interfaceMechanical apparatusSpace heating and ventilation safety systemsData acquisitionData management

The invention relates to the technical field of air conditioners, and particularly relates to a multi-connected unit remote installation and maintenance method and system based on a 5G network. The system comprises a multi-connected unit data acquisition module, a data management module and a plurality of interaction backgrounds, wherein each interaction background is provided with an image projector; and the data management module is in communication connection with the multi-connected unit data acquisition module, the data management module and the plurality of interaction backgrounds through the 5G network. The method comprises the following steps that the multi-connected unit data acquisition module acquires audio and video data of a multi-connected unit in a whole process stage; the data management module processes the audio and video data and then transmits the processed audio and video data to the corresponding interaction backgrounds; and the image projectors arranged on the interaction backgrounds display the corresponding audio and video data in a virtual three-dimensional image mode. According to the method and the system, the audio and video data of the multi-connected unit in the whole process stage are monitored in real time through the virtual three-dimensional image, and efficient and reliable work of the multi-connected unit can be guaranteed.

Owner:JIANGXI HAOJIN OUBO AIR CONDITIONING MFG CO LTD

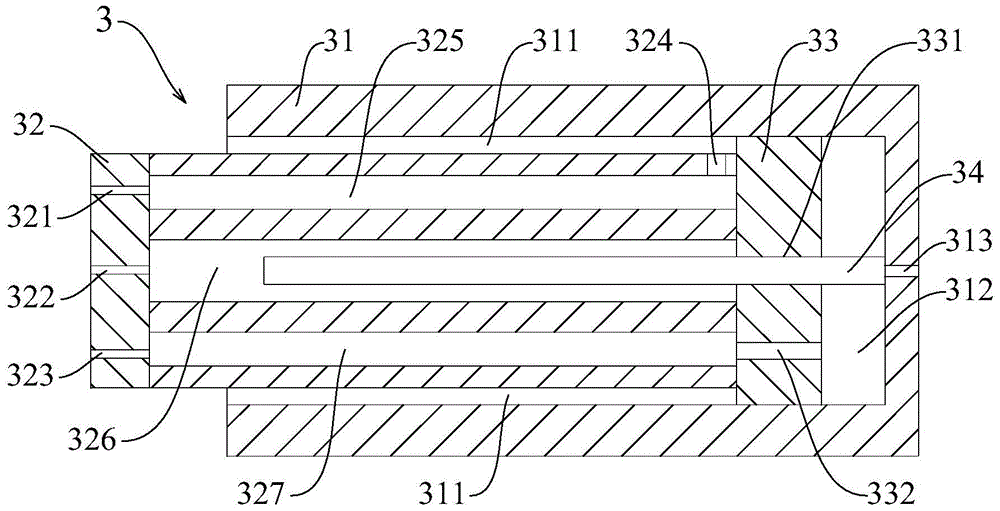

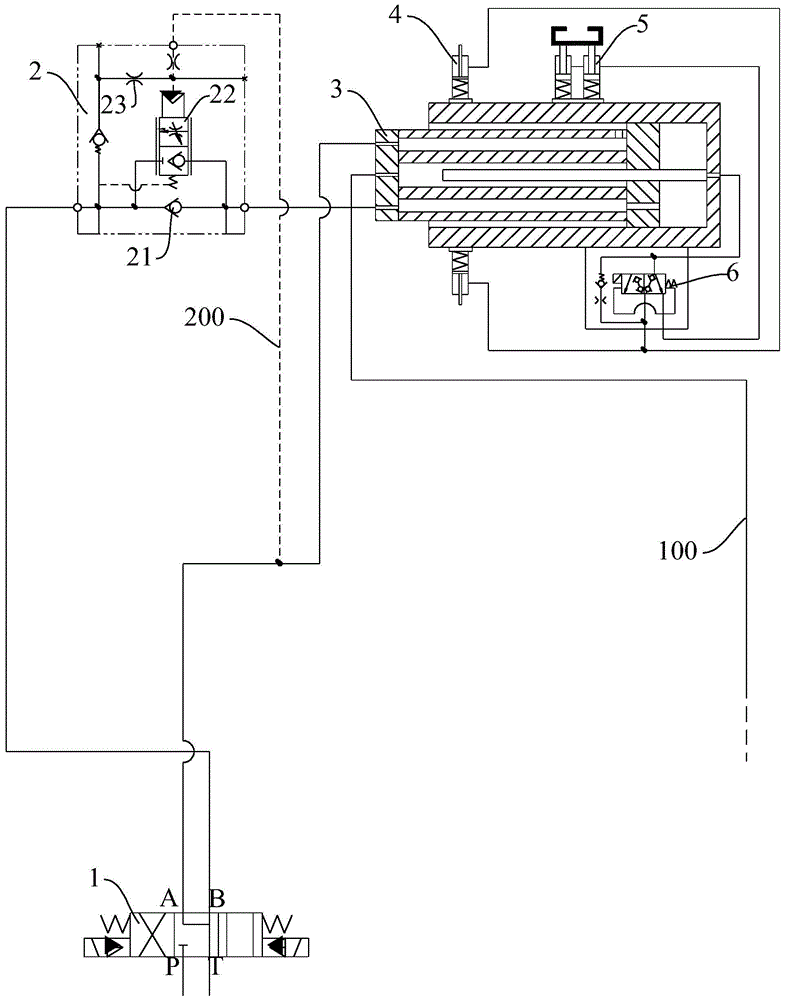

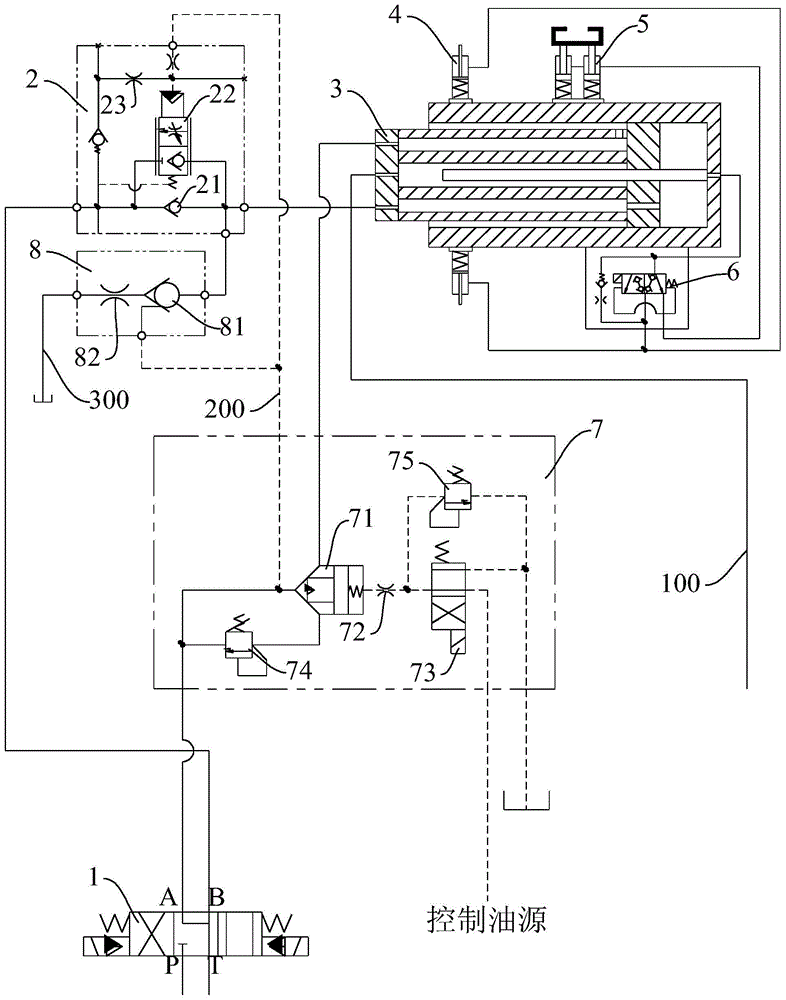

Boom telescopic buffer hydraulic system and crane

ActiveCN104692266BAvoid shockReduce shockFluid-pressure actuator safetyServomotor componentsPetroleum engineeringHydraulic control

The invention discloses a hydraulic system for telescopic buffer of a crane boom and a crane. The hydraulic system for telescopic buffer of the crane boom comprises a telescopic oil cylinder, a main valve and a balance valve, wherein a first working oil port and a second working oil port of the main valve are respectively connected to a rod chamber of the telescopic oil cylinder and a free oil inlet of the balance valve in a communication way, a free oil outlet of the balance valve is connected to a rodless chamber of the telescopic oil cylinder in a communication way, and the first working oil port is also connected to a control oil port of the balance valve in a communication way through a control oil line; and the hydraulic system for telescopic buffer of the crane boom also comprises an auxiliary pressure-relief oil line, a through flow damper and a hydraulic control pressure-relief on-off valve, wherein the oil inlet end of the auxiliary pressure-relief oil line is connected to the rodless chamber of the telescopic oil cylinder in a communication way, the through flow damper and the hydraulic control pressure-relief on-off valve are arranged on the auxiliary pressure-relief oil line, and the control oil port of the hydraulic control pressure-relief on-off valve is connected to the control oil line or the first working oil port in a communication way. By implementing the hydraulic system, impact generated by the balance valve or a pressure shunting damper when the crane boom is started to be shrunk can be effectively reduced.

Owner:SANY AUTOMOBILE HOISTING MACHINERY

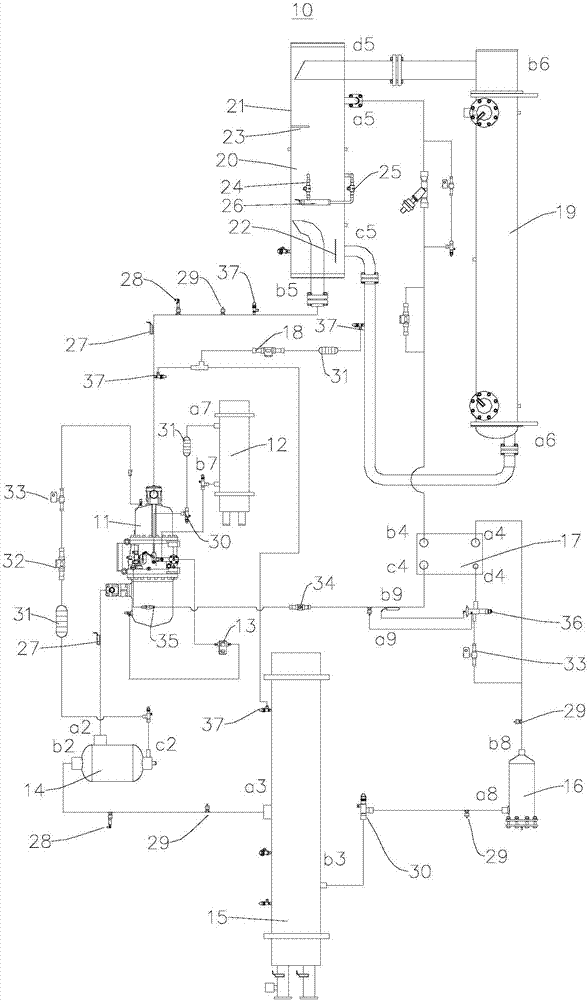

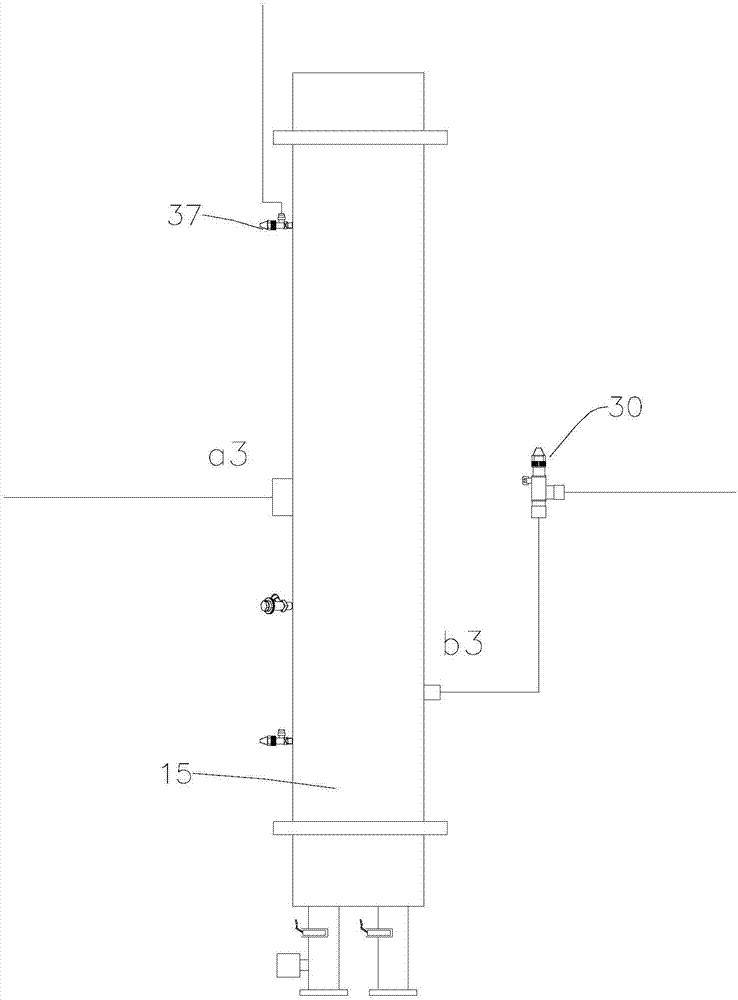

Siphonic water-cooling threaded rod saline water unit system

PendingCN107166790AImprove operational efficiencyIncrease oil return temperatureCompression machines with non-reversible cycleEvaporators/condensersSaline waterThermodynamics

The invention provides a siphonic water-cooling threaded rod saline water unit system and relates to the technical field of refrigerating. In the siphonic water-cooling threaded rod saline water unit system, a threaded rod compressor, an oil separator, a condenser and an economizer are sequentially connected, a first outlet b4 of the economizer is connected with a liquid inlet a5 of a gas-liquid separator through a liquid supply pipe, and an exhaust port b5 of the gas-liquid separator is connected with an air inlet b1 of the threaded rod compressor through an air suction pipe. A liquid outlet c5 of the gas-liquid separator is connected with a liquid inlet a6 of a sphonic evaporator through a descending circulating pipe, and an exhaust port b6 of the siphonic evaporator is connected with an air inlet d5 of the gas-liquid separator through an ascending circulating pipe. The system adopts the siphonic evaporator and the gas-liquid separator to form a circular refrigerating loop, the return oil temperature of the siphonic evaporator is raised through the economizer, the return oil viscosity is reduced, the siphonic evaporator returns oil more smoothly, and the unit running efficiency is improved.

Owner:成都美森制冷设备有限公司

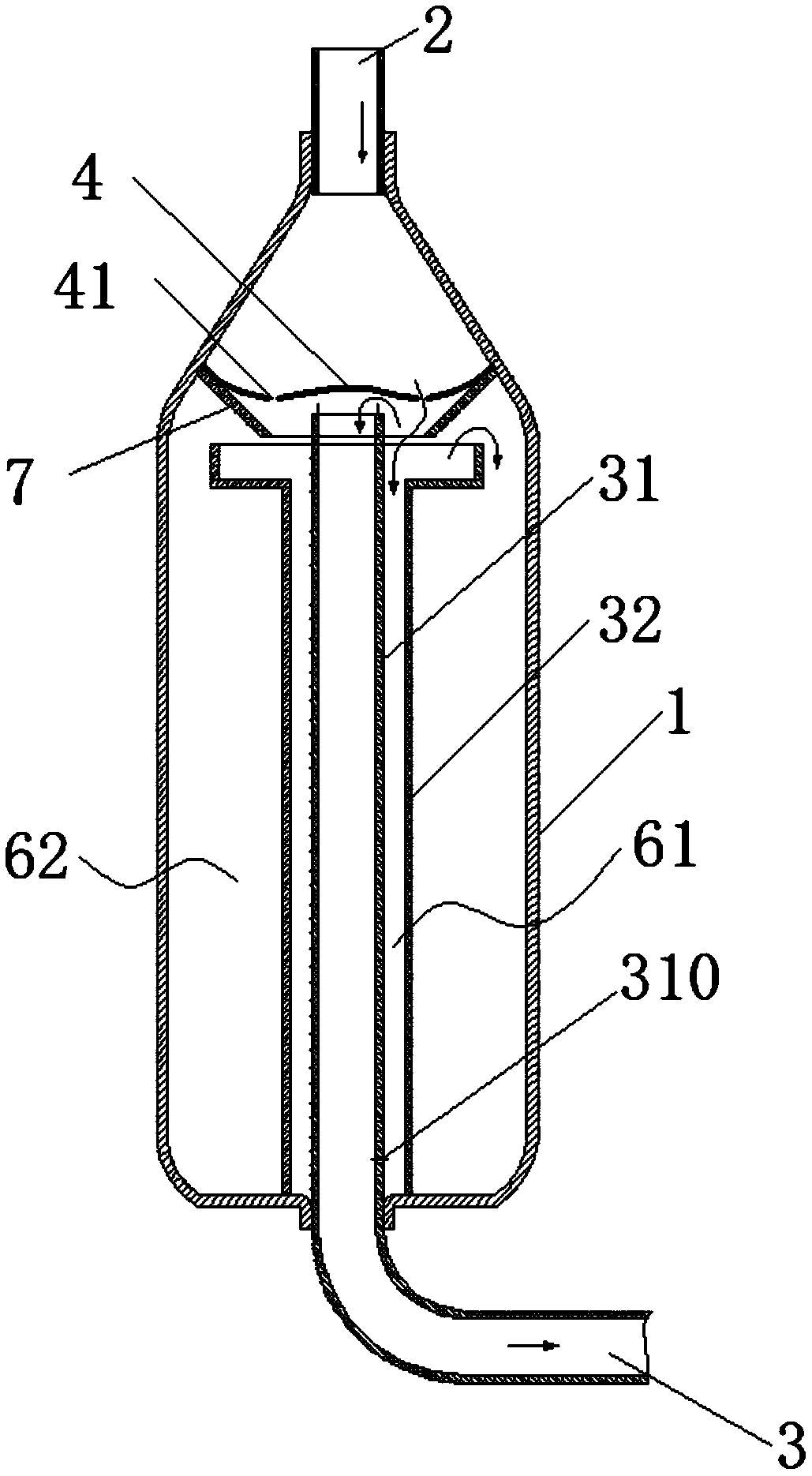

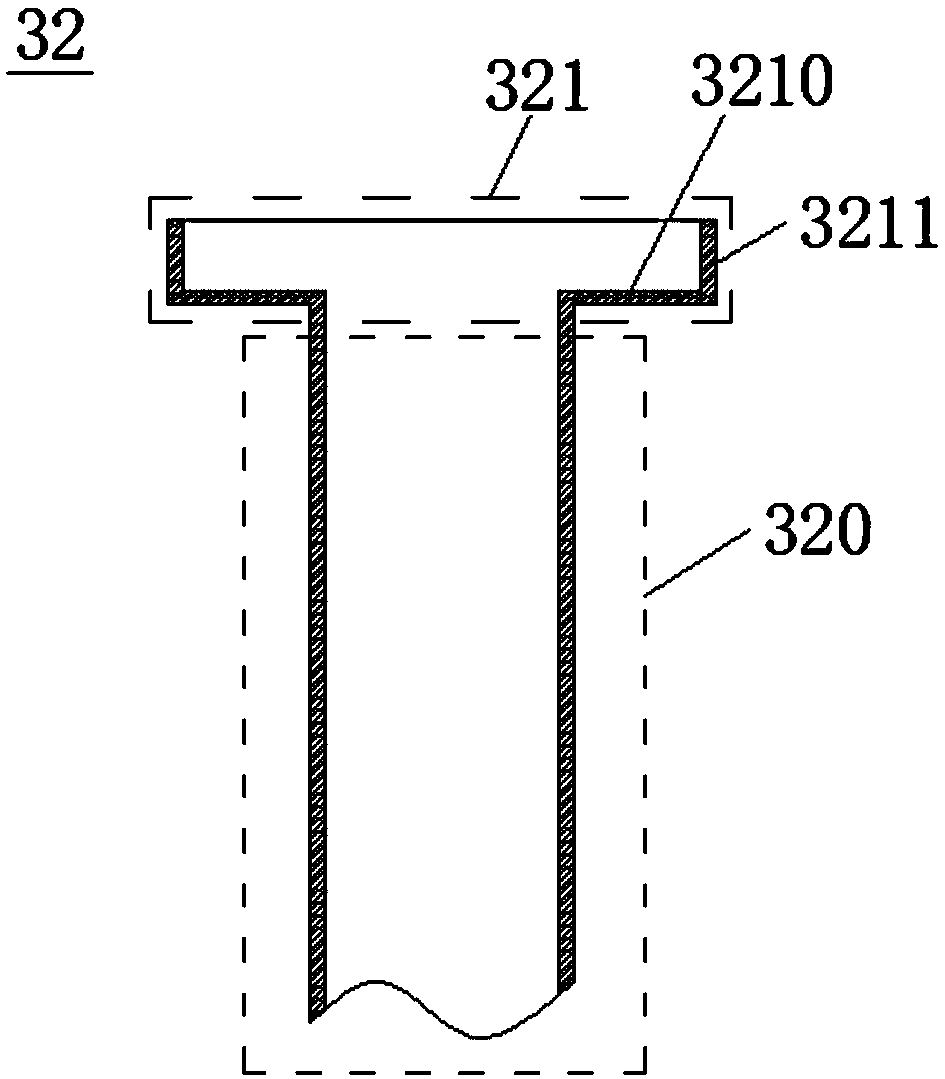

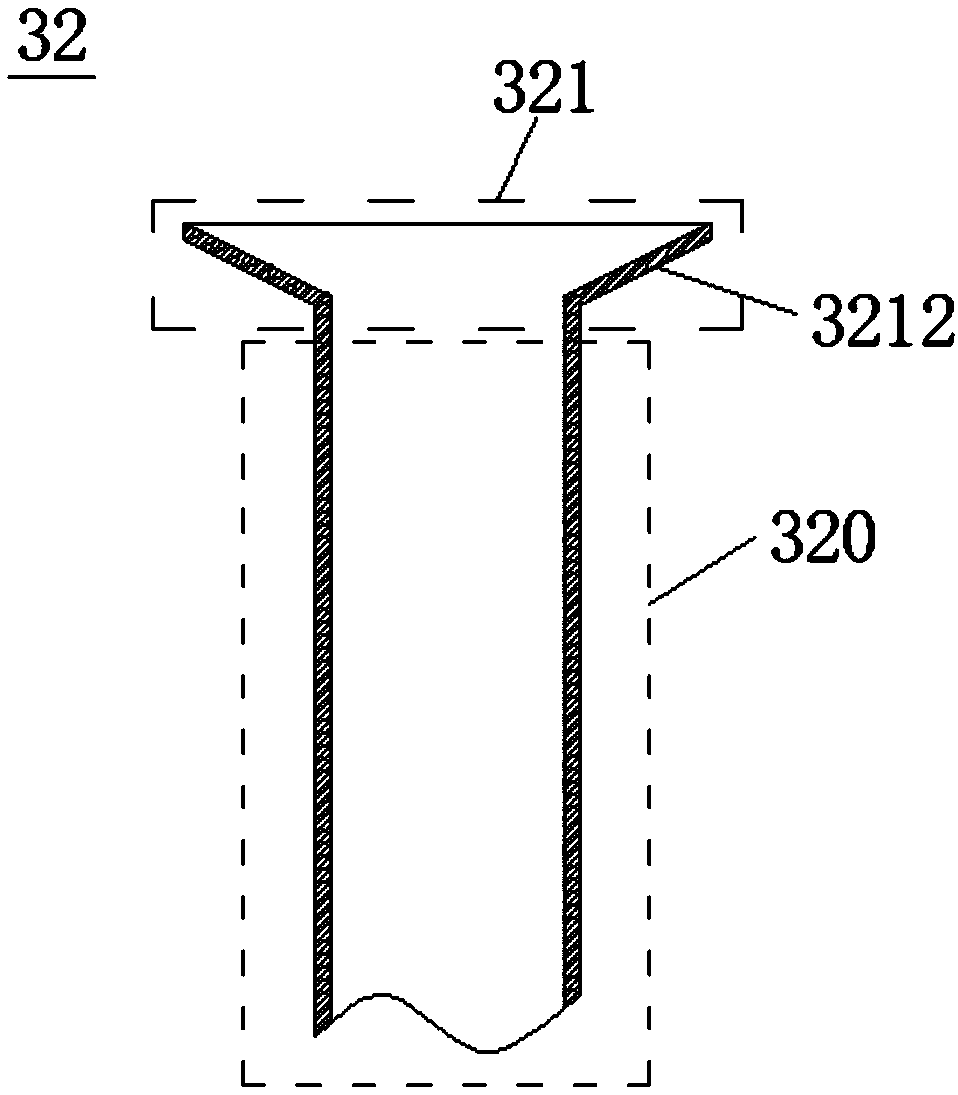

Liquid storage tank applied to compressor

InactiveCN109631431ASmooth oil returnAvoid inhalation of liquidRefrigeration componentsReturned AmountRefrigerant

The invention belongs to the field of compressor accessories, and discloses a liquid storage tank applied to a compressor. The liquid storage tank comprises a shell provided with an air inlet pipe andan air outlet pipe, and the air outlet pipe comprises an extending-in section which extends into the shell. The liquid storage tank further comprises a separator for separating out a liquid refrigerant, and a sleeve, wherein the separator is arranged between the air inlet pipe and the extending-in section, the sleeve sleeves the extending-in section, the end, away from the separator, of the sleeve is sealed, and the end, close to the separator, of the sleeve is used for receiving the liquid refrigerant which is obtained after separation by the separator. A first liquid storage space is formedbetween the sleeve and the extending-in section, and an oil return hole is formed in the pipe wall of the extending-in section and communicates with the first liquid storage space. According to the liquid storage tank applied to the compressor, flowing power of a liquid refrigerant and lubricating oil mixture can be guaranteed under the high-temperature condition with few refrigerants and the low-temperature condition with many refrigerants, the oil return amount is stable, and the requirement of a wide-environment-temperature operation heat pump system is met.

Owner:QINGDAO HAIER AIR CONDITIONER GENERAL CORP LTD

Cantilever type composite spindle with high hydrostatic pressure

InactiveCN106826547AImprove rigidityHigh rotation accuracyGrinding machine componentsHydrostatic pressureEngineering

The invention discloses a cantilever type composite spindle with high hydrostatic pressure. The cantilever type composite spindle with high hydrostatic pressure comprises an outer sleeve and a spindle, wherein a front end cover and a back end cover are mounted at front and back ends of the outer sleeve respectively, bearing bushes are mounted at two ends of an inner cavity of the outer sleeve, the spindle penetrates through inner cavities of the two bearing bushes, the front and back ends of the spindle penetrate out of the front end cover and the back end cover respectively, a flange for mounting a grinding wheel is mounted at the front end of the spindle, and a belt pulley is mounted at the back end; a plurality of concave oil grooves are formed in the inner walls of the bearing bushes, small holes which are communicated with the inner cavities and have the diameter of 0.5-0.7 mm are formed in the bush walls of the bearing bushes, gaps exist between the spindle and the inner walls of the bearing bushes, and an oil inlet structure for introducing hydraulic oil into the inner cavities of the bearing bushes via the small holes is formed in the wall of the outer sleeve; the cantilever type composite spindle with high hydrostatic pressure further comprises an oil return structure for leading the hydraulic oil out of the inner cavities of the bearing bushes. The cantilever type composite spindle with high hydrostatic pressure has the advantages of high rotation precision, high rigidity, long service life and the like.

Owner:新昌县华科机电设备有限公司

A falling-film water-cooled screw low-temperature solution unit

ActiveCN104697225BImprove heat transfer efficiencyReduce chargeCompressorCompression machines with non-reversible cycleEngineeringGas supply

The invention discloses a falling-film water-cooled screw low-temperature solution unit. The screw compressor communicates with the air inlet of a built-in oil condenser, and the oil outlet valve of the built-in oil condenser communicates with the suction pipeline of the screw compressor. One way of the liquid outlet of the condenser is connected with the energy-saving gas supply port of the screw compressor through the second channel of the economizer, and the other way is through the first channel of the oil return heat exchanger, the second channel of the economizer, the electronic expansion valve and the double-stage falling film evaporator The liquid inlet is connected, the gas outlet of the double-stage falling film evaporator is connected with the inlet of the screw compressor; the oil outlet valve of the double-stage falling film evaporator is connected with the second channel of the oil return heat exchanger and the middle inlet of the ejector , The outlet of the ejector communicates with the suction passage of the screw compressor. The invention creatively applies the falling film evaporator to the water-cooled screw low-temperature solution unit, which improves the heat exchange efficiency of the evaporator, saves the space of the unit with a built-in oil condenser, and the design of the oil circuit makes the oil return of the screw compressor safer and more efficient. more reliable.

Owner:南京冷德节能科技有限公司 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com