Patents

Literature

58 results about "Computer optimization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Computer optimization may mean: Solving optimization problem using a computer. Optimizing the performance of a computer system via hardware tuning and/or adjusting some operating system-related settings either directly or using a piece of computer system optimization software. e.g., using disk defragmentation software.

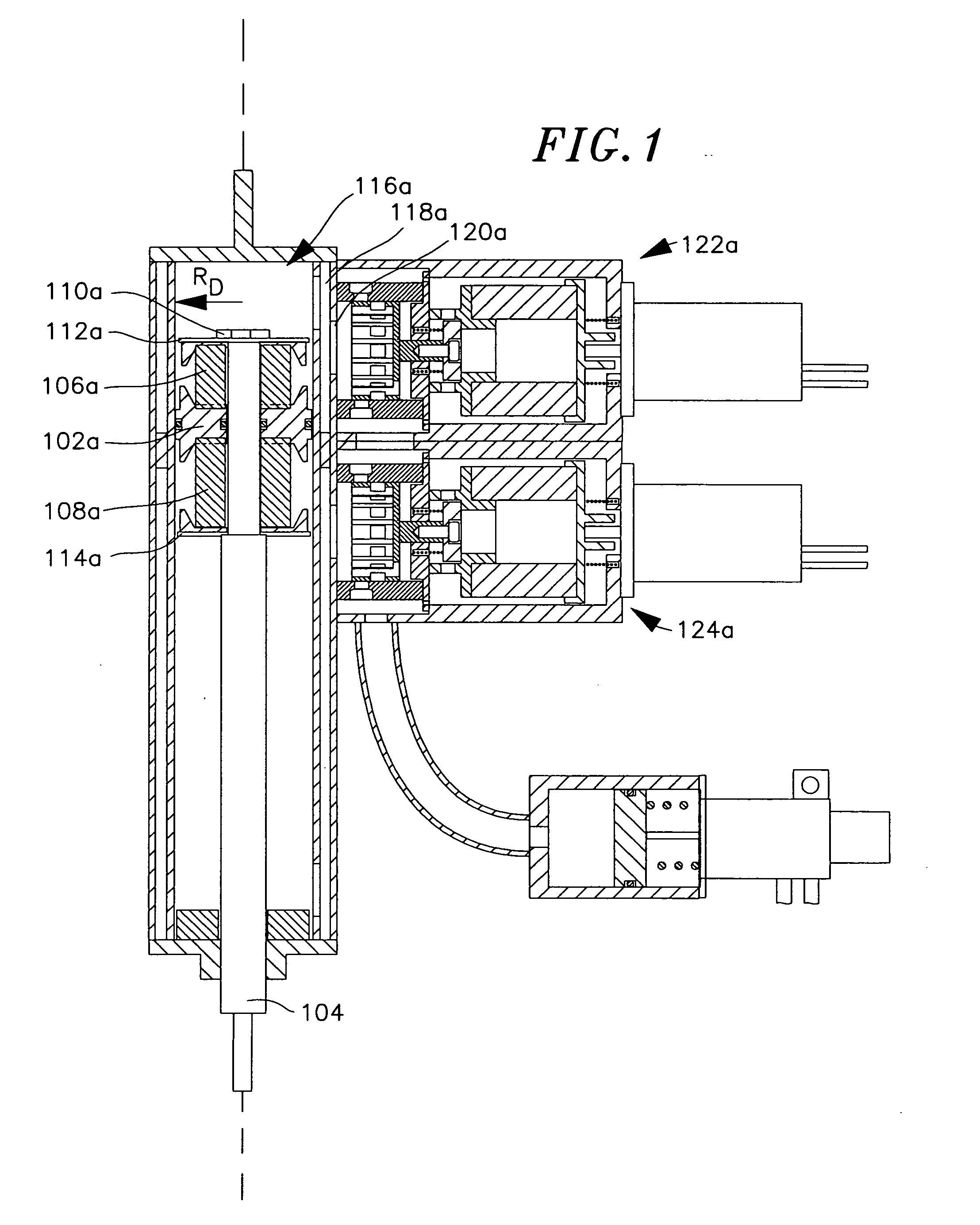

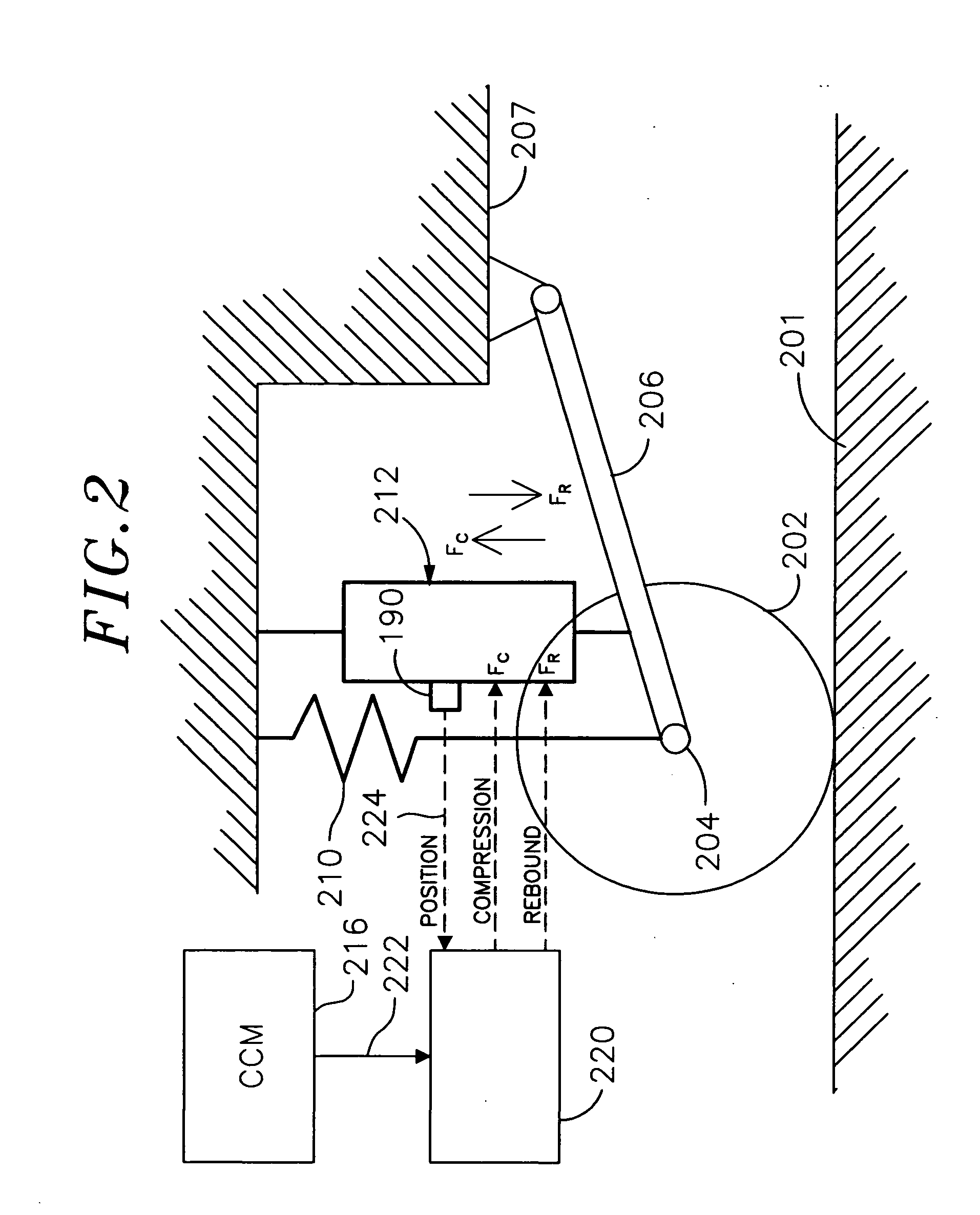

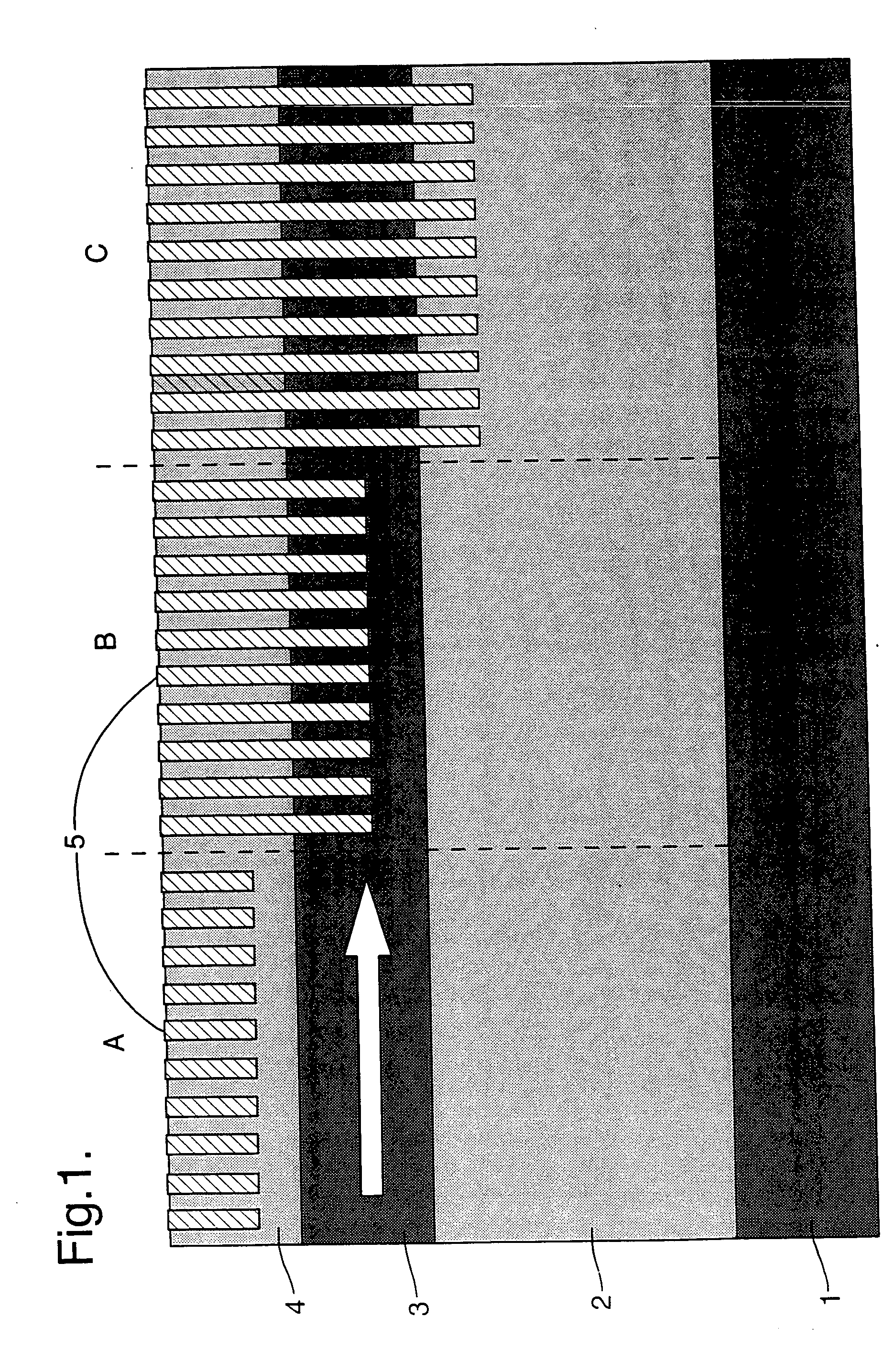

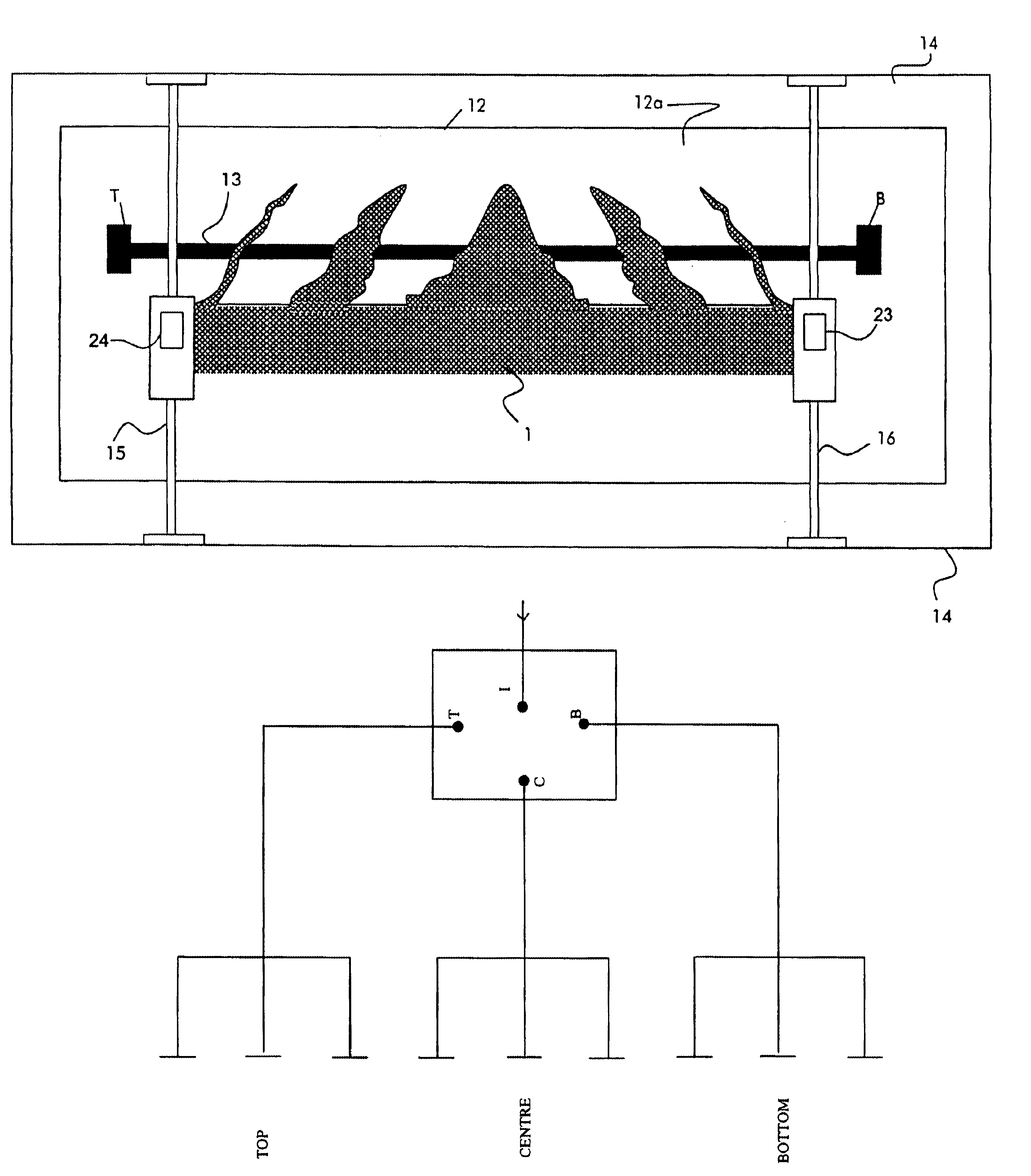

Enhanced computer optimized adaptive suspension system and method

InactiveUS7076351B2Minimizing body motionIncrease fluid pressureAuxillary drivesFunctional valve typesComputer optimizationControl signal

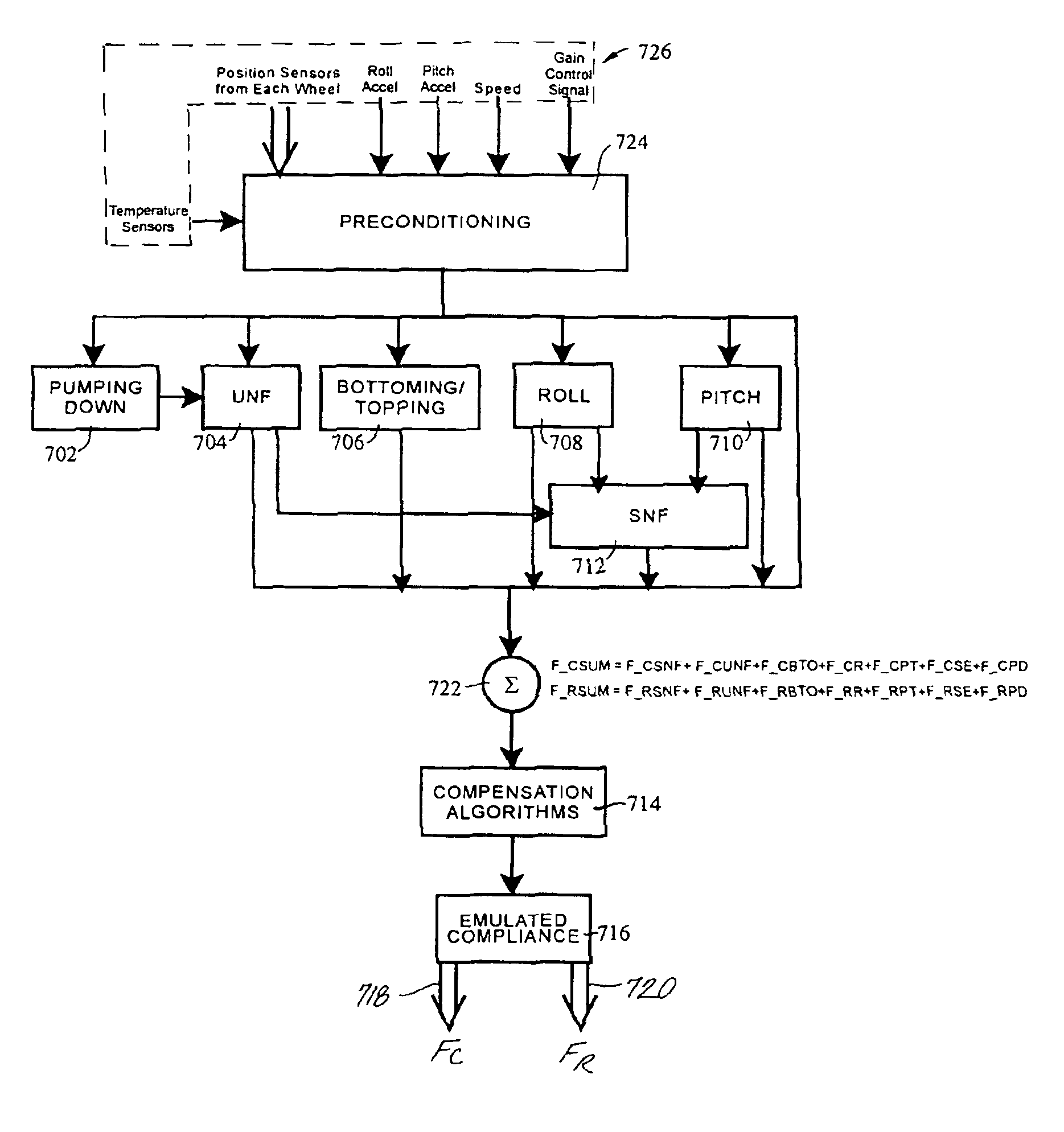

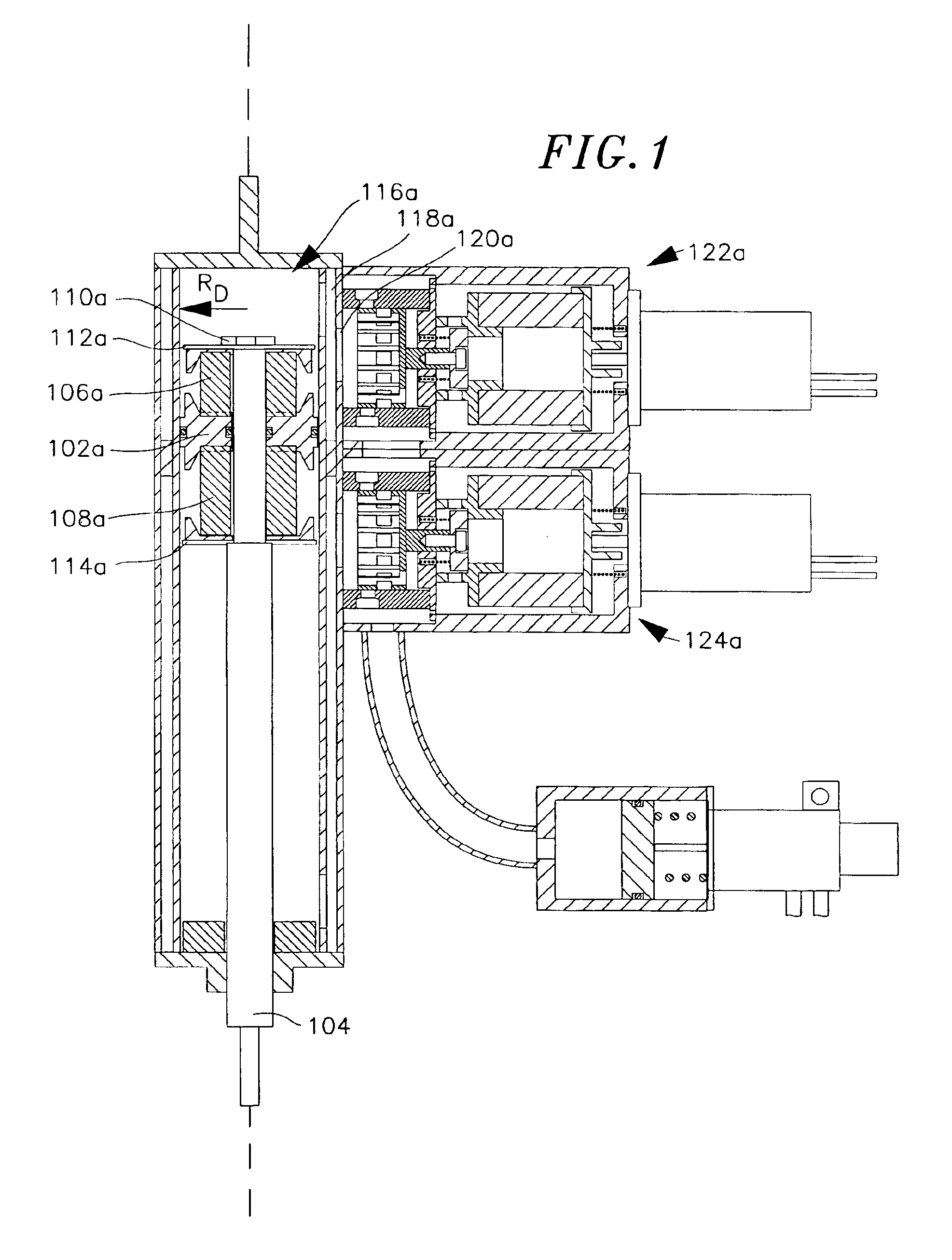

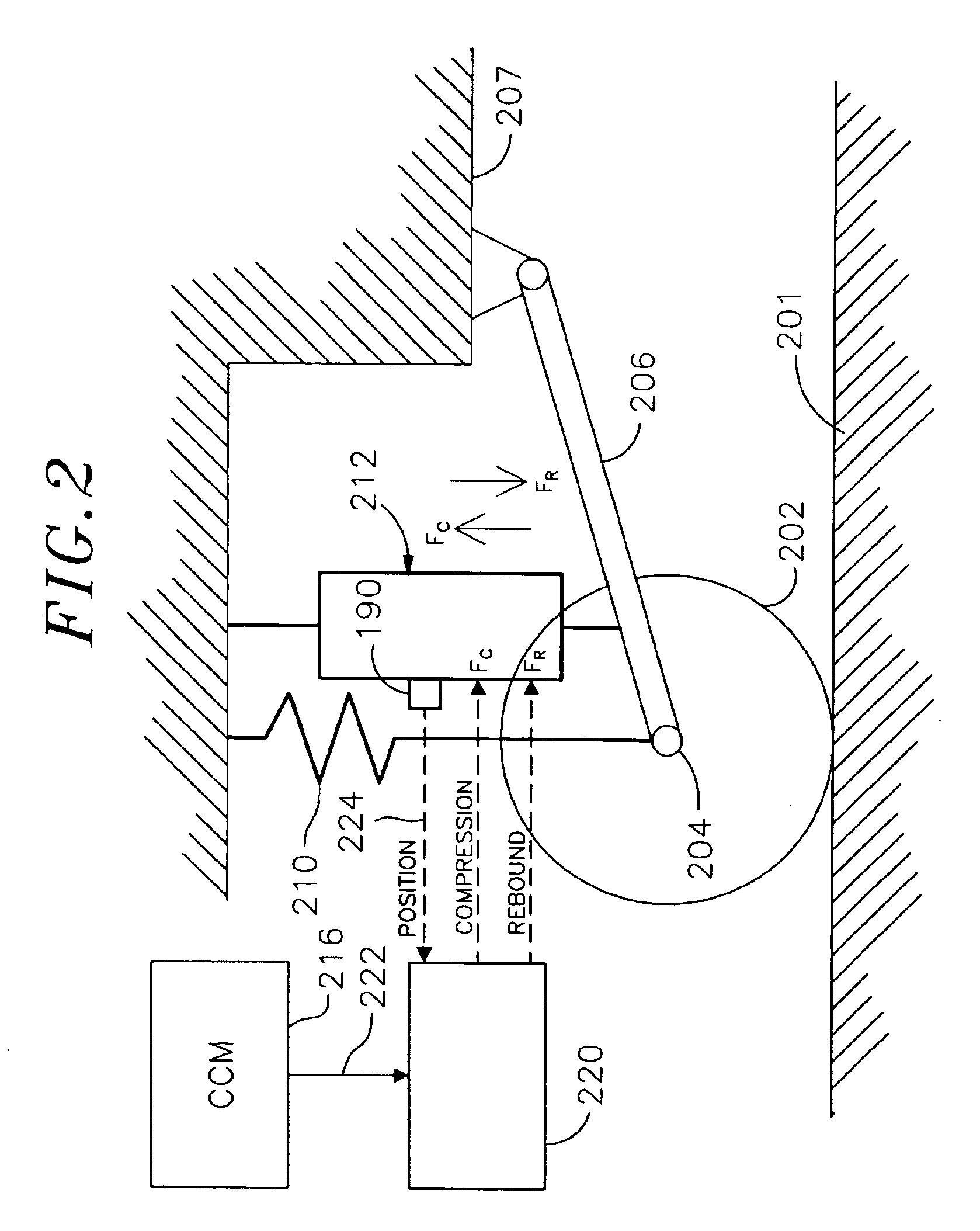

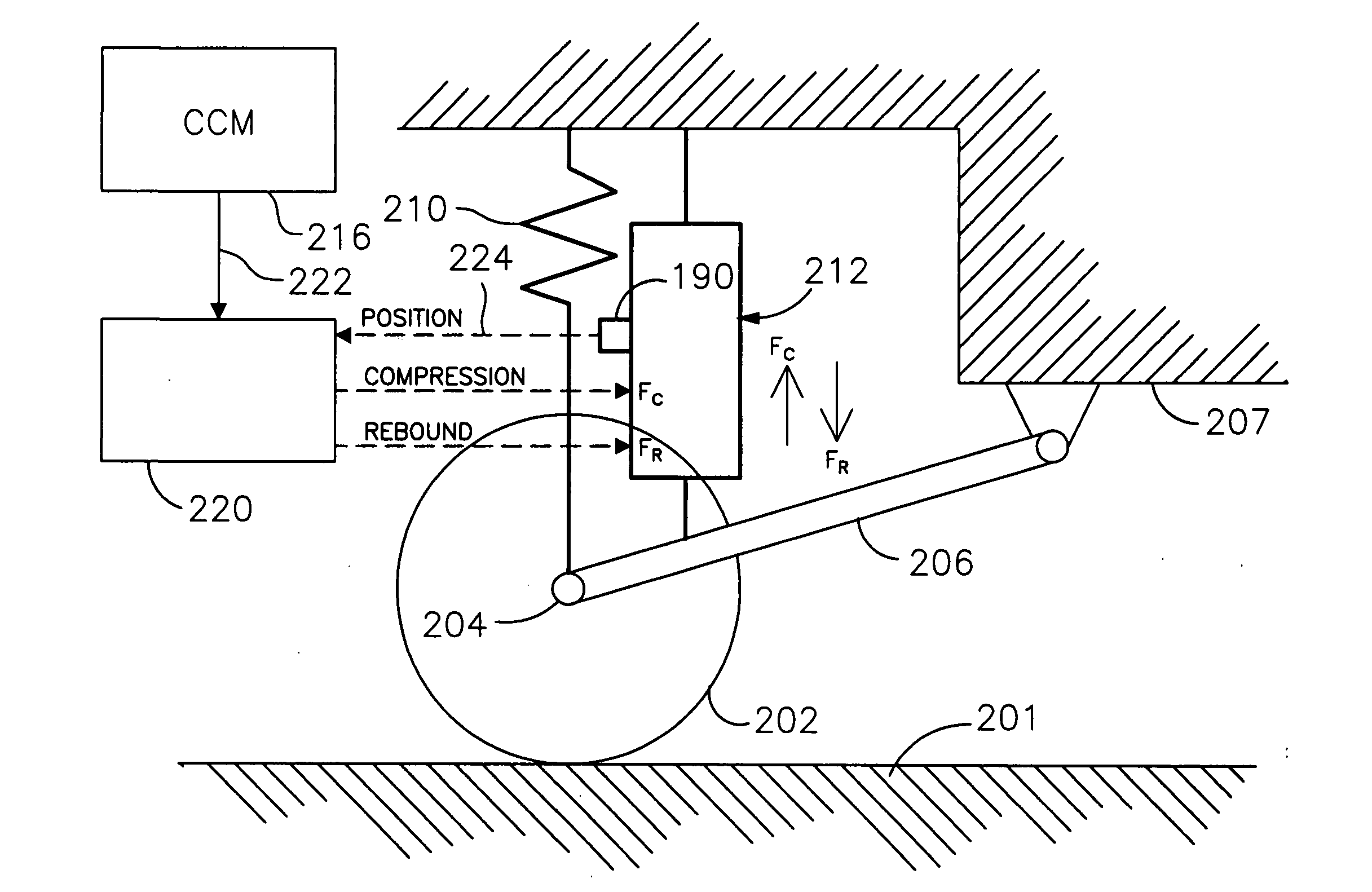

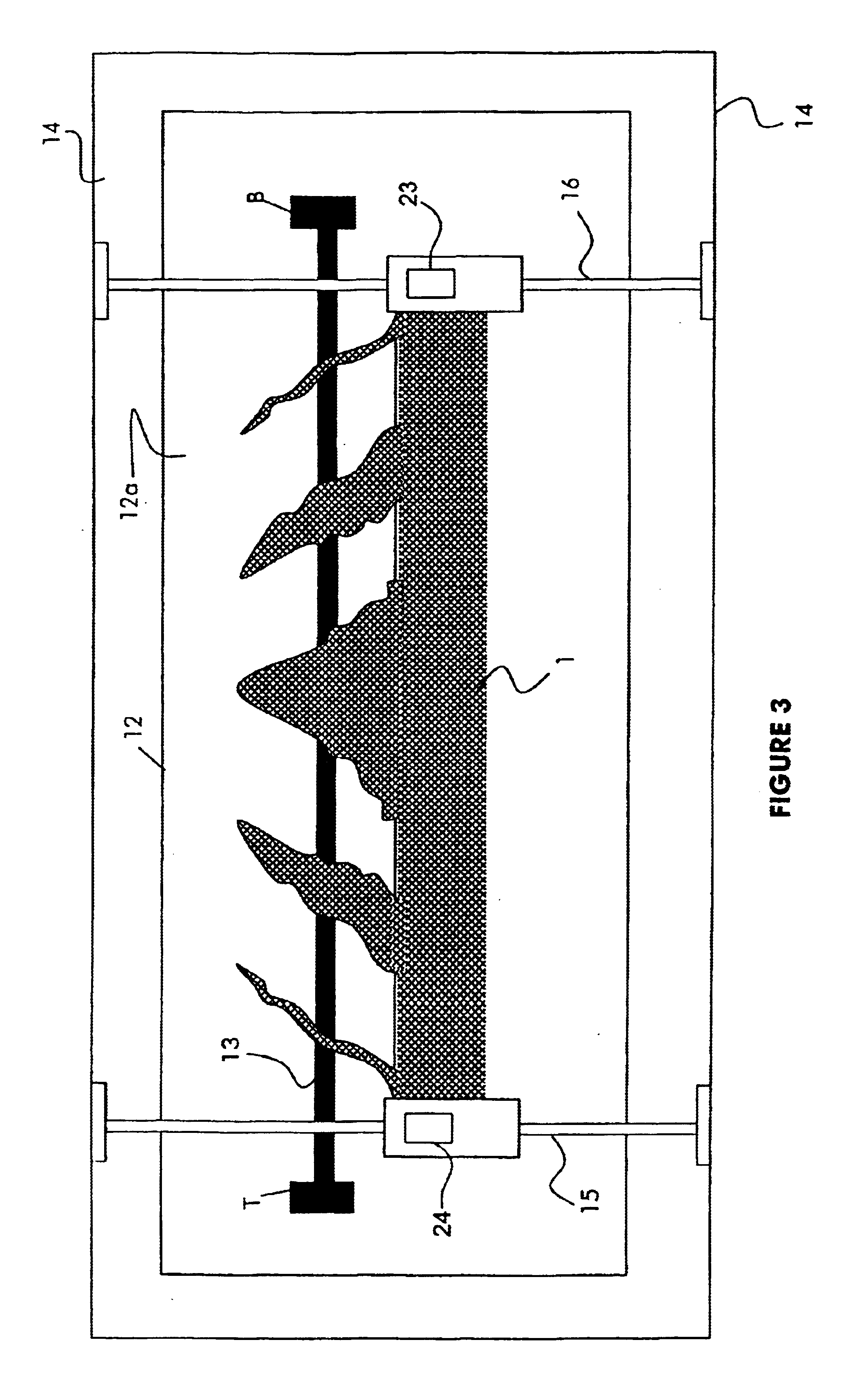

A system and method for controlling a damping system. The system has at least two dampers for damping between sprung and unsprung masses in the compression and rebound directions. Sensors generate signals based on position and other parameters of motion representative of the displacement between the sprung and unsprung masses. The process determines the appropriate compression and rebound forces to be applied at the wheels. A regulator responds to at least one of the independent compression and rebound control signals for adjusting, respectively, at least one of compression and rebound resisting forces of the dampers between the masses. Compliance for the dampers is emulated with software to produce the desired compliance forces. The distributed controller includes a processor that is responsive to signals representative of the position signals for forming the compression and rebound control signals for the regulator as a function of motion between the masses or a motion of a vehicle in which the dampers are located. The system has the capability of locking the suspension when parked.

Owner:WICKA JOHN D +1

Enhanced computer optimized adaptive suspension system and method

InactiveUS20050098401A1Minimizing body motionIncrease fluid pressureOperating means/releasing devices for valvesSpringsComputer optimizationControl signal

A system and method for controlling a damping system. The system has at least two dampers for damping between sprung and unsprung masses in the compression and rebound directions. Sensors generate signals based on position and other parameters of motion representative of the displacement between the sprung and unsprung masses. The process determines the appropriate compression and rebound forces to be applied at the wheels. A regulator responds to at least one of the independent compression and rebound control signals for adjusting, respectively, at least one of compression and rebound resisting forces of the dampers between the masses. Compliance for the dampers is emulated with software to produce the desired compliance forces. The distributed controller includes a processor that is responsive to signals representative of the position signals for forming the compression and rebound control signals for the regulator as a function of motion between the masses or a motion of a vehicle in which the dampers are located. The system has the capability of locking the suspension when parked.

Owner:GREAT NORTHERN TECH

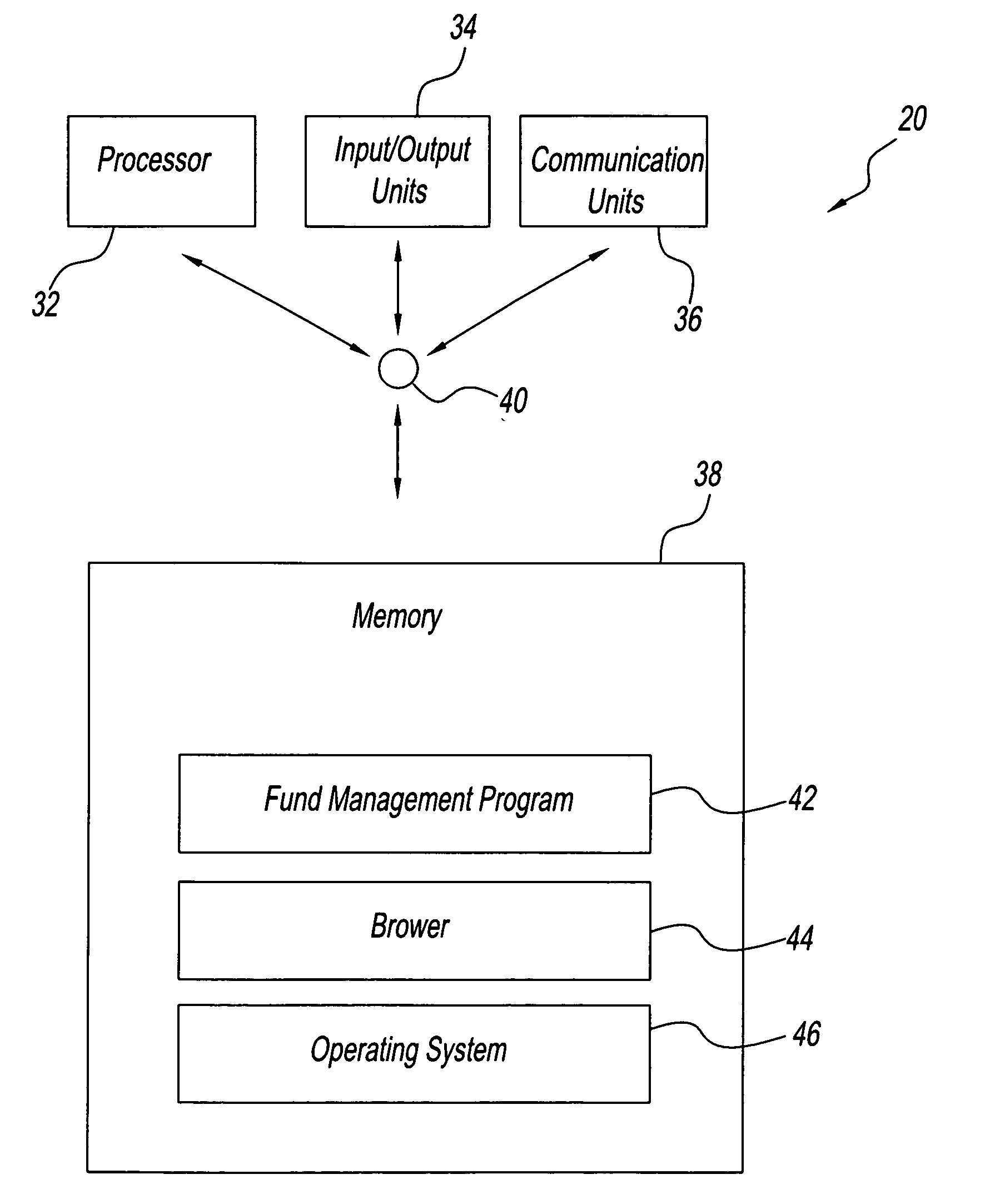

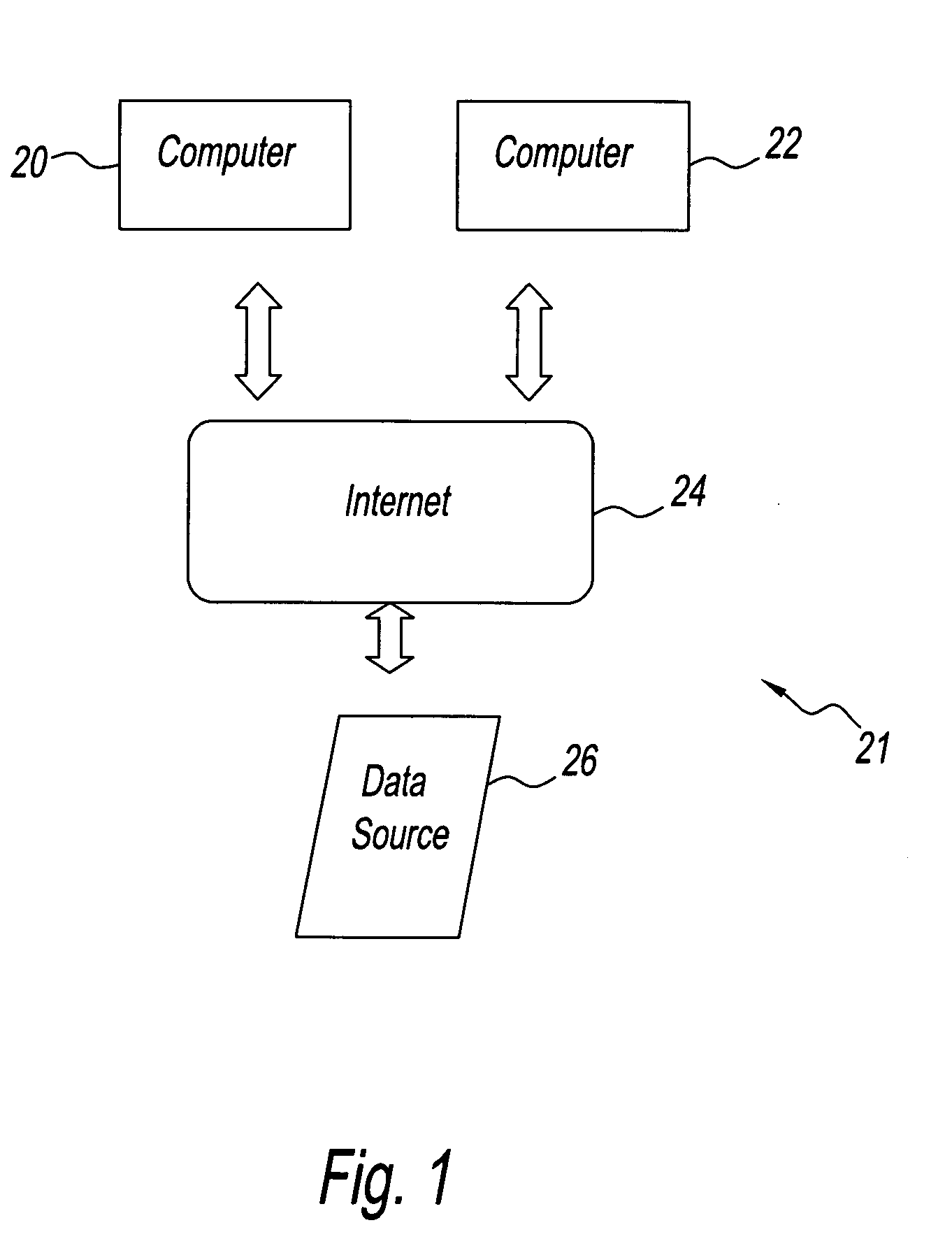

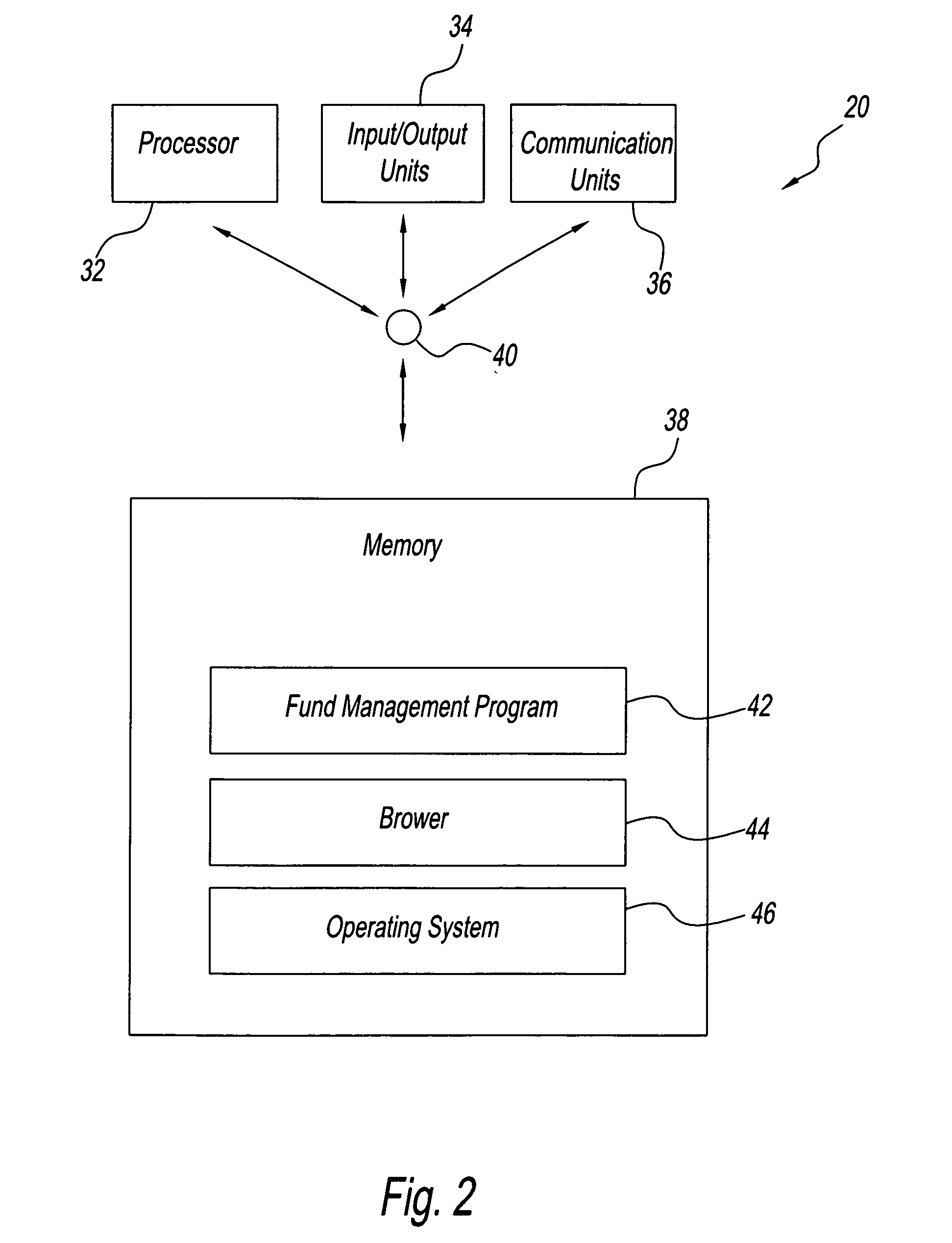

Fund management system and method

A dynamic and flexible method, system and apparatus for managing index mutual funds and index exchange traded funds (ETFs) through using and measuring Relative Strengths and Alphas of the underlying index components to periodically reweight the underlying index components. These reweightings are used in the daily rebalancing of the respective index mutual funds / ETFs to decrease market risk and seek to improve returns above those of the statically weighted index. The disclosure demonstrates how various mutual fund / ETF indexes are flexibly weighted according to Relative Strength and Alpha calculations each standing alone or used in combination. The determination of the relative weights of Relative Strength and Alpha can be made periodically by management using a back testing and computer optimization process. After periodic determination of index component weights the mutual fund / ETF index portfolio rebalancing can occur daily, multiple intervals intraday, or any interval which conforms to regulatory requirements. Portfolios suitable for this method and apparatus include equity, bonds, or hybrids (equity and bonds).

Owner:MCDOW RONALD A

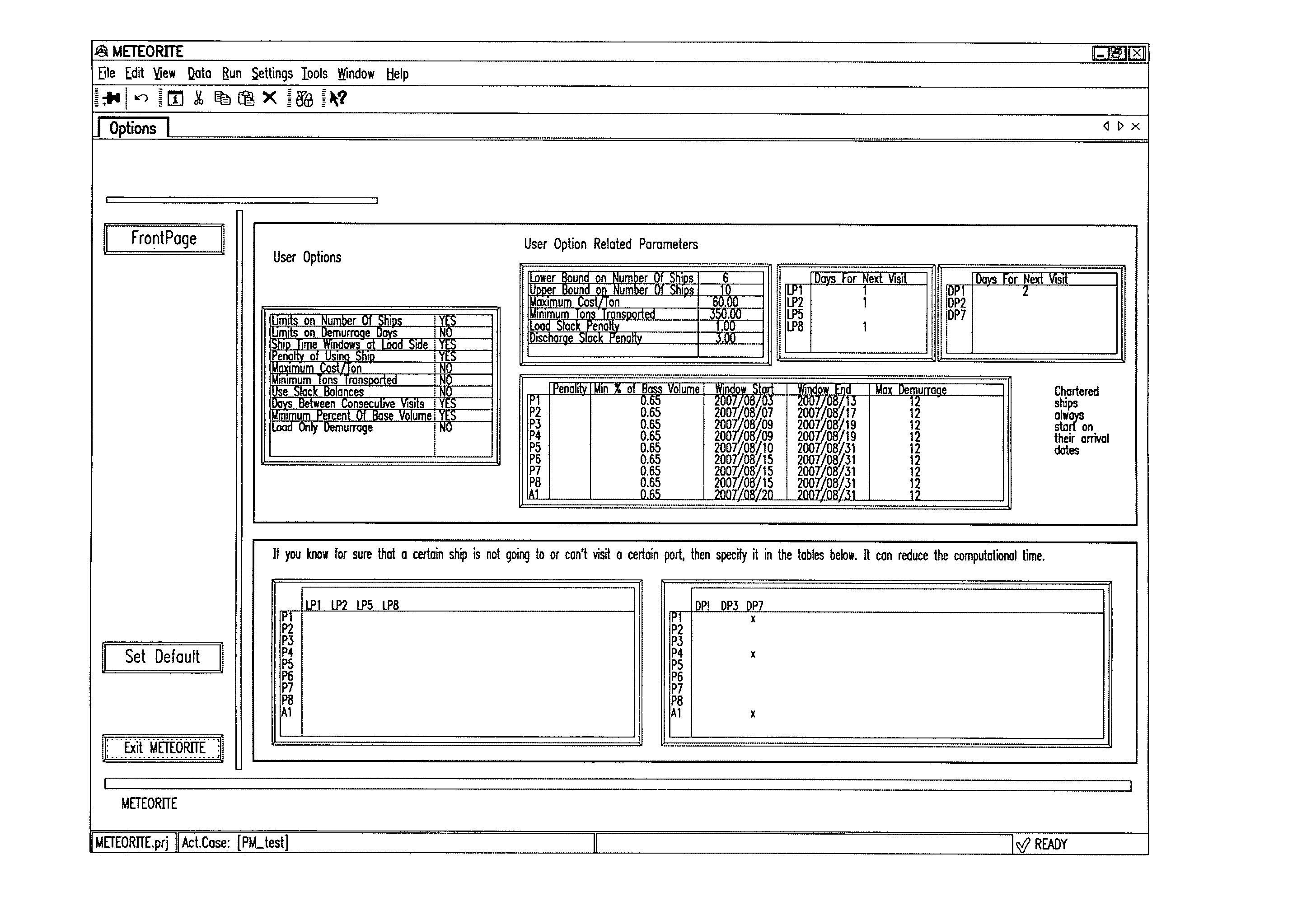

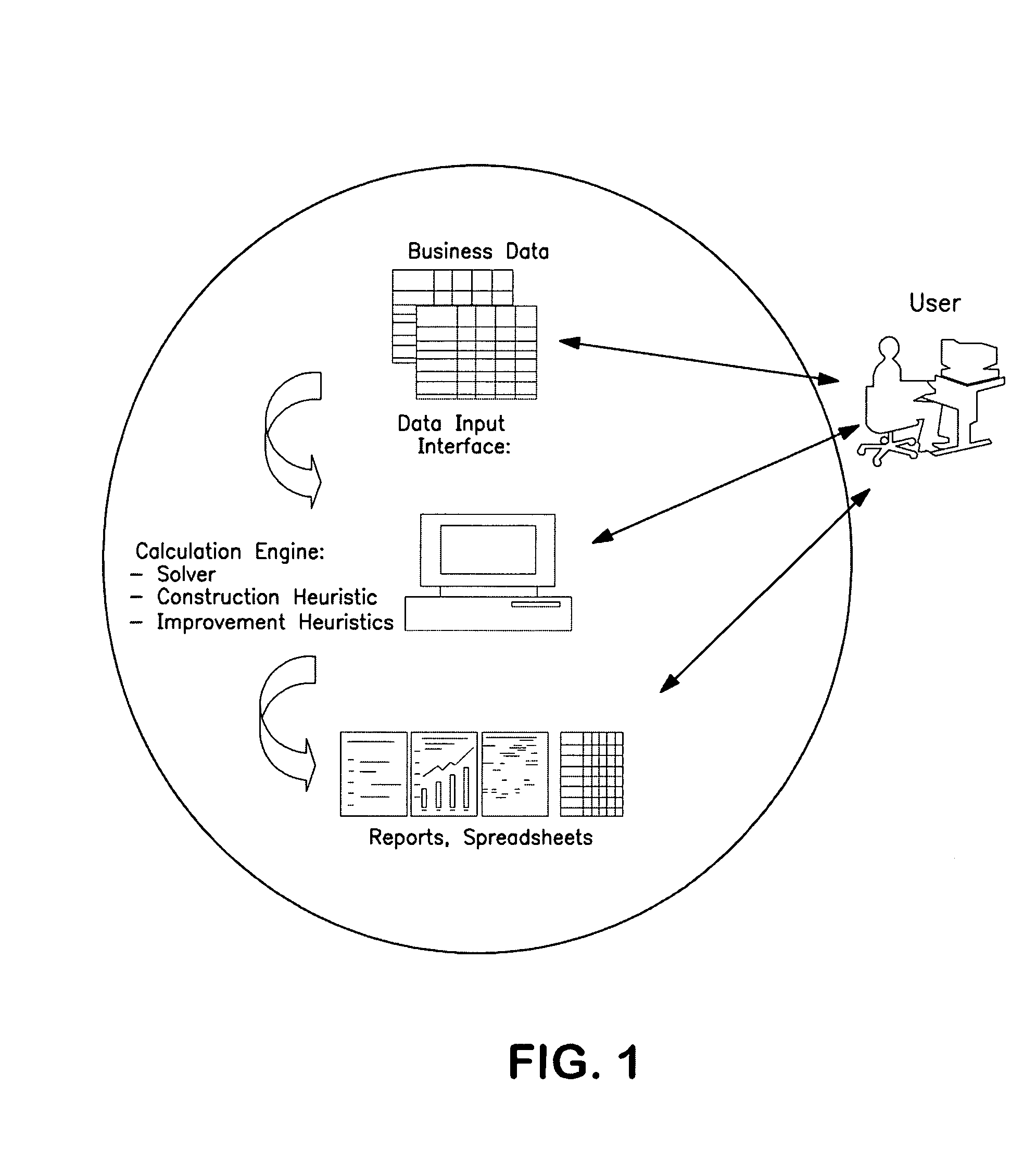

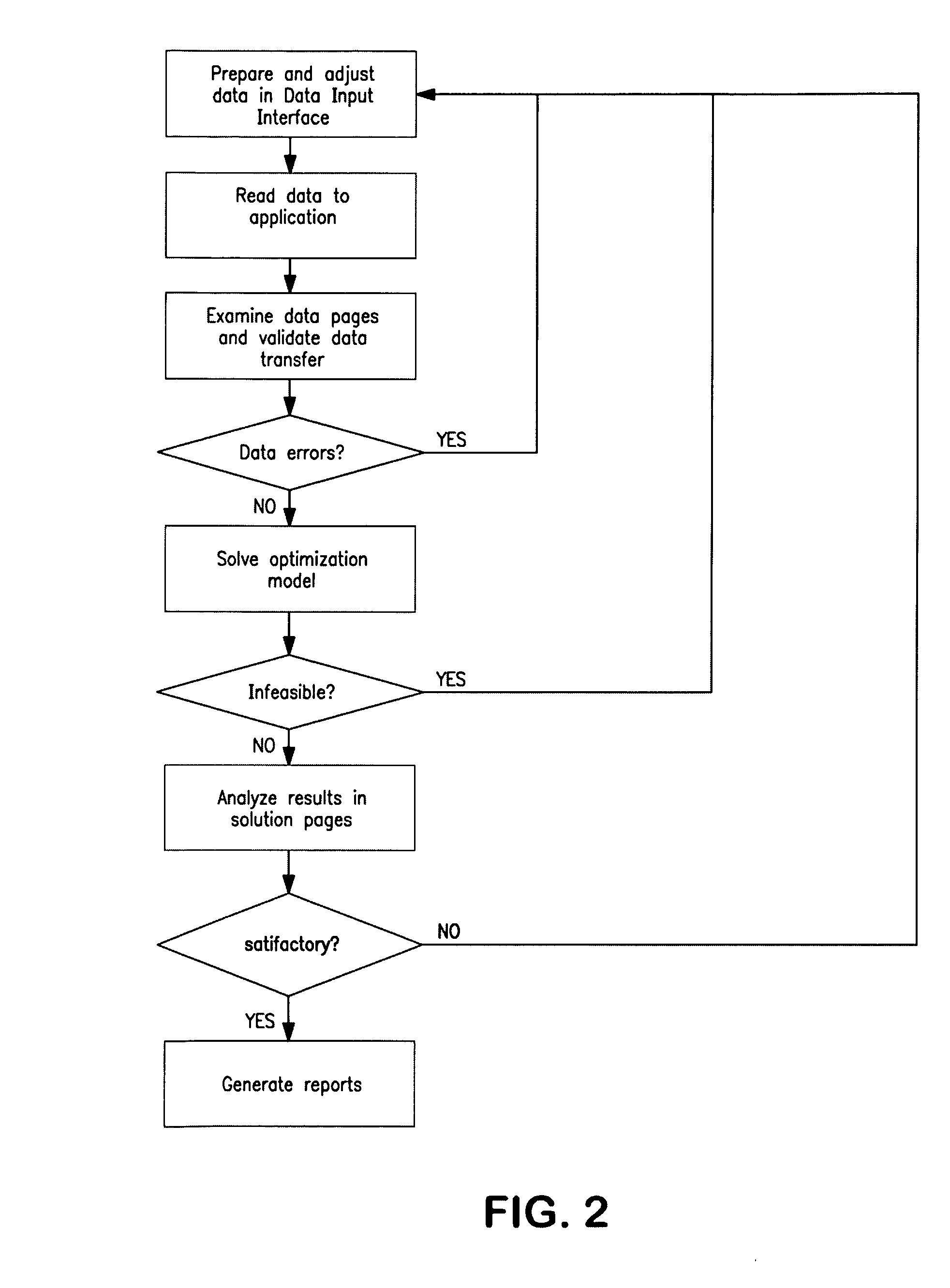

System for optimizing bulk product allocation, transportation and blending

ActiveUS20090192864A1Increase valueAugment deficitForecastingLogisticsComputer optimizationApplication software

A computer application loaded on a computer readable medium, a computer apparatus comprising the same, and process employing the same, is described herein. The computer application, when executed, causes a computer to optimize, for maximum net profit margin, the product allocation, transportation routing, transportation vehicle / route scheduling and, optionally, blending, of bulk products that are produced by and loaded from supply locations and delivered to and consumed by demand locations, using a heterogeneous fleet of transportation vehicles over a pre-defined period of time.

Owner:EXXON RES & ENG CO

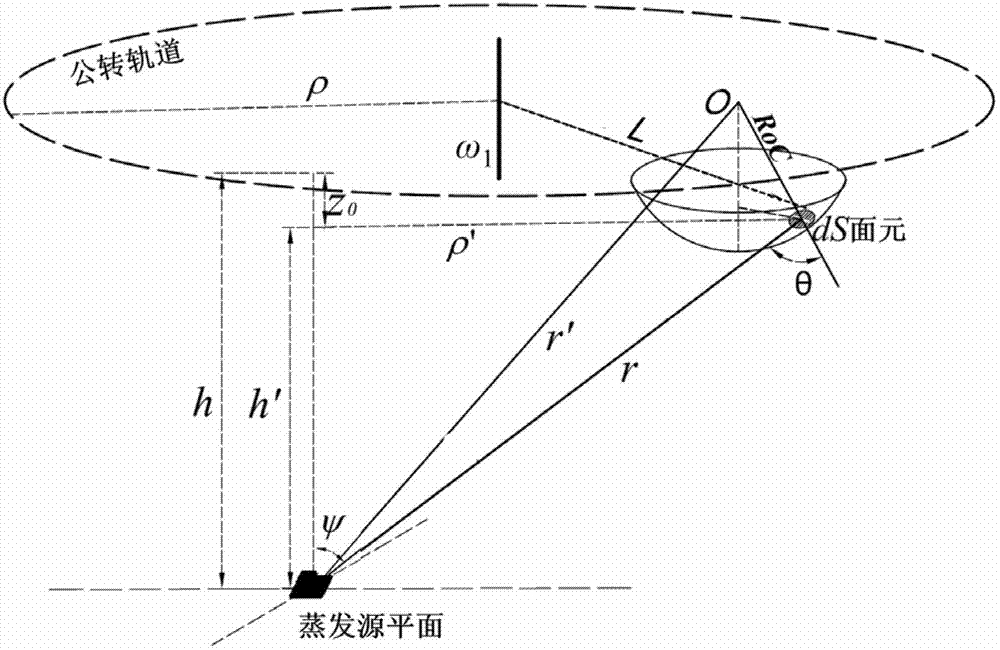

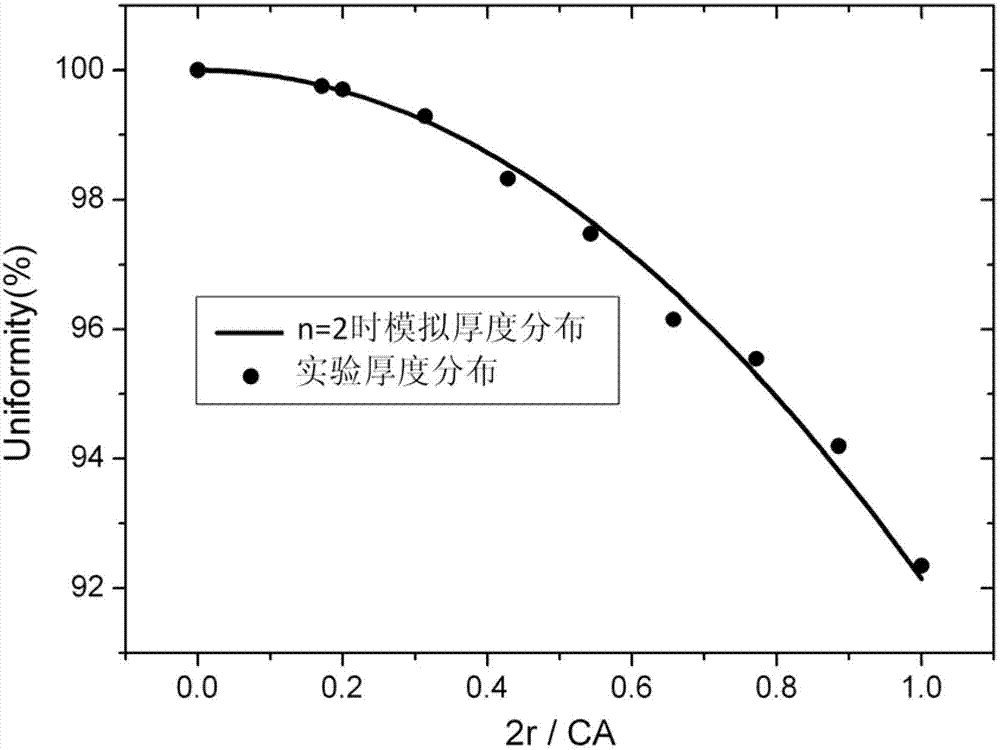

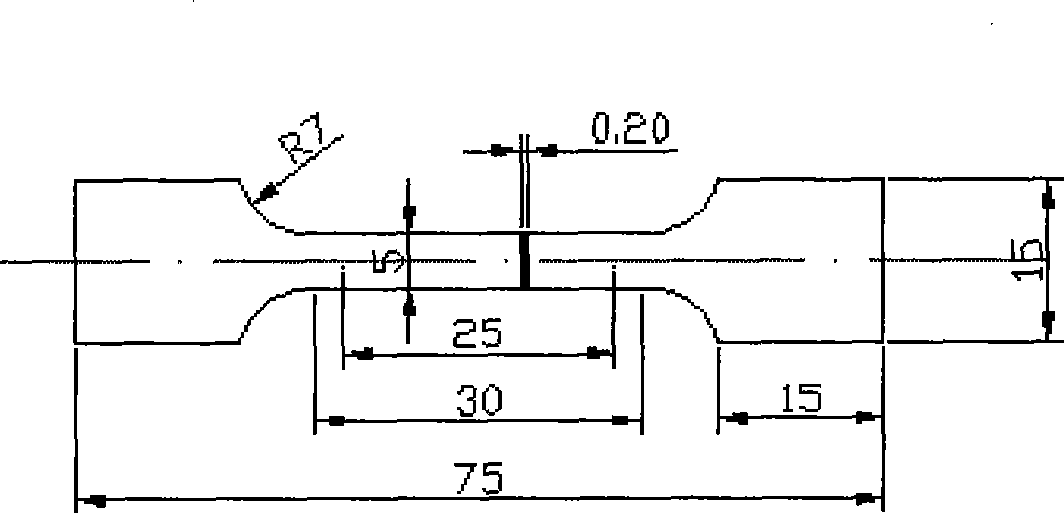

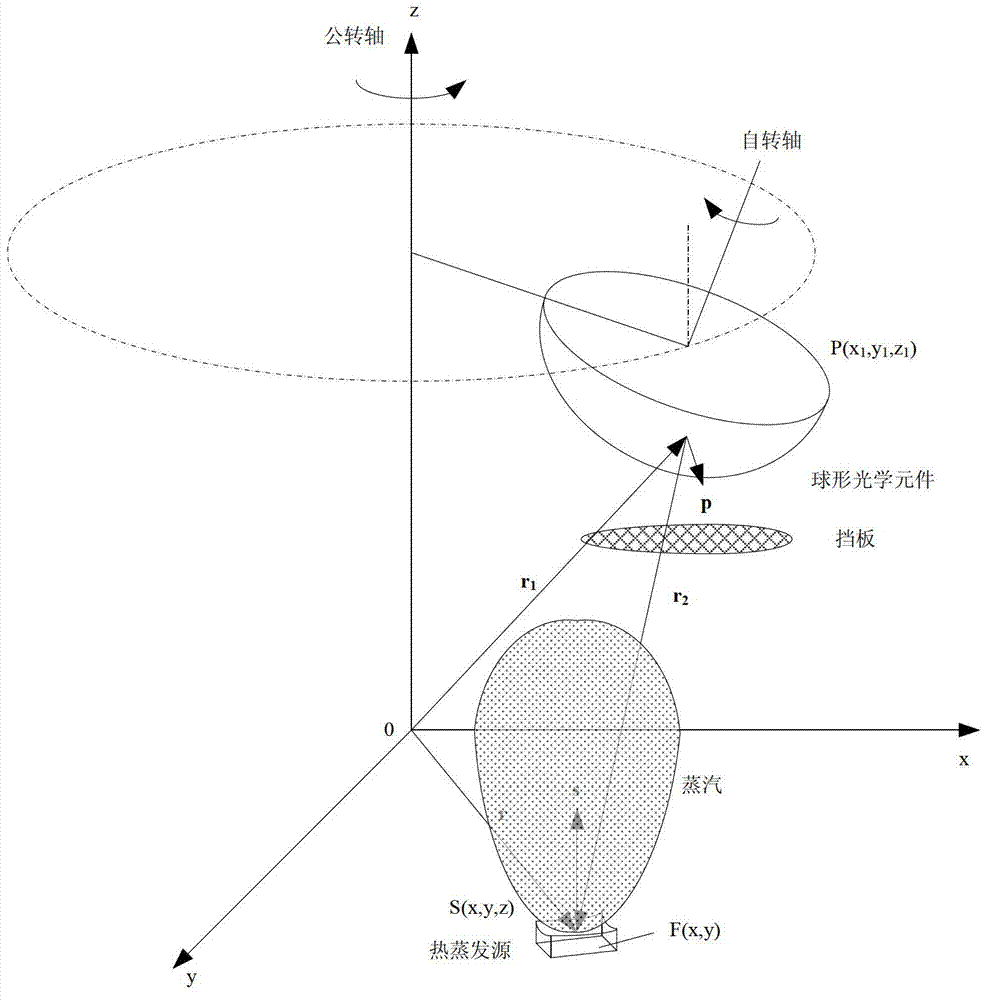

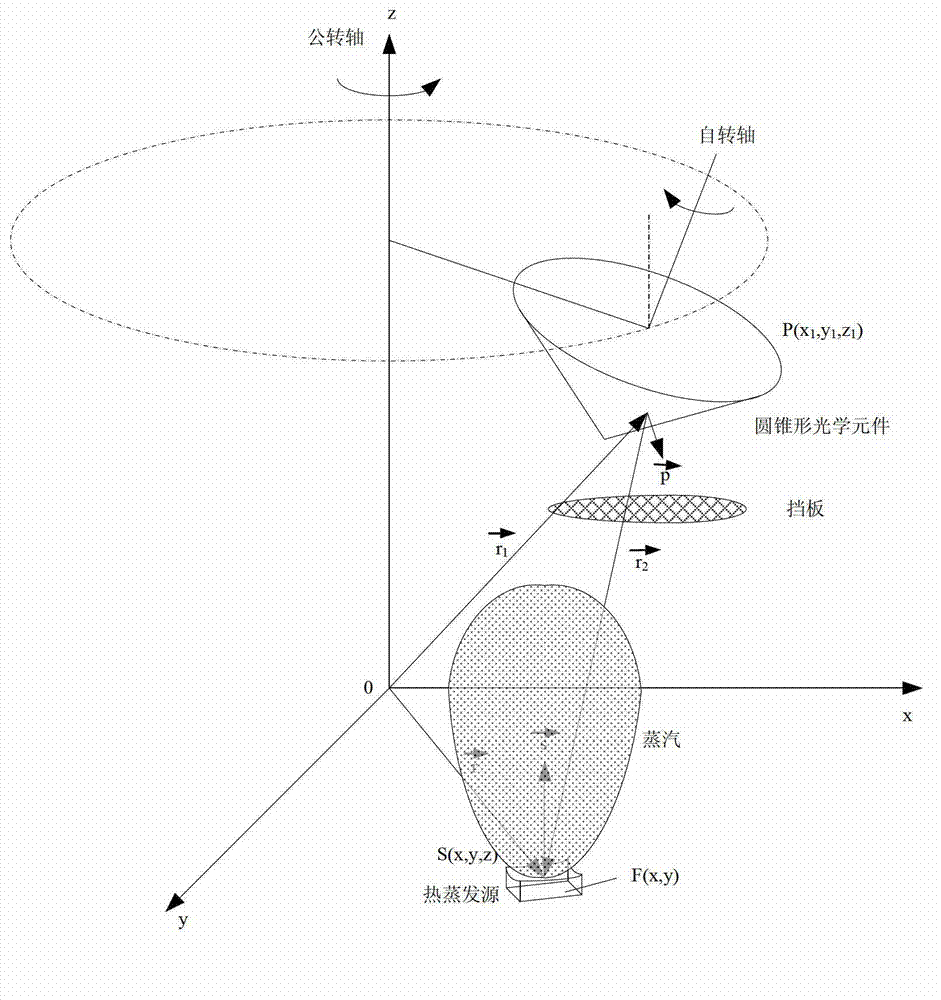

Method for designing coating uniformity correction mask for spherical optical elements on planetary rotating jigs of vacuum coating machines

ActiveCN102732844AImprove design efficiencyImprove thickness uniformityVacuum evaporation coatingSputtering coatingComputer optimizationMagnification

The invention discloses a method for designing a coating uniformity correction mask for spherical optical elements on planetary rotating jigs of vacuum coating machines, which is used for studying the film thickness distribution of a plane or spherical optical element (subjected to coating) on a planetary rotating jig through establishing a coating model in a vacuum environment. Through enabling an optical element coating process in a planetary rotating jig to be equivalent to a coating process in a simple rotating jig, the initial shape of the coating uniformity correction mask in the planetary rotating jig is designed. Through optimizing the arc length magnification factor of the correction mask by using a computer until the film thickness uniformity reaches the optimal result, the actual shape of the coating uniformity correction mask for the spherical optical elements is obtained. According to the invention, the control on the film thickness uniformity of the spherical optical element with a large caliber and a large caliber / curvature radius ratio can be realized, thereby obtaining the uniformity of multilayer-film spectral characteristics of the spherical optical element with a large caliber and a large caliber / curvature radius ratio.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

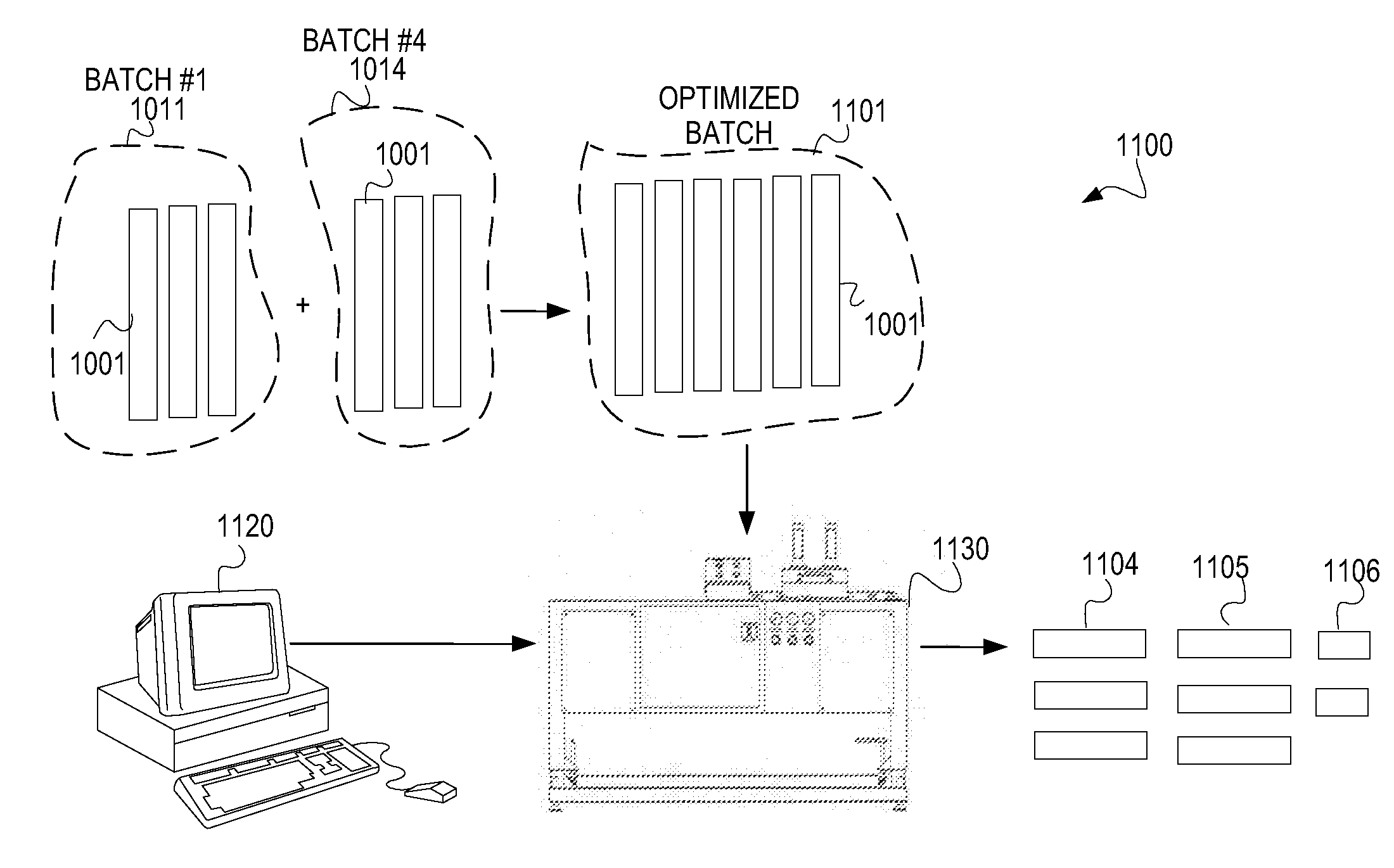

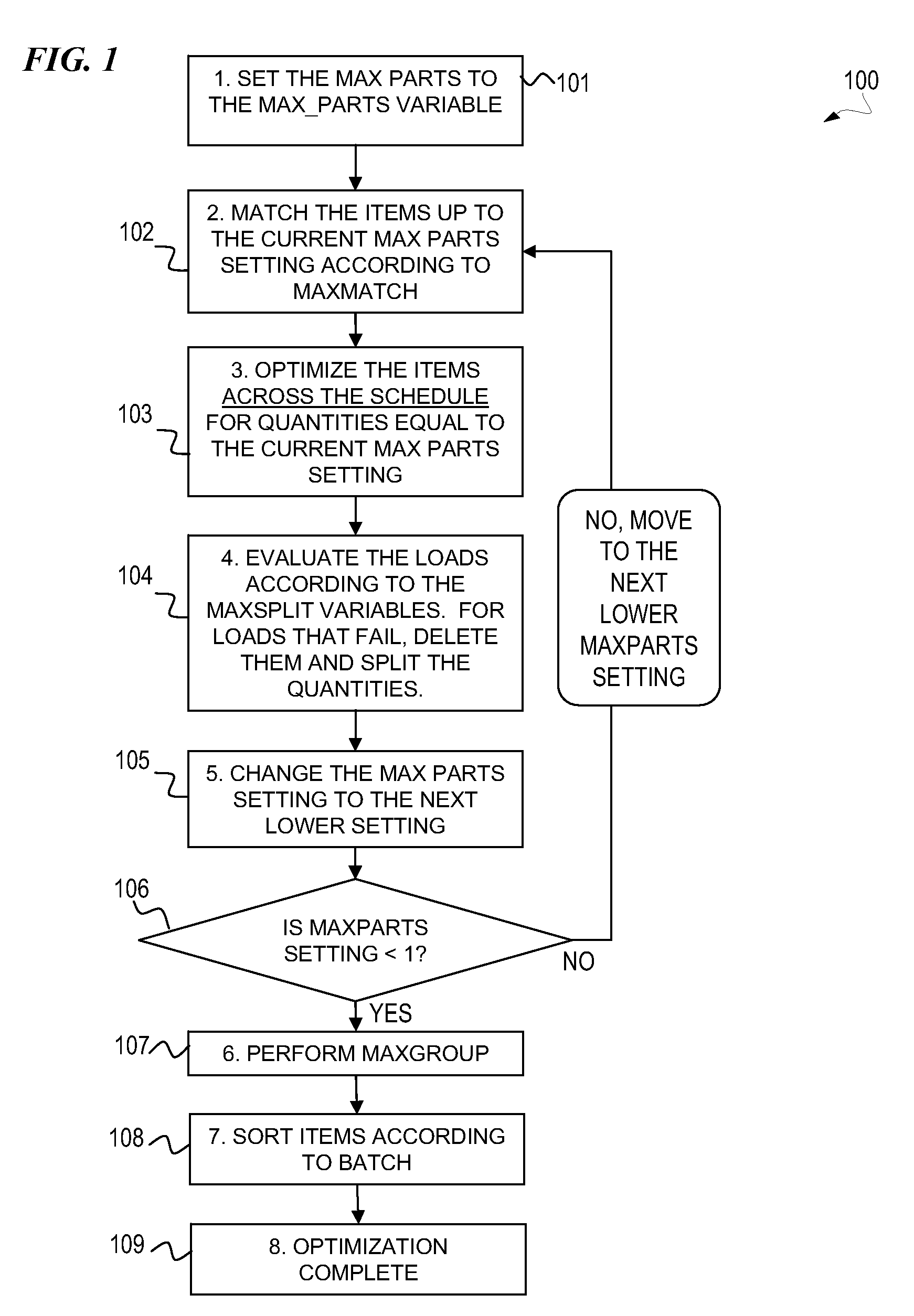

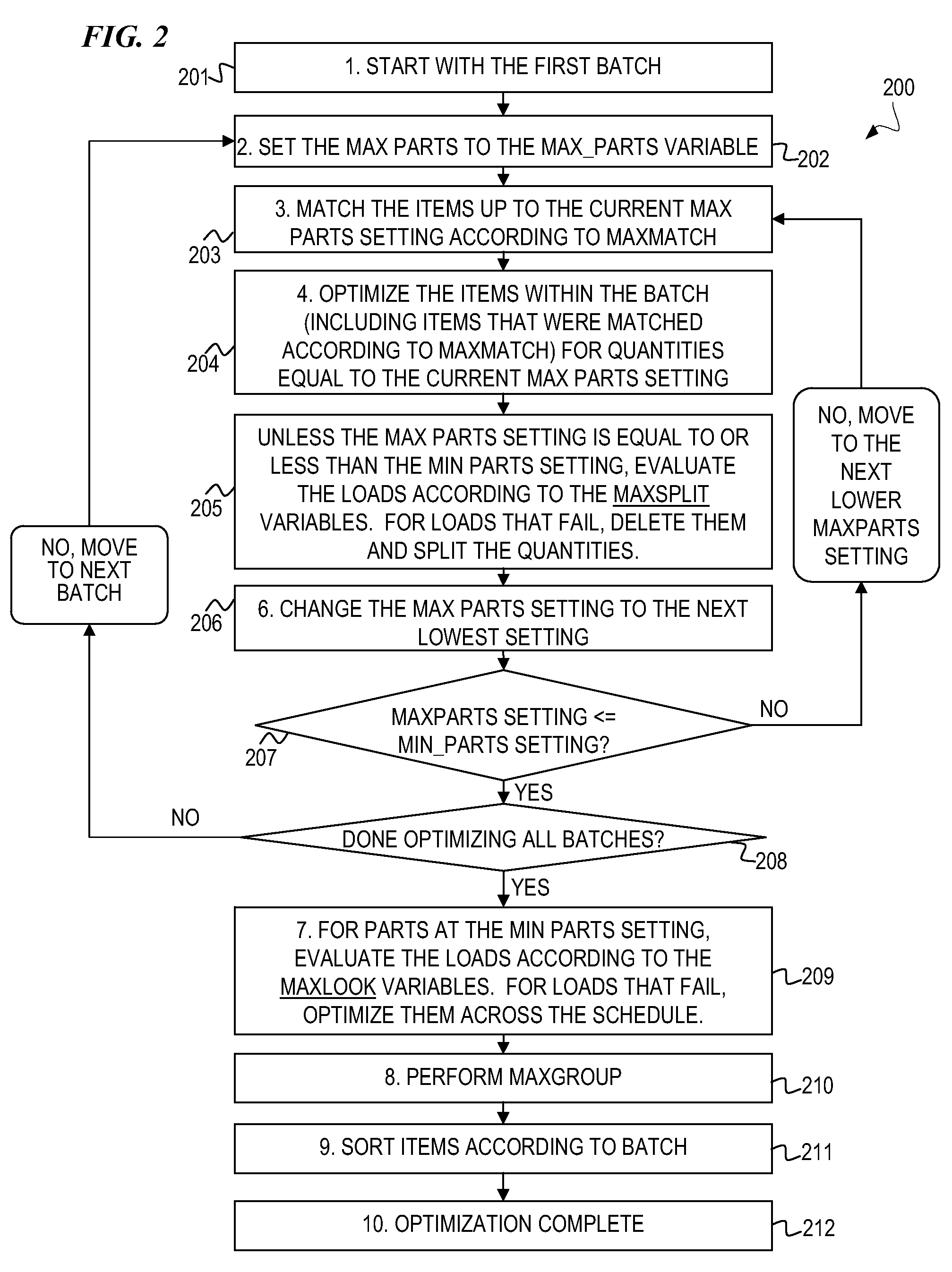

System and method for cutting-stock optimization across schedules and batches

ActiveUS20070270996A1Reduce in quantityReduce laborResourcesSpecial data processing applicationsComputer optimizationWater jet cutter

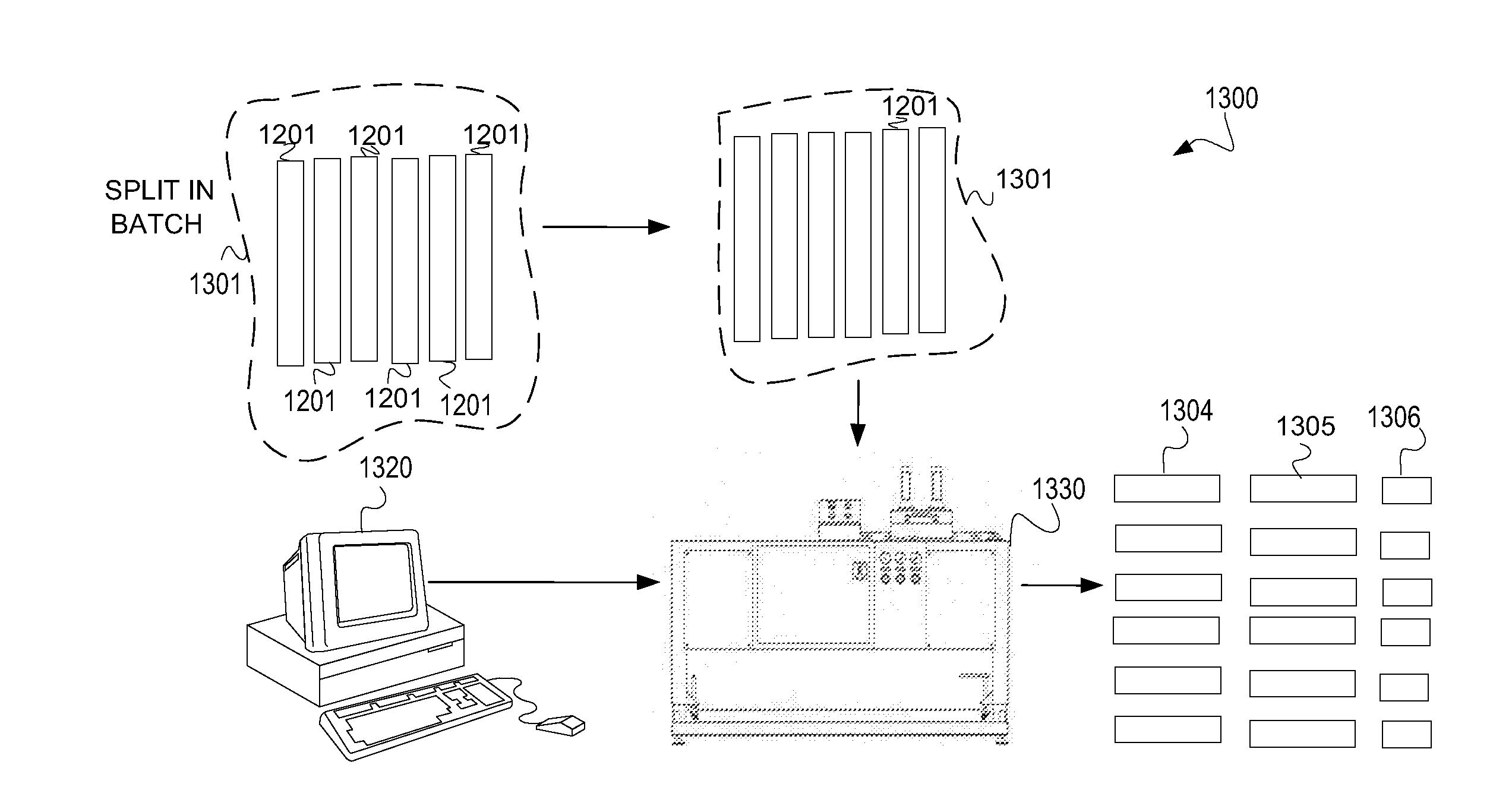

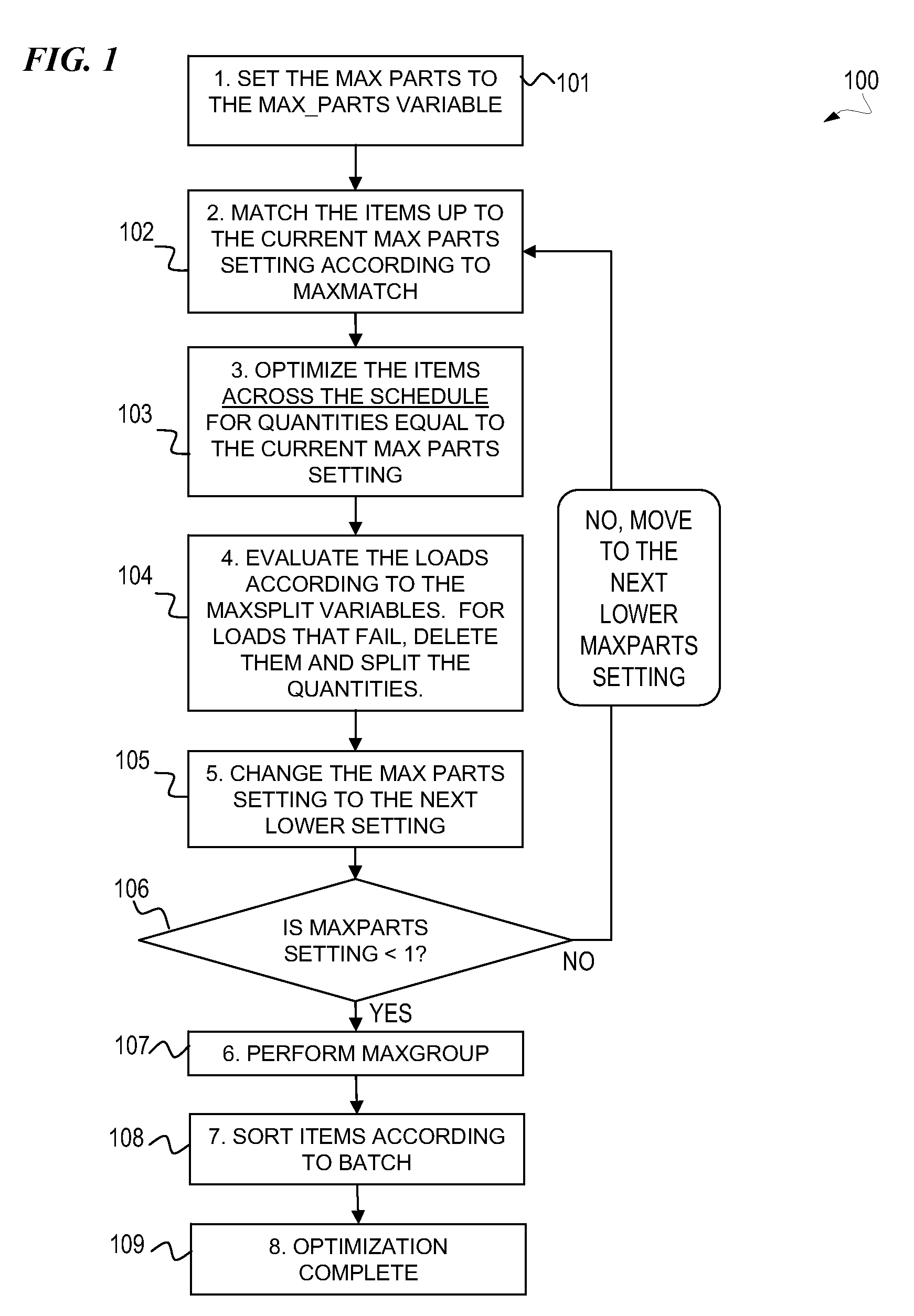

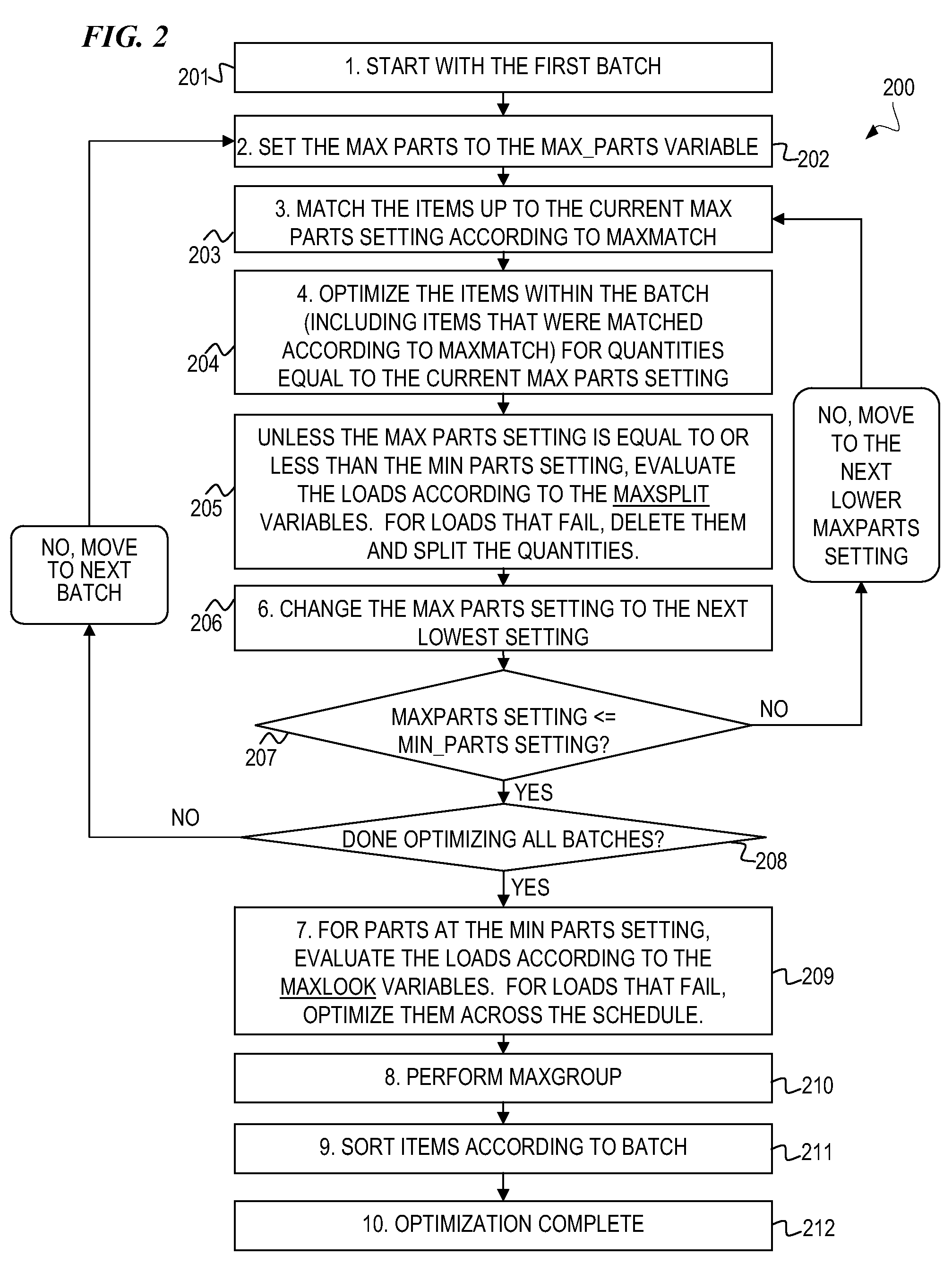

A method and system for optimizing cutting of various materials. In some embodiments, an algorithm optimizes cutting by grouping items to be cut, wherein a plurality of cutting-stock pieces are grouped together and aligned such that a single cut simultaneously cuts items from all of the pieces. Some embodiments optimize a combination of reduced labor cost, reduced materials cost (e.g., reducing scrap), and / or reduced time needed to obtain an inventory of pieces cut to specified lengths and shapes (checking the various permutations). Overall optimization of labor and material is achieved by a combination of fewer cuts and reduced waste. Some embodiments include a computer-readable medium having instructions executed by a computer that optimizes placement of cuts to obtain cut-part items, and optionally controls a saw, laser, water-jet cutter or the like. In some embodiments, a human operator making the cuts is instructed by the computer to achieve the optimization.

Owner:ROISE GEOFFREY J

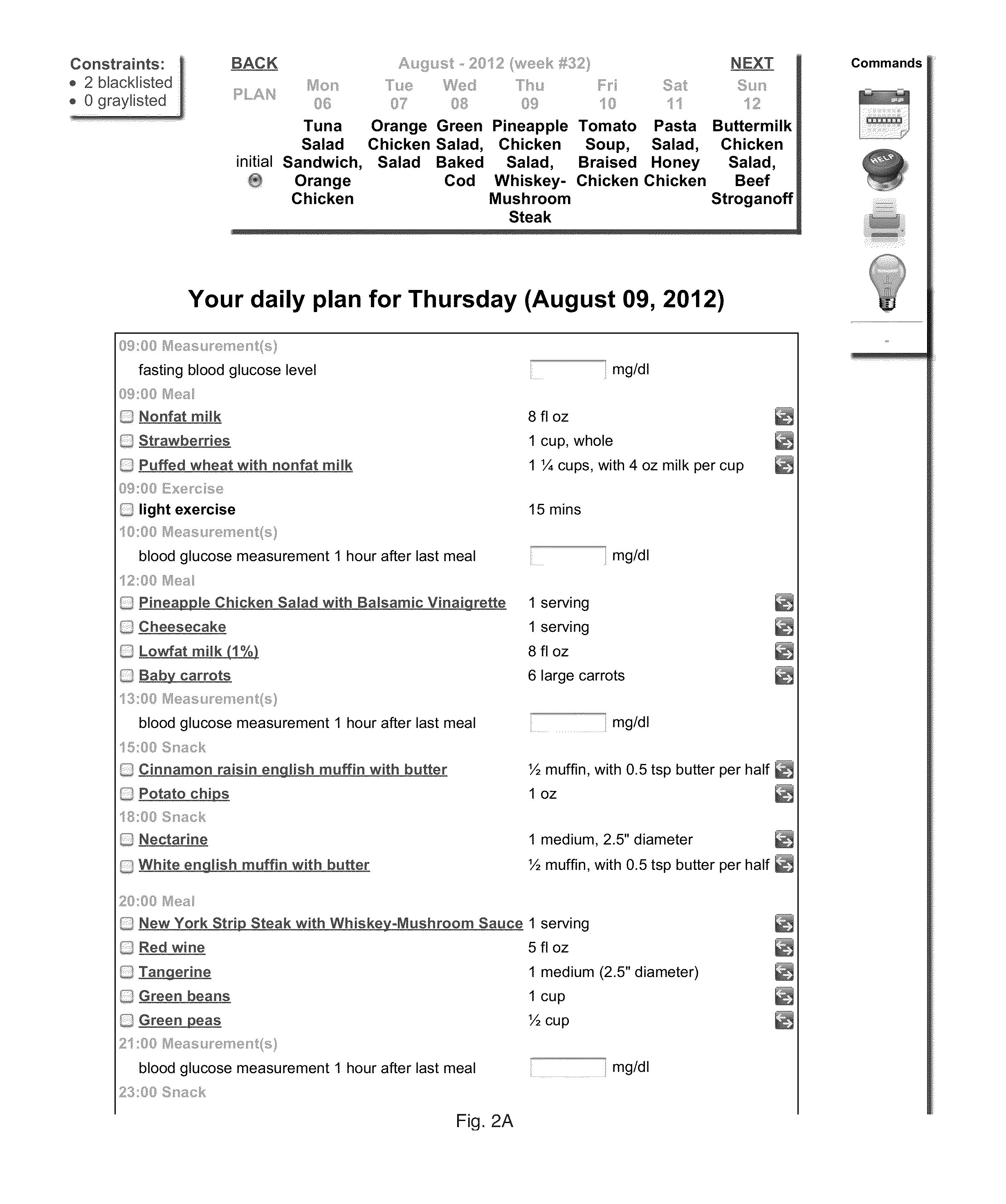

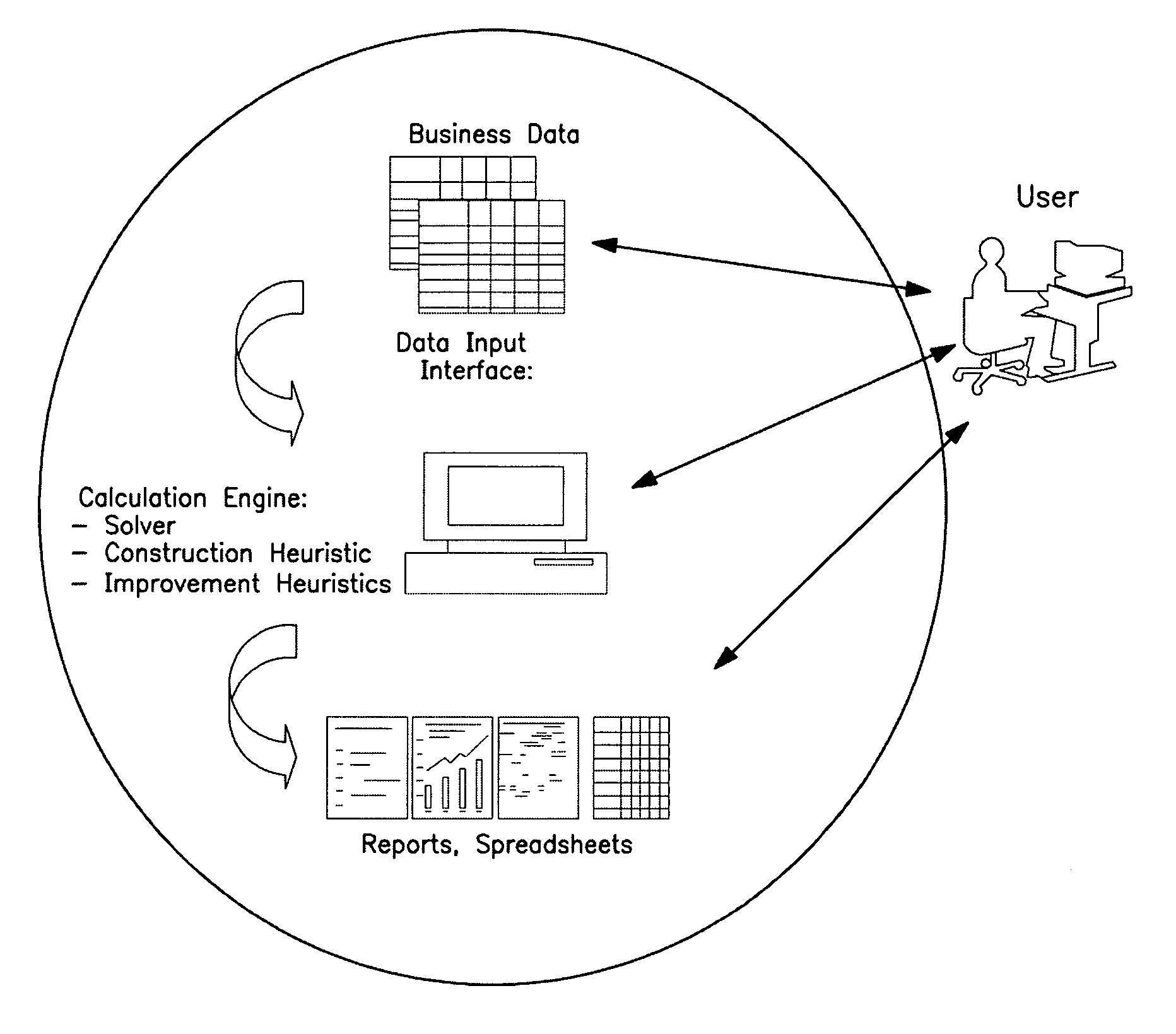

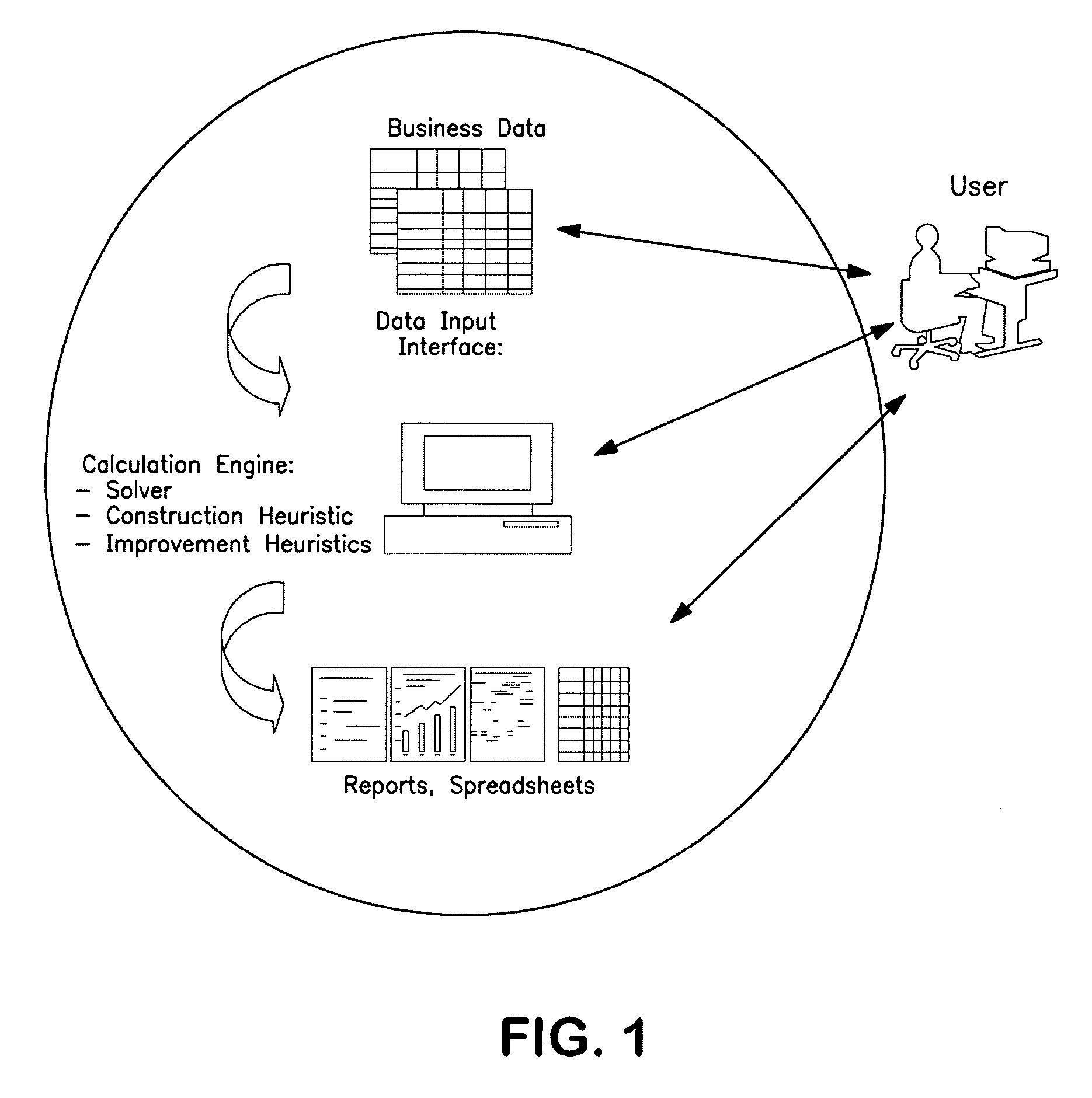

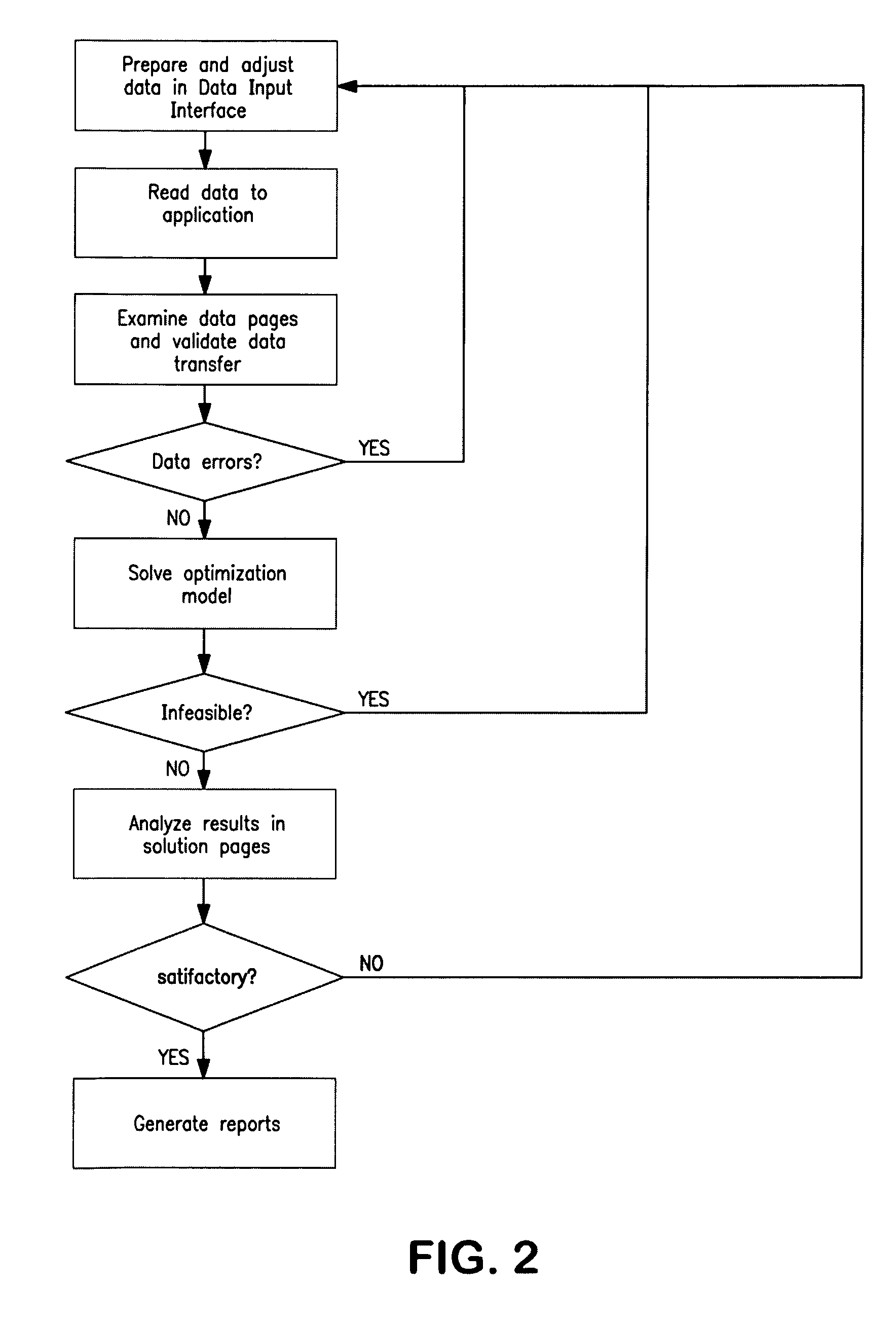

Optimization-based regimen method and system for personalized diabetes and diet management

InactiveUS20140052722A1Low costGreater strides more quicklyPhysical therapies and activitiesDigital data processing detailsDiabetes mellitusPersonalization

Methods and systems for determining computer optimization-based regimens and / or plans and / or programs for diet and health management are presented. A regimen and / or plan and / or program is generated by a computer (i) obtaining for an individual, a nutritional-based metabolic response as a function of time associated with a set of nutritional components, (ii) obtaining for the individual, an exercise-based metabolic response as a function of time associated a set of exercises available for performance by the individual, (iii) optimizing using computer optimization applied to the nutrition-based metabolic responses and the exercise-based metabolic responses, to determine a regimen defining for a time interval a sequence of one or more nutritional components to be ingested by the individual, and a sequence of one or more exercises to be performed by the individual, whereby one or more individual-based parameters are maintained in a predetermined range.

Owner:BERTSIMAS DIMITRIS J +1

System for optimizing bulk product allocation, transportation and blending

ActiveUS7797205B2Increase valueAugment deficitForecastingLogisticsComputer optimizationApplication software

A computer application loaded on a computer readable medium, a computer apparatus comprising the same, and process employing the same, is described herein. The computer application, when executed, causes a computer to optimize, for maximum net profit margin, the product allocation, transportation routing, transportation vehicle / route scheduling and, optionally, blending, of bulk products that are produced by and loaded from supply locations and delivered to and consumed by demand locations, using a heterogeneous fleet of transportation vehicles over a pre-defined period of time.

Owner:EXXON RES & ENG CO

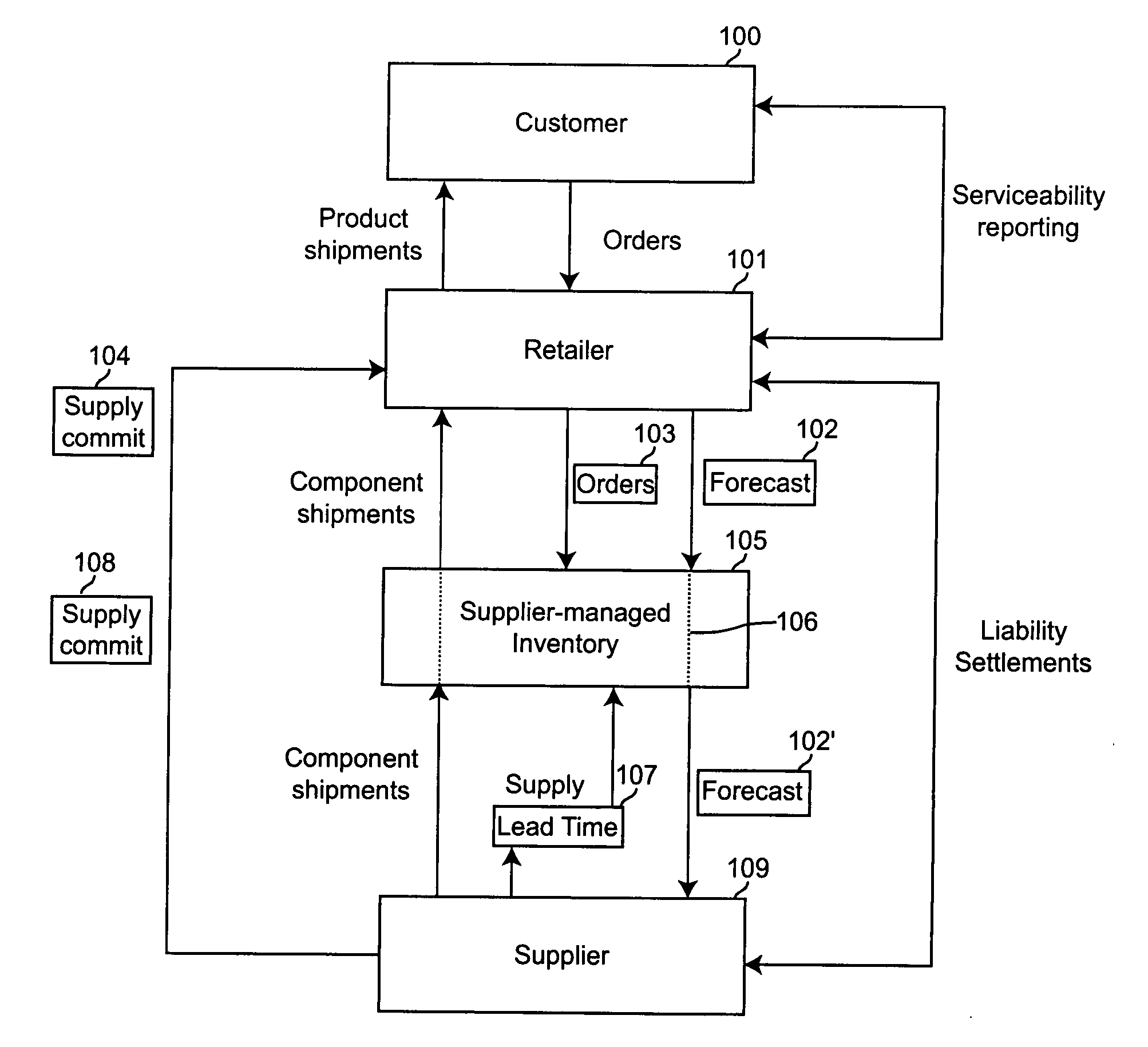

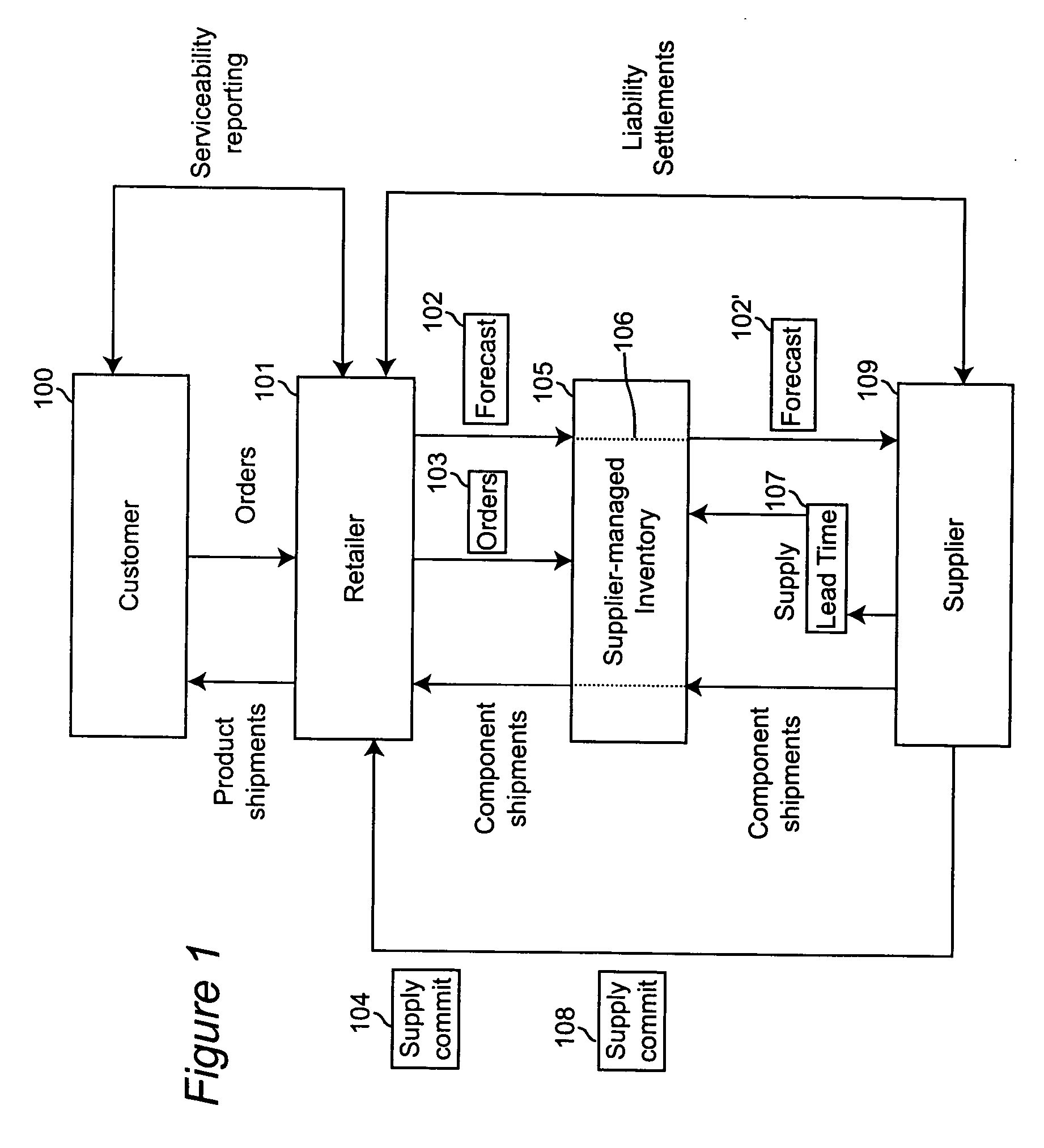

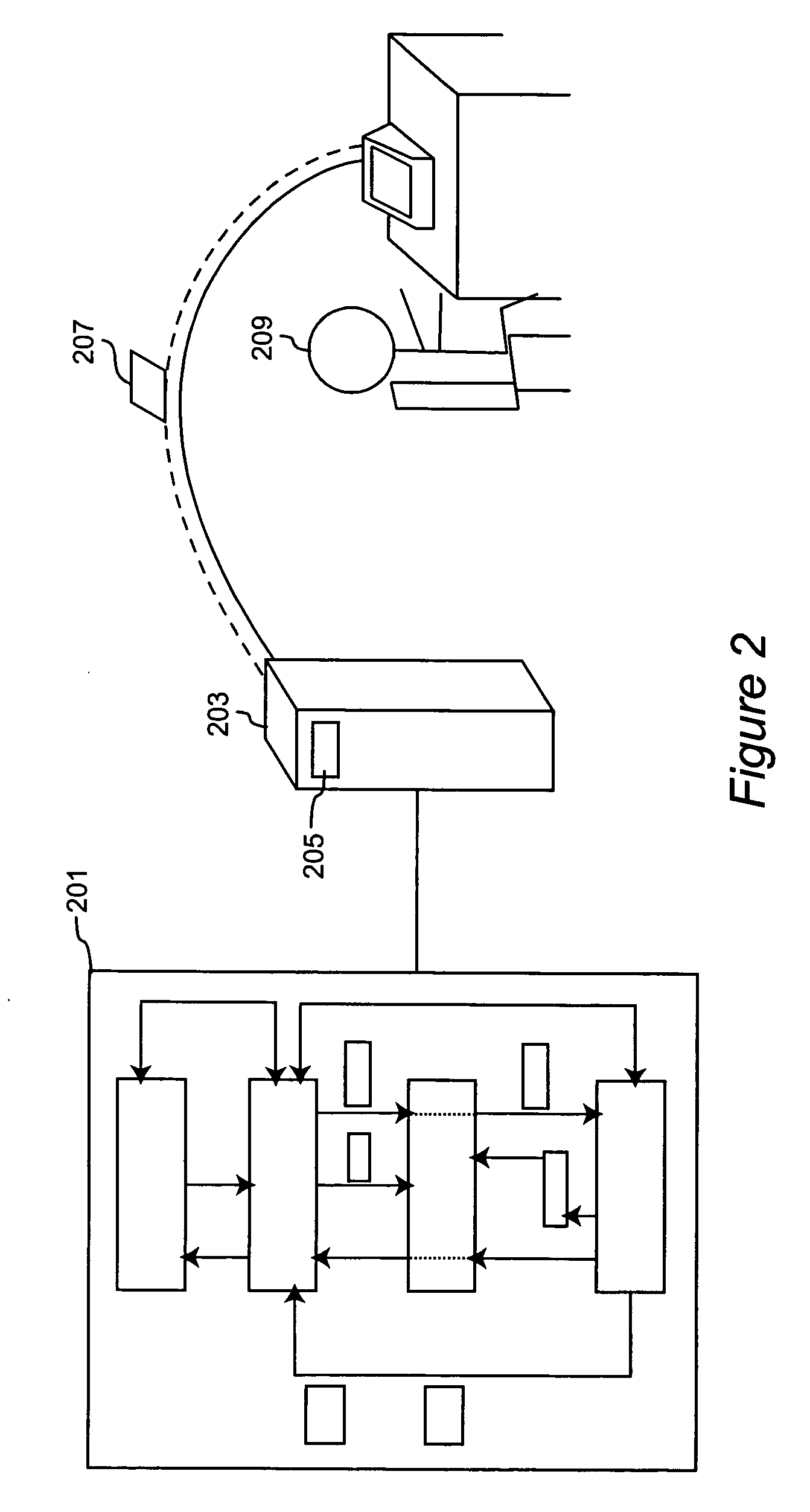

Method and system for balancing asset liability and supply flexibility in extended value networks

InactiveUS20070043602A1Mitigate asset riskMinimize exposureMultiprogramming arrangementsInformation technology support systemComputer optimizationOriginal equipment manufacturer

The present invention provides a method, a system, and a computer-readable medium with instructions for a computer to optimize one or more tradeoffs between or among serviceability, liability, and / or inventory in a multi-tier network of suppliers. The probabilistic optimization of tradeoffs enables assets stored at one or a plurality of tiers in the network to be optimally transferred downstream with certain probabilities. The multi-tier network of suppliers may consist of at least one original equipment manufacturer tier and at least one supplier tier.

Owner:IBM CORP

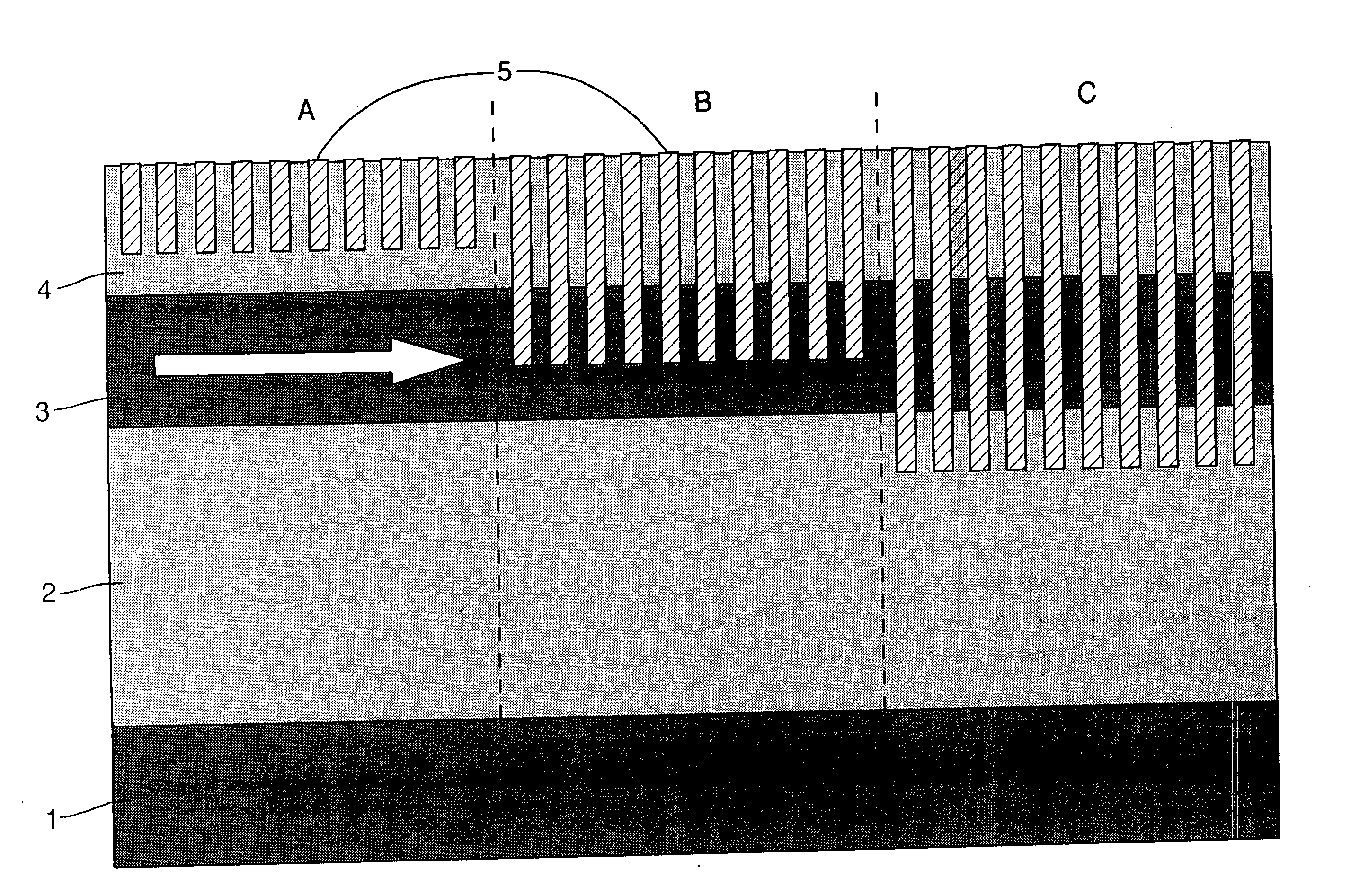

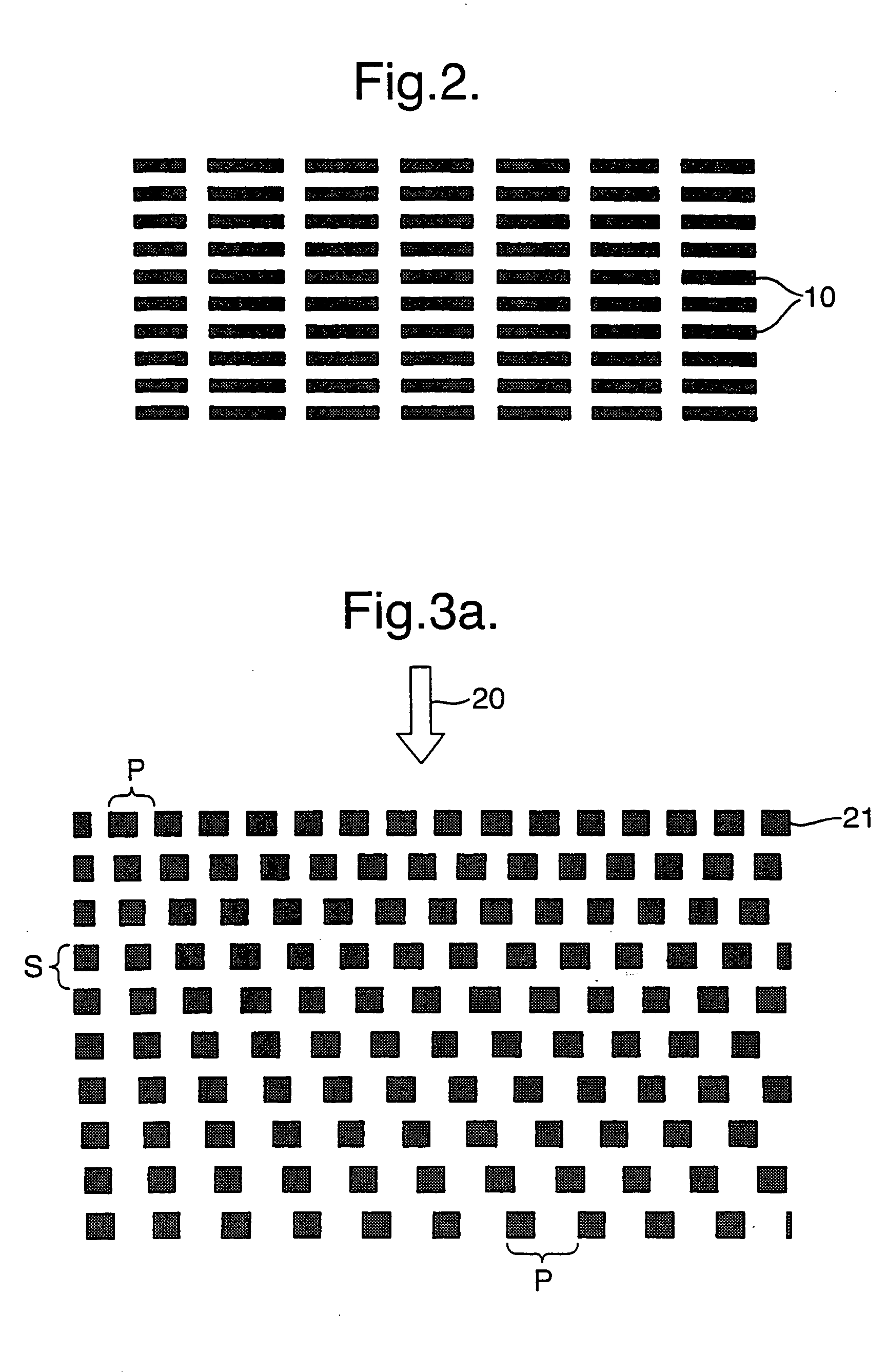

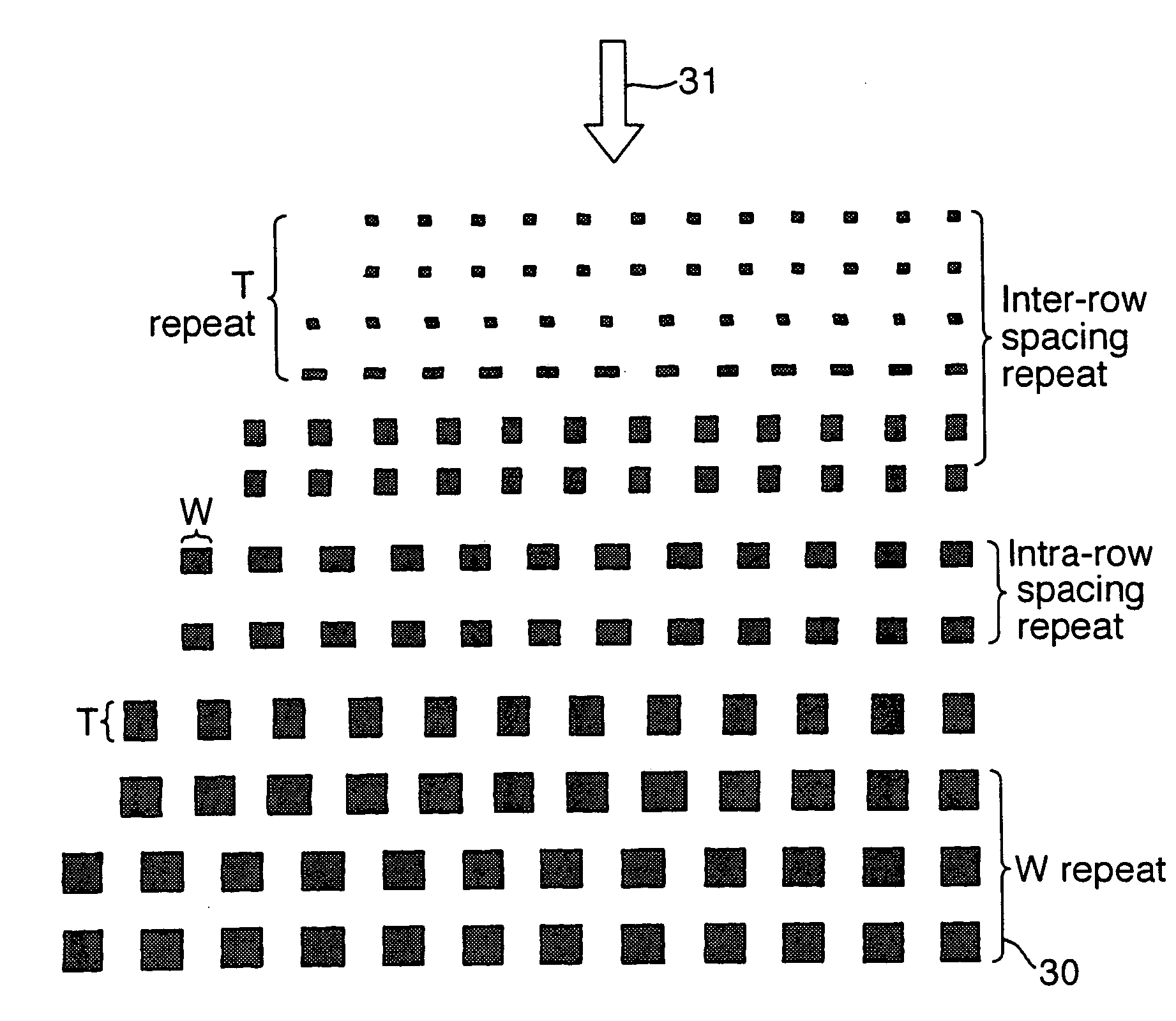

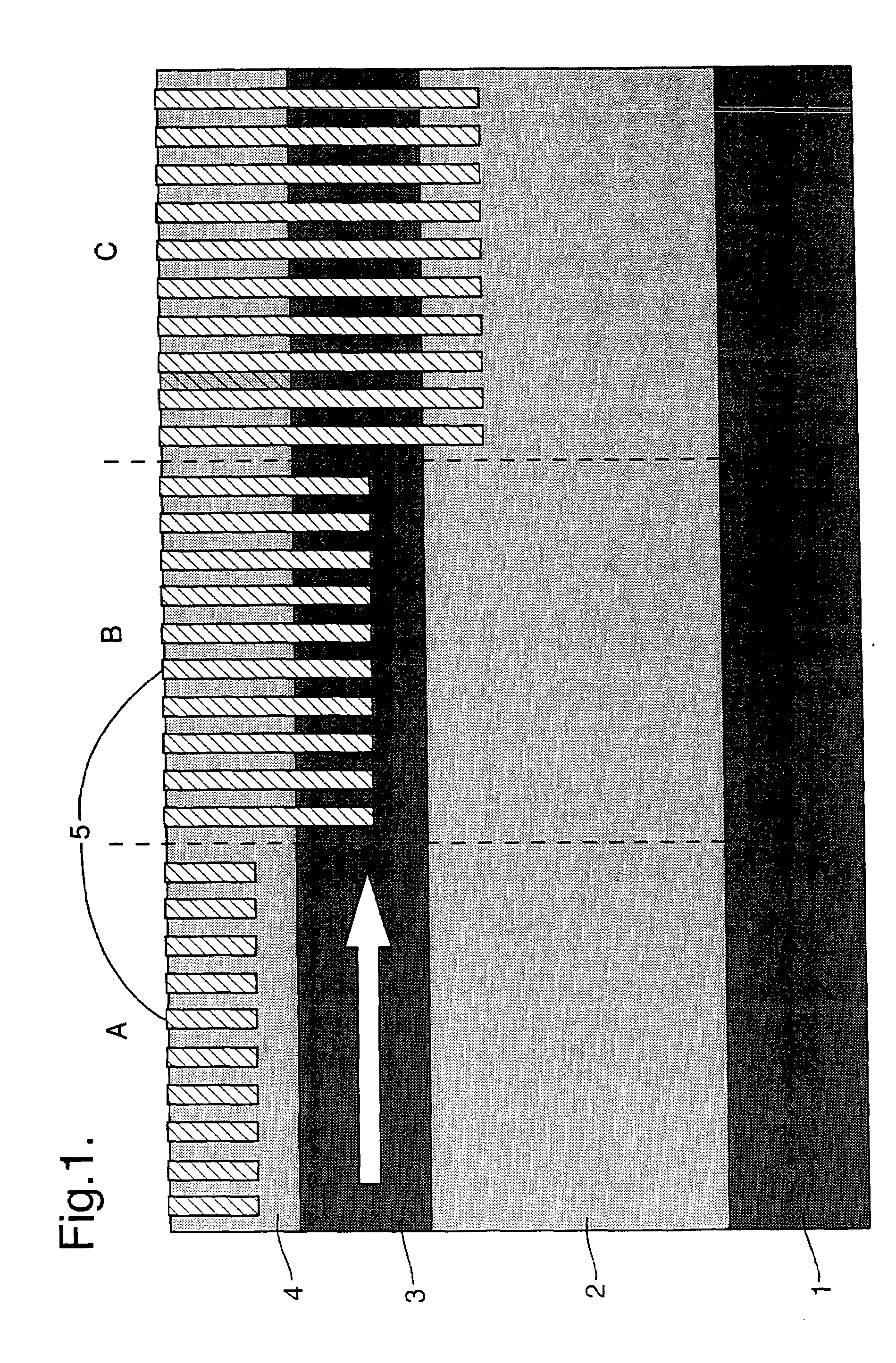

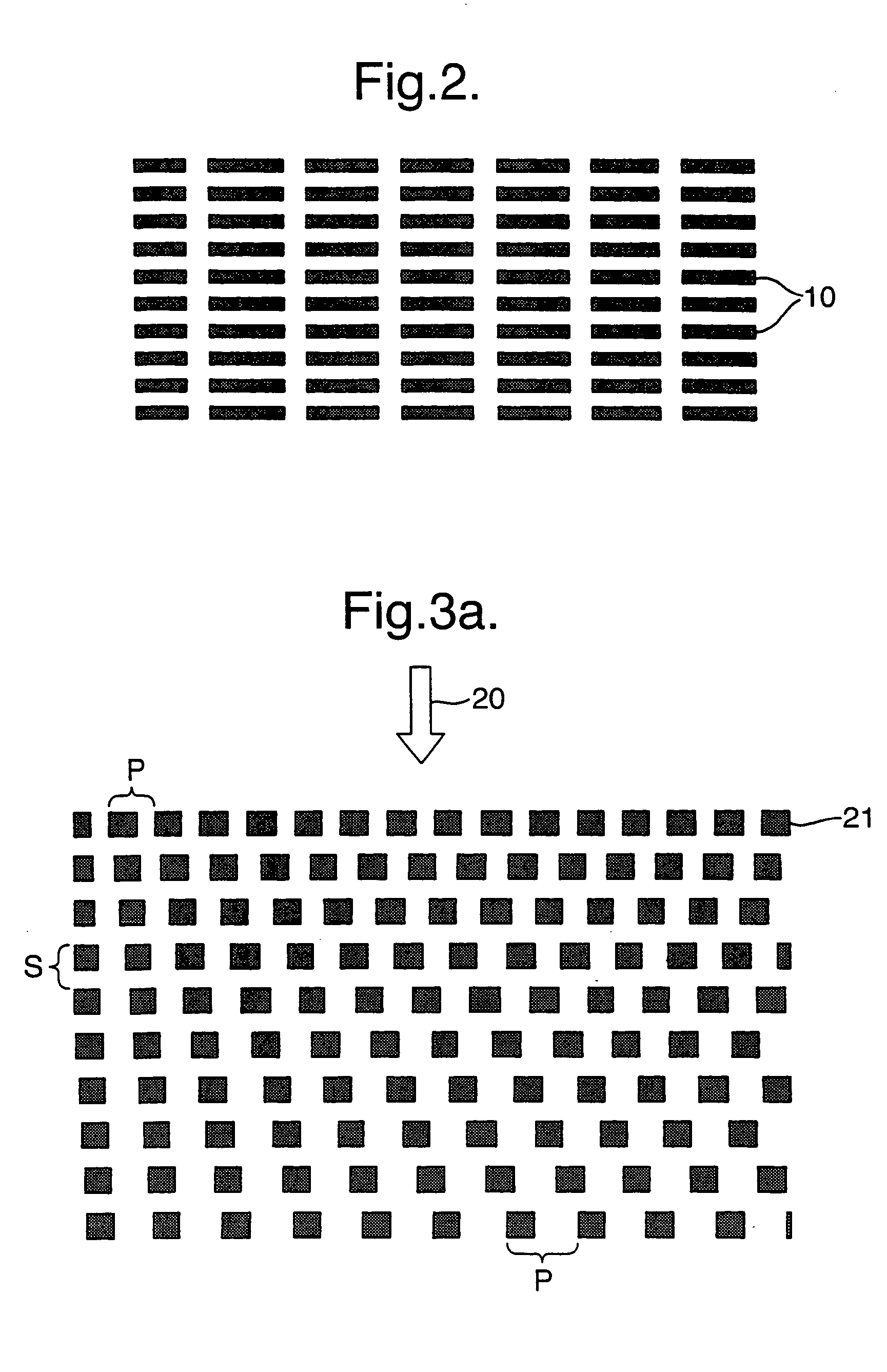

Photonic band structure devices

ActiveUS20050094956A1Quick applicationLow costNanoopticsOptical waveguide light guideComputer optimizationPhotonics

The invention provides a photonic structure comprising a first region (3) formed from a material having a first refractive index; and an array of sub-regions (5) formed in the first region, each sub-region having a refractive index different to the first refractive index; wherein the array of sub-regions (5) can be defined by a plurality of rows and columns, wherein the position of each sub-region relative to adjacent sub-regions in each row and the properties of the sub-regions across each row are defined by parameters of a first type, and the position of each row relative to adjacent rows, and the properties of the sub-regions along each column are defined by parameters of a second type; and wherein at least one parameter of a first type and at least one parameter of the second type is varied systematically and independently across the array. The present invention gives rise to structures with photonic band structures that can be tailored to a particular application. A variation in the first type of parameter has a different effect to a variation in the second type of parameter. Variation in a first type of parameter alters the diffracting properties of each row in the stack of rows. Variation in a second type of parameter affects the reflective properties of the structure. According to another aspect of the invention, a method for manufacturing photonic structures is provided including a computer optimisation process in the design stage.

Owner:QUANTUM NIL LTD +1

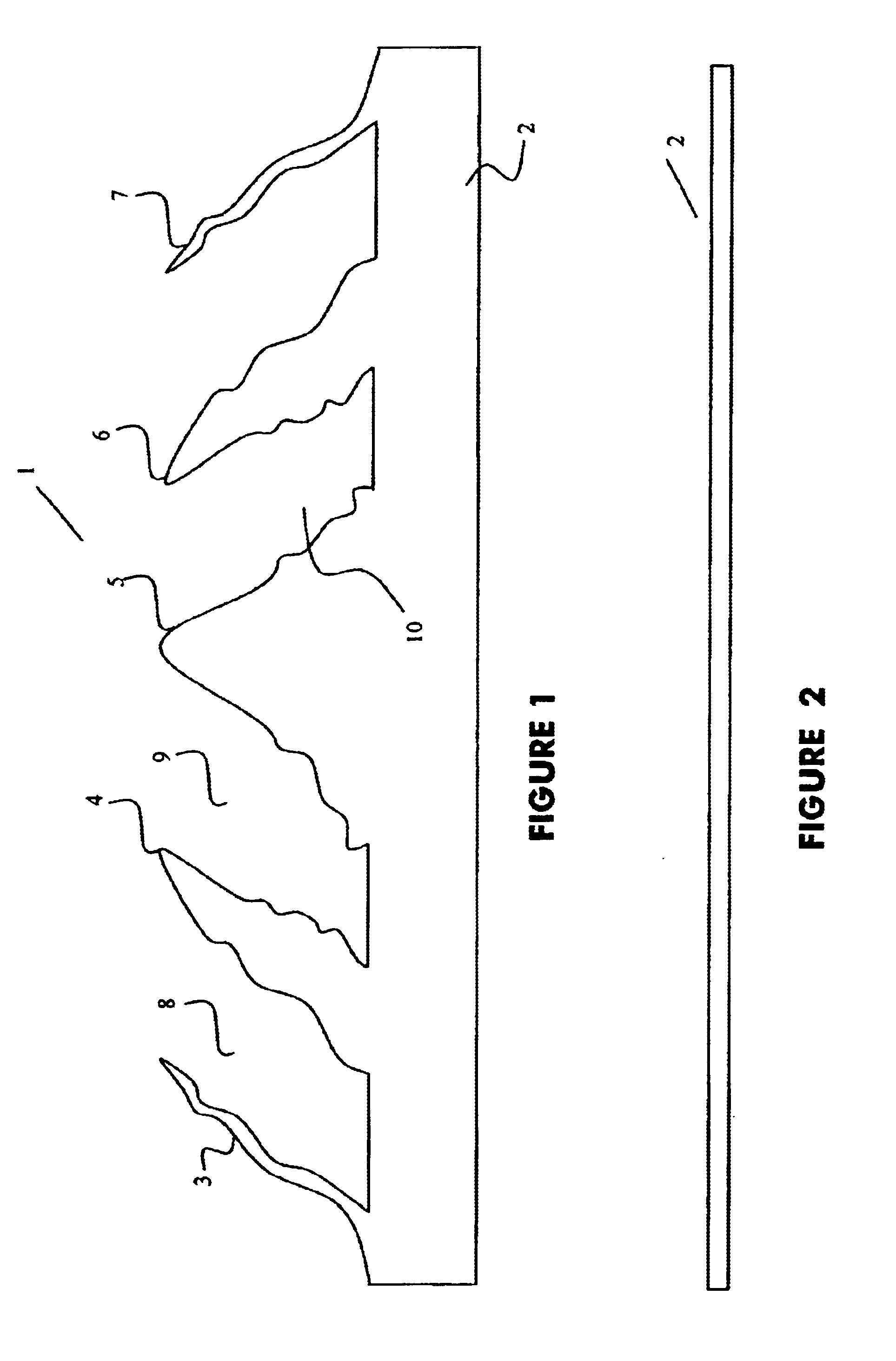

Phase shifter having differently shaped interactive elements and an antenna system formed therefrom

InactiveUS6816668B2Minimize reflectionDomestic stoves or rangesAir heatersDielectricComputer optimization

A phase shifter element for selectively varying the phase of signals of desired frequencies or frequency range passing through an adjacent transmission line associated with, for example, an antenna array to electrically down-tilt the array's electromagnetic wave pattern. The phase shifter element comprises a planar dielectric member having at least three discrete coplanar interactive segments extending from an edge thereof and arranged to movably overlap the adjacent transmission line to vary its dielectric constant. Optimum dimensions of each interactive segments and optimum widths of gaps defined by opposite edges of adjacent segments being determined by a computer optimisation program, such that the phase shifter element achieves a wide operating frequency and minimum aggregate reflection.

Owner:META PLATFORMS INC

System and method for cutting-stock optimization across schedules and batches

ActiveUS8010216B2Reduce in quantityReduce laborResourcesSpecial data processing applicationsComputer optimizationWater jet cutter

A method and system for optimizing cutting of various materials. In some embodiments, an algorithm optimizes cutting by grouping items to be cut, wherein a plurality of cutting-stock pieces are grouped together and aligned such that a single cut simultaneously cuts items from all of the pieces. Some embodiments optimize a combination of reduced labor cost, reduced materials cost (e.g., reducing scrap), and / or reduced time needed to obtain an inventory of pieces cut to specified lengths and shapes (checking the various permutations). Overall optimization of labor and material is achieved by a combination of fewer cuts and reduced waste. Some embodiments include a computer-readable medium having instructions executed by a computer that optimizes placement of cuts to obtain cut-part items, and optionally controls a saw, laser, water-jet cutter or the like. In some embodiments, a human operator making the cuts is instructed by the computer to achieve the optimization.

Owner:ROISE GEOFFREY J

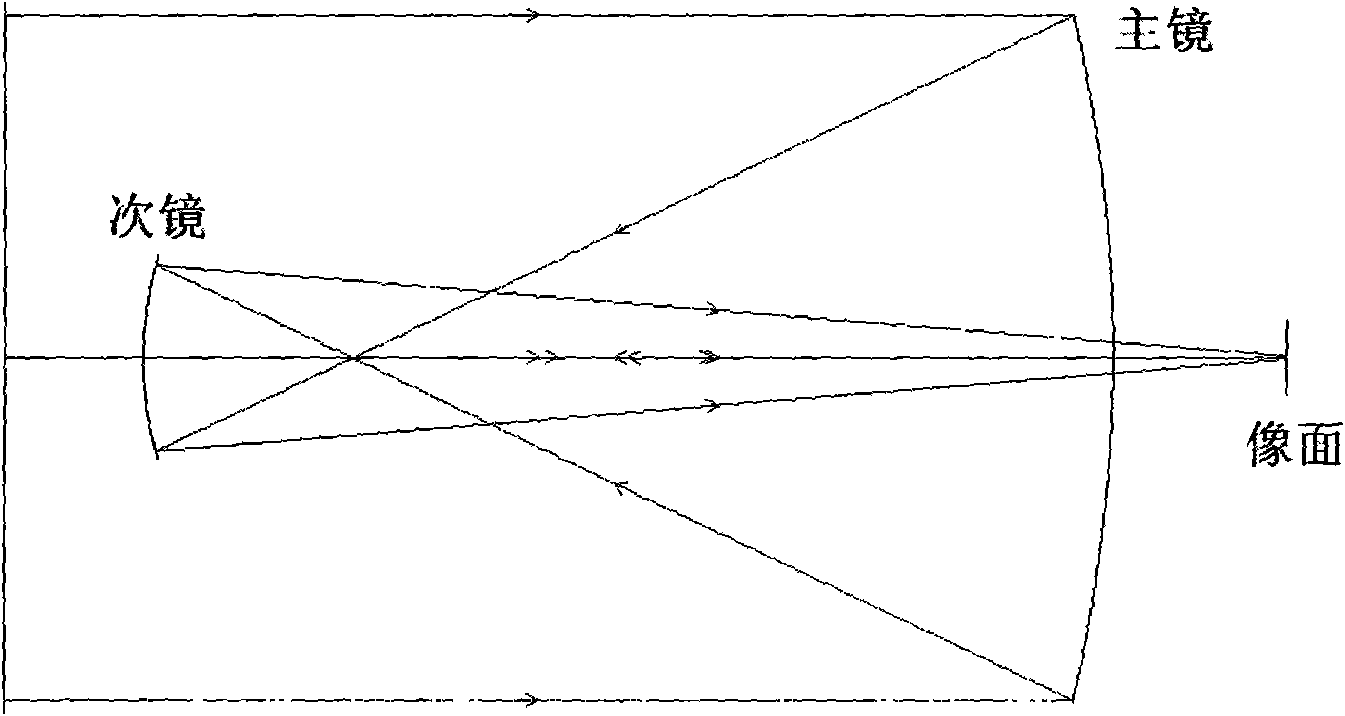

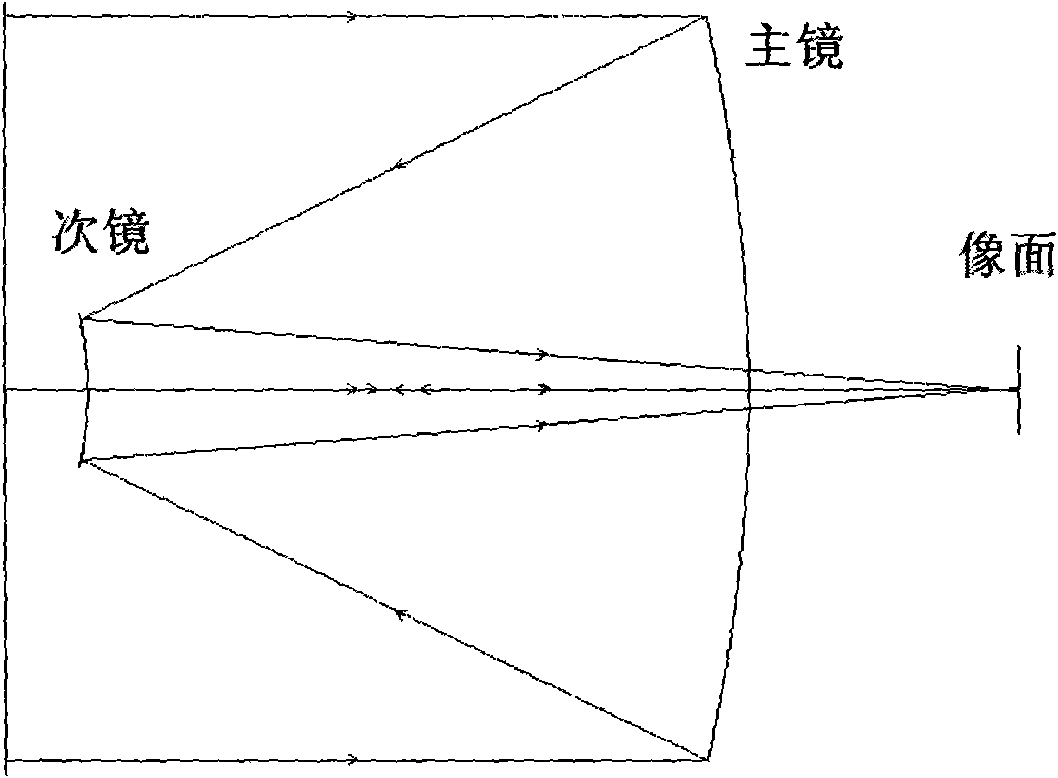

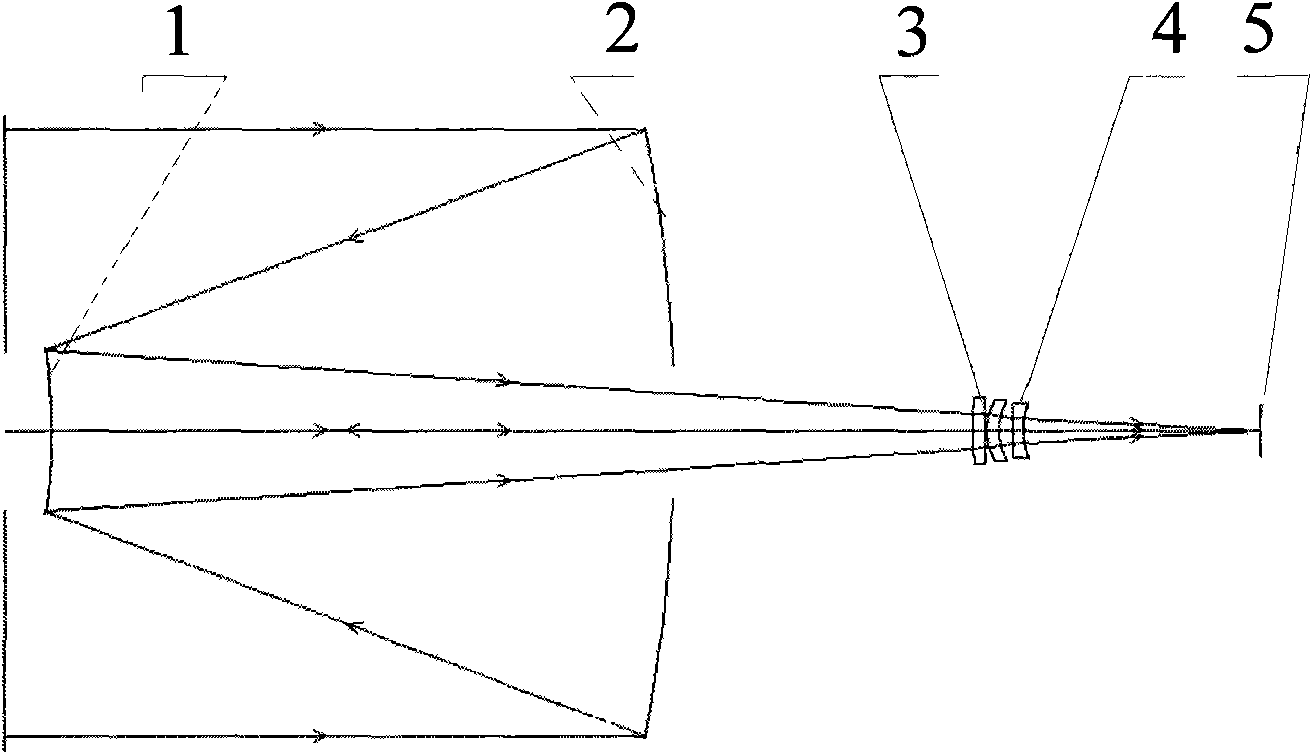

Optical imaging system and manufacturing method thereof

InactiveCN101598849AImprove image qualityExpand field of viewOptical articlesOptical elementsComputer optimizationImaging quality

The invention discloses an optical imaging system which comprises a secondary lens, a main lens, a correction lens group and an image field correction lens which are sequentially arranged. Four items of spherical aberration, coma aberration, astigmatism and image field curvature in monochromatic aberration are considered to be eliminated according to a third-order aberration theory. The main lens is a paraboloid; the secondary lens is a hyperboloid, and the conical coefficient of the hyperboloid of the secondary lens is determined according to the refractive index of the material of the secondary lens. Optimized by a computer, the image quality and the view field of the double reflection optical imaging system are obviously improved, and in the sights of a geometric spot diagram (SPOT), a modulation transfer function (MTF) and encircled energy (EE), the image quality of the optical imaging system basically reaches a diffraction limit.

Owner:SHANGHAI ENG CENT FOR MICROSATELLITES

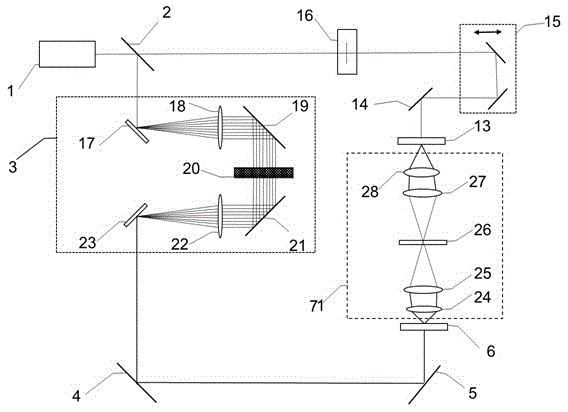

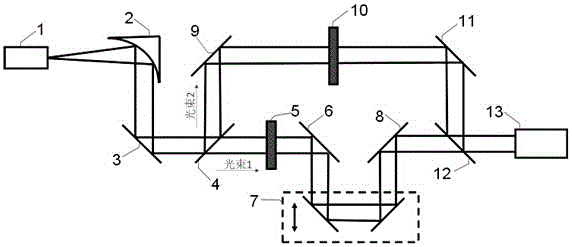

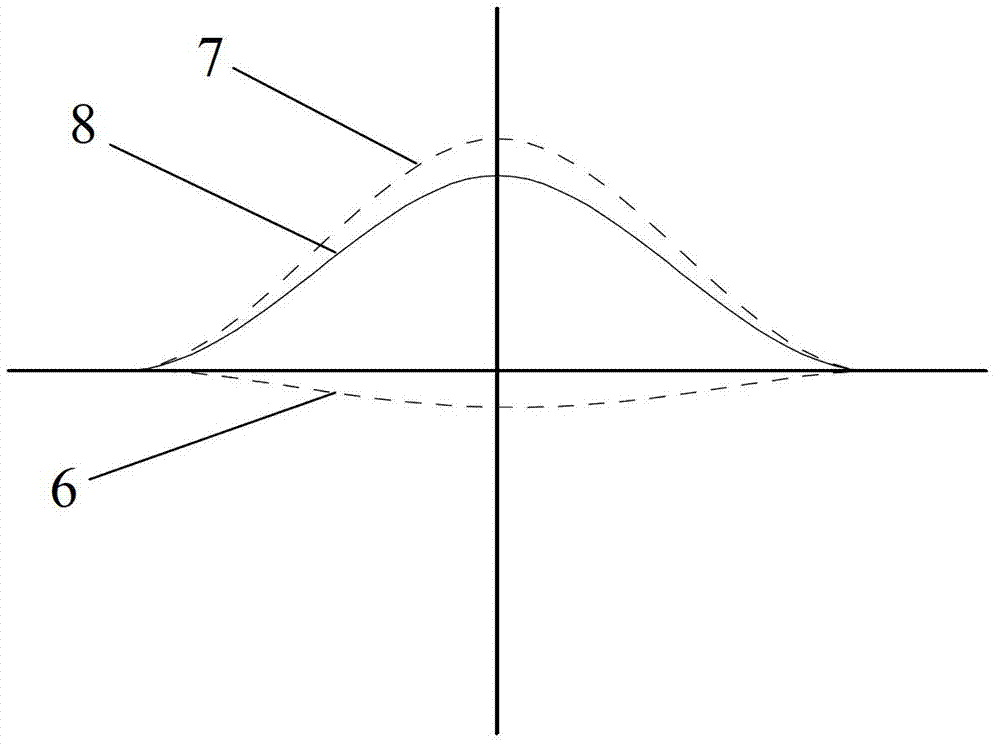

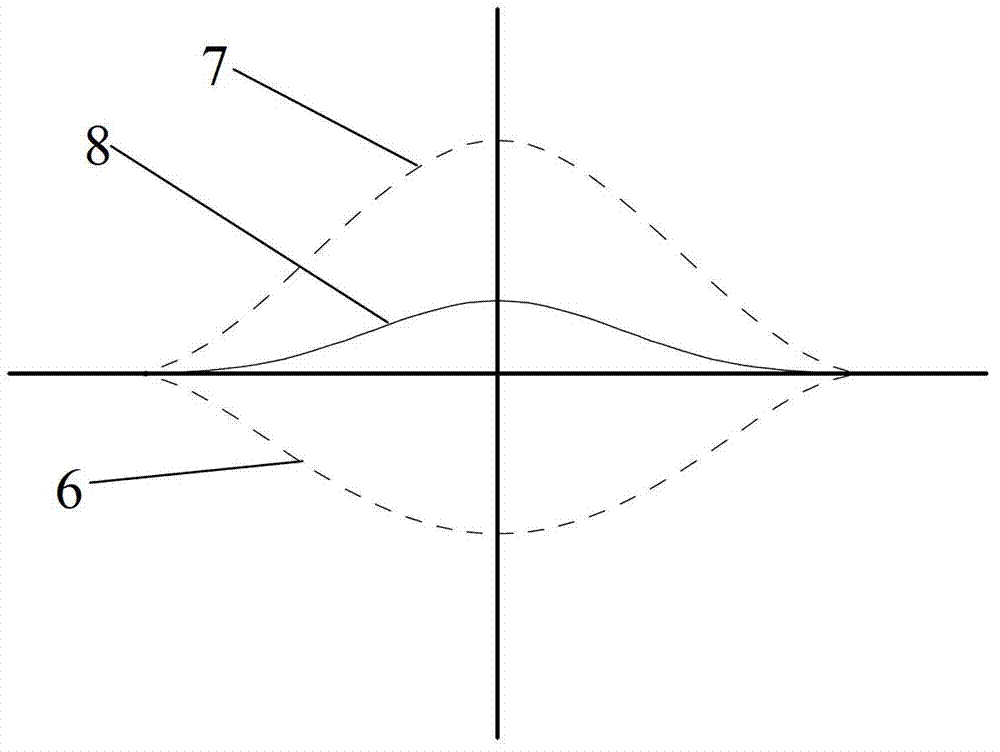

Method for improving frequency spectrum signal-to-noise ratio of tera-hertz optical detection system

InactiveCN105628642AImprove spectral signal-to-noise ratioImprove clarityMaterial analysis by optical meansComputer optimizationFrequency spectrum

The invention relates to a method for improving the frequency spectrum signal-to-noise ratio of a tera-hertz optical detection system. According to the method, a space optical modulator is added into the tera-hertz optical detection system for conditioning pumping light, so that the generated tera-hertz spectrum is centralized to the frequency band with the concentrated sample absorption peaks so as to improve the definition and the signal-to-noise ratio of the tested sample characteristic spectral lines; the data accurate rate is ensured; convenience is provided for later-period data analysis. Compared with the existing method for improving the signal-to-noise ratio, a space optical modulator is regulated through a computer optimization algorithm; the influence on an experiment result due to other interference factors caused by artificial system regulation is avoided. The method belongs to a method for conveniently, fast and efficiently obtaining the high-signal-to-noise-ratio and high-precision tera-hertz frequency spectrum.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

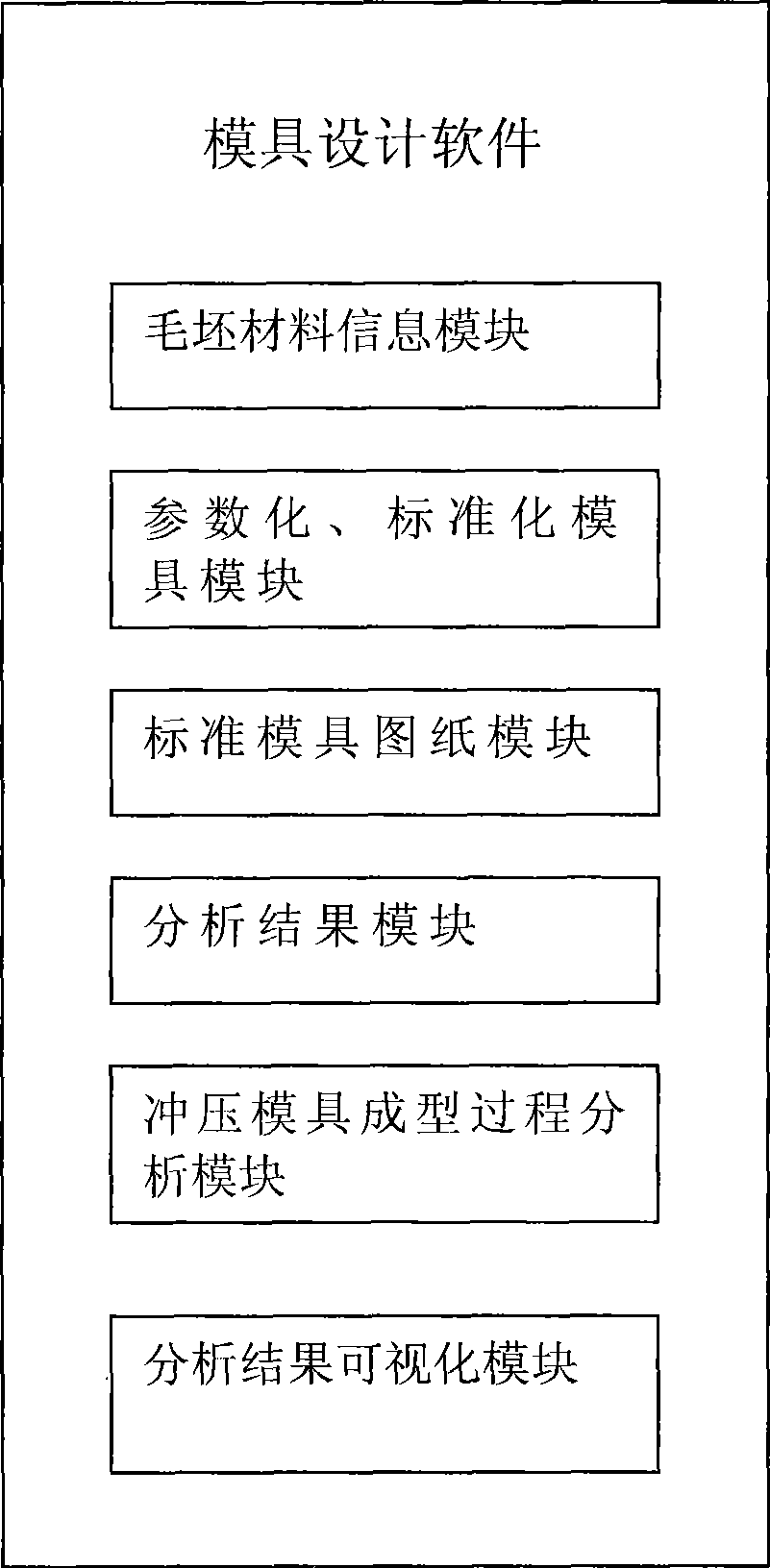

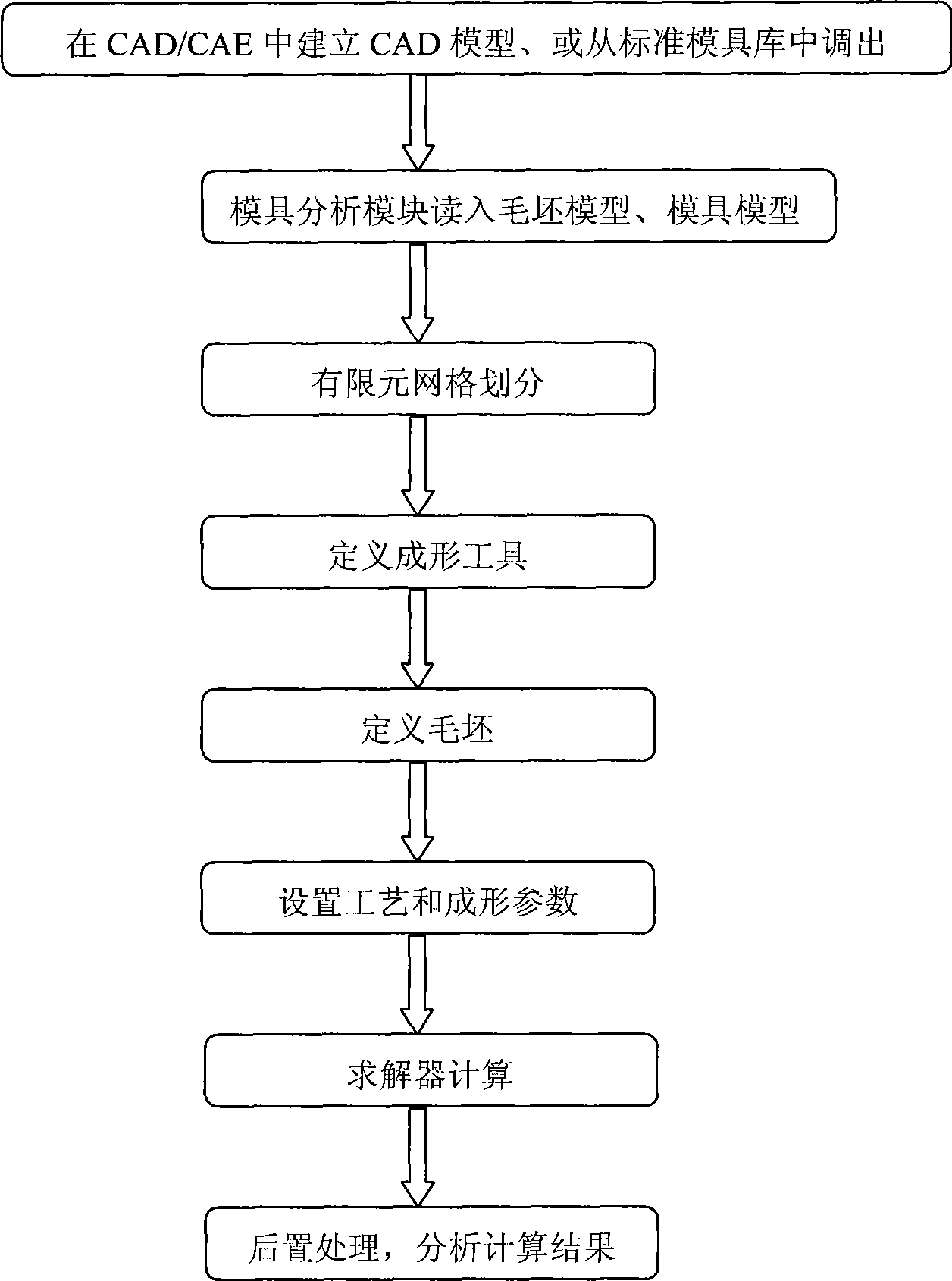

System and method for designing aerial fog jug forming and punching mold

InactiveCN101398865ARapid designEfficient designSpecial data processing applicationsPunchingRelevant information

A shaping-punching die designing system of a gas spray tank includes a blank material information module used for storing the relevant information of various blank materials, a parameterization and standardization die module used for storing the three dimensional and two dimensional die pictures of each part for manufacturing the gas spray tank; a standard die drawing module used for storing the three dimensional and two dimensional die pictures as well as the production assembling pictures of the dies during the working procedures for manufacturing each part of the gas spray tank in the actual production process; an analyzing result module used for storing the structural design picture of the original die during the shaping process for manufacturing different gas spray tank and the corresponding simulation analyzing result as well as the structural design information during the shaping process of a new gas spray tank and the analyzing result information whether the die structure of the shaping process has problems or not; the invention relates to a method for calculating the plastic deformation process of the blanks and the movement rule of a punch-die during each working procedure of punching and shaping of the top cover and the bottom cover of the gas spray tank as well as a method for designing the shaping-punching die of the gas spray tank. The invention fast and effectively reduces the cost by optimizing the die structure through a computer.

Owner:ZHEJIANG UNIV OF TECH

Photonic band structure devices

ActiveUS7248770B2Easily integrated into existing optical systemLower refractive indexNanoopticsOptical waveguide light guideComputer optimizationPhotonics

The invention provides a photonic structure comprising a first region (3) formed from a material having a first refractive index; and an array of sub-regions (5) formed in the first region, each sub-region having a refractive index different to the first refractive index;wherein the array of sub-regions (5) can be defined by a plurality of rows and columns, wherein the position of each sub-region relative to adjacent sub-regions in each row and the properties of the sub-regions across each row are defined by parameters of a first type, and the position of each row relative to adjacent rows, and the properties of the sub-regions along each column are defined by parameters of a second type; and wherein at least one parameter of a first type and at least one parameter of the second type is varied systematically and independently across the array.The present invention gives rise to structures with photonic band structures that can be tailored to a particular application. A variation in the first type of parameter has a different effect to a variation in the second type of parameter. Variation in a first type of parameter alters the diffracting properties of each row in the stack of rows. Variation in a second type of parameter affects the reflective properties of the structure.According to another aspect of the invention, a method for manufacturing photonic structures is provided including a computer optimisation process in the design stage.

Owner:QUANTUM NIL LTD +1

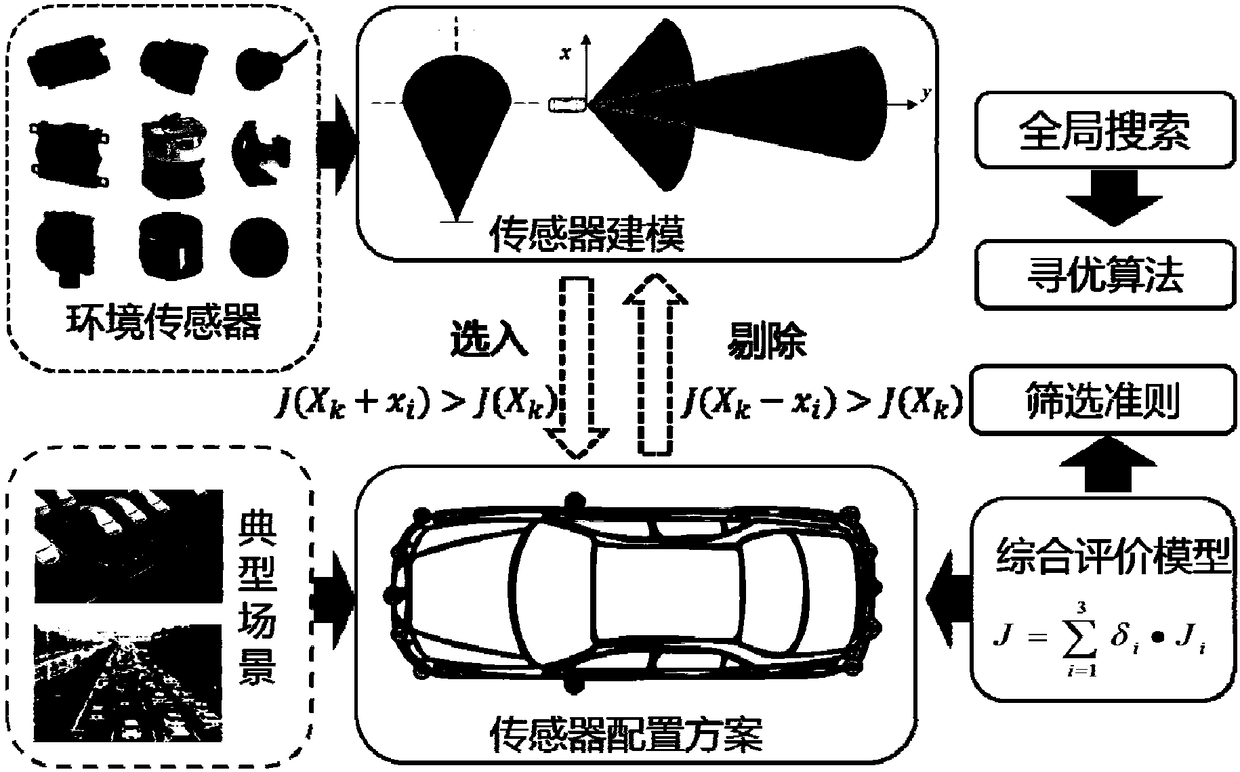

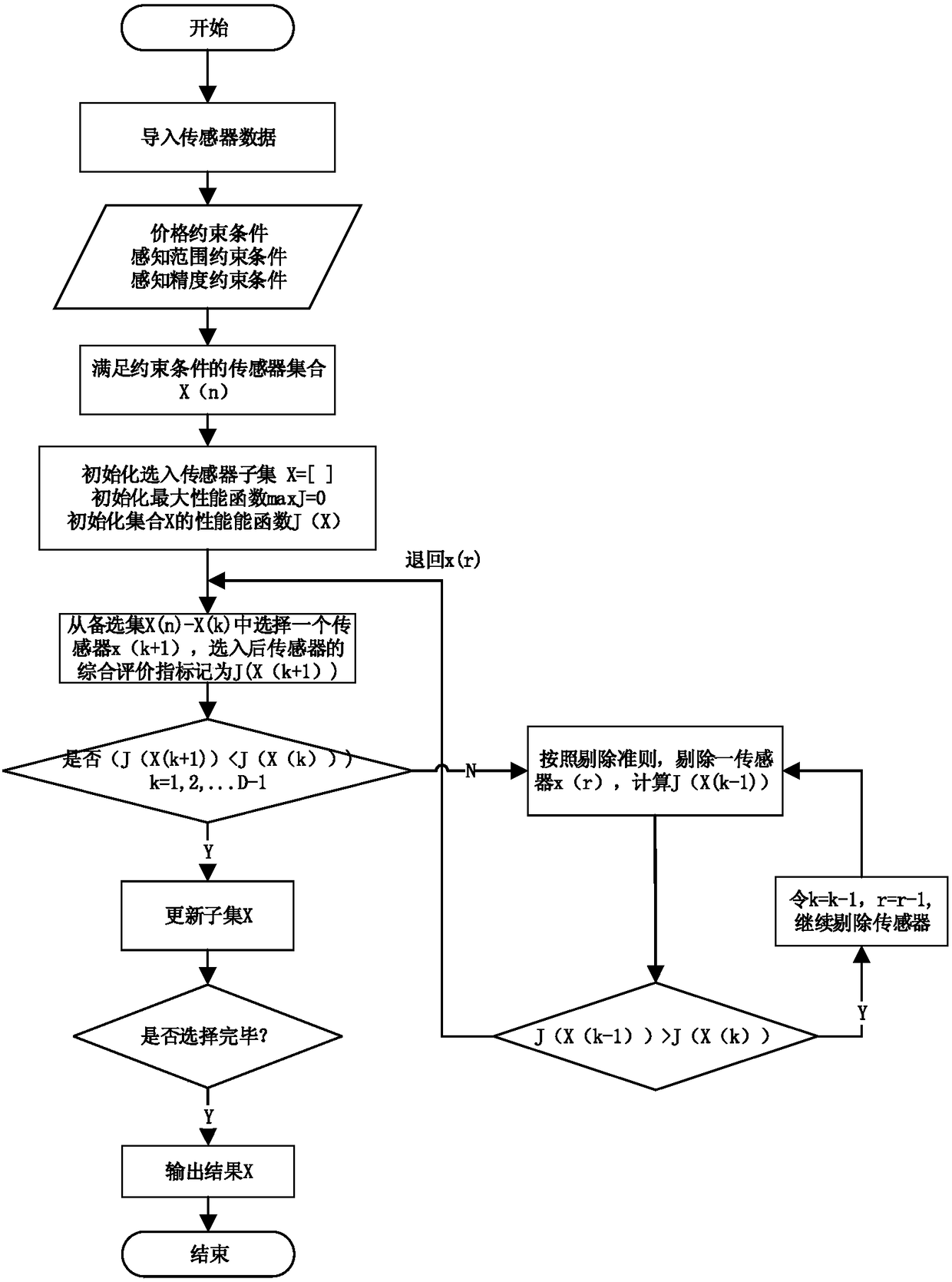

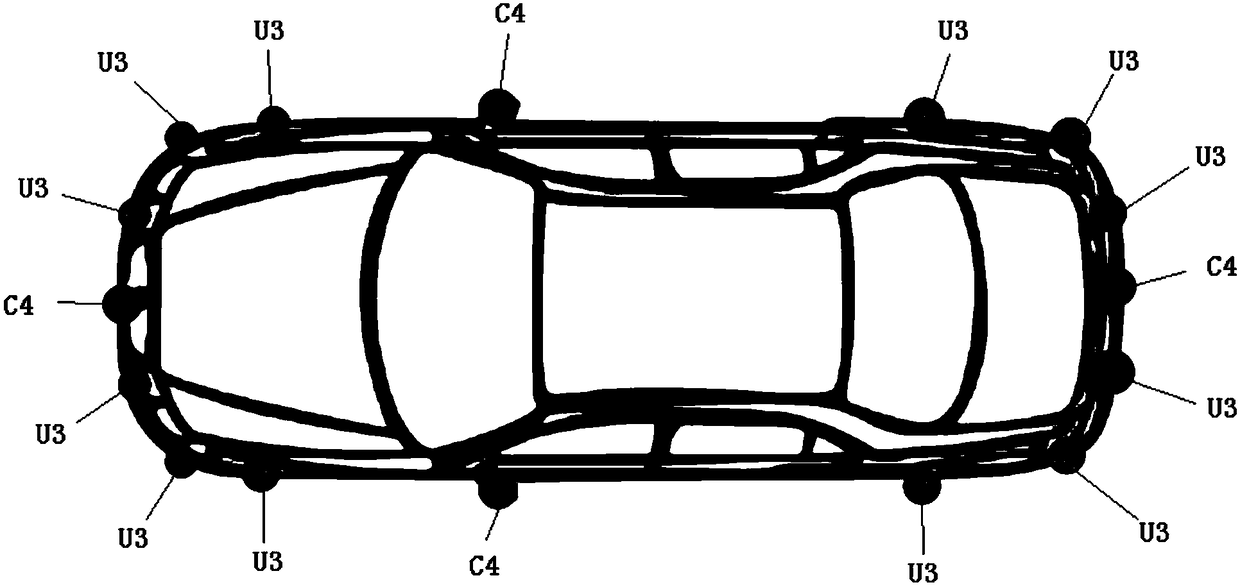

Optimization configuration method for automobile driving assistance system sensor

ActiveCN108304605ASimple compositionOptimize layoutGeometric CADDesign optimisation/simulationComputer optimizationConfiguration optimization

The invention relates to an optimization configuration method for an automobile driving assistance system sensor. The method is performed on an environmental perception sensor. The method comprises the following steps of performing a uniform description on environmental information perception of a driving assistance system based on a typical application scene; establishing a multi-dimensional comprehensive evaluation model of a sensor system; establishing a sensor perception function model; and performing a screening optimization process on an alternative sensor and an alternative installationposition by use of a global search algorithm. According to the optimization configuration method for the automobile driving assistance system sensor, the screening optimization and configuration optimization of a key sensor in the automobile driving assistance system are realized by use of a computer-optimized solution method, and the problem of optimization configuration of the key sensor in a complicated part supply system is solved.

Owner:TSINGHUA UNIV

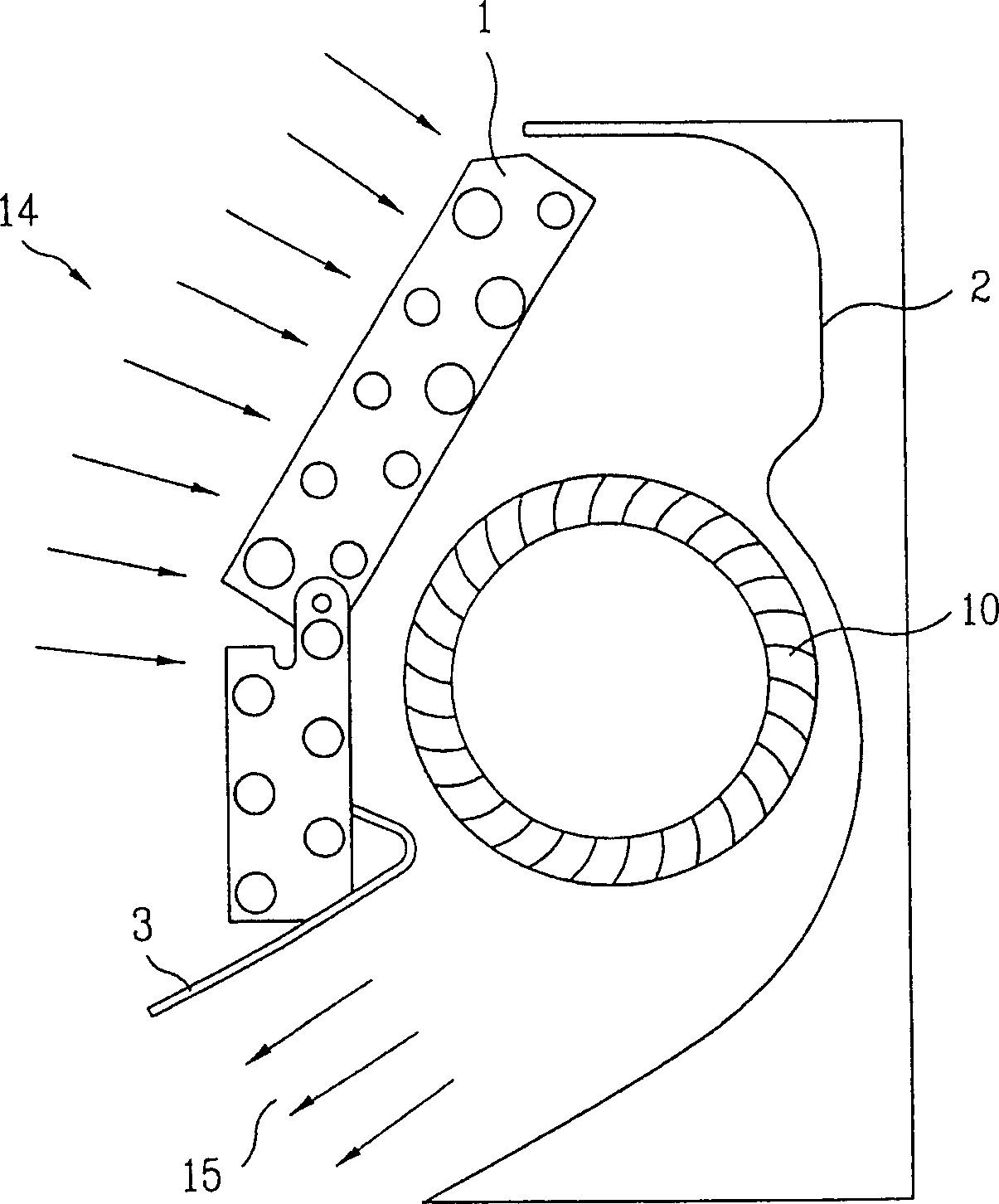

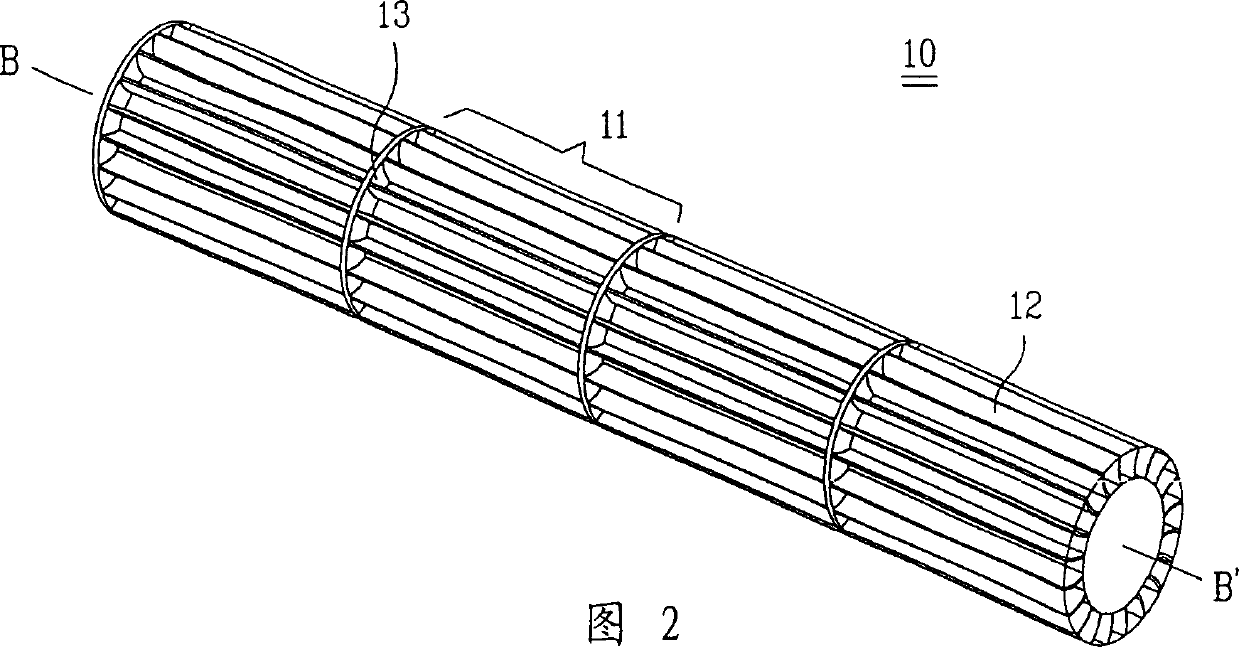

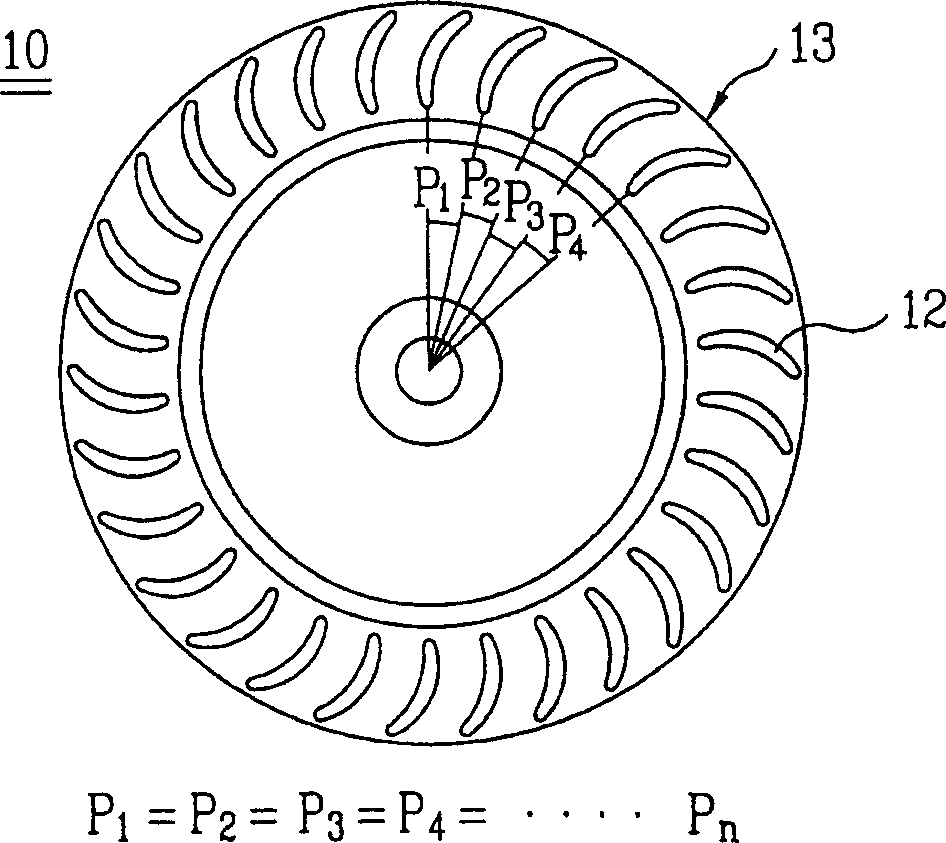

Transverse-flow fan and air conditioner using same

InactiveCN1455187AReduce noiseReduce vibrationPump componentsLighting and heating apparatusComputer optimizationEngineering

Cross flow fan, and air conditioner fitted with the same, the cross flow fan including a plurality of annular rims arranged at regular intervals along a horizontal direction, and a plurality of blades on a side surface of the rim vertical thereto, and along a circumference direction of the rim, wherein pitch angles between two adjacent blades are not regular, the pitch angle taking a center of the rim as an apex, and a number of blades are 32 or 35. The pitch angles of the blades are designed by a computer optimization method taking a number of the blades and the like as parameters.

Owner:LG ELECTRONICS INC

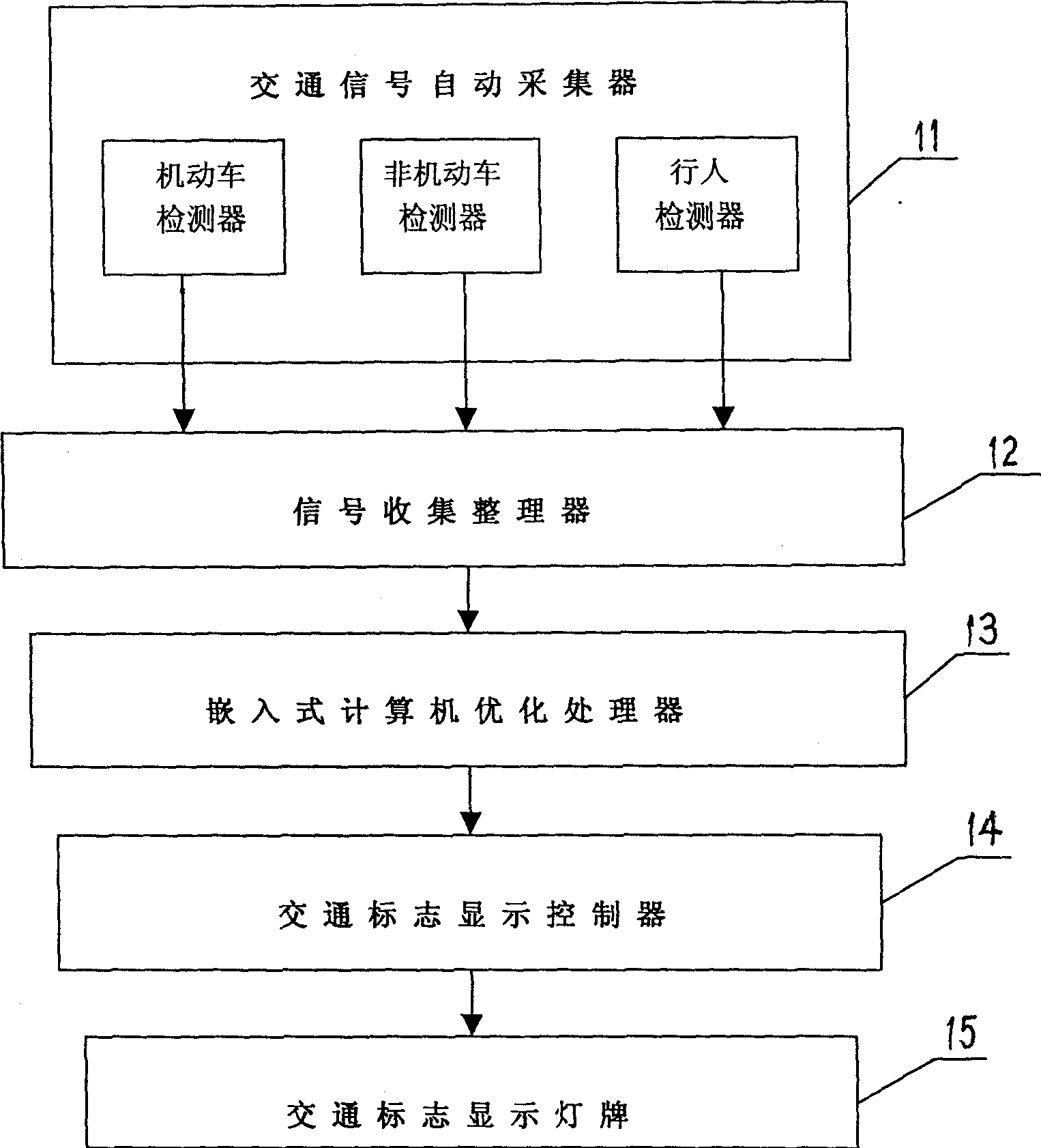

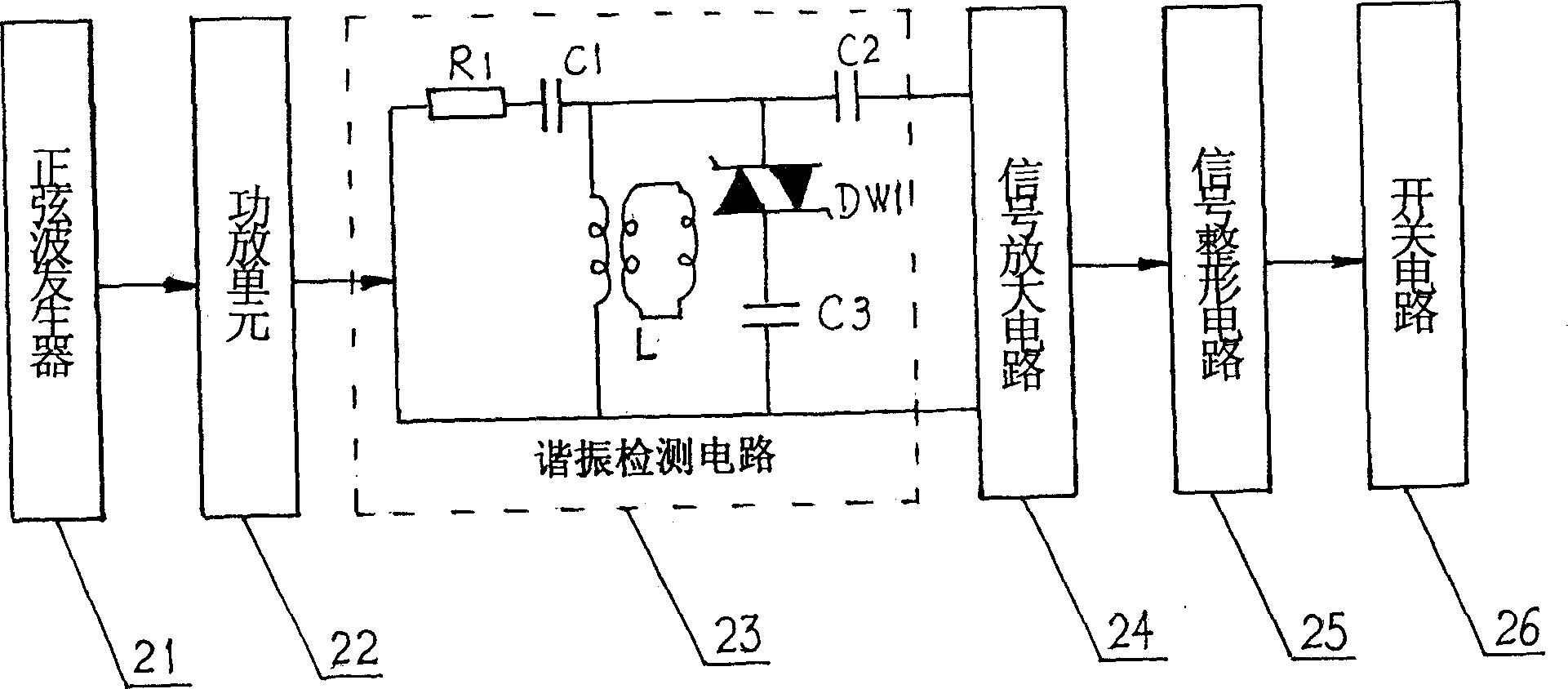

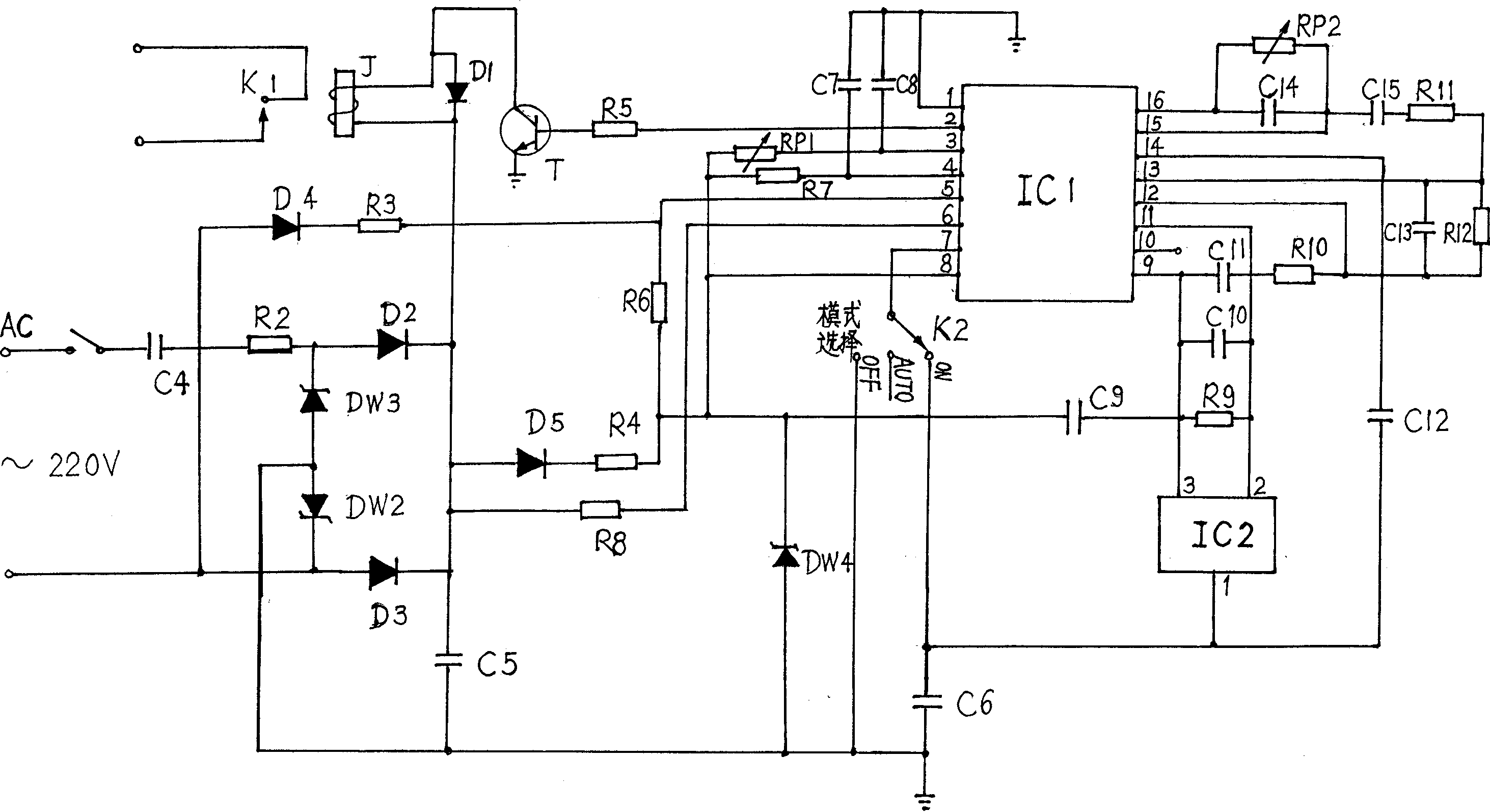

Adaptive traffic signal controller for intelligent traffic managing system

InactiveCN1716334AEfficient and orderly trafficReduce wasteControlling traffic signalsDetection of traffic movementComputer optimizationTraffic signal

The adaptive traffic signal controller for intelligent traffic managing system consists of automatic traffic signal acquiring unit, signal collecting and collating unit, embedded computerized optimizing processing unit, traffic mark display controller and lighting traffic mark displaying plate. Through the collection and collation of the road condition information and the logic treatment, signal is fed to the traffic mark display controller to make the lighting traffic mark displaying plate vary with the road condition. The present invention realizes the real-time scientific control of traffic to ensure the high traffic efficiency.

Owner:郭永平

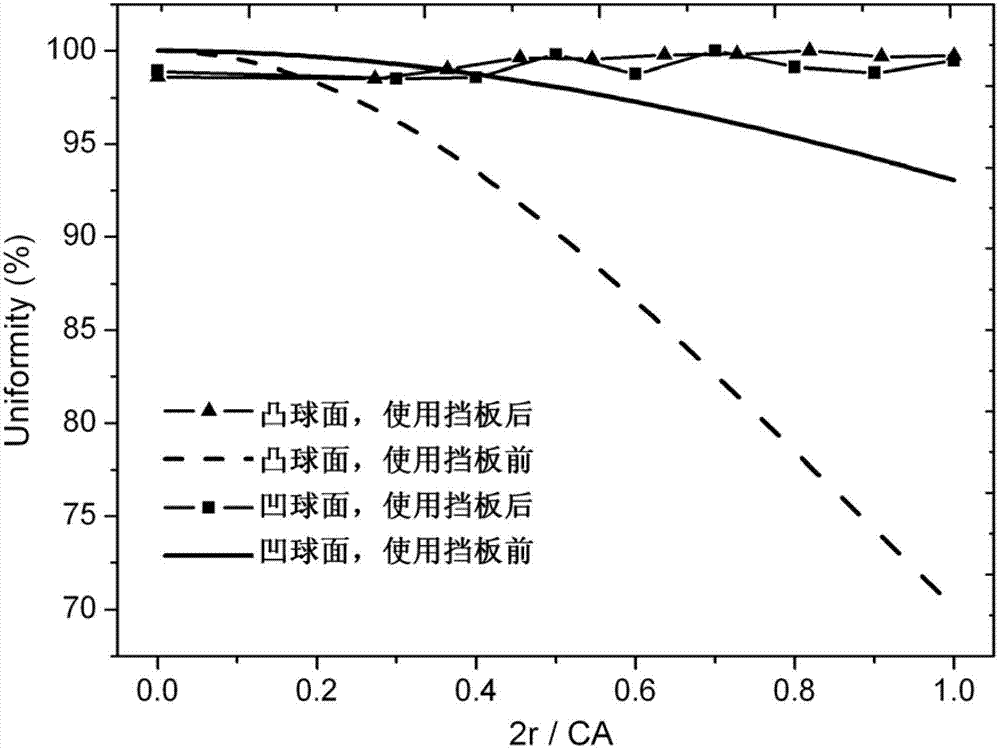

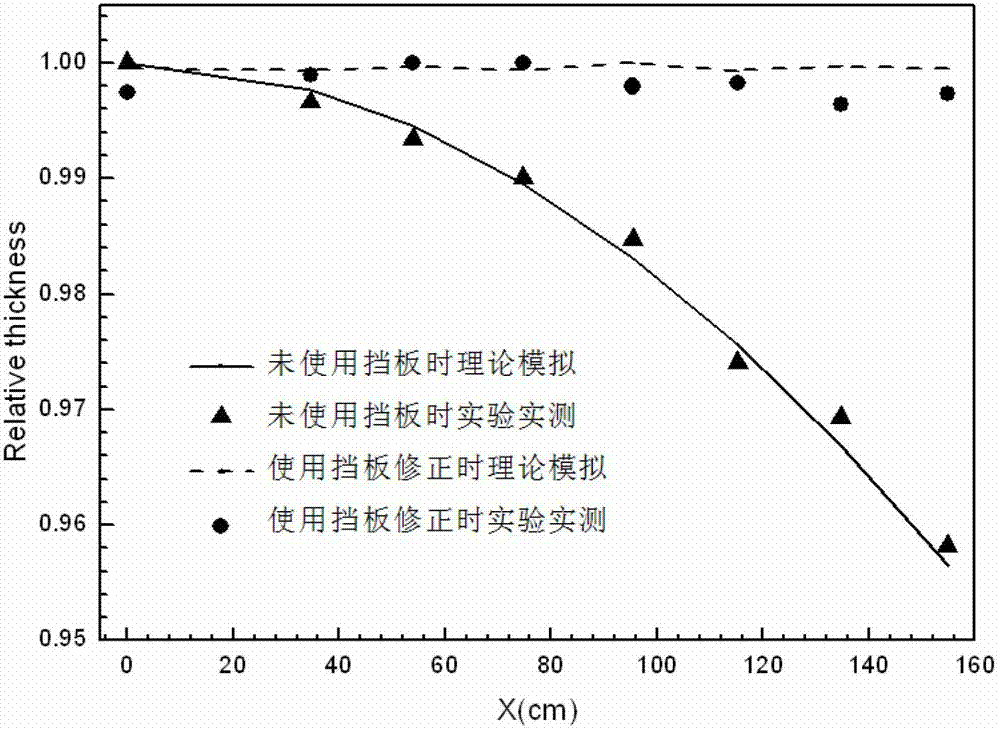

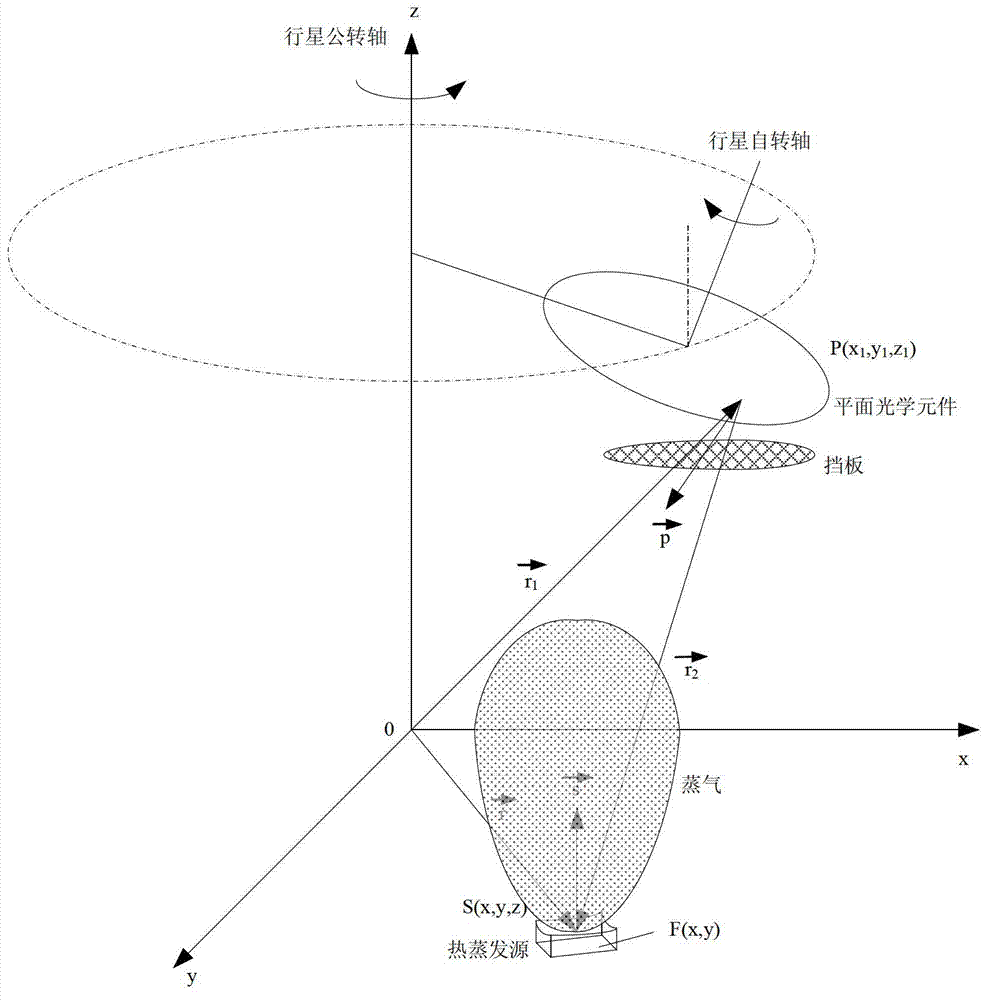

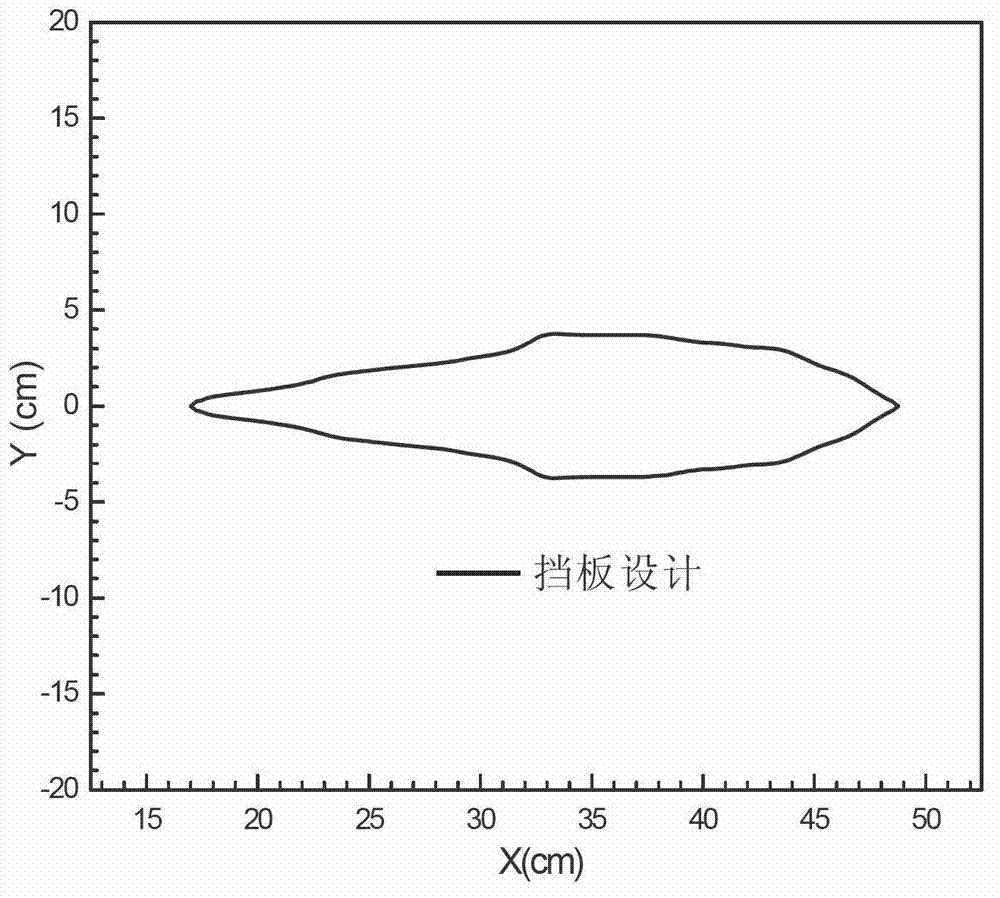

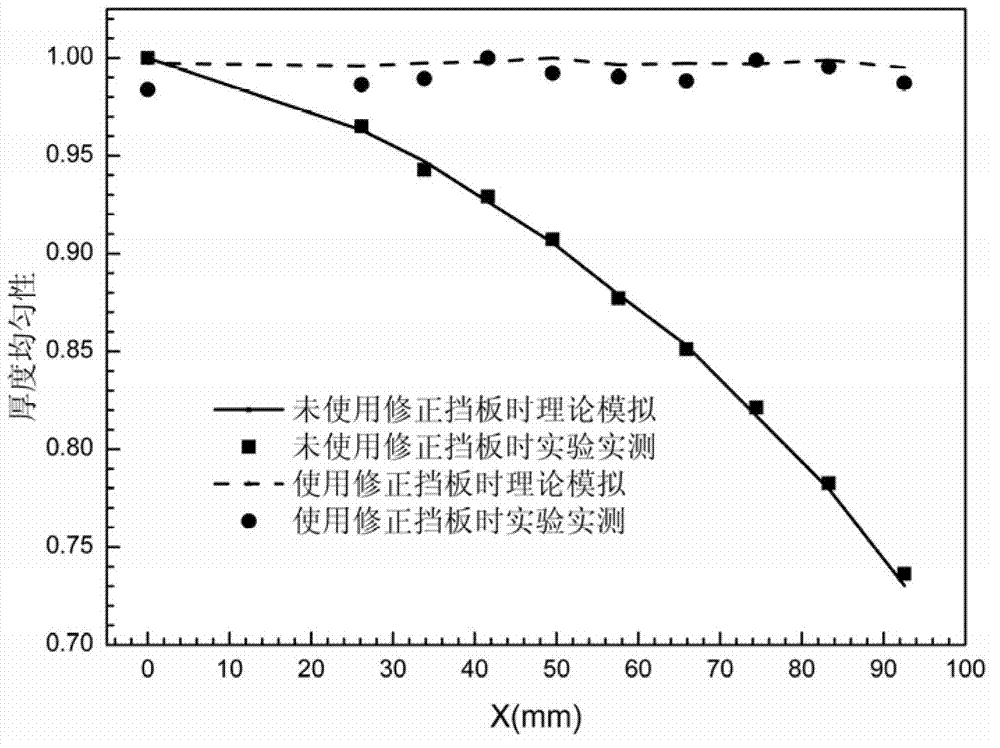

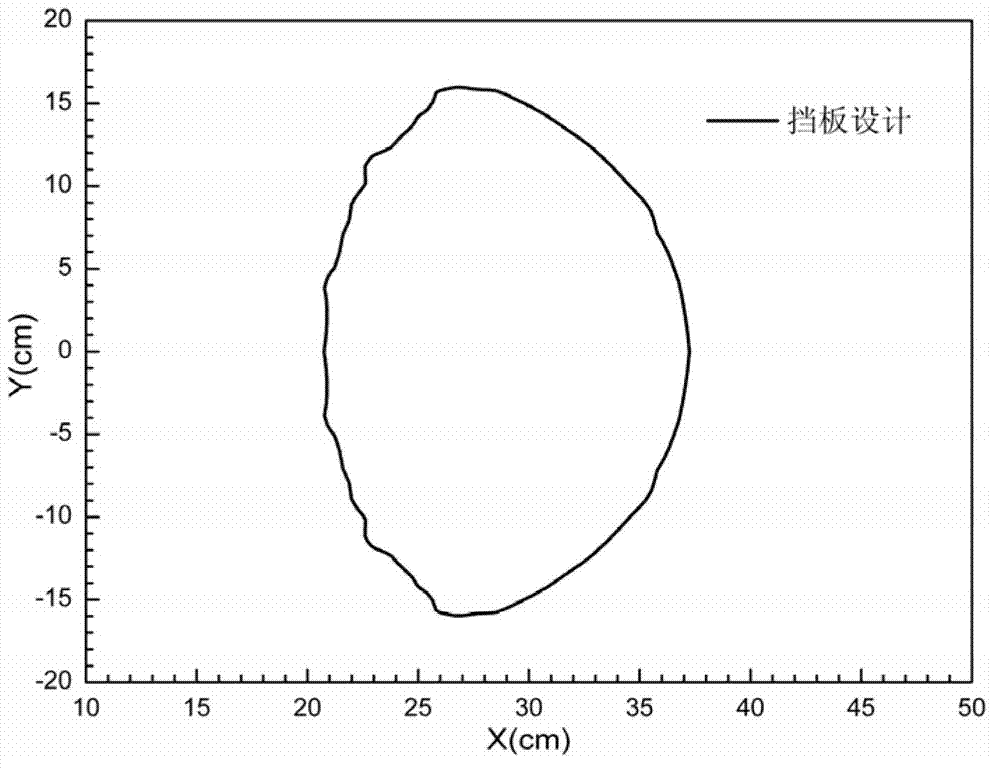

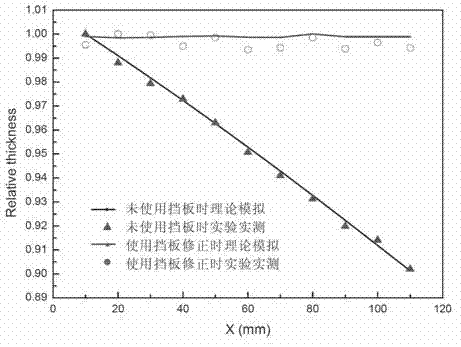

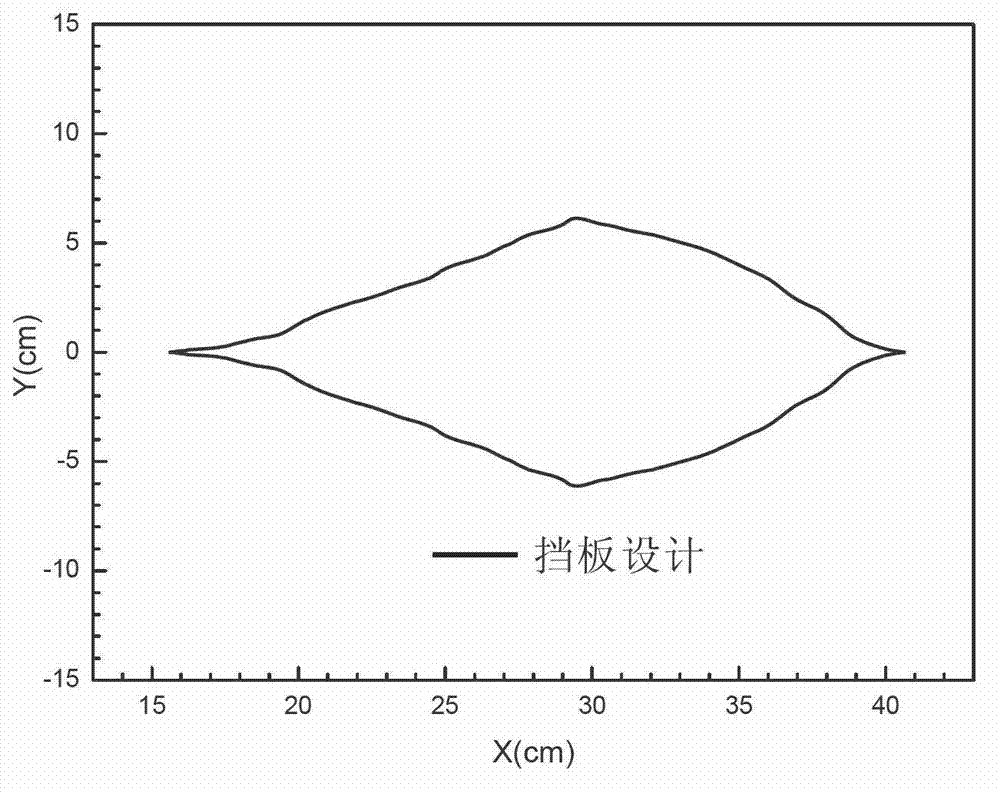

Design method of baffle for controlling distribution of film thickness of planar optical element in film coating planetary system

ActiveCN102776484AIn line with physical realityImprove optimization design efficiencyVacuum evaporation coatingSputtering coatingComputer optimizationEngineering

The invention provides a design method of a baffle for controlling distribution of film thickness of a planar optical element in a film coating planetary system. In a vacuum film coating process, the film material is delivered in a vacuum environment through an evaporating mode or a splashing mode, and forms a film with non-uniform thickness distribution on the surface of a planar optical element. Models are respectively established for really reflecting the distribution of the thickness of film deposited on the planar optical element in a planetary system of a vacuum film coating machine under the condition that a baffle is not used and the baffle is not used for correcting. The evaporating or splashing property of the film material in the vacuum film coating process is determined according to the film thickness distribution model under the condition that the baffle is not used, and then the distribution of the thickness of the film on the planar optical element in the planetary system of the vacuum film coating machine is simulated based on a film thickness distribution model theory in the presence of the correcting of the baffle. And finally the baffle design is optimized through a computer until the distribution of the thickness of the film on the planar optical element subject to the baffle correcting in the planetary system of the vacuum film coating machine meets the design requirement, so that the optimal baffle design is obtained. The design method can be applied to precisely controlling the distribution of the thickness of the film on the planar optical element.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

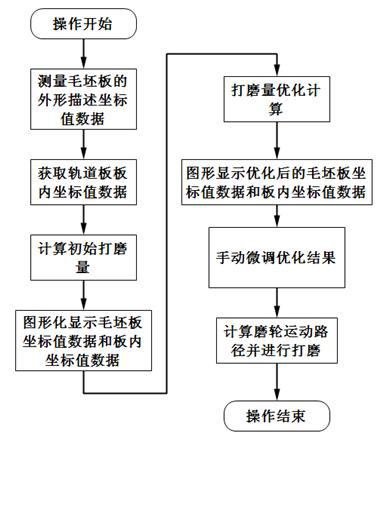

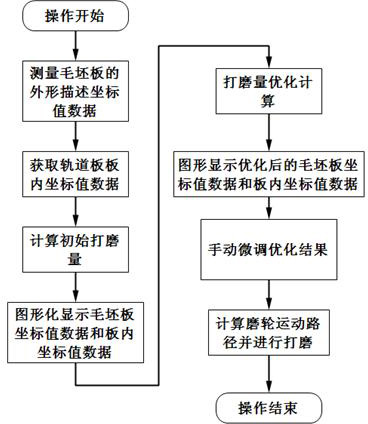

Vision-based track plate numerical controlled grinder optimization grinding method

The invention discloses a vision-based track plate numerical controlled grinder optimization grinding method, which is characterized in that a result optimized by a computer is displayed in an imaging manner so as to facilitate direct check of operators, the optimized result is further finely tuned manually so as to achieve optimal optimization result, thus completely realizing optimization grinding of the track plate numerical controlled grinder. The vision-based track plate numerical controlled grinder optimization grinding method comprises the technical steps as follows: conducting laser measurement on appearance data of a blank plate, obtaining the interior coordinate data of the track plate, calculating initial grinding quantity, displaying the coordinate data of the blank plate and the interior coordinate data in an imaging manner, conducting optimization on the grinding quantity with program, calculating the new grinding quantity after being optimized, displaying the coordinatedata of the blank plate and the interior coordinate data in an imaging manner, manually finely tuning the optimized result, calculating and grinding the motion route of a grinding wheel.

Owner:CHINA RAILWAY DESIGN GRP CO LTD

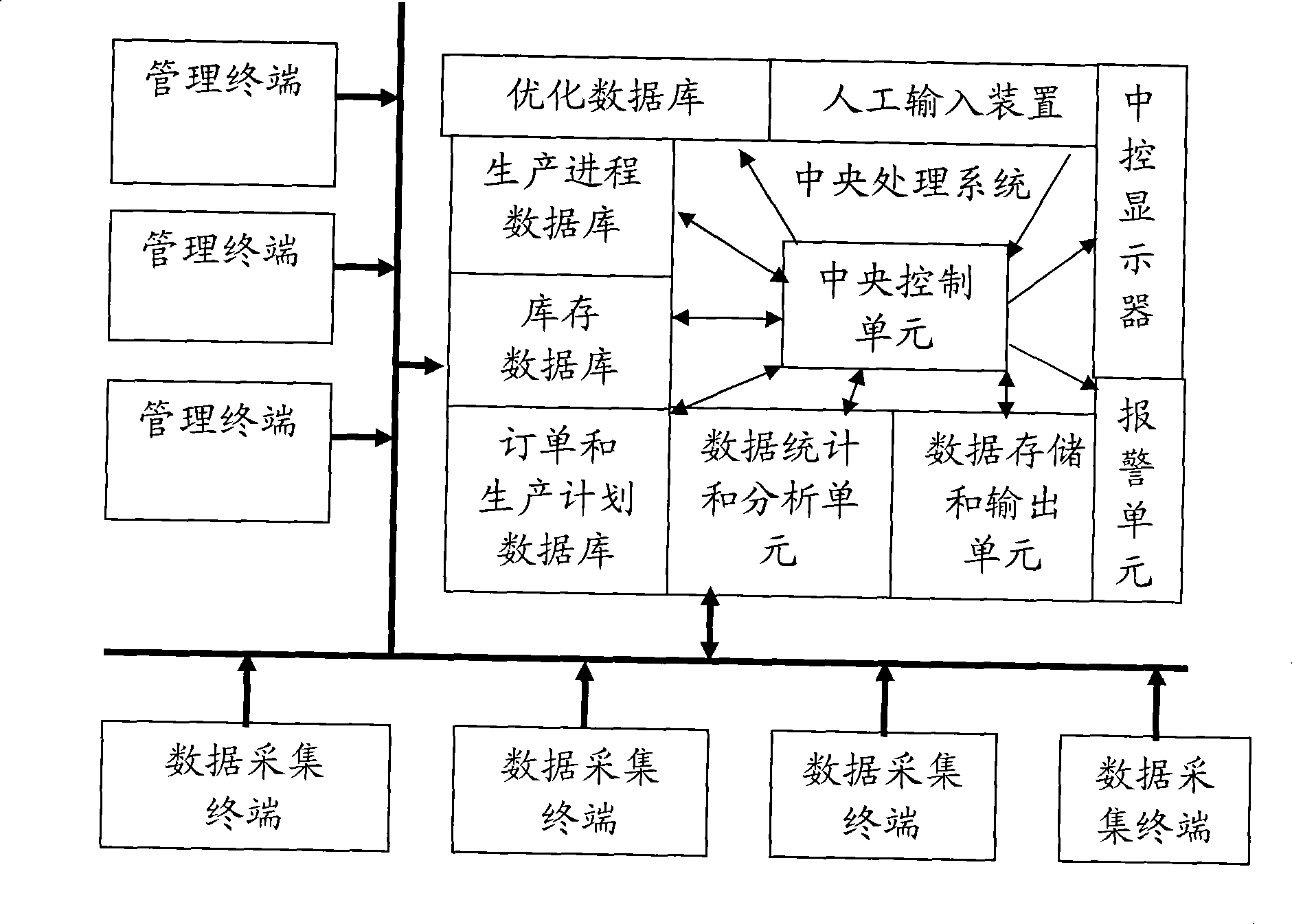

Computer optimized management and monitoring system for production enterprise

InactiveCN101470443AImprove positive benefitsReduce backlogTotal factory controlProgramme total factory controlComputer optimizationOrder form

The invention relates to a computer optimal management and monitor system for production enterprises, which mainly comprises a central processing system, a data collecting terminal and a managing terminal, wherein the data collecting terminal and the managing terminal are connected with cables of the central processing system, the data collecting terminal transmits warehouse in-and-out data of all types of goods, and production and storage data in each process of various products to the central processing system, the central processing system counts, analyzes and stores the warehouse in-and-out data, and the production and storage data in each process of each product, and the central processing system comprises an order and production plan database, a production process database and an inventory database, and is provided with a data statistic and analysis unit, a data storage and output unit, a manual input device and a central control unit. The system not only can reveal and analyze various inventory data, but can count and analyze actual production development status of various products in any time for bringing convenience to regulate the production development timely.

Owner:BEIJING AOTENGXUNDA SCI & TECH

Baffle plate design method for controlling membrane thickness distribution of spherical optical element in coating machine planet system

ActiveCN102953041AImprove optimization design efficiencyVacuum evaporation coatingSputtering coatingComputer optimizationEvaporation

The invention discloses a baffle plate design method for controlling membrane thickness distribution of a spherical optical element in a coating machine planet system. In a vacuum coating process, a membrane material is transmitted in a vacuum environment in an evaporation or sputtering mode, and a membrane of which thickness distribution is not uniform is formed on the surface of the spherical optical element. Membrane thickness distribution models capable of actually reflecting thickness distributions of membranes deposited on the spherical optical element in the vacuum coating machine planet system when a baffle plate is not used and when the baffle plate is used for correction are respectively established. According to the membrane thickness distribution model when the baffle plate is not used, evaporating or sputtering characteristics of the membrane material are determined in the vacuum coating process; and then based on the characteristics, the membrane thickness distribution model when the baffle plate is used for correction is used to theoretically simulate the membrane thickness distribution on the spherical optical element in the vacuum coating machine planet system. The baffle plate design is optimized through a computer until the membrane thickness distribution on the spherical optical element in the vacuum coating machine planet system, which is corrected by the baffle plate, reaches the design demand, and thus the optimal baffle plate design is obtained. Compared with the traditional baffle plate design method, the baffle plate design method provided by the invention has the advantage that the baffle plate design is optimized by using the computer, so that the accurate control of the membrane thickness distribution on the spherical optical element can be realized.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

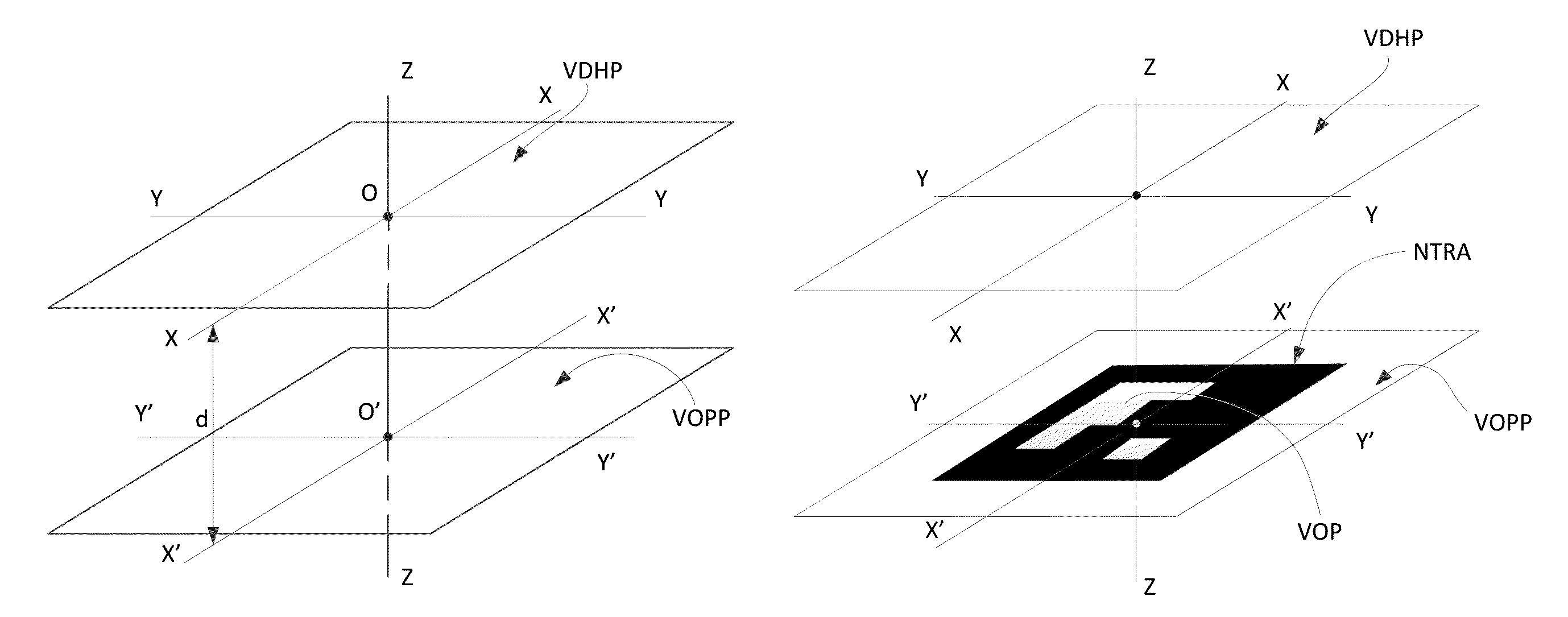

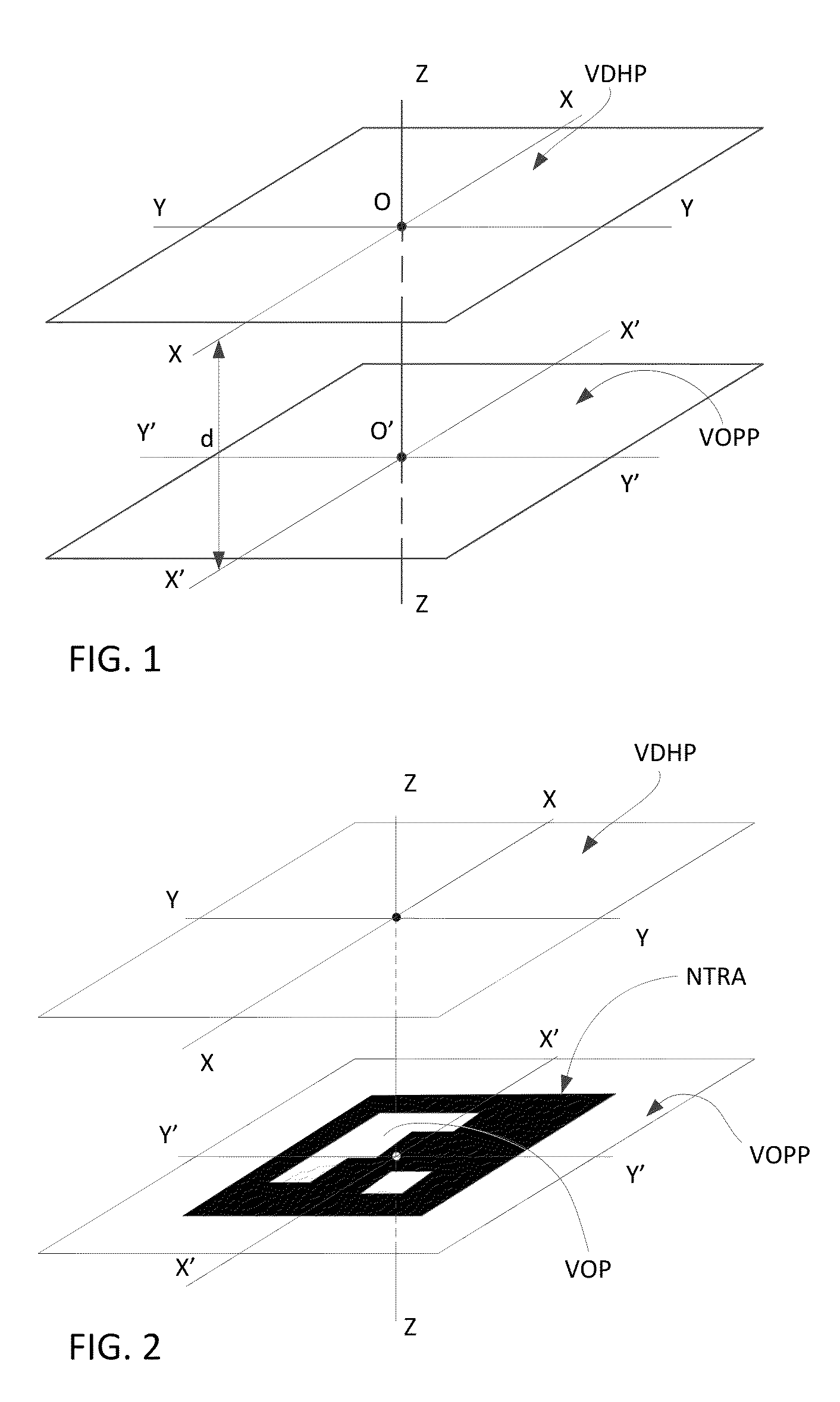

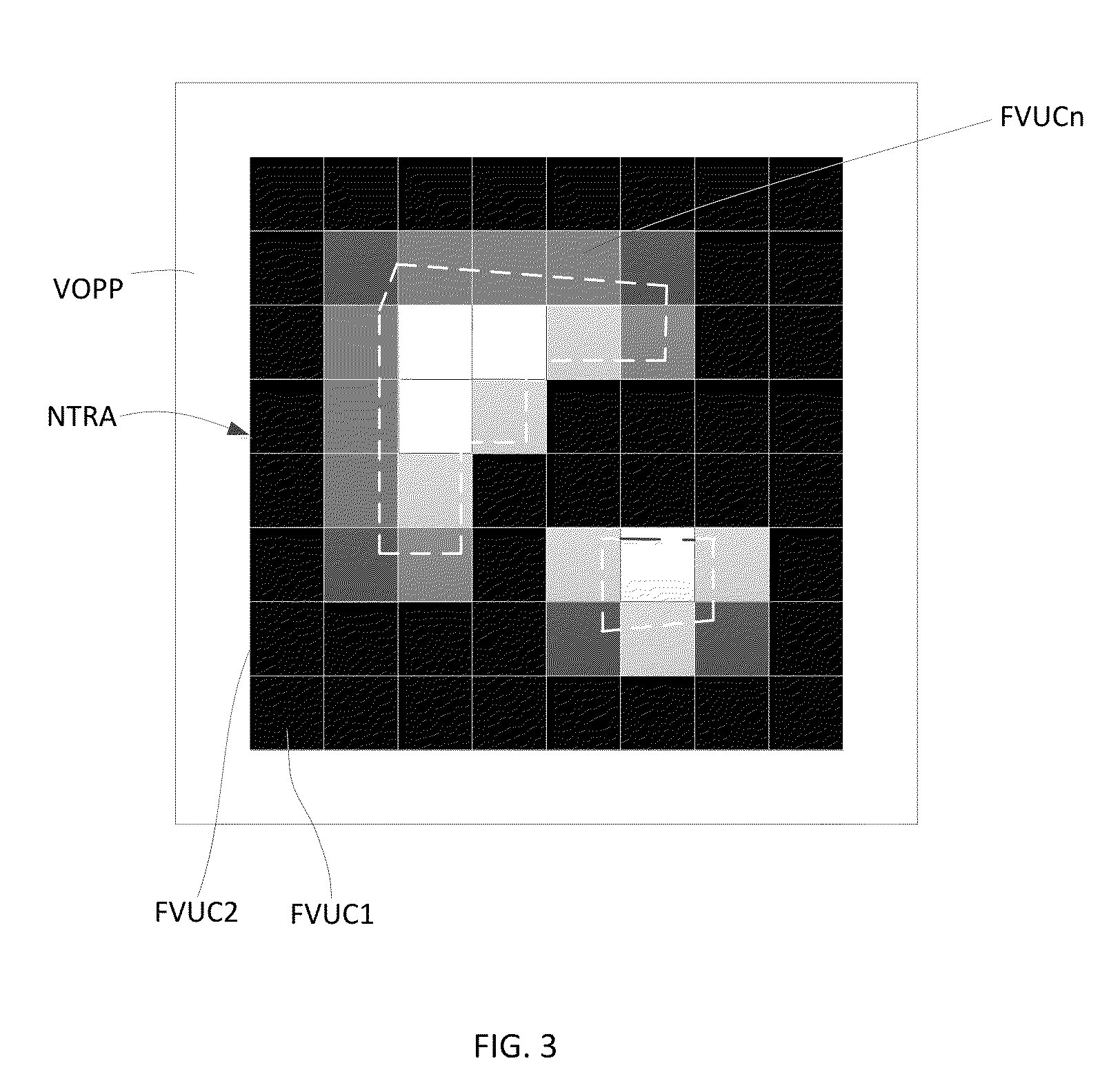

Method for synthesis and formation of a digital hologram for use in microlithography

ActiveUS9310768B2Reduce biasImprove image contrastHolographic object characteristicsPhotomechanical exposure apparatusVirtual cellComputer optimization

The invention describes a method of manufacturing a holographic mask capable of producing an image pattern that contains elements of a sub-wavelength size along with decreased deviations from the original pattern. The original pattern is converted into a virtual electromagnetic field and is divided into a set of virtual cells with certain amplitudes and phases, which are mathematically processed for obtaining the virtual digital hologram. The calculation of the latter is based on parameters of the restoration wave, which is used to produce the image pattern from the mask, and on computer optimization by variation of amplitudes and phases of the set of virtual cells and / or parameters of the virtual digital hologram for reaching a satisfactory matching between the produced image pattern and the original pattern. The obtained virtual digital hologram provides physical parameters of the actual digital hologram that is to be manufactured.

Owner:RAKHOVSKY VADIM

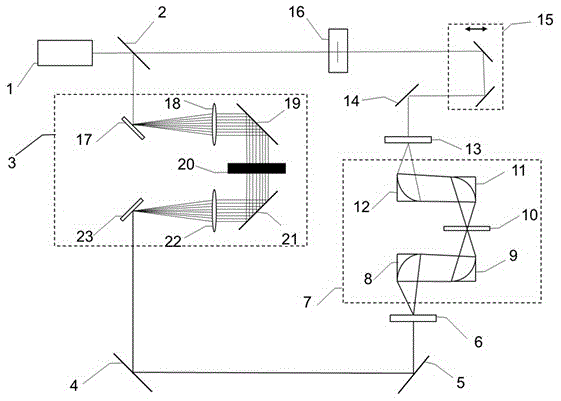

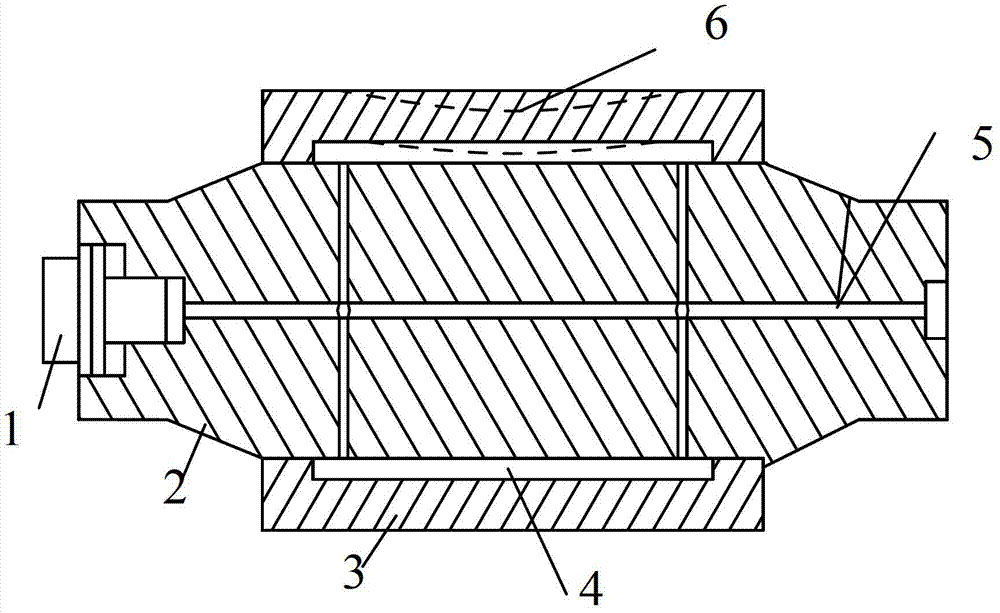

Light beam intensity, phase distribution and polarization modulation device

InactiveCN106569340AAccurate modulationLow costOptical elementsSpatial light modulatorComputer optimization

The invention relates to a light beam intensity, phase distribution and polarization modulation device. A femtosecond laser emits laser, and a light beam is adjusted to be a parallel light beam through a paraboloid mirror. The light beam passes through a first reflector, and reaches a beam splitting mirror to be divided into two light beams: the transmitting light beam passes by a first spatial light modulator and then passes by a second reflector to enter a time delay device, and finally passes through a third reflector to reach the beam splitting mirror; and the reflected light beam passes by a fourth reflector and then passes by a second spatial light modulator and a fifth reflector to reach a beam combiner; the combined light beam is outputted to a detection device. The first spatial light modulator, the second spatial light modulator and the detection device are connected with a computer. The spatial light modulators are controlled through a computer optimization algorithm, and achieve the modulation of light beam intensity, phase and polarization at the same time. The device is simple in structure, is low in device cost, and is wide in application range.

Owner:UNIV OF SHANGHAI FOR SCI & TECH

Method for designing inner roller type curve of sleeve of variable crown (VC) roller

InactiveCN102819637AWeaken shape control effectShape defect suppressionSpecial data processing applicationsComputer optimizationWave shape

The invention relates to a method for designing an inner roller type curve of a sleeve of a variable crown (VC) roller, and the method carries out a great amount of field tests and theoretical analysis and takes a full combination of characteristics of equipment and a process of the VC roller; and aims at problems that an oil pressure convex degree of the VC roller is eliminated by collapse displacement of the sleeve and a shape controlling effect of the roller is reduced when the VC roller rolls under a great rolling pressure, as well as a problem of a double-wave shape defect generated by a finished product strip steel, a computer design of an internal convex roller type of a VC roller sleeve is optimized, so that an inner wall of the sleeve is in local contact with the surface of a mandrel when the roller rolls under the great rolling pressure, thereby controlling the collapse displacement of the sleeve within an allowable range and inhibiting shape defects, such as double-wave; a shape controlling range of the VC roller is improved; and an appliation field of the VC roller is further widened.

Owner:YANSHAN UNIV

Technology for remanufacturing compressor

InactiveCN102889195ARealize combined assemblyEnables innovative structural installationsPositive displacement pump componentsPositive-displacement liquid enginesComputer optimizationScientific theory

The invention discloses a technology for remanufacturing (green) a compressor and a compressor remanufacturing enterprise (factory), and belongs to the field of general machinery. Based on a scientific theory of limitless service life design of parts such as a crank shaft box accounting for most of the total weight of the compressor, a crank shaft and a cylinder body, the conventional manufacturing, lossless detection and maintenance technology is succeeded; and a modern cold-spraying technology, a multifunctional computer optimal design, a vibration, reliability and structural completeness calculation technology and an intelligent monitoring and flexible measurement integrated technology are used. Reconstruction of a remanufacturing factory is provided; old machines which serve as waste materials fed into a steel refining furnace are subjected to green manufacturing by a scientific and multifunctional new technology in order to solve the problems of repeated energy consumption and pollution increasing which are caused by re-smelting the old machines; due to the remanufactured new machine, subsequent technology transformation of an enterprise is relatively high in adaptability; compared with the old machines or new machines of the same type, the remanufactured new machine saves energy, reduces consumption and runs safely; and the technology has the actual benefits of turning old into new and turning waste into treasure along with low investment and short period.

Owner:虞岩贵

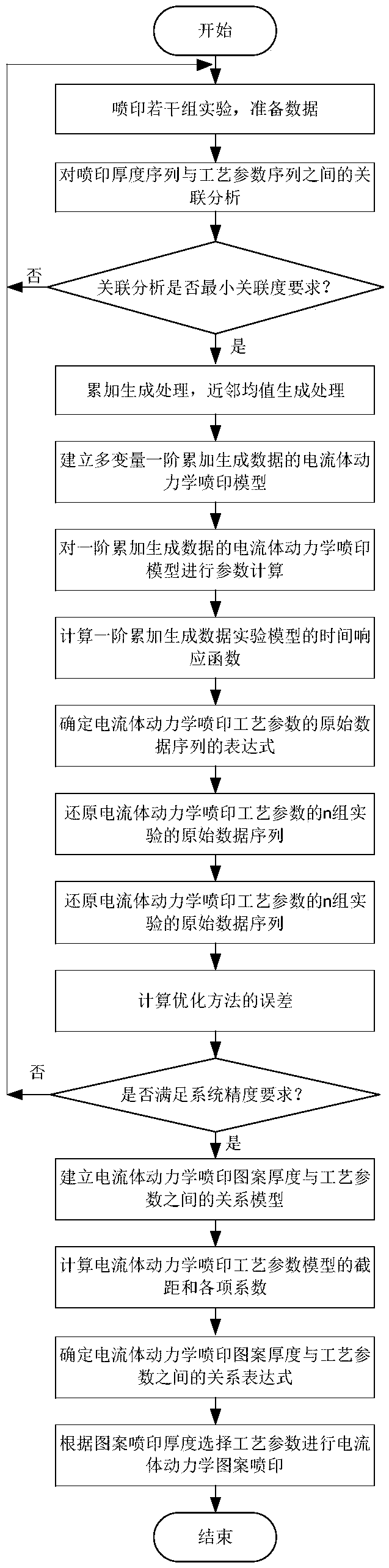

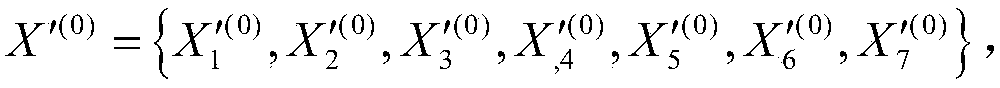

A process parameter optimization method of an electro-hydrodynamic uniformity jet printing pattern

ActiveCN109165439AUniform thicknessSave manpower and material resourcesDesign optimisation/simulationMulti-objective optimisationComputer optimizationMaterial resources

The invention discloses a process parameter optimization method of an electro-hydrodynamic uniformity jet printing pattern. A computer optimization method is combined with the electrohydrodynamic spray printing technology mechanism, according to a few experiments, the electrohydrodynamic printing patterns with different process parameters are obtained, and the process parameters of different jet printing patterns are optimized by the computer optimization method, so that that pattern jet printing efficiency is improved. The thickness model of the electrohydrodynamic spray printing pattern is obtained by the optimization method, which accords with the experimental results. Moreover, the optimum thickness range of the process parameters is given according to the pattern jet printing thickness, which makes the pattern thickness of electrohydrodynamic jet printing more uniform, not only saves manpower and material resources, but also saves time cost, at the same time, improves the efficiency of hydrodynamic jet printing and the quality of pattern jet printing.

Owner:JIAXING UNIV

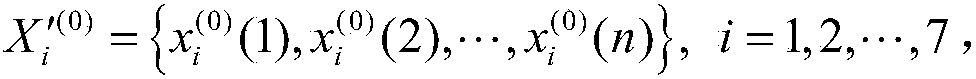

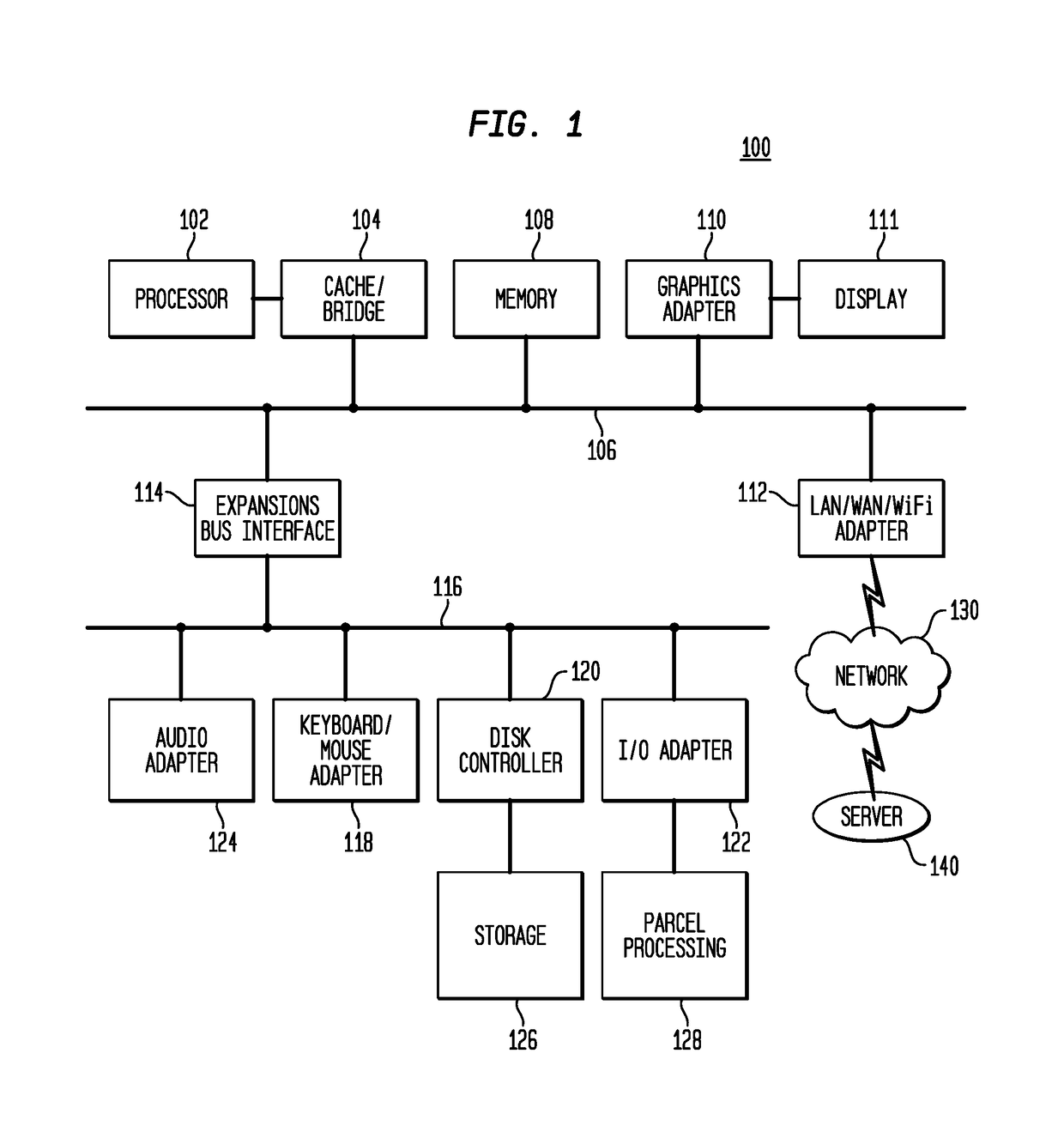

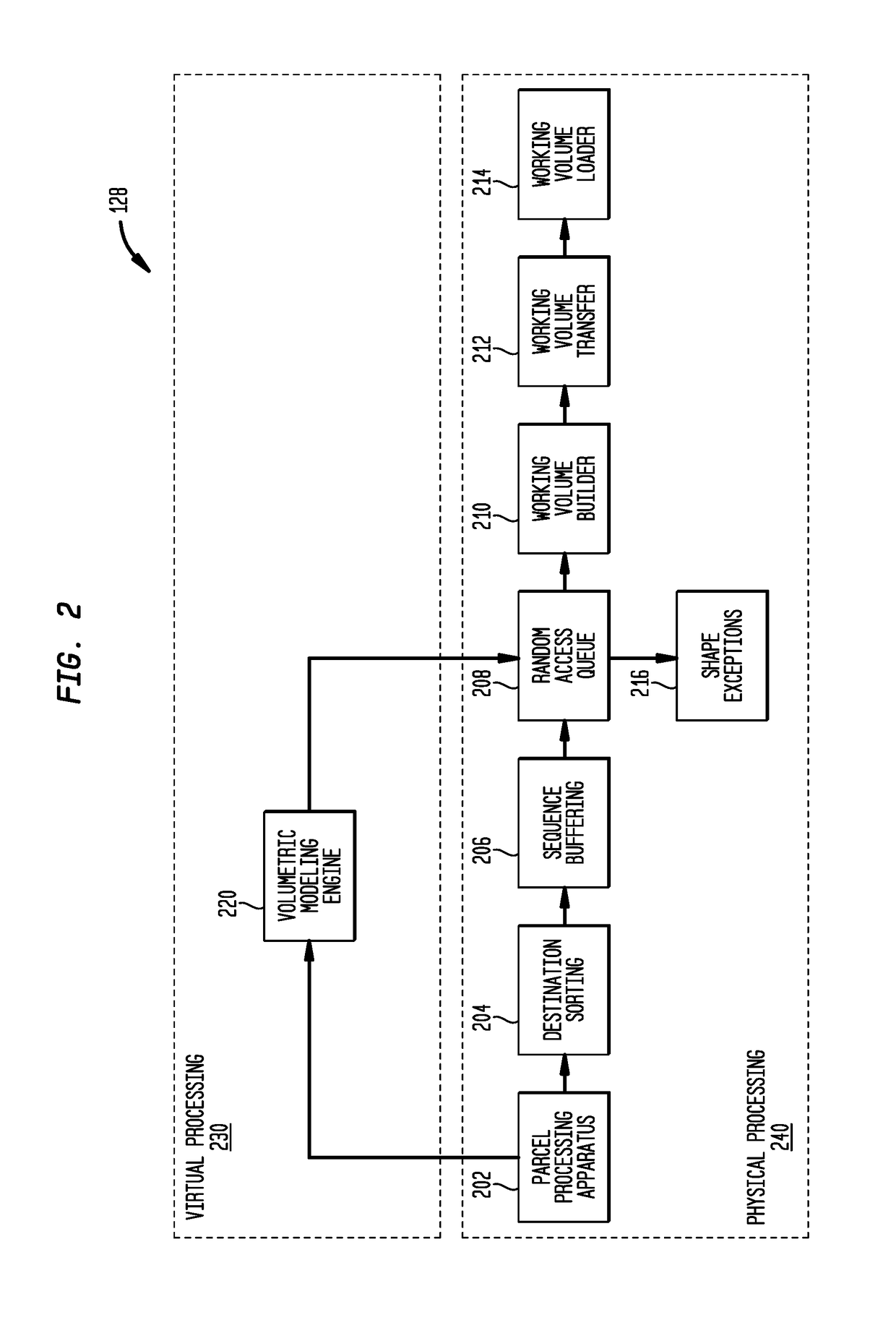

Computer Optimized Mixed Parcel Loading Equipment

A parcel processing system and method. A method includes receiving a plurality of items to be sorted. The method includes receiving a plurality of parcels by a parcel processing apparatus and producing parcel data corresponding to each of the parcels, the parcel data including physical dimensions and a weight for each parcel. The method includes designing a virtual stack of the plurality of parcels to occupy a working volume according to the parcel data by a volumetric modeling engine. The method includes building a physical stack of the parcels that corresponds to the virtual stack by a working volume builder, wherein the physical stack is thereafter transferred into the working volume in a container.

Owner:KÖRBER SUPPLY CHAIN LLC +1

Design method for baffle plate used for controlling film thickness distribution on conical optical element in film plating planetary system

ActiveCN102787301AImprove optimization design efficiencyVacuum evaporation coatingSputtering coatingSputteringComputer optimization

The invention provides a design method for a baffle plate used for controlling film thickness distribution on a conical optical element in a film plating planetary system. According to the invention, in the process of vacuum plating, a film material is transmitted in a vacuum environment in a manner of evaporation or sputtering and forms a film with nonuniformly distributed thickness on the surface of the conical optical element, a film thickness distribution model capable of reflecting actual thickness distribution of the film deposited on the conical optical element in a vacuum plating machine planetary system when the baffle plate is not used and a film thickness distribution model capable of reflecting actual thickness distribution of the film on the conical optical element when baffle plate correction is used are respectively established; evaporation or sputtering characteristics of the film material during vacuum plating are determined based on the film thickness distribution model when the baffle plate is not used, then film thickness distribution on the conical optical element is simulated by using theories for the film thickness distribution model when baffle plate correction is used, designing of the baffle plate is optimized by using a computer until film thickness distribution on the conical optical element in the vacuum plating machine planetary system meets design demands after utilization of baffle plate correction, and therefore, an optimal baffle plate design is obtained. The method provided by the invention can realize accurate control of film thickness distribution on the conical optical element.

Owner:INST OF OPTICS & ELECTRONICS - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com