A process parameter optimization method of an electro-hydrodynamic uniformity jet printing pattern

A technology of process parameter optimization and body dynamics, applied in multi-objective optimization, electrical digital data processing, design optimization/simulation, etc., can solve the problems of low efficiency, long experiment time and high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

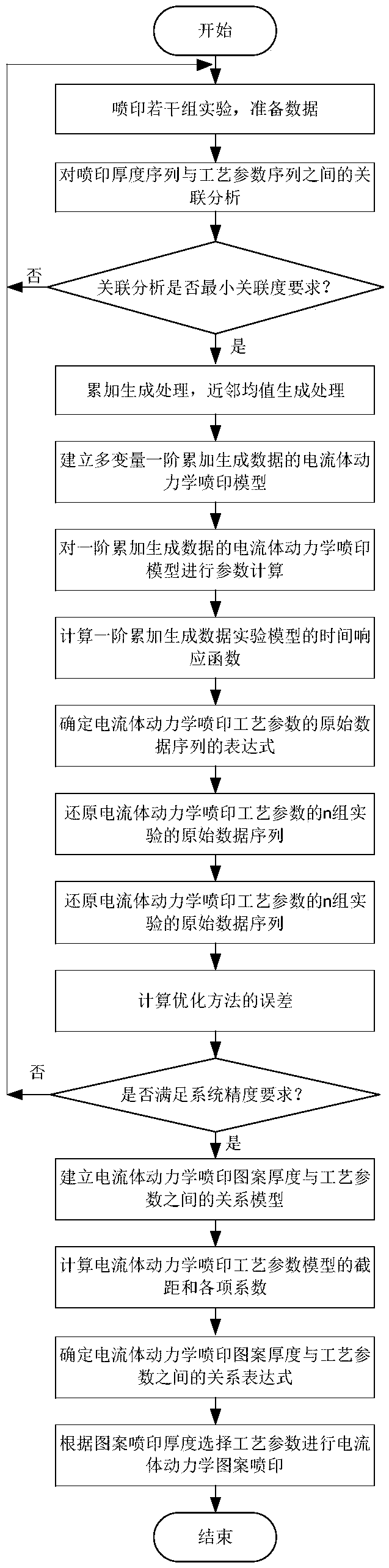

[0049] Embodiments of the present invention will be further described below with reference to the accompanying drawings:

[0050] The process parameter optimization method of a kind of electrohydrodynamic jet printing pattern provided by the present invention, it comprises the following steps:

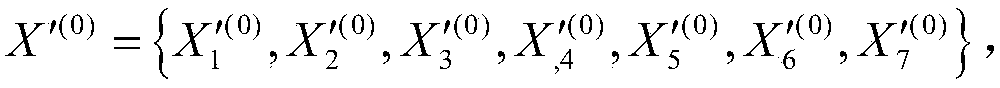

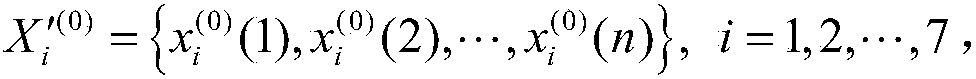

[0051] (1) For the printing solution of different materials, use the electrohydrodynamic printing equipment to print the pattern, and conduct several groups of experiments by controlling the nozzle diameter, applied voltage, spray height, injection pump flow rate, moving speed of the moving platform and other process parameters , after each group of experiments completes the electrohydrodynamic pattern printing, measure the thickness of several sampling points on the pattern, and calculate the average value of the thickness of the several sampling points, and obtain the pattern printing thickness of each group of experiments; complete several groups Experiment to obtain the pattern pri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com