Patents

Literature

87results about How to "Reduce motor speed" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

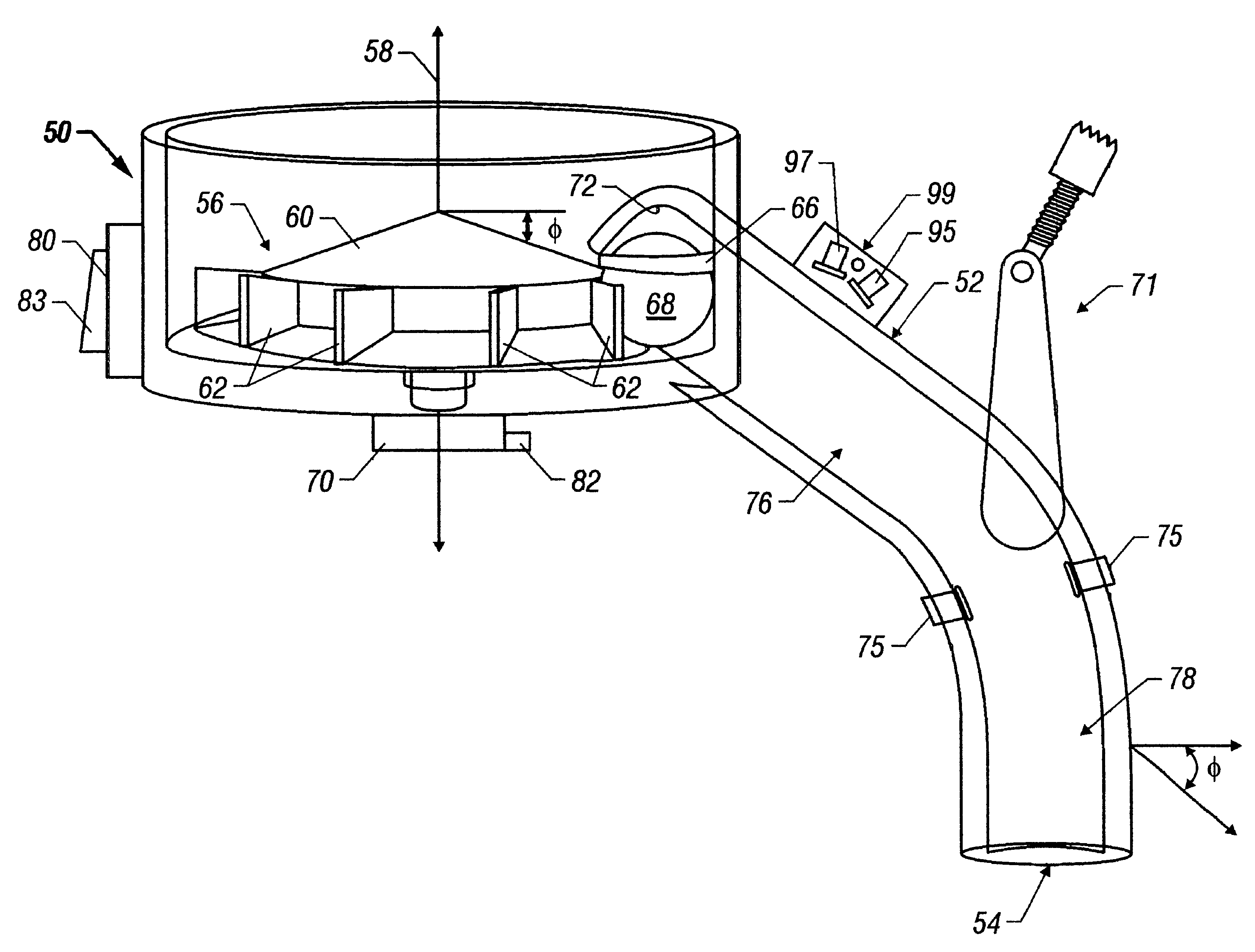

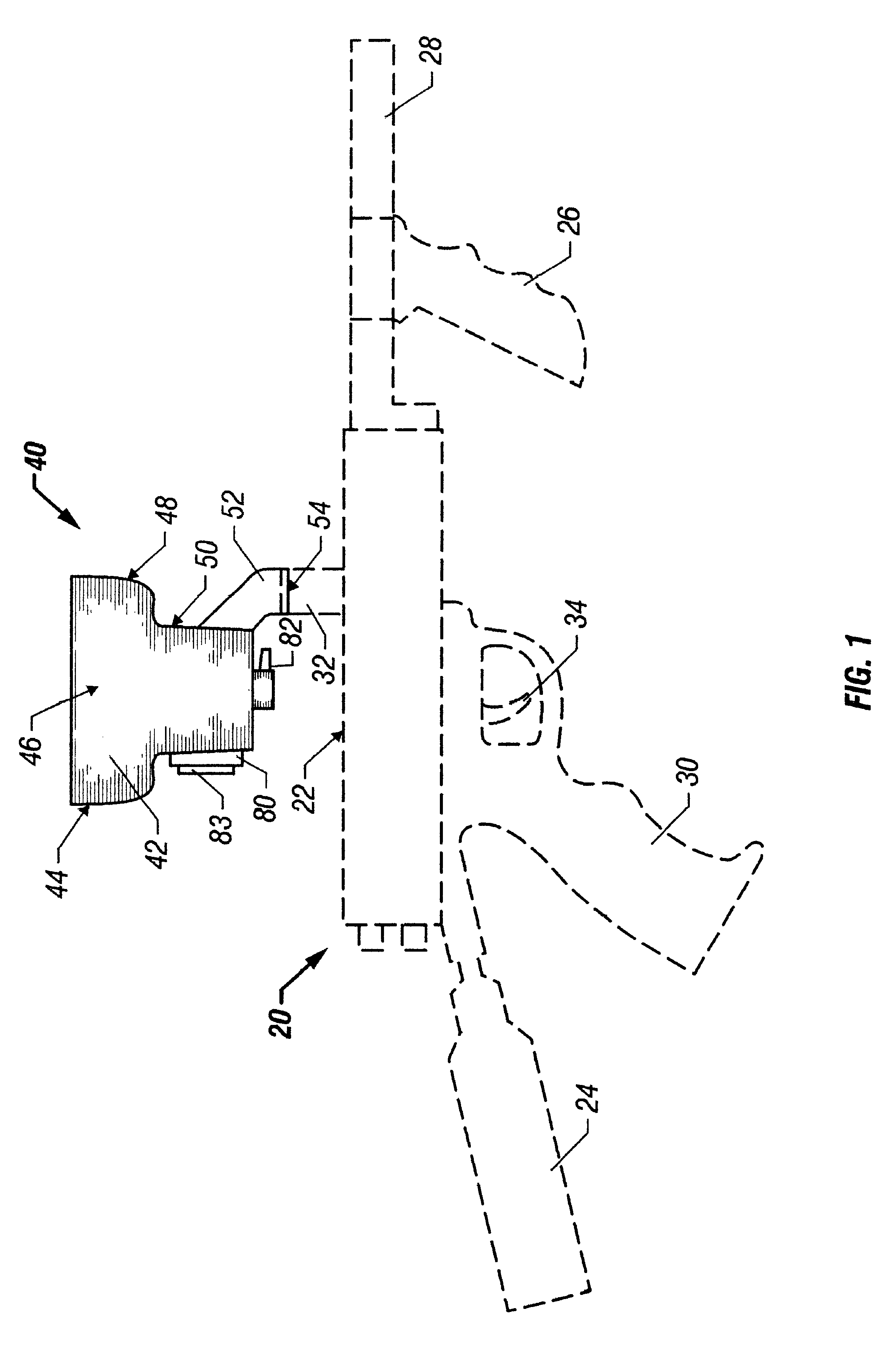

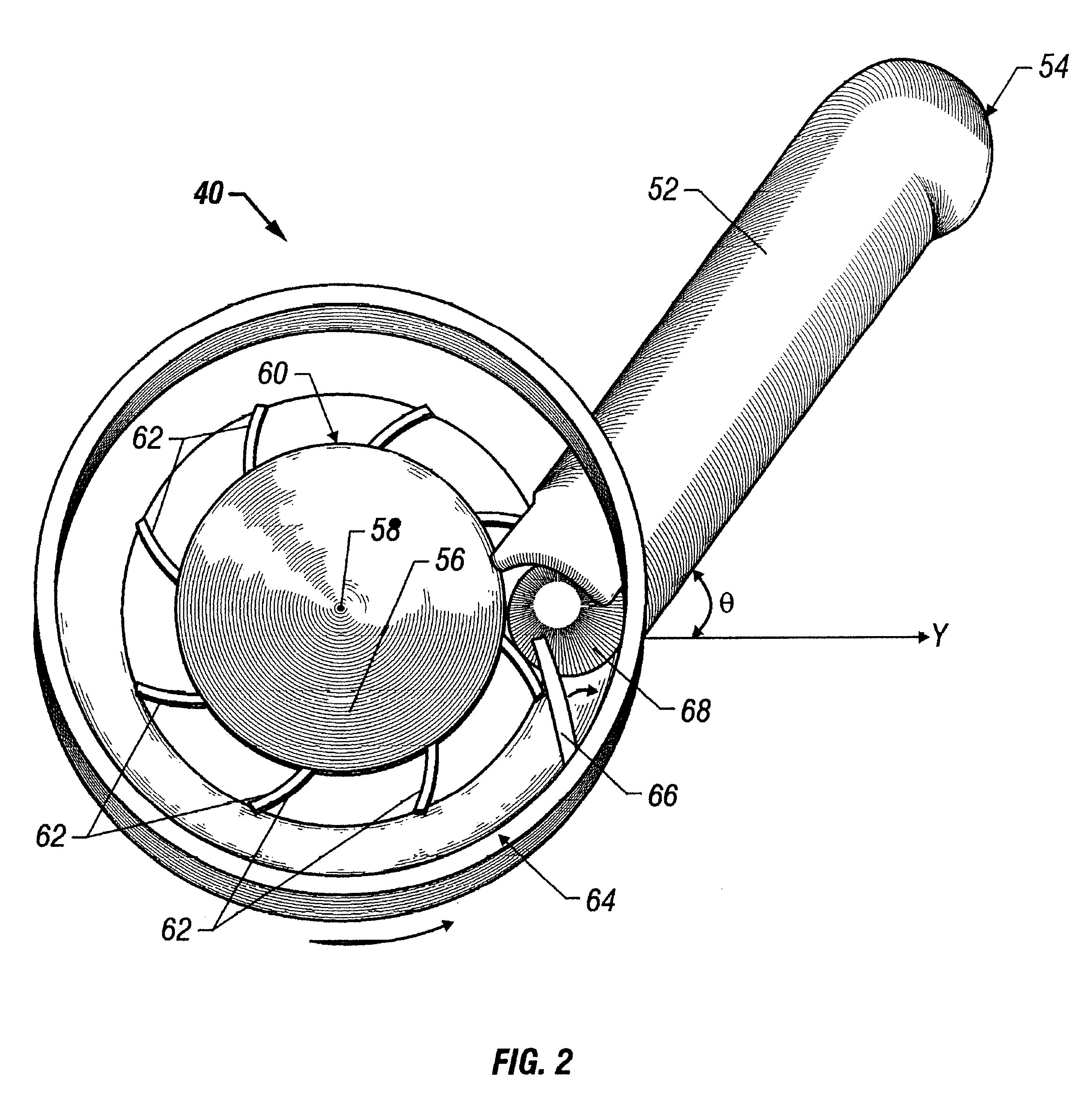

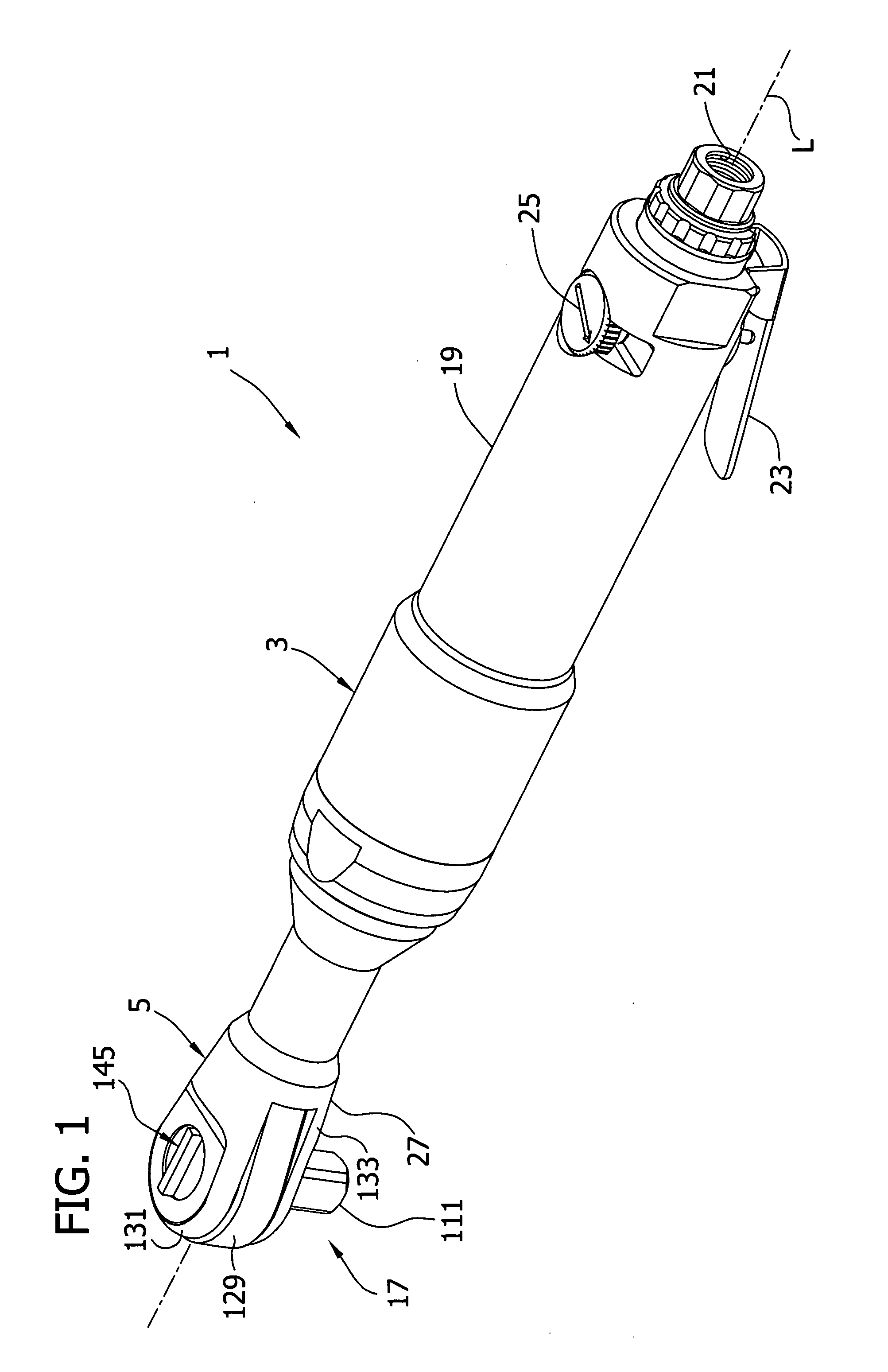

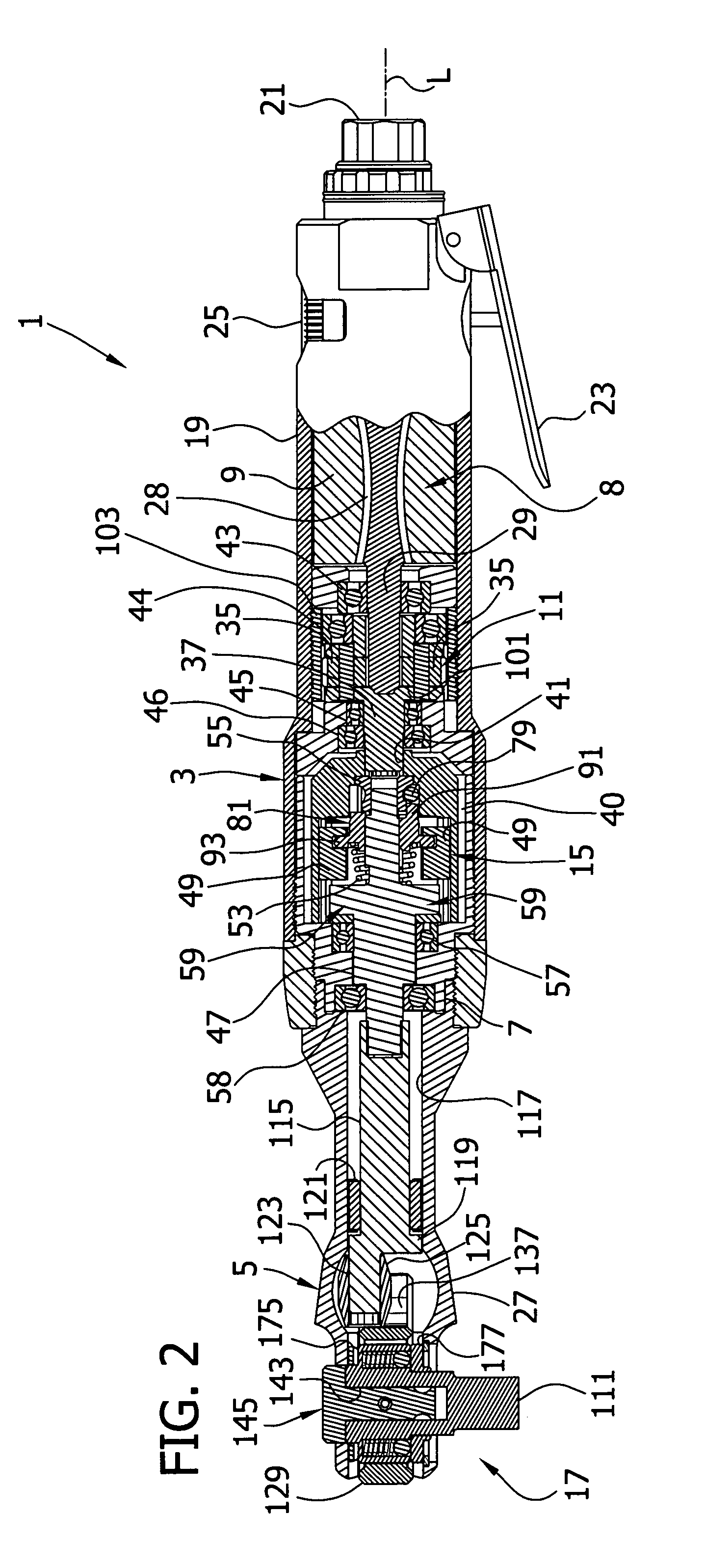

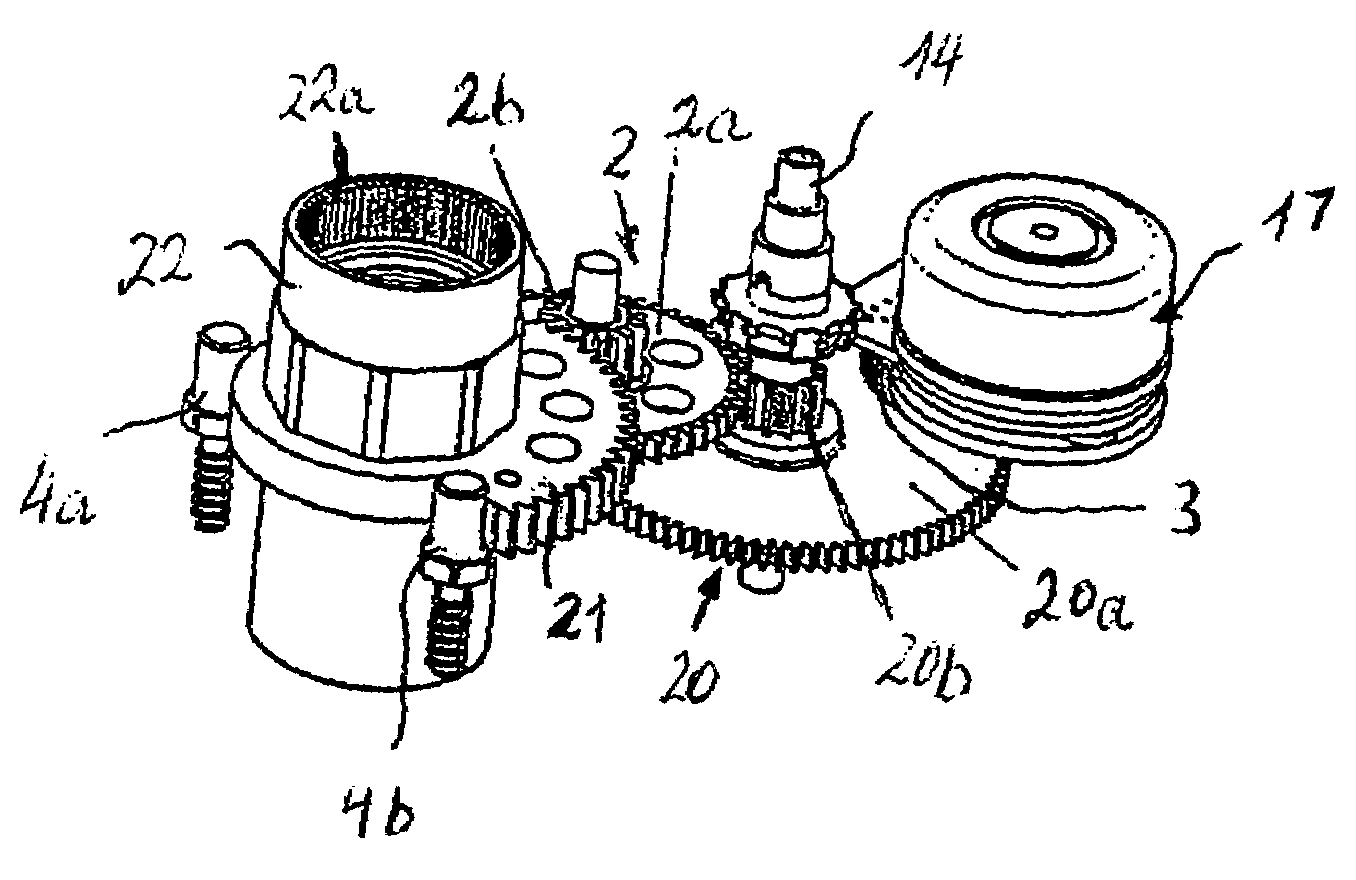

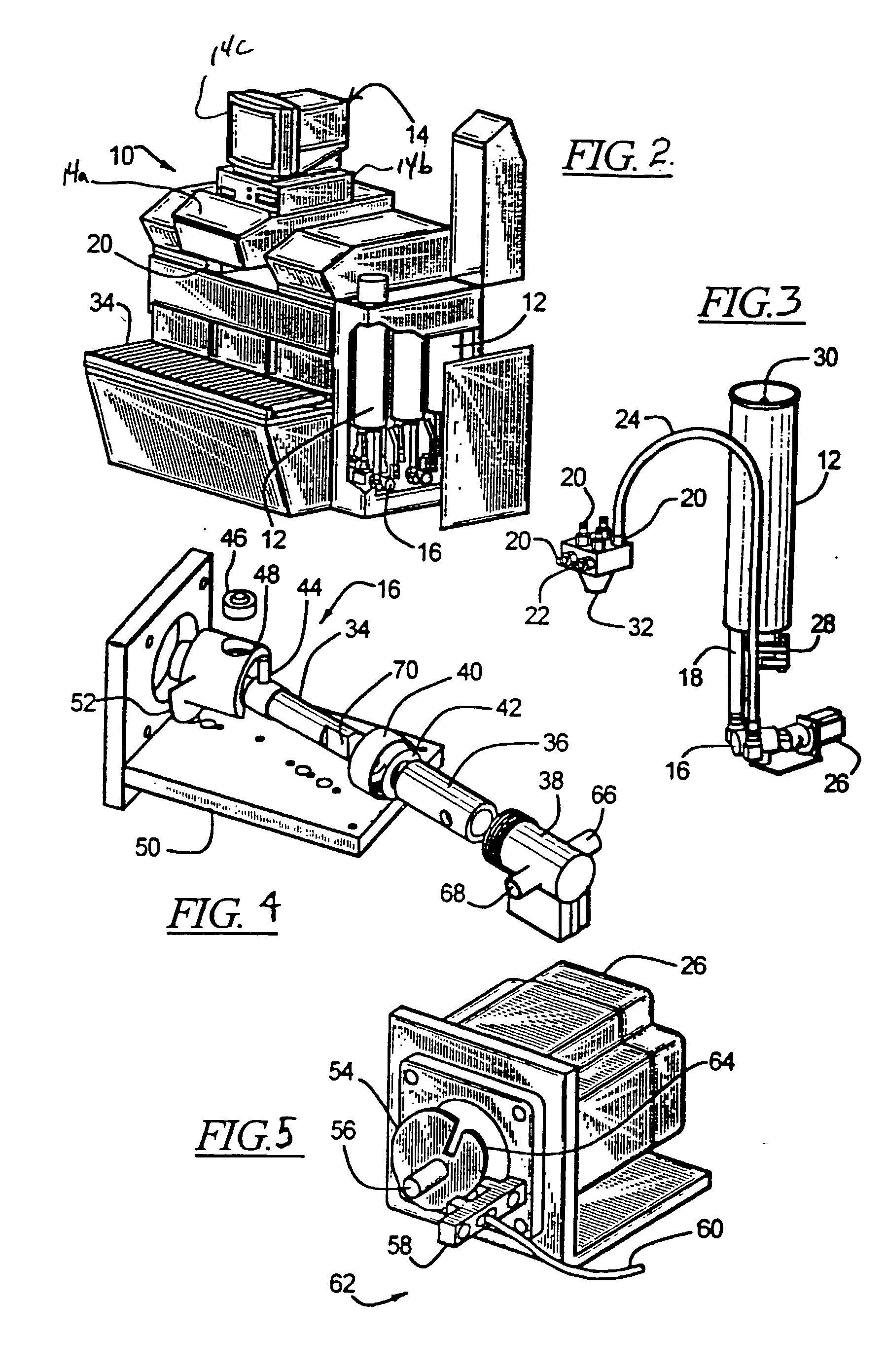

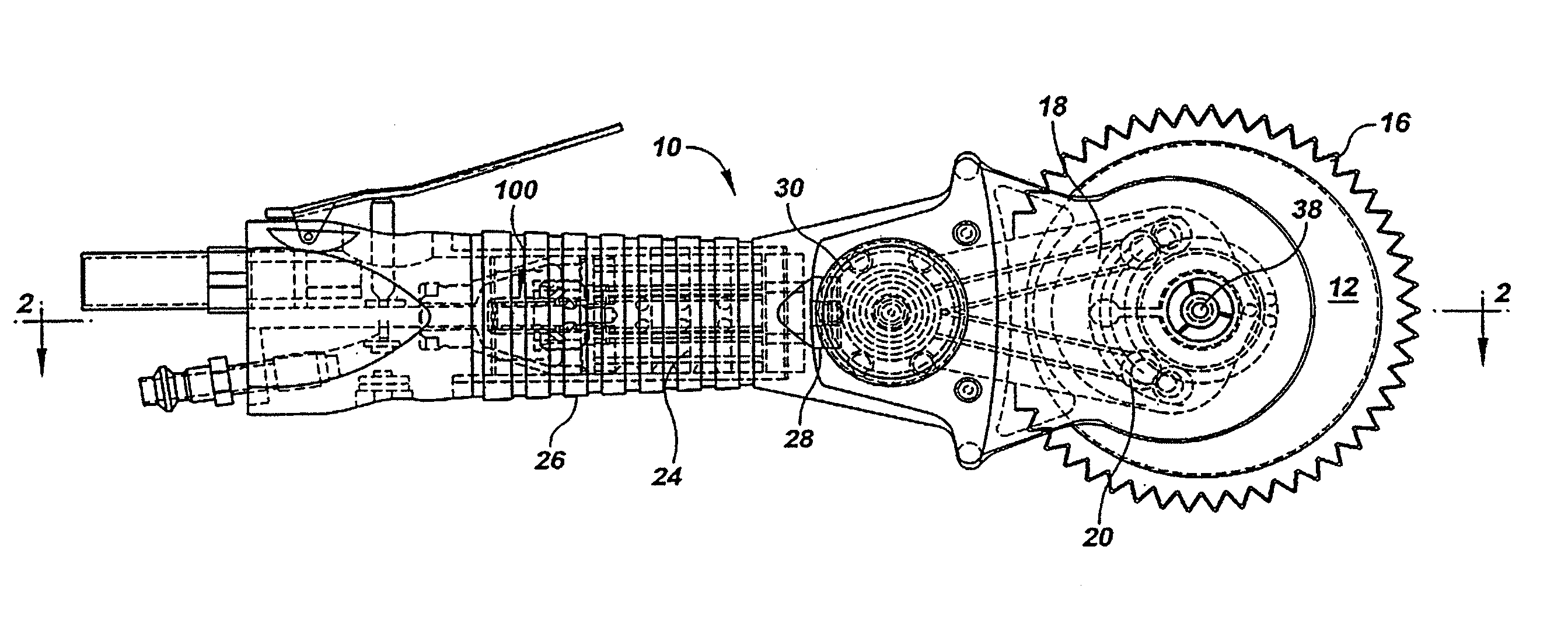

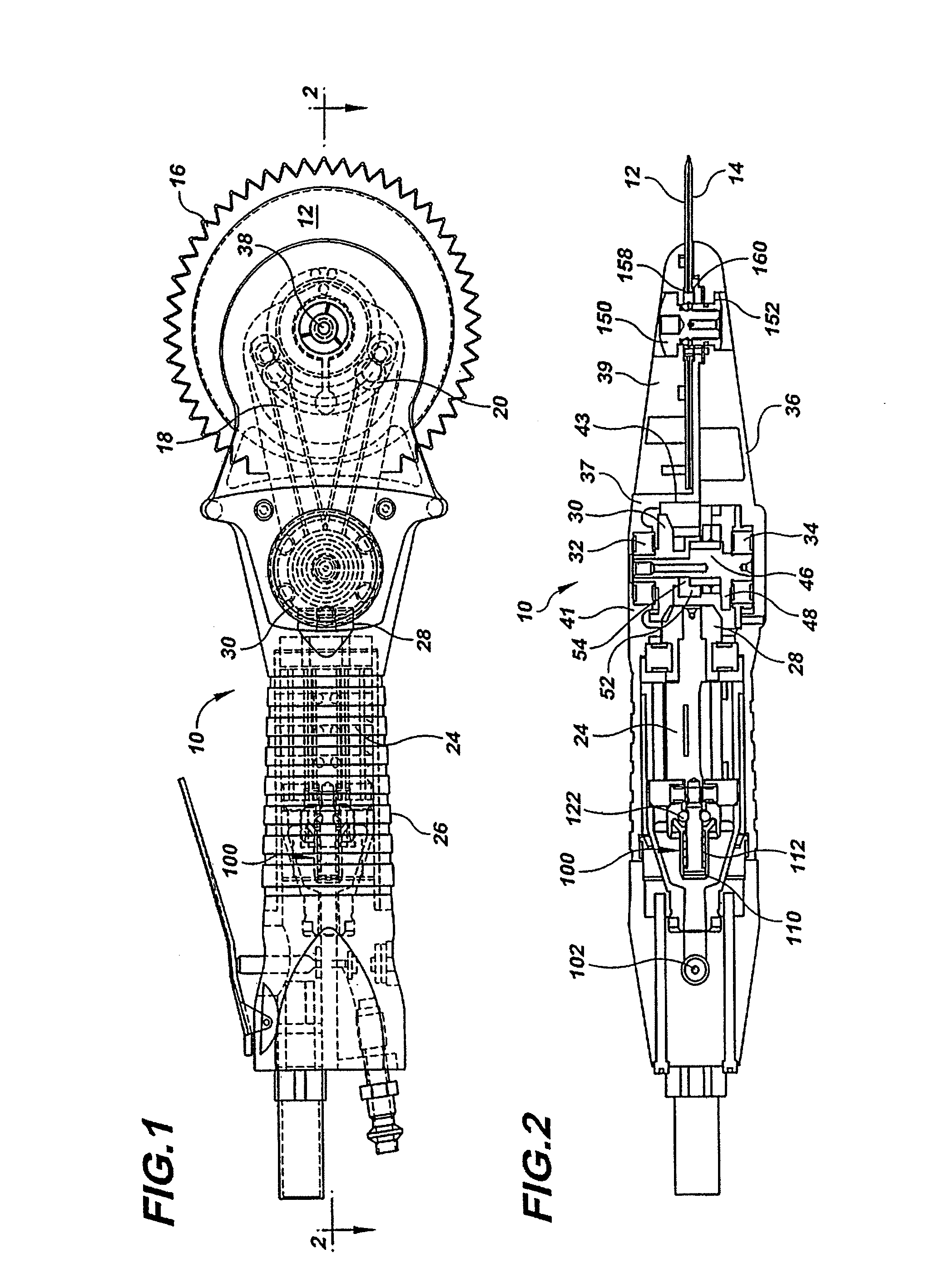

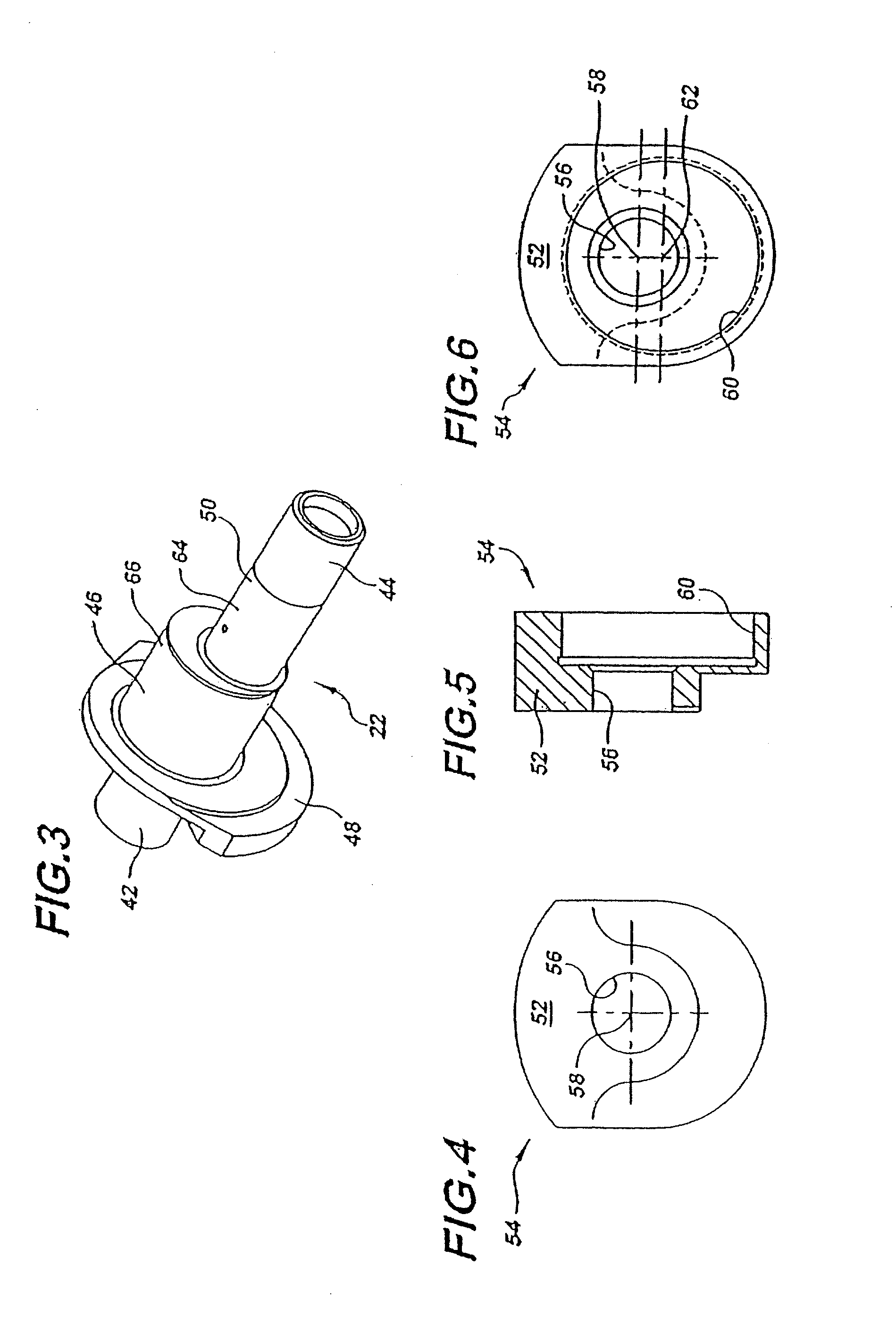

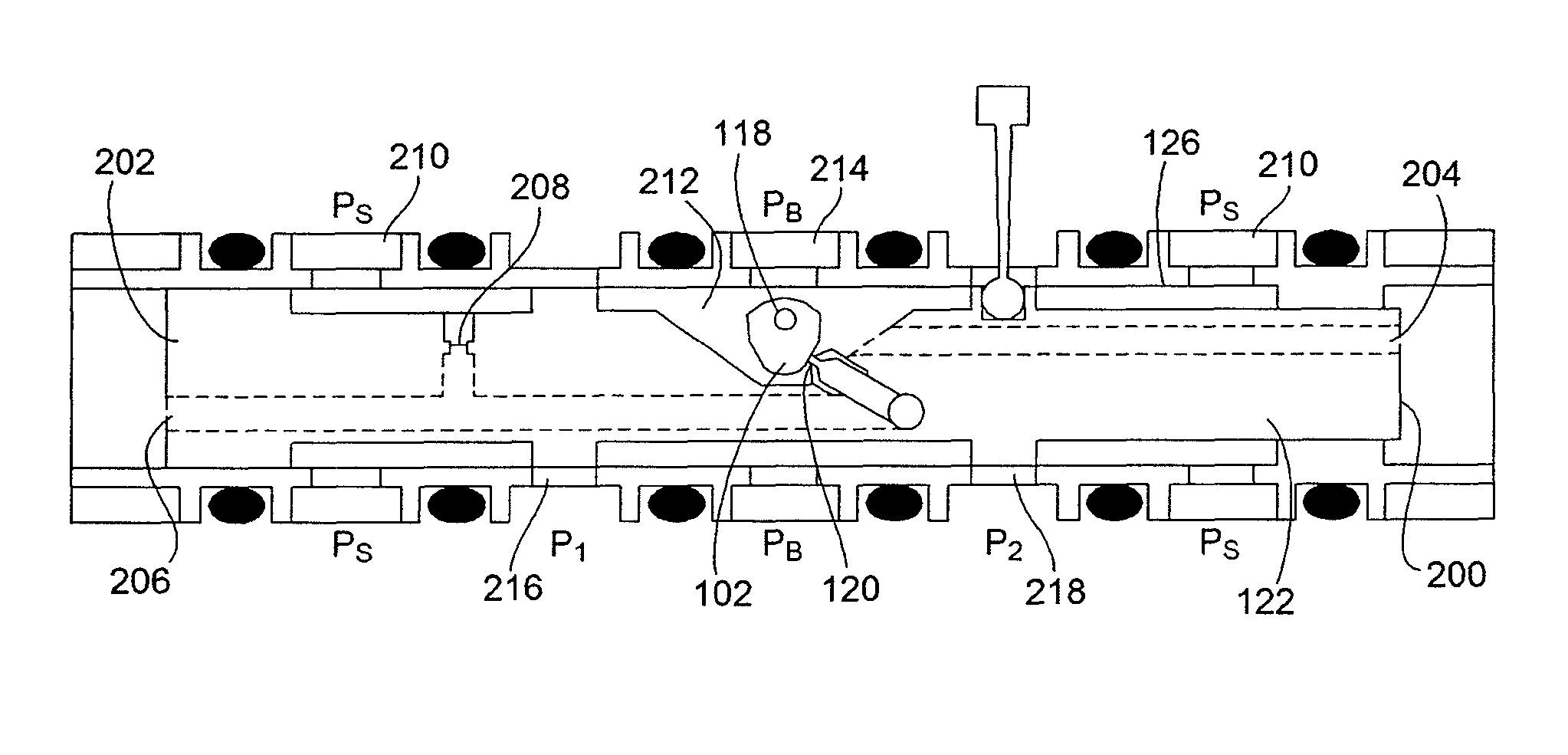

Rapid feed paintball loader with pivotable deflector

InactiveUS6502567B1Reduce motor speedIncrease speedCoin-freed apparatus detailsAmmunition loadingMechanical engineeringMicroprocessor

A rapid feed paintball loader for use upon a conventional paintball gun. The rapid feed paintball loader includes a container for holding a plurality of paintballs. At a bottom portion of the container is a rotatable drive cone having a plurality of vertical fins. Each fin forms a gap with an adjacent fin large enough to accommodate a paintball. At the bottom of the container is an exit tube which exits from the bottom portion of the container and leads to an inlet tube of the paintball gun. A tube extension is mounted on an interior surface of the container adjacent to the sloped exit portion of the exit tube. The tube extension is mounted at a height which is above the top feed surface of the fins, and which is approximately equal to the radius of a paintball. A pivotable deflector is also mounted on an interior surface of the container adjacent the tube extension to prevent paintball jams from occurring within the interior of the container. The deflector is positioned above the top feed surface of the fins and below the height of the tube extension. The paintball loader also includes a microprocessor to variably control the rotational speed of the drive cone.

Owner:PNC BANK NAT ASSOC

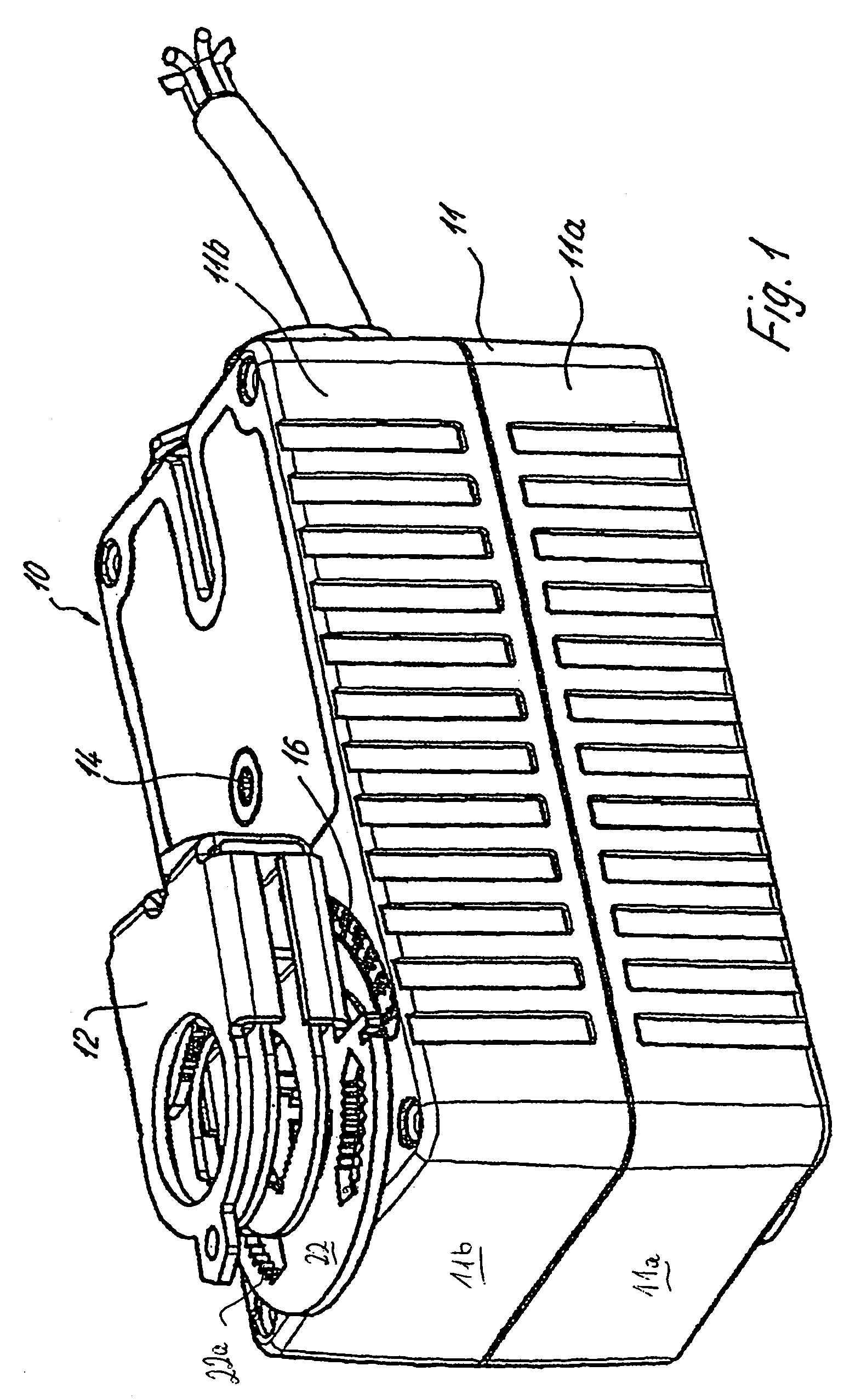

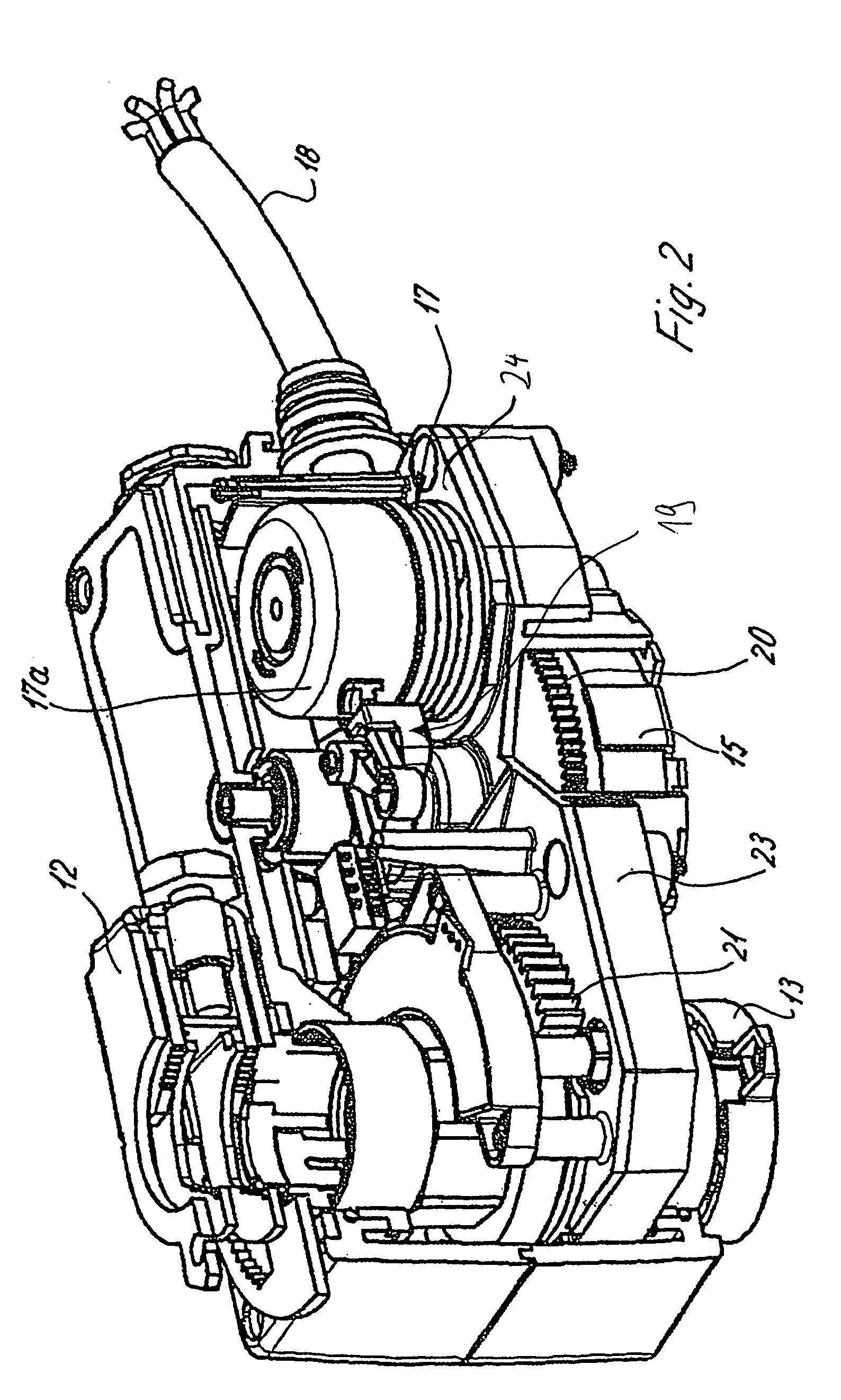

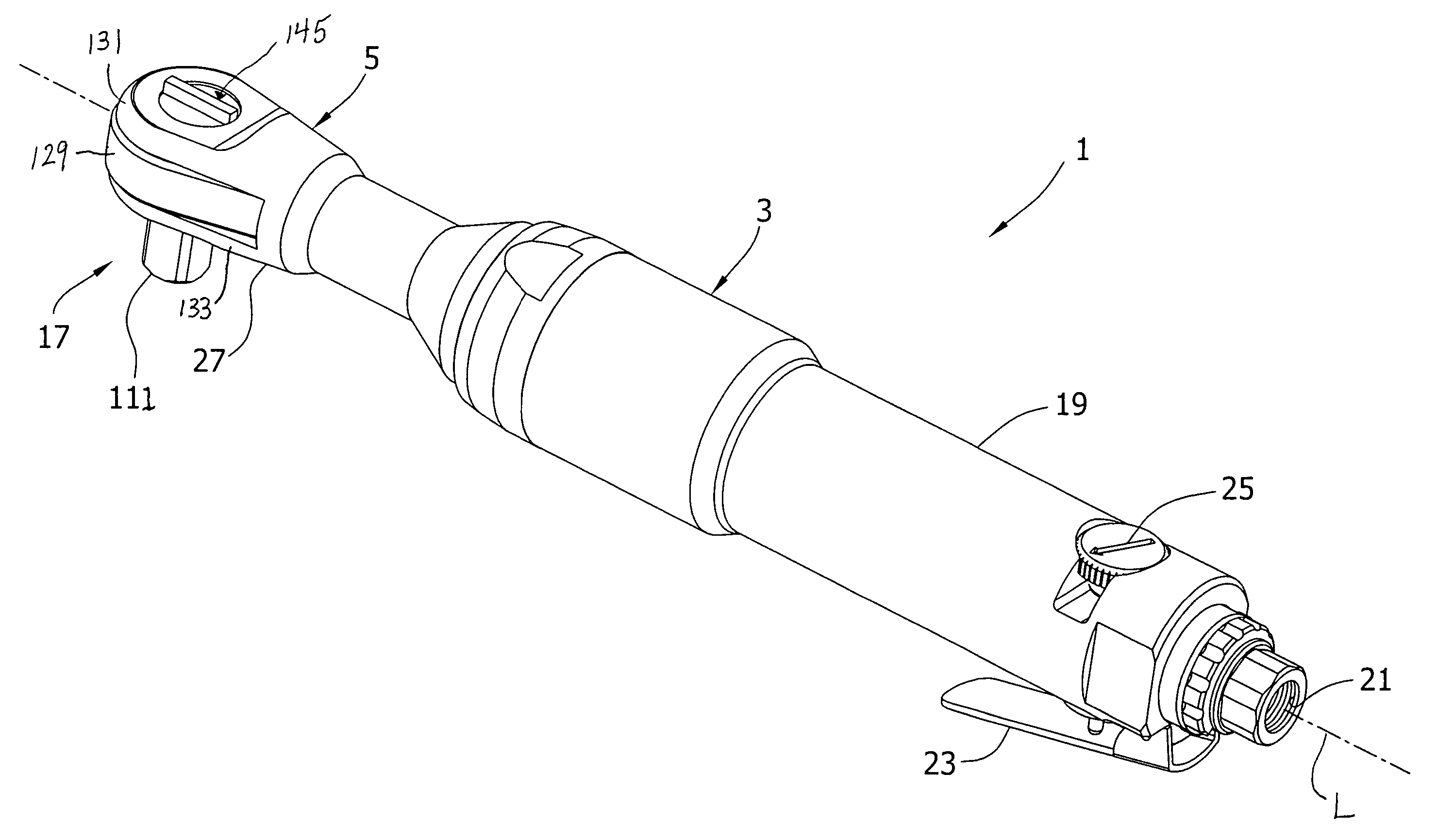

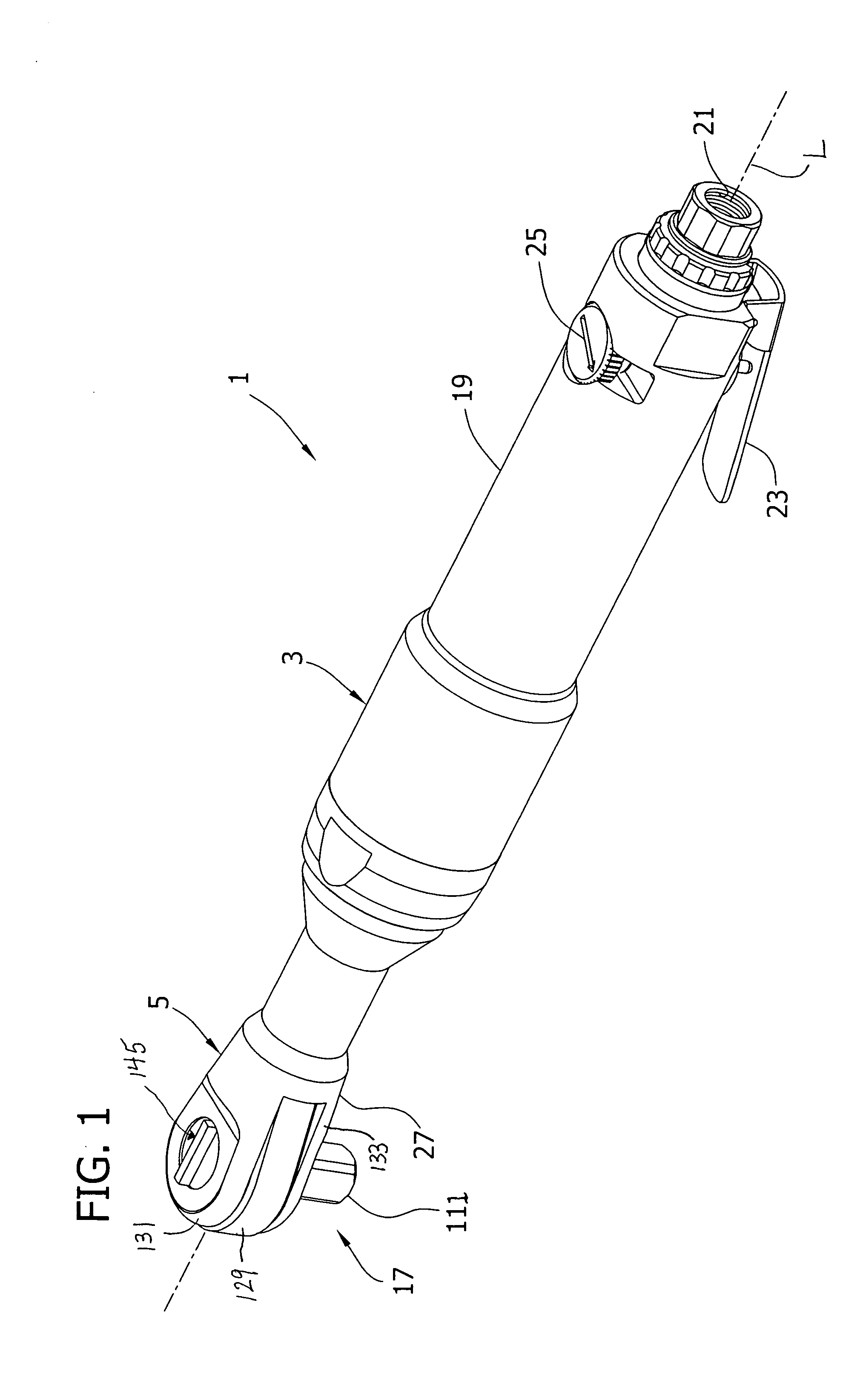

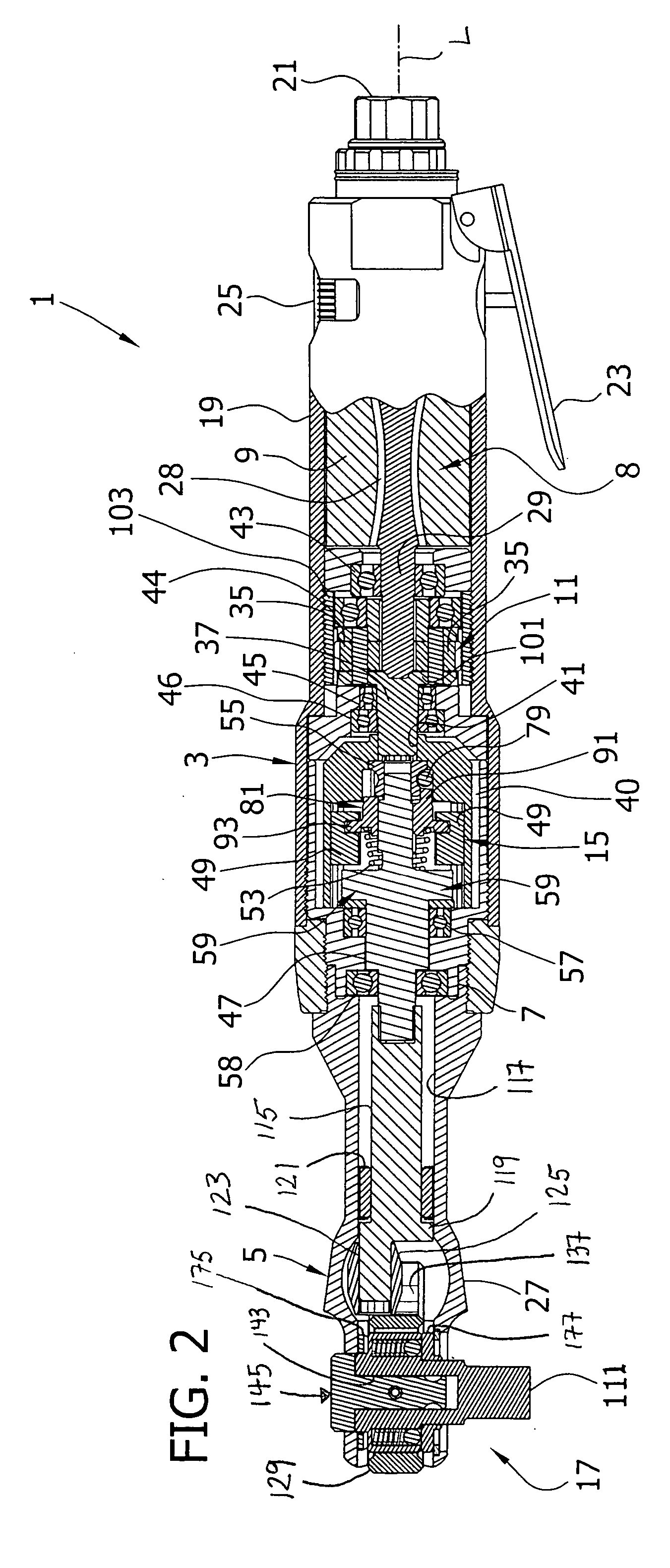

Hand tool with impact drive and speed reducing mechanism

ActiveUS7080578B2Reduce speedEasy to driveOperator-supported drilling machinesSpannersGear wheelHand tool

Owner:VESSEL FUKUCHIYAMA

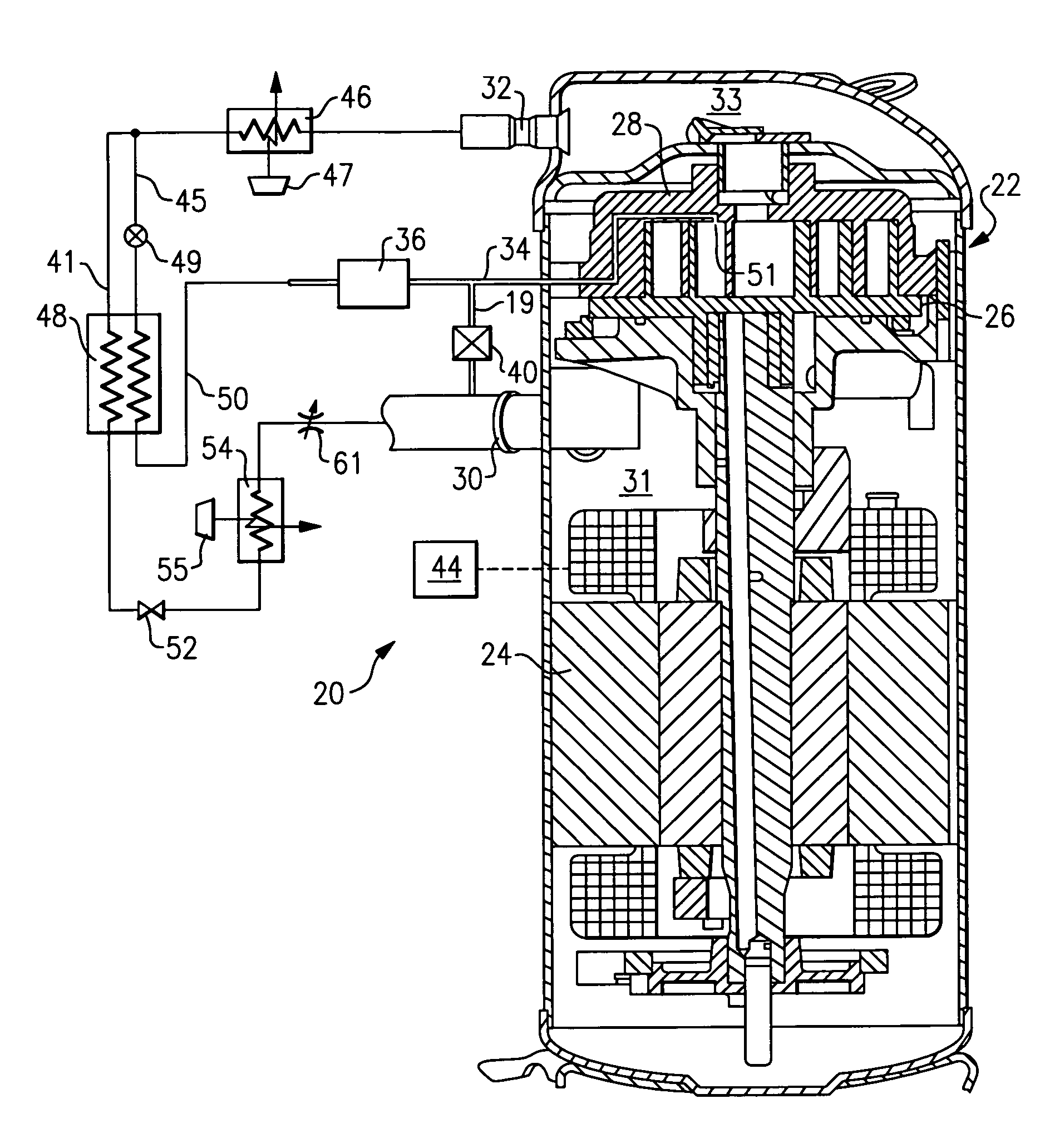

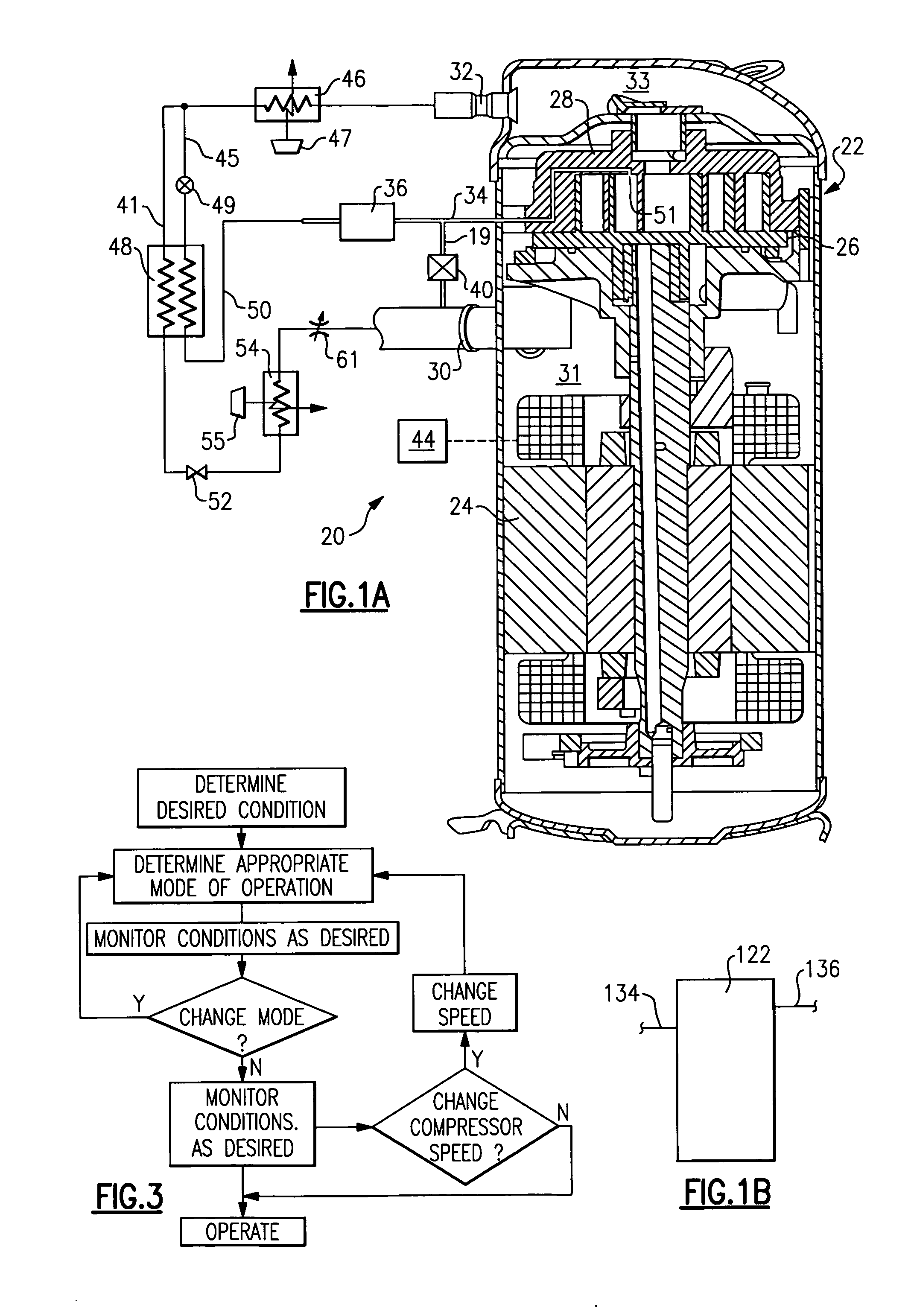

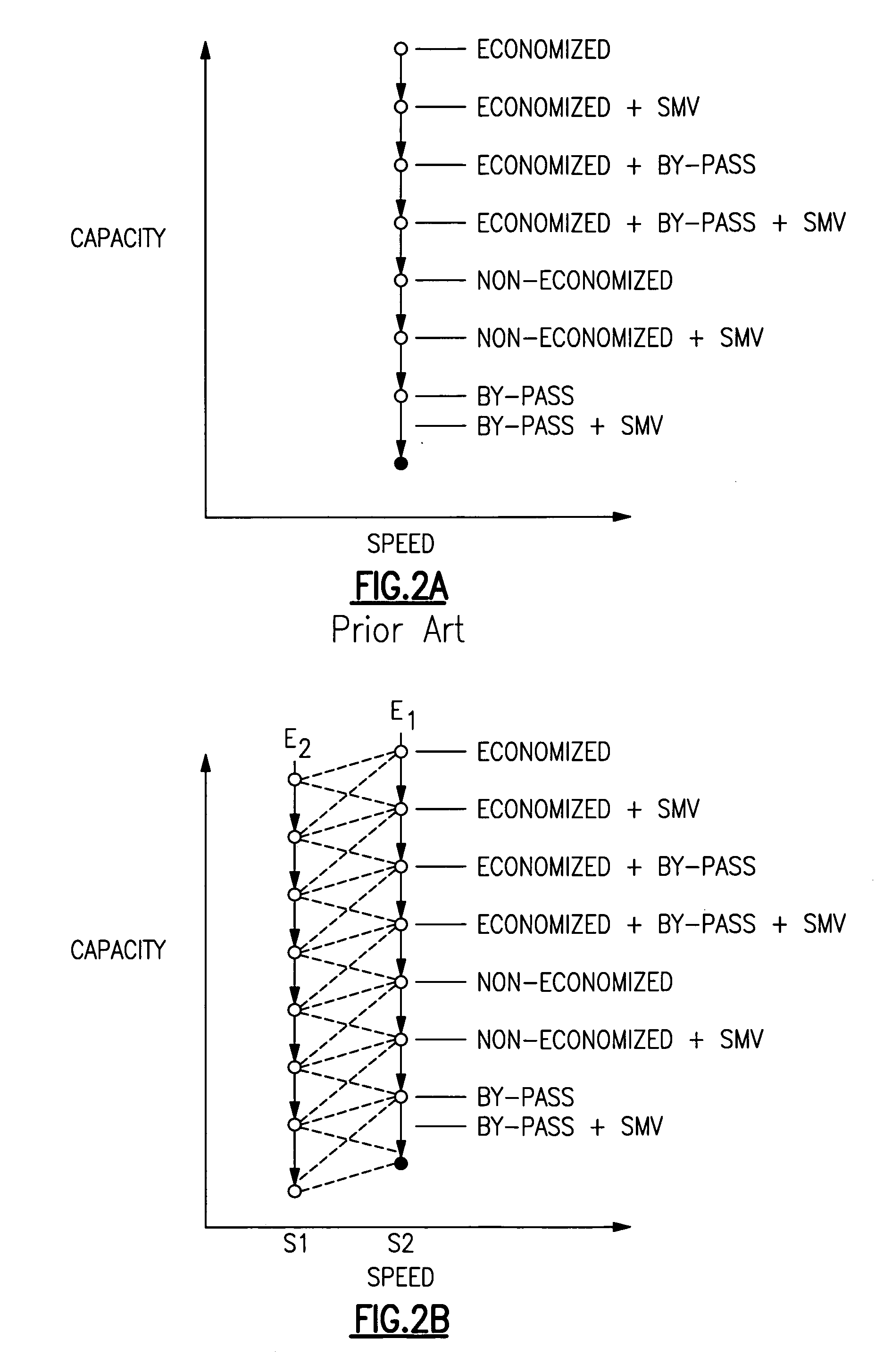

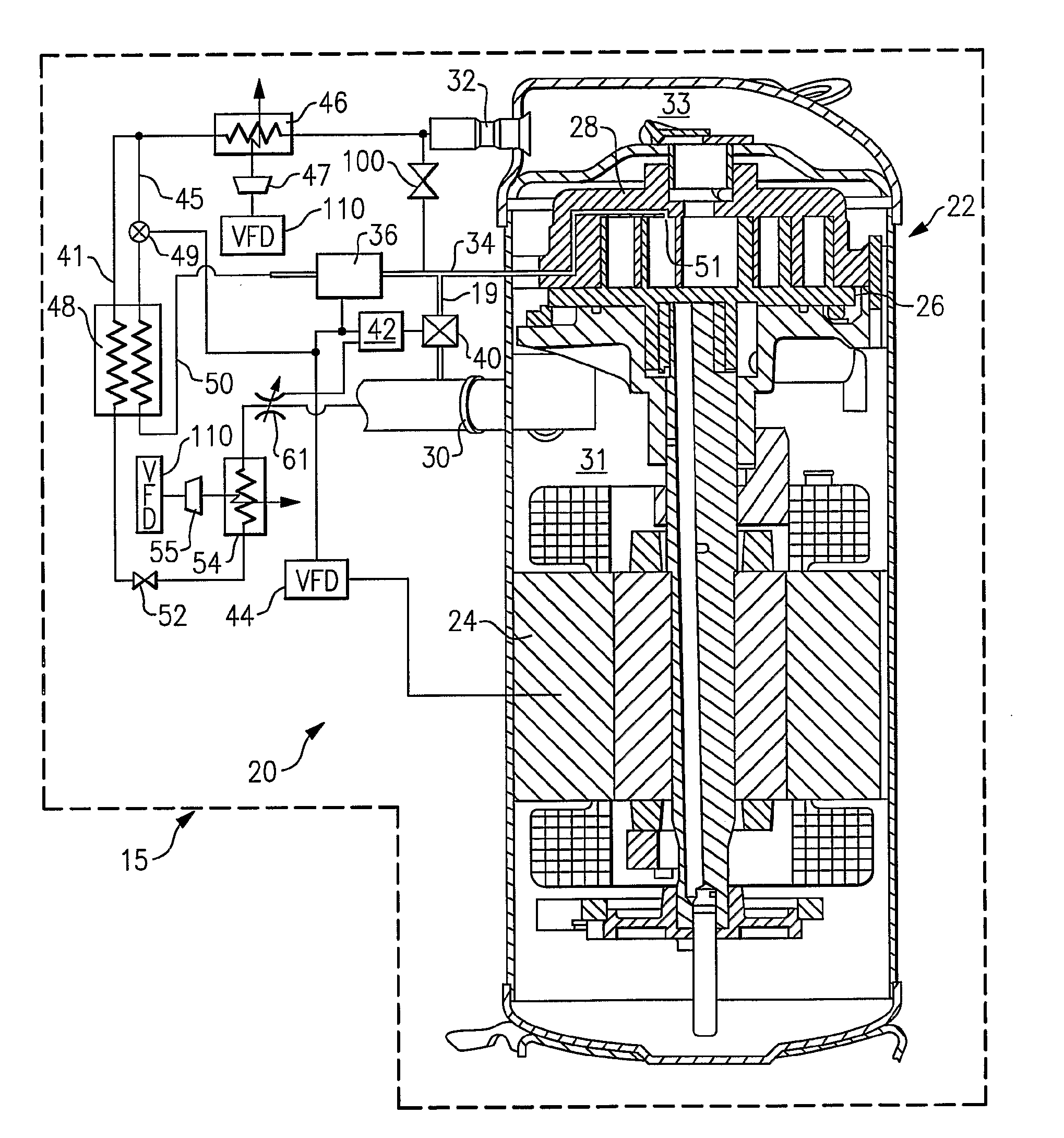

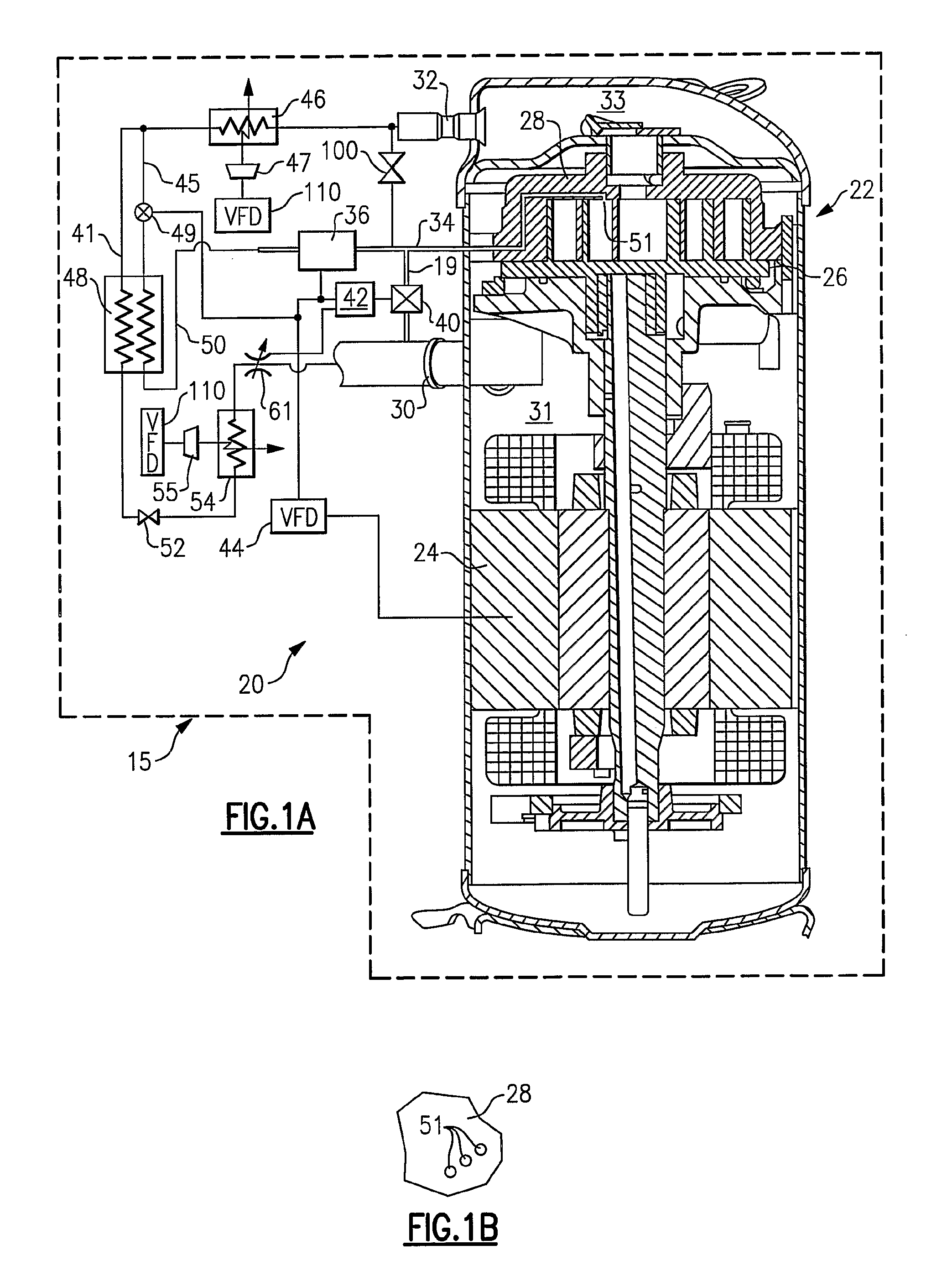

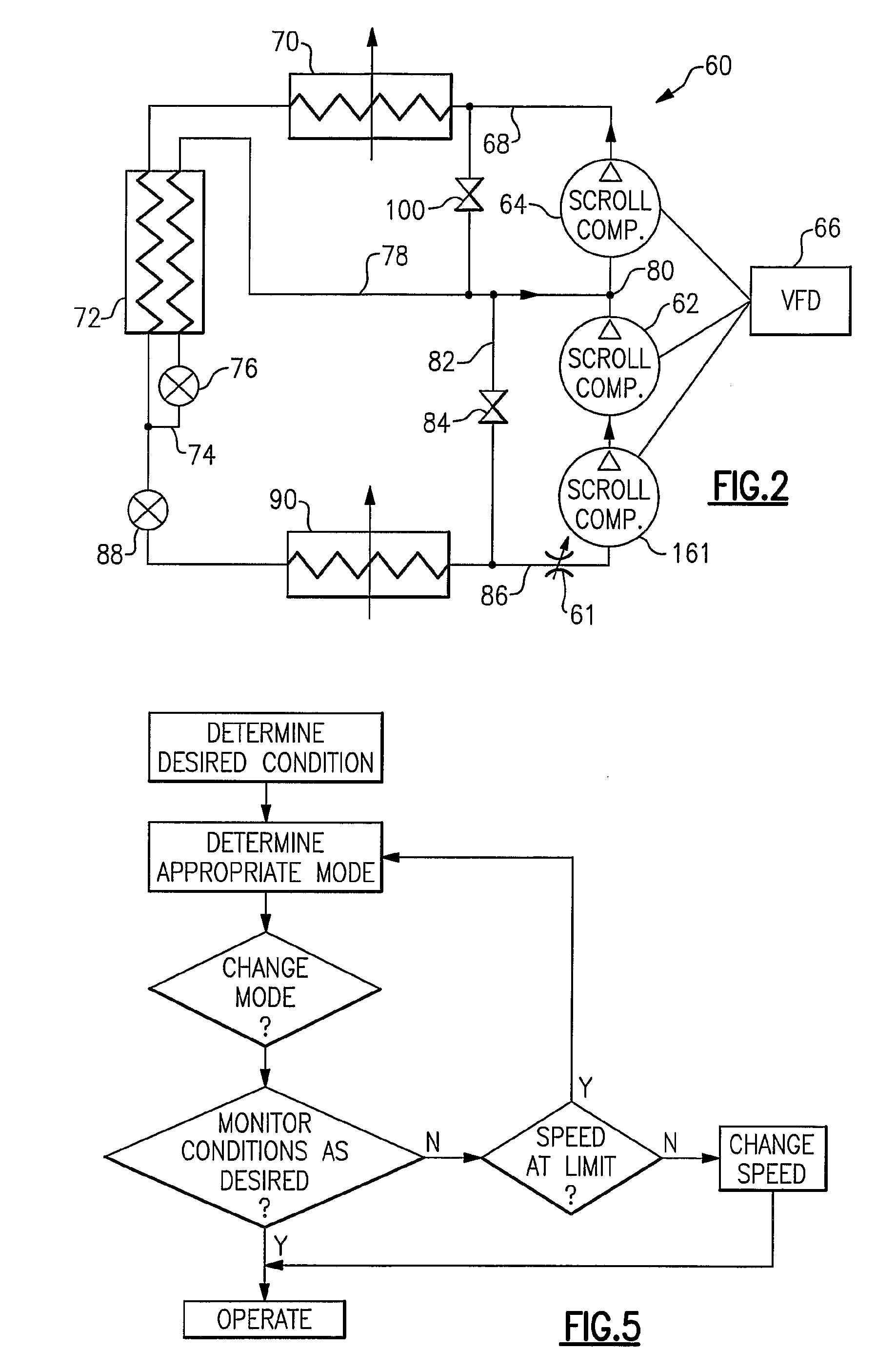

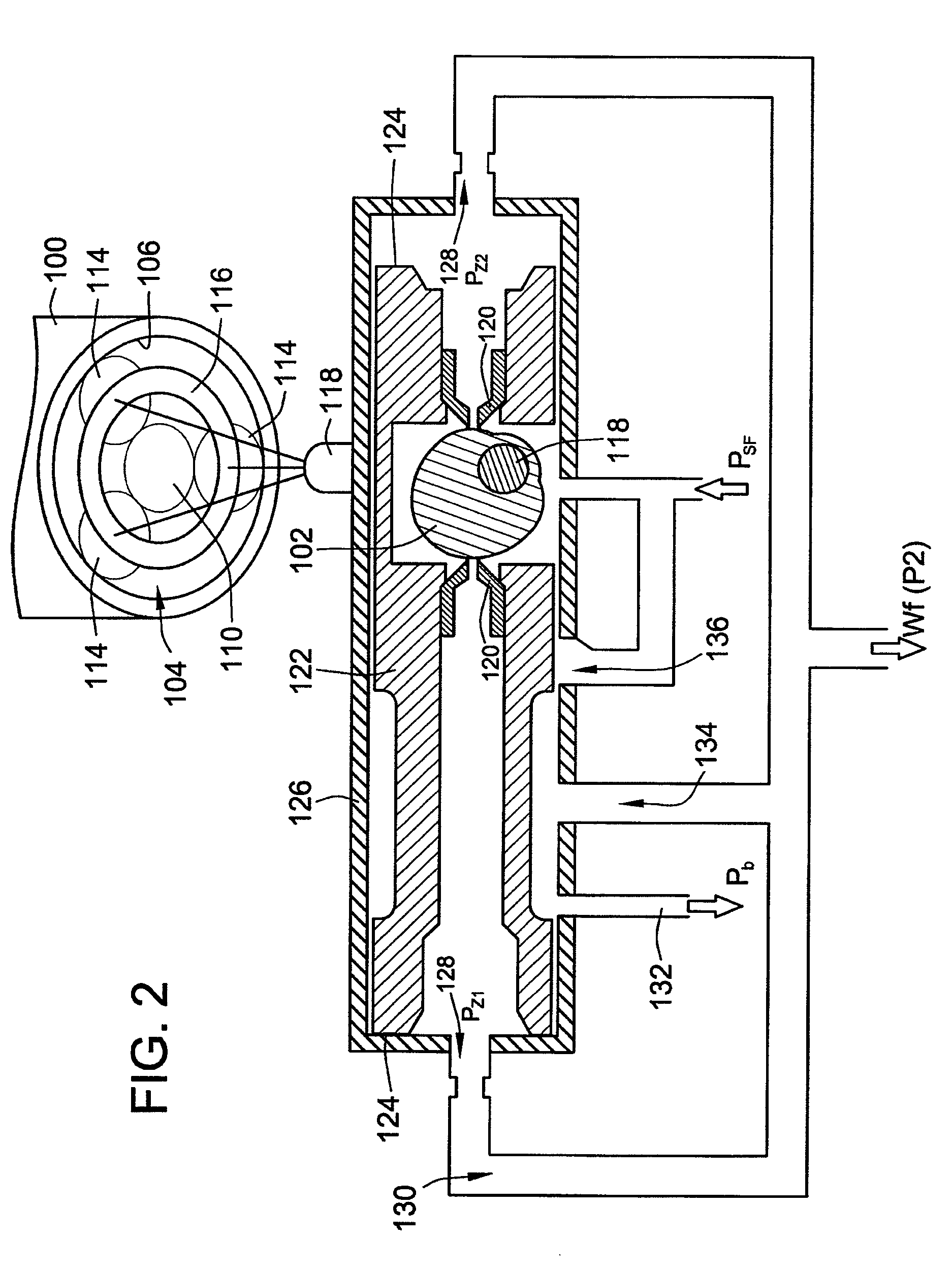

Refrigerant system with multi-speed scroll compressor and economizer circuit

InactiveUS20070130973A1Increase and decrease capacityIncrease control flexibilityCompression machines with non-reversible cycleVehicle heating/cooling devicesSystem capacityControl theory

A scroll compressor is provided with a multiple-speed motor. A control selects a speed for operating the motor, along with selecting between several available options for the system capacity adjustment to meet external load demands in a most efficient and reliable manner. The disclosed embodiment includes an economizer circuit, an unloader function, and an optional suction modulation valve. By utilizing each of these features in combination with the multi-speed motor for the compressor, the present invention is better able to tailor provided capacity to desired capacity.

Owner:SCROLL TECH

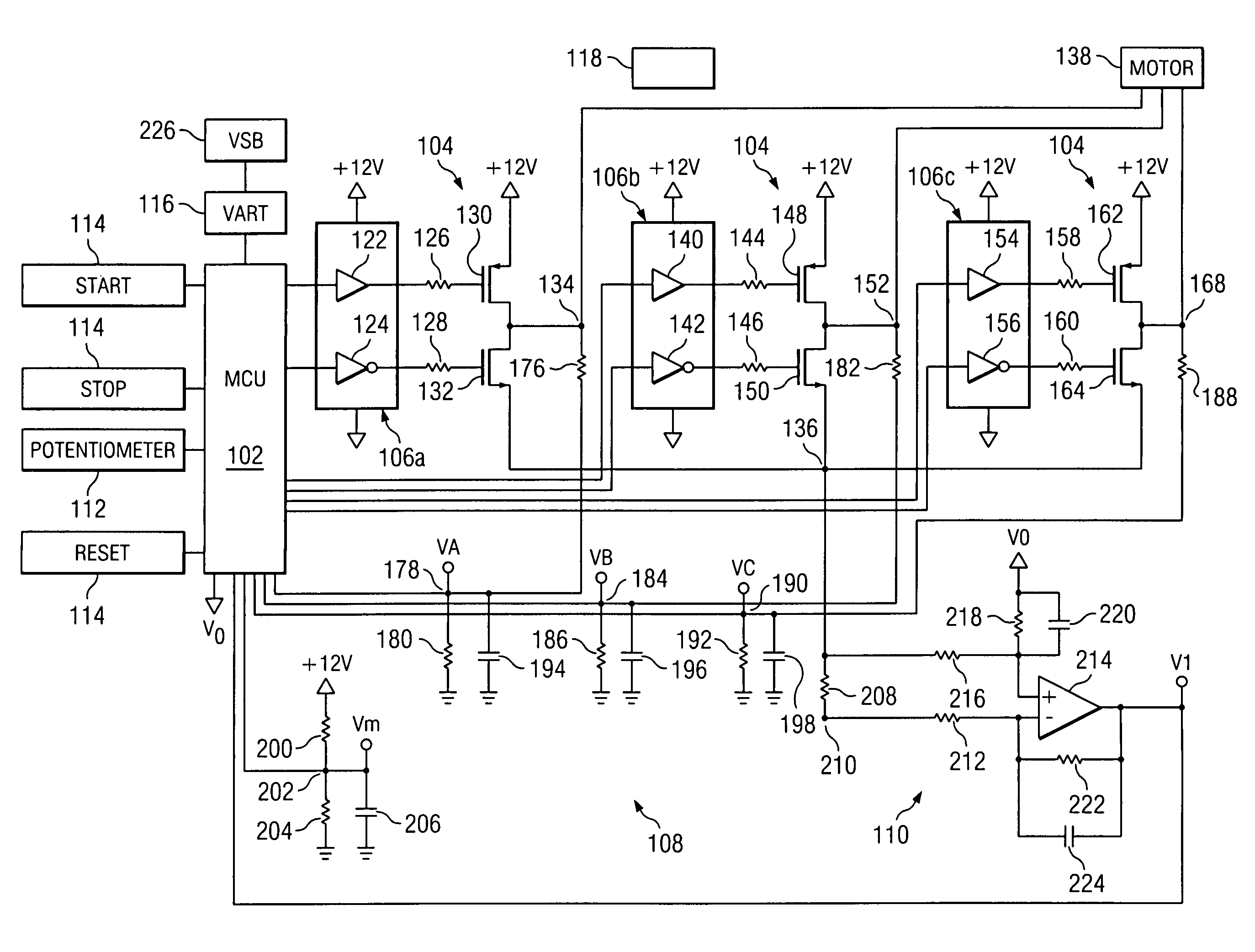

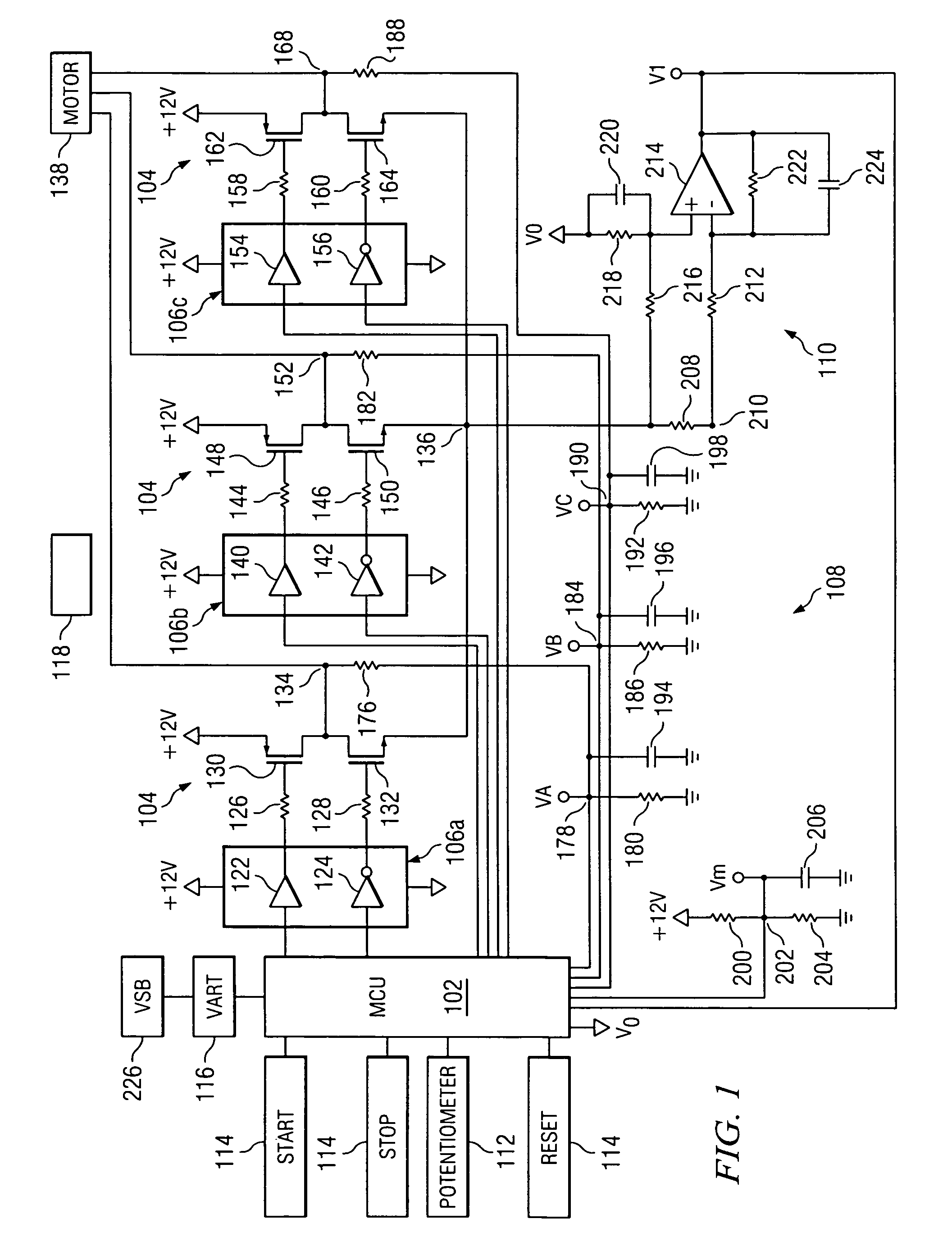

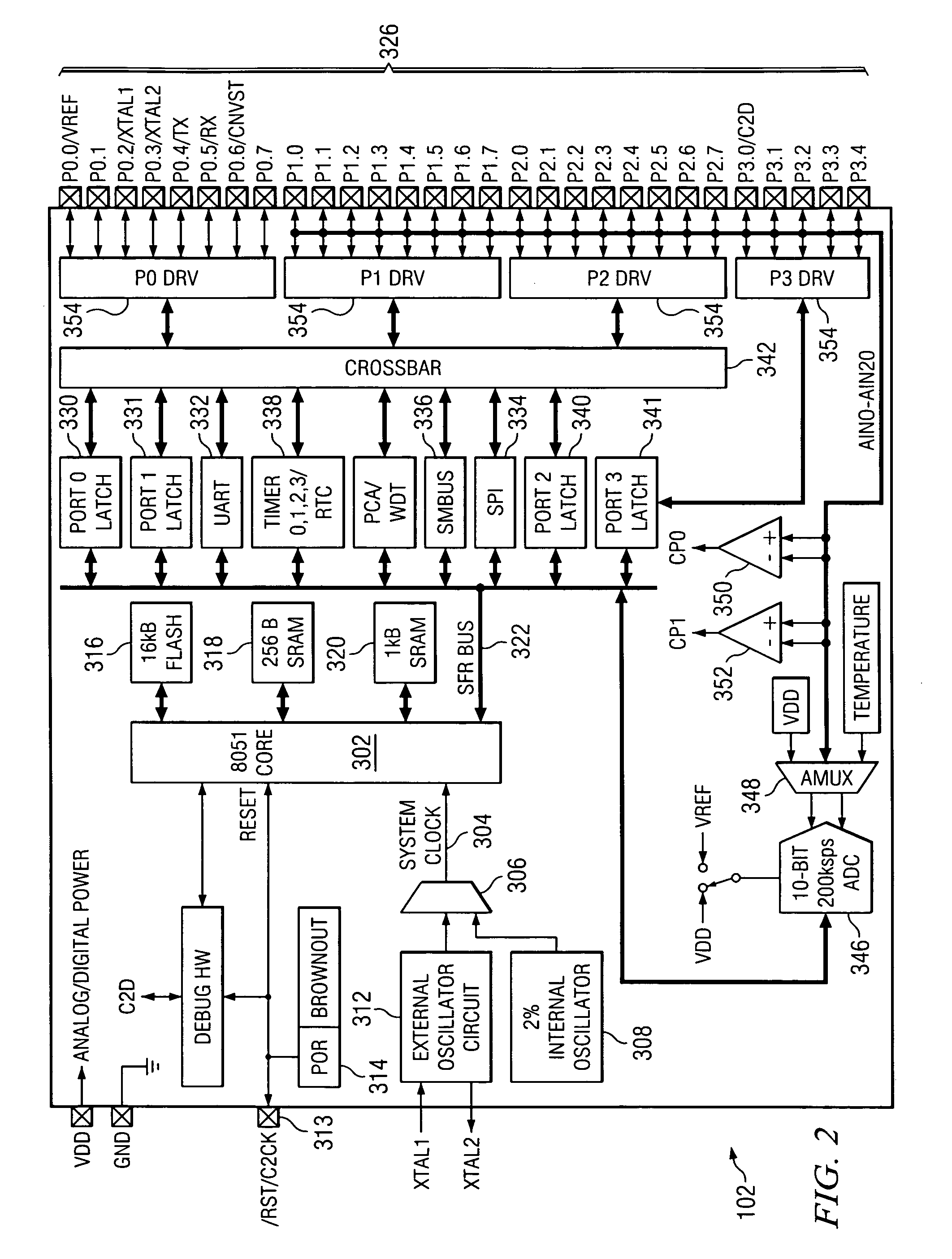

MCU control for brushless DC motor

ActiveUS6949900B1Reduce motor speedIncrease motor speedSynchronous motors startersAC motor controlPotentiometerThree phase windings

A processor for controlling a sensorless, brushless DC motor is disclosed comprising a first output for providing a control signal to a potentiometer controlling the speed and voltage of the DC motor. The processor also includes a second input for receiving a back-EMF voltage from an open phase of a three phase winding. The processor determines a digital error signal from the back-EMF voltage and generates a control signal responsive to the digital error signal. The control signal decreases the speed of the motor when the digital error signal is in a first range. The processor decreases both the speed and voltage of the motor when the digital error signal is in a second range. The processor increases the speed of the motor when the digital error signal is in a third range. The processor increases both the speed and voltage of the motor when the digital error signal is in a fourth range.

Owner:SILICON LAB INC

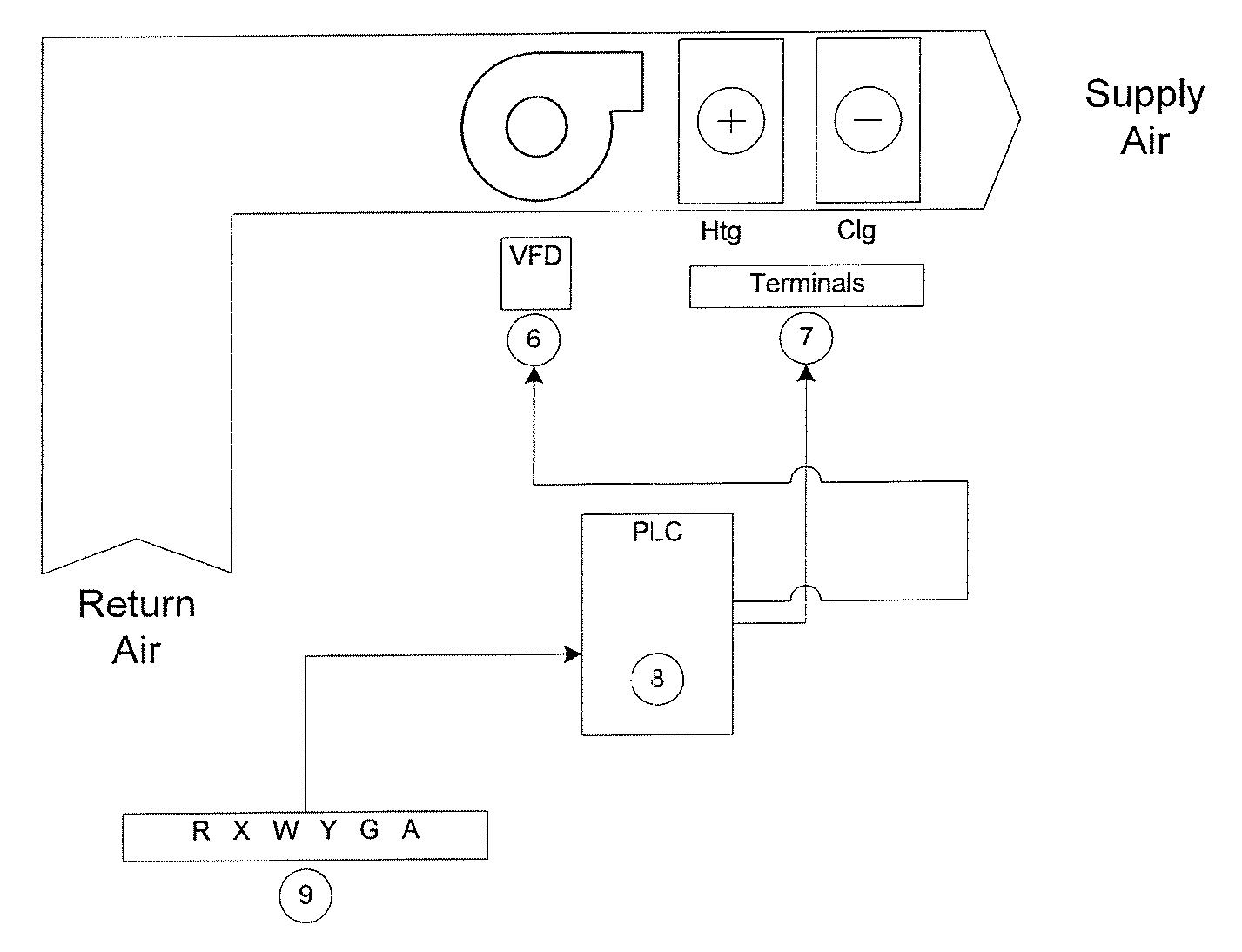

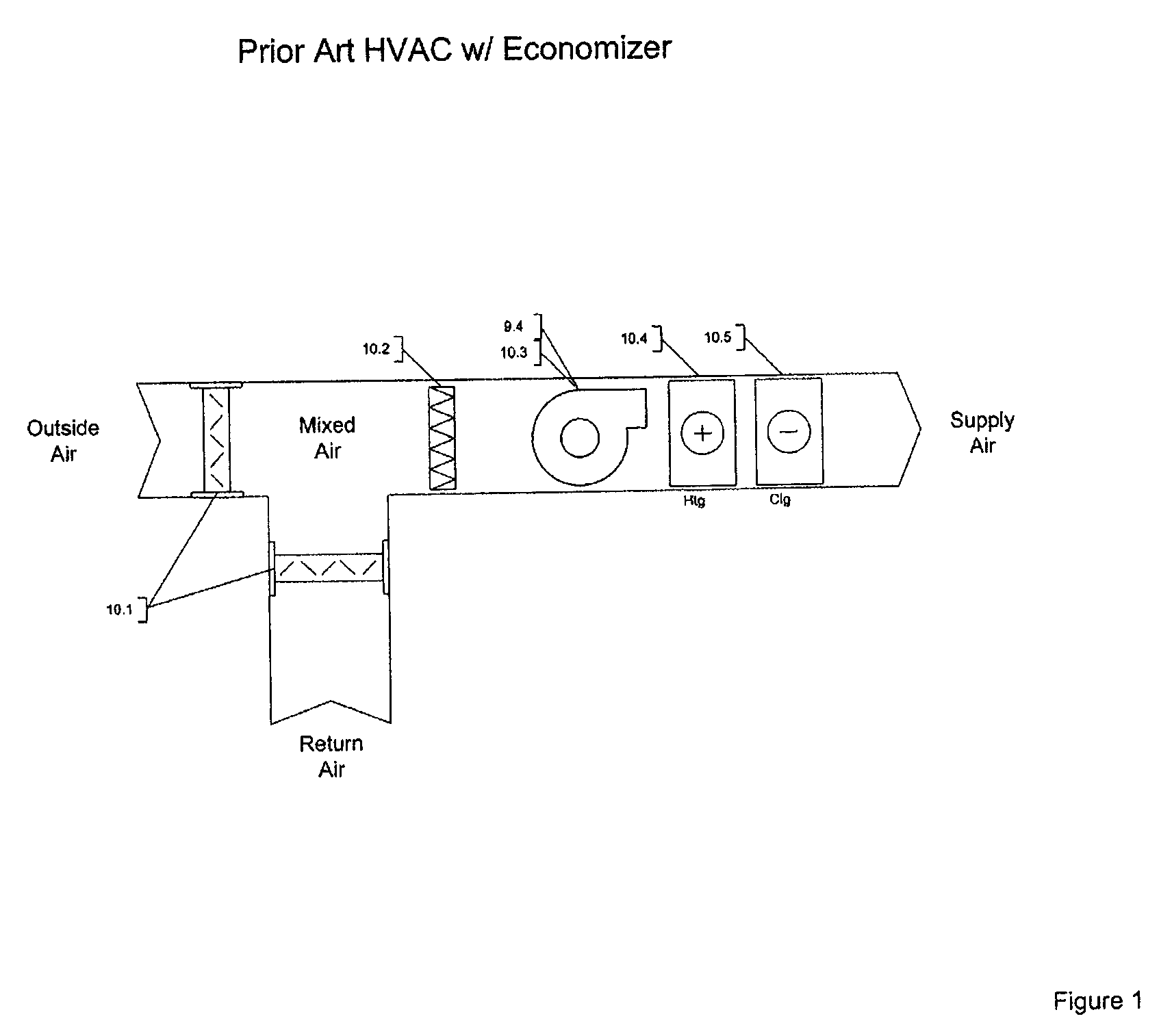

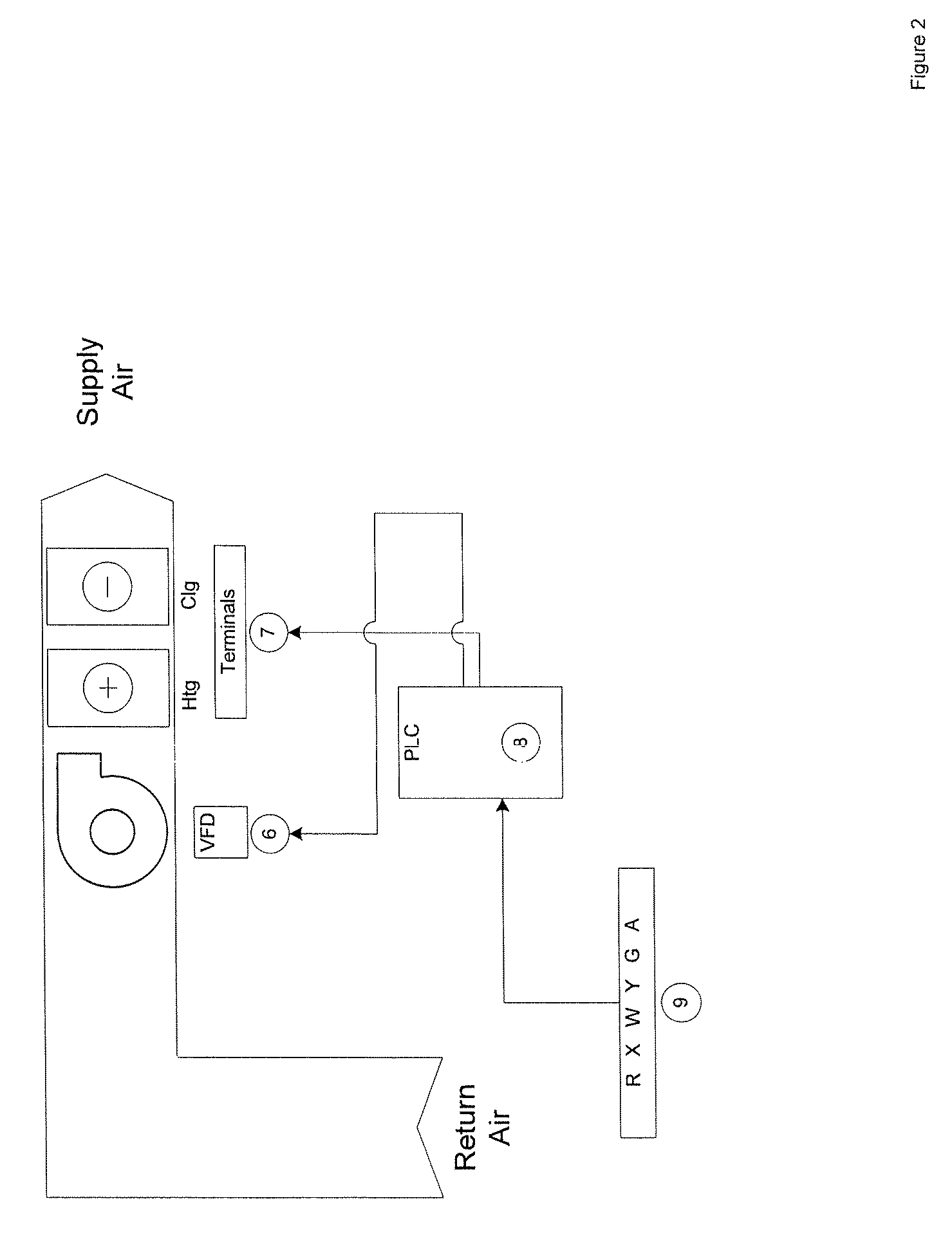

Energy reducing retrofit method for a constant volume HVAC system

ActiveUS8515584B2Meet matching needsShorten speedLevel controlSpace heating and ventilationEnergy expenditureEconomizer

An energy-reducing method and apparatus for retrofitting a constant volume HVAC system, with or without an economizer, that provides heating, cooling, and ventilation to occupants within a building space. The present invention includes the introduction of a programmable logic controller and variable frequency drive (VFD) that takes control of the existing fan, heating, cooling, and optional economizer operation. The controller is programmed for the reduction of fan speed in the heating and cooling modes. The reduction of the fan speed in the ventilation mode when the 100% operation is not needed saves significant energy of the existing constant volume HVAC system where the fan motor is designed to run 100% of the time. The fan speed may be further reduced upon a reduction in sensed occupancy levels of the space, such as with a CO2 sensor. Additionally, the fan speed may be reduced in the heating and / or cooling mode to further reduce energy consumption. The controller may also be programmed and equipped with sensors to allow simultaneous mechanical compressor cooling and economizer free cooling operation, for the operation of the economizer in response to the monitoring of outside air and return air to determine the preferred source for cooling operations, to keep the outside air damper closed during the unoccupied heating modes such as morning warm-up, and / or to provide fault detection. The retrofit method and apparatus may be employed in a stand-alone or networked version.

Owner:PRO STAR ENERGY SOLUTIONS LP

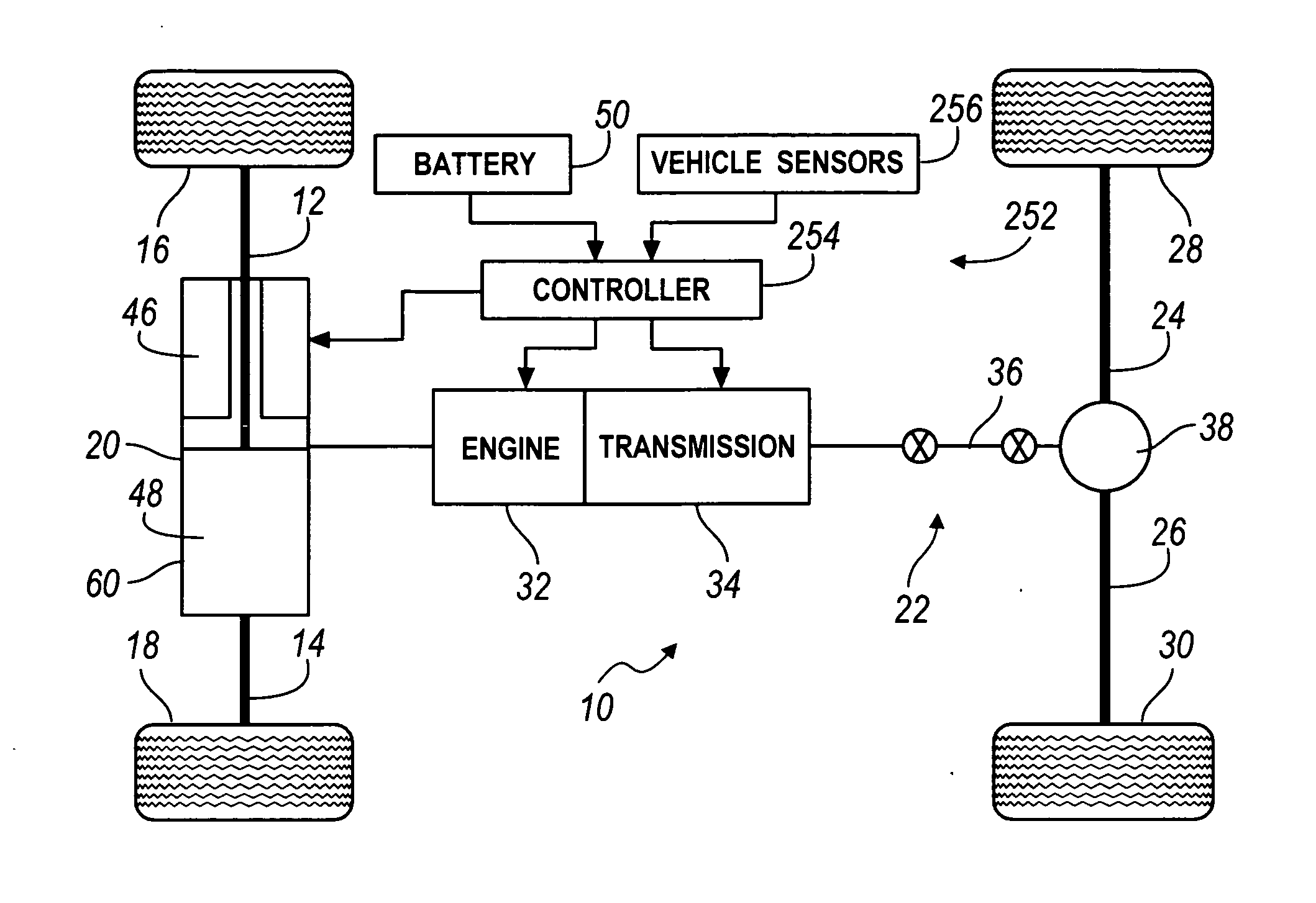

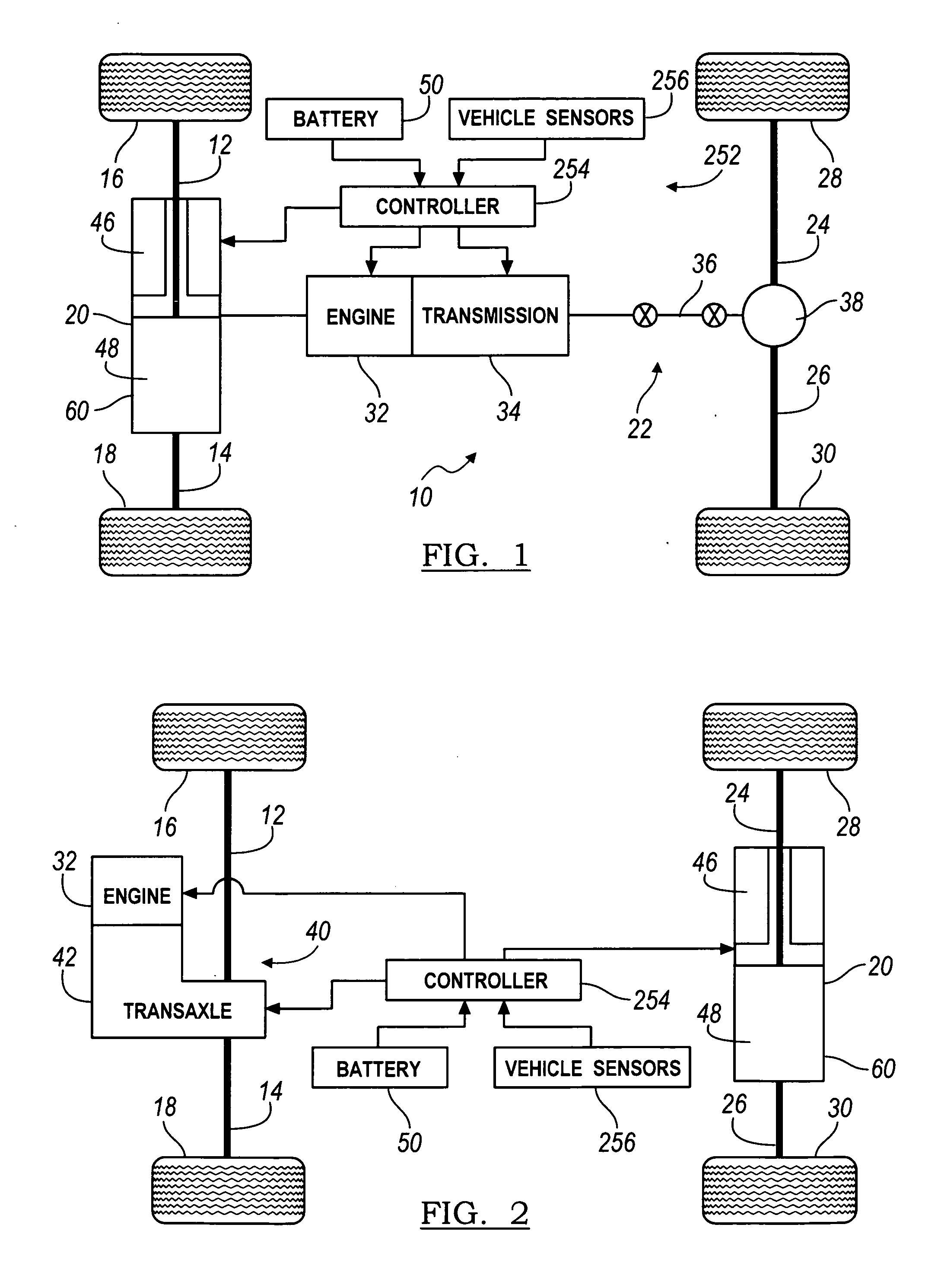

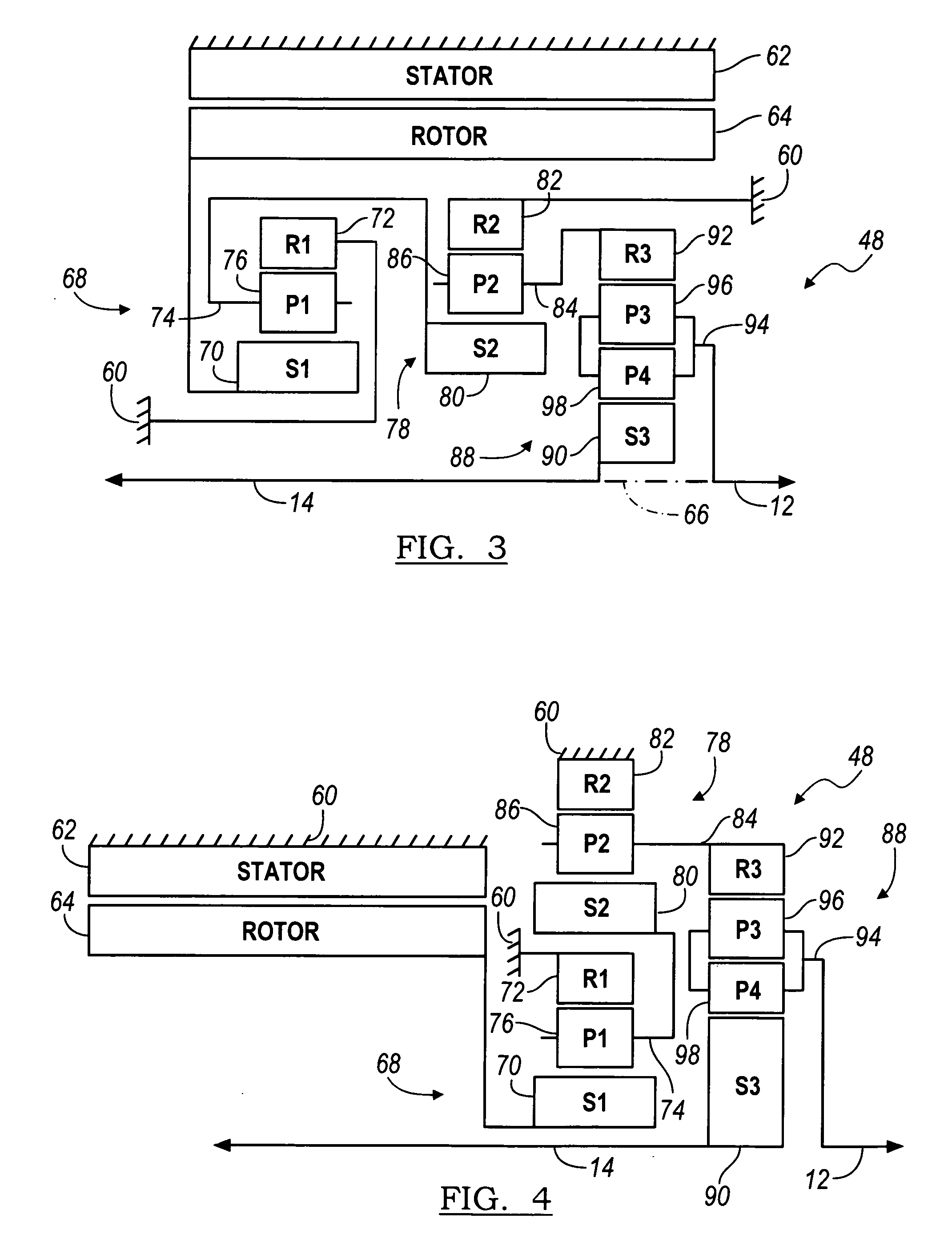

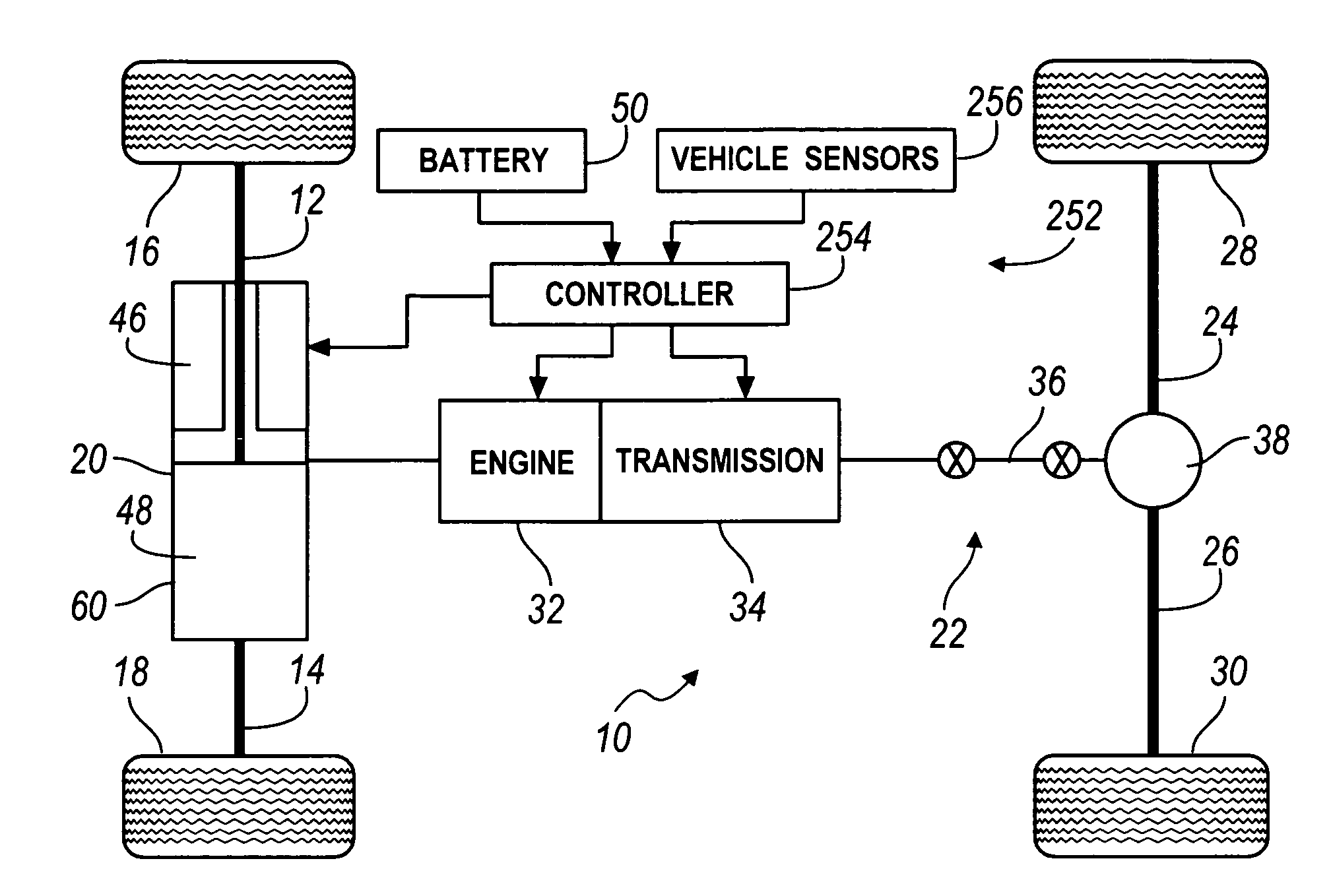

Speed reduction gear train with planetary differential for electric motor axle drive

InactiveUS20070259747A1Easy to packReduce motor speedElectric propulsion mountingGas pressure propulsion mountingElectricityElectric drive

An electric drive unit for a vehicle includes an electric motor, two output shafts, a first speed reduction planetary gearset driven by the motor, a second speed reduction gearset driven by an output of the first gearset, and a compound planetary differential gearset including an input driveably connected to the output of the second gearset, a first differential output driveably connected to the first output shaft, and a second differential output driveably connected to the second output shaft.

Owner:FORD GLOBAL TECH LLC

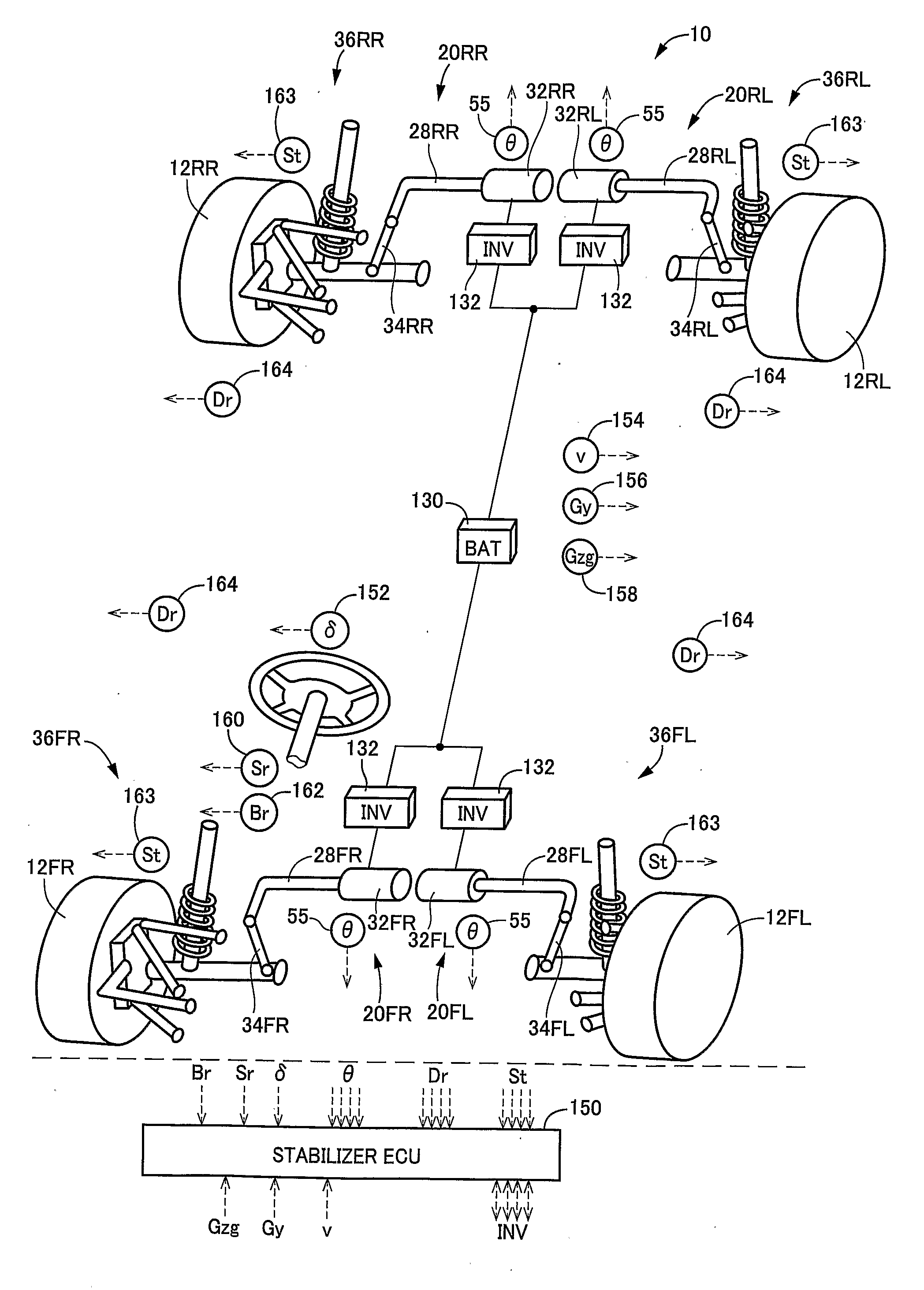

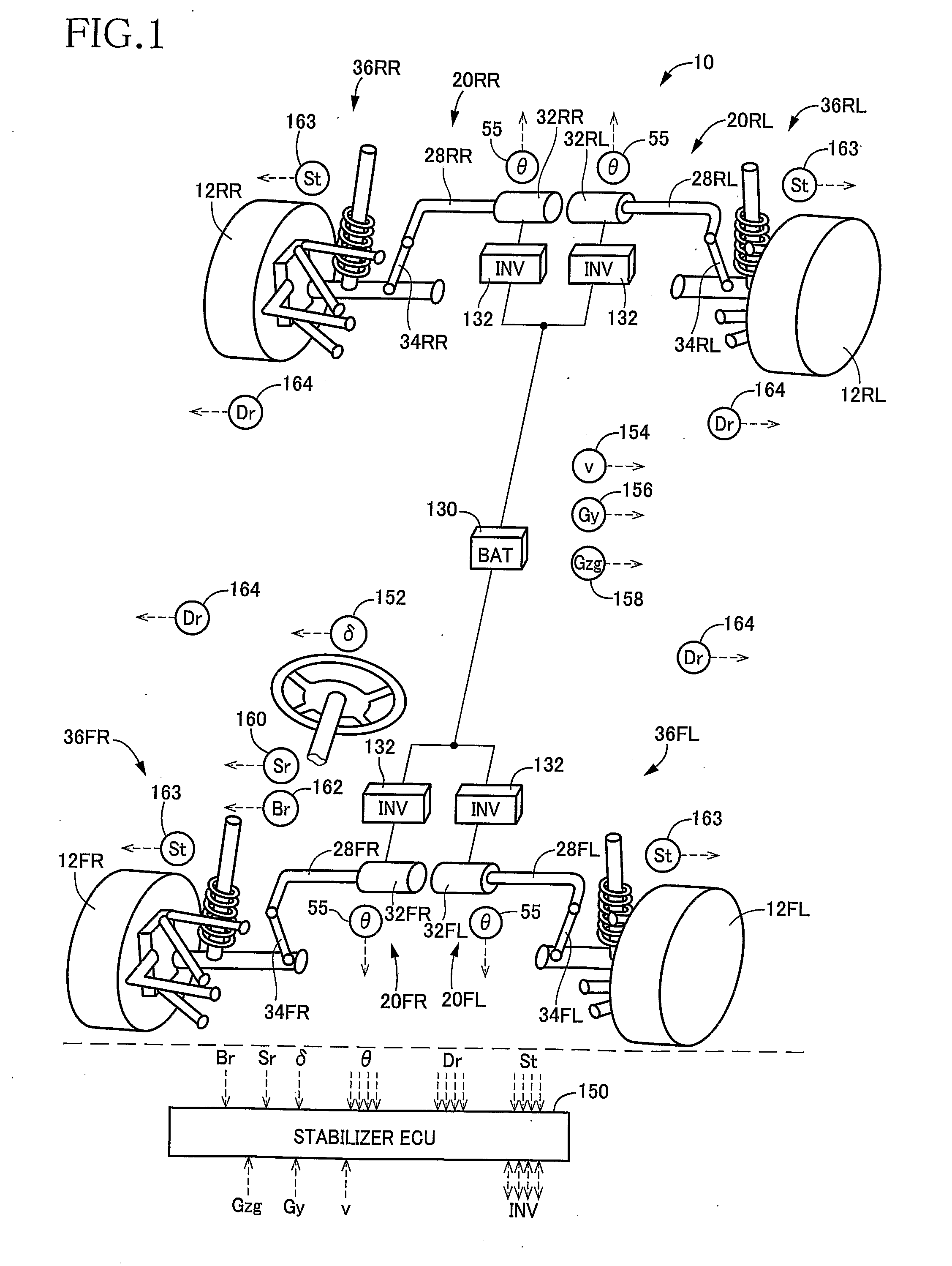

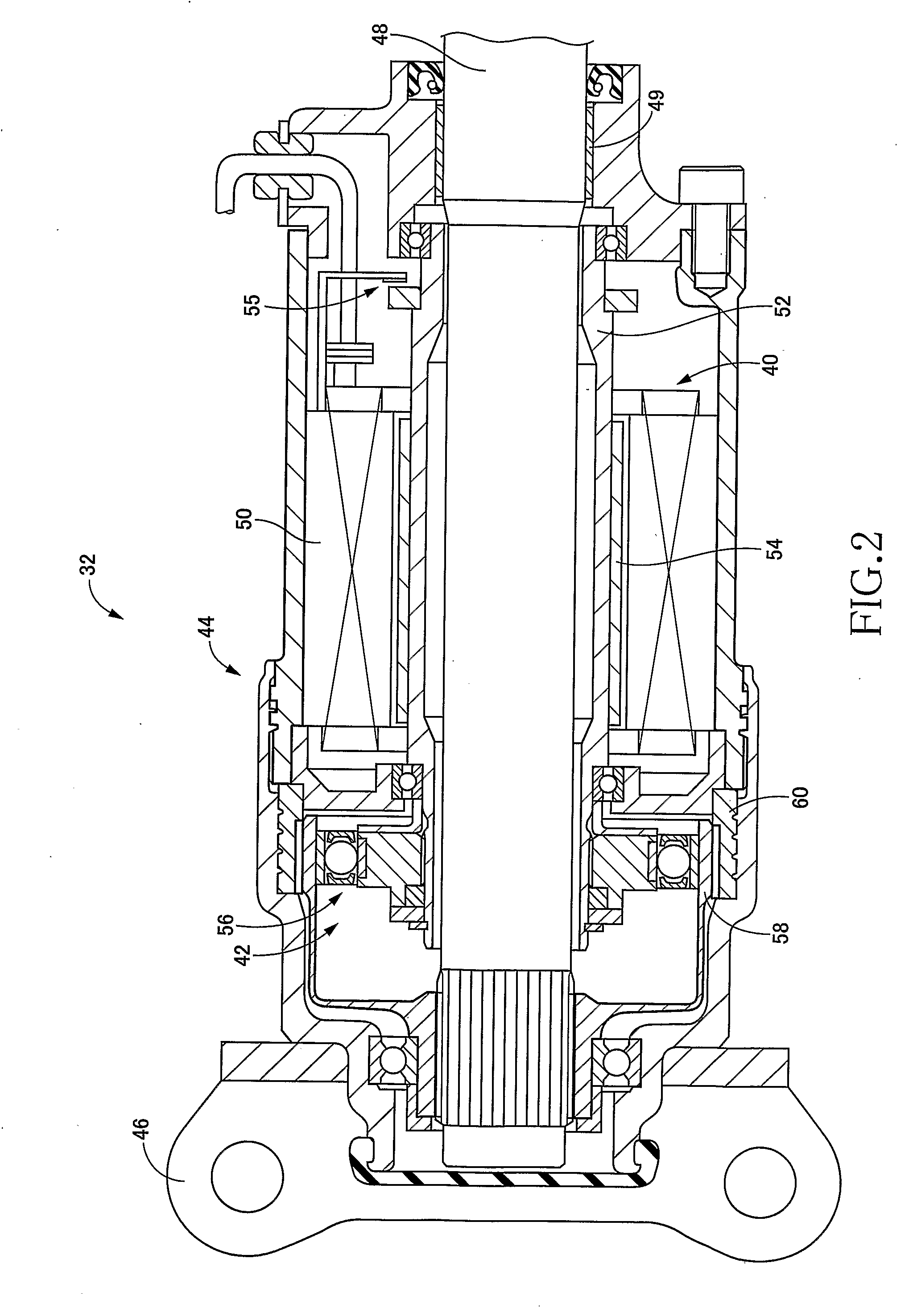

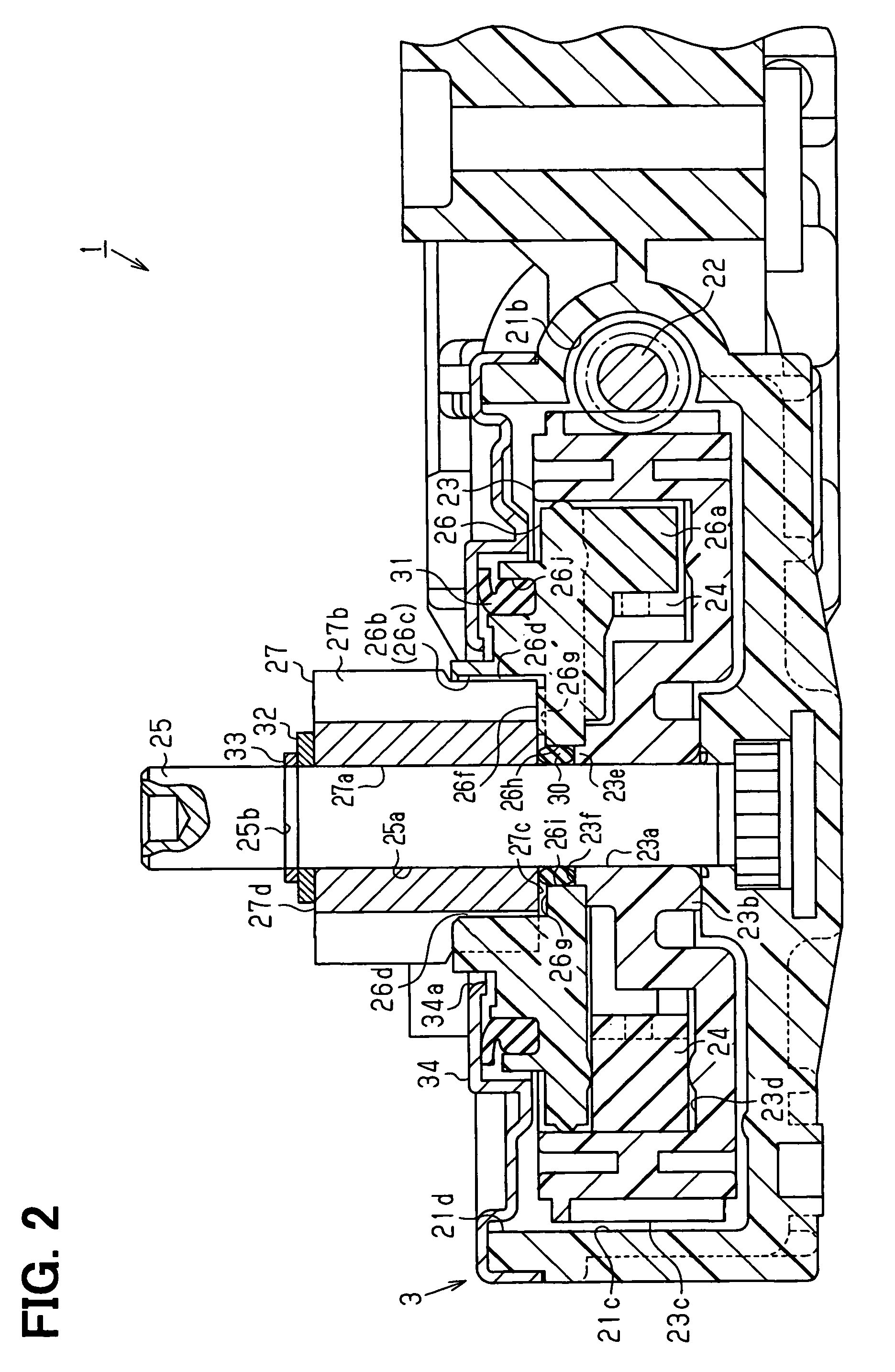

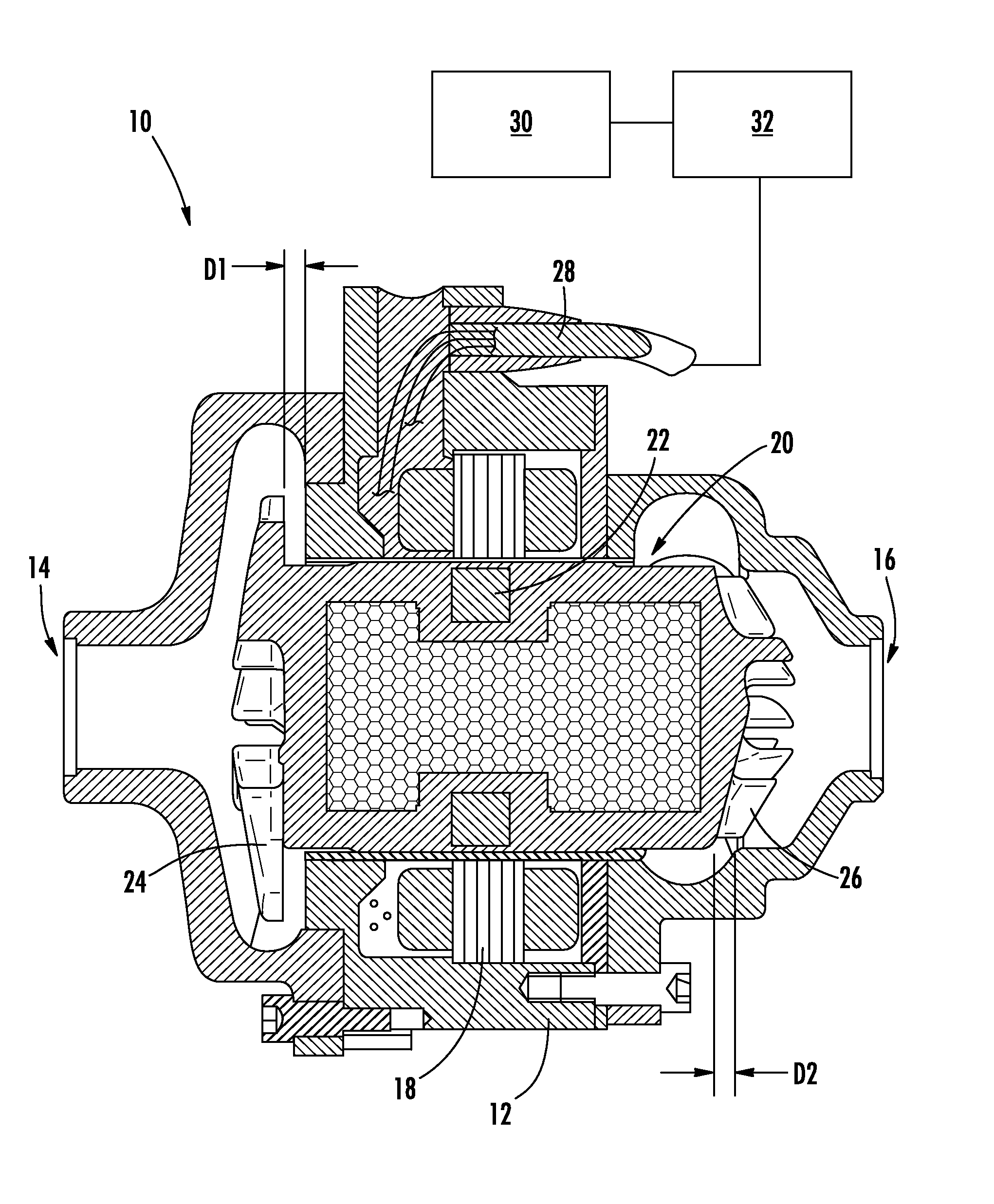

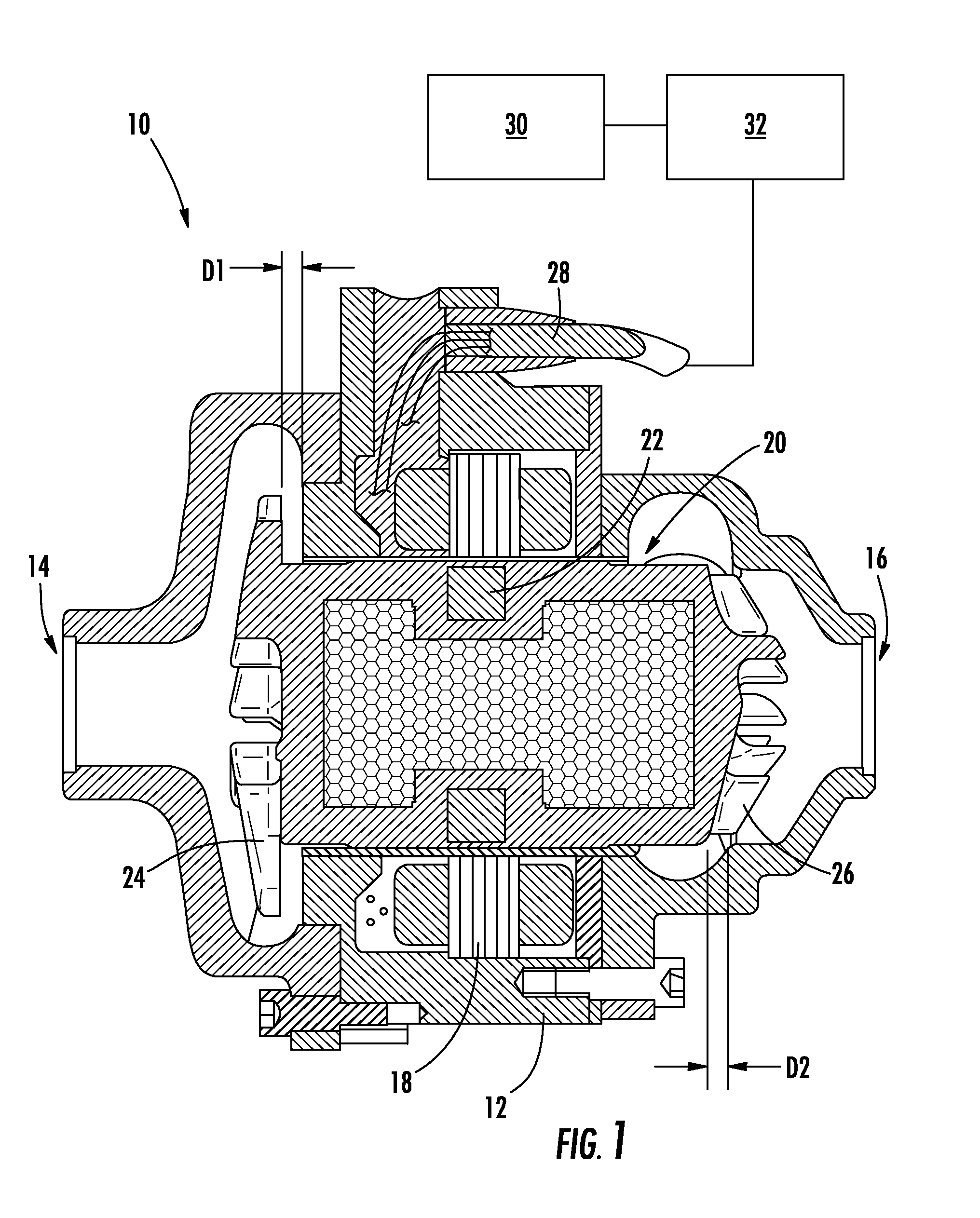

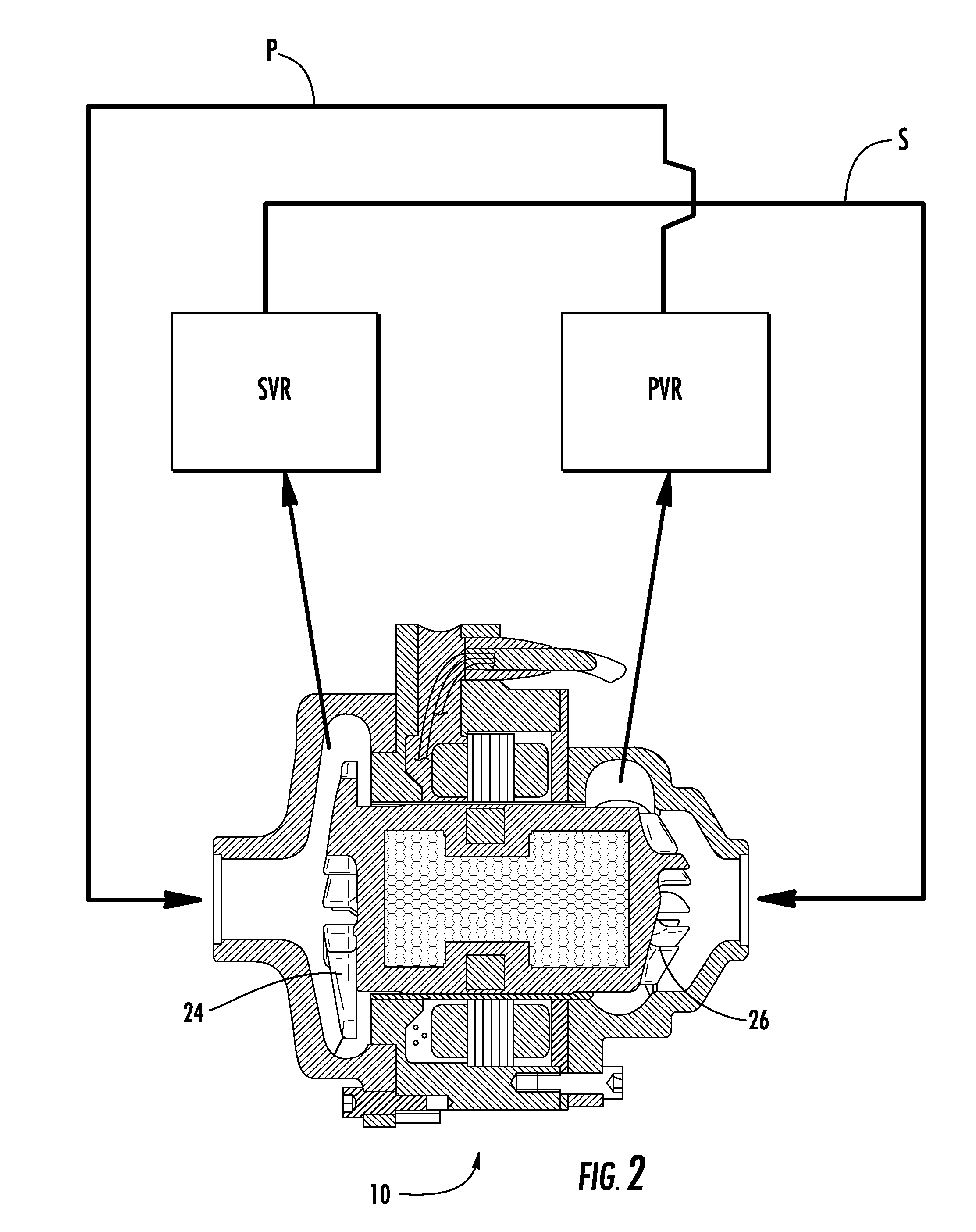

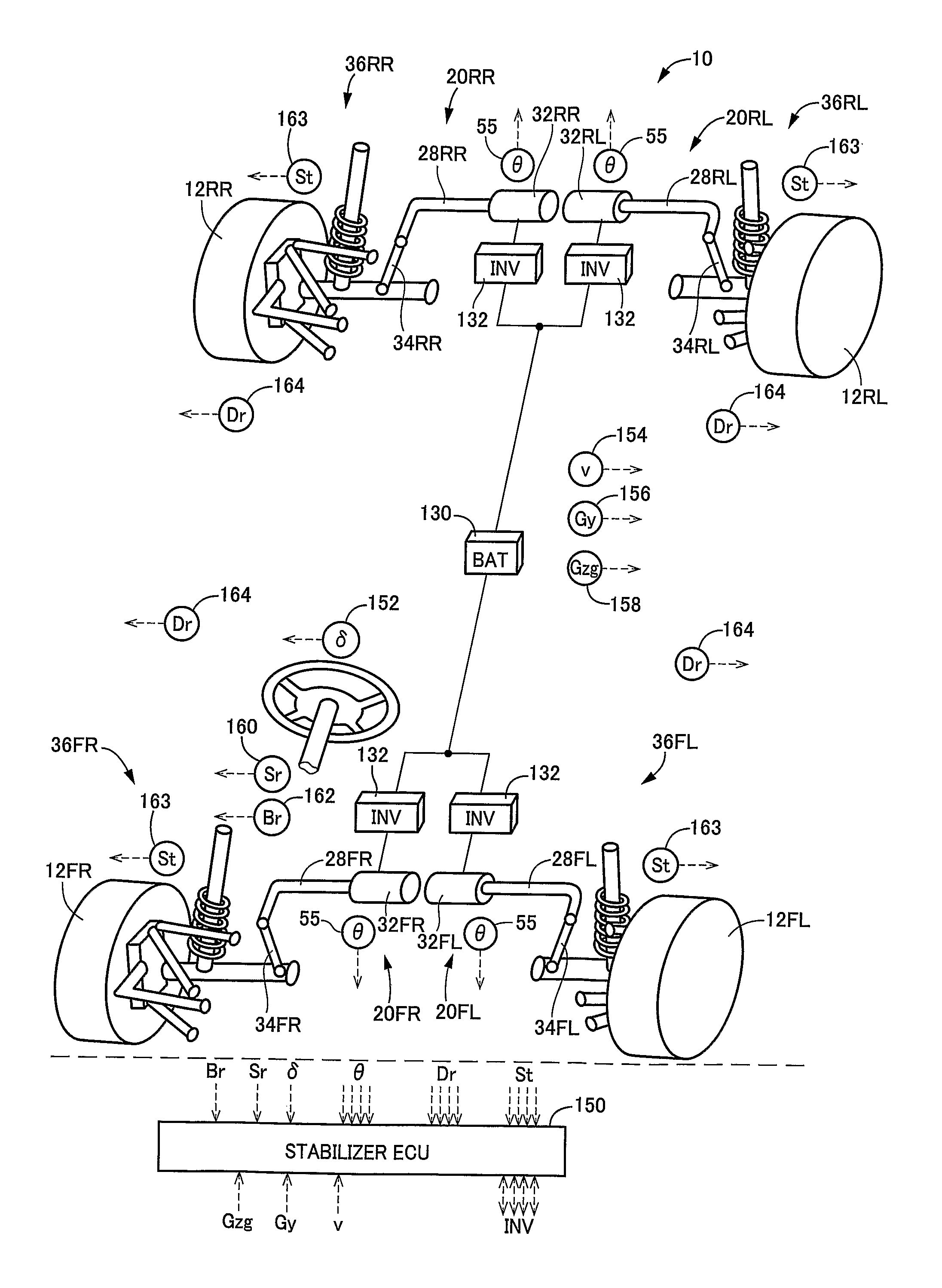

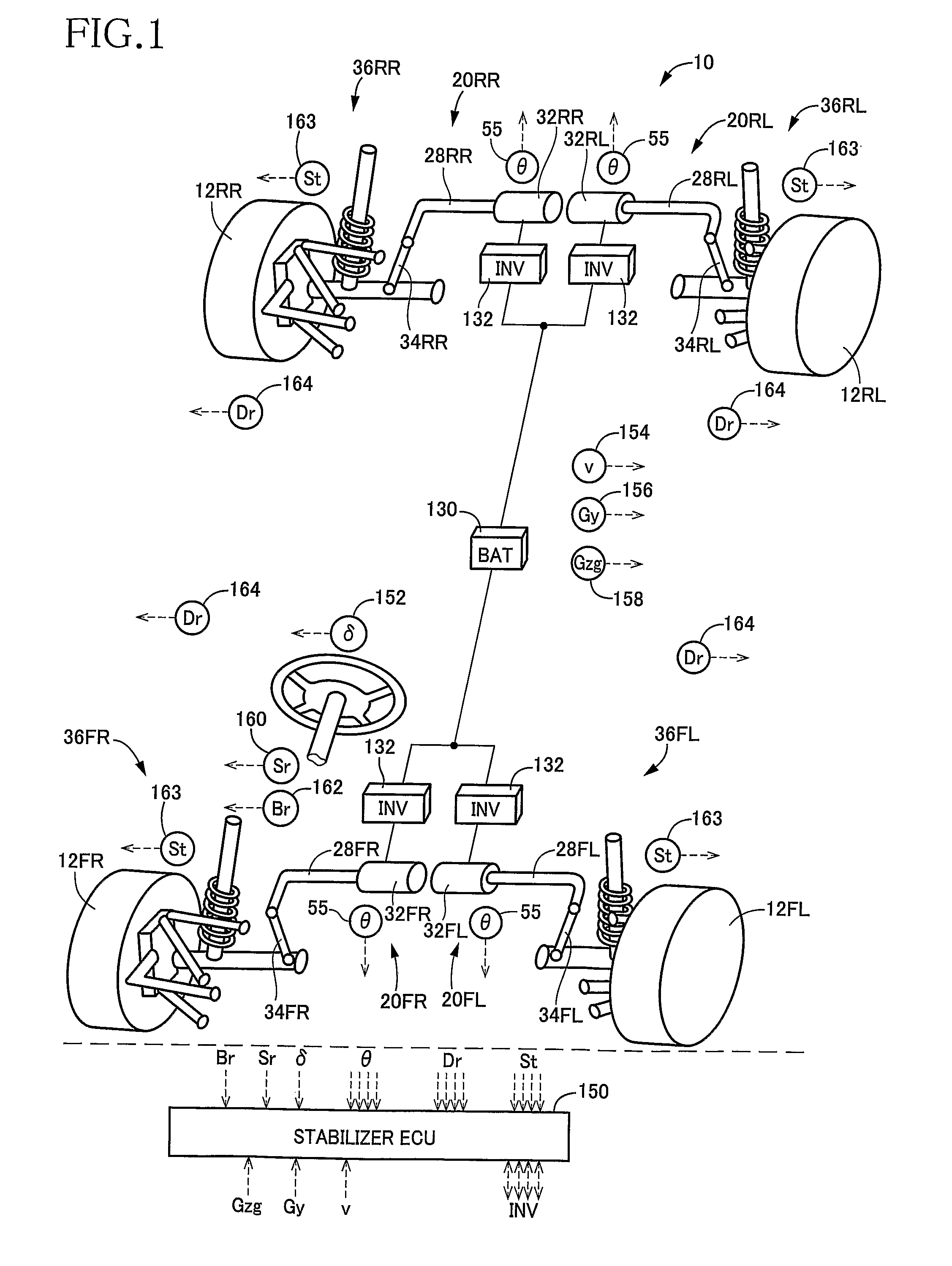

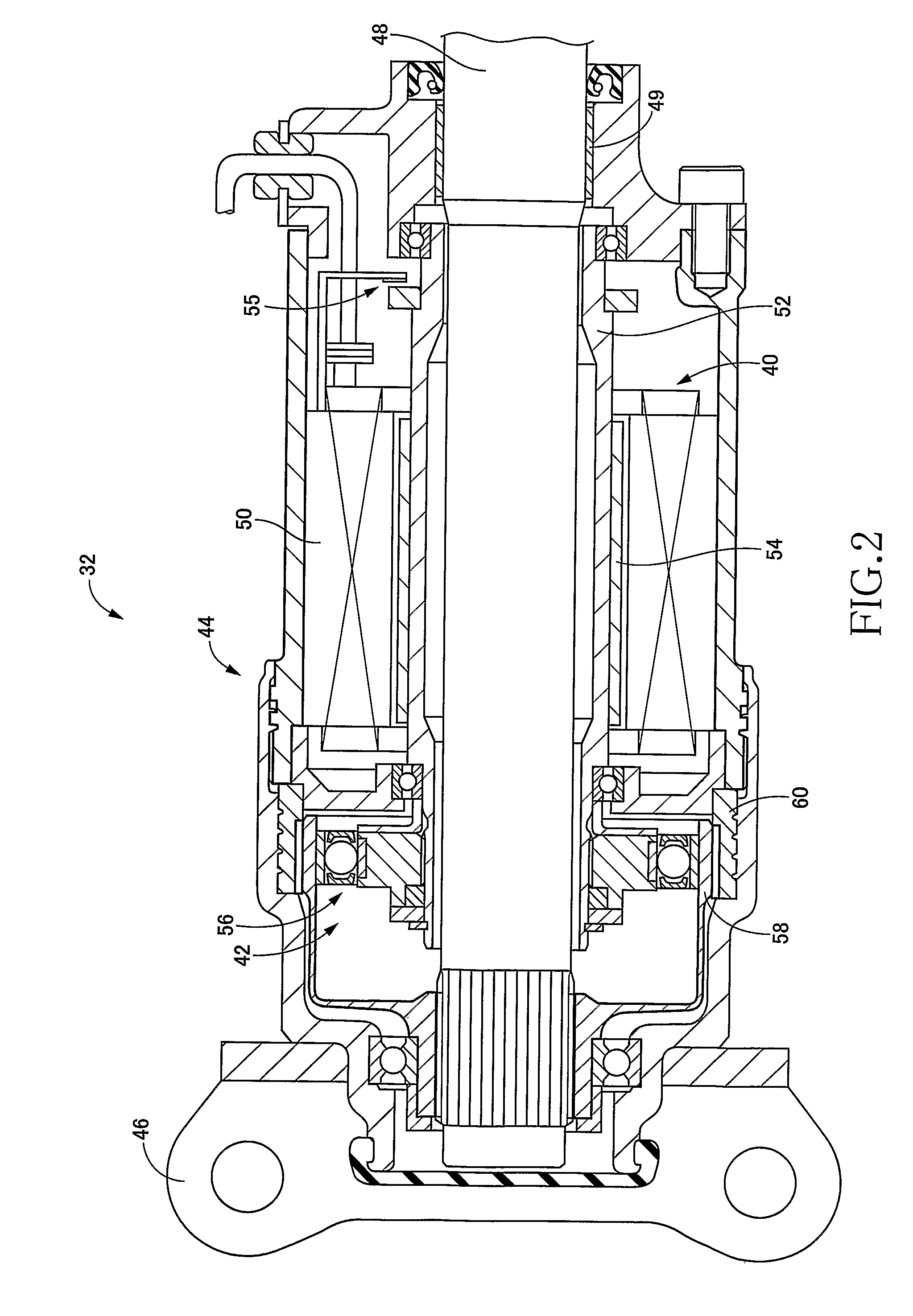

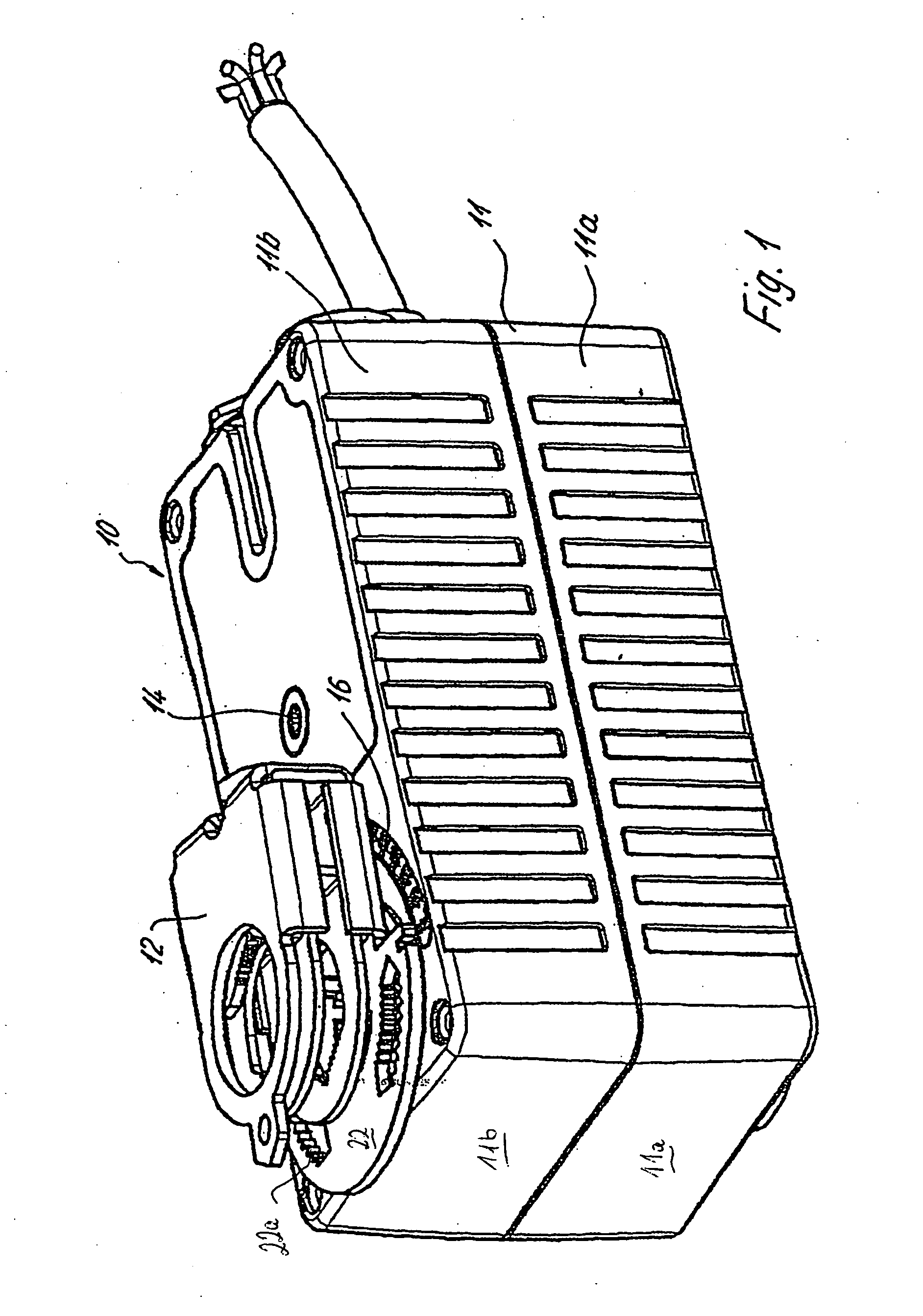

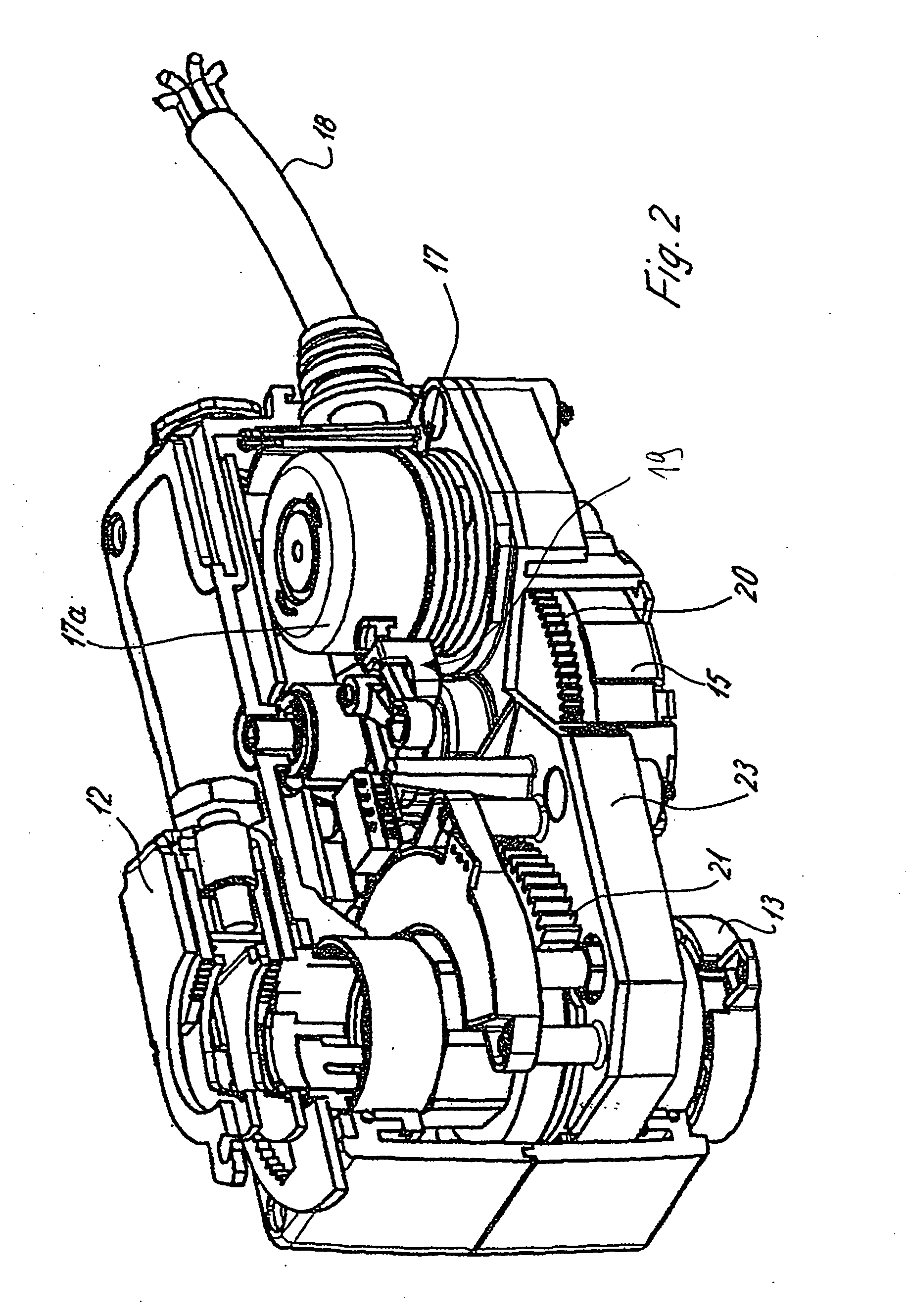

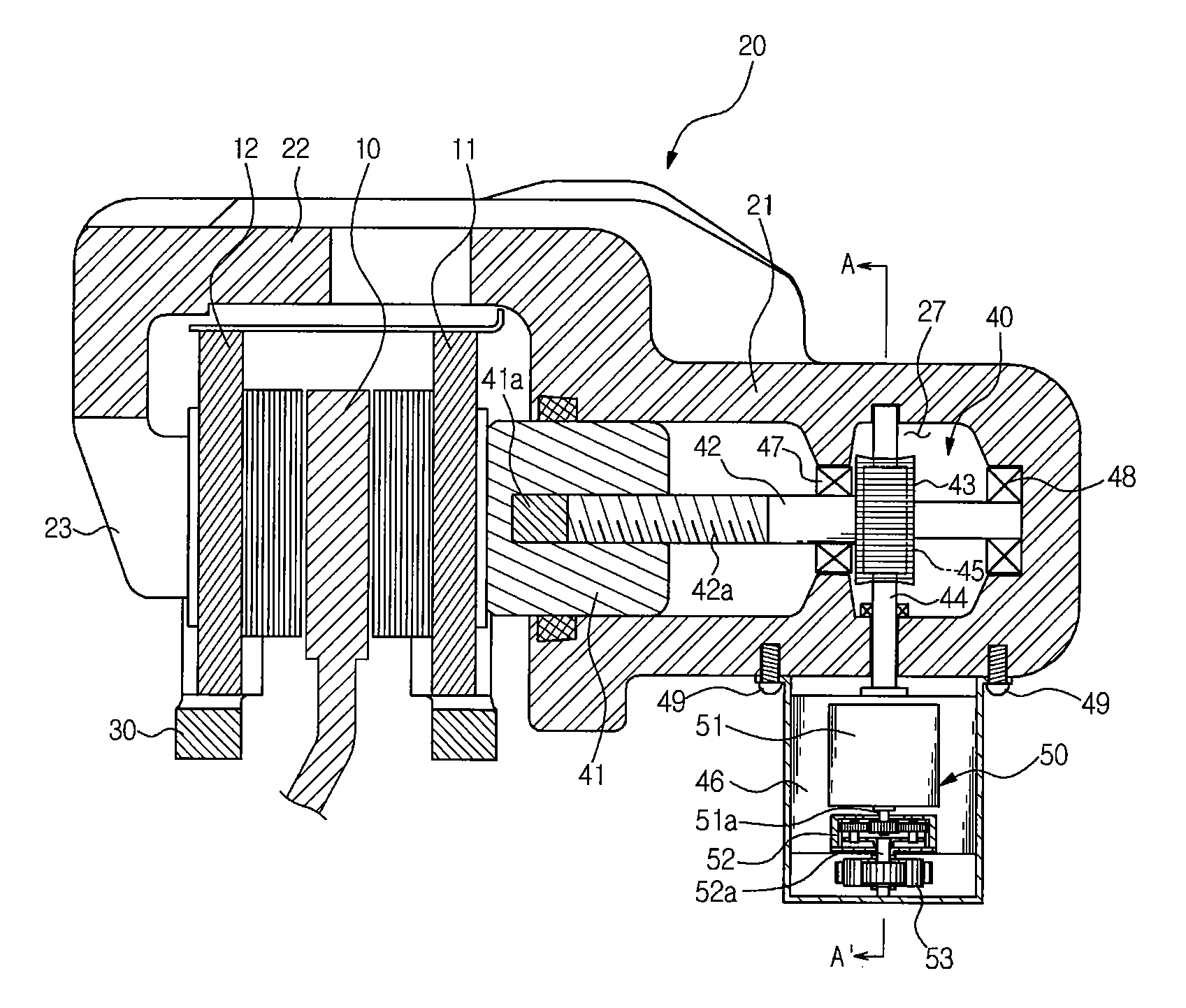

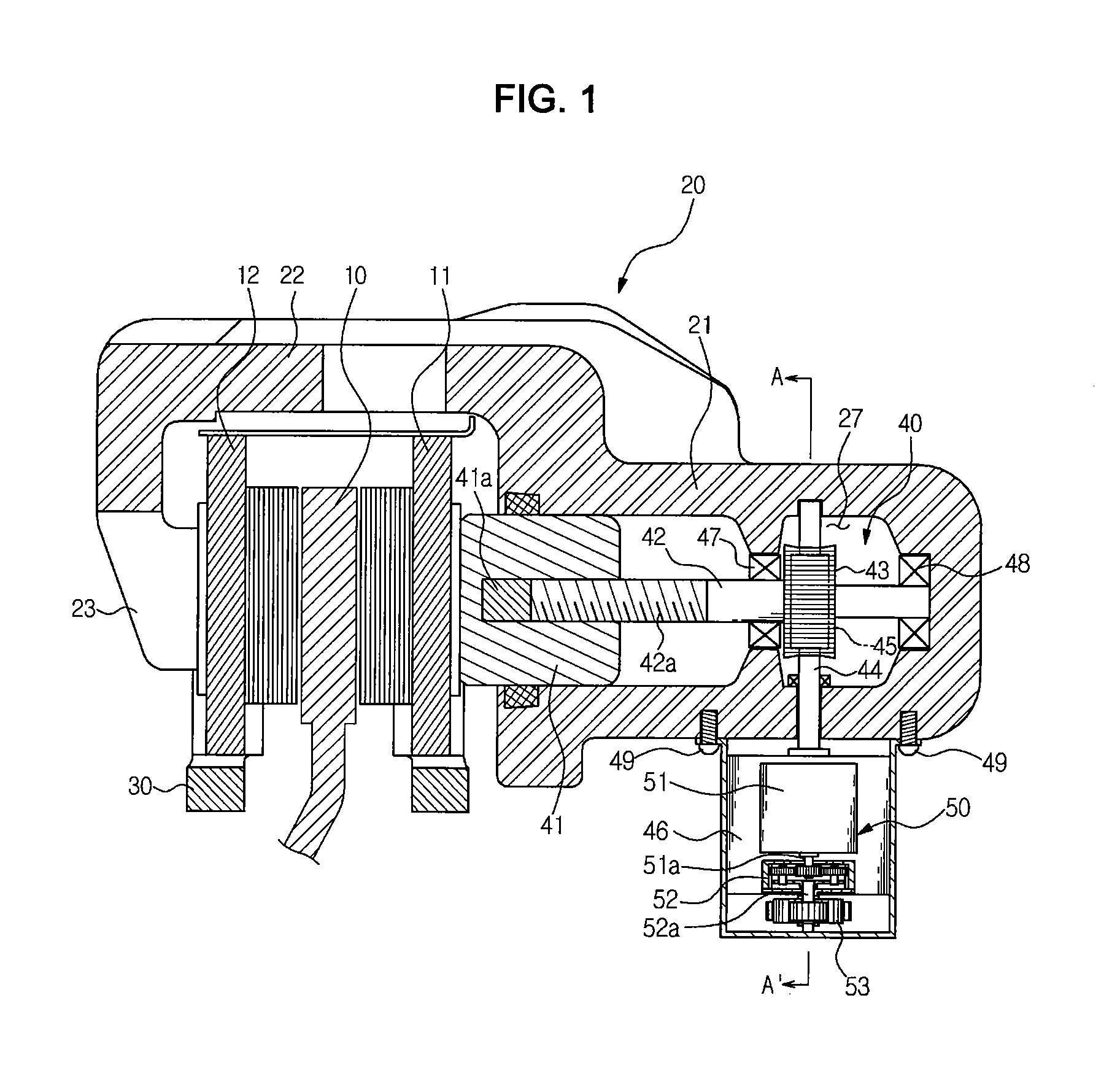

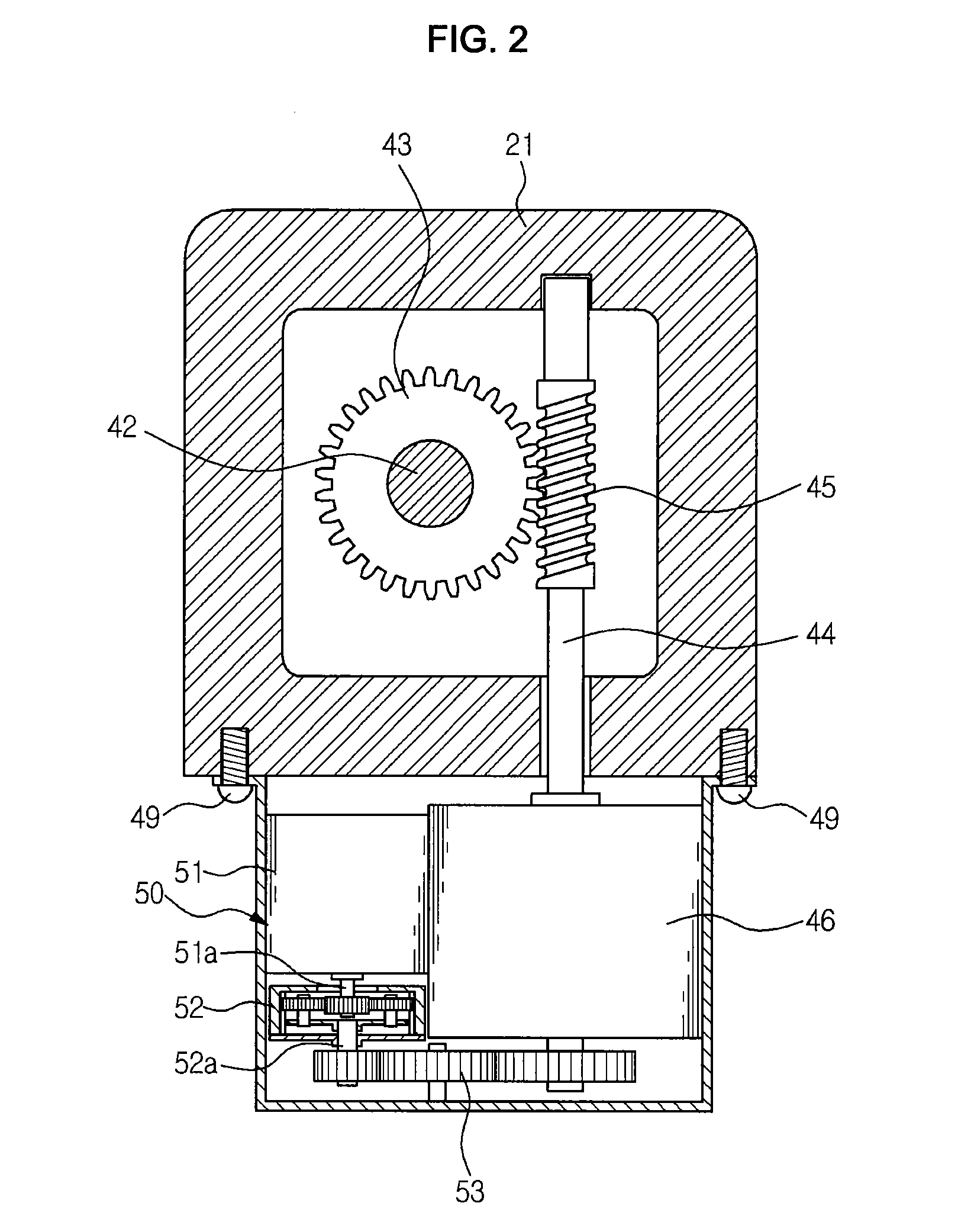

Vehicle stabilizer system

InactiveUS20090008887A1Reduce electric powerLow efficiencyInterconnection systemsResilient suspensionsActuatorControl theory

A stabilizer system for a vehicle, including: (a) a stabilizer bar (28) including (a-1) a torsion bar portion (90), and (a-2) an arm portion (92) that extends from the torsion bar portion toward a wheel (12) of the vehicle; and (b) an actuator (32) including (b-1) a motor (40), and (b-2) a speed reducer (42) that reduces a speed of the motor while transmitting a force of the motor to the torsion bar portion of the stabilizer bar. The stabilizer bar generates a stabilizing force which is dependent on a reaction generated as a result of torsion of the torsion bar portion, and which forces the wheel and the vehicle body in a direction toward each other or a direction away from each other The actuator allows the stabilizer bar to generate the stabilizing force whose magnitude is dependent on a magnitude of the motor force and is changeable depending on an amount of rotation of the torsion bar portion. The actuator includes an actuator-efficiency changing mechanism changing a negative efficiency of the actuator, depending on a direction of the force of the motor.

Owner:TOYOTA JIDOSHA KK

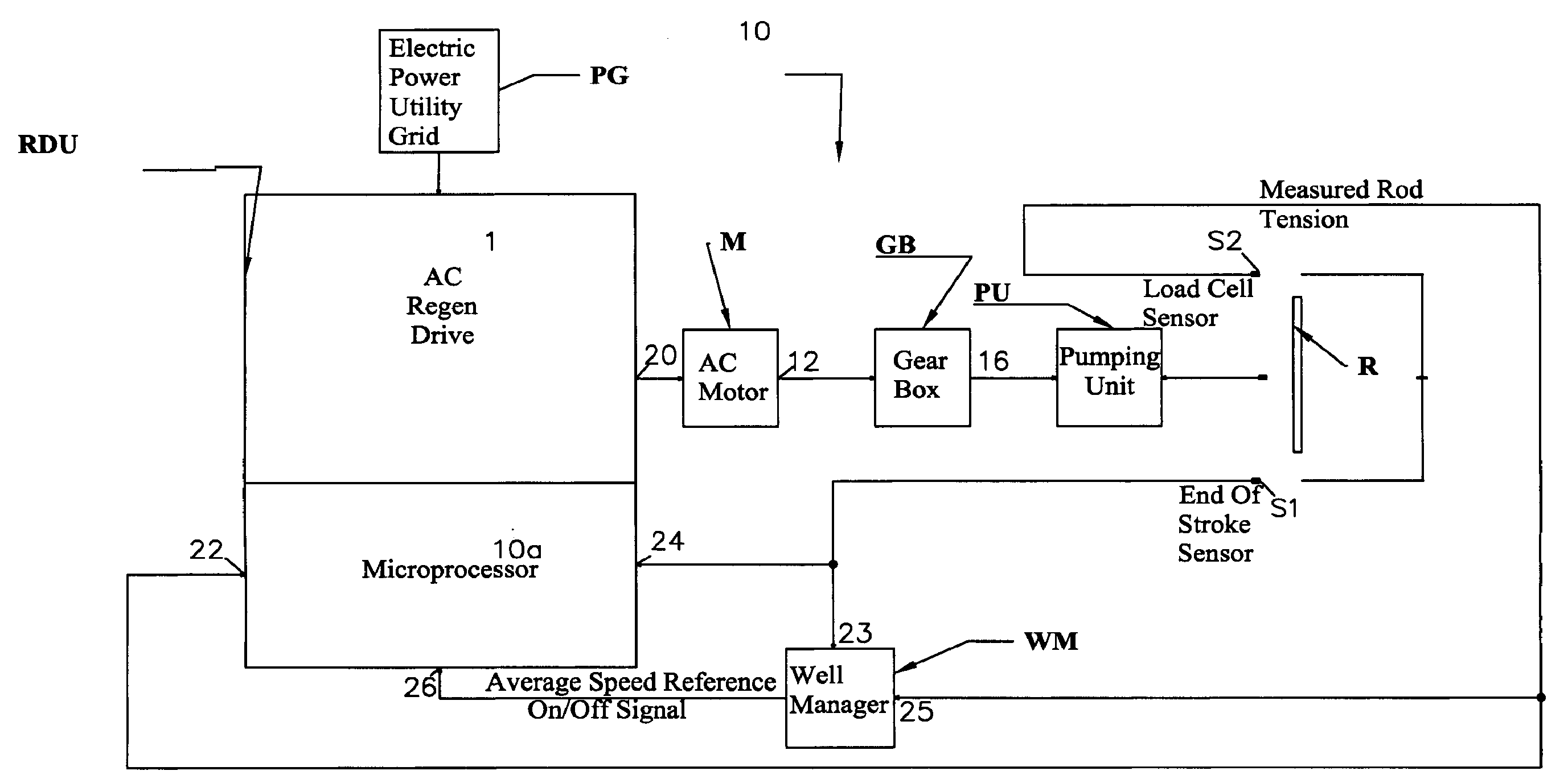

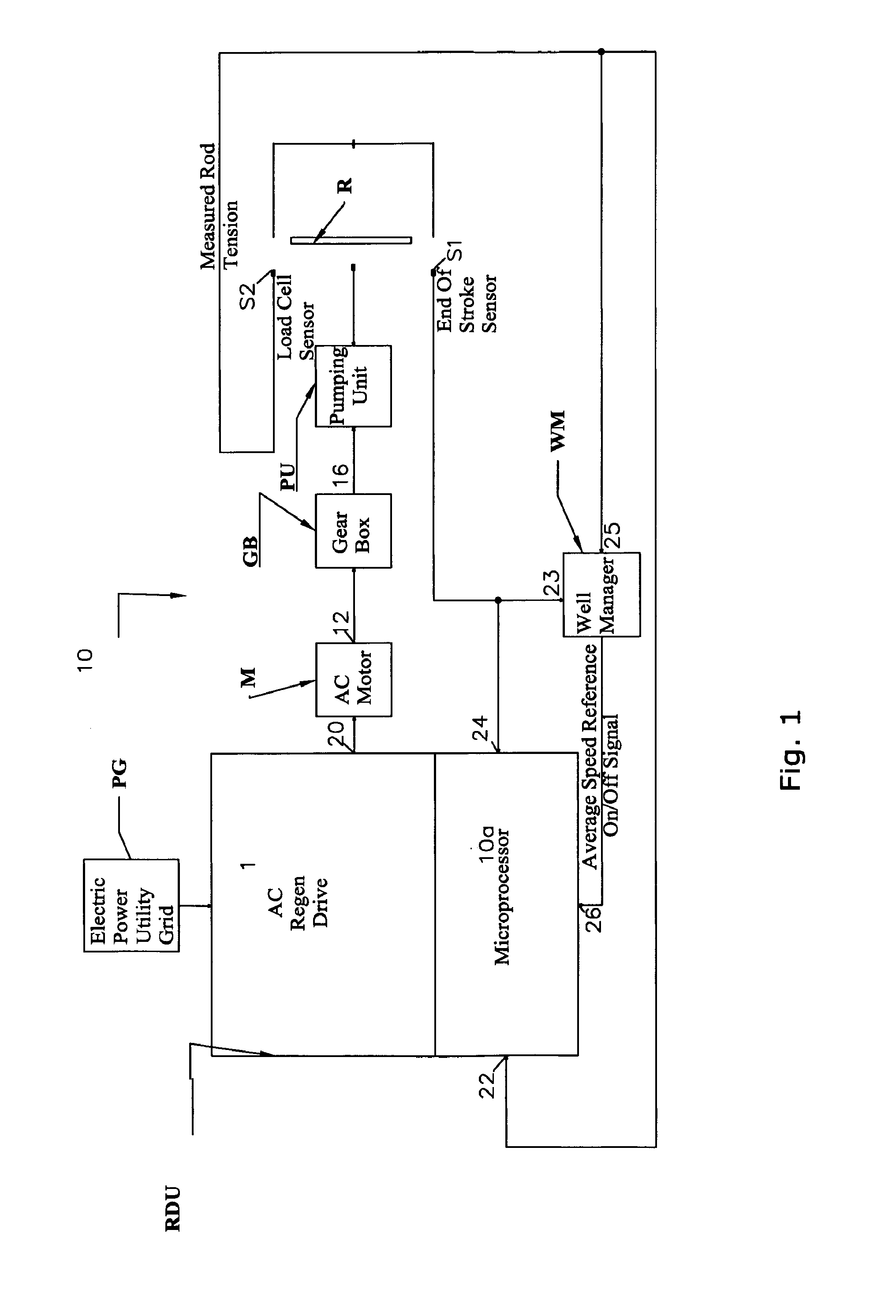

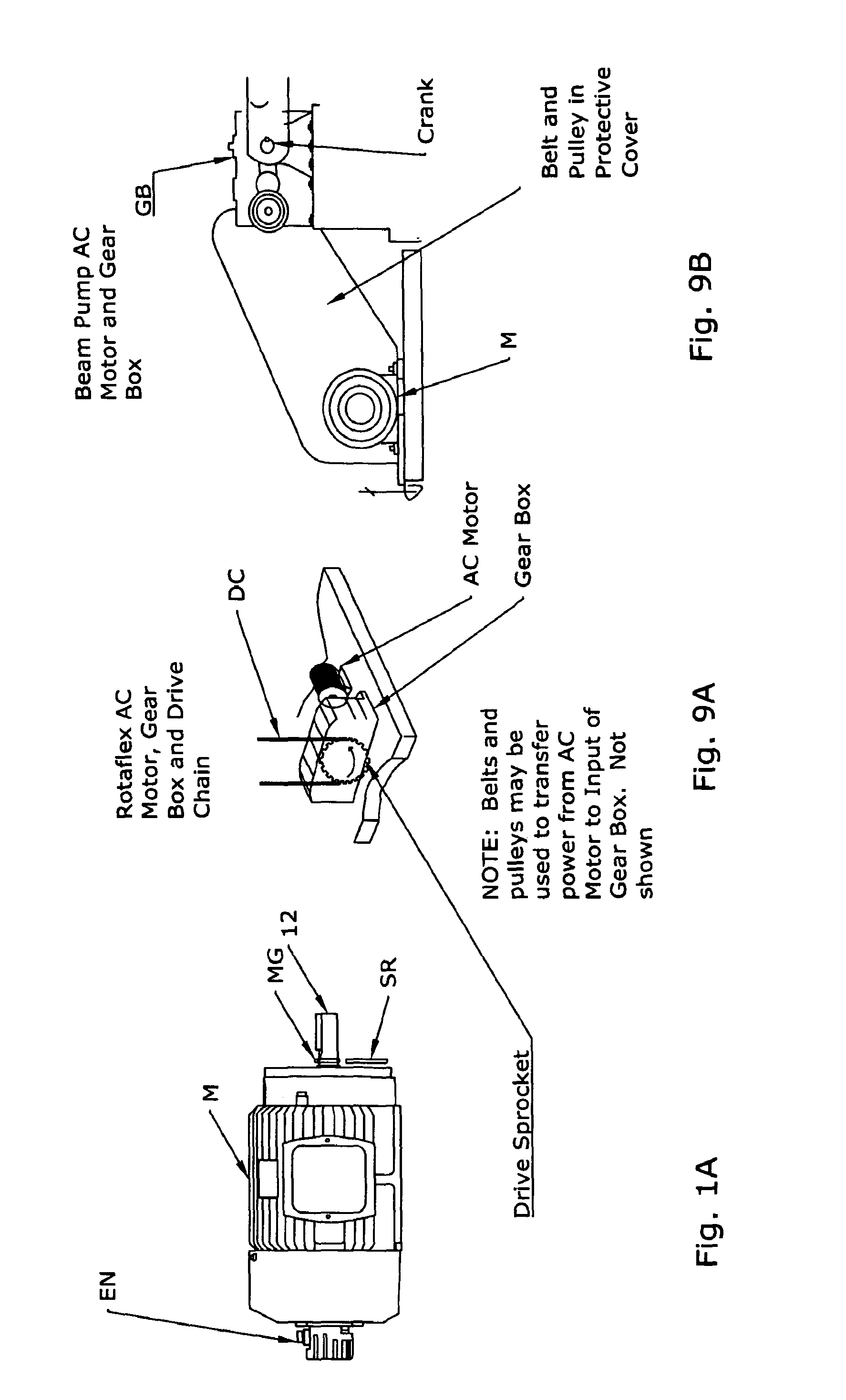

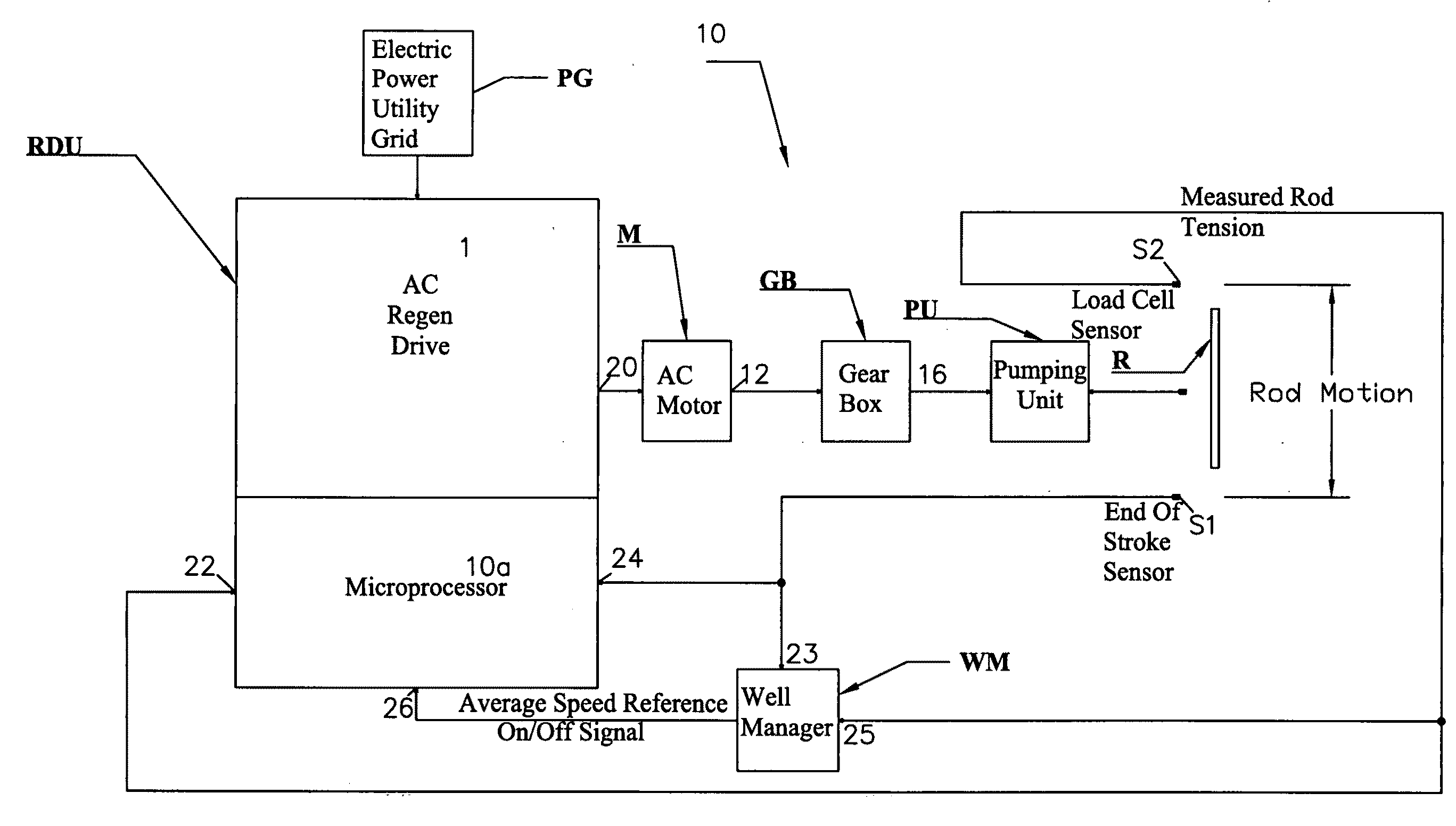

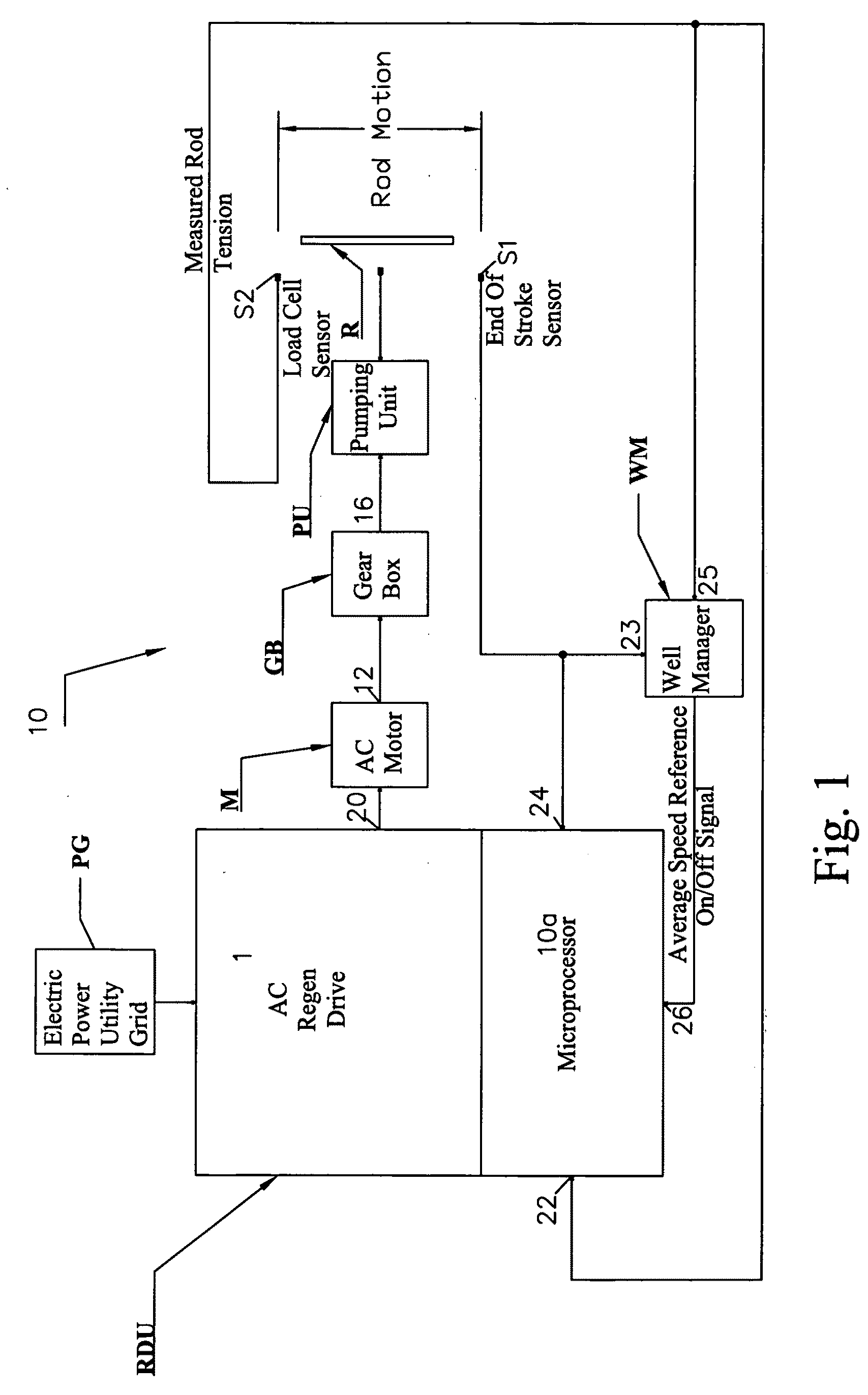

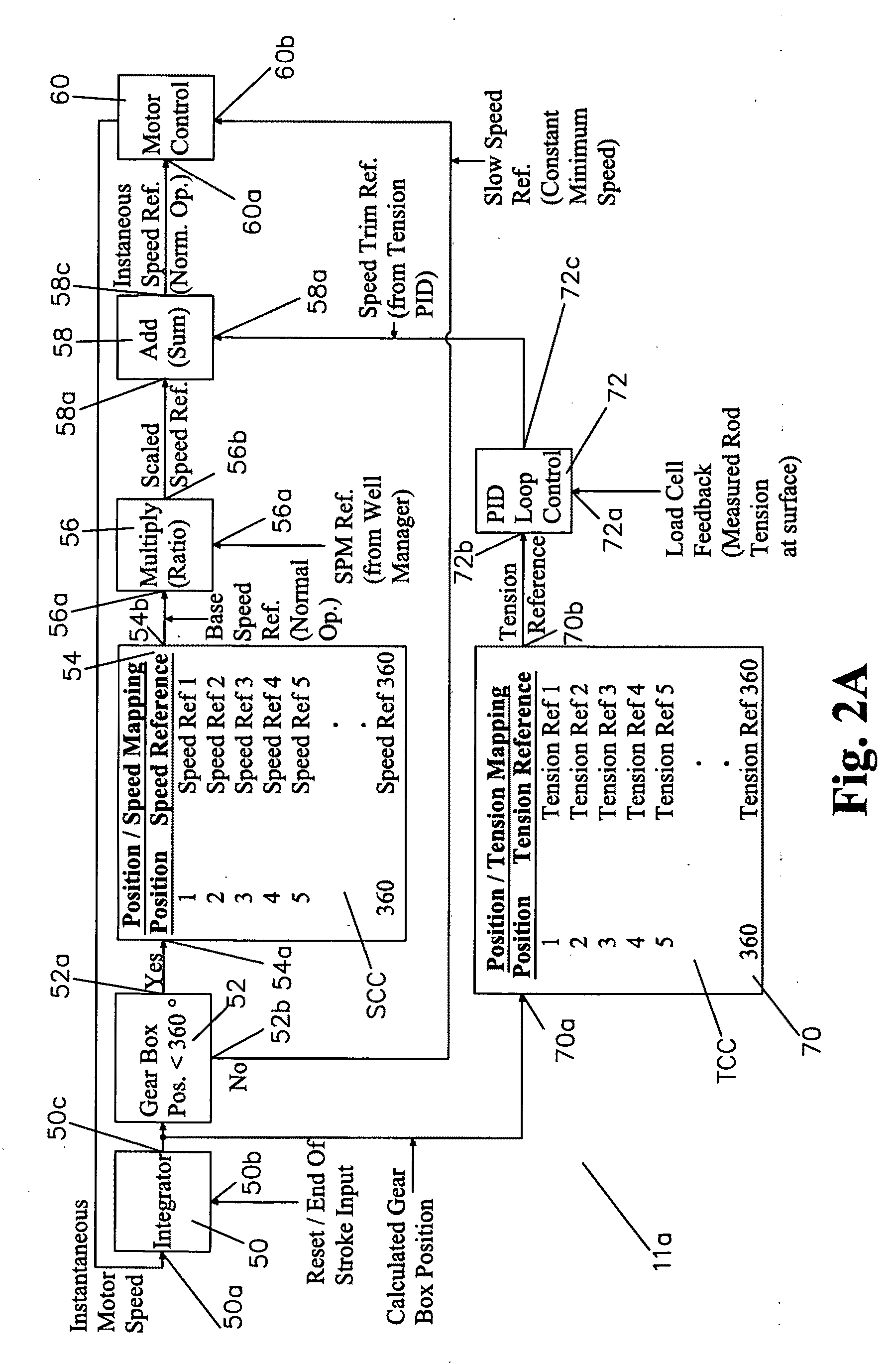

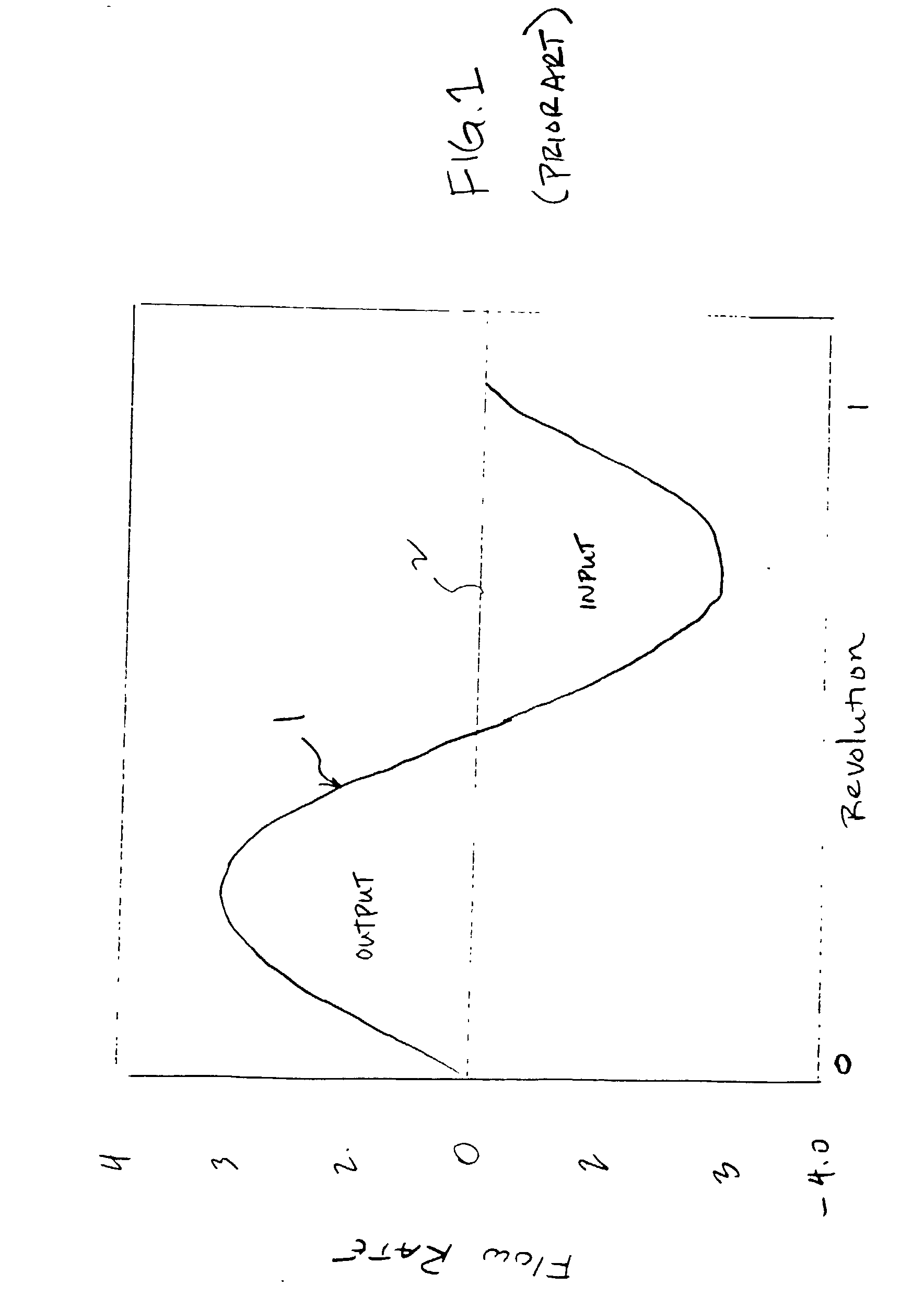

Pump control device, oil well with device and method

InactiveUS20120205119A1More energyPromote productionFlexible member pumpsFluid removalMotor speedPower grid

Owner:HAROLD WELLS ASSOC

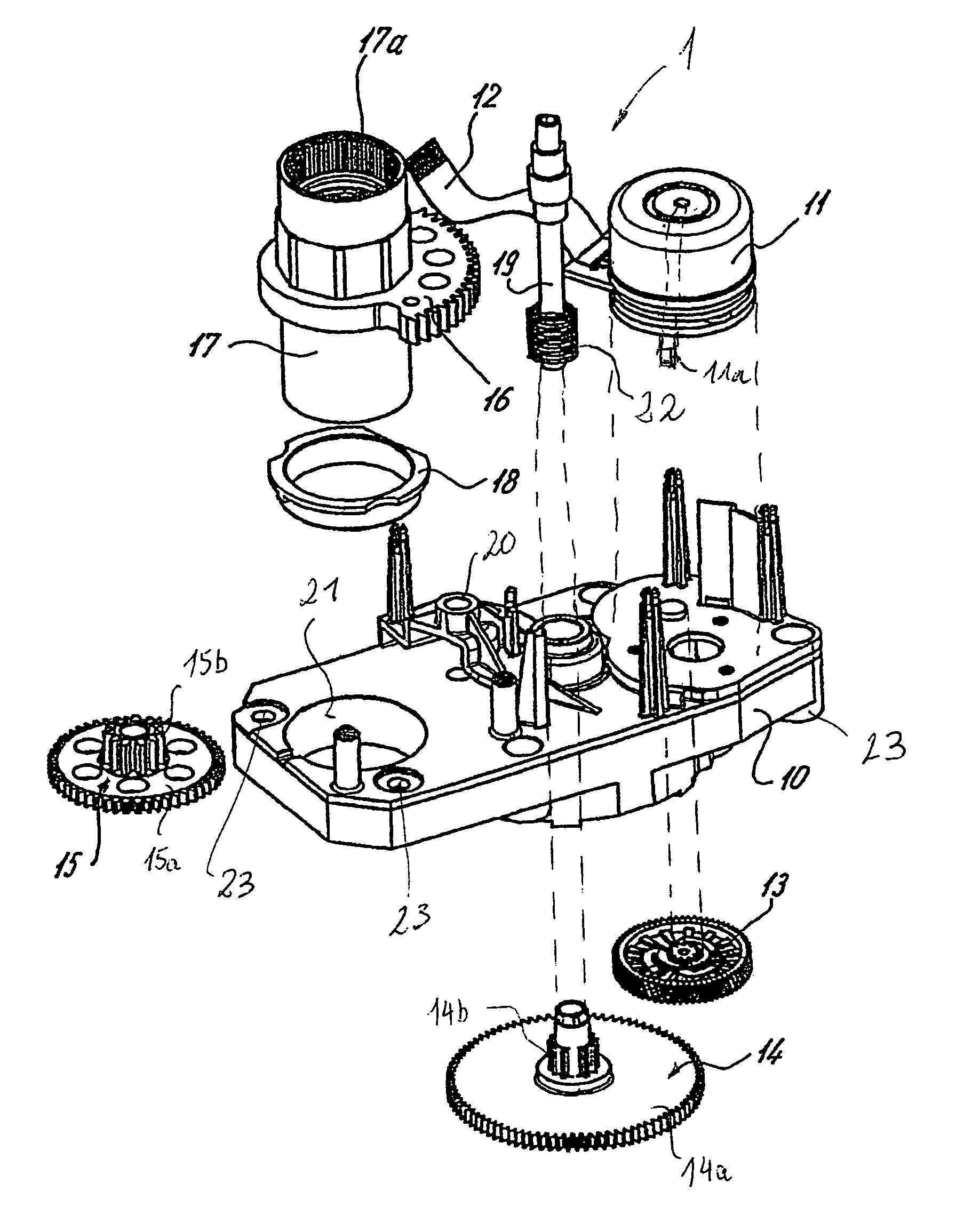

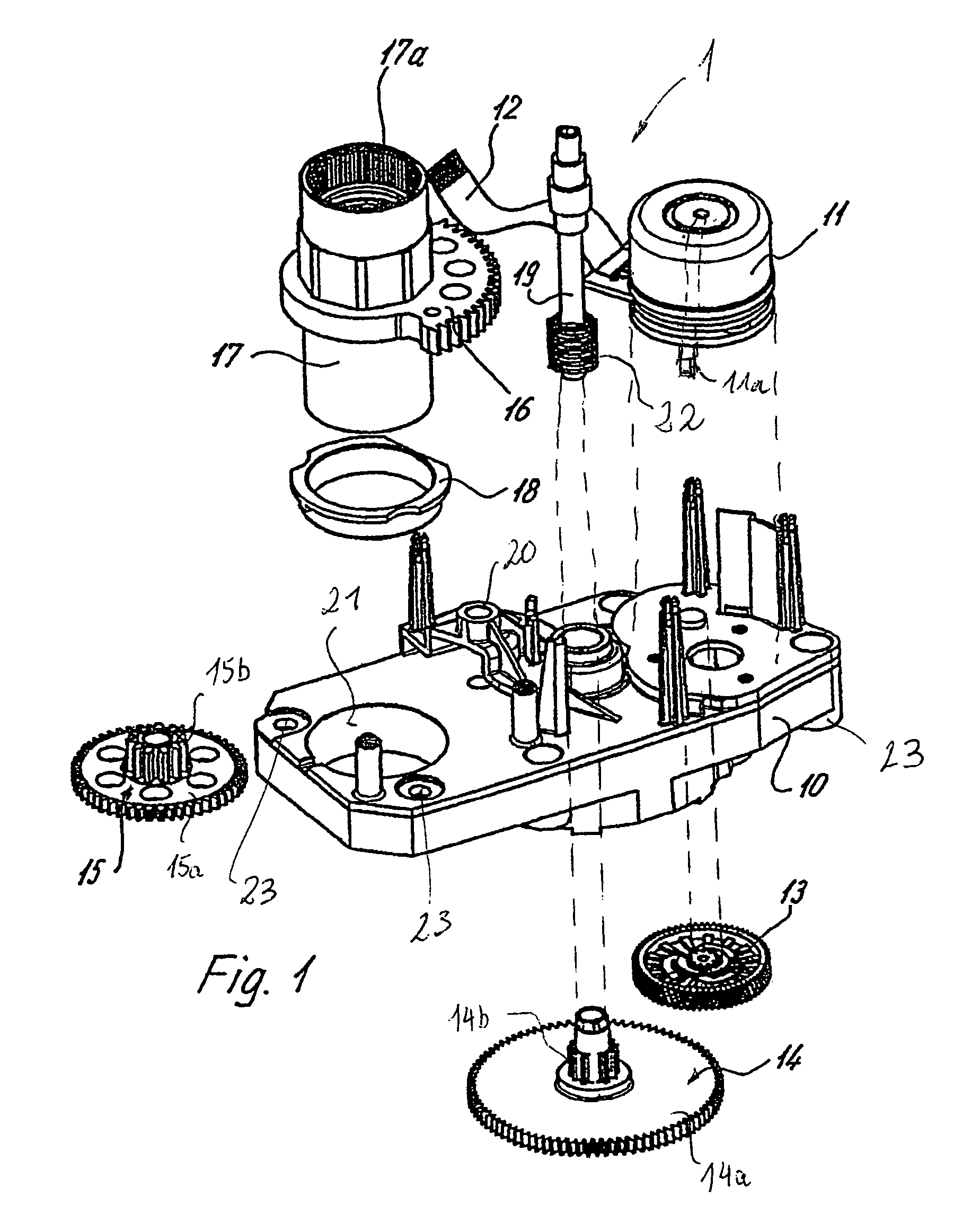

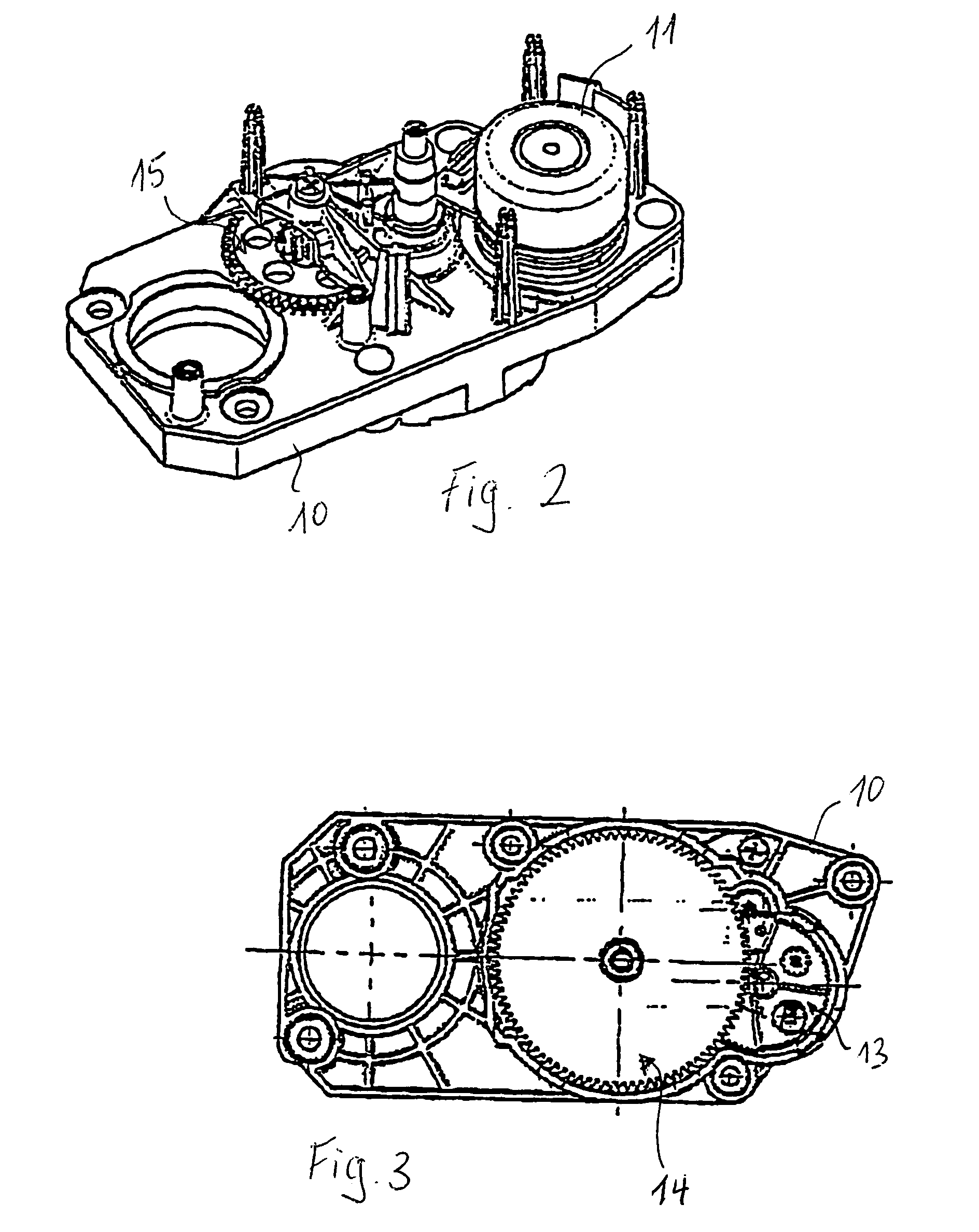

Electromotive adjustment device

InactiveUS7191678B2Raise the ratioUnlimited service lifeOperating means/releasing devices for valvesGearboxesBrushless motorsGear wheel

An electromotive adjustment device for adjusting a control element includes a housing and a gear mechanism which has a plurality of intermeshing gear wheels to define a drive train. In driving relationship with the gear mechanism is a drive motor which is constructed as a brushless motor with an external rotor and includes an output journal, whereby the output journal has a tooth portion in engagement with a helical spur gear wheel of the gear mechanism.

Owner:ELODRIVE STELLANTRIEBSTECHN

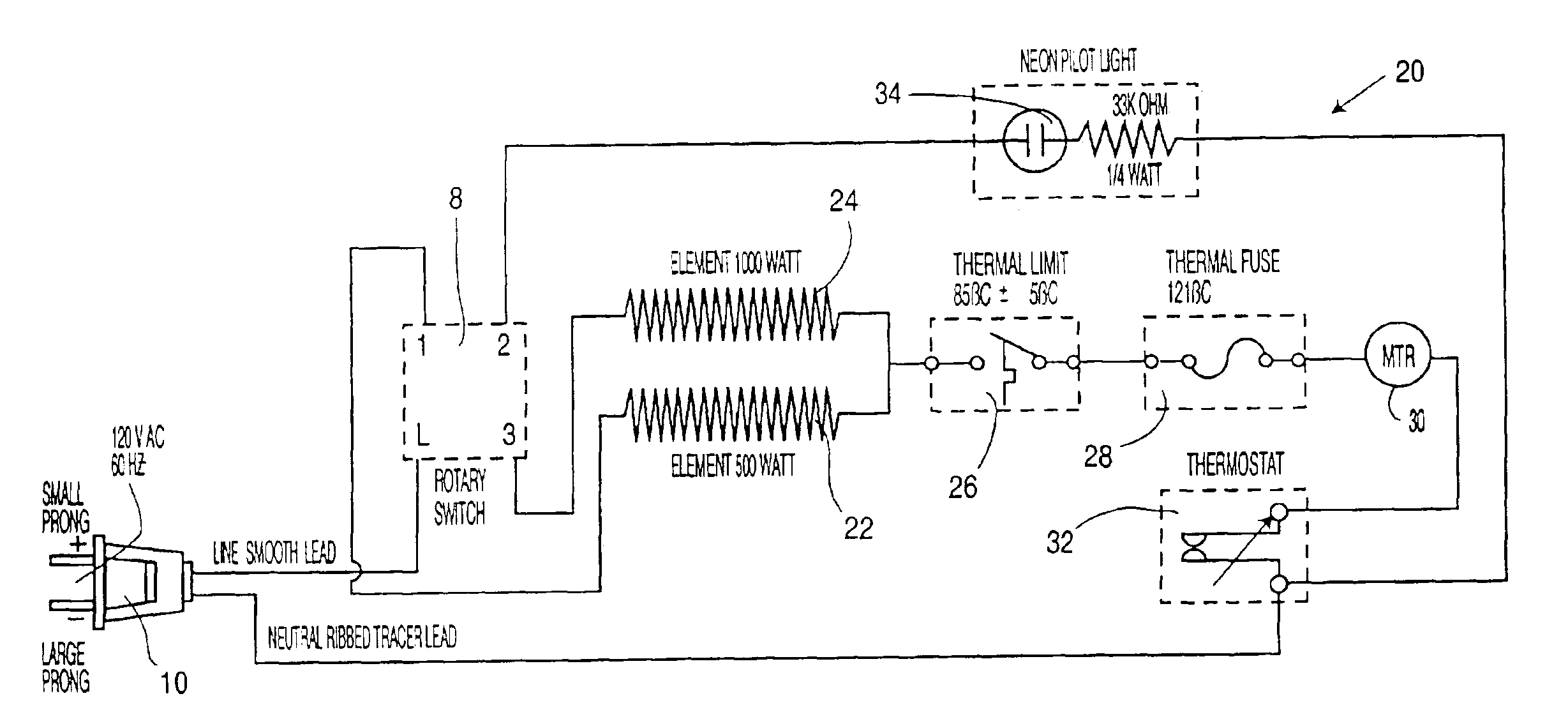

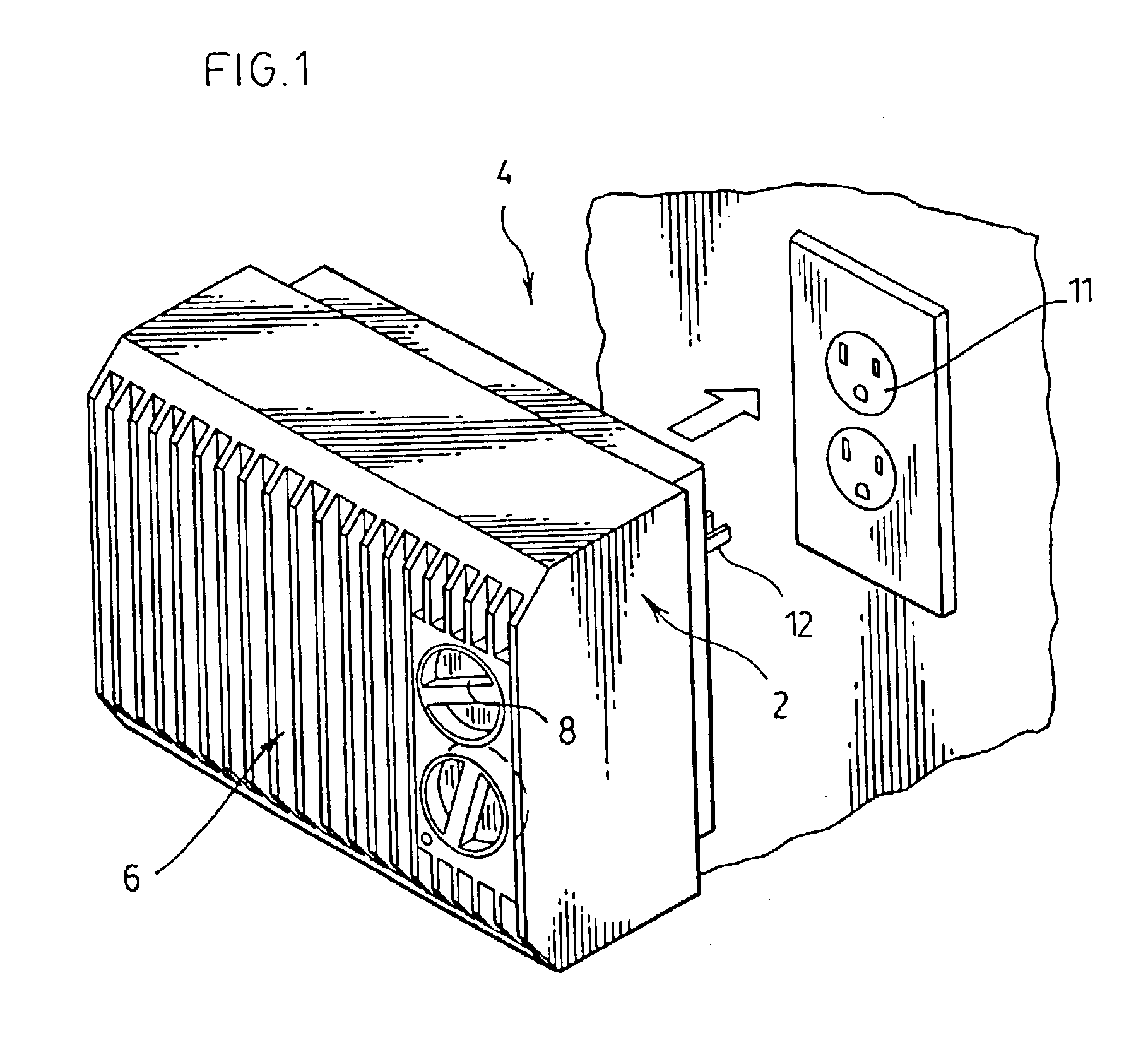

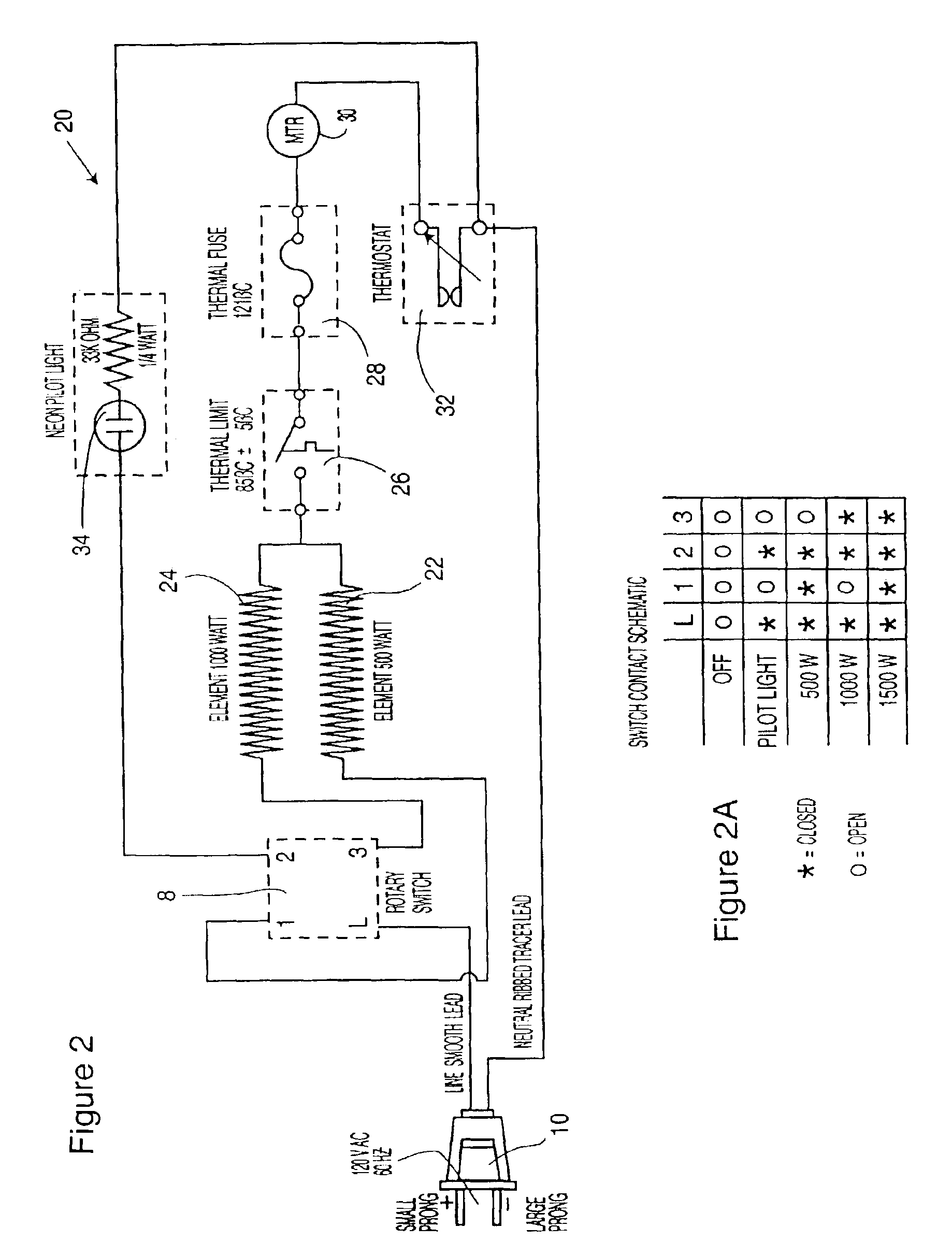

Electric circuit for portable heater

InactiveUS6940051B2Easy to manufactureControl safe operationAir heatersOhmic-resistance heating detailsElectrical resistance and conductancePower flow

A heater effectively uses a current controlled fan motor in series with a resistance heating arrangement. The fan motor preferably is wound with a gauge of wire to appropriate for the relatively high current provided to the fan motor. This arrangement is effectively used to adjust the fan speed to match the heat output when the heating arrangement has variable heat output. More desirable operating characteristics are achieved without increasing costs and fan motor manufacturing savings are realized. The portable heater preferably produces heat at different outputs and the current used to power the resistance heating arrangement is used to power the fan motor.

Owner:TATEISHI ART K

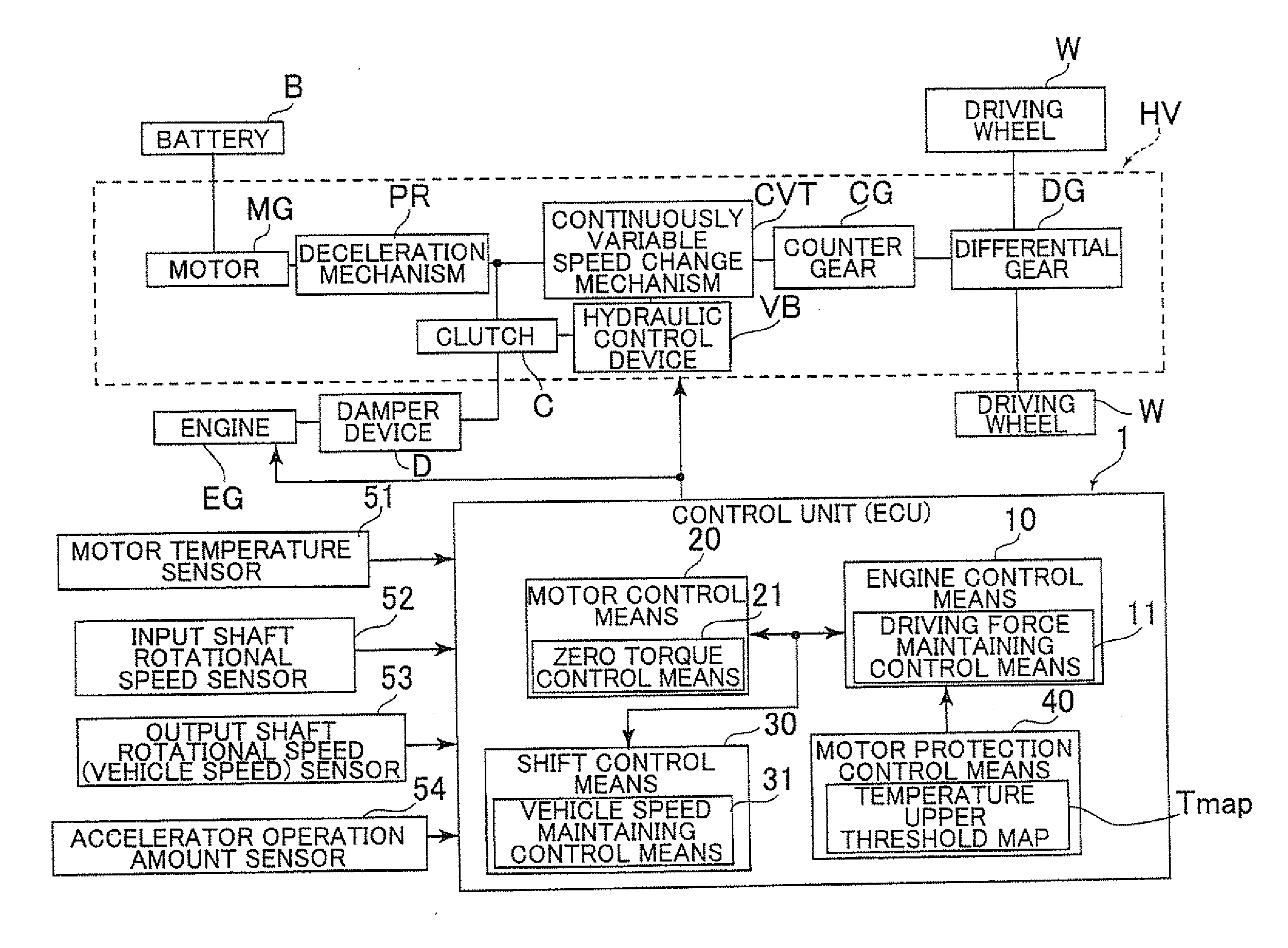

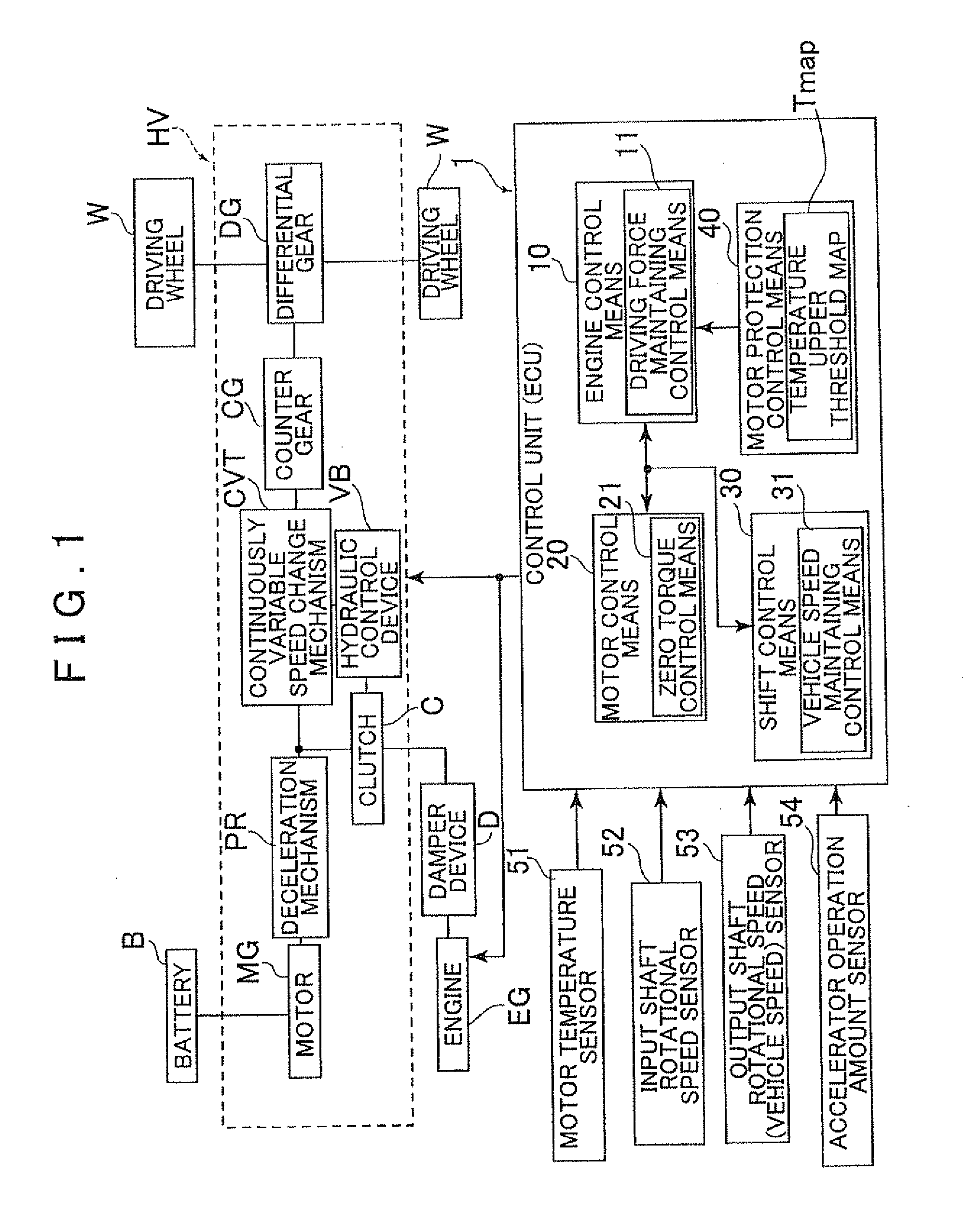

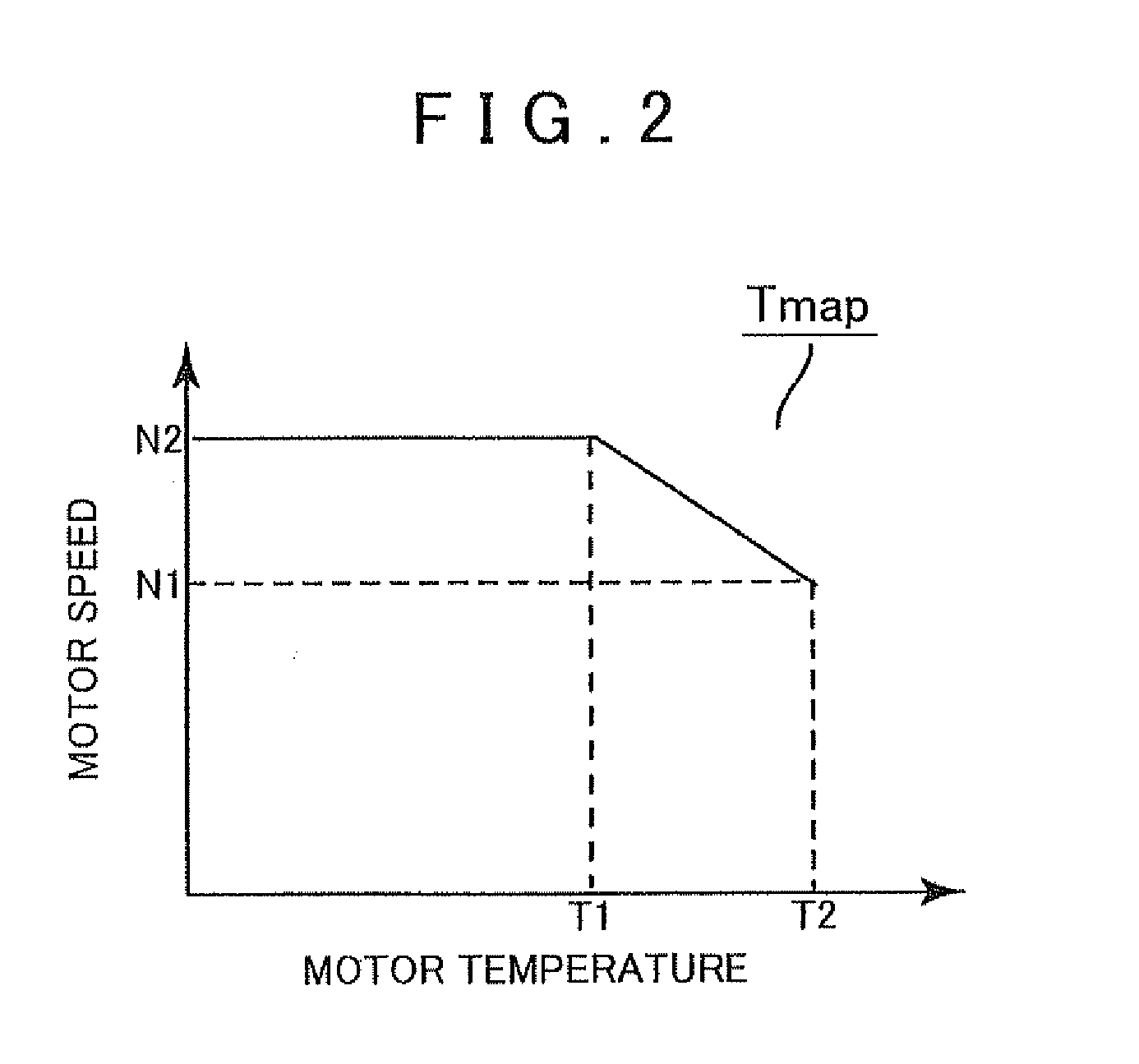

Control device of hybrid vehicle

InactiveUS20110232980A1Compact structureLow costSpeed controllerElectric devicesDrive wheelControl theory

A control device of a hybrid vehicle, configured with an engine; a motor that rotates together with the engine at least during traveling by using a driving force of the engine, and a speed change mechanism that shifts rotation of the engine and the motor to transmit the shifted rotation to a driving wheel. A zero torque control unit controls output torque of the motor to zero torque when a rotational speed of the motor reaches a predetermined rotation speed or more by driving rotation of the engine, and a motor temperature detection unit that detects a temperature of the motor. A motor protection control units that reduces a rotational speed of the engine when the temperature of the motor reaches an upper threshold value or more while the motor is being rotated at the predetermined rotational speed or more by the driving rotation of the engine.

Owner:AISIN AW CO LTD

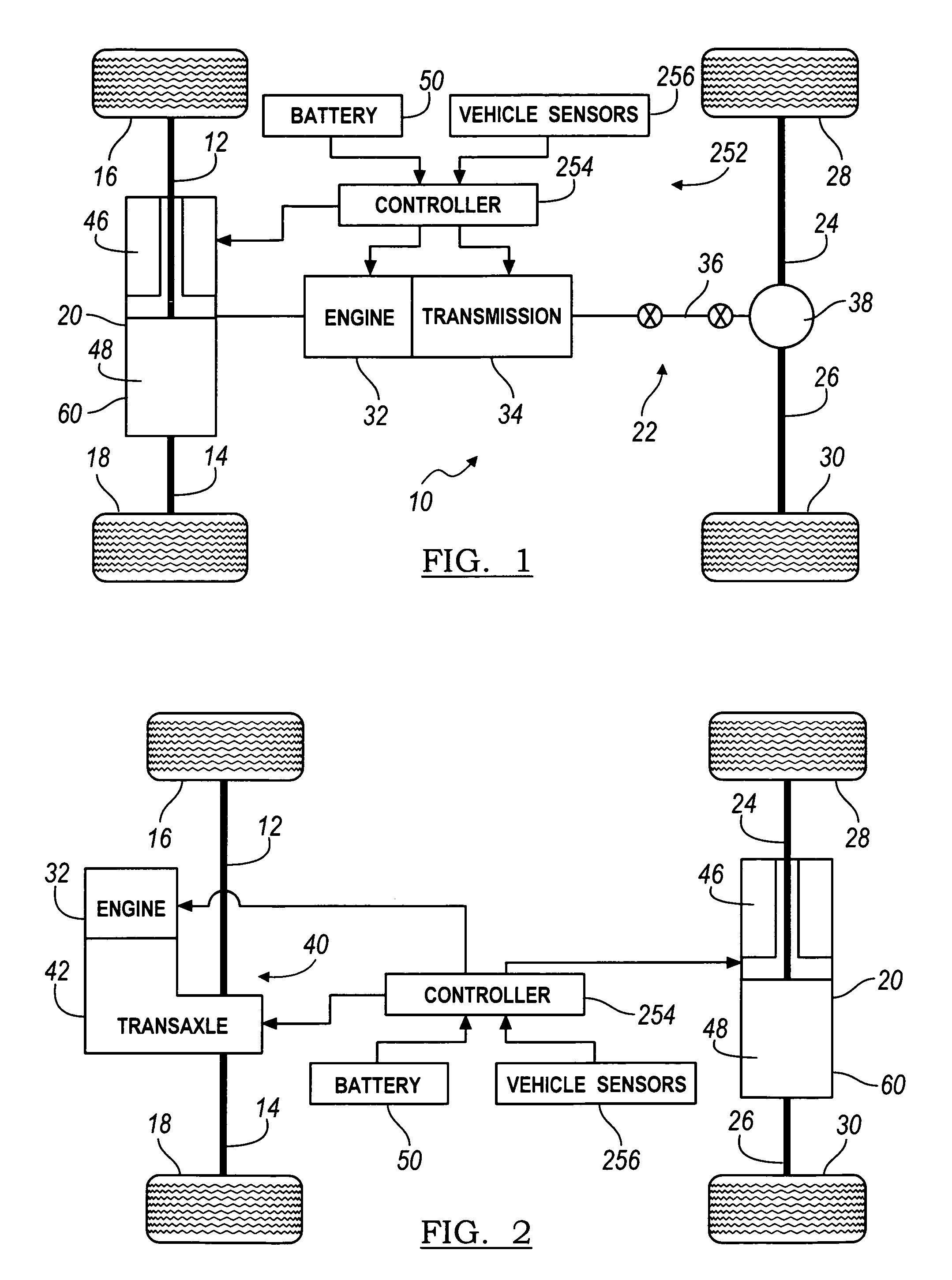

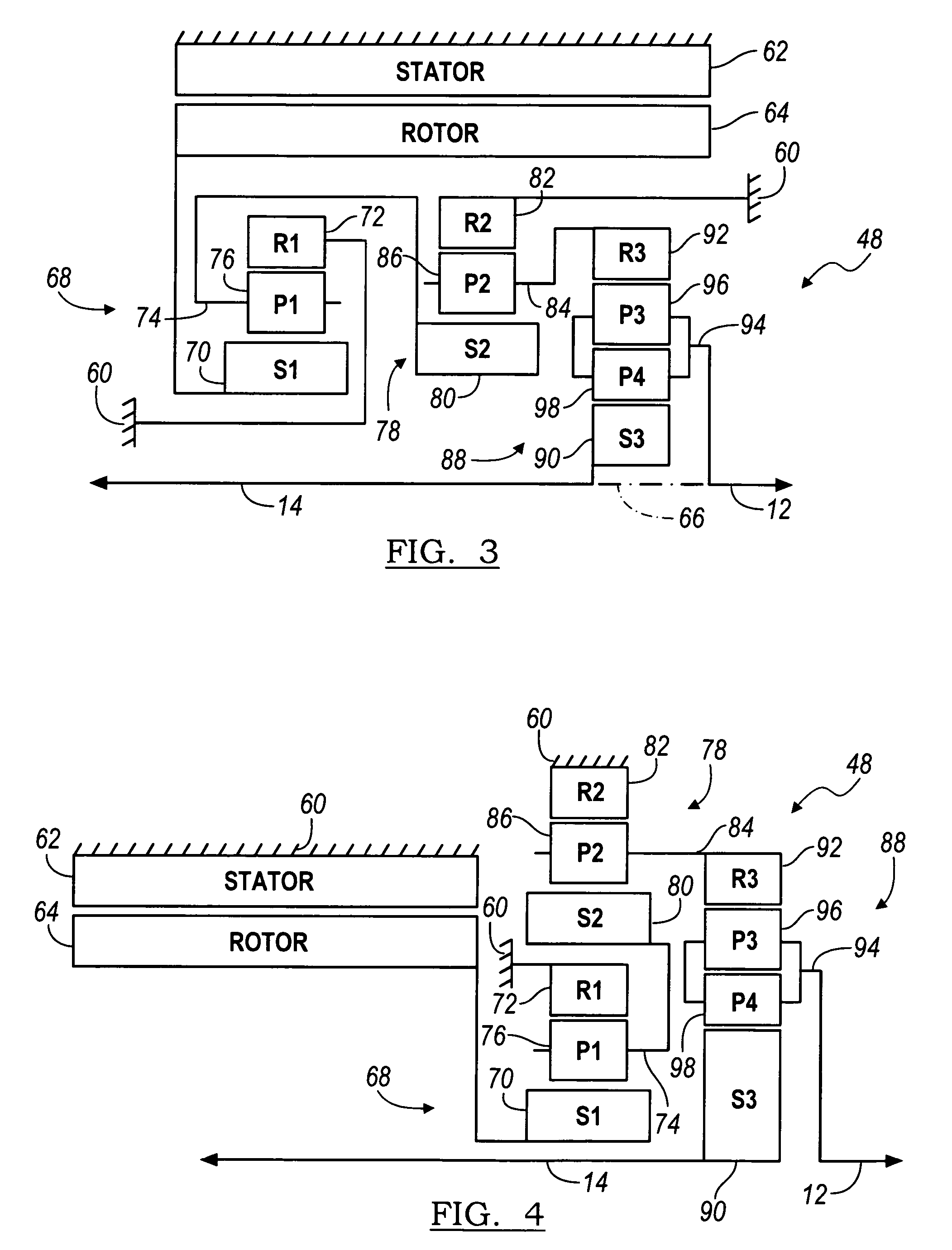

Speed reduction gear train with planetary differential for electric motor axle drive

InactiveUS7384357B2Easy to packReduce motor speedElectric propulsion mountingGas pressure propulsion mountingElectricityEngineering

An electric drive unit for a vehicle includes an electric motor, two output shafts, a first speed reduction planetary gearset driven by the motor, a second speed reduction gearset driven by an output of the first gearset, and a compound planetary differential gearset including an input driveably connected to the output of the second gearset, a first differential output driveably connected to the first output shaft, and a second differential output driveably connected to the second output shaft.

Owner:FORD GLOBAL TECH LLC

Pump control device, oil well with device and method

InactiveUS20110097214A1Extended service lifeLife maximizationFlexible member pumpsPump controlMotor speedElectric machine

A method of operating an oil well comprises applying through a variable frequency drive AC electrical energy from a power grid to an AC electric motor to operate a drive mechanism of an oil well pump. The motor speed is regulated in a manner to optimize oil production and maximize the operational life of the drive mechanism, decreasing motor speed by transferring the electrical energy to the power grid and increasing motor speed by transferring the electrical energy from the power grid to the motor. The drive mechanism has a predetermined stroke cycle and, over the course of each stroke cycle, the motor is operated at different regulated speeds initiated when the drive mechanism is at a predetermined position in each stroke cycle.

Owner:HAROLD WELLS ASSOC

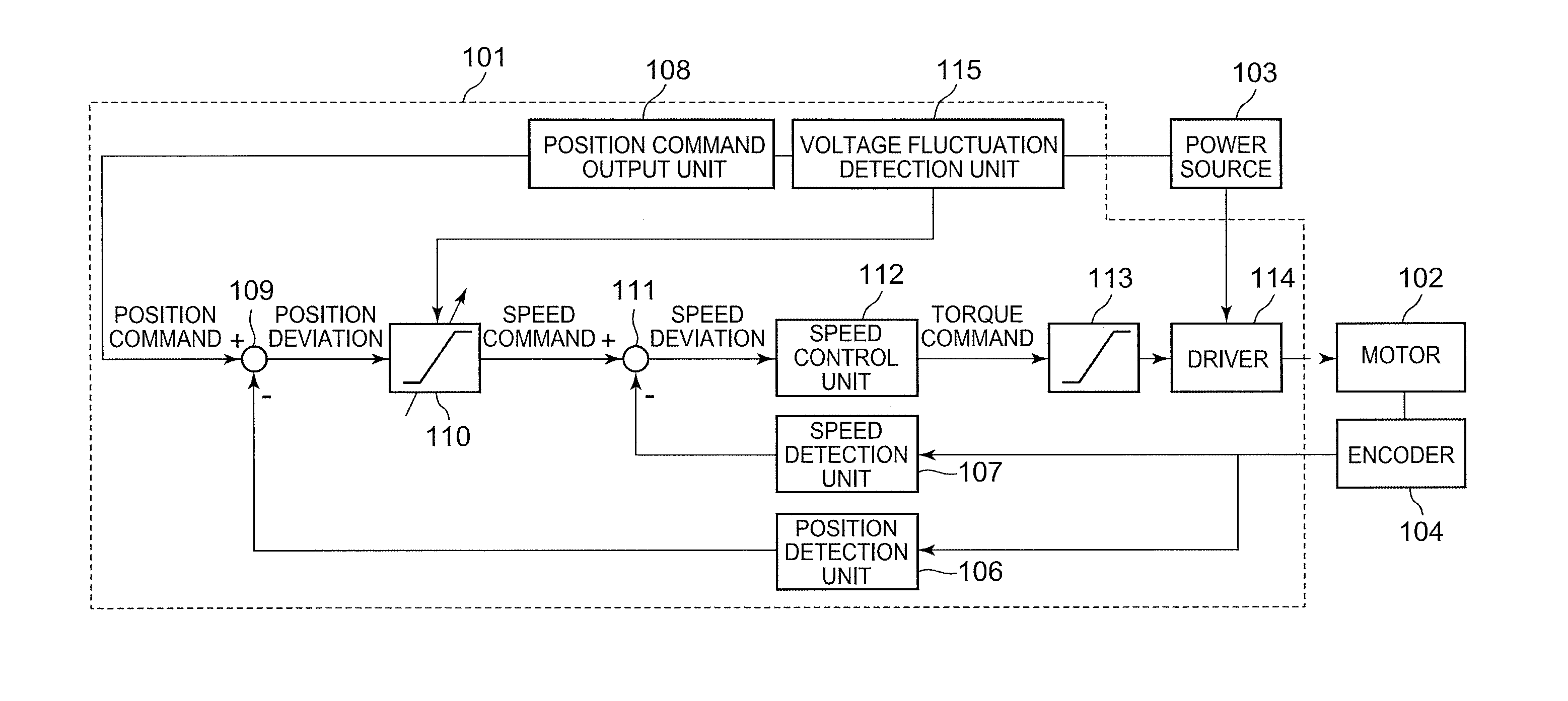

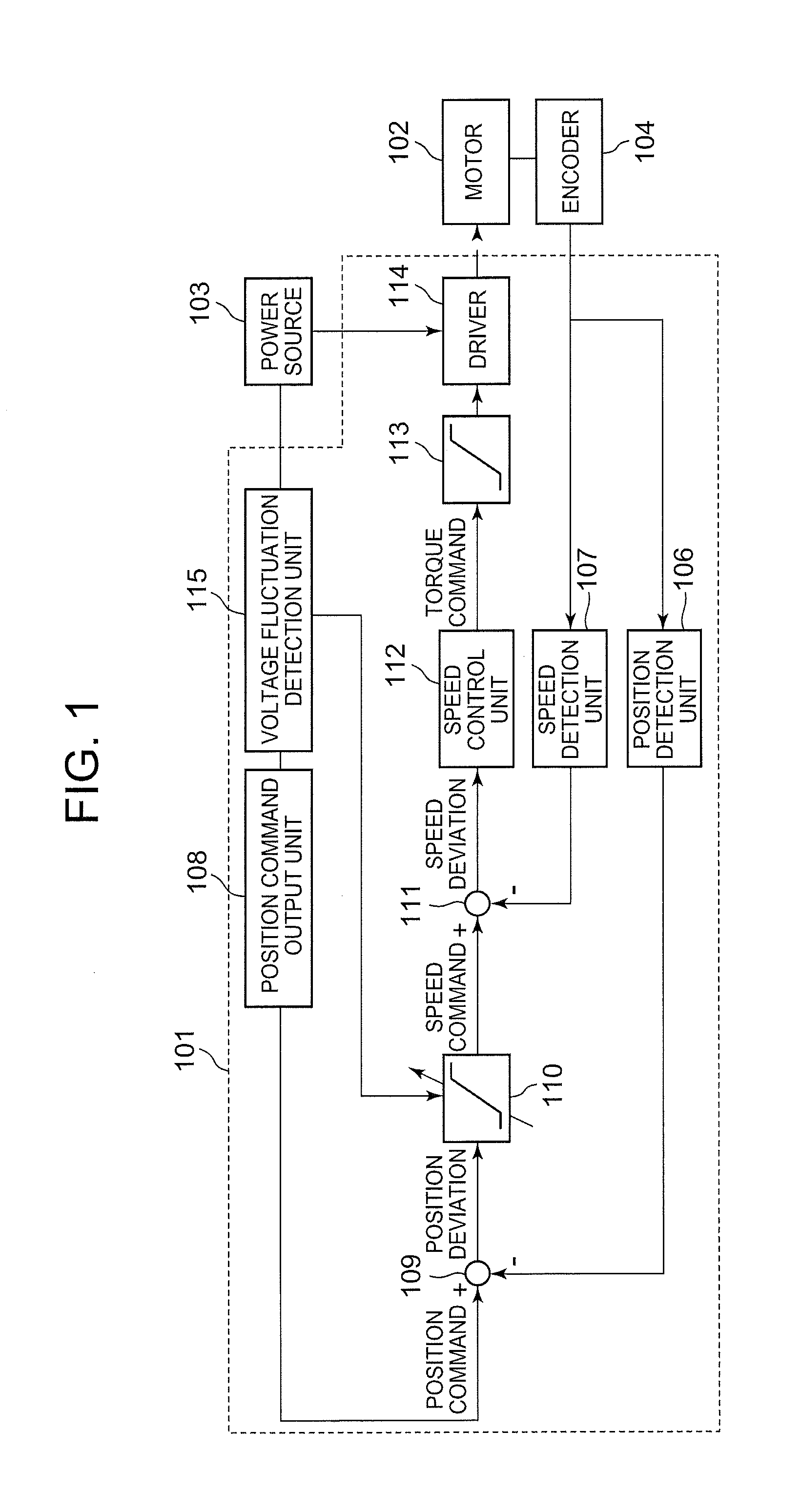

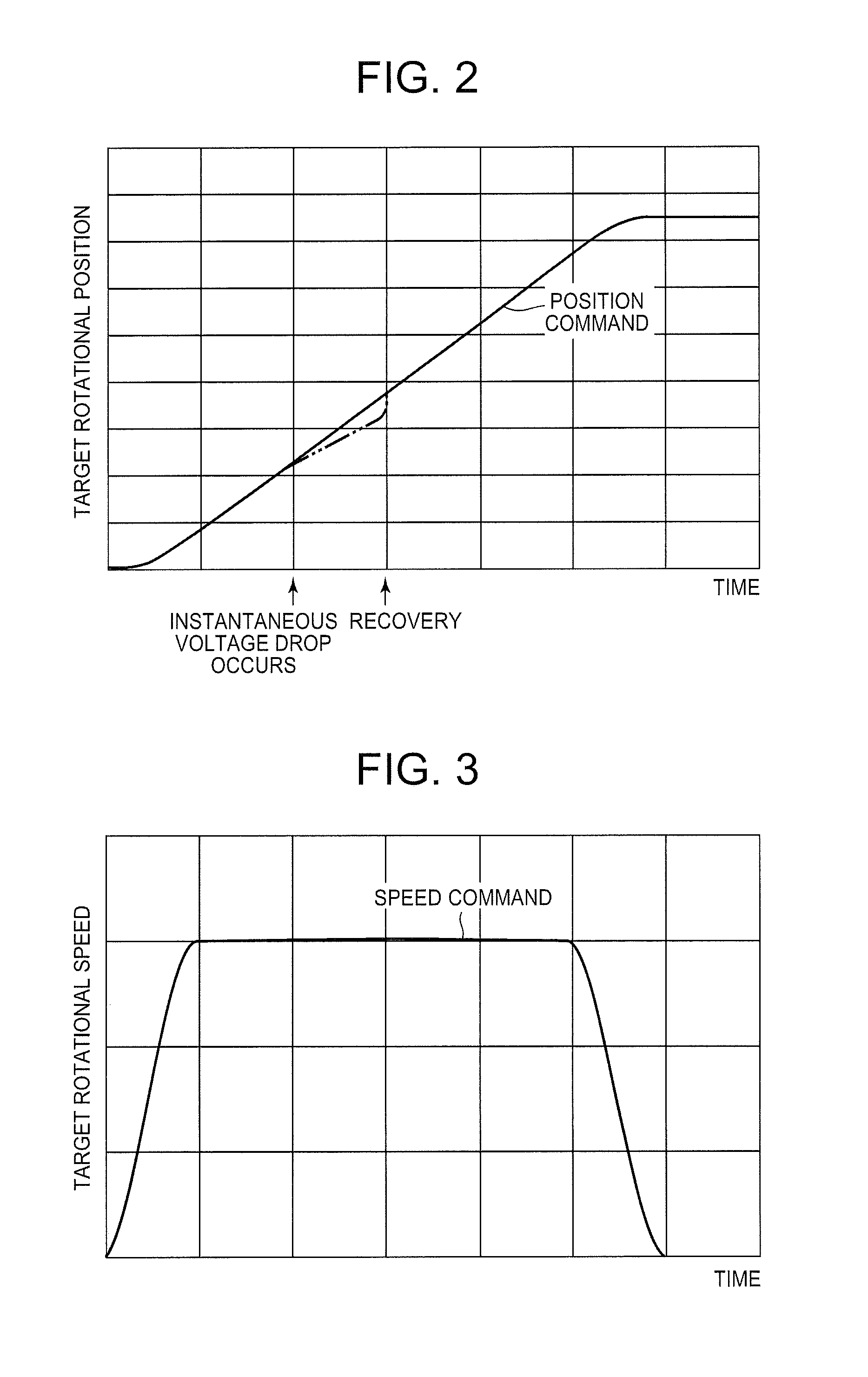

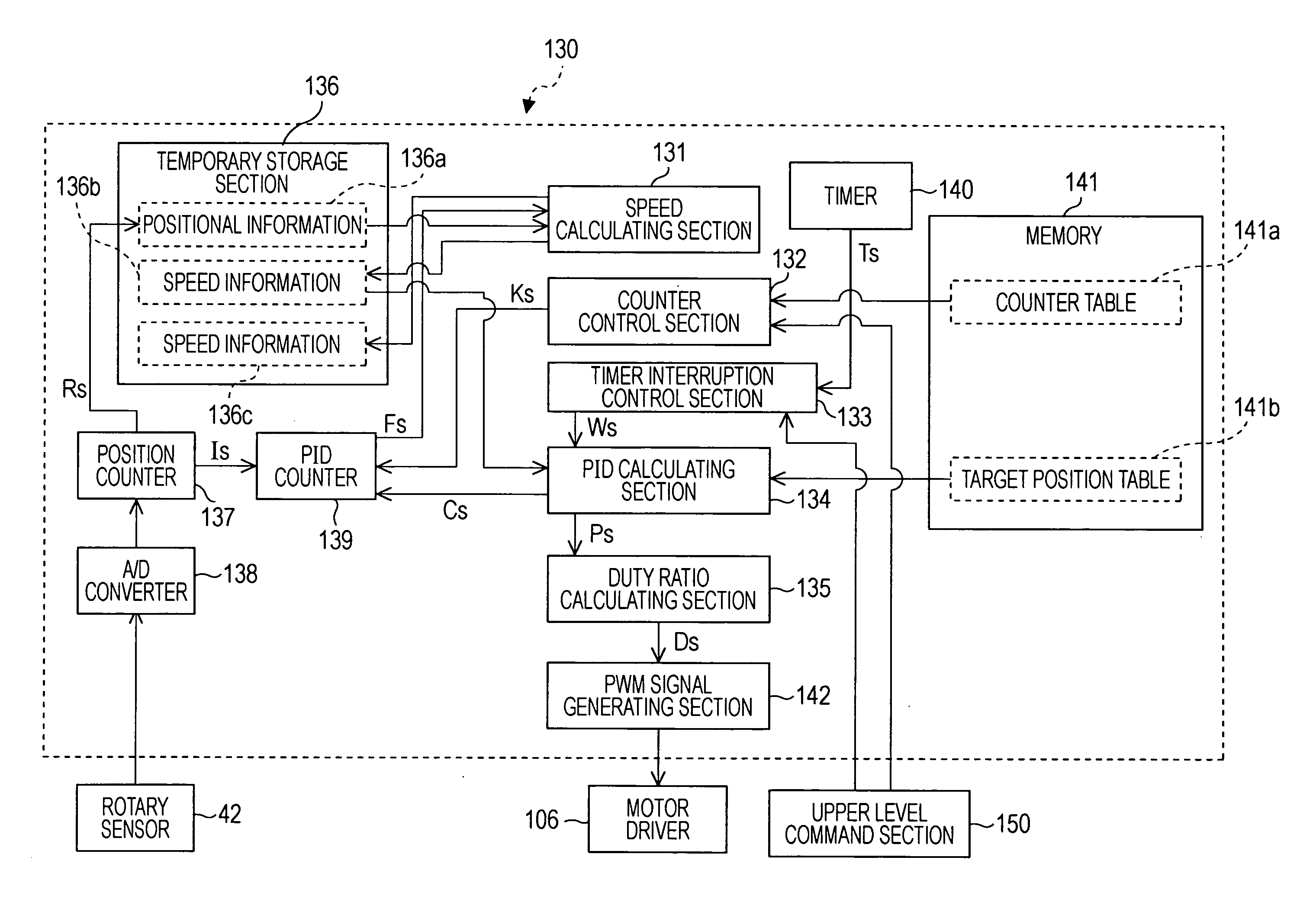

Motor control apparatus, motor control method, control system, and position estimation method to be used in control system

ActiveUS20140070752A1Accurate operationHighly precise position estimationElectric motor controlComputer controlMaximum levelEstimation methods

The present invention provides a motor control device capable of operating a robot properly without stopping a motor that operates the robot even when an instantaneous voltage drop occurs. The motor control device 10 that controls the robot operating motor 102 is equipped with the subtraction unit 109 that calculates the position deviation for which the actual rotational position is subtracted from the position command, the position control unit 110 that converts the position deviation to the speed command, the subtraction unit 111 that calculates the speed deviation for which the actual rotational speed measurement is subtracted from the speed command, the speed control unit 112 that converts the speed deviation to a torque command, the limiter 113 that sets the maximum level of the torque command, the driver 114 that drives the motor 102, and the voltage fluctuation detection unit 115 that detects the voltage fluctuation of the power source 103; in the motor control device 101, when an instantaneous voltage drop is detected by the voltage fluctuation detection unit 115, the position command output unit 108 varies the position command so as to reduce the rotational speed of the motor 102, and the position control unit 110 limits the speed command to be output.

Owner:SANKYO SEIKI MFG CO LTD

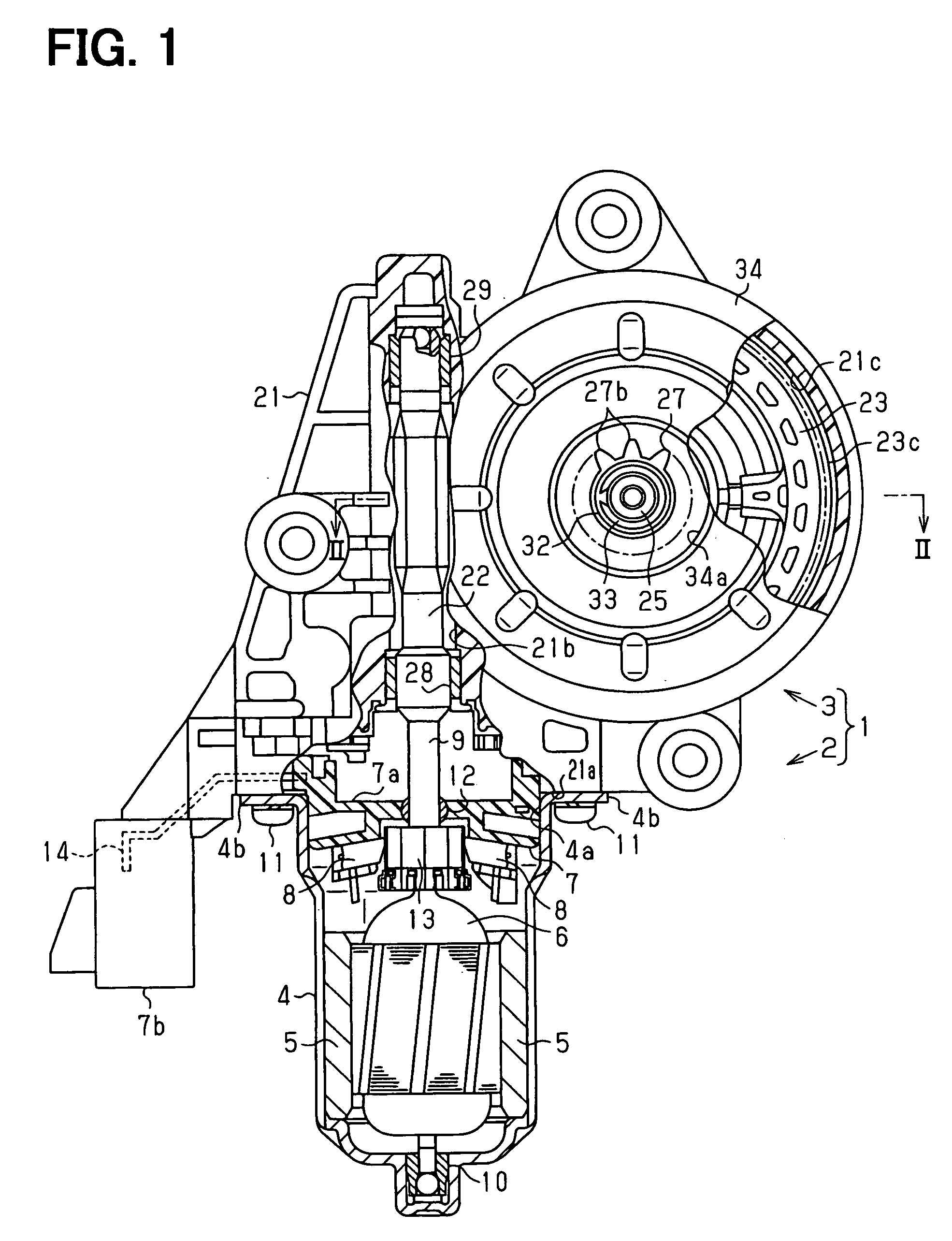

Geared motor

In a geared motor, a worm wheel, an O-ring, a transmission plate and an output gear are installed to a support shaft. The O-ring is placed in an inner space of a receiving through hole of the transmission plate, through which the support shaft is received. Grease is applied to an outer peripheral surface of the support shaft. A grease relief passage, which relieves the grease, extends between the output gear and the transmission plate.

Owner:DENSO CORP

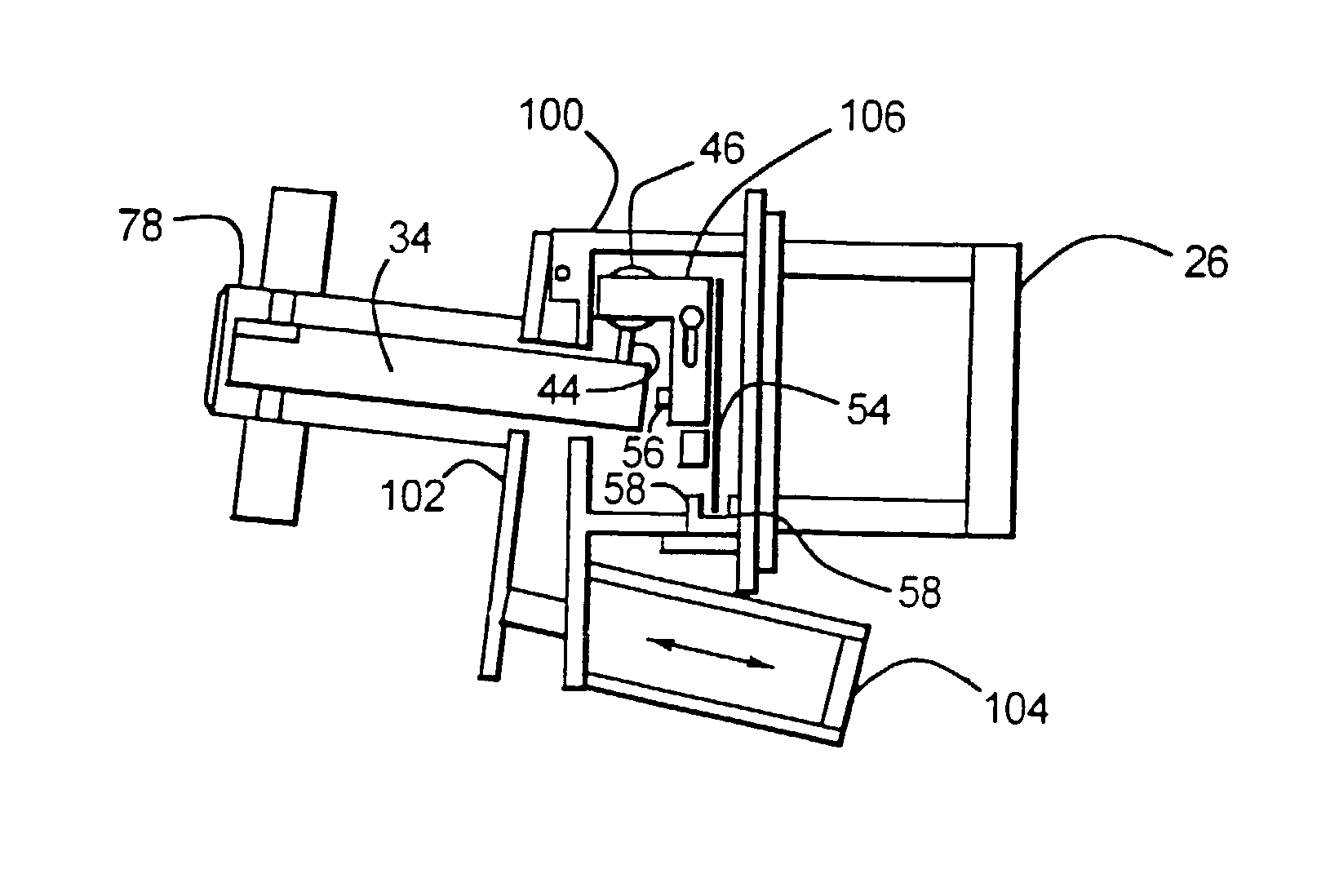

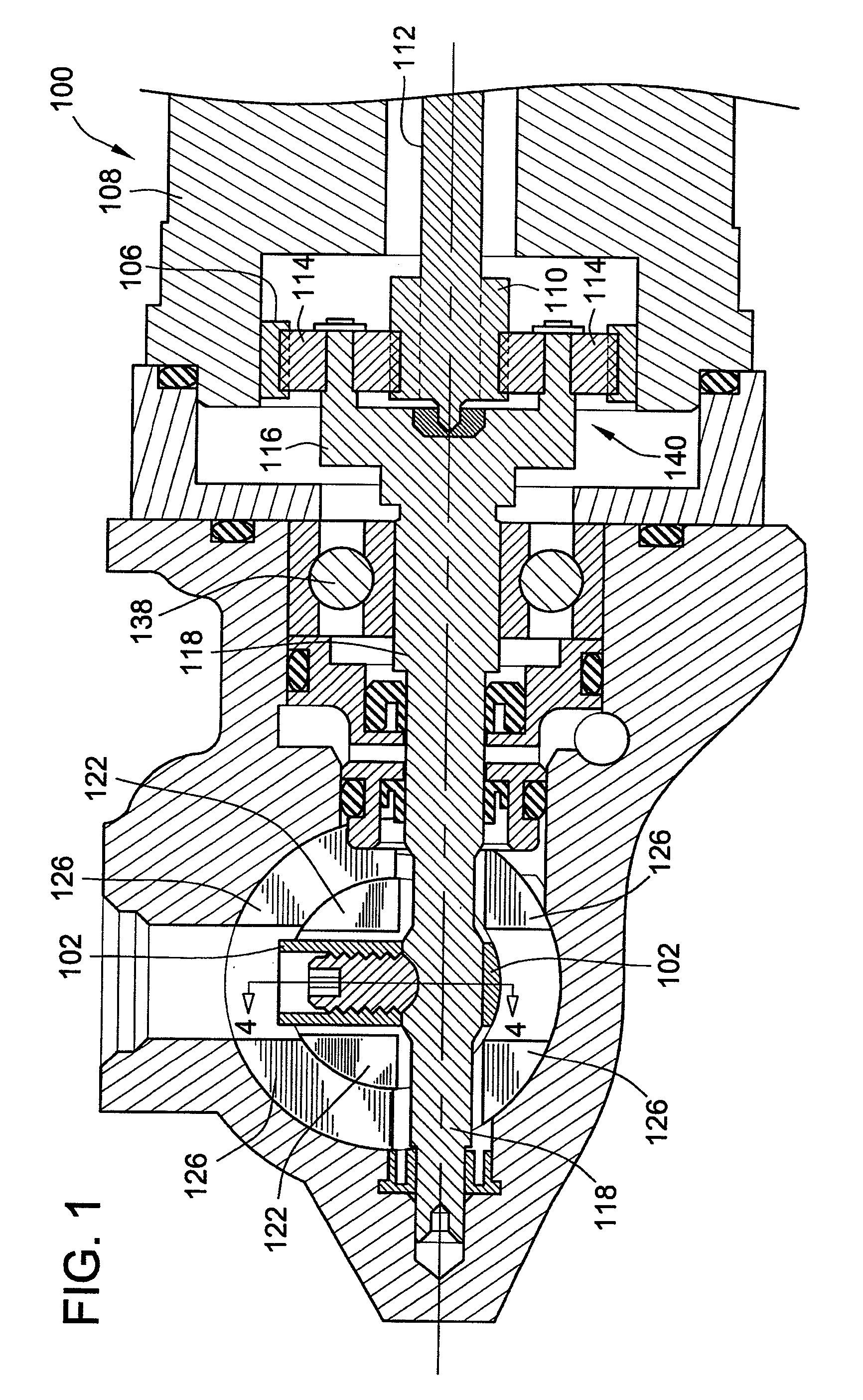

Nutating pump, control system and method of control thereof

InactiveUS20020197164A1Increase motor speedIncrease speedContracting/expanding measuring chambersPositive displacement pump componentsComputer control systemPiston

A fluid dispense system having a computer control system that operatively controls a stepper motor driving a pump. The stepper motor actuates the pump piston through partial revolutions. The computer control system determines the number of stepper motor steps required to pump a desired amount of fluid by the pump by rotating the piston through segments which are less than a full revolution. Further, the controller varies the speed of the stepper motor to avoid splashing of the dispense fluid and motor stalling.

Owner:FLUID MANAGEMENT LLC

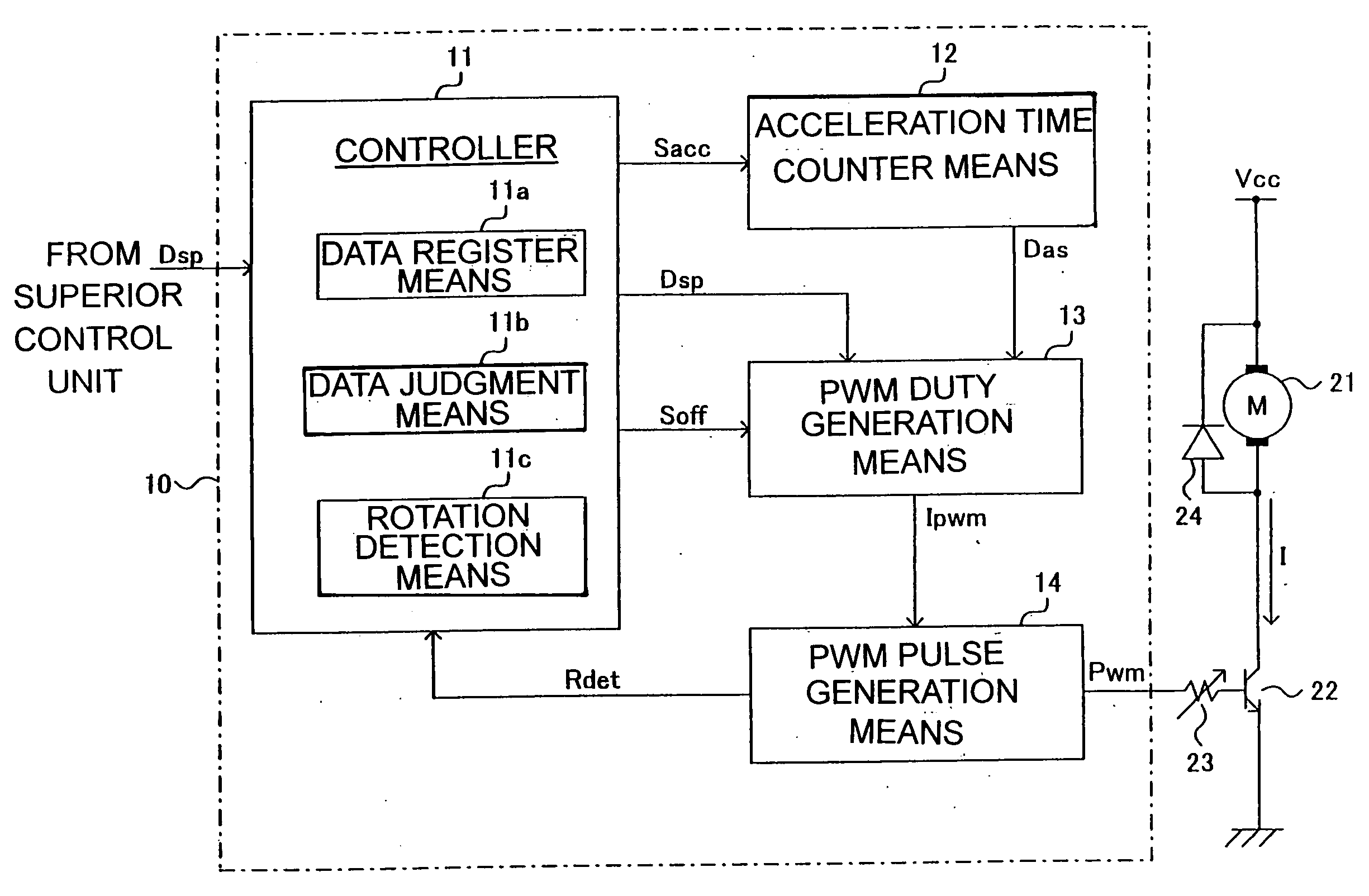

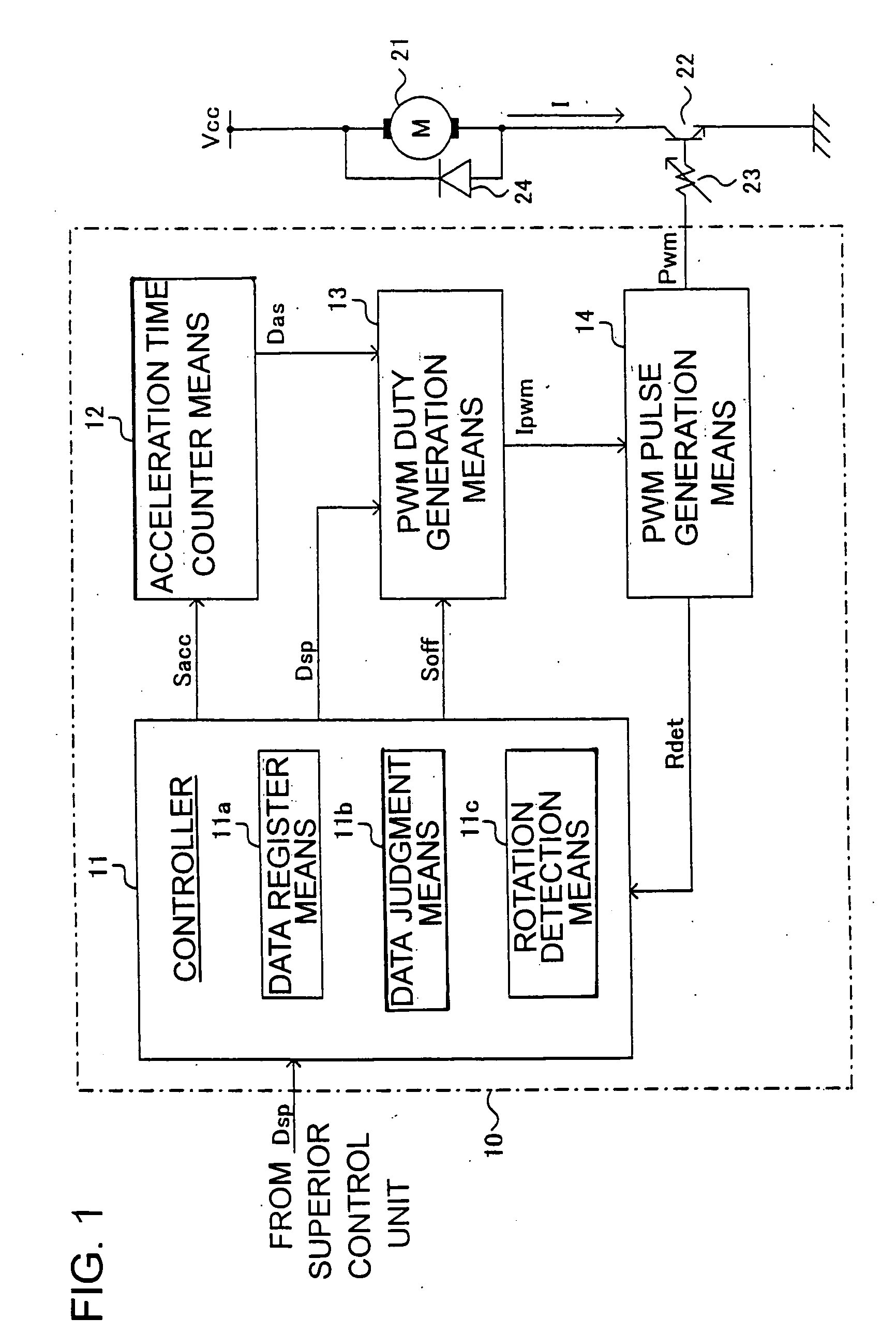

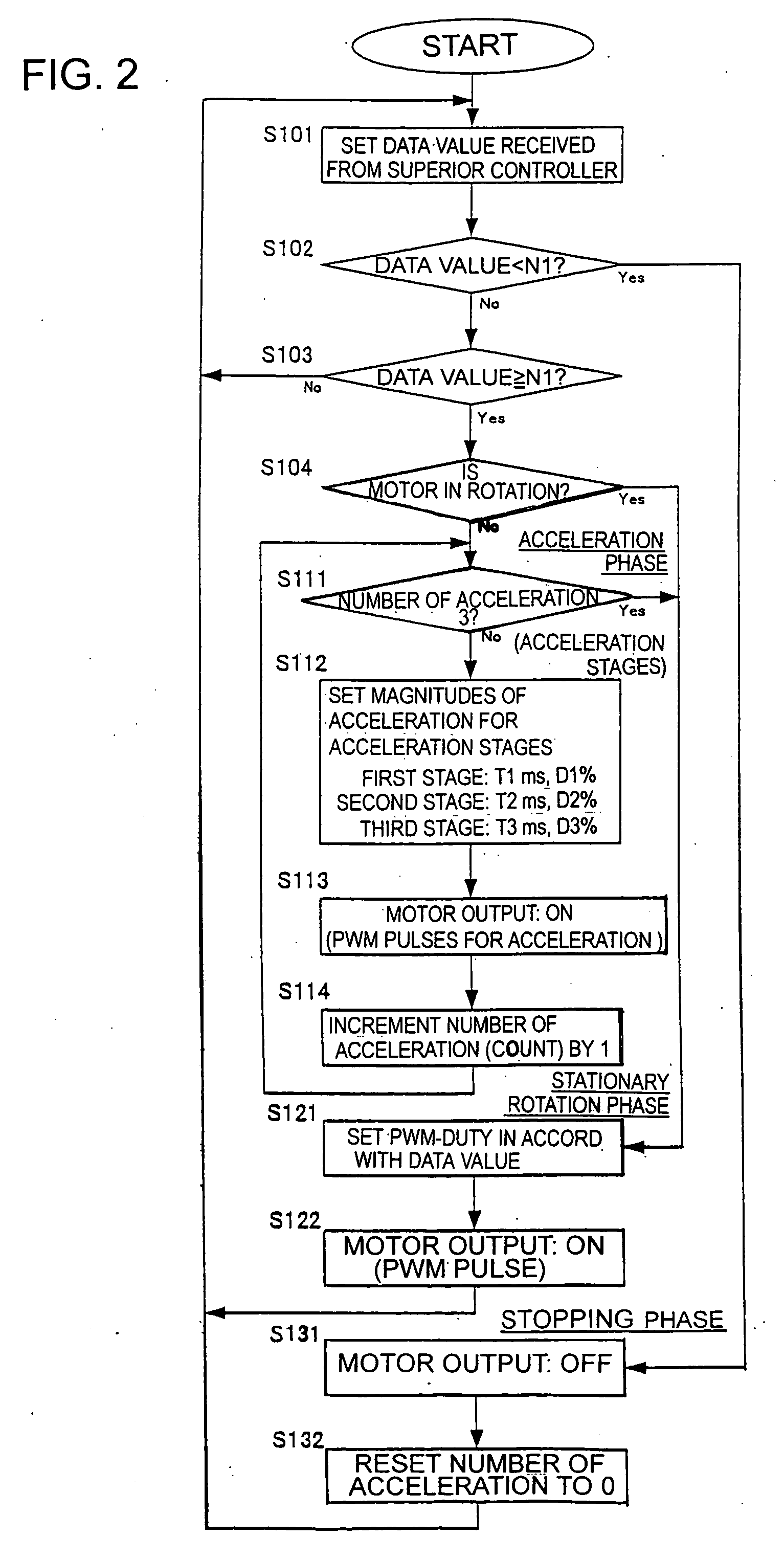

Dc motor drive unit

InactiveUS20070098373A1Improve abilitiesReduce motor speedField or armature current controlAc motor stoppersLoop controlControl system

In a DC motor drive unit having an open loop control system, a judgment is made as to whether an externally supplied speed instruction data instructs driving of the DC motor or not, based on the speed instruction data itself. If a judgment is made that the speed instruction data instructs driving of the DC motor, a switching means (e.g. switching transistor) connected to the DC motor is controlled by PWM pulses having prescribed duty ratios over a predetermined acceleration period to accelerate the DC motor. After the acceleration period, the switching means is controlled by the PWM pulses having a duty ratio as instructed by the speed instruction data to drive the DC motor. This scheme permits suppression of the startup current of the motor, and hence reduction of the withstand current of the switching transistor, while ensuring secure startup of the motor. In addition, the range of controllable speed of the DC motor can be broadened.

Owner:ROHM CO LTD

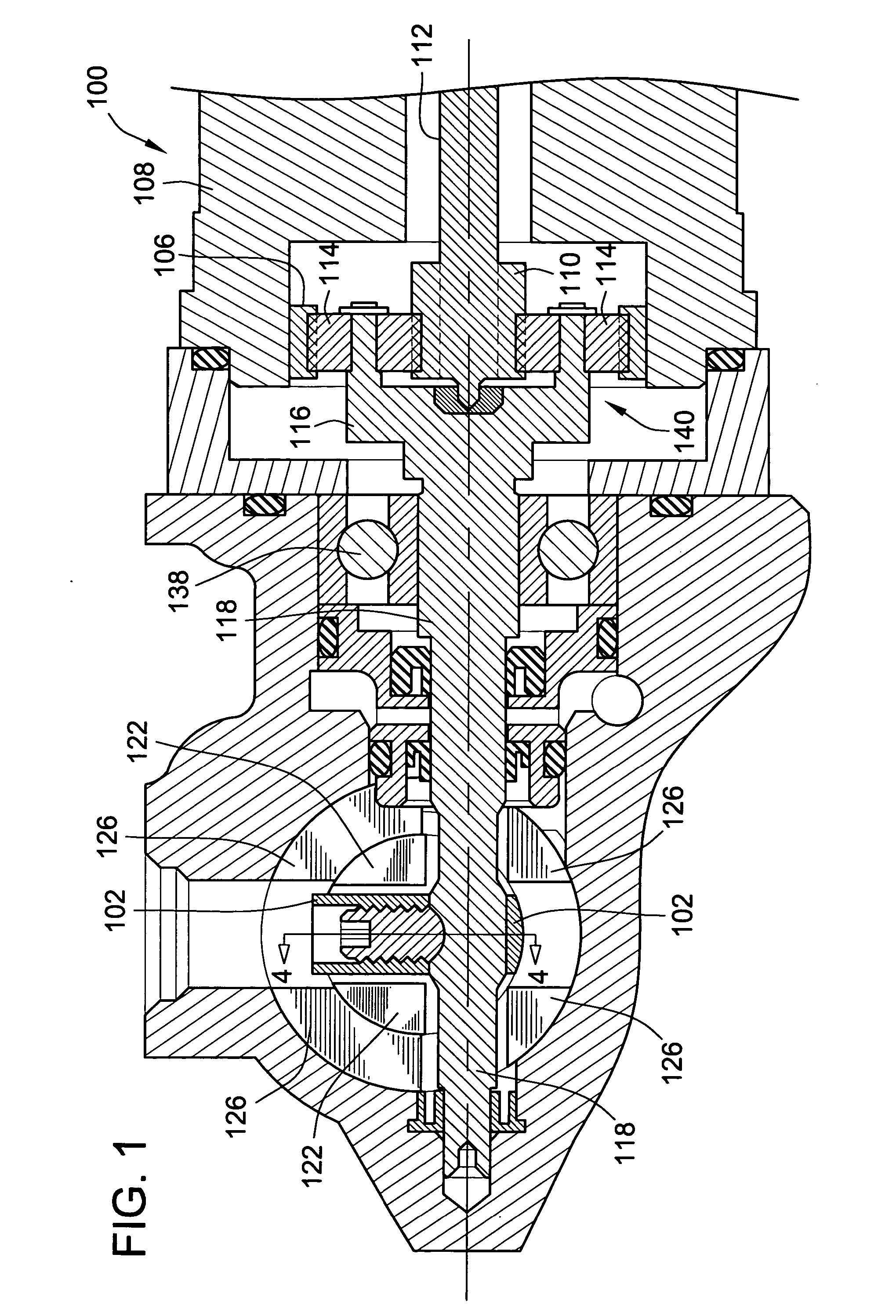

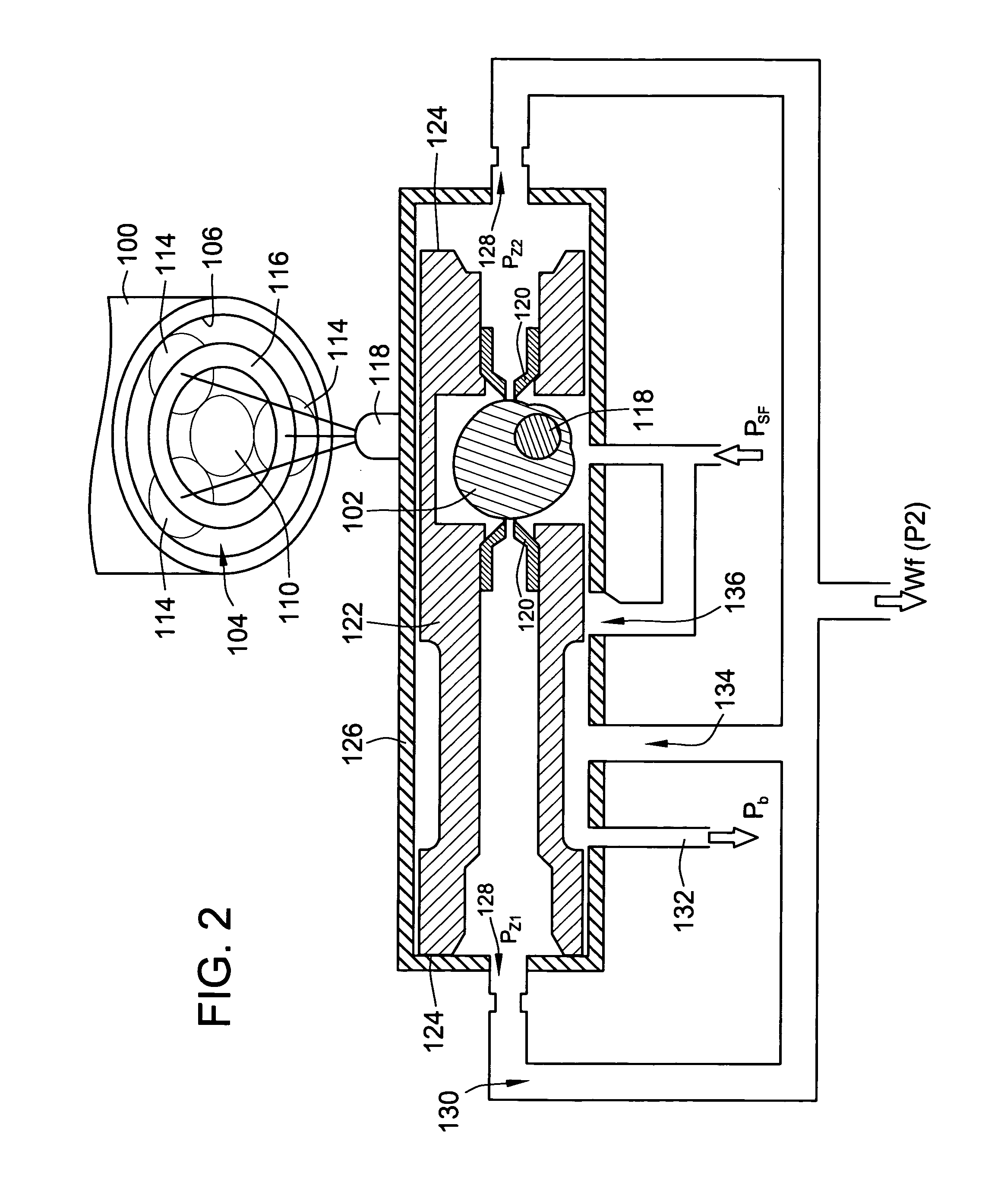

Stepper motor driven proportional fuel metering valve

ActiveUS20060218928A1Eliminate needReduce motor speedOperating means/releasing devices for valvesServomotor componentsPistonHigh energy

A low energy stepper motor driven fuel metering valve (FMV) that eliminates the need for a position sensor is provided. The stepper motor rotates a cam that replaces the flapper valve used in conventional systems. The cam rotation increases the gap between the cam and nozzle on one side of the cam and decreases the gap between the cam and nozzle on the other side. The gap differences affect the pressures on the spool piston ends, which forces the piston in the direction that will re-equalize the cam-nozzle gaps. As a result, the relatively low energy stepper motor controls the relatively high energy hydromechanical system via the dual cam-nozzle-orifice system. The cam is precision machined and assures stroke / degree gain accuracy. The hydraulic system assures the piston tracks the cam essentially perfectly except for the effects of piston stiction forces.

Owner:WOODWARD GOVERNOR CO

Refrigerant System With Variable Speed Scroll Compressor and Economizer Circuit

InactiveUS20080314057A1Increase and decrease capacityWide range of operationsEngine of arcuate-engagement typeOscillating piston enginesEngineeringControl theory

A scroll compressor system having a variable speed drive is utilized. By providing the economizer and / or bypass functions along with the variable speed drive, precise capacity adjustment between the discrete steps is achieved to exactly match load demands at a wide spectrum of operating conditions.

Owner:CARRIER CORP

Method for physiologic control of a continuous flow total artificial heart

ActiveUS20100174231A1Reducing peak motor speedReduce motor speedControl devicesBlood pumpsImpellerPhysiological control

A method is provided of controlling a pump including a electrical motor coupled to a rotor which carries first and second impellers at opposite ends thereof. The method includes: (a) driving the rotor using the motor, so as to circulate fluid from the first impeller through a first fluid circuit, the second impeller, a second fluid circuit, and back to the first impeller; (b) determining a resistance of the first fluid circuit, based on a first motor parameter; (c) determining a flow rate through the first fluid circuit based on a second motor parameter; and (d) varying at least one operational parameter of the pump so as to maintain a predetermined relationship between the flow rate and the resistance of the first fluid circuit.

Owner:THE CLEVELAND CLINIC FOUND

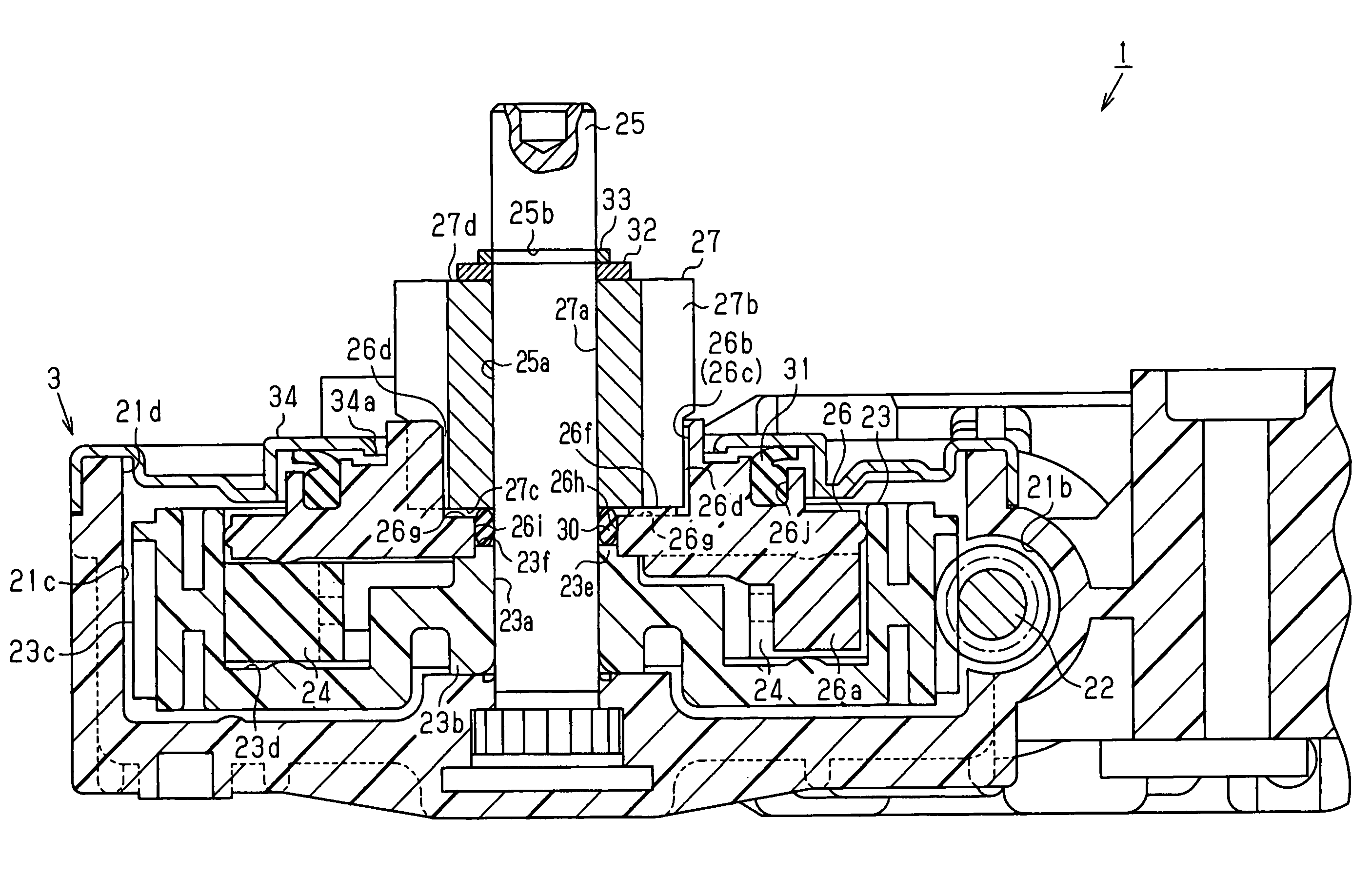

Vehicle stabilizer system

InactiveUS7798498B2Reduce loadLow efficiencyInterconnection systemsResilient suspensionsReduction driveReducer

A stabilizer system for a vehicle, including: (a) a stabilizer bar (28) including (a-1) a torsion bar portion (90), and (a-2) an arm portion (92) that extends from the torsion bar portion toward a wheel (12) of the vehicle; and (b) an actuator (32) including (b-1) a motor (40), and (b-2) a speed reducer (42) that reduces a speed of the motor while transmitting a force of the motor to the torsion bar portion of the stabilizer bar. The stabilizer bar generates a stabilizing force which is dependent on a reaction generated as a result of torsion of the torsion bar portion, and which forces the wheel and the vehicle body in a direction toward each other or a direction away from each other. The actuator allows the stabilizer bar to generate the stabilizing force whose magnitude is dependent on a magnitude of the motor force and is changeable depending on an amount of rotation of the torsion bar portion. The actuator includes an actuator-efficiency changing mechanism changing a negative efficiency of the actuator, depending on a direction of the force of the motor.

Owner:TOYOTA JIDOSHA KK

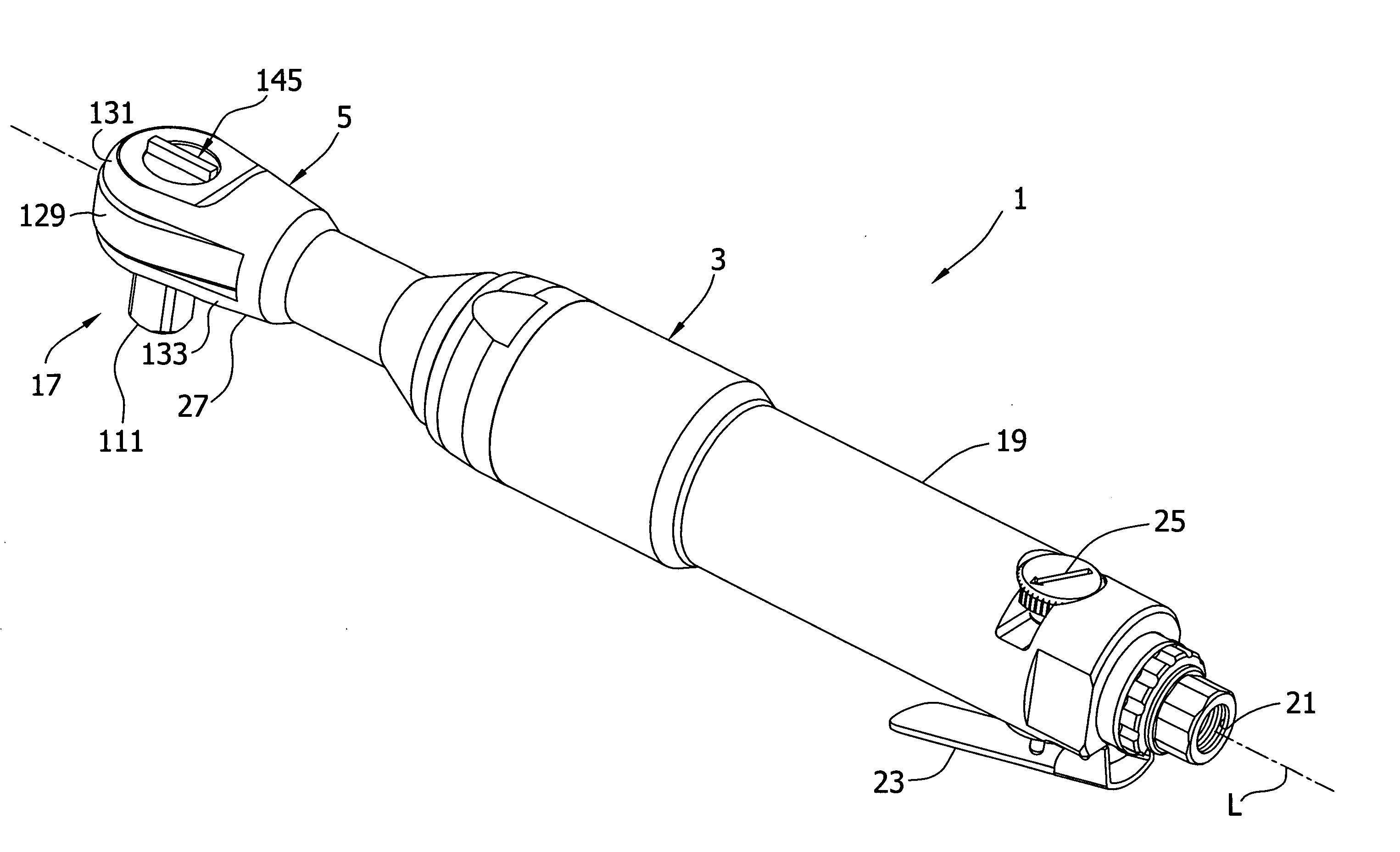

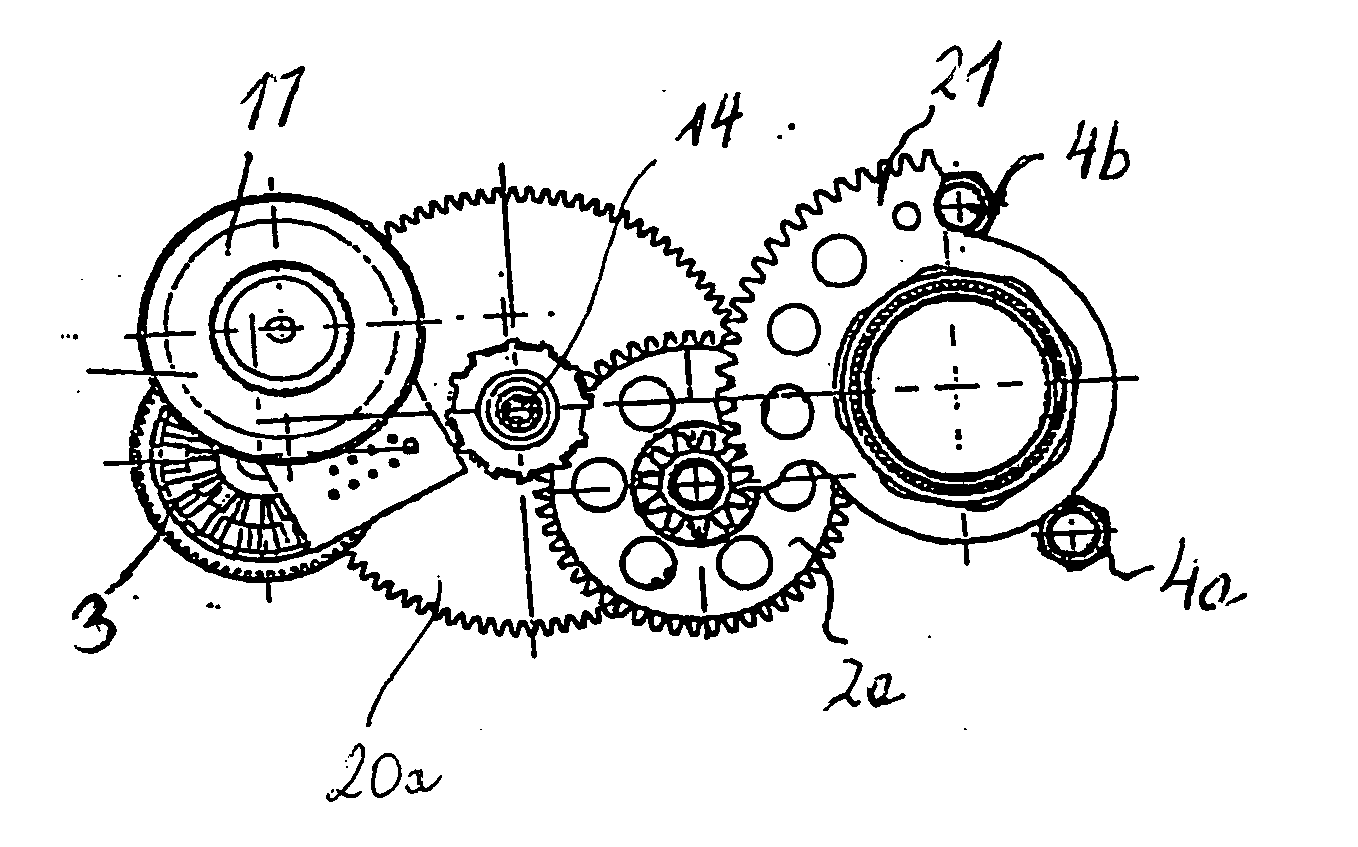

Hand tool with impact drive and speed reducing mechanism

ActiveUS20060053979A1Easy to driveReduce motor speedOperator-supported drilling machinesSpannersPneumatic motorFastener

A power driven tool useful for tightening and loosening a mechanical fastener includes an impact mechanism. Preferably, the tool is pneumatic and includes a ratchet head and an impact device for providing additional torque to the ratchet head. A planetary reduction gear reduces the high output speed of a pneumatic motor for input into the impact device and reduces wear on the impact device.

Owner:VESSEL FUKUCHIYAMA

Dehider with governor and strengthened blade

ActiveUS7722448B2Reduce motor speedShorten speedSkinning instrumentsRind cutting-off apparatusElectric machineryEngineering

Owner:JARVIS PROD

Electromotive adjustment device

InactiveUS20050109142A1Reduce component countEliminate needOperating means/releasing devices for valvesGearboxesDrive motorEngineering

An electromotive adjustment device for adjusting a control element includes a housing and a gear mechanism which has a plurality of intermeshing gear wheels to define a drive train. In driving relationship with the gear mechanism is a drive motor which is constructed as a brushless motor with an external rotor and includes an output journal, whereby the output journal has a tooth portion in engagement with a helical spur gear wheel of the gear mechanism.

Owner:ELODRIVE STELLANTRIEBSTECHN

Electric disk brake

ActiveUS20100126811A1Reduce motor speedPowerfulMechanically actuated brakesElectrodynamic brake systemsDrive shaftCalipers

Disclosed is an electric disc brake. The electric disc brake includes friction pads for pressing a disc, a carrier for supporting the friction pads, a caliper housing supported by the carrier such that the caliper housing moves back and forth to press the friction pads, and a pressing device for pressing the friction pads. The pressing device includes a pressing member moving back and forth in the caliper housing to press one of the friction pads, a screw shaft coupled to the pressing member, a worm wheel coupled to the screw shaft, a driving shaft crossing the screw shaft and having a worm gear engaged with the worm wheel, a motor for rotating the driving shaft in a forward direction or a reverse direction, and an auxiliary pressing device.

Owner:HL MANDO CORP

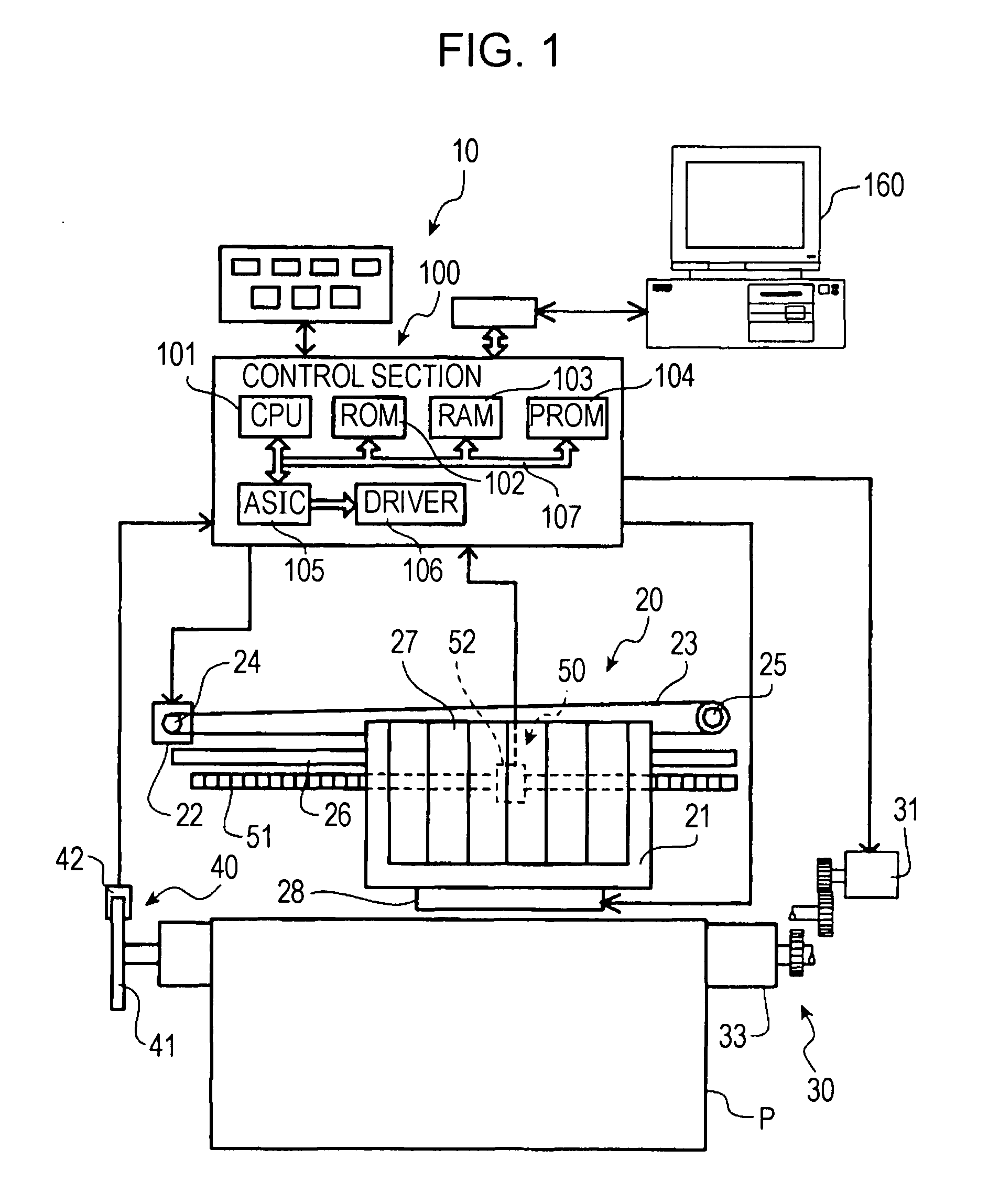

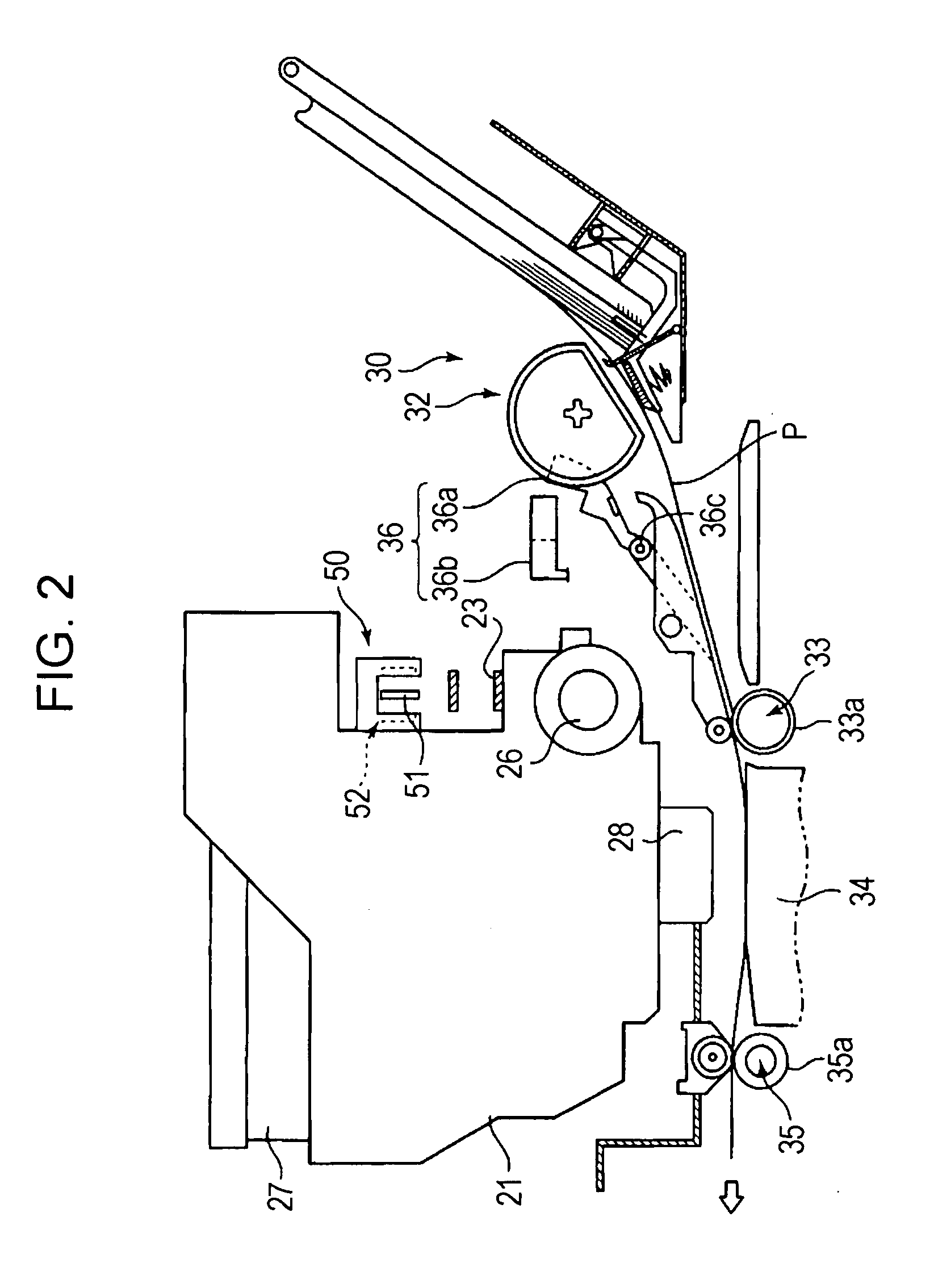

Printer and printing method

InactiveUS20080049062A1Guaranteed accuracyImprove accuracy of stopOther printing apparatusEngineeringElectric power

Owner:SEIKO EPSON CORP

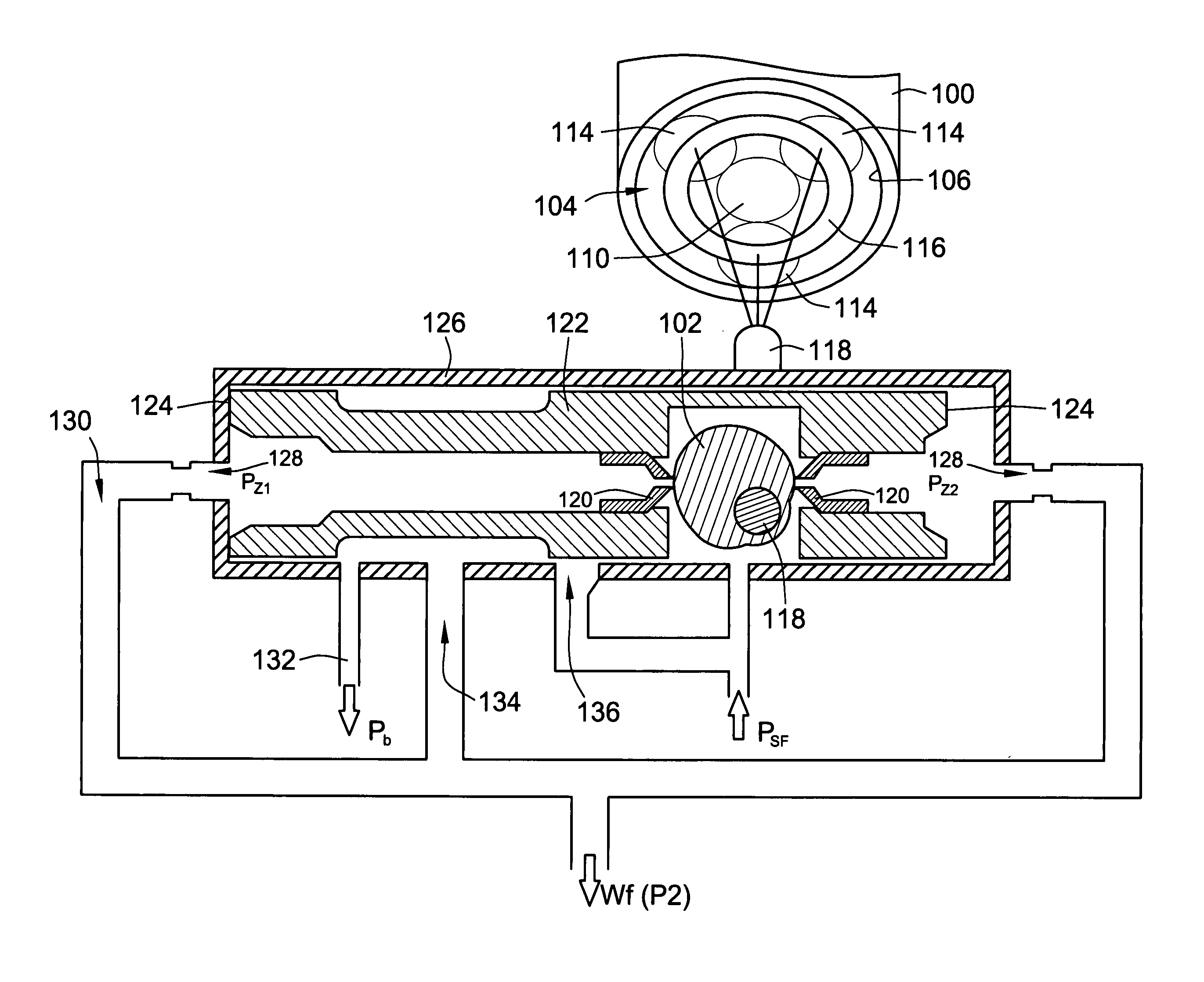

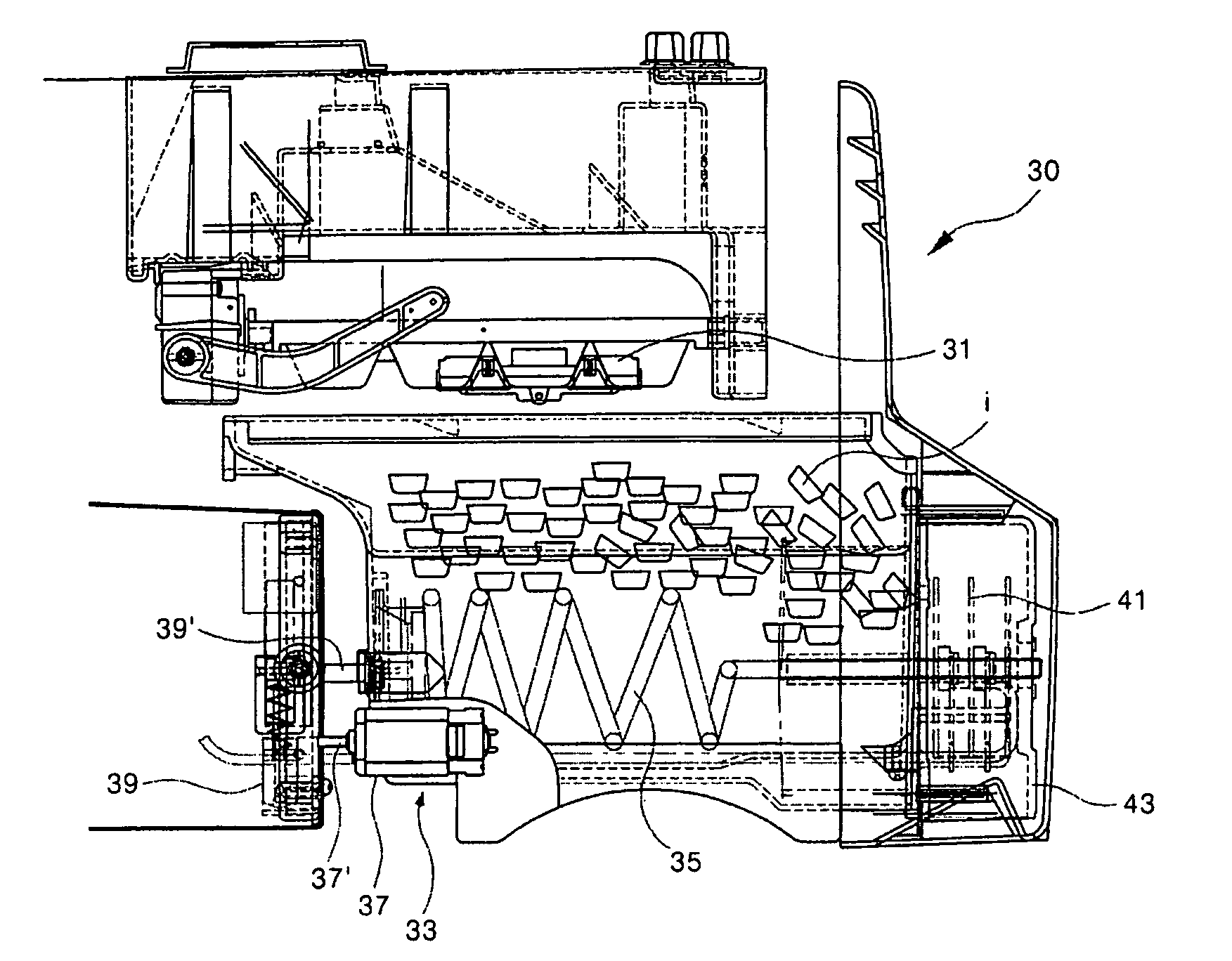

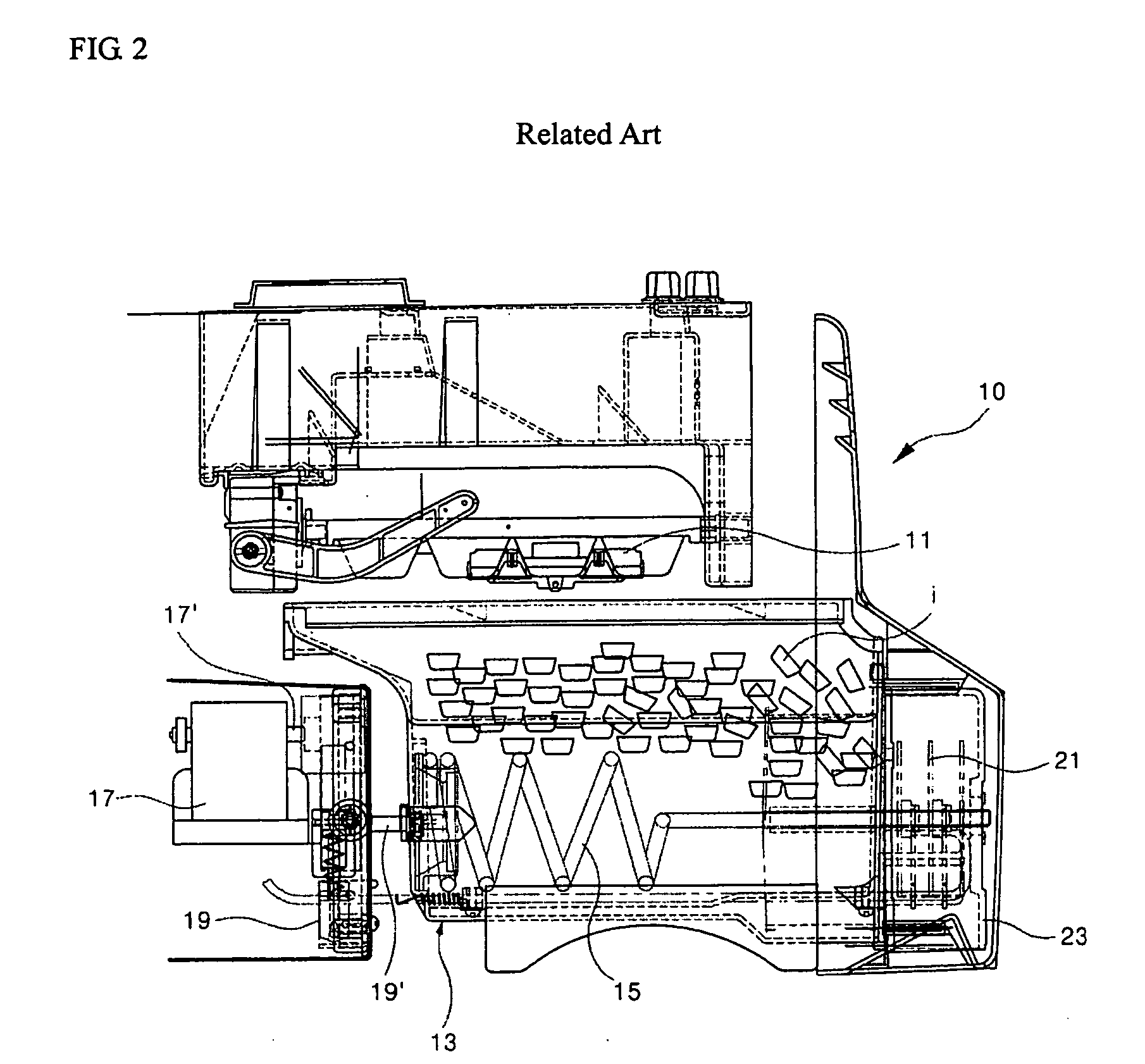

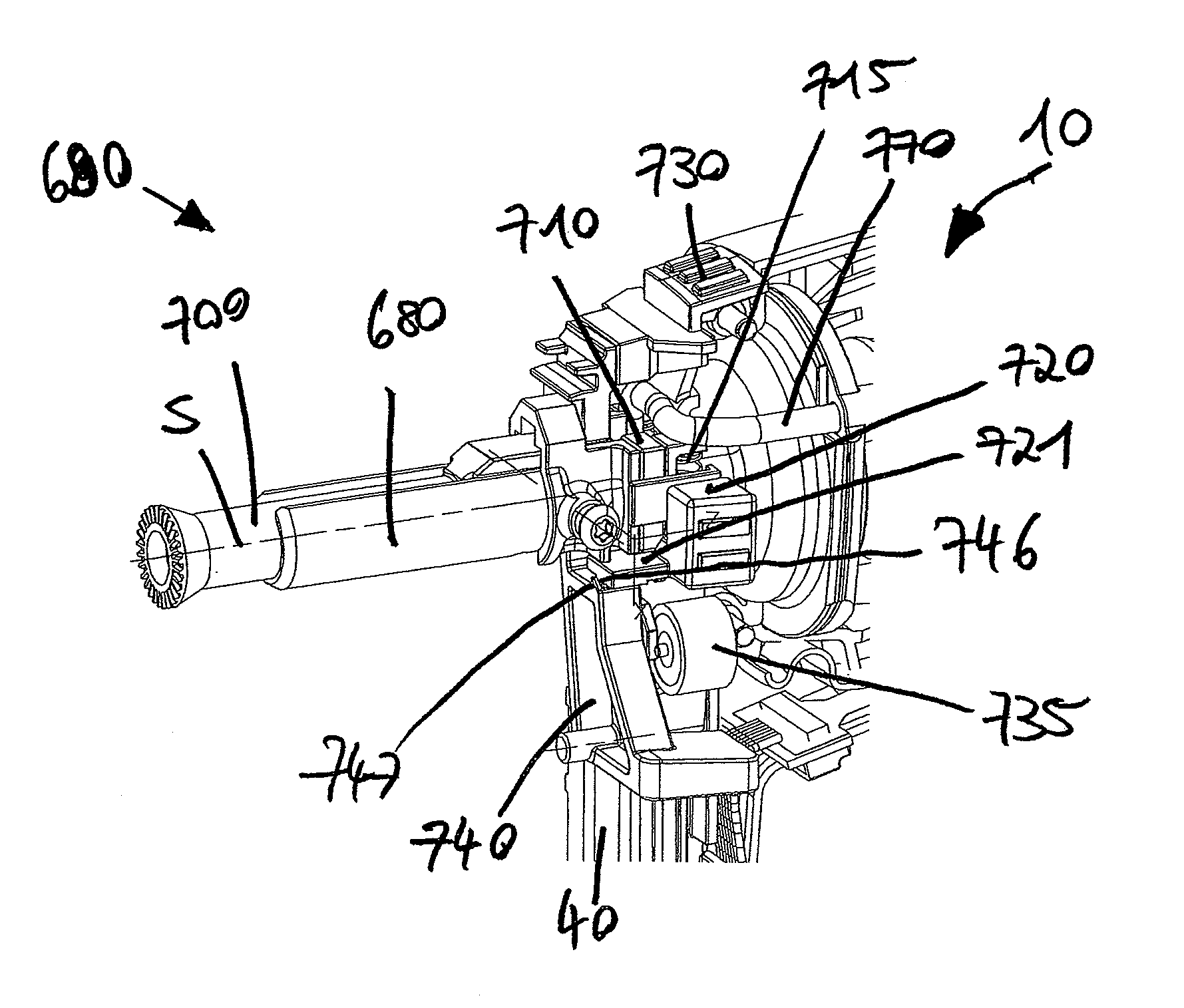

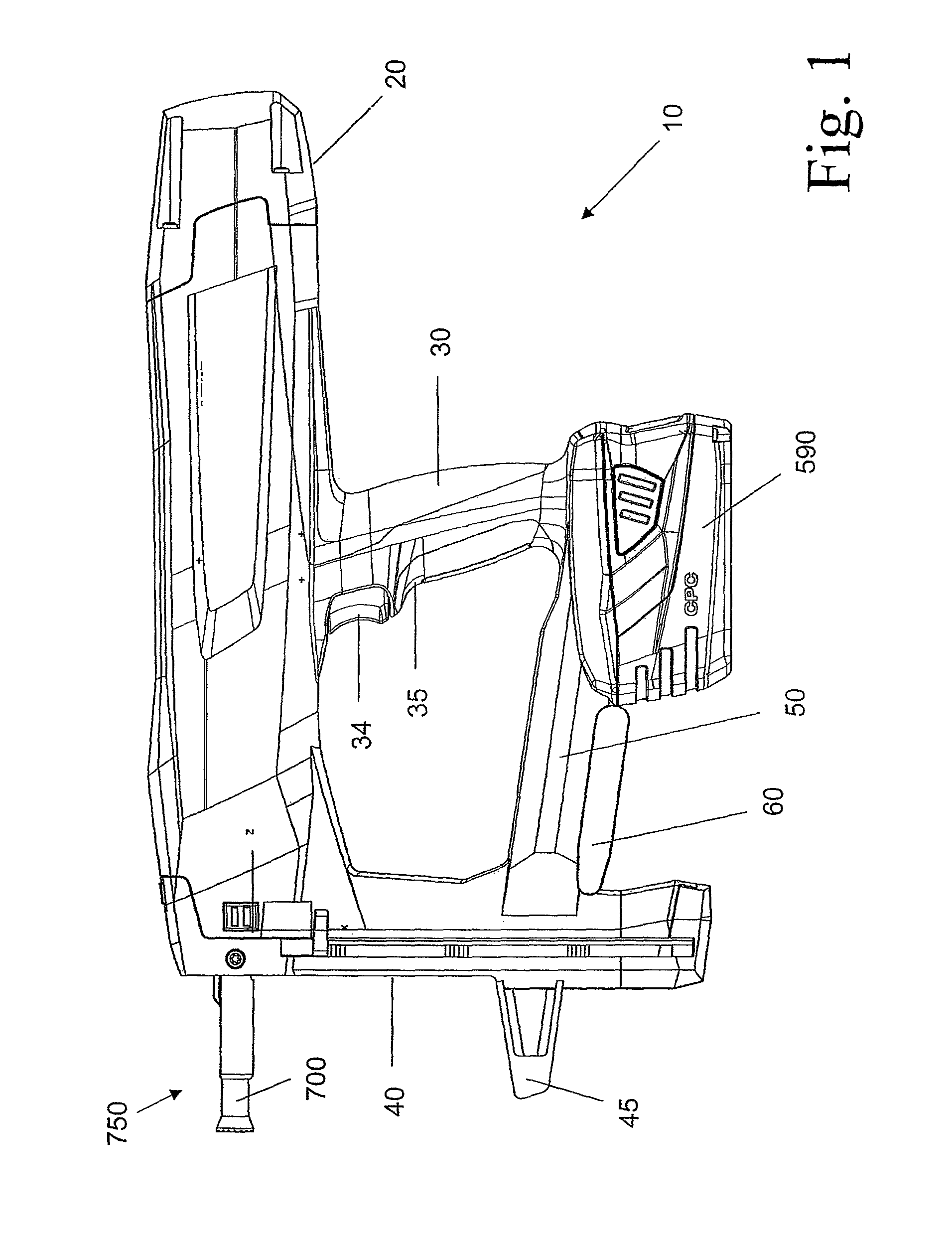

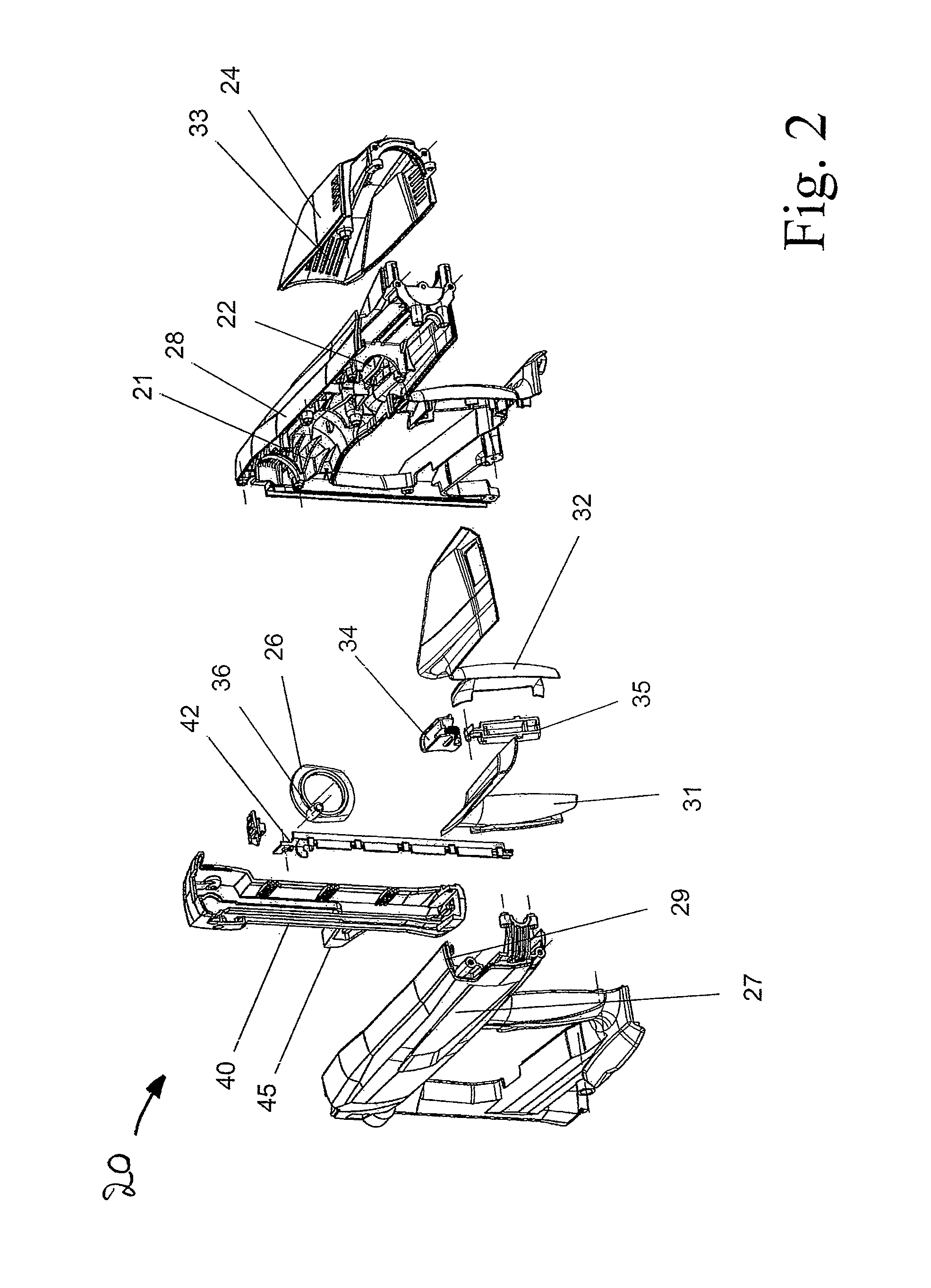

Ice transfer device for refrigerator, and control circuit thereof

ActiveUS20050241330A1CompactReduce motor speedLighting and heating apparatusIce productionDrive shaftEngineering

The present invention relates to an ice transfer device for a refrigerator, which can transfer ice made in an ice maker to a dispenser in the refrigerator, and a control circuit of the ice transfer device. The ice transfer device for a refrigerator according to the present invention comprises a storage container installed within the refrigerator to contain ice therein; a motor installed close to the storage container and having a motor shaft protruding in a direction opposite to a direction of transfer of the ice; a gearbox that is installed at a side opposite to a part for delivering the ice contained in the storage container to the outside, is connected to the motor shaft, and has a driving shaft protruding in the transfer direction of the ice to transmit a driving force while reducing a driving speed of the motor; and a transfer member installed within the storage container and connected to the driving shaft to push the ice forward by means of the driving of the motor. According to the present invention constructed as above, the formation of an unnecessary space in the interior of the refrigerator can be minimized, thereby improving the efficiency of use of a space.

Owner:LG ELECTRONICS INC

Driving device

ActiveUS8499991B2Suitable for transportationReduce motor speedStapling toolsPortable percussive toolsEnergy transferEngineering

According to one aspect of the application, a device for driving a fastening element into a substrate has an energy-transfer element for transferring energy to the fastening element. The energy-transfer element can move preferably between a starting position and a setting position, wherein the energy-transfer element is located, before a driving-in procedure, in the starting position and, after the driving-in procedure, in the setting position.According to another aspect of the application, the device comprises a mechanical-energy storage device for storing mechanical energy. The energy-transfer element is then suitable preferably for transferring energy from the mechanical-energy storage device to the fastening element.

Owner:HILTI AG

Stepper motor driven proportional fuel metering valve

ActiveUS7926512B2Eliminate needReduce motor speedOperating means/releasing devices for valvesServomotor componentsHigh energyHydraulic machinery

A low energy stepper motor driven fuel metering valve (FMV) that eliminates the need for a position sensor is provided. The stepper motor rotates a cam that replaces the flapper valve used in conventional systems. The cam rotation increases the gap between the cam and nozzle on one side of the cam. The gap difference affects the pressures on the spool piston ends, which forces the piston in the direction that will return the cam-nozzle gap to a distance that results in a pressure balance to return. As a result, the relatively low energy stepper motor controls the relatively high energy hydromechanical system via the cam-nozzle-orifice system. The cam is precision machined and assures stroke / degree gain accuracy. The hydraulic system assures the piston tracks the cam essentially perfectly except for the effects of piston stiction forces.

Owner:WOODWARD GOVERNOR CO

Adjustment drive

An adjustment drive includes a drive motor, and a drive train in driving relationship with the drive motor for reducing a motor speed of the drive motor. The drive train includes a plurality of gear wheels operated by the drive motor and intermeshing with one another to form a chain to define at least one gear stage, whereby at least the plurality of gear wheels is supported by a carrier that defines thereby a separate drive unit.

Owner:ELODRIVE STELLANTRIEBSTECHN

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com