Patents

Literature

3964 results about "Economizer" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Economizers (US and Oxford spelling), or economisers (UK), are mechanical devices intended to reduce energy consumption, or to perform useful function such as preheating a fluid. The term economizer is used for other purposes as well. Boiler, power plant, heating, refrigeration, ventilating, and air conditioning (HVAC) uses are discussed in this article. In simple terms, an economizer is a heat exchanger.

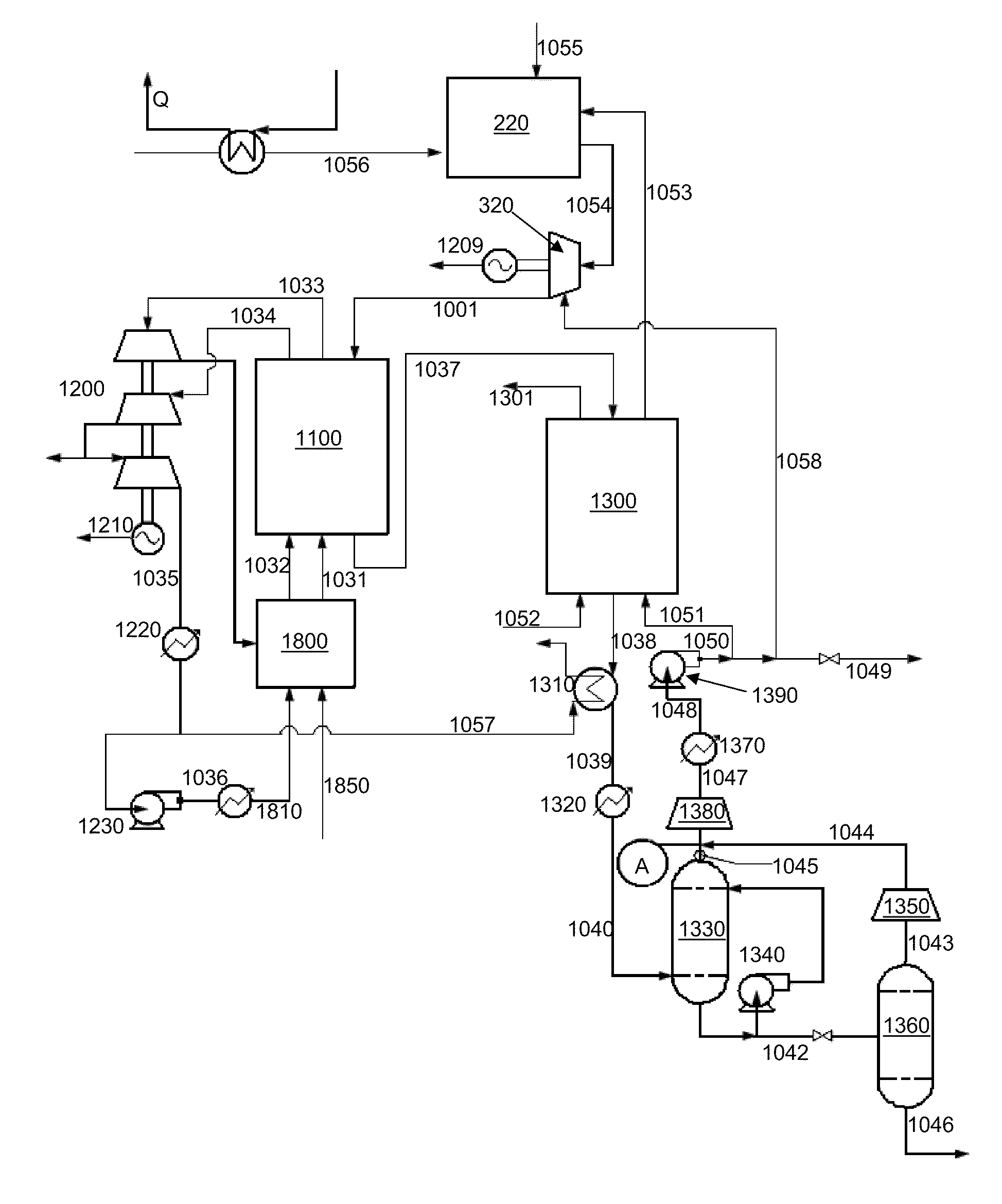

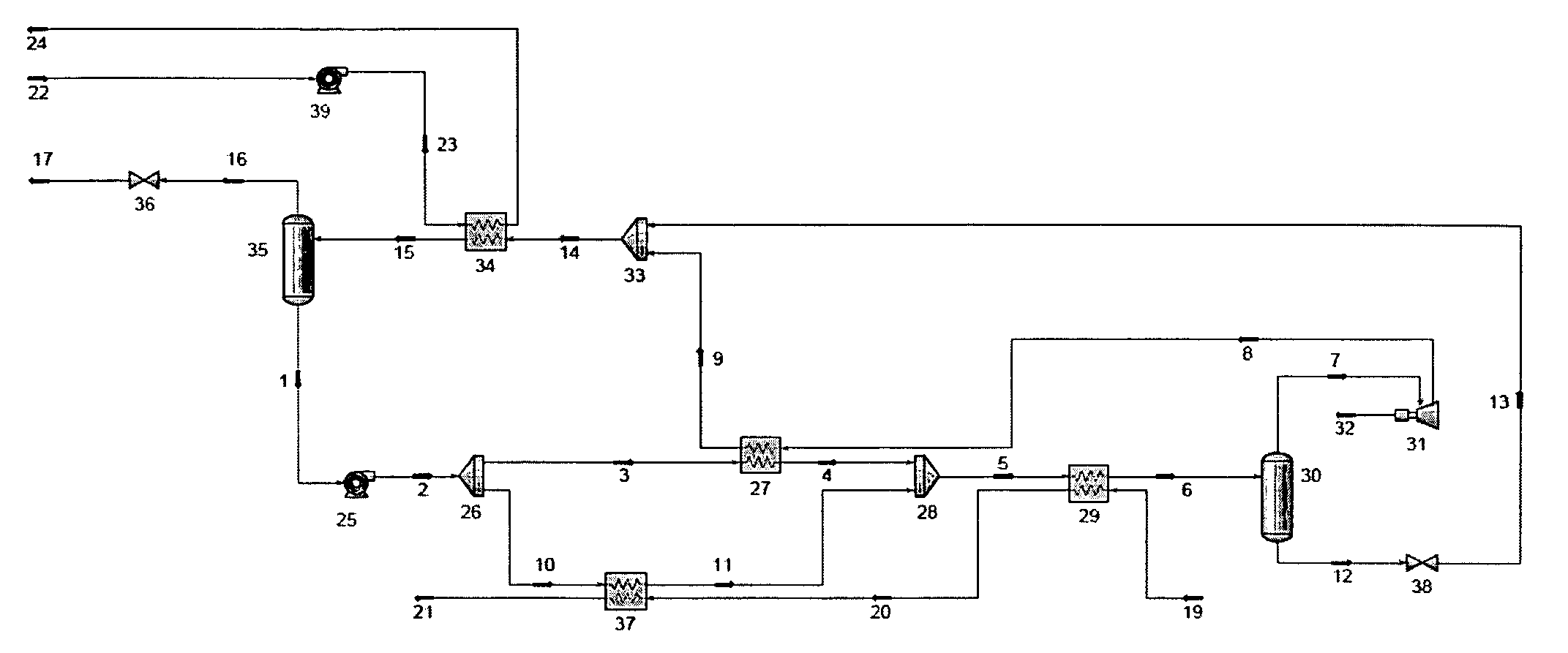

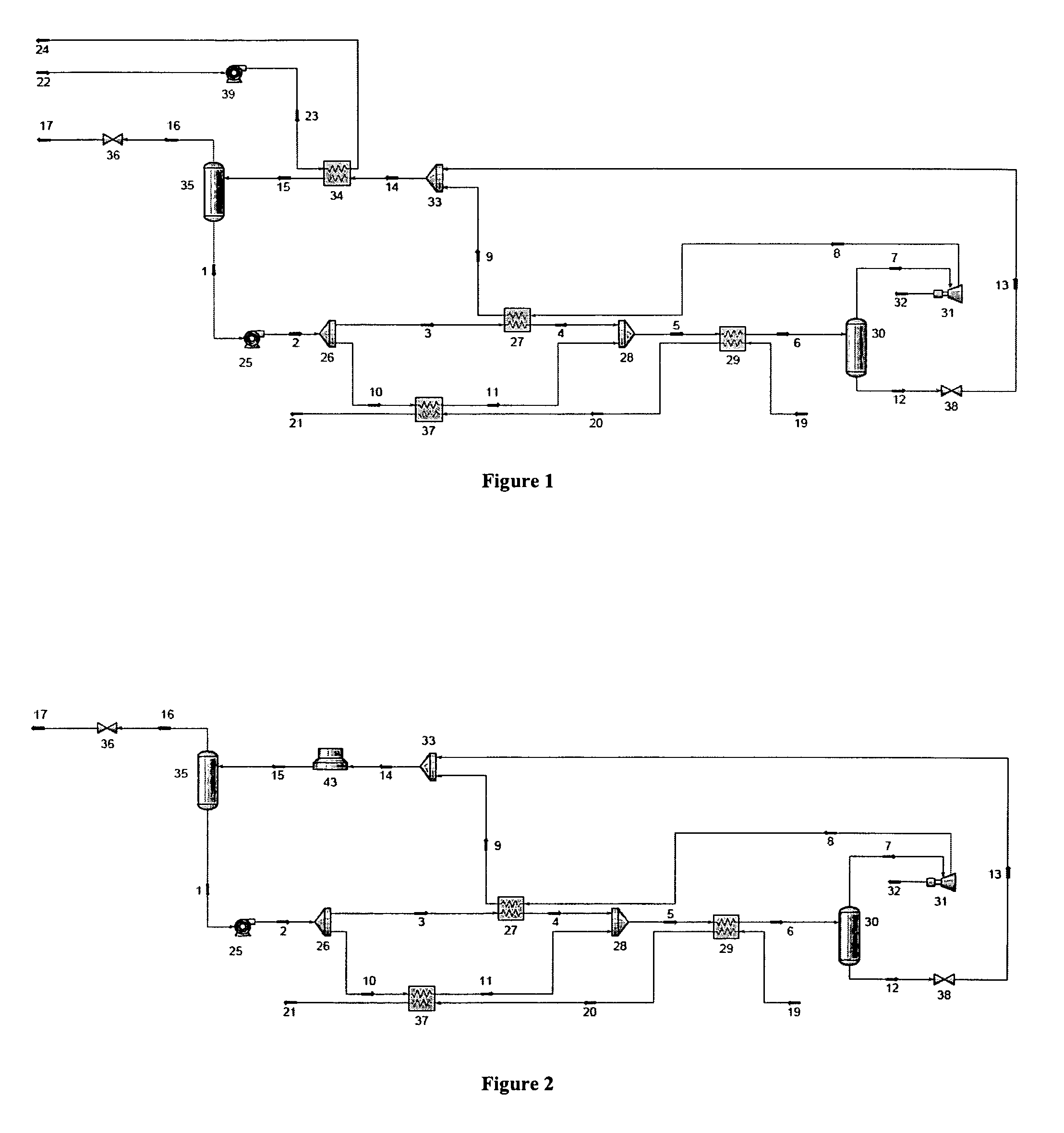

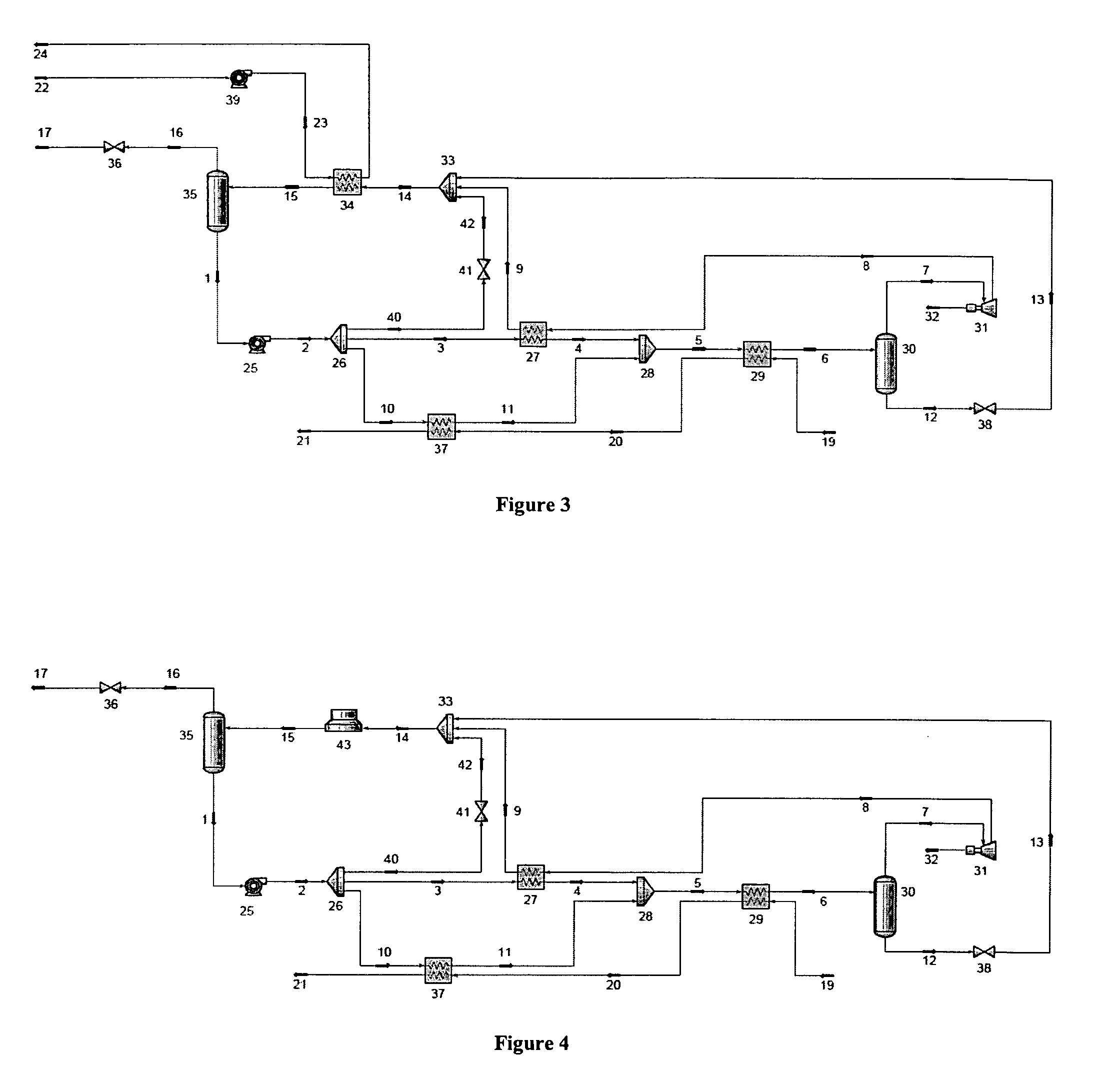

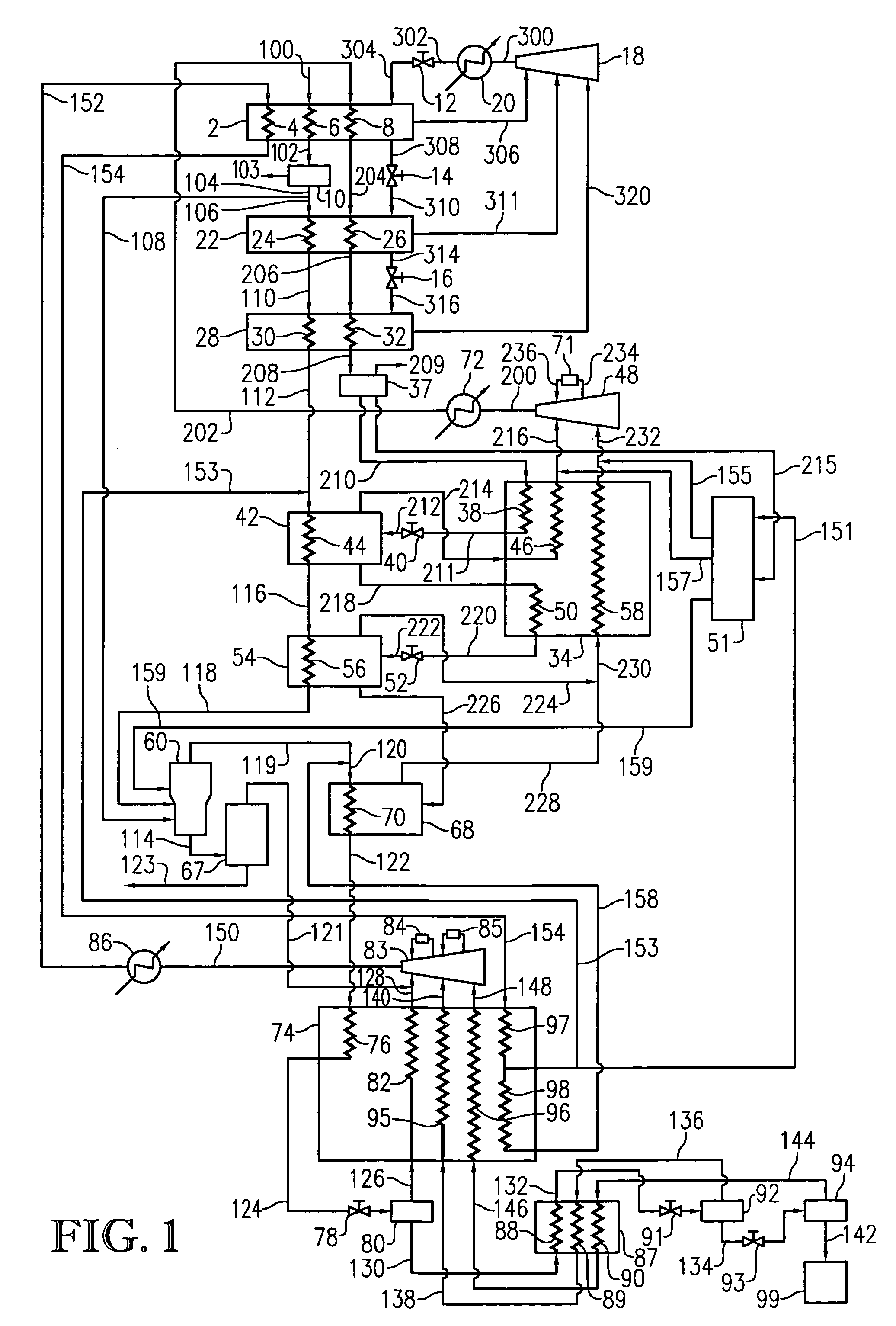

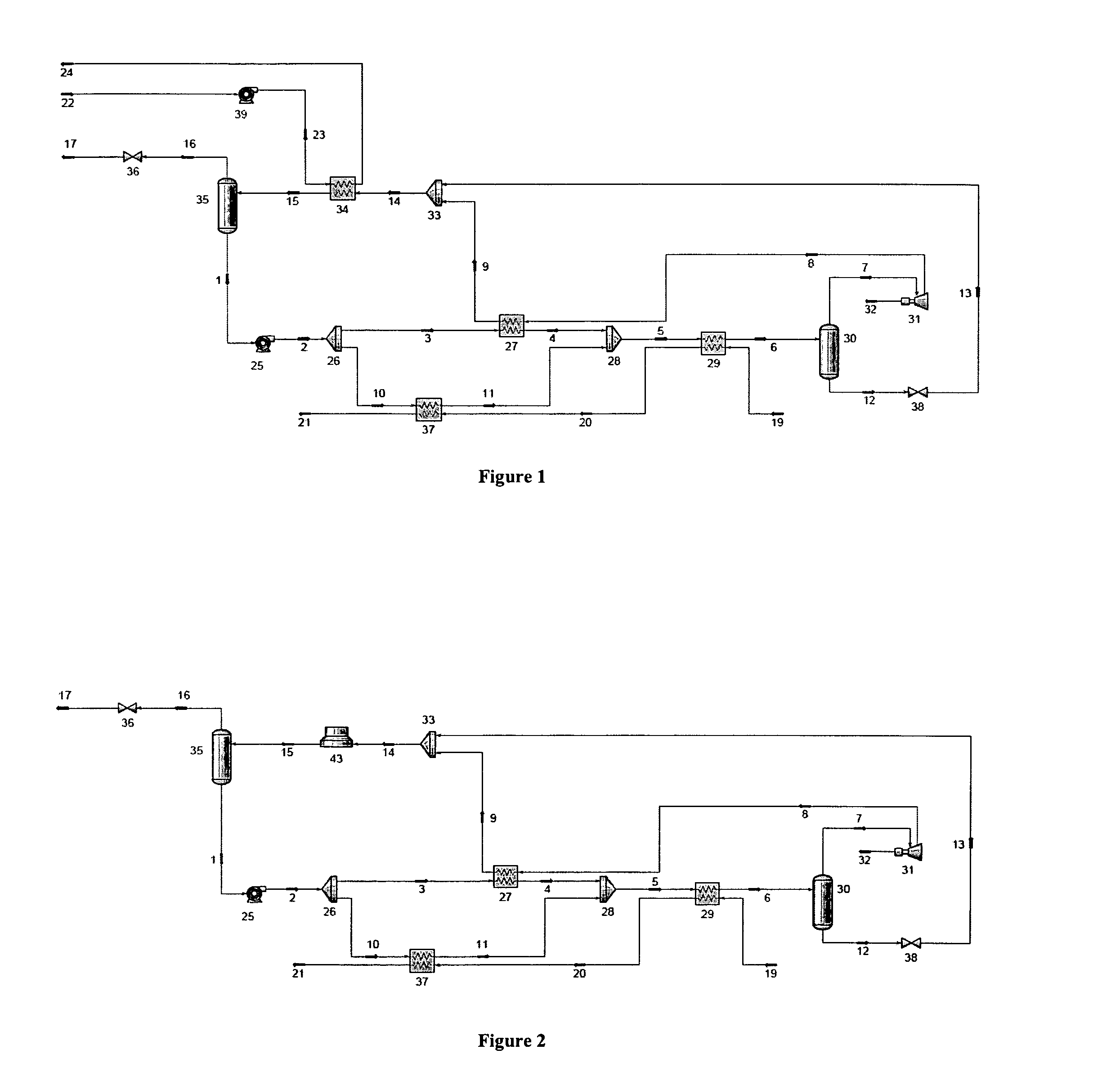

System and method for high efficiency power generation using a carbon dioxide circulating working fluid

ActiveUS20110179799A1Improve efficiencyIncrease pressure ratioSolidificationLiquefactionWorking fluidCombustor

The present invention provides methods and system for power generation using a high efficiency combustor in combination with a CO2 circulating fluid. The methods and systems advantageously can make use of a low pressure ratio power turbine and an economizer heat exchanger in specific embodiments. Additional low grade heat from an external source can be used to provide part of an amount of heat needed for heating the recycle CO2 circulating fluid. Fuel derived CO2 can be captured and delivered at pipeline pressure. Other impurities can be captured.

Owner:8 RIVERS CAPTTAL LLC

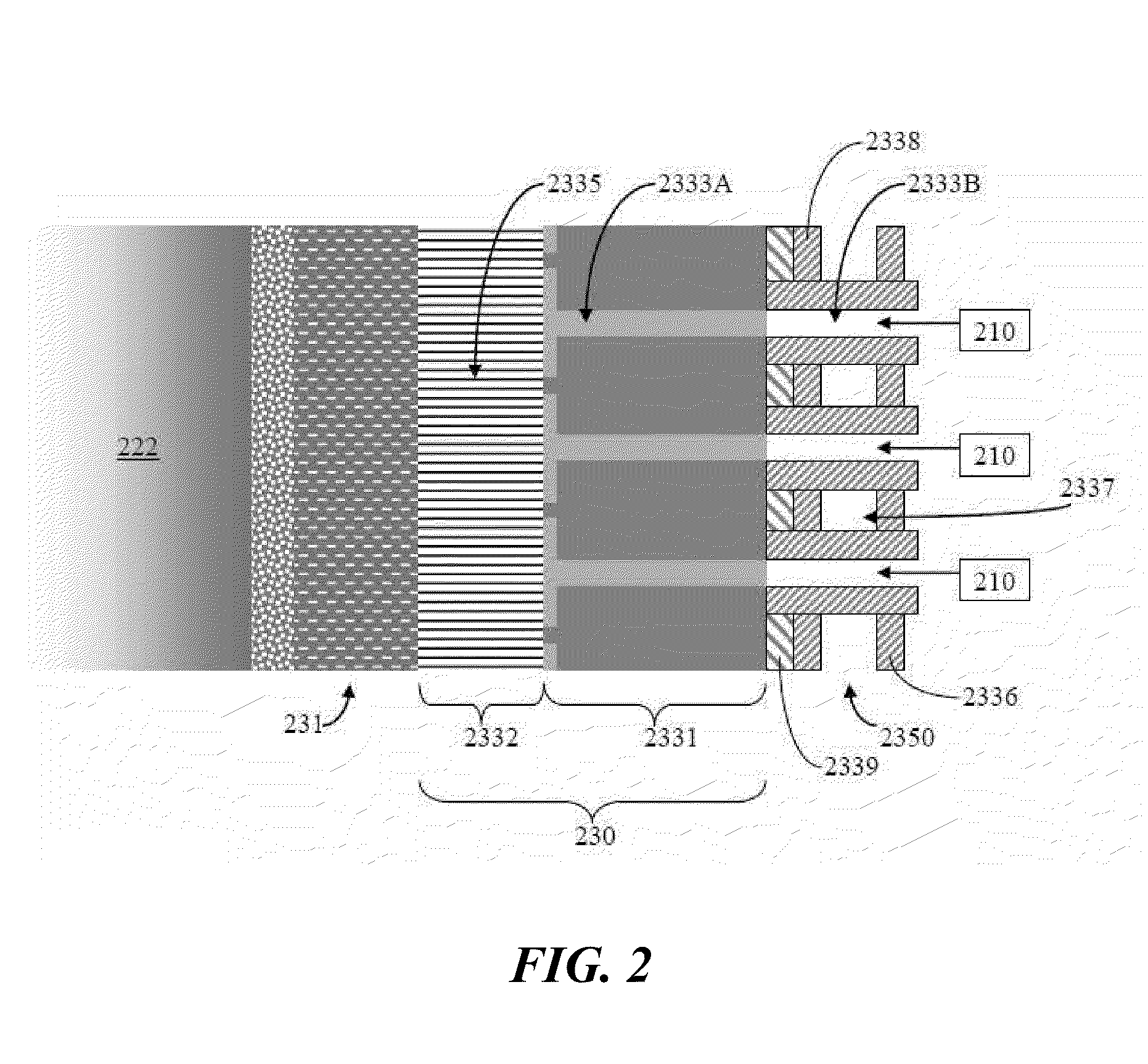

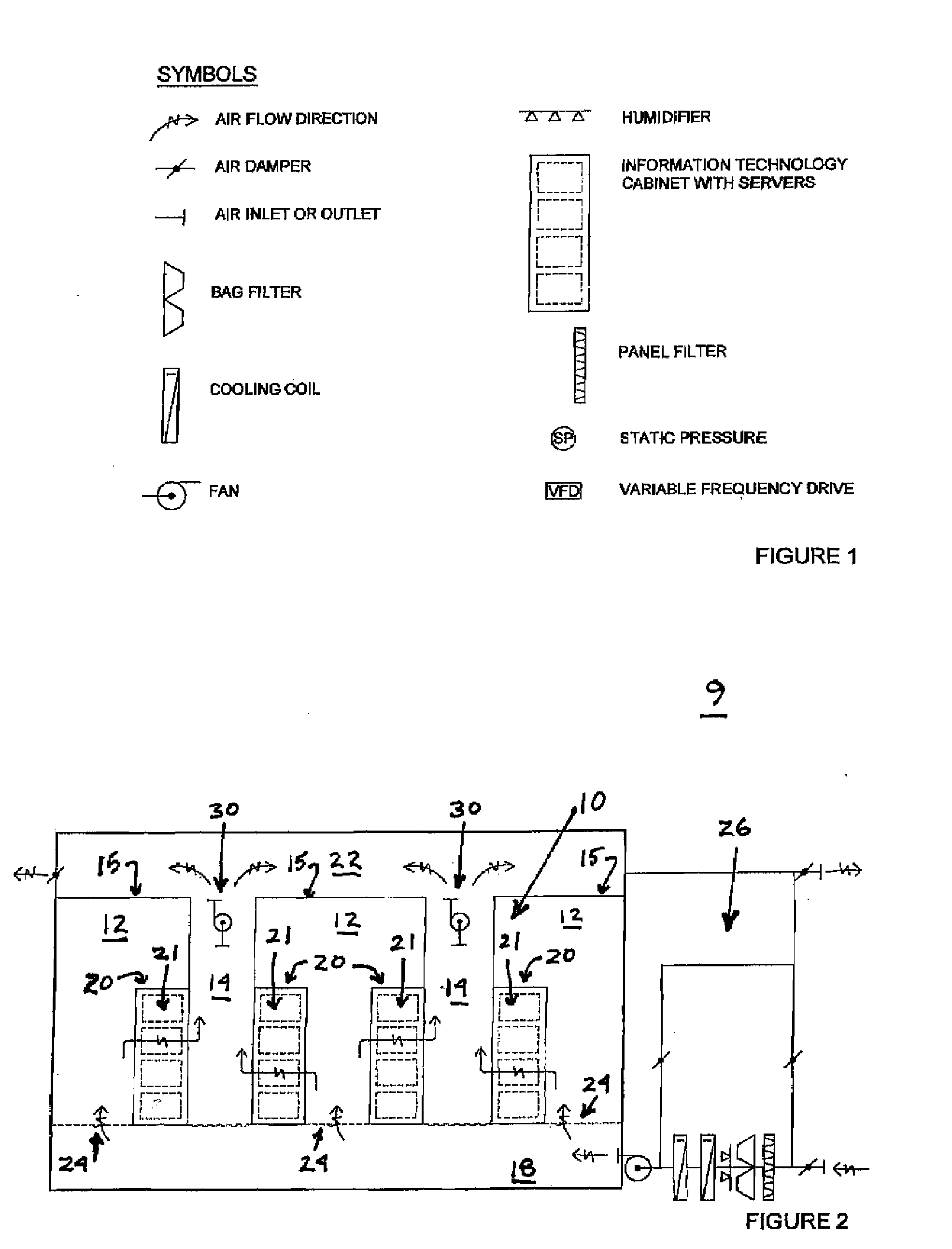

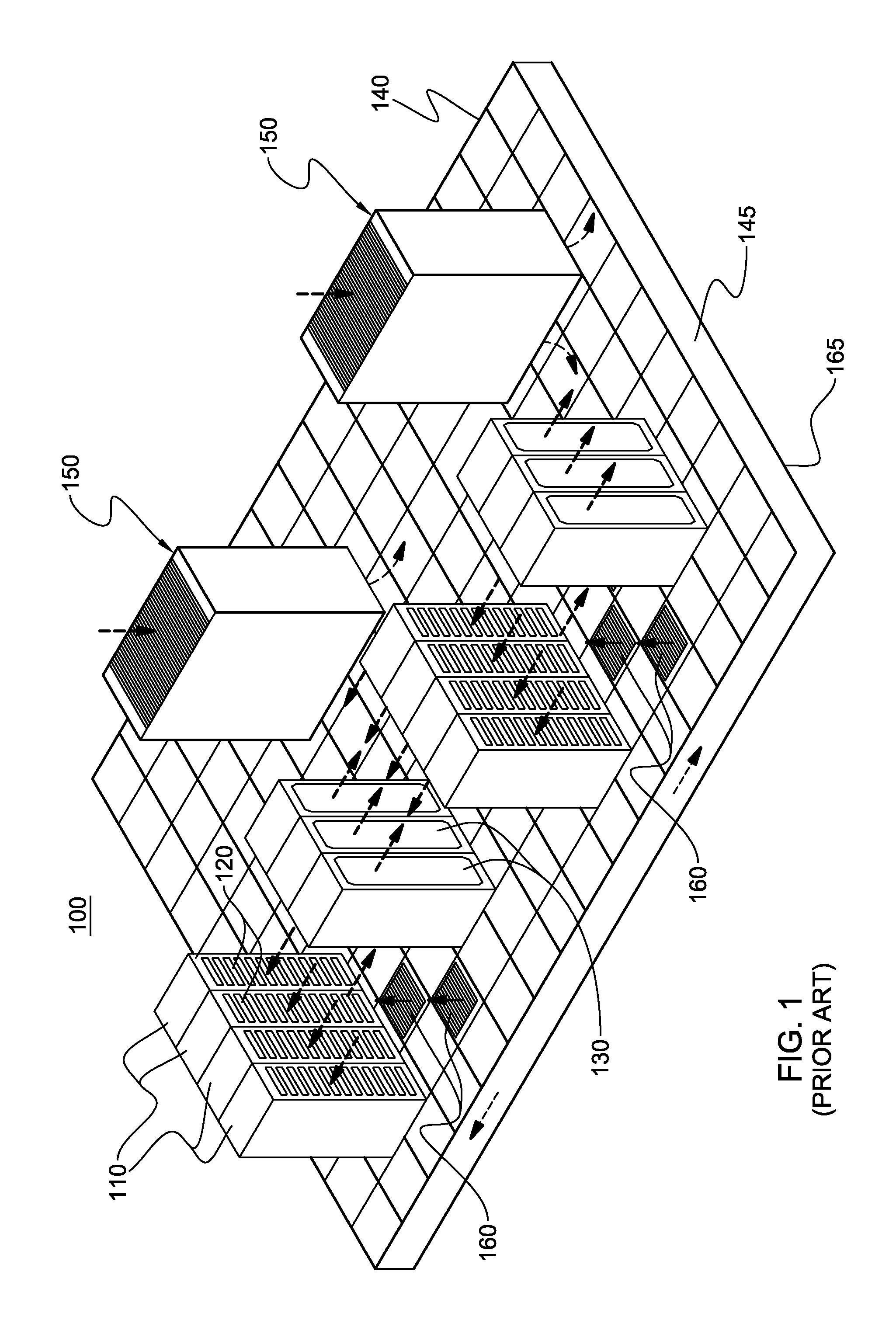

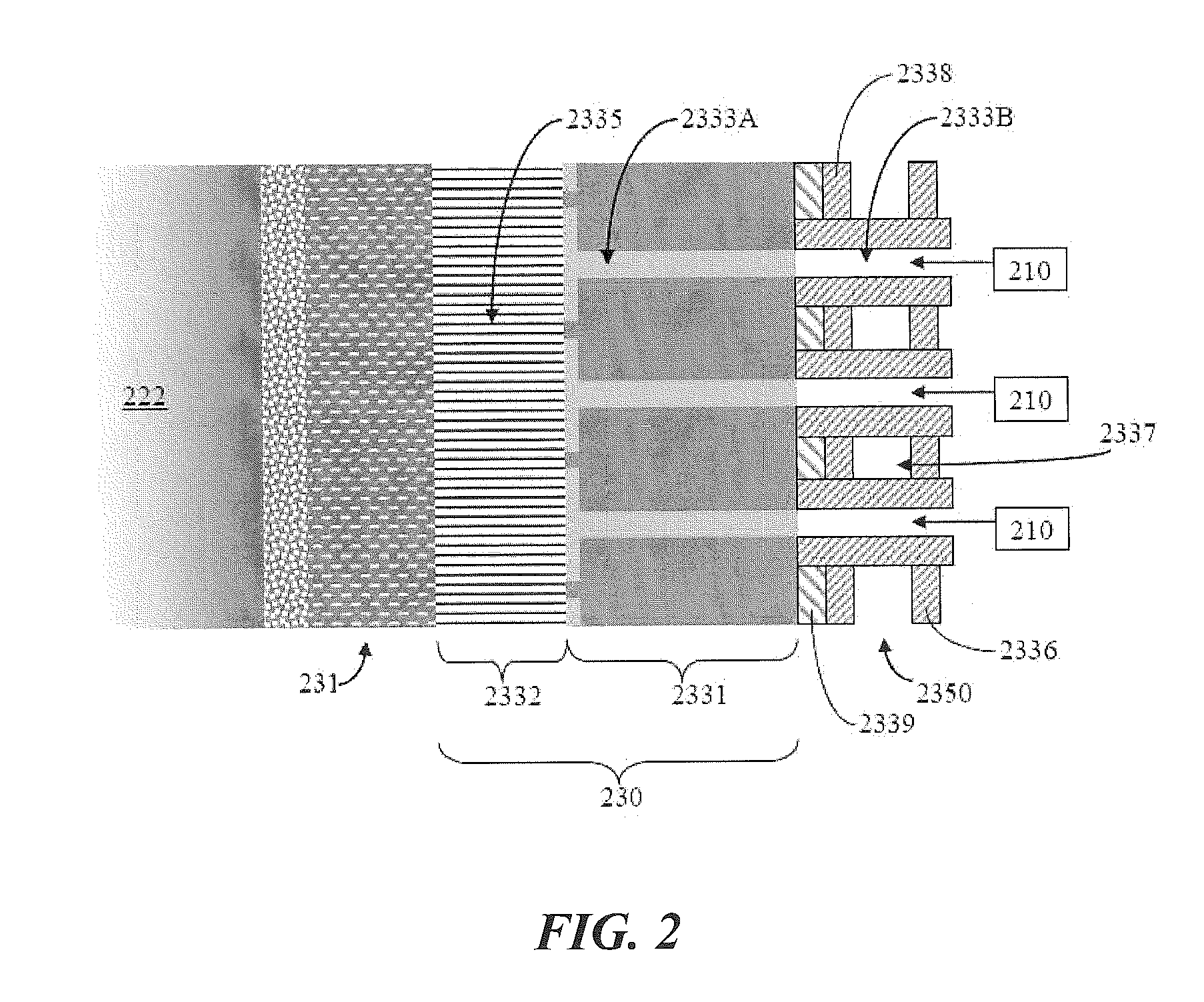

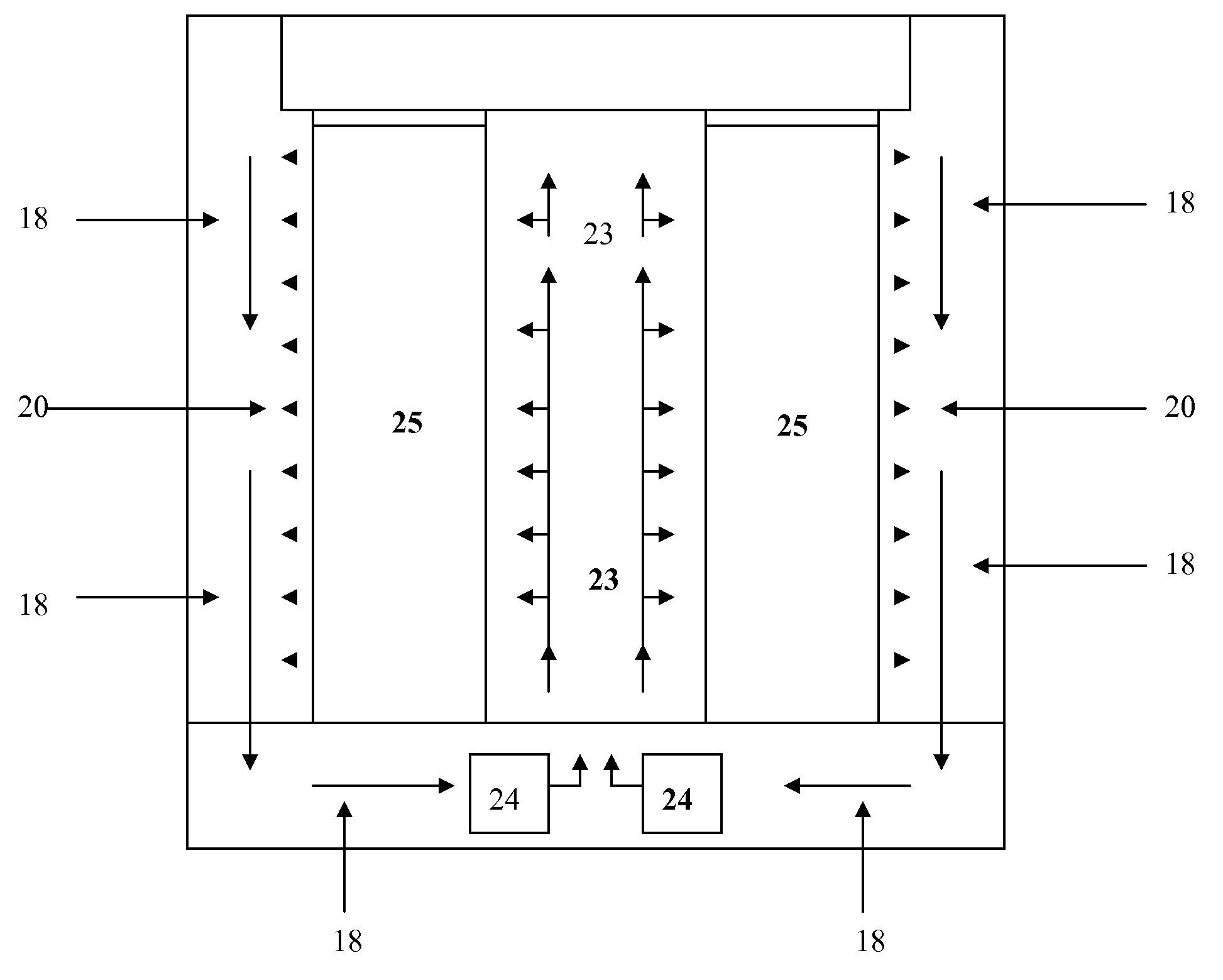

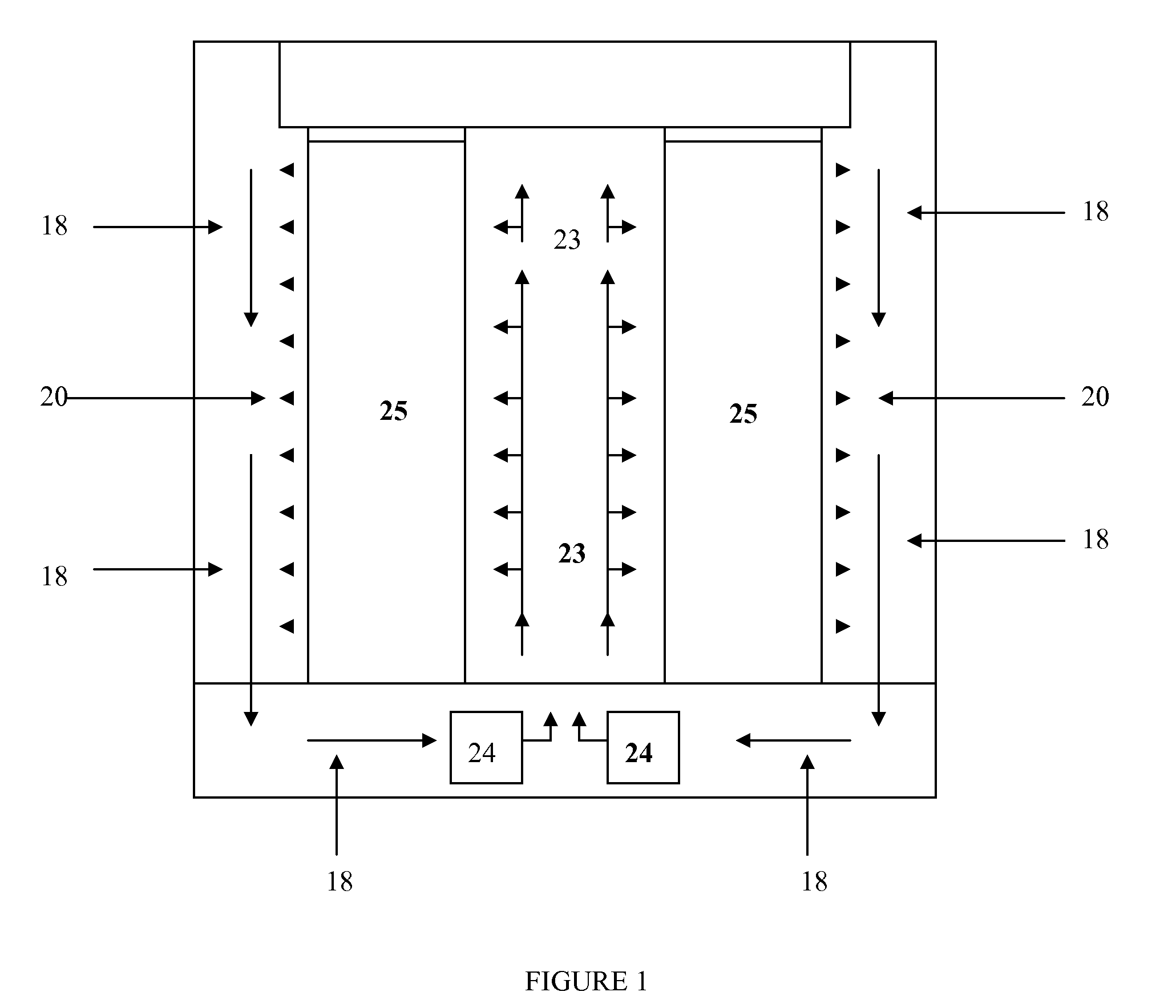

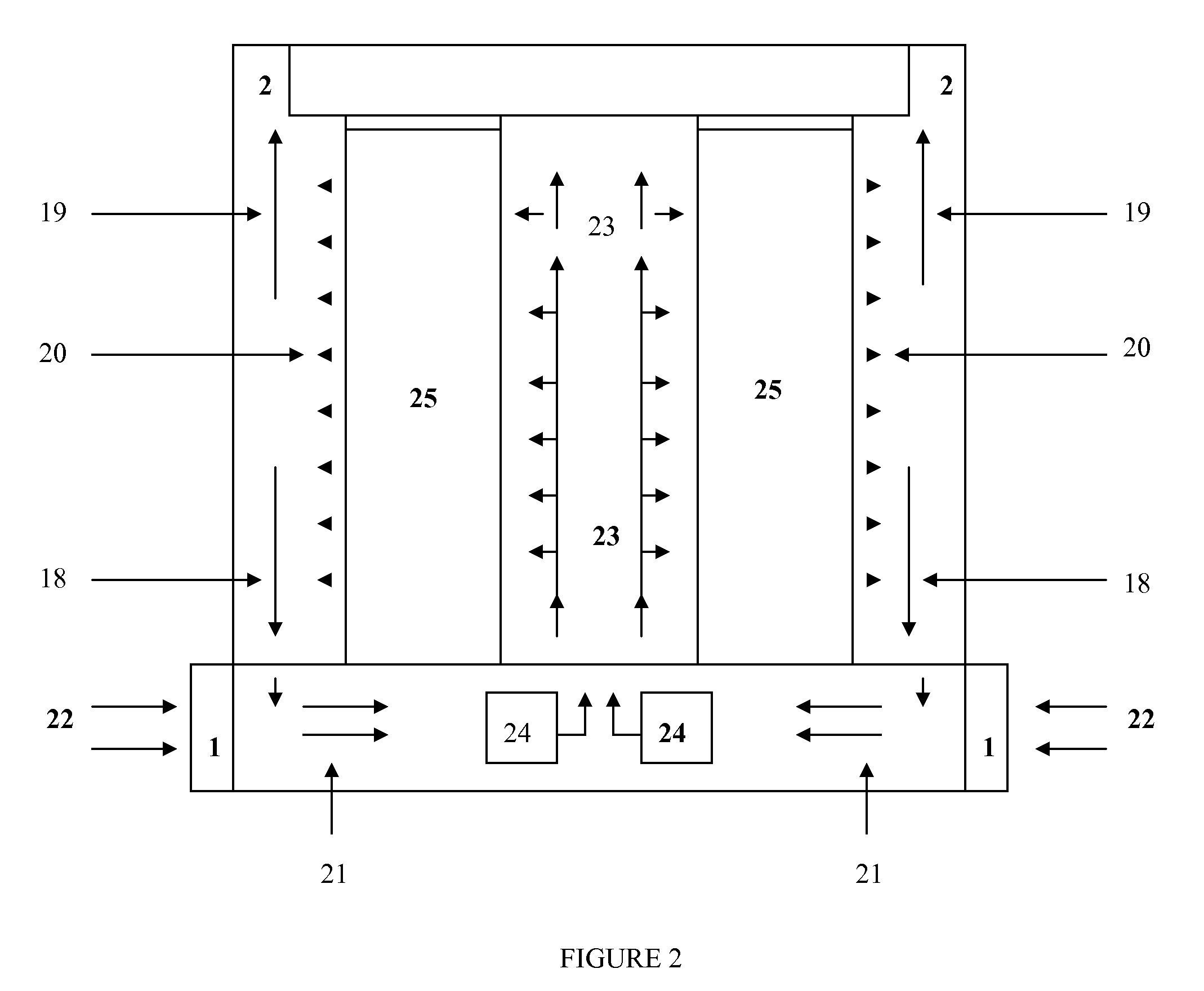

Cool design data center

ActiveUS20080185446A1Easy to solveAvoid uneven loadLighting and heating apparatusElectrical apparatus contructional detailsAir managementAir volume

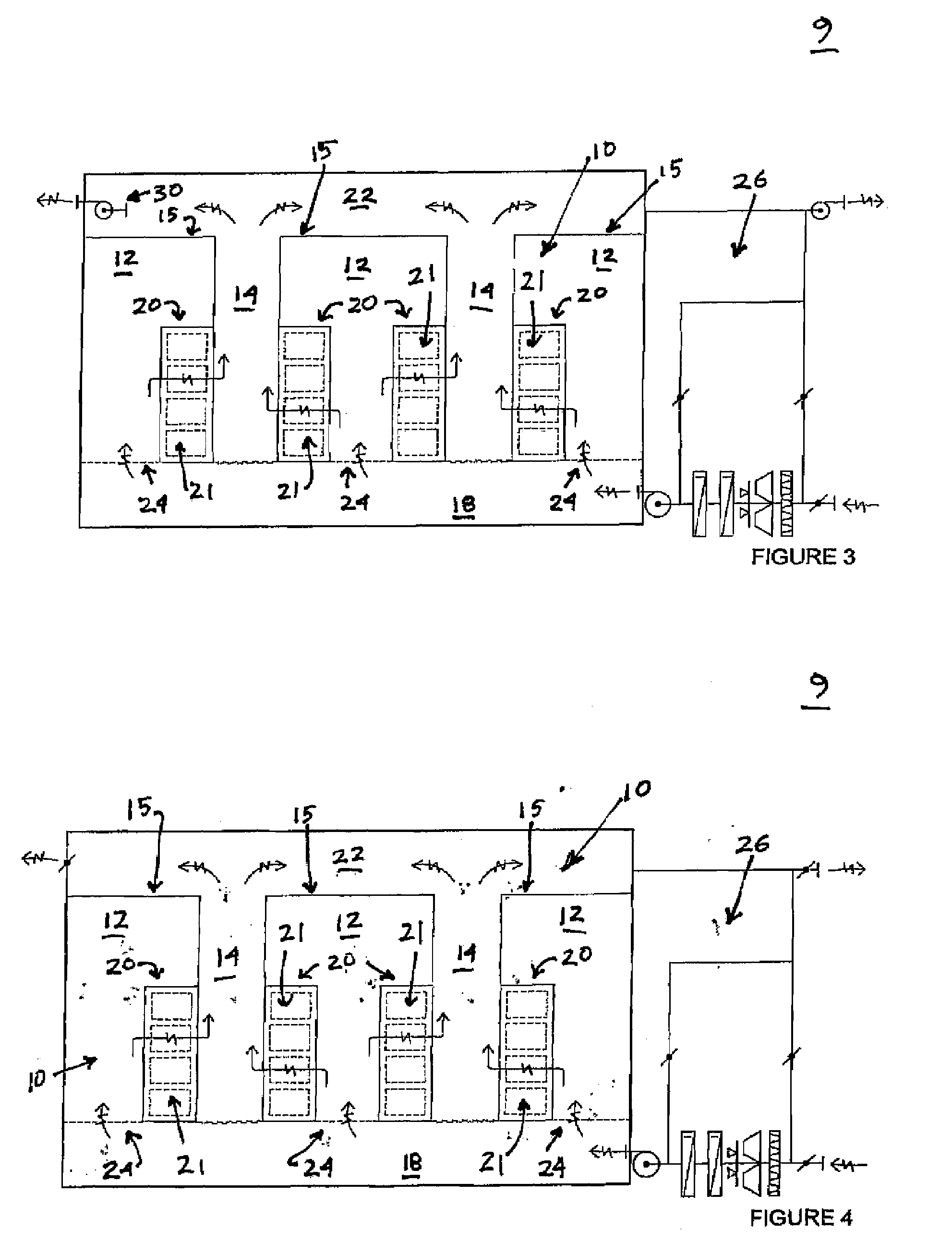

An improved solution for cooling a data center is provided. In an embodiment of the invention, a data center design that combines physical segregation of hot and cold air streams together with a data hall variable air volume system is provided. The invention is a data center design that resolves air management issues of re-circulation, bypass and load balance. Bypass is airflow supplied by the cooling units that directly returns without cooling servers. Recirculation airflow is server discharge warm air that returns directly without being cooled. Load balance is supplying the required server airflow. An embodiment includes physical segregation of cold and hot air streams and by providing variable air volume to match server load. Air segregation is done by enclosing the hot aisle end and above the cabinets. The air conditioning system provides variable air volume to the data hall (cold side) to meet server demands. The cooling plant consists of variable-air-volume air-cooling system, which cools air by air free cooling (economizer) and is supplemented with mechanical cooling in the warmer seasons.

Owner:HEWLETT-PACKARD ENTERPRISE DEV LP

System and method for high efficiency power generation using a carbon dioxide circulating working fluid

ActiveUS8959887B2Improve efficiencyIncrease pressure ratioSolidificationLiquefactionWorking fluidCombustor

The present invention provides methods and system for power generation using a high efficiency combustor in combination with a CO2 circulating fluid. The methods and systems advantageously can make use of a low pressure ratio power turbine and an economizer heat exchanger in specific embodiments. Additional low grade heat from an external source can be used to provide part of an amount of heat needed for heating the recycle CO2 circulating fluid. Fuel derived CO2 can be captured and delivered at pipeline pressure. Other impurities can be captured.

Owner:8 RIVERS CAPTTAL LLC

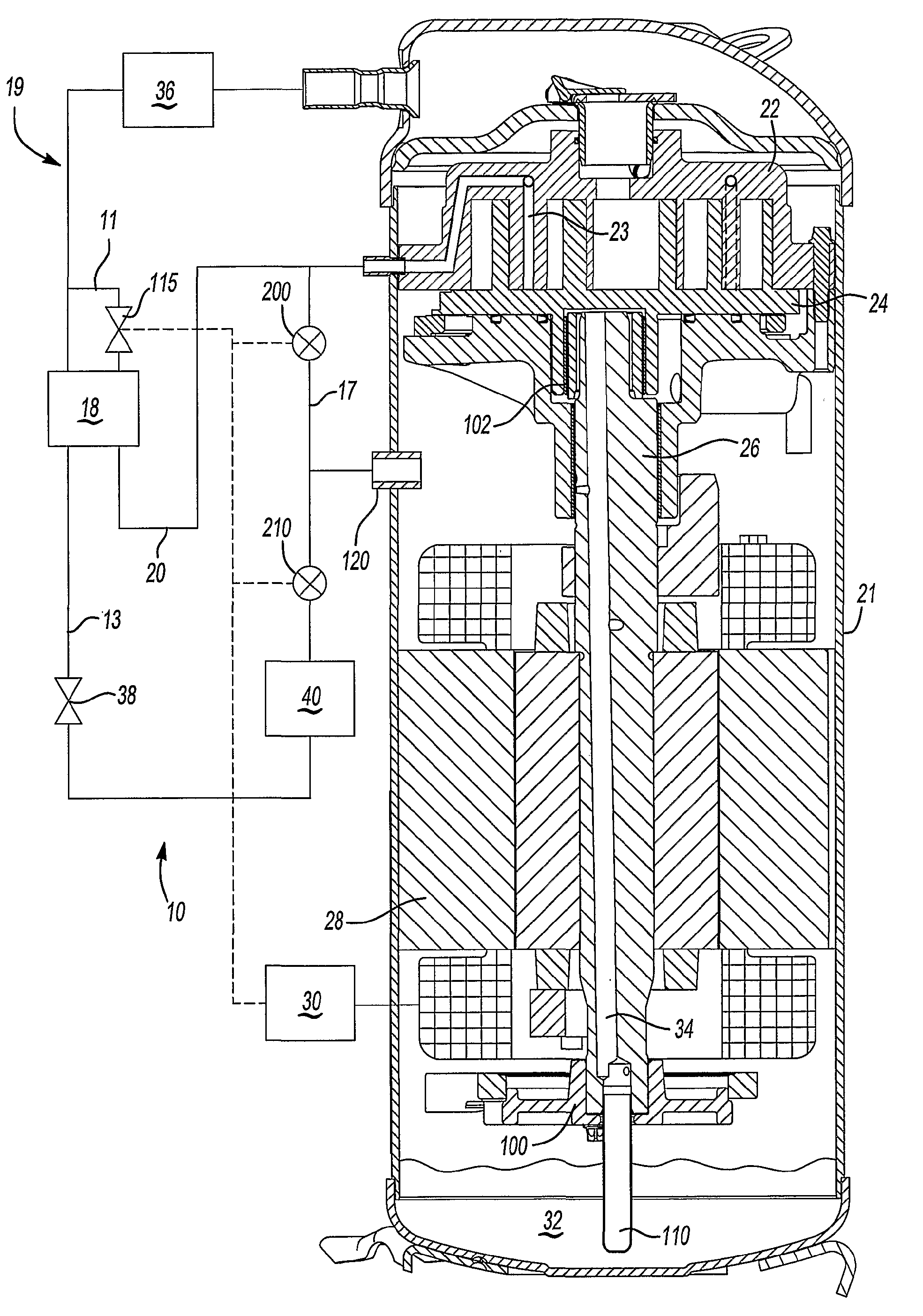

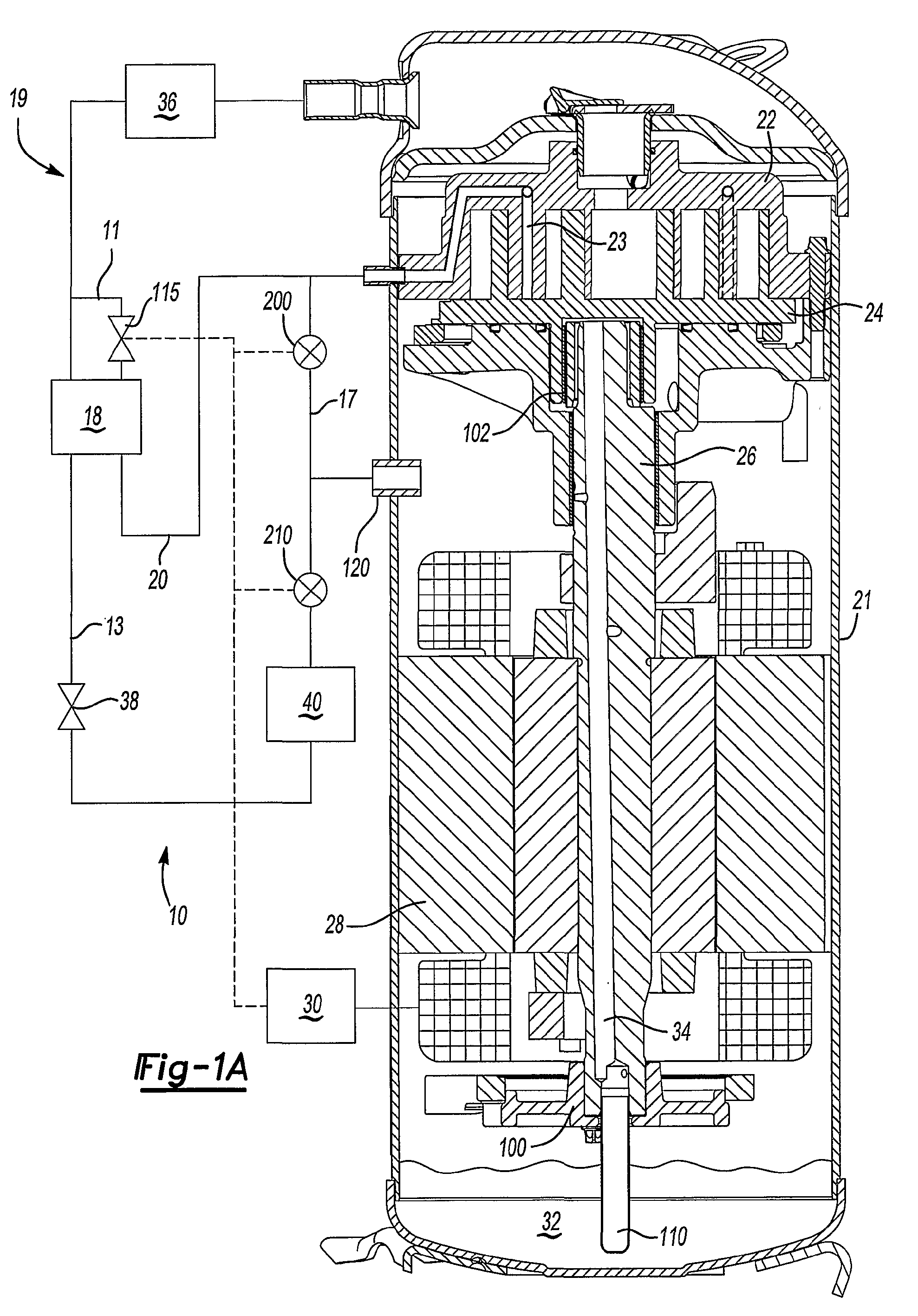

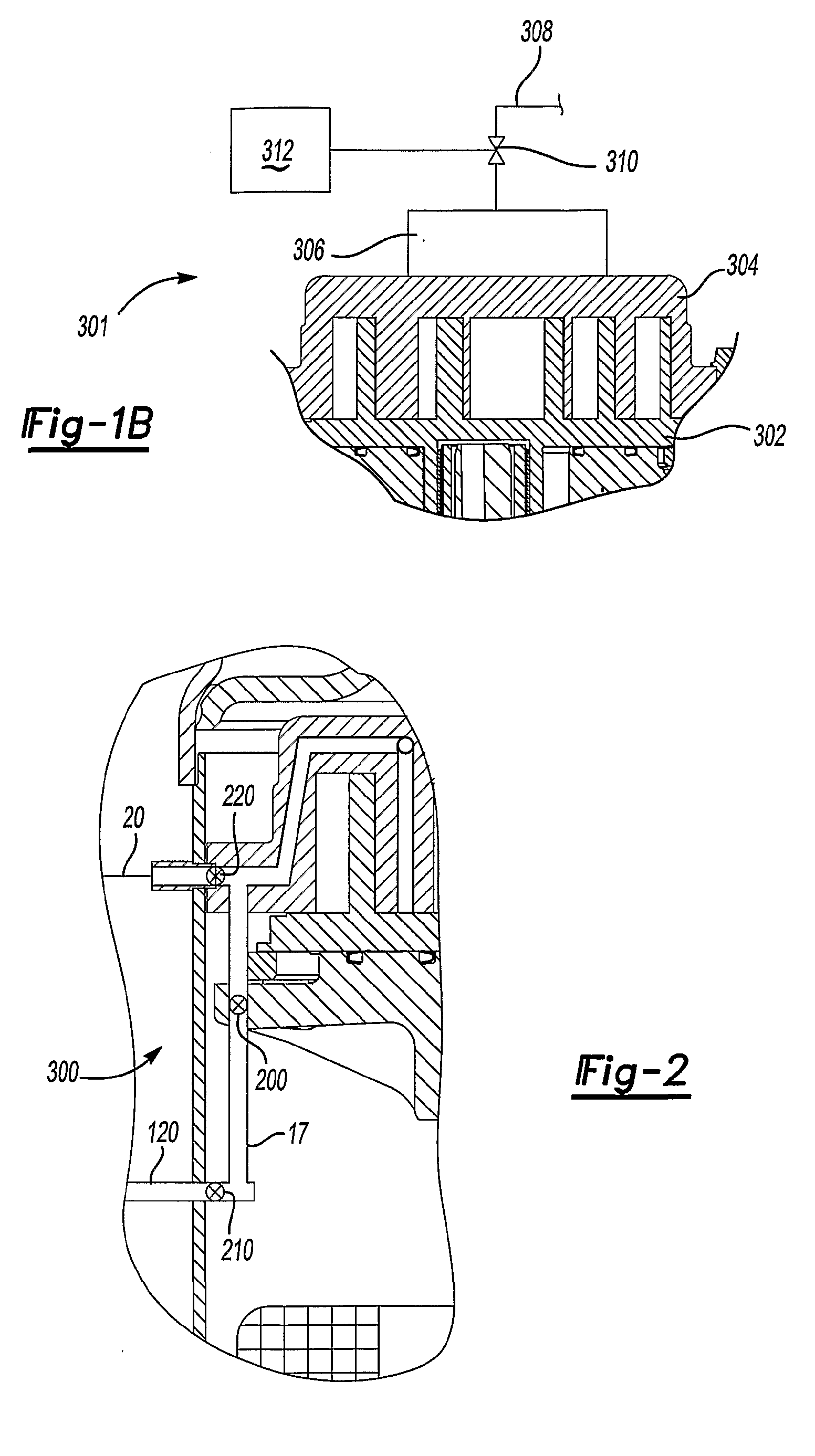

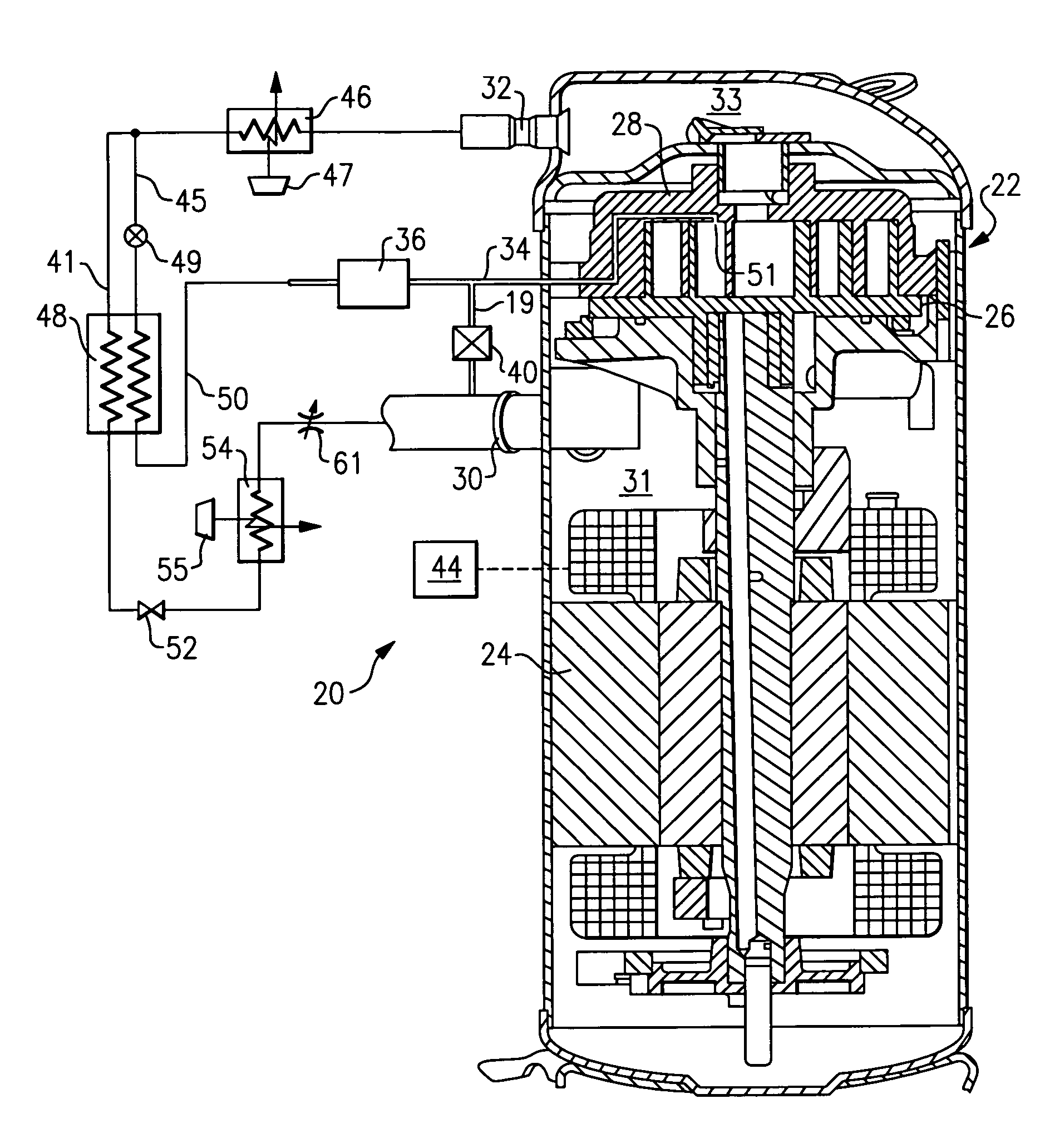

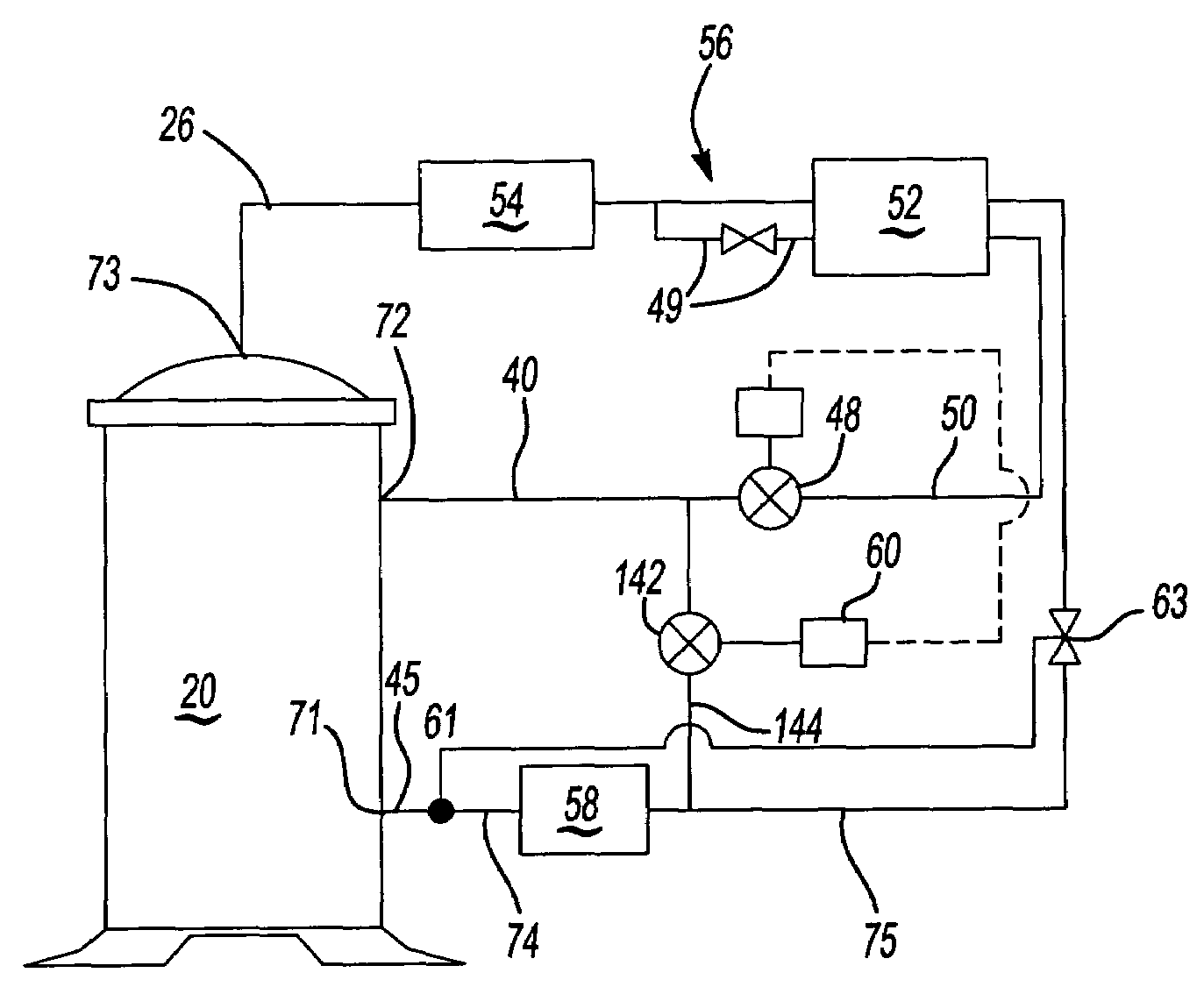

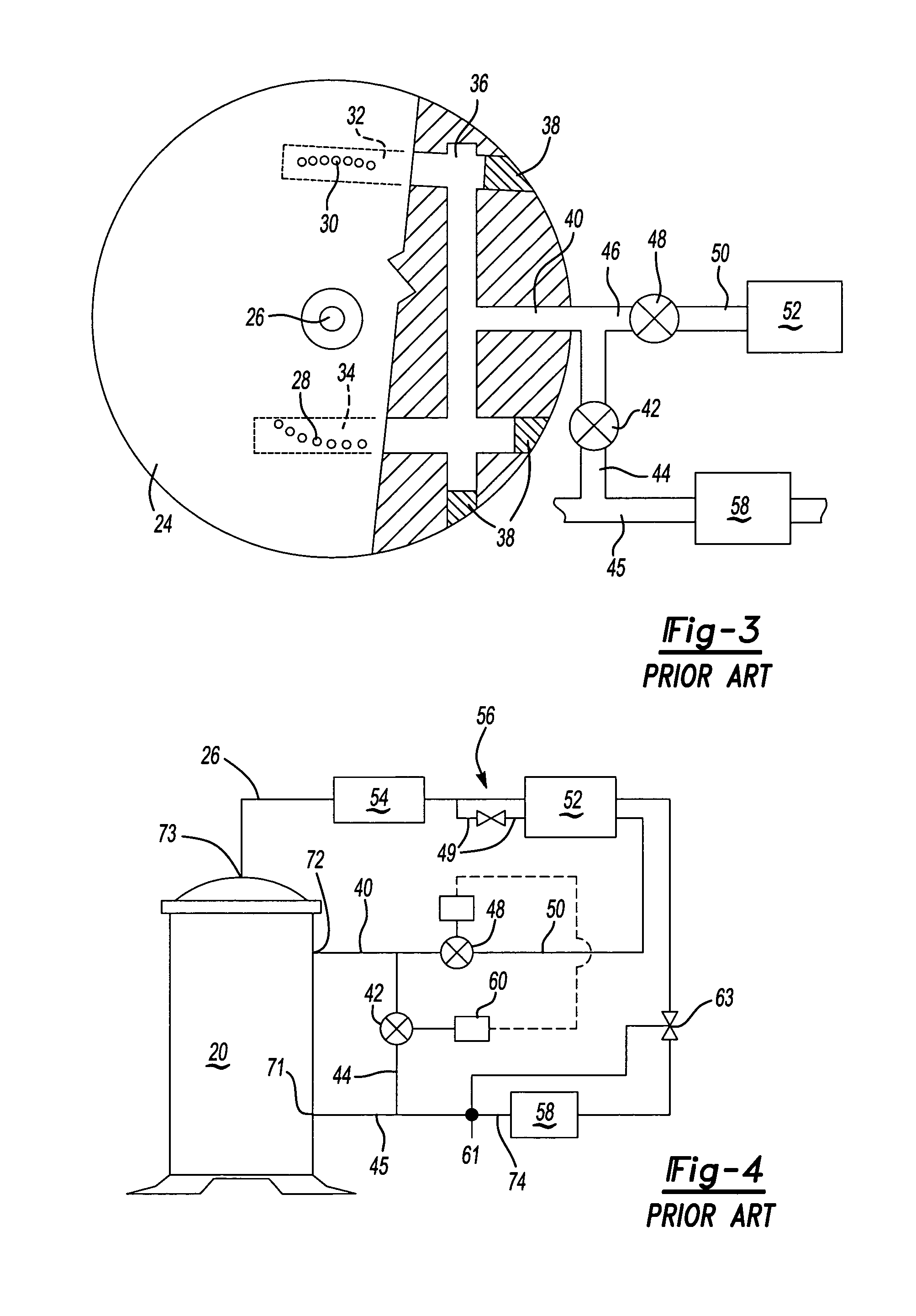

Loss of refrigerant charge and expansion valve malfunction detection

InactiveUS20050126190A1Thermometer applicationsRefrigeration safety arrangementEngineeringCharge loss

An actual superheat value in a refrigerant system is compared to an expected superheat level. If the actual superheat valve exceeds a certain predetermined value, this is an indication of refrigerant charge loss or a malfunctioning expansion device. In one example, the superheat valve is determined by comparing a difference between a saturated vapor temperature and an actual operating vapor temperature. The superheat determination can be made either at evaporator exit, economizer heat exchange exit or near the compressor discharge port.

Owner:CARRIER CORP

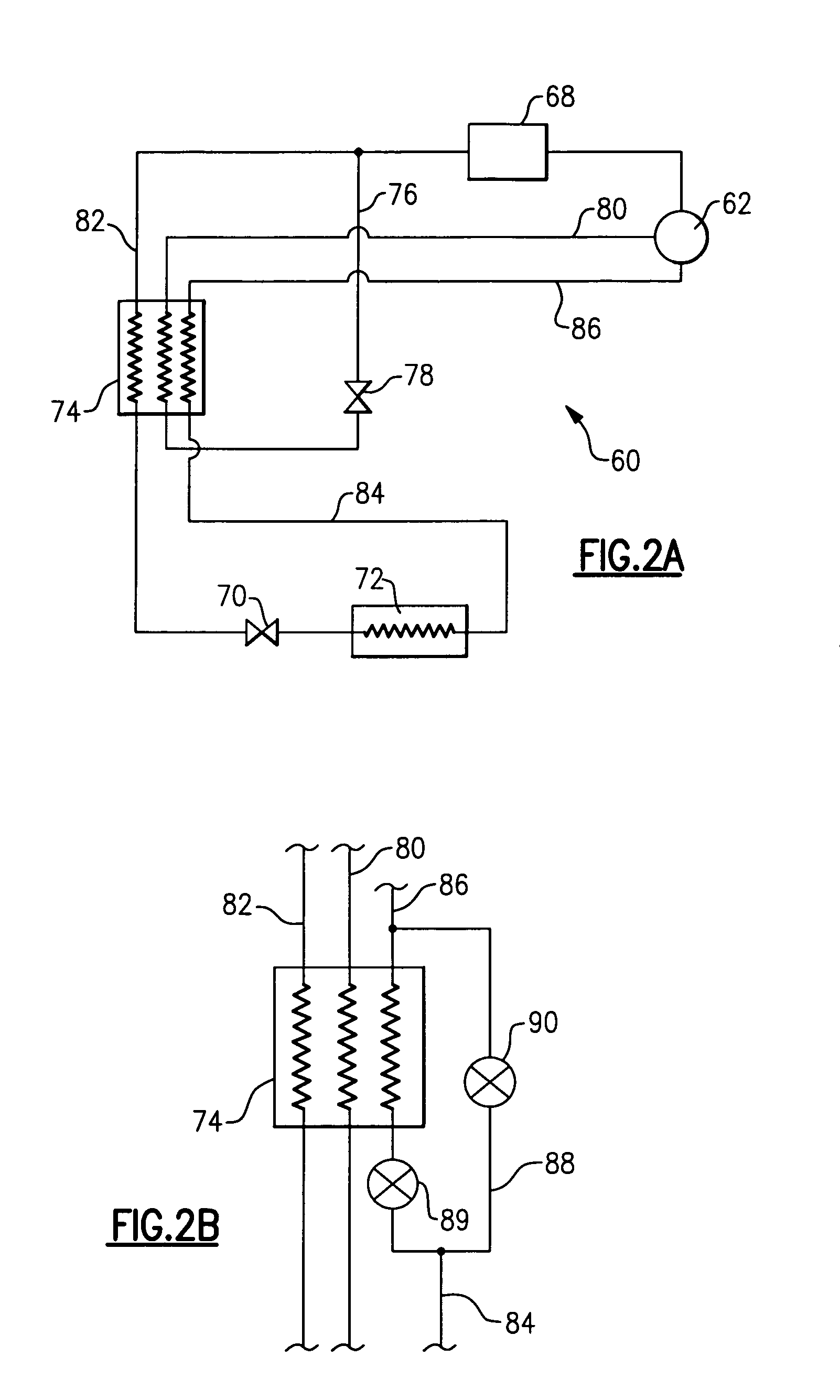

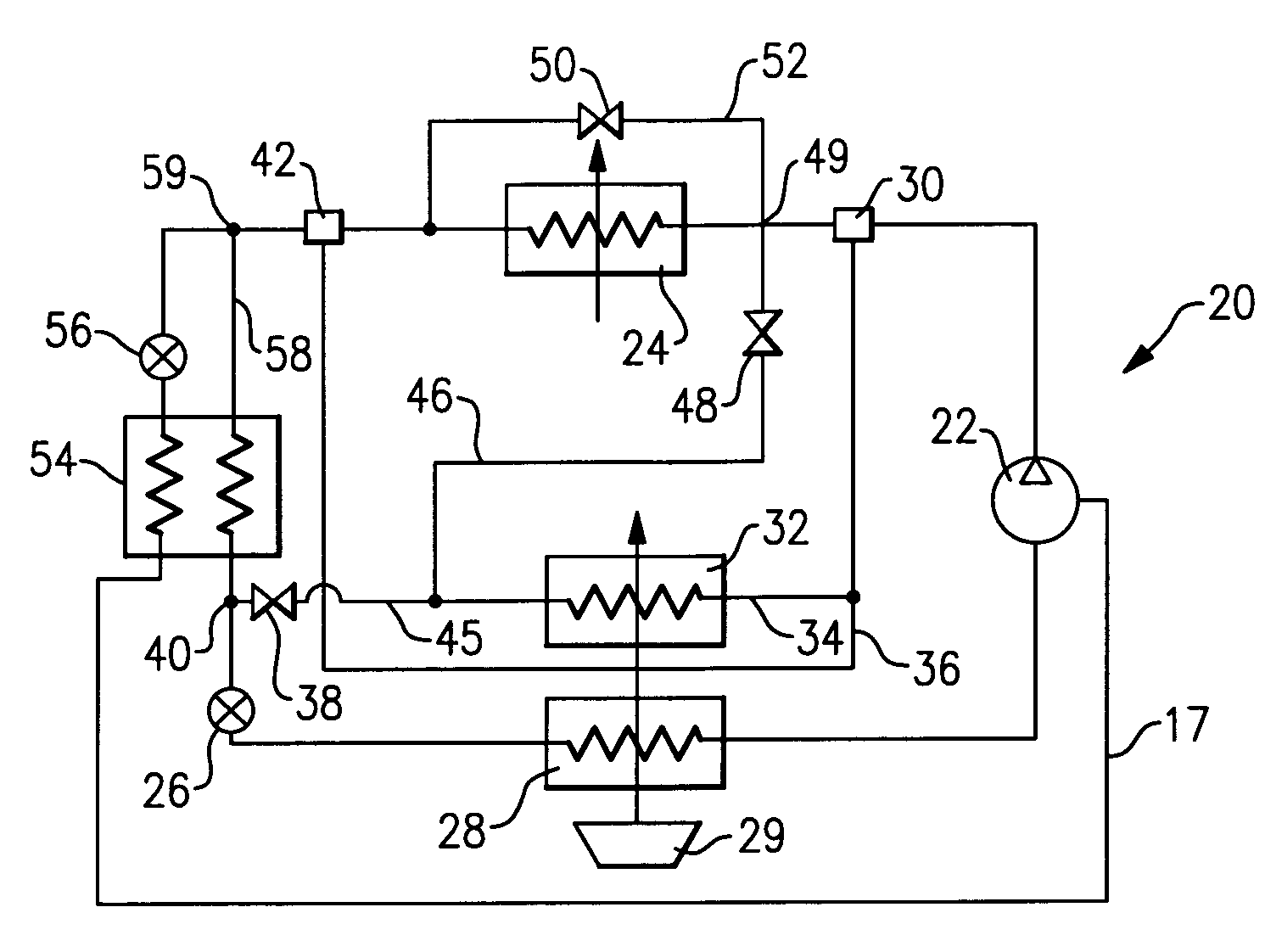

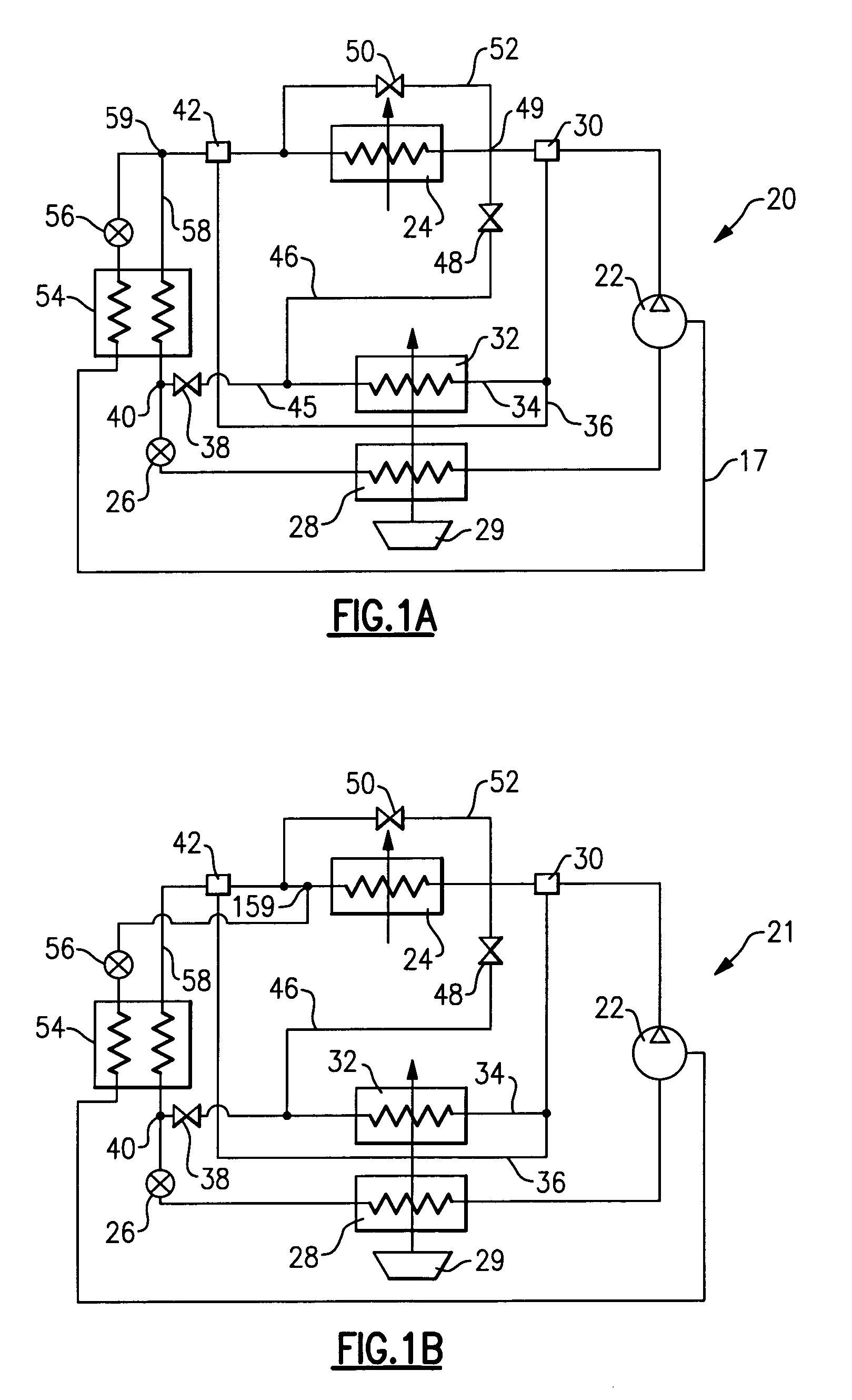

Refrigerant system with common economizer and liquid-suction heat exchanger

InactiveUS7114349B2Mechanical apparatusCompression machines with non-reversible cycleLine tubingEngineering

Owner:CARRIER CORP

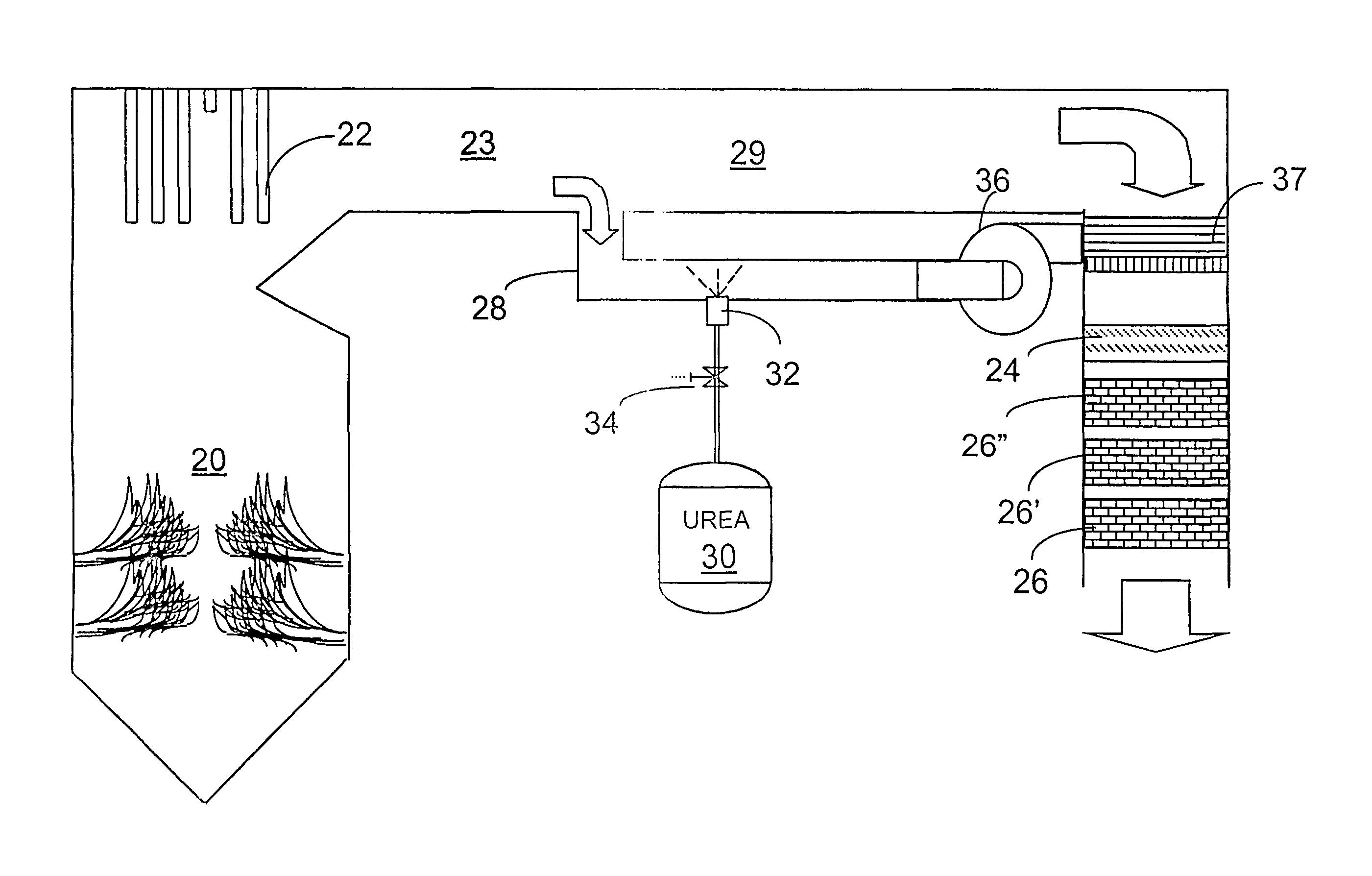

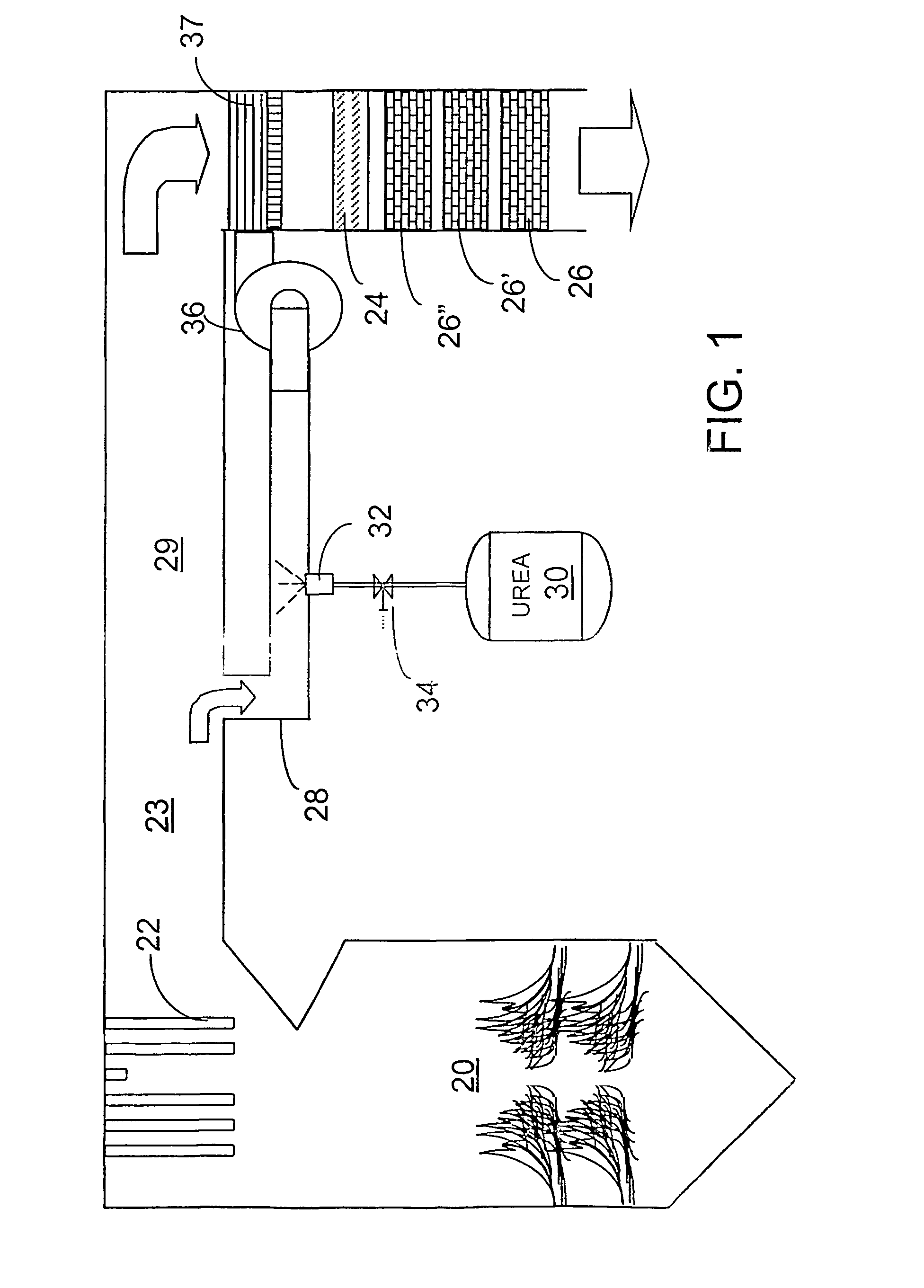

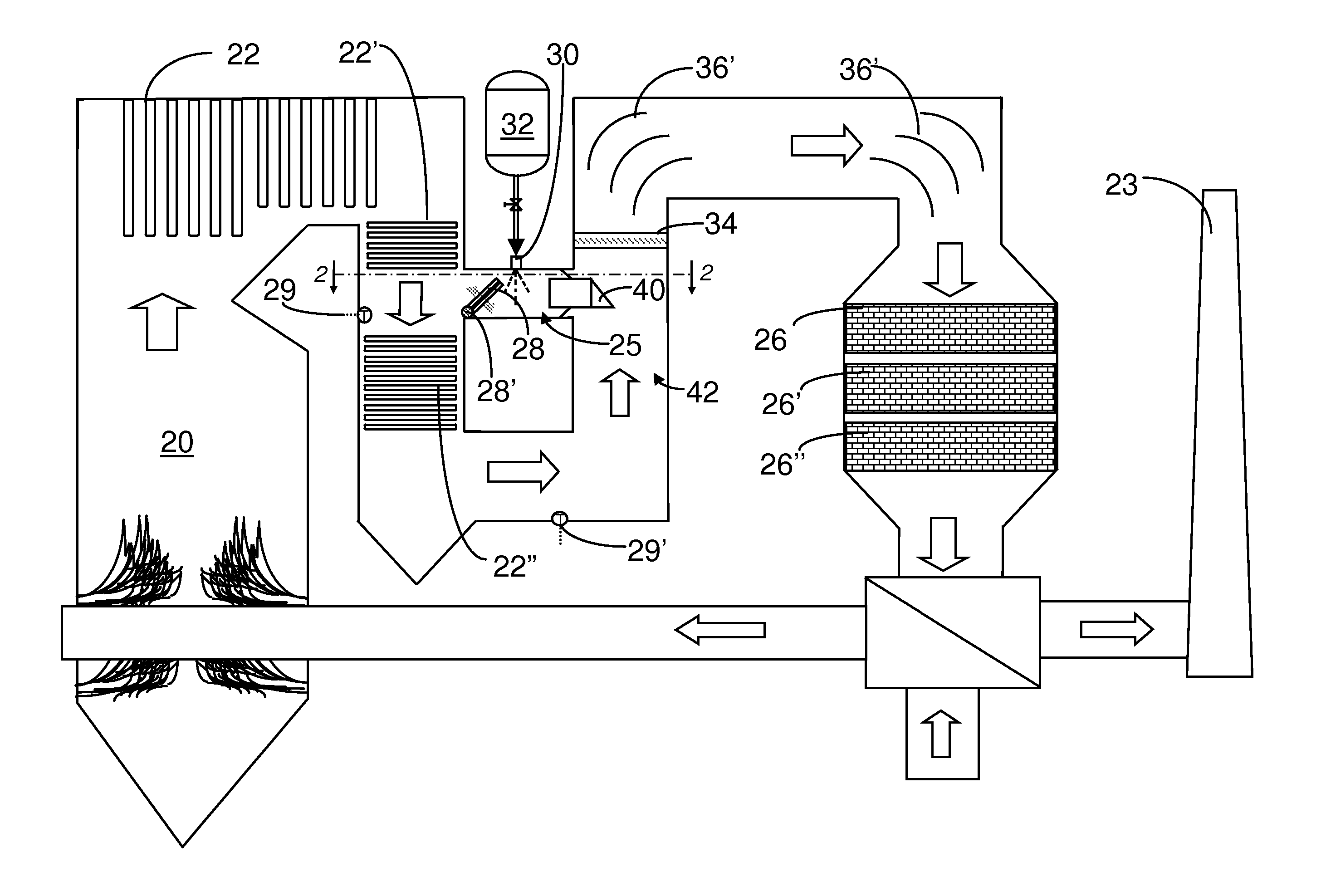

Selective catalytic reduction of nox enabled by sidestream urea decomposition

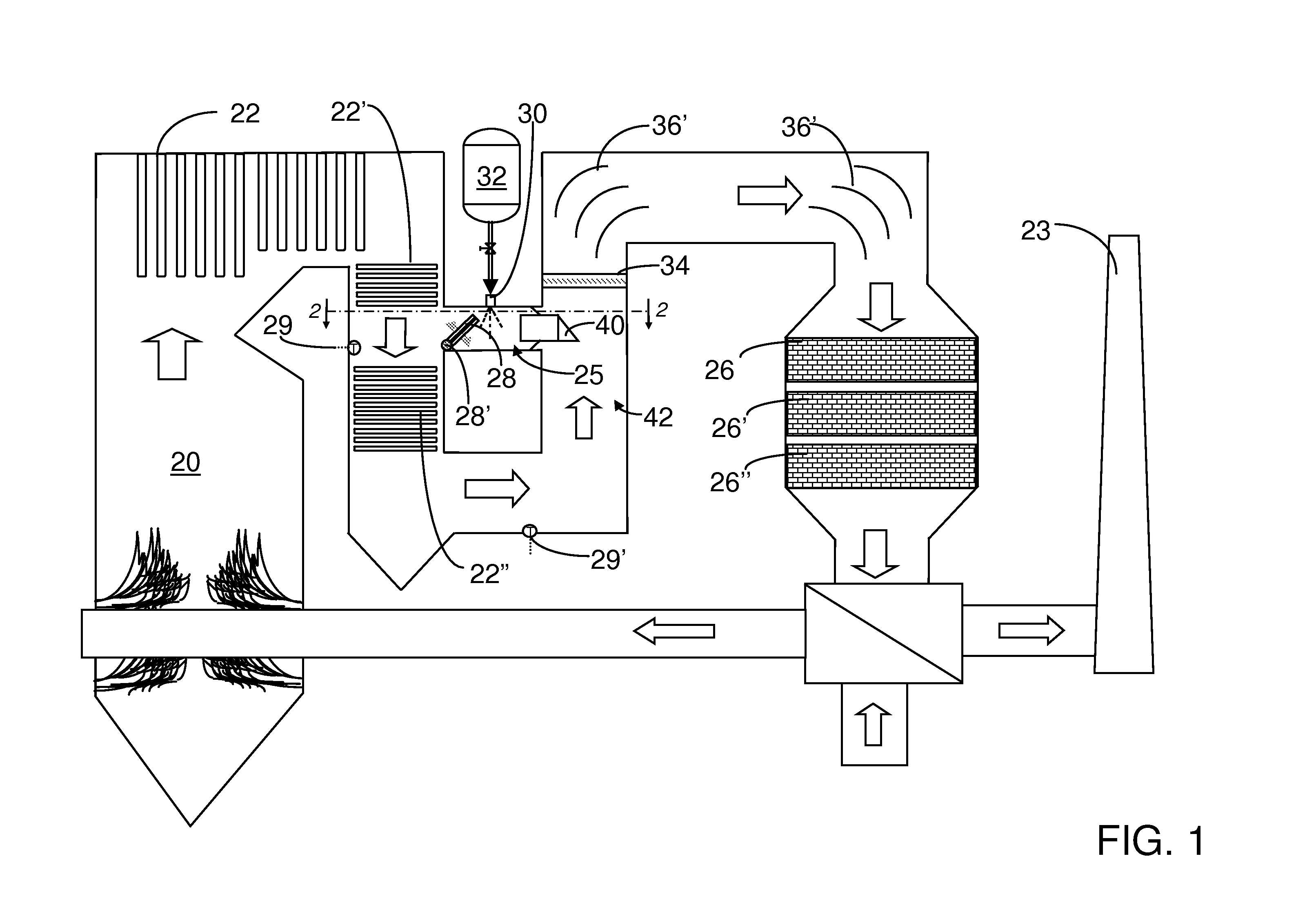

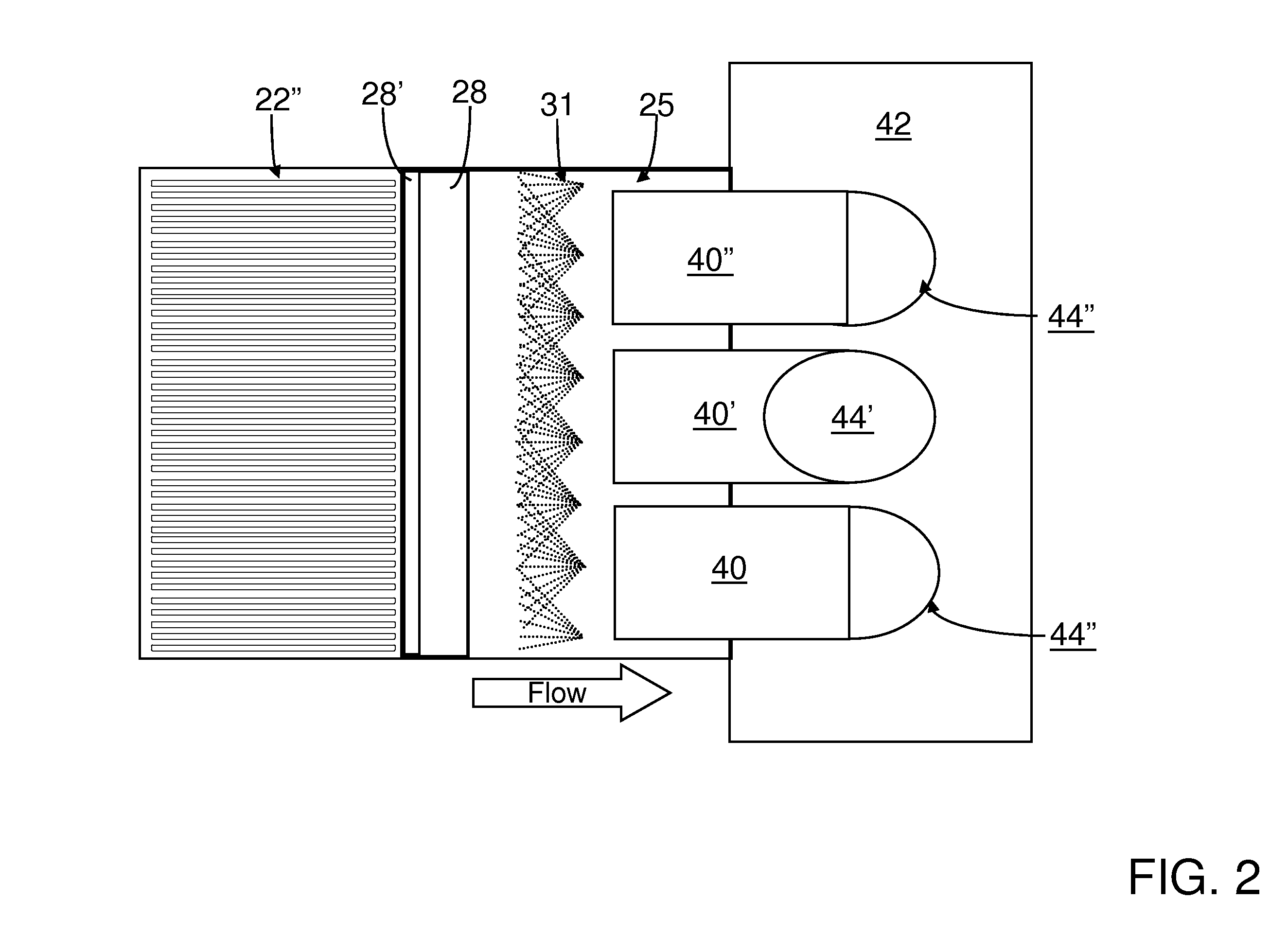

InactiveUS7090810B2Well mixedAccurate temperatureNitrogen compoundsInternal combustion piston enginesParticulatesSuperheater

A preferred process arrangement utilizes the enthalpy of the flue gas, which can be supplemented if need be, to convert urea (30) into ammonia for SCR. Urea (30), which decomposes at temperatures above 140 ° C., is injected (32) into a flue gas stream split off (28) after a heat exchanger (22), such as a primary superheater or an economizer. Ideally, the side stream would gasify the urea without need for further heating; but, when heat is required it is far less than would be needed to heat either the entire effluent (23) or the urea (30). This side stream, typically less than 3% of the flue gas, provides the required temperature and residence time for complete decomposition of urea (30). A cyclonic separator can be used to remove particulates and completely mix the reagent and flue gas. This stream can then be directed to an injection grid (37) ahead of SCR using a blower (36). The mixing with the flue gas is facilitated due to an order of magnitude higher mass of side stream compared to that injected through the AIG in a traditional ammonia-SCR process.

Owner:FUEL TECH

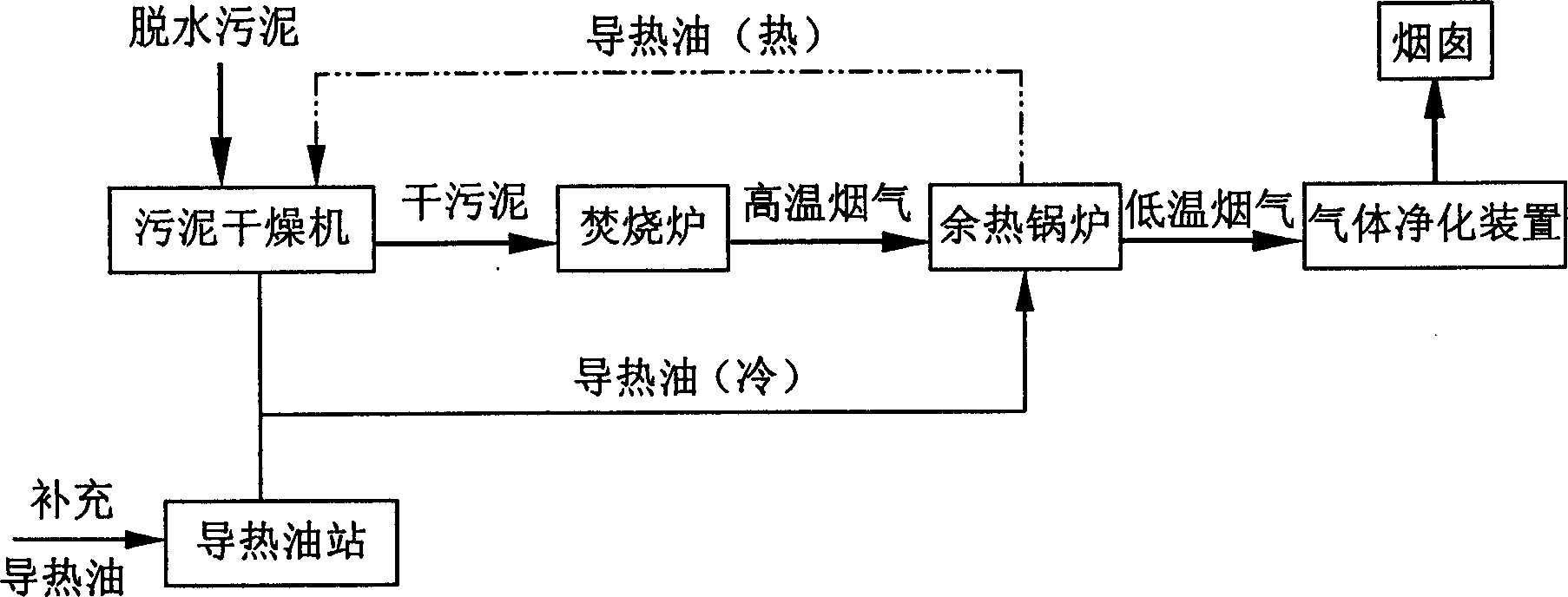

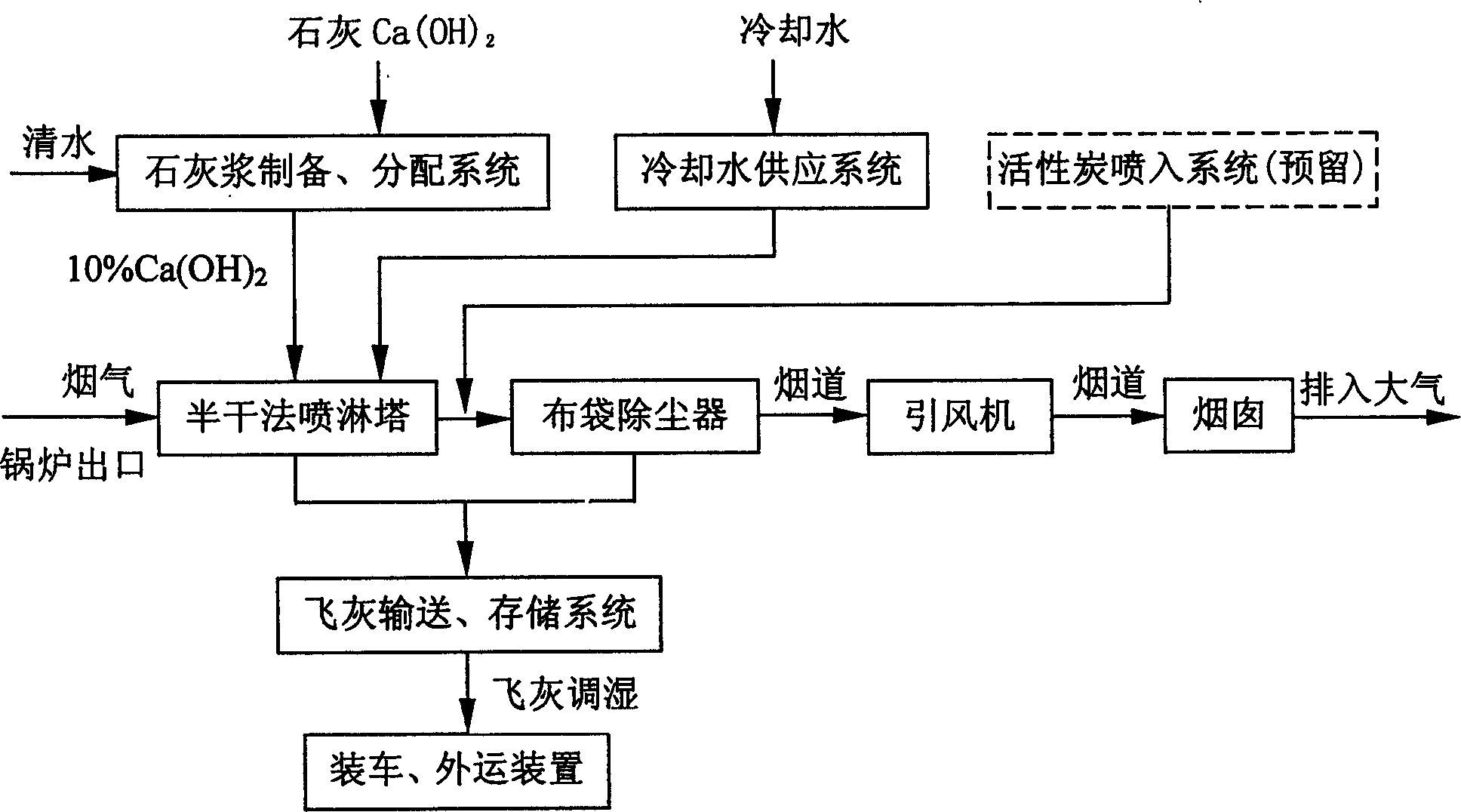

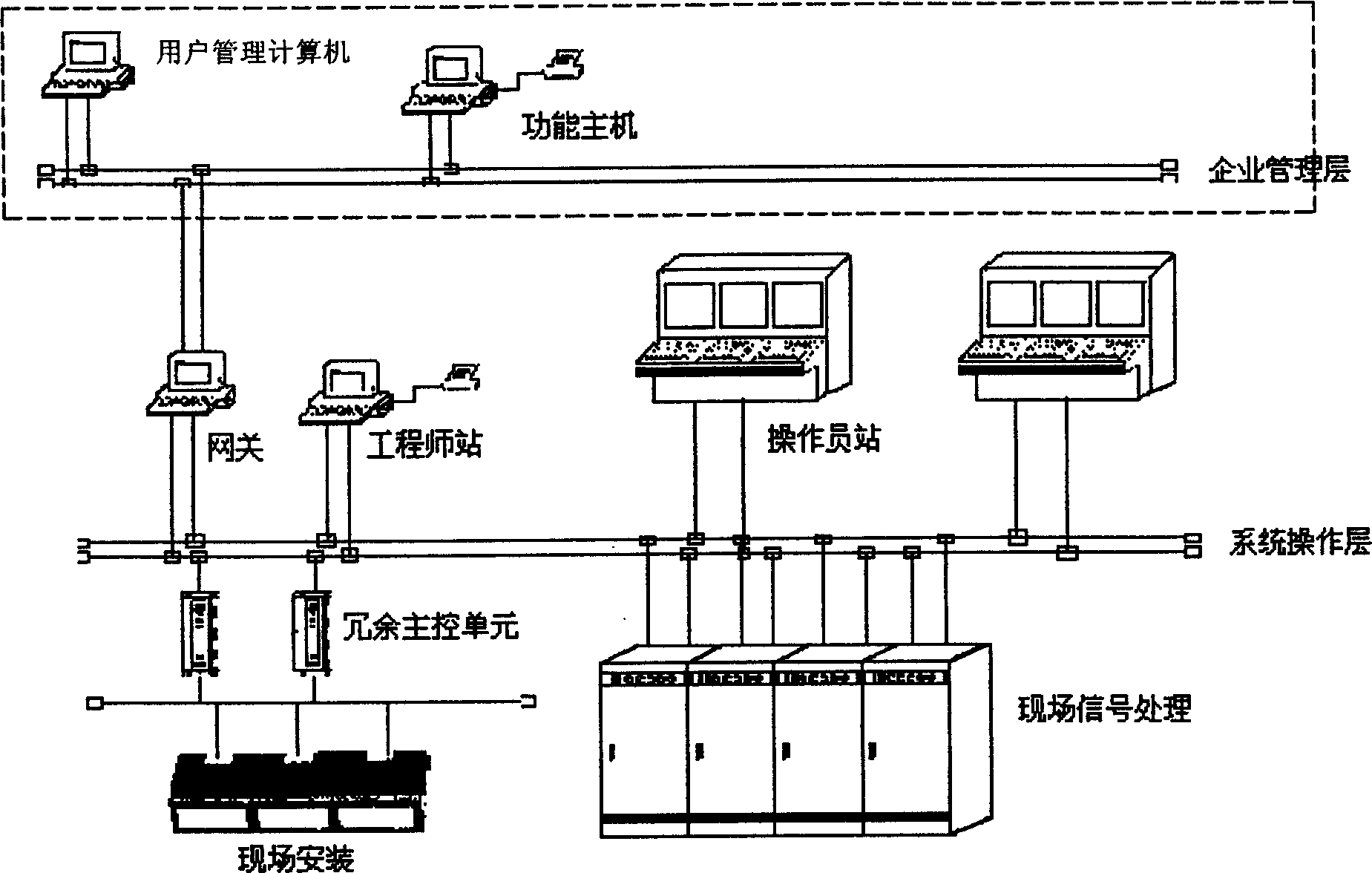

Sludge anhydration and burning process, and its systematic device

ActiveCN1800062ALow investment costLow running costSludge treatment by de-watering/drying/thickeningSludge treatment by oxidationAir preheaterHeat conducting

The invention relates to a sludge drying and burning technique and its system devices, applying to the handling of active sludge in urban sewage treatment plants, its process flows through: wet sludge stock house, measuring bin, sludge mixer, sludge dryer, granular splitter, cooler, drying products storage bin, incinerator, smoke gas cleaning devices, which is characterized by: said incinerator is bubbling fluid bed incinerator with coal economizer, air heater fixed in its end part, high-heat smoke gas generated by burning is used to heat heat-conducting oil and cool air individually, and heat-conducting oil after being heated is transferred to sludge dryer through the circulating pump to dry wet-sludge. The invention is characterized by: take heat-conducting oil as heating medium, use the heat generated by burning dry sludge to heat heat-conducting oil and then dry wet-sludge to make full use of resources; the volume-reducing quantity after drying and burning could reach over 90%; the percentage of desulphurization in incinerator could reach 75% as a result of adopting two stage technology of sulfur removal, and the gross percentage of desulphurization meets national environmental legislation requirements. The invention accomplishes the resources, volume reduction, and innocence of sludge.

Owner:贵州筑信水务环境产业有限公司

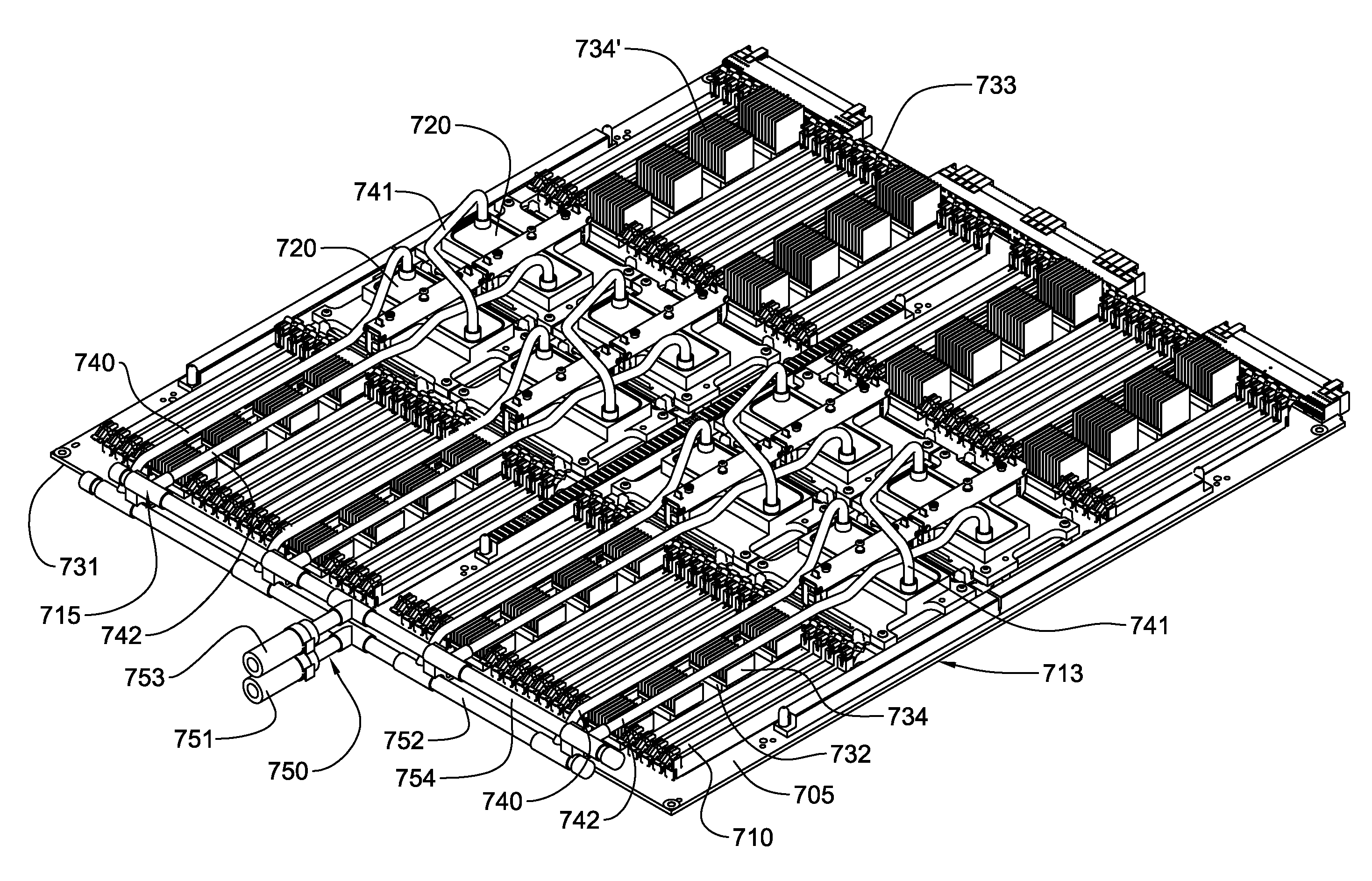

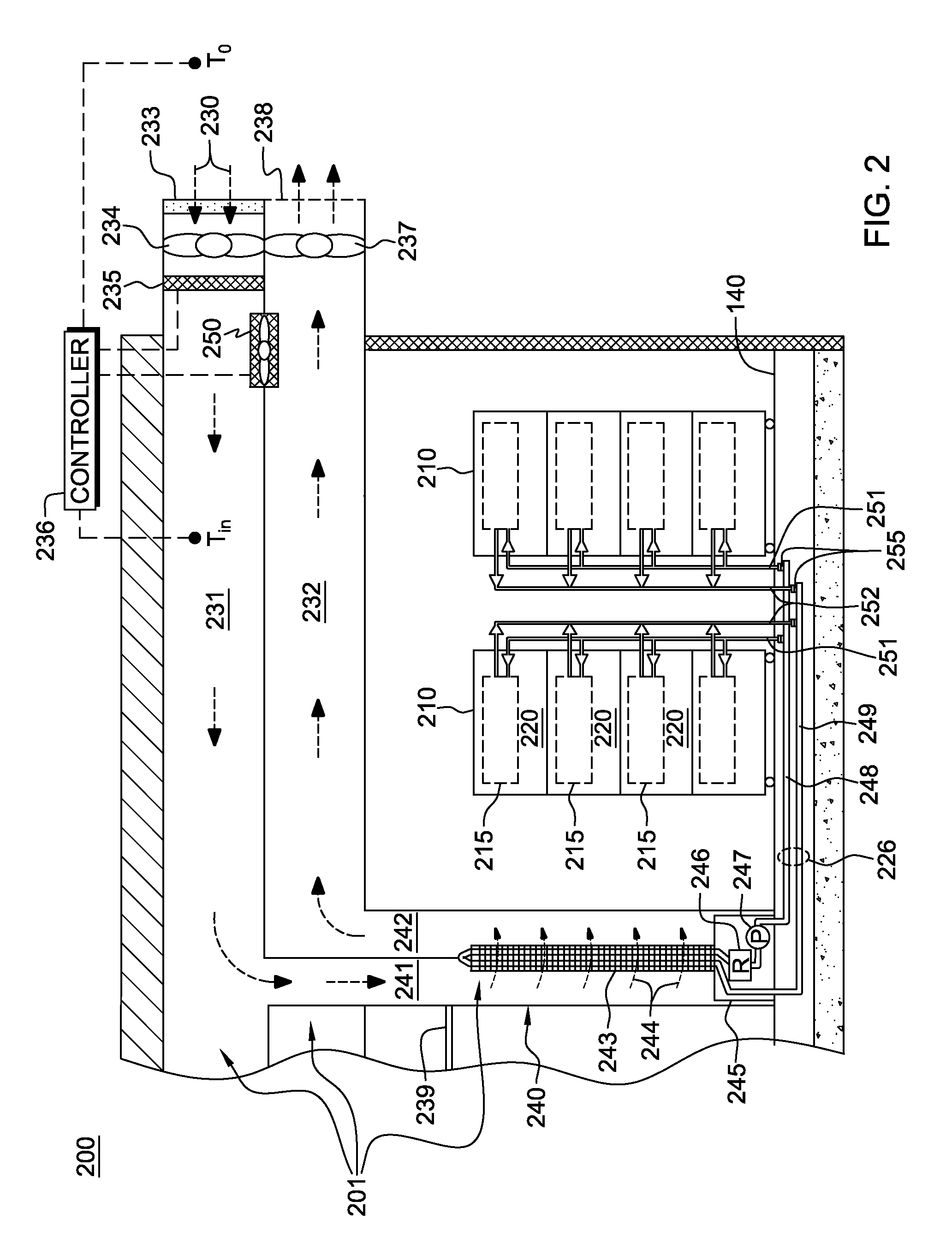

Data center cooling with an air-side economizer and liquid-cooled electronics rack(s)

InactiveUS20130021746A1Promote circulationFacilitate immersion-coolingDigital data processing detailsStationary conduit assembliesData centerNuclear engineering

A cooling apparatus and method are provided for cooling an electronics rack. The cooling apparatus includes an air-cooled cooling station, which has a liquid-to-air heat exchanger and ducting for directing a cooling airflow across the heat exchanger. A cooling subsystem is associated with the electronics rack, and includes a liquid-cooled condenser facilitating immersion-cooling of electronic components of the electronics rack, a liquid-cooled structure providing conductive cooling to electronic components of the electronics rack, or an air-to-liquid heat exchanger associated with the rack and cooling airflow passing through the electronics rack. A coolant loop couples the cooling subsystem to the liquid-to-air heat exchanger. In operation, heat is transferred via circulating coolant from the electronics rack, and rejected in the liquid-to-air heat exchanger of the cooling station to the cooling airflow passing across the liquid-to-air heat exchanger. In one embodiment, the cooling airflow is outdoor air.

Owner:IBM CORP

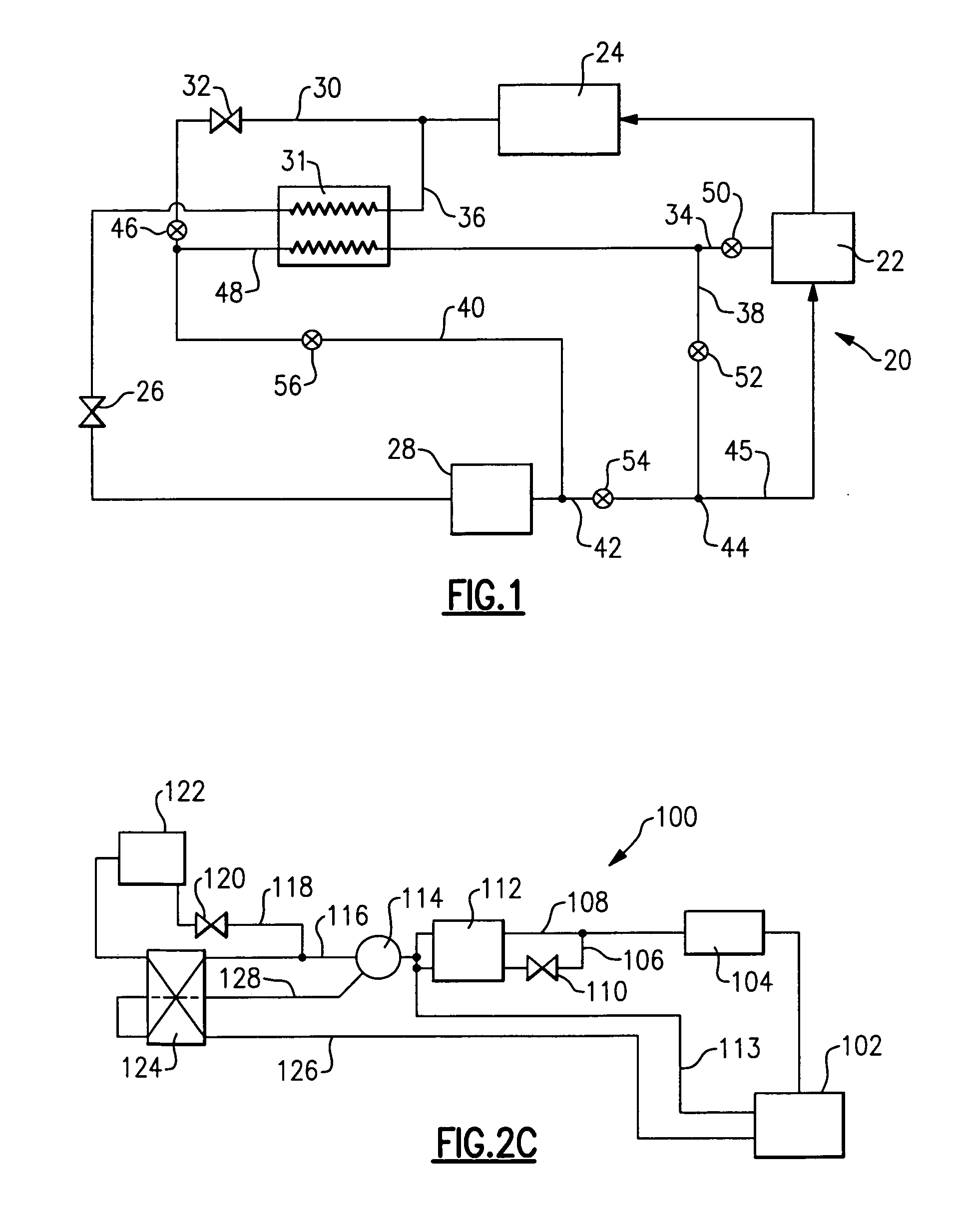

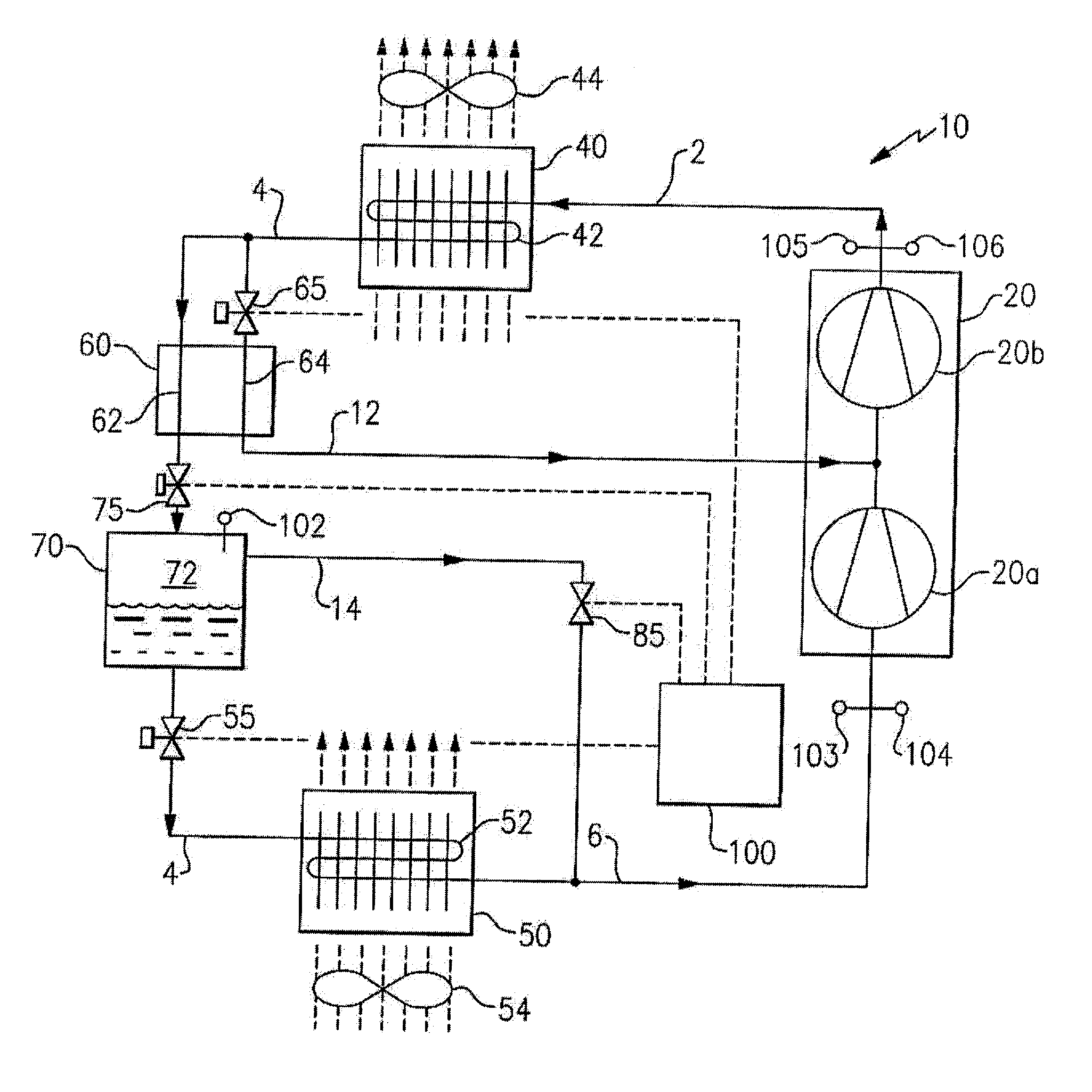

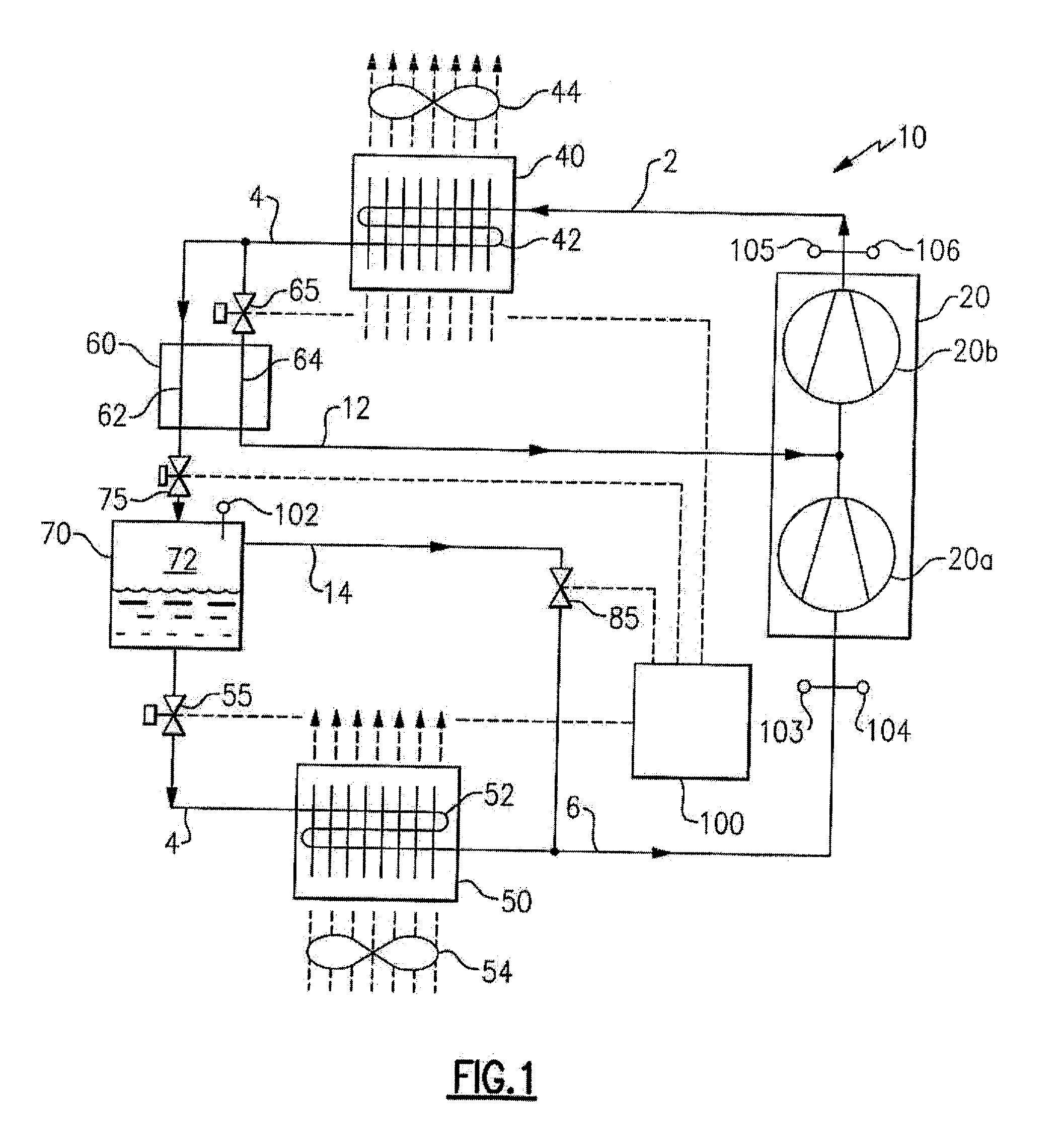

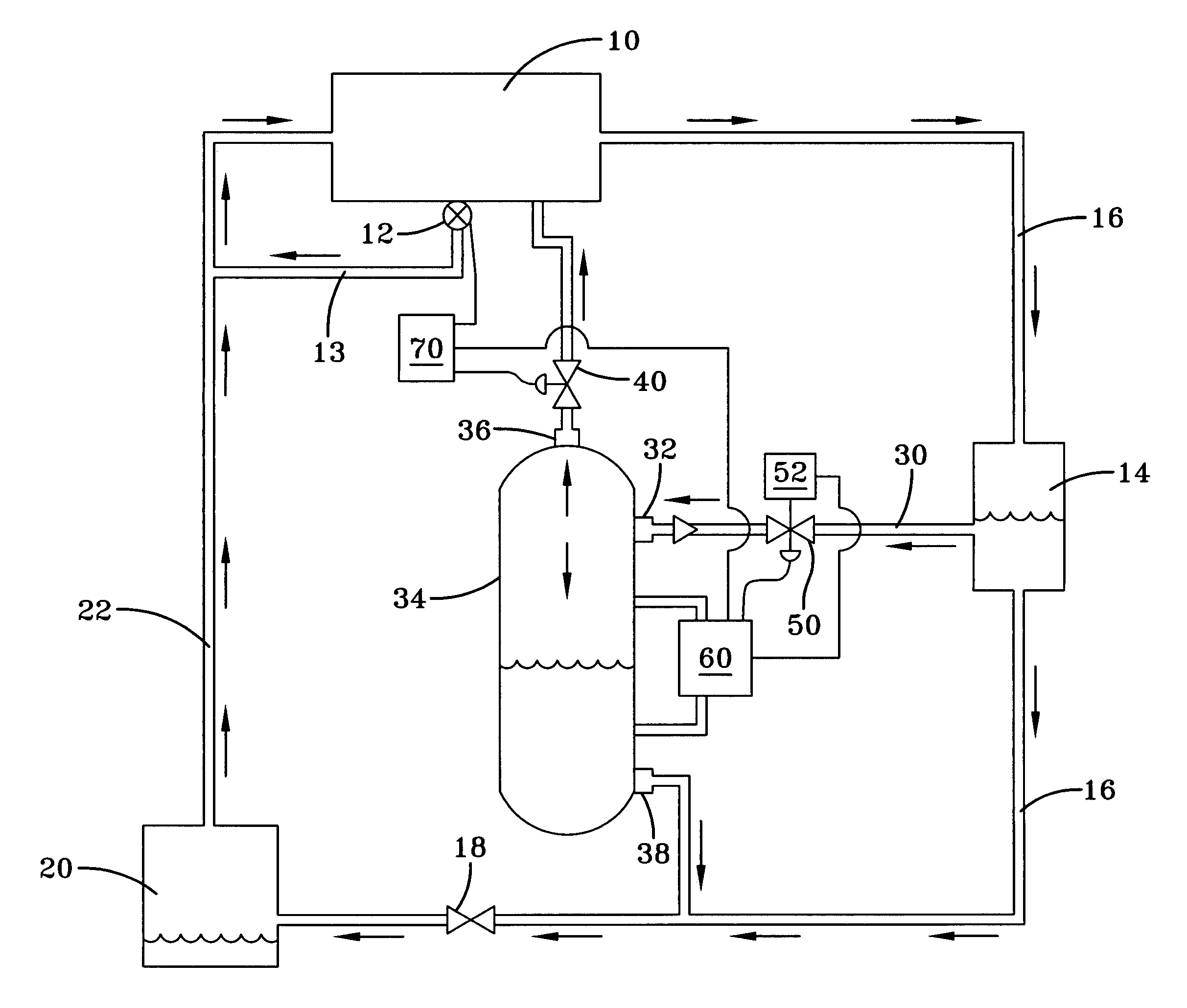

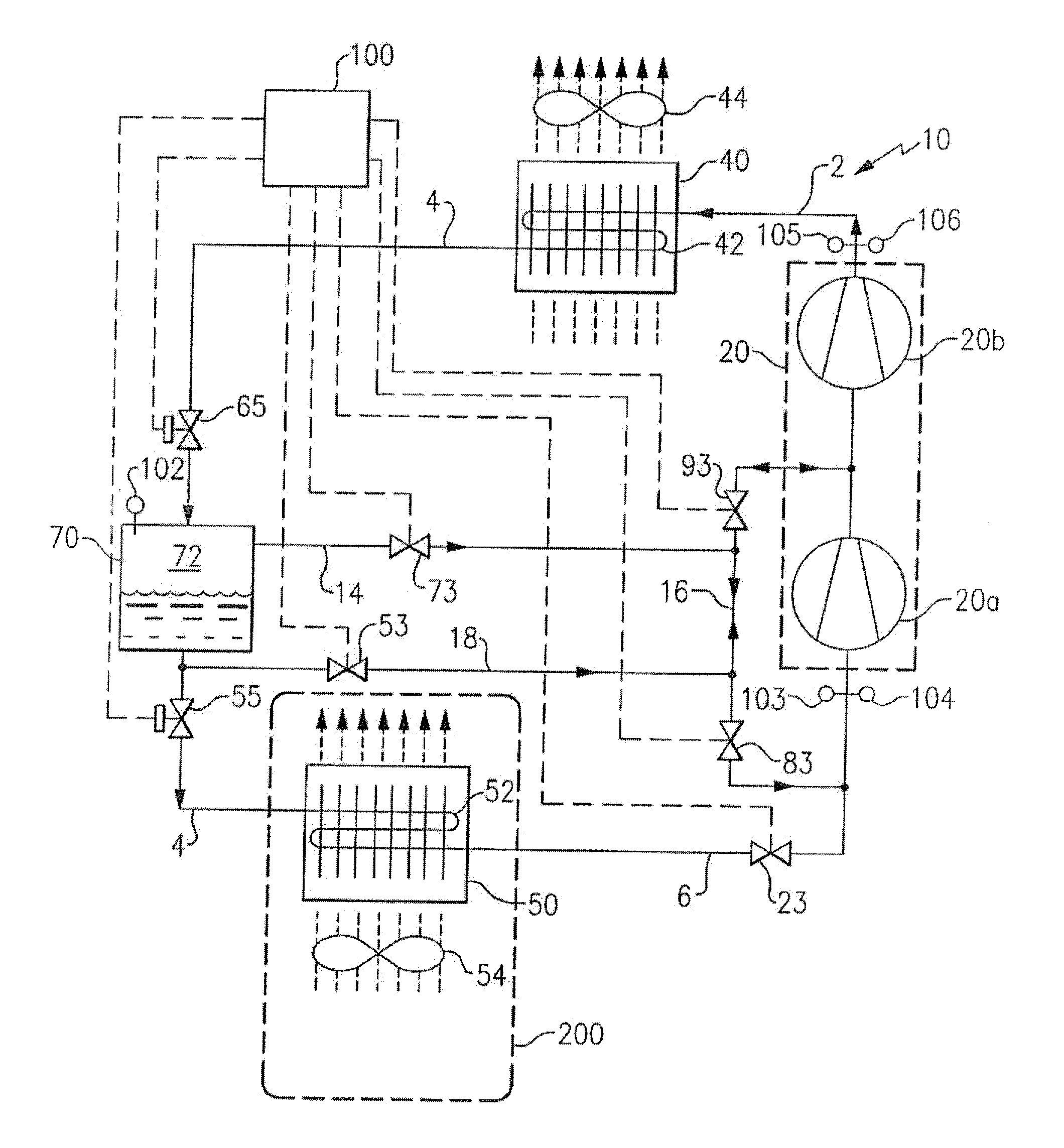

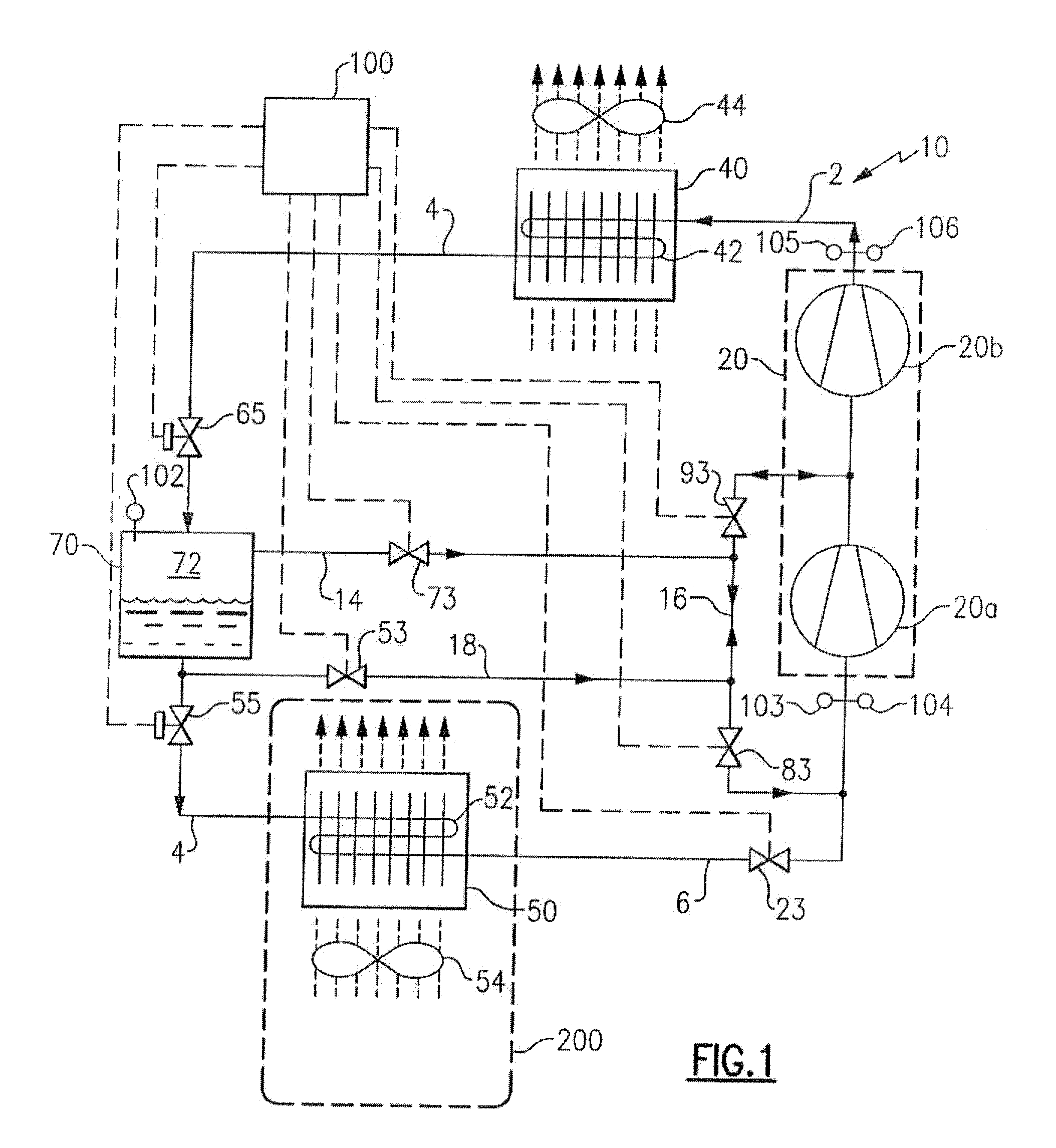

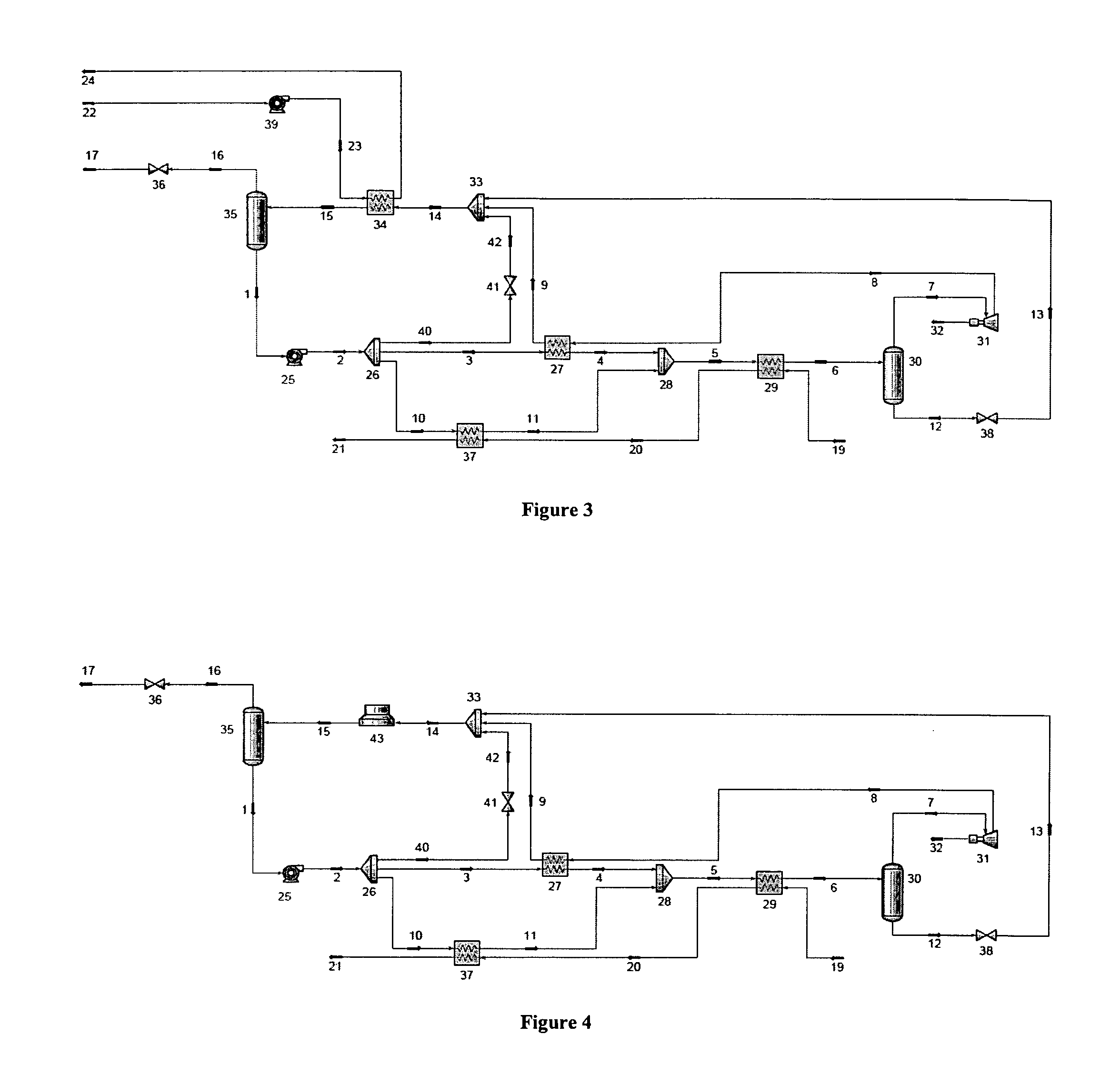

Transcritical refrigerant vapor compression system with charge management

InactiveUS20100132399A1Increase refrigerantCompression machines with non-reversible cycleVehicle heating/cooling devicesHeat rejectionEngineering

A refrigerant vapor compression system includes a refrigerant-to-refrigerant heat exchanger economizer and a flash tank disposed in series refrigerant flow relationship in the refrigerant circuit intermediate a refrigerant heat rejection heat exchanger and a refrigerant heat absorption heat exchanger. A primary expansion valve is interdisposed in the refrigerant circuit upstream of the refrigerant heat absorption heat exchanger and a secondary expansion valve is interdisposed in the refrigerant circuit upstream of the flash tank. The flash tank functions as a refrigerant charge storage reservoir wherein refrigerant expanded from a supercritical pressure to subcritical pressure separates into liquid and vapor phases. A refrigerant vapor bypass line is provided to return refrigerant vapor from the flash tank to the refrigerant circuit downstream of the refrigerant heat absorption heat exchanger. The primary expansion valve and a flow control valve interdisposed in the refrigerant vapor bypass provide refrigerant charge management.

Owner:CARRIER CORP

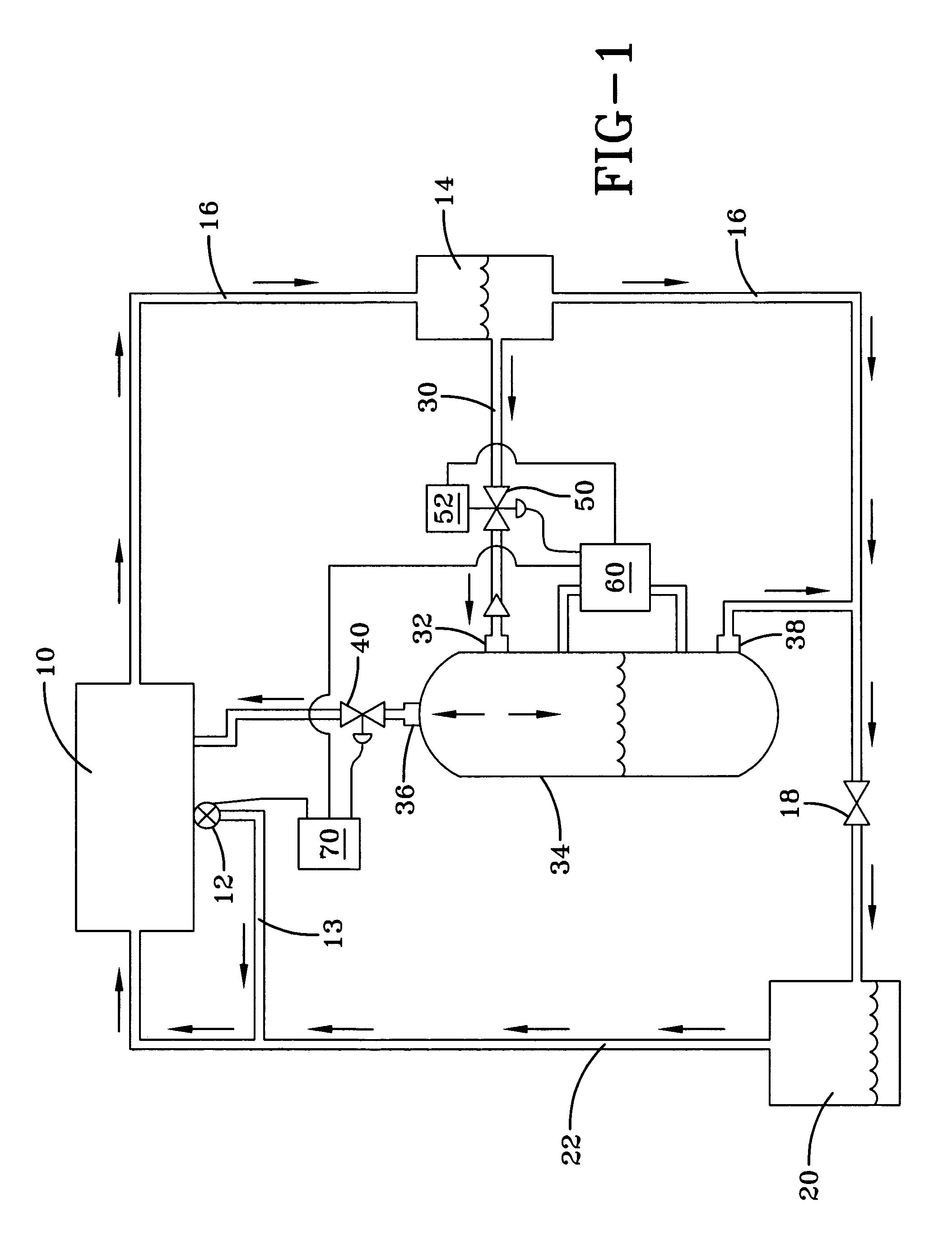

Refrigerant vapor compression system with flash tank economizer

A refrigerant vapor compression system includes a flash tank disposed in series refrigerant flow relationship in the refrigerant circuit intermediate a refrigerant heat rejection heat exchanger and a refrigerant heat absorption heat exchanger. A primary expansion valve is interdisposed in the refrigerant circuit upstream of the refrigerant heat absorption heat exchanger and a secondary expansion valve is interdisposed in the refrigerant circuit upstream of the flash tank. A refrigerant vapor line is provided to direct refrigerant vapor from the flash tank to an intermediate pressure stage of the compression process. A refrigerant-to-refrigerant heat exchanger operates to transfer heat from refrigerant flowing through the primary refrigerant circuit to refrigerant flowing through the refrigerant vapor line.

Owner:CARRIER CORP

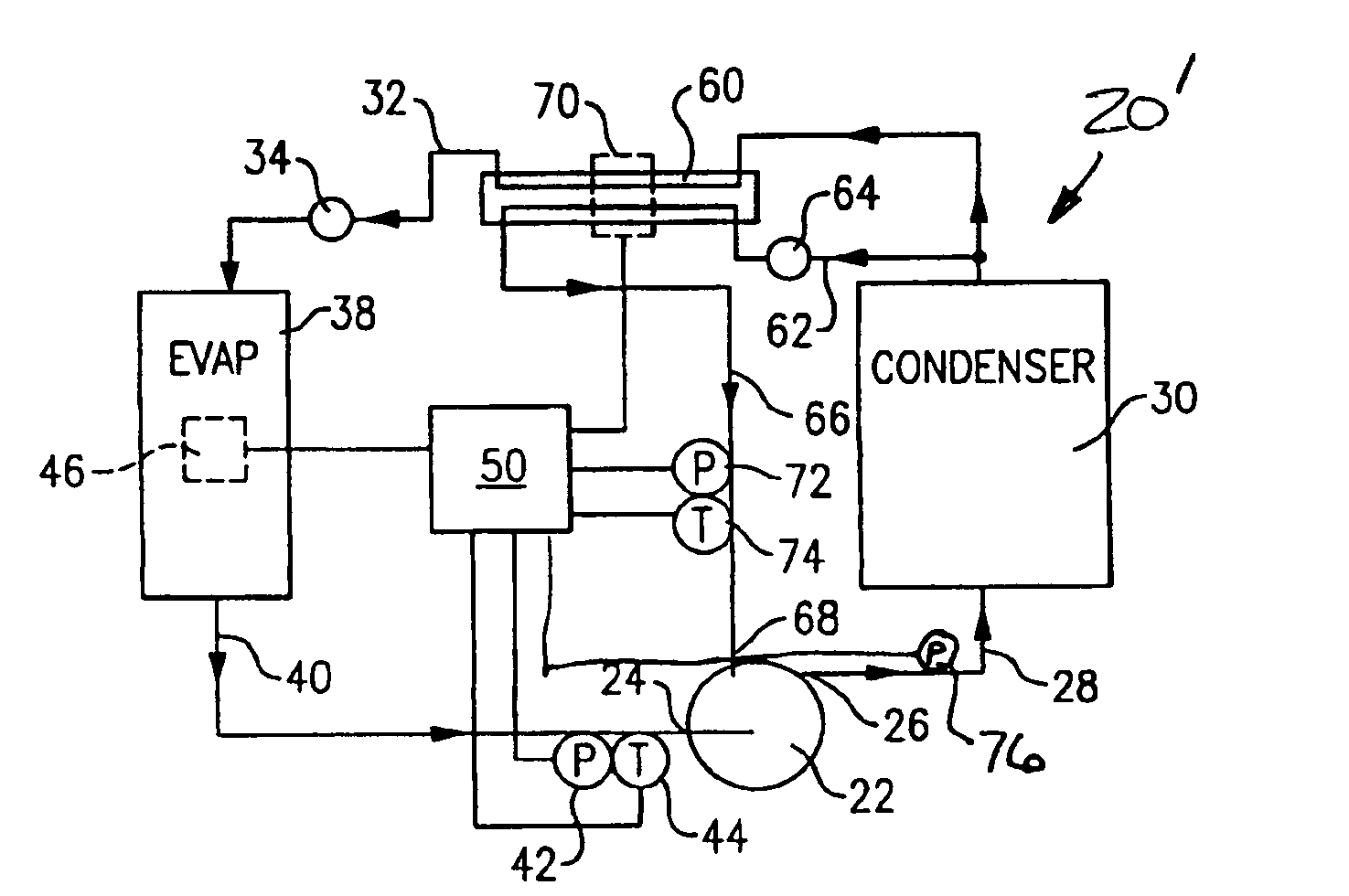

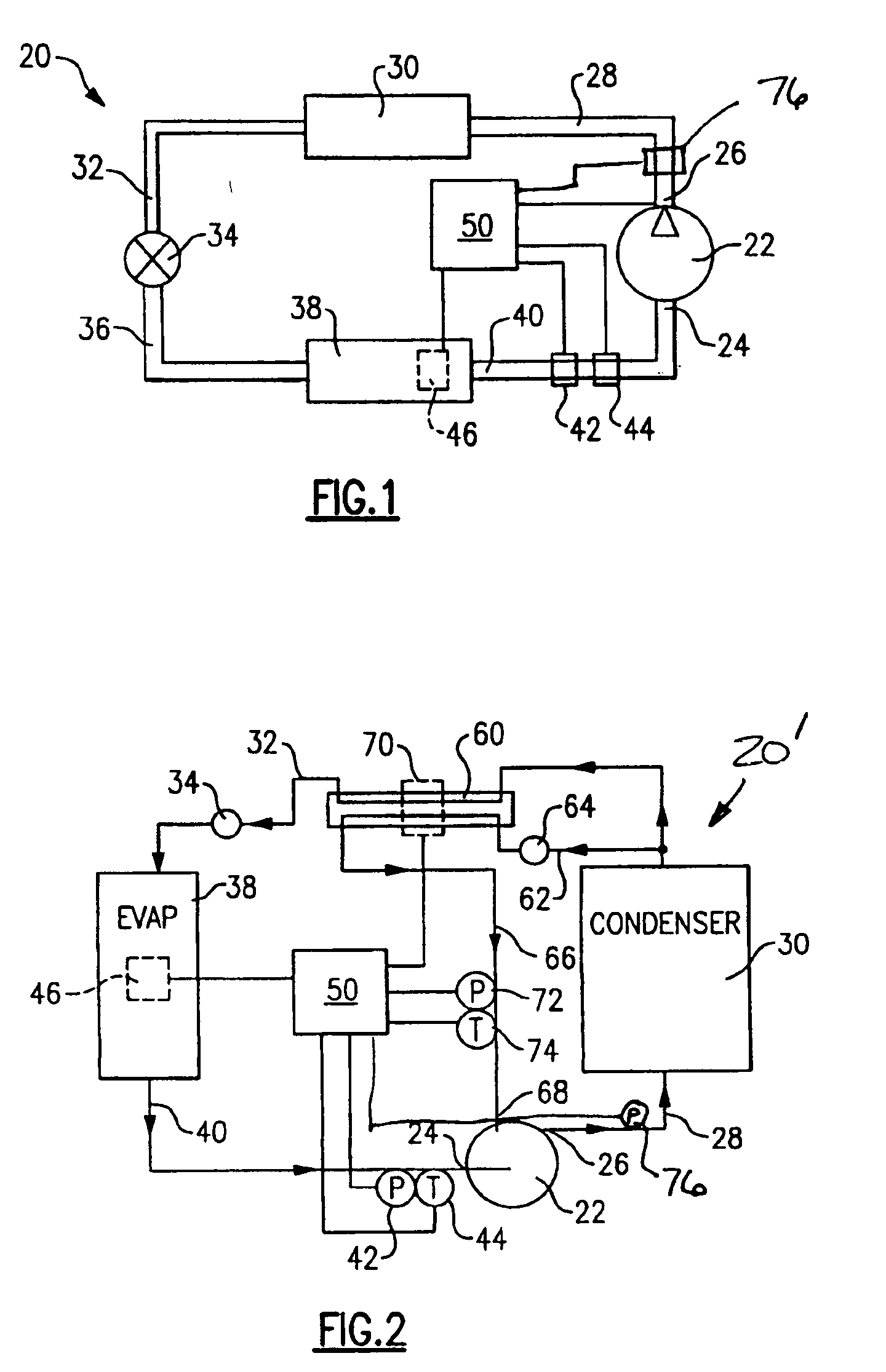

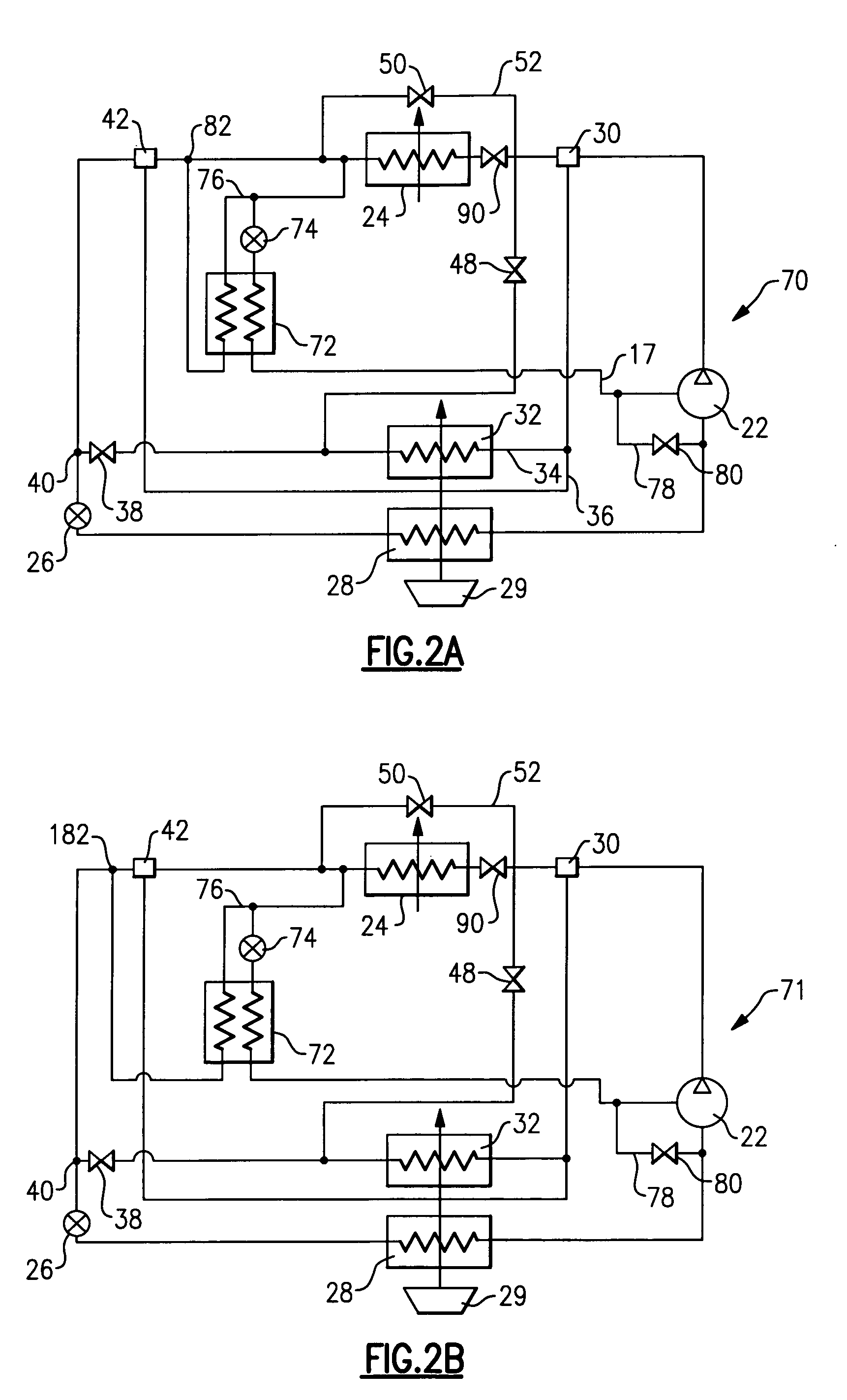

Hybrid tandem compressor system with multiple evaporators and economizer circuit

InactiveUS7228707B2Easy to controlMechanical apparatusCompression machines with non-reversible cycleInjection portHigh load

A tandem compressor refrigerant cycle with an economizer circuit is introduced to provide additional capacity and improve system efficiency. In this system, tandem compressors deliver compressed refrigerant to a common discharge manifold, and then to a common condenser. From the common condenser, the refrigerant passes to a plurality of evaporators, with each of the evaporators being associated with a separate environment to be conditioned. Each of the evaporators is associated with one of the plurality of compressors. By utilizing the common condenser, and yet a plurality of evaporators, the ability to independently condition a number of environments is achieved without the requirement of the same plurality of separate complete refrigerant circuits for each of the environments. In some embodiments, several of the plurality of compressors can be provided by compressor banks having its own plurality of compressors. Some of the compressors in the compressor bank can have intermediate injection ports to accept refrigerant vapor from the economizer circuit. In particular, the economizer circuit provides additional capacity to the evaporators with relatively high load requirements.

Owner:CARRIER CORP

System and method for high efficiency power generation using a carbon dioxide circulating working fluid

ActiveUS20130213049A1Improve efficiencyIncrease pressure ratioSolidificationLiquefactionWorking fluidCombustor

The present invention provides methods and system for power generation using a high efficiency combustor in combination with a CO2 circulating fluid. The methods and systems advantageously can make use of a low pressure ratio power turbine and an economizer heat exchanger in specific embodiments. Additional low grade heat from an external source can be used to provide part of an amount of heat needed for heating the recycle CO2 circulating fluid. Fuel derived CO2 can be captured and delivered at pipeline pressure. Other impurities can be captured.

Owner:8 RIVERS CAPTTAL LLC

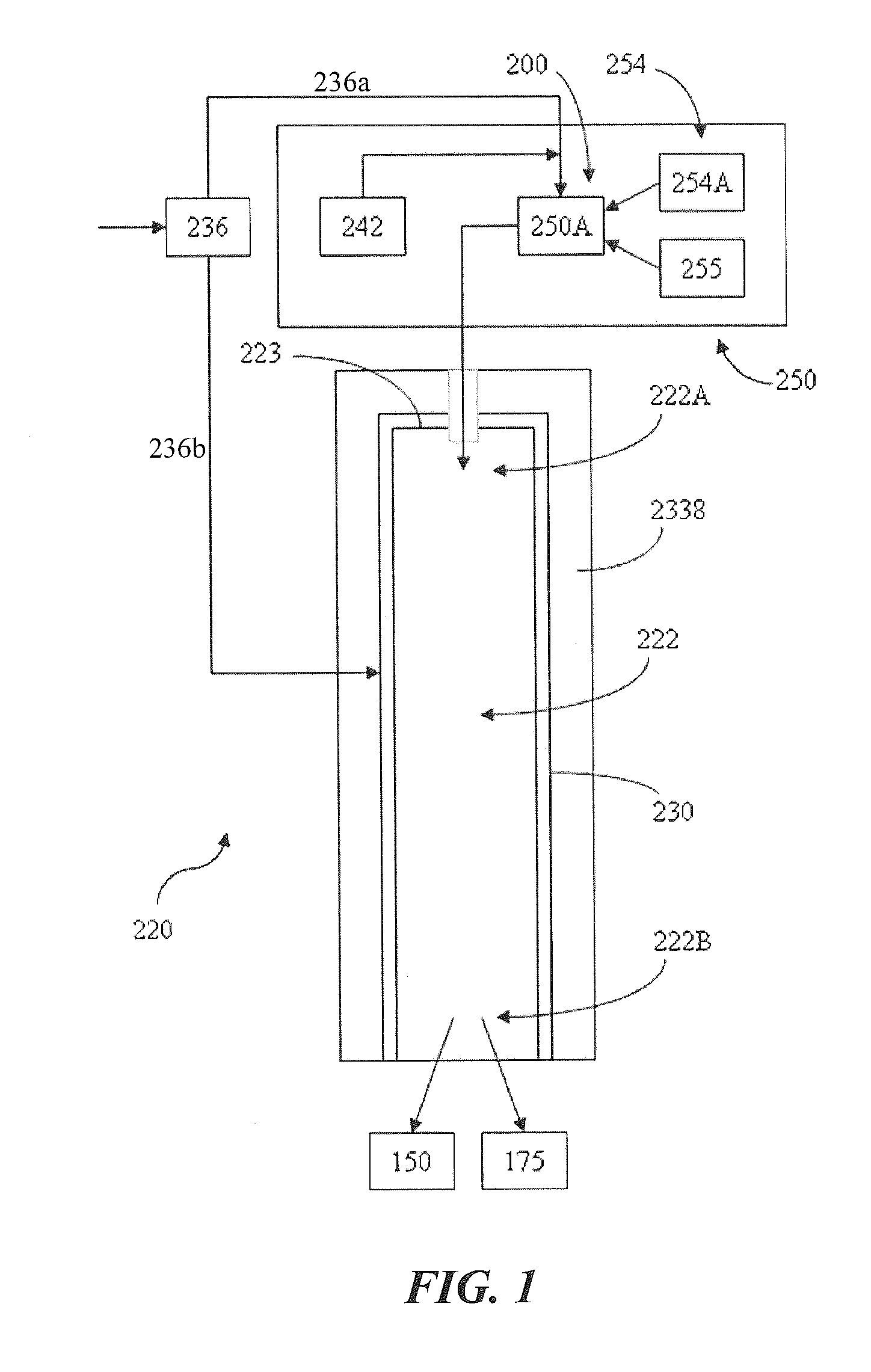

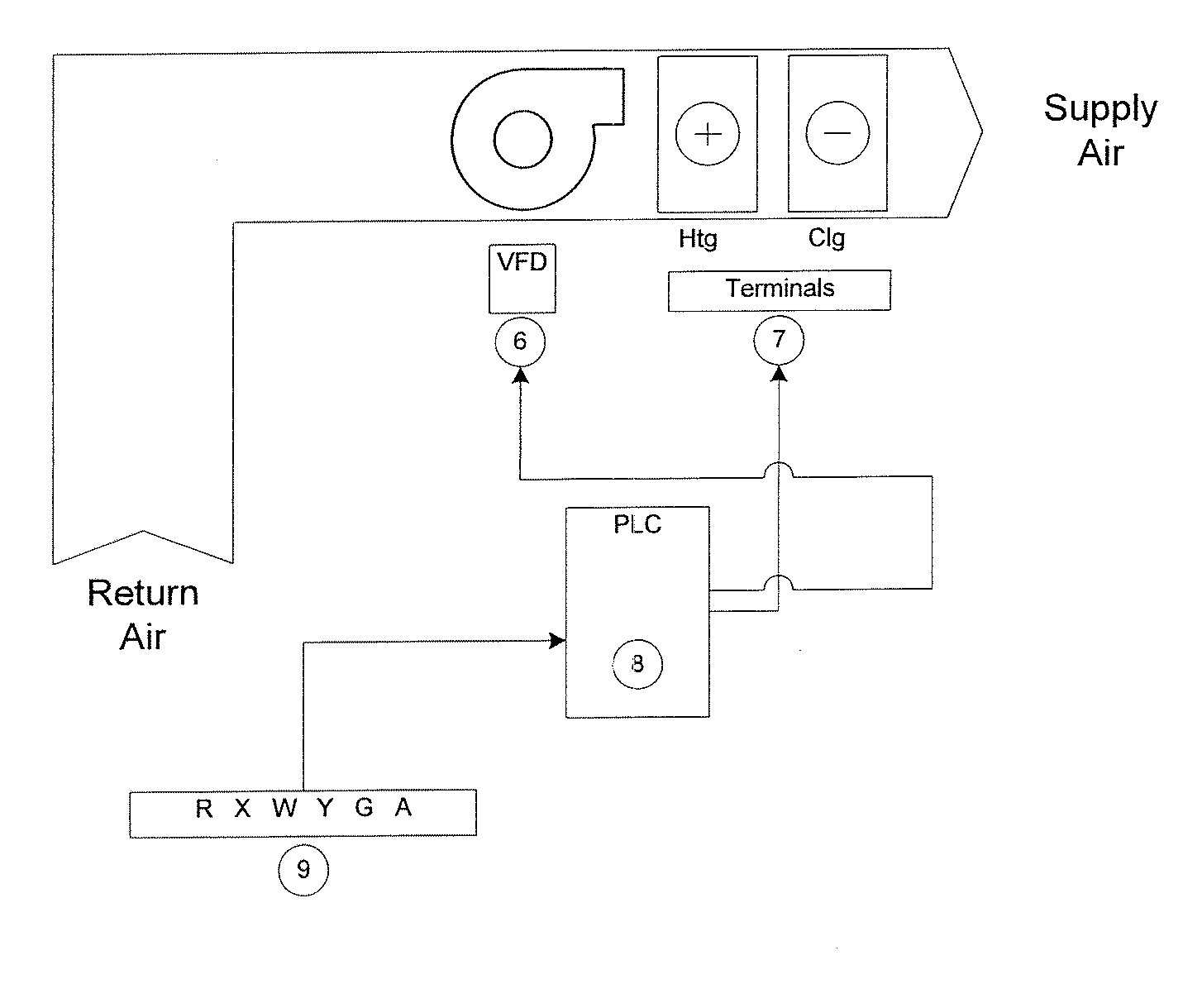

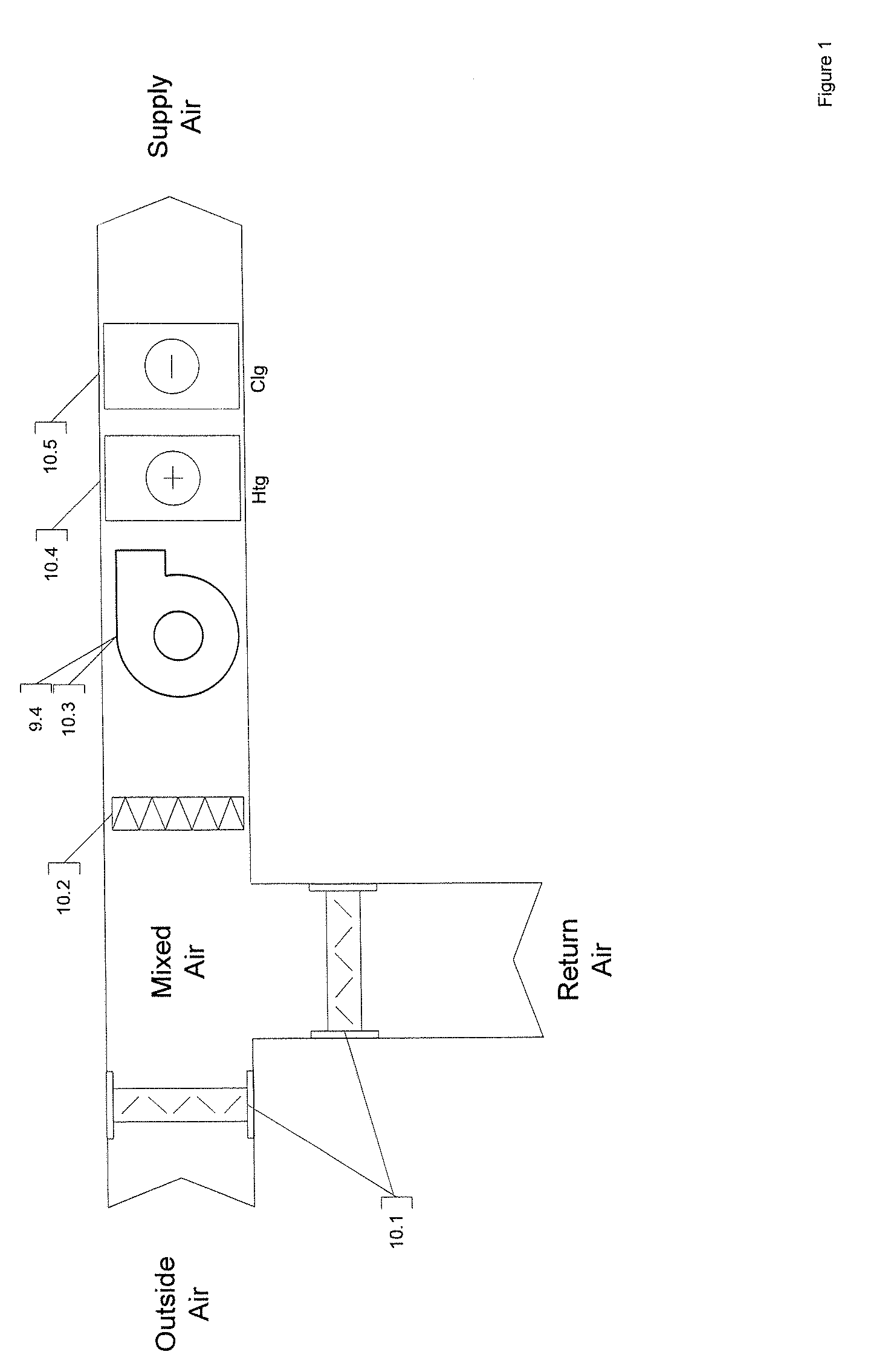

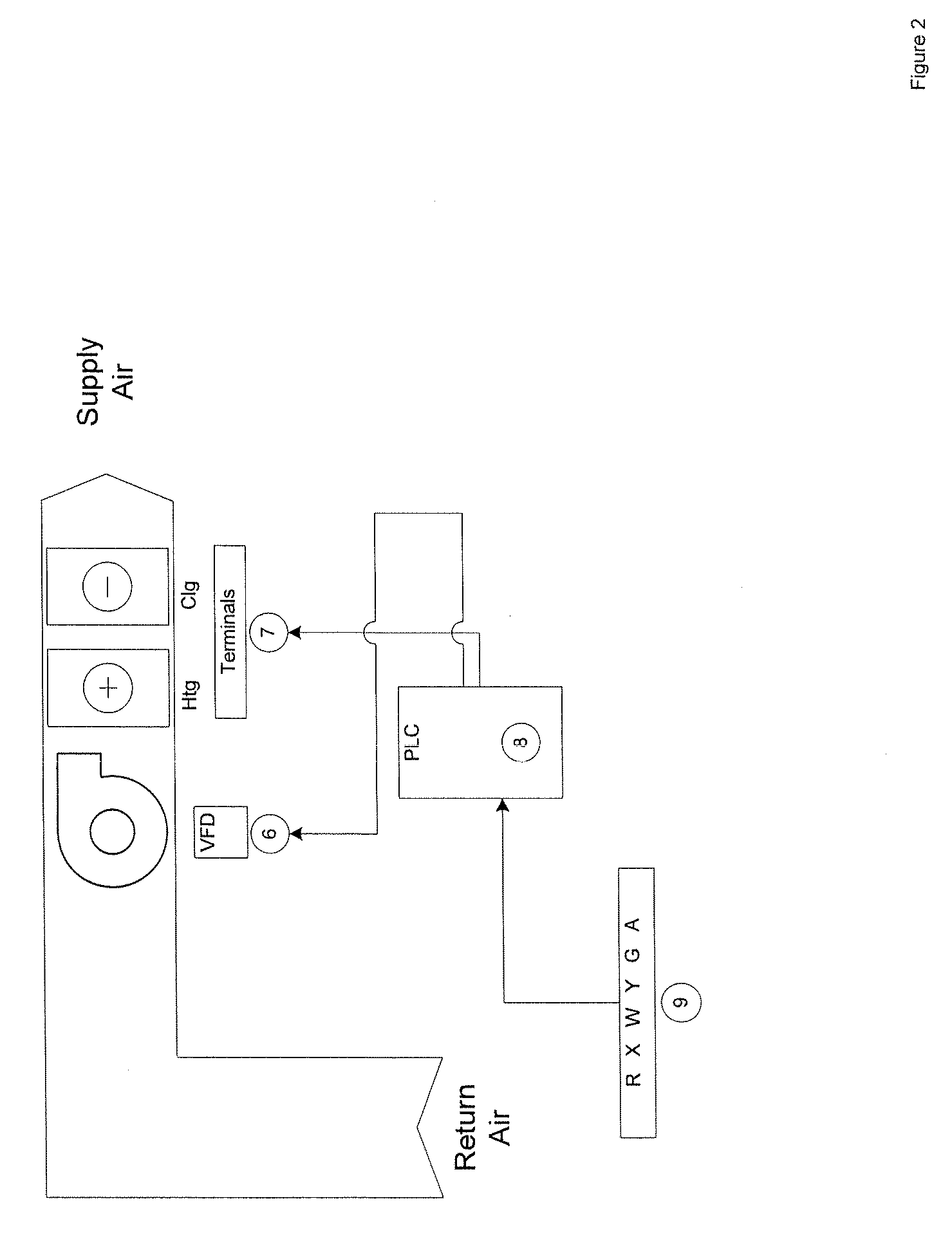

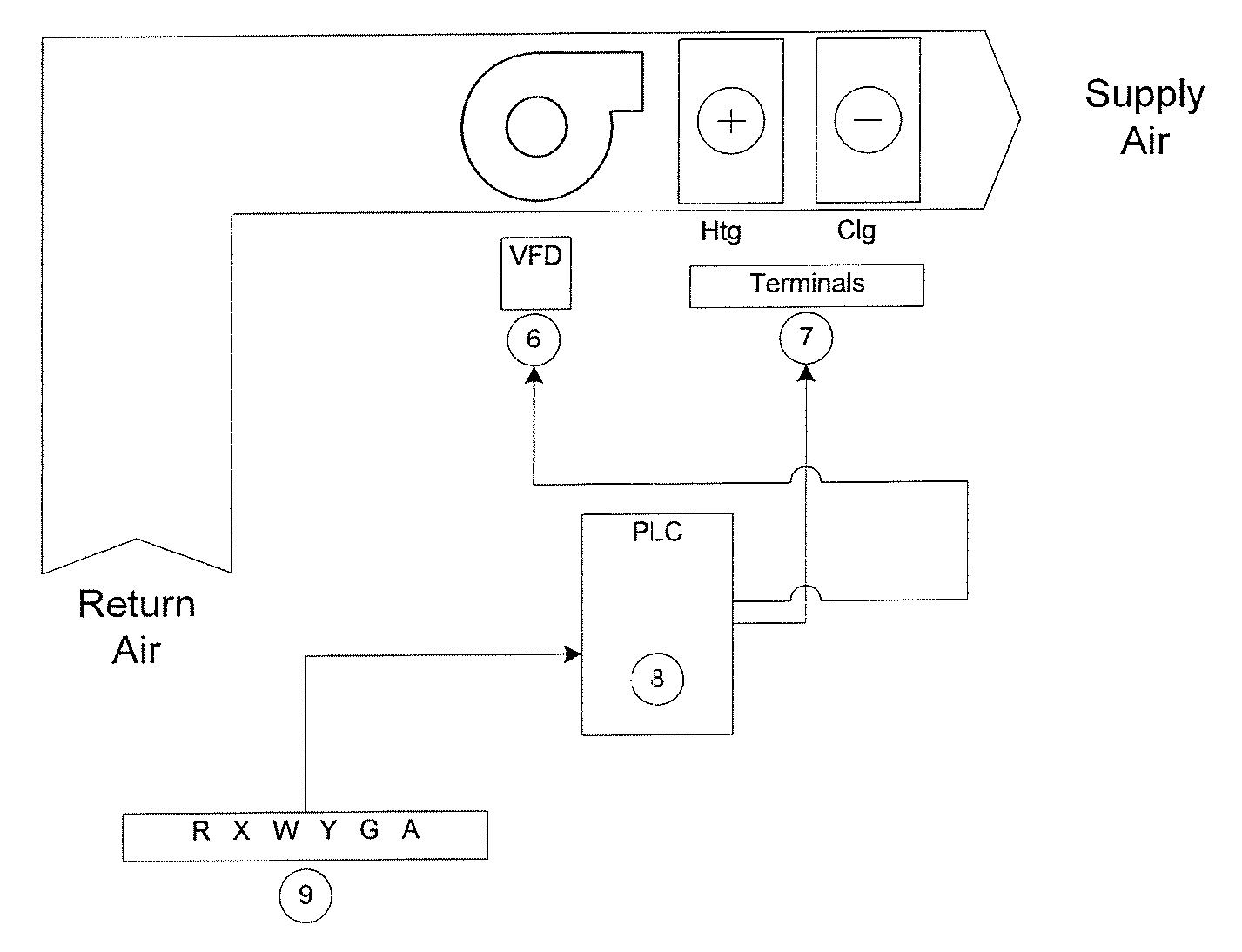

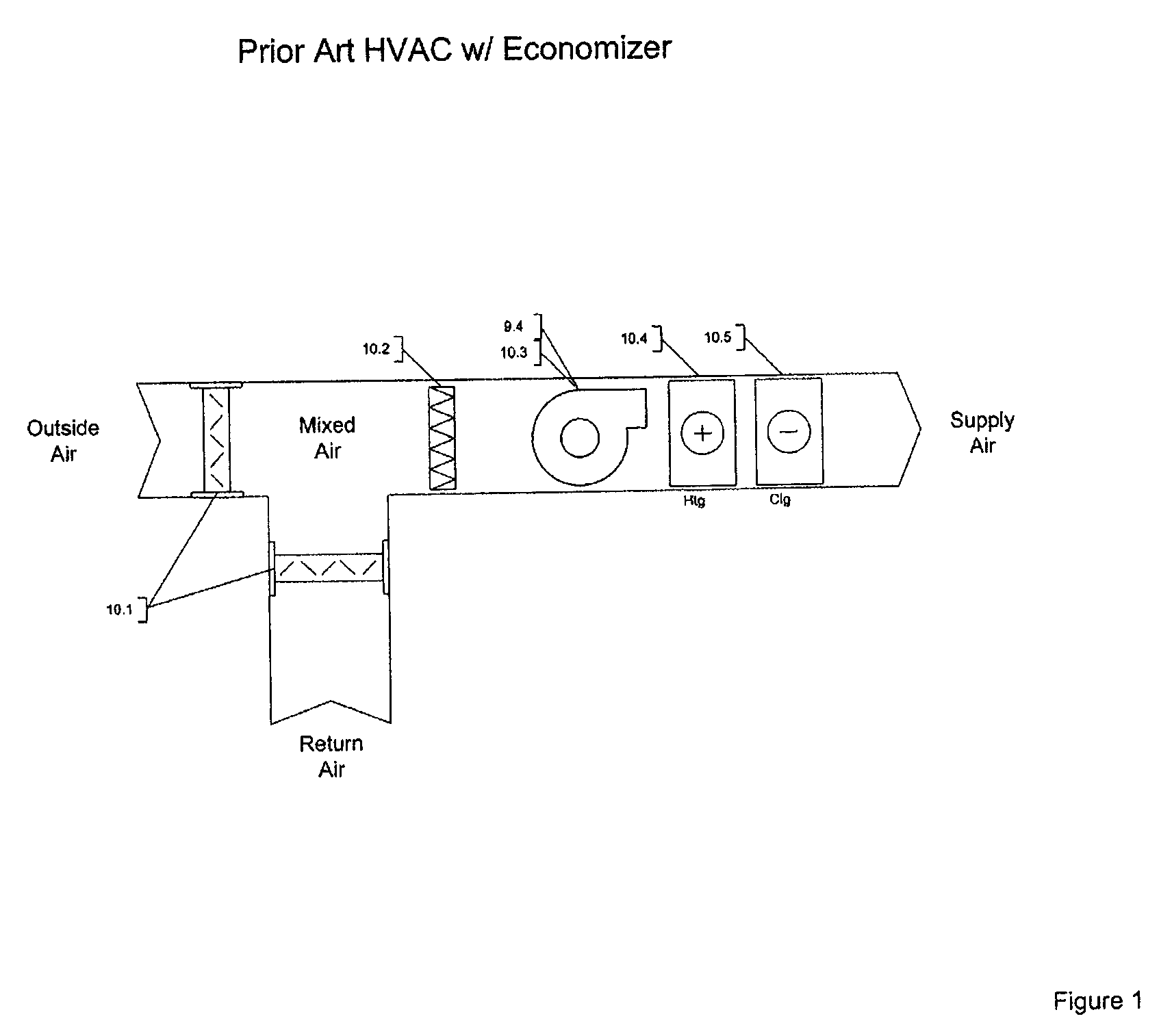

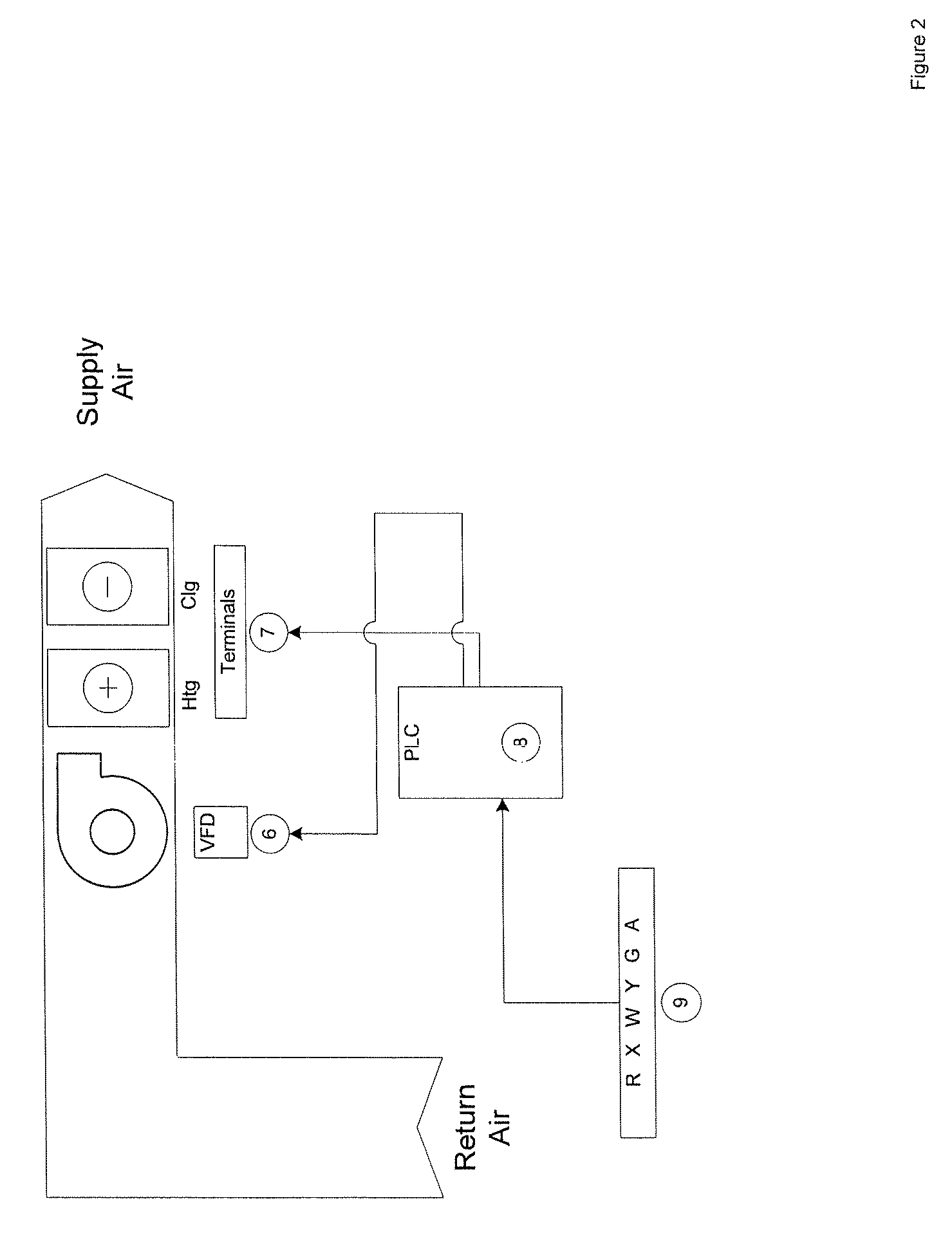

Energy reducing retrofit method and apparatus for a constant volume HVAC system

ActiveUS20110046790A1Match occupancy needReduce motor speedLevel controlSpace heating and ventilationProgrammable logic controllerFree cooling

An energy-reducing method and apparatus for retrofitting a constant volume HVAC system, with or without an economizer, that provides heating, cooling, and ventilation to occupants within a building space. The present invention includes the introduction of a programmable logic controller and variable frequency drive (VFD) that takes control of the existing fan, heating, cooling, and optional economizer operation. The controller is programmed for the reduction of fan speed in the heating and cooling modes. The reduction of the fan speed in the ventilation mode when the 100% operation is not needed saves significant energy of the existing constant volume HVAC system where the fan motor is designed to run 100% of the time. The fan speed may be further reduced upon a reduction in sensed occupancy levels of the space, such as with a CO2 sensor. Additionally, the fan speed may be reduced in the heating and / or cooling mode to further reduce energy consumption. The controller may also be programmed and equipped with sensors to allow simultaneous mechanical compressor cooling and economizer free cooling operation, for the operation of the economizer in response to the monitoring of outside air and return air to determine the preferred source for cooling operations, to keep the outside air damper closed during the unoccupied heating modes such as morning warm-up, and / or to provide fault detection. The retrofit method and apparatus may be employed in a stand-alone or networked version.

Owner:PRO STAR ENERGY SOLUTIONS LP

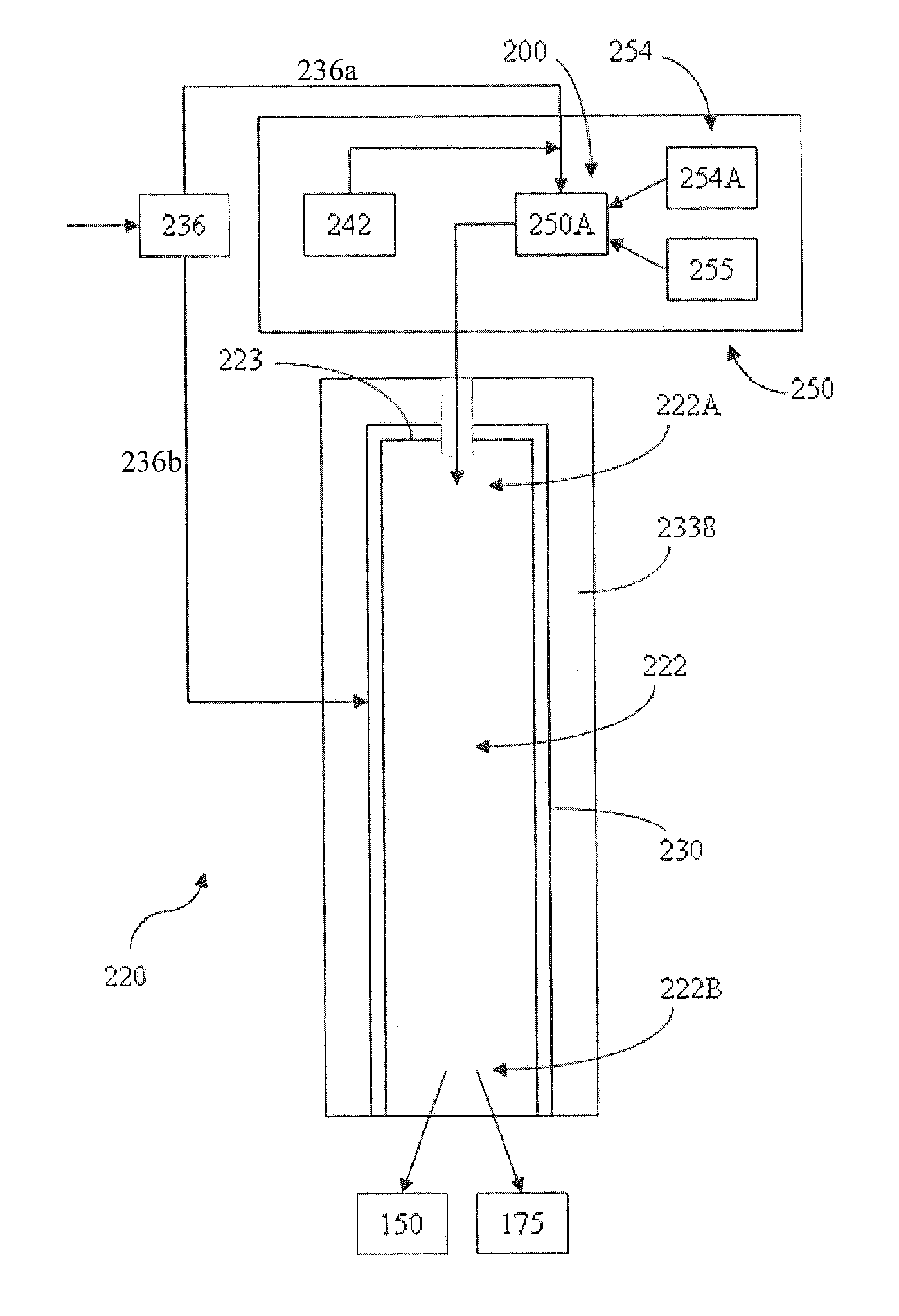

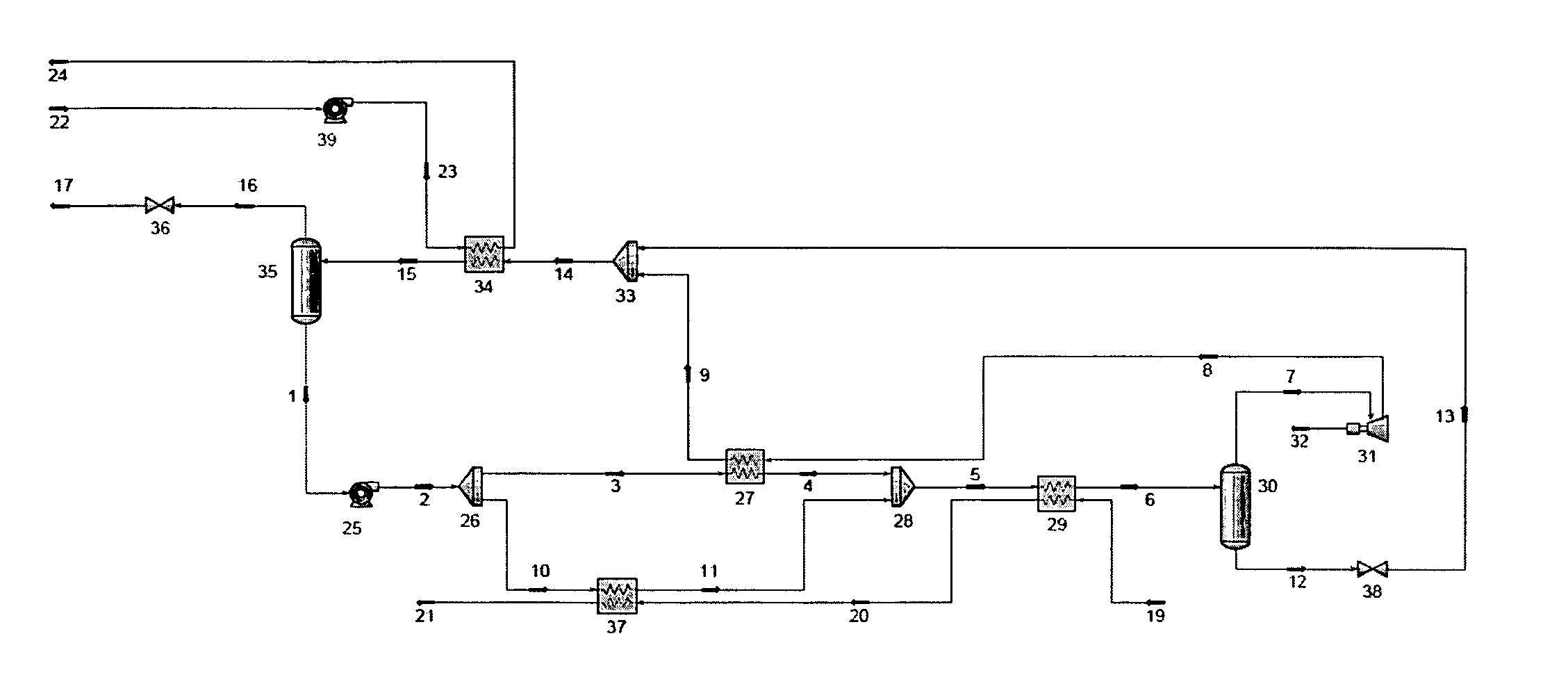

Power recovery and energy conversion systems and methods of using same

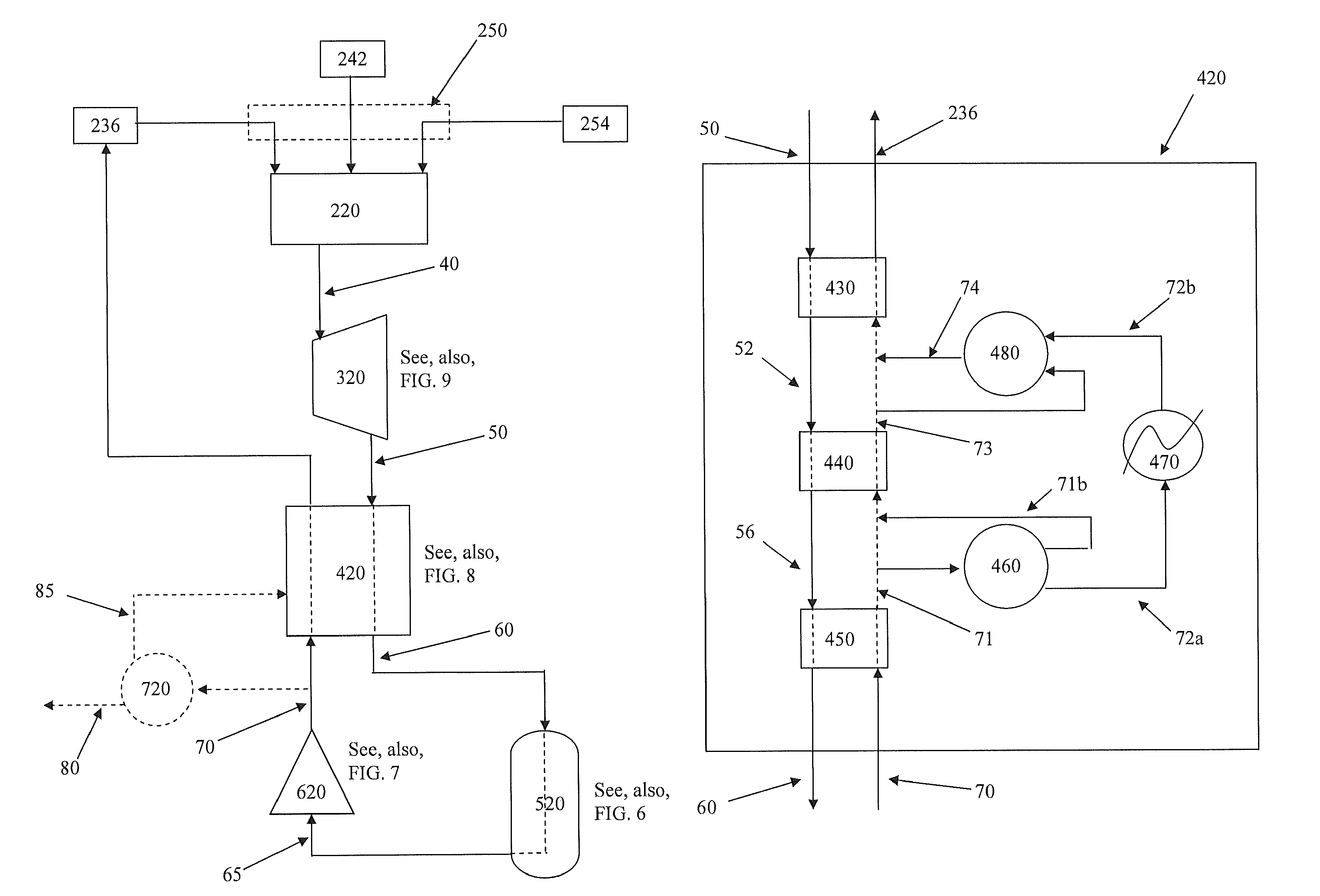

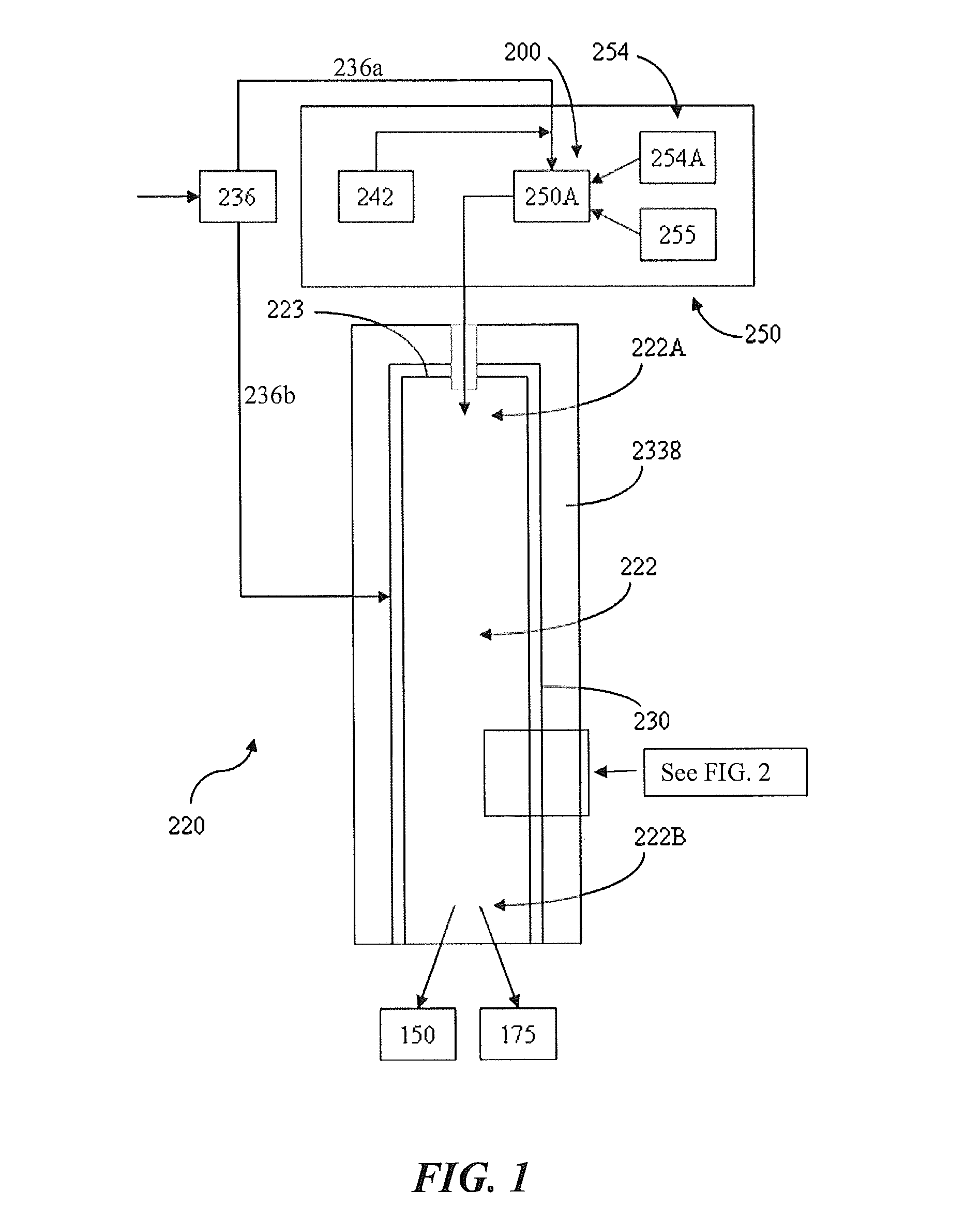

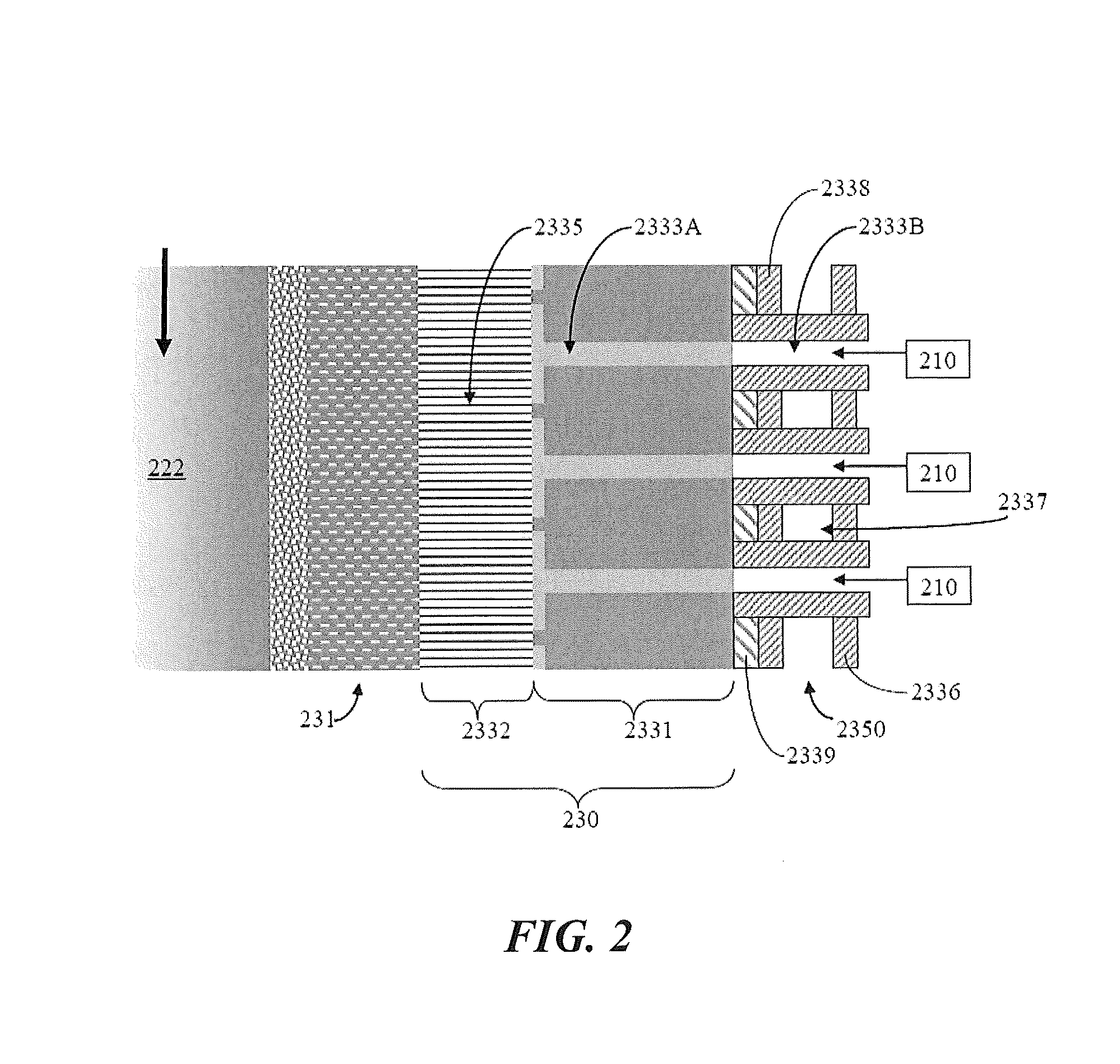

In various illustrative examples, the system may include heat recovery heat exchangers, one or more turbines or expanders, a desuperheater heat exchanger, a condenser heat exchanger, a separator, an accumulator, and a liquid circulating pump, etc. In one example, a bypass desuperheater control valve may be employed. The system comprises a first heat exchanger adapted to receive a heating stream from a heat source after passing through a second heat exchanger and a second portion of a working fluid, wherein, the second portion of working fluid is converted to a hot liquid via heat transfer. An economizer heat exchanger that is adapted to receive a first portion of the working fluid and the hot discharge vapor from at least one turbine may also be provided. The first and second portions of the working fluid are recombined in a first flow mixer after passing through the economizer heat exchanger and first heat exchanger, respectively. A second heat exchanger is provided that receives the working fluid from the first flow mixer and a hot heating stream from a heat source and convert the working fluid to a hot vapor. The hot vapor from the second heat exchanger is supplied to at least one turbine after passing through a separator designed to insure no liquid enters the said at least one turbine or expander. The hot, high pressure vapor is expanded in the turbine to produce mechanical power on a shaft and is discharged as a hot, low pressure vapor.

Owner:TAS ENERGY

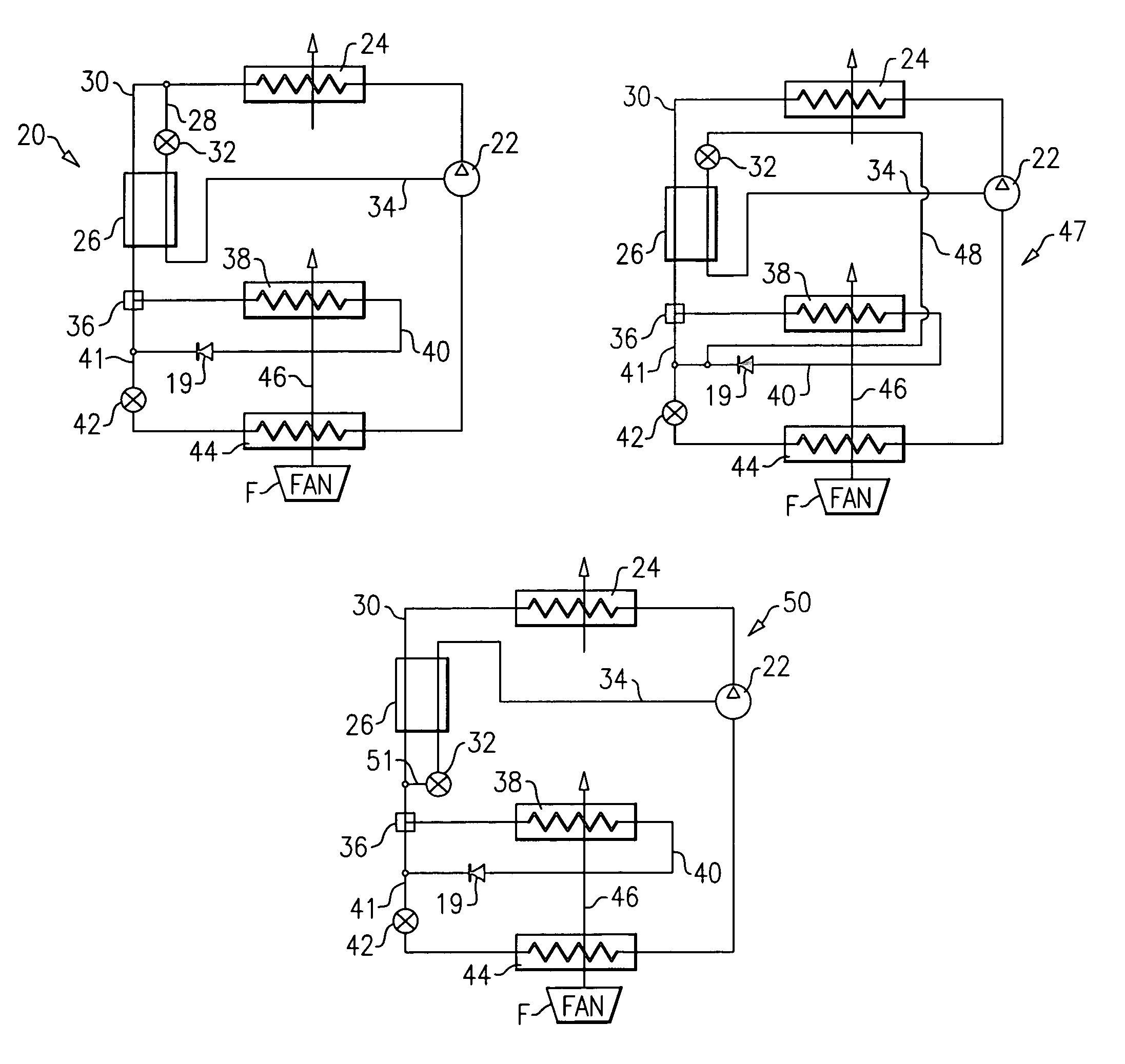

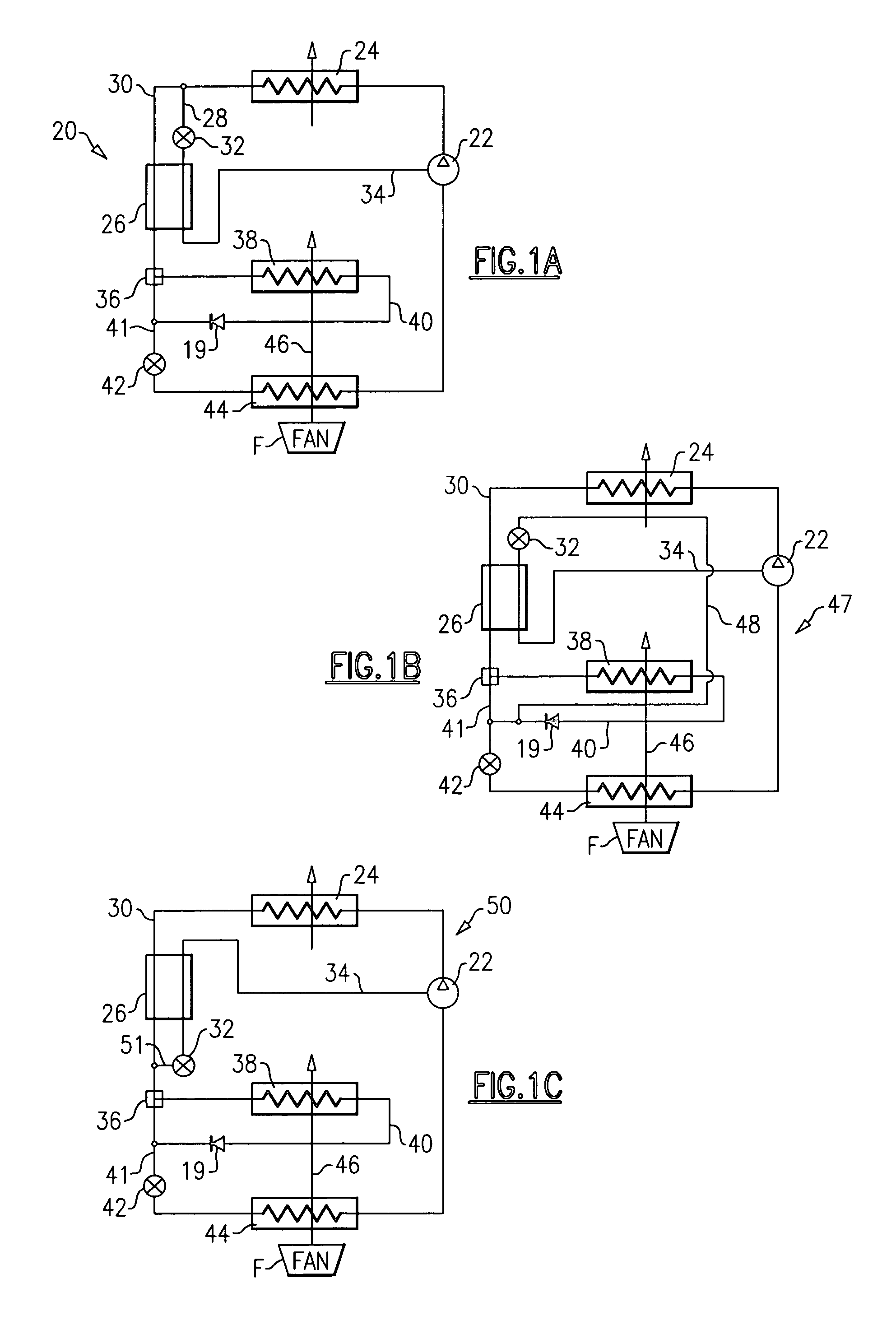

Hybrid reheat system with performance enhancement

ActiveUS6941770B1Reduce the temperatureMechanical apparatusFluid circulation arrangementPerformance enhancementOperation mode

An economizer loop is incorporated into the refrigerant system, which in conjunction with any selected reheat mode of operation, provides augmented performance, improved reliability, and enhanced control in meeting external heat load demands. A refrigerant system includes several features that can be selectively utilized alone or in combination with each other to provide an enhanced control over system cooling and dehumidification capability. In particular, a reheat coil is incorporated into the refrigerant system, and has alternative connection points to the main circuit, positioned both upstream and downstream of a condenser. Also, a flow control device allows a selective bypass around a condenser. In this manner, the refrigerant flowing through the reheat coil can be controlled to provide a desired level of temperature and humidity. Finally, the compressor may include an unloader feature such that additional steps in capacity control can be provided.

Owner:CARRIER CORP

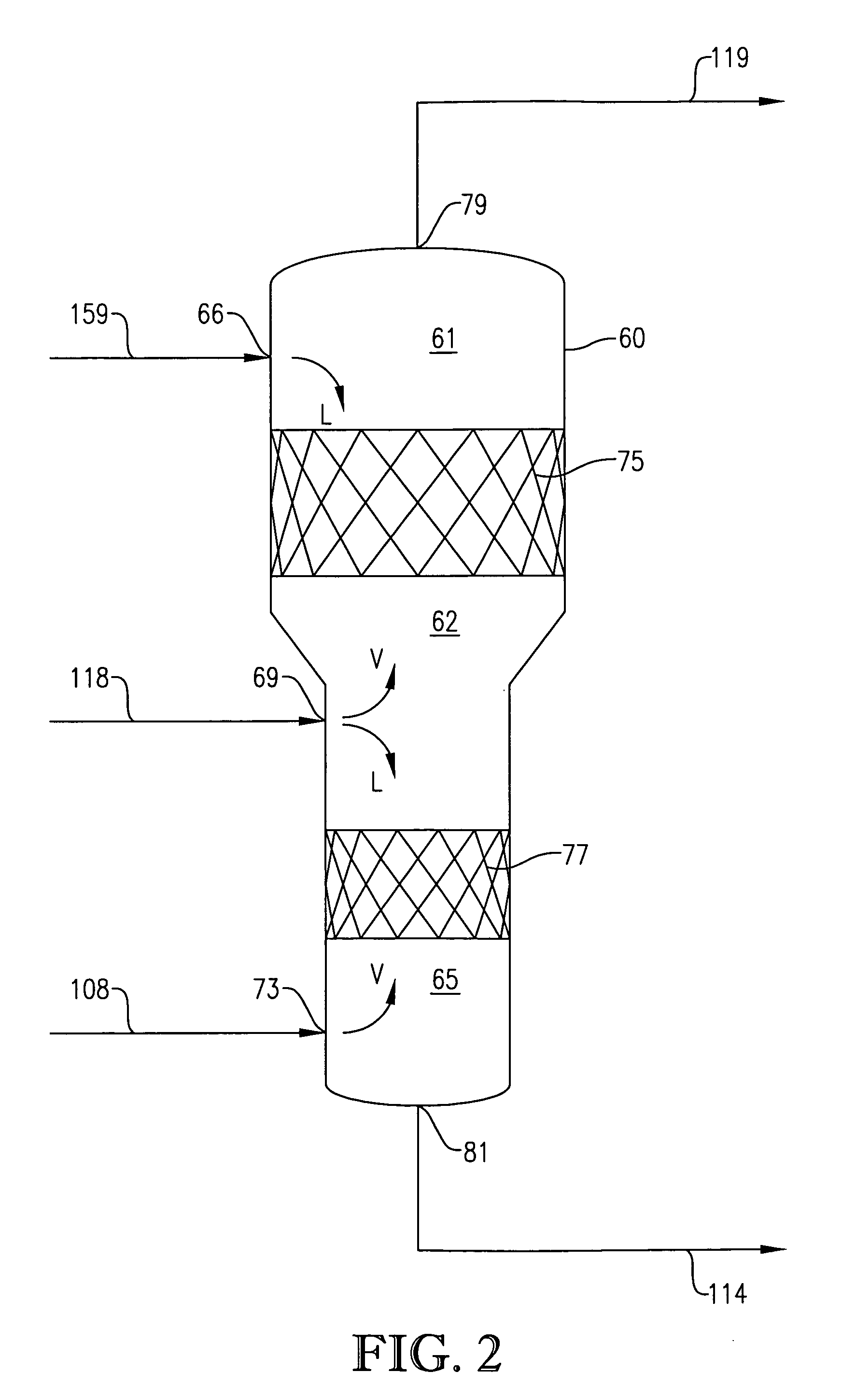

LNG system employing stacked vertical heat exchangers to provide liquid reflux stream

An improved apparatus and method for providing reflux to a refluxed heavies removal column of a LNG facility. The apparatus comprises stacked vertical core-in-kettle heat exchangers and an economizer disposed between the heat exchangers. The reflux stream originates from the methane-rich refrigerant of the methane refrigeration cycle. The liquid reflux stream generated by cooling the methane-rich stream in the vertical heat exchangers via indirect heat exchange with an upstream refrigerant.

Owner:CONOCOPHILLIPS CO

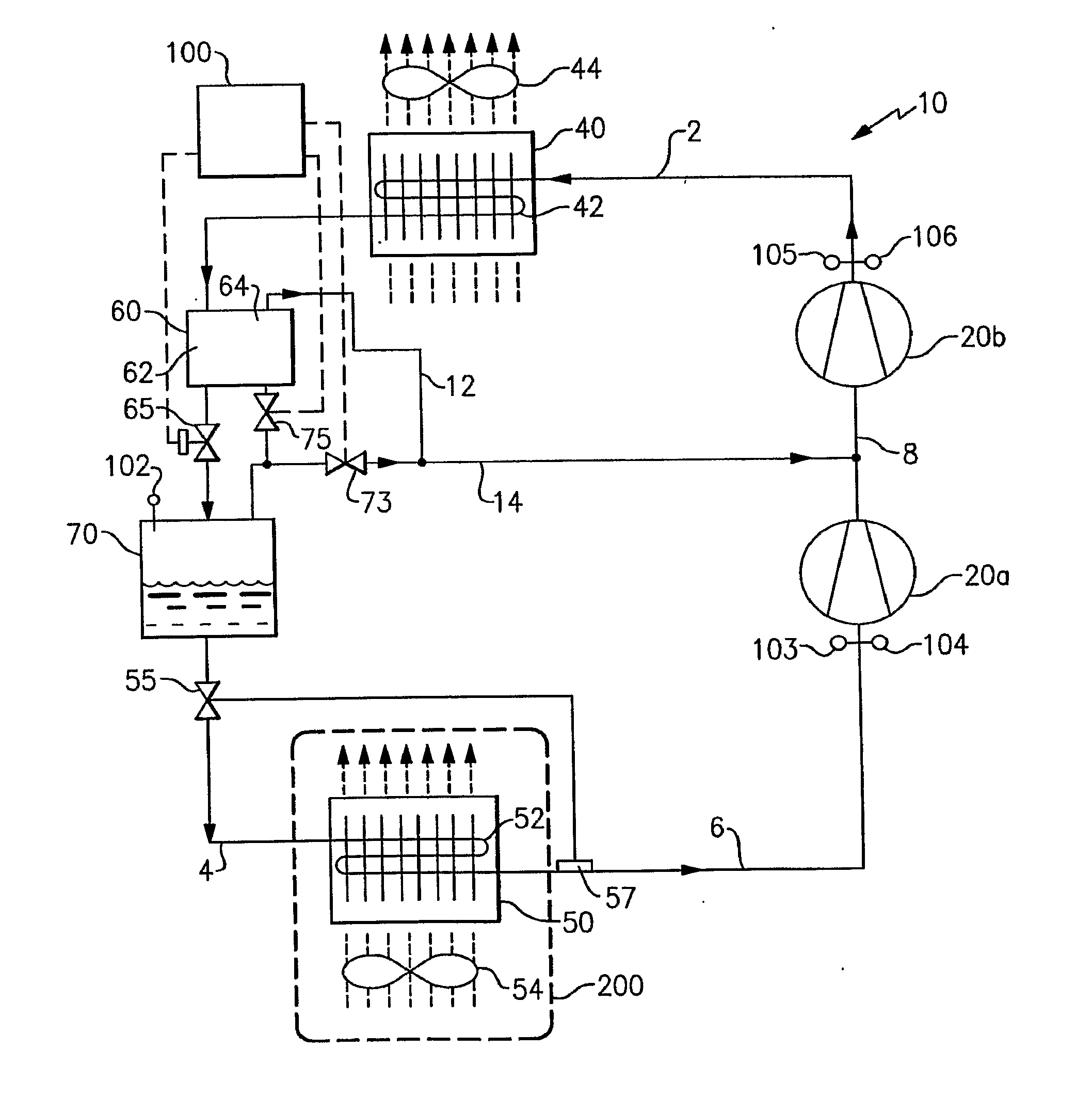

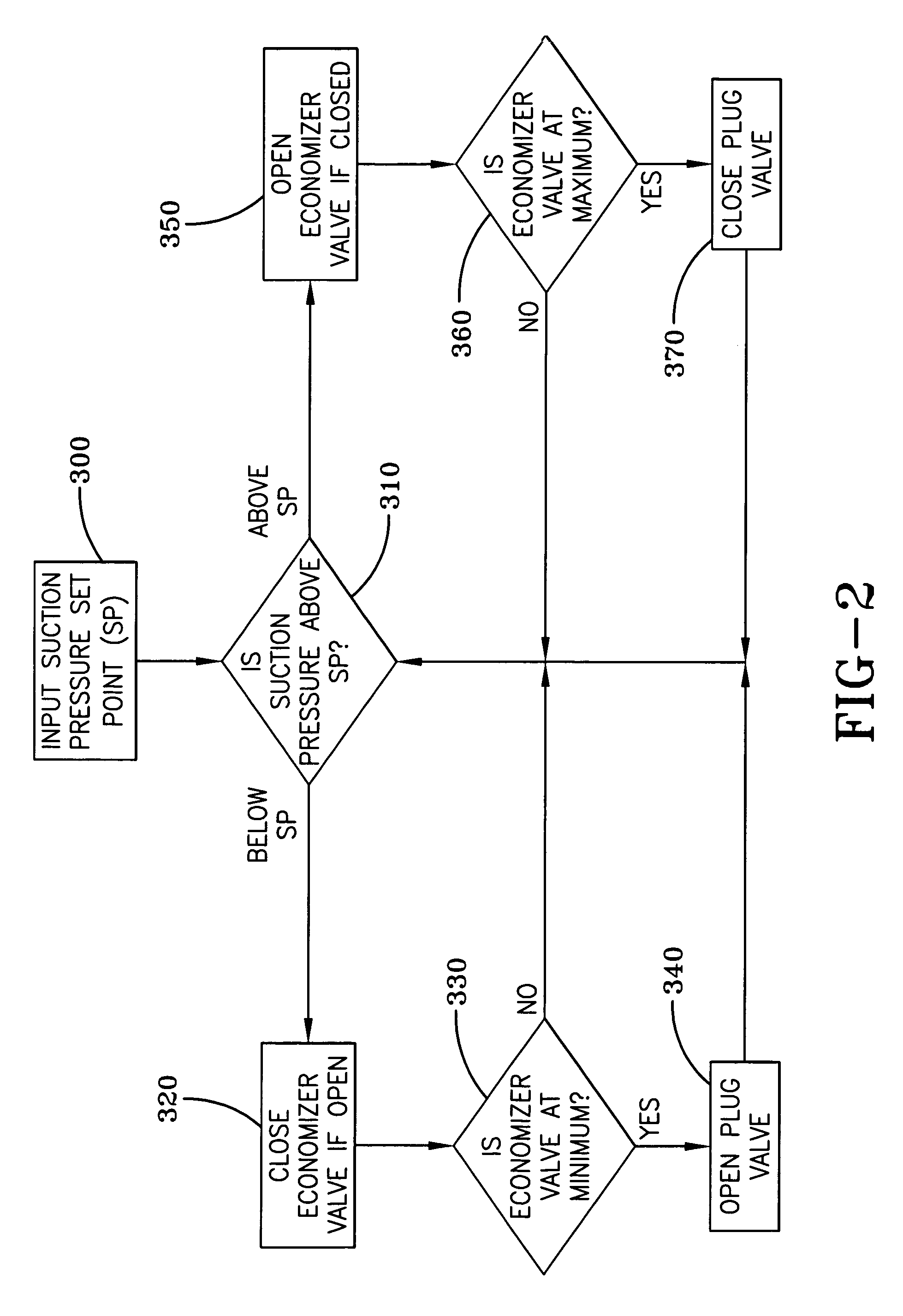

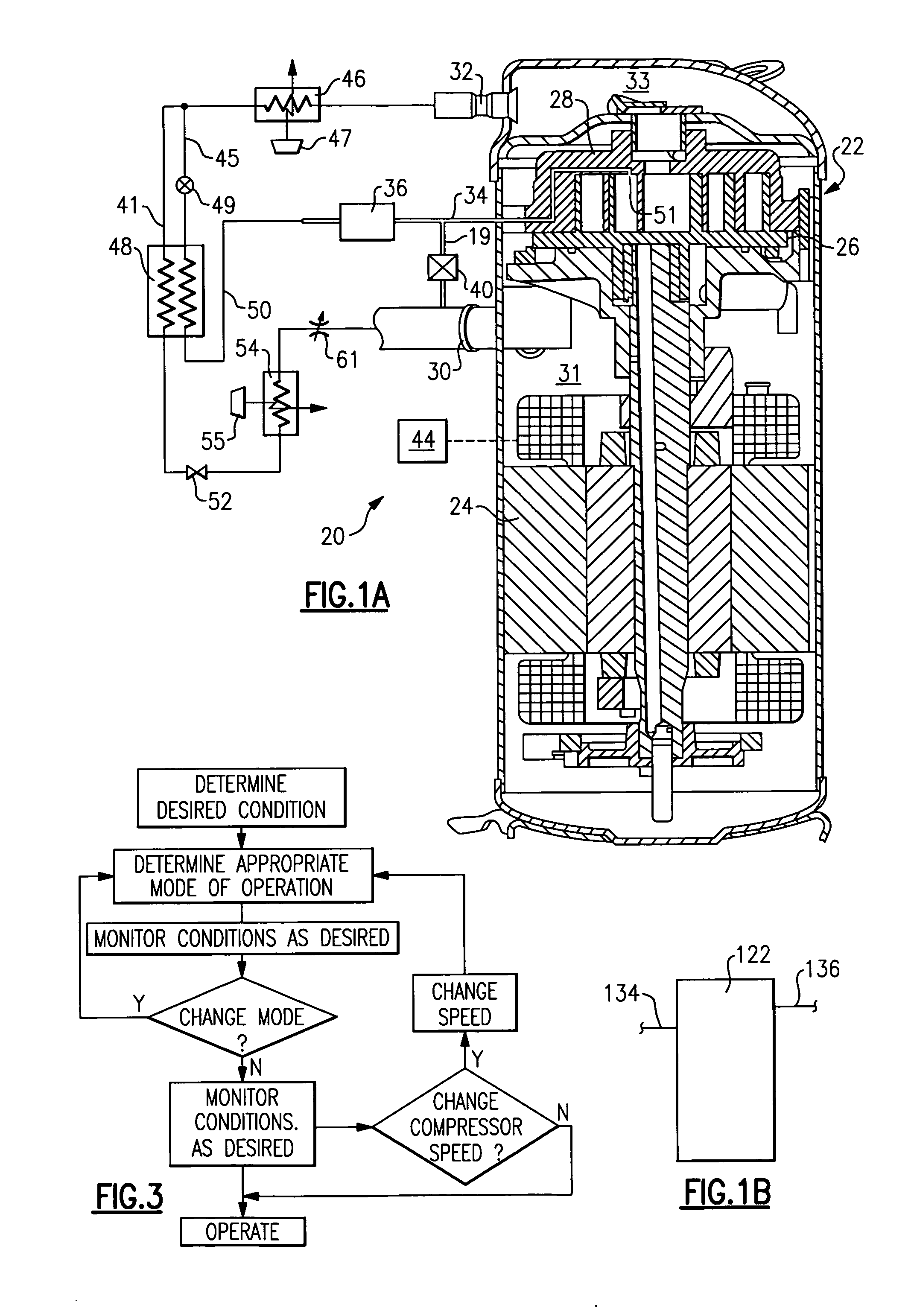

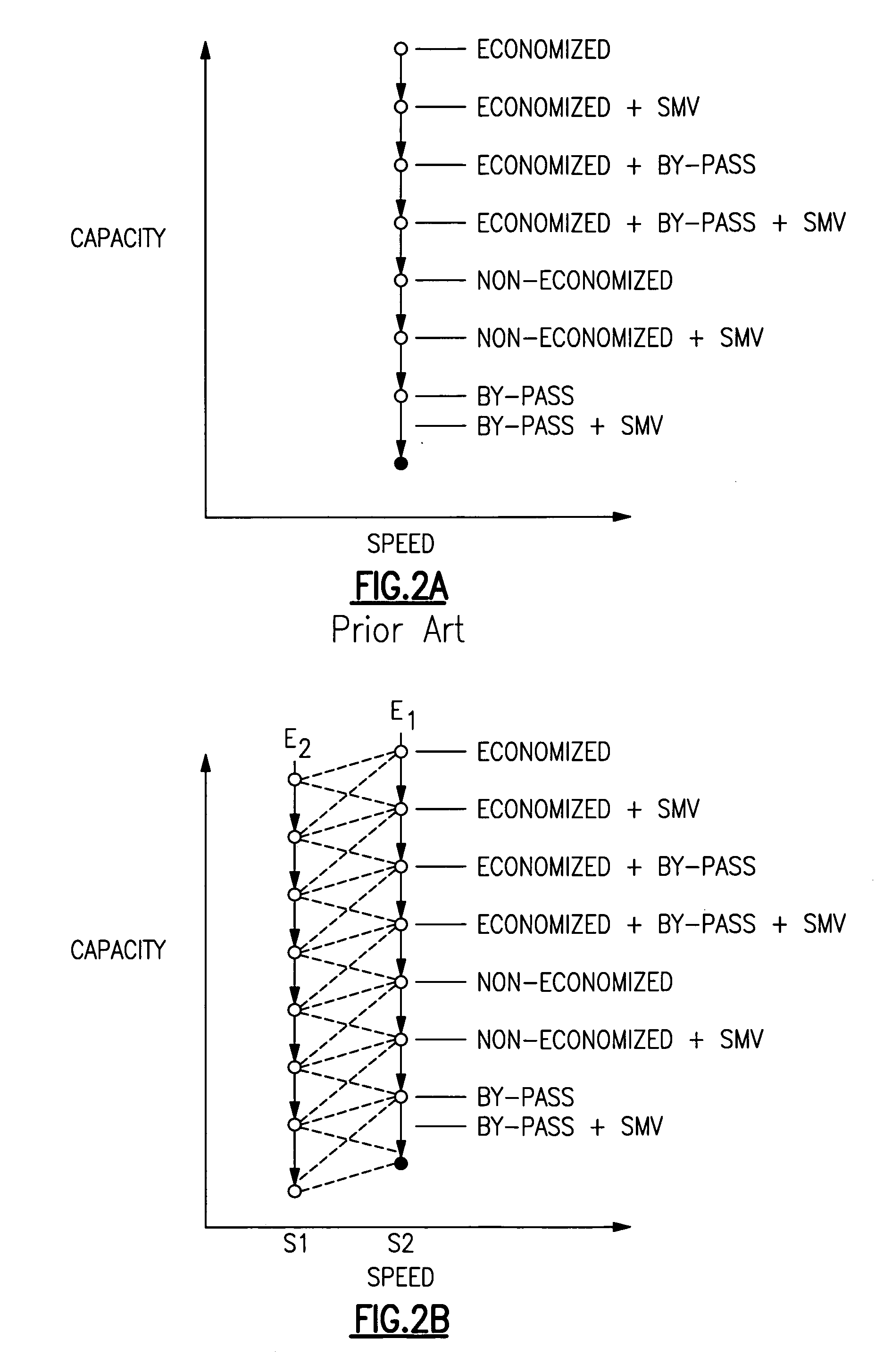

Capacity control for economizer refrigeration systems

ActiveUS6973797B2Efficient and flexible and reliable and variable capacity controlMechanical apparatusCompression machines with non-reversible cycleSystem capacityControl valves

An economizer-equipped refrigeration system and method is provided for simultaneous operation of at least one capacity control valve controlling an independent bypass circuit with operation and variable control of the economizer circuit to permit efficient, flexible, and reliable variable system capacity control, without leakage that sacrifices system peak capacity.

Owner:JOHNSON CONTROLS TYCO IP HLDG LLP

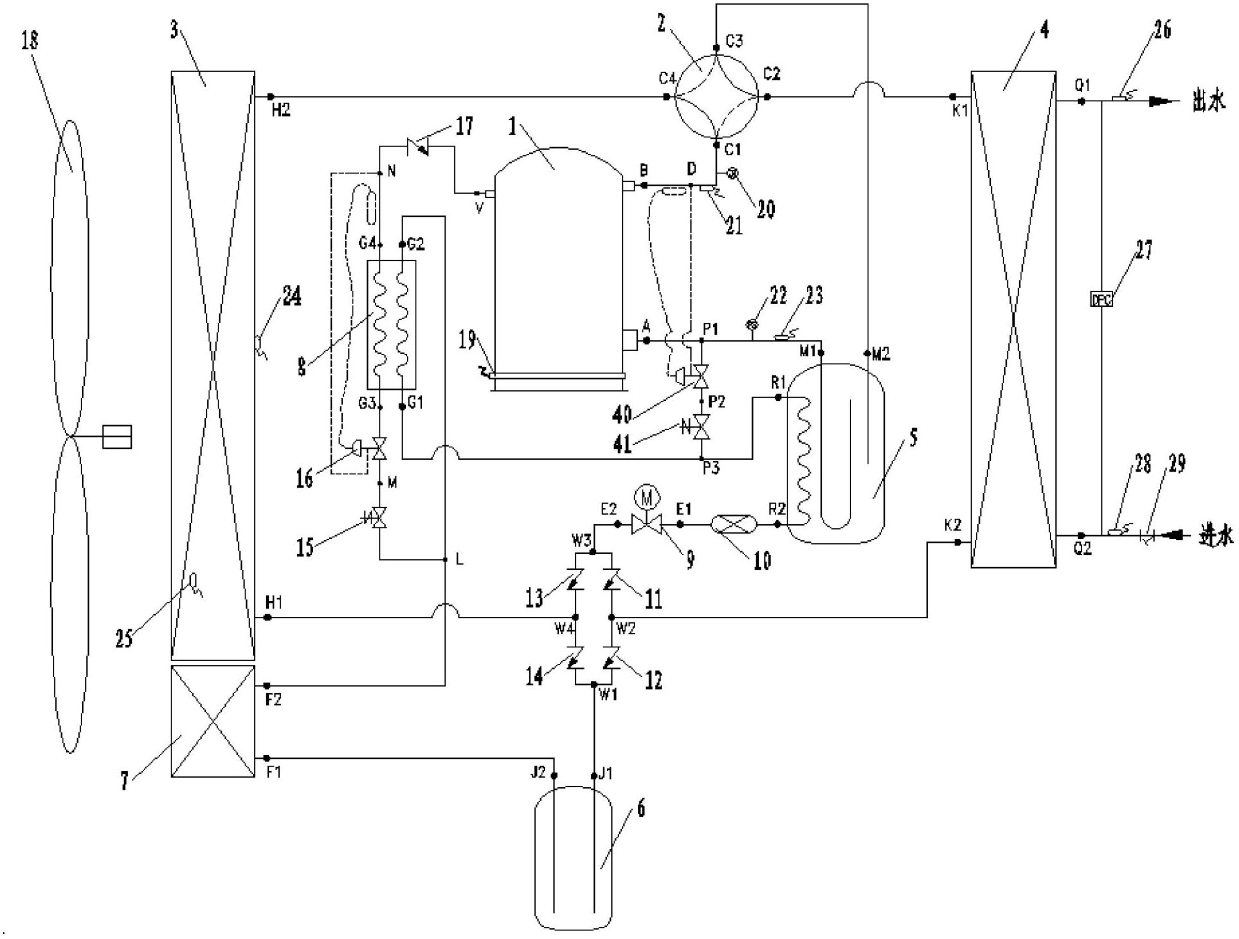

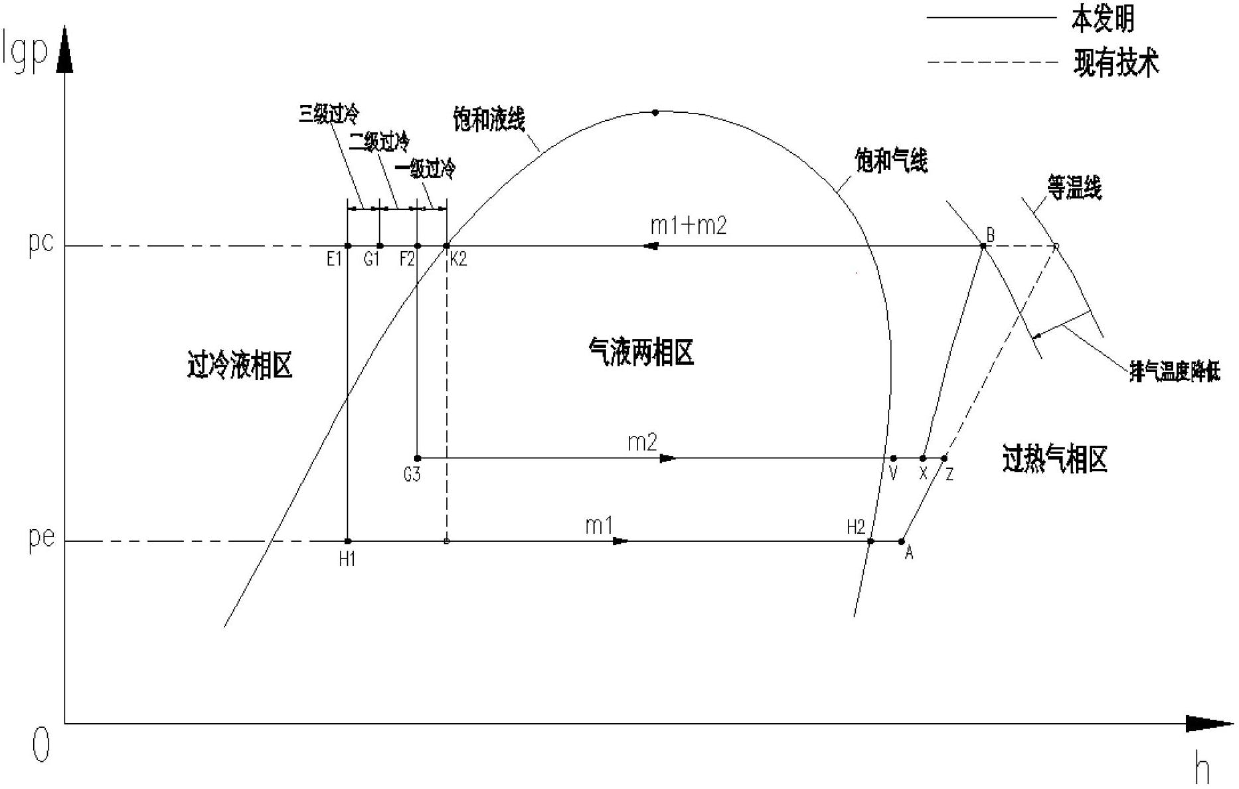

Air-cooled heat pump air conditioner

InactiveCN102679609AIncrease subcoolingLow heat recovery functionSubcoolersFluid circulation arrangementLiquid lineVapor–liquid separator

The invention discloses an air-cooled heat pump air conditioner which comprises a compressor, an outdoor coil, a heat exchanger, a main liquid line and supercooling devices, wherein the supercooling devices comprise two or three of a supercooling coil, an economizer and a liquid-vapor separator with a supercooling function, the supercooling devices are arranged on the main liquid line, and liquid state refrigerants which circulate in the main liquid line can achieve repeatedly the supercooling through the supercooling devices. According to the air-cooled heat pump air conditioner, the performance of cooling / heating circulation of the air-cooled heat pump air conditioner is effectively improved, so that the air-cooled heat pump air conditioner is stable and reliable in operation and energy saving in a low-temperature environment.

Owner:四川同达博尔置业有限公司

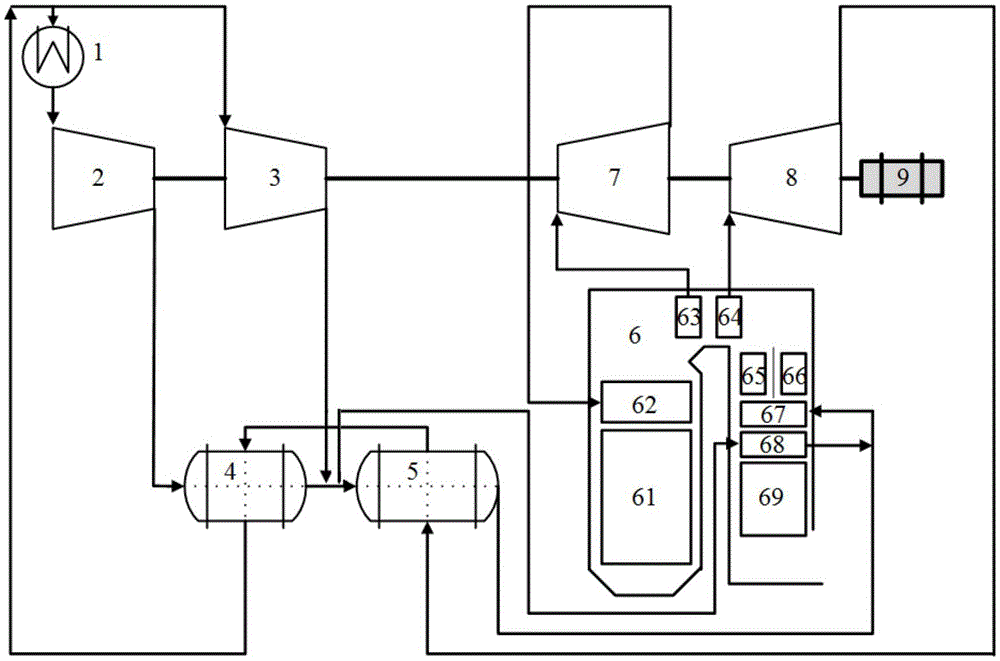

Coal-based supercritical carbon dioxide Brayton cycle double-split-flow efficient power generation system

ActiveCN105526576AReduce flue gas temperatureLower exhaust gas temperatureSteam engine plantsSteam boilersSuperheaterHigh pressure

The invention discloses a coal-based supercritical carbon dioxide Brayton cycle double-split-flow efficient power generation system which comprises a low-temperature regenerator, a precooler, a main compressor, a re-compressor, a high-temperature regenerator, a boiler, a high-pressure turbine, a low-pressure turbine and an electric generator. The boiler is composed of a combustion channel, a main heat exchange channel and a tail flue in the smoke flowing direction, wherein the combustion channel, the main heat exchange channel and the tail flue are communicated in sequence; a water-cooled wall and a reheating water-cooled wall are sequentially arranged in the combustion channel in the smoke flowing direction; a high-temperature superheater and a high-temperature reheater are sequentially arranged in the main heat exchange channel in the smoke flowing direction; a baffle, a coal economizer and a low-temperature coal economizer are sequentially arranged in the tail flue in the smoke flowing direction, and a low-temperature reheater and a lower-temperature superheater are arranged on the two sides of the baffle. According to the coal-based supercritical carbon dioxide Brayton cycle double-split-flow efficient power generation system, optimal combining of the coal-fired boiler and the supercritical carbon dioxide Brayton cycle can be achieved, and the heat exchange efficiency of the high-temperature regenerator, the thermal efficiency of the boiler and the efficiency of the power generation system are high.

Owner:XIAN THERMAL POWER RES INST CO LTD

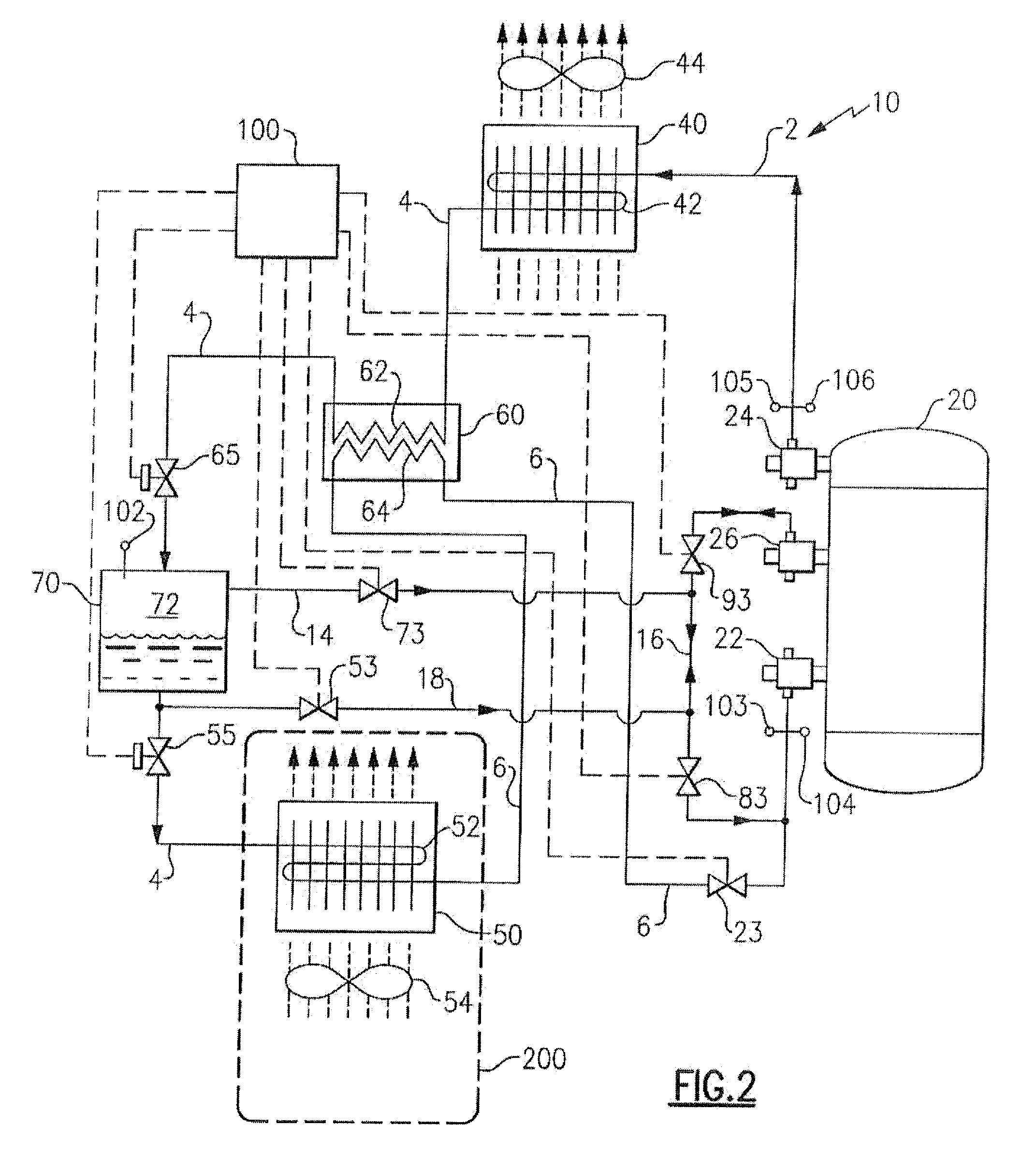

Refrigerant vapor compression system and method of transcritical operation

A refrigerant vapor compression system includes a flash tank economizer defining a separation chamber is disposed in the refrigerant circuit intermediate a refrigerant heat rejection heat exchanger and a refrigerant heat absorption heat exchanger. A primary expansion valve is interdisposed in the refrigerant circuit in operative association with and upstream of the refrigerant heat absorption heat exchanger and a secondary expansion valve is interdisposed in the refrigerant circuit in operative association and upstream of the flash tank economizer. A refrigerant vapor injection line establishes refrigerant flow communication between an upper portion of the separation chamber and an intermediate pressure stage of the system's compression device and a suction pressure portion of the refrigerant circuit. A refrigerant liquid injection line establishes refrigerant flow communication between a lower portion of said separation chamber and an intermediate pressure stage of the compression device and a suction pressure portion of the refrigerant circuit.

Owner:CARRIER CORP

Refrigerant System with Pulse Width Modulated Components and Variable Speed Compressor

InactiveUS20080223057A1Reduce refrigerant consumptionReduce capacityCompression machines with non-reversible cycleEfficient regulation technologiesLow speedLow load

A variable speed drive is provided for operating a compressor motor in a refrigerant system. When a low load situation has been determined by the refrigerant system controls, the variable speed drive operates the compressor motor at lower speed mode of operation. Further, the operation of the variable speed drive is combined with a pulse width modulation control of different system components. In particular, at least one valve or compressor can be can be rapidly cycled by the control to regulate amount of refrigerant passing through the valve or compressor. Example valves would include a shut-off valve for an economizer cycle, an unloader valve, or a suction modulation valve.

Owner:CARRIER CORP

Power recovery and energy conversion systems and methods of using same

In various illustrative examples, the system may include heat recovery heat exchangers, one or more turbines or expanders, a desuperheater heat exchanger, a condenser heat exchanger, a separator, an accumulator, and a liquid circulating pump, etc. In one example, a bypass desuperheater control valve may be employed. The system comprises a first heat exchanger adapted to receive a heating stream from a heat source after passing through a second heat exchanger and a second portion of a working fluid, wherein, the second portion of working fluid is converted to a hot liquid via heat transfer. An economizer heat exchanger that is adapted to receive a first portion of the working fluid and the hot discharge vapor from at least one turbine may also be provided. The first and second portions of the working fluid are recombined in a first flow mixer after passing through the economizer heat exchanger and first heat exchanger, respectively. A second heat exchanger is provided that receives the working fluid from the first flow mixer and a hot heating stream from a heat source and convert the working fluid to a hot vapor. The hot vapor from the second heat exchanger is supplied to at least one turbine after passing through a separator designed to insure no liquid enters the said at least one turbine or expander. The hot, high pressure vapor is expanded in the turbine to produce mechanical power on a shaft and is discharged as a hot, low pressure vapor.

Owner:TAS ENERGY

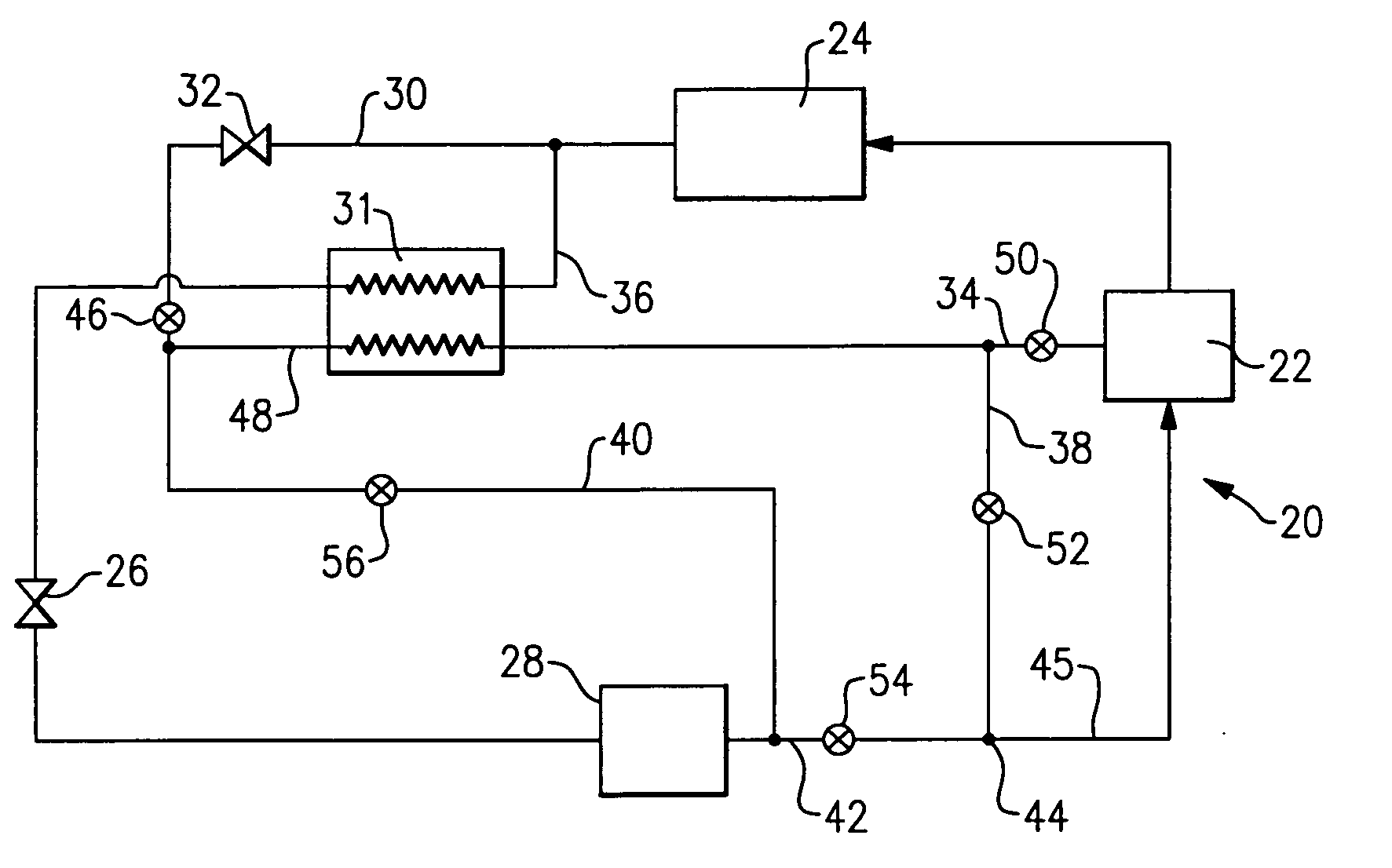

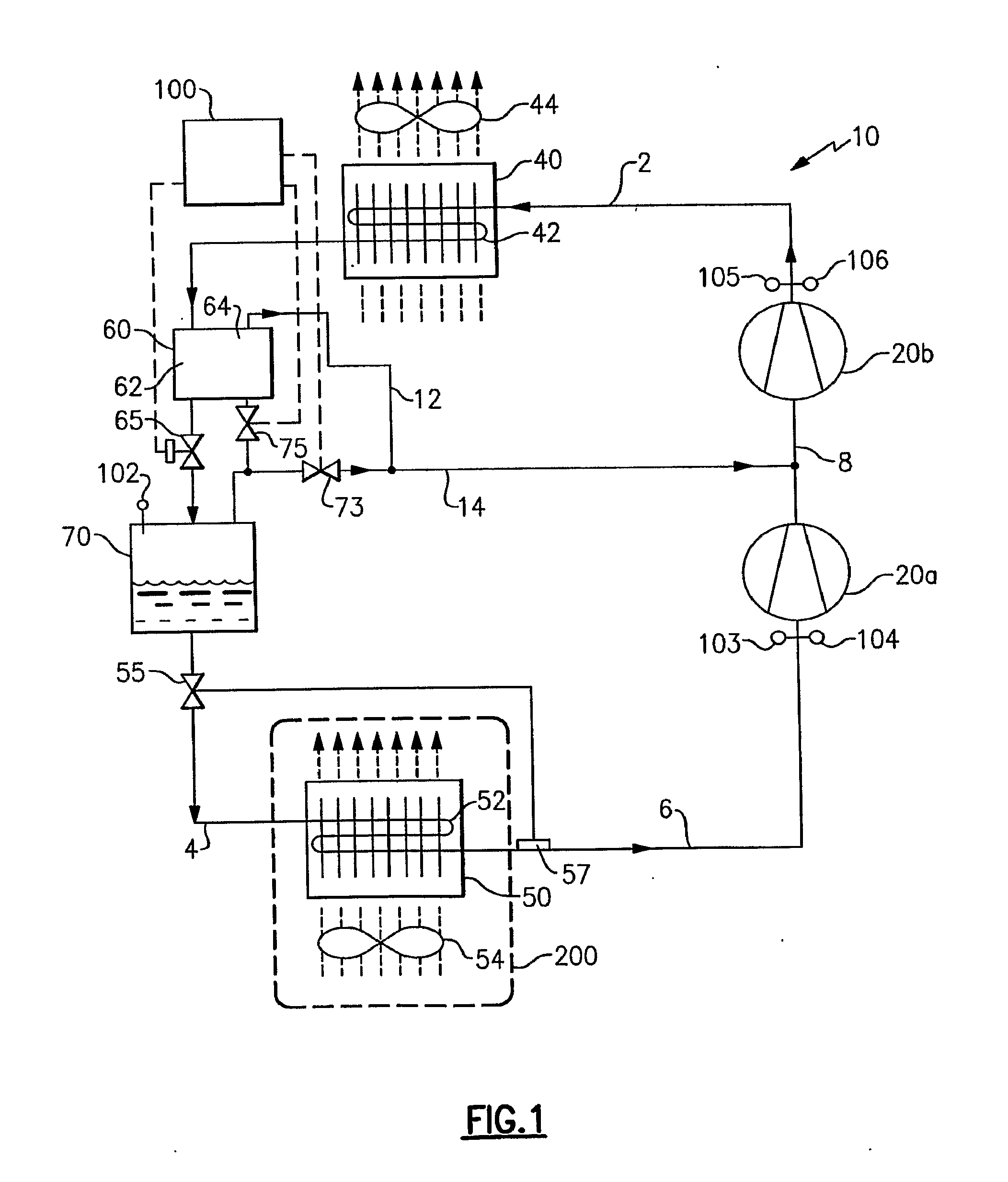

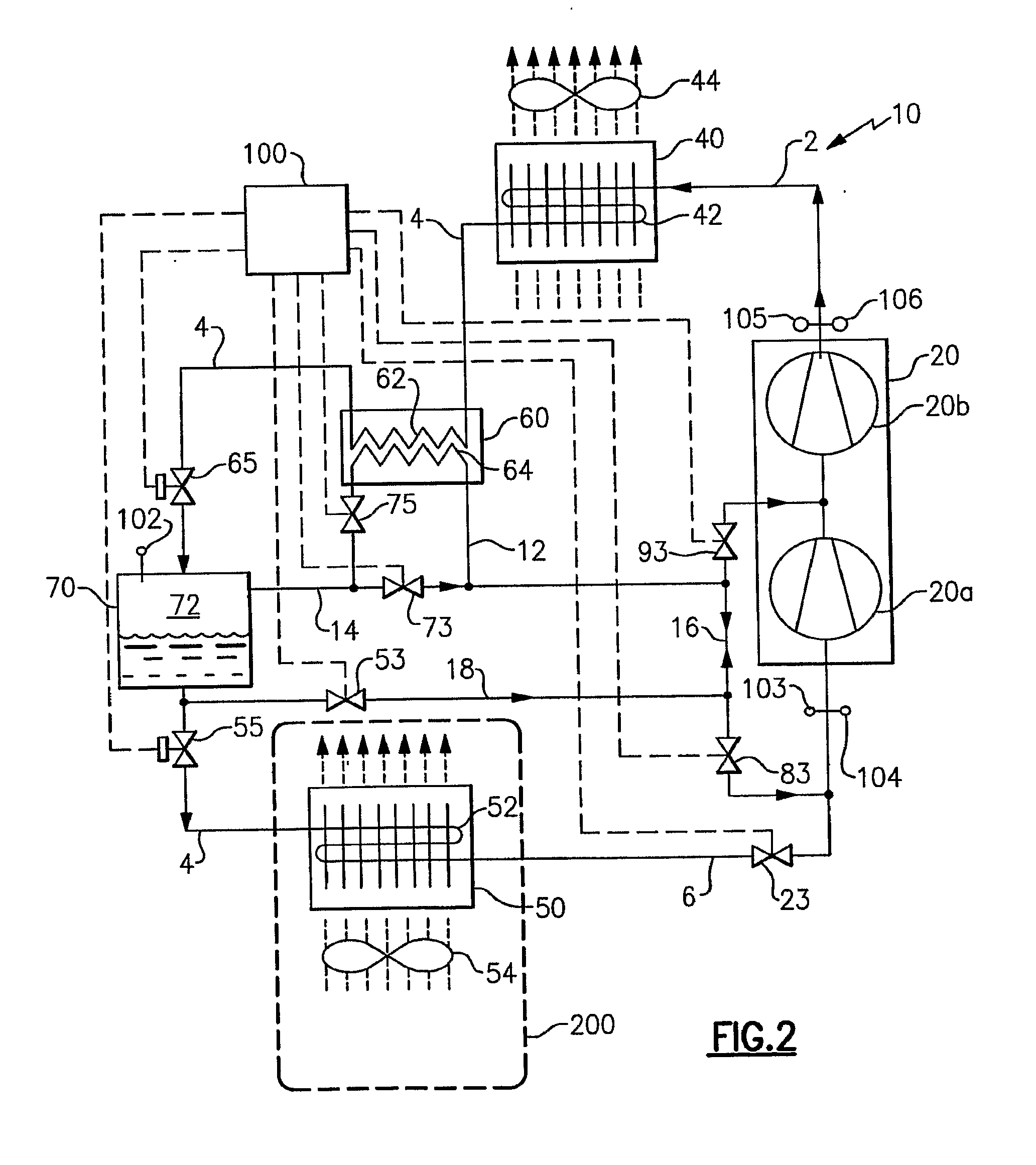

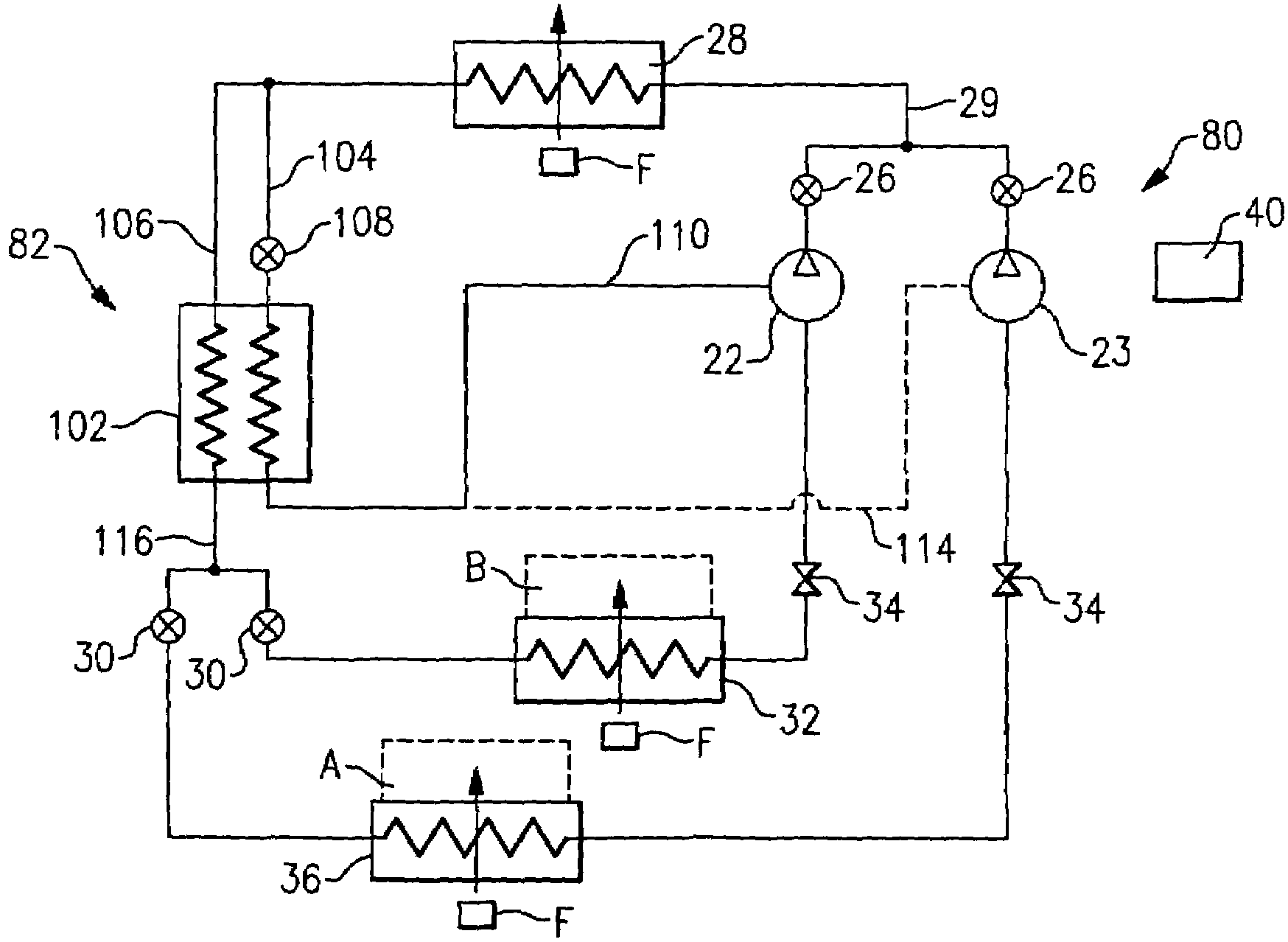

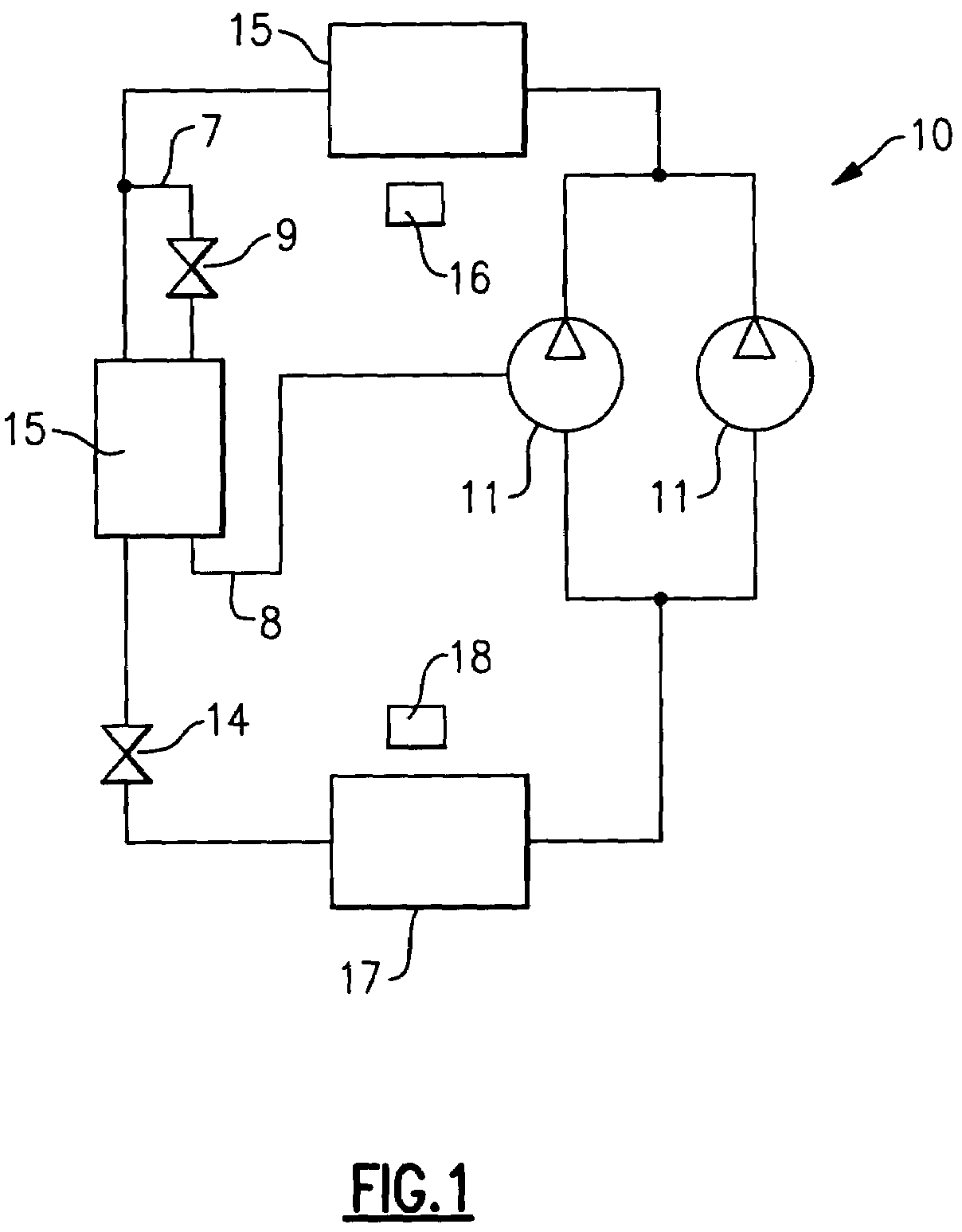

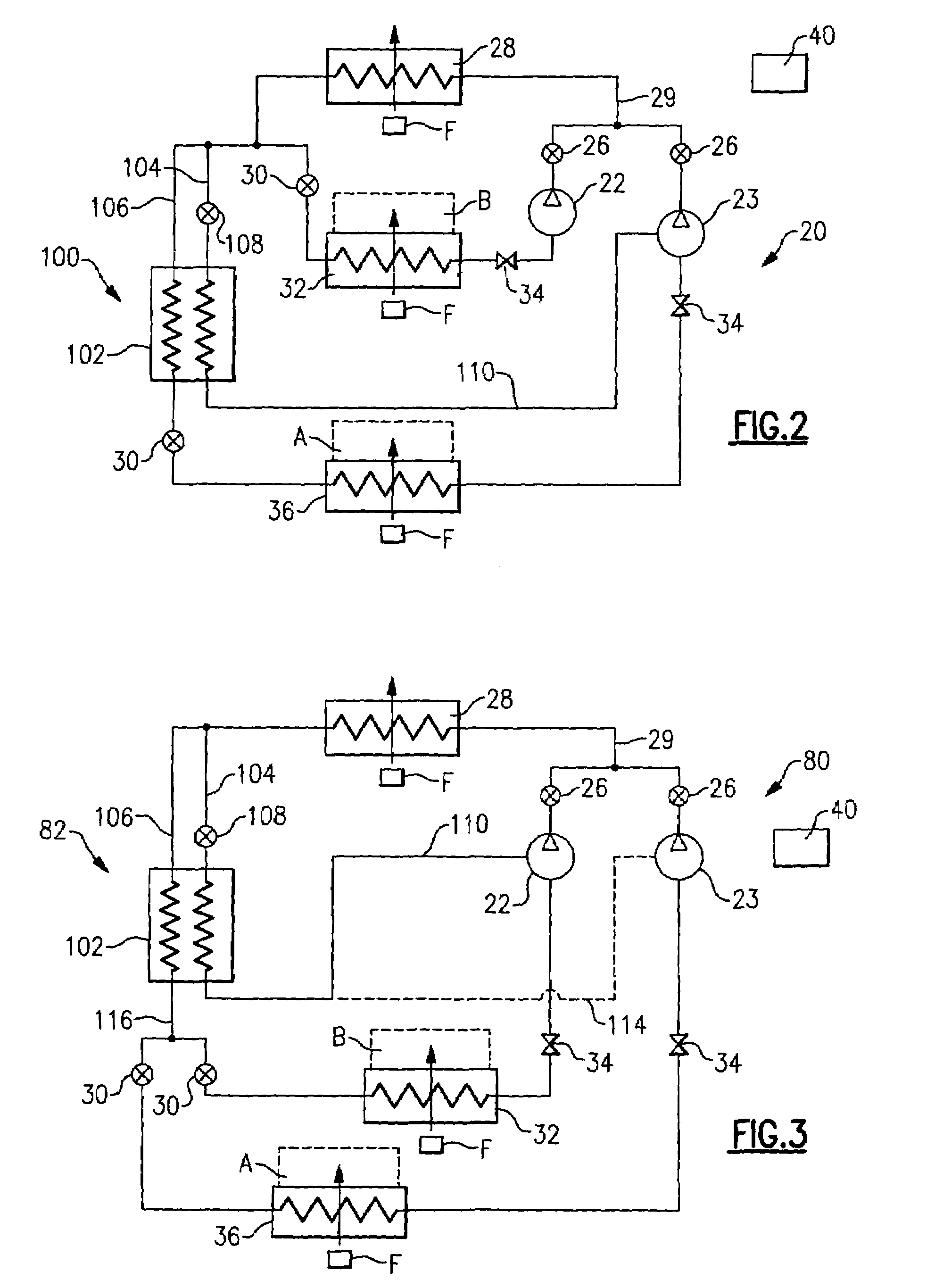

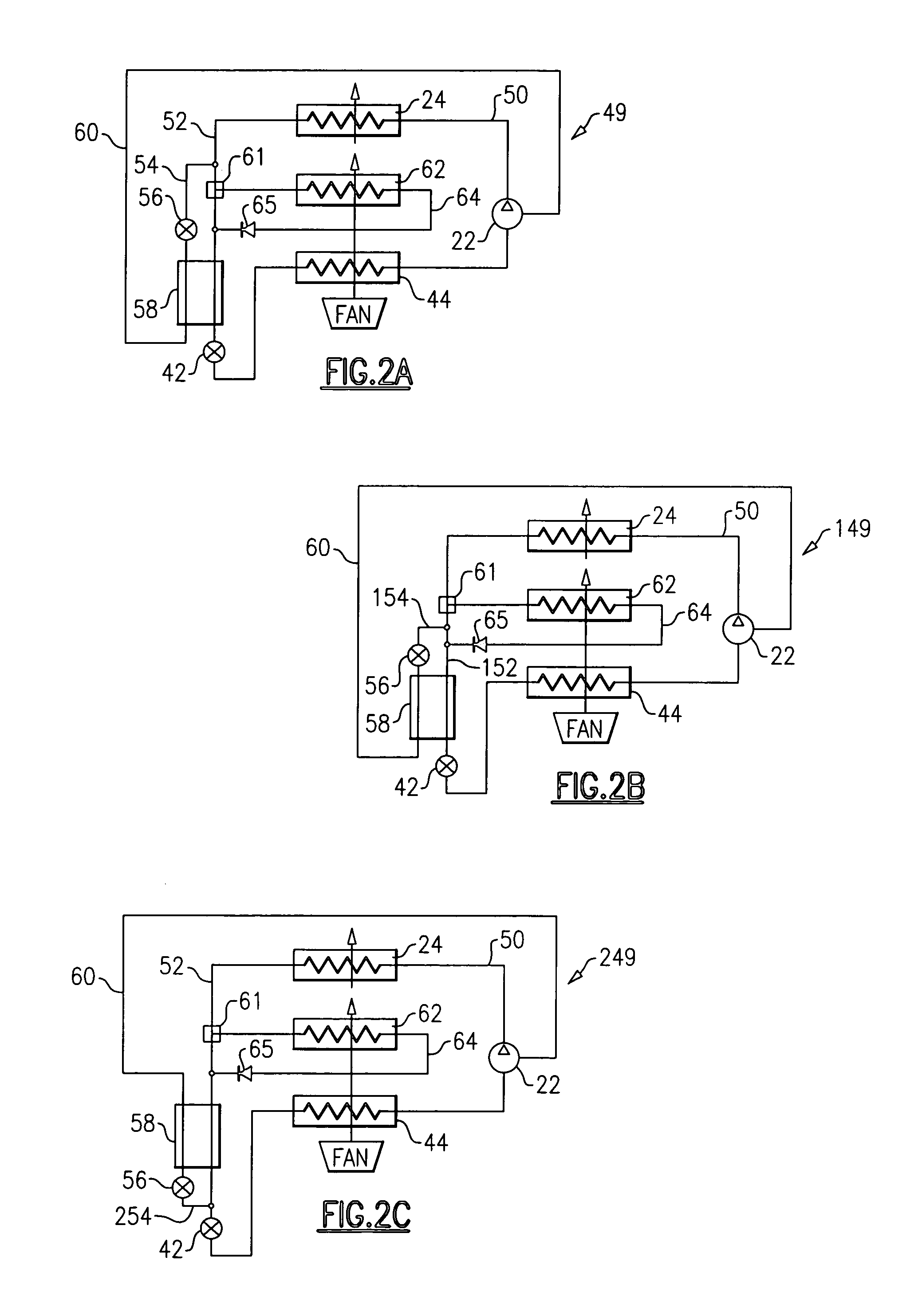

Refrigerant systems with reheat and economizer

ActiveUS7059151B2Improve system performanceReduce the temperatureEvaporators/condensersFluid circulation arrangementTemperature controlSystem configuration

Refrigerant system schematics are provided with enhanced humidity and temperature control of the air supplied to an environment to be conditioned. In particular, an economizer cycle is incorporated to be utilized in a combination with a reheat coil. Proposed system configurations enhance system performance characteristics, offer more steps of unloading, especially in the reheat mode of operation, and operate at improved reliability. Additionally, due to the enhanced performance of the economizer cycle, the reheat coil size can be reduced.

Owner:CARRIER CORP

Method and apparatus for data center air conditioning

Modular data center containers with modular components suitable for use with rack or shelf mount computing systems currently use cooling methods that do not include economizers due to size constraints of structural steel support infrastructure associated with modular data centers and removable economizers to facilitate portability of modular data centers. The modules allows introduction of outside air to the cooling cycle with the unique elements embodied within airside economizer components. The modules in conjunction with the data center represents a new and useful process to allow the economizer elements to bring outside air into the modular data center cooling cycle.

Owner:LARSEN ARTHUR E

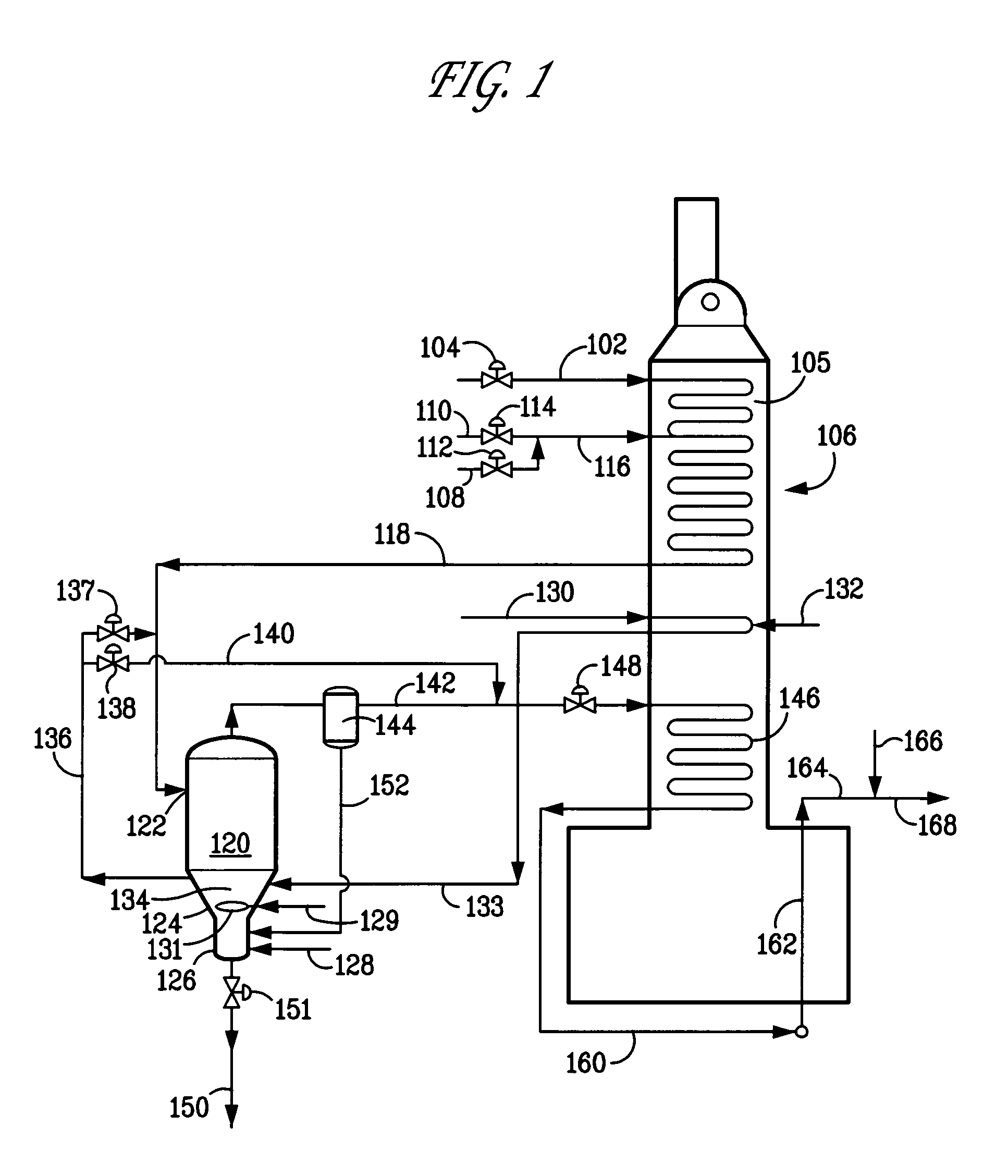

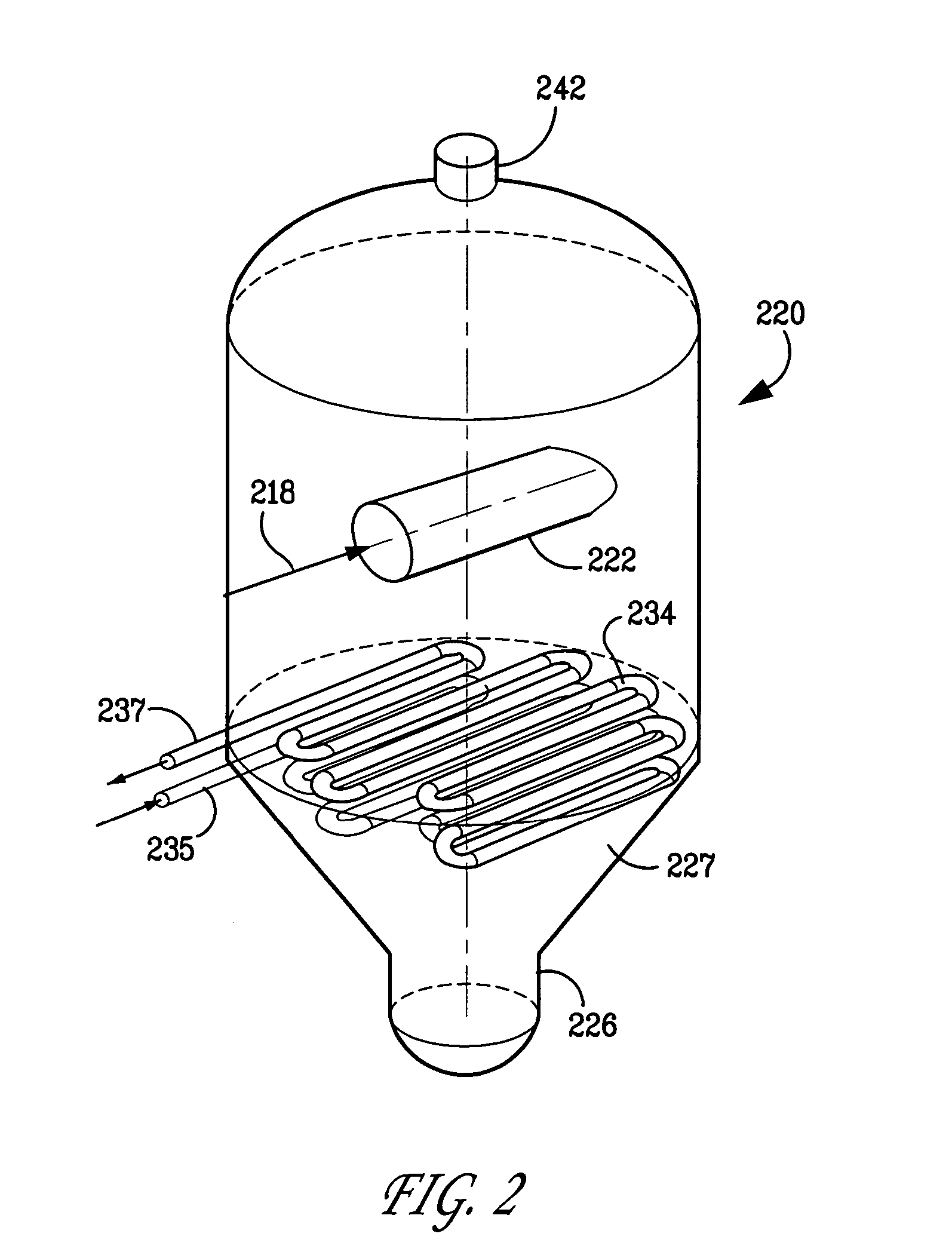

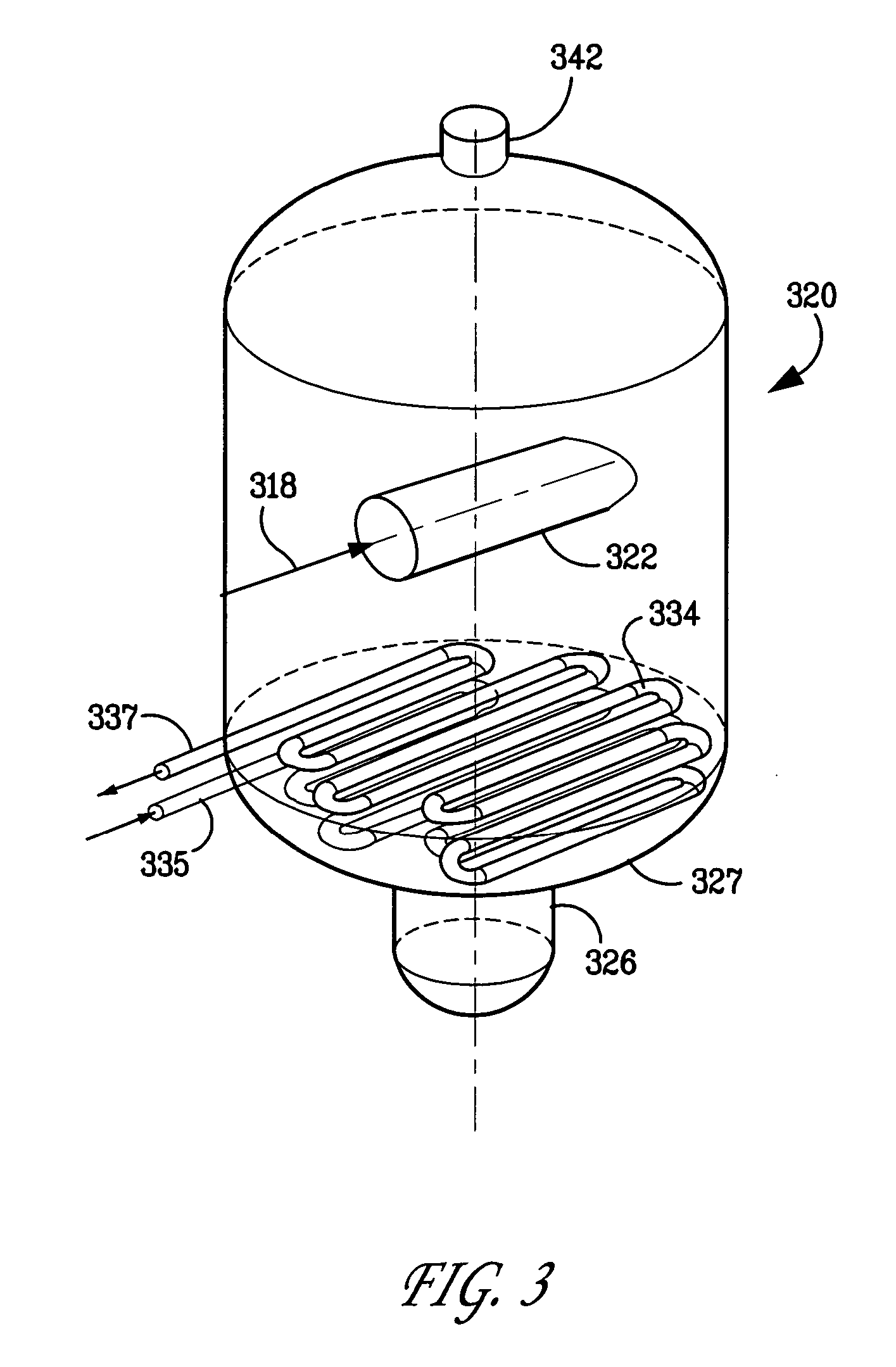

Process and apparatus for cracking hydrocarbon feedstock containing resid to improve vapor yield from vapor/liquid separation

ActiveUS20060089519A1Avoid excessive diameterReduce condensationThermal non-catalytic crackingHydrocarbonsGas phaseDiluent

A process for cracking hydrocarbon feedstock containing resid comprising: heating the feedstock, mixing the heated feedstock with a fluid and / or a primary dilution steam stream to form a mixture, flashing the mixture to form a vapor phase and a liquid phase which collect as bottoms and removing the liquid phase, separating and cracking the vapor phase, and cooling the product effluent. The process comprises at least two of the following conditions: (1) maintaining the bottoms under conditions to effect at least partial visbreaking; (2) reducing or eliminating partial vapor condensation during flashing by adding a heated vaporous diluent to dilute and superheat the vapor; (3) partially condensing the vapor within said flash / separation vessel by contacting with a condenser; (4) decoking internal surfaces and associated piping of the flash / separation vessel with air and steam; (5) utilizing a flash / separation vessel having an annular, inverted L-shaped baffle; and (6) regulating temperature in furnace tube banks used for heating by utilizing a desuperheater and / or an economizer. An apparatus for carrying out the process is also provided.

Owner:EXXONMOBIL CHEM PAT INC

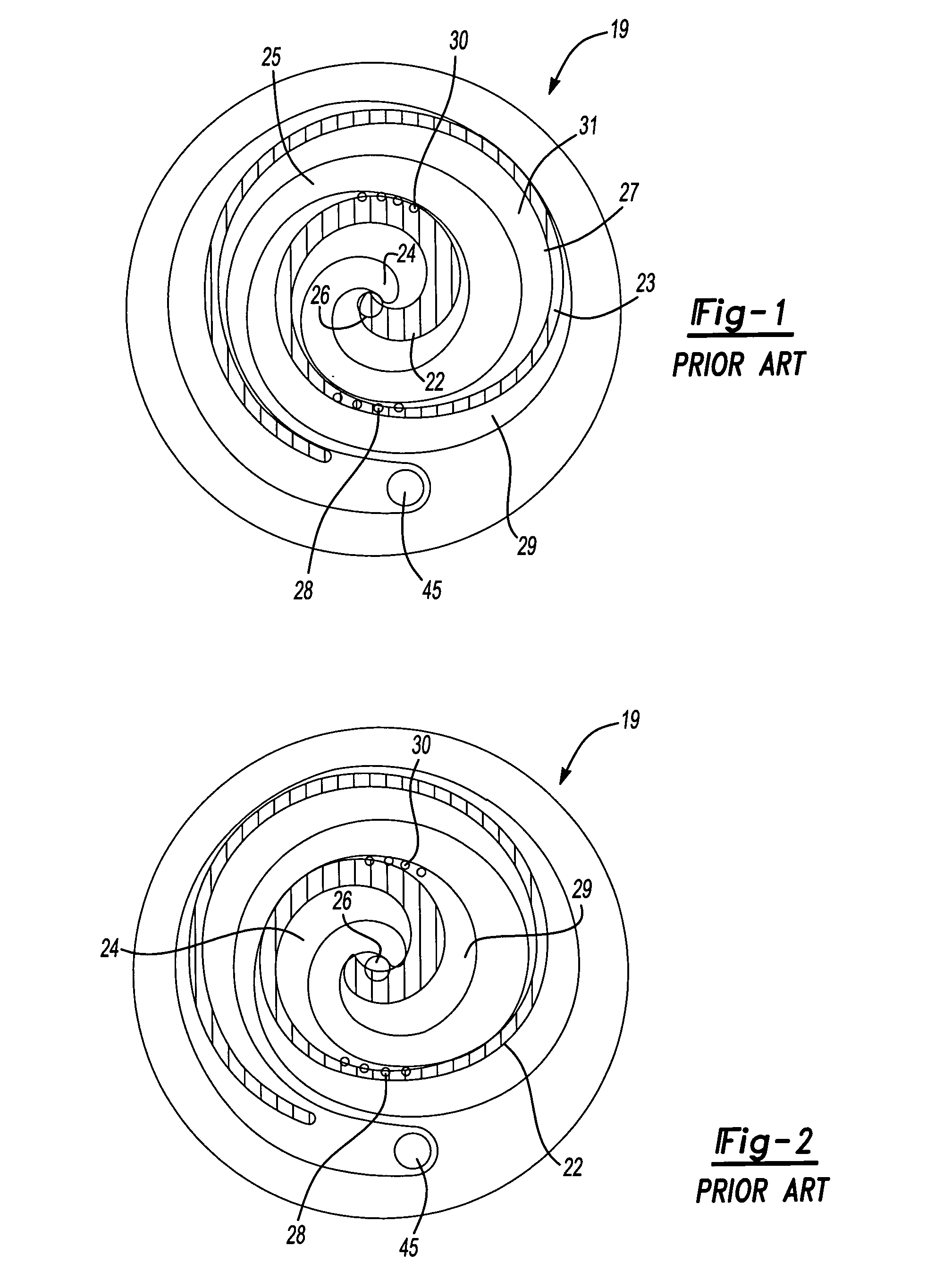

Refrigerant system with multi-speed scroll compressor and economizer circuit

InactiveUS20070130973A1Increase and decrease capacityIncrease control flexibilityCompression machines with non-reversible cycleVehicle heating/cooling devicesSystem capacityControl theory

A scroll compressor is provided with a multiple-speed motor. A control selects a speed for operating the motor, along with selecting between several available options for the system capacity adjustment to meet external load demands in a most efficient and reliable manner. The disclosed embodiment includes an economizer circuit, an unloader function, and an optional suction modulation valve. By utilizing each of these features in combination with the multi-speed motor for the compressor, the present invention is better able to tailor provided capacity to desired capacity.

Owner:SCROLL TECH

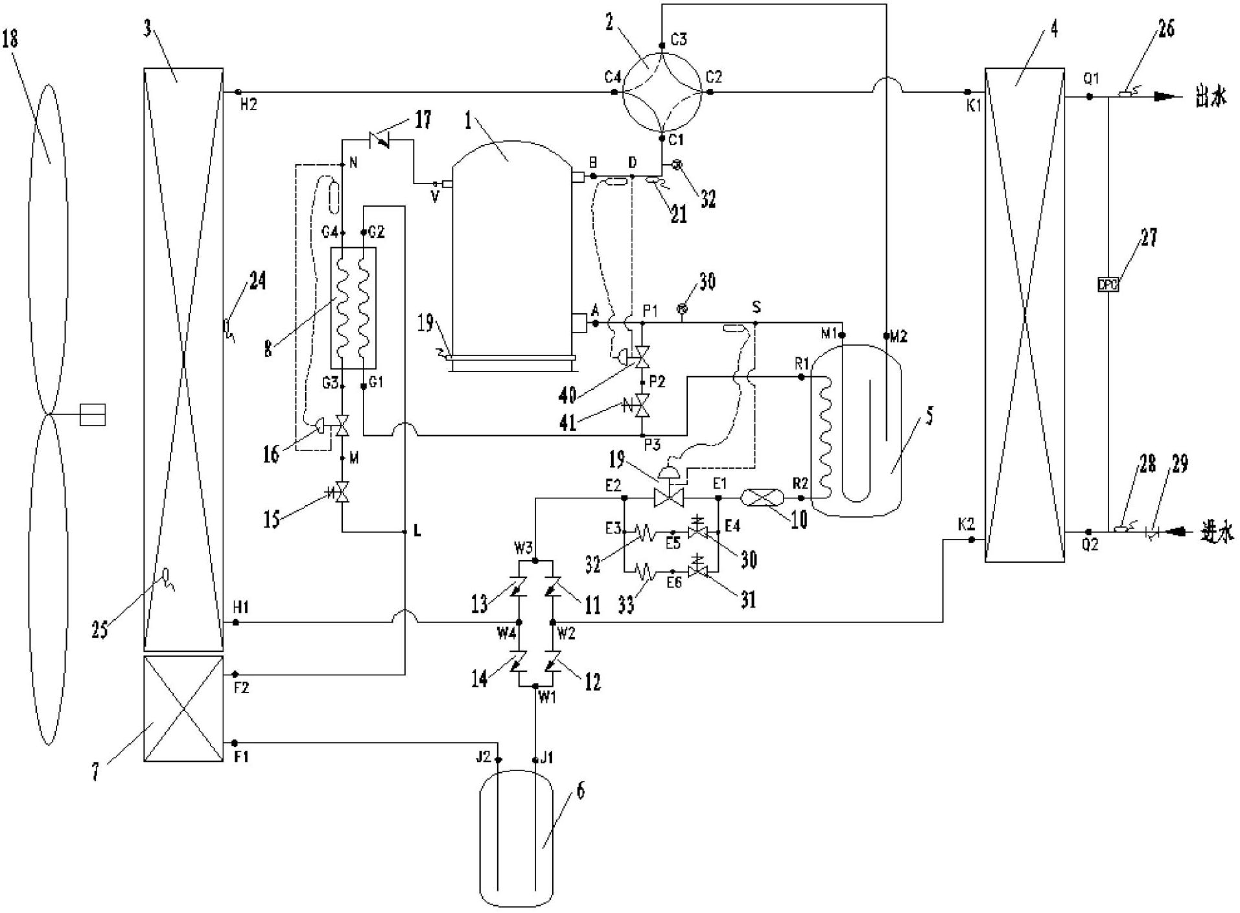

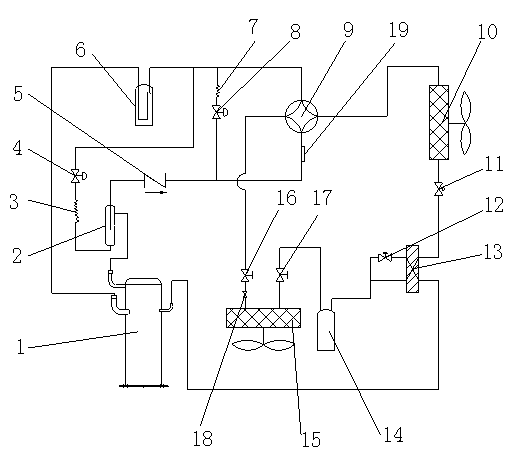

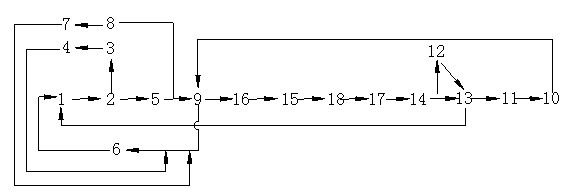

Enhanced vapor injection air-conditioning circulating system and control method thereof

ActiveCN103471275AImprove heating effectGuaranteed uptimeCompression machines with reversible cycleRefrigeration safety arrangementVapor–liquid separatorFour-way valve

The invention relates to a central air-conditioning system, in particular to a duct air conditioner, namely an enhanced vapor injection air-conditioning circulating system. A vapor injection side electronic expansion valve of the system is subject to discharge superheat control instead of vapor injection superheat control; high discharge superheat is guaranteed, and heating capacity of the system can be further improved by vapor injection; the system is especially applicable to variable frequency compressors; high heating capacity is kept even under different operating frequencies; the system operates stably and fluctuates little. The enhanced vapor injection air-conditioning circulating system comprises a controller, a compressor, a four-way valve, a vapor-liquid separator, an economizer, a solenoid valve and a coolant pipe. The compressor is a variable frequency compressor. The economizer is a plate economizer. The electronic expansion valve controls vapor injection. The vapor injection electronic expansion valve is subject to discharge superheat control instead of vapor injection superheat control; accordingly, high discharge superheat is guaranteed, and heating capacity of the system is further improved by vapor injection. The system is especially applicable to variable frequency compressors; the heating capacity is kept even under different operating frequencies; the system operates stably and fluctuates little.

Owner:QINGDAO HISENSE HITACHI AIR CONDITIONING SYST

Compressor with unloader valve between economizer line and evaporator inlet

InactiveUS6883341B1Simplifies compressor replacementIncrease oil flowEngine of arcuate-engagement typeOscillating piston enginesEngineeringRefrigerant

A compressor has an economizer injection line communicating into the compressor compression chambers. An unloader valve selectively communicates the economizer injection line back to a point upstream of the evaporator. When the compressor is run in unloaded mode, partially compressed refrigerant is thus returned to a point upstream of the evaporator. In unloaded mode, this results in a higher refrigerant mass flow through the evaporator, as compared to prior art where the bypassed refrigerant was returned downstream of the evaporator. This increases system efficiency by more effectively returning oil which otherwise might be left in the evaporator back to the compressor. Also, the amount of refrigerant superheat entering the compressor in unloaded operation is reduced as compared to the prior art compressor systems, wherein the bypassed refrigerant is returned directly to the compressor suction line. Reduced refrigerant superheat increases system efficiency, improves motor performance and reduces compressor discharge temperature.

Owner:CARRIER CORP

Energy reducing retrofit method for a constant volume HVAC system

ActiveUS8515584B2Meet matching needsShorten speedLevel controlSpace heating and ventilationEnergy expenditureEconomizer

An energy-reducing method and apparatus for retrofitting a constant volume HVAC system, with or without an economizer, that provides heating, cooling, and ventilation to occupants within a building space. The present invention includes the introduction of a programmable logic controller and variable frequency drive (VFD) that takes control of the existing fan, heating, cooling, and optional economizer operation. The controller is programmed for the reduction of fan speed in the heating and cooling modes. The reduction of the fan speed in the ventilation mode when the 100% operation is not needed saves significant energy of the existing constant volume HVAC system where the fan motor is designed to run 100% of the time. The fan speed may be further reduced upon a reduction in sensed occupancy levels of the space, such as with a CO2 sensor. Additionally, the fan speed may be reduced in the heating and / or cooling mode to further reduce energy consumption. The controller may also be programmed and equipped with sensors to allow simultaneous mechanical compressor cooling and economizer free cooling operation, for the operation of the economizer in response to the monitoring of outside air and return air to determine the preferred source for cooling operations, to keep the outside air damper closed during the unoccupied heating modes such as morning warm-up, and / or to provide fault detection. The retrofit method and apparatus may be employed in a stand-alone or networked version.

Owner:PRO STAR ENERGY SOLUTIONS LP

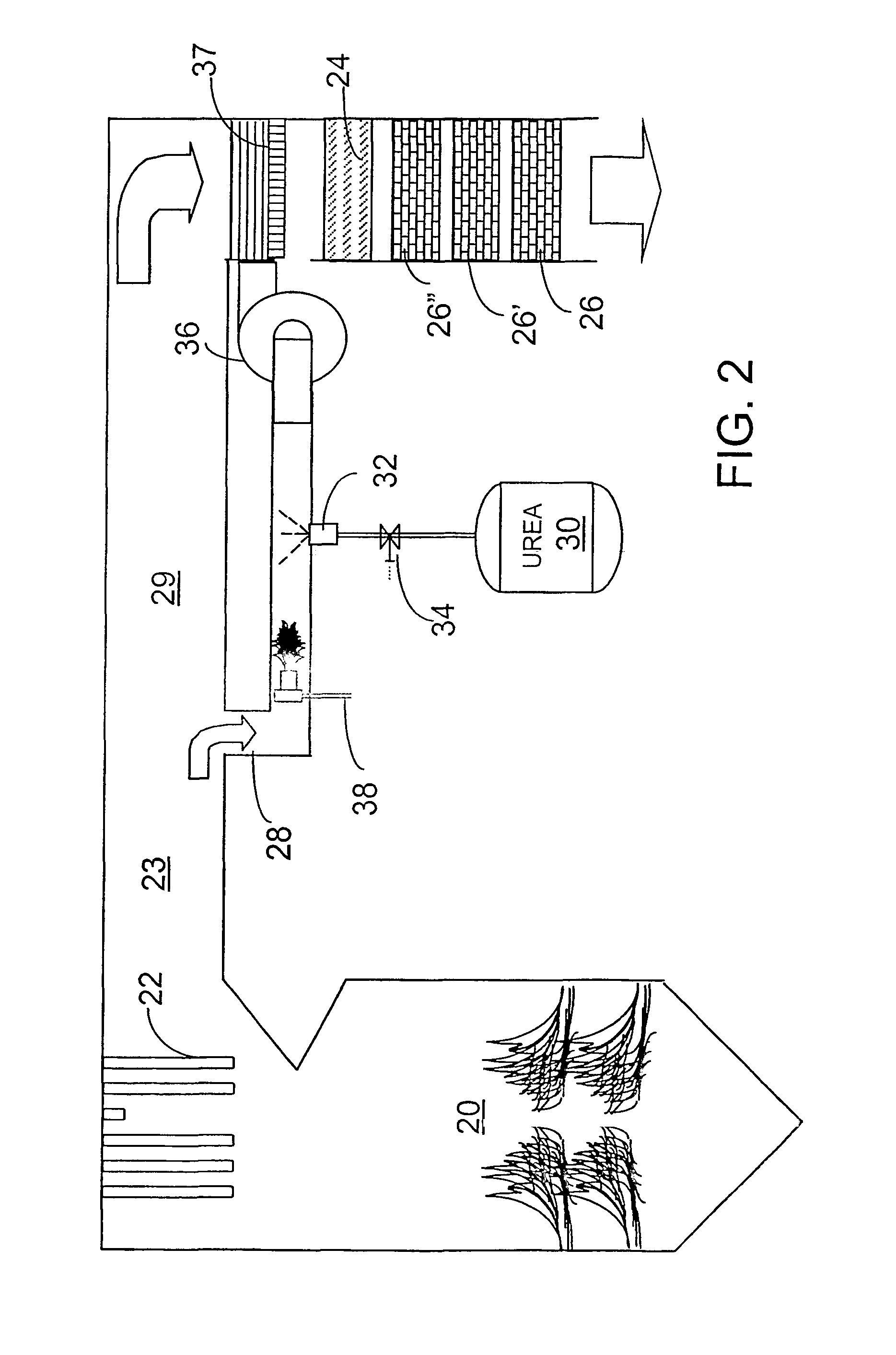

SELECTIVE CATALYTIC REDUCTION OF NOx ENABLED BY UREA DECOMPOSITION IN HEAT-EXCHANGER BYPASS

InactiveUS20070231232A1Well mixedAccurate temperatureCombination devicesNitrogen compoundsLow loadActive component

Disclosed are a process and apparatus for selective catalytic reduction of NOx. The process is enabled by passing a heat exchanger section, such as an economizer, of the boiler in advance of an SCR unit at low load conditions to enable NOx reduction even at low loads using urea instead of ammonia. In a preferred form, under high load conditions, the bypass can be almost fully closed and the economizer can be operated normally without excessively cooling the combustion gases, using only a portion of bypassed gases which are hot enough to decompose the urea into its active components including ammonia.

Owner:FUEL TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com