Siphonic water-cooled screw low-temperature solution unit

A low-temperature solution and siphon technology, which is applied in the direction of refrigerators, refrigeration components, refrigeration and liquefaction, etc., can solve the problems of increasing fluid flow resistance, increasing flow resistance, uneconomical, etc. Heater area and the effect of reducing the return oil viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

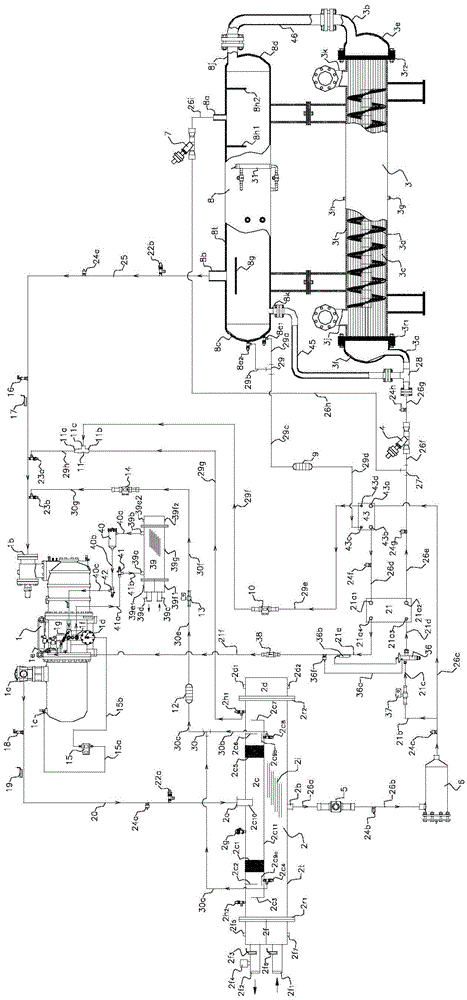

[0033] Examples: A siphonic water-cooled screw cryogenic solution unit, such as figure 1 Shown: Including: screw compressor 1, with built-in oil separator 2, siphon evaporator 3, gas-liquid separation cycle barrel 8, exhaust pipe 20, liquid supply system 26, suction pipe 25, oil return system .

[0034] An oil pressure difference switch 15 is provided between the high pressure detection port 1c and the oil pressure detection port 1d of the screw compressor 1, and is connected through an oil pressure pipe 15a and an oil pressure pipe 15b. There is also an oil cooler 39 on the oil path of the screw compressor 1. The oil cooler 39 is a water-cooled shell and tube heat exchanger. The refrigerant oil flows in the shell side and the cooling water flows in the tube side; the screw compressor oil outlet 1f The compressor oil outlet pipe 41a communicates with the inlet of the shut-off valve 41, and the outlet of the shut-off valve 41 communicates with the oil passage inlet 39a of the oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com