Patents

Literature

4039results about "Interconnection systems" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

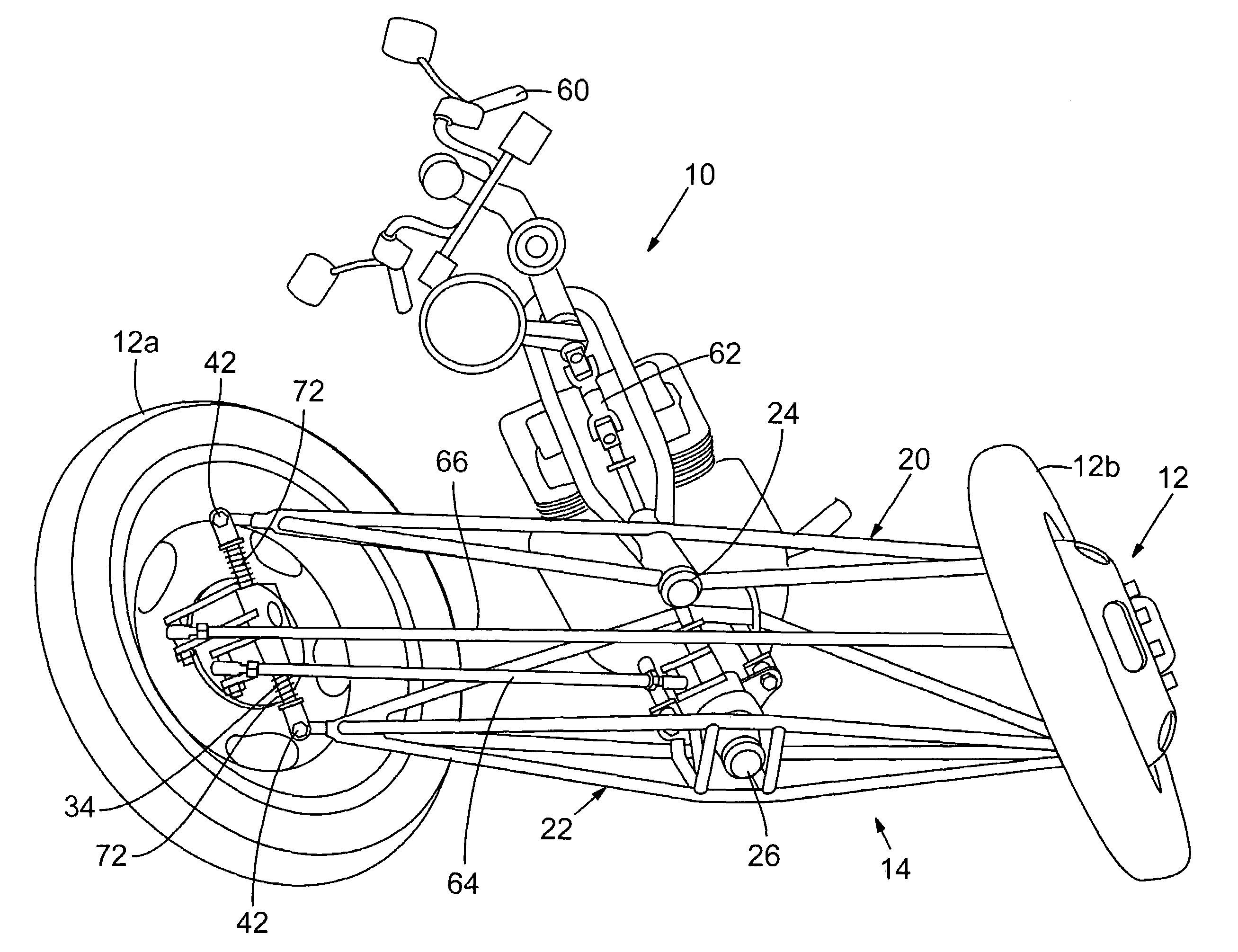

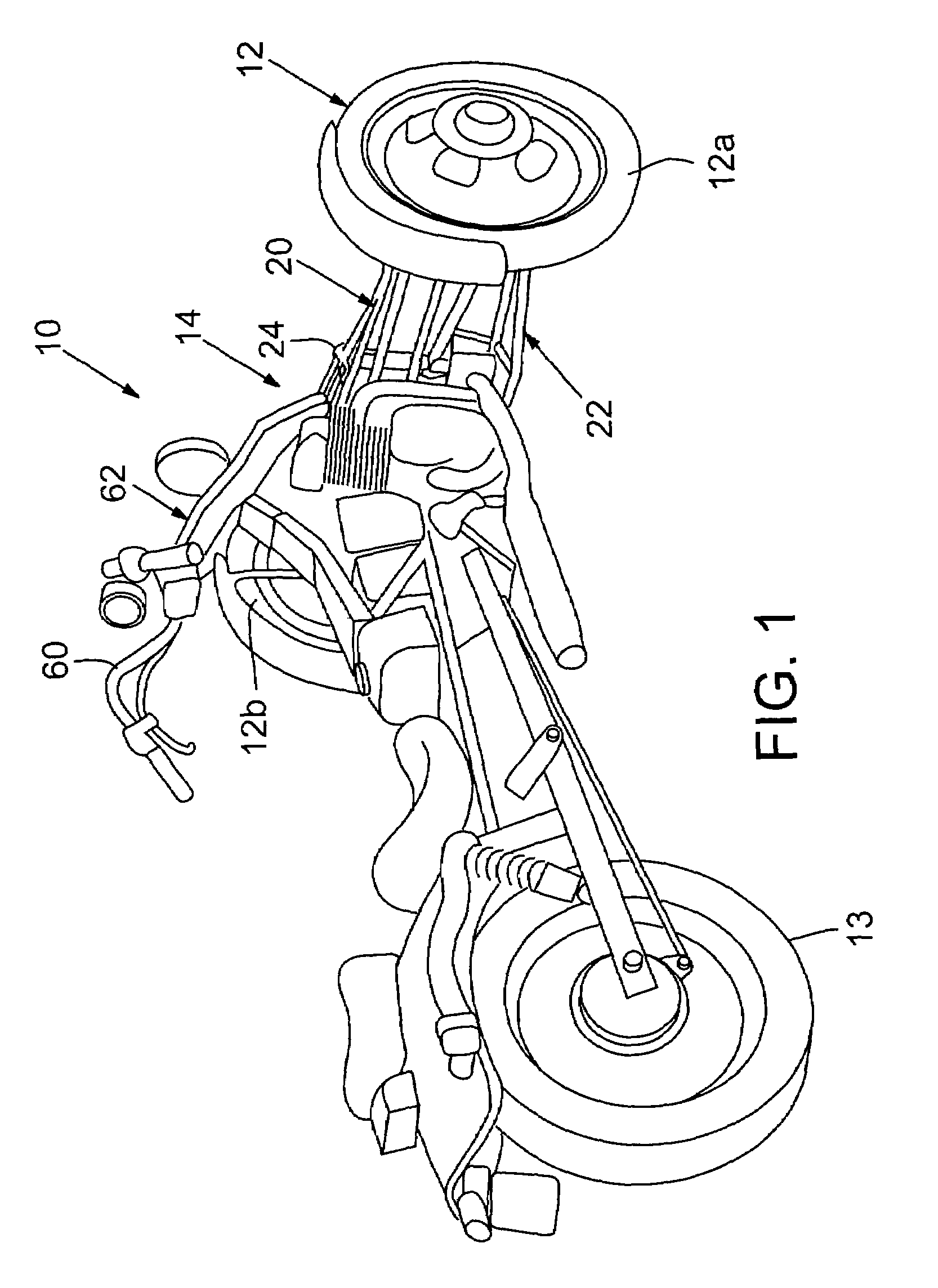

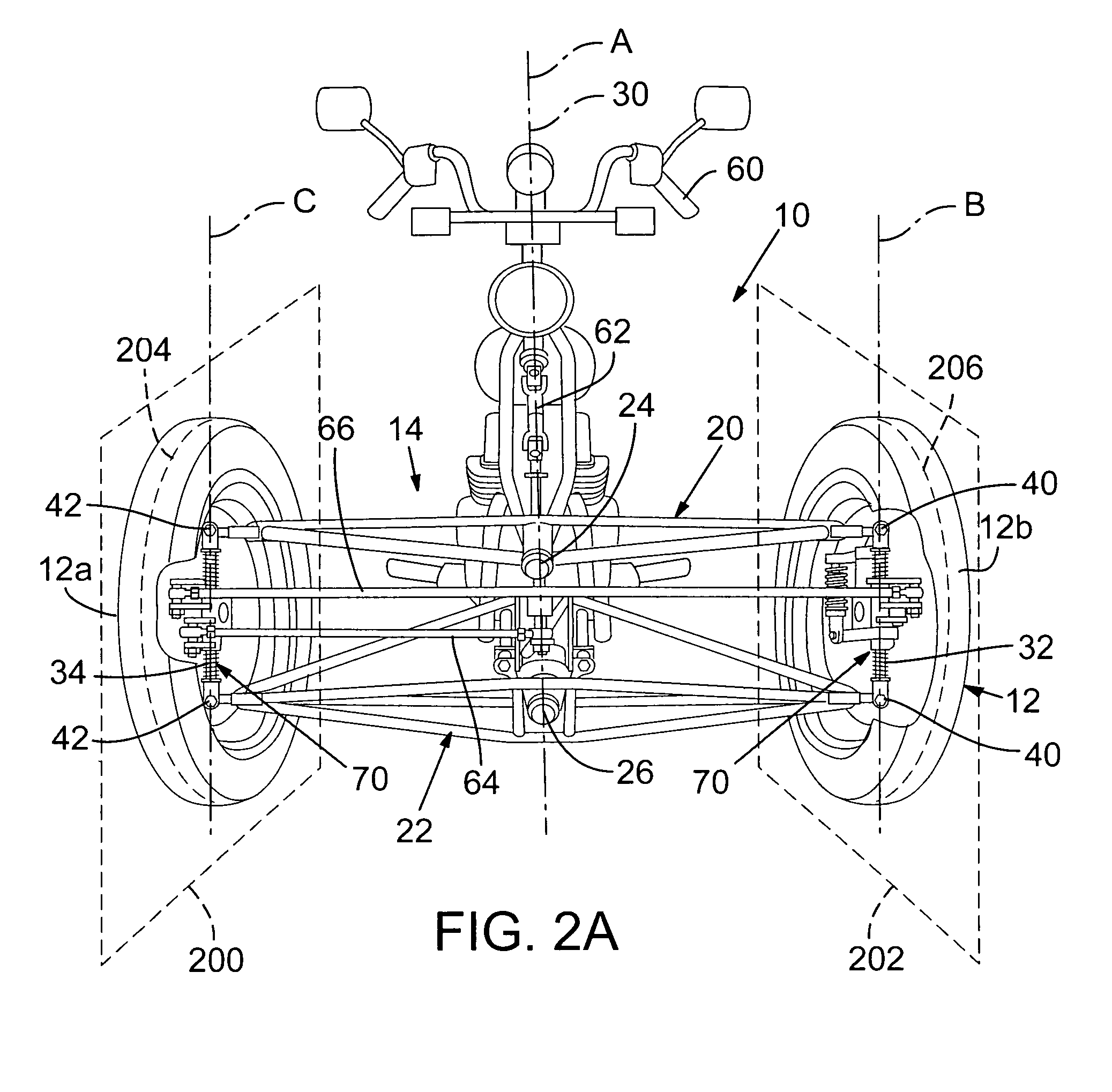

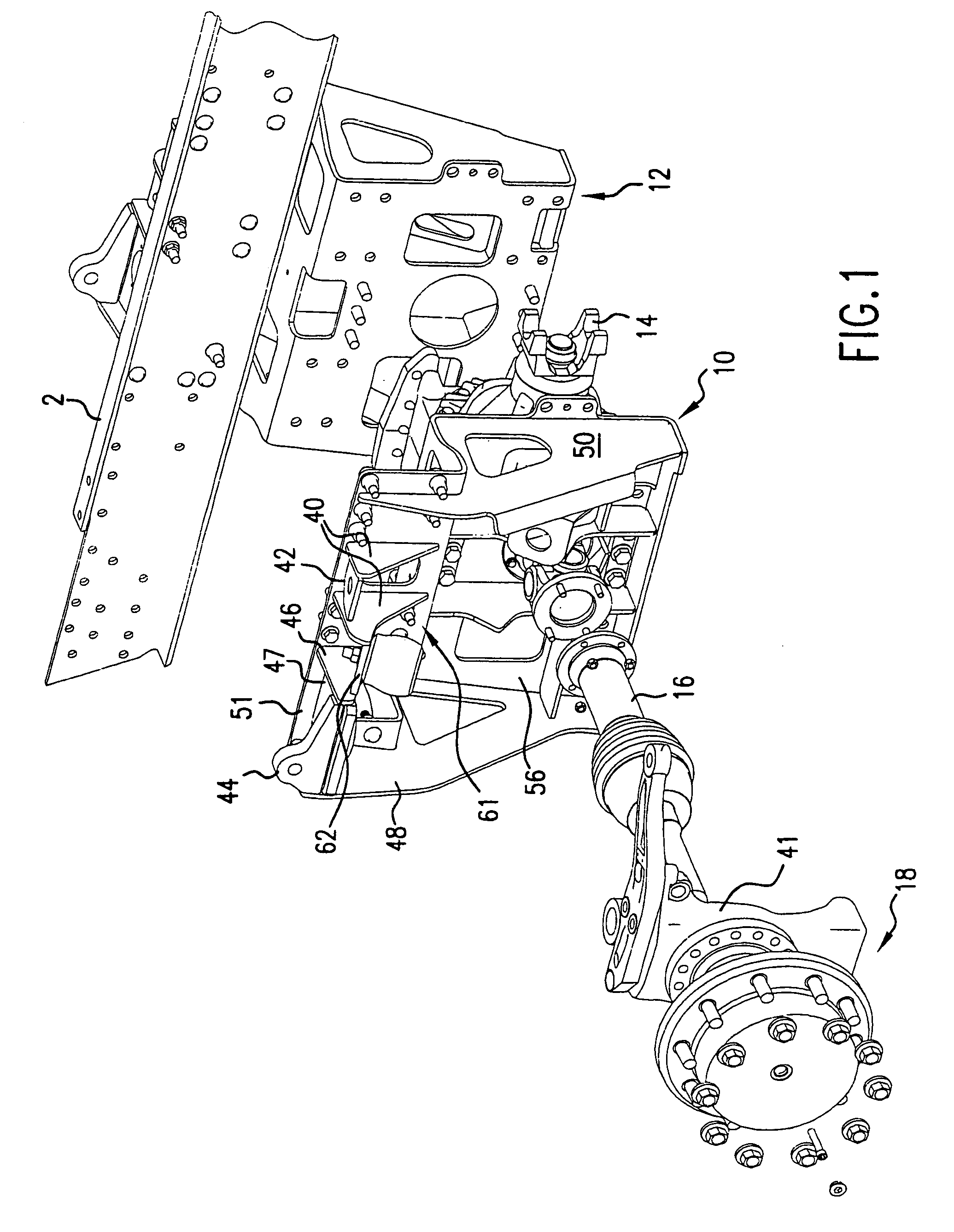

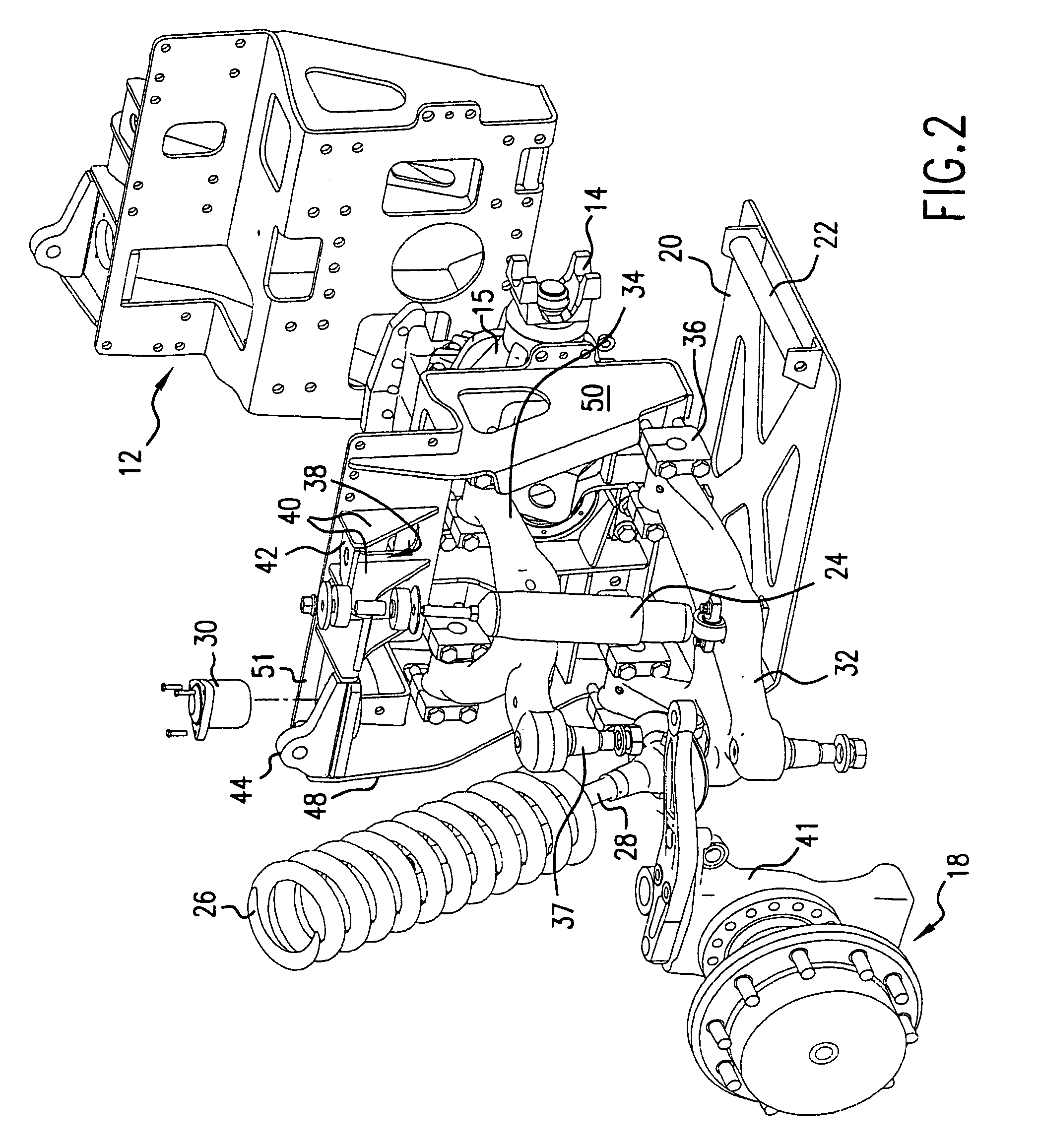

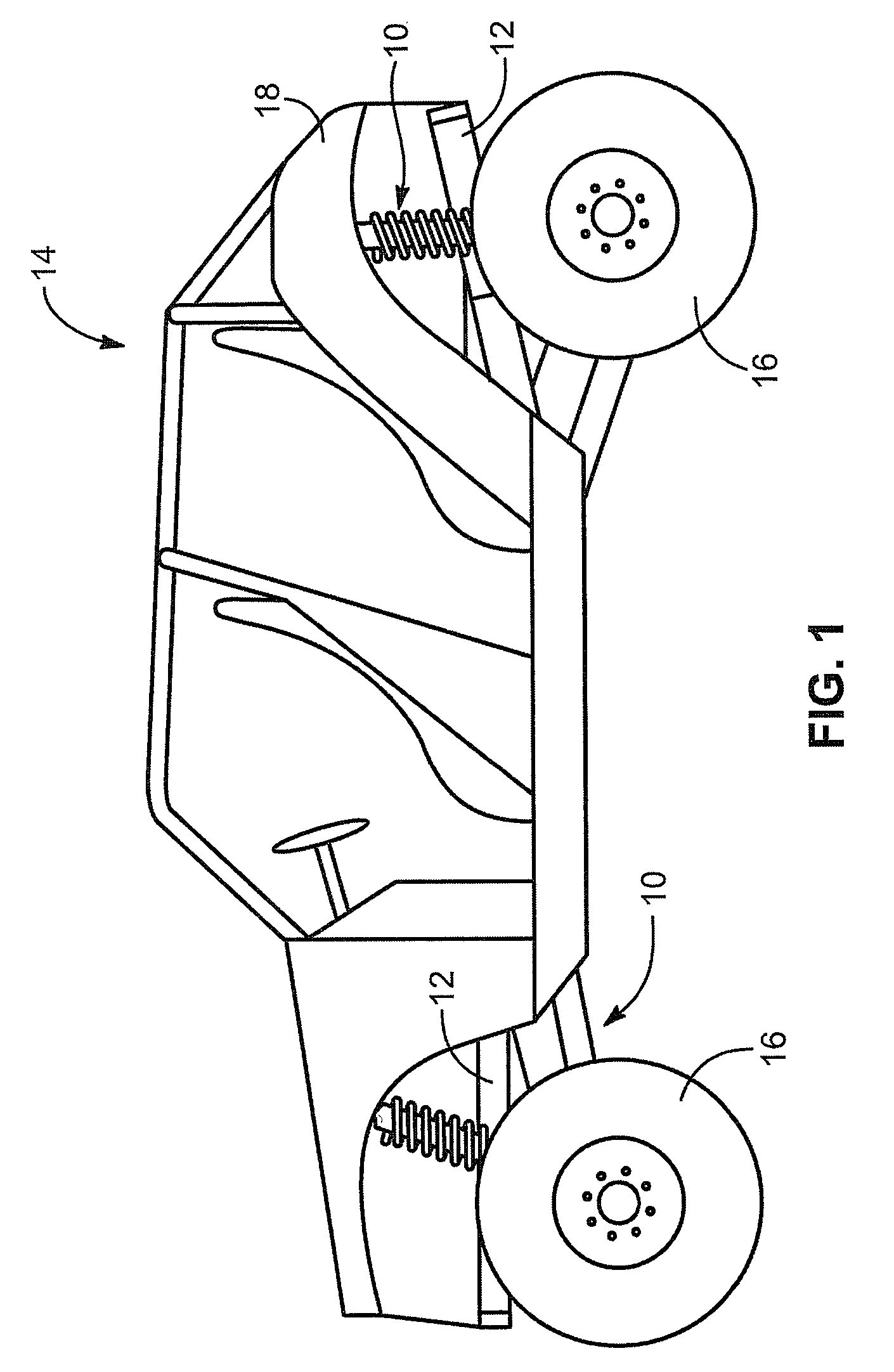

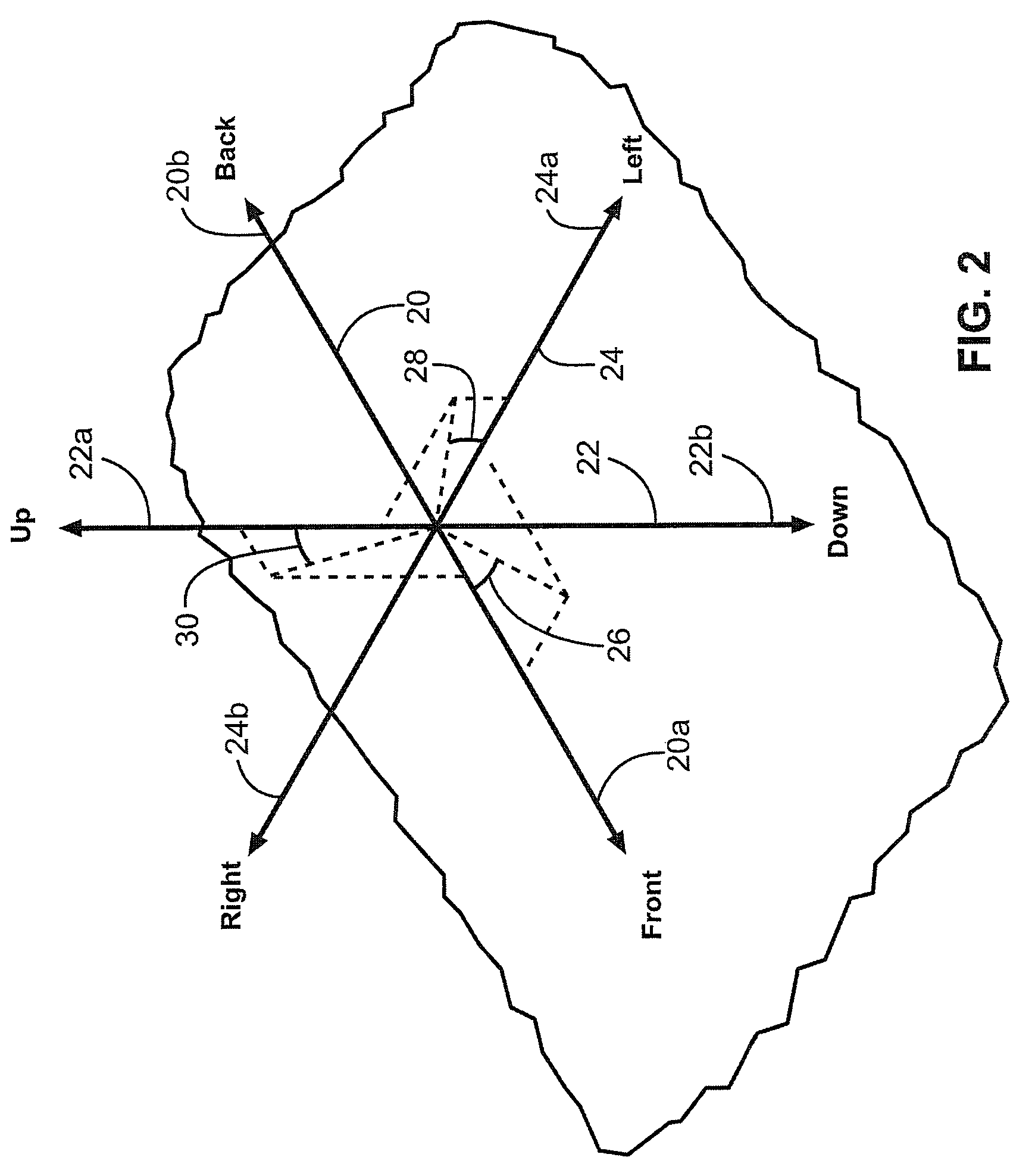

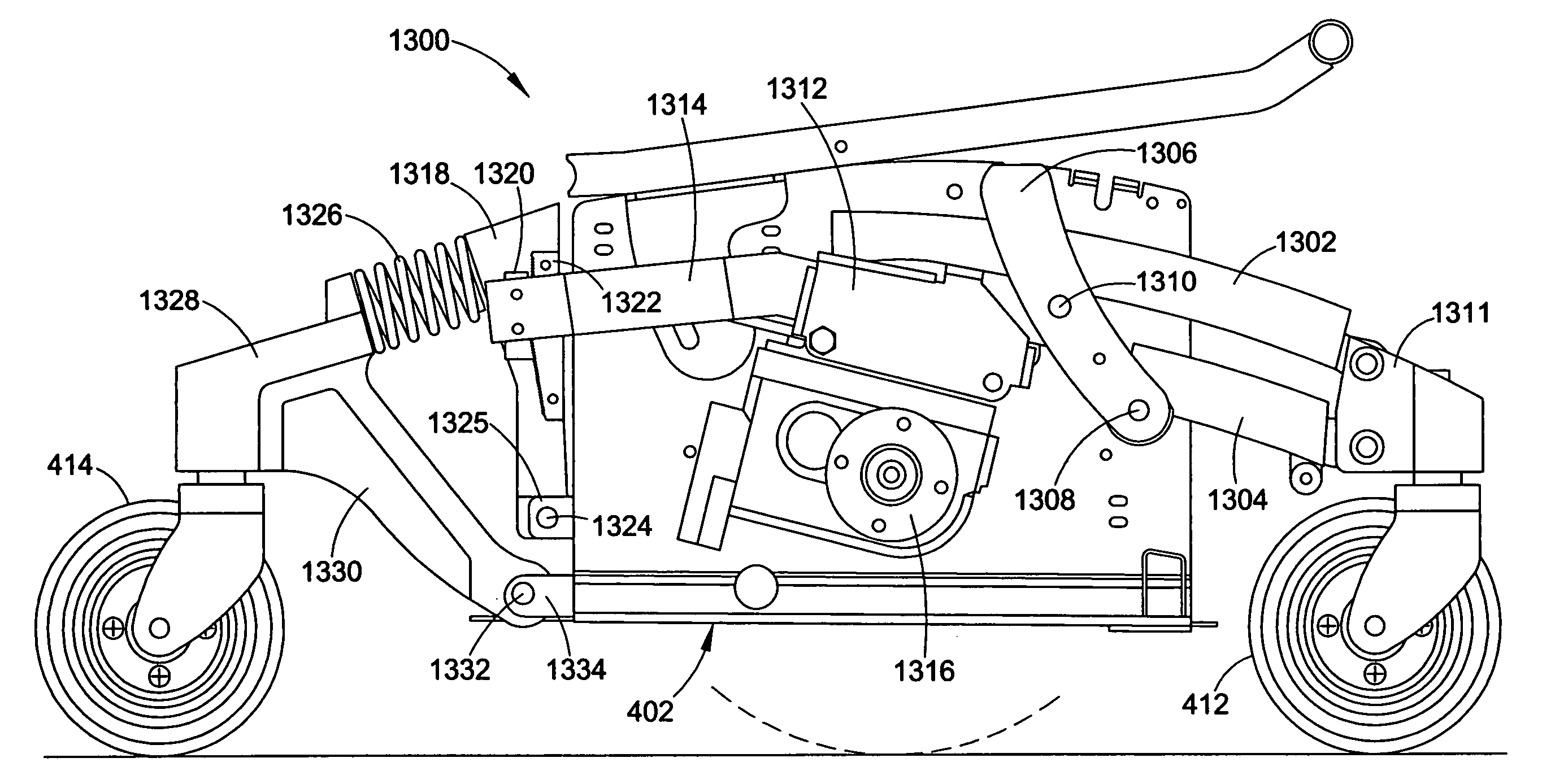

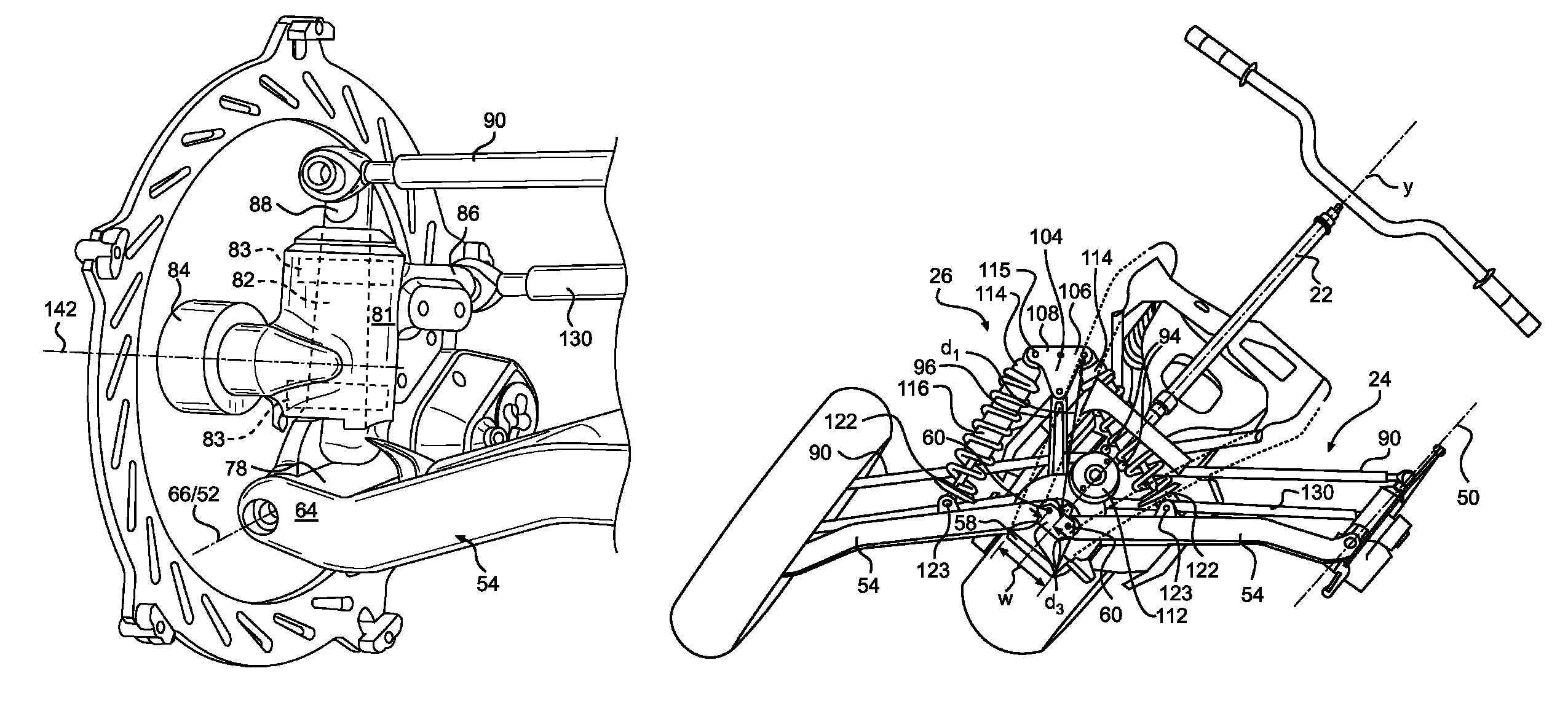

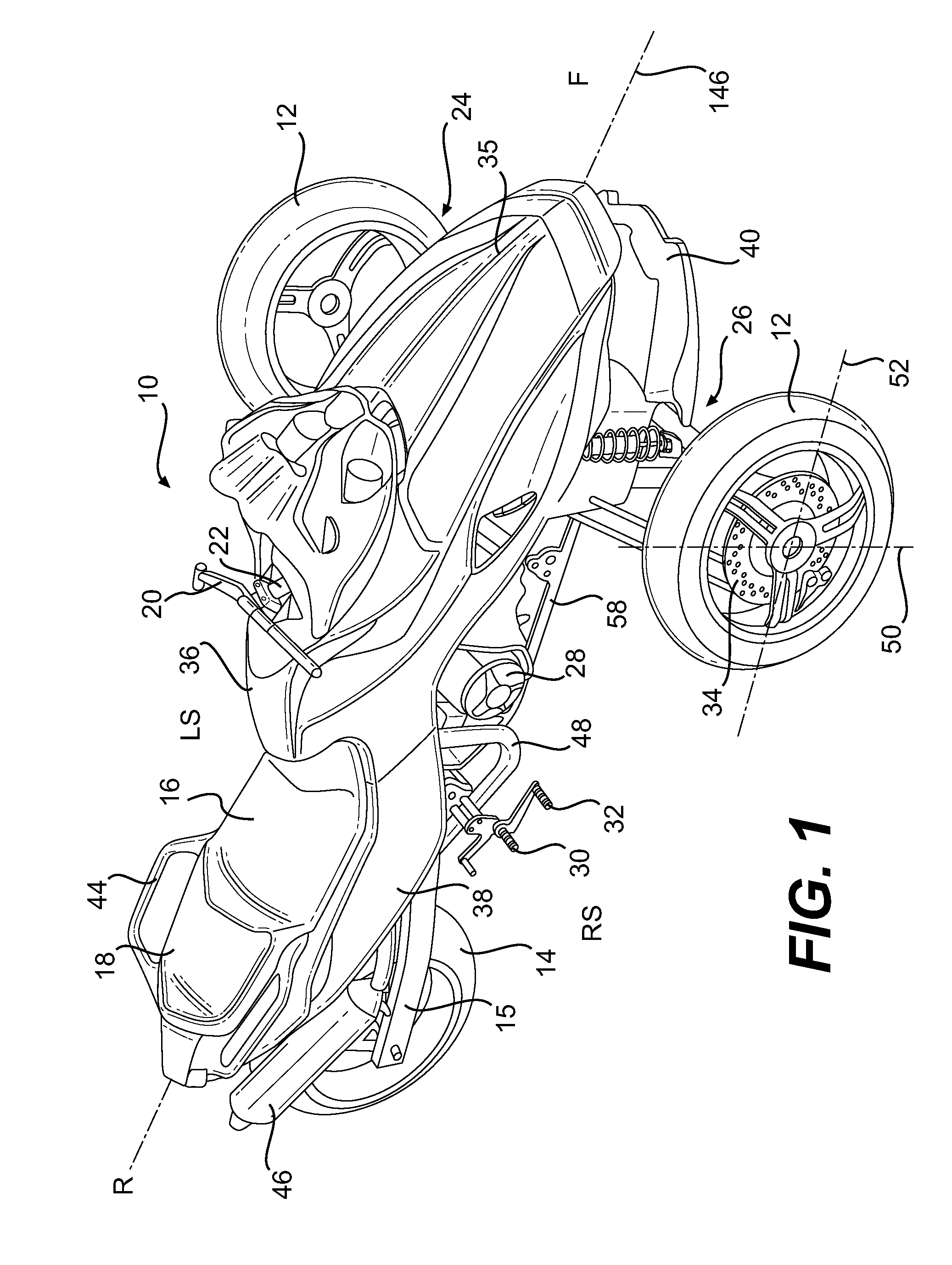

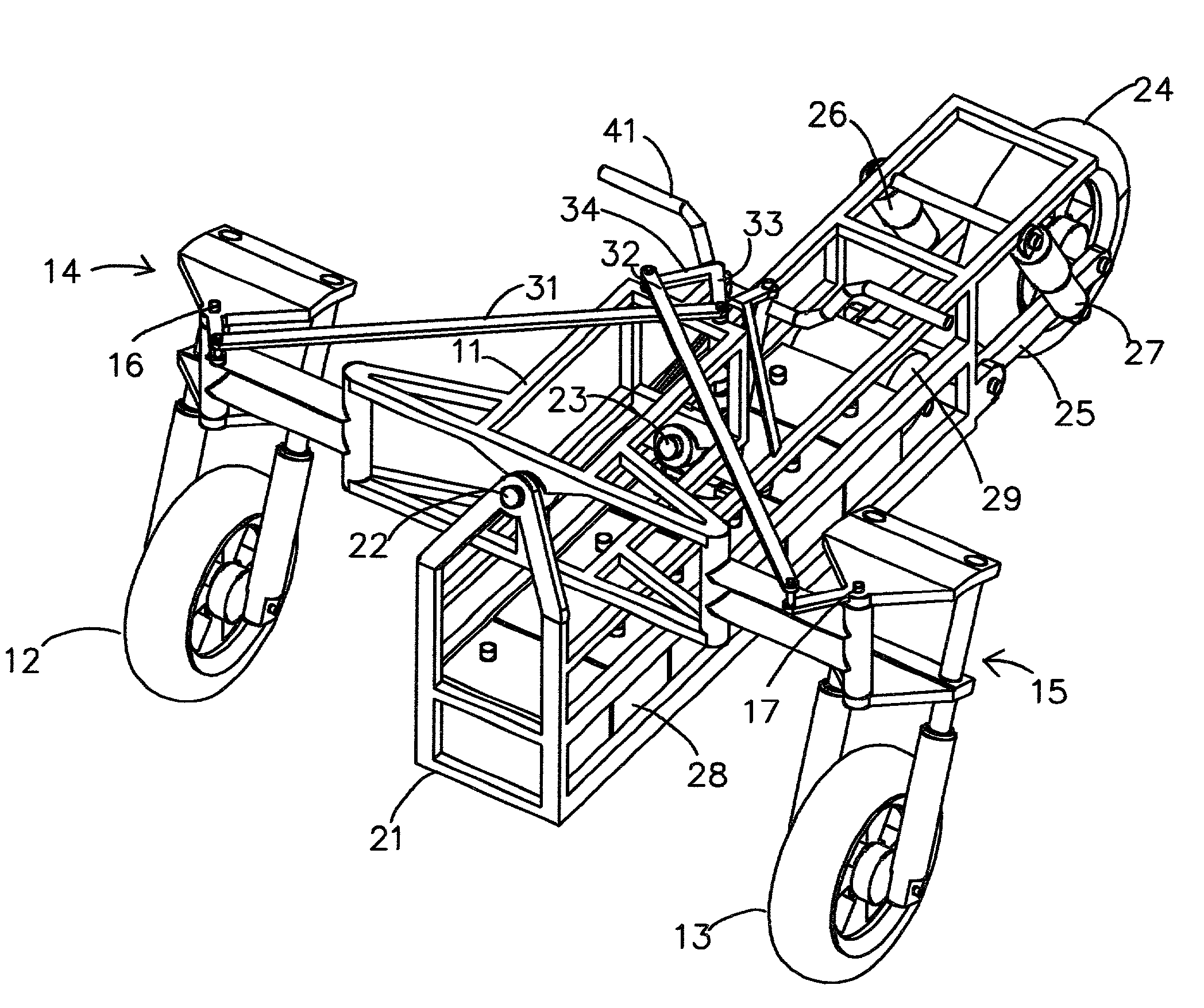

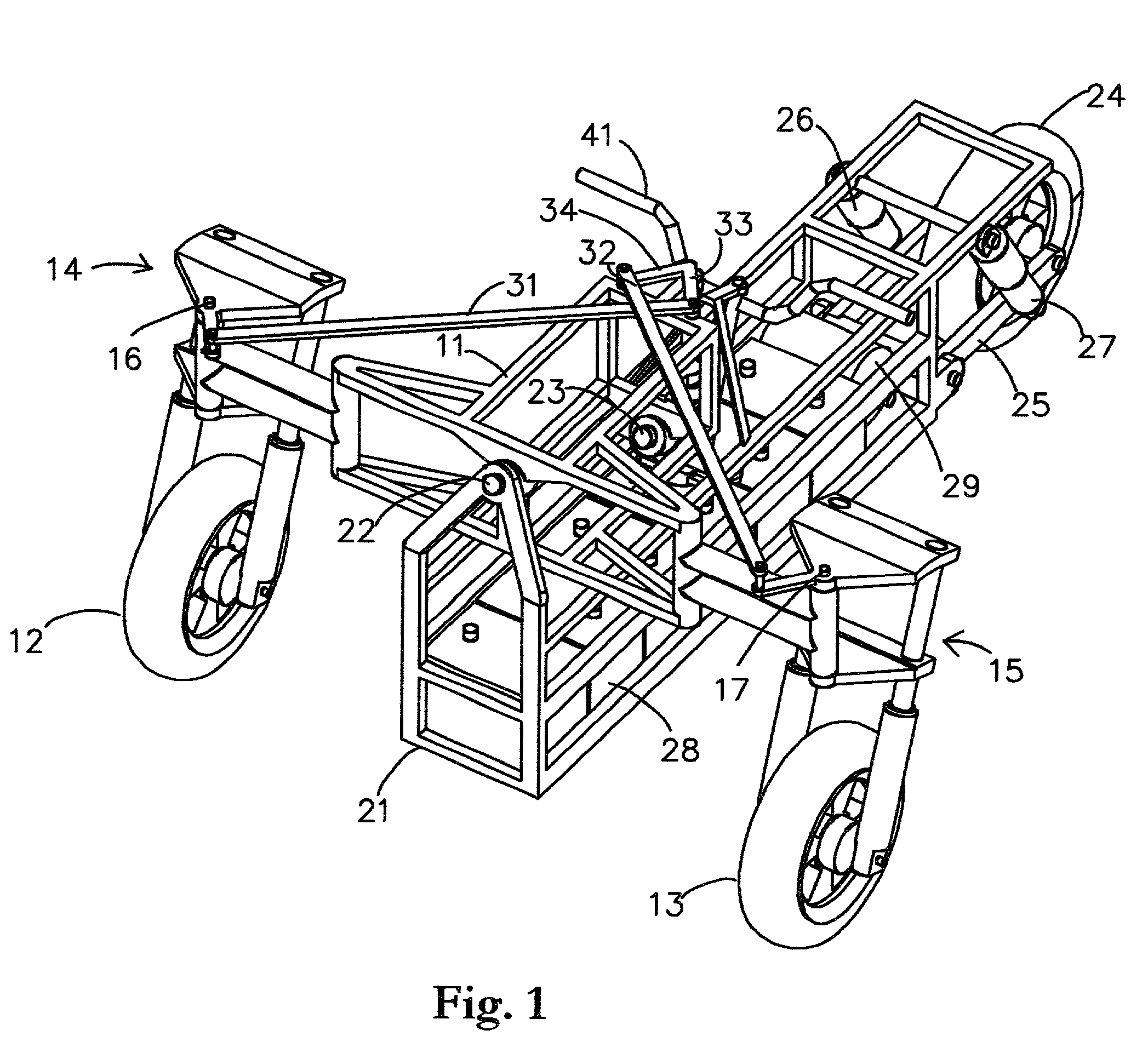

Tilting wheeled vehicle

ActiveUS7487985B1Complex control systemWheel based transmissionFrictional rollers based transmissionControl systemCaster angle

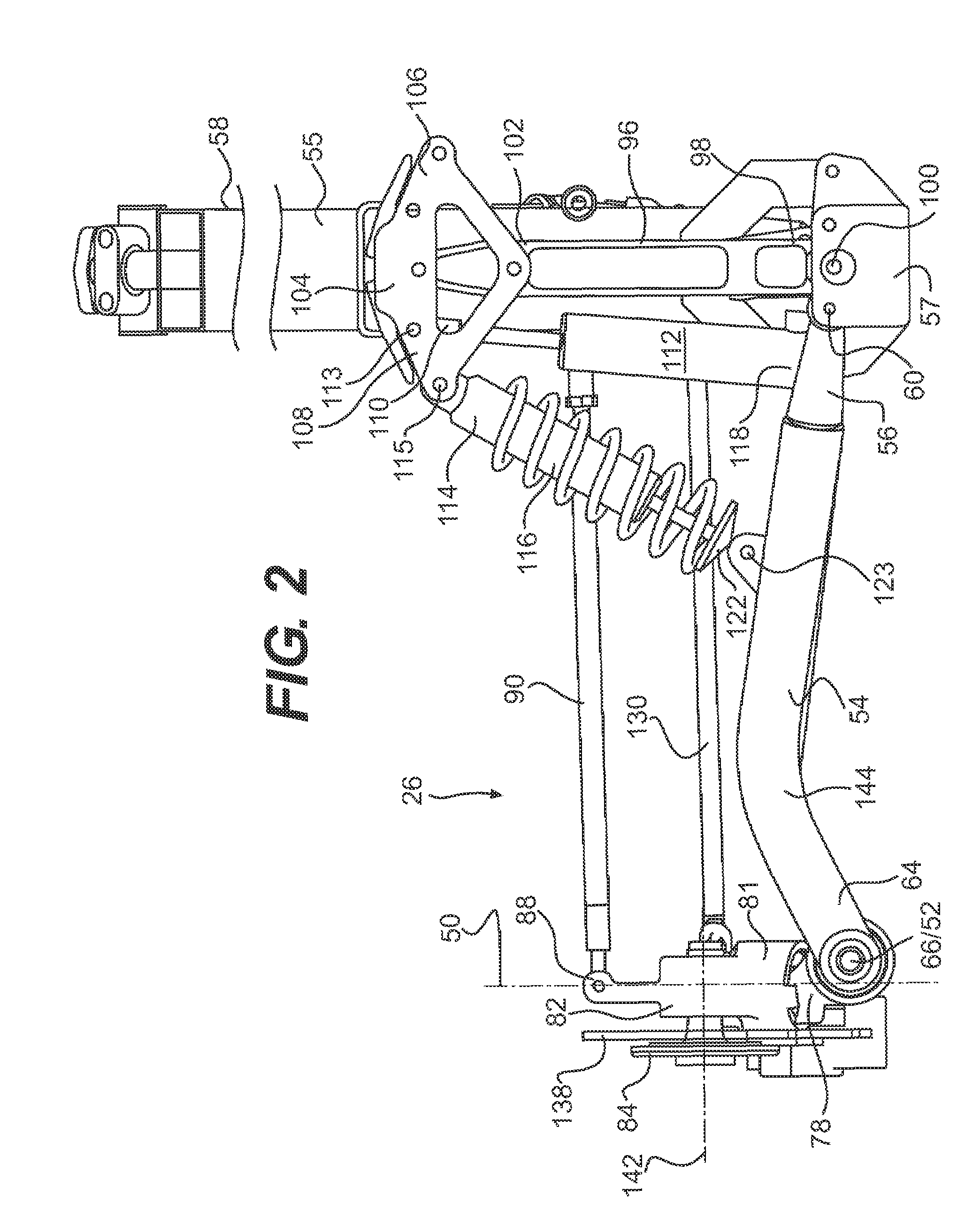

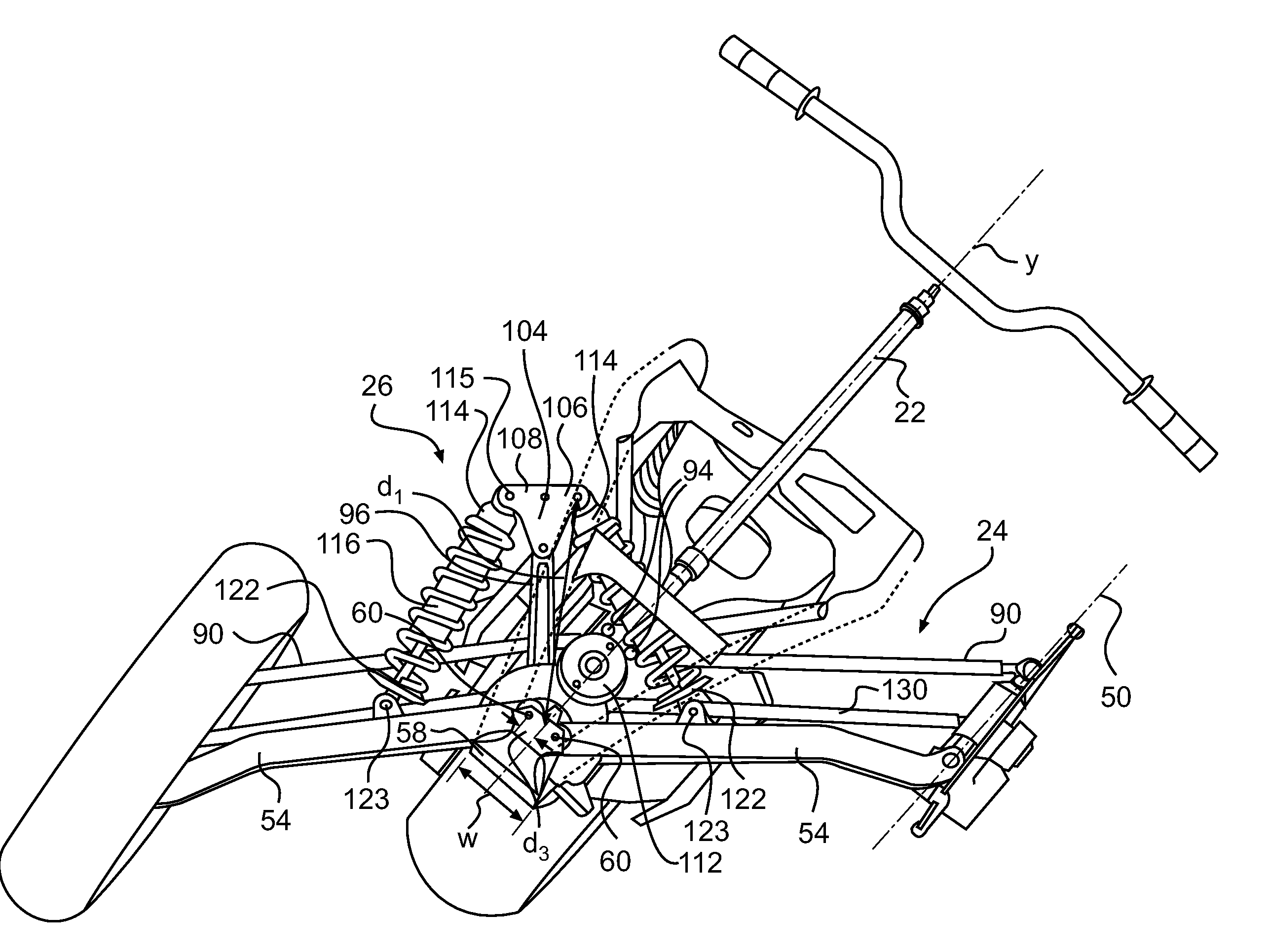

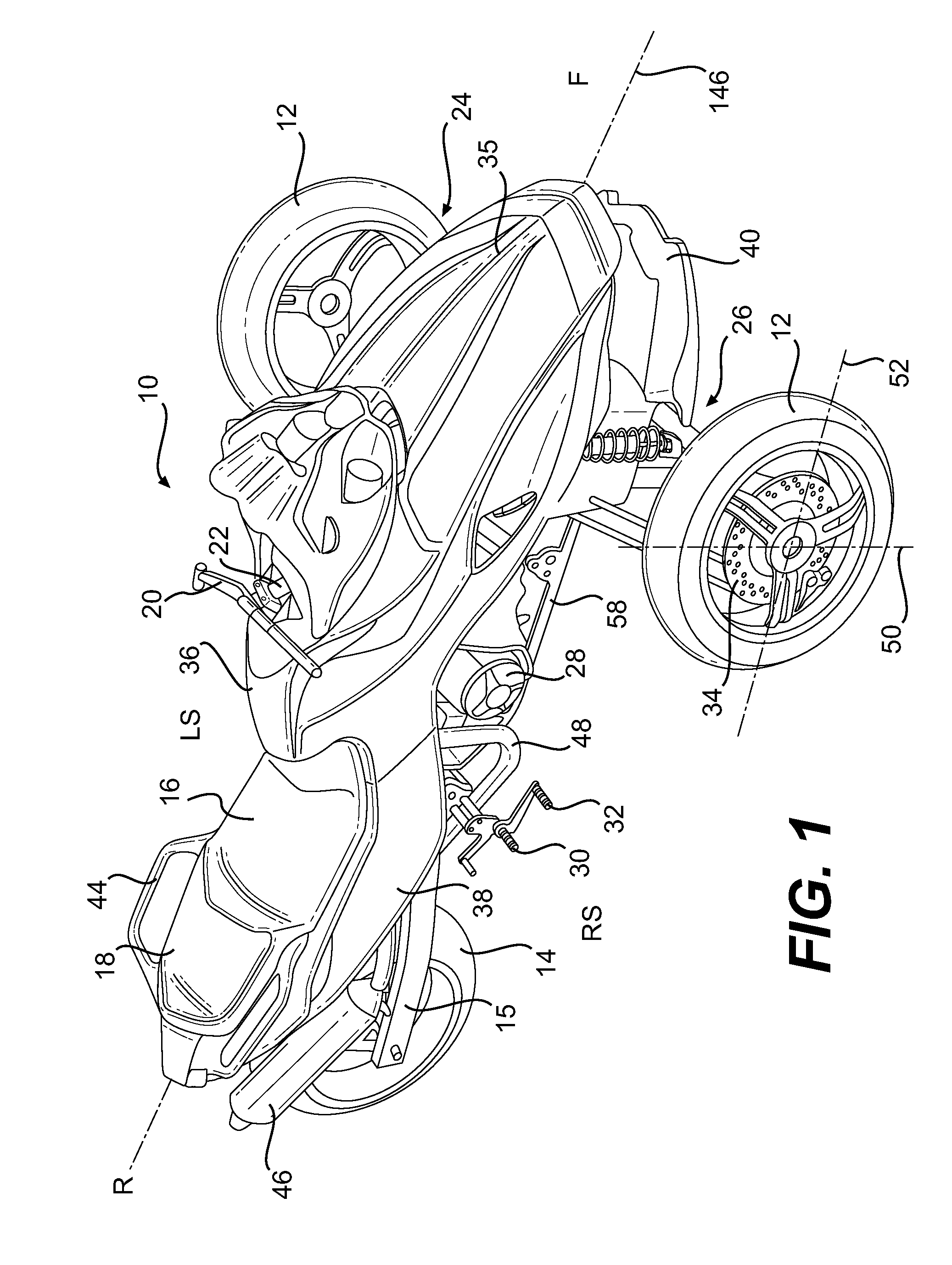

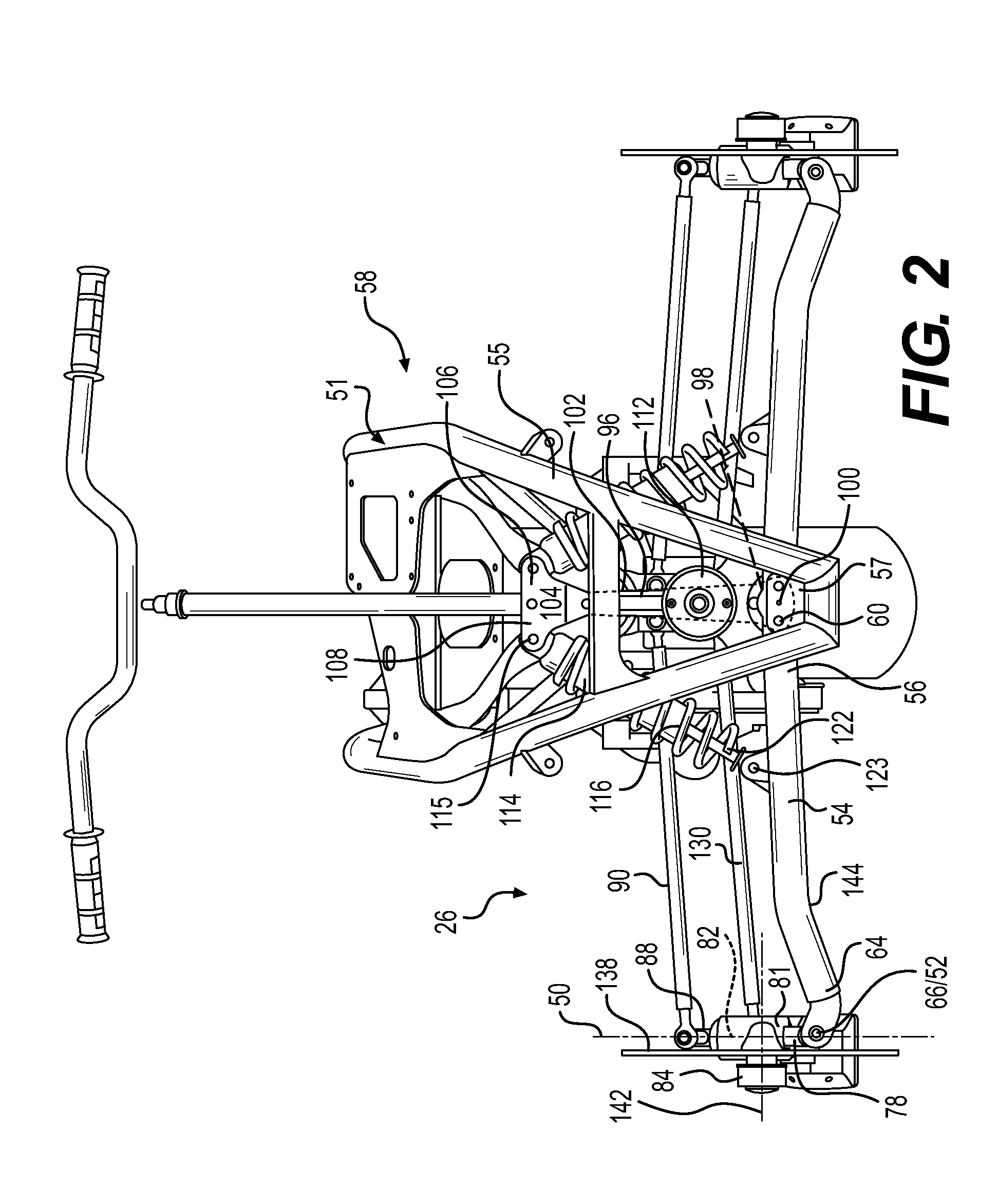

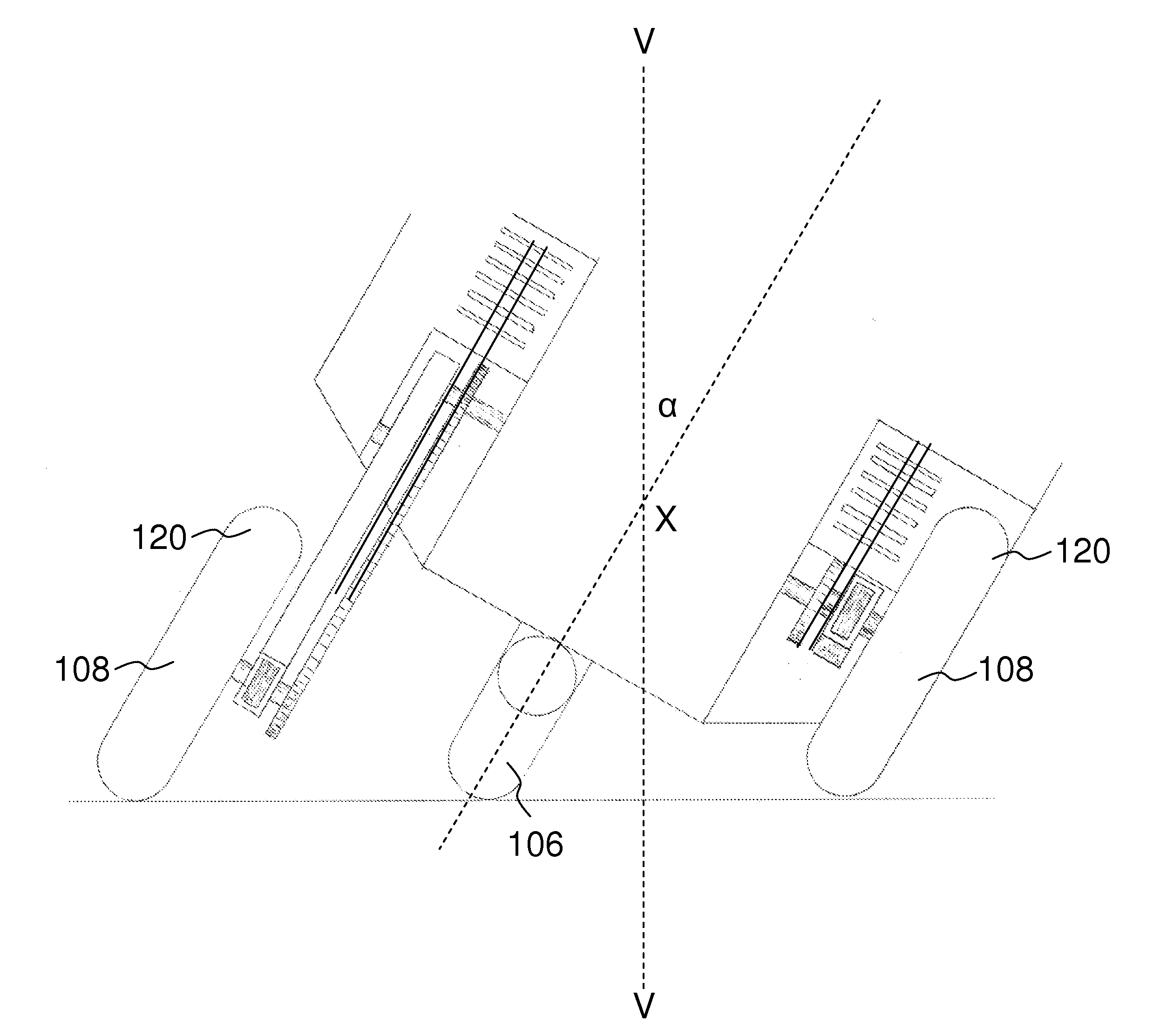

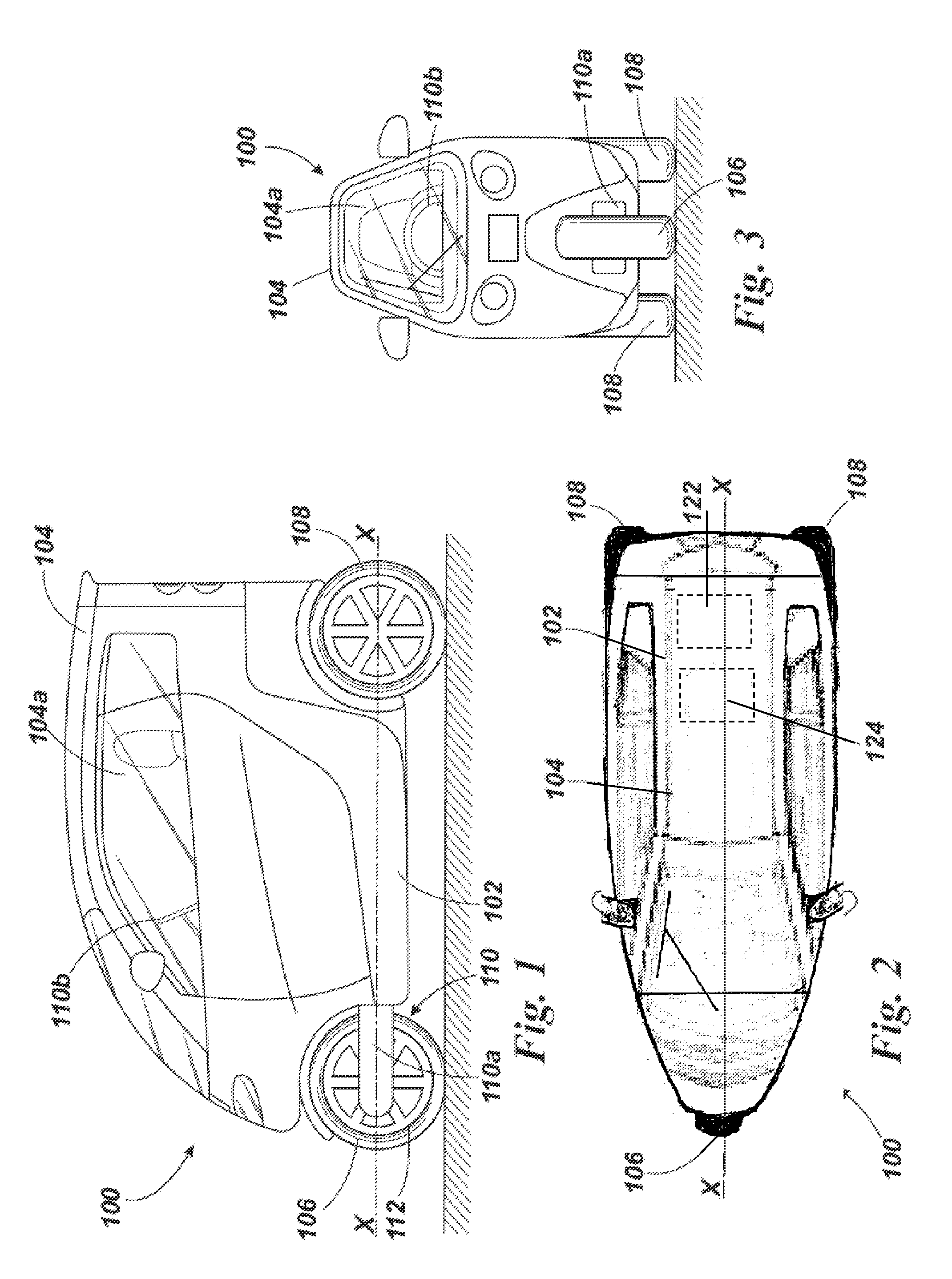

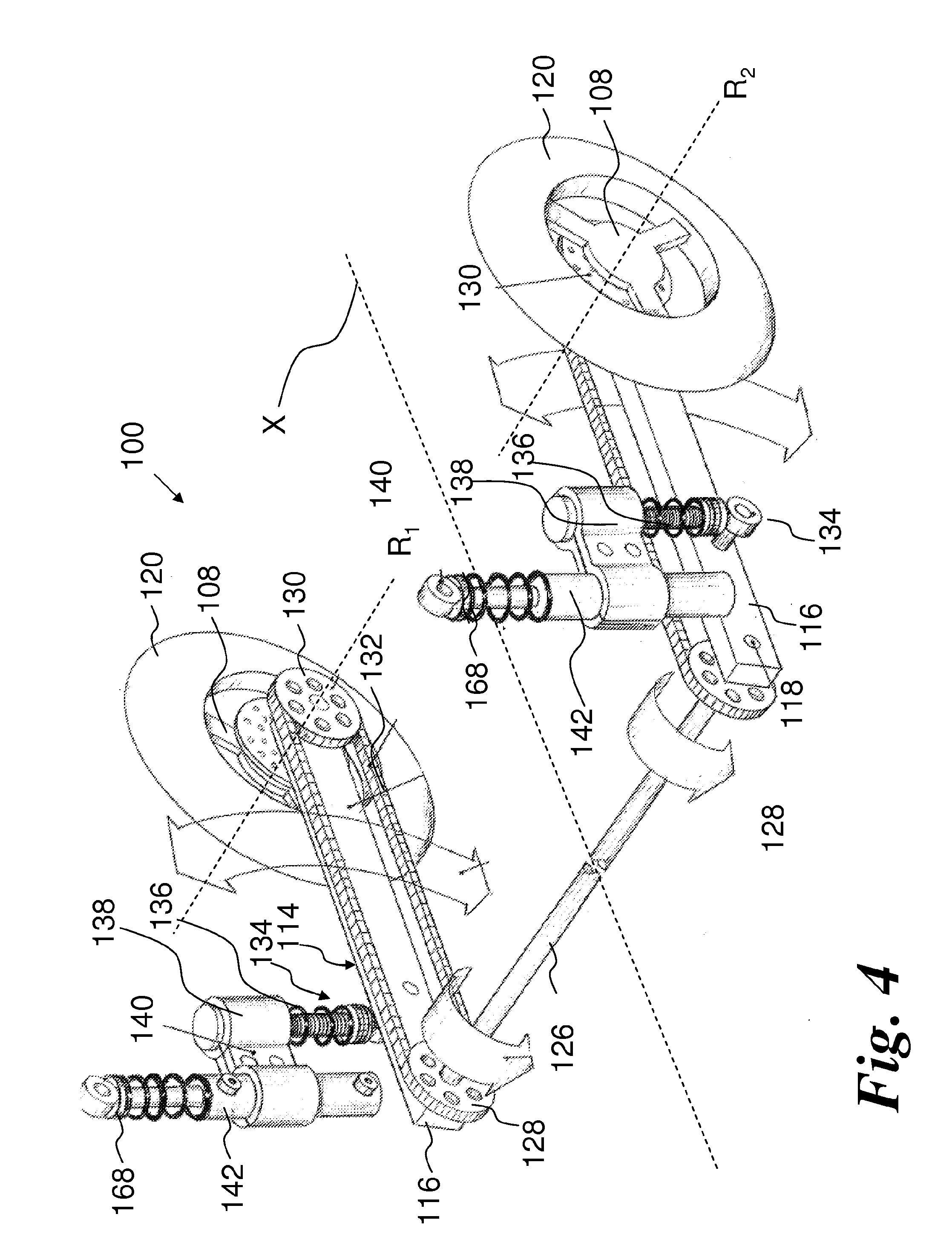

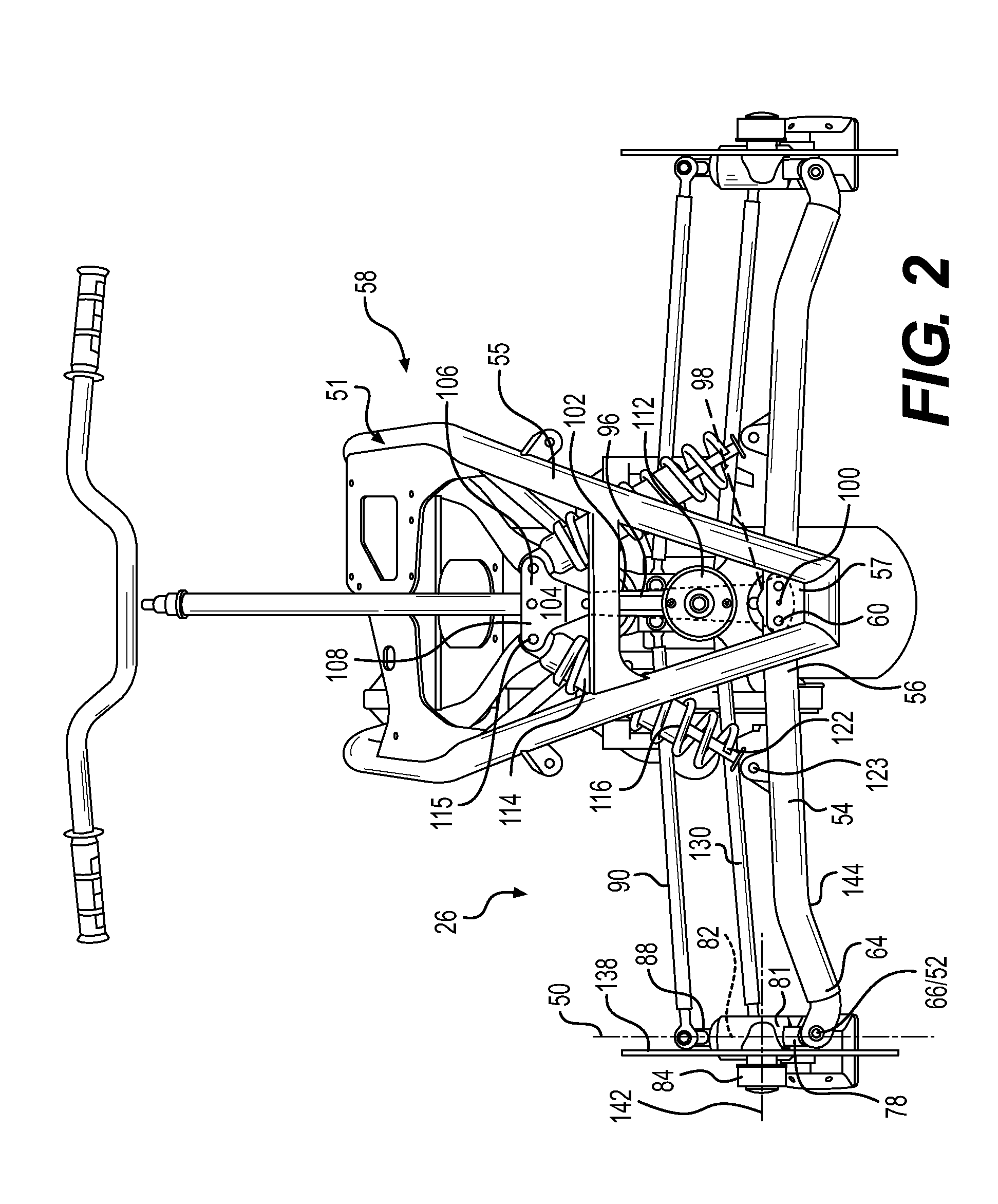

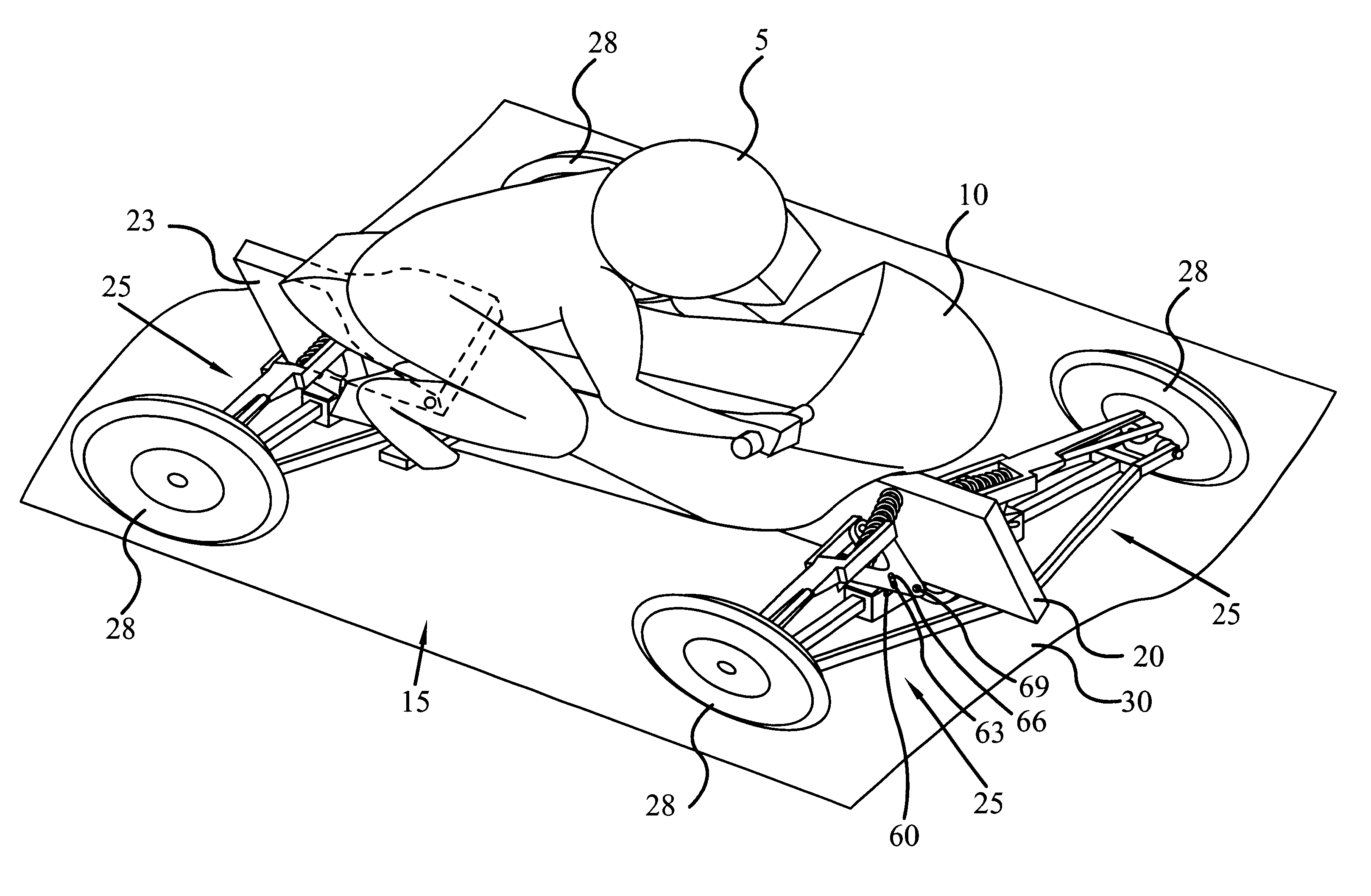

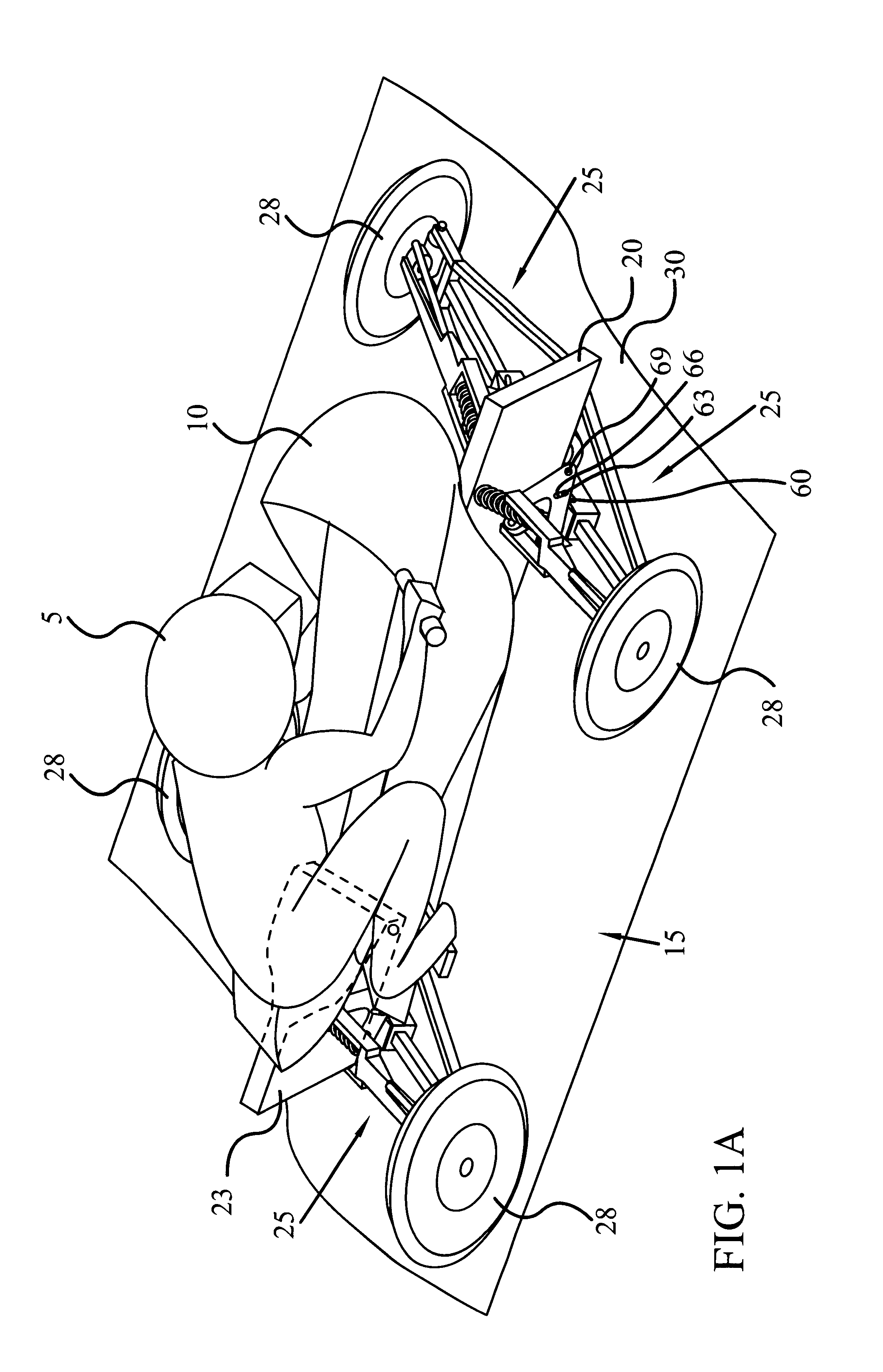

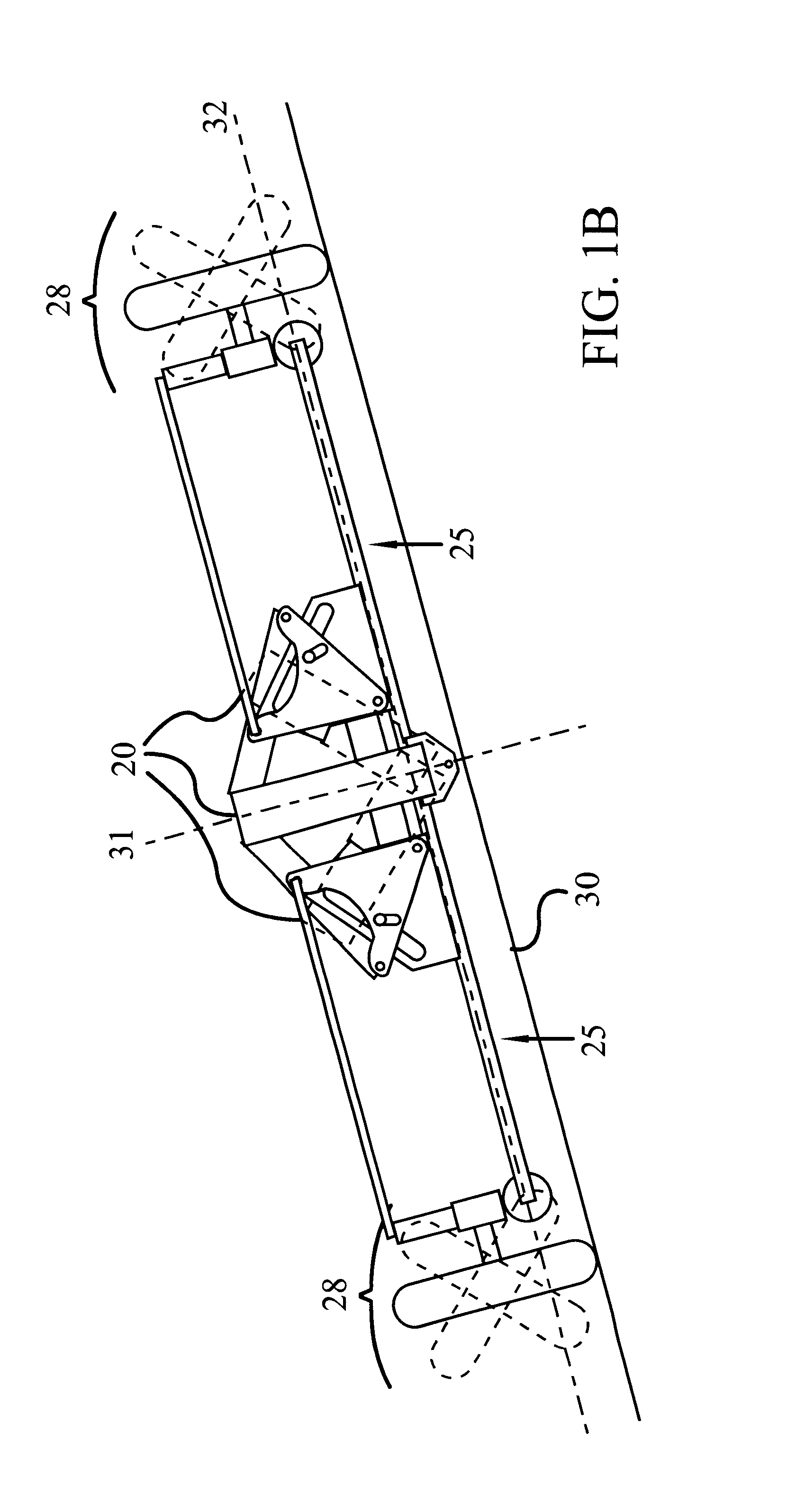

A tilting, preferably three-wheeled, vehicle is disclosed that has a tilting mechanism that allows the vehicle to have leaning characteristics substantially similar to those offered by an in-line two-wheeled vehicle, but that does not require complex linkages and / or control systems to operate effectively. A tilting linkage is operably secured to a frame to allow a pair of spaced apart wheels to remain substantially aligned with the plane of the vehicle throughout its range of movement while still allowing the steering axes of each wheel to intersect the substantially vertical centerline of each wheel. The linkage also allows the caster angle of each wheel's pivot axis can be optimized independently of the angle of the vehicle's handlebar steering shaft.

Owner:ARCIMOTO

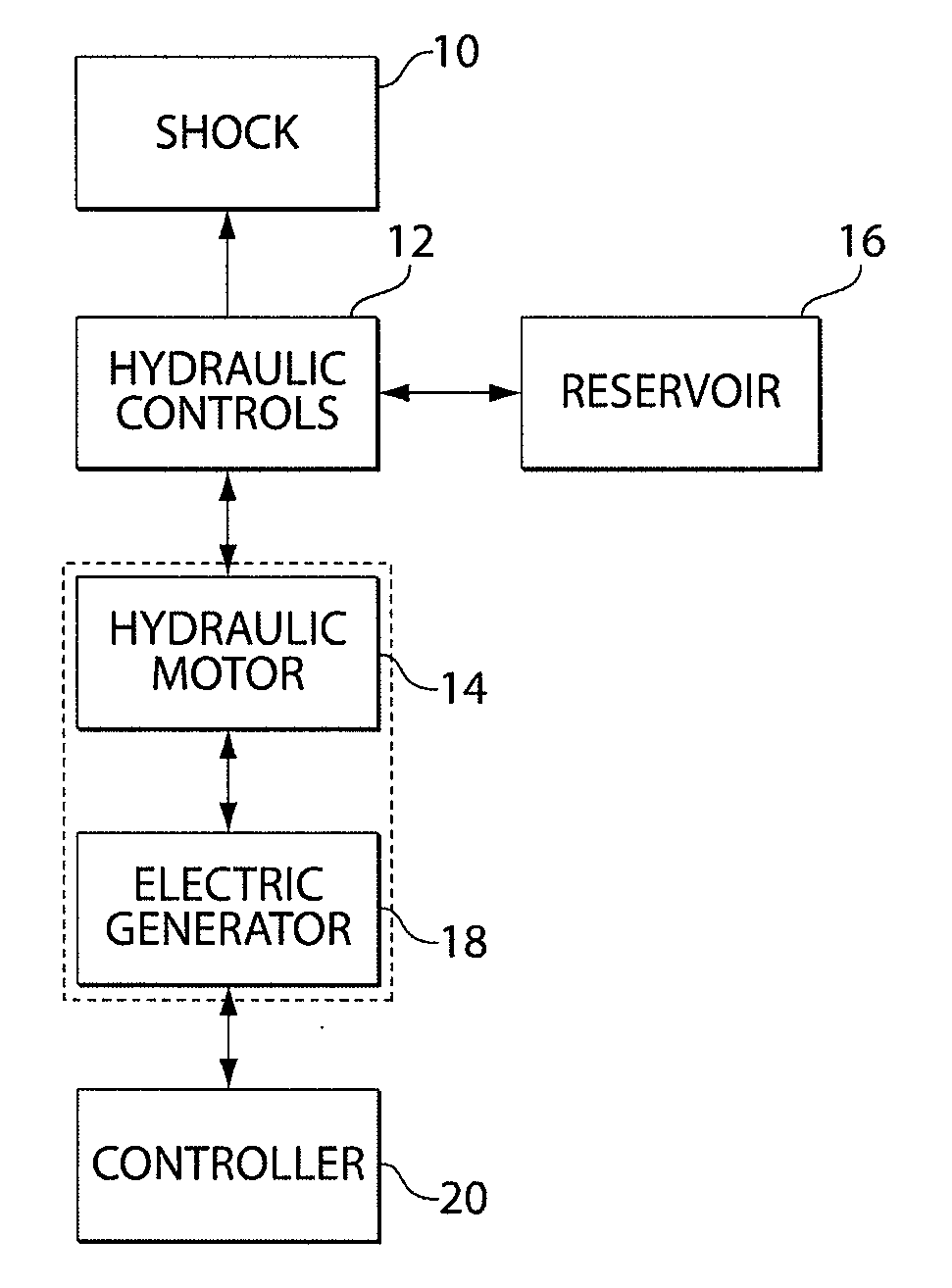

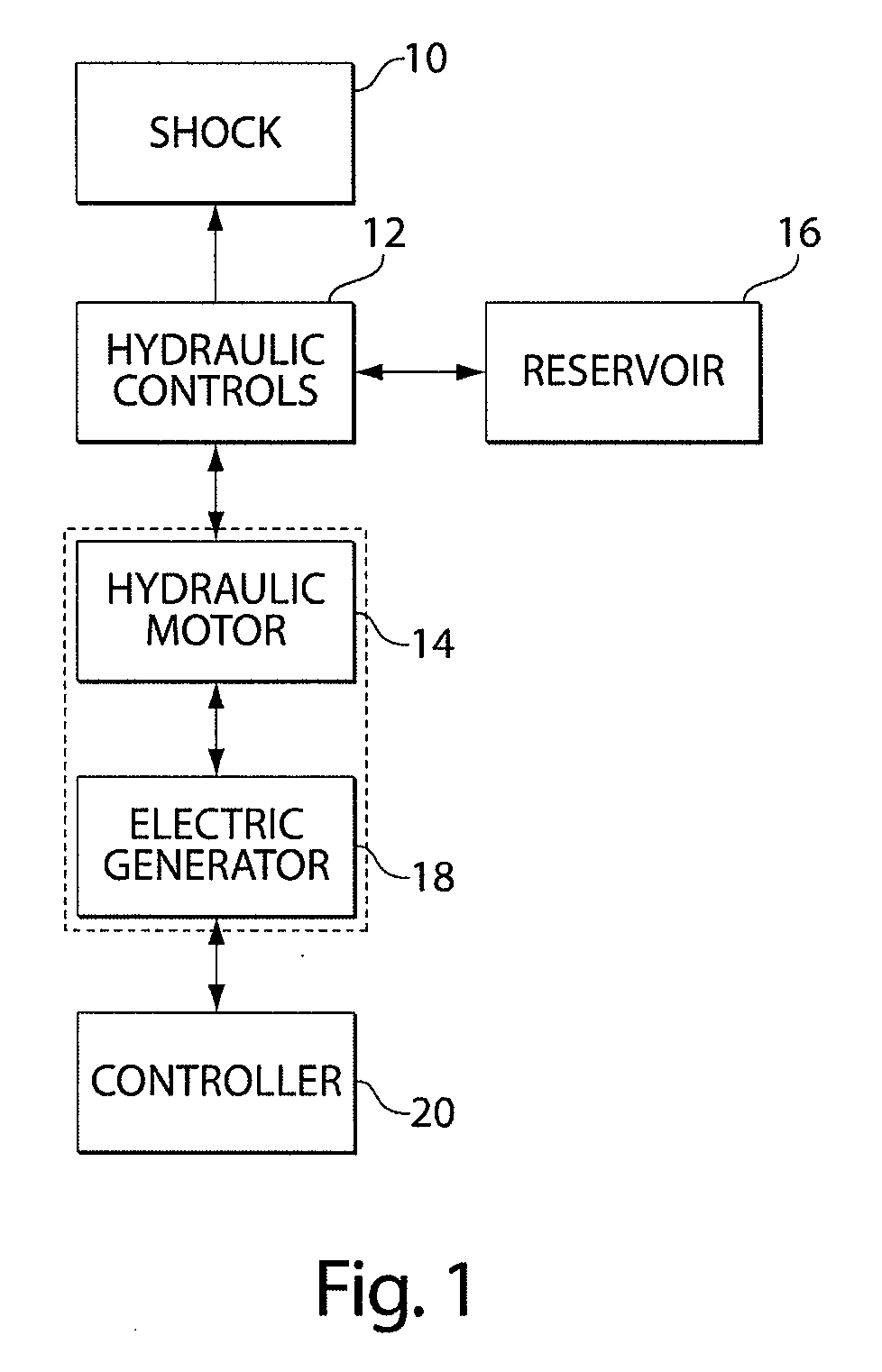

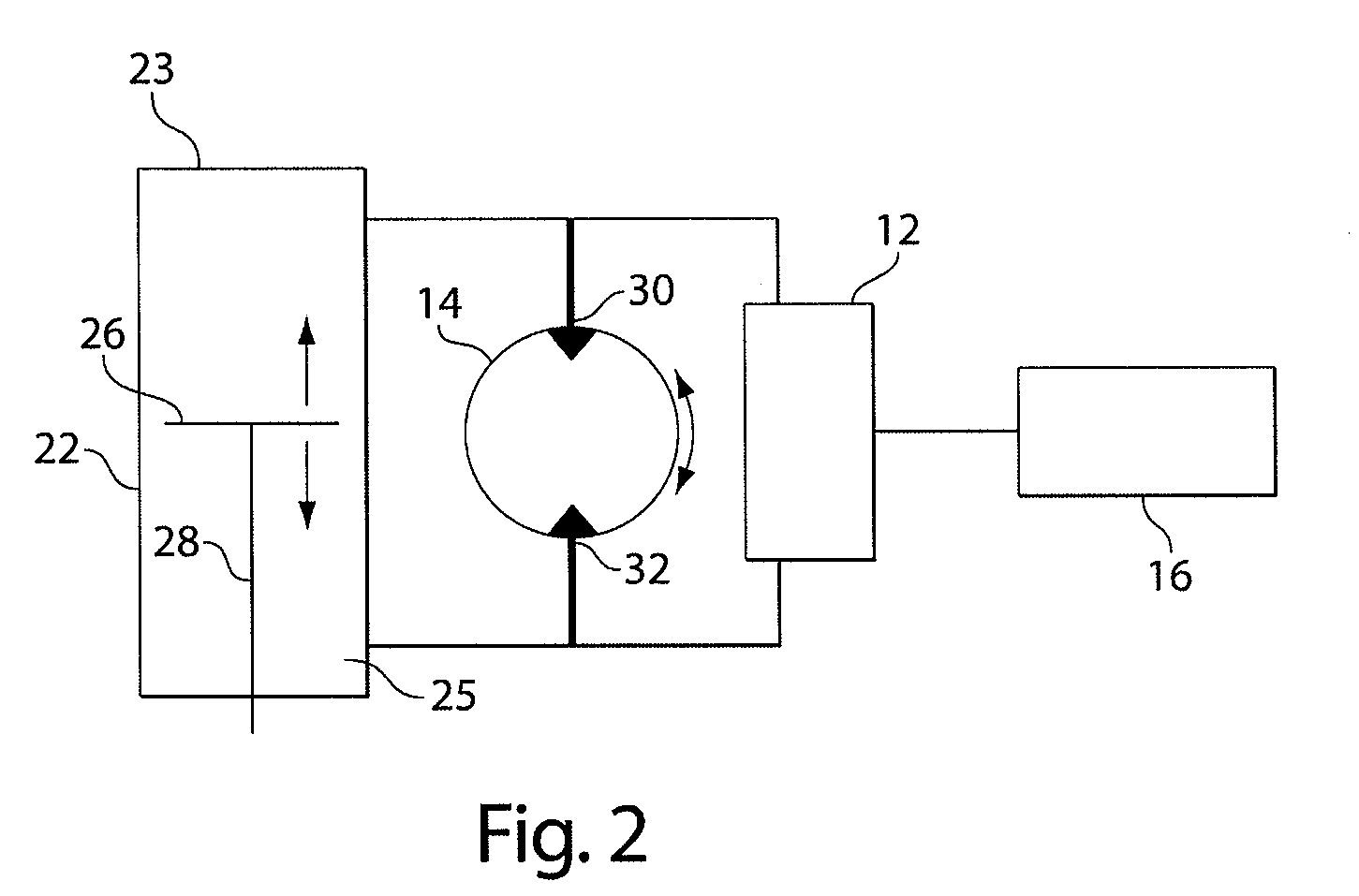

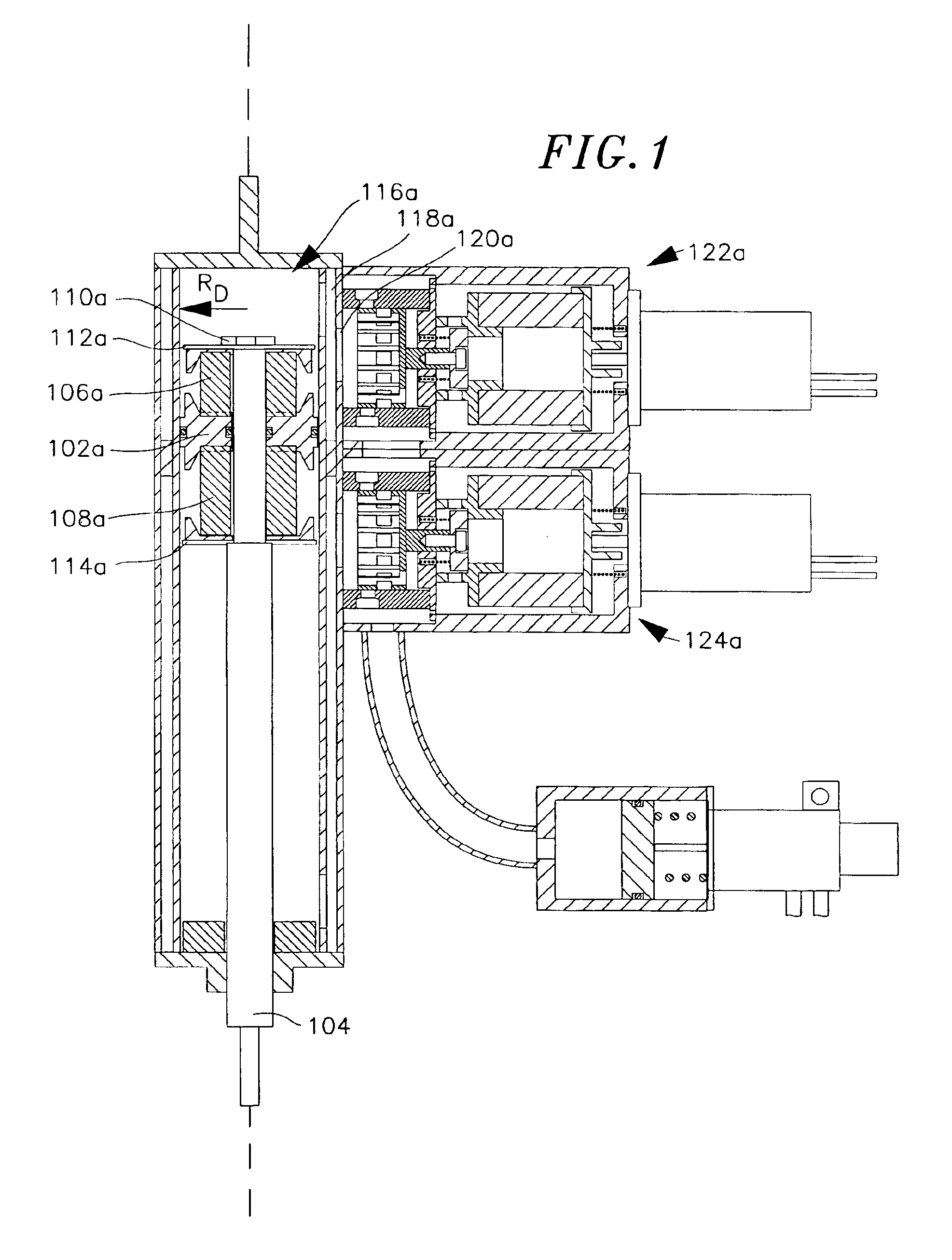

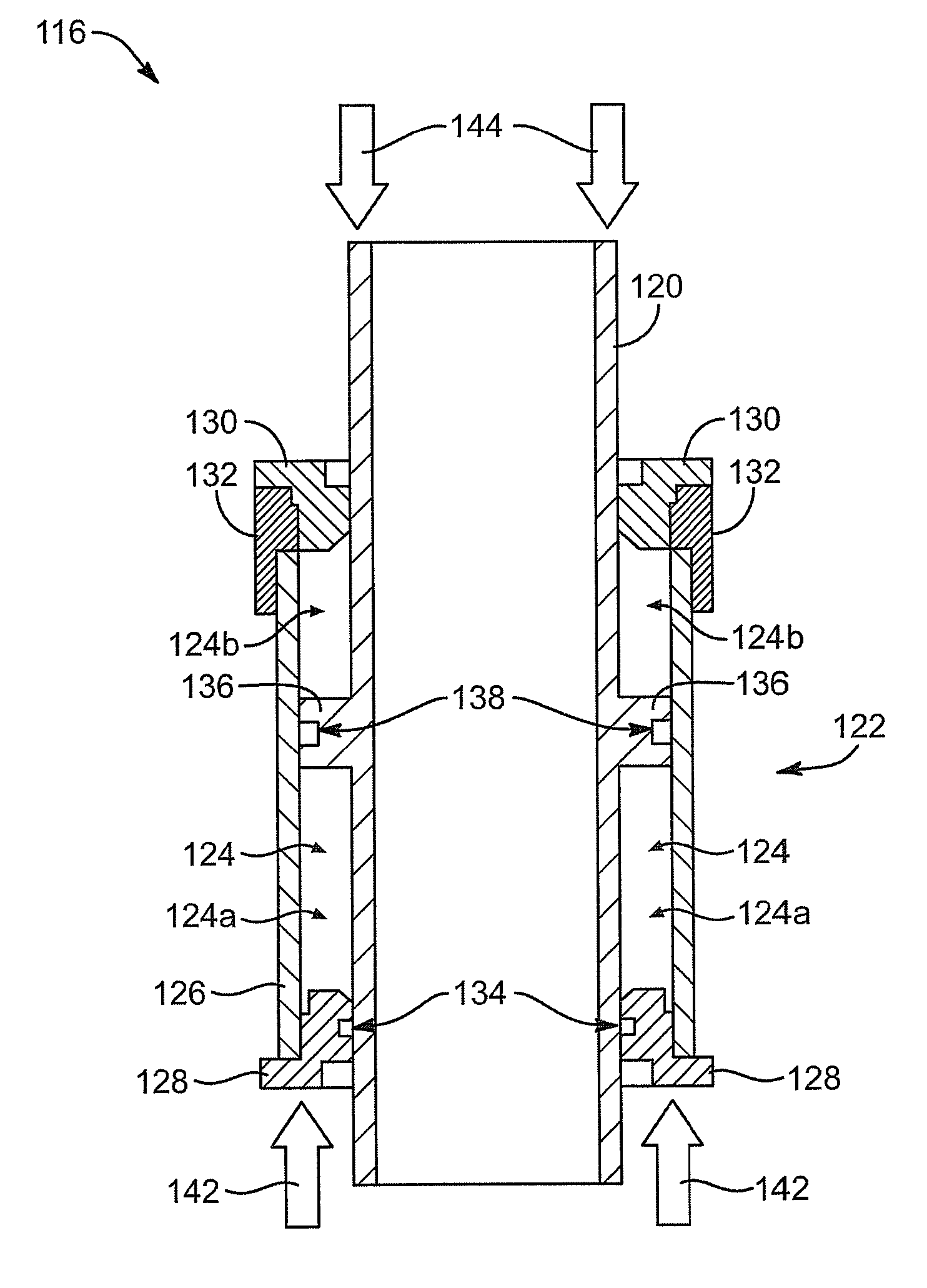

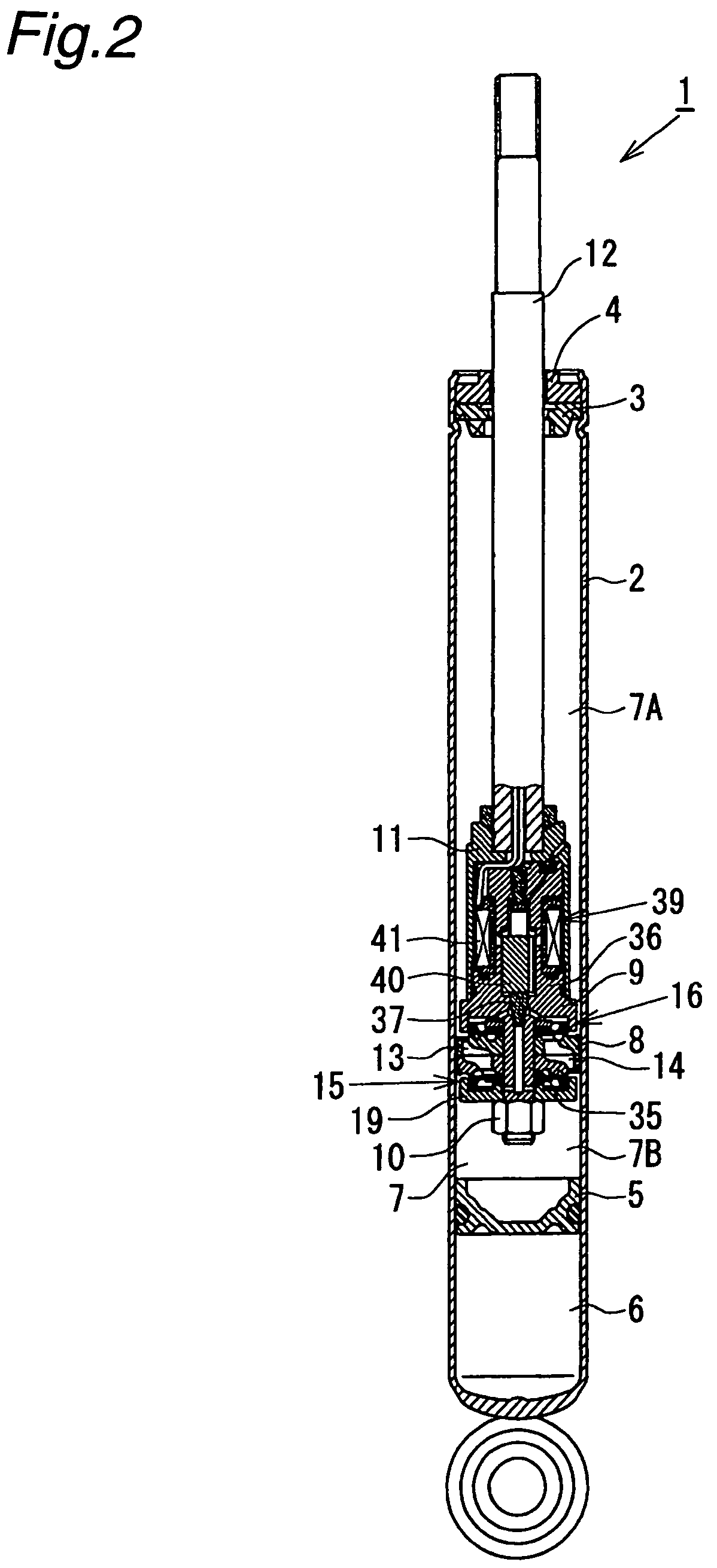

Regenerative shock absorber system

A regenerative shock absorber that include a housing and a piston that moves at least partially through the housing when the shock is compressed or extended from a rest position. When the piston moves, hydraulic fluid is pressurized and drives a hydraulic motor. The hydraulic motor, in turn, drives an electric generator that produced electric energy. The electric energy may be provided to a vehicle, among other things. The regenerative shock absorber may also provide ride performance that comparable to or exceeds that of conventional shock absorbers.

Owner:CLEARMOTION INC

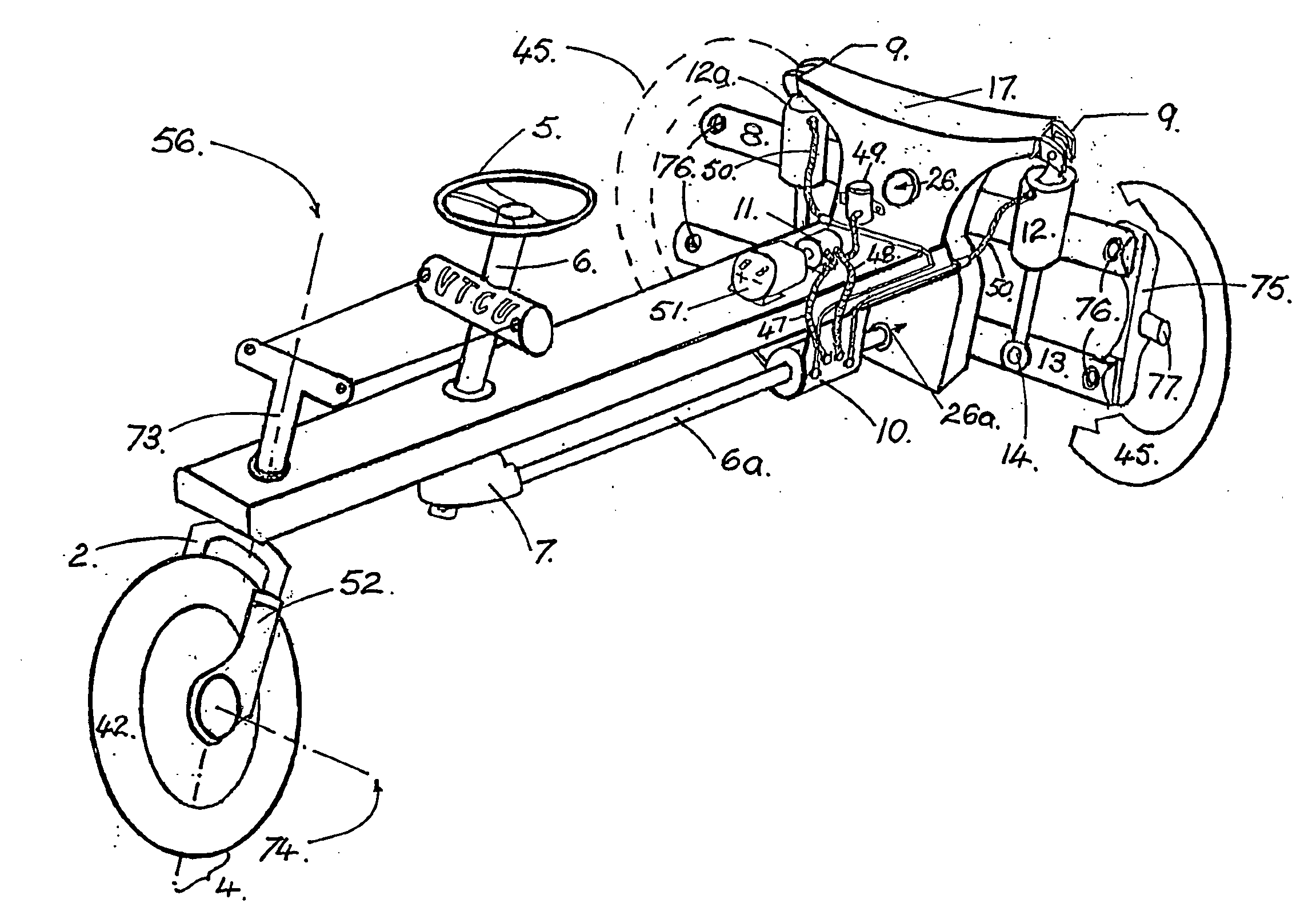

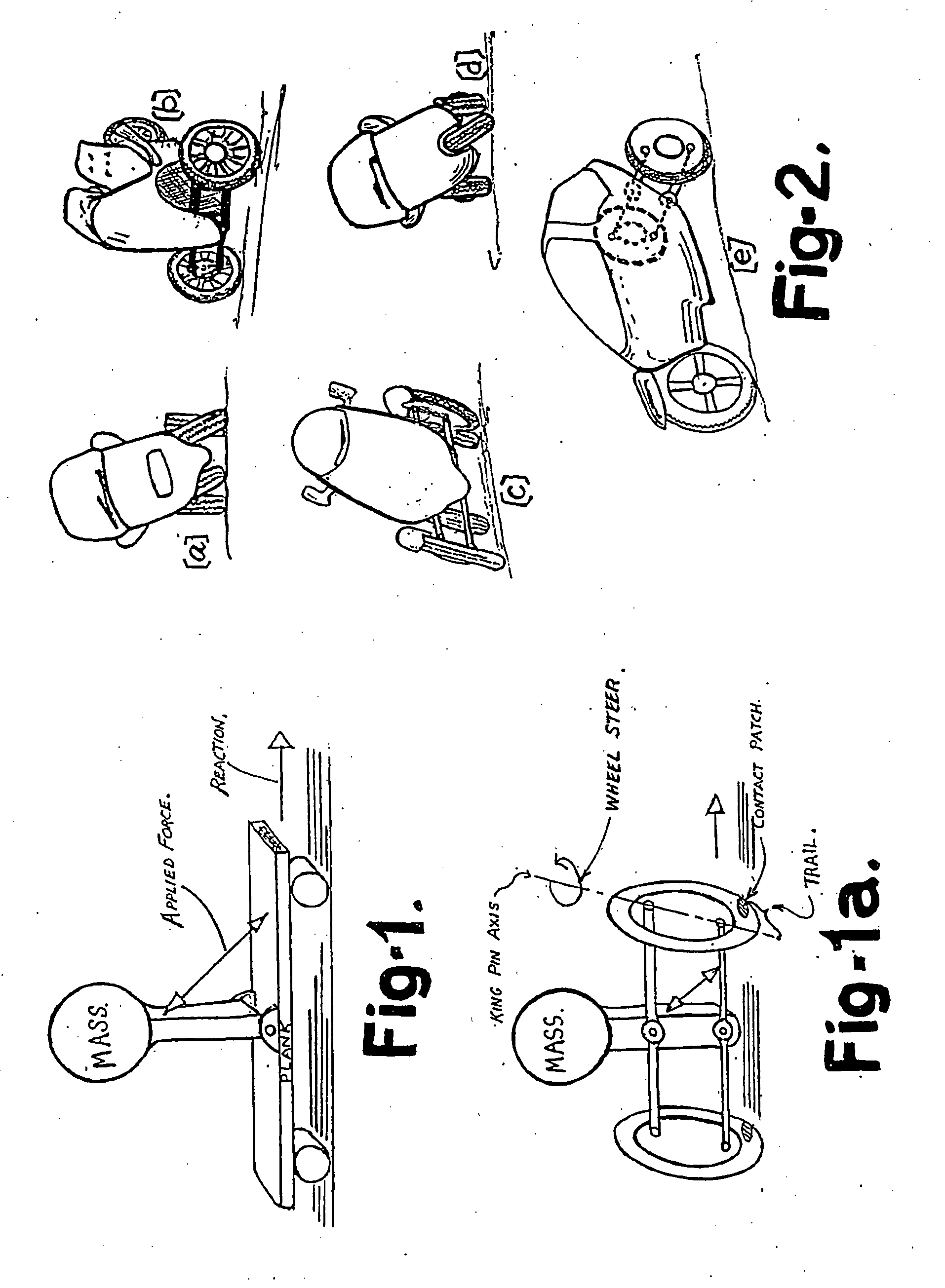

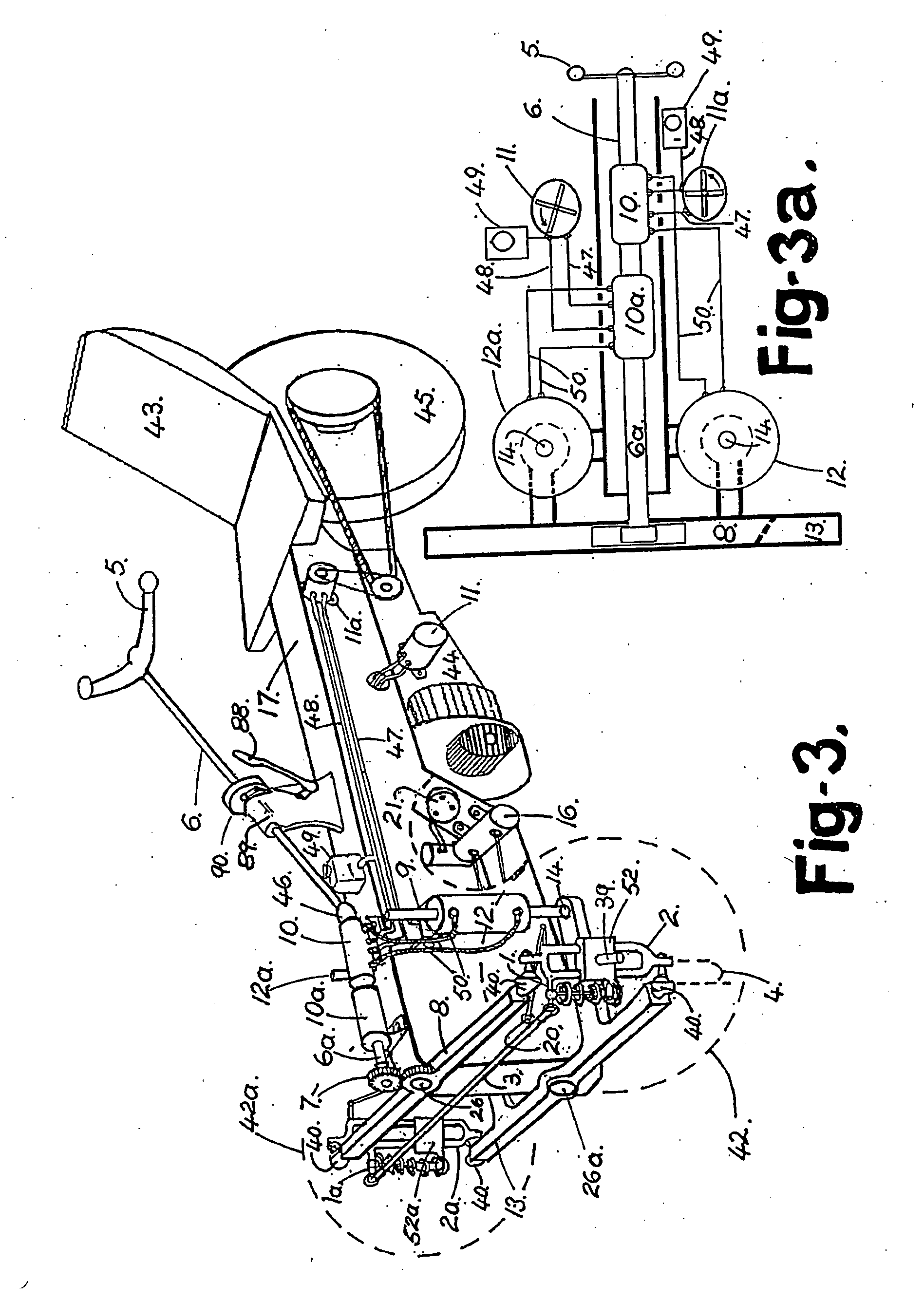

Tilting Vehicle

A tilting vehicle comprising at least one section (17) tiltable about the longitudinal axis of the vehicle, tilt registration means (20) recording variations in the tilt position of the tiltable section (17), a control element (5), tilt control means (12) connecting the control element (5) to the tilt section (17), at least three wheels (42, 42a, 45) including wheels (42, 42a) laterally spaced, a castoring element including at least one front wheel (42, 42a) able to tilt with the tiltable section (17) and dynamically directionally controllable due to the tilt and speed of the vehicle, a speed sensitive control signal transmitter (21), a variable force steer transmitter (16) connected to the castoring element, the tilt registration means (20) and to the speed sensitive control signal transmitter (21), the variable force steer transmitter (16) being able to exert a directing moment and / or positioning moment on the castoring element, that directs and / or positions the castoring element according to the tilt registration means (20) and the force exerted by the variable force steer transmitter (16), which is varied by control signals from the speed sensitive control signal transmitter (21).

Owner:JAMES PHILLIP RONALD

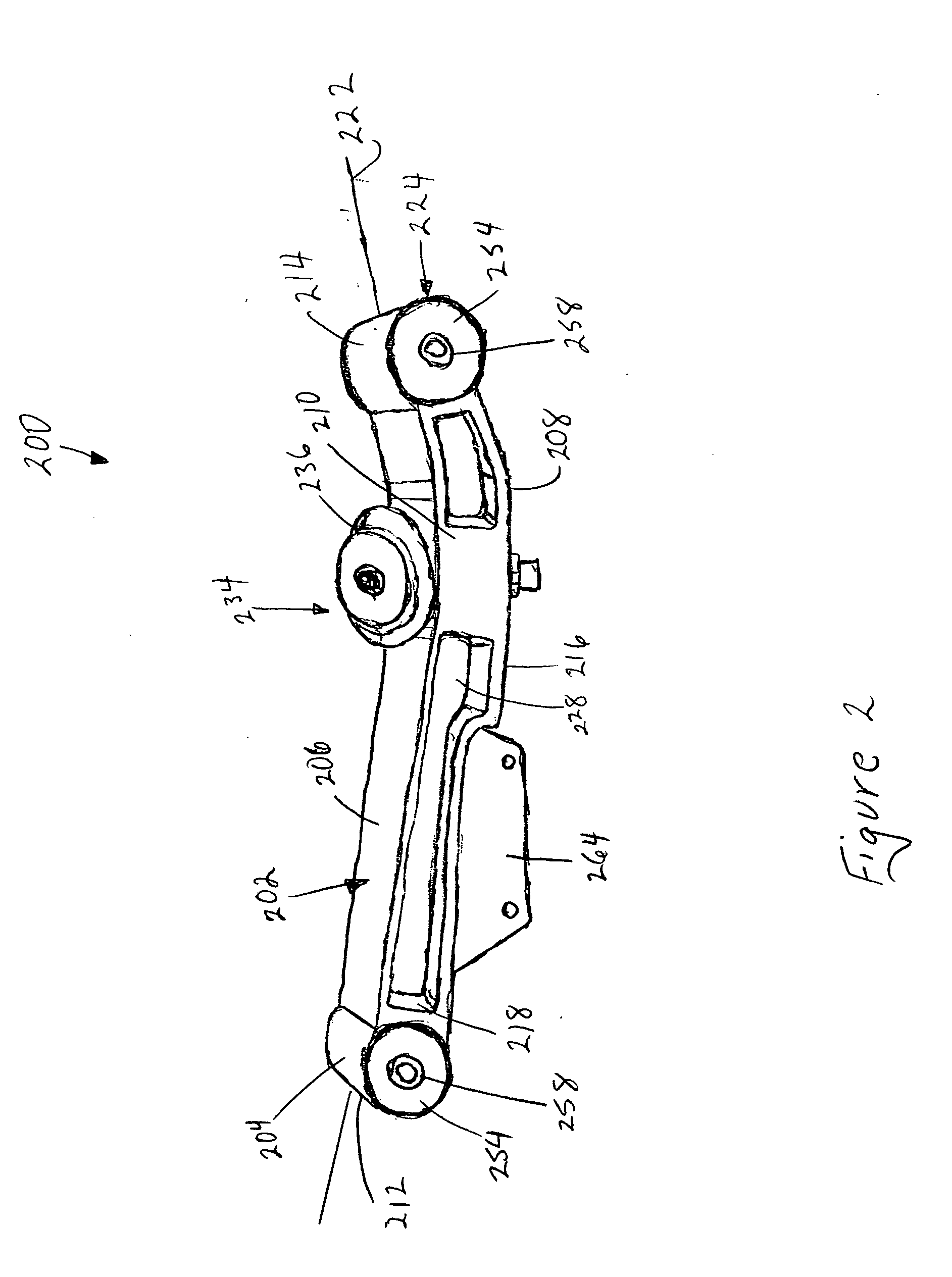

Mounting assembly for a vehicle suspension arm

A mounting assembly for use with a mounting surface includes an arm, a pin, a pair of clamping blocks and a fastener. The arm has a cylindrical bore at one end. The pin extends through the bore. Each block of the pair of clamping blocks includes a central opening and is circumferentially discontinuous about the central opening. Each clamping block further includes a slot defined by portions of the block. The slot is dimensioned to allow the pin to pass through the slot when the block is in an unclamped position and to tightly grip the pin when the block is in a clamped position. The fasteners extend across the slots and are configured to engage the mounting surface to mount the blocks to the mounting surface.

Owner:OSHKOSH CORPORATION

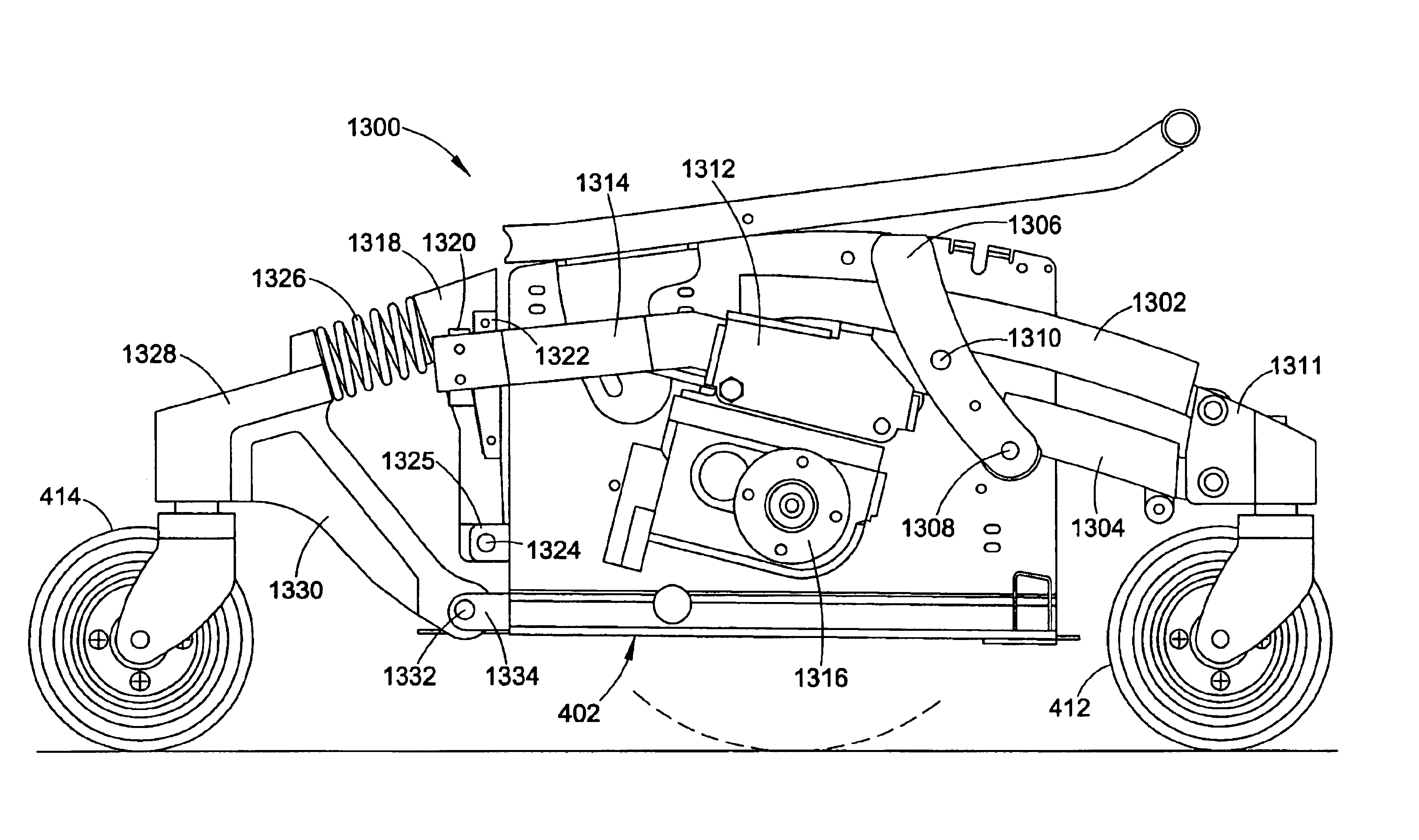

Vehicle having an anti-dive/lockout mechanism

InactiveUS6851711B2Pedestrian/occupant safety arrangementWheelchairs/patient conveyanceEngineeringLockout Mechanism

A suspension for a vehicle is provided. The suspension includes, for example, a frame and a releasable locking assembly. The releasable locking assembly has, for example, a first assembly movably coupled to the frame, a second assembly movably coupled to the frame, and wherein movement of the frame relative to the first and second assemblies causes the first and second assemblies to engage each other to limit further movement of the frame in at least a first direction.

Owner:INVACARE CORP

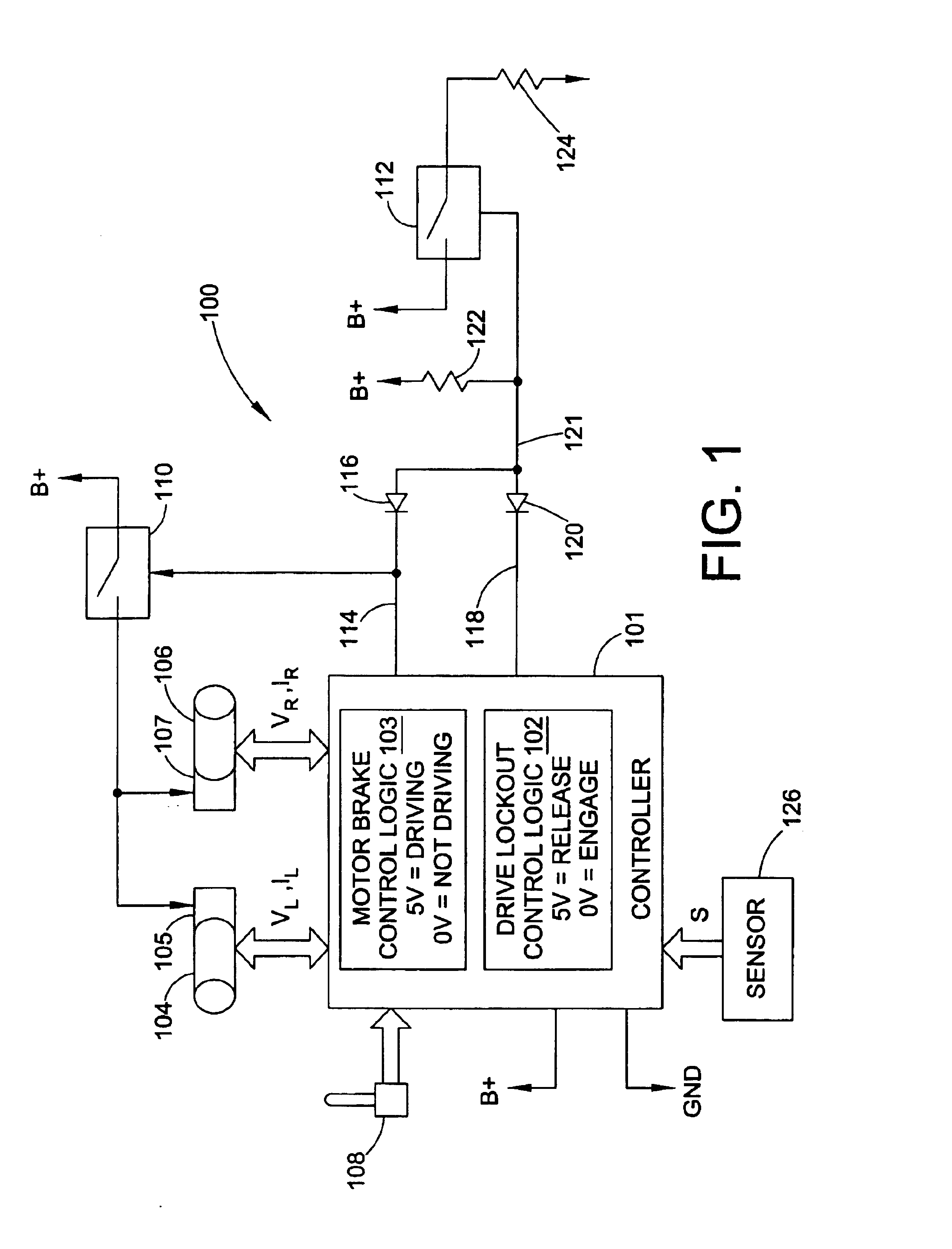

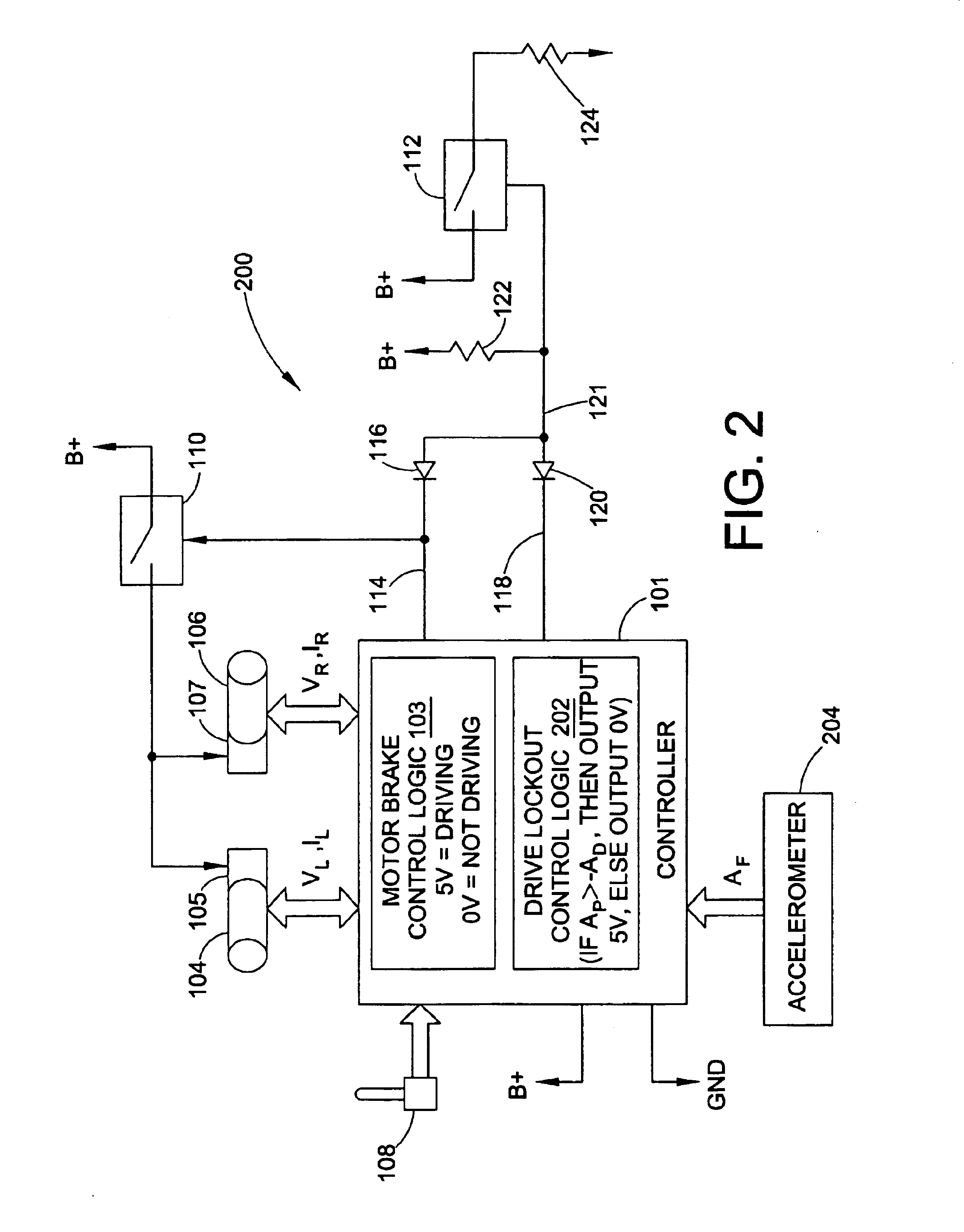

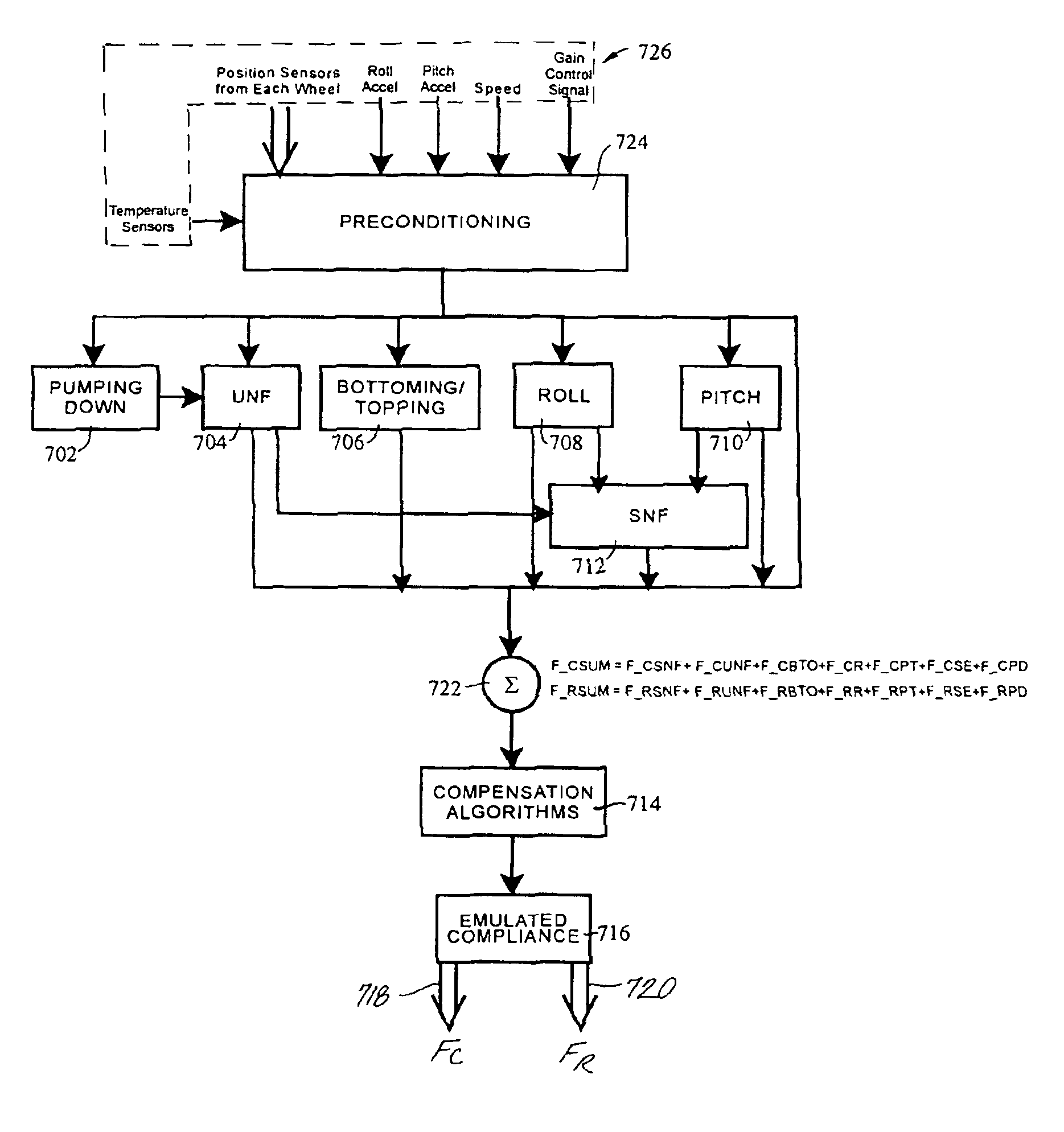

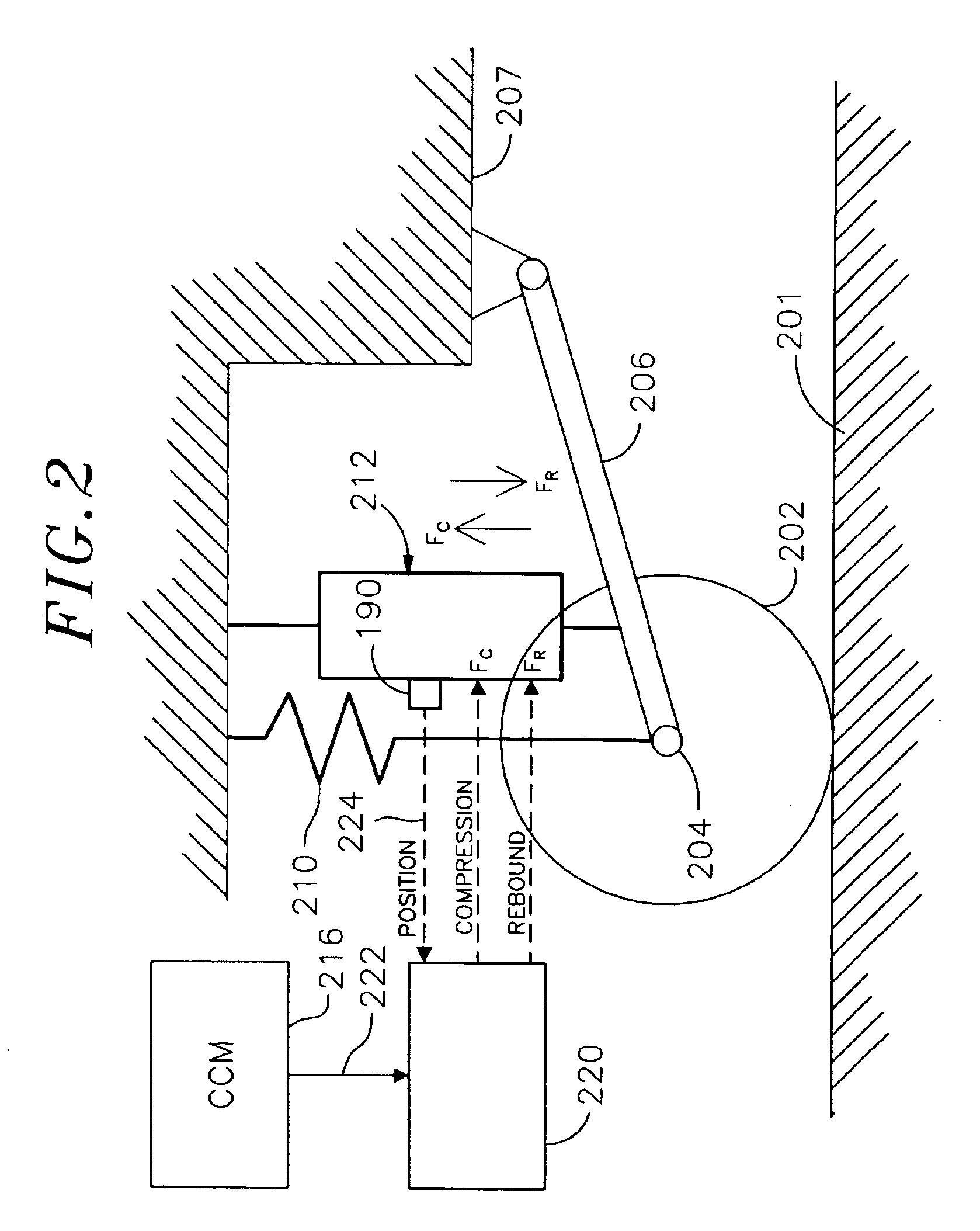

Enhanced computer optimized adaptive suspension system and method

InactiveUS7076351B2Minimizing body motionIncrease fluid pressureAuxillary drivesFunctional valve typesComputer optimizationControl signal

A system and method for controlling a damping system. The system has at least two dampers for damping between sprung and unsprung masses in the compression and rebound directions. Sensors generate signals based on position and other parameters of motion representative of the displacement between the sprung and unsprung masses. The process determines the appropriate compression and rebound forces to be applied at the wheels. A regulator responds to at least one of the independent compression and rebound control signals for adjusting, respectively, at least one of compression and rebound resisting forces of the dampers between the masses. Compliance for the dampers is emulated with software to produce the desired compliance forces. The distributed controller includes a processor that is responsive to signals representative of the position signals for forming the compression and rebound control signals for the regulator as a function of motion between the masses or a motion of a vehicle in which the dampers are located. The system has the capability of locking the suspension when parked.

Owner:WICKA JOHN D +1

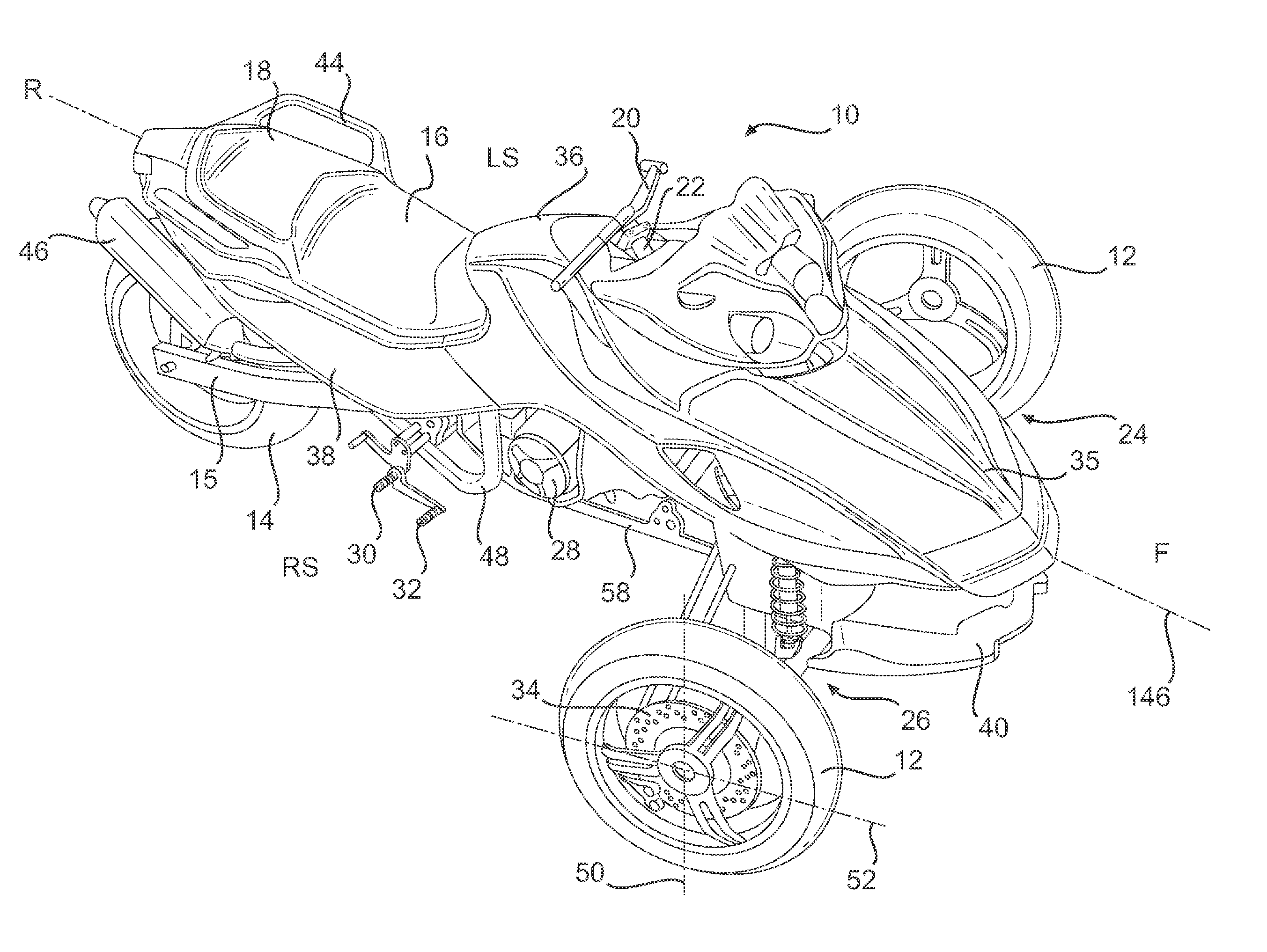

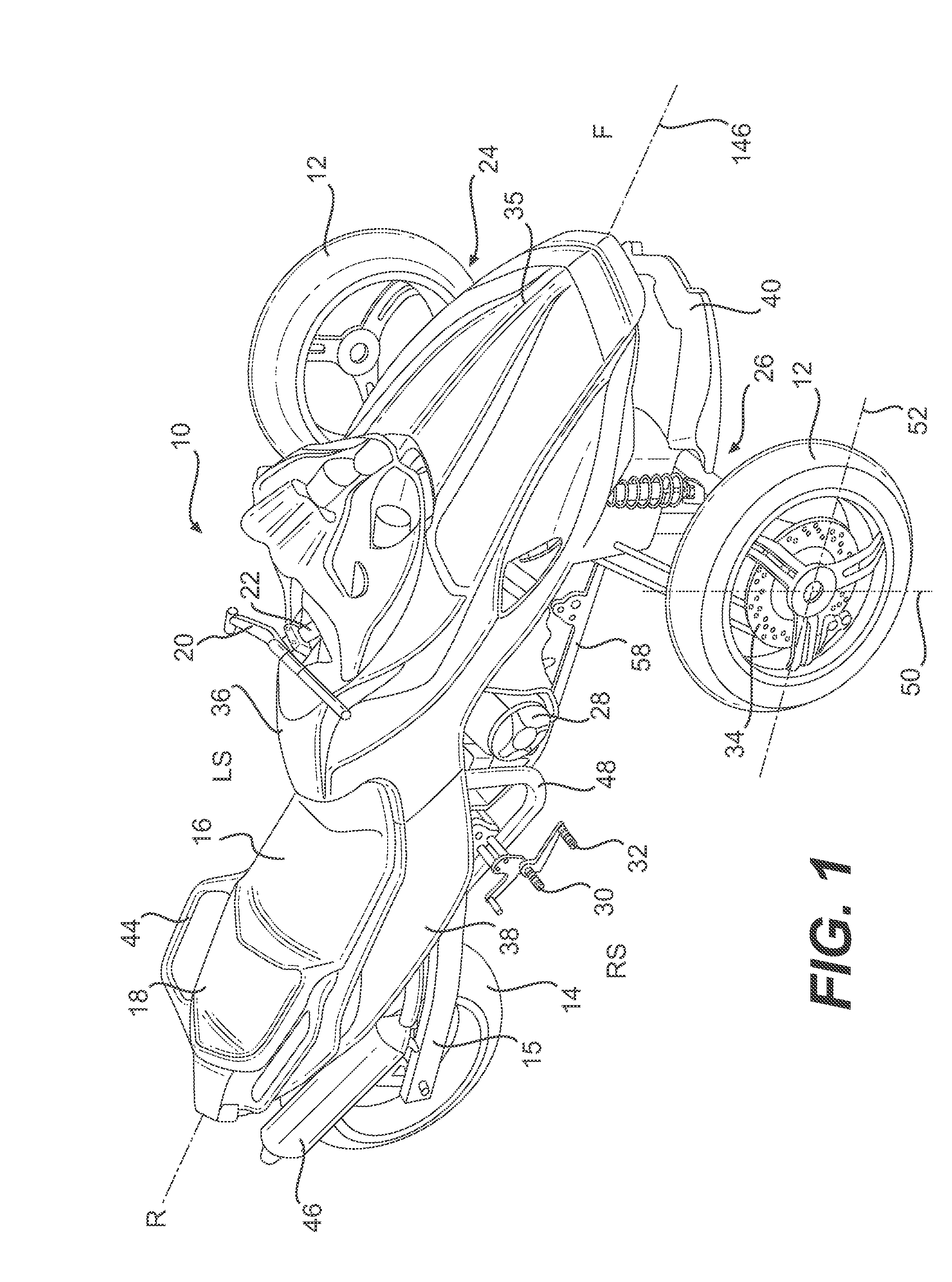

Leaning vehicle with tilting front wheels and suspension therefor

A leaning vehicle has a frame pivotally connected to the lower end of a shock tower, the pivotal connection defining a frame leaning axis wherein the frame is adapted to lean to a right side and to a left side relative to the shock tower about the frame leaning axis. The leaning vehicle includes an actuator operatively connected to the frame and to the shock tower which is adapted to impart a leaning motion to the frame relative to the shock tower about the frame leaning axis.

Owner:BOMBARDIER RECREATIONAL PROD INC

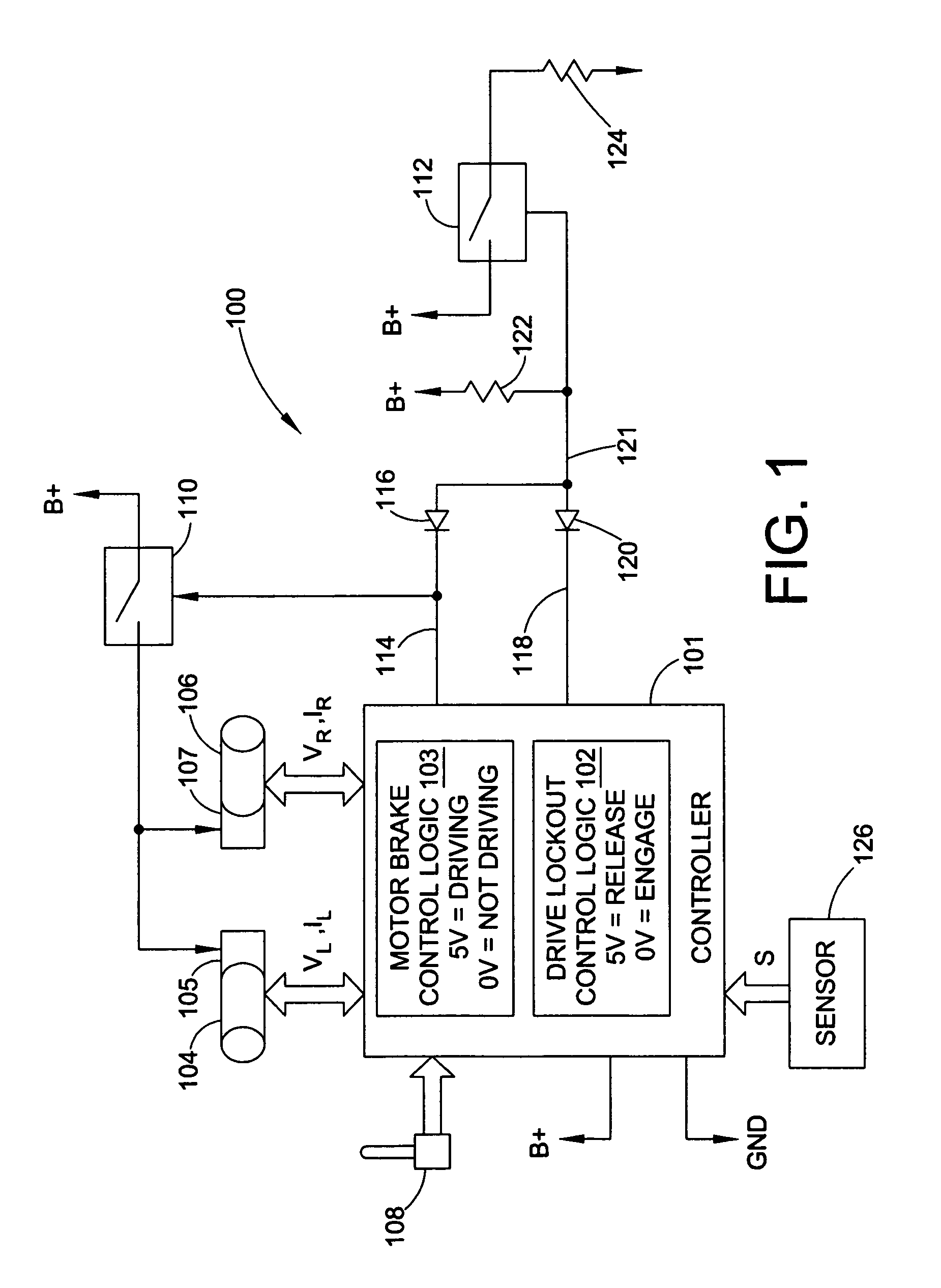

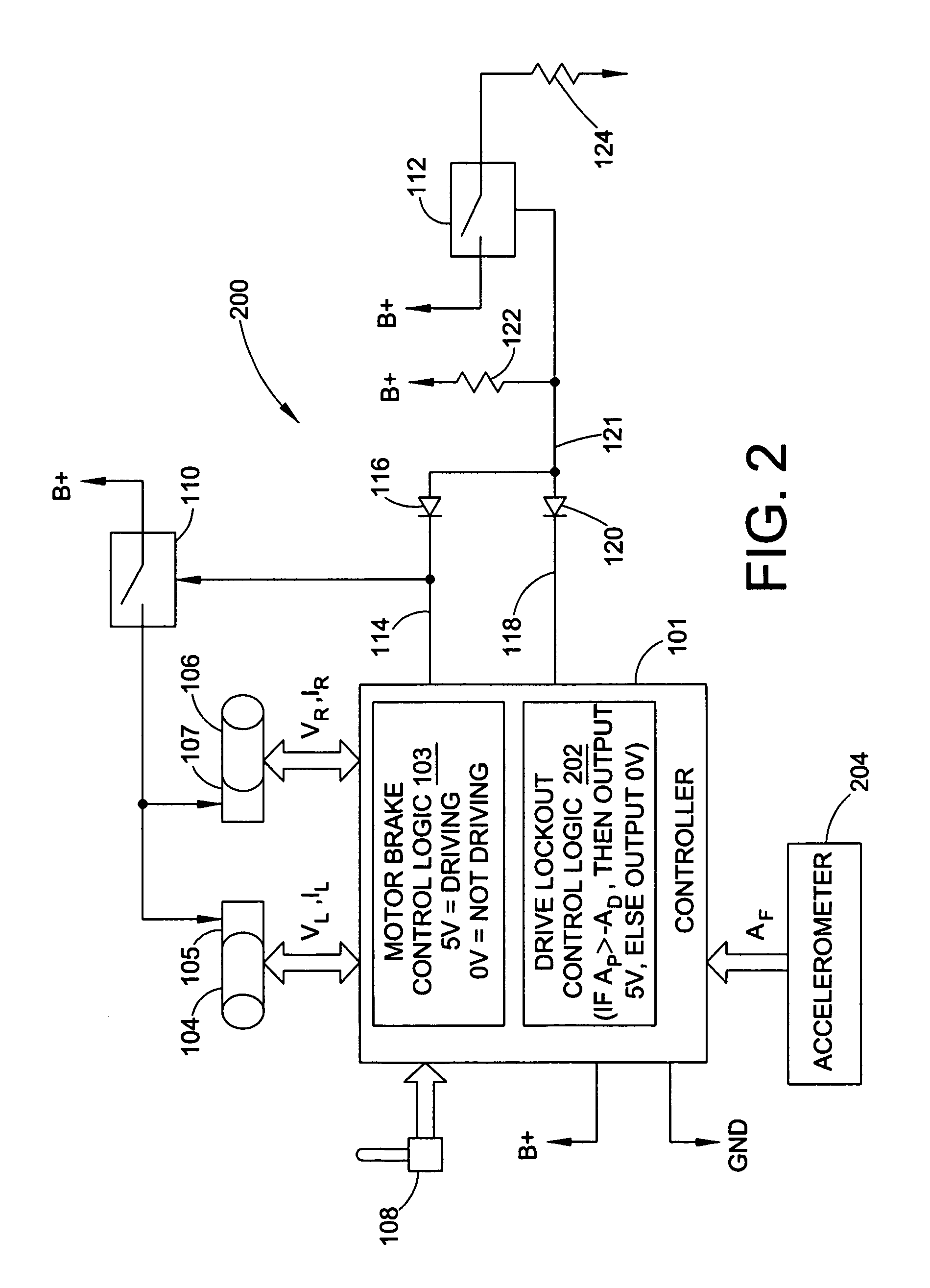

Control system for leaning vehicle

A leaning vehicle has a frame that pivots relative to a pivotable frame member about a pivot axis. A torque exerted on a steering assembly in a first direction causes the frame to pivot relative to the pivotable frame member in a second, opposite direction at least when the speed of the vehicle is above a first threshold speed, to steer the vehicle in the second direction. An actuator urges the frame toward an upright position when the frame is in a leaning position and a speed of the vehicle is below a second threshold speed. A method is also described, in which a torque is exerted on the frame in the direction opposite the steering torque when the speed above the first threshold speed. The torque exerted by the actuator is opposite the leaning angle when the speed of travel is below the second threshold speed.

Owner:BOMBARDIER RECREATIONAL PROD INC

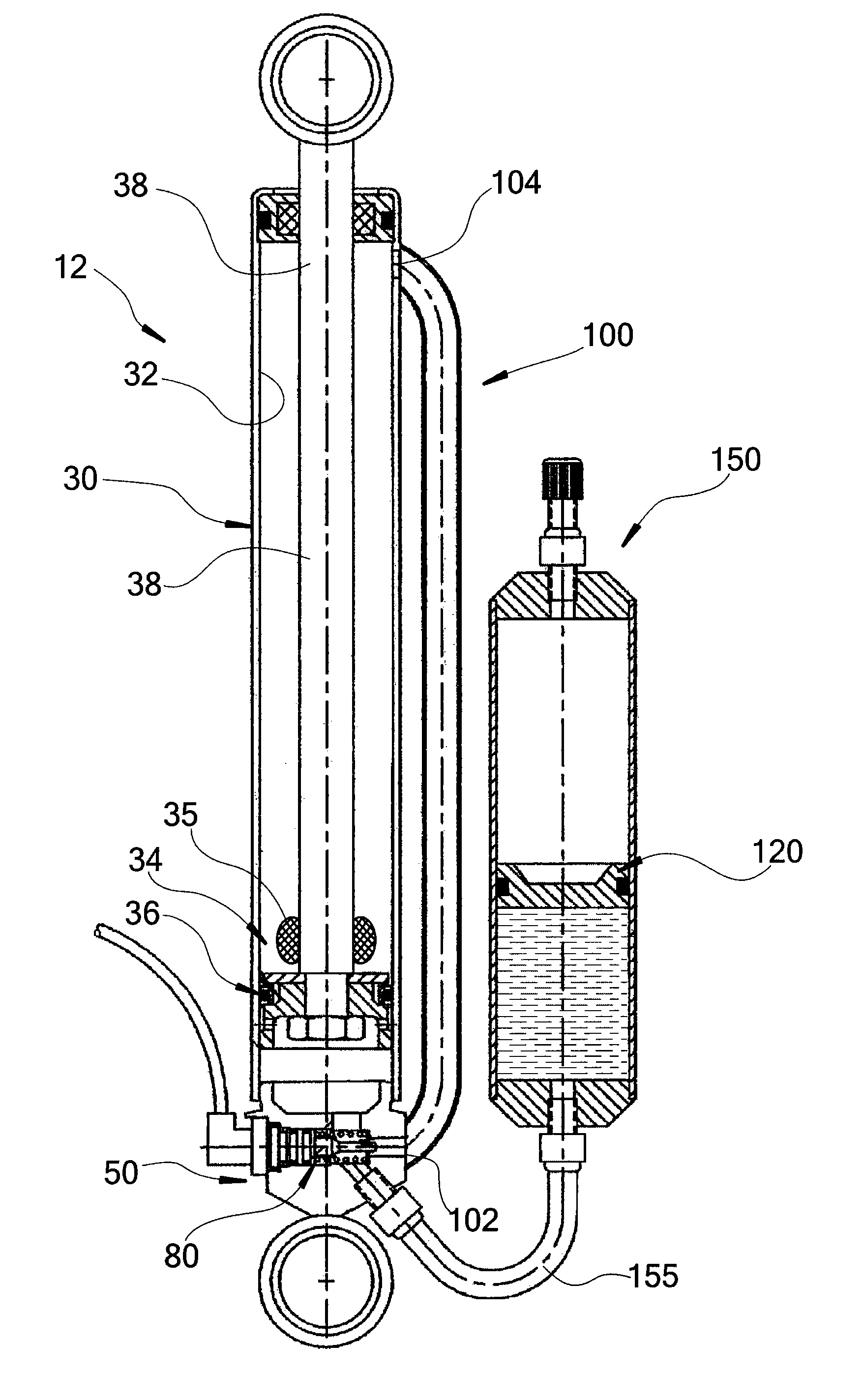

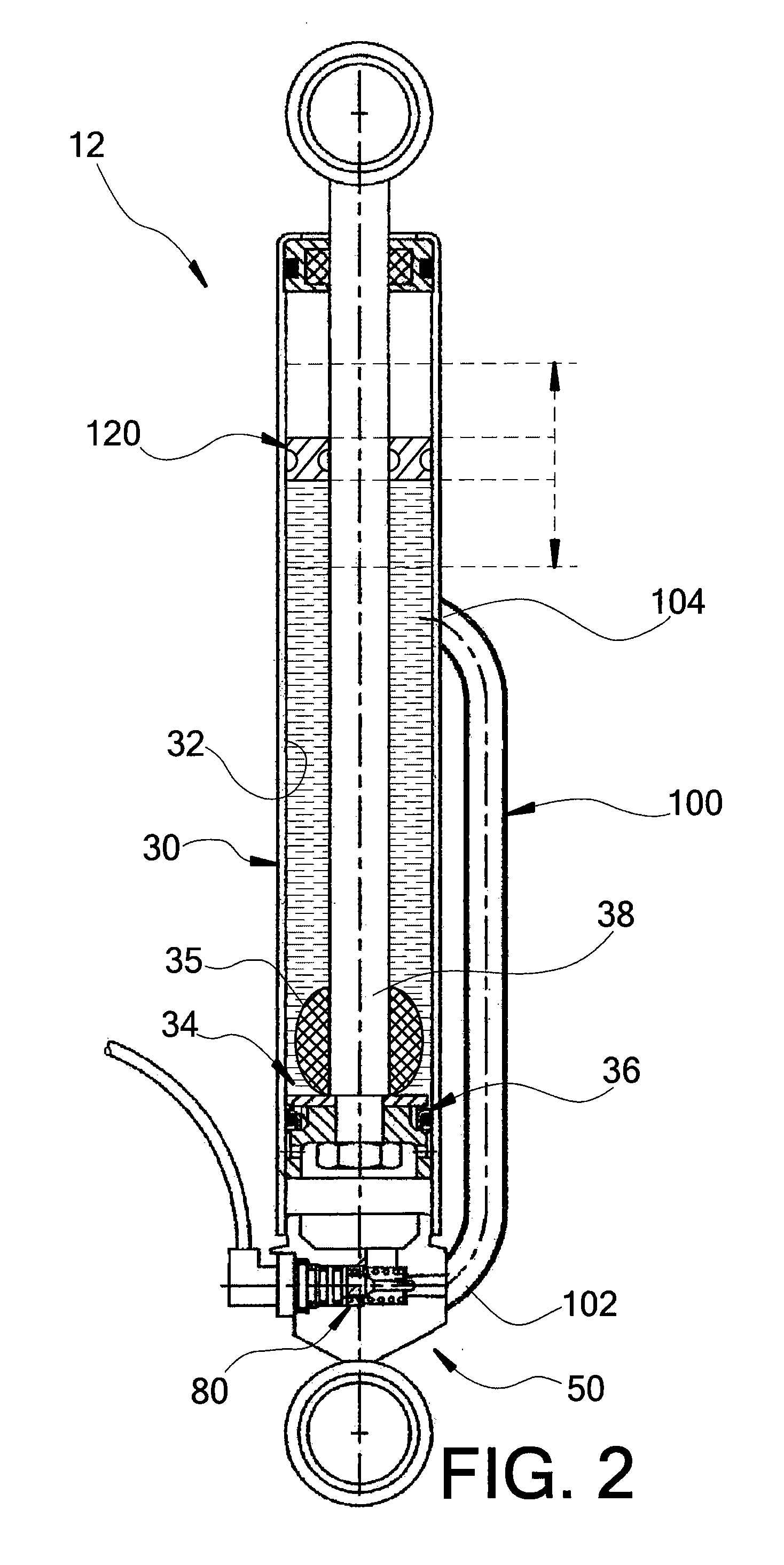

Adjustable Monotube Shock Absorber

A monotube shock absorber that can be adjusted remotely or otherwise, and a corresponding system are provided. The monotube shock absorber includes a body tube that houses a working piston therein and a bypass tube that is attached to but external with respect to the body tube. A control valve influences flow volume and rate of oil that passes through the bypass tube in a manner that correspondingly influences damping and / or other characteristics of the monotube shock absorber. The monotube shock absorber can include a floating piston separating a volume of gas from a volume of oil. The volumes of gas and oil may be entirely housed in the body tube or may be at least partially housed in an external reservoir that can include an anti-cavitation valve.

Owner:FURRER FREDRICK J

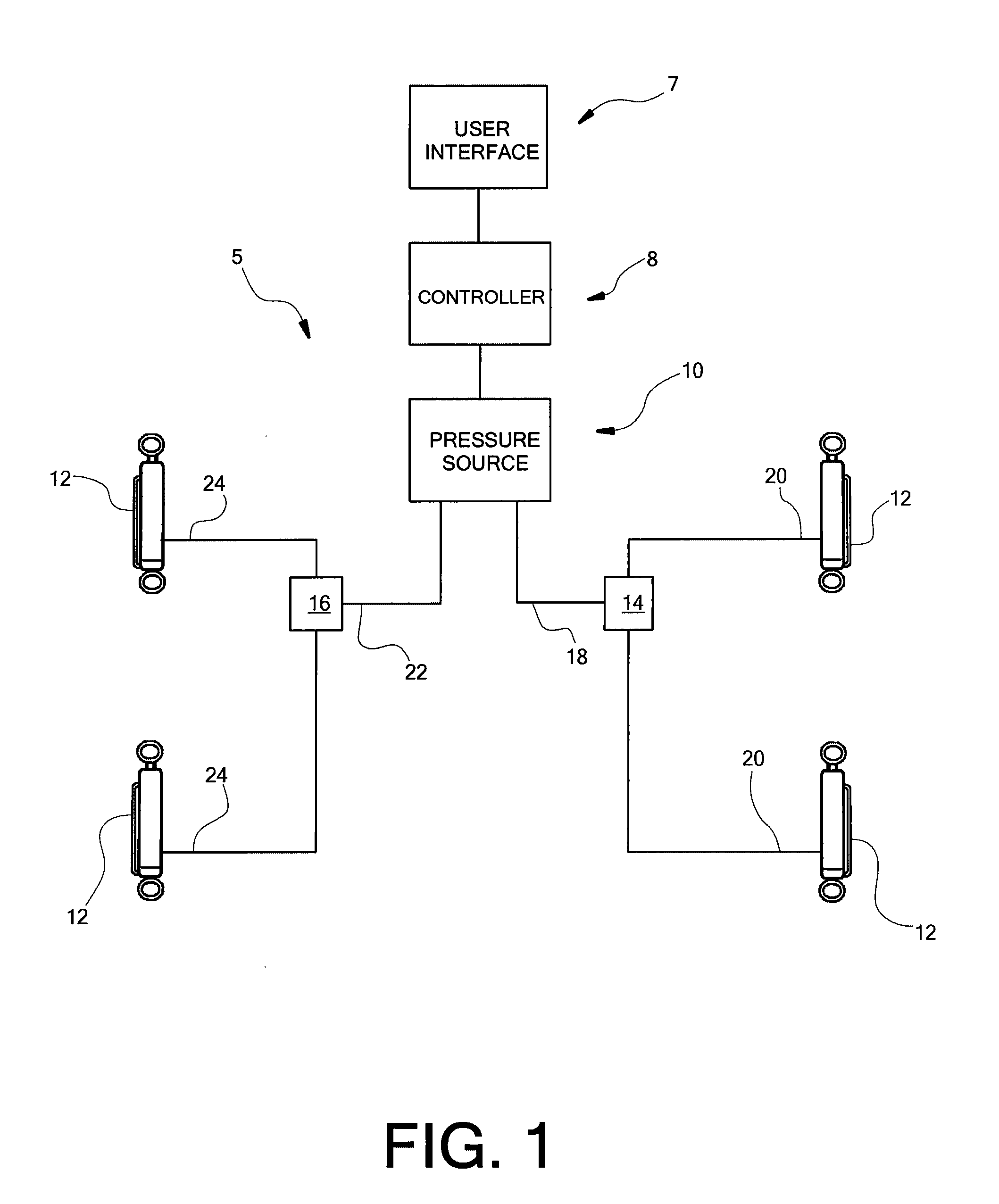

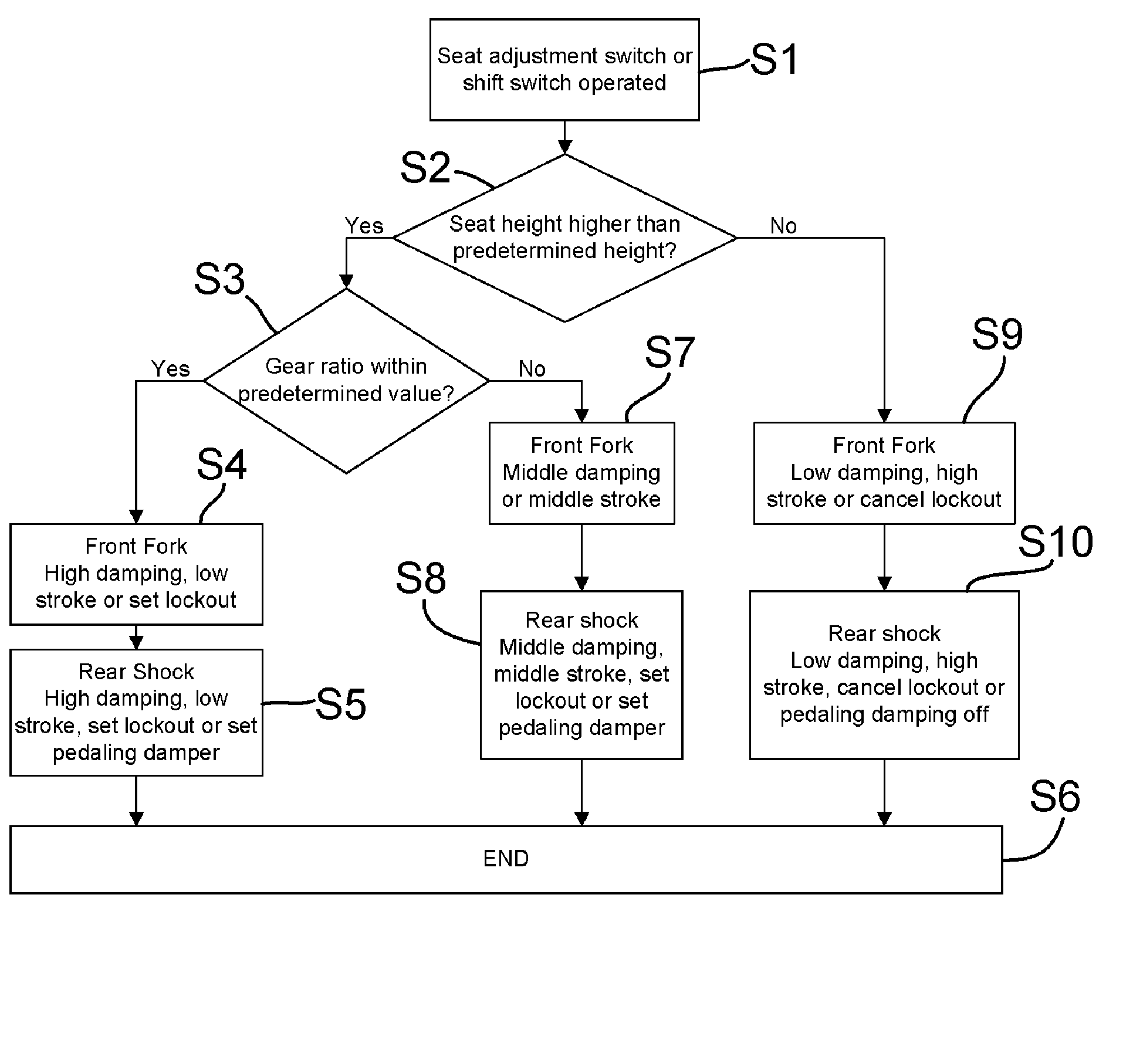

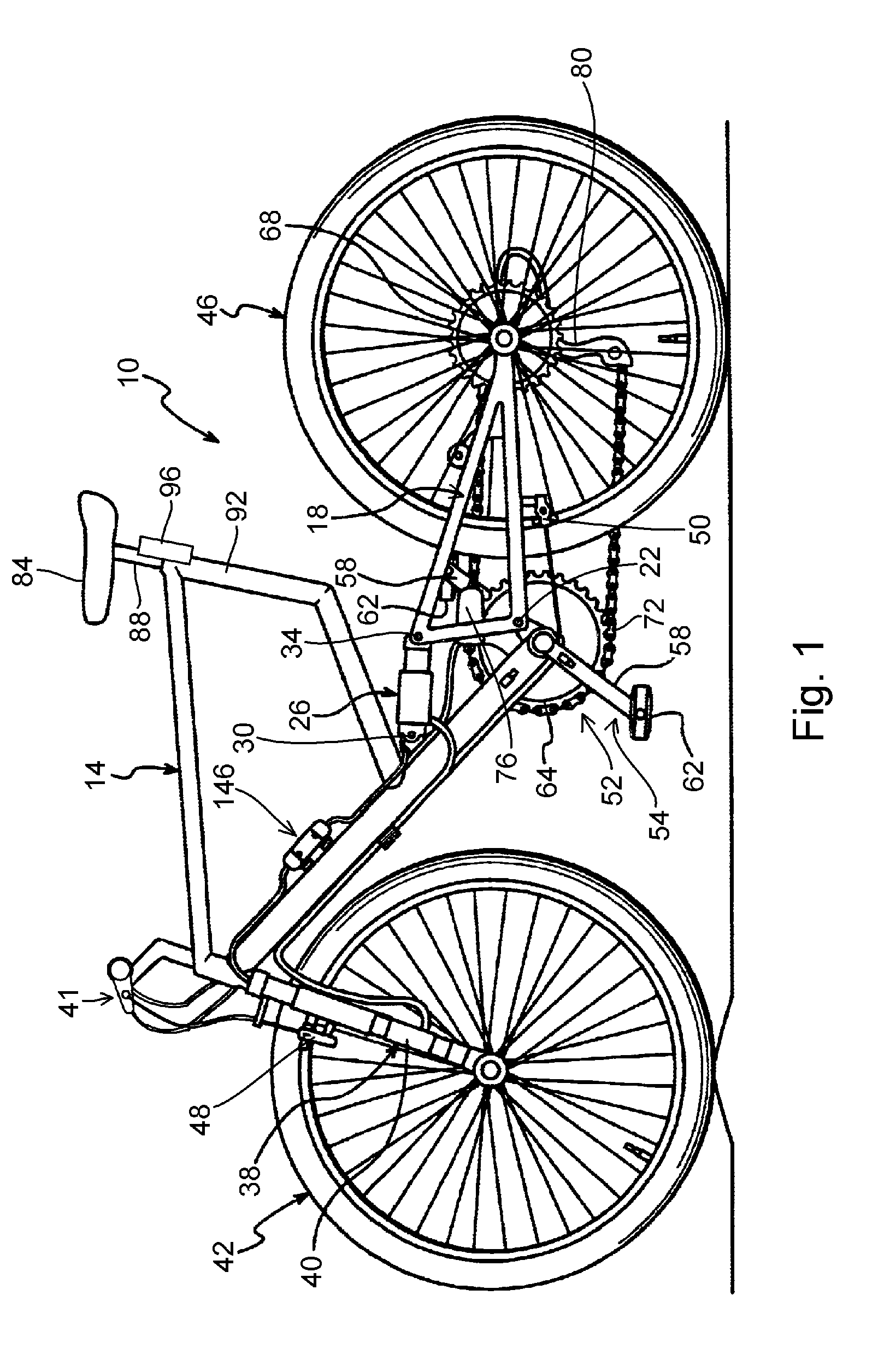

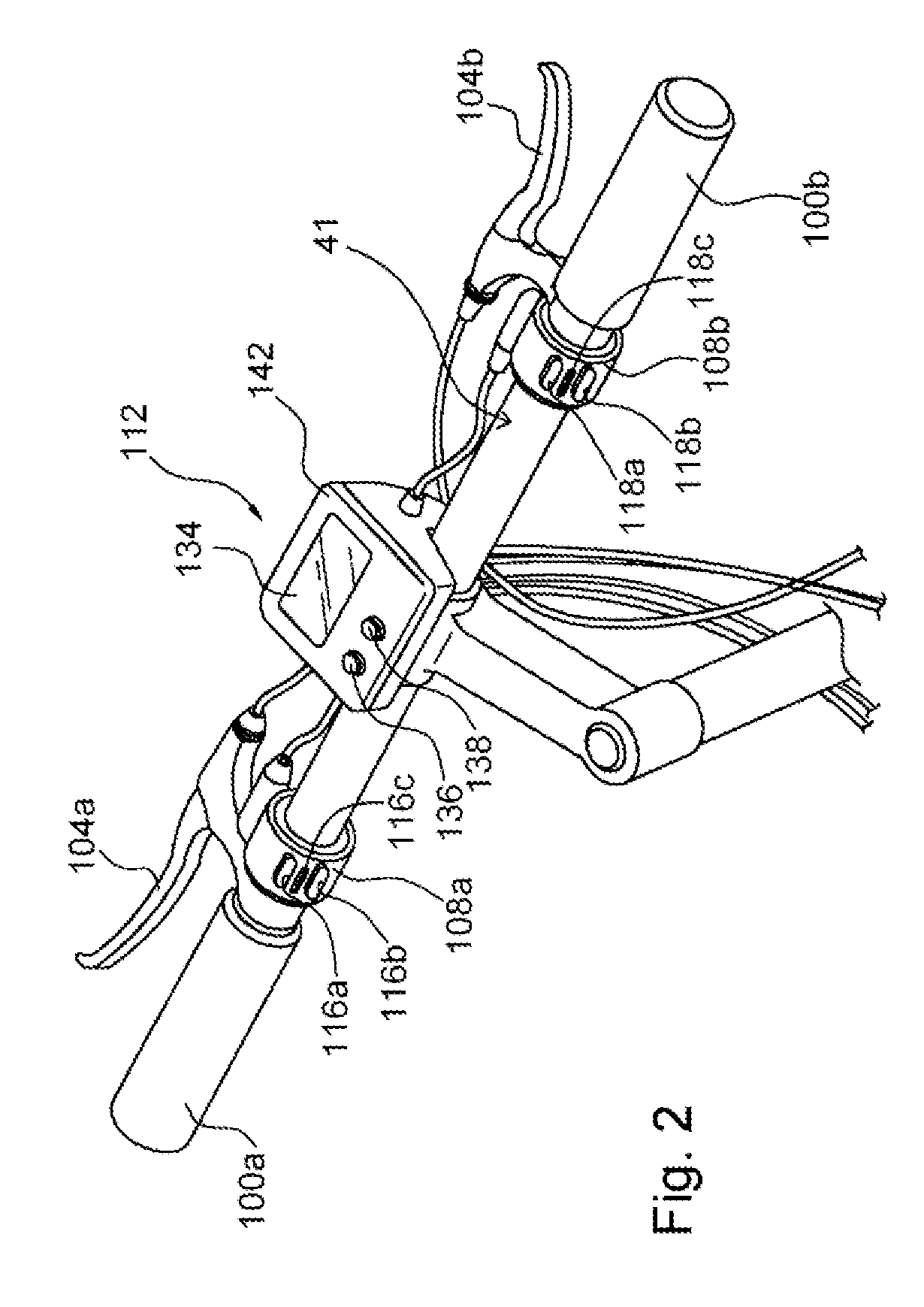

Apparatus for controlling a bicycle suspension element

Owner:SHIMANO INC

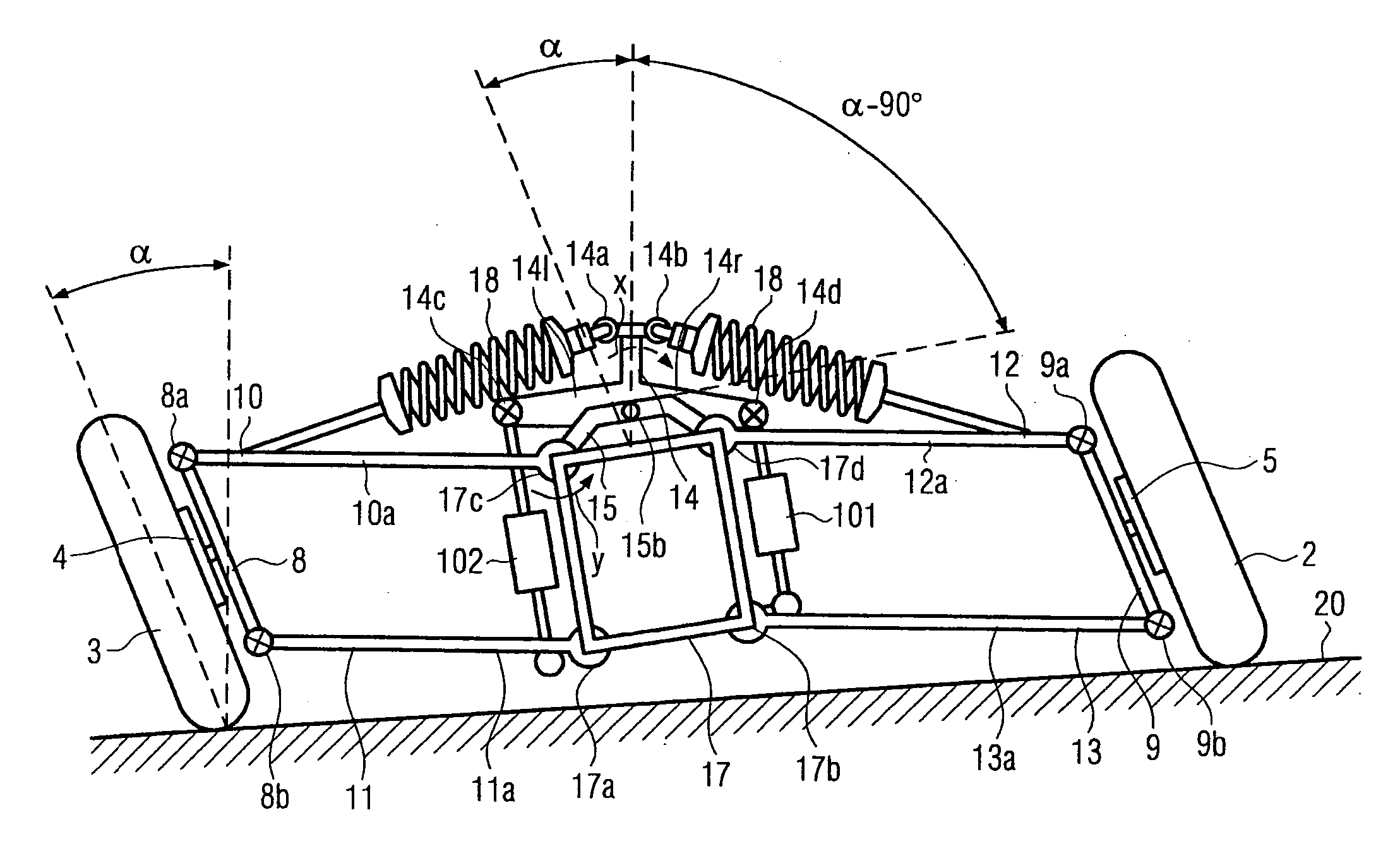

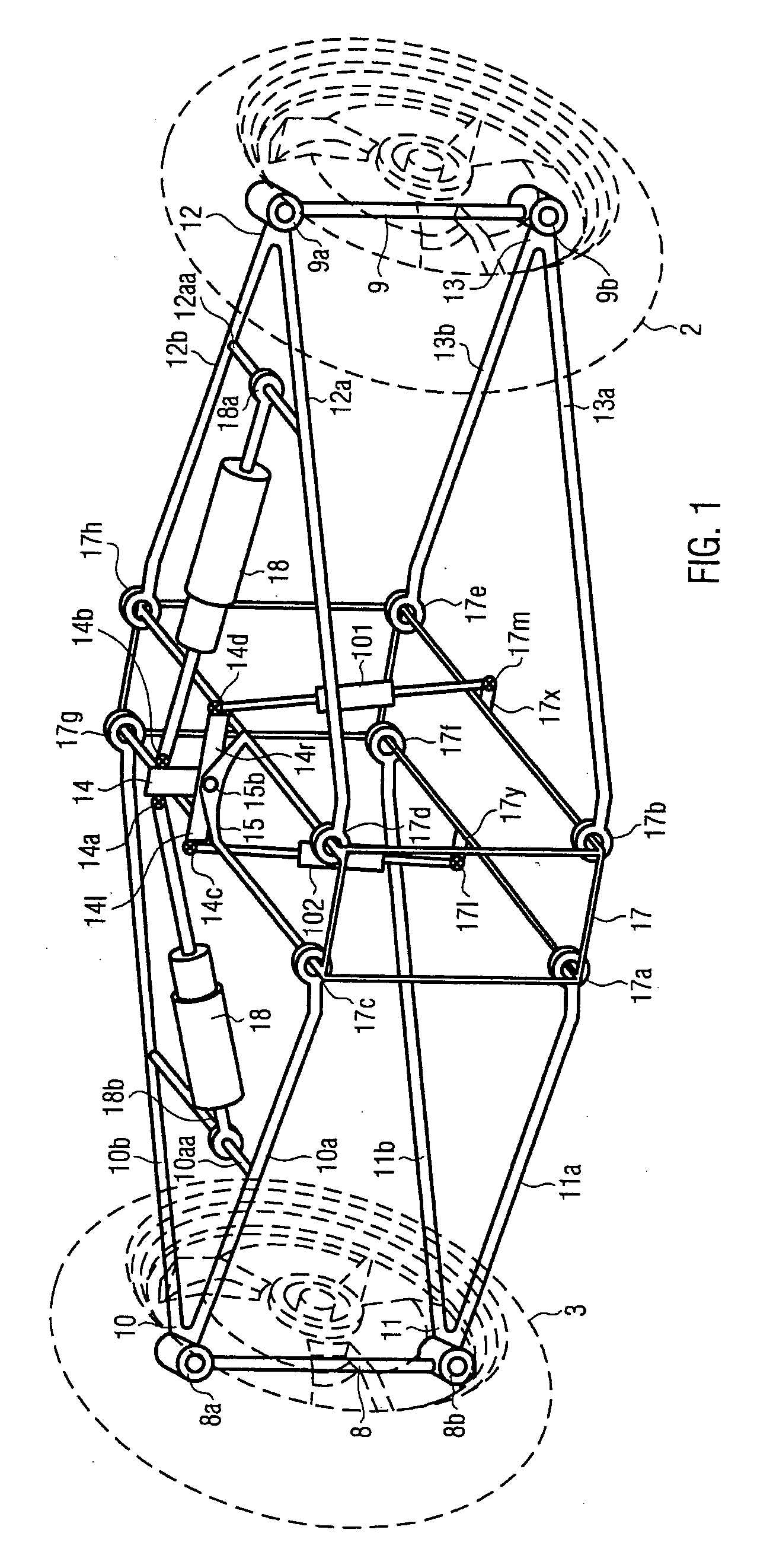

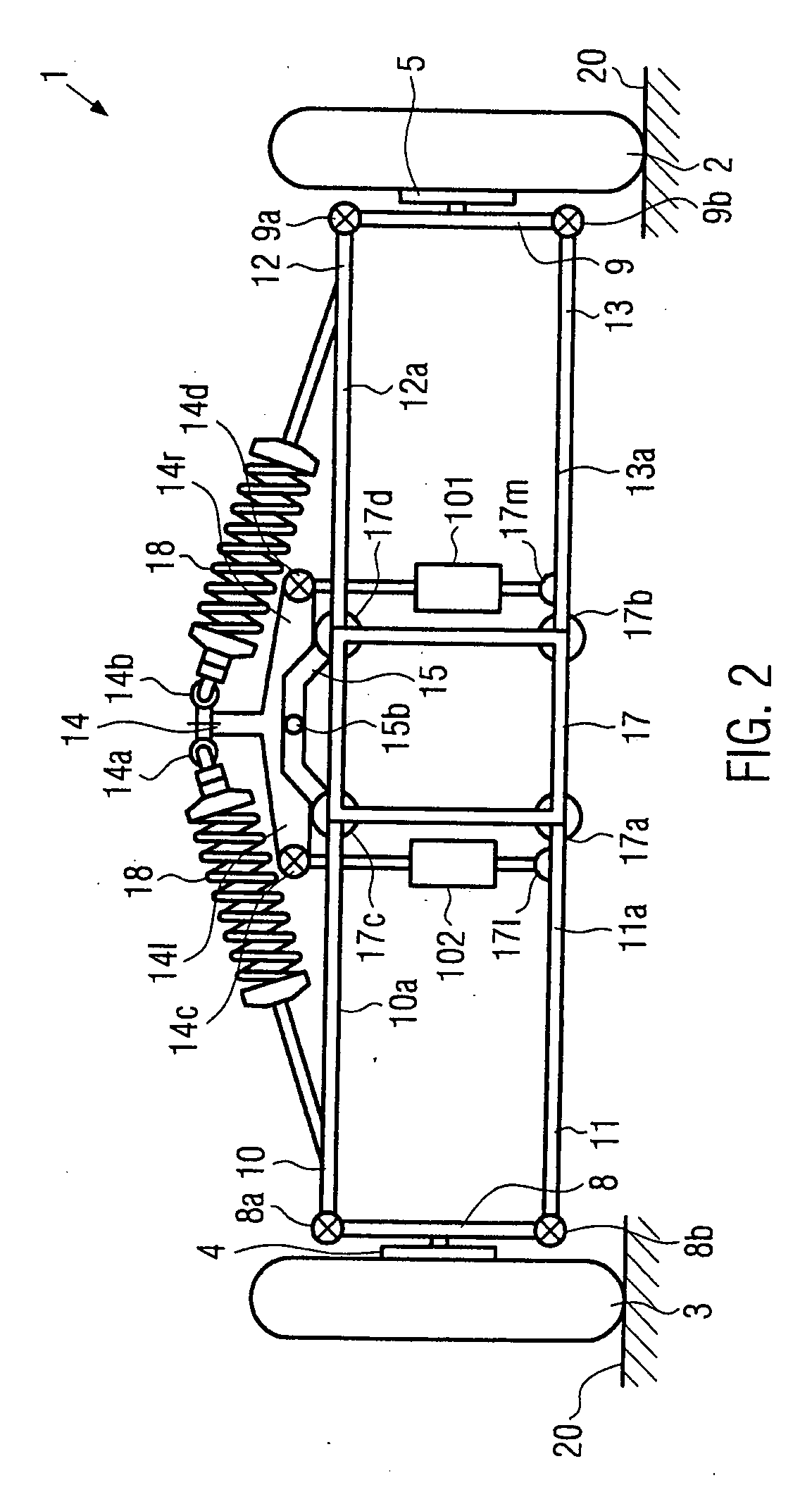

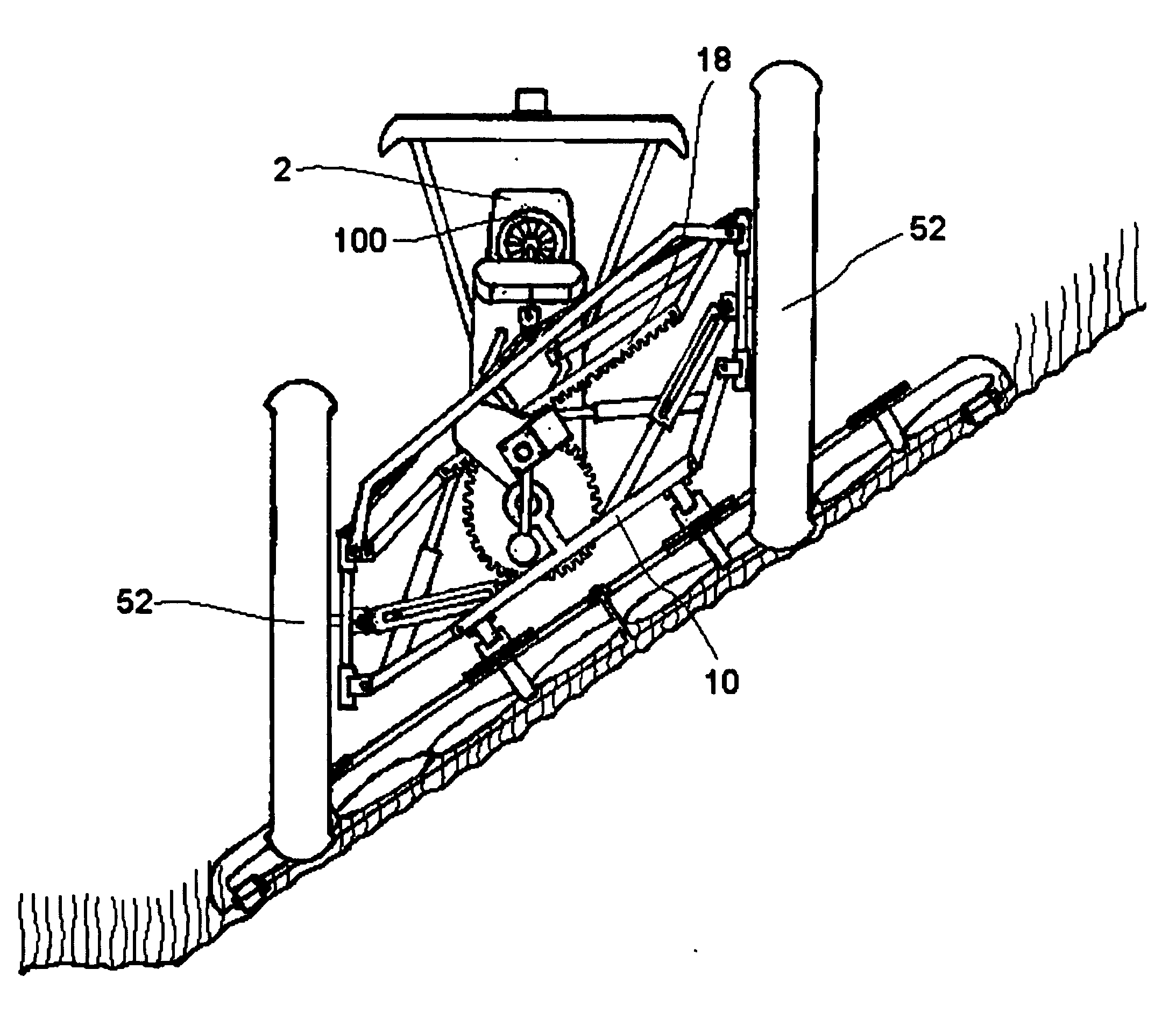

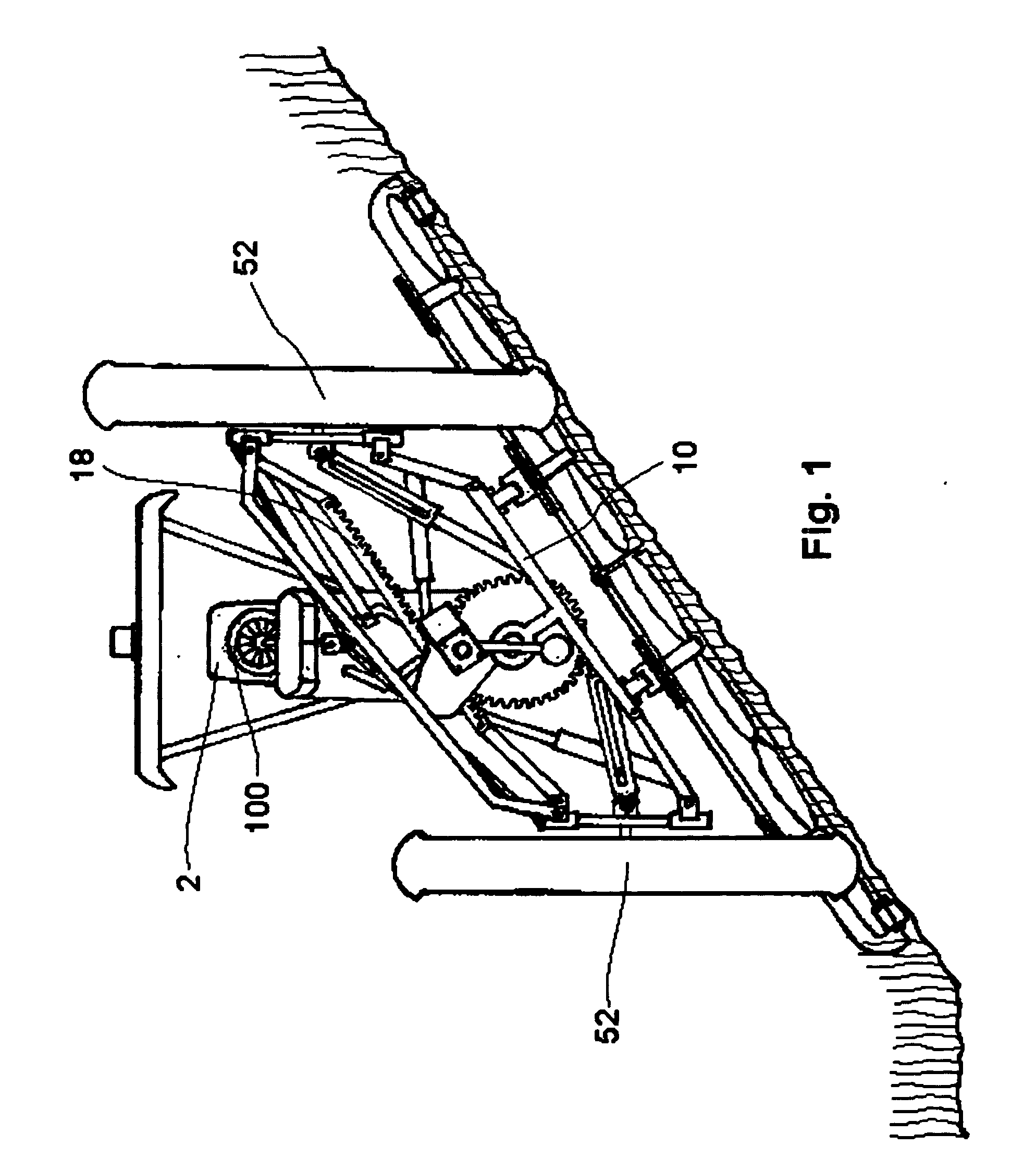

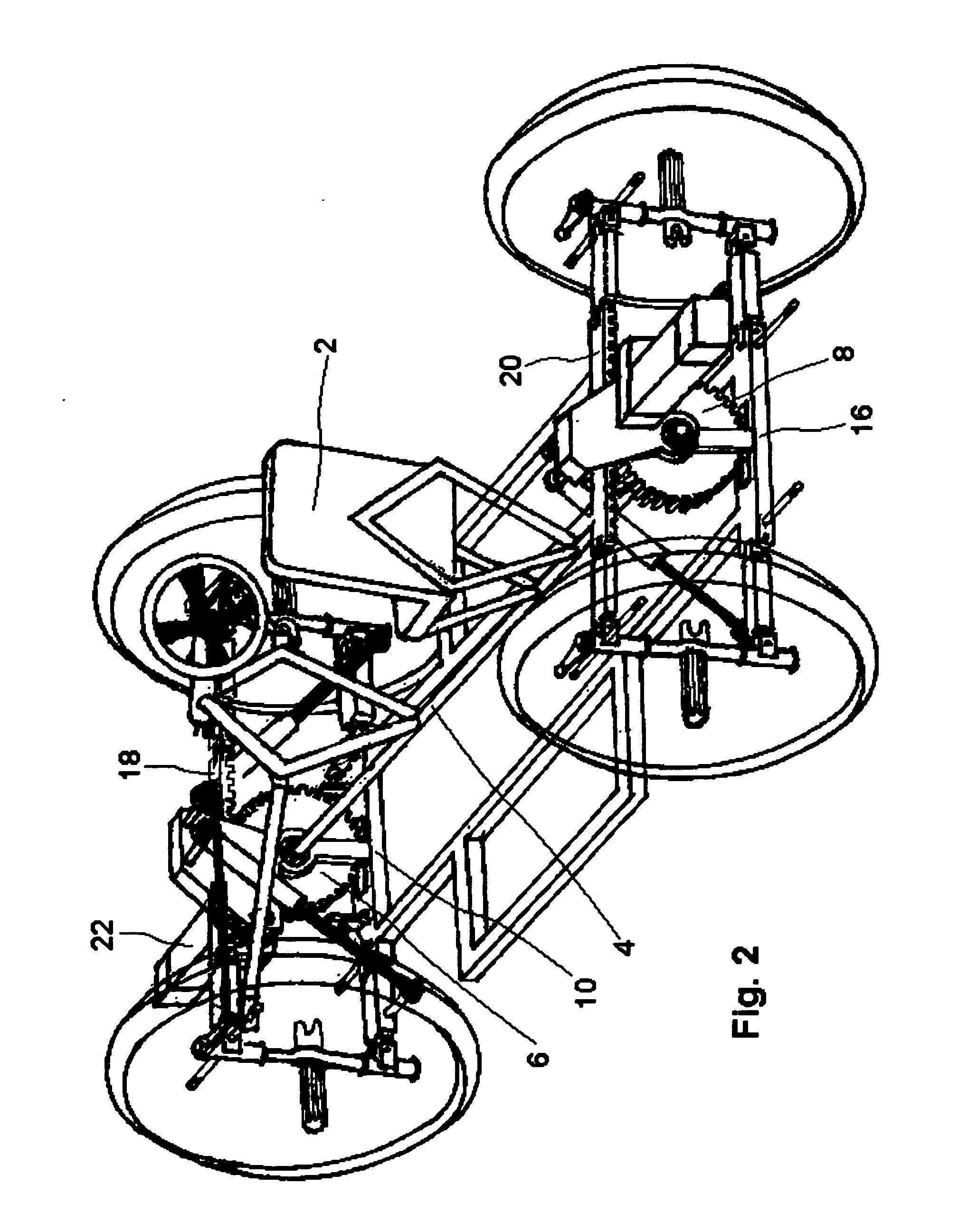

Suspension tilting module for a wheeled vehicle and a wheeled vehicle equipped with said suspension tilting module

A tilting suspension system is provided for two wheels (2, 3) of a vehicle (200) disposed on a common axle with the module comprising a rigid frame (17) adapted to be firmly fixed to the chassis of the vehicle so as to be tilted together with the whole vehicle and a tilting arm (14) pivotally linked to the rigid frame. The tilting of the rigid frame is obtained as a result of the counter torque arising when activating hydraulic actuating means (101, 102) pivotally interposed between the tilting arm (14) and the rigid frame (17), with the tilting arm being pivotally connected to shock absorbers (18). The tilting module further comprises suspension arms (10, 11, 12, 13) pivotally connected to the rigid frame, with the suspension arms supporting, in cooperation with supporting uprights, the two wheels thus allowing both tilting and steering of the two wheels. The hydraulic actuating means (101, 102) are actuated by a hydraulic pump (112) driven by an electric motor (108).

Owner:FONDAZIONE TORINO WIRELESS

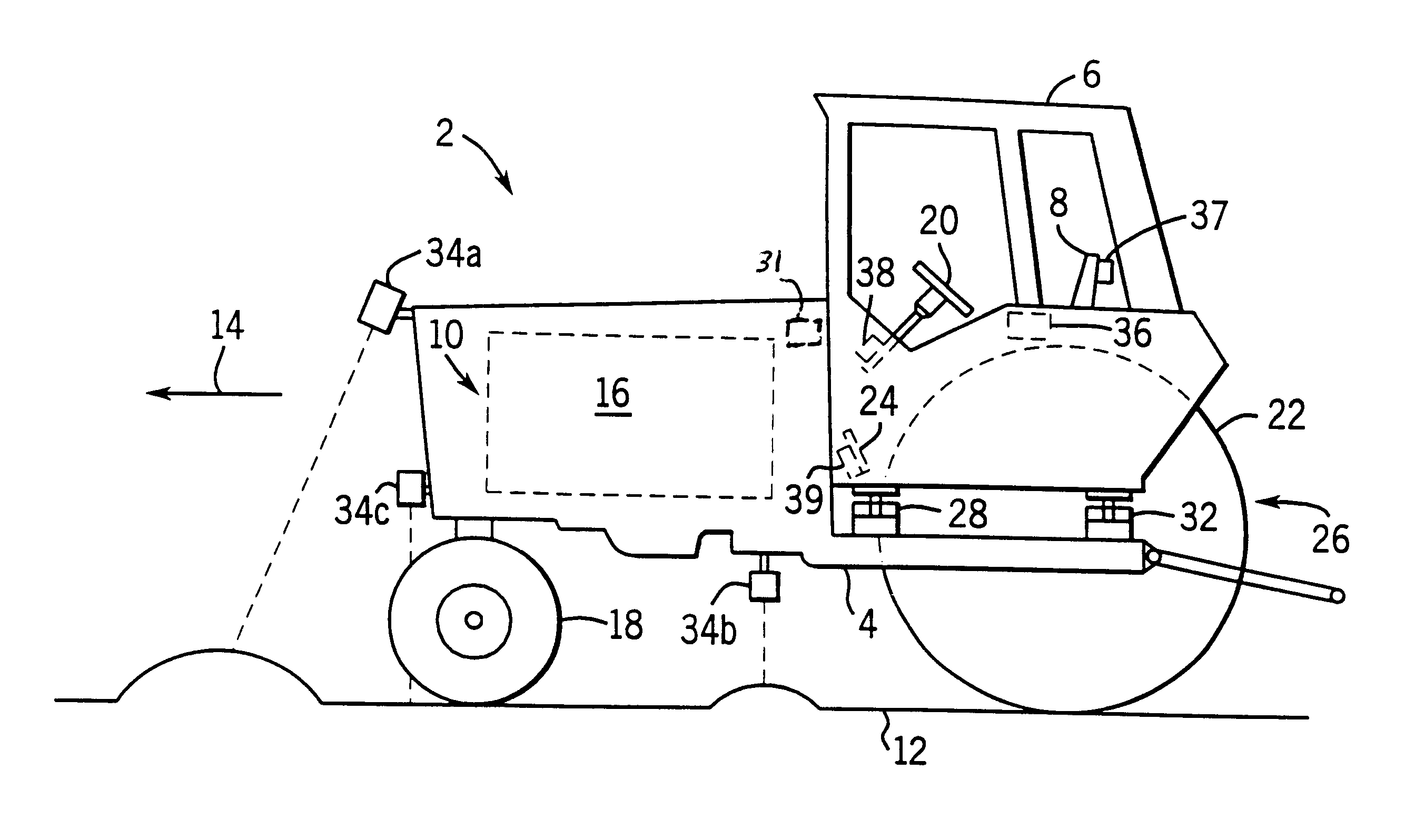

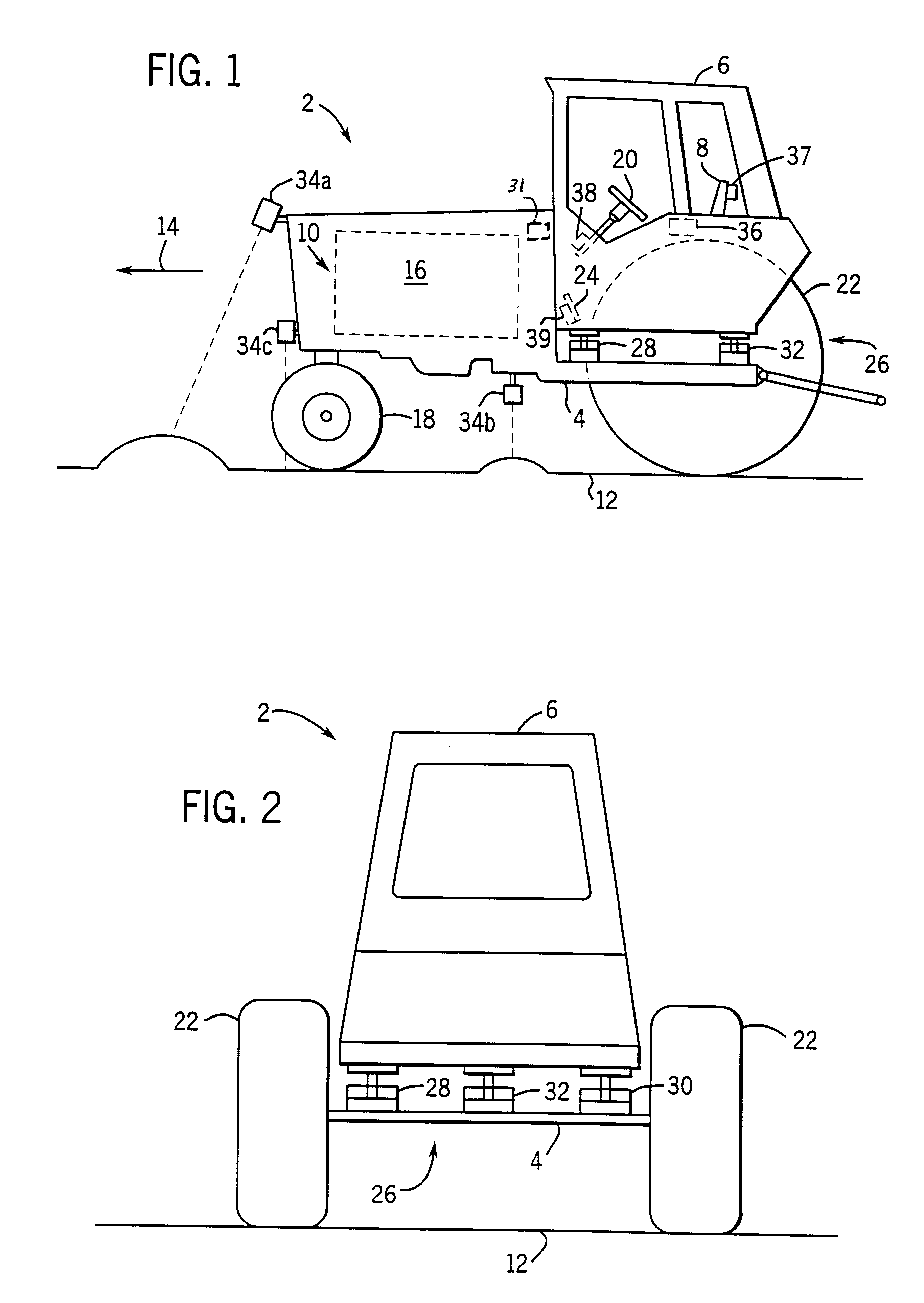

Apparatus for facilitating reduction of vibration in a work vehicle having an active CAB suspension system

InactiveUS6898501B2Reduce vibrationEar treatmentAnalogue computers for trafficEngineeringSignal processing

An apparatus and method for determining when a component of a work vehicle experiences vibration above a predetermined threshold, and responding to the vibration so that the vibration is reduced below the predetermined threshold. The apparatus, which is in a work vehicle that includes a chassis, an operator's cab and an active cab suspension system, includes a sensor that is configured to sense a quantity representative of the vibration experienced by the component of the work vehicle and to develop a first signal indicative of that quantity. The apparatus also includes a signal processor that is coupled to the sensor and is configured to develop, in response to the first signal, a second signal indicative of whether the vibration experienced by the component is above the predetermined threshold. The apparatus further includes a device that is coupled to the signal processor and, in response to the second signal, is either configured to provide an indication or configured to take an action to reduce the vibration below the predetermined threshold when the vibration is above the predetermined threshold.

Owner:BLUE LEAF I P INC +1

Adjustable-height suspension system

InactiveUS7857325B2Vehicle cleaning apparatusLoading/unloading vehicle arrangmentVehicle frameEngineering

A system for adjusting the height or spacing between the frame and axle of a vehicle. The system may operate by manipulating a suspension system connecting the frame to the axle and comprising shock assemblies. The system may include hydraulic spacers selectively changing in length in unison, thereby manipulating the equilibrium positions of the shock assemblies and changing the distance between the frame and axle. Between changes in length, the hydraulic spacers may act as a substantially rigid bodies.

Owner:SRATS

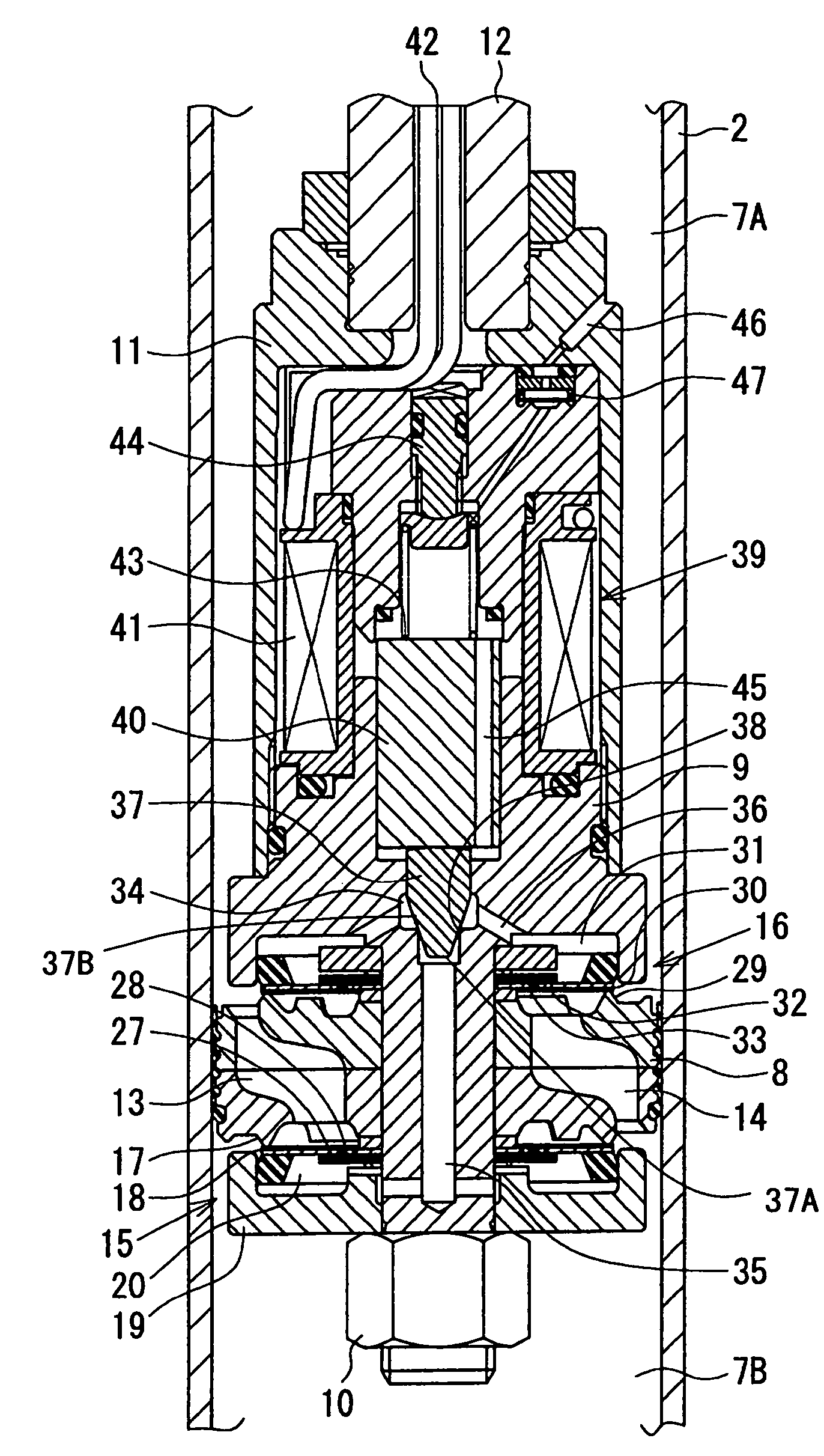

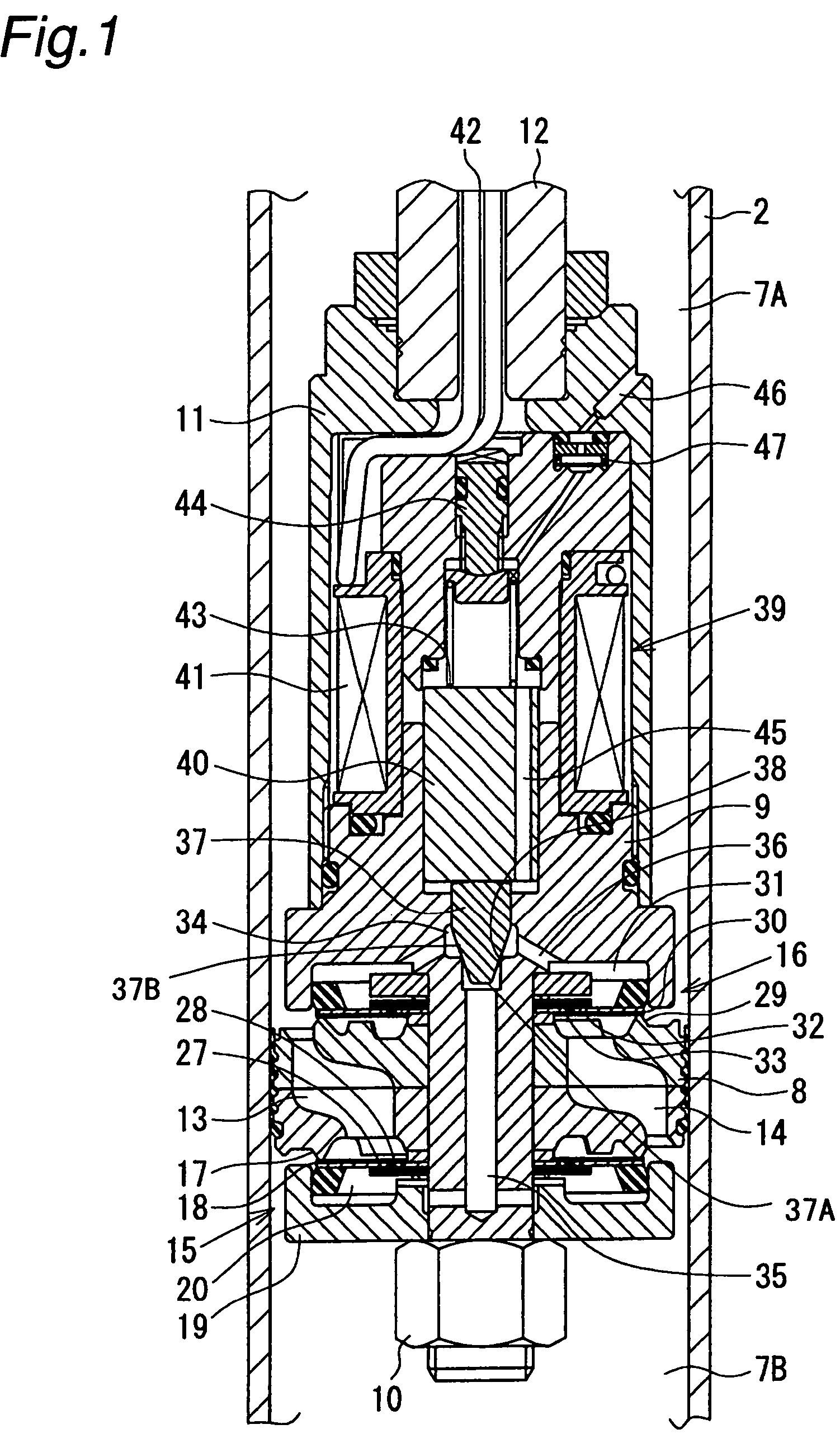

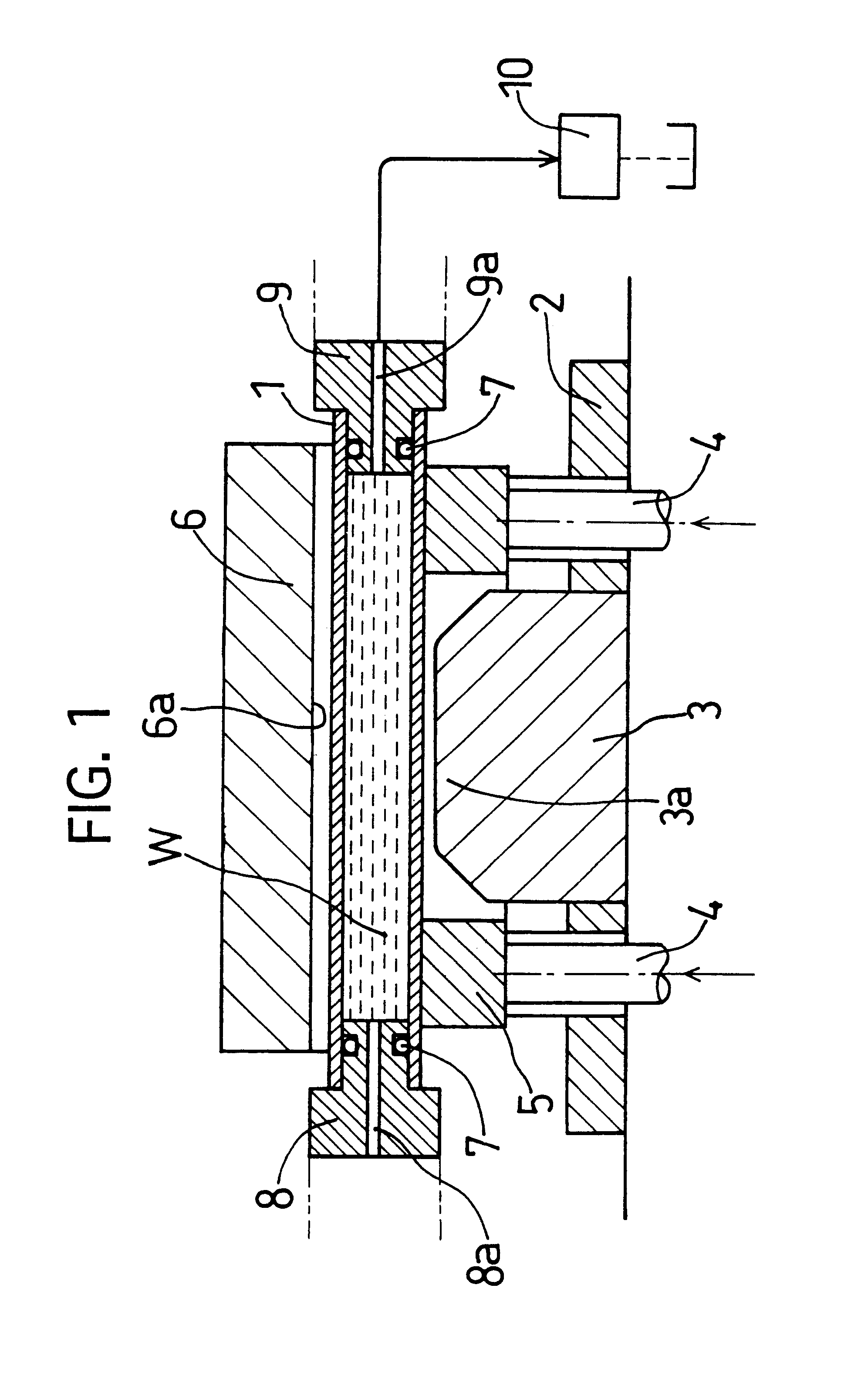

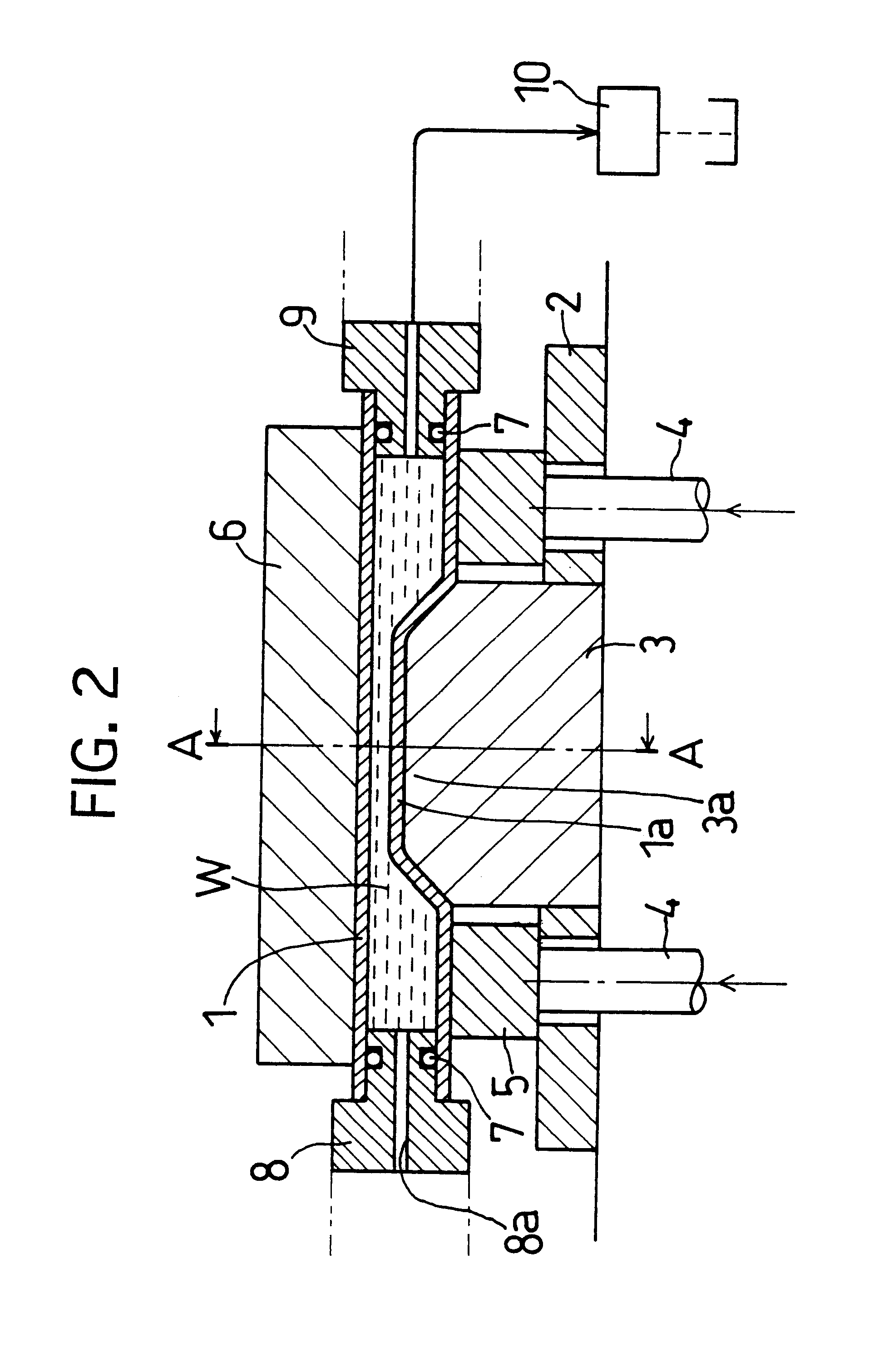

Controllable damping force hydraulic shock absorber

A controllable damping force hydraulic shock absorber including a pilot type damping valve having a back-pressure chamber for each of an extension stroke and a compression stroke. A piston connected to a piston rod is fitted into a sealed cylinder in which a hydraulic fluid is contained. During an extension stroke of the piston rod, the hydraulic fluid in an upper cylinder chamber flows to a lower cylinder chamber through an extension-side hydraulic fluid passage, an extension-side orifice hydraulic fluid passage, an extension-side back-pressure chamber, an axial hydraulic fluid passage, a radial hydraulic fluid passage, a compression-side back-pressure chamber, an extension-side check valve and a compression-side hydraulic fluid passage. During a compression stroke, the hydraulic fluid in the lower cylinder chamber flows to the upper cylinder chamber through the compression-side hydraulic fluid passage, the compression-side orifice passage, the compression-side back-pressure chamber, the radial hydraulic fluid passage, the axial hydraulic fluid passage, the extension-side back-pressure chamber, the compression-side check valve and the extension-side hydraulic passage. The hydraulic fluid passage for an extension stroke and the hydraulic fluid passage for a compression stroke have some elements in common, thus simplifying the structure of the controllable damping force hydraulic shock absorber.

Owner:HITACHI ASTEMO LTD

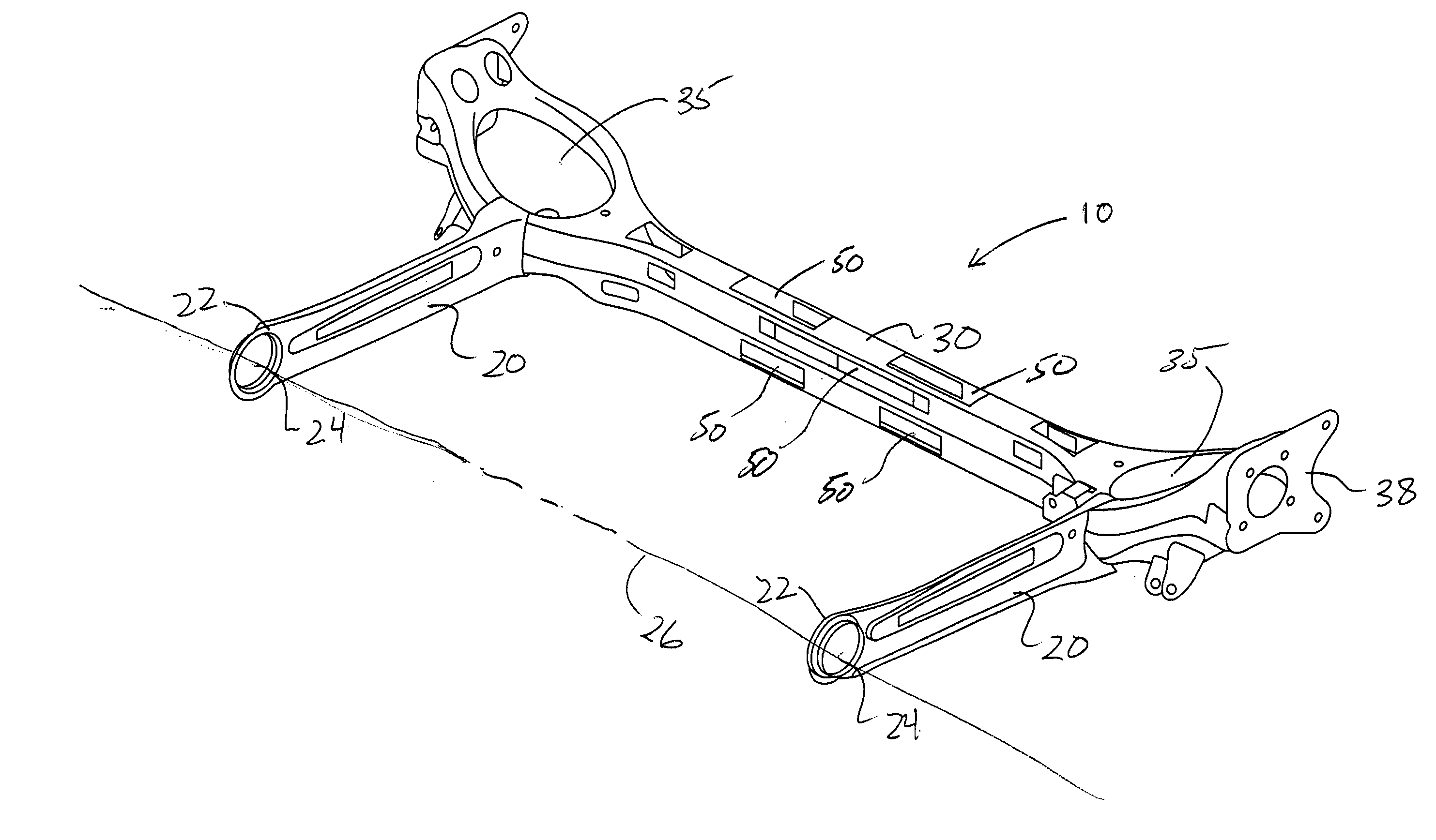

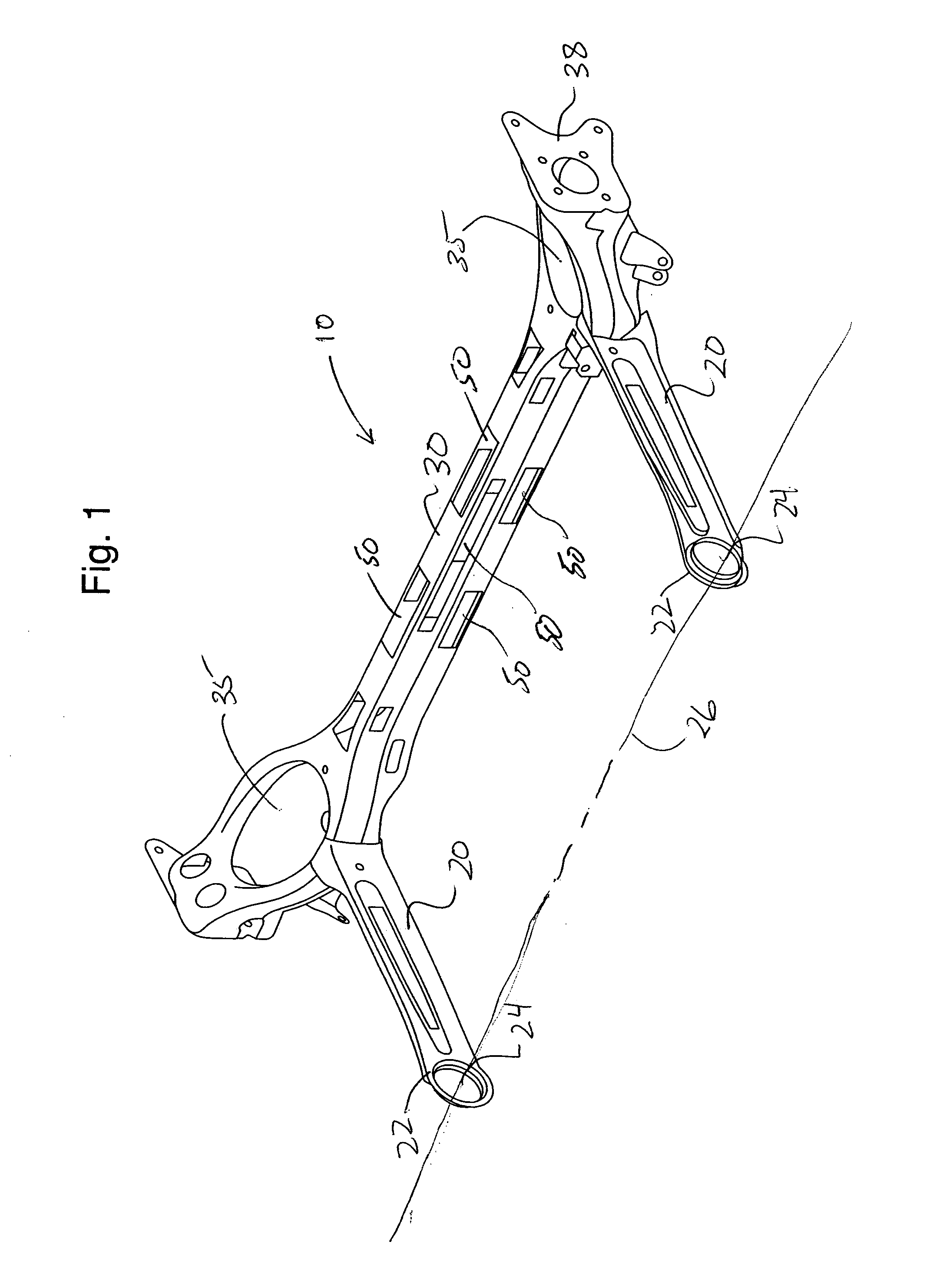

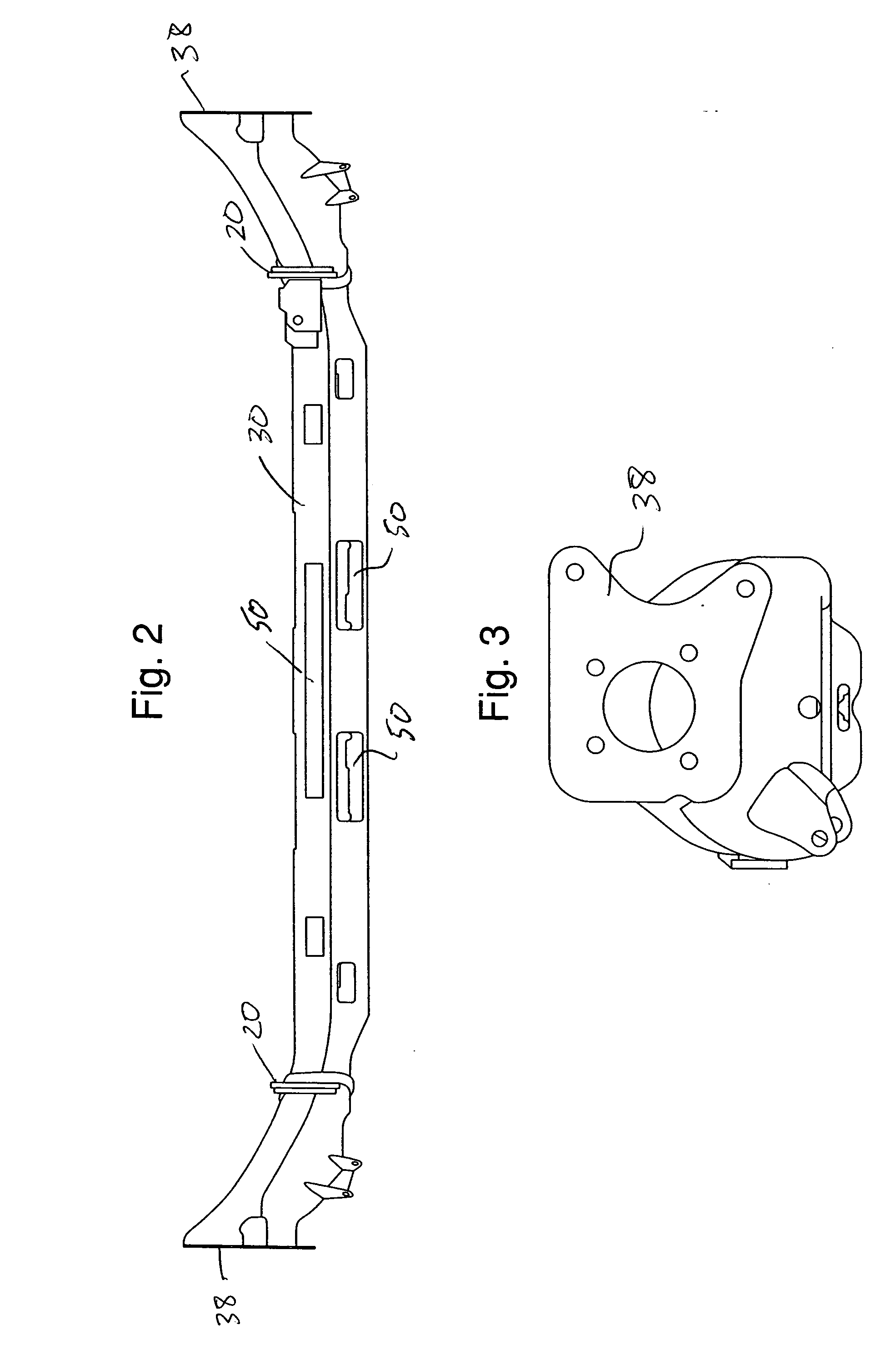

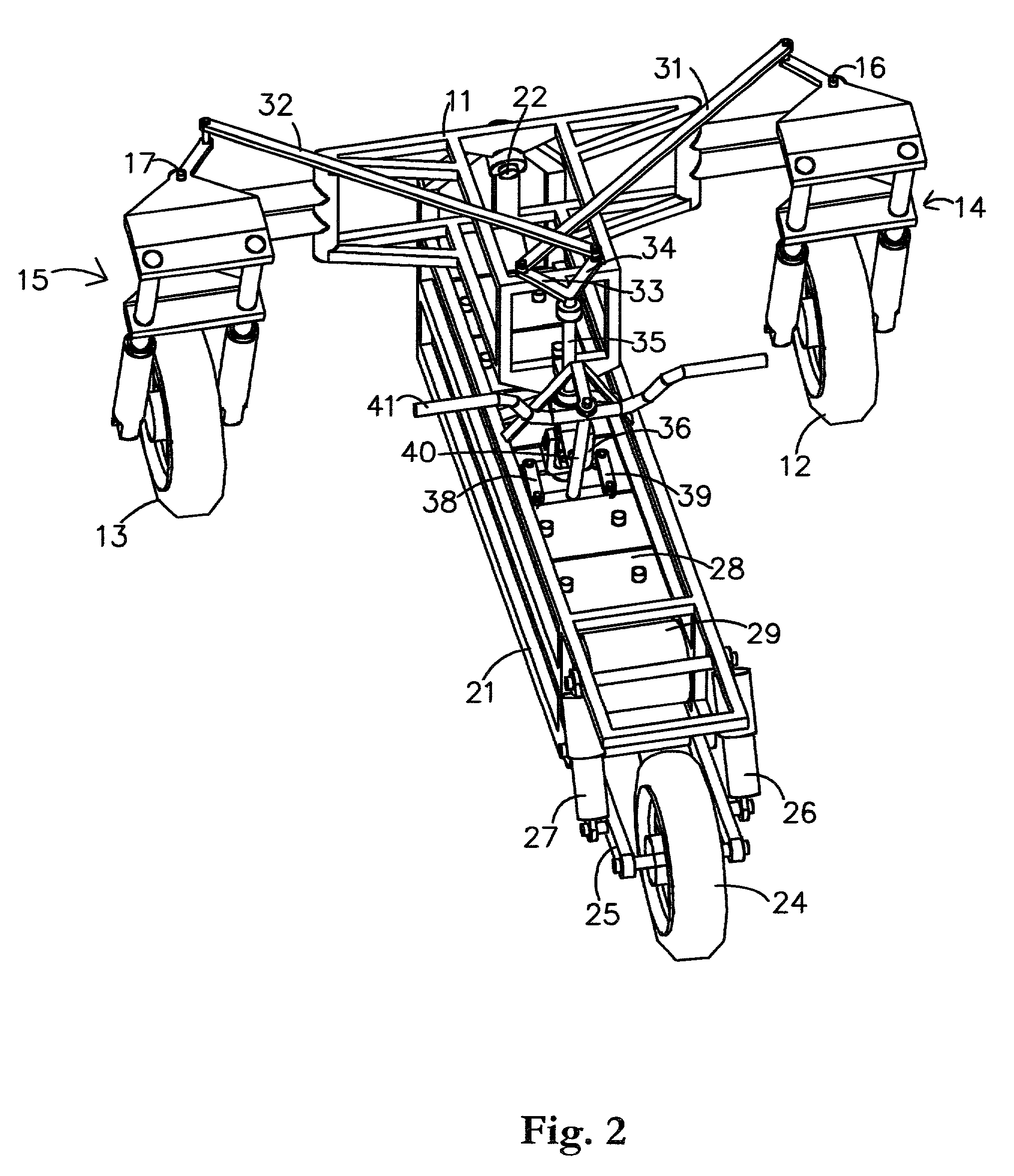

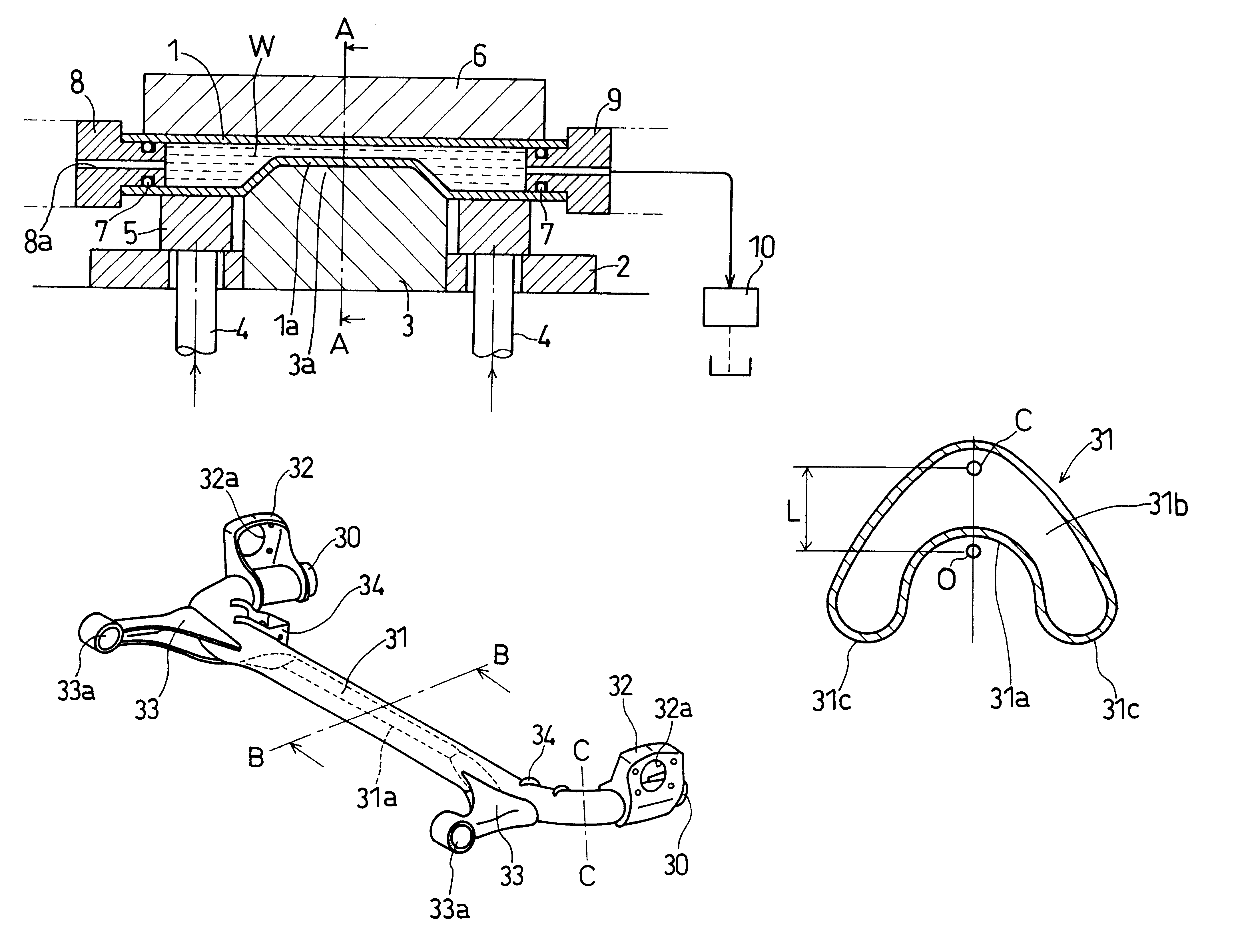

Torsion beam suspension member

A torsion beam suspension member using two u-shaped, stamped members that are superimposed and welded to form a torsion arm. No additional torsion tube or bar is needed. Tuning holes (rectangular, oblong, round or any other suitable shape) are used to change or tune the torsional resilience of the suspension. In the preferred embodiment, the tuning holes are oblong and located near the center of the cross member. The tuning holes are selected based on having target value for torsional compliance or resilience. The size, quantity and location of the tuning hole are chosen based on computer analysis. An optimization or iterative process is used to arrive at the final hole size, quantity and location.

Owner:DANA AUTOMOTIVE SYST GRP LLC

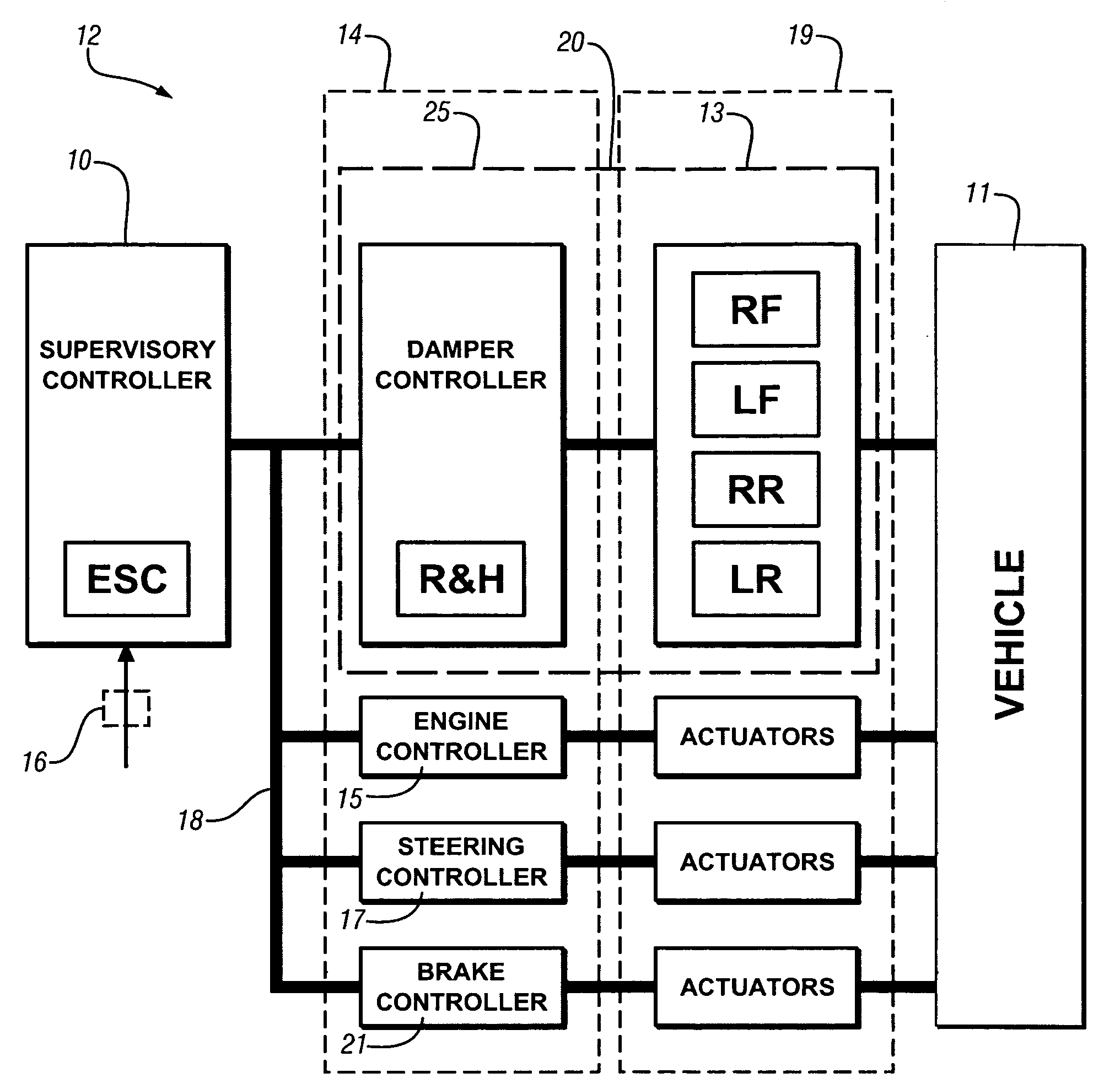

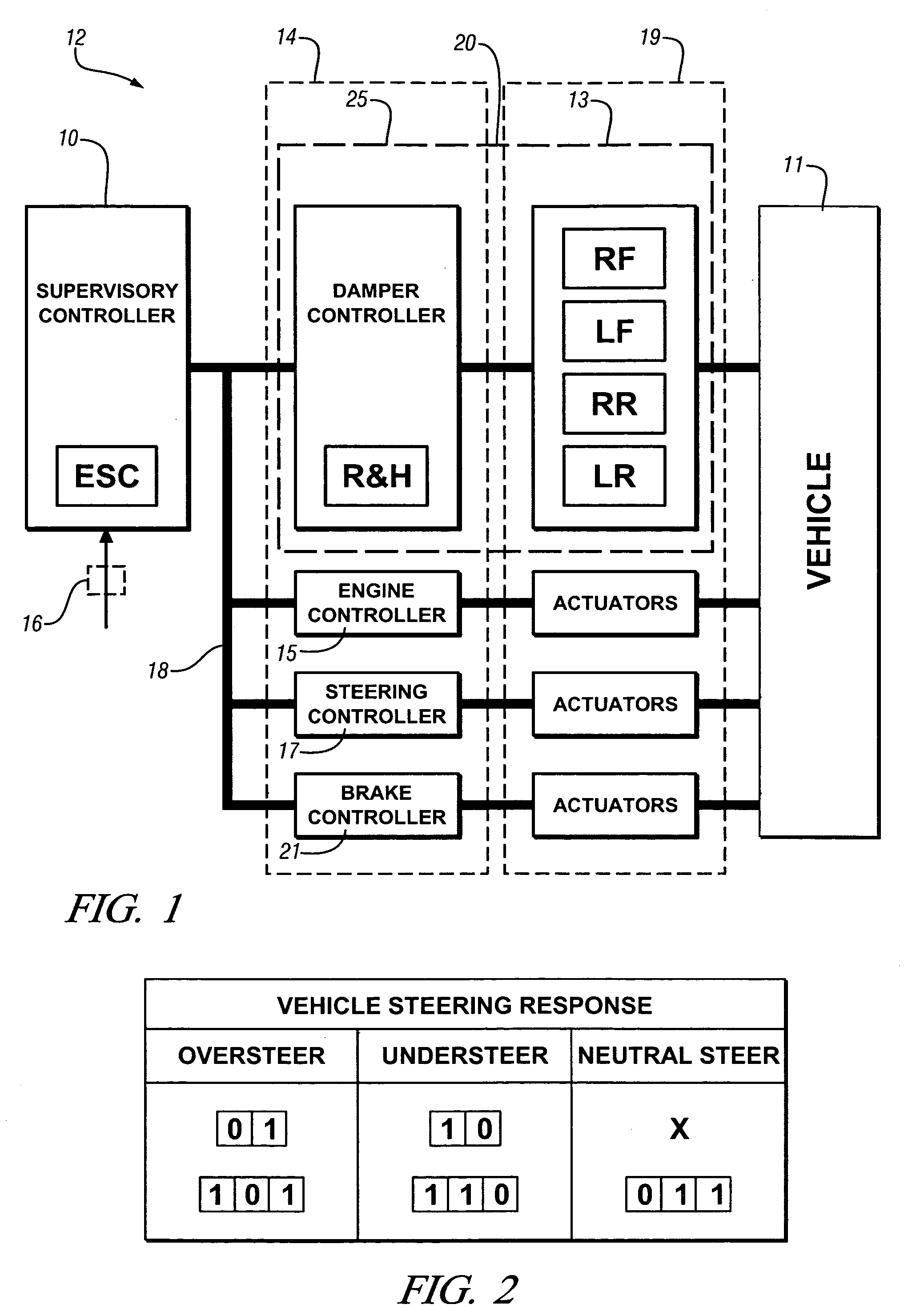

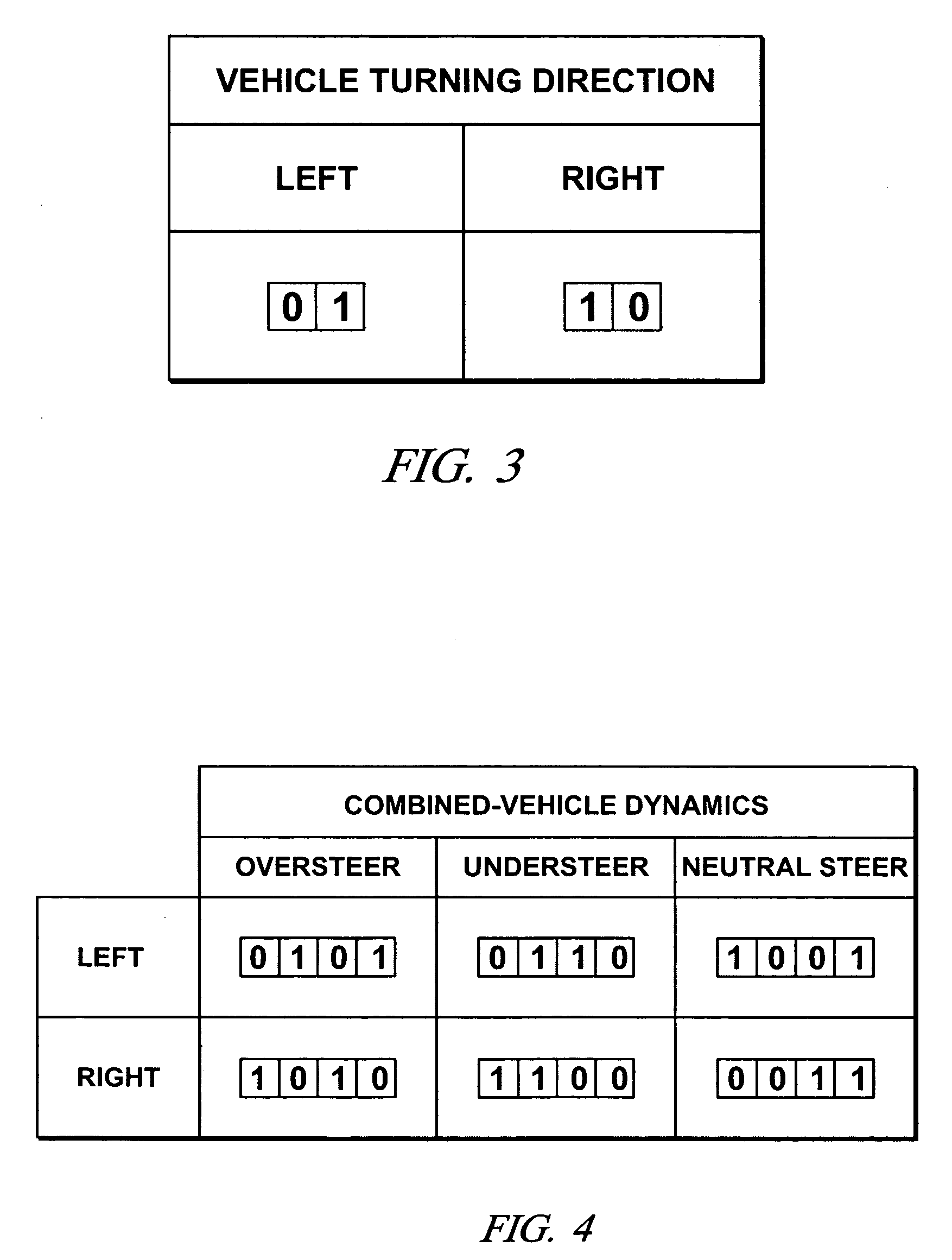

Suspension control calibration integrity

InactiveUS7684911B2Vehicle testingRegistering/indicating working of vehiclesVehicle dynamicsSemi active

A vehicle includes a semi-active suspension including suspension dampers controllably adjustable in accordance with electronic stability control commands and ride and handling commands. Vehicle steering response states, turning direction states and vehicle dynamics states are binary coded in respective state variables and suspension control calibrations are binary coded in calibration words. Integrity and security of state variables and calibration words are ensured in efficient binary digit resource allocation schemes.

Owner:GM GLOBAL TECH OPERATIONS LLC

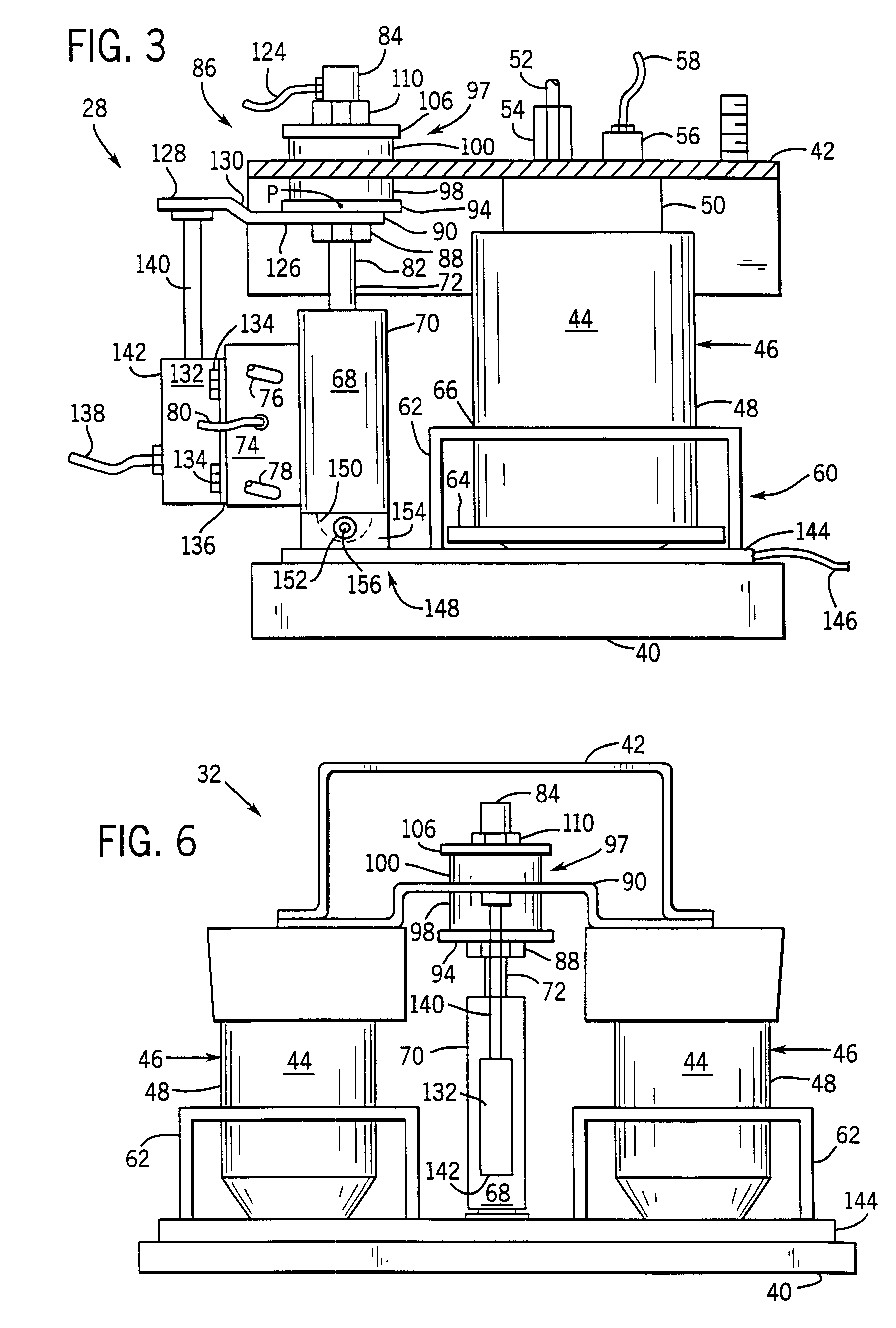

System and method for vehicle chassis control

ActiveUS20140312580A1Reduces or even eliminates tyre scrubReduce impactCyclesSteering deviceHydraulic cylinderHydraulic fluid

There is provided a vehicle comprising a chassis, two surface-engaging front wheels, at least one surface-engaging rear wheel and a propulsion unit for driving either the front wheels or the rear wheel or wheels. Each front wheel being connected to the chassis by means of a front wheel support assembly, wherein the front wheel support assembly comprises a hydraulic cylinder associated with each front wheel. Each hydraulic cylinder comprises a housing connected to one of the chassis and the front wheel support assembly, and a piston connected to the other of the front wheel support assembly and the chassis. The piston is moveable within the housing and arranged to divide the hydraulic cylinder into first and second chambers each having respective ports arranged to allow hydraulic fluid to enter and exit the respective chamber, the ports of the first chambers of each hydraulic cylinder being in fluid communication and the ports of the second chambers of each hydraulic cylinder being in fluid communication such that movement of hydraulic fluid from the first or second chamber of one hydraulic cylinder to the respective first or second chamber of the other hydraulic cylinder displaces the pistons of the hydraulic cylinders in opposing directions relative to the respective housings to enable the vehicle to tilt.

Owner:GALE DAVID ANDREW

Vehicle with movable and inwardly tilting safety body

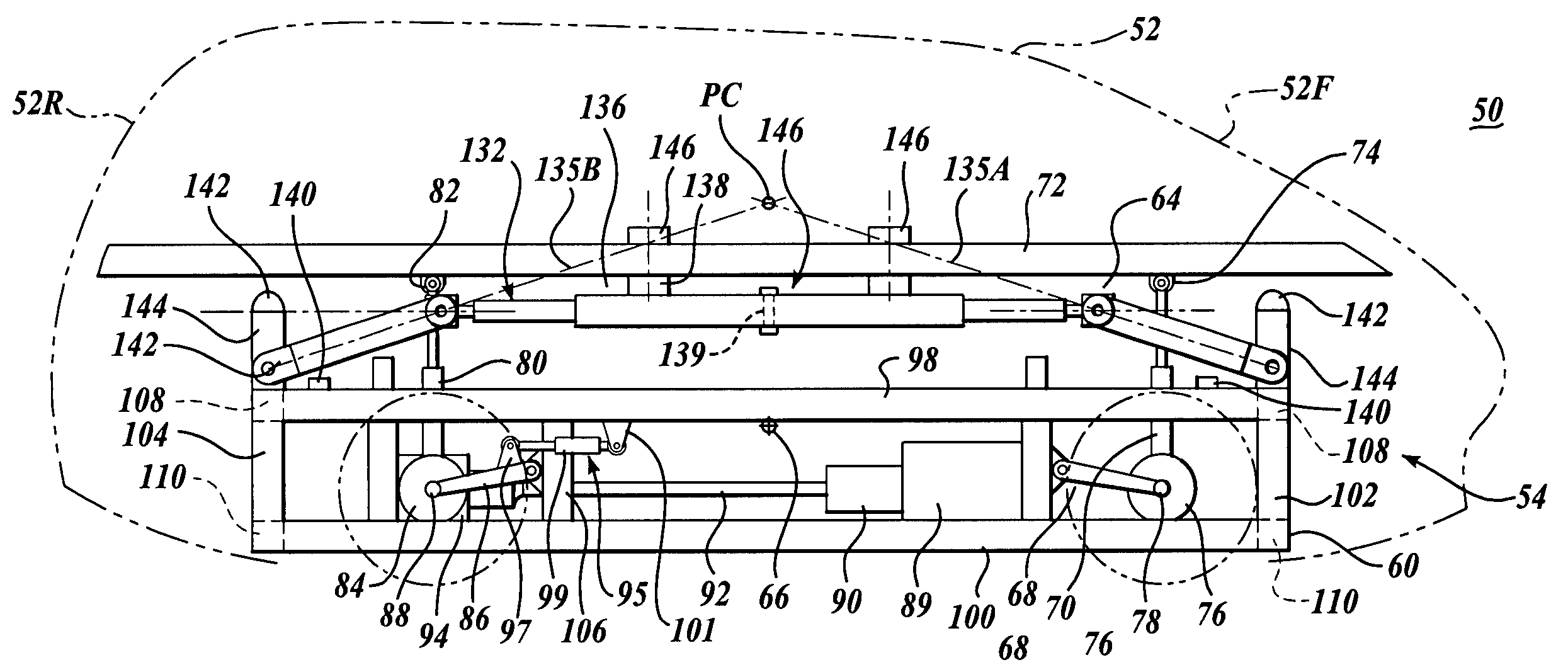

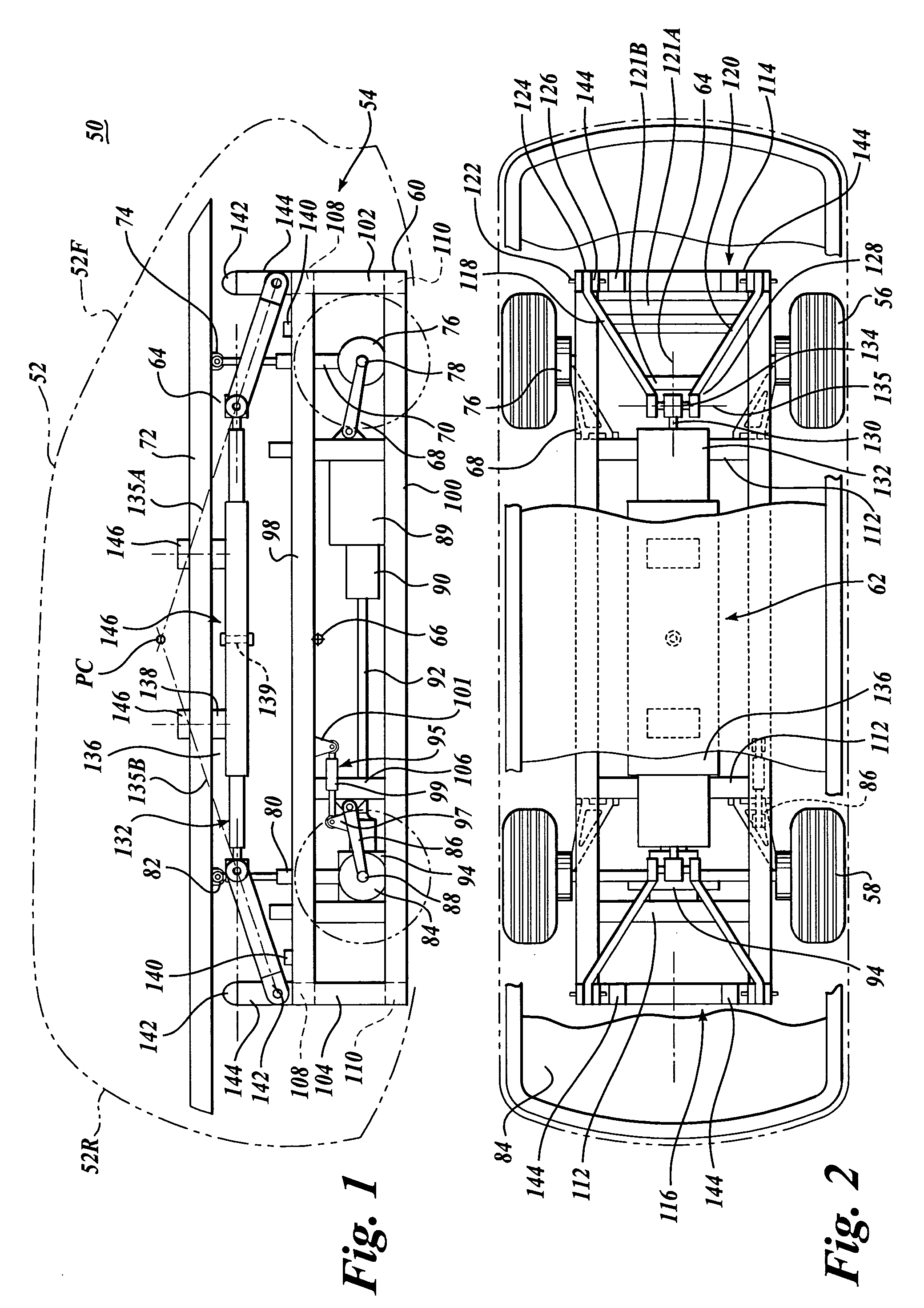

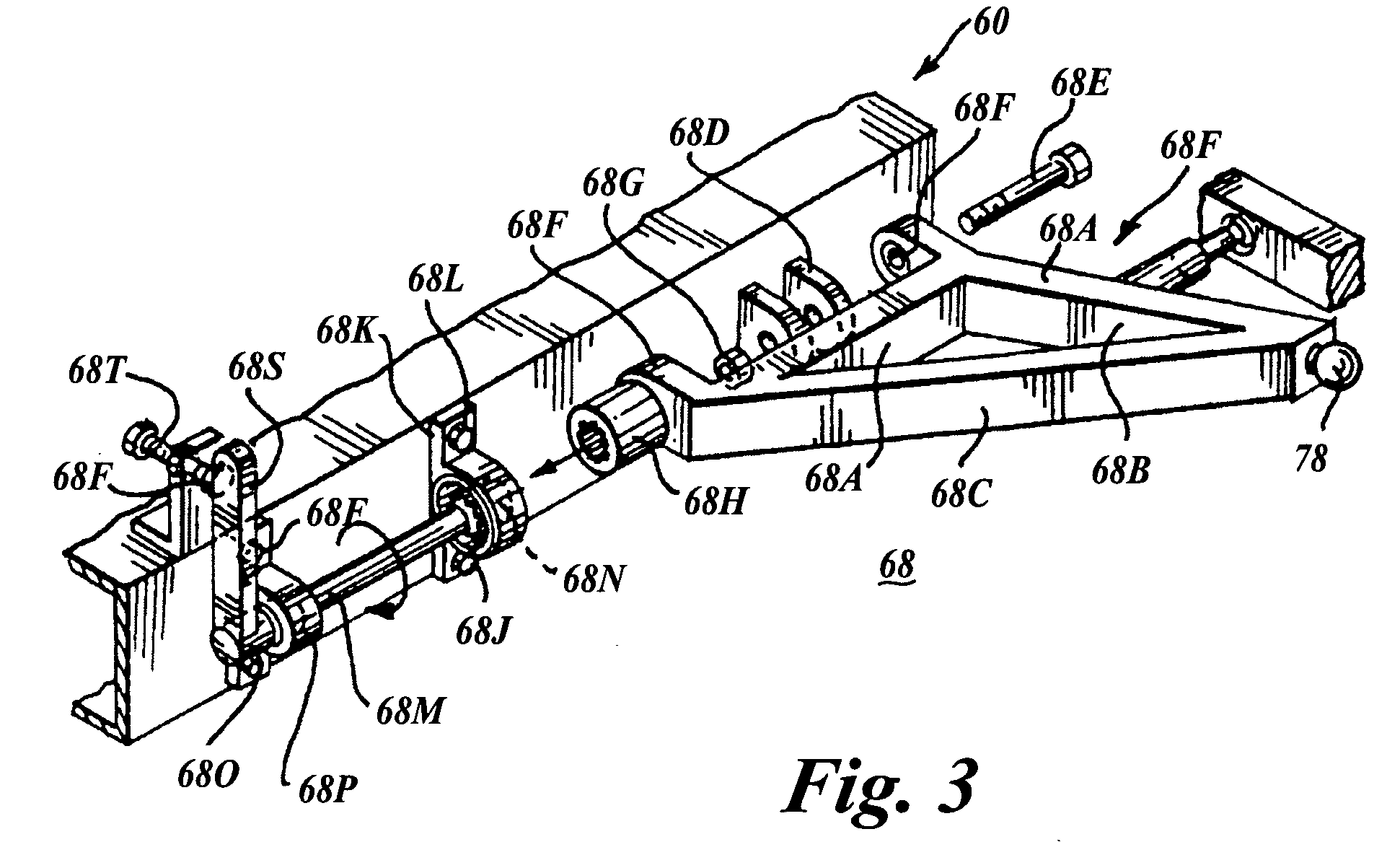

ActiveUS20050275181A1Reduce the detrimental effects on vehicle handlingImprove vehicle handlingVehicle body stabilisationVehicle cleaning apparatusEngineeringInterconnection

A suspension system for a vehicle (50c) having a body (52c) and a plurality of wheel support assemblies (56c, 58c) includes a tie structure (60c) interposed between the body and the wheel support assemblies. A first interconnection system (68c) interconnects the tie structure to the wheel support assemblies, and the second interconnection system (302) interconnects the tie structure and the body. The second interconnection system includes a plurality of link structures (304, 320) pivotally connected at one end to the tie structure, and pivotally connected at the opposite end to the body. Such link structures are oriented relative to the tie structure to extend towards a common point along a longitudinal axis (33B) of the tie structure.

Owner:MACISAAC WILLIAM L

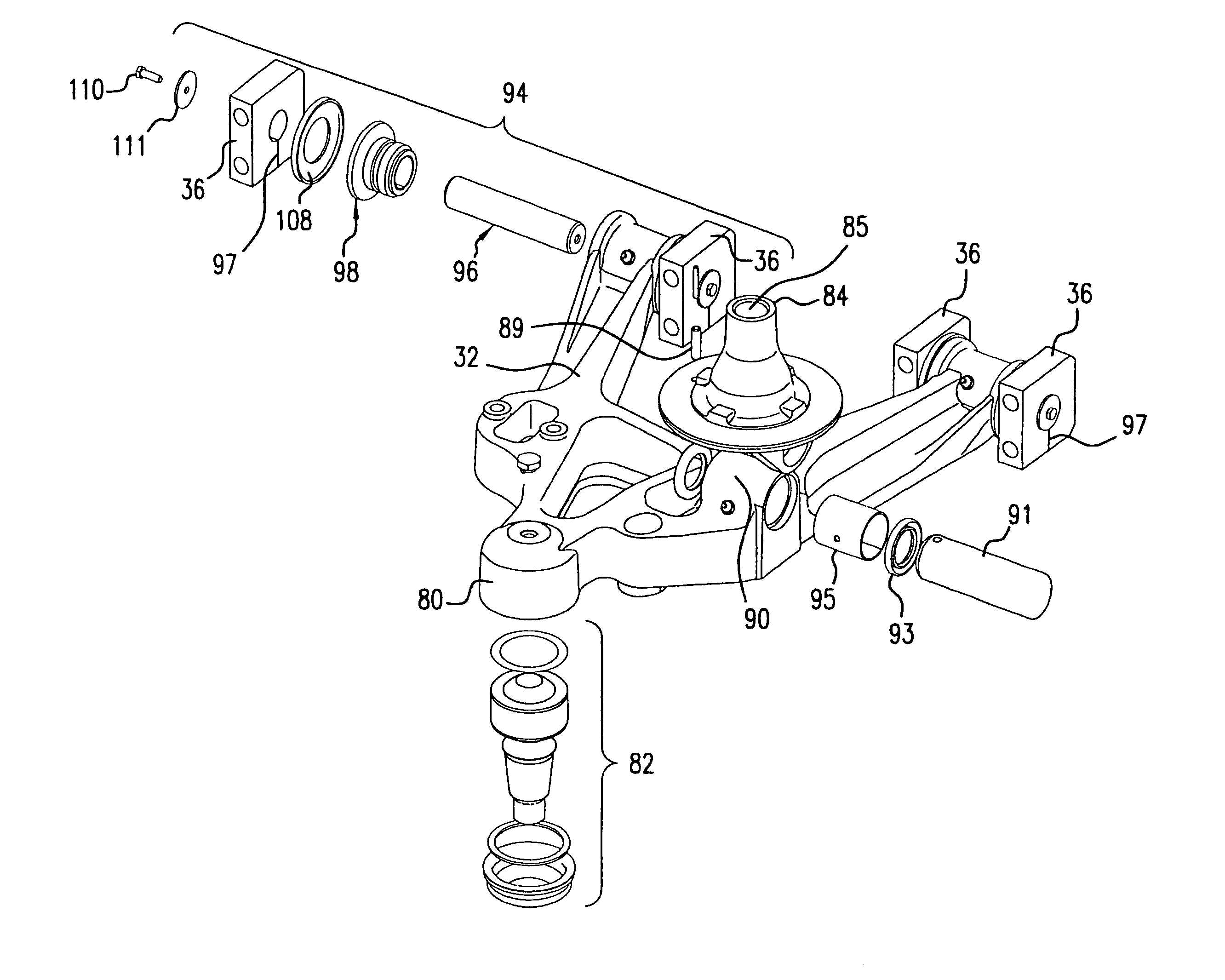

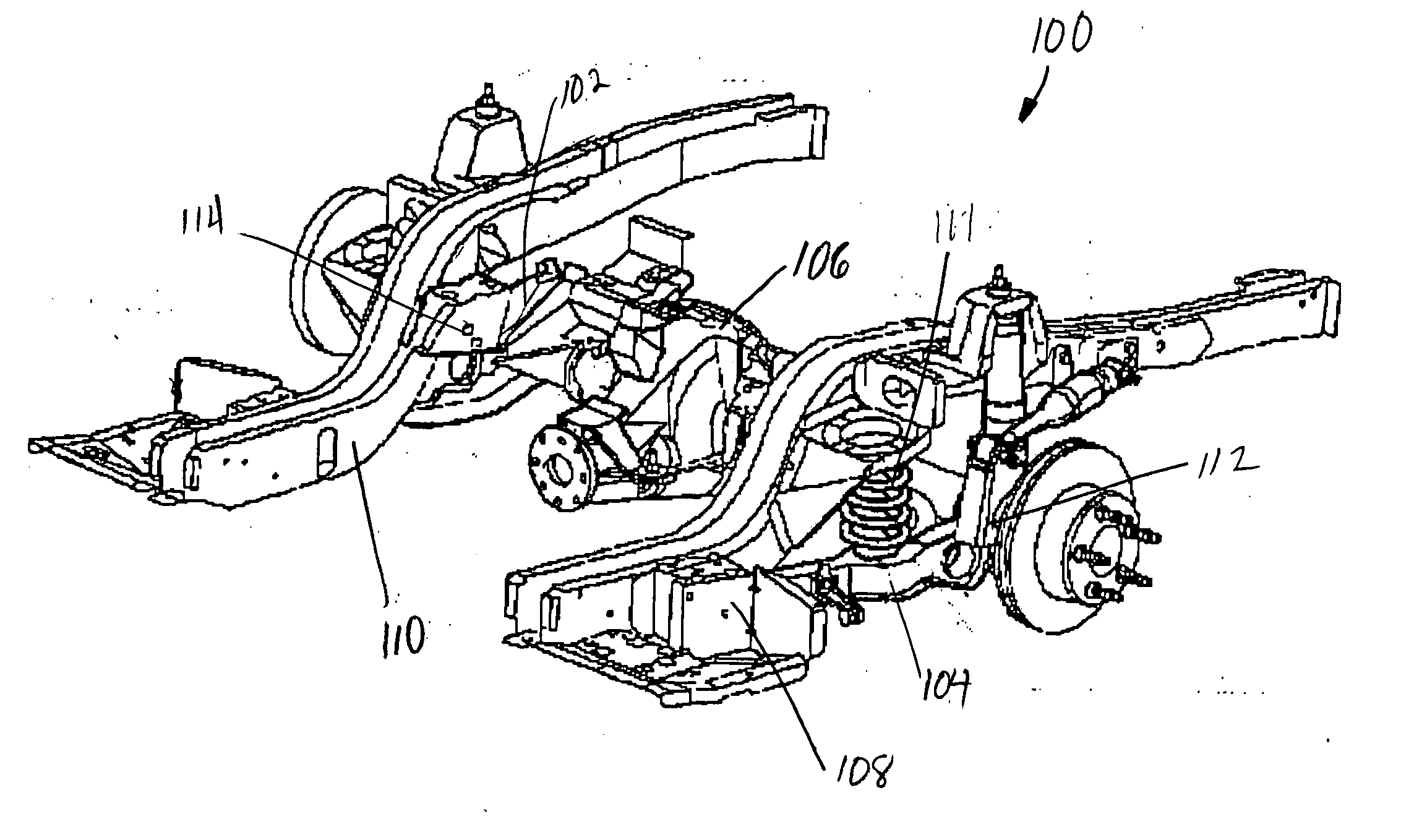

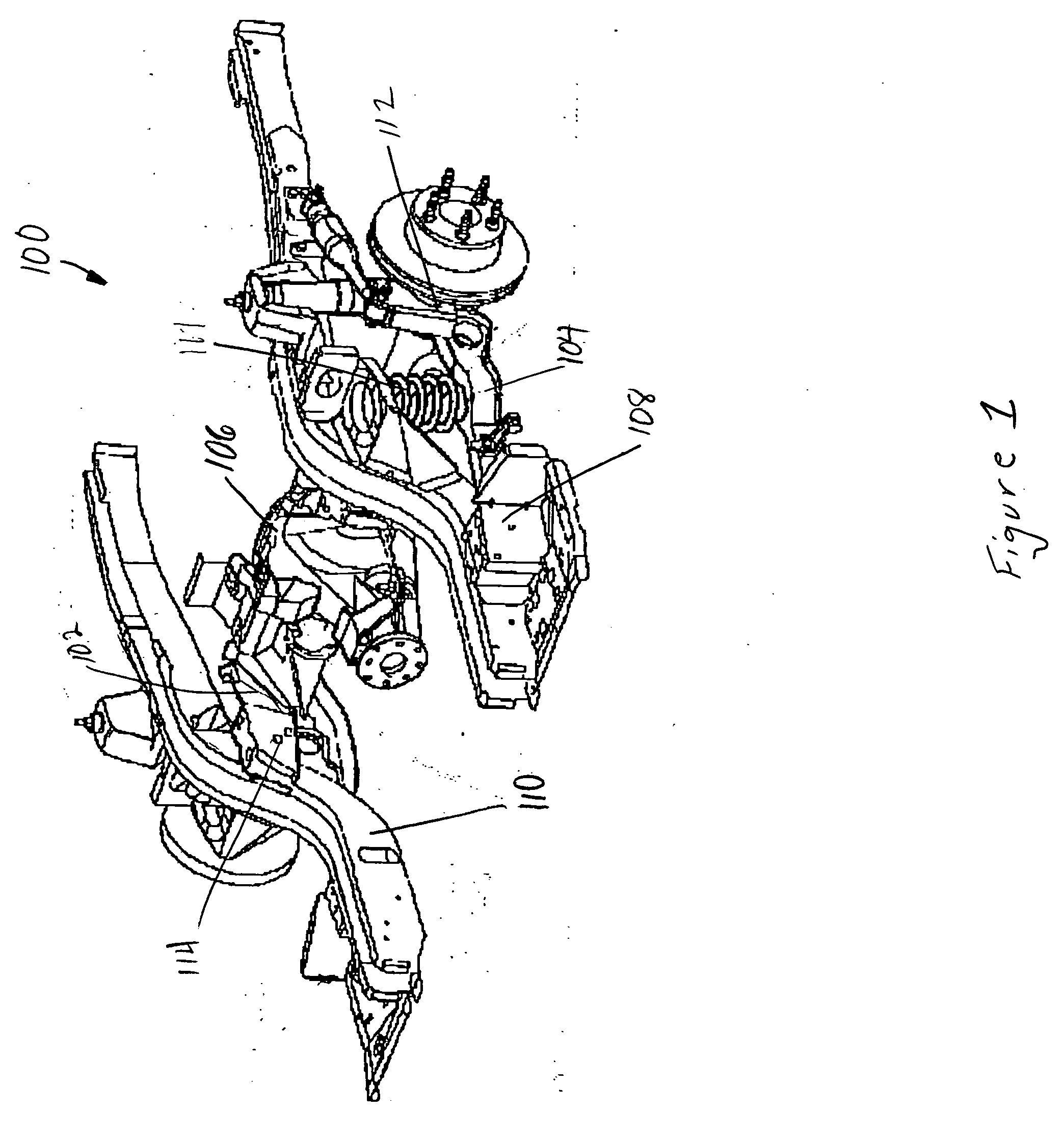

Lower control arm kit for vehicle with four link rear suspension

InactiveUS20060071441A1Reduce unsprung weightEasy to bendInterconnection systemsResilient suspensionsSpherical bearingControl arm

The present invention provides a suspension tuning device and kit for vehicles with four link rear suspensions. More specifically, the suspension tuning device generally comprises a pair of billet aluminum lower control arms each having a spring platform rotatably secured to a weight jacking bolt and a removable / replaceable sway bar attachment plate. Each end of the control arms include a transverse thru-bore adapted to accept a three part urethane bushing or a spherical bearing. The lower control arms are constructed to mount within a standard four link rear suspension, such as that supplied on a FORD MUSTANG, to permit quick suspension alterations throughout a predetermined range.

Owner:STEEDA AUTOSPORTS

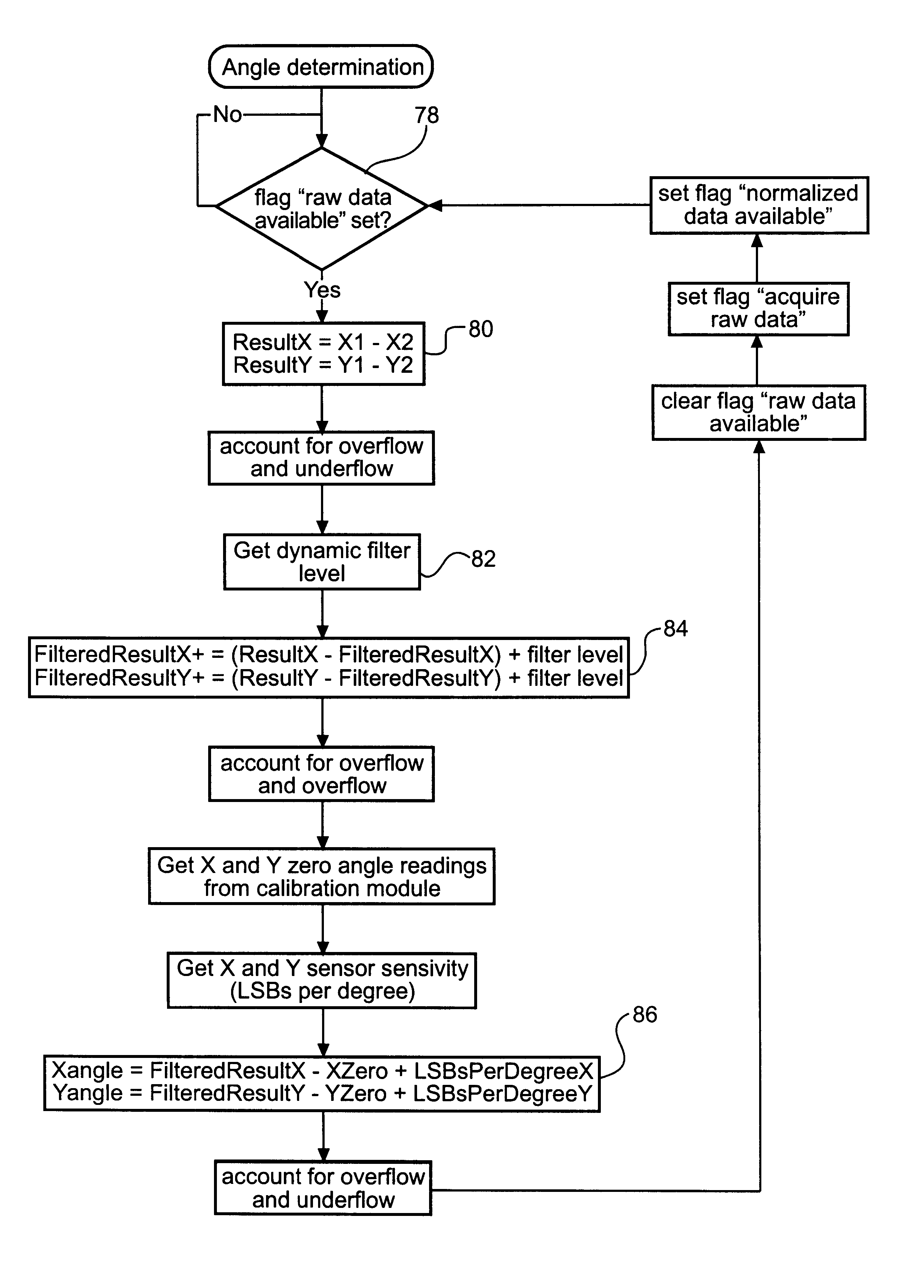

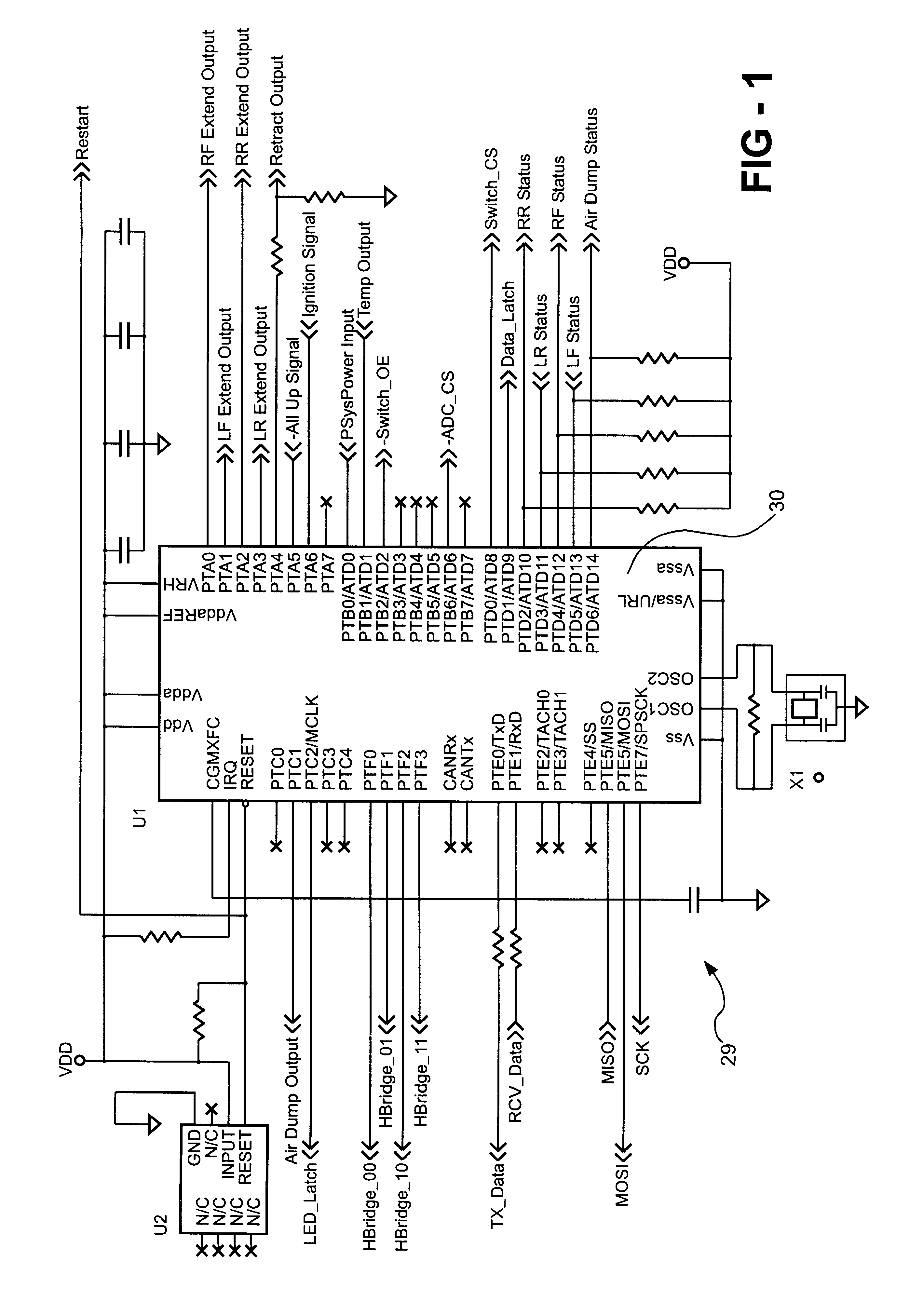

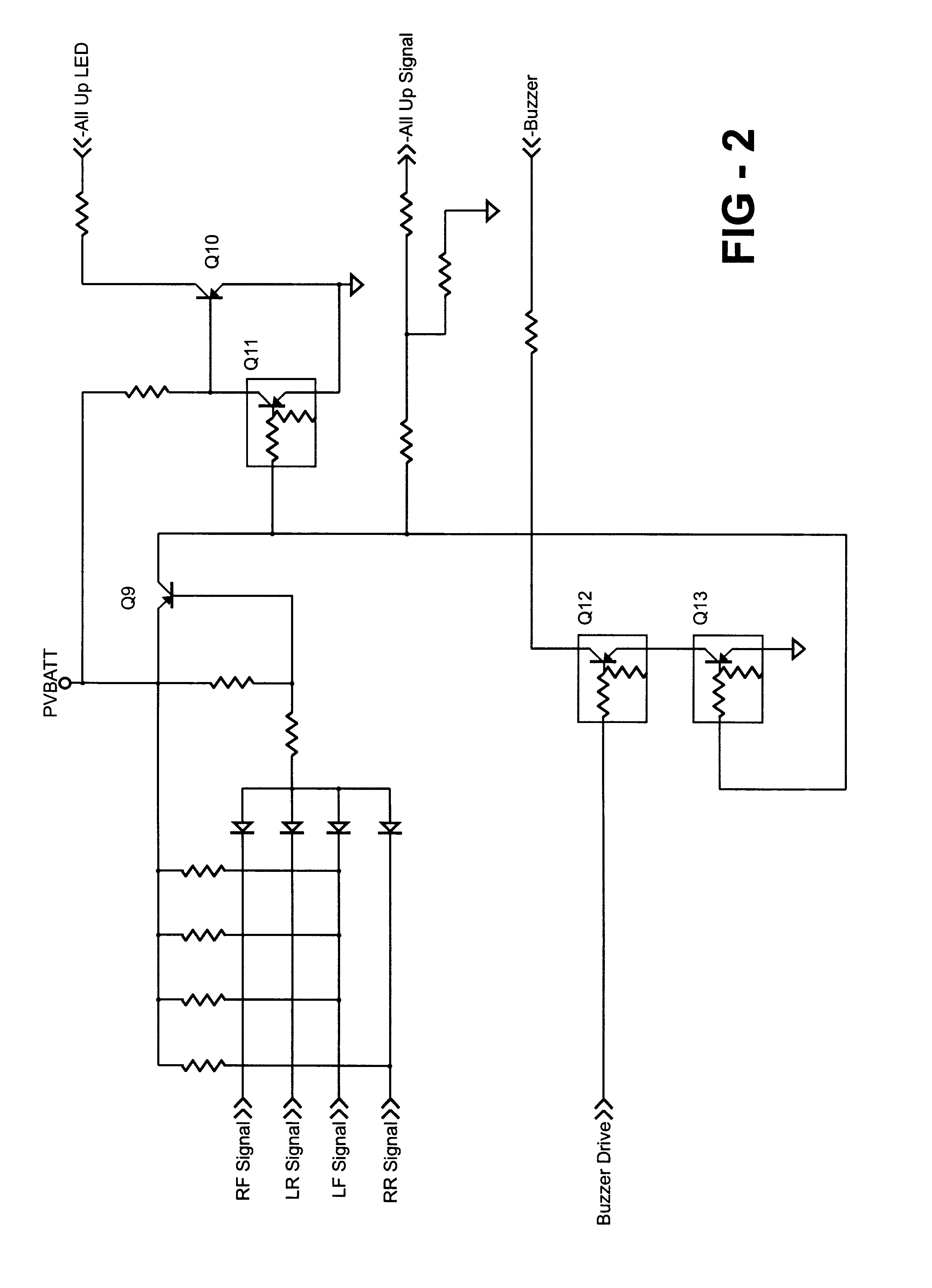

Vehicle leveling assembly

InactiveUS6584385B1Vehicle body stabilisationDigital data processing detailsMobile vehicleEngineering

A leveling assembly for analyzing the attitude of a structure such as a motor vehicle in two axes. The assembly drives leveling devices on the structure to correct the attitude of the structure relative to a calibrated reference point or attitude. The assembly includes a controller connected to the leveling devices and a proportional two-axis tilt sensor that is connected to the controller and supported on the structure. The tilt sensor provides analog signals to the controller that represent the attitude of the structure about longitudinal pitch and lateral roll axes. The controller also uses those signals to determine the attitude of the structure relative to a calibrated sensitivity factor and a user-defined zero point. This allows an operator or installer to determine which portion of the structure will be leveled without regard to the location of the tilt sensor and allows an installer to mount the tilt sensor at any point on the structure.

Owner:INNOVATIVE DESIGN SOLUTIONS

Four wheel drive stationary body vehicle having controlled wheel and passenger compartment lateral lean with independent steering

InactiveUS20050206101A1Comfortable independent lateral leanIncrease speedVehicle cleaning apparatusLoading/unloading vehicle arrangmentGear wheelControl theory

In this vehicular chassis system, the vehicle's passenger compartment and wheels incline toward the turning center side in such a manner, that the wheels can be tilted independently from steering. This vehicle has a steering apparatus controlling the steering, and a separate apparatus controlling the lateral leaning. The lean is controlled mechanically using a pendulum, and forced lateral leaned using a control unit, or manually with the transfer of body weight using several pinions with a set ratio to control the passenger compartment lateral lean in conjunction with the wheel lateral lean. An electric DC servo gear motor can be used to control the lateral lean, that intern moves a pinion, which moves a rack and lateral movable cross member, while controlling the lateral leaning wheels and pulling the tilt support bar pivotally attached to a passenger compartment in the same leaning direction.

Owner:BOUTON TODD RICHARD

Suspension with releasable locking system

InactiveUS7083195B2Pedestrian/occupant safety arrangementWheelchairs/patient conveyanceEngineeringMechanical engineering

A suspension for a vehicle is provided. The suspension includes, for example, a frame and a releasable locking assembly. The releasable locking assembly has, for example, a first assembly movably coupled to the frame, a second assembly movably coupled to the frame, and wherein movement of the frame relative to the first and second assemblies causes the first and second assemblies to engage each other to limit further movement of the frame in at least a first direction.

Owner:INVACARE CORP

Control system for leaning vehicle

A leaning vehicle has a frame that pivots relative to a pivotable frame member about a pivot axis. A torque exerted on a steering assembly in a first direction causes the frame to pivot relative to the pivotable frame member in a second, opposite direction at least when the speed of the vehicle is above a first threshold speed, to steer the vehicle in the second direction. An actuator urges the frame toward an upright position when the frame is in a leaning position and a speed of the vehicle is below a second threshold speed. A method is also described, in which a torque is exerted on the frame in the direction opposite the steering torque when the speed above the first threshold speed. The torque exerted by the actuator is opposite the leaning angle when the speed of travel is below the second threshold speed.

Owner:BOMBARDIER RECREATIONAL PROD INC

Vehicle lean and alignment control system

The amount of lean to be provided is determined by force sensors, the speed, and / or the angle of turn. Then the vehicle is leaned by actuators in the suspension in accordance with a predetermined protocol in an electronic control unit (ECU). The protocol also provides shock absorption by rapidly tracking a contour of a surface on which the vehicle rides. The suspension is provided by a plurality of arm assemblies each including a lower arm, an upper control arm, and an actuator motively connected to the lower arm and to the upper control arm. The arm assemblies are pivotally connected to the frame on a common axis. The arm assemblies generally form parallelograms and are actuated in concert to remain generally parallel to each other through a range of angles to adjust the lean of the vehicle. The arm assemblies are also actuated independently of each other to accommodate variations in the contour. In one aspect, an actuator controlled by an ECU can be replaced by a mechanical actuator that can be activated manually such as by a driver's own leaning weight.

Owner:MELCHER THOMAS WESLEY

Vehicle with a stabilized tilting section

In accordance with the present invention a vehicle comprises a tilting section and a hanging section both connected to each other. When the vehicle is stationary or traveling straight, gravity will pull the hanging section downwards which will stabilize and keep the tilting section upright. When the vehicle is turning, centrifugal force will swing the hanging section outward and tilt the tilting section inside the turn.

Owner:BAUTISTA ERIC SAQUETON

Irregular-section tubular body and axle beam for torsion beam and method of manufacturing the same

The invention provides a method of manufacturing an irregular section tubular body and axle beam. The axle beam has a tubular worked body that has sealed liquid therein and is press-formed by upper and lower press molds. One of the press molds has a convex mold portion to form a concave portion concaved in an axis perpendicular direction at an axial part of the axle beam. The press-forming of the tubular worked body is completed by a one stroke process using liquid pressure that increases as the internal volume of the worked body decreases due to formation of the concave portion. The concave portion extends substantially the length of the axle beam and has a substantially U-shaped or V-shaped cross-section forming a closed and sealed space.

Owner:TOYOTA JIDOSHA KK

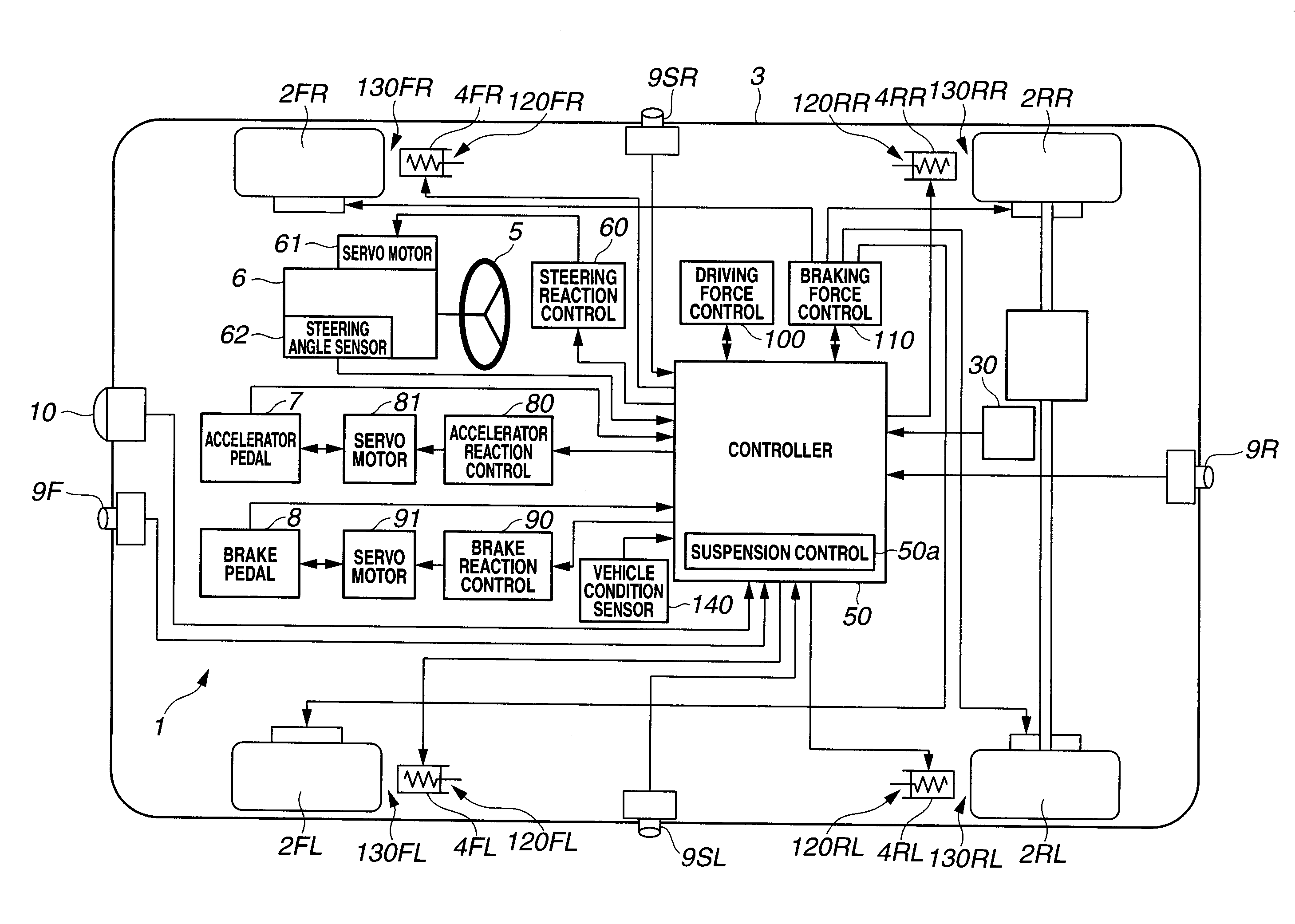

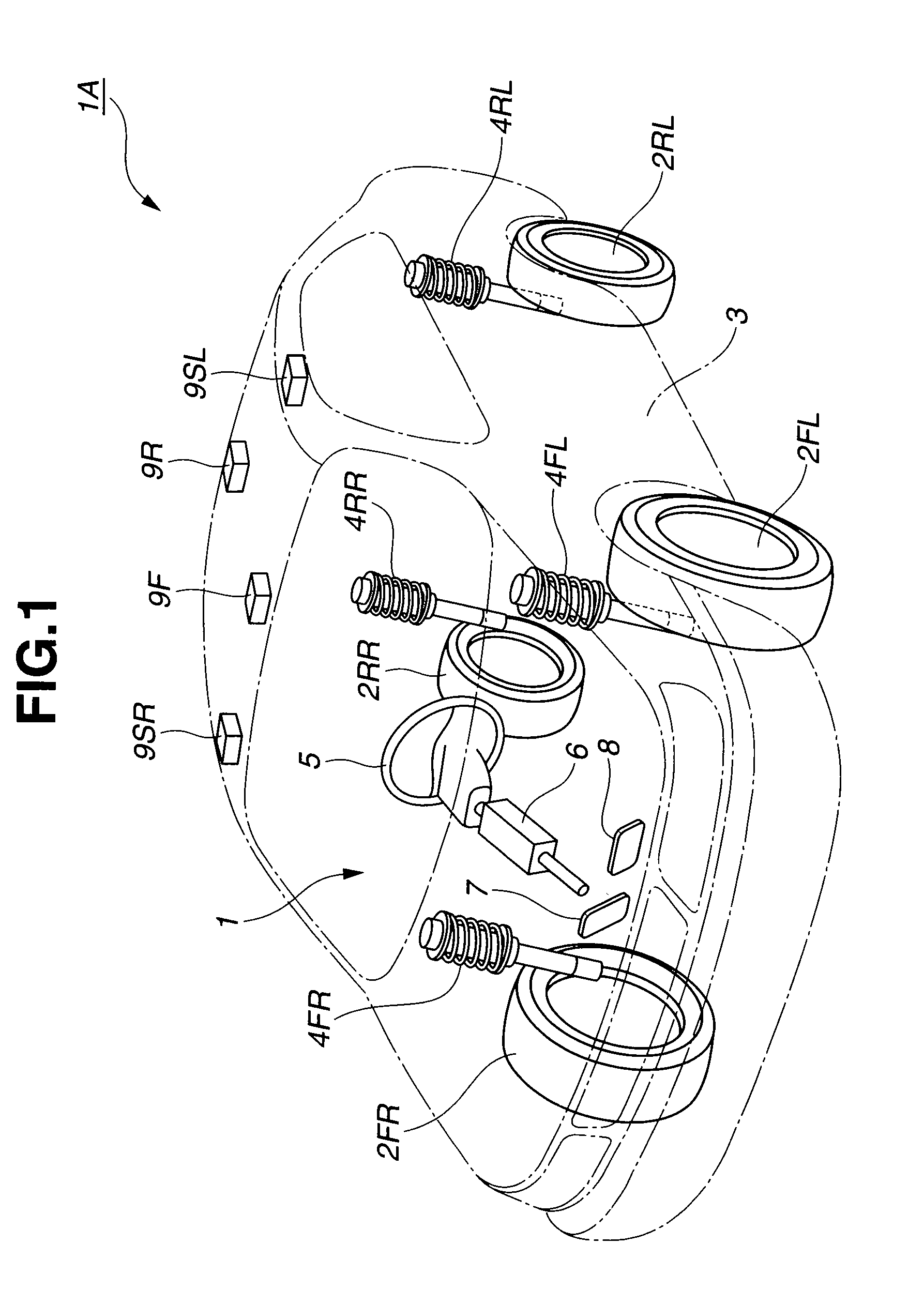

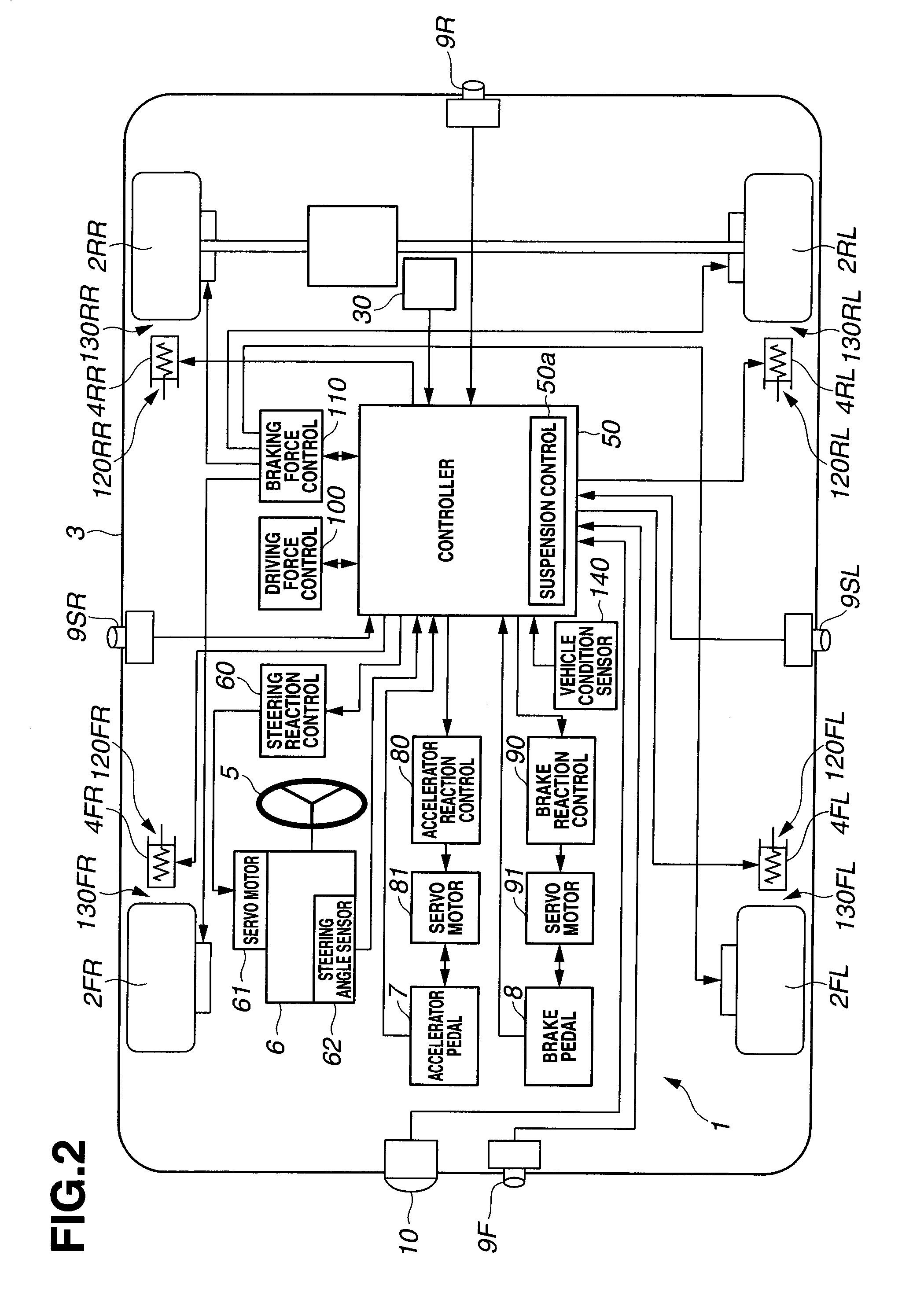

Vehicle driving operation support apparatus/process and cooperation control

ActiveUS20100222960A1Reduce riskSufficient supportVehicle testingVehicle seatsDriver/operatorVehicle behavior

A vehicle driving operation support apparatus for a vehicle, includes a sensing section to sense a traveling condition of the vehicle including a surrounding condition inclusive of an obstacle around the vehicle; and a control section to calculate a risk potential for the vehicle in accordance with the traveling condition. The control section performs a support control to support the driver in accordance with the risk potential, performs a first assist control to restrain disturbance (such as vibration from a road) transmitted to the driver in accordance with the risk potential, and performs a second assist control to produce inducement simulating a condition change (such as a vehicle behavior) attributable to an increase of the risk potential, in accordance with the risk potential. The control section further performs a cooperation control to coordinate the first assist control and the second assist control.

Owner:NISSAN MOTOR CO LTD

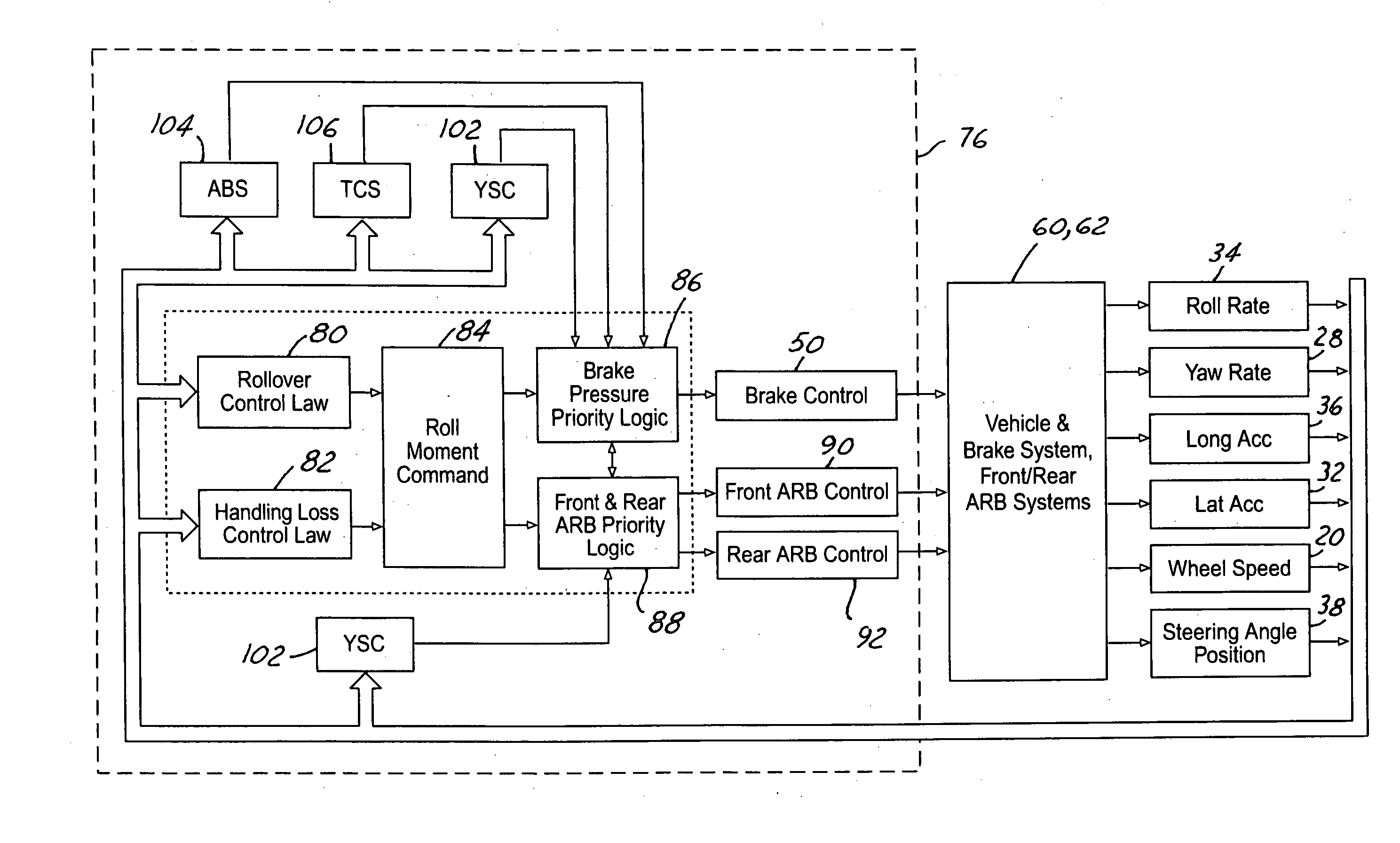

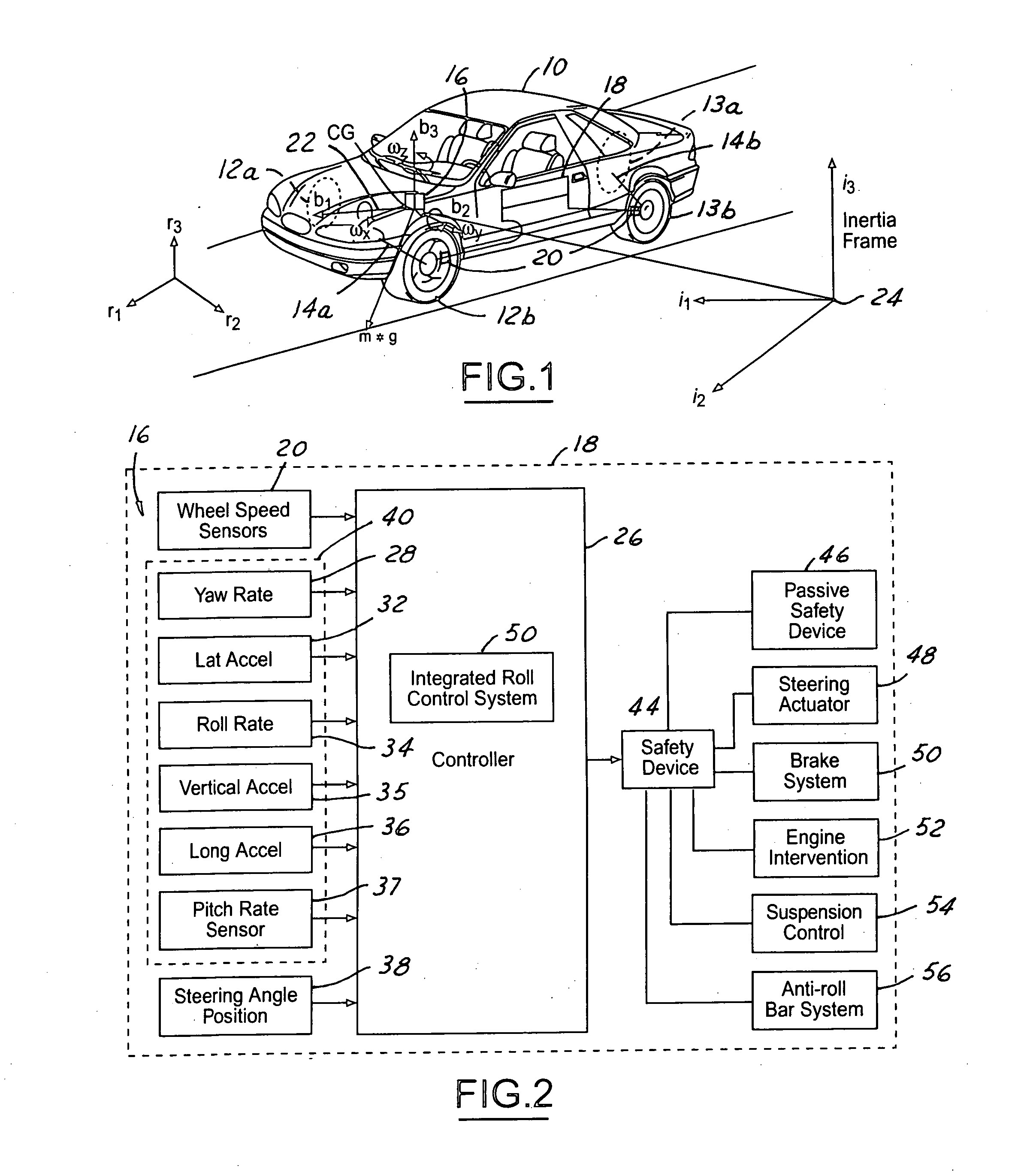

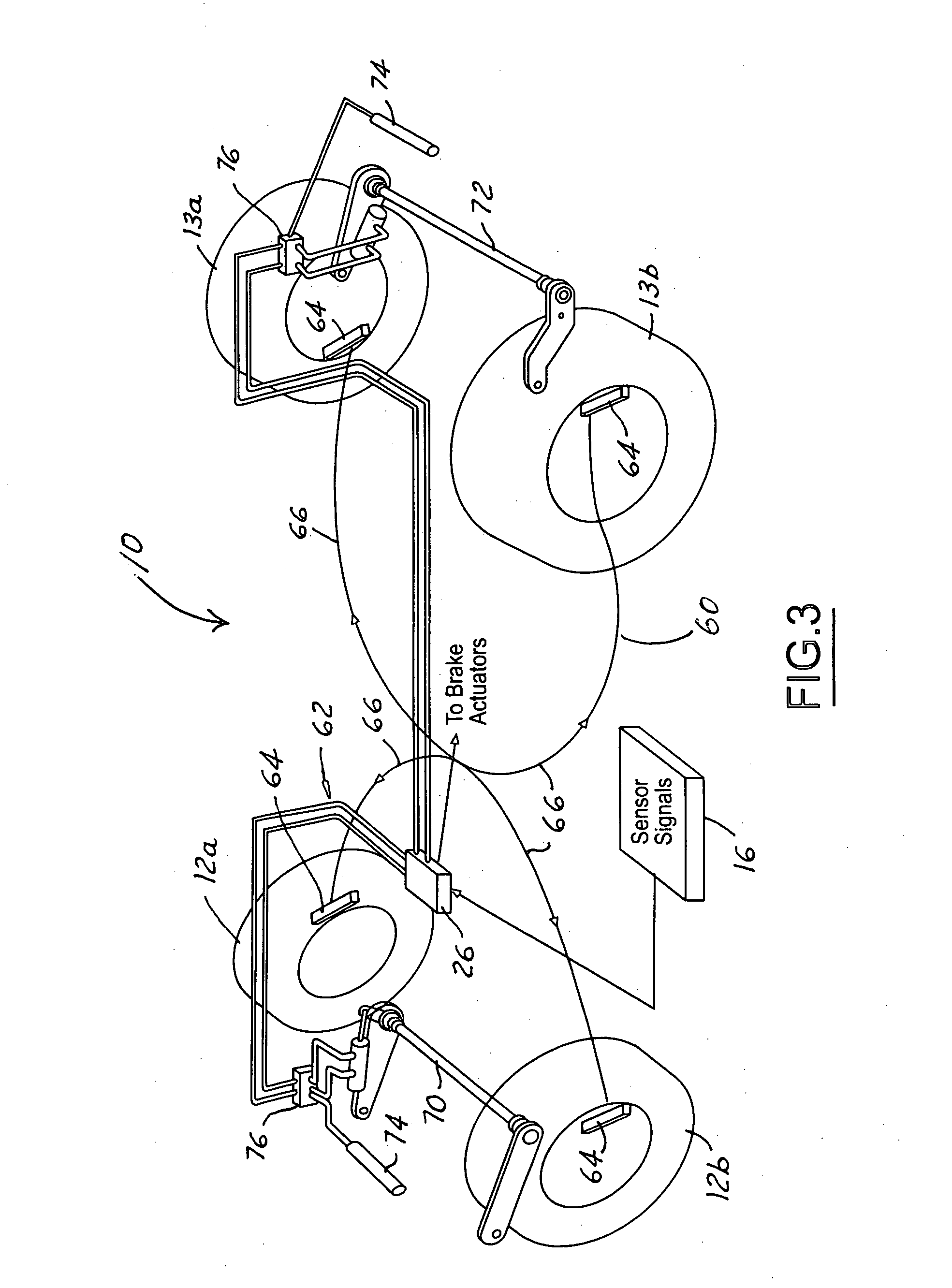

Roll stability control system for an automotive vehicle using coordinated control of anti-roll bar and brakes

InactiveUS20050131604A1Improve effective controlReduce anxietyDigital data processing detailsPedestrian/occupant safety arrangementRolloverAnti-roll bar

A roll stability control system (18) for an automotive vehicle (10) includes an active anti-roll bar system (62) and a rollover sensor (40) that generates a roll attitude signal indicative of a pending rollover of the vehicle. A controller (26) controls the active anti-roll bar system (62) to prevent the vehicle from rolling over in response to the roll attitude signal. The controller (26) may also control a brake system (60). The brake system may be used in addition to the active anti-roll bar system to prevent rollover of the vehicle.

Owner:FORD MOTOR CO +1

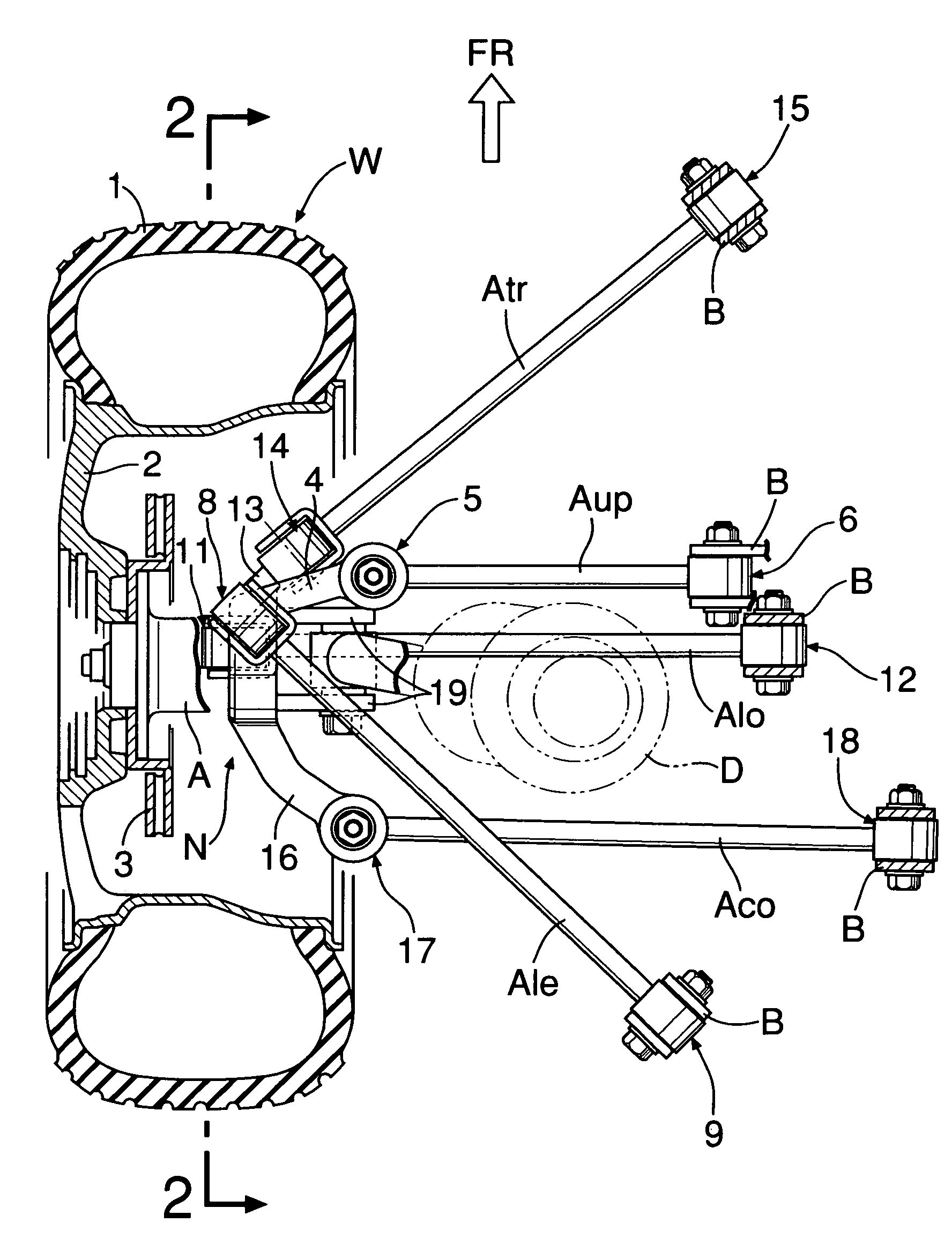

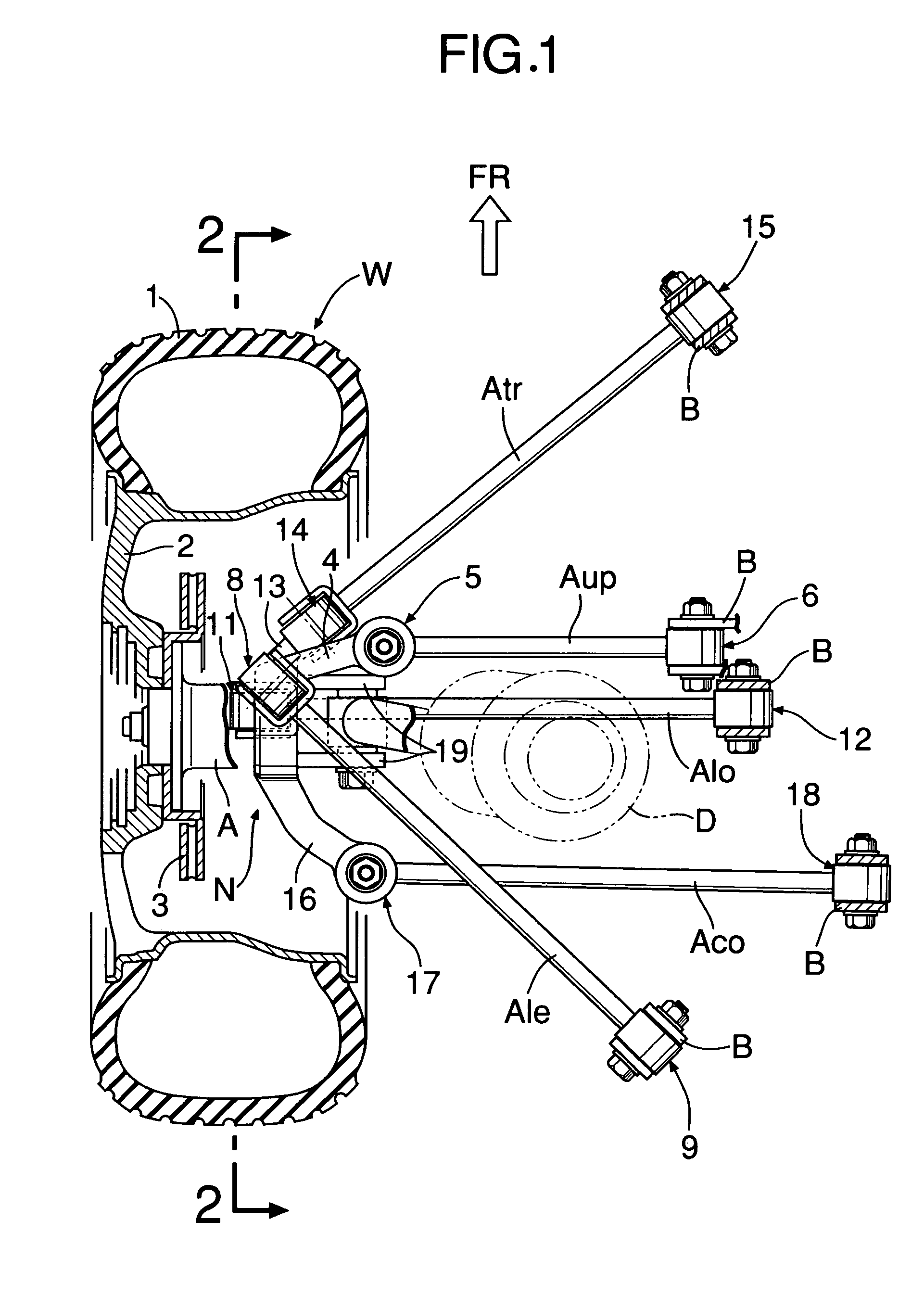

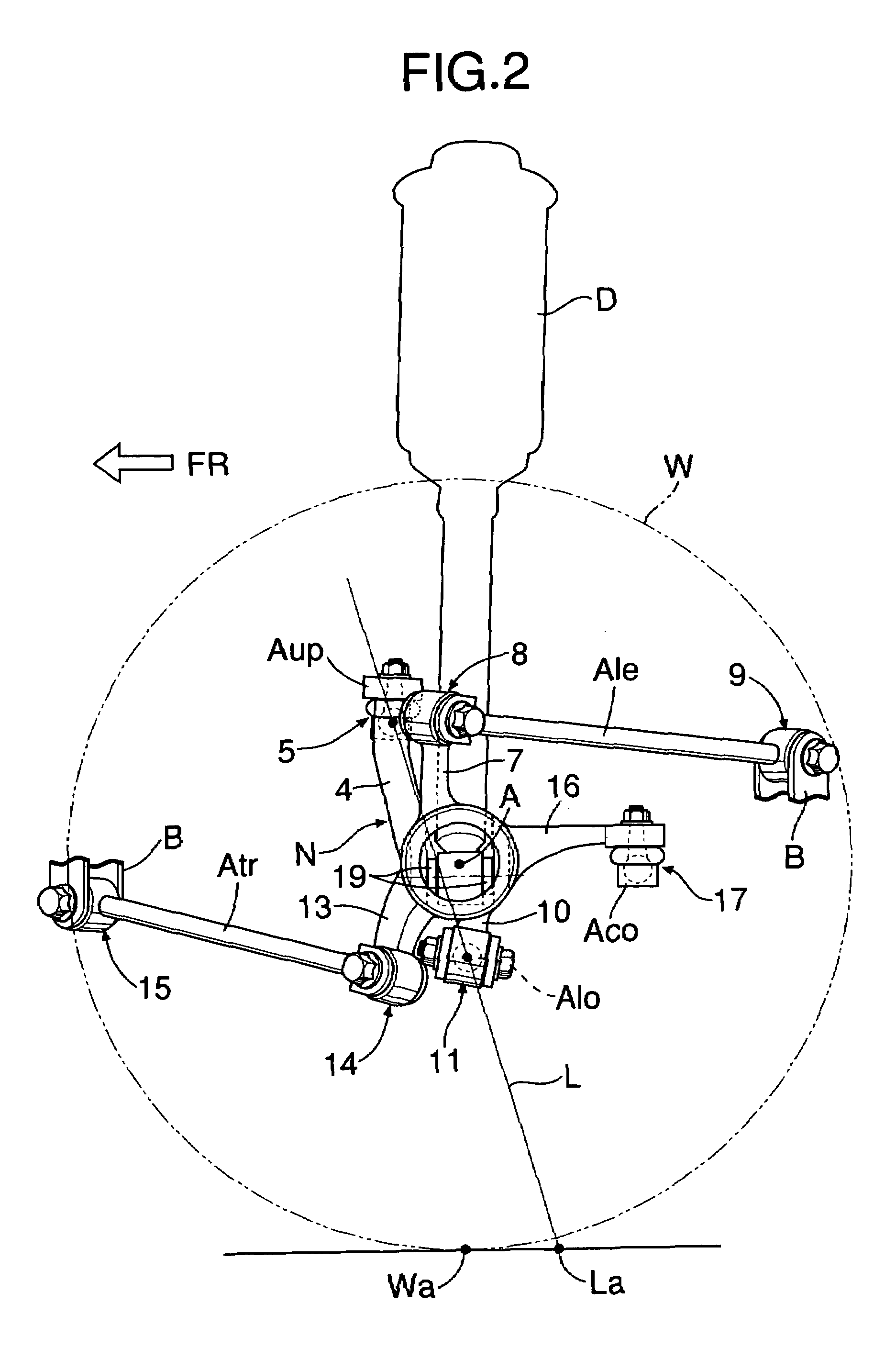

Vehicular rear suspension system

InactiveUS7258355B2Improve vehicle stabilityIncrease lateral stiffnessInterconnection systemsResilient suspensionsGround contactControl arm

A vehicular rear suspension system includes an upper arm, a lower arm, and a control arm, each of which is connected to a knuckle. A straight line passing through a ball joint and a rubber bushing joint intersects the road surface at an intersection point that is positioned behind a ground contact point of the rear wheel in the longitudinal direction of the vehicle body. The ball joint connects the upper arm to the knuckle, and the rubber bushing joint connects the lower arm to the knuckle. Longitudinal elastic coefficients of the three arms are set in a predetermined relationship. Therefore, the intersection point at which an elastic kingpin intersects the road surface is positioned without fail behind a point of action of a lateral force when turning in the longitudinal direction of the vehicle body to achieve a lateral force toe-in and enhanced steering stability of the vehicle.

Owner:HONDA MOTOR CO LTD

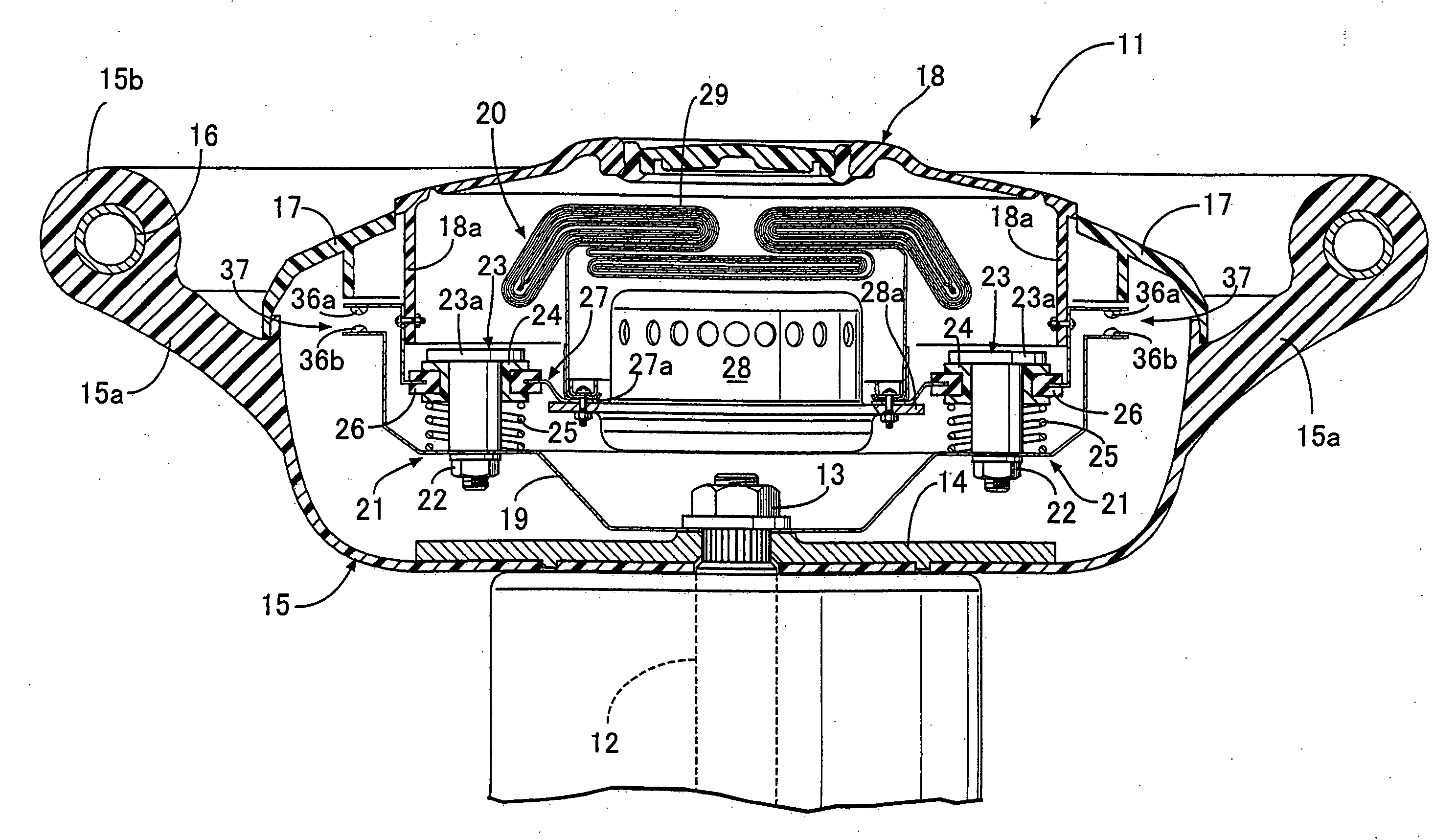

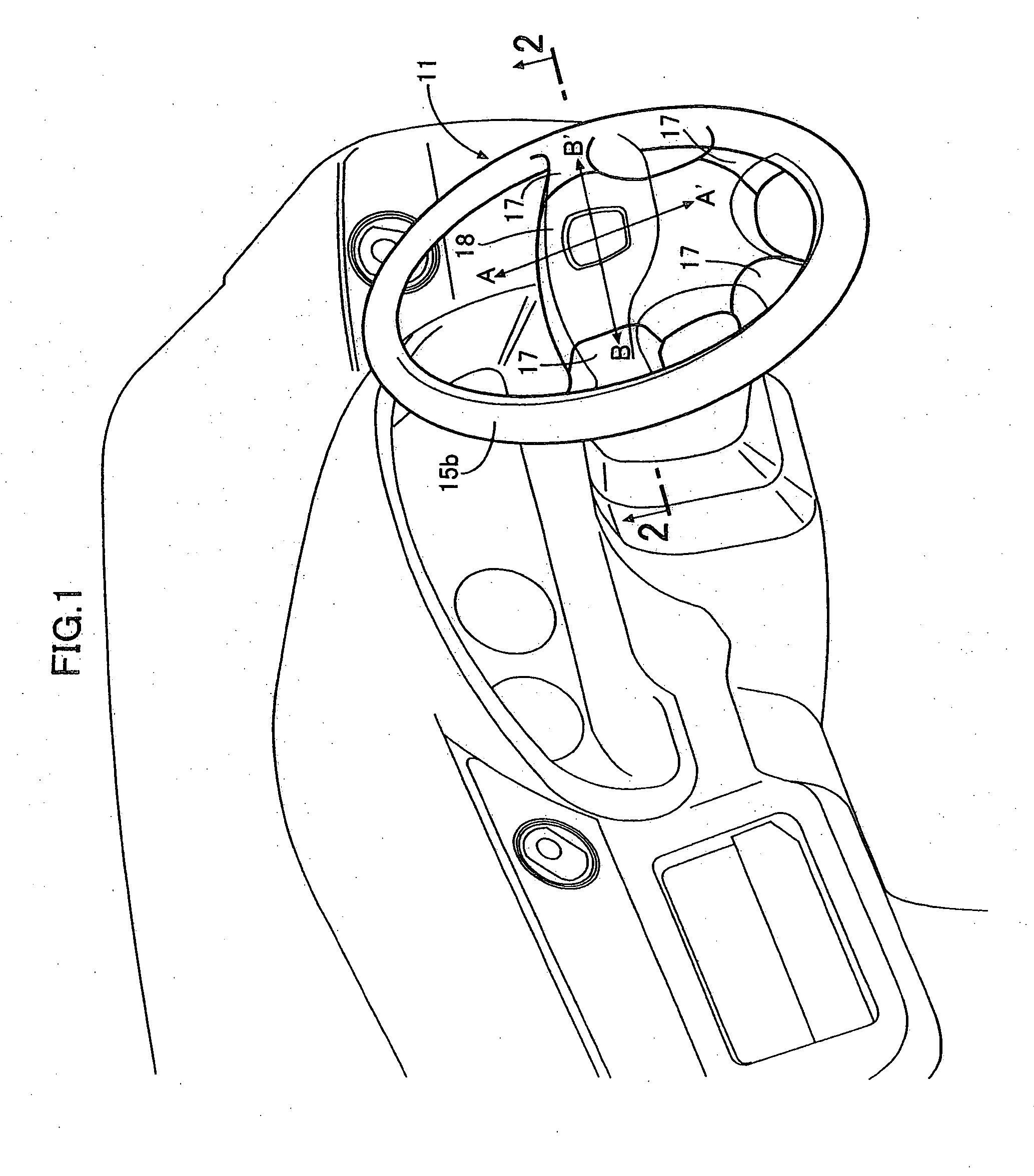

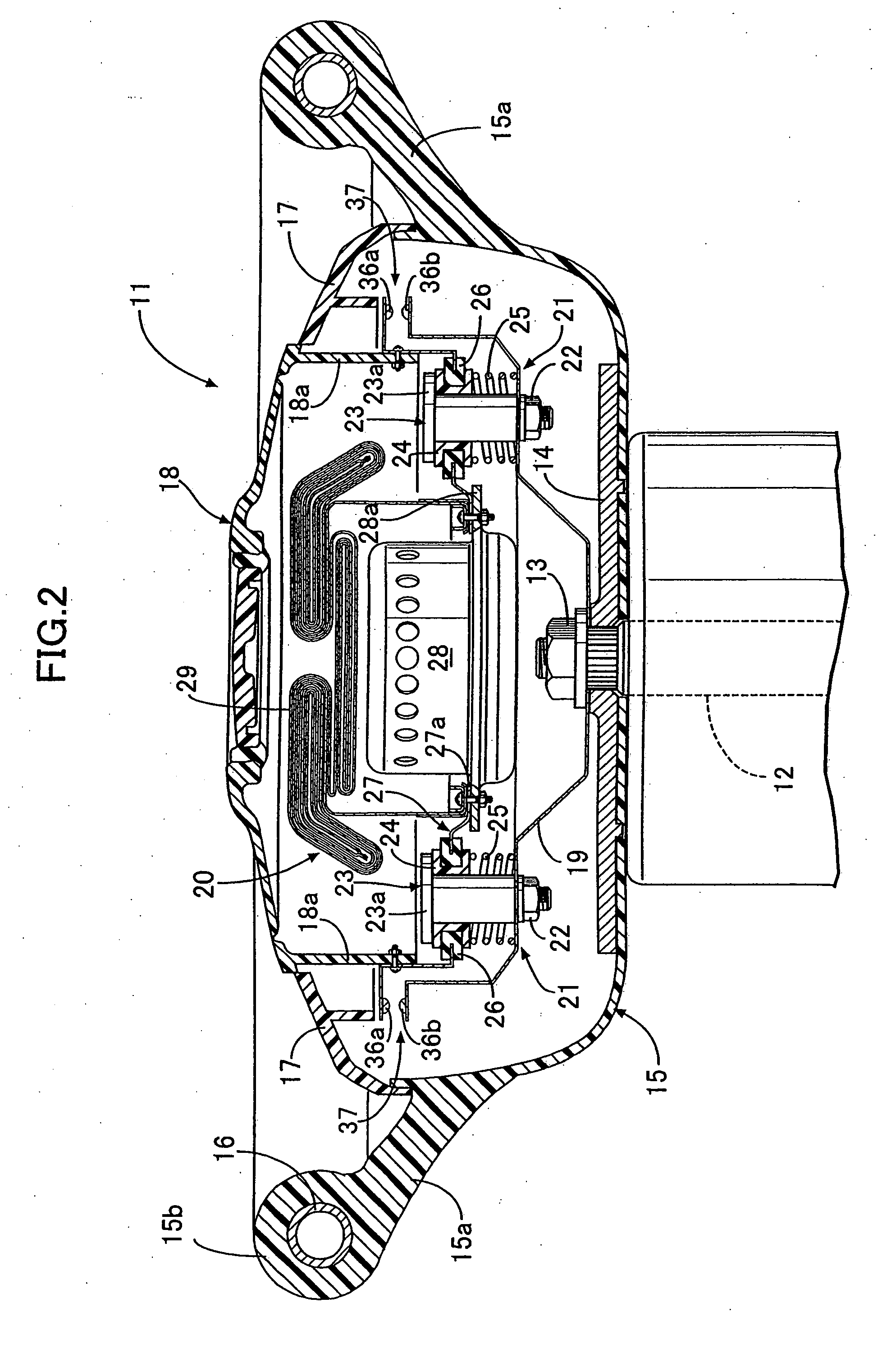

Vibration Reducing Structure for steering wheel

ActiveUS20090218739A1Reduce vibrationAffecting operabilityPortable framesHand wheelsSteering wheelCoil spring

A slider 24 is supported on a holder 19 of a steering wheel 11 via a coil spring 25 so as to be movable in a direction of an axis while an air bag module 20 is supported on a slider 24 via a damper spring 26 so as to be movable in a direction perpendicular to the axis. Since the coil spring 25 does not affect vibration of the air bag module 20 in the direction perpendicular to the axis, it is possible to set a spring constant of the coil spring 25 at a value appropriate for the operation of a horn switch 37, and to set a spring constant of the damper spring 26 at a value appropriate for the operation of the dynamic damper. As a result, it is possible to effectively reduce the vibration of the steering wheel 11 in the direction perpendicular to the axis with the dynamic damper without affecting the operability of the horn switch 37.

Owner:HONDA MOTOR CO LTD +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com